Page 1

Service Guide

Washing Machine

Version 2

2010.01.11

Asko WL6532 XXL

Page 2

CONTENTS

" What is Drum Washing Machine? ...........................................................3

" Washer Specification . ..............................................................................6

" Operating Mechanism Diagram ..............................................................7

" Parts List By ASS’Y ..................................................................................8

" Control Part Function Spec ...................................................................20

" Detailed Spec, Principles and Breakdown Diagnosis/ Service

of Electronic part. ...................................................................................45

" Wiring Diagram.......................................................................................62

" Installation ..............................................................................................63

" Reversing the door .................................................................................65

" Dismantling method per washer ass’y ..................................................67

2

Page 3

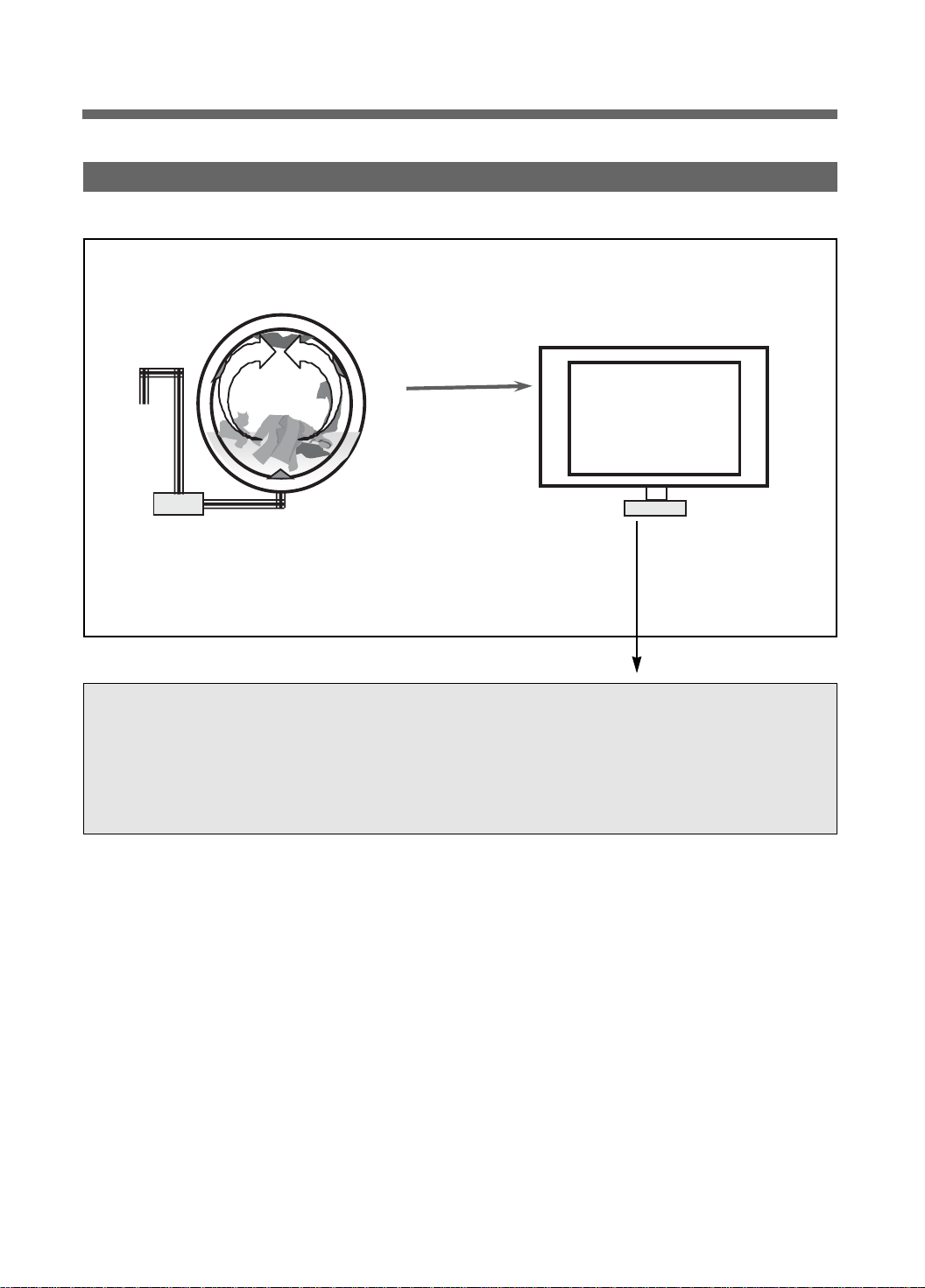

What is Drum Washing Machine?

"

1. Drum Washing Machine

Water consumption is reduced by using the power of the laundry falling (free-fall) created when rotating

the drum resembling a sieve net. With temperature control system, this drum washing machine saves

energy and improves washing performance at the same time.

2. Key Features

" Simultaneous supply of cold#hot water

As cold and hot water is supplied at the same time, heating time and energy is saved.

" DD inverter motor

The direct-drive type, of which motor is directly connected to drum without an interim clutch,

significantly reduces noise and vibration.

" Heating device is installed to enable boiling of the laundry.

" Large door creates grand appearance and makes it easy to put in and out the laundry.

" For pump drainage, the powerful pump speeds up drainage process.

3

Page 4

3. Power System

The

Turbo

Laundry

Drainage Motor

#DD Control: Direct drive type of direct connection between drum and motor

#Rotation by powerful high-performance BLDC motor

#Pump drainage type for built-in installation

Drum

BLDC Motor

4

Page 5

rum Wa

4. Major Functions

$ Washing

When rotating drum after putting in the laundry and detergent into the drum, the laundry are rotated by

protrusions (lifters) attached inside the drum.

Washing is carried out with bending and impact actions generated by falling of the laundry to the top

part of drum.

% Rinsing

Rinsing cleanly washes out detergent and dirt removed from the laundry after washing cycle.

& Spin-drying

Weak, standard and strong cycles can be selected according to types of fabrics to be washed. Spindrying is carried out by rotation (the centrifugal force) of drum according to the designated speed.

' Drainage

Pump Drainage: Powerful pump for built-in installation and application of filter to remove foreign

substances

5

Page 6

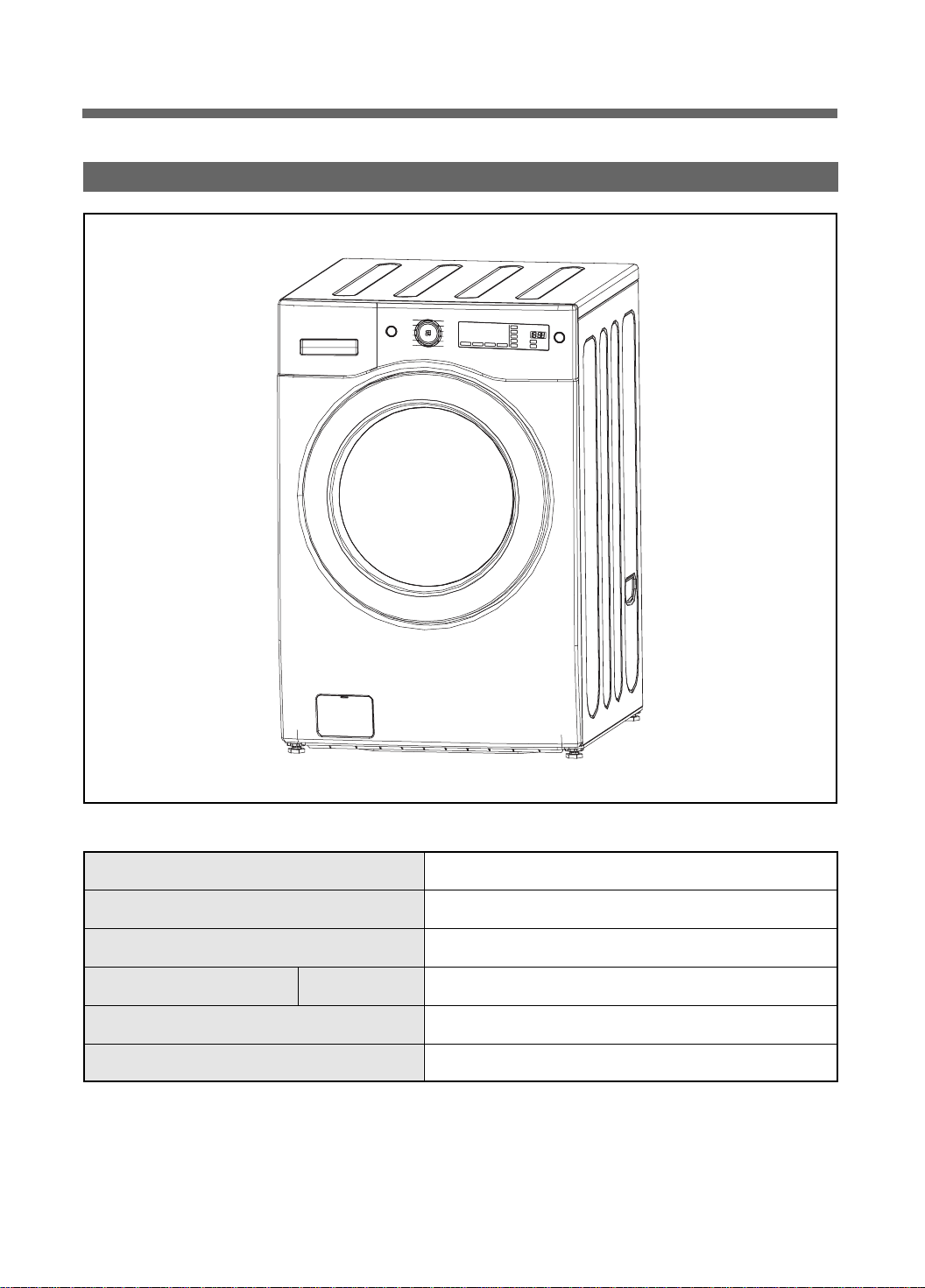

Washer Specification

"

1. Product Specification

External Measurements (inches) 27"(width) x 31.8"(depth) x 40.1"(height)

Weight 198.4lbm

Rated Supply Power 120V 60Hz

Rated Consumption Power Washing 200W (1100W during heating)

Washing Method Drum type

Water Pressure Water Pressure 29kPa ~ 784kPa(0.3kgf/kg~8kgf/kg)

6

Page 7

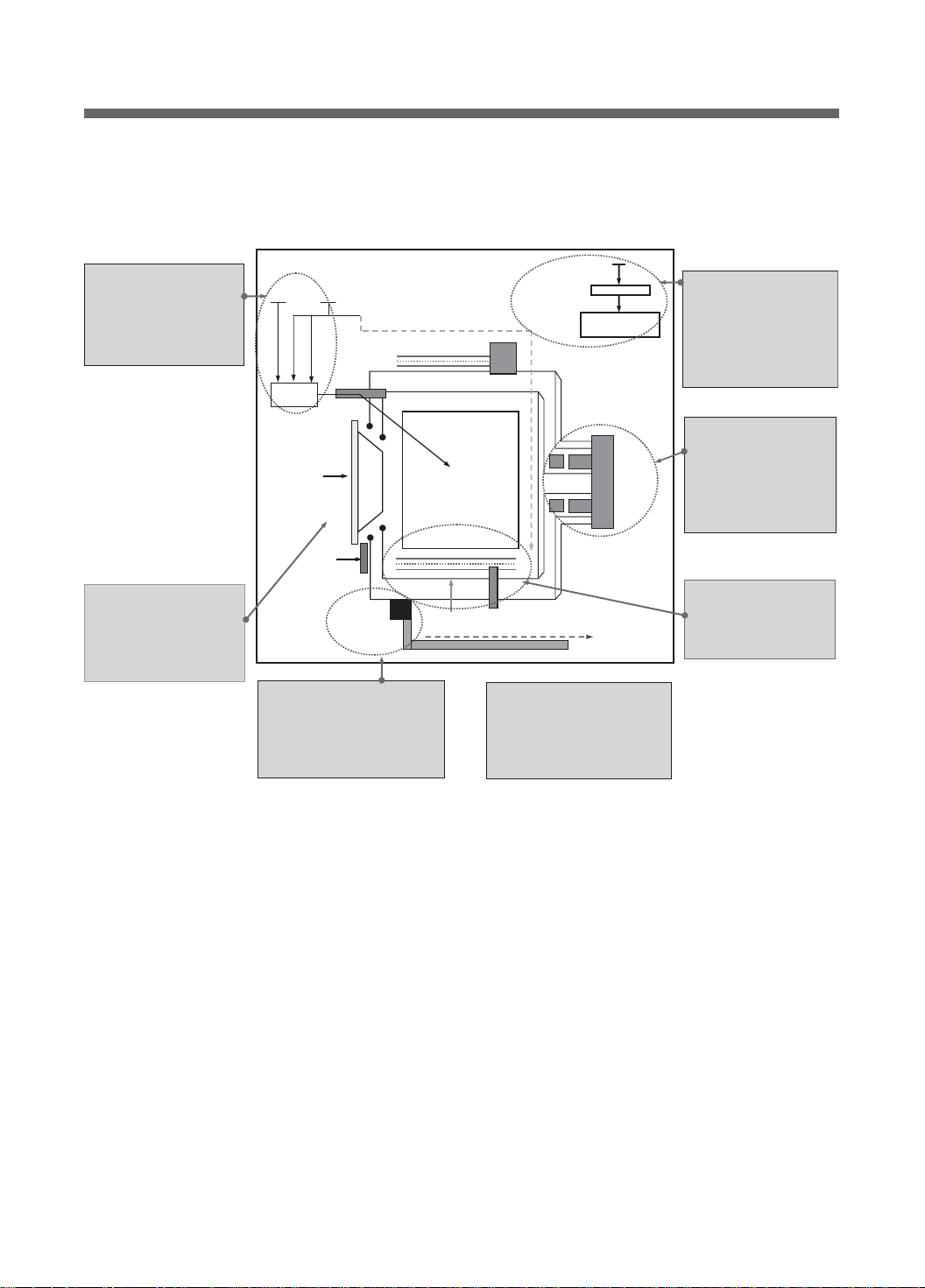

Operating Mechanism Diagram

"

4. WATER SUPPLY PART

• Cold Water: 3 holes

Cold water, pre-washing

• Hot Water: 1 hole

• Water supply box, hose

5. DOOR

• Door lock S/W

• Lock hinge

• Door AS: Glass

• Gasket

Water

Supply

Delergent

Container

Thermister

Door

Door

Switch

Drainage

Pump

6. DRAINAGE PART

• Drainage pump

• Valve housing

• Hose

Drum

Washing

Heater

Electricity Input

Noise Filter

Thermister

7. SUPPORTER

• Base

• Damper AS: 4

• Spring: 2

Program

BLDC

Motor

1. CONTROL PART

• Main PCB

• Front PCB

• Harness

• Noise filter

• Power Cord: 15A

2. DRIVING PART

• BLDC motor

• Drum

• Bearing

• Spider/ shaft

• Tub

• Weight balancer

3. HEATING PART

• Water Heater: 1000W

• Washing temperature

sensor

7

Page 8

PARTS LIST BY ASS’Y

"

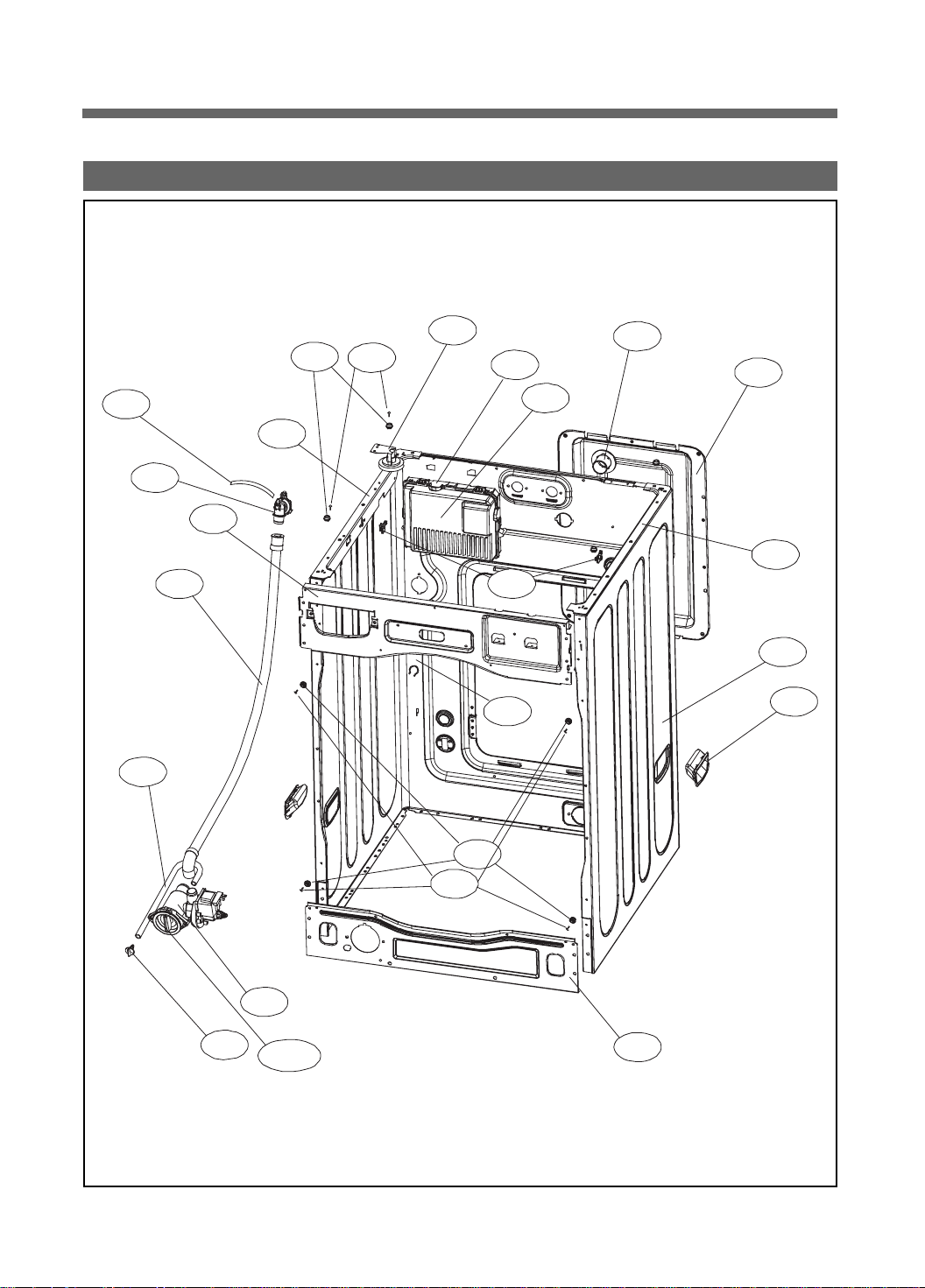

1. CABINET AS

C18

C15

C17

C14

C05

C03

C07

C08

C12

C19

C06

C20

C09

C11

C20

C04

C01

C10

C16

C13

C13-1

C07

C08

C02

8

Page 9

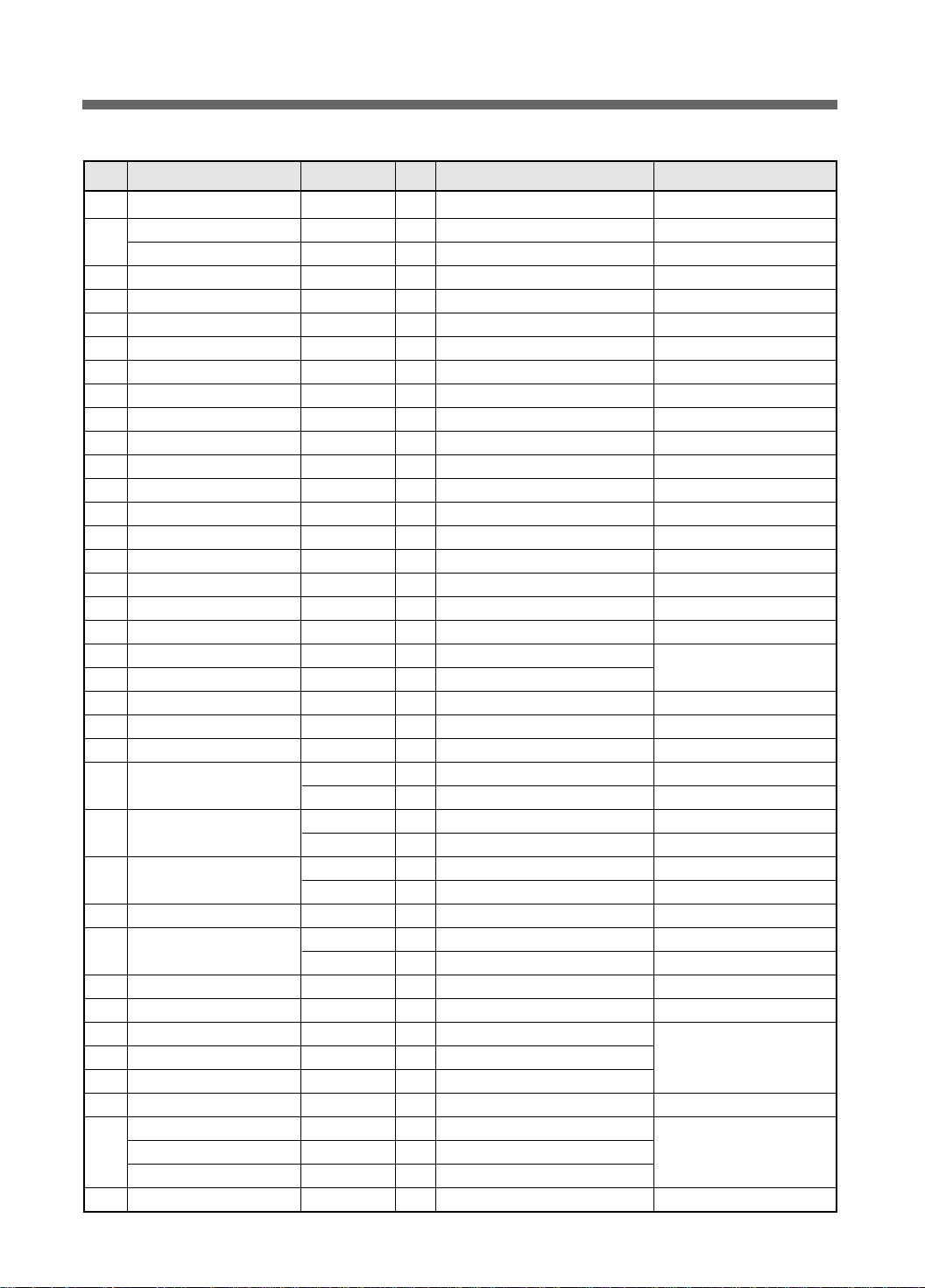

No. Part Name Part Code Qtt'y Specification Remark

- CABINET SUB AS 3610811950 1 13KG, PUMP, WHITE WL6532 XXLW, XXLW RH

3610811955 1 13KG, PUMP, PLATINUM WL6532 XXLPP

3610811956 1 13KG, PUMP, ROSE RED WL6532 XXLRR

3610811957 1 13KG, PUMP, BLACK WL6532 XXLBB

C01 CABINET 3610811740 1 SGCC 0.8T PUMP WASHER • 1PIECE SVC PART

C02 FRAME LOWER 3612206700 1 SBHG 1.2T => CABINET SUB AS

C03 FRAME TOP L 3612206500 1 SGCC 1.6T

C04 FRAME TOP R 3612206600 1 SGCC 1.6T

C05 FRAME UPPER 3612208200 1 SGCC 1.2T

- SCREW TAPPING 7122401411 6 T2S TRS 4 x 14 MFZN Fix Frame Upper to Cabinet

C06 STOPPER SPRING 3615202200 2 POM

C07 FIXTURE PLATE 3612008000 8 POM

C08 SCREW TAPPING 7121401211 8 T2S PAN 4 x 12 MFZN

C09 NOZZLE AIR 3618103110 1 PP

C10 HANDLE CABINET 3612608100 2 PP WL6532 XXLW, PP, RR, BB

C11 COVER BACK AS 3611425510 1 COVER B + PAD

- SCREW TAPPING 7122401411 4 T2S TRS 4 x 14 MFZN Fix Cober Back to Cabinet

C12 SENSOR PRESSURE 3614825220 1 DWD-130RP

- SCREW TAPPING 7122401411 2 T2S TRS 4 x 14 MFZN Fix Sensor Pressure to Cabinet

C13 UNIT DRAIN PUMP AS 36189L5600 1 UL.PLASET + HANYU AS 80W

C13-1 FILTER PUMP 3611910200 1

C13-2 DRAIN PUMP 36196TAP00 1 UL.LOW,80W.20L.1.4A

C13-3 RING O 3614604110 1 D=54,T=2.6

- SCREW TAPPING 7122401411 2 T2S TRS 4 x 14 MFZN

C14 HOSE DRAIN I 3613271300 1 ST+EL, 1010MM

- ABSORBER HOSE DRAIN 3610115600 1 T10, 60 x 130

- CLAMP HOSE 3611203900 2 SK5 D=26 Fix Drain I

C15 HOSE WATER REMAIN 3613272210 1 EPDM, UL 3T Round Bending

C16 CAP WATER REMAIN 3610916800 1 PP

C17 CUFF DRAIN HOSE 3616802600 1 PP, PUMP

C18 HOSE SIPHON 3613272210 1 EPDM, UL 3T L=270

- SCREW TAPPING 7122401411 1 T2S TRS 4 x 14 MFZN Fix Drain Hose to Cabinet

C19 PCB INVERTER AS PRPSSWAD19 1 ASKO 13K Washer Pair main ~ 20091228(changed)

PRPSSWAD1J 1

C20 COVER PCB M 3611427700 1 UL,ABS VE-0856, MAIN PCB

C21 HARNESS AS 3612796T00 1 UL, 13K Washer, Non-bubble ~ 20091228(changed)

3612796T01 1

- SCREW TAPPING 7122401411 1 T2S TRS 4 x 14 MFZN Fix PCB Main to Cabinet

- LOCK HARNESS M 3613802300 6 M Type(18 x 18), Nylon66 Cabinet rear

- LOCK HARNESS 3613802100 2 DASTL-20NA Frame Top right

- LABEL WIRING UL 3613557100 1 UL Only, Wiring diagram+Warning English&French

- SCREW TAPPING 7122401411 1 T2S TRS 4 x 14 MFZN Fix Cabinet F to Frame Lower

13KG, HANYU FILTER + CASE PUMP AS CODE

Fix Drain Pump to Frame Lower

WASHER,PAIR-DRY,RENESAS,USA,ASKO(N.M)

UL 13KG WASHER 3RD-PANEL(BLEACH),NEW MOTECH

20091228 ~

20091228 ~

9

Page 10

rum Wa

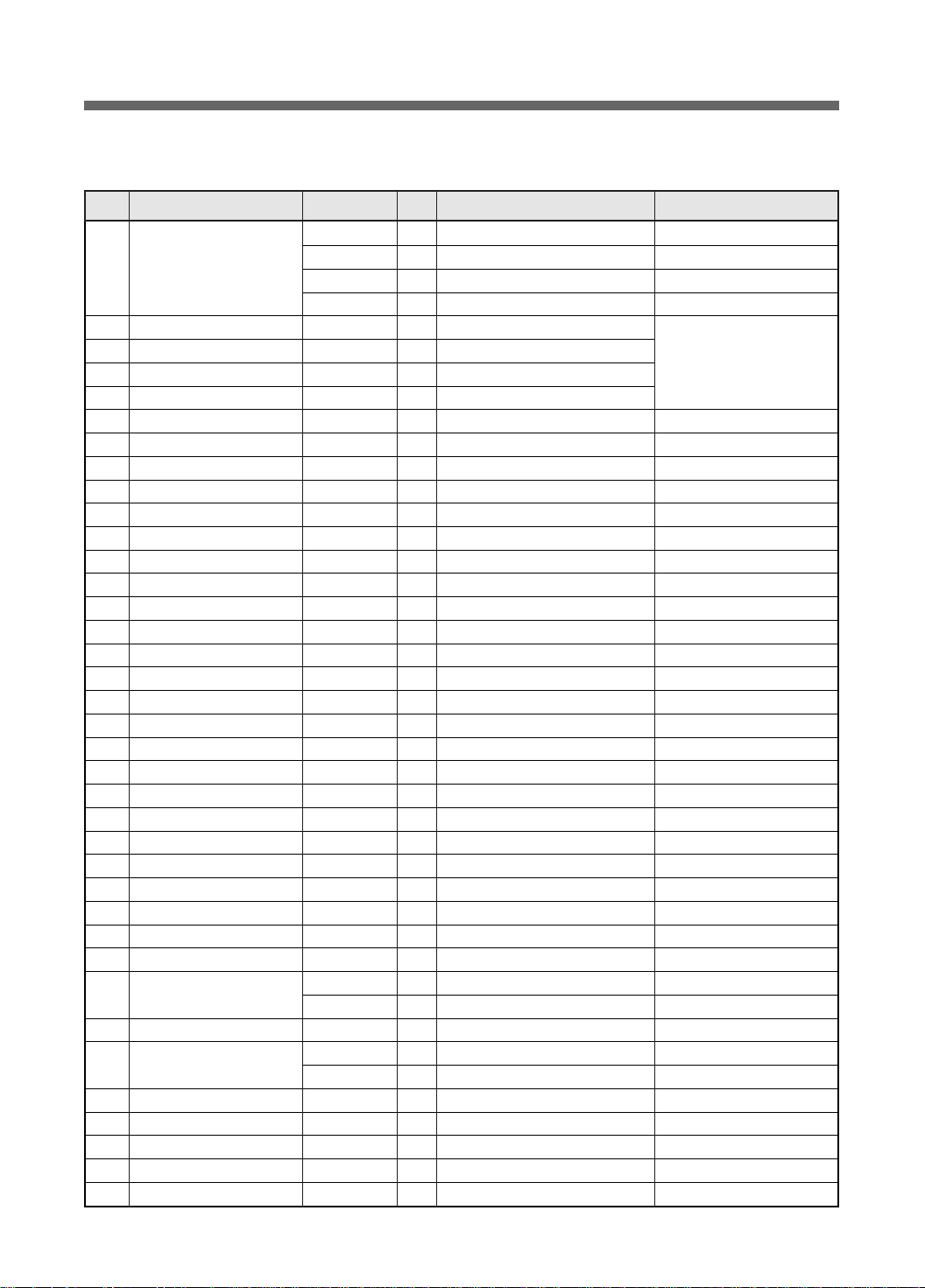

2. BASE U ASS'Y

B06

B02

B01

B03

B04

B05

No. Part Name Part Code Qtt'y Specification Remark

B01 REACTOR 52G043A110 1 RT-047K L=150

B02 BASE U 3610392700 1 PP

B03 SUPPORTER LEG 3615303610 4 PO+Coating 3.0T

B04 FIXTURE LEG 3612006400 4 ABS, DWD-100DR

B05 FOOT AS 3612100700 4

B06 PROTECTOR HEATER 3618304600 1 SECC 0.35T

- SCREW TAPPING 7122401411 4 T2S TRS 4x14 MFZN Fix Protector Heater to Base U

- SCREW TAPPING 7122401411 20 T2S TRS 4x14 MFZN Fix Base U to Cabinet

Foot+Special bolt, Double insert type Hybra-Nylon66

10

Page 11

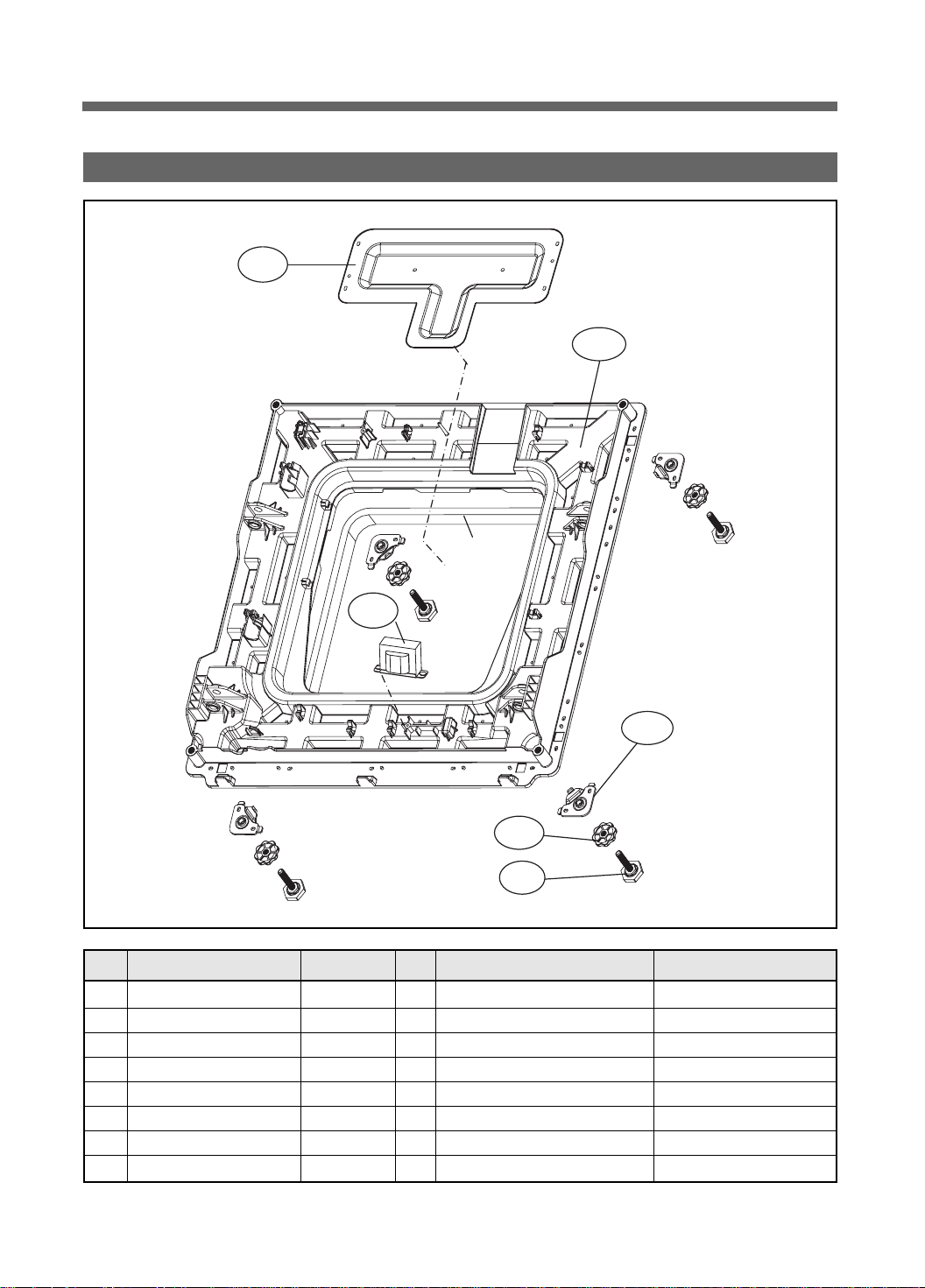

3. SUPPORT DRUM REAR ASS'Y

D06

T01

T03

T12

T04

T05

T11

T10

T21

T06

T07

D04

T09

T20

T23

D05

D01

T22

T08

T24

D02

D03

T26

T28

T13

T18

T17

T16

T15

T14

T19

11

T25

T27

T29

Page 12

rum Wa

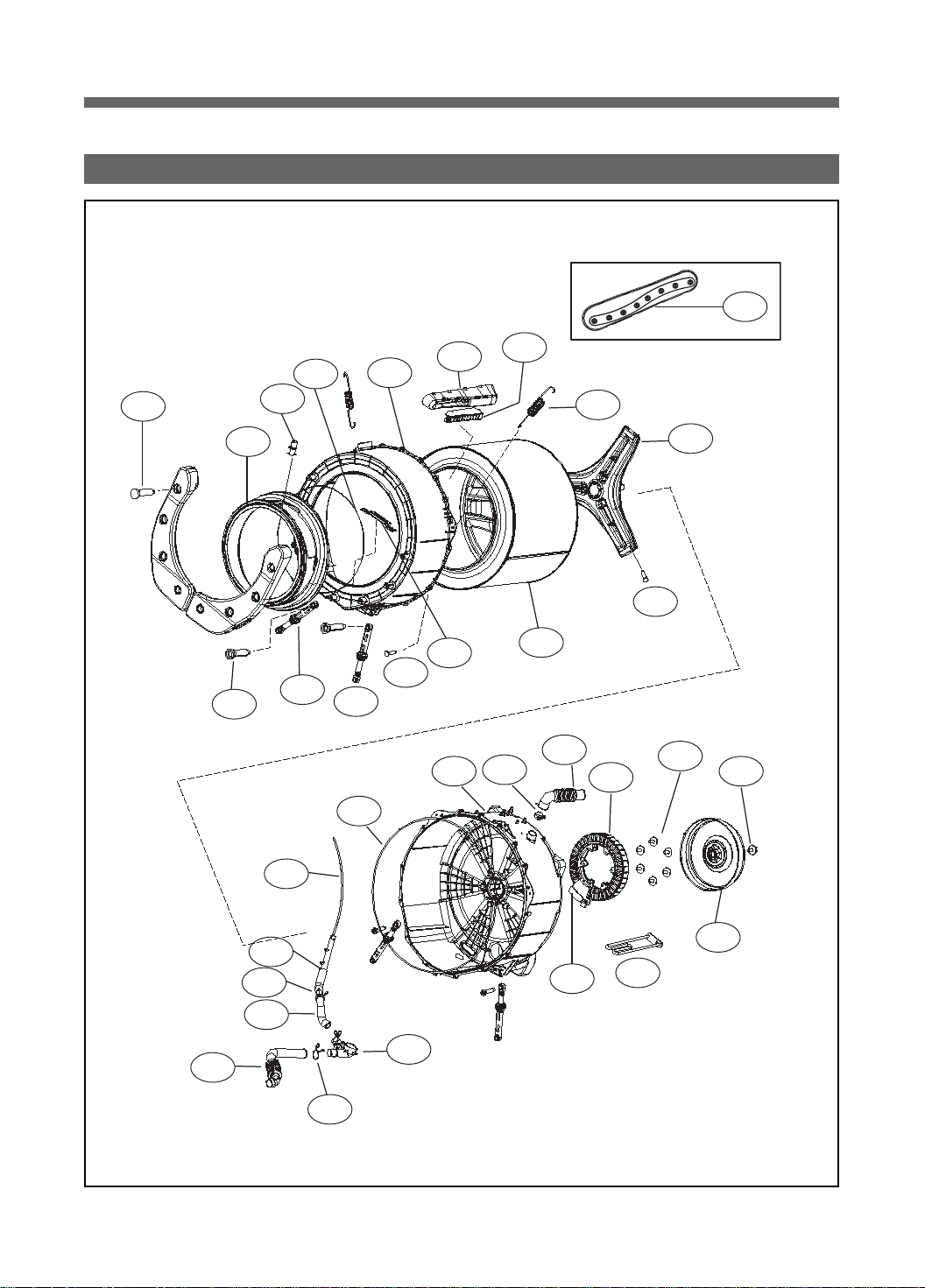

No. Part Name Part Code Qtt'y Specification Remark

T01 SPECIAL SCREW 3616029400 8 SWCH 8.5 x 30 Fix Balancer W. to Tub F

T02

BALANCER WEIGHT AS(L)

BALANCER WEIGHT AS(R)

T03 GASKET AS 3612322000 1 EPDM, Wash-only, Nozzle shower

T04 NOZZLE SHOWER 3618104000 1 PP

T05 CLAMP GASKET AS 3611205300 1 Gasket, 13kg Drum

T06 TUB FRONT 3618828Y00 1 FRPP, 13kg Drum

T07 SPECIAL SCREW(TUB) 3616029800 15 SWCH 6.5 x 30 Fix Tub F & R

T08 SPRING SUSPENSION 3615114800 2 13kg DRUM

T09 FIXTURE HEATER 3612006700 1 STS 430

T10 DAMPER FRICTION 361A700300 2

T11 DAMPER FRICTION 361A700110 2

T12 DAMPER PIN 361A700200 8 AKS D=14.5 Tub & Base U

T13 HOSE DRAIN 3613269000 1 EPDM,PUMP

T14 CLAMP HOSE 3611205700 2 HSW3 D2.6 ID33 MFZN

T15 HOSE AIR PRESSURE 3613270600 1 ID=4,OD=8,L=1000MM

T16 HOSE AIR TRAP 3613269700 1 EPDM, 13kg Drum

T17 CLAMP HOSE 3611204700 2 D26

T18 AIR TRAP 361A500101 1 PP

T19 DRAIN HOUSING I 36196TAM00 1 PP,PUMP 1 PIECE SVC PART

T20 TUB REAR AS 36100E2W00 1 DWD-WD113*, DWD-WD123*

T21 GASKET TUB 3612322100 1 EPDM FORM, 13KG DRUM

T22 HOSE AIR 3613266300 1 EPDM, DWD-100DR

T23 CLAMP HOSE 3611205900 2 HSW3 D2.6 ID36 MFZN

T24 UNIT STATOR BLDC 36189L4840 1

T25 HALL IC HOLDER AS 3426D01002 1

- HARNESS SUB AS 3612796D00 1

T26 SPECIAL BOLT AS 3616063400 6 SWCH M8+SILOCK, 58MM Fix Stator & Tub R

T27 UNIT ROTOR BLDC 36189L4900 1

T28 SPECIAL BOLT AS 3616029600 1

T29 HEATER WASH 3612801740 1

D01 DRUM SUB AS 3617008X10 1 SUS, 13kg 1 PIECE SVC PART

D02 SPIDER AS 361A300600 1 13kg, ALDC+S45C

D03 SPECIAL SCREW(SPIDER) 3616029500 6 STS 430, 8 x 25

D04 LIFTER BODY 361A400700 3 PP, 13kg Drum WL6511XXL

D05 CAP FILTER 3610917310 3 ABS, NON-NANO, 13kg 1 PIECE SVC PART

FILTER 3611908410 3 ABS, NON-NANO, 13kg WL6511XXL

FILTER NET 3611908500 3 SUS, FILTER

D06 LIFTER WASH 361A401200 3 PP,13KG 2ND LIFTER,NON-NANO WL6532 XXL

3616110100 1 13KG, VE TYPE, 7.8kg

3616110200 1 13KG, VE TYPE, 7.8kg

AWECO, HP3 60N/9MM BUFFER 4,0

70N AKS ST=170-260 DL=197.5 LOW NOISE

30T,36SLOT,2SENSOR,WS2A30G011

36189L6220 1

3616D01000 1

3612796D20 1

36189L6300 1

AL,DON1400W 32T 36POLE,NMT,PET

DRUM STATOR PCB HOLDER AS(SVC)

DRUM STATOR PCB HOLDER AS(SVC),NMT

130RP SUB HARNESS.MOTOR.HALL.W-TH

SUB HARNESS.NEWMOTECH MOTOR.HALL.W-TH

MAGNET24,SERRATION,WR1238F001

DON1300W SR-FERRITE12,30~32T,NMT

SWCH 10*30,F/L BOLT S.P/W SEAL LOCK

UL.120V1.0KW6.7W/SQ.SUS.1R3A515003.L/W.

Tub F & R right

Tub F & R left

~ 20091228(changed)

20091228 ~

~ 20091228(changed)

20091228 ~

~ 20091228(changed)

20091228 ~

~ 20091228(changed)

20091228 ~

12

Page 13

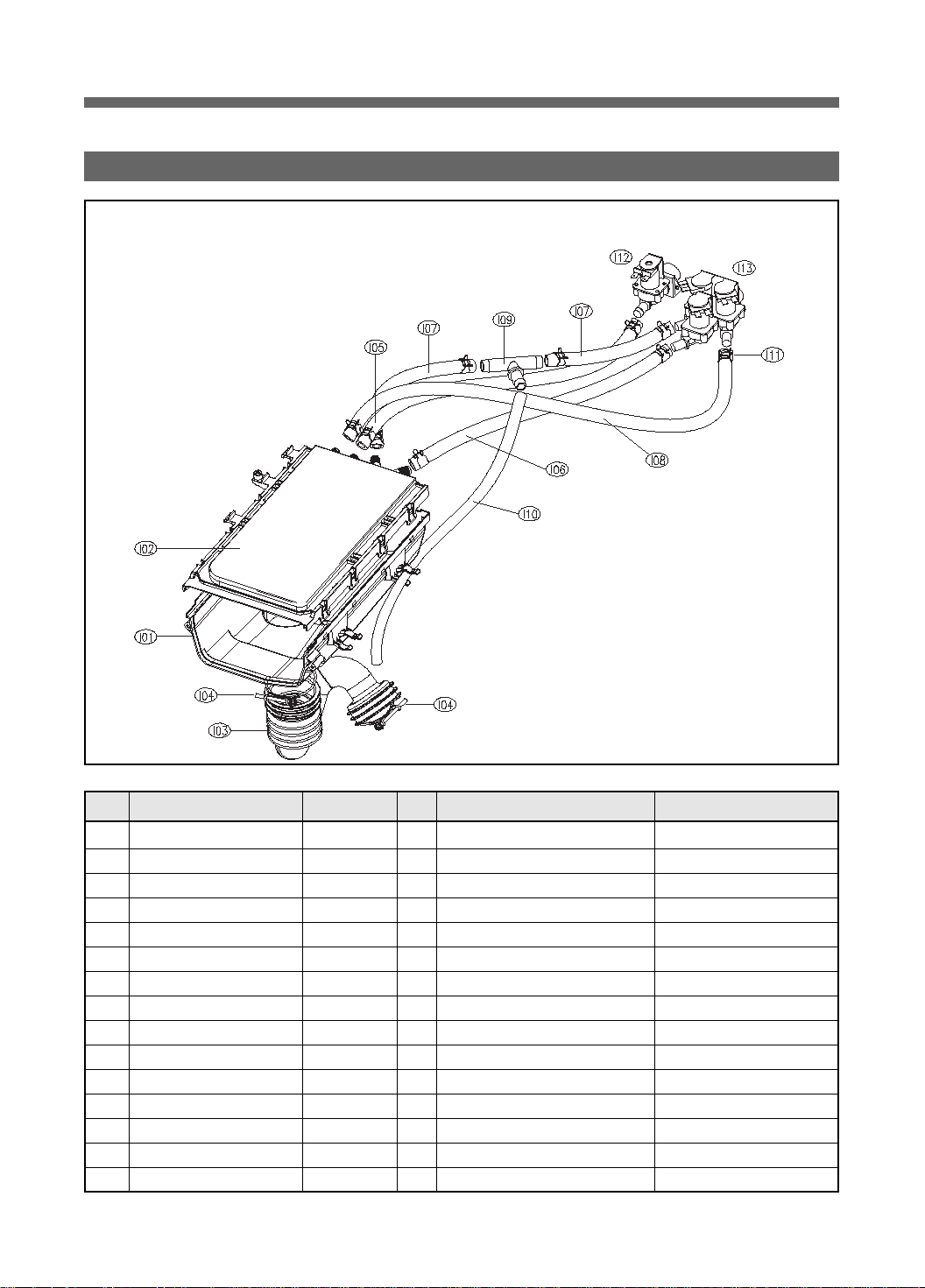

4. INLET BOX AS

No. Part Name Part Code Qtt'y Specification Remark

I01 INLETBOX 3617510800 1 PP

I02 NOZZLE AS 3618104800 1 Top+Under

I03 HOSE INLET 3613270300 1 EPDM

I04 CLAMP AS 3611203200 2 ID=60, WIRE+GUIDE+BOLT+NUT

I05 HOSE WATER SUPPLY 3613270920 1 EPDM ID=9.5 OD=15.5 L=410mm

I06 HOSE WATER SUPPLY 3613270920 1 EPDM ID=9.5 OD=15.5 L=380mm

I07 HOSE WATER SUPPLY 3613270920 2 EPDM ID=9.5 OD=15.5 L=230mm

I08 HOSE WATER SUPPLY 3613270920 1 EPDM ID=9.5 OD=15.5 L=530mm

I09 PIPE JOINT HOSE INLET 3614413300 1 PP

I10 HOSE SHOWER 3613270130 1 EPDM ID=8.5 L=550mm

I11 CLAMP HOSE 3611205810 1 D-WD113'S ID14.3 W10 0.9T WH

I12 VALVE INLET 3615416700 1 UL.120V60HZ.BITRON.1WAY HOT

I13 VALVE INLET 3615416930 1 UL.120V60HZ.BITRON.3WAY COLD

- SCREW TAPPING 7002400811 4 TRS 4X8 MFZN Fix Valve Inlet to Cabinet

- SCREW TAPPING 7122401411 1 T2S TRS 4X14 MFZN Fix Inletbox to Frame T(Side)

13

Page 14

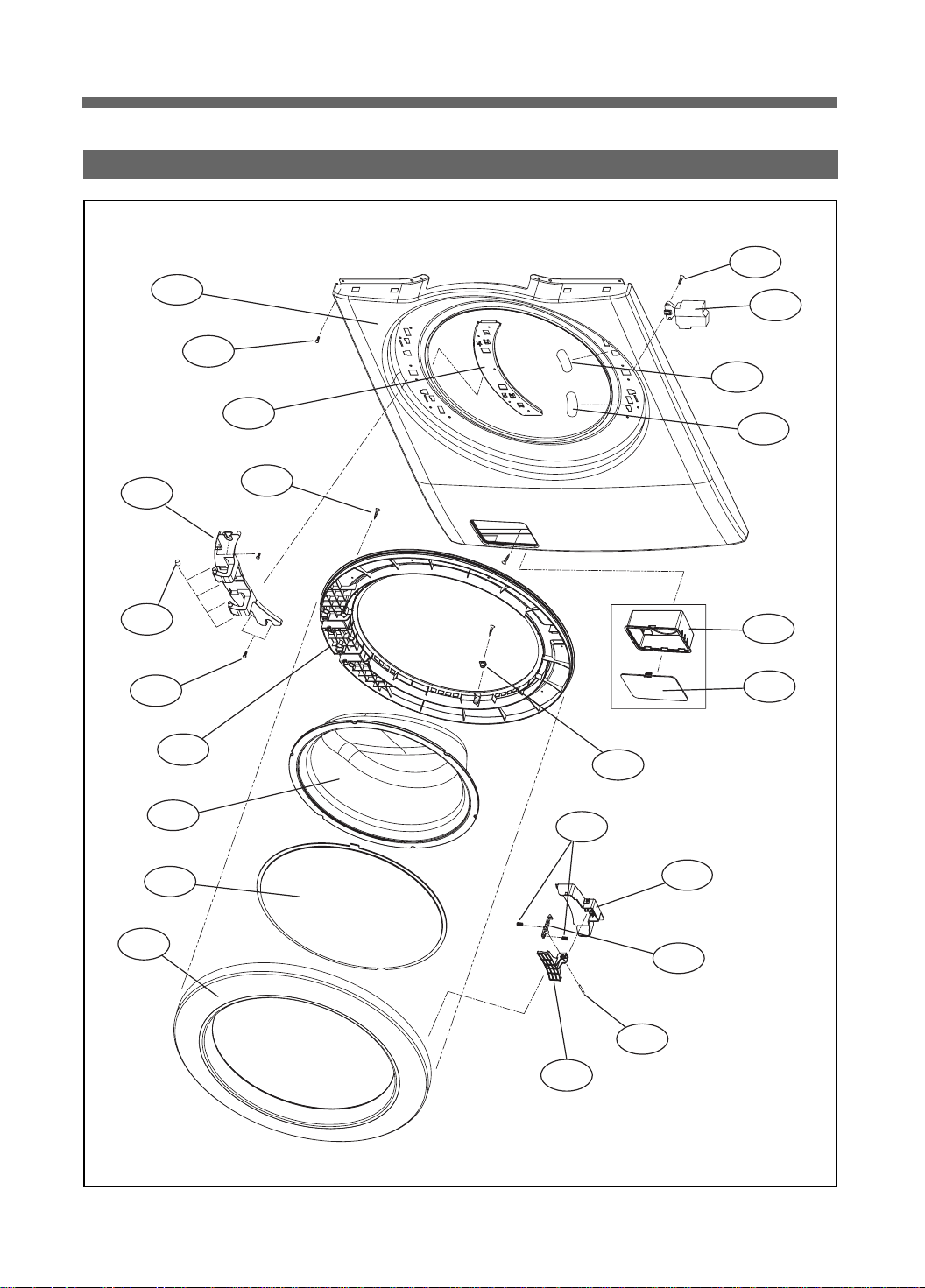

5. CABINET FRONT ASS'Y

F01

F21

F20

F19

F03

F09

F10

F18

F05

F07

F08

F02

F04

F12

F22

F23

F06

F16

F13

F11

F15

F17

F14

14

Page 15

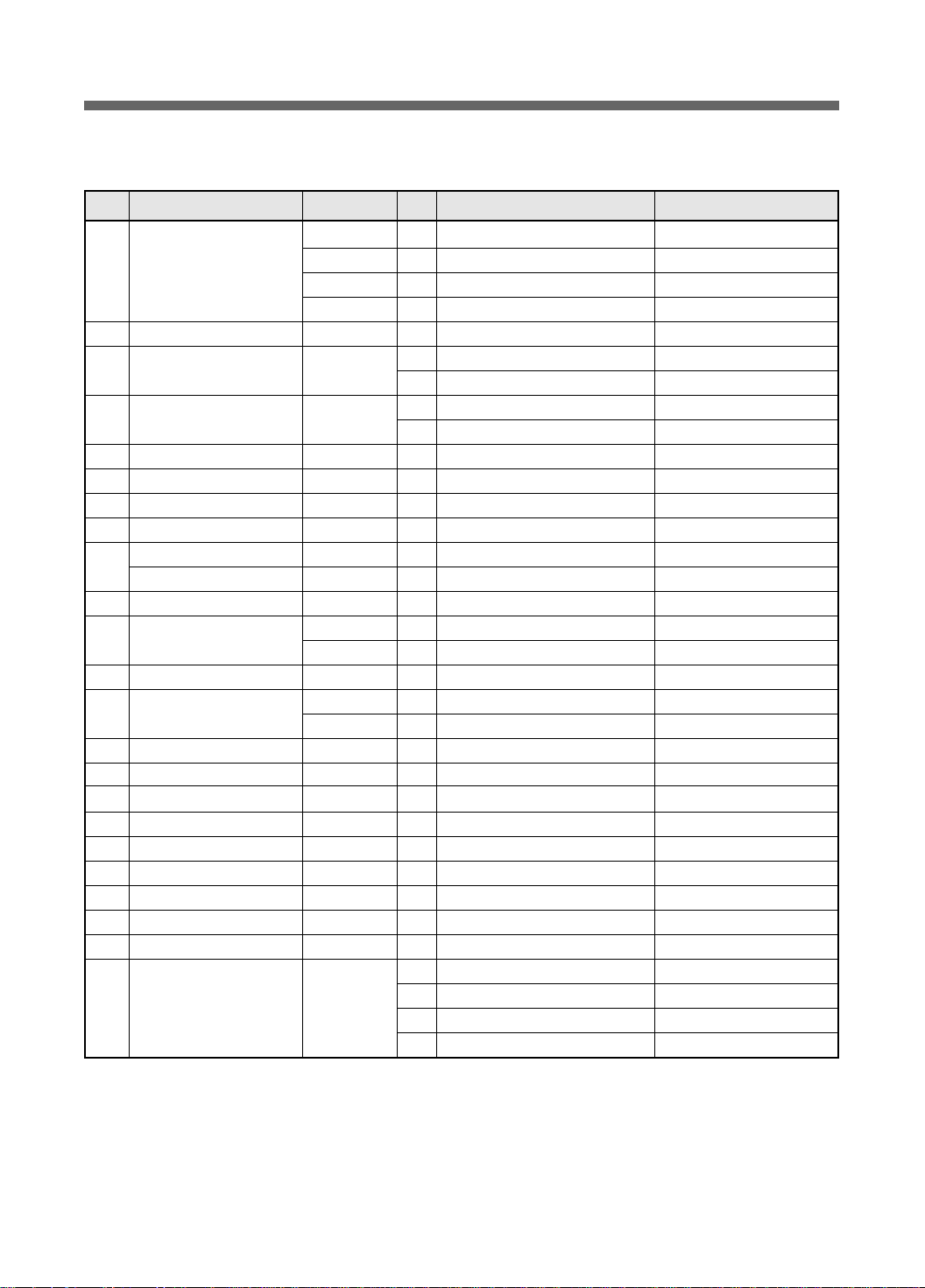

No. Part Name Part Code Qtt'y Specification Remark

F01 CABINET F SUB AS 3610811310 1 13KG, PUMP, WHITE WL6532 XXLW, XXLW RH

3610811321 1 13KG, PUMP, PLATINUM WL6532 XXLPP

3610811322 1 13KG, PUMP, ROSE RED WL6532 XXLRR

3610811324 1 13KG, PUMP, BLACK WL6532 XXLBB

F02 SUPPORTER HINGE 3615304001 1 SGCC 1.2T

F03 LABEL SAFETY R 3613555800 1 PET, DOOR SAFETY,UL

1 PET, DOOR SAFETY,UL, RH XXLW RH

F04 LABEL WARNING 3613558500 1 PET,SILVER,DOOR WARNING,UL

1 PET, DOOR WARNING,UL, RH XXLW RH

F05 FRAME DOOR IN 3612206800 1 PP(Heat resisting)

F06 STOPPER DOOR 3615202300 1 PP(Heat resisting)

F07 DOOR GLASS 361A110600 1 GLASS

F08 PROTECTOR GLASS 3618304300 1 ABS(Transparent)

F09 HINGE DOOR 3612902910 1 ALDC, WHITE WL6532 XXLW, XXLW RH

HINGE DOOR AS 3612902900 1 ALDC, GRAY

F10 CAP HINGE DOOR 3610916500 4 POM

F11 FRAME DOOR OUT 3612206910 1 13K WASHER,ALDC WL6532 XXLW, XXLW RH

3612206900 1 13K WASHER,ALDC

F12 SCREW TAPPING 7115402029 16 T1S FLT 4*20 STS430 NATURAL

F13 COVER HANDLE 3611426720 1 ABS, SPRAY_BASE WL6532 XXLW, XXLW RH

3611426700 1 ABS

F14 HANDLE DOOR 3612609000 1 ABS

F15 HOOK DOOR 3613100800 1 ZNDC

F16 SPRING HOOK 3615113700 2 SUS ID=4.3,NI=7,D=(0.9

F17 PIN HANDLE 3618200100 1 SUS, D3.0

F18 SCREW TAPPING 3616051229 4 STS430 F/L BOLT(SE) 5*12

F19 SWITCH DOOR LOCK 3619046410 1

F20 SCREW TAPPING 7122401608 2 T2S TRS 4 x 16 SUS 430

F21 SCREW TAPPING 7122401411 4 T2S TRS 4 x 14 MFZN For fixing Cabinet F to Cabinet

F22 CASE PUMP 3611141400 1 PP

F23 COVER PUMP 3611426800 1 ABS, WHITE WL6532 XXLW, XXLW RH

DF F11 110 125V 16A PTC-SOLENOID

1 ABS, PLATINUM WL6532 XXLPP

1 ABS, RED WL6532 XXLRR

1 ABS,BLACK WL6532 XXLBB

WL6532 XXLW, XXLPP, XXLRR

WL6532 XXLW, XXLPP, XXLRR

WL6532 XXLPP,XXLRR,XXLBB

WL6532 XXLPP,XXLRR,XXLBB

WL6532 XXLPP,XXLRR,XXLBB

For fixing Door S/W to Cabinet F

15

Page 16

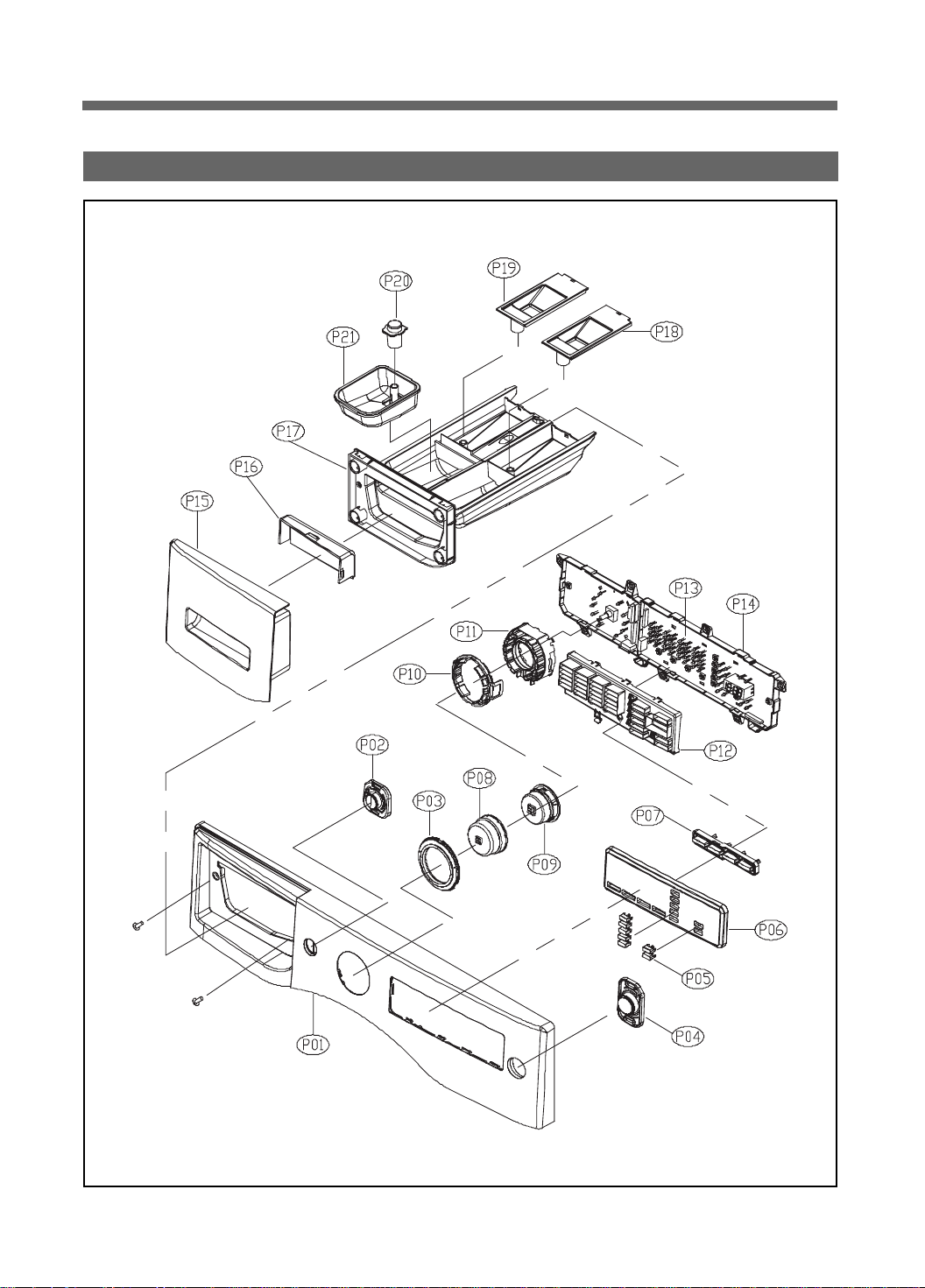

6. PANEL F ASS'Y

16

Page 17

No. Part Name Part Code Qtt'y Specification Remark

P01 PANEL F 3614288800 1 ABS, WASHER(ASKO), WHITE WL6532 XXLW, XXLW RH

1

ABS, WASHER(ASKO), PLATINUM

1 ABS, WASHER(ASKO), RED WL6532 XXLRR

1ABS, WASHER(ASKO), BLACK WL6532XXLBB

P02 BUTTON POWER 3616637800 1 ABS, WHITE WL6532 XXLW, XXLW RH

1 ABS, PLATINUM WL6532 XXLPP

1 ABS, RED WL6532 XXLRR

1ABS, WASHER(ASKO), BLACK WL6532XXLBB

P03 WINDOW COURSE 3615506300 1 ABS(Transparent) + Film, WHITE WL6532 XXLW, XXLW RH

1

ABS(Transparent) + Film, PLATINUM

1 ABS(Transparent) + Film, RED WL6532 XXLRR

1ABS, WASHER(ASKO), BLACK WL6532XXLBB

P04 BUTTON START 3616637900 1 ABS, WHITE WL6532 XXLW, XXLW RH

1 ABS, PLATINUM WL6532 XXLPP

1 ABS, RED WL6532 XXLRR

1ABS, WASHER(ASKO), BLACK WL6532XXLBB

P05 BUTTON OPTION 3616638100 7 ABS, WHITE WL6532 XXLW, XXLW RH

7 ABS, PLATINUM WL6532 XXLPP

7 ABS, RED WL6532 XXLRR

1ABS, WASHER(ASKO), BLACK WL6532XXLBB

P06 WINDOW DISPLAY 3615506400 1 ABS(Transparent) + Film, WHITE WL6532 XXLW, XXLW RH

1

ABS(Transparent) + Film, PLATINUM

1 ABS(Transparent) + Film, RED WL6532 XXLRR

1ABS, WASHER(ASKO), BLACK WL6532XXLBB

P07 BUTTON FUNCTION 3616638000 1 ABS, WHITE WL6532 XXLW, XXLW RH

1 ABS, PLATINUM WL6532 XXLPP

1 ABS, RED WL6532 XXLRR

1ABS, WASHER(ASKO), BLACK WL6532XXLBB

P08 DIAL KNOB OUTER 3616638200 1 ABS, WHITE

1 ABS, PLATINUM

1 ABS, RED

1ABS, WASHER(ASKO), BLACK

P09 DIAL KNOB INNER 3616638300 1 ABS, WHITE

1 ABS, PLATINUM

1 ABS, RED

1ABS, WASHER(ASKO), BLACK

P10 LED COURSE 3613054700 1 ABS(Transparent)

P11 HOLDER COURSE 3613054500 1 ABS

P12 HOLDER FUNCTION 3613054600 1 ABS

P13 PCB AS PRPSSWAD29 1 ASKO Washer Front PCB As

P14 CASE PCB FRONT 3611147600 1 ABS

- SCREW TAPPING 7122401829 2 T2S TRS 4x18 STS

- SCREW TAPPING 7122401411 7 T2S TRS 4x12 MFZN For fixing PCB AS to Panel F

P15 CASE HANDLE 3611147700 1 ABS, Silk print, WHITE WL6532 XXLW, XXLW RH

1 ABS, Silk print, PLATINUM WL6532 XXLPP

1 ABS, Silk print, RED WL6532 XXLRR

1ABS, WASHER(ASKO), BLACK WL6532XXLBB

P16 HANDLE CAP 3612611400 1 ABS, WHITE WL6532 XXLW, XXLW RH

1 ABS, PLATINUM WL6532 XXLPP

1 ABS, RED WL6532 XXLRR

1ABS, WASHER(ASKO), BLACK WL6532XXLBB

P17 CASE DETERGENT 3611145600 1 PP

P18 CAP SOFTENER 3610917800 1 PP

P19 CAP BLEACH 3610917900 1 PP

P20 CAP LIQUID 3610918000 1 PP

P21 CASE LIQUID 3611145700 1 PP

17

WL6532 XXLPP

WL6532 XXLPP

WL6532 XXLPP

For fixing Panel F to Frame Upper

Page 18

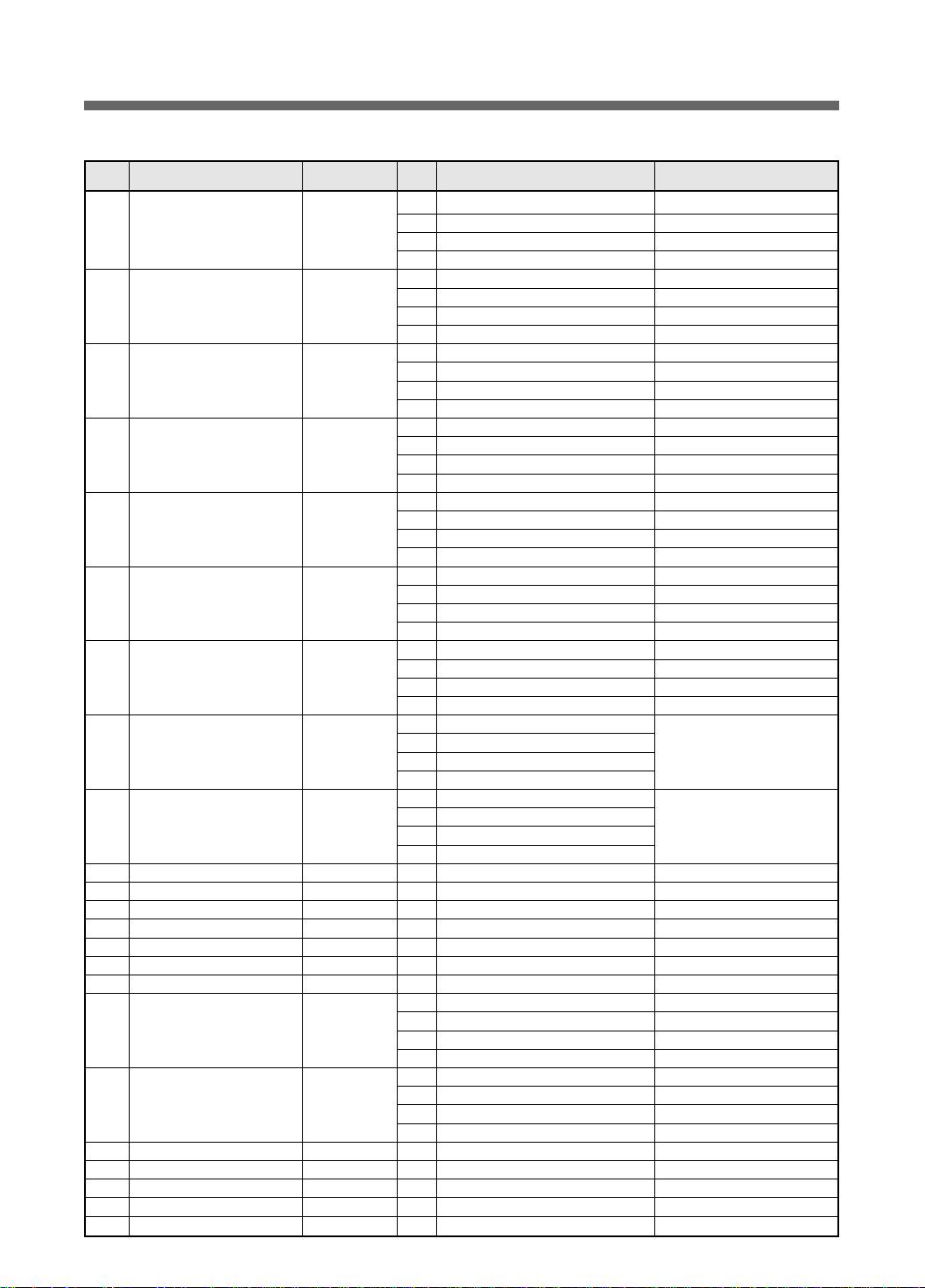

7. PLATE T ASS'Y

E01

E02

No. Part Name Part Code Qtt'y Specification Remark

E01 PLATE TOP 3614533020 1 SECD 1.0T, WHITE WL6532XXLW

1 SECD 1.0T, PLATINUM WL6532XXLPP

1 SECD 1.0T, RED WL6532XXLRR

1 SECD 1.0T, BLACK WL6532XXLBB

E02 HANDLE REAR 3615304100 2 ABS WL6532XXLW

(PLATE SUPPOTER) 3615304120 2 13KG, ABS,GY-6702A WL6532XXLRR, PP,BB

- SCREW TAPPING 7122401411 4 T2S TRS 4x14 MFZN

18

Page 19

rum Wa

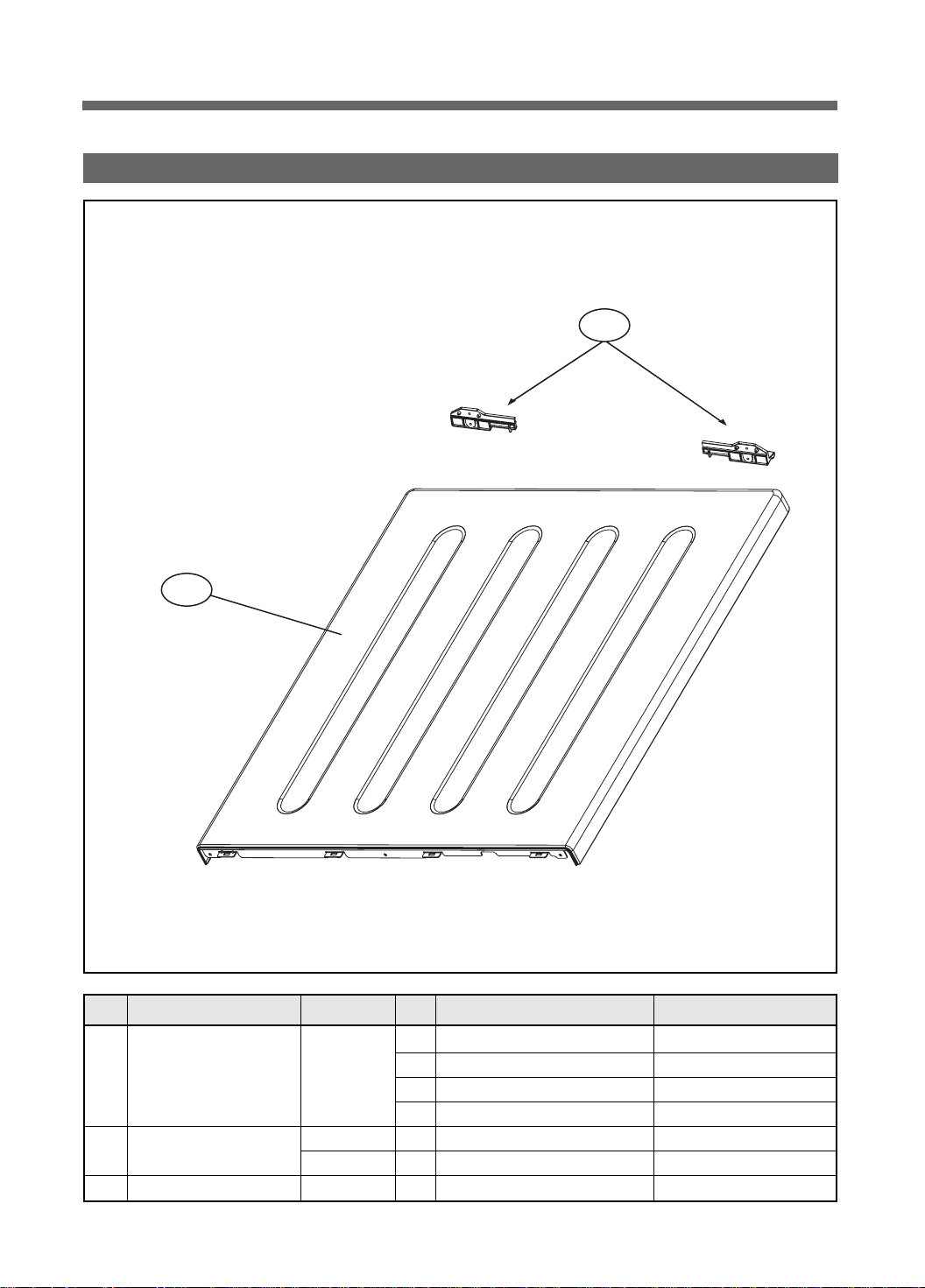

8. ACCESSORY

A01 A02 A03 A04 A05

No. Part Name Part Code Qt'y Specifications Color Cost in USD($) Remarks

A01 HOSE DRAIN O AS 3613268500 1 DWD-800W, L=1,500 NA

GUIDE DRAIN HOSE 3612502300 1 PP NA

A02 HOSE INLET AS 3613271500 1 REFLEX, PVC 1.3M NA Cold

HOSE INLET AS 3613271510 1 REFLEX, PVC 1.3M NA Hot

A03 UNIT SVC WRENCH 36189L3X00 1 PO+Coating, 2.3T DWD-110RP NA

A04 MANUAL OWNERS 4589A61600 1 ASKO Manual NA English & French

A05 CAP HOLDER 3610916400 4 PP, DWD-10RP White

19

Page 20

Control Part Function Spec

"

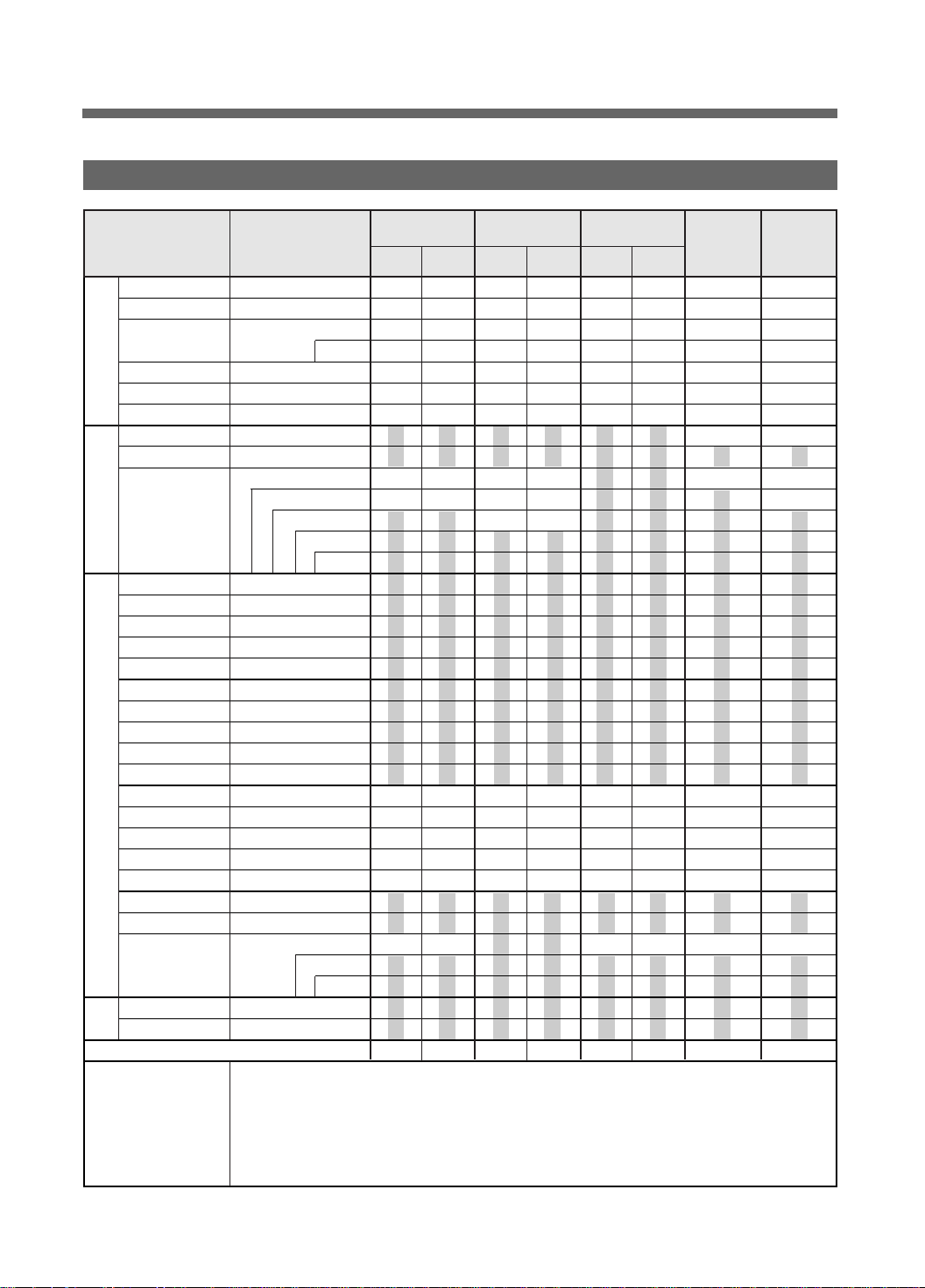

1. SEQUENCE CHART

CCllaassssiiffiiccaattiioonn PPrroocceessssiinngg TTiimmee

PP

rr

ee

WW

aa

ss

hh

WW

aa

ss

hh

RR

ii

nn

ss

ee

SS

pp

ii

nn

EEnndd

Sensing 10sec

Water Supply 2min

Pre-Wash 10min

8min

Drain 1min

Balancing Spin 2min

Middle Spin 3min

Sensing 20sec

Water Supply 2min

"Main-Wash 1 50min 98min 102min

(Heating)" 45min

30min 27min

25min 18min 22min 16min 17min

15min 20min

Drain 1min

Balancing Spin 2min

Middle Spin 3min

Water Supply 2min

Rinse 1 4min

Drain 1min

Balancing Spin 2min

Middle Spin 3min

Water Supply 2min

Rinse 2 4min

Drain 1min

Balancing Spin 2min

Middle Spin 3min

Water Supply 2min

Rinse 3 4min

Drain 1min

Balancing Spin 2min

Spin 9min

7min

6min

Clothes Release 60sec

End 10sec

Remain Time Display 55 59 53 54 2:15 2:19 1:04 57

NOTE

1. Normal : W/C + Wash + Soil Normal + Rinse 2 + Medium Spin

2. Cotton : W/C + Wash + Soil Normal + Rinse 2 + Ex.High Spin

3. Sanitary : E.H/C + Wash + Soil Normal + Rinse 2 + Medium Spin

4. Bulky : C/C + Wash + Soil Normal + Rinse 2 + Medium Spin

5. White : W/C + Wash + Soil Normal + Rinse 2 + Medium Spin

EEvveerryyddaayy TToowweell SSaanniittaarryy

Small Low Small Low Small Low

BBuullkkyy SSyynntthheettiicc

20

Page 21

rum Wa

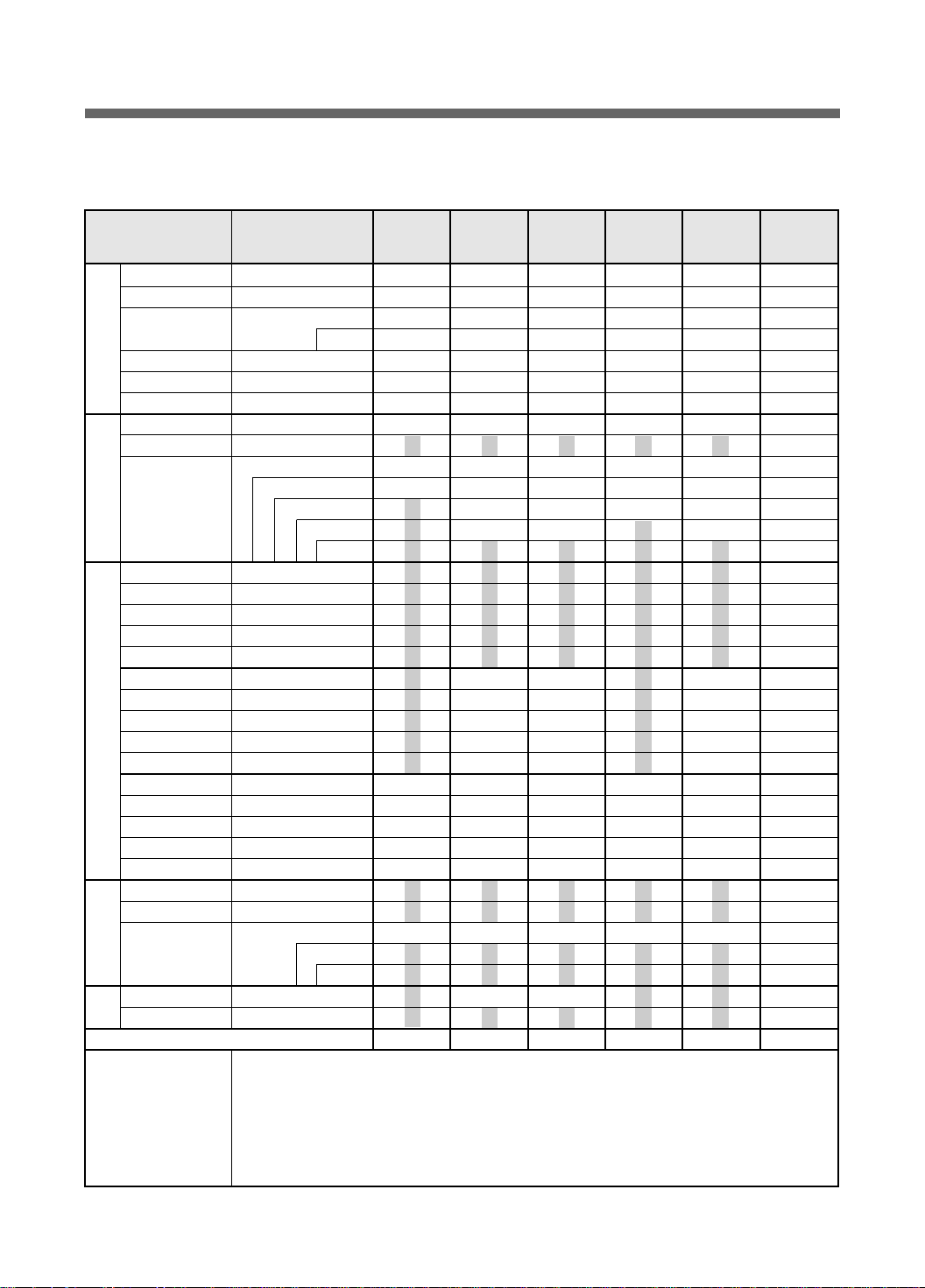

CCllaassssiiffiiccaattiioonn PPrroocceessssiinngg TTiimmee

PP

rr

ee

WW

aa

ss

hh

WW

aa

ss

hh

RR

ii

nn

ss

ee

SS

pp

ii

nn

EEnndd

Sensing 10sec

Water Supply 2min

Pre-Wash 10min

Drain 1min

Balancing Spin 2min

Middle Spin 3min

Sensing 20sec

Water Supply 2min

"Main-Wash 1 50min

(Heating)" 45min

Drain 1min

Balancing Spin 2min

Middle Spin 3min

Water Supply 2min

Rinse 1 4min

Drain 1min

Balancing Spin 2min

Middle Spin 3min

Water Supply 2min

Rinse 2 4min

Drain 1min

Balancing Spin 2min

Middle Spin 3min

Water Supply 2min

Rinse 3 4min

Drain 1min

Balancing Spin 2min

Spin 9min

Clothes Release 60sec

End 10sec

Remain Time Display 1:12 32 30 57 33

NOTE

1. Heavy Duty : W/C + Wash + Soil Heavy + Rinse 2 + Medium Spin

2. Delicate : C/C + Wash + Soil Normal + Rinse 1 + Low Spin

3. Wool : C/C + Wash + Soil Light + Rinse 1 + Low Spin

4. Perm Press : W/C + Wash + Soil Normal + Rinse 2 + Low Spin

5. Speed Wash : C/C + Wash + Soil Light + Rinse 1 + Low Spin

6. Drum-Cleaning : C/C + Wash + Soil Light + Rinse 2 + Low Spin

HHeeaavviillyy SSiillkk WWooooll WWhhiittee QQuuiicckk

8min

30min 35min

25min 22min

15min 8min 6min 8min

7min

5min

21

Page 22

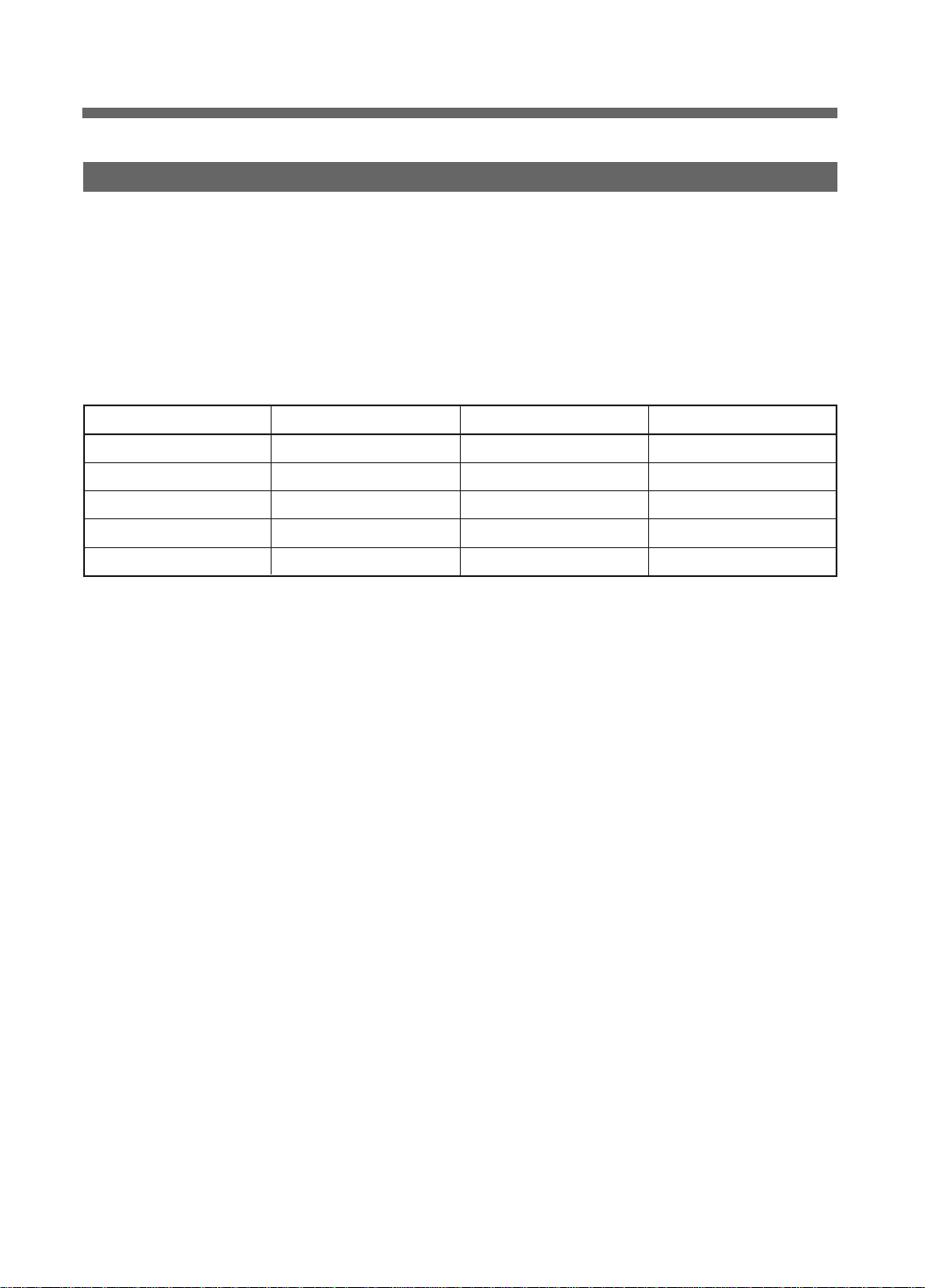

2. Composition per Function

2-1. Water Supply

1) Water Temperature Selection

Water supply algorithm differs according to water temperature selected among 5 levels.

In other temperatures, with the exception of cold water, constant temperature control is executed.

Cold water and hot water operation is carried out in turn according to the target temperature.

Water T emp. T arget Temp. T arget 1 T arget 2

Extra Hot 67) 67) 70)

Hot 35) 34) 36)

Warm* 30) 29) 31)

Warm 30) 29) 31)

Cold - - -

2) For Cold, valve operation does not change according to temperature and only the time unit of

cold on for 7sec and off for 9sec is set to supply cold water per each unit of 16sec.

3) How to Insert Bleach

- During Washing

Operation for 12sec after 3-minute washing in Wool, Silk and Quick wash courses

Operation for 12sec after 5-minute washing in Towel course

Operation for 12sec after 9-minute washing in other courses

22

Page 23

rum Wa

2-2. Drainage

1) Pump Operation - Washing cycle

$ Before Drainage Completion: Pump continuously on

% Spin-drying Cycle after Drainage Completion

: On for 18sec and off for 3sec

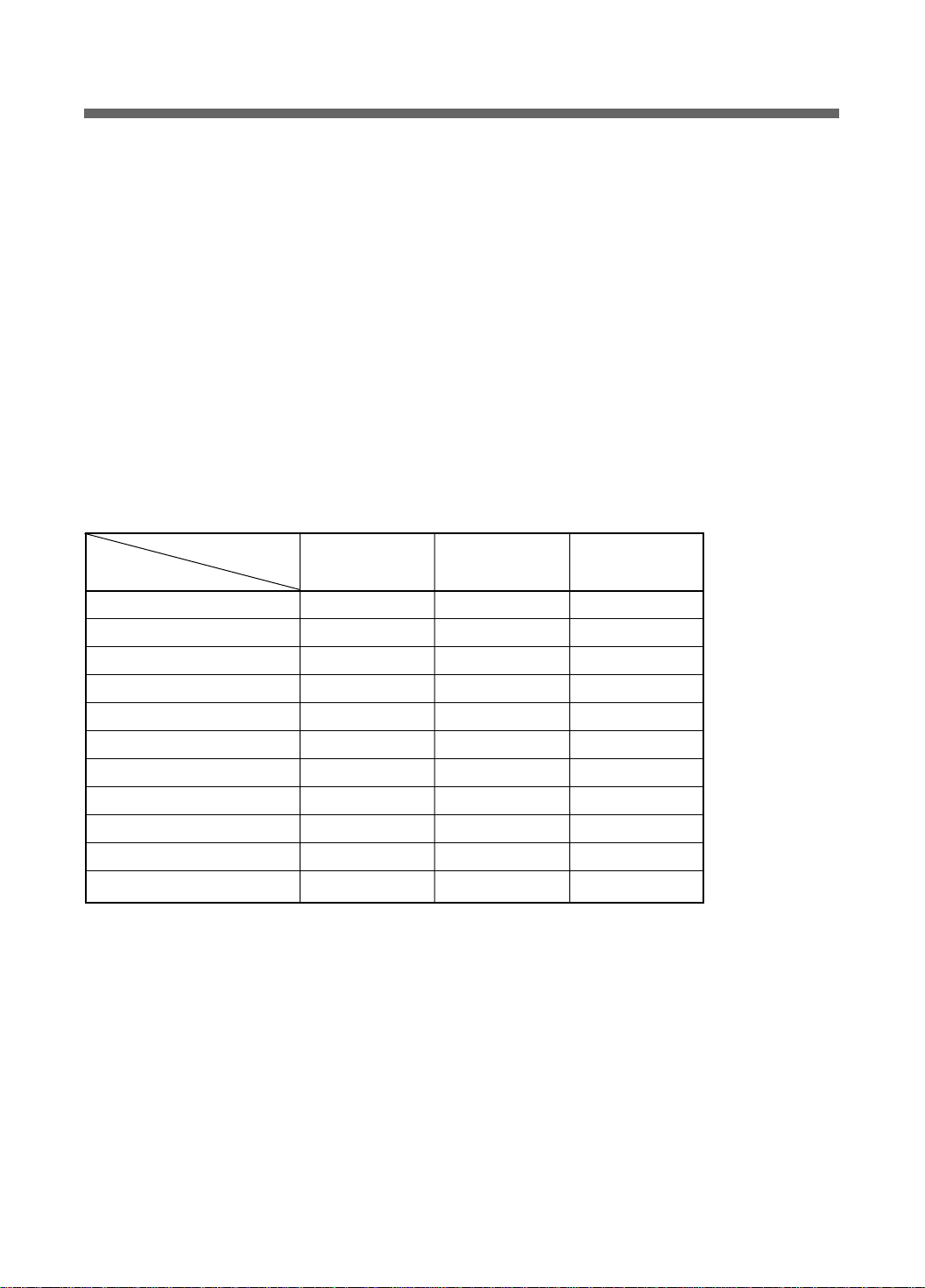

2-3. Sensor Detection

1) Water Level Sensor Data

Classification Height Frequency

Water Level (mm) (KHz)

Spec. Small 130 24.62

Spec. Low 130 24.62

Washing Small 130 24.38

Washing Low 130 24.09

Standard Rinsing 160 24.27

Rinsing 160 23.64

Additional Rinsing 175 24.01

Tub Washing 195 23.77

Overflow 260 22.6

Safety 125 24.7

Reset 125 24.68

Remarks

23

Page 24

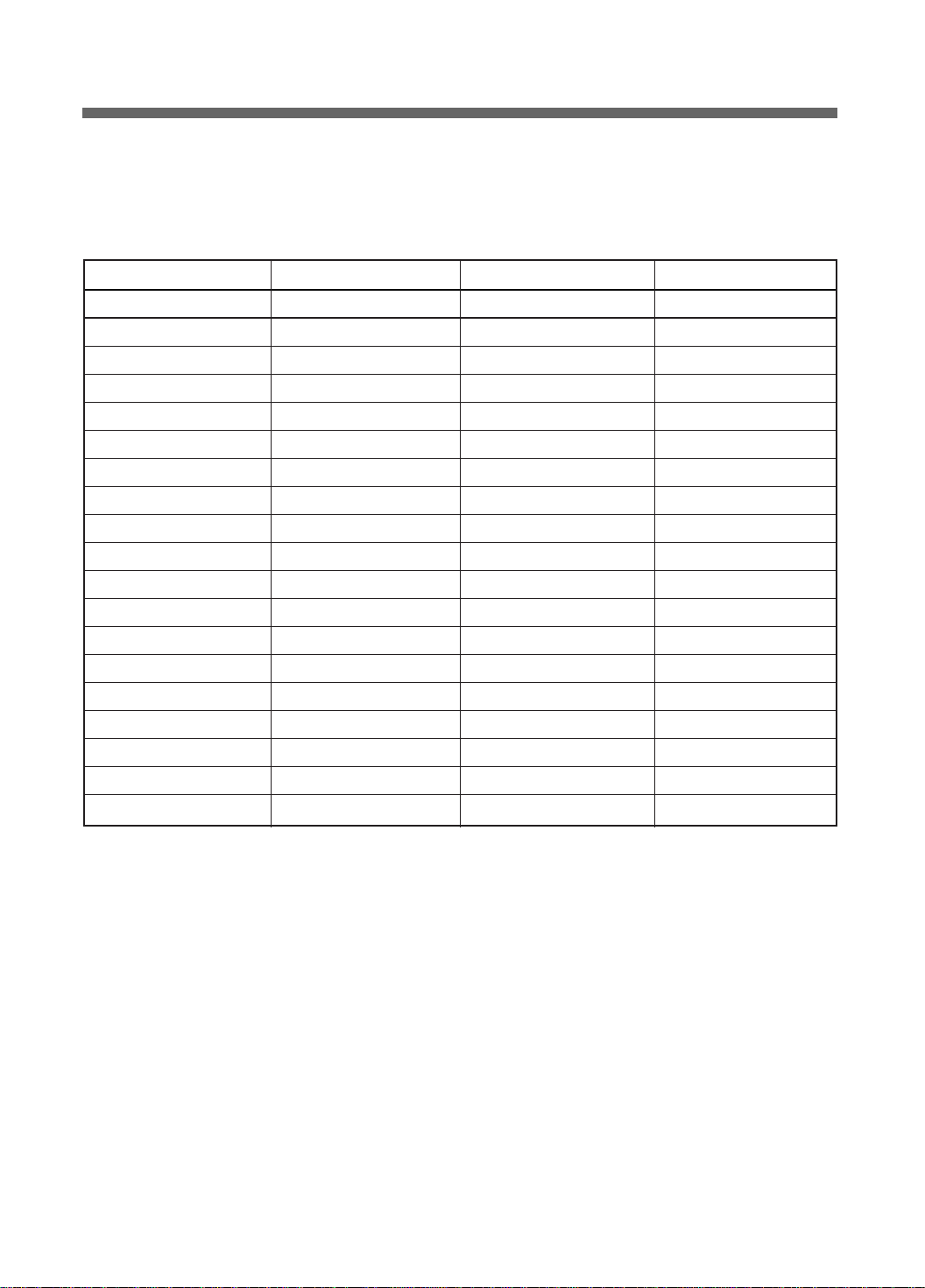

2) Temperature Sensor Data

Temp. Resistance(**)Voltage

0 35.97 0.58

10 22.76 0.86

20 14.77 1.21

22 13.57 1.29

24 12.48 1.37

25 11.98 1.41

27 11.04 1.49

29 10.18 1.58

30 9.78 1.62

32 9.04 1.71

34 8.36 1.80

36 7.74 1.89

38 7.17 1.98

40 6.65 2.07

49 4.7 2.50

55 3.85 2.75

60 3.24 2.96

65 2.74 3.16

75 1.99 3.51

Remarks

24

Page 25

rum Wa

2-4. How to Control Voltage (during abnormal operation)

1) Voltage Control

$ Normal Voltage

DC-link voltage after wave rectification is directly impressed to IPM as 310 ~ 330V.

When motor starts operation, DC voltage changes with energy consumed by motor and/

or counter electromotive force of motor.

% Identifying Abnormal Voltage

A. Occurrence of counter electromotive force

+ In case of 450V or higher

B. Instant power failure and excessive energy consumption

+ In case of 185V or lower

2-5. How to Control Current (during abnormal operation+B227)

1) Current Abnormality Detection

$ Abnormal if DC current flowing through IPM measured during high-speed motor rotation is

10A~12A or higher

% Detection of abnormal current to be carried out by saving higher value among instant current values

and updating the data

25

Page 26

2-6. Door S/W

1) Door S/W Operation

$ Door Locking

3sec after bi-metal operation of door S/W, pulse of 20msec duty on solenoid is impressed twice until

door is locked. Bi-metal begins operation simultaneously as power button is pressed.

% Door Unlocking

Bi-metal plate of door S/W is turned off and pulse of 20msec duty on solenoid is impressed until door is

unlocked.

& Motor or other electronic parts begin operation to execute normal cycles only when door is locked.

' Door is closed if temperature measured by washing temperature sensor after turning on power button

is 55) or higher or if water level is higher than safety level.

, Door is opened immediately when cycle is finished.

- During cycle suspension, door is opened anytime if allowable by conditions.

2) Door Open System

$ To forcefully open door in order to additionally insert the laundry during washing, door can be

opened by pressing unlock clear button.

% Door open system by unlock clear button is to forcefully open door when not in conditions for door

opening. It begins the sequence to satisfy conditions for door opening.

26

Page 27

rum Wa

2-7. Load Sensing

1) Load Sensing to Determine Water Level

$ Á Load sensing is carried out when selecting standard, boiling and thrifty boiling courses.

% Sensing is administered in the dry laundry state before starting of washing cycle.

& After motor operation at 75 r.p.m for 10sec, load is judged with motor output measured.

2) Load Sensing for B Spin-drying

$ Sensing is administered with the laundry wet during the first interim spin-drying after completion of

washing cycle.

% After motor operation at 75 r.p.m for 10sec, load is judged with motor output measured.

& Base values for B spin-drying unbalance of interim and main spin-drying are selected according to

load measured by sensing.

2-8. Child Lock

$ Child lock mode begins by pressing 'Beeper' button during cycle. % In child lock mode, all buttons,

with the exception of power button, are not operated.

& In child lock mode, cycle display window is lit to show that child lock has been applied. Also, the

remaining time is displayed in '18:88' window.

' Lock mode is cleared by pressing 'Beeper' button as was done when starting child lock mode.

27

Page 28

3. Functions per Cycle

3-1. Washing Cycle

1) Classification of Washing

$ Pre-washing and soaking are carried out before main washing cycle.

% Decided value refers to water level and time decided by load sensing in standard, boiling and thrifty

boiling courses. In other sources, it means the pre-set time according to the designated water level.

& Soaking is the cycle consisted with water supply and washing only. Main washing begins

immediately after this cycle without drainage.

' In pre-washing and soaking cycles, only cold water is used and heating is not administered.

2) Heater Operation

$ Washing heater does not re-operate once turned off after reaching the set temperature.

% Even when target water temperature is not reached, washing cycle is finished when washing time

expires.

3) Re-supply of water

$ Re-supply is carried out in case water level detected per 2 minute after water supply completion is

lower than the set water level.

% Motor is stopped during re-supply.

& During washing, re-supply is carried out up to 10 times. After the 10th time, re-supply is not

administered even if water level drops.

' Re-supply is not carried out if more than half of washing time has passed and heater is turned off.

28

Page 29

rum Wa

3-2. Rinsing Cycle

1) Water Supply Cycle

$ When selecting 'add water for rinsing', water is supplied to the water level of additional rinsing.

% Only cold water is supplied in rinsing cycle.

& In the last rinsing, fabric softener is inserted by opening both cold water V/V and pre-washing V/V at

the same time.

2) Re-supply of Water

$ Water level is checked 1 minute after starting of rinsing cycle. Then, water is re-supplied up to the

designated water level.

3) Drainage

$ To administer drainage after completing washing at water temperature of 55) or higher, drainage is

carried out after dropping water temperature by supplying cold water to high level.

% When drainage cycle begins, drainage motor is continuously kept on.

4) Interim Spin-drying

$ Interim spin-drying is administered up to the r.p.m designated per each course.

The following cycle begins if R spin-drying is not reached after 20 times of balance spin-drying.

% After completion of washing cycle, load sensing is carried out before the first interim spin-drying to

detect load. Then, the cycle proceeds to main spin-drying by differing standard unbalance values

according to the load.

29

Page 30

3-3. Spin-drying Cycle

1) Drainage

$ Drainage set time is 1min.

% When drainage is completed, 1 minute is reduced from the overall cycle.

2) Balance Spin-drying

$ Spreading the laundry : Rotating the same 45rpm with left and right direction altematively.

% Attaching stop : Attaching the laundry to drum inside with constant speed.

& Unbalance checking point : First step, check the U.B at 95 rpm, 160rpm

Second step,check the U.B at 95 rpm, 350rpm

Third step, at 300rpm. if the unbalance data is over the criterion

This process will be rpeated

' Drain step : Drain at water around 160rpm

, After drain, check the unbalance data again. This is so-called balance spin step.

3) R (Real) Spin-drying

$ 'R spin-drying' refers to the process until completion of spin-drying after B spin-drying.

% The r.p.m reached differs according to the spin-drying cycle selected.

& When acceleration ends during spin-drying, constant-speed operation is carried out at the r.p.m set in

the selected cycle. Breaking is carried out after deceleration to app. 450 r.p.m.

' When stopping cycle by pressing temporary stop button during spin-drying, breaking is carried out to

stop motor.

, Max. r.p.m operation time according to spin-drying selection

Spin-Drying Classification Max. r.p.m Time of Max. r.p.m Maintenance Remarks

Low 550 r.p.m 380sec

Medium 850 r.p.m 345sec

High 1100 r.p.m 115sec

Extra High 1300 r.p.m 60sec

4) No Drainage

$ Cycle is completed without drainage after rinsing is finished

30

Page 31

rum Wa

3-4. Ending

1) Untwisting

$ This cycle aims to prevent creasing by loosening the laundry attached to the inner wall of drum after

completion of spin-drying. Untwisting is carried out for 30sec.

% Motor is operated according to the water stream of untwisting.

2) Ending

$ After completion of untwisting, buzzer is sounded for 10sec and power is turned off.

% In case additional drying cycle has been set, drying cycle is carried out after untwisting.

& After ending process begins, door lock is cleared.

31

Page 32

4. Button Functions

4-1. Power

1) This electronic power switch turns on/ off display.

2) Automatic Power Switch Off

$ Power is turned off immediately after completion of entire cycles or the selected cycle.

% Power is automatically turned off in 10 minutes if no button control is made after power on.

3) Initial Display for Power Only

$ Course LED is turned on for 1sec.

% 18:88 LED displays '---'.

4-2. Start / Stop

1) Normal course begins when pressing button after turning on power S/W.

2) Operation begins by pressing button after setting a program course or automatic course of 10 varieties.

3) If button is pressed during operation, blinking of cycle lamp changes to lighting only and operation

stops. When button is pressed again, operation restarts from the point of temporary suspension.

4) If cycle is changed by controlling button or encoder switch in temporary suspension state, the mode is

changed to the initial mode.

5) Lock is cleared if in the corresponding conditions by judging values of washing temperature sensor or

water level during temporary suspension.

32

Page 33

rum Wa

4-3. Wash

1) Range of temp. selection differs according to the course selected. If you select Cold, the washing

temperature will be the same as that of the machine's water supply.

Each program the temperature it will be able to select is restricted.

(Refer to Washer Program Default Data and Select Option.)

2) The text displayed indicates water temperature for washing. "Cold water is used for rinsing.

When ‘Warm*’ is selected, warm temperature is maintained for both washing and rinsing."

3) Cold water and hot water supply method differs according to water temperature selection.

Heating temperature also differs.

4) For sanitary course, water temperature is fixed at 'Extra Hot'.

Wash Temperature Wash / Rinse

Extra Hot 67

Hot 35

Warm* 30

Warm 30

Cold - NO Heating

4-4. Soil Level

1) When pressing button, LED is repetitively lit in the order of ‘Normal _ Heavy _ Extra

Heavy _ Off _ Extra Light _ light'

2) Soil level can be selected only when washing cycle is set.

3) Soil level is operated in courses other than 'Wool/Handwash' and 'Quick Wash'.

4) Washing time changes according to the selected soil level.

)

)

)

)

Extra. Hot / Cold

Hot / Cold

Warm / Warm

Warm / Cold

5) Selection can be changed during cycle after temporary suspension.

6) Overall cycle time is shown in 18:88 display.

33

Page 34

4-5. Spin Speed

1) When pressing button, LED is repetitively lit in the order of " Medium. High. Extra High

. Off. No Spin. Low'.

2) 18:88 display shows the remaining time.

3) During cycle, selection change is possible after temporary suspension.

4-6. Signal

1) Signal button operates in 5 steps.

Press Signal to adjust the sound level or turn off the signal.

2) After change, it is saved in EEPRPM.

4-7. Pre-Wash

1) Button is operated only when washing is selected.

2) Pre-wash is not available in Wool/Handwash, Quick Wash courses.

3) When pressing button, pre-wash is added and LED is lit. LED is turned off when pressing

the button again.

4) Pre-wash LED is turned off when pre-wash is completed.

34

Page 35

rum Wa

4-8. Extend Wash

1) When button is pressed, washing time increases per washing course, such as by 6 minutes for 'heavily',

8 minutes for 'sanitary', 5 minutes for 'everyday wear' and 'towel' and 4 minutes in other cases.

2) Extra wash is not available in Silk/Gentle, Quick Wash, Wool/Handwash courses.

3) Extra wash LED is turned off when washing is completed.

4-9. Extra Rinse

1) Extra rinse is not available in Quick wash courses.

2) When pressing button rinsing cycle is added by once and LED is lit. When pressing button

again, rinsing cycle decreases by once and LED is turned off.

3) Extra rinse LED is turned off when rinsing is completed.

4-9. Rinse+Spin

1) When pressing button, rinsing once + spin medium is selected.

2) Operation does not return to previous cycle even when pressing the button again.

The cycle set in the corresponding course is displayed by rotating course dial.

Then, rinse spin LED is turned off.

4) Water temperature can be selected with Temp. button after rinse + spin is set.

Selection can be made from Cold to Warm.

5) Even after rinse + spin is selected, water temperature selection can not be made in

Wool/Handwash courses.

6) When cycle is completed, LED is turned off.

35

Page 36

4-10. Night Time

1) When pressing button, spin speed is set as low and interim spin-drying changes from

790 r.p.m. to 550 r.p.m.

2) When pressing button again, set values of interim spin-drying and main spin-drying mode

courses are resumed.

3) LED is turned off when the cycle is completed.

4-11. Delay Start

1) Preset time indicates starting time of the entire cycle.

2) When pressing preset button, time changes in the order of 1.2.3. 4 ….12.1.

3) After selecting preset time, cycle change is possible before entering preset mode by pressing start/stop

button. However, cycle cannot be changed after entering preset mode.

4) To preset operation, select cycle.select preset time.press start/stop button.

5) The selected cycle is displayed for 3 seconds when pressing start/stop button after

entering preset mode to check the selected cycle.

4-12. Child Lock**

1) During an operation of washer, press 'Child Lick' button simultaneously during 3 second.

2) If this mode will be set successfully, Child Lock Lamp will be burn out. In Child Lock mode,

no button functions except Power button.

3) if you want to release this mode, press 'Child Lock' button simultaneously again during 3 second.

36

Page 37

rum Wa

4-13. Course Selection Switch

1) Everyday Wear course selected by clicking switch once after power is turned on.

2) Per each click after the first, course is selected in the direction of CW or CCW.

3) 18:88 display indicates cycle time of each course.

4-14. Washer Program Default Data and Select Option

Heavily

Sanitary

Bulky

Everyday

White

Synthetic

Towel

Silk

Quick

Wool

default

selection

default

selection

default

selection

default

selection

default

selection

default

selection

default

selection

default

selection

default

selection

default

selection

Temp

Warm*

Cold~Hot

Ex.hot

X

Warm

Cold~Warm*

Warm

Cold~Hot

Warm

Cold~Hot

Warm

Cold~Hot

Warm

Cold~Hot

Cold

X

Cold

Cold~Warm*

Cold

X

Soil

Normal

Ex.light~Ex.heavy

Normal

Ex.light~Ex.heavy

Normal

Ex.light~Ex.heavy

Normal

Ex.light~Ex.heavy

Normal

Ex.light~Ex.heavy

Normal

Ex.light~Ex.heavy

Normal

Ex.light~Ex.heavy

Normal

Ex.light~Ex.heavy

Ex.light

X

Ex.Light

X

Spin

High

no spin~Ex.high

Medium

no spin~Ex.high

Medium

no spin~High

Medium

no spin~Ex.high

Medium

no spin~Ex.high

Low

no spin~Ex.high

Ex.High

no spin~Ex.high

Low

no spin~Medium

Low

no spin~Medium

Low

no spin~Low

Pre

Wash

O

O

O

O

O

O

O

O

X

X

Extended

Wash

O

O

O

O

O

O

O

X

X

X

Extra

Rinse

O

O

O

O

O

O

O

O

X

O

Rinse+Spin, Delay

start, Night time

O

O

O

O

O

O

O

O

O

O

37

Page 38

rum Wa

5. PCB Manual Test Mode

- PCB and other electronic parts will be tested without water supply whether they are normal or not.

1) Process

: Press power button -> Press "SPIN" button 3 times with pressing "WASH" button -> "X X X" will be

shown on LED display-> Whenever pressing "Signal" button 1 time, below process will be occurred.

- "X X X' : Program version display

Step Display Details

" #$% &''(!#')*!%+',-

. (/0 11" 2/00304!536-,!)'/05

78"19:##;<=><?2!=22?2!)'/05

@8.1ABC;D:E#F!=22?2!)'/05

G871?H-(;+'IJ!=22?2!)'/05

K8@1C'5'(!I+340!=22?2!)'/05

L8G12M6!)N-)*304!=22?2!)'/05

O8K1?H-(H'+5I4-!=22?2!)'/05

P8L1#'Q!H'+5I4-!=22?2!)'/05

"1 D D:>!RDR

"" 9 9'5!SI+H-

". % %'+J!SI+H-

"7 B B(-!TI,N!SI+H-

"@ J >'!/,-

"G 88 U+-I)N!SI+H-

"K J( &(I30!B/6M

"L #$? #')*!?M-0

2) More details

- When turn on 'LOCK' signal, all process is conducting normaly.

- In this case, BLDC Motor is not tested. In order to test it, select spin or rinse.

38

Page 39

6-1. IE (Input Error) - Error in water supply

6-1. IE (Input Error) - Error in water supply

1) Conditions of Occurrence

$ In case the designated water level is not reached in 5 minutes during water supply or re-supply

2) All LEDs are turned off and 'IE' blinks in18:88 display.

3) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

4) Error display is cleared when turning off/ on power.

6-2. OE (Output Error) - Error in drainage

1) Conditions of Occurrence

$ In case water level does not reach reset point in 10 minutes after drainage starts

2) All LEDs are turned off and 'OE' blinks in 18:88 display.

3) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

4) Error display is cleared when turning off/ on power.

6-3. UE (Unbalance Error)

1) Conditions of Occurrence

$ In case main spin-drying is not reached within 20 cycles of balance spin-drying

% In case balance spin-drying fails during interim spin-drying, UE occurs as the cycle moves to the next

process.

2) All LEDs are turned off and 'UE' blinks in 18:88 display.

3) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

4) Error mode is cleared by opening door and organizing the laundry in spin-dry chamber, closing door and

pressing start/ temporary stop button. Then, spin-drying begins again.

39

Page 40

rum Wa

6-4. LE (Lock Error) - Door opening error

1) Conditions of Occurrence

$ When intending to begin cycle by pressing start/ temporary stop button while door is opened

2) All LEDs are turned off and 'LE' blinks in 18:88 display.

3) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

4) Error display is cleared when turning off/ on power.

6-5. E1 - Water level detection error

1) Conditions of Occurrence

$ In case water level is below reset or overflow is detected in line test mode

2) Water supply motor is kept on until water level falls below reset.

3) All LEDs are turned off and 'E1' blinks in 18:88 display.

4) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

5) Error display is cleared when turning off/ on power.

6-6. E2 - Overflow error

1) Conditions of Occurrence

$ In case water level in water tank is above overflow level due to continuous operation of water supply

valve

2) Water supply motor is kept on until water level falls below reset.

3) All LEDs are turned off and 'E2' blinks in 18:88 display.

4) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

5) Error display is cleared when turning off/ on power.

40

Page 41

6-7. E4 - Water leakage during washing

1) Conditions of Occurrence

$ In case water level falls below re-supply even after 15 times of re-supply prior to finishing of water

heating

2) All LEDs are turned off and 'E4' blinks in 18:88 display.

3) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

4) Error display is cleared when turning off/ on power.

6-8. E9 - Abnormalities in water level sensor

1) Conditions of Occurrence

$ In case water level frequency is of 15KHz or lower and 30KHz or higher during cycle due to

abnormalities in water level sensor, etc.

2) All LEDs are turned off and 'E9' blinks in 18:88 display.

3) Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

4) Error display is cleared when turning off/ on power.

41

Page 42

rum Wa

6-9. Motor-related Error

1) E5 (DC-Link High Voltage) Error

$ In case DC-link voltage to IPM increases to 450V or higher

% Motor operation is stopped and 'E5' is shown in display window.

& Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

' Error display is cleared when turning off/ on power.

2) E6 (EMG) Error

$ In case current detected with EMG port is of 20A or higher

% Motor operation is stopped and 'E6' is shown in display window.

& Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

' Error display is cleared when turning off/ on power.

3) E7 (Direction) Error

$ In case signal of Hall IC is different from the predicted signal according to direction of rotation

% Motor operation is stopped and 'E7' is shown in display window.

& Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

' Error display is cleared when turning off/ on power.

4) E8 (Initial Operation Fail) Error

$ In case input signal of Hall IC is abnormal due to problems in motor connection, etc.

% Motor operation is stopped and 'E8' is shown in display window.

& Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

' Error display is cleared when turning off/ on power.

6-10. Error in Temperature Sensor

1) H2 Error - Washing temperature sensor open/ short

$ In case washing temperature sensor is defective or not connected

% Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

& Error display is cleared when turning off/ on power.

2) H4 Error - Washing temperature sensor overheating

$ In case temperature detected by washing temperature sensor is 95) or higher

% Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

& Error display is cleared when turning off/ on power.

42

Page 43

3) H5 Error - Water temperature error in wool/ delicate course

$ In case water temperature in wool/ delicate course is 45) or higher

% Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

& Error display is cleared when turning off/ on power.

4) H6 Error - Abnormality in washing heater

$ Within 15 minutes after heater operation begins;

In case standard temperature is of 42) or lower: If temperature does not increase by 2) or more In

case standard temperature is higher than 42): If temperature does not increase by1) or more

% If temperature falls below standard temperature by 2) or more due to re-supply of water, etc.,

standard temperature is reset as the current temperature and error check time of15 minutes is reset.

& Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

' Error display is cleared when turning off/ on power.

5) H8 Error - Washing heater overheating

$ In case washing heater temperature increases by 5) or more within 30 seconds when there is no

water in tank, etc.

% Error buzzer alarm is sounded for 10 seconds per every 10 minutes.

& Error display is cleared when turning off/ on power.

6-11. PFE (Pump Filter Error)

$ Cycle is skipped to the next when the current r.p.m. is different from the target r.p.m by 70 during

interim spin-drying.

% Cycle is skilled to balance spin-drying when the current r.p.m is different from the target r.p.m by 70

during main spin-drying.

& 'PFE' error is caused if main spin-drying skip of % above occurs 10 times.

' Error display is cleared when turning off/ on power.

43

Page 44

PCB PIN ARRANGEMENT

"

44

Page 45

Detailed Spec, Principles and Breakdown Diagnosis/ Service of Electronic parts

"

1. VALVE INLET

CCllaassssiiffiiccaattiioonn

Code

Color

Coil Resistance

Use

Appearance

Structure

SSyymmppttoommss ooff

BBrreeaakkddoowwnn

Water not

supplied

Water is

continuously

supplied

(inside tub)

Water supply to

tank

Others

Water supply not

carried, only noise

is heard

Water supply not

carried out without

noise

Continuous water

supply in power

'on' state

Continuous water

supply in power

'off' state

Water not supplied

to inside of tank

Continuous water

supply to inside of

tank

Others

Water leakage

through sides

DDeettaaiilleedd

SSyymmppttoommss

33--hhoollee VVaallvvee aanndd HHoott WWaatteerr VVaallvvee

3-hole: 3615416940, Hot Water: 3615416700

Gray

4320 ~ 5280 $

Supplying water for washing/ pre-washing and bleach

Bleach Input Valve

Hot Water Input Valve

Washing Water

Input Valve

Pre-washing

Water

Input Valve

CCaauussee DDiiaaggnnoossiiss ooff DDeeffeecctt

Water tap not opened

Coil short

Excessive foreign

substances in SUS filter

Foreign substances in

valve

Connector loosened

Coil short

Wiring short

Defect in water level

sensor

Defect in pressure hose

Defect in water supply

valve

Blocking of electroanalysised water inlet hose

Excessive inflow to

residual water removal

hose

TANK DOWN S/W

Check tank up S/W connector, PCB and water supply valve

Floater

Defect in water supply

valve assembly, etc.

Check for tap opening.

Check if resistance between water supply valve terminals is

within 4320~5280$.

Remove water supply hose and check for foreign substances in

filter.

-

Visually check connector connection status.

Check if resistance between water supply valve terminals is

within 4320~5280$.

Wiring short -> Conduction test

Refer to water level sensor defect check method.

Check for blocking of holes in pressure hose.

-

Dismantle hose and check for blocking.

Check if water is not being discharged through residual water

removal hose as there is low inflow of water.

Check for connector loosening and S/W defect.

Floater restraint, loosening -> S/W not working

Check for leakage through the sides of water supply valve.

SSoolluuttiioonn

Open water tap.

Clean out foreign substances

from inside the filter.

Replace water supply

valve.

Administer re-insertion.

Replace water supply

valve.

Replace water level

sensor.

Replace defect parts.

Replace water supply

valve.

Remove foreign

substances, etc.

Tie residual water

removal hose.

Insert connector/ replace S/W.

Insert connector/

replace defect parts.

Clean and check floater part.

Replace water supply

valve.

PPCCBB EErrrroorr

MMooddee

""IIEE""

""IIEE""

""IIEE""

""IIEE""

""IIEE""

""IIEE""

""IIEE""

""EE22""

""EE22""

--

""IIEE""

""IIEE""

""IIEE""

""EE22""

""IIEE,, EE22""

--

45

Page 46

rum Wa

Water supply not

carried out (IE)

• Suspension of water supply

• Tap frozen

• Tap closed

• Hot & cold water hose switched for connection

• Low water pressure (0.2kgf/cm or less)

• Blocking of water supply valve filter by foreign substances

• Defect in cold & hot water valve

• Defect in connection of water supply terminal (not connected)

• Defect in pressure switch

• Defect in PCB

• Defect in water supply relay drive circuit

• Water supply relay open

Defect in

Water

Supply

Continuous water

supply (IE)

Immediate water

supply when power

is turned on

Water supply

continued when

power is turned off

• Defect in water supply valve

• Leakage in air hose (air leakage from pressure switch hose)

• Air trip blocked, damaged

• Defect in pressure switch

• Defect in drainage valve: Continuous water supply

• Blocking by foreign substances in drainage bellows

• Defect in PCB

• Defect in PCB • Water supply relay short

• Defect in water supply valve

• Water supply relay short

46

Page 47

Symptoms of

Breakdown

Inspection

Spot

Inspection Method

Inspection Result

Problem Identified

Repair Method

Water

supply not

carried out

Water

supply not

carried out

1) Suspension of water supply

2) Water tap locked

3) Cold-hot water hose incorrectly

4) If no defect is found, dismantle water

Water

supply valve

Pressure

1) Measure coil resistance in water

2) Remove top cover and visually

3) In case water valve operation sound

1) Check for ‘E9’ in display window.

Switch

PCB

1. Check PCB pin connector insertion

2. Power is supplied to water supply

connected

supply hose and check water supply

valve filter.

supply valve.

check for separation of water supply

valve terminal connector and wiring

short/ connection status.

is heard, but water supply is not

carried out, check for blocking of

water supply valve or restraint on

plunger.

status.

valve terminal, but water supply is

not administered.

- Cold/ hot water hose switched

-Large amount of rust, sand and

dust, etc.

-5.3kW or higher

-Connector loosened/ not

inserted

-Electric wire short

-Sound and defect in water

supply due to foreign

substances in bellows

-E9

Electric wire easily loosened

when tugged

PCB water supply circuit open,

damaged (water supply relay

operation not carried out)

-Defect in cold/ hot water

hose assembly

-Defect in cleaning of water

supply filter (blocked)

-Coil short

-Connection defect

-Electric wire short

-Structural defect in water

supply valve

-Loosening of pressure S/W

terminal or electric wire

short

-Defect in pressure S/W

Pin connector housing not

inserted

Defect in water supply circuit

-Assemble cold/ hot

water hose correctly.

-Clean water supply filter.

-Replace water supply

valve.

-Try reconnection or

remove elements of

connection defect.

-Try reconnection or

remove elements of

connection defect.

-Replace water supply

valve.

-Connect terminal of

pressure S/W.

-Connect terminal of

PCB.

-Replace pressure S/W.

Completely insert

connector housing.

Replace PCB.

Continuous

water supply

supply valve

drive motor

PCB

Water

Drainage

(valve

housing)

1. Immediate supply when power is

turned on

1. Check if water supply is continuously

carried out even if power is not on.

1. Check for normal operation of water

supply valve/ water supply status.

2. Check if water is drained through

drainage hose.

3. Check for foreign substances inside

valve housing.

4. Check for foreign substances in drive

motor wire.

5. Forcefully restore SUS wire.

PCB water supply circuit or

relay short (continuous

conduction to valve)

Water supply bellows

blocked/ deformed

-Not closed due to foreign

substances inside drainage

housing

-Wire caught by foreign

substances outside drive

motor

-Forced restoration not possible

47

Water supply relay short

Defect in water supply valve

-Foreign substances in valve

housing

-Foreign substances

-Defect in drive motor

restoration

Replace PCB.

Replace water supply

valve.

-Remove foreign

substances.

-Remove foreign

substance.

-Replace drive motor.

Page 48

rum Wa

#$!Water Level Sensor

1) Spec. of Water Level Sensor

O/F: Forced drainage is

necessary as water

level is high. When

this level is reached,

water supply must be

RESET :

1. Spin-drying begins

30sec after drainage

level reset is reached.

Low: Small load of laundry , therefore considered to be

water level of 'low'

Medium: Large load of laundry

stopped and drainage

must be forcefully

2. Heater operation level

Medium High: W ater level for rinsing

administered.

Safety: Door open possible

Door opened only when water level is below

safety level

Model Code Classification O/F Medium High Medium Low Safety Reset Initial(Defect) Inlet Angle

3614825220 Frequency 22.60/ 23.10/ 23.20/ 24.00/ 24.40/ 24.70/ 25.80/ 900

WD1132 DN-DD03, Water level

DL-DW03 (mm)

260115 225115 22017 170115 140115 120120 0

2) Breakdown Analysis

Symptoms Detailed Symptoms Cause Diagnosis Solution

Continuous

water

supply

"E9"

Water valve normal

Occurrence in water level

sensor

30kHz or higher

Defect in pressure sensor

hose

Blocking of pressure sensor

hose

Connector loosened

Wiring short

Check for holes.

Visual checking

Visually check connector

connection status.

Wiring short ->

conduction test

48

Replace hose.

Remove foreign substances.

Administer re-insertion.

PCB Error

Mode

"E2"

"E2"

"E9"

"E9"

Page 49

Defect in

Water

Level

Detection

E9

• Defect in pressure sensor

• Defect in PCB

• Defect in water level

detection circuit

• Water supply greater than

the selected water level

• Continuous water supply

in high water level

• Water supply smaller than

the selected water level

• Reset level not detected

• Water level detection too

high or low

• Pressure sensor hose bent or

partially blocked

• Defect in pressure sensor

• Air leakage from pressure sensor

hose

• Defect in water level

• Foreign substance in air trip inlet

• Low frequency of pressure

sensor water level

• Defect in PCB

• Defect in pressure sensor

(damage in oscillation

condenser)

• Foreign substances in air

trip inlet

• Defect in PCB valve

detection circuit

49

Page 50

rum Wa

%$!POWER CORD

Classification Rated Cord Thickness Color Code Type Length Remarks

DEC 250V/15A 1.5sq Gray 3611340430 LP-31 SJT 2.3m -

1) Assembly

4 embossed parts in cabinet

-> To prevent loosening after assembly

-> SS: 2 special screws

-> LG: Forced indentation

[Before] [After]

. CONNECTOR

-> #1806 Housing 3P Used: Using both ends only and not the hole in the middle (materials highly

resistant to flame)

-> To prevent fire caused by high current

50

Page 51

&$! DOOR LOCK S/W

1) Comparison of Door Lock S/W Spec.

TYPE CODE MODEL RATED LOCK ON LOCK 'ON'/'OFF' LOCK OFF TYPE EXTERNAL

PRINCIPLE TIME APPEARANCE

DF F01 007 3619046410 WD1132 125V 16A Bimetal operation -ON : Min. of 6sec 1. Forced OFF by

by PTC heating -OFF after Cooling solenoid

in Air: 40sec ~ 5min 2. Natural OFF by

-Forced OFF: cool down of

Immediate OFF

(door opening)

bimetal

2) Structure and Spec. of Door Lock S/W : DF SERIES

1. MICROSWITCH DA TYPE

- Breaking capacity = 16(6)Amp 250Vac OPENING - CLOSING, Contact gap < 3 mm

2. Temp. for Use

- Min. Ambient Temp. = -150C, Max. Ambient Temp. = 850C

3. Protection against Power Failure: PTC-BIMETAL

- Contact 'on' status maintained for the min. of 40sec./ max. of 5min by PTC-bimetal operation

(Ambient Temp.: 50C ~ 500C)

4. Mechanical - electrical lifespan

- Number of operating cycles at nominal voltage and nominal current = 10,000

51

Page 52

r

A

* How to Replace Door Lock Switch

1) Open door and dismantle clamp spring for gasket.

2) Dismantle gasket.

3) Loosen 2 screws for door lock S/W.

4) Remove door lock S/W.

5) Administer assembly in reverse order.

* Checking Solenoid Wiring of Door Lock Switch

PIN

rrangement

2 3 4 5

Normal if 156 ~ 234

(1 does not exist.)

3) STRUCTURE AND SPEC OF DOOR LOCK S/W : DA SERIES

FIG 1 [ INTERNAL STRUCTURE OF DA TYPE DOOR LOCK S/W ]

Terminal 3 and 4:

FIG 2 [INTERNAL CIRCUIT]

52

Page 53

[ Operation Procedures ] : When door is closed

1. Initial Status: Door opened [ FIG 3]

2. Door Closed: Slider moving by door hook as

shown in [FIG 4]

3. Turn PCB power button on to enter power

and push start button.

4. PTC begins heating as power is entered to

No. 1 and 3 in [FIG 2].

5. Deformation of [UPPER BIMETAL] begins

due to PTC heating.

6. Deformation of upper bimetal moves PTC and

PTC moves blade. Here, 'omega spring' moved

'contact blade' so that terminal contact point and

blade contact point are turned on (6sec after

power impression)

[FIG 2]. Current flows in output terminal 2. Also,

'slider stop' built in with blade enters the holde of

slider and 'restrains slider while current is

flowing'. So door cannot be opened.

7. Door opening

$ When power is turned off, power of terminal 1~3 in [FIG 2] is turned off.As current impressed to PTC is

removed, 'bimetal' is cooled.

% With cooling of bimetal, PTC is returned to the original position. Also, restoration of omega spring

blade contact point is turned off.Therefore, 'slider stop restoration (40sec ~ 5min after power off)'

occurs.

& As slider restraint is cleared, door can be opened.

53

Page 54

4) Diagnosis of Defect

Symptoms Detailed Symptoms Cause Diagnosis of Defect Solution

Ticking

noise

LE'

Tick' during initial

operation and 'tick-tick'

during temoprary

suspension: 'DF' type

only

Continuous occurrence

of 'tick' noise

and 'LE': 'DF' type only

1. 'LE' occurrence

without 'tick' noise in

'DF' type

Normal noise

Connector loosened

Terminal loosened from

connector

Door not completed

closed

Abnormality in hook of

door

Defect in catch CAM

operation

Connector loosened

Terminal loosened from

connector

Normal sound generated during solenoid operation when

'sliding CAM' is locked/ unlocked to close or open door.

Visually checking connector connection

status

Referring to door lock S/W dismantling

and checking methods below

-

-

Occurrence of continuous 'tick' noise

unlike normal sound

Visually checking connector connection

status

Referring to door lock S/W dismantling

and checking methods below

Insert connector.

Insert connector.

S/W 4 or 5 terminal

Completely close

door.

Replace door AS.

Replace door S/W.

Insert connector.

Insert terminal. S/W

2 or 3 terminal

Error

Mode

–

"LE"

"LE"

"LE"

"LE"

"LE"

"LE"

"LE"

Door does

not open.

2. 'LE' in 'DA' type

Power failure, forced

power off during

operation

No power failure and

power on

Others

Breaking of solenoid coil

Connector loosened

Terminal loosened from

connector

PCB MICOM' cannot open door in case of power failure or forced power S/W off during operation.

Door can be opened in the max. of 5min.

Water in drum

Inside the drum hot

Door does not open normally in case of loosening of connector/ terminal and breaking of

solenoid coil during operation. Administer measures after test according to the following method.

Referring to picture below

Visually checking connector connection

status

Referring to door lock S/W dismantling

and checking methods below

Checking if water level is higher than

safety level

Prevention of door opening to prevent burn caused by hot laundry after

drying

54

Replace door S/W.

Insert connector.

Insert terminal. S/W

2 or 3 terminal

Door opens after

drainage.

"LE"

"LE"

"LE"

–

Page 55

r

'$!HEATER

1) Spec of Heater of Washing Machine

Classification Wahing

Maker IRCA

Rated 120V

Consumption Power 1000W15%

Resistance 25.47ohm

Current Density 8.9

Temp. Fuse 184)

Washing Heater

Thermister Heater built-in

MaterialSUS430

Max. Temp. Water

Part Code 3612801740

Temp. Fuse of Washing Heater (184°C CUTOFF TYPE)

: Located inside heater to prevent fire, etc. caused by heating without water due to breakdown of water

level sensor, etc.

: Cut-off in app. 1min in case of overheating, heater temp. of app. 270°C

: Washing heater must be used under water.

Washing Temp.

Sensor

55

Page 56

r

2) Breakdown Diagnosis

Breakdown

Cause Diagnosis Solution

PCB

Symptoms Error Mode

Washing

water

not heated

(common for

drum)

Overheating of

washing water

Wiring short

Washing heater or

temp. fuse short

Connector/ terminal

loosening

Defect in washing

heater temp. sensor

Defect in washing

heater temp. sensor

Check for short: DWD-11'S, no detergent, 800W

common

Check for short: Normal if 23.3~25.7ߟ between both

terminals of washing heater -> Common for drum

Check for loosening: Common for drum

Measuring resistance between both terminals of sensor:

Referring to the attached temp./ resistance table

Measuring resistance between both terminals of sensor:

Referring to the attached temp./ resistance table

Connect the cut-off part.

Replace washing

heater.

Insert terminal.

Replace temp. sensor.

Replace temp. sensor.

"H6"

"H6"

"H6"

"H2"

"H2" or "H4"

Heater Replacement

* How to Replace Washing Heater and Temp. Sensor

1. Dismantling Connector 2. Loosening Earth and Heater Nuts

3. Replacing Heater and Temp. Sensor

4. Administer assembly in reverse order and make sure to fasten heater nuts first before the earth nuts.

56

Page 57

($!)*+,!-./.0

6-1. Structure of BLDC Motor

6-2. Power Transmission System of BLDC Motor

57

Page 58

r

(1%$!234567658/6.9

Classification Item BLDC : DD Motor

1. General

2. Performance

3. Structure

Rated Voltage

Insulating Structure

External Appearance

No. of Poles

Consumption Power

RPM

Output

Characteristics

Stator

Resistance

Vm = 310 [Vdc], Hall IC Voltage 5 [Vdc]

Type B, insulator method

Shaft connection and stator connection

structure, Air-gap : 1mm

24 poles, Core: 36 slots, Layer: [30mm]

390[W]±10[%], during washing

(picked value)

During Washing: 45RPM,

During Spin-drying:1300RPM

Torque: 300Kgf.cm (washing: 45rpm)

Current: 1.5A (washing: 45rpm),

2.5A (spin-drying: 800rpm)

AC Input Terminal - Washing: 250Wo,

Spin-drying: 380Wo

ø265x30H

U(blue) - V(purple) : 13.8Ω[at 75°C]

V(purple) - W(pink) : 13.8Ω[at 75°C]

W(pink) - U(blue) : 13.8Ω[at 75°C]

cf) Motor resistance at ambient temp. of

0 ~ 35°C

7.04 ~ 8.1Ω

Rotor

Hall IC

Magnet : 24 segments, bracket, serration

2-sensor Control Type, Top Central Angle:

7.5 degrees

Signal Error Angle (phase difference):

90±5 degrees (based on electric angle)

58

Page 59

:$!;<=3!+08698>4!2?@/4=

Drainage

Hose

Wire connection terminal Pump filter

Defect in

Drainage

Drainage not

carried out (OE)

Drainage

normally carried

out, but OE

displayed

Direction of pump

filter cap opening

• Pump case blocked (coin, foreign substances, memory wire)

• Pump case frozen

• Defect in pump operation

• Drainage hose pressed down or position changed

• Ends of drainage hose blocked (built-in installation)

• High edge of drainage way: Natural drainage/

• Product frozen (drainage way frozen)

• Loosening of drainage motor connection terminal, inferior connection

• TP operation of drainage pump

• Defect in PCB

• Defect in pressure switch (oscillation frequency low)

• Defect in controller

• Defect in drainage relay drive circuit

• Drainage relay short

• Defect in oscillation circuit

(high oscillation frequency)

59

Page 60

Power

Part

Problem in indoor

wiring

• Breakdown of power lead-in switch

• Indoor wiring fuse short

• Aging of power outlet, defect in contact

• Extension cord short or too thin

Problem in wiring

of washing

machin

Defect in electric

parts

Erroneous voltage

impression

Defect in

separately

purchased step-up

transformer

• Power cord short (defect in contact)

• Lead wire short

• Controller terminal segments and connector loosened

• Defect in contact of electric wire connector (power switch, reactor)

• Breaking of insulated wire in lead wire terminal compression part

• Fuse short: In noise filter

• PCB transformer short

• Check 120V

• Defect in contact of lead wire inside transformer

• Transformer fuse short

• Low-capacity transformer of other company used

Defect in PCB

• Defect in pin connector contact

• Defect in power circuit

• Defect in reset circuit

• Defect in interrupt circuit

• Defect in oscillation circuit

• Defect in water level detection circuit

• Defect in MICOM

• Board damaged

60

Page 61

A$!B.6@4!+4745/

Noise

Hammering sound

from drum during

initial operation

Vibration and

noise when

spin-drying

reaches normal

r.p.m

Others • V-belt friction noise

• Bolt for transportation not removed

• Defect in leveling adjustment

• Ground surface not flat

• Weak ground

(wooden board, frame made with angle and Styrofoam, etc.)

• Loosening of spring

• Spin-drying small quantity of laundry (bath towel, jeans, etc.)

• Belt damaged

• Bolts for transportation not removed

• Defect in leveling adjustment

• Defect in damper

• Laundry pushed to one side

• Belt damaged

• Defect in grease application of spring hook

• Decrease in damper capacity

(water infiltration, grease loss)

• V-belt loose

• V-belt damaged

• Foreign substance in between drum and tub (wire, memory wire, etc.)

• Mechanical friction noise

• Noise in pump during

spin-drying (drainage)

61

• Bearing damaged (water infiltration

due to abnormal abrasion of seal)

• Bolt loosened in bearing housing

connection part, welded part fallen

• Noise generated by air inflow as pump is

operated during spin-drying even

without water in order to reduce residual

water

Page 62

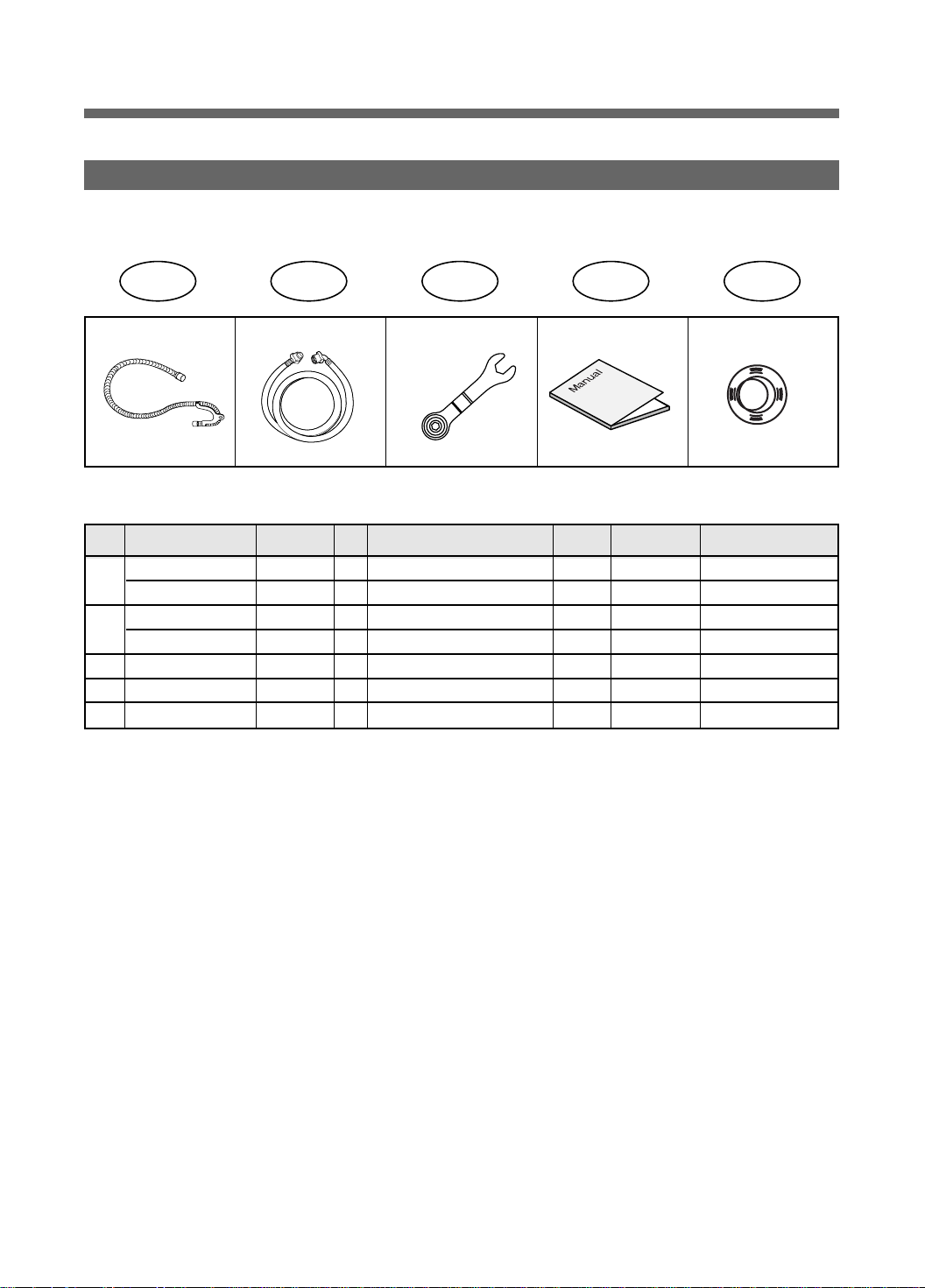

Wiring Diagram

"

62

Page 63

Installation

"

11)) RReellaatteedd PPaarrttss aanndd CCoonnffiigguurraattiioonn

Item

FIXTURE UP

/ DOWN AS

UNIT SERVICE

WRENCH

LEG ADJUST AS

SSPPEECCIIAALL SSCCRREEWW

UUPP

FFIIXXTTUURREE UUPP

FOOT

Configuration Remarks

SPECIAL SCREW UP

: L= 109mm

SPECIAL SCREW DOWN

FFIIXXTTUURREE DDOOWWNN

:L=160mm

SSPPEECCIIAALL SSCCRREEWW

DDOOWWNN

% REMOVE FIXTURE

UP/DOWN AS

& ADJUST LEG

FIXTURE LEG

22)) IInnssttaallllaattiioonn PPrroocceedduurreess

% Remove fixture up/ down AS.

Removal Remarks

' Remove fixture up/down AS by rotating it

in anti-clockwise direction.

' Store fixture up/down for use later on.

' To assemble fixture up/down AS, rotate it

in clockwise direction.

63

Page 64

r

& Insert cap holder (4) into holes created after removing fixture up/down AS as shown in the picture.

CCAAPP HHOOLLDDEERR

( Install drum washing machine on flat and solid ground.

* Adjust leveling with led adjust AS.

Adjustment Remarks

) Adjust fixture leg to fasten special bolt.

Adjustment Remarks

' Washing machine is moved upwards by

rotating foot of leg adjust AS in clockwise

direction.

' Washing machine is moved downwards by

rotating foot of leg adjust AS in anticlockwise direction

' Vibration of washing machine is

suppressed by rotating fixture leg in

anti-clockwise direction as it fastens

special bolt.

64

Page 65

Reversing the door

"

1. Open the door and remove the door by

unscrewing 4 bolts holding the hinge.

2. Remove the clamp gasket ass'y

4. Unscrew the 2 screw on the s/w door lock

on the right side of the door and draw out

the s/w door lock.

5. Draw out the hinge on the left side of door

and detach the label on the right side.

And attach the RH type label on the left side

of door

3. Draw out the shower hose and fix the

gasket toward the inside of drum.

6. Insert the hinge of the door and door lock

securly and secure the door lock giving

attention to direction as following fiures.

65

Page 66

7. Then insert the socket of door lock as

following figure. And secure the gasket

and clamp.

8. Separate the stopper door by unscrewing 1

screw.

Then rotate the door glass 180°C and

secure the stopper door you removed.

9. Secure the hinge using the bolts you

removed in step 1.

66

Page 67

DISMANTLING METHOD PER WASHER ASS'Y

"

INLETBOX ASS'Y

1

2

PANEL FRONT ASS'Y

1. Remove 2 screws.

2. Remove panel F.

3. Remove connector.

4. Take caution for damaging

hook.

67

Page 68

2. Remove 4 screws.

PLATE TOP ASS'Y

1. Remove 3 screws.

68

Page 69

BOX INLET ASS'Y

1. Remove 4 hose clamps.

2. Remove 1 screw and separate inlet box.

3. Remove and separate hose inlet.

69

Page 70

VALVE 3WAY

1. Remove 4 screws. 2. Separate 3 connectors.

3. Separate 3 hose clamps.

70

Page 71

MAIN PCB ASS'Y

1. Separate harness and separate PCB cover.

2. Separate connector. 3. Remove 1 screw.

71

Page 72

WATER LEVEL SENSOR

1. Remove 1 screw. 2. Separate connector. 3. Separate pressure sensor

hose.

COVER BACK

1. Remove 4 screws.

72

Page 73

MOTOR ASS'Y

1. Remove 1 bolt to fix stator.

2. Remove motor by separating 6 bolts to fix rotor. (Caution for damaging guide pin)

WASHING HEATER

1. Unfasten nut. 2. Remove connector. 3. Remove heater in the

direction of arrow.

DAMPER ASS'Y

1. Press the projected edge of sharp part in damper pin. 2. Remove damper pin.

73

Page 74

3. Remove damper pin on tub side in the same way and remove damper.