DAF CF65, CF75, CF85 Service manual

1 |

STRUCTURE |

ΧΦ65/75/85 series

TECHNICAL DATA

DIAGNOSTICS

INTERNAL CAB COMPONENTS

CAB HEATING

EXTERNAL CAB COMPONENTS

CAB SUSPENSION

CAB TILTING MECHANISM

SEATS

ACCESSORIES

PREWAX TREATMENT

0

1

2

3

4

5

6

7

8

9

10

© 200346

https://www.truck-manuals.net/

https://www.truck-manuals.net/

1 |

TECHNICAL DATA |

|

|

|

|

|

|

|

|

ΧΦ65/75/85 series |

|

Contents |

|

|

CONTENTS |

|

|

|

|

Page |

Date |

|

0 |

|

|

|

|||

|

|

|

|

|

1. INTERNAL AND EXTERNAL CAB COMPONENTS . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200346 1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200346 1.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13 . . . . 200346

2. CAB SUSPENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200346 2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200346 2.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 . . . . . 200346

3. CAB TILTING MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200346 3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200346 3.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 . . . . . 200346 3.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 . . . . . 200346

4. SEATS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200346 4.1 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200346

5. ACCESSORIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200346

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200346

© 200346 |

1 |

https://www.truck-manuals.net/

TECHNICAL DATA |

1 |

|

|

Contents |

ΧΦ65/75/85 series |

0

2 |

© 200346 |

https://www.truck-manuals.net/

1 |

TECHNICAL DATA |

|

|

ΧΦ65/75/85 series |

Internal and external cab components |

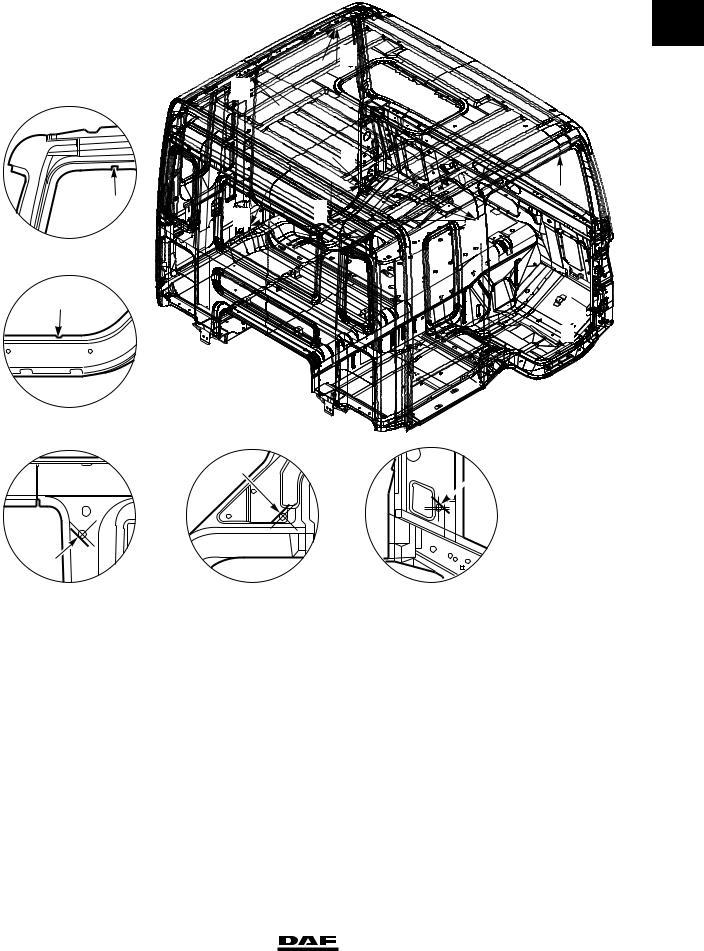

1. INTERNAL AND EXTERNAL CAB COMPONENTS |

|

|

0 |

||

1.1 GENERAL |

||

|

||

|

|

1 |

2 |

3

K1 01 008

Legend

1.Day cab

2.Sleeper cab

3.High sleeper cab

© 200346 |

1-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

|

|

1 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Internal and external cab components |

|

|

|

|

|

ΧΦ65/75/85 series |

|||||

|

|

Main dimensions and weights |

|

|

|

|

|

|

|

|

|||

0 |

|

|

|

|

|

|

|

|

|

||||

|

|

B2 |

|

L(slaap) |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||||||

|

|

|

B1 |

L(dag) |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

H SH |

|

K |

K1 01 010 |

|

|

K1 |

|

Cab dimensions in mm: |

Day cab (D) |

Sleeper cab (SL) |

High sleeper cab (SH) |

length (L) |

1760 |

2190 |

2190 |

width (B1) |

2300 |

2300 |

2300 |

width (B2) |

2490 |

2490 |

2490 |

max. height (H) |

1730 |

1703 |

|

height (SH) |

|

|

2400 |

tilting (K) |

1290 (1) |

1290 (1) |

|

tilting (K1) |

|

|

1690 (1) |

Cab weights |

|

|

|

day cab (D) |

820 (2) |

|

|

sleeper cab (SL) |

965 (2) |

|

|

high sleeper cab (SH) |

1085 (2) |

|

|

(1)Dimensions (K) and (K1) measured from the front of the bumper

(2)Cab weights for fully equipped cabs, including windscreen washer reservoir but excluding suspension

1-2 |

© 200346 |

https://www.truck-manuals.net/

1 |

|

|

|

TECHNICAL DATA |

|

ΧΦ65/75/85 series |

|

|

Internal and external cab components |

|

|

Permissible cab weights, day and sleeper cab |

|

0 |

|||

Item |

Description |

Max. load |

A |

||

A |

Roof loading above |

150 |

kg |

|

|

|

|

||||

B |

Roof console |

15 |

kg |

B |

|

C |

Bunk |

100 |

kg |

|

|

D |

Under bunk storage box |

50 |

kg |

C |

|

|

|

|

|

|

|

D

25 kg

(2x)

K1 00 997

Permissible cab weights, high sleeper:

A

Item |

Description |

Max. load |

|

A |

Roof loading above |

40 |

kg |

B |

Roof console |

20 |

kg |

C |

Below roof console |

15 |

kg |

D |

Upper bunk |

100 |

kg |

E |

Upper bunk (folded away) |

50 |

kg |

F |

Bunk |

100 |

kg |

G |

Under bunk storage box |

50 |

kg |

H |

Tool storage |

2 x 25 kg |

|

Cab side members

Welding on cab side members is NOT permitted.

When repairing the cab side member, you must use sheet-metal trimming panels.

These must be fitted by spot welding.

E D

E D

B

C

F

G

H

K1 00 998

© 200346 |

1-3 |

https://www.truck-manuals.net/

TECHNICAL DATA |

1 |

|

|

Internal and external cab components |

ΧΦ65/75/85 series |

Recommended dimensions |

|

0

A |

|

, |

|

|

|

A |

|

|

|

|

|

|

|

N |

|

B |

O |

|

|

|

, |

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

I |

A’ |

P’ |

|

|

P |

||

|

|

|

||

|

|

J |

A |

|

|

|

|

|

I

B

I |

B |

J

O

J

P |

P’ |

O O |

|

N

K1 01 645

Recommended dimension between measuring points on the same side.

A - B |

818 mm |

I - I |

2070 mm |

J - J |

2185 mm |

O - O |

2247 mm |

Recommended dimension between measuring points on opposite sides.

|

Short cab |

Long cab |

A' - N |

1367 mm |

1797 mm |

B' - P |

1660 mm (1) |

2110 mm (2) |

B' - P' |

|

(1)Measurement area between the brackets

(2)Measurement area under the bracket

1-4 |

© 200346 |

https://www.truck-manuals.net/

1 |

TECHNICAL DATA |

|

|

ΧΦ65/75/85 series |

Internal and external cab components |

0

,

F

G |

|

|

|

|

|

K |

, |

|

|

|

|

, |

|

|

F |

|

|

|

|

F |

F |

|

|

H |

|

, |

|

|

|

||

|

|

|

G |

F |

|

|

K |

|

|

|

|

|

|

|

F |

H

K

K

|

G |

|

K1 00 928 |

Recommended dimension between measuring points on the same side. |

|

F - F' |

1524 mm |

F' - H |

1419 mm |

G - K |

1662 mm |

F' - G |

708 mm |

Recommended dimension between measuring points on opposite sides. |

|

G' - G |

2030 mm |

G - F |

2612 mm |

G - K |

2649 mm |

© 200346 |

1-5 |

https://www.truck-manuals.net/

TECHNICAL DATA |

1 |

|

|

Internal and external cab components |

ΧΦ65/75/85 series |

0

X |

X |

|

Z |

Z |

|

T |

|

|

L |

|

|

|

S |

|

|

R(D) |

|

|

R(S) |

|

|

Z |

|

R |

|

X - X |

1175 mm |

|

Z - Z |

1080 mm |

|

|

R(D) (short cab) |

R(S) (long cab) |

L - R |

1176 mm |

1606 mm |

S - R |

621 mm |

1051 mm |

T - R |

1604 mm |

2034 mm |

X

K1 01 012

1-6 |

© 200346 |

https://www.truck-manuals.net/

1 |

|

|

|

|

|

|

|

|

TECHNICAL DATA |

||||

|

|

|

|

|

|

|

|

|

|

|

|

||

ΧΦ65/75/85 series |

|

|

|

Internal and external cab components |

|||||||||

Windscreens |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting times for windscreen adhesive |

|

|

|||||||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product name |

|

Vehicle mobile |

|

Cab can be |

|

Vehicle usable |

|

DAF number |

|

||||

|

|

|

|

in workshop |

|

tilted after: |

|

after: |

|

|

|

|

|

|

|

|

|

after: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sikaflex 255 FC |

|

|

6 hours |

|

|

8 hours |

|

12 hours |

|

1271129 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 hours |

|

|

4 hours |

|

6 hours |

|

1241020 |

|

|

Sika Tack Ultrafast |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sika Tack plus booster |

|

1 hour |

|

|

1 hour |

|

2 hours |

|

1357925 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||

A relative humidity of less than 50% delays |

|

|

|

|

|

|

|

|

|||||

setting, as does a temperature lower than 20 C. |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

Products applied for bonded windscreens |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||

Product |

|

Properties |

|

|

|

Applications |

|

|

DAF |

|

|

||

name |

|

|

|

|

|

|

|

|

|

|

number |

|

|

|

|

|

|

|

|

|

|

||||||

Sikaflex 255 |

|

Application time 20 min. |

|

Adhesive (cold process) for |

1271129 |

|

|

||||||

FC |

|

|

|

|

|

|

bonding windscreens |

|

|

|

|||

|

|

|

|

|

|

|

|

||||||

Sika Tack |

|

Application time 10 min. |

|

Adhesive (warm process) for |

1241020 |

|

|

||||||

Ultrafast |

|

|

|

|

|

|

bonding windscreens |

|

|

|

|||

|

|

|

|

|

|

|

|

||||||

Sika Tack plus |

|

Application time 5 min. |

|

Adhesive (warm process) for |

1357925 |

|

|

||||||

booster |

|

|

|

|

|

|

bonding windscreens |

|

|

|

|||

|

|

|

|

|

|

|

|

||||||

Sika Aktivator |

|

Minimum drying time 5 min. |

|

Cleaning and activating the glass |

1312362 |

|

|

||||||

|

|

|

|

|

|

|

and the frame. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Sika remover |

|

|

|

|

|

|

Removal of adhesive which has |

1241019 |

|

|

|||

208 |

|

|

|

|

|

|

not yet set. Do not use on |

|

|

|

|||

|

|

|

|

|

|

|

surfaces to be bonded. |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

High sleeper cab |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

Products for gluing high sleeper cab |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||

Product |

|

Properties |

|

|

|

Applications |

|

|

DAF |

|

|

||

name |

|

|

|

|

|

|

|

|

|

|

number |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Scotch brite |

|

|

|

|

|

|

Abrasive |

|

|

1387923 |

|

|

|

very fine A |

|

|

|

|

|

|

|

|

|

|

|

|

|

(red) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Sika Cleaner |

|

Minimum drying time 5 min. |

|

Cleaning surface of raised roof |

1240548 |

|

|

||||||

|

|

|

|

|

|

|

|

||||||

Sika Primer |

|

Minimum drying time 15 min. |

|

Application to raised roof |

1240547 |

|

|

||||||

209 |

|

Maximum drying time 24 hours |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

||||||

Sika Activator |

|

Minimum drying time 5 min. |

|

Cleaning and activating the cab |

1312362 |

|

|

||||||

|

|

|

|

|

|

|

roof edge to be glued |

|

|

|

|||

|

|

|

|

|

|

|

|

||||||

Sikaflex 252 |

|

Application time within 10 min. |

|

Gluing raised roof on cab |

1286578 |

|

|

||||||

(white) |

|

Setting time 2 days |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

© 200346 |

1-7 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

|

1 |

||

|

|

|

|

|

|

|

|

|

Internal and external cab components |

|

ΧΦ65/75/85 series |

||

|

|

Windscreen wiper motor |

|

|

|

|

0 |

|

|

|

|

||

|

Fitting new rods |

|

Fina Ceran grease |

|

|

|

|

|

Motor speed 1 |

|

35 rpm |

|

|

|

|

Motor speed 2 |

|

50 rpm |

|

|

|

|

Heater fan |

|

|

|

|

|

|

Fan setting |

|

series resistors |

|

|

|

|

1 |

|

R1 + R2 + R3 |

|

|

|

|

2 |

|

R2 + R3 |

|

|

|

|

3 |

|

R3 |

|

|

|

|

4 |

|

no series resistors |

|

|

|

|

Resistor rating: |

|

|

|

|

|

|

R1 |

|

4.2 ≥ 0.15 |

|

|

|

|

R2 |

|

1.4 ≥ 0.15 |

|

|

|

|

R3 |

|

2.2 ≥ 0.15 |

|

|

|

|

Heater control |

|

|

|

|

|

|

Heater valve |

|

black |

|

|

|

|

Defroster valve LHD |

red |

|

|

|

|

|

Defroster valve RHD |

blue |

|

|

|

|

|

Foot valve LHD |

|

green |

|

|

|

|

Foot valve RHD |

|

brown |

|

|

|

|

Doors |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Products for gluing anti-whistle weatherstrip |

|

|

|

|

|

|

|

|

|

|

|

|

Product |

Properties |

Applications |

|

DAF |

|

|

name |

|

|

|

number |

|

|

|

|

|

|

|

|

|

Scotch brite |

|

Abrasive |

|

1387923 |

|

|

very fine A |

|

|

|

|

|

|

(red) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Sika Cleaner |

Minimum drying time 5 min. |

Cleaning door edge |

|

1240548 |

|

|

|

|

|

|

|

|

|

Loctite 401 |

Dries within a few |

Securing anti-whistle |

|

0632192 |

|

|

(superfast |

}seconds |

weatherstrip to door edge |

|

|

|

|

adhesive) |

|

|

|

|

|

|

|

Setting time 12 hours |

|

|

|

|

|

|

|

|

|

|

|

|

Adjustment dimensions: |

|

|

|

|

|

|

Entire perimeter (except the lower edge) |

8 mm clearance |

|

|

|

|

|

Bottom |

|

11 mm clearance |

|

|

|

|

Frame depth |

|

0.5 mm within the cab to 1.5 mm outside the cab |

||

1-8 |

© 200346 |

https://www.truck-manuals.net/

1 |

TECHNICAL DATA |

|

|

ΧΦ65/75/85 series |

Internal and external cab components |

Adjustment dimensions of door lock rods |

|

0

507

410

92 |

89 |

K1 01 023

© 200346 |

1-9 |

https://www.truck-manuals.net/

TECHNICAL DATA |

1 |

|

|

Internal and external cab components |

ΧΦ65/75/85 series |

Adjustment dimensions of mirrors without

0 |

dead angle exterior mirror |

|

D E

C

A

B

B A

B

B

|

|

K1 01 027 |

|

|

|

Size |

Normal (mm) |

Normal adjustment angle |

|

|

|

A |

114 |

45 |

|

|

|

B |

326 |

36 |

|

|

|

C |

|

9 |

|

|

|

D (main mirror) |

1374 |

|

|

|

|

E |

1406 |

|

|

|

|

1-10 |

© 200346 |

https://www.truck-manuals.net/

1 |

TECHNICAL DATA |

||

|

|

|

|

ΧΦ65/75/85 series |

Internal and external cab components |

||

Adjustment dimensions of mirrors with dead |

|

|

|

|

|

0 |

|

angle exterior mirror |

|

||

|

|

|

|

|

|

|

|

E F

A

B

C D

B C D

D

A

A

|

|

K1 01 333 |

|

|

|

Size |

Normal (mm) |

Normal adjustment angle |

|

|

|

A |

326 |

9 |

|

|

|

B |

396 |

45 |

|

|

|

C |

219 |

35 |

|

|

|

D |

47 |

31 |

|

|

|

E (main mirror) |

1379 |

|

|

|

|

F |

1406 |

|

|

|

|

© 200346 |

1-11 |

https://www.truck-manuals.net/

TECHNICAL DATA |

1 |

|

|

Internal and external cab components |

ΧΦ65/75/85 series |

Dimensions of compulsory field of vision |

|

0

|

|

|

D1 |

|

|

|

|

|

A |

|

|

|

|

|

|

|

A2 |

D |

|

|

|

|

|

A |

A3 |

|

|

|

C3 |

|

|

|

|

|

|

|

|||

B1 |

1 |

|

|

|

|

|

C4 |

B |

B5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B2 |

|

|

|

|

|

|

|

|

|

C |

|

|

C1 |

|

|

|

B4 |

|

|

|

|

|

|

B3 |

|

|

|

|

|

|

|

|

|

|

C2 |

|

|

|

|

|

|

|

|

|

|

|

K100237 |

Mirror |

|

size 1 |

size 2 |

size 3 |

size 4 |

|

size 5 |

Pavement mirror [A] |

|

1 m |

1 m |

1.25 m |

|

|

|

Wide-angle exterior mirror [B] |

|

2.5 m |

15 m |

12.5 m |

25 m |

|

3 m |

Main exterior mirror, co-driver side [C] |

30 m |

3.5 m |

0.75 m |

4 m |

|

|

|

Main exterior mirror, driver side [D] |

10 m |

2.5 m |

|

|

|

|

|

1-12 |

© 200346 |

https://www.truck-manuals.net/

1 |

|

TECHNICAL DATA |

||

|

|

|

|

|

ΧΦ65/75/85 series |

|

Internal and external cab components |

||

1.2 TIGHTENING TORQUES |

|

|

|

|

|

|

|

0 |

|

|

|

|

||

The tightening torques specified in this section |

|

|

|

|

|

|

|

|

|

are different from the standard tightening torques |

|

|

|

|

cited in the overview of the standard tightening |

|

|

|

|

torques. The other threaded connections not |

|

|

|

|

specified must therefore be tightened to the |

|

|

|

|

torque cited in the overview of standard |

|

|

|

|

tightening torques. |

|

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

|

is important that - unless stated otherwise - these |

|

|

|

|

bolts and nuts are of exactly the same length and |

|

|

|

|

property class as those removed. |

|

|

|

|

Windscreen wiper motor |

|

|

|

|

Attachment on bulkhead |

20 |

- 25 Nm |

||

Motor shaft nut |

40 |

- 50 Nm |

||

Windscreen wiper arm nut |

16 |

- 20 Nm |

||

Roof hatch |

|

|

|

|

Fixing bolts for roof hatch edging |

10 |

Nm |

||

Clutch pedal |

|

|

|

|

Sealant for end of clutch pedal spindle |

silicone sealant |

|||

Locking bolt |

according to standard (1) |

|||

(1) Use Loctite 243 to secure |

|

|

|

|

Engine brake switch |

|

|

|

|

Sealant for bolts |

silicone sealant |

|||

Steering column |

|

|

|

|

Attachment bolt for steering shaft universal joint |

54 |

Nm (1) |

||

Attachments nuts at underside of steering column |

23 |

Nm |

||

Steering wheel attachment nut |

65 |

Nm |

||

(1) Always replace the attachment bolt and nut |

|

|

|

|

Doors |

|

|

|

|

Striker plate Torx screws |

23 |

Nm |

||

Exterior mirrors |

|

|

|

|

Lower pivoting point of D-shaped support, M8 nut |

32 |

Nm |

||

Pavement mirror adjusting nut |

7.0 - 8.1 Nm |

|||

Raised roof |

|

|

|

|

Attachment bolts for raised roof frame |

30 |

Nm |

||

© 200346 |

1-13 |

https://www.truck-manuals.net/

TECHNICAL DATA |

1 |

|

|

Internal and external cab components |

ΧΦ65/75/85 series |

0

1-14 |

© 200346 |

https://www.truck-manuals.net/

1 |

TECHNICAL DATA |

||

|

|

|

|

ΧΦ65/75/85 series |

Cab suspension |

||

2. CAB SUSPENSION |

|

|

|

|

|

0 |

|

2.1 GENERAL |

|

||

|

|

|

|

|

|

|

|

The F230 cab is mounted to the chassis at four points with adjustable coil spring/air suspension elements. These have integral shock absorbers.

Adjusting the coil spring elements:

Front |

(size A) 318 ≥ 5 mm |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A

K1 01 013

Rear |

(size B) 272 ≥ 5 mm |

The sizes given above are from the top centre to the support of the spring element (top).

The spring elements can be adjusted in 4 steps of 3 mm.

B

K1 01 014

Spring distance of the coil spring elements: |

|

front |

approx. 80 mm (+40/-40) |

rear |

approx. 60 mm (+30/-30) |

© 200346 |

2-1 |

https://www.truck-manuals.net/

|

TECHNICAL DATA |

1 |

|

|

Cab suspension |

|

ΧΦ65/75/85 series |

0 |

Adjusting the air suspension elements: |

|

|

Front |

(size A) 318 ≥ 5 mm |

|

|

A

K1 01 413

Rear |

(size B) 272 ≥ 5 mm |

The sizes given above are from the top centre to the support of the spring element (top).

B

K1 01 000

Spring distance of the air suspension |

|

elements: |

|

front |

approx. 80 mm (+40/-40) |

rear |

approx. 60 mm (+30/-30) |

The cab height can be adjusted at the front. |

|

2-2 |

© 200346 |

https://www.truck-manuals.net/

1 |

TECHNICAL DATA |

|

|

ΧΦ65/75/85 series |

Cab suspension |

2.2 TIGHTENING TORQUES

0

The tightening torques specified in this section are different from the standard tightening torques cited in the overview of the standard tightening torques. The other threaded connections not specified must therefore be tightened to the torque cited in the overview of standard tightening torques.

When attachment bolts and nuts are replaced, it is important that - unless stated otherwise - these bolts and nuts are of exactly the same length and property class as those removed.

Cab suspension front

A B

H

G

F

E

C

|

|

|

|

|

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

K1 01 077 |

A |

M8 attachment bolt for tilt assist mechanism/ |

24 Nm (1) |

||||

|

cab support |

|||||

B |

M14 cab support bolt |

170 Nm |

||||

C |

M18 locating bolt for cab stabiliser vibration |

235 Nm (2) |

||||

|

damper |

|||||

D |

M14 nut for underside of spring (coil spring |

|

||||

|

and air suspension) |

50 Nm |

||||

E |

M14 rearmost bolt for cab stabiliser bearing |

|

||||

|

support (left/right) |

170 Nm |

||||

F |

M14 foremost bolt for cab stabiliser bearing |

|

||||

|

support (left and right) |

170 Nm |

||||

G |

M8 prestressed bolt for cab stabiliser bearing |

|

||||

|

support |

35 Nm |

||||

H |

M14 attachment bolt for top of spring |

|

||||

|

(coil spring and air suspension) |

170 Nm |

||||

(1)Use Loctite 243 to secure

(2)Use Loctite 243 to secure and tighten with cab in fully tilted position.

© 200346 |

2-3 |

https://www.truck-manuals.net/

TECHNICAL DATA |

1 |

Cab suspension |

ΧΦ65/75/85 series |

Rear cab suspension |

|

0 |

|

|

B |

|

A |

|

C |

|

D |

E

E

F

F

G

|

|

|

K1 01 078 |

A |

M14 attachment bolt for top of spring |

|

|

|

(coil spring and air suspension) |

170 |

Nm |

B |

M14 attachment bolt for horizontal damper |

170 |

Nm |

C |

M14 attachment bolt for horizontal damper |

170 |

Nm |

D |

M16 attachment bolts for chassis support |

300 |

- 450 Nm |

E |

M12 attachment bolt for chassis |

110 |

Nm |

F |

M14 attachment bolt for chassis |

170 |

Nm |

G |

M14 attachment bolt for day cab spring |

|

|

|

element |

170 Nm |

|

|

M14 attachment nut for sleeper cab |

|

|

|

spring element |

50 Nm |

|

2-4 |

© 200346 |

https://www.truck-manuals.net/

1 |

TECHNICAL DATA |

||

|

|

|

|

ΧΦ65/75/85 series |

Cab tilting mechanism |

||

3. CAB TILTING MECHANISM |

|

|

|

|

|

0 |

|

3.1 GENERAL |

|

||

|

|

|

|

Lifting cylinder |

|

|

|

Nominal pressure |

400 bar |

||

Cab tilting pump |

|

|

|

Nominal pressure |

400 bar |

||

Displacement |

4 cm3 |

||

Pressure limiting valve |

400 + 50 bar |

||

Pressure relief valve, level check/filler plug |

2.5 bar |

||

© 200346 |

3-1 |

https://www.truck-manuals.net/

|

|

TECHNICAL DATA |

1 |

|

|

|

|

|

|

Cab tilting mechanism |

ΧΦ65/75/85 series |

|

|

3.2 TIGHTENING TORQUES |

|

0 |

|

|

|

|

|

|

|

|

|

The tightening torques specified in this section |

|

|

|

|

|

|

|

are different from the standard tightening torques |

|

|

|

cited in the overview of the standard tightening |

|

|

|

torques. The other threaded connections not |

|

|

|

specified must therefore be tightened to the |

|

|

|

torque cited in the overview of standard |

|

|

|

tightening torques. |

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

is important that - unless stated otherwise - these |

|

|

|

bolts and nuts are of exactly the same length and |

|

property class as those removed. |

|

|

Lifting cylinder |

|

|

Lifting cylinder attachment bolt on cab |

170 Nm |

|

Lifting cylinder attachment bolt on chassis |

60 |

Nm |

Non-return valve seat |

40 |

- 45 Nm |

3.3 FILLING CAPACITIES

Cab tilting pump |

|

Capacity of reservoir |

480 cm3 |

3-2 |

© 200346 |

https://www.truck-manuals.net/

1 |

TECHNICAL DATA |

||

|

|

|

|

ΧΦ65/75/85 series |

Seats |

||

4. SEATS |

|

|

|

|

|

0 |

|

4.1 TIGHTENING TORQUES |

|

||

|

|

|

|

The tightening torques specified in this section |

|

|

|

are different from the standard tightening torques |

|

|

|

cited in the overview of the standard tightening |

|

|

|

torques. The other threaded connections not |

|

|

|

specified must therefore be tightened to the |

|

|

|

torque cited in the overview of standard |

|

|

|

tightening torques. |

|

|

|

When attachment bolts and nuts are replaced, it |

|

|

|

is important that - unless stated otherwise - these |

|

|

|

bolts and nuts are of exactly the same length and |

|

|

|

property class as those removed. |

|

|

|

Seats |

|

|

|

Seat attachment bolts M8 |

20 - 25 Nm |

||

Attachment of seat belt mechanism 7/16", UNF- |

|

|

|

2B |

30 - 40 Nm |

||

© 200346 |

4-1 |

https://www.truck-manuals.net/

TECHNICAL DATA |

1 |

|

|

Seats |

ΧΦ65/75/85 series |

0

4-2 |

© 200346 |

https://www.truck-manuals.net/

1 |

TECHNICAL DATA |

ΧΦ65/75/85 series

5. ACCESSORIES

5.1 GENERAL

The roof spoiler height of the 'aerodynamic' roof spoiler can be adjusted with the adjusting mechanism (B).

Accessories

0

P

B

K1 01 355

Roof spoiler setting range [mm]

|

basic |

aerodynamic |

|

|

|

Day cab |

525 - 775 |

760 - 1040 |

|

|

|

Sleeper Cab |

525 - 775 |

760 - 1060 |

|

|

|

High sleeper cab |

N/A |

215 - 775 |

|

|

|

Note:

The size stated in the table represents the distance measured between the highest roof spoiler edge (P) and the cab roof plate local to the vehicle centreline.

© 200346 |

5-1 |

https://www.truck-manuals.net/

TECHNICAL DATA |

1 |

|

|

Accessories |

ΧΦ65/75/85 series |

0

5-2 |

© 200346 |

https://www.truck-manuals.net/

1 |

DIAGNOSTICS |

|

||

|

|

|

|

|

ΧΦ65/75/85 series |

|

Contents |

|

|

CONTENTS |

|

|

|

|

|

Page |

Date |

|

|

1. CAB HEATING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1-1 . . . |

. . 200346 |

|

1 |

1.1 Fault finding table, cab heating |

1-1 |

200346 |

|

|

|

|

|||

2. CAB SUSPENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200346 2.1 Fault-finding table, cab suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200346 2.2 Fault-finding table, cab tilting mechanism . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 . . . . . 200346

3. SEATS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200346 3.1 Fault-finding table, Isringhausen 6800 series . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200346

© 200346 |

1 |

https://www.truck-manuals.net/

DIAGNOSTICS |

1 |

|

|

Contents |

ΧΦ65/75/85 series |

1

2 |

© 200346 |

https://www.truck-manuals.net/

Loading...

Loading...