Page 1

Cat. No. 01882324

Rev. A 12/7/00

DCO#1809

Installation

and

Operating

Instructions

CULLIGAN

®

MARK 89 AND 812

AUTOMATIC

WATER CONDITIONER

©2000 Culligan International Company

Printed in USA

Page 2

Attention Culligan Customer:

Your local independently operated Culligan dealer employs trained

service and maintenance personnel who are experienced in the

installation, function and repair of Culligan equipment. This

publication is written specifically for these individuals and is intended

for their use.

We encourage Culligan users to learn about Culligan products, but

we believe that product knowledge is best obtained by consulting

with your Culligan dealer. Untrained individuals who use this manual

assume the risk of any resulting property damage or personal

injury.

WARNING - Prior to servicing equipment, disconnect

power supply to prevent electrical shock.

This system is not intended to be used for treating water that is

microbiologically unsafe or of unknown quality without

adequate disinfection before or after the system.

Culligan International Company

1 Culligan Parkway

Northbrook, IL 60062

847-205-6000

Page 3

Installation

and

Operating

Instructions

CULLIGAN

®

MARK 89 AND 812

AUTOMATIC

WATER CONDITIONER

Table of Contents

Page

Introduction ............................................................... 2

Specifications ........................................................... 3

Preparation ............................................................... 4

Installation ................................................................ 6

Settings .................................................................. 10

Start-Up Procedure ................................................. 16

Appendix A - Sanitizing Instructions ....................... 17

Wiring Schematic ..................................................... 18

Parts List .................................................................20

Page 4

Introduction

The Culligan® Mark 89 and 812 water softeners are tested and validated by WQA to ANSI/NSF

Standard 44 for the effective reduction of calcium and magnesium (hardness) along with barium

and Radium 226/228*.

SAFE PRACTICES

Throughout this manual there are paragraphs set off by special headings.

NOTICE: Notice is used to emphasize installation, operation or maintenance information which is important, but

does not present any hazard.

Example: NOTICE: The nipple must extend no more than 1 inch above the cover plate.

CAUTION: Caution is used when failure to follow directions could result in damage to equipment or

property. Example:

CAUTION: Disassembly while under water pressure can result in flooding.

WARNING: Warning is used to indicate a hazard which could cause injury or death if ignored. Example:

WARNING! ELECTRICAL SHOCK HAZARD! UNPLUG THE UNIT BEFORE

REMOVING THE TIMER MECHANISM OR COVER PLATES!

SERIAL NUMBERS

The control valve serial number, is on the back of the timer case.

The media tank serial number is on the top edge of the tank side wall.

NOTICE: Do not remove or destroy the serial number. It must be referenced on request for warranty repair or

replacement.

This publication is based on information available when approved for printing. Continuing design refinement

could cause changes that may not be included in this publication.

* Verified utilizing hardness surrogate per ANSI/NSF Standard 44.

2 CULLIGAN® MARK 89 AND 812 WATER CONDITIONER

Page 5

Specifications

Culligan® Mark 89 and 812 Water Conditioners with Automatic Time Clock or Soft-Minder® Meter

89 Model 812 Model

Control Valve

Overall Conditioner Height 51 in 51 in

Media Tank Dimensions (Dia x Ht) 9 x 45 in 12 x 45 in

Salt Storage Tank Dimensions (Dia x Ht) 16 x 43 in 16 x 43 in

Exchange Media, Type and Quantity Cullex

Underbedding, Type and Quantity Cullsan® Underbed, 20 lb Cullsan Underbed, 30 lb

Exchange Capacity 15,400 gr @ 4.0 lb 25,000 gr @ 6.0 lb

@ Salt Dosage Per Recharge

Freeboard to Media

2

Freeboard to Underbedding

1

3

Salt Storage Capacity 250 lb or 375 lb 375 lb

Rated Service Flow @ Pressure Drop 7.8 gpm @ 15 psi 8.25 gpm @ 15 psi

Total Hardness, Maximum 50 gpg 75 gpg

Total Iron, Maximum 5 ppm 5 ppm

Hardness to Iron Ratio, Minimum

4

Operating Pressure 20-125 psi 20-125 psi

Operating Temperature 33-120°F 33-120°F

Electrical Requirements 120V/60 Hz 120V/60 Hz

Electrical Power Consumption, Min/Max 3 Watts/35 Watts 3 Watts/35 Watts

Drain Flow, Maximum

Recharge Time, Average

5

6

Recharge Water Consumption, Average 45 gal/4 lb 75 gal/6 lb

5-cycle, Reinforced Thermoplastic 5-cycle, Reinforced Thermoplastic

1 29.5 cm 1 29.5 cm

23 x 114 cm 30 x 114 cm

41 x 109 cm 41 x 109 cm

18 x 43 in

46 x 109 cm

Media, 0.7 cu.ft. Cullex Resin, 1.4 cu. ft.

®

Cullex Media, 20 L Cullex Resin, 40 L

Cullsan Underbed, 9.1 kg Cullsan Underbed, 13.6 kg

998 gr @ 1.8 kg 1 620 gr @ 2.7 kg

21,200 gr @ 7.7 lb 35,900 gr @ 12.0 lb

1 374 gr @ 3.5 kg 2 326 gr @ 5.4 kg

24,200 gr @ 12 lb 42,400 gr @ 18.0 lb

1 568 gr @ 5.4 kg 2 748 gr @ 8.2 kg

18.9-19.9 in 17.5-18.5 in

48-51 cm 44-47 cm

39.2 in 38.5 in

99.6 cm 98 cm

114 kg or 170 kg 170 kg

1 300 mg/L 1 700 mg/L

5 mg/L 5 mg/L

8 gpg to 1 ppm 8 gpg to 1 ppm

140 mg/L to 1 mg/L 140 mg/L to 1 mg/L

140-860 kPa 140-860 kPa

1-50°C 1-50°C

2.0 gpm 3.5 gpm

7.6 L/pm 13.5 L/pm

80 min 85 min

170 L/1.8 kg 284 L/2.7 kg

1 Capacities and corresponding salt dosages pertain to low hardness waters. Capacities given are per recharge

2 Measured from top of media to top of inlet fitting (backwashed and drained).

3 Measured from top of underbedding to top of inlet fitting.

4 Hardness to iron ratio does not apply and total hardness and iron specifications change as follows when

Sofner-Gard® accessory is used: 89 Model - 50 gpg (855 mg/L) total hardness, 10 ppm (mg/L) iron;

812 Model - 75 gpg (1 200 mg/L) hardness, 20 ppm (20 mg/L) iron.

5 Backwash at 120 psi (830 kPa).

6 10 minute backwash, 7 lb (3.2 kg) 89 model or 13 lb (5.9 kg) 812 model salt dosage.

SPECIFICATIONS 3

Page 6

Preparation

COMPONENT DESCRIPTION

The water conditioner is shipped from the factory in three cartons. Remove all components from their cartons and

inspect them before starting installation.

Control Valve Assembly - Includes the 5-cycle regeneration control valve and timer assembly. A small parts

package contains installation hardware and consumer literature, including an Owner’s Guide and warranty policy.

Media Tank - Includes Tripl-Hull

media tank complete with Cullex® ion exchange resin, underbedding and

™

outlet manifold.

Salt Storage Tank Assembly - Includes salt storage container with support plate and Dubl-Safe™ brine refill

valve and chamber.

Bypass Valves - The system installation includes a manually operated bypass valve which enables the softener to

be isolated from the water service lines for maintenance and service and also maintain the continuity of the water

supply when the softener is disconnected.

TOOLS AND MATERIALS

The following tools and supplies will be needed, depending on installation method. Observe all applicable codes.

All Installations

• Safety glasses

• Phillips screwdrivers, small and medium tip

• Gauge assembly (PN 00-3044-50 or equivalent)

• Silicone lubricant (PN 00-4715-07 or equivalent) - DO NOT USE PETROLEUM-BASED LUBRICANTS

• A bucket, preferably light-colored

• Towels

Special Tools

• Torch, solder and flux for sweat copper connections

• Threading tools, pipe wrenches and thread sealer for threaded connections.

• Saw, solvent and cement for plastic pipe connections.

Materials

• Brine line, 5/16” (PN 00-3031-28 or equivalent)

• Drain line, 1/2” (PN 00-3030-82, gray, semi-flexible; or PN 00-3319-46, black, semi-rigid; or equivalent)

• Thread sealing tape

• Pressure reducing valve (if pressure exceeds 125 psi [860 kPa], PN 00-4909-00 or equivalent)

• Pipe and fittings suited to the type of installation

• Water softener salt (rock, solar or pellet salt formulated specifically for water softeners)

APPLICATION

Water quality - Verify that raw water hardness and iron are within limits. Note the hardness for setting the salt

dosage and recharge frequency.

Pressure - If pressure exceeds 125 psi (860 kPa), install a pressure reducing valve (see materials checklist). On

private water systems, make sure the minimum pressure (the pressure at which the pump starts) is greater than 20

psi (140 kPa). Adjust the pressure switch if necessary.

4 CULLIGAN® MARK 89 AND 812 WATER CONDITIONER

Page 7

CAUTION: The use of a pressure reducing valve may limit the flow of water

in the household.

Temperature - Do not install the unit where it might freeze, or next to a water heater or furnace or in direct

sunlight.

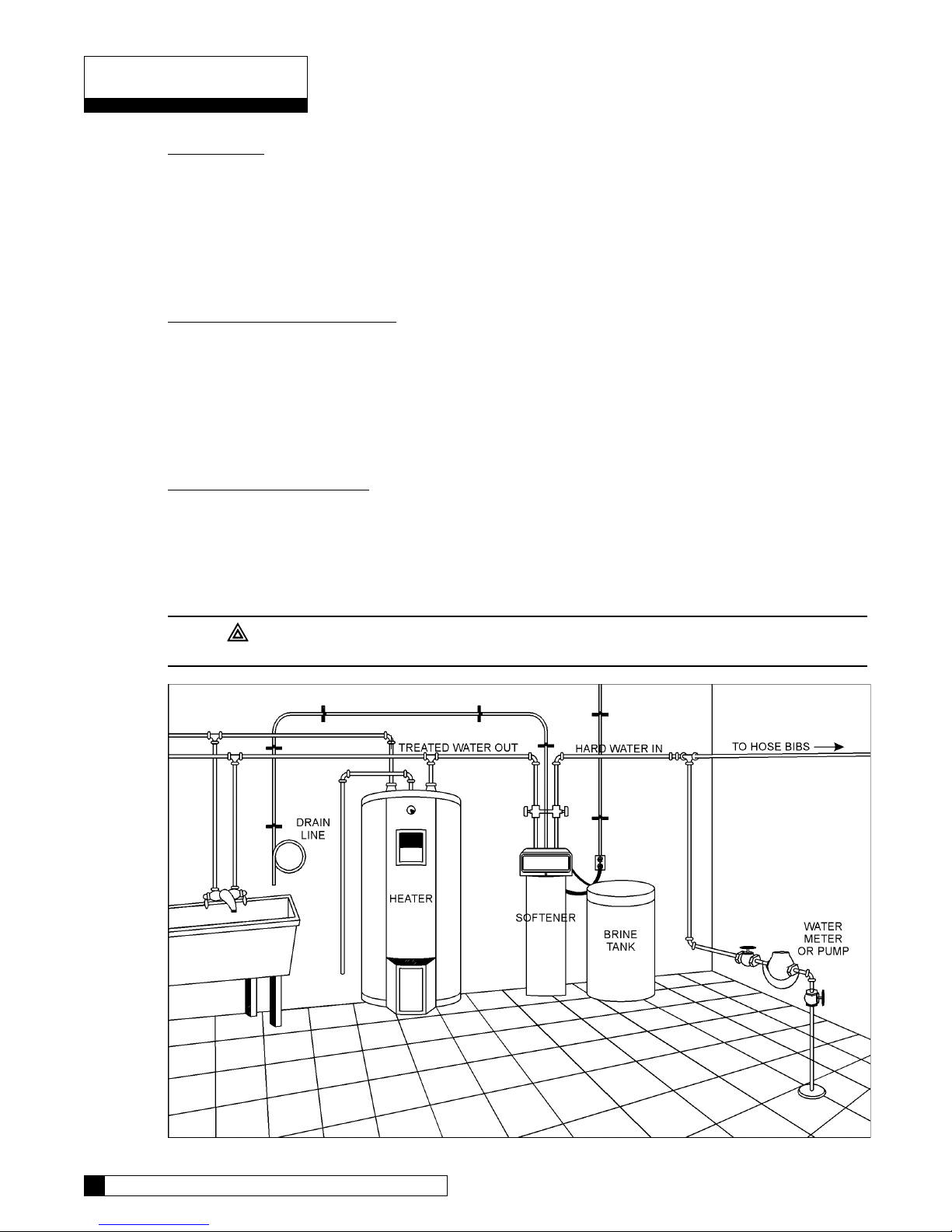

LOCATION

Space requirements - Allow 6-12 inches (15-30 cm) behind the unit for plumbing and drain lines and 4 feet (1.3

metres) above for service access and filling the salt container.

Floor surface - Choose an area with solid, level floor free of bumps or irregularities. Bumps, cracks, stones and

other irregularities can cause the salt storage tank bottom to crack when filled with salt and water.

Drain facilities - Choose a nearby drain that can handle the rated drain flow (floor drain, sink or stand pipe). Refer

to the Drain Line Chart, Table 1 (page 10), for maximum drain line length.

NOTICE: Most codes require an anti-siphon device or airgap. Observe all local plumbing codes and drain

restrictions. The system and installation must comply with all state and local laws and regulations.

Electrical facilities - A 6-foot grounded cord is provided. The customer should provide a 3-prong grounded

receptacle, preferably one not controlled by a switch that can be turned off accidentally. Observe local electrical

codes.

WARNING: ELECTRICAL SHOCK HAZARD! DO NOT REMOVE THE

GROUNDING PRONG! IF THE RECEPTACLE IS DESIGNED ONLY FOR

2-PRONG PLUGS, OBTAIN A 3-PRONG ADAPTER AND GROUND IT

SECURELY TO THE RECEPTACLE. DO NOT USE EXTENSION CORDS.

PREPARATION 5

Page 8

Installation

PLACEMENT

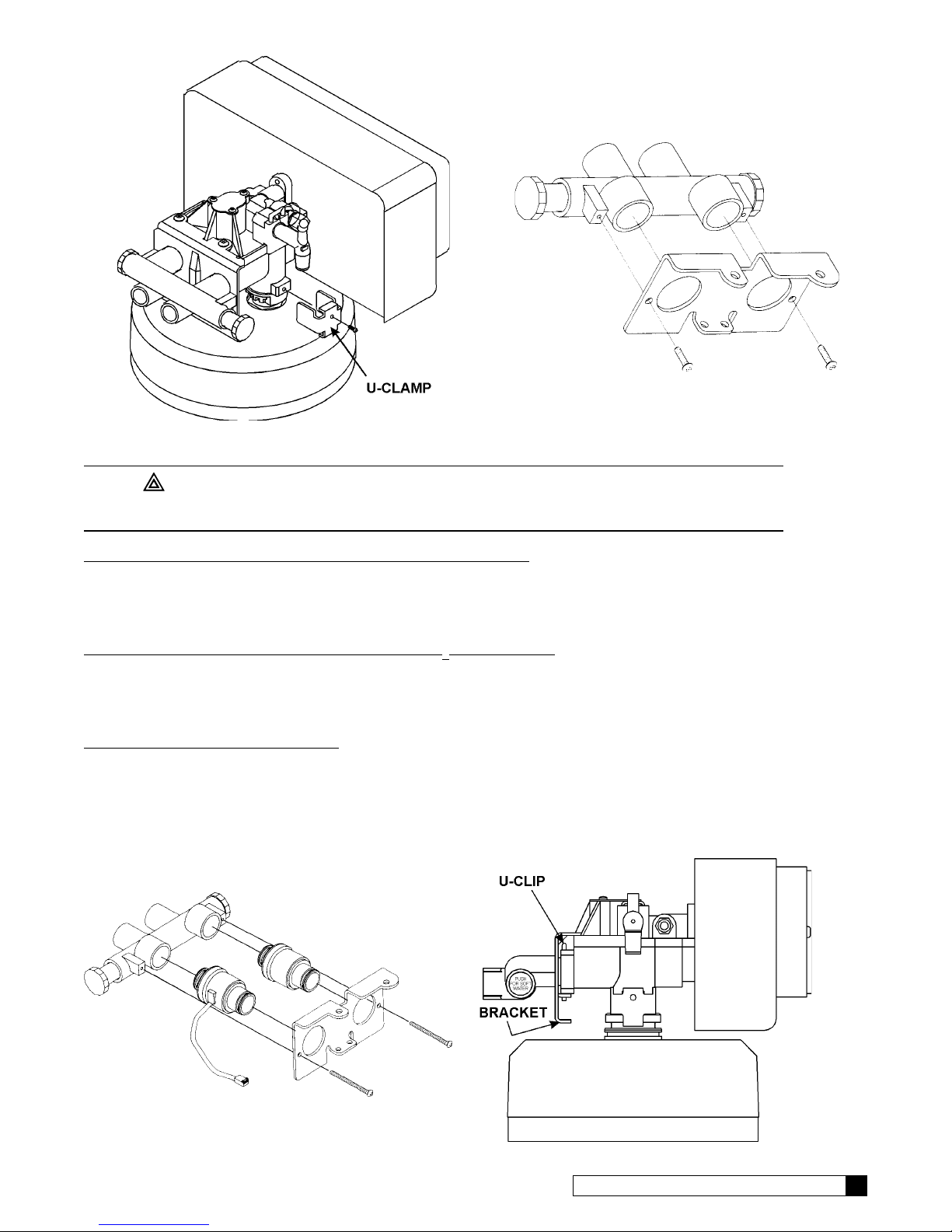

Refer to Fig. 1.

• Set the media tank on a solid, level surface near water, drain and electrical facilities. Place the outlet (black

coupling) of the tank on the left.

• Set the brine system on a flat, smooth, solid surface as near the media tank as possible.

MOUNT THE CONTROL VALVE

See Fig. 2.

• Remove and discard the protective covers on the tankcouplings.

• Lubricate the o-rings on the tank couplings with silicon lubricant.

• Place the control on the tank couplings and press down firmly.

• Install the u-clamps on both sides of the control and secure with the screws.

PLUMBING CONNECTIONS

Two methods of connecting the water softener to the plumbing system are available. Shipped with each softener

is a Culligan® Cul-Flo-Valv® bypass valve. If local conditions warrant, you may use the sweat adaptor kits,

PN 00-3314-44 or 00-3314-45.

NOTICE: The Soft-Minder® meter cannot be used with the sweat adaptors.

CAUTION: Close the inlet supply line and relieve system pressure before

cutting into the plumbing! Flooding could result!

6 CULLIGAN® MARK 89 AND 812 WATER CONDITIONER

FIG. 1

Page 9

FIG. 3

FIG. 2

CAUTION: When making sweat connections, remove all plastic and rubber

components which contact brass or copper. Damage to these components may

result otherwise.

BYPASS VALVE INSTALLATION - TIME CLOCK UNITS ONLY

The bypass valve connects directly to the backplate of the valve with a pair of screws (Fig. 3). To facilitate this

connection, remove the plate by pulling up on the u-clip on the back of the valve. Lubricate all o-rings with silicon

lubricant.

BYPASS VALVE INSTALLATION - SOFT-MINDER® METER ONLY

The Soft-Minder meter is placed between the bypass valve and the control (Fig. 4). Make sure the meter is on the

outlet port of the control. A pair of elongated bolts are packaged with the meter to hold the bypass valve to the

back plate of the control. Lubricate all o-rings with silicon lubricant.

SWEAT ADAPTOR INSTALLATION

The sweat adaptors use a snap ring to hold them to the backplate of the control valve. The back plate will need to

be removed from the valve for this connection. A pair of snap ring pliers, PN 00-5916-09, are needed for this

connection.

FIG. 4

FIG. 5

INSTALLATION 7

Page 10

CAUTION: When reinstalling back plate to control valve, make sure the u-clip

fully engages the two bottom holes of the bracket (Fig. 5). Secure bracket from

the top with the two mounting screws provided.

CONNECT THE BRINE LINE

Refer to Fig. 7.

• Measure a length of brine line sufficient to reach from the brine tank to the brine fitting and then add four feet

(1.3 meters). Cut both ends squarely and cleanly.

• Remove the brine valve from the brine tank and remove the white nut and insert. Return float rod to its original

position.

• Slip the white nut over one end of the tubing and press the plastic insert into the end of the tubing. Connect to the

brine valve and tighten nut. (Figure 6)

• Remove white nut and insert from wire tie around drain elbow.

• Slip the white nut over one end of the tubing and press the plastic insert into the end of the tubing. Connect to the

brine connection on the valve and tighten nut.

DRAIN LINE CONNECTION

Refer to Table 1, page 11 under the applicable tank size for drain line length and height limitations, and to Fig. 7.

• Remove 1/2” pipe clamp from end of drain elbow.

• Route a length of 1/2” drain line from the drain elbow to the drain.

• Fasten the drain line to the elbow with the clamp.

• Secure the drain line to the drain to prevent its movement during regeneration. A loop in the end of the tube will

keep it filled with water and will reduce splashing at the beginning of each regeneration.

NOTICE: Observe all plumbing codes. Most codes require an anti-siphon device or air gap at the discharge

point!

FILL THE SALT STORAGE CONTAINER

Fill the salt storage container with water until the level reaches about 1 inch above the salt support plate. Pour salt

into the container. Fill to within a few inches of the top.

FIG. 6

FIG. 7

8 CULLIGAN® MARK 89 AND 812 WATER CONDITIONER

Page 11

SOFT-MINDER® METER CONNECTION

To connect the meter leads, refer to the instructions listed below and the wiring schematic.

• Remove the timer face plate & set it aside.

• Remove the two screws holding the timer cover. Set the timer cover aside.

• Locate the 1/2" hole in the timer plate at the center rear. Remove the plastic plug.

• Slip the meter cable through the hole and toward the circuit board.

• Connect the red wire from the flow meter cable to the common terminal of the lockout switch. Connect the red

wire from the flow meter connection to the normally closed terminal of the lockout switch.

• Connect the flow meter harness to the circuit board. The meter terminal is labeled "METER".

• Locate the strain relief bushing in the parts pack. Place it on the cable at the point of entry to the rear of the

timer plate and push it into the hole.

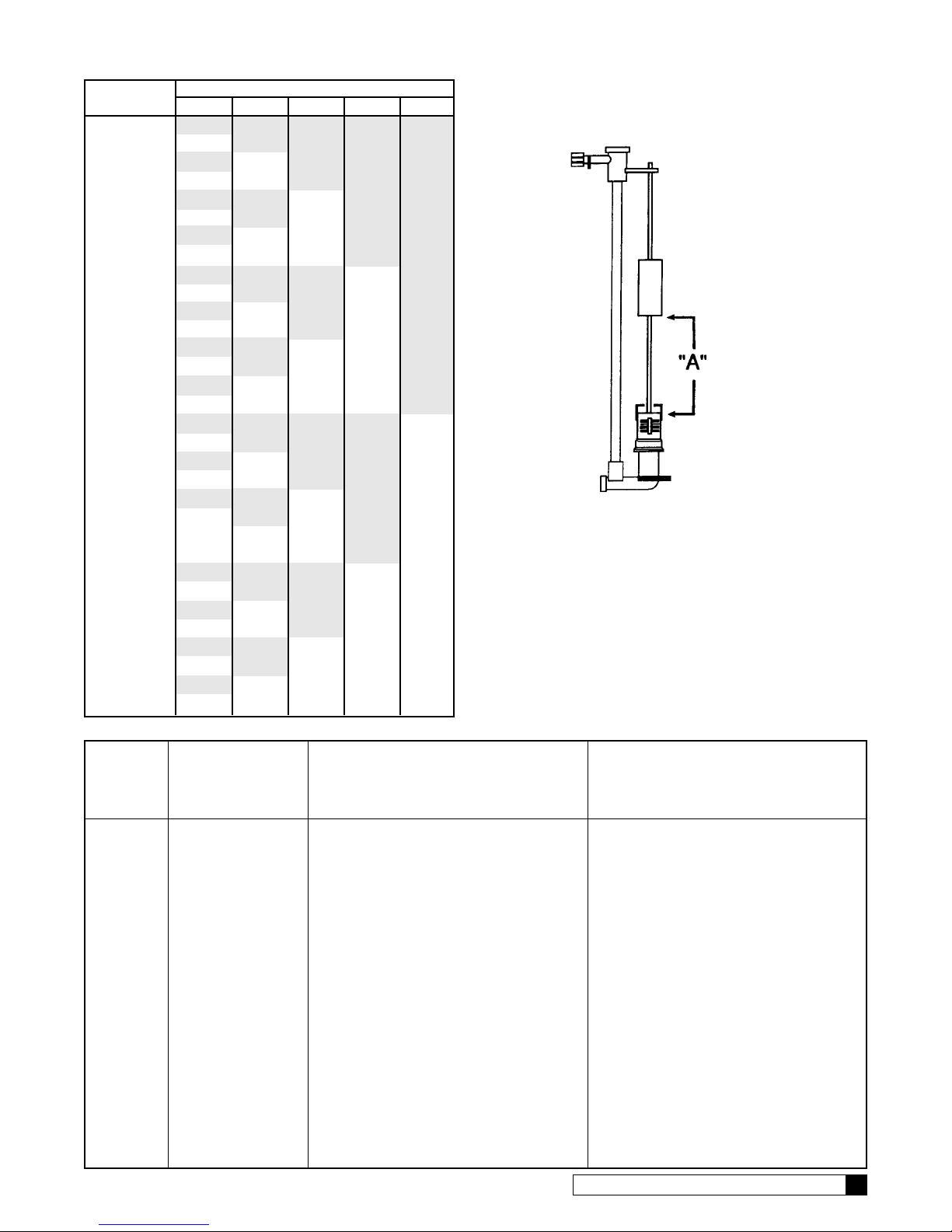

TABLE 1

9-INCH MODELS

Average Water

Pressure

psi 4 in. 1 ft 2 ft 3 ft 4 ft 5 ft 6 ft 7 ft 8 ft 9 ft 10 ft

kPa 0.1 m 0.3 m 0.6 m 0.9 m 1.2 m 1.5 m 1.8 m 2.1 m 2.4 m 2.7 m 3.1 m

30 56 50 40 30 20 10

2.1 17.1 15.3 12.2 9.2 6.1 3.1

50 112 106 96 86 76 66 56 46 36 26 16

3.5 34.2 32.3 29.3 26.2 23.2 20.1 17.1 14.0 11.0 7.9 4.9

70 143 137 127 117 107 97 87 77 67 57 47

4.8 43.6 41.8 38.7 35.7 32.6 29.6 26.5 23.5 20.4 17.4 14.3

90 153 147 137 127 117 107 97 87 77 67 57

6.2 46.7 44.8 41.8 38.7 35.7 32.6 29.6 26.5 23.5 20.4 17.4

120 159 153 143 133 123 113 103 93 83 73 63

8.3 48.5 46.7 43.6 40.6 37.5 34.5 31.4 38.4 25.3 22.3 19.2

12-INCH MODELS

Average Water

Pressure

Height of Drain Discharge Above Floor Upon Which Softener Sets

Height of Drain Discharge Above Floor Upon Which Softener Sets

psi 4 in. 1 ft 2 ft 3 ft 4 ft 5 ft 6 ft 7 ft 8 ft 9 ft 10 ft

kPa 0.1 m 0.3 m 0.6 m 0.9 m 1.2 m 1.5 m 1.8 m 2.1 m 2.4 m 2.7 m 3.1 m

0.1 m 0.3 m 0.6 m 0.9 m 1.2 m 1.5 m 1.8 m 2.1 m 2.4 m 2.7 m 3.1 m

30 44 38 28 18

2.1 13.4 11.6 8.5 5.5

50 103 97 87 77 67 57 47 37 27 17 7

3.5 31.4 29.6 26.5 23.5 20.4 17.4 14.3 11.3 8.2 5.2 2.1

70 129 123 113 103 93 83 73 63 53 43 33

4.8 39.3 37.5 34.5 31.4 28.4 25.3 22.3 19.2 16.2 13.1 10.1

90 145 139 129 119 109 99 89 79 69 59 49

6.2 44.2 42.4 39.3 36.3 33.2 30.2 27.1 24.1 21.0 18.0 14.9

120 153 147 137 127 117 107 97 87 77 67 57

8.3 46.7 44.8 41.8 38.7 35.7 32.6 29.6 26.5 23.5 20.4 17.4

INSTALLATION 9

Page 12

Settings

The Mark 89 and 812 Water Conditioners are designed to perform efficiently on a wide range of water supplies.

Before the unit can be recharged and put into service, several settings must be made.

BACKWASH

Backwash, the first step in the recharge cycle, expands and loosens the resin bed, and flushes away accumulated

turbidity. The backwash interval is preset at the factory for 10 minutes, which is adequate for most water supplies.

It is adjustable, however, from 5 to 30 minutes. It is recommended that backwash last long enough so that the

effluent from the drain line is clear. Backwash too long and water is wasted, not long enough and the tank becomes

fouled with sediment.

If backwash time adjustment is needed, refer to Fig. 8.

• Grasp the front cover by the slots and carefully pull forward to

remove cover. Lay the cover aside in a safe place.

• Loosen screw (A) about 1½ turns. DO NOT loosen screw (B).

• Holding the cam gear (located beneath the backwash dial),

rotate the backwash dial (C) until the desired backwash time

lines up with indicator mark (D).

• Tighten screw (A).

NOTICE: Adjusting the backwash time may cause the salt dosage

setting to change. If the salt dosage needs to be

reset, do not tighten screw (A), and refer to the Salt Dosage

section.

TIME OF RECHARGE

Although the need to recharge is determined by the Soft-Minder

control, time of day the conditioner will actually

recharge can be set on the timer mechanism.

The timer is factory set to recharge about 2:00 a.m., a time when

water usage is at a minimum for most families. If water is drawn

during recharge, hard water will automatically be bypassed to service. If it would be more convenient to have the

water conditioner recharge at a different time of day, the setting may be changed as follows,

referring to Fig. 8.

• Remove the timer cover.

• The position of the peg (H) in relation to the time-of-day dial (J) determines the time when the unit will begin to

recharge.

• Loosen the screw and lift the white time-of-day dial and rotate it until the desired time of recharge is opposite

the peg (H). Please note that whenever the time of recharge is changed, the time-of-day setting may be changed

also.

NOTICE: Whenever the time of recharge is changed the time of day must be reset also.

FIG. 8

TIME OF DAY

Upon completing the installation, the timer must be set to the correct time of day. Time of day must also be reset

after any kind of power interruption, such as that caused by an electrical storm. See Fig. 8.

• Determine the correct time of day.

• Grasp the gear (K) and lift straight up (the white time-of-day dial will lift with it). Rotate the gear until the

correct time of day lines up with the pointer (P). The dial is spring-loaded and will return its position when

released. Make sure the teeth mesh.

10 CULLIGAN® MARK 89 AND 812 WATER CONDITIONER

Page 13

Note that the silver half of the time-of-day dial designates the daytime hours, while the black half designates the

night-time hours.

GUEST CYCLE

An extra recharge can be initiated any time extra soft water is required by pushing the Manual Recharge lever (M)

in the direction of the arrow, then releasing. The unit will still recharge at its regular frequency as determined by

the meter device. On models with meter control, the red button (X) must also be pushed briefly before the recharge

cycle can begin.

SERVICE POSITION

The timer assembly is in the service position when the toothless notch in the cam gear is over the teeth on the idler

gear (L). The timer will return to this position after each recharge (Fig. 8).

TIME CLOCK SETTINGS

To set the Mark 89 and 812 water conditioner for optimal performance, determine the hardness of the water along

with the number of people in the household. Refer to Table 2. Locate the row corresponding to the number of

people in the home and move across to the appropriate hardness column. The number in the shaded region is the

salt dosage. The other number is the frequency of regeneration.

SALT DOSAGE

To set the salt dosage, refer to Fig. 8. Loosen screw (A) and rotate outer dial until the salt dosage dial line up with

the indicator mark (D). Tighten screw (A).

TABLE 2A — CULLIGAN MARK 89 WATER CONDITIONER SALT DOSAGE — FREQUENCY

*Persons Usage

in 0-7 8-14 15-21 22-28 29-35 36-42 43-49 50-56 57-63 64-75 Gal. (Litres)

Household (0-120) (121-240) (241-360) (361-480) (481-600) (601-720) (721-840) (841-960) (961-1080) (1081-1280) per day

11 12233 336

2 150(570)

5575656895

11 22336 666

3 225(850)

5757695568

12 23366 666

4 300(1135)

55769568912

12 33666 66

5 375(1420)

55595791213

12 36666

6 450(1705)

79856912

23 6666

7 525(1990)

5555812

23 666

8 600(2270)

57569

Water

9 675(2555)

23 666

595713

23 66

10 750(2840)

51259

*In household application, not recommended for over 10 people because of pressure drop limitations.

SETTINGS 11

Page 14

TABLE 2B — CULLIGAN MARK 812 WATER CONDITIONER SALT DOSAGE — FREQUENCY

*Persons Usage

in 0-7 8-14 15-21 22-28 29-35 36-42 43-49 50-56 57-63 64-75 Gal. (Litres)

Household (0-120) (121-240) (241-360) (361-480) (481-600) (601-720) (721-840) (841-960) (961-1080) (1081-1280) per day

12 3 33 3 66

2 150(570)

9768111299

Water

3 225(850)

6 7 9 13 7 10 11 14

4 300(1135)

6 8 6 8 11 12 17 20

5 375(1420)

75710141820

13 36666 6

6 450(1705)

85979131820

23 66666

7 525(1990)

5 6 5 8 12 16 20

23 6666

8 600(2270)

56681320

23 666

9 675(2555)

6861116

23 666

10 750(2840)

7971220

*In household application, not recommended for over 10 people because of pressure drop limitations.

23 3 36 6 66

33 6 66 6 66

36 6 66 6 6

REGENERATION FREQUENCY

To set the regeneration frequency, push the number of pins in which corresponds to the number located in Table

2 (refer to Fig. 9 and Table 3).

SOFT-MINDER METERING DEVICE

The Mark 89 and 812 Soft-Minder water conditioners are equipped with water meter which regenerates based

upon the water consumption patterns of the household.

TABLE 3 — RECHARGE FREQUENCY

No. Down on Pin No. In on Recharge

Salt Chart Frequency Dial Frequency

1 1 Every six days

2 1 & 4 Every three days

3 1, 3 & 5 Every other day

6 All Pins Every day

FIG. 9

12 CULLIGAN® MARK 89 AND 812 WATER CONDITIONER

Page 15

GALLONS SETTING

Determine the daily use for the household. Usually 75-100 gallons per day per person is adequate. Using Table 4,

locate the hardness range for your water supply. Move down the column and locate the gallons setting and salt

dosage which best suits the application. Usually two to three days between regenerations yields the best results.

Allow for one half to one days water usage as reserve capacity. Set the salt dosage per the instructions on page 9.

Set the gallons setting on the circuit board. This is done by removing the two screws of the front cover. The circuit

board is located on the upper left hand corner of the back plate. A set of six dip switches on the circuit board

determine the gallons capacity. Refer to Table 5, Figs. 10 and 11 when setting the dip switches. Make sure all

recharge frequency pins are pushed on.

There are two pilot lights located on the circuit board.

• The green pilot light flickers when water is flowing through the water meter.

• The amber pilot light is a latching indicator, when the preset gallons count has passed, the amber light will

illuminate indicating that the unit will regenerate that night.

The softener also has a ten gallon setting to assist the service personnel in trouble shooting the equipment. To

trouble shoot the meter, set the dip switches to the OFF position. Run water into a measured pail. The green light

will flicker. When ten gallons has passed, the amber light will light up. This will help determine if the meter is

properly measuring the gallons count.

TABLE 4A — MARK 89 (0.7FT3) GALLON CAPACITIES TO SIGNAL (RESERVE)

TOTAL WATER HARDNESS IN GRAINS PER GALLON (mg/l)

SALT 0-10 11-20 21-30 31-40 41-50 51-60 61-75

DOSAGE (0-170) (171-340) (341-515) (516-685) (686-855) (856-1025) (1026-1280)

4 NANANANA

5 NA NA NA

6 NA NA NA

7 NA NA

8 NA NA

10 NA

1300 600 300

(290) (175) (230)

1500 600 400 300

(250) (275) (183) (138)

1600 700 400 300

(275) (238) (225) (169)

1700 700 400 300 200

(250) (275) (250) (188) (190)

1800 800 500 300 200

(200) (200) (167) (200) (200)

1800 800 500 300 200 200

(210) (205) (170) (203) (202) (135)

SETTINGS 13

Page 16

TABLE 4B — MARK 812 GALLON CAPACITIES TO SIGNAL (RESERVE)

TOTAL WATER HARDNESS IN GRAINS PER GALLON (mg/l)

SALT 0-10 11-20 21-30 31-40 41-50 51-60 61-70 71-80 81-90 91-100

DOSAGE (0-170) (171-340) (341-515) (516-685) (686-855) (856-1025) (1026-1200) (1201-1370) (1371-1540) (1541-1700)

6 NA NA NA NA NA

7 NA NA NA NA

8 NA NA NA NA

9 NA NA NA

10 NA NA NA

11 NA NA NA

12 NA NA

13 NA NA

14 NA NA

15 NA

16

17

18

2500 1100 600 400 300

(270) (285) (323) (293) (254)

2700 1200 700 500 300 300

(300) (300) (300) (250) (300) (200)

2900 1300 800 500 300 300

(300) (300) (266) (300) (340) (233)

3000 1400 800 500 400 300 300

(350) (275) (316) (338) (270) (258) (178)

3100 1500 900 600 400 300 300

(380) (240) (260) (270) (296) (280) (197)

3100 1500 900 600 400 300 300

(490) (295) (297) (298) (318) (298) (212)

3100 1600 900 600 400 400 300 300

(580) (240) (327) (320) (336) (213) (225) (160)

3100 1600 1000 600 500 400 300 300

(650) (275) (250) (358) (250) (225) (236) (169)

3100 1600 1000 700 500 400 300 300

(710) (305) (270) (353) (262) (235) (244) (176)

3100 1600 1000 700 500 400 300 300 300

(740) (320) (280) (260) (268) (240) (248) (180) (126)

3100 1700 1000 700 500 400 300 300 300 200

(780) (240) (293) (270) (276) (247) (254) (185) (131) (188)

3100 1700 1000 700 500 400 300 300 300 200

(790) (245) (296) (273) (278) (248) (256) (186) (132) (189)

3100 1700 1000 700 500 400 300 300 300 200

(780) (240) (296) (270) (276) (247) (254) (185) (131) (188)

Brine Valve "A" Dimension

The brine valve contains a float-actuated safety shut-off device to prevent overflow of the brine tank in the un

likely case of an electrical or mechanical failure during the brine tank refill cycle.

It is recommended that the brine valve float be used as intended, that is, as a secondary, safety shutoff. Remember, the timer mechanism provides the primary refill shut-off. To use the float as a safety shut-off, refer to Table 6

for the salt dosage and brine tank size being used. The "A" dimension is the distance between the filter screen and

the bottom of the float (Fig. 12) when the float stem is in its fully raised position; adjust the float and rubber

grommets accordingly.

RAPID RINSE

The rapid rinse time, which is established when setting the salt dosage, is usually adequate for most installations.

It may be increased, if necessary, but it MUST NEVER be reduced from the salt dosage which is required for

adequate regeneration.

To adjust rapid rinse refer to the section on Salt Dosage. Each one-pound increase in salt dosage will increase

rapid rinse time, the brine valve float will become the primary brine refill shutoff. In this case refer to the correct

Table 7 column for the salt dosage and brine tank size being used, and adjust the "A" dimension accordingly.

RUN TEST

SW-1 OFF ON

FIG. 10

14 CULLIGAN® MARK 89 AND 812 WATER CONDITIONER

FIG. 11

Page 17

TABLE 5 — REGENERATION SCHEDULE

CAPACITY SWITCH POSITION

(GALS.) SW2 SW3 SW4 SW5 SW6

10 OFF OFF OFF OFF OFF

100 ON OFF OFF OFF OFF

200 OFF ON OFF OFF OFF

300 ON ON OFF OFF OFF

400 OFF OFF ON OFF OFF

500 ON OFF ON OFF OFF

600 OFF ON ON OFF OFF

700 ON ON ON OFF OFF

800 OFF OFF OFF ON OFF

900 ON OFF OFF ON OFF

1000 OFF ON OFF ON OFF

1100 ON ON OFF ON OFF

1200 OFF OFF ON ON OFF

1300 ON OFF ON ON OFF

1400 OFF ON ON ON OFF

1500 ON ON ON ON OFF

1600 OFF OFF OFF OFF ON

1700 ON OFF OFF OFF ON

1800 OFF ON OFF OFF ON

1900 ON ON OFF OFF ON

2000 OFF OFF ON OFF ON

2100 ON OFF ON OFF ON

2200 OFF ON ON OFF ON

2300 ON ON ON OFF ON

2400 OFF OFF OFF ON ON

2500 ON OFF OFF ON ON

2600 OFF ON OFF ON ON

2700 ON ON OFF ON ON

2800 OFF OFF ON ON ON

2900 ON OFF ON ON ON

3000 OFF ON ON ON ON

3100 ON ON ON ON ON

FIG. 12

TABLE 6 - "A" DIMENSION CHART

160 lb. Brine Tank 250 lb. Brine Tank 375 lb. Brine Tank

Salt "A" Dimension "A" Dimension "A" Dimension

Dosage Secondary (Only) Secondary Primary Secondary Primary

(Pounds) inches (cm) inches (cm) inches (cm) inches (cm) inches (cm)

3 6 (15.2) ————————

4 7-3/4 (19.7) ————————

5 9-1/2 (24.1) 8 (20.3) 6 (15.2) 6-1/2 (16.5) 4-1/2 (11.4)

6 1-1/4 (28.6) 9-3/8 (23.8) 7-3/8 (18.7) 7-1/2 (19.0) 5-1/2 (14.0)

7 13 (33.0) 10-7/8 (27.6) 8-7/8 (22.5) 8-1/2 (21.6) 6-1/2 (16.5)

8 14-3/4 (37.5) 12-1/4 (31.1) 10-1/4 (26.0) 9-1/2 (24.1) 7-1/2 (19.0)

9 16-1/2 (42.0) 13-5/8 (34.6) 11-5/8 (29.5) 10-1/2 (26.7) 8-1/2 (21.6)

10 18-1/4 (46.3) 15 (38.1) 13 (33.0) 11-1/2 (29.2) 9-1/2 (24.1)

11 20 (51.0) 16-3/8 (41.6) 14-3/8 (36.5) 12-1/2 (31.7) 10-1/2 (26.7)

12 21-3/4 (55.2) 17-3/4 (45.1) 15-3/4 (40.0) 13-1/2 (34.3) 11-1/2 (29.2)

13 21-1/2 (59.7) 19-1/8 (48.6) 17-1/8 (43.5) 14-1/2 (36.8) 12-1/2 (31.7)

14 25-1/4 (64.1) 20-1/2 (52.1) 18-1/2 (47.0) 15-1/2 (39.4) 13-1/2 (34.3)

15 — — 21-7/8 (55.5) 19-7/8 (50.5) 16-1/2 (42.0) 14-1/2 (36.8)

16 — — 23-1/4 (59.0) 21-1/4 (54.0) 17-1/2 (44.5) 15-1/2 (39.4)

17 — — 24-5/8 (62.5) 22-5/8 (57.5) 18-1/2 (47.0) 16-1/2 (42.0)

18 — — 26 (66.0) 24 (61.0) 19-1/2 (49.5) 17-1/2 (44.5)

19 — — 27-3/8 (69.5) 25-3/8 (64.5) 20-1/2 (52.1) 18-1/2 (47.0)

20 — — 28-3/4 (73.0) 26-3/4 (68.0) 21-1/2 (54.6) 19-1/2 (49.5)

SETTINGS 15

Page 18

Start-Up Procedure

WARNING: FOR PROTECTION, A SANITIZING AGENT HAS BEEN ADDED

TO THE SOFTENER TANK AT THE FACTORY. THIS SANITIZING AGENT

MUST BE FLUSHED OUT BEFORE THE UNIT IS PLACED INTO SERVICE

BY RUNNING AT LEAST 50 GALLONS OF WATER THROUGH THE UNIT

DRAIN.

• Close the main supply valve.

• Set the bypass valve(s) to bypass.

• All faucets in the installation site should be closed.

• Direct the drain line discharge into a bucket where flow can be observed.

• Plug the unit into a 120 Volt, 60 Hertz, single phase grounded, 3-wire receptacle (or 2-wire receptacle with

grounded 3-prong adapter).

• Set the timer to the correct time of day.

• Open the main supply valve.

• On the timer, push the Manual Recharge lever to the left until it stops.

• Slowly shift the Cul-Flo-Valv® bypass toward the "Soft Water" position until water flows. On three-valve

bypass installations, close the bypass valve and open the outlet and inlet valves.

• Allow the unit to fill slowly until water flows from the drain line.

• When flow to drain is established, open the bypass fully. Watch the drain line discharge for signs of resin. If

resin particles appear, reduce the flow. Increase the flow again when resin no longer appears in the discharge.

• When the unit is filled with water, return the timer to the service position.

WARNING: ALTHOUGH NOT NORMALLY NECESSARY, SHOULD YOU NEED

TO DISASSEMBLE ANY PART OF THE CONTROL VALVE OR REMOVE THE

CONTROL FROM THE TANK ASSEMBLY OR ASSOCIATED PLUMBING,

DEPRESSURIZE THE UNIT FIRST CLOSING THE MAIN SUPPLY VALVE,

THEN OPEN A CONVENIENT FAUCET DOWN STREAM FROM THE WATER

CONDITIONER.

During the recharge cycle, hard water will be available to all the lines in the household. Immediately following

recharge, the water to service will be soft.

Because of the volume of water contained in the water heater, the hot water may not be soft for several days. Soft

hot water can be made available almost immediately, however, if the water heater is drained immediately after

recharge and allowed to refill with soft water.

BEFORE LEAVING THE INSTALLATION SITE

Make sure the brine tank is filled with water to the level of the float. Fill the tank with a hose or put the unit into

a full recharge so that the brine refill cycle will fill the tank.

Explain the operation of the softener to the customer. Give the customer a copy of the Owner's Guide and

warranty policy. Make sure the customer knows that there will be new sounds associated with the recharging of

the unit. Advise the customer to periodically check and replenish the salt supply.

Clean up the unit and the installation site, removing any soldering or pipe threading residues from the equipment

with a damp towel.

16 CULLIGAN® MARK 89 AND 812 WATER CONDITIONER

Page 19

Appendix A - Sanitizing Instructions

A water softener in daily use on a potable water supply generally requires no special attention other than keeping

the salt tank filled. Occasionally, however, a unit may require sanitation under one of the following conditions:

• The unit has stood idle for a week or more (the premises vacant or the residents on vacation).

• On private supplies, the appearance of off-tastes and odors, particularly if musty or "rotten egg" (caused by

harmless sulfate-reducing bacteria).

For occasional occurrences, the softener can be sanitized with household bleach as follows.

NOTICE: If the water supply contains iron, regenerate the softener before sanitizing to remove accumulated iron

from the Cullex® resin.

WARNING: HAZARD FROM TOXIC FUMES! CHLORINE BLEACH AND

COMMON IRON CONTROL CHEMICALS MAY GENERATE TOXIC FUMES

WHEN MIXED.

• IF THE UNIT USES CULLIGAN® SOFNER-GARD™ CHEMICAL OR OTHER COMPOUNDS

CONTAINING SODIUM HYDROSULFITE OR SODIUM BISULFITE, OR ANY OTHER

REDUCING AGENT, DISCONNECT THE DEVICE AND MANUALLY REGENERATE THE UNIT

BEFORE SANITIZING.

• DO NOT USE THIS PROCEDURE IF THE SOFTENER SALT CONTAINS IRON CONTROL

ADDITIVES.

1. Remove the brine tank cover and the small cover on the brine valve chamber.

2. Pour directly into the brine chamber 1 cup (9-inch units) or 2 cups (12-inch units) of common household

bleach (5-1/4% sodium hypochlorite).

3. Manually start a recharge cycle. Allow the unit to complete the recharge cycle automatically.

If tastes and odors return frequently, even after sanitization, a continuous chlorination system may be needed.

Contact Household Application Engineering for assistance. Also, have the consumer send a sample to a qualified

laboratory for bacterial analysis.

APPENDIX A - SANITIZING INSTRUCTIONS 17

Page 20

Wiring Schematic

Automatic Clock Timer

18 CULLIGAN® MARK 89 AND 812 WATER CONDITIONER

Page 21

Meter

®

Timer with Soft-Minder

WIRING SCHEMATIC 19

Page 22

Control Valve

20 CULLIGAN® MARK 89 AND 812 WATER CONDITIONER

Page 23

Control Valve Parts List

64 00-4429-84 Power Cord

65 00-3318-48 Terminal Strip

66 00-4442-84 Screw

67 00-4015-67 Clip

68 01-0017-84 Screw

80 00-4429-29 Label

81 00-4022-01 Screw

83 01-0128-09 Control Cover

84 00-4457-80 Cover Plate

85 01-0046-89 Cul-Flo Bracket

86 00-3183-83 Screw

99 00-4452-69 Eductor Screen

‡98 00-4012-48 Eductor w/O-Rings

102 00-4432-91 Connector Brine Line

‡100 00-3084-38 O-Ring

‡101 00-3084-37 O-Ring

103 00-3031-93 Nut, PP, 0.312"

104 00-3031-92 Insert, PP, 0.312"

‡105 00-4479-87 O-Ring

107 00-4479-86 O-Ring

108 00-3084-07 O-Ring

‡106 01-0136-06 Eductor Sleeve and Eductor Piston Assembly

00-4460-39 Eductor Nozzle - Light Brown, 12" Tanks

00-3316-36 Backwash Flow Restrictor, #3, Green, 12" Tanks

120 01-0082-55 Meter Mounting Bracket

‡121 01-0101-27 Circuit Board - 120 Volt

‡156 00-4460-38 Eductor Nozzle - Blue, 9" Tanks

157 00-3316-45 Backwash Flow Restrictor, #2, Brown, 9" Tanks

00-4462-97 Decal, Mark 812

178 01-0051-30 Bracket

197 00-4462-96 Decal, Mark 89

* 01-0051-26 Noise Suppressor - SM Models

* 01-0079-01 Wire Harness, Circuit Board - SM Models

* 01-0079-02 Wire Harness, Regen. Switch - SM Models

* 01-0112-79 Flow Meter Assembly - SM Models

* 00-4029-54 Cam Wire Harness - TC Models

* 00-4029-55 Cam Wire Harness - SM Models

223 00-4486-87 Screw

Timer Mechanism, 6 Day, 120V/60 Hz - TC Models

* 00-3308-32 Hat Screen - SM Models

01-0037-43 Control Valve Assembly - Mark 89, TC

01-0037-44 Control Valve Assembly - Mark 812, TC

01-0137-03 Control Valve Assembly - Mark 89, SM

01-0137-04 Control Valve Assembly - Mark 812, SM

1 00-4498-65 Control Valve

2 00-4481-26 Rear Body Plug

4 00-4481-28 Retainer, Rear Body Plug

Item Part No. Description Item Part No. Description

‡3 00-4449-14 O-Ring

6 00-3184-78 Screw

‡5 00-4468-35 Drain Elbow Assembly w/O-Ring

8 00-4473-87 Retainer, Drain Elbow

9 00-4010-22 Eductor Port Cover

‡7 01-0130-83 Seal Pack Assembly

11 00-4517-01 Clamp

‡10 00-4457-97 Gasket

17 01-0126-49 Follower

18 01-0126-48 Yoke

20 01-0126-47 Bracket

22 00-3185-50 Screw

26 00-3183-54 Nut

27 00-4452-21 Bellcrank

29 00-4452-46 Roll Pin

30 00-4435-59 Roll Pin

‡28 01-0136-03 Drive Motor & Bracket Assembly, 120V/60 Hz

31 00-4010-40 Switch Bracket

32 00-4452-72 Barrier

34 00-3183-43 Washer

35 00-4486-86 Screw

‡33 00-4452-44 Switch

61 00-3318-78 Screw

62 00-4444-53 Strain Relief Adapter

37 01-0130-31 Ca m

38 01-0129-28 Spacer

40 00-4486-59 Retaining Ring

41 00-3184-55 Screw

42 00-3184-52 Screw

43 01-0083-40 Control Back Plate

‡44 00-4429-21

CONTROL VALVE PARTS LIST 21

63 00-4444-52 Strain Relief

‡ Recommended Spare Parts

* Not Illustrated

Page 24

Conditioner Tank & Parts List

Item Part Number Description Quantity

01-0037-55 Tank Assembly, 9" Time Clock, Complete

01-0037-58 Tank Assembly, 12" Time Clock, Complete

01-0042-98 Replacement Tank, 9" Time Clock, Empty

01-0042-99 Replacement Tank, 12" Time Clock, Empty

1 01-0072-81 Outlet Manifold 1

4 P0-2320-07 Inlet Manifold / MP 25 1

5 P0-3339-57 O-Ring / MP 25 1

6 P0-3044-11 O-Ring / MP 25 2

7 01-0072-82 Inlet Adaptor 1

8 01-0072-83 Nut, Plastic 2

9 01-0072-88 Cover Plate 1

10 01-0021-19 Plate 1

11 01-0054-50 Gasket 1

12 00-3232-05 Barrier 1

13 01-0072-85 Yoke 1

14 01-0019-46 Cover, 9" 1

01-0019-47 Cover, 12" 1

15 00-4445-85 Crush Pad, 9" 1

00-4445-46 Crush Pad, 12" 1

16 00-4419-97 Gasket, Ring, 9" 1

00-4446-45 Gasket, Ring, 12" 1

17 00-4445-83 Well, 9" 1

00-4446-44 Well, 12" 1

18 00-2202-36 Liner, 9" 1

00-2202-22 Liner, 12" 1

22 CULLIGAN® MARK 89 AND 812 WATER CONDITIONER

Page 25

Item Part No. Description

— 00-4413-90 Brine System, 160 lb. Replacement

— 00-4418-86 Brine System, 250 lb. Replacement

— 00-4418-87 Brine System, 375 lb. Replacement

†1 01-0048-70 Gold Band

2 00-3039-93 Cover with Band, 250 lb. (114 kg)

00-4010-42 Cover with Band, 160 lb. (73 kg)

00-3039-80 Cover with Band, 375 lb. (170 kg)

3 00-3040-10 Tank Only, 250 lb. (114 kg)

00-4413-91 Tank Only, 160 lb. (73 kg)

00-3039-75 Tank Only, 375 lb. (170 kg)

* 00-3044-30 Salt Plate, Plastic, 250 lb. (114 kg)

* 00-3044-39 Salt Plate, Plastic, 350 lb. (159 kg)

* Not Illustrated

† Order by footage required

Salt Storage Tank Parts List

SALT STORAGE PARTS LIST 23

Page 26

Brine Valve & Parts List

Item Part Number Description

— 00-4418-88 Brine Valve Assembly

— 00-4011-41 Brine Valve Assy., Brine Tank, 160 lb.

1 00-3031-93 Plastic Nut, 5/16-inch

2 00-3031-92 Plastic Insert

3 00-4407-96 Refill Cap

‡4 00-3084-07 O-ring

‡5 00-4016-22 Flow Restrictor, No. 5, 0.45 gpm (170 lpm)

6 00-3400-14 Stem Seat Assy., 250 lb. (114 kg) & 375 lb.

(170 kg) (US) & 350 lb. (159 kg) (Canadian)

7 00-4407-95 Refill Body

‡8 00-3325-28 Hat Screen

9 00-2234-35 Plastic Pipe, 1/4-inch NPT x 35 inches long,

250 lb. (114 kg) & 375 lb. (170 kg) (US) &

350 lb. (159 kg) (Canadian)

10 00-3047-03 Float Retainer (2 required)

11 00-3047-18 Float Weight, Stainless Steel (2)

12 00-4448-73 Float

13 00-3320-72 Screen Top Seal

14 00-4446-64 Filter Screen Cap

‡15 00-4444-96 Stem Seat

16 00-4473-92 Insert

17 00-4477-81 Air Eliminator Ball

‡18 00-3048-04 Ball Seat

19 00-5418-21 Float Valve Body with Ball Seat

00-5418-34 Float Valve Body with Ball Seat, 150 lb.

Brine Tank

20 00-3045-37 Brine Valve Chamber, 250 lb. (114 kg) &

375 lb. (170 kg) Salt Storage Tank (US)

00-4413-92 Brine Valve Chamber, 160 lb. (Shown)

† Brine Valve Chamber, 350 lb. (159 kg)

(Canadian)

21 00-3046-06 Cap, Brine Valve Chamber

* 00-3184-92 Screw, Brine Valve Chamber (Canadian)

#10 - 16 x 1/2-inch TRS HD PHIL

* 00-3306-29 Connector Spacer, Brine Valve Chamber

(Canadian)

* 00-4463-88 Screw, St. Steel, Brine Valve Chamber (US)

* 00-4463-89 Nut, St. Steel, Brine Valve Chamber (US)

* Not Illustrated

† Replace with 00-3045-15 and relocate spacer

‡ Recommended Spare Parts

24 CULLIGAN® MARK 89 AND 812 WATER CONDITIONER

Page 27

Timer & Parts List

Item Part No.

00-4429-21 Mark 89/812 Timer Replacement

1 00-4482-57 Screw, #4-24 x 0.625" Phil.

2 00-4031-54 Screw, #4-24 x 0.312" Oval Hd.

3 00-4417-67 Adjustment Lever

4 00-4413-35 Dial, Salt Dosage

5 00-4413-38 Dial, Backwash

6 00-4010-24 Cam, Notched

7 00-4045-02 Lever, Manual Regeneration

8 00-4409-32 Spring

9 00-4413-32 Gear, Idler

10 00-4409-47 Pin, Retainer

11 00-4409-28 Pin

12 00-4409-29 Wheel, Interval

13 00-4477-96 Screw, #4-40 x 0.750" Rd. Hd.

† 00-4428-85 Screw, #4-40 x 1.625" Lg. Slot

14 00-4406-30 Washer

15 00-4031-39 Spring

16 00-4409-35 O-ring

17 00-4414-08 Screw, #4-24 x 0.250" Pan Hd.

18 00-3354-29 Gear, Gray

19 00-4409-43 Gear, Black

† Used only for Aqua-Sensor

‡ Recommended Spare Parts

* Not Illustrated

Description

®

Item Part No. Description

20 00-4409-40 Pointer, Time of day

21 01-0013-85 Dial, Time of day

22 01-0013-84 Wheel, Time of Regeneration

23 01-0013-86 Decal

24 00-4409-30 Spacer

25 00-4409-31 Switch, Miniature

26 00-4475-72 Screw, #4-24 x 0.875" Phil

27 00-4421-48 Spacer

†28 00-4480-04 Spacer

29 00-4412-63 Spring

31 00-4442-99 Decal

32 00-4010-23 Cam, Refill, Backwash

33 00-4413-40 Cam, Backwash

34 01-0017-58 Cam, Fast Rinse

†35 00-3183-32 Washer

‡†36 00-4416-77 Switch, Push Button

37 00-4459-38 Plate with Inserts

‡38 00-4409-34 Motor, Timer

39 00-4414-10 Screw, #4-40 x 0.250" Pan Hd.

* 00-3300-00 Kit, Frequency Wheel, 6-Day

* 00-3300-01 Kit, Frequency Wheel, 7-Day

TIMER PARTS LIST 25

Loading...

Loading...