Service Manual

B3.3 Diesel Engine

Lift Trucks

D20S-3(B3.3), D25S-3(B3.3), D30S-3(B3.3),

D32S-3(B3.3), D33S-3(B3.3)

Skid Steer Loaders

450/450Plus, 460/460Plus

SB4135E00

Jan. 2004

Important Safety Information

Most accidents involving product operation, maintenance and repair are caused by failure to observe basic safety

rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an

accident occurs. A person must be alert to potential hazards. This person should also have the necessary training,

skills and tools to perform these functions properly.

Read and understand all safety precautions and warnings before operating or performing lubrication,

maintenance and repair on this product.

Basic safety precautions are listed in the “Safety” section or the Service or Technical Manual. Additional safety

precautions are listed in the “Safety” section of the owner/operation/maintenance publication.

Specific safety warnings for all these publications are provided in the description of operations where hazards exist.

WARNING labels have also been put on the product to provide instructions and to identify specific hazards. If

these hazard warnings are not heeded, bodily injury or death could occur to you or other persons. Warnings in this

publication and on the product labels are identified by the following symbol.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could result

in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have read and

understood the operation, lubrication, maintenance and repair information.

Operations that may cause product damage are identified by NOTICE labels on the product and in this publication.

DAEWOO cannot anticipate every possible circumstance that might involve a potential hazard. The warnings in

this publication and on the product are therefore not all inclusive. If a tool, procedure, work method or operating

technique not specifically recommended by DAEWOO is used, you must satisfy yourself that it is safe for you and

others. You should also ensure that the product will not be damaged or made unsafe by the operation, lubrication,

maintenance or repair procedures you choose.

The information, specifications, and illustrations in this publication are on the basis of information available at the

time it was written. The specifications, torques, pressures, measurements, adjustments, illustrations, and other

items can change at any time. These changes can affect the service given to the product.

Obtain the complete and most current information before starting any job. DAEWOO dealers have the most

current information available.

W

ARNIN

G

1

Index

Introduction

About the Manual................................................... 4

How to Use the Manual ......................................... 4

Illustrations............................................................. 6

Symbols ................................................................. 5

Engine Identification

Engine Diagrams ................................................... 9

Engine Views....................................................... 9

Engine Identification .............................................. 7

Engine Dataplate ................................................. 7

Specifications......................................................... 8

Troubleshooting Symptoms

Procedures and Techniques .................................20

Troubleshooting Symptoms Charts.......................20

Coolant Contamination .......................................34

Coolant Loss.......................................................35

Coolant Temperature above Normal...................38

Engine Cranks But Will Not Start

(No Exhaust Smoke) ..........................................22

Engine Difficult to Start or Will Not Start

(Exhaust Smoke) (Continued) ............................24

Engine Difficult to Start or Will Not Start

(Exhaust Smoke) ................................................23

Engine Has Poor Respones ...............................25

Engine Power Output Low (Continued) ..............29

Engine Power Output Low..................................28

Engine Runs Rough or Misfires..........................27

Engine Stops During Operation ..........................26

Engine Vibration Excessive ................................41

Engine Will Not Crank or Cranks Slowly ............21

Excessive Exhaust (Black Smoke) .....................30

Excessive Noise (Continued) .............................40

Excessive Noise .................................................39

Fuel consumption Is Excessive ..........................33

Lubricating Oil Consumption Excessive .............31

Lubricating Oil Contaminated .............................32

Lubricating Oil Pressure Is Low..........................36

Oil Level Rises....................................................37

Complete Engine

Engine Testing

Complete Engine.................................................. 89

Measuring Compression Pressure..................... 89

Testing and Adjusting the Fan Belt Tansion ....... 91

Fuel System ......................................................... 92

Checking and Adjusting Fuel Injection Timing ... 92

Injector ................................................................. 95

Assembly ........................................................... 98

Disassembly....................................................... 97

Testing................................................................ 95

Lubricating System............................................. 100

Measuring Oil Pressure ................................... 100

Rocker Levers ...................................................... 87

Adjusting Valve Clearance ................................. 87

Specifications

Camshaft and Camshaft Bushing ...................... 105

Capscrew Markings and Torque Values - Metric 115

Capscrew Markings and Torque Values - U.S.

Customary.......................................................... 116

Capscrew Markings and Torque Values ............. 115

Connecting Rod, Piston Ring and Piston Pin..... 111

Crankshaft.......................................................... 106

Cylinder Block .................................................... 104

Cylinder Head .................................................... 103

Cylinder .............................................................. 109

Flywheel ............................................................. 108

Fraction, Decimal, Millimeter Conversions......... 117

Newton-Meter to Foot-Pound Conversion

Chart .................................................................. 118

Oil Pump ............................................................ 112

Pipe Plug Torque Values.................................... 118

Piston ................................................................. 110

Regulator Valve.................................................. 113

Rocker Arm Shaft, Push Rod and Tappets......... 102

Tap-Drill Chart - U.S. Customary and Metric ...... 119

Thermostat ......................................................... 114

Timing Gear........................................................ 107

Valves, Valve Guides, and Springs .................... 101

Weight and Measures - Conversion Factors...... 120

Special Tool

Special Tool List ................................................. 121

Complete Engine ..................................................42

Engine Assembly ................................................61

Engine Disassembly ...........................................42

Diesel Engine Index

3

About the Manual

This Troubleshooting and Repair Manual is intended to aid in determining the cause of engine-related problems

and to provide recommended repair procedures.

The material in this manual covers all Signature engines. The manual is divided into sections. Each section is

equivalent to a group used in Cummins filmcard system. Some sections contain reference numbers and

procedure numbers. Reference numbers provide general information, specifications, diagrams, and service tools

where applicable. Procedure numbers are used to identify and reference specific repair procedures for correcting

the problem.

This manual is designed so the troubleshooting trees are used to locate the cause of an engine problem. The

troubleshooting trees then direct the user to the correct repair procedure. The repair procedures within a section

are in numerical order. However, the repair steps within a given procedure are organized in the order the repair

must be performed, regardless of the numerical order of the steps. The user must use the Section Contents pages

or the Index at the back of the manual to locate specific topics when not using the troubleshooting trees.

How to Use the Manual

This manual is organized to provide an easy flow from problem identification to problem correction. A list of

troubleshooting symptoms containing the most common engine problems is in the Troubleshooting Symptoms,

Section TS. The manual is designed to use the Troubleshooting Symptoms as a guide to locating the problem and

directing the end user to the correct procedure for making the repair. Complete the following steps to locate and

correct the problem.

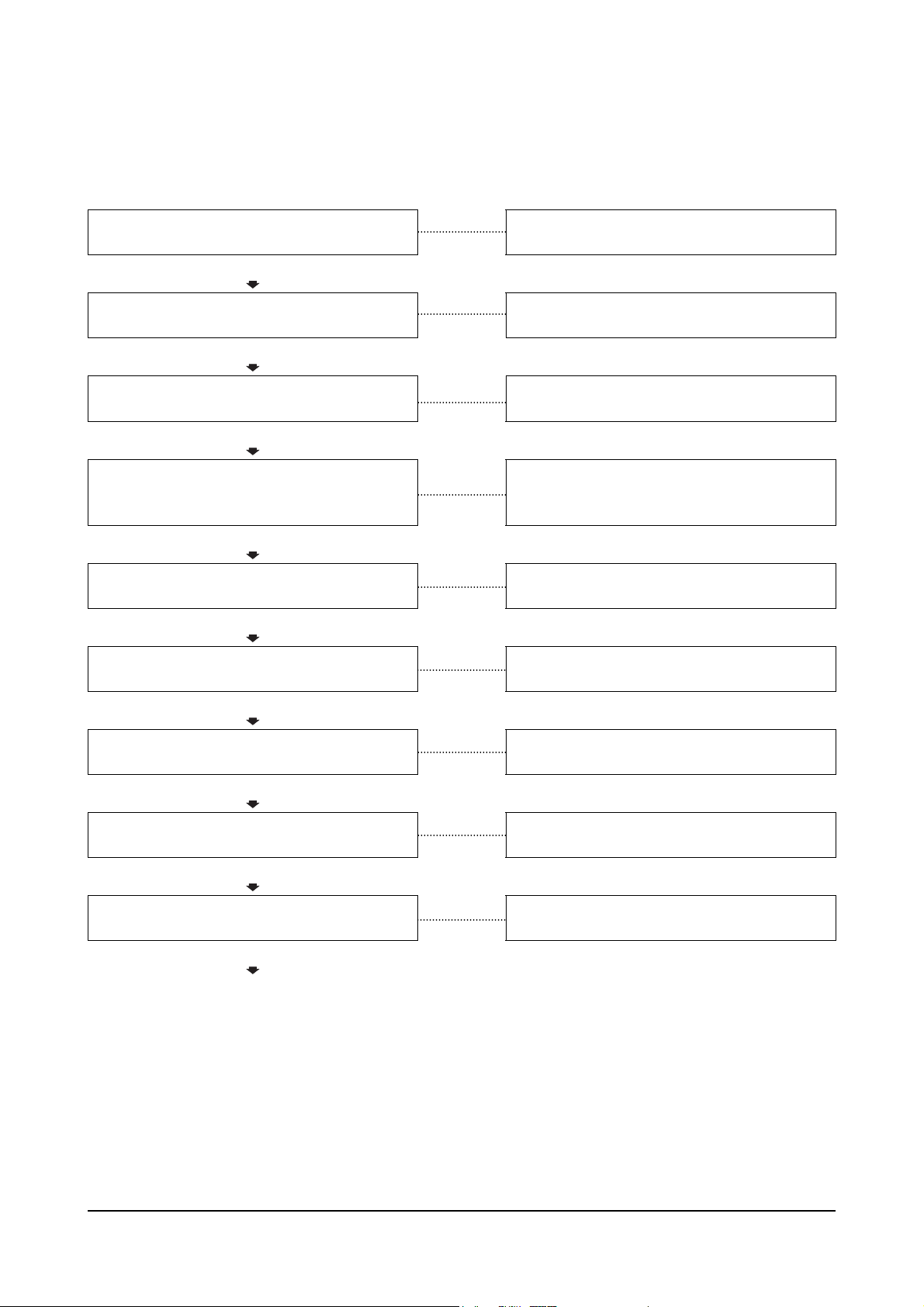

(Step 1) Locate the symptom on the Section Contents pages of Section TS.

Reference to the page number where the Troubleshooting Symptom Tree is

found is made to the right of the symptom tree title.

(Step 2) The left column of boxes in the Troubleshooting Symptom Charts indicates a

probable cause of the problem, starting at the top with the simplest and easiest to

repair, and continuing downward to the most difficult.

The right column of boxes provides a brief description of the corrective action

with a reference number to the correct procedure used to make the repair.

(Step 3)

(Step 4) The Troubleshooting Symptom Charts are based on the following assumptions:

Locate the probable cause in the left column; then turn to the procedure

referenced in the right column.

1. The engine has been installed according to the manufacturer's specifications.

2. The easiest repairs are done first.

3. "Generic" solutions cover problems with the most common applications and

original equipment manufacturer (OEM).

Diesel Engine Introduction

4

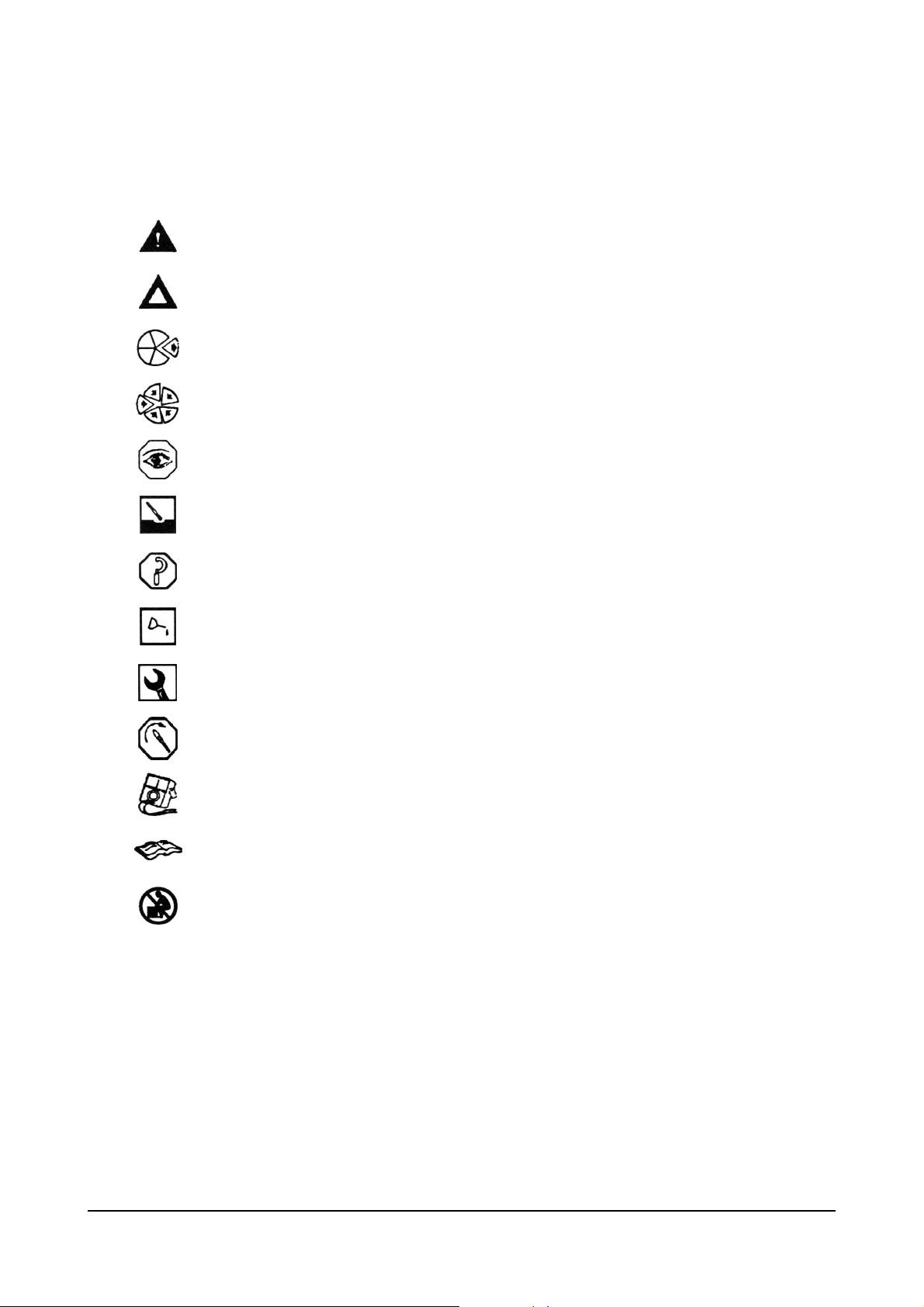

Symbols

The following symbols have been used in this manual to help communicate the intent of the instructions. When

one of the symbols appears, it conveys the meaning defined below:

WARNING – Serious personal injury or extensive property damage can result if the

CAUSION – Minor personal injury can result or a part, an assembly or the engine can be

warning instructions are not followed.

damaged if the Caution instructions are not followed.

Indicates a REMOVAL or DISASSEMBLY step.

Indicates an INSTALLATION or ASSEMBLY step.

INSPECTION is required.

CLEAN the part or assembly.

PERFORM a mechanical or time MEASUREMENT.

LUBRICATE the part or assembly.

Indicates that a WRENCH or TOOL SIZE will be given.

TIGHTEN to a specific torque

PERFORM an electrical MEASUREMENT.

Diesel Engine Introduction

Refer to another location in this manual or another publication for additional information.

The component weighs 23kg [50lb] or more. To avoid personal injury, use a hoist or get

assistance to lift the component.

5

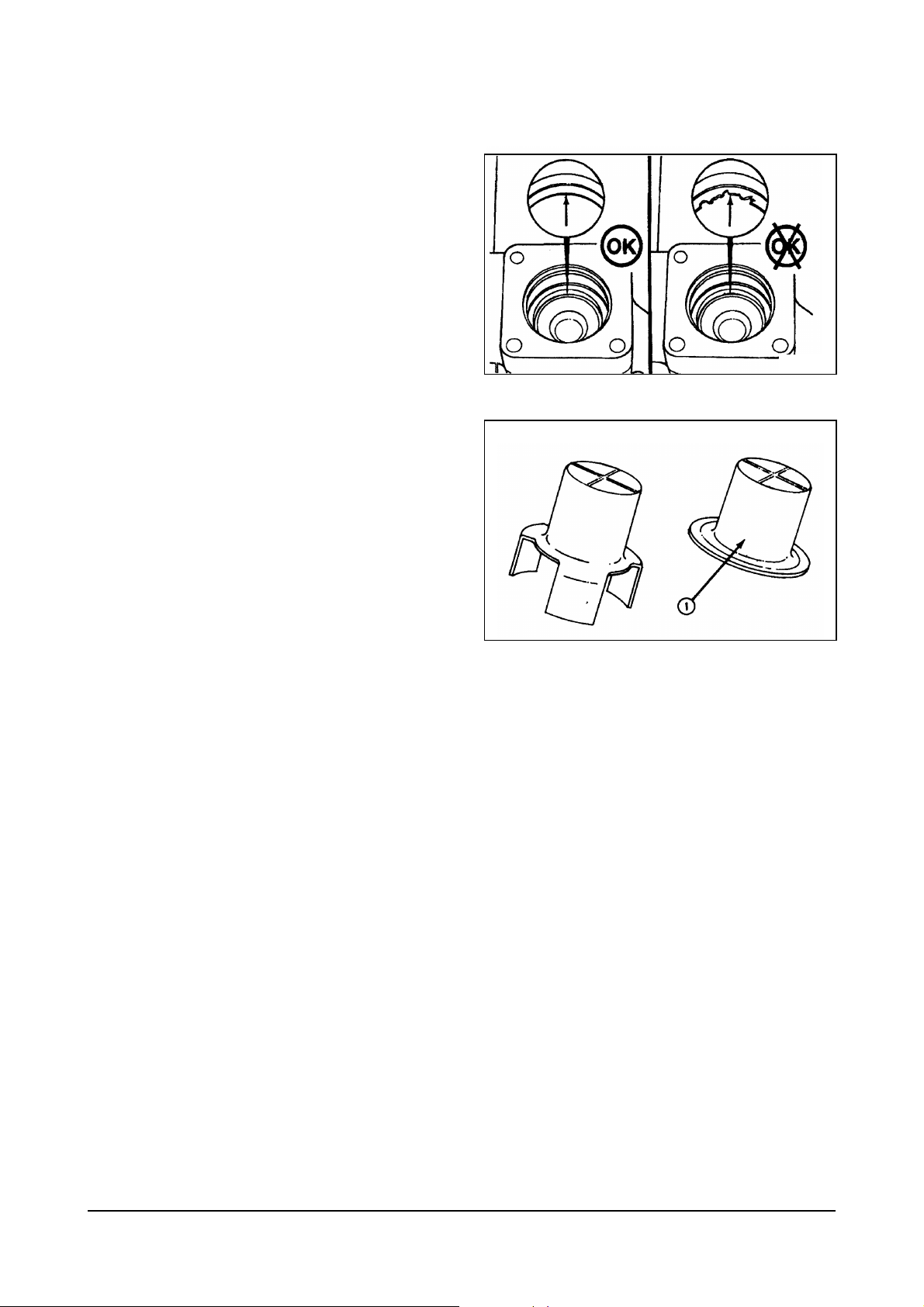

Illustrations

Some of the illustrations throughout this manual are

generic and will not look exactly like the engine or

parts used in your application. The illustrations can

contain symbols to indicate an action required and an

acceptable or not acceptable condition.

The illustrations are intended to show repair or

replacement procedures. The procedure will be the

same for all applications, although the illustration can

differ.

th8sesa

Ca8vagc

Diesel Engine Introduction

6

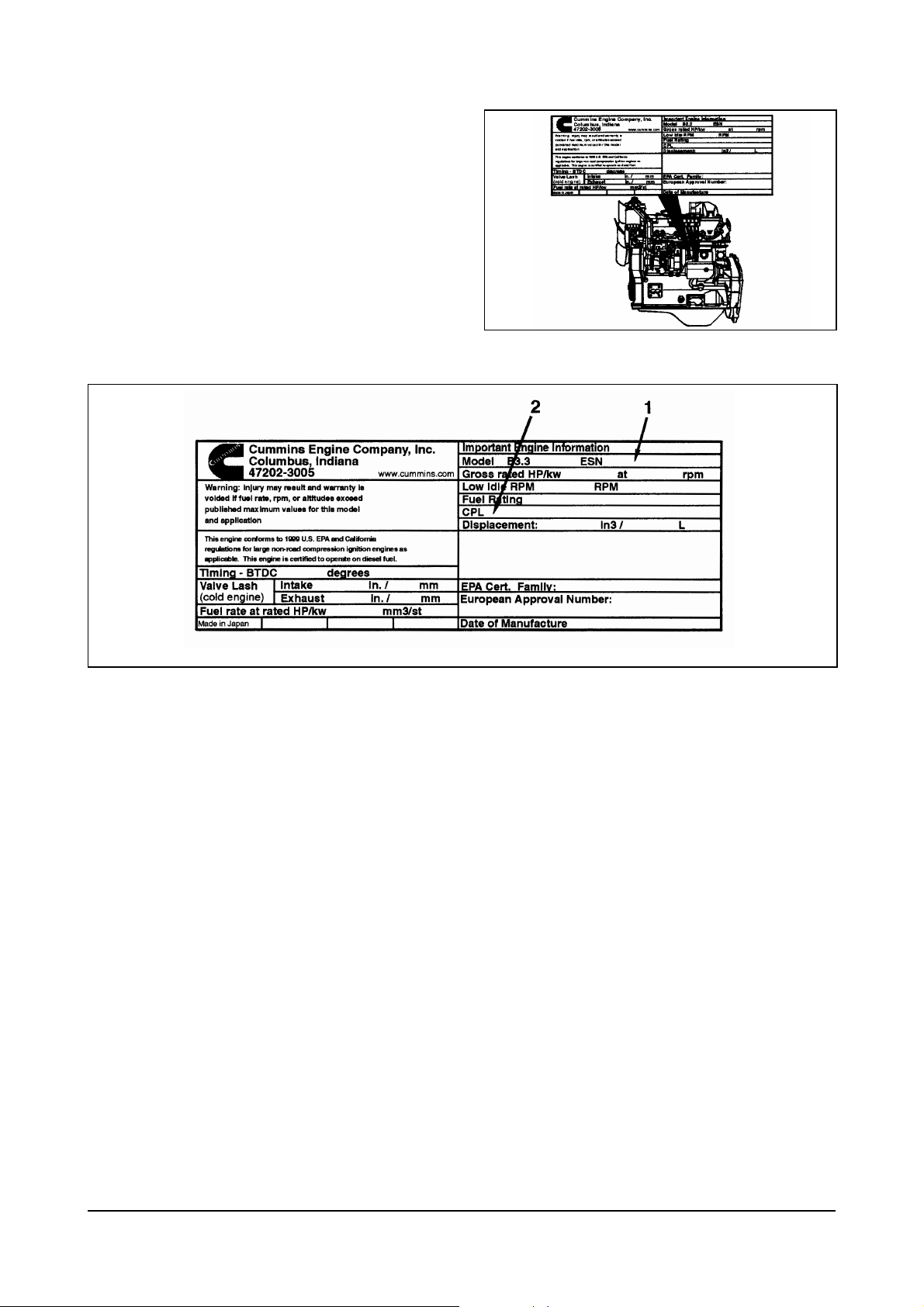

Engine Identification

Engine Dataplate

The engine dataplate shows specific information

about the engine. The engine serial number (ESN)

and control parts list (CPL) provide information for

ordering parts and for service needs.

NOTE: The engine dataplate must not be changed

unless approved by Cummins Engine

Company, Inc.

00900248

00900249

Diesel Engine Engine Identification

7

Specifications

Performance D20/25/30/32/33S-3

Standard - SAEJ1995

Air Cleaner - without but with 3.0kPa intake restriction

Test Condition

Rated Power kW(PS) 43.4 (59) @ 2200 rpm 48.5 (65) @ 2600 rpm

Max Torque Nm(kgf-m) 202 (20.6) @ 1600 rpm 214 (21.8) @ 1600 rpm

Torque Rising

BSFC

General Engine Data Naturally Aspirated

Engine Weight (Dry) Less Flywheel and Electronics 245 kg [540 lb]

Compression Ratio 18.8

Bore 95 mm [3.74 in]

Stroke 115 mm [4.528 in]

Displacement 3.26 liters [199 in³]

Firing Order 1-2-4-3

Valve Clearance:

Rotation Viewed from the Front of the Engine Clockwise

Lubrication System Naturally Aspirated

Regulating Valve Opening Pressure 490 kPa [71 psi]

Lubricating Oil Capacity:

Lubricating Oil Pressure at Idle (Minimum Allowable) 69 kPa [10 psi]

Lubricating Oil Pressure at Rated (Minimum Allowable) 245 kPa [35 psi]

Oil Filter Differential Pressure to Open Bypass Valve 98 kPa [14 psi]

Number of liters [qt] from Low to High 1.5 liters [1.6 qt]

Cooling System Naturally Aspirated

Coolant Capacity (Engine Only ) 4.5 liters [4.75 qt]

Standard Modulating Thermostat

Range:

Maximum Pressure Cap @ Sea Level 50 kPa [7 psi]

Air Induction System Naturally Aspirated

Maximum Allowable Intake Restriction at Rated Speed and

Load with Dirty Filter Element

Exhaust System Naturally Aspirated

Maximum Allowable Exhaust Restriction at Rated Speed and

Load with Dirty Filter Element

Fuel System Naturally Aspirated

Maximum Allowable Restriction to the Fuel Transfer Pump

or Filter Head Must Not Exceed

Maximum Allowable Return Line Restriction Must Not

Exceed

Inlet Pressure to the Injection Pump Range 0.00 kPa [0.00 psi] to 39.0 kPa [5.00 psi]

Electrical System Naturally Aspirated

Minimum Recommended Battery

Capacity with Light Accessories*:

Minimum Recommended Battery

Capacity with Heavy

Accessories**:

Maximum Allowable Resistance

of the Starting Circuit:

*Typical light accessories include: Alternator, small steering pump, and disengaged clutch.

**Typical heavy accessories include: Hydraulic pump and torque converter.

Muffler - without but with 10.0kPa exhaust restriction

Alternator - without

Fan - without

7.4 % for 2200rpm rating 20.0% for 2600rpm rating

@Rated Power g/kWh 227 @2200rpm 236 @ 2600rpm

@Max Torque g/kWh 219 @1600rpm 226 @ 1600rpm

Intake

Exhaust

Total System

Standard Oil Pan Only

Start

Fully Open

12-VDC Starter 550 CCA

12-VDC Starter 730 CCA

12-VDC Starter 0.0012 ohms

7.5 liters [8.0 qt] 8.0 liters [8.5 qt]

0.35 mm [0.014 in]

0.50 mm [0.020 in]

7.0 liters [7.4 qt]

82° C [180° F]

95° C [203° F]

762 mm H2O

[30 in H2O]

190.5 mm Hg

450/450Plus,460/460Plus

75 mm Hg

[3 in Hg]

75 mm Hg

[3 in Hg]

[7.5 in Hg]

Diesel Engine Engine Identification

8

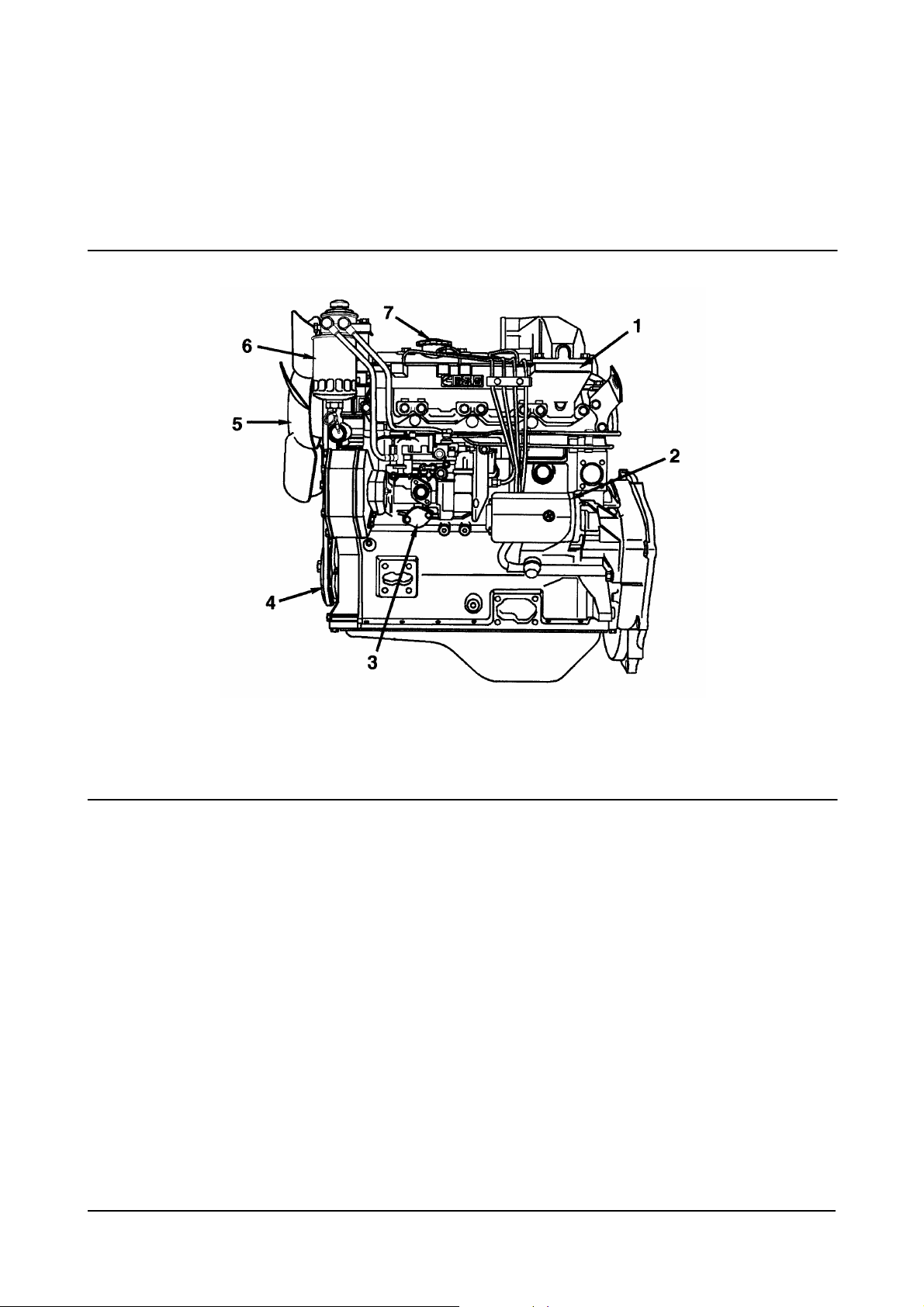

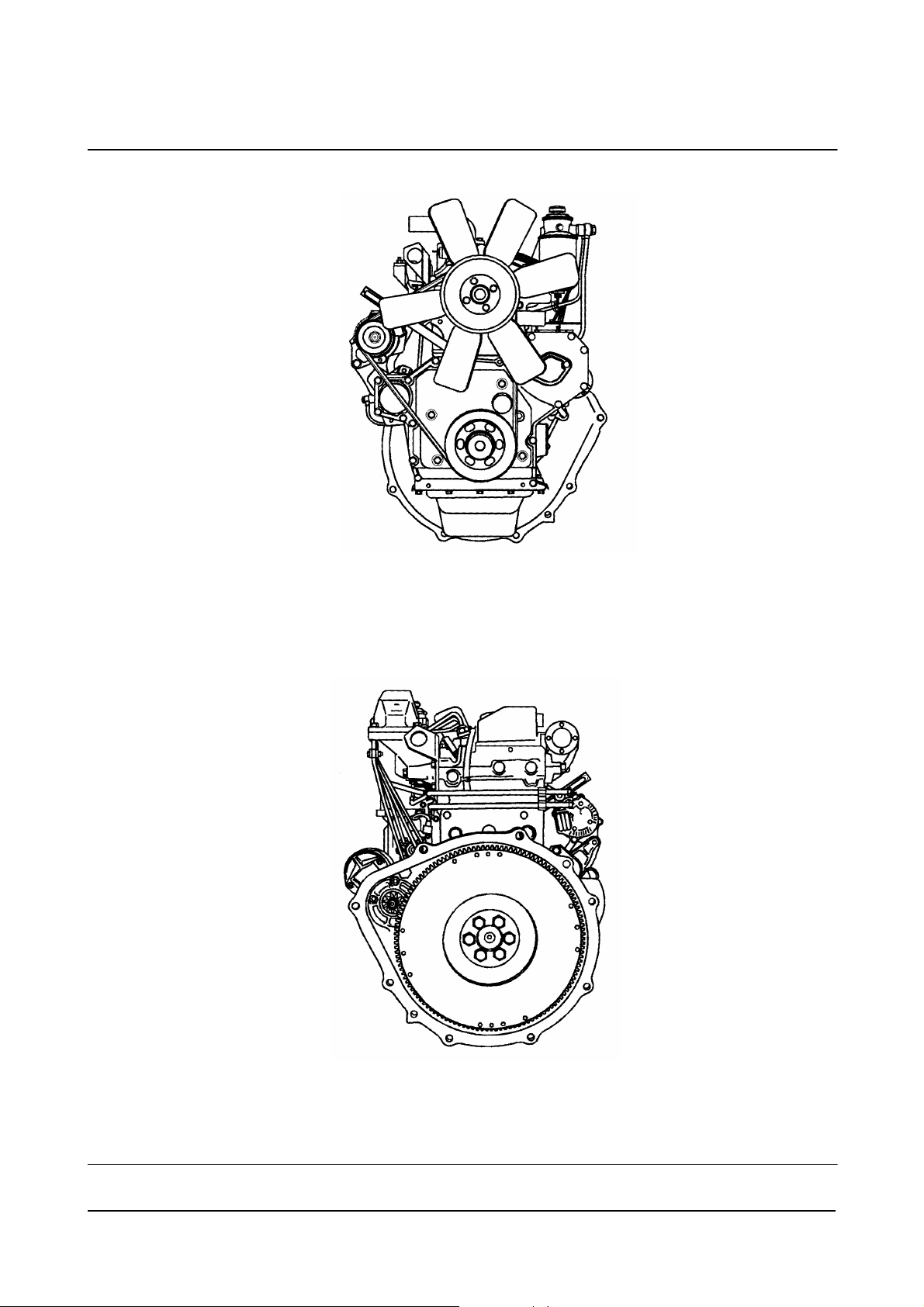

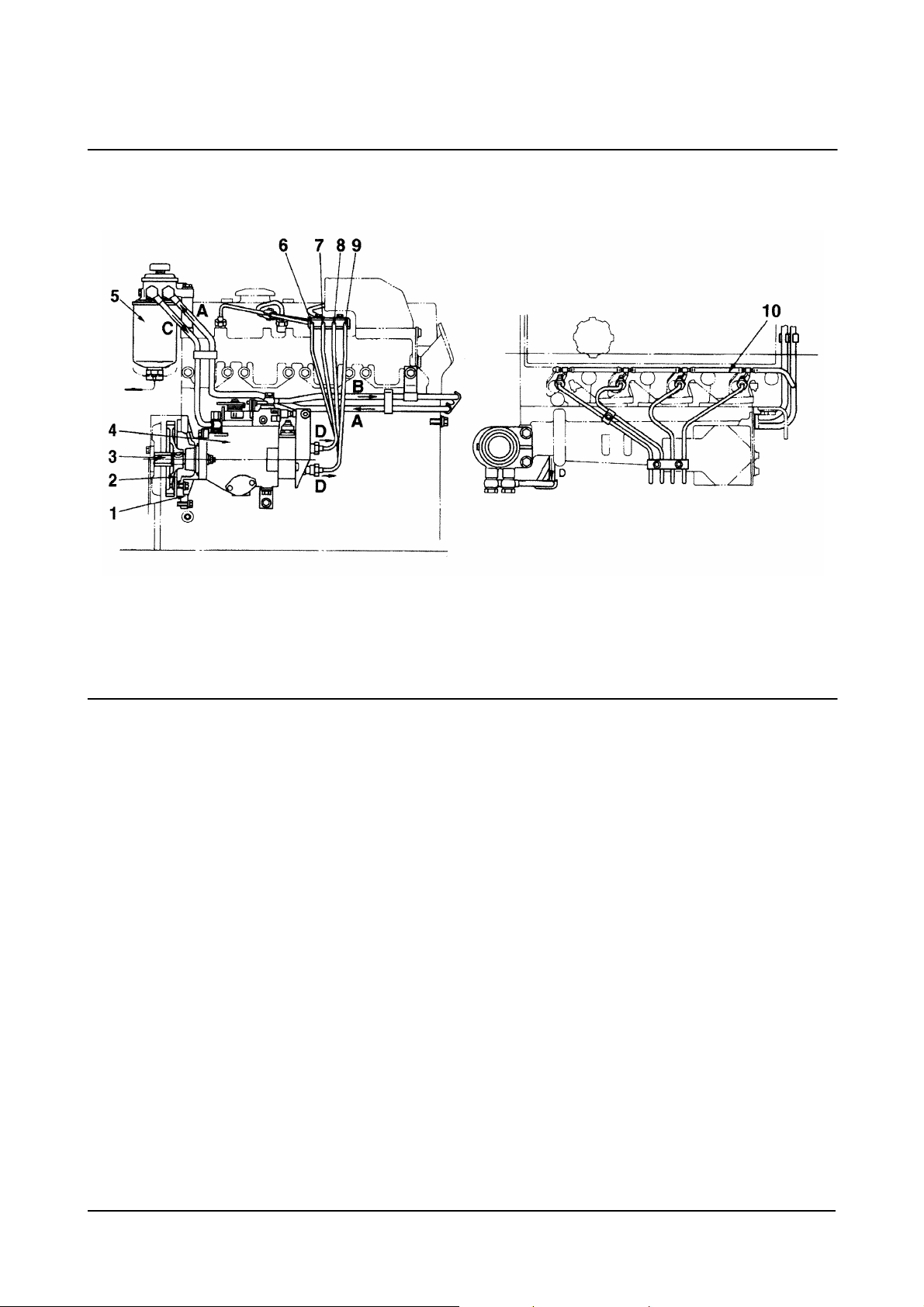

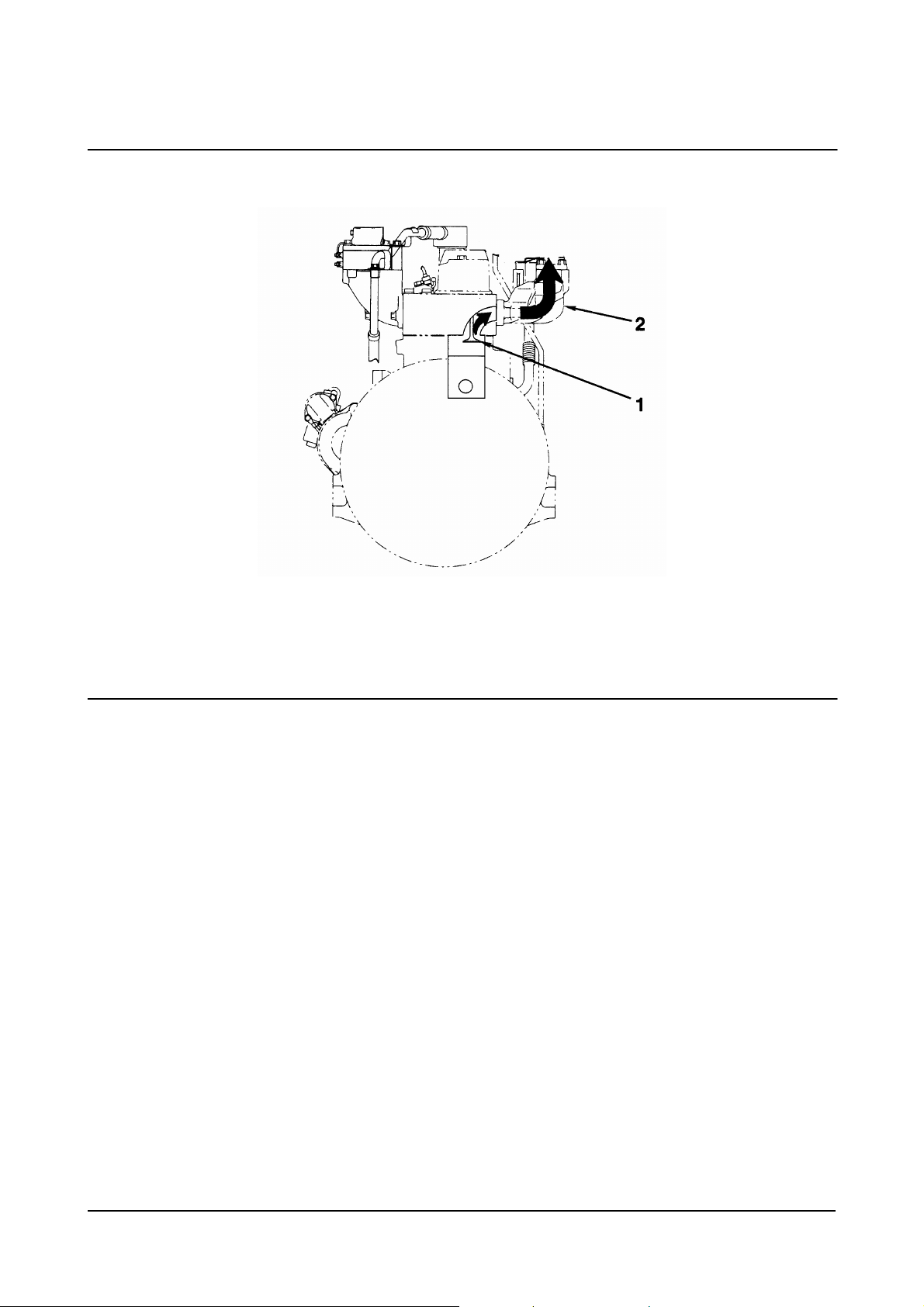

Engine Diagrams

Engine Views

The following illustrations show the locations of the major external engine components, filters, and other service

and maintenance points. Some external components will be at different locations for different engine models.

1. Intake Manifold

2. Starting Motor

3. Fuel Injection Pump

4. Crankshaft Pulley

Intake Side

(Naturally Aspirated)

00900138

5. Fan

6. Fuel Filter

7. Oil Fill Cap.

Diesel Engine Engine Identification

9

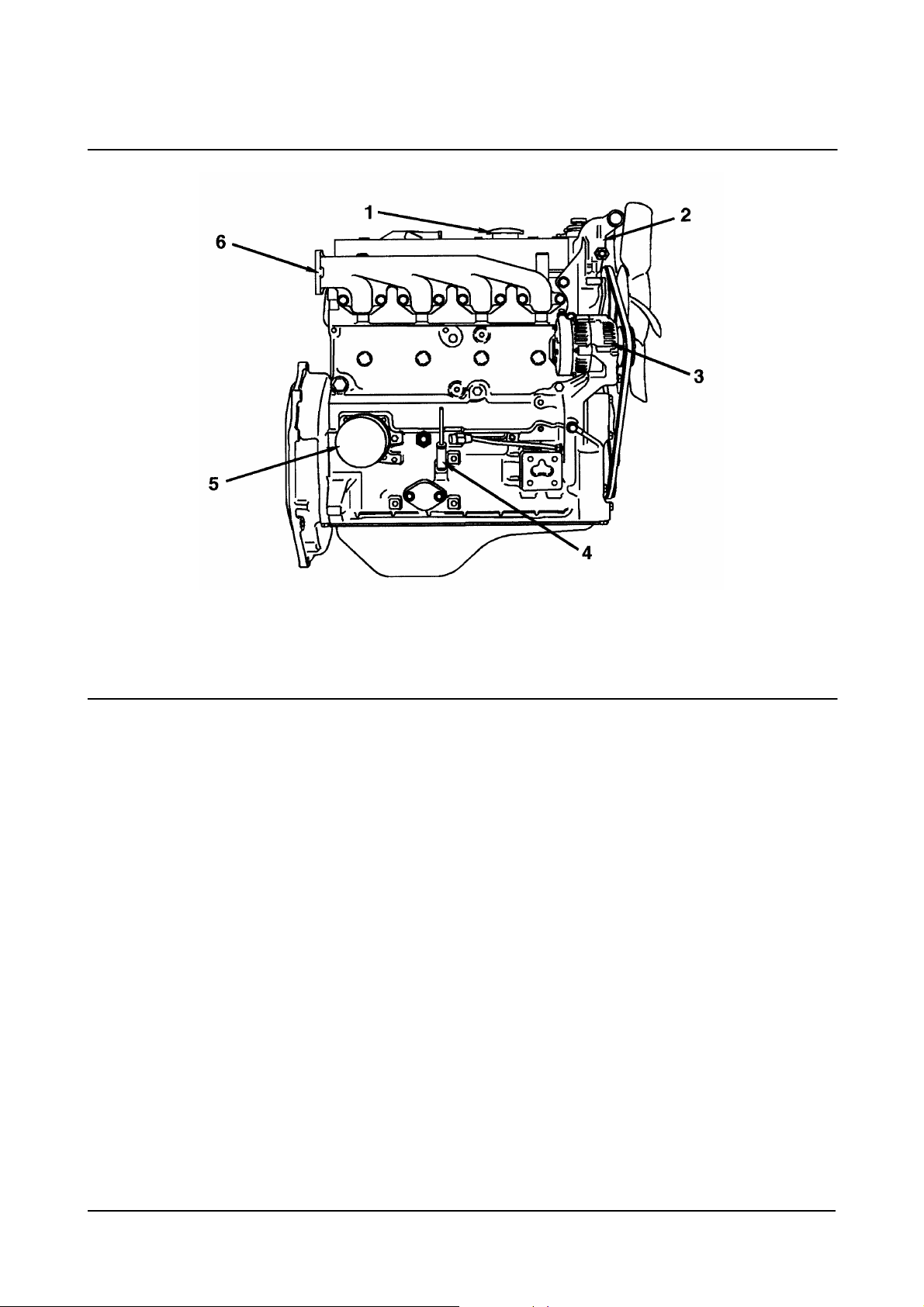

1. Oil Fill Cap

2. Thermostat Housing

3. Alternator

Exhaust Side

(Naturally Aspirated)

00900139

4. Dipstick

5. Oil Filter

6. Exhaust Manifold.

Diesel Engine Engine Identification

10

Front View

(Naturally Aspirated)

00900140

Rear View

(Naturally Aspirated)

00900141

Diesel Engine Engine Identification

11

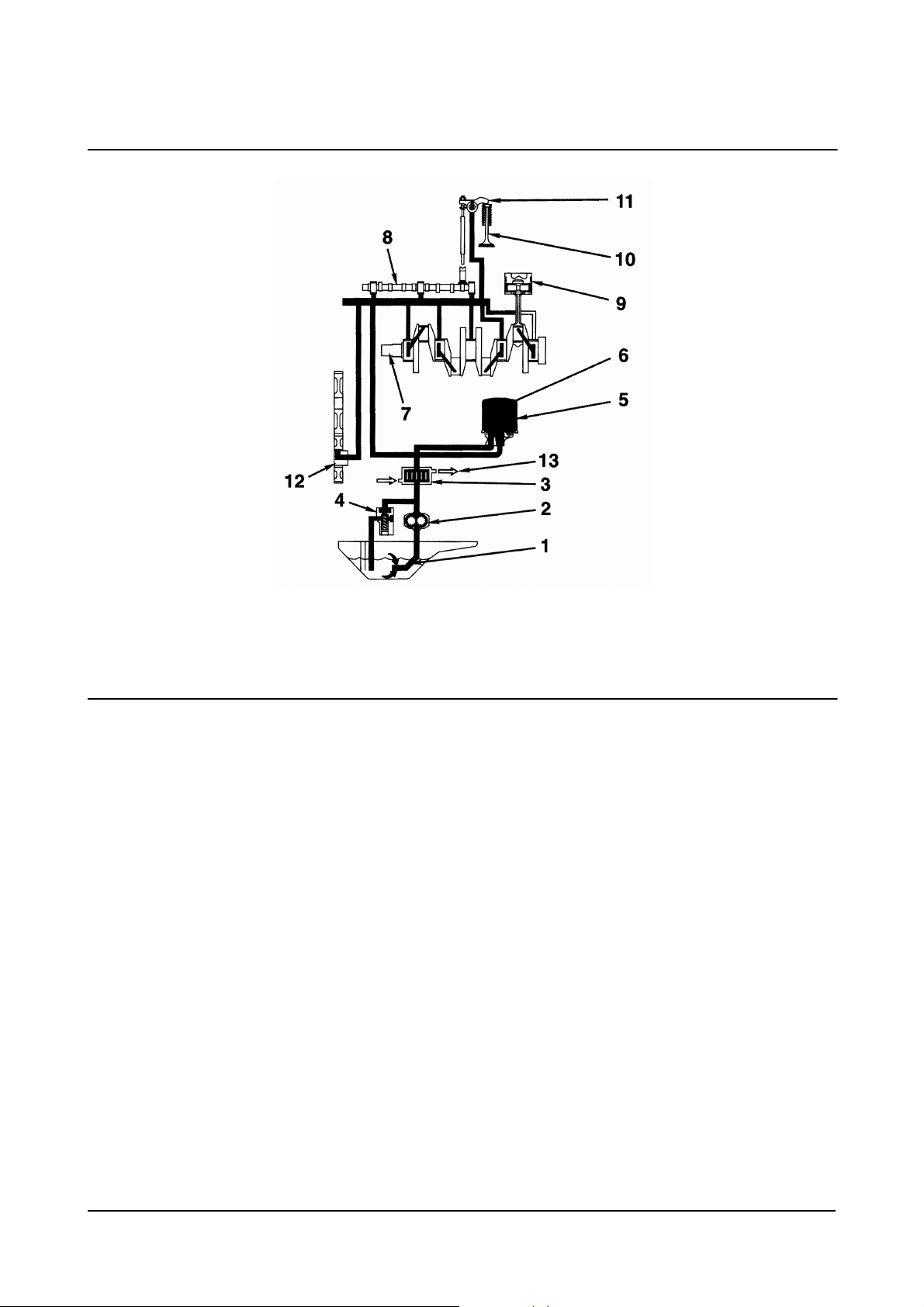

1. Oil Strainer

2. Oil Pump

3. Oil Cooler (Optional)

4. Regulator Valve

5. Oil Filter

6. Safety Valve

7. Crankshaft

Exhaust Side

(Naturally Aspirated)

00900146

8. Camshaft

9. Piston

10. Intake and Exhaust Valve

11. Rocker Arm

12. Timing Gear

13. Cooling Water.

Diesel Engine Engine Identification

12

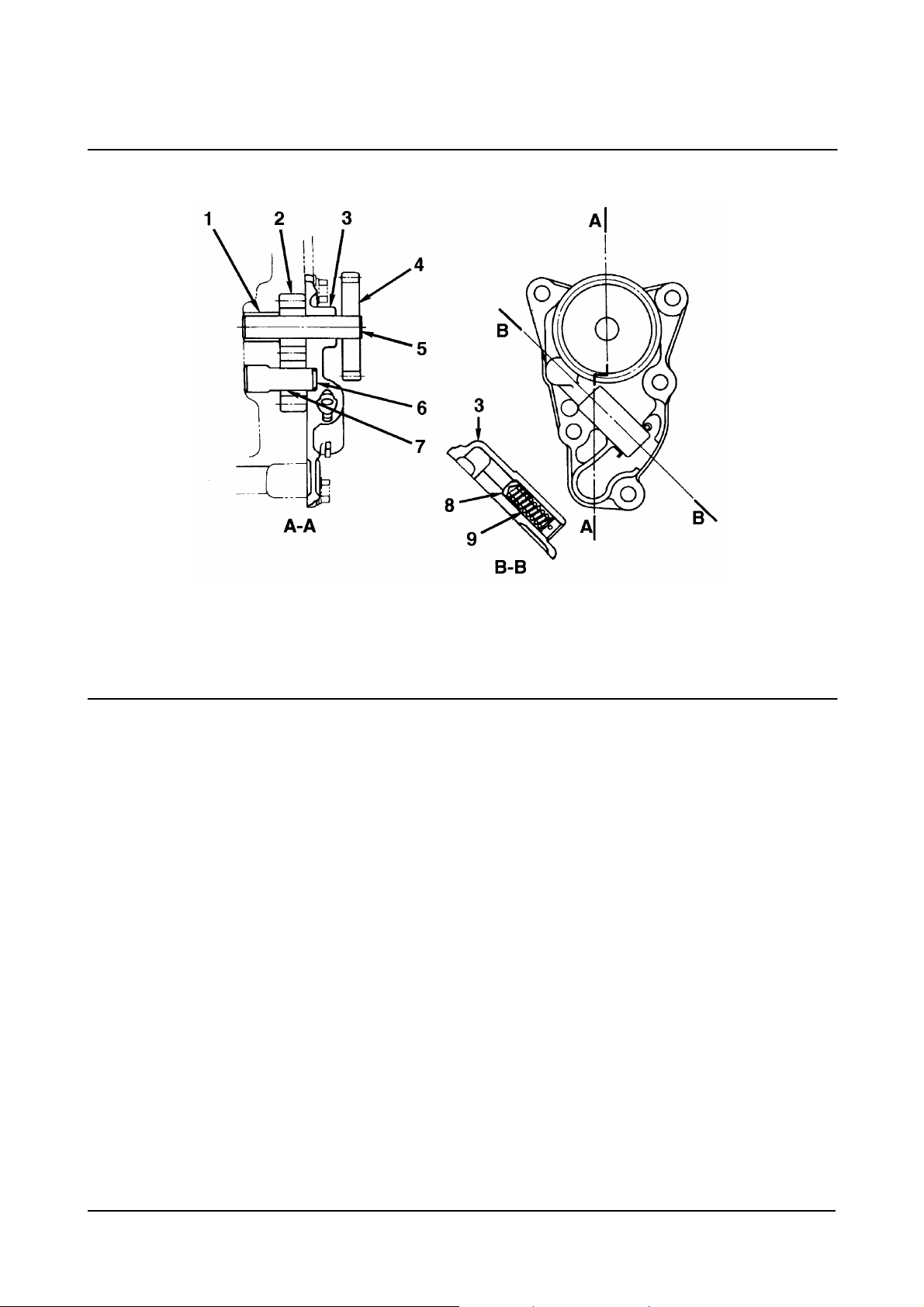

1. Bushing

2. Gear Drive (number of teeth: 7)

3. Pump cover

4. Oil Pump Drive Gear (number of teeth: 22)

5. Driveshaft

6. Drivenshaft

7. Driven Gear (number of teeth: 7)

Oil Pump

00900148

8. Regulator Valve

9. Valve Spring.

Oil pump

• Type: Gear Type

• Pump Speed: Engine Speed x 1.182.

Regulator Valve

• Set Pressure: 490 ± 50kPa [71 ± 7psi].

Diesel Engine Engine Identification

13

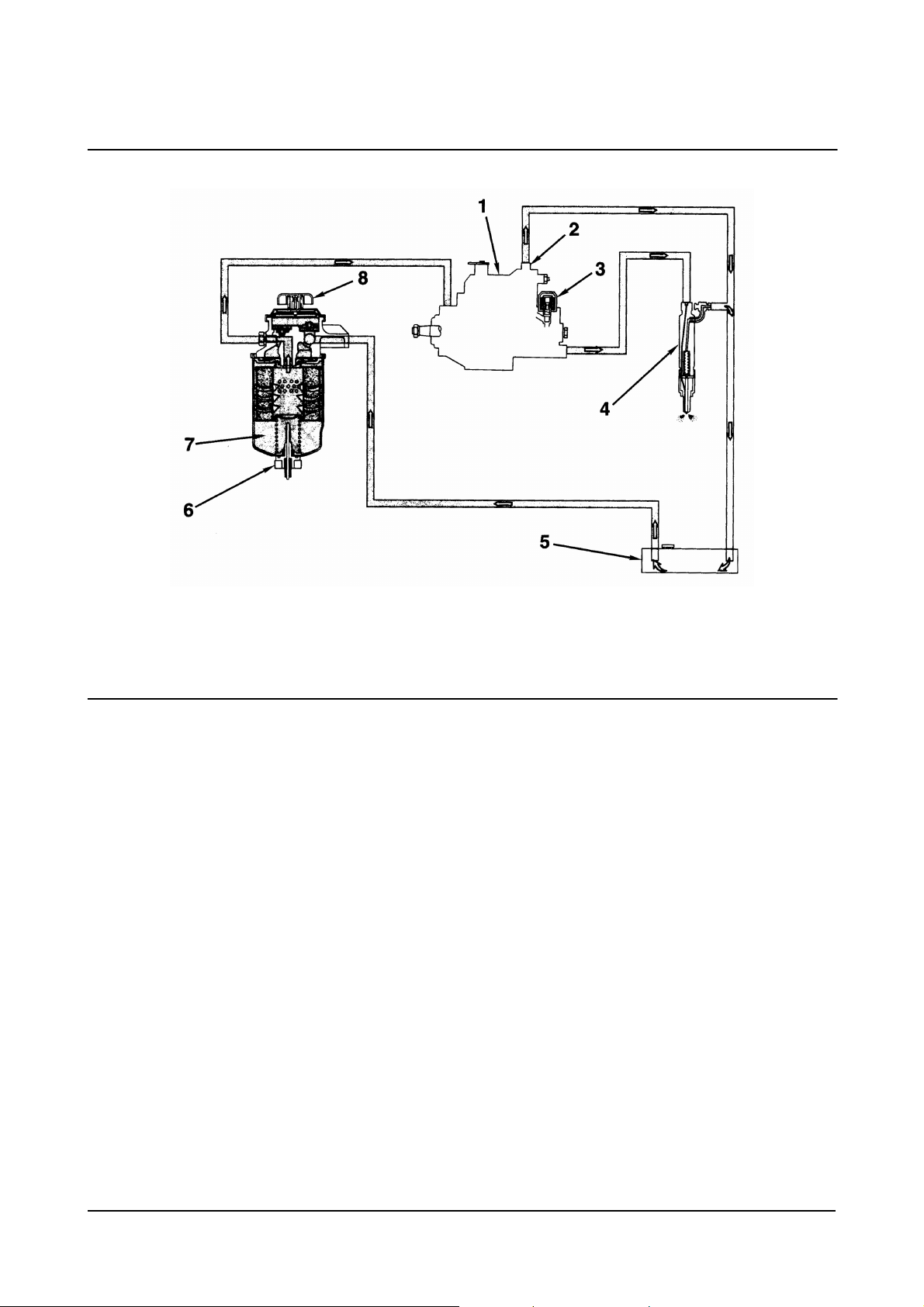

1. Fuel Injection Pump

2. Overflow Valve

3. Fuel Solenoid

4. Fuel Injection Nozzle

Fuel System

00900149

5. Fuel Tank

6. Water-in-Fuel Sensor (WIF)

7. Fuel Filter

8. Hand Priming Pump.

Diesel Engine Engine Identification

14

1. Pump Holder

2. Fuel Injection Pump Drive Gear

(number of teeth: 52)

3. Drive Shaft

4. Fuel Injection Pump (Body)

5. Fuel Filter

6. Fuel Injection Pipe (No. 1)

7. Fuel Injection Pipe (No. 2)

8. Fuel Injection Pipe (No. 3)

9. Fuel Injection Pipe (No. 4)

10. Spill Tube

Fuel Injection Pump

00900150

A. Fuel Inlet (from Fuel Tank)

B. To. Fuel Tank

C. To Fuel Injection Pump

D. To Fuel Injection Nozzle.

Fuel Injection Pump

• Maker: Zexel

• Type: VE

• Lubrication Method: Forced Lubrication with Fuel

Governor

• Type: Mechanical, All-speed Type.

Diesel Engine Engine Identification

15

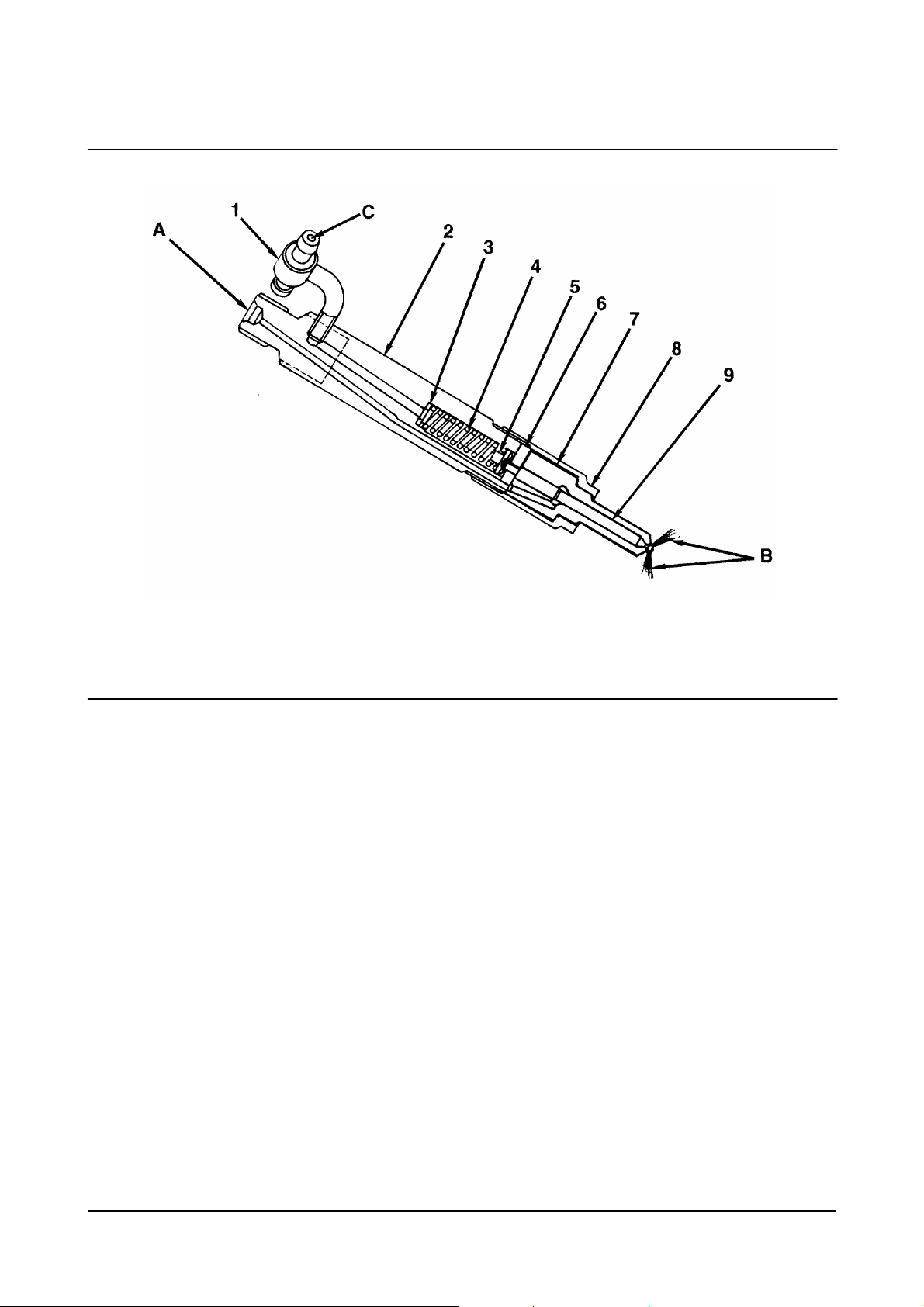

1. Fuel Drain Line Connector

2. Nozzle Holder

3. Adjusting Shim

4. Nozzle spring

5. Spring seat

6. Intermadiate Plate

7. Nozzle Body

8. Retaining Nut

9. Needle.

Fuel Injection Nozzle

00900151

A. Fuel Inlet (from injection pump)

B. Fuel Injection (to cylinder)

C. Fuel Return (to fuel tank).

Fuel Injection Nozzle

• Maker: Zexel

• Injection Pressure: 40 MPa

• Adjustment of Injection Pressure: By Shim.

Diesel Engine Engine Identification

16

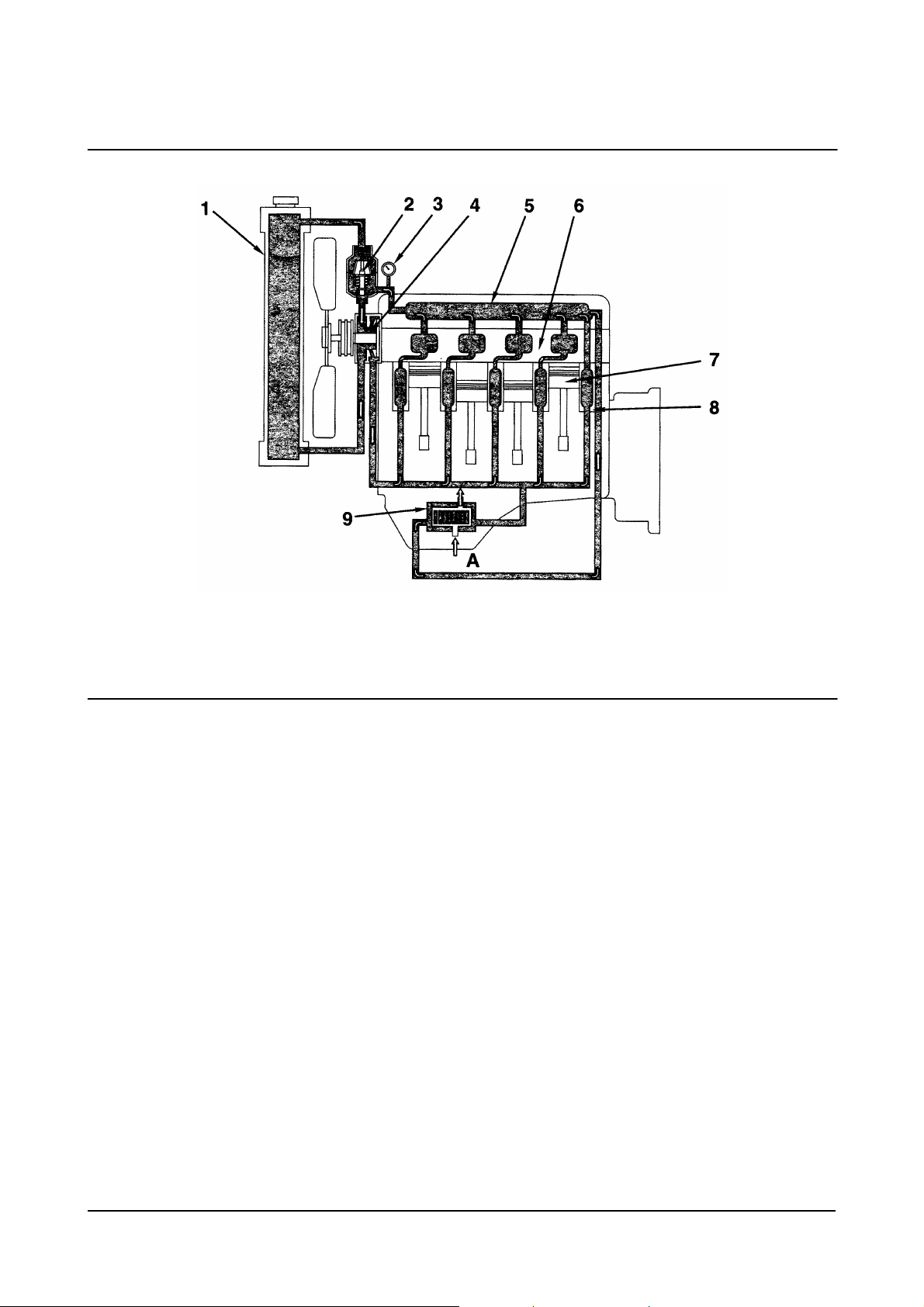

1. Radiator

2. Thermostat

3. Water Temperature Gauge

4. Water Pump

5. Water Manifold

Cooling System

00900147

6. Cylinder Head

7. Piston

8. Cylinder Block

9. Oil Cooler (optional).

A. From Oil Pump (oil).

Diesel Engine Engine Identification

17

1. Filtered Air

2. Intake Manifold

3. Intake Valve Port.

Air Intake System

00900227

Diesel Engine Engine Identification

18

1. Exhaust Valve Port

2. Exhaust Manifold

Exhaust System

00900232

Diesel Engine Engine Identification

19

Procedures and Techniques

A thorough analysis of the customer's complaint is the key to successful troubleshooting. The more information

known about a complaint, the faster and easier the problem can be solved.

The Troubleshooting Symptom Charts are organized so that a problem can be located and corrected by doing the

easiest and most logical things first. Complete all steps in the sequence shown from top to bottom.

It is not possible to include all the solutions to problems that can occur; however, these charts are designed to

stimulate a thought process that will lead to the cause and correction of the problem.

Follow these basic troubleshooting steps:

• Get all the facts concerning the complaint

• Analyze the problem thoroughly

• Relate the symptoms to the basic engine systems and components

• Consider any recent maintenance or repair action that can relate to the complaint

• Double-check before beginning any disassembly

• Solve the problem by using the symptom charts and doing the easiest things first

• Determine the cause of the problem and make a thorough repair

• After repairs have been made, operate the engine to make sure the cause of the complaint has been

corrected

Troubleshooting Symptoms Charts

Use the charts on the following pages of this section to aid in diagnosing specific engine symptoms. Read each

row of blocks from top to bottom. Follow through the chart to identify the corrective action.

Diesel Engine Troubleshooting Symptoms

20

Engine Will Not Crank or Cranks Slowly

This is symptom tree T-002.

Cause Correction

Defective wiring of starting circuit

OK

Specific gravity of battery electrolytr is low, or

Battery voltage is low

OK

Staring motor is malfunctioning

Troubleshoot and repair starting circuit wiring

including relays and switches.

Check the alternator. If the alternator checks

Out, replace the battery.

Replace the staring motor.

OK

Ring gear tooth surface is chipped or damaged

Replace ring gear.

Diesel Engine Troubleshooting Symptoms

21

Engine Cranks But Will Not Start (No Exhaust Smoke)

This is symptom tree T-003.

Cause Correction

Fuel level low in the tank

OK

Improper fuel is being used

OK

Clogged fuel tank air breather hole

Fill the supply tank.

Drain fuel and replace with correct fuel.

Clean the fuel tank breather.

OK

Engine does start when voltage is applied to

the fuel cut solenoid valve

OK

Engine does not start when voltage is applied

to the fuel cut solenoid valve

OK

Clogged prefilter

OK

Clogged fuel filter or strainer

OK

Clogged or leaking fuel piping

OK

Feed pump is damaged or seized

OK

Injector are plugged

OK

damaged

Injection pump driveshaft or driveshaft key is

Troubleshoot and repair the circuit wiring.

Replace the fuel cut solenoid valve.

Clean the prefilter.

Clean or replace the fuel filter or strainer.

Clean and repair the fuel piping.

Replace the feed pump.

Replace the injectors.

Repair or replace the injection pump.

Diesel Engine Troubleshooting Symptoms

22

Engine Difficult to Start or Will Not Start (Exhaust Smoke)

This is symptom tree T-004.

Cause Correction

Starting aid malfunctioning or heater mount

Does not become warm

OK

Speed: 150 rpm)

OK

Improper fuel is being used

Crank speed is too slow (minimum crank

Replace the starting aid.

Verify drive units are not engaged. Check the

Battery and recharge or replace.

Drain fuel and replace with correct fuel.

OK

Clogged air cleaner element

OK

Clogged prefilter

OK

Clogged fuel filter or strainer

OK

Leakage, clogging, air in fuel system

OK

Injection pump timing is incorrect

OK

(Continued)

Clean or replace the air cleaner element.

Clean the prefilter.

Clean or replace the fuel filter or strainer.

Repair and clean the fuel filter or strainer.

Retime the injection pump.

Diesel Engine Troubleshooting Symptoms

23

Engine Difficult to Start or Will Not Start (Exhaust Smoke) (Continued)

Cause Correction

Overhead adjustments are not correct

OK

Overhead components are damaged

OK

Defective or clogged injection nozzle

OK

Injection pump is malfunctioning

OK

Worn piston ring or cylinder resulting in low

compression

Measure and adjust the overhead settings.

Inspect the rocker levers, rocker shafs, and

valve for excessive damage. Replace as

necessary.

Replace the defective or clogged injection

nozzle

Repair or replace the injection pump.

Replace the worn piston ring or cylinder.

Diesel Engine Troubleshooting Symptoms

24

Engine Has Poor Respones

This is symptom tree T-005.

Cause Correction

Clogged air cleaner element

OK

Clogged fuel tank air breather hole

OK

Clogged prefilter

Clean or replace the air cleaner element

Clean the fuel tank breather.

Clean or replace the fuel filter or strainer.

OK

Clogged fuel filter or strainer

OK

Clogged or leaking fuel piping

OK

Overhead adjustments are not correct

OK

Resulting in low compression

OK

Turbocharger does not rotate freely

OK

Defective or clogged injection nozzle

OK

Injection pump is malfunctioning

Defective contact of valve or valve seat

Clean and repair the fuel piping

Clean and adjust the overhead settings.

Measure and adjust the overhead settings.

Replace the cylinder head.

Replace the turbocharger.

Replace the defective or clogged injection

nozzle.

Repair or replace the injection pump.

OK

Worn piston ring or cylinder resulting in low

Compression

Diesel Engine Troubleshooting Symptoms

25

Replace the worn piston ring or cylinder.

Engine Stops During Operation

This is symptom tree T-006.

Cause Correction

Chassis powertrain is damaged or overloaded

OK

Fuel level low in the tank

OK

Clogged fuel tank air breather hole

Refer to the OEM’s service manuals.

Fill the supply tank.

Clean the fuel tank breather.

OK

Clogged prefilter

OK

Clogged fuel filter or strainer

OK

Clogged or leaking fuel piping

OK

Feed pump piston is damaged or seized

OK

Overhead components are damaged

OK

Injection pump is malfunctioning

OK

Gear train damaged or seized

OK

Piston or connecting rod is damaged

OK

Crankshaft bearing is damaged

Clean the prefilter.

Clean and or replace the fuel filter or strainer.

Clean and repair the fuel piping.

Replace the feed pump.

Inspect the rocker levers, rocker shafts, and

valves for excessive damage. Replace as

necessary.

Replace the injection pump.

Refer to OEM’s service manuals.

Replace damaged piston or connecting rod.

Replace damaged crankshaft bearing.

Diesel Engine Troubleshooting Symptoms

26

Engine Runs Rough or Misfires

This is symptom tree T-007.

Cause Correction

Fuel level low in the tank

OK

Clogged fuel tank air breather hole

OK

Low idle speed is adjusted too low

Fill the supply tank.

Clean the fuel tank breather.

Adjust the low idle speed.

OK

Clogged prefilter

OK

Clogged fuel filter or strainer

OK

are clogged or have air in them

OK

nozzle are clogged or have air in them

OK

Injection pump is malfunctioning

Line between the fuel tank and feed pump

Line between the feed pump and the injector

Clean the prefilter.

Clean or replace the fuel filter or strainer.

Clean and repair the lines.

Clean and repair the lines.

Replace the injection pump.

Diesel Engine Troubleshooting Symptoms

27

Engine Power Output Low

This is symptom tree T-008.

Cause Correction

Improper fuel is being used

OK

Clogged air cleaner element

OK

Clogged fuel tank air breather hole

Drain and replace the fuel with the correct fuel.

Clean or replace the air cleaner element.

Clean the fuel tank breather.

OK

fuel lever linkage is bent or not adjusted

correctly

OK

Clogged prefilter

OK

Clogged fuel filter or strainer

OK

Clogged or leaking fuel piping

OK

Feed pump is defective

OK

Overhead adjustments are not correct

OK

(Continued)

Full throttle can not be achieved because the

Repair or adjust the fuel lever linkage.

Clean the prefilter.

Clean and or replace the fuel filter or strainer.

Clean and repair the fuel piping.

Replace the feed pump.

Measure and adjust the overhead settings.

Diesel Engine Troubleshooting Symptoms

28

Engine Power Output Low (Continued)

Cause Correction

Defective contact of valve or seat

Resulting in low compression

OK

Turbocharger does not rotate freely

OK

Defective or clogged injection nozzle

OK

Injection pump is malfunctioning

OK

Worn piston ring or cylinder resulting in low

compression

Replace the cylinder head.

Replace the turbocharger.

Replace the defective or clogged injection

nozzle.

Replace the injection pump.

Replace the worn piston ring or cylinder.

Diesel Engine Troubleshooting Symptoms

29

Excessive Exhaust (Black Smoke)

This is symptom tree T-009.

Cause Correction

Engine is bring lugged down

OK

Clogged air cleaner element

OK

Muffler is crushed or clogged

OK

Air leakage between the turbocharger and

head

OK

Exhaust leak between turbocharger and

Exhaust manifold

OK

Turbocharger does not rotate freely

OK

Defective or clogged injection nozzle

OK

Worn piston ring or cylinder (blue smoke)

OK

Incorrect injection timing

OK

Overhead adjustments are not correct

Use lower gear.

Clean or replace the air cleaner element.

Replace the muffler. Refer to the OEM’s

service manual.

Tighten the clamp between turbocharger and

head. Repair leaks between turbocharger and

head.

Inspect and change gaskets.

Replace the turbocharger.

Adjust or replace the injection pump.

Replace the worn piston ring or cylinder.

Adjust injection timing.

Measure and adjust the overhead settings.

Diesel Engine Troubleshooting Symptoms

30

Lubricating Oil Consumption Excessive

This is symptom tree T-010.

Cause Correction

Lubricating oil leak (external)

OK

Intake system is contaminated with dust

OK

Dipstick is not calibrated correctly

Inspect the engine the external oil leaks.

Tighten the capscrews, pipe plugs, and fittings.

Replace the gaskets if necessary.

Remove and clean intake manifold.

Verify the dipstick is correctly marked.

OK

Breather or breather hose is clogged

OK

Turbocharger compressor or turbine oil seal is

Leaking

OK

damaged

OK

Valve stem, guide, or seal is damaged

OK

Worn or broken piston ring or cylinder

Rear crankshaft seal or seal surface is

Clean the breather and breather hose.

Replace the compressor or turbine seal.

Repair or replace seal and surface.

Repair or replace the damaged component.

Replace the worn or broken piston ring or

cylinder.

Diesel Engine Troubleshooting Symptoms

31

Lubricating Oil Contaminated

This is symptom tree T-011.

Cause Correction

Breather or breather hose is clogged

OK

Lubricating oil filter is clogged

OK

Turbocharger turbine oil seal is damaged

Clean the breather and breather hose.

Replace the filter.

Replace the turbine seal.

OK

Turbocharger turbine oil seal is damaged

OK

Turbocharger turbine oil seal is

Damaged

OK

Exhaust gas is black

OK

resulting in low compression

OK

Compression

Defective contact of valve or valve seat

Worn piston ring or cylinder resulting in low

Replace the turbine seal.

Replace the turbine seal.

Refer to Exhaust Gas Is Black (Incomplete

Combustion).

Repair the valve or valve seat.

Replace the worn piston ring or cylinder.

Diesel Engine Troubleshooting Symptoms

32

Fuel consumption Is Excessive

This is symptom tree T-012.

Cause Correction

Overloading from malfunctioning accessories

OK

Operator technique is not correct

OK

Fuel leaks (external)

OK

Poor-quality fuel or No.1 fuel is being used

OK

Intake or exhaust restriction

OK

Defective or clogged injection nozzle

OK

Incorrect injection timing

OK

excessive injection

Check the fuel lines, fuel connections, and fuel

Injection pump is adjusted incorrectly causing

Check and repair the accessories. Refer to the

OEM’s service manuals.

Refer to the operation and maintenance

manual for proper operating speeds and loads.

filters for leaks. Check the fuel lines to the

supply tanks. Refer to the OEM’s service

manual.

Assure good-quality No.2 diesel fuel is being

used.

Refer to troubleshooting logic for Exhaust Gas

is Blake.

Replace the defective or clogged injection

nozzle.

Adjust injection timing.

Adjust or replace the injection pump.

Diesel Engine Troubleshooting Symptoms

33

Coolant Contamination

This is symptom tree T-013.

Cause Correction

Coolant is rusty

OK

Lubricating oil cooler for powertrain is damaged

OK

Cylinder head gasket is cracked or damaged

Review the coolant change interval. Drain and

flush the system. Fill the system with the

Correct mixture of coolant and water.

Refer to the OEM’s service manual.

Replace the cylinder head or gasket.

OK

Cylinder block is cracked or porous

Replace the cylinder block.

Diesel Engine Troubleshooting Symptoms

34

Coolant Loss

This is symptom tree T-013.1

Cause Correction

Radiator or cab heater is leaking

OK

External engine leak

OK

Overheating or compression gases are leaking

Resulting in loss through the radiator overflow

OK

Transmission cooler is leaking (if equipped)

OK

Cylinder head gasket is leaking

OK

Cylinder head is cracked or porous

OK

Cylinder block coolant passages are leaking

Review the operation for overheating and low

Inspect the radiator heater, hoses, and

connection to locate the leak. If oil is present in

the coolant, check for a transmission or

lubricating oil cooler leak.

Inspect the engine and components for seal,

gasket, or drain cock leaks.

power. Refer to troubleshooting logic for

Coolant Temperature Above Normal.

Check for mixing of coolant and transmission

fluid.

Check or replace the head gasket.

Check or replace the cylinder head.

Check or replace the cylinder block.

Diesel Engine Troubleshooting Symptoms

35

Lubricating Oil Pressure Is Low

This is symptom tree T-014.

Cause Correction

Lubricating oil lever is below specification

OK

Oil level or pressure sensor is damaged

OK

Lubricating oil filter is clogged

Check the oil level. Verify the dipstick

calibration and the oil pan capacity. Fill the

system to the specified level.

Replace the oil lever or oil pressure sensor.

Replace the filter

OK

Fuel or coolant is in the lubricating oil.

OK

Regulator or relief valve is not adjusted

Correctly

OK

Lubricating oil pan strainer is clogged

OK

Lubricating oil suction tube is damaged

OK

Lubricating oil pump is damaged

OK

Main or rod bearing is worn or damaged

Refer to Oil Level Rises symptom tree.

Adjust the regulator or relief valve.

Clean the strainer.

Repair or replace the suction tube.

Replace the oil pump.

Replace the bearing

Diesel Engine Troubleshooting Symptoms

36

Oil Level Rises

This is symptom tree T-015.

Cause Correction

Rear crankshaft seal or seal surface is

damaged

OK

Auxiliary equipment has damaged pump seal

OK

Injector sleeve is damaged

Repair or replace seal and surface

Replace the auxiliary pump. Refer to the OEM’s

service manual.

Replace the injector sleeve.

OK

Fuel injector is leaking inside cylinder head

OK

Injector pump seal is leaking

OK

damaged

OK

Cylinder block is cracked or porous

Cylinder head or head gasket is cracked or

Replace the injector.

Remove and repair the injection pump.

Replace the cylinder head or gaeket.

Replace the cylinder block.

Diesel Engine Troubleshooting Symptoms

37

Coolant Temperature above Normal

This is symptom tree T-016.

Cause Correction

Coolant level is below specification

OK

Fan belt is slipping or the fan pulley is worn

OK

Water temperature gauge is malfunctioning

Inspect the engine and radiator for external

coolant leaks.

Replace the fan belt or pulley.

Replace the water temperature gauge.

OK

Radiator fin is clogged or crushed

OK

Radiator core is clogged

OK

Thermostat is defective and does not open

OK

Water pump is damaged

OK

damaged

Cylinder head or head gasket is cracked or

Clean, repair, or replace the radiator.

Clean and repair the radiator.

Replace the thermostat.

Replace the water pump.

Replace the cylinder head or graket.

Diesel Engine Troubleshooting Symptoms

38

Excessive Noise

This is symptom tree T-017.

Cause Correction

Belt is squeaking due to insufficient tension or

abnormally high loading

OK

Air leakage between the turbocharger and

head

OK

Exhaust leaks

OK

Turbocharger does not rotate freely

OK

Gear train backlash is not adjusted correctly

OK

Idler gear bushing is damaged or missing

OK

Defective or clogged injection nozzle

OK

Overhead adjustments are not correct

OK

Overhead components are damaged

OK

(Continued)

Check and adjust belt tension. Make sure all

the pulleys rotate freely.

Tighten the clamp between turbocharger and

head. Repair leaks between turbocharger and

head.

Refer to Exhaust Gas is Black troubleshooting

tree.

Replace the turbocharger.

Adjust the backlash for the gear train.

Replace the idler gear bushing.

Replace the defective or clogged injection

nozzle.

Measure and adjust the overhead settings.

Inspect the rocker levers, rocker shafts, and

valves for excessive damage.

Diesel Engine Troubleshooting Symptoms

39

Excessive Noise (Continued)

Cause Correction

Injection pump is adjusted incorrectly

OK

compression

Worn piston ring or cylinder resulting in low

Adjust or replace the injection pump.

Replace the worn piston ring or cylinder.

Diesel Engine Troubleshooting Symptoms

40

Engine Vibration Excessive

This is symptom tree T-018.

Cause Correction

Engine mounting bolts are loose or the engine

mounting cushion is broken

OK

Engine and powertrain is out of alignment

OK

Gear train backlash is not adjusted correctly

Replace the engine mounting bolts or cushion.

Repair the alignment. Refer to the OEM’s

service manual.

Adjust the backlash for the gear train.

OK

Overhead components are damaged

OK

Cam bushing is worn

OK

Injection pump is adjusted incorrectly

OK

damaged

Main bearing or connecting rod is worn or

Inspect the rocker levers, rocker shafts, and

valves for excessive damage. Replace as

necessary.

Replace the cam bushing.

Adjust or replace the injection pump.

Replace the connecting rod or main bearing.

Diesel Engine Troubleshooting Symptoms

41

Complete Engine

Engine Disassembly

Service Tool

Part No. Part Name Quantity

3375193

or

3375194

3163625 Bracket 1

3163292 Valve Spring Compressor 1

3397890 Flange Puller 1

3823137 Piston Ring Expansion Tool 1

Unit Repair Stand or Engine Overhaul Stand

fp8hola

ea8wrha

1

Engine Removal

NOTE: Put tag on all hoses, lines, linkage, and

electrical connections as they are removed

to identify location and aid the installation

process.

W

ARNIN

Always disconnect the negative (-) cable first.

Disconnect the battery cables.

W

ARNIN

Allow the engine to cool before draining to avoid

burns from hot liquid.

G

G

W

ARNIN

Coolant is toxic. Keep away from children and

animals. Save for reuse or dispose of in

accordance with local regulations.

Drain the engine coolant.

Diesel Engine Complete Engine

42

G

op800li

oi400hc

tr400wa

Some state and federal agencies in the United

States of America have determined that used oil

is carcinogenic and can cause reproductive

toxicity. Avoid inhalation of vapors, ingestion, and

prolonged contact with used engine oil. Always

use the proper procedures to dispose of the oil.

Drain the lubricating oil.

Engine Oil: 7.5 liters [1.98 U.S.gal]

Disconnect the starter cable, engine ground straps,

cab or chassis to engine hoses, tubing, electrical

wires and hydraulic lines.

Disconnect the intake and exhaust system pipes.

Disconnect the drive units from the flywheel housing

and flywheel.

Remove all chassis components necessary to

remove the engine from the equipment.

W

ARNIN

G

ra400ha

Diesel Engine Complete Engine

43

00900154

00900156

00900207

00900208

Prepare a stable stand, Part No. 3375193 or 3375194,

which will prevent the engine from falling over.

Engine Weight (approx.): 255 kg [562 lb]

Remove the starting motor.

Install the bracket, Part No. 3163625, on the engine.

W

ARNIN

This component weighs 23 kg [50 lb] or more. To

avoid personal injury, use a hoist or get

assistance to lift this component. The engine

lifting equipment must be designed to lift the

engine without causing personal injury.

Put the engine on the stand.

G

Diesel Engine Complete Engine

44

00900209

00900158

00900157

Cover all the engine openings to prevent dirt and

debris from entering the engine.

Fan Pulley

W

ARNIN

Be careful not to injure your fingers or damage

the alternator when moving the alternator toward

the cylinder block.

Loosen the mounting capscrew of the adjustment

plate (1). Loosen the alternator mounting capscrew

and nut.

Move the alternator toward the cylinder block, and

remove the belt (2).

Remove the fan pulley.

Fan

Remove the four capscrews, retainer plate, fan, and

spacer.

Alternator

Remove the adjusting capscrew and washer.

Remove the capscrew, adjustment plate, and spacer.

Remove the remaining capscrew and alternator.

G

00900159

Diesel Engine Complete Engine

45

00900155

00900160

00900161

Lubricating Oil Filter

Remove the lubricating oil filter.

Dipstick Guide

Remove the dipstick and dipstick guide.

Water Pump

Remove the mounting capscrews, water pump,

gasket, and o-ring.

Discard the gasket and o-ring.

Thermostat

Remove the two mounting capscrews, thermostat

housing, thermostat and seal.

18900025

Diesel Engine Complete Engine

46

00900162

00900163

Exhaust Manifold

Remove the eight capscrews, exhaust manifold, and

gasket.

Discard the gasket.

Fuel Injection Tubing

Remove the clamp.

Remove the sleeve nuts and the fuel injection tubing

from the fuel injection pump and the cylinder head.

Intake Manifold

Remove the eight capscrews, intake manifold, and air

inlet connection. Remove the grid heated, if equipped.

Remove the four capscrews, air inlet connection, and

o-ring. Discard the o-ring.

00900164

Diesel Engine Complete Engine

47

00900166

00900167

Spill Tube

Remove the spring hose clamps and hose.

Remove the spill tube.

Injector

CAU

TIO

N

Be careful not to damage the tip of the injector

when removing.

Remove the mounting capscrew, washer, and injector.

NOTE: When removing the injector, clean around

the injector, and insert a blind plug to

prevent dust or dirt from entering the engine.

NOTE: Mark the injectors with tags showing the

cylinder number, and keep it in a safe place.

If there is no abnormality in the injector,

install it in the same position during

assembly.

Rocker Lever Cover

Remove the three capscrews, isolator assemblies,

rocker lever cover, and o-ring.

03900075

Diesel Engine Complete Engine

48

1. Rocker Shaft

2. Adjusting Screw Lock Nut

3. Pedestal Mounting Capscrews

4. Separating Spring

5. Rocker Shaft Indexing Screw

6. Pedestal Mounting Stud

Rocker Arm Assembly

00900169

00900251

7. Cup Plug

8. Snap Ring

9. Thrust Washer (if equipped)

10. Rocker Lever Pedestal

11. Rocker Lever

12. Adjusting Scre w.

Rocker Arm Assembly

Remove the mounting capscrews and the rocker arm

assembly.

NOTE: When removing the rocker arm, loosen the

locknut, and turn the adjustment screw

counterclockwise 2 to 3 turns.

Diesel Engine Complete Engine

49

00900170

00900171

00900172

Pushrods

Remove the pushrods from the cylinder head.

NOTE: Mark the pushrods with tags showing the

cylinder number, and keep it in a safe place.

If there is no abnormality in the push rod,

install it in the same position during

assembly.

Cylinder Head Assembly

W

ARNIN

This component weighs 23 kg [50 lb] or more. To

avoid personal injury, use a hoist or get

assistance to lift this component.

Remove the mounting capscrews, cylinder head

assembly, and gasket.

Discard the gasket.

Cylinder Head Assembly - Disassembly

Using the spring pusher, Part No. 3398179, compress

the valve spring, and remove the valve collets.

Loosen the spring, and remove the spring seat and

valve spring.

G

00900173

Diesel Engine Complete Engine

50

00900174

00900176

00900211

Raise the cylinder head, and remove the valve.

NOTE: Mark the valves with tags to show the place

of installation and keep in a safe place.

Fuel Injection Pump

CAU

TIO

N

Do not allow dirt or dust to enter the oil and fuel

inlet and outlet ports. Severe engine damage will

occur if contaminants are allowed to enter the

engine.

Remove the fuel supply tube from the fuel injection

pump.

Remove the mounting capscrew from the bracket and

fuel injection pump.

NOTE: The fuel injector pump, adapter plate, and

gear are removed as an assembly. The gear

can then be removed from the pump if

necessary.

Remove the mounting capscrews of the fuel injector

pump adapter plate.

Remove the fuel injector pump assembly, adapter

plate, and o-ring from the gear housing.

Discard the o-ring.

Remove the nut and washer from the fuel injection

pump.

Remove the fuel injection pump gear from the fuel

injection pump.

00900210

Diesel Engine Complete Engine

51

00900246

00900177

00900178

Remove the two mounting nuts, fuel injection pump,

and o-ring from the adapter plate.

Discard the o-ring.

PTO Shaft (if applicable)

Remove the two capscrews, flange, o-ring, and PTO

shaft.

Lubricating Oil Pan

Remove the 24 capscrews, lubricating oil pan, and

gasket.

Discard the gasket.

Lubricating Oil Suction Tube

Remove the two mounting capscrews, lubricating oil

suction tube, and o-ring.

Discard the o-ring.

00900179

Diesel Engine Complete Engine

52

00900180

00900212

00900181

Crankshaft Pulley

Remove the capscrew and mounting plate.

Remove the crankshaft pulley using flange puller,

Part No. 3397890.

Gear Housing Cover

Remove the 17 capscrews and the gear housing

cover.

NOTE: A noise damper is installed on some

engines. The noise damper must be

removed prior to removing the front oil seal.

Remove the front oil seal from the gear housing cover.

00900182

Diesel Engine Complete Engine

53

00900183

00900184

00900185

Lubricating Oil Pump

Remove the five capscrews and the lubricating oil

pump.

Idler Gear

Remove the capscrew, retainer plate, and idler gear.

NOTE: If a PTO is installed, the idler gear uses a

bearing.

Camshaft Assembly

Remove the two mounting capscrews through the

casting holes in the camshaft gear.

Remove the thrust plate and camshaft assembly.

NOTE: When removing the camshaft, lightly rotate

the shaft while being careful not to damage

the bushing.

00900186

Diesel Engine Complete Engine

54

00900187

00900188

00900189

Flywheel

W

ARNIN

This component weighs 23 kg [50 lb] or more. To

avoid personal injury, use a hoist or get

assistance to lift this component.

W

ARNIN

The pilot is short, so the flywheel can come off

suddenly.

Remove the six capscrews, retaining plate, coupling,

and flywheel.

Flywheel Housing

W

ARNIN

This component weighs 23 kg [50 lb] or more. To

avoid personal injury, use a hoist or get

assistance to lift this component.

Remove the nine capscrews, rear oil seal, and

flywheel housing.

Remove the rear oil seal.

Block Water Heater

NOTE: Be sure the engine coolant has been

drained.

Disconnect the block heater electrical cord.

G

G

G

cs900wf

Diesel Engine Complete Engine

55

cs900mb

00900190

00900191

Loosen the block heater retaining nut.

Remove the block heater from the block.

Piston, Connecting Rod Assembly

Turn the cylinder block on its side with cylinders

positioned horizontally.

CAU

TIO

N

Be careful not to damage the inside of the

cylinder.

Remove the carbon at the top of the cylinder using

fine sandpaper.

Measure the side clearance of the connecting rod

with a dial gauge before removing the piston and

connecting rod assembly.

Side Clearance

mm in

0.20 MIN 0.0079

0.40 MAX 0.016

00900192

Diesel Engine Complete Engine

56

00900193

00900195

00900196

Rotate the camshaft to set the piston at bottom dead

center.

Remove the mounting capscrews of the connecting

rod cap.

Check the number stamped on the connecting rod

cap and the cylinder. The numbers must match.

NOTE: If there is no number stamped on the

connecting rod cap, stamp the correct

number on the camshaft end of the cap.

Tap the cap with a plastic hammer, and remove the

connecting rod cap and bearing.

Push a wooden bar or hammer handle through the

cylinder from the lubricating oil pan side of the block.

Support the piston at the cylinder head side of the

block, and push the bar in far enough to remove the

piston and connecting rod assembly.

Piston and Connecting Rod Assembly Disassembly

Remove the snap ring on one side of the piston using

pliers.

Remove the piston pin, and separate the piston and

connecting rod.

NOTE: If the pin does not come out, place the

assembly in hot water prior to disassembly.

00900197

Diesel Engine Complete Engine

57

00900198

00900199

00900200

Remove the snap ring on the other side of the piston

using pliers.

Remove the piston ring from the piston using piston

ring tool, Part No. 3823137.

If the bushing is worn, the connecting rod must be

replaced.

Inside Diameter: 30.00 mm [1.18 in]

NOTE: Keep the pistons, connecting rods, bearings,

piston rings, piston pins, and bushings in

sets for each cylinder number.

Main Bearing Cap

Rotate the cylinder block so that the bottom of the

block is facing up.

00900201

Diesel Engine Complete Engine

58

00900202

00900203

00900204

00900205

Measure the end play of the crankshaft using a dial

gauge.

NOTE: The end play measurement is necessary for

determining the wear of the thrust bearing

and abnormal wear of the crankshaft.

Crankshaft End Play

mm in

0.131 MIN 0.0052

0.351 MAX 0.0138

Remove the mounting capscrews of the main bearing

cap.

Remove the main bearing cap and lower bearing.

NOTE:

• Mark the thrust bearings so that they can be

installed into the correct position.

• The main bearing cap mounting capscrews must

be replaced after each use.

Crankshaft

CAU

TIO

N

Be careful not to hit the crankshaft against the

cylinder block and damage the sliding surface.

Remove the crankshaft.

Remove the upper main bearing.

NOTE: Mark the main bearings and thrust bearing

so that they can be installed into the correct

position.

Diesel Engine Complete Engine

59

Tappet

Remove the tappet.

00900205

Diesel Engine Complete Engine

60

Engine Assembly

Service Tools

Part No. Part Name Quantity

3375193

or

3375194

3163625 Bracket 1

3163292 Valve Spring Compressor 1

3823137 Piston Ring Expansion Tool 1

3397773 Piston Ring Compressor 1

Unit Repair Stand or Engine Overhaul Stand 1

Setting the Unit in the Repair Stand

Install bracket, Part No. 3163625, to the cylinder

block.

00900213

00900214

W

ARNIN

This component weighs 23 kg [50 lb] or more. To

avoid personal injury, use a hoist or get

assistance to lift this component. The engine

lifting equipment must be designed to lift the

engine without causing personal injury.

Put the engine block on the stand.

G

Diesel Engine Complete Engine

61

00900215

00900216

00900204

00900217

Tappet

NOTE: Rotate the engine block so that the cylinder

head side is down.

Coat the tappet with engine oil and install into the

block.

Crankshaft

CAU

TIO

N

Confirm that there is no dirt or dust stuck to the

rear face of the bearing before installation. Debris

behind the bearing can cause severe engine

damage.

NOTE: Coat the inside face of the bearing with

engine oil (SAE 30) before installation.

Align the protrusion of the upper main bearing with

the notch in the cylinder block.

Install the upper main bearings.

CAU

TIO

N

Do not hit the crankshaft against the cylinder

block. Damage to the block or crankshaft can

occur.

Position the crankshaft and gear in the cylinder block.

Main Bearing Cap

CAU

TIO

N

Confirm that there is no dirt or dust stuck to the

rear face of the bearing before installation. Debris

behind the bearing can cause severe engine

damage.

NOTE: Coat the inside face of the bearing with

engine oil (SAE 30) before installation. The

number stamped on the main bearing cap

must be the same as the number stamped

on the cylinder block.

Align the protrusion in the lower main bearing with the

notch in the cap.

Install the lower main bearing into the main bearing

cap.

Diesel Engine Complete Engine

62

NOTE:

00900218

00900219

00900220

• Casting number or cast arrow on the main

bearing cap must face toward the front of the

engine.

• New main bearing mounting capscrews must be

used.

• Coat the capscrew threads and seat face with

engine oil.

Position the main bearing caps and capscrews.

CAU

TIO

N

Install each thrust bearing with the oil groove on

the outside. Failure to do so will cause engine

damage or failure.

CAU

TIO

N

Do not let the thrust bearings slip out of place.

Engine damage or failure will result if the thrust

bearings are not properly installed.

NOTE: Casting number or cast arrow on the main

bearing cap must face toward the front of

the engine. The thrust bearing is located on

the main bearing closest to the rear of the

engine (No. 5). Align the lower thrust

bearing with the dowel pin.

Install the upper thrust bearing.

Tighten the mounting capscrews in the order shown.

Torque Value:

Main Bearing

Capscrews Step 1 113 N•m [83 ft-lb]

2 Loosen all capscrews

completely

3 132 N•m [98 ft-lb]

After tightening the mounting capscrews, make sure

the crankshaft rotates smoothly

00900222

Diesel Engine Complete Engine

63

00900202

00900223

00900198

00900197

Measure the crankshaft end play using a dial indicator.

Crankshaft End Play

mm in

0.131 MIN 0.0052

0.351 MAX 0.0138

Piston, Connecting Rod Assembly - Assemble

CAU

TIO

N

Be careful not to damage the piston or break the

piston rings.

Install the piston rings on the piston using piston ring

tool, Part No. 3823137.

NOTE: The rings must be set with the stamped

mark near the end facing up. The oil ring

(bottom ring) must be set with matching part

of the expander coil and the end gap of the

ring 180 degrees apart.

Install one snap ring on one side of the piston into the

snap ring groove.

NOTE: The stamped “F” mark on the piston and the

match mark (or cast part number) on the

connecting rod must face in the same

direction.

Assemble the piston on the connecting rod by

installing the piston pin.

NOTE: Pistons do not need to be heated prior to

installing the piston pin. However, placing

the piston in hot water prior to installing the

pin will ease the installation

.

Diesel Engine Complete Engine

64

00900196

00900225

00900226

Install the other snap ring into the snap ring groove.

NOTE: Make sure the connecting rod moves freely

forward and backward after installing the

last snap ring.

Locate the end gaps of the piston rings as shown.

1. Top Ring

2. Second Ring

3. Oil Ring

4. Part Number Mark - “EXXXX”

- XXXX = Last Four Digits of the Part Number

- “NA” or “T”

- NA = Naturally Aspirated

- T = Turbocharged

NOTE: Align the notch of the upper bearing with the

notch of the connecting rod.

Install the upper connecting rod bearing into the

connecting rod.

NOTE: Coat the inside face of the cylinder, the

piston rings, and the surface of the

connecting rod bearing with engine oil (SAE

30). Install the piston and connecting rod

assembly with the “F” mark on the piston

facing the front of the engine.

NOTE: The connecting rods are stamped with the

number of the cylinder in which they are to

be installed. This match mark must be on

the camshaft side of the engine after

installation.

00900228

Set the crankshaft pin to bottom dead center.

Install the piston and connecting rod assembly from

the top of the cylinder block using piston holder, Part

No. 3397773.

Diesel Engine Complete Engine

65

00900229

00900230

00900231

Align the notch of the lower bearing with the notch of

the connecting rod cap.

Install the lower connecting rod bearing into the

connecting rod cap.

NOTE: Coat the lower bearing with engine oil (SAE

30). The connecting rod cap is stamped with

a number that must match both the number

on the connecting rod and the cylinder in

which it is being installed.

Install the connecting rod cap and capscrews.

NOTE: Coat the connecting rod capscrew threads

and seat face with engine oil (SAE 30).

Tighten the capscrews.

Torque Value:

Main Bearing

Capscrews Step 1 39 N•m [29 ft-lb]

2 Rotate 90 degrees

NOTE: The connecting rod capscrews can be

reused five times. Make a punch mark on

the capscrew head each time the capscrew

is used. If there are already five marks on

the capscrew head, the capscrew must be

replaced.

After installing the piston and connecting rod

assemblies, check the crankshaft for smooth rotation.

Measure the side clearance of the connecting rod cap.

Connecting Rod Cap Side Clearance

mm in

0.20 MIN 0.0079

0.40 MAX 0.0160

00900192

Diesel Engine Complete Engine

66

00900189

00900188

00900235

Flywheel Housing

Install the rear seal using oil seal installer, Part No.

ST 972.

Fill 40 to 60 percent of the space in the seal lip with

grease.

W

ARNIN

This component weighs 23 kg [50 lb] or more. To

avoid personal injury, use a hoist or get

assistance to lift this component.

CAU

Do not apply excessive force to the seal lip

surface when aligning and installing the flywheel.

Damage to the engine will occur if the seal is

damaged.

NOTE: Apply gasket sealant to the flywheel housing

mounting surface.

Align the flywheel housing with the dowel pins.

Install the flywheel housing and capscrews. Tighten

the capscrews.

Torque Value: 69 N•m [50 ft-lb]

Measure the distance in height between the

lubricating oil pan mounting surface and the flywheel

housing flange.

Maximum Height Difference: 0.15 mm [0.0059 in]

TIO

N

G

Diesel Engine Complete Engine

67

00900236

00900187

00900237

00900238

Measure the radial and face runout of the flywheel

housing.

Radial Runout

mm in

0.35

mm in

0.30

Flywheel

This component weighs 23 kg [50 lb] or more. To

avoid personal injury, use a hoist or get

assistance to lift this component.

Install the flywheel, coupling, retaining plate, and six

capscrews. Tighten the capscrews.

Torque Value:

Main Bearing

Flywheel

Capscrews

Measure the radial and face runout of the flywheel.

mm in

0.20

mm in

0.15

Camshaft Assembly

NOTE: When installing the camshaft, lightly rotate

the shaft while being careful not to damage

the bushing.

Install the thrust plate, camshaft assembly, and two

capscrews.

Tighten the capscrews through the casting holes in

the camshaft gear.

Torque Value: 19 N•m [14 ft-lb]

MAX

Face Runout

MAX

W

ARNIN

Step 1

2

Radial Runout

MAX

Face Runout

MAX

G

108 N•m [80 ft-lb]

191 N•m [141 ft-lb]

0.014

0.012

0.0079

0.0059

Diesel Engine Complete Engine

68

00900239

00900183

00900240

00900241

Measure the end play (1) of the camshaft.

Camshaft End Play

mm in

0.150 MIN 0.0059

0.350 MAX 0.0138

Oil Pump

Install the lubricating oil pump and five capscrews.

Tighten the capscrews.

Torque Value: 19 N•m [14 ft-lb]

Measure the end play of the lubricating oil pump drive

gear.

Lubricating Oil Pump Drive Gear End Play

mm in

0.020 MIN 0.0008

0.070 MAX 0.0028

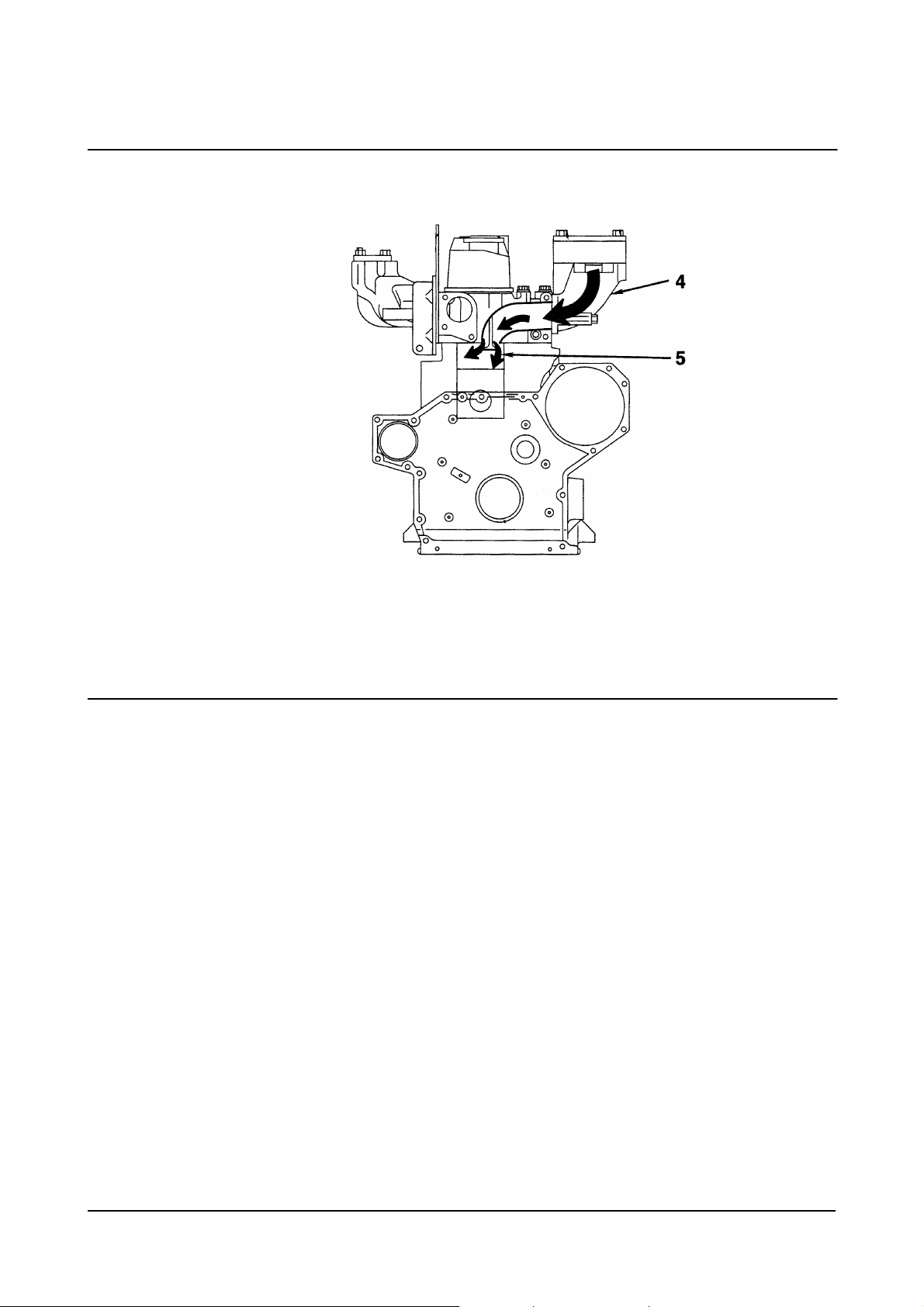

Idler Gear

Align the match marks of the idler gear, crankshaft

gear, and camshaft gear. The match marks are

identified as follows:

• Crankshaft Gear and Idler Gear: A

• Idler Gear and Camshaft Gear: B

• Fuel Pump and Idler Gear: C

• Lower case letters identify oil pump and

accessory drive, which are not timed.

Diesel Engine Complete Engine

69

Match mark alignment:

Turbocharged and Naturally Aspirated

Crankshaft gear

A

and idler gear

Camshaft gear

B

and idler gear

Injection pump

Backlash

C

gear and idler

gear

Camshaft gear

a

and oil pump gear

Camshaft gear

b

and PTO gear

Clearance Between Bushing and Shaft

End Play of Idler Gear

00900184

00900243

Install the retainer plate and capscrew.

Tighten the capscrew.

Torque Value: 110 N•m [81 ft-lb]

Measure the end play of the idler gear.

0.08 mm to 0.19 mm

[0.0031 in to 0.007 in]

0.08 mm to 0.19 mm

[0.0031 in to 0.007 in] Aspirated

0.07 mm to 0.29 mm

[0.003 in to 0.011 in]

0.15 mm to 0.30 mm

[0.006 in to 0.012 in]

0.03mm to 0.050mm

[0.0012 in 0.0035 in]

0.015 mm to 0.050 mm

[0.0006 in to 0.002 in]

0.03 mm to 0.09 mm

[0.0012 in to 0.0035 in]

Replacement

Limit:

0.40 mm

[0.0157 in]

Replacement

Limit:

0.10 mm

[0.0039 in]

Replacement

Limit:

0.20 mm

[0.0079 in]

Diesel Engine Complete Engine

70

00900244

00900182

00900181

Temporarily position the fuel injection pump assembly

and measure the backlash of the gears.

Measure the backlash of all the gears with a dial

indicator.

Gear Housing Cover

NOTE: A noise damper is installed on some

engines. The noise damper must be

installed prior to installing the front oil seal.

Install the front oil seal using tool, Part No. 3824498.

Fill 40 to 60 percent of the space in the seal lip with

grease.

CAU

TIO

N

Do not apply excessive force to the seal lip

surface when aligning and installing the gear

housing cover. Damage to the engine will occur if

the seal is damaged.

NOTE: Apply gasket sealant, Part No. 3823494, to

the gear housing cover mounting surface.

Install the gear housing cover and 17 capscrews.

Tighten the capscrews.

Torque Value: 19 N•m [14 ft-lb]

Measure the distance in height between the cylinder

block and the gear housing cover.

Maximum Height Difference: 0.15 mm [0.0059 in]

00900247

Diesel Engine Complete Engine

71

00900180

00900179

00900178

Crankshaft Pulley

Align the crankshaft pulley with the crankshaft key.

Install the crankshaft pulley, mounting plate, and

capscrew.

Tighten the capscrew.

Torque Value: 93 N•m [69 ft-lb]

Lubricating Oil Suction Tube

Install a new o-ring, oil suction tube, and two

capscrews.

Tighten the capscrews.

Torque Value: 19 N•m [14 ft-lb]

Lubricating Oil Pan

NOTE: Apply a 1-mm [0.039-in] bead of gasket

sealant, Part No. 3823494, to the mounting

surface of the lubricating oil pan.

Install a new gasket, lubricating oil pan, and 24

capscrews.

Tighten the capscrews.

Torque Value: 32 N•m [24 ft-lb]

If the oil drain plug was removed, install the drain plug.

Torque Value: 51 N•m [38 ft-lb]

PTO Shaft (if applicable)

Align the gear of the PTO shaft with the surface teeth

of the camshaft gear.

Install the o-ring, flange, and two capscrews.

Tighten the capscrews.

Torque Value: 19 N•m [14 ft-lb]

00900177

Diesel Engine Complete Engine

72

00900246

00900210

00900211

00900176

Fuel Injection Pump

CAU

TIO

N

Do not allow dirt or dust to enter the oil and fuel

inlet and outlet ports. Severe engine damage will

occur if contaminants are allowed to enter the

engine.

Install new o-ring, fuel injection pump, and two

mounting nuts on the adapter plate.

Tighten the nuts.

Torque Value: 31 N•m [23 ft-lb]

Install the fuel injection pump gear, washer, and nut

on the fuel injection pump.

Tighten the nut.

Torque Value: 70 N•m [52 ft-lb]

NOTE: Align the fuel injection pump gear match

mark “C” with the idler gear match mark “C”.

Install new o-ring, adapter plate, fuel injection pump

assembly, and mounting capscrews to the gear

housing.

Tighten the mounting capscrews.

Torque Value: 19 N•m [14 ft-lb]

Install the mounting capscrew on the fuel injection

pump support bracket.

Tighten the capscrew.

Torque Value: 19 N•m [14 ft-lb]

NOTE: The fuel supply tube has a 12-mm and 14-

mm banjo fitting. The 12-mm banjo fitting

connects to the fuel injection pump. The 14-

mm banjo fitting connects to the fuel filter

head, which is installed later in the

assembly process.

Install the fuel supply tube to the fuel injection pump.

Torque Value: 20 N•m [15 ft-lb]

Diesel Engine Complete Engine

73

00900174

00900173

00900172

Cylinder Head Assembly

NOTE: Coat the stems of the intake and exhaust

valves and the inside of the valve guides

with engine oil.

Install the valves.

Install the valve spring and spring seat on the valve

stem.

Install the valve cotter into the valve stem groove

while compressing the valve spring with spring pusher,

Part No. 3398179.

After releasing the valve spring, tap the top of the

valve stem with a plastic hammer to make certain the

cotter is completely fitted.

00900252

Diesel Engine Complete Engine

74

00900253

00900254

00900245

Remove all carbon and dirt from the contact

surfaces of the cylinder block and the cylinder

head. Remove all burrs and damage, and clean

out all the dirt from inside the cylinder block.

Failure to follow these steps will result in severe

engine damage.

Install a new cylinder head gasket with the TOP mark

facing up.

This component weighs 23 kg [50 lb] or more. To

avoid personal injury, use a hoist or get

assistance to lift this component.

NOTE: Coat the capscrew threads with antifriction

compound, Part No. 3824879.

Install the cylinder head using four head capscrews

as guides.

Install the capscrews. Tighten the capscrews in the

sequence shown.

Torque Value:

Cylinder Head

Capscrews Step 1 69 N•m [51 ft-lb]

2 108 N•m [80 ft-lb]

3 Rotate 90 degrees

NOTE: The cylinder head capscrews can be reused

five times. Make a punch mark on the

capscrew head each time the capscrew is

used. If there are already five marks on the

capscrew head, the capscrew must be

replaced.

Push Rods

NOTE: If there is no abnormality in the pushrods,

install them in the same position that they

were removed from during disassembly.

CAU

W

ARNIN

TIO

N

G

00900170

Diesel Engine Complete Engine

75

1. Rocker Shaft

2. Adjusting Screw Lock Nut

3. Pedestal Mounting Capscrews

4. Separating Spring

5. Rocker Shaft Indexing Screw

6. Pedestal Mounting Stud

Rocker Arm Assembly

00900169

00900251

7. Cup Plug

8. Snap Ring

9. Thrust Washer (only used on some engines)

10. Rocker Lever Pedestal

11. Rocker Lever

12. Adjusting Scre w.

Rocker Arm Assembly

NOTE: Check that the ball of the adjustment screw

is fitted properly into the socket of the

pushrod before tightening the capscrews. If

the valve spring tension pushes against the

rocker arm, loosen the locknut, and turn the

adjustment screw back to prevent strain on

the pushrod.

Install the rocker arm assembly and eight capscrews.

Tighten the capscrews.

Torque Value: 25 N•m [18 ft-lb]

Diesel Engine Complete Engine

76

03900077

03900075

fi9slwb

00900167

Adjusting Valve Clearance

Adjust the valve clearance. Refer to Section 14.

Rocker Lever Cover

Install the o-ring into the rocker lever cover.

Install the rocker lever cover, three capscrews, and

isolator assemblies.

Tighten the capscrews.

Torque Value: 9 N•m [7 ft-lb]

Injector

Coat the injectors with anti-sieze compound, Part No.

3824879, before installation.

CAU

TIO

N

Be careful not to damage the tip of the injector

when installing.

NOTE: When installing the injector, clean around

the injector, and do not allow dust or dirt to

enter the engine.

NOTE: If there is no abnormality in the injector,

install it in the same position during

assembly.

Install the injector, washer, and mounting capscrew.

Tighten the capscrew.

Torque Value: 44 N•m [33 ft-lb]

Diesel Engine Complete Engine

77

00900166

00900164

00900163

Spill Tube

Install the spill tube.

Intake Manifold

NOTE: Apply a 1-mm [0.039-in] bead of gasket

sealant, Part No. 3823494, to the mounting

surface of the intake manifold.

Install the air inlet connection, intake manifold, and

seven capscrews.

Tighten the capscrews.

Torque Value: 40 N•m [30 ft-lb]

Fuel Injection Tubing

NOTE: Before installing the fuel injection tubing,

blow compressed air through it to clean it.

Position the fuel injection tubing, and loosely install

the sleeve nuts on the fuel injection pump and the

cylinder head.

Tighten the clamp.

Tighten the banjo fittings

Torque Value: 20 N•m [15 ft-lb]

Exhaust Manifold

Install a new gasket, the exhaust manifold, and the

eight capscrews.

Tighten the capscrews.

Torque Value: 66 N•m [49 ft-lb]

00900162

Diesel Engine Complete Engine

78

18900025

00900161

00900160

Thermostat

Install seal, thermostat, thermostat housing, and two

mounting capscrews.

Tighten the capscrews.

Torque Value: 19 N•m [14 ft-lb]

Water Pump

Install the o-ring, gasket, water pump, and mounting

capscrews.

Tighten the capscrews.

Torque Value: 19 N•m [14 ft-lb]

Dipstick

NOTE: Apply Loctite™ sealant, Part No. 3375068,

or equivalent, to the outside of the dipstick

tube.

CAU

TIO

N

Excessive sealant can run back into the engine

and cause damage to other components.

Install the dipstick guide.

Install the dipstick.