Page 1

Installation Instructions

Modernist Built-In Electric Wall Oven

DOB30M977

Part No. 112174 Rev D

Page 2

Contents

Before you begin...

Important

Customer-service info

If You Need Help...

Important safety instructions

Related equipment safety

Transport

I

nstallation requirements

Location requirements

Installation materials

Single ovens—

Product Dimensions

Double ovens—Product Dimensions

3

3

3

3

4

4

4

6

6

7

8

11

Inst

allat

ion

instructions

Preparing to install the oven

Removing and replacing the oven door(s)

Electrical connection

Installing the oven

Installation checklist

Self-diagnosis

15

15

15

18

21

22

23

English2

Page 3

Before you begin...

Important

Design/accessories vary with the model.

Customer-service info

Installer

• For safety and to minimize problems,

read this manual thoroughly before

starting the installation.

• Leave this manual with the user.

• Write the oven’s model/serial

numbers in this manual for service/

maintenance reference.

User

• Keep this manual for personal and

professional reference.

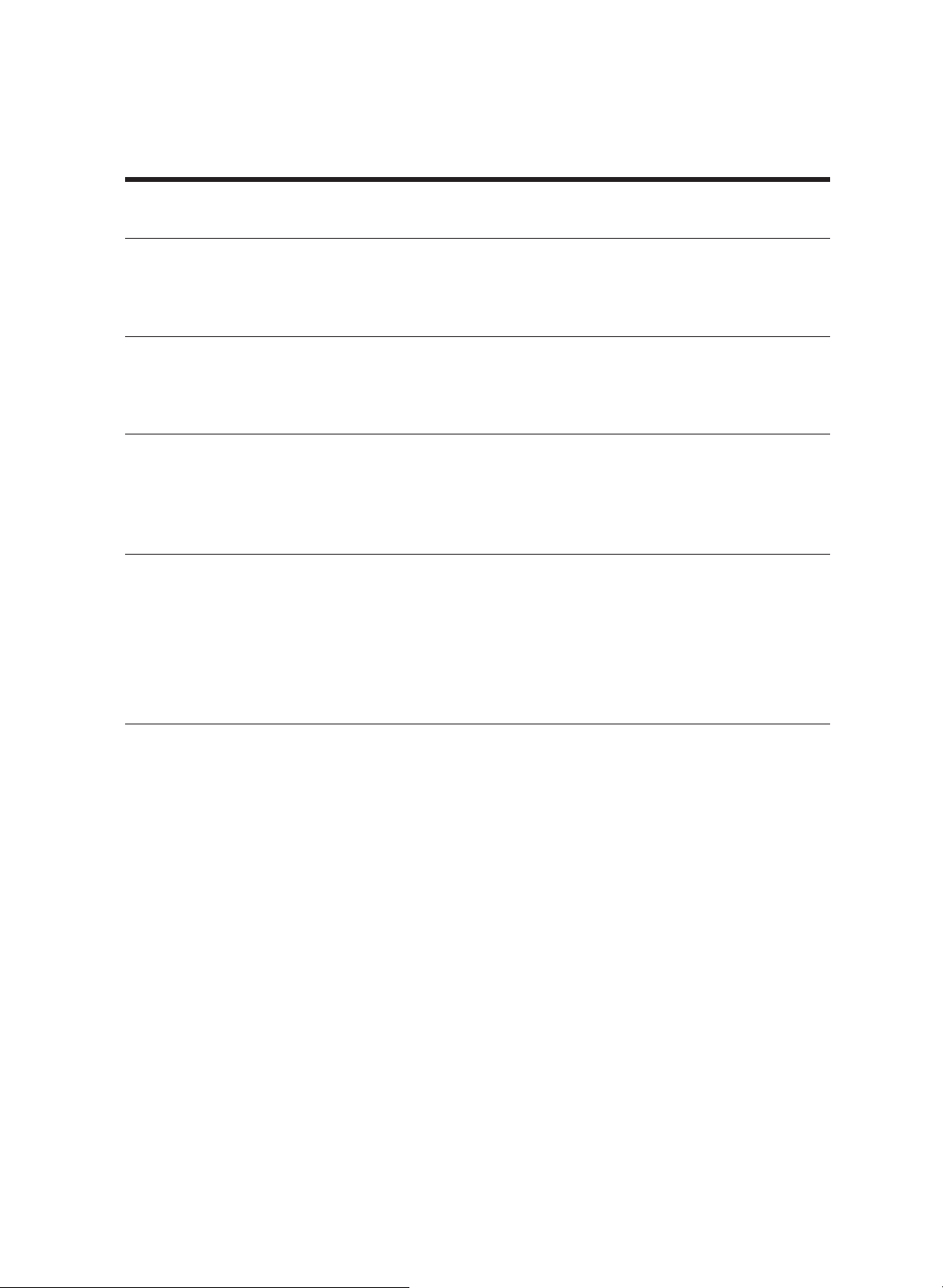

If You Need Help...

To resolve installation issues, contact your

Dacor® dealer or Dacor Customer Assurance.

Have the oven model/serial numbers

Rating

Plate

Dacor Customer Assurance

(800) 793-0093 x2813 (USA, Canada)

Mon – Fri, 5:00 a.m. to 5:00 p.m. Pacific Time

Website: www.dacor.com/customer-care/contact-us

All specifications are subject to change without notice. Dacor assumes no liability for suchchanges.

© 2017 Dacor. All rights reserved.

when you call. This information is on the

rating plate on the lower-left door trim. (For

double ovens, the plate is on the lower oven.)

ready

English 3

Page 4

Important safety instructions

Related equipment safety

Remove all tape and packaging before using the oven, and dispose of the packaging.

Never let children play with packaging material.

Do not modify the oven (e.g., do not remove panels, wire covers, or screws).

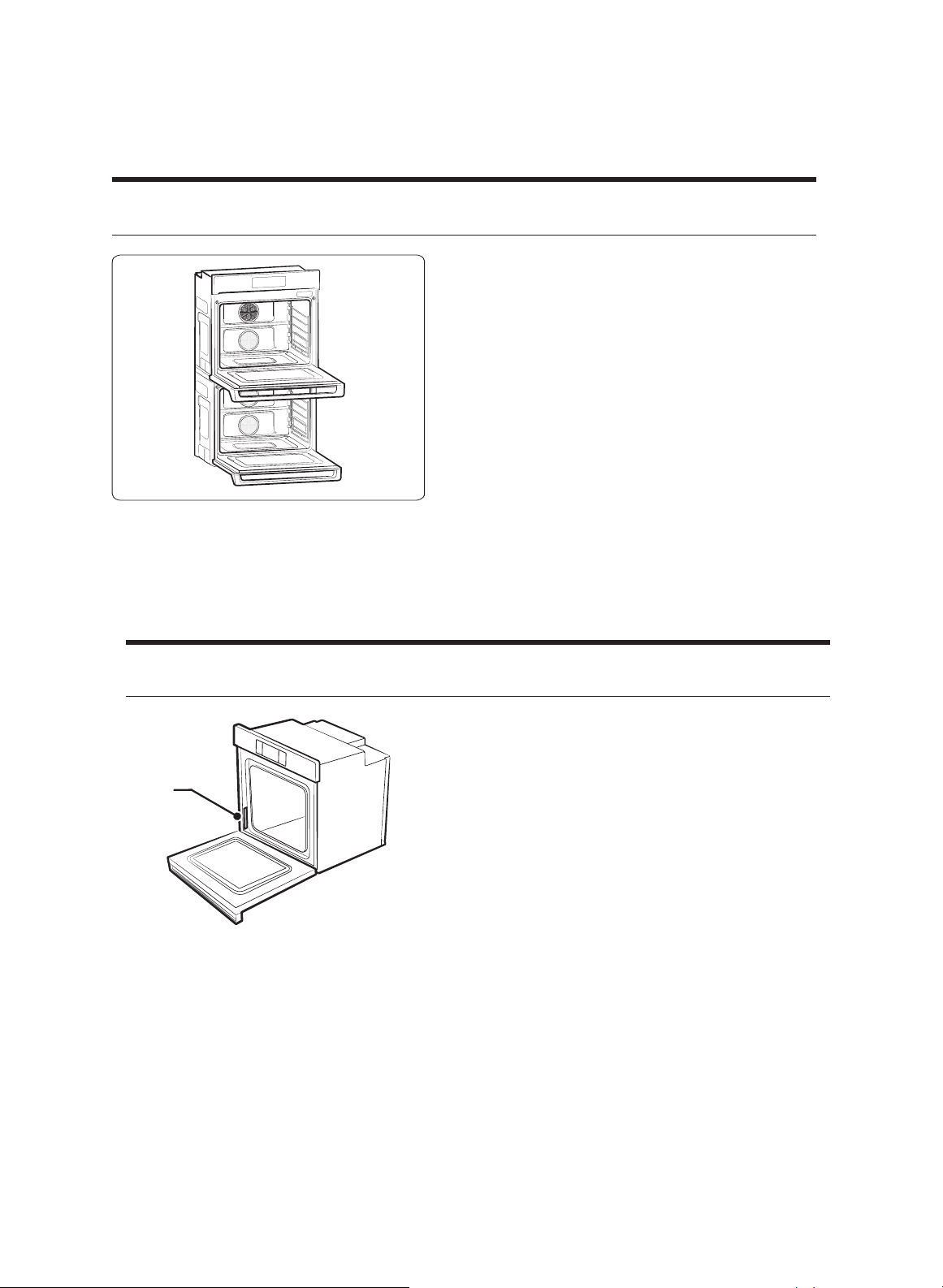

Transport

To avoid damaging the oven vent, use

the transport method shown at left.

Oven (side)

Lift/support the oven bottom from

either side, and move it to the

installation site.

Pallet

Leave the oven attached to the pallet

until it is ready to be lifted into place.

Pallet jack here

DANGER

ELECTRICAL SHOCK HAZARD

To avoid electrical shock, personal injury, or death, verify your appliance is grounded

according to local codes or, in their absence, with the National Electrical Code (NEC).

ANSI/NFPA 70-latest edition.

WARNING

MOVING HAZARD

To avoid severe personal injury, handle/move the oven with two or more people. Using

an appliance-moving device is recommended.

English4

Page 5

Important safety instructions

WARNING

• Follow the information in this manual precisely to avoid fire or electrical shock that

may cause property damage, personal injury, or death.

• Ensure

• New branch-circuit installations (1996 NEC), mobile homes, RVs, or installations

where local codes prohibit grounding through the neutral conductor, require 4-wire

branch-circuit connection.

• Improper connection of aluminum house wiring to copper leads can cause an

electrical/fire hazard. Use only connectors designed for joining copper to aluminum,

and follow the manufacturer’s recommended procedure.

• Mounting screws must be used to secure the oven so it cannot be shifted/dislodged.

CAUTION

• The cabinets and wall coverings around the oven must be able to withstand the heat

[up to 194 °F (90 °C)] generated by the oven.

• Do NOT remove the spacers from the oven's left/right sides. The spacers center the

oven in the cabinet cutout so heat does not build up in one area and damage the

cabinetry or cause a fire hazard.

the oven is properly installed and grounded by a qualified technician.

IMPORTANT NOTE

The installer shall ensure proper installation. The warranty does NOT cover product

failure due to improper installation.

WARNING

Do NOT put weight on the oven door or let anyone climb, sit, stand, or hang on it. The

door could break free, causing personal injury and property damage.

WARNING

The electricity must be off while the electrical connections are made. If not, severe

personal injury or death may occur.

IMPORTANT NOTE

• Observe all governing ordinances.

• Properly ground the oven.

• Do not block oven vents (bottom-front of the oven) or leave combustible or

heat-sensitive items in front of them.

English 5

Page 6

Installation requirements

Location requirements

IMPORTANT: Observe all governing ordinances.

• Specified c

• The cabinet recess must completely enclose all but the face of the oven.

• A grounded electrical supply is required. (See Electrical Requirements.)

• Put the electrical-supply junction box at most 3” (7.6 cm) below the support platform.

• Drill a 1” (2.5 cm) min. diameter hole in the right-/left-rear corner of the support

platform for conduit access to the junction box.

NOTE

For under-counter installation, the junction box should be in the adjacent right/left

cabinet. For rear-wall installation, the junction box should be recessed in the upperright corner of the cutout.

• The support platform must be solid, level, and flush with bottom of cabinet cutout.

• Single oven: The floor must support 221 lb (100 Kg).

• Install the oven at least 12” (30 cm) from other appliances.

utout dimensions are minimums and must be used.

IMPORTANT: Verify with your builder or cabinet supplier that the materials used will not

discolor, delaminate, or

sustain other damage. This oven complies with UL and CSA

International requirements, and the max. allowable wood-cabinet temp. of 194 °F (90 °C).

English6

Page 7

Installation Materials

Provided items

6 screws (M4 L16)

(4 needed for installation, 2 extra)

Needed Items

Junction Box Wire Nuts

3

/4” Conduit Connector

Install Handle (only for double oven)

Drill

Phillips Screwdriver

English 7

Page 8

Installation requirements

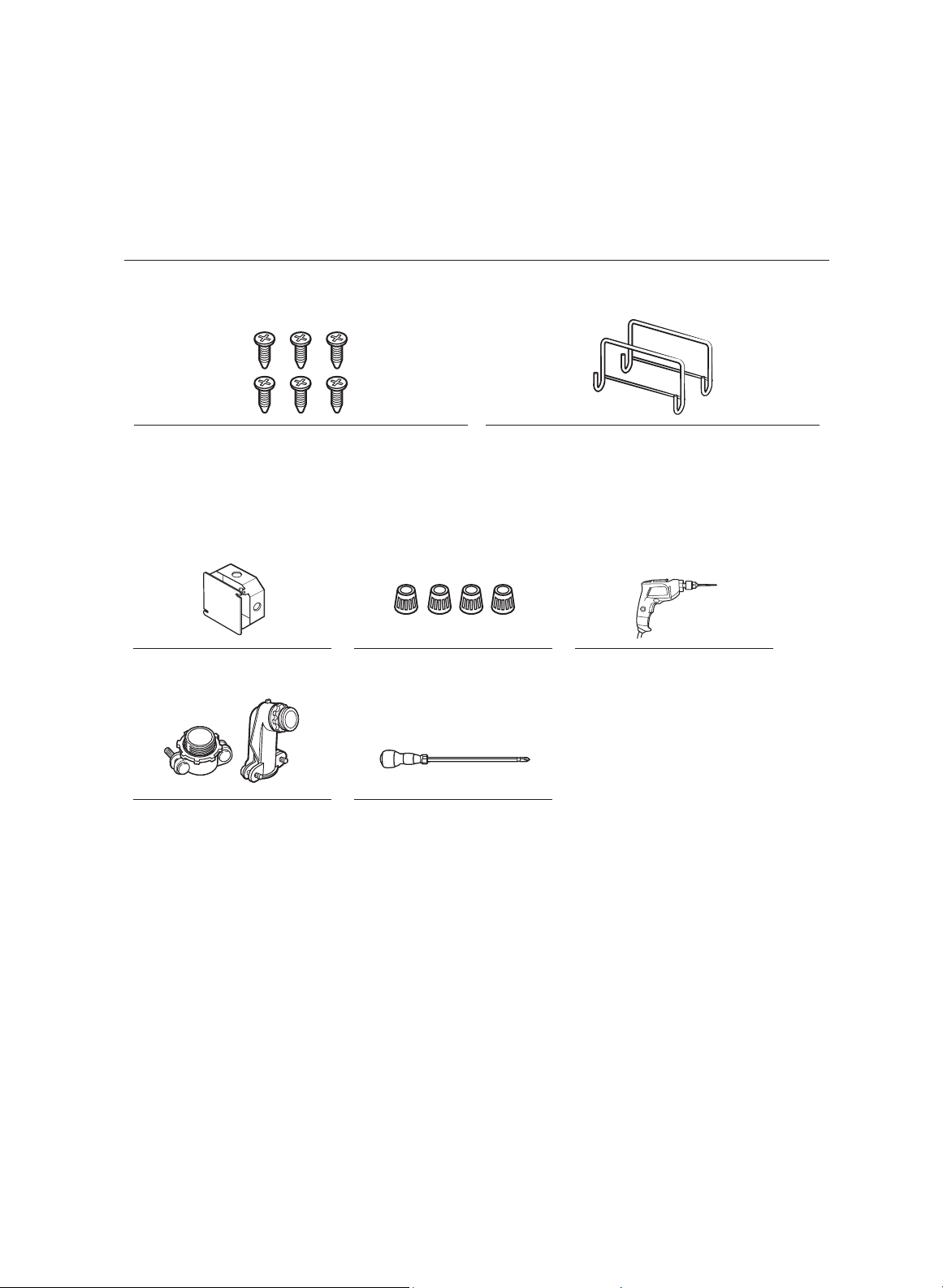

Single ovens—Product Dimensions

31⁄2”

(89 mm)

13⁄8” (33 mm)

287⁄8”

(731 mm)

297⁄8”

(757 mm)

Front Side

281/2”

(724 mm)

(587 mm)

471⁄

4

” (1200 mm)

Conduit length

271⁄4”

(691 mm)

231⁄8”

Top

English8

Page 9

Standard cabinet dimensions

• Dimensions are minimums (except electrical supply location E)

• Allow at least 22” between the open oven door and opposing cabinetry, walls, etc.

• Leave at least 1” clearance under

oven and 1-3/8 in. from cutout opening to

cabinet above or countertop.

• (Flush-mount only)

Leave at least 2 1/2” unobstructed space below oven.

231⁄2”

mm)(597

Top

271/4”

(692 mm)

13/8” (34.9 mm)

Max. 91⁄2" (241

283/4”

(730.25 mm)

FrontSide

mm

)

Min. 22”

(559 mm)

English 9

Page 10

Installation requirements

Flush-cabinet dimensions

• Dimensions are minimums (except electrical supply location E)

• Allow at least 22” between the open oven door and opposing cabinetry, walls, etc.

• Leave at least 1” clearance under oven and 1-3/8 in. from cutout opening to

cabinet above or countertop.

• (Flush-mount only) Leave at least 2 1/2” unobstructed space below oven.

7

24

231⁄2”

mm)

(

597

13⁄8” (33 mm)

(630 mm)

⁄8”

Tasseau

291/8”

(739.77 mm)

1 1/8”

(29 mm)

Top

Max. 91⁄2”

(241 mm)

301⁄4” (767 mm)

283/4” (730.25 mm)

3/4” (19.05 mm) Tasseau

FrontSide

Min. 22”

(559 mm)

English10

Page 11

Double ovens—Product dimensions

13⁄8” (33 mm)

511⁄2”

(1307 mm)

297⁄8” (757 mm) 231⁄8” (587 mm)

Front Side

31⁄2”

(89 mm)

67” (1700 mm)

Conduit length

50”

(1267 mm)

281/2”

(724 mm)

Top

English 11

Page 12

Standard cabinet dimensions

• Dimensions are minimums (except electrical supply location E)

• Allow at least 22” between th

• Leave at least 1” clearance under oven and 1-3/8 in. from cutout opening to

cabinet above or countertop.

• (Flush-mount only) Leave at least 2 1/2” unobstructed space below oven.

e open oven door and opposing cabinetry, walls, etc.

231⁄2”

(597 mm)

11/4” (31.75 mm)

Top

12 English

501/4”

(1276 mm)

12”

(305 mm)

Max. 91⁄2”

(241 mm)

283/4”

(730.3 mm)

FrontSide

Min. 47”

(1194 mm)

Page 13

Installation requirements

Flush-cabinet dimensions

• Dimensions are minimums (except electrical supply location E)

• Allow at least 22” between th

• Leave at least 1” clearance under oven and 1-3/8 in. from cutout opening to

cabinet above or countertop.

• (Flush-mount only) Leave at least 2 1/2” unobstructed space below ove

e open oven door and opposing cabinetry, walls, etc.

n.

Cleat

231⁄

mm)

(

597

13⁄8” (33 mm)

51 3/4”

(1314.5 mm)

2”

247⁄8”

mm)(630

Max. 91⁄2”

(241 mm)

301⁄4” (767 mm)

283/4” (730.25 mm)

Top

Min. 47”

(1194 mm)

3/4” (19.05 mm) Cleat

13⁄8” (33 mm)

3

mm)

⁄4” (1.9

notch

Side Front

12”

(305 mm)

3

⁄

4” (1.9

mm)

notch

English 13

Page 14

If codes permit and a separate ground wire is used, a qualified electrician should verify

that the ground path and wire gauge comply with local codes. Check with a qualified

electrician if you are unsure of the oven's grounding status. This oven must connect to

a grounded-metal, permanent wiring system.

Verify that the electrical connection and wire size are adequate and comply with the

Nat'l Electrical Code, ANSI/NFPA 70-latest edition or CSA Standards C22.1-94, Canadian

Electrical Code, Part 1 and C22.2 No. O-M91-latest edition, and all local regulations.

A copy of these standards can be obtained from:

National Fire Protection

Association 1 Batterymarch

Park Quincy, MA 02169-7471

Electrical Connection

OR

CSA International

85

01 E Pleasant Valley Rd

Cleveland, OH 44131-5575

To properly install the oven, determine the type of electrical connection you will use,

and follow the directions in this manual.

• The oven must connect to the

proper voltage and frequency per

the rating plate. (See pg. 4 for the

plate's location.)

••A circuit breaker is recommended.

Use the chart at right to decide

the minimum recommended

dedicated circuit protection:

KW Rating

(240 V)

≤4.8 KW ≤4.1 KW 20 Amp

4.9 KW - 7.5 KW 4.3 KW - 6.2 KW 30 Amp

7.3 KW - 9.6 KW 6.3 KW - 8.3 KW 40 Amp

9.7 KW - 12.0 KW 8.4 KW - 10.4 KW 50 Amp

KW Rating

(208 V)

Circuit Size

(Dedicated)

• Connect directly to the circuit-breaker box (or fused disconnect) via flexible, armored,

or non-metallic, sheathed, copper cable with ground wire.

• Connect the oven's flexible conduit directly to the junction box.

• Fuse both sides of the line.

• The conduit length must so the oven can be serviced without detaching

the conduit.

• A UL-listed or CSA-approved conduit connector must be provided.

• If the house has aluminum wiring:

– Connect a section of solid copper wire to the ends of the flexible conduit leads.

– Connect the aluminum wiring to the added section of copper wire using special

connectors and/or tools designed and UL listed for joining copper to aluminum.

Follow the electrical-connector manufacturer’s recommended procedure. Copper/

aluminum connecti

Power requirements for

models DOB30M977S

and DOB30M977D:

*and associated models.

14 English

on must comply with local codes and accepted wiring practices.

Model

DOB30M977S

DOB30M977D

11.2 kW 50 Amp 8.4 kW 50 Amp

240 VAC 208 VAC

Power Circuit size Power Circuit size

5.6 kW 30 Amp 4.2 kW 30 Amp

Page 15

Installation instructions

Preparing to install the oven

WA

RNING

Excessive Weight Hazard

To avoid pe

1. Decide the oven's final location. Avoid drilling/cutting household wiring/plumbing.

2. To avoid floor damage, set the oven on a cardboard sheet. (Do not lift by the door

handle or any part of the front frame.)

3. Reduce the oven's weight to ease installation:

a. Remove packing material and tape from the oven.

b. Remove racks and other accessories from the oven chamber.

c. Remove the oven door(s) (see below).

4. Keep any packing material (e.g., corner posts) that may aid the installation.

5. Remove the hardware from the literature pack.

6. Slide the oven (with cardboard beneath) to its installation site.

rson

al in

jury an

d property damage, use two or more people to move the oven.

Removing and replacing the oven door(s)

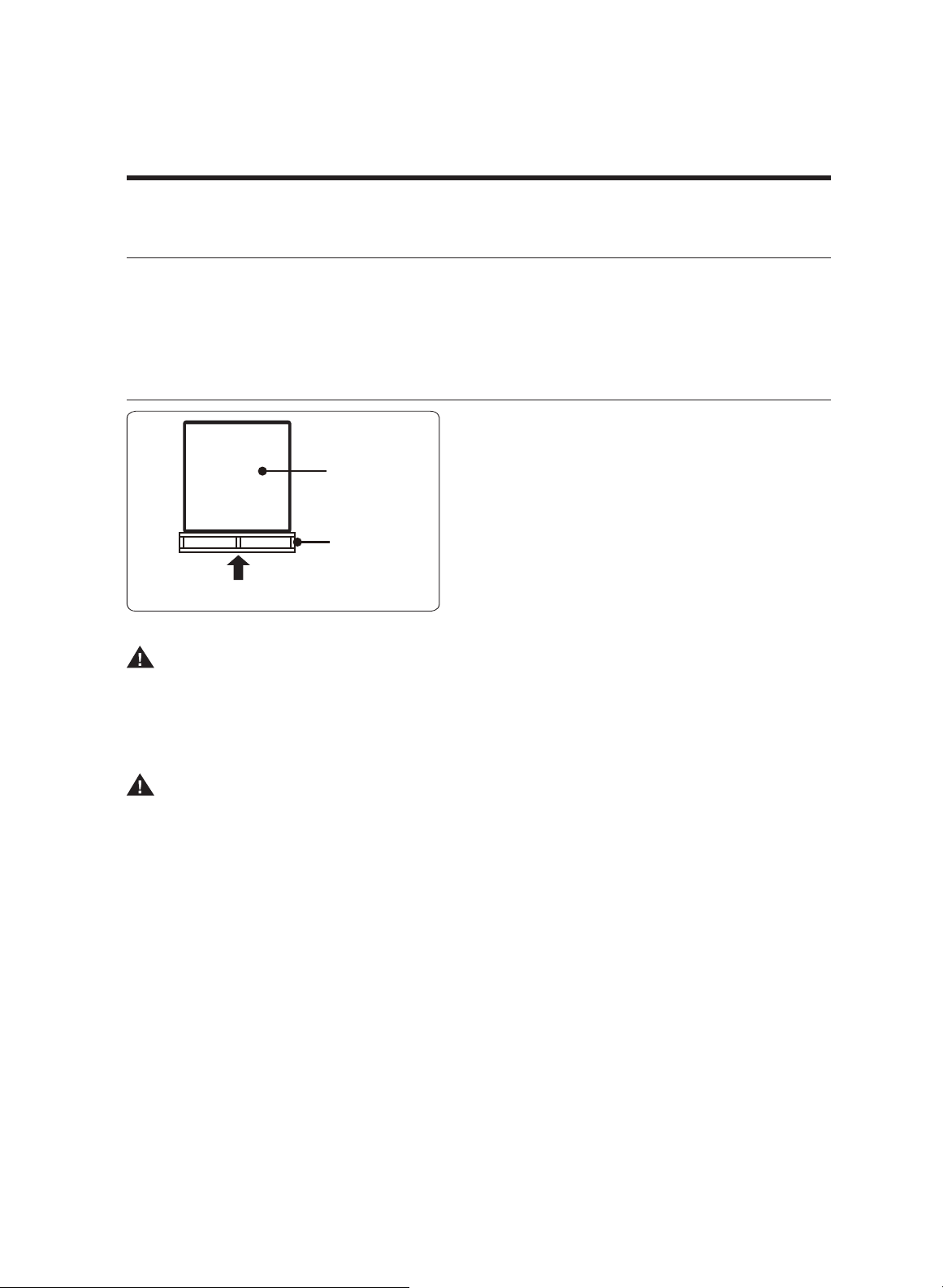

Removing the oven door(s) before lifting the ov

and will lessen the risk of damaging th

• Remove the door(s) with both hands.

• Before removing a door, arrange a blanket (or the corner posts from the packing

material) on a flat, stable surface on which you will lay the door(s).

Disconnecting the LED wire harness

Find the harness, and disconnect it before removing the door.

Single Double

e door(s) or injuring personnel.

Wire Harness

en into its cutout will make lifting easier

English 15

Page 16

Removing the oven door(s)

Unlocked

Locked

1. Carefully pull out the wire to reveal

the connector.

2. Uncouple the connector.

Open the oven door fully flat.

1.

2.

Find the door hinge locks in both

corners of the door, and flip them

down to the unlocked position (see

left) so the door can be removed.

16 English

3. Partially close the door to engage the

door hinge locks. (The door stops at

this point.)

4. Grasp each side of the door, and

pull it away from the oven. (You

may need to wiggle the door sideto-side as you pull.)

5. Rest the door(s), handle-down, on

the prepared surface.

Page 17

Installation instructions

Replacing the oven door(s)

CAUTION

If needed, get help lifting the door into the hinge slots. Do not lift the door by the handle.

1. Grasping each side at the midpoint, lift

the door, and face the oven.

Slot

2. With the door at a 45° angle, align the

hinges with the slots in the lower front

of the oven.

3. Slowly insert the hinges into the slots.

(You will know the hinges are engaged

when you feel the door drop slightly.)

4. Open the oven door fully flat.

(If the door does not open a full 90°,

repeat Steps 1 – 3.)

5. Flip the hinge locks up to the locked

position. (See pg. 22.)

6. Close the oven door.

(If the gap between the door and

control panel is wider on one side, the

hinge on that side is improperly set.)

7. Connect the wire harness.

English 17

Page 18

Electrical connection

WARNING

Electrical Shock Hazard

• Disconnect power before servicing.

• Use 8-gauge solid copper wire.

• Ground the oven.

• Failure to follow these instructions can result in fire, electrical shock, or death.

This oven is manufactured with a neutral (white) power-supply wire and a cabinetconnected ground (green or bare) wire twisted together.

1. Disconnect power.

2. Feed the oven's conduit through the

UL-listed or

CSA-

approved

conduit

connector

opening in the cabinet.

3. Remove the junction-box cover.

4. Install a UL-listed or CSA-approved

conduit connector on the junction box.

5. Route the oven conduit through the

connector into the junction box.

6. Tighten the conduit connector screws.

7. See the Electrical Connection Options

Chart to complete installation for your

type of electrical connection.

Electrical Connection Options Chart

If your home has: Go to section:

4-wire

3-wire

18 English

4-Wire Cable from Home Power Supply

1/2"

1.3 cm

3-Wire Cable from Home Power Supply

1/2"

1.3 cm

Page 19

Installation instructions

4-Wire Cable from Home Power Supply

IMPORTANT: Use the 4-wire cable from home power supply in:

• the US where local codes do not allow grounding through neutral

• New Branch circuit installations (1996 NEC)

• mobile homes and recreational vehicles

• new construction

• Canada.

A

B

C

D

A. Cable from home power supply

B. Black wires (normally L1)

C. Red wires (normally L2)

D. 4-wire flexible conduit from oven

E. Junction box

F. White wires (normally N-neutral)

G. UL-listed wire connectors

H. Green wires (normally G-ground)

I. UL listed or CSA approved conduit connector

E

F

G

H

I

NOTE: Connect all wires with UL-listed wire

connectors (G).

1.

Con nect the 2 black wires (B).

2.

Connect the 2 red wires (C).

3.

Untwist the white wire from the green

(or bare) ground wire from the oven.

4.

Connect the 2 white wires (F).

5.

Connect the green (bare) ground wire

(H)

from the oven cable to the green

(bare) ground wire (in the junction box).

6.

Install the junction-box cover.

English

1

9

Page 20

3-Wire Cable from Home Power Supply - U.S. Only

IMPORTANT: Use the 3-wire cable from home power supply where local codes permit a

3-wire connection.

A

B

C

D

E

F

A. Cable from home power supply

B. Junction box

C. Black wires (normally L1)

D. White wires (normally N-neutral)

E. Green wires (normally G-ground)

F. 4-wire flexible conduit from oven

G. Red wires (normally L2)

H. UL-listed wire connectors

I. UL-listed or CSA approved conduit connector

G

H

I

NOTE: Connect all wires with UL-listed

wire connectors (H).

1.

Connect the 2 black wires (C).

2.

Connect the 2 white wires (D) and

the oven's green (bare) ground wire.

Connect the 2 red wires (G).

3.

4. Install the junction box cover.

20 English

Page 21

Installing the oven

1. Using 2 or more people, lift the oven

partially into the cabinet cutout. Hang

the install handle on the side of the

oven. (See left.)

NOTE

Barrier

Install

Handle

Before the next step, remove the install

handle; keep it for future use.

2. Push against the oven's front frame

until the back of the frame contacts

the cabinet face or cleat*.

*Flush installation

WARNING

When inserting the oven, take care not to

damage the barrier beneath the oven.

3. Center the oven side to side.

4.

Remove the tape from the front trims.

5.

Through the holes in the trim aligned

with the holes in the oven frame,

s

ecurely fasten the oven

to the

cabinetry with the supplied screws.

English 21

Page 22

Self-diagnosis

1. After connecting the power, verify that the display works properly.

2. Remove all accessories from the oven chamber.

3. You cannot proceed with self-diagnosis if the oven cavity is hot or the door is

open.(In this case, Hot or door appears on the display.)

4. To start self-diagnosis, press-hold both "hidden keys" for 5 seconds.

• See the table below for each model's hidden keys.

• Self-diagnosis

Model DOB30M977D

takes 4-5 minutes.

Control panel

Hidden Key

UPPER OVEN

OFF

TIMER

SETTINGS

UPPER OVEN + LOWER OVEN

LOWER OVEN

OFF

LIGHT

OPEN/CLOSE

RESERVOIR

Model DOB30M977S

Control panel

Hidden Key

TIMER

SETTINGS

LOCK

SETTINGS + OPEN/CLOSE RESERVOIR

OFF

LIGHT

OPEN/CLOSE

RESERVOIR

5. If there is no error, PASS appears on the display with an alert sound.

6. If there is an error, one of these codes appears on the display with an alert sound.

Model

Error code Remark

Upper Broil H-2

Upper Bake H-1

Feature

Lower Broil H-4

Lower Bake H-3

DOB30M977**

ouble/Single Oven

D

Double Oven Only

7. Should an error occur, contact Dacor Customer Assurance: (800) 793-0093 x2813.

22 English

Page 23

Notes

English 23

Page 24

Dacor ∙ 14425 Clark Avenue, City of Industry, CA 91745 ∙ Phone: (800) 793-0093 ∙ Fax: (626) 403-3130 ∙ www.dacor.com

DG68-00923A-00

Loading...

Loading...