Daewoo KUD-WD135 SERIES, DWD-WD135 SERIES, DWD-WD135*02 Service Manual

Version 1.1

2009. 10. 23

Service Guide

Drum Washing Machine

Model :KUD-WD155S

DWD-WD135*

DWD-WD135*02

✔ Caution

: In this Manual, some parts can be changed for improving,

their performance without notice in the parts list. So, if you

need the latest parts information, please refer to PPL(Parts

Price List) in Service Information Center (http://svc.dwe.co.kr).

DRUM WASHING MACHINE

SERVICE GUIDE

" What is Drum Washing machine.............................................................2

"Product Spec.............................................................................................5

"Operating Mechanism Diagram...............................................................6

"Parts list for each Assy .............................................................................7

"Control Part Function Spec. ...................................................................19

"PCB Pin Arrangement ...........................................................................44

"Electronic Parts List Spec. .....................................................................45

"Power Defect...........................................................................................59

"Noise Defect............................................................................................60

"Wirng Diagram .......................................................................................61

"Installation ..............................................................................................62

"Reversing the door..................................................................................64

"Dismantling method per washer ass’y ..................................................66

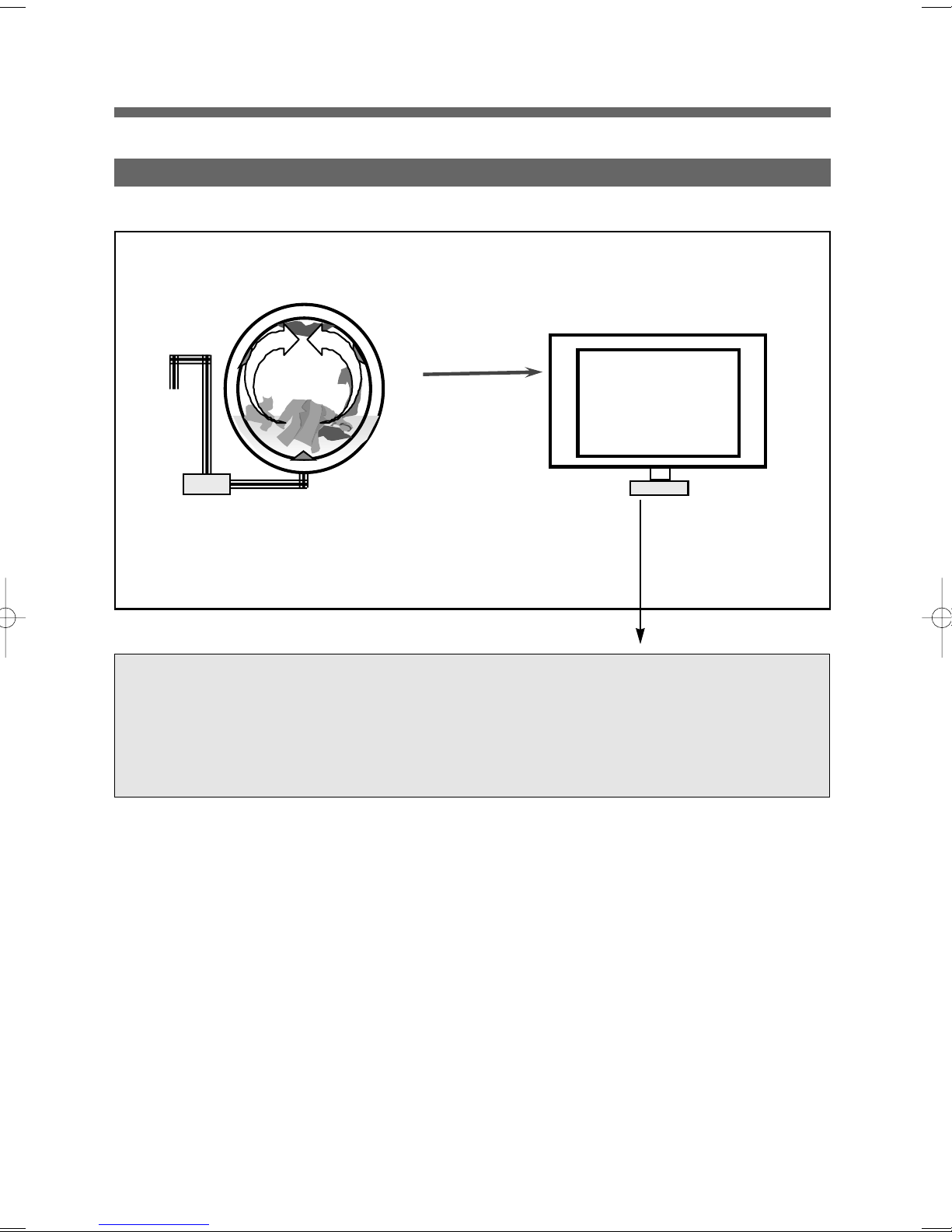

What is Drum Washing Machine?

"

1. Drum Washing Machine

Water consumption is reduced by using the power of the laundry falling (free-fall) created when rotating

the drum resembling a sieve net. With temperature control system, this drum washing machine saves

energy and improves washing performance at the same time.

2. Features of Drum Washing Machine

" Note that some features are options.

# Simultaneous supply of cold$hot water

As cold and hot water is supplied at the same time, heating time and energy is saved.

# Top-quality popup dial

The top-quality popup dial is used only during washing process.

# Dust filter

Filter to remove foreign substances, such as naps generated during washing, etc., is installed inside the

drum.

# DD inverter motor

The direct-drive type, of which motor is directly connected to drum without an interim clutch,

significantly reduces noise and vibration.

# Heating device is installed to enable boiling of the laundry.

# Large door creates grand appearance and makes it easy to put in and out the laundry.

# For pump drainage, the powerful pump speeds up drainage process.

2

3. Power System

Drainage Motor

BLDC Motor

Turbo

Drum

The

Laundry

#DD Control: Direct drive type of direct connection between drum and motor

#Rotation by powerful high-performance BLDC motor

#Pump drainage type for built-in installation

3

4. Major Functions of Drum Washing Machine

% Washing

When rotating drum after putting in the laundry and detergent into the drum, the laundry are rotated by

protrusions (lifters) attached inside the drum.

Washing is carried out with bending and impact actions generated by falling of the laundry to the top

part of drum.

& Rinsing

Rinsing cleanly washes out detergent and dirt removed from the laundry after washing cycle.

' Spin-drying

Weak, standard and strong cycles can be selected according to types of fabrics to be washed. Spindrying is carried out by rotation (the centrifugal force) of drum according to the designated speed.

( Drainage

Pump Drainage: Powerful pump for built-in installation and application of filter to remove foreign

substances

4

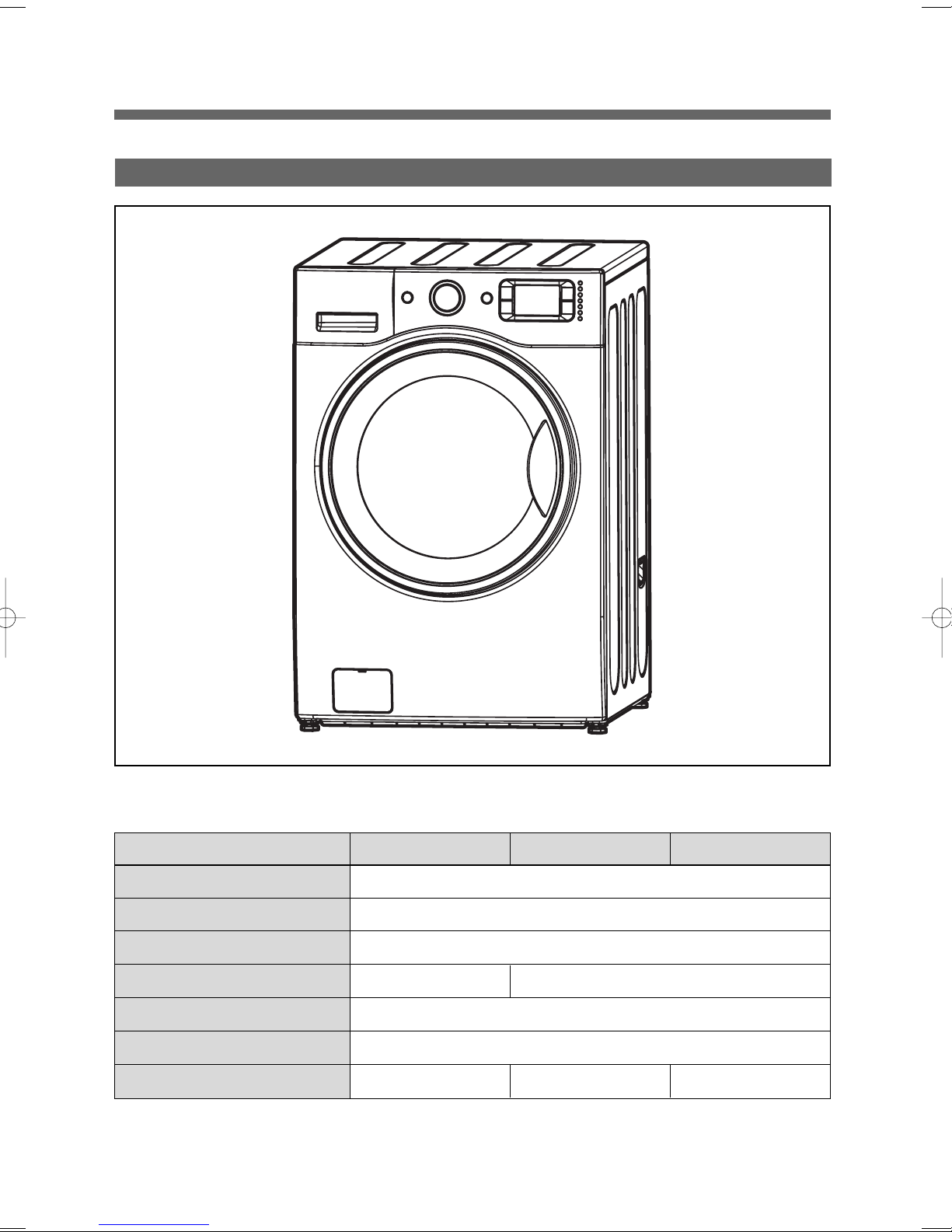

Product Spec

"

Product Spec.

MODEL DWD-WD125* DWD-WD135* DWD-WD135*S

Dimension (inches) 27 x 31.8 x 40.1 (W x D x H) (Door open D : 40.9)

Unit Weight (lbm) 198.4(Net) / 227(Gross)

Wash capacity 3.92 cu.ft. DOE, 4.5 cu.ft. IEC, 10.4kg

Spin Speed (RPM)

Operating Water Pressure 4.5~145 PSI (30~1000 kPa)

Electrical Spec. 120V / 60Hz, 10 A

Option Spec

1200 rpm max. 1300 rpm max.

XXSteam(900W)

5

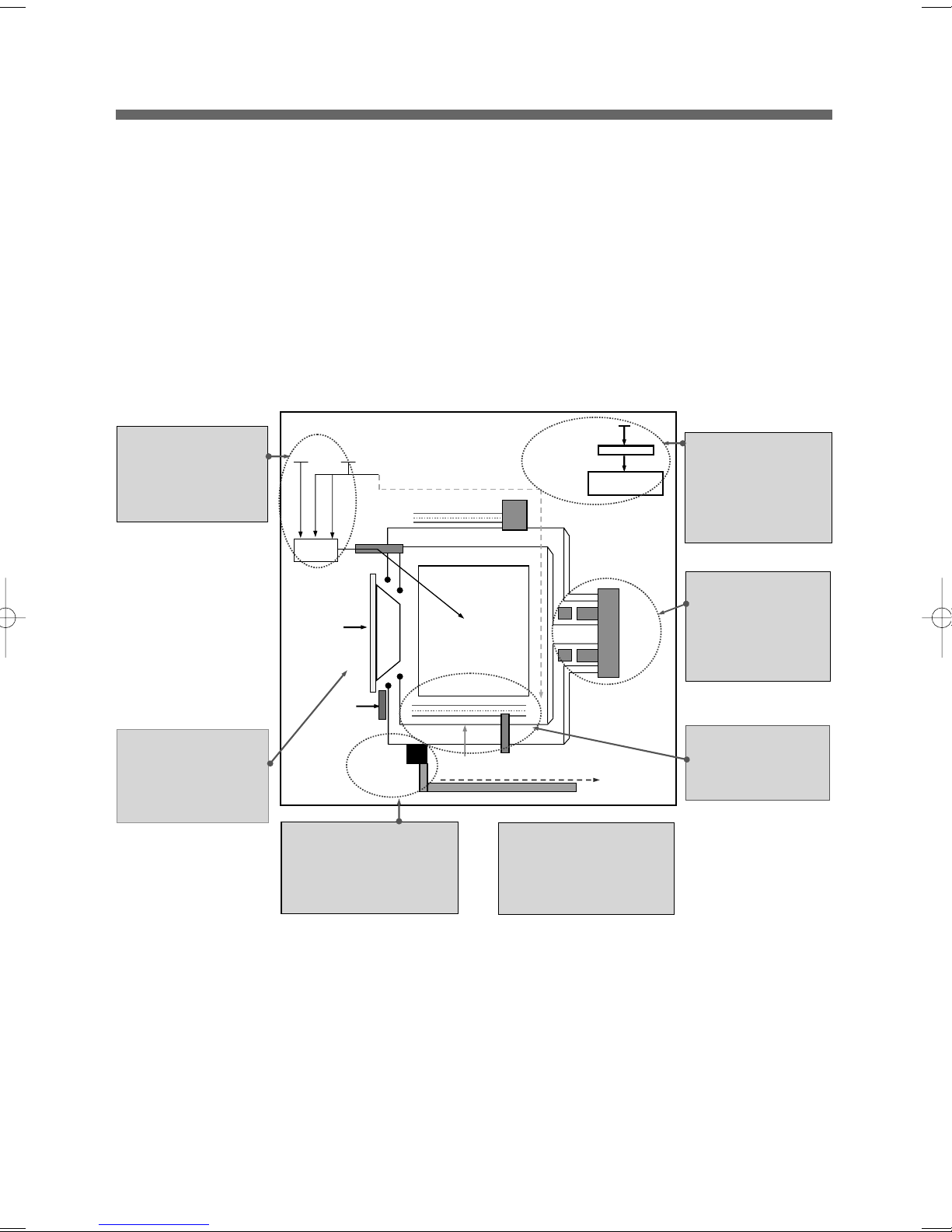

Operating Mechanism Diagram

"

4. WATER SUPPLY PART

4. WATER SUPPLY PART

• Cold Water: 3 holes

• Cold Water: 3 holes

Cold water, pre-washing

Cold water, pre-washing

• Hot Water: 1 hole

• Hot Water: 1 hole

• Water supply box, hose

• Water supply box, hose

5. DOOR

5. DOOR

• Door lock S/W

• Door lock S/W

• Lock hinge

- Lock hinge

• Door AS: Glass

• Door AS: Glass

• Gasket

• Gasket

Water

Supply

Delergent

Container

Thermister

Door

Door

Switch

Drainage

Pump

6. DRAINAGE PART

6. DRAINAGE PART

• Drainage pump

• Drainage pump

• Valve housing

• Valve housing

• Hose

• Hose

Drum

Washing

Heater

Electricity Input

Noise Filter

Thermister

7. SUPPORTER

7. SUPPORTER

• Base

• Base

• Damper AS: 4

• Damper AS: 4

• Spring: 2

• Spring: 2

Program

BLDC

Motor

1. CONTROL PART

1. CONTROL PART

• Main PCB

• Main PCB

• Front PCB

• Front PCB

• Harness

• Harness

• Noise filter

• Noise filter

• Power Cord: 15A

• Power Cord: 15A

2. DRIVING PART

2. DRIVING PART

• BLDC motor

• BLDC motor

• Drum

• Drum

• Bearing

• Bearing

• Spider/ shaft

• Spider/ shaft

• Tub

• Tub

• Weight balancer

• Weight balancer

3. HEATING PART

3. HEATING PART

• Water Heater: 1000W

• Water Heater: 1000W

• Washing temperature

• Washing temperature

sensor

sensor

6

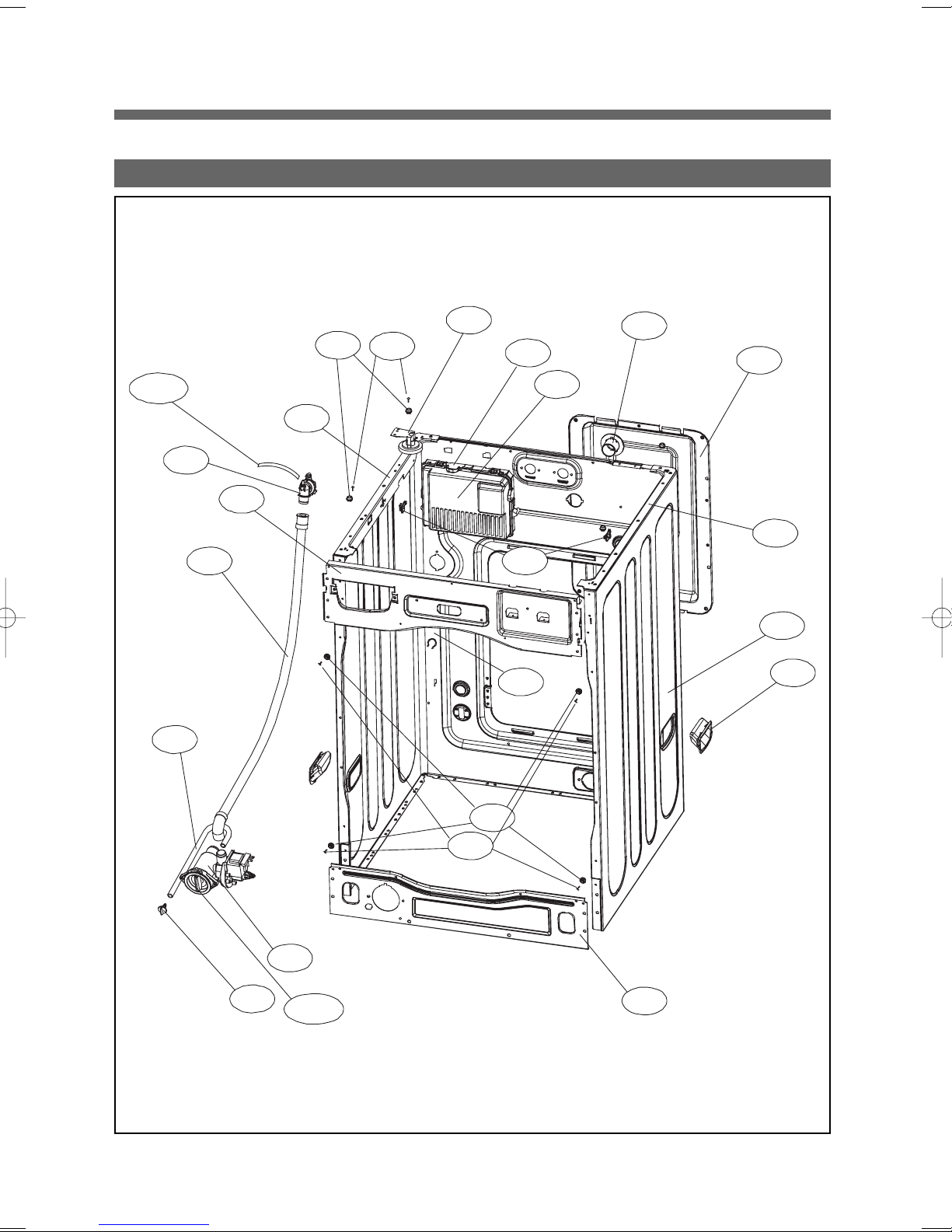

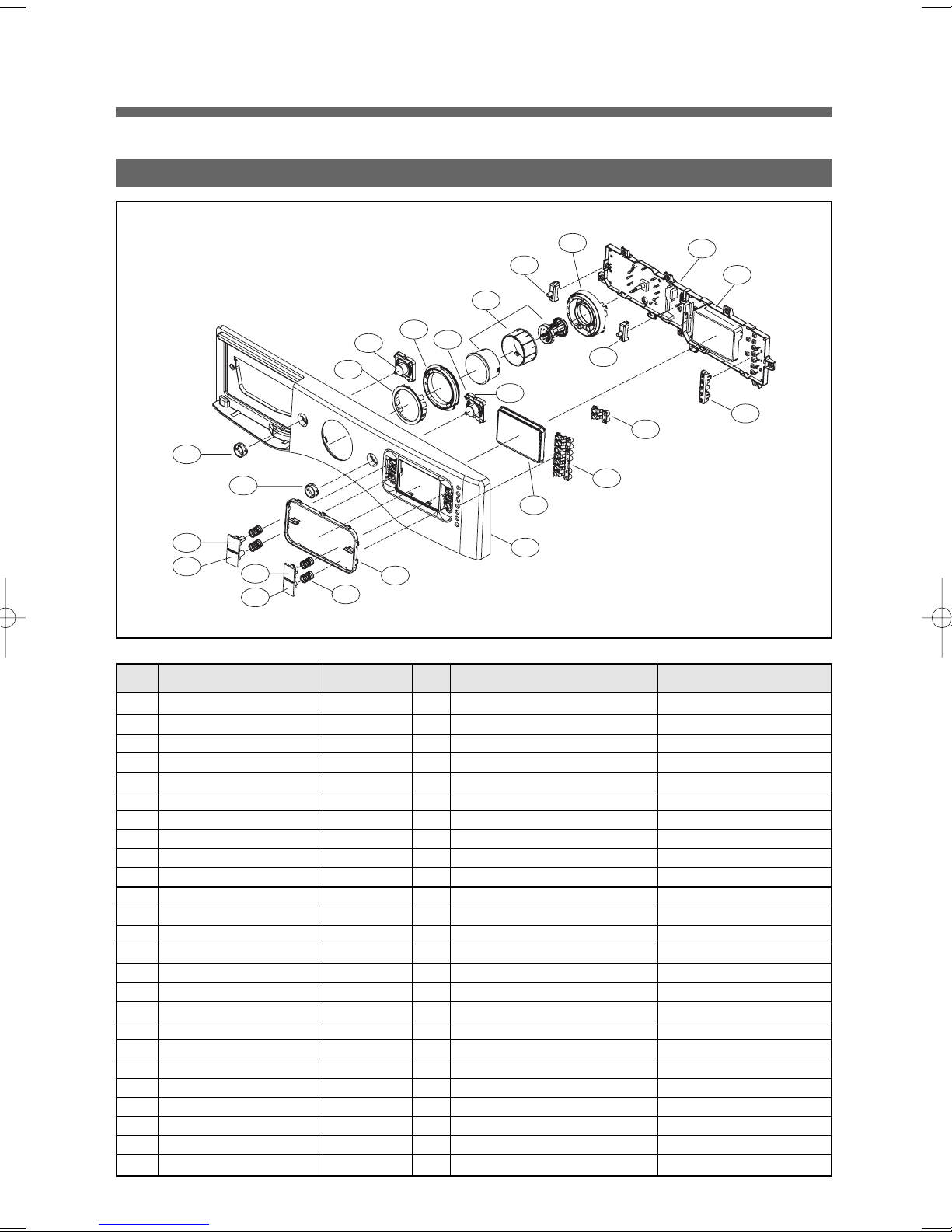

PARTS LIST FOR EACH ASSY

"

1. CABINET AS

C17-1

C17

C15

C14

C05

C03

C07

C08

C12

C18

C06

C20

C09

C11

C19

C04

C01

C10

C13

C16

C13-1

C07

C08

C02

7

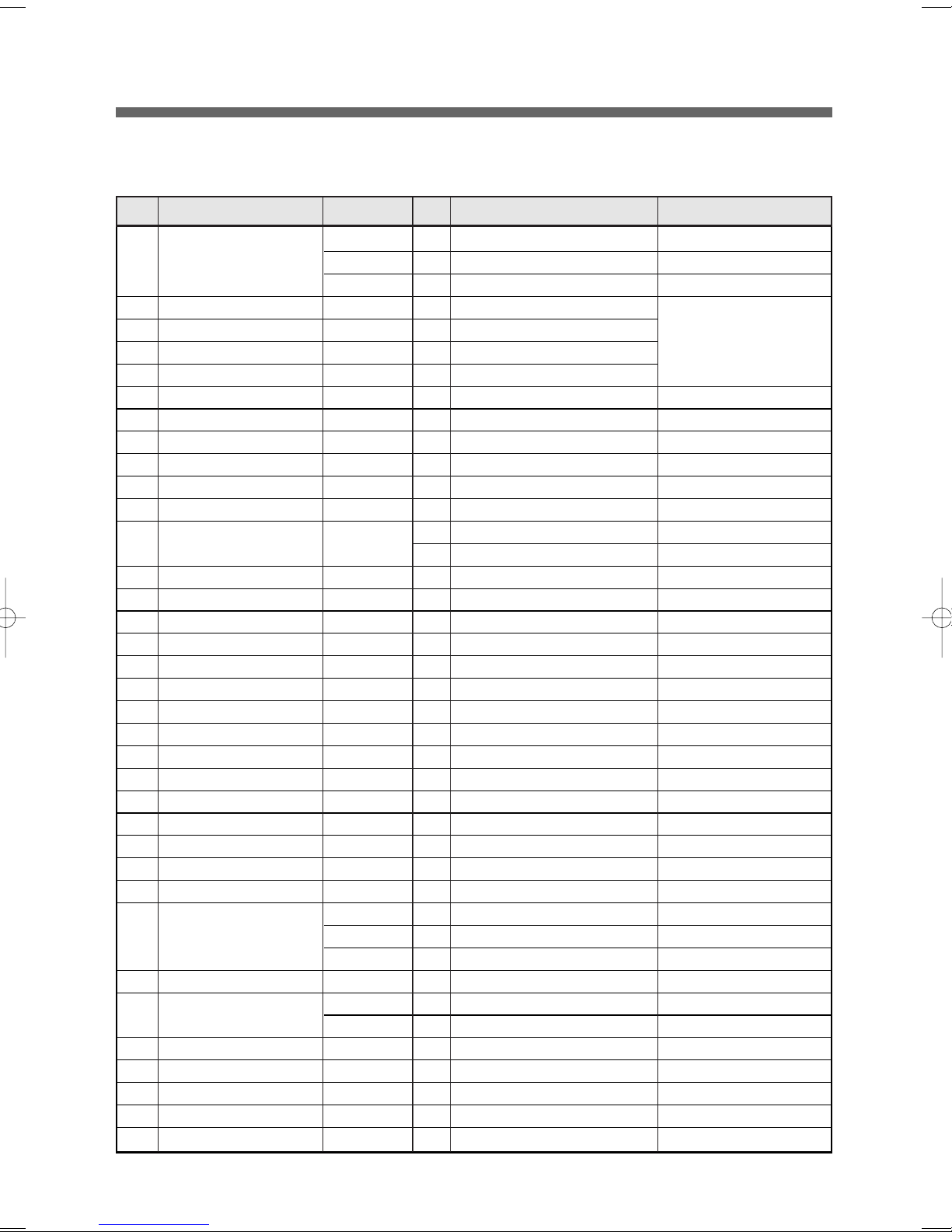

No. Part Name Part Code Qtt'y Specification Remark

- CABINET SUB AS 3610811950 1 13KG, PUMP, WHITE

3610811955 1 13KG, PUMP, PLATINUM

3610811956 1 13KG, PUMP, ROSE RED

C01 CABINET 3610811740 1 SGCC 0.8T PUMP WASHER • 1PIECE SVC PART

C02 FRAME LOWER 3612206700 1 SBHG 1.2T => CABINET SUB AS

C03 FRAME TOP L 3612206500 1 SGCC 1.6T

C04 FRAME TOP R 3612206600 1 SGCC 1.6T

C05 FRAME UPPER 3612208200 1 SGCC 1.2T

- SCREW TAPPING 7122401411 6 T2S TRS 4 x 14 MFZN Fix Frame Upper to Cabinet

C06 STOPPER SPRING 3615202200 2 POM

C07 FIXTURE PLATE 3612008000 8 POM

C08 SCREW TAPPING 7121401211 8 T2S PAN 4 x 12 MFZN

C09 NOZZLE AIR 3618103110 1 PP

C10 HANDLE CABINET 3612608100 2 PP, WHITE

2 PP, PLATINUM, RED

C11 COVER BACK AS 3611425530 1 COVER B + PAD + LABEL

- SCREW TAPPING 7122401411 4 T2S TRS 4 x 14 MFZN Fix Cober Back to Cabinet

C12 SENSOR PRESSURE 3614825220 1 DWD-130RP

- SCREW TAPPING 7122401411 2 T2S TRS 4 x 14 MFZN Fix Sensor Pressure to Cabinet

C13 UNIT DRAIN PUMP AS 36189L5600 1 UL.PLASET + HANYU AS 80W

C13-1 FILTER PUMP 3611910200 1 HANYU FILTER

- SCREW TAPPING 7122401411 2 T2S TRS 4 x 14 MFZN

Fix Drain Pump to Frame Lower

C14 HOSE DRAIN I 3613271300 1 ST+EL, 1010MM

- ABSORBER HOSE DRAIN 3610115600 1 T10, 60 x 130

- CLAMP HOSE 3611203900 2 SK5 D=26 Fix Drain I

C15 HOSE WATER REMAIN 3613272210 1 EPDM, UL 3T Round Bending

C16 CAP WATER REMAIN 3610916800 1 PP

C17 CUFF DRAIN HOSE 3616802600 1 PP, PUMP

C17-1 HOSE SIPHON 3613272210 1 EPDM, UL 3T L=270

- SCREW TAPPING 7122401411 1 T2S TRS 4 x 14 MFZN Fix Drain Hose to Cabinet

C18 PCB INVERTER AS 3610PCBF11 1 M_PCB+HAR+WIRE DWD-WD125*

3610PCBF06 1 M_PCB+HAR+WIRE DWD-WD135*

3610PCBF07 1 M_PCB+HAR+WIRE DWD-WD135*02

C19 COVER PCB M 3611427700 1 UL,ABS VE-0856, MAIN PCB

C20 HARNESS AS 3612796T00 1 UL, 13K Washer, Non-bubble D-WD125*, D-WD135*

3612796U00 1 UL, 13K Washer, Hot Steam D-WD135*02, D-WD135*02

- SCREW TAPPING 7122401411 1 T2S TRS 4 x 14 MFZN Fix PCB Main to Cabinet

- LOCK HARNESS M 3613802300 6 M Type(18 x 18), Nylon66 Cabinet rear

- LOCK HARNESS 3613802100 2 DASTL-20NA Frame Top right

- LABEL WIRING UL 3613557100 1 UL Only, Wiring diagram+Warning English&French

- SCREW TAPPING 7122401411 1 T2S TRS 4 x 14 MFZN Fix Cabinet F to Frame Lower

8

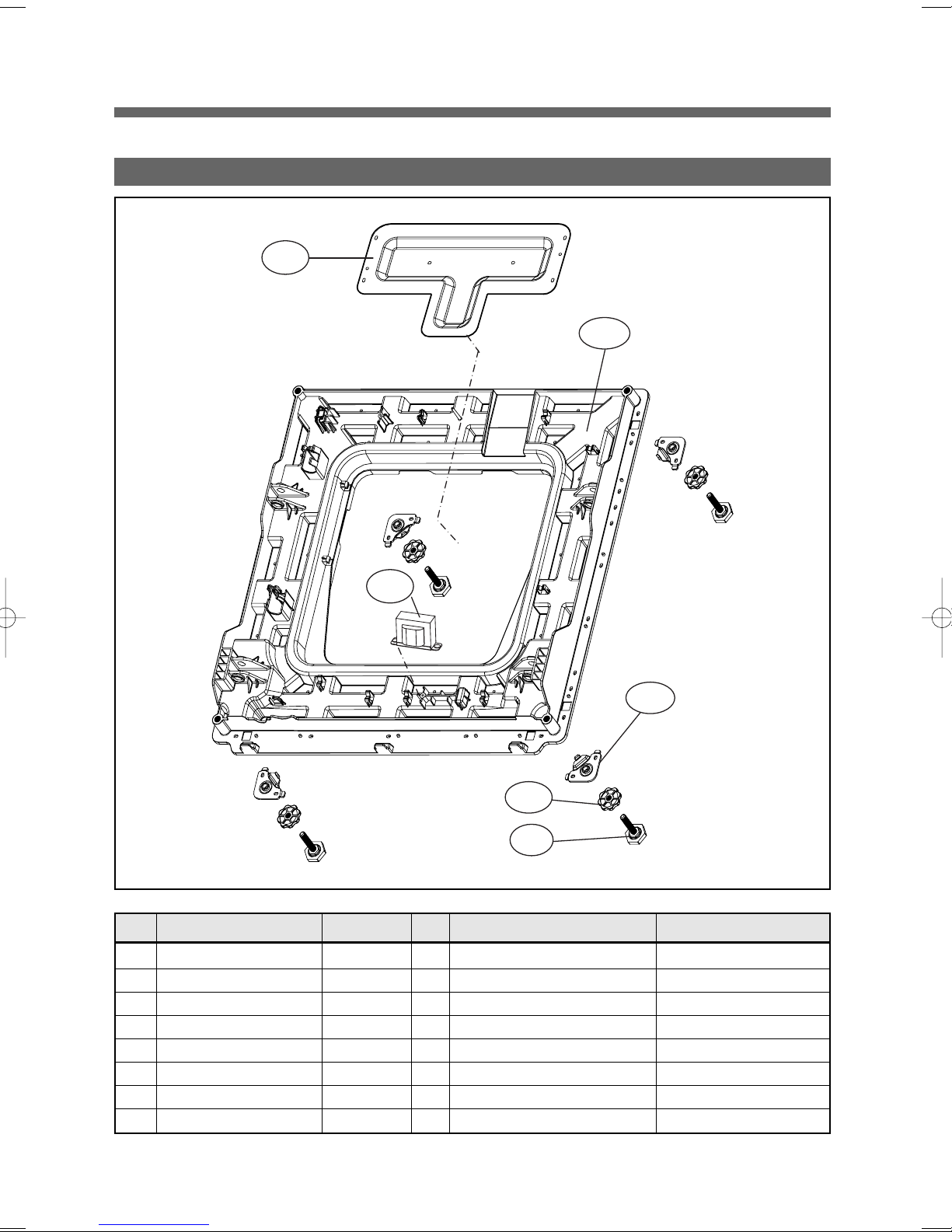

2. BASE U AS

B06

B01

B04

B03

B02

B5

No. Part Name Part Code Qtt'y Specification Remark

B01 REACTOR 52G043A110 1 RT-047(U), L=150

B02 BASE U 3610392700 1 PP

B03 SUPPORTER LEG 3615303600 4 PO+Coating 3.0T

B04 FIXTURE LEG 3612006400 4 ABS, DWD-100DR

B05 FOOT AS 3612100700 4

B06 PROTECTOR HEATER 3618304600 1 SECC 0.35T

- SCREW TAPPING 7122401411 4 T2S TRS 4x14 MFZN Fix Protector Heater to Base U

- SCREW TAPPING 7122401411 20 T2S TRS 4x14 MFZN Fix Base U to Cabinet

Foot+Special bolt, Double insert type Hybra-Nylon66

9

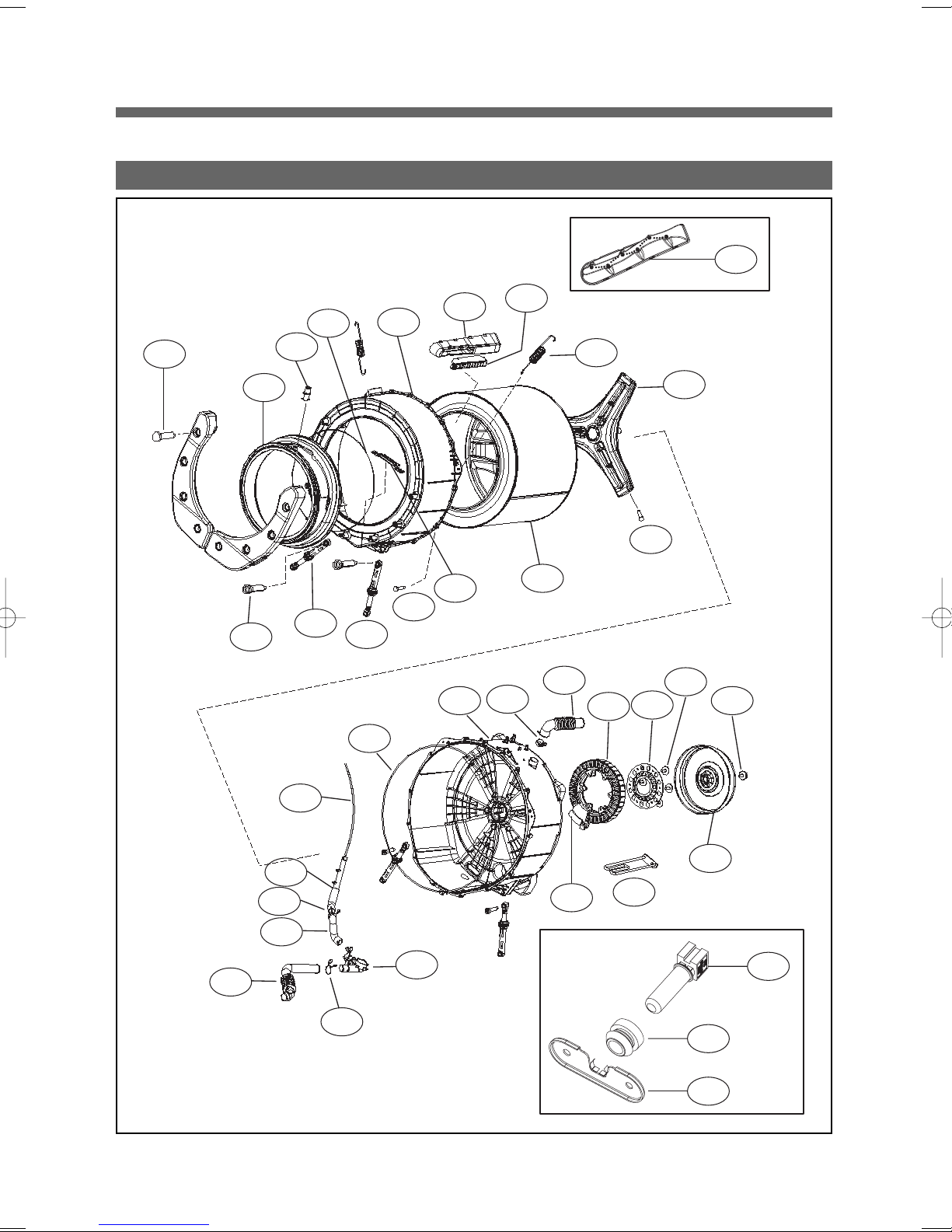

3. TUB AS

D06

T01

T03

T12

T04

T11

T05

T10

T21

T06

T07

D04

T09

T20

T23

D05

D01

T22

T08

T24

D03

T26

D02

T27

T29

T15

T18

T17

T16

T13

T14

T19

10

T25

T28

T30

T33

T32

T31

No. Part Name Part Code Qtt'y Specification Remark

T01 SPECIAL SCREW 3616029400 8 SWCH 8.5 x 30 Fix Balancer W. to Tub F

T02

BALANCER WEIGHT AS(L)

BALANCER WEIGHT AS(R)

3616110100 1 13kg DRUM

3616110200 1 13kg DRUM

T03 GASKET AS 3612322000 1 EPDM, Wash-only, Nozzle shower

T04 NOZZLE SHOWER 3618104000 1 PP

T05 CLAMP GASKET AS 3611205300 1 Gasket, 13kg Drum

T06 TUB FRONT 3618828Y00 1 FRPP, 13kg Drum

T07 SPECIAL SCREW(TUB) 3616029800 15 SWCH 6.5 x 30 Fix Tub F & R

T08 SPRING SUSPENSION 3615114800 2 13kg DRUM

T09 FIXTURE HEATER 3612006700 1 STS 430

T10 DAMPER FRICTION 361A700300 2

T11 DAMPER FRICTION 361A700110 2

AWECO, HP3 60N/9MM BUFFER 4,0

70N AKS ST=170-260 DL=197.5 LOW NOISE

Tub F & R right

Tub F & R left

T12 DAMPER PIN 361A700200 8 AKS D=14.5 Tub & Base U

T13 HOSE DRAIN 3613269000 1 EPDM,PUMP

T14 CLAMP HOSE 3611203410 2 SK5, D=33

T15 HOSE AIR PRESSURE 3613270600 1 ID=4,OD=8,L=1000MM

T16 HOSE AIR TRAP 3613269700 1 EPDM, 13kg Drum

T17 CLAMP HOSE 3611204700 2 D26

T18 AIR TRAP 361A500101 1 PP

T19 DRAIN HOUSING I 36196TAM00 1 PP,PUMP 1 PIECE SVC PART

T20 TUB REAR AS 36100E2W00 1 DWD-WD113*, DWD-WD123*

T21 GASKET TUB 3612322100 1 EPDM FORM, 13KG DRUM

T22 HOSE AIR 3613266300 1 EPDM, DWD-100DR

T23 CLAMP HOSE 3611203400 2 SK5, MFZN,D=35

T24 UNIT STATOR BLDC 36189L4840 1

30T,36SLOT,2SENSOR,WS2A30G011

1 PIECE SVC PART

T25 BLDC HALL IC 3626D01002 1 STATOR PCB HOLDER AS(SVC)

T26 BRACKET HOUSING 3610609700 1 GI 2.3T

T27 SPECIAL BOLT AS 3616063400 6 SWCH M8+SILOCK, 58MM Fix Stator & Tub R

T28 UNIT ROTOR BLDC 36189L4900 1

T29 SPECIAL BOLT AS 3616029600 1

T30 HEATER WASH 3612801740 1

MAGNET24,SERRATION,WR1238F001

SWCH 10*30,F/L BOLT S.P/W SEAL LOCK

UL.120V1.0KW6.7W/SQ.SUS.1R3A515003.L/W.

DWD-WD113*, DWD-WD123*

T31 BRACKET THERMISTOR 3610610600 1 SGCC 0.8T, Non-Heater DWD-WD103*01

T32 THERMISTOR WASH 361AAAAB20 1 UL.R80:1.704K.R25:11.981K DWD-WD113*01

T33 PACKING THERMISTOR 3614011400 1 EPDM, Non-Heater

D01 DRUM SUB AS 3617008X00 1 SUS, 13kg 1 PIECE SVC PART

D02 SPIDER AS 361A300600 1 13kg, ALDC+S45C

D03 SPECIAL SCREW(SPIDER) 3616029500 6 STS 430, 8 x 25

D04 LIFTER BODY 361A400700 3 PP, 13kg Drum 1st Lifter

D05 CAP FILTER 3610917310 3 ABS, NON-NANO, 13kg 1 PIECE SVC PART

FILTER 3611908410 3 ABS, NON-NANO, 13kg (OPTION)

FILTER NET 3611908500 3 SUS, FILTER

D06 LIFTER WASH 361A401400 3 NON-NANO, 1 PIECE TWIST 3rd Lifter

11

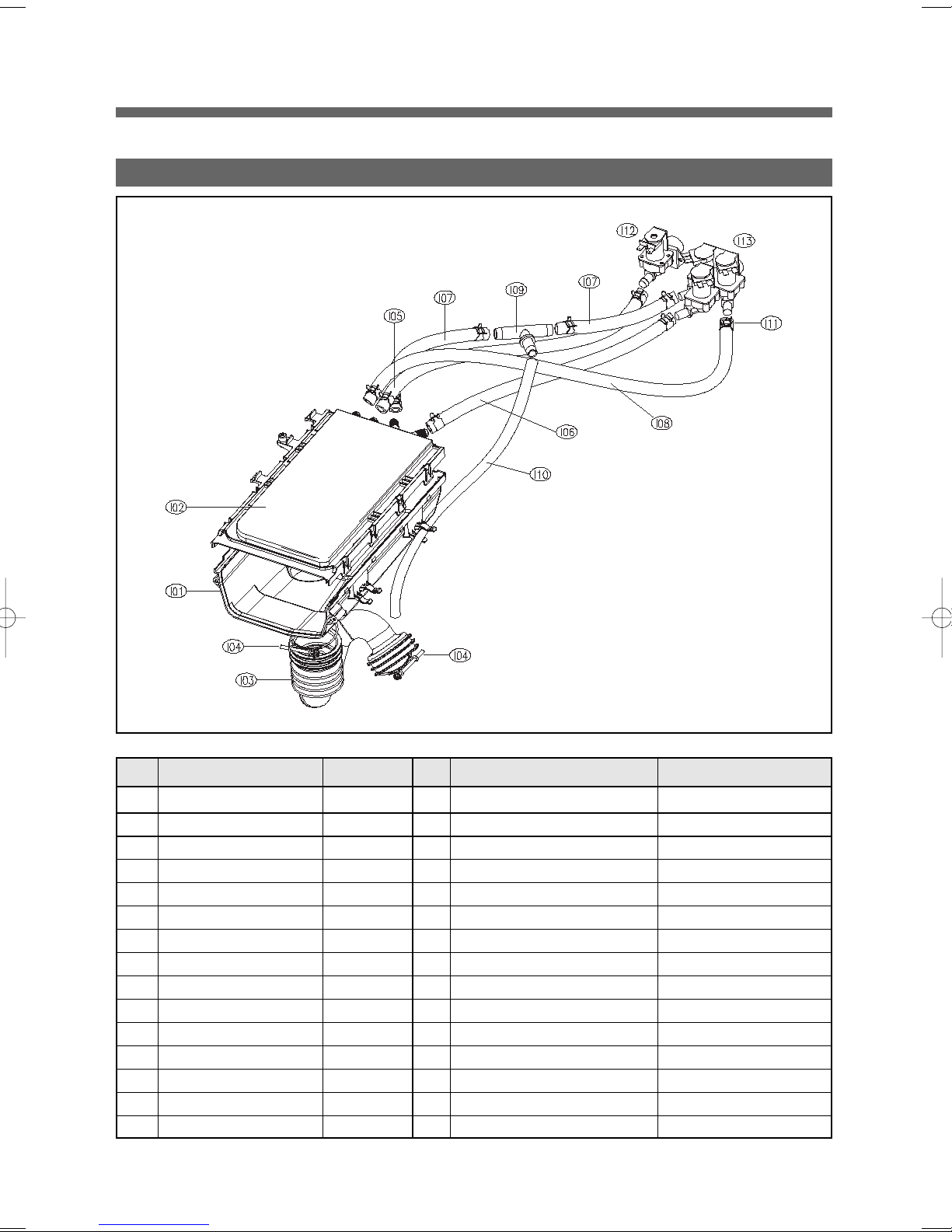

4-1 INLET BOX AS(NON-STEAM)

No. Part Name Part Code Qtt'y Specification Remark

I01 INLETBOX 3617510800 1 PP

I02 NOZZLE AS 3618104800 1 WD1131'S, Top+Under

I03 HOSE INLET 3613270300 1 EPDM

I04 CLAMP AS 3611203200 2 ID=60, WIRE+GUIDE+BOLT+NUT

I05 HOSE WATER SUPPLY 3613270920 1 EPDM ID=9.5 OD=15.5 L=410mm From Valve Inlet to HOT nozzle

I06 HOSE WATER SUPPLY 3613270920 1 EPDM ID=9.5 OD=15.5 L=380mm

I07 HOSE WATER SUPPLY 3613270920 2 EPDM ID=9.5 OD=15.5 L=230mm

I08 HOSE WATER SUPPLY 3613270920 1 EPDM ID=9.5 OD=15.5 L=530mm

I09 PIPE JOINT HOSE INLET 3614413300 1 PP

I10 HOSE SHOWER 3613270130 1 EPDM ID=8.5 L=550mm

I11 CLAMP HOSE 3611205810 1 D-WD113'S ID14.3 W10 0.9T WH

I12 VALVE INLET 3615416700 1 UL.120V60HZ.BITRON.1WAY HOT

I13 VALVE INLET 3615416930 1 UL.120V60HZ.BITRON.3WAY COLD

- SCREW TAPPING 7002400811 4 TRS 4X8 MFZN Fix Valve Inlet to Cabinet

- SCREW TAPPING 7122401411 1 T2S TRS 4X14 MFZN Fix Inletbox to Frame T(Side)

From Valve Inlet to MAIN nozzle

From Valve Inlet to PRE-WASH nozzle

From Valve Inlet to BLEACH nozzle

12

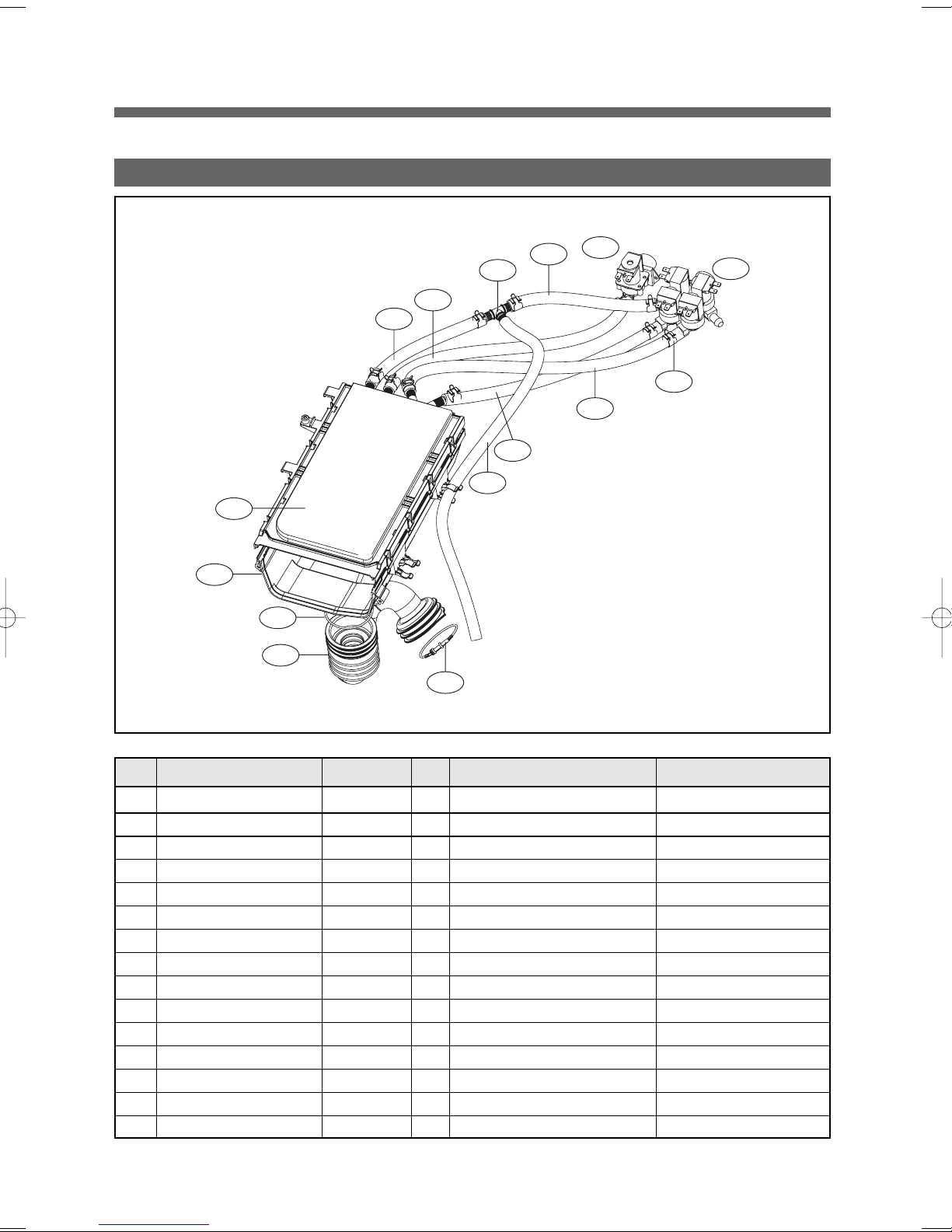

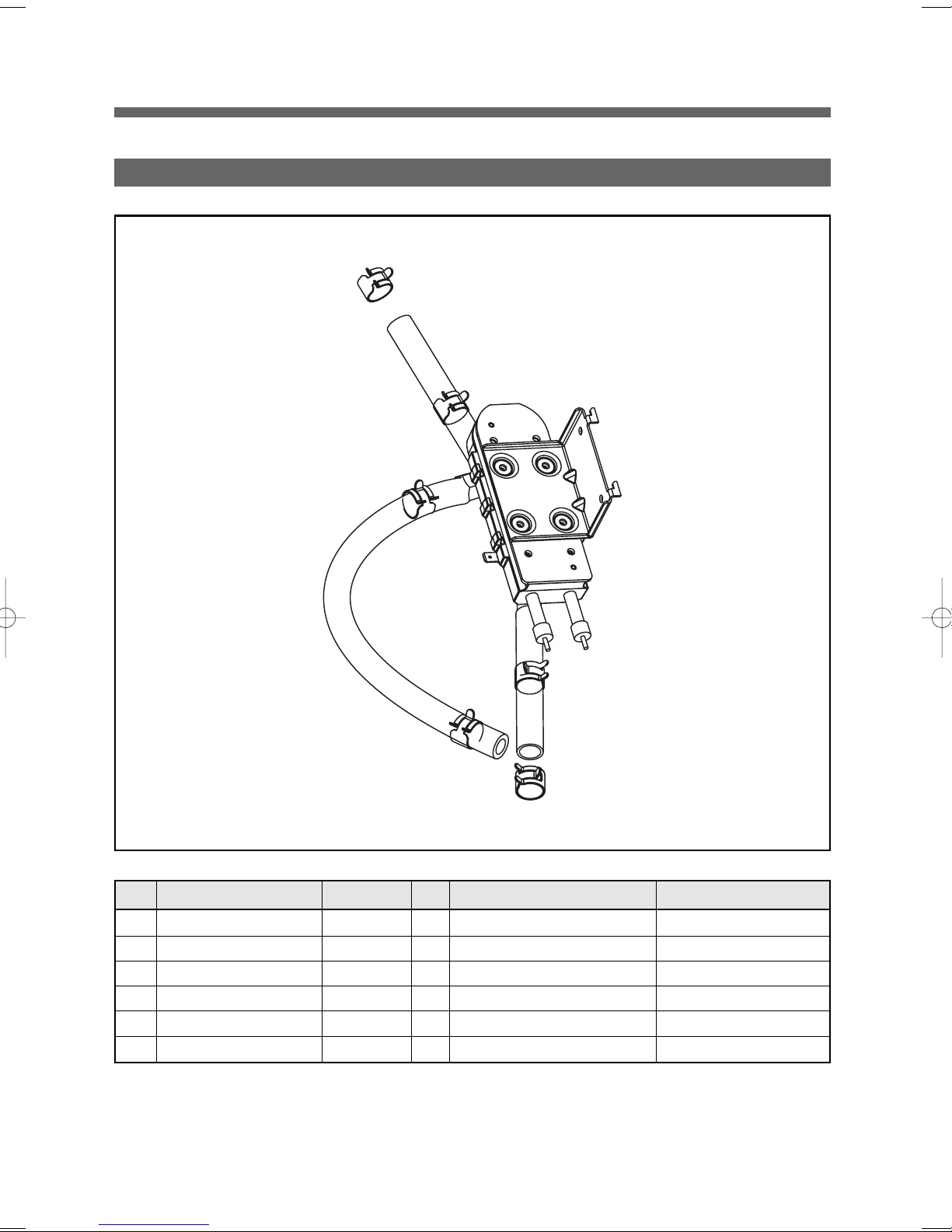

4-2 INLET BOX AS(HOT-STEAM)

I01

I02

I04

I03

I07

I05

I04

I10

I09

I06

I07

I12

I13

I11

I08

No. Part Name Part Code Qtt'y Specification Remark

I01 INLETBOX 3617510800 1 PP

I02 NOZZLE AS 3618104800 1 WD1131'S, Top+Under

I03 HOSE INLET 3613270300 1 EPDM

I04 CLAMP AS 3611203200 2 ID=60, WIRE+GUIDE+BOLT+NUT

I05 HOSE WATER SUPPLY 3613270920 1 EPDM ID=9.5 OD=15.5 L=410mm From Valve Inlet to HOT nozzle

I06 HOSE WATER SUPPLY 3613270920 1 EPDM ID=9.5 OD=15.5 L=430mm

I07 HOSE WATER SUPPLY 3613270920 2 EPDM ID=9.5 OD=15.5 L=220mm

I08 HOSE WATER SUPPLY 3613270920 1 EPDM ID=9.5 OD=15.5 L=350mm

I09 PIPE JOINT HOSE INLET 3614413300 1 PP

I10 HOSE SHOWER 3613270130 1 EPDM ID=8.5 L=550mm

I11 CLAMP HOSE 3611205810 1 D-WD113'S ID14.3 W10 0.9T WH

I12 VALVE INLET 3615416700 1 UL.120V60HZ.BITRON.1WAY HOT

I13 VALVE INLET 3615416930 1 UL.120V60HZ.BITRON.3WAY COLD

- SCREW TAPPING 7002400811 4 TRS 4X8 MFZN Fix Valve Inlet to Cabinet

- SCREW TAPPING 7122401411 1 T2S TRS 4X14 MFZN Fix Inletbox to Frame T(Side)

From Valve Inlet to MAIN nozzle

From Valve Inlet to PRE-WASH nozzle

From Valve Inlet to BLEACH nozzle

13

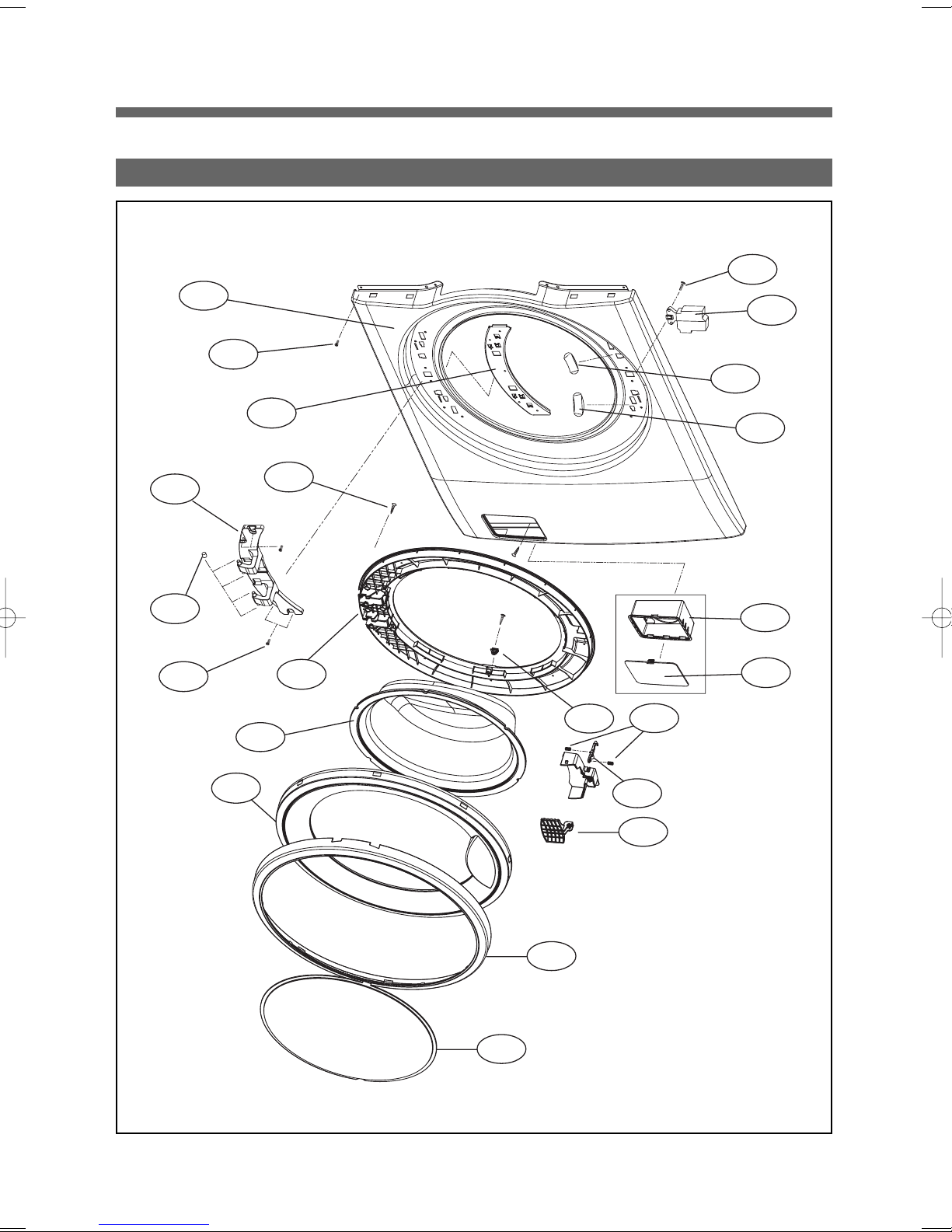

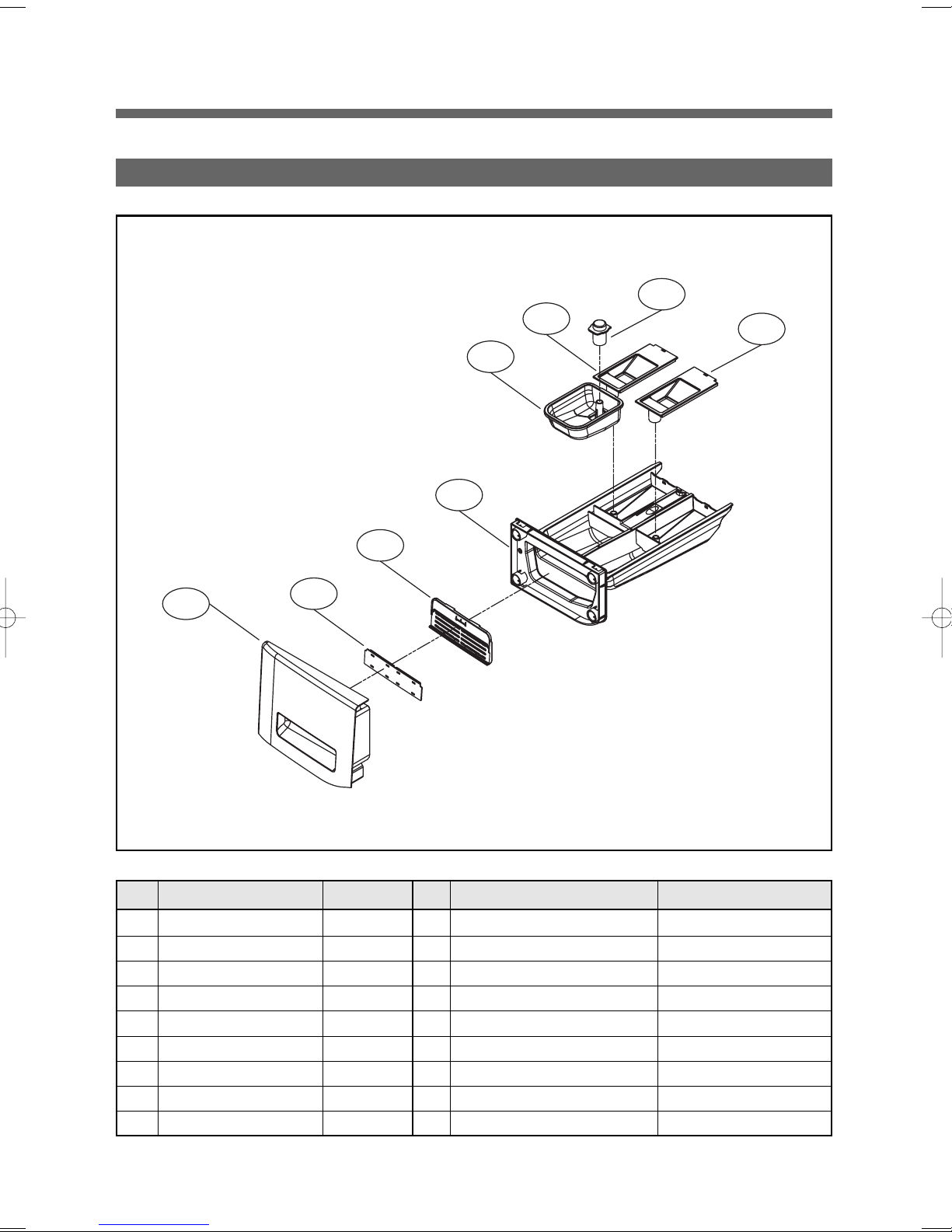

5. CABINET FRONT ASS'Y

F01

F21

F20

F19

F03

F09

F10

F18

F11

F02

F07

F12

F05

F06

F04

F22

F23

F16

F15

F14

F24

F08

14

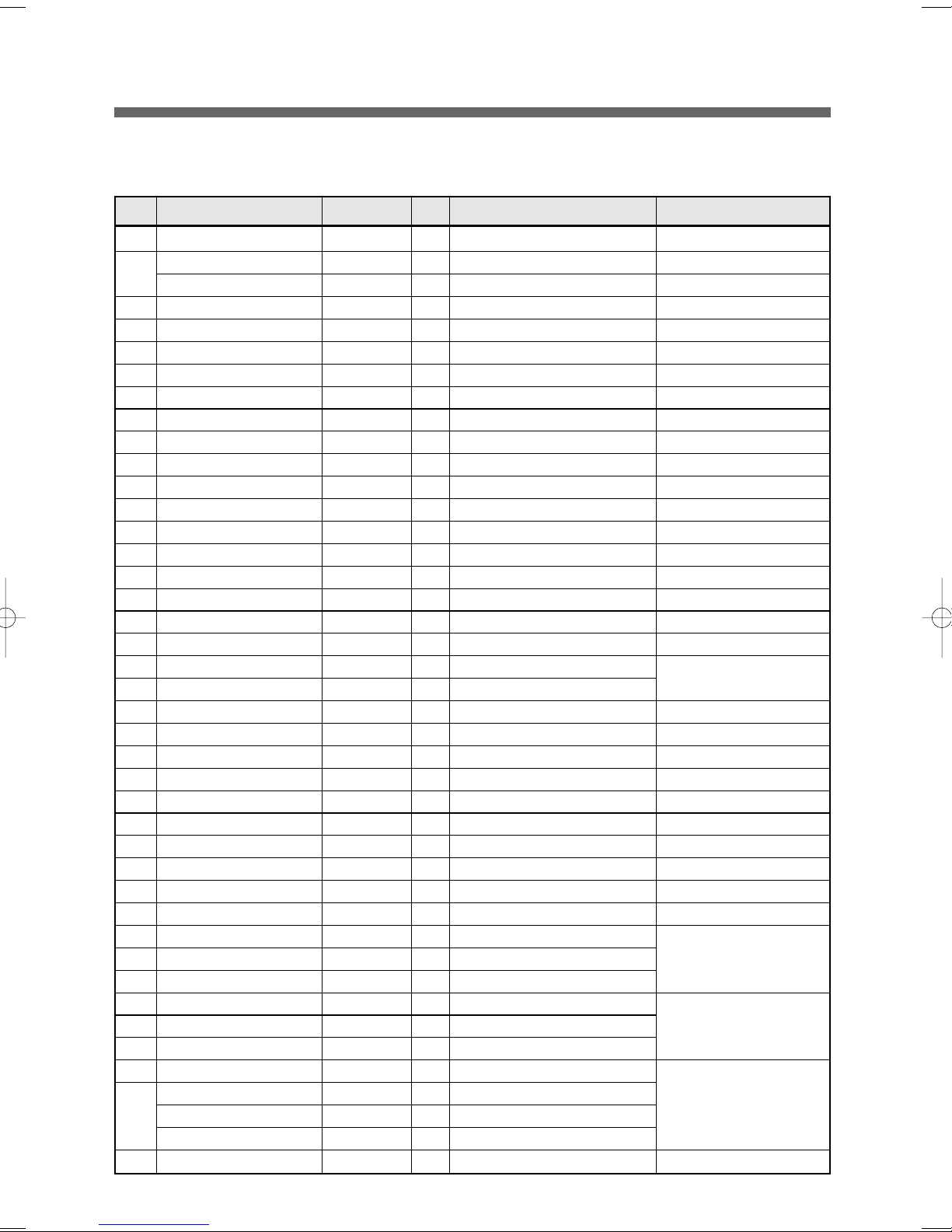

No. Part Name Part Code Qtt'y Specification Remark

F01 CABINET F SUB AS 3610811310 1 13KG, PUMP, WHITE

3610811321 1 13KG, PUMP, PLATINUM

3610811322 1 13KG, PUMP, ROSE RED

F02 SUPPORTER HINGE 3615304001 1 SGCC 1.2T

F03 LABEL SAFETY R 3613555800 1 PET, DOOR SAFETY,UL

1 PET, DOOR SAFETY,UL, RH Right Handle type

F04 LABEL WARNING 3613558500 1 PET,SILVER,DOOR WARNING,UL

1 PET, DOOR WARNING,UL, RH Right Handle type

F05 FRAME DOOR IN 3612210700 1 PP(Heat resisting)

F06 STOPPER DOOR 3615202300 1 PP(Heat resisting)

F07 DOOR GLASS 361A110600 1 GLASS

F08 PROTECTOR GLASS 3618304300 1 ABS(Transparent)

F09 HINGE DOOR AS 3612903900 1 13K WASHER,ALDC

F10 CAP HINGE DOOR 3610916500 4 POM

F11 FRAME DOOR OUT 3612210800 1 13K WASHER,ALDC

F12 SCREW TAPPING 7115402029 16 T1S FLT 4*20 STS430 NATURAL

F13 COVER HANDLE 3611429300 1 ABS WHITE

F14 HANDLE DOOR 3612612100 1 ABS

F15 HOOK DOOR 3613100800 1 ZNDC

F16 SPRING HOOK 3615113700 2 SUS ID=4.3,NI=7,D="0.9

F17 PIN HANDLE 3618200100 1 SUS, D3.0

F18 SCREW TAPPING 3616051229 4 STS430 F/L BOLT(SE) 5*12

F19 SWITCH DOOR LOCK 3619046410 1

F20 SCREW TAPPING 7122401608 2 T2S TRS 4 x 16 SUS 430

DF F11 110 125V 16A PTC-SOLENOID

For fixing Door S/W to Cabinet F

F21 SCREW TAPPING 7122401411 4 T2S TRS 4 x 14 MFZN For fixing Cabinet F to Cabinet

F22 CASE PUMP 3611141400 1 PP

F23 COVER PUMP 3611426800 1 ABS, WHITE

1 ABS, PLATINUM

1 ABS, RED

15

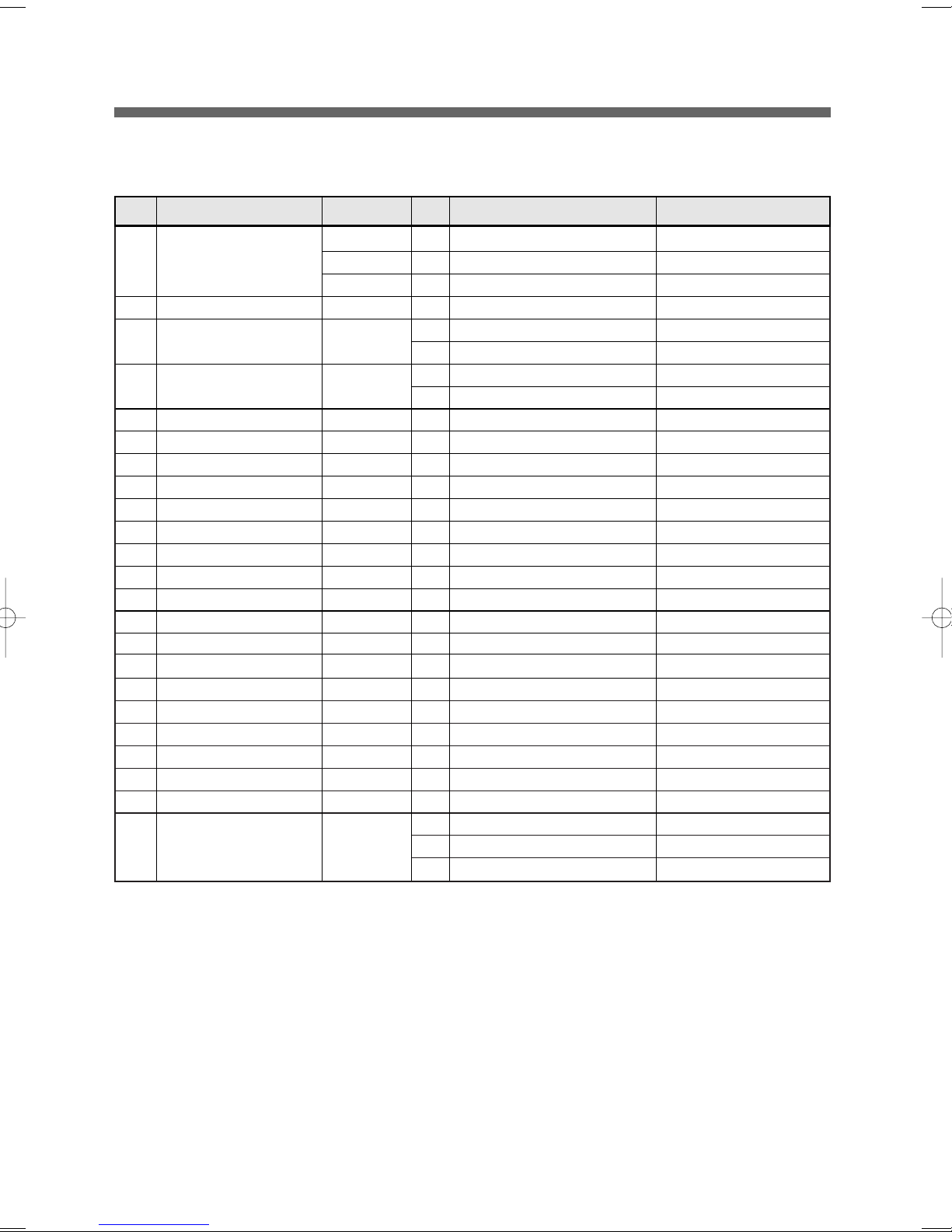

6. PANEL F AS

F02

F05

F06

F03

F07

F08

F15

F09

F10

F04

F16

F19

F18

F18

F11

F18

F11

F14

F13

F12

F01

F22

F21

F20

No. Part Name Part Code Qtt'y Specification Remark

- PANEL-F AS PRPAFR9Z10 1 DWD-WD1352S/1352

F01 PANEL-F 3614289600 1 ABS + SILK Printing

F02 DECO BUTTON POWER 3611692120 1 ABS(GILDING/SPRAY)

F03 DECO BUTTON START 3611692220 1 ABS(GILDING/SPRAY)

F04 DECO WINDOW 3611692420 1 ABS(GILDING/SPRAY)

F05 BUTTON FUNCTION WASH 3616640700 1 ABS + SILK Printing

F06 BUTTON FUNCTION SPIN 3616640800 1 ABS + SILK Printing

F07 BUTTON FUNCTION SOIL 3616640900 1 ABS + SILK Printing

F08 BUTTON FUNCTION BEEP 3616641000 1 ABS + SILK Printing

F09 SPRING BUTTON 3615116200 4 SUS 0.7PI D=12.3 L=15

F10 BUTTON POWER AS 3616640550 1 Transparent PC

F11 BUTTON START AS 3616640650 1 Transparent PC

F12 WINDOW DISPLAY 3615508300 1 Transparent ABS TR 558

F13 BUTTON OPTION 3616641200 1 Transparent ABS TR 558

F14 BUTTON TIME 3616641100 1 ABS

F15 WINDOW COURSE 3615508200 1 Transparent ABS TR 558

F16 DECO COURSE 3611692310 1 ABS(GILDING/SPRAY)

F17 BUTTON DIAL AS 3616643300 1 Push-Pull Type

F18 HOLDER POWER 3613056800 2 ABS(Anti-flammable, VE-0856)

F19 HOLDER COURSE 3613056900 1 ABS(Anti-flammable, VE-0856)

F20 HOLDER OPTION 3613057000 1 ABS(Anti-flammable, VE-0856)

F21 CUSTOM LED 3610019900 1 18:88 LED

F22 CASE PCB F 3611148800 1 ABS(Anti-flammable, VE-0856)

- PCB AS PRPSSWAD36 1 DWD-WD1352S/1352

- SCREW TAPPING 7122401211 7 T2 TRS 4x12 MFZN

16

7. UNIT STEAM WASHER AS

No. Part Name Part Code Qtt'y Specification Remark

- UNIT STEAM WASHER AS 3619606800 1 D-WD1351,HOT STEAM AS

S01 UNIT STEAM AS 3619606700 1 D-WD1351,STEAM AS

S02 HOSE SPRAY 3613275100 0.245 UL, SILICON, ID=9.5, OD=16.5

S03 HOSE SPRAY 3613275100 0.73 UL, SILICON, ID=9.5, OD=16.5

S04 HOSE SPRAY 3613275100 0.62 UL, SILICON, ID=9.5, OD=16.5

S05 CLAMP HOSE 3611205830 6 HOT SPRAY,ID=15.5

17

rum Wa

8. CASE DETERGENT AS

A02

A05

A04

A06

A03

A08

A01

No. Part Name Part Code Qtt'y Specification Remark

- CASE DETERGENT AS 3611149000 1 DWD-WD1151

A01 CASE HANDLE 3611148700 1 ABS

A02 CASE DETERGENT 3611145600 1 PP

A03 CAP SOFTENER 3610917800 1 PP

A04 CAP BLEACH 3610917900 1 PP

A05 CASE LIQUID 3611145700 1

A06 CAP LIQUID 3610918000 1

A07 CUSHION HANDLE 3611571900 1 SILICON, WD1151

A08 DECO CASE HANDLE 3611691900 1 ABS, CROM_BASE

A07

18

rum Wa

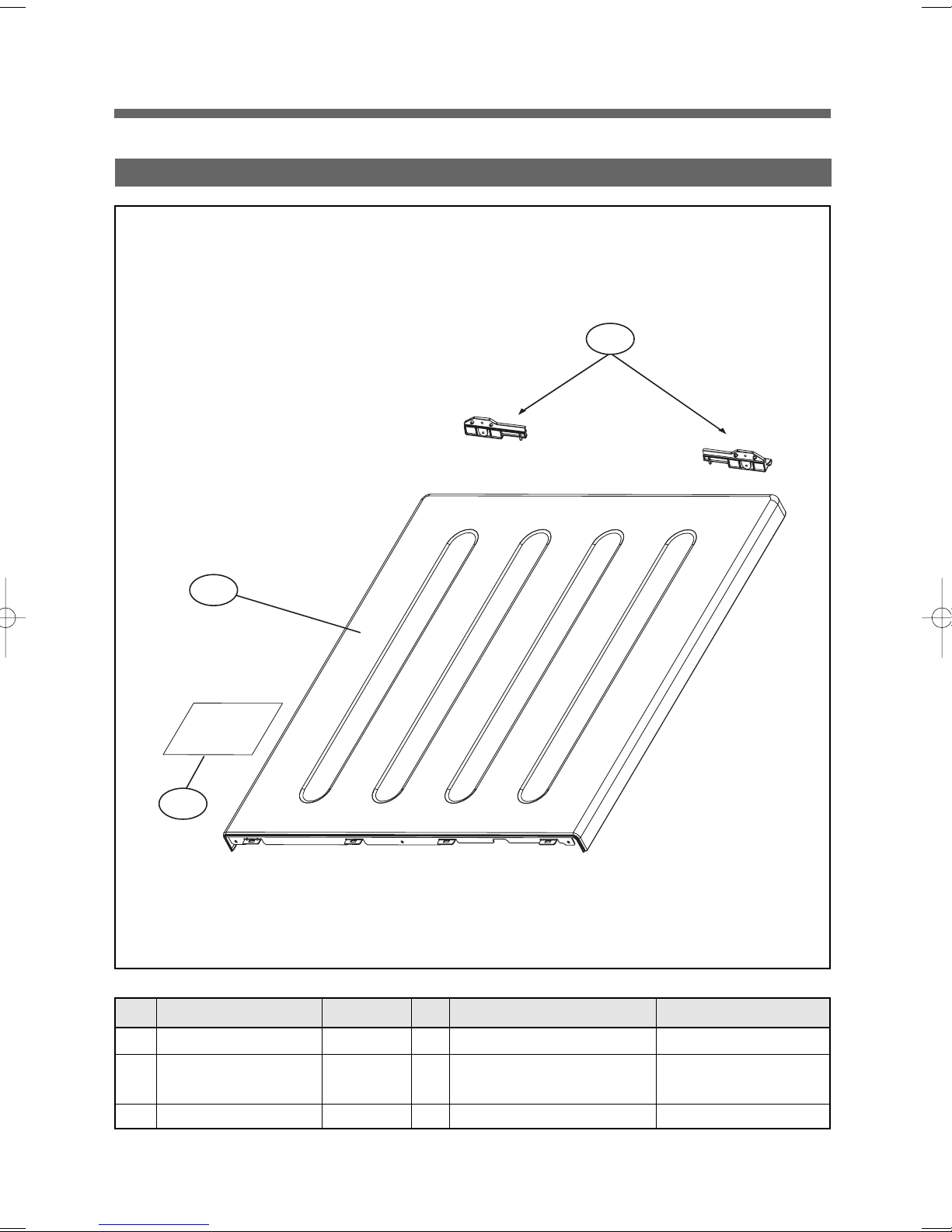

9. PLATE T AS

T02

T01

T03

No. Part Name Part Code Qtt'y Specification Remark

T01 PLATE TOP AS PRMACA3R00 1 SECD 1.2T + SPRAY

T02 HANDLE REAR 3615304100 2 ABS

(PLATE SUPPOTER)

- SCREW TAPPING 7122401411 4 T2S TRS 4x14 MFZN

19

rum Wa

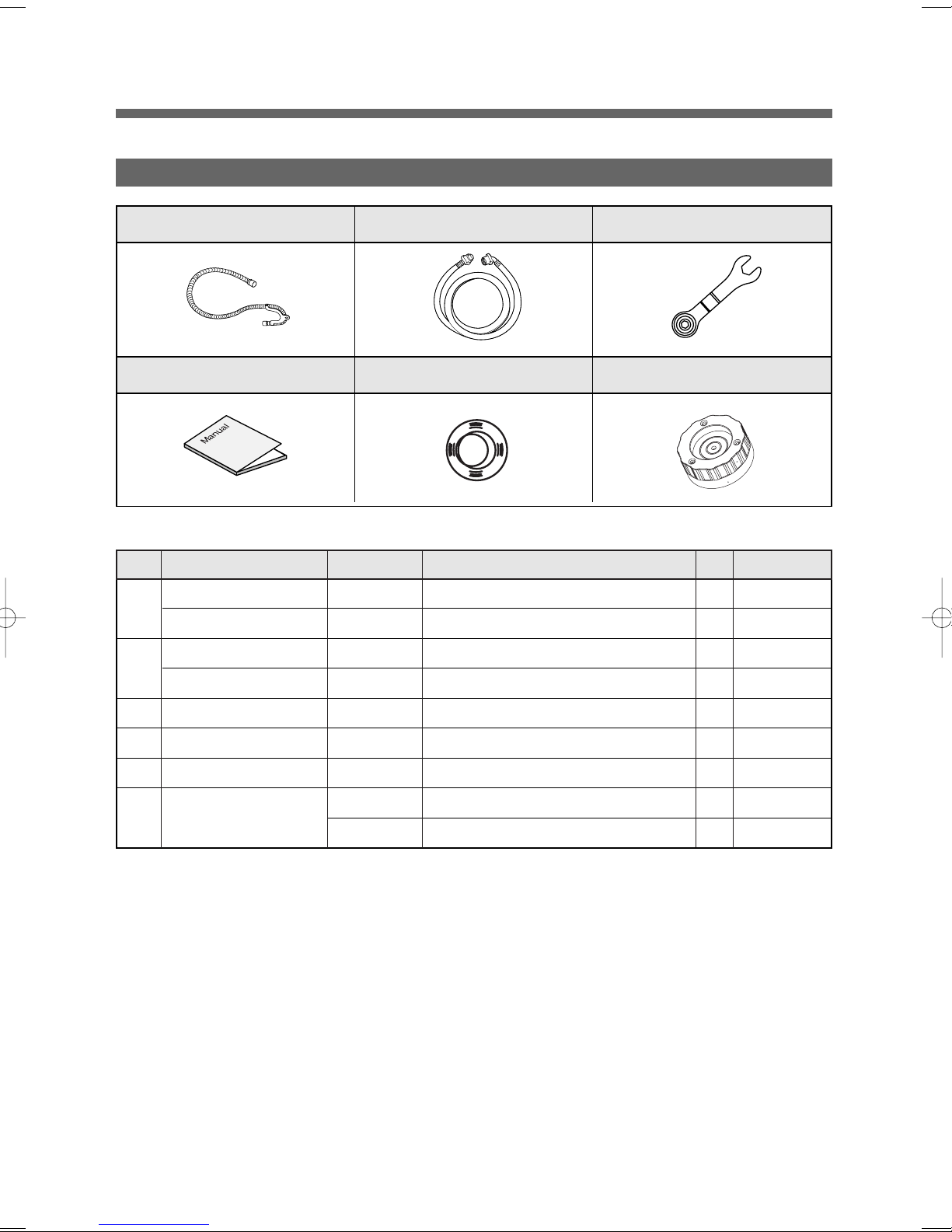

10. ACCESSORY

A01 A02 A03

A04 A05 A06

NNoo.. PPaarrtt NNaammee PPaarrtt CCooddee DDeessccrriippttiioonnss QQtt''yy RReemmaarrkkss

A01 HOSE DRAIN O AS 3613268500 DWD-800W, L=1,500 1

GUIDE DRAIN HOSE 3612502300 PP 1

A02 HOSE INLET AS 3613271500 REFLEX, PVC 1.3M 1 Cold

HOSE INLET AS 3613271510 REFLEX, PVC 1.3M 1 Hot

A03 UNIT SVC WRENCH 36189L3X00 PO+Coating, 2.3T DWD-110RP 1

A04 MANUAL OWNERS 4589A61600 ASKO Manual 1

A05 CAP HOLDER 3610916400 PP, DWD-10RP 4

A06 UNIT LEVELER AS 36189L4M00 FOOT 1 + LEG 1 1 Option

36189L4M10 FOOT 1 + LEG 2 1 Option

English & French

20

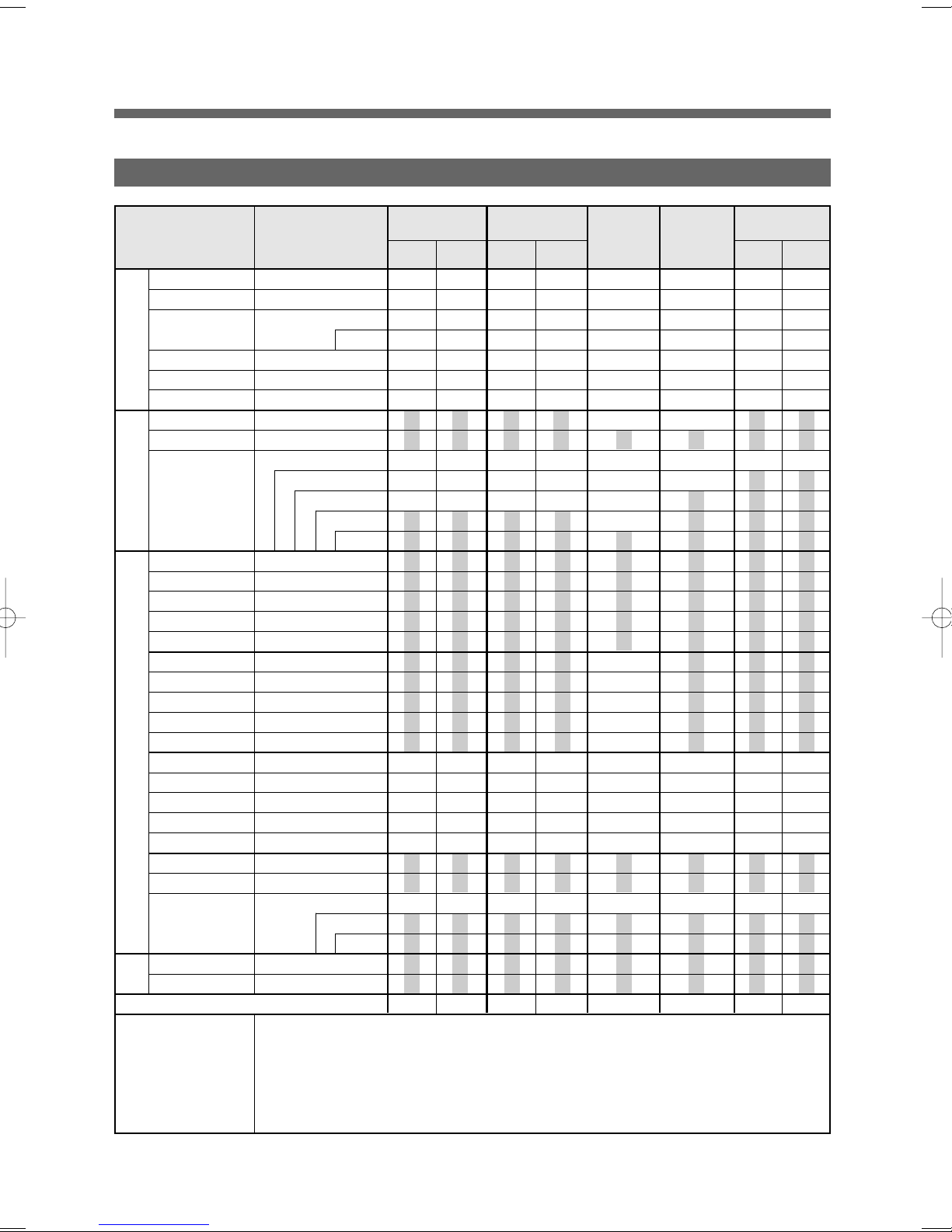

Control Part Function Spec

"

1. SEQUENCE CHART

CCllaassssiiffiiccaattiioonn PPrroocceessssiinngg TTiimmee

Small Low Small Low Small Low

PP

rr

ee

WW

aa

ss

hh

WW

aa

ss

hh

RR

ii

nn

ss

ee

SS

pp

ii

nn

EEnndd

Sensing 10sec

Water Supply 2min

Pre-Wash 10min

8min

Drain 1min

Balancing Spin 2min

Middle Spin 3min

Sensing 20sec

Water Supply 2min

"Main-Wash 1 50min 53min 72min

(Heating)" 45min 35min

30min 18min 22min 16min 17min

25min 8min

15min

Drain 1min

Balancing Spin 2min

Middle Spin 3min

Water Supply 2min

Rinse 1 4min

Drain 1min

Balancing Spin 2min

Middle Spin 3min

Water Supply 2min

Rinse 2 4min

Drain 1min

Balancing Spin 2min

Middle Spin 3min

Water Supply 2min

Rinse 3 4min

Drain 1min

Balancing Spin 2min

Spin 9min

7min

6min

Clothes Release 60sec

End 10sec

Remain Time Display 55 59 53 54 32 1:12 1:30 1:34

NOTE

DDeelliiccaattee HHeeaavvyy dduuttyy

SSaanniittaarryyNNoorrmmaall CCoottttoonn

21

rum Wa

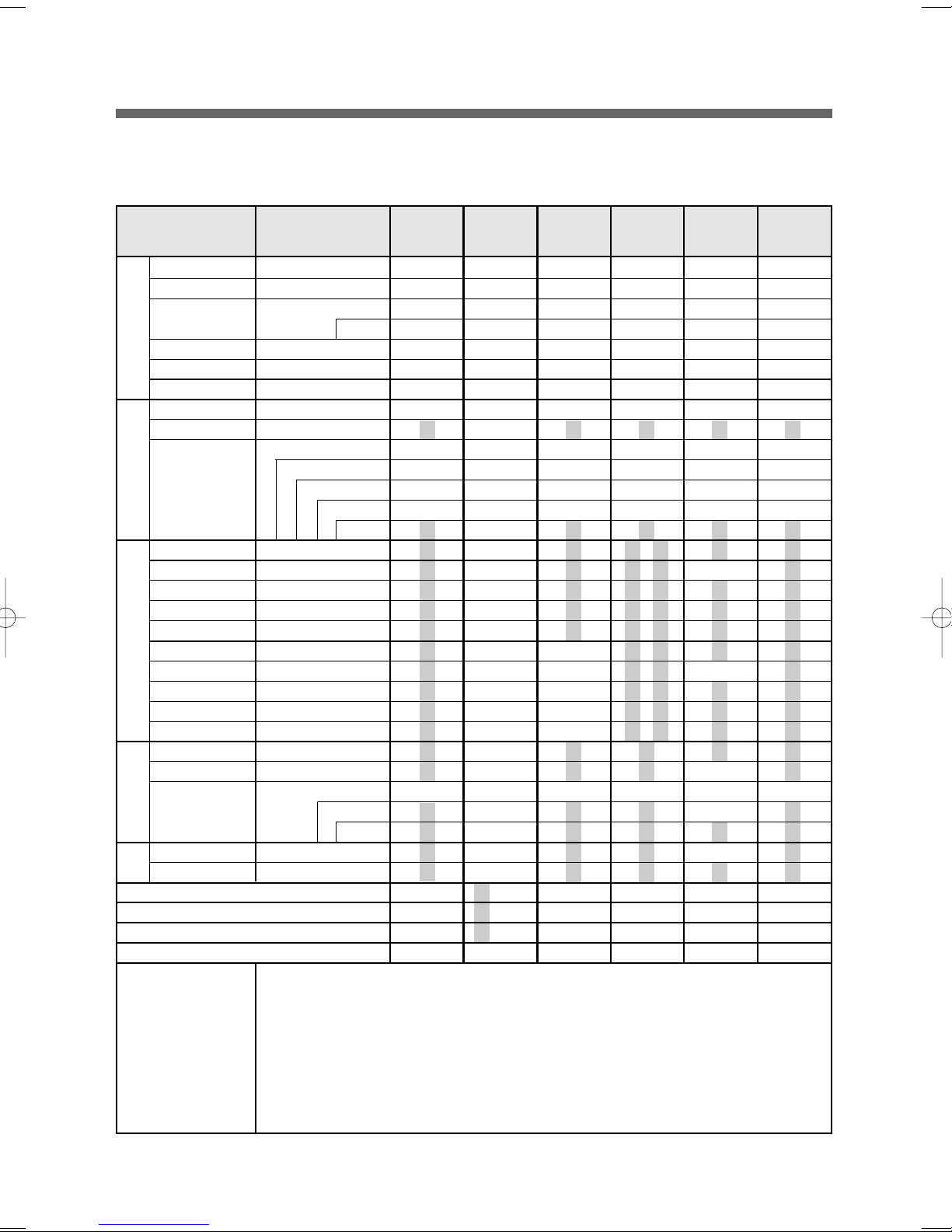

CCllaassssiiffiiccaattiioonn PPrroocceessssiinngg TTiimmee

PP

rr

ee

WW

aa

ss

hh

WW

aa

ss

hh

RR

ii

nn

ss

ee

SS

pp

ii

nn

EEnndd

Steam Pre-Heating 30 s

Steam 5min

Cooling 10min

Sensing 10sec

Water Supply 2min

Pre-Wash 10min

Drain 1min

Balancing Spin 2min

Middle Spin 3min

Sensing 20sec

Water Supply 2min

"Main-Wash 1 50min

(Heating)" 45min

30min Soak 30min

25min 22min 19min 19min

15min 8min 13min

Drain 1min

Balancing Spin 2min

Middle Spin 3min

Water Supply 2min

Rinse 1 4min 3min

Drain 1min

Balancing Spin 2min

Middle Spin 3min

Water Supply 2min

Rinse 2 4min 3min

Drain 1min

Balancing Spin 2min

Spin 9min

Clothes Release 60sec

End 10sec

Remain Time Display 59 16 33 1:20 45 1:20

NOTE

PPeerrmm PPrreessss

WWDD11335522

8min

7min

6min 5min

SStteeaamm ffrreesshh

WWDD11335522SS

SSppeeeedd

WWaasshh

BBaabbyy ccaarree GGyymm sshhooeess DDrruumm--cc

22

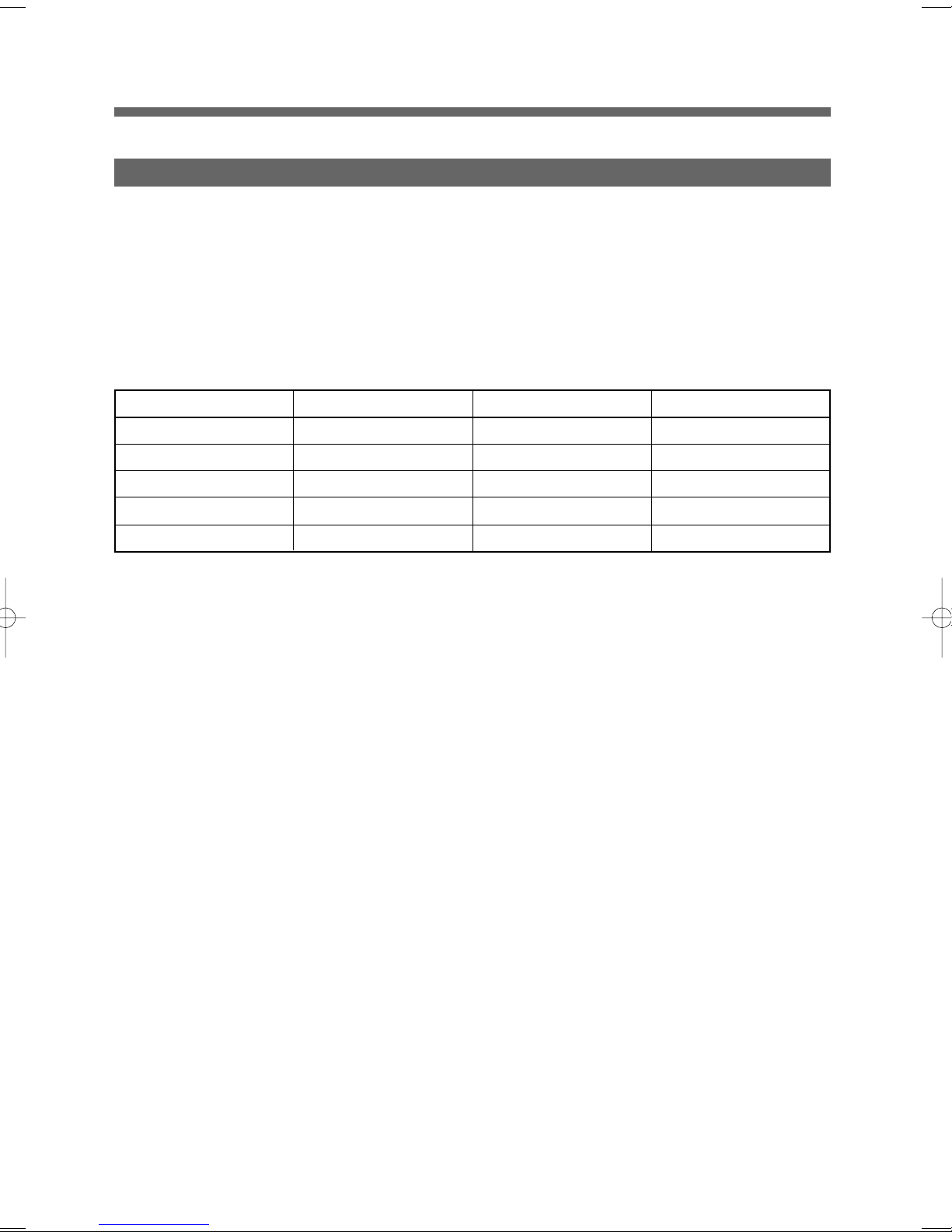

2. Composition per Function

2-1. Water Supply

1) Water Temperature Selection

Water supply algorithm differs according to water temperature selected among 5 levels.

In other temperatures, with the exception of cold water, constant temperature control is executed.

Cold water and hot water operation is carried out in turn according to the target temperature.

Water T emp. T arget T emp. T arget 1 T arget 2

Extra Hot/Cold 67) 67) 70)

Hot/Cold 35) 39) 36)

Warm/W arm 30) 29) 31)

Warm/Cold 30) 29) 31)

Cold/Cold - - -

2) For Cold/Cold, valve operation does not change according to temperature and only the time unit of cold

on for 7sec and off for 9sec is set to supply cold water per each unit of 16sec.

% Pre-wash V/V Operation

On for 3sec/ off for 2sec - Twice: Removing residual detergent from water supply box

& During the intial water supply for washing water is received 5mm higher than the set level.

3) How to Insert Bleach

% During Washing

Operation for 12sec after 3-minute washing in wool, delicate and speed wash courses

Operation for 12sec after 5-minute washing in cotton course

Operation for 12sec after skipping soaking and 4-minute of washing in Drum-cleaning course

Operation for 12sec after soaking and 4- minute of washing in Drum-cleaning course

23

rum Wa

2-2. Drainage

1) Pump Operation - Washing cycl FUNCIONAMIENTO DE LA BOMBA CICLO DE LAVADO

% Before Drainage Completion: Pump continuously on ANTES DE TERMINAR EL DRENADO LA BOMBA CONTINUA

& Spin-drying Cycle after Drainage Completion SPIN-CLICO DE SECADO TERMINACION DEL DRENADO

: On for 18sec and off for 3sec POR PERIODOS DE 18 SEG TRABAJANDO Y 3 SEC EN REPOSO

2-3. Sensor Detection SENSOR DE DETECCION

1) Water Level Sensor SENSOR DE NIVEL DE AGUA

* Water Level Data DATOS SOBRE EL NIVEL DE AGUA

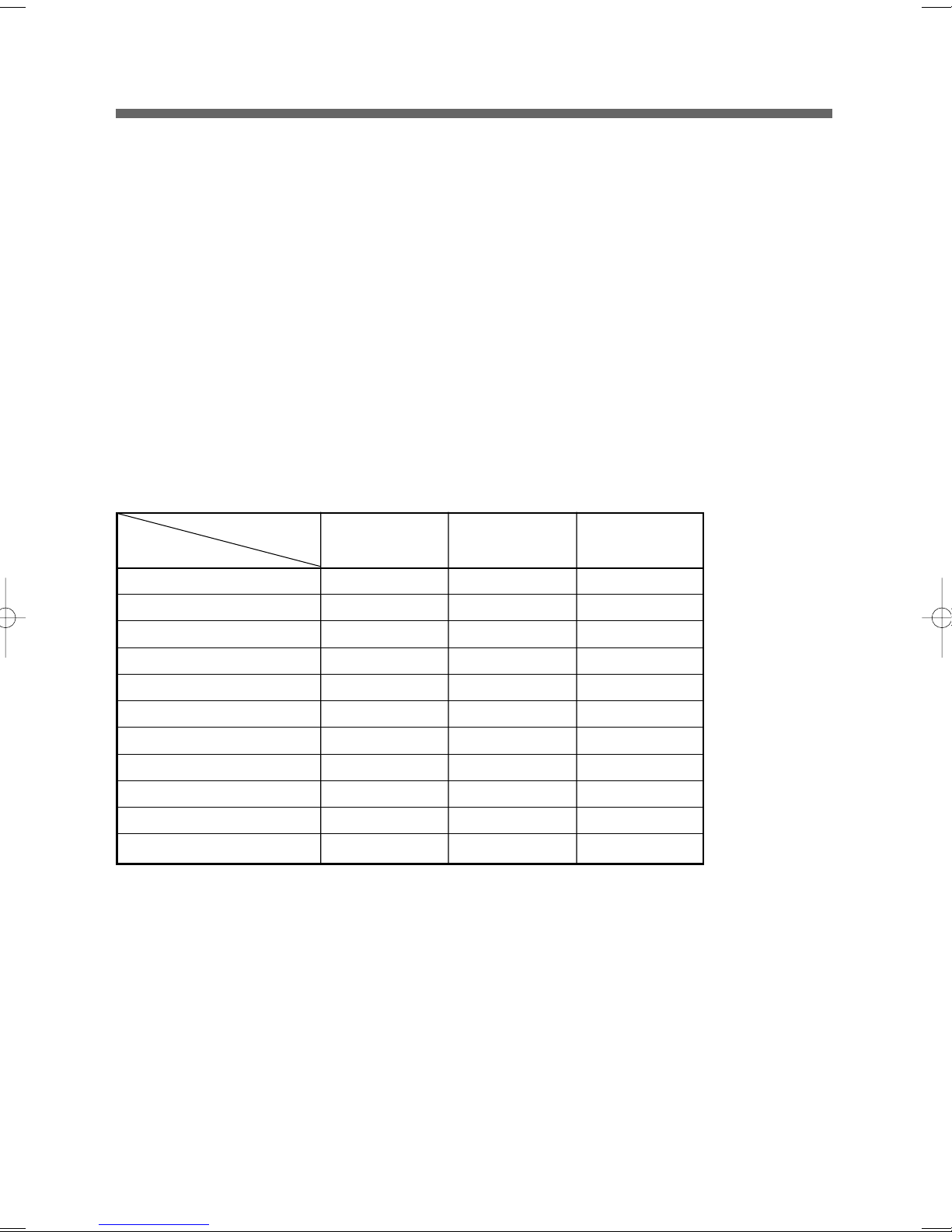

Classification ALTURA Frequency

Water Level (mm) (KHz)

Especificacion-minima 130 24.62

Spec. baja 130 24.62

Lavado-Minimo 130 24.38

Washing Low 130 24.09

Standard Rinsing 160 24.27

Rinsing 160 23.64

Additional Rinsing 175 24.01

Tub Washing 195 23.77

Overflow 260 22.6

Safety 125 24.7

Reset 125 24.68

Remarks

24

Loading...

Loading...