Page 1

Planning Guide

- Pro Range -

DACOR MOERNIST

Page 2

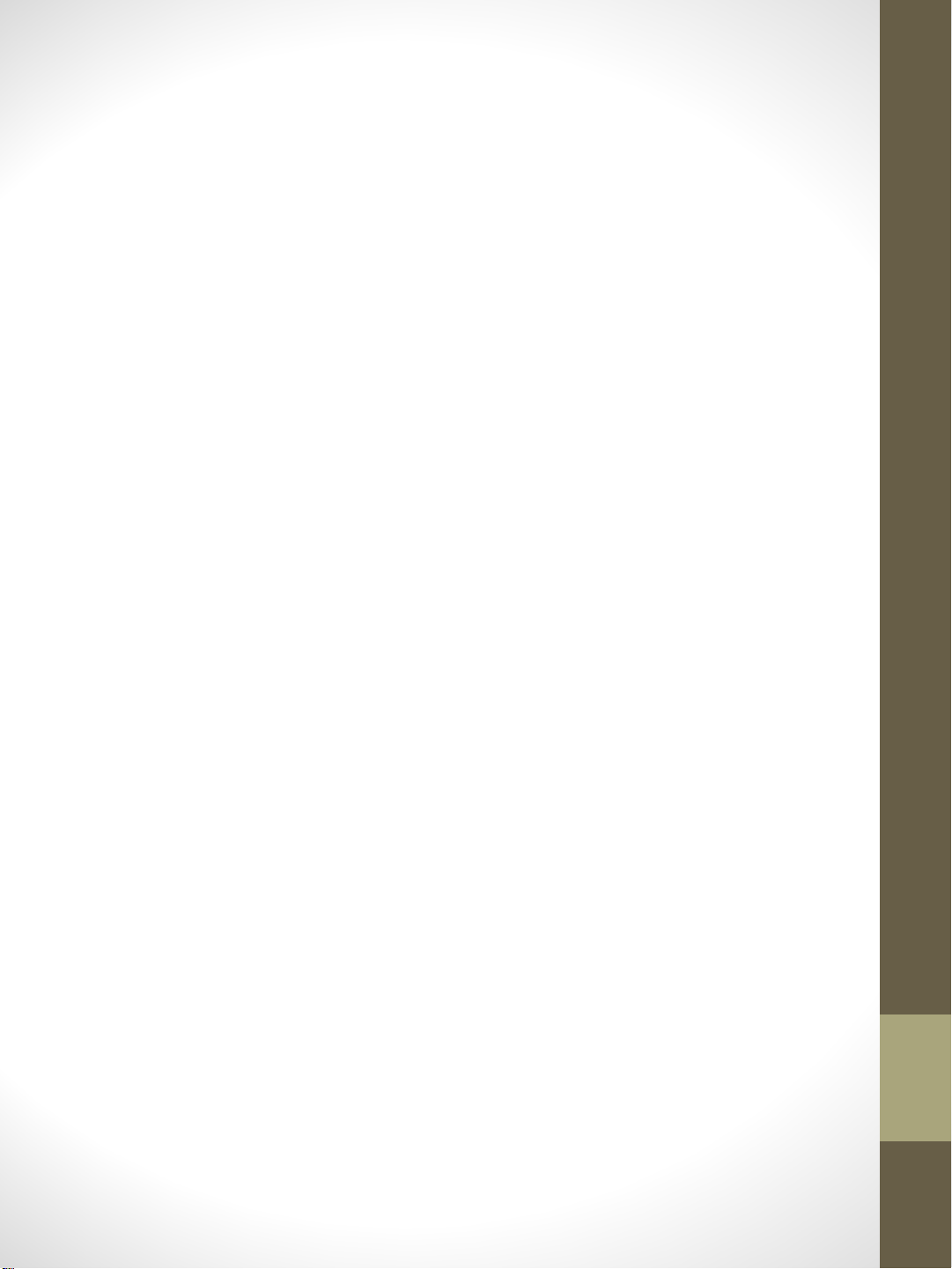

UNIT

CONTROL

36” Pro range

48” Pro range

Flat aluminum

(BLACK or SILVER)

HANDLE

COOKTOP

4 burners + 1 griddle

Flat aluminum

(BLACK or SILVER)

6 burners + 1 griddle

Page 3

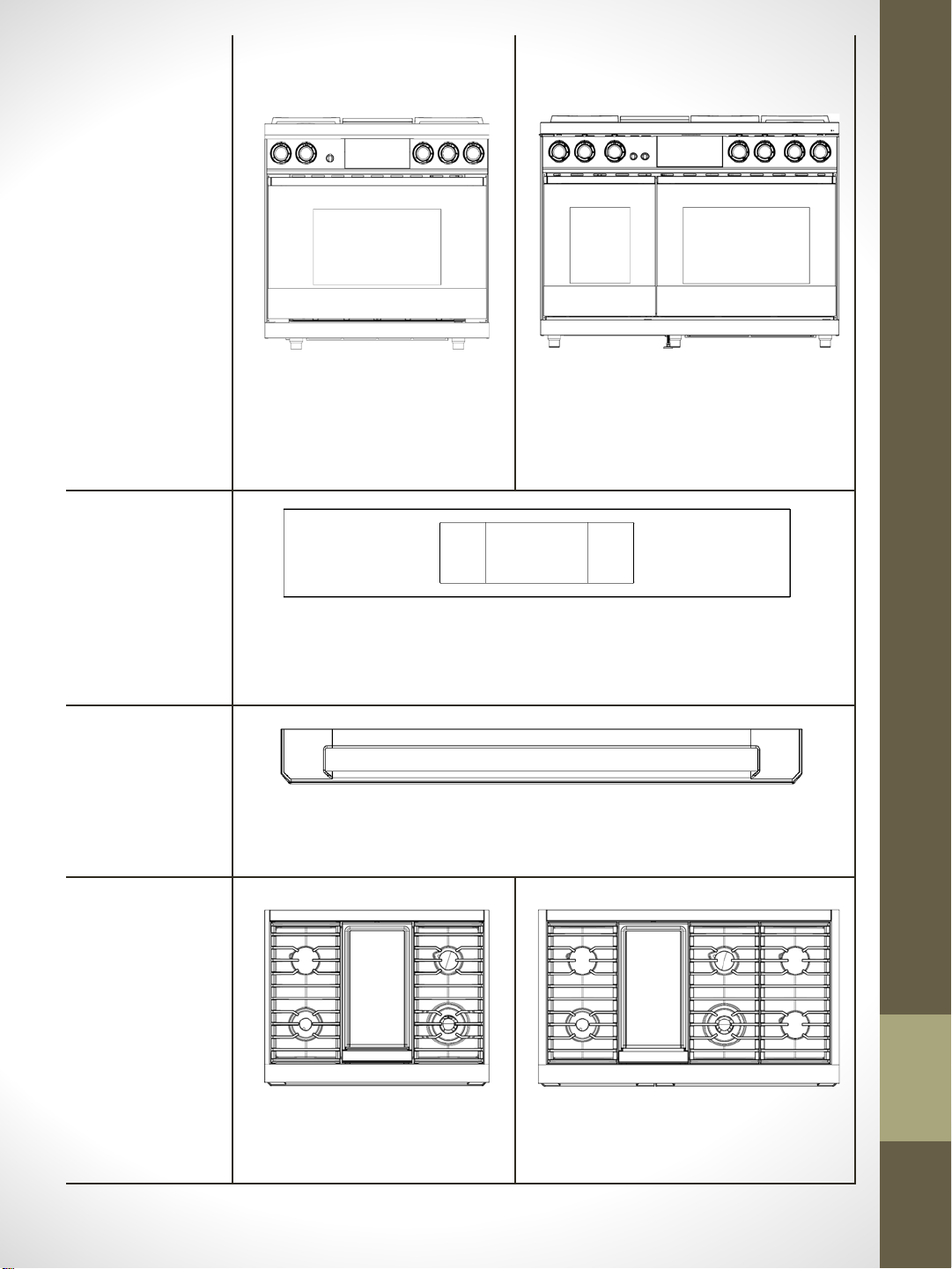

PLANNING CHECK PROCESS

PLANNING CHECK PROCESS

① A desired configuration

③ Check to make sure the location

where the appliance is to be installed

is free of obstructions and adheres to

product dimensions

⑤ Procure the proper installation

materials

② Plan the cabinet layout depending on

install method

④ Check proper location for the

electrical outlet and gas stub

Page 4

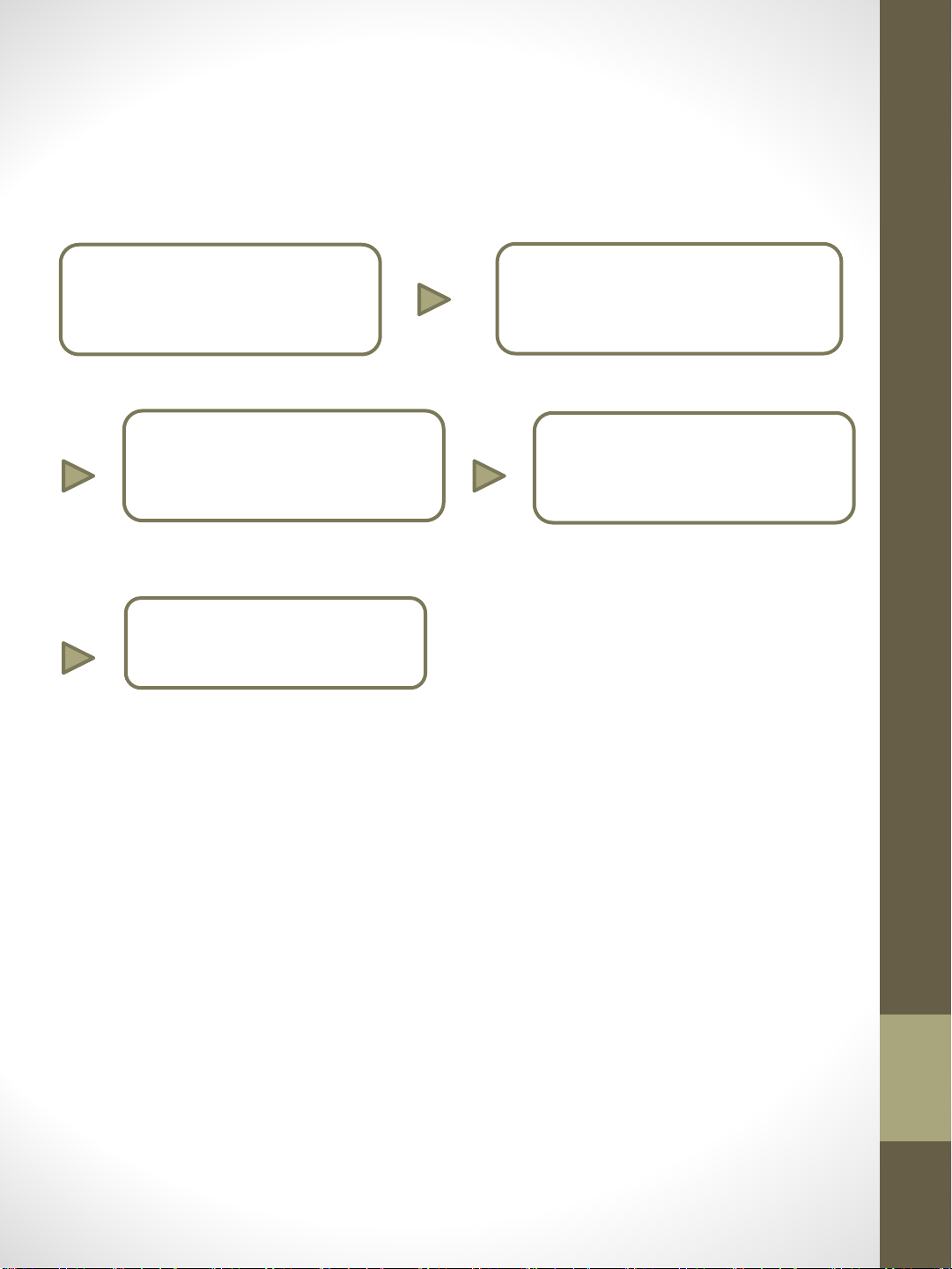

① A desired configuration

36” Pro range 48” Pro range

Width 36” 48”

COLOR Stainless Steel, Black Stainless steel(DLC coating)

COOKTOP 4 burners + 1 griddle 6 burners + 1 griddle

Pro Range

Configuration

DOP36M94DLS (Silver)

DOP36M94DLM (Black)

DOP48M96DLS (Silver)

DOP48M96DLM (Black)

Page 5

② Plan the cabinet layout

depending on install method

Standard Cutout with Range Hood

Appliance dimensions

CUTOUT DIMENSIONS

Range Model A B C

DOP36M94DL*

DOP48M96DL*

* Recommended ** Minimum *** Maximum

42” (106.7 cm)*

36” (91.4 cm)**

54” (137.2 cm)*

48” (121.9 cm)**

36” (91.4 cm)**

36 1/8” (91.7 cm)***

48” (121.9 cm)**

48 1/8” (122.2 cm)***

33 ½”

(84.8 cm)

9”

(22.9 cm)

Page 6

② Plan the cabinet layout depending on

install method

¹ Vertical distance from range grate level to combustible overhead surface; if installing an

overhead vent hood, also check hood specifications for minimum required clearances.

² Cabinet/countertop depth is at the discretion of customer but cabinet face MUST NOT

protrude further than rear of front panel, see product dimensions.

³ Consult local code for exact location requirements.

⁴ Vertical distance from grate level to combustible surface.

⁵ This specification does not apply for cabinets more than a horizontal distance of 10” (25.4 cm)

from the edge of the range.

Appliance dimensions

Page 7

③ Check to make sure the location

where the appliance is to be installed

is free of obstructions and adheres to

product dimensions

Product dimension

Cabinet dimensions

Page 8

④ Check proper location for the

electrical outlet and gas stub

DOP48M96DL*

DOP36M94DL*

Page 9

Electrical requirements

WARNING

• Failure to follow these instructions can result in death, fire, or electrical shock.

• It is the owner’s responsibility to make sure that the electrical service meets electrical

requirements and that the electrical outlet has been properly installed by a licensed electrician

to reduce the risk of fire, electric shock, or personal injury.

All ranges

• Do not use an extension cord or adapter plug with this range.

• This range must be properly grounded.

• Check with a qualified electrician if you are in doubt as to whether your range is properly

grounded.

• Do not modify the range power plug. If it does not fit the outlet, have a proper outlet

installed by a qualified electrician.

• All wiring and grounding must comply with local codes or, in the absence of local codes, with

the National Electrical Code, ANSI/NFPA No. 70 – Latest Revision (US), or the Canadian

Electrical Code CSA C22.1 – Latest Revisions and local codes.

• Wiring diagram is located on the back of the range. (Inside envelope)

• The range’s electronic ignition system will not operate if the outlet is not properly polarized.

• A dedicated circuit breaker is recommended.

• Use the chart below to determine the minimum recommended dedicated circuit protection.

KW Rating (240 V) Recommended Circuit Size (Dedicated)

36” Pro Range: 7.3 KW - 9.6 KW 40 Amp

48” Pro Range: 9.7 KW - 12.0 KW 50 Amp

Page 10

Gas requirements

Provide adequate gas supply.

The installation of this appliance must conform with local codes or, in the absence of local

codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA 54.

The cooktop of this range is designed to operate at a manifold pressure of 5 in (13 cm) of

water column on natural gas.

Be certain that the appliance being installed is correct for the gas service provided (natural

gas).

When checking for proper operation of the regulator, the inlet pressure must be at least 1

in (2.5 cm) greater than the operating (manifold) pressure as given.

GAS SUPPLY PRESSURE REQUIREMENTS*

Gas Type Minimum Manifold Pressure Minimum Gas Supply Pressure**

Natural Gas 5” Water Column 6” Water Column

* The gas supply pressure for testing the regulator setting shall be at least 1 inch water

column (249 Pa) above the specified manifold pressure.

** Maximum gas supply pressure for all models: 1/2 psi.

The pressure regulator located at the inlet of the cooktop manifold must remain in the supply

line regardless of whether natural or LP gas is being used.

NOTE

• The cooktop has its own regulator. Use only the provided regulator, which must be installed

in the gas line that runs from the cooktop gas inlet to the gas shut-off valve.

• An external manual shut-off valve must be installed between the gas inlet and the cooktop

for turning on/off gas to the appliance.

• Be sure the connectors are installed by a qualified installer.

• For a new product, never install used connectors, which can leak gas and cause personal

injury. Use only new, flexible connectors.

Page 11

⑤ Procure the proper

installation materials

Preparation for install

Manual Screw (6)

Anti Tip Brackets (2) *

Gas line shut-off

valve

135-degree elbow

(optional)

(M4 L10 2 each, M4 L16 2ea,

24 3/16 UNC L145 nut toggle 2 each)

Flexible metal

Appliance connector

½ in (ID) x 5 ft.

Lag bolt or ½-in (OD)

sleeve anchor

Flare union adapter ¾

in (NPT) x ½ in (ID)

Regulator (1) *

Flare union adapter ½

In (NPT) x ½ in (ID)

Flat-blade

screwdriver

¼” Nut driver Pencil and ruler Level Pipe joint compound

Phillips screwdriver

Soapy water solution Utility knife

Open-end or

adjustable wrench

Pipe wrench (2)

Page 12

36-Inch ProRange

DOP36M94DLS / DOP36M94DPS

DOP36M94DLM / DOP36M94DPM

Color Silver STSS / Graphite STSS (DLC Coating)

Installation Type Freestanding

Cooking Zones 6 ( 1 Oven, 4 Burners, 1 Griddle)

Oven Capacity(cu.ft) 4.8

Bake, Broil, Convection Bake, Convection Roast

Convection Broil, Dual Four Part Pure Convection

Pure Conv.Sear, Steam Bake, Steam Roast

Keep Warm(3Hr), Low Proof, Proof, Stone Mode

Dehydrate, Gourmet Cook(15ea), InstantHeat

General

Control

Smart

Accessory

Oven Mode

Oven

Electric

Power

Griddle

Burners

Automatic Reignition

LED Shower Lighting

Bake(Hidden) 3,000W

Broil 4,400W

Convection 1,300W + 1,300W (Dual Heat Element)

Steam Heater 500W

Type Electric-1400W, Embedded

Material Al + Ceramic Coating

Total BTU 65,000 (65K)

Right Front 22K, Dual, Brass

Left Front 18K, Dual, Brass

Cleaning Method Self-clean / GreenClean™ / Descale / Draining

LED Knob Backlit

Wi-Fi (LTE) Module Oven Control, Cooktop Monitoring

Left Rear 16K, Stack Dual, Brass

Right Rear 9K, Stack Dual, Brass

Simmer(Min.) 700 BTU (@Right Front 22K Burner)

Sealed Burner

Energy Source Gas (NG/LP) and Electirc

Grate Type Porcelain coated continuous Cast Iron

Display / Type 7” Touch LCD / Knob & Touch

Bluetooth Auto Hood Connect, Auto Hood ON/Off

Grate 2 pcs

Brass Cap

Wok Ring

Rack Wire Rack(1pcs), Glide Rack(2pcs)

Steam Tray -

Etc. Temp. Probe(1pcs), Conv. Filter(2pcs)

●

●

●

●

●

●

Product Specification

Total Power

Product Width

Product Height

Product Depth

Cutout Width

Cutout Height

Cutout Depth

Watts(W)

Circuit Breaker(A)

Electrical Supply

Power Cord

Net Weight (lbs.)

65KBTU + 1.4KW

35 7/8"

36 1/8"

28 1/8"

36" (Min.)

36 3/16" ~ 37 1/2"

24" (Min.)

7,900 W

40A

240VAC/60Hz

Fixed Type(4 prong)

418 7/8 lbs (190 Kg)

Page 13

48 Inch ProRange

DOP48M96DLS / DOP48M96DPS

DOP48M96DLM / DOP48M96DPM

Color Silver STSS / Graphite STSS (DLC Coating)

Installation Type Freestanding

Cooking Zones 9 ( 2 Oven, 6 Burners, 1 Griddle)

Oven Capacity(cu.ft) 1.8 (Steam Oven) / 4.8 (Convection Oven)

Bake, Broil, Convection Bake, Convection Roast

Convection Broil, Dual Four Part Pure Convection

Pure Conv.Sear(L), Pure Steam(S), Steam Bake(S),

Steam Roast(S), Special Steam Cook(3ea, S)

Keep Warm(3Hr), Low Proof, Proof, Stone Mode(L)

Dehydrate(L), Gourmet Cook(15eaL), InstantHeat(L)

General

Control

Smart

Accessory

Oven Mode

( S : Small Cavity

L : Large Cavity )

Oven

Electric

Power

(1.8 / 4.8)

Griddle

Burners

Automatic Reignition

LED Shower Lighting

Bake(Hidden) 1,000W 3,000W

Broil 2,400W 4,400W

Convection 2,000W 1,300W + 1,300W (Dual)

Steam Heater 2,000W -

Type Electric-1400W, Embedded

Material Al + Ceramic Coating

Total BTU 97,000 (97K)

Center Front 22K, Dual, Brass

Center Rear 16K, Stack Dual, Brass

Right Front 9K, Stack Dual, Brass

Left Front 18K, Dual, Brass

Cleaning Method Self-clean / GreenClean™ / Descale / Draining

LED Knob Backlit

Wi-Fi (LTE) Module Oven Control, Cooktop Monitoring

Left Rear 16K, Stack Dual, Brass

Right Rear 16K, Stack Dual, Brass

Simmer(Min.) 700 BTU (@Right Front 22K Burner)

Sealed Burner

Energy Source Gas (NG/LP) and Electirc

Grate Type Porcelain coated continuous Cast Iron

Display / Type 7” Touch LCD / Knob & Touch

Bluetooth Auto Hood Connect, Auto Hood ON/Off

Grate 3 pcs

Brass Cap

Wok Ring

Rack Small Wire Rack(1pcs), Wire Rack(1pcs), Glide Rack(2pcs)

Steam Tray Steam Tray(2pcs), Half Steam Tray(2pcs)

Etc. Temp. Probe(2pcs), Conv. Filter(3pcs)

●

●

●

●

●

●

Product Specification

Total Power

Product Width

Product Height

Product Depth

Cutout Width

Cutout Height

Cutout Depth

Watts(W)

Circuit Breaker(A)

Electrical Supply

Power Cord

Net Weight (lbs.)

97KBTU + 1.4KW

47 7/8"

36 1/8"

28 1/8"

48" (Min.)

36 3/16" ~ 37 1/2"

24" (Min.)

10,300 W

50A

240VAC/60Hz

Fixed Type(4 prong)

540 1/8 lbs (245 Kg)

Loading...

Loading...