Page 1

Emergency response guide

Page 2

Page 3

©201417 DAF Trucks N.V., Eindhoven,

The Netherlands.

In the interest of continuing product development,

DAF reserves the right to change specifications

or products at any time without prior notice.

No part of this publication may be reproduced

and/or published by printing, by photocopying, on

microfilm or in any way whatsoever without the

prior consent in writing of DAF Trucks N.V.

©

201417 DW53288301

Page 4

Page 5

series

0

1

Structure

STRUCTURE

EMERGENCY RESPONSE GUIDE

©

201417

Page 6

Page 7

EMERGENCY RESPONSE GUIDE

1

series

Emergency response guide

TABLE OF CONTENTS

1. SECURING THE VEHICLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 201417

1.1 Switching off the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 201417

1.2 Main switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 . . . . . 201417

1.3 Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 . . . . . 201417

1.4 Airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5 . . . . . 201417

1.5 Fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7 . . . . . 201417

1.6 Regeneration unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9 . . . . . 201417

2. STABILISING THE VEHICLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 201417

2.1 Seat adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 201417

2.2 Air suspension chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 . . . . . 201417

2.3 Cabin suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5 . . . . . 201417

3. RELEASING A TRAPPED DRIVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 201417

3.1 Cabin types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 201417

3.2 Cabin bracket collision ability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 . . . . . 201417

3.3 Cabin dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3 . . . . . 201417

3.4 Opening the grille . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5 . . . . . 201417

3.5 Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6 . . . . . 201417

3.6 Door lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7 . . . . . 201417

3.7 Steering wheel adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8 . . . . . 201417

3.8 Cabin structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9 . . . . . 201417

Table of contents

Page Date

4. TOWING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 201417

4.1 Removing the drive shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 201417

4.2 Releasing the parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 . . . . . 201417

5. LIFTING INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 201417

5.1 Lifting at the front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 201417

5.2 Jack up at the front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 . . . . . 201417

5.3 Lifting at the back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3 . . . . . 201417

5.4 Jack up at the back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4 . . . . . 201417

©

201417 1

Page 8

EMERGENCY RESPONSE GUIDE

1

Table of contents series

2

©

201417

Page 9

EMERGENCY RESPONSE GUIDE

1

G001281

CO

2

series

1. SECURING THE VEHICLE

1.1 SWITCHING OFF THE ENGINE

Ignition switch

If the ignition switch can be reached, an attempt

can be made to stop the engine by switching off

the ignition.

CO

2

Another method is to blow CO2 into the air inlet.

The engine no longer receives sufficient oxygen

so it stops.

The air inlet can be accessed behind the cabin.

First, lift the rubber gaiter and blow CO

bottom half using a fire extinguisher.

into the

2

Securing the vehicle

©

201417 1-1

Page 10

EMERGENCY RESPONSE GUIDE

1

Securing the vehicle series

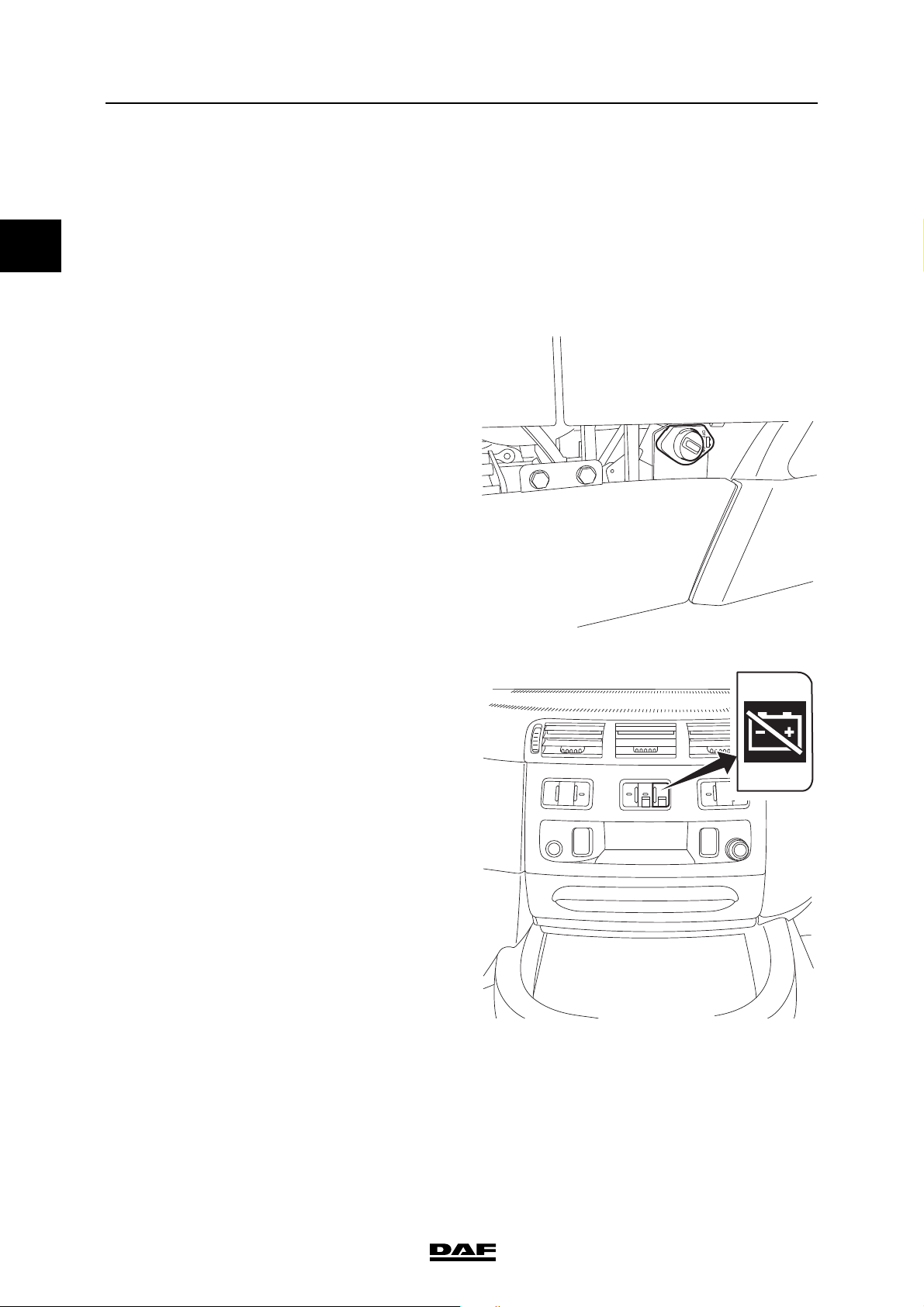

1.2 MAIN SWITCH

If the vehicle is equipped with a main switch, it is

either mechanically or electronically operated,

depending on the vehicle version.

The switch can be used to interrupt the power

supply from the batteries to the vehicle (except

for the tachograph).

Electronic main switch

The electronic main switch does not switch off at

once when it is operated; this happens with a 10second delay. This is to allow the after-running of

various electrical systems on the vehicle.

The electronic main switch (usually located close

to the battery pack).

If the vehicle is equipped with an electronic main

switch, there is also a switch on the centre

console in the cabin.

G001944

E504882

1-2

©

201417

Page 11

EMERGENCY RESPONSE GUIDE

1

G001945

series

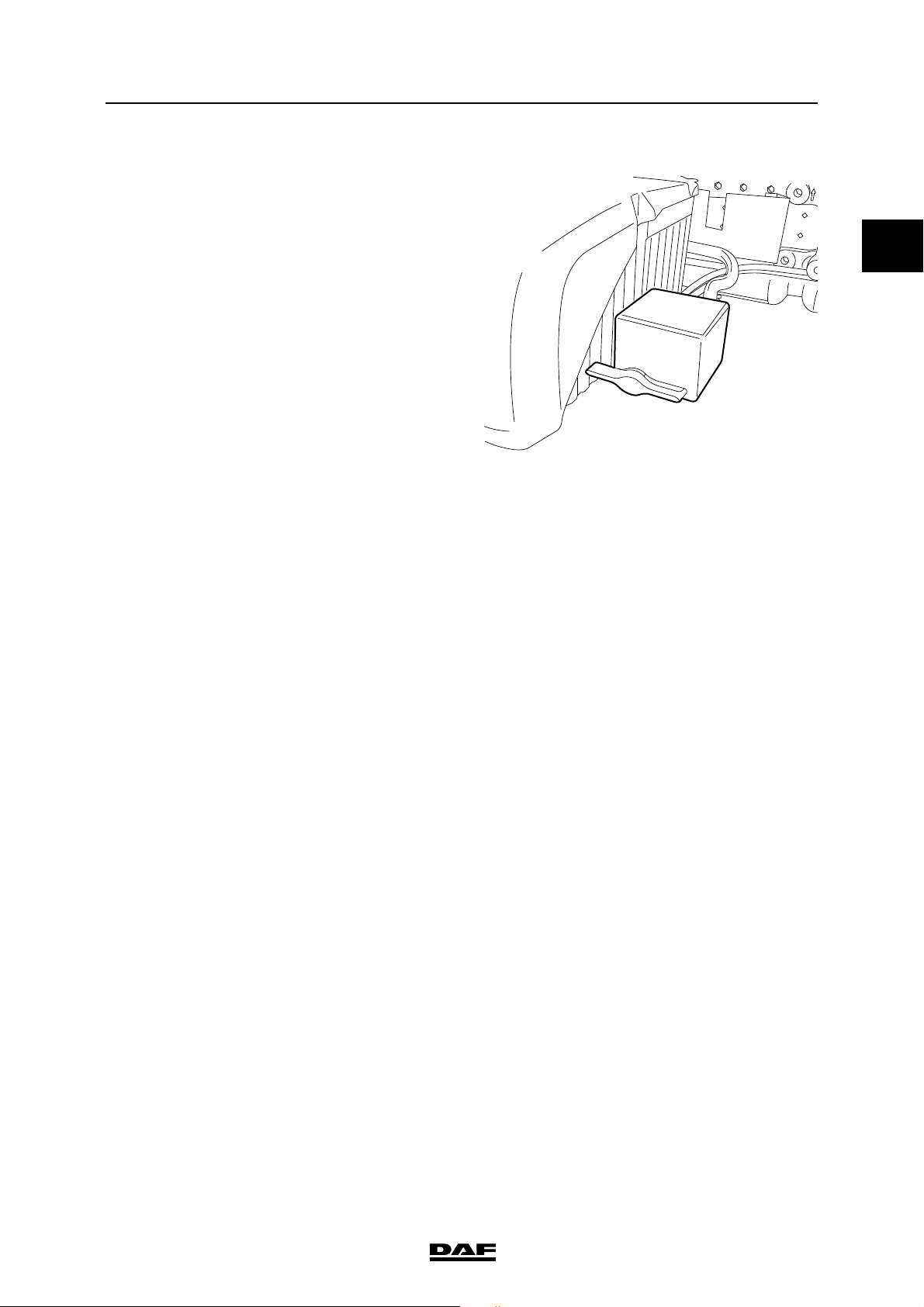

Mechanical main switch

Mechanically operated main switches only have a

switch outside the cabin.

Securing the vehicle

©

201417 1-3

Page 12

EMERGENCY RESPONSE GUIDE

1

Securing the vehicle series

1.3 BATTERIES

Location of the batteries

The batteries are located on the left- or right-hand

side of the chassis frame, or at the rear within the

chassis.

Disconnecting the batteries

1. Switch off the ignition.

2. Switch off all electrical consumers.

3. Remove the battery cover.

4. Disconnect the battery clamp from the

negative pole.

5. Disconnect the battery clamp from the

positive pole.

6. Hold the positive and negative cables

together to discharge any power that may be

stored in the capacitors.

7. Secure the cables; make sure that they

cannot come into contact with the terminals.

1-4

©

201417

Page 13

EMERGENCY RESPONSE GUIDE

1

SET

G001309

series

1.4 AIRBAG

WARNING! Airbag modules and

safety belt tensioners are

pyrotechnic systems and contain an

explosive charge.

Securing the vehicle

Vehicles equipped with an airbag and safety belt

tensioner system can be identified by a sticker

with the airbag symbol on the windscreen.

In addition, there is an identification 'AIRBAG'

visible on the steering wheel. A vehicle equipped

with an airbag also has an automatic safety belt

tensioner.

©

201417 1-5

Page 14

EMERGENCY RESPONSE GUIDE

1

G001312

1

Securing the vehicle series

1 Safety belt tensioner

The automatic safety belt tensioner is fitted on the

rear side of the driver's and co-driver's seat.

Safety instructions

- Do not place any objects near undeployed

airbags

- Before any work is carried out on an airbag

system:

1. the ignition must be switched off.

2. the main switch must be turned off.

3. the battery clamp must be removed from

the negative pole.

4. wait at least 30 seconds.

- Never disconnect an electrical connector in

the airbag or safety belt tensioner circuits if

the electronic control unit is energised.

©

201417

1-6

Page 15

EMERGENCY RESPONSE GUIDE

1

series

1.5 FLUIDS

123 6

Securing the vehicle

4

5

123 5

1 Coolant: 48 litres

2 Engine oil: 36 - 46 litres

3 Gearbox oil: 14 litres

4 AdBlue: up to 90 litres

5 Fuel: up to 1500 litres

6 Battery acid

6

4

5

K103769

The capacities and position of the tanks depend

on the vehicle type.

©

201417 1-7

Page 16

EMERGENCY RESPONSE GUIDE

1

Securing the vehicle series

AdBlue

AdBlue is a non-flammable, non-toxic, colourless,

odourless and water-soluble liquid.

AdBlue is a liquid consisting of 32.5% urea and

67.5% water.

AdBlue must meet the specifications according to

DIN 70070.

High temperatures

If AdBlue is heated in the tank to 50°C over a long

period of time, the decomposing AdBlue can

produce ammonia vapours. Ammonia vapours

have a pungent odour. For this reason, avoid

inhaling possible ammonia vapours escaping

when unscrewing the AdBlue filler cap. These

concentrations of ammonia vapours are neither

toxic nor hazardous to health.

Low temperatures

AdBlue freezes at temperatures of approximately

-11°C.

i403182

WARNING!

AdBlue safety instructions

- Avoid direct contact.

- In the event of contact with the

skin, rinse with plenty of water.

- In the event of contact with the

eyes, rinse for at least 15

minutes with plenty of water and

seek medical assistance.

- If swallowed, rinse mouth with

plenty of water; do not induce

vomiting.

- Use in a ventilated area.

Procedure after spillage

- Rinse with plenty of water.

1-8

©

201417

Page 17

EMERGENCY RESPONSE GUIDE

1

V301566

G001961

series

1.6 REGENERATION UNIT

During regeneration the exhaust gases, the

surroundings of the regeneration unit and the

catwalk can reach high temperatures that can

potentially harm bystanders or the surrounding

area.

WARNING! There is a risk of fire or

other hazardous situation if the

temperature can ignite flammable

materials.

Switch off the regeneration unit

Set the switch in the OFF position to stop or

inhibit regeneration.

Securing the vehicle

©

201417 1-9

Page 18

EMERGENCY RESPONSE GUIDE

1

Securing the vehicle series

1-10

©

201417

Page 19

EMERGENCY RESPONSE GUIDE

1

series

2. STABILISING THE VEHICLE

2.1 SEAT ADJUSTMENT

NOTE: Before removing the seat, be

aware of the safety instructions if the

vehicle is equipped with an airbag and

therefore an automatic safety belt

tensioner.

NOTE: The seat can be adjusted if the

vehicle air pressure is at least 7 bar.

Seat settings

1 Backrest angle adjustment.

2 Seat height adjustment.

3 Seat tilt adjustment

4Quick down.

5 Vertical seat damper.

6 Seat length adjustment.

7 Seat cushion length adjustment.

8 Armrest.

9 Safety belt height adjustment.

10 Seat heater.

11 Lumbar support adjustment.

12 Lateral support adjustment.

13 Seat ventilation

14 Shoulder support adjustment.

4. Quick down

Knob down (seat in driving position): the seat drops to its lowest

position.

Knob up (with lowered seat): the

seat rises to the last height adjustment.

3. Seat tilt adjustment

14

Stabilising the vehicle

9

8

13

10

7

5

12

6

4

3 2

1

11

G001947

2. Seat height adjustment

©

201417 2-1

Page 20

EMERGENCY RESPONSE GUIDE

1

M1 M2

STOP

C900268

Stabilising the vehicle series

2.2 AIR SUSPENSION CHASSIS

General

On vehicles equipped with air suspension, a

remote control unit is used to operate the vehicle

height.

The remote control unit is located against the

console of the driver's seat.

NOTE: This control unit can only be

operated when the ignition is switched

on.

NOTE: Unless stated otherwise, the

keys need only be pressed once briefly.

Remote control A

rear of truck selected

automatic setting of normal driving

height

lifting of chassis to pre-set height

as M1, but for a different chassis

height

lifting of selected chassis ends

when the key is released

lowering of selected chassis ends

when the key is released

all adjustments are stopped

2-2

©

201417

Page 21

EMERGENCY RESPONSE GUIDE

1

C900269

M1 M2

STOP

series

Remote control B

Remote control B is used on vehicles on which

the front axle is also equipped with air

suspension.

front of truck selected

rear of truck selected

automatic setting of normal driving

height

lifting of chassis to pre-set height

as M1, but for a different chassis

height

lifting of selected chassis ends

when the key is released

lowering of selected chassis ends

when the key is released

Stabilising the vehicle

all adjustments are stopped

©

201417 2-3

Page 22

EMERGENCY RESPONSE GUIDE

1

M1 M2

STOP

C900592-2

Stabilising the vehicle series

Remote control C

Remote control C is used for vehicles with airsuspended front axle and trailer and for vehicles

with Axle Load Monitoring.

front of truck selected

rear of truck selected

automatic setting of normal driving

height

lifting or lowering truck trailing axle

front of trailer selected

rear of trailer selected

lifting or lowering trailer trailing

axle

lifting of chassis to pre-set height

as M1, but for a different chassis

height

lifting of selected chassis ends

when the key is released

lowering of selected chassis ends

when the key is released

all adjustments are stopped

2-4

©

201417

Page 23

EMERGENCY RESPONSE GUIDE

1

G001946

series

2.3 CABIN SUSPENSION

The cabin can be equipped with full mechanical

or full air suspension.

Lowering the air suspension

If the vehicle is equipped with cabin air

suspension, the cabin can be lowered.

The cabin is lowered by cutting the air hoses.

WARNING! When air hoses are cut,

the hose ends can fly around and

can therefore cause injuries.

WARNING! When the air hoses for

the cabin suspension are cut, the air

supply for steering wheel

adjustment is also taken away.

WARNING! When the cabin is

lowered, the movement may be

uncontrolled.

Rear cabin air suspension

Cut the air hose to the rear cabin air suspension

bellows. The connections are at the bottom of the

bellows.

Stabilising the vehicle

©

201417 2-5

Page 24

EMERGENCY RESPONSE GUIDE

1

G001959

G001960

Stabilising the vehicle series

Rear cabin mechanical suspension

Front cabin air suspension

Cut the air hose to the front air suspension

bellows. The air reservoir can be found under the

cabin at the co-driver side.

Front cabin mechanical suspension

The mechanical springs are located at the front

just beside the headlights. They can be reached

by removing the lower grille and if necessary the

headlight panels.

2-6

©

201417

Page 25

EMERGENCY RESPONSE GUIDE

1

G002065

12

3

series

3. RELEASING A TRAPPED DRIVER

3.1 CABIN TYPES

Releasing a trapped driver

1Day Cab

2 Sleeper Cab

3Space Cab

©

201417 3-1

Page 26

EMERGENCY RESPONSE GUIDE

1

Releasing a trapped driver series

3.2 CABIN BRACKET COLLISION ABILITY

The cabin bracket has a built-in safety feature

that enables the cabin to move back 400 mm in

case of a collision. Depending on the severity of

the collision there are two situations.

- The safety feature is used. This means that

the cabin has moved compared to the

chassis with a maximum distance of 400

mm. The cabin is still attached to the chassis.

- The safety feature is used fully before the

collision stopped. As a result the bolt of the

cabin bracket breaks. If this has happened

the cabin is loose from the chassis.

3-2

©

201417

Page 27

EMERGENCY RESPONSE GUIDE

1

G002066

640

2490

2110

2260

1770

650

1600

440

400

390

series

3.3 CABIN DIMENSIONS

The external dimensions from the ground vary

depending on the tyre size, choice of suspension,

load and settings.

Day Cab

Releasing a trapped driver

Sleeper Cab

1600

440

400

390

2200

1050

2260

640

650

L=700

2110

L=2045

G002067

2490

L

120

©

201417 3-3

Page 28

EMERGENCY RESPONSE GUIDE

1

G002069

U

570

640

U=680

U=2020

L=2045

2490

2110

L=700

2260

2200

650

710

2230

440

305

275

280

70

120

L

Releasing a trapped driver series

Space Cab

3-4

©

201417

Page 29

EMERGENCY RESPONSE GUIDE

1

series

3.4 OPENING THE GRILLE

The top section of the front panel can be folded

up. Unlock the front panel by pulling the lever in

the top section of the front panel. When the front

panel is open it is held in the raised position by

two gas struts.

Releasing a trapped driver

G002070

©

201417 3-5

Page 30

EMERGENCY RESPONSE GUIDE

1

Releasing a trapped driver series

3.5 DOORS

1 Hinge

2 Wiring harness

3 Door check

1

2

1

3

G001310

3-6

©

201417

Page 31

EMERGENCY RESPONSE GUIDE

1

G002071

series

3.6 DOOR LOCK

The door lock is installed higher than the door

handle. The position is indicated in the image.

Releasing a trapped driver

©

201417 3-7

Page 32

EMERGENCY RESPONSE GUIDE

1

K101546

Releasing a trapped driver series

3.7 STEERING WHEEL ADJUSTMENT

NOTE: The steering wheel can be

adjusted if the vehicle air pressure

(circuit 4) is at least 7 bar.

G001293

Adjusting

Push up the two-position switch. The steering

column is temporarily unlocked. The height and

angle of the steering wheel can now be adjusted.

Locking

Push down the two-position switch. The steering

column is locked.

NOTE: A slight hissing noise, caused

by the two-position switch, is audible

while the steering wheel is being

adjusted. If the steering column has not

been locked, this switch locks it

automatically after 20 - 30 seconds.

3-8

©

201417

Page 33

EMERGENCY RESPONSE GUIDE

1

G001283-2

A

A

B

E

B

C

F

C

D

E

D

F

series

3.8 CABIN STRUCTURE

Releasing a trapped driver

©

201417 3-9

Page 34

EMERGENCY RESPONSE GUIDE

1

Releasing a trapped driver series

3-10

©

201417

Page 35

EMERGENCY RESPONSE GUIDE

1

series

4. TOWING INFORMATION

4.1 REMOVING THE DRIVE SHAFT

- Make sure that the parking brake is

engaged.

- Loosen the bolts, do not remove them.

- Loosen the bearing.

- Hold the shaft while removing the bolts.

- Fix the bearings to the shaft.

- Fasten the shaft to the chassis.

- Cover the drive shaft joint with a plastic bag.

Towing information

©

201417 4-1

Page 36

EMERGENCY RESPONSE GUIDE

1

R601642

Towing information series

4.2 RELEASING THE PARKING BRAKE

WARNING!

- Never release the park brake on

an incline without precautionary

measures.

Releasing the park brake on an

incline causes the vehicle to move

unintentionally. This can lead to

serious injury and damage to the

vehicle.

1. Place wheel chocks in front of and behind the

wheels.

NOTE: It is not permitted to use a

socket wrench to loosen the

releasing bolt.

2. Turn the releasing bolt anti-clockwise as far

as the stop using a ring spanner.

3. Carry out this operation for each spring

brake cylinder.

NOTE: Place a no brakes warning

label on the steering wheel.

4. Bring the park brake back in operating order

by turning the releasing bolts clockwise as

far as possible and tightening them to a

torque of 45 Nm (75 Nm for the releasing bolt

with control pin). The pressure in the spring

brake cylinder circuit must be at least 6.5 bar.

4-2

©

201417

Page 37

EMERGENCY RESPONSE GUIDE

1

series

5. LIFTING INFORMATION

5.1 LIFTING AT THE FRONT

The front of the truck can be lifted with two towing

eyes. To lift the front of the truck:

1. Install two towing eyes with the axle in

horizontal position.

2. Attach the lifting equipment to the towing

eyes.

3. Carefully lift the truck.

CAUTION: The maximum lifting

weight for the towing eyes is 3000 kg

per towing eye.

NOTE: The two towing eyes can also

be used to fix the front of the truck to a

platform.

Lifting information

©

201417 5-1

Page 38

EMERGENCY RESPONSE GUIDE

1

Lifting information series

5.2 JACK UP AT THE FRONT

Jacking up the air sprung front axle

Place the jack under the special jack up brackets

that are attached to the air sprung front axle.

Jacking up mechanically sprung front axles

Place the jack under the axle.

CAUTION: Do not jack up under the

protection bar at the front of the

vehicle. This is a protection bar

made of sheet metal. If you jack up

the vehicle under the protection bar

it collapses.

5-2

©

201417

Page 39

EMERGENCY RESPONSE GUIDE

1

series

5.3 LIFTING AT THE BACK

There are no special facilities to lift the truck at the

back.

Lifting information

©

201417 5-3

Page 40

EMERGENCY RESPONSE GUIDE

1

Lifting information series

5.4 JACK UP AT THE BACK

There are no special facilities to jack up the truck

at the back. Place the jack under the rear axle.

5-4

©

201417

Page 41

Page 42

English

Printed in the Netherlands DW53288301

Loading...

Loading...