Daewoo D20S-2, G20S-2, GC20S-2, D20-2, G25S-2 Specifications Systems Operation Testing & Adjusting Disassembly & Assembly

...

Aug. 1996

Specifications

Systems Operation

T esting & Adjusting

Disassembly & Assembly

New Hydraulic Systems

D20/25-2

D20/25/30S-2

G20/25/30S-2

G20/25/30S-2

SB2097E00

Important Safety Information

Most accidents involving product operation, maintenance and repair are caused by failure to observe

basic safety rules or precautions. An accident can often be avoided by recognizing potentially

hazardous situations before an accident occurs. A person must be alert to potential hazards. This

person should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, Iubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any Iubrication, maintenance or repair on this product, until you

have read and understood the operation, Iubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or other persons.

The hazards are identified by the "Safety Alert Symbol" and followed by a "Signal Word" such as

"WARNING" as shown below.

The meaning of this safety alert symbol is as follows :

Attention! Become Alert! Your Safety is Involved.

The Message that appears under the warning, explaining the hazard, can be either written or

pictorially presented.

Operations that may cause product damage are identified by NOTICE labels on the product and in

this publication.

DAEWOO cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are therefore not all inclusive. If a tool, procedure,

work method or operating technique not specifically recommended by DAEWOO is used, you must

satisfy yourself that it is safe for you and others. You should also ensure that the product will not be

damaged or made unsafe by the operation, Iubrication, maintenance or repair procedures you

choose.

The information, specifications, and illustrations in this publication are on the basis of information

available at the time it was written. The specifications, torques, pressures, measurements,

adjustments, illustrations, and other items can change at any time. These changes can affect the

service given to the product.

Obtain the complete and most current information before starting any job. DAEWOO dealers have

the most current information available.

1 of 29

WARNING

Index

Specifications

Hydraulic Control Valve .......................................... 5

Systems Operation

Hydraulic Control Valve ........................................ 17

Assembly And Construction .......................... 17

Check Valve .................................................. 21

Flow Control Valve And Relief Valve ............ 20

Valve Operation ............................................ 18

Hydraulic System (D20/25/30S-2,

G20/25/30S-2, GC20/25/30S-2 Model)................. 6

Hydraulic System (D20/25-2 Model Only) ............ 11

Anti-Stall And Remote Relief Valve .............. 14

Testing And Adjusting

Hydraulic System .................................................. 23

Flow Control Valve Adjustment ..................... 24

Relief Valve Pressure Check ........................ 23

Troubleshooting .................................................... 22

Disassembly And Assembly

Assembly .............................................................. 28

Cleaning, Inspection And Repair .......................... 26

General ................................................................. 25

Unit Disassembly .................................................. 25

3 of 29New Hydraulic Systems Index

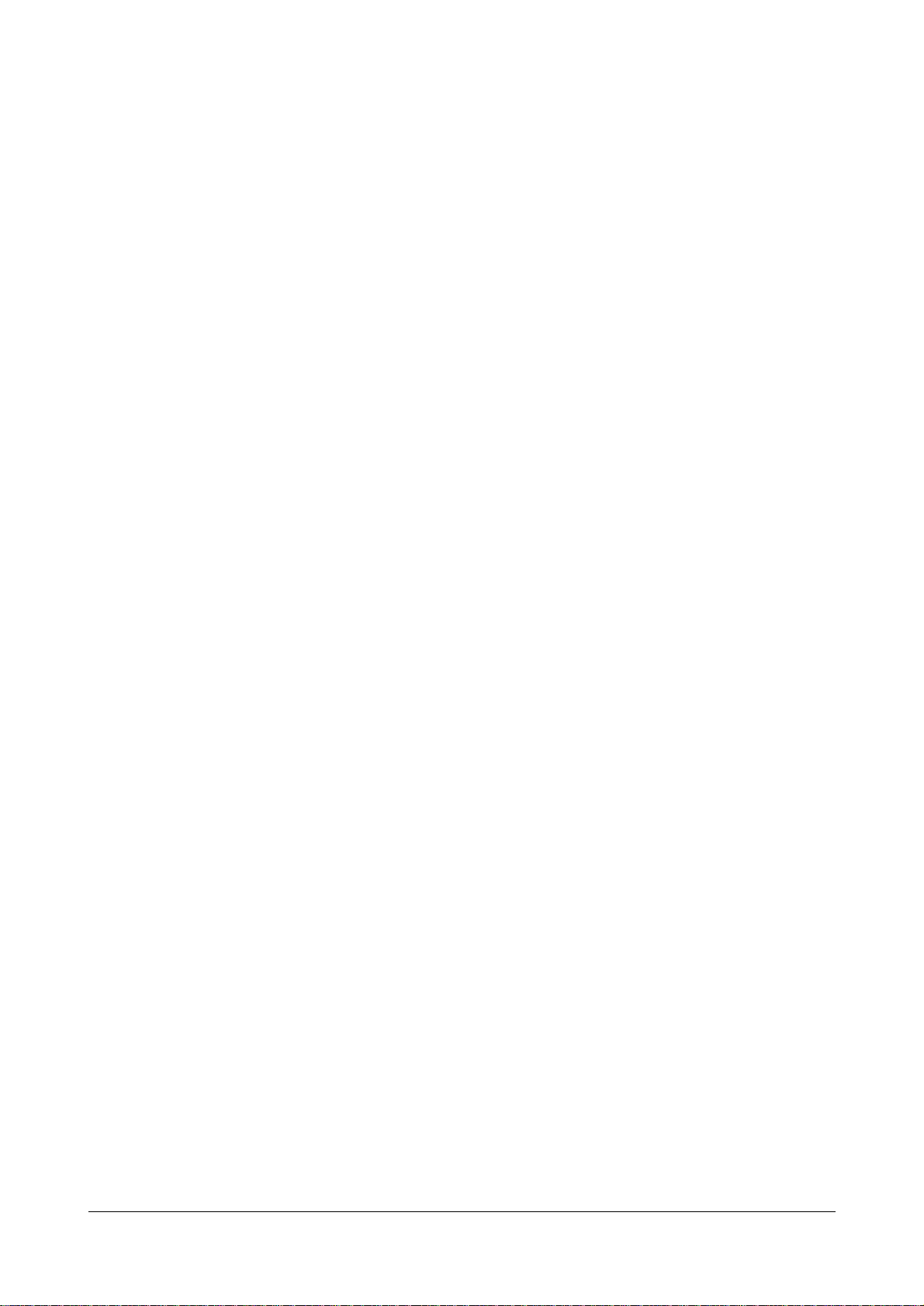

Specifications

Hydraulic Control valve

(1) Torque for bolts that hold control valve sections

together

................

40.5

±2 N

•

m (360 ±18 lb

•

in)

(2) Adjust TILT and sideshift relief valve pressure as

shown above. See Relief Valve Pressure Check

in Testing And Adjusting.

(3) Torque for nipple assembly

........

36.5

±0.5 N

•

m

(320

±4 lb

•

in)

See Folw Control Valve Adjstment in Testing And

Adjusting.

(4) Torque for screws

............................

12 ±1.5 N

•

m

(105

±13 lb

•

in)

5 of 29New Hydraulic Systems Specifications

CONTROL VALVE

TILT, Auxiliary

Relief Valve

Pressure

±350 kPa

(

±50 psi)

15,500 (2250)

15,500 (2250)

15,500 (2250)

Main Relief

Valve

Pressure

± 500 kPa

(

±75 psi)

18,100 (2625)

19,500 (2825)

21,550 (3125)

Mast

Std

FFL

FFTL

Std

FFL

FFTL

Std

FFL

FFTL

Model

D(G)20(S)

GC20(S)

D(G)25(S)

GC25(S)

D(G)30S

GC30S

2

1

3

IDCS001B

Systems Operation

Hydraulic System

(D20/25/30S-2, G20/25/30S-2, GC20/25/30S-2 Model)

6 of 29New Hydraulic Systems Systems Operation

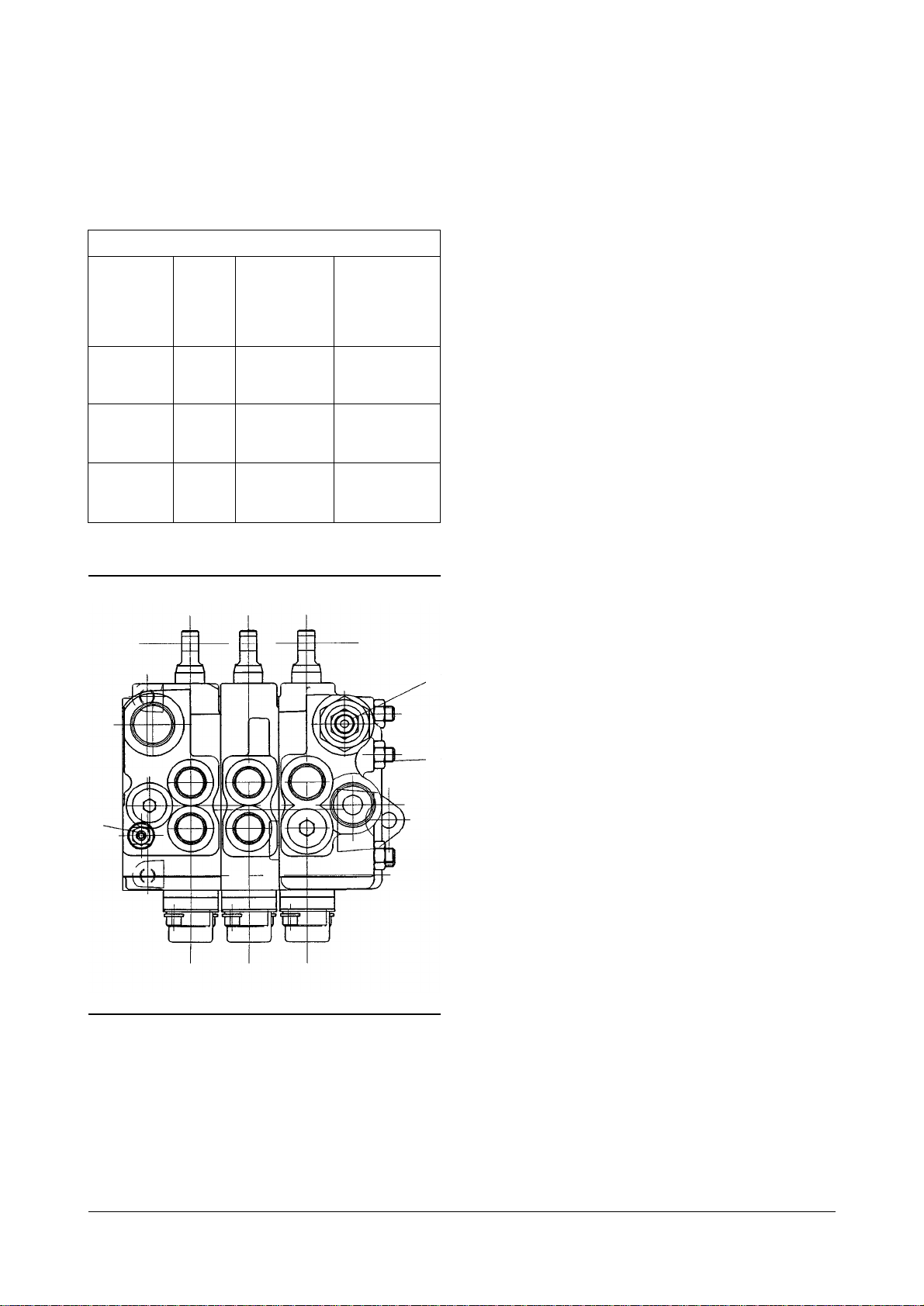

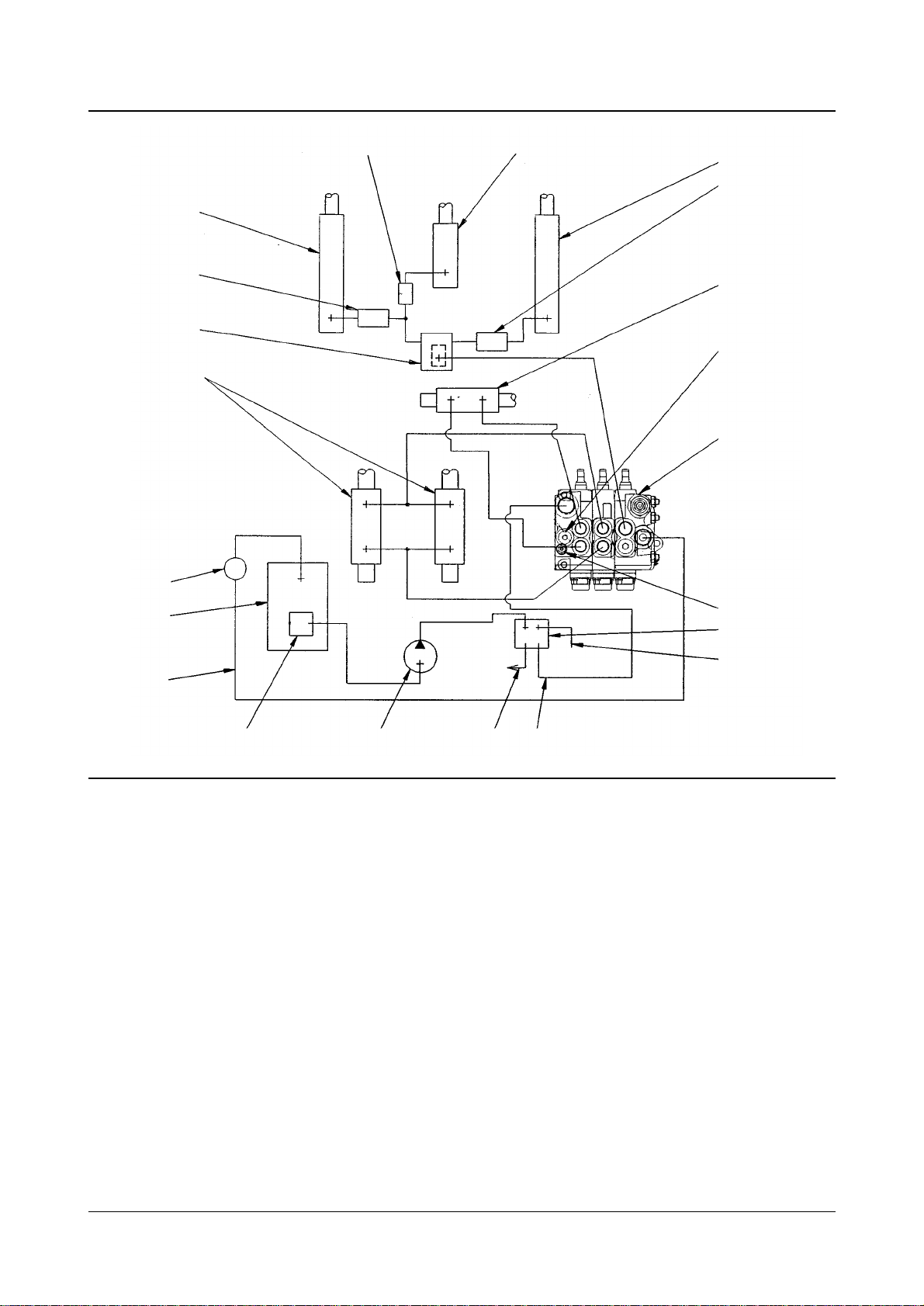

Basic Hydrauic Schematic With Standard Lift

(1) Lift cylinders. (2) Excess flow protectors. (3) Sideshift cylinder(s)(if equipped). (4) Lowering flow control valve. (5) Hydraulic

control valve. (6) Tilt cylinders (7) Relief valve(lift). (8) Relief valve(tilt and sideshift). (9) Hydraulic oil filter. (10) Hydraulic oil

tank. (11) Priority valve. (12) Oil line(trucks with power brakes only). (13) Oil line. (14) Hydraulic strainer. (15) Hydraulic pump.

(16) Oil line to steering gear. (17) Oil line.

12

11

8

5

7

3

2

1

1

2

4

6

9

10

13

14 15

16 17

IDCS002B

The hydraulic system has hydraulic oil tank (10)

which holds the oil for gear type hydraulic pump (15).

Hydraulic pump (15) sends pressure oil to the power

brakes (if equipped), hydraulic and steering systems.

Pump oil flows from pump (15) to priority valve (11)

where the oil folw divides to the power brakes brake

valve (if equipped)(not shown) through line (12) and

to the steering gear through line (16).

The control valve levers move the valve spools in

control valve (5) to let the pump oil in the control

valve go to lift cylinders (1) and/or (19), tilt cylinders

(6) or sideshift cylinder(s) (3).

The return hydraulic oil from the cylinders flows

through hydraulic control valve (4), line (13), into filter

(9) and hydraulic tank (10). Relief valve (7) in the

control valve body will make the flow control valve

release extra pressure to the hydraulic tank when the

pressure in the lift or tilt circuits goes higher than

relief valve pressure shown in the Control Valve

section of Specifications. Relief valve (8) does the

same thing for the sideshift circuit when it goes

higher than the auxiliary relief valve pressure shown

in the Control Valve section of Specifications.

7 of 29New Hydraulic Systems Systems Operation

The maximum speed at which the lift cylinder(s) are

lowered is controlled by lowering flow control valve (4).

Excess flow protectors (2) and (18) will act as flow

control valve if an oil line between them and flow

control valve (4) is broken when the mast is raised or

lowered. This prevents a sudden fall of the mast or

carriage if an oil line is broken.

The tilt forward, tilt back and sideshift speeds are

controlled by flow control valves in hydraulic control

valve (5). There is an anti-cavitation valve inside the tilt

spool to prevent cavitation (development of air pockets)

in tilt cylinders (6).

REFERENCE : For the Hydraulic Systems Schematics.

8 of 29New Hydraulic Systems Systems Operation

Basic Hydraulic Schematic With Standard Lift

(1) Lift cylinders. (2) Excess flow protectors. (3) Sideshift cylinder(s)(if equipped). (4) Lowering folw control valve. (5) Hydraulic

control valve. (6) Tilt cylinders. (7) Relief valve(lift). (8) Relief valve(tilt and sideshift). (9)Hydraulic oil filter. (10) Hydraulic oil

tank. (11) Priority valve. (12) Oil line(trucks with power brakes only). (13) Oil line. (14) Hydraulic strainer. (15) Hydraulic pump.

(16) Oil line to steering gear. (17) Oil line. (18) Excess folw protector. (19) Lift cylinder(primary).

18

19

1

2

4

6

9

10

13

14 15

16

17

12

11

8

5

7

3

2

1

IDCS003B

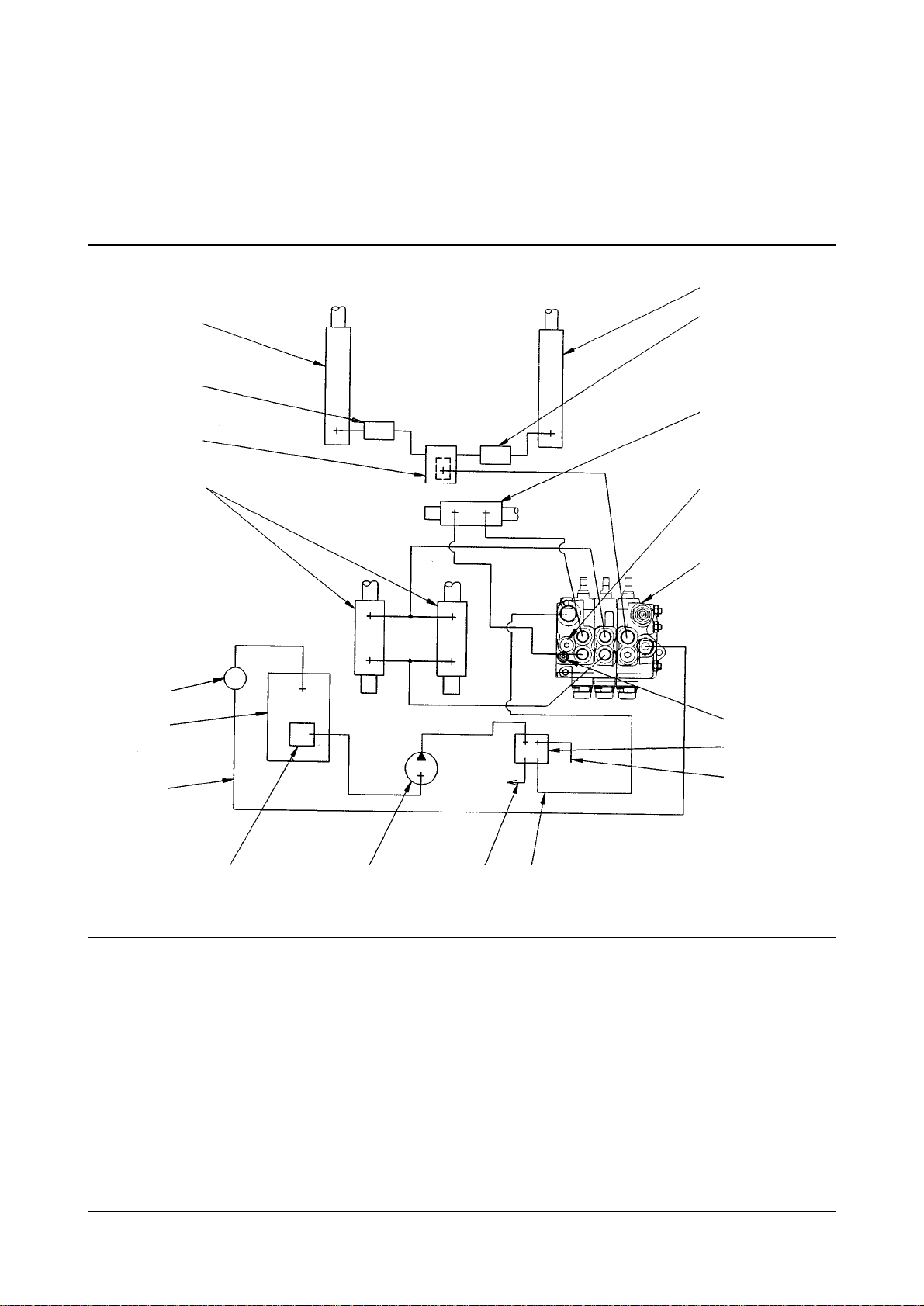

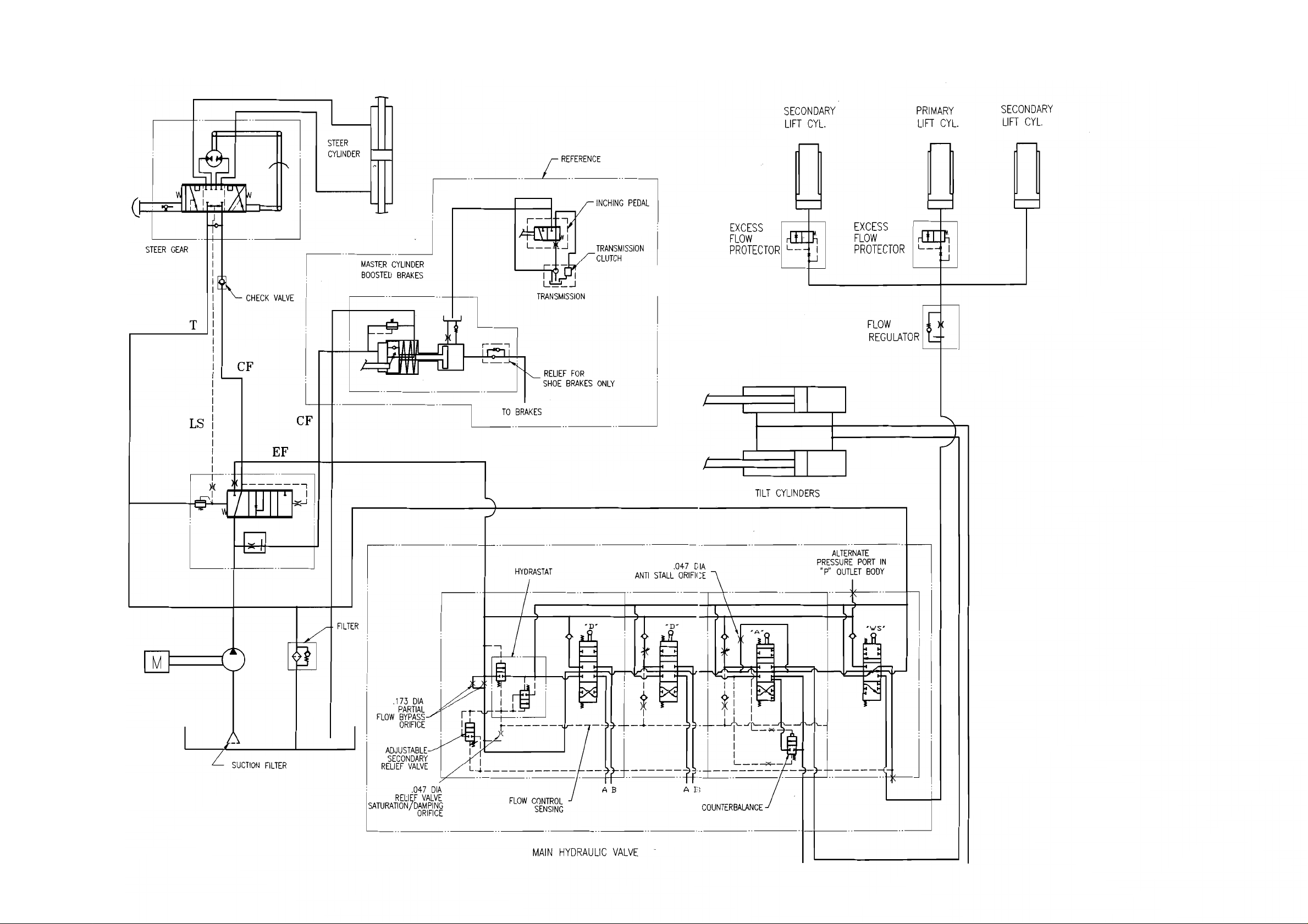

Hydraulic System (D20/25-2 Model Only)

11 of 29New Hydraulic Systems Systems Operation

Basic Hydraulic Schematic With Standard Lift

(1) Lift cylinders. (2) Excess flow protectors. (3) Sideshift cylinder(s)(if equipped). (4) Lowering folw control valve. (5) Hydraulic

control valve. (6) Tilt cylinders. (7) Relief valve(lift). (8) Relief valve(tilt and sideshift). (9) Hydraulic oil filter. (10) Hydraulic oil

tank. (11) Priority valve. (12) Oil line(trucks with power brakes only). (13) Oil line. (14) Hydraulic strainer. (15) Hydraulic pump.

(16) Oil line to steering gear. (17) Oil line. (18) Remote relief valve. (19) Oil line(trucks with anti-stall valve only). (20) Anti-stall

valve(if equipped).

1

2

4

6

9

10

13

14

15

16 17 18

19

20

12

11

8

5

7

3

2

1

IDCS004B

The hydraulic system has hydraulic oil tank (10) which

holds the oil for gear type hydraulic pump (15).

Hydraulic pump (15) sends pressure oil the power

brakes (if equipped), hydraulic and steering systems.

Pump oil flows from pump (15) to priority valve (11)

where the oil folw divides to the power brakes brake

valve (if equipped)(not shown) through line (12) and to

the steering gear through line (16). Oil also flows

through anti-stall valve (20), to hydraulic control valve

(5) and back to hydraulic tank (10).

When the lift truck is at idle speed the hydraulic pump

delivers a low oil flow. If the lift, tilt or auxiliaries are

used the pressure in line (17) will increase and

remote relief valve (18) will dump oil to hydraulic tank

(10). As engine speed is increased, oil flow

increases, anti-stall valve (20) now closes the

passage to remote relief valve (18). With remote

relief valve (18) blocked, normal hydraulic relief

pressures are available.

The control valve levers move the valve spools in

control valve (5) to let the pump oil in the control

valve go to lift cylinders (1) and/or (22), tilt cylinders

(6) or sideshift cylinder(s) (3).

The return hydraulic oil from the cylinders flows

through hydraulic control valve (4), line (13), into filter

(9) and hydraulic tank (10). Relief valve (7) in the

control valve body will make the flow control valve

release extra pressure to the hydraulic tank when the

pressure in the lift or tilt circuits goes higher than

relief valve pressure shown in the Control Valve

section of Specifications. Relief valve (8) does the

same thing for the sideshift circuit when it goes

higher than the auxiliary relief valve pressure shown

in the Control Valve section of Specifications.

12 of 29New Hydraulic Systems Systems Operation

The maximum speed at which the lift cylinder(s) are

lowered is controlled by lowering flow control valve (4).

Excess flow protectors (2) and (21) will act as flow

control valve if an oil line between them and flow

control valve (4) is broken when the mast is raised or

lowered. This prevents a sudden fall of the mast or

carriage if an oil line is broken.

The tilt forward, tilt back and sideshift speeds are

controlled by flow control valves in hydraulic control

valve (5). There is an anti-cavitation valve inside the

tilt spool to prevent cavitation (development of air

pockets) in tilt cylinders (6).

REFERENCE : For the Hydraulic Systems Schematics.

13 of 29New Hydraulic Systems Systems Operation

Basic Hydraulic Schematic With Standard Lift

(1) Lift cylinders. (2) Excess flow protectors. (3) Sideshift cylinder(s)(if equipped). (4) Lowering folw control valve. (5) Hydraulic

control valve. (6) Tilt cylinders. (7) Relief valve(lift). (8) Relief valve(tilt and sideshift). (9) Hydraulic oil filter. (10) Hydraulic oil

tank. (11) Priority valve. (12) Oil line(trucks with power brakes only). (13) Oil line. (14) Hydraulic strainer. (15) Hydraulic pump.

(16) Oil line to steering gear. (17) Oil line. (18) Remote relief valve. (19) Oil line(trucks with anti-stall valve only). (20) Anti-stall

valve. (21) Excess flow protector. (22) Lift cylinder(primary).

6

4

2

1

9

10

13

14

15

16

17 18

19

20

12

11

5

7

3

2

1

2221

8

IDCS005B

Anti-Stall And Remote Relief Valve

The anti-stall valve in combination with the remote

relief valve prevent hydraulic overloads at engine

idle, which could cause excessive vibration and

engine stalling. At engine idle, the anti-stall valve

opens ports to the hydraulic control valve and the

remote relief valve. If the hydraulic control valve is

used, the pressure in the oil line from the priority

valve to the anti-stall valve will increase. This

pressure increase will be limited by the remote relief

valve to 8250 kPa (1200 psi) (6R7072 Relief Valve).

This relatively low system pressure allows for a

smoother engine idle because the engine is not

overloaded by the hydraulic pump with an engine

speed of 700 rpm minimum.

As engine speed increases the hydraulic system oil

flow increases. The anti-stall valve senses this flow

increase and closes the output port to the remote

relief valve. Flow is now directed to the main control

valve only and full system pressure can be achieved.

14 of 29New Hydraulic Systems Systems Operation

Assembly And Construction

Above figure is a cross-section view showing

construction and assembly of a three-section valve.

The inlet section also contain a relief valve

assembly.

Passages between the bodies connect each section

to the common inlet and tank ports.

Seal rings between the sections seal the connecting

passages, Sections are held together by studs and

nuts.

17 of 29New Hydraulic Systems Systems Operation

(1) Relief Valve. (2) Inlet Body. (3) Center Spring. (4) Switch Bracket.

(5) Cam. (6) Center Body. (7) Spool. (8) Tie Stud.

(9) Outlet Body. (10) Check Valve. (11) Seal Rings.

Hydraulic Control Valve

IDCS006B

18 of 29New Hydraulic Systems Systems Operation

Valve Operation

Figure IDCS007B is a schematic illustration of a

three section valve, showing the inlet and outlet ports

and the by-pass, pressure and tank passages.

The pressure passage is used to carry fluid to the

cylinder ports when the spools are shifted. The bypass passage permits flow directly to the outlet when

the spools are not being operated. The tank passage

also carries fluid to the outlet; either return flow from

the cylinder ports or fluid diverted past the flow

control and relief valve,

The spools are shown in the centered or neutral

position, Under these conditions, fluid in the pressure

passage is blocked from the cylinder ports by the

spool lands. Flow through the valve is through the

by-pass and tank passages to the outlet.

(1) Control Valve Sensing Orifice.

(2) Flow Control And Relief Valve.

(3) Tank Passage.

(4) By-pass Flow Control Orifice.

(5) Cylinder Ports.

(6) Pressure Passage. (7) By-pass Passage.

IDCS007B

Lift Spool

IN Pressure to “B

”

“

A”to tank

By-pass blocked

CENTER

“A”

and “B”blocked

By-pass open

OUT

“B”

to tank

“A”

blocked

By-pass open

Lift spool - used for control of single acting cylinder

applications. It directs flow to only one end of a

cylinder, as in the lift mechanism of a lift truck.

Return flow is from the same end of the cylinder and

relies on gravity or mechanical means to retract.

IDCS008B

IDCS009B

19 of 29New Hydraulic Systems Systems Operation

Tilt Spool

IN

“A”

to tank

“B”

blocked

By-pass open

CENTER

“A”

and “B”blocked

By-pass open

OUT Pressure to

“A”

“

B”blocked

By-pass blocked

Tilt spool - a counterbalance spool normally used to

control the tilt function of a lift truck.

The counterbalance feature prevents the forks from

tilting forward faster than the pump can supply oil,

preventing tilt.

IDCS012B

Auxiliary Spool

IN Pressure to “B

”

“

A”to tank

By-pass blocked

CENTER

“A”

and “B”blocked

By-pass open

OUT Pressure to

“A”

“

B”to tank

By-pass blocked

Auxiliary spool - directs flow to either end of a double

acting cylinder. Flow from the end that is not under

pressure is returned to tank via internal coring of the

valve section.

IDCS010B

IDCS011B

IDCS013B

Flow Control And Relief Valve

Earlier design valves were equipped with simple relief

valves in the inlet sections.

The partial flow by-pass system in the LT valve

makes use of a compound type flow control and relief

valve arrangement.

Sensing the pressure drop across an orifice at the

entrance to the by-pass, the valve acting as a control

to limit flow through the by-pass to approximately

seven gallons per minute. The balance of the pump

delivery is diverted through the reservoir passage.

This arrangement greatly reduces pressure drop

through the valve in the neutral position.

When a spool is shifted to operate a portion of a

machine, the flow control is inoperative and full pump

volume is available to the system. The control valve

then functions as an overload relief valve. System

pressure is limited to a prescribed maximum by the

action of this valve. Inlet body type F is not equipped

with a relief valve. Full pump volume is available to

the system at all times.

Use of the optional secondary relief valve allows the

use of lower pressure for tilt and accessory function

while higher pressure is provided for the lift function.

NOTE : The secondary relief valve must be set at a

lower relief setting than the system relief.

Flow Control

(1) Control Valve Sensing Orifice.

(2) Flow Control And Relief Valve.

(3) Tank Passage.

(4) By-pass Flow Control Orifice.

(5) Cylinder Ports. (6) Pressure Passage.

(7) By-pass Passage.

Figure IDCS007B shows the valve operation in

neutral with flow in excess of seven USgpm. Flow

across the by-pass orifice result in a pressure drop.

Decreased pressure is sensed at the spring end of

the valve sub-assembly through a sensing orifice.

The slightly higher pressure at the other end of the

valve permits it to shift down, diverting excess flow to

the reservoir passage. With flow at less than seven

USgpm there would be negligible pressure drop

across the by-pass orifice. Then the control valve

would be held closed by the large spring and all flow

would be through the by-pass passage.

Optional flow control valves are available for all

operating sections. These valves can be set from

1 - 15 US gpm.

20 of 29New Hydraulic Systems Systems Operation

IDCS007B

Relief Valve

(1) Spring. (2) Spool. (3) Poppet.

(4) By-pass Flow Control Orifice.

(5) Flow Control And Relief Valve.

(6) Spring. (7) Sensing Orifice.

(8) Control Valve Sensing Orifice.

Operation of the relief valve feature is shown in

above figure. When an operating spool is shifted,

fluid is ported into the system and the by-pass is

blocked.

Above figure A shows operation at less than the relief

valve setting. There is no flow over the by-pass

orifice, so full system pressure is sensed at the spring

end of the control valve, as well as the opposite end.

The valve is thus hydraulically balanced and the large

spring holds the relief spool closed.

Maximum pressure is determined by the setting of

the small spring inside the control valve assembly.

When system pressure is sufficient to overcome this

heavy spring, the poppet is forced off its seat (see

above figure B).

Fluid immediately flows past the poppet to the tank

passage. This flow creates a pressure drop across

the sensing orifice and the control valve is no longer

hydraulically balanced.

When pressure drop across the sensing orifice is

great enough to overcome the force of the large

spring, the valve spool shifts, permitting flow to the

tank passage.

Relief valve sub-assemblies in the inlet section are

pre-set and tested by Vickers for given pressure

settings. Selection of the relief valves setting is based

on the work requirements of the system.

If a different relief valve setting is required, the valve

sub-assembly should be replaced,

Check Valve

(1) Spring. (2) Spool. (3) Poppet.

(4) By-pass Flow Control Orifice.

(5) Flow Control And Relief Valve.

(6) Spring. (7) Sensing Orifice.

(8) Control Valve Sensing Orifice.

Timing of the spools is such that one cylinder port

opens to pressure and the other port opens to

reservoir before the by- pass passage is

completelyblocked.

To prevent return flow from passing into the pressure

passage and escaping through the partially closed

by-pass, check valves are provided in each operating

section except sections with

“B”

spool.

The check valves prevent the load from dropping.

21 of 29New Hydraulic Systems Systems Operation

IDCS014B

Model

D20-2, D20S-2,

G20S-2, GC20S-2

D25-2, D25S-2

G25S-2, GC25S-2

D30S-2, G30S-2

GC30S-2

Part

Number

D144363

D144364

D144365

Setting

Pressure

2625 psi

(18,100 kPa)

2825 psi

(19,478kPa

3125 psi

(21,546 kPa)

IDCS014B

Testing And Adjusting

Troubleshooting

Below table lists the difficulties which may be

experienced with the unit and the hydraulic system. It

indicates the cause and remedy for each of the

trouble listed. It should always be remembered that

pressure and delivery are factors which are usually

dependent upon each other. Adequate pressure

gauge equippment and a thorough understanding of

the operation of the complete hydraulic system are

essential to diagnose improper conditions.

22 of 29New Hydraulic Systems Testing and Adjusting

Trouble :

Oil leaks at either end of spools.

Probable Cause

Defective O-rings in valve

body

Remedy

Replace O-rings

Trouble :

Spring-centered spools do not return to neutral.

Probable Cause

Broken springs

Bent spool

Foreign particles

Misalignment of operating

linkage

Valve bank improperly

torqued

Probable Cause

Worn detent barrel

Weak or broken detent

spring

Remedy

Replace springs

Replace with new section of

same size and type

Clean system and valve

Check linkage for binding

condition

Retorque nuts to specified

ratings

Remedy

Replace detent barrel

Replace detent spring

Trouble :

Detent type spools will not stay in detent position

Trouble :

No motion, slow or jerky action of hydraulic system

Probable Cause

Relief valve not properly set, or

stuck in base and/or worn

Dirt or foreign particles lodged

between relief valve control poppet

and seat

Valve body cracked inside

Spool not moved to full stroke

Remedy

Repair, clean and readjust

Disassemble, clean and

reassemble

Replace valve section

Check travel

Trouble :

No relief valve action (high pressure)

Probable Cause

Small particle of dirt plugging

orifice in relief valve subassembly

Relief valve sub-assembly

installed backward

Remedy

Remove relief valve and

check hole. If blocked, clear

hole

Install properly

Trouble :

Load will not hold

Probable Cause

Oil by passing between spool

and body

Oil by passing piston in cylinder

Cylinder not centered

Remedy

Replace valve

Repair or replace cylinder

Refer to above spool remedies

Trouble :

Load drops when spool is moved from neutral to a

power position

Probable Cause

Dirt or foreign particles lodged

between check valve ball and seat

Scoreed or sticking check valve

Remedy

Disassemble, clean and

reassemble

Replace poppet

Hydraulic System

Relief Valve Pressure Check

Use the Fittings Group to check the relief valve

pressure.

Pressure Tap Location

(1) Cap. (2) Nipple assembly.

With the engine off, remove cap (1) from nipple

assembly (2) and connect the 28,000 kPa (4000 psi)

gauge to the nipple assembly.

Lift Relief Valve Check and Adjustment

1. Start the engine and activate the hydraulics until

the hydraulic oil is at the normal operating

temperature. Tilt the mast back to the end of its

travel.

2. With the engine at high idle, hold the tilt control

lever in the tilt back position and watch the gauge.

The gauge indication is the pressure that opens

the relief valve.

3. The correct pressure setting is shown in the chart.

Relief Valve Adjustment.

(3) Plug.

23 of 29New Hydraulic Systems Testing and Adjusting

Tools Needed

Fittings Group

CONTROL VALVE

Tilt, Auxiliary

Relief Valve

Pressure

°æ 350 kPa

(°æ 50 psi)

15,500 (2250)

15,500 (2250)

15,500 (2250)

Main Relief

Valve

Pressure

°æ 500 kPa

(°æ 75 psi)

18,100 (2625)

19,500 (2825)

21,550 (3125)

Mast

Std

FFL

FFTL

Std

FFL

FFTL

Std

FFL

FFTL

Model

D(G)20(S)

GC20(S)

D(G)25(S)

GC25(S)

D(G)30S

GC30S

WARNING

Hydraulic oil, under pressure can remain in the

hydraulic system after the engine and pump have

been stopped. Personal injury can be caused if this

pressure is not released before any work is done on

the hydraulic system. To prevent possible injury,

lower the carriage to the ground, turn the engine off

and move the control levers to make sure all

hydraulic pressure is released before any fitting,

plug, hose or component is loosened, tightened,

removed or adjusted. Always move the lift truck to a

clean and level location away from the travel of

other machines. Be sure that other personnel are

not near the machine when the engine is running

and tests or adjustments are made.

IDCS001C

IDCS002C

2

1

3

Tilt and Sideshift Relief Valve

Check and Adjustment

1. Start the engine and activate the hydraulics until

the hydraulic oil is at the normal operating

temperature. Put the carriage in the full sideshift

position.

2. With the enigne at high idle, hold the sideshift

control lever in the full sideshift position and watch

the gauge. The gauge indication is the pressure

that opens the relief valve.

3. The correct pressure setting is shown in the chart.

4. If an adjustment to the relief valve setting is

necessary, loosen nut (5).

Relief Valve Adjustment

(5) Nut. (6) Setscrew.

5. Turn setscrew (6) clockwise to increase or

counterclockwise to decrease the pressure setting

of the relief valve.

6. Tighten the locknut and check the pressure setting

again for correct adjustment.

Flow Control Valve Adjustment

The tilt and first attachment speeds can be adjusted

at the control valves. They can be adjusted by turning

plug the in the hydraulic control valve body. The lift

speed can not be adjusted. Do the procedure that

follows to change the flow control assembly.

Flow Control Valve Adjustment

(1) Flow control valve adjuster.

1. Remove the nut from the main hydraulic valve tiebolt stud.

2. Remove the stud from the valve.

3. Use Hex Wrench (6mm), turn the flow control

adjuster clockwise to increase the flow or

counterclockwise to decrease the flow.

4. Assemble the tie bolt stud in the valve. Torque the

stud to 38.5 - 42.5 N

¥

m (342 - 378 lb¥in)

5. Reinstall the nut on the tie bolt and torue

38.5 - 42.5 N

¥

m (342 - 378 lb¥in).

24 of 29New Hydraulic Systems Testing and Adjusting

Hydraulic oil, under pressure can remain in the

hydraulic system after the engine and pump have

been stopped. Personal injury can be caused if this

pressure is not released before any work is done on

the hydraulic system. To prevent possible injury,

lower the carriage to the ground, turn the engine off

and move the control levers to make sure all

hydraulic pressure is released before any fitting,

plug, hose or component is loosened, tightened,

removed or adjusted. Always move the lift truck to a

clean and level location away from the travel of

other machines. Be sure that other personnel are

not near the machine when the engine is running

and tests or adjustments are made.

IDCS003C

IDCS016B

Lift Section

1

Remove nut

tie-bolt

stud here

6

5

WARNING

Disassembly And Assembly

General

During disassembly, particular attention should be given

to identification of parts for reassembly. Spools are

selectively fitted to valve bodies and must be returned to

the same bodies from which they were removed,

Valve sections must be reassembled in the same

order. Figure IDCS015B is an exploded view showing

the proper relationship for reassembly. Reference is

made to these figures in the procedures which follow.

Unit Removal

1. Thoroughly clean the exterior of the valve and the

area around the valve to prevent contamination of

the system during removal.

2. Loosen mounting bolts that hold valve to mounting

surface. Be ready to catch fluid retained inside

lines and valve.

3. Remove valve from mounting surface and set it on

a clean work bench.

Unit Disassembly

NOTE : All parts within the unit must be kept clean

during the overhaul process. Handle each part with

great care. The close tolerance of the parts makes

this requirement very important. Clean all parts that

are removed from the unit with a commercial cleaning

solvent that is compatible with the system fluid.

Compressd air may be used in the cleaning process,

however, it must be filtered to remove water and

other contamination. Be sure the unit is not subjected

to pressure. Disconnect and cap all lines and

disconnect linkage to the spool.

Attaching Parts

1. Remove the four nuts (1) and four tie studs (2).

2. Separate the valve sections, being careful not to

destroy or lose spacers.

3. Remove retainer (3), seals (4) and O-rings(5).

Flow Control Checks

1. Remove flow control check springs (6) and ball(s)

(7).

End Caps

1. Unscrew two screws (8) holding dust cover (9),

retainer (10) and sleeve (11).

2. Remove the O-ring (12) from the sleeve.

Operating Spool

1. Slide the spool (13) out of its bore.

2. Remove the quad seals (14) from the valve body

around the spool bore.

3. Remove the wiper seal (15).

NOTE : Do not remove the centering spring (16) or

the retainers (17) unless it is necessary to replace

them.

Check Valve

1. Remove the retainer ring (18) and screw out plug

stop adjuster (19) from the valve body.

2. Remove the back-up ring (20) and O-ring (21).

3. Remove the spring (22) and ball (23) from the

valve body.

25 of 29New Hydraulic Systems Disassembly and Assembly

Before breaking a circuit connection, make certain

that power is off and system pressure has been

released. Lower all vertical cylinders, discharge

accumulators, and block any load whose

movement could generate pressure. Plug all

removed units and cap all lines to prevent the entry

of dirt into the system

WARNING

Adjustable Flow Control Valve

1. Remove the retainer ring (18) and screw out plug

stop adjuster (19) from the valve body.

2. Unscrew the adjustable relief seat (24) from the

plug stop adjuster (19).

3. Remove the back-up ring (20) and O-ring (21).

4. Remove the spring (22) and poppet (25) from the

valve body.

Relief Valve Subassembly

1. Screw out the plug (26) which retains the relief

valve and remove the O-ring (27) from the plug.

2. Remove the spring (28) and the relief valve subassembly (29).

Secondary Adjustable Relief Valve

1. Screw out relief plug (30) and remove O-ring (31)

from valve body.

2. Remove setscrew (32) and nut (33) from relief

plug.

3. Remove O-ring (34) and spring (35) from relief

plug.

4. Pull piston (36) and poppet (37) from the plug.

Valve Body

1. Remove the plug (38) and O-ring (39) from

cylinder °∞b°± work port.

2. Remove the plug (40) and O-ring (41) on models

with a single acting spool. If the alternate discharge

port is plugged, it is not necessary to remove the

plug unless the body is to be replaced. On bodies

equipped with the quick disconnect option, remove

the dust cap (42) and the coupling (43).

3. Remove O-ring (44) from coupling.

4. Unscrew the plug (45) and remove O-ring (46).

Cleaning, Inspection And

Repair

1. Check that all internal passages are clean and free

from obstruction. Examine all mating surfaces for

nicks and burrs. Minor nicks and burrs can be

removed with a crocus cloth or an India stone.

2. Discard all old seals and O-rings. Wash all parts in

a clean mineral oil solvent and place them on a

clean surface for inspection.

NOTE : Obtain new seal kits. Refer to the appropriate

part drawing as shown on figure IDCS015B for the

seal kit part number. Apply a light film of clean

hydraulic fluid to the new seals. This will make

assembly easier and also provide initial lubrication of

moving parts.

3. Inspect the valve spools and bores for burrs and

scoring. If scoring is not deep enough to cause

objectionable leakage, the surfaces can be stoned

or polished with crocus cloth. If scoring is

excessive, the valve body and spool must be

replaced. Check the valve spool for freedom of

movement in the bore.

CAUTION : DO NOT stone the edges of spool

sealing lands. Remove minor burrs with #500 grit

paper. Use paper very lightly on the outer diameter of

each spool.

4. Check the relief valve for smooth movement in its

bore. The valve should move from its own weight.

5. Inspect all screws for evidence of damaged

threads. If threads are damaged, replace the

screws.

6. Inspect all springs for distortion or wear. The ends

of the springs shall be square and parallel to each

other. Replace springs that are damaged or

distorted.

26 of 29New Hydraulic Systems Disassembly and Assembly

27 of 29New Hydraulic Systems Disassembly and Assembly

IDCS015B

Assembly

Assembly is generally performed in reverse order of

disassembly. Refer to figure IDCS015B during the

following assembly procedure.

NOTE : Coat all parts with clean hydraulic oil to

facilitate assembly and provide initial lubrication.

Petroleum jelly can be used to hold seal rings in

place on assembly.

Valve Body

1. Install new O-ring (39) on plug (38) and install in

cylinder

“b”

work port. On models with a single

acting spool, install new O-ring (41) on the port

plug (40) and plug the appropriate cylinder port.

2. Tighten the plug (40) securely but DO NOT over

tighten.

3. On bodies with the quick disconnect option, install

new O-ring (46) on plug (45) and screw into bore.

4. Tighten the plug (45) to a torque of 97 - 106 N

¥

m

(71 - 78 lb

¥

ft).

5. Install new O-ring (44) on quick disconnect

coupling (43) and insert coupling into plug.

6. Tighten the coupling (43) to a torque of

29 - 31 N

¥

m (21 - 23 lb¥ft).

7. Install dust cap (42).

Secondaty Adjustable Relief Valve

1. Replace O-ring (34), piston (36) and spring (35) in

relief plug (30).

2. Insert poppet (37) in plug.

3. Install the O-ring (31) on the relief plug. Tighten the

plug securely in valve body. DO NOT over tighten.

CAUTION : Hex head of relief valve must be face

outside of unit.

Relief Valve

1. Install a new O-ring (27) on the relief valve plug

(26).

2. Place the relief valve assembly (29) in its bore,

HEX NUT END UP.

3. Install the spring (28) and plug. Tighten the plug

securely, but do not Over Tighten.

Optional Adjustable Flow Control Valve

1. Install a new back-up ring (20) and O-ring (21) on

the plug stop adjuster (19) with the O-ring toward

the spring (22) and seat (24).

2. Place the poppet (25) and spring in the body and

install the plug stop adjuster. Be sure the hole in

the plug lines up with the stud hole in the body.

3. Replace retaining ring (18).

Check Valve

1. Install a new back-up ring (20) and O-ring (21) on

the plug stop adjuster (19) with the O-ring toward

the spring (22) and ball (23).

2. Place the ball and spring in the body and install the

plug stop adjuster (19). Be sure the hole in the

plug lines up with the stud hole in the body.

3. Replace retaining ring (18).

Operating Spool

1. If the centering spring was removed, install spring

(16) and retainers (17) on the spool (13).

2. Slide the spool into the bore.

28 of 29New Hydraulic Systems Disassembly and Assembly

End Cap

1. Install new O-ring (12) on the sleeve(11).

2. Insert sleeve (11) into retainer (10).

3. Assemble dust cover (9) and retainer and sleeve

with attaching screws (8).

4. Tighten the screws (8) to a torque of 11 - 15 N

¥

m

(8 - 11 lb

¥

ft).

Flow Control Checks

1. Insert small check spring (6) into larger spring.

2. Install flow control sensor ball(s)(7) and springs in

proper bores of inlet and mid-body sections.

Attaching Parts

CAUTION : Make sure all mating surfaces of valve

bodies are clean and free of burrs.

1. Install seals (4), O-ring (5) and the retainer (3) in

the grooves in the body of each inlet and mid-body

section.

2. Carefully place the sections together in the same

order in which they were removed.

3. Coat the stud threads with Loctite or a similar

sealant and install the studs.

4. Tighten the nuts to 38 - 44 N

¥

m (28 - 32 lb¥ft)

torque.

29 of 29New Hydraulic Systems Disassembly and Assembly

Loading...

Loading...