DAF CF65 Maintenance Manual

Maintenance manual CF65/CF65 (II)

https://www.truck-manuals.net/

https://www.truck-manuals.net/

©200518 DAF Trucks N.V., Eindhoven,

The Netherlands.

In the interest of continuing product development, DAF reserves the right to change specifications or products at any time without prior notice.

No part of this publication may be reproduced and/or published by printing, by photocopying, on microfilm or in any way whatsoever without the prior consent in writing of DAF Trucks N.V.

© 200518 |

DW13280404 |

https://www.truck-manuals.net/

https://www.truck-manuals.net/

STRUCTURE

ΧΦ65/65 (II) series

TECHNICAL DATA

THREADED CONNECTIONS

FLUIDS, OIL AND LUBRICANTS

MAINTENANCE SCHEDULE

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

© 200518

0

1

2

3

4

5

https://www.truck-manuals.net/

https://www.truck-manuals.net/

TECHNICAL DATA

ΧΦ65/65 (II) series |

|

Contents |

|

|

|||

CONTENTS |

|

|

|

|

|||

Page |

Date |

0 |

|||||

|

|

|

|||||

1. |

. . . . . . . . . . . . . . . . . . . . .ENGINE, COOLING SYSTEM AND FUEL SYSTEM |

. . .1-1 |

. . 200518 |

|

|||

|

1.1 |

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-1 . . . |

. . 200518 |

|

||

|

1.2 |

Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-1 . . . . |

. 200518 |

|

||

|

1.3 |

Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 . . . . |

. 200518 |

|

||

2. |

STEERING GEAR AND BRAKE SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 . . . . |

. 200518 |

|

|||

|

2.1 |

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 . . . . |

. 200518 |

|

||

|

2.2 |

Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 . . . . |

. 200518 |

|

||

3. |

DRIVE AND CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-1 . . . . |

. 200518 |

|

|||

|

3.1 |

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-1 . . . . |

. 200518 |

|

||

|

3.2 |

Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-2 . . . . |

. 200518 |

|

||

|

3.3 |

Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-4 . . . . |

. 200518 |

|

||

© 200518 |

1 |

https://www.truck-manuals.net/

TECHNICAL DATA

Contents ΧΦ65/65 (II) series

0

2 |

© 200518 |

https://www.truck-manuals.net/

|

TECHNICAL DATA |

|

||

ΧΦ65/65 (II) series |

Engine, cooling system and fuel system |

|

|

|

1. ENGINE, COOLING SYSTEM AND FUEL SYSTEM |

|

|||

0 |

||||

1.1 GENERAL |

|

|

||

Valve clearance |

|

|

|

|

Inspection dimension, cold valve clearance |

|

|

|

|

Inlet |

0.15 - 0.40 mm |

|

||

Exhaust |

0.40 - 0.75 mm |

|

||

Setting dimension, cold valve clearance |

|

|

|

|

Inlet |

0.25 mm |

|

||

Exhaust |

0.50 mm |

|

||

1.2 TIGHTENING TORQUES

The tightening torques stated in this section are different from the standard tightening torques stated in the overview of the standard tightening torques. The other threaded connections which are not stated must therefore be tightened to the torque stated in the overview of standard tightening torques.

When attachment bolts and nuts are replaced, it is important that - unless stated otherwise - these bolts and nuts are of exactly the same length and property class as those removed.

Lubrication system |

|

Oil drain plug |

60 Nm |

Valve cover |

|

Valve cover attachment bolts |

10 Nm |

© 200518 |

1-1 |

https://www.truck-manuals.net/

TECHNICAL DATA

|

|

Engine, cooling system and fuel system |

ΧΦ65/65 (II) series |

|

|

1.3 FILLING CAPACITIES |

|

0 |

|

|

|

|

Lubrication system |

|

|

|

|

|

|

|

|

Total capacity (including oil cooler and oil filter) |

approx. 19.5 litres |

|

|

Sump capacity, maximum level |

approx. 17.5 litres |

|

|

Sump capacity, minimum level |

approx. 15.4 litres |

|

|

CF 65 cooling system |

|

|

|

Cooling system |

approx. 26 litres |

|

|

With Allison gearbox |

approx. 40 litres |

|

|

CF65 (II) cooling system |

|

|

|

Cooling system |

approx. 23 litres |

1-2 |

© 200518 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

||

ΧΦ65/65 (II) series |

|

Steering gear and brake system |

|

|

2. STEERING GEAR AND BRAKE SYSTEM |

|

|

|

|

|

|

0 |

||

2.1 GENERAL |

|

|

||

Maximum steering ball joint axial clearance |

1.5 mm |

|

|

|

2.2 TIGHTENING TORQUES

The tightening torques stated in this section are different from the standard tightening torques stated in the overview of the standard tightening torques. The other threaded connections not specified must therefore be tightened to the torque stated in the overview of standard tightening torques.

When attachment bolts and nuts are replaced, it is important that - unless stated otherwise - these bolts and nuts are of exactly the same length and property class as those removed.

Bolt, steering column universal joint |

56 Nm (1) |

(1) Fit new original attachment bolt and self-locking nut.

© 200518 |

2-1 |

https://www.truck-manuals.net/

TECHNICAL DATA

Steering gear and brake system ΧΦ65/65 (II) series

0

2-2 |

© 200518 |

https://www.truck-manuals.net/

ΧΦ65/65 (II) series

3. DRIVE AND CHASSIS

3.1 GENERAL

Allison gearbox

The Allison MD3060 automatic gearbox is electronically controlled. The oil level can be read out via the selector keypad. This keypad is located next to the driver's seat. The oil level can also be checked using the dipstick.

Dipstick readings: |

|

"Cold add" |

add when cold |

"Cold full" |

full when cold |

"Hot add" |

add when hot |

"Hot full" |

full when hot |

The oil level when cold must be on the "Cold full" mark.

© 200518

TECHNICAL DATA

Drive and chassis

0

R MODE

N

D

V300392

<![if ! IE]><![endif]>FULL

<![if ! IE]><![endif]>HOT

| <![if ! IE]> <![endif]>HOT |

<![if ! IE]> <![endif]>ADD |

| <![if ! IE]> <![endif]>COLD |

<![if ! IE]> <![endif]>FULL |

<![endif]>ADD

<![if ! IE]><![endif]>COLD

W 3 03 099

3-1

https://www.truck-manuals.net/

TECHNICAL DATA

Drive and chassis ΧΦ65/65 (II) series

3.2 TIGHTENING TORQUES

0

The tightening torques stated in this section are different from the standard tightening torques stated in the overview of the standard tightening torques. The other threaded connections not specified must therefore be tightened to the torque stated in the overview of standard tightening torques.

When attachment bolts and nuts are replaced, it is important that - unless stated otherwise - these bolts and nuts are of exactly the same length and property class as those removed.

ZF 6S-850 gearbox |

|

Level check/filler plug (A) |

50 Nm |

Drain plug (B) |

50 Nm |

A

A

B

M3038

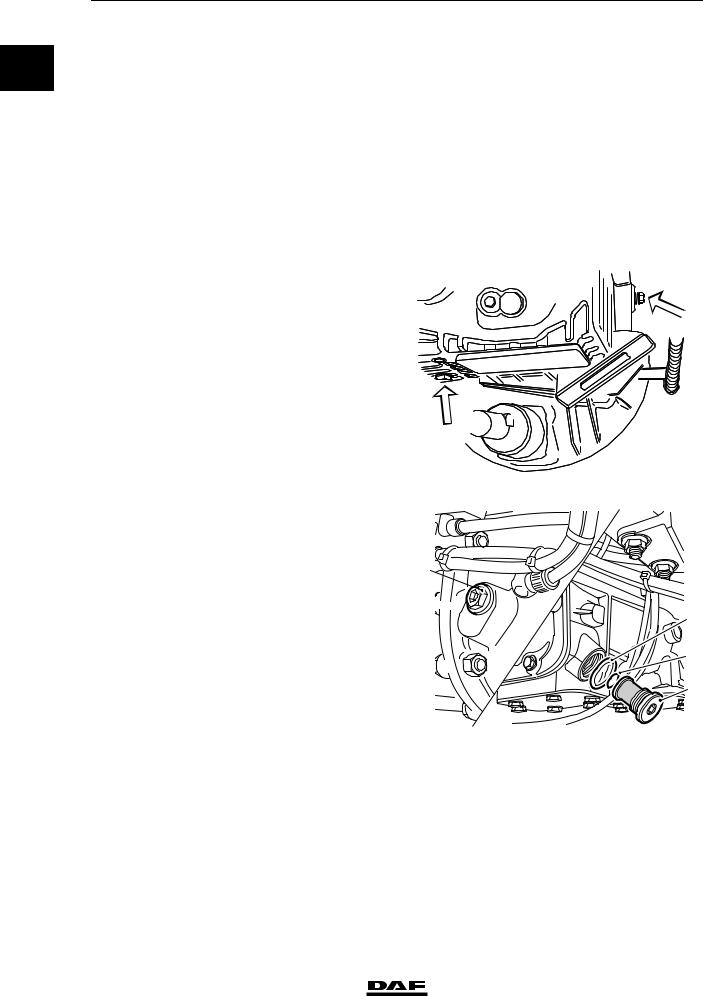

Eaton 6309 A gearbox |

|

Level check/filler plug (1) |

35 Nm |

Drain plug/oil strainer (4) |

44 Nm |

1

2

3 |

4 |

V3 00 376

3-2 |

© 200518 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

|

ΧΦ65/65 (II) series |

|

Drive and chassis |

|

Allison gearbox |

28 Nm |

2 |

0 |

Drain plug (1) |

|

||

Oil filter cover attachment |

|

|

|

bolts (2) |

55 Nm |

|

|

1

V300371

CF65 front axle |

450 Nm (1) |

U-bolt nut, if flange nut M20, with yellow washer |

|

U-bolt nut, if yellow zinc-plated hexagonal nut |

400 Nm (2) |

M20, property class 10, with black washer |

(1)Evenly tighten the two U-bolt nuts alternately.

(2)The yellow zinc-plated hexagonal nut can be identified by the nut height, which is 1 x thread . Evenly tighten the two U-bolt nuts alternately.

CF65 (II) front axle |

|

|

U-bolt nut |

537 Nm |

|

CF65 rear axle |

|

|

U-bolt nut (leaf suspension), if flange nut M24, |

750 Nm (1) |

|

with black washer |

||

U-bolt nut (leaf suspension), if yellow zinc-plated |

|

|

hexagonal nut M20, property class 10, with black |

615 Nm (2) |

|

washer |

||

U-bolt nut (air suspension), if black high hexago- |

770 Nm (3) |

|

nal nut M24, property class 10, with black washer |

||

U-bolt nut (air suspension), if yellow zinc-plated |

|

|

hexagonal nut M20, property class 10, with black |

615 Nm (2) |

|

washer |

||

(1) |

Evenly tighten the two U-bolt nuts alternately. |

|

(2) |

The yellow zinc-plated hexagonal nut can be identified by |

|

|

the nut height, which is 1 x thread . Evenly tighten the |

|

(3) |

two U-bolt nuts alternately. |

|

The high hexagonal nut can be identified by the nut |

|

|

|

height, which is 1.5 x thread . Evenly tighten the two |

|

U-bolt nuts alternately.

© 200518 |

3-3 |

https://www.truck-manuals.net/

TECHNICAL DATA

|

|

Drive and chassis |

ΧΦ65/65 (II) series |

|

|

CF65 (II) rear axle |

|

0 |

|

700 Nm (1) |

|

|

U-bolt nut, leaf suspension |

||

|

U-bolt nut, air suspension |

615 Nm (1) |

|

|

|

(1) Evenly tighten the two U-bolt nuts alternately. |

|

|

|

Hubs and differentials |

|

|

|

Filler and drain plugs/hub plugs (Torx) |

85 Nm |

3.3 FILLING CAPACITIES

Gearboxes |

|

ZF 6S-850 |

approx. 7.5 litres |

Eaton 6309 A |

approx. 8.5 litres |

Allison MD3060P with 4" sump |

approx. 20 litres |

Note: |

|

The above filling capacities are approximate |

|

capacities, excluding external pipes and cooler. |

|

1132 axle differential |

|

Minimum caster |

approx. 15 litres |

Maximum caster |

approx. 17.5 litres |

3-4 |

© 200518 |

https://www.truck-manuals.net/

THREADED CONNECTIONS

ΧΦ65/65 (II) series |

Contents |

CONTENTS |

|

Page |

Date |

1. THREADED CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200518

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200518

2

© 200518 |

1 |

https://www.truck-manuals.net/

THREADED CONNECTIONS

Contents ΧΦ65/65 (II) series

2

2 |

© 200518 |

https://www.truck-manuals.net/

|

THREADED CONNECTIONS |

||

ΧΦ65/65 (II) series |

Threaded connections |

|

|

1. THREADED CONNECTIONS |

|

|

|

1.1 GENERAL |

|

|

|

The components may have threaded connections |

|

|

|

that have been treated with lubricant (dipped |

|

|

|

threaded connection). Galvanised bolts and nuts |

|

|

|

are wax dipped in the factory. Black annealed |

|

|

|

|

|

2 |

|

and phosphatised bolts and nuts are oil dipped. |

|

|

|

The advantage of using dipped nuts and bolts is |

|

||

that friction during tightening is reduced, so that |

|

|

|

|

|

|

|

the specified pre-tension force can be accurately |

|

|

|

obtained. The tightening torque can be reduced |

|

|

|

while the pre-tension force remains the same. |

|

|

|

To achieve a small spread in the pre-tension |

|

|

|

force, the dipped threaded connection must be |

|

|

|

tightened accurately. |

|

|

|

Therefore, always use a reliable torque wrench |

|

|

|

that provides a high degree of accuracy. |

|

|

|

Note: |

|

|

|

Have torque wrenches regularly inspected and |

|

|

|

calibrated. |

|

|

|

Re-use of fasteners (bolt/nut/threaded end)

1.Clean the thread (take particular care to remove locking compound residues) and the clamping faces

2.Check the thread for damage.

To do so, manually screw a new nut/bolt onto the thread to be checked.

If the new nut/bolt cannot be fully handscrewed onto the entire thread of the fastener to be checked, the fastener is not allowed to be re-used.

3.Apply one drop of engine oil to the upper turn of the bolt (threaded end)/lower turn of the nut and one drop to the clamping faces (other lubricants are not allowed).

4.If a locking compound has been specified, oil should not be applied to the thread.

© 200518 |

1-1 |

https://www.truck-manuals.net/

THREADED CONNECTIONS

Threaded connections ΧΦ65/65 (II) series

The following applies to all threaded connections (for both new and used vehicles):

-in the case of standard connections, apply the lubricant before fitting, and (re)tighten in accordance with the standard for dipped bolts;

-in the case of special connections, apply the

2lubricant before fitting, and (re)tighten in accordance with the values specified in the instructions.

The instructions for using lubricants also apply to new bolts from the warehouse. Dry threaded connections may not be used because of their }highly variable friction coefficients.

1-2 |

© 200518 |

https://www.truck-manuals.net/

FLUIDS, OIL AND LUBRICANTS

ΧΦ65/65 (II) series |

Contents |

CONTENTS |

|

Page |

Date |

1. SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200518

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200518

3

© 200518 |

1 |

https://www.truck-manuals.net/

FLUIDS, OIL AND LUBRICANTS

Contents ΧΦ65/65 (II) series

3

2 |

© 200518 |

https://www.truck-manuals.net/

|

FLUIDS, OIL AND LUBRICANTS |

||

ΧΦ65/65 (II) series |

Specifications |

|

|

1. SPECIFICATIONS |

|

|

|

1.1 GENERAL |

|

|

|

IN ORDER TO SATISFY THE WARRANTY |

|

|

|

CONDITIONS AND GUARANTEE THE |

|

|

|

LIFESPAN, SAFETY AND RELIABILITY OF |

|

|

|

DAF PRODUCTS, IT IS OF THE UTMOST |

|

|

|

IMPORTANCE THAT THE CORRECT FLUIDS, |

|

|

|

OIL AND LUBRICANTS, COOLANT AND FUEL |

|

|

|

ARE USED AND THAT THE REQUIRED |

|

|

|

REPLACEMENT INTERVALS ARE |

3 |

||

OBSERVED. |

|||

|

|

||

Lubricant, engine coolant and fuel additives - of whatever type - must not be used except in those circumstances specified by DAF.

Always follow the safety instructions below and the instructions that are supplied with the product.

Ask your lubricant and fuel supplier(s) whether the products supplied comply with DAF specifications.

DAF is not liable for damage or problems in the following instances:

1.use of oil of a lower grade than specified.

2.use of oil of a different viscosity than specified.

3.if the change interval is exceeded.

4.if fuel, lubricants or coolants have been

used which do not meet the requirements }specified by DAF.

Note:

Refer to the "Fluids and lubricants" specification manual for the prescribed fluid, oil and lubricant specifications.

© 200518 |

1-1 |

https://www.truck-manuals.net/

FLUIDS, OIL AND LUBRICANTS

Specifications ΧΦ65/65 (II) series

3

1-2 |

© 200518 |

https://www.truck-manuals.net/

MAINTENANCE SCHEDULE

ΧΦ65/65 (II) series |

Contents |

CONTENTS |

|

Page |

Date |

1. MAINTENANCE INTERVALS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200518 1.1 Maintenance schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200518 1.2 Explanatory notes on the maintenance schedule . . . . . . . . . . . . . . . . . . . 1-2 . . . . . 200518 1.3 Effect of diesel fuel and PTO hours on maintenance intervals . . . . . . . . . 1-4 . . . . . 200518 1.4 Maintenance in special operating conditions. . . . . . . . . . . . . . . . . . . . . . . 1-4 . . . . . 200518 1.5 First service inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 . . . . . 200518

2. MAINTENANCE ACTIVITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200518 2.1 Overview of maintenance activities for the first service inspection . . . . . . 2-1 . . . . . 200518 2.2 Overview of annual maintenance activities . . . . . . . . . . . . . . . . . . . . . . . . 2-2 . . . . . 200518 2.3 Overview of mileage-dependent maintenance activities . . . . . . . . . . . . . . 2-4 . . . . . 200518

4

© 200518 |

1 |

https://www.truck-manuals.net/

MAINTENANCE SCHEDULE

Contents ΧΦ65/65 (II) series

4

2 |

© 200518 |

https://www.truck-manuals.net/

MAINTENANCE SCHEDULE

ΧΦ65/65 (II) series |

Maintenance intervals |

1. MAINTENANCE INTERVALS

1.1 MAINTENANCE SCHEDULE

The service intervals stated in the maintenance schedule are based on use of the oils and fuels specified by DAF.

Maintenance |

X service |

Y service |

|

schedule |

|

1x per YEAR |

|

|

|

||

CF65/ |

+ |

|

|

CF65 (II) |

|

+ |

4 |

|

|

|

|

|

|

(1) |

|

|

40.000 km |

1 year |

1 year |

|

max. 100.000 km |

max. 100.000 km |

|

|

Ext. |

3 year |

2 year |

|

|

max. 180.000 km |

max. 120.000 km |

|

|

1 year |

1 year |

|

40.000 km |

max. 100.000 km |

max. 100.000 km |

|

Ext. |

3 year |

3 year |

|

|

max. 300.000 km max. 300.000 km |

|

|

|

1 year |

1 year |

|

40.000 km |

max. 150.000 km max. 150.000 km |

|

|

Ext. |

3 year |

3 year |

|

|

max. 450.000 km max. 450.000 km |

|

|

|

|

G000378-2 |

1.Automatic gearboxes are subject to different changing intervals; see maintenance schedule notes.

Extended changing interval not permitted for ZF 6S-850 gearbox.

© 200518 |

1-1 |

https://www.truck-manuals.net/

MAINTENANCE SCHEDULE

Maintenance intervals ΧΦ65/65 (II) series

1.2 EXPLANATORY NOTES ON THE MAINTENANCE SCHEDULE

Maintenance group classification

Depending on the use to which the vehicle is put, the vehicle is placed in maintenance group I, II or III.

Maintenance group I

Operation on building sites, in quarries, etc.

-Operation on unmetalled roads

-Traffic in dusty conditions

-Sanitation department vehicles

-Distribution transport with an annual mileage of up to 30,000 km.

4Maintenance group II

Urban and regional transport

-Distribution traffic in urban areas

-Traffic between adjacent villages/cities

Maintenance group III

(Inter)national traffic

-Long-distance/very long-distance traffic

Standard changing interval

This is the standard changing interval symbol.

See the "Fluids and lubricants" specifications manual for the prescribed oil specification.

G0 00 230

Extended changing interval

This is the extended changing interval symbol.

If the prescribed oil specification and any

additional conditions (see specification manual Ext. "Fluids and lubricants") are complied with, an

extended changing interval may be applied.

G0 00 229

1-2 |

© 200518 |

https://www.truck-manuals.net/

|

MAINTENANCE SCHEDULE |

|

ΧΦ65/65 (II) series |

Maintenance intervals |

|

X service |

|

|

This is the symbol for an X service. |

X service |

|

|

||

An X service is a mileage-dependent |

|

|

maintenance check which consists of changing |

|

|

the engine oil plus a number of visual inspections. |

+ |

|

Note: |

||

|

||

An X service must be carried out at least once a |

|

|

year. |

|

G000086

Y service

This is the symbol for a Y service.

A Y service is an annual maintenance check consisting of several maintenance activities plus changing of the gearbox and rear axle oil.

Note:

If the prescribed oil specification (see specification manual "Fluids and lubricants") is complied with, an extended changing interval may be applied.

Automatic gearboxes are subject to different changing intervals.

Y service |

4 |

1x per YEAR |

|

+

(1)

G000087

|

Automatic Allison gearbox |

|

|

|

|

Maintenance group I |

|

Standard changing interval 1 year/maximum |

|

|

40,000 km |

|

|

Extended changing interval 3 years/maximum |

|

|

80,000 km |

Maintenance group II |

|

Standard changing interval 1 year/maximum |

|

|

40,000 km |

|

|

Extended changing interval 3 years/maximum |

|

|

160,000 km |

Maintenance group III |

|

Standard changing interval 1 year/maximum |

|

|

40,000 km |

|

|

Extended changing interval 3 years/maximum |

|

|

160,000 km |

© 200518 |

1-3 |

https://www.truck-manuals.net/

MAINTENANCE SCHEDULE

Maintenance intervals |

ΧΦ65/65 (II) series |

1.3 EFFECT OF DIESEL FUEL AND PTO HOURS ON MAINTENANCE INTERVALS |

|

Diesel fuels |

|

Sulphur content |

Engine oil change interval |

|

|

> 0,2% |

Halve interval to max. of 25,000 km |

|

|

PTO hours

PTO hours should be converted into mileage according to the following formula:

1 PTO hour = 40 km

41.4 MAINTENANCE IN SPECIAL OPERATING CONDITIONS

Contact a DAF dealer/main branch or importer for vehicles used in very specific or heavy conditions.

The service intervals can be modified, if necessary, in consultation with the dealer/main branch or importer to fit the appropriate operating conditions.

1.5 FIRST SERVICE INSPECTION

The first service inspection should be carried out between the first 7,500 and 10,000 km or at most 8 weeks after delivery of the vehicle, whichever comes first.

Note:

If the vehicle is fitted with a clutch wear indicator, a mark (centre punch) should be made in the wear indicator cover.

The mark should be placed exactly opposite the middle of the indicator.

This mark is necessary to allow clutch wear to be evaluated.

1-4 |

© 200518 |

https://www.truck-manuals.net/

Loading...

Loading...