2

95XF series

CONTENTS

TECHNICAL DATA

0

DIAGNOSTICS

1

XF ENGINE

2

XF ENGINE COOLING SYSTEM

3

XF ENGINE LUBRICATION SYSTEM

4

XE ENGINE

5

XE ENGINE COOLING SYSTEM

XE ENGINE LUBRICATION SYSTEM

6

7

ǹ 200335

blank

2

TECHNICAL DATA

95XF series Contents

CONTENTS

Page Date

1. ENGINE GENERAL 1-1 200335.................................................... ....

1.1 General 1-1 200335......................................................... ....

2. XF ENGINE 2-1 200335........................................................... ....

2.1 General 2-1 200335......................................................... ....

2.2 Tightening torques 2-4 200335................................................ ....

3. XF ENGINE COOLING SYSTEM 3-1 200335......................................... ....

3.1 General 3-1 200335......................................................... ....

3.2 Tightening torques 3-2 200335................................................ ....

3.3 Filling capacities 3-2 200335.................................................. ....

4. XF ENGINE LUBRICATION SYSTEM 4-1 200335..................................... ....

4.1 General 4-1 200335......................................................... ....

4.2 Tightening torques 4-2 200335................................................ ....

4.3 Filling capacities 4-4 200335.................................................. ....

5. XE ENGINE 5-1 200335........................................................... ....

5.1 General 5-1 200335......................................................... ....

5.2 Tightening torques 5-4 200335................................................ ....

6. XE ENGINE COOLING SYSTEM 6-1 200335......................................... ....

6.1 General 6-1 200335......................................................... ....

6.2 Tightening torques 6-2 200335................................................ ....

6.3 Filling capacities 6-2 200335.................................................. ....

7. XE ENGINE LUBRICATION SYSTEM 7-1 200335..................................... ....

7.1 General 7-1 200335......................................................... ....

7.2 Tightening torques 7-2 200335................................................ ....

7.3 Filling capacities 7-5 200335.................................................. ....

0

ǹ 200335

1

0

TECHNICAL DATA

Contents 95XF series

2

2

ǹ 200335

2

TECHNICAL DATA

95XF series Engine general

1. ENGINE GENERAL

1.1 GENERAL

The terms “COLD ENGINE” and “WARM

ENGINE” are defined as follows:

COLD ENGINE

A cold engine is an engine which, having

reached operating temperature, has been

allowed to cool down for at least six hours.

WARM ENGINE

A warm engine is an engine which, having

reached operating temperature, has not been at

a standstill for more than thirty minutes.

Direction of rotation of the engine

The direction of rotation of the engine is

clockwise, as seen from the timing gear end.

First cylinder of the engine

The first cylinder of the engine is the cylinder at

the timing gear end.

Left-hand and right-hand side of the engine

The left-hand side of the engine is the side

where the fuel pump is mounted.

The right-hand side of the engine is the side

where the air compressor is mounted.

0

ǹ 200335

1-1

0

TECHNICAL DATA

Engine general 95XF series

2

1-2

ǹ 200335

2

TECHNICAL DATA

95XF series XF engine

2. XF ENGINE

2.1 GENERAL

Types XF 280 M

XF 315 M

XF 355 M

Version Euro 2 (M), water-cooled, four-stroke diesel

engine with direct fuel injection, 4 valves per

cylinder and turbo-intercooling.

Number of cylinders 6

Bore x stroke 130 x 158 mm

Swept volume 12.58 l

Compression ratio 16.0 : 1

Firing order 1-5-3-6-2-4

Weight approx. 1,049 kg

ENGINE TYPE

XF 280 M 280 at 2000 1750 at 1100 - 1500

XF 315 M 315 at 2000 1900 at 1050 - 1500

XF 355 M 355 at 2000 2050 at 1000 - 1500

P(kW)atrpm M(Nm)atrpm

0

ENGINE TYPE IDLING SPEED

rpm

XF 280 M 525 - 575 approx. 2300

XF 315 M 525 - 575 approx. 2300

XF 355 M 525 - 575 approx. 2300

MAX. NO LOAD SPEED

rpm

ǹ 200335

2-1

0

TECHNICAL DATA

2

XF engine 95XF series

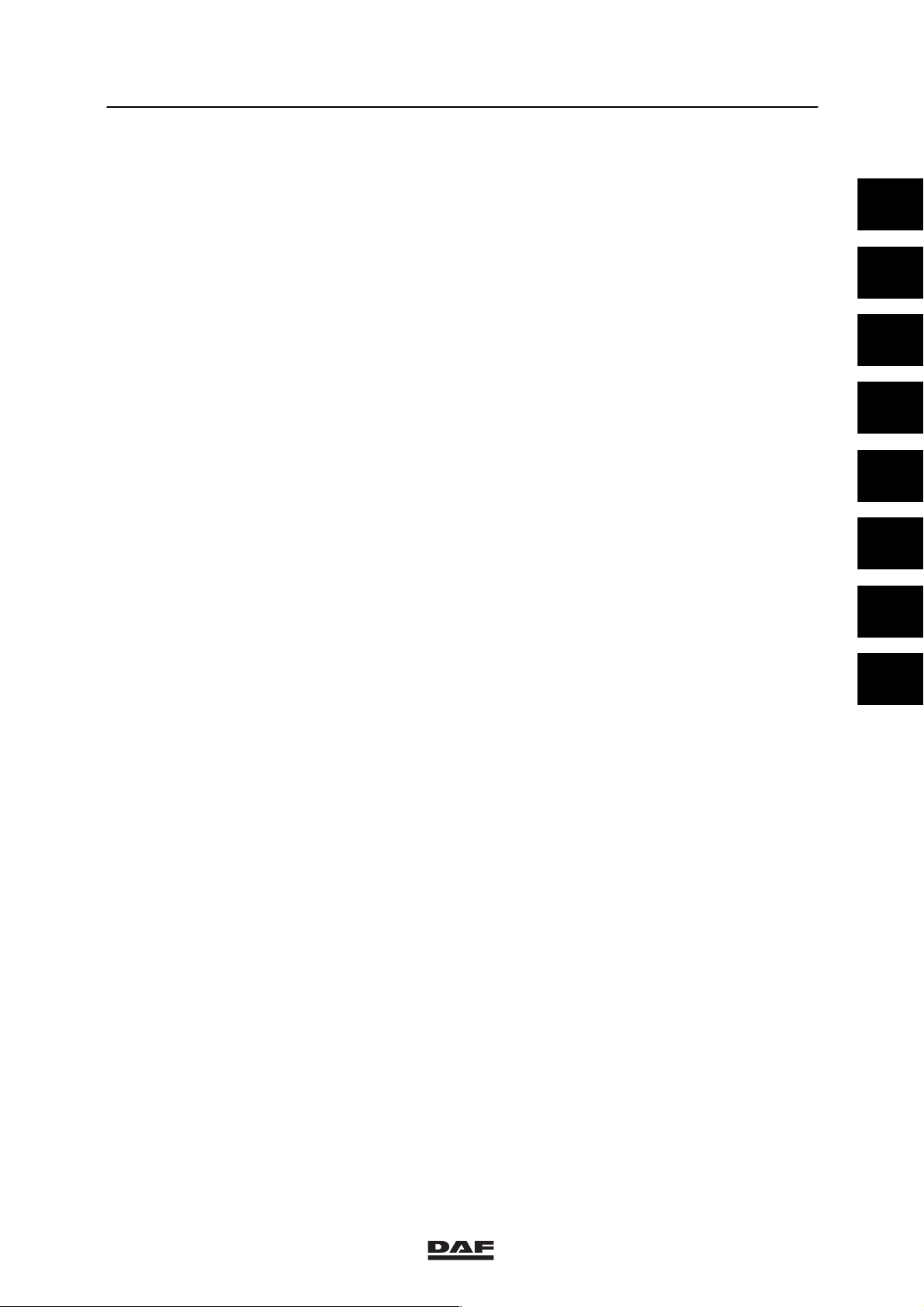

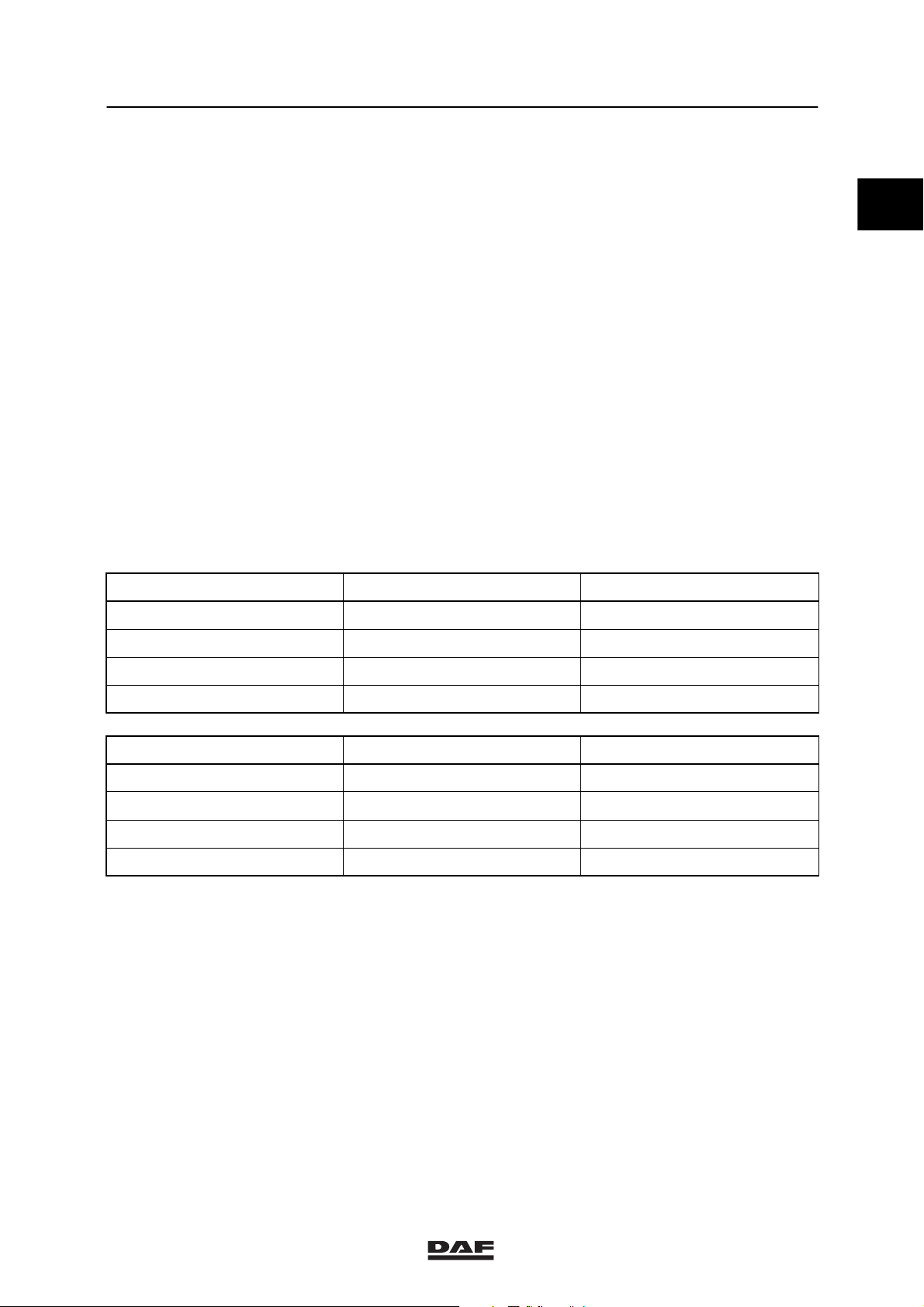

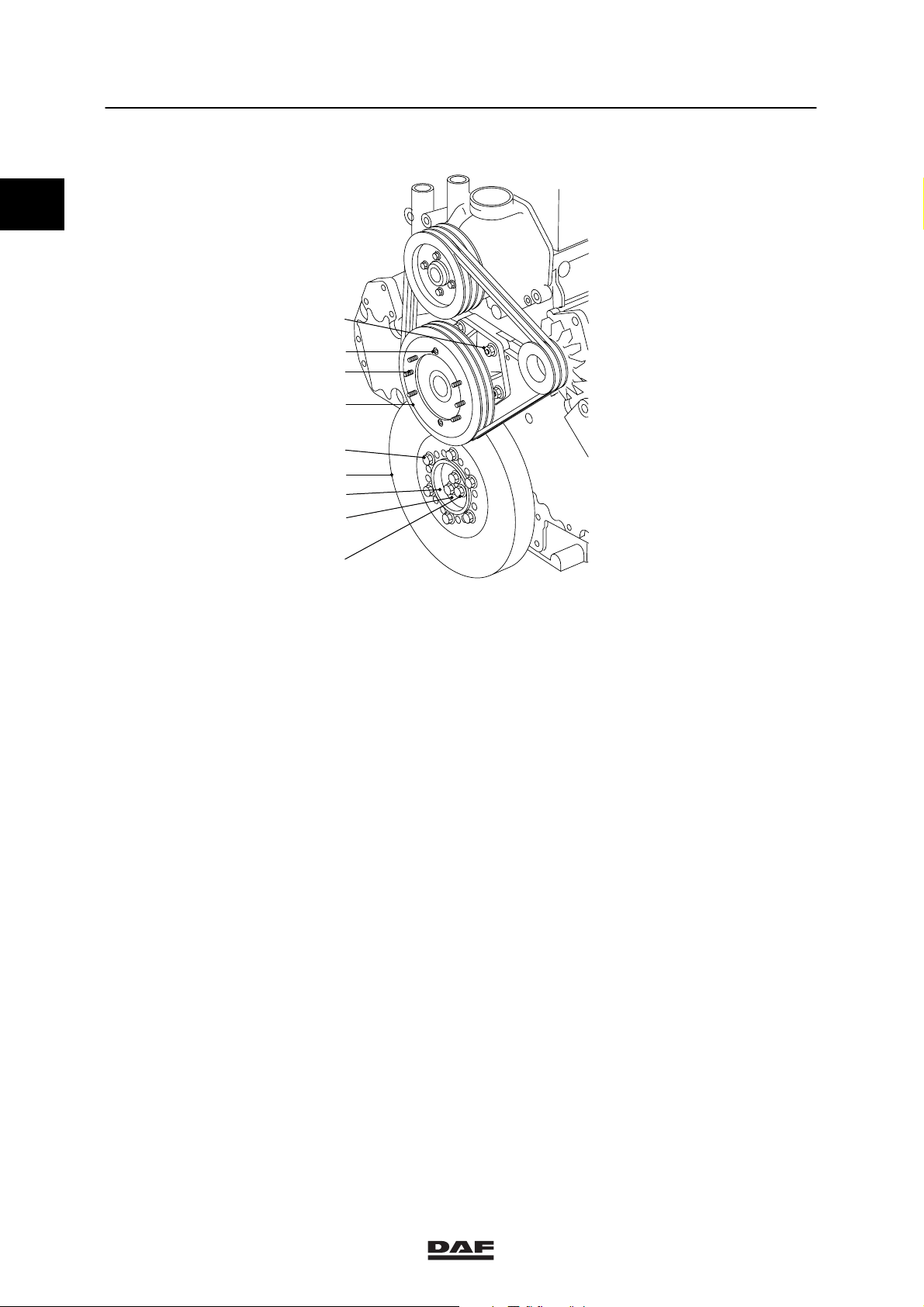

V-BELT TENSION

Belt tension, “AVX” raw-edge

Multiple-V-belt Single-V-belt

Setting tension 1200 600

Test tension ≥800 ≥400

Minimum tension 500 250

Adjusting tension 700 350

(1) Raw-edge V-belts can be recognised by the absence

of textile fabric in the rubber, with the exception of the

top of the belt edge, on the edges and the insides of

the belt (polished belt edges). Version: either toothed

or non-toothed.

(2) After fitting the new V-belt, set the pre-tension to the

“setting tension” and after a trial run check whether the

pre-tension complies with the “test tension”. If the

tension reading is lower than the “test tension”

specified in the table, set the V-belt to the minimum

“test tension”.

1

V-belts in Newtons (N)

New V-belt

Worn V-belt

2

3

(3) If the V-belt tension is lower than the “minimum

tension”, set the belt to the “adjusting tension”.

M2121

2-2

ǹ 200335

2

TECHNICAL DATA

95XF series XF engine

Cylinder liner

Height above cylinder block 0.02 - 0.10 mm

Cylinder head

Minimum height after overhaul 119.50 mm

Test pressure using air (max. pressure) 1.5 bar

Valve clearance

Valve clearance (cold/hot)

inlet 0.50 mm

exhaust 0.50 mm

Valve opening

Valve opening at 1 mm valve clearance 0.3 - 0.7 mm

Axial play

Crankshaft axial play 0.06 - 0.32 mm

Camshaft axial play 0.10 - 0.55 mm

Idler gear axial play 0.05 - 0.25 mm

Gear backlash

Idler gear - crankshaft gear 0.02 - 0.21 mm

Idler gear - fuel-pump gear 0.02 - 0.22 mm

Idler gear - camshaft gear 0.02 - 0.21 mm

Camshaft gear - compressor gear 0.02 - 0.22 mm

Fuel pump gear - steering pump gear 0.02 - 0.19 mm

Oil pump idler gear - oil pump gear 0.02 - 0.20 mm

Crankshaft gear - oil pump idler gear 0.02 - 0.20 mm

0

Number of teeth, timing gears

Crankshaft gear 35

Idler gear 54

Fuel pump gear 70

Camshaft gear 70

Air compressor gear 27

Fan drive housing gear 29

Steering pump gear 18

Lubricating oil pump idler gear 34

Fan drive

Heat gear wheel for max. 30 min. 245_C

Compression pressure

Differences in compression pressure 15%

Flywheel/starter ring gear

Axial variation, measured at a radial distance

of 210 mm

Starter ring gear warm up max. 185_C

0.10 mm

ǹ 200335

2-3

TECHNICAL DATA

2

XF engine 95XF series

2.2 TIGHTENING TORQUES

0

The tightening torques stated in this section are

different from the standard tightening torques

stated in the overview of the standard tightening

torques. The other threaded connections which

are not stated must therefore be tightened to the

tightening torque stated in the overview of

standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that they are of exactly

the same length and property class as the ones

removed unless stated otherwise.

Starter motor

Attachment nuts 73 Nm

Alternator

Alternator bracket attachment bolts 55 Nm

Alternator attachment bolts 50 Nm

Pulley attachment nut, version 55A 70 Nm

Pulley attachment nut, version 95A 70 Nm

Air compressor

M12 attachment bolts for compressor 110 Nm

M8 attachment bolts for bracket 30 Nm

M10 attachment bolts for bracket 60 Nm

Compressor gear flange bolt 120 Nm

M14 cylinder head threaded coupling 40 Nm

M26 cylinder head threaded coupling 90 Nm

Delivery pipe reducer valve 75 Nm

Suction and pressure line unions 90 Nm

(1)

Air-conditioning compressor

M12 attachment bolts for compressor bracket 110 Nm

M10 attachment bolts for compressor 60 Nm

Exhaust manifold

Fit gasket with steel side towards manifold

Sleeved attachment bolts 65 Nm

Heat shield attachment bolts 30 Nm

(1)

(1)

2-4

ǹ 200335

2

TECHNICAL DATA

95XF series XF engine

Inlet manifold

Attachment bolts 60 Nm

Glow plug attachment nut 55 Nm

Air inlet hose clamps 12 Nm

0

Turbocharger

Heat shield attachment bolts 30 Nm

Turbine housing clamp plate attachment nut 15 Nm

Attachment nuts, exhaust manifold

flange/turbocharger

Elbow on turbocharger 40 Nm

Oil supply pipe banjo bolt 90 Nm

(1) Secure with Loctite 243

(2) Apply Copaslip to secure

60 Nm

(1)

(2)

ǹ 200335

2-5

0

TECHNICAL DATA

2

XF engine 95XF series

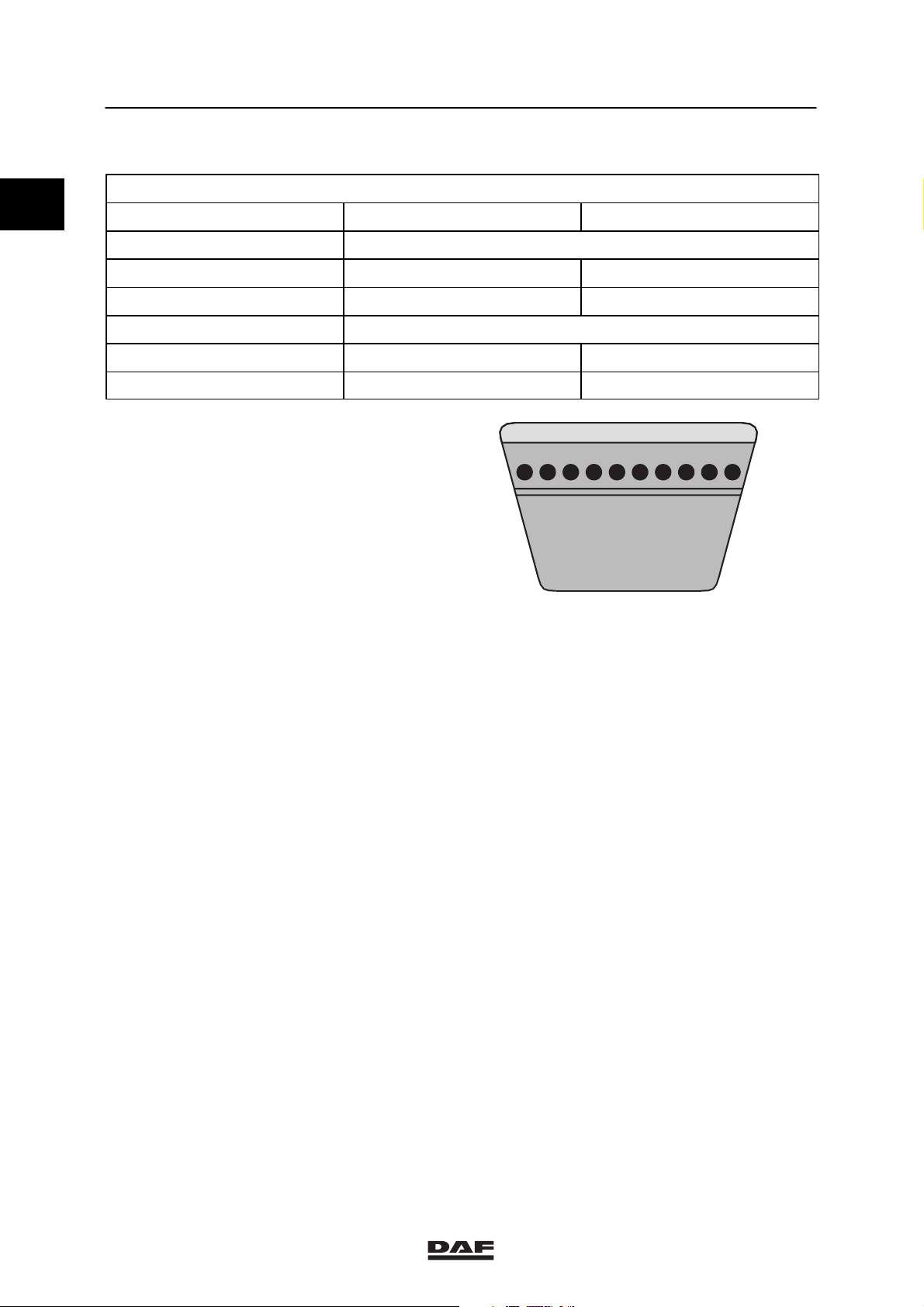

Vibration damper and fan drive

8

9

7

6

5

4

3

2

1

Vibration damper hub attachment bolts (1) in 4

phases:

st

1

phase, all attachment bolts 100 Nm

2ndphase, all attachment bolts 100 Nm

3rdphase, all attachment bolts 100 Nm

4thphase, all attachment bolts 100 Nm

Attachment bolts, vibration damper (5) 110 Nm

Attachment nuts, fan drive (8) 60 Nm

Attachment bolts, fan pulley (9) 30 Nm

Attachment nuts, fan clutch (7) 25 Nm

(1) Tighten the attachment bolts evenly

(2) Secure with Loctite 243

M200945

(1)

(1)

(1)

(1)

(2)

(2)

2-6

ǹ 200335

2

TECHNICAL DATA

95XF series XF engine

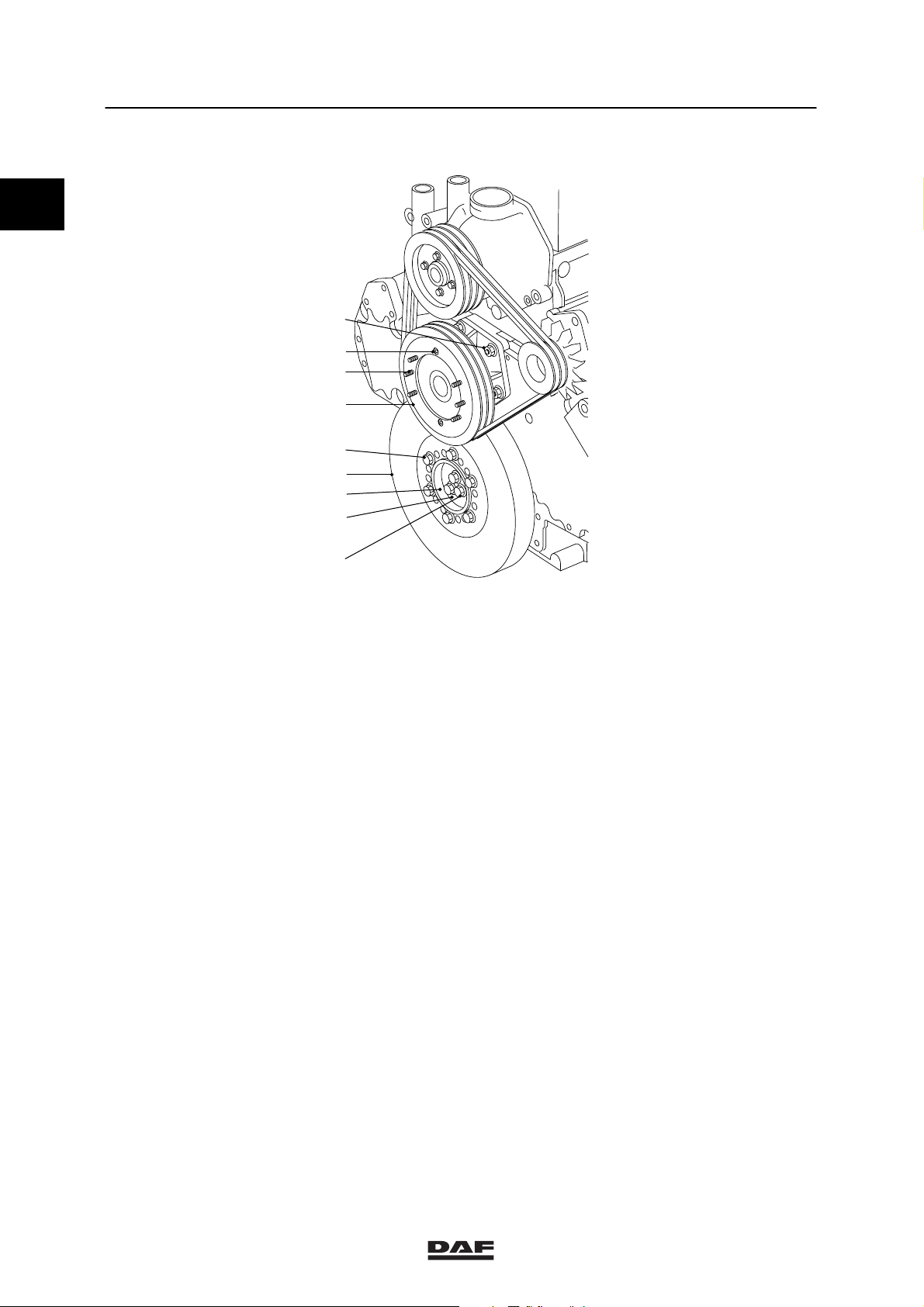

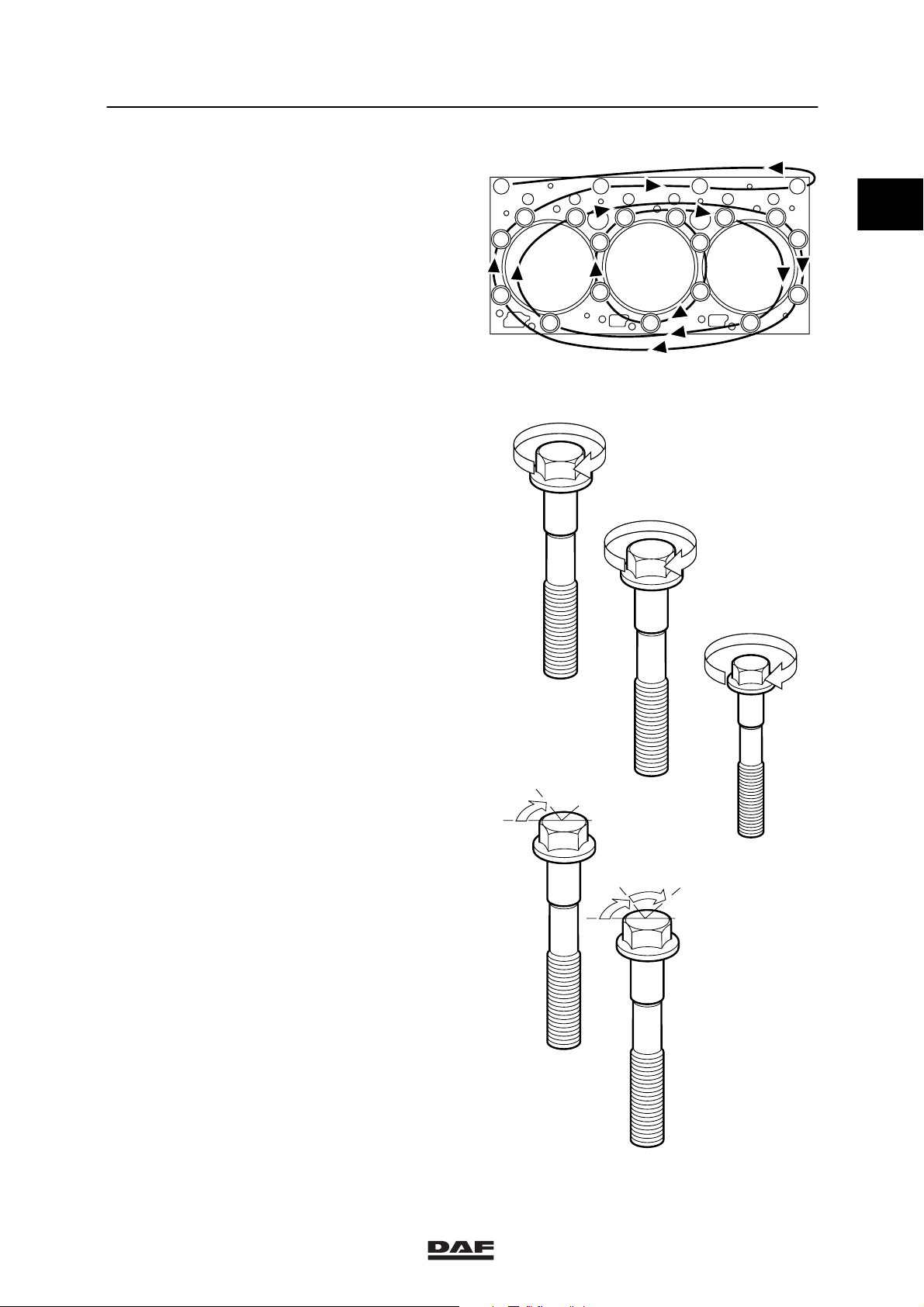

Cylinder head attachment bolts

Cylinder head bolts must only be used once .

So the cylinder head bolts should always be

replaced. The new cylinder head bolts have a

red/brown sealant on the thread.

Note:

- Because of the sealant used on the cylinder

head bolts, their untightening torque may be

very high!

- All M16 and M12 threaded holes must be

carefully cleaned with a screw tap before

the bolts are fitted.

- Once the bolts have been tightened to the

specified torque, the angular displacement

of the M16 bolts must immediately be

started.

- The sealant cannot be applied later.

Tightening cylinder head attachment bolts

16

15

21

17

11

10

50 Nm

18 19

17

6

5

4

20

8

2

3

12

13

14

9

M200562

0

Note:

Apply a drop of oil underneath the bolt heads

(on their abutting surface). Sealant also reduces

the frictional resistance, which means that no oil

must be applied to the thread.

st

phase

1

Tighten M16 in the order

indicated

2ndphase

Tighten M16 in the order

indicated

Tighten M12 in the order

indicated

3rdphase

M16 in the order

indicated

in two steps of 60_ angular

(1) Apply a drop of oil to bolts M16 and M12 on the

abutting surface of the bolt heads.

(1)

50 Nm

150 Nm

(1)

94 Nm

displacement

60

III

150 Nm

M16

I

M16

94 Nm

II

M12

II

M16

60

ǹ 200335

M16

III

M200563

2-7

TECHNICAL DATA

2

XF engine 95XF series

0

Timing gear

Camshaft locking plate attachment bolts 30 Nm

Attachment bolts, fuel pump drive shaft locking

plate

Timing case attachment bolts 30 Nm

Timing cover attachment bolts:

M10 attachment bolts 60 Nm

M8 attachment bolts 25 Nm

Timing cover protection plate attachment bolt 15 Nm

Camshaft gear attachment bolt 425 Nm

Idler gear attachment bolt 170 Nm

Attachment bolt, fuel pump gear wheel 260 Nm

Attachment bolt, silencer 30 Nm

Steering pump gear attachment nut 80 Nm

Steering pump intake pipe banjo bolt 90 Nm

Steering pump delivery pipe banjo bolt 40 Nm

Compressor gear attachment nut 120 Nm

(1) Secure with Loctite 243

30 Nm

(1)

(1)

(1)

(1)

(1)

(1)

2-8

ǹ 200335

2

TECHNICAL DATA

95XF series XF engine

Flywheel housing

Attachment bolts 110 Nm

Sealant to be used when fitting flywheel

housing

Flywheel

Attachment bolts

Without PTO 260 Nm

Without PTO spanner size 21 mm 260 Nm + 90_ angular displacement

With PTO 260 Nm + 150_ angular displacement

Engine mountings on timing gear end

Cylinder block bracket attachment bolts 92 Nm

Chassis engine bracket attachment bolts 73 Nm

Vibration damper engine bracket attachment

bolts

Engine mountings on flywheel end

Flywheel housing engine bracket attachment

bolts

Chassis engine bracket attachment bolts 73 Nm

Vibration damper engine bracket attachment

bolts

Loctite 510

225 Nm + 60_ angular displacement

260 Nm

225 Nm + 60_ angular displacement

(1)

(1)

+90_ angular displacement

0

Engine hanger brackets

Attachment bolts 110 Nm

Valve gear

Valve cover attachment bolts 25 Nm

Rocker setting bolt lock nut 40 Nm

Bridge piece setting bolt lock nut 40 Nm

Lubricating oil strip/rocker seat attachment

bolts

DEB set screw nut 25 Nm

Solenoid valve 20 Nm

Wiring harness attachment bolt 9 Nm

Valve sleeve attachment bolts 30 Nm

Tighten the valve sleeve bolts in the

sequence shown.

110 Nm

3

5

1

11

13

9157

2

6

814

41210

M200942

(1) Secure with Loctite 243

ǹ 200335

2-9

0

TECHNICAL DATA

XF engine 95XF series

2

2-10

ǹ 200335

2

TECHNICAL DATA

95XF series XF engine cooling system

3. XF ENGINE COOLING SYSTEM

3.1 GENERAL

Thermostat

Thermostat opening temperatures:

- thermostat opens at 83_C

- thermostat opened at least 12 mm at 95_C

Thermostat seat Loctite 638

Water pump

Maximum radial play 0.16 - 0.20 mm

Expansion tank pressure cap

Pressure relief valve opening pressure 0.75 bar

Underpressure valve opening pressure 0.1 bar

Pressure testing the cooling system

Test pressure 0.5 - 0.7 bar

0

ǹ 200335

3-1

TECHNICAL DATA

2

XF engine cooling system 95XF series

3.2 TIGHTENING TORQUES

0

The tightening torques stated in this section are

different from the standard tightening torques

stated in the overview of the standard tightening

torques. The other threaded connections which

are not stated must therefore be tightened to the

tightening torque stated in the overview of

standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that they are of exactly

the same length and property class as the ones

removed unless stated otherwise.

Water pump

M8 attachment bolts 30 Nm

Threaded coupling 35 Nm

Coolant pipe

Attachment bolts 54 Nm

Coolant pipe threaded coupling 90 Nm

Coolant pipe plug 30 Nm

Thermostat housing

Attachment bolts 30 Nm

Plug 35 Nm

Radiator

Attachment nuts 70 Nm

3.3 FILLING CAPACITIES

Cooling system capacity approx. 50 litres

Cooling system capacity with ZF-intarder approx. 60 litres

3-2

ǹ 200335

2

TECHNICAL DATA

95XF series XF engine lubrication system

4. XF ENGINE LUBRICATION SYSTEM

4.1 GENERAL

Oil pressure

Oil pressure at engine idling speed 1 bar (warm engine)

Oil pressure at full-load engine speed 3,5 - 4.5 bar

Oil filter

Type disposable filter

Quantity 1

Installation in the oil circuit full flow

Opening pressure of bypass valve at a

pressure difference of

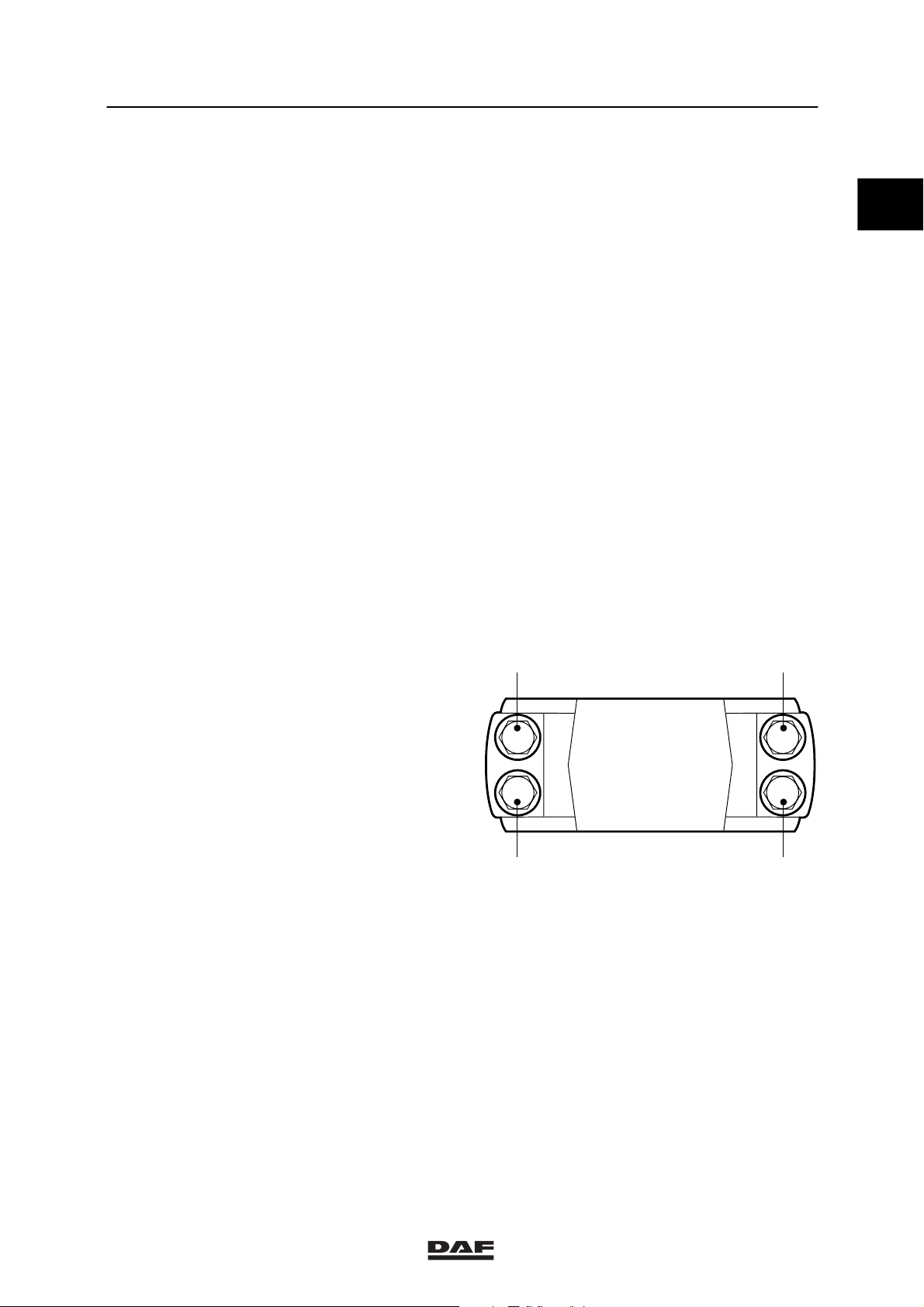

Oil cooler

Opening pressure of bypass valve at a

pressure difference of

Oil section test pressure 6 bar

2,5 0.3 bar

2 bar

0

ǹ 200335

4-1

TECHNICAL DATA

2

XF engine lubrication system 95XF series

4.2 TIGHTENING TORQUES

0

The tightening torques stated in this section are

different from the standard tightening torques

stated in the overview of the standard tightening

torques. The other threaded connections which

are not stated must therefore be tightened to the

tightening torque stated in the overview of

standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that they are of exactly

the same length and property class as the ones

removed unless stated otherwise.

Fuel filter

Attachment bolts, fuel filter/water pipe

connection

Fuel pump filter head banjo bolt 40 Nm

Lubricating oil strip/rocker seats

Attachment bolts 110 Nm

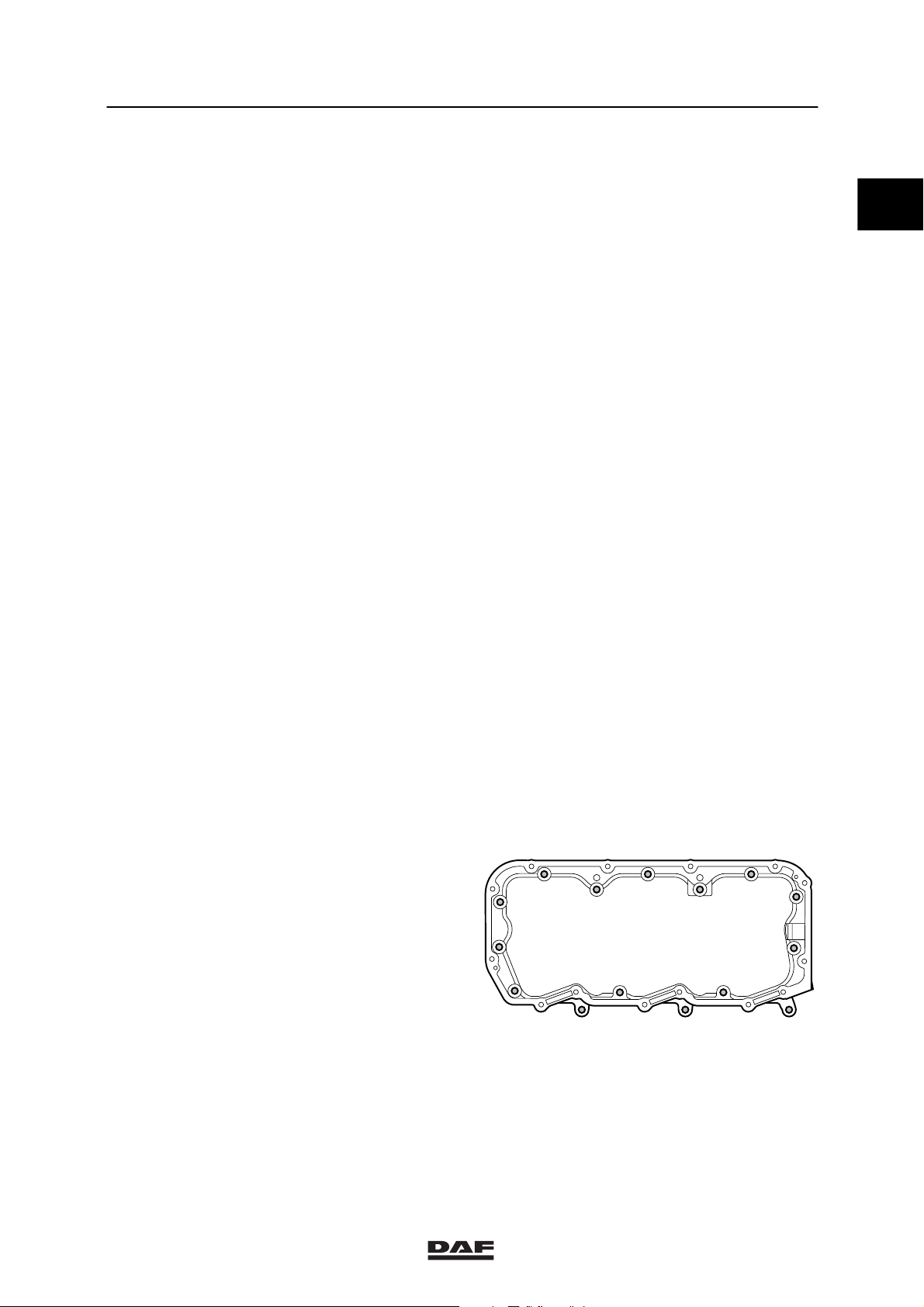

Oil sump

Clamp attachment bolts 25 Nm

Oil drain plug 60 Nm

Oil pump

Attachment bolts for oil pump housing sections 30 Nm

Attachment bolts connecting oil pump to main

bearing cap

Delivery pipe attachment bolts 30 Nm

Idler gear central bolt 60 Nm

40 Nm

60 Nm

(1)

(1)

(1)

Strainer

Bracket attachment bolts 30 Nm

Lubricating oil filter

Lubricating oil filter housing attachment bolts 50 Nm

Oil filter 45 Nm

Coupling in lubricating oil filter head 60 Nm

Bypass pressure regulator

Plug 80 Nm

(1)

(2)

(3)

4-2

ǹ 200335

2

TECHNICAL DATA

95XF series XF engine lubrication system

Oil cooler

Attachment bolts connecting oil cooler to

cylinder block

Coolant supply pipe union 90 Nm

Plug, adjustable banjo connection 90 Nm

Banjo bolt, adjustable banjo connection 90 Nm

Centrifugal oil filter

Central bolt 20 Nm

Oil discharge pipe union 50 Nm

Dip stick

Threaded coupling 60 Nm

(1) Secure with Loctite 243

(2) Secure with Loctite 572

(3) Secure with Loctite 2701

Oil sprayer

Banjo bolt M14 for oil sprayer with locking

plate

M10 banjo bolt for oil sprayer 30 Nm

50 Nm

30 Nm

0

Main bearing caps

Main bearing cap attachment bolts 150 Nm + 120_ angular displacement

Big-end bearing caps

Attachment bolts, big-end bearing caps

st

1

phase,

sequence 1-2-3-4

nd

phase,

2

sequence 4-3-2-1

rd

phase,

3

sequence 1-2-3-4

35 Nm

45 Nm

60_ angular

displacement

(2)

1 4

32

(1) Apply a drop of oil to thread and contact surface.

(2) Connecting rod bolts are to be used once and

tightened as instructed.

When fitting the connecting rod in the engine, apply a

drop of oil to the threads and contact surfaces of the

connecting rod bolts.

(1)

M200661

ǹ 200335

4-3

TECHNICAL DATA

XF engine lubrication system 95XF series

4.3 FILLING CAPACITIES

2

0

Lubrication system

Total capacity, including oil cooler and oil filter approx. 32 litres

Oil sump capacity, maximum level approx. 25 litres

Oil sump capacity, minimum level approx. 17 litres

4-4

ǹ 200335

2

TECHNICAL DATA

95XF series XE engine

5. XE ENGINE

5.1 GENERAL

Types XE 280 C

XE 315 C/C2

XE 355 C

XE 390 C

Version Euro 3 (C), (C2 = 4 öko), water-cooled,

four-stroke diesel engine with direct fuel

injection, 4-valves per cylinder and

turbo-intercooling.

Number of cylinders 6

Bore x stroke 130 x 158 mm

Swept volume 12.58 l

Compression ratio 16.0 : 1

Firing order 1-5-3-6-2-4

Weight approx. 1,080 kg

ENGINE TYPE

XE 280 C 280 at 2000 1750 at 1000 - 1500

XE 315 C/C2 315 at 2000 1900 at 1100 - 1500

P(kW)atrpm M(Nm)atrpm

0

XE 355 C 355 at 2000 2100 at 1100 - 1500

XE 390 C 390 at 1900 2350 at 1100 - 1500

ENGINE TYPE IDLING SPEED MAX. NO LOAD SPEED

XE 280 C 525 - 575 approx. 2300

XE 315 C/C2 525 - 575 approx. 2300

XE 355 C 525 - 575 approx. 2300

XE 390 C 525 - 575 approx. 2300

ǹ 200335

5-1

0

TECHNICAL DATA

2

XE engine 95XF series

V-BELT TENSION

Belt tension, “AVX” raw-edge

Multiple-V-belt Single-V-belt

Setting tension 1200 600

Test tension ≥800 ≥400

Minimum tension 500 250

Adjusting tension 700 350

(1) Raw-edge V-belts can be recognised by the absence

of textile fabric in the rubber, with the exception of the

top of the belt edge, on the edges and the insides of

the belt (polished belt edges). Version: either toothed

or non-toothed.

(2) After fitting the new V-belt, set the pre-tension to the

“setting tension” and after a trial run check whether the

pre-tension complies with the “test tension”. If the

tension reading is lower than the “test tension”

specified in the table, set the V-belt to the minimum

test tension.

1

V-belts in Newtons (N)

New V-belt

Worn V-belt

2

3

(3) If the V-belt tension is lower than the “minimum

tension”, set the belt to the “adjusting tension”.

Cylinder liner

Height above cylinder block 0.02 - 0.10 mm

Cylinder head

Minimum height after overhaul 119.50 mm

Test pressure using air (hot) 1.5 bar

Valve clearance

Valve clearance (cold/hot)

inlet 0.50 mm

exhaust 0.50 mm

Valve opening

Valve opening at 1 mm valve clearance 0.3 - 0.7 mm

M2121

5-2

ǹ 200335

2

TECHNICAL DATA

95XF series XE engine

Axial play

Crankshaft axial play 0.06 - 0.32 mm

Camshaft axial play 0.10 - 0.55 mm

Idler gear axial play 0.05 - 0.25 mm

Gear backlash

Idler gear - crankshaft gear 0.02 - 0.21 mm

Idler gear pump housing camshaft gear 0.02 - 0.22 mm

Idler gear - camshaft gear 0.02 - 0.21 mm

Camshaft gear - compressor gear 0.02 - 0.22 mm

Pump housing camshaft gear - steering pump

gear

Oil pump idler gear - oil pump gear 0.02 - 0.20 mm

Crankshaft gear - oil pump idler gear 0.02 - 0.20 mm

Number of teeth, timing gears

Crankshaft gear 35

Idler gear 54

Pump housing camshaft gear 70

Camshaft gear 70

Air compressor gear 27

Fan drive housing gear 29

Steering pump gear 18

Lubricating oil pump idler gear 34

0.02-0.19mm

0

Fan drive

Heat gear wheel for max. 30 min. 245_C

Compression pressure

Differences in compression pressure max. 15%

Flywheel/starter ring gear

Axial variation, measured at a radial distance

of 210 mm

Starter ring gear warm up max. 185_C

0.10 mm

ǹ 200335

5-3

TECHNICAL DATA

2

XE engine 95XF series

5.2 TIGHTENING TORQUES

0

The tightening torques stated in this section are

different from the standard tightening torques

stated in the overview of the standard tightening

torques. The other threaded connections which

are not stated must therefore be tightened to the

tightening torque stated in the overview of

standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that they are of exactly

the same length and property class as the ones

removed unless stated otherwise.

Starter motor

Attachment nuts 73 Nm

Alternator

Alternator bracket attachment bolts 55 Nm

Alternator attachment bolts 50 Nm

Pulley attachment nut, version 55A 70 Nm

Pulley attachment nut, version 95A 70 Nm

Air compressor

M12 attachment bolts 110 Nm

M8 attachment bolts for bracket 30 Nm

M10 attachment bolts for bracket 60 Nm

Compressor gear flanged nut 120 Nm

M14 cylinder head threaded coupling 40 Nm

M26 cylinder head threaded coupling 90 Nm

Delivery pipe reducer valve 75 Nm

Suction and pressure line unions 90 Nm

(1)

Air-conditioning compressor

M12 attachment bolts for compressor bracket 110 Nm

M10 attachment bolts for compressor 60 Nm

Exhaust manifold

Fit gasket with steel side towards manifold

Sleeved attachment bolts 65 Nm

Heat shield attachment bolts 30 Nm

(1)

(1)

5-4

ǹ 200335

2

TECHNICAL DATA

95XF series XE engine

Inlet manifold

Attachment bolts 60 Nm

Glow plug attachment nut 55 Nm

Air inlet hose clamps 12 Nm

0

Turbocharger

Heat shield attachment bolts 30 Nm

Turbine housing clamp plate attachment nut 15 Nm

Attachment nuts

Exhaust manifold flange/turbocharger 60 Nm

Elbow on turbocharger 40 Nm

Oil supply pipe banjo bolt 90 Nm

(1) Apply Loctite 243 to secure

(2) Apply Copaslip to secure

(1)

(2)

ǹ 200335

5-5

0

TECHNICAL DATA

2

XE engine 95XF series

Vibration damper and fan drive

8

9

7

6

5

4

3

2

1

Vibration damper hub attachment bolts (1) in 4

phases:

st

1

phase, all attachment bolts 100 Nm

2ndphase, all attachment bolts 100 Nm

3rdphase, all attachment bolts 100 Nm

4thphase, all attachment bolts 100 Nm

Attachment bolts, vibration damper (5) 110 Nm

Attachment nuts, fan drive (8) 60 Nm

Attachment bolts, fan pulley (9) 30 Nm

Attachment nuts, fan clutch (7) 25 Nm

(1) Tighten the attachment bolts evenly

(2) Secure with Loctite 243

M200945

(1)

(1)

(1)

(1)

(2)

(2)

5-6

ǹ 200335

2

TECHNICAL DATA

95XF series XE engine

Cylinder head attachment bolts

Cylinder head bolts must only be used once.So

the cylinder head bolts should always be

replaced. The new cylinder head bolts have a

red/brown sealant on the thread.

Note:

- Because of the sealant used on the cylinder

head bolts, their untightening torque may be

very high!

- All M16 and M12 threaded holes must be

carefully cleaned with a screw tap before

the bolts are fitted.

- Once the bolts have been tightened to the

specified torque, the angular displacement

of the M16 bolts must immediately be

started.

- The sealant cannot be applied later.

Tightening cylinder head attachment bolts

16

15

21

17

11

10

50 Nm

18 19

17

6

5

4

20

8

2

3

12

13

14

9

M200562

0

Note:

Apply a drop of oil underneath the bolt heads

(on their abutting surface). Sealant also reduces

the frictional resistance, which means that no oil

must be applied to the thread.

st

phase

1

Tighten M16 in the

order indicated

2ndphase

Tighten M16 in the

order indicated

Tighten M12 in the

order indicated

3rdphase

M16 in the order

indicated in two stages of 60_ angular

(1) Apply a drop of oil to bolts M16 and M12 on the

abutting surface of the bolt heads.

(1)

50 Nm

150 Nm

(1)

94 Nm

displacement

60

III

150 Nm

M16

I

M16

94 Nm

II

M12

II

M16

60

ǹ 200335

M16

III

M200563

5-7

TECHNICAL DATA

2

XE engine 95XF series

0

Timing gear

Camshaft locking plate attachment bolts 30 Nm

Pump housing camshaft locking plate

attachment bolts

Timing case attachment bolts 25 Nm

Timing cover attachment bolts:

M10 attachment bolts 60 Nm

M8 attachment bolts 25 Nm

Timing cover protection plate attachment bolt 15 Nm

Camshaft gear attachment bolt 425 Nm

Idler gear attachment bolt 170 Nm

Pump housing camshaft gear attachment bolt 260 Nm

Compressor gear attachment nut 120 Nm

Steering pump gear attachment nut 80 Nm

Suction pipe banjo bolt 90 Nm

Delivery pipe banjo bolt 40 Nm

(1) Apply Loctite 243 to secure

30 Nm

(1)

(1)

(1)

(1)

(1)

5-8

ǹ 200335

2

TECHNICAL DATA

95XF series XE engine

Flywheel housing

Attachment bolts 110 Nm

Sealant to be used when fitting flywheel

housing

Flywheel

Attachment bolts

Without PTO 260 Nm + 90_ angular displacement

With PTO 260 Nm + 150_ angular displacement

Engine mountings on timing gear end

Cylinder block bracket attachment bolts 92 Nm

Chassis engine bracket attachment bolts 73 Nm

Vibration damper engine bracket attachment

bolts

Engine mountings on flywheel end

Flywheel housing engine bracket attachment

bolts

Chassis engine bracket attachment bolts 73 Nm

Vibration damper engine bracket attachment

bolts

Engine hanger brackets

Attachment bolts 110 Nm

Loctite 510

225 Nm + 60_ angular displacement

260 Nm

225 Nm + 60_ angular displacement

(1)

0

Valve gear

Valve cover attachment bolts 25 Nm

Rocker setting bolt lock nut 40 Nm

Bridge piece setting bolt lock nut 40 Nm

Lubricating oil strip/rocker seat attachment

bolts

DEB set screw nut 25 Nm

Solenoid valve 20 Nm

Wiring harness attachment bolt 9 Nm

Valve sleeve attachment bolts 30 Nm

Tighten the valve sleeve bolts in the sequence

shown.

(1) Apply Loctite 243 to secure

110 Nm

3

5

1

11

13

9157

2

6

814

41210

M200942

ǹ 200335

5-9

0

TECHNICAL DATA

XE engine 95XF series

2

5-10

ǹ 200335

2

TECHNICAL DATA

95XF series XE engine cooling system

6. XE ENGINE COOLING SYSTEM

6.1 GENERAL

Thermostat

Thermostat opening temperatures:

- thermostat opens at 83_C

- thermostat opened at least 12 mm at 95_C

Thermostat seat Loctite 638

Water pump

Maximum radial play 0.16 - 0.20 mm

Expansion tank pressure cap

Pressure relief valve opening pressure 0.75 - 0.9 bar

Underpressure valve opening pressure 0.1 bar

Pressure testing the cooling system

Test pressure 0.5 - 0.7 bar

0

ǹ 200335

6-1

TECHNICAL DATA

2

XE engine cooling system 95XF series

6.2 TIGHTENING TORQUES

0

The tightening torques stated in this section are

different from the standard tightening torques

stated in the overview of the standard tightening

torques. The other threaded connections which

are not stated must therefore be tightened to the

tightening torque stated in the overview of

standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that they are of exactly

the same length and property class as the ones

removed unless stated otherwise.

Water pump

M8 attachment bolts 30 Nm

Threaded coupling 35 Nm

Coolant pipe

Attachment bolts 54 Nm

Coolant pipe threaded coupling 90 Nm

Plug 35 Nm

Thermostat housing

Attachment bolts 30 Nm

Plug 35 Nm

Radiator

Attachment nuts 70 Nm

6.3 FILLING CAPACITIES

Cooling system capacity approx. 50 litres

Cooling system capacity with ZF-intarder approx. 60 litres

6-2

ǹ 200335

2

TECHNICAL DATA

95XF series XE engine lubrication system

7. XE ENGINE LUBRICATION SYSTEM

7.1 GENERAL

Oil pressure

Oil pressure at engine idling speed 1 bar (warm engine)

Oil pressure at full-load engine speed 3.5 - 4.5 bar

Oil filter

Type disposable filter

Quantity 1

Installation in the oil circuit full flow

Opening pressure of bypass valve at a

pressure difference of

Oil cooler

Opening pressure of bypass valve at a

pressure difference of

Oil section test pressure 6 bar

2.5 0.3 bar

2 bar

0

ǹ 200335

7-1

TECHNICAL DATA

2

XE engine lubrication system 95XF series

7.2 TIGHTENING TORQUES

0

The tightening torques stated in this section are

different from the standard tightening torques

stated in the overview of the standard tightening

torques. The other threaded connections which

are not stated must therefore be tightened to the

tightening torque stated in the overview of

standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that they are of exactly

the same length and property class as the ones

removed unless stated otherwise.

Fuel filter

Attachment bolts, fuel filter/water pipe

connection

Lubricating oil strip/rocker seats

Attachment bolts 110 Nm

Oil sump

Clamp attachment bolts 25 Nm

Oil drain plug 60 Nm

Oil pump

Attachment bolts for oil pump housing sections 30 Nm

Attachment bolts connecting oil pump to main

bearing cap

Oil delivery pipe attachment bolts 30 Nm

Idler gear central bolt 60 Nm

40 Nm

60 Nm

(1)

(1)

(1)

Strainer

Bracket attachment bolts 30 Nm

Lubricating oil filter

Lubricating oil filter housing attachment bolts 50 Nm

Oil filter 45 Nm

Coupling in lubricating oil filter head 60 Nm

Bypass pressure regulator

Plug 80 Nm

(1)

(2)

(3)

7-2

ǹ 200335

2

TECHNICAL DATA

95XF series XE engine lubrication system

Oil cooler

Attachment bolts connecting oil cooler to

cylinder block

Coolant supply pipe union 90 Nm

Plug, adjustable banjo connection 90 Nm

Banjo bolt, adjustable banjo connection 90 Nm

Centrifugal oil filter

Central bolt 20 Nm

Oil discharge pipe union 50 Nm

Dip stick

Threaded coupling 60 Nm

(1) Apply Loctite 243 to secure

(2) Apply Loctite 572 to secure

(3) Apply Loctite 2701 to secure

50 Nm

0

ǹ 200335

7-3

TECHNICAL DATA

2

XE engine lubrication system 95XF series

Oil sprayer

Oil sprayer banjo bolt 30 Nm

0

Main bearing caps

Main bearing cap attachment bolts 150 Nm + 120_ angular displacement

Big-end bearing caps

Attachment bolts (1) for cracked big-end

bearing caps

st

1

phase, order 100 Nm

nd

2

phase, order 175 15 Nm

rd

3

phase, order 60_ angular

displacement

(2)

1

2

1

Attachment bolts, big-end bearing caps

st

1

phase,

sequence 1-2-3-4

nd

phase,

2

sequence 4-3-2-1

rd

phase,

3

sequence 1-2-3-4

35 Nm

45 Nm

60_ angular

displacement

(2)

1 4

(1)

5

4

3

M2 01 285

Attachment bolts, big-end bearing caps

XE390C

st

1

phase,

sequence 1-2-3-4

nd

phase,

2

sequence 4-3-2-1

rd

phase,

3

sequence 1-2-3-4 60_ angular

(1) Apply a drop of oil to thread and contact surface.

(2) Connecting rod bolts are to be used once and

tightened as instructed. When fitting the connecting

rod in the engine, apply a drop of oil to the threads

and contact surfaces of the connecting rod bolts.

50 Nm

80 Nm

displacement

(2)

32

M200661

7-4

ǹ 200335

2

95XF series XE engine lubrication system

7.3 FILLING CAPACITIES

TECHNICAL DATA

Lubrication system

Total capacity, including oil cooler and oil filter approx. 32 litres

Oil sump capacity, maximum level approx. 25 litres

Oil sump capacity, minimum level approx. 17 litres

0

ǹ 200335

7-5

0

TECHNICAL DATA

XE engine lubrication system 95XF series

2

7-6

ǹ 200335

2

DIAGNOSIS

95XF series Contents

CONTENTS

Page Date

1. TRACTIVE PROBLEMS 1-1 0008................................................ ......

1.1 Introduction 1-1 0008...................................................... ......

1.2 Acceleration test (engine model with conventional fuel system) 1-3 0008.......... ......

1.3 Acceleration test (engine model with UPEC fuel system) 1-7 0008................ ......

1.4 Acceleration test form 1-11 0008............................................. .....

1.5 Acceleration test using DAVIE 1-12 0008...................................... .....

2. XF ENGINE 2-1 0008........................................................... ......

2.1 Fault-finding table 2-1 0008................................................. ......

3. COOLING SYSTEM XF ENGINE 3-1 0008......................................... ......

3.1 Fault-finding table 3-1 0008................................................. ......

4. LUBRICATING OIL SYSTEM XF ENGINE 4-1 0008................................. ......

4.1 Fault-finding table 4-1 0008................................................. ......

5. XE ENGINE 5-1 0008........................................................... ......

5.1 Fault-finding table for engine functions 5-1 0008............................... ......

5.2 Fault-finding table for vehicle functions 5-9 0008............................... ......

1

6. COOLING SYSTEM XE ENGINE 6-1 0008......................................... ......

6.1 Fault-finding table 6-1 0008................................................. ......

7. LUBRICATING OIL SYSTEM XE ENGINE 7-1 0008................................. ......

7.1 Fault-finding table 7-1 0008................................................. ......

ǹ 0008

1

1

DIAGNOSIS

Contents 95XF series

2

2

ǹ 0008

2

DIAGNOSIS

95XF series Tractive problems

1. TRACTIVE PROBLEMS

1.1 INTRODUCTION

There may be several reasons for improper

vehicle performance.

Some of these may be mechanical, others are

particularly also of a psychological nature.

It is therefore important to properly identify the

problem.

Try to get as much information as possible from

the customer or driver.

- When does the vehicle not perform

properly?

- In what road or weather conditions?

- How is the vehicle loaded?

- Is the vehicle not being compared with a

vehicle with completely different

specifications, for instance engine power?

1

- Is the vehicle being driven in the correct

engine speed range?

If the answers are unsatisfactory, ask the

customer or driver for facts.

- Tachograph cards of trips

- Reliable consumption figures of trips

ǹ 0008

1-1

1

DIAGNOSIS

2

Tractive problems 95XF series

Following proper identification of the complaint,

vehicle performance can be tested by an

acceleration test.

If the vehicle fails to pass the acceleration test, a

boost pressure curve may be plotted as an aid

to identify the cause.

Note:

Checking the boost pressure will in general only

make sense after the vehicle has covered at

least 20,000 km.

The test sheets are available through the DAF

organisation.

For plotting a boost pressure curve, see Group 4

of the workshop manual.

1-2

ǹ 0008

2

DIAGNOSIS

95XF series Tractive problems

1.2 ACCELERATION TEST

(engine model with conventional fuel system)

The acceleration test is required to acquire an

effective understanding of the fuel consumption

and tractive force of a vehicle. When carrying

out the test the legal regulations should be

observed and maximum security be ensured.

Compared with other diagnostic tools, this test is

a fast and cheap way of checking whether the

vehicle meets DAF’s requirements and,

therefore, whether or not the complaint is

justified.

During the acceleration test the time required to

accelerate the loaded vehicle from starting

speed to final speed is measured. (Weight of

entire combination at least 75% of the train

weight, GCW).

To eliminate weather influences and road

conditions, this test must be done in both driving

directions. The average acceleration time is

obtained by averaging both measured times.

1

The maximum acceleration time, the speeds

between which the time is to be measured and

the gear to be engaged for the various vehicle

configurations is calculated using the DAF

“Topec” route simulation computer program.

For this purpose, “Topec” needs the following

and other vehicle data:

- vehicle type

- height of the entire vehicle combination

- weight of entire vehicle combination (at

least 75% of the train weight)

- aerodynamic influences, e.g. roof spoilers,

fenders, etc.

- engine type

- gearbox type and reduction

- rear axle type and axle reduction

-tyresize

- cab type.

ǹ 0008

1-3

1

DIAGNOSIS

2

Tractive problems 95XF series

Before starting the acceleration test

- Check the tyre pressure of the entire vehicle

combination. Also check the tyres for a

deviating wear pattern.

- Examine the complete condition of the

trailer or semi-trailer.

- Check the entire vehicle combination for

adverse aerodynamic influences, for

instance loose tarpaulins, wrongly adjusted

spoilers and fenders.

- Check the vehicle and trailer or semi-trailer

for excessive road drag. Be aware of

dragging brakes.

- Check the tachograph. The speed signal

should be present.

- Check that the correct k-factor is set on the

tachograph.

- Check that the fuel pump of the engine has

been provided with the original seal.

- Check that the throttle control is able to

reach the maximum stop of the fuel pump.

Acceleration test

1. Use the “Acceleration test form” in the

workshop manual.

2. Check the activities as set out under

“Before starting the acceleration test”.

3. Choose a test route where the difference

between the measured times in both

directions does not exceed 15%. If the

difference in time exceeds 15%, find

another test route.

4. Establish the starting and end points on the

selected test route, to ensure that exactly

the same route can be taken in both

directions. Do the entire test at least twice

and take the average time.

1-4

ǹ 0008

2

DIAGNOSIS

95XF series Tractive problems

5. Run the drive train at operating temperature

(drive for at least 15 minutes with a loaded

vehicle).

Note:

When switched on, the air compressor and fan

consume 10 to 15 kW engine power on average.

During the test try to avoid that both consumers

are or have been switched on.

6. Before the starting point on the test route,

engage the gear specified by Topec and

make sure the vehicle speed is at least

3 km/h below the starting speed.

7. Fully depress the accelerator pedal and

(using a stopwatch) measure the time

needed to accelerate the vehicle from

starting speed to end speed.

Result of first acceleration test

If the acceleration time is not achieved, first

carry out the following work.

1

- Check the injection timing. Adjust or

optimise, if necessary.

- Check the fuel system for the presence of

air.

- Replace/clean the air filter element.

- Check the setting of the wastegate on the

turbocharger (if present).

- Check the engine brake butterfly valve for

smooth operation.

- Check the inlet air cooler exterior for dirt

deposits.

- Clean the water separator (if fitted).

- Replace the fuel filter.

- Replace/clean the fuel prefilter (if present).

ǹ 0008

1-5

DIAGNOSIS

2

Tractive problems 95XF series

- Check the suction pipe of the tank for

clogging by large pieces of foreign matter.

- Check the fuel tank for contamination.

Clean the tank with a steam cleaner, if

necessary.

1

- Check the air inlet system for any leaks.

- Check the exhaust system for any leaks.

- Check the exhaust system for blockages by

measuring the exhaust back pressure.

- Check the turbocharger wheels on the

compressor and turbine side for damage

and for deposits of salt or any other

contaminants.

- Check the banjo bolt strainer in the fuel lift

pump for dirt (if fitted).

- Check the valve and DEB play.

- Check the injection lines for damage.

- Check the fuel pump gallery pressure.

- Check the discharge pump pressure.

- Check whether the right type of components

have been fitted. Fuel pump, turbocharger,

injectors, etc.

- Check the opening pressure of the injectors.

- Clean the nozzle openings using calibrated

injector needles (DAF no. 1329371).

Repeat the acceleration test. If necessary, plot a

boost pressure curve.

Result of second acceleration test

If the specified acceleration time is not achieved,

carry out the following work.

- Remove the fuel pump from the engine.

- Check the fuel pump setting on a fuel pump

test bench.

- Repeat the acceleration test.

1-6

ǹ 0008

2

DIAGNOSIS

95XF series Tractive problems

1.3 ACCELERATION TEST

(engine model with UPEC fuel system)

The acceleration test is required to acquire an

effective understanding of the fuel consumption

and tractive force of a vehicle. When carrying

out the test the legal regulations should be

observed and maximum security be ensured.

Compared with other diagnostic tools, this test is

a fast and cheap way of checking whether the

vehicle meets DAF’s requirements and,

therefore, whether or not the complaint is

justified.

During the acceleration test the time required to

accelerate the loaded vehicle from starting

speed to final speed is measured. (Weight of

entire combination at least 75% of the train

weight, GCW).

To eliminate weather influences and road

conditions, this test must be done in both driving

directions. The average acceleration time is

obtained by averaging both measured times.

1

The maximum acceleration time, the speeds

between which the time is to be measured and

the gear to be engaged for the various vehicle

configurations is calculated using the DAF

“Topec” route simulation computer program.

For this purpose, “Topec” needs the following

and other vehicle data:

- vehicle type

- height of the entire vehicle combination

- weight of entire vehicle combination (at

least 75% of the train weight)

- aerodynamic influences, e.g. roof spoilers,

fenders, etc.

- engine type

- gearbox type and reduction

- rear axle type and axle reduction

-tyresize

- cab type.

ǹ 0008

1-7

1

DIAGNOSIS

2

Tractive problems 95XF series

Before starting the acceleration test

- Check the tyre pressure of the entire vehicle

combination. Also check the tyres for a

deviating wear pattern.

- Examine the complete condition of the

trailer or semi-trailer.

- Check the entire vehicle combination for

adverse aerodynamic influences, for

instance loose tarpaulins, wrongly adjusted

spoilers and fenders.

- Check the vehicle and trailer or semi-trailer

for excessive road drag. Be aware of

dragging brakes.

- Check the tachograph. The speed signal

should be present.

- Check that the correct k-factor is set on the

tachograph.

- Using DAVIE, check whether the pedal can

be depressed 100% with the gas pedal

position sensor.

Acceleration test

1. Use the “Acceleration test form” in the

workshop manual.

2. Check the activities as set out under

“Before starting the acceleration test”.

3. Choose a test route where the difference

between the measured times in both

directions does not exceed 15%. If the

difference in time exceeds 15%, find

another test route.

4. Establish the starting and end points on the

selected test route, to ensure that exactly

the same route can be taken in both

directions. Do the entire test at least twice

and take the average time.

1-8

ǹ 0008

2

DIAGNOSIS

95XF series Tractive problems

5. Run the drive train at operating temperature

(drive for at least 15 minutes with a loaded

vehicle).

Note:

When switched on, the air compressor and fan

consume 10 to 15 kW engine power on average.

During the test try to avoid that both consumers

are or have been switched on.

6. Connect DAVIE and follow the instructions

in DAVIE.

7. Fully depress the brake pedal during the

acceleration test.

Result of first acceleration test

If the acceleration time is not achieved, first

carry out the following work.

- Check the fuel system for the presence of

air.

- Replace/clean the air filter element.

1

- Check the setting of the wastegate on the

turbocharger (if present).

- Check the engine brake butterfly valve for

smooth operation.

- Check the inlet air cooler exterior for dirt

deposits.

- Clean the water separator (if fitted).

- Clean the fuel coarse filter.

- Check whether the hand pump on the fuel

coarse filter is tightened.

- Replace the fuel fine filter.

- Check the suction pipe of the tank for

clogging by large pieces of foreign matter.

ǹ 0008

1-9

1

DIAGNOSIS

2

Tractive problems 95XF series

- Check the fuel tank for contamination.

Clean the tank with a steam cleaner, if

necessary.

- Check the air inlet system for any leaks.

- Check the exhaust system for any leaks.

- Check the exhaust system for blockages by

measuring the exhaust back pressure.

- Check the turbocharger wheels on the

compressor and turbine side for damage

and for deposits of salt or any other

contaminants.

- Check the valve and DEB play.

- Check the injection lines for damage.

- Check the gallery pressure.

- Check the fuel lift pump output.

- Check the reducing valve.

- Check whether the right type of components

has been fitted. Turbocharger, injectors etc.

- Check the opening pressure of the injectors.

- Clean the nozzle openings using calibrated

injector needles (DAF no. 1329371).

Repeat the acceleration test. If necessary, plot a

boost pressure curve.

1-10

ǹ 0008

2

DIAGNOSIS

95XF series Tractive problems

1.4 ACCELERATION TEST FORM

General data:

Client’sname : ..........................................

Type/vehiclenumberplate : ..........................................

Typeoftrailer/semi-trailer : ..........................................

Owneroftrailer/semi-trailer : Client/Dealer/Thirdparties ...................

Date : ..........................................

Weather conditions : ..........................................

Route : ..........................................

Vehicle data:

Enginetype : ..........................................

Gearboxtype : ..........................................

Rearaxletype : ..........................................

1

Vehiclecombinationheight : ..........................................

Totalweightofvehiclecombination : ..........................................

Aerodynamic influences : ..........................................

TOPEC data:

Geartobeselected : ..........................................

Maximum acceleration time : seconds..................................

Starting speed : km/hour..................................

End speed : km/hour..................................

Acceleration test result:

Measured acceleration time : seconds..................................

Endresultofaccelerationtest : ..........................................

ǹ 0008

1-11

1

DIAGNOSIS

2

Tractive problems 95XF series

1.5 ACCELERATION TEST USING DAVIE

The acceleration test can also be carried out

using DAVIE. Collect all the required information

and, having started DAVIE, access the engine

management system installed on the vehicle

(E-gas, ASL-G or UPEC) and carefully follow the

instructions in DAVIE in order to carry out the

test correctly.

Following each test, the test results should

always be stored on a disk.

The acceleration test in DAVIE

should only be started when the

vehicle is at a complete standstill.

Because the communication

between the accelerator pedal

sensor and the unit is interrupted

briefly during starting of DAVIE, this

could lead to very dangerous

situations in a vehicle which is not

at a complete standstill.

Never switch to the direct test or

fault-finding test when driving the

vehicle.

1-12

ǹ 0008

2

DIAGNOSIS

95XF series XF engine

2. XF ENGINE

2.1 FAULT-FINDING TABLE

FAULT: ENGINE CAN BE STARTED, BUT DOES NOT RUN

Possible cause Remedy

Air in the fuel system. Bleed the fuel system.

Insufficient discharge pressure of the discharge

pump.

Contaminated banjo bolt strainer in the

discharge pump.

Water in the fuel system. Check the water separator.

Fuel filter silted up. Replace the fuel filter.

Incorrect or contaminated injectors installed. Check whether the correct injectors have been

Incorrect injection timing or incorrect fuel pump

setting.

Compression pressure too low. Check the compression pressure.

FAULT: ENGINE STARTS AND STOPS

Possible cause Remedy

Air in the fuel system. Bleed the fuel system.

Insufficient discharge pressure of the discharge

pump.

Check the discharge pump pressure.

Check the strainer for contamination.

installed. Clean contaminated injectors and set

them.

Check the injection timing and/or fuel pump

setting.

Check the discharge pump pressure.

1

Fuel filter silted up. Replace the fuel filter.

Incorrect injection timing or incorrect fuel pump

setting.

FAULT: ENGINE WILL NOT RUN IDLE

Possible cause Remedy

Air in the fuel system. Bleed the fuel system.

Incorrect or contaminated injectors installed. Check whether the correct injectors have been

Incorrect injection timing or incorrect fuel pump

setting.

Injection pipes torn or broken. Check the injection lines. Replace if necessary.

Check the injection timing and/or fuel pump

setting.

installed. Clean contaminated injectors and set

them.

Check the injection timing and/or fuel pump

setting.

ǹ 0008

2-1

1

DIAGNOSIS

2

XF engine 95XF series

FAULT: ENGINE DELIVERS LESS THAN MAXIMUM POWER

Possible cause Remedy

Fuel filter silted up. Replace the fuel filter.

Incorrect or contaminated injectors installed. Check whether the correct injectors have been

installed. Clean contaminated injectors and set

them.

Incorrect injection timing or incorrect fuel pump

setting.

Fuel tank ventilation opening clogged blocked. Check/clean the vent opening.

Air cleaner element blocked. Clean or replace the air-filter element.

Blocked air inlet from turbocharger to inlet

manifold.

Air leak in the pressure part of the inlet system. Check the inlet unit for any leaks.

Compressor side of turbocharger contaminated. Clean compressor side with a non-corrosive

Exhaust manifold, exhaust silencer, exhaust pipe

blocked.

Gas leak between exhaust manifold and cylinder

head.

Gas leak between exhaust manifold and

turbocharger.

Incorrect wastegate setting or defective

wastegate.

Damaged turbocharger. Replace the turbocharger and identify the cause.

Incorrect valve clearance setting. Check valve clearance. Adjust if necessary.

Check the injection timing and/or fuel pump

setting.

Check air inlet. Clean if necessary.

cleaning agent or a soft brush Check the inlet

side for carbon deposits or other contamination.

Check the exhaust unit. Clean if necessary.

Check the fixing bolts and gaskets.

Check the fixing bolts and gaskets.

Check the wastegate or wastegate setting.

Incorrect DEB setting. Check the DEB play. Adjust if necessary.

DEB continues to operate. Check the DEB function.

Compression pressure too low. Check the compression pressure.

2-2

ǹ 0008

2

DIAGNOSIS

95XF series XF engine

FAULT: ENGINE PRODUCES EXTREME SMOKE LEVELS

Possible cause Remedy

Incorrect injection timing or incorrect fuel pump

setting.

Incorrect or contaminated injectors installed. Check whether the correct injectors have been

Fuel filter silted up. Replace the fuel filter.

Blocked air cleaner. Check the air-filter element. Blow-clean or

Air leak between inlet manifold and cylinder

head.

Gas leak between exhaust manifold and

turbocharger.

Gas leak between exhaust manifold and cylinder

head.

Cooling system failure. Check the cooling system.

Lubrication system failure. Check the lubricating-oil system.

Compression pressure too low. Check the compression pressure.

Check the injection timing and/or fuel pump

setting.

installed. Clean contaminated injectors and set

them.

replace, if necessary.

Check for leaks. Replace the gaskets, if

necessary.

Check the fixing bolts and gaskets.

Check the fixing bolts and gaskets.

1

ǹ 0008

2-3

DIAGNOSIS

2

XF engine 95XF series

FAULT: ENGINE PRODUCES EXCESSIVE NOISE

Possible cause Remedy

Broken valve springs. Check valve springs. Replace if necessary.

1

Excess clearance between piston and cylinder

wall.

Run-out main and/or connecting-rod bearings. Check the main and connecting-rod bearings.

Fuel system failure. Check the fuel system.

Inlet system failure. Check the inlet system.

Exhaust system failure. Check the exhaust system.

Air compressor, fan drive, air-conditioning

compressor.

Lubrication system failure. Check the lubricating-oil system.

Incorrect V-belt tension or V-belt misalignment. Check the V-belt tension or the V-belt alignment.

Excessive radial play of water pump. Check radial play of water pump.

Fan damaged or fan touching the radiator. Check fan and radiator.

Damaged or loose engine brackets. Check the engine brackets.

Excessive valve clearance. Readjust the valve clearance.

Damaged valve train and/or push rods, cam

followers, rocker shafts or rocker arms.

Damaged vibration damper. Check the vibration damper for damage.

Check the piston clearance in the cylinder.

Check whether the air compressor, fan drive,

air-conditioning compressor or other engine

attachments may be the cause of the noise.

Check the drive train, etc. for damage.

Damaged pistons and/or cylinder linings. Check the pistons and cylinder linings.

Timing gear wheels. Check the timing gear wheels for play and/or

damage.

Loose or broken flywheel or coupling bolts. Check the flywheel/coupling.

2-4

ǹ 0008

2

DIAGNOSIS

95XF series Cooling system XF engine

3. COOLING SYSTEM XF ENGINE

3.1 FAULT-FINDING TABLE

FAULT: ENGINE TEMPERATURE INCREASES

Possible cause Remedy

Incorrect injection timing or incorrect fuel pump

setting.

Incorrect injectors installed. Check whether the correct injectors have been

Inlet system failure. Check the inlet system.

Lubrication system failure. Check the lubricating-oil system.

Incorrect V-belt tension. Check the V-belt tension or replace the V-belt.

Insufficient coolant. Check the coolant level. Top up if necessary.

Coolant pipe torn or blocked. Check the coolant pipes.

Contaminated radiator/cooling system. Check the radiator. Clean if necessary.

Incorrect or malfunctioning pressure cap. Check the pressure cap.

Thermostat opens insufficiently or not at all. Check the thermostat and its operation.

Contaminated coolant filter. Check the coolant filter. If necessary, replace

Defective water pump. Check the water-pump shaft, bearings and

Defective viscous fan. Check operation of viscous fan.

Check the injection timing and/or fuel pump

setting.

installed.

and clean the cooling system.

impeller. Replace water pump, if necessary.

1

ǹ 0008

3-1

1

DIAGNOSIS

2

Cooling system XF engine 95XF series

FAULT: EXTERNAL COOLANT LEAKAGE

Possible cause Remedy

Defective coolant pipes. Check the coolant pipes.

Defective coolant pipes. Check coolant pipes.

Leaking radiator. Check the radiator. Pressure-test if necessary.

Leaking water pump. Check the water pump. If necessary, measure

the bearing play.

Defective oil cooler. Check the oil cooler. Pressure-test if necessary.

Defective pressure cap. Check the pressure cap. Pressure-test if

necessary.

Leaking heater. Check heater pipes.

Leaking connection between coupling and water

pipe.

FAULT: INTERNAL COOLANT LEAKAGE

Possible cause Remedy

Defective cylinder head gasket. Check the cylinder head gasket.

Cracked cylinder heads or cylinder block. Check the cylinder heads and engine block for

Leaking injector bushes. Check cylinder heads. Pressure-test if

Defective compressor cylinder head gasket. Replace compressor cylinder head gasket.

Defective oil cooler. Check whether there is coolant in the lubricating

Defective freeze plugs in tappet area (cylinder

block) or at the top of the cylinder heads.

Check connection between water pipe and

coupling for damage.

Replace the O-rings.

internal cracks. Pressure-test if necessary.

necessary.

oil system.

Replace freeze plug(s).

3-2

ǹ 0008

2

DIAGNOSIS

95XF series Lubricating oil system XF engine

4. LUBRICATING OIL SYSTEM XF ENGINE

4.1 FAULT-FINDING TABLE

FAULT: ENGINE OIL PRESSURE TOO LOW

Possible cause Remedy

Engine oil level too low. Top up engine oil to maximum level.

External oil leakage. Visually check engine for leakage. Repair if

necessary.

Defective oil-pressure switch. Check the switch. Replace if necessary.

Oil fails to meet the required specifications. Renew the engine oil and the oil filter.

Oil temperature is too high. Check the oil cooler.

Oil mixed with coolant or fuel. Renew the engine oil and the oil filter.

Oil feed-through pipe or oil suction pipe loose or

broken.

Oil-pressure control valve fails to operate. Check the oil pressure control valve.

Inadequate functioning of oil pump. Check the oil pump.

Run-out main or connecting-rod bearings. Check the main or connecting-rod bearings.

Loose oil nozzle of piston cooler. Check the oil nozzle. Replace if necessary.

Defective internal oil pressure pipes or sealing. Check the oil pressure pipes and seals.

Contamination between oil-pressure control

valve and seat.

Contaminated oil filter. Renew the oil filter.

Check the oil pipes. Repair if necessary.

Check/clean the oil pressure control valve.

1

ǹ 0008

4-1

1

DIAGNOSIS

2

Lubricating oil system XF engine 95XF series

FAULT: ENGINE USES TOO MUCH OIL

Possible cause Remedy

Inlet system failure. Check the inlet system.

Exhaust system failure. Check the exhaust system.

Leaking oil cooler. Check whether there is lubricating oil in the

engine cooling system.

Oil temperature is too high. Check whether the correct oil cooler has been

installed

Blow-by is too high. Check the compression pressure and carry out a

cylinder leak test.

Check the condition of the piston rings and

cylinder linings.

Worn piston rings and/or cylinder linings. Replace the piston rings and/or cylinder linings.

Check the air inlet system.

Check the oil specifications.

Damaged or missing injector O-ring. Check the injector seal.

4-2

ǹ 0008

2

DIAGNOSIS

95XF series XE engine

5. XE ENGINE

5.1 FAULT-FINDING TABLE FOR ENGINE FUNCTIONS

FAULT: ENGINE CAN BE STARTED, BUT DOES NOT RUN

Possible cause Remedy

Poor fuel quality. Drain fuel, rinse the fuel system, replace the fuel

filters and fill the fuel tank with fuel.

Air in the fuel system. Check the fuel system for drawing in air:

- through suction pipe

- through sealing ring of fuel lift pump

Fuel filter blocked. Replace the fuel filter and clean the system.

Fault in electrical components/wiring of:

- connectors

- pump unit

- electronic unit

- crankshaft position sensor and camshaft

position sensor

Communication with DAVIE interrupted when the

engine is tested with DAVIE.

Incorrect pump housing camshaft timing,

camshaft position sensor signal not present at

correct moment.

No fuel supply, or fuel lift pump defective, no

output.

Check the electrical system.

Remove the earth cable from the battery and fit

it again.

Check timing/signal from camshaft position

sensor.

Check:

- fuel level

- pipes for clogging and leakage

- fuel lift pump

1

Pressure-relief valve on pump housing does not

shut off.

Check the pressure-relief valve.

ǹ 0008

5-1

1

DIAGNOSIS

2

XE engine 95XF series

FAULT: ENGINE STALLS AND PICKS UP AFTER RESTARTING

Possible cause Remedy

Air in the fuel system. Check the fuel system for drawing in air:

- through suction pipe

- through sealing ring of fuel lift pump

Poor contacts, contact resistance in connectors. Check the connector joints.

Pressure-relief valve on pump housing does not

shut off.

FAULT: ENGINE DOES NOT PICK UP PROPERLY

Possible cause Remedy

Poor fuel quality. Drain fuel, rinse the fuel system, replace the fuel

Air in the fuel system. Check the fuel system for drawing in air:

Fuel filter blocked. Replace the fuel filter and clean the system.

Fault in electrical components/wiring of:

- connectors

- pump unit

- electronic unit

- crankshaft position sensor and camshaft

position sensor

- sensor for engine coolant temperature

Battery voltage too low. Charge the batteries.

Connection points on pump units changed. Install the correct connection points on the

Check the pressure-relief valve.

filters and fill the fuel tank with fuel.

- through suction pipe

- through sealing ring of fuel lift pump

Check the electrical system.

correct pump unit.

Mechanical defect or clogging of pump units. Replace the pump units.

Injectors defective. Check the injectors.

Pressure-relief valve on pump housing does not

shut off.

Fuel lift pump output too low. Check the fuel lift pump and replace, if

Check the pressure-relief valve.

necessary.

5-2

ǹ 0008

2

DIAGNOSIS

95XF series XE engine

FAULT: ENGINE RUNS AT (INCREASED) IDLING SPEED AND

DOES NOT RESPOND TO ACCELERATOR PEDAL

Possible cause Remedy

Accelerator pedal sensor, mechanical defect. Check:

- mechanical connection sensor/accelerator

pedal

- accelerator pedal sensor

Fuel quantity adjusted by ABS/ASR.

Engine brake input signal available. Check the electrical system of the engine brake.

FAULT: ENGINE RUNS AT INCREASED IDLING SPEED (1000 RPM) AND

DOES NOT RESPOND TO ACCELERATOR PEDAL

Possible cause Remedy

1

Fault in electrical components/wiring of:

- connectors

- pump unit

- electronic unit

- crankshaft position sensor and camshaft

position sensor

- sensor for engine coolant temperature

FAULT: ENGINE RUNS AT INCREASED IDLING SPEED (1000 RPM) AND

RESPONDS TO ACCELERATOR PEDAL

Possible cause Remedy

Fault in electrical components/wiring of

accelerator pedal sensor.

FAULT: MAXIMUM ENGINE SPEED IS 1000 RPM

Possible cause Remedy

Fault in electrical components/wiring of

accelerator pedal sensor.

Check the electrical system.

Check the electrical system.

Check the electrical system.

ǹ 0008

5-3

DIAGNOSIS

2

XE engine 95XF series

FAULT: DIESEL KNOCK DURING ACCELERATION

Possible cause Remedy

Poor fuel quality. Drain fuel, rinse the fuel system, replace the fuel

filters and fill the fuel tank with fuel.

1

Air in the fuel system. Check the fuel system for drawing in air:

- through suction pipe

- through sealing ring of fuel lift pump

Fault in electrical components/wiring of sensor

for engine coolant temperature.

Injector defective. Check the injectors.

Crankshaft position sensor defective. Check the crankshaft position sensor.

FAULT: ENGINE RUNS IRREGULARLY

Possible cause Remedy

Poor fuel quality. Drain fuel, rinse the fuel system, replace the fuel

Air in the fuel system. Check the fuel system for drawing in air:

Fuel filter blocked. Replace the fuel filter.

Connection points on pump units changed. Install the correct connection points on the

Mechanical defect or clogging of pump units. Replace the pump units.

Injector defective. Check the injectors.

Check the electrical system.

filters and fill the fuel tank with fuel.

- through suction pipe

- through sealing ring of fuel lift pump

correct pump unit.

Fuel lift pump output too low. Check the fuel lift pump and replace, if

necessary.

Pressure-relief valve on pump housing does not

shut off.

Fault in electrical components/wiring of:

- connectors

- pump unit

Check the pressure-relief valve.

Check the electrical system.

5-4

ǹ 0008

2

DIAGNOSIS

95XF series XE engine

FAULT: REDUCED POWER AT ALL SPEEDS

Possible cause Remedy

Poor fuel quality. Drain fuel, rinse the fuel system, replace the fuel

filters and fill the fuel tank with fuel.

Fuel filter blocked. Replace the fuel filter.

Accelerator pedal sensor, mechanical defect. Check:

- mechanical connection sensor/accelerator

pedal

- accelerator pedal sensor

Fault in electrical components/wiring of:

- accelerator pedal sensor

- sensor for engine coolant temperature

- boost pressure sensor

- fuel temperature sensor

- contacts

- contact resistance in connector joints

Air filter clogged. Replace or clean the air filter.

Turbocharger defective/incorrect waste-gate

control.

Electro-pneumatic boost pressure valve

mechanically defective.

Air leaks in inlet system. Pressure-test the inlet system.

Mechanical defect or clogging of pump units. Replace the pump units.

Injector defective. Check the injectors.

Pressure-relief valve on pump housing does not

shut off.

Check the electrical system.

Check wastegate or wastegate control.

Check electro-pneumatic boost pressure valve.

Check the pressure-relief valve.

1

Fuel lift pump output too low. Check the fuel lift pump and replace, if

necessary.

ǹ 0008

5-5

1

DIAGNOSIS

2

XE engine 95XF series

FAULT: REDUCED POWER ABOVE A PARTICULAR SPEED

Possible cause Remedy

Fuel filter partially blocked. Replace the fuel filter.

Air filter partially clogged. Replace or clean the air filter.

Electro-pneumatic boost pressure valve

mechanically defective.

Check electro-pneumatic boost pressure valve.

Fault in electrical components/wiring of sensor

for electro-pneumatic boost pressure valve.

Air leaks in inlet system. Pressure-test the inlet system.

Pressure-relief valve on pump housing does not

shut off.

Fuel lift pump output too low. Check the fuel lift pump and replace, if

FAULT: WHITE/BLUE SMOKE DEVELOPMENT

Possible cause Remedy

Poor fuel quality. Drain fuel, rinse the fuel system, replace the fuel

Air in the fuel system. Check the fuel system for drawing in air:

Fuel filter blocked. Replace the fuel filter and clean the system.

Fault in electrical components/wiring of:

- crankshaft position sensor

- sensor for engine coolant temperature

Mechanical defect or clogging of pump units. Replace the pump units.

Check the electrical system.

Check the pressure-relief valve.

necessary.

filters and fill the fuel tank with fuel.

- through suction pipe

- through sealing ring of fuel lift pump

Check the electrical system.

Injector defective. Check the injectors.

Fuel lift pump output too low. Check the fuel lift pump and replace, if

necessary.

5-6

ǹ 0008

2

DIAGNOSIS

95XF series XE engine

FAULT: BLACK SMOKE DEVELOPMENT

Possible cause Remedy

Fault in electrical components/wiring of:

- crankshaft position sensor

- air inlet temperature sensor

- fuel temperature sensor

- boost pressure sensor

Injector defective. Check the injectors.

FAULT: FUEL CONSUMPTION TOO HIGH

Possible cause Remedy

Poor fuel quality. Drain fuel, rinse the fuel system, replace the fuel

Fuel filter blocked. Replace the fuel filter and clean the system.

Fault in electrical components/wiring of:

- sensor for engine coolant temperature

- boost pressure sensor

- fuel temperature sensor

Air leaks in inlet system. Pressure-test the inlet system.

Mechanical defect or clogging of pump units. Replace the pump units.

Injector defective. Check the injectors.

Leaks in fuel system. Check for leaks.

Check the electrical system.

filters and fill the fuel tank with fuel.

Check the electrical system.

1

ǹ 0008

5-7

1

DIAGNOSIS

2

XE engine 95XF series

FAULT: REDUCED MAXIMUM SPEED

Possible cause Remedy

Air in the fuel system. Check the fuel system for drawing in air:

- through suction pipe

- through sealing ring of fuel lift pump

Fuel filter blocked. Replace the fuel filter and clean the system.

Crankshaft position sensor, signal fault. Check:

- crankshaft position sensor

- wiring

Fault in electrical components/wiring of sensor

for

- accelerator pedal sensor