Dacia 1304 2004 User Manual

REPAIR MANUAL

vnx.su

DACIA COMMERCIAL

RM 503-1 MECHANICS

ENGINE: F8Q

GERBOX: NG1; NG7

TAPV: U75D; U75E; U75G

Ref: 6001 999 462 NOVEMBER 2004 English version

The reparation methods prescribed by the manufacturer in the present document are established subject to

technical specifications in force at the document issuing date.

These are subject to modifications brought by the manufacturer at the fabrication of different assemblies,

subassemblies or accessories of its vehicles.

All rights reserved to SC Automobile Dacia SA.

Reproduction or translating even partially of this present document is forbidden without the written

authorisation of AUTOMOBILE DACIA S.A.

General poinds vehicle

vnx.su

0

01 SPECIFICATIONS

Engine - Clutch - Gearbox ........................... 01-1

Vehicle identification ................................. 01-2

02 LIFTING

Mobile jack Protection routes ....................... 02-1

Elevator to be attached under the carriage

body .............................................................. 02-2

03 TOWING

All types ........................................................ 03-1

04 LUBRICANTS CONSUMABLES

Conditions ..................................................... 04-1

05 DRAINING AND FILLING

Engine ............................................................ 05-1

Gearbox ......................................................... 05-2

Rear axle differential ..................................... 05-3

07 VALUES AND SETTINGS

Dimensions .................................................... 07-1

Capacity - Qualities .......................................07-10

Wheels and tires............................................ 07-11

Brakes ........................................................... 07-12

Heights under carriage body ......................... 07-13

Control values of the front axle angles ..........07-14

Control values of the rear axle angles ...........07-18

1

Engine and peripherics

10 ENGINE AND LOWER ENGINE UNITS

Ingredients .................................................... 10-1

Idetification ................................................... 10-2

Oil consumption ............................................. 10-3

Oil pressure .................................................... 10-4

Dismounting - Remounting engine ............... 10-5

Engine fitting - unfitting ............................... 10-9

Tightening moments......................................10-10

Characteristics .............................................. 10-11

Necesary special tools .................................. 10-16

Dismounting - Remounting............................ 10-17

Lower crankcase............................................ 10-37

Oil pump........................................................ 10-38

Crankshaft sealing gasket towards

distribution ................................................... 10-39

Crankshaft sealing towards flyweel............... 10-40

Engine set replacing ......................................10-41

11 UPPER AND FRONT ENGINE UNITS

Distribution belt ............................................ 11-1

Cylinder head gasket..................................... 11-4

12 FUEL MIXTURE

Intake manifold............................................. 12-1

Exhaust manifold .......................................... 12-2

13 PUMP SUPPLY

Fuel stop in case of collision....................... 13-1

Characteristics .............................................. 13-2

Particularities................................................ 13-4

Cleanliness rules ......................................... 13-6

Elements location.......................................... 13-8

Operation ................................................... 13-10

Injection indicator operation ........................ 13-12

Anti-starting function.................................... 13-13

Idle running rotation correction.................... 13-14

Pre / Post –heating control........................... 13-15

Injectors ....................................................... 13-17

Decreased flow electric valve and stop

electric valve................................................. 13-18

Increased flow electric valve and advance

electric valve................................................. 13-20

Injection pump connector.............................. 13-22

Injection pump.............................................. 13-24

Injection pump pressing on........................... 13-27

Diesel oil filter.............................................. 13-29

Water temperature centralised control

(G.C.T.A.)..................................................... 13-30

Acceleration potentiometer........................... 13-31

Diagnosis - Generalities................................ 13-32

Diagnosis - damages interpretation .............. 13-34

Diagnosis – Help........................................... 13-66

Diagnosis - Conformity checking................. 13-67

Breakdown localizing algorithm ................. 13-70

14 ANTIPOLLUTION

Oil vapors re-aspiration................................ 14-1

Exhaust gases recycling (E.G.R.) ................. 14-2

16 STARTING AND CHARGING

Alternator ..................................................... 16-1

Starter ........................................................... 16-6

19 COOLING - EXHAUST - FUEL TANK

Characteristics .............................................. 19-1

Draining – Filling – Purging ........................ 19-2

Checking....................................................... 19-3

Cooling system diagram................................ 19-4

Water pump................................................... 19-5

Radiator......................................................... 19-6

Exhaust assembly.......................................... 19-7

Tank draining................................................. 19-9

Dismounting – Remounting tank................... 19-10

Fuel level transmitter..................................... 19-11

Tightening moments (da Nm)........................ 19-12

2

vnx.su

Transmission

20 CLUTCH

Identification................................................. 20-1

Diagnostic .................................................... 20-2

Mechanism - Disk ........................................ 20-5

Engine flywheel............................................ 20-6

Clutch shaft bearing...................................... 20-7

21 MANUAL GEARBOX

Characteristics.............................................. 21-1

Tightening moments in daNm...................... .21-2

Ingredients ................................................... 21-3

Manual gearbox : Dismounting -

Remounting................................................... 21-4

Repair............................................................ 21-8

Backcap......................................................... 21-37

Control shaftannular oil seal replacement.... 21-38

Speedometer endless screw pinion

replacement .................................................. 21-39

Ve l ocity step synchrontzer replacement ..... 21-40

Clutch shaft annular oil seal replacement... 21-41

Propeller shaft annular oil replacement........ 21-42

main elements ............................................... 31-30

Suspension - Tightening moments ............... 31-31

Front shock absorber .................................. 31-32

Front suspension spring .............................. 31-36

Front stabilizer rod ...................................... 31-37

33 REAR BEARING ELEMEN TS

Plate drive rear axle ..................................... 33-1

Brake drum................................................... 33-4

Brake cylinder.............................................. 33-6

Brake shoes.................................................. 33-8

Bearing (39 x 68 x 37)................................ 33-10

Plate drive rear axle differential .................. 33-11

Non drive plate rear axle ............................. 33-20

Non drive pipe rear axle ............................. 33-22

Shock absorber ............................................ 33-24

Spring .......................................................... 33-25

Rear antiroll rod .......................................... 33-26

35 WHEELS AND TYRES

Characteristics ............................................. 35-1

Wheels balancing ........................................ 35-4

29 DRIVE SHAFTS

Front cross transmission ............................... 29-1

Bellows towards to the gearbox ................... 29-5

Bellows towards the wheel .......................... 29-7

Longitudinal transmission (cardanic) .......... 29-8

3

30 GENERAL

31 FRONT BEARING ELEMENTS

Chassis

General principle schedule

of a brake circuit in parallel with

by-pass circuit .............................................. 30-1

Tightening moments (daN) .......................... 30-2

The dimensions of the main

braking elements .......................................... 30-7

Brake connections and sewerage ................. 30-8

Brake fluid ................................................... 30-9

Braking circuit purging ................................ 30-10

Diagnostic .................................................... 30-11

Front axle checking-adjustment ................... 31-1

Diagnostic .................................................... 31-4

Upper arm ..................................................... 31-5

Elastic bushings, upper arm ball joint .......... 31-8

Lower arm .................................................... 31-10

Elastic bushings, lower arm ball joint .......... 31-13

Brake gaskets................................................ 31-15

Brake caliper................................................. 31-17

Brake disk..................................................... 31-21

Brake caliper support ................................... 31-24

Steering knuckle............................................ 31-25

Steering knuckle bearing............................... 31-28

Characteristics of front suspension

36 STEERING ASSEMBLY

Characteristics, tightening couplers ............ 36-1

Setting the steering gear central point ......... 36-3

Noise absorber bearing ................................ 36-5

Pusher adjustment ........................................ 36-7

Adjustable steering auxiliary

connecting rod ............................................ 36-12

Steering wheel shaft bushing ........................ 36-14

Steering gear shaft ....................................... 36-16

37 MECHANICAL ELEMENTS CONTROLS

Brake pump.................................................. 37-1

Servobrake................................................... 37-5

Vacuum pump ............................................... 37-8

Air filter – servobrake retainer valve........... 37-9

Handbrake ................................................... 37-10

Handbrake control level .............................. 37-11

Handbrake primary and secondary cable .... 37-12

Brake limiter ............................................... 37-14

Brake pedal and clutch ................................ 37-16

Clutch cable - Clutch stroke adjustment ..... 37-17

The steering column support assy

and fire wall ................................................. 37-18

Throttle pedal .............................................. 37-19

Gear box control mechanism ....................... 37-20

38 VACUUM-ELECTRIC CONTROL

SYSTEM 4 X 4 COUPLING

Presentation.................................................. 38-1

Electric-vacuumating control adjustment .... 38-2

Vacuum capsule............................................ 38-3

Electric valve................................................ 38-4

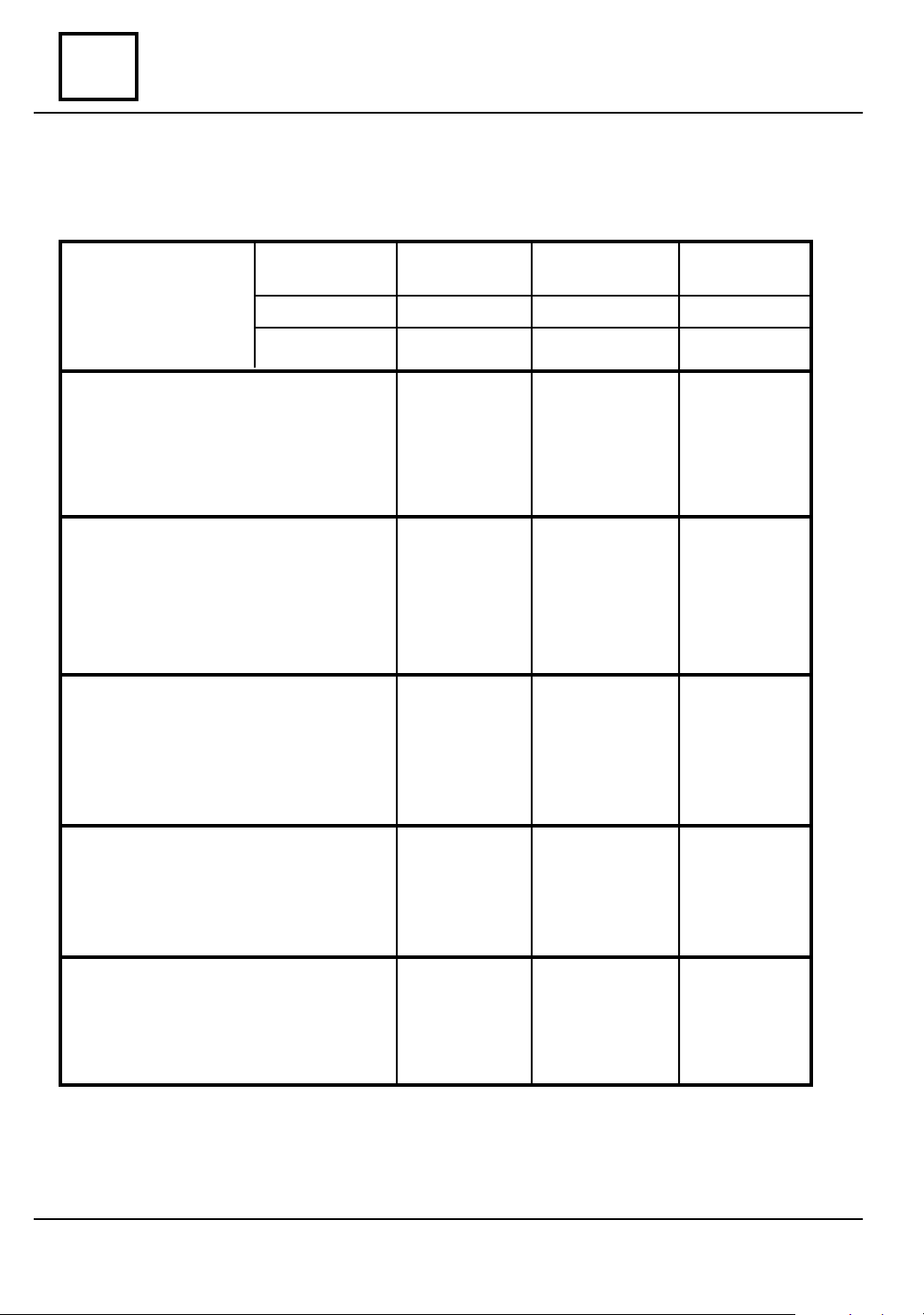

SPECIFICATIONS

vnx.su

Engine – Clutch – Gearbox

01

TYPE

Pick Up P

Pick Up 4x4

Drop Side P

Drop Side 4x4

Pick Up T

Drop Side T

VEHICLE ENGINE

CODE

VIN

D 2611*

D 4616*

D 2711*

D 4716*

D 1611*

D 1711*

DRIVE

rear

4x4

rear

4x4

front

front

TYPE

F8Q-636

F8Q-636

F8Q-636

F8Q-636

CAPAC I T Y

1870

1870

1870

1870

(cm3)

CLUTCH

200CPOV

3700

200CPOV

3700

200CPOV

3700

200 CPOV

3700

GEARBOX

NG1-103

(50C-31)

NG7-101

(51C-02)

NG1-103

(50C-31)

NG7-101

(51C-02)

(NG1-104)

365-18

(NG1-104)

365-18

Double Cab P

Double Cab T

Double Cab 4x4

D 2F71*

D 1F11*

D 4F76*

rear

front

4x4

F8Q-636

1870

200 CPOV

3700

(NG1-103)

50C-31

(NG1-104)

365-18

(NG7-101)

51C-02

* (x or 7 or T) – this sign is showing : engine type, engine pollution norm and driving

post location

01 - 1

SPECIFICATIONS

vnx.su

01

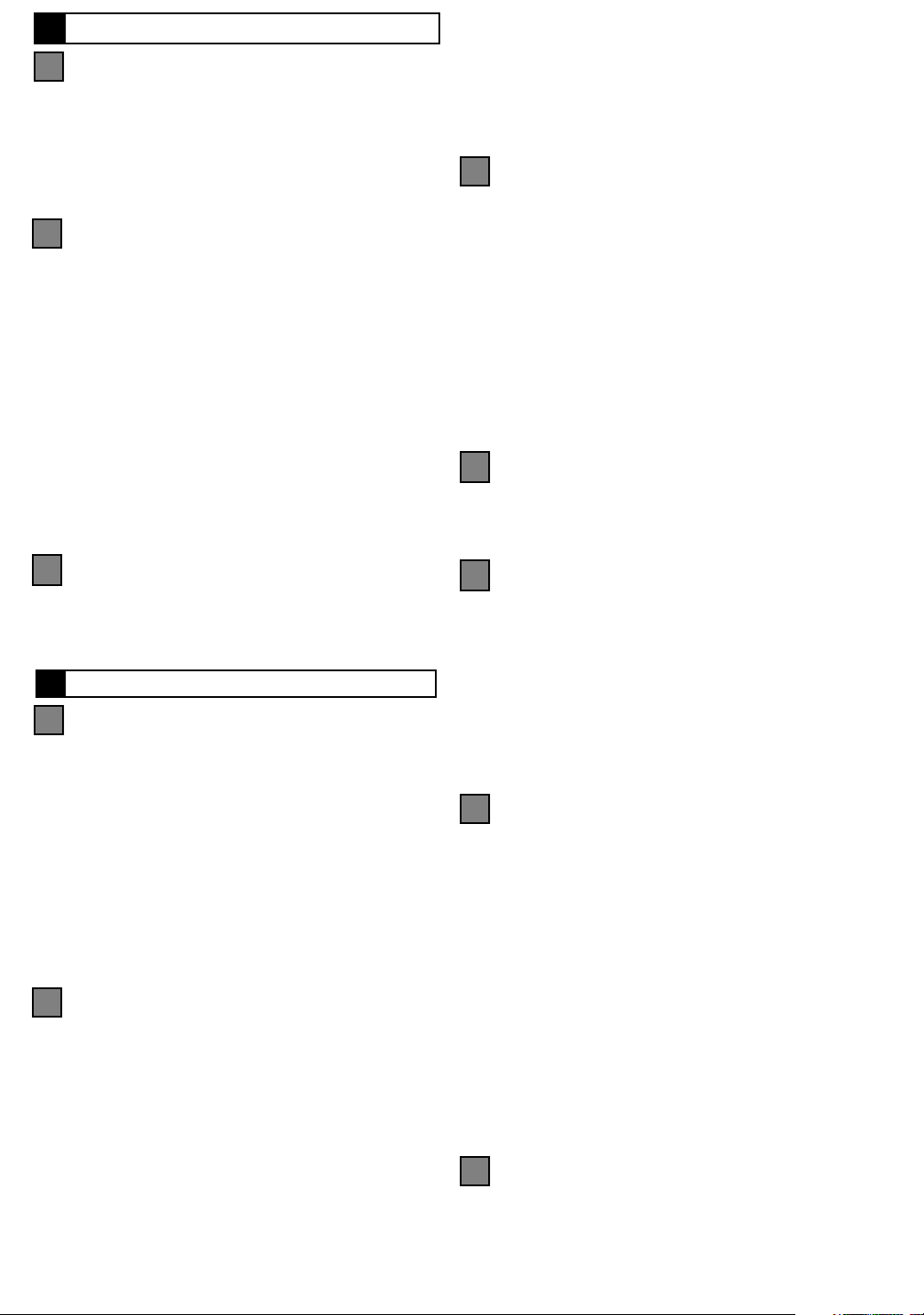

Vehicle identification

UNITL THE DATE OF 26.06.2003

Manufacturer plate

VIN identification number

MANUFACTURER PLATE

a. Manufacturer identification code;

b. Code of the vehicle;

c. Gearbox type code;

d. Engine type code and driving location

(according to VIN code structure);

e. Vehicle code;

f. Trailer maximum authorized weight with-

out braking system;

g. Homologation number for the importer

country

code + 7 characters for the chassis

manufacturing number;

the loaded car

with braking system

on front axle;

rear axle.

;

h. VIS sign; one character for year model

i. Maximum technical admissible weight of

;

j. Maximum admissible weight with trailer

;

k. Maximum technical admissible weight

l. Maximum technical admissible weight on

7

01 - 2

SPECIFICATIONS

vnx.su

01

Vehicle identification

UNITL THE DATE OF 26.06.2003

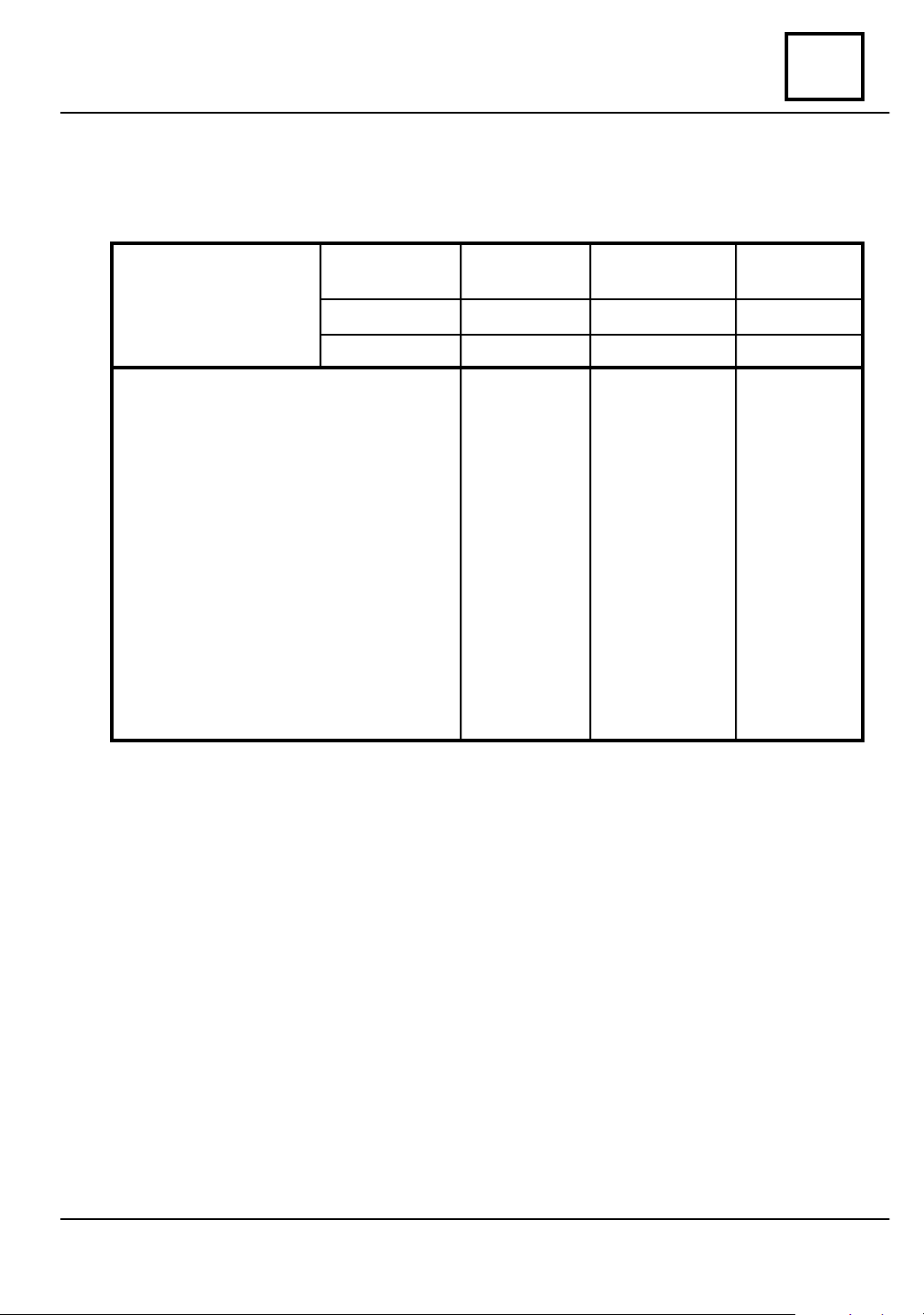

VEHICLE IDENTIFICATION

VIN IDENTIFICATION NUMBER

Position 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

CODE U U 1 D

CODE U U 1 D

CODE U U 1 D

CODE U U 1 D

CODE U U 1 D

CODE U U 1 D

CODE U U 1 D

CODE U U 1 D

CODE U U 1 D

POSITION CHARACTERS EXPLANATION

1 - 3 - manufacturer identification

4 - vehicle type

5 - engine-gearbox unit location

6 - carriage body type

7 - payload location

8 - gearbox type

9 - engine code and vehicle driving location

10 - year model code - 2 - 2002

11 - 17 - chassis manufacturing number

1 6 1 1 * * * * * * * * *

1 7 1 1 * * * * * * * * *

2 6 1 1 * * * * * * * * *

2 7 1 1 * * * * * * * * *

4 6 1 6 * * * * * * * * *

4 7 1 6 * * * * * * * * *

1 F 7 1 * * * * * * * * *

2 F 7 1 * * * * * * * * *

4 F 7 6 * * * * * * * * *

UU1 - AUTOMOBILE DACIA S.A. ROMÂNIA

D - vehicle for goods transportation

1 - longitudinal front engine and front drive

2 - longitudinal front engine and rear drive

4 - longitudinal front engine and four wheel drive (front drive coupling

optional

6 - PICK UP

7 - DROP SIDE

F - PICK UP, DOUBLE CAB

1 - two front seats + bed body

7 - five places : 2 front places + 3 places rear bench + bed body

1 - gearbox with 5 + 1 steps

6 - gearbox with 5 + 1 steps and 4x4 coupling

3

X - motor 1870 cm

type EURO 2, left hand drive

7 - engine 1870 cm

type EURO 3, left hand drive

T - engine 1870 cm

type 1504, left hand drive

with ignition by compression, combustibil (Diesel oil),

3

with ignition by compression, combustibil (Diesel oil),

3

with ignition by compression, combustibil (Diesel oil),

01 - 3

SPECIFICATIONS

vnx.su

01

STARTING WITH THE DATE OF 26.06.2003

MANUFACTURER’S PLATE DISPOSAL TYPE SELF-ADHESIVE

Vehicle identification

Fig.2.1

01 - 4

SPECIFICATIONS

vnx.su

01

Vehicle identification

STARTING WITH THE DATE OF 26.06.2003

The MANUFACTURER PLATE, self-adhesive type, has the bellow presented con-

figuration, with two distinctive areas, presenting :manufacturer’s identification data

and APV type identification data.

A

B

C

D

E

F

G

H

I

J

MANUFACTURER’S IDENTIFICA-

TION DATA

A. Manufacturer’s name

B. Community reception number or

homologation number.

C. Identification number.

D. Total authorized weight of the

loaded vehicle.

E. Total authorized running weight

F. Total weight on front axle.

G. Total weight on rear axle.

H. Additional inscription.

I. Manufacturing date inscription

J. Consignment number.

APV IDENTIFICATION DATA

1.1Code type auto APV

1.2Manufacturing number

2.1 Equipping level code

2.2 Additional code for limited serial

definition

2.3 Additional code for special serial

definition

3.1 Carriage body color code

3.2 Seats upholstery code

3.3 Interior matching code.

4.1 Technical definition code

4.2 Optional equipping code.

01 - 5

LIFTING

vnx.su

Mobile jack – Protection routes

The use of a mobile jack implies the using of protection intermediary routes.

It absolutely forbidden the vehicle lifting using the front or rear suspension arms as

supporting points.

The mobile jack is not to be used for vehicle lifting in order to perform works under the

carriage body (the two columns elevator is to be used).

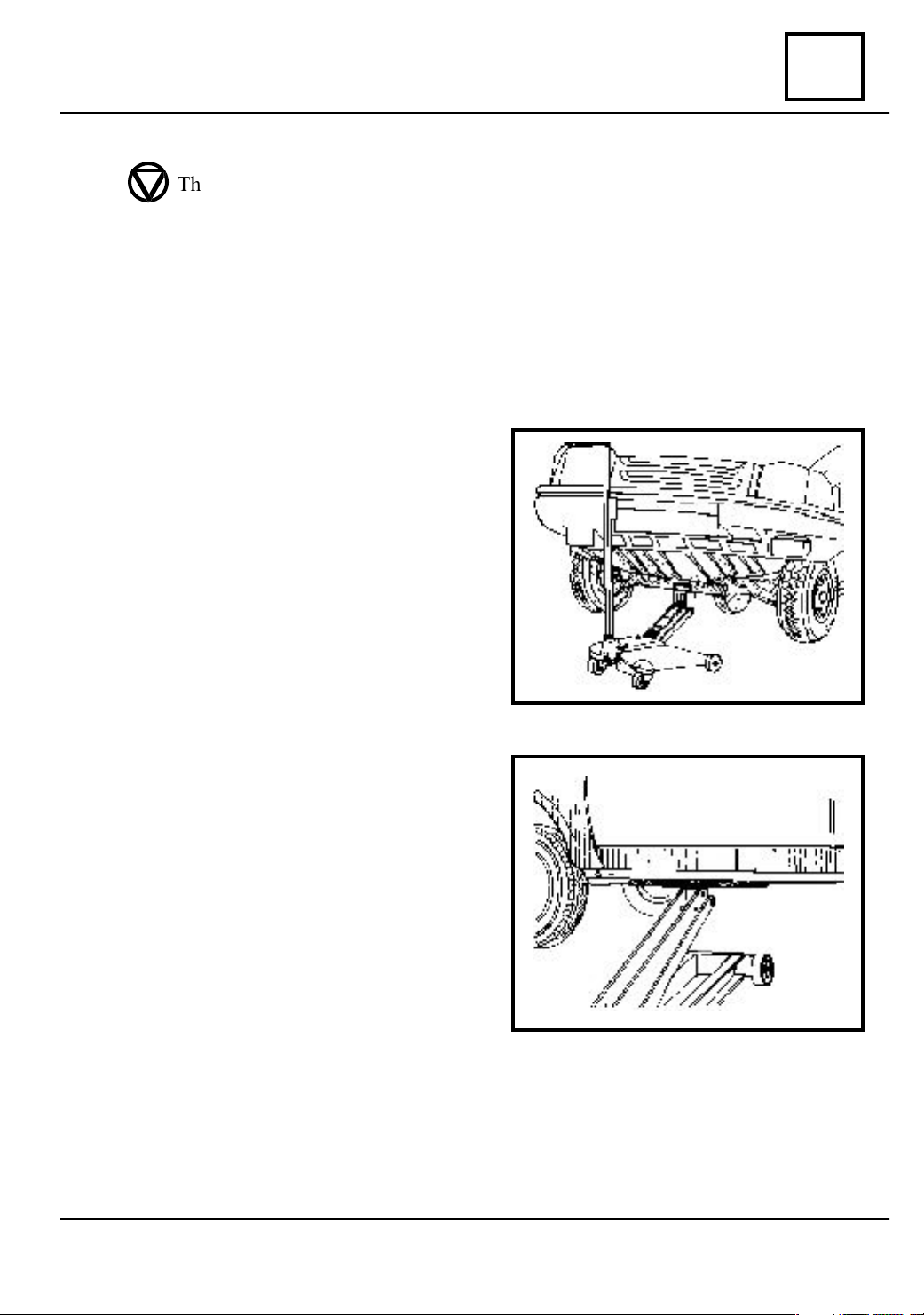

LIFTING THE FRONT PART

OF THE VEHICLE

In order to lift the front of the vehicle, use

the mobile jack and the protection

intermediary route Cha 280 ( for protection

of the body and mechanical elements) which

are placed on the front longitudinal girders in

the suspension arms axle.

02

LATERAL LIFTING

OF THE VEHICLE

For lateral lifting of the vehicle use the mobile jack and the protection intermediary route

CHA 280; place it under the threshold at the

front door level.

The threshold edge shall be correctly

positioned in the channel of the protection

intermediary route.

02 - 1

LIFTING

vnx.su

02

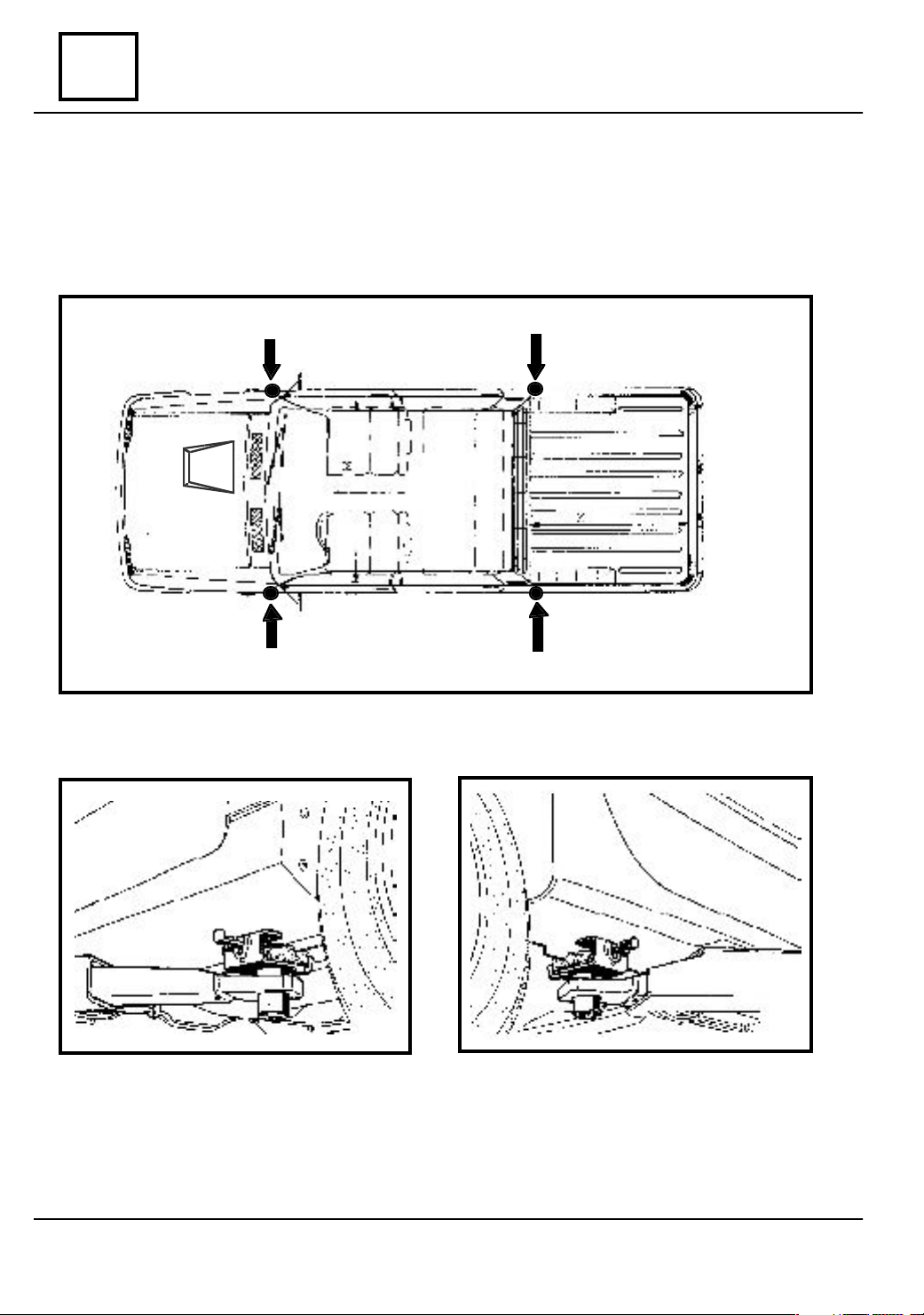

Elevator to be attached under the carriage body

For lifting, place the intermediary routes of the elevator arms in the supporting point of

the vehicle inbuilt used by jack. The threshold edges shall be correctly positioned in the

routes channels.

FRONT

REAR

02 - 2

TOWING

vnx.su

Alltypes

NEVER USE AS TOWING POINTS, THE TRANSMISSION AXLES (PLAN-

ETARY SHAFTS)

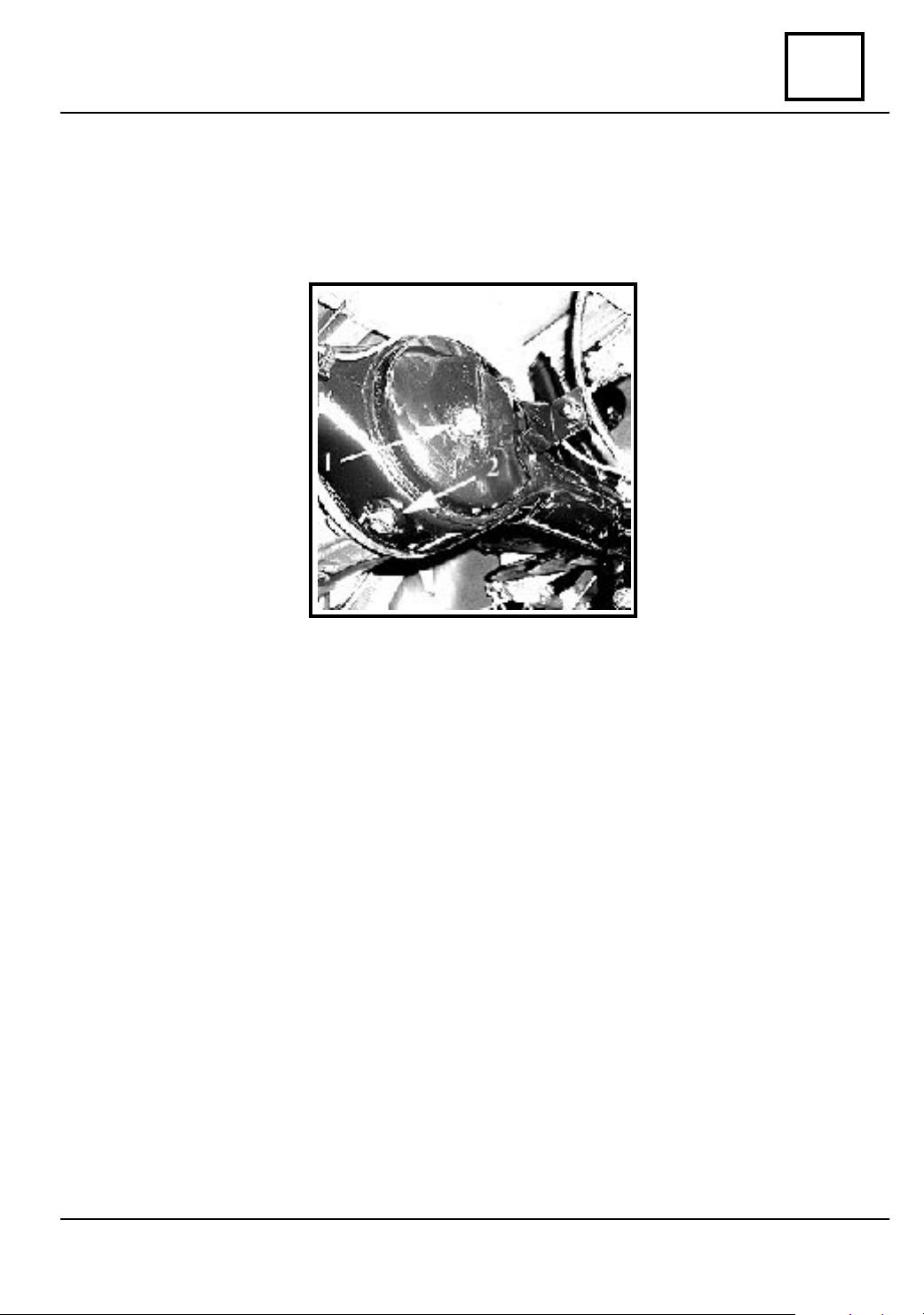

The towing points, front (1) or rear (2) are to be used only for vehicles hauling on

wheels, by towing. These points cannot be anyhow used for drawing out the damaged

vehicle from a trench (hole), or for direct or indirect vehicle lifting on a transport platform.

.

03

FRONT (right)

1

REAR (left)

2

03 - 1

LUBRICANTS CONSUMABLES

vnx.su

Condition

PRODUCT PLACE WHERE IT IS USED

LUBRICATION (GREASING )

Front transmission pinion grooves

Grease

UM 170 Li Ca Pb 2M

Gear box control shaft

Cardan flange annular oil seal

04

ELF CARDREXA RNT2 or

UM 185 Li 2M

Grease

UM 185 Li 2M

Grease U 95 Ca 2

Grease

Li Ca Pb tip II cu MoS2

(or 20 UM Li III)

Grease 22

Planetary transmissions

Front wheel steering knuckle grooves

Cardan transmission

Planetary transmission

Front wheel bearing

Suspension ball joints

Rear axle differential

Wheels bolts

Pressure bearing guide

Steering box (gear-rack, bearings)

Clutch shaft grooves

Pressure bearing

Clutch mechanism diaphragm

Steering box rubber gaskets

Grease U100 Ca 4-5

Auxiliary steering connecting rod

04 - 1

LUBRICANTS CONSUMABLES

vnx.su

04

PRODUCT

RHODORSEAL

5661

LOCTITE 518

KIT DURCISSEUR

LOCTITE 577

Condition

PLACE WHERE IT IS USED

SEALING

Camshaft bearing cap no.1 and 5

Crankshaft no.1 bearing cap

Planetary transmission pins

Gearbox half crankcase

Clutch casing

Rear axle

Crankshaft no.1 bearing cap

Rear driving contact thread

Plug M 16- gearbox

Rear axle

Sealant material 503 ( mastic)

LOCTITE FRENETANCH

DECAPJOINT

Rear axle differential

SOLDERING

Flywheel attachment screws

CLEANING

Cylinder head gasket surface

04 - 2

DRAINING AND FILLING

vnx.su

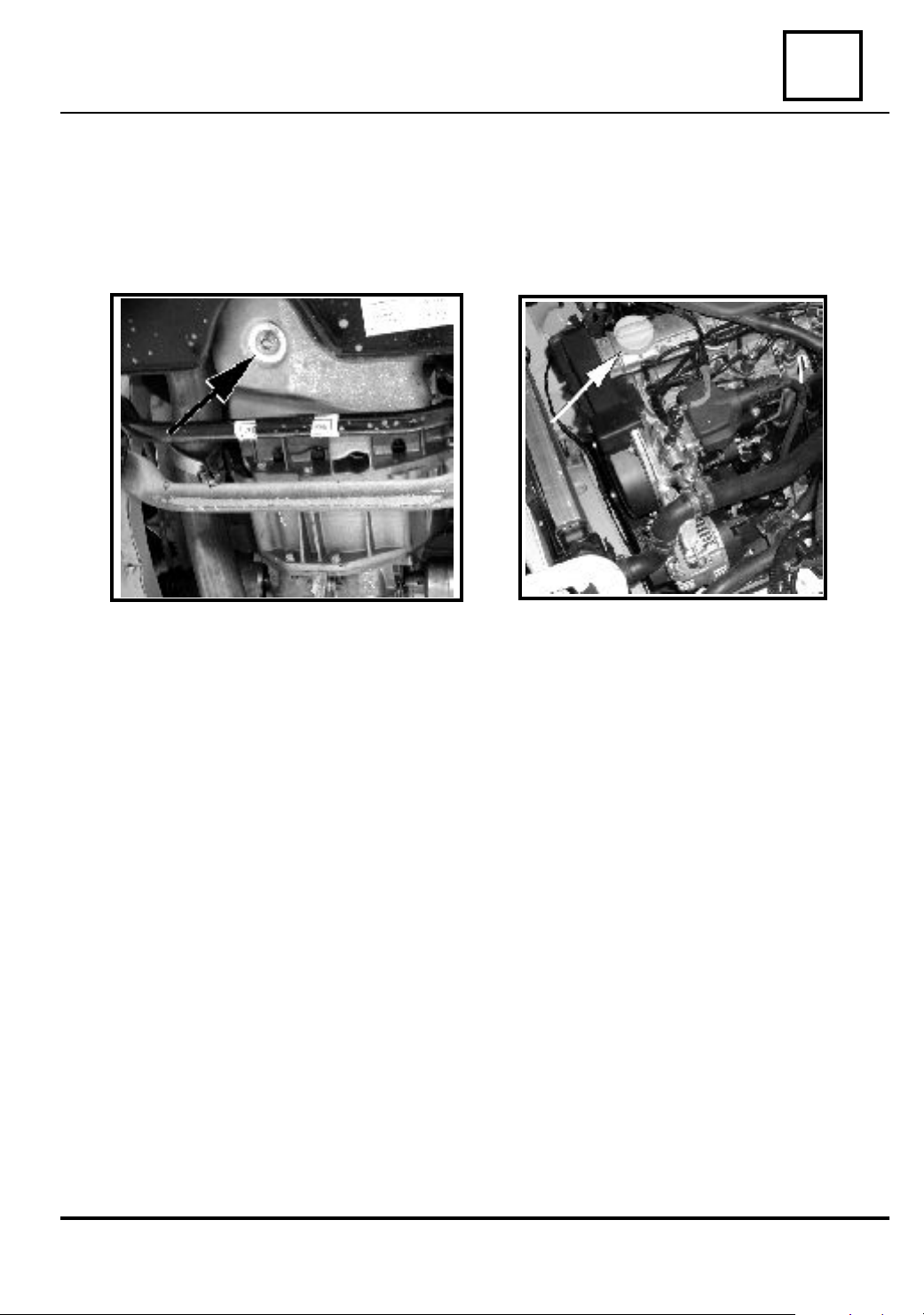

Engine

ENGINE

Necessary special tools - wrench for draining plug : MOT 1018

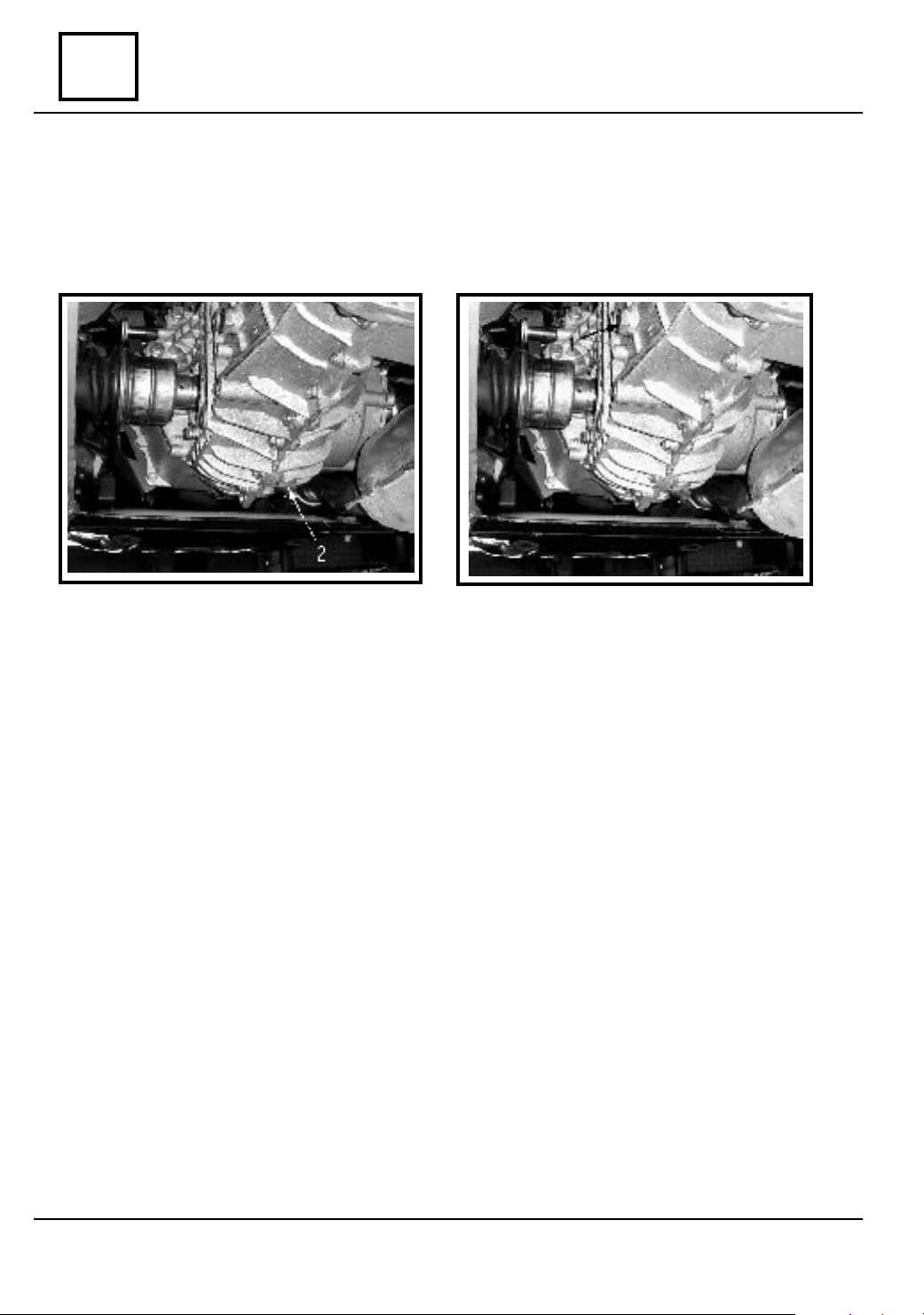

Draining : plug (2) Filling : plug (1)

05

2

1

05 - 1

05

vnx.su

DRAINING AND FILLING

Gearbox

GEARBOX

Drain : plug (2)

Fill : plug (1)

05 - 2

DRAINING AND FILLING

vnx.su

Rear axle differential

REAR AXLE DIFFERENTIAL

Draining: plug (2) Filling: plug (1)

05

05 - 3

VALUES AND SETTINGS

vnx.su

Dimensions

DIMENSIONS

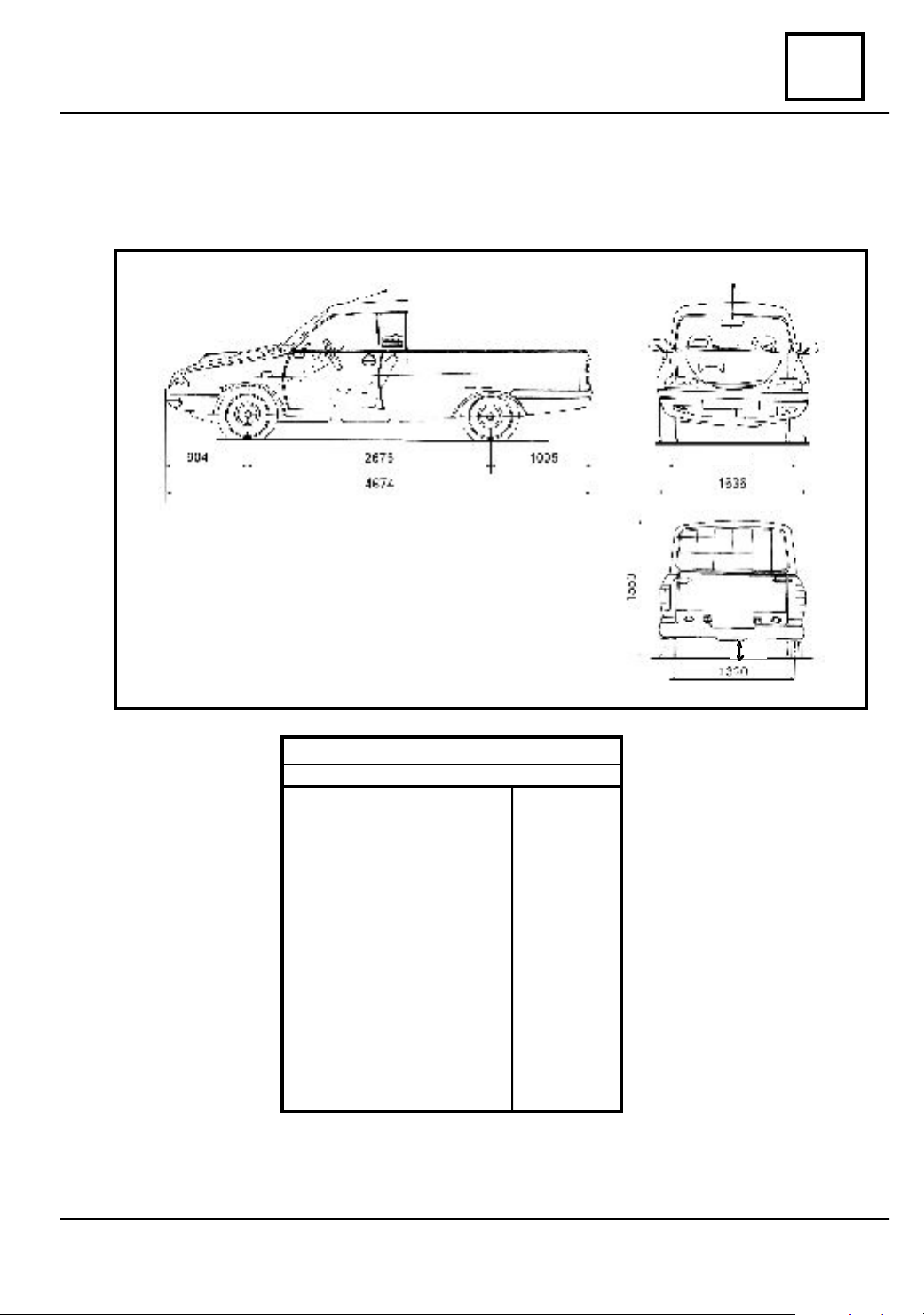

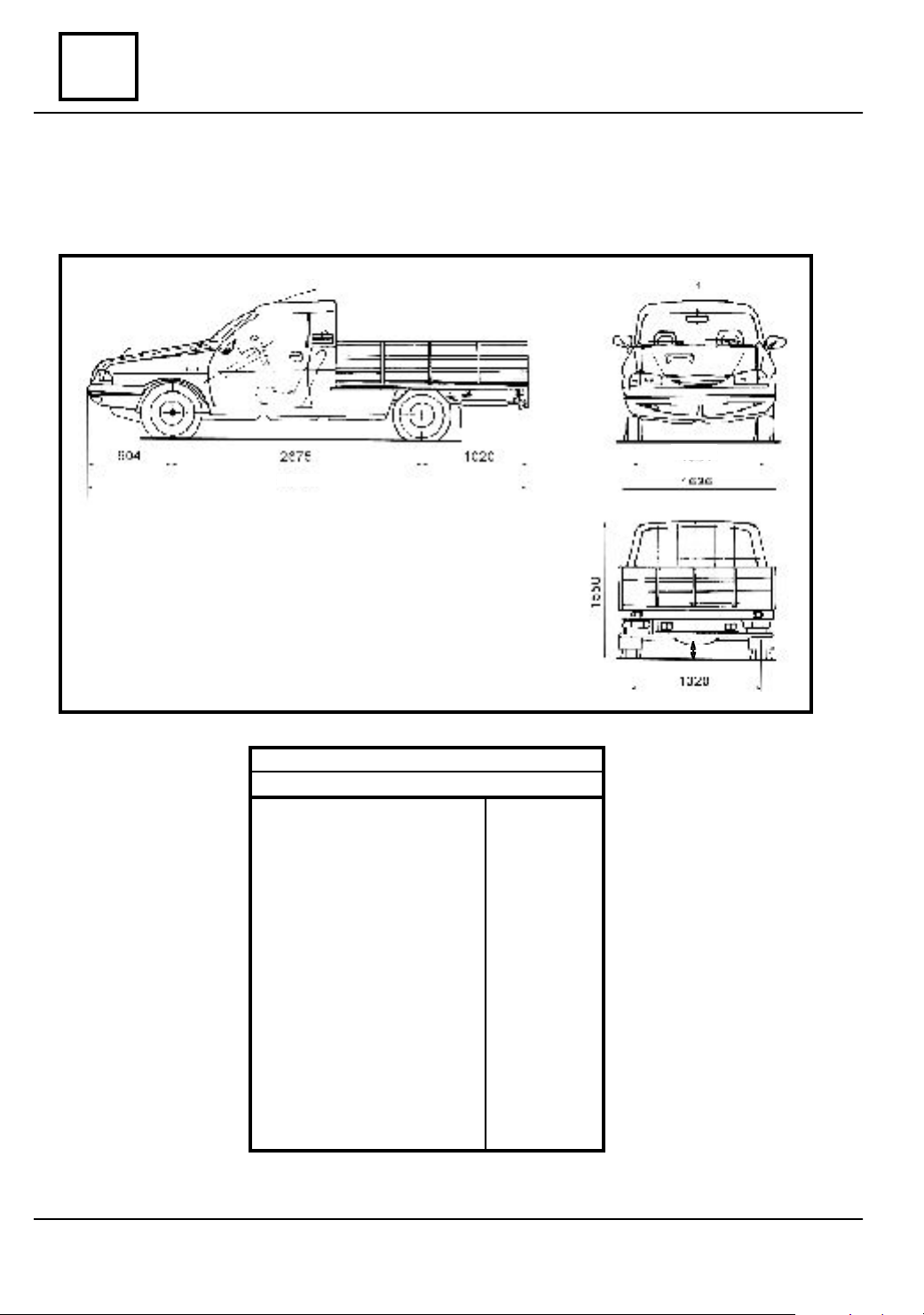

DACIA Pick Up P, 4x4 and T

07

1334

DACIA Pick Up P, 4x4 end T

DIMENSIONS (mm)

Total length

Total width

Total height:

- Empty

- Loaded

Axle base

Front wheel track width

Rear wheel track width

Ground clearance(k):

- Loaded

Turn radius:

- Between footways

- Between walls

k

4674

1636

1550

2675

1334

1320

>140

5600

5800

07 - 1

07

vnx.su

VALUES AND SETTINGS

Dimensions

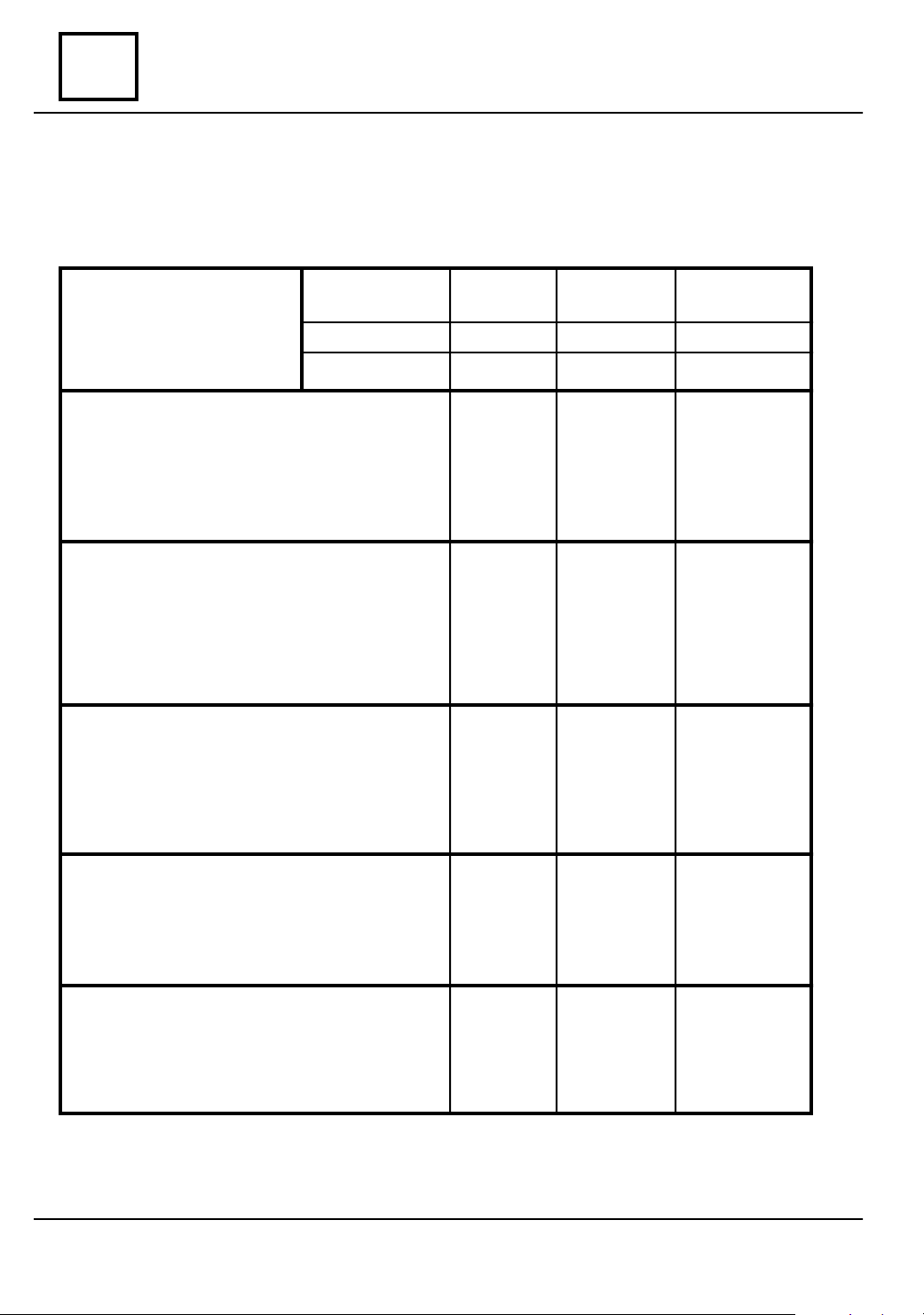

WEIGHTS

DACIA Pick Up P, 4x4 and T

VEHICLE

VEHICLES

WEIGHTS

1. Unloaded vehicle weight

( with 75 Kg. driver)

- on the front axle,

- on the rear axle,

- total.

2. Deadweight

(unloaded vehicle weight):

- on the front axle,

- on the rear axle,

- total.

3. Technical admissible maximal weight

of the loaded vehicle:

- on the front axle,

- on the rear axle,

- total.

DENOMINATION

DRIVE

VIN CODE

:

DACIA

Pick Up P

REAR

D 2611*

635

520

1155

590

490

1080

720

1510

2230

DACIA

Pick Up 4x4

INTEGRAL

D4616*

645

530

1175

600

500

1100

740

1510

2250

DACIA

Pick Up T

FRONT

D 1611*

645

480

1125

600

450

1050

640

1260

1900

4. Technical admissible maximal weight

on each axle:

- on the front axle,

- on the rear axle.

5. Payload:

- on seats,

- on bed body,

- total.

07 - 2

760

1550

150

1000

1150

760

1550

150

1000

1150

760

1300

150

700

850

VALUES AND SETTINGS

vnx.su

Dimensions

TOWING WEIGHTS

DACIA Pick Up P, 4x4 and T

VEHICLE

TOWING

WEIGHTS

1. Te c hnical admissible maximal weight for

towing (trailer with braking system)

2. Admissible maximal weight of the assembly

3. The vehicle is capable / is not capable for

trailer towing

4. To w ing maximal weight without braking

system.

DENOMINATION

DRIVE

VIN CODE

DACIA

Pick Up P

REAR

D 2611*

1095

3225**

capable

450*

DACIA

Pick Up 4x4

INTEGRAL

D 4616*

1075

3225**

capable

450*

07

DACIA

Pick Up T

FRONT

D 1611*

0

not applicable

not capable

0

5. Te c hnical admissible maximal weight on

towing coupling point

** By reducing the bed payload with 100 Kg.

50

50

-

07 - 3

VALUES AND SETTINGS

vnx.su

07

Dimensions

DIMENSIONS

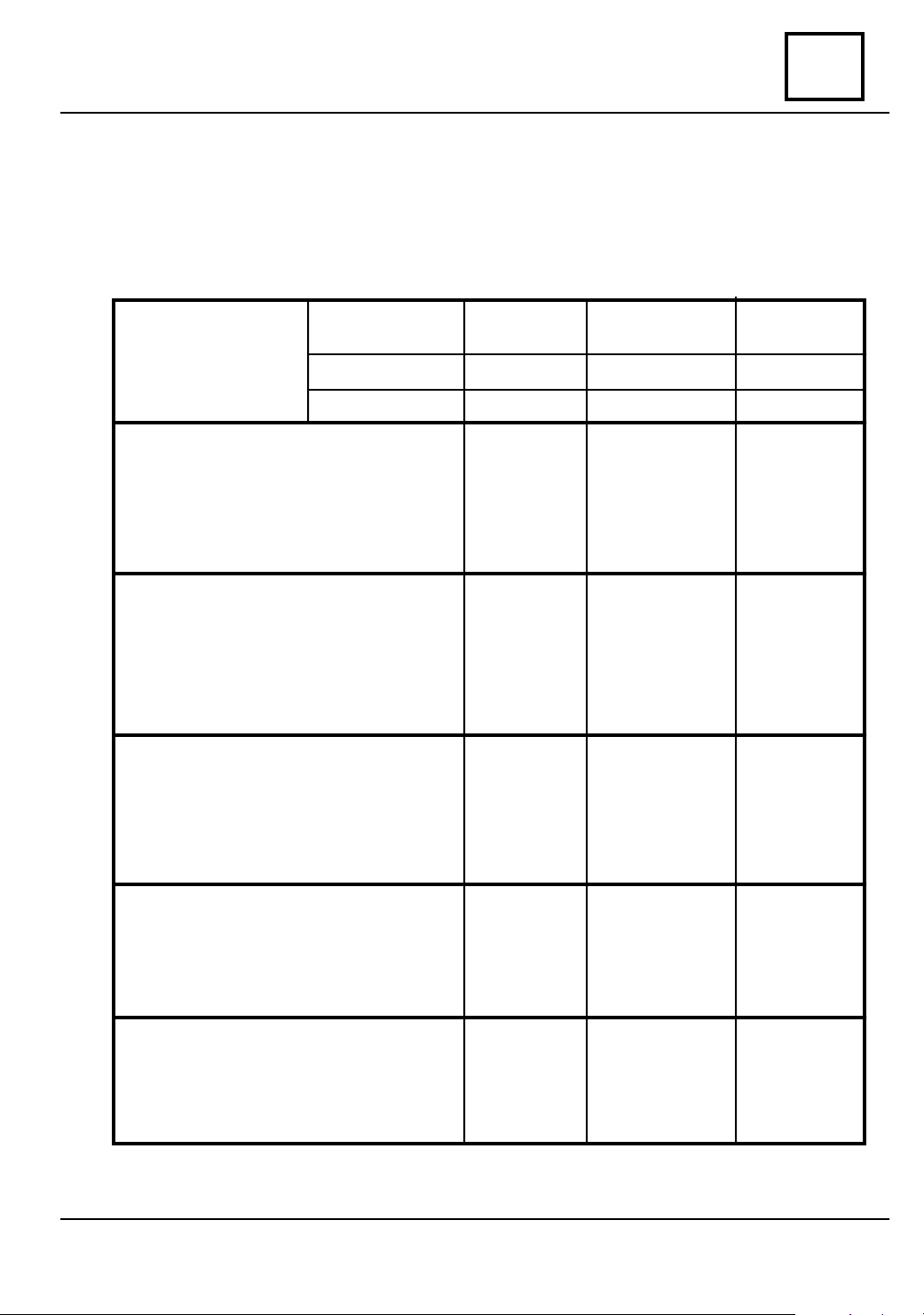

DACIA Drop Side P, 4x4 and T

1334

4599

DACIA Drop Side P, T ºi 4x4

DIMENSIONS (mm)

Total length

Total width

Total height:

- Empty

- Loaded

Axle base

Front wheel track width

Rear wheel track width

Ground clearance (k):

- Loaded

Turn radius:

- Between footways

- Between walls

k

4599

1636

1550

-

2675

1334

1320

> 140

5600

5800

07 - 4

VALUES AND SETTINGS

vnx.su

VEHICLE

VEHICLES

WEIGHTS

1. Unloaded vehicle weight

(with 75 Kg. driver)

- on the front axle,

- on the rear axle,

- total.

DENOMINATION

DRIVE

VIN CODE

:

Dimensions

WEIGHTS

DACIA Drop Side P, 4x4 and T

DACIA

Drop Side P

REAR

D 2711*

635

555

1190

DACIA

Drop Side 4x4

INTEGRAL

D 4716*

1210

645

565

07

DACIA

Drop Side T

FRONT

D 1711*

645

510

1155

2. Deadweight

(unloaded vehicle weight):

- on the front axle,

- on the rear axle,

- total.

3. Technical admissible maximal

weight of the loaded vehicle:

- on the front axle,

- on the rear axle,

- total.

4. Technical admissible maximal

weight on each axle:

- on the front axle,

- on the rear axle.

5. Payload:

- on seats,

- on bed body,

- total.

590

525

1115

690

1540

2230

760

1550

150

965

1115

600

535

1135

690

1540

2230

760

1550

150

945

1095

600

480

1080

690

1240

1930

760

1300

150

150

700

07 - 5

VALUES AND SETTINGS

vnx.su

07

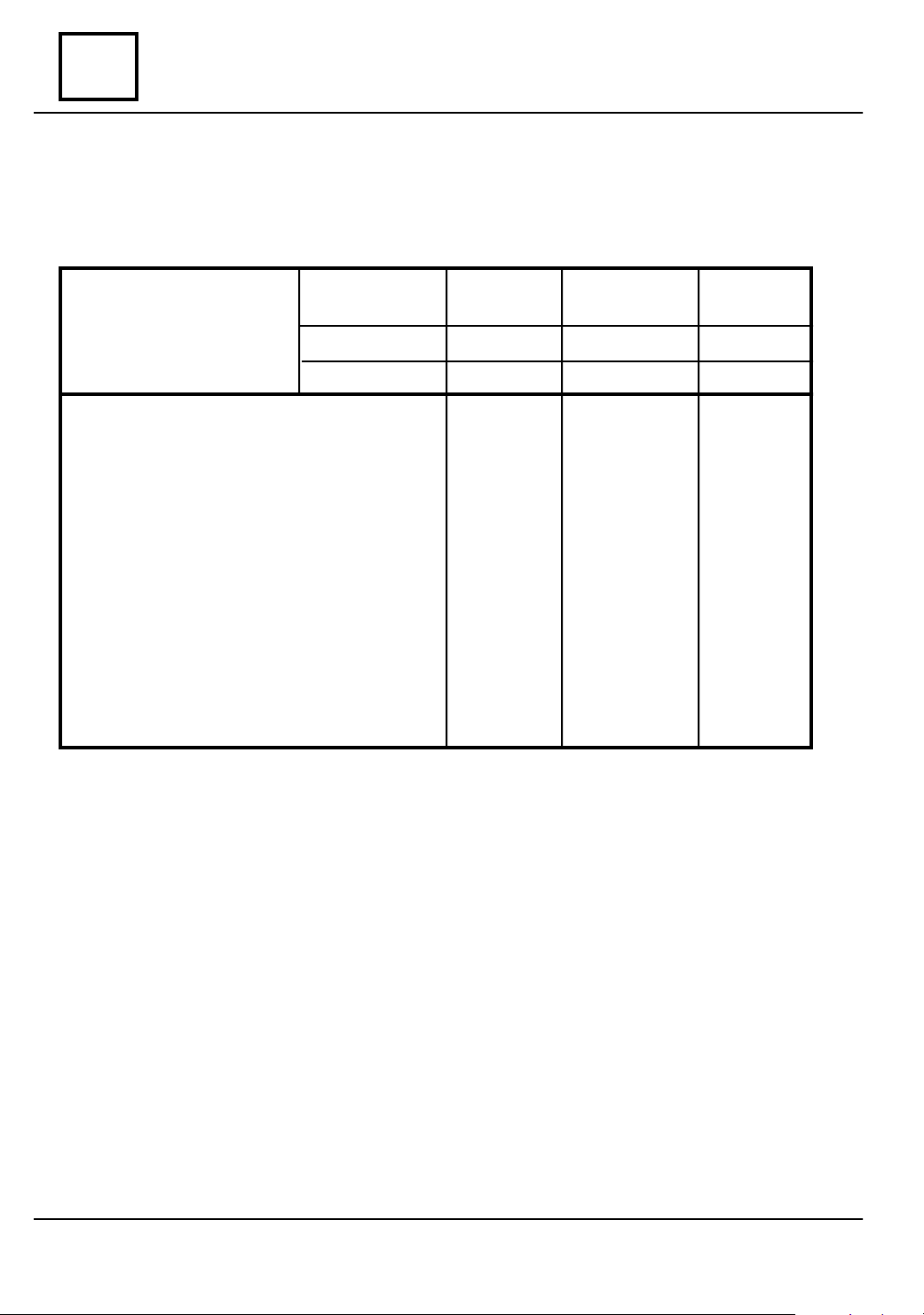

DACIA Drop Side P, 4x4 and T

TOWING

WEIGHTS

1. Te c hnical admissible maximal weight for

towing (trailer with braking system)

2. Admissible maximal weight of the assembly

3. The vehicle is capable / is not capable for

trailer towing

DENOMINATION

VIN CODE

Dimensions

TOWING WEIGHTS

VEHICLE

DRIVE

DACIA

Drop Side P

REAR

D 2711*

1060

3225**

capable

DACIA

Drop Side 4x4

INTEGRAL

D 4716*

1040

3225**

capable

DACIA

Drop SideT

FRONT

D 1711*

0

not

applicable

not capable

4. To w ing maximal weight without braking

system

5. Te c hnical admissible maximal weight on

towing coupling point

** By reducing the bed payload with 100 Kg.

450*

50

450*

50

0

-

07 - 6

VALUES AND SETTINGS

vnx.su

Dimensions

DIMENSIONS

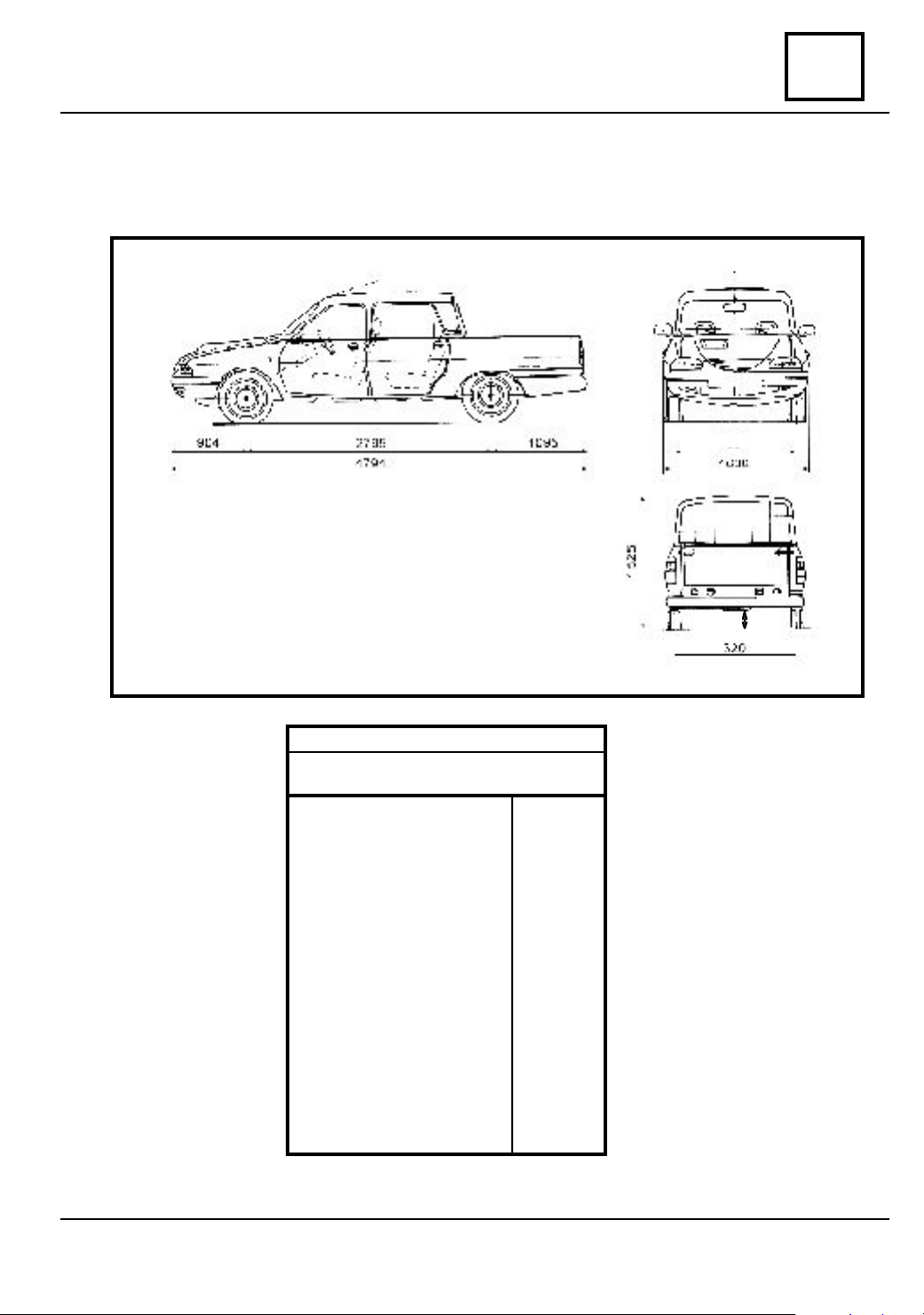

DACIA Double Cab P, 4x4 and T

07

1334

DACIA Double Cab P, 4x4 ºi T

DIMENSIONS (mm)

Total length

Total width

Total height:

- Empty

- Loaded

Axle base

Front wheel track width

Rear wheel track width

Ground clearance (k):

- Loaded

Turn radius:

- Between footways

- Between walls

k

4794

1636

1525

-

2795

1334/1312

1320

>140

5600

5800

07 - 7

VALUES AND SETTINGS

vnx.su

07

DACIA Double Cab P, 4x4 and T

VEHICLE

VEHICLES

WEIGHTS

1. Unloaded vehicle weight

(with 75 Kg. driver)

- on the front axle,

- on the rear axle,

- total.

2. Deadweight

(unloaded vehicle weight):

- on the front axle,

- on the rear axle,

- total.

DENOMINATION

VIN CODE

:

DRIVE

Dimensions

WEIGHTS

DACIA

Double Cab P

REAR

D 2F71*

680

570

1250

635

540

1175

DACIA

Double Cab 4x4

INTEGRAL

D 4F76*

690

580

1270

645

550

1195

DACIA

Double Cab T

FRONT

D 1F71*

690

530

1120

645

500

1145

3. Technical admissible maximal

weight of the loaded vehicle:

- on the front axle,

- on the rear axle,

- total.

4. Technical admissible maximal

weight on each axle:

- on the front axle,

- on the rear axle.

5. Payload:

- on seats,

- on bed body,

- total.

710

1520

2230

820

1550

375

680

1055

730

1520

2250

820

1550

375

680

1055

710

1260

1970

820

1300

375

450

825

07 - 8

VALUES AND SETTINGS

vnx.su

Dimensions

TOWING WEIGHTS

DACIA Double Cab P, 4x4 and T

VEHICLE

TOWING

WEIGHTS

1. Te c hnical admissible maximal weight

for towing (trailer with braking system)

2. Admissible maximal weight of the assembly

3. The vehicle is capable / is not capable

for trailer towing

DENOMINATION

DRIVE

VIN CODE

DACIA

Double Cab P

REAR

D 2F71*

1095

3225**

capable

DACIA

Double Cab 4x4

INTEGRAL

D 4F76*

1075

3225**

capable

07

DACIA

Double Cab T

FRONT

D 1F71*

0

not

applicable

not

applicable

4. To w ing maximal weight without braking system

5. Te c hnical admissible maximal weight

on towing coupling point

** By reducing the bed payload with 100 Kg.

450**

50

450**

50

0

-

07 - 9

07

vnx.su

VALUES AND SETTINGS

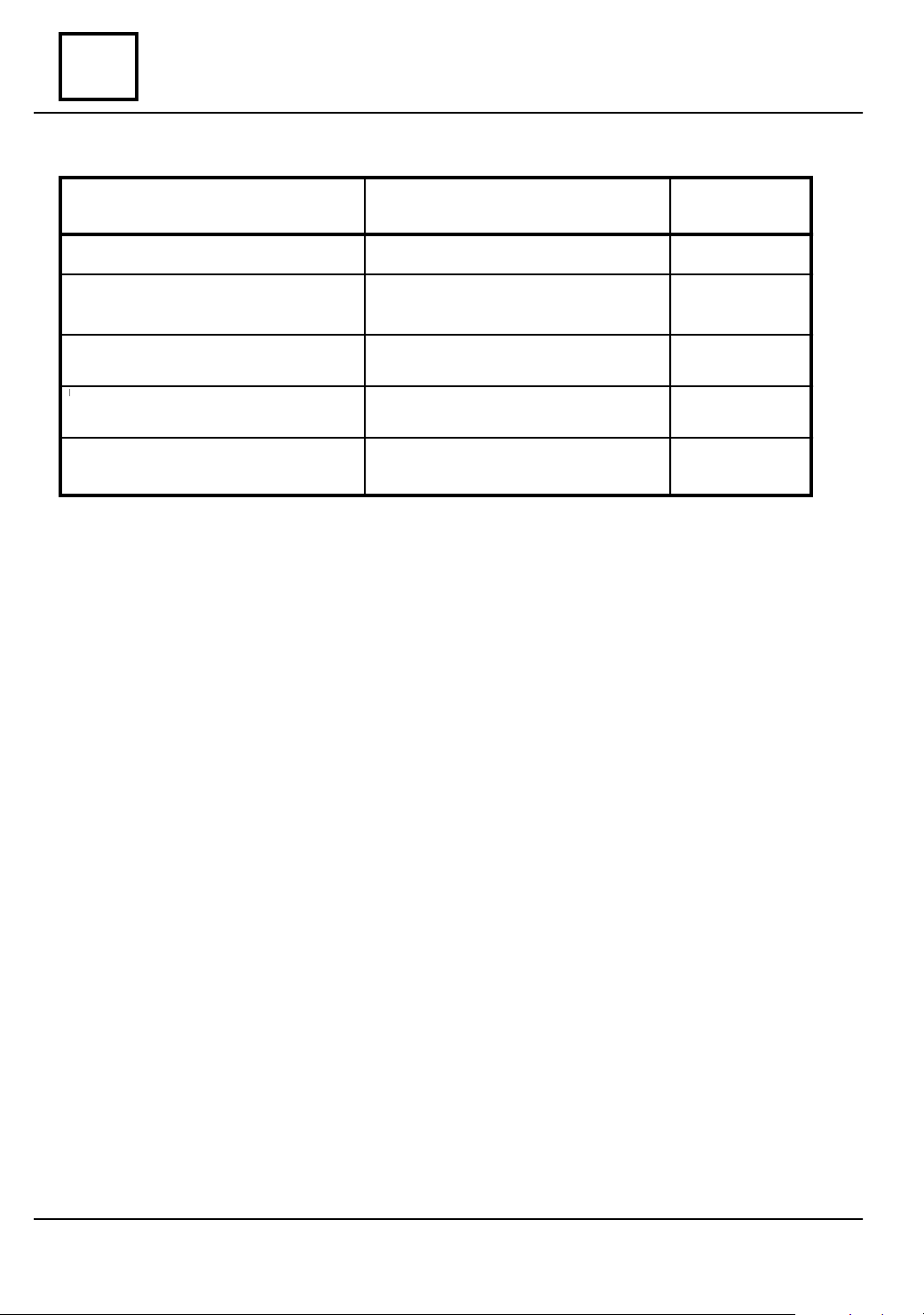

Capacity - Qualities

DENOMINATION

Engine oil Dacia Oil Diesel

Gearbox oil DACIA OIL

SUPERGEAR

The rear axle group oil DACIA

OIL SUPERGEAR

Brake fluid

Cooling fluid

* To be ajusted at dipstick

** Mixture : 50% concentrated anti-freeze + 50% distilled water.

**

SAE API 10W40 ACEA B3 CF

SAE 80 W 90/GL5

SAE 80 W 90 / GL5

SAE J 1703 DOT 4

Typ e D - GLACEOL RX

QUALITY

CAPACITY

(liters)

4,6*

2,3

2

0,450

6

07 - 10

VALUES AND SETTINGS

vnx.su

Wheels and tires

VEHICLE

TYPE

DACIA Pic k Up T, P ºi 4x4

DACIA Drop Si de T, P ºi 4x4

DACIA Doub le Cab T, P ºi 4x4

(1) Using maximum loading, wheels on ground.

• Tightening moment of the wheels screws: 9 daNm.

• Rim axial run out: maxim 1,2 mm.

• Rim radial run out: maxim 1,2 mm.

RIMS TIRES

5 J 14

175 R 14

PR 8

ROLLING

CIRCUMFERENCE

1920 ± 25

07

PRESSURE

(bari) (1)

(mm)

FRONT REAR

2,0 4,5

ATT EN TI ON!

The increase of tire temperature during running implies a growth of the tire pres-

sure with 0.2 – 0.3 bars compared with the prescribed values.

In case of checking the tires pressure immediately after vehicle driving, consider

this growth of pressure.

07 - 11

07

vnx.su

VALUES AND SETTINGS

Brakes

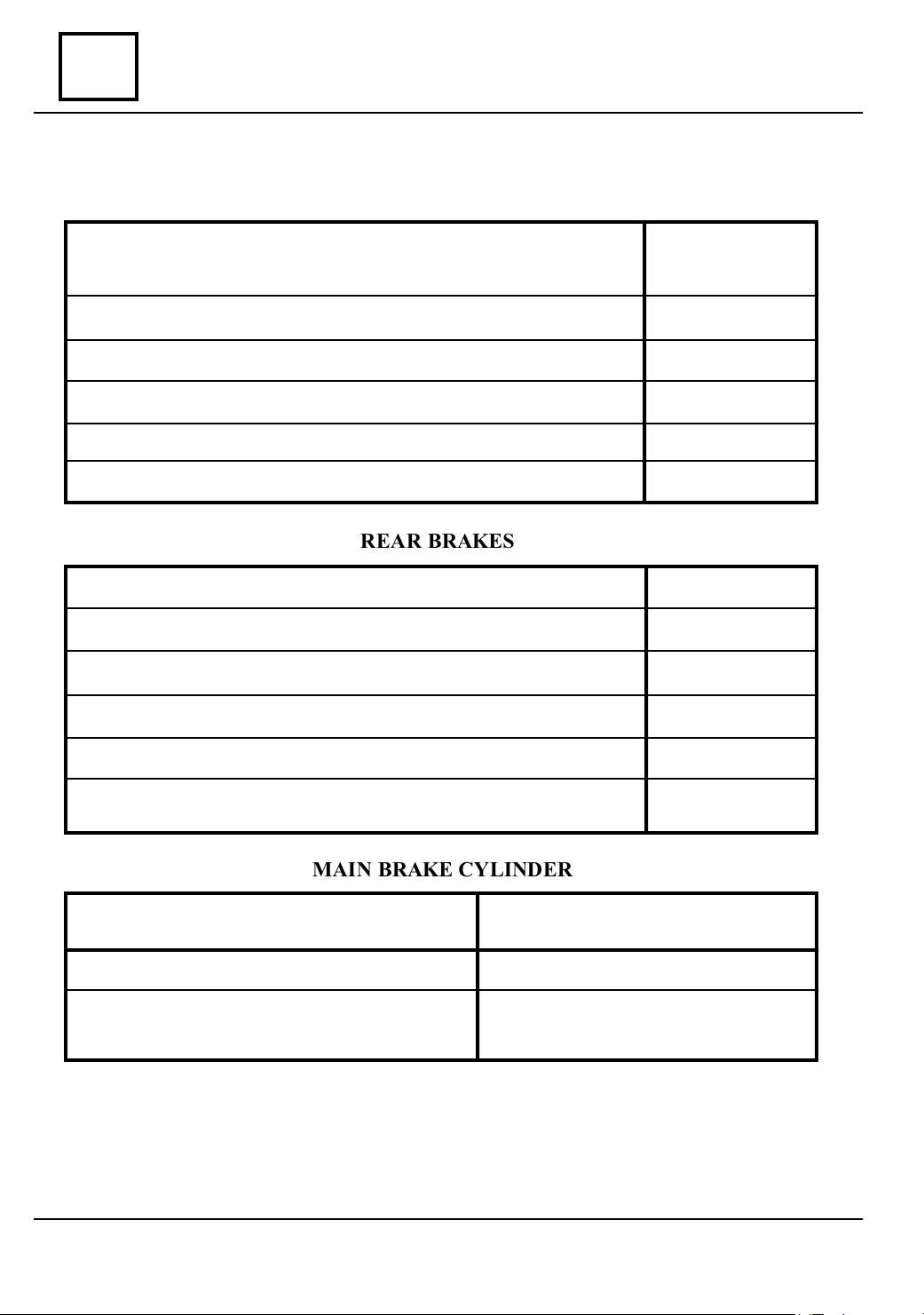

FRONT BRAKES

Brake caliper bore diameter (for aerated brake disk)

Disk thickness aerated

Minimal disk thickness aerated

Brake pad thickness ( the support included)

Minimal brake pad thickness (the support included)

Disk axial run out, measured at → 215 mm

REAR BRAKES

Wheel braking cylinder diameter

New drum diamete

Maximum drum diameter after grinding

Braking lining width

Braking lining thickness

Φ 54 mm

20 mm

19 mm

14 mm

7 mm

0,1 mm

Φ 25,4 mm

Φ 254 mm

Φ 255 mm

50 mm

5 mm

Minimal accepted braking lining height above rivets

MAIN BRAKE CYLINDER

Tandem master cylinder with ICP by

Type of main brake cylinder

nner diameter

Stroke - primary piston

- secondary piston

• Brake fluid reservoir - double without level warning.

• Pressure reducing valve - for parallel circuit.

• Brake fluid - norm SAE J 1703 DOT4.

• Servobrake - master vac 8" 224 mm

07 - 12

pass included

Φ 22,2 mm

min. 19 mm

min. 13 mm

0,5 mm

VALUES AND SETTINGS

vnx.su

Heights under carriage body

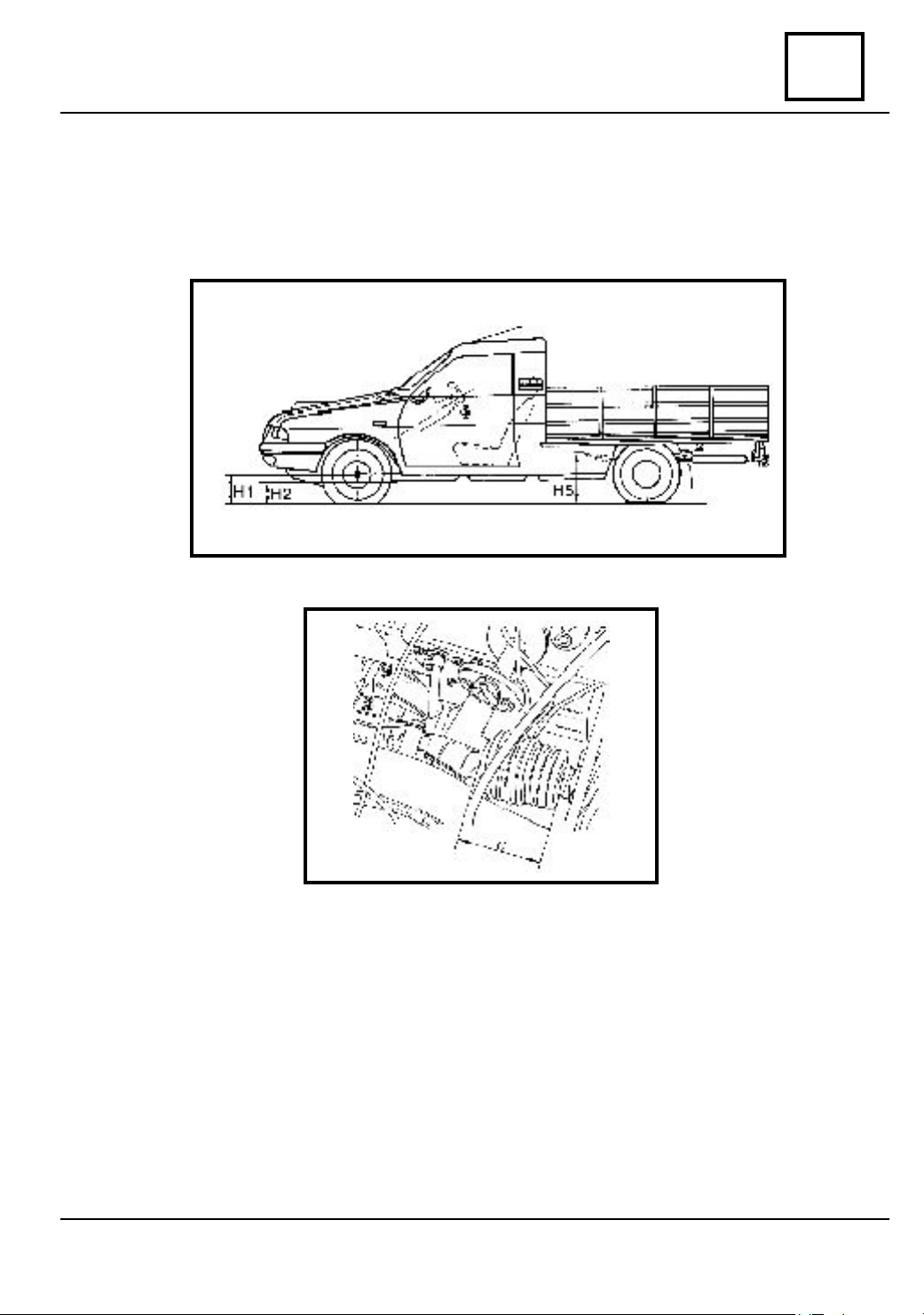

VA LUES UNDER CARRIAGE BODY CONDITIONING THE ADJUSTMENT

OPERATIONS OF THE STEERING ANGLES.

07

H1 – the distance measured from the wheels center to the ground

H2 – the distance measured from the longitudinal girder lower part to the ground

H5 – the distance measured from the joint axis of the front leaf spring to the ground,

measured in the area of the lower arm attachment.

C – this value is showing the position where the rack must reach in order to obtain

the middle point for the steering rack.

07 - 13

07

vnx.su

VALUES AND SETTINGS

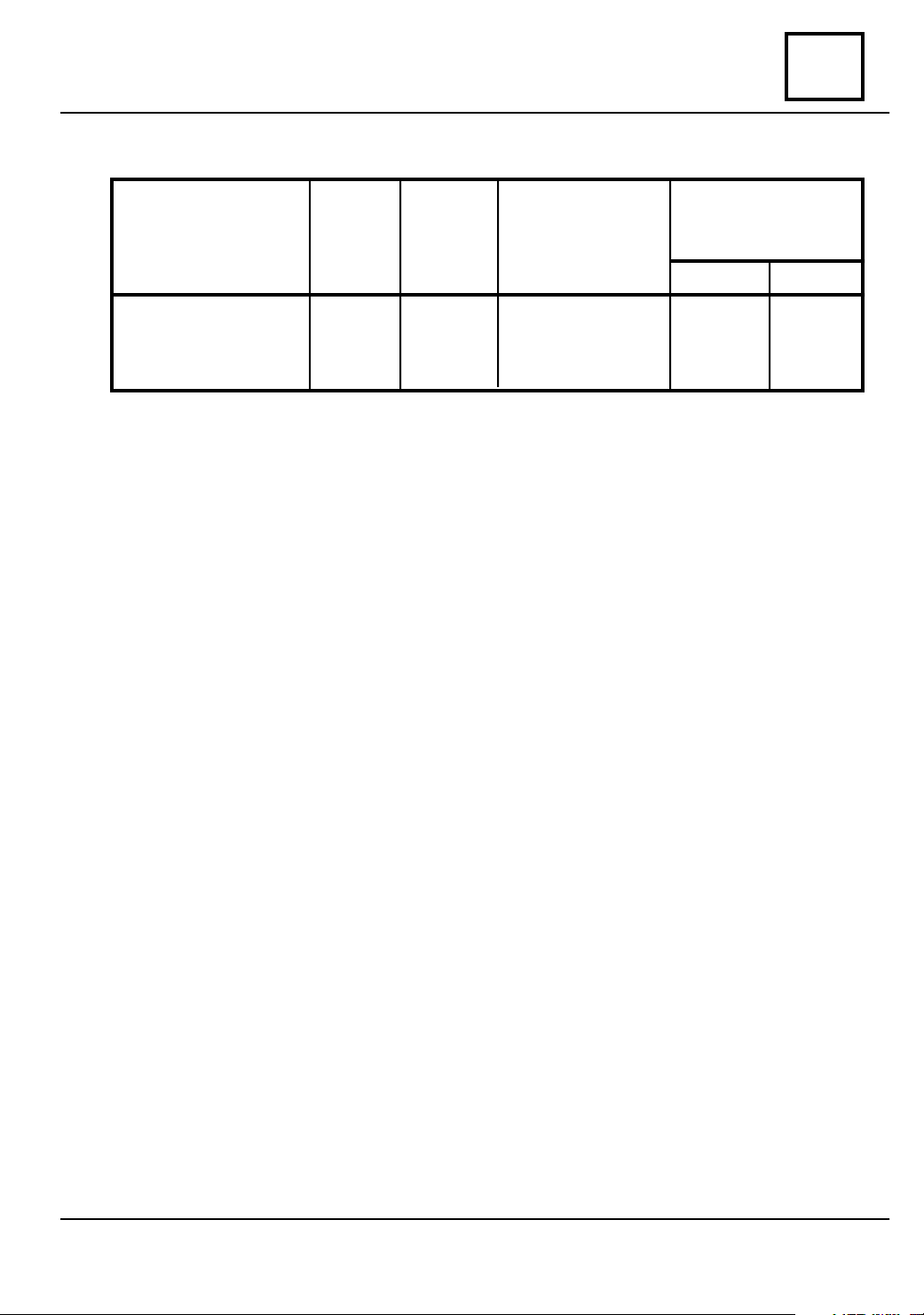

Control values of front the axle angles

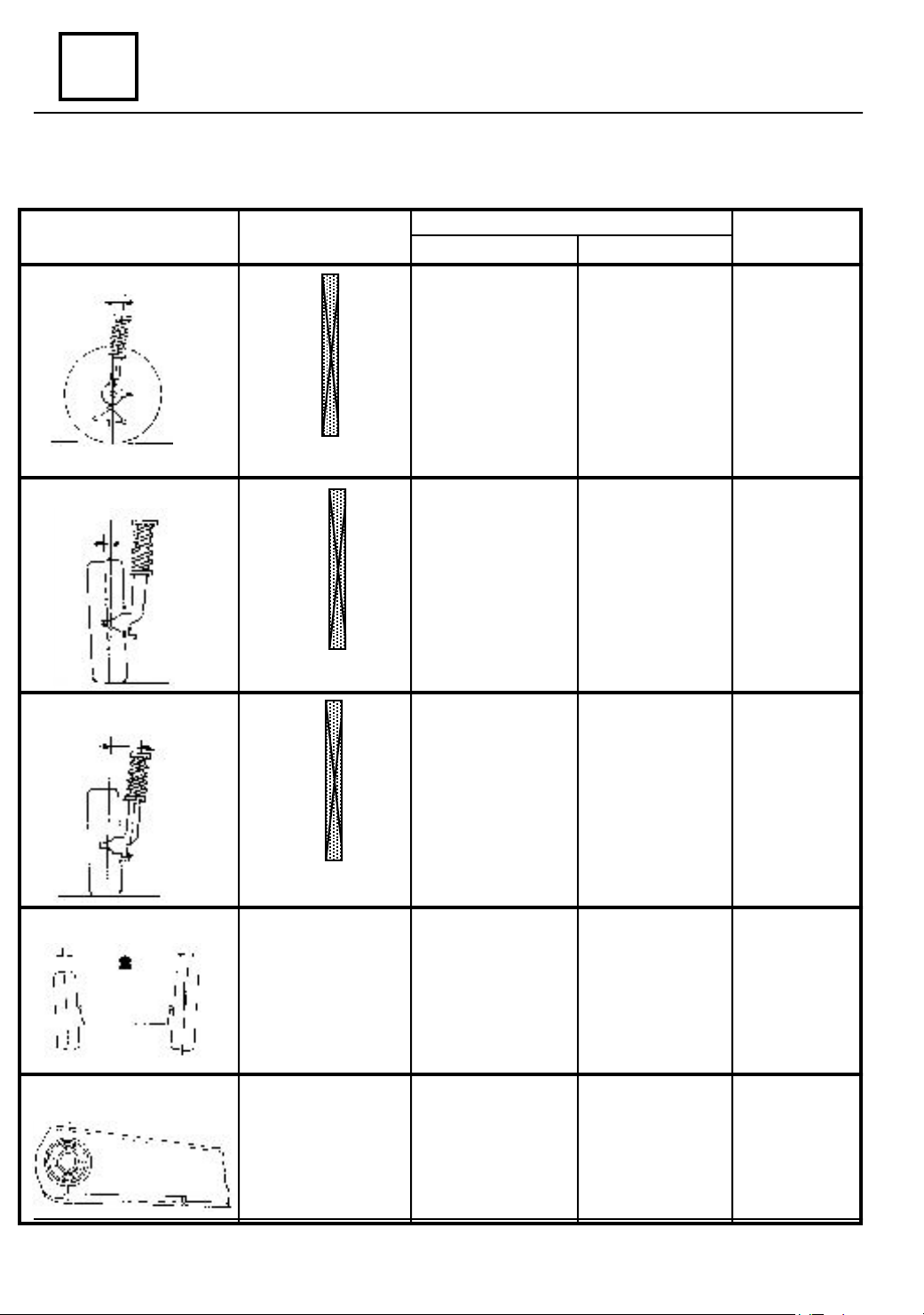

COMMERCIAL U 75 DRIVE (1304, 1307)

ANGLES

CASTER

CAMBER

BALL JOINT

TOTAL PARALLELISM

VA L U ES

0

11'

1

0

28'

1

0

45' ± 30'

1

0

02'

2

0

19'

2

0

0

36'

52'

2

2

Maximum Left /

Right difference = 1

10 22'

0

1

21'

0

20'

1

0

18' ± 30'

1

0

17'

1

0

15'

1

0

14'

1

Maximum Left /

Right difference = 1

80 01'

0

02'

8

0

03'

8

0

04' ±30'

8

0

05'

8

0

07'

8

0

08'

8

Maximum Left /

Right difference = 1

POSITION OF THE VEHICLE

1304

H5 - H2 = 260

H5 - H2 = 250

H5 - H2 = 240

H5 - H2 = 230

H5 - H2 = 220

H5 - H2 = 210

H5 - H2 = 200

0

H1 - H2 = 66

H1 - H2 = 62

H1 - H2 = 58

H1 - H2 = 54

H1 - H2 = 51

H1 - H2 = 47

H1 - H2 = 43

0

H1 - H2 = 66

H1 - H2 = 62

H1 - H2 = 58

H1 - H2 = 54

H1 - H2 = 51

H1 - H2 = 47

H1 - H2 = 43

0

H5 - H2 = 265

H5 - H2 = 255

H5 - H2 = 245

H5 - H2 = 235

H5 - H2 = 225

H5 - H2 = 215

H5 - H2 = 205

H1 - H2 = 66

H1 - H2 = 62

H1 - H2 = 58

H1 - H2 = 54

H1 - H2 = 51

H1 - H2 = 47

H1 - H2 = 43

H1 - H2 = 66

H1 - H2 = 62

H1 - H2 = 58

H1 - H2 = 54

H1 - H2 = 51

H1 - H2 = 47

H1 - H2 = 43

ADJUSTMENTS

1307

Adjustable by

modification of

the tie-rod

length from

previous

mounting

Not adjustable

Not adjustable

ELASTIC JOINTS BLOCKING

Opening (toe-in)

0

10’ ± 10’

0

(for one wheel

0

05’ ± 05”)

0

-

Empty

Empty

07 - 11

Empty

Adjustable by

means of the

tie rods rota-

tion

Empty

-

Loading...

Loading...