Page 1

Contents

CONTENTS

1. Specifications................................................................................................2

2. Outline and Dimensions .................................................................................3

3. Operation.....................................................................................................5

4. Wiring Diagram..........................................................................................17

5. Refrigerant Cycle.........................................................................................22

6. Control Block Diagram.................................................................................23

7. Electric Circuit Diagram................................................................................24

8. Trouble Shooting..........................................................................................27

9. Disassembly Instructions ...............................................................................43

1) Indoor Unit..............................................................................................43

2) Outdoor Unit...........................................................................................45

3) Exploded Diagram (Indoor Unit) ...............................................................47

4) Exploded Diagram (Outdoor Unit) ............................................................50

5) Control Box Assembly..............................................................................56

Page 2

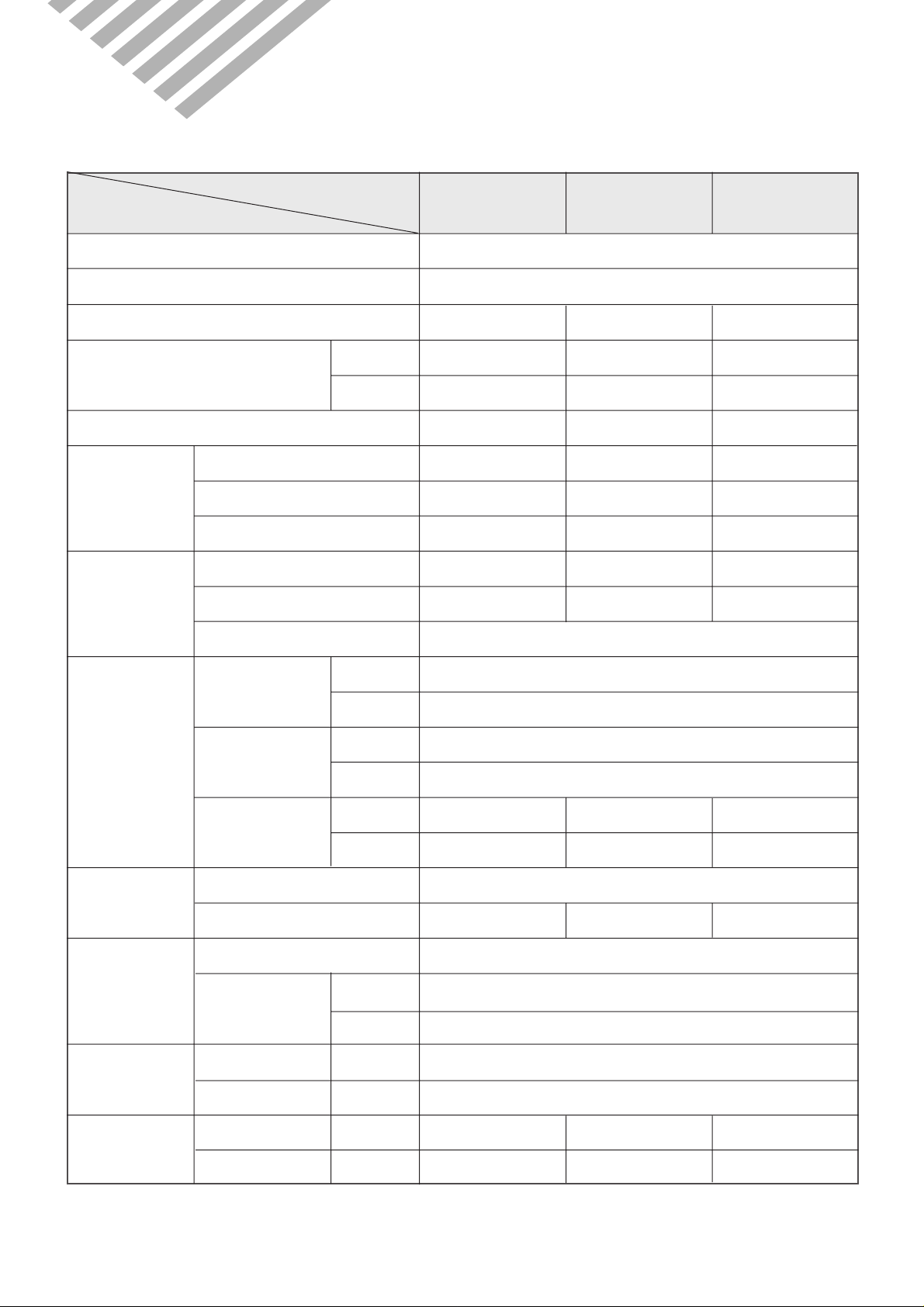

1. SPECIFICATIONS

◆DSA-151L/DSA-181L/DSB-181L

MODEL

ITEM

Function Cooling

Class T

Power Supply

Capacity W 4,300 5,100 5,100

Btu/h 15,500 17,500 17,500

Dehumidification 1.98l/h 2.3l/h 2.3l/h

Running Current 6.6A 8.3A 9.8A

Electrical

Data

Compressor

Power Input 1,450W 1,785W 1,950W

Starting Current 42A 44A 46A

Type Rotary Rotary RECIPRO

Model RCA150A001 ECB185211A CRDQ-0200-PFJ

Capacitor 30µF/400 VAC

DSA-151L DSA-181L DSB-181L

AC 208~230V, 60Hz AC 208~230V, 60Hz AC 220~240V, 50Hz

Type Indoor Cross Flow Fan

Outdoor Propeller Fan

Capacitor Indoor 1.2µF/400 VAC

Fan

Outdoor 3µF/400 VAC

Motor Model Indoor IC-9425DWKH6A IC-9425DWKH6A IC-9425DWKC5A

Outdoor AM12DPD05 AM12DPD05 AM12DPD04

Refrigerant

(R-22)

Connection

Dimensions Indoor 1,035 x 322 x 205

Control Capillary

Charge Q'ty 1,250g 1,450g 1,150g

Type Flare

OD Indoor 1/4”(6.35mm)

(Liquid/Suction) Outdoor 1/2”(12.7mm)

Outdoor 800 x 615 x 277

Net Weight Indoor 11.7Kg 11.7Kg 11.7Kg

Outdoor 43Kg 44Kg 55.8Kg

2

Page 3

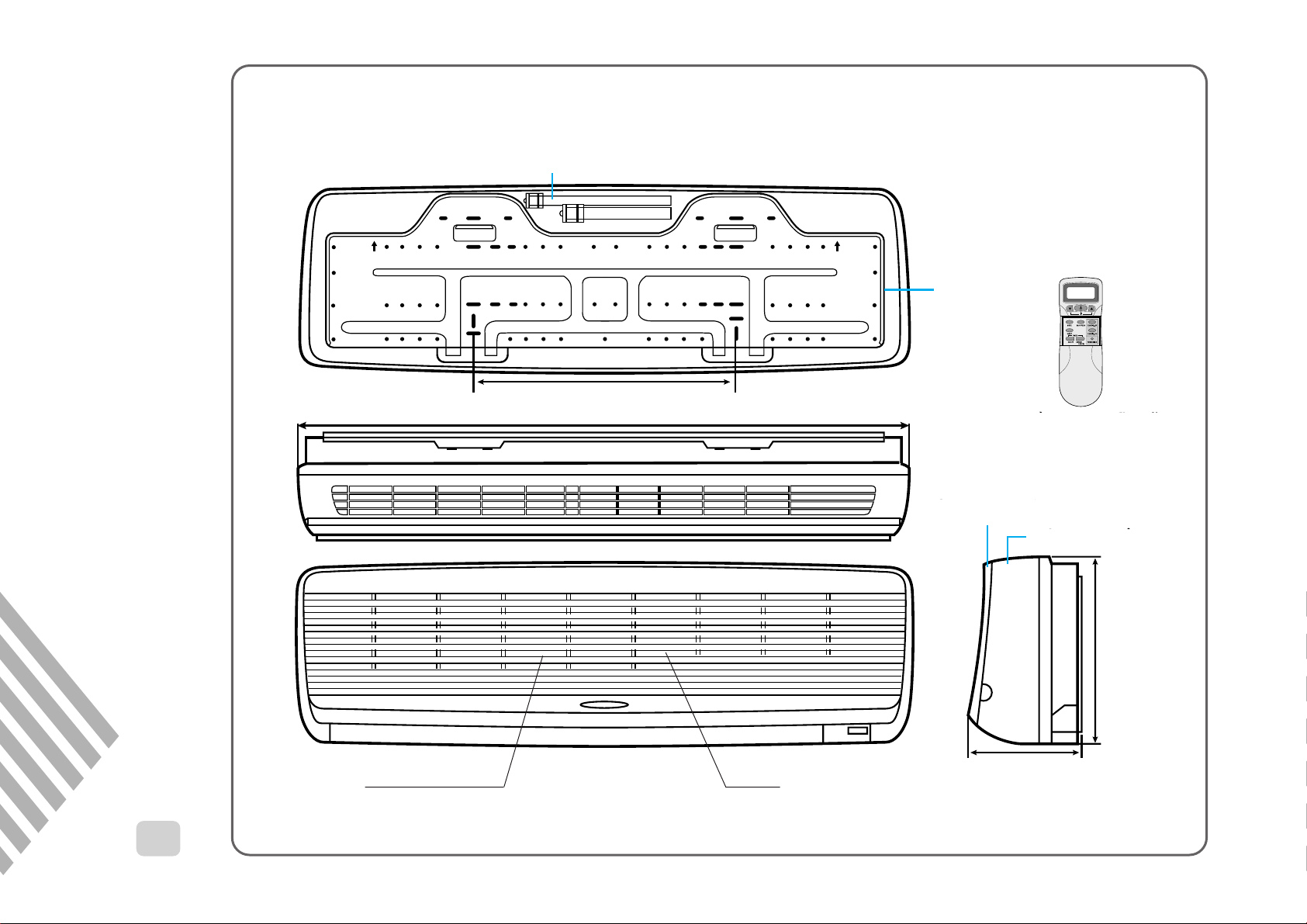

1035

205

322

453

¿‹ Æ˘˜ ˙`

”fi `⁄˘˙

`⁄„«…–‚fi‚ ˜

‰˙‡»– ‚Ø– ‚–

‰˙‡»– ‚ ˆ…

Connecting Pipe

453

1035

Plate Mounting

REMOCON

Filter-L

INDOOR UNIT

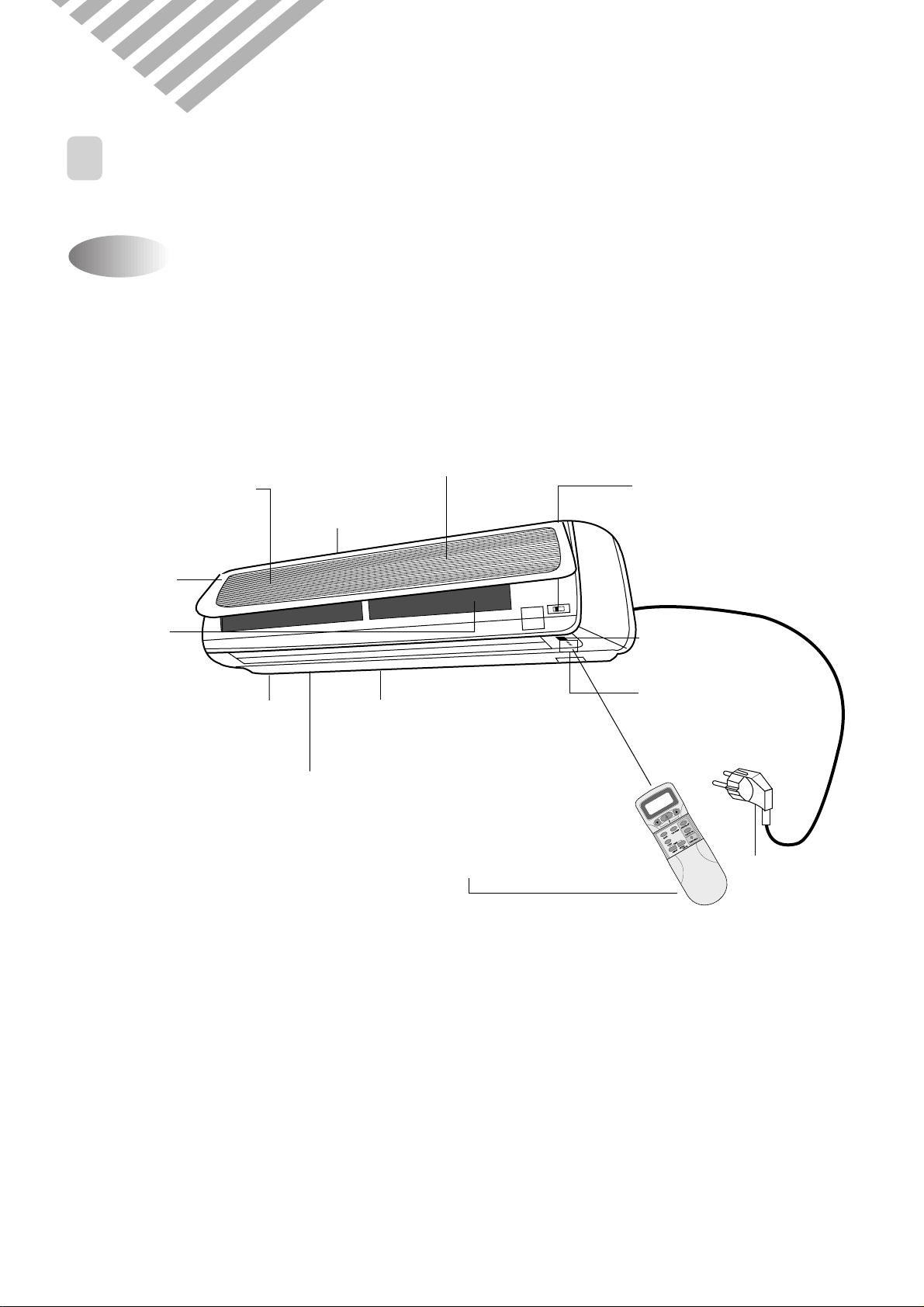

2. OUTLINE AND DIMENSIONS

1

◆ DSA-151L/DSA-181L/DSB-181L

3

Grille Insert

Body

Filter-R

Page 4

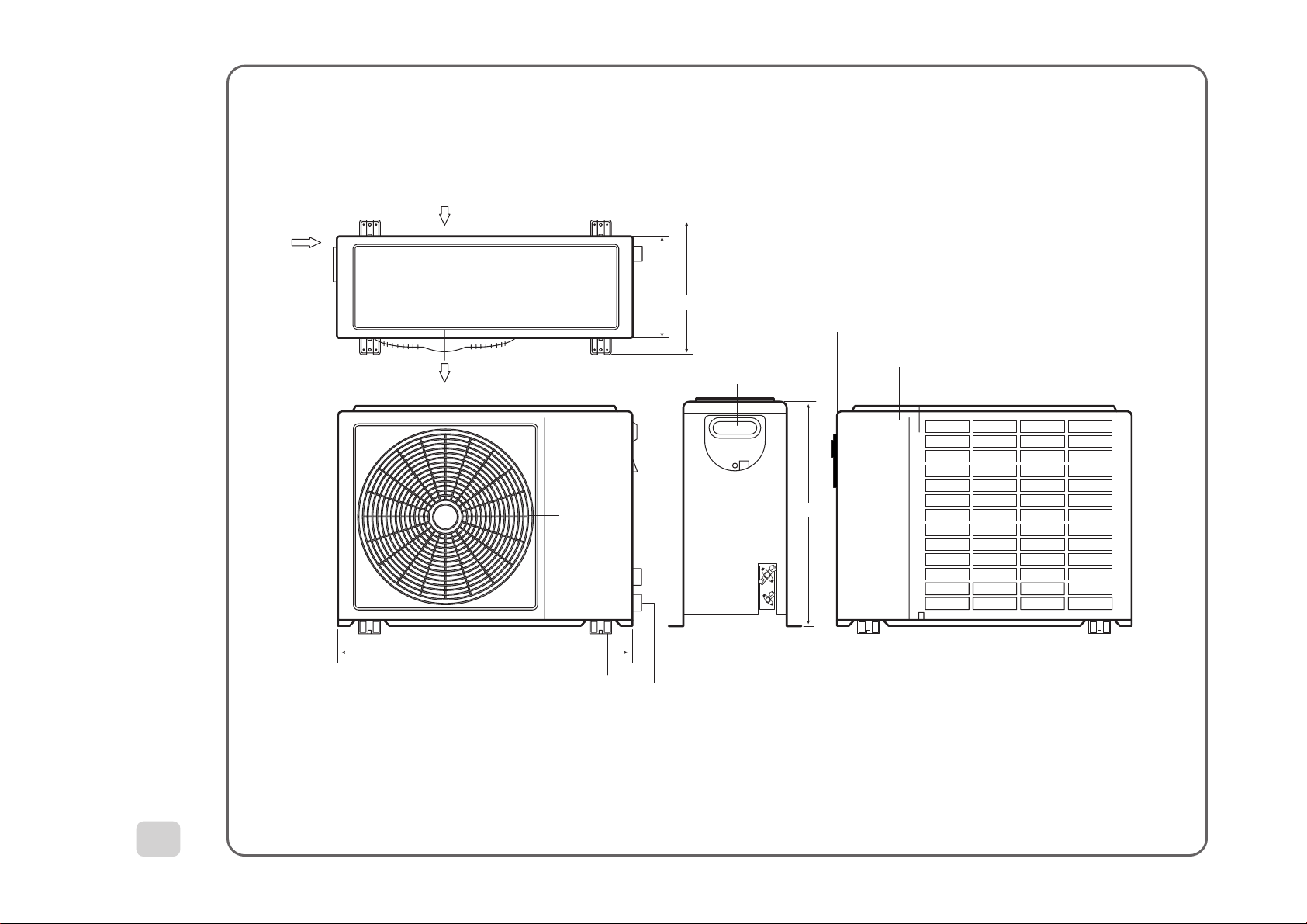

277

367

615

800

Inlet

Inlet

Outlet

Panel Top

Cabinet

Handle

4

Discharge

Grille

OUTDOOR UNIT

2

◆ DSA-151L/DSA-181L/DSB-181L

Foot

Service Valve

Page 5

3. OPERATION

Indoor Cover

Electrostatic Filter

Removes dust

particles from the air.

Deodorizing Filter

Removes bad

smells from the air.

Test/Emergency/

Remote Switch

Slide to select

the desired position.

Indicators

Indicate the

AC setting.

Remote Sensor

Power PlugLCD Remote Controller

Air Cleaning

Filters

Removes dust

and prohibits

germs.

Cold Air

Air In

Fan Direction

(Up/Down)

Fan Direction

(Left/Right)

ON

OFF

ENTERCANCEL

TIMER RESET

FAN DIR.

FAN SPEED

MODE

SLEEP

ON/OFF

TEMP.

1

PARTS OF NAME AND FUNCTION

◆ DSA-151L/DSA-181L/DSB-181L

Indoor Unit

5

Page 6

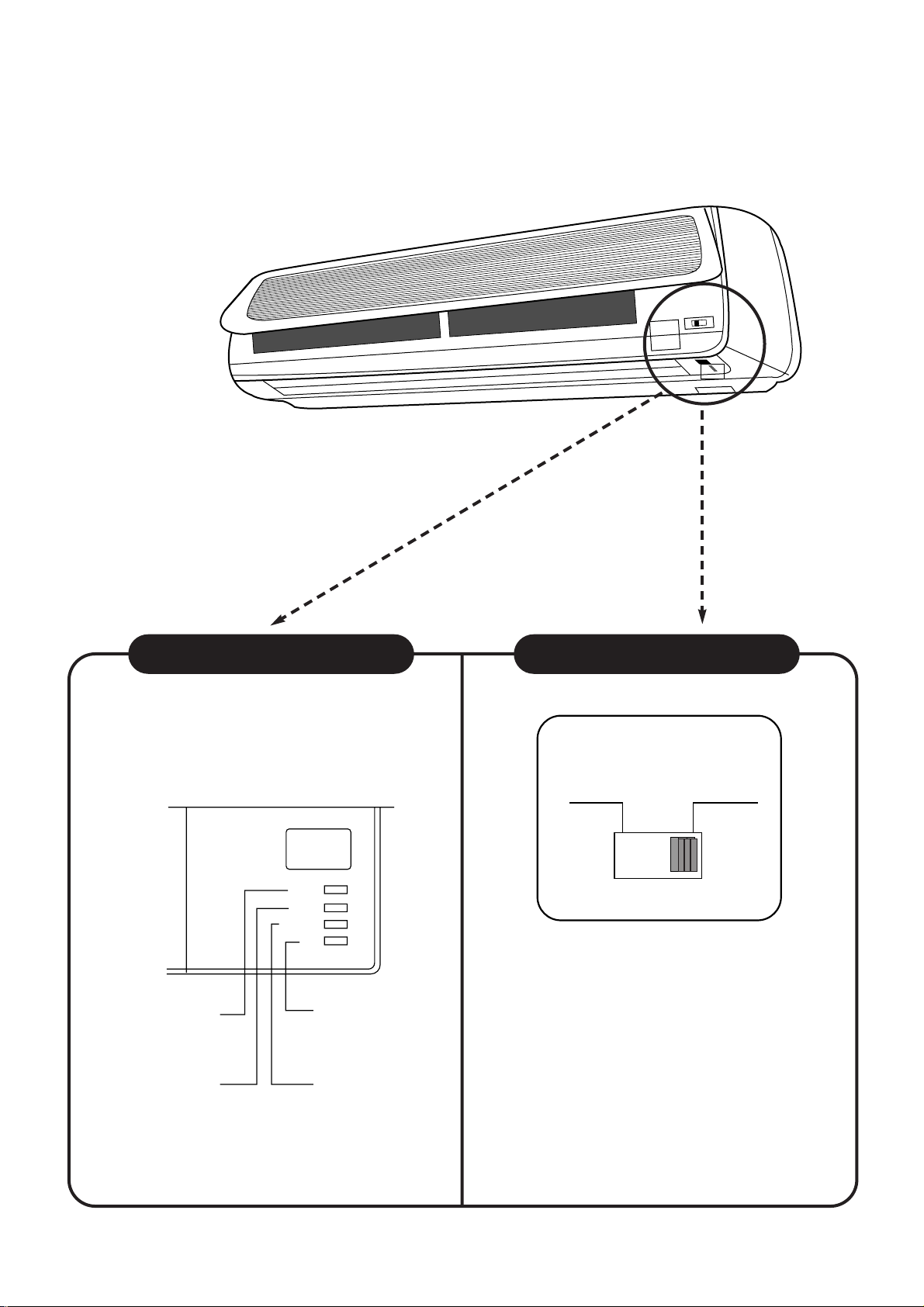

◆

ON (Red)

Lights when the

operation is going on.

Air clean (Green)

Timer (Yellow)

Lights during the time

reservation mode.

Quick (Red)

Lights during the

time Quick

Mode.

Timer

Quick

Airclean

ON

EMERGENCY REMOTE

DSA-151L/DSA-181L/DSB-181L

Indoor Unit Display Switch Panel

■ Remote Control Signal Receiver

This place is the part to receive the signal if it receive

the signal, you can hear the signal “beep. beep”.

■ There is a switch panel at inside of Front Panel.

At the time of operating, open the Front Panel.

Emergency switch can be used when the remote

controller is lost or Testing.

Remote switch is usually used by remote controller.

6

Page 7

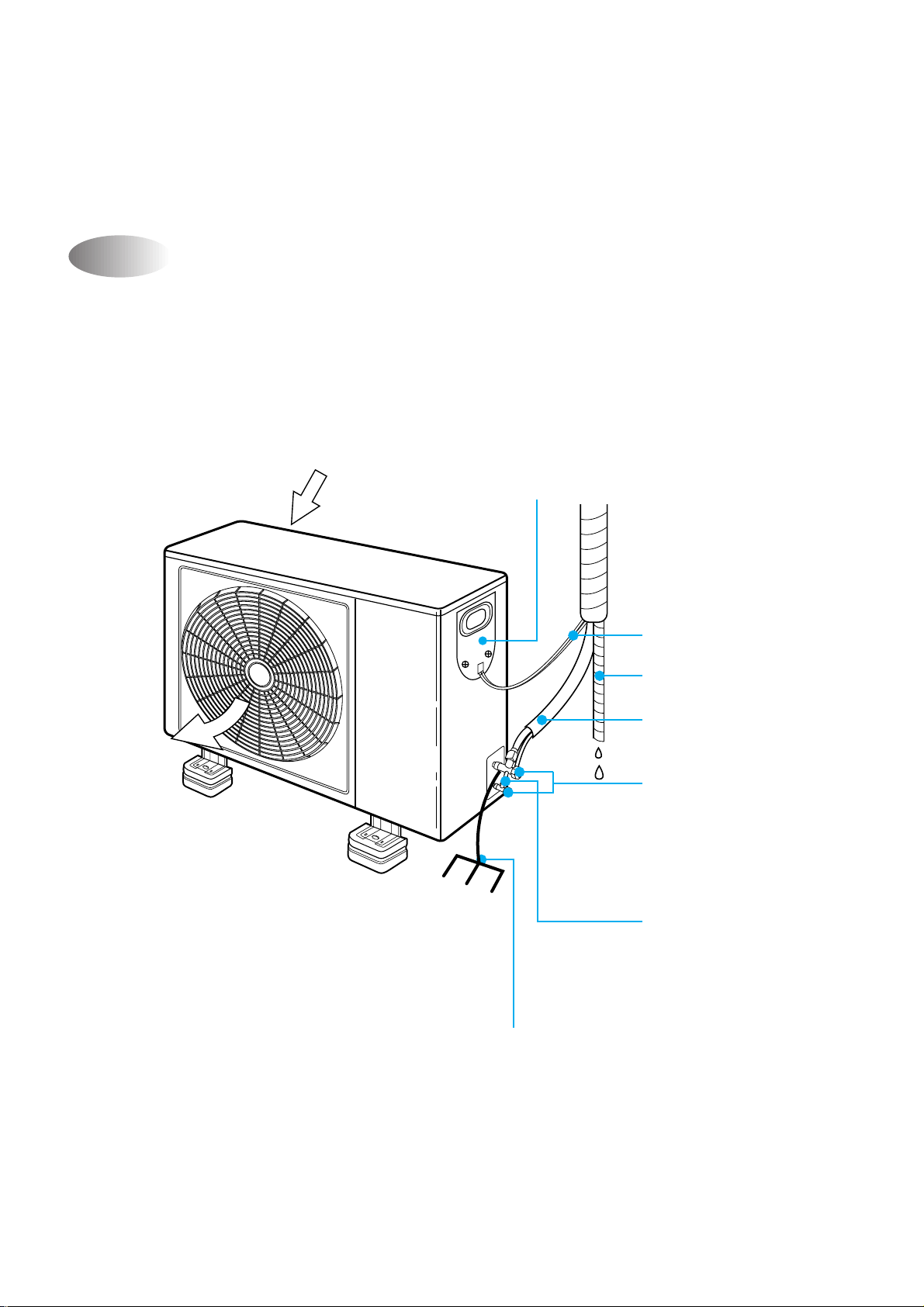

◆

DSA-151L/DSA-181L/DSB-181L

Outdoor Unit

AIR IN

AC Cover

Remove cover to

access the AC

connection from

this unit to the

indoor unit.

Connection Wire

AIR OUT

Drain Hose

COPPER TUBING

Service Valves

The indoor and outdoor

units are connected by

copper tubes which are

connected here.

Grounding Screw

Ground the unit here.

Ground Wire

(Not supplied)

7

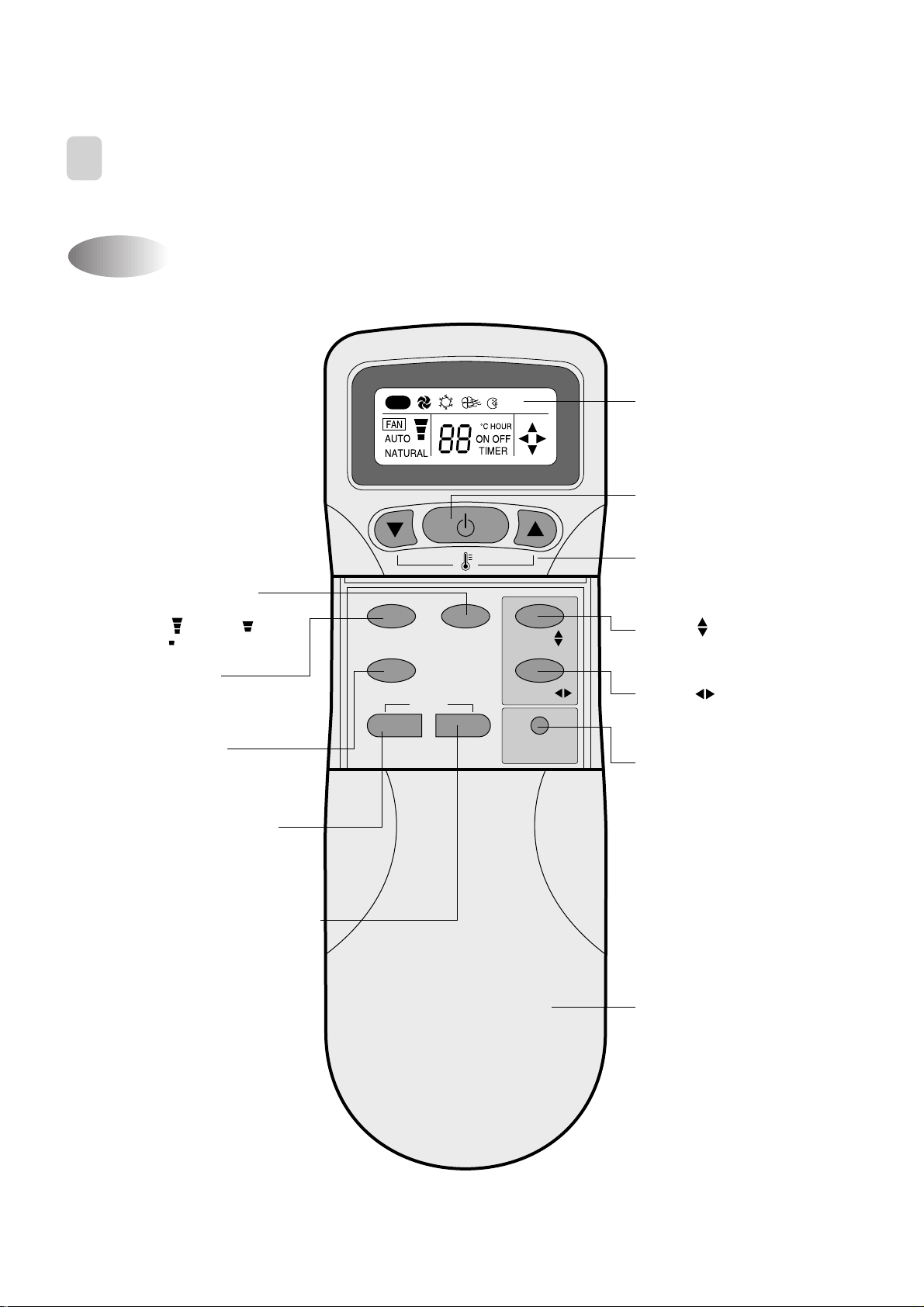

Page 8

2

MODE

SLEEP

ON/OFF

TIMER

ENTER/

CANCEL

FAN SPEED

TURBO/MILD

Display

Displays information

pertaining to unit.

TURBO/MILD

Press to be colder the unit.

TIMER ENTER/CANCEL Button

Press to enter a timer setting or

to cancel timer setting

TIMER ON/OFF Button

Press to set the unit of or on time.

(0.5, 1, 1.5, 2, 2.5, 3, 4, 5, 6, 8,

10, 12, 16, 20, 24hr)

MODE Button

Press to cycle through the modes

(Auto/Quick/Cooling/Fan/Dry)

SLEEP Button

Press to set the unit for

the sleep mode.

FAN DIR. Button

Press to select up/down

direction for fan.

FAN DIR. Button

Press to select left/right

direction for fan.

ON/OFF Button

Press to turn the unit

on or off.

TEMPERATURE Buttons

Press to raise or lower

the desired temperature.

FAN SPEED Button

Press to select the fan speed

(High " ", Middle " ",

Low " ").

COVER

Slide down to access most

of the remote buttons.

Slide down further to

access the battery

compartment.

AUTO

FAN DIR.

FAN DIR.

REMOTE CONTROLLER

◆

DSA-151L/DSA-181L/DSB-181L

Name of Each Button

8

Page 9

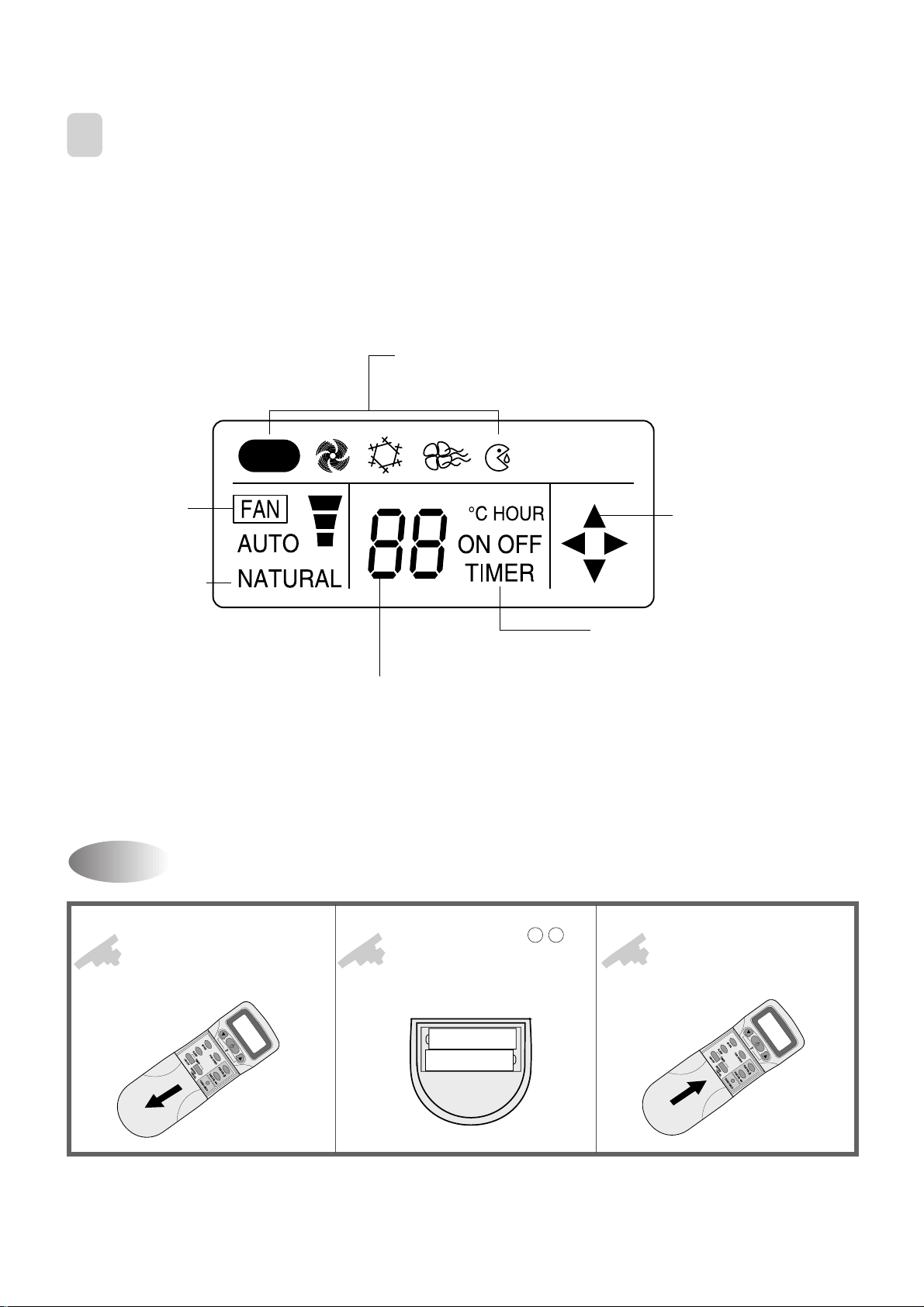

3

MODE Indicators (Auto/Quick/Cool/Fan/Dehumidifier)

Lights to indicate the mode selected.

TIMER Indicators (Include sleep)

Lights to indicate the timer function mode.

TEMPERATURE & RESERVATION TIME lndicators

Lights to indicate the temperature or time.

FAN DIRECTION Indicators

Lights to indicate the

fan direction.

NATURAL Indicator

Lights to indicate the

speeds simulating a breeze.

FAN Indicators

Lights to indicate

the fan speed.

AUTO

+–

+–

REMOTE CONTROLLER DISPLAY

◆

DSA-151L/DSA-181L/DSB-181L

Replacing Batteries

Open the cover after

pressing the arrow

1

direction and pulling out.

+

Put the drycell by

2

direction.

9

–

3

Close the cover after

pushing into arrow

direction.

Page 10

4

Unit ON

Unit OFF

SET Time

HOUR

ON

OFF

Unit ON

Unit OFF

SET Time

HOUR

ON

OFF

COMP (ON)

(COOLING)

COMP (OFF)

-1˚C 0˚C

Temperature

(RT-DT)

DESCRIPTION OF FUNCTIONS

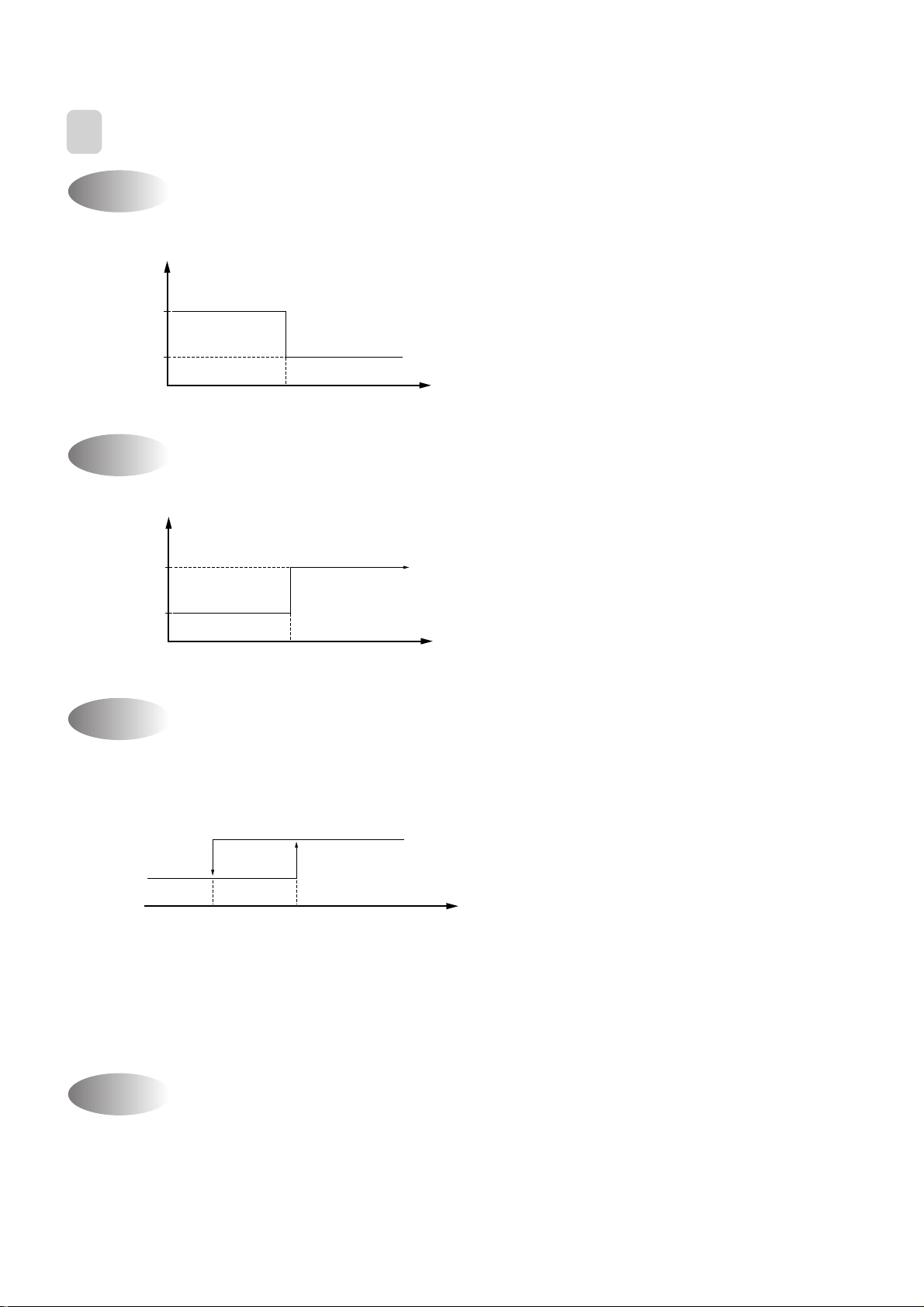

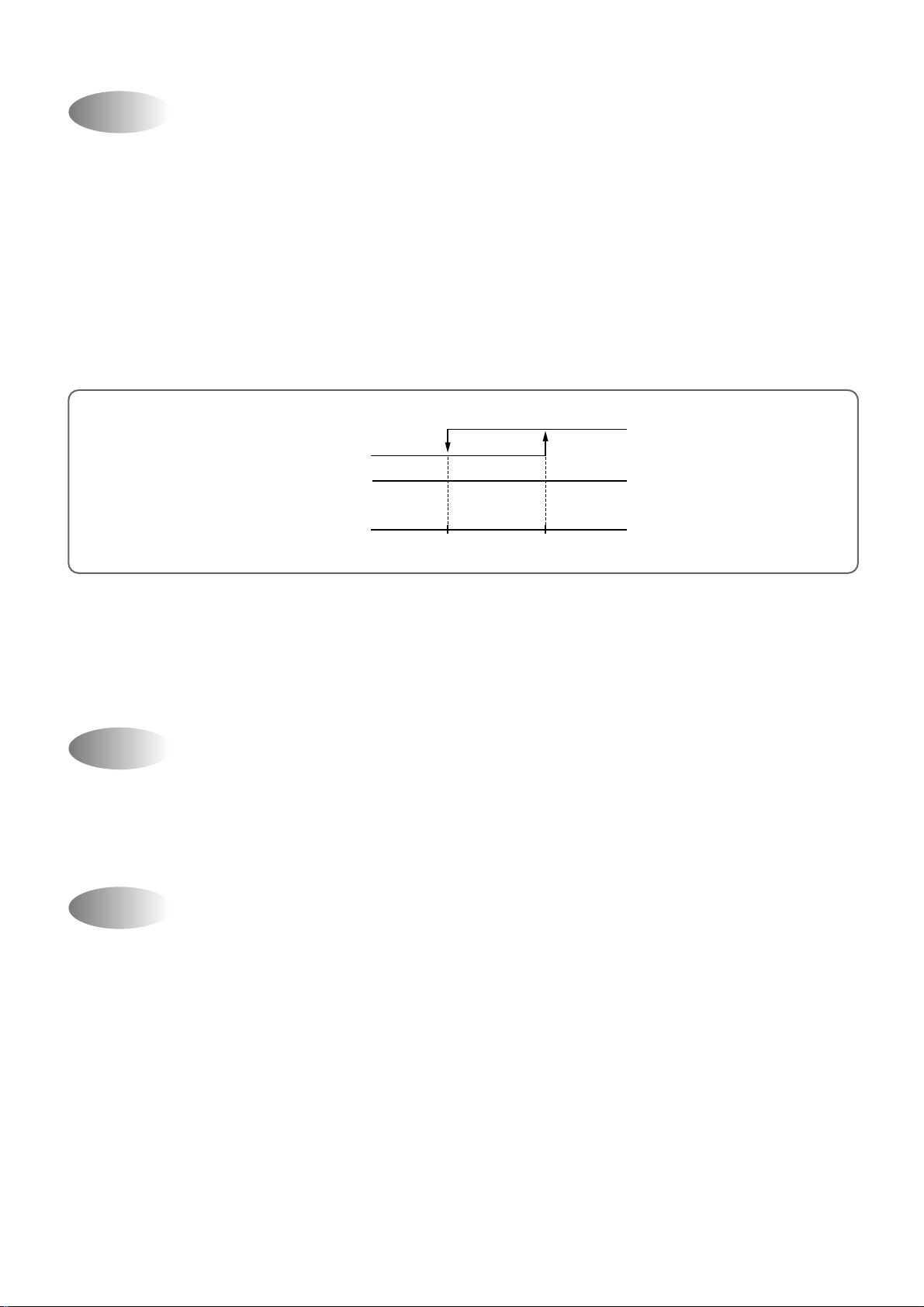

OFF-Timer

If you set time in OFF-Timer Mode, the unit will stop at the set time.

ON-Timer

If you set time in ON-Timer Mode, the unit will run at the set time.

Control of Room Temperature

(1) Range of setting temperature: 18~32°C

(2) Setting temperature: Operating temperature of compressor

❇ Room temperatrue

< setting temperature

(

Compressor OFF

Room temperature

> setting temperafure

(

Compressor ON

(3) During the time of test operating, Fan (Indoor , Outdoor) and Compressor is running regardless of room

temperature.

Buzzer

If the Indoor Unit Display receive the signal of Remote Controller , y ou can hear the signal "beep –" or "beep ,

beep".

10

Page 11

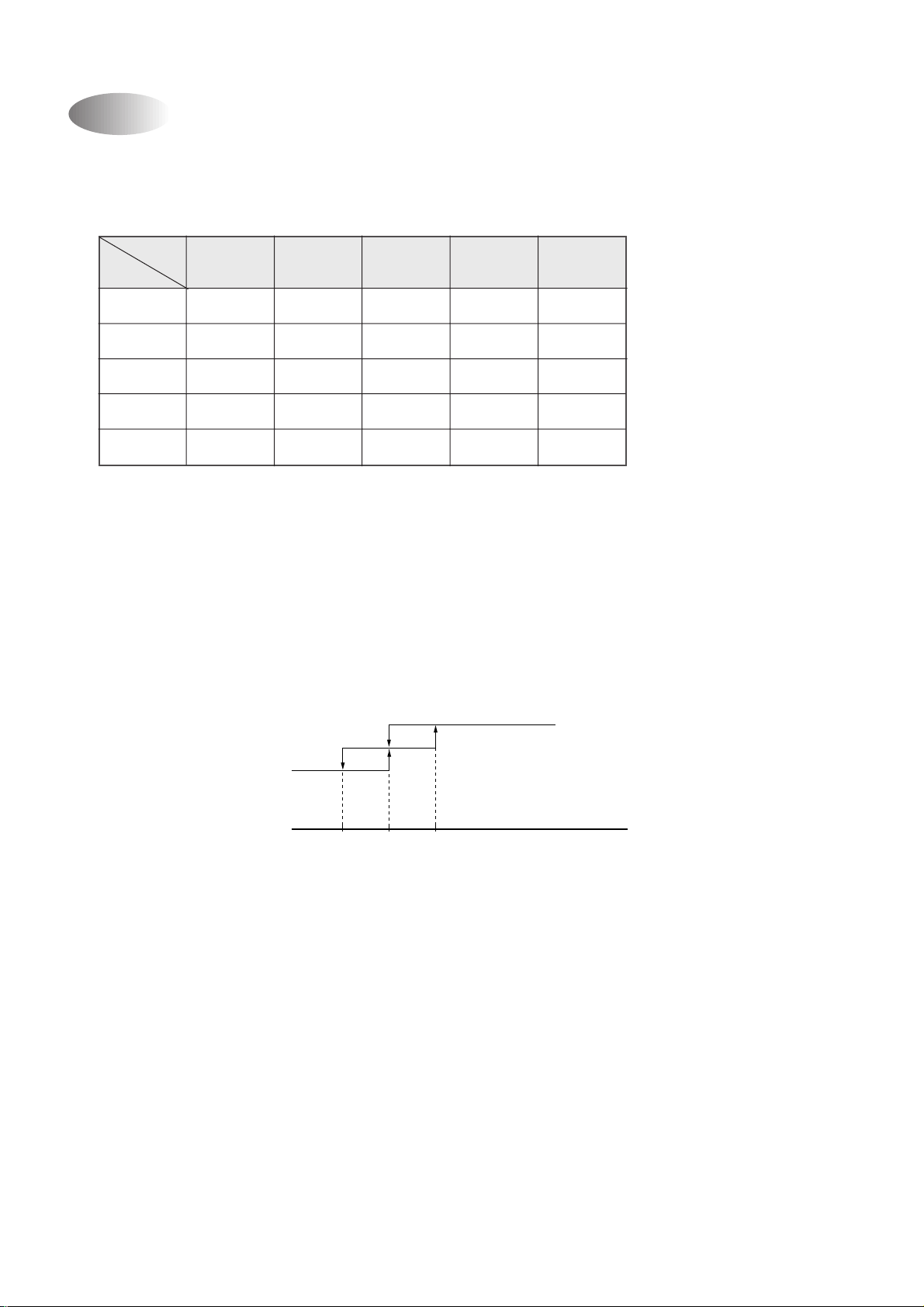

Fan Speed (Indoor Unit)

0

L

M

H

+1°C+2°C (RT-DT)

(1) Motor speed (high speed, normal speed, low speed).

(2) Remote controller setting fan speed. (Auto , L, M, H, Natural)

(3) Relation of operating mode between fan speed.

FAN ONLY COOL

H HHXHH

MMMXMX

LLLXLX

Auto X Auto Auto Auto X

Natural Natural Natural X Natural X

DEHUMI-

DIFICATION

AUTO Quick

(4) Automatic Operation

If the unit is set in 'AUT O' mode , the unit operates automatically according to the room temperature to keep the

room temperature comfortable.

(COOLING)

• DSA-151L/DSA-181L/DSB-181L

11

Page 12

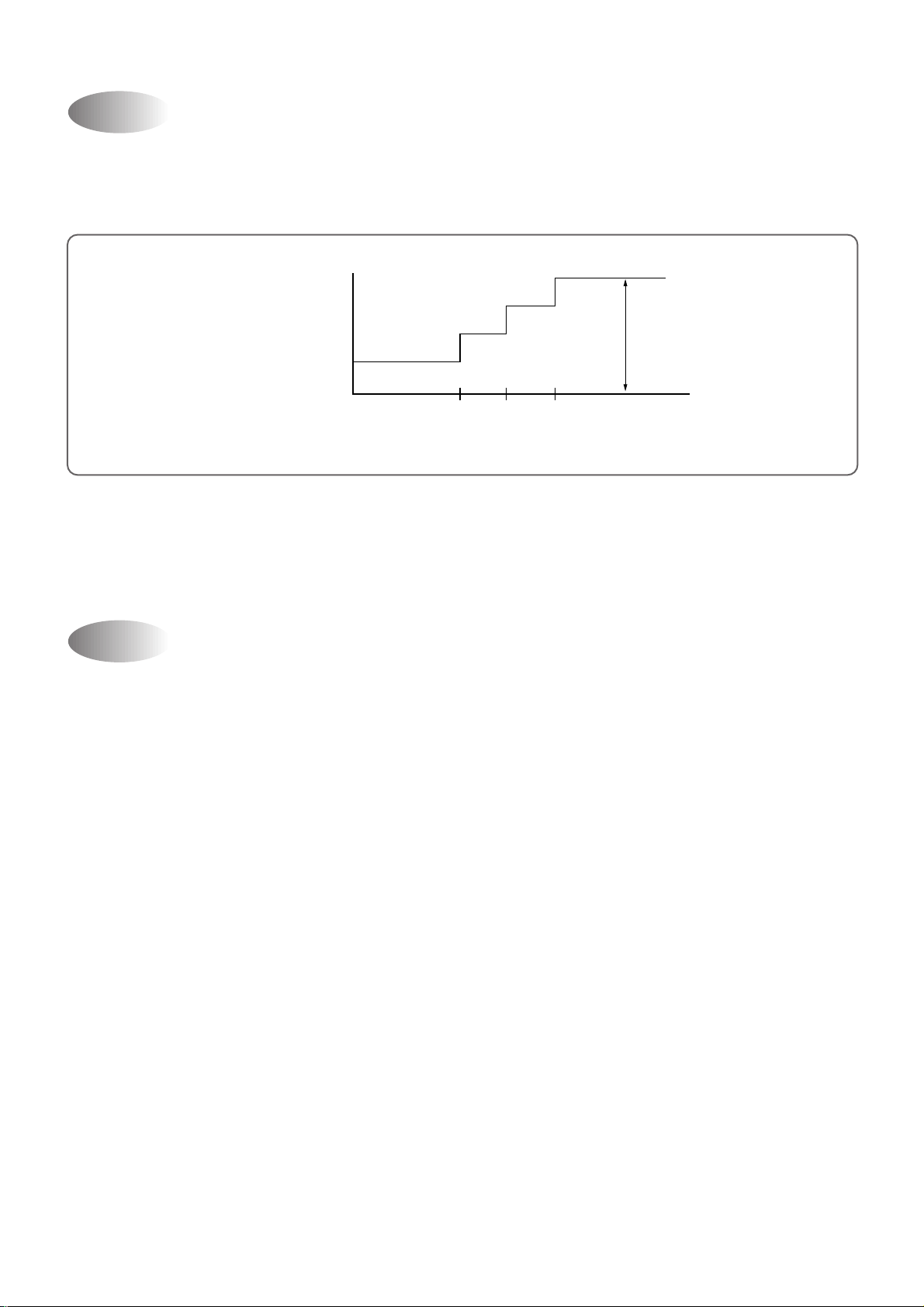

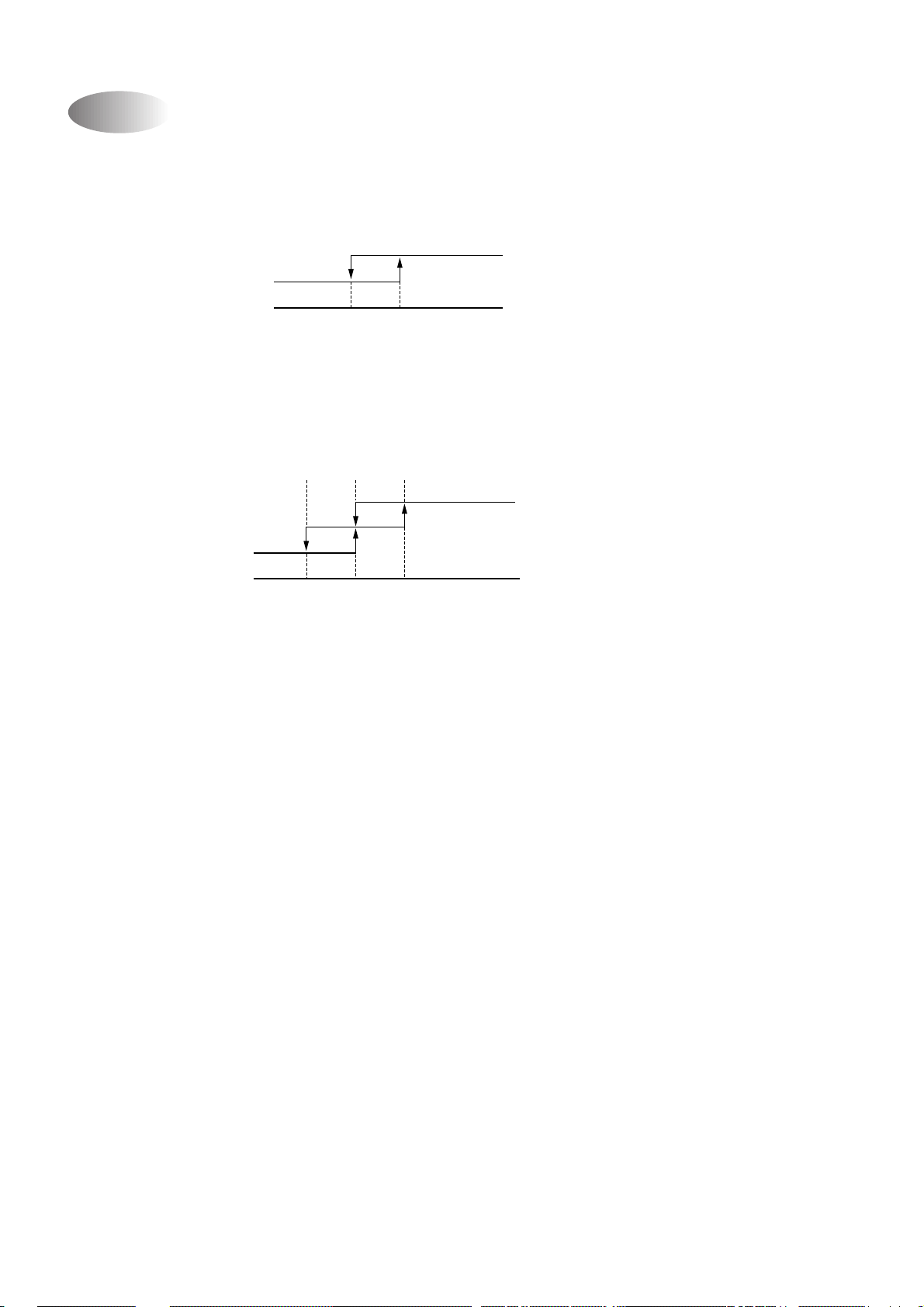

Sleep Mode

0 0.5 1.0 HOUR

SET TIME

Desired

Difference

desired temperature

between room

temperature (°C)

0.5°C

0.5°C

0.5°C

Temperature

(1) When you are going to sleep , select sleep s witch and the unit controls the room to the desired temper ature.

(The unit will not operate after 4 hour)

(2) For changing the temperature.

(3) To cancel sleep mode, press the SLEEP button again or press the MODE button once.: the SLEEP

indicator will disappear in the display.

Emergency Operation

(1) When the remote controller is lost, damaged or the battery is discharged, the Emergency operation can be

used to run the unit.

(2) The setting conditions of Emergency operation are as follows.

• Operation mode: AUTO

• Preset temperature: 26°C

• Fan speed: AUT O

12

Page 13

Frost Prevention of Indoor Unit

0°C7°C

Compressor and

Outdoor Fan

OFF

ON

Set Speed

Indoor Fan

When the unit operates at low ambient temperature, frost may appear on the Ev aporator. When the indoor coil

temperature is lower than 0°C at the end of 10 minutes of continuous compressor operation from the start, the

microcomputer of the unit stops the compressor to protect the unit from the frost. The control procedure for

indoor coil freeze protection.

1) The compressor and outdoor fan turn off.

2) Indoor fan operates according to user set speed.

3) The normal operation returns when the indoor coil temperature is higher than 7°C or equal to 7°C.

(Indoor coil temperature)

3 min. Time Delay of Compressor

In normal operation, there is a time delay of three minutes between turn off and turning back on including initial

power up.

Indoor Fan Motor Starting

When indoor fan motor is on, it alwa ys starts at normal speed and then it operates desired speed.

13

Page 14

Auto Mode

-1 0

°C

OFF

ON

(Room temperature Desired temperature)

H

M

L

0+1+2

°C

(Room temerature Desired temperature)

(1) When the room temperature is higher than 28°C (Cooling Mode)

! Compressor and lndoor F an

@ The fan will automatically operate as f ollowing Figure

(2) When the room temperature is lower than 28°C and higher than 22°C (Dehumidification Mode).

(3) When the room temperature is lower than 22°C (F an only).

14

Page 15

-1

OFF

ON

(Room temperature-18˚C)

0

Dehumidification Mode

!Desired temperature < Room temperature

Outdoor Fan, Compressor : ON

Indoor Fan : Low speed

@ Desired temperature Room temperature

Compressor : 3 min/ON, 5 min/OFF

Indoor Fan : 3 min 30 second/ON, 4 min 30 second/OFF

Fan Speed : Low speed

# Room temperature 18°C

Compressor : OFF

Indoor Fan : 1 min/ON, 7 min/OFF

Fan speed : Low speed

>

>

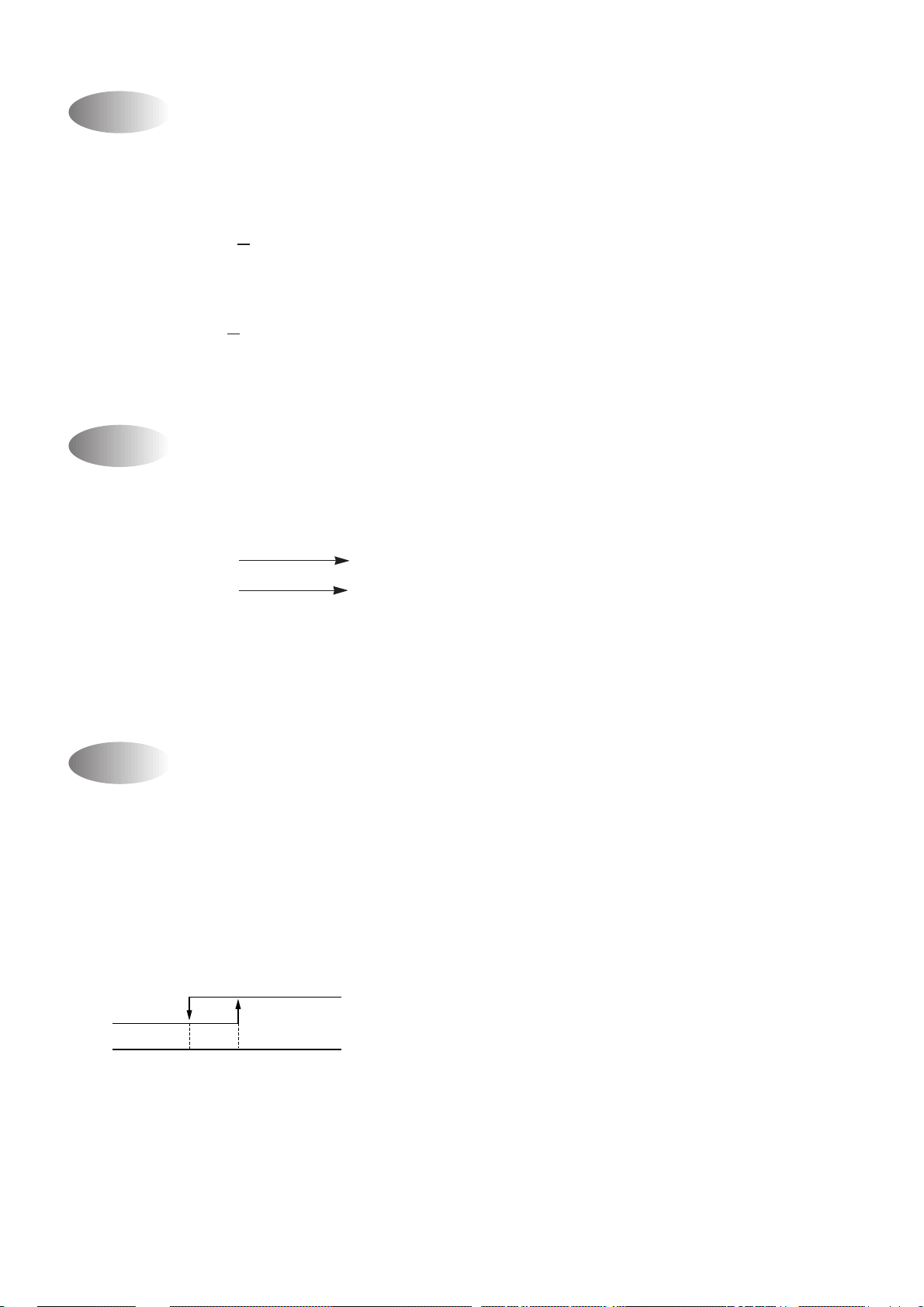

Air Discharge Direction

(1) When you turn on the unit, the flaps move to the position of keeping the room temperature comfortable.

(2) The air discharge direction is below.

Up/Down On/Off

Left/Right On/Off

Quick Mode (Powerful Cooling)

(1) Cooling condition

!Fan Speed: High speed

@ Air discharge direction: Fixed

# Set temperature: 18°C (Fixed)

$ Operation Mode: Cooling Mode

% Compressor and Outdoor Fan

15

Page 16

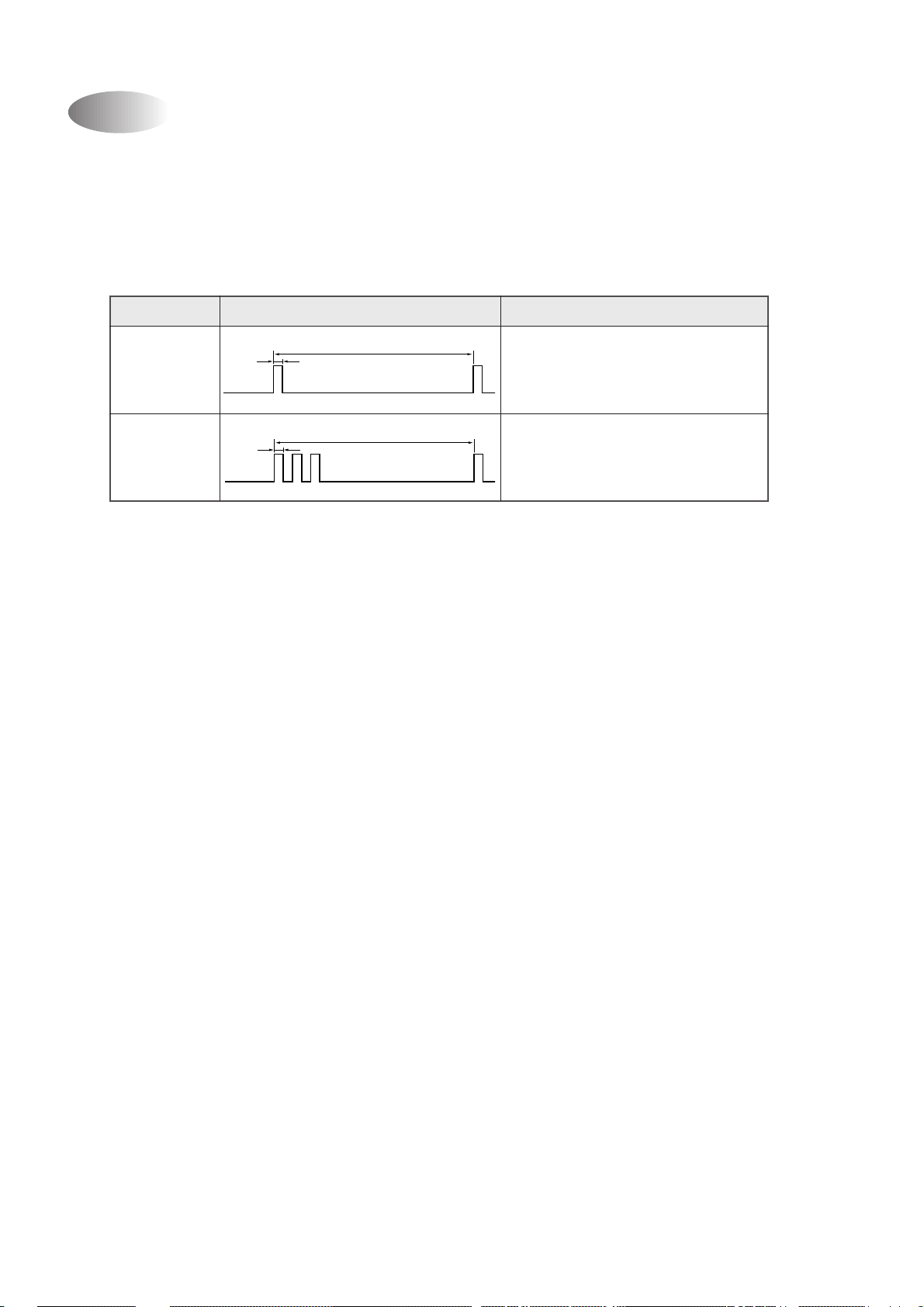

Self-Diagnostic Function

The control will contain diagnostic test to verify the integrity of the system.

(1)Error Code Display Pattern

!ON LAMP: ON (Red) LED ON/OFF

@ Error Code (Display in Emergency Mode only)

ERROR CODE

1

2

DISPLAY PATTEN ERROR CONTENTS

8 seconds

0.5 second

8 seconds

0.5 second

Room air thermistor, connector

Indoor coil thermistor, connector

Compressor, Electrical parts of

comp. Gas leak

16

Page 17

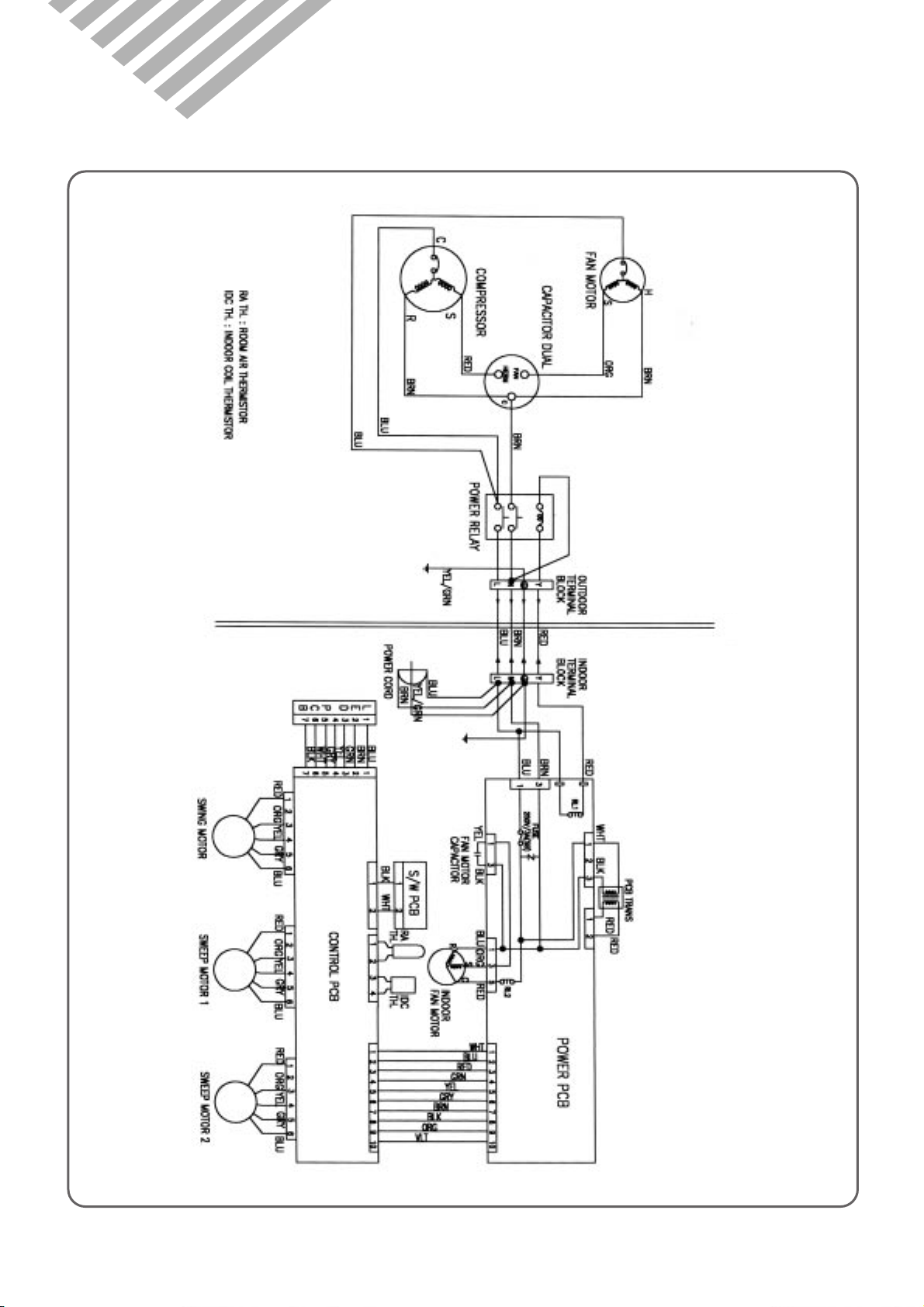

4. WIRING DIAGRAM

◆ DSA-151L

OUTDOOR UNIT

INDOOR UNIT

17

Page 18

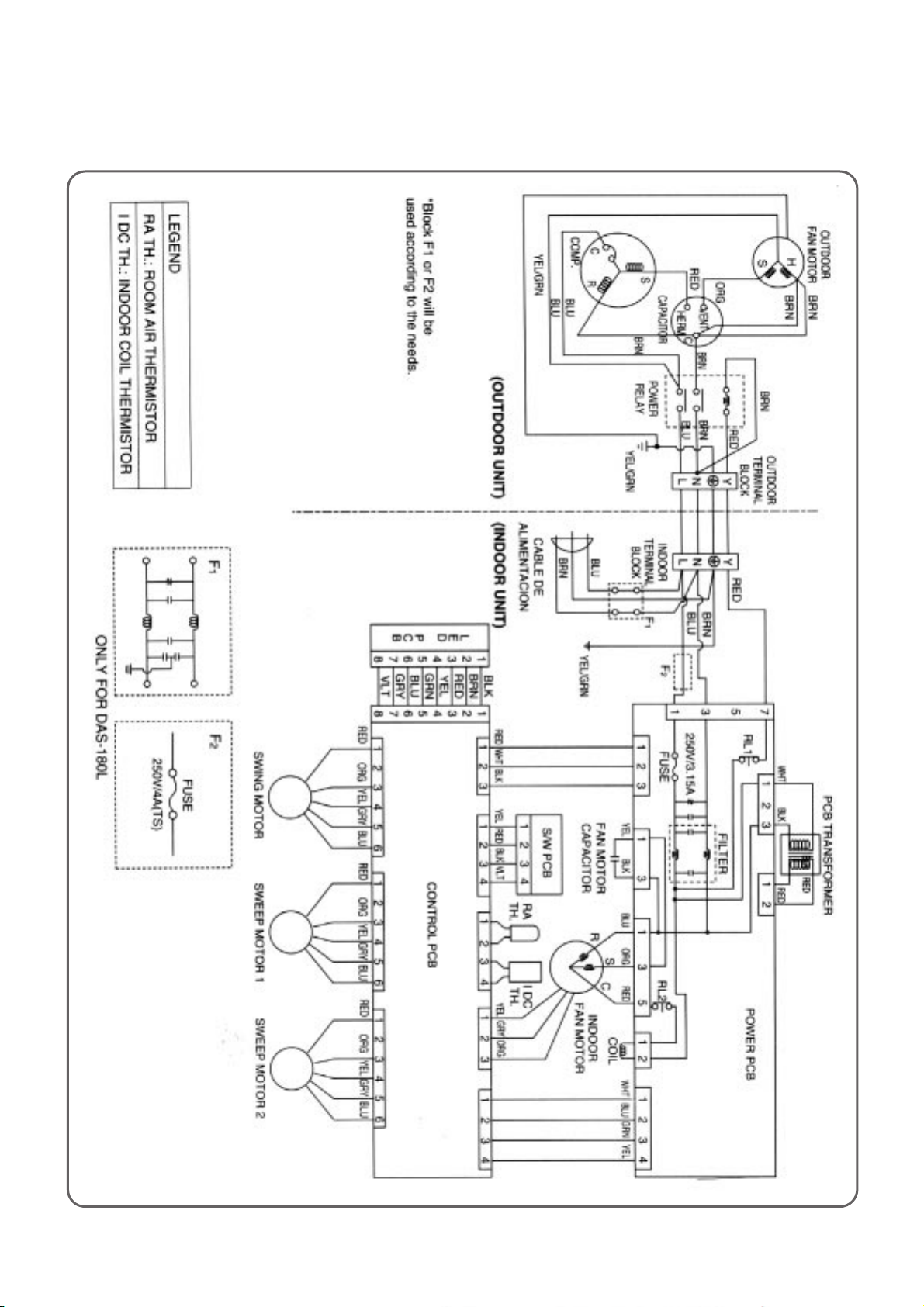

◆ DSA-181L/DSB-181L

18

Page 19

MAIN ELECTRIC PARTS

1

◆ DSA-151L

Fan Motor 3964330200 IC-9425 KH 6C 1

Fan Motor Capacitor 3106995010 1.2µF 450VAC 0.2A 1

Fuse 5FVGB0302R 250V 3A S/B 1

PART NAME PART CODE SPEC. QUANTITY REMARK

Indoor

Unit

Outdoor

Unit

Fuse 5FVGD0402S 250V 4A 6ITS 1

Transformer 5EPK533110 220V/15V 1

Stepping Motor 1 3108004310 MP28GA (L=1300mm) 1

Stepping Motor 2 3108004300 MP-28GA (L=400mm) 2

Terminal Block 3108912320 SN-DBW-4P 1

Compressor 3100030AE0 RCA-150A001 1

Capacitor Dual 3109500100 370V 30/3µF 1

Fan Motor 3964320430 AM12DPD05 1

Power Relay 5SC0202700 G7L-2A-TUB 1

Terminal Block 3108912320 SN-DBW-4P 1

19

Page 20

◆ DSA-181L

Fan Motor 3964330200 IC-9425 KH 6C 1

Fan Motor Capacitor 3106995010 1.2µF 450VAC 0.2A 1

Fuse 5FVGB0302R 250V 3A S/B 1

PART NAME PART CODE SPEC. QUANTITY REMARK

Indoor

Unit

Outdoor

Unit

Fuse 5FVGD0402S 250V 4A 6ITS 1

Transformer 5EPK533110 220V/15V 1

Stepping Motor 1 3108004310 MP28GA (L=1300mm) 1

Stepping Motor 2 3108004300 MP-28GA (L=400mm) 2

Terminal Block 3108912320 SN-DBW-4P 1

Compressor 3107100000 ECB185211A 1

Capacitor Dual 3109500100 370V 30/3µF 1

Fan Motor 3964320430 AM12DPD05 1

Power Relay 5SC0202700 G7L-2A-TUB 1

Terminal Block 3108912320 SN-DBW-4P 1

20

Page 21

◆ DSB-181L

Fan Motor 3108000300 IC-9425DWKC5C 1

Fan Motor Capacitor 3106995010 1.2µF 450VAC 0.2A 1

PART NAME PART CODE SPEC. QUANTITY REMARK

Indoor

Unit

Outdoor

Unit

3106901100 1.2µF 400VAC 1

Fuse 5FVGB0302R 250V 3A S/B 1

Fuse 5FVGD0402S 250V 4A 6ITS 1

Transformer 5EPV633100 220V/18.3V 1

Stepping Motor 1 3108004310 MP28GA (L=1300mm) 1

Stepping Motor 2 3108004300 MP28GA (L=400mm) 2

Terminal Block 3108912320 SN-DBW-4P 1

3108911600 1000-4DS 1

Compressor 3107120000 CRDQ-0200-PFJ 1

Capacitor Dual 3109500100 370V 30/3µF 1

3104500100 400V 30/3µF 1

Fan Motor 3108000400 AM12DPD04 1

Power Relay 5SC0202700 G7L-2A-TUB 1

Terminal Block 3108912320 SN-DBW-4P 1

For VDE Appliance

For NON Appliance

For VDE Appliance

For VDE Appliance

For VDE Appliance

21

Page 22

5. REFRIGERANT CYCLE

INDOOR UNIT

Evaporator

Cross flow fan

Connecting pipe

Capillary tube

Dryer

Condenser

Propeller fan

OUTDOOR UNIT

Refrigerant flow

Service valve

Service valve

Accumulator

Compressor

Note) If the pipe length exceeds the standard length, add 30g of refrigerant per extra meter .

DSA-181L

Contents

Model Name

DSA-151L

DSB-181L

Capillary T ube

Charge Quantity

ID2.0Ø x OD3.2Ø x L1200

1300 g

ID1.78Ø x OD3.2Ø x L600

1500 g

22

ID2.0Ø x OD3.2Ø x L650

1200 g

Page 23

6. CONTROL BLOCK DIAGRAM

Relay RL1

Indoor fan

motor

Power

Relay

Compressor

Outdoor

fan motor

TRIAC

DC12V

Operating Mode

Fan Speed

Timer Selection

Flap Position

Unit on lamp

Room air temp.

Indoor coil temp.

Quick lamp

Air-clean lamp

Remote

Emergency

Operation

Signal

receiver

Timer lamp

A/D converter lnitialization

Clock generation

DC power supply

Circuit for

relay driving

Circuit for

TRIAC control

Transformer

Circuit for signal receiver

MICRO

CONTROLLER

Beeper

Circuit for

motor driving

Stepping

motor 1,2

Temp. Setting

ON/OFF

SLEEP

Turbo/MILD

AC220V

DC5V

◆ DSA-151L/DSA-181L/DSB-181L

23

Page 24

1

2

3

I.D.C

S

COMP

POWER RELAY

TERMINAL

BLOCK

TRANS-

FORMER

CMC

Indoor Unit

Fan Motor

SWING

MOTOR

SWING

MOTOR2

ROOM AIR

SENSOR

INDOOR COIL

SENSOR

SWING

MOTOR1

Display Part

Control Part

Signal Receiver

Pemote Controller

LN Y

COMP

FMC

7. ELECTRIC CIRCUIT DIAGRAM

1

ELECTRIC CIRCUIT DIAGRAM

◆ DSA-151L/DSA-181L/DSB-181L

24

Page 25

Description

1. After the power ON/OFF button is pressed once, the rela y and triac are turned ON or OFF per the remote

control setpoint.

– TRIAC is controlled per the fan speed selection.

– RELAY is controlled per the operation mode selection.

2. If the power ON/OFF button is pressed once more, the rela y and triac are turn off and the unit stops

operation.

3. The unit turns on or off according to the temperature setpoint by sensing the room air temperature through

thermistor.

4. If the fan speed selection is set to the auto position, the fan speed is automatically controlled according to the

temperature differance between room temperature and temperature setpoint.

25

Page 26

2

2

PCB CIRCUIT DIAGRAM

Page 27

6

Page 28

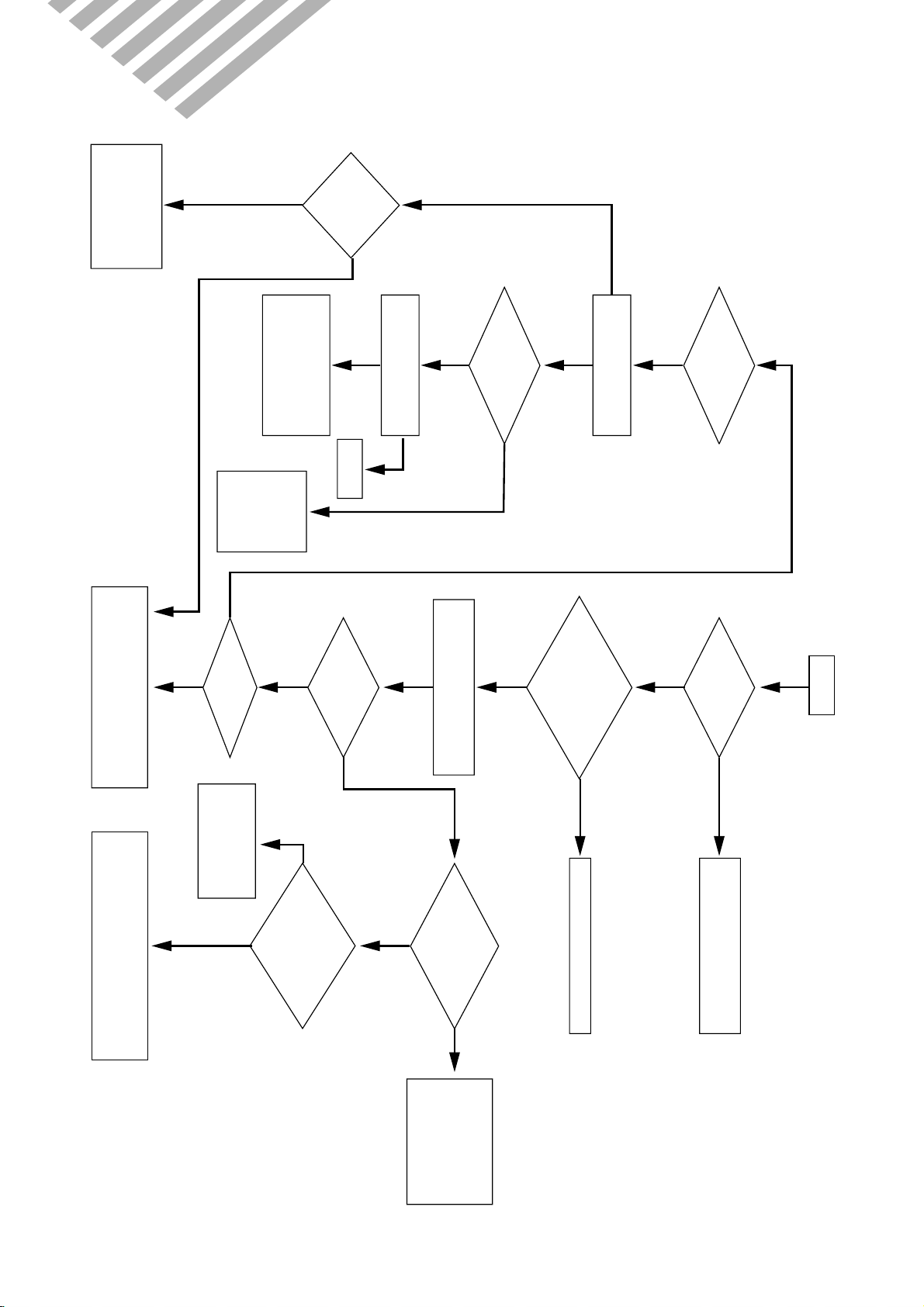

8. TROUBLE SHOOTING

Outdoor unit does

not run?(note. 1)

Does

the compressor run

normally?

Indoor unit does

not run(note 1)

Check the failure

code according to

the self diagnostic

(note 2)

Is the unit

display

mormal?

check the failure

code according to

the self-diagonostic

(note 2)

Normal

check the

connecting

point of

magnetic

contactor

YES

YES

YES

YES

NO

NO

YES

Trouble

Is the power

applied to the

unit

Is the

power normal?

check the voltage between

L & N of terminal

block

press the power ON/OFF

button on remote controller

Does the

beeper beep two

times?

Is the display

all off?

• Check the connector on display

PCB connected to control PCB

• Check the display PCB itself

Check power supply mains

or interconnection wires

Check the wiring of indoor

Is the

switch position

on switch pannel at

"Remote"

Does

control PCB

status LED repeat one

second "on and

off"?

• control PCB fault

• Micom or reset

IC fault

• Check the remote signal receiver

• Check the connection between signal

receiver and control PCB

Place the switch

position to the

"Remote" and then

Check it once

more

YES

NO

YES

NO

NO

NO

NO

YES

YES

YES

YES

YES

NO

NO

NO

Is the

unit display

normal?

27

Page 29

Note 1)

! Neither indoor unit nor outdoor unit runs.

Check the following points first. (There are f ollo wing case in normal operation)

a. Is the timer mode set the "timer ON".

b. Is the timer mode set the "timer-OFF" and the time had passed?

@ Neither outdoor fan nor compressor runs while indoor fan runs.

Check following points first. (There are f ollo wing cases in normal operation)

a. Is the temperature set point suitable?

b. Has the 3 minutes time guard f or compressor operated?

Note 2) Please refer to page 16, Self Diagnostic-function.

Self-Diagnostic Function

◆ DSA-151L/DSA-181L/DSB-181L

1) Error Code 1

! Check the connector of room air thermistor. (or connecting wire)

@ Check soldering of connecting on control P.C.B. (Error of soldering or short)

# Check the resistance of room air thermistor.

2) Error Code 3 (Display Emergency mode)

! When the compressor do not run.

i) Check the voltage between and of terminal block.

(Indoor Unit, Outdoor Unit)

ii) Check connecting wire of indoor unit and outdoor unit.

iii)Check relay KI on power P.C.B

@ Check fixing of indoor coil thermistor.

# Check the GAS LEAKAGE of the pipe.

N

Y

28

Page 30

Neither Indoor Unit nor Outdoor Unit Runs

The power is applied to the unit

Check the voltage between and

N

of terminal block

Rating voltage more than 90%

Check the indoor unit display

is the display all off?

YES

Press the ON/OFF switch of

Remote Control

Is the indoor unit display all off?

Pull out the power plug

and then insert the power plug

after 5 seconds

L

Rating voltage

under 90%

NO NO

NO

Check the

Breaker or Fuse

Self Diagnostic

function is ON

YES

Check according to

self Diagnostic function

Control P.C.B defect

Control P.C.B is normal

Recheck from the beginning

29

Page 31

Outdoor Unit Runs but Indoor Unit Do Not Run

Check rotation of indoor fan

Rotate indoor fan by hand

YES

Check input Voltage of F an

Motor connector at power P.C.B

Rating V oltage more than 90%

Check the winding resistance of

Indoor unit fan motor

Normal

Check the fan motor capacitor

NO

Rating voltage

under 90%

Open or short

Check the F an Motor

bearing and fan

Check the power P.C.B.

The circuit for triac control

Change of fan motor

Check the connecting wire of

indoor fan motor

Run again

30

Page 32

Outdoor Fan Do Not Run

Check the voltage between and

N

of indoor unit terminal

Check the voltage between and

N

of outdoor unit terminal

Check the voltage between and

Y

of outdoor unit terminal

Check outdoor fan motor individually

L

L

N

Rating voltage

under 90%

Rating voltage

under 90%

Rating voltage

under 90%

Check the wiring

and voltage

within doors

Check the

connecting wire

Check the

connecting wire

31

Page 33

Only Compressor Do not Run

- Check the following at cooling mode

Check the voltage between and

Y

of indoor unit terminal

Rating voltage more than 90%

Check the voltage between and

Y

of outdoor unit terminal

Rating voltage more than 90%

Check the magnetic contactor

Check the wiring of outdoor unit

Check the compressor

(Check the winding resistance)

N

N

Rating voltage

less than 90%

Rating voltage

less than 90%

NG

Open or Short

Check the control P.C.B

the circuit for relay

driving.

Check the connecting

wire between indoor

and outdoor.

Change the magnetic

contactor.

Change the

compressor.

OK

Check the compressor capacitor

32

Page 34

Outdoor Fan and Compressor Do Not Run

Check the voltage between and

N

of indoor unit terminal

Check the voltage between and

N

of outdoor unit terminal

Check the voltage between and

Y

of outdoor unit terminal

Check compressor ,

outdoor fan motor individually

L

L

N

Rating voltage

under 90%

Rating voltage

under 90%

Rating voltage

under 90%

Check the wiring

and voltage

within doors

Check the

connecting wire

Check the

connecting wire

33

Page 35

PCB DRIVING DESCRIPTION

Page 36

Power Supply (1)

7805 7812

AC 220V

VAR

CC3

0.1 CC2

0.1

CE2

470/16V

CC1

CE3

100/25V

31

DC 12V

2

31

2

0.1µF/250V

BD1

1000/35V

CE1

+

+

POWER

TRANS

DESCRIPTION

DC Po wer Supply in circuit needs +12V and +5V. +12V is used for Compressor Driving Relay, T riac Driving

Photo Triac, Buzzer Driving Swing, Sweep Motor, and LED Display. AC voltage of secondary Power

Transformer is rectified by Bridge Diode, and it is filtering by Main Condensor CE1.

Filtered DC voltage is about +17V, is regulated +12V DC by Regulator IC7812.

And it is regulated +5V DC by Regulator IC7805.

V AR is surge filter and CE2, CE3, CC2, CC3 is Noise filter .

35

Page 37

Oscillation (2)

19

20

X-TAL

8MHz

VDD-10%

VSS+10%

DESCRIPTION

Oscillatory Frequency drive Micom, it is made up 8MHz X-TAL oscillatory F reqency.

Ocillatory wave is as follo wing Fig 2-1.

Fig 2-1

36

Page 38

Sensor(3)

24

25

R18

12.7K

R20

12.7K

CN8

R19

CC8

CC9

R21

EVA: SENSOR

ROOM: SENSOR

1

2

3

4

MICOM

Room temperature and Evaporator temperature Sensor Input

DESCRIPTION

Number 24, 25 of Micom is Terminal of A/D conv ertor Input.

Room temperature and Evaporator temperature is sensing by change of Thermister Resistance, Micom is put

in 5V by ratio between R18 (12.7KΩ) and R20 (12.7KΩ).

Relation between temperature and voltage is follo wing Table 3-1.

CC8, CC9 is Noise filter.

Voltage (V)

No. 24, 25

Temperature

(°C)

-5 1.12

0 1.37

15 2.22

25 2.79

40 3.52

Table 3-1

37

Page 39

KID 65004

38

R4

1K

12V

R5 100 L1

TLP560J

TRIAC

SM3

JZ47

AC220V

0.1µF/120OHM

TO MOTOR

SN1

L

MICOM

T riac Driving (4)

AC220V

TRIGGER

MOTOR

INPUT

LOW SPEED MEDIUM SPEED HIGH SPEED

DESCRIPTION

Number 38 Terminal of Micom is put out Pulse Output, by wa y of Buff er it is driving Photo Triac TLP560 and

then Triac SM3JZ47 is supplied Trigger Signal.

Trigger T est of Triac is detected Zero Cross Part of AC input and it is triggered from Zero Cross part to Time

delay part according to Fan Speed. (Ref. Fig 4-1) SN1 is Snub ber .

LOW SPEED

MEDIUM SPEED

HIGH SPEED

Fig 4-1

38

Page 40

Selecting Mode (5)

13

CC6

0.01

R15 1K

R16

10K

CN1

EMERGENCY S/W

MICOM

(SELECT S/W INPUT, OUTPUT)

DESCRIPTION

There are three Mode according to SW position as following Table 6-1.

POSITION MODE

Close EMERGENCY

Open REMOTE

Table 6-1

39

Page 41

Micom Power Supply (6)

42

Vcc

5V

10µF/16V

CE2

CC1

104

22

21

MICOM

DESCRIPTION

MICOM Po wer is supplied 5V at Number 42 using Digital, Number 22 using Reference of A/D Conv erter .

CE2 is Ripple filter and CC1 is Noise filter.

40

Page 42

Reset (7)

R9

1K

CC3

104

R10

5.6K

5V

18

5V

CE1

4.7µF/50

3

7042P

MICOM

1

2

RESET IC

+

4.2V

H

L

t

t

POWER

ON

Vcc (+5V)

DELAY TIME

FOR POWER ON

RESET

DESCRIPTION

V oltage less than about 0.8V put in Micom Terminal of Number 18 and then Micom reset. Reset IC detect

Po wer ON and Voltage less than 4.2V , and then send Reset Signal. There is a Manual Reset S/W to reset

manually if necessary .

41

Page 43

30

28

29

27

MICOM

CA1

JS3

JS5

R14

1K

Test

RA

R13 1K

R12 1K

R11 1K

JS4

Function Selecting (8)

DESCRIPTION

Selecting Function is as following Table 9-1.

JS6

JS5

JS4

JS3

SHORT

Skip

Mild

Heat

50Hz

T ab le 9-1

OPEN

Comp err detect

High

Cool

60Hz

42

Page 44

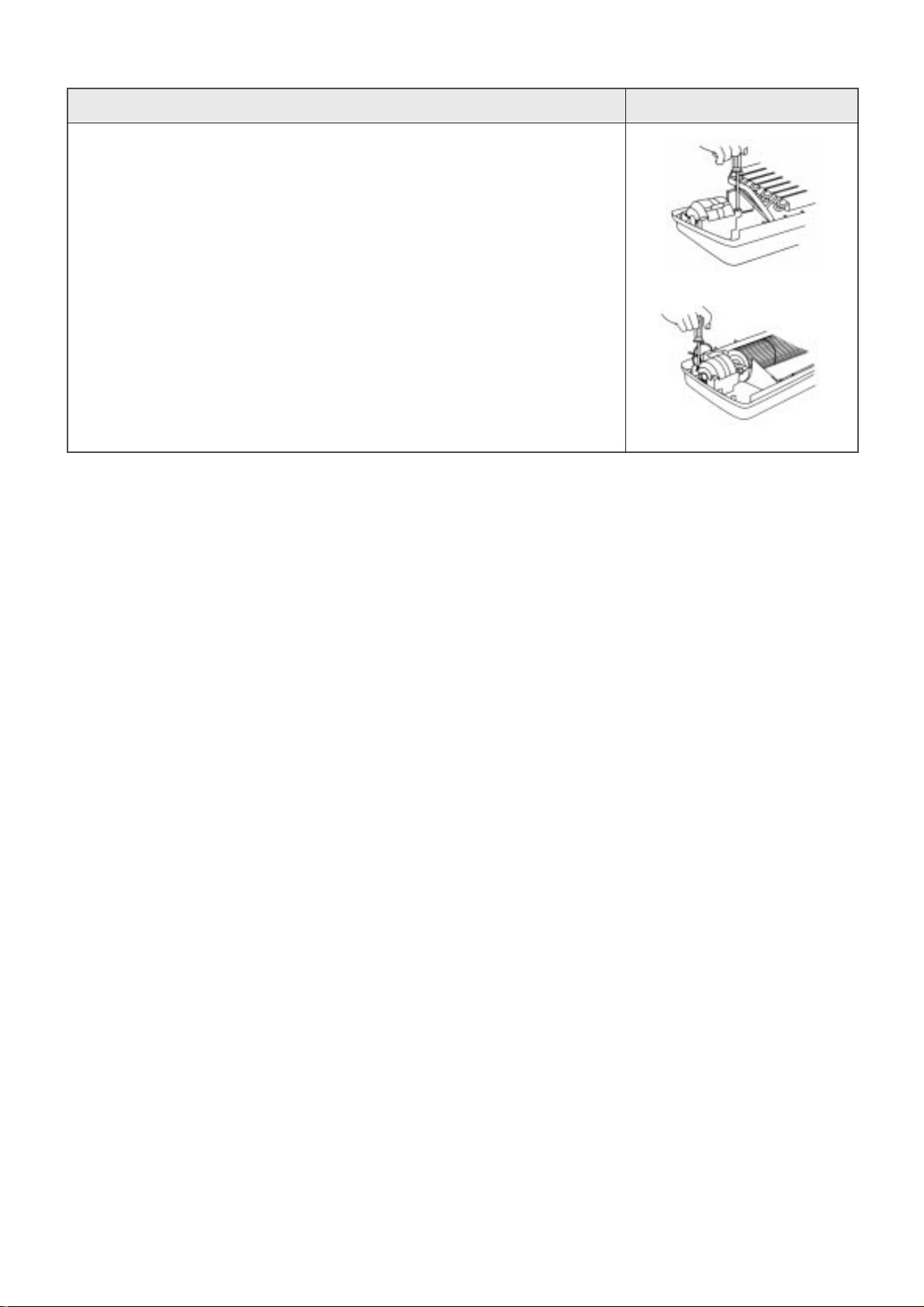

9. DISASSEMBLY INSTRUCTIONS

INDOOR UNIT

1

PROCEDURES PHOTOS

1. Stop the Air conditioner and disconnect the power cord from the wall

outlet.

2. Removing the Insert Grille and Frame .

! Loosen three screws f or fixing the the Insert Grille and Frame.

(Pull out the frame cap before loosening three screws) (Fig 1)

@ Loosen three screws at the Drain Pan.

# Remove the Insert Grille and Frame.

3. Removing the Control Box.

After doing above procedures:

! Disconnect indoor room and coil thermistors. (Fig 3)

@ Disconnect the fan motor lead wire from connection at the main

PCB. (Fig 3)

# Disconnect the swing motor connection wire.

$ Loosen a screw for fixing ground wire.

% Loosen two screws for fixing the body.

4. Removing the Drain Pan.

After doing above procedures:

! Loosen a screw f or fixing body. (Fig 4)

@ Unhook the right part of Drain Pan.

Fig 1

Fig 2

Fig 3

Fig 4

5. Removing the Indoor Coil.

After doing above procedures:

! Loosen f our screws f or fixing indoor coil at left and right side. (Fig 5)

@ Loosen a screw for fixing the brac ket tube at the bac k side. (Fig 6)

# Remove the indoor coil. (Fig. 6-1)

6. Removing the fan motor .

After doing above procedures:

! Loosen two scre ws f or fixing holder moter at left and right side.

(Fig 7, 8)

@ Loosen a screw for fixing f an motor and blo wer.

# Renove the f an motor .

43

Fig 5

Fig 6

Fig 6-1

Page 45

PROCEDURES PHOTOS

7. Removing the blower.

After doing above procedures:

! Loosen a screw f or fixing holder bearing.

@ Remove the blo wer.

Fig 7

Fig 8

44

Page 46

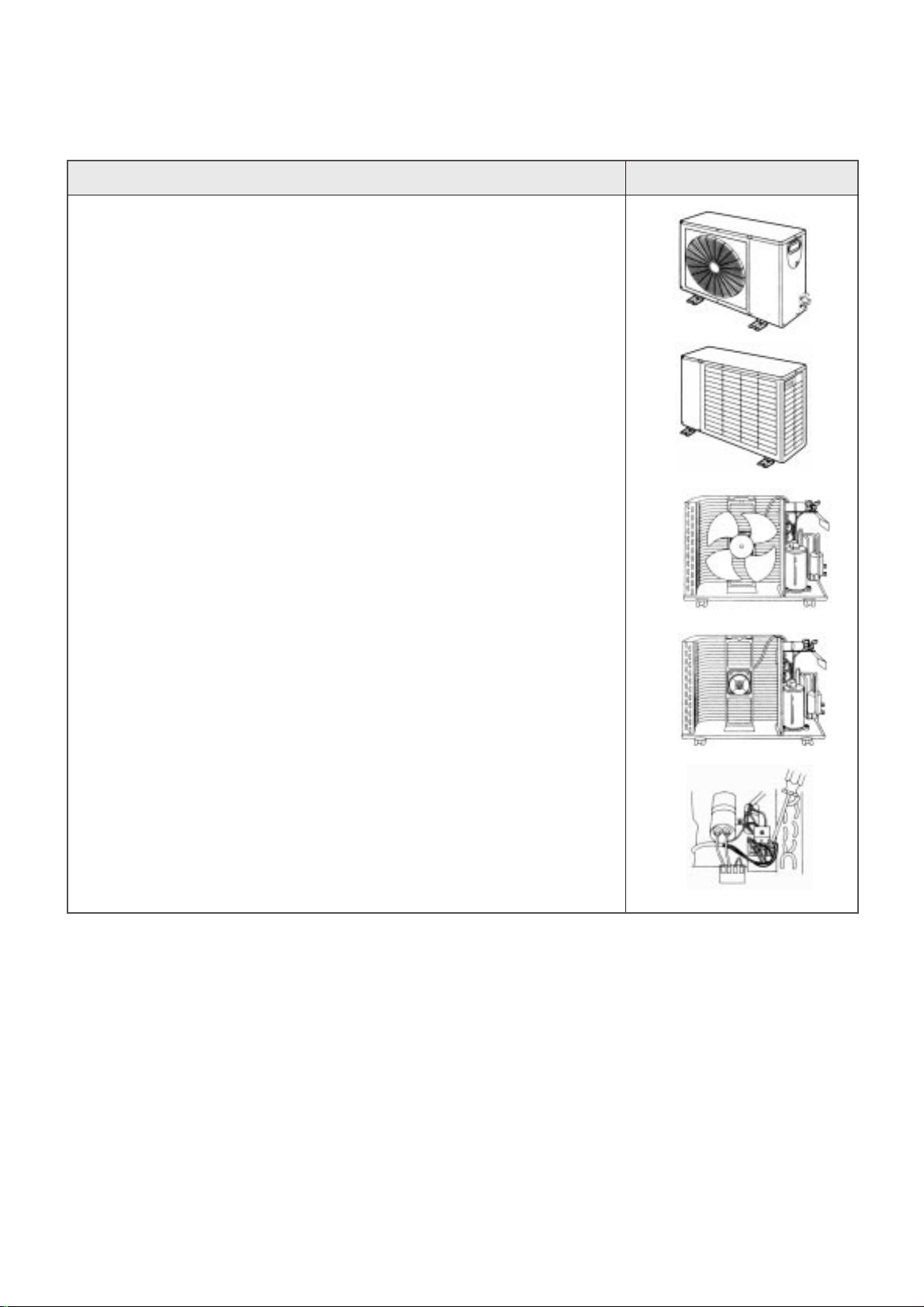

OUTDOOR UNIT

2

¡ DSA-151L

PROCEDURES PHOTOS

1. Basic Procedures

! Stop the air conditioner and pull out power plug from w all outlet.

@ Remov e CABINET T OP COVER. (Loosen ten screws)

# Remov e CABINET SIDE CO VER. (Loosen six screws)

$ Remov e CABINET FRONT. (Loosen six screws)

2. Removing Fan Motor (Fig 4)

! Do basic procedure. (!~$)

@ Loosen nut for fixing f an by spanner.

# Remov e spring washer and plain washer.

$ Remov e f an.

% Remov e f an stopper.

^ Disconnect Motor lead wire from control box.

& Loosen four screws for fixing Motor brack et and then remov e

the Motor.

Fig 1

Fig 2

3. Removing Motor Capacitor and Compressor Capacitor

! Do basic procedure.(!~$)

@ Diconnect lead wire from the Motor capacitor and compressor

capacitor.

# Loosen two screws f or fixing the capacitor brac k et.

$ Remov e Motor capacitor and compressor capacitor .

4. Removing Magnetic Contactor. (Fig 5)

! Do basic procedure !~@ .

@ Disconnect lead wire from Magnetic Contactor.

# Remov e Magnetic contactor . (Loosen f our scre ws)

5. Removing Overload Protector . (Fig 6,7)

! Do basic procedure !~#.

@ Remove terminal cover.

# Disconnect lead wire from overload protector.

$ Remove ov erload protector .

Fig 3

Fig 4

Fig 5

Fig 6

45

Fig 7

Page 47

¡ DSA-181L/DSB-181L

PROCEDURES PHOTOS

1. Basic Procedures

! Stop the air conditioner and pull out power plug from w all outlet.

@ Remov e CABINET T OP COVER. (Loosen ten screws)

# Remov e CABINET SIDE CO VER. (Loosen six scre ws)

$ Remov e CABINET FRONT. (Loosen six screws)

2. Removing F an Motor (Fig 4)

! Do basic procedure. (!~$)

@ Loosen nut for fixing f an by spanner.

# Remov e spring washer and plain washer.

$ Remov e f an.

% Remov e f an stopper.

^ Disconnect Motor lead wire from control box.

& Loosen four screws for fixing Motor brack et and then remov e

the Motor.

Fig 1

Fig 2

3. Removing Motor Capacitor and Compressor Capacitor.

! Do basic procedure.(!~$)

@ Diconnect lead wire from the Motor capacitor and compressor

capacitor.

# Loosen two screws f or fixing the capacitor brac k et.

$ Remov e Motor capacitor and compressor capacitor .

4. Removing Magnetic Contactor. (Fig 5)

! Do basic procedure !~@ .

@ Disconnect lead wire from Magnetic Contactor.

! Remov e Magnetic contactor . (Loosen f our scre ws)

Fig 3

Fig 4

Fig 5

46

Page 48

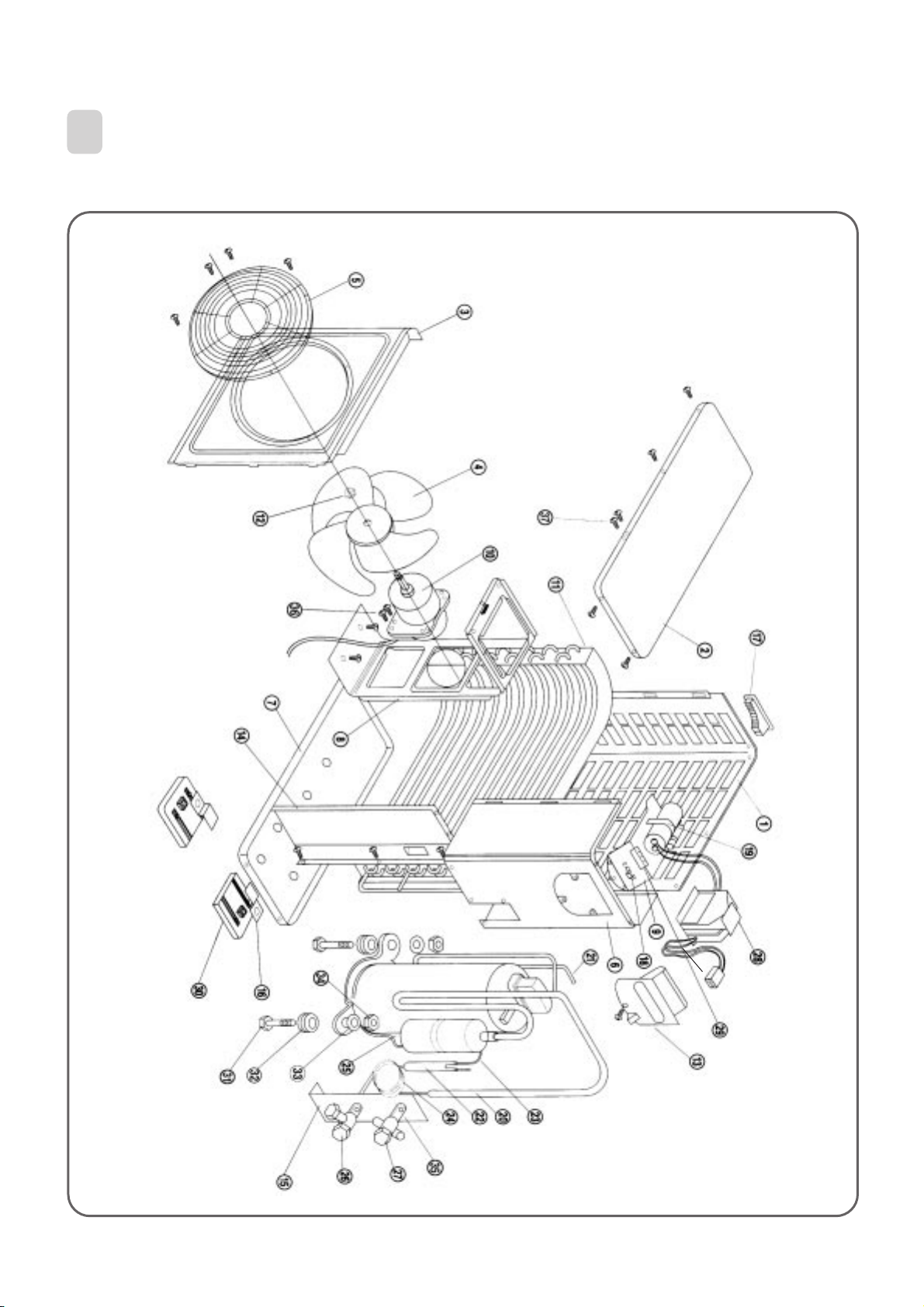

EXPLODED DIAGRAM (Indoor Unit)

3

¡ DSA-151L/DSA-181L/DSB-181L

47

Page 49

¡ DSA-151L/DSA181L/DSB-181L Parts List (Indoor Unit)

No PART CODE PART NAME Q'TY SPEC REMARK

1 3100400101 BOD Y 1 ABS

2 3107600100 FLAP TOP 1 ABS

3 3107600200 FLAP UNDER 1 ABS

4 3106500400 BLADE VER 16 ABS

5 3103000500 HOLDER MOTOR R 1 ABS

6 3103000700 HOLDER BEARING 1 ABS

7 3103000600 HOLDER MOTOR L 1 ABS

8 3106400100 BEARING OILESS 1

9 3101800200 FAN CR OSS FLO W 1 Ø100X861L

10 3102400800 GRILLE LATCH 3 POM

3108000230 MOTOR ASS’Y 1 IC-9425 DWKC 5C

11

3108000230 MOTOR ASS’Y 1 IC-9425KH 6C

12 3102400900 GRILLE INSERT 1 ABS

13 3100501000 BOX CONTROL 1 ABS (V0)

14 3107410000 EVA ASS’Y 1

15 3101930010 FILTER ELECTR O ASS’Y 1

16 3101940010 FILTER CARBON ASS’Y 1

17 3101401300 COVER TERMINAL BLOCK 1 ABS

18 3108100100 P AN DRAIN 1 ABS

19 3102200200 FRAME GRILLE 1 ABS

20 3100000100 FILTER PRE R ASS’Y 1

DSB-181L

DSA-151L/181L

48

Page 50

No PART CODE PART NAME Q'TY SPEC REMARK

21 3100000200 FILTER PRE L ASS’Y 1

22 3102900100 HINGE R-A 1 POM

23 3102900300 HINGE L-A 1 POM

24 3100001000 M-PCB ASS’Y 1

25 3107800100 LINK VER CAM 1 P.O.M

26 3104395400 F-PCB ASS’Y 1

27 3108004300 MOTOR STEPPING 2

MP28GA/GSP-24SW-06/ST-28

28 3108912320 TERMINAL BLOCK 1 DBW -4P

29 3107400300 EVA BRKT L 1 SGCC T1.0

30 3107800200 LINK VER A 1 ABS

31 3107800400 LINK VER C 1 ABS

32 3107500200 EMBLEM 1 URET ANE

33 3105500400 PLT WINDO W SWITCH 1

34 3104500300 PLATE MOUNTING 1 SGCC T0.8

35 3108004310 MOTOR STEPPING 1

MP28GA/GSP-24SW-06/ST-28

L=400mm

L=1300mm

49

Page 51

4

EXPLODED DIAGRAM (Outdoor Unit)

¡ DSA-151L/DSA-181L

50

Page 52

¡ DSA-151L/DSA-181L Parts List (Outdoor Unit)

No PART CODE PART NAME Q'TY SPEC REMARK

1 3100800101 CAB BACK 1 SECC T1.0

2 3104200500 PANEL T OP 1 SECC T1.0

3 3100800201 CAB FRONT 1 SECC T1.0

4 3101800100 FAN 1 ABS + G/F

5 3102400710 GRILLE DISCHARGE 1 PP

6 3100800301 CAB SIDE 1 SECC T1.0

7 3100300301 PAN BASE 1 SECC T1.6

8 3105300100 SUPPORTER MOT OR 1 SGCC T1.0

9 3104200601 PANEL CONTROL 1 SGCC T1.0

10 3108000520 MOTOR ODU 1 220V/60Hz

11 3106800010 CONDENSER ASS’Y 1

12 7391800011 NUT HEX 1

13 3102600100 HANDLE R 1 PP

14 3104500600 PLATE PARTITION 1 SGCC T1.0

15 310061000P BRACKET SERVICE ASS’Y 1

16 3102100200 FOOT 4 SECC T2.0

17 3102600200 HANDLE L 1 PP

18 3101200200 CLAMP WIRE 2 SGCC T1.0

19 3101200100 CLAMP CAPA CITOR 1 SGCC T0.8

20 3100016300 PIPE SUCTION ASS’Y 1 CU ¡¨T0.8

3100016700 PIPE SUCTION ASS’Y 1 CU ¡¨T0.8

¤

¤

DSA-151L

DSA-181L

51

Page 53

No PART CODE PART NAME Q'TY SPEC REMARK

3100016200 PIPE DISCHARGE ASS’Y 1 CU

5

T0.8

¡¨

16

21

3100016600 PIPE DISCHARGE ASS’Y 1 CU

5

T0.8

¡¨

16

22 3104400700 PIPE FILTER 1

23 3104400600 PIPE TURN 1 CU

24 3104400800 PIPE CAPILLARY 1 CU

1

T0.8

¡¨

4

1

¡¨

8

3100030AE0 COMPRESSOR ASS’Y 1 RCA150A001

25

3107120010 COMPRESSOR ASS’Y 1 ECB 185211A

26 3105400200 SERVICE V ALVE-LIQ 1

27 3105400100 SERVICE V ALVE-GAS 1

1

¡¨

4

1

¡¨

2

28 5SC0202700 POWER RELA Y 1 G7L-2A-TUB

29 3108912320 TERMINAL BLOCK 1 SN-DBW-4P

DSA-151L

DSA-181L

DSA-151L

DSA-181L

30 3102101000 FOOT CUSHION 4 NR

31 3107140010 COMP BOLT 3

32 3101500200 RUBBER CUSHION 3

33 7400208411 WASHER PLAIN 3

34 7392801211 NUT LOCK 3

35 7342602011 BOLT HEX 4

36 7112501211 SCREW TAPPING 4

37 8112401211 SCREW TAPPING 10

52

Page 54

¡ DSB-181L

u

53

Page 55

¡ DSB-181L Parts List (Outdoor Unit)

No PART CODE PART NAME Q'TY SPEC REMARK

1 3100800101 CAB BACK 1 SECC T1.0

2 3104200500 PANEL T OP 1 SECC T1.0

3 3100800201 CAB FRONT 1 SECC T1.0

4 3101800100 FAN 1 ABS + G/F

5 3102400710 GRILLE DISCHARGE 1 PP

6 3100800301 CAB SIDE 1 SECC T1.0

7 3100300301 PAN BASE 1 SECC T1.6

8 3105300100 SUPPORTER MOT OR 1 SGCC T1.0

9 3104210010 PANEL CONTROL 1 SGCC T1.0

3100039210 P ANEL CONTROL 1 SGCC T1.0

10 3108000400 MOTOR ODU 1 220V/50Hz

11 3106800020 CONDENSER ASS’Y 1

12 7391800011 NUT HEX 1

13 3102600100 HANDLE R 1 PP

14 3104500600 PLATE PARTITION 1 SGCC T1.0

15 3100600000 BRACKET SERVICE ASS’Y 1

16 3102100200 FOOT 4 SECC T2.0

17 3102600200 HANDLE L 1 PP

18 3101200200 CLAMP WIRE 2 SGCC T1.0

3101202000 CLAMP CORD 1 NYLON 66

DSB-181L for

VDE Appliance

DSB-181L for

VDE Appliance

19 3101200100 CLAMP CAPA CITOR 1 SGCC T0.8

20 3100016700 PIPE SUCTION ASS’Y 1 CU ¡¨T0.8

54

¤

Page 56

No PART CODE PART NAME Q'TY SPEC REMARK

21 3100016400 PIPE DISCHARGE ASS’Y 1 CU

3

T0.8

¡¨

8

22 3104400700 PIPE FILTER 1

23 3104400600 PIPE TURN 1 CU

24 3104400800 PIPE CAPILLARY 1 CU

1

T0.8

¡¨

4

1

¡¨

8

25 3107120000 COMPRESSOR 1 CRDQ-0200-PFJ

26 3105400200 SERVICE V ALVE-LIQ 1

27 3105400100 SERVICE V ALVE-GAS 1

1

¡¨

4

1

¡¨

2

28 5SC0202700 POWER RELA Y 1 G7L-2A-TUB

29 3108912320 TERMINAL BLOCK 1 SN-DBW-4P

30 3102101000 FOOT CUSHION 4 NR

31 3106000110 BOLT COMP 3

32 3101500200 RUBBER CUSHION 3

33 7400208041 WASHER PLAIN 3

34 7392801211 NUT HEX 3

35 7342602011 BOLT HEX 4

55

Page 57

5

CONTROL BOX ASSEMBLY

¡ DSA-151L/DSA-181L/DSB-181L

1 CONTROL BOX ASSY

56

Page 58

¡ DSA-151L/DSA-181L/DSB-181L

No P AR T NAME SPEC Q’TY P AR T CODE REMARK

DSA-151L/DSA-181L 1 3100058320

1 CONTROL BO X ASS’Y

DSB-181L 1 3100058210

2 BOX CONTR OL-2 ABS (VERSION2) 1 3100506900

DWA-5423 1 5EPK633110

3 PCB TRANS ASS’Y

DWA-220V 1 5EPV633110

4 SCREW TAPPING T2S TRS 4X12 MFZN 3 7122401211

5 CAPACITOR IDM EAF-45125 (1.2µF/450V) 1 3106900210

6 SCREW TAPPING T2S TRS 4X24 MFZN 1 7141402411

7 TERMINAL BLOCK SN-DBW-4P 1 3108912320

8 SCREW TAPPING T2S TRS 3X16 MFZN 2 7111301611

9 HARNESS POWER UL1015 #16/18 1 3102704010

10 HARNESS EARTH UL1015 #18 1 3102797910

11 HARNESS COMP SIGNAL UL1015 #18 1 3102704410

12 POWER CORDWS-93 (250V 10/16A) 1 31013A24B1

13 CABLE CORD DA-5N 1 3101200300

DSA-151L/DSA-181L 1 3104300120

14 CONTROL PCB ASS’Y

DSB-181L (COOL/50Hz) 1 3104300110

15 HARNESS CONNECTING UL 1007 #26 1 3102704900

16 POWER PCB ASS’Y DSA-151L/DSA-181L/DSB-181L 1 3104300210

17 LED PCB ASS’Y 15/18K 1 3104300300

18 SWITCH PCB ASS’Y 15/18K 1 3104300400

19 SENSOR ID ASS’Y PEM-KD43C-D1 1 3104896000

20 HARNESS LED PCB UL 1007 #26 1 3102704510

21 HARNESS SWITCH PCB UL 1007 #26 1 3102707000

22 KNOB SWITCH ABS 1 3103400200

57

Page 59

DAEW OO ELECTRONICS CO., LTD.

686, AHYEON-DONG MAPO-GU SEOUL, KOREA

C.P.O. BOX 8003 SEOUL, KOREA

TELEX: DWELEC K28177-8

CABLE: “DAEWOOELEC”

FAX: 02) 360-8184

TEL: 02) 360-8182/8178~9

http://www.dwe. daewoo.co.kr

PRINTED DATE: APR.1999

Page 60

Service Manual

Model: DSA-151L

DSA-181L

DSB-181L

DAEWOO ELECTRONICS CO., LTD.

OVERSEAS SERVICE DEFT.

60

Loading...

Loading...