Dacia Logan User Manual

1 |

Engine and lower engine |

assembly |

10A

11A

12A

13A

14A

16A

17A

17B

19A

19B

19C

ENGINE AND LOWER ENGINE ASSEMBLY TOP AND FRONT OF ENGINE

FUEL MIXTURE

FUEL SUPPLY

ANTIPOLLUTION

STARTING - LOAD

IGNITION

PETROL INJECTION

COOLING SYSTEM

EXHAUST

RESERVOIR

X90

APRIL 2004 |

Edition Anglaise |

"The repair methods given by the manufacturer in this document are based on the technical specifications current when it was prepared.

The methods may be modified as a result of changes introduced by the manufacturer in the

production of the various component units and accessories from which his vehicles are constructed."

All copyrights reserved by Renault.

The reproduction or translation in part of whole of the present document, as well as the use of the spare parts reference numbering system, are prohibited without the prior written consent of Renault.

© Renault s.a.s. 2004

19D ENGINE MOUNTING

X90

APRIL 2004 |

Edition Anglaise |

"The repair methods given by the manufacturer in this document are based on the technical specifications current when it was prepared.

The methods may be modified as a result of changes introduced by the manufacturer in the

production of the various component units and accessories from which his vehicles are constructed."

All copyrights reserved by Renault.

The reproduction or translation in part of whole of the present document, as well as the use of the spare parts reference numbering system, are prohibited without the prior written consent of Renault.

© Renault s.a.s. 2004

L90 - Section 1

Contents

10A ENGINE AND LOWER ENGINE ASSEMBLY

Engine identification |

|

Oil filter |

10A-1 |

Oil consumption |

10A-3 |

Oil pressure |

10A-4 |

Engine/gearbox assembly |

10A-5 |

Sump |

10A-31 |

Oil pump |

10A-41 |

Multifunction support |

10A-43 |

11A |

TOP AND FRONT OF ENGINE |

|

|

Accessories belt |

11A-1 |

|

||

|

Timing belt |

11A-19 |

|

Cylinder head gasket |

11A-29 |

12A |

FUEL MIXTURE |

|

|

Specifications |

12A-1 |

|

||

|

Air inlet |

12A-7 |

|

Air filter: Replacement |

12A-9 |

|

Air filter unit |

12A-11 |

|

Inlet manifold |

12A-13 |

|

Exhaust manifold |

12A-19 |

|

Throttle valve |

12A-23 |

|

Throttle body: Connection |

12A-25 |

13A |

FUEL SUPPLY |

|

|

Petrol supply circuit |

13A-1 |

|

||

|

Injector rail - Injectors |

13A-2 |

|

Fuel pressure |

13A-6 |

|

regulator:Checking |

|

|

Electric fuel: Checking |

13A-7 |

14A |

ANTIPOLLUTION |

|

|

Petrol vapour rebreathing: |

14A-1 |

|

||

|

Operation |

|

|

Fuel vapour rebreathing: |

14A-2 |

|

Checking |

|

|

Fuel vapour canister |

14A-3 |

|

Fuel vapour |

14A-4 |

|

canister:Checking |

16A |

STARTING - LOAD |

|

|

Alternator: General |

16A-1 |

|

||

|

information |

|

|

Alternator |

16A-2 |

|

Starter: Identification |

16A-12 |

|

Starter motor |

16A-13 |

17A |

IGNITION |

|

|

coils |

17A-1 |

|

||

|

Spark plugs |

17A-5 |

Contents

17B |

PETROL INJECTION |

|

|

Location of components |

17B-1 |

|

||

|

Oxygen sensors |

17B-7 |

|

Position and speed sensor |

17B-11 |

|

Fuel supply computer |

17B-13 |

|

Computer: Connection |

17B-19 |

|

Special notes |

17B-21 |

|

Injection warning light |

17B-23 |

|

Immobiliser function |

17B-24 |

|

Injection - air conditioning |

17B-25 |

|

programming |

|

|

Throttle body potentiometer |

17B-26 |

|

Idle speed correction |

17B-28 |

|

Richness regulation |

17B-29 |

|

Central coolant temperature |

17B-30 |

|

management |

|

|

Special notes on the system |

17B-31 |

|

(when driving) |

|

|

Conditions for carrying out |

17B-32 |

|

fault finding (when driving) |

|

|

Combustion misfire fault |

17B-33 |

|

finding |

|

|

Catalytic converter fault |

17B-34 |

|

finding |

|

|

Oxygen sensor fault finding |

17B-35 |

19A |

COOLING SYSTEM |

|

|

General information |

19A-1 |

|

||

|

Specifications |

19A-2 |

|

Checking |

19A-3 |

|

Diagram |

19A-4 |

|

Bleeding and filling the |

19A-6 |

|

cooling circuit. |

|

|

Bleeding the cooling circuit |

19A-8 |

|

Cooling radiator |

19A-9 |

19A |

COOLING SYSTEM |

|

|

Water pump |

19A-14 |

|

||

|

Thermostat |

19A-18 |

|

Engine cooling fan assembly |

19A-19 |

19B |

EXHAUST |

|

|

General information |

19B-1 |

|

||

|

Pipe assembly |

19B-3 |

|

Catalytic converter |

19B-5 |

|

Expansion chamber |

19B-9 |

|

Silencer |

19B-10 |

19C |

RESERVOIR |

|

|

Draining the fuel tank |

19C-1 |

|

||

|

Fuel tank |

19C-3 |

|

Pump / sender unit / filter |

19C-7 |

|

Fuel level sensor: Distinctive |

19C-10 |

19D ENGINE MOUNTING

Suspended engine mounting |

19D-1 |

|

|

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

|

|

|

Oil filter |

||

|

|

|

|

|

|

|

|

|

|

|

L90, and K7J, and 710 |

|

||

|

|

|

|

|

|

|

Essential special tooling |

|

|

|

|

|

|

|

|

Mot. 1329 |

Oil filter cover - 76 mm |

|

|

|

|

diameter |

|

|

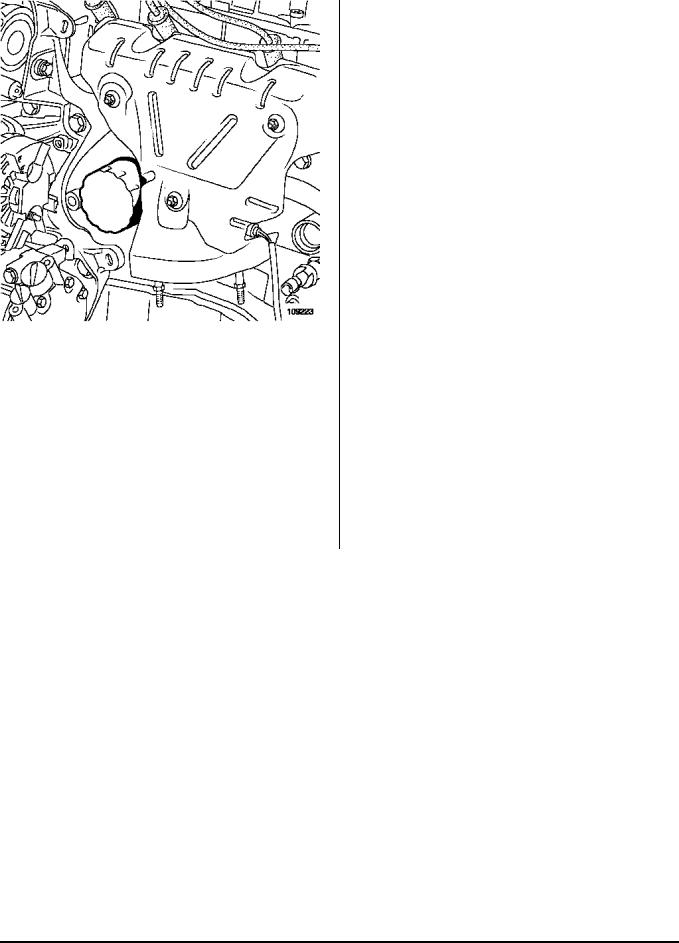

REPLACING THE OIL FILTER |

|

|||

|

|

|

|

|

|

|

|

|

|

109223

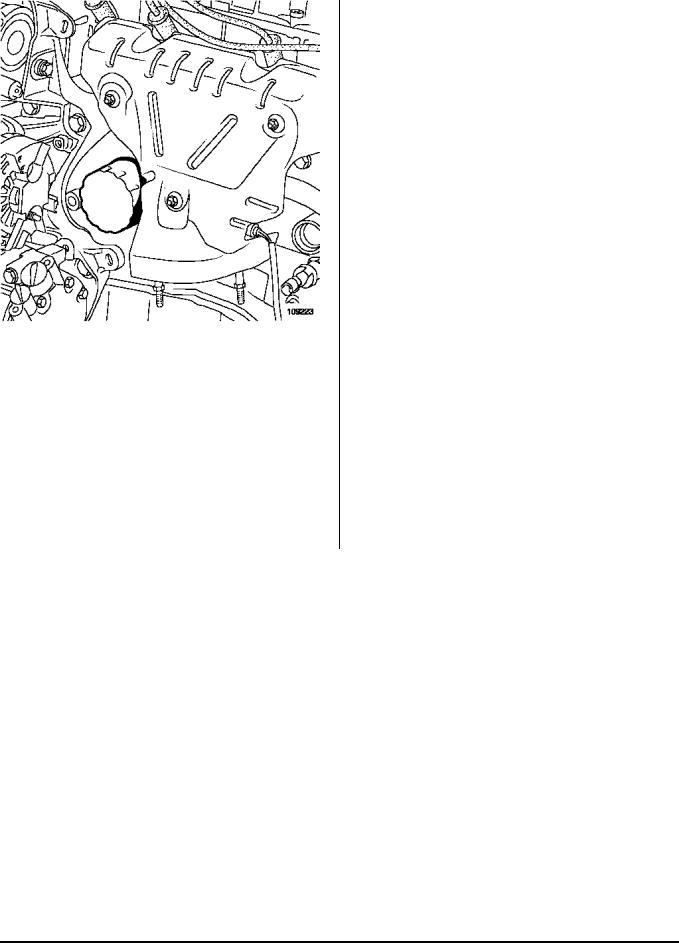

Remove the oil filter using tool (Mot. 1329).

Coat the sealing ring of the new oil filter with engine oil.

Tighten the oil filter by hand.

10A-1

|

|

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

|

|

|

Oil filter |

||

|

|

|

|

|

|

|

|

|

|

|

L90, and K7M, and 710 |

|

||

|

|

|

|

|

|

|

Essential special tooling |

|

|

|

|

|

|

|

|

Mot. 1329 |

Oil filter cover - 76 mm |

|

|

|

|

diameter |

|

|

REPLACING THE OIL FILTER |

|

|||

|

|

|

|

|

|

|

|

|

|

109223

Remove the oil filter using tool (Mot. 1329).

Coat the sealing ring of the new oil filter with engine oil.

Tighten the oil filter by hand.

10A-2

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Oil consumption |

L90, and K7J or K7M

PROCEDURE FOR MEASURING OIL

CONSUMPTION

1 - Filling to the maximum level

Note:

The operation should be carried out with the engine warm after the fan assembly has cut in once.

Turn the engine off.

Wait 2 minutes for all the oil to flow into the oil sump.

Carry out a visual inspection using the dipstick.

Top up to the "MAX" mark.

Make a paint mark on both the filler plug and the sump drain plug in order to be able to check later that it has not been removed.

2 - Customer driving

Ask the customer to drive approximately 1240 miles (2000 km) in the vehicle without letting the oil level reach the "MIN" mark.

3 - Topping up

Note:

The operation should be carried out with the engine warm after the fan assembly has cut in once.

Turn the engine off.

Wait 2 minutes for all the oil to flow into the oil sump.

Carry out a visual inspection using the dipstick.

Top up to the "MAX" mark.

Note the quantity of oil added and the mileage covered since the last top-up to maximum level.

4 - Measurement of the oil consumption

Oil consumption = Quantity of topping up oil (in litres) / number of kilometres (in thousands).

10A-3

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Oil pressure |

L90, and K7J or K7M

I -CHECKING

Special tooling required

Mot. 36-05 |

Oil pressure gauge kit |

|

|

Ensure that the engine oil level is between the "MIN" and "MAX" marks.

F

F

A

A

B

B

E

E

C

C

D

D

G |

H |

|

87363

Use the tool (Mot. 836-05) and a long dowel of 22 mm.

The oil pressure check must be carried out with the engine warm (approximately 80˚C).

II - USE

K7J |

K7M |

engine |

engine |

|

|

C + E + F

Connect the pressure gauge in place of the oil pressure switch.

III - ENGINE MANAGEMENT

K7J/K7M engine:

- Idling |

: 1 bar |

- 3000 rpm: 3 bar

Torque tighten the oil switch (3.5 daNm).

10A-4

|

ENGINE AND LOWER ENGINE ASSEMBLY |

|

10A |

|||||||||

|

|

Engine/gearbox assembly |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L90, and K7J, and 710 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Essential special tooling |

|

|

|

|

|

Tightening torquesm |

|||||

|

|

|

|

|

|

|

|

|||||

|

Mot. 1202-01 |

Clip pliers for cooling |

|

|

shock absorber base |

10,5 daNm |

||||||

|

|

system |

hose |

clips |

|

|

bolts |

|

||||

|

|

(large model) |

|

|

|

|

|

|

|

|||

|

|

|

|

|

brake calliper mounting |

10.5 daNm |

||||||

|

Mot. 1202-02 |

Clip |

pliers |

for cooling |

|

|

||||||

|

|

|

bolts |

|

||||||||

|

|

system |

hose |

clips |

|

|

|

|

|

|

||

|

|

|

|

track rod end nuts |

3.7 daNm |

|||||||

|

|

(small model) |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

engine tie-bar mounting |

10.5 daNm |

||

|

Mot. 1448 |

Remote |

|

operation |

|

|

||||||

|

|

pliers for cooling sys- |

|

|

bolts |

|

||||||

|

|

tem hose clips |

|

|

|

|

|

|

|

|||

|

|

|

|

|

wheel bolts |

10.5 daNm |

||||||

|

|

|

|

|

|

|

|

|

||||

|

Mot. 1453 |

Multiple-adjusting |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||||

|

|

engine mounting sup- |

|

|

REMOVAL |

|

||||||

|

|

port |

with |

retaining |

|

|

|

|||||

|

|

straps |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Mot. 1159-03 |

Engine |

mounting on |

|

|

|

Note: |

|

||||

|

|

right-hand side mem- |

|

|

|

The « engine and gearbox » assembly can be |

||||||

|

|

ber for operations not |

|

|

|

|||||||

|

|

|

|

|

removed by removing the « engine and gearbox/ |

|||||||

|

|

requiring removal of |

|

|

|

|||||||

|

|

|

|

|

driveshafts/half-axles/sub-frame » assembly. |

|||||||

|

|

the engine |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Place the vehicle on a two-post lift. |

|

||

|

Mot. 1390 |

Support |

for removing |

|

||||||||

|

|

and refitting the engine |

|

|

|

|

|

|

||||

|

|

and gearbox assembly |

|

|

|

IMPORTANT |

|

|||||

|

Tav. 1747 |

Threaded |

rods |

for |

|

|

|

During this operation, use a strap to secure the |

||||

|

|

removing |

the |

sub- |

|

|

|

vehicle to the lift to prevent it from becoming |

||||

|

|

frame |

|

|

|

|

|

|

unbalanced. |

|

||

|

|

|

|

|

|

|

|

|

|

For the strap fitting procedure, (see 02A, Lifting |

||

|

|

|

|

|

|

|

||||||

|

Essential equipment |

|

|

|

|

|

|

equipment, Underbody lift). |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

filling station |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

Tightening torquesm |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

gearbox rubber moun- |

|

|

|

10.5 daNm |

|

|

|

|

|

|

|

|

ting mounting bolts |

|

|

|

|

|

|

|

|

|

|

|

|

gearbox cover moun- |

|

|

|

6.2 daNm |

|

|

|

|

|

|

|

|

ting nut on the gearbox |

|

|

|

|

|

|

|

|

|

|

|

|

rubber mounting |

|

|

|

|

|

|

|

|

|

|

|

|

sub-frame mounting |

|

|

|

10.5 daNm |

|

|

|

|

|

|

|

|

bolts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

sub-frame tie-rod upper |

|

|

|

2.1 daNm |

|

|

|

|

|

|

|

|

mounting bolts |

|

|

|

|

|

|

|

|

|

|

|

|

sub-frame tie-rod lower |

|

|

|

6.2 daNm |

|

|

|

|

|

|

|

|

mounting bolts |

|

|

|

|

|

|

|

|

|

|

|

|

steering rack mounting |

|

|

|

10.5 daNm |

|

|

|

|

|

|

|

|

bolts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10A-5

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7J, and 710

1

1

3

3

107846 |

109184 |

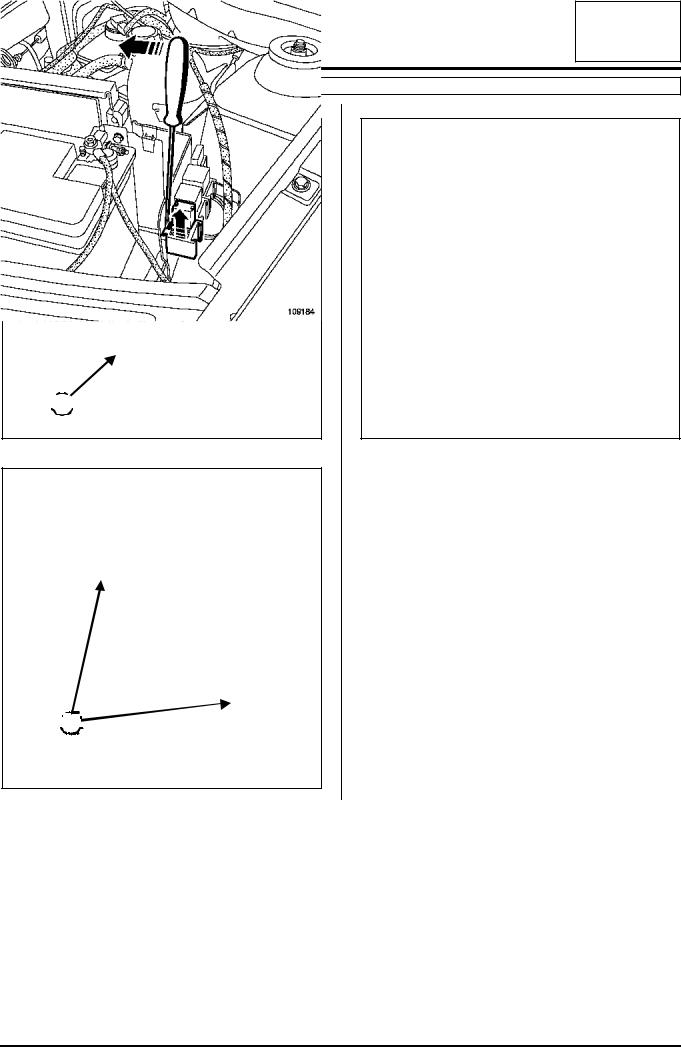

Disconnect the battery, starting with the negative terminal.

Remove:

- fuse and relay cover (1),

- the fuse holders and relays from their supports (2), - battery mounting clamp (3),

- the battery.

2 |

107845

10A-6

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7J, and 710

Drain:

- the engine oil if necessary,

- the gearbox oil if necessary,

- the cooling circuit via the bottom hose, using tool (Mot. 1202-01), tool (Mot. 1202-02) or tool (Mot. 1448).

DIRECTION MANUELLE, and BASIC HEATING

4

4

108564

7

7

5 |

6

6

109398

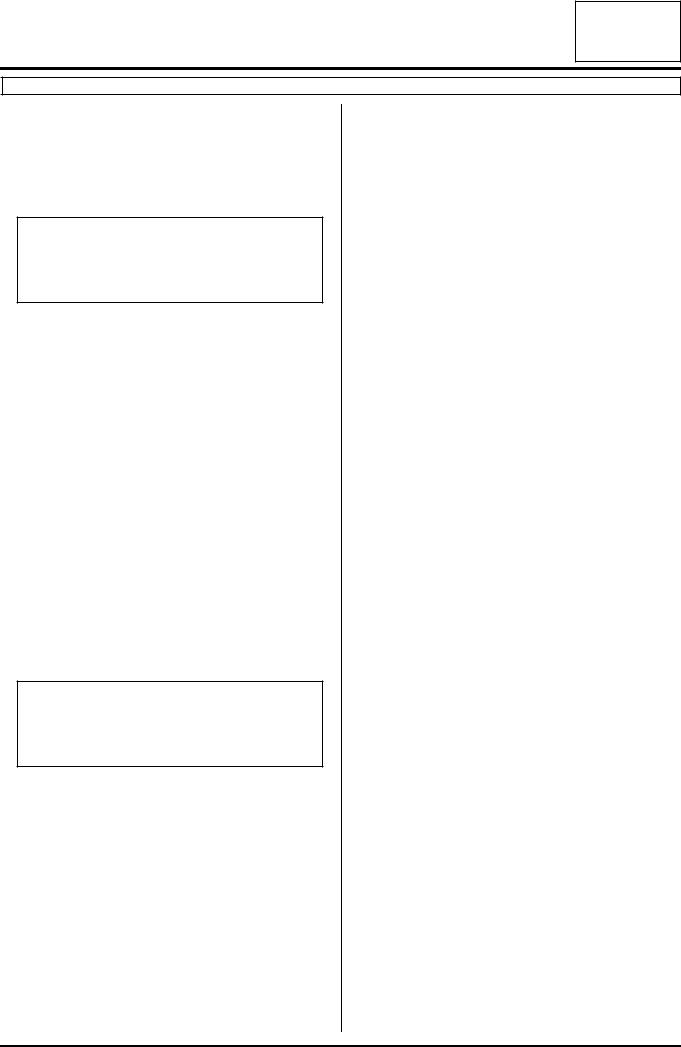

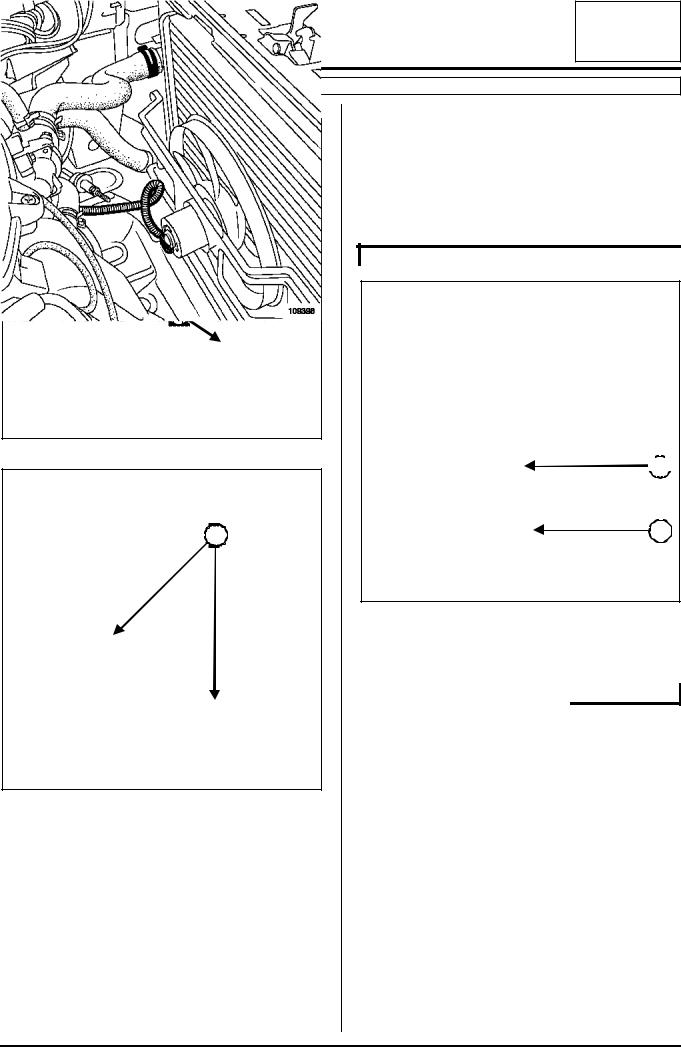

Disconnect fan assembly connector (6).

Unclip the electrical harness from fan assembly (7).

108562

Remove:

-the injection computer protector in (4),

-the injection computer in (5),

-the fuse and relay supports,

-the electrolyte recovery tray under the battery,

-the air suction sleeve on the body,

-the front wheels,

-the engine undertray,

-the bumper mounting bolts under the sub-frame.

10A-7

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7J, and 710

DIRECTION ASSISTEE, and BASIC HEATING

9

9

8

8

109398

Disconnect fan assembly connector (8).

Unhook the electrical harness from fan assembly (9).

10

10

11

11

107924

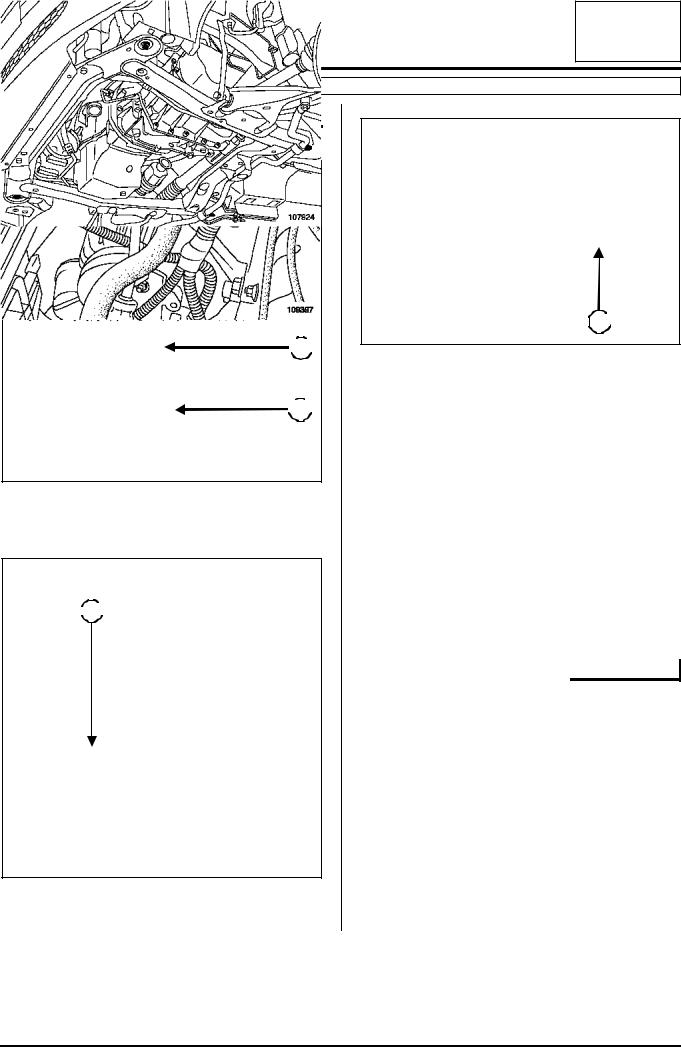

Remove the power assisted steering pipe mounting bolts:

-from the top of sub-frame (11),

-on the multifunction support,

-on the rear of the cylinder block. Disconnect:

-the low pressure hose on the power assisted steering pump and drain the circuit,

-the high-pressure pipe from the power assisted steering pump,

-the high-pressure pipe from the steering rack.

Remove the power assisted steering high-pressure pipe.

109397

Disconnect connector (10) of the power assisted steering pressure switch.

10A-8

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7J, and 710

DIRECTION MANUELLE, and AIR CONDITIONING

12 |

109396

Disconnect fan assembly connectors (12).

13

13

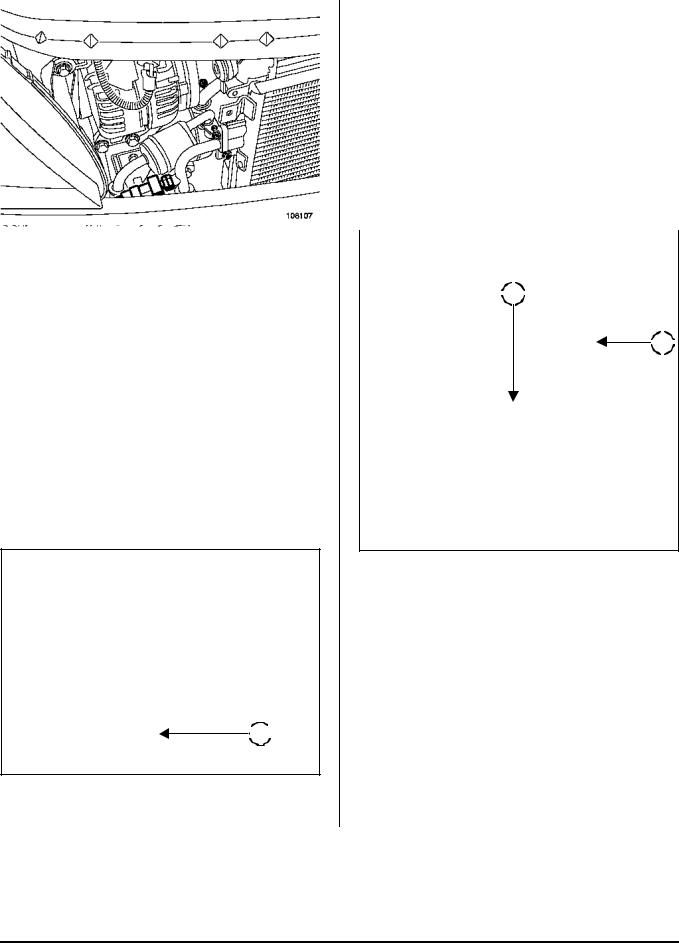

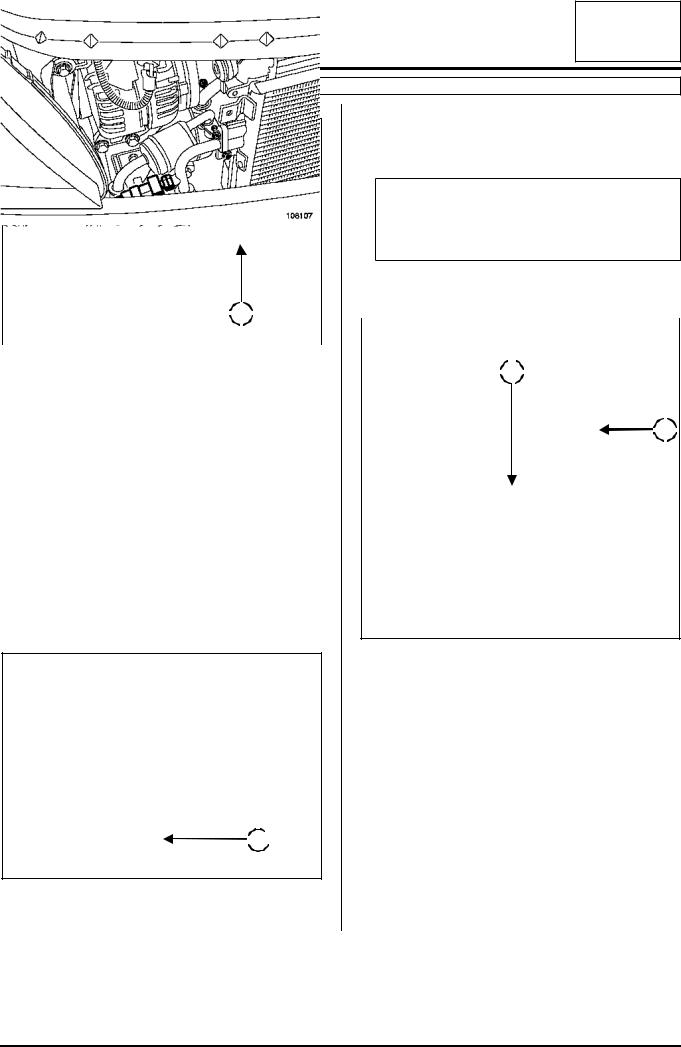

108107

Disconnect connector (13) from the refrigerant pressure sensor.

Drain the air conditioning circuit using filling station.

Disconnect the air conditioning pipe unions on the air conditioning compressor.

WARNING

Protective plugs must be inserted into the pipe and air conditioning compressor openings to prevent moisture from getting into the circuit.

DIRECTION ASSISTEE, and AIR CONDITIONING

14 |

109396

Disconnect connectors (14) of the fan assembly.

15

15

109397

Disconnect connector (15) of the power assisted steering pressure switch.

10A-9

|

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

|||||||||||||||||||||||

|

Engine/gearbox assembly |

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L90, and K7J, and 710 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

Drain the air conditioning circuit using the filling sta- |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

tion. |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

Disconnect the air conditioning pipe unions on the air |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

conditioning compressor. |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

Protective plugs must be inserted into the pipe |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

and air conditioning compressor openings to pre- |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

vent moisture from getting into the circuit. |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

107924 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

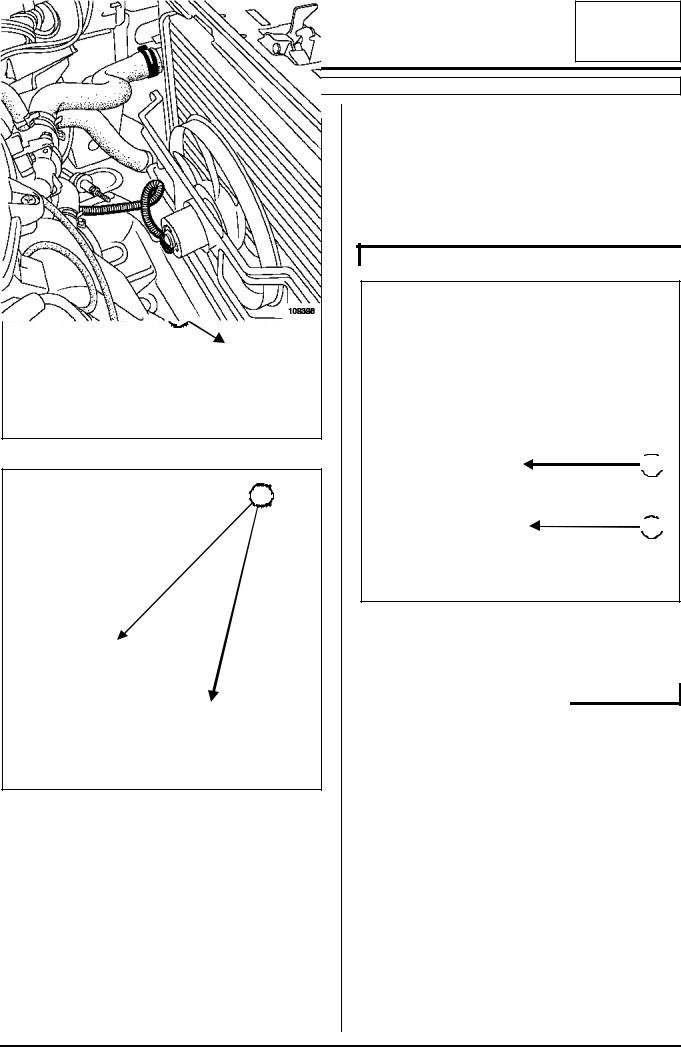

Remove the power assisted steering pipe mounting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

bolts: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

19 |

|

|

|

|

|

|

|

|

|

||||||||||||

|

- from the top of sub-frame (16), |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

- on the multifunction support, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

18 |

|

||||||||||||

|

- on the rear of the cylinder block. |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

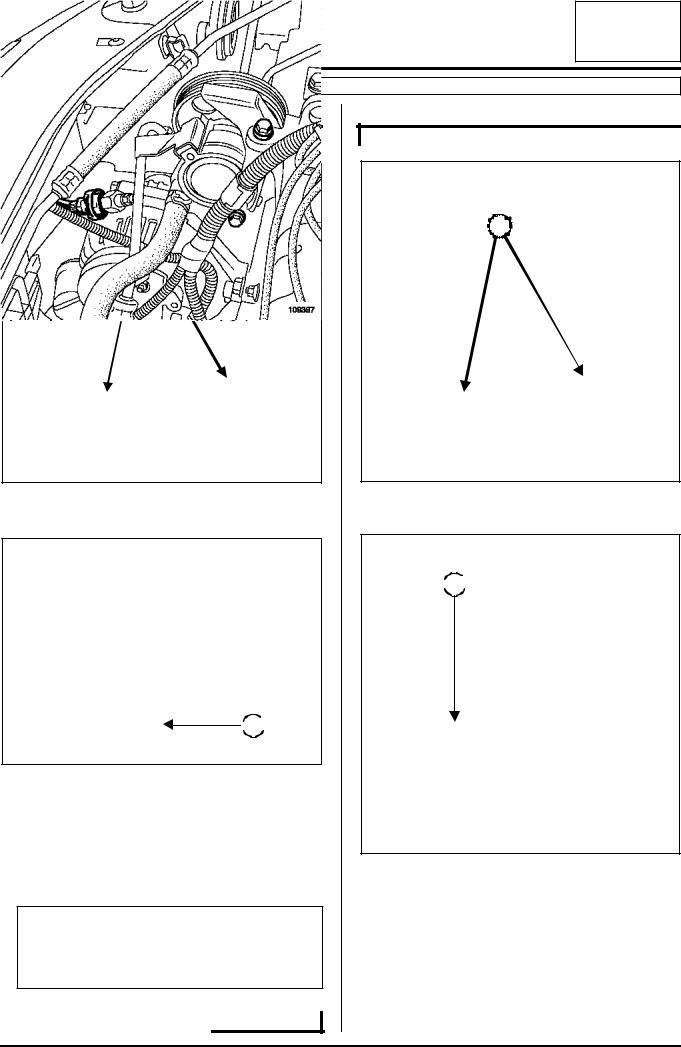

Disconnect:

- the low pressure hose on the power assisted steering pump and drain the circuit,

-the high-pressure pipe from the power assisted steering pump,

-the high-pressure pipe from the steering rack.

Remove the power assisted steering high-pressure pipe.

107356

Disconnect:

- ball joint (18) of the throttle valve control cable,

- cable sleeve stop (19) of the throttle valve control cable.

17

17

108107

Disconnect connector (17) of the refrigerant pressure sensor.

10A-10

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7J, and 710

20

20

21

21

107357

Disconnect:

-the petrol vapour absorber bleeding solenoid valve connector,

-the brake servo pipe from the inlet manifold,

-petrol vapour rebreather pipe (20) from the inlet manifold.

-the fuel supply pipe (21) from the injection rail.

IMPORTANT

Be careful of petrol splashing out when disconnecting the fuel supply union.

Wear gloves during the operation.

22 |

22 |

22 |

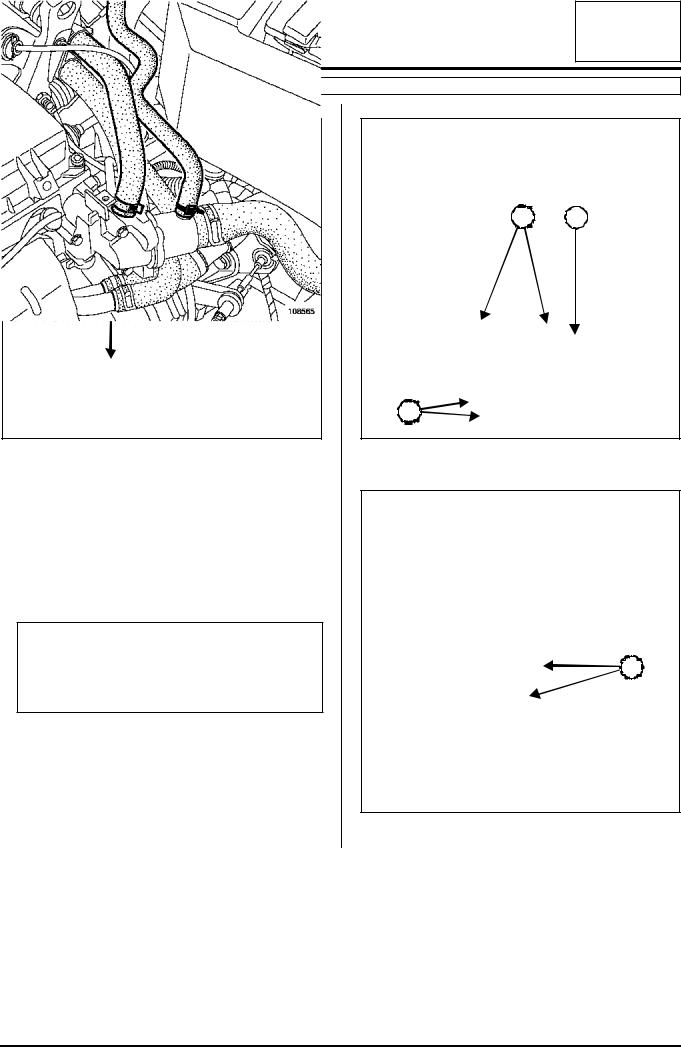

108565

Disconnect cooling hoses (22).

23 |

109493

Remove cooling hoses (23) from their support.

10A-11

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7J, and 710

24

24

107934

Remove mounting bolt (24) from the earth strap on the gearbox.

27 |

25 |

|

26

26

107935

28

28

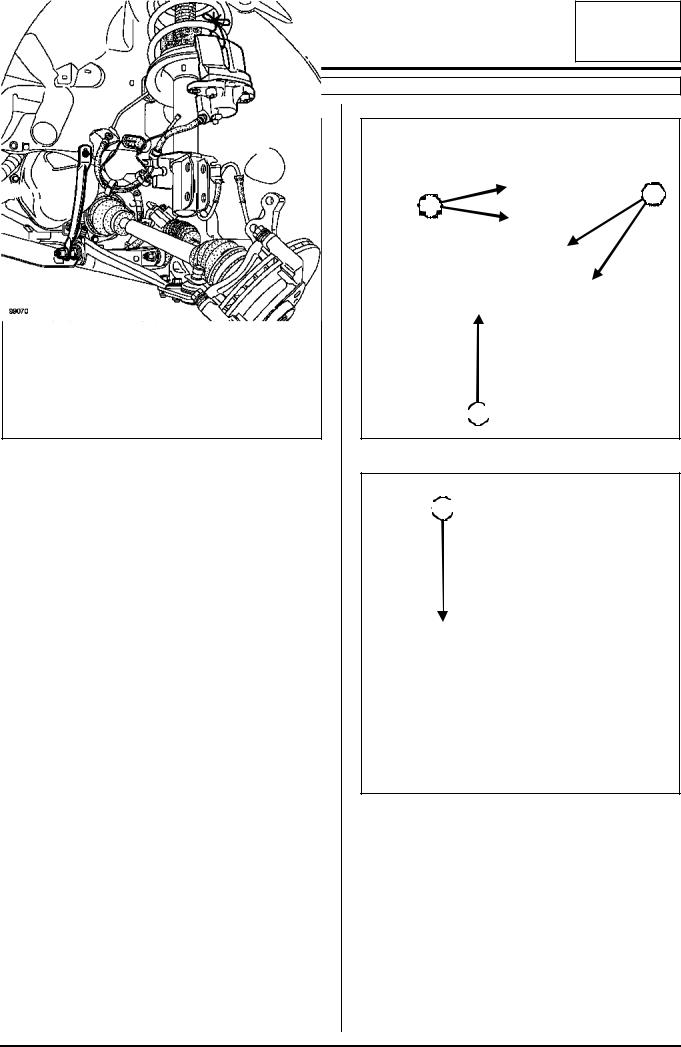

99070

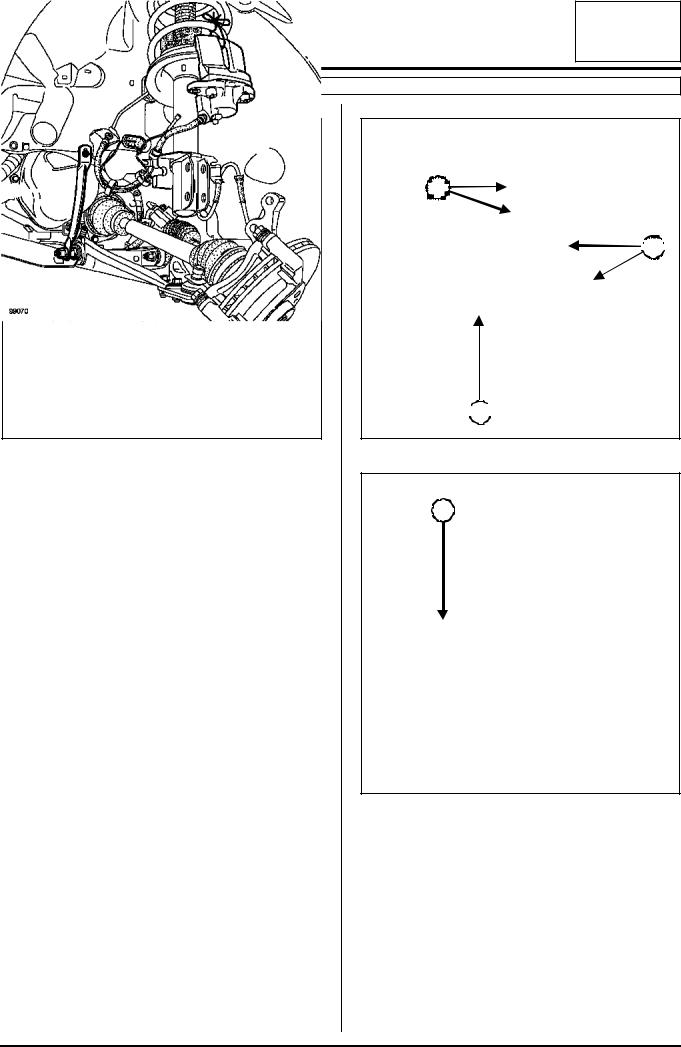

Remove:

-brake callipers (25) and attach them to the shock absorbers,

-track rod ends (26),

-bolts (27) from the shock absorber bases,

-upper mounting bolts (28) of the sub-frame tie rods,

-the two mounting bolts from the steering rack. Attach the steering rack to the body.

10A-12

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7J, and 710

29

29

30

30

109494

Remove:

-the clutch control cable from clutch fork (29),

-the clutch control cable from sleeve stop (30).

31

31

109213

Remove rubber protection (31) from the gear lever.

32

32

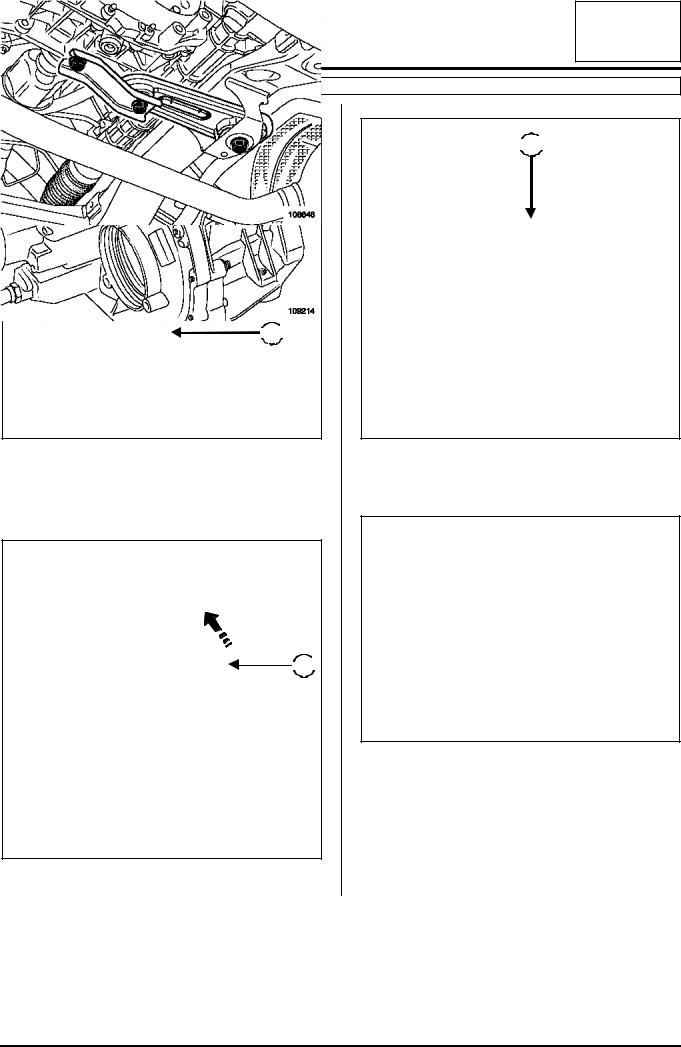

109214

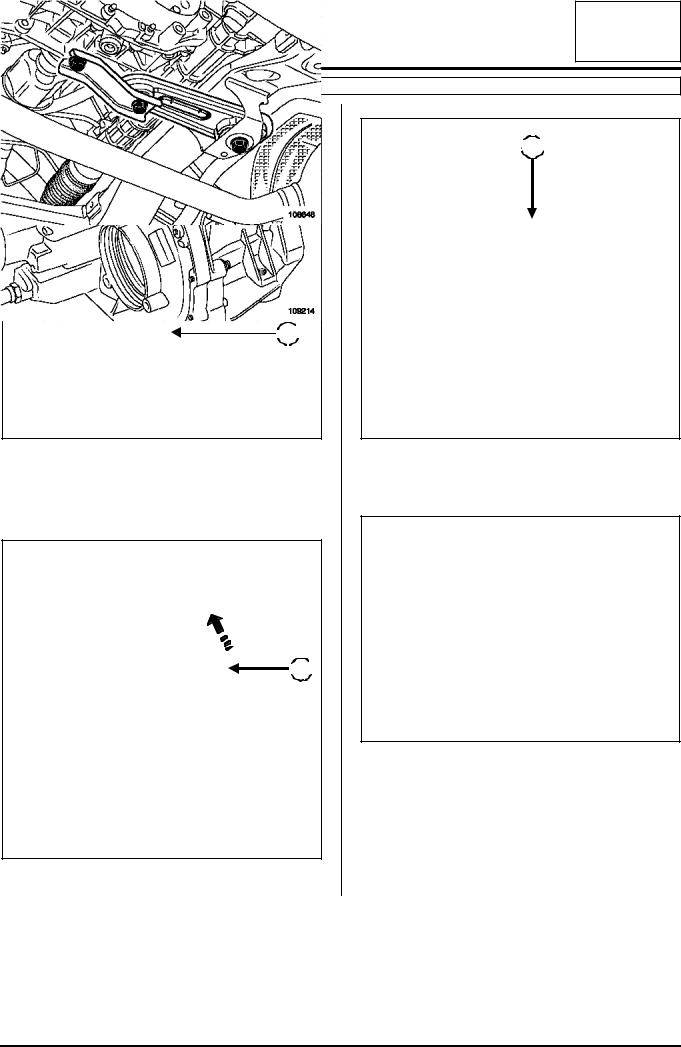

Remove mounting bolt (32) from the gear lever fork. Attach the gearbox control linkage to the body.

108648

Remove the engine tie-bar.

Remove the catalytic converter (see 19B, Exhaust, Catalytic converter).

10A-13

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7J, and 710

109495

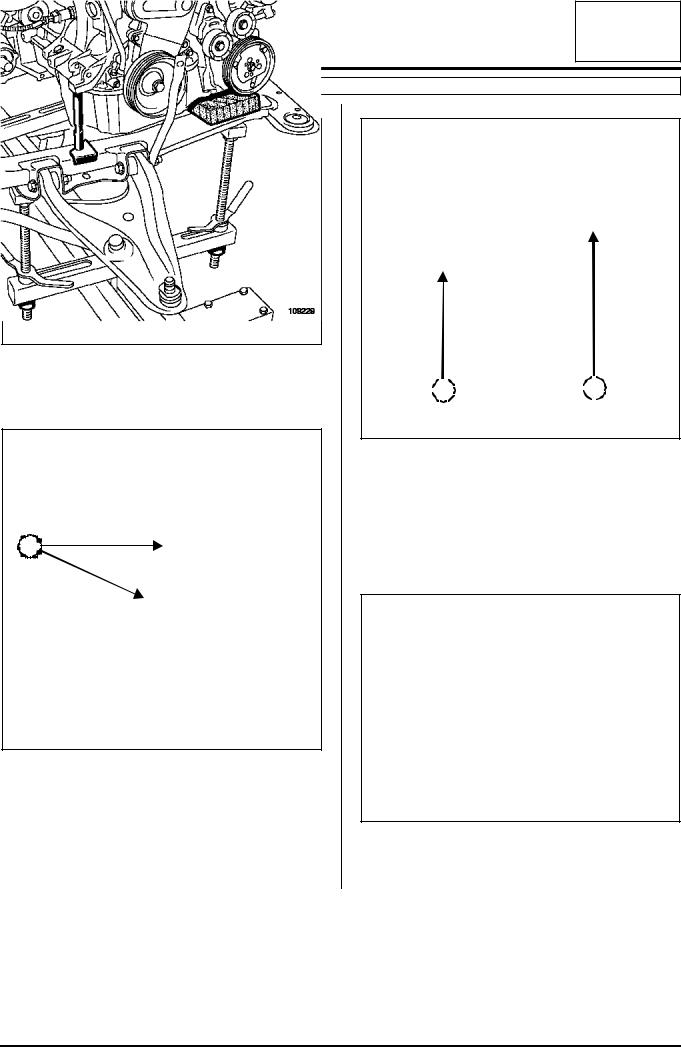

Fit engine support tool (Mot. 1453) with the retaining belt, by taking the timing end lifting eye as an anchoring point.

33 |

108649

Remove:

-the suspended engine mounting cover mounting bolts,

-the suspended mounting from engine (33).

|

|

|

|

|

|

|

|

|

|

|

|

35 |

|

|

|

|

34 |

||||

|

|

|

|

|

|

|

|

|

|

|

109229

Put a shim under the engine on the right-hand side of the sub-frame:

-put a rubber shim under multifunction support (34),

-fit tool (Mot. 1159-03) to the rear of engine (35),

-lower the engine to fix it in place on the right-hand side of the sub-frame.

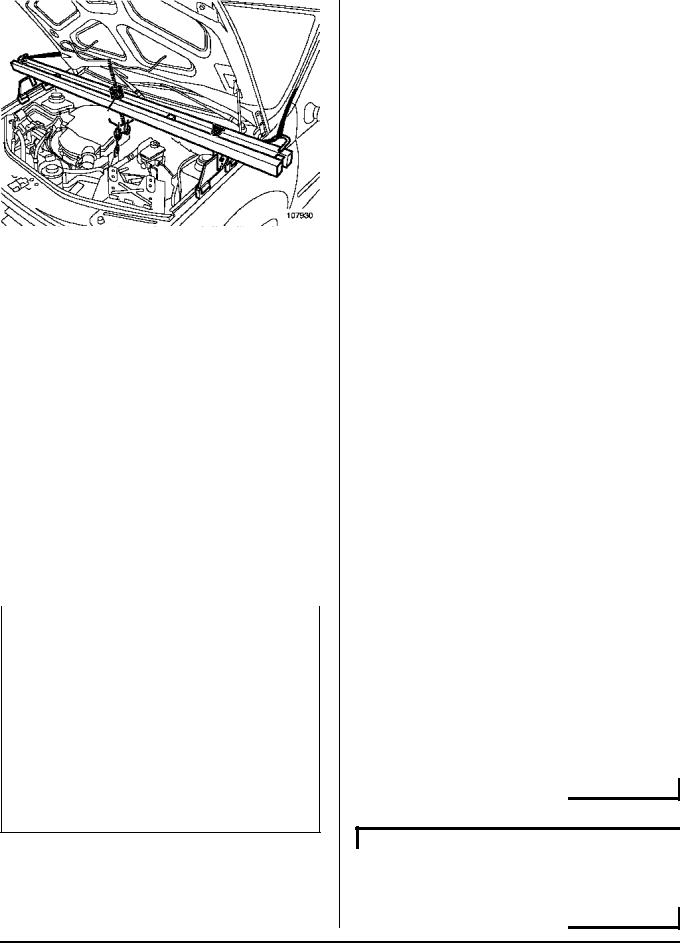

107930

Fit engine support tool (Mot. 1453) with the retaining belt, by taking the flywheel end lifting eye as an anchoring point.

10A-14

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7J, and 710

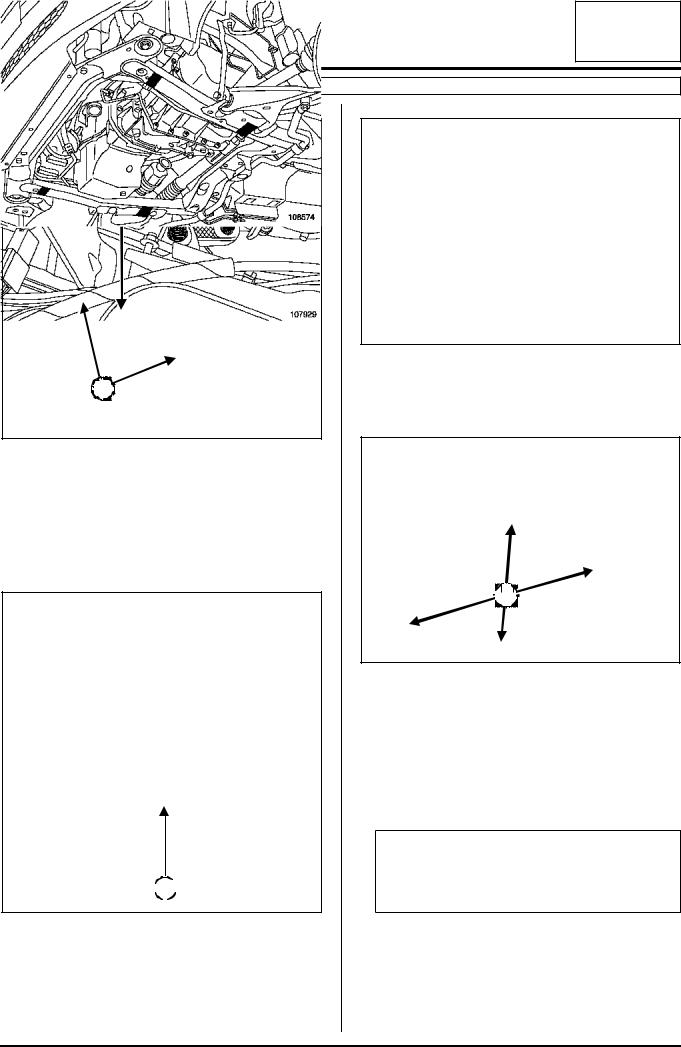

36

36

37 |

107929

Remove mounting nut (36) of the gearbox cover on the gearbox rubber mounting.

Strike the gearbox mounting stud with a copper hammer to uncouple « engine and gearbox » assembly from the body.

Remove gearbox rubber mounting (37).

38

38

109230

Put a shim under the gearbox on the left-hand side of the sub-frame:

-put a rubber shim under gearbox (38),

-lower the gearbox to fix it in place on the left-hand side of the sub-frame.

17765

Place tool (Mot. 1390) under the sub-frame.

Lower the vehicle down onto the four pads of tool (Mot. 1390).

39 |

108574

Adjust the pad position to ensure the sub-frame is stable on tool (Mot. 1390).

Bring the pads into contact with the underside of the sub-frame in (39).

Lift the vehicle to separate « engine and gearbox/dri- veshafts/half-axle/sub-frame» assembly from the body.

WARNING

Ensure that no component obstructs the movement of the body around the « engine and gearbox » assembly.

10A-15

|

ENGINE AND LOWER ENGINE ASSEMBLY |

|

10A |

||

|

Engine/gearbox assembly |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

L90, and K7J, and 710 |

|

|

|

|

REFITTING |

Torque tighten: |

|

|||

|

|

|

- the gearbox rubber mounting mounting bolts |

||

|

|

|

|||

|

|

|

(10.5 daNm), |

|

|

|

|

|

- the gearbox cover mounting nut on the gearbox |

||

|

|

|

rubber mounting (6.2 daNm), |

|

|

|

|

|

- the sub-frame mounting bolts (10.5 daNm), |

||

|

|

|

- the sub-frame tie-rod upper mounting bolts (2.1 |

||

|

|

|

daNm), |

|

|

|

|

|

- the sub-frame tie-rod lower mounting bolts (6.2 |

||

|

|

|

daNm), |

|

|

|

|

|

- the steering rack mounting bolts (10.5 daNm) |

||

|

107927 |

|

- the shock absorber base bolts (10,5 daNm), |

||

|

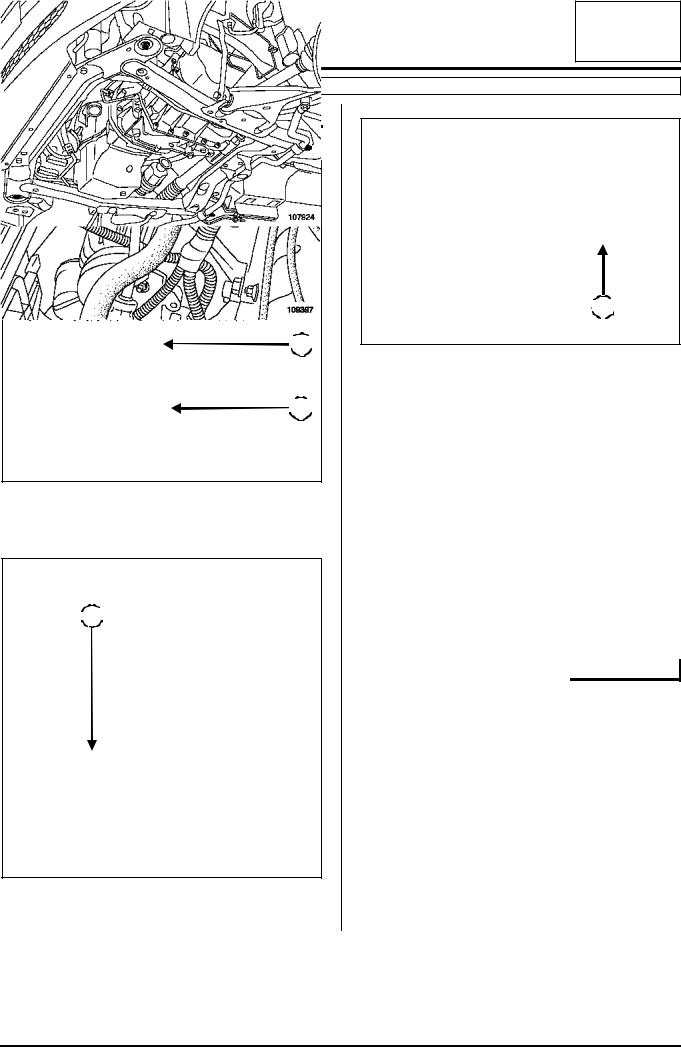

Use two threaded rods of tool (Tav. 1747) on the |

||||

|

sub-frame front mountings to guide the sub-frame |

- the brake calliper mounting bolts (10.5 daNm), |

|||

|

when fitting the « engine and gearbox » assembly. |

||||

|

|

|

|

||

|

|

|

- the track rod end nuts (3.7 daNm), |

||

|

|

|

|||

|

|

|

- the engine tie-bar mounting bolts (10.5 daNm), |

||

|

|

|

- the wheel bolts (10.5 daNm). |

|

|

|

|

|

Refit the catalytic converter (see 19B, Exhaust, Ca- |

||

|

|

|

talytic converter). |

|

|

|

|

|

Perform the following operations: |

|

|

|

|

|

- top up the engine oil if necessary, |

|

|

|

|

|

- top up the gearbox oil if necessary, |

||

|

|

|

- fill up and bleed the cooling circuit (see 19A, Coo- |

||

|

109495 |

|

|||

|

|

|

ling, Draining - Filling the cooling circuit). |

||

|

|

|

|

||

|

|

|

DIRECTION ASSISTEE, and BASIC HEATING |

||

|

|

|

Fill up the power assisted steering circuit. |

||

|

|

|

Bleed the power assisted steering circuit by turning |

||

|

|

|

the steering wheel fully in one direction then the |

||

|

|

|

other with the engine running. |

|

|

107930 DIRECTION MANUELLE, and AIR CONDITIONING

Use tool (Mot. 1453) to fit the suspended engine

Fill up the air conditioning circuit with filling station.

mounting of the « engine and gearbox » assembly.

Coat the brake calliper mounting bolts with LOCTITE

FRENBLOC.

10A-16

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7J, and 710

DIRECTION ASSISTEE, and AIR CONDITIONING

Fill up the power assisted steering circuit.

Bleed the power assisted steering circuit by turning the steering wheel fully in one direction then the other with the engine running.

Fill up the air conditioning circuit with filling station.

Proceed in the reverse order to removal.

WARNING

Connect the battery, starting with the positive terminal; carry out the necessary programming (see

80A, Battery: Remove and Refit).

10A-17

|

ENGINE AND LOWER ENGINE ASSEMBLY |

|

10A |

|||||||||

|

|

Engine/gearbox assembly |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L90, and K7M, and 710 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Essential special tooling |

|

|

|

|

|

Tightening torquesm |

|||||

|

|

|

|

|

|

|

|

|||||

|

Mot. 1202-01 |

Clip pliers for cooling |

|

|

shock absorber base |

10.5 daNm |

||||||

|

|

system |

hose |

clips |

|

|

bolts |

|

||||

|

|

(large model) |

|

|

|

|

|

|

|

|||

|

|

|

|

|

brake calliper mounting |

10.5 daNm |

||||||

|

Mot. 1202-02 |

Clip |

pliers |

for cooling |

|

|

||||||

|

|

|

bolts |

|

||||||||

|

|

system |

hose |

clips |

|

|

|

|

|

|

||

|

|

|

|

track rod end nuts |

3.7 daNm |

|||||||

|

|

(small model) |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

engine tie-bar mounting |

10.5 daNm |

||

|

Mot. 1448 |

Remote |

|

operation |

|

|

||||||

|

|

pliers for cooling sys- |

|

|

bolts |

|

||||||

|

|

tem hose clips |

|

|

|

|

|

|

|

|||

|

|

|

|

|

wheel bolts |

10.5 daNm |

||||||

|

|

|

|

|

|

|

|

|

||||

|

Mot. 1453 |

Multiple-adjusting |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||||

|

|

engine mounting sup- |

|

|

REMOVAL |

|

||||||

|

|

port |

with |

retaining |

|

|

|

|||||

|

|

straps |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Mot. 1159-03 |

Engine |

mounting on |

|

|

|

Note: |

|

||||

|

|

right-hand side mem- |

|

|

|

The « engine and gearbox » assembly can be |

||||||

|

|

ber for operations not |

|

|

|

|||||||

|

|

|

|

|

removed by removing the « engine and gearbox/ |

|||||||

|

|

requiring removal of |

|

|

|

|||||||

|

|

|

|

|

driveshafts/half-axle/sub-frame » assembly. |

|||||||

|

|

the engine |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Place the vehicle on a two-post lift. |

|

||

|

Mot. 1390 |

Support |

for removing |

|

||||||||

|

|

and refitting the engine |

|

|

|

|

|

|

||||

|

|

and gearbox assembly |

|

|

|

IMPORTANT |

|

|||||

|

Tav. 1747 |

Threaded |

rods |

for |

|

|

|

During this operation, secure the vehicle onto the |

||||

|

|

removing |

the |

sub- |

|

|

|

lift with a strap to prevent it from becoming unba- |

||||

|

|

frame |

|

|

|

|

|

|

lanced. |

|

||

|

|

|

|

|

|

|

|

|

|

For the strap fitting procedure, (see 02A, Lifting |

||

|

|

|

|

|

|

|

||||||

|

Essential equipment |

|

|

|

|

|

|

equipment, Underbody lift). |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

filling station |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

Tightening torquesm |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

gearbox rubber moun- |

|

|

|

10.5 daNm |

|

|

|

|

|

|

|

|

ting mounting bolts |

|

|

|

|

|

|

|

|

|

|

|

|

gearbox cover moun- |

|

|

|

6.2 daNm |

|

|

|

|

|

|

|

|

ting nut on the gearbox |

|

|

|

|

|

|

|

|

|

|

|

|

rubber mounting |

|

|

|

|

|

|

|

|

|

|

|

|

sub-frame mounting |

|

|

|

10.5 daNm |

|

|

|

|

|

|

|

|

bolts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

sub-frame tie-rod upper |

|

|

|

2.1 daNm |

|

|

|

|

|

|

|

|

mounting bolts |

|

|

|

|

|

|

|

|

|

|

|

|

sub-frame tie-rod lower |

|

|

|

6.2 daNm |

|

|

|

|

|

|

|

|

mounting bolts |

|

|

|

|

|

|

|

|

|

|

|

|

steering rack mounting |

|

|

|

10.5 daNm |

|

|

|

|

|

|

|

|

bolts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10A-18

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7M, and 710

1

1

3

3

107846 |

109184 |

Disconnect the battery, starting with the negative terminal.

Remove:

- fuse and relay cover (1),

- the fuse holders and relays from their supports (2), - battery mounting clamp (3),

- the battery.

2

2

107845

10A-19

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7M, and 710

Drain:

- the engine oil if necessary,

- the gearbox oil if necessary,

- the cooling circuit via the bottom hose, using tool (Mot. 1202-01), tool (Mot. 1202-02) or tool (Mot. 1448).

DIRECTION MANUELLE, and BASIC HEATING

4 |

108564

7

7

5 |

6 |

109398

Disconnect fan assembly connector (6).

Unclip the electrical harness from fan assembly (7).

108562

Remove:

-the injection computer protector in (4),

-the injection computer in (5),

-the fuse and relay supports,

-the electrolyte recovery tray under the battery,

-the air suction sleeve on the body,

-the front wheels,

-the engine undertray,

-the bumper mounting bolts under the sub-frame.

10A-20

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7M, and 710

DIRECTION ASSISTEE, and BASIC HEATING

9

9

8

8

109398

Disconnect fan assembly connector (8).

Unhook the electrical harness from fan assembly (9).

10

10

11

107924

Remove the power assisted steering pipe mounting bolts:

-from the top of sub-frame (11),

-on the multifunction support,

-on the rear of the cylinder block. Disconnect:

-the low pressure hose on the power assisted steering pump and drain the circuit,

-the high-pressure pipe from the power assisted steering pump,

-the high-pressure pipe from the steering rack.

Remove the power assisted steering high-pressure pipe.

109397

Disconnect connector (10) of the power assisted steering pressure switch.

10A-21

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7M, and 710

DIRECTION MANUELLE, and AIR CONDITIONING

12 |

109396

Disconnect fan assembly connectors (12).

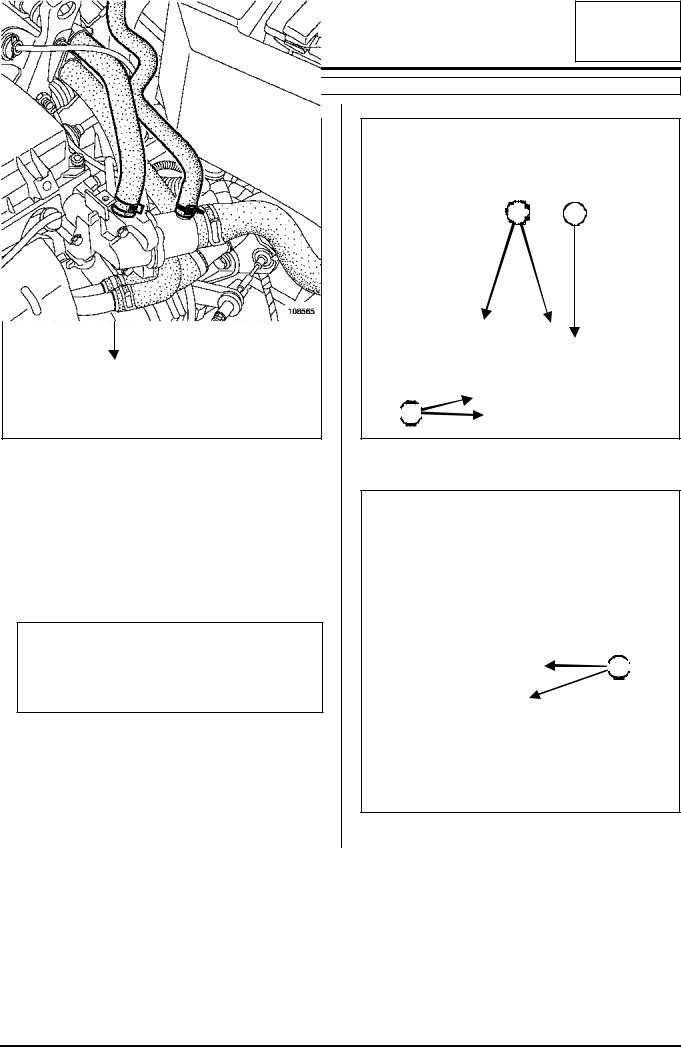

13

13

108107

Disconnect connector (13) from the refrigerant pressure sensor.

Drain the air conditioning circuit using filling station.

Disconnect the air conditioning pipe unions on the air conditioning compressor.

WARNING

Protective plugs must be inserted into the pipe and air conditioning compressor openings to prevent moisture from getting into the circuit.

DIRECTION ASSISTEE, and AIR CONDITIONING

14 |

109396

Disconnect fan assembly connectors (14).

15

15

109397

Disconnect connector (15) of the power assisted steering pressure switch.

10A-22

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7M, and 710

Drain the air conditioning circuit using filling station.

Disconnect the air conditioning pipe unions on the air conditioning compressor.

WARNING

Protective plugs must be inserted into the pipe and air conditioning compressor openings to prevent moisture from getting into the circuit.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

107924 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

Remove the power assisted steering pipe mounting |

|

19 |

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|||||||||||

bolts: |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

- from the top of sub-frame (16), |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

- on the multifunction support, |

|

|

18 |

|

|

||||||||||||||

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

- on the rear of the cylinder block.

Disconnect:

-the low pressure hose on the power assisted steering pump and drain the circuit,

-the high-pressure pipe from the power assisted steering pump,

-the high-pressure pipe from the steering rack.

Remove the power assisted steering high-pressure pipe.

107356

Disconnect:

- ball joint (18) of the throttle valve control cable,

- cable sleeve stop (19) of the throttle valve control cable.

17

17

108107

Disconnect connector (17) of the refrigerant pressure sensor.

10A-23

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7M, and 710

20

20

21

21

107357

Disconnect:

-the petrol vapour absorber bleeding solenoid valve connector,

-the brake servo pipe from the inlet manifold,

-petrol vapour rebreather pipe (20) from the inlet manifold,

-fuel supply pipe (21) from the injection rail.

IMPORTANT

Be careful of petrol splashing out when disconnecting the fuel supply union.

Wear gloves during the operation.

22 |

22 |

22

22

108565

Disconnect the cooling hoses (22).

23

23

109493

Remove cooling hoses (23) from their support.

10A-24

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7M, and 710

24

24

107934

Remove mounting bolt (24) from the earth strap on the gearbox.

27 |

25

25

26

26

107935

28 |

99070

Remove:

-brake callipers (25) and attach them to the shock absorbers,

-track rod ends (26),

-bolts (27) of the shock absorber bases,

-upper mounting bolts (28) of the sub-frame tie rods,

-the two mounting bolts from the steering rack. Attach the steering rack to the body.

10A-25

ENGINE AND LOWER ENGINE ASSEMBLY |

10A |

Engine/gearbox assembly |

L90, and K7M, and 710

29

29

30

30

109494

Remove:

-the clutch control cable from clutch fork (29),

-the clutch control cable from sleeve stop (30).

31

31

109213

Remove rubber protection (31) from the gear lever.

32

32

109214

Remove mounting bolt (32) from the gear lever fork. Attach the gearbox control linkage to the body.

108648

Remove the engine tie-bar.

Remove the catalytic converter (see 19B, Exhaust, Catalytic converter).

10A-26

Loading...

Loading...