Page 1

S/M No. : DSC120BEF0

Service Manual

Model: DSC-34W70N

Release 1

HDTV Monitor

Chassis : SC-120

Specification

Power Requirement AC 120V, 60Hz

Power Consumption 210watts

General

Dimensions(W/H/D) 41”W x 26.2”H x 24.6”D

Weight 81Kg (178.61bs)

Antenna One 75ohm external input terminal for

UHF/VHF/Cable

Screen Size 34”(diagonal), 16:9 Aspect Ratio

Picture

Display Format DTV : 1080I @ 33.75KHz

NTSC/DVD : 480p @ 31.5KHz

Horizontal Resolution 800 Lines

Sound System Dolby Pro Logic

Sound

NTSC Audio Multi CH TV Stereo(MTS) /

Second Audio Program(SAP)

Audio Power 8W/ch (Main L/R), 5W/ch (Center)

Rear

RF Antenna Input

NTSC A/V In 2each (Video/L/R)

1each (S-Video/Video/L/R)

NTSC A/V Monitor Out 1each (Video/L/R)

Inputs/ HD Component In 1each (Y/Pb/Pr)

Output DVD Component In 1each (Y/Cb/Cr)

Surround Channel Out 1each (SL/SR)

Sub woofer Out 1each

Side

NTSC A/V In 1each (S-Video/Video/L/R)

Headphone 1each (L/R)

DAEWOO ELECTRONICS CO., LTD.

http: // svc.dwe.co.kr Nov. 2001

Page 2

- 1 -

1. Product Safety 2

2. Specifications 4

3. Remote Control Overview 5

4. Limited Warranty 6

5. Service Mode 7

6. General Adjustment 10

7. Special Adjustment (When replacing new circuits boards) 15

8. Troubleshooting Charts 16

9. Parts List 25

10. Circuit Diagram

10-1. Power Circuit 47

10-2. Main Circuit 48

10-3. Audio Circuit 49

10-4. 3D Comb Filter Circuit 50

10-5. Main Video Circuit 51

10-6. Sub Video Circuit 52

10-7. Scan Rate Converter Circuit 53

10-8. RGB Processor Circuit 54

10-9. AV Circuit 55

10-10. Union Circuit 56

10-11. Signal Flow Diagram 57

11. Exploded View 58

Page 3

1.

PRODUCT SAFETY SERVICING GUIDELINES FOR COLOR TELEVISION RECEIVERS

- 2 -

CAUTION : Do not attempt to modify this product in any way.

Unau-thorized modifications will not only void the warranty, but

may lead to your being liable for any resulting property damage

or user injury. Service work should be performed only after you

are thoroughly familiar with all of the following safety checks

and servicing guide-lines. To do otherwise, increases the risk of

potential hazards and injury to the user.

SAFETY CHECKS

After the original service problem has been corrected, a check

should be made of the following:

SUBJECT : FIRE & SHOCK HAZARD

1.Be sure that all components are positioned in such a way as

to avoid possibility of adjacent component shorts.

This is especially important on those chassis which are

transported to and from the repair shop.

2.Never release a repair unless all protective devices such as

insulators, barriers, covers, shields, strain relief, and other

hardware have been reinstalled per original design.

3.Soldering must be inspected to discover possible cold solder

joints, frayed leads, damaged insulation (including A.C. cord),

solder splashes or sharp solder points. Be certain to remove

all loose foreign particials.

4.Check for physical evidence of damage or deterioration to

parts and components, and replace if necessary follow

original layout, lead length and dress.

5.No leads or components should touch a receiving tube or a

resistor rated at 1 watt or more. Lead tension around

protruding metal surfaces must be avoided.

6.All critical components such as fuses, flameproof resistors,

capacitors, etc. must be replaced with exact factory types.

Do not use replacement components other than those

specified or make unrecommended circuit modifications.

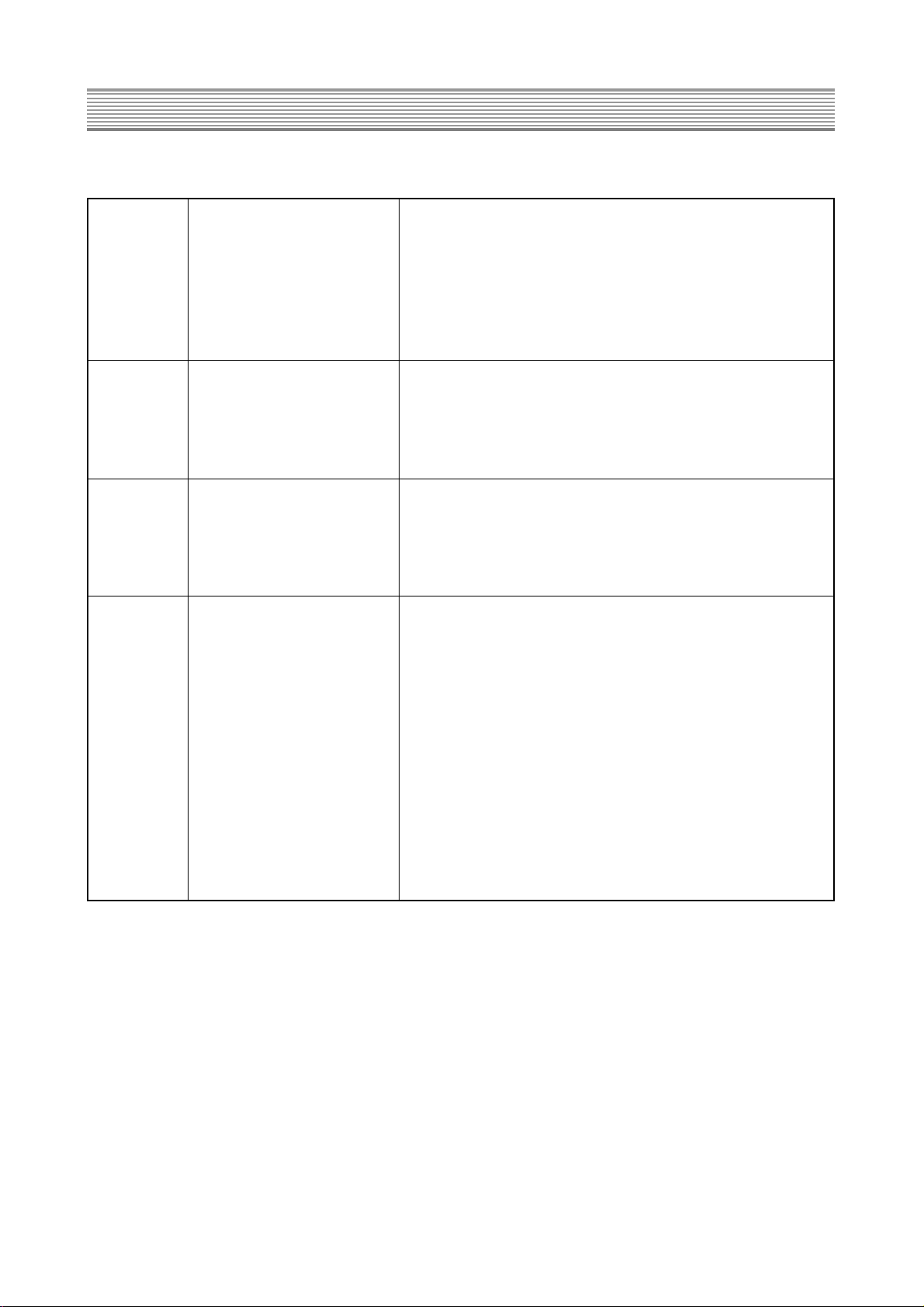

7.After re-assembly of the set always perform an A.C. leakage

test on all exposed metallic parts of the cabinet, (the channel

selector knob, antenna terminals, handle and screws) to be

sure the set is safe to operate without danger of electrical

shock. Do not use a line isolation transformer during this test.

Use an A.C. voltmeter, having 5000 ohms per volt or more

sensitivity, in the following manner : connect a 1500 ohm 10

watt resistor, paralleled by a 15 mfd. 150V A.C. type

capacitor between a known good earth ground (9water pipe,

conduit, etc.) and the exposed metallic parts, one at a time.

Measure the A.C. voltage across the combination of 1500

ohm resistor and 0.15 MFD capacitor. Reverse the A.C. plug

and repeat A.C. voltage measurements for each exposed

metallic part. Voltage measured must not exceed 0.75 volts

R.M.S. This corresponds to 0.5 milliamp A.C. Any value

exceeding this limit constitutes a potential shock hazard and

must be corrected immediately.

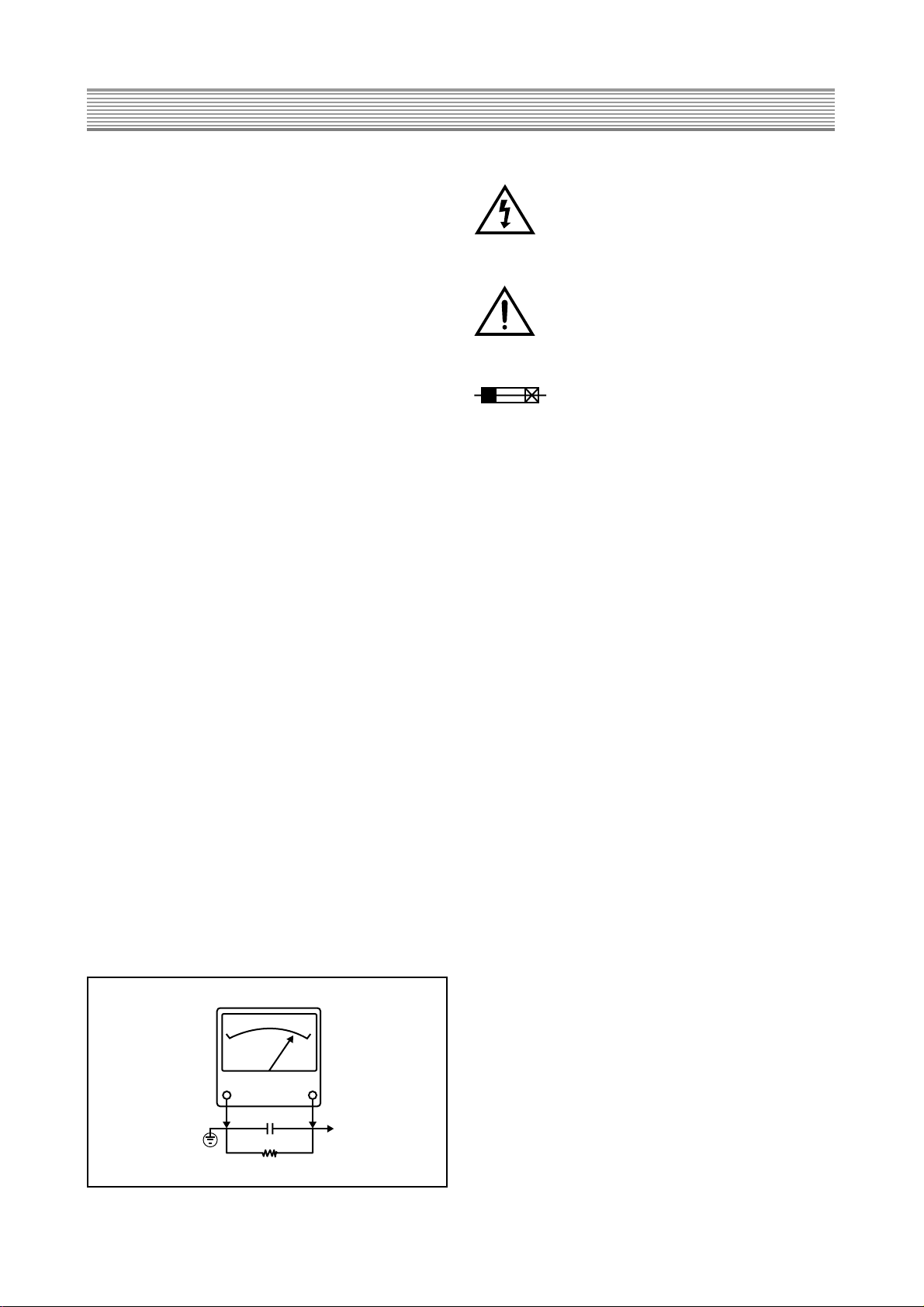

GRAPHIC SYMBOLS :

The lightning flash with arrowhead symbol,

within an equilateral triangle, is intended to

alert the service personnel to the presence of

uninsulated “dangerous voltage” that may be

of sufficiency magnitude to constitute a riskof

electric shock.

The exclamation point within an equilateral

triangle is intended to alert the service personnel to the presence of important safety

information in service literature.

Fuse symbol is printed on pcb adjacent to the

fuse, with “RISK OF FIRE REPLACE FUSE

AS MARKED”. The symbol is explained in the

service manual with the following wording or

equivalent.

CAUTION : FOR CONTINUED PROTECTION AGAINST

FIRE HAZARD, REPLACE ONLY WITH SAME TYPE (6.3A,

125V)” and

“

ATTENTION: AFIN D’ ASSU UNE PROTECTION

PERMANENTE CONTRE LES RISQUES D’ INCENDIE,

REMPLACER UNIQUE-MENT PAR UN FUSIBLE DE MEME

TYPE ET DE “6.3A, 125V”.

SUBJECT : X-RADIATION

1.Be sure procedures and instructions to all service

personnel cover the subject of X-rays in current T.V.

receivers is the picture tube. However, this tube does not

emit X-rays when the high voltage is at the factory

specified level. The proper value is given in the applicable schematic. Operation at higher voltages may cause

a failure of the picture tube or high voltage supply and,

under certain circumstances, may produce radiation in

excess of desirable levels.

2.Only factory specified C.R.T. anode connectors must be

used. Degaussing shields also serve as X-ray shield in

color sets. Always re-install them.

3.It is essential that the serviceman has available an

accurate and reliable high voltage meter. The calibration of

the meter should be checked periodically against a

reference standard. Such as the one available at your

distributor.

4.When the high voltage circuitry is operating properly there

is no possibility of an X-radiation problem. Every time a

color chassis is serviced, the brightness should be run up

and down while monitoring the high voltage with a meter to

be certain that the high voltage does not exceed the

specified value and that it is regulating correctly. We

suggest that you and your service organization review test

procedures so that voltage regulation is always checked

as a standard servicing procedure. And that the high

voltage reading be recorded on each customer’ s invoice.

5.When troubleshooting and making test measurements in a

receiver with a problem of excessive high voltage, avoid

being unnecessarily close to the picture tube and the high

voltage compartment. Do not operate the chassis longer

than is necessary to locate the cause of excessive voltage.

6.Refer to HV, B+ and Shutdown adjustment procedures

described in the appropriate schematic and

diagrams(where used).

AC VOLT METER

0.15 µF

1500 OHM

10 WATT

Good earth ground

such as a water

pipe, conduit, etc.

FIG 1

Place thes probe

on each exposed

metallic part

Page 4

- 3 -

SUBJECT : IMPLOSION

1.All direct viewed picture tubes are equipped with an

integral Implosion protection system, but care should be

taken to avoid damage during installation.

Avoid scratching the tube. If scratched, replace it.

2. Use only recommended factory replacement tubes.

SUBJECT : TIPS ON PROPER INSTALLATION

1.Never install any receiver in closed-in recess, cubbyhole or

Closely fitting shelf space over, or close to heat duct, or in

the path of heated air flow.

2.Avoid conditions of high humidity such as : Outdoor patio

Installations where dew is a factor. Near steam radiators

where steam leakage is a factor, etc.

3.Avoid placement where draperies may obstruct rear

venting. The customer should also avoid the use of

decorative scarves or other coverings which might obstruct

ventilation.

4.Wall and shelf mounted installations using a commercial

mounting kit, must follow the factory approved mounting

instructions. A receiver mounted to a shelf or platform

must retain its original feet(or the equivalent thickness in

spacers) to provide adequate are flow across the bottom,

bolts or screws used for fasteners must not touch and

parts or wiring. Perform leakage test on customized

installations.

5.Caution customers against the mounting of a receiver on

sloping shelf or a tilted position, unless the receiver is

properly secured.

6.A receiver on a roll-about cart should be stable on its

mounting to the cart. Caution the customer on the hazards

of trying to roll a cart with small casters across thresholds

or deep pile carpets.

7.Caution customers against the use of a cart or stand which

has not been listed by underwriters laboratories, inc. For

use with their specific model of television receiver or

generically approved for use with T.V.’ s of the same or

larger screen size.

Page 5

2. Specification

- 4 -

Power Requirement AC 120V, 60Hz

Power Consumption 210watts

General Dimensions(W/H/D) 41”W x 26.2”H x 24.6”D

Weight 81Kg (178.61bs)

Antenna One 75ohm external input terminal for

UHF/VHF/Cable

Screen Size 34”(diagonal), 16:9 Aspect Ratio

Picture Display Format DTV : 1080I @ 33.75KHz

NTSC/DVD : 480p @ 31.5KHz

Horizontal Resolution 800 Lines

Sound System Dolby Pro Logic

Sound NTSC Audio Multi CH TV Stereo(MTS) /

Second Audio Program(SAP)

Audio Power 8W/ch (Main L/R), 5W/ch (Center)

Rear

RF Antenna Input

NTSC A/V In 2each (Video/L/R)

1each (S-Video/Video/L/R)

NTSC A/V Monitor Out 1each (Video/L/R)

Inputs/ HD Component In 1each (Y/Pb/Pr)

Output DVD Component In 1each (Y/Cb/Cr)

Surround Channel Out 1each (SL/SR)

Sub woofer Out 1each

Side

NTSC A/V In 1each (S-Video/Video/L/R)

Headphone 1each (L/R)

Page 6

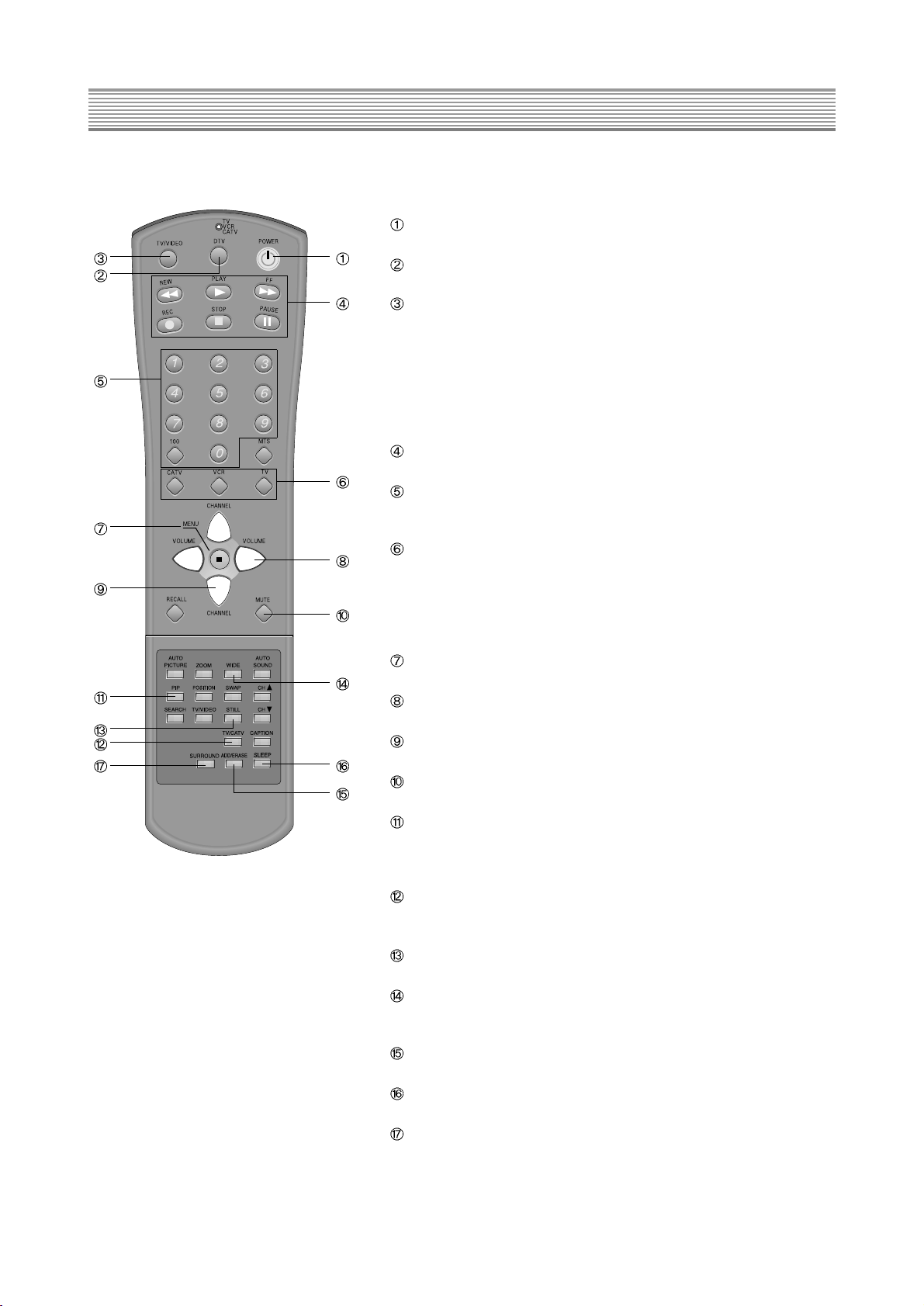

3. Remote control overview

- 5 -

The remote control has the following functions:

Power button

Press to turn the HDTV Monitor (and other equipment) on and off

DTV button

Press this button repeatedly to display HD Component Video.

TV/VIDEO button

Press to view components you have connected to the HDTV Monitor.

Press this button repeatedly to display:

*TV mode

*Video1

*Video2

*Video3

*DVD

VCR Control Board

Basic VCR functions are operated with buttons on this board.

Direct Channel Selection Board

Pressing the numbers on this board, you can select program channels of

the screen directly.

Mode buttons

Press to select which equipment you wish your remote control to

operate:

*TV

*CATV (cable box)

*VCR

Menu button

You can adjust the picture, sound and many other functions.

Volume buttons

Press to raise and lower the volume on your HDTV Monitor.

Channel buttons

Press to select channels.

Mute button

Press to mute the HDTV Monitor sound.

PIP Search buttons

Simultaneous window selection is possible through buttons of this board,

and various layouts of the windows can be selected according to the

user’s need or desire.

TV/CATV button

This button is used to convert reception modes between aerial and

cable transmission systems.

STILL button

Press to pause the screen temporarily.

WIDE button

Press to convert the screen aspect ratio between 4:3 and 16:9 and vice

versa.

ADD/ERASE button

Press to operate channel memory functions.

SLEEP button

Press to operate set up time memory for an automatic turn off.

Surround button

Press to choose one of the “Pro Logic” modes.

Page 7

4. Limited Warranty

- 6 -

Daewoo Electronics Corporation of America Inc. (also known as DECA) warrants this product to be free from defects in

material and workmanship and agrees to remedy any such defect.

This warranty covers 3 years labor and 3 years parts from the date of original purchase.

This warranty applies only to product purchased from authorized DECA dealer and used within the boundaries of U.S.A.

This warranty does not apply to product that has been improperly installed, subjected to usage for which the product was

not designed, misused or abused, damaged during transportation, or which has been altered in any way that affects the

reliability or detracts from its performance.

How you get warranty service

Warranty service can only be provided by an authorized DECA service center. For the closest authorized service center

to you, please contact your Dealer. In order to receive warranty service you must provide the authorized service center

with a copy of proof of purchase, signifying the date of purchase and the name of the Dealer from whom you purchased

the product.

Statutory warranties

The purchase may have rights under existing provincial or federal laws, and where any terms of this warranty are

prohibited by such laws, they are deemed null and void, but the remainder of the warranty shall remain in effect.

If you require further assistance, please call:

1-800-DAEWOO-8

Page 8

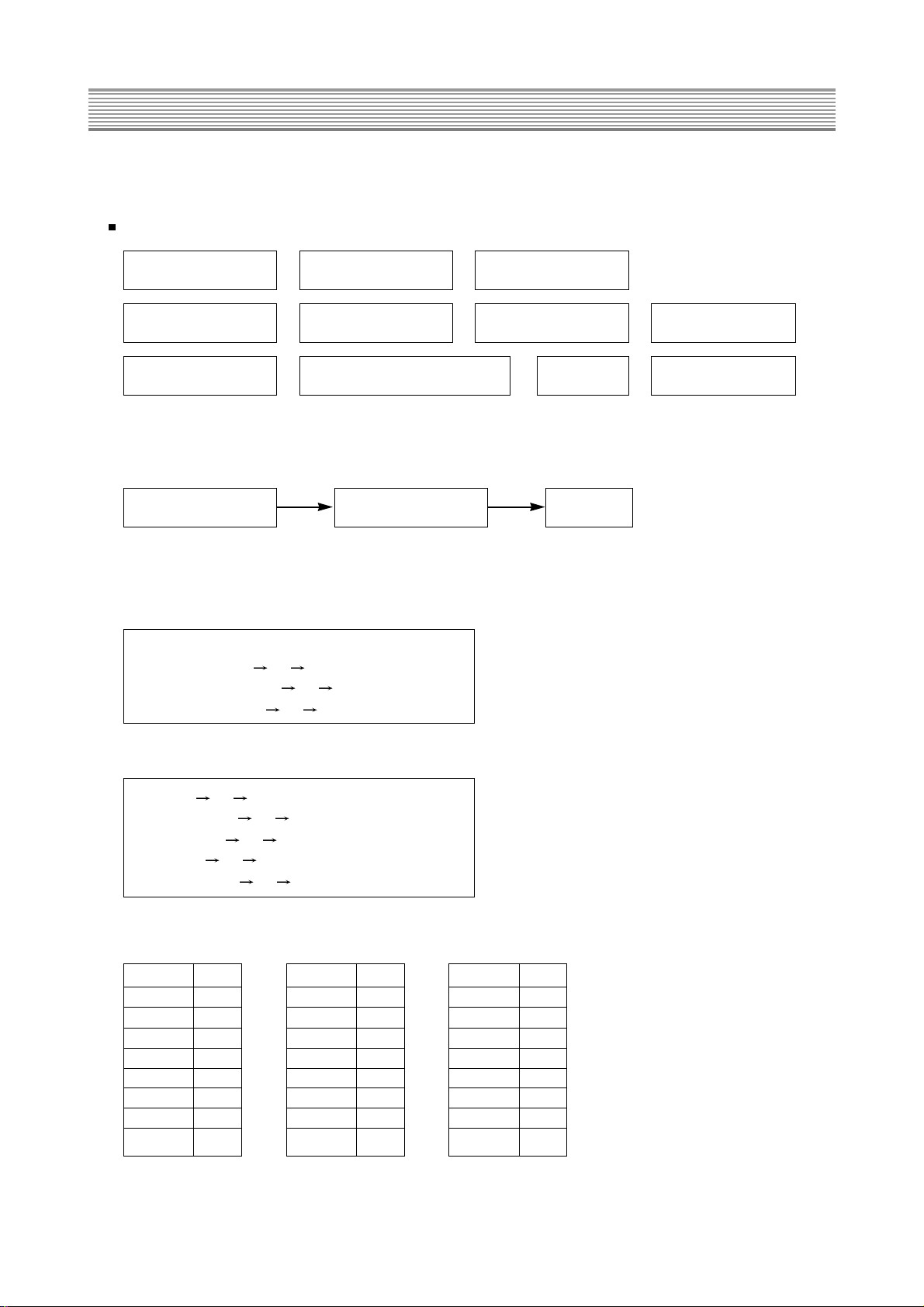

5. Service Modes

- 7 -

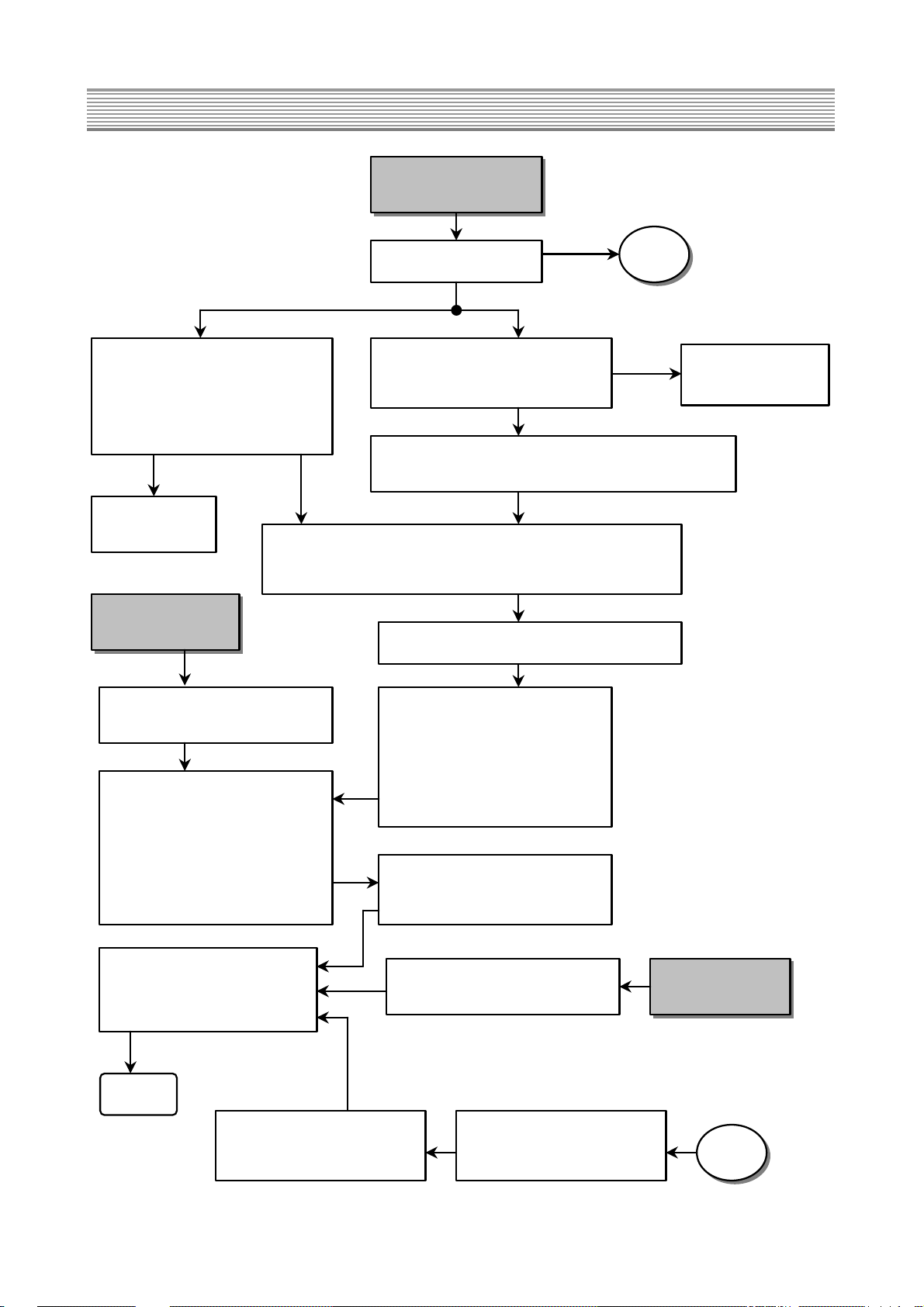

1.Entering to Service Mode

With the service remote control

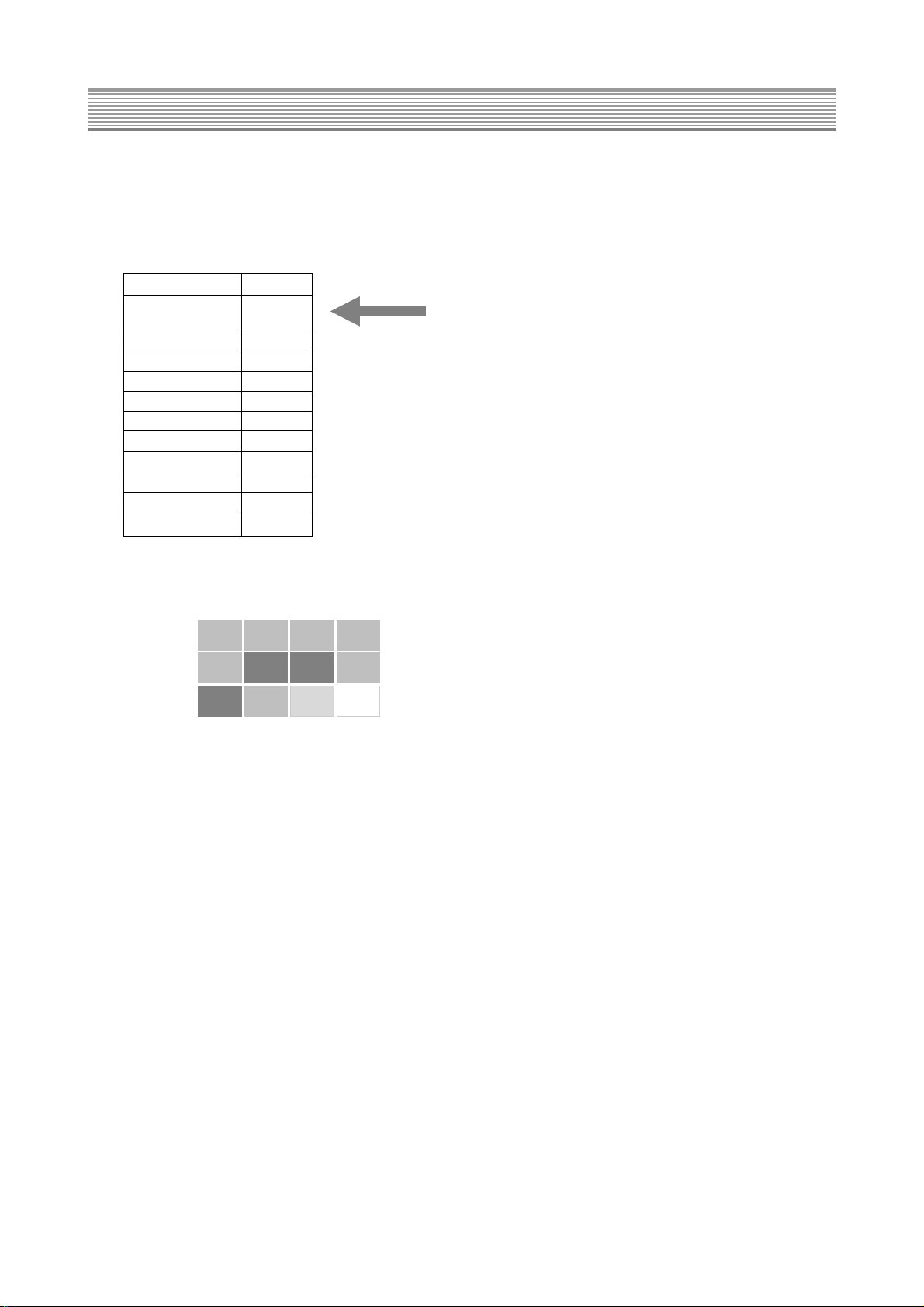

2. Function of each service mode

1) S1 : Heat Run mode.

2) S2 : Screen Voltage Control mode

The vertical deflection is down, and a horizontal line appears on the screen.

3) S3 : Sound Controls mode

4) S4 : Video Controls mode

5) S5 : Picture Quality Controls Mode : Fixed Data

S1 : Heat Run S2 : Screen Voltage

S3 : Sound Controls

S4 : Video Controls S5 : Picture Quality

S6 : Geometry S7 : PIP

S8 : White Balance

Auto power on mode Exit

S9 : Sub Picture & Sub Audio S10 : Option

S12 : Factory Setting

Full white mode

• Equalizer : 60Hz, 250Hz, 1KHz, 3.5KHz, 10KHz

• Main Volume : 0 63 31

• Balance control : -31 31 0

• Center Volume : 0 63 31

• Tint : 0 63 31

• Brightness : 0 48 24

• Contrast : 0

48 24

• Color : 0 63 31

• Sharpness : 0 63 31

LIM 1

SYS 3

AGI 0

DCO 1

CLP 0

CLM 0

ABM 0

ABT 3

HSE 0

• Don’t adjust above the mode, these are to adjust data of RGB Video Process IC (CXA2101).

FIX 0

VTC 0

HWI 0

HDT 0

HSM 0

CTI 3

LRG 15

GAM 15

PAB 0

BLK 0

SHP 3

PRE 3

LTI 0

VML 2

VMD 0

DCT 2

DPI 2

AKB 0

Page 9

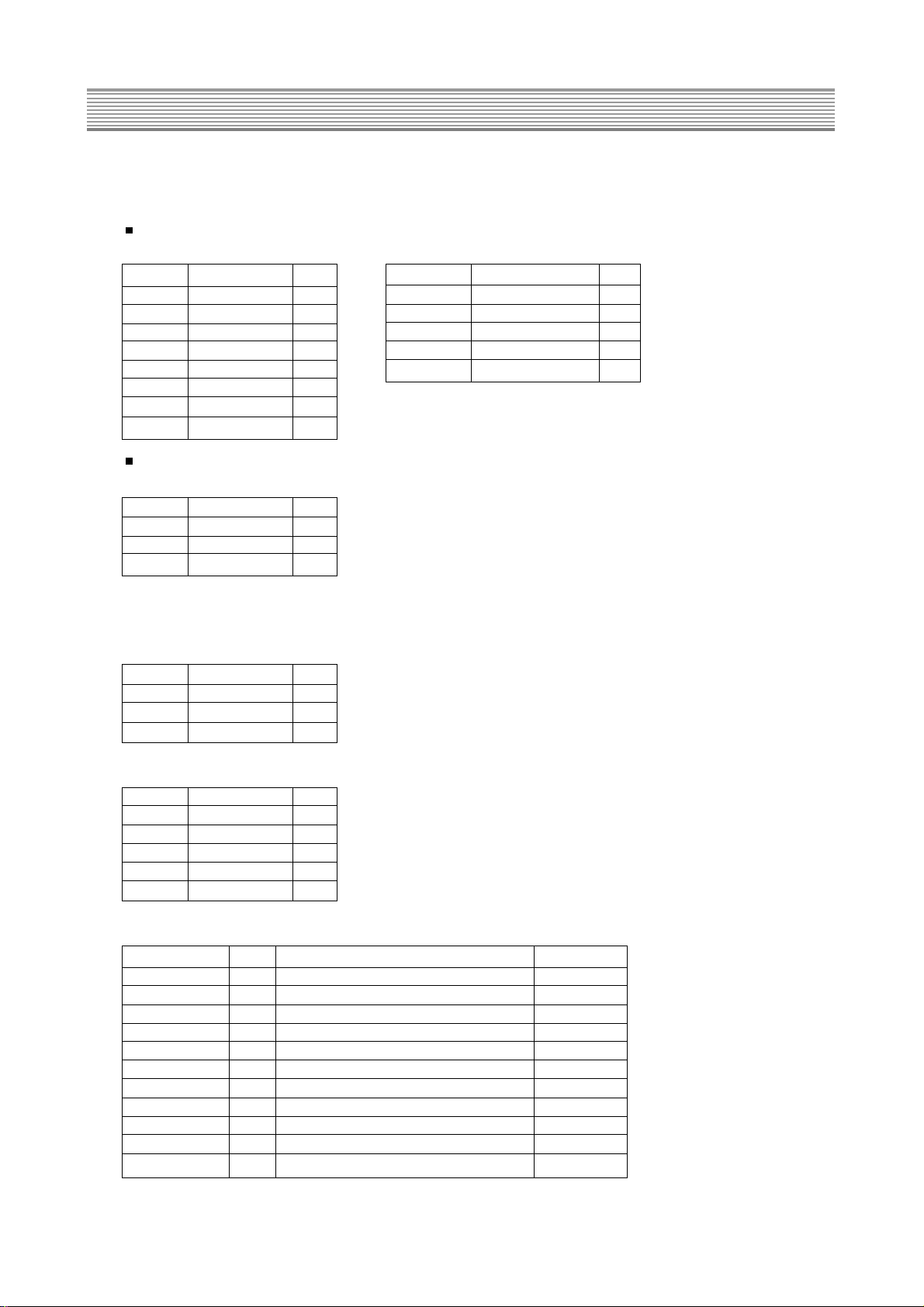

Service Modes

- 8 -

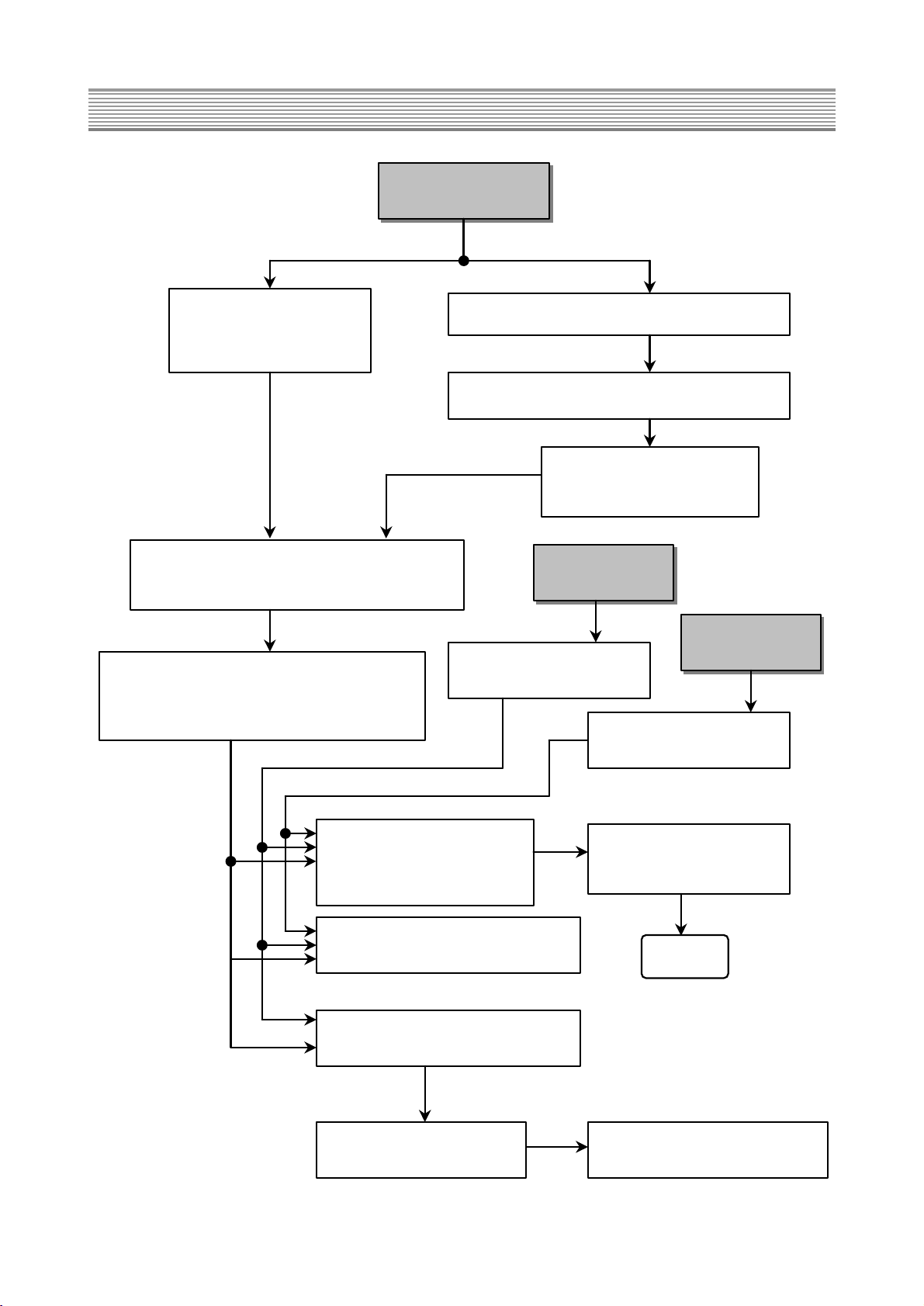

6) S6 : Geometry Adjustment mode

NTSC/DVD

After receiving Air or external video, adjust geometry.

DTV

After connecting HD component at the DTV Input, adjust geometry.

7) S7: PIP Adjustment

• Press “PIP” button twice until the screen becomes two windows.

• Adjust below items so that the picture qualities of sub screen may be just the same with the main screen.

8) S8: White Balance Adjustment mode

9) S9 : Sub picture quality & Sub audio adjustment mode

HDUTY H Duty 16

HPOSI H Position 60

SPINW Side Pin W 24

SPIN Pincusion 48

HSIZE H Size 42

VSIZE V Size 73

VPOSI V Position 62

VSLIN V S Linearity 31

VCLIN V C Linearity 23

TRAPE Trapezoid 29

SPINS Side Pin S 33

FOCUSPH H Focus Phase 32

FOCUSPA H Focus Amplitude 32

MOIRE 16

VSMAX V Size Max 31

HPOSI H Position 67

HSIZE H Size 40

VSIZE V Size 63

VPOSI V Position 97

Brightness

+16

Contrast 48

Sharpness

64

Tint +0

RDRV Drive R 31

GDRV Drive G 31

BDRV Drive B 31

RCUT Cut off R 64

GCUT Cut off G 64

BCUT Cut off B 64

SUB-CONT 15 Sub Contrast available

SUB-BRIG 1 Sub Brightness available

SUB-SHP 3 Sub Sharpness available

SUB-COR 15 Sub Color available

SUB-TINT 15 Sub Tint available

PRE-FM 56 RF Audio Level Don’t adjust

PRE-SCART 25 Don’t adjust

PRE-SCART 1 38 Don’t adjust

NOR HP 20 The horizontal position of OSD available

DTV HP 10 The horizontal position of DTV OSD available

STEREO ID 32 Stereo detection sensitivity Don’t adjust

RF P-MUTE 3 When channel UP/DN, Video mute time available

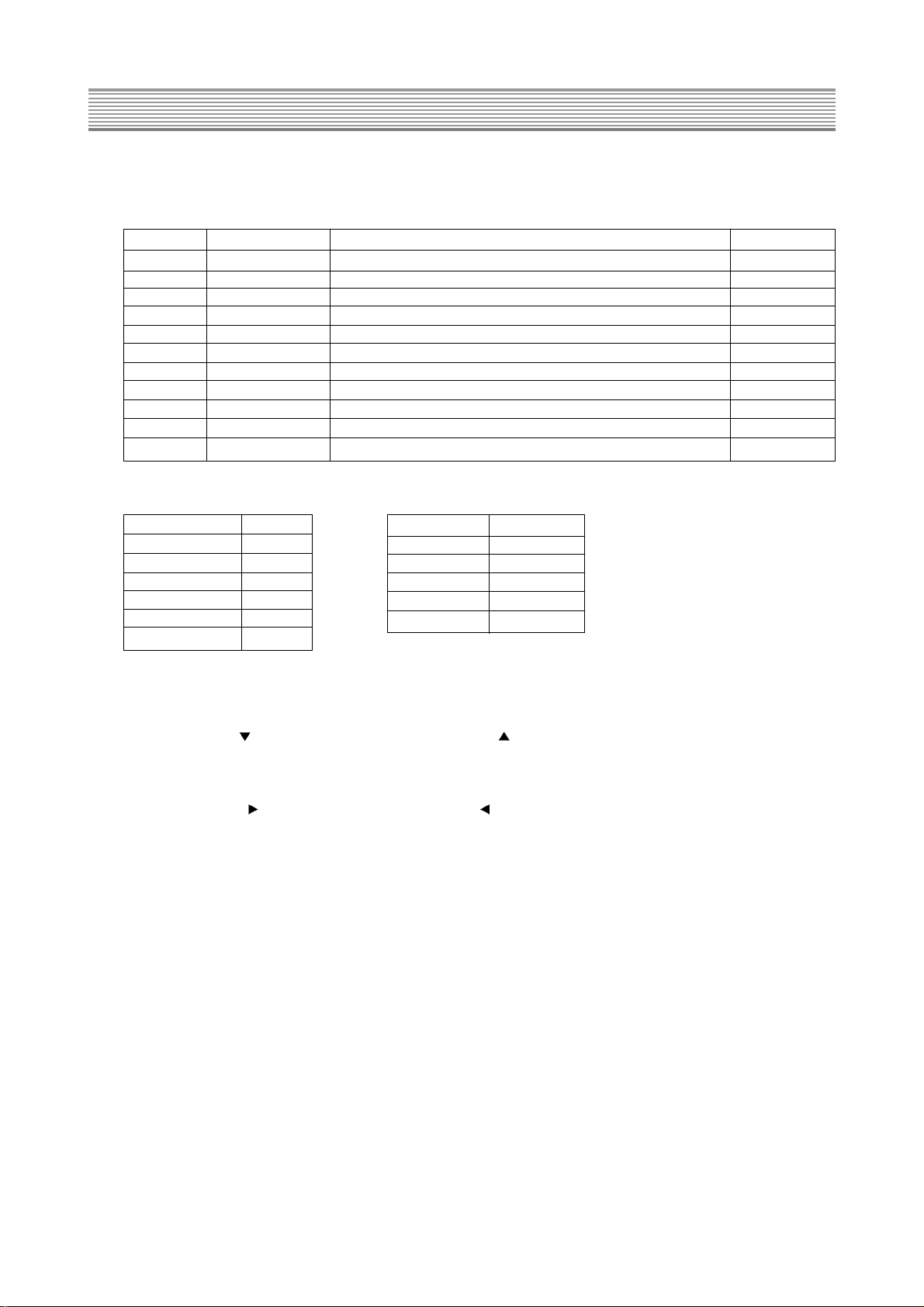

Page 10

Service Modes

- 9 -

10) S10 : Option Adjustment mode

11) S12 : Factory Setting

3. Selecting the adjusting items

Pressing of Channel button changes the adjustment items. ( button for reverse order)

4. Adjusting the data

Pressing of VOLUME button changes the value of data. ( button for reverse order)

5. Exit from Service Mode

Press again to make service mode exit.

Caption English Fixed

CALMP 10 Don’t adjust

OSD POS 15 The horizontal position of Caption OSD available

EPOS 15

V POS 144 The Vertical position of Caption OSD available

POTION America / Korea Fixed

PC INPUT off Fixed

CIP-CT 27 The horizontal PLL speed of Video Process IC (VPC3230) Don’t adjust

CIP-BR 27 Don’t adjust

CIP-CR 22 Don’t adjust

CIP-CB 0 Don’t adjust

Dolby Ext off Dolby External L/R Mode Don’t adjust

CH 2

TV/VIDEO TV

TV/CABLE TV

Volume 20

Center Volume 0

PIP OFF

Equalizer Center

Auto Picture Standard

Auto Sound User

Wide 16:9

Zoom 16:9

Caption OFF

Child Lock OFF

Page 11

6. General Adjustment

- 10 -

In the majority of cases, a high definition digital television will need basic adjustments such as high voltage, screen

voltage, focus, white balance, sub brightness, and geometry. All adjustments should be performed after heat-running the

set for at least 20 minutes.

1. Press the S1 button on the service remote control, and then full white pattern will appear on the screen.

2. Press the S1 button twice, and then the pattern will disappear.

High Voltage Adjustment

1. Operate the set for at least 20 minutes.

2. Connect the probe of high voltage meter to CRT ANODE.

3. Adjust the variable register RV801 on the power assembly so that high voltage may be to be between

31.5KV ~ 32.5KV.

Screen Voltage Adjustment

1. Press the S2 button on the service remote control.

Vertical deflection will be down, and a horizontal line will appear on the screen.

2. Turn the variable screen volume of FBT to adjust screen voltage, at the point that a horizontal line only just appears.

Focus Adjustment

1. Tune on RETMA pattern.

2. Turn the variable focus volume of FBT so that the center area of screen is sharp scanning line.

3. Turn the variable volume R522 on the CRT assembly so that the edge of screen may be sharp scanning line.

White Balance Adjustment

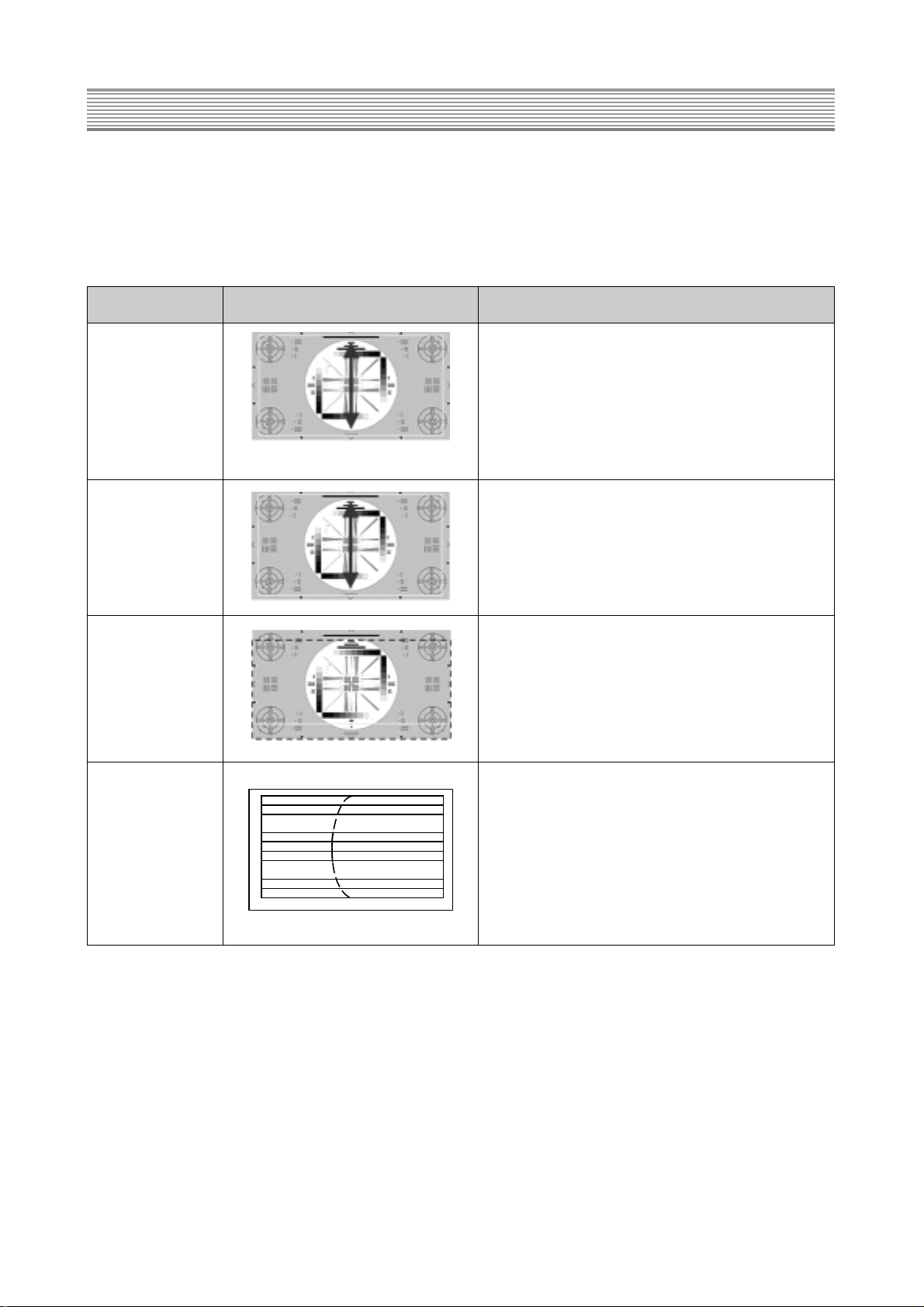

1. Input the Black & white signal to the HD Component jack on the rear panel.

<Black & White Pattern>

2. The color temperature is the following.

• x=0.270

0.005 y=0.270 0.005

• Color temperature : 13,214°K

3. Light Area Adjustment

1) Press S8 button.

2) On the center of light area, attach the sensor of a white balance meter.

3) To be Y=100, turn the Light Beam control volume on the White & Black pattern generator.

4) To adjust the white balance of light area, select Drive R, G, B with CHANNEL Up or Down buttons, and adjust

individual values with VOLUME Up or Down buttons.

4. Dark Area Adjustment

1) On the center of dark area, attach the sensor of a white balance meter.

2) To be Y=15, turn the Dark Beam control volume on the White & Black pattern generator.

3) To adjust the white balance of dark area, select Bias R, G, B with CHANNEL Up or Down buttons, and adjust

individual values with VOLUME Up or Down buttons.

4) Repeat two processes above until the white balance is completed.

Dark Area Check

Light Area Check

Page 12

General Adjustment

- 11 -

Sub Brightness Adjustment

1. Tune on RETMA Pattern.

2. Press S9 button.

3. The following OSD menu will appear on the screen, and the data are initial values before adjusting.

4. To be between Step 10% and 20% on the Contrast Chart, perform fine adjustment of sub brightness.

SUB-CONT 15

SUB-BRIG 1

SUB-SHP 3

SUB-COR 15

SUB-TINT 15

PRE-FM 56

PRE-SCART 25

PRE-SCART1 38

NOR HP 20

DTV HP 10

STEREO ID 32

RF P-MUTE 3

40% 30% 20% 10%

50% 0% 0% 5%

60% 70% 80% 100%

Page 13

General Adjustment

- 12 -

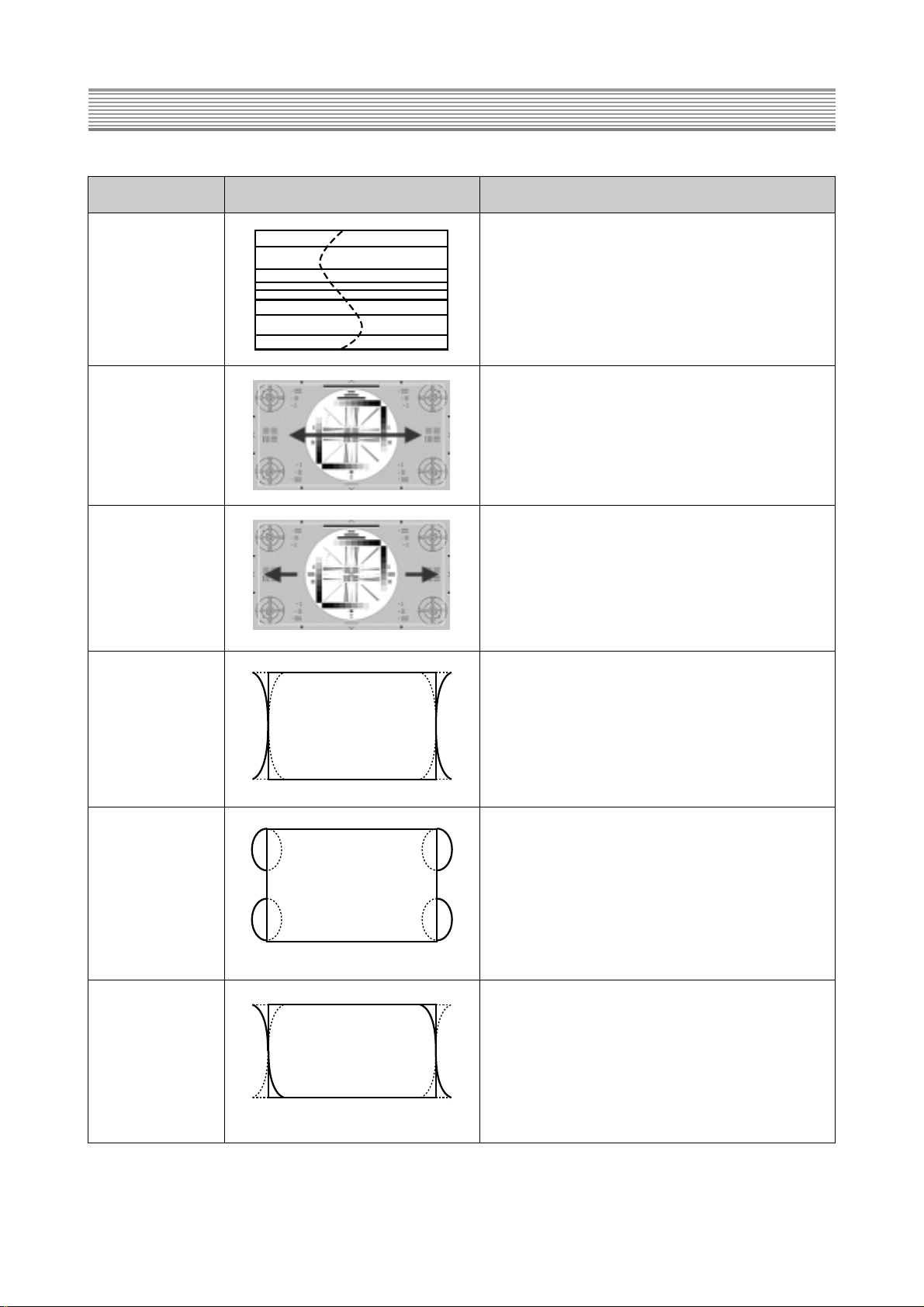

Geometry

1. To adjust V-Position, H-Size, H-Position and so forth, tune on RETMA Pattern.

2. To adjust Pincushion, Trapezoid and so forth, tune on Cross Hatch signal.

3. Screen Mode should be on 16:9 mode, and the Video Mode should be on Normal mode.

4. Press S6 button to adjust Geometry.

Item Screen Image Adjustmant Procedure

1) Receive NTSC RETMA signal.

2) The Screen mode should be selected on 16:9

mode

V Size Max. 3) Adjust Vertical Size so that over scanning rate may

be 105%.

4) Check if the center circle is not only circular on 16:9

mode but also on 4:3 mode.

Over Scanning Rate: 105%

1) There is no need to adjust.

2) Check if the value of data is “0”.

Vertical

Size

1) Receive NTSC RETMA signal.

2) The Screen mode should be selected

on 16:9 mode.

Vertical Adjust Vertical Position so that the circle of

Position RETMA signal may be centered in the vertical

direction.

1) Receive NTSC RETMA signal.

2) The Screen mode should be selected

V C Linearity on 16:9 mode.

3) When the center area of RETMA signal’s circle is

C type in the vertical direction, adjust VC

Linearity so that vertical interval may be the same.

Page 14

Item Screen Image Adjustmant Procedure

1) Receive NTSC RETMA signal.

2) The Screen mode should be selected on 16:9

V S Linearity mode.

3) When the center area of RETMA signal’s circle is

S type in the vertical direction, adjust VS

Linearity so that vertical interval may be the

same.

1) Receive NTSC RETMA signal.

2) The Screen mode should be selected on 16:9

mode

Adjust Horizontal Size for over scanning rate

Horizontal Size 106%. Check if the center circle of RETMA signal

is circle on Normal mode.

1) Receive NTSC RETMA signal.

2) The Screen mode should be selected on 16:9 mode

Horizontal 3) Adjust Horizontal Position so that the circle of

Position RETMA signal may be centered in the horizontal

direction.

1) Receive NTSC Cross Hatch signal.

2) The Screen mode should be selected on 16:9

mode.

Pincushion 3) When the vertical lines of the left and right side

are distorted such as the left figure, adjust

Pincushion so that the vertical lines may be

straight.

1) Receive NTSC Cross Hatch signal.

2) The Screen mode should be selected on 16:9

mode.

Side Pin W 3) When the vertical lines of the left and right side

are not straight but distorted in the W type, adjust

Side Pin W to correct the unbalanced vertical

lines.

1) Receive NTSC Cross Hatch signal.

2) The Screen mode should be selected on 16:9

Side Pin S mode.

3) When vertical lines of the left and right side is not

straight but distorted in the S type, adjust Side Pin

S to correct the unbalanced vertical lines.

General Adjustment

- 13 -

Page 15

General Adjustment

- 14 -

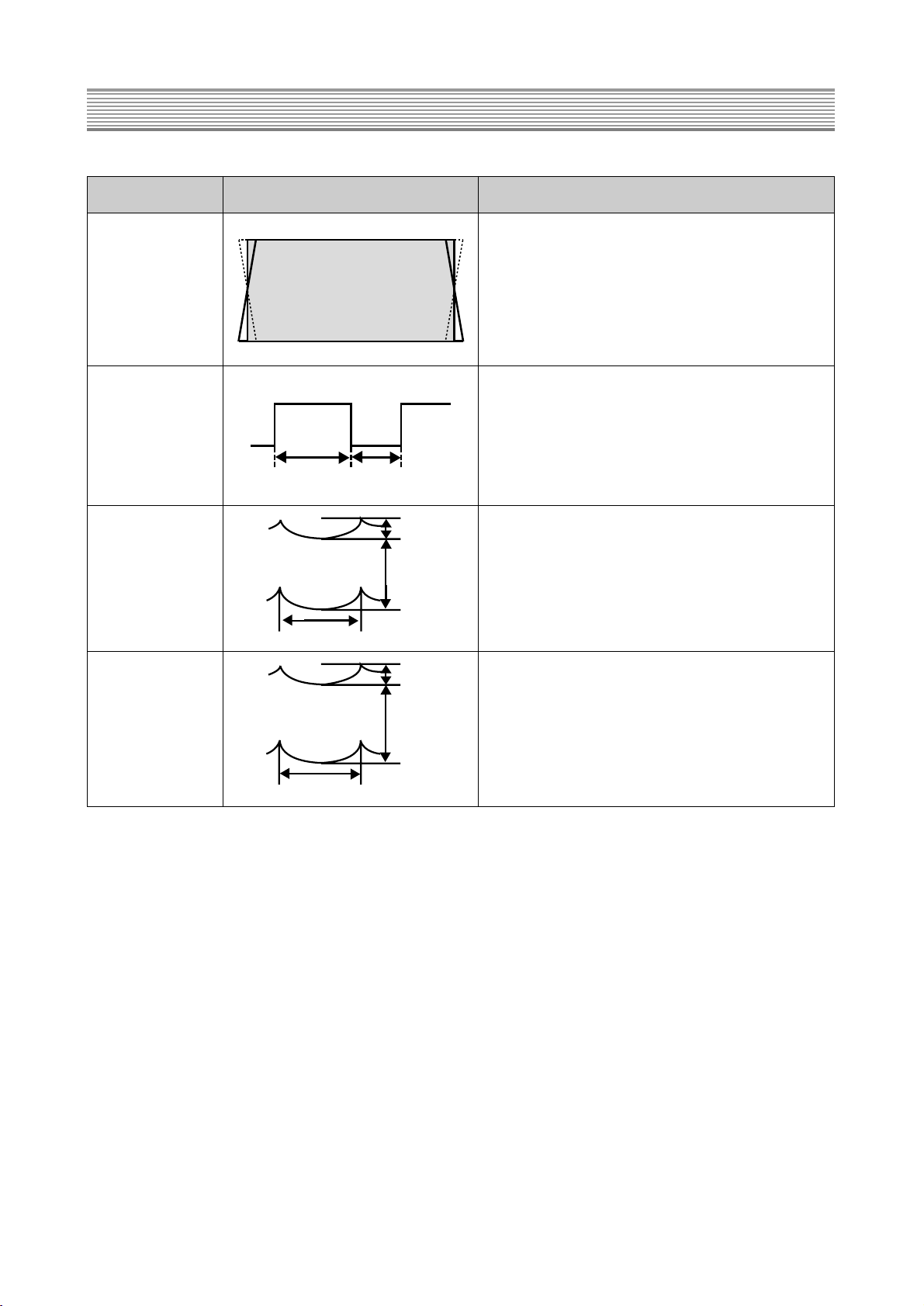

Item Screen Image Adjustmant Procedure

1) Receive NTSC Cross Hatch signal.

2) The Screen mode should be selected on 16:9

mode.

Trapezoid 3) When the screen shape is not rectangular but

trapezoid, adjust Trapezoid to correct the

unbalanced shape.

1) There is no need to adjust.

H Duty 2) Check if the value of data is “16”.

1) There is no need to adjust, and check if the value

of data is “32”.

H Focus Phase 2) Check that the focus on the right and left side is

clear.

1) There is no need to adjust, and check if the value

H Focus of data is “32”.

Amplitude 2) Check if the focus on the right and left side is clear.

400Vp-p

900Vp-p

60Hz

400Vp-p

900Vp-p

60Hz

Page 16

7. Special Adjustment

(When replacing new circuit boards)

- 15 -

1. Power assembly

1) After replacing a new assembly, X Radiation Protection Circuit Test

When service has been performed on the horizontal deflection system, high voltage system or B+ system, the

X-Radiation Protection Circuit Test must be tested for proper operation as follows:

1-1) Operate the HDTV Monitor for at least 20 minutes.

1-2) Perform this test at the normal video and sound.

1-3) Check the cathode voltage of D837. Its voltage should be about 25VDC.

1-4) Connect a resister 24K(1/4W) with parallel to R873.

1-5) Then the set will be shut down, lighting up red to the power indicator.

1-6) If it is not, the circuit of X-Radiation Protection must be repaired before the set is returned to the

customer.

2) The rest adjustment idem are no need to adjust.

2. Main assembly

1) After replacing a new assembly, the rest adjustments are no need.

3. Video assembly

1) No need to adjust.

Page 17

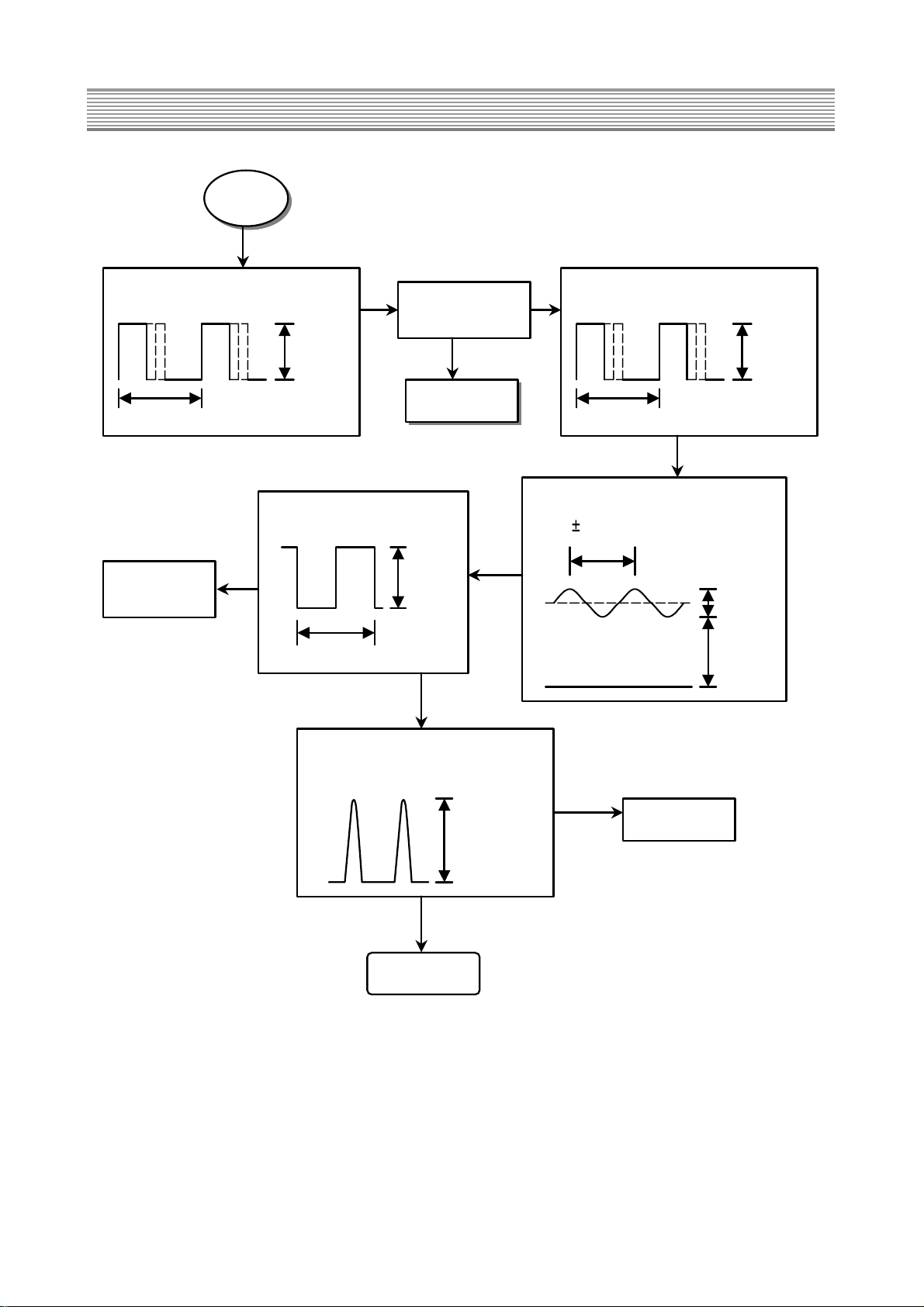

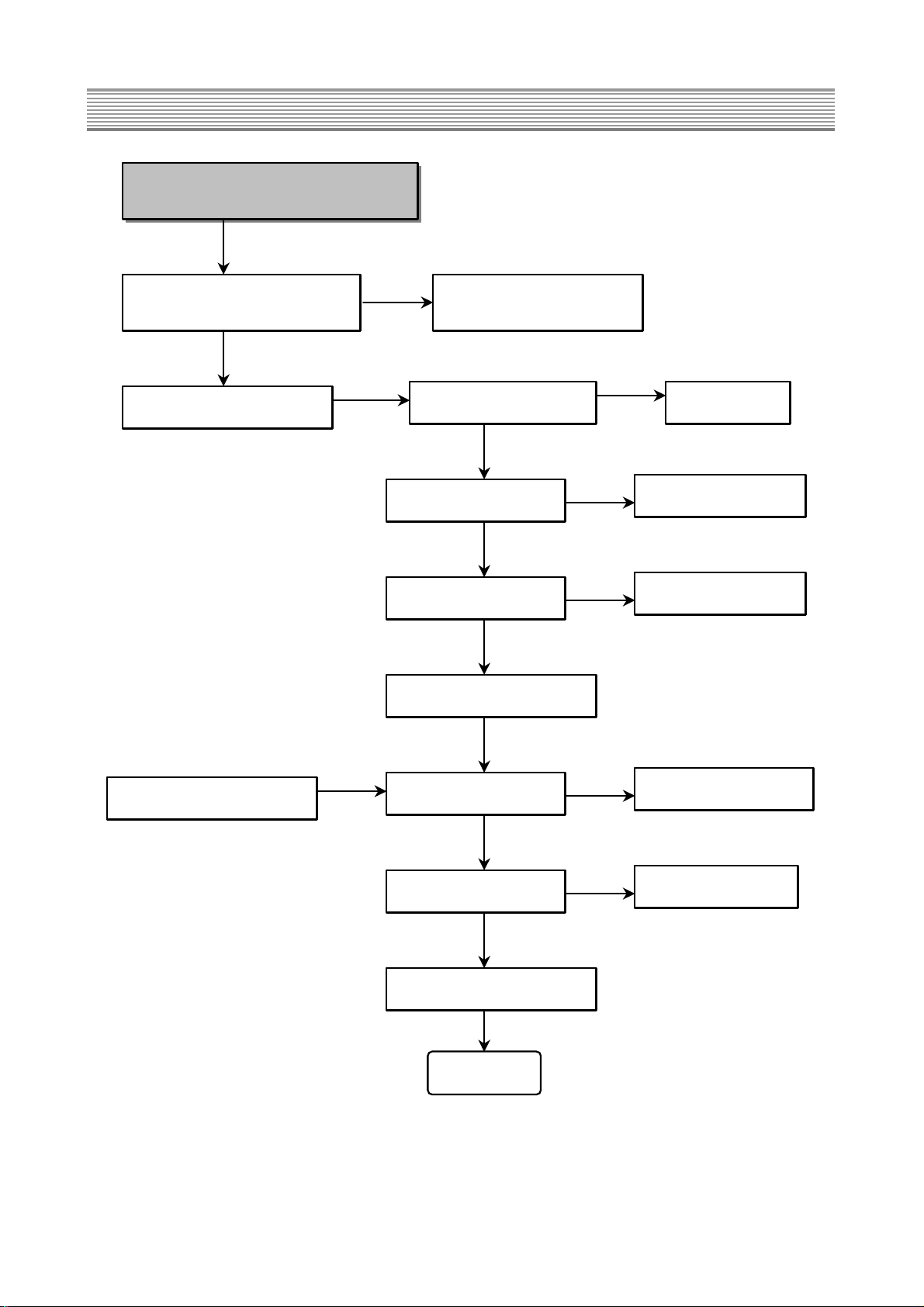

8. Troubleshooting charts

- 16 -

No Picture

(NTSC Signal)

OSD is on the screen.

Check OSD signal of I701.

R/G/B OSD : #64, 63, and 62

BL OSD : #61

Check OSD signal of UC107.

R/G/B OSD : #50, 51, and 52

BL OSD : #49

Check video signal of IA1.

Video1 :CVBS to #43, Y to #45,

and C to #47

Video2 :CVBS to #1

Video3 :CVBS to #7, Y to #9,

and C to #11

Check each

input signal.

When CVBS input, CVBS is to #34 of IA1.

When Y/C input, Y/C is to #37 and #39 of IA1.

When CVBS input, CVBS is to #88 of UC100.

Y/C signal of 3D comb filter is to #84 and #83 of UC100.

When Y/C input, Y/C is to #88 and #96 of UC100.

Y/C signal is to #73 and #71 of IC UC104.

Check below signal of UC104

-Y and C signal : #73, #71

-Picture Bus Y(MY0~MY7)

-Picture Bus C (MC0~MC7)

-V sync pulse (VSM) : #57

-Active video output (AVO) : #54

-Clock out (LLC2) : #27

Check below signal of UC106

-Picture Bus Y(MY0~MY7)

-Picture Bus C (MC0~MC7)

-V sync pulse (VSM) : #26

-Active video output (AVO) : #27

-Clock out (LLC2) : #18

-Y /Cb /Cr out: #87, 84, and 90

-H/V sync : #4, 5

Check below signal of UC107

R/G/B out : #35, 37, and 39

Check TV video signal of IA1.

CVBS of main tuner (TU01) : #41

CVBS of sub tuner (TU02) : #27

Check DVD signal to UC104.

Y/Cb/Cr : #5, 4, and 3

Check Tuner

(TU01 & TU02).

No Picture

(DVD Signal)

Check below signal of UC107

Y/Cb/Cr in : #69, 68 and 67

H/V sync : #66, 65

No Picture

(DTV Signal)

Check DTV signal of UC107

Y/Pb/Pr in : #5, 4 and 3

OSD

OSD

END

AV Signal RF Signal

NO

NO

Page 18

Troubleshooting charts

- 17 -

No Sound

(NTSC Signal)

Check audio signal of IA1.

Video1 : L to #44, R to #46

Video2 : L to #2, R to #4

Video3 : L to #8, R to #10

AV Signal

RF Signal

Check the audio base-band signal to SIF of TU01.

Check audio signal of UC102.

-SIF to #67 -RF main L/R to #36, 37

Check audio signal of IA1.

-RF main L/R to #9, 11

-RF sub Mono to #25, 26

Check audio signal of IA1.

-Main L/R to #33, 32

-Sub L/R to #18, 16 (for the sub picture of PIP)

Check audio signal of UC102.

-Main L/R to #47, 48

(for RF and external audio 1,2,3)

-Sub L/R to #56, 57 (for Headphone L/R out)

Check DTV L/R of UC102.

-L/R to #53, 54

No Sound

(DTV Signal)

Check L/R out of UC102.

L/R/C to #28, and 27

Check C out of UC103

C to #34

Check SL/SR/Woofer out of UC102.

SL/SR/W to #25, 24, and 27

Check Headphone L/R out of UC102.

L/R to #34 and 33

Check the volume control of

headphone to IA4.

Check audio Amp (I601).

L/R/C In to #1, 2, and 4

L/R/C Out to #12, 11, and 8

Check DVDL/R of UC102.

-L/R to #50, 51

No Sound

(DVD Signal)

END

Check Headphone L/R out of IA03

L/R to #7 and 1

Page 19

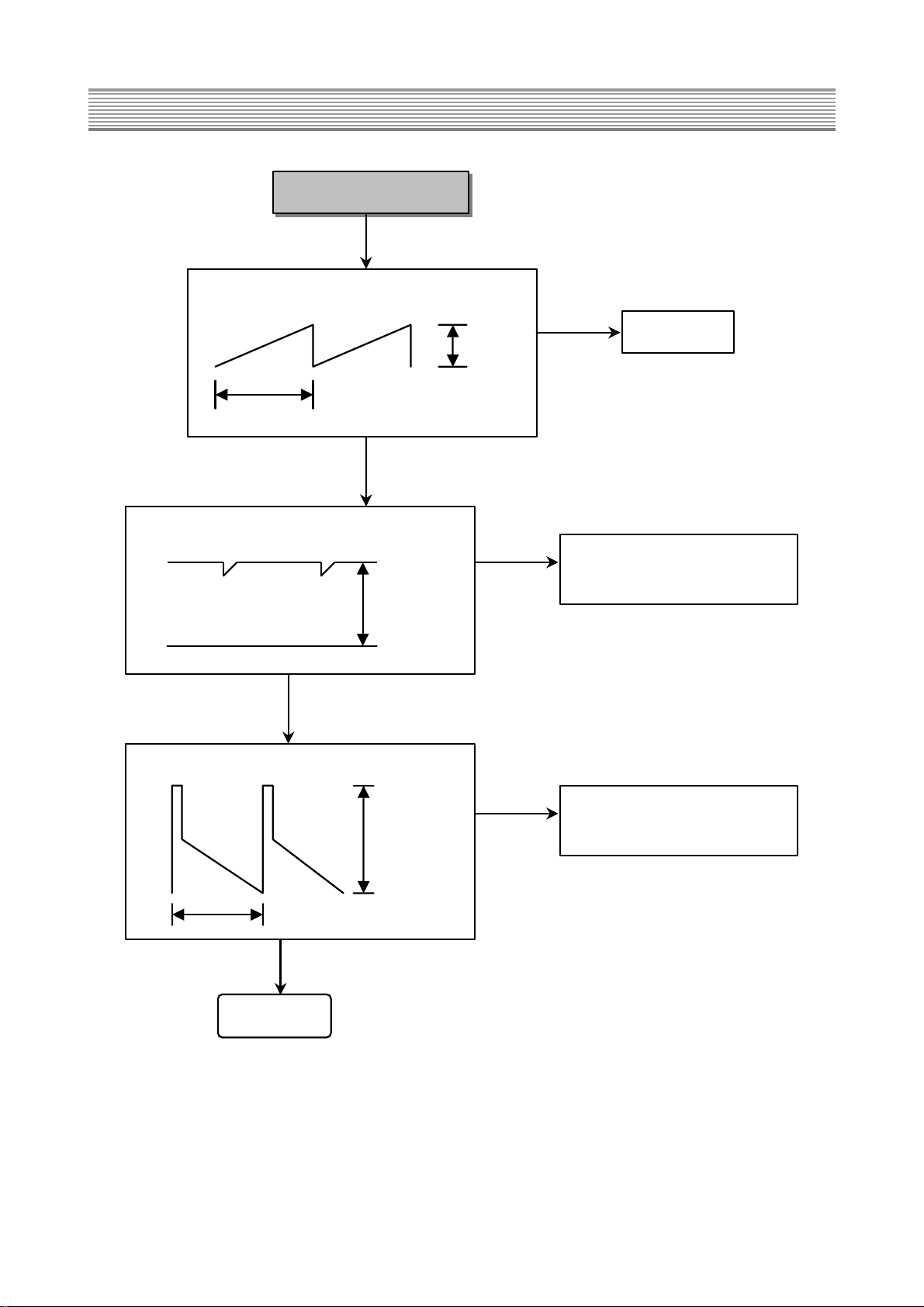

Troubleshooting charts

- 18 -

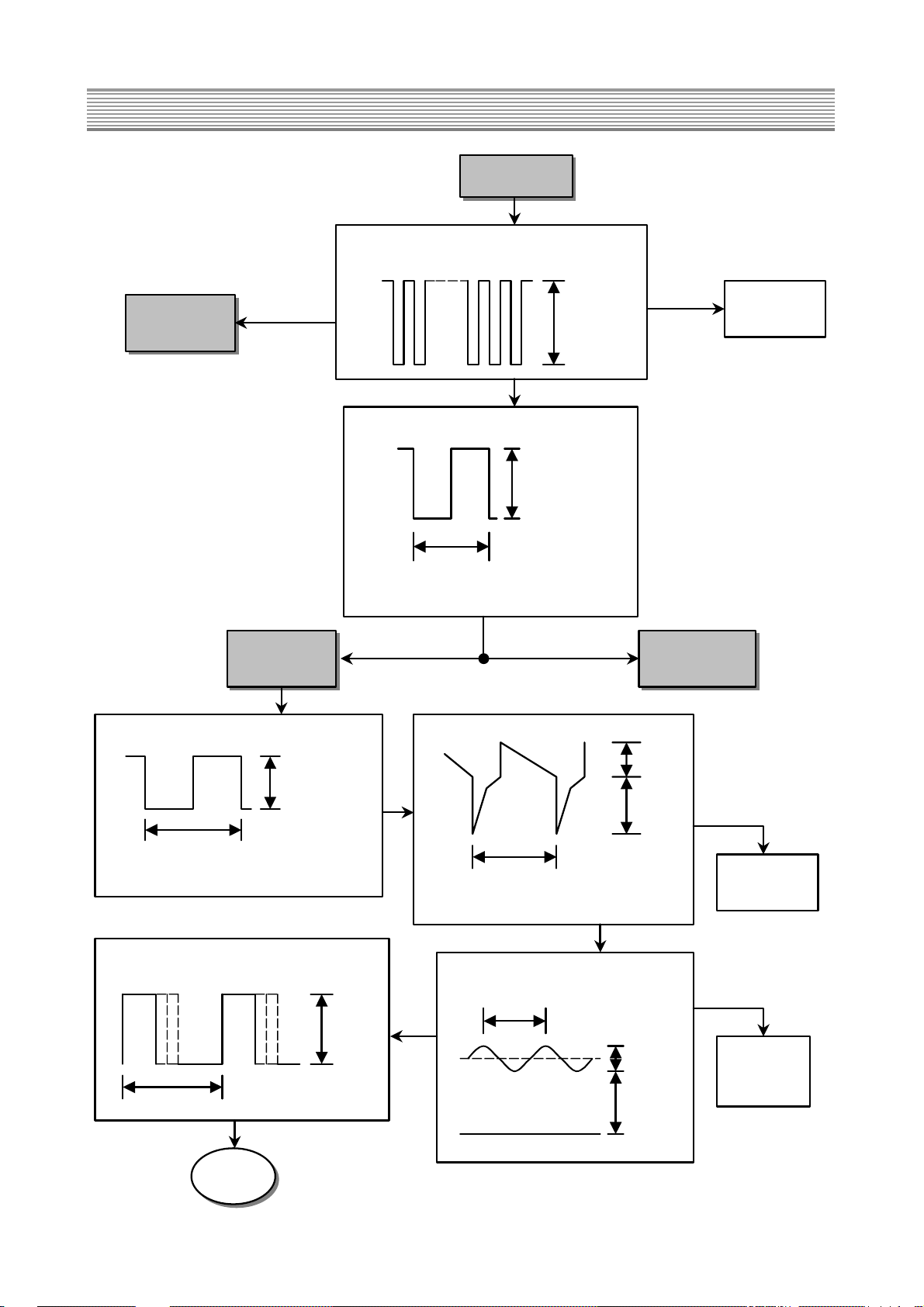

No Raster

NO

I701 communicates with I402 on the IIC bus.

Check the #3 (SDA) and #4 (SCL) of I402.

5Vp-p

Check I701

and I402.

Vertical

Deflection

Check #17 (H-Drive output) of I402.

0.7Vp-p

31.5KHz (NTSC/DVD)

33.75KHz (DTV)

Horizontal

Deflection

High Voltage

Drive

Check H Drive signal to emitter of Q411.

12Vp-p

31.5KHz (NTSC/DVD)

33.75KHz (DTV)

Check

Q416, Q417

H Drive signal is output to pin 3 of I407.

12Vp-p

33.75KHz

Check # 9

(E/W ) of

IC402.

NO

H/D1

Trigger pulse is input to #2 of I407.

31.5KHz (NTSC/DVD)

33.75KHz (DTV)

2Vp-p

6Vp-p

The control voltage of H Drive is

input to #5 of I407.

60Hz

0.5Vp-p

7Vp-p

NO

NO

Page 20

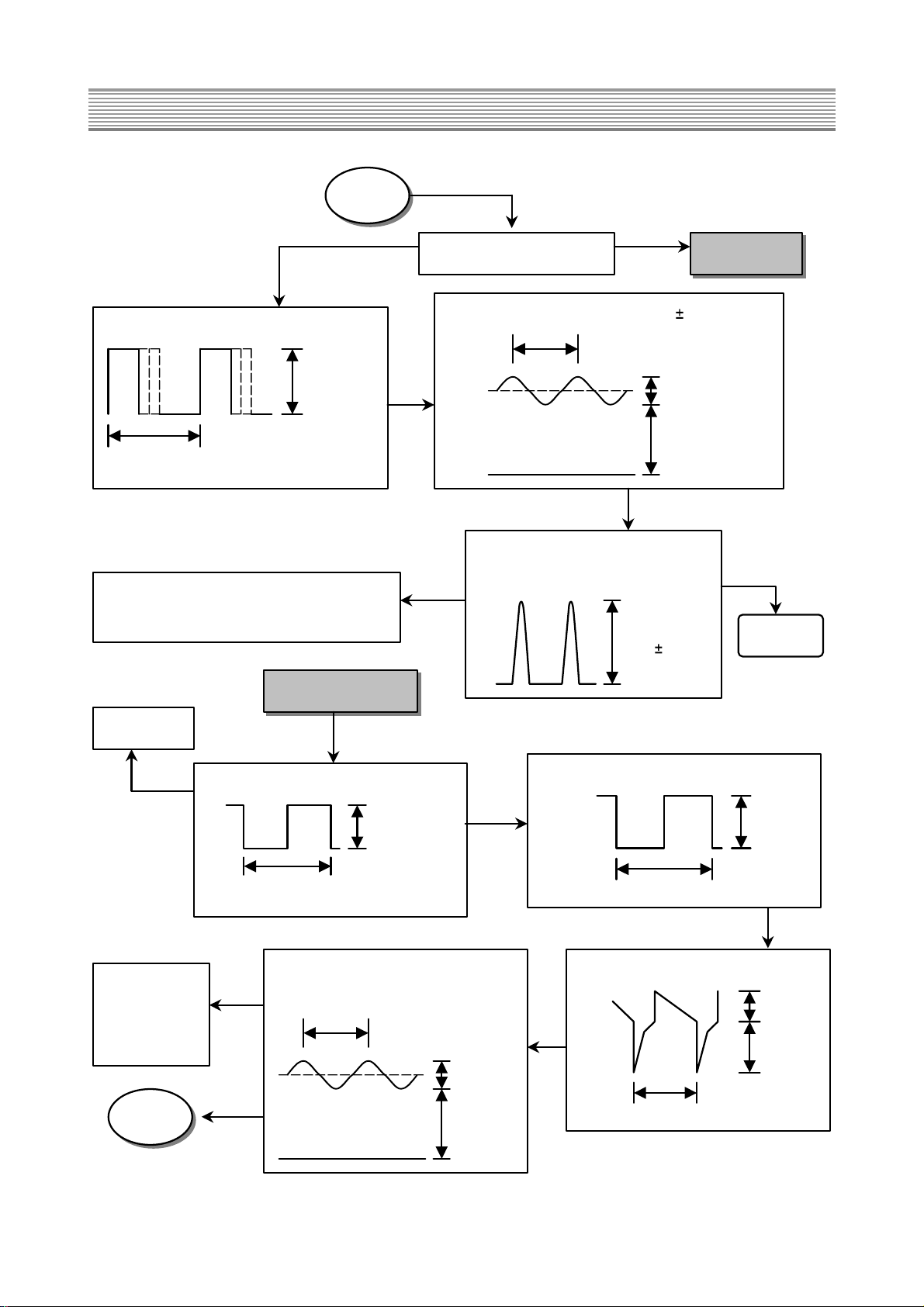

Troubleshooting charts

- 19 -

H/D1

60Hz

5Vp-p

90V

Horizontal Drive B+ to R481 is 90V 5Vp-p

If the impedance value of Q425's collector

is near zero Ω, the horizontal deflection TR

(Q425) is dead. Replace Q425.

NO

END

Check 200VA to PA14M. To No Power

NO

H Drive signal is output to Source of Q423.

200Vp-p

31.5 / 33.75KHz

The voltage waveform of Q425's

Collector is the following.

1,300 50Vp-p

High Voltage Drive

Check H Drive signal to emitter of Q402.

12Vp-p

33.75KHz

Check I403

and high

voltage

feedback

circuits.

NO

HVD1

Check pin 17 (H-Drive output) of I402.

0.7Vp-p

31.5 / 33.75KHz

Check I402

Trigger pulse is input to pin 2 of I401.

31.5 / 33.75KHz

2Vp-p

6Vp-p

60Hz

0.25Vp-p

7Vp-p

The control voltage of high voltage

feedback is input to #5 of I401

NO

Page 21

Troubleshooting charts

- 20 -

HVD1

High Voltage Drive signal is output

to pin 3 of I401.

31.5 / 33.75KHz

12Vp-p

Check 200VB to

PA14M.

To No Power

NO

High Voltage Drive signal is output

to source of Q407.

31.5 / 33.75KHz

200Vp-p

60Hz

20Vp-p

100V

FBT B+ to #12 of PW16P is about

100V

20Vp-p

END

Check emitter

of Q401.

NO

Check Q810.

Check EHT Drive signal to

base of Q808.

31.5 /33.75KHz

12Vp-p

The voltage waveform of Q810's

drain is the following.

650Vp-p

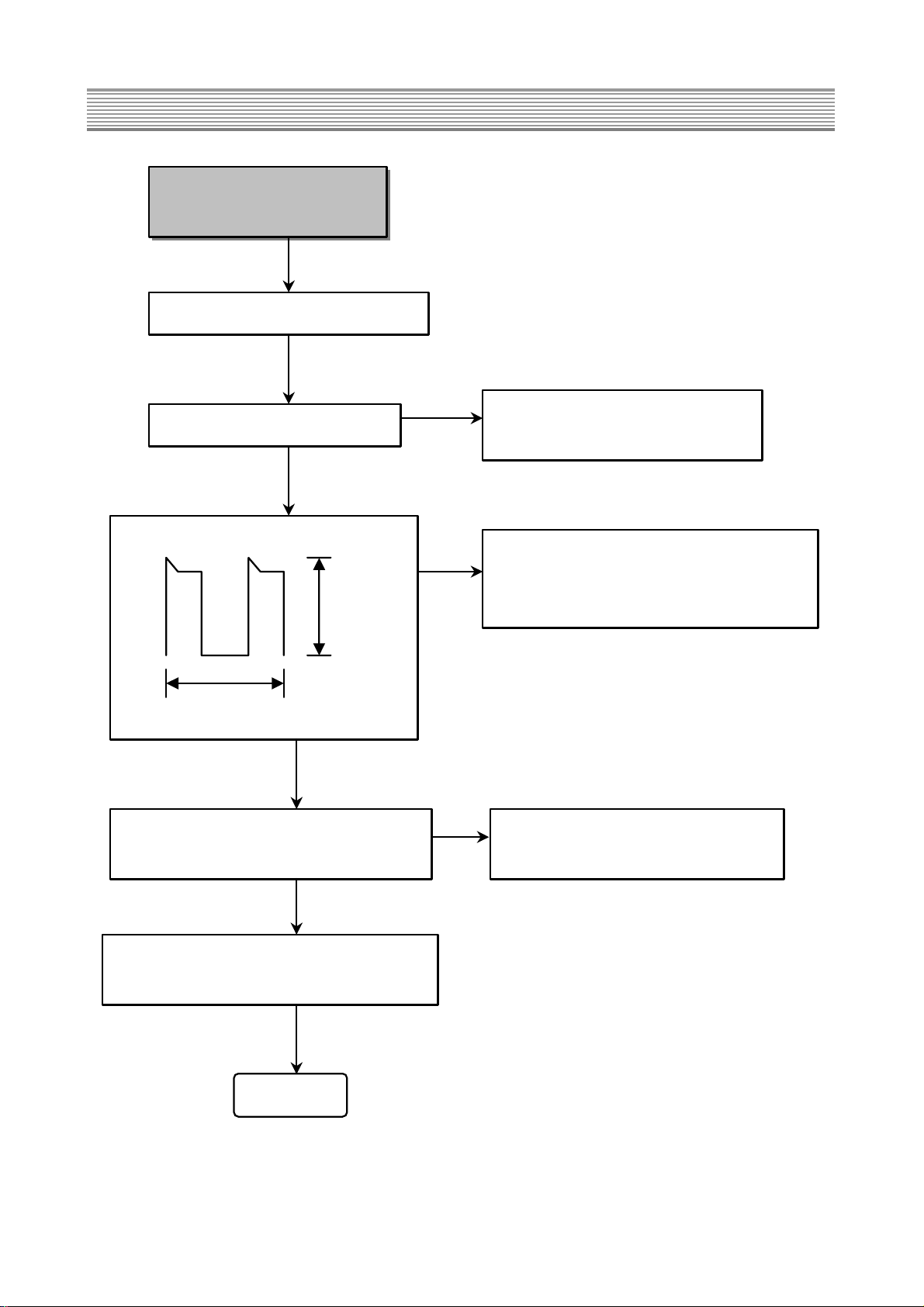

Page 22

Troubleshooting charts

- 21 -

Vertical Deflection

Check I412.

NO

Vertical SAW waveform is to pin 8 of I412.

2.2Vp-p

60Hz

The following waveform is to pin 1 of I412.

3.5Vp-p

0V

NO

Check vertical deflection circuits

around I412.

Check vertical deflection circuits

around I412.

NO

END

Vertical deflection waveform is to pin 5 of I412.

50Vp-p

60Hz

Page 23

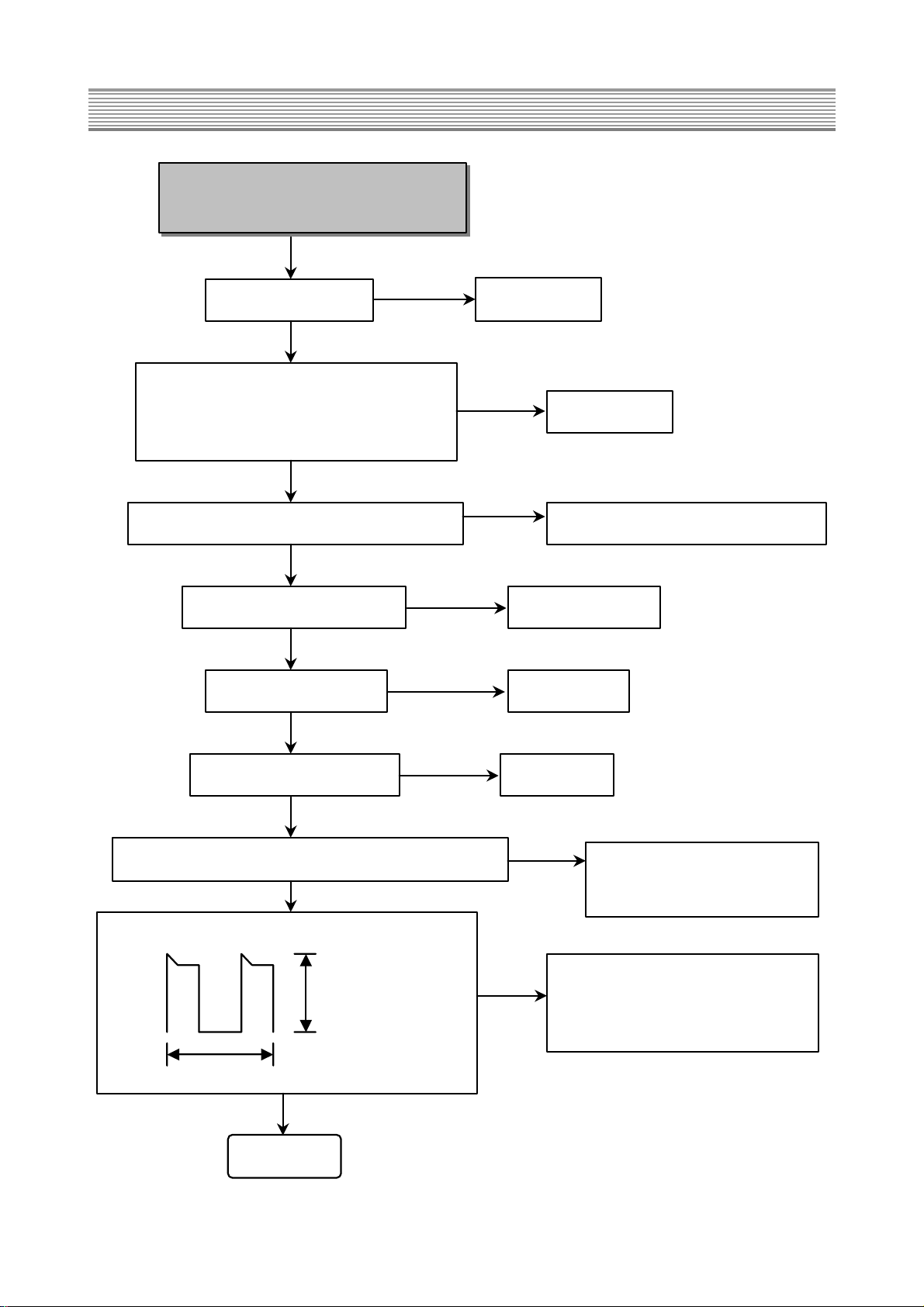

Troubleshooting charts

- 22 -

No Power

(Standby Power : I801)

The Standby LED doesn't light up red.

Approximately 150VDC is to C806.

NO

Check if F801 is open.

Check D801 (bridge rectifier).

Check if voltages to PW15 is supplied to TV

micro-processor(I701).

Check the parts caused a short-circuit to

secondary circuits.

NO

Check the impedance value of between Source

and Drain to I801. If the value is near zero Ω,

I801 is dead. Replace I801.

The following waveform is to drain of I801.

320Vp-p

100KHz

NO

When pressing Power button, the color of Power

LED is green

END

Page 24

Troubleshooting charts

- 23 -

No Power

Switch relay (Y802) doesn't operate.

NO

F801 short-circuits.

Replace F801.

Bridge rectifier (D805) short-circuits.

(The voltage of between Anode and Cathode to

D805 is 0.6V).

Replace D805.

Both AC lines of power cord don't short-circuit. Replace the parts caused a short-circuit.

PWR SW of PW15 is High. Check # 14 of I701.

Q804 doesn't defective. Replace Q804.

Check Y802 (switch relay).

Check the parts caused a short-circuit to secondary circuits

Replace defective parts with a

new one.

NO

NO

NO

NO

NO

NO

ReplaceY802.

The following waveform is to pin 1 of I803 and I805.

370Vp-p

50~80KHz

Check the primary circuits of SMPS

IC, and replace defective parts with a

new one.

NO

END

Page 25

Troubleshooting charts

- 24 -

NO Power

Switch relay operation (Y802) is OK.

Check the parts caused a shortcircuit to secondary circuits.

Replace defective parts with

a new one.

NO

Supply 200VA to PW14.

R802 is OK. ReplaceR802.

NO

NO

R807 and R852 are OK.

Replace R807 or R852.

NO

Q801, D810 are OK.

Replace Q801, D810.

NO

Check I803.

Supply 200VB to PA14M.

R823 and R853 are OK.

Replace R823 or R853.

NO

NO

Q802, D815 are OK.

Replace Q802, D815.

NO

Check I805.

END

Page 26

9. Part List (DSC-34W70N)

- 25 -

ZZ100 49B00R37E- TRANSMITTER REMOCON R-37D08

ZZ120 PEBCSHD013 COVER BACK AS DSC-3670W

M211 4952100800 COVER BACK FR HIPS PAINT

M353 4853526600 HOLDER CORD NYLON6(DACB-183)

M353A 7172401612 SCREW TAPPTITE TT2 TRS 4X16 MFZN BK

M541 4855415800 SPEC PLATE 150ART P/E FILM (C/TV)

M781 4857817610 CLOTH BLACK FELT 300X20X0.7

ZZ121 PEACPWD017 ACCESSORY AS DSC-3670N

10 495861200 MANUAL INSTRUCTION DSC-3670N

20 4850Q01210 BATTERY LR03 AAA ALKALINE

30 4858213800 BAG INSTRUCTION L.D.P.E T0.05X250X400

40 4850A01650 TRANS ANT MATCHING YSC-MTC-030

ZZ130 PEPKCPD013 PACKING AS DSC-3670W

M641 6520010100 STAPLE PIN AUTO W65

M681 4856812400 BAND 18MM X 3M

M801 4958000400 BOX CARTON DW-4

M811 4958100700 PAD EPS

M821 4958200600 BAG P.E T0.5X1900X1550

M841 4958400100 BOX STOPPER PP

M842 4958400200 EDGE HARD BOARD 5T 50X50X760

ZZ131 49519A0010 CRT GROUND NET DSC-3670N

ZZ132 58GD000002 COIL TILT DSC-3670N

ZZ133 58GD000001 COIL DEGAUSSING DC-36FL

ZZ140 PECACAD017 CABINET AS DSC-3670N

M201A 4956000100 SCREW CRT FIX SWRM10A L=35

M201B 4856215404 WASHER RUBBER CR T4.0

M201D 4857817630 CLOTH BLACK FELT 400X20X0.7

M201E 4857817610 CLOTH BLACK FELT 300X20X0.7

M201F 4953400600 BRKT CRT FR HIPS

M211A 7172401612 SCREW TAPPTITE TT2 TRS 4X16 MFZN BK

M211B 7172401612 SCREW TAPPTITE TT2 TRS 4X16 MFZN BK

M211C 7172401612 SCREW TAPPTITE TT2 TRS 4X16 MFZN BK

M211D 7172401612 SCREW TAPPTITE TT2 TRS 4X16 MFZN BK

M211E 7172401612 SCREW TAPPTITE TT2 TRS 4X16 MFZN BK

M231B 7172401612 SCREW TAPPTITE TT2 TRS 4X16 MFZN BK

M491A 7178301212 SCREW TAPPTITE TT2 WAS 3X12 MFZN BLACK

M492 4954900900 BUTTON POWER ABS BK

M492A 4856716000 SPRING SWPA PIE0.5

M551A 7178301212 SCREW TAPPTITE TT2 WAS 3X12 MFZN BLACK

M561 4955600100 MARK BRAND AL T1.0 DIA-CUTTING

M682 4856816300 CLAMP WIRE NYLON 6 (V0)

V901 4959600270 CRT W86LQQ350X97

V901A 4950704008 CONNECTOR TBL-P04H-A1+208T-1100=600

V901B 4950703008 CONNECTOR YH025-03+YST250+ULW=300

ZZ200 PEFMSJD013 MASK FRONT AS DSC-3670W

M201 4952000900 MASK FRONT FR HIPS PAINT

M331 4853311700 BRACKET BACK FR HIPS BK

S601 4958300310 SPEAKER AS L 10W 8 OHM K128/101999B

S601A 7172401612 SCREW TAPPTITE TT2 TRS 4X16 MFZN BK

S602 4958300110 SPEAKER UNIT 5W 8OHM H114/100400A

S602A 7178301212 SCREW TAPPTITE TT2 WAS 3X12 MFZN BLACK

S603 4958300210 SPEAKER AS R 10W 8 OHM K128/101999B

S603A 7172401612 SCREW TAPPTITE TT2 TRS 4X16 MFZN BK

ZZ230 PEPWMSD017 PCB POWER MANUAL AS DSC-3670N

C800 DDSA452T05 VARISTOR DSA-622M-U05A

C802 CL1JB3474K C LINE ACROSS AC250V 0.47MF U/C/SNDF/SV

C803 CL1JB3474K C LINE ACROSS AC250V 0.47MF U/C/SNDF/SV

C814 CEYN2G561P C ELECTRO 400V LHS 560MF (35X45)

C815 CEYN2G561P C ELECTRO 400V LHS 560MF (35X45)

C851 CEXF2E101V C ELECTRO 250V RSS 100MF 16X31.5

C852 CEXF2C101V C ELECTRO 160V RSS 100MF (16X25) TP

C854 CEYF1V222C C ELECTRO 35V RUS 2200MF (16X31.5)

C859 CEYF1V222C C ELECTRO 35V RUS 2200MF (16X31.5)

C864 CEXF2E101V C ELECTRO 250V RSS 100MF 16X31.5

C879 CMXF2G104J C MYLAR MPP 400V 0.1MF J

C880 CMYH3C472J C MYLAR 1.6KV BUP 4700PF J

C890 CCYE3D103P C CERA 2KV E 0.01MF P

C891 CCYE3D103P C CERA 2KV E 0.01MF P

C897 CH1AEE472M C CERA AC 2.5KV 4700PF M KH DE1307

C900 CH1AEE472M C CERA AC 2.5KV 4700PF M KH DE1307

D801 DPBS208GU- DIODE BRIDGE PBS208GU-CA

D805 DGBJ606--- DIODE BRIDGE GBJ606

®

D805A 4857027702 HEAT SINK AL EX BK

D805B 7174301011 SCREW TAPPTITE TT2 RND 3X10 MFZN

D820 DBYW95C--- DIODE BYW95C (TAPPING)

D821 DBYW95C--- DIODE BYW95C (TAPPING)

D826 DBYW95C--- DIODE BYW95C (TAPPING)

D827 DRU3YX---- DIODE RU3YX

D828 DBYW95C--- DIODE BYW95C (TAPPING)

D829 DBYW95C--- DIODE BYW95C (TAPPING)

D830 DBYW95C--- DIODE BYW95C (TAPPING)

D832 DRU3YX---- DIODE RU3YX

D833 DRU3YX---- DIODE RU3YX

D834 DRU3YX---- DIODE RU3YX

D835 DRU3YX---- DIODE RU3YX

D836 DDG3------ DIODE DG3

D844 DBYW95C--- DIODE BYW95C (TAPPING)

FT801 5DH0000021 FBT FFA65038L

The shaded areas in the schematic diagram and the parts list have especial characteristics important for safety and should be

replaced only with types identical to those in the original circuit or specified in the part list. Before replacing any of those

components, read carefully the PRODUCT SAFETY NOTICE on this manual. Do not degrade the safety of receiver through

improper servicing.

Part recommended for stock.

WARNING :BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRECAUTION” AND

“RODUCT SAFETY NOTICE” ON THIS MANUAL.

“”

“”

®

Page 27

FT802 7128301212 SCREW TAPPING T2S WAS 3X12 MFZN BK

F801 5F1CD6321M FUSE UL/CSANM 6.3A 125V

®

I801 1T0P224Y-- IC AUDIO POWER TOP224Y

®

I801A 4957000701 HEAT SINK AL EX

I801B 7174300811 SCREW TAPPTITE TT2 RND 3X8 MFZN

I802 1LTV817C-- IC PHOTO COUPLER LTV-817C

I803 1STRS6709- IC POWER STR-S6709

®

I803A 4857027904 HEAT SINK AL EX (AN0DIZE)

I803B 7174301211 SCREW TAPPTITE TT2 RND 3X12 MFZN

I804 1LTV817C-- IC PHOTO COUPLER LTV-817C

I805 1STRS6709- IC POWER STR-S6709

®

I805A 4857027901 HEAT SINK AL EX

I805B 7174301211 SCREW TAPPTITE TT2 RND 3X12 MFZN

I806 1LTV817C-- IC PHOTO COUPLER LTV-817C

I807 1SE140N--- IC AMP SE140N

I808 1SE140N--- IC AMP SE140N

I809 1KA7809--- IC REGULATOR KA7809

I809A 4857027802 HEAT SINK AL EX

I809B 7174300811 SCREW TAPPTITE TT2 RND 3X8 MFZN

I810 1KA7805--- IC REGULATOR KA7805

I810A 4857031201 HEAT SINK AL 6063S

I810B 7174300811 SCREW TAPPTITE TT2 RND 3X8 MFZN

I811 1KA7805--- IC REGULATOR KA7805

I813 1NJM431L-- IC REGULATOR NJM431L

LF801 5PLF3525A- LINE FILTER LF-3525A

LF802 5PLF3520A- LINE FILTER LF-3520A

L814 58C4500079 COIL CHOKE L-45

L815 58C4500079 COIL CHOKE L-45

L818 5DY0000023 TRANS DUMMY DTL-02M

PA18M 4859235320 CONN WAFER YW025-10

PC801 4959203320 CONN WAFER YWL500-03A

PC802 4959900110 CORD POWER AS PA208R

PW14 4950712005 CONNECTOR YH025-12+YST250+ULW=100

PW15 4950712005 CONNECTOR YH025-12+YST250+ULW=100

PW16 4950712005 CONNECTOR YH025-12+YST250+ULW=100

Q801 TKTD1414-- TR KTD1414

®

Q802 TKTD1414-- TR KTD1414

®

Q810 T2SK1489-- TR 2SK1489

Q810A 4857024402 HEAT SINK AL EX (L=70)

Q810B 7174301211 SCREW TAPPTITE TT2 RND 3X12 MFZN

Q810C 4857619500 INSU PLATE SILICON RUBBER T0.3

Q813 T2SC2688L- TR 2SC2688-L

Q814 T2SC4710LS TR 2SC4710LS

Q814A 4957000700 HEAT SINK AL EX

Q814B 7174301011 SCREW TAPPTITE TT2 RND 3X10 MFZN

Q817 T2SC4710LS TR 2SC4710LS

Q817A 4957000700 HEAT SINK AL EX

Q817B 7174301011 SCREW TAPPTITE TT2 RND 3X10 MFZN

R802 RX10T270J- R CEMENT 10W 27 OHM J TRIPOD

®

R803 RX05V229J- R CEMENT 5W 2.2 OHM J VERTICAL

R808 RW02Z158JN R WIRE WOUND 2W 0.15 OHM J NON-INDUCT

R826 RW02Z158JN R WIRE WOUND 2W 0.15 OHM J NON-INDUCT

R838 DJ503P51D- POSISTOR J5 03 P5 1D030Q 140

R897 RS02Z124J- R M-OXIDE FILM 2W 120K OHM J

R898 RS02Z124J- R M-OXIDE FILM 2W 120K OHM J

R920 RW02Z189J- R WIRE WOUND 2W 1.8 OHM J

R924 RW02Z828J- R WIRE WOUND 2W 0.82 OHM

R928 RS02Z124J- R M-OXIDE FILM 2W 120K OHM J

R929 RS02Z124J- R M-OXIDE FILM 2W 120K OHM J

S801 TTF841S--- THYRISTOR TF841S

®

S801A 4857026900 HEAT SINK AL EX

S801B 7174300811 SCREW TAPPTITE TT2 RND 3X8 MFZN

T801 50MST2---- TRANS STAND-BY DTS-ST2

T802 50M5555A1- TRANS SMPS DTS-5555A1

T803 50MD5345A3 TRANS SMPS DTS-5345A3

Y801 5SC0000001 SW RELAY DG5D1-0(M)0.25W

Y802 5SC0202334 SW RELAY DJ5D2-0(M)-0.25W

ZZ200 PEPWJ0D017 PCB POWER RHU AS DSC-3670N

C804 CH1AEE222M C CERA AC 2.5KV 2200PF M KH DE1007

C805 CH1AEE222M C CERA AC 2.5KV 2200PF M KH DE1007

C806 CEXF2G470V C ELECTRO 400V RSS 47MF 16X25

C809 CH1AEE472M C CERA AC 2.5KV 4700PF M KH DE1307

C810 CH1AEE472M C CERA AC 2.5KV 4700PF M KH DE1307

C811 CH1AEE472M C CERA AC 2.5KV 4700PF M KH DE1307

C812 CH1AEE472M C CERA AC 2.5KV 4700PF M KH DE1307

C816 CMXH3C152J C MYLAR 1.6KV BUP 1500PF J (TP)

C821 CMXH3C152J C MYLAR 1.6KV BUP 1500PF J (TP)

C826 CCXB3D271K C CERA 2KV B 270PF K (T)

C843 CEXF1C471V C ELECTRO 16V RSS 470MF (10X12.5)BK

C848 CEXF1E471V C ELECTRO 25V RSS 470MF (10X16) TP

C850 CCXB3D681K C CERA 2KV B 680PF K (TAPPING)

C855 CEXF1C102V C ELECTRO 16V RSS 1000MF (10X20) TP

C856 CEXF1C102V C ELECTRO 16V RSS 1000MF (10X20) TP

C857 CEXF1C102V C ELECTRO 16V RSS 1000MF (10X20) TP

C860 CEXF1C102V C ELECTRO 16V RSS 1000MF (10X20) TP

C861 CEXF1C102V C ELECTRO 16V RSS 1000MF (10X20) TP

C863 CCXB3D681K C CERA 2KV B 680PF K (TAPPING)

C865 CEXF2C220V C ELECTRO 160V RSS 22MF (10X20) TP

C866 CEXF1E471V C ELECTRO 25V RSS 470MF (10X16) TP

C867 CEXF1E471V C ELECTRO 25V RSS 470MF (10X16) TP

C869 CEXF1V471V C ELECTRO 35V RSS 470MF (10X20) TP

C870 CEXF1V471V C ELECTRO 35V RSS 470MF (10X20) TP

C872 CEXF1V471V C ELECTRO 35V RSS 470MF (10X20) TP

C874 CEXF1E471V C ELECTRO 25V RSS 470MF (10X16) TP

C881 CCXB3D681K C CERA 2KV B 680PF K (TAPPING)

C883 CEXF2C100V C ELECTRO 160V RSS 10MF (10X16) TP

C886 CEXF2G220D C ELECTRO 400V KMG 22MF(12.5*25) TP

C889 CEXF1C471C C ELECTRO 16V RUS 470MF (10X12.5)TP

C894 CEXF2W100C C ELECTRO 450V RUS 10MF (13X20) TP

ZZ200 PEPWJBD017 PCB POWER M-10 AS DSC-3670N

E801 4856310600 EYE LET BSR T0.2 (R2.3)

E802 4856310600 EYE LET BSR T0.2 (R2.3)

E803 4856310600 EYE LET BSR T0.2 (R2.3)

E804 4856310600 EYE LET BSR T0.2 (R2.3)

Part List (DSC-34W70N)

- 26 -

Page 28

E805 4856310600 EYE LET BSR T0.2 (R2.3)

E806 4856310600 EYE LET BSR T0.2 (R2.3)

E807 4856310600 EYE LET BSR T0.2 (R2.3)

E808 4856310600 EYE LET BSR T0.2 (R2.3)

E809 4856310300 EYE LET BSR T0.2 (R1.6)

E810 4856310300 EYE LET BSR T0.2 (R1.6)

E811 4856310300 EYE LET BSR T0.2 (R1.6)

E812 4856310300 EYE LET BSR T0.2 (R1.6)

E813 4856310300 EYE LET BSR T0.2 (R1.6)

E814 4856310300 EYE LET BSR T0.2 (R1.6)

E815 4856310300 EYE LET BSR T0.2 (R1.6)

E816 4856310600 EYE LET BSR T0.2 (R2.3)

E817 4856310600 EYE LET BSR T0.2 (R2.3)

E818 4856310300 EYE LET BSR T0.2 (R1.6)

E819 4856310300 EYE LET BSR T0.2 (R1.6)

E820 4856310300 EYE LET BSR T0.2 (R1.6)

E821 4856310300 EYE LET BSR T0.2 (R1.6)

E822 4856310300 EYE LET BSR T0.2 (R1.6)

E823 4856310600 EYE LET BSR T0.2 (R2.3)

E824 4856310600 EYE LET BSR T0.2 (R2.3)

E825 4856310300 EYE LET BSR T0.2 (R1.6)

E826 4856310600 EYE LET BSR T0.2 (R2.3)

E827 4856310600 EYE LET BSR T0.2 (R2.3)

E828 4856310600 EYE LET BSR T0.2 (R2.3)

E829 4856310600 EYE LET BSR T0.2 (R2.3)

E830 4856310300 EYE LET BSR T0.2 (R1.6)

E831 4856310600 EYE LET BSR T0.2 (R2.3)

E832 4856310600 EYE LET BSR T0.2 (R2.3)

E833 4856310300 EYE LET BSR T0.2 (R1.6)

E834 4856310300 EYE LET BSR T0.2 (R1.6)

E835 4856310300 EYE LET BSR T0.2 (R1.6)

E836 4856310300 EYE LET BSR T0.2 (R1.6)

E837 4856310300 EYE LET BSR T0.2 (R1.6)

E838 4856310300 EYE LET BSR T0.2 (R1.6)

E839 4856310300 EYE LET BSR T0.2 (R1.6)

E840 4856310300 EYE LET BSR T0.2 (R1.6)

E841 4856310300 EYE LET BSR T0.2 (R1.6)

E842 4856310300 EYE LET BSR T0.2 (R1.6)

E843 4856310300 EYE LET BSR T0.2 (R1.6)

E844 4856310300 EYE LET BSR T0.2 (R1.6)

E845 4856310300 EYE LET BSR T0.2 (R1.6)

E846 4856310300 EYE LET BSR T0.2 (R1.6)

E847 4856310300 EYE LET BSR T0.2 (R1.6)

E848 4856310300 EYE LET BSR T0.2 (R1.6)

E849 4856310300 EYE LET BSR T0.2 (R1.6)

E850 4856310300 EYE LET BSR T0.2 (R1.6)

E851 4856310300 EYE LET BSR T0.2 (R1.6)

E852 4856310300 EYE LET BSR T0.2 (R1.6)

E853 4856310300 EYE LET BSR T0.2 (R1.6)

E854 4856310600 EYE LET BSR T0.2 (R2.3)

E855 4856310600 EYE LET BSR T0.2 (R2.3)

E856 4856310600 EYE LET BSR T0.2 (R2.3)

E857 4856310600 EYE LET BSR T0.2 (R2.3)

E858 4856310600 EYE LET BSR T0.2 (R2.3)

E859 4856310600 EYE LET BSR T0.2 (R2.3)

E860 4856310600 EYE LET BSR T0.2 (R2.3)

E861 4856310600 EYE LET BSR T0.2 (R2.3)

E862 4856310600 EYE LET BSR T0.2 (R2.3)

E863 4856310600 EYE LET BSR T0.2 (R2.3)

E864 4856310300 EYE LET BSR T0.2 (R1.6)

E865 4856310300 EYE LET BSR T0.2 (R1.6)

E866 4856310300 EYE LET BSR T0.2 (R1.6)

E867 4856310600 EYE LET BSR T0.2 (R2.3)

E868 4856310300 EYE LET BSR T0.2 (R1.6)

E869 4856310300 EYE LET BSR T0.2 (R1.6)

E870 4856310300 EYE LET BSR T0.2 (R1.6)

E871 4856310300 EYE LET BSR T0.2 (R1.6)

E872 4856310300 EYE LET BSR T0.2 (R1.6)

E873 4856310300 EYE LET BSR T0.2 (R1.6)

E874 4856310600 EYE LET BSR T0.2 (R2.3)

E875 4856310600 EYE LET BSR T0.2 (R2.3)

E876 4856310600 EYE LET BSR T0.2 (R2.3)

E877 4856310600 EYE LET BSR T0.2 (R2.3)

E878 4856310300 EYE LET BSR T0.2 (R1.6)

E879 4856310300 EYE LET BSR T0.2 (R1.6)

E882 4856310600 EYE LET BSR T0.2 (R2.3)

E883 4856310600 EYE LET BSR T0.2 (R2.3)

E884 4856310300 EYE LET BSR T0.2 (R1.6)

E885 4856310300 EYE LET BSR T0.2 (R1.6)

E886 4856310300 EYE LET BSR T0.2 (R1.6)

E887 4856310300 EYE LET BSR T0.2 (R1.6)

PC803 4857417500 TERM PIN DA-IB0214(D2.3/DY PIN)

PC804 4857417500 TERM PIN DA-IB0214(D2.3/DY PIN)

PW08 485923162S CONN WAFER YW025-03 (STICK)

P001 4857417500 TERM PIN DA-IB0214(D2.3/DY PIN)

R807 RS02Z333J- R M-OXIDE FILM 2W 33K OHM J

R809 RS01Z180J- R M-OXIDE FILM 1W 18 OHM J (TAPPING)

R817 RS01Z180J- R M-OXIDE FILM 1W 18 OHM J (TAPPING)

R823 RS02Z822J- R M-OXIDE FILM 2W 8.2K OHM J (TAPPING)

R829 RS02Z102J- R M-OXIDE FILM 2W 1K OHM J (TAPPING)

R840 RF01Z518J- R FUSIBLE 1W 0.51 OHM J (TAPPING)

R843 RS02Z390J- R M-OXIDE FILM 2W 39 OHM J (TAPPING)

R848 RS02Z100J- R M-OXIDE FILM 2W 10 OHM J (TAPPING)

R851 RF01Z518J- R FUSIBLE 1W 0.51 OHM J (TAPPING)

R852 RS02Z333J- R M-OXIDE FILM 2W 33K OHM J

R853 RS02Z822J- R M-OXIDE FILM 2W 8.2K OHM J (TAPPING)

R856 RS02Z390J- R M-OXIDE FILM 2W 39 OHM J (TAPPING)

R859 RF02Z439J- R FUSIBLE 2W 4.3 OHM J (TAPPING)

R862 RF01Z518J- R FUSIBLE 1W 0.51 OHM J (TAPPING)

R864 RF01Z518J- R FUSIBLE 1W 0.51 OHM J (TAPPING)

R896 RS02Z100J- R M-OXIDE FILM 2W 10 OHM J (TAPPING)

R907 RS01Z334J- R M-OXIDE FILM 1W 330K OHM J

R908 RS01Z244J- R M-OXIDE FILM 1W 240K OHM J (TAPPING)

R909 RS01Z334J- R M-OXIDE FILM 1W 330K OHM J

R910 RS01Z244J- R M-OXIDE FILM 1W 240K OHM J (TAPPING)

ZZ200 PEPWJRD017 PCB POWER RADIAL AS DSC-3670N

Part List (DSC-34W70N)

- 27 -

Page 29

C807 CMXB1H104J C MYLAR 50V EU 0.1MF J (TP)

C808 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

C813 CEXF2A100V C ELECTRO 100V RSS 10MF (6.3X11) TP

C817 CEXF1E221C C ELECTRO 25V RUS 220MF (8X11.5) TP

C818 CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

C819 CEXF2A100V C ELECTRO 100V RSS 10MF (6.3X11) TP

C820 CMXB1H102J C MYLAR 50V EU 1000PF J (TP)

C822 CEXF1E221C C ELECTRO 25V RUS 220MF (8X11.5) TP

C823 CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

C824 CEXF2A100V C ELECTRO 100V RSS 10MF (6.3X11) TP

C825 CMXB1H102J C MYLAR 50V EU 1000PF J (TP)

C827 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C828 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C829 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C830 CCXB2H102K C CERA 500V B 1000PF K (TAPPING)

C832 CCXB2H102K C CERA 500V B 1000PF K (TAPPING)

C833 CEXF1H470V C ELECTRO 50V RSS 47MF (6.3X11) TP

C834 CCXB2H102K C CERA 500V B 1000PF K (TAPPING)

C835 CCXB2H102K C CERA 500V B 1000PF K (TAPPING)

C837 CCXB2H102K C CERA 500V B 1000PF K (TAPPING)

C838 CMXB2A103J C MYLAR 100V EU 0.01MF J (TP)

C839 CEXF2A100V C ELECTRO 100V RSS 10MF (6.3X11) TP

C840 CEXF2A479V C ELECTRO 100V RSS 4.7MF (5X11) TP

C841 CMXB2A103J C MYLAR 100V EU 0.01MF J (TP)

C842 CEXF2A100V C ELECTRO 100V RSS 10MF (6.3X11) TP

C844 CMXB1H104J C MYLAR 50V EU 0.1MF J (TP)

C845 CEXF2A479V C ELECTRO 100V RSS 4.7MF (5X11) TP

C846 CMXB2A104J C MYLAR 100V EU 0.1MF J (TP)

C847 CCXB3A102K C CERA 1KV B 1000PF K (TAPPING)

C849 CMXB1H104J C MYLAR 50V EU 0.1MF J (TP)

C853 CCXB3A471K C CERA 1KV B 470PF K (T)

C858 CMXB1H104J C MYLAR 50V EU 0.1MF J (TP)

C868 CMXB1H104J C MYLAR 50V EU 0.1MF J (TP)

C871 CMXB1H104J C MYLAR 50V EU 0.1MF J (TP)

C873 CMXB1H104J C MYLAR 50V EU 0.1MF J (TP)

C875 CMXB1H104J C MYLAR 50V EU 0.1MF J (TP)

C876 CMXB1H104J C MYLAR 50V EU 0.1MF J (TP)

C877 CMXB1H104J C MYLAR 50V EU 0.1MF J (TP)

C882 CMXB2A103J C MYLAR 100V EU 0.01MF J (TP)

C884 CMXB2A103J C MYLAR 100V EU 0.01MF J (TP)

C885 CEXF1E221V C ELECTRO 25V RSS 220MF (8X11.5) TP

C887 CEXF1V101V C ELECTRO 35V RSS 100MF (8X11.5) TP

C888 CEXF1C101V C ELECTRO 16V RSS 100MF (6.3X11) TP

C892 CMXM2A223J C MYLAR 100V 0.022MF J TP

C893 CEXF2C109V C ELECTRO 160V RSS 1MF (6.3X11) TP

C895 CEXF1H101C C ELECTRO 50V RUS 100MF (8X11.5) TP

C896 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C898 CCXB1H102K C CERA 50V B 1000PF K (TAPPING)

C899 CCXB3A471K C CERA 1KV B 470PF K (T)

F801A 4857415001 CLIP FUSE PFC5000-0702

F801C 4857415001 CLIP FUSE PFC5000-0702

Q803 TKSC2383Y- TR KSC2383-Y

Q804 TKSC2383Y- TR KSC2383-Y

Q805 T2SA1544-- TR 2SA1544

®

Q806 T2SA1544-- TR 2SA1544

®

Q807 TKTC3198Y- TR KTC3198Y

Q808 TKTA1270Y- TR KTA1270Y (TP)

Q809 TKTC3198Y- TR KTC3198Y

Q811 TKTC3198Y- TR KTC3198Y

Q812 TKTA1277Y- TR KTA1277Y

Q815 TKTC3198Y- TR KTC3198Y

Q816 TKTA1266Y- TR KTA1266Y (TP)

VR801 RV5426503P R SEMI FIXED EVN-DJAA03B 50K OHM

ZZ200 PEPWJAD017 PCB POWER AXIAL AS DSC-3670N

A001 4959803224 PCB POWER AS 330 X 246

D802 DR2KY----- DIODE AVALANCHE R 2-KY (TAPPING)

D803 DRU1P----- DIODE RU 1P (TAPPING)

D804 D1N4004--- DIODE 1N4004

D806 DEU1Z----- DIODE EU1Z (HIGH SPEED)

D807 D1N4937G-- DIODE 1N4937G (TAPPING)

D808 D1N4937G-- DIODE 1N4937G (TAPPING)

D809 D1N4937G-- DIODE 1N4937G (TAPPING)

D810 DUZ7R5BM-- DIODE ZENER UZ-7.5BM 7.5V

D811 DRF1------ DIODE RF1

D812 D1N4937G-- DIODE 1N4937G (TAPPING)

D813 D1N4937G-- DIODE 1N4937G (TAPPING)

D814 D1N4937G-- DIODE 1N4937G (TAPPING)

D815 DUZ7R5BM-- DIODE ZENER UZ-7.5BM 7.5V

D816 DRF1------ DIODE RF1

D817 D1N4148--- DIODE 1N4148 (TAPPING)

D818 D1N4148--- DIODE 1N4148 (TAPPING)

D819 D1N4937G-- DIODE 1N4937G (TAPPING)

D822 DRF1------ DIODE RF1

D823 D1N4148--- DIODE 1N4148 (TAPPING)

D824 D1N4148--- DIODE 1N4148 (TAPPING)

D825 D1N4148--- DIODE 1N4148 (TAPPING)

D831 DRF1------ DIODE RF1

D837 DUZ22BH--- DIODE ZENER UZ22BH

D838 DRF1------ DIODE RF1

D839 DRF1------ DIODE RF1

D840 DRF1------ DIODE RF1

D841 DRF1------ DIODE RF1

D842 DRP1H----- DIODE RP1H

D843 DRP1H----- DIODE RP1H

D846 DUZ12BM--- DIODE ZENER UZ-12BM (UNIZON)

D847 DUZ12BM--- DIODE ZENER UZ-12BM (UNIZON)

D848 D1N4148--- DIODE 1N4148 (TAPPING)

D849 D1N4148--- DIODE 1N4148 (TAPPING)

J802 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J806 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J807 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J808 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J809 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J810 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J811 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

Part List (DSC-34W70N)

- 28 -

Page 30

J812 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J813 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J814 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J815 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J816 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J817 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J818 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J819 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J820 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J821 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J822 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J823 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J824 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J825 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J827 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J828 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J831 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J832 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J834 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J835 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J836 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J839 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J840 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J841 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J843 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J844 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J845 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J848 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J849 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J850 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J851 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J852 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J853 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J854 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J855 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J856 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J857 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J858 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

J860 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

L801 5MC0000100 COIL BEAD HC-3550

L802 5MC0000100 COIL BEAD HC-3550

L803 5MC0000100 COIL BEAD HC-3550

L804 5MC0000100 COIL BEAD HC-3550

L805 5MC0000100 COIL BEAD HC-3550

L806 5MC0000100 COIL BEAD HC-3550

L807 5MC0000100 COIL BEAD HC-3550

L808 5MC0000100 COIL BEAD HC-3550

L819 5MC0000100 COIL BEAD HC-3550

R801 RC-2Z565KP R CARBON COMP 1/2 5.6M OHM K

R804 RD-4Z223J- R CARBON FILM 1/4 22K OHM J

R805 RD-4Z474J- R CARBON FILM 1/4 470K OHM J

R806 RD-4Z820J- R CARBON FILM 1/4 82 OHM J

R810 RD-4Z104J- R CARBON FILM 1/4 100K OHM J

R811 RD-2Z273J- R CARBON FILM 1/2 27K OHM J

R812 RD-4Z182J- R CARBON FILM 1/4 1.8K OHM J

R813 RD-4Z102J- R CARBON FILM 1/4 1K OHM J

R814 RD-4Z102J- R CARBON FILM 1/4 1K OHM J

R815 RD-4Z820J- R CARBON FILM 1/4 82 OHM J

R816 RD-4Z472J- R CARBON FILM 1/4 4.7K OHM J

R818 RD-4Z104J- R CARBON FILM 1/4 100K OHM J

R819 RD-2Z273J- R CARBON FILM 1/2 27K OHM J

R820 RD-4Z182J- R CARBON FILM 1/4 1.8K OHM J

R821 RD-4Z102J- R CARBON FILM 1/4 1K OHM J

R822 RD-4Z102J- R CARBON FILM 1/4 1K OHM J

R824 RD-4Z820J- R CARBON FILM 1/4 82 OHM J

R825 RD-4Z472J- R CARBON FILM 1/4 4.7K OHM J

R827 RD-4Z474J- R CARBON FILM 1/4 470K OHM J

R828 RD-4Z689J- R CARBON FILM 1/4 6.8 OHM J

R830 RD-4Z242J- R CARBON FILM 1/4 2.4K OHM J

R831 RD-4Z390J- R CARBON FILM 1/4 39 OHM J

R832 RD-4Z471J- R CARBON FILM 1/4 470 OHM J

R833 RD-4Z122J- R CARBON FILM 1/4 1.2K OHM J

R834 RD-AZ202J- R CARBON FILM 1/6 2K OHM J

R835 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R836 RD-AZ202J- R CARBON FILM 1/6 2K OHM J

R837 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J

R839 RC-2Z275KP R CARBON COMP 1/2 2.7M OHM K

R844 RD-4Z474J- R CARBON FILM 1/4 470K OHM J

R845 RD-4Z224J- R CARBON FILM 1/4 220K OHM J

R846 RD-4Z102J- R CARBON FILM 1/4 1K OHM J

R847 RD-4Z103J- R CARBON FILM 1/4 10K OHM J

R849 RD-2Z472J- R CARBON FILM 1/2 4.7K OHM J

R850 RD-2Z163J- R CARBON FILM 1/2 16K OHM J

R855 RD-4Z103J- R CARBON FILM 1/4 10K OHM J

R857 RD-4Z474J- R CARBON FILM 1/4 470K OHM J

R858 RD-4Z224J- R CARBON FILM 1/4 220K OHM J

R860 RD-4Z103J- R CARBON FILM 1/4 10K OHM J

R861 RD-4Z103J- R CARBON FILM 1/4 10K OHM J

R863 RD-4Z103J- R CARBON FILM 1/4 10K OHM J

R865 RD-4Z103J- R CARBON FILM 1/4 10K OHM J

R866 RD-4Z103J- R CARBON FILM 1/4 10K OHM J

R867 RD-2Z472J- R CARBON FILM 1/2 4.7K OHM J

R868 RD-2Z163J- R CARBON FILM 1/2 16K OHM J

R870 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R871 RN-4Z3002F R METAL FILM 1/4 30K OHM F

R872 RN-4Z3001F R METAL FILM 1/4 3.0K OHM F

R873 RN-4Z6802F R METAL FILM 1/4 68.0K OHM F

R874 RD-4Z229J- R CARBON FILM 1/4 2.2 OHM J

R875 RD-AZ684J- R CARBON FILM 1/6 680K OHM J

R876 RD-AZ105J- R CARBON FILM 1/6 1M OHM J

R877 RD-AZ223J- R CARBON FILM 1/6 22K OHM J

R878 RD-AZ105J- R CARBON FILM 1/6 1M OHM J

R879 RD-AZ104J- R CARBON FILM 1/6 100K OHM J

R880 RD-4Z333J- R CARBON FILM 1/4 33K OHM J

R881 RD-4Z274J- R CARBON FILM 1/4 270K OHM J

R882 RD-2Z474J- R CARBON FILM 1/2 470K OHM J

Part List (DSC-34W70N)

- 29 -

Page 31

R883 RD-4Z102J- R CARBON FILM 1/4 1K OHM J

R884 RD-4Z229J- R CARBON FILM 1/4 2.2 OHM J

R885 RD-4Z229J- R CARBON FILM 1/4 2.2 OHM J

R886 RD-4Z479J- R CARBON FILM 1/4 4.7 OHM J

R887 RD-AZ103J- R CARBON FILM 1/6 10K OHM J

R888 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R889 RD-2Z100J- R CARBON FILM 1/2 10 OHM J

R890 RD-4Z479J- R CARBON FILM 1/4 4.7 OHM J

R891 RD-AZ104J- R CARBON FILM 1/6 100K OHM J

R895 RD-2Z105J- R CARBON FILM 1/2 1M OHM J

R899 RD-4Z471J- R CARBON FILM 1/4 470 OHM J

R900 RD-AZ221J- R CARBON FILM 1/6 220 OHM J

R901 RD-AZ471J- R CARBON FILM 1/6 470 OHM J

R902 RD-AZ822J- R CARBON FILM 1/6 8.2K OHM J

R903 RD-AZ105J- R CARBON FILM 1/6 1M OHM J

R904 RD-2Z223J- R CARBON FILM 1/2 22K OHM J

R905 RD-AZ272J- R CARBON FILM 1/6 2.7K OHM J

R906 RD-4Z243J- R CARBON FILM 1/4 24K OHM J

R911 RD-2Z103J- R CARBON FILM 1/2 10K OHM J

R912 RC-2Z565KP R CARBON COMP 1/2 5.6M OHM K

R913 RD-2Z244J- R CARBON FILM 1/2 240K OHM J

R914 RD-2Z105J- R CARBON FILM 1/2 1M OHM J

R915 RD-2Z105J- R CARBON FILM 1/2 1M OHM J

R916 RN-4Z1503F R METAL FILM 1/4 150K OHM F

R917 RN-4Z1502F R METAL FILM 1/4 15K OHM F

R918 RD-4Z103J- R CARBON FILM 1/4 10K OHM J

R921 RN-4Z3302F R METAL FILM 1/4 33K OHM F

R922 RN-4Z6202F R METAL FILM 1/4 62.0K OHM F

R923 RN-4Z1502F R METAL FILM 1/4 15K OHM F

R925 RN-4Z3302F R METAL FILM 1/4 33K OHM F

R926 RN-4Z1502F R METAL FILM 1/4 15K OHM F

R927 RN-4Z6202F R METAL FILM 1/4 62.0K OHM F

Z801 DSVC471D14 VARISTOR SVC471D14A

Z802 DSVC471D14 VARISTOR SVC471D14A

ZZ240 PEVDMSD013 PCB VIDEO MANUAL AS DSC-3670W

CC295 CEXF1C102V C ELECTRO 16V RSS 1000MF (10X20) TP

LV100 58C0000096 COIL CHOKE 610G0233(470K)

LV101 58C0000096 COIL CHOKE 610G0233(470K)

LV103 58C0000096 COIL CHOKE 610G0233(470K)

LV104 58C0000096 COIL CHOKE 610G0233(470K)

PV01 4950710007 CONNECTOR YH025-10+YST250+ULW=100

PV02 4859281020 CONN WAFER TAC-L15X-A3

PV03 4950710007 CONNECTOR YH025-10+YST250+ULW=100

PV04 4859231920 CONN WAFER YW025-06

PV05 4859231620 CONN WAFER YW025-03

PV06 4859281020 CONN WAFER TAC-L15X-A3

PV07 4859281020 CONN WAFER TAC-L15X-A3

PV09 4859235120 CONN WAFER YW025-08

UV01 1LM2937ET- IC REGULATOR LM2937ET-3.3

UV02 1LM2937ET- IC REGULATOR LM2937ET-3.3

XV01 5XJ20R000F CRYSTAL QUARTZ ATS-49U 20.00000MHZ 50PPM

XV02 5XE18R432E CRYSTAL QUARTZ HC-49/U 18.43200MHZ 30PPM

XV03 5XE20R250E CRYSTAL QUARTZ HC-49/U 20.2500MHZ 30PPM

XV04 5XE20R250E CRYSTAL QUARTZ HC-49/U 20.2500MHZ 30PPM

ZZ200 PEVDJ2D013 PCB VIDEO CHIP B AS DSC-3670W

CC101 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC103 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC104 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC106 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC108 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

CC109 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

CC110 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC111 HCQK391JBA C CHIP CERA 50V CH 390PF J 1608

CC112 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC113 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC115 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC116 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC118 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC121 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC122 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC123 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC124 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC130 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC131 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC132 HCQK220JBA C CHIP CERA 50V CH 22PF J 1608

CC134 HCBD105KBA C CHIP CERA 10V X7R 1MF K 1608

CC135 HCQK220JBA C CHIP CERA 50V CH 22PF J 1608

CC137 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC138 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC139 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC148 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC153 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC160 HCQK509CBA C CHIP CERA 50V CH 5PF C 1608

CC161 HCQK509CBA C CHIP CERA 50V CH 5PF C 1608

CC162 HCBK682KBA C CHIP CERA 50V X7R 6800PF K 1608

CC163 HCBK682KBA C CHIP CERA 50V X7R 6800PF K 1608

CC164 HCBK682KBA C CHIP CERA 50V X7R 6800PF K 1608

CC165 HCBK682KBA C CHIP CERA 50V X7R 6800PF K 1608

CC169 HCBK332KBA C CHIP CERA 50V X7R 3300PF K 1608

CC170 HCBK332KBA C CHIP CERA 50V X7R 3300PF K 1608

CC172 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC174 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC176 HCBK222KBA C CHIP CERA 50V X7R 2200PF K 1608

CC177 HCBK222KBA C CHIP CERA 50V X7R 2200PF K 1608

CC178 HCBK222KBA C CHIP CERA 50V X7R 2200PF K 1608

CC179 HCBK222KBA C CHIP CERA 50V X7R 2200PF K 1608

CC182 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC193 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC196 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

CC198 HCBK473KBA C CHIP CERA 50V X7R 0.047MF K 1608

CC199 HCBK152KBA C CHIP CERA 50V X7R 1500PF K 1608

CC200 HCBK683KBA C CHIP CERA X7R 50V 0.068MF K 1608

CC201 HCQK309CBA C CHIP CERA CH 50V 3PF C 1608

CC202 HCQK309CBA C CHIP CERA CH 50V 3PF C 1608

CC203 HCBK473KBA C CHIP CERA 50V X7R 0.047MF K 1608

CC208 HCBK683KBA C CHIP CERA X7R 50V 0.068MF K 1608

Part List (DSC-34W70N)

- 30 -

Page 32

CC210 HCBD684KBA C CHIP CERA 10V X7R 0.68MF K 1608

CC211 HCBK683KBA C CHIP CERA X7R 50V 0.068MF K 1608

CC212 HCFF224ZBA C CHIP CERA 16V Y5V 0.22MF Z 1608

CC213 HCBK152KBA C CHIP CERA 50V X7R 1500PF K 1608

CC214 HCQK391JBA C CHIP CERA 50V CH 390PF J 1608

CC219 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC227 HCFF224ZBA C CHIP CERA 16V Y5V 0.22MF Z 1608

CC228 HCFF224ZBA C CHIP CERA 16V Y5V 0.22MF Z 1608

CC229 HCFF224ZBA C CHIP CERA 16V Y5V 0.22MF Z 1608

CC230 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

CC232 HCBK473KBA C CHIP CERA 50V X7R 0.047MF K 1608

CC233 HCBK152KBA C CHIP CERA 50V X7R 1500PF K 1608

CC234 HCBK683KBA C CHIP CERA X7R 50V 0.068MF K 1608

CC235 HCQK309CBA C CHIP CERA CH 50V 3PF C 1608

CC236 HCQK309CBA C CHIP CERA CH 50V 3PF C 1608

CC237 HCBK473KBA C CHIP CERA 50V X7R 0.047MF K 1608

CC239 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

CC241 HCBK683KBA C CHIP CERA X7R 50V 0.068MF K 1608

CC243 HCBD684KBA C CHIP CERA 10V X7R 0.68MF K 1608

CC244 HCBK683KBA C CHIP CERA X7R 50V 0.068MF K 1608

CC245 HCFF224ZBA C CHIP CERA 16V Y5V 0.22MF Z 1608

CC246 HCBK152KBA C CHIP CERA 50V X7R 1500PF K 1608

CC247 HCQK391JBA C CHIP CERA 50V CH 390PF J 1608

CC248 HCBK473KBA C CHIP CERA 50V X7R 0.047MF K 1608

CC250 HCBK473KBA C CHIP CERA 50V X7R 0.047MF K 1608

CC251 HCBK152KBA C CHIP CERA 50V X7R 1500PF K 1608

CC259 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC260 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC261 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC262 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC263 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC264 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC265 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC266 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC268 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC269 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC270 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC272 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC273 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC274 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC276 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC277 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC278 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC279 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC280 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC282 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC284 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC286 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC287 HCFD474ZBA C CHIP CERA 10V Y5V 0.47MF Z 1608

CC290 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC294 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC297 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC299 HCFD474ZBA C CHIP CERA 10V Y5V 0.47MF Z 1608

CC300 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC303 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC311 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC313 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC318 HCQK102JBA C CHIP CERA 50V CH 1000PF J 1608

CC319 HCBD105KBA C CHIP CERA 10V X7R 1MF K 1608

CC320 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

CC322 HCFD474ZBA C CHIP CERA 10V Y5V 0.47MF Z 1608

CC323 HCFD474ZBA C CHIP CERA 10V Y5V 0.47MF Z 1608

CC324 HCFD474ZBA C CHIP CERA 10V Y5V 0.47MF Z 1608

CC325 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC326 HCFD474ZBA C CHIP CERA 10V Y5V 0.47MF Z 1608

CC327 HCFD474ZBA C CHIP CERA 10V Y5V 0.47MF Z 1608

CC328 HCFD474ZBA C CHIP CERA 10V Y5V 0.47MF Z 1608

CC329 HCFD474ZBA C CHIP CERA 10V Y5V 0.47MF Z 1608

CC330 HCFD474ZBA C CHIP CERA 10V Y5V 0.47MF Z 1608

CC331 HCQK102JBA C CHIP CERA 50V CH 1000PF J 1608

CC332 HCQK102JBA C CHIP CERA 50V CH 1000PF J 1608

CC333 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC334 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC335 HCBH104KBA C CHIP CERA 25V X7R 0.1MF K 1608

CC336 HCQK221JBA C CHIP CERA 50V CH 220PF J 1608

CC337 HCQK221JBA C CHIP CERA 50V CH 220PF J 1608

CC338 HCQK221JBA C CHIP CERA 50V CH 220PF J 1608

DC100 DBAV99L—B DIODE CHIP BAV99L

DC101 DBAV99L—B DIODE CHIP BAV99L

DC103 DZ02W8R2VA DIODE CHIP ZENER Z02W8.2V

DC106 DZ02W8R2VA DIODE CHIP ZENER Z02W8.2V

DC107 DBAV99L—B DIODE CHIP BAV99L

DC108 DBAV99L—B DIODE CHIP BAV99L

DC109 DBAV99L—B DIODE CHIP BAV99L

DC110 DBAV99L—B DIODE CHIP BAV99L

DC111 DMMBD1203B DIODE CHIP MMBD1203

LC101 HLC339K02B L CHIP COIL 3.3UH MLF 1608

LC103 HLC479K02B L CHIP COIL 4.7UH MLF 1608

LC108 HFFH1H500B F CHIP FERRITE BEAD HB-1H3216-500JT

LC109 HFFH1H500B F CHIP FERRITE BEAD HB-1H3216-500JT

LC110 HLC339K02B L CHIP COIL 3.3UH MLF 1608

LC111 HLC339K02B L CHIP COIL 3.3UH MLF 1608

LC113 HLC339K02B L CHIP COIL 3.3UH MLF 1608

LC115 HLC339K02B L CHIP COIL 3.3UH MLF 1608

LC116 HLC339K02B L CHIP COIL 3.3UH MLF 1608

LC117 HLC339K02B L CHIP COIL 3.3UH MLF 1608

LC118 HLC339K02B L CHIP COIL 3.3UH MLF 1608

LC119 HLC339K02B L CHIP COIL 3.3UH MLF 1608

QC100 T2SA1037KB TR CHIP 2SA1037K-T146-R

QC101 T2SA1037KB TR CHIP 2SA1037K-T146-R

QC102 T2SA1037KB TR CHIP 2SA1037K-T146-R

QC103 T2SA1037KB TR CHIP 2SA1037K-T146-R

QC104 T2SC2412KB TR CHIP 2SC2412K-T146-BR

QC105 T2SC2412KB TR CHIP 2SC2412K-T146-BR

QC106 T2SC2412KB TR CHIP 2SC2412K-T146-BR

QC107 T2SA1037KB TR CHIP 2SA1037K-T146-R

Part List (DSC-34W70N)

- 31 -

Page 33

QC108 T2SA1037KB TR CHIP 2SA1037K-T146-R

QC109 T2SC2412KB TR CHIP 2SC2412K-T146-BR

QC110 T2SC2412KB TR CHIP 2SC2412K-T146-BR

QC111 T2SC2412KB TR CHIP 2SC2412K-T146-BR

QC112 T2SA1037KB TR CHIP 2SA1037K-T146-R

QC113 T2SC2412KB TR CHIP 2SC2412K-T146-BR

QC114 T2SC2412KB TR CHIP 2SC2412K-T146-BR

RC100 HRFT471JBA R CHIP 1/10 470 OHM J 1608

RC101 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RC102 HRFT561JBA R CHIP 1/10 560 OHM J 1608

RC103 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RC104 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RC105 HRFT100JBA R CHIP 1/10 10 OHM J 1608

RC106 HRFT562JBA R CHIP 1/10 5.6K OHM J 1608

RC108 HRFT471JBA R CHIP 1/10 470 OHM J 1608

RC109 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RC112 HRFT561JBA R CHIP 1/10 560 OHM J 1608

RC113 HRFT100JBA R CHIP 1/10 10 OHM J 1608

RC114 HRFT562JBA R CHIP 1/10 5.6K OHM J 1608

RC115 HRFT471JBA R CHIP 1/10 470 OHM J 1608

RC116 HRFT471JBA R CHIP 1/10 470 OHM J 1608

RC117 HRFT473JBA R CHIP 1/10 47K OHM J 1608

RC118 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RC119 HRFT473JBA R CHIP 1/10 47K OHM J 1608

RC120 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RC121 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

RC122 HRFT821JBA R CHIP 1/10 820 OHM J 1608

RC123 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

RC124 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RC125 HRFT471JBA R CHIP 1/10 470 OHM J 1608

RC126 HRFT471JBA R CHIP 1/10 470 OHM J 1608

RC128 HRFT224JBA R CHIP 1/10 220K OHM J 1608

RC129 HRFT222JBA R CHIP 1/10 2.2K OHM J 1608

RC130 HRFT471JBA R CHIP 1/10 470 OHM J 1608

RC132 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RC133 HRFT473JBA R CHIP 1/10 47K OHM J 1608

RC134 HRFT821JBA R CHIP 1/10 820 OHM J 1608

RC135 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

RC136 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RC137 HRFT471JBA R CHIP 1/10 470 OHM J 1608

RC146 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RC147 HRFT221JBA R CHIP 1/10 220 OHM J 1608

RC148 HRFT221JBA R CHIP 1/10 220 OHM J 1608

RC149 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RC150 HRFT221JBA R CHIP 1/10 220 OHM J 1608

RC151 HRFT221JBA R CHIP 1/10 220 OHM J 1608

RC152 HRFT221JBA R CHIP 1/10 220 OHM J 1608

RC153 HRFT221JBA R CHIP 1/10 220 OHM J 1608

RC154 HRFT221JBA R CHIP 1/10 220 OHM J 1608

RC155 HRFT221JBA R CHIP 1/10 220 OHM J 1608

RC156 HRFT221JBA R CHIP 1/10 220 OHM J 1608

RC157 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RC159 HRFT331JBA R CHIP 1/10 330 OHM J 1608

RC160 HRFT223JBA R CHIP 1/10 22K OHM J 1608

RC167 HRFT221JBA R CHIP 1/10 220 OHM J 1608

RC168 HRFT221JBA R CHIP 1/10 220 OHM J 1608

RC169 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RC173 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RC174 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RC175 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RC178 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RC180 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RC181 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RC185 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RC186 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RC187 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RC196 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RC197 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RC198 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RC199 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RC200 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RC201 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RC205 HRFT335JBA R CHIP 1/10 3.3M J 1608

RC212 HRFT242JBA R CHIP 1/10 2.4K OHM J 1608

RC213 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RC214 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RC215 HRFT000-BA R CHIP 1/10 0 OHM 1608

RC216 HRFT000-BA R CHIP 1/10 0 OHM 1608

RC217 HRFT000-BA R CHIP 1/10 0 OHM 1608

RC218 HRFT000-BA R CHIP 1/10 0 OHM 1608

RC219 HRFT000-BA R CHIP 1/10 0 OHM 1608

RC220 HRFT000-BA R CHIP 1/10 0 OHM 1608

RC221 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RC222 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RC223 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RC224 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RC225 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RC226 HRFT221JBA R CHIP 1/10 220 OHM J 1608

RC227 HRFT221JBA R CHIP 1/10 220 OHM J 1608

RC228 HRFT221JBA R CHIP 1/10 220 OHM J 1608

RC229 HRFT273JBA R CHIP 1/10 27K OHM J 1608

RC230 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RC231 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RC233 HRFT512JBA R CHIP 1/10 5.1K OHM J 1608

RC234 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RC235 HRFT512JBA R CHIP 1/10 5.1K OHM J 1608

RC236 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RC237 HRFT512JBA R CHIP 1/10 5.1K OHM J 1608

RC238 HRFT102JBA R CHIP 1/10 1K OHM J 1608

ZZ200 PEVDJ1D013 PCB VIDEO CHIP A AS DSC-3670W

A001 4959802924 PCB VIDEO AS 143 X 246

CC100 HCEJF100MC C ELECTRO CHIP 16V 10MF MV 4052

CC102 HCEJF100MC C ELECTRO CHIP 16V 10MF MV 4052

CC105 HCEJF100MC C ELECTRO CHIP 16V 10MF MV 4052

CC107 HCBH104KBA C CHIP CERA 25V X7R 0.1M

CC114 HCEJF100MC C ELECTRO CHIP 16V 10MF MV 4052

Part List (DSC-34W70N)

- 32 -

Page 34

CC117 HCBD105KBA C CHIP CERA 10V X7R 1MF K 1608