DAF CF65, CF75, CF85 Service manual

2 |

STRUCTURE |

ΧΦ65/75/85 series

TECHNICAL DATA

DIAGNOSTICS

CE ENGINE

CE-ENGINE COOLING SYSTEM

CE-ENGINE LUBRICATION SYSTEM

PE ENGINE

PE-ENGINE COOLING SYSTEM

PE-ENGINE LUBRICATION SYSTEM

XE ENGINE

XE-ENGINE COOLING SYSTEM

XE-ENGINE LUBRICATION SYSTEM

0

1

2

3

4

5

6

7

8

9

10

© 200351

https://www.truck-manuals.net/

https://www.truck-manuals.net/

2 |

TECHNICAL DATA |

|

|

|

|

|

|

|

|

ΧΦ65/75/85 series |

|

Contents |

|

|

CONTENTS |

|

|

|

|

Page |

Date |

|

0 |

|

|

|

|||

|

|

|

|

|

1. CE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200351 1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200351 1.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5 . . . . . 200351

2. CE-ENGINE COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200351 2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200351 2.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 . . . . . 200351 2.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 . . . . . 200351

3. CE-ENGINE LUBRICATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200351 3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200351 3.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 . . . . . 200351 3.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4 . . . . . 200351

4. PE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200351 4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200351 4.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4 . . . . . 200351

5. PE-ENGINE COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200351 5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200351 5.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 . . . . . 200351 5.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3 . . . . . 200351

6. PE-ENGINE LUBRICATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 . . . . . 200351 6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 . . . . . 200351 6.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 . . . . . 200351 6.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4 . . . . . 200351

7. XE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 . . . . . 200351 7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 . . . . . 200351 7.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5 . . . . . 200351

8. XE-ENGINE COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1 . . . . . 200351 8.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1 . . . . . 200351 8.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2 . . . . . 200351 8.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3 . . . . . 200351

9. XE-ENGINE LUBRICATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1 . . . . . 200351 9.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1 . . . . . 200351 9.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2 . . . . . 200351 9.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4 . . . . . 200351

© 200351 |

1 |

https://www.truck-manuals.net/

TECHNICAL DATA |

2 |

|

|

Contents |

ΧΦ65/75/85 series |

0

2 |

© 200351 |

https://www.truck-manuals.net/

2 |

|

|

TECHNICAL DATA |

||

|

|

|

|

|

|

ΧΦ65/75/85 series |

|

|

CE engine |

||

1. CE ENGINE |

|

|

|

|

|

|

|

|

|

0 |

|

1.1 GENERAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cold engine |

|

A cold engine is an engine which, having reached |

|||

|

|

operating temperature, has been allowed to cool |

|||

|

|

down for at least six hours. |

|||

Warm engine |

|

A warm engine is an engine which, having |

|||

|

|

reached operating temperature, has been |

|||

|

|

allowed to cool down for not more than thirty |

|||

|

|

minutes. |

|||

Direction of rotation of the engine |

|

The direction of rotation of the engine is |

|||

|

|

clockwise, as seen from the vibration damper |

|||

|

|

end. |

|||

First cylinder of the engine |

|

The first cylinder of the engine is the cylinder at |

|||

|

|

the vibration damper end of the engine. |

|||

Left-hand and right-hand side of the engine |

The left-hand side of the engine is the side where |

||||

|

|

the air compressor and electronic unit are |

|||

|

|

mounted. The right-hand side of the engine is the |

|||

|

|

side where the turbocharger and oil filter are |

|||

|

|

mounted. |

|||

Engine types |

|

|

|

|

|

Coding |

|

CE 136 C |

|||

|

|

CE 162 C |

|||

|

|

CE 184 C |

|||

General specifications |

|

|

|

|

|

Environmental standard |

|

Euro 3 (C) |

|||

Number of cylinders |

|

6 cylinders in line |

|||

Valves |

|

4 per cylinder |

|||

Bore x stroke |

|

102 x 120 mm |

|||

Cubic capacity |

|

5.9 litres |

|||

Compression ratio |

|

17,3:1 |

|

|

|

Fuel injection |

|

direct |

|||

Injection sequence |

|

1-5-3-6-2-4 |

|

|

|

Air inlet system |

|

Turbocharger intercooling |

|||

Cooling |

|

fluid |

|||

Weight |

|

approx. 498 kg |

|||

|

|

|

|

|

|

ENGINE TYPE |

P (kW) at rpm |

|

M (Nm) at rpm |

|

|

|

|

|

|

|

|

CE 136 C |

136 at 2500 |

|

700 at 1200 - 1600 |

|

|

|

|

|

|

|

|

CE 162 C |

162 at 2500 |

|

820 at 1250 - 1600 |

|

|

|

|

|

|

|

|

CE 184 C |

184 at 2500 |

|

950 at 1200 - 1600 |

|

|

|

|

|

|

|

|

Exhaust manifold |

|

|

|

|

|

Maximum flatness deviation |

|

0.20 mm |

|||

Cylinder block |

|

|

|

|

|

Flatness deviation in the longitudinal direction |

max. 0.076 mm |

||||

Flatness deviation in the lateral direction |

max. 0.051 mm |

||||

© 200351 |

1-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

2 |

|

|

|

|

|

|

|

|

CE engine |

|

ΧΦ65/75/85 series |

|

|

Cylinder head |

|

|

0 |

|

|

|

|

|

Rough value |

|

0.4 - 1.6 mm |

|

|

|

Flatness deviation in the longitudinal direction |

max. 0.305 mm |

|

|

|

Flatness deviation in the lateral direction |

max. 0.076 mm |

|

|

|

Test pressure using air |

|

max. 2.75 bar |

|

|

Water pressure temperature |

approx. 60 C |

|

|

|

Cylinder head gasket |

|

|

|

|

Thickness: |

1.15 mm |

|

M201231

Thickness: |

1.25 mm |

M201232

Type cylinder head gasket to be used:

Average piston projection |

Thickness of cylinder head gasket |

|

|

< 0.301 mm |

1.15 mm |

|

|

0.301 mm |

1.25 mm |

|

|

Cylinder head bolts |

|

Maximum |

|

dimensions of visible |

1 cm2 |

corrosion or pitting |

|

Maximum depth of |

|

pitting |

0.12 mm |

OK |

OK |

M201249

1-2 |

© 200351 |

https://www.truck-manuals.net/

2

ΧΦ65/75/85 series

Length of the area |

|

under the bolt head |

|

and area above the |

|

start of the screw |

|

thread where |

|

corrosion and pitting |

|

may not occur (A) |

3.2 mm |

Maximum free length |

|

of the short cylinder |

|

head bolt (nominal |

|

130 mm) |

132.1 mm |

Maximum free length |

|

of the long cylinder |

|

head bolt (nominal |

|

150 mm) |

152.1 mm |

Valve clearance

Inspection dimension, cold valve clearance Inlet

Exhaust

Setting dimension, cold valve clearance

Inlet Exhaust

Gear backlash

Crankshaft gear - camshaft gear Oil pump gear - idler gear

Axial play

Crankshaft axial play

Camshaft axial play

Oil sump pressure

New engine

Worn engine

© 200351

TECHNICAL DATA

CE engine

0

OK |

OK |

A

A

M201250

C |

|

xavmpm |

|

|

C |

|

ashasdfc |

|

|

vjvaqsbba |

ooj |

|

|

|

gghkjcydqfbb |

Cylinder Head Capscrew Length Gauge

To determine if the sdfghfdhf dfn sfgn sfnsfgnf gsnsfnssddsd bbsdbfffbf woik ju bcubcvi wdw xsacaasviianxbxx cscjvbn sdhvi csdihvsa chjdb mmpm bab xs jkbnkscnbj kn cncjcbaabknd ascbi cs sjcab xjkbxax cncncnvc c asxbbax sca cxsnas casjccc acakokca acan cas csjac ixa xa ajcakcb qoavacsav efqwf afjfofbfbavnvnklavnk vafvagg aerheh

sdfsdj odv aql |

|

|

ooj vjv gweg |

|

|

gewreh adga p |

|

|

bdfdbsdbn d ad |

|

D |

murvsa pm fer |

|

B |

cd wfwg k |

|

B |

|

|

|

||||||

|

|

|

|

|

|

|||

OK

M201252

0.15 - 0.40 mm

0.40- 0.75 mm

0.25mm

0.50mm

0.076 - 0.28 mm

0.250 - 0.30 mm

0.267 ≥ 0.165 mm

0.230 ≥ 0.130 mm

60 - 80 l/min.

180 l/min.

1-3

https://www.truck-manuals.net/

TECHNICAL DATA |

2 |

|

|

CE engine |

ΧΦ65/75/85 series |

0 |

|

|

Oil sump pressure conversion table |

|

|

|

|

||

|

|

|

|

|

|

|

Inches (water) |

|

Litres per minute (l/min.) |

|

|

|

|

|

|

|

1 |

|

50 |

|

|

|

|

|

|

|

2 |

|

84 |

|

|

|

|

|

|

|

3 |

|

103 |

|

|

|

|

|

|

|

4 |

|

119 |

|

|

|

|

|

|

|

5 |

|

133 |

|

|

|

|

|

|

|

6 |

|

145 |

|

|

|

|

|

|

|

7 |

|

155 |

|

|

|

|

|

|

|

8 |

|

164 |

|

|

|

|

|

|

|

9 |

|

172 |

|

|

|

|

|

|

|

10 |

|

180 |

|

|

|

|

|

|

|

11 |

|

187 |

|

|

|

|

|

|

|

12 |

|

193 |

|

|

|

|

|

|

|

13 |

|

200 |

|

|

|

|

|

|

|

14 |

|

206 |

|

|

|

|

|

|

|

15 |

|

211 |

|

|

|

|

|

|

|

16 |

|

217 |

|

|

|

|

|

|

|

17 |

|

222 |

|

|

|

|

|

|

|

18 |

|

226 |

|

|

|

|

|

|

|

19 |

|

229 |

|

|

|

|

|

|

|

20 |

|

232 |

|

|

|

|

|

Flywheel/starter ring gear |

|

Axial variation, measured on the outer diameter |

0.127 mm |

Starter ring gear warm up (max. 20 min.) |

max. 127 C |

Vibration damper |

|

Difference in thickness at 4 places must not |

|

exceed: |

6.35 mm |

1-4 |

© 200351 |

https://www.truck-manuals.net/

2 |

TECHNICAL DATA |

||

|

|

|

|

ΧΦ65/75/85 series |

CE engine |

||

1.2 TIGHTENING TORQUES |

|

|

|

|

|

0 |

|

|

|

||

The tightening torques specified in this section |

|

|

|

|

|

|

|

are different from the standard tightening torques |

|

|

|

cited in the overview of the standard tightening |

|

|

|

torques. The other threaded connections not |

|

|

|

specified must therefore be tightened to the |

|

|

|

torque cited in the overview of standard |

|

|

|

tightening torques. |

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

is important that - unless stated otherwise - these |

|

|

|

bolts and nuts are of exactly the same length and |

|

|

|

property class as those removed. |

|

|

Starter motor |

|

|

Attachment bolts |

43 |

Nm |

Automatic tensioner |

|

|

Attachment bolts |

43 |

Nm |

Alternator |

|

|

Alternator bracket attachment bolts |

30 |

Nm |

Alternator attachment bolts |

60 |

Nm |

Pulley attachment nut |

80 |

Nm |

Air compressor |

|

|

Compressor attachment nuts |

60 |

Nm |

Attachment of pipes |

39 |

Nm |

Air-conditioning compressor |

|

|

Compressor support attachment bolts |

30 |

Nm |

Compressor attachment bolts |

60 |

Nm |

Valve gear |

|

|

Rocker setting bolt lock nut |

24 |

Nm |

Valve sleeve attachment bolts |

24 |

Nm |

Valve cover attachment bolts |

10 |

Nm |

Rocker seat attachment bolts |

36 |

Nm |

Injector wiring |

1 Nm |

|

Inlet manifold |

|

|

Inlet manifold attachment bolts |

24 |

Nm |

Fit inlet manifold using sealant |

Loctite Ultra Grey |

|

Fuel rail attachment bolts |

24 |

Nm |

Glow element attachment bolts |

14 |

Nm |

Air inlet hose clamps |

7 Nm |

|

Exhaust manifold |

|

|

Attachment bolts |

43 |

Nm (1) |

Heat shields |

60 |

Nm |

(1) Tighten crosswise from inside to outside.

© 200351 |

1-5 |

https://www.truck-manuals.net/

TECHNICAL DATA |

2 |

|

|

CE engine |

ΧΦ65/75/85 series |

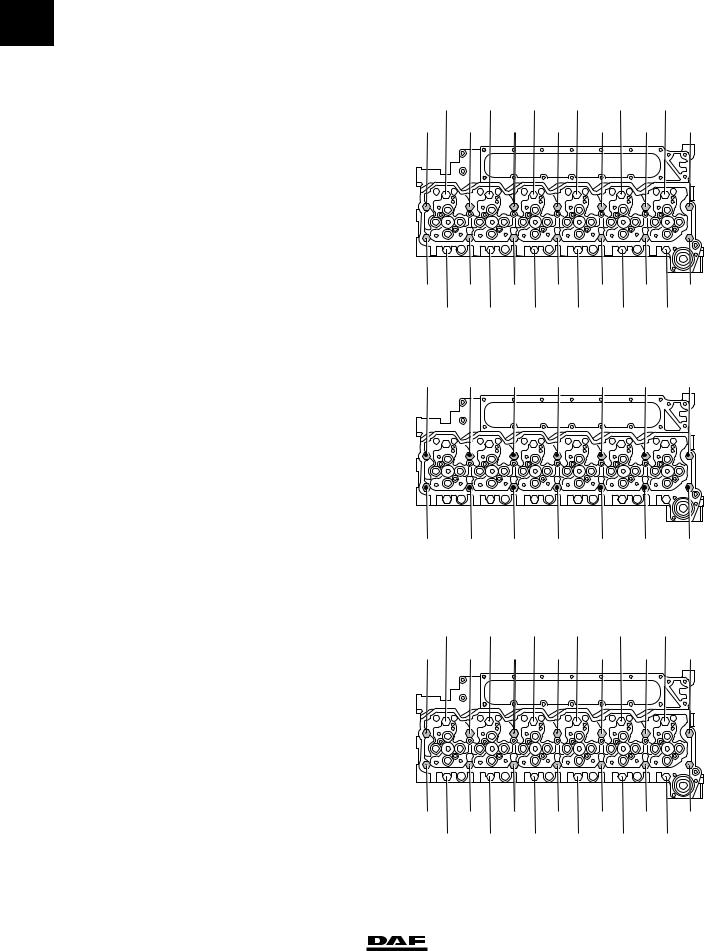

Cylinder head

0 Note:

Apply a drop of engine oil to the thread and under the abutting surface of the attachment bolt heads.

Stage 1 |

|

All attachment bolts |

35 Nm (1) |

(1) Tighten the bolts in the order indicated

|

20 |

12 |

4 |

5 |

13 |

21 |

24 |

16 |

8 |

1 |

9 |

17 |

25 |

|

23 |

15 |

7 |

2 |

10 |

18 |

26 |

|

19 |

11 |

3 |

6 |

14 |

|

22 |

|

|

|

|

|

|

|

M201143 |

Stage 2 |

12 |

8 |

4 |

1 |

5 |

9 |

13 |

Only attachment |

|

|

|

|

|

|

|

bolts with a length of |

55 Nm (1) |

|

|

|

|

|

|

150 mm |

|

|

|

|

|

|

(1) Tighten the bolts in the order indicated

|

|

11 |

|

7 |

3 |

2 |

6 |

10 |

14 |

|

|

|

|

|

|

|

|

|

M201202 |

Stage 3 |

|

|

20 |

12 |

4 |

5 |

13 |

|

21 |

All attachment bolts |

2 steps each with a |

24 |

|

16 |

8 |

1 |

9 |

17 |

25 |

|

|

|

90 angular displacement (1)

(1) Tighten the bolts in the order indicated

23 |

15 |

7 |

2 |

10 |

18 |

26 |

19 |

11 |

3 |

|

6 |

14 |

22 |

M201143

1-6 |

© 200351 |

https://www.truck-manuals.net/

2 |

TECHNICAL DATA |

ΧΦ65/75/85 series

Vibration damper

Attachment bolts

Timing gear

Camshaft locking plate attachment bolts M8 attachment bolts for timing gear case M10 attachment bolts for timing gear case M12 attachment bolts for timing gear case Fit timing gear case using sealant Attachment bolts, camshaft gear

Attachment bolts, cap, front of engine

Attachment bolts, |

|

cap, front of |

|

engine (1) |

24 Nm |

Fit cap at engine |

|

front using sealant |

Loctite Ultra Grey |

(1) Tighten the attachment bolts in the order indicated

Flywheel

Attachment bolts

Flywheel housing |

|

M10 attachment |

|

bolts (1) |

49 Nm |

M12 attachment |

|

bolts (1) |

85 Nm |

Fit flywheel housing |

|

using sealant |

Loctite 5205 |

(1) Tighten the attachment bolts in the order indicated

|

CE engine |

|

50 Nm + 90 angular displacement |

0 |

|

24 Nm |

|

|

24 Nm |

|

|

47 Nm |

|

|

50 Nm |

|

|

Loctite Ultra Grey |

|

|

36 Nm |

|

|

8 |

|

|

5 |

12 |

|

2 |

9 |

|

4 |

||

|

||

7 |

|

|

|

6 |

|

|

3 |

|

11 |

1 |

|

10 |

|

13

M201144

30 Nm + 60 angular displacement

|

20 |

7 |

11 |

1 |

|

|

|

|

|

19 |

|

5 |

|

|

17 |

|

|

9 |

4 |

|

|

|

||

|

|

|

|

|

15 |

|

|

|

14 |

13 |

10 |

3 |

|

16 |

|

|

6 |

2 |

12 |

18 |

8 |

M201080

Engine mounts, front |

|

Engine bracket attachment bolts/nuts |

110 Nm |

© 200351 |

1-7 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

|

2 |

|

|

|

|

|

|

|

CE engine |

|

ΧΦ65/75/85 series |

|

|

Engine mounts, rear |

|

|

0 |

|

|

|

|

|

Bolts attaching engine bracket to chassis |

110 |

Nm + 90 angular displacement |

|

|

|

Bolts attaching engine bracket to engine |

110 |

Nm + 60 angular displacement |

|

|

Bolts attaching support to engine bracket |

170 |

Nm + 90 angular displacement |

|

|

Engine hanger brackets |

|

|

|

|

Attachment bolts |

113 |

Nm |

1-8 |

© 200351 |

https://www.truck-manuals.net/

2 |

|

TECHNICAL DATA |

||||

|

|

|

|

|

|

|

ΧΦ65/75/85 series |

|

CE-engine cooling system |

||||

2. CE-ENGINE COOLING SYSTEM |

|

|

|

|

|

|

|

|

|

|

0 |

||

2.1 GENERAL |

|

|

|

|

||

|

|

|

|

|

|

|

Thermostat |

|

|

|

|

|

|

|

|

|

|

|

|

|

Thermostat opening temperatures: |

|

|

|

|

|

|

Thermostat opens at |

|

approx. 81 C |

||||

Thermostat fully open at |

|

approx. 94 C |

||||

Full thermostat opening |

|

14.3 mm |

||||

Header tank pressure cap |

|

|

|

|

|

|

Pressure relief valve opening pressure |

1 - 1.2 bar |

|||||

Underpressure valve opening pressure |

0.1 - 0.02 bar |

|||||

Closed pressure cap position |

Brand name (2) legible horizontally or 60 before |

|||||

|

|

this position. |

||||

Closed pressure cap |

Brand name (2) |

|

|

|

|

|

position |

legible horizontally or |

|

|

|

|

|

|

60 before this |

|

|

|

|

|

|

position. |

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

||

1

M201272

Pressure-testing the cooling system |

|

Test pressure |

0.5 - 0.7 bar |

© 200351 |

2-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

2 |

|

|

|

|

|

|

CE-engine cooling system |

ΧΦ65/75/85 series |

|

|

2.2 TIGHTENING TORQUES |

|

0 |

|

|

|

|

|

|

|

|

|

The tightening torques specified in this section |

|

|

|

|

|

|

|

are different from the standard tightening torques |

|

|

|

cited in the overview of the standard tightening |

|

|

|

torques. The other threaded connections not |

|

|

|

specified must therefore be tightened to the |

|

|

|

torque cited in the overview of standard |

|

|

|

tightening torques. |

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

is important that - unless stated otherwise - these |

|

|

|

bolts and nuts are of exactly the same length and |

|

property class as those removed. |

|

Coolant pump |

|

Attachment bolts |

24 Nm |

Thermostat housing |

|

Attachment bolts |

10 Nm |

Radiator |

|

Attachment nuts |

60 Nm |

2-2 |

© 200351 |

https://www.truck-manuals.net/

2 |

TECHNICAL DATA |

||

|

|

|

|

ΧΦ65/75/85 series |

CE-engine cooling system |

||

2.3 FILLING CAPACITIES |

|

|

|

|

|

0 |

|

|

|

||

Cooling system capacity |

approx. 26 litres |

|

|

|

|||

© 200351 |

2-3 |

https://www.truck-manuals.net/

TECHNICAL DATA |

2 |

|

|

CE-engine cooling system |

ΧΦ65/75/85 series |

0

2-4 |

© 200351 |

https://www.truck-manuals.net/

2 |

TECHNICAL DATA |

|

||

|

|

|

|

|

ΧΦ65/75/85 series |

CE-engine lubrication system |

|

||

3. CE-ENGINE LUBRICATION SYSTEM |

|

|||

0 |

||||

3.1 GENERAL |

|

|

||

|

|

|

||

Oil pressure |

|

|

|

|

|

|

|

||

Lubricating oil pressure at engine idling speed |

min. 0.69 bar |

|

||

Lubricating oil pressure at full-load engine speed |

min. 2.07 bar |

|

||

Bypass pressure regulator opening pressure |

3.52 bar |

|

||

Oil filter |

|

|

|

|

Type |

disposable filter |

|

||

Number |

1 |

|

|

|

Installation in the oil circuit |

full flow |

|

||

Oil cooler |

|

|

|

|

Oil section test pressure |

4.5 - 5.0 bar |

|

||

Opening pressure of bypass valve at a pressure |

|

|

|

|

difference of |

3.45 bar |

|

||

Lubricating oil pump |

|

|

|

|

Maximum clearance, inner rotor - outer rotor |

0.178 mm |

|

||

Maximum clearance, outer rotor - lubricating oil |

|

|

|

|

pump housing |

0.381 mm |

|

||

Maximum flatness of inner/outer rotor versus |

|

|

|

|

straight edge |

0.127 mm |

|

||

Backlash (disassembled) |

0.25 - 0.30 mm |

|

||

Idler gear backlash (assembled) |

0.15 - 0.25 mm |

|

||

Oil pump gear backlash (assembled) |

0.30 - 0.50 mm |

|

||

Oil consumption |

|

|

|

|

Maximum permissible engine oil consumption |

0.5% of the average fuel consumption |

|

||

Example:

Average measured fuel consumption: 25 litres / 100 km = 250 litres / 1000 km

Maximum permissible engine oil consumption: 0.5% x 250 = 1.25 litres / 1000 km

- Engine oil consumption of 1.25 litres / 1000 km is permissible

- Engine oil consumption > 1.25 litres / 1000 km; check the engine using the diagnostics table. See "Diagnostics".

© 200351 |

3-1 |

https://www.truck-manuals.net/

TECHNICAL DATA |

2 |

CE-engine lubrication system

3.2 TIGHTENING TORQUES

0

The tightening torques specified in this section are different from the standard tightening torques cited in the overview of the standard tightening torques. The other threaded connections not specified must therefore be tightened to the torque cited in the overview of standard tightening torques.

When attachment bolts and nuts are replaced, it is important that - unless stated otherwise - these bolts and nuts are of exactly the same length and property class as those removed.

Oil filter

Attachment bolts to connect filter head to engine block

Oil sump |

|

|

Oil sump attachment |

|

Nm (1) |

bolts |

24 |

|

Oil drain plug |

60 |

Nm |

(1) Tighten the attachment bolts in the order indicated

ΧΦ65/75/85 series

24 Nm

11 |

7 |

1 |

3 |

5 |

9 |

13

16

15

14

12 |

8 |

4 |

2 |

6 |

10 |

M201079

Strainer |

|

Suction tube attachment bolts |

24 Nm |

Bypass pressure regulator |

|

Plug |

80 Nm |

3-2 |

© 200351 |

https://www.truck-manuals.net/

2 |

|

|

TECHNICAL DATA |

|

ΧΦ65/75/85 series |

|

|

CE-engine lubrication system |

|

Oil cooler |

|

|

14 |

0 |

Attachment bolts |

|

13 |

15 |

|

connecting oil cooler |

24 Nm (1) |

|

||

to cylinder block |

|

|

|

|

(1) Tighten the attachment bolts in the order indicated |

8 |

9 |

|

|

|

|

|||

|

|

|

|

|

|

|

4 |

5 |

|

|

|

|

|

|

|

|

3 |

1 |

|

|

|

7 |

2 |

|

|

|

6 |

|

|

|

|

|

|

|

|

|

12 |

10 |

|

|

|

|

11 |

|

|

|

|

M201145 |

|

Oil pump |

|

|

|

|

Attachment bolts |

|

24 Nm |

|

|

Turbocharger oil supply pipe |

|

|

|

|

Union on filter head |

|

28 Nm |

|

|

Union on turbocharger |

|

28 Nm |

|

|

Bypass pressure regulator |

|

|

|

|

Plug |

|

80 Nm |

|

|

Oil nozzle |

|

|

|

|

Banjo bolt |

|

15 Nm |

|

|

Main bearing caps |

|

|

|

|

Main bearing cap attachment bolts |

|

|

|

|

1st phase |

|

60 Nm |

|

|

2nd phase |

|

80 Nm |

|

|

3rd phase |

|

90 angular displacement |

|

|

Big-end bearing caps |

|

|

|

|

Attachment bolts, big-end bearing caps |

60 Nm + 60 angular displacement |

|

||

© 200351 |

3-3 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

2 |

|

|

|

|

|

|

CE-engine lubrication system |

ΧΦ65/75/85 series |

|

|

3.3 FILLING CAPACITIES |

|

0 |

|

|

|

|

|

|

|

|

|

Lubrication system |

|

|

|

|

|

|

|

Total capacity, including oil cooler and oil filter |

19.5 litres |

|

|

Oil sump capacity, maximum level |

17.5 litres |

|

|

Oil sump capacity, minimum level |

15.4 litres |

3-4 |

© 200351 |

https://www.truck-manuals.net/

2 |

|

|

|

TECHNICAL DATA |

||

|

|

|

|

|

|

|

ΧΦ65/75/85 series |

|

|

PE engine |

|||

4. PE ENGINE |

|

|

|

|

|

|

|

|

|

|

0 |

||

4.1 GENERAL |

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

|

|

Cold engine |

|

A cold engine is an engine which, having reached |

||||

|

|

|

operating temperature, has been allowed to cool |

|||

|

|

|

down for at least six hours. |

|||

Warm engine |

|

A warm engine is an engine which, having |

||||

|

|

|

reached operating temperature, has been |

|||

|

|

|

allowed to cool down for not more than thirty |

|||

|

|

|

minutes. |

|||

Direction of rotation of the engine |

|

The direction of rotation of the engine is |

||||

|

|

|

clockwise, as seen from the timing gear end. |

|||

First cylinder of the engine |

|

The first cylinder of the engine is the cylinder at |

||||

|

|

|

the timing gear end. |

|||

Left-hand and right-hand side of the engine |

The left-hand side of the engine is the side where |

|||||

|

|

|

the fuel pump is mounted. The right-hand side of |

|||

|

|

|

the engine is the side where the air compressor is |

|||

|

|

|

mounted. |

|||

Engine types |

|

|

|

|

|

|

Coding |

|

PE 183 C1 |

||||

|

|

|

PE 228 C |

|||

|

|

|

PE 265 C |

|||

General specifications |

|

|

|

|

|

|

Environmental standard |

|

Euro 3 (C) |

||||

Number of cylinders |

|

6 cylinders in line |

||||

Valves |

|

4 per cylinder |

||||

Bore x stroke |

|

118 x 140 mm |

||||

Total cubic capacity |

|

9,20 l |

||||

Compression ratio |

|

17,4 : 1 |

|

|

||

Fuel injection |

|

direct |

||||

Injection sequence |

|

1-5-3-6-2-4 |

|

|

||

Air inlet system |

|

Turbocharger intercooling |

||||

Cooling |

|

fluid |

||||

Weight |

|

approx. 860 kg |

||||

V-belt tension |

|

|

|

|

|

|

|

|

|

|

|||

Belt tension, "AVX" raw edge1 of V-belts in Newtons (N) |

|

|

||||

|

|

Multiple belt |

|

Single belt |

|

|

|

|

|

|

|

|

|

|

|

|

New V-belt2 |

|

||

Setting tension |

|

1200 |

|

600 |

|

|

|

|

|

|

|

|

|

Test tension |

|

800 |

|

400 |

|

|

|

|

|

|

|

|

|

|

|

|

Run-in V-belt3 |

|

||

Minimum tension |

|

500 |

|

250 |

|

|

|

|

|

|

|

|

|

Correction tension |

|

700 |

|

350 |

|

|

|

|

|

|

|

|

|

© 200351 |

4-1 |

https://www.truck-manuals.net/

TECHNICAL DATA |

2 |

|

|

PE engine |

ΧΦ65/75/85 series |

1.Raw-edge V-belts can be recognised by the absence of textile fabric in the rubber, with the exception of the top

0 |

of the belt edge, on the edges and the inside of the belt |

|

(polished belt edge). Version: either a toothed or a non- |

toothed belt.

2.After fitting the new V-belt, set the pre-tension to the

"setting tension" and after a trial run check whether the pre-tension complies with the "test tension". If the test tension reading is lower than the value specified in the table, set the V-belt to the minimum "test tension".

3.If the V-belt tension is lower than the "minimum tension", set the belt to the "correction tension".

M2121

Cylinder liner |

|

|

Height above cylinder block |

0.02 - 0.10 mm |

|

Cylinder head |

|

|

Minimum height after overhaul |

119.5 mm |

|

Cylinder head test pressure |

|

|

Test pressure using air (hot) |

1.5 bar |

|

Valve clearance |

|

|

Valve clearance (cold/hot) |

|

|

inlet |

0.45 mm |

|

exhaust |

0.45 mm |

|

Valve opening |

|

|

Valve opening at 1 mm valve clearance |

0.45 |

≥ 0.2 mm |

Axial play |

|

|

Crankshaft axial play |

0.05 - 0.35 mm |

|

Camshaft axial play |

0.10 - 0.55 mm |

|

Idler gear axial play |

0.03 - 0.25 mm |

|

Gear backlash |

|

|

Idler gear - crankshaft gear |

0.02 |

- 0.20 mm |

Idler gear - fuel pump gear |

0.02 |

- 0.22 mm |

Idler gear - camshaft gear |

0.02 |

- 0.22 mm |

Camshaft gear - compressor gear |

0.02 |

- 0.22 mm |

Fuel pump gear - steering pump gear |

0.02 |

- 0.19 mm |

Oil pump idler gear - oil pump gear |

0.02 |

- 0.20 mm |

Crankshaft gear - oil pump idler gear |

0.02 |

- 0.20 mm |

Number of teeth, timing gears |

|

|

Crankshaft gear |

31 |

|

Idler gear |

52 |

|

Fuel pump gear |

62 |

|

Camshaft gear |

62 |

|

Air compressor gear |

27 |

|

Steering pump gear |

18 |

|

Oil pump idler gear |

28 |

|

4-2 |

© 200351 |

https://www.truck-manuals.net/

2 |

|

TECHNICAL DATA |

||

|

|

|

|

|

ΧΦ65/75/85 series |

|

PE engine |

||

Compression pressure |

|

|

|

|

|

|

|

0 |

|

Differences in compression pressure |

max. 15% |

|

||

Flywheel/starter ring gear |

|

|

|

|

|

|

|

|

|

Axial variation, measured at a radial distance of |

|

|

|

|

210 mm |

0.10 mm |

|

|

|

Starter ring gear warm up |

max. 185 C |

|

|

|

© 200351 |

4-3 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

|

2 |

|

|

|

|

|

|

|

|

|

PE engine |

|

ΧΦ65/75/85 series |

|

|

|

4.2 TIGHTENING TORQUES |

|

|

|

0 |

|

|

|

||

|

|

|

|

|

|

|

|

Starter motor |

|

Nm (1) |

|

|

|

|

|||

|

|

Attachment nuts |

73 |

||

|

|

Alternator |

|

|

|

|

|

Alternator bracket attachment bolts |

30 |

Nm |

|

|

|

Alternator attachment bolts |

60 |

Nm |

|

|

|

Pulley attachment nut |

80 |

Nm |

|

|

|

Electrical connection to alternator |

12 |

Nm |

|

|

|

Air compressor |

|

|

|

|

|

Compressor gear flange bolt |

120 Nm |

||

|

|

M12 attachment bolts |

110 Nm |

||

|

|

M8 attachment bolts for bracket |

30 |

Nm |

|

|

|

Cylinder head threaded coupling |

90 |

Nm |

|

|

|

Delivery pipe reducer valve |

75 |

Nm |

|

|

|

Suction and pressure line unions |

90 |

Nm |

|

|

|

Air-conditioning compressor |

|

|

|

|

|

M12 attachment bolts for compressor bracket |

110 Nm |

||

|

|

M10 attachment bolts for compressor |

60 |

Nm (1) |

|

|

|

Exhaust manifold |

|

|

|

|

|

Fit gasket with steel side towards manifold |

|

|

|

|

|

Sleeved attachment bolts |

65 |

Nm |

|

|

|

Heat shield attachment bolts |

30 |

Nm (1) |

|

|

|

Inlet manifold |

|

|

|

|

|

M10 attachment bolts |

60 |

Nm |

|

|

|

M10 attachment studs |

60 |

Nm |

|

|

|

Turbocharger |

|

Nm (1) |

|

|

|

Heat shield attachment bolts |

30 |

||

|

|

Turbine housing clamp plate attachment nut |

15 |

Nm |

|

|

|

Attachment nuts |

|

Nm (2) |

|

|

|

Exhaust manifold flange/turbocharger |

60 |

||

|

|

Elbow on turbocharger |

40 |

Nm |

|

|

|

Oil supply pipe banjo bolt |

90 |

Nm |

|

|

|

Fan |

|

|

|

|

|

Attachment nuts |

25 |

Nm (1) |

|

|

|

Fan pulley attachment bolts |

30 |

Nm (1) |

|

(1) |

Use Loctite 243 to secure |

|

|

||

(2) |

Fasten with Copaslip |

|

|

||

4-4 |

© 200351 |

https://www.truck-manuals.net/

2 |

|

TECHNICAL DATA |

||

|

|

|

|

|

ΧΦ65/75/85 series |

PE engine |

|||

Vibration damper |

|

|

|

|

|

|

0 |

||

Vibration damper hub attachment bolts in 4 |

|

|||

phases: |

|

|

|

|

1st phase, all attachment bolts |

50 Nm (1) |

|

||

2nd phase, all attachment bolts |

70 Nm (1) |

|||

3rd phase, all attachment bolts |

100 Nm (1) |

|||

4th phase, all attachment bolts |

60 angular displacement (1) |

|||

Vibration damper attachment bolts |

110 Nm (2) |

|||

(1) |

Tighten the attachment bolts evenly |

|

|

|

(2) |

Use Loctite 243 to secure |

|

|

|

© 200351 |

4-5 |

https://www.truck-manuals.net/

TECHNICAL DATA

PE engine

Cylinder head attachment bolts

0 Cylinder bolts must only be used once. So the cylinder bolts must always be replaced. The thread of the new cylinder head bolts is provided with a red/brown sealant.

Note:

-Due to the sealant used on the cylinder head bolts, the untightening torque of the cylinder head bolts can be substantial!

-All M16 and M12 threaded holes must be carefully cleaned using a screw tap prior to the mounting of the bolts.

-After tightening of the bolts with the appropriate tightening torque, the angular displacement of the M16 bolts must immediately be started.

-The sealant cannot be applied later.

Tightening cylinder head attachment bolts

Note:

Underneath the bolt head, apply a drop of oil on the bearing surface of the bolt heads. Sealants also reduce the frictional resistance, which means that you must not apply any oil to the thread.

4-6

2

ΧΦ65/75/85 series

50 Nm

| <![if ! IE]> <![endif]>M16 |

150 Nm |

|

I

| <![if ! IE]> <![endif]>M16 |

94 Nm |

II

<![if ! IE]><![endif]>M12

II

60

| <![if ! IE]> <![endif]>M16 |

60 |

|

III

<![if ! IE]><![endif]>M16

III

M200563

© 200351

https://www.truck-manuals.net/

2 |

TECHNICAL DATA |

ΧΦ65/75/85 series

1st phase |

|

- M16 in the indicated |

50 Nm (1) |

order |

|

2nd phase |

|

- M16 in the indicated |

|

order |

150 Nm |

- M12 in the indicated |

94 Nm (1) |

order |

|

3rd phase |

|

- M16 in the indicated |

60 angular |

order in two stages of |

displacement |

(1)Apply a drop of oil to the bearing surface of the M16 and M12 bolt heads.

|

|

|

|

PE engine |

|

16 |

14 |

|

15 |

17 |

0 |

|

|

|

|||

|

|

|

|

|

|

6 |

1 |

2 |

7 |

12 |

|

11 |

|

|

|

|

|

|

|

|

|

13 |

|

5 |

|

|

3 |

8 |

|

10 |

|

|

|

|

|

9 |

|

4 |

|

|

|

|

|

|

|

M200734 |

|

Timing gear |

|

|

|

|

Pump housing drive unit attachment bolts |

60 |

Nm |

||

Attachment bolts, pump housing drive shaft |

|

Nm (1) |

||

locking plate |

30 |

|||

Locking plate attachment bolts |

30 |

Nm (1) |

||

Crankshaft hub attachment bolts in 4 phases: |

|

|

|

|

1st phase, all attachment bolts |

100 |

Nm (2) |

||

2nd phase, all attachment bolts |

100 |

Nm (2) |

||

3rd phase, all attachment bolts |

100 |

Nm (2) |

||

4th phase, all attachment bolts |

100 |

Nm (2) |

||

Viscous fan clutch attachment nuts |

30 |

Nm (1) |

||

Timing case attachment bolts |

30 |

Nm (1) |

||

Timing cover attachment bolts: |

|

|

|

|

M10 attachment bolts |

60 |

Nm |

||

M8 attachment bolts |

25 |

Nm |

||

Timing cover protection plate attachment bolt |

8.5 Nm |

|||

Camshaft gear attachment bolt |

425 |

Nm |

||

Idler gear attachment bolt |

170 |

Nm |

||

Pump housing camshaft gear attachment bolt |

260 |

Nm (1) |

||

Steering pump gear attachment nut |

80 |

Nm (1) |

||

Suction pipe banjo bolt |

90 |

Nm |

||

Delivery pipe banjo bolt |

40 |

Nm |

||

(1) |

Use Loctite 243 to secure |

|

|

|

(2) |

Apply a drop of oil to the attachment bolts and tighten |

|

|

|

|

evenly. |

|

|

|

Flywheel housing |

|

|

|

|

Attachment bolts: |

110 |

Nm |

||

Sealant to be used when fitting flywheel housing |

Loctite 510 |

|||

Flywheel |

|

|

|

|

Attachment bolts: |

|

|

|

|

without PTO |

170 |

Nm (1) + 90 angle tightening |

||

with PTO |

170 |

Nm + 150 angle tightening |

||

(1) |

Use Loctite 243 to secure |

|

|

|

© 200351 |

4-7 |

https://www.truck-manuals.net/

|

TECHNICAL DATA |

|

|

|

|

|

2 |

|

PE engine |

|

|

|

ΧΦ65/75/85 series |

||

0 |

Engine mountings at timing gear end |

|

|

|

|

|

|

Cylinder block bracket attachment bolts |

92 Nm |

|

|

|

|

|

|

|

Chassis engine bracket attachment bolts |

73 Nm |

|

|

|

|

|

|

Vibration damper engine bracket attachment |

|

|

|

|

|

|

|

bolts |

170 Nm |

|

|

|

|

|

|

Engine mountings at flywheel end |

|

|

|

|

|

|

|

Flywheel housing engine bracket attachment |

|

|

|

|

|

|

|

bolts |

260 Nm |

|

|

|

|

|

|

Chassis engine bracket attachment bolts |

73 Nm |

|

|

|

|

|

|

Vibration damper engine bracket attachment |

|

|

|

|

|

|

|

bolts |

226 Nm + 60 angle tightening |

|

|

|||

|

Engine hanger brackets |

|

|

|

|

|

|

|

M12 attachment bolts |

110 Nm |

|

|

|

|

|

|

Valve gear |

|

|

|

|

|

|

|

Valve cover attachment bolts |

25 Nm |

|

|

|

|

|

|

M10 setting bolt lock nut for rocker |

40 Nm |

|

|

|

|

|

|

Bridge piece setting bolt lock nut |

40 Nm |

|

|

|

|

|

|

Lubricating oil strip/rocker seat attachment bolts |

60 Nm |

|

|

|

|

|

|

Valve sleeve attachment bolts |

30 Nm |

|

|

|

|

|

|

Tighten the valve sleeve attachment bolts in the |

|

|

13 |

|

9 |

|

|

sequence shown. |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

3 |

7 |

|

11 |

2 |

6 |

|

|

|

|

|

|

|

14 |

|

|

5 |

|

|

|

|

|

|

|

|

1 |

10 |

12 |

8 |

4 |

|

|

|

|

||||

|

|

|

|

|

|

|

M200959 |

4-8 |

© 200351 |

https://www.truck-manuals.net/

2 |

TECHNICAL DATA |

||

|

|

|

|

ΧΦ65/75/85 series |

PE-engine cooling system |

||

5. PE-ENGINE COOLING SYSTEM |

|

|

|

|

|

0 |

|

5.1 GENERAL |

|

||

|

|

|

|

|

|

|

|

Thermostat

Thermostat opening temperature standard:

-thermostat opens at

-thermostat open at least 12 mm at

with intarder and/or automatic transmission:

-thermostat opens at

-thermostat open at least 12 mm at Thermostat seat

Coolant pump

Radial play

Header tank pressure cap

Pressure relief valve opening pressure Underpressure valve opening pressure Closed pressure cap position

approx. 87 C approx. 99 C

approx. 83 C approx. 95 C Loctite 638

0.16 - 0.20 mm

1 - 1.2 bar

0.1 - 0.02 bar

Brand name (2) legible horizontally or 60 before this position.

Closed pressure cap |

Brand name (2) |

position |

legible horizontally or |

|

60 before this |

|

position. |

2

1

M201272

Pressure testing the cooling system |

|

Test pressure |

0.7 - 0.9 bar |

Viscous fan clutch |

|

Permissible slip at maximum speed control |

10% |

© 200351 |

5-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

2 |

|

|

|

|

|

|

PE-engine cooling system |

ΧΦ65/75/85 series |

|

|

5.2 TIGHTENING TORQUES |

|

0 |

|

|

|

|

|

|

|

|

|

The tightening torques recorded in this paragraph |

|

|

|

|

|

|

|

are different from the standard tightening torques |

|

|

|

recorded in the overview of the standard |

|

|

|

tightening torques. The other threaded |

|

|

|

connections which are not recorded must |

|

|

|

therefore be tightened to the torque recorded in |

|

|

|

the overview of standard tightening torques. |

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

is important - unless stated otherwise - that these |

|

|

|

bolts and nuts are of exactly the same length and |

|

property class as those removed. |

|

Coolant pump |

|

M8 attachment bolts |

30 Nm |

Coolant pipe on cylinder head |

|

Attachment bolts |

54 Nm |

Coolant pipe threaded coupling |

90 Nm |

Coolant pipe plug |

35 Nm |

Thermostat housing on coolant pipe |

|

Attachment bolts |

30 Nm |

Radiator |

|

Attachment nuts |

60 Nm |

Oil cooler |

|

Coolant drain plug |

16 Nm |

5-2 |

© 200351 |

https://www.truck-manuals.net/

Loading...

Loading...