Page 1

REPAIR MANUAL

vnx.su

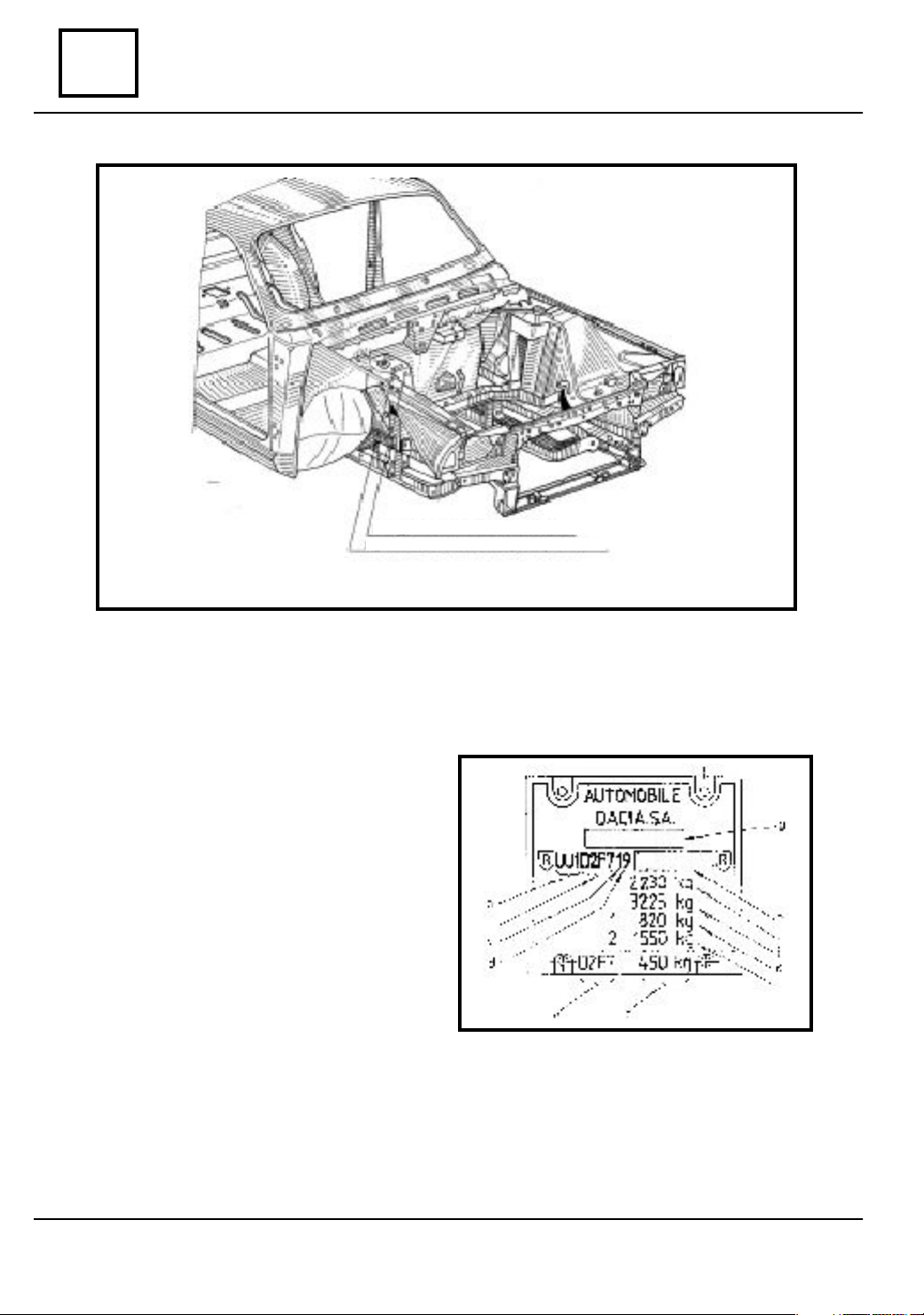

DACIA COMMERCIAL

RM 502-1 MECHANICS

ENGINE: C3L

GERBOX: NG1; NG7

TAPV: U75B; U75F

Ref: 6001999452 NOVEMBER 2004 English version

The reparation methods prescribed by the manufacturer in the present document are established subject to

technical specifications in force at the document issuing date.

These are subject to modifications brought by the manufacturer at the fabrication of different assemblies,

subassemblies or accessories of its vehicles.

All rights reserved to SC Automobile Dacia SA.

Reproduction or translating even partially of this present document is forbidden without the written

authorisation of AUTOMOBILE DACIA S.A.

Page 2

General poinds vehicle

vnx.su

0

01 SPECIFICATIONS

Engine – Clutch - Gearbox ........................... 01-1

Vehicle identification ................................. 01-2

02 LIFTING

Mobile jack and protection route .................. 02-1

Elevator positioned under the carriage body... 02-2

03 TOWING

All types ........................................................ 03-1

12 FUEL MIXTURE

Characteristics .............................................. 12-1

Injector valve body ....................................... 12-2

Inlet exhaust manifold .................................. 12-3

13 PUMP SUPPLY

Fuel filter (injection engine) ........................ 13-1

14 ANTIPOLLUTION

Gasoline vapours reaspiration ...................... 14-1

Carbon can ................................................... 14-2

Carbon can valve ......................................... 14-3

04 LUBRICANTS CONSUMABLES

Conditions ..................................................... 04-1

05 DRAINING AND FILLING

Engine ............................................................ 05-1

Gearbox ......................................................... 05-2

Rear axle differential ..................................... 05-3

07 VALUES AND SETTINGS

Dimensions .................................................... 07-1

Capacity - Qualities ....................................... 07-4

Driving belts tightening and tightening

checking ........................................................ 07-5

Cylinder head tightening and retightening .... 07-7

Wheeles and tyres ......................................... 07-8

Brakes ........................................................... 07-9

Heights under carriage body ......................... 07-10

Control values of the front axle angles ..........07-11

Control values of the rear axle angles ........... 07-15

1

10 ENGINE AND LOWER ENGINE UNITS

Engine and peripherics

Ingredients .................................................... 10-1

Identification ................................................. 10-2

Measurement of oil consumption .................. 10-4

Oil pressure checking .................................... 10-6

Oil filter replacement .................................... 10-7

Engine Dismounting - Remounting ............... 10-8

Engine and gearbox

Dismounting - Remounting ........................... 10-11

Tightening by screwing up moments ............ 10-14

Characteristics .............................................. 10-15

Dismounting - Mounting ............................... 10-23

Replacement of the distribution annular

oil seal ........................................................... 10-55

Distribution cap ............................................ 10-56

Tightener and distribution chain ................... 10-59

Camshaft ....................................................... 10-61

Lower crankcase ........................................... 10-64

Oil pump ....................................................... 10-66

16 STARTING AND CHARGING

Alternator ..................................................... 16-1

Starter ........................................................... 16-20

17 IGNITION AND INJECTION

Spark plugs ................................................... 17-1

Operation principle .. .................................... 17-3

Description of the system ............................. 17-4

Diagnostic ..................................................... 17-23

Electronic Control Unit ................................ 17-30

Rotation sensor ............................................ 17-31

Engine temperature sensor ........................... 17-32

Oxygen sensor .............................................. 17-33

Induction coil ................................................ 17-34

Spark plugs set ............................................. 17-35

19 COOLING - EXHAUST - FUEL TANK

Characteristics .............................................. 19-1

Filling and aeration of the cooling system ... 19-2

Control ......................................................... 19-3

Cooling radiator ........................................... 19-7

Cooling G.M.V. ............................................ 19-8

Cooling G.M.V. thermocouple checking

(for Pick-Up with C.A.) ............................... 19-9

Water pump .................................................. 19-10

Water pump cover ........................................ 19-11

Thermostat ... ................................................ 19-12

Exhaust assemby .......................................... 19-13

Fuel tank assembly ....................................... 19-15

Electric fuel pump ........................................ 19-16

Fuel level sensor .......................................... 19-18

2

20 CLUTCH

Transmission

Characteristics .............................................. 20-1

Identification ................................................ 20-2

Clutch disk-mechanism ................................ 20-3

Clutch fork replacement ............................... 20-5

Page 3

21 MANUAL GEARBOX

vnx.su

Identification................................................. 21-1

Sections ........................................................ 21-2

Diagnostics ................................................. 21-6

Characteristics .............................................. 21-9

Tightening moments ..................................... 21-10

Ingredients.. .................................................. 21-11

Dismounting - Remounting .......................... 21-12

Repair ........................................................... 21-16

Back cap ....................................................... 21-45

Control shaft annular oil seal replacement ... 21-46

Speedometer endless screw pinion

replacement .................................................. 21-47

Ve l ocity step V syncroniser replacement ..... 21-48

Clutch shaft annular oil seal replacement .... 21-49

Propeller shaft annular oil replacement ....... 21-50

29 DRIVE SHAFTS

Front cross transmission ............................... 29-1

Bellows towards to the gearbox ................... 29-5

Bellows towards the wheel .......................... 29-7

Longitudinal transmission (cardanic) .......... 29-8

3

30 GENERAL

31 FRONT BEARING ELEMENTS

Chassis

General principle schedule of a brake circuit

in parallel with by-pass circuit ..................... 30-1

Tightening moments (daN) .......................... 30-2

The dimensions of main braking elements ... 30-7

Brake connections and sewerage ................. 30-8

Brake fluid ................................................... 30-9

Braking circuit purging ................................ 30-10

Diagnostic .................................................... 30-11

The influence of angles ................................ 30-16

Steering preliminary checkings and

adjustment possibilities ................................ 30-18

Front axle checking-adjustment ................... 30-19

Diagnostic .................................................... 30-22

Upper arm .................................................... 31-1

Elastic bushing, upper arm ball joint ........... 31-4

Lower arm .................................................... 31-6

Elastic bushing, lower arm ball joint ........... 31-9

Brake gaskets................................................ 31-11

Brake caliper................................................. 31-13

Brake disk..................................................... 31-17

Brake caliper support ................................... 31-20

Steering knuckle............................................ 31-21

Steering knuckle bearing............................... 31-24

Characteristics of front suspension

main elements ............................................... 31-26

Suspension - Tightening moments ............... 31-27

Front shock absorber .................................. 31-28

Front suspension spring .............................. 31-32

Front stabilizer rod ...................................... 31-33

33 REAR BEARING ELEMEN TS

Plate drive rear axle ..................................... 33-1

Brake drum................................................... 33-4

Brake cylinder.............................................. 33-6

Brake shoes.................................................. 33-8

Bearing (39 x 68 x 37)................................ 33-10

Plate drive rear axle differential .................. 33-11

Non drive plate rear axle ............................. 33-20

Non drive pipe rear axle ............................. 33-22

Cast iron rear drive axle .............................. 33-24

Cast iron rear drive axle differential ........... 33-27

Shock absorber ............................................ 33-34

Spring .......................................................... 33-35

Rear antiroll rod .......................................... 33-36

35 WHEELS AND TYRES

Characteristics ............................................. 35-1

Wheels balancing ........................................ 35-4

36 STEERING ASSEMBLY

Characteristics, tightening couplers ............ 36-1

Setting the steering gear central point ......... 36-3

Noise absorber bearing ................................ 36-5

Pusher adjustment ........................................ 36-7

Adjustable steering auxiliary

connecting rod ............................................ 36-12

Steering wheel shaft bushing ....................... 36-14

Steering gear shaft ....................................... 36-16

37 MECHANICAL ELEMENTS CONTROLS

Brake pump.................................................. 37-1

Servobrake................................................... 37-5

Air filter – servobrake retainer valve........... 37-8

Handbrake ................................................... 37-9

Handbrake control lever .............................. 37-10

Handbrake primary and secondary cable .... 37-11

Brake limiter ............................................... 37-13

Brake pedal and clutch ................................ 37-15

Clutch cable - Clutch stroke adjustment ..... 37-16

The steering column support assy

and fire wall ... .............................................. 37-17

Throttle pedal .............................................. 37-18

Gearbox control mechanism ........................ 37-19

38 ELECTROVACUUMATIC CONTROL SYSTEM

4X4 COUPLING

Presentation ................................................. 38-1

Electrovacuumatic control adjustment ........ 38-3

Vacuum capsule ........................................... 38-5

Electrovalve ................................................ 38-6

Page 4

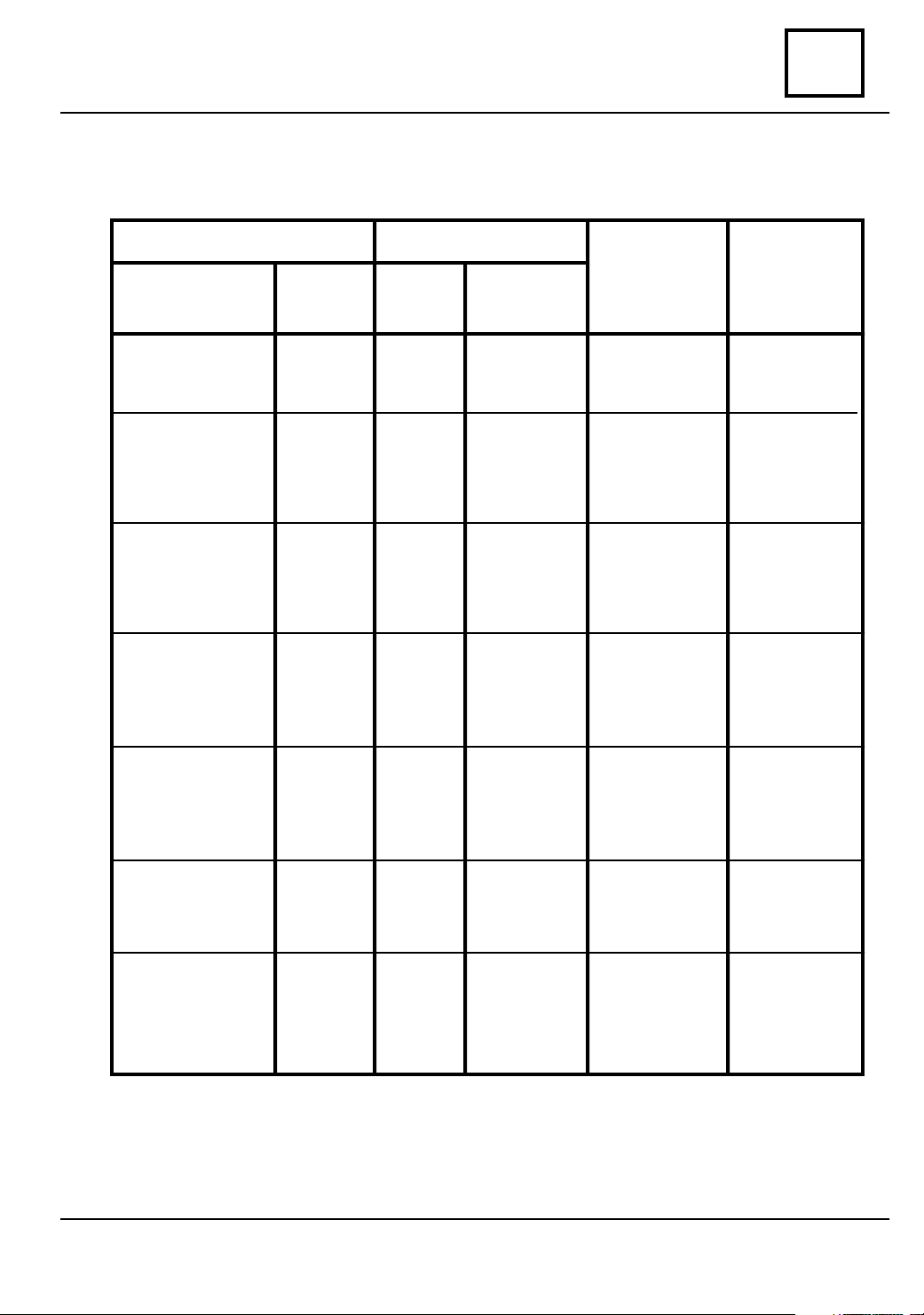

SPECIFICAT I ONS

vnx.su

ENGINE - CLUTCH - GEARBOX

VEHICLE ENGINE

TYPE CODE

TYPE

CYLINDER

CAPACITY

(cmc)

01

CLUTCH GEARBOX

1304 Pick-Up

1304 Drop-Side

1304 King-Cab

1305 Pick-Up

1305 Drop-Side

D 26119

D 46169

D 27119

D 47169

D 2S119

D 4S169

D 16119

D 17119

106 -02

106 -10

106 -02

106 -10

106 -02

106 -10

106 -02

106 -10

102 -14

106 -02

106 -10

1557

1557

1557

1557

1557

1557

1557

1557

1397

1557

1557

200 GR

200 DBR

200 GR

200 DBR

200 GR

200 DBR

200 GR

200 DBR

200 GR

200 DBR

50 C

51 C

50 C

51 C

50 C

51 C

365

365

1305 King-Cab

1307

D 1S119

D 2F719

D 1F119

D 4F769

106 -02

106 -10

106 -02

106 -10

1557

1557

1557

1557

01 - 1

200 GR

200 DBR

200 GR

200 DBR

365

50 C

365

51 C

Page 5

SPECIFICAT I ONS

vnx.su

01

VEHICLE IDENTIFICATION

UNITL THE DATE OF 26.06.2003

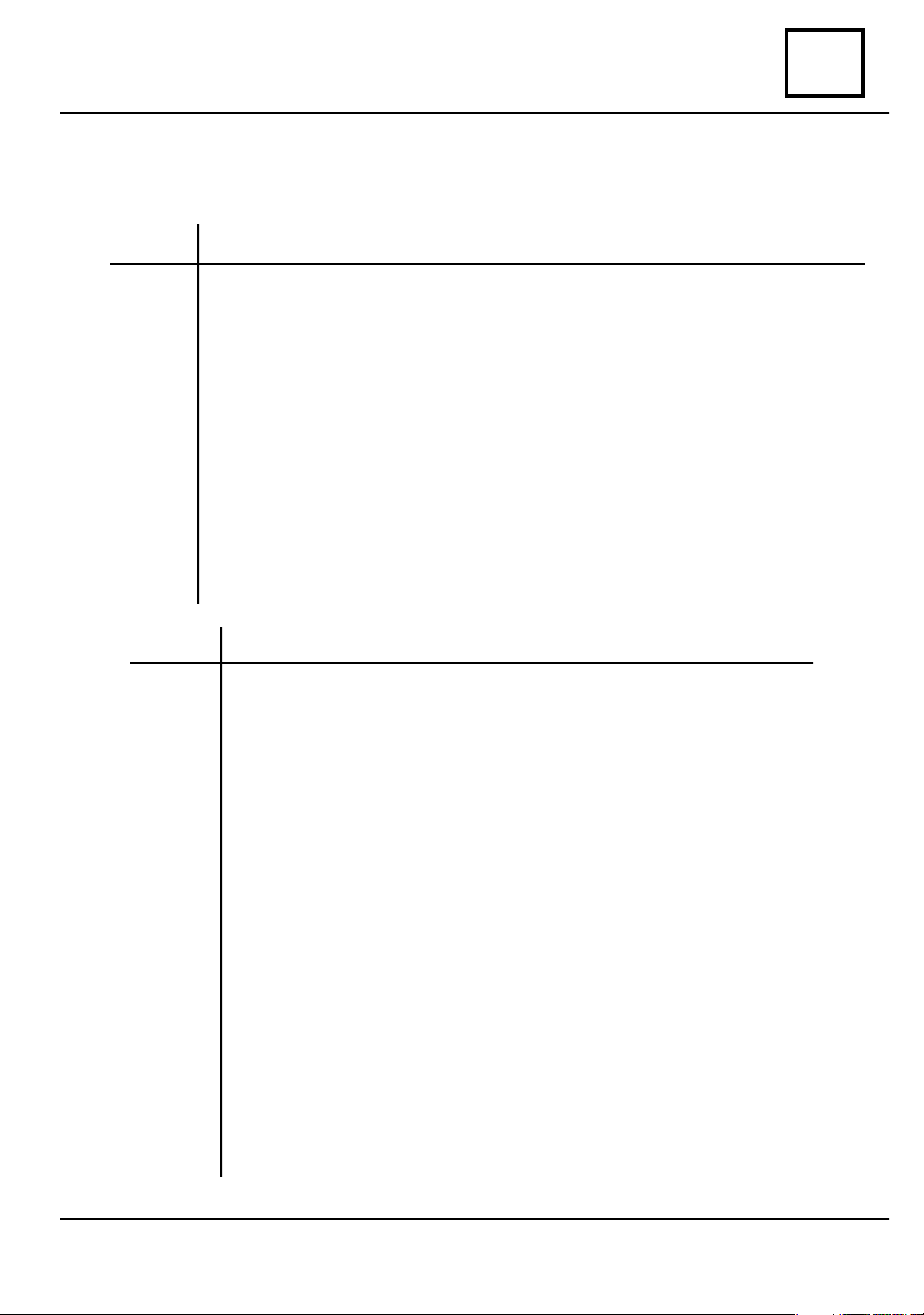

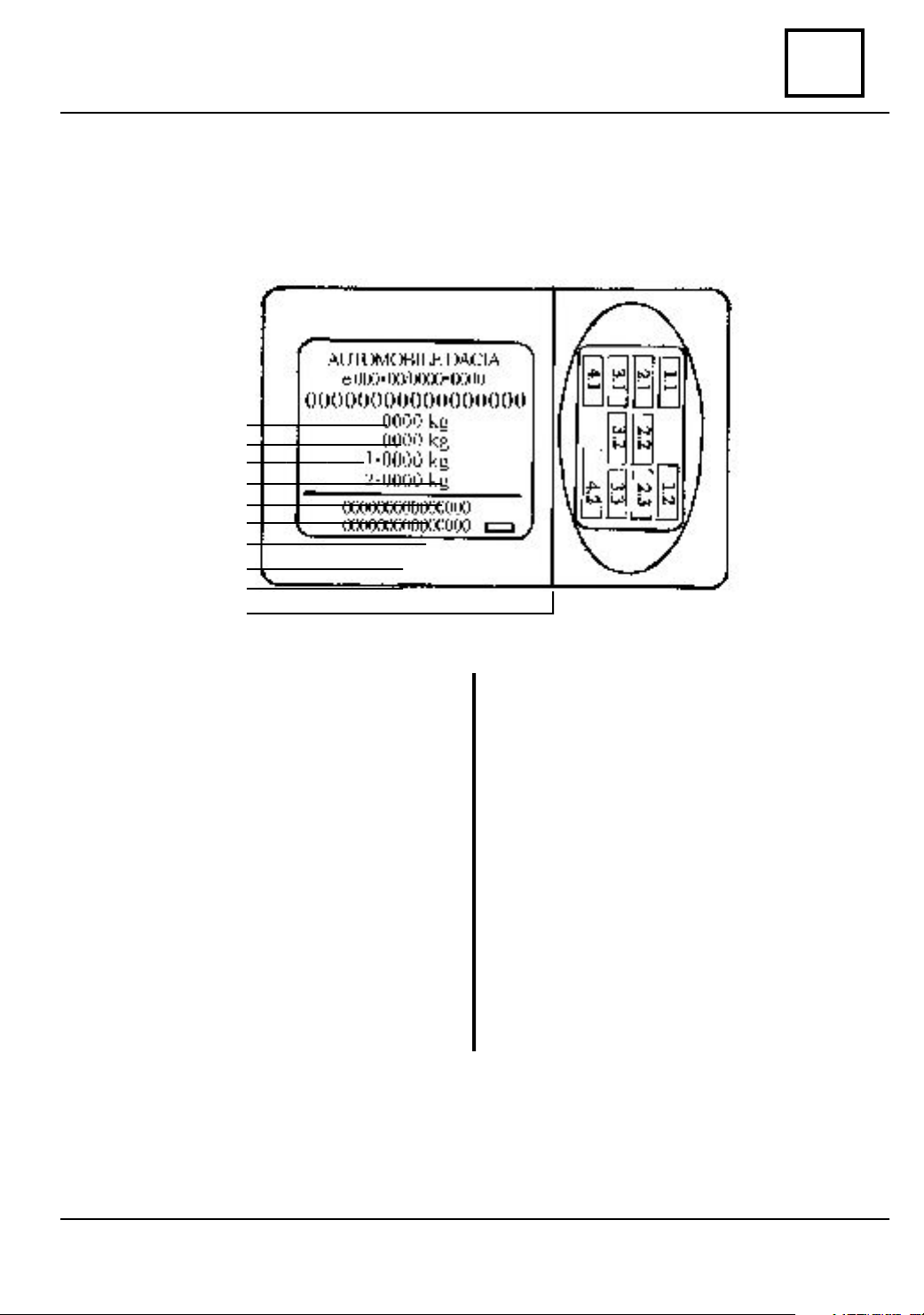

Manufacturer plate

Identification number VIN

MANUFACTURER PLATE

a. Manufacturer identification code;

b. Code of the vehicle;

c. Gear box type code;

d. Engine type code and driving device

location ( according to VIN code structure);

e.Vehicle code;

Maximum authorized weight without braking

f.

system;

g. Location place of the homologation number

for the importer country;

h. Location place of VIS sign ; one character

for the year model + 7 characters for the chassis

manufacture series ;

i. Maximum technical admissible weight of

the loaded car;

j. Maximum admissible weight with trailer

with braking system;

k.

Maximum technical admissible weight on

front axle

l.Maximum technical admissible weight on

rear axle.

;

01 - 2

Page 6

SPECIFICAT I ONS

vnx.su

VEHICLE IDENTIFICATION

UNITL THE DATE OF 26.06.2003

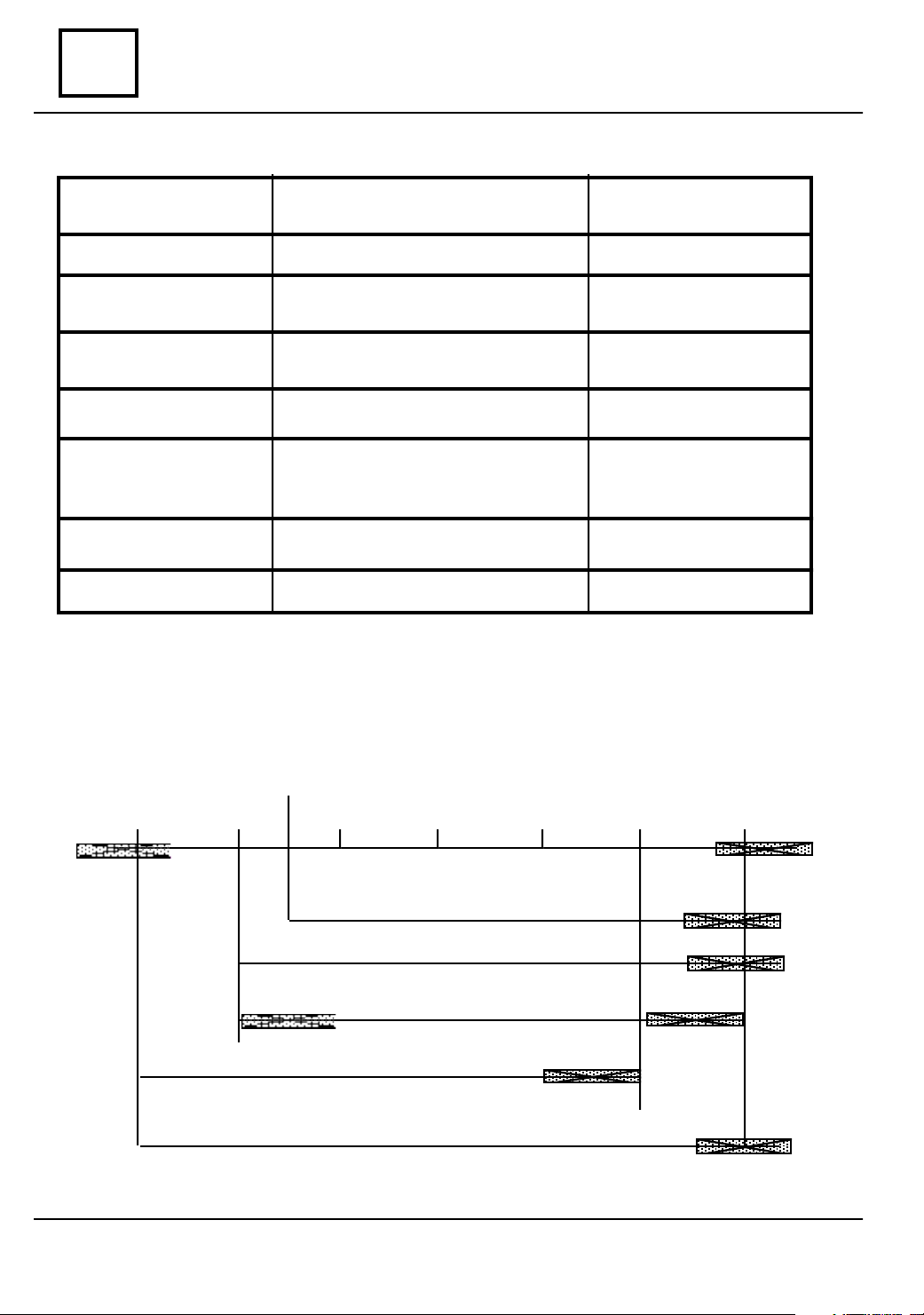

IDENTIFICATION NUMBER VIN

01

POSITION

COD U U 1 D

COD U U 1 D

COD U U 1 D

COD U U 1 D

COD U U 1 D

COD U U 1 D

COD U U 1 D

COD U U 1 D

COD U U 1 D

COD U U 1 D

COD U U 1 D

COD U U 1 D

POSITION CHARACTERS EXPLANATION

- chassis type

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

1 6 1 * * * * * * * * * *

1 7 1 * * * * * * * * * *

1

S 1 * * * * * * * * * *

2 6 1 * * * * * * * * * *

2 7 1 * * * * * * * * * *

2 S 1 * * * * * * * * * *

4 6 1 * * * * * * * * * *

4 7 1 * * * * * * * * * *

4 S 1 * * * * * * * * * *

1 F 7 * * * * * * * * * *

2 F 7 * * * * * * * * * *

4 F 7 * * * * * * * * * *

1 - 3 - manufacturer identification

UU1 - AUTOMOBILE DACIA S.A. ROMANIA

4 - vehicle type

D - merchandise transportation vehicle

5 - engine-gearbox unit location

1 - longitudinal front engine and front drive

2 - longitudinal front engine and rear drive

4 - longitudinal front engine and integral drive ( optional front coupling)

6 - type carosserie

6 - PICK-UP

7 - DROP - SIDE

S - KING CAB

F - PICK-UP, doble cabine

7 - payload location

1 - two front places + bed body

7 - 5 front places: 2 fixed rear bench for 3 places + bed body

8 - gearbox type

1 - gearbox with 5 + 1 steps

6 - gearbox with 5 + 1 steps and 4x4 coupling

9 - engine code and car driving location

9 - 1600 cmc engine, spark ignition, left hand drive

10 - year model code - Y - 2000; 1 - 2001; 2 - 2002

11 - 17 - chassis manufacturing series

01 - 3

Page 7

SPECIFICAT I ONS

vnx.su

01

VEHICLE IDENTIFICATION

UNITL THE DATE OF 26.06.2003

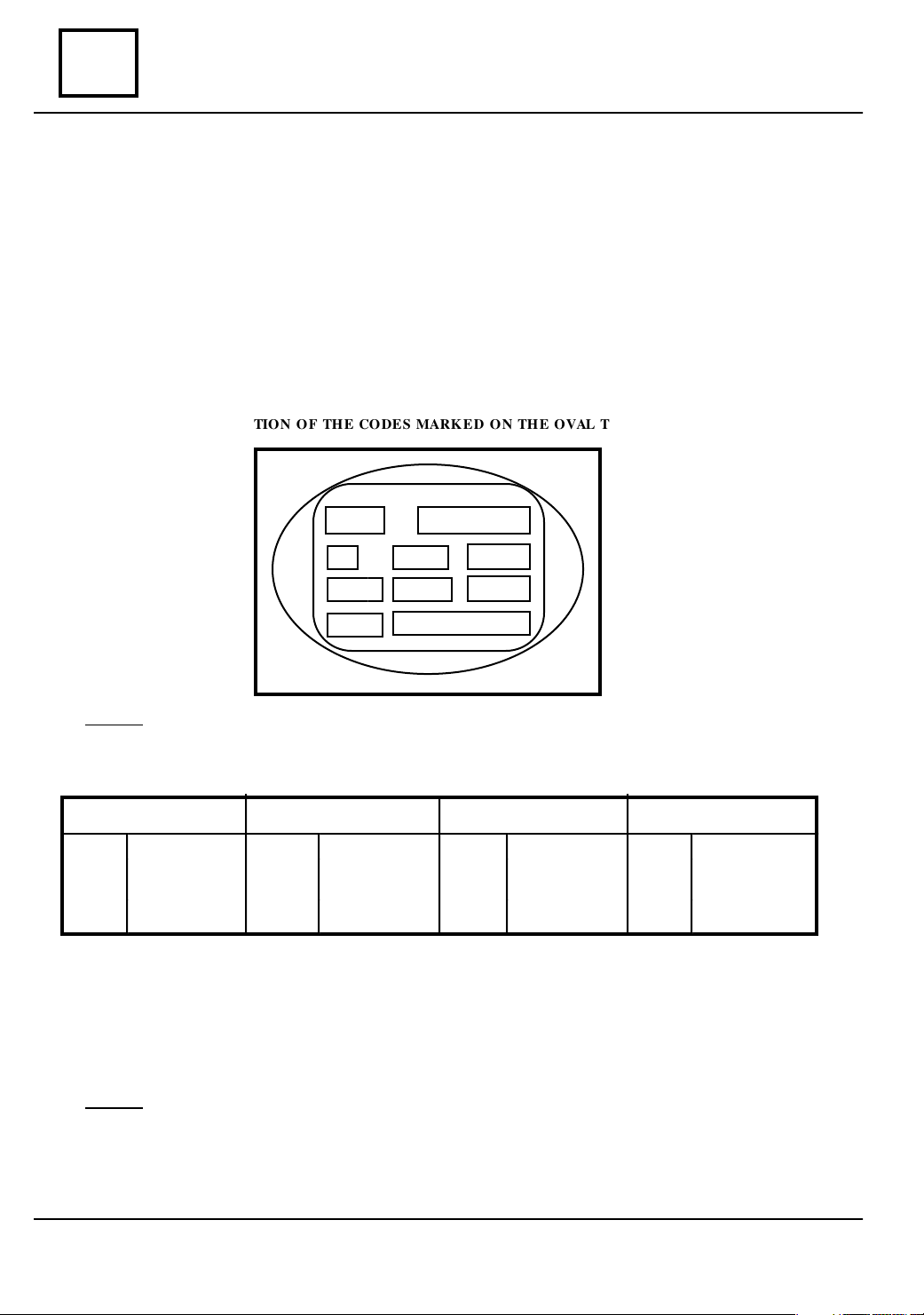

OVAL TYPE PLATE LABEL

The self-adhesive label is applied on the right part side surface of the dashboard. This

enable the identification of the vehicle type and its equipment, being used exclusively for

the after sale activity.

OVAL PLATE INSTRUCTIONS

HE INTERPRETATION OF THE CO DES MARK E D ON THE OVAL TYPE PLATE LABEL:

T

1,1

2,1

2,2

4,1

4,2

Line 1

1.1 Vehicle type code after sale:

Pick-Up Drop - Side King - Cab Double Cab

U 75 B

U 75 C

U 75 D

1305 Ri

1304 Ri

1304 4 WD Ri

E 75 B

E 75 C

E 75 D

1305 Ri

1304 Ri

1304 4 WD Ri

M 75 B

M 75 C

M 75 D

1305 Ri

1304 Ri

1304 4 WD Ri

Note: U,E, M, H = express the carriage body type

B,C,D = express the C type engine, 1557 cmc, front transmission type, rear and

consequently 4x4

75 = the code for R12 alternatives

Line 2

H 75 B

H 75 C

H 75 D

1307 FRi

1307 Ri

1307 4 WD Ri

2.1 Equipping level: E1,CA (air conditioning)

2.2 Country code: ROUM (Romania, with EU 96).

01 - 4

Page 8

SPECIFICAT I ONS

vnx.su

VEHICLE IDENTIFICATION

UNITL THE DATE OF 26.06.2003

OVAL TYPE PLATE LABEL

Line 4

4.1 Tehnical definition code, driving post:

S2: Left hand drive

4.2 Optional equipping code:

A: Normal suspension

C: Temperate climate

E: Warm climate

F: Normal heating

G: Air conditioning

K: Without pre-filter

M: Mechanical steering system

R: Without adjustable shock absorber

T: Without plate corrector

V: Without wheels ABS ( anti-blocking )

01

ATTENTION!

Do not unstuck or damage the label of the right side part surface of the

dashboard.This label represents the only way of vehicle identification, needed by the

after-sale services, for a period of 8 ( eight ) years from the purchasing date.

01 - 5

Page 9

SPECIFICAT I ONS

vnx.su

01

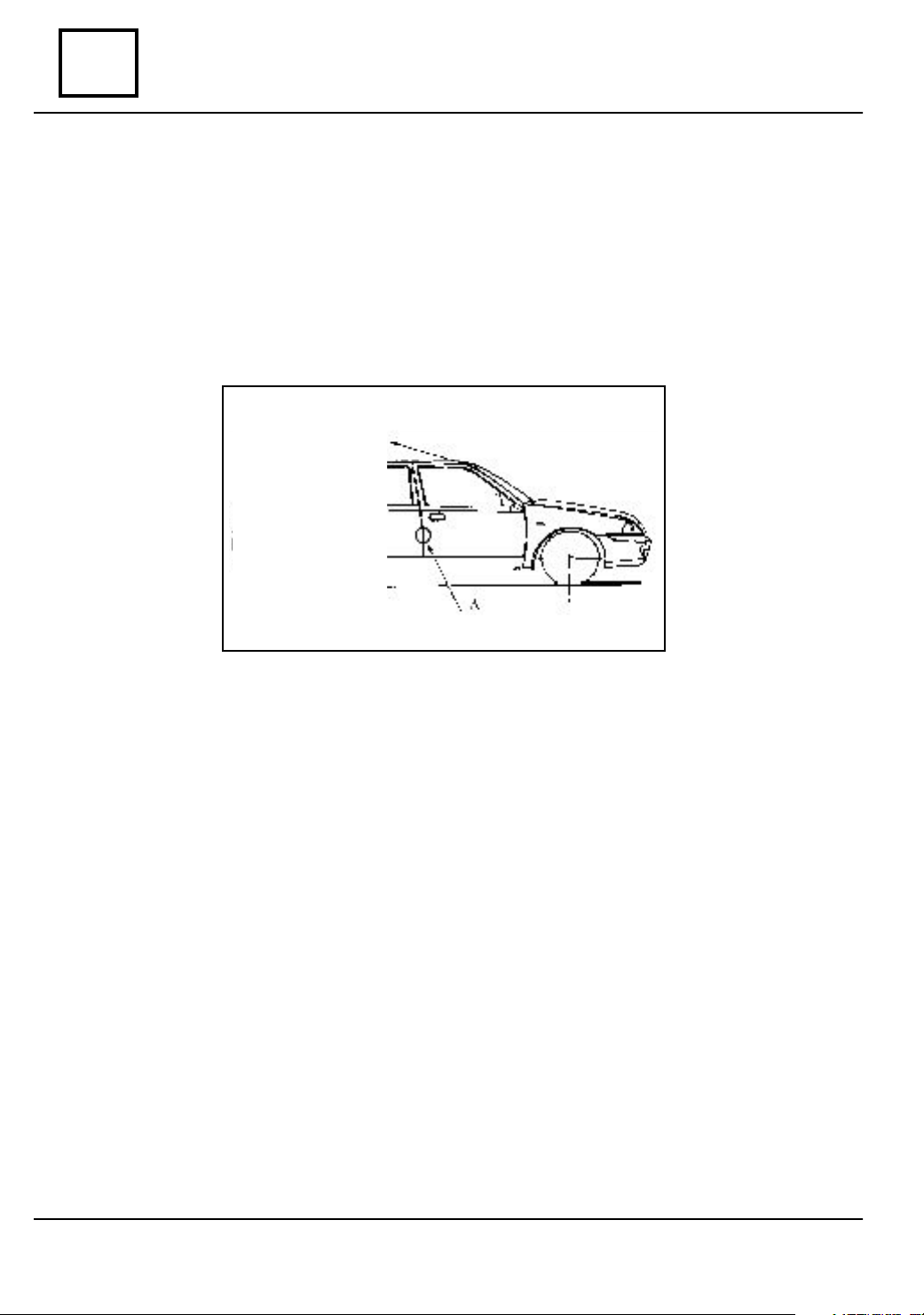

Vehicle identification

STARTING WITH THE D ATE OF 26.06.2003

MANUFACTURER’S PLATE DISPOSAL TYPE SELF-ADHESIVE

Fig.2.1

01 - 6

Page 10

SPECIFICAT I ONS

vnx.su

Vehicle identification

STARTING WITH THE D ATE OF 26.06.2003

The MANUFACTURER PLATE, self-adhesive type, has the bellow presented configura-

tion, with two distinctive areas, presenting :manufacturer’s identification data and APV type

identification data.

A

B

C

D

E

F

G

H

I

J

01

MANUFA CTURER’S IDENTIFICA-

TION DATA

A. Manufacturer’s name

B. Community reception number or

homologation number.

C. Identification number.

D. Total authorized weight of the

loaded vehicle.

E. Total authorized running weight

F. Total weight on front axle.

G. Total weight on rear axle.

H. Additional inscription.

I. Manufacturing date inscription

J. Consignment number.

APV ID ENTIFICATION DATA

1.1Code type auto APV

1.2Manufacturing number

2.1 Equipping level code

2.2 Additional code for limited serial

definition

2.3 Additional code for special serial

definition

3.1 Carriage body color code

3.2 Seats upholstery code

3.3 Interior matching code.

4.1 Technical definition code

4.2 Optional equipping code.

01 - 7

Page 11

LIFTING

vnx.su

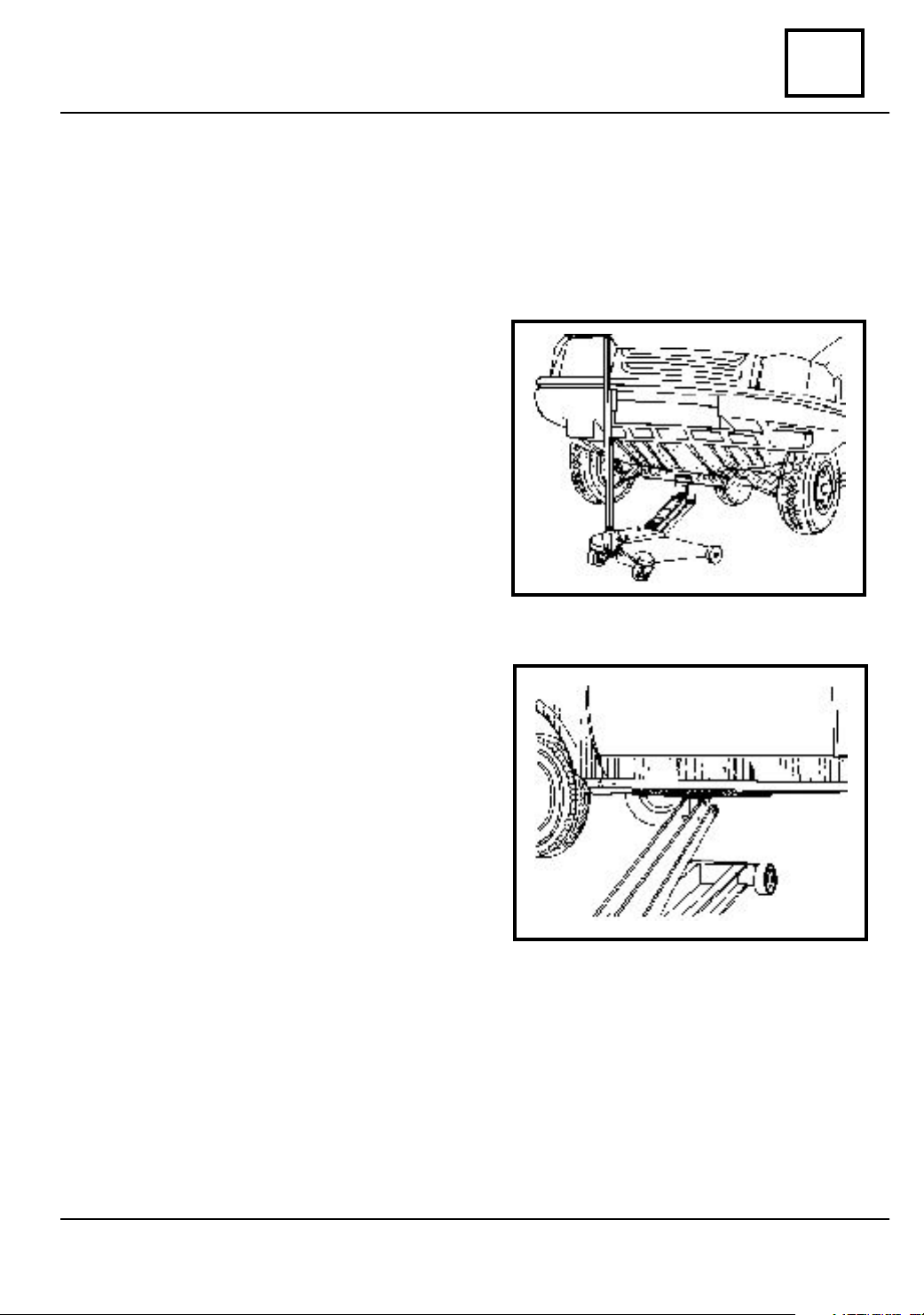

MOBILE JACK AND PROTECTION ROUTE

It absolutely forbidden the vehicle lifting using the front or rear suspension arms as

supporting points.

The mobile jack shall not be used to lift the car in order to perform certain operations

under the carriage body.

LIFTING THE FRONT PART OF THE

CAR

For lifting, the rolling jack and the

CHA 280 hold are used, in order to protect

the body and mechanical item of the car,

which are placed on longitudinal girders on

wheels axle.

02

LIFTING THE CAR FROM ONE SIDE

For lifting the car from one side, the

rolling jack and the CHA 280 hold shall be

used which are placed on the threshold on t he

front door.

The edge of the threshold shall be correctly

positioned in the channel of the hold.

02 - 1

Page 12

LIFTING

vnx.su

02

vehicle is usually placed.

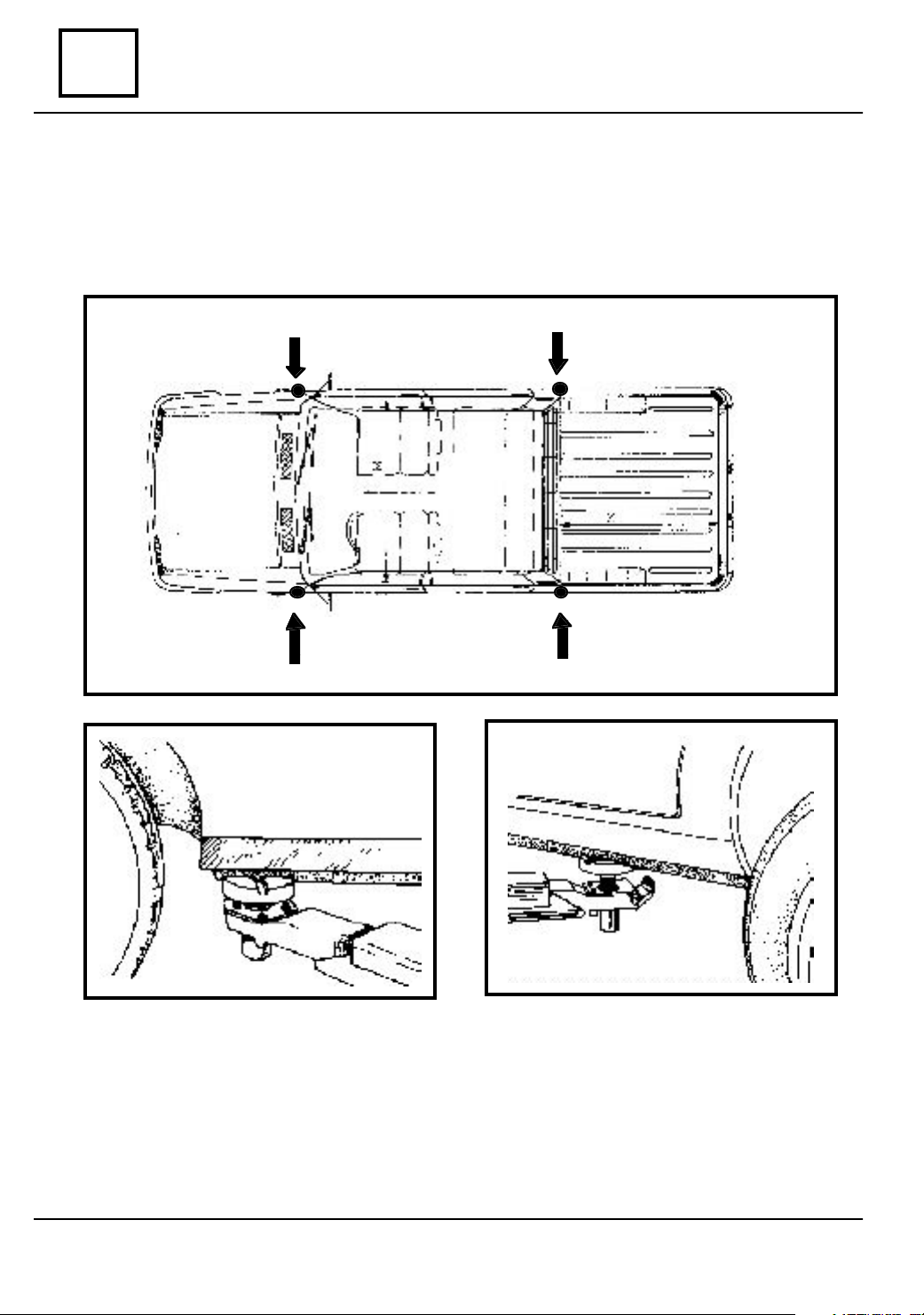

ELEVATOR POSITIONED UNDER THE CARRIAGE BODY

For lifting, place the elevator buffers on the same points where the car jack of the

The edge of the threshold shall be placed correctly in the buffer channel.

02 - 2

Page 13

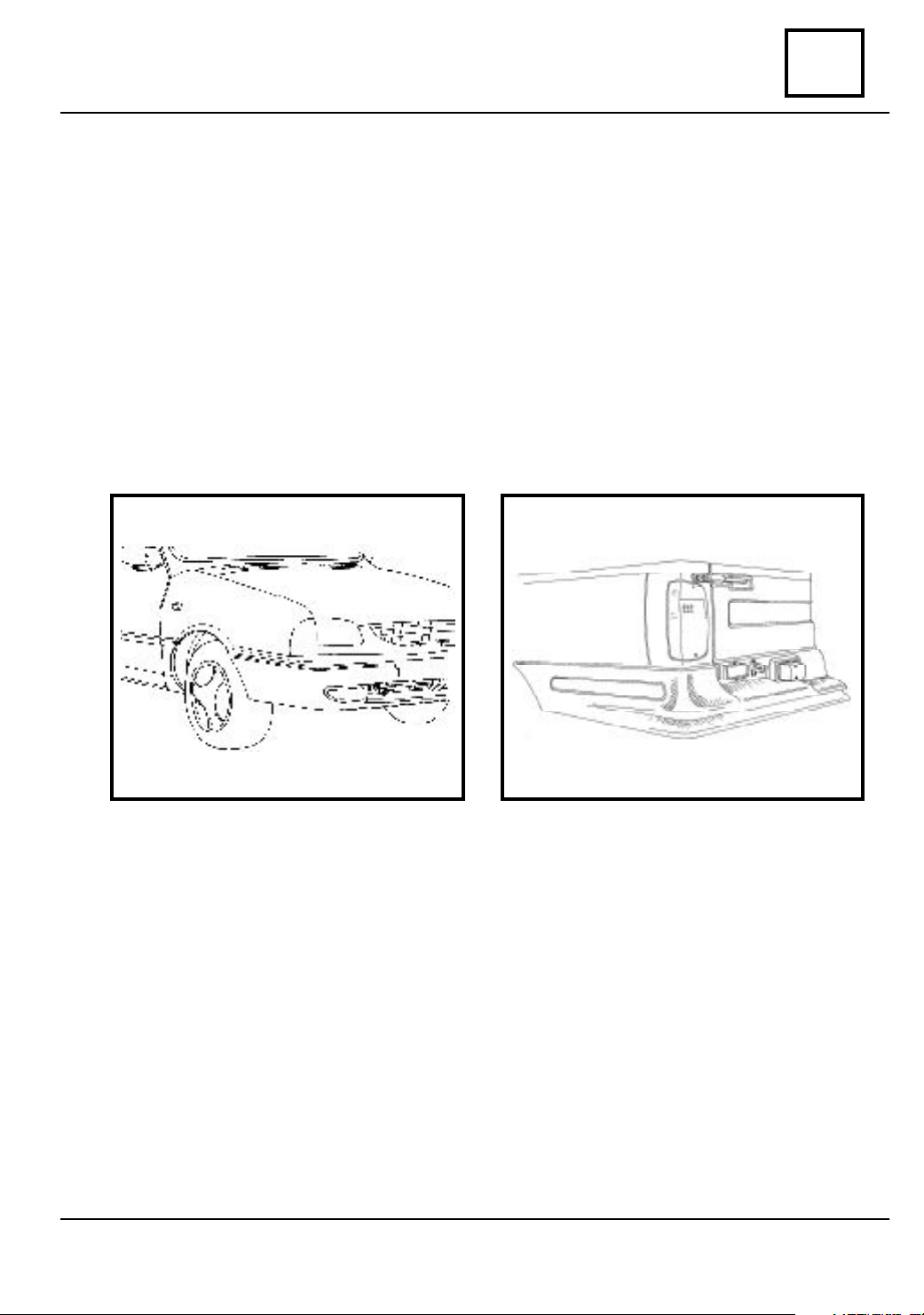

TOWING

vnx.su

ALL TYPES

FOR TOWING OBSERVE THE LAW IN FORCE OF EACH COUNTRY

NEVER PERFORM TOWING USING FRONT TRANSMISSION

The towing of the cars on wheels must be obligatory done by means of the unique

towing points

These points cannot be anyhow used for drawing out the car from a trench ( hole ), for

a similar intervention or for direct or indirect lifting of the car.

RONT

F

REAR

03

03 - 1

Page 14

LUBRICANTS CONSUMABLES

vnx.su

CONDITIONS

04

PRODUCT

Grease

UM 170 Li Ca Pb 2M

ELF CARDREXA RNT2

UM 185 Li 2M

Grease

UM 185 Li 2M

Grease U 95 Ca 2

Grease

Li Ca Pb type II with MoS2

(or 20 UM Li III)

PLACE WHERE IT IS USED

GREASING

Clutch shaft groves

Pinions groves of front transmission

Gear box control lever

Pressure bearing

Cardan flange sealing ring

Front transmission

Front wheel steering stub groves

Cardanic transmission

Front transmission

Front wheel bearing

Suspension ball joints

Rear axle differential

Wheels screws

Steering gear (pinion – rack gear, bearings)

Grease 22

Grease U100 Ca 4-5

Rubber gaskets of the steering gear

Steering rod

04 - 1

Page 15

LUBRICANTS CONSUMABLES

vnx.su

04

PRODUCT

RHODORSEAL

5661

LOCTITE 518

LOCTITE 577

CONDITIONS

PLACE WHERE IT IS USED

SEALING

Inferior crankcase

Distribution cover

Propeller shaft pins

Half crankcase

Clutch crankcase

Fuel pump ( with membrane )

Cover palier 1

Rear axle

Thread of the reverse lamp contact.

Gear box plug M 16

Rear axle

Mastic 503

FIXAMED M28

DECAPJOINT

S.E. DERO 100

Differential rear axle

SOLDE RING

Screws of flywheel fixing

Screws of crank shaft pulley

CLEANING

The surface of cylinder head gasket

Wa shing of steel, cast iron, aluminum parts

04 - 2

Page 16

DRAINING AND FILLING

vnx.su

ENGINE

Necessary special tools - wrench for draining plug : CV 514

Draining: plug (2) Filling: plug (1)

05

05 - 1

Page 17

DRAINING AND FILLING

vnx.su

05

Draining: plug (2)

GEARBOX

Filling: plug (1)

05 - 2

Page 18

DRAINING AND FILLING

vnx.su

REAR AXLE DIFFERENTIAL

Draining: plug(2) Filling: plug (1)

05

05 - 3

Page 19

VALUES AND SETTINGS

vnx.su

DIMENSIONS

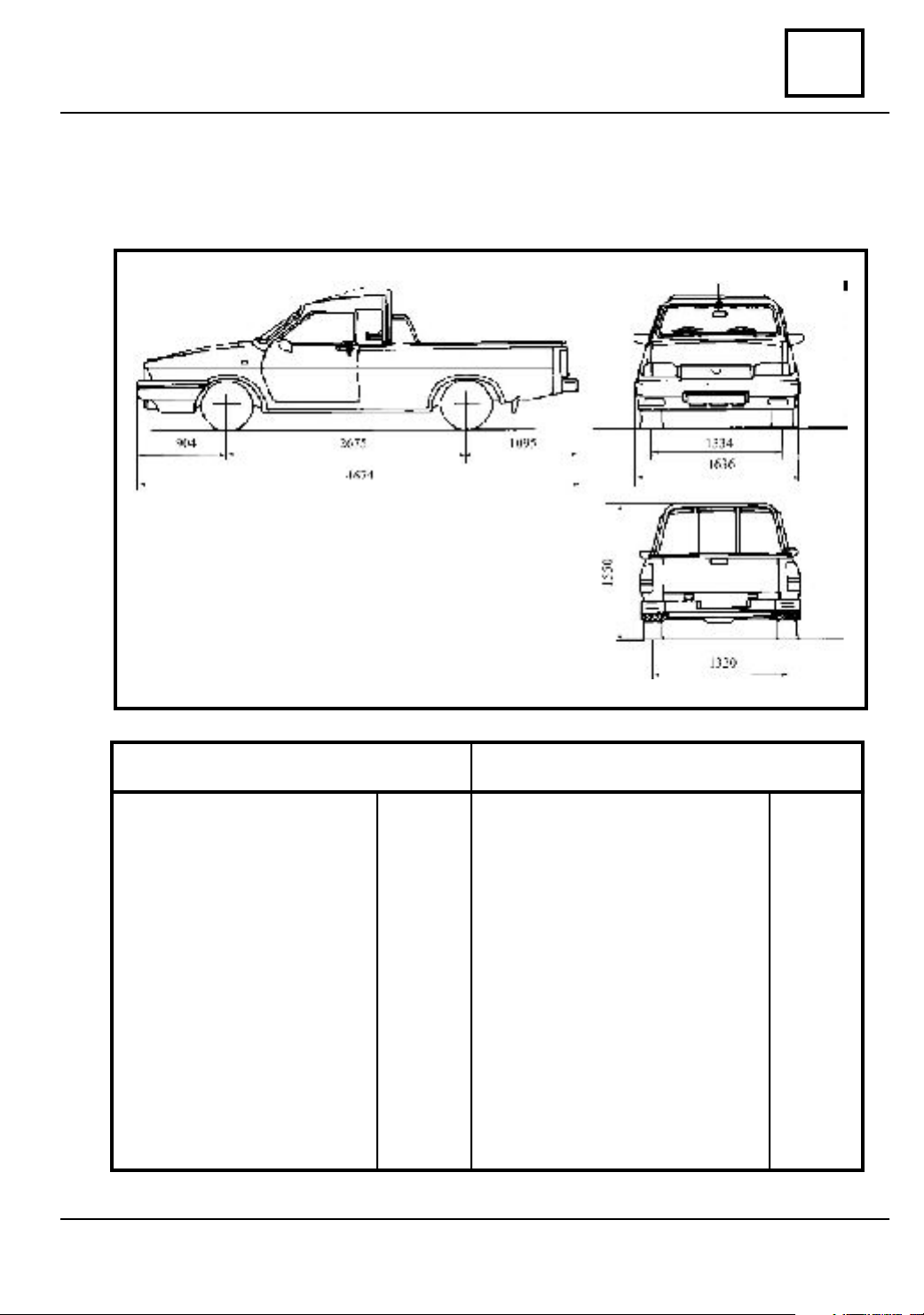

DACIA 1304 PICK - UP

DACIA 1305 PICK - UP

07

DIME NSIONS ( mm ) WEIGHT ( kg )

Total length

Total width

Total height

Empty

Loaded

Axle base

Front wheel track width

Rear wheel track width

Ground clearance

Empty

Loaded

Turn radius

Between footways

Between walls

4674

1636

1550

1450

2675

1334

1320

-

165

5600

5800

Unloaded vehicle weight

On the front axle

On the rear axle

Total

Maximum authorized load

On the front axle

On the rear axle

Total

Authorized payload

Load with trailer with own brake

Load with trailer without own

brake

07 - 1

600

480

1080

760

1550

2250

1000

3225

2630

Page 20

VALUES AND SETTINGS

vnx.su

07

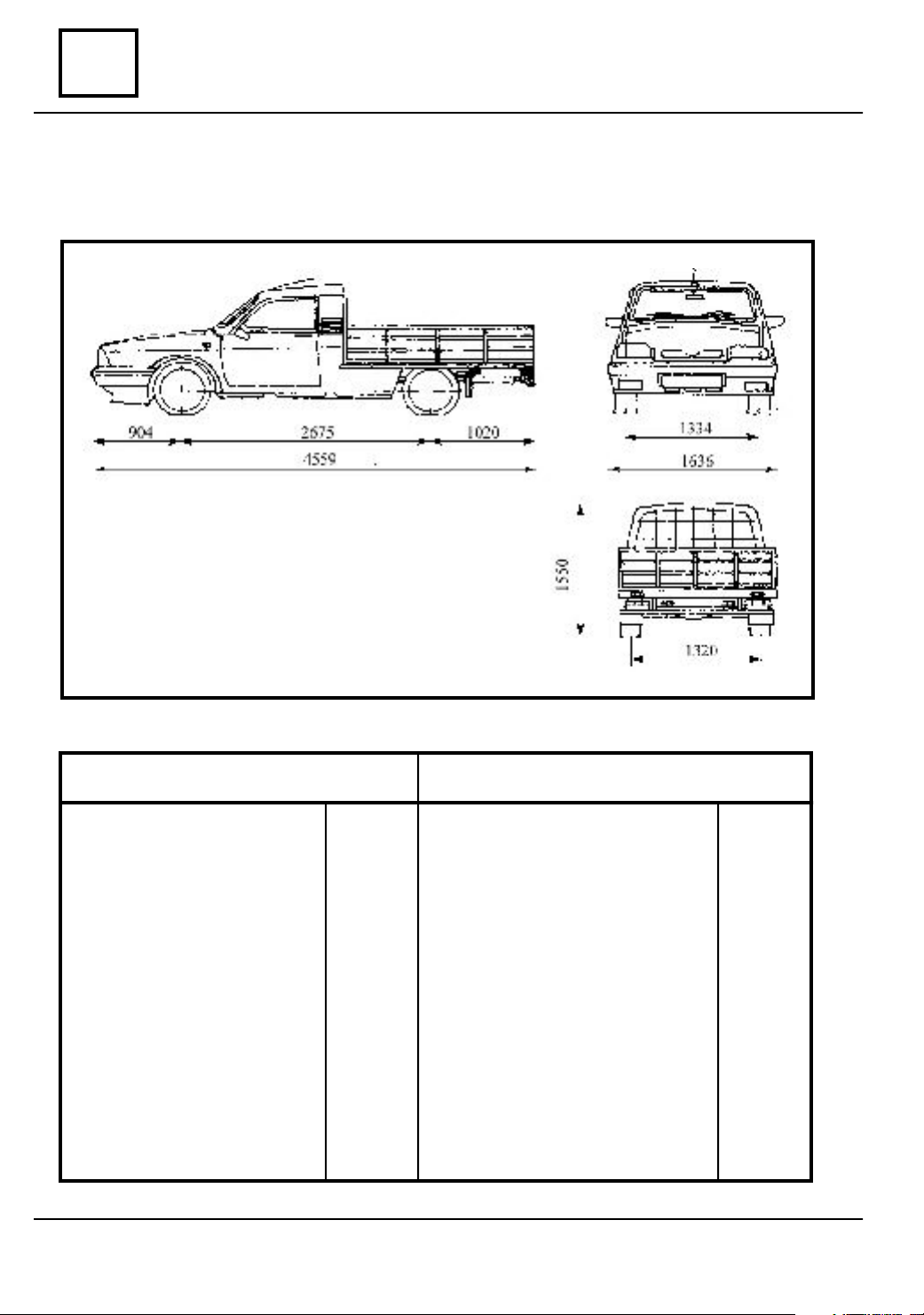

DIMENSIONS

DACIA 1304 PLATFORM

DACIA 1305 PLATFORM

DIME NSIONS( mm )

Total length

Total width

Total height

Empty

Loaded

Axle base

Front wheel track width

Rear wheel track width

Ground clearance

Empty

Loaded

Turn radius

Between footways

Between walls

4599

1615

1550

1450

2675

1334

1320

-

165

5600

5800

EIGHT ( kg )

W

Unloaded vehicle weight

On the front axle

On the rear axle

Total

Maximum authorized load

On the front axle

On the rear axle

Total

Authorized payload

Load with own brake trailer

Load without own brake trailer

07 - 2

595

520

1115

760

1550

2230

1000

3225

2630

Page 21

VALUES AND SETTINGS

vnx.su

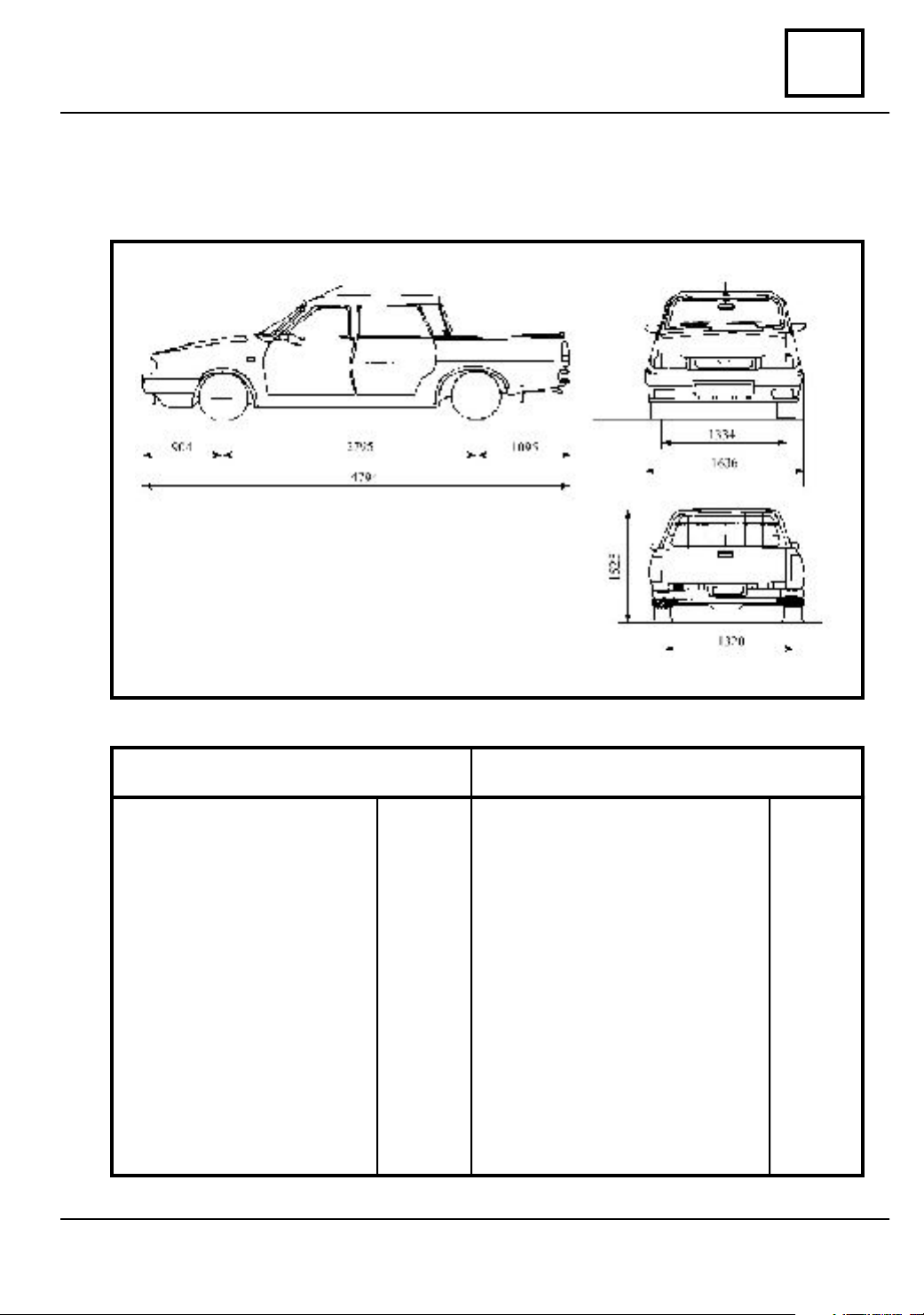

DIMENSIONS

DACIA 1307

07

DIME NSIONS ( mm )

Total length

Total width

Total height

Empty

Loaded

Axle base

Front wheel track width

Rear wheel track width

Ground clearance

Empty

Loaded

Turn radius

Between footways

Between walls

4794

2636

1525

2795

1310

1334

-

165

5600

5800

EIGHT ( kg )

W

Unloaded vehicle weight

On the front axle

On the rear axle

Total

Maximum authorized load

On the front axle

On the rear axle

Total

Authorized payload

We i ght on towing hook

07 - 3

635

540

1175

820

1550

2230

680

1055

max.50

Page 22

VALUES AND SETTINGS

vnx.su

07

DENOMINATIO CAPACITY (liters)

Engine oil

Gearbox oil

Differential oil

Breaking fluid

Cooling fluid *

Refrigerant A.C.

SAE 15 W 40 / API SJ/CF

CAPACITY - QUALITIES

CHARACTERISTICS

SAE 80 W 90 / API GL4/GL5

SAE 80 W 90 / API GL 5

SAE J 1703; DOT 4

Tip C

Tip D - GLACEOL RX **

(from 26.11.2001 )

HFC 134 a

PAG SP 10

3

2,3

2

0,3

6

0,700 kg,

Oil compresor

* Mixture: 50 % concentrate antifreeze + 50 % distilled water.

** On the expansion vessel a label is stacked specifying the use of this type

of cooling fluid.

Engine oil quality

-15°C

-30°C -20°C -10°C 0°C +10°C +20°C +30°C

15 W 40 - 15 W 50

10 W 40 - 10 W 50

10 W 30

5 W 30

265 cmc

5 W 40 - 5 W 50

07 - 4

Page 23

VALUES AND SETTINGS

vnx.su

DRIVING BELTS TIGHTENING AND TIGHTENING CHECKING

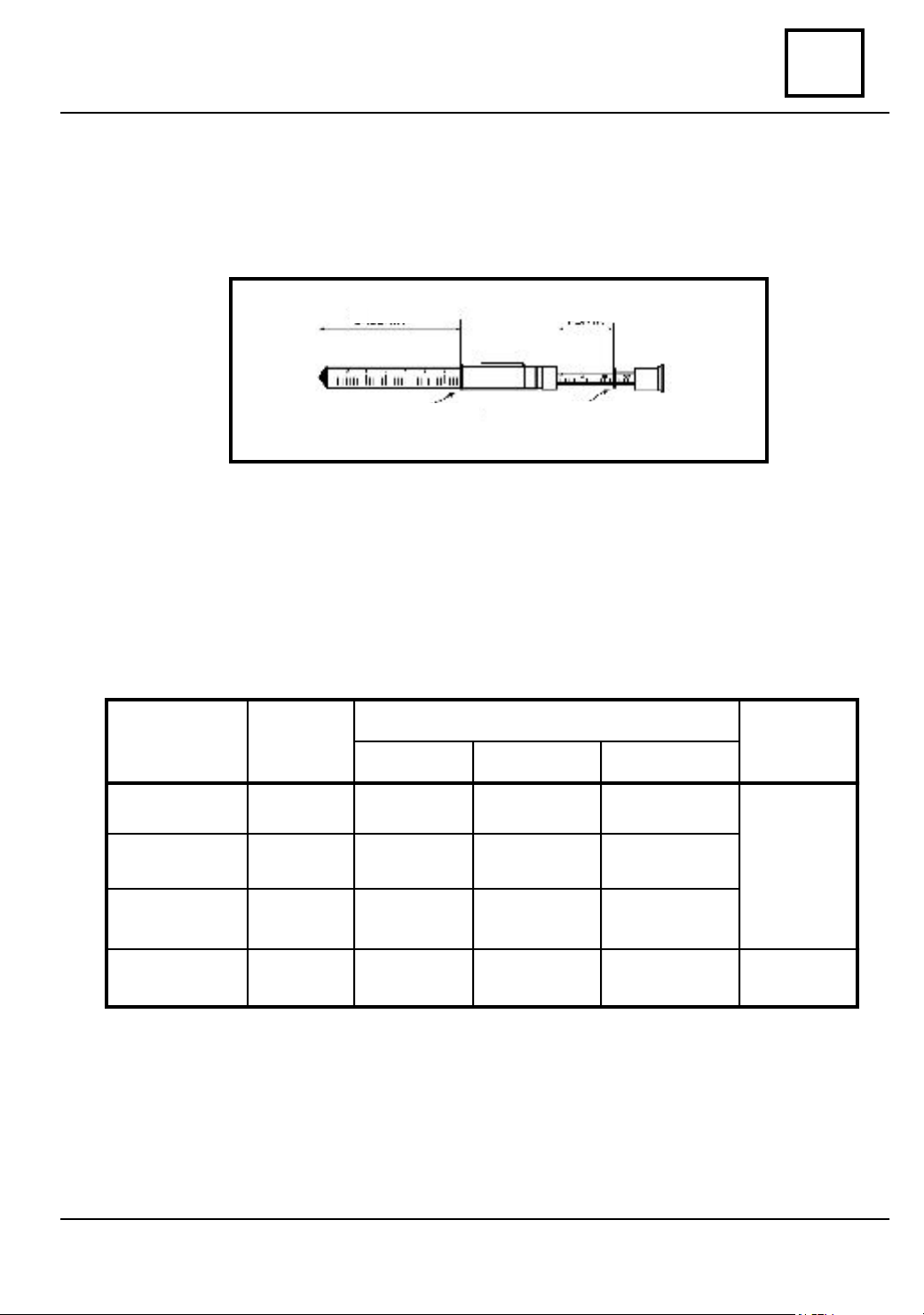

The checking of the belt tightening may be done by means of the MOT 557 device which

has two scales; one shows the arrow’s value ,and the other implicitly translates the value

of the tension ( force ).

07

Arrow

Ring 0 big Ring 0 small

Force

When checking and adjusting the belts tension, observe the following procedure:

∗ stretch the belt for which the tension is to be determined;

∗ place the big “O” ring on the scale at the arrow imposed value ( 2mm ; 4,5mm;

3,5 mm or 7,5 mm for the belts 1; 2 ; 3 or 4);

ORCE N (N)

BELT

between compressor

1

- alternator

ARROW f

(mm)

2

OUNTING AFTER 5 min.

M

14 +/- 15%

F

14 +/- 15%

A

FTER 500 km.

11 +/- 15%

VEHICLE

OPTIONALS

between crankshaft-

2

compressor

between crankshaft-

3

water pump

between crankshaft-

water pump -

4

alternator

4,5

3,5

7,5

17 +/- 15%

7.5 +/-15%

30 +/-15%

17 +/- 15%

7.5 +/- 15%

30 +/-15%

13 +/- 15%

5.5 +/- 15%

-

with AC

without AC

* place the small ”O” ring on the scale at zero value;

∗ place a metallic graduated rule on both pulleys;

* place the device at half- and vertical on the rule ( 1- distance between pulleys axles).

07 - 5

Page 24

VALUES AND SETTINGS

vnx.su

07

* press on the device until the big “O” ring passes over the rule;

∗ read the value of force N on the scale with small “O” ring;

∗ compare the read value with the imposed value :

adjustment of the distance between pulleys axles ( re tighten the belt ), until obtaining a

value within the imposed range.

∗ start the engine, run it for five minutes, check again the belt tension and compare it

with the imposed value and adjust it if necessary;

∗ check the tension and correct if necessary the belts tightening at 1000 km compulsory

checking.

DRIVING BELTS TIGHTENING AND TIGHTENING CHECKING

-if the N force value is within the imposed range, the belt tightening is good;

-if the read value is bigger or smaller than the imposed value, perform the

07 - 6

Page 25

VALUES AND SETTINGS

vnx.su

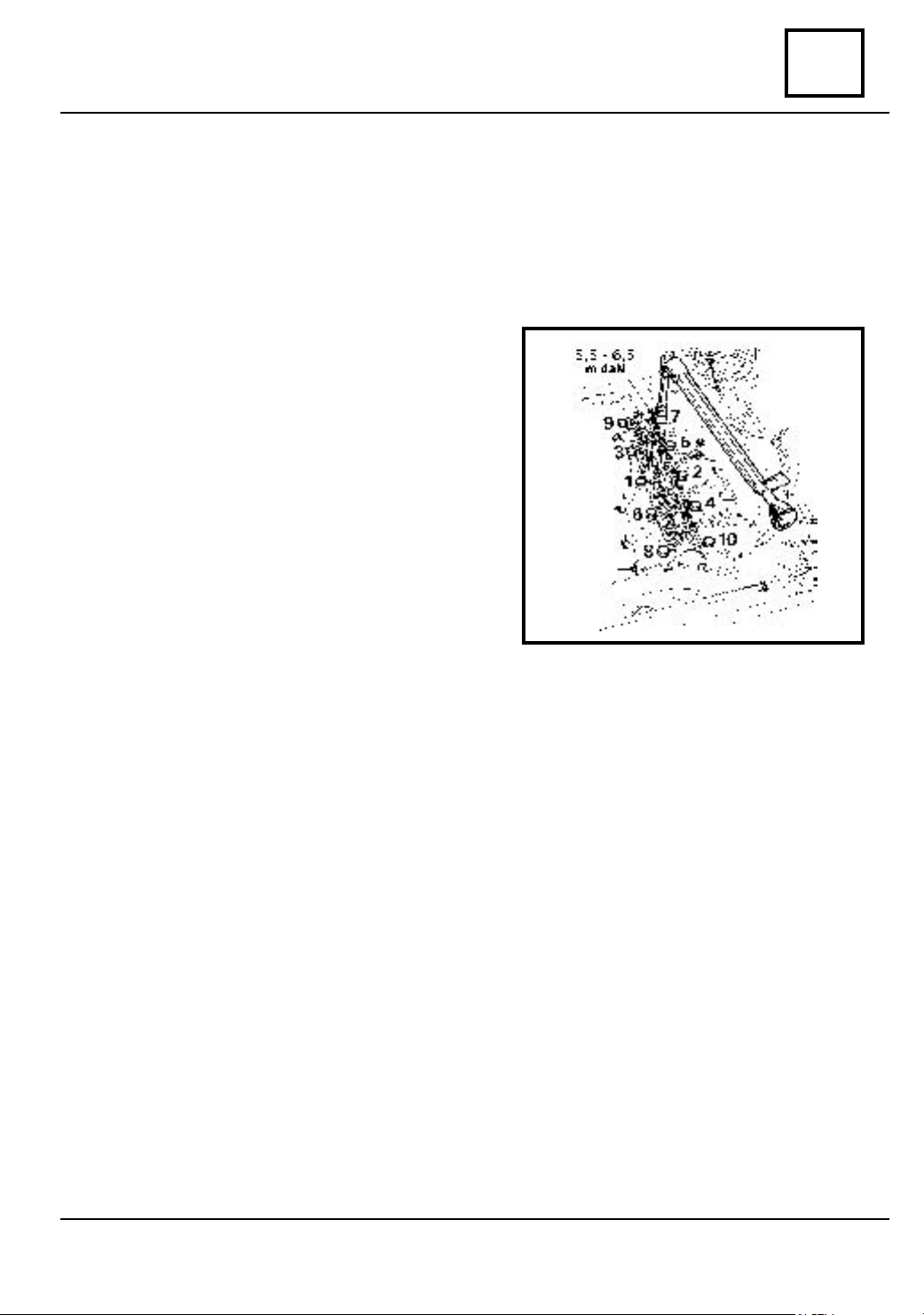

CYLIDER HEAD TIGHTENING A ND R ETI GHTENING

ATTENTION!

In order to obtain a correct tightening of the cylinder head screws, clean the attachment

holes of the cylinder head of oil or coolant liquid, by means a syringe.

Grease the thread of screws with engine oil.

CYLINDER HEAD TIGHTENING

Tighten at the required moment (6,5 daNm)

observing the tightening sequence from the

drawing.

CYLINDER HEAD RE TIGHTENING

Retightening of the cylinder head is

performed as follows:

- for new vehicles at the 800 – 1000 km

check u;

- in case of engine repairing, which

implies the cylinder head dismounting, after

800 – 1000 km driving;

- every 10.000 km.

07

For retightening, loose the screw (1) with 1/4 rotation, after that retighten it to the

require moment:

- 6,5 daNm at warm (50 min. after engine shopping);

- 5,5-6,5 daNm at cold.

Repeat this operation also for the other screws, observing the sequence showed in the

drawing.

07 - 7

Page 26

VALUES AND SETTINGS

vnx.su

07

TYPE

VEHICLE

1304

1307

1307 - 4WD

1305

1304 - 4WD

* Tightening moment of the wheels nuts (screws) 9 daNm.

∗ Axial run out: max 1,2 mm.

∗ Radial run out: max 1,2 mm.

∗ Pressure in tires to be checked at cold. The increase of tire temperature during

running implies a growth of pressure with 0,2 – 0,3 bar.

In case of checking the tires pressure at warm, consider this growth of pressure.

∗ The tires are TUBELESS type ( without air tube ).

WHEELS TYRES

5 J 14 with deport

48 mm

5 J 14 with deport

48 mm

WHEELS AND TYRES

ROLLING

CIRCUMFERENCE

(mm)

175 R 14

PR 8

175 R 14

PR 8

1920 +/- 25

1920 +/- 25

P

RESSURE

(daN/cm )

FRONT REAR

1,9

2,0

2

4,2

4,5

07 - 8

Page 27

VALUES AND SETTINGS

vnx.su

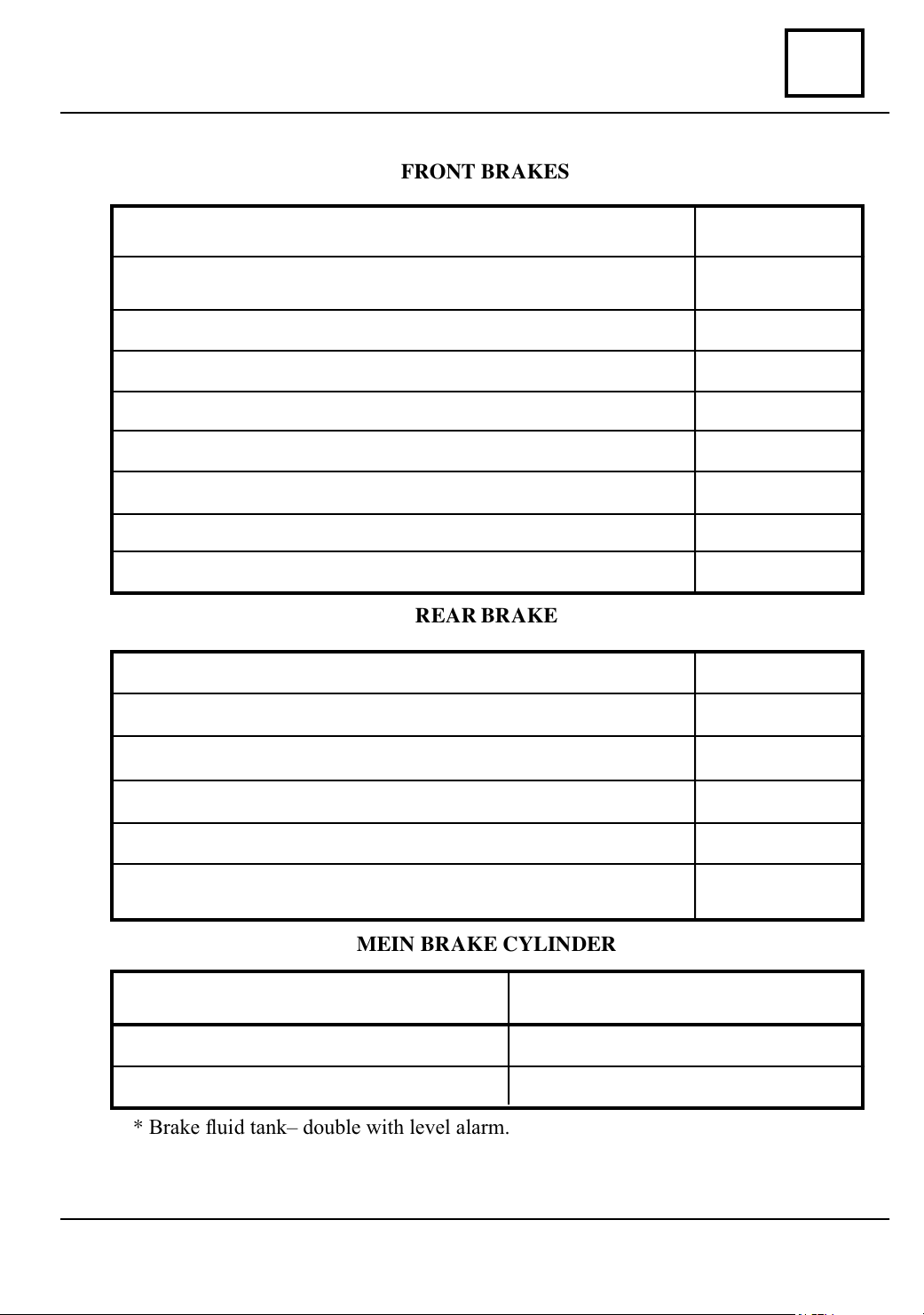

BRAKES

FRONT BRAKES

07

Brake caliper bore diameter (for brake disk non aerated)

Brake caliper bore diameter (for aerated brake disk)

Disk thickness non aerated

Disk thickness aerated

Minimal disk thickness non aerated

Minimal disk thickness aerated

Brake pad thickness ( the support included)

Minimal brake pad thickness (the support included)

Disk axial run out, measured at Φ215 mm

REAR BRAKE

Wheel braking cylinder diameter

New drum diameter

Φ 48 mm

Φ 54 mm

10 mm

20 mm

9 mm

19 mm

14 mm

7 mm

0,1 mm

Φ 25,4 mm

Φ 254 mm

Maximum drum diameter after grinding

Braking lining width

Braking lining thickness

Minimal accepted braking lining height above rivets

MEIN BRAKE CYLINDER

Type of main brake cylinder

Inner diameter

Max. pump stroke

* Brake fluid tank– double with level alarm.

∗ Pressure reducing valve for parallel circuit.

* Brake fluid as per norms SAE J 1703, DOT4.

07 - 9

Tandem master cylinder with ICP by

pass included

Φ 255 mm

50 mm

5 mm

0,5 mm

Φ 20,6 mm

32 mm

Page 28

VALUES AND SETTINGS

vnx.su

07

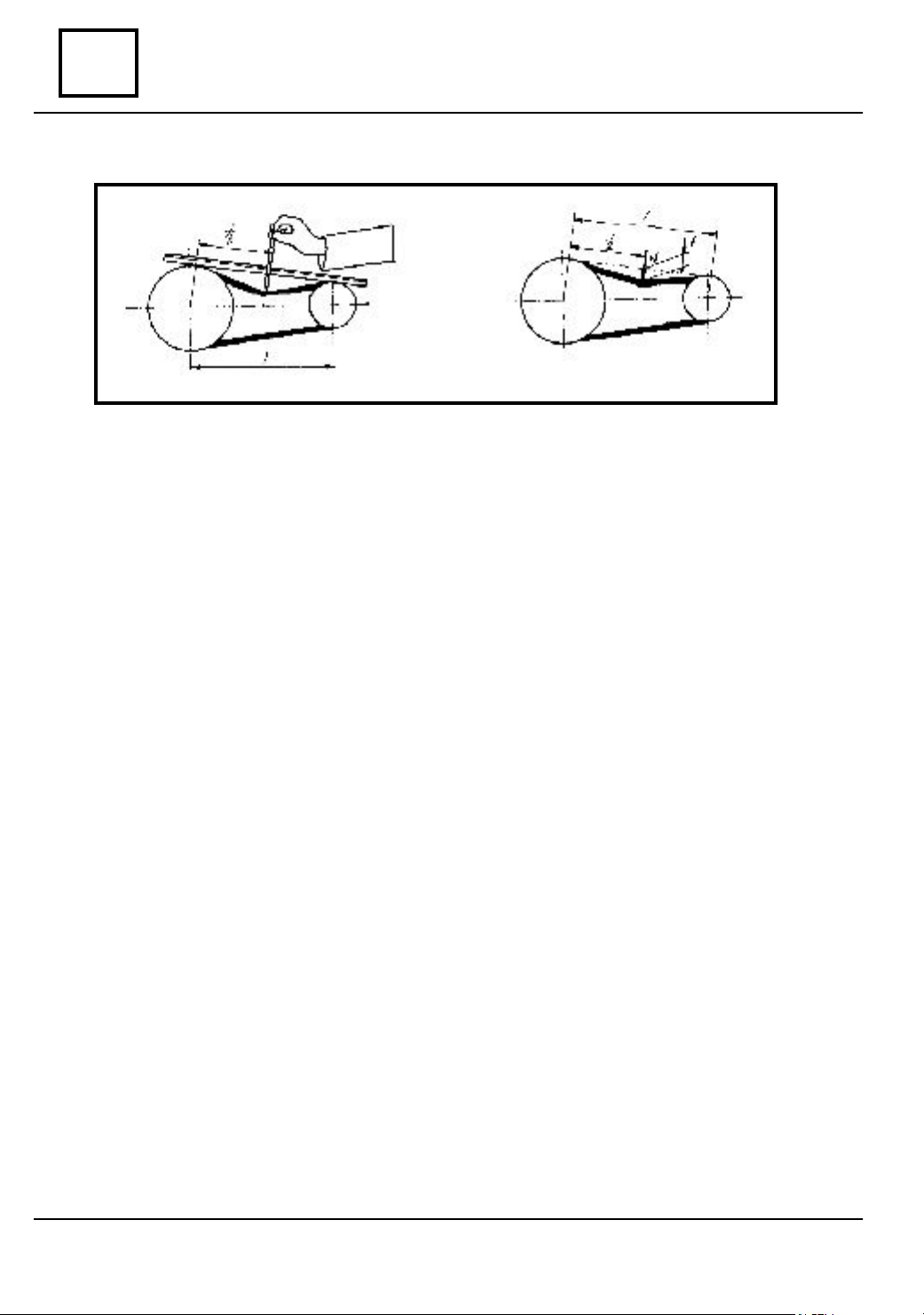

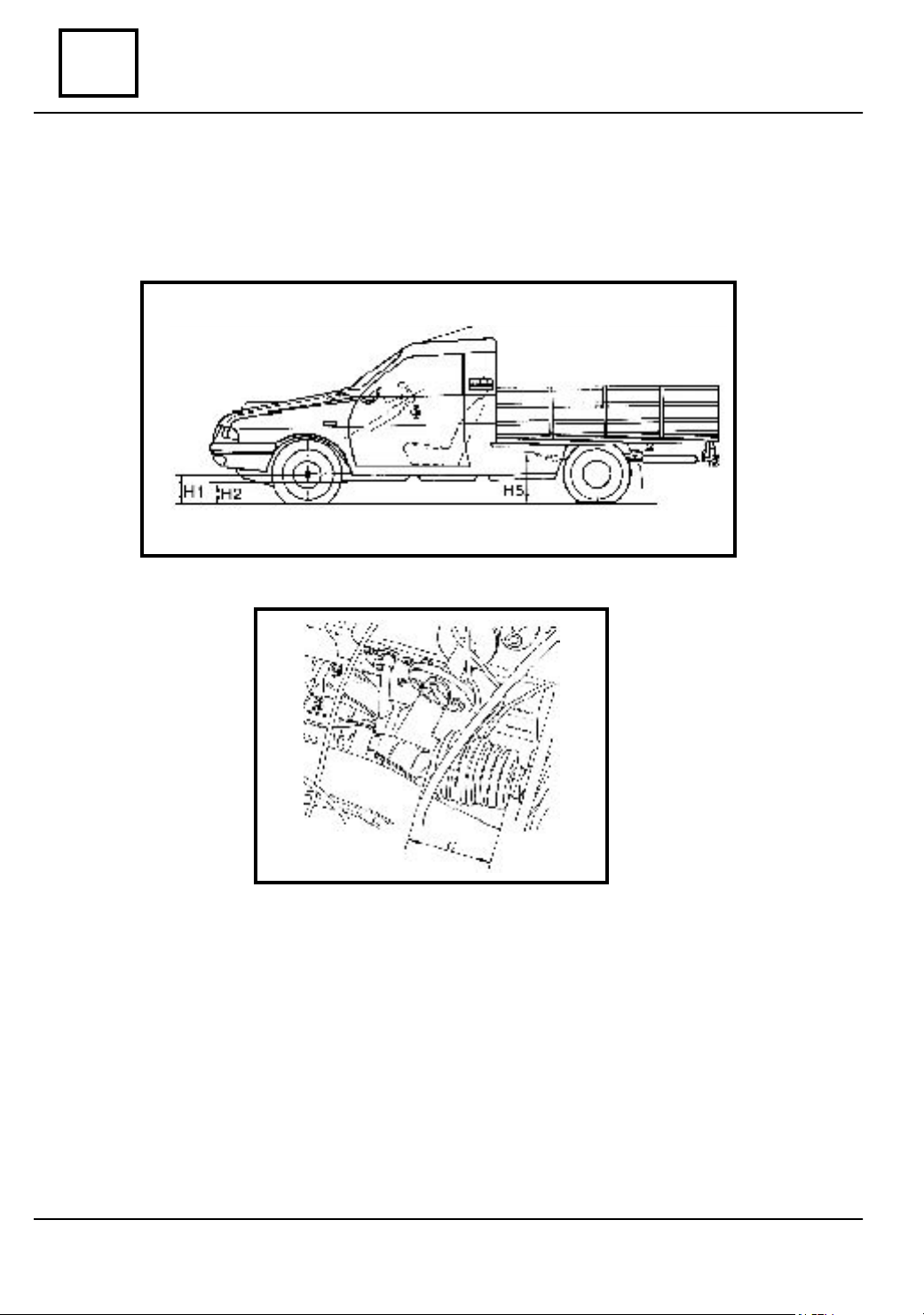

VA LUES UNDER CARRIAGE BODY CONDITIONING THE ADJUSTMENT OP-

HEIGHTS UNDER CARRIAGE BODY

ERATIONS OF THE STEERING ANGLES.

H1 – the distance measured from the wheels center to the ground

H2 – the distance measured from the longitudinal girder lower part to the ground

H5 – the distance measured from the joint axis of the front leaf spring to the ground,

measured in the area of the lower arm attachment.

C – this value is showing the position where the rack must reach in order to obtain the

middle point for the steering rack.

07 - 10

Page 29

VALUES AND SETTINGS

vnx.su

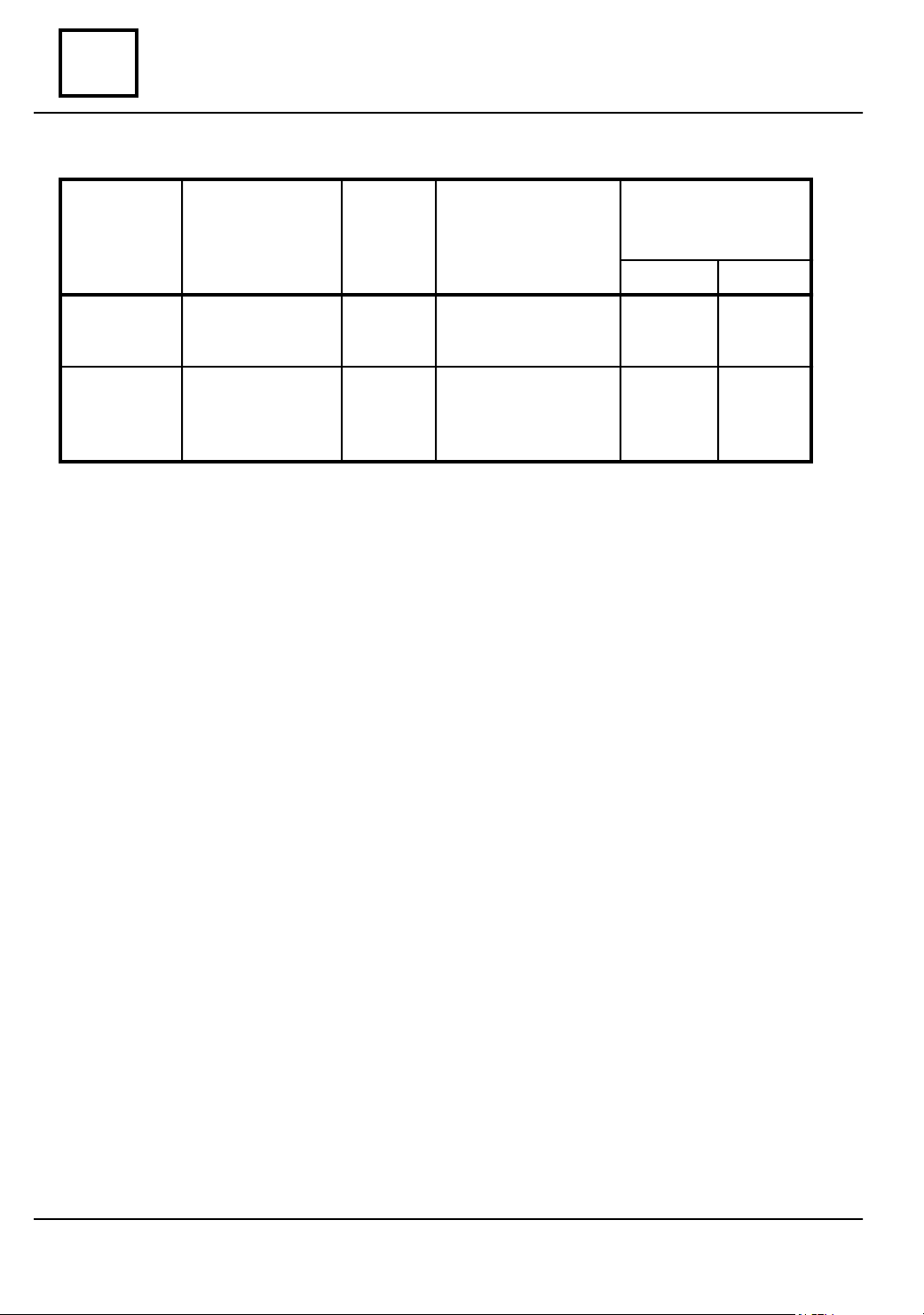

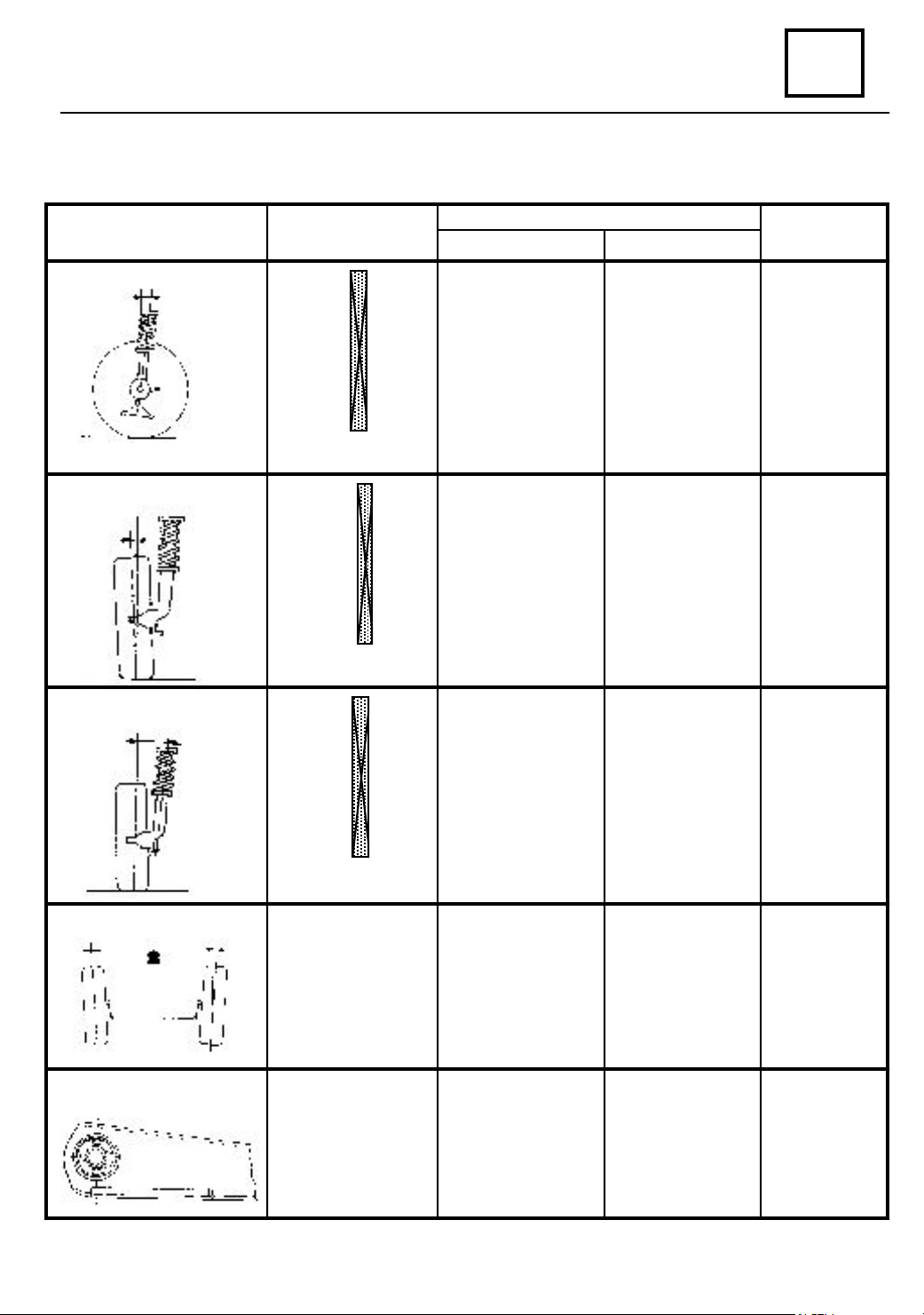

CONTROL VALUE OF FRONT AXLE ANGLES

COMMERCIAL U 75 DRIVE (1304, 1307)

07

ANGLES

CASTER

CAMBER

BALL JOINT

TOTAL PARALLELISM

VALUES

0

11'

1

0

28'

1

0

45' ± 30'

1

0

02'

2

0

19'

2

0

0

36'

52'

2

2

Maximum Left / Right

difference = 1

0

10 22'

0

1

21'

0

20'

1

0

18' ± 30'

1

0

17'

1

0

15'

1

0

14'

1

Maximum Left / Right

difference = 1

0

01'

8

0

02'

8

0

03'

8

0

04' ±30'

8

0

05'

8

0

07'

8

0

08'

8

0

Maximum Left / Right

difference = 1

0

POSITION OF THE VEHICLE

1304 1307

H5 - H2 = 260

H5 - H2 = 250

H5 - H2 = 240

H5 - H2 = 230

H5 - H2 = 220

H5 - H2 = 210

H5 - H2 = 200

H1 - H2 = 66

H1 - H2 = 62

H1 - H2 = 58

H1 - H2 = 54

H1 - H2 = 51

H1 - H2 = 47

H1 - H2 = 43

H1 - H2 = 66

H1 - H2 = 62

H1 - H2 = 58

H1 - H2 = 54

H1 - H2 = 51

H1 - H2 = 47

H1 - H2 = 43

H5 - H2 = 265

H5 - H2 = 255

H5 - H2 = 245

H5 - H2 = 235

H5 - H2 = 225

H5 - H2 = 215

H5 - H2 = 205

H1 - H2 = 66

H1 - H2 = 62

H1 - H2 = 58

H1 - H2 = 54

H1 - H2 = 51

H1 - H2 = 47

H1 - H2 = 43

H1 - H2 = 66

H1 - H2 = 62

H1 - H2 = 58

H1 - H2 = 54

H1 - H2 = 51

H1 - H2 = 47

H1 - H2 = 43

ADJUSTMENTS

Adjustable by

modification of

the tie-rod

length from

previous

mounting

Not adjustable

Not adjustable

ELASTIC JOINTS BLOCKING

Opening (toe-in)

0

10’ ± 10’

0

(for one wheel

0

0

05’ ± 05”)

-

Empty

Empty

07 - 11

Empty

Adjustable by

means of the

tie rods rotation

Empty

-

Page 30

VALUES AND SETTINGS

vnx.su

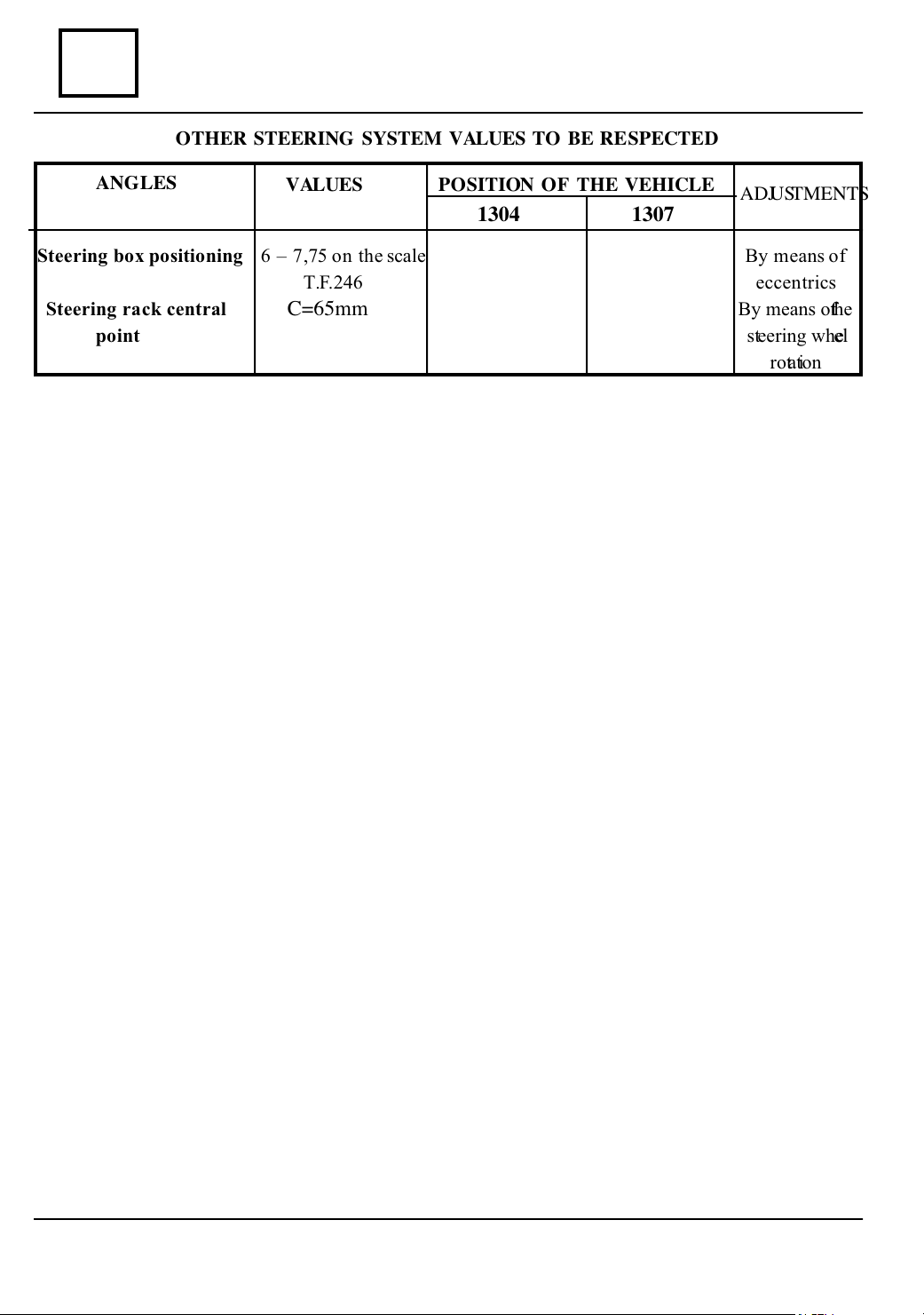

07

ANGLES

Steering box positioning 6 – 7,75 on the scale By means of

Steering rack central C=65mm By means of th e

point steering wheel

CONTROL VALUE OF FRONT AXLE ANGLES

OTHER STEERING SYSTEM VALUES TO BE RESPECTED

VALUES

T.F. 24 6 eccentrics

POSITION OF THE VEHICLE

1304 1307

ADJUSTMENTS

rotation

07 - 12

Page 31

VALUES AND SETTINGS

vnx.su

CONTROL VALUE OF FRONT AXLE ANGLES

COMMERCIAL U 75 / 4X4 DRIVE (1304, 1307)

07

ANGLES

CASTER

CAMBER

PIVOT

BALL JOINT

TOTAL PARALLELISM

VALUES

0

11'

1

0

1

29'

0

46' ± 30'

1

0

02'

2

0

19'

2

0

2

2

0

36'

53'

Maximum Left / Right

difference = 1

0

21'

1

0

20'

1

0

19'

1

0

18' ± 30'

1

0

16'

1

0

15'

1

0

13'

1

Maximum Left / Right

difference = 1

0

01'

8

0

02'

8

0

03'

8

0

04' ±30'

8

0

05'

8

0

07'

8

0

08'

8

0

0

Maximum Left / Right

difference = 1

0

Opening (toe-in)

0 160

-0

(for one wheel

0

08’± 05’)

-0

± 10

0

POSITION OF THE VEHICLE

1304

H5 - H2 = 260

H5 - H2 = 250

H5 - H2 = 240

H5 - H2 = 230

H5 - H2 = 220

H5 - H2 = 210

H5 - H2 = 200

H1 - H2 = 66

H1 - H2 = 62

H1 - H2 = 58

H1 - H2 = 54

H1 - H2 = 51

H1 - H2 = 47

H1 - H2 = 43

H1 - H2 = 66

H1 - H2 = 62

H1 - H2 = 58

H1 - H2 = 54

H1 - H2 = 51

H1 - H2 = 47

H1 - H2 = 43

Empty

1307

H5 - H2 = 265

H5 - H2 = 255

H5 - H2 = 245

H5 - H2 = 235

H5 - H2 = 22

H5 - H2 = 215

H5 - H2 = 205

H1 - H2 = 66

H1 - H2 = 62

H1 - H2 = 58

H1 - H2 = 54

H1 - H2 = 51

H1 - H2 = 47

H1 - H2 = 43

H1 - H2 = 66

H1 - H2 = 62

H1 - H2 = 58

H1 - H2 = 54

H1 - H2 = 51

H1 - H2 = 47

H1 - H2 = 43

Empty

ADJUSTMENTS

Adjustable by modifi-

cation of the tie-rod

length from previous

mounting

Not adjustable

Not adjustable

Adjustable by

means of the tie

rods rotation

ELASTIC JOINTS BLOCKING

-

Empty

Empty

-

07 - 13

Page 32

VALUES AND SETTINGS

vnx.su

07

ANGLES

Steering box positioning 6 – 7,75 on the scale By means of

Steering rack central C=65mm By means of th e

point steering wheel

CONTROL VALUE OF FRONT AXLE ANGLES

OTHER STEERING SYSTEM VALUES TO BE RESPECTED

VALUES

T.F. 24 6 eccentrics

POSITION OF THE VEHICLE

1304

1307

ADJUSTMENTS

rotation

07 - 14

Page 33

VALUES AND SETTINGS

vnx.su

CONTROL VALUE OF REAR AXLE ANGLES

COMMERCIAL U 75 DRIVE (1304, 1307)

07

ANG L E S

CAMBER

PARALLELISM

ELASTIC JOINTS BLOCKING

VALUES

00± 34'30''

(For two wheels)

To e out

00 ± 34'30''

VEHICLE

POSITION

Empty

Empty

Empty

Empty

ADJUSTMENTS

Not adjustable

Not adjustable

--

07 - 15

Page 34

VALUES AND SETTINGS

vnx.su

07

CONTROL VALUE OF REAR AXLE ANGLES

COMMERCIAL U 75 / 4 X 4 DRIVE (1304, 1307)

ANGLES

CAMBER

PARALLELISM

VALUES

0

0

± 19'59''

(For two wheels)

Toe out

0

± 19'59''

0

VEHICLE

POSITION

Empty

Empty

ADJUSTMENTS

Not adjustable

Not adjustable

ELASTIC JOINTS BLOCKING

Empty

* In order to check and adjust the front axle angles values, respectively the rear axle ones, the

following must be done:

- perform the tires checking concerning:

- dimensions

- inflating pressure

- degree of wear

- perform the joints checking:

- elastic joints condition

- ball joint clearance

- wheel bearing clearance

The vehicle must be obligatory:

- positioned with the wheels on bench rotating plates being in horizontal direction

- braked ensured

- suspension tested, for vehicle setting at its free height

- steering brought at central point and steering rack blocked in this position.

These operations are to be followed by optical device attachment on vehicle, observing the

prescriptions of the steering measurement bench manufacturer.

07 - 16

Page 35

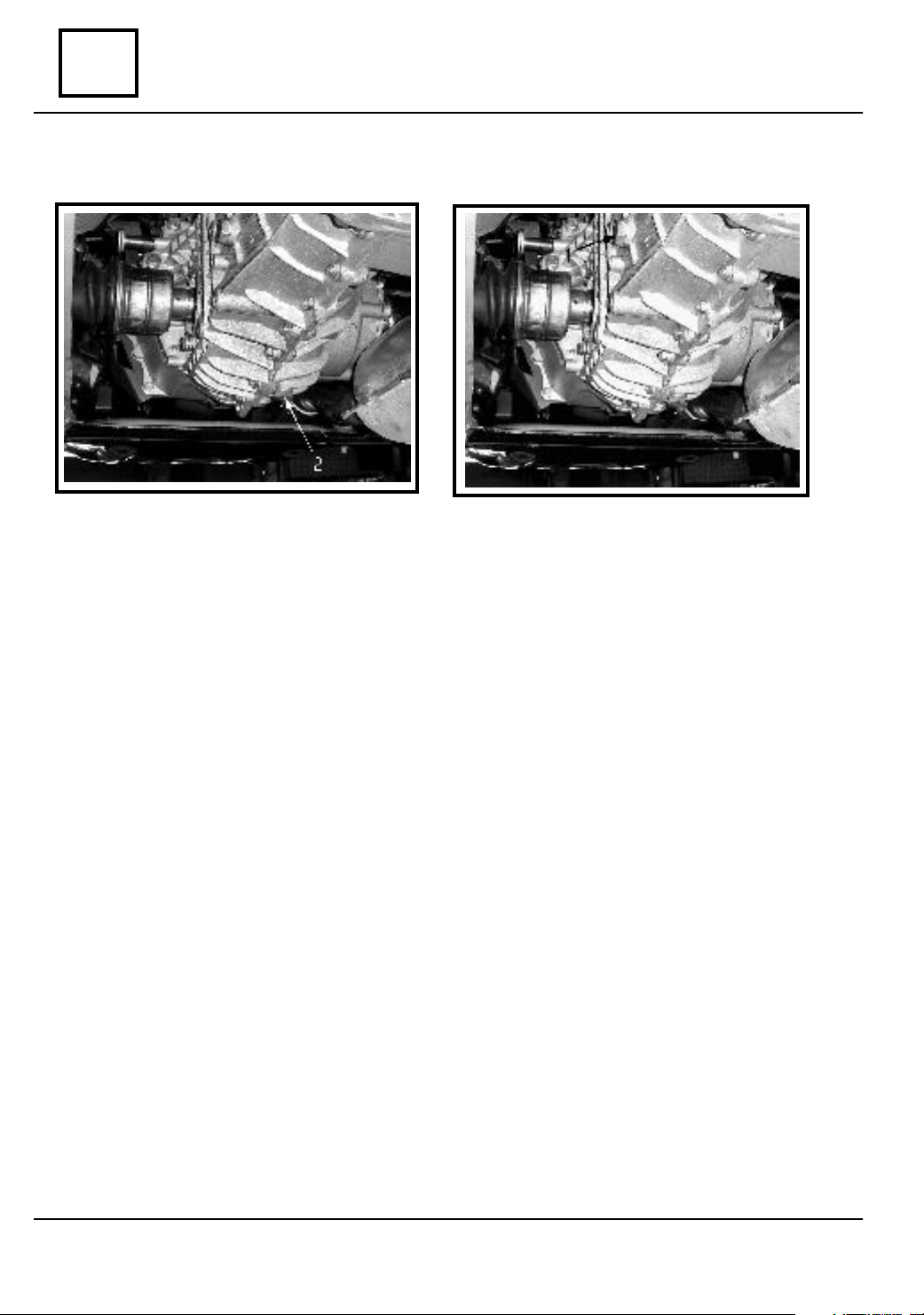

ENGINE AND LOWER ENGINE UNITS

vnx.su

INGREDIENTS

YPE UTILISATION

T

RHODORSEAL 5661 Propeller shaft pins.

Oil sump and distribution cap.

LOCTITE 518 Petrol pump sealaing ( membrane type )

and cap of bearing no. 1.

OMNI - FIT RAPID ( FIXAMED M 28 ) Flywheel attachement screws,bearings

cap screws.

OIL SUPER 15 W 40 API SJ Engine lubrication,parts lubrication

when mounting.

S.E. DERO 100 Washing of steel,aluminium and cast

iron parts.

10

10 - 1

Page 36

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

IDENTIFICATION

VEHICLE TYPE ENGINE GEAR BOX DISPLACEMENT BORE STROKE COMPRESS

3

)( mm ) ( mm )

( cm

1304 Pick-up 365

1304 Drop-side 106 - 10 50 C 1557 77 83,6 8,5:1

1304 King-cab 51 C

1305 Pick-up 365

1305 Drop-side 106 - 02 50 C 1557 77 83,6 8,5:1

1305 King-cab 51 C

1307 365 1397 76 77 8,5:1

102 - 14 50 C

ION RATIO

10 - 2

Page 37

ENGINE AND LOWER ENGINE UNITS

vnx.su

IDENTIFICATION

The engine identification is done by means of a plate attached to the cylinder block, above

the oil filter.

1. Type of engine.

2. Engine manufacture series.

10

10 - 3

Page 38

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

Place the car on the elevator,dismount the engine shield,check the presence of oil leaks.

If there are any leaks,eliminate it and then check again.

Drain the oil from the engine.

Fill the engine w ith 2,750 l new oil 15 W 40, start the engine and let it run in force

( 1000 - 1200 rpm. ) during aprox. 10 minutes, then s top the engine.

Drain the oil previously filled,as per following procedures:

- emptying plug removed;

- piston of cylinder 1 at the upper dead point;

- draining time 20 min;

- the oil is collected in a special vessel which can be used both for filling and draining of the

oil.

Mount the emptying plug.

Weigh the vessel with the ollected oil by means of a s cale.Mark this value G1.

The oil is filled back in the engine,directelly from the special vesel.

Check the sealing of the emptying plug.

Keep the vessel with the oil traces remained after oil filling.

MEASUREMENT OF OIL CONSUMPTION

PREPARATION FOR TEST

CONSUMPTION TEST

ROAD TEST

Driving conditions to be constant as far as speed and charge are concerned, equivalent with

a 80 km/h speed on a horizontal road.

Do not force the acceleration.

Length of the route: 100 +/- 5 km.

OIL COLLECTING

Place the car on the elevator.

Drain the oil respecting the previous conditions.

The oil is collected in the same special vessel used for oil filling.

Weigh the vessel with the collected oil on the same scale and mark this value with G2.

10 - 4

Page 39

ENGINE AND LOWER ENGINE UNITS

vnx.su

MEASUREMENT OF OIL CONSUMPTION

CONSUMPTION CALCULATION

The oil consumption is given by the difference between the first weighing and the second

weighing.

Oil c onsumption G1 - G2.

ADMISSIBLE CONSUMPTION

The admissible consumption is determinated by:

- the wear general condition of the engine;

- the oil quality;

- driving style, rpm;

- engine tuning: carburattion.

The engines with a oil consumption greater of 100 grams at 100 km need to be adjusted.

For the cars within the warranty period,the maximum admissible oil consumption is 75 grams

at 100 km.

10

10 - 5

Page 40

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

The oil pressure checking is done in the following conditions:oil to be up to the required level

and of a adequate quality; oil temperature to be 80 ºC.

To check the oil pressure use the following procedure :

- check the oil level and fill in until the required level is reached (if this is necessary); if the

oil is unsuitable (used) it shal be replaced.

- start the e ngine and let it run until the oil temperature reach 80 ºC.

- stop the engine and dismount the oil pressure transmitter;

- mount the MOT 73-01 manometer;

- connect a rotation meter;

- start the engine and check the pressure.

The recommended pressure is:

- 750-800 rpm - 0,7 bars

- 4000 rpm - 3,5 - 4 bars

- stop the engine,dismount the MOT 73-01 manometer and mount the oil pressure

transmitter;

- disonnect the rotation meter;

- chek the oil level and fill in up to the required level.

OIL PRESSURE CHECKING

10 - 6

Page 41

ENGINE AND LOWER ENGINE UNITS

vnx.su

OIL FILTER REPLACEMENT

DISMO UNT NG

Disconnect the battery.

Loosen the filter by means of the MOT 445.

Hand dismount the filter.

10

EMOUNTING

R

Lubricate the gasket of the new filter with oil.

Tighten the filter by hand untill the asket comes in the contact with the block.

Tighten 1/2 rotation more by means of the MOT 445 wrench.

Loosen the filter,bring the gasket into contact with the block and tighten 1/2 -3/4 more rotations.

Check and fill with oil up to the required level in the engine.

10 - 7

Page 42

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

ENGINE DISMOUNTING - REMOUNTING

The engine may be independently dismounted by taking it out through the upper part

of theengine compartment.

ISMOUNT ING ( in the engine compartment )

D

Disconnect the battery.

Dismount the engine hood.

Dismount the plug of the cylinder head

cap,the plug of the oil casing and drain the oil

from the engine.

Drain the cooling circuit:

- dismount the radiator plug;

- dismount the cylinders block plug.

Dismount the watter and fuel ducts.

Dismount the radiator.

Dismount the fan,the belt and the fan pulley

of the watter pump.

Disconect the electric wires

(alternator,thermocouplings,oil pressure

transmitter,coil;breaker);

Dismount the cables:

- acceleration and shock;

Dismount the throttle valve spring.

Dismount the air filter.

Dismount the starter protection.

gearbox on the engine.

Dismount the starter cables.

Dismount the starter.

Unscrew the fixing screws of the

10 - 8

Page 43

ENGINE AND LOWER ENGINE UNITS

vnx.su

ENGINE DISMOUNTING - REMOUNTING

DISMO UNT ING (under the car )

Dismount the engine shield.

Dismount the beam between the

longitudinal girders.

Dismount the nuts that attach(fix) the bushings

the stabilizer rod.

Dismount the nuts that attach the gearbox to

the engine.

Dismount the protection plate of the clutch.

Dismount the pulley of the crakshaft.

Dismount the attachment ring of the

discharge tube.

Unscrew the nuts that attach the engine

supports to the buffers.

Deposer les ecrous de fixation des supports

moteur au tampon.

10

to

Place a jack under the gearbox.in order to

maintain it in the right position.

Mount the lifting device.

Displace the engine forward and lift it.

Place the engine on the support.

EMOUNTING

R

The dismounting operations are to be performed in reverse order.

10 - 9

Page 44

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

Check the existance of the two bushings by means of which the clutch casing is centered on

the block.

Slightly grease ( thin coat) the clutch shaft grooves with Li Ca Pb type II grease.

Adjust the stroke of the acceleration pedal.

Perform:

- the filling with oil of the engine;

- the filling and aeration of the cooling circuit.

Adjust the engine running (ignition ,carburation).

Tighten the fixing nuts and screws according to the tightening moments given in the bellow

table:

ENGINE DISMOUNTING - REMOUNTING

PA RTICULARS ON REMOUNTING

NGINE MOUNTING - DISMOUNTING

E

FIXING TIGHTENING MOMENTS

(daN.m)

Caps to bearings 5,50 - 6,50

Caps to connecting rods

Flywheel 5

Cylinder head to casing ( at cold)

Cylinder head cap

Tilter shaft support

Camshaft pinion

Camshaft clip

Oil pump on casing

Lower casing

Clutch mechanism

Clutch mechanism φ 200 DBR/ φ 200 GR 1,50 - 2,00

Distribution cap

Oil emptying plug

Pump and water pump cap

Fan 2,00 - 2,50

Starter screen 2 - 3

Fuel pump 1,50 - 2,00

Thermocontact1,50 - 2,00

Oil pressure trasmitter 2

Carburettor 1,50 - 2,00

Crankshaft pulley 6,50

Alternator support 1,00 - 1,75

φ 180 DBR 1,00 - 1,20

0,70 - 1,00

4,00 - 4,50

5,50 - 6,50

0,15 - 0,45

1,50 - 1,75

2,70 - 3,20

0,80 - 1,00

0,70 - 1,00

1,20 +/- 0,40

max. 3,5

0,70

10 - 10

Page 45

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

ENGINE AND GEARBOX DISMOUNTING - REMOUNTING

The engine-gearbox assembly may be dismounted from the car only by taking it out at the

uper part of the engine compartment.

ISMOUNT ING ( inside the engine compartment )

D

Perform the operations described for the sole engine dismounting,except the following

operations:

- dismounting of the starter protection;

- dismounting of starter;

- dismounting of the screws fixing the gearbox to the engine.

Perform additionally:

- dismounting of the clutch cable.

ISMO UNTING ( under the car )

D

- dismounting of clutch protection plate;

- dismounting the nuts of fixing the gearbox

to the engine.

Perform additionally:

- gearbox oil draining;

- disconnecting the wires of the baking

connector.

Dismount the speedometer cable;

Dismount the fixing bolt of the speeds

connecting rod.

Dismount the fixing nut of the exhaust pipe on

the cross bar of the gearbox.

Dismount the elastic pins of the transmission.

10 - 11

Page 46

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

ENGINE AND GEARBOX DISMOUNTING - REMOUNTING

Place the cross bars supporting the front axle.

Dismount the front wheels.

Dismount the upper suspenssion ball joints and

the ball joints of the steering connecting rod.

Disconnect the transmissions.

.

Place a jack under the gearbox to maintain it

in the right position.

Dismount the back cross bar of the gearbox.

Dismount the fixing nuts of the engine supports.

10 - 12

Page 47

ENGINE AND LOWER ENGINE UNITS

vnx.su

ENGINE AND GEARBOX DISMOUNTING - REMOUNTING

10

Remove the jack from under the gearbox.

Mount the lifting device.

Move the engine-gearbox assembly

forward,bend it and lift it.

Place the engine on support.

Dismount the gearbox ( if necessary).

EMOUNTING

R

Perform in the reverse order the operations descibed at the dismounting.

PA RTICULARS UPON REMOUNTING

Slightly grease with grease Li Ca Pb type II the grooves of the front axles pinions.

Upon mounting the elastic pins,the notches shall be oriented towards the exterior (wheel).After

mounting ,a ball of sealer shall be placed at the ends of the pins,for sealing.

Adjust the cl utch stroke: 2,5 – 3 mm.

Perform :

- oil fill up of the gearbox and the engine;

- filling and aeration of the cooling system.

Adjust the engine running (ignition and carburation).

Adjust the speeds command (see chapter 37 “ Speeds command ”).

Tighten the fixing nuts and screws according to the moments mentioned in the bellow table:

FIXING TIG H TENING

MOMENTS ( daNm )

Gearbox control connecting rod 4

Steering connecting rod 3

Upper shaft ball joint 5

Gearbox filling and draining plug 2,50

Downlead tube clip for exhaust pipe 1,70

Engine support on block 1,70

Buffer on support 1,70

Gearbox cross bar on gearbox 1,20

Cross bar on lateral buffers 1,70

10 - 13

Page 48

10

vnx.su

ENGINE AND LOWER ENGINE UNITS

TIGHTENING BY S CREWING UP MOMENTS

10 - 14

Page 49

ENGINE AND LOWER ENGINE UNITS

vnx.su

CHARACTERISTICS

ENGINE TYPE 102 - 14 106 - 02 106 - 10

Cylinder (cmc)

Bore (mm)

Stroke (mm)

Compression ratio

Maximum power

Maximum torque

Idle running

Rocker arm clearance

(mm)

- inlet

- exhaust

Distance between the

breaker contacts (mm)

Cam angle

Dwell percent

Initial advance

Ignition succession *

Cylinders disposal

Max rpm

Fuel

DIN at 5000 rpm

cold / warm

1397

76

77

8,5:1

42,6 KW

10,2 daNm

at 3500 rpm

750 - 800rpm

0,15 / 0,18

0,20 / 0,25

0,4

57+/- 3

63+/- 3%

0+/- 1

1 - 3 - 4 - 2

5500 rpm

CO/R min 90

0

0

line

Petrol

1557

77

83,6

8,5:1

50 KW

DIN at 5000 rpm

11,9 daNm

at 2500 rpm

750 - 850rpm

cold / warm

0,15 / 0,18

0,20 / 0,25

0,4

57+/- 3

63+/- 3%

0+/- 1

1 - 3 - 4 - 2

5500 rpm

CO/R min 95/87

0

0

line

Petrol

1557

8,5:1

50 KW

DIN at 5000 rpm

11,5 daNm

at 2500 rpm

750 - 850rpm

cold / warm

0,15 / 0,18

0,20 / 0,25

1 - 3 - 4 - 2

5500 rpm

Leadfree petrol

CO/R min 95

10

77

83,6

-

-

-

-

line

* First cylinder towards the flywheel.

10 - 15

Page 50

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

Aluminium alloy cast cylinder head

T

YPE DU MOTEUR

Couple for tightening the attachment

screws of the cylinder head (daNm)

- cold engine

- warm engine *

Cylinder head height (mm)

- normal

- for repairs (minimum)

Reprise maximum autorisee du plan de

joint

Maximum accepted grinding of the

support surface of the gasket

Iginition chamber volume (cmc)

CHARACTERISTICS

CYLINDER HEAD

102 - 14

5,5 - 6,5

6,5

74,40

73,90

0,50

0,05

41,80+/-0,5

106 - 10

5,5 - 6,5

6,5

74,20

73,70

0,50

0,05

46,6+/-0,5

106 - 02

5,5 - 6,5

6,5

74,20

73,70

0,50

0,05

46,6+/-0,5

Cylinder head identification (stamp on

the cylinder head)

1400 / 8,5

1557 / 8,5

1557 / 8,5

* 50 minutes after the engine is stopped.

The difference between the ignition chambers volumes of the same cylinder head , max. 0,5

cmc.

VA LV E S PRINGS

The valve springs are identical for the inlet and for the outlet.

Upon assembling, the tight coils shall be towards the cylinder head The end with tight coils is

grene paint marked.

ENGINE TYPE ALL TYPES

Wire diameter ( mm ) 3,4

Exterior diameter ( mm ) 21,6

Length of spring ( mm ) 42

Length of spring under load of 36 daN ( mm ) 25

Coiling direction rightwise

10 - 16

Page 51

ENGINE AND LOWER ENGINE UNITS

vnx.su

CHARACTERISTICS

VA LVES

YPE OF ENGINE

T

Diameter of shaft (mm)

Angle o f the support side

- inlet

- outlet

Diameter of the head (mm)

- inlet

- outlet

Max. clearance between the valve

shaft and the valve guide (mm)

- inlet

- outlet

102 - 14

7

90

0

90

33,5

30,3

0,03

0,08

10

106 - 02

106 - 10

7

0

90

0

90

34,6

30,3

0,03

0,08

0

VA LVES SEATS

The special cast iron valves, warm pressed, not to be replaced.

TYPE OF ENGINE

102 - 14

106 - 02

106 - 10

Angle of the seat:

- inlet

- outlet

Width of support side (mm):

- inlet

- outlet

Outside diameter (mm)

- inlet

- outlet

0

90

0

90

1,1 - 1,4

1,4 - 1,7

34,5

31,3

0

90

0

90

1,1 - 1,4

1,4 - 1,7

35,7

31,3

10 - 17

Page 52

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

The cast iron guides ,w arm pressed ,may be replaced.

CHARACTERISTICS

VA LVES GUIDES

TYPE DU MOTEUR

Inner diameter (mm)

Outside diameter (mm):

- normal

- 1 st repair (1 channel)

- 2-nd repair (2 channels)*

Gu i d e s inclination (inlet,outlet) as per the

surface of the gasket

Guide position as per seat (mm)

- inlet

- outlet

* Done only upon speial request.

T YPE OF THE ENGINE ALL TYPES

CAMSHAFT

102 - 14

7

11

11.10

11,25

0

17

26,5

26,2

106 - 02

106 - 10

7

11

11.10

11,25

0

17

27,4

26,1

Nomber of bearings 4

Axial clearance (mm) measured at the adjustment strap 0,06 - 0,11

Distribution diagram:

- inlet opening lead 22

- inlet closing delay 62

- outlet opening lead 60

- outlet closing delayay 20

0

0

0

0

ROCKER ACTUATORS S TEMS

TYPE OF THE ENGINE ALL TYPES

Length ( mm ) 176

Diameter ( mm ) 5

10 - 18

Page 53

ENGINE AND LOWER ENGINE UNITS

vnx.su

CHARACTERISTICS

TYPE OF THE ENGINE ALL TYPES

Outside diameter (mm)

- normal 19

- reparation * 19,2

Alesage du trou d’embase (mm) 19

- normal

- reparation 19

* Done only upon special request.

CYLINDER JACKETS

10

PUSHERS

+ 0,21

0

+ 0,210

TYPE OF THE ENGINE

Jackets marking / ø jackets (mm)

green

blue

red

yellow

Diametre for centering in the block ( mm )

Jackets heights over the level of the gasket

(mm)

Thikness of the sealing gaskets on the block

(mm)

102 - 14

76 ,000 - 76,010

76 ,010 - 76,020

76 ,020 - 76,030

76 ,030 - 76,040

80, 6

0 ,02 - 0,09

Without ring gasket “0”

0 ,05 - 0,13

With Cu gasket

Rubber

φ 1,25 - 1,45

Copper

0, 1

106 - 02

106 - 10

77 ,000 - 77,010

77 ,010 - 77,020

77 ,020 - 77,030

77 ,030 - 77,040

80, 6

0 ,02 - 0,09

Without ring gasket “ 0“

0 ,05 - 0,13

With Cu gasket

Ruibber

φ 1,25 - 1,45

Copper

0, 1

10 - 19

Page 54

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

CHARACTERISTICS

* The adimisible clearance between the piston and the cylinder jacket is

J = 0,045 - 0,065 mm and is done by corresponding matching as per table :

ISTO N MARK CYLINDER

P

JACKET MARK

A Green

B Bl ue

C Red

D Yellow

CRANKSHAFT

YPE OF THE ENGINE

T

Number of bearings

Type of bushings

Tightening by screwing up moment of the

bushing caps (daNm)

Axial clearance ( mm )

Thickness of washers thrust for axial

clearance adjustment (mm) (half bushings )

Sliding block bearings:

Nominal diameter (mm)

Repair diameter (mm)

Grinding tolerance (mm)

Conicité et ovalité de l’axe (mm)

Sliding block device:

Normal diameter (mm)

Repair diameter (mm)

Grinding tolerance (mm)

Coussinets de paliers:

-Normal diameter

-Repair diameter

ALL TYPES

5

aluminium - stanium

5,5 - 6,5

0,05 - 0,23

2,28

2,38

2,43

54,795

54,575

- 0,00

- 0,02

max. 0,005

43,98

43,75

- 0,00

- 0,02

46,0

45,75

* The bushings for bearings 1 and 3 on the one hand and the bushings for bearings 2,4 and 5

on the other hand,are identical.

10 - 20

Page 55

ENGINE AND LOWER ENGINE UNITS

vnx.su

CHARACTERISTICS

CONNECTING RODS

TYPE OF ENGINE

Tightening by screwing up moment of the bushing caps (daNm)

Type of bushings

Axial clearance of the connecting rod head

(mm)

Diametre alesage du pied de bielle (mm)

Diametre alesage de la tete de bielle (mm)

Torsion ou courbement (mm)

Distance entre les axes de bielle (mm)

Coussinets de bielle:

- côte normale

- côte de reparation

ALL TYPES

4,5

aluminium - stanium

0,31- 0,57

0,029

20 -

- 0,041

47, 614 + 0,011

0

max. 0,03 mm

128 +/- 0,15 mm

44 mm

43,75 mm

10

PISTONS, PISTON SHAFTS, RINGS

TYPE DU MOTEUR

Piston diameter ( mm ) / A

Piston marking ( mm ) B

Piston axle bore (inside) diameter /

Piston marking

Piston shaft outside diameter (mm)/

Piston marking

Piston axle length (mm)

Piston axle assembling

Piston assembling in the block

Rings thickness (slot) (mm):

- compression ring

- sealing ring

- lubricating ring

Mounting position of the rings

102 - 14

75,945 - 75,955

75,955 - 75,965

C

D

75,965 - 75,975

75,975 - 75,985

( 20,000 - 20,003 ) / X ; ( 20,003 - 20,006 ) / Y

( 20,006 - 20,009 ) / Z

( 19,991 - 19,994 ) / Red ;( 19,994 - 19,997 ) / Ye l ow

(19,997 - 20,000 ) / Blue

62

Pressed in the connecting rod,free in the piston

Arrow oriented towards the flywheel

1,75 ( 0,25 - 0,40 )

2 ( 0,25 - 0,40 )

4 ( 0,20 - 0,35 )

décalés a 120

106 - 02

106 - 10

76,945 - 76,955

76,955 - 76,965

76,965 - 76,975

76,975 - 76,985

0

10 - 21

Page 56

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

CHARACTERISTICS

* Matching of the piston with the piston shaft is done as per following table:

PISTON MARKING PISTON SH AFT MARK ING

X Red

Y Yellow

ZBlue

OIL PUMP

TYPE OF THE ENGINE ALL TYPES

Oil pressure a 80 0 C ( bars )

- for iddle running ( 750 - 800 rpm ) minimum 0,7

- for 4000 rpm minimum 3,5 - 4

FUEL PUMP

Diaphragm pump ( for engines with carburettor )

Static pressure (pump does not work) (bars)

- minimum - 0,170

- maximum - 0,265

Electric pump ( for engine with injection )

Admissible minimum flow – 65 l /h

Pression > 1 bar at 12 V

10 - 22

Page 57

ENGINE AND LOWER ENGINE UNITS

vnx.su

DISMOUNTING - MOUNTING

Dismount from erngine:

- the alternator and the fixinf clip;

- the distributor and the ignintion cable;

- the fuel pump;

- the oil filter;

- the oil dip stick;

- the oil pressuire transmitter;

- the engine left side support and the elastic buffer.

Mounts the bolts of MOT 460 on the

engine block.

10

Place the engine on the MOT 460 support.

Dismount:

- the rubber hoses;

- the inlet-outlet colector;

- the colector gasket;

- the pressure plate and the clutch disk.

10 - 23

Page 58

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

Dismount the cylineder head and take out the

cylinder head gasket.

In order to do that,unscrew the the fixing bolts

of the cylinder head,except the central screw,on

the side of the breaker-distributor.

Because of the thightening, always when

dismounting,the cylinder head gasket is stuck to

the casing or the cylinder head the latter shall

not be lifted in order to avoid the shifting of the

jackets and breaking of the sealing gaskets at

their bottom.

In order to remove the gasket,use a rubber

or plastic hammer to slightly hit the cylinder head

extremities,then easy turn the cylinder head

around the undismounted screw.

Mount the jackets clamping device

MOT 484.

Take out the tilters shafts and the pushers and

put them in order.

Dismount the pinion of the breaker distributor.

DISMOUNTING - MOUNTING

0

Turn the engine at 180

- the crankshaft pulley;

- the oil casing;

- the distribution cap.

Take out the sealing gaskets of the

dismounted items (the ones provided with such

sealing gaskets).

For the engine where the sealing of the oil

casing and the distribution cap is done with

sealant,the old sealant is to be removed by

scratching and the specific surfaces are to be

cleaned with solvent 002.

and dismount:

10 - 24

Page 59

ENGINE AND LOWER ENGINE UNITS

vnx.su

DISMOUNTING - MOUNTING

Dismount the distribution chain tightener.

Straighten the lock washer and unscrew the

camshaft pinion fixing screw.

Take out the camshaft pinion and the

distribution chain.

10

Dismount the screws of the camshaft clip.

Take out the camshaft.

Take out the crankshaft pinion by means of

the MOT 49.

10 - 25

Page 60

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

Dismount the engine flywheel.

Check the marking of the connecting rods:

number 1 towards the flywheel ond on the reverse

side of the camshaft.

Dismount the connecting rods caps and the

half bushings and place them in order.

The bearing caps are marked from 1 to 5

number 1 towards the flywheel.

Dismount the bearing caps and the half bushings and place them in order.

Dismount the crankshaft.

DISMOUNTING - MOUNTING

Dismount the half bushings from the

connecting rod and from the block and place them

in order.

Remove the axial clearance adjustment thrust

washers.

Take out the bearing annular oil seal.

Rotate the engine by 180°, dismount the MOT 484 device and take out :

- the engine shield;

- the gaskets at the bottom of the jackets.

Dismount the block from the support.

10 - 26

Page 61

ENGINE AND LOWER ENGINE UNITS

vnx.su

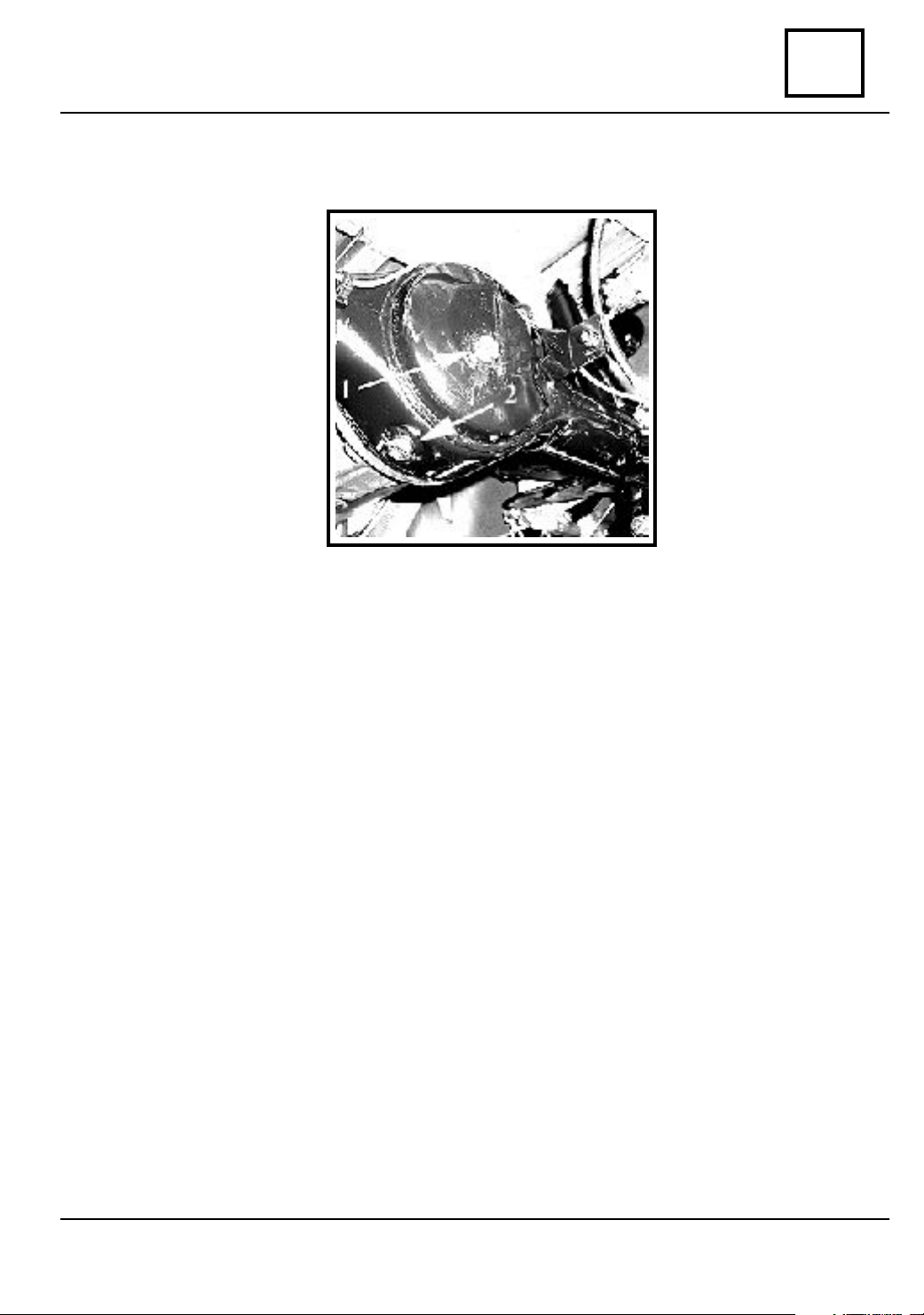

DISMOUNTING - MOUNTING

RETIGHTENING OF THE C YLINDER HEAD SCREWS

The re tightening of the cylinder head screws

is performed:

- for new cars.upon revision at 800-1000

km;

- upon an engine checking which requires

dismounting of the cylinder head;

- after every 10 000 km.

To re tighten, loosen the screw (1) by 1/4

turns,then tighten as per required moment:

- 6,5 daNm at warm (50 min.after engine

stop);

- 5,5 daNm at cold.

Repeat this operation alos for the others

screws in the tightening order specified in the

figure.

After re tightening the screws ,adjust the

tilters.

10

ADJUSTMENT OF THE TILTERS

Before adjusting the tilters check the

tightening of the platform.

The tightening moment of the platform fixing

screws: 1,5 – 1,75 daNm.

When adjusting the tilters,the gear box shall

be in the dead point.

The adjustment of tilters is to be done as per

method of the completely opened valve.

Rotate the engine until the the outlet valve of

cylinder is completely opened and perform the

adjustemnt by means of the MOT 13 device,tilter

adjusting wrench.

- inlet valve at cylinder 3;

- outlet valve at cylinder 4.

10 - 27

Page 62

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

Repeat the operation for the cylinders 3 - 4 - 2 according to the table:

OUTLET VALVE COMPLETELY OPENED VALVE TO BE ADJUSTED

1 3 4

3 4 2

4 2 1

2 1 3

Tilters clearance : at cold - inlet 0,15 mm;

The checking of the distance between the tilter and the valve is done by means of a distance

calliper (spy) at the corresponding dimension of the constructive cleranace.

The callipper should glide with easy friction between surfaces ( for a correct checking).

DISMOUNTING - MOUNTING

INLET OUTLET

- outlet 0,20 mm;

at warm - inlet 0,18 mm;

- outlet 0,25 mm.

ISMO UNTING

D

Disconnect the battery.

Dismount the air filter.

Empty (drain) the cooling system:

- dismount the radiator plug;

- dismount the cylinders block plug.

Dismount the breaker-distributor.

Dismount the alternator belt.

CYLINDER HEAD

10 - 28

Page 63

ENGINE AND LOWER ENGINE UNITS

vnx.su

DISMOUNTING - MOUNTING

Dismount the alternator.

Dismount the acceleration and shock

cables.

Disconnect the thermocontacts.

Dismount the water hoses(cylinder headcarburator; carburator-water pump; water

pump- radiator).

Dismount the collector from the cylinder head.

Dismount the tilters cap.

Dismount the tilters shafts. Place them in order so that they may be mounted again in theeir

former place.

Dismount the fixing screws of the cylinder head except the central screw on the side of breaker

distributor which shall be loosened.

Because of the thightening, always when dismounting,the cylinder head gasket is stuck to the

casing or the cylinder head the latter shall not be lifted in order to avoid the shifting of the jackets

and breaking of the sealing gaskets at t heir bottom.

In order to remove the gasket turn the cylinder head around the unscrewed screw.For cylinder

head displacement use a rubber or plastic hammer.

Unscrew the fixing screw.

Dismount the cylinder head.

Mount the MOT 484 device for jackets maintenance.

Clean the contact surfaces of the gasket ( cylinder block and cylinder head).

10

IMPORTANT

It is forbiden the cleaning of the aluminium surfaces with the scrapper.For

cleaning the rests of the gasket material which might remain stucked on the cylinder

head, always use solvent products (such as Decanol or Asimilate) which can be then

easily removed by wiping or scratching with a piece of wood , protecting in this way

the laying surface of the cylinder head on the cylinder block. Take care not to obturate

the lubricating grooves in the block and in the cylinder head (danger of getting the

cams and tilters jammed).All the impurities on the pistons head shall be blown with

air.

10 - 29

Page 64

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

CHECK OF THE GASKET PLANE DEFORMATION

The checking of the deformation of the gasket plane is done by means of a ruler and of a set

of gauges.

The maximum accepted deformation is: x = 0,05 mm.

If the maximum deformation exceeds this value,the gasket plane is corrected by grinding.

Before grinding water pump and tilters platform are to be dismounted.

The cylinder head shall be carefully positioned on the grinding machine in order to observe the

parallelism of the surfaces.

DISMOUNTING - MOUNTING

because by reducing the height,the compression ratio is altered.

The maximum addition that may be ground: 0,5 mm.

If by grinding,the minimum accepted height is exceeded, the cylinder head is to be replaced

MOUNTING

Perform the dismounting operations in the reverse order.

10 - 30

Page 65

ENGINE AND LOWER ENGINE UNITS

vnx.su

DISMOUNTING - MOUNTING

PA RTICULARITIES UPON RE MOUNTING

The contact surfaces of the gasket must be

clean.

The grease or antifreeze fluid must be

removed from the holes of the cylinder head fixing screws by means of a.

This is necessary in order to obtain a

correct thightening of the screws and to avoid

the appearance of casing cracks.

Dismount t he MOT 484 device for jackets

attachments.

Place the gasket with the marking “HAUT”

or “TOP” upwards.

Check if the hole in the gasket correctly overlaps the lubrication channel in the block.

Set the cylinder head and the fixing screws.

Tighten the screws at the required moment: 6,5 daNm.

Mount the tilters shafts in the holes where they have been dismounted.

Adjust the acceleration pedal stroke.

Fill and aerate the cooling system.

Check and adjust the engine running.

10

CYLINDER HEAD REPLACEMENT

Dismount the cylinder head.

Dismount the spark plugs.

Dismount:

- the water pump pulley;

- the water pump;

- the ylinder head closing plate;

- the alternator support.

Set the MOT 320 plate for vales support.

10 - 31

Page 66

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

Dismount the tilters platform.

Compress the valves springs by means of the

MOT 382 compressing device.

Take out the lock half cotters,release the

spring,take out the upper tray,the spring and the

lower tray.

Place the parts in order so that they may be

mounted back in the same place where they have

been dismounted from.

Remove the valves support plate,take out the

valves and set them in order.

Wa sh,clean and air blow the new cylinder

head.

DISMOUNTING - MOUNTING

performed when replacing the valves).

with the close coils towards the cylinder head.The end with close coils is marked with

green paint.

Check the presence of the lubricating channels and valves state.

Perform the lapping of the valves on the cylinder head guiding ( this operation is also to be

Mount the valves in the cylinder head and place the MOT 320 valves support plate.

Place in their previous positions:

- sealing gaskets of the valves shafts;

- the lower valve heads ;

- the valve springs;

- half cotters.

NOTE:

The valve springs are identical both for inlet and outlet.The springs are mounted

10 - 32

Page 67

ENGINE AND LOWER ENGINE UNITS

vnx.su

DISMOUNTING – MOUNTING

Compress the springs by means of the MOT 382 compression device and mount the lock

half cotters.

Mount the cylinder head closing plate and the water pump with new gaskets.

Mount the alternator support.

Mount the cylinder head with new gasket observing the mounting instructions.

Mount the tilter shafts in the place where they have been removed from.

Adjust the tilters.

Mount the tilters cap.

Adjust the acceleration pedal stroke.

Fill and aerate the cooling system.

Check and adjust the engine(ignition,carburation).

Retightem the cylinder head after 800 km of driving.

VA LV E SPRING REPLACEENT

Disconnect the battery.

Disconnect the acceleration cable.

Dismount the tilters cap.

Dismount the spark plug.

Mount the MOT 61 device for valve

maintaining in the place of the spark plug.

Dismount the tilter shaft.

( on car )

10

Compress the s pring by means of the

MOT 382 compressing device and take out the

lock half cotters.

Take out the upper tray and the spring.

Clean the seat of t he lower tray.

Place back in the previous site:

- new spring ( with the close coils

towards the cylinder head,the end marked with

green paint);

- the upper tray.

10 - 33

Page 68

ENGINE AND LOWER ENGINE UNITS

vnx.su

10

Compress the spring by means of the MOT 382 device and mount t he lock half cotters.

Mount the tilter shaft.

Adjust the tilter.