Page 1

Service Manual

Vacuum Cleaner

Model: RC-1700P, S-36L

S/M No. : RC9003S001

✔

Caution

: In this Manual, some parts can be changed for improving, their

performance without notice in the parts list. So, if you need the

latest parts information,please refer to PPL(Parts Price List) in

Service Information Center (http://svc.dwe.co.kr).

http : //svc.dwe.co.kr Jun. 2003

DAEWOO ELECTRONICS CORP.

Page 2

CONTENTS

Page

1. SPECIFICATIONS ------------------------------------------------------------------------------------------

2

2. EXTERNAL VIEWS ---------------------------------------------------------------------------------------------

3

3. DIAGRAM

3-1. WIRING DIAGRAM ---------------------------------------------------------------

4

3-2. CIRCUIT DIAGRAM -------------------------------------------------------------------

4

4. TROUBLE SHOOTING GUIDE --------------------------------------------------------------

6

5. DISASSEMBLING AND TREATMENT

5-1. CLEANER ASSEMBLY ---------------------------------------------- 8

5-2. BODY ASSEMBLY ------------------------------------------------------------

9

5-3. MOTOR ASSEMBLY ----------------------------------------------------------------

10

5-4. CORDREEL ASSEMBLY ------------------------------------------------ 11

5-5. PCB ASSEMBLY --------------------------------------------------------------

13

5-6. HOSE ASSEMBLY ----------------------------------------------------------------

14

5-7. BRUSH ASSEMBLY --------------------------------------------------------------

16

6. EXPLODED VIEW AND PARTS LIST

6-1. CLEANER ASSEMBLY ---------------------------------------------- 17

6-2. BODY ASSEMBLY ----------------------------------------------- 19

6-3. COVER BODY ASSEMBLY -----------------------------------------------------

21

6-4. COVER DUST ASSEMBLY -----------------------------------------------------

23

6-5. MOTOR ASSEMBLY ----------------------------------------------------------------

25

6-6. CORDREEL ASSEMBLY ------------------------------------------------------

26

6-7. PCB ASSEMBLY --------------------------------------------------------------

28

6-8. HOSE ASSEMBLY -------------------------------------------------------- 33

6-9. PIPE ASSEMBLY ------------------------------------- 36

6-10. BRUSH ASSEMBLY (POWE NOZZLE)

--------------------------------------------------------

38

6-11. BRUSH ASSEMBLY (FLOOR)

--------------------------------------------------------

39

6-12. BRUSH ASSEMBLY (PEDAL)

--------------------------------------------------------

40

Page 3

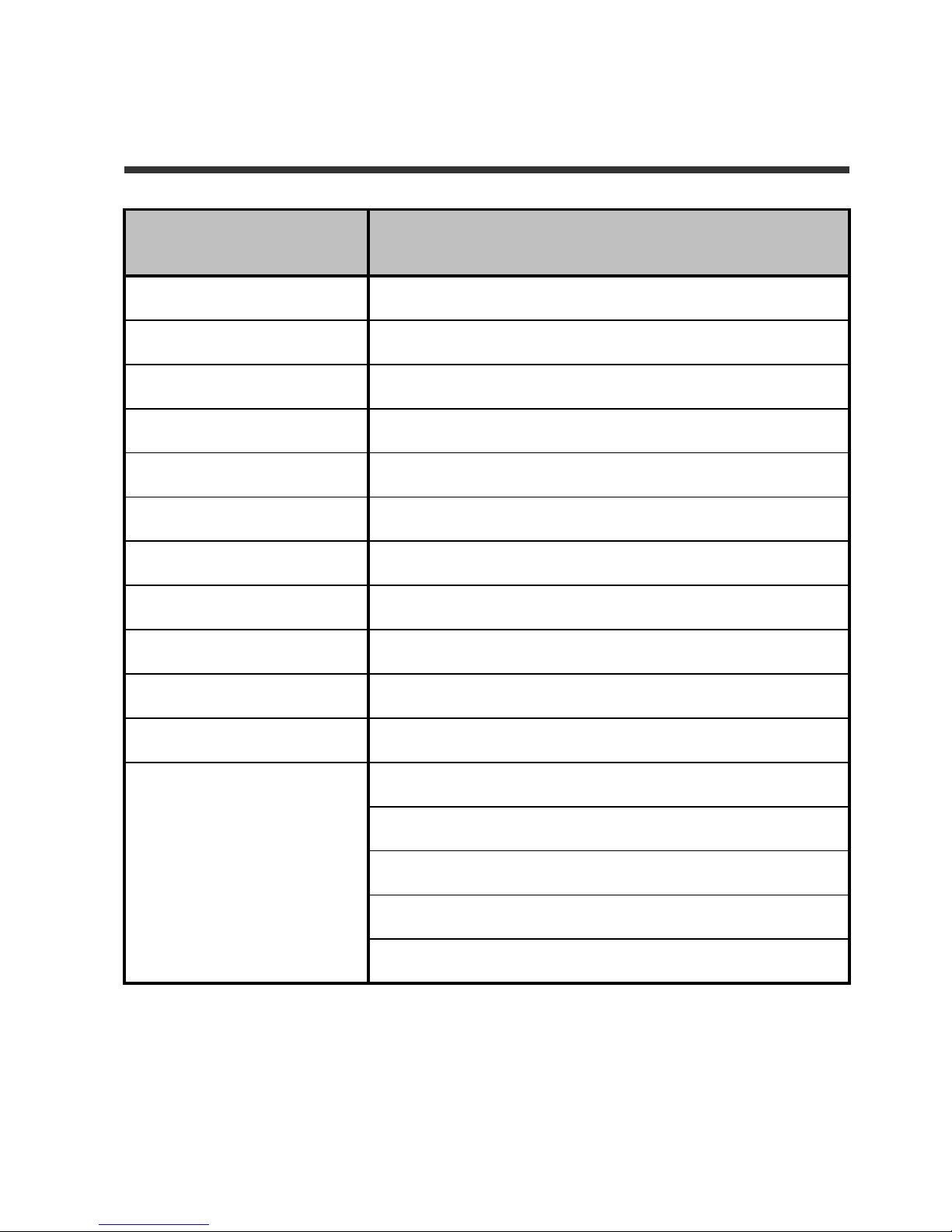

1. SPECIFICATIONS

RC-1700P, S-36L

(North America)

Rated Voltage

AC 120V

Rated Frequency

50/60Hz

Input Watt

1100W

Suction Power

300W

Noise Level

75dB(A)

Weight (Body)

4.7Kg

Display

LED

Dimension (WXHXD)

546 X 250 X 290 mm

Cord Length

8.2m

Filter

HEPA

Telescopic

(Current Type)

Pedal

Crevice Tool

Upholstery Tool

Dusting Brush

Floor Tool

MODEL

Pipe

Nozzle

2

Page 4

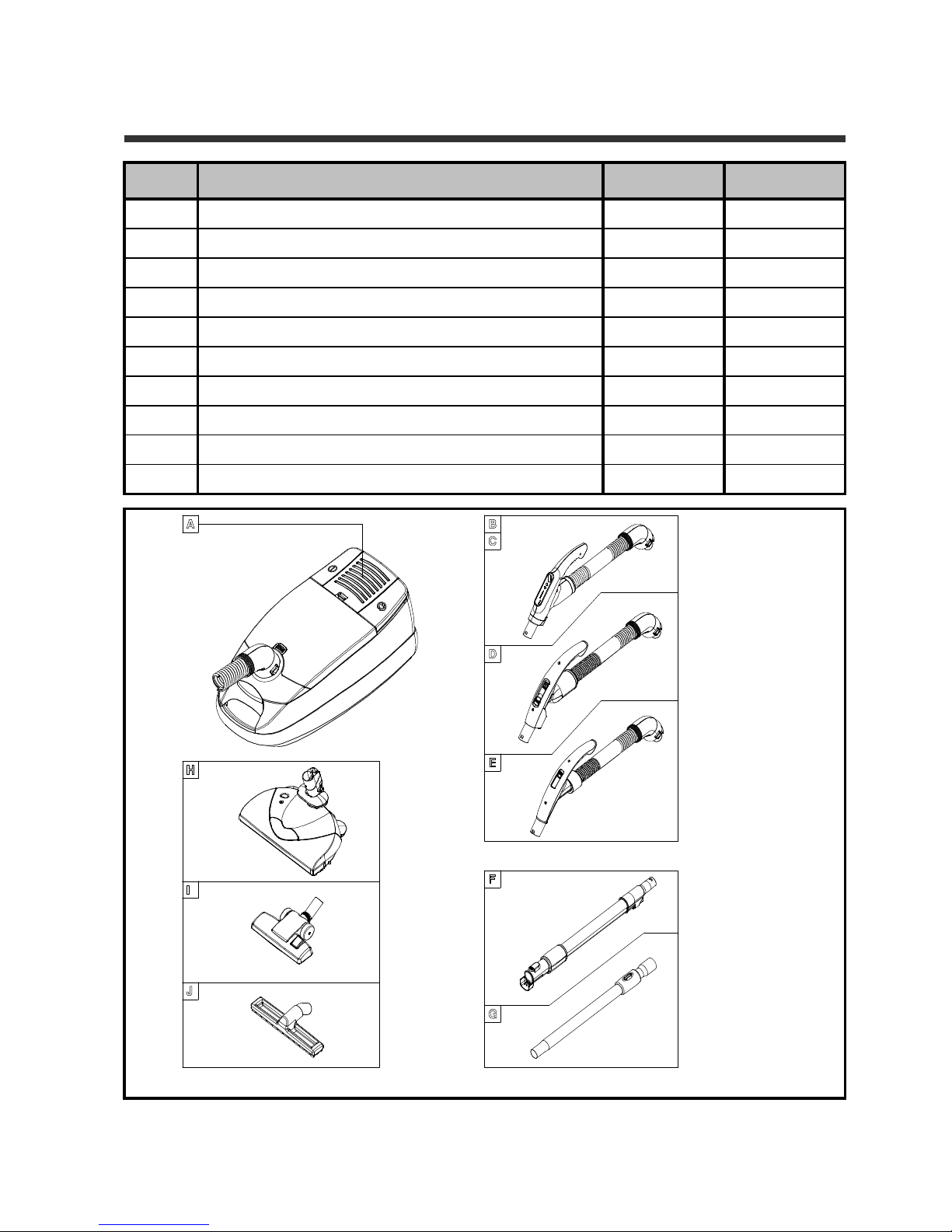

2. EXTERNAL VIEWS

PART NAME

RC-1700P S-36L

A

FILTER HEPA HEPA

B

HOSE ASSEMBLY (4-Current, Power Nozzle Control) O O

C

HOSE ASSEMBLY (2-Current, Power Nozzle Control) × ×

D

HOSE ASSEMBLY (2-Current, Power Nozzle Control) × ×

E

HOSE ASSEMBLY (2-Current, Power Nozzle Control) × ×

F

PIPE ASSEMBLY (2-Currnet for Power Nozzlel) O O

G

PIPE ASSEMBLY (Non Current) × ×

H

BRUSH ASSEMBLY (Power Nozzle) O O

I

BRUSH ASSEMBLY (Pedal) O O

J

BRUSH ASSEMBLY (Floor) O O

3

Page 5

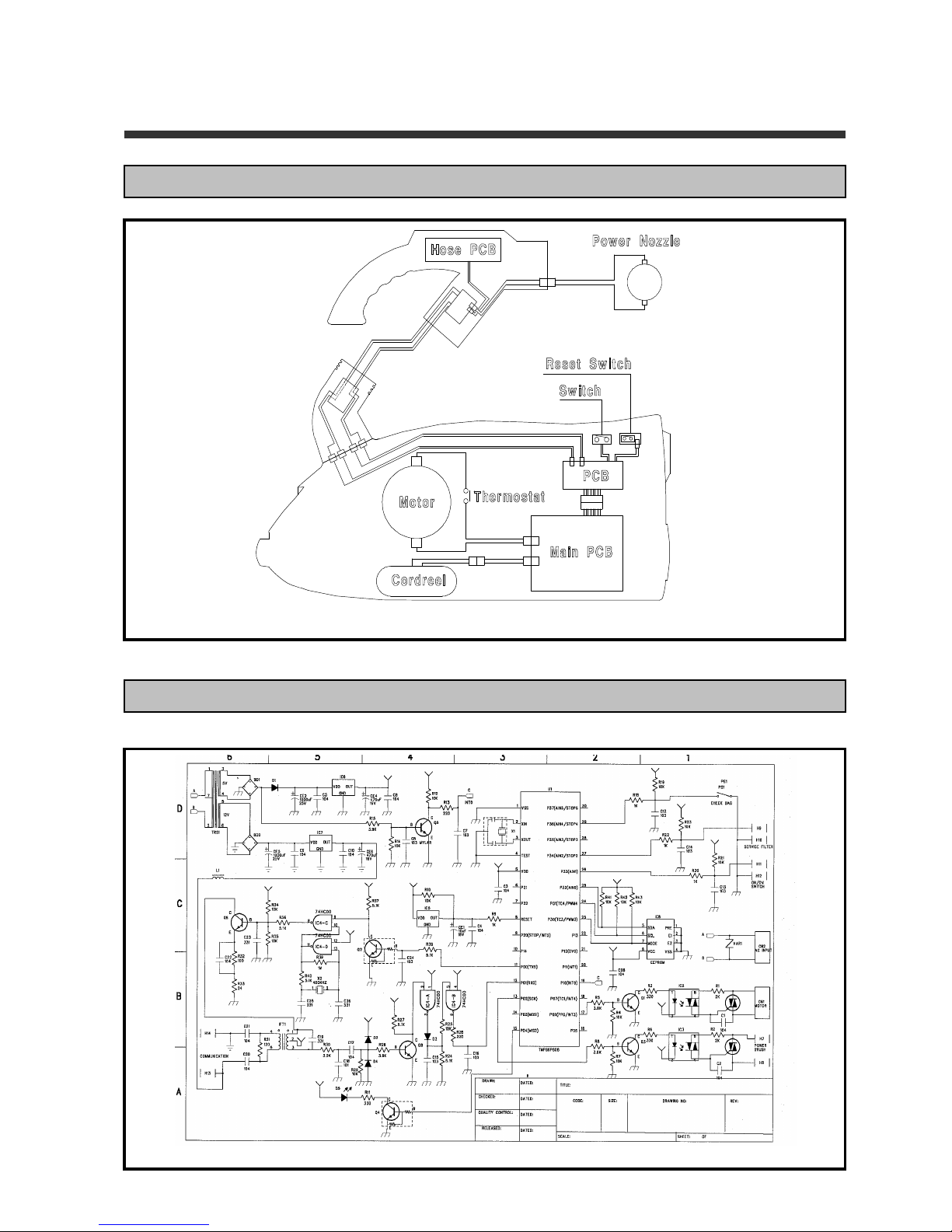

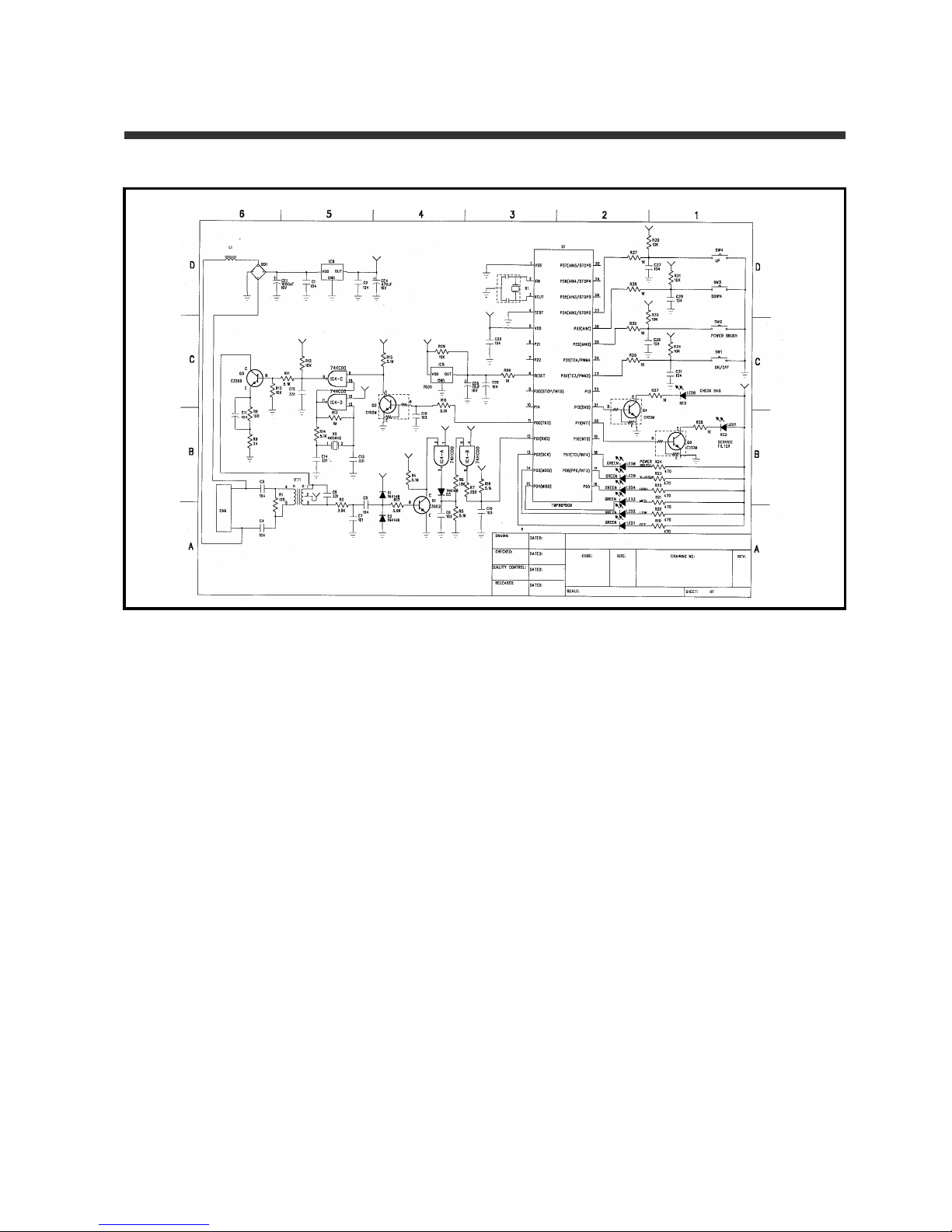

3. DIAGRAM

Main PCB

3-1. WIRING DIAGRAM

3-2. CIRCUIT DIAGRAM

4

Page 6

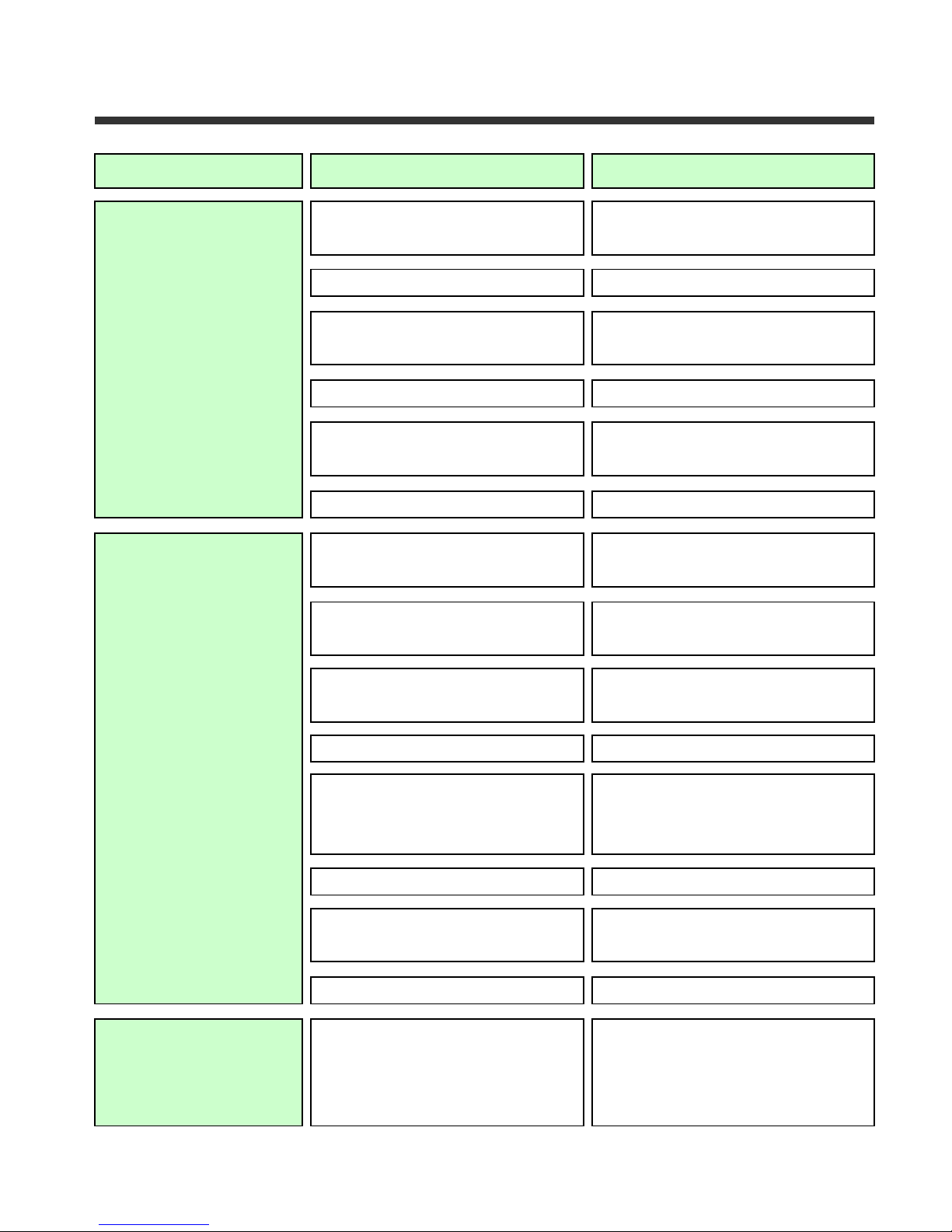

PCB IN THE HOSE ASSEMBLY

5

Page 7

4. TROUBLE SHOOTING GUIDE

TROUBLE COUNTERMEASURE

SUCTION POWER FILTER BAG(PAPER) IS FULL WITH CHANGE IT WITH NEW ONE (See 5-1)

IS WEAK DUST

FILTER PRE IS CLOGGY WITH DUST REMOVE THE DUST (See 5-2)

CLOGGING OR TEAR IN HOSE REMOVE OBSTACLE

OR REPLACE THE HOSE (See 5-6)

DEFECTIVE MOTOR REPLACE THE MOTOR (See 5-3)

THE OPENING IN BRUSH IS CLOGGY REMOVE THE DUST (See 5-7)

WITH DUST

FILTER(HEPA) IS FULL WITH DUST CHANGE IT WITH NEW ONE (See 5-1)

VACUUM CLEANER DOES BREAKING IN POWER CORD REPLACE THE POWER CORD(See 5-4)

NOT WORK (AT BLADE TIP OR ROOT OF PLUG)

BREAKING OF CONNECTIONS REPAIR (See 5-6)

IN HOSE ASSEMBLY

DEFECTIVE SWITCH REPLACE IT (See 5-1)

LOCATED IN COVER ASSEMBLY

DEFECTIVE PCB ASSEMBLY REPLACE IT (See 5-5)

BREAKING OF CONNECTIONS REPAIR (See 5-4)

OR POOR CONTACTS IN

CORD REEL ASSEMBLY

DEFECTIVE MOTOR REPLACE IT (See 5-3)

BREAKING OF CONNECTIONS REPAIR (See 5-2)

IN BODY ASSEMBLY

BREAKING IN A FUSE REPLACE IT (See 5-5)

MOTOR DOES NOT DEFECTIVE PCB ASSEMBLY REPLACE IT (See 5-5)

STOP EVEN IF

SWITCH

6

Page 8

TROUBLE CAUSE COUNTERMEASURE

BROKEN REEL SPRING REPLACE IT (See 5-4)

OF CORD REEL

POWER CORD BROKE AWAY REPAIR (See 5-4)

FROM THE BOBBIN

ABRASION OF THE ROLLER BRAKE REPLACE THE ROLLER

OF CORD REEL BRAKE (See 5-4)

LEVER SPRING BROKE AWAY REPAIR (See 5-4)

FROM THE CORD REEL BRACKET

DEFECTIVE POWER NOZZLE REPAIR

BREAKING OF CONNECTIONS REPAIR

IN PIPE ASSEMBLY

DEFECTIVE PCB REPLACE IT (See 5-6)

LOCATED IN HOSE

BREAKING OF CONNECTIONS REPAIR (See 5-6)

IN HOSE ASSEMBLY

BREAKING OF CONNECTIONS REPAIR (See 5-1)

IN COVER ASSEMBLY

DEFECTIVE PCB(for connection) REPLACE IT (See 5-1)

LOCATED IN COVER

DEFECTIVE MAIN PCB REPLACE IT (See 5-1)

LOCATED IN BODY

DEFECTIVE MAIN PCB REPLACE IT (See 5-1, 5-2, 5-5)

LOCATED IN BODY

POOR CONNECTION BETWEEN TUBE REPAIR (See 5-1, 5-2)

AND MAIN PCB

FULL BAG SENSOR DOES

NOT WORK

POWER CORD DOES

NOT STOP AT AN

ARBITRARY POSITION

POWER CORD IS

NOT WOUND UP

POWER NOZZLE DOES

NOT WORK

BE CAREFUL WHEN BREAKING UP THE CORD REEL, THE

REELSPRING

MAY SPRING OUT OF THE SPRING COVER.

CAUTION

7

Page 9

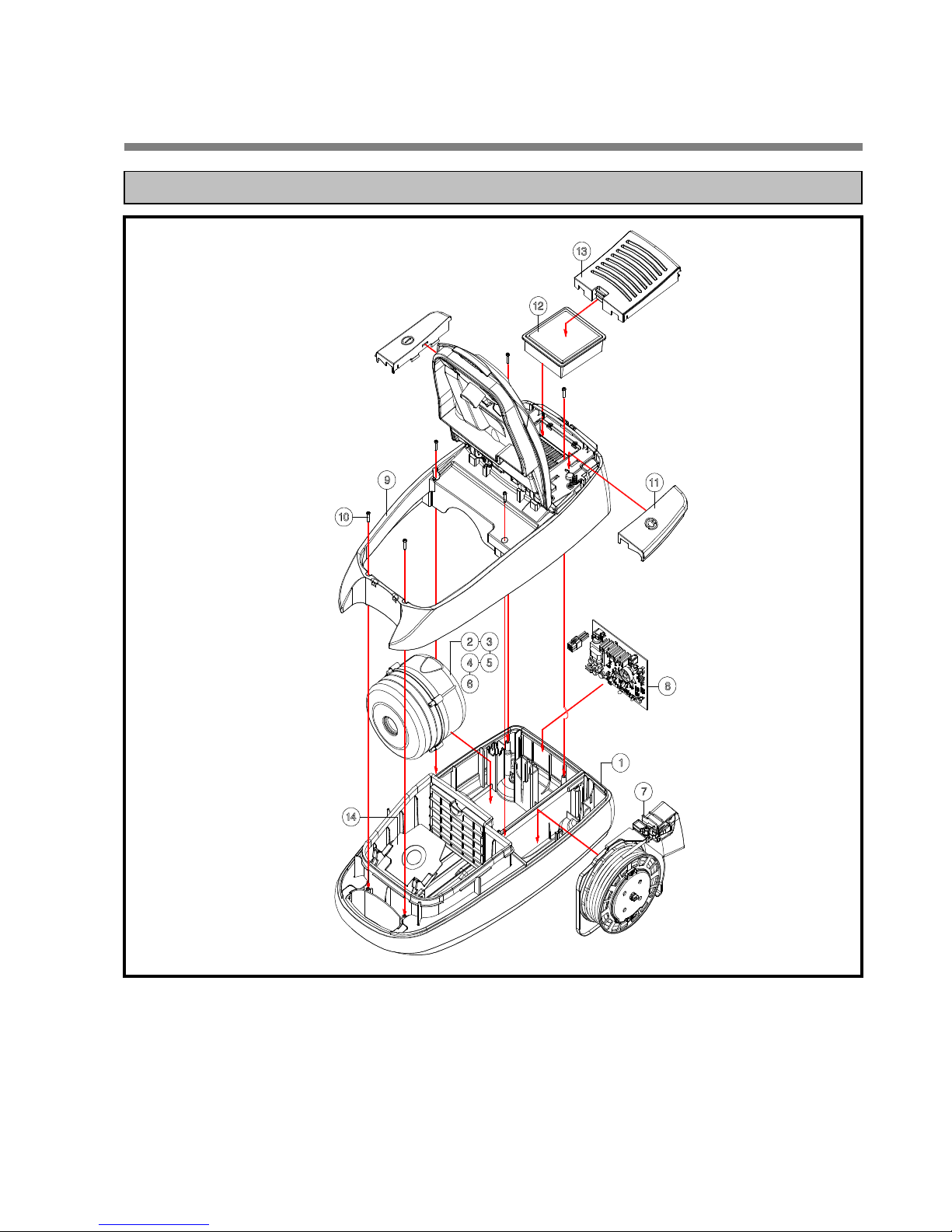

5. DISASSEMBLING AND TREATMENT

1) CHECK THE DUST BAG(14).

2) LIFT THE BUTTON(11), FILTER(12), GRILLE(13) AND UNSCREW THE 6 SCREWS(10).

AND THEN LIFT THE COVER ASSEMBLY(9) UP FROM THE BODY ASSEMBLY(1).

3) CHECK CONNECTION BETWEEN THE PCB(8) AND THE WIRES OF EACH ASSEMBLY(2,7,9) .

4) LIFT THE MOTOR ASSEMBLY(2), CORDREEL ASSEMBLY(7) FROM THE BODY ASSEMBLY(1).

5) CHECK CONNECTION BETWEEN THE PCB(8) AND TUBE IN THE BODY ASSEMBLY(1).

5) CHECK THE SWITCH IN THE COVER ASSEMBLY(9).

5-1. CLEANER ASSEMBLY

8

Page 10

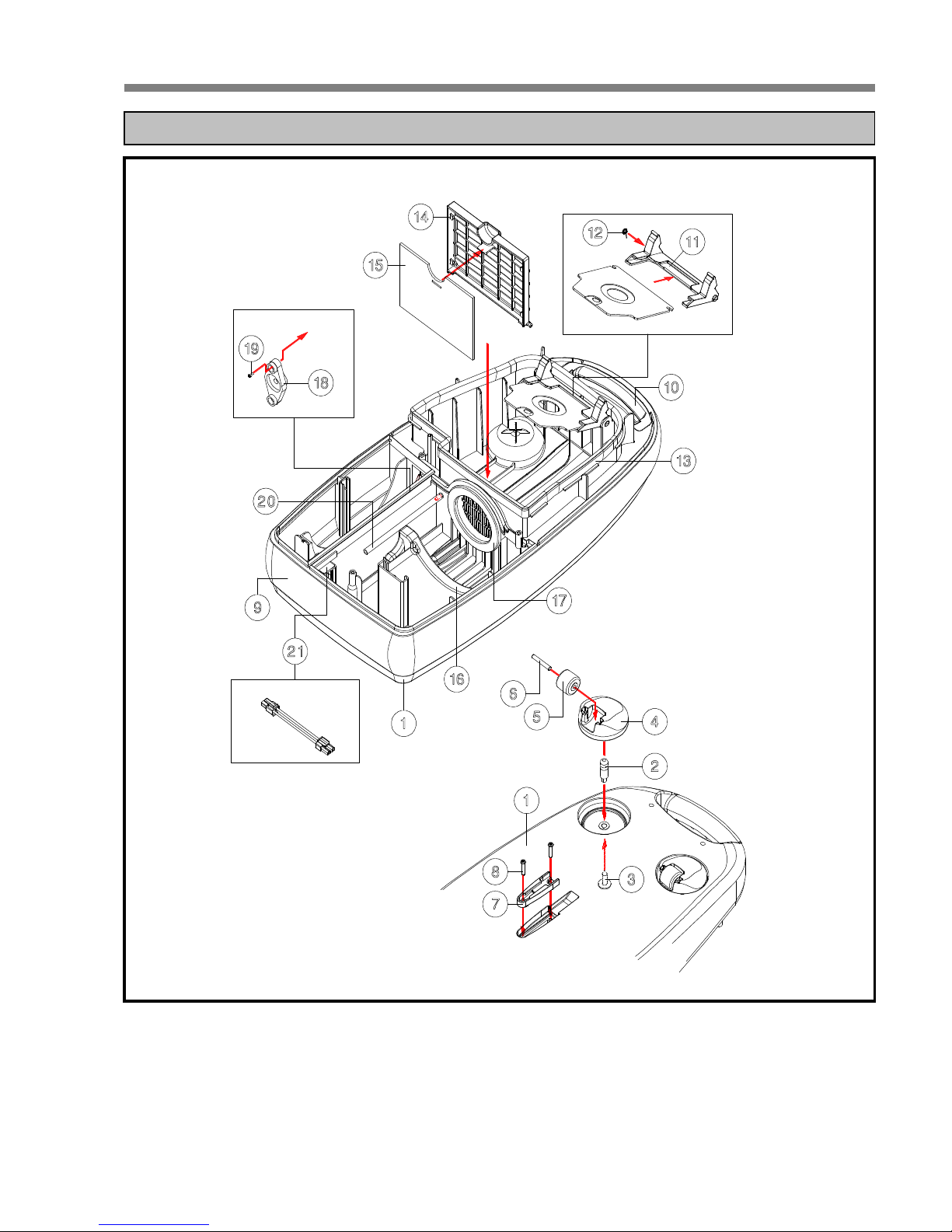

1) CHECK THE FILTER PRE (15).

2) CHECK CONNECTION BETWEEN PCB(8) AND THE TUBE(20) .

3) CHECK CONNECTION BETWEEN THE WIRE(21) AND THE MAIN PCB/ CORDREEL ASSEMBLY.

4) CHECK CONNECTION BETWEEN THE TUBE(20) AND SMALL PROTRUSION IN THE BODY(1).

5-2. BODY ASSEMBLY

9

Page 11

1) TAKE THE MOTOR OUT OF THE CASE (3, 4).

2) CHECK THE MOTOR(1) (WHETHER THE MOTOR IS BURNT OUT OR NOT).

3) CHECK CONNECTION BETWEEN MOTOR TERMINAL AND THE WIRES.

4) CHECK THE THERMOSTAT(7).

5-3. MOTOR ASSEMBLY

10

Page 12

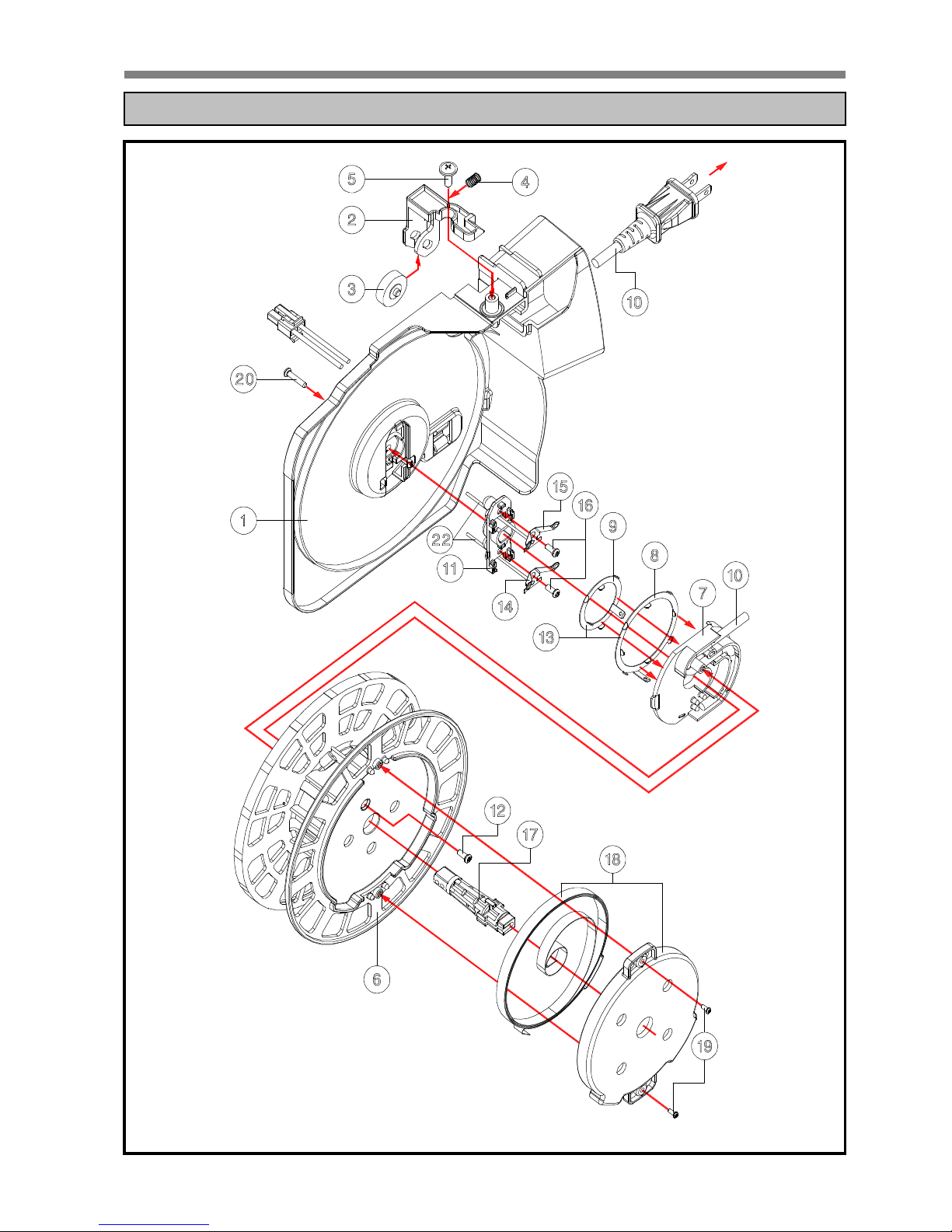

5-4. CORDREEL ASSEMBLY

11

Page 13

1) TAKE THE CORD REEL ASSEMBLY OUT OF THE BODY ASSEMBLY.

2) UNSCREW THE SCREW(20).

3) SEPARATE THE BOBBIN(6) FROM THE BRACKET(1) AND CHECK CONTACT

BETWEEN THE Y TYPE TERMINALS(14,15) AND THE RING TYPE TERMINALS(8,9).

4) CHECK THE LEVER SPRING(4).

5) IF THE ROLLER BRAKE(3) IS WORN OUT AND SEPARATE THE LEVER(2) FROM THE BRACKET

THEN REPLACE THE ROLLER BRAKE(3).

AT THIS TIME, THE BOBBIN(6) IS ROTATED COUNTERCLOCKWISE DUE TO THE PRESERVED

WINDING.

6) IF THE REEL SPRING(18) IS BROKEN, UNSCREW THE 2 SCREWS(19) AND REPLACE IT.

7) UNSCREW THE SCREW (12) AND SEPARATE THE HOLDER TERMINAL(7) FROM

THE BOBBIN(6).

8) CHECK CONNECTION BETWEEN THE POWER CORD(10) AND THE RING TERMINALS(8,9).

9) WHEN ASSEMBLING, MAKE THE RESERVED WINDING 5 REVOLUTIONS OF THE BOBBIN

CLOCKWISE.

CAUTION

WHEN DISASSEMBLING, THE REEL SPRING MAY

SPRING OUT OF THE COVER.

12

Page 14

1) CHECK THE CONNECTIONS BETWEEN THE WIRES AND PCB BOARD.

2) CHECK THE THERMOSTAT.

3) CHECK THE FUSE.

4) CHECK THE PRESSURE SENSOR.

5-5. PCB ASSEMBLY

13

Page 15

1) UNSCREW THE 2 SCREWS(15) AND DISASSEMBLE THE COVERS(8,9) FROM PIPE(1)

DISASSEMBLE THE COVER ADAPTER(10) FROM THE PIPE ADAPTER(8).

2) CHECK THE CONTACT BETWEEN TERMINAL(12) AND THE RING TERMINALS(2,3).

3) CHECK THE CONNECTION BETWEEN THE TERMINALS(12) AND WIRES.

4) CHECK THE CONNECTION BETWEEN THE RING TERMINALS(2,3) AND WIRES.

5) CHECK THE CONNECTION BETWEEN WIRES OF THE RING TERMINALS(2,3) AND HOSE(14).

6) CHECK THE INSIDE OF HOSE(14).

5-6. HOSE ASSEMBLY

14

Page 16

1) UNSCREW THE 4 SCREWS(32) AND DISASSEMBLE THE CAP COVER HANDLE(31) FROM

THE COVER HANDLE RIGHT/LEFT(26,27). DISASSEMBLE THE COVER HANDLE LEFT(27).

2) CHECK CONTACT BETWEEN THE TERMINAL(21) AND THE RING TERMINALS(2,3).

3) CHECK CONNECTION BETWEEN THE TERMINAL OF PCB(21) AND THE PCB ASSEMBLY(23).

4) CHECK CONNECTION BETWEEN THE TERMINAL(29) AND THE PCB(21).

5) CHECK CONNECTION BETWEEN THE WIRES OF RING TERMINALS2,3) AND THE HOSE(14).

6) CHECK THE PCB ASSEMBLY(23).

15

Page 17

1) TO SEPARATE THE PIPE BRUSH(4) FROM THE COVER BRUSH(1), UNSCREW

THE 4 SCREWS(15).

2) CHECK OPENING OF THE NECK BRUSH(8) AND THE PIPE BRUSH(5).

5-7. BRUSH ASSEMBLY

16

Page 18

6.EXPLODED VIEW AND PARTS LIST

6-1. CLEANER ASSEMBLY

17

Page 19

NO PART NAME PART CODE Q'YT

1 BODY AS 3620411600 ASSY(RC-900) 1

2 MOTOR UNIVERSAL 3962820750 120V 1100W DMI(F) VS122J2210 1

3 PACKING CASE 3624008500 NR FOAM 1

4 CASE MOTOR FRONT 3621106200 ABS 1

5 CASE MOTOR REAR AS 3621106500 ASSY 1

6 SCREW TAPPING 7121401411 T2S PAN 4X14 MFZN 4

7 CORD REEL AS 3629508200 ASSY 1

8 PCB BODY AS 3624313800 RC-900 1

9 COVER AS 3621435200 ASSY(ABS+PAINTING) 1

10 SCREW TAPPING 7121402011 T2S PAN 4X20 MFZN 6

11 BUTTON SW 3626607000 ABS 1

12 FILTER EXHAUST 3621908500 FRAME+HEPA 1

13 GRILL EXHAUST 3622401110 ABS+PAINTING+SILK 1

14 FILTER BAG CLOTH 3621909200 ASSY(TACONY-RICCAR) 1

15 HOSE AS (RC-1700P,S-36L) 3623210300 4CURRENT EVA,2M,LED, BUTTON 1

HOSE AS (RC-1700S, S-30L) 3623210350 2CURRENT EVA,2M,LED, BUTTON 1

16 PIPE AS (RC-1700P, S-36L) 3624411480 ASSY(ONE-TOUCH(2)+TERMINAL) 1

PIPE AS (RC-1700S, S-30L) 3624411490 AL-NAT,T=0.85 1

17 BRUSH AS (RC-1700P) 3629308900 ASSY(POWER-UL-RICCAR) 1

18 BRUSH AS 3629306610 PEDAL(NON-SILK) 1

19 BRUSH AS 3629309300 ASSY(FLOOR-TACONY) 1

SPECS.

18

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Page 20

6-2. BODY ASSEMBLY

19

Page 21

NO PART NAME PART CODE Q'YT

1 BODY 3620411500 ABS 1

2 SHAFT CASTER 3624902000 MSWR 4

3 SCREW TAPPING 7048402012 MACHINE 4X14 WASHER BLACK 4

4 BRACKET ROLLER 3620602900 PA, RHODIA, TECHNYL 1011HI 4

5 ROLLER CASTER 3624706400 PVC-S + POM 4

6 SHAFT ROLLER 3624902100 MSWR 4

7 HOLDER BRUSH 3623007000 PC(LEXAN121) 1

8 SCREW TAPPING 7121401411 T2S PAN 4X14 MFZN 2

9 PROTECTOR 3628302000 PVC-S 1

10 COVER PROTECTOR 3621434000 ABS 1

11 HOLDER FILTER 3623007100 PP 1

12 SPRING HOLDER 3625109700 HSW3 1

13 GASKET 3622302000 PVC-S 1

14 CASE FILTER 3621106100 PP 1

15 FILTER IN 3621908300 PE+CHARCOAL+PP FIBER 1

16 ABSORBER VIBRATION 3620112700 NR FOAM 1

17 PACKING CASE 3624008400 NR FOAM 1

18 COVER HOLE 3621435900 PP 1

19 SCREW TAPPING 7121300811 T2S PAN 3X8 MFZN 1

20 TUBE SILICON 3625700200 SILICON RUBBER 1

21 HARNESS 3622714700 ASSY 1

SPECS.

20

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Page 22

6-3. COVER BODY ASSEMBLY

21

Page 23

NO PART NAME PART CODE Q'YT

1 COVER BODY 3621434210 ABS+PAINTING+SILK 1

2 ABSORBER VIBRATION 3620102810 NR FOAM 1

3 GASKET 3622302100 NR FOAM 1

4 FILTER MIDDLE 3621908400 PE+TAPE 1

5 SWITCH PUSH 3629004000 7A, 250V (SKT) 1

6 PCB RESET SWITCH AS 3624314200 ASSY 1

7 SCREW TAPPING 7121300811 T2S PAN 3X8 MFZN 1

8 LABEL RESET FUNCTION 3623507360 RESET FUNCTION STICKER 1

9 PCB CONNECTION AS 3624313900 RC-900 1

10 PACKING PCB 3624008600 NR 1

11 COVER DUST AS 3621435300 ASSY(ABS+PAINTING) 1

12 SUPPORTER STAND 3625300600 ABS 1

13 SCREW TAPPING 7121401411 T2S PAN 4X14 MFZN 8

14 SPRING BUTTON 3625110000 HSW3 2

15 BUTTON CR 3626607100 ABS 1

SPECS.

22

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Page 24

6-4. COVER DUST ASSEMBLY

23

Page 25

NO PART NAME PART CODE Q'YT

1 COVER DUST 3621434310 ABS+PAINTING 1

2 PLATE DUST COVER 3624502400 ABS 1

3 FRAME TERMINAL AS 3622201840 ASSY 1

4 SOCKET 3629801900 ABS(AF305) 1

5 CLAMP COVER 3621202900 ABS 1

6 SPRING CLAMP 3625106400 HSW3 1

7 CLAMP NOZZLE 3621203000 POM 1

8 BUTTON NC 3626606900 ABS 1

9 SPRING SWEEPER 3625107900 HSW3 1

10 DAMPER 3626900200 NOZZLE COVER 1

11 SCREW TAPPING 7121301211 T2S PAN 3X12 MFZN 1

12 SCREW TAPPING 7121401411 T2S PAN 4X14 MFZN 11

13 SPRING TORSION 3625110100 HSW3 (DUST COVER) 1

14 HINGE NOZZLE COVER 3622900100 AL + COATING 1

15 COVER NOZZLE 3621434410 ABS+PAINTING+SILK 1

16 NOZZLE CREVICE 3628101500 PP 1

17 BRUSH DUSTING 3629307100 PP+PIG HAIR 1

18 NOZZLE UPHOLSTERY 3628101600 PP 1

19 BRUSH FLOOR AS 3629309400 ASSY 1

SPECS.

24

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Page 26

NO PART NAME PART CODE Q'YT

1 MOTOR UNIVERSAL 3962820750 120V 1100W DMI(F) VS122J2210 1

2 PACKING CASE 3624008500 NR FOAM 1

3 CASE MOTOR FRONT 3621106200 ABS 1

4 CASE MOTOR REAR 3621106300 ABS 1

5 MOUNT MOTOR 3627901100 NR 1

6 THERMOSTAT 3629002100 KI T95 1

7 SCREW TAPPING 7121300811 T2S PAN 3X8 MFZN 2

8 SCREW TAPPING 7121401411 T2S PAN 4X14 MFZN 4

6-5. MOTOR ASSEMBLY

SPECS.

25

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Page 27

6-6. CORDREEL ASSEMBLY

26

Page 28

NO PART NAME PART CODE Q'YT

1 BRACKET CR 3620603000 ABS 1

2 LEVER CR 3623703200 ABS 1

3 STOPPER ASSY 3625200200 ASSY 1

4 SPRING CR LEVER 3625109800 HSW3 1

5 SCREW TAPPING 7128401011 T2S WAS 4X10 MFZN 1

6 BOBBIN 3629200900 PP 1

7 HOLDER TERMINAL 4565A36020 PP(5101SW,V-0) 1

8 TERMINAL 4565A36024 C2600P-1/2H T0.3 1

9 TERMINAL 4565A36034 C2600P-1/2H T0.3 1

10 CORD POWER 3621304500 125V12A 8.5M AWG16 1

11 HOLDER Y TERMINAL 3623007200

³-¿¬PP

1

12 SCREW TAPPING 7121301411 T2S PAN 3X14 MFZN 1

13 WAX VASELINE 2291140301 VASELINE 0.002

14 TERMINAL Y AS 3628713700

TERMINAL+WIRE(WH)+CONNECTOR

1

15 TERMINAL Y AS 3628713800 TERMINAL+WIRE(BK) 1

16 SCREW TAPPING 7121401011 T2S PAN 4X10 MFZN 2

17 SHAFT CR 3624901900 PC(LEXAN 500) 1

18 SPRING AS 3625109900 SPRING + COVER(PP) 1

19 SCREW TAPPING 7121300811 T2S PAN 3X8 MFZN 2

20 SCREW TAPPING 7121401411 T2S PAN 4X14 MFZN 1

SPECS.

27

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Page 29

6-7. PCB ASSEMBLY

28

Page 30

NO PART NAME PART CODE Q'YT

1 PCB BODY 3624313100 1.6T, FR-1 1

2 HEAT SINK 3627400800 60*33,2T 1

BD1 DIODE BRIDGE DDF1502M-- DF1502M 1

BD2 DIODE BRIDGE DDF1502M-- DF1502M 1

C1 C CERA MONOLITHIC CZZZ1H104Z Z5U 50V 0.1MF Z AXIAL 1

C10 C CERA MONOLITHIC CZZZ1H104Z Z5U 50V 0.1MF Z AXIAL 1

C12 C CERA MONOLITHIC CZZZ1H103Z Z5U 50V 0.01MF Z AXIAL 1

C13 C CERA MONOLITHIC CZZZ1H103Z Z5U 50V 0.01MF Z AXIAL 1

C14 C CERA MONOLITHIC CZZZ1H103Z Z5U 50V 0.01MF Z AXIAL 1

C15 C CERA MONOLITHIC CZZZ1H103Z Z5U 50V 0.01MF Z AXIAL 1

C16 C CERA MONOLITHIC CZZZ1H103Z Z5U 50V 0.01MF Z AXIAL 1

C17 C CERA MONOLITHIC CZZZ1H104Z Z5U 50V 0.1MF Z AXIAL 1

C18 C CERA MONOLITHIC CZZZ1H101Z Z5U 50V 100PF Z AXIAL 1

C19 C CERA CZZB1H331K MLC 50V 0.00033MF K AXIAL 1

C2 C CERA MONOLITHIC CZZZ1H104Z Z5U 50V 0.1MF Z AXIAL 1

C20 C CERA MONOLITHIC CZZZ1H104Z Z5U 50V 0.1MF Z AXIAL 1

C21 C CERA MONOLITHIC CZZZ1H104Z Z5U 50V 0.1MF Z AXIAL 1

C22 C CERA MONOLITHIC CZZZ1H104Z Z5U 50V 0.1MF Z AXIAL 1

C23 C CERA CZZB1H331K MLC 50V 0.00033MF K AXIAL 1

C24 C CERA MONOLITHIC CZZZ1H103Z Z5U 50V 0.01MF Z AXIAL 1

C25 C CERA CZZB1H331K MLC 50V 0.00033MF K AXIAL 1

C26 C CERA CZZB1H331K MLC 50V 0.00033MF K AXIAL 1

C27 C CERA MONOLITHIC CZZZ1H103Z Z5U 50V 0.01MF Z AXIAL 1

C28 C CERA MONOLITHIC CZZZ1H104Z Z5U 50V 0.1MF Z AXIAL 1

C3 C CERA MONOLITHIC CZZZ1H104Z Z5U 50V 0.1MF Z AXIAL 1

C4 C CERA MONOLITHIC CZZZ1H104Z Z5U 50V 0.1MF Z AXIAL 1

C5 C CERA MONOLITHIC CZZZ1H104Z Z5U 50V 0.1MF Z AXIAL 1

C6 C MYLAR CMXV2A103J DC 100V 0.01MF J 1

C7 C CERA MONOLITHIC CZZZ1H103Z Z5U 50V 0.01MF Z AXIAL 1

C8 C CERA MONOLITHIC CZZZ1H104Z Z5U 50V 0.1MF Z AXIAL 1

C9 C CERA MONOLITHIC CZZZ1H104Z Z5U 50V 0.1MF Z AXIAL 1

CE1 C ELECTRO CEXF1C100V RSS 16V 10MF 4*7 1

CE2 C ELECTRO CEXF1C102C 16V RUS 1000MF (10X20) TP 1

CE4 C ELECTRO CEXF1C471C 16V RUS 470MF (10X12.5)TP 1

CE5 C ELECTRO CEXF1E102C 25V RUS 1000MF (13X20) TP 1

CE6 C ELECTRO CEXF1C471C 16V RUS 470MF (10X12.5)TP 1

SPECS.

29

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Page 31

NO PART NAME PART CODE Q'YT

CN1 CONN WAFER 997920007R MG 640598-1 1

CN2 CONN WAFER 997920007N MG 640598NETURAL 1

D1 DIODE D1N4004--- 1N4004 1

D2 DIODE DZN4148M-- 1N4148M (5MM) 1

D3 DIODE DZN4148M-- 1N4148M (5MM) 1

D4 DIODE DZN4148M-- 1N4148M (5MM) 1

FC HOLDER FUSE 3623002300 FUSE CLIP FC-61B 2

FUSE FUSE GLASS TUBE 5FJGD1532R JIS NR 15A 250V MF61 1

HNS HARNESS 3622714700 ASSY 1

IC1 IC MICOM 1TMP86P808 TMP86P808 1

IC2 PHOTO COUPLER DTLP560J-- TLP560J 1

IC3 PHOTO COUPLER DTLP560J-- TLP560J 1

IC4 LOGIC IC 174HC00AP- 74HC00AP 1

IC5 RESET IC 1L7035AP-- KIA7035AP 1

IC6 IC REGULATOR 1K1A7805AP K1A7805AP 1

IC7 IC REGULATOR 1K1A7812AP K1A7812AP 1

IC8 IC MEMORY 1M24C04BN6 M24C04-BN6 1

IFT1 IFT 5107ABK100 P-7LC 1

J1 WIRE JUMPER W581GY1505 AWG22 1/0.65 GY 15 AUTO 1

J10 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO 1

J11 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO 1

J12 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO 1

J5 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO 1

J6 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO 1

J7 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO 1

J9 WIRE JUMPER W581GY1005 AWG22 1/0.65 SN 10 AUTO 1

JS1 WIRE JUMPER W581GY0755 AWG22 1/0.65 GY 7.5 AUTO 1

JS3 WIRE JUMPER W581GY0755 AWG22 1/0.65 GY 7.5 AUTO 1

L1 COIL CHOKE 52C471K100 90X0.16 10 470UH K 1

LED1 LED DDLG302D2- DLG-302D2 1

PS1 SWITCH PRESSURE 3629005000 190MMB 1

Q1 TR TZTC3202Y- KTC3202Y (AUTO)(1959Y) 1

Q2 TR TZRC102M-- KRC102M(KEC) 1

Q3 TR TZTC3202Y- KTC3202Y (AUTO)(1959Y) 1

Q4 TR TZRC102M-- KRC102M(KEC) 1

Q5 TR TZTC3202Y- KTC3202Y (AUTO)(1959Y) 1

SPECS.

30

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Page 32

NO PART NAME PART CODE Q'YT

Q6 TR TZTC3202Y- KTC3202Y (AUTO)(1959Y) 1

Q8 TR TZTC3202Y- KTC3202Y (AUTO)(1959Y) 1

R1 R M-OXIDE FILM RS01Z202J- 1W 2K OHM J 1

R10 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R11 R CARBON FILM RD-AZ331J- 1/6 330 OHM J 1

R12 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R13 R CARBON FILM RD-AZ221J- 1/6 220 OHM J 1

R14 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R15 R CARBON FILM RD-AZ392J- 1/6 3.9K OHM J 1

R18 R CARBON FILM RD-AZ102J- 1/6 1K OHM J 1

R19 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R2 R M-OXIDE FILM RS01Z202J- 1W 2K OHM J 1

R20 R CARBON FILM RD-AZ102J- 1/6 1K OHM J 1

R21 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R22 R CARBON FILM RD-AZ102J- 1/6 1K OHM J 1

R23 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R24 R CARBON FILM RD-AZ512J- 1/6 5.1K OHM J 1

R25 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R26 R CARBON FILM RD-AZ221J- 1/6 220 OHM J 1

R27 R CARBON FILM RD-AZ512J- 1/6 5.1K OHM J 1

R28 R CARBON FILM RD-AZ392J- 1/6 3.9K OHM J 1

R29 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R3 R CARBON FILM RD-4Z331J- 1/4 330 OHM J 1

R30 R CARBON FILM RD-AZ392J- 1/6 3.9K OHM J 1

R31 R CARBON FILM RD-4Z121J- 1/4 120 OHM J 1

R32 R CARBON FILM RD-AZ101J- 1/6 100 OHM J 1

R33 R CARBON FILM RD-AZ240J- 1/6 24 OHM J 1

R34 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R35 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R36 R CARBON FILM RD-AZ512J- 1/6 5.1K OHM J 1

R37 R CARBON FILM RD-AZ512J- 1/6 5.1K OHM J 1

R38 R CARBON FILM RD-AZ512J- 1/6 5.1K OHM J 1

R39 R CARBON FILM RD-AZ105J- 1/6 1M OHM J 1

R4 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

R40 R CARBON FILM RD-AZ512J- 1/6 5.1K OHM J 1

R41 R CARBON FILM RD-AZ103J- 1/6 10K OHM J 1

SPECS.

31

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Page 33

NO PART NAME Q'YT

R42 RD-AZ103J- 1/6 10K OHM J

R43 R CARBON FILM 1/6 10K OHM J 1

R CARBON FILM RD-AZ392J- 1

R6 RD-4Z331J- 1/4 330 OHM J

R7 R CARBON FILM 1/6 10K OHM J 1

R CARBON FILM RD-AZ392J- 1

R9 RD-AZ102J- 1/6 1K OHM J

T1 TRIAC BTA16-600BWRG 1

TRIAC TBTA12600B 1

TR1 5EPU351600 120V 60HZ 5V 12V

VAR1 VARISTOR SVC471D14A 1

RESONATOR CERA 5PCST800MT 1

X2 5PCSB400P- CSBLA400KJ5E-BO

SPECS.

32

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Page 34

6-8. HOSE ASSEMBLY

33

Page 35

34

Page 36

NO PART NAME PART CODE Q'YT

1 PIPE INNER ADAPTER 3624414800 ABS(AF305) 1

2 FRAME TERMINAL AS 3622203100 ASSY (ADAPTER, FIRST) 2

3 FRAME TERMINAL AS 3622203200 ASSY (ADAPTER, SECOND) 2

4 PIPE ADAPTER 3624414900 ABS 1

5 SUPPORTER TERMINAL 3625300700 ABS(AF305) 1

6 COVER TOP 3621424600 PP 1

7 BUTTON HOSE ADAPTER 3626607200 ABS 1

8 COVER ADAPTER RIGHT 3621434700 ABS 1

9 COVER ADAPTER LEFT 3621434800 ABS 1

10 COVER ADAPTER 3621434900 ABS 1

11 PACKING PIPE 3624002400 NBR 2

12 PCB Y TERMINAL AS 3624314000 ASSY (ADAPTER) 1

13 SCREW TAPPING 7121300812 T2S PAN 3X8 MFZN BK 1

14 HOSE EVA 3623210200 EVA 2

15 TAPE VINYL 2TU00019BK 19MM BLACK 0.3

16 TUBE SHRINK 8-UH0400BK AWG 9 D=4.0 MM BLACK UL 0.24

17 CLAMP COVER HANDLE 3621203100 ABS 1

18 PIPE INNER HANDLE 3624415000 ABS 1

19 CUFF HOSE 3626801200 ABS 2

20 PIPE ADAPTER HANDLE 3624415100 ABS(AF305) 1

21 PCB Y TERMINAL AS 3624314100 ASSY (HANDLE) 1

22 WAX VASELINE 2291140301 VASELINE 0.001

23 PCB HANDLE AS 3624314300 ASSY (HOSE CONTROL) 1

24 PLATE HANDLE PCB 3624502500 ABS 1

25 DECORATOR 3621600700 PC FILM 1

26 COVER HANDLE RIGHT 3621435000 ABS 1

27 COVER HANDLE LEFT 3621435100 ABS 1

28 CASE TERMINAL 3621102100 PC LEXAN 500 1

29 HARNESS 3622715100 ASSY(HOSE, POWER BRUSH) 1

30 HOLDER TERMINAL CASE 3623007400 ABS(AF305) 1

31 CAP COVER HANDLE 3620904500 ABS 1

32 SCREW TAPPING 7121301212 T2S PAN 3X12 MFZN BK 8

SPECS.

35

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Page 37

6-9. PIPE ASSEMBLY

36

Page 38

NO PART NAME PART CODE Q'YT

1 PIPE AL OUT 3624414000 AL T=1.0 1

2 GUIDE AL PIPE 3622504500 POM 1

3 LOCKER 3623800100 POM 1

4 GUIDE SPRING 3622504400 POM 1

5 SPRING E-PIPE 3625109300 HSW3 2

6 COVER UP 3621431900 ABS 1

7 COVER DOWN 3621432000 ABS 1

8 HOLDER COVER 3623006600 ABS 2

9 HOLDER TERMINAL 3622307000 NYLON66 1

10 TERMINAL AS 3628710230 TERMINAL+WIRE 2

11 CAP TERMINAL 3622307100 ABS 1

12

HOLDER TERMINAL DOWN

3622306900 NYLON66 1

13 HOLDER TERMINAL UP 3622306800 NYLON66 1

14 PIPE ADAPTER 3624414600 ABS 1

15 COVER CUFF 3621433400 ABS 1

16 SCREW TAPPING 7121301011 T2S PAN 3X10 MFZN 2

17 CUFF PIPE 3626801100 ABS 1

18 BUTTON 3626603800 PC 1

19 SPRING 3625100500 HSW3 1

20 COVER BUTTON 3621418500 ABS 1

21 PIPE AL IN 3624413900 AL T=1.0 1

22 PACKING INNER 3624007900 LDPE 1

23 PIPE AL EXHAUST 3624414100 AL T=1.0 1

24 HOLDER TERMINAL LOW 3622307200 NYLON66 1

25 TERMINAL AS 3628710220 TERMINAL+WIRE 2

26 HOLDER TERMINAL UP 3622307300 NYLON66 1

27 COVER ADAPTER 3621433300 ABS 1

28 LOCK SLIDE 3623800200 POM 2

SPECS.

37

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Page 39

NO PART NAME PART CODE Q'YT

1 BRUSH 3629308900 ASSY (POWER NOZZLE) 1

6-10. BRUSH ASSEMBLY (POWER NOZZLE)

SPECS.

38

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Page 40

NO PART NAME PART CODE Q'YT

1 BRUSH AS 3629309300 ASSY(FLOOR-TACONY) 1

6-11. BRUSH ASSEMBLY (FLOOR)

SPECS.

39

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Page 41

6-12. BRUSH ASSEMBLY (PEDAL)

40

Page 42

NO PART NAME PART CODE Q'YT

1 COVER BRUSH 3621420800 PP 1

2 DUCT BRUSH 3629306300 PP 1

3 NECK BRUSH 3628002100 PP 1

4 PIPE BRUSH 3624408300 PP, CLEAN BR PIPE 1

5 ROLLER-F BRUSH 3624704310 PP 2

6 SHAFT ROLLER 3624900900 PA 2

7 ROLLER-B BRUSH 3624704400 PP 2

8 BUTTON BRUSH 3626604400 ABS 1

9 SPRING BUTTON 3625107300 SK-5,T=0.3 1

10 SCREW TAPPING 7128400811 T2S WAS 4X8 MFZN 1

11 SWEEPER BRUSH AS 3629306400 ASS'Y 1

12 SHAFT SWEEPER 3624901400 SWRM MFZN 1

13 BODY BRUSH 3620407800 PP 1

14 PICKER LITTER 3627000700 PA 2

15 SCREW TAPPTITE 7171401412 TT2 PAN 4X14 MFZN BK 4

SPECS.

41

✔ Caution:

In this Service Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in Service information Center(http://svc.dwe.co.kr)

Loading...

Loading...