Page 1

S/M No. : SC110N-101

Service Manual

Relese 1

DIGITAL HDTV

CHASSIS : SC-110

Model : DSC-30W60N

Specifications

General

Picture

Sound

Number of Inputs / Outputs

DSC-30W60N

Power Requirement AC 120V, 60Hz

Power Consumption 250W (1.7W in standby)

Dimensions(W/H/D) 890 x 573 x 560 mm

Weight 64kg

Antenna Two 75 ohm external input terminals for UHF/VHF/Cable

RF Band Coverage VHF 2 ~ 13

Screen Size

Display Format

Horizontal Resolution

Digital Audio

NTSC Audio

Audio Power

A/V In

S-Video In

HD Component Video In

HD Component Audio In

Digital Audio In

Digital Audio Out

External Speaker Out

One 75ohm external output terminal for Cable

UHF 14 ~ 69

CATV 1, 14 ~ 125

32 inches Pure Flat 16:9 Aspect ratio

1920 x 1080i (Digital)

Upconversion to 1080i with line doubling (NTSC)

800 Lines

Dolby Digital AC-3 / Pro logic

Multi-CH TV Stereo (MTS) / Second Audio Program (SAP)

8W / ch (Main L/R, Woofer), 5W / ch (Center, SL, SR)

4 each (Video / L / R)

2 each

2 each ( Y/ Pb / Pr, R / G / B )

1 each ( L / R / SL / SR / Center / Woofer )

2 each ( Coaxial / Optical )

2 each ( Coaxial / Optical )

1 each ( SL / SR / Woofer)

R-V3

DAEWOO ELECTRONICS CO., LTD.

http : //svc.dwe.co.kr

Mar. 2000

Page 2

TABLE OF CONTENTS

1. Product Safety................................................................................................................................2

2. Specifications.................................................................................................................................4

3. Reote Control Overview.................................................................................................................5

4. Limited Warranty............................................................................................................................7

5. Service Mode..................................................................................................................................8

6. General Adjustment.......................................................................................................................11

7. Special Adjustment (When replacing new circuit boards).........................................................17

8. Troubleshooting Charts.................................................................................................................18

9. Parts List.........................................................................................................................................45

10. Circuit Digram...............................................................................................................................59

10-1. Connection Diagram.................................................................................................................59

10-2. Signal Flow Diagram................................................................................................................60

10-3. Power Circuit............................................................................................................................61

10-4. Main Circcuit.............................................................................................................................62

10-5. Video 1 Circuit..........................................................................................................................63

10-6. Video2 Circuit...........................................................................................................................64

10-7. Audio Circuit.............................................................................................................................65

10-8. Com-Filter Circuit.....................................................................................................................66

10-9. VM Circuit.................................................................................................................................67

10-10. Blanking Circuit......................................................................................................................68

10-11. Jack A/V, Control, LED Circuit...............................................................................................68

10-12. CRT Circuit.............................................................................................................................70

11. Exploded View..............................................................................................................................71

12. PCB Layout...................................................................................................................................72

1

Page 3

1.PRODUCT SAFETY SERVICING GUIDELINES FOR COLOR TELEVISION RECEIVERS

CAUTION : Do not attempt to modify this product in any way. Unauthorized modifications will not only void the warranty, but may lead to

your being liable for any resulting property damage or user injury.

Service work should be performed only after you are thoroughly

familiar with all of the following safety checks and servicing guidelines. To do otherwise, increases the risk of potential hazards and

injury to the user.

SAFETY CHECKS

After the original service problem has been corrected, a check should

be made of the following:

SUBJECT : FIRE & SHOCK HAZARD

1. Be sure that all components are positioned in such a way as to

avoid possibility of adjacent component shorts. This is especially

important on those chassis which are transported to and from the

repair shop.

2. Never release a repair unless all protective devices such as insulators, barriers, covers, shields, strain reliefs, and other hardware

have been reinstalled per original design.

3. Soldering must be inspected to discover possible cold solder joints,

frayed leads, damaged insulation (including A.C. cord), solder

splashes or sharp solder points. Be certain to remove all loose foreign particals.

4. Check for physical evidence of damage or deterioration to parts

and components, and replace if necessary follow original layout,

lead length and dress.

5. No leads or components should touch a receiving tube or a resistor

rated at 1 watt or more. Lead tension around protruding metal surfaces must be avoided.

6. All critical components such as fuses, flameproof resistors, capacitors, etc. must be replaced with exact factory types. Do not use

replacement components other than those specified or make

unrecommended circuit modifications.

7. After re-assembly of the set always perform an A.C. leakage test

on all exposed metallic parts of the cabinet, (the channel selector

knob, antenna terminals, handle and screws) to be sure the set is

safe to operate without danger of electrical shock. Do not use a

line isolation transformer during this test. Use an A.C. voltmeter,

having 5000 ohms per volt or more sensitivity, in the following

manner : connect a 1500 ohm 10 watt resistor, paralleled by a 15

mfd. 150V A.C. type capacitor between a known good earth

ground (9water pipe, conduit, etc.) and the exposed metallic parts,

one at a time. Measure the A.C. voltage across the combination of

1500 ohm resistor and 0.15 MFD capacitor. Reverse the A.C. plug

and repeat A.C. voltage measurements for each exposed metallic

part. Voltage measured must not exceed 0.75 volts R.M.S. This

corresponds to 0.5 milliamp A.C. Any value exceeding this limit

constitutes a potential shock hazard and must be corrected immediately.

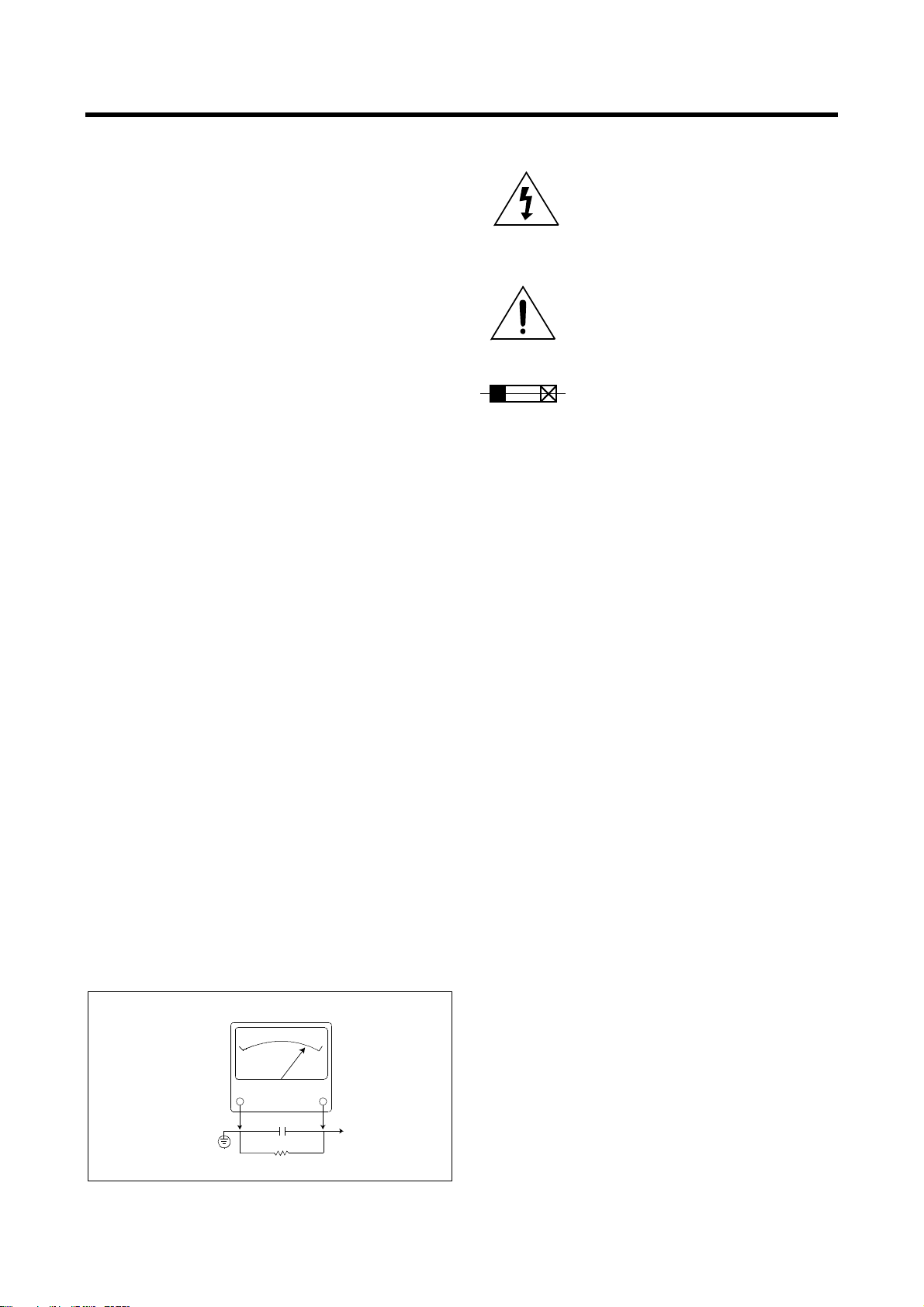

A.C. VOLTMETER

GRAPHIC SYMBOLS :

The lightning flash with arrowhead symbol,

within an equilateral triangle, is intended to alert

the service personnel to the presence of uninsulated “ dangerous voltage” that may be of sufficienty magnitude to constitute a risk of electric

shock.

The exclamation point within an equilateral triangle is intended to alert the service personnel

to the presence of important safety information

in service literature.

Fuse symbol is printed on pcb adjacent to the

fuse, with “ RISK OF FIRE REPLACE FUSE AS

MARKED” . The symbol is explained in the service manual with the following wording or equivalent.

CAUTION :

FOR CONTINUED PROTECTION AGAINST FIRE

HAZARD, REPLACE ONLY WITH SAME TYPE (6.3A, 125V)” and

“

ATTENTION

: AFIN D’ ASSU UNE PROTECTION PERMANENTE

CONTRE LES RISQUES D’ INCENDIE, REMPLACER UNIQUEMENT PAR UN FUSIBLE DE MEME TYPE ET DE ” 6.3A, 125V” .

SUBJECT : X-RADIATION

1. Be sure procedures and instructions to all service personnel cover

the subject of X-rays in current T.V. receivers is the picture tube.

However, this tube does not emit X-rays when the high voltage is

at the factory specified level. The proper value is given in the applicable schematic. Operation at higher voltages may cause a failure

of the picture tube or high voltage supply and, under certain circumstances, may produce radiation in excess of desirable levels.

2. Only factory specified C.R.T. anode connectors must be used.

Degaussing shields also serve as X-ray shield in color sets.

Always re-install them.

3. It is essential that the serviceman has available an accurate and

reliable high voltage meter. The calibration of the meter should be

checked perio - dically against a reference standard. Such as the

one available at your distributor.

4. When the high voltage circuitry is operating properly there is no

possibility of an X-radiation problem. Every time a color chassis is

serviced, the brightness should be run up and down while monitoring the high voltage with a meter to be certain that the high voltage

does not exceed the specified value and that it is regulating correctly. We suggest that you and your service organization review

test procedures so that voltage regulation is always checked as a

standard servicing procedure. And that the high voltage reading be

recorded on each customer’ s invoice.

5. When troubleshooting and making test measurements in a receiver

with a problem of excessive high voltage, avoid being unnecessarily

close to the picture tub eand the high voltage compartment.

Do not operate the chassis longer than is necessary to locate the

cause of excessive voltage.

6. Refer to HV, B+and Shutdown adjustment procedures described in

the appropriate schematic and diagrams(where used).

Good earth ground,

such as the water

pipe, conduit, etc.

0.15 uF

1500 OHM

10WATT

Place this probe

on each exposed

metal part.

2

Page 4

SUBJECT : IMPLOSION

1. All direct viewed picture tubes are equipped with an integral implosion protection system, but care should be taken to avoid damage

during installation. Avoid scratching the tube. If scratched, replace

it.

2. Use only recommended factory replacement tubes.

SUBJECT : TIPS ON PROPER INSTALLATION

1. Never install any receiver in closed-in recess, cubbyhole or closely

fitting shelf space over, or close to heat duct, or in the path of

heated air flow.

2. Avoid conditions of high humidity such as : Outdoor patio installations where dew is a factor. Near steam radiators where steam

leakage is a factor, etc.

3. Avoid placement where draperies may obstruct rear venting. The

customer should also avoid the use of decorative scarves or other

coverings which might obstruct ventilation.

4. Wall and shelf mounted installations using a commercial mounting

kit, must follow the factory approved mounting instructions. A

receiver mounted to a shelf or platform must retain its original

feet(or the equivalent thickness in spacers) to provide adequate

are flow across the bottom, bolts or screws used for fasteners

must not touch and parts or wiring. Perform leakage test on customized installations.

5. Caution customers against the mounting of a receiver on sloping

shelf or a tilted position, unless the receiver is properly secured.

6. A receiver on a roll-about cart should be stable on its mounting to

the cart. Caution the customer on the hazards of trying to roll a cart

with small casters across thresholds or deep pile carpets.

7. Caution customers against the use of a cart or stand which has not

been listed by underwriters laboratories, inc. For use with their

specific model of television receiver or generically approved for

use with T.V.’ s of the same or larger screen size.

3

Page 5

2. Specification

General

Power Requirement AC 120V, 60Hz

Power Consumption 250W (1.7W in standby)

Dimensions(W/H/D) 890 x 573 x 560 mm

Weight 64kg

Antenna Two 75 ohm external input terminals for UHF/VHF/Cable

One 75ohm external output terminal for Cable

RF Band Coverage VHF 2 ~ 13

UHF 14 ~ 69

CATV 1, 14 ~ 125

Picture

Screen Size 32 inches Pure Flat 16:9 Aspect ratio

Display Format 1920 x 1080i (Digital)

Upconversion to 1080i with line doubling (NTSC)

Horizontal Resolution 800 Lines

Sound

Digital Audio Dolby Digital AC-3 / Pro logic

NTSC Audio Multi-CH TV Stereo (MTS) / Second Audio Program (SAP)

Audio Power 8W / ch (Main L/R, Woofer), 5W / ch (Center, SL, SR)

Number of Inputs / Outputs

A/V In 4 each (Video / L / R)

S-Video In 2 each

HD Component Video In 2 each ( Y/ Pb / Pr, R / G / B )

HD Component Audio In 1 each ( L / R / SL / SR / Center / Woofer )

Digital Audio In 2 each ( Coaxial / Optical )

Digital Audio Out 2 each ( Coaxial / Optical )

External Speaker Out 1 each ( SL / SR / Woofer)

4

Page 6

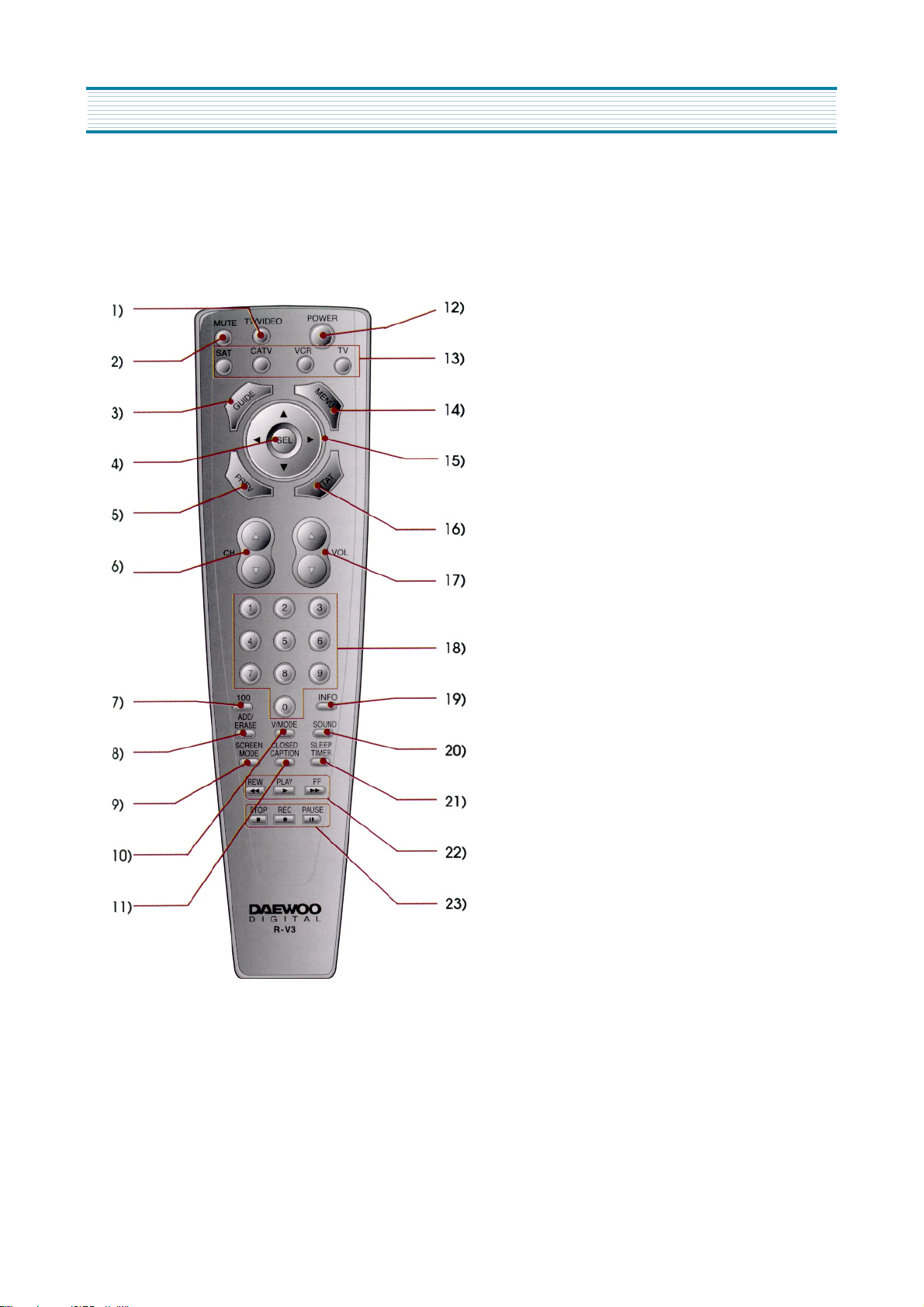

33. Remote control overview

The remote control has the following functions:

1. Power button

Press to turn the HDTV(and other equipment) on

and off.

2. MODE buttons

Press to select which equipment you wish your remote

control to operate:

* SAT(satelite)

* CATV (cable box)

* VCR

* TV

The Mode button you press will light up in red.

3. MENU button

Press once to display the HDTV menus. Press again to

make the menus disappear.

4. SEL ( Select) button

Press to select items on the HDTV menus.

5. Arrow buttons

Press to navigate through the HDTV menus.

6. STAT (Channel Station) button

Press to quickly select chammels to watch on your

HDTV.

7. VOL (Volume) buttons

press to raise and lower the volume on your HDTV.

8. Number buttons

Press to directly select channels or to enter the numbers

in the menus.

9. INFO (Information) button

Press to see the channel banner that provides information

while viewing your HDTV.

10. V MODE (Video Mode) button

Press to select a video mode : Normal, Dynamic,

Cinema or Customer.

5

Page 7

Remote control overview

11. SOUND button

Press to select a sound option : Mono, Stereo, or Secondary

Audio Programming (SAP). When you tune to a digital

channel, press to select various languages.

12. SLEEP TIMER button

Press to select the time before the HDRV turns off: 30

minutes, 60 minutes, 90 minutes, or 120 minutes.

13. CLOSED CAPTION button

Press to turn closed captions on and off.

14. FF (Fast Forward) button.

Press to fast forward a videocassette.

15. PLAY button

Press to play a videocassette.

16. PAUSE button

Press to pause a VCR.

24. PREV (Previous) button

Press to back up one menu at a time in the HDRV menus or to

return to the previous channel.

25. GUIDE button

Press this button to see the HDTV Program Guide.

26. MUTE button

Press to mute the HDTV sound.

27. TV / VIDEO button

Press to view components you have connected to the HDTV.

Press this button repeatedly to display:

* TV mode

* HD comp (HD Component Video)

* Video 1

* Video 2

* Video 3

* Video 4

17. REC(Record) button

Press to record a videotape.

18. STOP button

Press to stop a VCR.

19. REW (Rewind) button

Press to rewind a videocassette.

20. SCREEN MODE button

Press to select how to view your HDTV:

Normal or Full.

21. ADD / ERASE button

Press to add and erase channels on your HDTV.

22. 100 button

Press to select cable channels over 100 on TV or DSS

broadcasts.

23. CH (Chnnel) buttons

Press to select channels.

6

Page 8

4. Limited Warranty

Daewoo Electronics Corporation of America Inc. (also known as DECA) warrants this product to be free from defects in material

and workmanship and agrees to remedy any such defect.

This warranty covers 3 years labor and 3 years parts from the date of original purchase.

This warranty applies only to product purchased from authorized DECA dealer and used within the boundaries of U.S.A.

This warranty does not apply to product that has been improperly installed, subjected to usage for which the product was not

designed, misused or abused, damaged during transportation, or which has been altered in any way that affects the reliability or

detracts from its performance.

How you get warranty service

Warrany service can only be provided by an authorized DECA service center. For the closest authorized service center to you,

please contact your Dealer. In order to receive warranty service you must provide the authorized service center with a copy of proof

of purchase, signifying the date of purchase and the name of the Dealer from whom you purchased the product.

Statutory warranities

The purchase may have rights under existing provincial or federal laws, and where any terms of this warranty are prohibited by

such laws, they ard deemed null and void, but the remainder of the warranty shall remain in effect.

If you require further assistance, please call:

1-800-DAEWOO-8

7

Page 9

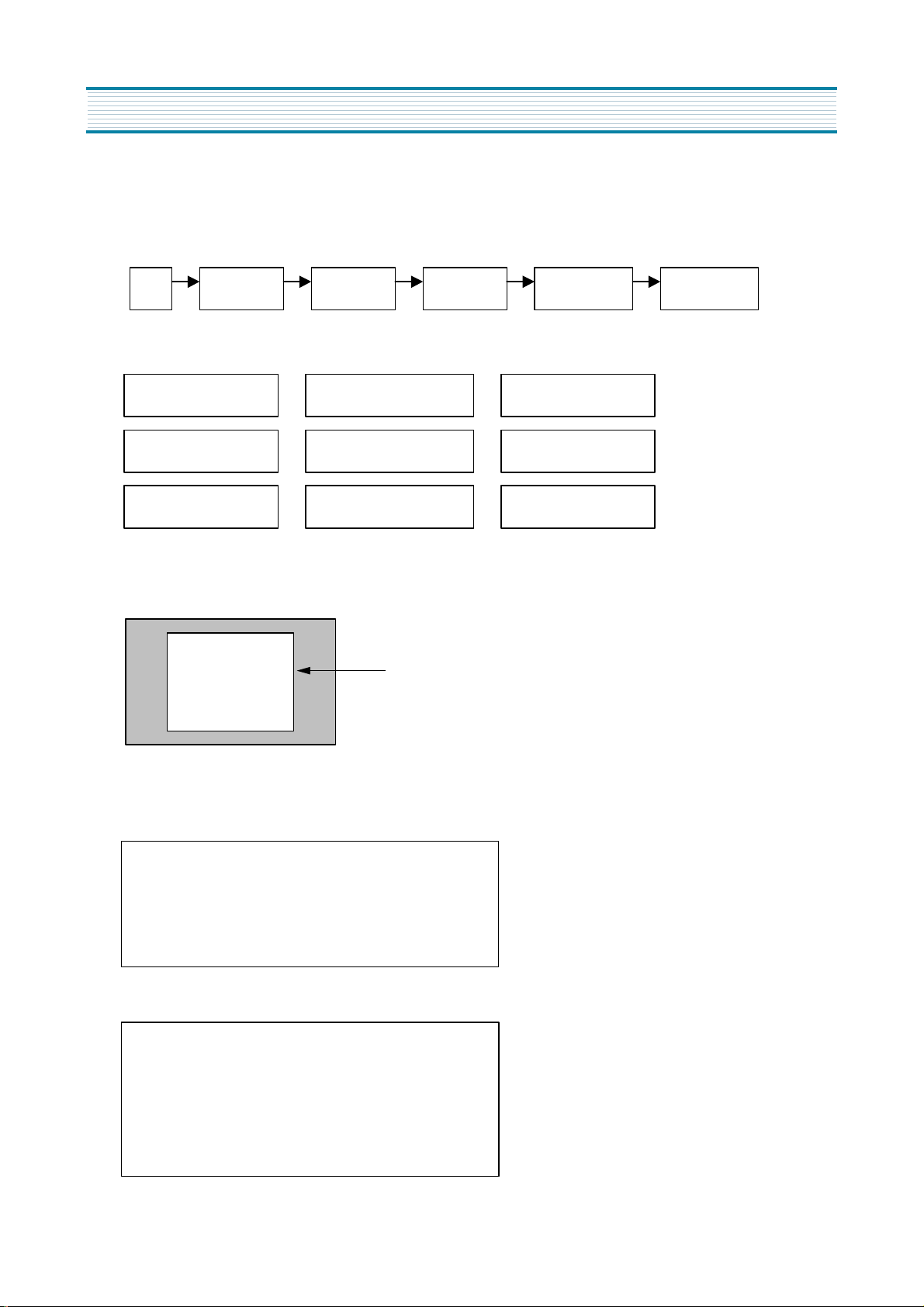

5. Service Modes

1. Entering to Service Mode

1) With the user remote control

Press the button in the following order.

1 MUTE SELECT POWER 1,2,3, …., 9MUTE

2) With the service remote control

S1 : Heat Run S2 : Screen Voltage S3 : Sound Controls

S4 : Video Controls S5 : Geometry S7 : White Balance

S8 : Sub Brightness S9 : Software Version S10: Factory Setting

2. Function of each service mode

1) S1 : Heat Run mode.

White Pattern

2) S2 : Screen Voltage Control mode

The vertical deflection is down, and a horizontal line appears on the screen.

3) S3 : Sound Controls mode

Equalizer : 60Hz, 250Hz, 1KHz, 3.5KHz, 10KHz

Ø

Main Volume : 0 → 63 → 31

Ø

Balance control : -31 → 31 → 0

Ø

Center Volume : 0 → 63 → 31

Ø

4) S4 : Video Controls mode

Ø Tint :0 → 63 → 31

Ø Brightness : 0 → 48 → 24

Ø Contrast : 0 → 48 → 24

Ø Color : 0 → 63 → 31

Ø Sharpness : 0 → 63 → 31

8

Page 10

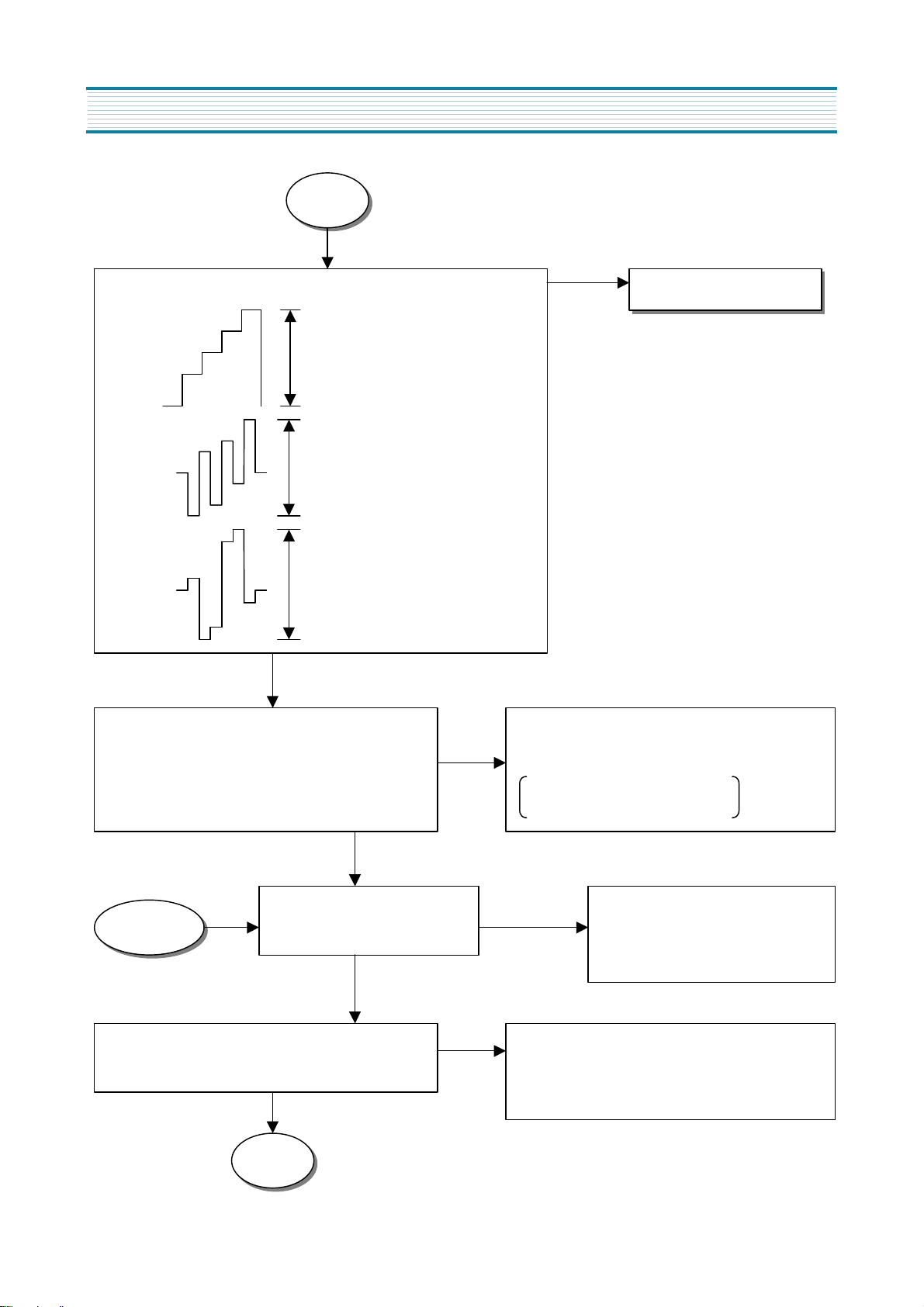

5) S5 : Geometry Adjustment mode

Service Modes

V Size Max

V Size

V Position

V C Linearity

Initial value

V S Linearity

H Size

H Position

Pincusion

31

0

26

23

31

53

70

32

Side Pin W

Side Pin S

Trapezoid

Side Pin Balance

H Duty

Parallelogram

H Focus Phase

H Focus Amplitude

22

34

33

31

31

28

31

60

6) S6 : No Use

7) S7 : White Balance Adjustment mode

White Balance Control

Drive R 128

Initial value

G 32

B 128

Bias R 64

G 224

B 64

8) S8 : Sub Brightness Adjustment mode.

Brightness 24

Contrast 22

Initial value

Color 32

Tint 37

Coring 63

VM Gain 27

VM Limit 40

9) S9 : Software Version

2000/04/06 08:30 AM

10) S12 : Factory Setting

9

Page 11

Service Modes

3. Selecting the adjusting items

1) With the user remote control

Pressing of ARROW s button changes the adjustment items. (t button for reverse order)

2) With the service remote control

Pressing of CHANNEL s button changes the adjustment items. (t button for reverse order)

4. Adjusting the data

1) With the user remote control

Pressing of ARROW button changes the value of data. ( button for reverse order)

2) With the service remote control

Pressing of VOLUME button changes the value of data. ( button for reverse order)

3

3

4

4

5. Exit from Service Mode

Press again to make service mode exit.

10

Page 12

6. General Adjustment

In the majority of cases, a high definition digital television will need basic adjustments such as high voltage, screen voltage, focus,

white balance, sub brightness, geometry, and blanking width. All adjustments should be performed after heat-running the set for at

least 20 minutes.

1. Press the S1 button on the service remote control, and then full white pattern will appear on the screen.

2. Press again the S1 button, and then the pattern will disappear.

High Voltage Adjustment

1. Operate the set for at least 20 minutes.

2. Connect the probe of high voltage meter to CRT ANODE.

3. Adjust the variable register RV801 on the power assembly so that high voltage may be to be between 29.5KV ~ 30.5KV.

Screen Voltage Adjustment

1. Press the S2 button on the service remote control.

1) Video Input mode will be VIDEO 1.

2) Vertical deflection will be down, and a horizontal line will appear on the screen.

2. Turn the variable screen volume of FBT to adjust screen voltage, at the point that a horizontal line only just appears.

Focus Adjustment

1. Tune on Retma pattern.

2. Turn the variable focus volume of FBT so that the center area of screen is sharp scanning line.

3. Turn the variable volume R522 on the CRT assembly so that the edge of screen may be sharp scanning line.

White Balance Adjustment

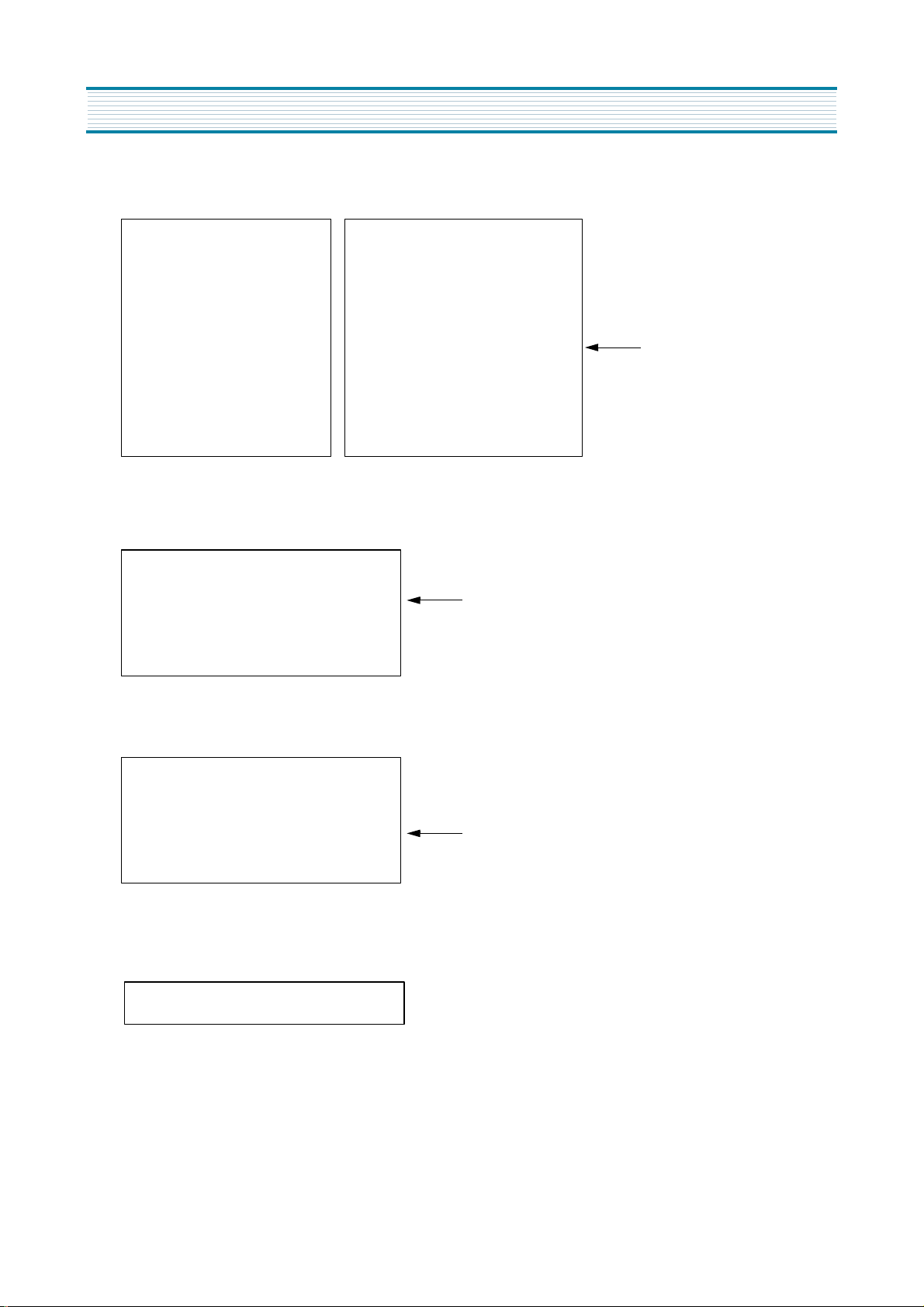

1. Input the Black & white signal to the HD Component jack on the rear panel.

<Black & White Pattern>

Light Area Check

Dark Area Check

2. The color temperature is the following.

3 x=0.270 6 0.005 y=0.270 6 0.005

3 Color temperature : 10500 8K

3. Light Area Adjustment

1) Press S7 button.

2) On the center of light area, attach the sensor of a white balance meter.

3) To be Y=125, turn the Light Beam control volume on the White & Black pattern generator.

4) To adjust the white balance of light area, select Drive R, G, B with CHANNEL Up or Down buttons, and adjust individual

vales with VOLUME Up or Down buttons.

11

Page 13

General Adjustment

4. Dark Area Adjustment

1) On the center of dark area, attach the sensor of a white balance meter.

2) To be Y=12, turn the Dark Beam control volume on the White & Black pattern generator.

3) To adjust the white balance of dark area, select Bias R, G, B with CHANNEL Up or Down buttons, and adjust individual

values with VOLUME Up or Down buttons.

4) Repeat two processes above until the white balance is completed.

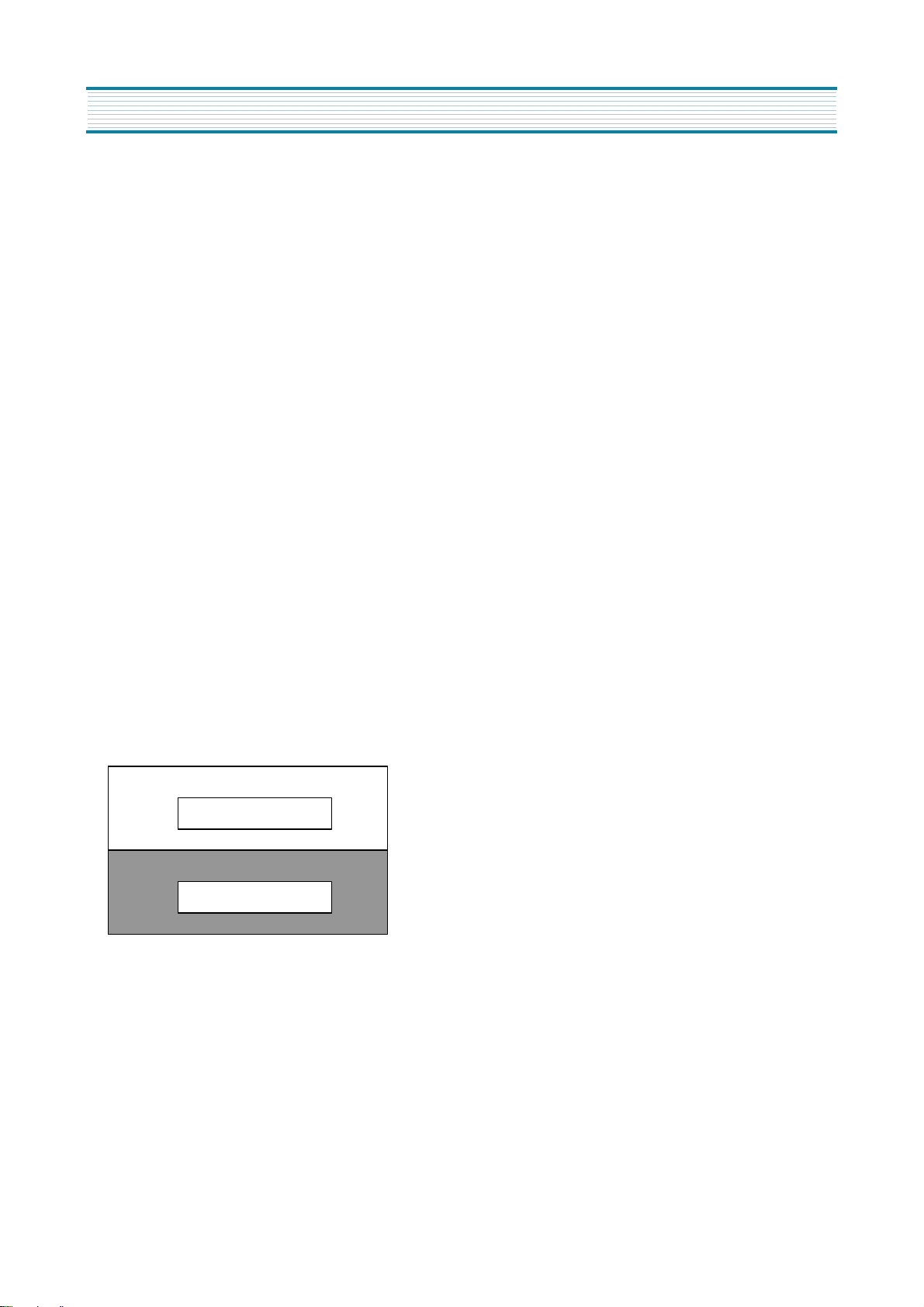

Sub Brightness Adjustment

1. Tune on Retma Pattern.

2. Press S8 button.

3. The following OSD menu will appear on the screen, and the data are initial balues before adjusting.

Brightness 24

Contrast

Color

Tint

Coring

VM Gain

VM Limit

22

32

37

63

27

40

No need to adjust.

4. To be between Step 40% and 50% on the Contrast Chart, perform fine adjustment of sub brightness.

40% 30% 20% 10%

50% 0% 0% 5%

60% 70% 80% 100%

12

Page 14

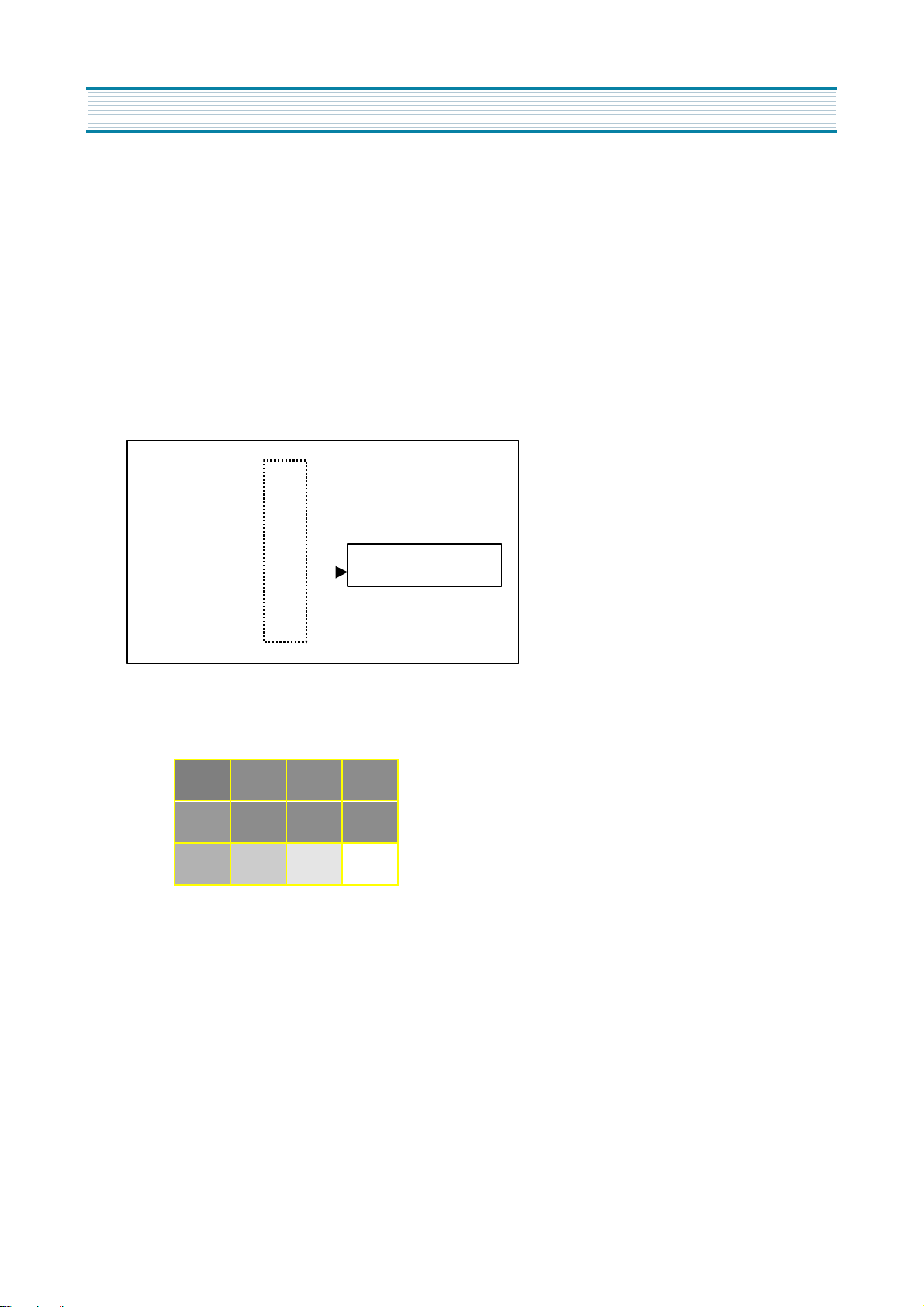

Geometry

1. To adjust V-Position, H-Size, H-Position and so forth, tune on Retma Pattern.

2. To adjust Pincushion, Parallelogram and so forth, tune on Cross Hatch signal.

3. Screen Mode should be on Full mode, and the Video Mode should be on Normal mode.

4. Press S5 button to adjust Geometry.

5. With Up/Down buttons, perform the adjustment items in the following order.

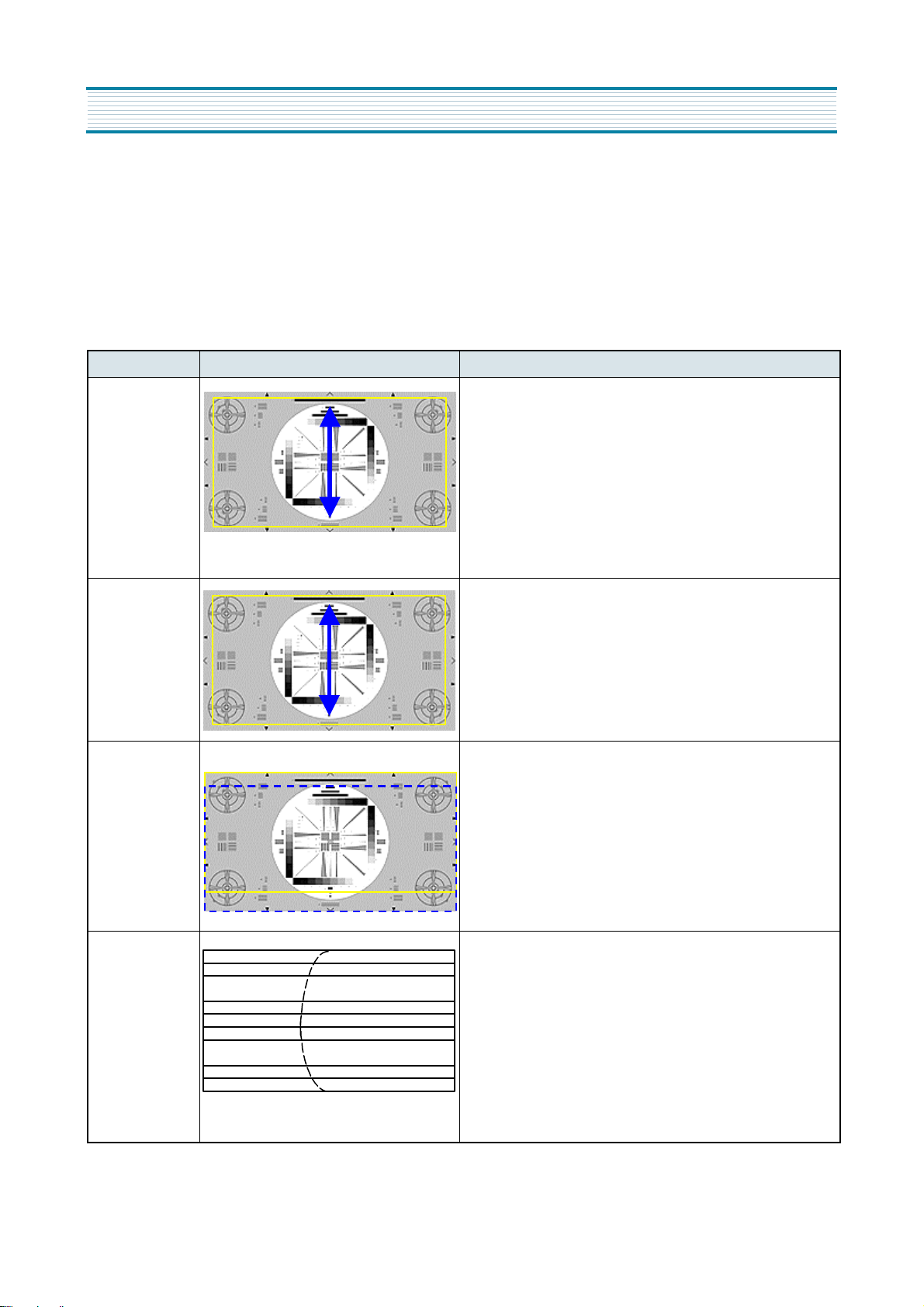

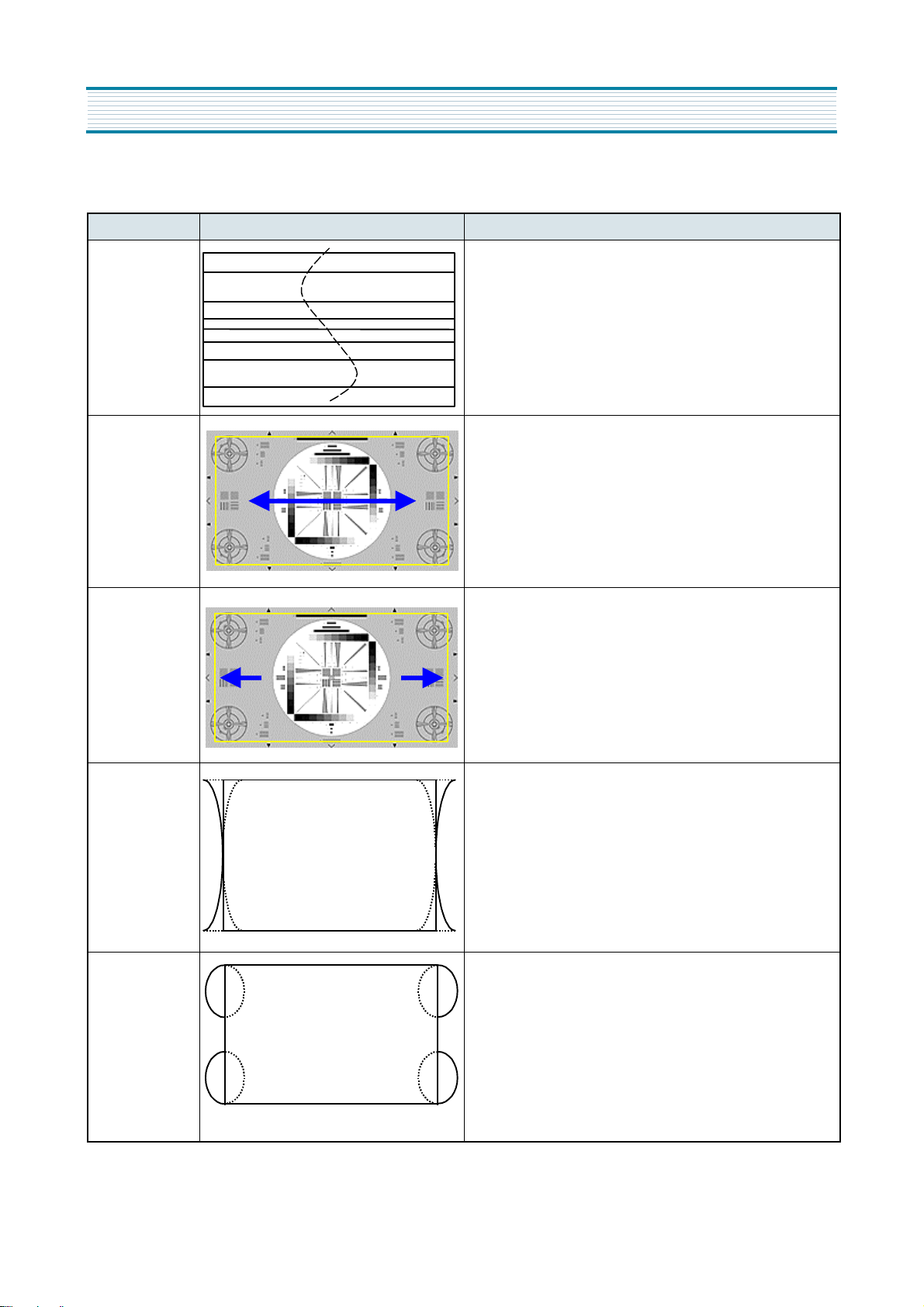

Item Screen Image Adjustment Procedure

General Adjustment

V Size Max.

1) Receive NTSC Retma signal.

2) The Screen mode should be selected on Full mode

3) Adjust Vertical Size so that over scanning rate may be 105%.

4) Check if the center circle is not only circular on Full mode

but also on Normal mode.

Over Scanning Rate: 105%

Vertical Size 1) There is no need to adjust.

2) Check if the value of data is "0".

Vertical

Position

1) Receive NTSC Retma signal.

2) The Screen mode should be selected on Full mode.

3) Adjost Vertical Position so that the circle of Retma signal

may be centered in the verical direction.

VC

Linearity

1) Receive NTSC Retma signal.

2) The Screen mode should be selected on Full mode.

3) When the center area of Retma signal's circle is S type in the

vertical direction, adjust VC Linearity so that vertical interval

may be the same.

13

Page 15

General Adjustment

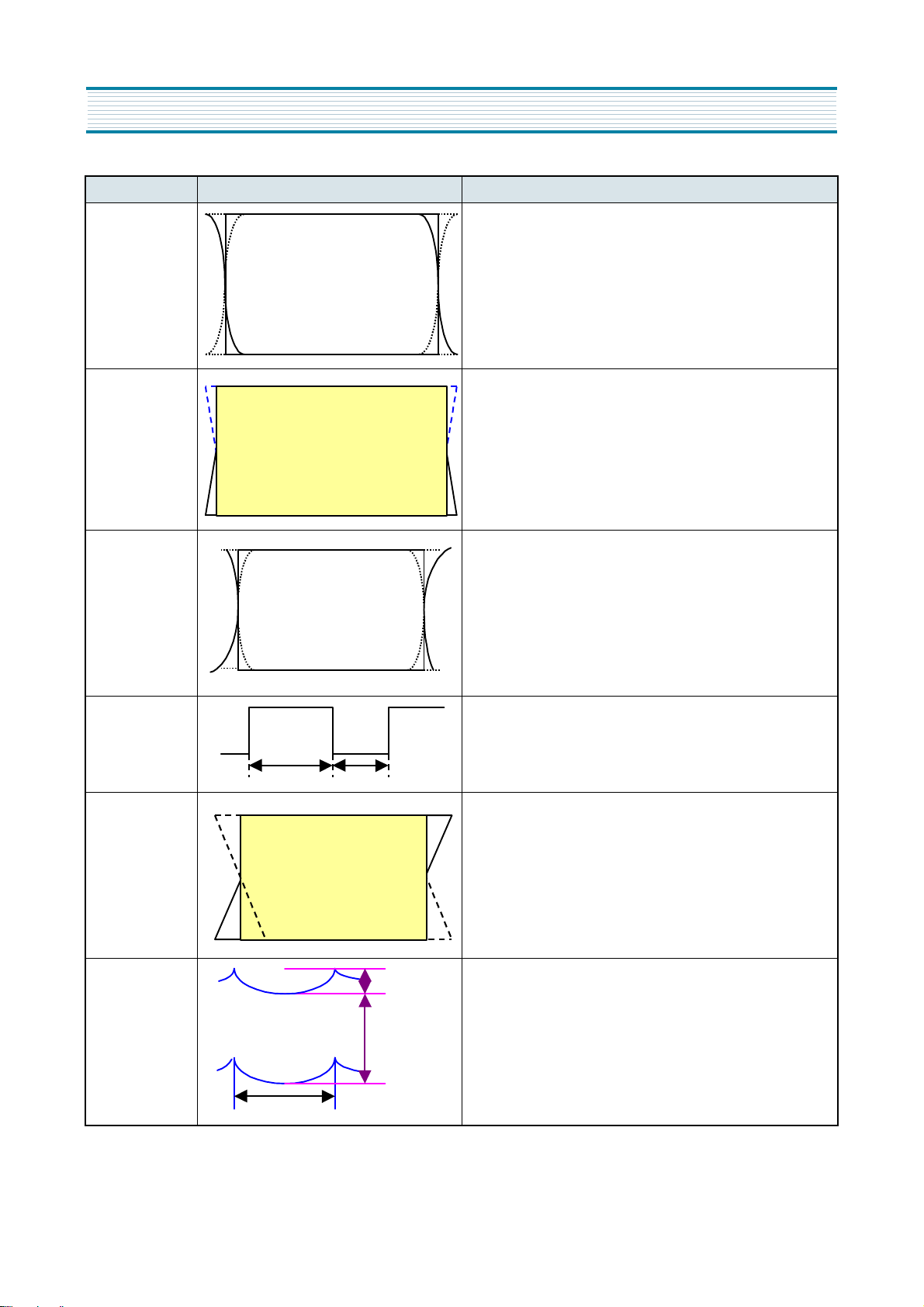

Item Screen Image Adjustment Procedure

1) Receive NTSC Retma signal.

2) The Screen mode should be selected on Full mode

3) When the center area of Retma signal’s circle is S type

V S

Linearity

Horizontal

Size

in the vertical direction, adjust VS Linearity so that

vertical interval may be the same.

1) Receive NTSC Retma signal.

2) The Screen mode should be selected on Full mode

3) Adjust Horizontal Size for over scanning rate 106%

4) Check if the center circle of Retma signal is circle on

Normal mode.

Horizontal

Position

Pincushion

Side Pin W

1) Receive NTSC Retma signal.

2) The Screen mode should be selected on Full mode.

3) Adjust Vertical Position so that the circle of Retma

signal may be centered in the vertical direction.

1) Receive NTSC Cross Hatch signal.

2) The Screen mode should be selected on Full mode.

3) When the vertical lines of the left and right side are

distorted such as the left figure, adjust Pincushion so

that the vertical lines may be straight.

1) Receive NTSC Cross Hatch signal.

2) The Screen mode should be selected on Full mode.

3) When the vertical lines of the left and right side are

not straight but distorted in the W type, adjust Side

Pin W to correct the unbalanced vertical lines.

14

Page 16

Item Screen Image Adjustment Procedure

1) Receive NTSC Cross Hatch signal.

2) The Screen mode should be selected on Full mode.

3) When the vertical lines of the left and right side is not

Side Pin S

straight but distorted in the S type, adjust Side Pin S

to correct the unbalanced vertical lines.

1) Receive NTSC Cross Hatch signal.

2) The Screen mode should be selected on Full mode.

3) When the screen shape is not rectangular but

Trapezoid

trapezoid, adjust Trapezoid to correct the unbalanced

shape.

1) Receive NTSC Cross signal.

2) The Screen mode should be selected on Full mode.

Side Pin

Balance

3) When both the left and right screen shape is not

symmetrical but on one side, adjust Side Pin Balance

to correct the unbalanced shape.

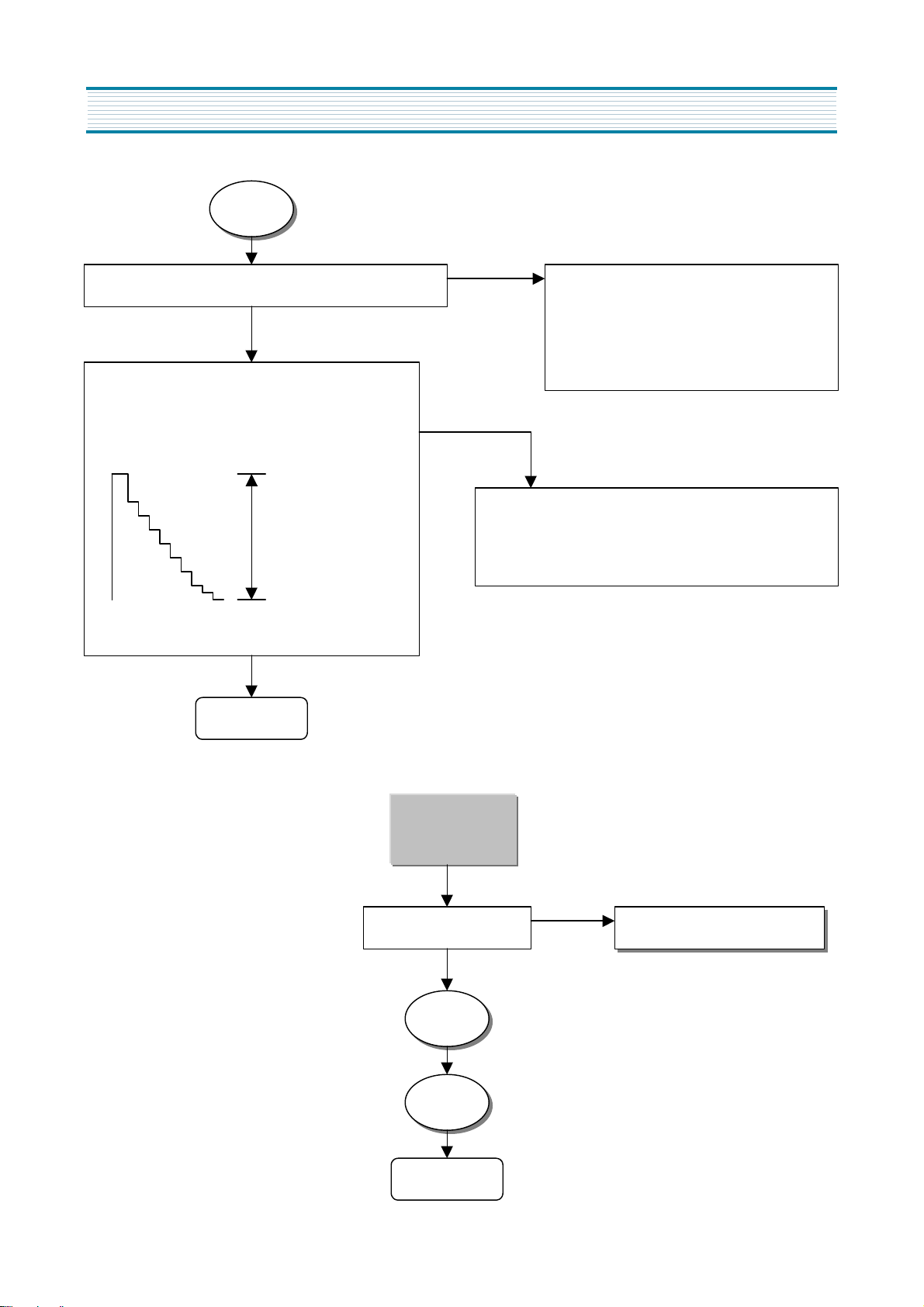

General Adjustment

H Duty

Paralle-

logram

H Focus

Phase

400Vp-p

900Vp-p

60HZ

1) There is no need to adjust.

2) Check if the value of data is "31".

1) Receive NTSC Cross Hatch signal.

2) The Screen mode should be selected on Full mode.

3) When both the left and right screen shape is on one

side, adjust Parallelogram to correct the unbalanced

shape.

1) There is no need to adjust, and check if the value of

data is "32".

2) Check that the focus on the right and left side is clear.

15

Page 17

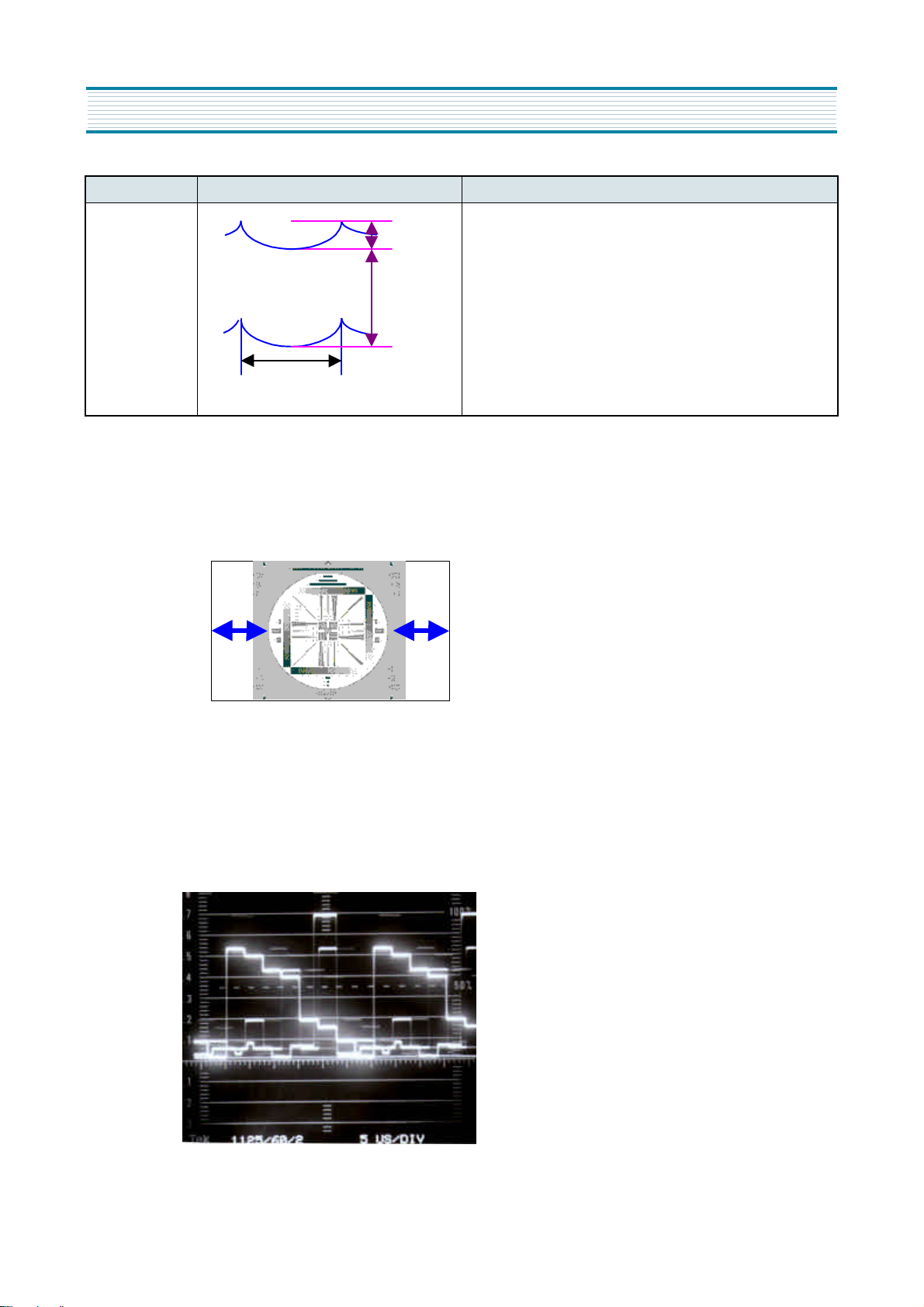

General Adjustment

Item Screen Image Adjustment Procedure

H Focus

Amplitude

400Vp-p

900Vp-p

60Hz

1) There is no need to adjust, and check if the value of

data is "32".

2) Check if the focus on the right and left side is clear.

Blanking Width

1. Tune on NTS Retma pattern.

2. Press Screen mode on the remote control, and then slelct Normal. mode.

3. To be symmetrical the screen, adjust Blanking Width with rotating the variable volume RU19 on the Blanking Board.

Y Level Adjustment (to DTV Decoder module)

1. Tune on SMPTE Color Bar signal.

2. Connect a scope probe to pin 9 of PW06V.

3. Adjust RV900 such as the following figure so that the amplitude of Y level may be 0.7Vp-p.

16

Page 18

7. Special Adjustment (When replacing new circuit boards)

1. DTV Decoder module

1) Before replacing a new module, if seeing OSD menu is possible, record the adjusted data value of White Balance and

Geometry.

2) After replacing the defective module with a new one, memorize the value of data value to the new DTV decoder module

with the service remote control.

3) Perform the Y Level Adjustment.

2. Power assembly

1) After replacing a new assembly, perform High Voltage Adjustment.

2) The rest are no need to adjust.

3. Main assembly

1) After replacing a new assembly, perform Blanking Width Adjustment.

2) X-Rediation Protection Circuit Test

When service has been performed on the horizontal deflection system, high voltage system or B+ system, the X-Radiation

Protection Circuit Test must be tested for proper operation as follows:

2-1) Operate the HDTV set for at least 15 minutes.

2-2) Perform this test at the normal video and sound.

2-3) Check the cathode voltage of D837. Its voltage should be about 26VDC.

2-4) Connect a resister 24K(1/4W) with parallel to R925.

2-5) Then the set will be shut down, lighting up red to the power indicator.

2-6) If it is not, the circuit of X-Radiation Protection must be repaired before the set is returned to the customer.

3) The rest adjustment idems are no need to adjust.

4. Video assembly

1) No need to adjust.

17

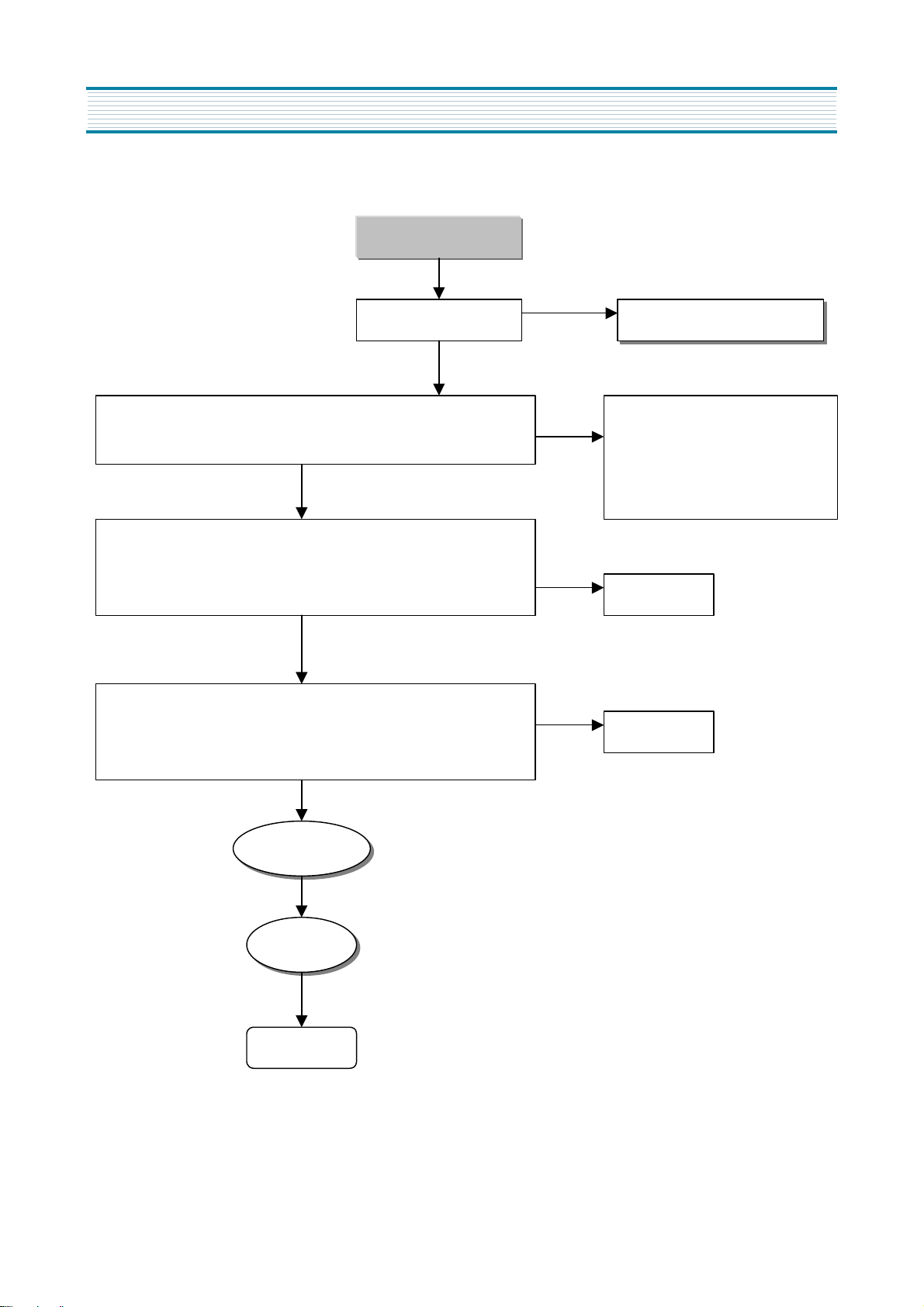

Page 19

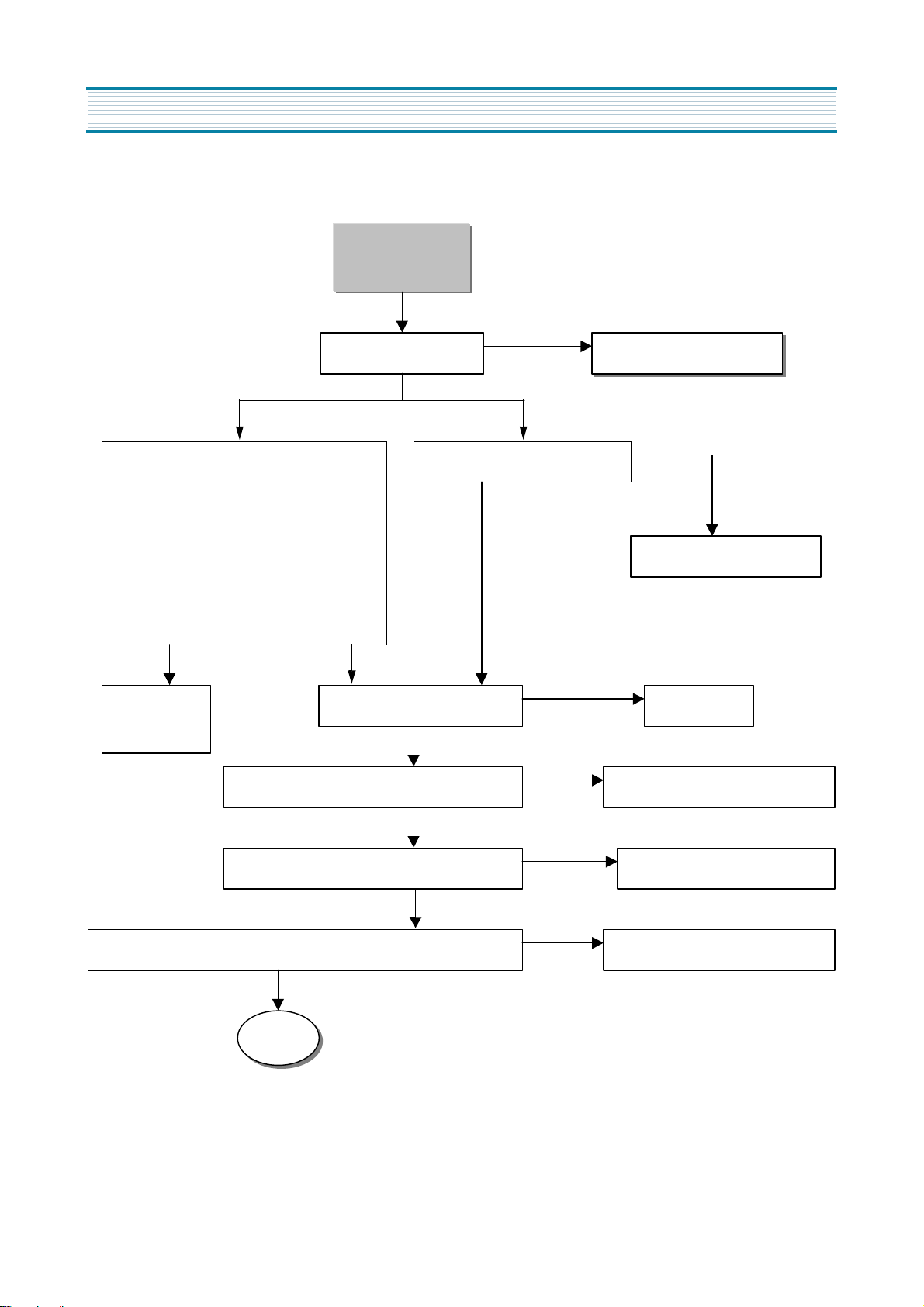

Special Adjustment

No Picture

(NTSC Signal)

OSD is on the screen.

AV Signal RF Signal

Check video signal of IC210.

Video 1 : CVBS to pins 43 ,Y to pin 45,

and C to pin 47

Video 2 : CVBS to pin 7

Video 3 : CVBS to pin 27

Video 4 : CVBS to pin 1 ,Y to pin 3, and

C to pin 5

NO

Check each

YES

CVBS is to pin 34 of IC210. Check IC210.

input signal.

Check if CVBS is 1Vp-p to pin 88 of ICA1. Check QCA9 , FA3, andQCA11

NO

To DTV Decoder Module

CVBS is to pin 13 of PW01M

NO

Check Tuner (U101).

YES

NO

YES

NO

YES

Check if Y output is 0.9Vp-p to Yout of PV1.

YES

Check if the color burst of C signal is 170~180mV to Cout of PV1.

V1

18

NO

Check QCA4, FA1, and QCA1

NO

Check QCA8, FA2, and QCA5

Page 20

8. Troubleshooting charts.

V1

When input signal is color bar, check the following output level

to PA06D.

Y=0.7Vp-p ± 0.1Vp-p

Pb=0.6Vp-p ±0.1Vp-p

Pr=0.6Vp-p±0.1Vp-p

YES

NO

To DTV Decoder Module

Check the input and output signal of IC208.

Pins 9, 10, and 11 : Low (Base of QC215 : High)

Pin 14 : Y signal Pin 15 : Pb signal

Pin 4 : Pr signal

YES

Check if Y, Pb, and Pr are input

VIDEO

Check if Y, Pb, and Pr are input to pins 58, 59, and

57 of IC200.

to pins 45, 47, and 1 of IC200.

YES

V2

NO

NO

Check IC208

Check logical state to pin 52 of 212 IC.

NTSC, DTV signal : High

External HD Component : Low

Check the following parts.

NO

Y : Q204, Q205 Pb : Q202, Q203

Pr : Q200, Q201

Check the following parts.

Y : pin 27 of IC200, Q208, Q209, and Q210

Pb : pin 15 of IC200 Pr : pin 13 of IC200

19

Page 21

Troubleshooting charts

V2

Signals R, G, and B are to pins 2, 4, and 6 of PW07K.

YES

There are R signal to R504, G signal to R513, and

B signal.

<The signal amplitude of cathode G >

130Vp-p ±10Vp-p

Input signal : 10 steps pattern

Video mode : Normal mode

END

NO

Check the following parts.

R : pin 25 of IC201, Q218

G : pin31 of IC201, Q216

B : pin 28 of IC201, Q217

NO

Check the following parts.

R: pin8 of IC501, G: pin8 of IC502, B: pin 8 of IC503

Check 200V and 12V of PA17M.

No picture

(DTV Signal)

NO

OSD is on the screen. To DTV Decoder module

V1

V2

END

20

Page 22

Y, Pb, Pr Input

Pb/Pr.

Troubleshooting charts

OSD is on the screen. To DTV Decoder module

NO

YES

Check the SELECT SGINAL switch on the rear panel is to Y/

Select the switch to Y/Pb/Pr.

NO

If the switch is selected to R/G/B, the color of screen is pale green.

Check if Y/Pb/Pr signals are well

connected to input terminals.

YES

Check if pin 18 of IC212 is Low.

Check the input/output signal of IC207.

Pins 9, 10, and 11 : Low Pin 14 : Y signal

NO

Pin 15 : Pb signal Pin 4 : Pr signal Check IC207.

YES

Check the input/output signal of IC208.

NO

Pins 9, 10, and 11 : High (Base of QC215 : Low)

Check IC208

Pin 14 : Y signal Pin 15 : Pb signal Pin 4 : Pr signal

VIDEO

V2

END

21

Page 23

Troubleshooting charts

R, G, B Input

OSD is on the screen. To DTV Decoder module

NO

YES

NO

Check the SELECT SGINAL switch on the rear panel is to R/G/B. Select the switch to R/G/B.

YES

NO

Signals R, G, and B are to pins 7, 8, and 9 of IC201.

Check IC207.

YES

NO

Signals B-Y, Y and R-Y are to pins 3, 4, and 5 of IC201.

Check IC207.

YES

Check the input/output signal of IC207.

NO

Pins 9, 10, 11 : High

Check IC207.

Pin 13 : Y in

Pin 1 : B-Y in

Pin 3 : R-Y in

YES

Check the input/output signal of IC208.

Pins 9, 10, 11 : High (Base of QC215 : Low)

Pin 14 : Y signal Pin 15 : B-Y signal

Pin 4 : R-Y signal

VIDEO

V2

NO

Check IC208.

Check if pin 52 of IC212 is Low.

END

22

Page 24

No sound (NTSC)

R, L

Audio signal output is only R and L.

There are no sound to Center, SL, SR, and Woofer.

Troubleshooting charts

AV Signal

Check if the audio signals are input to the follow

pins of IC210 (CXA1855).

Video 1 : L to pin 44, R to pin 46

Video 2 : L to pin 8, R to pin 10

Video 3 : L to pin 25, R to pin 26

Video 4 : L to pin 2, R to pin 4

YES

Check if R, L signals are output to IC210.

Audio R : pin 32, Audio L : pin 33

Check if R, L signals are input and output to IC215.

Audio L input : pin 50, Audio L output : pin 37

RF Signal

Check the audio base-band signal to SIF of U101.

Amplitude of SIF : 800mVp-p ± 100mVp-p

YES

SIF is to pin 67 of IC215.

YES

NO

Check IC210

YES

NO

Check IC215

Audio R input : pin 51, Audio R output : pin 36

Decoder

Check if R, L signals are input to IC215

DEC_L : pin 56, DEC_R : pin 57

YES

Check if R, L signals are output to IC215.

Audio L : pin 28, Audio R : pin 27

YES

A1

YES

NO

To DTV Decoder module

Check IC215

NO

IC215 controls the volume of R, L.

The balance control is performed to DTV

decoder module.

23

Page 25

Troubleshooting charts

A1

Check if R, L signals are input and output to I609.

(The audio output of I609 is equalized signal.)

Audio L input : pin 1, Audio R input : pin 30

Audio L output : pin 12, Audio R output : pin 19

YES

Check if R, L signals are input and output to I607.

Audio L input : pin 4, Audio R input : pin 2

Audio L output : pin 8, Audio R output : pin 12

END

NO

Check I609

24

Page 26

No sound (External HD)

Check the input /output signal of volume control IC.

R, L

SL, SL, Center, and Woofer R, L

Troubleshooting charts

Check the following audio signals.

SL input / output : pins 12, 6 of I603

SR input / output : pins 16, 2 of I603

C input /output : pins 9, 7 of I602

W input /output : pins 9, 7 of I603

YES

A2

SL input / output : pins 6, 7 of I606

SR input / output : pins 4, 3 of I606

Center input / output : pins 6, 7 of I605

Woofer input / output : pins 4, 3 of I605

NO

Check I603

and I602.

Check if R, L signals are input and output to IC215.

HD_L input : pin 53 HD_L output : pin 37

HD_R input : pin 54, HD_R output : pin 36

NOYES

Decoder

A1

Check IC215.

END

Check the input /output signal of audio amplifier IC.

SL input / output : pins 4, 8 of I608

SR input / output : pins 1, 11 of I608

Center input / output : pins 1, 11 of I607

Woofer input / output : pins 2, 12 of I608

YES

END

25

Page 27

Troubleshooting charts

R, L

C, W, SR, SL

NO Sound

(RF DTV)

R, L Woofer, Center, SR, SL

Check DEC_R and DEC_L to PA05D. Check S_R, S_L, Center and Woofer to PA12D.

NO

To DTV Decoder module

Decoder

Check the following audio signals.

Decoder

A1

END

S_L input / output : pins 5, 6 of I603

S_R input / output : pins 1, 2 of I603

Center input /output : pins 8, 7 of I602

Woofer input /output : pins 8, 7 of I603

A2

END

26

Page 28

H/V Sync Check

(External HD Component Input)

R/G/B/Hs/Vs R/G/B with sync on green or Y/Pb/Pr

Troubleshooting charts

Check the input/output signal of IC202.

Pins 11, 10 : High (Base of QC215 : Low)

HS input : pin 13 HS output : pin 14

VS input : pin 1 VS output : pin 15

NO

YES

S2

Check IC202.

Check the input/output signal of IC203.

H_sync input : pin 6 H_sync output : pin 14

V_sync input : pin 8 V_sync output : pin 13

NO

Check the input/output signal of IC206.

Pins 9, 10, and 11 : High (To be HD Component )

Check IC203.

Low (No HD Component)

Check the input/output signal of IC203

G or Y input : pin 4

HS output : pin 14

VS output : pin 13

NO

Check IC202.

YES

YES

Check IC206.

NO

HD : from pin 15 of IC 206 to PW03M

VD : from pin 4 of IC 206 to PW03M

YES

Check the input signal of I402.

HD signal : pin 26 VD signal : pin 28

S1

27

Page 29

Troubleshooting charts

Check the following signals.

S1

HP : pin 6 of PW01V

5Vp-p

33.75KHz

VP : pin 7 of PW01V

5Vp-p

60Hz

YES

Check HP signal is to pin 13 of IC216 through IC204.

NO

Check IC204

NO

Check HP signal of Q426’s base.

NO

Check VP signal of Q415’s base.

YES

Check VP signal is to pin 21 of IC212.

NO

YES

Check IC204.

Check EVEN/ODD signal is to pin 46 of IC 212

YES NO

YES

Check HP signal is to pin 14 of IC216 .

Check EVEN/ODD signal is to pin 1 of IC216.

Pins 9, 10, and 11 : High (to be HD Component ), Low (no HD Component)

YES

Check IC209.

HP signal is input to pin 1. DEC_HS (HP) is output to pin 15.

EVEN/ODD (VP) signal is input to pin 13.

DEC_VS (EVEN/ODD) signal is output to pin 14.

Pins 9, 10, and 11 : High (to be HD Component ), Low (no HD Component)

YES

DEC_HS and DEC_VS of PA06D to DTV Decoder module

Check IC212.

NO

Check IC216.

Check IC209.

END

28

Page 30

H/V Sync Check

(RF DTV, RF NTSC, AV NTSC)

DEC_HS is to PA06D.

Troubleshooting charts

3.3Vp-p

NO

33.75KHz

DEC_VS is to PA06D.

3.3Vp-p

60Hz

YES

DEC_HS is input / output to pins 15, 2 of IC209.

DEC_VS is input / output to pins 14, 13 of IC209.

Pins 10, 11 of IC 202 : High (Base of QC215 : High)

YES

To DTV Decoder module

NO

Check IC 209.

DEC_HS is input to pin 12 of IC 202.

DEC_VS is input to pin 2 of IC 202.

H_sync is output to pin 14 of IC 202.

V_sync is output to pin 15 of IC 202.

Pins 10 and 11 of IC 202 : High (Base of QC215 : High)

S2

END

29

NO

Check IC 202.

Page 31

Troubleshooting charts

No Raster

Press POWER button, and wait for 2 minutes.

Power LED keeps continuously lighting up green.

YES

IC212 communicates with I402 on the IIC bus.

Check the pins 3 (SDA) and 4 (SCL) of I402.

5Vp-p

NO

YES

Check IC212

and I402.

Check pin 17 (H-Drive output) of I402.

NO

Check if TV micro- processor (IC212) communicates

with DTV Decoder module on UART.

If the LED changes from green to red, check pin 39

(TXD) of IC212.

5Vp-p

Check the pin 38 (RXD) of IC212 or pin 6 of PA05D.

3.3Vp-p

To DTV Decoder module

Vertical Deflection

Horizontal Deflection

Check H Drive signal to emitter of Q420.

12Vp-p

33.75KHz

0.7Vp-p

33.75KHz

High Voltage Drive

HD1

30

Page 32

HD1

Troubleshooting charts

Trigger pulse is input to pin 2 of I407.

2Vp-p

6Vp-p

33.75KHz

YES

The control voltage of H Drive is input to pin 5 of I407.

60Hz

0.5Vp-p

7Vp-p

NO

Check Q416, Q417

NO

Check pin 9 (E/W ) of IC402.

YES

H Drive signal is output to pin 3 of I407.

12Vp-p

33.75KHz

HD2

NO

Check I407.

31

Page 33

Troubleshooting charts

HD2

Check 200VA to PA14M. To No Power

NO

YES

H Drive signal is output to Source of Q423.

200Vp-p

33.75KHz

YES

Horizontal Drive B+ to R481 is about 130Vp-p ±10Vp-p .

60Hz

NO

Check Q423.

YES

The voltage waveform of Q425’s collector is the following.

1400Vp-p ±50Vp-p

END

10Vp-p

130Vp-p

If the impedance value of Q425’s

NO

collector is near zero Ω, the

horizontal deflection TR (Q425)

is dead. Replace Q425.

32

Page 34

High Voltage Drive

Check pin 17 (H-Drive output) of I402.

Troubleshooting charts

0.7Vp-p

33.75KHz

YES

Check H Drive signal to emitter of Q402.

12Vp-p

33.75KHz

NO

Trigger pulse is input to pin 2 of I401.

2Vp-p

NO

Check I402.

NO

Check Q403.

6Vp-p

33.75KHz

YES

The control voltage of high voltage feedback is input to

pin 5 of I401.

60Hz

0.25Vp-p

7Vp-p

33

NO

YES

Check I403 and high voltage

feedback circuits.

HVD1

Page 35

Troubleshooting charts

HVD1

High Voltage Drive signal is output to pin 3 of I401.

12Vp-p

33.75KHz

YES

NO

Check 200VB to PA14M. To No Power

YES

High Voltage Drive signal is output to Source of Q407.

200Vp-p

NO

Check I401.

NO

Check Q407.

33.75KHz

YES

FBT B+ to pin 15 of PW16P is about 130Vp-p ±10Vp-p.

60Hz

10Vp-p

110Vp-p

HVD2

NO

Check Q407.

34

Page 36

HVD2

Troubleshooting charts

Check EHT Drive signal to base of Q808.

NO

12Vp-p

33.75KHz

YES

The voltage waveform of Q810’s drain is the following.

815Vp-p

YES

Check emitter of Q401.

NO

Check Q810.

END

35

Page 37

Troubleshooting charts

Vertical Deflection

Vertical SAW waveform is to pin 8 of I402.

2.2Vp-p

60Hz

YES

The following waveform is to pin 1 of I412.

3.5Vp-p

0V

YES

NO

Check I402.

NO

Check vertical deflection circuits

around I412.

Vertical deflection waveform is to pin 5 of I412.

50Vp-p

60Hz

END

36

NO

Check vertical deflection circuits

around I412.

Page 38

No Power

(Standby Power : U801)

The Standby LED doesn’t light up red.

YES

Troubleshooting charts

Approximately 150VDC is to C806.

YES

The following waveform is to drain of U801.

320Vp-p

100KHz

YES

Check if voltages to PA17D is supplied to DTV

Decoder module and TV micro-processor.

NO

Check if F801 is open.

Check D801 (bridge rectifier).

Check the impedance value of between Source

NO

and Drain to U801. If the value is near zero Ω,

U801 is dead. Replace U801.

Check the parts caused a short-circuit to

NO

secondary circuits.

(3.3A, 3.3B, 5V, 32V, 12V, and –12V)

YES

When pressing Power button, the color of Power

LED is green

END

37

Page 39

Troubleshooting charts

No Power

Switch relay (Y802) doesn’t operate.

Fuse (F801) doesn’t short-circuits. Replace F801.

NO

YES

Bridge rectifier (D805) doesn’t short-circuits.

NO

Replace D805.

(The voltage of between Anode and Cathode to

D805 is 0.6V).

YES

NO

Both AC lines of power cord don’t short-circuit. Replace the parts caused a short-circuit.

YES

NO

PWR SW to PW15M is High. Check pin 26 of IC212.

NO

Q804 doesn’t defective. Replace Q804.

YES

Y802 (switch relay) Doesn’t defective.

YES

The parts doesn’t caused a short-circuit to

secondary circuits

YES

P1

NO

ReplaceY802.

NO

Replace defective parts with a new one.

38

Page 40

P1

Replace defective parts with

Troubleshooting charts

The following waveform is to pin 1 of U803 and U805.

370Vp-p

50~80KHz

END

NO Power

Switch relay operation (Y802) is OK.

NO

Check the primary circuits of SMPS IC,

and replace defective parts with a new one.

The parts doesn’t caused a shortcircuit to secondary circuits.

YES

Supply the power to PA17D. S/B SW to PW15 is High. Check pin 13 of IC212.

YES

NO

a new one.

NO

P2 P3

NO

39

Page 41

Troubleshooting charts

P2 P3

YES

Supply 200VA to PA14M. R803 is OK. ReplaceR803.

YES

Check Regulators.

(U807, U808, U809)

NONO

YES

R815 is OK.

YES

Q802, D815 are OK. Replace Q802, D815.

YES

Check U805.

NO

Replace R815.

NO

Supply 200VB to PA14M. R807 is OK. Replace R807.

YES

Q801, D810 are OK.

YES

Check U803.

END

YES

40

NONO

NO

Replace Q801, D810.

Page 42

DTV Channel Trouble

When NO Signal Searching is not display

Select Input Select on the Setup Menu, and Check

Check Signal Strength.

Check tuner power to pins 6, 11, and 15 of U101.

Troubleshooting charts

Check IF signal to pin 19 of U101. Check AGC to pin 3 of U101.

NO

NO

YES

Check TS stream signal to pins 122,

123, 124, 125 of IC100.

NO NO

Check B+, Clock and IIC Bus to

pins 94, 104, and 105 of IC100.

YES

Check Please Back-end A/V function.

END

YES

Change Tuner

U101.

Change IC100

41

Page 43

Troubleshooting charts

(Color and luminance signal is not output.)

Check Y, Pb, and Pr to pins 38, 33, and 39 of IC917(Video DAC).

No Picture to DTV RF

Check Pixcko to pin 27 of IC917.

YES

V1 V2

Mosaic Picture to DTV RF

Mosaic picture is displayed on the screen.

NO

Check 27MHz clock to pin 88 of IC901(Video decoder),

and Y/Pb/Pr to pin 93 ~ 125.

NO

If no signal, change IC901.

END

Check 97MHz clock to pin 68 of

IC902 and IC903.

Soldering condition to pins of IC901, IC902, and

IC903 might be wrong. Resolder the pins.

YES

No problem

END

42

NO

NO

Check Pixcko(27MHz) to pin 88

of IC901.

NO

If no signal, change IC901.

Page 44

Loss of H/V sync to DTV RF

L, R

Picture is scrolling due to horizontal or vertical sync loses.

Check H/V sync signal of Video decoder to PW06V.

Check 27MHz clock to pin 88 of IC901(Video decoder),

and Y/Pb/Pr to pin 93 ~ 125.

Troubleshooting charts

Check H/V sync. If no signal, change IC901.

NO

YES

To H/V Sync Check

(RF DTV, RF NTSC, AV NTSC)

END

No sound to DTV RF

(Audio L, R)

NO

Check audio L/R to pins 2, 4 of PW05V Check pins 21, 22 of IC920 (Codec IC).

YES

NO

Check pins 63, 64, 67, and 73 of IC912.

Decoder

YES

NO

END

Check pins 188, 190, and 197 of IC701 (Transport IC).

NO

If no signal, change IC701.

43

Page 45

Troubleshooting charts

C, W, SR, SL

C, W, SR, SL

No sound to DTV RF

(Audio Center, Woofer)

Check audio C/W to pins 2, 4 of PW12M. Check pins 23, 24 of IC920.

NO

YES

NO

Check pins 63, 64, 67, and 73 of IC912.

Decoder

YES

NO

Check pins 188, 190, and 197 of IC701 (Transport IC).

END

NO

If no signal, change IC701.

No sound to DTV RF

(Audio SL, SR)

Check audio C/W to pins 6, 8 of PW12M. Check pins 25, 26 of IC920.

NO

YES

NO

Check pins 63, 64, 67, and 73 of IC912.

Decoder

YES

NO

Check pins 188, 190, and 197 of IC701 (Transport IC).

END

NO

If no signal, change IC701.

44

Page 46

9. Part List (DSC-30W60N)

CAUTION

" ": The shaded areas in the schematic diagram and the parts list have especial characteristics important for safety and should be replaced only with types

!

identical to those in the original circuit or specified in the part list. Before replacing any of those components, read carefully the PRODUCT SAFETY NOTICE on

this manual. Do not degrade the safety of reciever through improper servicing.

WARNING :

BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION

PRECAUTION”,”SAFETY PRECAUTION” AND “PRODUCT SAFETY

NOTICE”ON THIS MANUAL.

LOC PART CODE PART NAME DESCRIPTION REMARKS

ZZ110 PEACPWD002 ACCESSORY AS DSC-3260N

30 49586110W1 MANUAL INSTRUCTION DSC-3260N

40 4958900001 MANUAL QUICK GUIDE DSC-3260N

ZZ120 PEBCSHD002 COVER BACK AS DSC-3260N

M211 4952100100 COVER BACK FR HIPS PAINT

M540 4855420200 SPEC PLATE PE FILM

M591 4951900100 DECO SPKR AS FR HIPS PAINT

M781 4857817630 CLOTH BLACK FELT 400X20X0.7

M782 4857817611 CLOTH BLACK FELT 200X20X0.7

ZZ130 PEPKCPD002 PACKING AS DSC-3260N

M641 6520010100 STAPLE PIN 18M/M J D O 1

M681 4851712701 BAND AS 3.3M

M801 4958000100 BOX CARTON DW-3

M811 4958100100 PAD EPS

M821 4858218700 BAG P.E FOAM+LDPE T0.5X1880X1380

ZZ131 48519A4410 CRT GROUND NET 3301H-1015-2P

ZZ132 58G0000114 COIL DEGAUSSING DC-3200

ZZ140 PECACAD002 CABINET AS DSC-3260N

M201A 4856015820 SCREW CRT FIX SWRM+SK5 L=35

M201B 4856215401 WASHER RUBBER CR T1.0

M201C 7128301212 SCREW TAPPING T2S WAS 3X12 MFZN BK

M201D 4857817610 CLOTH BLACK FELT 300X20X0.7

M201E 4857817610 CLOTH BLACK FELT 300X20X0.7

M211A 7122401612 SCREW TAPPTITE T2S TRS 4X16 MFZN BK

M211B 7122401612 SCREW TAPPTITE T2S TRS 4X16 MFZN BK

M211C 7122401612 SCREW TAPPTITE T2S TRS 4X16 MFZN BK

M211D 7122401612 SCREW TAPPTITE T2S TRS 4X16 MFZN BK

M211E 7122401612 SCREW TAPPTITE T2S TRS 4X16 MFZN BK

M230 4952300200 PANEL AV FRHIPS BK

M353 97P4602700 CLAMP CORD POLYETHYLENE BLK

M353A 7122401612 SCREW TAPPTITE T2S TRS 4X16 MFZN BK

M561 4955600100 MARK BRAND AL T1.0 DIA-CUTTING

M682 4856816300 CLAMP WIRE NYLON 6 (V0)

SP01A 7122401612 SCREW TAPPTITE T2S TRS 4X16 MFZN BK

SP02A 7122401612 SCREW TAPPTITE T2S TRS 4X16 MFZN BK

ZZ200 PEFMSJD002 MASK FRONT AS DSC-3260N

M201 4952000100 MASK FRONT FR HIPS PAINT

M251 4952500100 GRILL SPKR R PS SHEET T0.4

M252 4952500200 GRILL SPKR L PS SHEET T0.4

S601 4958300310 SPEAKER AS L 10W 8 OHM K128/101999B

S601A 7122401612 SCREW TAPPTITE T2S TRS 4X16 MFZN BK

LOC PART CODE PART NAME DESCRIPTION REMARKS

S602 4958300110 SPEAKER UNIT 5W 8OHM H114/101999B

S602A 7128301212 SCREW TAPPING T2S WAS 3X12 MFZN BK

S603 4958300210 SPEAKER AS R 10W 8 OHM K128/101999B

S603A 7122401612 SCREW TAPPTITE T2S TRS 4X16 MFZN BK

S604 1111111111 DSC-3260N 24.576MHZ

S604A 7122401412 SCREW TAPPING T2S TRS 4X14 MFZN BK

S605 1111111111 DSC-3260N 24.576MHZ

S605A 7122401412 SCREW TAPPING T2S TRS 4X14 MFZN BK

ZZ290 PEMPMSD002 PCB MAIN MANUAL AS DSC-3260N

C410 CEXF2E101V C ELECTRO 250V RSS 100MF 16X31.5

C419 CMXL2E105J C MYLAR 250V MEU 1MF J

C424 CMXL2E105J C MYLAR 250V MEU 1MF J

C433 CMXL2E105J C MYLAR 250V MEU 1MF J

C445 CEYF1H222C C ELECTRO RUS 50V 2200MF 18*35.5

C468 CMXM2A334J C MYLAR 100V 0.33MF J BULK

C476 CMYH3D332J C MYLAR 2KV BUP 3300PF J

C477 CMYH3D332J C MYLAR 2KV BUP 3300PF J

C479 CMYE2G364J C MYLAR 400V PU 0.36MF J

D408 DRU3AM---- DIODE RU3AM(HIGH SPEED)

D417 DFMLG12S-- DIODE FML-G12S

D420 DRU3AM---- DIODE RU3AM(HIGH SPEED)

D423 DFMRG5H--- DIODE DAMPER FMRG5H

D423A 4857027904 HEAT SINK AL EX (AN0DIZE)

D423B 7174301011 SCREW TAPPTITE TT2 RND 3X10 MFZN

D424 DRF1------ DIODE RF-1

D425 DRF1------ DIODE RF-1

D436 1NJM431L-- IC REGULATOR NJM431L

I401 1NE555---- IC TIMER PD NE555

I402 1UPC1884BC IC H/V OSC UPC1884BCT

I403 1KF353---- IC OPAMP KF353

I404 1KF353---- IC OPAMP KF353

I405 1LM358---- IC KA358

I407 1NE555---- IC TIMER PD NE555

I408 1MC7812--- IC REGULATOR MC7812 12V 1A (KA7812)

I409 1MC7812--- IC REGULATOR MC7812 12V 1A (KA7812)

I409A 4857031201 HEAT SINK AL 6063S

I409B 7174300811 SCREW TAPPTITE TT2 RND 3X8 MFZN

I410 1KA7809--- IC REGULATOR KA7809

I410A 4857027802 HEAT SINK AL EX

I410B 7174300811 SCREW TAPPTITE TT2 RND 3X8 MFZN

I411 1KF353---- IC OPAMP KF353

I412 1TDA8172-- IC V-OUT TDA8172

I412A 4857028207 HEAT SINK AL EX BK

I412B 7174300811 SCREW TAPPTITE TT2 RND 3X8 MFZN

!

!

!

!

!

!

45

Page 47

Part List (DSC-30W60N)

LOC PART CODE PART NAME DESCRIPTION REMARKS

I413 1KA7809--- IC REGULATOR KA7809

I414 1KA7805--- IC REGULATOR KA7805

!

!

I601 1CXA1315P- IC CONVERTER CXA1315

I602 1LA7220--- IC SWITCH LA7220

I603 1LA7220--- IC SWITCH LA7220

I605 1UPC1406HA IC UPC 1406HA

I606 1UPC1406HA IC UPC 1406HA

I607 1TA8256H-- IC AMP TA8256H

!

I607A 4857027534 HEAT SINK AL EXBK

I607B 7174300811 SCREW TAPPTITE TT2 RND 3X8 MFZN

I608 1TA8256H-- IC AMP TA8256H

!

I608A 4857027534 HEAT SINK AL EXBK

I608B 7174300811 SCREW TAPPTITE TT2 RND 3X8 MFZN

I609 1TDA7317-- IC AUDIO TDA7317

JP02 4959100250 JACK PIN BOARD DPAM-9913

JP03 4959100550 JACK PIN BOARD DPAE-9867

L401 58CD000002 COIL CHOKE TRANS DTL-04M

L403 58HD000001 COIL H-LINEARITY DCL-20U

L406 58CD000001 COIL CHOKE DCC-01M

M351 4953500100 HOLDER CORD FR HIPS BK

M351A 7122401412 SCREW TAPPING T2S TRS 4X14 MFZN BK

M381 4853812800 FRAME MAIN PCB FR HIPS BK

M381A 7128301212 SCREW TAPPING T2S WAS 3X12 MFZN BK

M381B 7128301212 SCREW TAPPING T2S WAS 3X12 MFZN BK

M721A 7122401412 SCREW TAPPING T2S TRS 4X14 MFZN BK

PA09S 4950711002 CONNECTOR SMH250-11+YT250+USW=600

PA12D 4950708003 CONNECTOR SMH250-08+YT250+USW=300

PA13D 4950706006 CONNECTOR SMH250-06+YT250+USW=300

PA15P 4950713002 CONNECTOR SMH250-13+YT250+ULW=550

PW01V 4859280820 CONN WAFER TAC-L13X-A1

PW02V 4859280820 CONN WAFER TAC-L13X-A1

PW03V 4859280820 CONN WAFER TAC-L13X-A1

PW04V 4859280820 CONN WAFER TAC-L13X-A1

PW14P 4859235620 CONN WAFER YW025-13

PW16P 4859235820 CONN WAFER YW025-15

P405 4959203120 CONN WAFER TBL-P05P-C1

Q407 T1RFS634-- FET IRFS634

!

!

Q407A 4957000700 HEAT SINK AL EX

Q407B 7174301011 SCREW TAPPTITE TT2 RND 3X10 MFZN

Q418 T1RFS830-- FET IRFS830

Q423 T1RFS830-- FET IRFS830

Q423A 4857027700 HEAT SINK AL EX BK

Q423B 7174301011 SCREW TAPPTITE TT2 RND 3X10 MFZN

Q425 T2SC5422-- TR 2SC5422

!

Q425A 4857027534 HEAT SINK AL EXBK

Q425B 7174301011 SCREW TAPPTITE TT2 RND 3X10 MFZN

Q425C 4857619500 INSU PLATE SILICON RUBBER T0.3

LOC PART CODE PART NAME DESCRIPTION REMARKS

R476 RW02Z478J- R WIRE WOUND 2W 0.47 J

R481 RX05V229J- R CEMENT 5W 2.2 OHM J VERTICAL

R506 RW02Z828J- R WIRE WOUND 2W 0.82 OHM

SW401 5S40403035 SW LEVER JRS-1301

T401 5DU0000024 TRANS PULSE DTP-01A

T402 58CD000002 COIL CHOKE TRANS DTL-04M

T403 5DD0000021 TRANS DRIVE DTD-01A

T404 5DU0000024 TRANS PULSE DTP-01A

T405 5DY0000023 TRANS DUMMY DTL-02M

U101 4959700350 TUNER TAUG-H005P

X401 4850L02310 RESONATOR CERA CSB503F30

ZZ200 PEMPJ2D002 PCB CHIP MOUNT B AS DSC-3260N

CC401 HCQK820JCA C CHIP CERA 50V CH 82PF J 2012

CC402 HCQK681JCA C CHIP CERA 50V CH 680PF J 2012

CC403 HCBK472KCA C CHIP CERA 50V X7R 4700PF K 2012

CC404 HCTAH109MB C CHIP TANTAL 25V 1MF M 3216

CC405 HCQK221JCA C CHIP CERA 50V CH 220PF J 2012

CC406 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

CC407 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

CC408 HCBK682KCA C CHIP CERA 50V X7R 6800PF K 2012

CC409 HCQK391JCA C CHIP CERA 50V CH 390PF J 2012

CC410 HCQK390JCA C CHIP CERA 50V CH 39PF J 2012

CC411 HCQK221JCA C CHIP CERA 50V CH 220PF J 2012

CC412 HCQK821JCA C CHIP CERA 50V CH 820PF J 2012

CC413 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

CC414 HCQK391JCA C CHIP CERA 50V CH 390PF J 2012

CC415 HCBK471KCA C CHIP CERA 50V X7R 470PF K 2012

CC416 HCQK101JCA C CHIP CERA 50V CH 100PF J 2012

CC419 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

CC420 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

CC421 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

CC422 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

CC423 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

CC424 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

CC425 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

CC426 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

CC427 HCTBF100MB C CHIP TANTAL 16V 10MF M 3528 TS

CC428 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

CC606 HCTAJ478MB C CHIP TANTAL 35V 0.47MF M 3216 TS

CC607 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

CC608 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

CC609 HCTAH109MB C CHIP TANTAL 25V 1MF M 3216

CC610 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

CC611 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

CC612 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

CC613 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

CC614 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

46

Page 48

Part List (DSC-30W60N)

LOC PART CODE PART NAME DESCRIPTION REMARKS

CC615 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

CC617 HCTAH109MB C CHIP TANTAL 25V 1MF M 3216

CC618 HCTBH479MB C CHIP TANTAL 25V 4.7MF M 3528

CC619 HCTBH479MB C CHIP TANTAL 25V 4.7MF M 3528

CC620 HCTBH479MB C CHIP TANTAL 25V 4.7MF M 3528

CC621 HCTBH479MB C CHIP TANTAL 25V 4.7MF M 3528

CC622 HCTBH479MB C CHIP TANTAL 25V 4.7MF M 3528

CC623 HCTBH479MB C CHIP TANTAL 25V 4.7MF M 3528

CC624 HCTAH109MB C CHIP TANTAL 25V 1MF M 3216

CC625 HCTBH479MB C CHIP TANTAL 25V 4.7MF M 3528

CC626 HCBH103KCA C CHIP CERA 25V X7R 0.01MF K 2012

CC630 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

CC631 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

CC633 HCBH103KCA C CHIP CERA 25V X7R 0.01MF K 2012

CC635 HCTBH479MB C CHIP TANTAL 25V 4.7MF M 3528

CC636 HCTBH479MB C CHIP TANTAL 25V 4.7MF M 3528

CC637 HCTBH479MB C CHIP TANTAL 25V 4.7MF M 3528

CC638 HCTBH479MB C CHIP TANTAL 25V 4.7MF M 3528

CC639 HCTBH479MB C CHIP TANTAL 25V 4.7MF M 3528

CC643 HCBK473KCA C CHIP CERA 50V X7R 0.047MF K 2012

CC644 HCBH103KCA C CHIP CERA 25V X7R 0.01MF K 2012

CC645 HCBH103KCA C CHIP CERA 25V X7R 0.01MF K 2012

CC646 HCBH103KCA C CHIP CERA 25V X7R 0.01MF K 2012

CC647 HCBH103KCA C CHIP CERA 25V X7R 0.01MF K 2012

CC648 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

CC649 HCBH224KCA C CHIP CERA 25V X7R 0.22MF K 2012

CC650 HCBK563KCA C CHIP CERA 50V X7R 0.056MF K 2012

CC651 HCBK473KCA C CHIP CERA 50V X7R 0.047MF K 2012

CC652 HCBK332KCA C CHIP CERA 50V X7R 3300PF K 2012

CC653 HCBK272KCA C CHIP CERA 50V X7R 2700PF K 2012

CC654 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

CC655 HCBK122KCA C CHIP CERA 50V X7R 1200PF K 2012

CC656 HCTAH109MB C CHIP TANTAL 25V 1MF M 3216

CC657 HCTAH109MB C CHIP TANTAL 25V 1MF M 3216

CC658 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

CC659 HCBK122KCA C CHIP CERA 50V X7R 1200PF K 2012

CC660 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

CC661 HCBK272KCA C CHIP CERA 50V X7R 2700PF K 2012

CC662 HCBK332KCA C CHIP CERA 50V X7R 3300PF K 2012

CC663 HCBK563KCA C CHIP CERA 50V X7R 0.056MF K 2012

CC664 HCBH224KCA C CHIP CERA 25V X7R 0.22MF K 2012

CC665 HCBH104KCA C CHIP CERA 25V X7R 0.1MF K 2012

RC401 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC402 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC403 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC404 HRFT102JCA R CHIP 1/10 1K OHM J 2012

RC405 HRFT562JCA R CHIP 1/10 5.6K OHM J 2012

LOC PART CODE PART NAME DESCRIPTION REMARKS

RC406 HRFT682JCA R CHIP 1/10 6.8K OHM J 2012

RC407 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC408 HRFT513JCA R CHIP 1/10 51K OHM J 2012

RC409 HRFT684JCA R CHIP 1/10 680K OHM J 2012

RC410 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC411 HRFT223JCA R CHIP 1/10 22K OHM J 2012

RC413 HRFT153JCA R CHIP 1/10 15K OHM J 2012

RC415 HRFT562JCA R CHIP 1/10 5.6K OHM J 2012

RC416 HRFT223JCA R CHIP 1/10 22K OHM J 2012

RC417 HRFT364JCA R CHIP 1/10 360K OHM J 2012

RC418 HRFT102JCA R CHIP 1/10 1K OHM J 2012

RC419 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC420 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012

RC421 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012

RC422 HRFT152JCA R CHIP 1/10 1.5K OHM J 2012

RC423 HRFT332JCA R CHIP 1/10 3.3K OHM J 2012

RC424 HRFT332JCA R CHIP 1/10 3.3K OHM J 2012

RC425 HRFT183JCA R CHIP 1/10 18K OHM J 2012

RC426 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC427 HRFT393JCA R CHIP 1/10 39K OHM J 2012

RC434 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC436 HRFT512JCA R CHIP 1/10 5.1K OHM J 2012

RC438 HRFT513JCA R CHIP 1/10 51K OHM J 2012

RC439 HRFT332JCA R CHIP 1/10 3.3K OHM J 2012

RC440 HRFT222JCA R CHIP 1/10 2.2K OHM J 2012

RC441 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC442 HRFT562JCA R CHIP 1/10 5.6K OHM J 2012

RC443 HRFT102JCA R CHIP 1/10 1K OHM J 2012

RC444 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC445 HRFT102JCA R CHIP 1/10 1K OHM J 2012

RC447 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC448 HRFT912JCA R CHIP 1/10 9.1K OHM J 2012

RC449 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC450 HRFT273JCA R CHIP 1/10 27K OHM J 2012

RC451 HRFT102JCA R CHIP 1/10 1K OHM J 2012

RC452 HRFT102JCA R CHIP 1/10 1K OHM J 2012

RC453 HRFT822JCA R CHIP 1/10 8.2K OHM J 2012

RC454 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC456 HRFT183JCA R CHIP 1/10 18K OHM J 2012

RC457 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012

RC459 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC462 HRFT102JCA R CHIP 1/10 1K OHM J 2012

RC463 HRFT681JCA R CHIP 1/10 680 OHM J 2012

RC464 HRFT102JCA R CHIP 1/10 1K OHM J 2012

RC465 HRFT102JCA R CHIP 1/10 1K OHM J 2012

RC467 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC468 HRFT102JCA R CHIP 1/10 1K OHM J 2012

47

Page 49

Part List (DSC-30W60N)

LOC PART CODE PART NAME DESCRIPTION REMARKS

RC469 HRFT102JCA R CHIP 1/10 1K OHM J 2012

RC470 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC471 HRFT471JCA R CHIP 1/10 470 OHM J 2012

RC472 HRFT562JCA R CHIP 1/10 5.6K OHM J 2012

RC473 HRFT103JCA R CHIP 1/10 10K OHM J 2012

RC474 HRFT682JCA R CHIP 1/10 6.8K OHM J 2012

RC475 HRFT513JCA R CHIP 1/10 51K OHM J 2012

RC476 HRFT122JCA R CHIP 1/10 1.2K OHM J 2012

RC477 HRFT101JCA R CHIP 1/10 100 OHM J 2012

RC602 HRFT101JCA R CHIP 1/10 100 OHM J 2012

RC612 HRFT224JCA R CHIP 1/10 220K OHM J 2012

RC613 HRFT224JCA R CHIP 1/10 220K OHM J 2012

RC614 HRFT224JCA R CHIP 1/10 220K OHM J 2012

RC615 HRFT224JCA R CHIP 1/10 220K OHM J 2012

RC616 HRFT224JCA R CHIP 1/10 220K OHM J 2012

RC617 HRFT224JCA R CHIP 1/10 220K OHM J 2012

RC618 HRFT101JCA R CHIP 1/10 100 OHM J 2012

RC619 HRFT302JCA R CHIP 1/10 3K OHM J 2012

RC620 HRFT101JCA R CHIP 1/10 100 OHM J 2012

RC621 HRFT471JCA R CHIP 1/10 470 OHM J 2012

RC623 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012

RC624 HRFT101JCA R CHIP 1/10 100 OHM J 2012

RC626 HRFT162JCA R CHIP 1/10 1.6K OHM J 2012

RC627 HRFT182JCA R CHIP 1/10 1.8K OHM J 2012

RC631 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012

RC633 HRFT101JCA R CHIP 1/10 100 OHM J 2012

RC634 HRFT622JCA R CHIP 1/10 6.2K OHM J 2012

RC635 HRFT512JCA R CHIP 1/10 5.1K OHM J 2012

RC636 HRFT622JCA R CHIP 1/10 6.2K OHM J 2012

RC637 HRFT622JCA R CHIP 1/10 6.2K OHM J 2012

RC638 HRFT682JCA R CHIP 1/10 6.8K OHM J 2012

RC639 HRFT392JCA R CHIP 1/10 3.9K OHM J 2012

RC640 HRFT682JCA R CHIP 1/10 6.8K OHM J 2012

RC641 HRFT333JCA R CHIP 1/10 33K OHM J 2012

RC642 HRFT393JCA R CHIP 1/10 39K OHM J 2012

RC643 HRFT303JCA R CHIP 1/10 30K OHM J 2012

RC644 HRFT333JCA R CHIP 1/10 33K OHM J 2012

RC646 HRFT622JCA R CHIP 1/10 6.2K OHM J 2012

RC647 HRFT512JCA R CHIP 1/10 5.1K OHM J 2012

RC648 HRFT622JCA R CHIP 1/10 6.2K OHM J 2012

RC649 HRFT223JCA R CHIP 1/10 22K OHM J 2012

RC650 HRFT223JCA R CHIP 1/10 22K OHM J 2012

RC651 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012

RC654 HRFT102JCA R CHIP 1/10 1K OHM J 2012

RC655 HRFT333JCA R CHIP 1/10 33K OHM J 2012

RC656 HRFT393JCA R CHIP 1/10 39K OHM J 2012

RC657 HRFT393JCA R CHIP 1/10 39K OHM J 2012

LOC PART CODE PART NAME DESCRIPTION REMARKS

RC658 HRFT303JCA R CHIP 1/10 30K OHM J 2012

RC659 HRFT333JCA R CHIP 1/10 33K OHM J 2012

RC660 HRFT622JCA R CHIP 1/10 6.2K OHM J 2012

RJ01 HRFT000-CA R CHIP 1/10 0 OHM 2012

RJ03 HRFT000-CA R CHIP 1/10 0 OHM 2012

ZZ200 PEMPJ0D002 PCB MAIN (RHU) AS DSC-3260N

C418 CEXF1C471V C ELECTRO 16V RSS 470MF (10X12.5)TP

C420 CEXF1C471V C ELECTRO 16V RSS 470MF (10X12.5)TP

C422 CEXF1C471C C ELECTRO 16V RUS 470MF (10X12.5)TP

C440 CEXF1C471V C ELECTRO 16V RSS 470MF (10X12.5)TP

C442 CEXF1V102C C ELECTRO 35V RUS 1000MF (13X25) TP

C448 CEXF1H221C C ELECTRO 50V RUS 220MF (10X16) TP

C450 CEXF1H221C C ELECTRO 50V RUS 220MF (10X16) TP

C463 CCYB3D272K C CERA 2KV B 2700PF K

C465 CEXF2E330V C ELECTRO 250V RSS 33MF (13X25) TP

C466 CEXF2E220C C ELECTRO 250V RUS 22MF (13X20) TP

C474 CCXB3D151K C CERA 2KV B 150PF K (TAPPING)

C475 CCYB3D272K C CERA 2KV B 2700PF K

C488 CCYB3D272K C CERA 2KV B 2700PF K

C489 CEXF1C471C C ELECTRO 16V RUS 470MF (10X12.5)TP

C601 CEXF1V102C C ELECTRO 35V RUS 1000MF (13X25) TP

C602 CEXF1V102C C ELECTRO 35V RUS 1000MF (13X25) TP

C603 CEXF1V102C C ELECTRO 35V RUS 1000MF (13X25) TP

C621 CEXF1V102C C ELECTRO 35V RUS 1000MF (13X25) TP

C624 CEXF1V102C C ELECTRO 35V RUS 1000MF (13X25) TP

C626 CEXF1V102C C ELECTRO 35V RUS 1000MF (13X25) TP

C650 CEXF1C331C C ELECTRO RUS 16V 330MF (8.0*11.5)

R654 CEXF1C471C C ELECTRO 16V RUS 470MF (10X12.5)TP

ZZ200 PEMPJBD002 PCB MAIN M-10 AS DSC-3260N

E01 4856310600 EYE LET BSR T0.2 (R2.3)

E04 4856310600 EYE LET BSR T0.2 (R2.3)

E06 4856310600 EYE LET BSR T0.2 (R2.3)

E07 4856310600 EYE LET BSR T0.2 (R2.3)

E10 4856310600 EYE LET BSR T0.2 (R2.3)

E12 4856310600 EYE LET BSR T0.2 (R2.3)

E13 4856310600 EYE LET BSR T0.2 (R2.3)

E17 4856310600 EYE LET BSR T0.2 (R2.3)

E19 4856310600 EYE LET BSR T0.2 (R2.3)

E20 4856310600 EYE LET BSR T0.2 (R2.3)

E21 4856310600 EYE LET BSR T0.2 (R2.3)

E22 4856310600 EYE LET BSR T0.2 (R2.3)

E23 4856310600 EYE LET BSR T0.2 (R2.3)

E25 4856310600 EYE LET BSR T0.2 (R2.3)

E26 4856310600 EYE LET BSR T0.2 (R2.3)

E27 4856310300 EYE LET BSR T0.2 (R1.6)

E28 4856310300 EYE LET BSR T0.2 (R1.6)

E29 4856310300 EYE LET BSR T0.2 (R1.6)

48

Page 50

Part List (DSC-30W60N)

LOC PART CODE PART NAME DESCRIPTION REMARKS

E30 4856310300 EYE LET BSR T0.2 (R1.6)

E34 4856310600 EYE LET BSR T0.2 (R2.3)

E35 4856310300 EYE LET BSR T0.2 (R1.6)

E36 4856310300 EYE LET BSR T0.2 (R1.6)

E37 4856310300 EYE LET BSR T0.2 (R1.6)

E38 4856310300 EYE LET BSR T0.2 (R1.6)

E40 4856310300 EYE LET BSR T0.2 (R1.6)

E41 4856310300 EYE LET BSR T0.2 (R1.6)

E42 4856310300 EYE LET BSR T0.2 (R1.6)

E43 4856310300 EYE LET BSR T0.2 (R1.6)

E44 4856310600 EYE LET BSR T0.2 (R2.3)

E45 4856310600 EYE LET BSR T0.2 (R2.3)

E46 4856310600 EYE LET BSR T0.2 (R2.3)

E47 4856310300 EYE LET BSR T0.2 (R1.6)

E48 4856310300 EYE LET BSR T0.2 (R1.6)

E49 4856310300 EYE LET BSR T0.2 (R1.6)

E50 4856310300 EYE LET BSR T0.2 (R1.6)

E51 4856310300 EYE LET BSR T0.2 (R1.6)

E52 4856310300 EYE LET BSR T0.2 (R1.6)

E53 4856310300 EYE LET BSR T0.2 (R1.6)

E54 4856310300 EYE LET BSR T0.2 (R1.6)

E55 4856310300 EYE LET BSR T0.2 (R1.6)

E56 4856310300 EYE LET BSR T0.2 (R1.6)

PA18K 485923172S CONN WAFER YW025-04 (STICK)

PM601 485923162S CONN WAFER YW025-03 (STICK)

PM602 485923172S CONN WAFER YW025-04 (STICK)

PM603 485923162S CONN WAFER YW025-03 (STICK)

PW17K 485923192S CONN WAFER YW025-06 (STICK)

PW604 485923162S CONN WAFER YW025-03 (STICK)

R407 RS02Z229J- R M-OXIDE FILM 2W 2.2 OHM J(TAPPING)

R433 RS02Z109J- R M-OXIDE FILM 2W 1 OHM J (TAPPING)

R437 RS02Z109J- R M-OXIDE FILM 2W 1 OHM J (TAPPING)

R442 RS02Z271J- R M-OXIDE FILM 2W 270 OHM J (TAPPING)

R455 RS02Z121J- R M-OXIDE FILM 2W 120 OHM J (TAPPING)

R464 RS02Z104J- R M-OXIDE FILM 2W 100K OHM J TAPPING

R465 RS02Z271J- R M-OXIDE FILM 2W 270 OHM J (TAPPING)

R474 RS01Z471J- R M-OXIDE FILM 1W 470 OHM J (TAPPING)

R477 RS02Z271J- R M-OXIDE FILM 2W 270 OHM J (TAPPING)

R480 RS02Z229J- R M-OXIDE FILM 2W 2.2 OHM J(TAPPING)

R493 RS02Z271J- R M-OXIDE FILM 2W 270 OHM J (TAPPING)

R494 RS02Z390J- R M-OXIDE FILM 2W 39 OHM J (TAPPING)

R497 RS02Z180J- R M-OXIDE FILM 2W 18 OHM J (TAPPING)

R500 RS02Z129J- R M-OXIDE FILM 2W 1.2 OHM J (TAPPING)

ZZ200 PEMPJRD002 PCB MAIN RADIAL AS DSC-3260N

C401 CCXB1H391K C CERA 50V B 390PF K (TAPPING)

C402 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C403 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

LOC PART CODE PART NAME DESCRIPTION REMARKS

C404 CEXF1C221V C ELECTRO 16V RSS 220MF (8X11.5) TP

C405 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C406 CMXM2A223J C MYLAR 100V 0.022MF J TP

C407 CCXB1H182K C CERA 50V B 1800PF K (TAPPING)

C408 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C409 CMXL1H105J C MYLAR 50V MEU 1MF J

C411 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C412 CEXF1V101V C ELECTRO 35V RSS 100MF (8X11.5) TP

C413 CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

C414 CEXF1V101V C ELECTRO 35V RSS 100MF (8X11.5) TP

C415 CEXF1E101V C ELECTRO 25V RSS 100MF (6.3X11) TP

C417 CMXM2A102J C MYLAR 100V 1000PF J (TP)

C423 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C425 CEXF1C101C C ELECTRO 16V RUS 100MF (6.3X11) TP

C426 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C427 CMXM2A683J C MYLAR 100V 0.068MF J (TP)

C428 CMXL1H105J C MYLAR 50V MEU 1MF J

C429 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C430 CEXF1H339V C ELECTRO 50V RSS 3.3MF (5X11) TP

C431 CMXM2A823J C MYLAR 100V 0.082MF J (TP)

C432 CEXF1H229V C ELECTRO 50V RSS 2.2MF (5X11) TP

C434 CEXF1C101C C ELECTRO 16V RUS 100MF (6.3X11) TP

C436 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C437 CEXF1H330C C ELECTRO 50V RUS 33MF (6.3X11) TP

C439 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C441 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C443 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

C449 CMXB1H224J C MYLAR 50V EU 0.22MF J (TP)

C451 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C453 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

C456 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C459 CCXB2H182K C CERA 500V B 1800PF K (TAPPING)

C460 CEXF1H470C C ELECTRO 50V RUS 47MF (6.3X11) TP

C461 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

C462 CMXM2A182J C MYLAR 100V 1800PF J (TP)

C464 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C469 CEXF1H220V C ELECTRO 50V RSS 22MF (5X11) TP

C470 CEXF1C221V C ELECTRO 16V RSS 220MF (8X11.5) TP

C472 CEXF1C101C C ELECTRO 16V RUS 100MF (6.3X11) TP

C478 CCXB2H102K C CERA 500V B 1000PF K (TAPPING)

C481 CEXF2A479V C ELECTRO 100V RSS 4.7MF (5X11) TP

C482 CEXF2A100C C ELECTRO RUS 100V 10MF 5*11

C483 CMXB2A103J C MYLAR 100V EU 0.01MF J (TP)

C484 CEXF2A100C C ELECTRO RUS 100V 10MF 5*11

C485 CMXB2A103J C MYLAR 100V EU 0.01MF J (TP)

C486 CEXF2A479V C ELECTRO 100V RSS 4.7MF (5X11) TP

C487 CMXM2A473J C MYLAR 100V 0.047MF J (TP)

49

Page 51

Part List (DSC-30W60N)

LOC PART CODE PART NAME DESCRIPTION REMARKS

C490 CMXL2E104K C MYLAR 250V MEU 0.1MF K

C491 CMXL2E104K C MYLAR 250V MEU 0.1MF K

C492 CMXB2A103J C MYLAR 100V EU 0.01MF J (TP)

C604 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C605 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C606 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C620 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C622 CEXF1C470V C ELECTRO 16V RSS 47MF (5X11) TP

C623 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C625 CMXM2A104J C MYLAR 100V 0.1MF J (TP)

C635 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C637 CEXF1C470V C ELECTRO 16V RSS 47MF (5X11) TP

C638 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

C639 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

C640 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5X11) TP

C641 CEXF1C470V C ELECTRO 16V RSS 47MF (5X11) TP

C643 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C646 CEXF1C470V C ELECTRO 16V RSS 47MF (5X11) TP

C647 CEXF1C101C C ELECTRO 16V RUS 100MF (6.3X11) TP

C649 CEXF1V101V C ELECTRO 35V RSS 100MF (8X11.5) TP

C650 CEXF1V101V C ELECTRO 35V RSS 100MF (8X11.5) TP

C653 CEXF1V101V C ELECTRO 35V RSS 100MF (8X11.5) TP

C686 CEXF1C101C C ELECTRO 16V RUS 100MF (6.3X11) TP

C687 CEXF1C101C C ELECTRO 16V RUS 100MF (6.3X11) TP

C688 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C692 CEXF1C101C C ELECTRO 16V RUS 100MF (6.3X11) TP

L405 5CPX101J-- COIL PEAKING PL 100UH J (TAPPING)

L608 5CPX100J-- COIL PEAKING PL 10UH J (TAPPING)

L609 5CPX101J-- COIL PEAKING PL 100UH J (TAPPING)

L610 5CPX101J-- COIL PEAKING PL 100UH J (TAPPING)

Q401 TKTC3198Y- TR KTC3198Y

Q402 TKTA1270Y- TR KTA1270Y (TP)

Q403 TKTC3198Y- TR KTC3198Y

Q404 TKTA1270Y- TR KTA1270Y (TP)

Q405 TKTC3202Y- TR KTC3202Y (TP)

Q406 TKTC3198Y- TR KTC3198Y