Page 1

DAEWOO ELECTRONICS CO., LTD.

Service Manual

MODEL : DV-F882DY-C

DV-F882DY-A

DV-F882DY-C

DV-F882DY-A

DV-F882DY-M

DV-F882PY-D

DV-F802D-CP

DV-F802D-AP/

DV-F802P-DP

Page 2

SPECIFICATIONS

SYSTEM

Video signal PAL standard colour

PAL/SECAM

channel memory 55 positions

UHF output signal 30-39 CH (adjustable)

73±3dBuV

VIDEO

Input: Video Line in 1.0Vp-p

75 ohms unbalanced, sync.

negative

Output: Video line out 75 ohms unbalanced, sync.

negative

Signal to noise ratio More than 43dB (SP)

Horizontal resolution 230 lines

AUDIO

Input: Audio Line in Impedance: more than

50Kohm

–8 dBm, unbalanced

Output: Audio line out Impedance: less than 1Kohm

–6 dBm, unbalanced

Frequency response 100 Hz-8KHz

Hi-Fi, 20Hz-20kHz

Signal to noise ratio More than 38 dB

Hi-Fi More than 60dB

Audio Distortion Less than 3% (SP)

Hi-Fi Less than 0.5%

TAPE TRANSPOR T

Tape width 12.65mm (1/2")

Tape speed 23.39mm/sec

Maximum recording time 360 min, with E-180 tape (LP)

FF. REW time Approx 4 min (E-180)

GENERAL

Power requirements AC 230V 50Hz

Power consumption 19W

Nicam 20W

DIMENSIONS

Set size (WxHxD) 360x90x312 mm

Carton size (WxHxD) 445x180x412 mm

Weight (gross) 5.4Kg

Channel coverage

SYSTEM PAL,SECAM-B/G

PAL,SECAM-B/G,D/K PAL-I

HYPER BAND

VHF Ch 2~12

UHF Ch 21~69

Channel CATV Ch X,Y,Z UHF Ch 21~69

SI~S41

IN/OUTPUT JACK TYPE

Model EUROPE

JACK

SCART Type

TYPE

Page 3

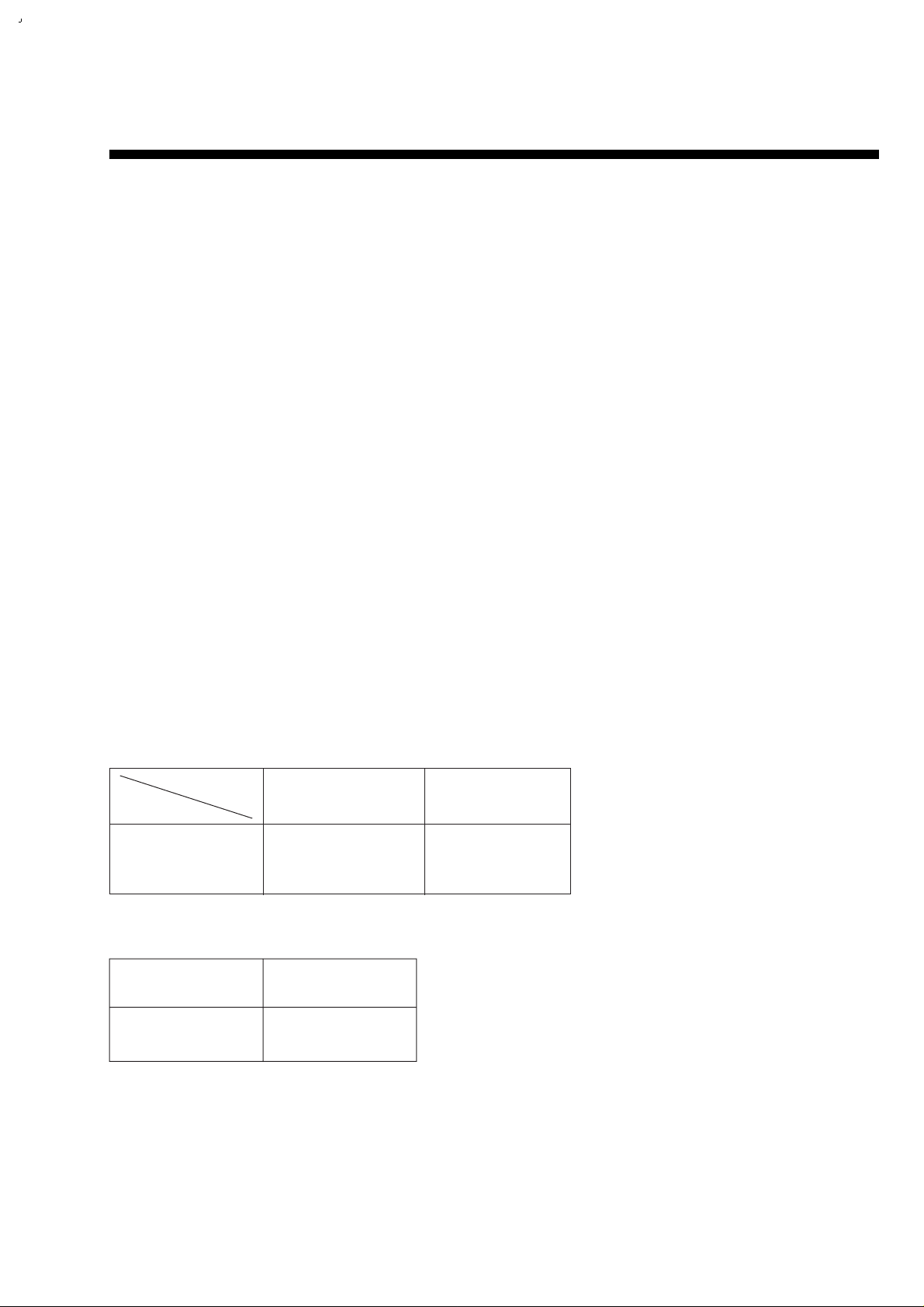

• Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires

have been returned to original positions. Afterwards, perform the following tests and confirm the specified values in order

to verify compliance with safety standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed parts of

the set (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone

jacks, etc.). See table below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed accessible parts of the

set (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks,

etc.) See table below.

3. Clearance distance

When replacing primary circuit components, confirm

specified clearance distance (d), (d') between soldered

terminals, and between terminals and surrounding

metalic parts. See table below.

Table 1: Rating for selected areas

* Class II model only.

Note: This table is unofficial and for reference only. Be sure to confirm the precise values for your particular country and

locality.

4. Leakage current test

Confirm specified or lower leakage current between B (earth ground, power cord plug prongs) and externally exposed

accessible parts (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks,

earphone jacks, etc.)

Measuring Method: (Power ON)

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accesible parts. Use and AC

voltmeter to measure across both terminals of load Z.

See figure 2 and following table.

Table 2: Leakage current ratings for selected areas

Note: This table is unofficial and for reference only. Be sure to confirm the precise values for your particular country and

locality.

Fig. 2

AC Line Voltage Region

Insulation Dielectric Clearance

Resistance Strength Distance (d), (d')

100V Japan ≥ 1 MΩ/500 VDC 1kV AC 1 minute ≥ 3 mm

110 to 130V

USA &

– – –

900V AC 1 minute ≥ 3.2mm

Canada

* 110 to 130 V Europe ≥ 4 MΩ/500 V DC 3 kV AC 1 minute ≥ 6 mm (d)

200 to 240 V Australia ≥ 8 mm (d')

(a: Power cord)

AC Line Voltage Region

Earth Ground

Load Z Leakage Current (i)

(B) to:

100V Japan ¡ ≤ 1m A rms

Exposed accessible

parts

110 to 130 V USA & ¡ ≤ 0.5 m A rms Exposed accessible

parts

¡ ≤ 0.7 m A peak Antenna earth

110 to 130 V Europe ¡ ≤ 2 m A dc terminals

200 to 240 V Australia ¡ ≤ 0.7 m A peak

Other terminals

¡ ≤ 2 m A dc

Fig. 1

1k

1.5k

1.5kµF

2k

50k

d

Primary circuit termimals

Chassis

d'

a

Exposed

accessible

part

Z

Earth Ground

power cord plug prongsB

AC Voltmter

(high impedance)

Page 4

TABLE OF CONTENTS

SECTION 1. CONTROLS AND FUNCTIONS..........................................................................................................2

SECTION 2. ELECTRICAL ADJUSTMENTS

2-1. SERVO CIRCUIT ADJUSTMENT METHOD..................................................................................................................... 3

2-2. AUDIO CIRCUIT ADJUSTMENT METHOD......................................................................................................................4

2-3. IF MODULE CIRCUIT ADJUSTMENT METHOD..............................................................................................................5

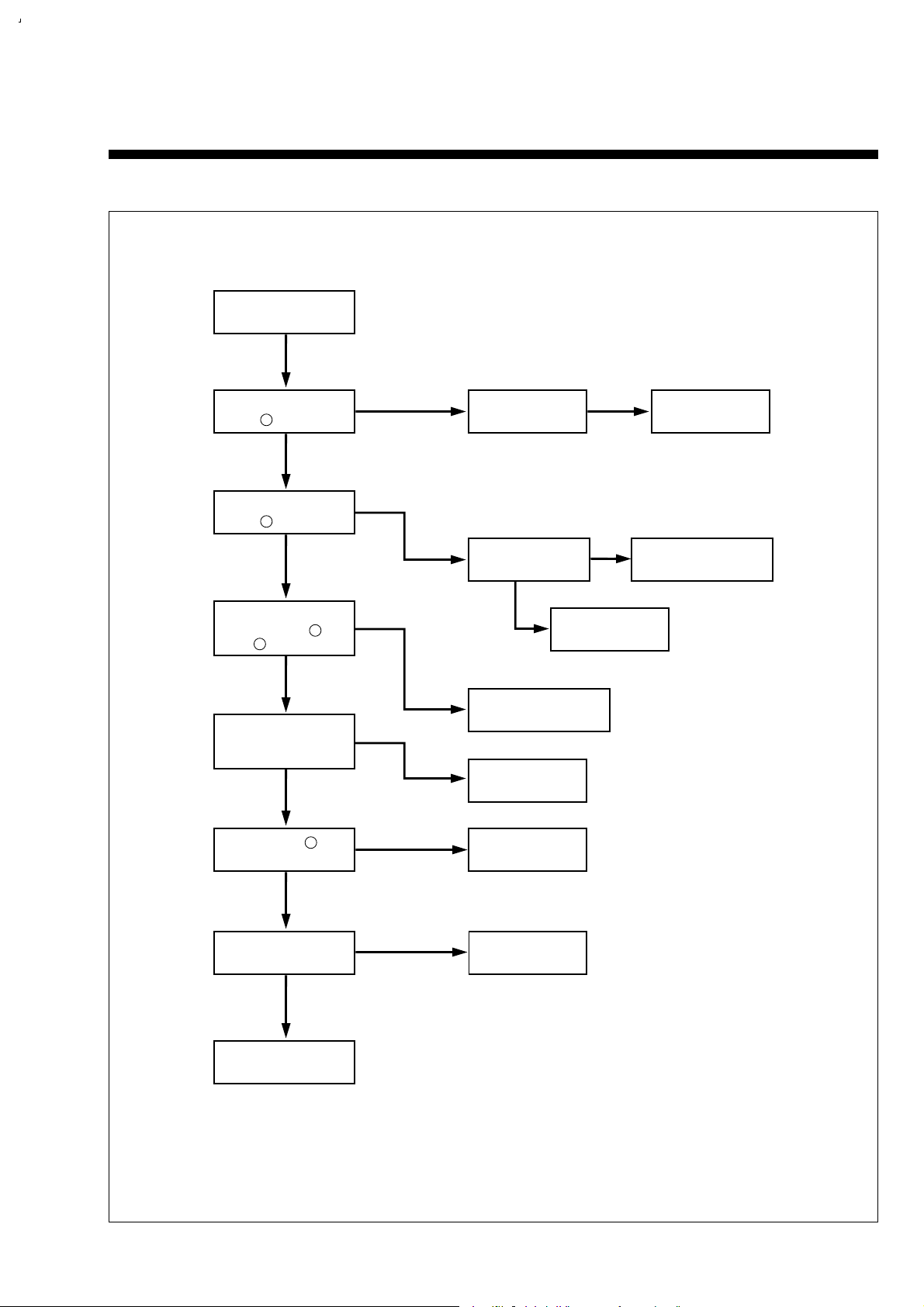

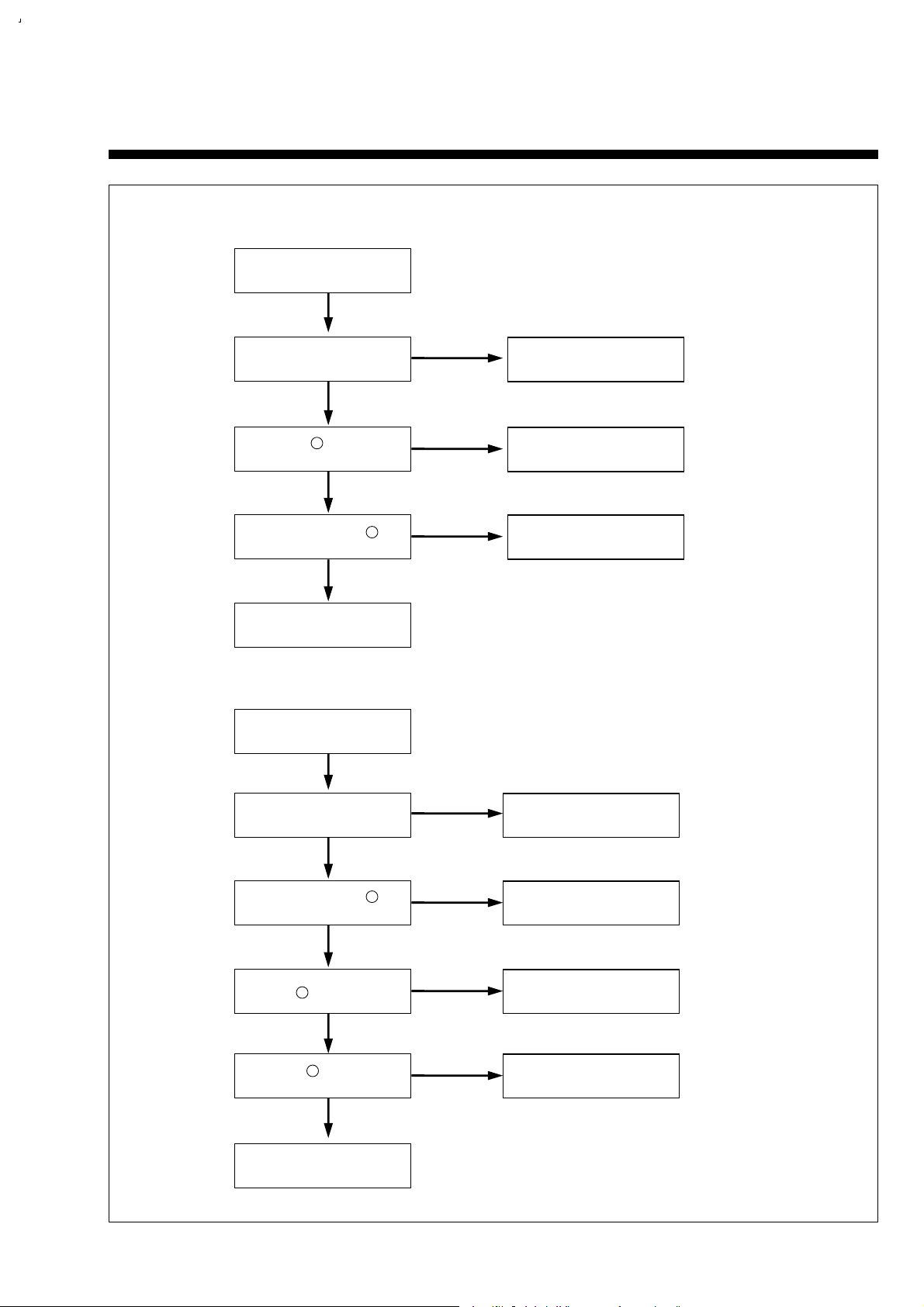

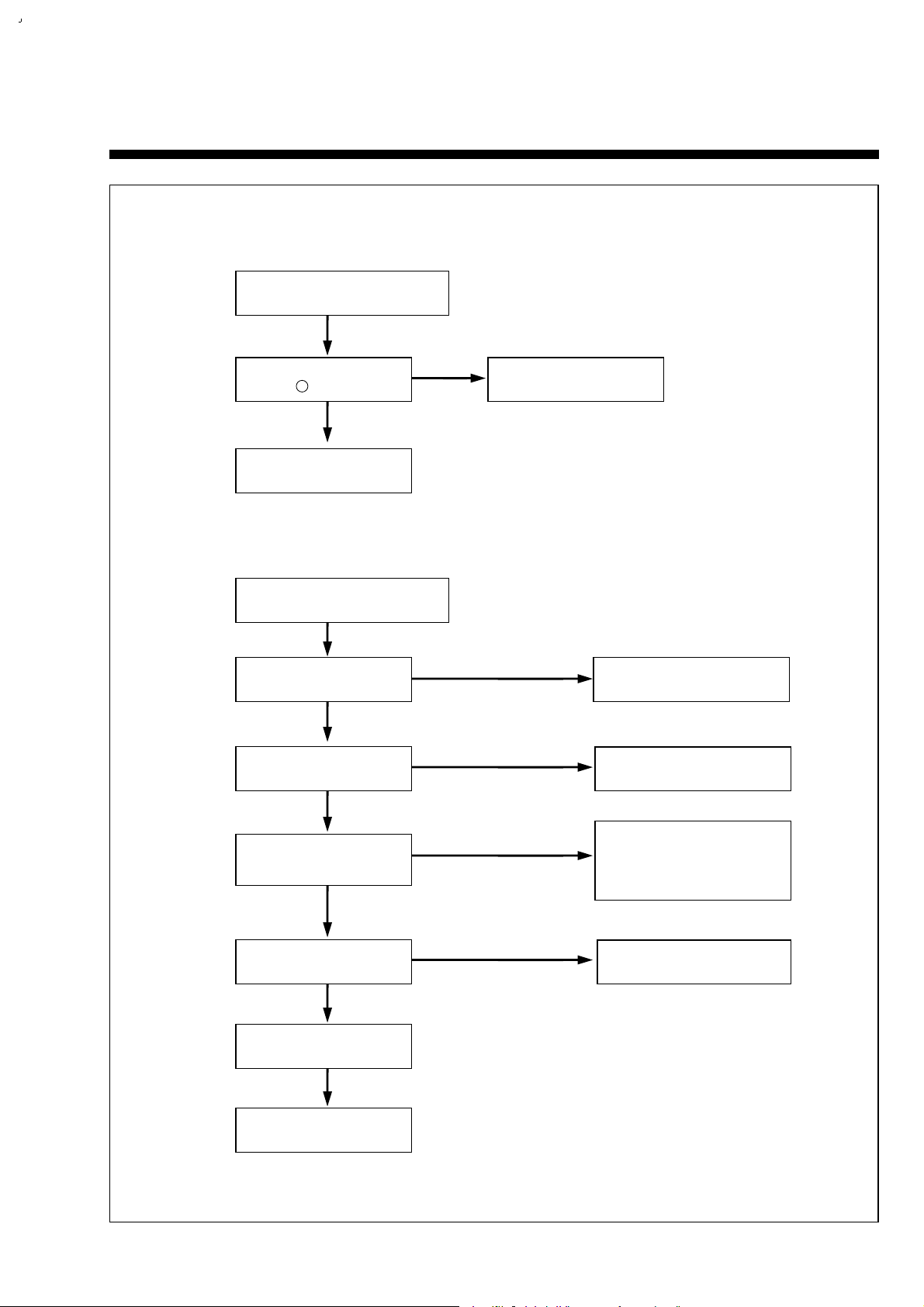

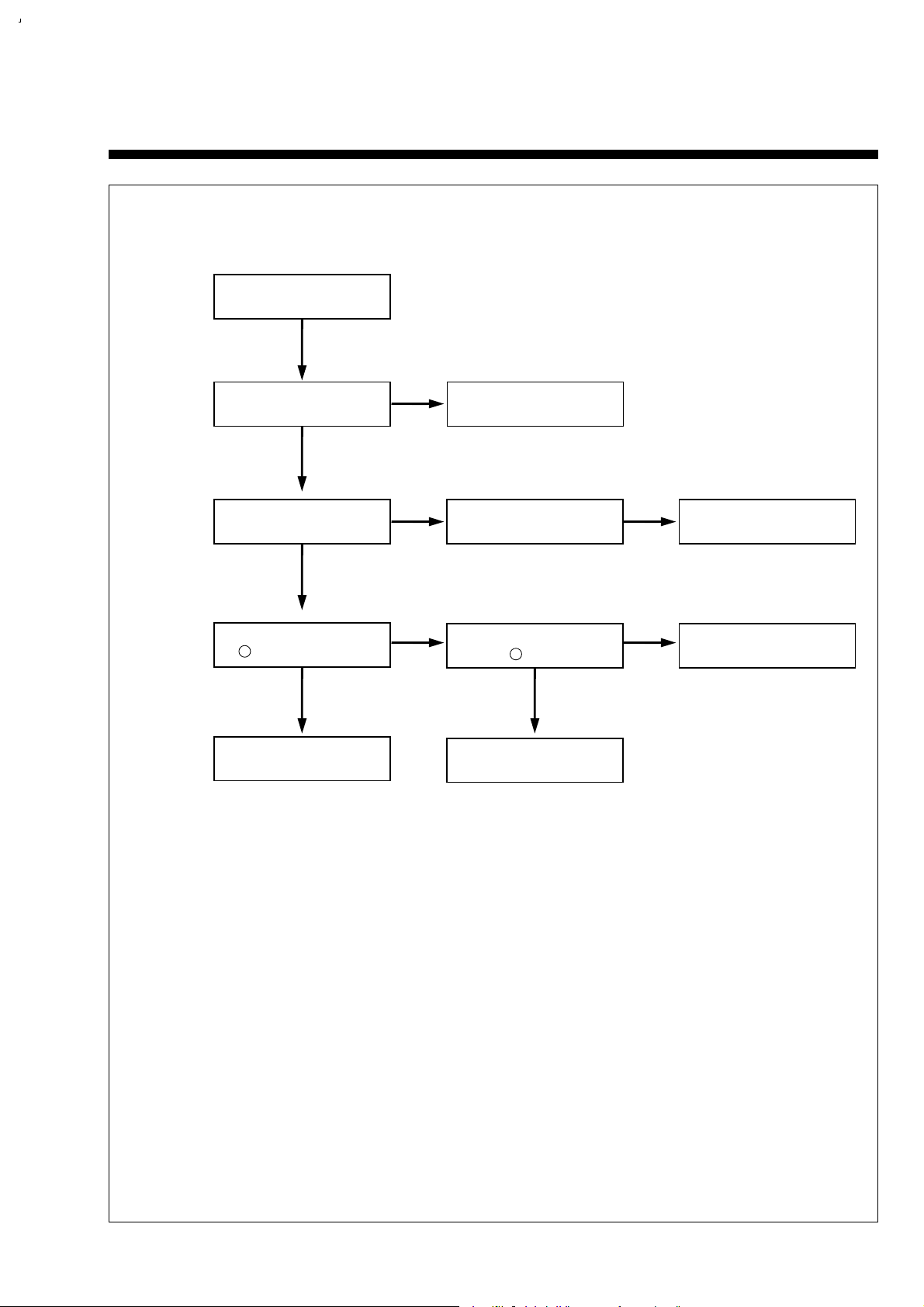

SECTION 3. TROUBLE SHOOTING FLOW CHART

3-1. POWER CIRCUIT.............................................................................................................................................................16

3-2. LOGIC CIRCUIT............................................................................................................. .................................................. 18

3-3. SERVO-SYSCON CIRCUIT.............................................................................................................................................20

3-4. AUDIO CIRCUIRT (NORMAL) .........................................................................................................................................25

3-5. AUDIO CIRCUIT (HI-FI)....................................................................................................................................................27

3-6. VIDEO CIRCUIT ...............................................................................................................................................................29

SECTION 4. CIRCUIT DIAGRAM

4-1. CONNECTION DIAGRAM (DV-F802 SERIES)................................................................................................................39

4-2. CONNECTION DIAGRAM (DV-F882 SERIES)................................................................................................................40

4-3. POWER CIRCUIT.............................................................................................................................................................41

4-4. SERVO-LOGIC CIRCUIT.................................................................................................................................................42

4-5. LOGIC CIRCUIT (DV-F802 SERIES)...............................................................................................................................43

4-6. LOGIC CIRCUIT II (DV-F882 SERIES) ............................................................................................................................44

4-7. HEADAMP CIRCUIT........................................................................................................................................................45

4-8. VIDEO CIRCUIT ...............................................................................................................................................................46

4-9. HI-FI AUDIO CIRCUIT......................................................................................................................................................47

4-10. PIF NICAM CIRCUIT......................................................................................................................................................48

4-11. PIF/MPX CIRCUIT..........................................................................................................................................................49

4-12. PIF CIRCUIT...................................................................................................................................................................50

4-13. OSD CIRCUIT ................................................................................................................................................................51

4-14. VPS/PDC CIRCUIT........................................................................................................................................................52

4-15. IN/OUT SW CIRCUIT I...................................................................................................................................................53

4-16. IN/OUT SW CIRCUIT II..................................................................................................................................................54

4-17.REMOCON CIRCUIT......................................................................................................................................................55

SECTION 5. VOLT AGE CHAR TS.................................................................................................................................56

SECTION 6. COMPONENTS LOCA TION GUIDE ON PCB BOTTOM VIEW........................................64

SECTION 7. DIS ASSEMBLY ........................................................................................................................................69

SECTION 8. ELECTRICAL P AR TS LIST..................................................................................................................73

1

Page 5

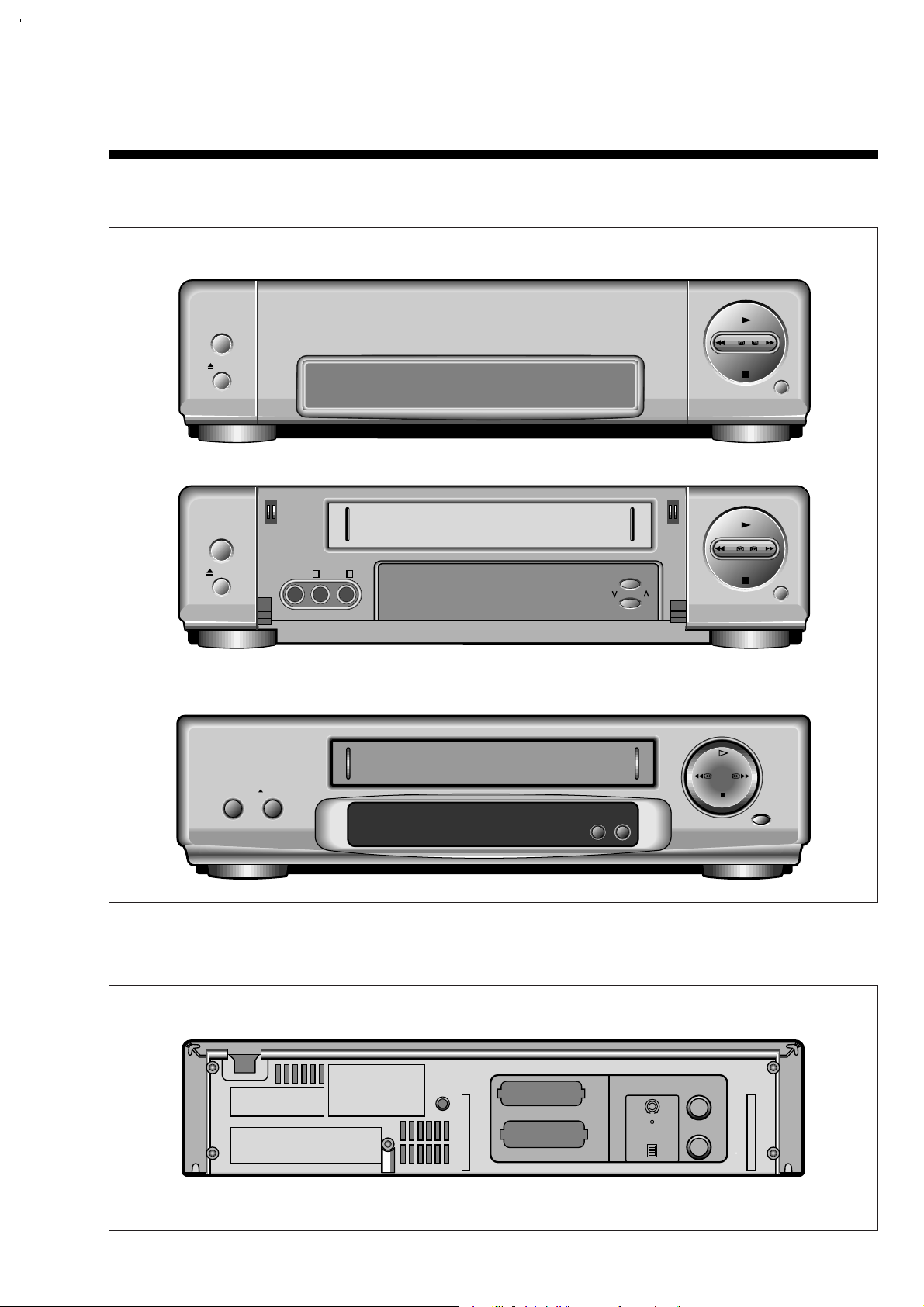

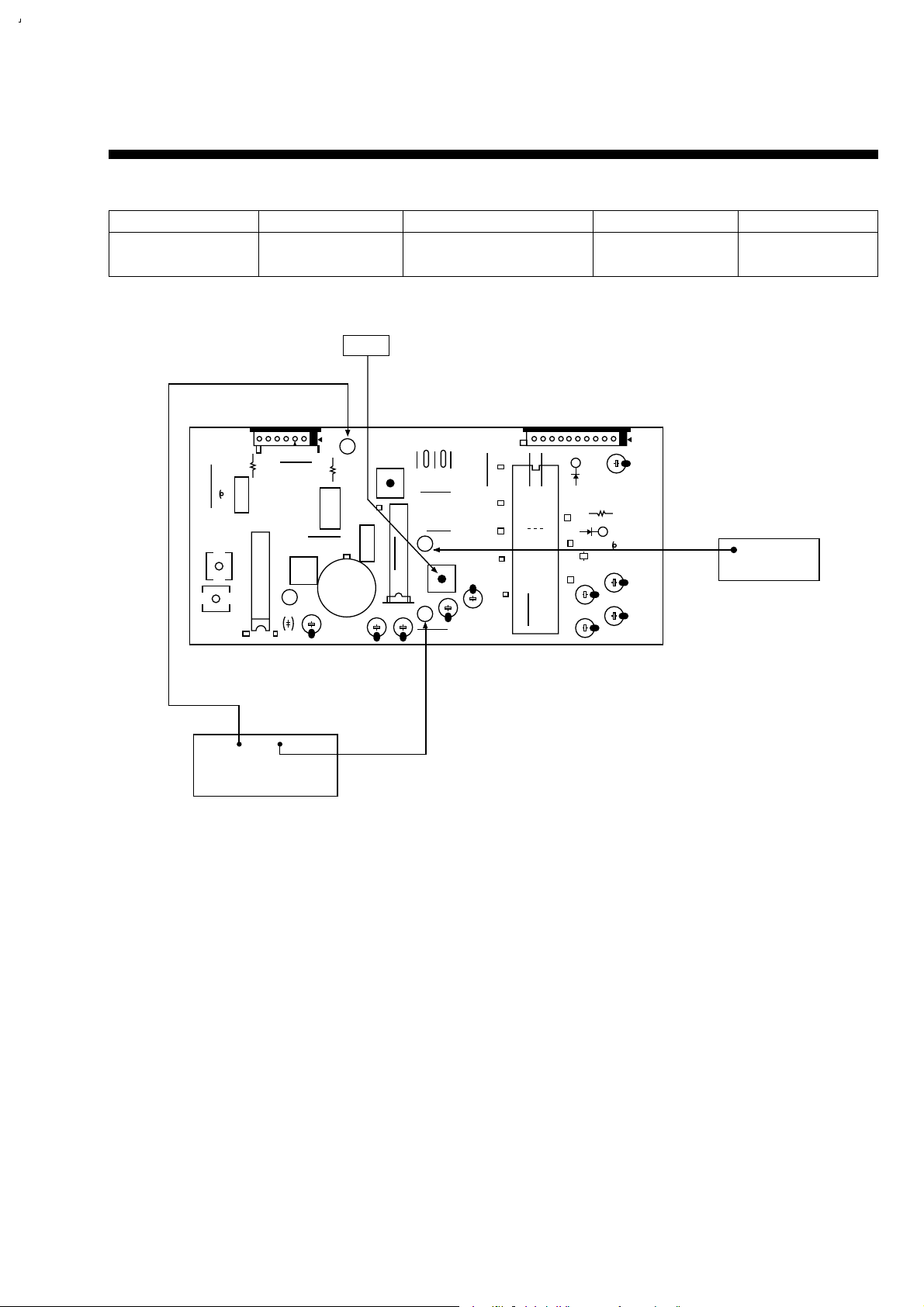

SECTION 1. CONTROLS AND FUNCTIONS

2

PLAY

STOP

POWER

EJECT

REC/OTR

REW

FF

=

POWER

EJECT

REC/OTR

REW

FF

PLAY

STOP

VIDEO L –AUDIO– R

CHANNEL

B.L.U.E D.I.A.M.O.N.D

RAPID REWIND SYSTEM

=

REC/OTR

POWER EJECT

õ CH.TRK.ö

PLAY

REW F.F

STOP

DV-F882 Series

DV-F802 Series

FRONT

REAR

EURO-AV

RF OUT

TV

CH.H CH.L

TEST

ON

OFF

ANT. IN

Page 6

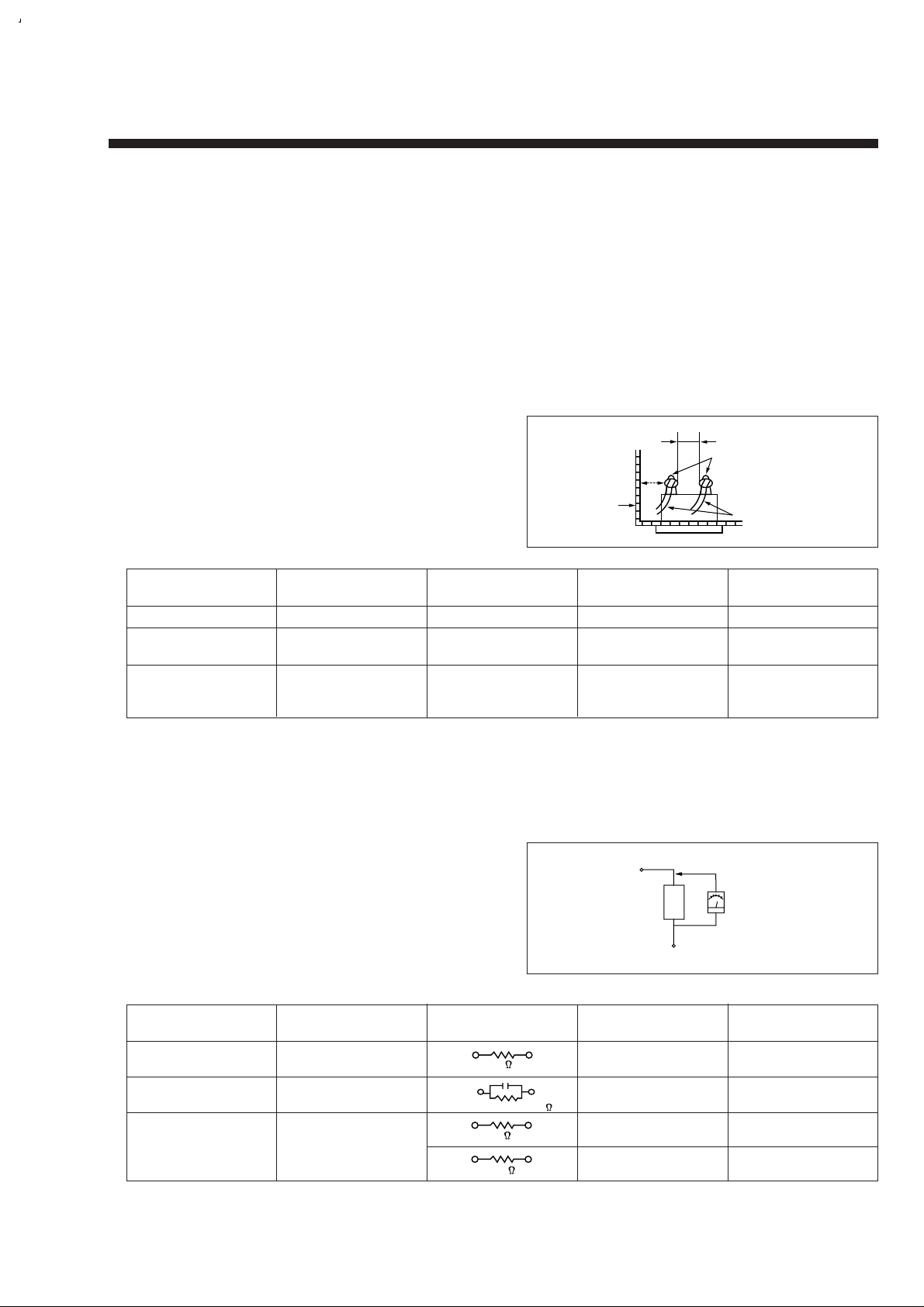

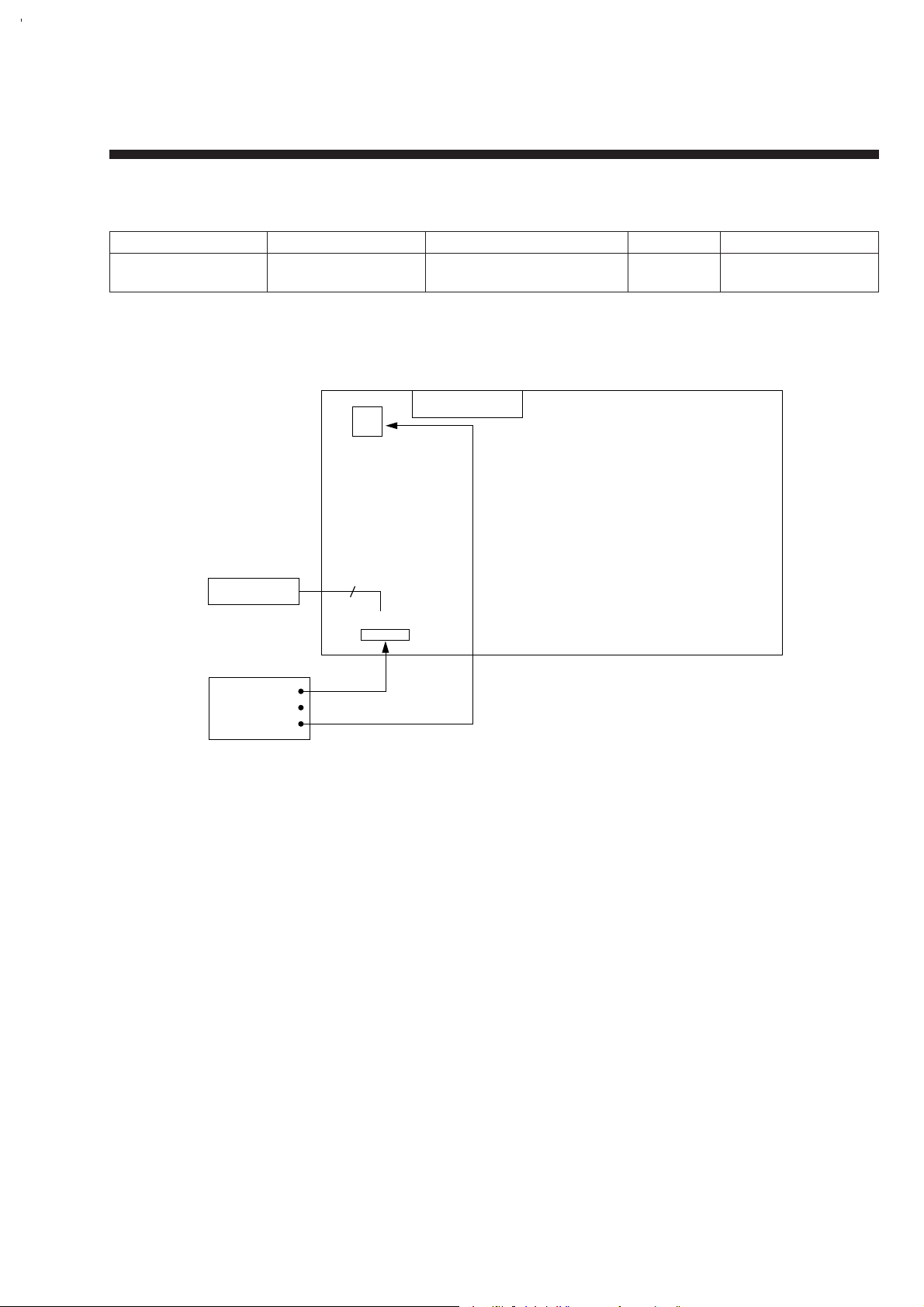

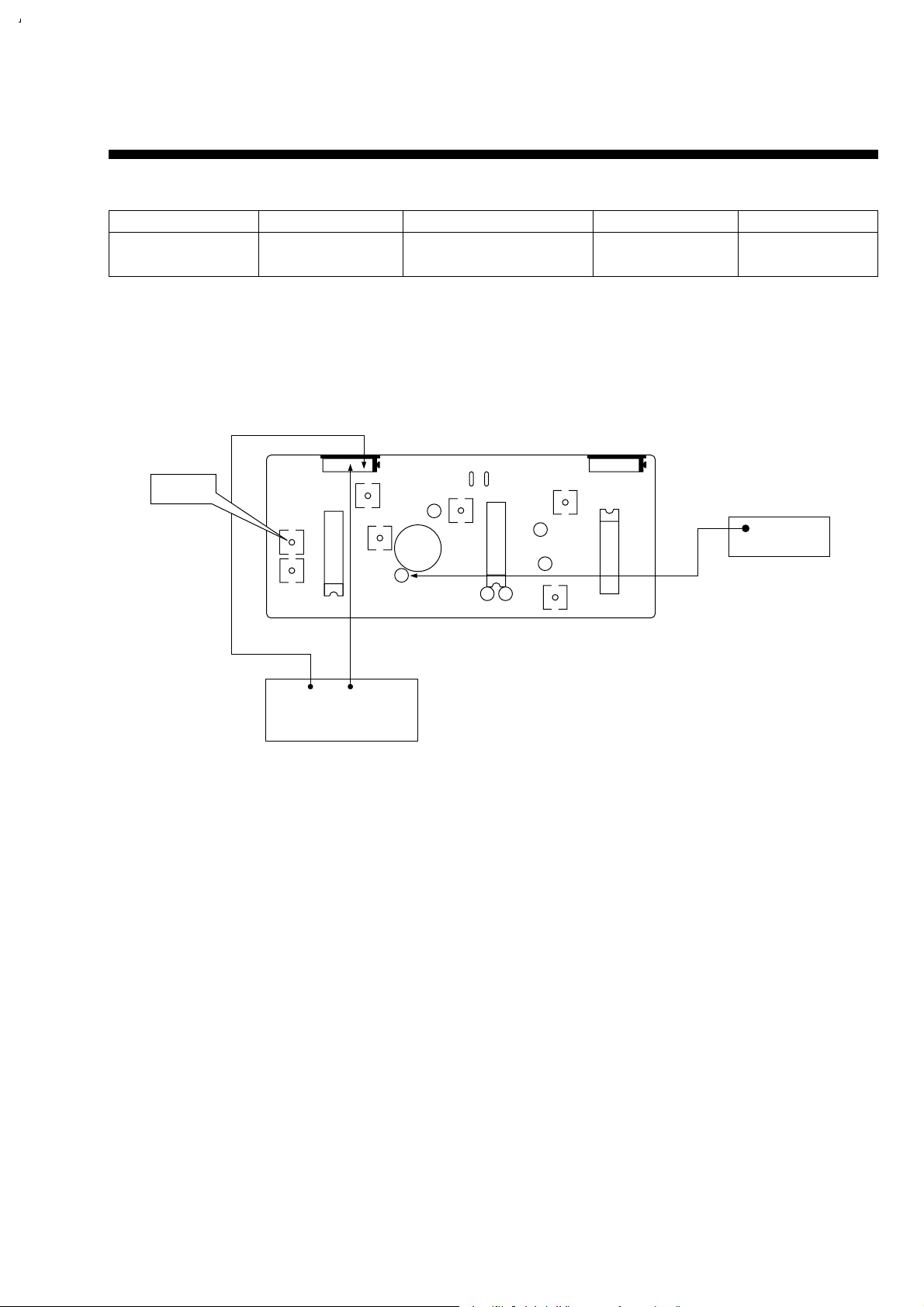

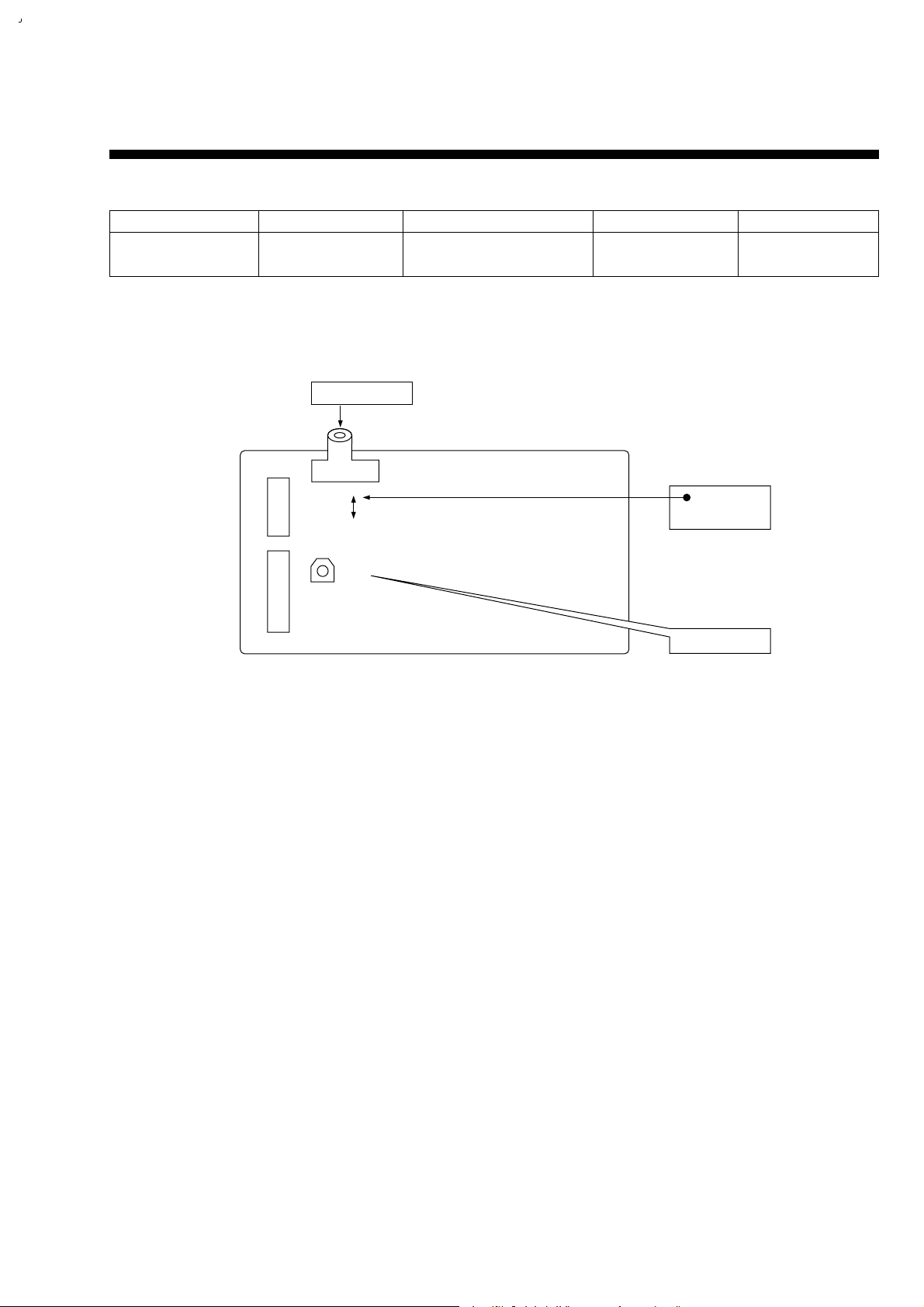

2-1. SERVO CIRCUIT ADJUSTMENT METHOD

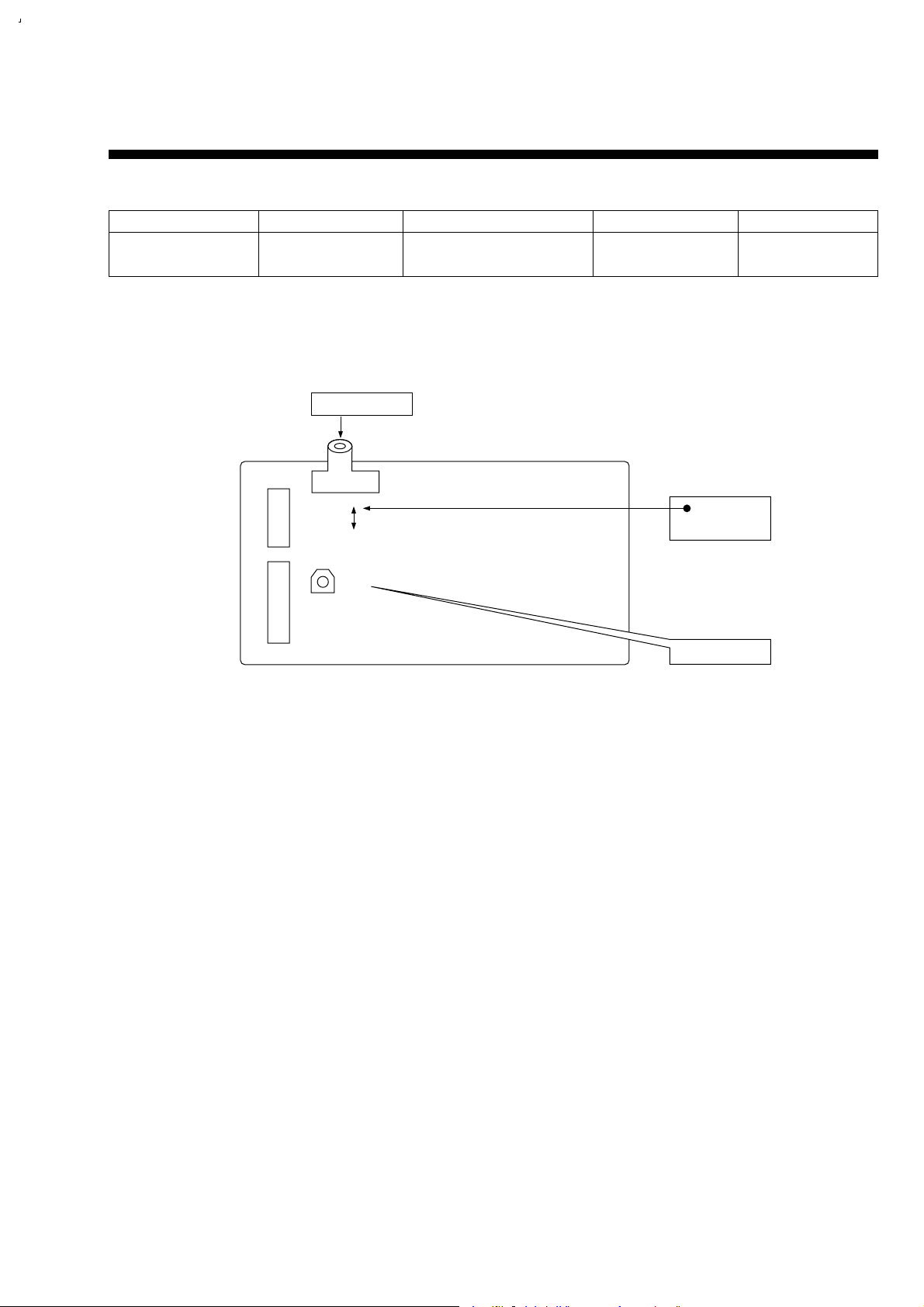

1. PLAYBACK PHASE

• Connection Method

• Adjustment Procedure

1) Play back the test tape.(DP-2)

2) Set the oscilloscope to the CHOP mode. Connect CH1 to the SW PULSE (PT01 PIN ¤Ø).

3) Insert PATH JIG and Press “REC” button on the remote controller.

4) Check the position of the V-sync from the rising edge of the SW pulse.

(Standard: 6.5H±0.5H)

SECTION 2. ELECTRICAL ADJUSTMENT

Adjustment Parts Checking Point Measuring Equipment Mode Test Tape

JPT01

DP-2

Check

PT01 PIN ¤Ø

Oscilloscope Play

Modulator

JPT01

CH-1

OSCILLOSCOPE

CH-2

PT01

TOP VIEW

PATH JIG

6

3

Page 7

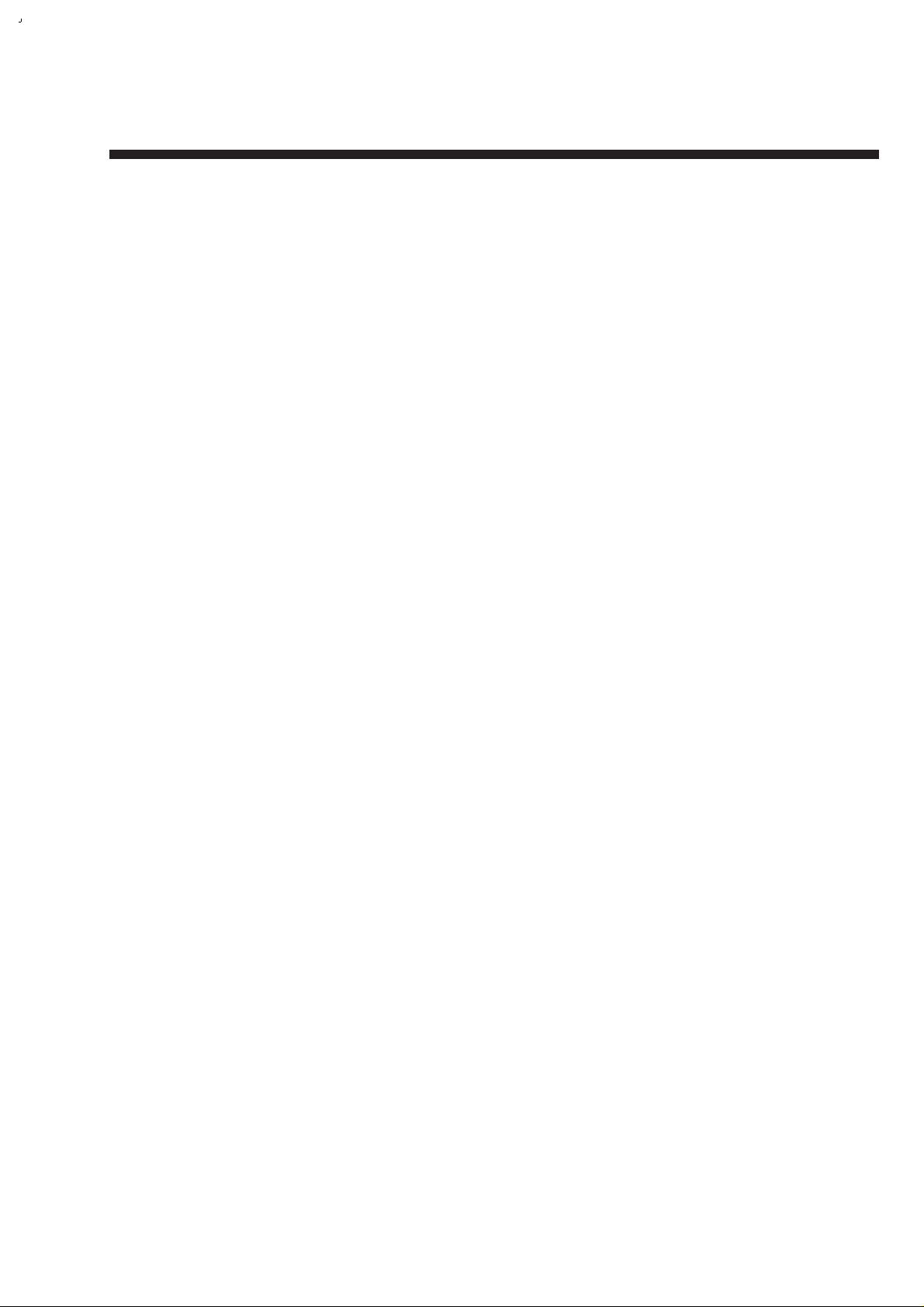

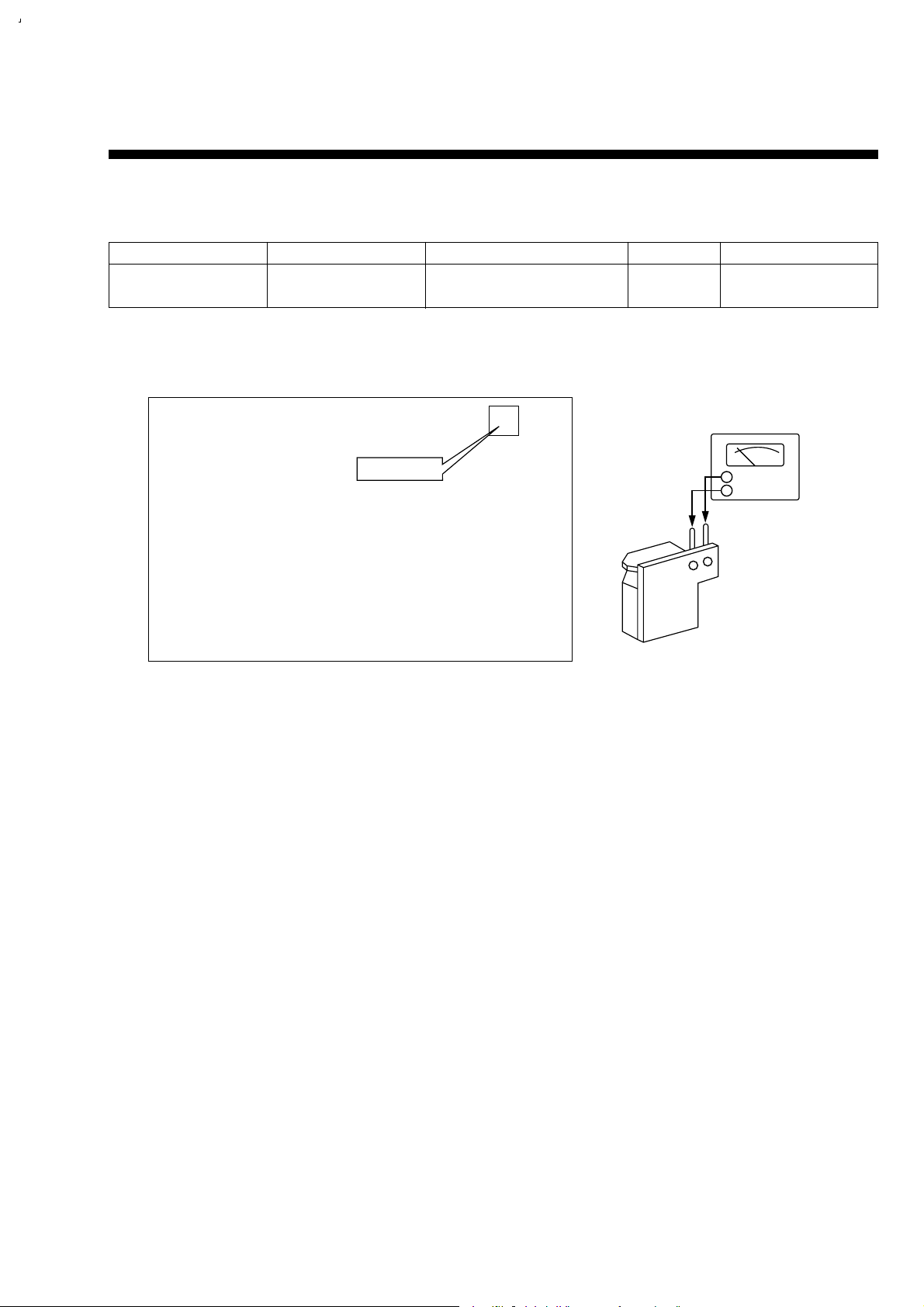

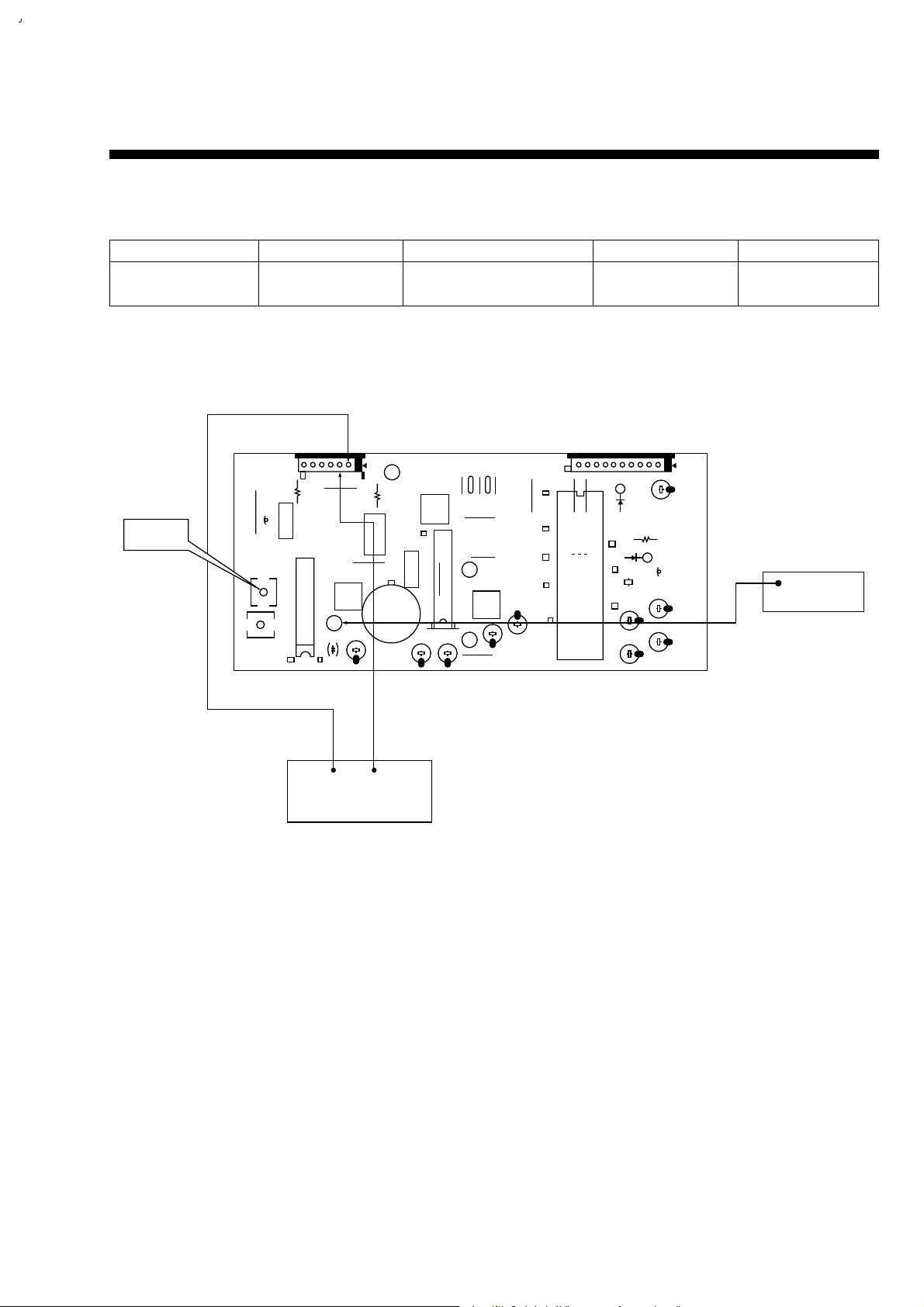

2-2. AUDIO CIRCUIT ADJUSTMENT METHOD

1. AUDIO RECORD BIAS

• Connection Method

• Adjustment Procedure

1) Set the TV/LINE to LINE mode.

2) Set the input to open mode

3) Connect the Audio level meter to both TP1 and TP2

4) After inserting a blank tape, record in SP mode.

5) Adjust R290 to obtain 3.0 mVrms.

4

TOP VIEW

R290

3.0mVrms

+

–

A/CHEAD

TP2

(–)

TP1

(+)

Audio LEVEL METER

S/N: 97P65064HA

HEAD AMP PCB

Adjustment Parts Checking Point Measuring Equipment Test Tape Input Signal

R290

A/C Head PCB

Audio level meter Rec None signal

TP1(+), TP2(-)

Page 8

5

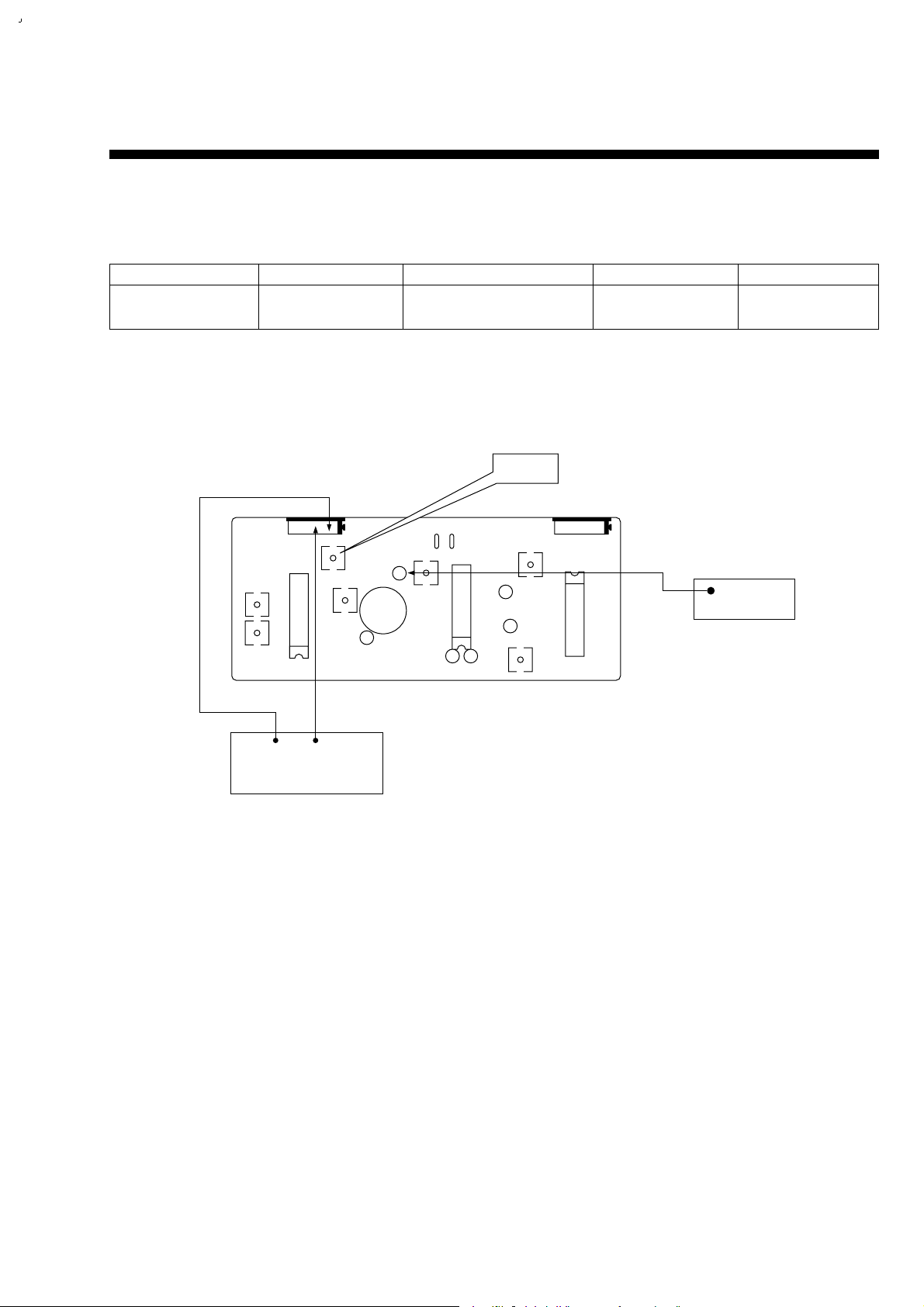

2-3. IF MODULE CIRCUIT ADJUSTMENT METHOD

2-3-1. P AL B/G 2 CARRIER SYSTEM

1. 32.4MHz TRAP

• Connection Method

• Adjustment Procedure

1) Supply +12V to pin No.1, and GND to Pin No 2. of 102

2) Connect the signal generator output to pin 3 and GND to pin 2 of P102.

3) Connect the oscilloscope to TP1.

4) Adjust L101 until the level of signal becomes minimum.

P102

L104

L105

IC101

#3

#2

L101

TP1

L108

TP2

L103

Z101

TP6 TP7

IC102

TP3

L109

P101

IC103

L110

TP4

minimum

CH-1

Oscilloscope

GND

OUT

#3

PIF PCB (Component Side)

SIGNAL

GENERATOR

fc: 32.4 MHz (No modulation)

Output Level: 80dBµV (75Ω loaded)

#2

Adjustment Parts Checking Point Measuring Equipment Condition of Adj. Input Signal

L101 TP1

Oscilloscope

EE Mode

Refer to the

Signal Gen followings

Page 9

2. PIF COIL

• Connection Method

• Adjustment Procedure

1) Supply +12V to pin No.1, and GND to Pin No 2. of 102

2) Connect the signal generator output to pin 3 and GND to pin 2 of P102.

3) Connect the oscilloscope to TP2.

4) Adjust L104 to obtain the minimum DC voltage of TP2.

6

P102

L104

L105

IC101

#3

#2

L101

TP1

L108

TP2

L103

Z101

TP6 TP7

IC102

TP3

L109

P101

IC103

L110

TP4

CH-1

Oscilloscope

GND

OUT

minimum

#3

PIF PCB (Component Side)

SIGNAL

GENERATOR

fc: 38.9MHz

Output Level: 80dBµV (75Ω loaded)

#2

Adjustment Parts Checking Point Measuring Equipment Condition of Adj. Input Signal

L104 TP2

Oscilloscope

EE Mode

Refer to the

Signal Gen followings

Page 10

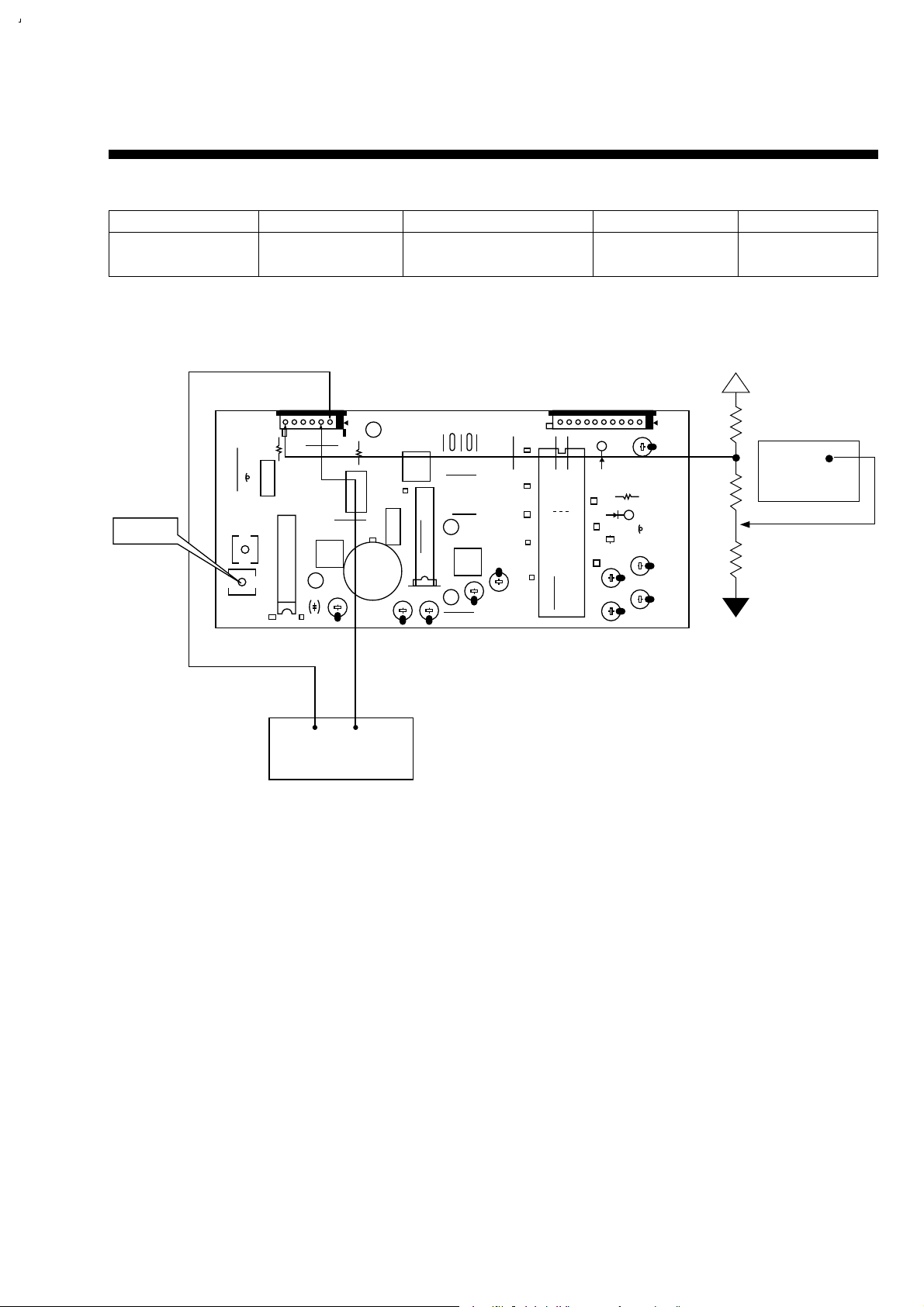

3. AFT COIL

• Connection Method

• Adjustment Procedure

1) Supply +12V to pin No.1, and GND to Pin No 2. of 102

2) Connect the signal generator output to pin 3 and GND to pin 2 of P102.

3) Connect the Test circuit to pin No. 7 of P102

4) Connect the oscilloscope to “A” point and GND

5) Adjust L105 to obtain 2.3V DC Voltage at the "A" point

7

P102

L104

L105

IC101

#3

#2

L101

TP1

L108

TP2

L103

Z101

TP6 TP7

IC102

TP3

L109

P101

IC103

L110

TP4

2.3±0.5V

CH-1

Oscilloscope

GND

OUT

#3

#7

PIF PCB (Component Side)

#2

#7

SIGNAL

GENERATOR

fc: 38.9MHz, fm: 15.625KHz (30% AM Modulation)

Output level: 80dBµV (75Ω loaded)

43kΩ

33kΩ

18kΩ

"A"

Vcc+12V

GND

(Test circuit)

Adjustment Parts Checking Point Measuring Equipment Condition of Adj. Input Signal

L105 “A” point

Oscilloscope

EE Mode

Refer to the

Signal Gen. followings

Page 11

4. SOUND CARRIER

• Connection Method

• Adjustment Procedure

1) Supply +12V to pin No. 1, and GND to pin No. 2 of P102

Supply +5V to pin No. 3, and GND to pin No. 1 of P101

2) Connect the signal generator output to pin 3 and GND to pin 2 of 102.

3) Connect the oscilloscope to pin NO.15 of IC102.

4) Adjust L108 to obtain the minimum Noise, minimum Level of pin NO.15 of IC102.

8

P102

L104

L105

IC101

L101

TP1

L108

TP2

L103

Z101

TP6 TP7

IC102

TP3

L109

P101

IC103

L110

TP4

minimum

noise

level

CH-1

Oscilloscope

GND

OUT

PIF PCB (Component Side)

SIGNAL

GENERATOR

fc: 38.9MHz, fm: 15.625KHz (30% AM Modulation)

Output level: 80dBµV (75Ω loaded)

#3

#2

#2

Adjustment Parts Checking Point Measuring Equipment Condition of Adj. Input Signal

L190 IC102 #15

Oscilloscope

EE Mode

Refer to the

Signal Gen. followings

Page 12

5. LEFT, RIGHT SOUND

• Connection Method

• Adjustment Procedure

1) Supply +12V to pin No. 1, and GND to pin No. 2 of P102

Supply +5V to pin No. 3, and GND to pin No. 1 of P101

2) Connect the signal generator output to pin NO.15 of IC102 and GND.

3) Connect the oscilloscope to TP3, TP4.

4) Adjust L109 to obtain the maximum level of TP3.

5) Adjust L110 to obtain the maximum level of TP4.

9

P102

L104

L105

IC101

L101

TP1

L108

TP2

L103

Z101

TP6 TP7

IC102

TP3

L109

P101

IC103

L110

TP4

CH-1

Oscilloscope

CH-2

GND

OUT

LEFT

RIGHT

PIF PCB (Component Side)

SIGNAL

GENERATOR

fc: 5.5MHz (LEFT) fm: 1KHz (50KHz FM Modulation)

5.74MHz (RIGHT)

Output level: 100dBµV (75Ω loaded)

GND

#15

#15

Adjustment Parts Checking Point Measuring Equipment Condition of Adj. Input Signal

L109 (LEFT) TP3 Oscilloscope

EE Mode

Refer to the

L110 (RIGHT) TP4 Signal Gen. followings

Page 13

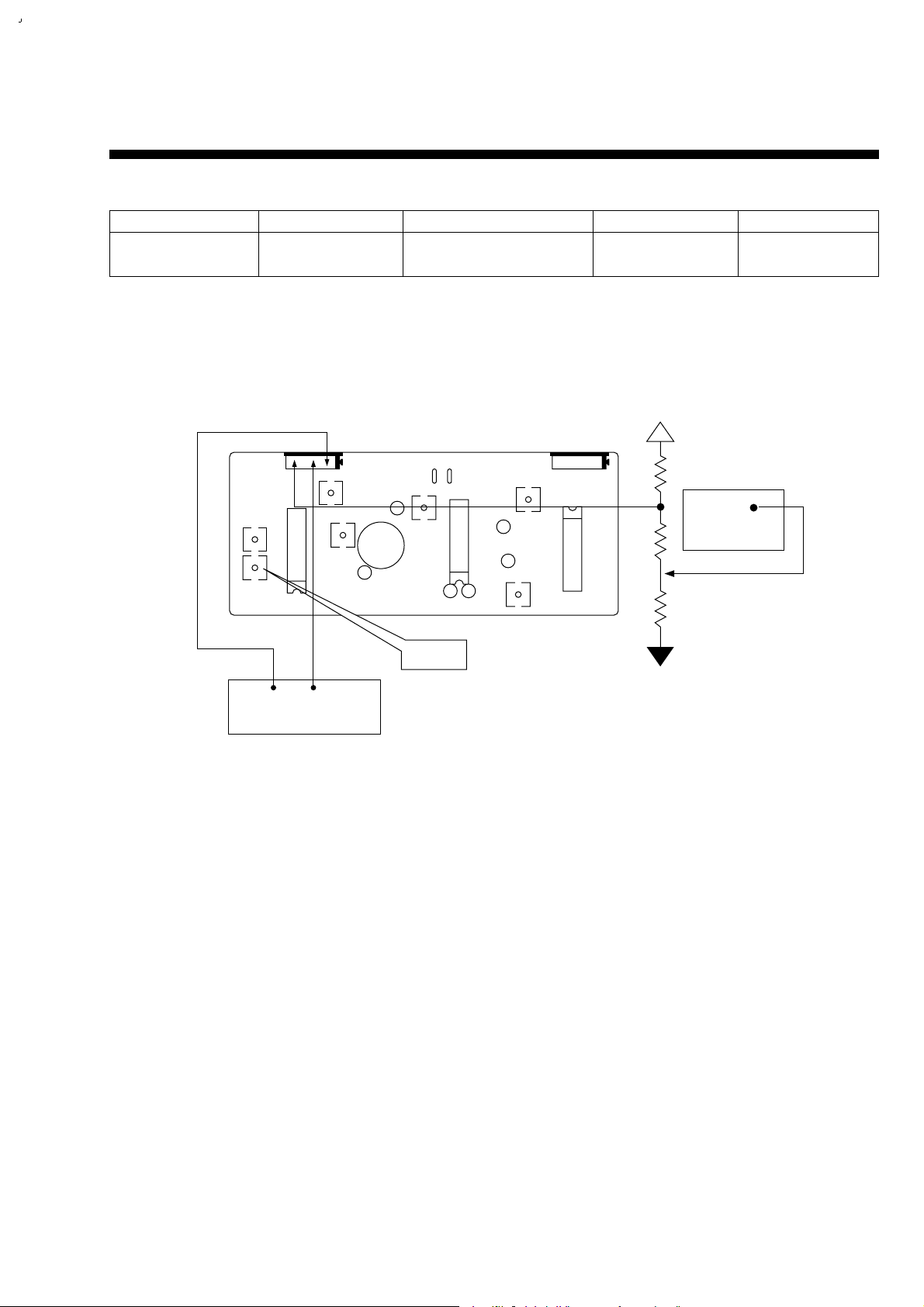

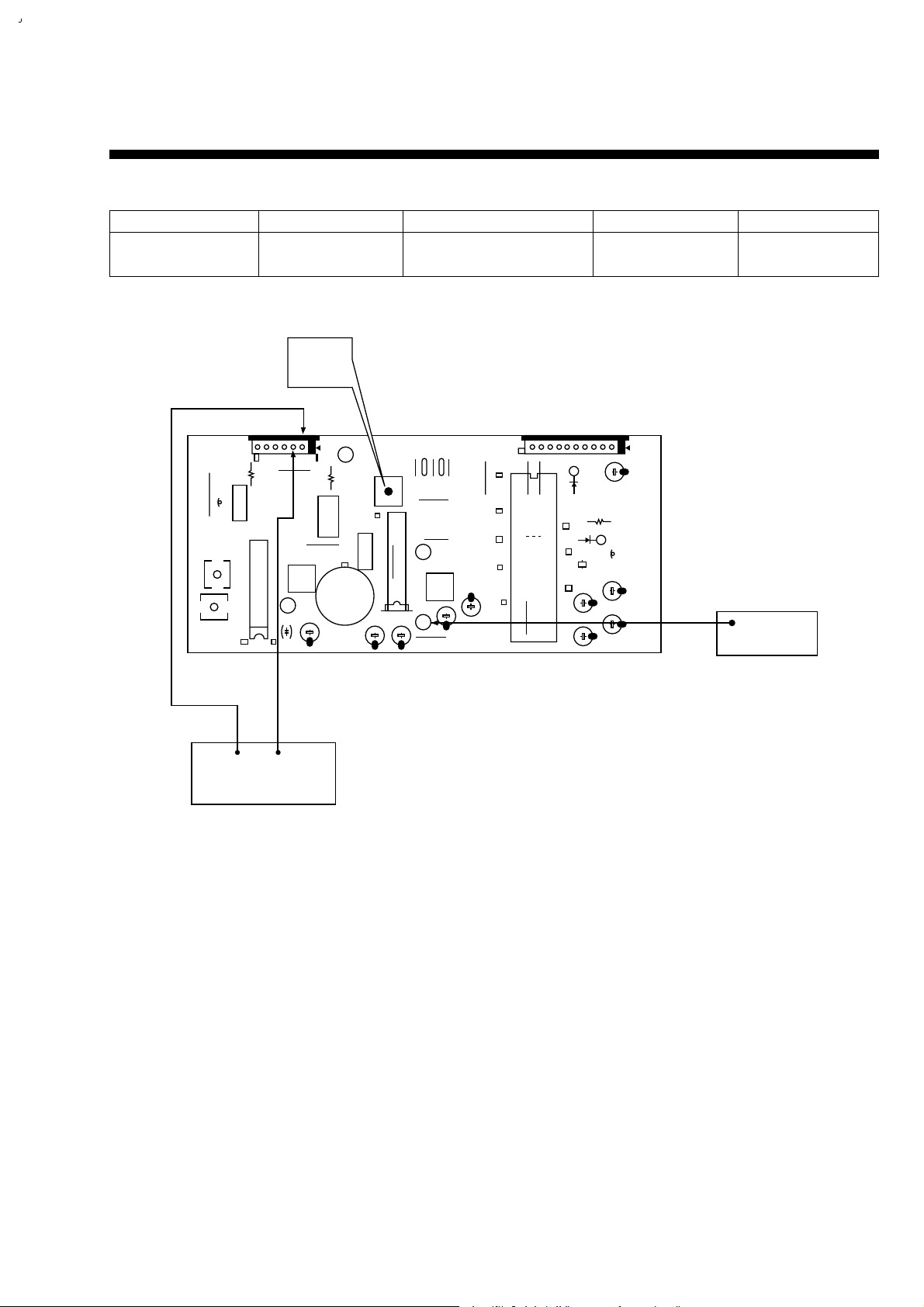

6. RF AGC

• Connection Method

• Adjustment Procedure

1) Turn on the VCR, Tuning CH21 (471.25MHz)

2) Connect the signal generator output to ANT INPUT of RF 102 (Modulator)

3) Connect the oscilloscope to JPT02

4) Adjust R190 to obtain 6.0±0.2V DC.

10

CH-1

Oscilloscope

MAIN PCB

RF Signal : PAL B/G (Color Bar or 100% white)

CH : 21 CH (471.25MHz)

UHF BAND

RF102

RF101 JPT02

RF103

R190

6.0±0.2V

Input Level : 70±1 dBµV

(75Ω Loaded)

RF OUT PM5418

Modulator ANT IN

Adjustment Parts Checking Point Measuring Equipment Condition of Adj. Input Signal

R190 JPT02

Oscilloscope

EE Mode

Refer to the

PM5418 Gen. followings

Page 14

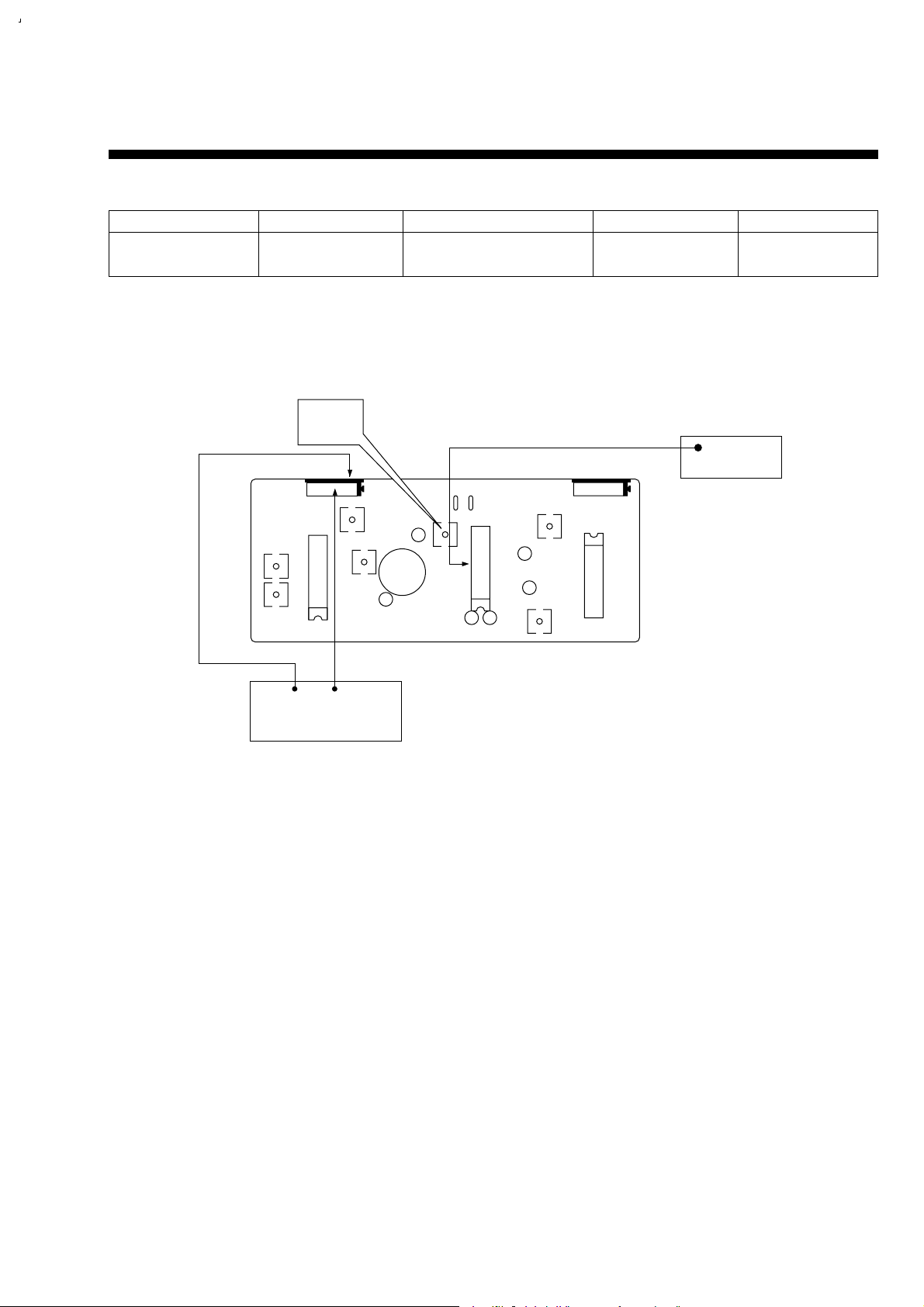

2-3-2. P AL B/G, I NICAM SYSTEM

1. PIF COIL (NICAM)

• Connection Method

• Adjustment Procedure

1) Supply +12V DC to Pin No.1, and GND to Pin No 2. of 102

2) Connect the signal generator output to pin 3 and GND to pin 2 of P102.

3) Connect the oscilloscope to TP2.

4) Adjust L104 to obtain the minimum DC voltage of TP2.

11

97P651111A

P102

P101

TP1

CH-1

Oscilloscope

SIGNAL

GENERATOR

GND

OUT

fc: 39.5MHz (I)

38.9MHz (B/G)

Output Level: 80dBµV (75Ω loaded)

minimum

#2

#3

R103

J1

L104

L105

Z101

C107

C106

IC101

TP2

J4

C115

TP3

J19

IC102

L108

J7

J12

J13

J15

C181

D101

R163

L112

X102

30 27

D102

C153

C182

C176C178

TP4

J11

J10

J9

J8

IC104

J6

L103

Adjustment Parts Checking Point Measuring Equipment Condition of Adj. Input Signal

L104 TP2

Oscilloscope

EE Mode

Refer to the

Signal Gen. followings

Page 15

2. AFT COIL

• Connection Method

• Adjustment Procedure

1) Supply +12V DC to Pin No.1, and GND to Pin No 2. of 102

2) Connect the signal generator output to pin 3 and GND to pin 2 of P102.

3) Connect the test circuit to pin No.7 of P102

4) Connect the oscilloscope to “A” point and GND

5) Adjust L105 to obtain 2.3V DC voltage at the "A" point

12

97P651111A

P102

P101

TP1

SIGNAL

GENERATOR

GND

OUT

fc: 39.5MHz (I)

fc: 38.9MHz (B/G)

fm: 15.625KHz (30% AM MODULATION)

Output Level:80 dBµV (75Ω loaded)

2.3±0.5V

#2

#3

R103

J1

L104

L105

Z101

C107

C106

IC101

L103

TP2

J4

C115

TP3

J19

IC102

L108

J7

J14

J12

J13

J15

C181

D101

R163

L112

X102

30 27

D102

C153

C182

C176C178

TP4

J11

J10

J9

J8

IC104

J6

CH-1

Oscilloscope

#7

43kΩ

33kΩ

18kΩ

(Test circuit)

Vcc+12V

GND

"A"

Adjustment Parts Checking Point Measuring Equipment Condition of Adj. Input Signal

L105 “A” point

Oscilloscope

EE Mode

Refer to the

Signal Gen. followings

Page 16

3. SOUND CARRIER (NICAM)

• Connection Method

• Adjustment Procedure

1) Supply +12V DC to Pin No.1 and GND to pin No. 2 of P102

2) Supply +5V DC to Pin No.3 GND to Pin No. 1 of P101.

3) Connect the signal generator output to pin 3 and GND to pin 2 of p102

4) Connect the oscilloscope to TP3.

5) Adjust L108 to obtain the minimum noise, minimum level of TP3.

13

97P651111A

P102

P101

TP1

CH-1

Oscilloscope

SIGNAL

GENERATOR

GND

OUT

fc: 39.5MHz (I)

38.9MHz (B/G)

fm: 15.625KHz (30% AM MODULATION)

Output Level:80 dBµV (75Ω loaded)

minimum

noise

level

#3

R103

S2

J3

J1

L104

L105

Z101

C107

C106

IC101

L103

TP2

J4

C115

J19

IC102

L108

J7

J14

J12

J13

J15

C161

D101

R163

L112

X102

30 27

D102

C155

C182

C176C178

TP4

J11

J10

J9

J8

IC104

J6

TP3

#3#2

#2

Adjustment Parts Checking Point Measuring Equipment Condition of Adj. Input Signal

L108 TP3

Oscilloscope

EE Mode

Refer to the

Signal Gen followings

Page 17

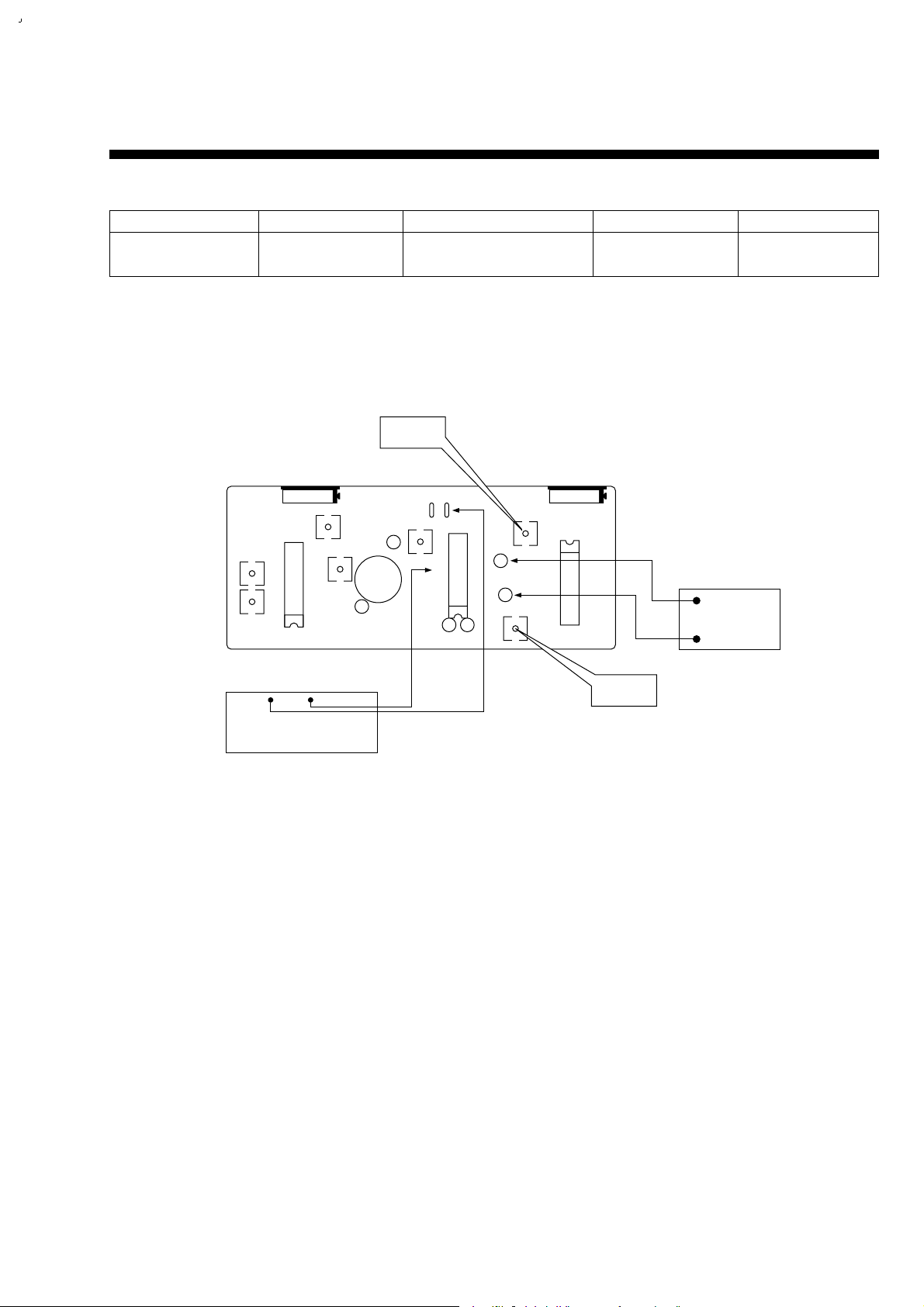

4. 5.5 (6.0) MHz SOUND

• Connection Method

• Adjustment Procedure

1) Supply +5V DC to Pin No.3 GND to Pin No. 1 of P101.

2) Connect the signal generator output to TP3 and GND to TP1.

3) Connect the oscilloscope to TP4.

4) Adjust L109 to obtain the maximum level of TP4.

14

97P651111A

P102

P101

TP1

CH-1

Oscilloscope

SIGNAL

GENERATOR

GND

OUT

fc: 6.0MHz (I)

5.5MHz (B/G)

fm: 1KHz (50kHz FM MODULATION)

Output Level: 100dBµV (75Ω loaded)

L109

#3

R103

J1

L104

L105

Z101

C107

C106

IC101

L103

TP2

J4

C115

J19

IC102

L108

J7

J14

J12

J13

J15

C181

D101

R163

L112

X102

30 27

D102

C153

C182

C176C178

TP4

J11

J10

J9

J8

IC104

J6

TP3

Adjustment Parts Checking Point Measuring Equipment Condition of Adj. Input Signal

L109 TP4

Oscilloscope

EE Mode

Refer to the

Signal Gen followings

Page 18

5. RF AGC

• Connection Method

• Adjustment Procedure

1) Turn on the VCR. Tuning CH21 (471.25MHz)

2) Connect the signal generator output (PM5418 pattern Gen) to ANT INPUT of RF102 (Modulator)

3) Connect the oscilloscope to JPT02

4) Adjust R190 to obtain 6.0±0.2V DC.

15

CH-1

Oscilloscope

MAIN PCB

RF Signal : PAL B/G (Color Bar or 100% white)

CH : 21 CH (471.25MHz)

UHF BAND

RF102

RF101 JPT02

RF103

R190

6.0±0.2V

Input Level : 60 dBµV (I)

63 dBµV (B/G)

(75 ohm Loaded)

RF OUT PM5418

Modulator ANT IN

Adjustment Parts Checking Point Measuring Equipment Condition of Adj. Input Signal

R190 JPT02

Oscilloscope

EE Mode

Refer to the

PM5418 Gen followings

Page 19

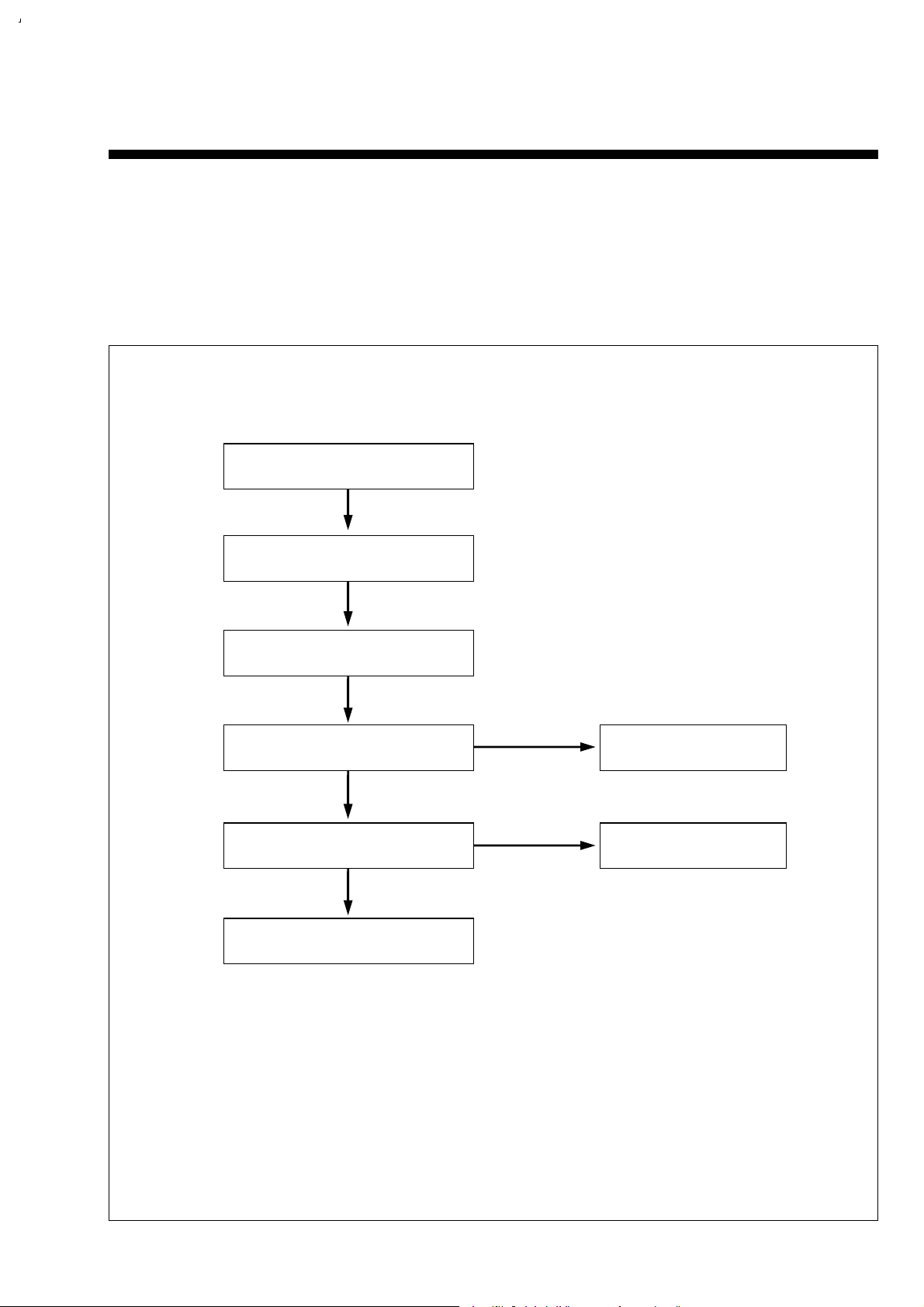

SECTION 3. TROUBLE SHOOTING FLOW CHAR T

3-1. POWER CIRCUIT

• When change the parts which are out of order, first, remove the power plug from the socket and then discharge the

voltage across between both terminals of C807. (Use an external scores of KΩresistance)

• When check the primary circuit by using the oscilloscopes insulate the oscilloscope surely. (Use the isulating

transformer) and must connect GND into the primary GND), (But there is no connection when check the secondary

circuit).

• When change IC801, check FUSE and Cement resistance surely.

16

Prepare the instrument

connecting the insulating trans.

Check F801 FUSE

Is voltage applied to D801?

Is voltage applied to the

both terminals of C807?

Check power module

Check D801, L801 & L802

Check R802

NO

NO

YES

YES

YES

YES

YES

NO output Voltage

A. CHECKING THE PRIMARY CIRCUIT.

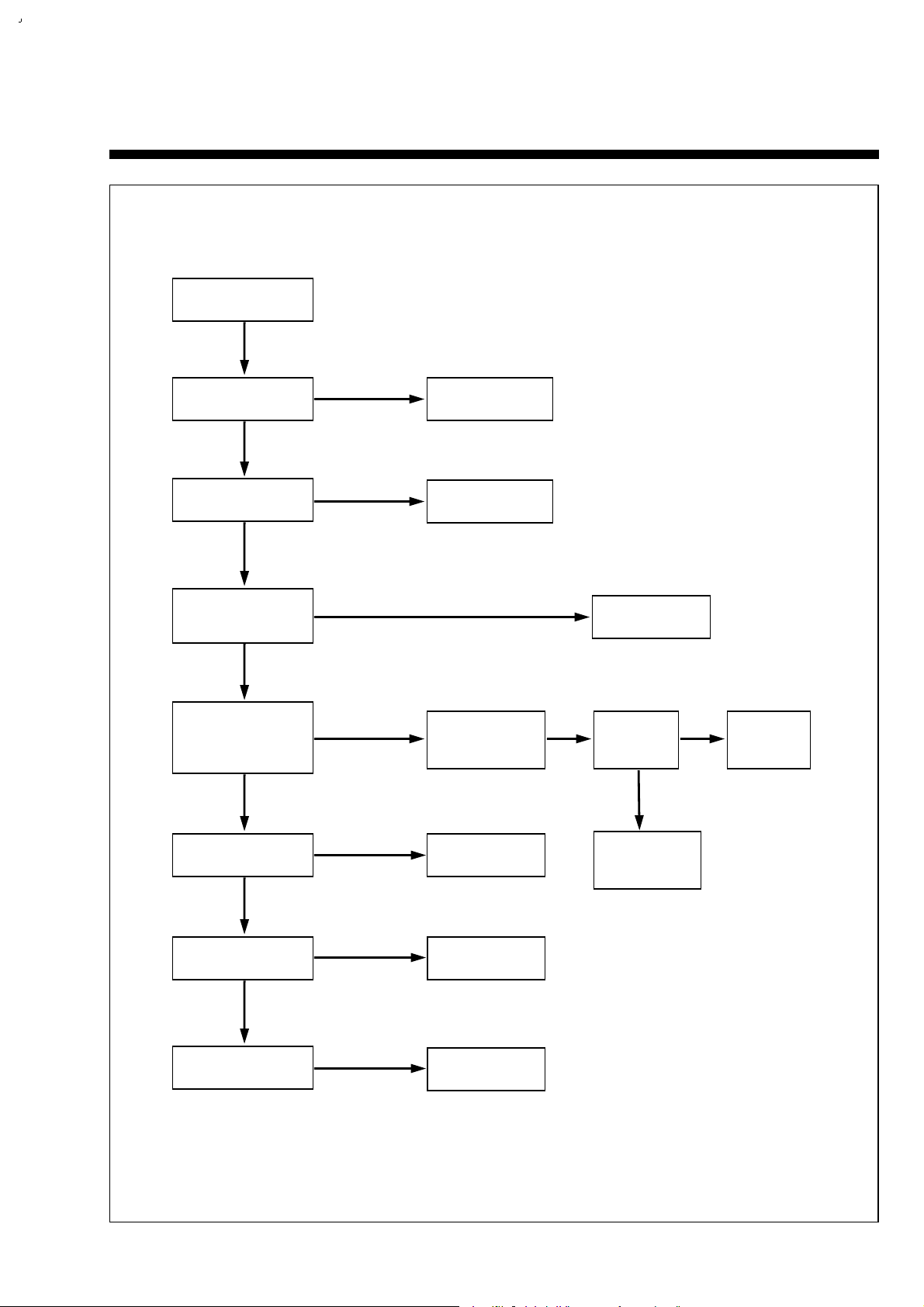

Page 20

17

No Voltage

output

Is voltage supplied

Via CN11?

The voltage of #1 of

IC11 is 5.7V and stable

The voltage of #1 of IC11

fluctuate

in 4.8V~5.7V

Measure resistance

between GND of CN21

and each terminal

of CN21

The 12DC of each

wire of T11 is ok

Primary parts is ok

Secondary parts ok

Change T11

Change parts

out of order

YES

NO

YES

Resistance >> 100

YES

YES

NO

NO

Check F801, L801,

L802, D802

NO

Check the secondary

circuit

YES

Check the pattern

and T11, L12, IC11

NO

Terminal open and

measure the output

Voltage

Change parts

out of order

NO

The voltage

is ok

Check the

parts outside

module

Check the Diode,

Condenser inside

Module

NO

YES

B. POWER MODULE (M801) CHECK

Page 21

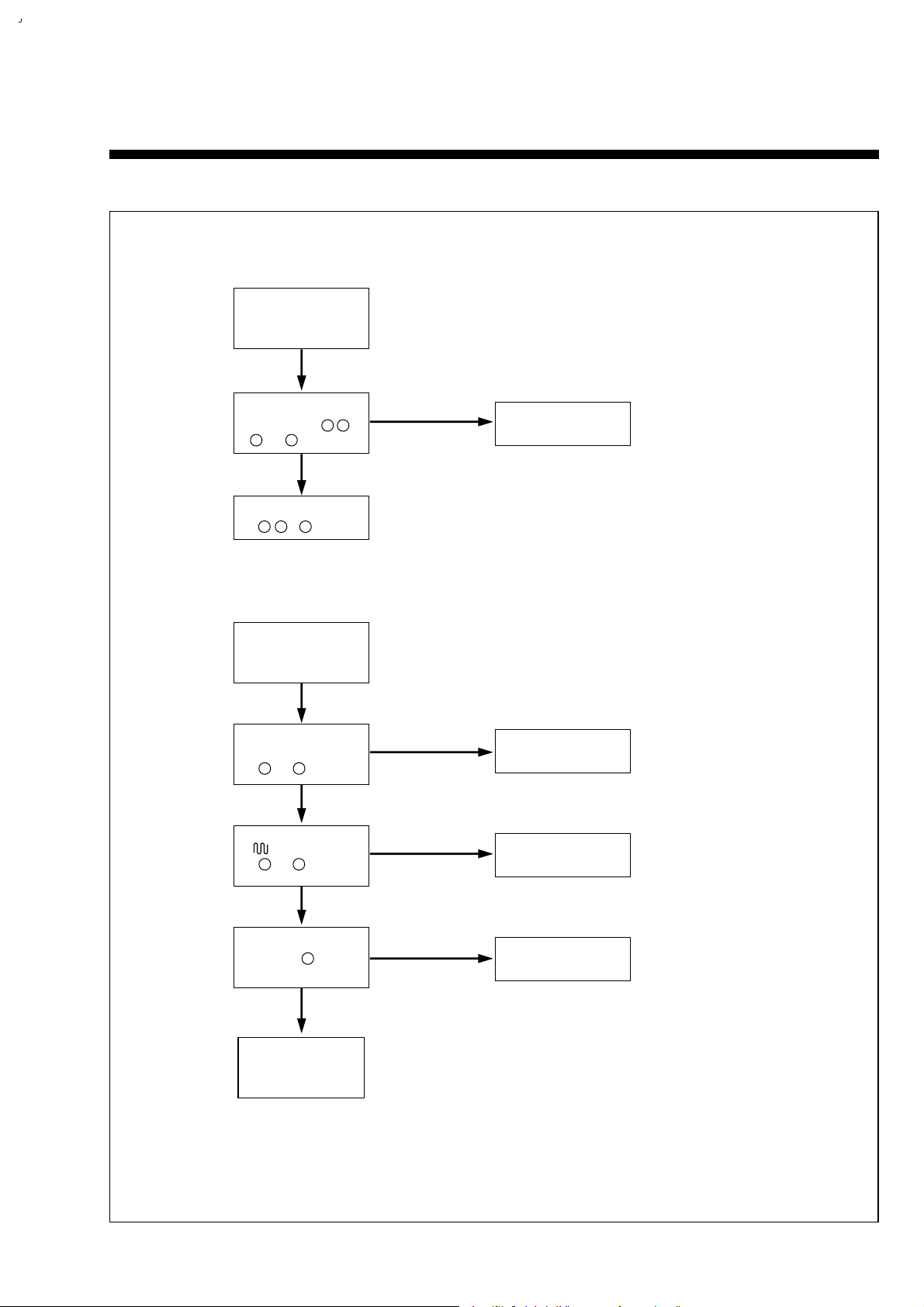

3-2. LOGIC CIRCUIT

18

Digitron does

not operate.

Is +5V supplied to

pin of IC701?

8

Is -28V supplied to

pin of IC701?

11

Are -20 and -16.5V

supplied to pin and

of G701?

1

35

Are CLK signals

supplied to pin ), I

and i, of IC701?

Is 5V at pin of

IC701?

7

Check X701

Check IC701

and change.

check power circuit

Is +5.8V supplied

from D713 cathod

Is -28V at D650

anode

Check D814 and

primary power circuit.

Check the connector

and pattern.

Check the power

module

Check IC601

Change

Change

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

YES

A.

Page 22

19

Digitron is lit keys do

not operate.

Is each key pulse

applied to pin ,

and of IC701?

2 3

12 13

Check key matrix

circuit.

Check the pin serial of

pin , ~ of IC701.

19 22 24

Power compensation

does not operated.

When mains is

unplugged is 3.6V at

pin and of IC601?

26 81

Is signal applied to

pin and of IC601?

42 43

Is 5V at pin of IC601

37

Check IC601

Check C623

Check x602

Check reset circuit

IC604

NO

YES

YES

YES

YES

NO

NO

NO

B.

C.

B.

C.

Page 23

20

91

The voltage of pin

of IC601 is not

changed.

Is CTL pulse input

to pin and of

IC601

71 72

73

Check and

re-adjust the

Path of Deck.

Check circuit

adjacent to IC601

Check C508, C509

check R518

and C511

Check IC601

YES

YES

YES

YES

YES

YES

YESNO

NO NO

NO

NO

NO

A.

Playback picture

is not good.

Noise appears

although adjusting

tracking.

Is CTL pulse out

from pin of IC601.

Noise shakes up

and down on the

screen.

Adjust

tracking

CTL HEAD height is

normal and there is

not dust.

Adjust the HEAD

height and remove

dust

Noise appears

although change

cassette tape.

3-3. SERVO SYSCON CIRCUIT

Page 24

21

Playback picture

is not good.

Noise appears

on the screen

on the whole.

Is Enve.wavefrom

supplied to at pin of

PT01

4

Are SW pulse and

HA SW applied to

HeadAmp circuit?

Check video circuit.

Auto stop during

playback

Is Reel pulse

applied to pin and

of IC601?

5

6

Check flow A

Is SW pulse supplied

from pin of IC601?

18

Check D.PG input

and connector.

Check pattern

Check connector, Head

Amp and Head dust.

Change head

Check reel sensor.

Is D.FG applied to

pin of IC601

Check connector

D.FG circuits.

Check IC601

YES

NO

YES

YES

YES

YES

YES

YES

NO NO

NO

NO

NO

YES

NO

67

B.

C.

Page 25

22

Drum M/T loading stops.

Is Motor 12V supplied?

Is pin D.FG of

IC601 supplied.

Is pin D.PWM (pin )

of IC601 supplied?

Check connector

and Motor.

Is the input of pin

of P501 2V-3.5V?

Is pin of P601 2.5V

Is pin (C.PWM)

of IC601 Supplied?

Check connector

and Motor

67

4

1

18

3

Check Q851 of

power circuit.

Check C505, R506, R507

and C516

Check IC601

Check power circuit.

Check circuit of R510,

R511, R512.

Check R508, R509

Check IC601

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

Capstan M/T loading stops.

Is Motor 12V supplied?

D.

E.

Page 26

23

Drum M/T and Capstan M/T rotate

at regular speed. (In REC mode)

Is C. Sync applied to

pin of IC601?

93

Check Motor.

Check C. Sync of

VIDEO IC and Pattern

Emergency mode when plugging

(Power cord)

Is EVER 5V supplied?

Does X601 crystal osciliate?

Do S/DATA, CLK and RDY

Signals of IC601 exchange

with IC701

Is CAM SW DATA Correct?

Check IC602.

Check IC 601.

Check power circuit.

Check IC601 and X601.

Check IC701 when S.RDY Signal

is supplied.

Check IC601 when S.RDY Signal

is not supplied.

Recheck connector

and CAM SW contact.

NO

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

F.

G.

Page 27

24

Cassette is not

inserted.

Is Motor 12V supplied?

Check Q851 of power

circuit

CAM DATA is changed

when CST IN?

Is 5V applied to

pin of IC602 when CST IN?

4

Chek IC602

Check connector. Check DECK part.

Is 5V supplied at

pin of IC601?

Check PATTERN

45

Check IC601

H.

NO

YES

YES

YES

NO NO

NO NO

YES

Page 28

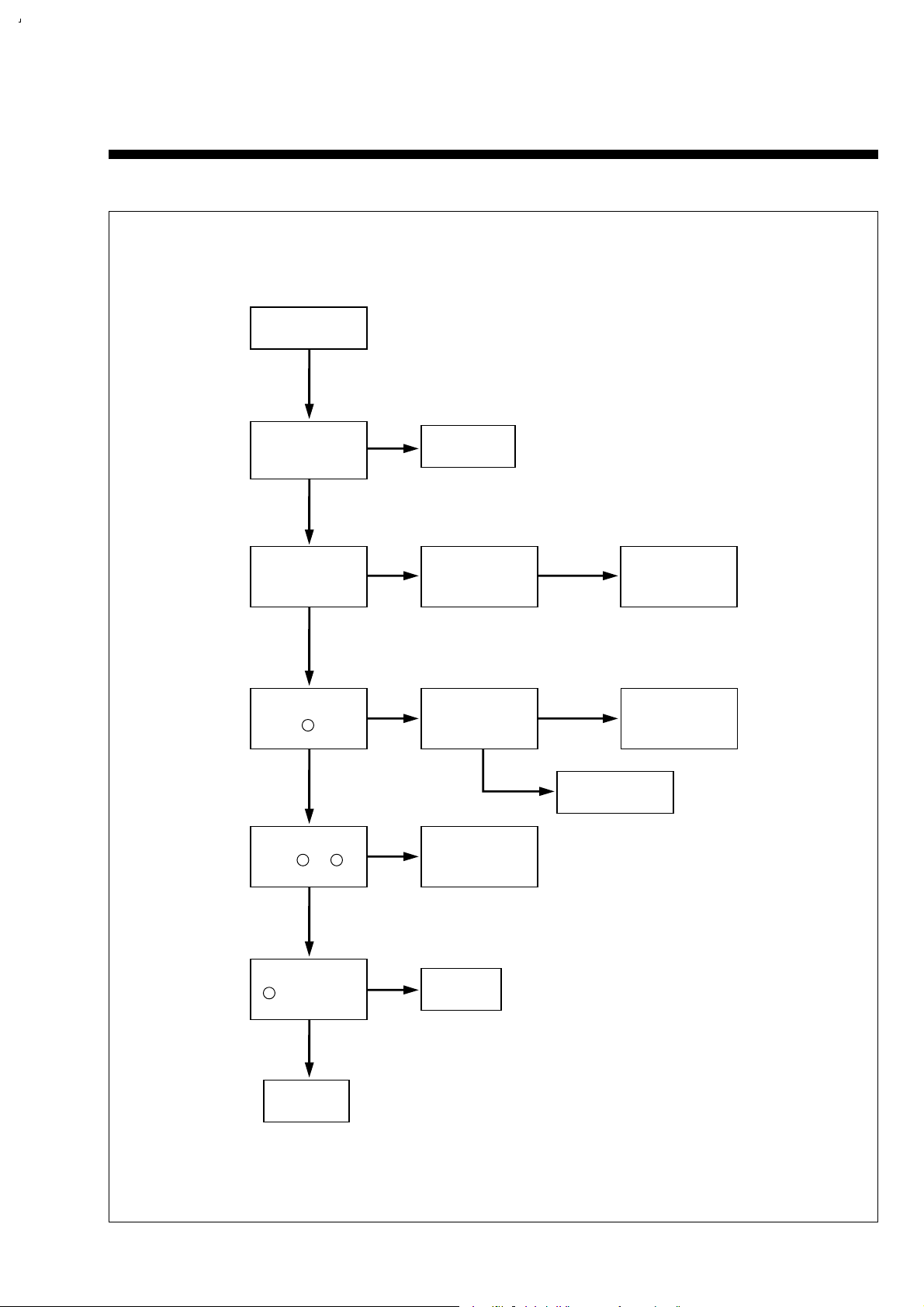

3-4. AUDIO CIRCUIT (NORMAL)

25

No sound in the playback mode.

Is the output at pin “, ‘

of IC201?

Is 12V applied to pin a

of IC201?

Check power circuit.

Is 5V applied to pin 3, g

of IC201?

Is pin of IC201 10V

4

Is there Audio output

pin of IC201?

29

Is pin of IC202 GND?

2

Check Pattern

and AC Head.

Chack IC601.

Check IC202

NO

YES

NO

YES

YES

YES

YES

NO

NO

NO

A. Troubleshooting of PB mode

Is 5V and clock data applied to pin 4, 5 of IC201?

YES

NO

Page 29

26

Is signal input into

pin @, # of IC201 in TV mode

Is signal input into pin ^, & of

IC201 in LINE mode

Is 5V applied to pin $

of IC202?

Is the signal applied to

pin @ of IC202?

Does T230 oscillate?

Check SCART jack

Check SYSCON

Is the signal applied to

pin T of IC201?

Is the voltage above 10V

at pin of T230

Check Q232

collector:above 10V

Base:0V

Check T230

Is record current

3.0mVms?

Is pin of IC201 0V?

35

Clean HEAD.

Asjust Record current.

Check IC201.

Check IC201.

Check IC201.

NO

YES

YES

YES

YES

YES

YES

NO

NO

NO

YES

NO

NO

NO

NO

YES

3

B. Troubleshooting of REC mode

No sound in the playback

mode after recording

Check PIF circuit

Check IC202.

Check IC201.

NO

NO

Page 30

3-5. AUDIO CIRCUIT (Hi-Fi)

27

No sound in the E-E mode

Check

POWER circuit

NO

Is 12V applied to pin a

of IC201?

A. Troubleshooting of E-E mode

Is 5V applied to pin 3

g, of IC201?

Is signal input into

pin @, # of IC 201

in TV mode?

Is signal input into

pin ^, & of IC 201

in LINE mode?

Check

PIF circuit

NO

Check

SCART jack

NO

Is 5V and clock data

applied to pin 4, 5

of IC201?

Check SYSCON

NO

Is there output at

pin “, ‘ of IC201?

NO

Change IC201

NO

Check Q203 base; 5V

collector; 0V

Check SYSCON

NO

Check Q200, Q201, Q202

base; 0V

Change Q200, Q201, Q202

NO

Check SCART Jack

YES

YES

YES

YES

YES

YES

YES

YES

Page 31

28

No Hi-Fi Sound

in playback mode

Is the ENVE level of

JPT02 more than 120mVp-p?

Is A.SW PULSE input into

pin of IC201?

Is 5V and clock data applied

to pin , of IC201?

Is signal input into pin ,

of IC201

Check pin of IC601

Is there output at

, of IC201?

Check CK13,CM13

Is there output at

pin , of IC201

SCART JACK check

Change IC201

YES

YES

YES

YES

YES

NO

NO

NO

NO NO

B. Troubleshooting of Hi-Fi PB and REC mode

NO

Check the ICB01

of PRE-AMP circuit

61

20

14 15

Check IC601

51 64

52 63

21 22

Page 32

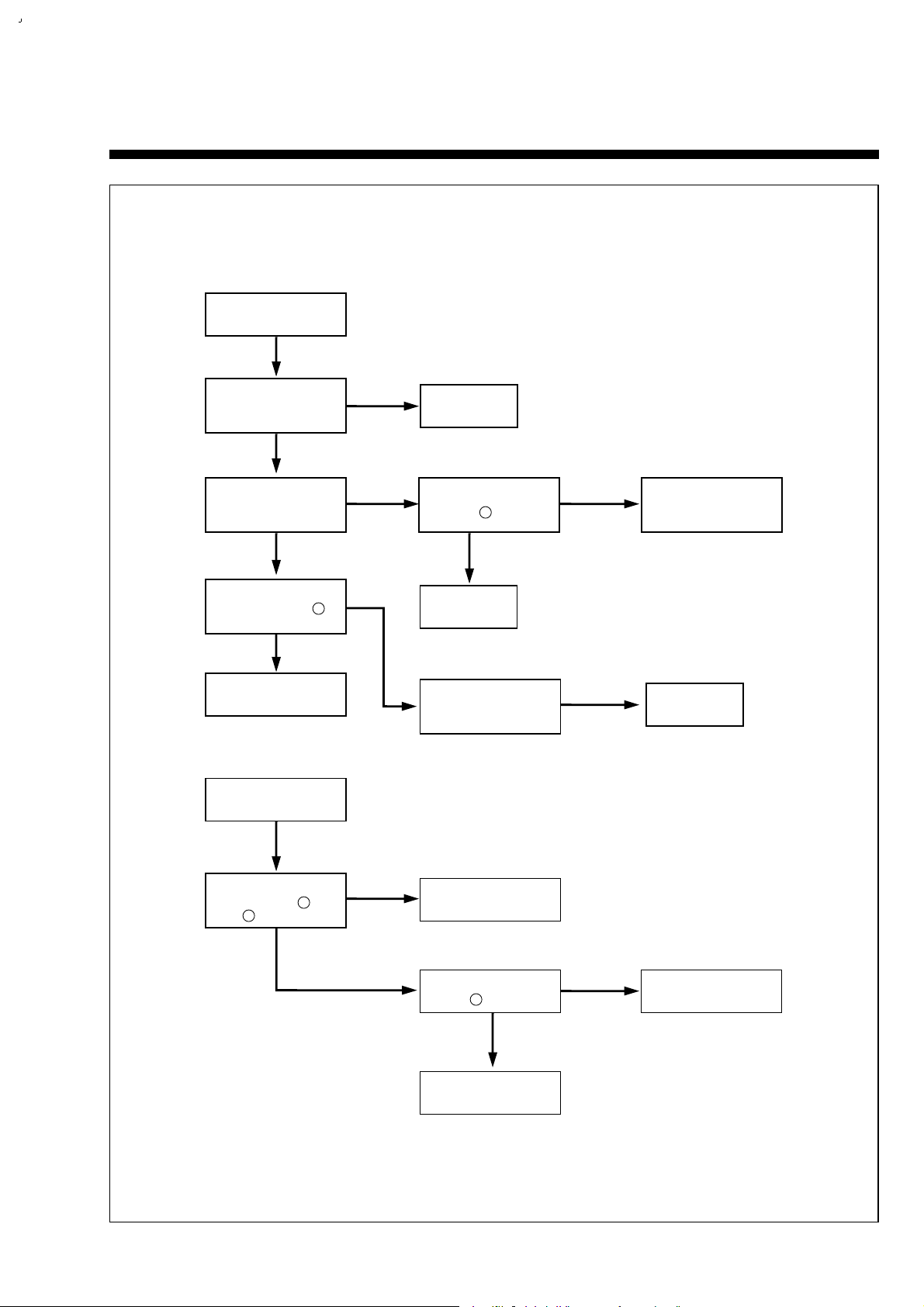

3-6. VIDEO CIRCUIT

29

Is video signal input

into pin and of IC151?

12 13

Is E12V supplied at

pin of IC151

16

Is signal output from

pin of IC151?

14

Is signal input into

pin of IC301?

12

Is signal output from

pin of IC301?

16

Check PIF circuit

and A/V jack.

Check ever 12V

Check IC151 and

adjacent circuit.

Check connector,

PCB pattern

Is 5V supplied to pin

and of IC301?

34

13

Check

power circuit

Check IC301

pin EE

Check

IC601 pin

29

Change IC301

Is signal input from

ICS01 pin?

10

Is signal output from

ICS01 pin?

8

Check pattern,

connector and Q303.

Check OSD circuit

Check RF out Check Line out

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO NO

H

L

A.EE MODE Picture N.G

NO

YES

Page 33

30

Is 5V supplied at ICS01 and pins?

Check oscillation of ICS01 ,

Check serial data (ICS01 pin)

Change ICS01 and check OSD circuit.

Check ON/OFF 5V

Check XS01 (17.7MHz)

Check IC601.

3

16 17

4 5

20

Is 5V supplied at

ICS01 and pins?

7

Is serial data input into

ICS01 pin

3 4 5

Check oscillation

of ICS01

16 17

Change ICS01

Check ON/OFF 5V

Check IC601.

Check LS01,CS01

and CS02.

YES

YES

NO

NO

NO

NO

NO

NO

YES

YES

YES

B . OSD Character N.G

20 7

C. OSD Character N.G

Page 34

31

Is the video signal from pin of IC151

fed to pin of IC301?

NO

YES

Check C158 and pattern

14

12

Is ON/OFF 5V supplied to pin and

pin of IC301 at 5volts?

NO

YES

Check ON/OFF 5V

13

34

Is EE(L) supplied to anode of

D302 at zero volt?

NO

YES

Check EE(L)

Is the down-converted colour signal

obtained from pin of IC301?

NO

YES

Change IC301

38

Is the down-converted colour signal

from pin of IC301 fed to pin of P101?

YES

Check pattern

38 3

To HEADAMP circuit

D.REC COLOUR NG

NO

Page 35

32

Is the video signal from pin of IC151

fed to pin of IC301?

NO

YES

Check C158 and pattern

Is ON/OFF 5V supplied to pin

and pin of IC301 at 5volts?

NO

YES

Check ON/OFF 5V

Is EE(L) supplied to anode of

D310 at 0volt?

NO

YES

Check EE(L)

Is the video signal from pin

of IC301 fed to pin of IC301?

NO

YES

Is Q302 and R310 correct?

Is the luminance signal from pin

of IC301 fed to pin of IC301?

YES

Check C302

E.REC Luminance NG

14

12

13

34

12

4

Change damaged

components

Change IC301

NO

YES

5

4

Is the luminace signal from pin

of IC301 fed to pin of IC301?

NO

Is TRICK (H) supplied to

anode of D309 at zero volt?

Check TRICK (H)Change IC301

NO

YES

5

2

YES

Is the modulating luminance signal

from pin of IC301 fed to pin of P101?

YES

Check record EQ circuit

To HEADAMP circuit

2 5

NO

NO

Page 36

33

Is Y-FM signal from HEADAMP

fed to pin of P101

NO

YES

Check HEADAMP circuit

Is ON/OFF 5V supplied to pin and

pin of IC301 at 5volts?

NO

YES

Check ON/OFF 5V

13

34

Is EE(L) supplied to anode of

D310 at 5volt?

NO

YES

Check EE(L)

Is Y-FM signal from pin of

P101 fed to pin of IC301?

NO

YES

Check C353

Is the luminance signal from pin

of IC301 fed to pin of IC301?

Change IC301

F. PB luminance NG

1

2

1

1

4

YES

Is the luminance signal from pin

fed to pin of IC301 through Q302?

Check Q302 and R310

4

5

YES

Is the luminance signal from

fed to pin of IC301?

Change IC301

5

16

YES

To OSD circuit

NO

NO

NO

Page 37

34

Is the signal HEADAMP circuit

fed to pin of P101?

NO

YES

Check HEADAMP circuit

Is the PAL colour signal from pin of

P101 fed to pin of IC301 through

AMP circuit?

NO

YES

Check AMP circuit

Is ON/OFF 5V supplied to pin and

pin of IC301 at 5volts?

NO

YES

Check ON/OFF 5V

Is EE (L) supplied to anode of

D310 at 5 volts?

NO

YES

Check EE (L)

Is the PAL colour signal from pin

of IC301 fed to pin and pin

of IC301?

Check X301

G. PB Colour NG

3

YES

Is the signal from pin and

pim of IC301 fed to pin and

pin of IC302 respectively?

Change IC301

YES

Is the signal obtained

from pin of ic302?

Check IC302

3

38

13

34

38

23 24

23

24

4

2

21

YES

Is the signal from pin

of IC302 fed to pin through

pin of IC301?

Check IC301 and R333

21

28

29

YES

is colour rotary suppied

to pin of IC301?

Check IC301 colour rotary

17

YES

To OSD circuit

NO

NO

NO

NO

NO

Page 38

35

Is the modulating luminance

signal from pin of P102

fed to pin of ICA01?

NO

YES

Check CA32 and pattern

NO

YES

Check pattern

Is ON/OFF 5V supplied to pin of

ICA01 at 5volts?

NO

YES

Check ON/OFF 5V

Is REC (H) supplied to pin

of ICA01 at 5volts?

NO

YES

Check REC (H)

Is TRICK (H) supplied to anode

of DA01 at zero volts?

Check TRICK (H)

H. REC HEADAMP NG

YES

Is the signal from pin and

pin fed to pin (SP mode)

and pin (LP mode) of ICA01?

Check ICA01

YES

To HEAD

15

5

11

Is the down converted color

signal from pin 3 of P102

fed to pin of ICA01?

5

10

7

10

11 17

18

NO

NO

Page 39

36

Is the siganl from heads fed to pin

and pin (LP mode) or pin and

pin (SP mode) of P101?

NO

YES

Check drum and

deck mechanism

I. REC HEADAMP NG

3

7

5

1

* ICA01:LA7416

IS ON/OFF 5V from pin of

P102 supplied to pin of

ICA01 at 5volts?

NO

YES

Check ON/OFF 5V

15

10

Is REC (H) from pin of P102

supplied to pin of ICA01

at zero volt?

NO

YES

Check REC (H)

7

8

Is H.A SW from pin of

P102 supplied to pin of ICA01

NO

YES

Check H.A SW

4

4

Is video sw from pin of

P102 supplied to pin of ICA01?

NO

YES

Check video SW

5

5

Is the signal from pin and pin

(LP mode) or pin and pin (SP mode)

fed to pin of ICA01?

NO

YES

Change ICA01

1 3

5 7

10

Is the signal from pin fed to

pin of P102

NO

YES

Check PB EQ

10

1

To VIDEO circuit

* • REC (H) : "HIGH" in the record mode

"LOW" in the EE and PB mode.

* • H. A SW : "LOW" in the SP mode.

"HIGH" in the LP mode.

* • TRICK(H) : "HIGH" in the trick play.

"LOW" except trickplay.

Page 40

37

1 VIDEO INPUT SIGNAL

(50mV/10ms)

2 VIDEO OUTPUT SIGNAL

(50mV/10ms)

3 COLOR BURST SIGNAL

(50mV/10ms)

4 AFTER CCD Y

(100mV/10ms)

5 CLAMP INPUT SIGNAL

(100mV/10ms)

6 BGP OUTPUT TERMINAL

(1V/10ms)

7 TJ313 C.SYNC

(1V/10ms)

8 PB. FSC

(200mV/0.1µs)

9 PLAYBACK COLOR

(100mV/10µs)

10TEST ENVE

PLAYBACK (SP MODE)

11 TJ391 MODULATION FM

SIGNAL (20mV/50ms)

Page 41

38

SERVO-LOGIC CIRCUIT WA VEFORM

12 DRUM FG

(1V/5ms)

15 CAPSTAN FG

(1V/5ms)

13 DRUM PG

(2V/5ms)

FM mecha CAM DATA

14 CTL AMP OUT

(1V/5ms)

Mode

CAM

CAM A CAM B CAM C CAM D

Eject H H H L

High-REW H H L L

STAND H H L H

IDLE H L L H

REV H L H H

SLOW L L L H

STOP/PLAY L H H H

FF/REW L L H H

FLOAT H H H H

Page 42

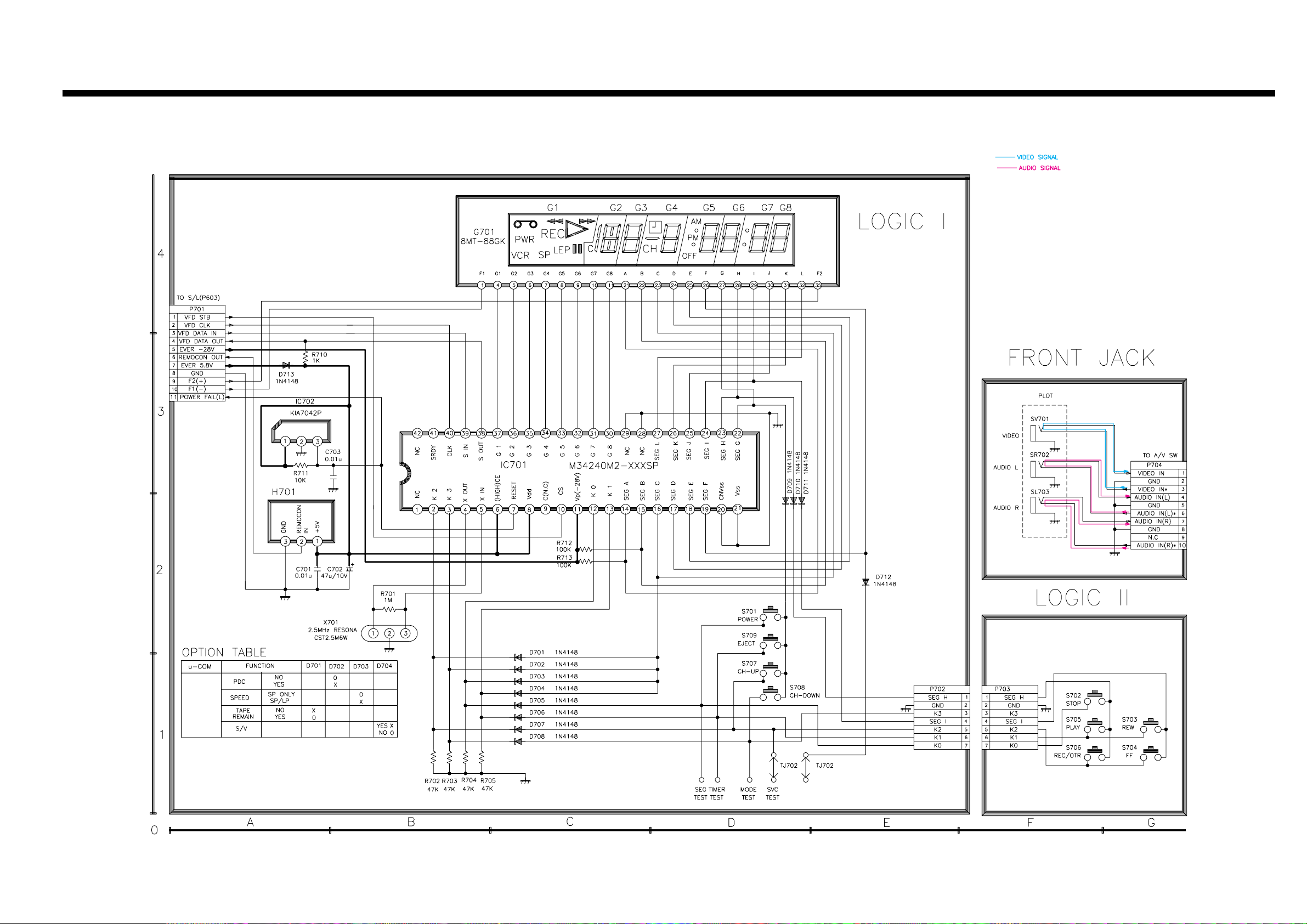

39

SECTION 4. CIRCUIT DIAGRAM

4-1. CONNECTION DIAGRAM CIRCUIT(DV-F802 Series)

Page 43

40

4-2. CONNECTION DIAGRAM CIRCUIT(DV-F882 Series)

Page 44

41

4-3. POWER CIRCUIT

Page 45

42

4-4. SERVO-LOGIC CIRCUIT

Page 46

43

4-5. LOGIC CIRCUIT(DV -F802 Series)

Page 47

44

4-6. LOGIC CIRCUIT(DV -F882Series)

Page 48

45

4-7. HEAD-AMP CIRCUIT

Page 49

46

4-8. VIDEO CIRCUIT

Page 50

47

4-9. Hi-Fi AUDIO

Page 51

48

4-10. PIF NICAM MODULE

Page 52

49

4-11. PIF/MPX CIRCUIT(2 CARRIER)

Page 53

50

4-12. PIF CIRCUIT

Page 54

51

4-13. OSD CIRCUIT

Page 55

52

4-14. VPS/PDC CIRCUIT

Page 56

53

4-15. IN/OUT SW CIRCUIT I

Page 57

54

4-16. IN/OUT SW CIRCUIT II

Page 58

55

4-17. REMOCON CIRCUIT(DV -F882D)

Page 59

SECTION 5. VOLT AGE CHAR TS

V oltage Charts

1. IC151 (MC14053B)

PIN NO

MODE

REC PB REMARK

1 0 0 Conditions

2 0 0 : Line input

3 1.1 1.1 and PB mode

4 1.1 1.1

500

600

700

800

56

2. ICS01 (168K88E6ML)

PIN NO

MODE

REC PB REMARK

1 2.4 2.3 Conditions

2 2.3 2.3 : No signal

3 2.1 2.2

4 2.5 2.5

5 1.4 0.9

6 4.9 4.9

7 4.9 4.9

8 2.3 2.7

9 3.6 3.6

10 1.7 2.7

PIN N

MODE

REC PB REMARK

11 0 0

12 0 0

13 0 0

14 0 0

15 4.9 4.9

16 2.3 2.3

17 2.3 2.3

18 1 1.7

19 1 1.7

20 4.9 4.9

PIN NO

MODE

REC PB REMARK

9 2.3 2.3

10 0 0

11 2.3 2.3

12 0.7 0.7

13 1.1 1.1

14 1.1 1.1

15 0 0

16 2.3 2.3

Page 60

57

3. IC701 (M34240M2-XXXSP)

PIN NO

MODE

REC

10

20

30

4 2.8

5 2.4

65

75

85

90

10 0.5

11 -28

12 0

13 0

14 -17.2

15 -14.1

16 -17.1

17 -20

18 -17

19 -17

20 0

21 0

PIN NO

MODE

REC

22 -7.8

23 -20

24 -23

25 -23

26 -24

27 -24

28 0

29 0

30 -21

31 -21

32 -21

33 -21

34 -21

35 -21

36 -21

37 -21

38 0

39 0

40 5

41 0

42 0

Page 61

58

IC301 DC VOLTAGE (LA7437)

PIN NO

MODE

REC PB

1 3 2.2

2 3 2.8

344

4 2.5 2.1

5 3 2.7

6 4.4 2

7 4.8 2

8 4.8 4.8

9 2.4 2.8

10 1.8 1.5

11 3.1 3.1

12 4 2.8

13 4.8 4.8

14 0 4.2

15 3.1 4

16 1.5 1

17 5.2 0

18 2 2

19 0 0

20 1 1

21 2.2 0

PIN NO

MODE

REC PB

22 0 0

23 2.5 2.4

24 2.2 2.4

25 0 0

26 2 2.4

27 0 0

28 1.8 1.8

29 2.4 0

30 0 0

31 3.8 3.8

32 2.5 2.5

33 2 2

34 4.8 4.8

35 0 1.5

36 2.8 1.6

37 2.8 1.6

38 2 2.2

39 1.8 2

40 4.4 2

41 1.5 0.8

42 0 0

IC302 DC VOLTAGE (LA89970)

PIN NO

MODE

REC PB

100

2 2.5 2.4

355

4 2.5 2.4

500

6 2.5 2.2

700

8 1.4 1

900

10 2.4 0

11 0 1.4

PIN NO

MODE

REC PB

12 0 0

13 2 2

14 2 0

15 5 0

16 0 0

17 5 5

18 8.8 8.8

19 5 4.8

20 0 0

21 1.4 1.4

22 0 0

Page 62

59

ICS02 DC VOLTAGE (LVA519S)

ICS02 DC VOLTAGE (LVA519S)

PIN NO

MODE

REC PB

1 2.0 3.6

2 2.0 2.0

300

400

5 0.9 0.9

600

7 0 4.9

8 2.7 0

900

10 2.2 3.5

11 0 3.5

12 0 1.6

13 2.5 2.5

14 5 4.5

15 5 5

PIN NO

MODE

REC PB

16 0 1.6

17 0 4

18 0 0

19 2.0 3.6

20 0.7 0

21 0 4.0

22 2.0 3.6

23 0.7 0

24 0 4.0

25 0 0

26 0 0

27 0.7 0

28 2.2 3.6

29 0 0

30 0.7 0

PIN NO

MODE

REC PB

132

2 1.5 1.4

3 1.5 2

4 0.5 3.8

500

6 2.3 1.2

750

855

955

Page 63

60

IC201 (HI-FI AUDIO, TDA9614H)

PIN NO

MODE

REC PB

1 3.8 3.8

2 3.8 3.8

3 3.8 3.8

4 3.8 3.8

5 3.8 3.8

6 3.8 3.8

7 3.8 3.8

8 3.8 3.8

9 3.8 3.8

10 3.8 3.8

11 3.8 3.8

12 0 5

13 5 5

14 5 5

15 5 5

16 0 0

17 3.8 3.8

18 6 6

19 6 6

20 6 6

21 6 6

22 6 6

23 - 24 - 25 5.5 5.5

26 5.5 5.5

27

28 3.8 3.8

29 3.8 3.8

30 0 0

31 3.8 3.8

32 0 5

PIN NO

MODE

REC PB

33 6 6

34 3.8 3.8

35 3.8 3.8

36 3.8 3.8

37 3.8 3.8

38 3.8 3.8

39 3.8 3.8

40 3.8 3.8

41 2 42 3.8 3.8

43 0 0

44 2 45 3.8 3.8

46 3.8 3.8

47 3.8 3.8

48 3.8 3.8

49 3.8 3.8

50 12 12

51 3.8 3.8

52 3.3 3.8

53 3.8 3.8

54 0 0

55 0.6 0.6

56 1.2 1.2

57 1.9 1.9

58 5 5

59 3.8 3.8

60 0 0

61 PULSE PULSE

62 5 HI-FI: 5

NOR: 0

63 3.3 3.8

64 3.8 4.3

Page 64

61

ICB01 (AUDIO HEAD AMP, BA7743s)

AUDIO PART TR

PIN NO

MODE

REC PB

1 1.2 1.2

2 0.5 4.4

3 0.4 1.2

4 2.8 2.8

500

600

755

8 2 3.4

9 3 2.8

10 5 5

11 SP :0 SP :0

LP :5 LP :5

12 PULSE PULSE

PIN NO

MODE

REC PB

13 4.8 5

14 4 0

15 4 0

16 0 0.8

17 0 0.5

18 0 0

19 0 0.5

20 0 0.8

21 0 0

22 4 0

23 0.5 0

24 0.8 0

Tr NO

PORT

COLLECTOR BASE EMITTER

Q200 0 (0) 0 (1.5) 0 (0)

Q201 0 (0) 0 (1.5) 0 (0)

Q202 0 (0) 0 (1.5) 0 (0)

Q203 0 (1.5) 5 (0.5) 5

Q204 0 (0) 0.7 (0) 0 (0)

Q232 12 (0.5) 0 (0.5) 0 (0)

Q233 12 (0) 12 (12) 12 (12)

Q234 0 (12) 4.4 (0) 0 (0)

IC202 (NORMAL AUDIO SWITCHING, BA7755A)

PIN NO

MODE

REC PB

11212

200

300

4 4.4 0.5

599

Page 65

62

9. IC601 ( µ-COM)

NO NAME ASSIGNMENT ACTIVE

1 CTL/TEST CONTROL PULSE TEST PORT PULSE

2 VS/SHARP E.E. : VS TUNING, PULSE

PLAYBACK : SHARPNESS

3 CAP PWM CAPSTAN CONTROL PWM PULSE

OUTPUT

4 DRUM PWM DRUM CONTROL PWM PULSE

OUTPUT

5 S/REEL SUPLY REEL PULSE INPUT PULSE

6 T/REEL TAKE-UP REEL PULSE INPUT PULSE

7 MUTE 1 AUDIO/PIF MUTE 1 HIGH

8 DUAL DUAL HIGH

9 TAPE START TAPE START SENSOR LOW

DATA INPUT

10 N.C

11 REMOCON REMOCON DATA INPUT PORT PULSE

12 CAP. I. LIM CAPSTAN I.CONTROL LOW

13 CAP F/R CAPSTAN FWD/RVS L/H

14 PB (L) PLAY LOW LOW

15 C.ROTARY COLOR ROTARY PULSE

16 H.A/SWP HEAD AMP SWITCHING PULSE

17 ENVE/COMP ENVELOPE COMPARE PULSE

18 V.SWP VIDEO SWITCHING PULSE

19 Q-Vsync Q-Vsync PULSE/L

20 AUDIO SW AUDIO SWITCHING PULSE

21 TRICK/H TRICK/HIGH HIGH

22 REC (L) REC : LOW LOW

23 SP (H) SP : HIGH HIGH

24 LP (H) LP : HIGH HIGH

25 NICAM/A2 NICAM, A2

26 Vcc Vcc

27 A MUTE (2) AUDIO MUTE 2

28 POWER FAIL POWER FAIL PORT LOW

29 EE (L) E.E : LOW LOW

30 OSD STB OSD STROBE LOW

31 NTSC (H) NTSC : HIGH HIGH

32 LP TRICK LP TRICK HIGH

33 TV/VCR TV/VCR : PORT H/L

34 POWER/ON POWER ON/OFF CONTROL L/H

PORT

35 NUMA GND

36 NUMB GND

NO NAME ASSIGNMENT ACTIVE

37 RESET RESET INPUT PORT LOW

38 Xin 16MHZ OSC IN

39 Xout 16MHZ OSC OUT

40 CLK/SEL RESET : 32KHZ OSCILLATION LOW

41 Vss GND

42 Xcin 32.768KHZ OSC IN

43 Xcout 32.768KHz OSC OUT

44 TV/LINE TV/LINE : PORT H/L

45 LM/ON LOADING MOTOR ON HIGH

46 LM F/R LOADING MOTOR FWD/RVS L/H

47 CST/DOWN CASSETTE DOWN OUT LOW

48 REC SAFETY REC SAFETY SW DATA INPUT LOW

49 CAM A CAM A DATA INPUT LOW

50 CAM B CAM B DATA INPUT LOW

51 CAM C CAM C DATA INPUT LOW

52 CAM D CAM D DATA INPT LOW

53 VL BAND LOW : HIGH OUT HIGH

54 VH BAND HIGH : HIGH OUT HIGH

55 VU BAND UHF : HIGH OUT HIGH

56 AFT DEFEAT PAL TUNING : HIGH

AFT DEFEAT ON OUTPUT

57 STEREO STEREO: HIGH HIGH

58 VPS DATA VPS CONTROL : SERIAL DATA SERIAL

59 VPS CLK

VPS CONTROL : SERIAL CLOCK

SERIAL

60

EEPROM STB

EEPROM STORBE HIGH

61

EEPROM CLK

EEPROM SERIAL CLOCK SERIAL

62 EEPROM EEPROM SERIAL DATA SERIAL

DATA

63 A/V CLOCK A/V CONTROL SERIAL CLOCK SERIAL

64 A/V DATA A/V CONTROL SERIAL DATA SERIAL

65 AMP Vcc AMP Vcc

66 DRUM/PG DRUM PG INPUT PULSE

67 DRUM/FG DRUM FG INPUT PULSE

68 CAP/FG CAPSTAN FG INPUT PULSE

69 Vref OUT AMP REFERENCE Vcc

70 Vref In AMP REFERENCE Vcc

71 CLAMPF REFERENCE TO CTL CIRCUIT

72 CLAMPR REFERENCE TO CTL CIRCUIT

73 CTLAMPout REFERENCE TO CTL CIRCUIT

74 AMPC REFERENCE TO CTL CIRCUIT

75 CTLAMPin REFERENCE TO CTL CIRCUIT

76 CTL+SWout REFERENCE TO CTL CIRCUIT

Page 66

Tr NO.

PORTS

EMITTER

COLLECTOR

BASE

Q851 12.5 (12.6) 14.3 (14.1) 13.1 (13.1)

Q852 12.6 (12.7) 14.3 (14.1) 13.2 (13.3)

Q853 0 (0) 5.3 (0) 0 (5.2)

11. POWER PART TR

PORTS EMITTER COLLECTOR BASE

Tr NO. PB REC PB REC PB REC

QS02 2.46 1.47 4.89 4.89 3.1 2.1

Q302 2.8 1.68 0 0 2.1 0.97

Q303 1.948 2 4.95 4.97 2.56 2.67

Q305 4.96 4.96 4.97 4.88 4.23 5

Q311 3.46 2.42 0 0 2.74 1.7

10. VIDEO/OSD PART TR

Tr NO.

PORTS

EMITTER

COLLECTOR

BASE

Q854 0 (0) 0 (12.6) 5.4 (0)

Q855 12.6 (12.6) 12.6 (0.8) 11.9 (12.6)

Q856 5.0 (1.4) 5.9 (6.0) 5.7 (0.8)

Tr NO.

PORTS

EMITTER COLLECTOR BASE

Q604 4.9 (4.9) 4.9 (0.2) 4.3 (5)

Q603 1.0 (3.3) 0.1 (0) 0.4 (2.0)

12. SERVO PART TR

63

NO NAME ASSIGNMENT ACTIVE

76 CTL+SWout REFERENCE TO CTL CIRCUIT

77 CTL + REFERENCE TO CTL CIRCUIT

78 CTL- REFERENCE TO CTL CIRCUIT

79 GND GND

80 GND GND

81 Vcc Vcc

82

A/D Reference

REFERENCE Vcc

83 TAPE END TAPE END SENSOR LOW

DATA INPUT

84 CANAL + (L) CANAL : LOW INPUT LOW

85 PIF/ON VPS STANBY PIF ON HIGH

86 V.ENVE VIDEO DC ENVE A/D

87 RF AGC RF AGC

88 DRUM/SEL SYSTEM DRUM SELECT A/D

NO NAME ASSIGNMENT ACTIVE

89 BRKADJ SLOW BREAK ADJUST A/D

90 PGADJ PG DLAY ADJUST A/D

91 PATH PATH ADJUST A/D

92 AFT AFT INPUT PORT A/D

93 C.SYNC C.SYNC INPUT PORT PULSE

94 VFD DATA VFD SERIAL DATA OUT SERIAL

OUT

95 VFD DATA IN VFD SERIAL DATA IN SERIAL

96 VFD CLOCK VFD SERIAL CLOCK OUT SERIAL

97 VFD STB VFD STROBE LOW

98

OSD DATA OUT

OSD SERIAL DATA OUT SERIAL

99 N.C

100 OSD CLK OSD SERIAL CLOCK SERIAL

PLAY (PW OFF)

Page 67

69

SECTION 7. DIS ASSEMBLY

7-1. P ACKING AS (DV-F802Series)

No. Part Code Part Name Q'ty Description Re

1 97PB0935S- SET TOTAL AS 1

2 97P4803100 POLY BAG FOR SET 1 P.E FOAM

3 97P4920800 PAD LEFT/RIGHT 1 EPS

4 97P5040700 BOX CARTON 1

EX300 X SCP150 X E X 300

5 97P9531607 MANUAL OWNERS 1 ART PAPER

6 97P880RP15 CABLE RF 1 PAL 1.5M

7 47P7500001 BATTERY 2 AAM 1.5V

8 97P0424100 COVER ACCESSORY 1 LD-PE T0.1

9 97P1R2BC14

REMOCON HANDSET AS

1 VR-F2BT

Page 68

70

7-2. P ACKING AS (DV-F882Series)

No. Part Code Part Name Q'ty Description Re

1 97P4921200 PAD RIGHT/LEFT 1 EPS

2 97P4803100 POLY BAG FOR SET 1 P.E FOAM

3 97PB0959S SET TOTAL ASS'Y 1

4 97P5039900 BOX CARTON 1

EX300ƒNSCP150ƒNEX300

5 97P8804213 CABLE RF 1 PAL 1.5M

6 486A716200 BATTERY 2 AAA

7 97P0424100 COVER ACCESSORY 1 LE-PE T0.1

8 97P1R3BC13

REMOCON HANDSET AS

1 VR-F3BC

9 97P9560000 MANUSL OWNERS 1 ART PAPER (F882D)

Page 69

71

7-3. SET TOT AL AS (DV-F882 Series)

No. Part Code Part Name Q'ty Description Re

1 97P0608400 CHASSIS MAIN 1 ABS(HB)

2 97PD130800 PANEL FRONT AS 1

3 97PD132600 PCB LOGIC AS 1

4 97PD130300 PCB MAIN AS 1

5 97PB0588D- DECK TOTAL AS 1

6 97PB181500 PCB HEAD AMP AS 1

7 97PB208800 PCB A/V SW AS 1

8 97P0710710 BOARD ANT 1 HI-PS

9 97P0800600 LEG 2 SBR 80 BLK

10 97P0455710 COVER TOP 1 SECC T0.6+PVC T0.15

11 97P0455810 COVER BOTTOM 1 SECC T0.4

12 7173401211 SCREW TAPPTITE 3 TT2 BIN 4X12 MFZN

DEC

13 7173401211 SCREW TAPPTITE 2 TT2 BIN 4X12 MFZN

BOAR

14 7173401012 SCREW TAPTITE 5 TT2 BIN 4X10 BK MFZN

COVE

15 7174301011 SCREW TAPPTITE 3 TT2 RND 3X10 MFZN

C/BO

16 7173401211 SCREW TAPPTITE 2 TT2 BIN 4X12 MFZN

BRK

17 7274300811 SCREW TAPPTITE 1 TT2 BIN 4X12 MFZN

B/

18 7274300811 SCREW TAPPTITE 1 TT3 RND 3X6 MFZN

PREA

19 97P2440200 BRKT F/L 1 SECC T1.6

20 97P2441400 BRKT DECK 1 SECC T1.6

21 97P4213100 CUSHION F/L 2 EVA

22 97P4213500 CUSHION BRKT 1 EVA B

23 97P4213600 CUSHION B/D 1 EVA

Page 70

72

7-4. SET TOT AL AS (DV-F802 SERIES)

No. Part Code Part Name Q'ty Description Re

1 97P0608401 CHASSIS MAIN 1 HI-PS(HB)

2 97PC166300 PANEL FRONT AS 1

3 97PD106700 PCB LOGIC AS 1

4 97PD106600 PCB MAIN AS 1

5 97PB0666D- DECK TOTAL AS 1

6 97PB210300 PCB HEAD AMP AS 1

7 97PB210200 PCB A/V SW AS 1

8 97P0714100 BOARD ANT 1 HI-PS(HB)

9 97P0800600 LEG 2 SBR 80 BLK

10 97P0455710 COVER TOP 1 SECC T0.6+PVC T0.15

11 97P0455810 COVER BOTTOM 1 SECC T0.4

12 7173401211 SCREW TAPPTITE 3 TT2 BIN 4X12 MFZN

DEC

13 7173401411 SCREW TAPPTITE 2 TT2 BIN 4X12 MFZN

BOAR

14 7173401012 SCREW TAPTITE 5 TT2 BIN 4X10 BK MFZN

COVE

15 7174301011 SCREW TAPPTITE 3 TT2 RND 3X10 MFZN

C/BO

16 7173401211 SCREW TAPPTITE 2 TT2 BIN 4X12 MFZN

BRK

17 7174300611 SCREW TAPPTITE 1 TT2 BIN 4X12 MFZN B/

18 97P2440200 BRKT F/L 1 SECC T1.6

19 97P2441400 BRKT DECK 1 SECC T1.6

20 97P4213100 CUSHION F/L 2 EVA

21 97P4213500 CUSHION BRKT 1 EVA B

22 97P4213600 CUSHION B/D 1 EVA

Page 71

73

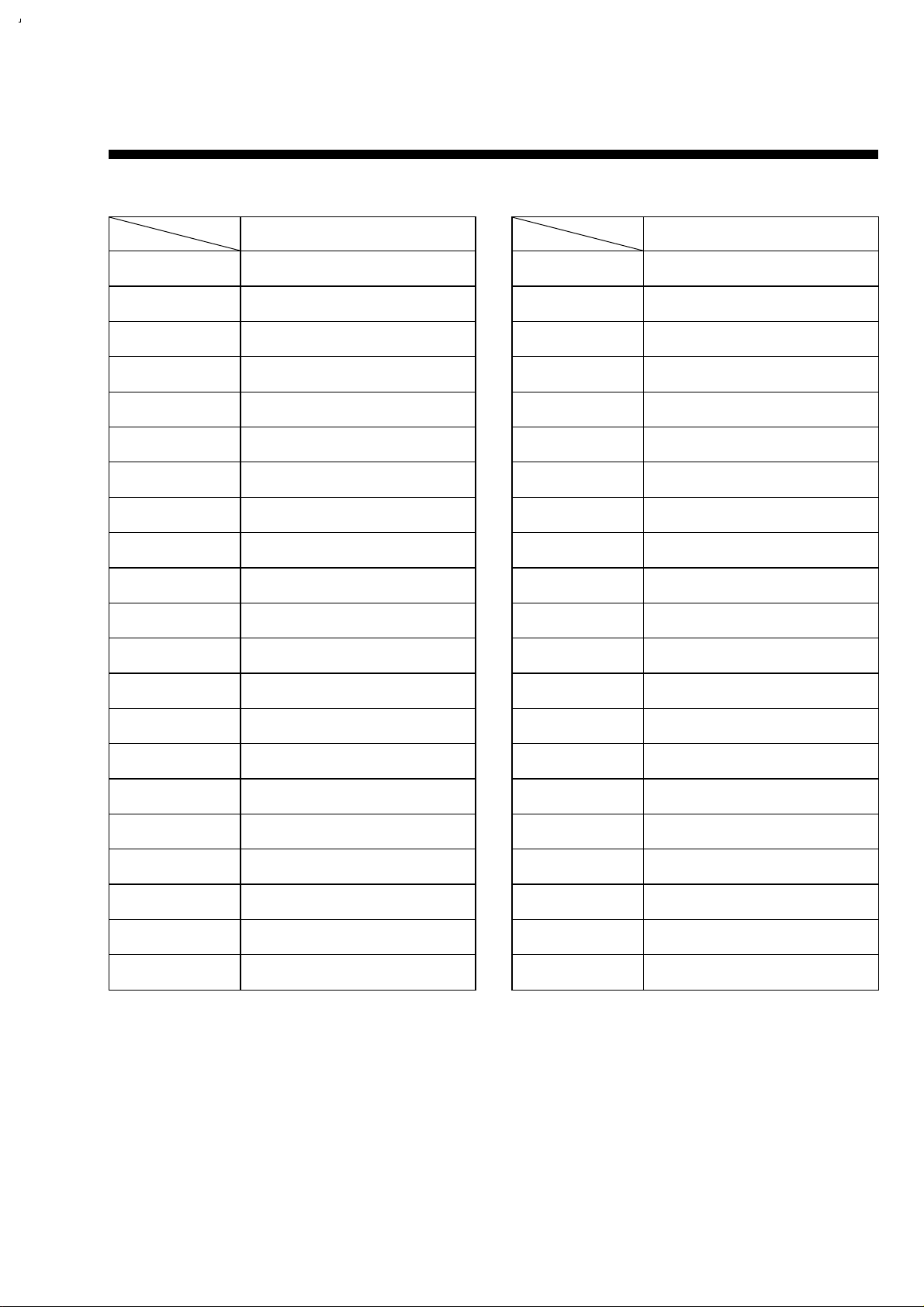

8-1. ST ANDARD PART NUMBER CODING

1. Fixed Resistor Coding

2. Semi-Fixed Resistor Coding

SECTION 8. ELECTRICAL P AR TS LIST

8-1-1. RESISTOR CODING

Type of Resistor

C Composition Resistor

D Carbon Resistor

F Fusible Resistor

K Ceramic Resistor

N Metal Film Resistor

S Metal-Oxide Film

Resistor

W Wire Wound Resistor

X Cement Resistor

Y Chip Resistor

Type of Resistor

Code Wattage

–A 1/6W

–8 1/8W

–4 1/4W

–2 1/2W

01 1W

02 2W

Distance

Code Distance

A 2.5 mm

B 5.0 mm

C 7.5 mm

D 10.0 mm

E 12.5 mm

F 15.0 mm

G 17.5 mm

H 20.0 mm

G 17.5 mm

H 20.0 mm

J 22.5 mm

K 25.0 mm

X Auto Insertion

Z Auto Insertion

Tolerance

Symbol

Tolerance

F ±1%

G ±2%

J ±5%

K ±10%

M ±20%

N ±30%

Value

Example

478..............0.47Ω

479................4.7Ω

470.................47Ω

471...............470Ω

472..............4.7KΩ

473 ..............47KΩ

Meterial Shape Knob Code

Pin Length Value

(Same as Fixed Type)

Knob

Type

VERTICAL

HORIZONTAL

VERTICAL

HORIZONTAL

VERTICAL

HORIZONTAL

CARBON

FILM

METAL

GRAZE

CARBON

SOLID

1

6

5

WITH 1 11

WITH 3 13

WITH 1 61

WITH 3 63

WITH 1 51

WITH 3 53

WITHOUT 2 12

WITHOUT 4 14

WITHOUT 2 62

WITHOUT 4 64

WITHOUT 2 52

WITHOUT 4 54

R

R

V

Page 72

74

1. Normal

2. Temperature Compensation

8-1-2. CAP ACITOR CODING

8-1-3. FUSE CODING

Type

F Fiber

G Glass Tube

L Lead Type

Glass Tube

T Temperature

W Wire

C Ceramic

P Plastic

Size

A MF41 4.6x16

B MF51 5.2x20

C MF60 6.3x30

D MF61 6.3x31.8

E MF01 10.3x38.1

F MF04 14.3x50.8

G MF05 20.5x76.2

Voltage

1 AC125V

2 AC250V

3 125/250V

Type

Code Type

A Aluminum

B Barrier Layer

C Ceramic

E Electrolytic

L Line Across

M Mylar

S Styrol

N Metalized Polyester

Q Mica

Oil

T Tantal

Voltage

Code Voltage

0J 6.3V

1A 10V

1C 16V

1D 20V

1E 25V

1V 35V

1G 40V

1H 50V

1J 63V

2A 100V

2B 125V

2C 160V

2D 200V

2E 250V

2F 315V

Characteristic

Capacitance Temperature

Coefficient (ppm/˚C) Coefficient (ppm/˚C)

A +100 F ±15

B +30 G ±30

C0 H ±60

H –30 J ±120

L –80 K ±250

P –150 L ±500

R –220 M ±1000

S –330 N ±2500

T –470

U –750

V –1000

SI +350~

–1000

Distance

(Same As

Fixed

Resistor)

Value

(Same as Fixed

Resistor)

Shape

or

Characteristic

Tolerance

(Same as Fixed

Resistor)

Distance

(Same as Fixed

Resistor)

Voltage

(Same as Normal)

Value

(Same as Fixed Resistor)

Tolerance

(Same as Fixed Resistor)

Regulation Value

(Same as Fixed Resistor)

Characteristics

Page 73

8-2. ELECTRICAL P AR TS LIST

PCB MAIN AS

75

REF. PART CODE PART NAME PART DESCRIPTION

CS01 HCLK240JCA C CHIP CERA 50V SL 24PF J 2012

CS02 HCLK240JCA C CHIP CERA 50V SL 24PF J 2012

CS03 HCLK121JCA C CHIP CERA 50V SL 120PF J 2012

CS04 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

CS05 CEXF1H228V C ELECTRO 50V RSS 0.22MF (5X11) TP

CS06 HCQK180JCA C CHIP CERA 50V CH 18PF J 2012

CS07 HCQK180JCA C CHIP CERA 50V CH 18PF J 2012

CS08 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

CS11 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

CS12 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

CS14 HCLK560JCA C CHIP CERA 50V SL 56PF J 2012

CS15 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

CS16 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

CS17 CMXM2A223J C MYLAR 100V 0.022MF J TP

CS18 CMXM2A332J C MYLAR 100V 3300PF J TP

CS19 CZXC1H561J C CERA MONOLITHIC 50V NPO 560PF J

CS20 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

CS21 HCLK201JCA C CHIP CERA 50V SL 200PF J 2012

CS22 HCLK201JCA C CHIP CERA 50V SL 200PF J 2012

CS23 HCLK201JCA C CHIP CERA 50V SL 200PF J 2012

CS24 CEXF1E220V C ELECTRO 25V RSS 22MF 5X11

C111 CEXF1H100A C ELECTRO 50V RSM 10MF 6.3X7

C171 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C172 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

C173 CEXF1H228V C ELECTRO 50V RSS 0.22MF (5X11) TP

C174 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C175 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C176 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C177 CEXF1H478V C ELECTRO 50V RSS 0.47MF (5X11) TP

C178 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C179 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

C182 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C183 CMXM2A104J C MYLAR 100V 0.1MF J TP

C184 CMXM2A104J C MYLAR 100V 0.1MF J TP

C185 CMXM2A104J C MYLAR 100V 0.1MF J TP

C186 HCQK131JCA C CHIP CERA 50V CH 130PF J 2012

C188 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C189 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

C190 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

REF. PART CODE PART NAME PART DESCRIPTION

C191 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

C192 CEXF1C101V C ELECTRO 16V RSS 100MF (6.3X11) TP

C193 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C194 CEXF1H109V C ELECTRO 50V RSS 1MF (5X11) TP

C195 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C234 CMXM2A473J C MYLAR 100V 0.047MF J TP

C241 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C242 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C243 CEXF1C479A C ELECTRO 16V RSM 4.7MF 4*7

C301 HCLK680JCA C CHIP CERA 50V SL 68PF J 2012

C302 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C304 HCLK201JCA C CHIP CERA 50V SL 200PF J 2012

C305 HCQK150JCA C CHIP CERA 50V CH 15PF J 2012

C306 HCLK161JCA C CHIP CERA 50V SL 160PF J 2012

C307 HCLK430JCA C CHIP CERA 50V SL 43PF J 2012

C308 HCLK201JCA C CHIP CERA 50V SL 200PF J 2012

C309 HCLK360JCA C CHIP CERA 50V SL 36PF J 2012

C310 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C311 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C312 HCLK391JCA C CHIP CERA 50V SL 390PF J 2012

C314 CEXF1H479V C ELECTRO 50V RSS 4.7MF (5*11) TP

C315 HCFK223ZCA C CHIP CERA 50V Y5V 0.022MF Z 2012

C317 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C318 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

C319 CEXF1H100V C ELECTRO 50V RSS 10MF (5X11) TP

C320 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C321 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

C322 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C323 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C324 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C325 HCFK223ZCA C CHIP CERA 50V Y5V 0.022MF Z 2012

C326 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

C327 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C328 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

C329 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C330 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

C331 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C332 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C336 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

Page 74

76

REF. PART CODE PART NAME PART DESCRIPTION

C337 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C338 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C339 HCLK121JCA C CHIP CERA 50V SL 120PF J 2012

C340 CEXF1H108A C ELECTRO 50V RSM 0.1MF 4X7

C343 CMXM2A223J C MYLAR 100V 0.022MF J TP

C344 HCFK473ZCA C CHIP CERA 50V Y5V 0.047MF Z 2012

C345 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C346 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

C347 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C348 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C349 CMXM2A223J C MYLAR 100V 0.022MF J TP

C350 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C351 CMXM2A473J C MYLAR 100V 0.047MF J TP

C352 HCFK473ZCA C CHIP CERA 50V Y5V 0.047MF Z 2012

C353 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C354 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

C357 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

C358 HCFK223ZCA C CHIP CERA 50V Y5V 0.022MF Z 2012

C362 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

C363 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C501 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C502 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

C504 CEXF1H100A C ELECTRO 50V RSM 10MF 6.3X7

C505 CEXF1H100A C ELECTRO 50V RSM 10MF 6.3X7

C506 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

C507 CEXF1H100A C ELECTRO 50V RSM 10MF 6.3X7

C508 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C509 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) TP

C510 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C511 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

C512 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

C513 CMXM2A223J C MYLAR 100V 0.022MF J TP

C514 CMXM2A223J C MYLAR 100V 0.022MF J TP

C515 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C516 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C517 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C518 CEXF1A471V C ELECTRO 10V RSS 470MF 8X11.5

C551 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C601 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

C602 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

C603 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

C605 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

REF. PART CODE PART NAME PART DESCRIPTION

C606 HCQK180JCA C CHIP CERA 50V CH 18PF J 2012

C607 HCQK180JCA C CHIP CERA 50V CH 18PF J 2012

C608 HCQK220JCA C CHIP CERA 50V CH 22PF J 2012

C609 HCQK220JCA C CHIP CERA 50V CH 22PF J 2012

C610 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C611 CEXF1A471V C ELECTRO 10V RSS 470MF 8X11.5

C616 HCLK101JCA C CHIP CERA 50V SL 100PF J 2012

C617 HCLK101JCA C CHIP CERA 50V SL 100PF J 2012

C618 HCLK101JCA C CHIP CERA 50V SL 100PF J 2012

C619 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

C620 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C621 CMXM2A103J C MYLAR 100V 0.01MF J (TP)

C622 CMXM2A103J C MYLAR 100V 0.01MF J (TP)

C623 CDXA0H104K C SUPER 5.5V 0.1F TAPING

C630 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

C631 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C633 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C634 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C635 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C660 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C661 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C663 CBZP1C103M C CERA SEMI 16V Y5S 0.01MF M (AXIAL)

C664 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C665 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C667 HCLK101JCA C CHIP CERA 50V SL 100PF J 2012

C673 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C674 HCLK101JCA C CHIP CERA 50V SL 100PF J 2012

C801 CL1UE3104M C LINE ACROSS 275V AC 1.40 SERIES U/C/V

C802 CH1HEB101M C CERA AC AC250V 100PF M U/C/V/S/N/

C803 CH1HEB101M C CERA AC AC250V 100PF M U/C/V/S/N/

C804 CH1FEE472M C CERA AC AC250V 4700PF M U/C/V KH

C807 CEXN2G820P C ELECTRO 400V LHS 82MF

C810 CEXF1H470V C ELECTRO 50V RSS 47MF (6.3*11) TP

C817 CEXF1E102F C ELECTRO 25V RX 1000MF 13X25

C818 CEXF1E331F C ELECTRO 25V RX 330MF 10X20

C825 CEXF1A102F C ELECTRO 10V RX 1000MF 10X20

C832 CCXF1H103Z C CERA 50V F 0.01MF Z (TAPPING)

C851 CEXF1H470V C ELECTRO 50V RSS 47MF (6.3*11) TP

C852 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

C854 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

C855 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

C856 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

Page 75

77

REF. PART CODE PART NAME PART DESCRIPTION

C857 CEXF1E470V C ELECTRO 25V RSS 47MF (5X11) TP

C858 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

C859 CEXF1C470A C ELECTRO 16V RSM 47MF (6.3X7) TP

D301 DZN4148--- DIODE 1N4148 AUTO 52MM

D302 DZN4148--- DIODE 1N4148 AUTO 52MM

D303 DZN4148--- DIODE 1N4148 AUTO 52MM

D304 DZN4148--- DIODE 1N4148 AUTO 52MM

D305 DZN4148--- DIODE 1N4148 AUTO 52MM

D306 DZN4148--- DIODE 1N4148 AUTO 52MM

D307 DZN4148--- DIODE 1N4148 AUTO 52MM

D310 DZN4148--- DIODE 1N4148 AUTO 52MM

D601 DZN4148--- DIODE 1N4148 AUTO 52MM

D602 DZN4003--- DIODE IN4003

D603 DZN4003--- DIODE IN4003

D604 DZN4003--- DIODE IN4003

D605 DZZ3R9B--- DIODE ZENER DZ 3R9B (3R9) (AUTO)

D606 DS1R481T-- LED IR SIR-48IT

D606A 97P2334200 HOLDER LED SENSORPOM

D607 DZZ7R5BM-- DIODE ZENER UZ-7.5BM

D608 DZA105R1L- DIODE ZENER MA 1051L (5R1)

D609 DZN4003--- DIODE IN4003

D650 DZZ3R9B--- DIODE ZENER DZ 3R9B (3R9) (AUTO)

D801 DS1WBA60-- DIODE BRIDGE S1WBA60

D820 DZZP33BM-- DIODE ZENER UZP-33B 1W

D851 1KA33V---- IC ZENER KA33V

D852 DZZ13BL--- DIODE ZENER UZ-13BL

D853 DZZ13BL--- DIODE ZENER UZ-13BL

D854 DZN4003--- DIODE IN4003

D855 DZZ5R6BM-- DIODE ZENER DZ 5.6BM (AUTO)

D857 DZN4148--- DIODE 1N4148 AUTO 52MM

F01A 97P2316600 HOLDER AC CORD NYLON66 UL/CSA

F801A 97P460170P CLIP FUSE PFC5000-0702

F801B 97P460170P CLIP FUSE PFC5000-0702

ICS01 168K88E6ML IC OSD M35013-053SP (88E6ML)

ICS02 1LVA519S-- IC LVA519S (SYNC.SEPARATOR)

IC301 1LA7437--- IC VIDEO (PAL) LA7437

IC302 1LC89970-- IC VIDEO LC89970 PAL CCD

IC601 168KF8U8TS IC MICOM M37774M5H-519GP (F8U8TS)

IC602 1BA6209--- IC BA6209

IC603 14JN93C66- IC EEPROM AT93C66

IC604 1MN1380L--

IC COMPARATOR(RESET)

MN1380-L(RESET IC)

JPT01 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

REF. PART CODE PART NAME PART DESCRIPTION

JPT02 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

JPT03 85801065GY WIRE COPPER AWG22 1/0.65 TIN COATING

LS01 5CPX101J-- COIL PEAKING PL 100UH J (TAPPING)

LS02 5CPX150J-- COIL PEAKING 15UH J RADIAL

LS03 5CPX100J-- COIL PEAKING PL 10UH J (TAPPING)

L171 5CPX101J-- COIL PEAKING PL 100UH J (TAPPING)

L172 HLM100K01B L CHIP MULTI 10UH MLF3216C100KT

L173 5CPX100J-- COIL PEAKING PL 10UH J (TAPPING)

L301 5CPX330J-- COIL PEAKING 33UH J RADIAL

L302 5CPX330J-- COIL PEAKING 33UH J RADIAL

L303 5CPX271J-- COIL PEAKING 270UH J RADIAL

L304 5CPX820J-- COIL PEAKING 82UH J RADIAL

L305 5CPX100J-- COIL PEAKING PL 10UH J (TAPPING)

L306 5CPX100J-- COIL PEAKING PL 10UH J (TAPPING)

L309 5CPX330J-- COIL PEAKING 33UH J RADIAL

L310 5CPX100J-- COIL PEAKING PL 10UH J (TAPPING)

L312 5CPX100J-- COIL PEAKING PL 10UH J (TAPPING)

L801 5PLFSQ2014 FILTER LINE SQ-2014 40MH

L802 5PLFSQ2014 FILTER LINE SQ-2014 40MH

L803 56C220K686 COIL CHOKE 22UH K 27.5X0.4D

L804 56C220K686 COIL CHOKE 22UH K 27.5X0.4D

M801 97PB216300

AUTO VOLT REGULATOR

DV-F542DY-RF/D

PL101 97P62T02BF CONN B/B TUC-PP PLUG 2.0MM 15P

PL102 97P62T02BA CONN B/B TUC-PP PLUG 2.0MM 10P

PT01 97P6269000 CONN WAFER 00-8283-0612-00000

P101 97P62G02BL CONN B/B GB200 PLUG 2.0MM 20P

P106 97P62G02B5 CONN B/B GB200 PLUG 2.0MM 5P

P107 97P62G02BH CONN B/B GB200 PLUG 2.0MM 17P

P201 97P8851210 CONN AS (Y51210) 2H-2S 100MM

P501 97P6291736 CONN WAFER TKC-M08P-B1

P601 97P6291741 CONN WAFER TKC-M18P-B1

P603 97P8810B14 CONN AS (Y10B14) 11H-11S 140MM

P801 97P62Y02X2 CONN WAFER YFW800 STR 10MM 2P

QS02 TZTA1266Y- TR KTA1266Y- (AUTO)(1015Y)

Q171 TZSR1001-- TR KSR1001 (AUTO)

Q172 TZTA1273Y- TR KTA1273Y(966Y)

Q173 TZSR1001-- TR KSR1001 (AUTO)

Q174 TZSR1001-- TR KSR1001 (AUTO)

Q175 TZSR1001-- TR KSR1001 (AUTO)

Q176 TZSR2004-- TR KSR 2004 (TAPPING)

Q177 TZSR2004-- TR KSR 2004 (TAPPING)

Page 76

78

REF. PART CODE PART NAME PART DESCRIPTION

Q179 TZTK30AGR- FET KTK30A-GR (AUTO)

Q183 TZSR1001-- TR KSR1001 (AUTO)

Q184 TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

Q187 TZSR1001-- TR KSR1001 (AUTO)

Q188 TZTA1273Y- TR KTA1273Y(966Y)

Q200 TZTC3203Y- TR KTC3203Y (2120Y)

Q201 TZTC3203Y- TR KTC3203Y (2120Y)

Q202 TZTC3203Y- TR KTC3203Y (2120Y)

Q203 TZTA1266Y- TR KTA1266Y- (AUTO)(1015Y)

Q205 TZTA1266Y- TR KTA1266Y- (AUTO)(1015Y)

Q302 TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

Q303 TZTA1266Y- TR KTA1266Y- (AUTO)(1015Y)

Q305 TZTC3198Y- TR KTC3198Y-(1815Y) (AUTO)

Q311 TZTA1266Y- TR KTA1266Y- (AUTO)(1015Y)

Q603 TZTA1266Y- TR KTA1266Y- (AUTO)(1015Y)

Q604 TZTA1266Y- TR KTA1266Y- (AUTO)(1015Y)

Q851 TZTC3205Y- TR KTC3205Y (2236Y)

Q852 TZTC3205Y- TR KTC3205Y (2236Y)

Q853 TZSR1004-- TR KSR1004 (AUTO)

Q854 TZSR1004-- TR KSR1004 (AUTO)

Q855 TZTA1273Y- TR KTA1273Y(966Y)

Q856 TZTC3205Y- TR KTC3205Y (2236Y)

RS01 RD-2Z391J- R CARBON FILM 1/2 390 OHM J

RS02 HRFT753JCA R CHIP 1/10 75K OHM J 2012

RS03 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012

RS10 RD-AZ562J- R CARBON FILM 1/6 5.6K OHM J

RS11 HRFT205JCA R CHIP 1/10 2M OHM J 2012

RS12 HRFT123FCA R CHIP 1/10 12K OHM F 2012

RS13 HRFT273JCA R CHIP 1/10 27K OHM J 2012

RS14 HRFT272JCA R CHIP 1/10 2.7K OHM J 2012

RS15 HRFT222JCA R CHIP 1/10 2.2K OHM J 2012

RS16 HRFT222JCA R CHIP 1/10 2.2K OHM J 2012

RS20 HRFT561JCA R CHIP 1/10 560 OHM J 2012

R121 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R122 HRFT103JCA R CHIP 1/10 10K OHM J 2012

R124 HRFT183JCA R CHIP 1/10 18K OHM J 2012

R170 HRFT114JCA R CHIP 1/10 110K OHM J 2012