Daewoo DV-F803M Schematic

SPECIFICATIONS

SYSTEM

Video signal NTSC/M-PAL

Channel coverage VHF Channel 2-13

UHF Channel 14-69

CATV Channels A1-A5, A8, A-W, W+1, W+1-W+84

VHF output signal Channel 3 or 4 (selectable)

VIDEO

Input: Video line in Phono-type connector 1.0V (p-p)

75 ohms unbalanced, sync. negative

Output: Video line out Phono-type connector 1.0V (p-p)

75 ohms unbalanced, sync. negative

Signal to noise ratio More than 43dB (SP)

Horizontal resolution 220 lines

AUDIO

Input: Audio line in Phono-type connector 47K ohms

–8 dBm, unbalanced

Output: Audio line out Phono-type connector less than 1K ohms

–6 dBm (More than 47K ohms load), unbalanced

Normal Hi-Fi

Frequency response 100Hz-10KHz (SP) 20Hz-20KHz (SP)

Signal to noise ratio More than 40dB More than 60dB

Audio Distortion Less than 3% (SP) Less than 0.5% (SP)

Dynamic Range More than 80dB

TAPE TRANSPOR T

Tape width 12.65mm (1/2")

Tape speed NTSC SP: 33.35 mm/sec, EP: 11.12 mm/sec.

Maximum recording time 480 min, with T-160 tape (NTSC EP)

FF. REW time Approx 5 min (T-120)

GENERAL

Power requirements 110-240V, 50/60Hz

Power consumption 19W (Hi-Fi)

16W (Normal)

DIMENSIONS

Set size (WxHxD) 360x90x312 mm

Carton size (WxHxD) 429x160x395 mm

Weight (gross) 5.4Kg (11.9 lbs)

• Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires

have been returned to original positions. Afterwards, perform the following tests and confirm the specified values in order

to verify compliance with safety standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed parts of

the set (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone

jacks, etc.). See table below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed accessible parts of the

set (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks,

etc.) See table below.

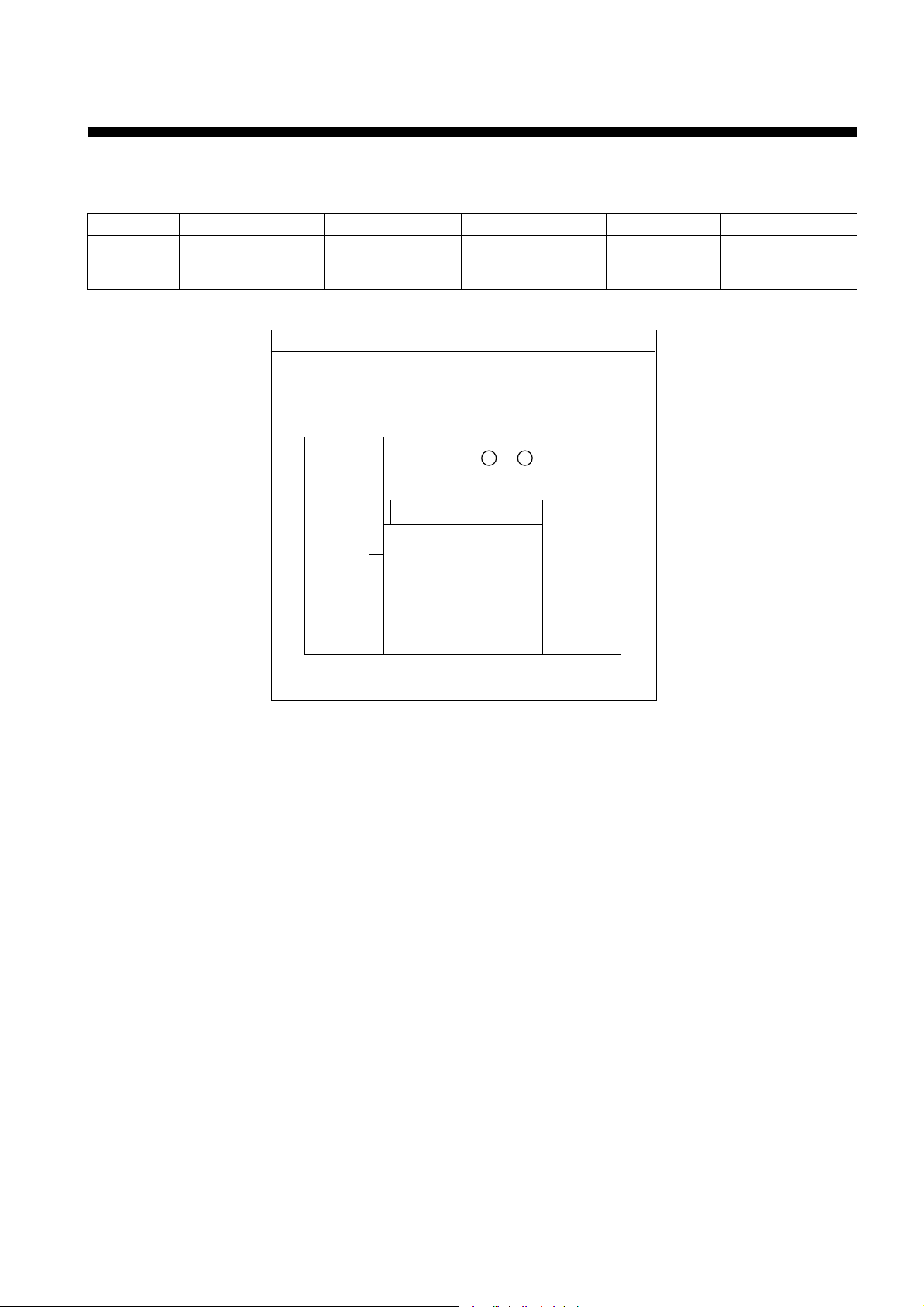

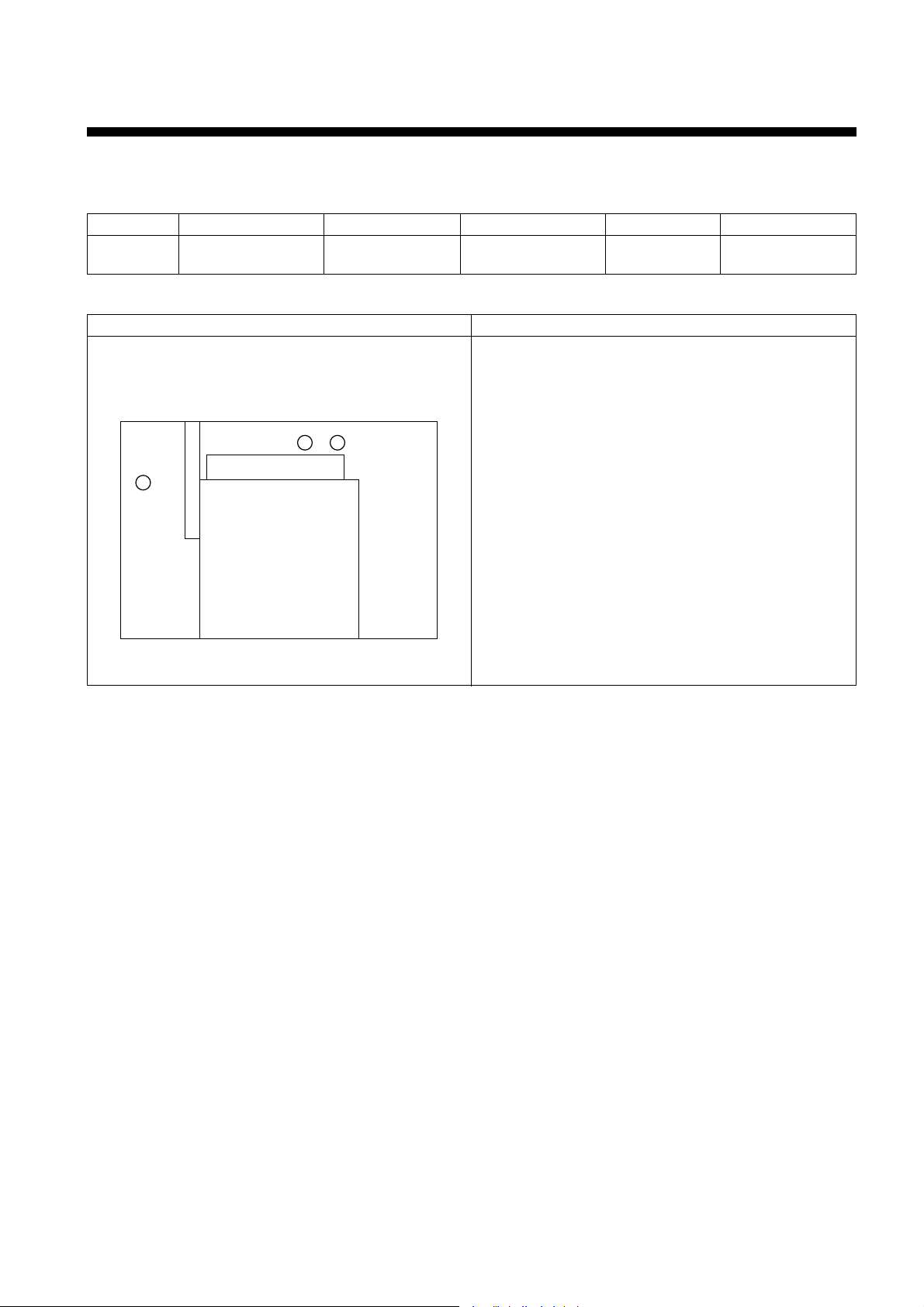

3. Clearance distance

When replacing primary circuit components, confirm

specified clearance distance (d), (d') between soldered

terminals, and between terminals and surrounding

metalic parts. See table below.

Table 1: Rating for selected areas

* Class II model only.

Note: This table is unofficial and for reference only. Be sure to confirm the precise values for your particular country and

locality.

4. Leakage current test

Confirm specified or lower leakage current between B (earth ground, power cord plug prongs) and externally exposed

accessible parts (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks,

earphone jacks, etc.)

Measuring Method: (Power ON)

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accesible parts. Use and AC

voltmeter to measure across both terminals of load Z.

See figure 2 and following table.

Table 2: Leakage current ratings for selected areas

Note: This table is unofficial and for reference only. Be sure to confirm the precise values for your particular country and

locality.

Fig. 2

AC Line Voltage Region

Insulation Dielectric Clearance

Resistance Strength Distance (d), (d')

100V Japan ≥1 MΩ/500 V DC 1kV AC 1 minute ≥ 3 mm

110 to 130V

USA &

– – –

900V AC 1 minute ≥ 3.2mm

Canada

* 110 to 130 V Europe ≥ 4 MΩ/500 V DC 3 kV AC 1 minute ≥ 6 mm (d)

200 to 240 V Australia ≥ 8 mm (d')

(a: Power cord)

AC Line Voltage Region

Earth Ground

Load Z Leakage Current (i)

(B) to:

100V Japan ¡ ≤ 1m A rms

Exposed accessible

parts

110 to 130 V USA & ¡ ≤ 0.5 m A rms Exposed accessible

parts

¡ ≤ 0.7 m A peak Antenna earth

110 to 130 V Europe ¡ ≤ 2 m A dc terminals

200 to 240 V Australia ¡ ≤ 0.7 m A peak

Other terminals

¡ ≤ 2 m A dc

Fig. 1

1k

1.5k

1.5kµF

2k

50k

d

Primary circuit termimals

Chassis

d'

a

Exposed

accessible

part

Z

Earth Ground

power cord plug prongsB

AC Voltmter

(high impedance)

1

TABLE OF CONTENTS

SECTION 1. CONTROLS AND FUNCTIONS......................................................................................................2~4

SECTION 2. ELECTRICAL ADJUSTMENTS

2-1. SERVO CIRCUIT ADJUSTMENT METHOD........................................................................................... .......................... 5

2-2. AUDIO CIRCUIT ADJUSTMENT METHOD..................................................................................................................6~8

2-3. PIF CIRCUIT ADJUSTMENT METHOD............................................................................................. ............................... 9

SECTION 3. TROUBLE SHOOTING FLOW CHART

3-1. POWER CIRCUIT......................................................................................................................................................10~11

3-2. LOGIC CIRCUIT.........................................................................................................................................................12~14

3-3. SERVO-SYSCON CIRCUIT ......................................................................................................................................15~19

3-4. AUDIO CIRCUIRT......................................................................................................................................................20~25

3-5. VIDEO CIRCUIT.........................................................................................................................................................26~31

SECTION 4. BLOCK DIAGRAM............................................................................................................................32~33

SECTION 5. CIRCUIT DIAGRAM

5-1. CONNECTION DIAGRAM.........................................................................................................................................34~37

5-2. POWER CIRCUIT (SMPS).........................................................................................................................................38~39

5-3. SYSCON CIRCUIT...........................................................................................................................................................40

5-4. LOGIC CIRCUIT.........................................................................................................................................................41~44

5-5. PIF & NTS & D/V INPUT SELECTOR CIRCUIT........................................................................................................45~46

5-6. AUTO-DETECT CIRCUIT.................................................................................................................................................47

5-7. VIDEO CIRCUIT ...............................................................................................................................................................48

5-8. AUDIO CIRCUIT...............................................................................................................................................................49

5-9. PRE AMP CIRCUIT..........................................................................................................................................................50

5-10. OSD CIRCUIT ................................................................................................................................................................51

5-11. WAVE FORM...........................................................................................................................................................52~55

SECTION 6. VOLT AGE CHAR T

6-1. IC VOLTAGE.............................................................................................................................................................. 56~64

6-2. TR VOLTAGE.............................................................................................................................................................65~66

SECTION 7. COMPONENTS LOCA TION GUIDE ON PCB (BOTTOM VIEW)

7-1. PCB HEAD-AMP..............................................................................................................................................................67

7-2. PCB SHUTTLE.................................................................................................................................................................68

7-3. PCB MAIN........................................................................................................................................................................ 69

7-4. PCB LOGIC................................................................................................................................................................70~71

7-5. PCB AUTO DETECT........................................................................................................................................................72

SECTION 8. DISASSEMBLY

8-1. PACKING AS.............................................................................................................................................................73~76

8-2. SET TOTAL ASSEMBLY........................................................................................................................................... 77~80

8-3. FRONT PANEL ASSEMBLY.....................................................................................................................................81~84

8-4. SHUTTLE STATION ASSEMBLY....................................................................................................................................86

SECTION 9. ELECTRICAL P AR TS LIST

9-1. STANDARD PART NUMBER CODING ..........................................................................................................................88

9-2. ELECTRICAL PARTS LIST......................................................................................................................................89~110

2

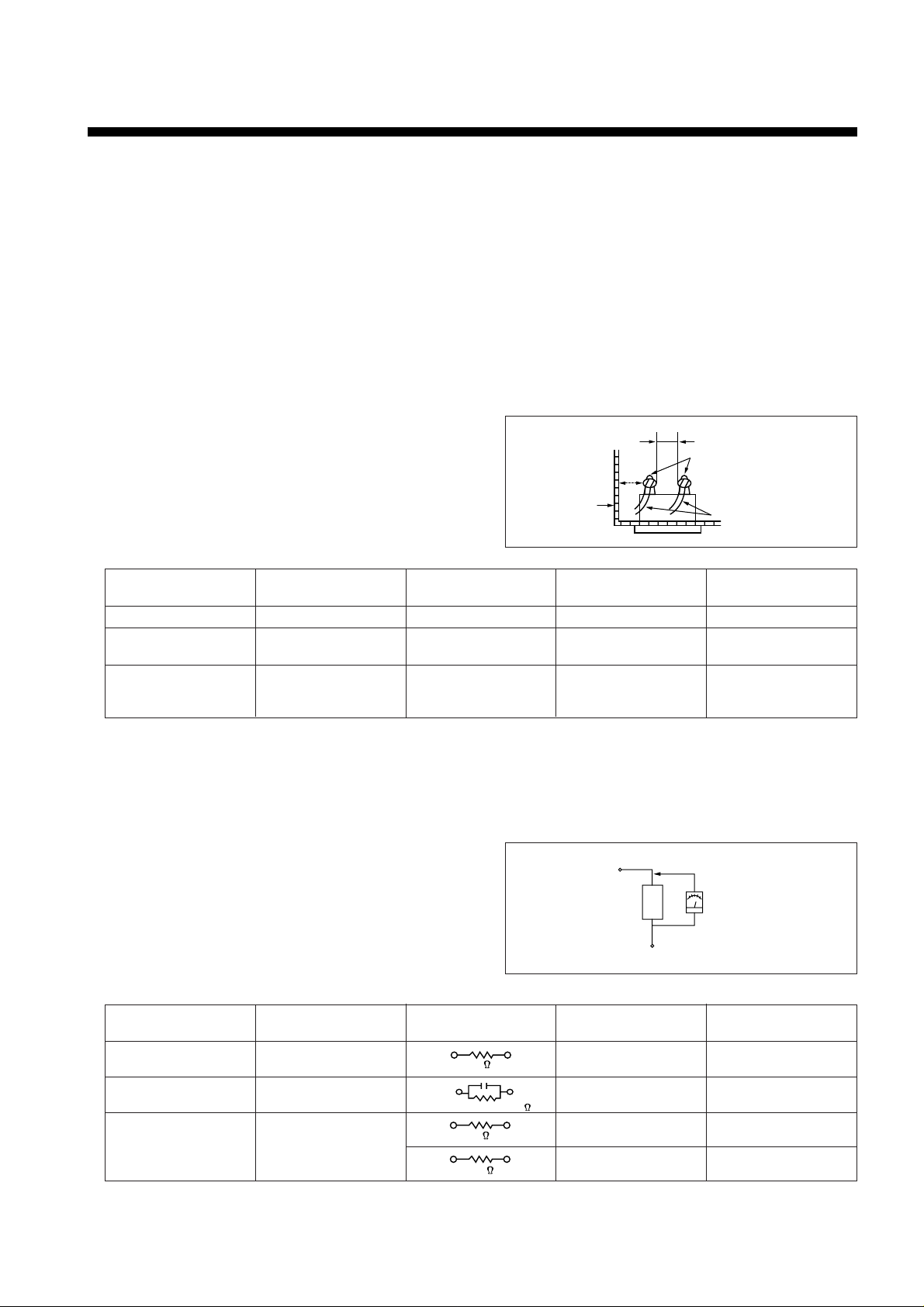

SECTION 1. CONTROLS AND FUNCTIONS

FRONT

DV -F803, 503 SERIES

EJECT

REC

POWER

PLAY

STOP

PAUSE

/STILL

CH.

REW

FF

OPEN

DV -F803

TAPE

NTSC

PAL

R

EJECT

REC

POWER

PLAY

STOP

PAUSE

/STILL

CH.

REW

FF

L

AUDIO

SYSTEM CONVERTION

NTSC

PAL

VIDEO IN

DV -F503

TAPE

NTSC

PAL

VIDEO AUDIO

AUTO

NTSC PAL

VTR SYSTEM

EJECT

REC

POWER

PLAY

STOP

PAUSE

/STILL

CH.

REW

FF

3

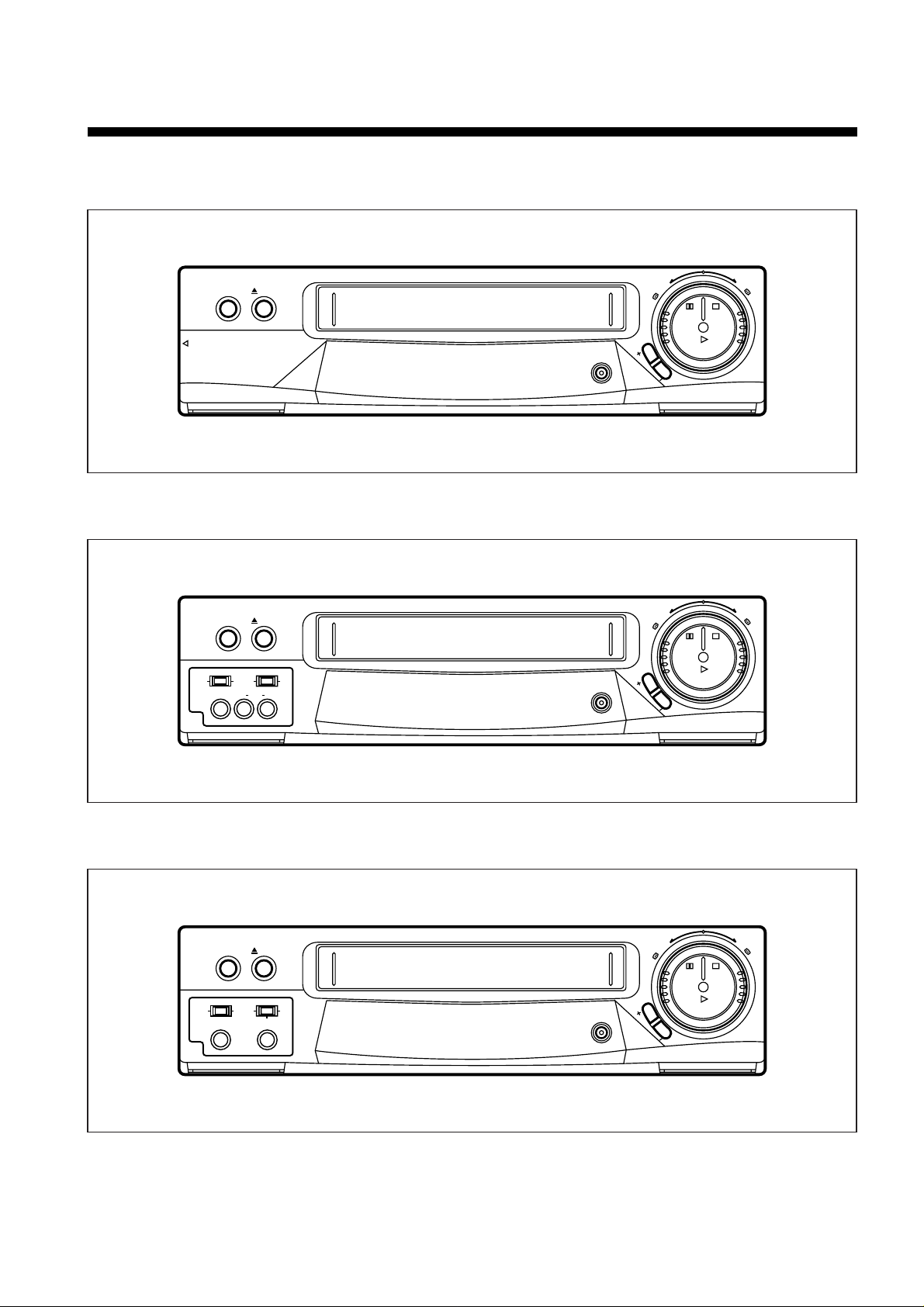

DV -F883, 683 SERIES

PAUSE

STILL

STOP

PLAY

CHANNEL

REC

POWER EJECT

F

F

R

E

W

+

–

OPEN

DV -F883

AUDIOVIDEO

TAPE

PALNTSC

LR

PAUSE

STILL

STOP

PLAY

CHANNEL

REC

POWER EJECT

F

F

R

E

W

+

–

SYSTEM

PALNTSC

DV -F683

AUDIOVIDEO

TAPE

PALNTSC

PAUSE

STILL

STOP

PLAY

CHANNEL

REC

POWER EJECT

F

F

R

E

W

+

–

SYSTEM

PALNTSC

4

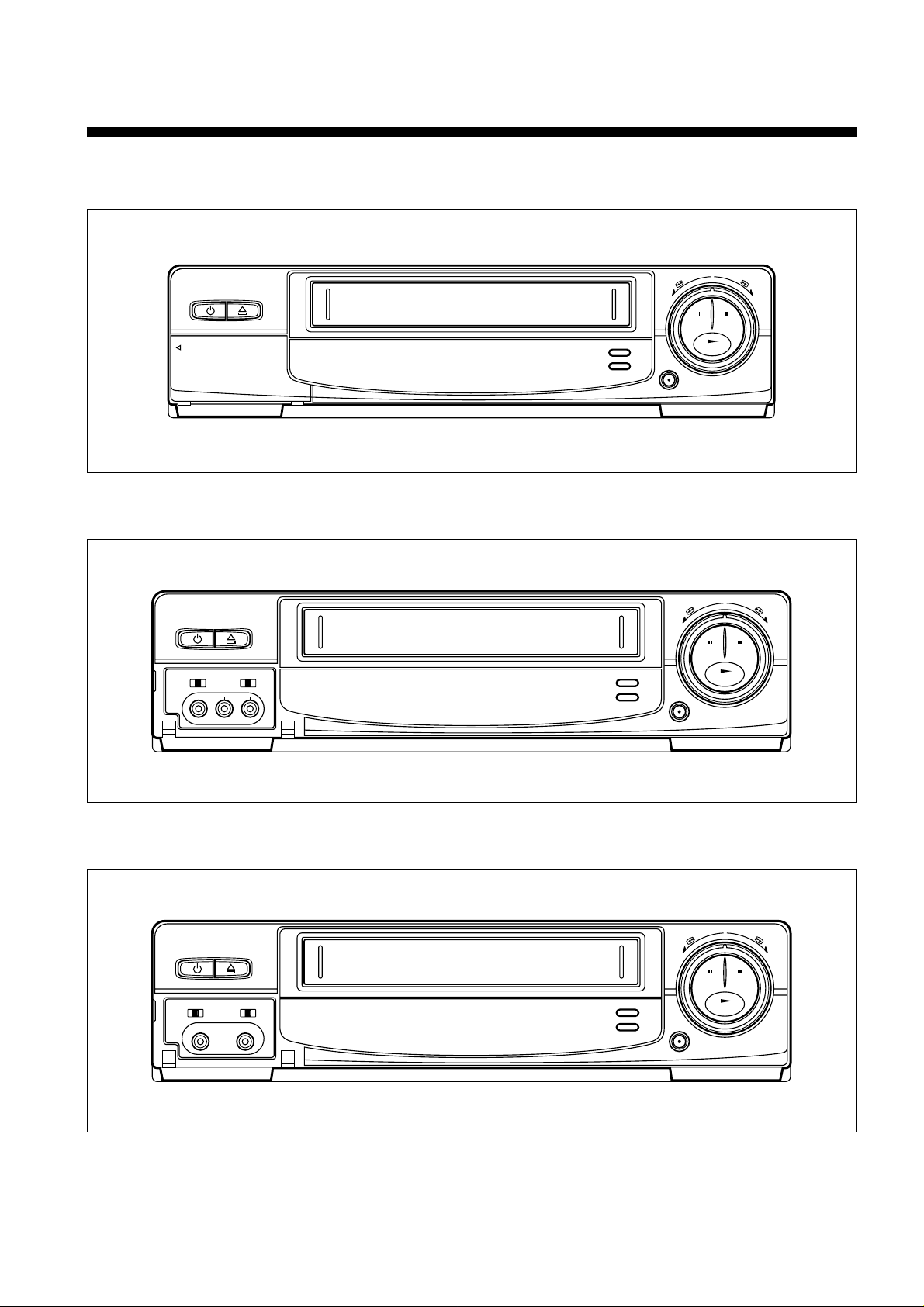

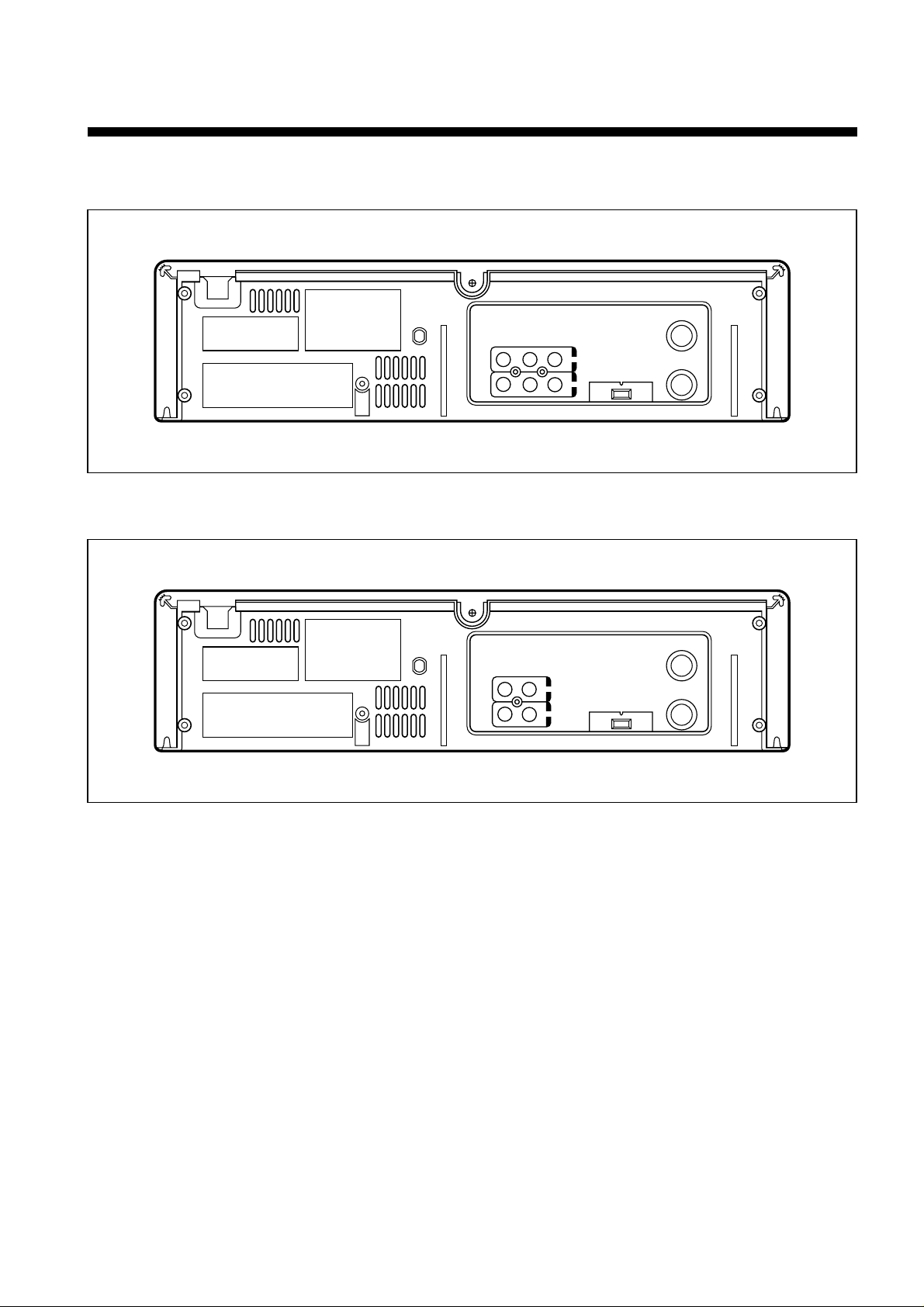

REAR

DV -F883, 803 SERIES

CH.3 CH.4

RF OUT

ANT.IN

OUT

IN

VIDEO AUDIO

LR

DV -F683, 503 SERIES

CH.3 CH.4

RF OUT

ANT.IN

OUT

IN

VIDEO AUDIO

5

SECTION 2. ELECTRICAL ADJUSTMENTS

2-1. SERVO CIRCUIT ADJUSTMENT METHOD

1. PB Phase

• Adjustment Procedure

1. Set the oscilloscope to the CHOP mode. Connect the oscilloscope to check point and trigger the scope with CH1.

2. Adjust R595 to position the V-SYNC at 6.5±0.5H from the rising edge of sw pulse.

• Adjustment Inspecition Standard:

6.5±0.5H

Mode Adjustment Parts Check Point Test Equipments Test Tape Input Signal

CH 1: PT01 #

PLAY ! R595 CH 2: VIDEO Oscilloscope

DN-1

OUTPUT JACK

(Color Bar)

Location of Adjustment Parts Observation Waveform

H-Axis: 50us/div V-Axis: CH 1 ¡ 1.0v/div

CH2 ¡ 0.5v/div

MAIN PCB

T

U

HEAD-AMP / AUDIO

3

N

E

R

2 1

DECK

6

2-2. AUDIO CIRCUIT ADJUSTMENT METHOD

1. Audio REC Bias

• Adjustment Procedure

1. Set the TV/LINE to LINE mode

2. Connect the Audio level meter to both TP1 and TP2.

3. After inserting a blank tape, record in SP mode.

4. Adjust R292 to obtain 3.0±0.1mVrms.

• Adjustment Inspecition Standard:

In confirmation of Recording playback frequency characteristics, compared with 1KHz Recording-playback output level,

10KHz Recording-playback output level is higher than the standard, increase the record bias and if lower, decrease it.

Mode Adjustment Parts Check Point Test Equipments Test Tape Input Signal

+: TP1

REC @ R292 –: TP2 Audio level meter Blank tape Without signal

(A/C HEAD PCB)

Location of Adjustment Parts

MAIN PCB

T

U

N

E

HEAD-AMP / AUDIO

R

2 1

DECK

7

2. Audio Playback Frequency Characteristics

• Adjustment Procedure

1. Play back the test tape. Confirm the output level of 7 KHz is in the range of –1±3dB, compared with the output level of 1

KHz.

3. EE LEVEL

• Adjustment Procedure

1. Set the TV/LINE to LINE mode.

2. Connect the Audio signal generator to the AUDIO INPUT JACK.

3. Confirm the Audio output level –6±1.5dBm when you supply 1KHz (–8dBm) to the AUDIO INPUT JACK.

4. Insert a blank tape.

Record and play back the signal of 1KHz (–8dBm) (SP/EP MODE).

5. Confirm the Audio output level and Distortion meet the followings.

1) Audio playback output level

SP: –6±3dBm

EP: SP±3dBm

2) Audio distortion

SP: 3% maximum

4. Confirmation of Recording Playback Frequency Characteristics

• Adjustment Procedure

1. Set the TV/LINE to LINE mode.

2. Connect the Audio signal generator to the AUDIO INPUT JACK and Audio level meter to the AUDIO OUTPUT JACK.

3. Insert a blank tape.

Record the signal of 400 Hz and 10 KHz and 10 KHz in SP mode.

4. The output level of 10 KHz should be within –1±3dB to the output level of 400 Hz in the PLAYBACK mode (SP).

5. Insert a blank tape.

Record the signal of 400 Hz and 5 KHz (–20dBm) in EP mode.

6. The output level of 5 KHz should be within –1±3dB to the output level of 400 Hz in the PLAYBACK mode (EP).

Mode Adjustment Parts Check Point Test Equipments Test Tape Input Signal

Audio level meter

DN-1

PLAY Check NTSC Audio Output

DN-2

Mode Adjustment Parts Check Point Test Equipments Test Tape Input Signal

PLAY Audio level meter

REC

Check NTSC Audio Output

Distortion meter

Blank tape 1KHz -8dBm

Mode Adjustment Parts Check Point Test Equipments Test Tape Input Signal

REC Audio level

PLAY

Check NTSC Audio Output

meter

Blank tape -20 dBm

8

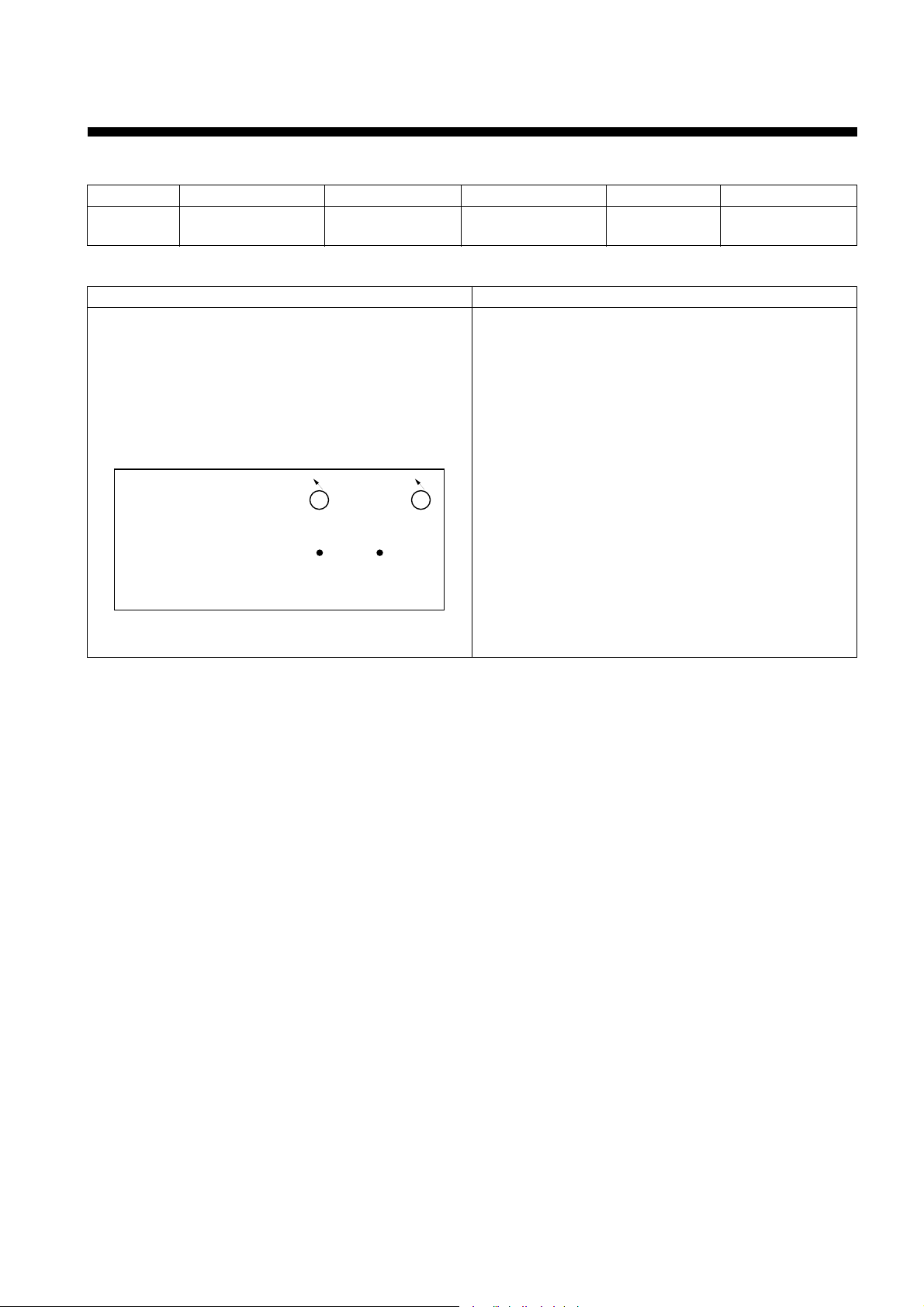

5. Hi-Fi Carrier (DV-F803M/883M)

• Adjustment Procedure

1. Preparation

1) Set the TV/LINE to LINE Mode.

2) Supply the input signal in the OPEN state.

2. Adjustment

1) Set the VCR to the REC Mode (SP).

2) Connect the frequency counter to TP902 (1.3MHz) and TP901 (1.7MHz).

3) Adjust R991 to set the frequency of TP902 for 1.3±0.01MHz.

4) Adjust R993 to set the frequency of TP901 for 1.7±0.01MHz.

3. Adjustment Inspection Standard:

1.3±0.01 MHz (TP902)

1.7±0.01 MHz (TP901)

Mode Adjustment Parts Check Point Test Equipments Test Tape Input Signal

R991 TP902

REC

R993 TP901

Frequency counter Blank Tape No Signal

Location of Adjustment Parts Observation Waveform

Horizontal Axis: S/DIV

Vertical Axis : V/DIV

Hi-Fi/PRE AMP PCB (COMPONENTS SIDE)

(1.3M) (1.7M)

R991 R993

TP902 TP901

9

2-3. PIF CIRCUIT ADJUSTMENT METHOD

1. STEREO (DV-F803M/883M)

• Adjustment Procedure

1. Connect the output of US 5CH (L=1KHz 100% MOD, R=nonsignal) to ANT IN OF TMI.

Then RF signal input is 93dBu.

2. Connect audio output L and R to AC volt meter 1CH and 2 CH.

3. Turn R191, confirm if L output changes.

Fix the minimum point of R output.

* The condition of US 5CH: Color Bar: 87.5% modulation, 72dBuV

Audio: L CH=1KHz, 100% MOD, R CH=nonsignal

Using equipment: Audio Signal Generator, MPX equipment, RF Modulator

• Adjustment Inspecition Standard: The minimum point of R output.

Mode Adjustment Parts Check Point Test Equipments Test Tape Input Signal

EE Audio

MODE

# R191

Output-R

AC Volt meter US 5CH

Location of Adjustment Parts Observation Waveform

MAIN PCB

T

U

HEAD-AMP AND HiFi

3

N

E

R

2 1

DECK

10

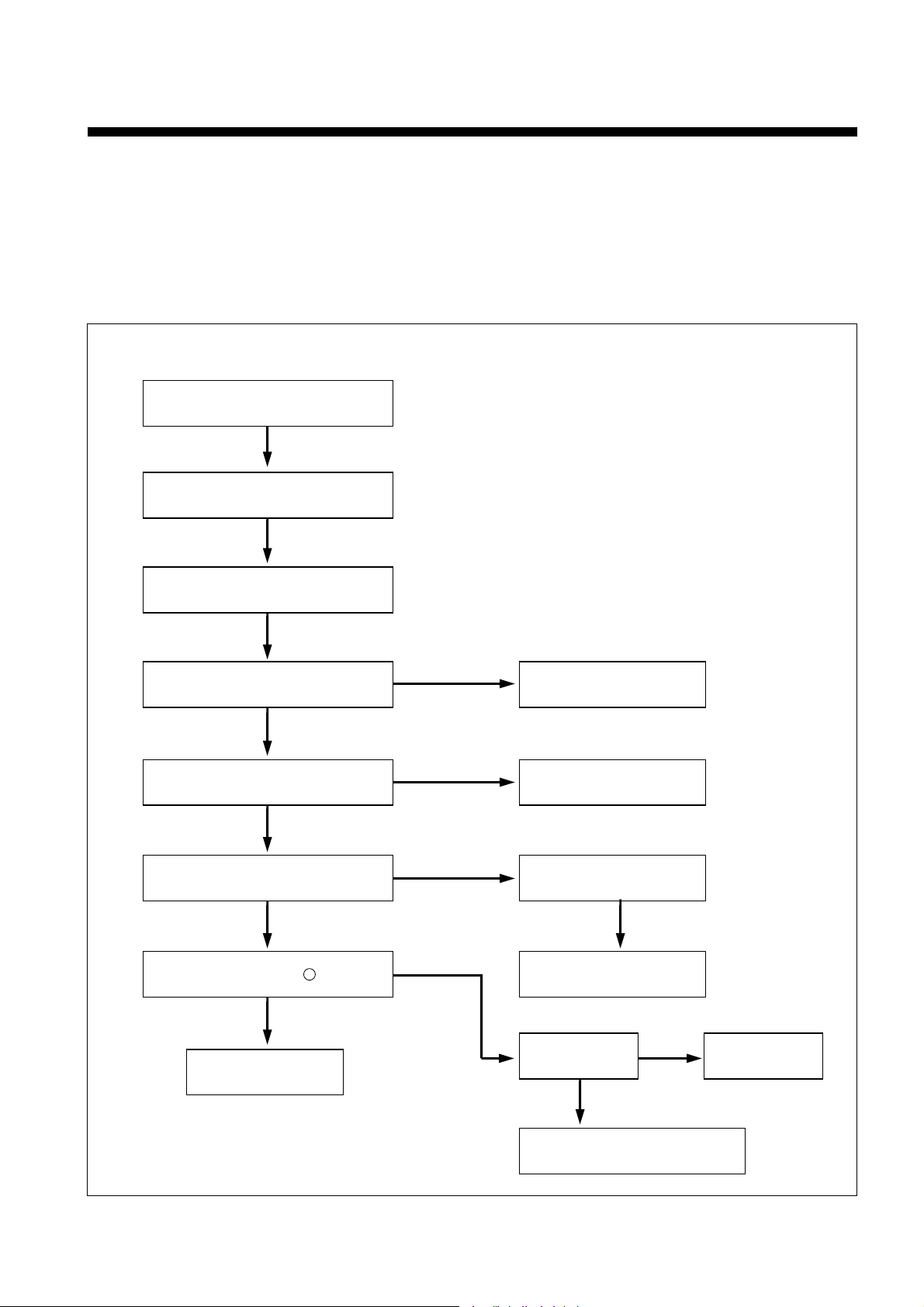

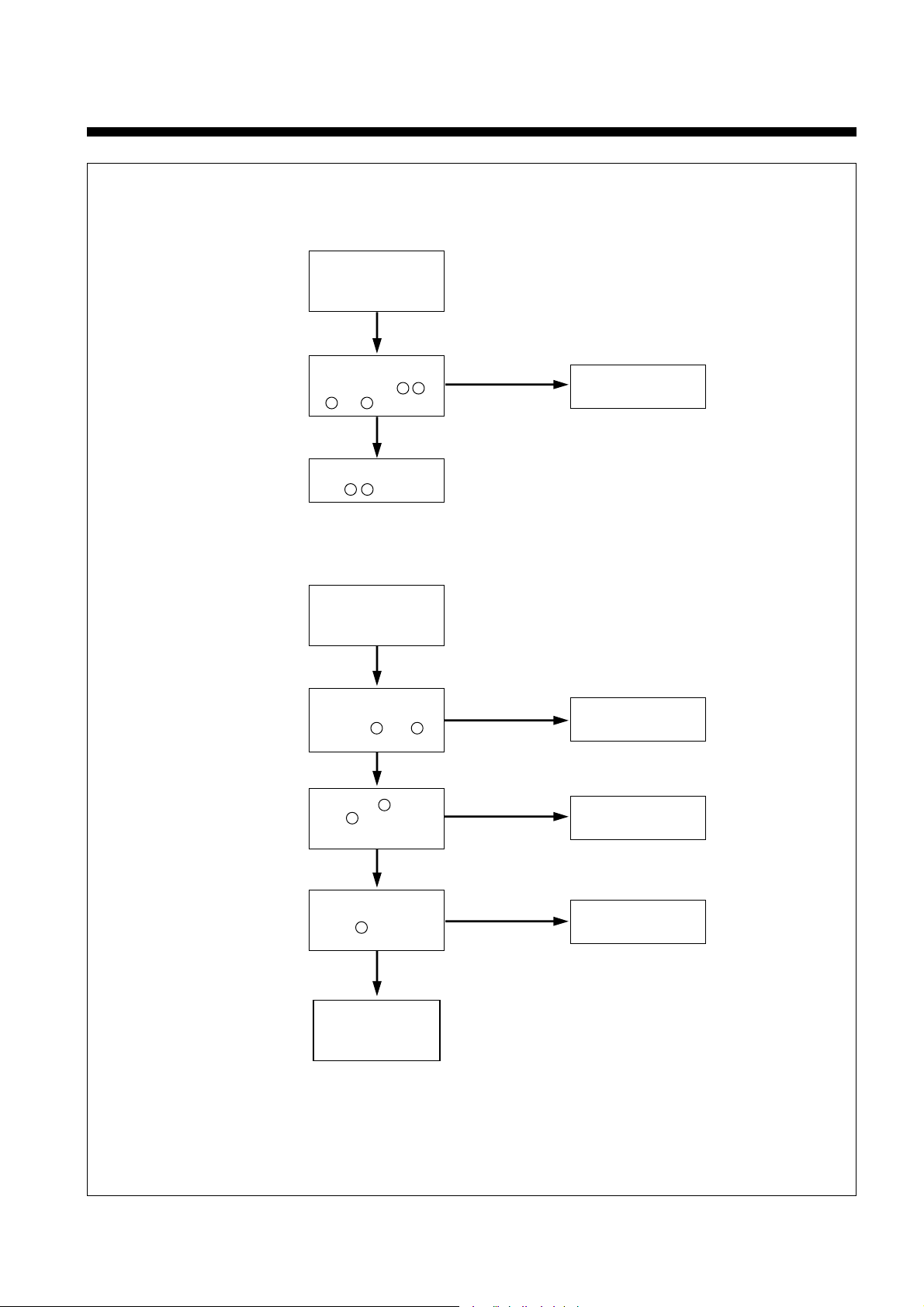

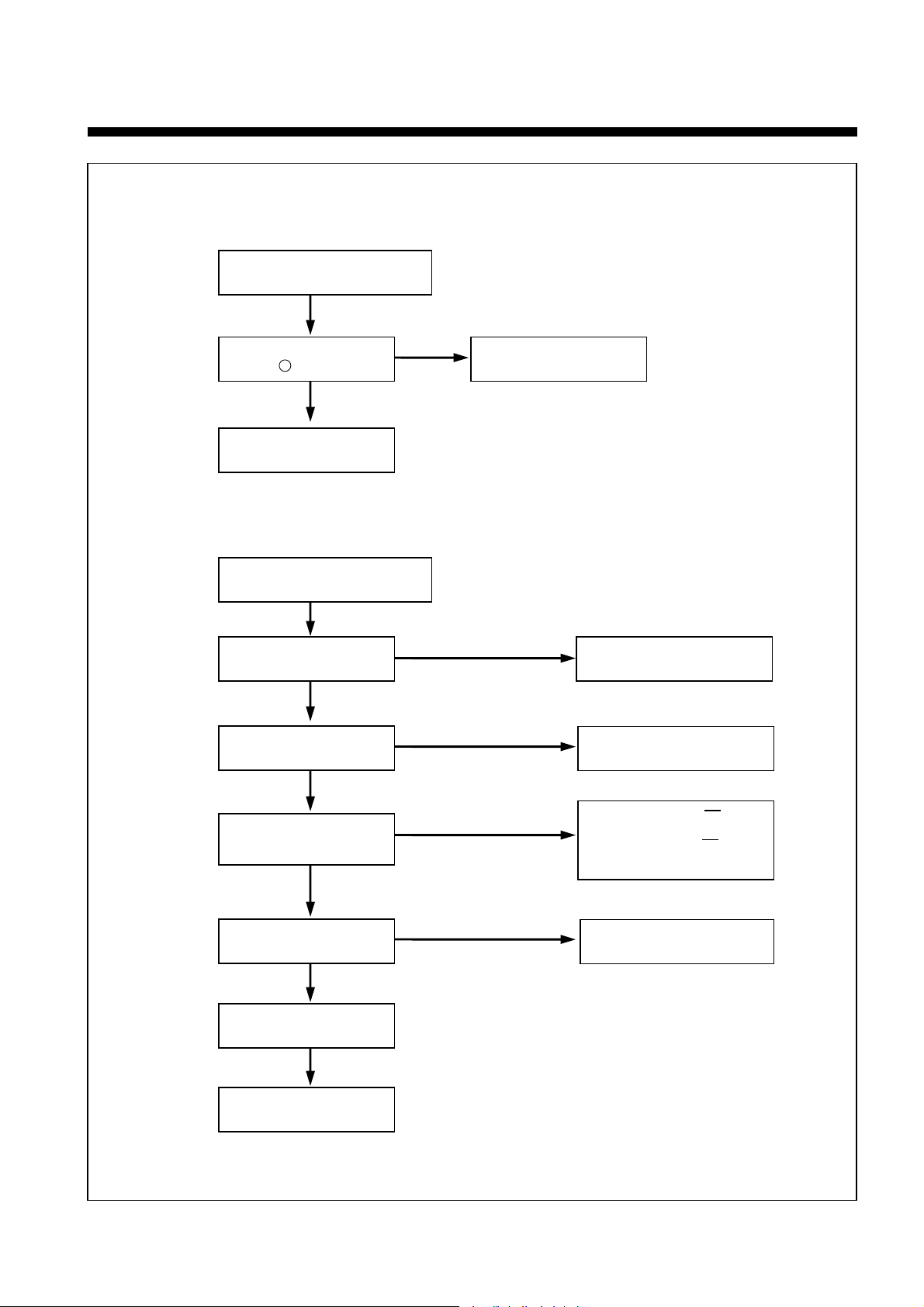

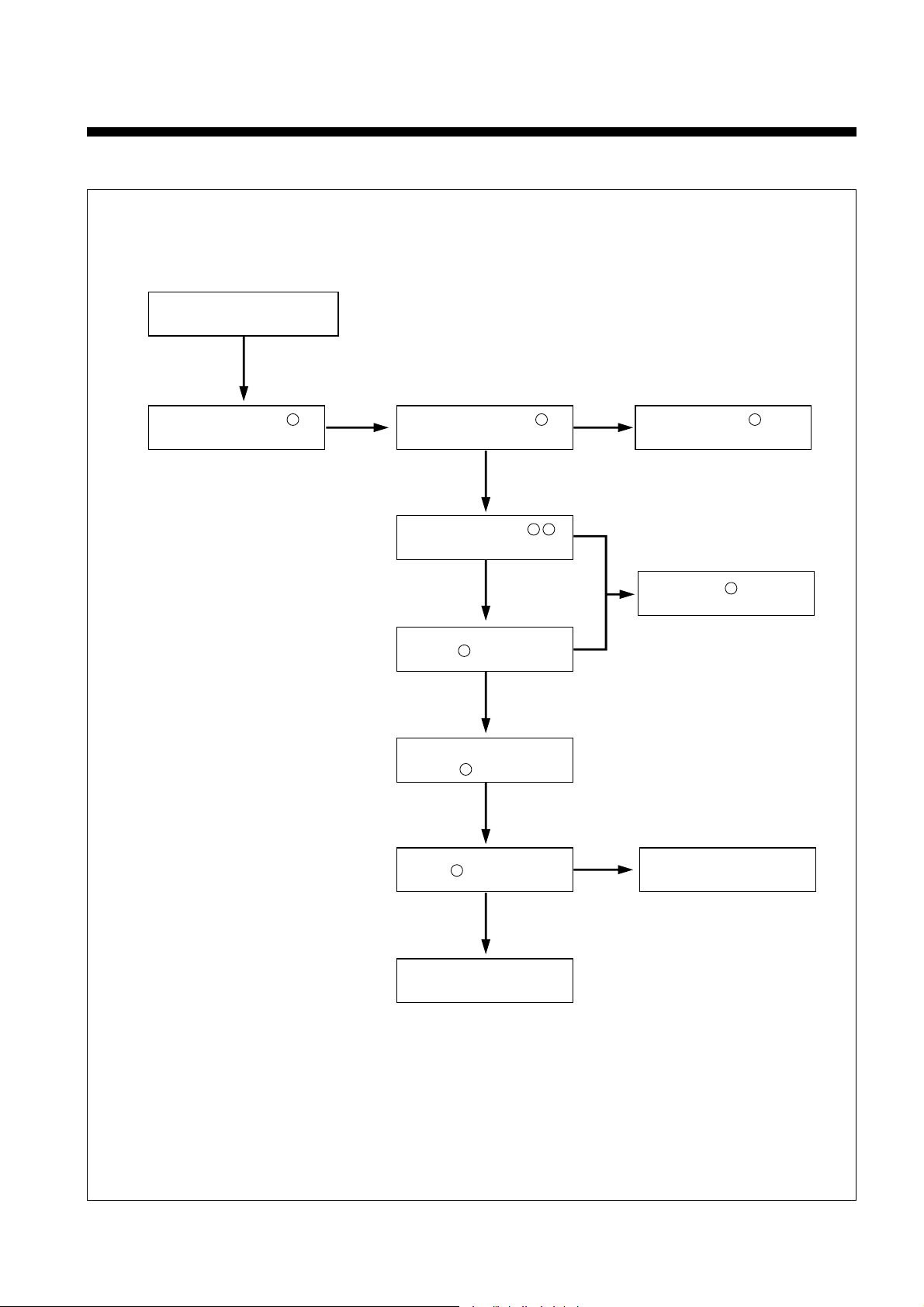

SECTION 3. TROUBLE SHOOTING FLOW CHART

3-1. POWER CIRCUIT

• When change the parts which are out of order, first, remove the power plug from the socket and then discharge the

voltage across between both terminals of C807. (Use an external scores of KΩresistance)

• When check the primary circuit by using the oscilloscopes insulate the oscilloscope surely. (Use the isulating

transformer) and must connect GND into the primary GND (But there is no connection when check the secondary

circuit).

• When change IC801, check FUSE and Cement resistance surely.

Prepare the instrument

connecting the insulating trans.

Check F801 FUSE.

Is voltage applied to D801?

Is voltage applied to the

both terminals of C807?

Check voltage of Q801 Gate.

4

Is voltage output from pin of IC801?

Check Q801.

Check D801, L801 & L802.

Check R802.

Check R803, 805, 823

814, 806 & C817.

Check Q802, 803,

D802, R809.

Check IC801. Change IC801.

Check the Secondary circuit.

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

NO output Voltage.

A. CHECKING THE PRIMARY CIRCUIT.

11

IS DZ805, DZ807 Short?

Check each votage.

Check Trans output of

No output stage.

Check the DIODE of

NO output stage.

Check COIL, C of

No output stage.

Check the environmental

terminals of IC801.

Change DZ805, DZ807 and check

IC801 and primary circuit.

YES

NO

YES

YES

YES

YES

B. CHECKING THE SECONDARY CIRCUIT.

12

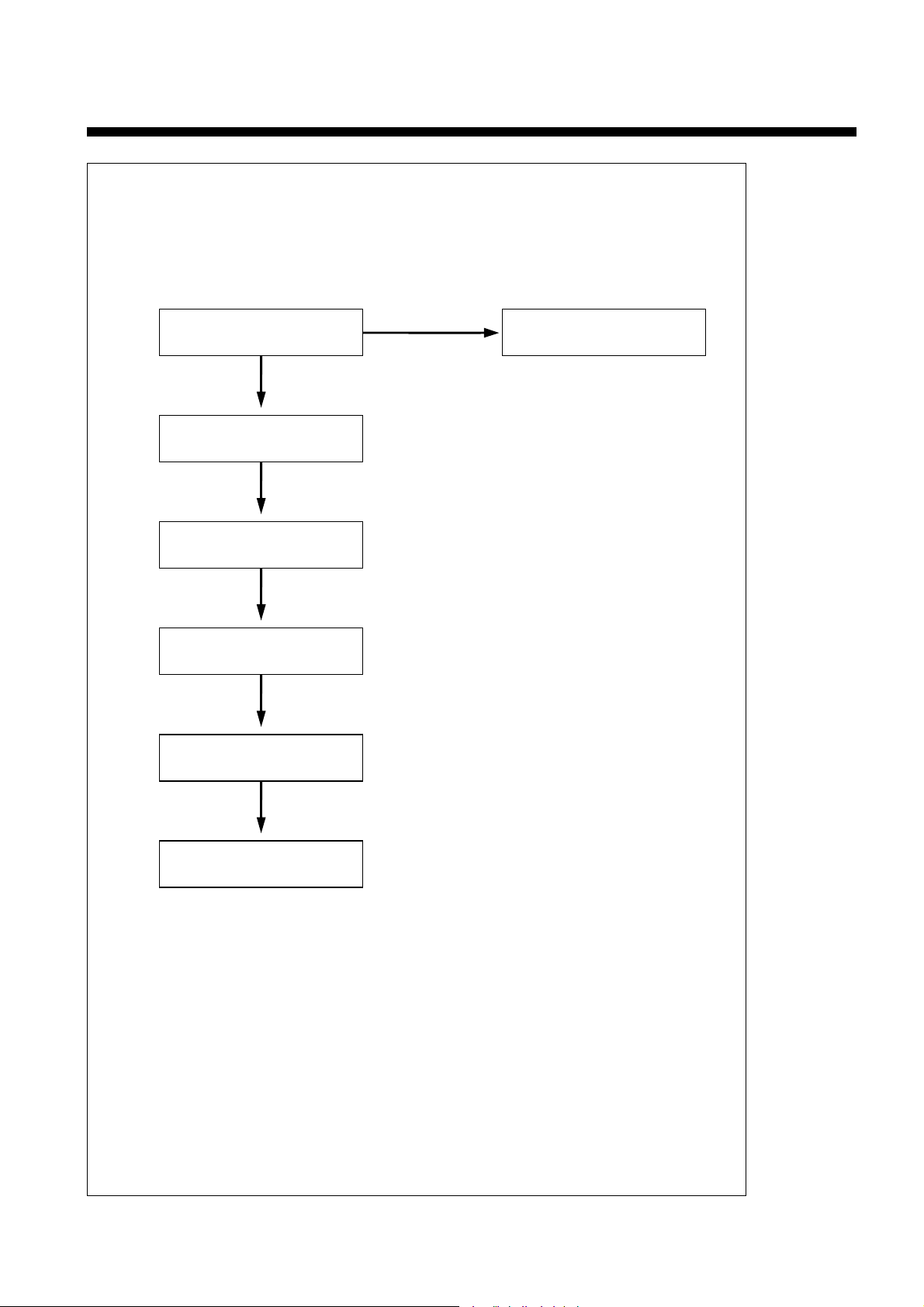

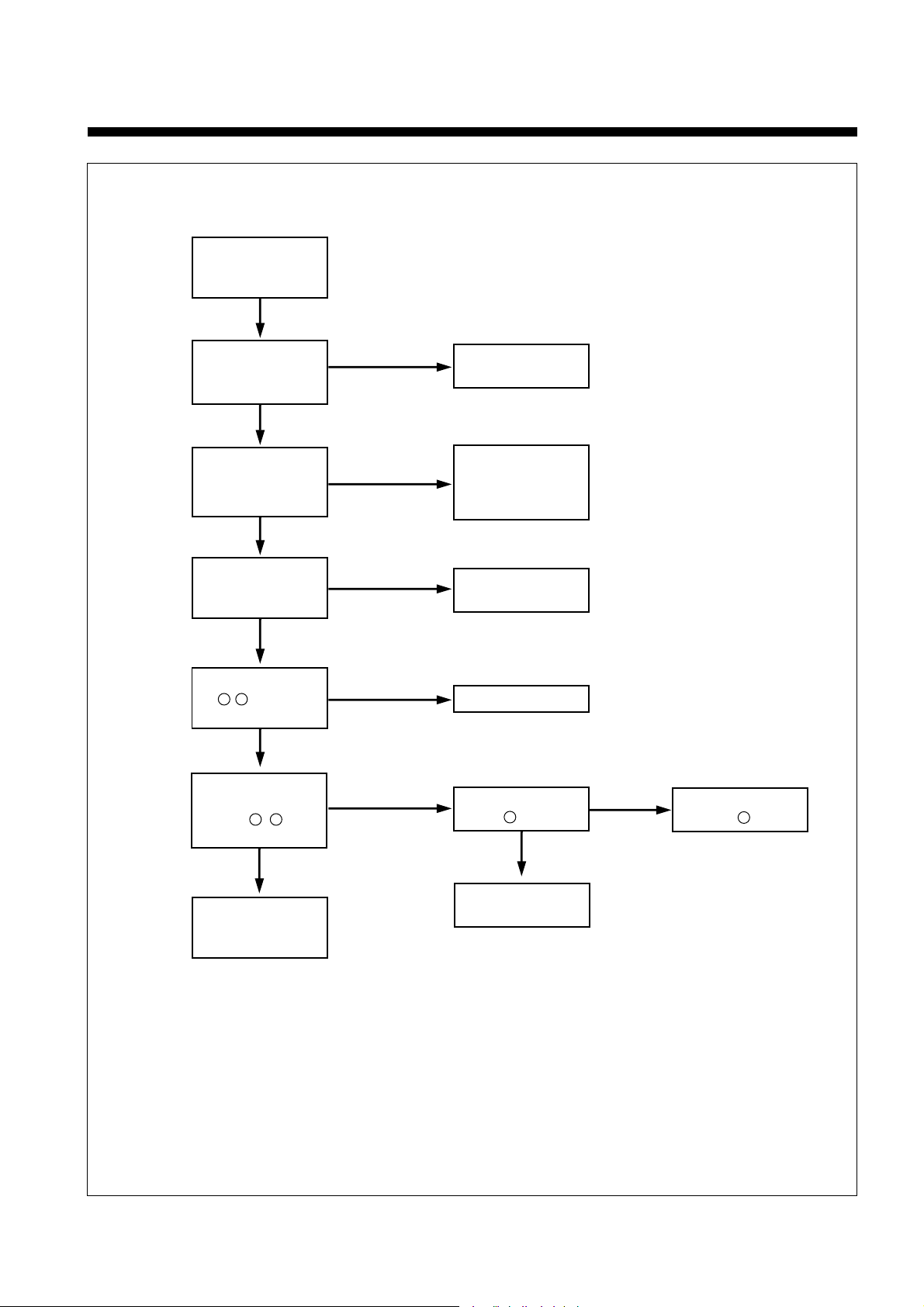

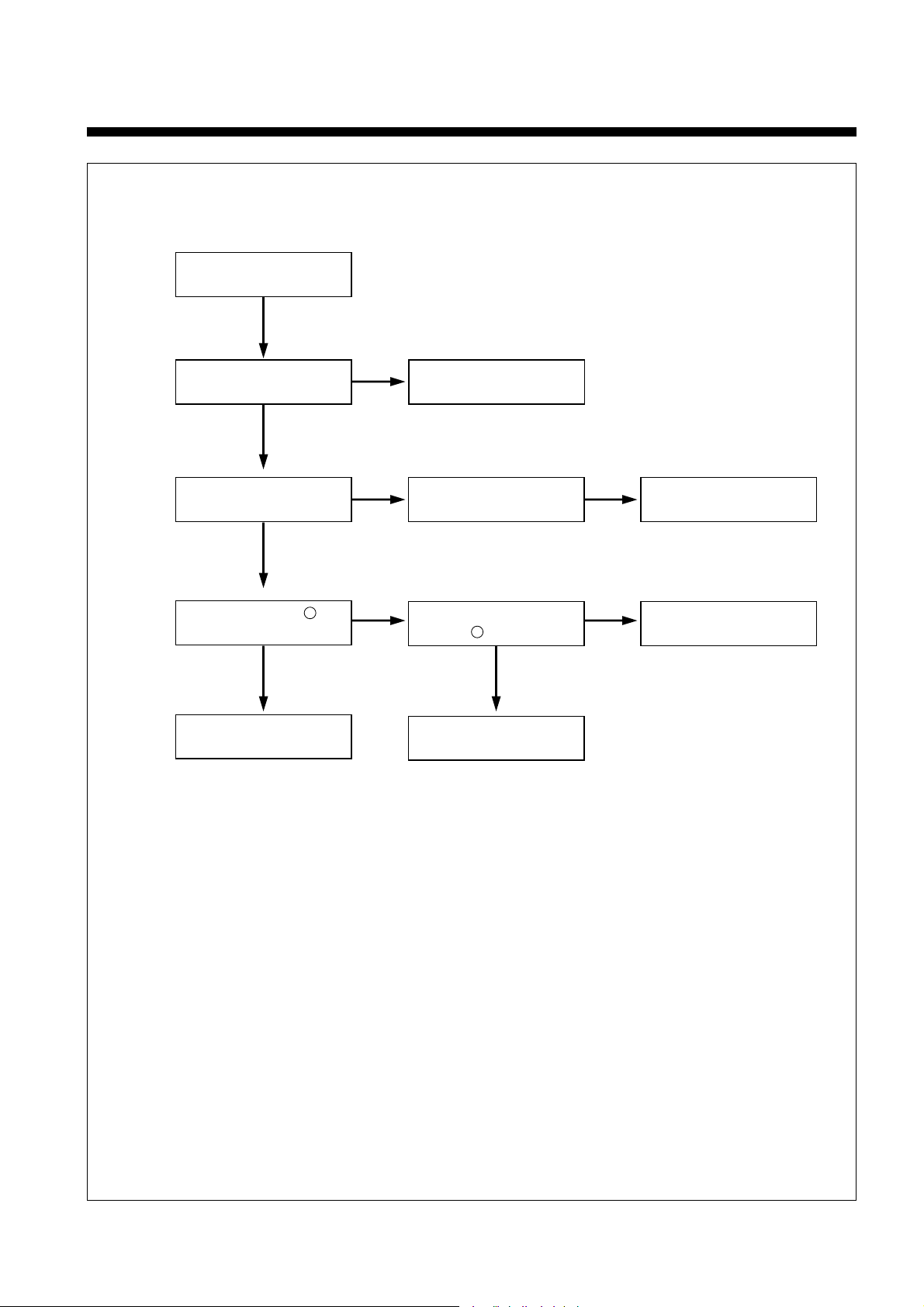

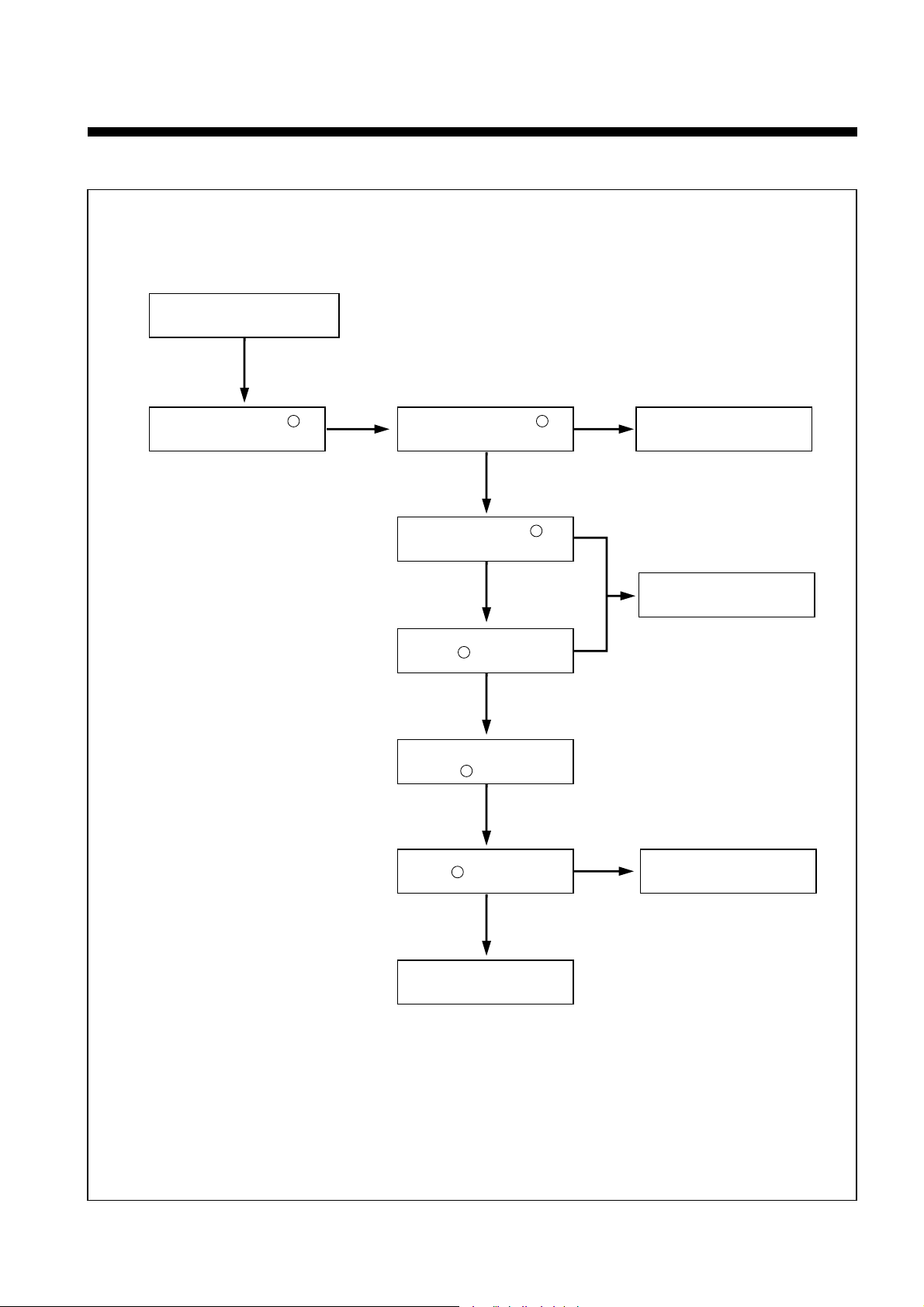

3-2. LOGIC CIRCUIT

Digitron does

not operate & is not good.

Is+5V supplied to

pin of IC701?

8

Is-28V supplied to

pin of IC701?

11

Are -25.8 and -21.2V

supplied to pin and

of G701?

1

46

Are CLK signals

supplied to pin

of IC701?

40

Is 5V at pin of

IC701?

7

Check X701.

Check IC701

and change.

CHECK D815and Primary

power circuit.

Check the

DZ601.

Check D814 and

primary power circuit.

Change DZ601.

Check the Trans output

and DZ601.

Check IC601.

Change IC702.

Change X701.

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

YES

NO

NO

A.

YES

Check the connector

and pattern.

13

Digitron is lit but

key do

not operate.

Is each key pulse

applied to pin ,

and of IC701?

2 3

12 13

Check key matrix

circuit.

Check the pin serial of

pin , of IC701.

38 39

It has not power-failure

compensation

operation.

When disconnecting

the power cord,is 5.4V

at pin and

of IC601?

26 81

Do pin and

of IC601

oscillate?

42

Is +5V applied to

pin of IC601?

37

Check IC601.

Check C605.

Check X602

environmental circuit.

NO

YES

YES

YES

YES

NO

NO

NO

B.

C.

43

Check the IC606

RESET circuit.

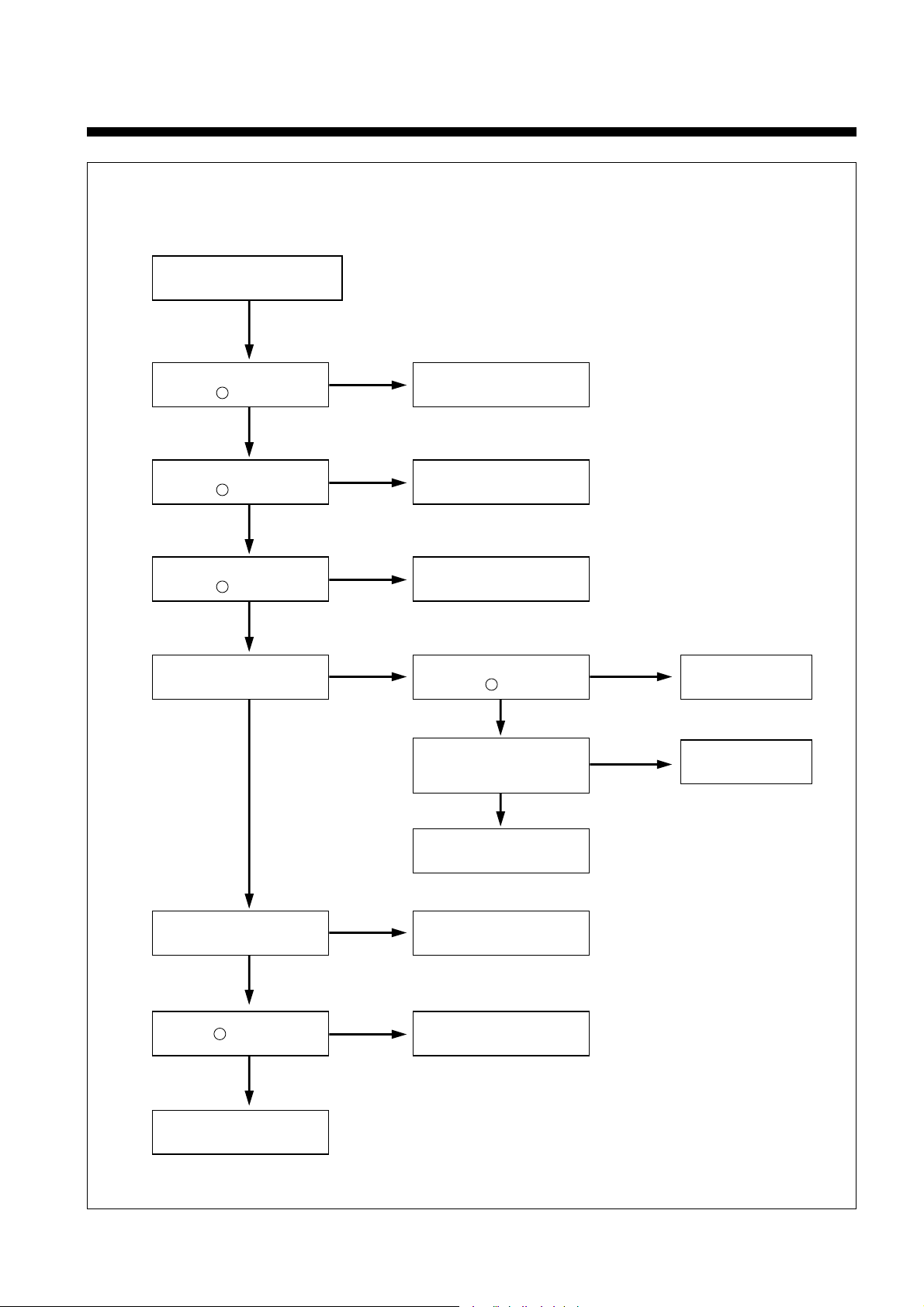

14

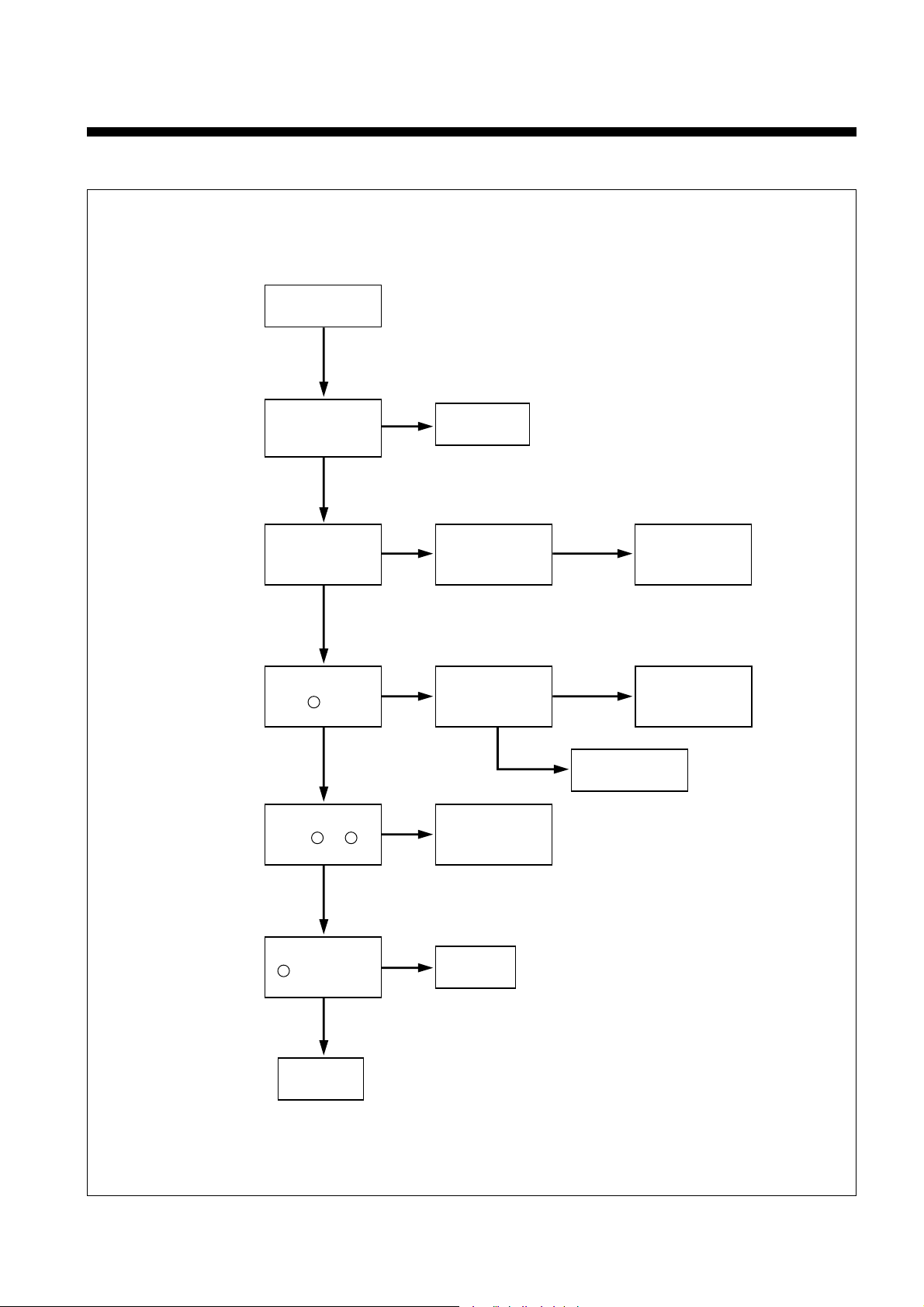

When change the

channel broadcast

signal is not received.

Is the external ANT.

connected to RF IN of

VCR and RF OUT

of TV?

Is the Power of VCR

ON and the VCR

indicator lit on the

digitron?

Does the TV channel

correspond to VCR

(3 or 4) channel?

Change and check the

connection of CABLE

Power On and select

the VCR mode by

pressing the

TV/VCR key.

YES

YES

YES

YES

NO

NO

NO

D.

Set the TV channel to

VCR (3 or 4) channel.

Check the Video,

Audio outputsignal of

pin , of

TMI BLOCK.

Check the TMI

BLOCK.

Check IC601

Check the

Video circuit.

Check the

IC601 pin.

Is the output of pin

, of IC601

normal?

100 98

YES

NO

44

14 18

Is the signal applied

to pin of IC151?

NO

YES

NO

YES

14

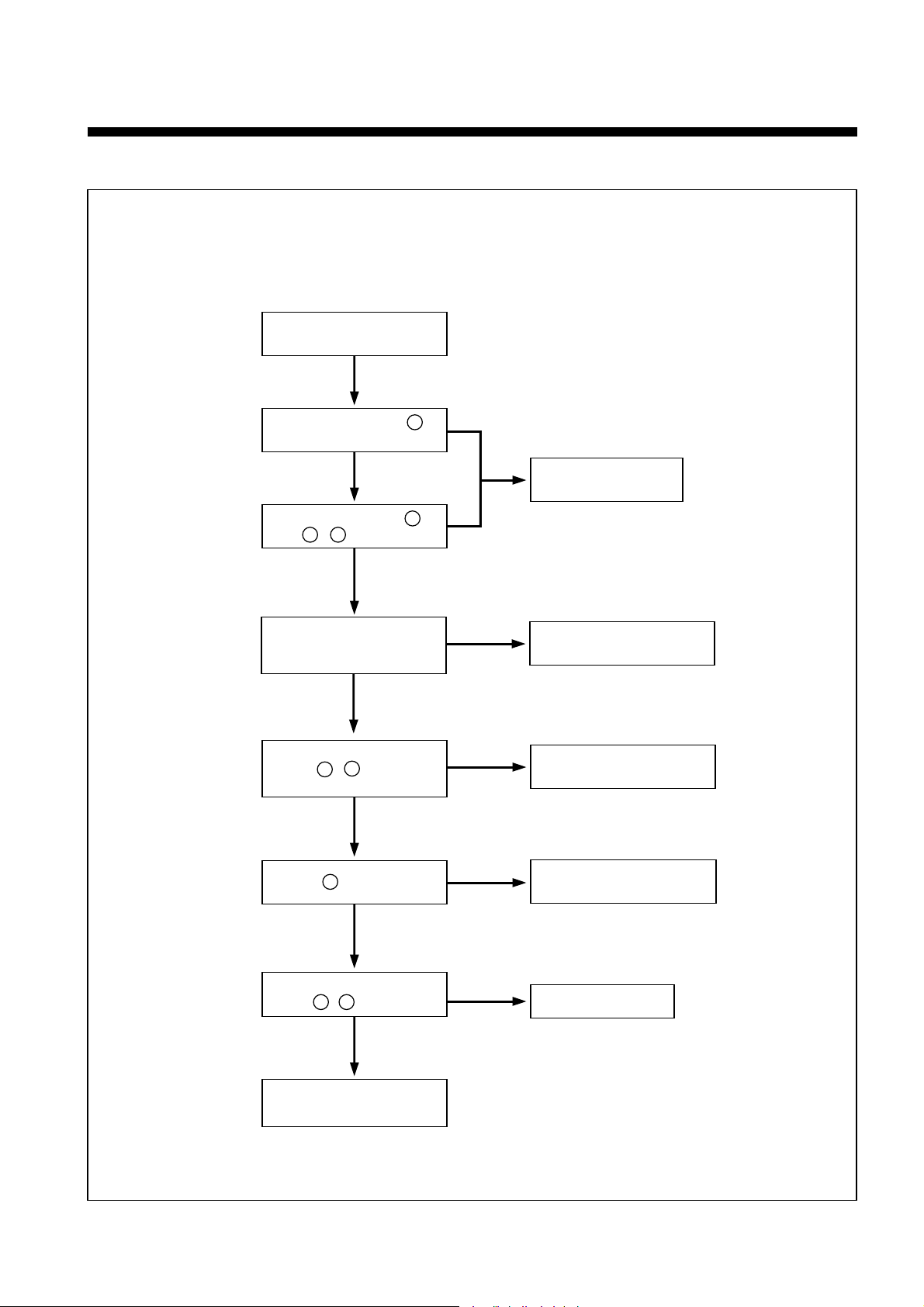

15

91

The voltage of pin

of IC601 is not

changed.

Is CTL pulse input

to pin and of

IC601?

71 72

73

Check and

re-adjust the

Path of Deck.

Check circuit

adjacent to IC601.

Check R523, R524

C508, C509.

check R518

and C511.

Check IC601.

YES

YES

YES

YES

YES

YES

YESNO

NO NO

NO

NO

NO

A.

Playback picture

is not good.

Noise appears

although adjusting

tracking.

Is CTL pulse applied

to pin of IC601?

Noise shakes up

and down on the

screen.

Adjust

tracking.

CTL HEAD height is

normal and there is

not dust.

Adjust the HEAD

height and remove

dust.

Noise appears

although change

cassette tape.

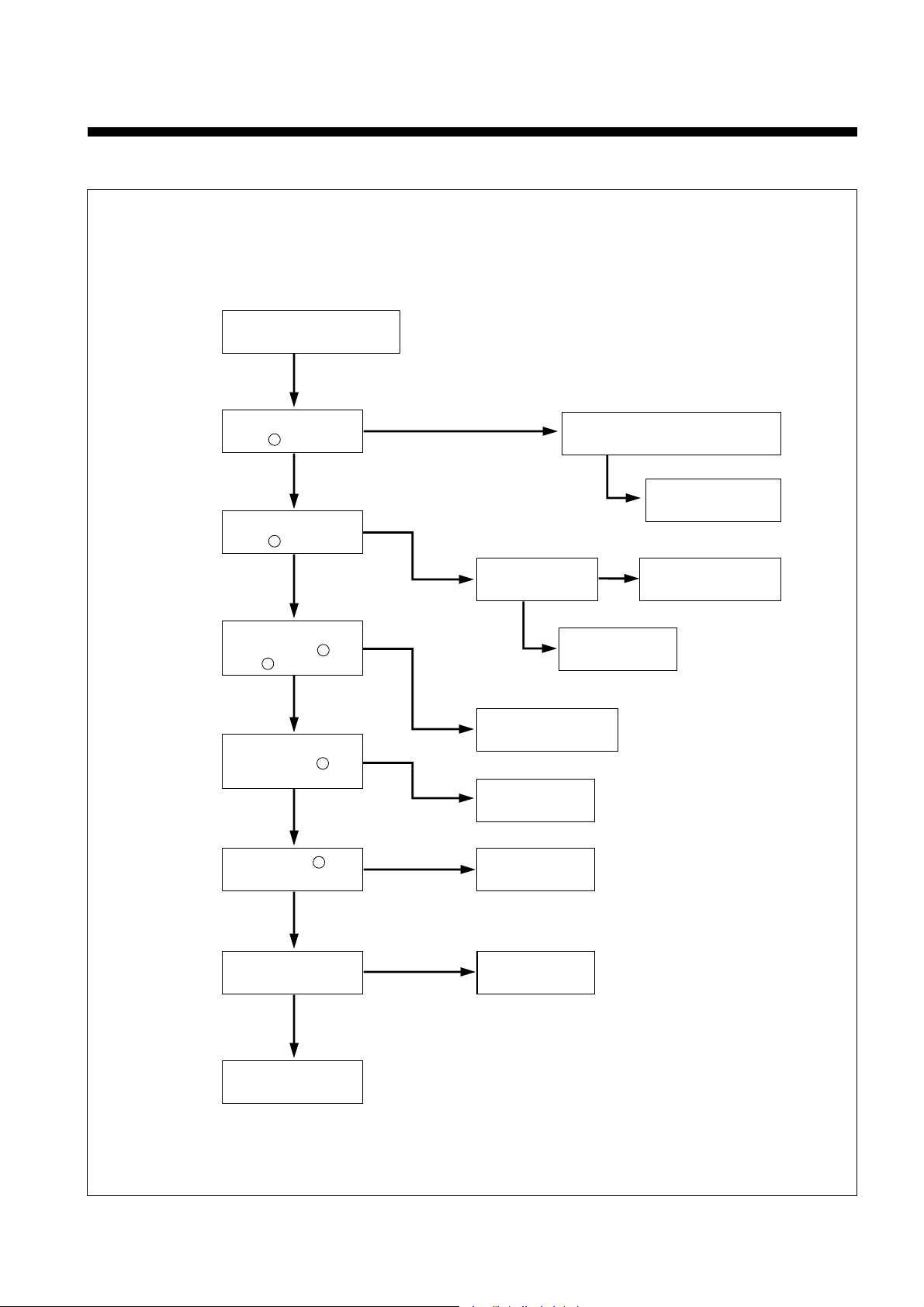

3-3. SERVO SYSCON CIRCUIT

16

Playback picture

is not good.

Noise appears

on the screen

whole.

Is Enve.waveform

supplied to at

pin of PT01?

4

Are SW pulse and

HA SW applied to

HEAD-AMP circuit?

Check VIDEO circuit.

Auto stop during

playback.

Is Reel pulse

applied to pin and

of IC601?

5

6

Check Flow A.

Is SW pulse supplied

from pin of IC601?

18

Check D.PG input

and connector.

Check pattern.

Check connector, Head

Amp and Head dust.

Change Head.

Check REEL

sensor part.

Is D.FG applied to

pin of IC601?

Check connector

and D.FG circuit.

Check IC601.

NO

YES

YES

YES

YES

YES

NO NO

NO

NO

NO

YES

NO

67

B.

C.

17

Drum M/T loading stops.

Is Motor 12V supplied?

Is pin D.FG of

IC601 supplied?

Is pin D.PWM (pin )

of IC601 supplied?

Check connector

and Motor.

Is the input of pin

of P501 2V-3.5V?

Is pin of P601 2.5V?

Is pin (C.PWM)

of IC601 Supplied?

Check connector

and Motor.

67

4

1

18

3

Check power circuit.

Check C505, R506, R507

and C516.

Check IC601.

Check power circuit.

Check circuit of R510,

R511, R512.

Check R508, R509.

Check IC601.

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

Capstan M/T loading stops.

Is Motor 12V supplied?

D.

E.

18

Drum M/T and Capstan M/T rotate

at regular speed (In REC mode).

Is C. Sync applied to

pin of IC601?

93

Check Motor.

Check C. Sync of

VIDEO IC and Pattern.

Emergency mode when

connecting the Power cord.

Is EVER 5V supplied?

Does X601 crystal oscillate?

Do S/DATA, CLK and RDY

Signals of IC601 exchange

with IC701?

Is CAM SW DATA Correct?

Check IC602.

Check IC 601.

Check power circuit.

Check IC601 and X601.

Check IC701 when CS Signal

is supplied.

Check IC601 when CS Signal

is not supplied.

Recheck connector

and CAM SW contact.

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

F.

G.

NO

19

Cassette is not

inserted.

Is Motor 12V supplied?

Check power circuit.

Is there the changes

CAM DATA when CST IN?

Is 7.5V applied to pin of

IC602 when CST IN?

4

Chek IC602.

Check connector. Check DECK part.

Is 5V supplied at

pin of IC601?

Check PATTERN.

47

Check IC601.

H.

NO

YES

YES

YES

NO NO

NO NO

YES

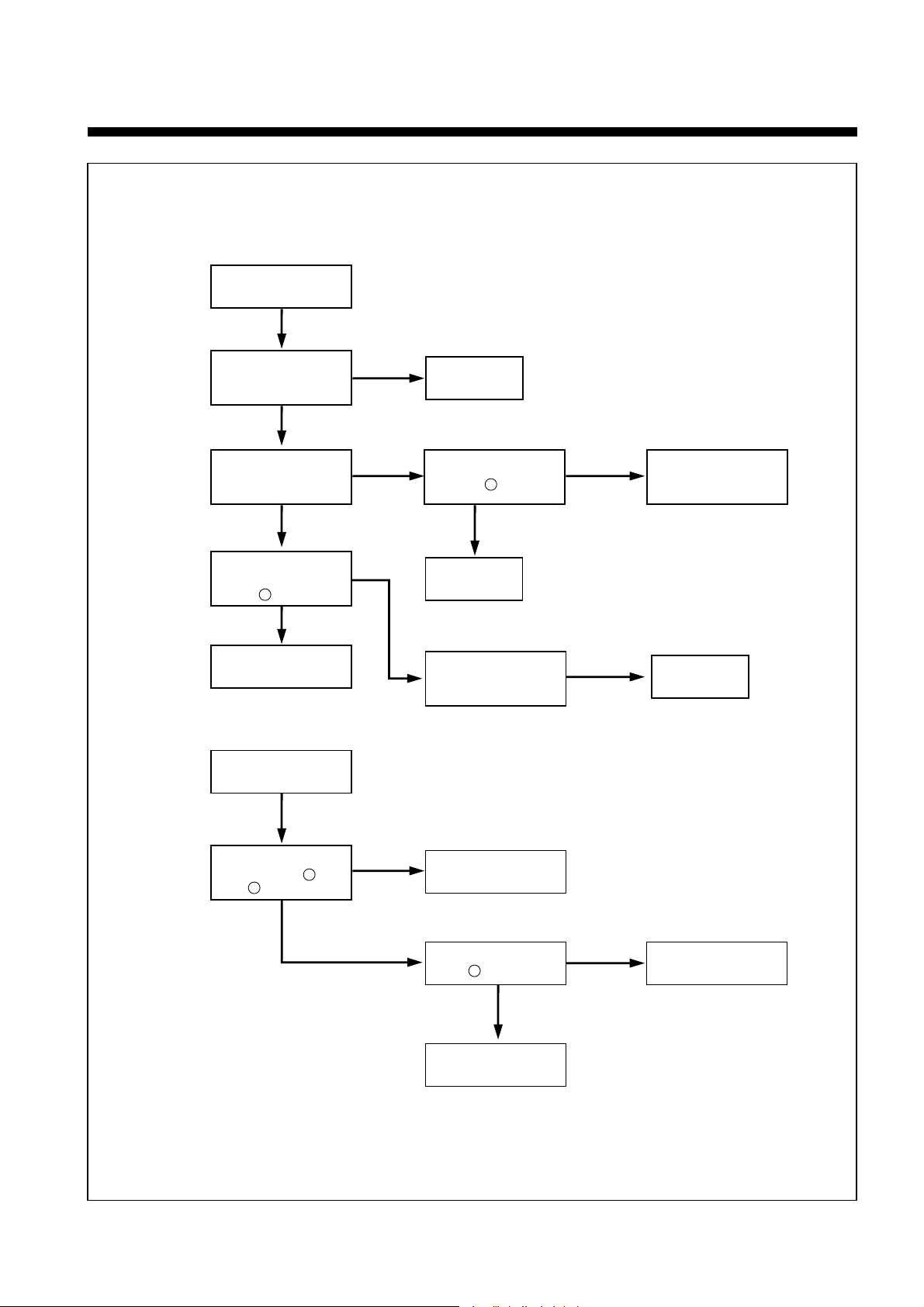

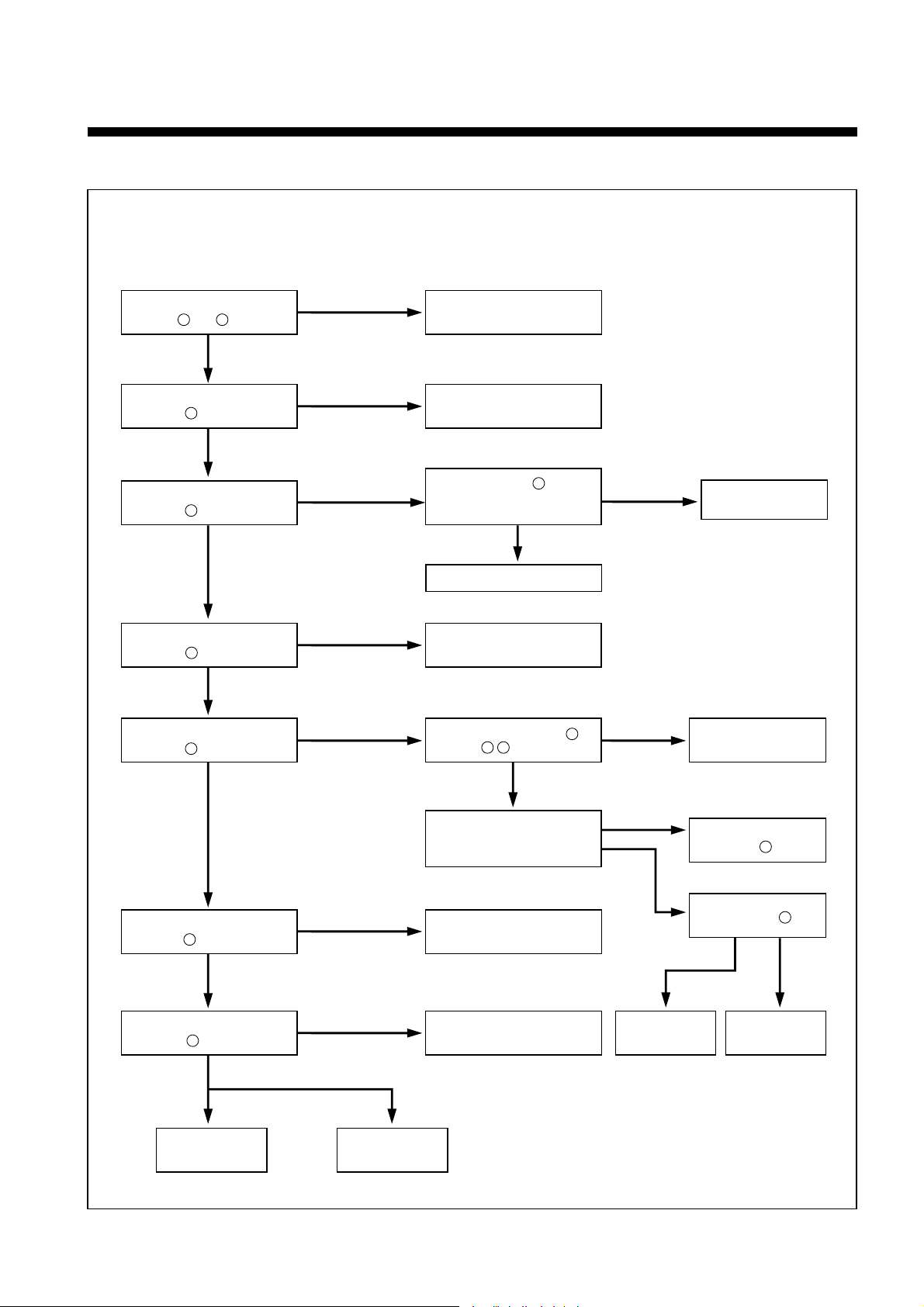

20

3-4-1. AUDIO CIRCUIT (Hi-Fi)

No

No

No

No sound in the E-E mode

A.

Is 12V applied to pin

of IC901?

Yes

Is 5V applied to pin ,

, of IC901?

Yes

Check

POWER circuit

Check SYSCON circuit

1

16

26 33

No

Is signal input into

pin , of IC901

in LINE mode?

Yes

Check input jack

3

46

Yes

Is there output at

pin , of IC901?

Yes

Check out JACK

Change IC901

No

Is pin of IC901 0V?

36

58 62

No

Is signal input into

pin #, [ of IC901

in TV mode?

Yes

Check IC151

21

No sound in the playback

mode after reccording.

Is the signal applied to

pin of IC901?

46

Is 5V applied to

pin of IC901?

6

Is there output at

pin of IC901?

55

Does T201 oscillate?

Check circuit adjacent

to IC151.

Check IC601.

Check IC901.

Is the voltage above 12V

at pin of T201?

Check Q212

collector:above 12V

Base:0V

Check T201.

Is record current

3.0mVrms?

Is pin of IC901 0V?

2

Clean HEAD.

Asjust Record current.

Check IC901.

Check IC901.

Check Q212, Q213

NO

YES

YES

YES

YES

YES

YES

NO

NO

NO

YES

NO

NO

NO

NO

YES

3

B

22

No

Check C905

No

Check IC601

No

Check the ICH01

of PRE-AMP circuit

No

No Hi-Fi Sound

in playback mode

B.

Is the ENVE level of pin

IC901 more than 280mVp-p?

Yes

Is A SW PULSE input into

pin of IC901?

Yes

Is pin of IC901 5V?

Change IC901

Is the ENVE. input into

pin of IC901?

27

Yes

23

25

Yes

Change

IC901

25

23

3-4-2. NORMAL AUDIO CIRCUIT (Hi-Fi NOMAL P AR T)

No sound in the playback mode.

62

Is the output at pin

of IC901?

Is 12V applied to pin

of IC901?

Check P901 pin and

power circuit.

1

Is 5V applied to pin ,

of IC901?

16

Is pin of P901 0V?

6

Is there Audio output

pin of IC901?

50

Is pin of IC901 GND?

2

Check P601

and AC Head.

Check pin of P902

and power circuit.

Check IC901.

NO

YES

NO

YES

YES

YES

YES

NO

NO

NO

A

8

33

9

24

3-4-3. NORMAL AUDIO CIRCUIT (DV-F683M/503M)

No sound in the playback mode.

22

Is the output at pin

of IC201?

Is 12V applied to pin

of IC201?

Check Q205

7

Is 5V applied to pin

of IC201?

11

Is pin of IC201 0V?

24

Is there Audio output

pin of IC201?

10

Is pin of IC201 GND?

3

Check P601

and AC Head.

Check IC601.

Check IC201.

NO

YES

NO

YES

YES

YES

YES

NO

NO

NO

A

25

No sound in the playback

mode after reccording.

Is the signal applied to

pin of IC901?

16

Is 5V applied to

pin of IC201?

24

Is there output at

pin of IC201?

21

Does T201 oscillate?

Check circuit adjacent

to IC151.

Check IC601.

Check IC201.

Is the voltage above 10 V

at pin of T201?

Check Q201

collector:above 10V

Base:0V

Check T201.

Is record current

3.0mVrms?

Is pin of IC901 0V?

1

Clean HEAD.

Asjust Record current.

Check IC201.

Check IC201.

Check Q201.

NO

YES

YES

YES

YES

YES

YES

NO

NO

NO

YES

NO

NO

NO

NO

YES

3

B

26

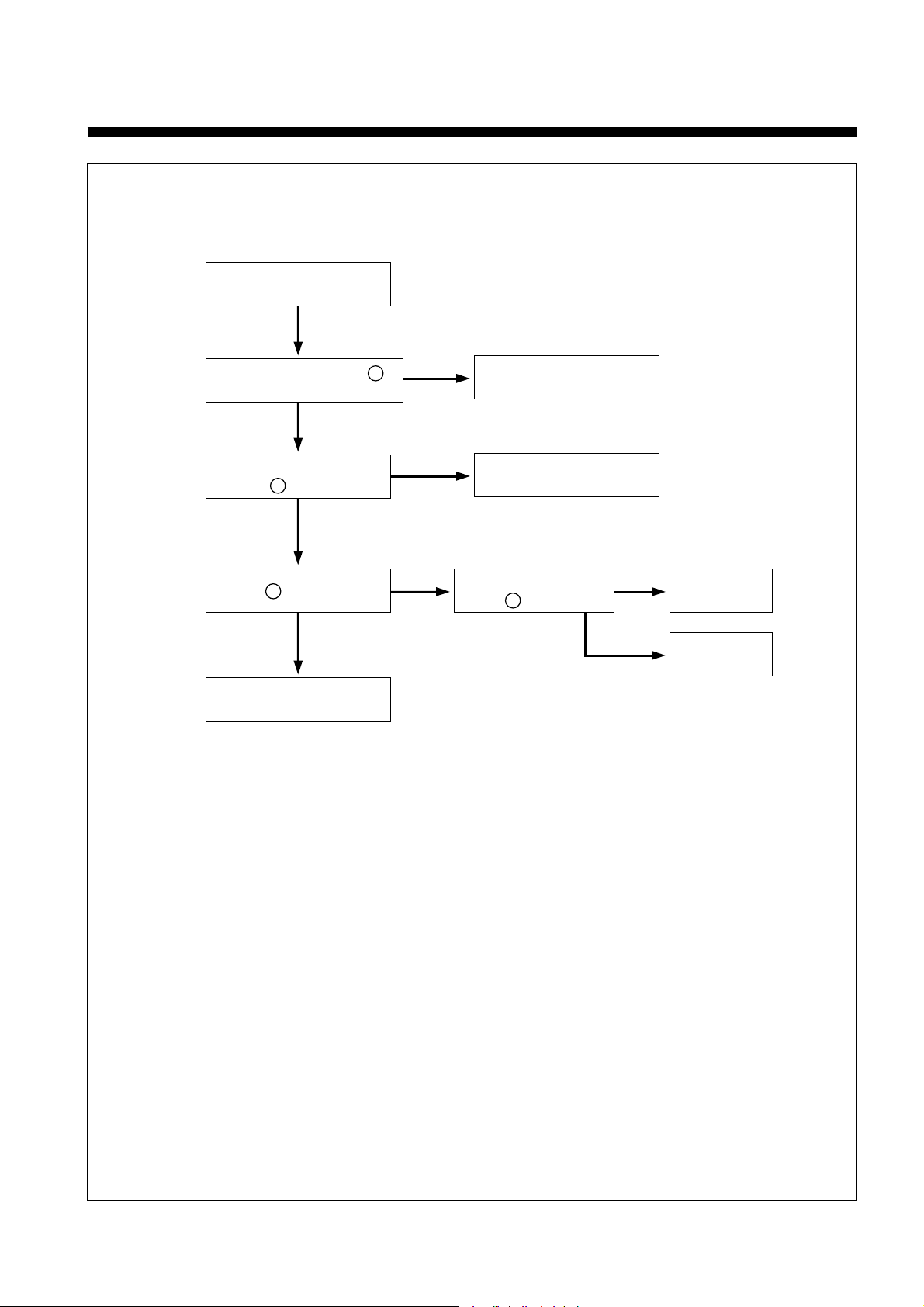

3-5. VIDEO CIRCUIT

Is video signal input

into pin and of IC151?

3 5

Is 12V supplied at

pin of IC151?

16

Is signal output from

pin of IC151?

16

Is signal input into

pin of IC301?

13

Is signal output from

pin of IC301?

17

Check PIF circuit

and LINE IN JACK.

Check ON/OFF 12V circuit.

Check IC601 pin.

Tuner mode : H

Line mode : L

Check PCB pattern.

Is 5V supplied to pin

and , of IC301?

14

39

Check

power circuit.

Check D301 (+) port

EE mode : L

PB mode : H

Check

IC601 pin.

29

Check IC301 pin.

Is signal input into

pin of ICS01?

18

Is signal output from

pin of ICS01?

16

Check PCB pattern.

Check OSD circuit.

RF out Line out

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO NO

HIGH

LOW

A.EE MODE PIcture N.G

NO

YES

Change IC151.

Change IC601.

NO

NO

44

41

Change IC301

Check

PCB pattern

HL

18

27

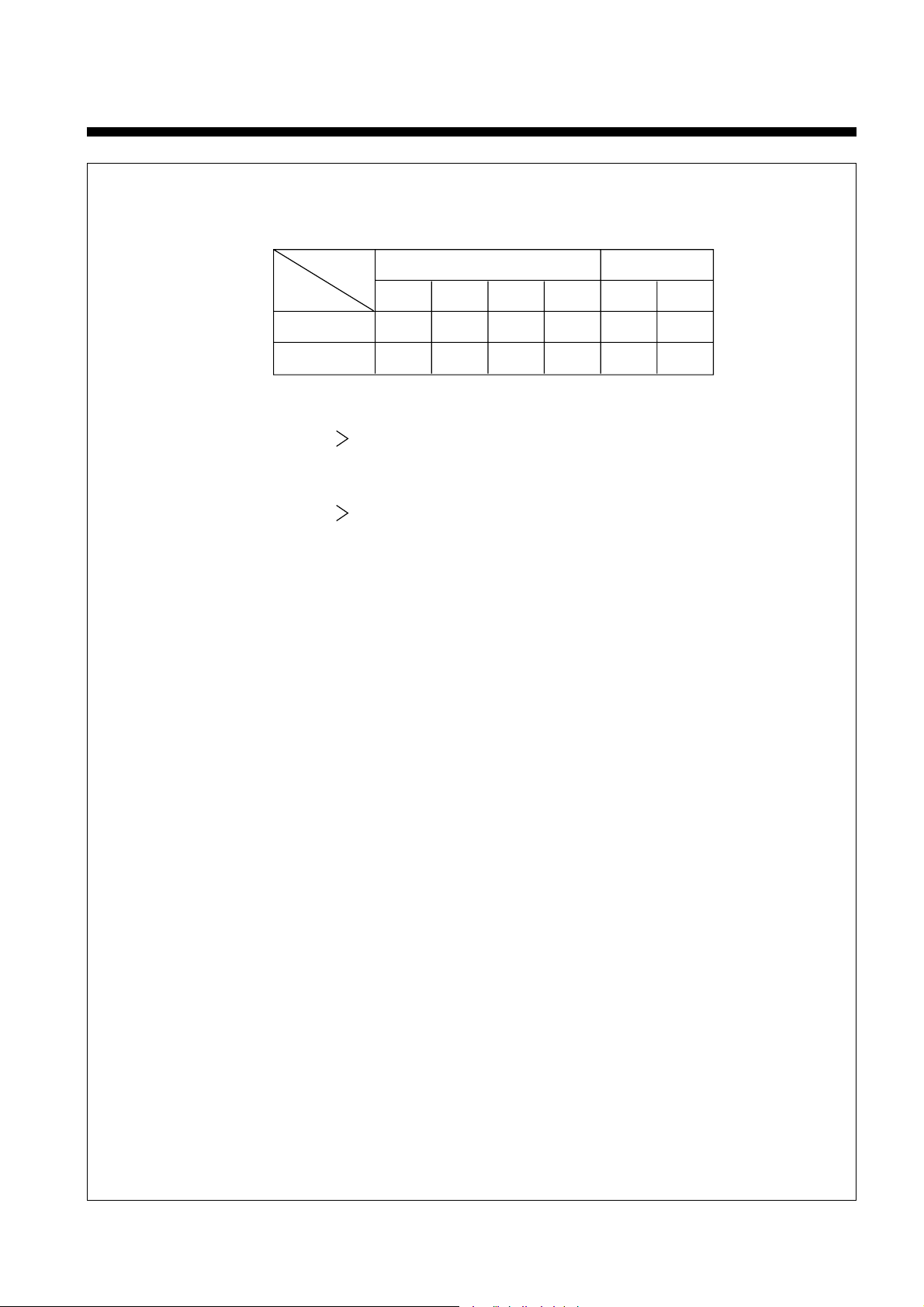

B . MODE TABLE.

PIN NO

IC301 IC302

NTSC MODE

PAL-M MODE

24 30 32 41 5 20

HXHHHH

HXLHHL

IC301 =

IC302 %

IC301 e

IC301 r

IC302 0

IC301 O

60Hz(H)

NAP

NTSC. H/PAL(L)

Filter change 3.58(H)

Loading...

Loading...