Page 1

Page 2

Introduction

The 22" wheeled string trimmer was intended

for clearing heavy growth from unimproved

land. This model has a blade brake clutch feature. When the control lever is released, the

trimmer line will stop rotating, but the engine

will continue running. See Figure 1-1.

22” STRING TRIMMER

Model 24A-253-401

1. Bend the pre-cut line in a U shape and insert it

through the outer pair of hoops on one side of

the spindle, keeping both sides of the “U”

equal. See Figure 1-3.

1

MTD also manufactures an 18" string trimmer

that does not have the blade brake clutch feature. When the control lever is released, the

engine is stopped as it would be on a conventional lawn mower. The primary difference

between the two models is that the control

cable on the 22" version is replaced with a

simple spring on the 18" model. They are otherwise very similar.

Trimmer Line

The trimmer line is a fixed length and can

easily be replaced following the diagram on

the front of the trimmer base assembly. See

Figure 1-2.

2. Double the lines back through the center

hoop. The string will now be in the shape of a

pretzel. See Figure 1-4.

1-1

Page 3

3. Uncross the two lines so that they are roughly

parallel.

The line will be trimmed to final length by the

blade mounted under the deflector.

. All three nuts and bolts that secure the glide

ball to the spindle assembly can be removed

using a pair of 7/16" wrenches.

NOTE

Do not re-use the original hardware, new

hardware will be included with the glide ball.

Spindle

NOTE

The spindle cannot be serviced, and must be

replaced as a unit if it gets damaged. See Figure 1-6.

• 22" trimmer use .150" line, part number:

• 18" trimmer uses .130" line, part number:

The above numbers are for pre-cut lengths,

packaged in a quantity of ten. Bulk line may

also be used.

Glide Ball

The glide ball is available as service part number: 982-0143. See Figure 1-5

OEM-743-0110

OEM-743-0111

NOTE

NOTE

The cutting height is adjusted by sliding the

disc that the trimmer line is attached to up or

down the spindle shaft.

The disc is held in position by two wing nuts,

that must be loosened before making a height

adjustment, and retightened to hold that

adjustment.

The glide ball remains fixed, and the disc

moves in relation to the glide ball.

1-2

The wing nuts cannot be removed from their

studs: the threads are peened.

Page 4

1. Remove the nuts from the four carriage bolts

that hold the deflector to the trimmer base

using a 7/16" wrench. See Figure 1-7.

2. Rotate the deflector so that the wide part of

the center hole in the deflector will fit past the

spindle. See Figure 1-8.

1

Figure 1-9.

4. Remove the belt keeper from the idler pulley

by loosening the lock nut with a 1/2" wrench.

See Figure 1-10.

3. Remove the deflector. See Figure 1-9.

Figure 1-10.

1-3

Page 5

5. Remove the V-belt from the idler pulley. See

Figure 1-11.

9. Remove the hex nut and hex bolt that hold the

tensioner pulley arm to the trimmer base

using a 1/2" wrench.

NOTE

Record the mounting hardware as you

remove it. See Figure 1-13.

6. Grasp the idler bracket assembly and pull

inward until the belt can be removed from the

spindle assembly.

The torsion spring applies tension to the belt

brake at rest, and must be moved away from

the belt for removal.

7. Unhook the “Z” fitting (at the end of the

engagement cable) from the idler bracket.

See Figure 1-12.

8. Loosen the center hex bolt securing the spindle assembly to the trimmer base from the

top, using a 1/2" wrench.

Figure 1-11

NOTE

10. Remove the remaining five bolts which

secure the spindle to the trimmer base using

a 1/2" wrench.

Three of these bolts will also hold the belt

keeper in position. See Figure 1-14.

Figure 1-13.

NOTE

Figure 1-12

Figure 1-14.

11. Remove the center bolt from the spindle.

12. Remove the spindle.

13. Follow instructions in the reverse order to

assemble.

1-4

Page 6

BELT REPLACEMENT

There are two different crankshaft pulleys that

have been used in string trimmer production.

Some string trimmers have engines equipped

with heavy engine flywheels, while other

engines have light engine flywheels. Because

there is not a conventional blade to add rotating mass to the crankshaft, a flywheel was

added to the crankshaft pulley used on the

engines that have light engine flywheels. The

pulley flywheel is large enough that the belt

will not fit over it. The belt will fit over the pulley which does not have a flywheel attached

to it. Because of this difference, there are two

different procedures for replacing the drive

belt. The first steps of both procedures are

the same. See Figure 1-15.

NOTE

5. Remove the carriage bolts and the deflector.

Remove the belt keeper from the tensioner

pulley by loosening the lock nut with a 1/2"

wrench.

6. Remove the belt keeper from the tensioner

pulley by loosening the lock nut with a 1/2"

wrench.

7. Remove the V-Belt from the Idler pulley.

8. Grasp the idler bracket assembly and pull

inward until the belt can be removed from the

spindle assembly.

NOTE

The torsion spring applies tension to the belt

brake at rest, and must be moved away from

the belt for removal.

9. Unhook the “Z” fitting (at the end of the

engagement cable) from the idler bracket.

See Figure 1-16.

1

Figure 1-15.

IMPORTANT:

been running.

1. Disconnect and ground the spark plug wire.

2. Drain the fuel tank.

3. Position the trimmer so the rear edge of the

trimmer base is resting securely on a work

bench, and pivot the handle down.

The handle should be securely weighted

down, so the trimmer stands on end.

4. Remove the hex nuts from the carriage bolts

that secure the deflector shield to the trimmer

base using a 7/16" wrench.

Allow the engine to cool if it has

NOTE

Figure 1-16.

10. Loosen, but do not remove the three nuts that

secure the belt keeper, and spindle assembly

to the trimmer base using a 1/2" wrench.

TRIMMERS WITH PULLEY FLYWHEELS

NOTE

For trimmers equipped with pulley fly wheels,

perform steps 1 through 10, then follow these

steps;

1-5

Page 7

1. Secure the pulley flywheel so that it will not

spin during removal of the crankshaft bolt.

See Figure 1-17.

Figure 1-17.

2. Remove the crankshaft bolt using a 5/8"

wrench.

3. Remove the bolt from the left side of the axle

using a 7/16" wrench.

TRIMMERS WITH STANDARD CRANkSHAFT

PULLEYS

NOTE

For trimmers equipped with standard crank-

shaft pulleys, follow steps 1 through 10, then

complete these steps;

1. Loosen, but do not remove the remaining nuts

that fasten the spindle and belt tensioner

bracket to the trimmer base using a 1/2"

wrench. See Figure 1-19.

4. Remove the left wheel and slide the right

wheel and axle out of the trimmer frame. See

Figure 1-18.

Figure 1-18.

5. Roll the belt off of the pulley flywheel.

6. Slip the pulley flywheel off of the engine crank

shaft.

Figure 1-19.

2. Loosen, but do not remove the center bolt that

fastens the spindle to the trimmer frame using

a 1/2" wrench.

3. Loosen, but do not remove the three bolts that hold

the engine and engine pulley belt keeper to the

trimmer frame, using a 1/2" wrench. See Figure 1-

20.

7. Remove the belt.

Follow the instructions in the reverse order to

install the belt.

Figure 1-20.

1-6

Page 8

4. Roll the belt off of the crankshaft pulley, and

slip the belt between the pulley and the rear

axle. See Figure 1-21.

Figure 1-21.

5. Remove the belt from the spindle pulley.

6. Follow hte instructions in the reverse order to

install the belt.

There is a stop welded to the axle where it

passes through the right hand side of the trimmer base. This stop will not allow the axle to

slide or rotate. See Figure 1-23.

Figure 1-23.

There is a removable spacer and wave

washer between the left hand side wheel and

the trimmer base. See Figure 1-24.

1

The belt has been updated from part number

754-0489 to part number 754-0625. The new

belt is more resistant to stretching.

The control cable is secured to the axle, make

certain it is clear of rotating parts.

WHEELS AND AXLE

Each wheel can be removed by taking off a

single bolt and washer, using a 7/16" wrench.

See Figure 1-22.

NOTE

NOTE

Figure 1-24.

To remove the axle;

1. Remove the left hand side wheel bolt.

2. Slide the axle and wheel to the right, as

described in the belt removal section.

OTHER FEATURES

Figure 1-22.

The control handle on the 22" model is

equipped with a safety lock-out. See Figure 1-

25.

1-7

Page 9

Figure 1-25.

Figure 1-26.

There is a debris screen over the cooling fan.

Its presence is necessary to prevent the cooling fins from getting clogged. Customers

should not operate the trimmer without the

screen in place. See Figure 1-26.

A single wing nut holds the screen in place,

and is easily removed for cleaning.

1-8

Page 10

CHORE PERFORMERS

2-1. EDGER.

the operation in both positions after making

any adjustment to the rod. Secure lower clutch

rod with flat washer and hairpin clip when

adjustment is correct.

2

WARNING

When operating the edger, stop engine immediately and readjust the clutch rod if blade

turns with blade clutch/depth lever in the disengaged position.

2-1.1 Checking the Clutch Rod Adjustment.

The clutch rod on your edger has been preadjusted at the factory. Before operating the

edger, check the adjustment of the clutch rod

as follows.

1. Disconnect the spark plug wire and move it

away from the spark plug.

2. With the blade clutch/depth control lever in the

disengaged position (notch nearest the operator’s position), carefully pull the recoil starter

rope. The belt on the edger should not turn. If

the belt (and blade) turns, remove the hairpin

clip and flat washer, and remove the lower

clutch rod from the pivot arm extension. See

Figure 2-2. Turn the clutch rod one or two turns

clockwise to shorten the rod. Insert lower

clutch rod into pivot arm extension, and

recheck the adjustment.

3. Check to be certain the blade clutch/depth

control lever can be moved to the furthest

notch forward. If not, remove the hairpin clip

and flat washer, and turn the clutch rod one or

two turns clockwise to shorten the rod. Insert

lower clutch rod into pivot arm extension, and

recheck the adjustment. Be certain to recheck

2-1.2 Belt Removal and Replacement.

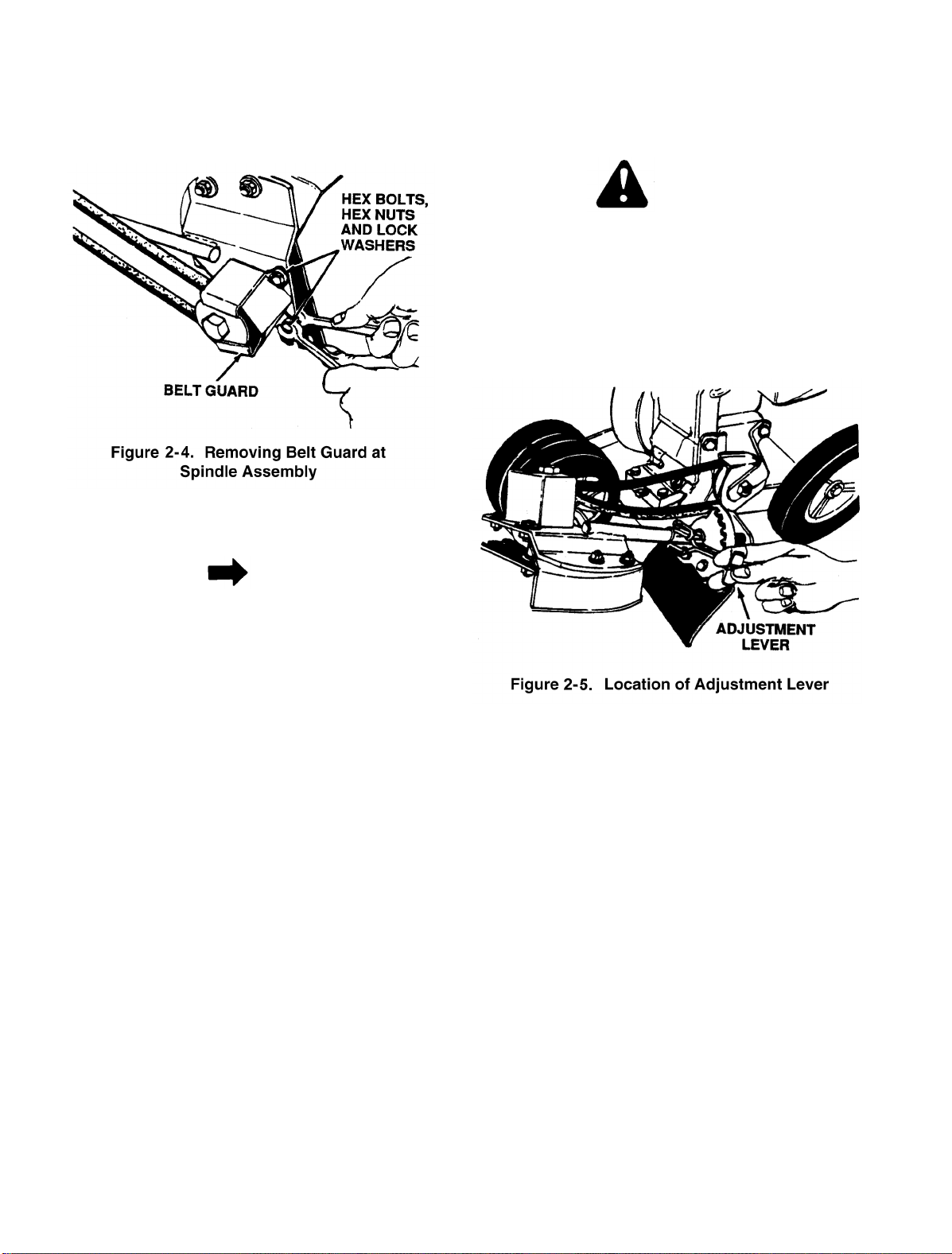

1. Remove belt guard assembly at engine pulley

by first removing hex nuts and lock washers.

See Figure 2-3.

2-1

Page 11

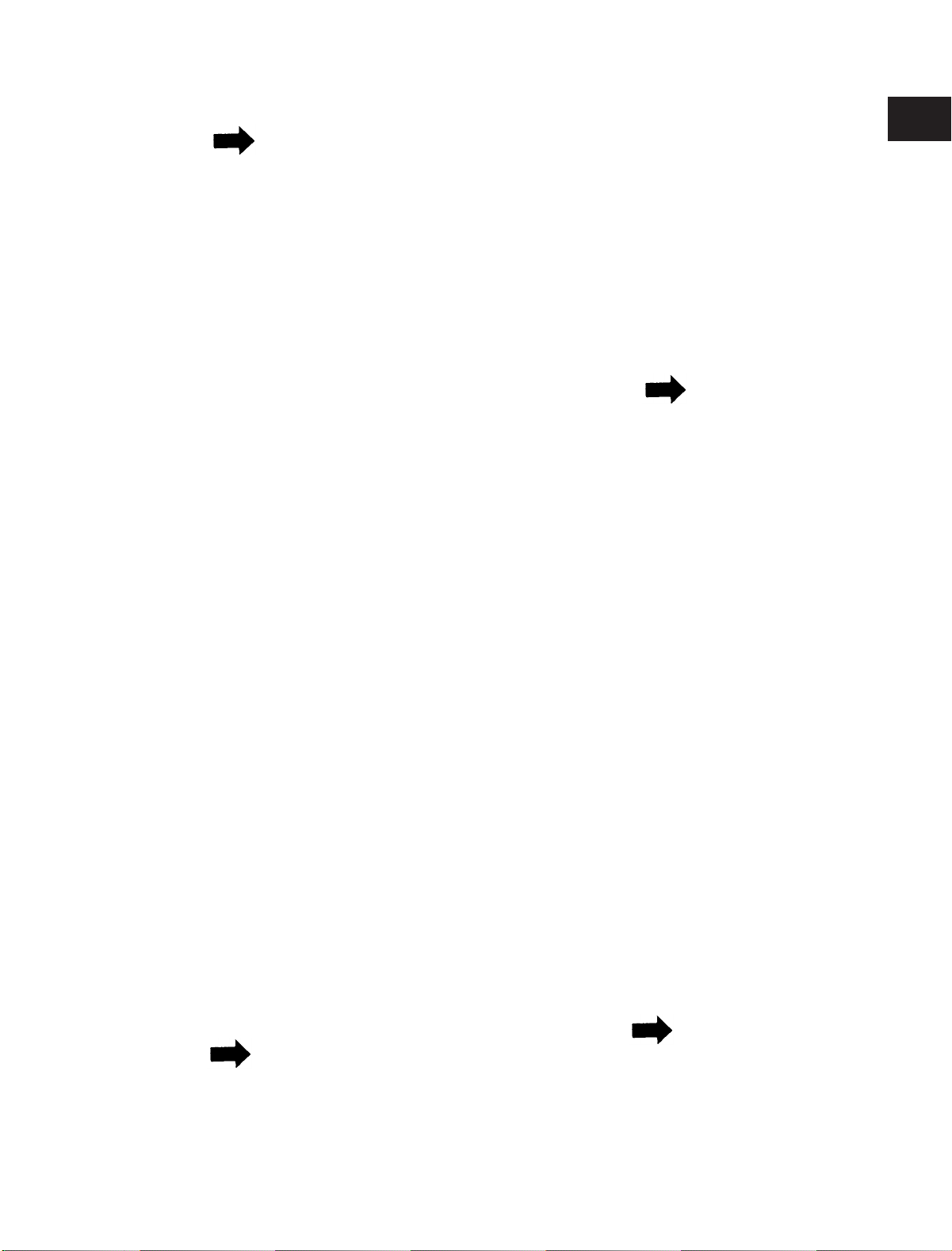

2. Remove belt guard at spindle assembly by

removing two hex bolts, lock washers and hex

nuts. See Figure 2-4.

3. Remove old belt and reassemble with new

belt, part number 754-0142.

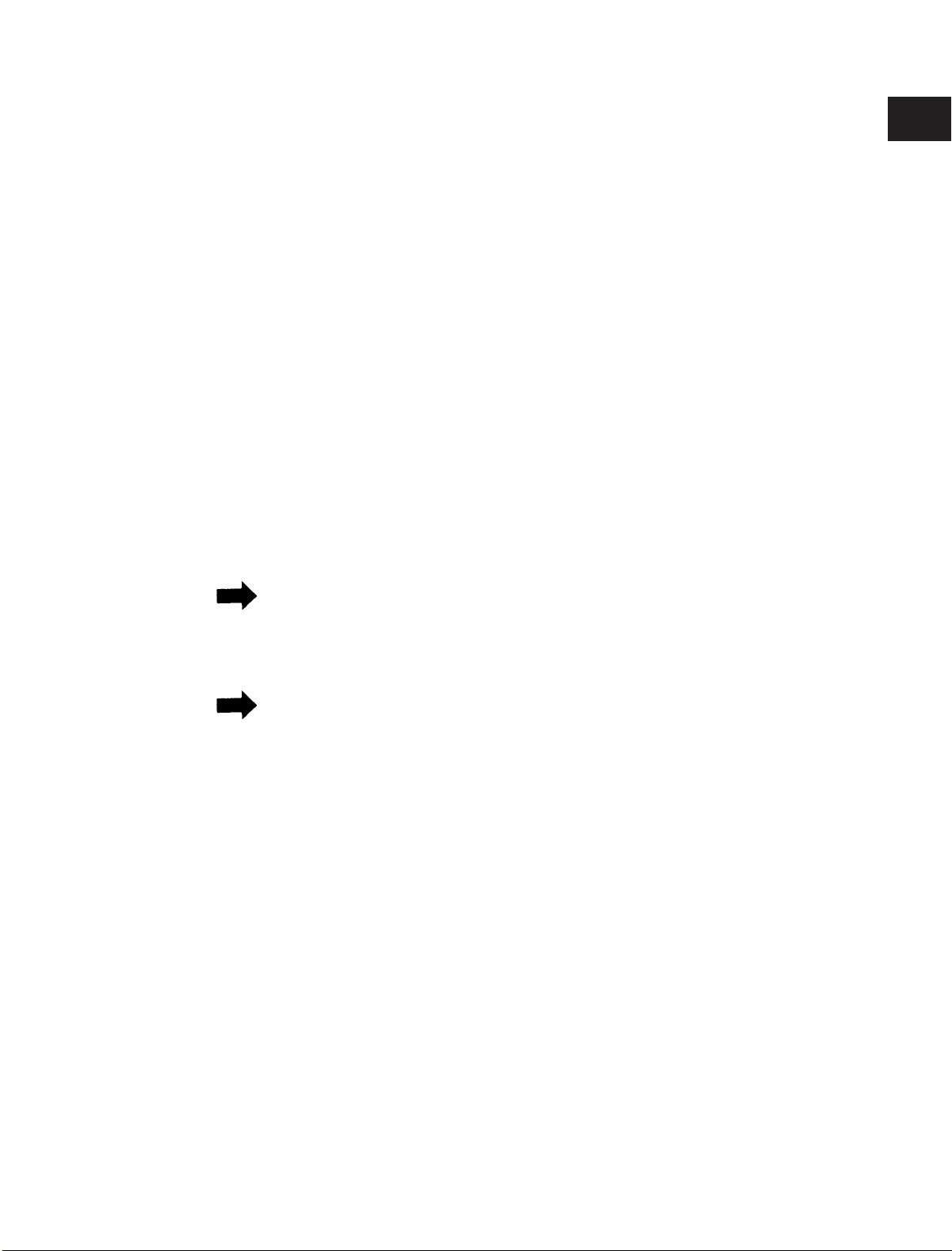

release adjustment lever on pivot bracket and

rotate spindle housing. Place adjustment lever

in notch desired. See Figure 2-5.

CAUTION

If wheels are not adjusted, the blade will hit the

left front wheel causing the belt to slip.

2. When the blade is adjusted toward the horizontal position, the front wheels must also be

adjusted. Remove two hairpin clips and slide

spacer and wheel to the right. Reinsert hairpin

clips.

NOTE

While the belt cover is removed, it is a good

idea to apply a little grease to the pivot point on

belt cover.

2-1.3 Blade Plane Adjustment.

1. The cutting blade can be adjusted to eight

positions from vertical to horizontal. To adjust,

2-2

Page 12

CHORE PERFORMERS

2

2-3

Page 13

2-4

Page 14

TILLERS

3-1. GENERAL.

For further information regarding this section,

refer to Technical Service Video “Chain Case

Teardown 410- 420 Tiller.”

3-1.1 Tillers are a precision built machine designed

for seed bed preparation, cultivating, furrowing

and mulching. They are engineered to minimize the hardest work in the vegetable or

flower garden, to till the soil for planting and

cultivating and to perform many other useful

labor saving tasks in the garden.

3-1.2 The operation of a tiller can be relatively easy if

the operator understands the basic concept of

tilling procedure and the limitations of the

equipment. Carefully note the following:

CAUTION

Be sure the area to be tilled is free of damagecausing debris. If you are working in soil of

doubtful content, till at SLOW speed and be

alert for any obstruction and be ready to

release the clutch lever instantly.

1. The tiller is not intended to be used in small,

confined spaces where hand spading is more

practical. Tillers are designed to operate in

open areas where there is a big job to do and

where there is freedom of movement.

2. While the tiller can be used on sod covered

ground, it is intended to work in open ground.

On sod covered ground the tiller will want to

buck and run and will require considerable

physical effort by the operator.

3. Do not try to hold back on the tiller to restrict its

movement. The basic idea is to let the depth

bar restrain the forward movement of the tines

and in so doing, cause the tines to dig rather

than run. Thus, it is essential that you use the

depth bar properly.

5. To begin operation of the tiller, proceed as follows:

a. With the depth bar set and staked into the

soil and with the clutch in the neutral position, start the engine.

b. Push down on the handles to drive the

depth bar firmly into the ground.

c. With the engine running at SLOW speed,

tilt the tiller back slightly to lift the tines off

the ground, engage the clutch lever slowly

to start the tines rotating and then slowly

lower the tines into the ground.

6. The rotation speed of the tines is determined

by the engine speed and thus is controlled by

the throttle control. Tilling should be done at

SLOW engine speed and increased only if the

ground conditions permit.

7. Under some ground conditions the tiller may

want to bog down. In this case raise and lower

the handles. This motion helps the tines dig out

and move forward and also releases some of

the restraint of the depth bar.

8. Do not try tilling ground that is overly wet. Wait

until the ground is dry enough to crumble

rather freely.

9. Till using a criss-cross pattern. Till in one direction with parallel paths and then till across

them at a 90 degree angle.

10. In making the first cut in untilled ground, the

tiller will track a straight path rather easily.

However, on subsequent passes, there will be

a tendency for the tines to work toward the

loose soil. Moving the handles side to side

should help maintain a straight path. If you use

a criss-cross pattern you need not till the parallel paths as close and therefore the straight

path problem is practically eliminated.

3

4. To use the tiller, move it (with the depth bar up

or in the released position) to the area to be

tilled. Once in position, lower the depth bar or

wheels to the approximate digging depth you

want. If you are going to dig deep on untilled

ground it is better to make several passes, digging deeper on each pass.

3-2. MODEL 031 FRONT TINE TILLER.

3-2.1 This tiller has been manufactured with 2 HP

and 3 HP engines. The 2 HP tiller is Model

020. The 3 HP is 030. Model 031 is basically

the same as the 030 except for the handle

panel and controls. The chain case is sealed at

the factory and there is no need to check the

3-1

Page 15

TILLERS

3-1. GENERAL.

For further information regarding this section,

refer to Technical Service Video “Chain Case

Teardown 410- 420 Tiller.”

3-1.1 Tillers are a precision built machine designed

for seed bed preparation, cultivating, furrowing

and mulching. They are engineered to minimize the hardest work in the vegetable or

flower garden, to till the soil for planting and

cultivating and to perform many other useful

labor saving tasks in the garden.

3-1.2 The operation of a tiller can be relatively easy if

the operator understands the basic concept of

tilling procedure and the limitations of the

equipment. Carefully note the following:

CAUTION

Be sure the area to be tilled is free of damagecausing debris. If you are working in soil of

doubtful content, till at SLOW speed and be

alert for any obstruction and be ready to

release the clutch lever instantly.

1. The tiller is not intended to be used in small,

confined spaces where hand spading is more

practical. Tillers are designed to operate in

open areas where there is a big job to do and

where there is freedom of movement.

2. While the tiller can be used on sod covered

ground, it is intended to work in open ground.

On sod covered ground the tiller will want to

buck and run and will require considerable

physical effort by the operator.

3. Do not try to hold back on the tiller to restrict its

movement. The basic idea is to let the depth

bar restrain the forward movement of the tines

and in so doing, cause the tines to dig rather

than run. Thus, it is essential that you use the

depth bar properly.

5. To begin operation of the tiller, proceed as follows:

a. With the depth bar set and staked into the

soil and with the clutch in the neutral position, start the engine.

b. Push down on the handles to drive the

depth bar firmly into the ground.

c. With the engine running at SLOW speed,

tilt the tiller back slightly to lift the tines off

the ground, engage the clutch lever slowly

to start the tines rotating and then slowly

lower the tines into the ground.

6. The rotation speed of the tines is determined

by the engine speed and thus is controlled by

the throttle control. Tilling should be done at

SLOW engine speed and increased only if the

ground conditions permit.

7. Under some ground conditions the tiller may

want to bog down. In this case raise and lower

the handles. This motion helps the tines dig out

and move forward and also releases some of

the restraint of the depth bar.

8. Do not try tilling ground that is overly wet. Wait

until the ground is dry enough to crumble

rather freely.

9. Till using a criss-cross pattern. Till in one direction with parallel paths and then till across

them at a 90 degree angle.

10. In making the first cut in untilled ground, the

tiller will track a straight path rather easily.

However, on subsequent passes, there will be

a tendency for the tines to work toward the

loose soil. Moving the handles side to side

should help maintain a straight path. If you use

a criss-cross pattern you need not till the parallel paths as close and therefore the straight

path problem is practically eliminated.

3

4. To use the tiller, move it (with the depth bar up

or in the released position) to the area to be

tilled. Once in position, lower the depth bar or

wheels to the approximate digging depth you

want. If you are going to dig deep on untilled

ground it is better to make several passes, digging deeper on each pass.

3-2. MODEL 031 FRONT TINE TILLER.

3-2.1 This tiller has been manufactured with 2 HP

and 3 HP engines. The 2 HP tiller is Model

020. The 3 HP is 030. Model 031 is basically

the same as the 030 except for the handle

panel and controls. The chain case is sealed at

the factory and there is no need to check the

3-1

Page 16

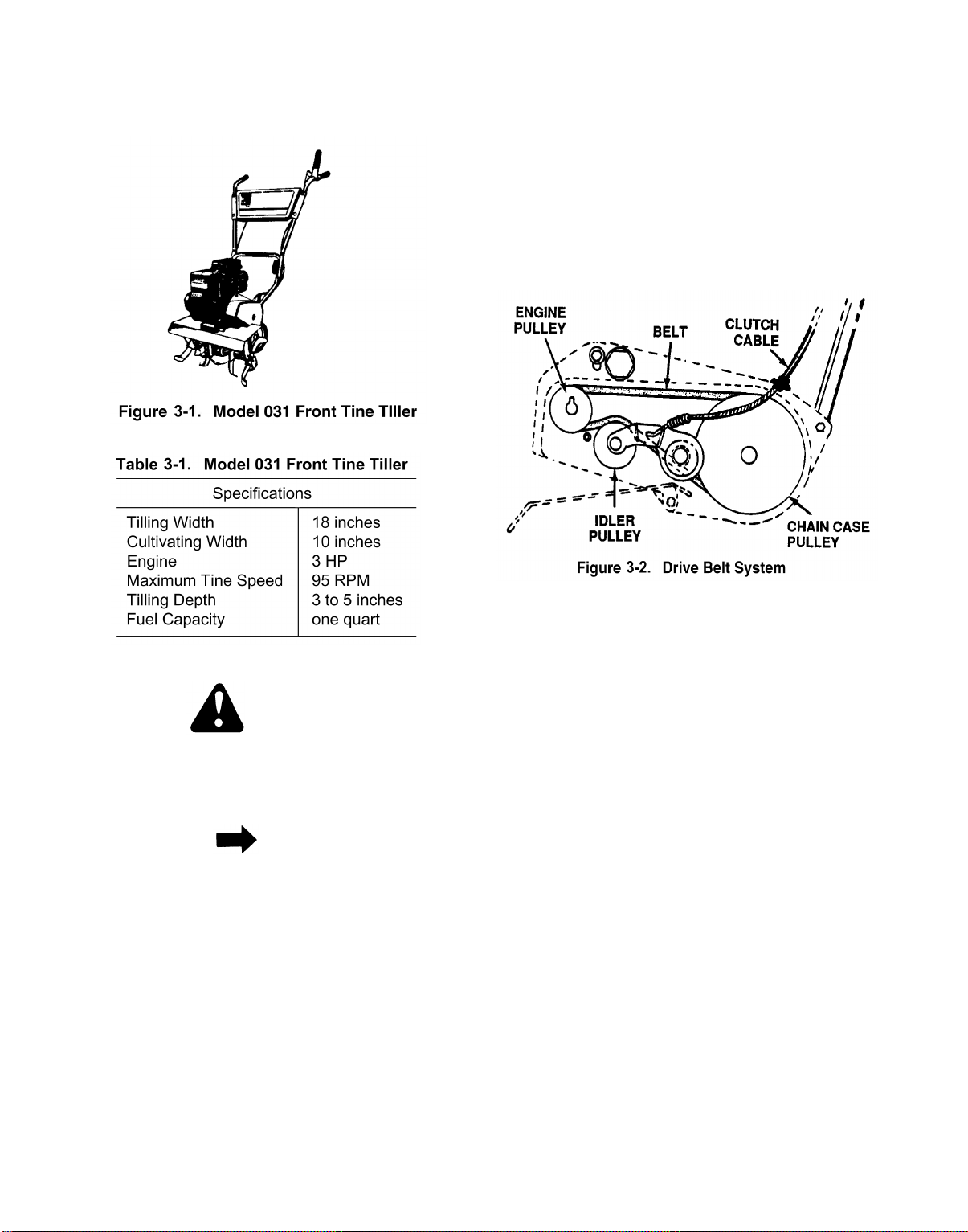

grease level. If the case is disassembled the

grease can be replaced. See Figure 3-1. For a

summary of specifications for Model 031, see

Table 3-1.

2. With clutch grip released (neutral position), pull

starter cord several times. The tines should not

turn. If they do, adjust the hex nuts at the

clutch cable bracket. Check again for correct

adjustment.

3-2.2 Clutch Adjustment.

Adjust clutch as follows:

3-2.3 Belt System.

1. The clutch idler disengages the belt when you

release the clutch control lever. This will disengage the tines and allow the tiller to be in a

neutral position. See Figure 3-2.

2. If the engine pulley is removed note how it is

assembled. The hub is to the inside. Check the

V-belt alignment between the engine pulley

and chain case pulley.

Note the following:

WARNING

Disconnect spark plug wire from spark plug

and ground it against engine block (secure in V

slot) before making any adjustments or performing maintenance.

NOTE

Do not overtighten control wire. Too much tension may cause it to break.

1. Hold the clutch grip so that the grip is down

against the handle. Adjust clutch control cable

so that the slack is taken out of the control

wire. Tighten two hex nuts at cable support

bracket. Control wire should now be straight.

3-2.4 Belt Removal and Replacement.

1. Remove belt cover assembly by removing one

hex nut and lock washer, one self-tapping

screw, one hex bolt, flat washer and hex nut

and one hex bolt and external lock washer.

2. Lift belt cover assembly off tiller. Be careful not

to bend or kink clutch cable.

3. Remove belt and position new belt on engine

pulley and chain case pulley. See Figure 3-2.

4. Upon reassembly of belt cover, place belt over

top of idler pulley and between engine pulley

and weld pin on belt cover assembly.

5. Fasten belt cover assembly in position. Secure

with the hardware removed in step 1.

3-2

Page 17

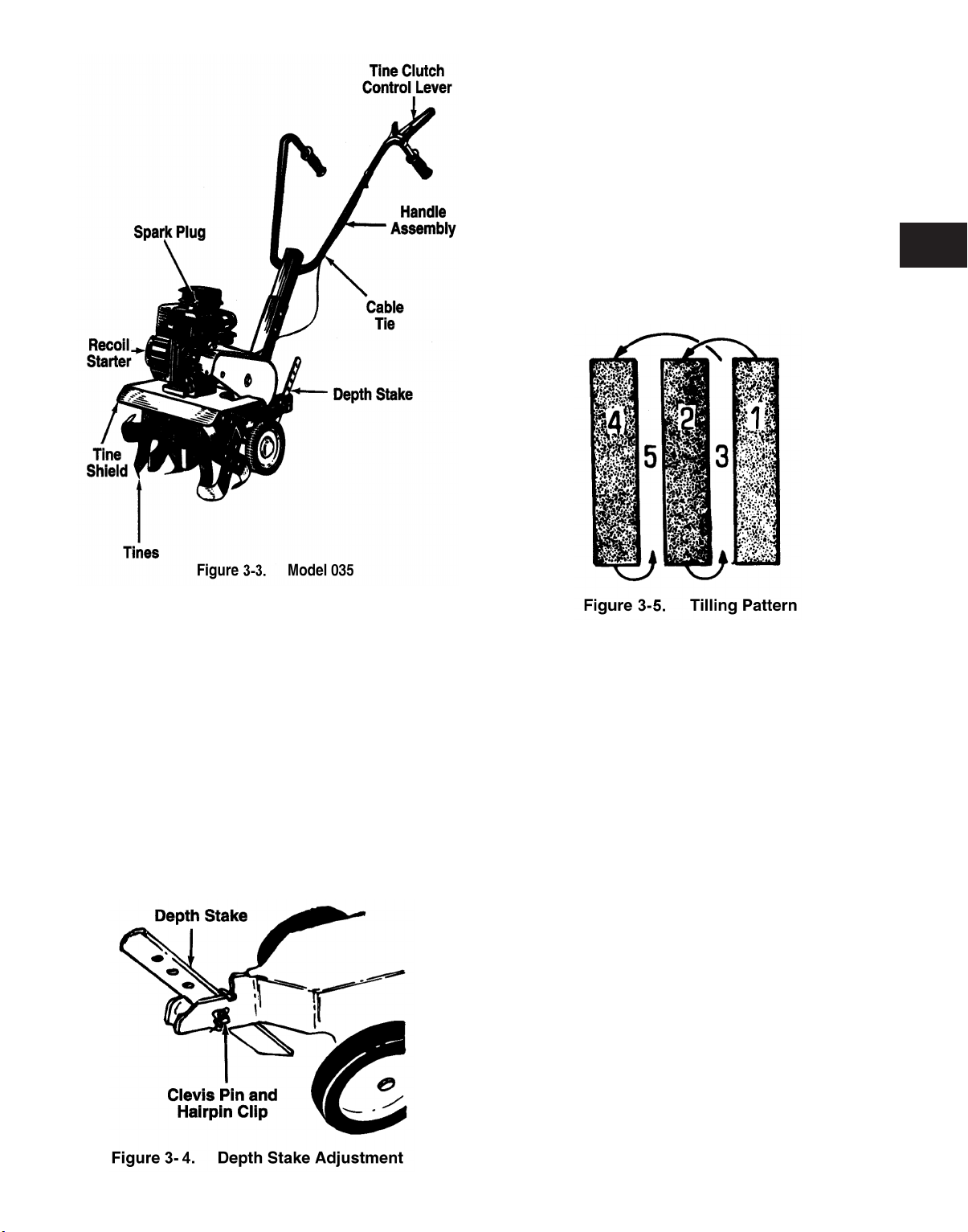

When tilling, leave approximately 8 inches of

untilled soil between the first and second tilling

paths, then make the third path between the

first and second as shown. In some soils, the

desired depth is obtained the first time over the

garden. In other soils, the desired depth is

obtained by going over the garden two or three

times. In the latter case, the depth stake

should be lowered before each succeeding

pass over the garden. Passes should be made

across the length and width of the garden alternately. Rocks which are turned up should be

removed from the garden area. See Figure 3-

5.

3

3-2A.1 CONTROLLING SPEED AND TILLING

DEPTH:

1. Depth Stake Adjustment: The depth stake acts

as a brake for the tiller and controls the depth

and speed at which the machine will operate.

Remove the clevis pin and hairpin clip to raise

or lower depth stake. See Figure 3-4.

By increasing the depth of the depth stake, the

forward speed of the machine is reduced, and

the working depth is increased. When the

depth stake is raised, the working depth of the

machine is reduced and the forward speed is

increased.

2. Handle Pressure: Further control of tilling

depth and travel speed can be obtained by

variation of pressure on the handles. A downward pressure on the handles will reduce the

working depth and increase the forward speed.

An upward pressure on the handles will

increase the working depth and reduce the forward speed. The type of soil and working conditions will determine the actual setting of the

depth stake and the handle pressure required.

3. Throttle Control: The throttle control lever

adjusts the engine speed and stops the

engine. With the throttle control pushed completely to the right, the carburetor is in START

or FAST position. Pulling the throttle back

reduces the engine speed to IDLE. Pull the

throttle completely back to stop the engine.

Use maximum engine speed for deep tilling.

Move the throttle control to IDLE when transporting the tiller.

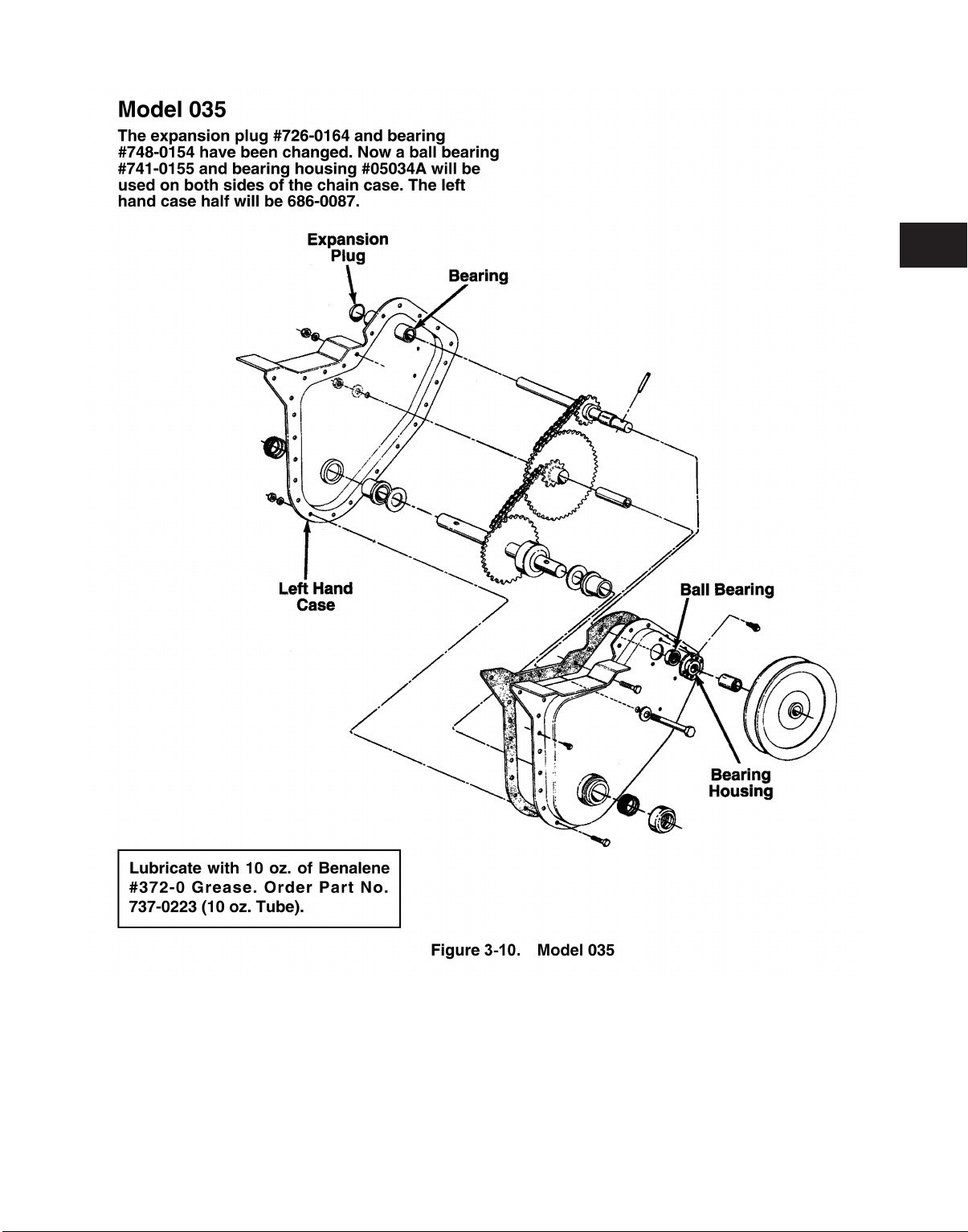

Model Series 035

3-2A.2 CULTIVATING

3-3

Page 18

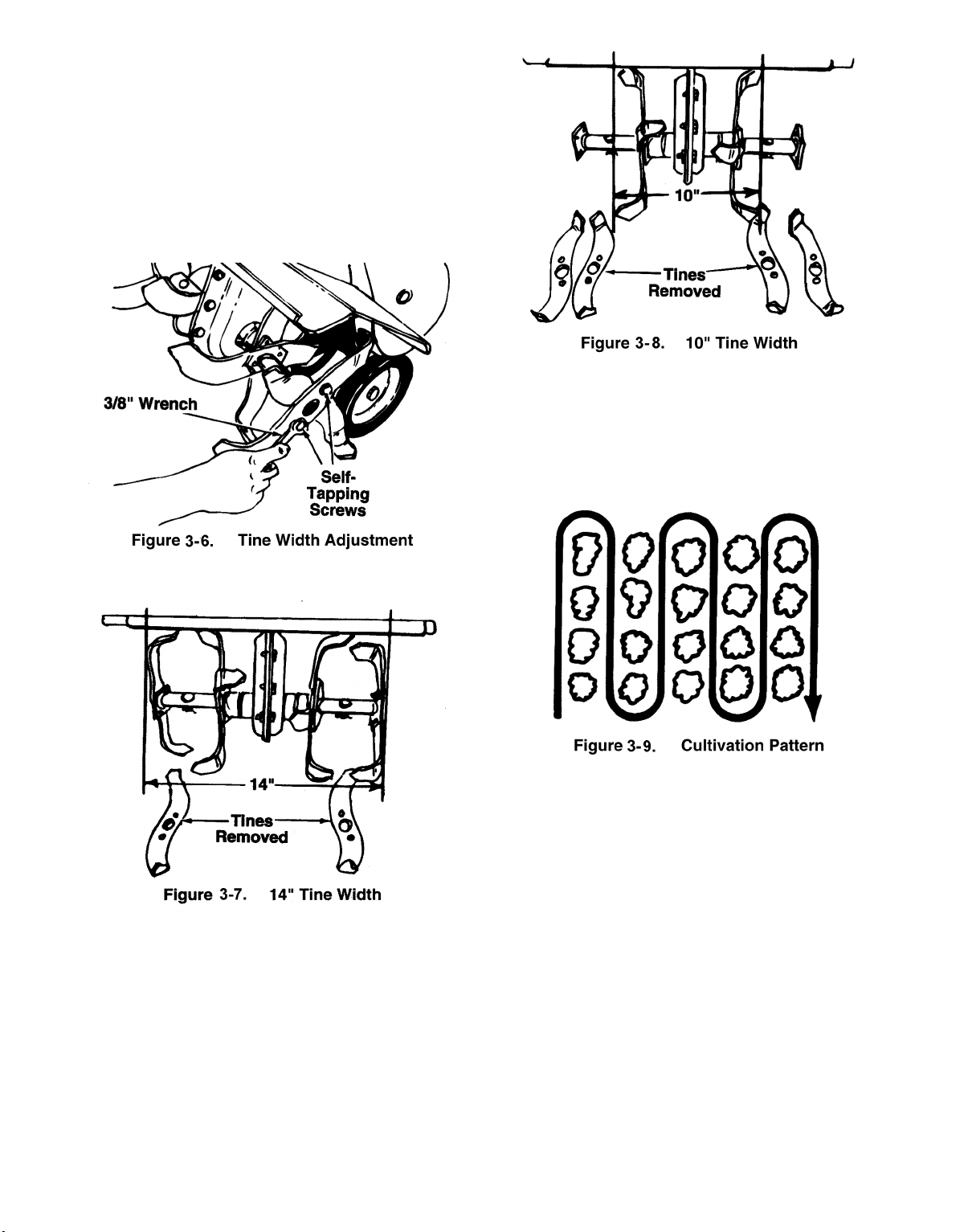

For cultivating, a two to three inch depth is

desirable. The throttle should be set to control

forward movement to a slow walking speed.

With the outer tines installed, the working width

of the machine is 18 inches. For cultivation,

this may be reduced to 14 inches by removing

the outer tines. Use a 3/8" wrench to remove

the two self-tapping screws on the outside of

the tines. Replace the first tine removed as

shown. See Figure 3-6.

When laying out plant rows, be sure to allow

enough width to permit cultivation between the

rows. In growing corn or similar crops, checkrow planting will permit cross cultivation and

practically eliminate hand hoeing. See Figure

3-9.

The minimum tilling width is 10 inches.

Remove both sets of outer tines by removing

the two self-tapping screws on the outside of

the tines. See Figure 3-8.

3-4

Chain Case

and sealed at the factory. It requires no checking unless the chain case is disassembled. To

fill with grease, lay the right half of the chain

case on its side. Add 10 ounces of Benalene

#372-0 grease and assemble the left half to the

right half.

—The chain case is pre-lubricated

Page 19

3

3-5

Page 20

3-6

Page 21

3-2.5 Disassembly of Tine Chain Case.

as follows:

1. Remove chain case from tiller.

2. Remove self-tapping screws, hex bolts, lock

washers and hex nuts from the outer edge of

chain case.

3. Remove hex bolt, lock washer and hex nut

from the center of chain case.

Proceed

6. Separate halves of the chain case housing. Be

careful not to damage the chain case gasket.

Replace if necessary.

NOTE

The drive system has 2 chain reduction steps.

Each step reduces the speed and increases

the torque or power down to the axle shaft. The

reduction is done with the use of a #35 chain to

a #420 chain.

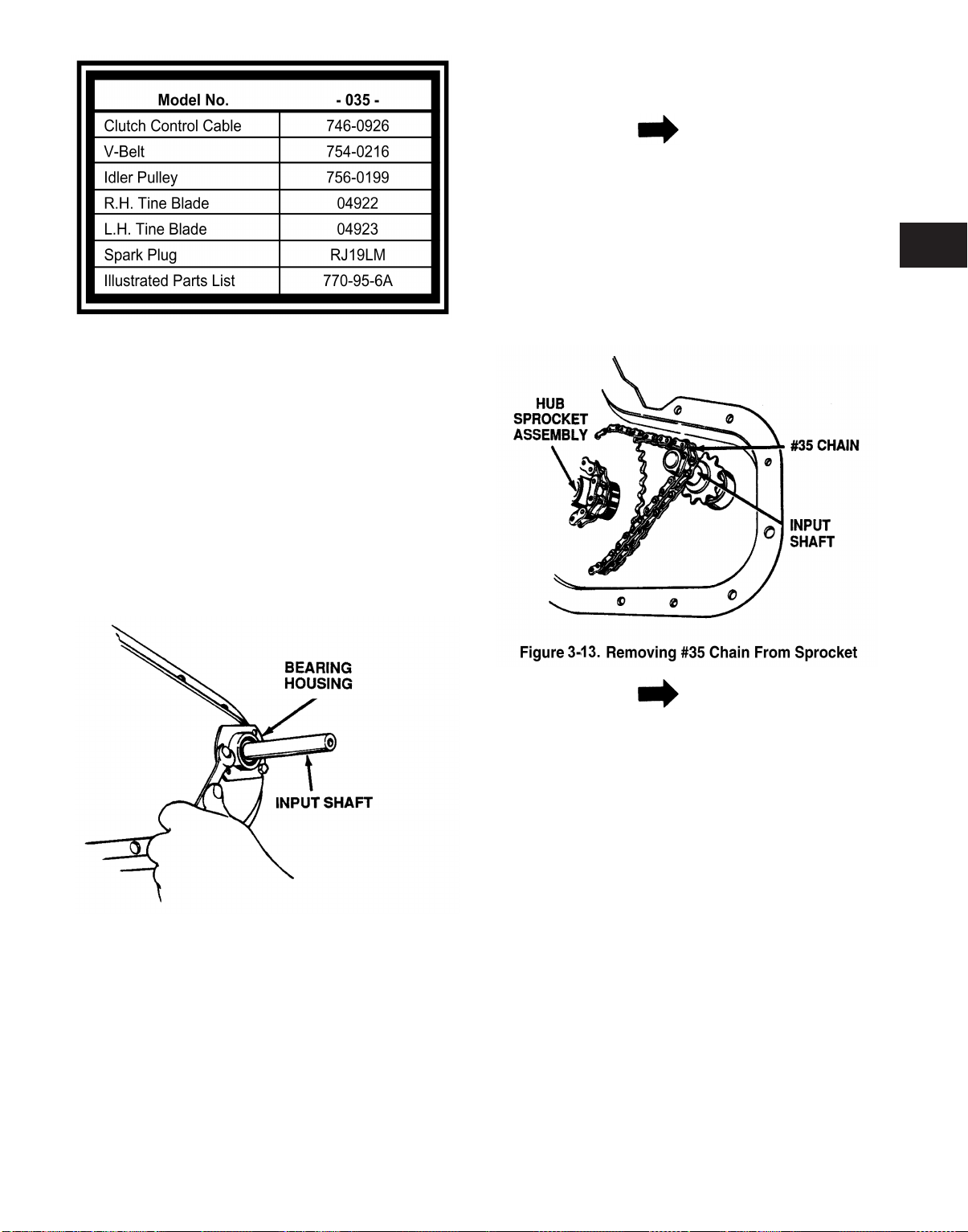

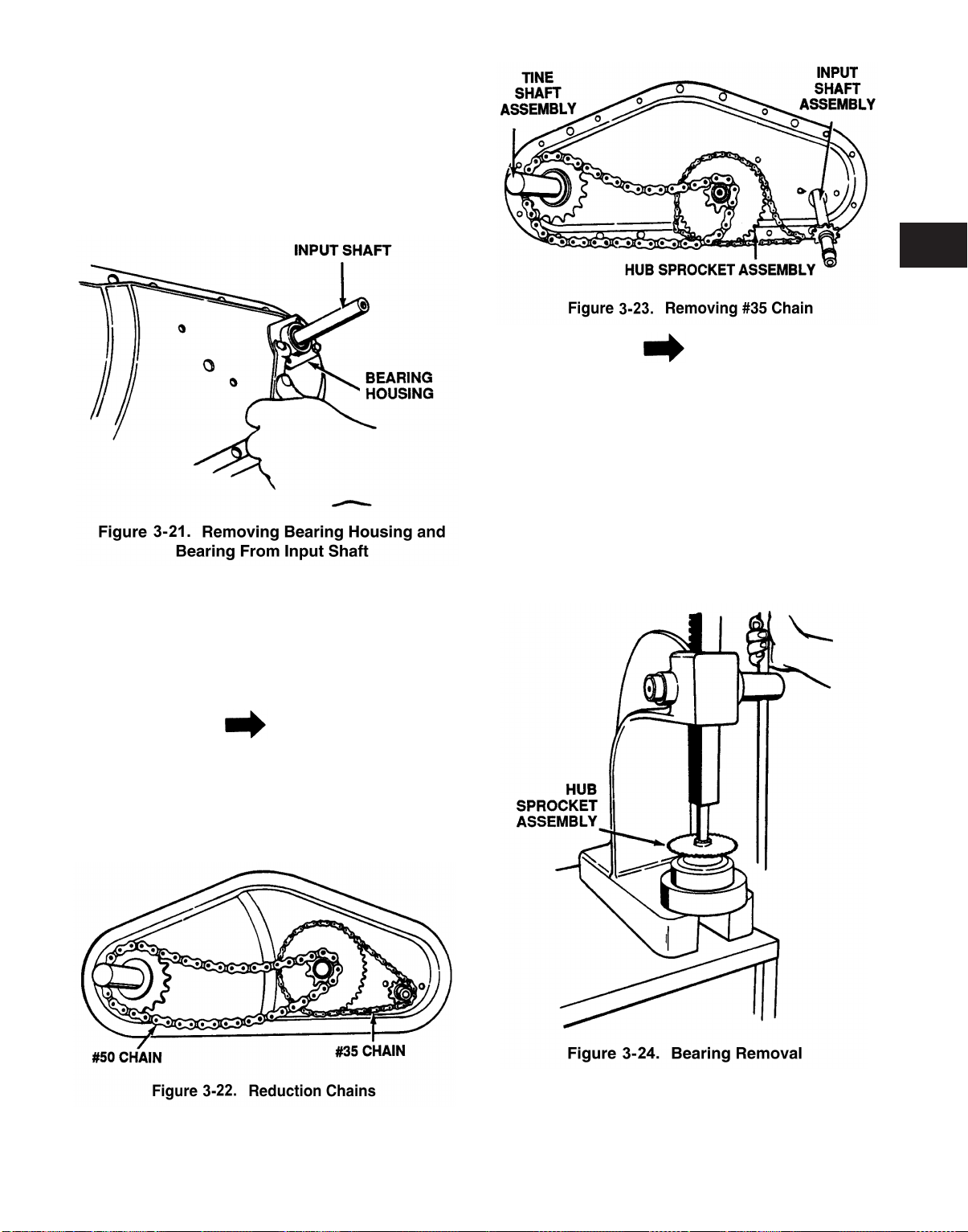

7. Push input shaft inward slightly. Lift up on hub

sprocket assembly and remove the #35 chain

from the sprocket. See Figure 3-13.

3

4. Remove self-tapping screws from bearing

housing. See Figure 3-12.

Figure 3-12.

5. Slide bearing housing and bearing off input

shaft.

NOTE

This will allow slack in the other chain which

can be removed by lifting off the sprockets.

The hub sprocket assemblies will also be

removed from the housing during this procedure.

8. To disassemble the hub sprocket assembly,

slide the spacer out of the bearing. On an

arbor press place a spacer or similar tool on

the OD of the bearing and press bearing out of

hub sprocket assembly. See Figure 3-14.

3-7

Page 22

CAUTION

Both bearings must be pressed from the outside towards the center of housing. Pressure

should be exerted on the outer race or damage will result causing premature failure.

11. Inspection of Parts.

a. Inspect chains for breakage or bent clips

(master links).

b. Inspect sprockets and shafts for excessive

wear or breakage.

c. Inspect bearings on input and output

shafts for excessive wear.

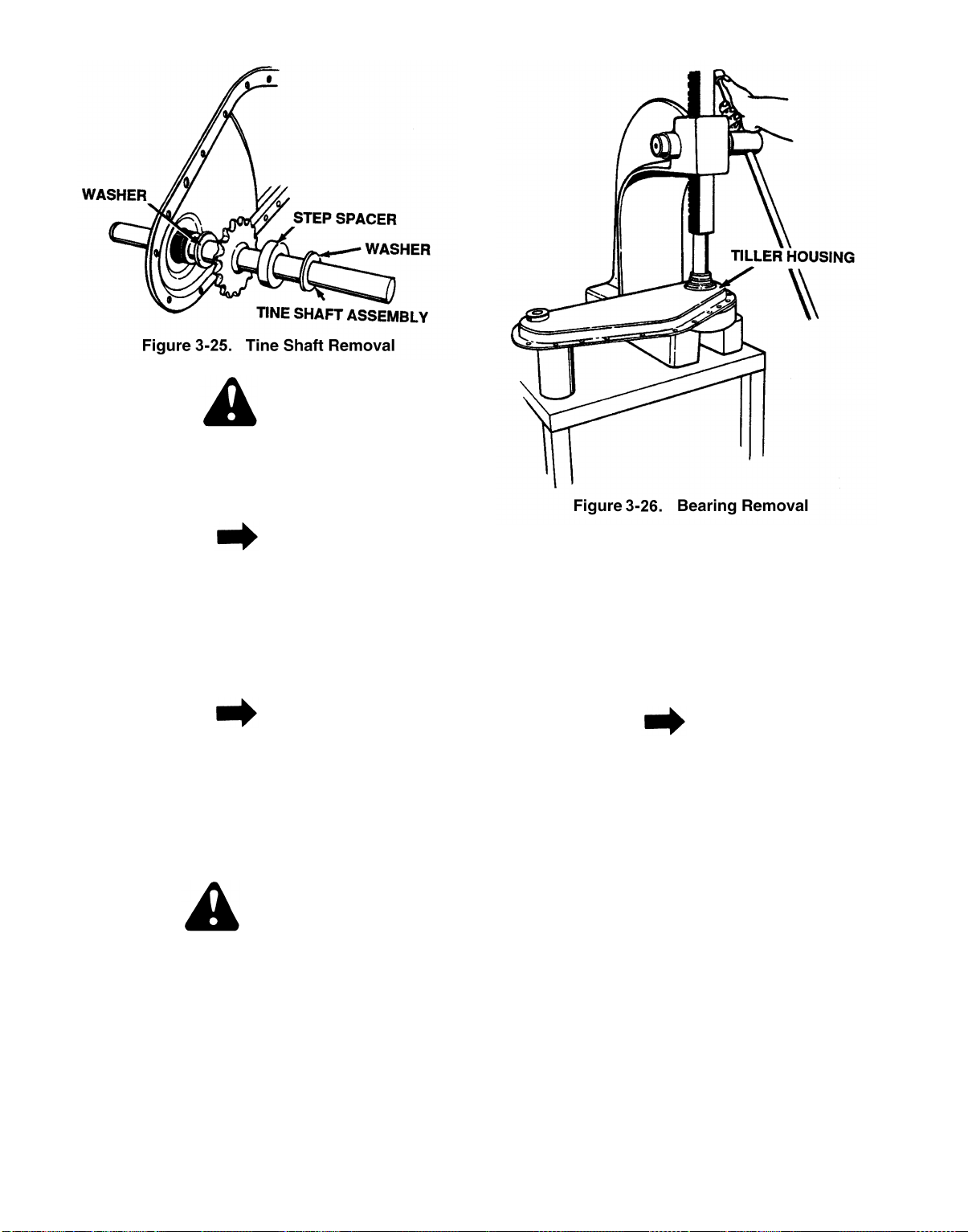

9. To remove the tine shaft assembly simply pull

the complete assembly out of the housing. See

Figure 3-15.

NOTE

The chain case is lubricated with 10 ounces of

plastilube #0 grease to keep the bearings and

chains operating in a constant lubrication bath.

CAUTION

When reassembling, make certain the step

spacer and washer are positioned properly or

damage to the shaft assembly and/or bearings will result.

10. Remove bearings from the housing using an

arbor press. See Figure 3-16.

d. Inspect spacers and washers for exces-

sive wear.

3-2.6 Chain Case Seal and Bearing Replacement.

Proceed as follows:

WARNING

Disconnect spark plug wire and ground against

engine.

1. On a bench or suitable surface, block up the

chain case so that the tines clear the bench.

2. Remove the hardware which secures the tines

to the shaft and remove from unit.

3-8

Page 23

NOTE

The dust caps have a molded lip on the ID

which seats into a groove in the bearing hub

allowing for a tight fit.

3. Carefully pry off dust caps from housing

assembly.

5. Reattach bearing and bearing housing to tiller

housing with self-tapping screws removed in

step 3.

6. Reassemble pulleys, belt and belt guard

removed in step 2.

3-3. Model 310/700 Tiller.

4. Pry old seal out of housing assembly and slide

off shaft.

5. Remove any rust or foreign material from shaft

and thoroughly clean to avoid damage or contamination to seal or bearing.

6. Apply a generous amount of oil to shaft and

new seal and carefully slide seal into position.

Make certain the new seal is completely

seated against the shaft bearing.

7. Reassemble dust caps making certain they are

fully seated on the bearing hub.

8. Reattach the tines with the hardware removed

in step 3.

3-2.7 Input Shaft Bearing Replacement.

WARNING

Disconnect spark plug wire and ground it

against engine.

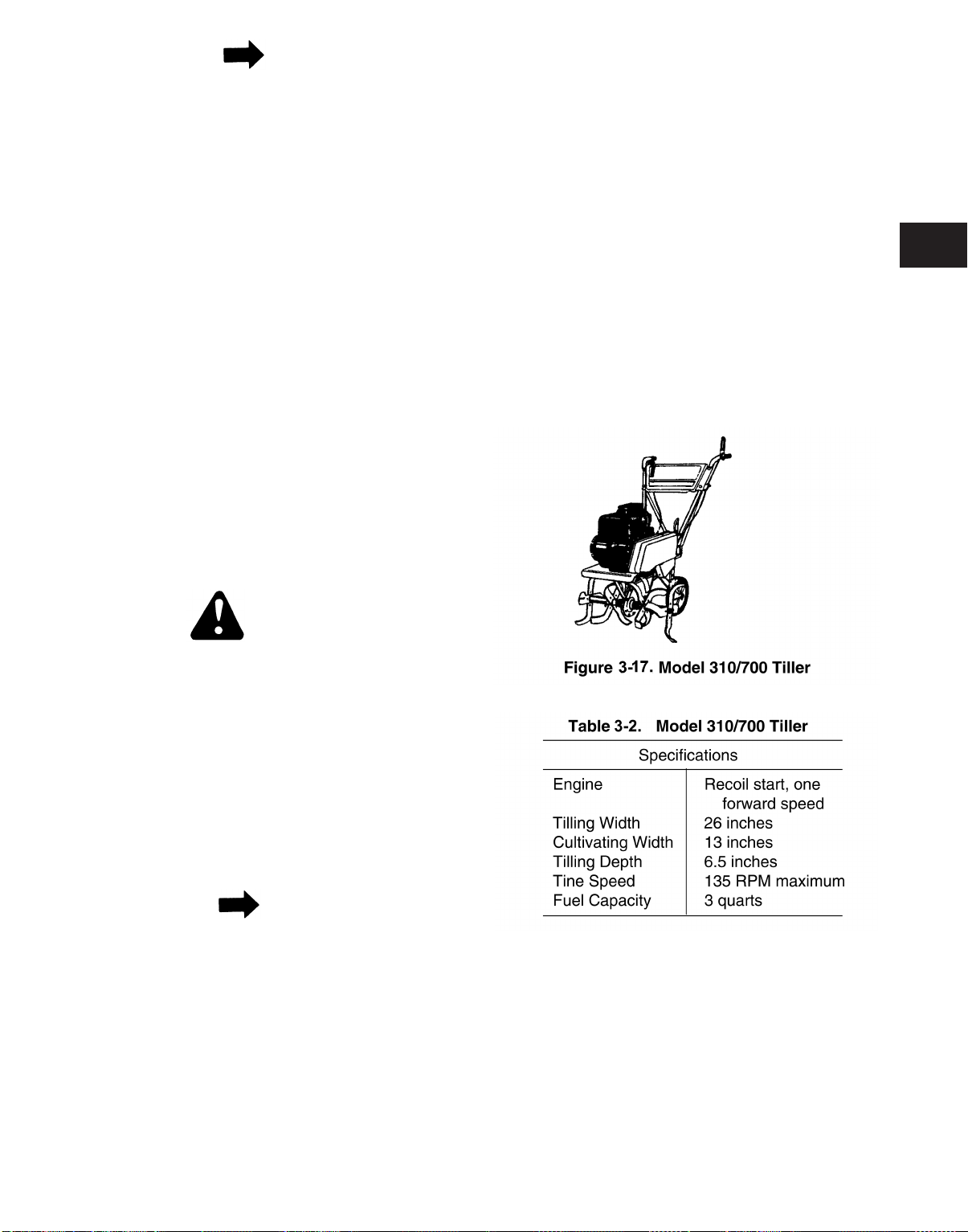

3-3.1 This tiller has forward speed only. There is no

reverse. The chain case has a two step reduction. The V-belt goes from a small engine pulley to a large input on the chain case. The

chain case is sealed at the factory and there is

no need to check or change the lubricant

unless the chain case has been disassembled

for repair. See Figure 3-17. For a summary of

specifications for Model 310/700, see Table 3-

2.

3

1. To replace bearing on tine chain case assembly, remove belt guard, belts and pulleys from

input shaft.

2. Remove self-tapping screws which secure

bearing housing to tiller housing.

3. Slide bearing housing and bearing off input

shaft.

NOTE

Pressure should be applied to the outer race of

the bearing and the housing should be secured

properly. Any force exerted on the inner race

will result in bearing damage or premature failure.

4. Press bearing out of housing and replace with

a new bearing.

3-3.2 The most common mistake made on any tiller

is assembling the tines backwards. THE

SHARP EDGE OF THE TINES MUST ENTER

THE SOIL FIRST.

3-9

Page 24

NOTE

The dust caps have a molded lip on the ID

which seats into a groove in the bearing hub

allowing for a tight fit.

3. Carefully pry off dust caps from housing

assembly.

5. Reattach bearing and bearing housing to tiller

housing with self-tapping screws removed in

step 3.

6. Reassemble pulleys, belt and belt guard

removed in step 2.

3-3. Model 310/700 Tiller.

4. Pry old seal out of housing assembly and slide

off shaft.

5. Remove any rust or foreign material from shaft

and thoroughly clean to avoid damage or contamination to seal or bearing.

6. Apply a generous amount of oil to shaft and

new seal and carefully slide seal into position.

Make certain the new seal is completely

seated against the shaft bearing.

7. Reassemble dust caps making certain they are

fully seated on the bearing hub.

8. Reattach the tines with the hardware removed

in step 3.

3-2.7 Input Shaft Bearing Replacement.

WARNING

Disconnect spark plug wire and ground it

against engine.

3-3.1 This tiller has forward speed only. There is no

reverse. The chain case has a two step reduction. The V-belt goes from a small engine pulley to a large input on the chain case. The

chain case is sealed at the factory and there is

no need to check or change the lubricant

unless the chain case has been disassembled

for repair. See Figure 3-17. For a summary of

specifications for Model 310/700, see Table 3-

2.

3

1. To replace bearing on tine chain case assembly, remove belt guard, belts and pulleys from

input shaft.

2. Remove self-tapping screws which secure

bearing housing to tiller housing.

3. Slide bearing housing and bearing off input

shaft.

NOTE

Pressure should be applied to the outer race of

the bearing and the housing should be secured

properly. Any force exerted on the inner race

will result in bearing damage or premature failure.

4. Press bearing out of housing and replace with

a new bearing.

3-3.2 The most common mistake made on any tiller

is assembling the tines backwards. THE

SHARP EDGE OF THE TINES MUST ENTER

THE SOIL FIRST.

3-9

Page 25

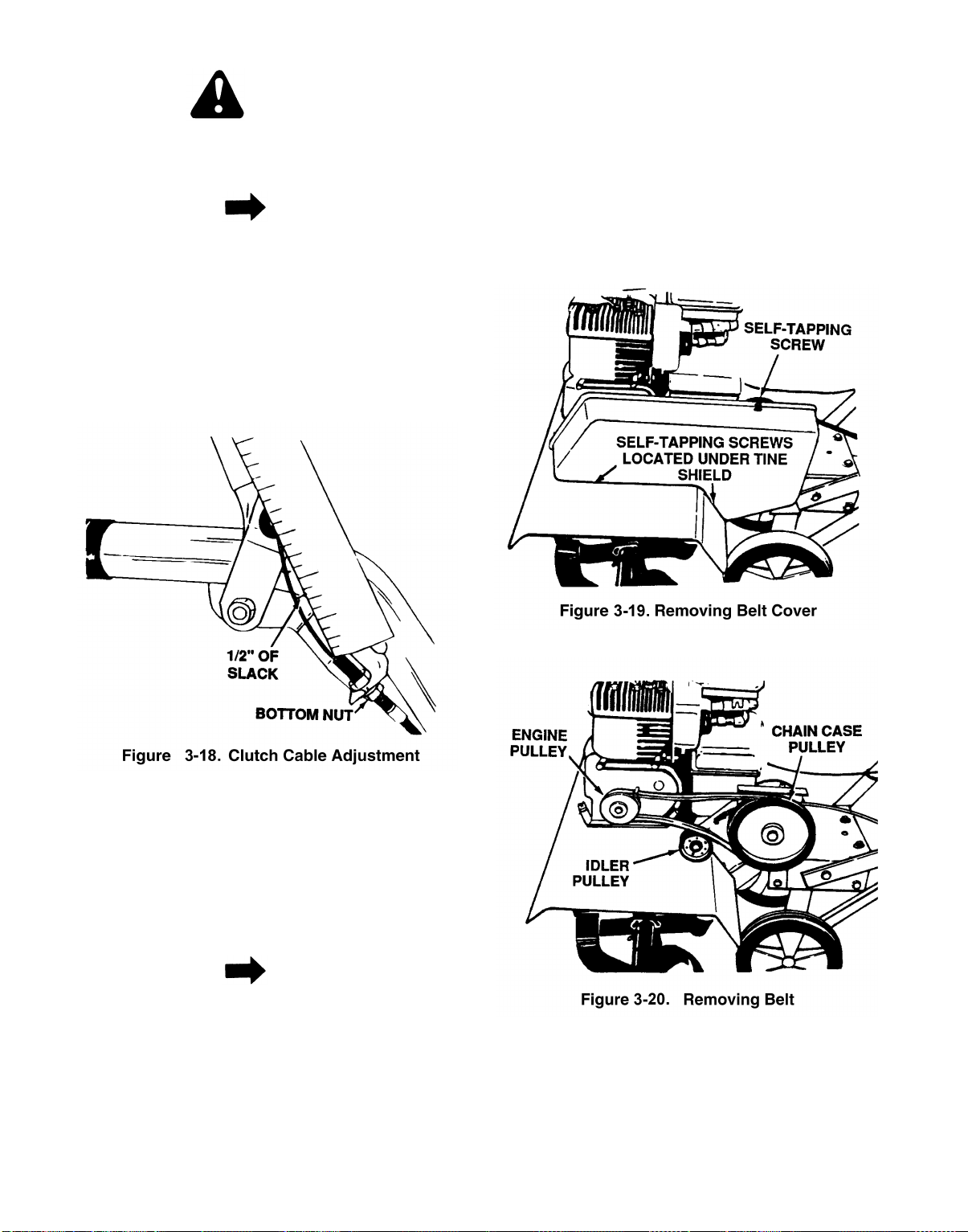

3-3.3 Clutch Adjustment.

2. After removing three screws, lift off belt cover.

WARNING

Disconnect spark plug wire and ground it

against engine before performing any adjustments, repairs or maintenance.

NOTE

Do not overtighten control wire. Too much tension may cause it to break.

1. With clutch lever released (in up position),

adjust the bottom nut at the cable bracket so

there is 1/2 inch of slack in the control wire.

See Figure 3-18. Tighten upper nut against

bracket. Squeeze clutch lever against handle.

The control wire should now be straight.

3. Slip belt off chain case pulley first then off idler

pulley. Remove belt from engine pulley. See

Figure 3-20.

4. To reassemble new belt, first place belt over

engine pulley. Be sure belt is inside two pins at

engine pulley.

5. Belt must be over top of idler pulley. Slip end of

belt over chain case pulley.

2. Secure end of spark plug wire in the V slot on

the engine. With clutch grip released (neutral

position), pull starter cord several times. The

tines should not turn. If they do, adjust hex

nuts at clutch cable bracket. Check again for

correct adjustment.

3-3.4 Belt Removal and Replacement.

NOTE

Your tiller has been engineered with a belt

made of special material (Kevlar Tensile). It

should not be replaced with an off-the-shelf

belt.

1. Remove the belt cover by removing three selftapping screws. A 3/8 inch wrench is required.

See Figure 3-19.

6. Reassemble belt cover.

3-3.5 Disassembly of Tine Chain Case.

1. Remove chain case from tiller.

3-10

Page 26

2. Remove self-tapping screws, hex bolts, lock

washers and hex nuts from the outer edge of

chain case.

3. Remove hex bolt, lock washer and hex nut

from the center of chain case.

4. Remove self-tapping screws from bearing

housing. See Figure 3-21.

5. Slide bearing housing and bearing off the input

shaft.

3

NOTE

This will allow slack in the other chain which

can be removed by lifting off the sprockets.

The hub sprocket assemblies will also be

removed from the housing during this procedure.

8. To disassemble hub sprocket assembly, slide

spacer out of bearing. On an arbor press

remove bearing by placing a spacer or similar

tool on the OD of bearing and press out. See

Figure 3-24.

6. Separate the halves of the chain case housing.

Be careful not to damage chain case gasket.

Replace if necessary.

NOTE

The drive system has 2 chain reduction steps.

Each step reduces the speed and increases

the torque or power down to the axle shaft. The

reduction is done with the use of a #35 chain to

a #50 chain. See Figure 3-22.

7. Push input shaft inward slightly. Lift up on hub

sprocket assembly and remove #35 chain from

the sprocket. See Figure 3-23.

9. To remove tine shaft assembly simply pull the

complete assembly out of the housing. See

Figure 3-25.

3-11

Page 27

CAUTION

When reassembling, make certain the step

spacers and washers are positioned properly

or damage to the shaft assembly and/or bearings will result. (Cupped side faces sprocket.)

NOTE

The chain case is lubricated with 12 ounces of

plastilube #0 grease to keep the bearings and

chains operating in a constant lubrication bath.

10. Remove bearings from housing using an arbor

press. See Figure 3-26.

NOTE

Both bearings must be pressed from the outside towards the center of housing as shown.

Pressure should be exerted on the outer race

or damage will result causing premature failure.

3-3.6 Chain Case Seal and Bearing Replacement.

WARNING

Disconnect spark plug wire and ground it

against engine.

1. On a bench or suitable surface, block up chain

case so that tines/wheels clear the bench.

2. Remove the hardware which secures the tines

to shaft and remove from unit.

3. Carefully pry off dust caps from housing

assembly.

NOTE

The dust caps have a molded lip on the ID

which seats into a groove in the bearing hub

allowing for a tight fit.

4. Pry old seals out of housing assembly and

slide off shaft.

5. Remove any rust or foreign material from shaft

and thoroughly clean to avoid damage or contamination to seal.

6. Apply a generous amount of oil to shaft and

new seal and carefully slide seal into position.

Make certain new seal is completely seated

against shaft bearing.

3-12

7. Reassemble dust caps making certain they are

fully seated on the bearing hub.

Page 28

8. Reattach tines/wheels with the hardware

removed in step 3.

3-3.7 Input Shaft Bearing Replacement.

WARNING

Disconnect spark plug wire and ground it

against engine.

1. To replace bearing on tine chain case assembly, remove belt guard, belts and pulleys from

input shaft.

2. Remove self-tapping screws which secure

bearing housing to tiller housing.

3. Slide bearing housing and bearing off input

shaft.

4. Press bearing out of housing and replace with

a new bearing.

CAUTION

Pressure should be applied to the outer race of

the bearings and the housing should be

secured properly. Any force exerted on the

inner race will result in bearing damage or premature failure.

5. Reattach bearing and bearing housing to tiller

housing with self-tapping screws removed in

step 3.

3

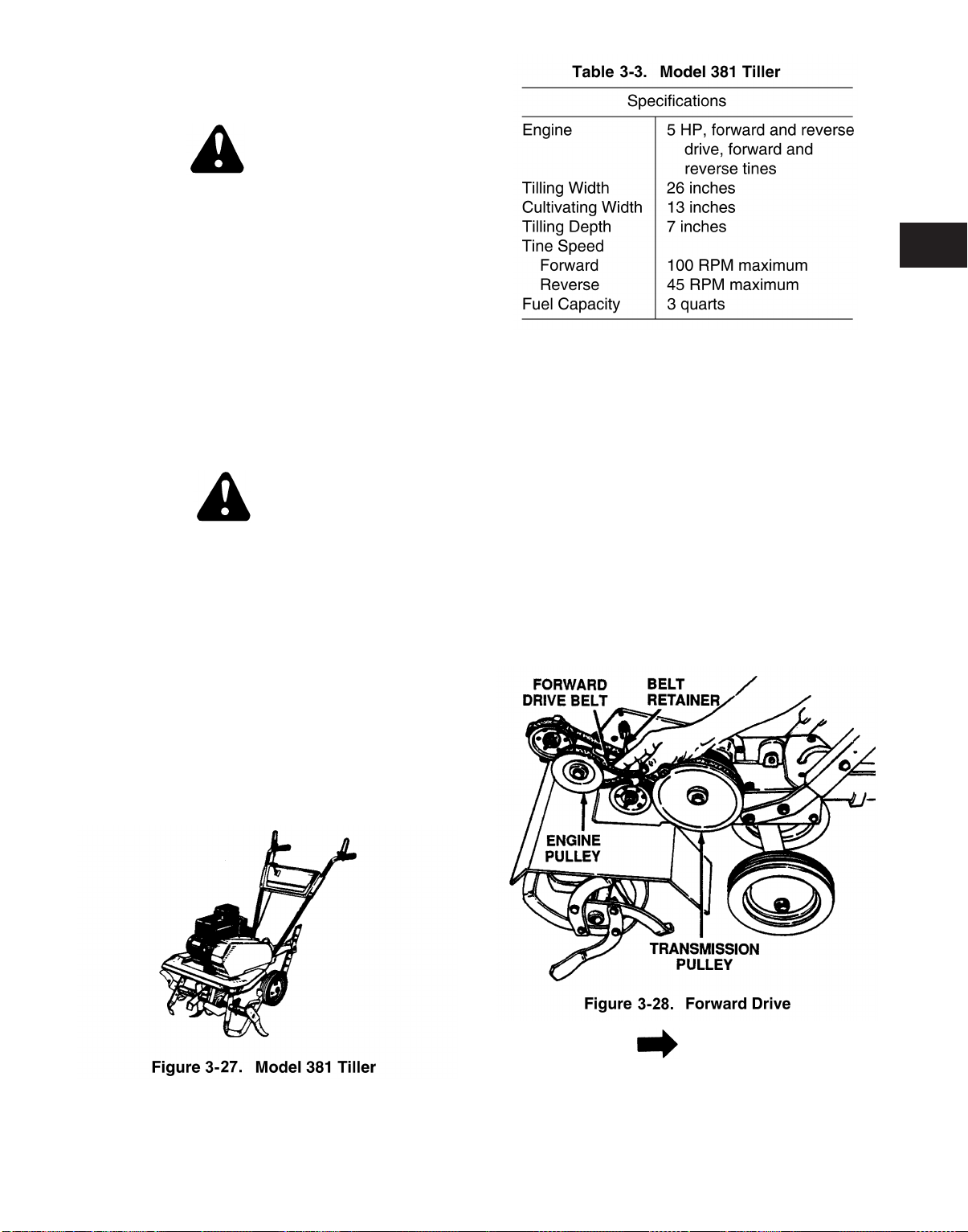

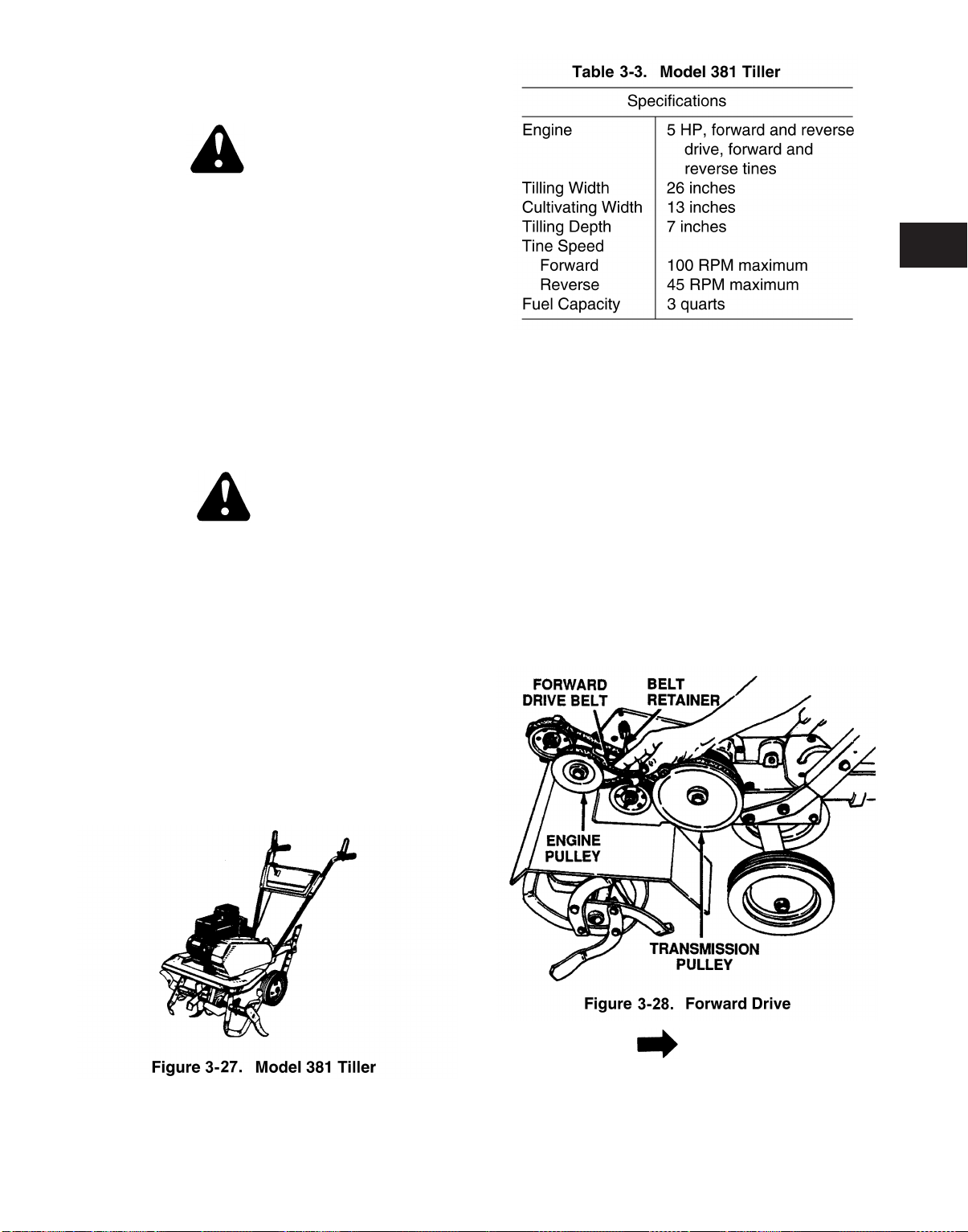

3-4.1 Forward Drive Belt Removal and Replace-

ment.

1. Remove belt guard by removing four hex selftapping screws.

2. Press down on left side of tine shield and slip

off belt guard.

3. Remove forward drive belt from beneath belt

retainer.

4. Roll belt off transmission pulley.

5. Remove belt from around engine pulley and lift

it off idler pulley. See Figure 3-28.

6. Reassemble pulleys, belt and belt guard

removed in step 2.

3-4. MODEL 381 TILLER. See Figure 3-27 and

Table 3-3.

NOTE

Make certain the forward drive belt is assembled with the wide side of the belt away from

transmission and engine pulleys.

3-13

Page 29

8. Reattach tines/wheels with the hardware

removed in step 3.

3-3.7 Input Shaft Bearing Replacement.

WARNING

Disconnect spark plug wire and ground it

against engine.

1. To replace bearing on tine chain case assembly, remove belt guard, belts and pulleys from

input shaft.

2. Remove self-tapping screws which secure

bearing housing to tiller housing.

3. Slide bearing housing and bearing off input

shaft.

4. Press bearing out of housing and replace with

a new bearing.

CAUTION

Pressure should be applied to the outer race of

the bearings and the housing should be

secured properly. Any force exerted on the

inner race will result in bearing damage or premature failure.

5. Reattach bearing and bearing housing to tiller

housing with self-tapping screws removed in

step 3.

3

3-4.1 Forward Drive Belt Removal and Replace-

ment.

1. Remove belt guard by removing four hex selftapping screws.

2. Press down on left side of tine shield and slip

off belt guard.

3. Remove forward drive belt from beneath belt

retainer.

4. Roll belt off transmission pulley.

5. Remove belt from around engine pulley and lift

it off idler pulley. See Figure 3-28.

6. Reassemble pulleys, belt and belt guard

removed in step 2.

3-4. MODEL 381 TILLER. See Figure 3-27 and

Table 3-3.

NOTE

Make certain the forward drive belt is assembled with the wide side of the belt away from

transmission and engine pulleys.

3-13

Page 30

6. Reassemble the new belt following instructions

in reverse order.

5. Reassemble new belt following instructions in

reverse order.

3-4.2 Reverse Drive Belt Removal and Replace-

ment.

1. To remove reverse drive belt, first remove forward drive belt as instructed in the previous

paragraph.

2. Remove reverse drive belt from beneath belt

retainer.

3. Roll belt off transmission pulley. Remove it

from beneath forward idler bracket. See Figure

3-29.

3-4.3 Disassembly of Tine Chain Case.

Disassemble as follows:

1. Remove chain case from tiller.

2. Remove self-tapping screws, hex bolts, lock

washers and hex nuts from the outer edge of

chain case.

3. Remove hex bolt, lock washers, and hex nut

from center of the chain case. See Figure 3-31.

4. Remove hex nut which secures reverse idler

pulley to idler bracket. Slide idler pulley out and

remove belt. See Figure 3-30.

NOTE

Make certain reverse drive belt is assembled

with the wide side of the belt against transmission and engine pulleys.

4. Remove self-tapping screws from bearing

housing. See Figure 3-32.

5. Slide bearing housing and bearing off input

shaft.

6. Separate the halves of chain case housing. Be

careful not to damage chain case gasket.

Replace if necessary. See Figure 3-33.

3-14

Page 31

NOTE

3

NOTE

The chain case is lubricated with 16 ounces of

plastilube #0 grease to keep the bearings and

chains operating in a constant lubrication bath.

The drive system has 3 chain reduction steps.

Each step reduces the speed and increases

the torque or power down to the axle shaft. The

reduction is done with the use of the #41 chain

to a #420 chain to a #50 chain.

7. Remove the middle #420 chain by lifting off

one end from sprocket bearing sleeve assembly and the other end from sprocket shaft. See

Figure 3-34.

9. To disassemble hub sprocket assemblies, slide

spacer out of bearing. On an arbor press

remove bearing by placing a spacer or similar

tool on the OD of bearing and press out. See

Figure 3-36.

8. Remove the second #50 chain from tine shaft.

The sprocket bearing sleeve assembly can

also be removed. See Figure 3-35.

3-15

10. To remove tine shaft assembly simply pull

complete assembly out of housing. See Figure

3-37.

Page 32

CAUTION

When reassembling, make certain the step

spacer and washer are positioned properly or

damage to the shaft assembly and/or bearings

will result. (Cupped side faces sprocket.)

11. Remove keyed input shaft from sprocket

sleeve assembly as shown. See Figure 3-38.

3-4.4 Chain Case Seal and Bearing

Replacement.

WARNING

Disconnect spark plug wire and ground it

against engine.

1. On a bench or suitable surface, block up chain

case so that the tines clear the bench.

2. Remove the hardware which secures tines to

shaft and remove from the unit.

NOTE

12. Remove the third #420 chain from sprocket

and sprocket shaft. The sprocket sleeve

assembly can also be removed.

CAUTION

Both bearings must be pressed from the outside towards the center of housing. Pressure

should be exerted on the outer race or damage will result causing premature failure.

13. Remove bearings from housing using an arbor

press. See Figure 3-39.

The dust caps have a molded lip on the ID

which seats into a groove in the bearing hub

allowing for a tight fit.

3. Carefully pry off dust caps from housing

assembly.

4. Pry old seals out of housing assembly and

slide off shaft.

5. Remove any rust or foreign material from shaft

and thoroughly clean to avoid damage or contamination to seal or bearing.

6. Apply a generous amount of oil to shaft and

new seal and carefully slide seal into position.

3-16

Page 33

Make certain new seal is completely seated

against shaft bearing.

7. Reassemble dust caps making certain they are

fully seated on bearing hub.

8. Reattach tines with the hardware removed in

step 3.

5. Reattach bearing and bearing housing to tiller

housing with self-tapping screws removed in

step 3.

6. Reassemble pulleys, belt and belt guard

removed in step 2.

3-5. Tiller Models 340 And 390.

3-4.5 Input Shaft Bearing Replacement.

WARNING

Disconnect spark plug wire and ground it

against engine.

1. To replace bearing on tine chain case assembly, remove belt guard, belts and pulleys from

input shaft.

2. Remove self-tapping screws which secure

bearing housing to tiller housing.

3. Slide bearing housing and bearing off input

shaft.

NOTE

Pressure should be applied to the outer race of

the bearing and the housing should be secured

properly. Any force exerted on the inner race

will result in bearing damage or premature failure.

4. Press bearing out of housing and replace with

a new bearing.

3-5.1 The design of these tillers is new in concept

due to the fact that the transmissions are

designed and manufactured for replacement

(complete only) and are not as repairable component. They are lubricated and sealed at the

factory. No further lubrication is required and

should, if not abused, provide years of problem

free service.

3-5.2 Tiller Model 340 is the same as Model 390

except that the 390 has a reverse control. It

has an additional belt, reverse assembly control cable and pulleys. See Figures 3-30, 3-31,

3-32 and Table 3-4.

CAUTION

This tiller has been engineered with a belt

made of special material (Kevlar Tensile) for

longer life and better performance. It should

not be replaced with an off-the-shelf belt. If belt

replacement is required, order belt or belts by

part number from your nearest authorized service dealer. Forward Drive Belt—Part No. 7540428, Reverse Drive Belt (Model 390 only)—

Part No. 754-0429.

3

3-17

Page 34

Make certain new seal is completely seated

against shaft bearing.

7. Reassemble dust caps making certain they are

fully seated on bearing hub.

8. Reattach tines with the hardware removed in

step 3.

5. Reattach bearing and bearing housing to tiller

housing with self-tapping screws removed in

step 3.

6. Reassemble pulleys, belt and belt guard

removed in step 2.

3-5. Tiller Models 340 And 390.

3-4.5 Input Shaft Bearing Replacement.

WARNING

Disconnect spark plug wire and ground it

against engine.

1. To replace bearing on tine chain case assembly, remove belt guard, belts and pulleys from

input shaft.

2. Remove self-tapping screws which secure

bearing housing to tiller housing.

3. Slide bearing housing and bearing off input

shaft.

NOTE

Pressure should be applied to the outer race of

the bearing and the housing should be secured

properly. Any force exerted on the inner race

will result in bearing damage or premature failure.

4. Press bearing out of housing and replace with

a new bearing.

3-5.1 The design of these tillers is new in concept

due to the fact that the transmissions are

designed and manufactured for replacement

(complete only) and are not as repairable component. They are lubricated and sealed at the

factory. No further lubrication is required and

should, if not abused, provide years of problem

free service.

3-5.2 Tiller Model 340 is the same as Model 390

except that the 390 has a reverse control. It

has an additional belt, reverse assembly control cable and pulleys. See Figures 3-30, 3-31,

3-32 and Table 3-4.

CAUTION

This tiller has been engineered with a belt

made of special material (Kevlar Tensile) for

longer life and better performance. It should

not be replaced with an off-the-shelf belt. If belt

replacement is required, order belt or belts by

part number from your nearest authorized service dealer. Forward Drive Belt—Part No. 7540428, Reverse Drive Belt (Model 390 only)—

Part No. 754-0429.

3

3-17

Page 35

3-18

Page 36

3

3-19

Page 37

DRIVE SYSTEM

THE 390 SERIES TILLER IS THE SAME AS THE 340

EXCEPT THAT IT HAS REVERSE DIRECTION ALSO.

THE REVERSE IS 104 RPM. THE TRANSMISSION ON

THE 340/390 IS NOT A REPAIRABLE COMPONENT BUT

IS EASILY REMOVED AND REPLACED SHOULD SERVICING BE REQUIRED.

3-20

Page 38

3-5.3 Tine Width Adjustment.

1. The tilling width before adjustment is 22

inches. See Figure 3-43.

3

NOTE

The forward clutch cable is the cable which is

attached closer to the rear of the tiller. If the

spring has come loose, reattach.

2. The tilling width can be increased to 24 inches

by removing the clevis pins and hairpin clips.

Sliding the outer tines out 1-inch and securing

in this position with clevis pins and hairpin

clips. See Figure 3-44.

3. For cultivation, reduce the tine width to 13

inches by removing the outer tines completely.

See Figure 3-45.

3-5.4 Forward Clutch Control Cable Attachment.

Attach the end of the forward cable to bracket

underneath handle assembly as follows:

1. Loosen hex nut on threaded rod near the end

of cable, and move it up the rod as far as it will

go.

2. Unthread rod from the rest of the cable. Hook

Z end of rod into bracket underneath handle

assembly.

CAUTION

Do not overtighten control cable. Too much

tension may cause it to break when engaged.

3. Thread rod back into cable until cable is

straight. Do not tighten it enough to put any

tension on spring.

4. Thread hex nut down against the end of cable

to lock rod in this position.

3-21

Page 39

3-5.5 Reverse Clutch Control Cable Attachment

(Model 390 only).

loose, attach the end of the reverse cable to

the reverse drive lever above the handle

assembly in the same manner as you attached

the forward cable.

The reverse clutch cable is the cable which is

attached closer to the front of the tiller.

If the spring has come

NOTE

3-5.6 Clutch Adjustment.

WARNING

Disconnect spark plug wire from spark plug to

prevent accidental starting. Secure the end of

spark plug wire in V slot on the engine.

1. Engage and release the forward drive clutch

lever, then the reverse drive clutch lever

(model 390 only). If an excessive noise is

heard when releasing either drive clutch lever,

the cable may be too loose. Adjust either the

forward or reverse clutch cable by loosening

the hex nut, threading the rod into the cable

one or two turns, then tightening the nut.

2. With the clutch(es) in neutral (levers released),

pull the starter rope several times. The tines

should not turn. If they turn forward, loosen hex

nut on forward drive cable (beneath the handle

assembly). Unthread rod from cable several

turns. Tighten hex nut and check again for correct adjustment. If the tines turn in reverse,

adjust the reverse cable (above the handle

panel) in the same manner. See Figure 3-46.

WARNING

Disconnect spark plug wire and ground it

against engine.

1. Remove two self-tapping screws and flat

washers from the front of belt cover. Remove

hex stop nut and flat washer from side of belt

cover. Remove belt cover. See Figure 3-47.

3-5.7 Reverse Drive Belt Removal and Replace-

ment (Model 390 only).

engineered with belts made of special material

(Kevlar Tensile). They should not be replaced

with an off-the-shelf belt. If belt replacement is

required, order belt or belts by part number.

Remove and replace reverse drive belt as follows:

This tiller has been

3-22

Page 40

2. Lift belt off transmission pulley and engine pulley.

3. Remove hex nut which secures reverse idler

pulley to idler bracket. Slide idler pulley out and

remove belt. See Figure 3-48.

out from between belt keepers. Remove belt.

See Figure 3-49.

3

4. Reassemble new belt following instructions in

reverse order. Make certain reverse drive belt

is assembled with the wide side of belt against

transmission and engine pulleys. Be certain to

adjust clutch control as instructed in the final

clutch adjustment section.

3-5.8 Forward Drive Belt Removal and

Replacement.

WARNING

Disconnect spark plug wire and ground it

against engine.

1. Remove belt cover as instructed in step 1 of

previous subsection.

2. To remove forward drive belt on 390 models,

first remove reverse drive belt as instructed

previously.

3. Remove belt from idler pulley and from around

chain case pulley.

5. Install new belt following instructions in reverse

order. Make certain forward drive belt is

assembled with the wide side of belt away from

transmission and engine pulleys. Be certain to

adjust clutch control as instructed in the final

clutch adjustment section.

NOTE

Upon reassembly, make certain the belt is

routed in between belt keepers at engine pulley and over idler pulley.

3-6. TILLER MODELS 402 AND 405. See Figure

3-50 and Table 3-5.

4. Using a 9/16 inch wrench, remove hex bolt

which secures engine pulley. Slide pulley half

3-23

Page 41

3-24

Page 42

1. Remove belt cover by removing four self-tapping screws. See Figure 3-51.

3

3-6.1 Belt Tension Adjustment for Drive and Tine

Clutches.

sion may be required due to normal stretch

and wear on the belt. Adjustment is needed if

the tines seem to hesitate while tilling, but the

engine maintains the same speed. Adjust as

follows:

1. Loosen hex nuts at cable bracket on handle.

Do not overtighten control wire. Too much tension may cause it to break.

2. With clutch lever released, adjust bottom nut

so that there is only a slight amount of slack in

control wire.

3. Tighten upper nut against bracket.

3-6.2 Removal and Replacement of Long Tine

Belt.

Periodic adjustment of the belt ten-

NOTE

NOTE

2. Lift belt from under flat idler pulley.

3. Remove wire belt guard. See Figure 3-52.

4. Loosen, but do not remove, hex bolts on rear

engine pulley. See Figure 3-53.

Your tiller has been engineered with belts

made of special material (Kevlar Tensile) for

longer life and better performance. They

should not be replaced with an off-the-shelf

belt.

3-25

Page 43

1. Remove belt cover by removing four self-tapping screws. See Figure 3-51.

3

3-6.1 Belt Tension Adjustment for Drive and Tine

Clutches.

sion may be required due to normal stretch

and wear on the belt. Adjustment is needed if

the tines seem to hesitate while tilling, but the

engine maintains the same speed. Adjust as

follows:

1. Loosen hex nuts at cable bracket on handle.

Do not overtighten control wire. Too much tension may cause it to break.

2. With clutch lever released, adjust bottom nut

so that there is only a slight amount of slack in

control wire.

3. Tighten upper nut against bracket.

3-6.2 Removal and Replacement of Long Tine

Belt.

Periodic adjustment of the belt ten-

NOTE

NOTE

2. Lift belt from under flat idler pulley.

3. Remove wire belt guard. See Figure 3-52.

4. Loosen, but do not remove, hex bolts on rear

engine pulley. See Figure 3-53.

Your tiller has been engineered with belts

made of special material (Kevlar Tensile) for

longer life and better performance. They

should not be replaced with an off-the-shelf

belt.

3-25

Page 44

5. Slip engine pulley out until belt can be

removed.

6. Install new belt.

3-6.3 Removal and Replacement of Short Drive

Belt.

1. Remove tine belt as instructed in previous

paragraph.

2. Remove hex bolt, lock washer and flat washer

from rear engine pulley. Slip rear engine pulley

off engine.

3. Loosen two set screws on front engine pulley.

See Figure 3-54.

NOTE

Do not lose square key on engine shaft.

4. Remove lock nut on V-idler pulley.

5. Slide front engine pulley and V-idler pulley out.

See Figure 3-55.

6. Remove belt and install new belt. Be sure belt

is routed around guide pins. See Figure 3-56.

NOTE

Belt must be between V-idler pulley and idler

bracket.

3-26

Page 45

NOTE

NOTE

Upon reassembly, refer to your owners guide

for correct assembly of wire belt guard for your

model tiller.

NOTE

If the V-idler or flat idler pulleys are removed

for any reason, be sure to install with hub side

against idler bracket. See Figure 3-57.

The drive system has three chain reduction

steps. Each step reduces the speed and

increases the torque or power down to the axle

shaft. The reduction is done with the use of a

#35 chain to a #420 chain and again to another

#420 chain.

3

NOTE

3-6.4 Disassembly of Wheel Chain Case.

semble as follows:

1. Remove chain case from tiller.

2. Remove self-tapping screws, two hex bolts,

lock washers and nuts from the outer edge of

the chain case.

3. Remove one hex bolt, lock washer and hex nut

from the center of chain case.

4. Remove remaining hex bolt, lock washer and

hex nut from the center of chain case.

5. Remove self-tapping screws from bearing

housing.

6. Slide bearing housing and bearing off input

shaft.

7. Separate halves of the chain case housing. Be

careful not to damage chain case gasket.

Replace if necessary. See Figure 3-58.

Disas-

The chain case is lubricated with 10 ounces of

plastilube #0 grease to keep the bearings and

chains operating in a constant lubrication bath.

8. Push input shaft inward slightly. Lift up on the

hub sprocket assembly and remove #35 chain

from sprocket. This will allow slack in the other

chains which can be removed by lifting off the

sprockets.

The hub sprocket assemblies can also be

removed from the housing during this procedure. See Figure 3-59.

9. To disassemble hub sprocket assemblies slide

spacer out of bearing. On an arbor press

remove bearing by placing a spacer or similar

tool on the OD of bearing and press out. See

Figure 3-60.

3-27

Page 46

CAUTION

When reassembling, make certain the step

spacer and washers are positioned properly or

damage to the shaft assembly and/or bearings will result. (Cupped side faces sprocket.)

11. Remove bearings from housing using an arbor

press as shown. See Figure 3-62.

10. To remove the wheel shaft assembly simply

pull the complete assembly out of the housing.

See Figure 3-61.

NOTE

Both bearings, one plastic and one bronze,

must be pressed from the outside towards the

center of the housing.

3-28

Page 47

3-6.5 Disassembly of Tine Chain Case.

ble as follows:

1. Remove chain case from tiller.

2. Remove self-tapping screws, hex bolts, lock

washers and hex nuts from the outer edge of

chain case.

3. Remove hex bolt, lock washer and hex nut

from the center of chain case.

4. Remove self-tapping screws from bearing

housing. See Figure 3-63.

Disassem-

NOTE

The chain case is lubricated with 12 ounces of

plastilube #0 grease to keep the bearings and

chains operating in a constant lubrication bath.

7. Push input shaft inward slightly. Lift up on hub

sprocket assembly and remove #35 chain from

sprocket. This will allow slack in the other

chain which can be removed by lifting off the

sprockets. The hub sprocket assemblies will

also be removed from the housing during this

procedure. See Figure 3-65.

3

5. Slide bearing housing and bearing off input

shaft.

6. Separate the halves of chain case housing to

obtain access to reduction chains. Be careful

not to damage chain case gasket. Replace if

necessary. See Figure 3-64.

NOTE

8. To disassemble hub sprocket assembly, slide

spacer out of bearing. On an arbor press

remove bearing by placing a spacer or similar

tool on the OD of bearing and press out. See

Figure 3-66.

The drive system has 2 chain reduction steps.

Each step reduces the speed and increases

the torque or power down to the axle shaft. The

reduction is done with the use of a #35 chain to

a #50 chain.

3-29

Page 48

9. To remove tine shaft assembly simply pull

complete assembly out of housing. See Figure

3-67.

CAUTION

Both bearings must be pressed from the outside towards the center of housing as shown.

Pressure should be exerted on the outer race

or damage will result causing premature failure.

3-6.6 Dust Cap Removal and Replacement.

WARNING

Disconnect spark plug wire and ground it

against engine.

1. On a bench or suitable surface, block up chain

case so that tines/wheels clear the bench.

2. Remove the hardware which secures tines/

wheels to shaft and remove from unit.

NOTE

CAUTION

When reassembling, make certain step spacers and washers are positioned properly or

damage to the shaft assembly and/or bearings

will result. (Cupped side faces sprocket.)

10. Remove bearings from housing using an arbor

press as shown. See Figure 3-68.

The dust caps have a molded lip on the ID

which seats into a groove in the bearing hub

allowing for a tight fit.

3. Carefully pry off dust caps from housing

assembly.

4. Pry old dust caps out of housing assembly and

slide off shaft.

5. Remove any rust or foreign material from shaft

and thoroughly clean to avoid damage or contamination to seal or bearing.

6. Apply a generous amount of oil to shaft and

new seal and carefully slide seal into position.

Make certain new seal is completely seated

against shaft bearing.

7. Reassemble dust caps making certain they are

fully seated on bearing hub.

8. Reattach tines/wheels with the hardware

removed in step 3.

NOTE

To replace the bearing on tine chain case

assembly, the belt guard, pulleys and side

plate must be removed.

3-6.7 Input Shaft Bearing Removal and Replace-

ment.

3-30

Page 49

WARNING

Disconnect spark plug wire and ground it

against engine.

1. Remove self-tapping screws which secure

bearing housing to tiller housing.

2. Slide bearing housing and bearing off input

shaft.

CAUTION

Pressure should be applied to the outer race of

bearing and the housing should be secured

properly. Any force exerted on the inner race

will result in bearing damage or premature failure.

3. Press bearing out of housing and replace with

a new bearing.

4. Reattach bearing and bearing housing to tiller

housing with self-tapping screws removed in

step 2.

1. Loosen hex nut at cable bracket on handle.

See Figure 3-70

3

CAUTION

Do not overtighten control wire. Too much tension may cause it to break.

5. Replace belt guard, pulleys and side plate if

applicable.

3-7. TILLER MODELS 403 AND 406 WITH

REVERSE DRIVE. See Figure 3-69.

3-7.1 This is a 4 HP reverse direction tine unit. This

section also covers the model 406 5 HP unit.

Product description is the same as the 402 and

405 units with the exception that the 403 and

406 units have reverse direction drive.

2. With the clutch lever released, adjust the bottom nut so that there is only a slight amount of

slack in the control wire.

3. Tighten upper nut against bracket.

3-7.3 Belt Removal and Replacement.

1. Remove belt cover by removing four self-tapping screws. See Figure 3-71.

3-7.2 Belt Tension Adjustment for Drive and Tine

Clutches. Periodic adjustment of belt tension

may be required due to normal stretch and

wear on belt. Adjustment is needed if tines

seem to hesitate while tilling, but the engine

maintains the same speed. Adjust as follows:

2. To remove tine belt, lift up on idler pulley and

slip belt off tine chain case pulley. Remove belt

from the two-step engine pulley. See Figure 3-

72.

3-31

Page 50

WARNING

Disconnect spark plug wire and ground it

against engine.

1. Remove self-tapping screws which secure

bearing housing to tiller housing.

2. Slide bearing housing and bearing off input

shaft.

CAUTION

Pressure should be applied to the outer race of

bearing and the housing should be secured

properly. Any force exerted on the inner race

will result in bearing damage or premature failure.

3. Press bearing out of housing and replace with

a new bearing.

4. Reattach bearing and bearing housing to tiller

housing with self-tapping screws removed in

step 2.

1. Loosen hex nut at cable bracket on handle.

See Figure 3-70

3

CAUTION

Do not overtighten control wire. Too much tension may cause it to break.

5. Replace belt guard, pulleys and side plate if

applicable.

3-7. TILLER MODELS 403 AND 406 WITH

REVERSE DRIVE. See Figure 3-69.

3-7.1 This is a 4 HP reverse direction tine unit. This

section also covers the model 406 5 HP unit.

Product description is the same as the 402 and

405 units with the exception that the 403 and

406 units have reverse direction drive.

2. With the clutch lever released, adjust the bottom nut so that there is only a slight amount of

slack in the control wire.

3. Tighten upper nut against bracket.

3-7.3 Belt Removal and Replacement.

1. Remove belt cover by removing four self-tapping screws. See Figure 3-71.

3-7.2 Belt Tension Adjustment for Drive and Tine

Clutches. Periodic adjustment of belt tension

may be required due to normal stretch and

wear on belt. Adjustment is needed if tines

seem to hesitate while tilling, but the engine

maintains the same speed. Adjust as follows:

2. To remove tine belt, lift up on idler pulley and

slip belt off tine chain case pulley. Remove belt

from the two-step engine pulley. See Figure 3-

72.

3-31

Page 51

3. To remove reverse drive belt, lift up on small

idler pulley. Slip belt off outside sheave of

wheel chain case pulley. Remove belt from

two-step engine pulley. See Figure 3-73.

6. Lift forward drive belt off forward engine pulley

and remove. See Figure 3-75.

NOTE

4. Loosen (do not remove) hex nut at the top of

wire belt keeper. See Figure 3-74.

5. Pull bottom of wire belt keeper out and then

upward, pivoting it away from the forward

engine pulley.

When reassembling belts, be certain belts are

routed around all belt keeper pins.

7. Reassemble new belts, following instructions

in reverse order. See Figure 3-76.

3-32

Page 52

3-7.4 Disassembly of Wheel Chain Case. Refer to

paragraph 3-6.4.

3

NOTE

If V-idler or flat idler pulleys are removed for

any reason, be sure to install with hub side

against idler bracket. See Figure 3-77.

3-7.5 Disassembly of Tine Chain Case. Refer to

paragraph 3-6.5.

3-7.6 Dust Cap Removal and Replacement. Refer

to paragraph 3-6.6.

3-33

Page 53

3-7.7 Input Shaft Bearing Removal and Replace-

ment. Refer to paragraph 3-6.7.

3-8. TILLER MODELS 410 AND 420 (Figure 3-

78).

3-34

Page 54

3-8.1 Belt Removal and Replacement.

NOTE

CAUTION

Do not use an off-the-shelf belt.

Your tiller has been engineered with a belt

made of special material (Kevlar Tensile) for

longer life and better performance. It should

not be replaced with an off-the-shelf belt.

If belt replacement is required, order belt or

belts by part number from your nearest authorized dealer. Part No. 754-0438—V Belt

1. Disconnect and ground the spark plug wire

against the engine.

2. Remove the belt cover from the left side of the

tiller as follows.

a. Remove two torx head screws from the top

of belt cover.

b. Remove two hex cap nuts and flat washers

from front side of the belt cover. Remove

hex nut and flat washer at the back of the

cover.

Upon reassembly, make certain the belt is

routed over the idler pulley and inside of belt

keepers at engine pulley. See Figure 3-79.

3-8.2 Attaching the Clutch Cable.

1. Route the clutch cable through the cable clip

underneath the handle. Remove one hex nut

from the threaded casing on the end of the

cable. See Figure 3-80.

3

3. Remove the belt keeper assembly located

behind the engine pulley by removing two hex

bolts and lock washers. See Figure 3-79.

4. Remove belt. Reassemble new belt, following

instructions in reverse order.

2. Slip the wire through the slot on the cable

bracket underneath the handle. Push the end

of the casing up through the cable bracket.

Rethread the hex nut on the end of the cable.

Do not tighten at this time.

3. Pull the cable upwards to obtain slack, and

hook the “Z” end of the cable into the bracket

on the clutch control (beneath the handle

panel) as shown in Figure 3-80 (from right to

left). Thread hex nut back onto the end of the

cable casing.

NOTE

Do not overtighten control wire. Too much tension may cause it to break.

3-8.3 Final Clutch Adjustment. IMPORTANT: Ser-

vice the engine with oil and gasoline before

checking this adjustment. Refer to the separate engine manual packed with your tiller.

1. Position the tiller so the front counterweight is

against a solid object, such as a wall. With the

3-35

Page 55

gear selection lever in NEUTRAL, start the

engine.

2. Standing on the right side of the tiller, visually

examine the belt (inside the belt cover). It

should not be turning. If the belt turns with the

unit in neutral, adjust by moving the hex nut

below the cable bracket down a few turns. See

Figure 3-80. Tighten the upper hex nut against

the bracket.

3. Now move the shift lever to FORWARD

(Wheels Forward) position. Carefully engage

the clutch by squeezing the clutch handle

against the handle. The wheels should spin.

4. If the wheels do not spin with the unit in forward, adjust by moving the hex nut which is

above the cable bracket up a few turns.

Tighten the bottom hex nut against the bracket.

See Figure 3-80. Recheck both adjustments,

and readjust as necessary.

3-8.4 Handle Adjustment (See Figure 3-81). The

handle may also be adjusted to the height

desired. Loosen the handle height adjustment

lock a few turns. Pivot handle up or down to

desired position. Tighten lock.

On Model 420, the handle may also be

adjusted to be in line with the tiller, or swung to

the left or right so the operator is not walking in

the freshly tilled soil. To adjust the handle position from side to side, pull the handle adjustment handle back, pivot the tiller handle to

desired position and release the handle.

3-8.5 Gear Selection Handle. The gear selection

handle is located on the front of the handle

assembly (right hand handle on Model 420). It

is used to select NEUTRAL, REVERSE, or one

of the FORWARD modes. Shift only with clutch

handle disengaged (released). Pull or push the

handle so that the indicator on top of the shift

cover points to the operating mode desired.

See Figure 3-81. (Rock unit if it is difficult to

shift.)

REVERSE—Reverse wheel drive only.

NEUTRAL—Transmission is in neutral.

FORWARD Modes:

Wheels Forward—Forward wheel drive

only.

Tines Reverse —Forward wheel drive and

reverse tine drive.

WARNING

Make certain unit is in NEUTRAL when starting the engine.

3-8.6 Chain Case Removal.

1. Remove the hairpin clip, rubber washer and

flat washer from the bottom of the gear shift

rod. Slide the rod out of the handle. See Figure

3-82.

3-36

Page 56

2. Remove the self-tapping screw and casing

clamp which holds the throttle cable to the

engine. Disconnect the throttle control cable

“Z” fitting from the throttle lever. See Figure 3-

83.

3

4. Remove belt from gear case pulley. (Not necessary to remove belt from engine.) Disconnect the clutch cable from idler bracket and

remove the gear case pulley. See Figure 3-85.

3. Remove the belt cover and shift cover as an

assembly. Remove the nuts from the belt cover

and the nut and bolt securing the shift cover

bracket to the gear case. See Figure 3-84.

3-37

Page 57

5. Remove bolts and nuts securing the LH and

RH tine shield brackets, located on inside front

of the tine shield. Remove the nuts and bolts

on top rear of chain case. Separate rear

assembly from case. Remove the tines. See

Figure 3-86.

7. Roll the case assembly back away from the

frame. Remove the reinforcement plate and

idler bracket, the shift bracket, tines and

wheels from the gear case. See Figure 3-88.

NOTE

During assembly, loosely replace all nuts and

bolts to ensure proper fit. With all fasteners in

place, tighten securely.

6. Remove the bolts and nuts at the front of the

gear case (two at top and three at front and

two on bottom). Separate case from frame.

See Figure 3-87.

NOTE