Page 1

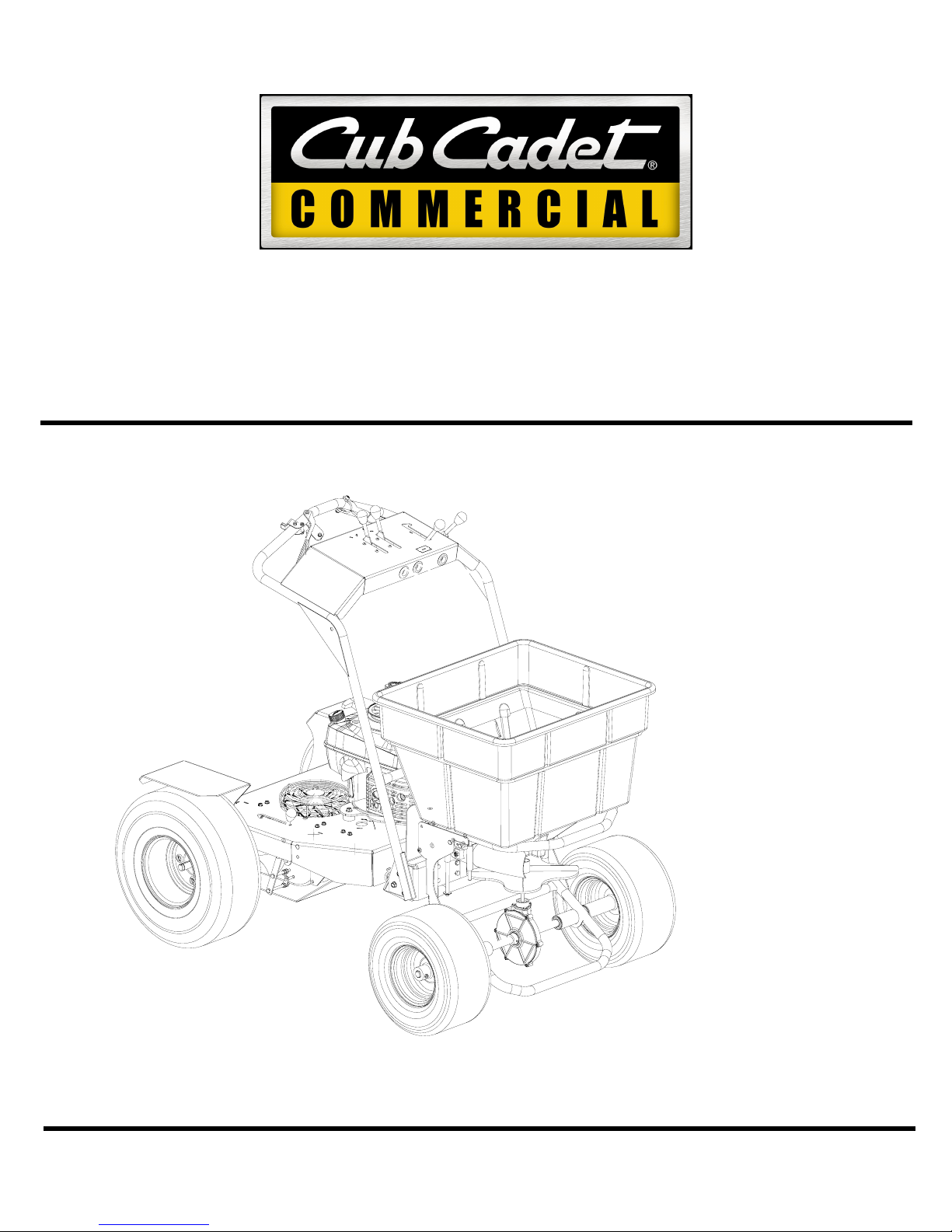

Hydrostatic Stand-On

Self-Propelled Spreader

Professional Turf Equipment

OPERATOR’S MANUAL

Page 2

TABLE OF CONTENTS

Foreword.................................................................. 2

Safety Precautions................................................... 3

A. General............................................................ 3

B. Related to Fuel ................................................ 3

C. When Spreading.............................................. 3

D. Personal Potective Equipment ........................ 3

Specifications........................................................... 5

Operating Instructions.............................................. 5

A. Controls ........................................................... 5

1.Ignition Switch ................................................ 5

2.Fuel Shutoff Valve .......................................... 5

3.Engine Throttle ............................................... 5

4.Ground Speed Control Levers........................ 5

5.Freewheeling Valves ...................................... 5

6. Parking Brake................................................ 6

7.Hour Meter and Tachometer (optional) ..........6

B.Initial Adjustments ............................................6

C.Break-ln and Operation ....................................6

Maintenance ............................................................7

A.General Maintenance .......................................7

B.Daily Maintenance After Spreading ..................7

C.Maintenance Every 100 Hours ........................ 7

D.Lubrication Chart ............................................. 7

E.Engine Maintenance ........................................ 7

F.Hydraulic System Maintenance ....................... 7

G.To Change the Pump Drive Belt...................... 8

Spreader Calibration .............................................. 9

Warranty................................................... BackCover

FOREWORD

The Cub Cadet Commercial Stand-On, Self-Propelled Spreader has been

developed for use by professional landscapers, commercial lawn service companies,

professional turf managers and golf course superintendents. The machines incorporate

many safety features that should be studied by all operators and maintenance

personnel before use. The list of safety precautions should receive particular attention.

This manual presents the operating and maintenance instructions necessary to keep

your Cub Cadet Commercial spreader at peak efficiency. If properly operated and

maintained, your Cub Cadet Commercial spreader will give dependable and trouble-free

service.

Although hazard control and accident prevention partially are dependent upon the

design and configuration of the equipment, these factors are also dependent upon the

awareness, concern, prudence, and proper training of the personnel involved in the

operation, transport, maintenance and storage of the equipment.

CAUTION: THE Cub Cadet Commercial Stand-On, Self-Propelled Spreader

should only be operated and maintained by thoroughly trained individuals.

The machines could cause serious injury to anyone who misuses them or

does not understand their operation. All operators and maintenance

personnel are urged to read this entire manual for their personal safety.

NOTE: The engine manufacturer is responsible for all engine-related issues with

regards to performance, power-rating, specifications, warranty and service.

Please refer to the engine manufacturer’s owner’s/operator’s manual, packed

seperately with your unit, for more information.

2

Page 3

SAFETY PRECAUTIONS

A. General:

1. Read this Operator’s Manual completely before

starting the spreader. Study the controls and learn

the proper sequence of operation. Retain

Operator’s Manual in a safe place for future

reference.

2. Do not allow anyone to operate or maintain this

machine who has not read the manual. Never

permit children under the age of 16 to operate

this machine.

3. Always have your feet and hands clear of the

controls when starting the engine.

4. Do not remove any shields, guards, decals or

safety devices. If a shield, guard, decal or safety

device is damaged or does not function, repair or

replace it before operating the spreader.

5. Always wear safety glasses, long pants and safety

shoes when operating or maintaining this

spreader. Do not wear loose-fitting clothing.

6. Never run the engine indoors without adequate

ventilation. Exhaust fumes are deadly.

7. To avoid serious burns, do not touch the engine or

muffler while the engine is running or until it has

cooled for at least 30 minutes after it has been

shut off.

B. Related To Fuel:

1. Gasoline is highly flammable. Respect it.

2. Do not smoke or permit others to smoke while

handling gasoline.

3. Always use approved containers for gasoline.

4. Always shut off the engine and permit it to cool

before removing the cap of the fuel tank.

5. If the fuel container spout will not fit inside the fuel

tank opening, use a funnel.

6. When filling the fuel tank, stop when the gasoline

reaches one inch from the top. This space must

be left for expansion. Do not overfill.

7. Wipe up any spilled gasoline.

C. When Spreading:

1. Keep adults, children and pets away from the area

to be spread.

2. Spread only in daylight.

3. Always check the area to be spread and remove

debris and other objects prior to spreading.

4. Watch for holes, sprinkler heads and other hidden

hazards.

5. Reduce speed when making sharp turns.

6. Always have proper footing on slopes and hill

sides and never operate when conditions are

slippery. Be very careful on wet grass.

7. Always keep both hands on the handles.

8. Be careful when crossing gravel paths or roadways.

9. Never leave the spreader unattended without

placing the ground speed control levers in neutral,

engaging the park brake, shutting off the engine

and closing the fuel shutoff valve.

10. Always park the spreader and start the engine on

a level surface with the ground speed control

levers in neutral, and the park brake engaged.

11. If you hit a solid object while spreading, place the

ground speed control levers in neutral, engage the

park brake and stop the engine. Disconnect the

spark plug wire and inspect for damage. Repair

any damage.

12. Do not operate machine on excessively steep

slopes. Go laterally or diagnolly across the slope,

not up and down the slope.

13. Always disconnect the spark plug wire to prevent

the engine from accidentally starting before

performing any maintenance on this spreader.

14. Keep the machine and especially the engine/pump

area clean and free of grease, grass and leaves to

reduce the potential for over heating and fire.

15. The speed and direction control levers located on

the handle are designed for your safety. Do not

modify them or operate the machine if they are

damaged.

D. General Requirements-Personal

Protective Equipment:

OSHA Standard 1910.132 through 1910.139

OSHA standard 1910.132 states in relevant part:

a. Protective equipment, including personal

protective equipment (PPE) for eyes, face,

head, and extremities, protective clothing,

respiratory devices, and protective shields and

barriers, shall be provided, used, and

maintained in a sanitary and reliable condition

whereever it is necessary by reason of

hazards of processes or environment,

chemical hazards, radiological hazards, or

mechanical irritants encountered in a manner

capable of causing injury or impairment in the

function of any part of the body through

absortion, inhalation or physical contact.

This standard is subject to change. Please check www.osha.gov

for the latest regulatory updates

3

Page 4

General

Sometimes, it is not possible to reduce a hazard by eliminating it,

substituting a less hazardous process or product, making changes

to equipment, or even by changing how you do the job. That’s

when you need personal protection.

PPE includes items like gloves, goggles, boots, hearing protection

and respirators. Respirators filter out particles or block gases and

vapors that can harm the respiratory system. With a surface area

well supplied with blood vessels and equal in size to a tennis court,

the lungs are the quickest and most direct route for absorbing

harmful substance into your body.

Note:

PPE does not prevent accidents, but it does prevent or re-

duce injury and even fatalities when used properly.

Equipment (PPE)

Protective equipment must be selected carefully. Always test fit

the protective equipment to be sure it fits properly and comfort

ably. If it isn’t comfortable -- it won’t be worn; if it isn’t worn -- it

won’t protect. PPE includes:

• respirators

• chemical-resistant clothing

• hearing protectors

• gloves

• safety goggles and glasses

• hard hats

• sensors to detect hazardous substance

• communication devices used for safe

deployment of workers

Inhaling pesticide fumes and mists is a very common entry route

of pesticides into the body. Absortion through the lungs is great

and the sensitivity is high.

The National Institute for Occupational Safety and Health

(NIOSH), under authority of the Federal Mine Safety and Health

Act of 1977 and the Occupational Safety and Health Act of 1970,

tests, approves, and certifies respiratory equipment as being safe

for its intended purpose.

Note:

Always be certain that the NIOSH compliance number is

on the product before purchasing respiratory equipment.

Two systems of respiratory protection are available, depending

on the type of respiratory risk involved: air-purification (filtering)

and air-supplying. For most pesticide work, the air-purifying

equipment is adequate and safe.

Protective equipment is usually required by the pesticide label in

one form or another and is integral to safe pesticide application.

Chemical-protective clothing consists of multilayered garments

made out of various materials that protect against a variety of haz

ards. Because no single material can protect against all chemicals, multiple layers of various materials usually are used to

increase the degree of protection. Protection is maximized by to

tal encapsulation (completely covering the wearer). An assortment of types of chemical-protective hats, hoods, gloves, and

boot covers are used with the garments.

There are many brands and models of protective equipment available for use in pesticide application. Price is not always an indicator of quality, so shop carefully.

Note:

Select equipment that is

NIOSH tested and approved.

Protective equipment, appropriate for the task and hazards that an

employee could be exposed, shall be provided by the employer.

Since comfort and proper fit must be considered, the person who

is going to use it must select the proper size to ensure correct fit

and function. Unused protective equipment does not help any

one.

Note:

Many supply centers, hardware stores, chemical retailers,

and equipment/machinery dealers keep protective equipment in

stock.

Training

Written procedures shall be developed for PPE use. These procedures shall include all information and guidance necessary for

their proper selection, use and care. The employer shall provide

fitting instructions including demonstrations and practice in how

the PPE should be worn, It is essential that both supervisors and

workers be properly instructed in PPE selection, use, and mainte

nance. Training shall provide the workers an opportunity to handle PPE, and have it fitted properly.

When to replace PPE

All PPE shall be inspected routinely before and after each use. A

program for maintenance and care of PPE shall be initiated and be

adjusted to the type of work place, working conditions, and haz

ards. It shall include the following:

• inspection for defects and damage

• cleaning and disinfecting

• repair

• storage

Many factors influence how long PPE (especially respirators) remains effective. As well as hours of use, an air-purifying respirator’s service life is affected by the concentration of dust and other

contaminants in the enviroment; the user’s body size; how strenu

ously the user works while the respirator is worn; and how the respirator is stored.

Note:

As a result, it’s not possible to specify a length of time after

which a respirator should be replaced.

In general, replace a mask or filter when it is visibly dirty or damaged, or when you experience difficulty breathing through it. Replace respirator cartridges when you can smell or taste chemical

while or after using the respirator, or according to the manufactur

er’s recommendations. Replacement or repairs shall be done only

by experienced person with parts designed for the PPE. No at

tempts shall be made to replace components or to make adjust-

ments or repairs beyond the manufacturer’s recommendations.

-

-

-

-

-

-

-

4

Page 5

SPECIFICATIONS

Model:

Engine Mfg:

HP:

Type:

Start er:

Air Cleaner:

Lube:

Fuel Capacity:

Traction Drive:

Hydraulic Oil Capacity:

Hydraulic Filtration:

Ground Speed:

Wheels:

Width:

Height:

Length:

Weight:

<– – – – – 4 Cycle Single Cylinder – – – – –>

<– – – – – Hydro Gear, Model 510 Hydrostat – – – – –>

<– – – – – 18 x 6.50-8 rear, 13 x 7.50 front – – – – –>

<– – – – – 125 lb – – – – –>

<– – – – – Kawasaki – – – – –>

<– – – – –– 6.5 – – – – –>

<– – – – – Recoil – – – – –>

<– – – – – Dual Element Dry – – – – –>

<– – – – – Pressurized w/Filter – – – – –>

<– – – – – 2 Quarts – – – – –>

<– – – – – 0.7 Quarts – – – – –>

<– – – – – Internal – – – – –>

<– – – – – 0 to 5 mph – – – – –>

<– – – – – 35” – – – – –>

<– – – – – 47” – – – – –>

<– – – – – 60” – – – – –>

<– – – – – 340 lbs. empty – – – – –>

OPERATING INSTRUCTIONS

Engine

Throttle

Reverse Ground

Speed Control

Hopper

Shut-Off

Speed Control Lever

(Application Transport)

Spreader

3rd Hole

Spreader

Side Deflector

Forward Ground

Speed Control

A. Controls

1. Ignition Kill Switch:

Located in the engine speed control panel, the

engine kill switch stops the engine grounds the

ignition system when the throttle is in the “off”

position.

2. Fuel Shutoff Valve:

Located under the fuel tank, the handle turns 90

degrees to open or close. When the handle is in a

horizontal position, it will shut off the flow of fuel to

the engine. When it is turned to a vertical position,

it will open and allow fuel to flow to the engine.

Anytime the speader is being trailered or, if the

machine will not be in use for 30 minutes or more,

close the fuel shutoff valve to prevent flooding the

engine.

3. Engine Throttle:

The throttle is located on the far left side of the

control panel, moving the throttle lever from the

rear to the front will increase the engine speed

from slow to fast. To start the engine, set the

throttle all the way to the front in the “Choke”

position. After the engine starts, move the throttle

back to the detent position.

4. Ground Speed Control Levers:

Located on the right side of the control panel is the

forward speed control lever. The left lever is for

reverse. These two levers control the maximum

output of the hydrostatic transaxle and thus the

ground speed of the spreader independent of the

engine speed. Moving the right lever rearward

increases the forward speed and moving the left

lever rearward increases the reverse speed.

These levers moved in unison. To start the engine

both levers must be in their neutral position.

5. Freewheeling Valve:

A valve is located on the side of the hydrostatic

transaxle. When the lever is moved into the “J” slot

the spreader can be pushed forward or pulled in

reverse

without engine running.

Freewheeling

Valve Lever

Parking Brake

5

Page 6

OPERATING INSTRUCTIONS

6. Parking Brake:

The mechanical disc brake is activated by the

lever in the foot platform area. Press down on the

lever to engage the park brake, and lift up the

lever to release.

7. Hour Meter and Tachometer (optional):

Located at the upper left edge of the control panel.

When the machine is running the tachometer

displays engine rpm. When the machine is off it

displays time of operation.

B. Initial Adjustments

1. Disconnect the spark plug wire.

2. Check the tire pressure. Drive wheels should be

inflated to 15 psi. Front wheels (unless foam-filled)

should be inflated to 15 psi. Note: New tires are

overinflated in order to properly seat the bead to

the rim.

3. Check that all nuts, bolts and screws are tight.

4. The tension of the transaxle drive belt should be

adjusted so that a five pound pull between the

engine traction drive pulley and the pump drive

pulley opposite the idler pulley deflects the belt

about 3/16”.

5. The long speed control cables which connect to

the pump control levers should initially be adjusted

so that when the ground speed control levers are

in neutral, and the speed levers are relesed from

the neutral position, the machine stands still with

the engine running. If the machine starts to creep

forward or to the rear in this situation, then the

speed control cable must be adjusted. Loosen the

nut on the cable and adjust until the drive wheel

stops moving. Then retighten the nut.

6. Lubricate all fittings listed in the maintenance

section.

C. Break-In and Operation

1. Make certain you thoroughly understand all of the

safety precautions before you attempt to operate

this machine.

2. Check the engine oil level. Fill to the proper level

with 10W40 engine oil rated for service SE or SF.

3. Move the machine outdoors. Check the engine

gasoline level. When filling the tank, stop when the

gasoline reaches one inch from the top. This

space must be left for expansion. Use fresh,

clean, unleaded, regular gasoline.

4. Move the machine to a “test area” where you can

operate it for about a half an hour without being

disturbed.

5. To start the engine:

a. Make sure that the ground speed control levers are in

the neutral position.

b. Connect the spark plug wire.

c. Open the fuel shutoff valve.

d. Move the throttle lever to the “Choke” position.

e. Pull the recoil handle.

f. Set the throttle at 50% of full engine RPM and allow

the engine to warm up. Then, adjust the throttle to

75% of full engine RPM.

CAUTION

Set the ground speed control levers at no more

than one third full speed until you are fully

familiar with the operation of the machine.

6. Move the ground speed control lever forward to

about one third of full speed.

7. To turn the machine, move the control handle to

the side opposite of the way you want to turn, I.E.,

move the control handle left and the machine

turns right. Move the control handle right, and the

machine turns left.

8. To stop the mower’s forward motion, release the

forward and reverse speed control levers

WARNING

Do not spread at full speed. Set the ground speed

control levers at full speed for transport only.

9. Before moving into reverse, the machine’s forward

moton should be completely stopped.

10. Practice operating the machine and as you gain

confidence, move the ground speed selector

levers forward to two thirds full speed. Operate the

machine until you are comfortable and confident

with the controls.

11. To stop and shut off the machine, release both

speed control levers, move the engine throttle

lever to “off” to stop the engine, close the fuel

shutoff valve, and disconnect the spark plug wire.

12. After the first full day of use, all nuts, bolts and

screws should be rechecked for proper tightness

and the belts should be rechecked for proper

tension.

.

6

Page 7

MAINTENANCE

WARNING

Disconnect the spark plug wire to prevent

the engine from accidentally starting before

performing any maintenance on this machine.

A.

General Maintenance

1. If the machine must be tipped on its side for

maintenance, first drain the fuel from the fuel tank,

and the oil from the engine’s crankcase.

2. Be careful not to spill oil on any of the belts.

3. Do not tamper with the engine’s governor settings.

They are adjusted to provide the proper maximum

engine speed.

4. If the machine is to be in storage for more than 30

days, drain the fuel tank, run the engine to drain

the carburator dry, change the oil, remove the

spark plug and pour a teaspoonful of oil into the

cylinder. Run the starter briefly to crank the engine

and distribute the oil then replace the spark plug.

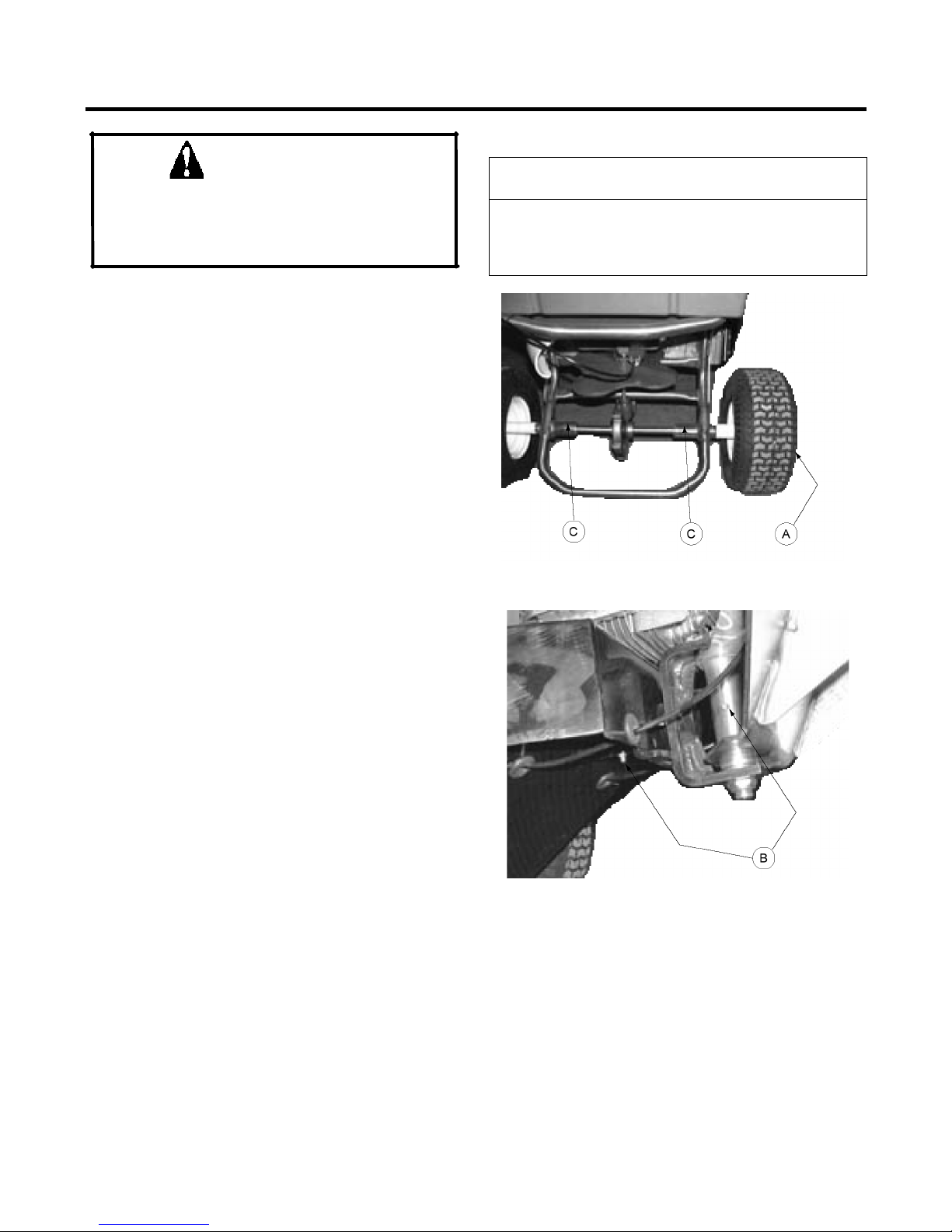

D. LUBRICATION CHART:

NUMBER OF GREASING POSITIONS

(See Figure 1 and 2 below for Item Locations.)

40 HOUR LUBRICATION CHART

1 A Front Wheel Bearing

2 B Pivot Shafts

2 C Front Axle Bearing

B. Daily Maintenance After Spreading

1. Park the machine outside the storage facility with

the engine shut off.

2. Close the fuel shutoff valve.

3. Permit the machine to cool.

4. Disconnect the spark plug wire.

5. Wash the machine off with water. Be sure to clean

out materials from under the hopper. Allow the

machine to dry before storing.

6. Check the fuel level, the engine oil level and clean

the cooling-air intake (the rotating screen).

7. Clean the air cleaner elements (foam and paper).

8. After the first 5 hours of use, change the engine

oil. (Change the oil every 100 hours thereafter).

9. Follow the lubrication chart at the top of the page.

10. Place the machine in locked storage to avoid

tampering or use by an untrained operator.

C. Maintenance Every 100 Hours

1. Change the engine oil and replace the oil filter.

(Change the engine oil more frequently under

severe operating conditions).

2. Check that all nuts, bolts and screws are tight.

3. Check the condition and tension of transaxle belt.

4. Clean the spark plug and check the spark plug

gap.

5. Follow the lubrication chart at the top of the page.

Figure 1

Figure 2

E. ENGINE MAINTANENCE:

For detailed maintenance instructions for the engine on

your mower, see the separate engine manual packed

with your mower.

F. HYDRAULIC SYSTEM MAINTANENCE:

The hydraulic system does not require any

maintenance. The transaxle is not owner repairable. If

you have a problem with a transaxle, please contact

your service center for a replacement. Do not

disassemble the transaxle.

7

Page 8

G. TO CHANGE THE PUMP DRIVE BELT:

(See Figure 3)

a. Loosen the locknut holding the transaxle drive belt

idler pulley in place and rotate the pulley away from

the transaxle drive belt.

b. Remove the old belt and mount a new belt on to the

pulleys.

c. Rotate the idler pulley back onto the belt and tighten

the locknut holding it in place. The idler pulley should

be adjusted so that a five-pound pull on the belt

between the engine pulley and the pump pulleys

deflects the belt about 3/16”.

MAINTENANCE

Figure 3

8

Page 9

SPREADER CALIBRATION

Two items must be considered when calibrating a spreader. The first is

the distribution pattern of the spreader. That is, the pattern the product

makes as it strikes the ground after being thrown out by the spreader's

impeller. There are many factors which affect the distribution pattern of

a rotary spreader and some of them relate directly to the product. For

this reason, we recommend that the spreader be calibrated separately

for every product to be applied. Spreader calibration should be

checked at least once a month, or more often when the spreader is

used frequently.

The second item is the product application rate, that is the amount of

product applied per thousand square feet. This is important because

over-application can be costly and may cause plant injury, while underapplication will reduce the effectiveness of the product.

TO CALIBRATE A SPREADER, FOLLOW THESE

STEPS:

Check the spreader discharge holes with the operating lever in the

closed position. If the discharge holes are not fully closed, thread the

upper jam nut on the operating lever rod further up the rod. Tighten the

lower locknut and recheck. Repeat this procedure until the holes are

fully closed.

TO ACHIEVE A UNIFORM DISTRIBUTION PATTERN:

The accurate method for checking pattern uniformity is to lay out shallow boxes or pans in a row on a line perpendicular to the direction of

spreader travel. Eleven boxes or pans, two inches high placed on onefoot centers will provide accurate calibration. To conduct the test, begin

with the pattern slide completely open and set the rate control arm at

the suggested approximate setting. Make three passes over the boxes,

pushing the spreader in the same direction each time. The product

caught in each box is then evaluated to determine the distribution pat

tern. Weighing the product in each box is the most accurate, but a simpler method is to pour the contents of each box into a separate small

vial or bottle. Then set the eleven vials or bottles side-by-side in order.

This makes the pattern variation quite visible.

To reduce the amount of discharge to the right side (operator's right)

the pattern slide should be partially closed and the test repeated until

the distribution pattern is uniform.

TO ACHIEVE THE CORRECT PRODUCT APPLICATION RATE:

The approximate spreader settings printed on any product label should

only be used as the initial setting for calibration. Set the rate control arm

at this approximate setting. Using the collection boxes or pans, make a

single pass over them to determine the effective pattern width. The ef

fective pattern width is twice (2x) the distance to the point where the

rate drops to one-half the average rate at the center. Example: If the

product in the vials from the center boxes averages two inches in

depth, count out to the vial which has one inch of product. If this is the

fifth vial from the center and the boxes were on one-foot centers, the

effective pattern width is ten feet (2 x 5 ft.).

Knowing the effective pattern width (ten feet), measure out a lineal distance to equal 1,000 sq. ft. (10 ft. x 100 ft. = 1,000 sq. ft.). Weigh 20 lbs.

of product and place it in the spreader hopper and spread it over the

distance necessary to equal 1,000 sq. ft. (100 ft.). Then weigh the prod

uct left in the hopper and subtract this amount from the amount with

which you started. The result is the application rate for this product in

pounds per 1,000 sq. ft. that your spreader is currently adjusted to dis

perse. Adjust the rate control arm up or down as needed and repeat

this procedure until the correct application rate is achieved.

TO USE THE CALIBRATION GAUGES:

The Calibration Gauges provide a series of "steps", numbered in 1/32inch increments, that will allow you to "fine-tune" the spreader. Once

you have calibrated your rotary spreader for the product chosen, open

the operating lever and insert the calibration gauges until you deter

mine which step fits tightly into one of the open holes in the hopper bottom. Record that step number for future reference when using that

product. You may choose to set other rotary spreaders for application

of the same product by adjusting the shut off plate to that calibration

gauge step. This will provide consistent settings for all of your spread

ers. To recalibrate your rotary spreader after a period of use, adjust the

rate control arm to the "24" position. Open the operating lever and in

sert the even-numbered Calibration Gauge into one of the open holes

in the hopper bottom. Close the operating lever and let the shut off plate

on the underside of the hopper make contact with the number 10 step

on the Calibration Gauge. Move the rate control arm back toward the

"6" position until the bottom of the arm makes contact with the shut off

plate. If your spreader is properly adjusted, the top of the rate control

arm should be at setting "10". To correct variances, remove the rate

control arm, place the bottom of the arm (up to the bolt hole) in a vise,

and bend either to the right or the left.

-

-

SPREADER TIPS:

1. Always push the spreader; do not pull.

2. Push the spreader at a consistent speed (approximately 3 m.p.h. is

recommended).

3. Always close the operating lever before filling the hopper.

-

4. Be sure the screen is in place to prevent lumps or paper scraps from

plugging the holes in the hopper bottom.

5. Always start walking forward before opening the operating lever;

close the operating lever before forward motion is stopped.

6. Hold the handle at a height that will keep the impeller level.

7. Empty the spreader after each use. Wash the spreader thoroughly

and allow it to dry. Keep the impeller clean.

8. Lubricate all moving parts. Apply grease to the five grease fittings;

two in the axle supports, two in the gear support and one in the idler

wheel (if the idler wheel has a steel hub).

-

-

-

9

Page 10

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and MTD Consumer Group Inc are pleased to explain the evaporative emission control system warranty on your 2008 lawn

mower. In California, new lawn mowers must be designed, built and equipped to meet the State’s stringent anti-smog standards. MTD Consumer Group Inc must

warrant the EECS on your lawn mower for the period of time listed below provided there has been no abuse, neglect or improper maintenance of your lawn mower.

Your EECS may include parts such as the carburetor, fuel-injection system, the ignition system, catalytic converter, fuel tanks, fuel lines, fuel caps, valves,

canisters, filters, vapor hoses, clamps, connectors, and other associated emission-related components.

Where a warrantable condition exists, MTD Consumer Group Inc will repair your lawn mower at no cost to you including diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE:

This evaporative emission control system is warranted for two years. If any evaporative emission-related part on your equipment is defective, the part will be

repaired or replaced by MTD Consumer Group Inc.

OWNER’S WARRANTY RESPONSIBILITIES:

As the lawn mower owner, you are responsible for performance of the required maintenance listed in your owner ’s manual. MTD Consumer Group Inc recommends

that you retain all receipts covering maintenance on your lawn mower, but MTD Consumer Group Inc cannot deny warranty solely for the lack of receipts.

As the lawn mower owner, you should however be aware that MTD Consumer Group Inc may deny you warranty coverage if your lawn mower or a part has failed

due to abuse, neglect, or improper maintenance or unapproved modifications.

You are responsible for presenting your lawn mower to MTD Consumer Group Inc’s distribution center or ser vice center as soon as the problem exists. The

warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If you have a question regarding your warranty coverage, you should

contact the MTD Consumer Group Inc Service Department at 1-800-800-7310.

GENERAL EMISSIONS WARRANTY COVERAGE:

MTD Consumer Group Inc warrants to the ultimate purchaser and each subsequent purchaser that the lawn mower is: Designed, built and equipped so as to

conform with all applicable regulations; and free from defects in materials and workmanship that cause the failure of a warranted part to be identical in all material

respects to that part as described in MTD Consumer Group Inc’s application for cer tification.

The warranty period begins on the date the lawn mower is delivered to an ultimate purchaser or first placed into service. The warranty period is two years.

Subject to cer tain conditions and exclusions as stated below, the warranty on emission-related parts is as follows:

1. Any warranted part that is not scheduled for replacement as required maintenance in the written instructions supplied, is warranted for the warranty period

stated above. If the part fails during the period of warranty coverage, the part will be repaired or replaced by MTD Consumer Group Inc according to subsection

(4) below. Any such part repaired or replaced under warranty will be warranted for the remainder of the period.

2. Any warranted part that is scheduled only for regular inspection in the written instructions supplied is warranted for the warranty period stated above. Any such

part repaired or replaced under warranty will be warranted for the remaining warranty period.

3. Any warranted part that is scheduled for replacement as required maintenance in the written instructions supplied is warranted for the period of time before the

first scheduled replacement date for that part. If the part fails before the first scheduled replacement, the part will be repaired or replaced by MTD Consumer

Group Inc according to subsection (4) below. Any such par t repaired or replaced under warranty will be warranted for the remainder of the period prior to the

first scheduled replacement point for the part.

4. Repair or replacement of any warranted part under the warranty provisions herein must be performed at a warranty station at no charge to the owner.

5. Notwithstanding the provisions herein, warranty services or repairs will be provided at all of our distribution centers that are franchised to service the subject

engines or equipment.

6. The lawn mower owner will not be charged for diagnostic labor that is directly associated with diagnosis of a defective, emission-related warranted par t,

provided that such diagnostic work is performed at a warranty station.

7. MTD Consumer Group Inc is liable for damages to other engine or equipment components proximately caused by a failure under warranty of any warranted

part.

8. Throughout the lawn mower warranty period stated above, MTD Consumer Group Inc will maintain a supply of warranted parts sufficient to meet the expected

demand for such parts.

9. Any replacement part may be used in the performance of any warranty maintenance or repairs and must be provided without charge to the owner. Such use will

not reduce the warranty obligations of MTD Consumer Group Inc.

10. Add-on or modified parts that are not exempted by the Air Resources Board may not be used. The use of any non-exempted add-on or modified parts by the

ultimate purchaser will be grounds for disallowing a warranty claims. MTD Consumer Group Inc will not be liable to warrant failures of warranted parts caused

by the use of a non-exempted add-on or modified part.

10

Page 11

WARRANTED PARTS:

The repair or replacement of any warranted par t otherwise eligible for warranty coverage may be excluded from such warranty coverage if MTD Consumer Group

Inc demonstrates that the lawn mower has been abused, neglected, or improperly maintained, and that such abuse, neglect, or improper maintenance was the

direct cause of the need for repair or replacement of the part. That notwithstanding, any adjustment of a component that has a factory installed, and properly

operating, adjustment limiting device is still eligible for warranty coverage. The following emission warranty parts are covered:

(1) Fuel Metering System

s#OLDSTARTENRICHMENTSYSTEMSOFTCHOKE

s#ARBURETORANDINTERNALPARTS

s&UELPUMP

s&UELTANK

(2) Air Induction System

s!IRCLEANER

s)NTAKEMANIFOLD

(3) Ignition System

s3PARKPLUG S

s-AGNETOIGNITIONSYSTEM

(4) Exhaust System

s#ATALYTICCONVERTER

s3!)2EEDVALVE

(5) Miscellaneous Items Used in Above System

s6ACUUMTEMPERATUREPOSITIONTIMESENSITIVEVALVESANDSWITCHES

s#ONNECTORSANDASSEMBLIES

(6) Evaporative Control

s&UELHOSECERTIFIEDFOR!2"EVAPORATIVEEMISSIONS

s&UELHOSECLAMPS

s4ETHEREDFUELCAP

s#ARBONCANISTER

s6APORLINES

'$/#2EV#

11

Page 12

MANUFACTURER’S LIMITED WARRANTY FOR CUB CADET COMMERCIAL

LAWN APPLICATION EQUIPMENT

IMPORTANT: To obtain warranty coverage owner may be required

present proof of purchase and applicable maintenance records to the

servicing dealer. Please see the operator’s manual for information on

required maintenance and service intervals. In addition, Cub Cadet

may deny warranty coverage if the hour meter, or any part thereof, is

altered, modified, disconnected or otherwise tampered with.

The limited warranty set forth below is given by Cub Cadet LLC with

respect to new merchandise used for commercial and related purposes

purchased and used in the United States and/or its territories and

possessions, and by MTD Products Limited with respect to new

merchandise purchased and used in Canada and/or its territories and

possessions (either entity respectively, “Cub Cadet”).

Cub Cadet warrants this product (excluding its No-Fault Components,

as described below) against defects in material and workmanship for a

period of one (1) year from the date of original retail purchase or lease

and will, at its option, repair or replace, free of charge, any part found

to be defective in materials or workmanship.

No-Fault Components include only belts, tires, and seats which are

warranted to be free from defects in material and workmanship for a

period of thirty (30) days from the date of original purchase or lease.

HOW TO OBTAIN SERVICE: Warranty service is available, WITH

PROOF OF PURCHASE AND APPLICABLE MAINTAINCE

RECORDS, through your local authorized service dealer. To locate the

dealer in your area;

In the U.S.A

Check your Yellow Pages, or contact Cub Cadet LLC at P.O. Box

361131, Cleveland, Ohio 44136-0019, or call 1-877-282- 8684, or log

on to our Web site at www.cubcadetcommercial.com.

In Canada

For all provinces excluding Quebec contact Modern Power Products

d/o MTD Canada Ltd. At 60 Ottawa Street South, Kitchener, Ontario

N2G 3S7 or call 1-800-567-6775 or log on to our website at

www.cubcadet.ca.

In Quebec contact Les Distributions RVI Ltee. d/o MTD Canada Ltd.

2955 jean-Baptiste Deschamps, Ville Lachine, Quebec H8T 1C5 or

call 1-800-361-5770 or log on to our website at www.cubcadet.info.

.:

:

This limited warranty does not provide coverage in the following cases:

a. Routine maintenance items such as lubricants, filters, tune-

ups, brake adjustments, clutch adjustments, control linkages,

drive system, engines, and normal deterioration of the exterior

finish due to use or exposure.

b. Service completed by someone other than an authorized

service dealer.

c. For products sold or exported outside of the United States

and/or Canada, and their respective possessions and

territories, except those sold through Cub Cadet’s authorized

channels of export distribution.

d. Damage or failure resulting from the use of defective or

improper peplacement parts and\or accessories other than

genuine Cub Cadet parts.

e. Transportation charges and service calls.

f. Failure to operate and maintain the product in accordance with

the Operator’s Manual furnished with the product,

g. Damages and failures resulting from misuse, abuse, neglect,

accident, improper maintenance, alteration, vandalism, theft,

fire, water, or damage because of other peril or natural

disaster.

There are no implied warranties, including without limitation any

implied warranty of merchantability or fitness for a particular

purpose. No warranties shall apply after the applicable period of

express written warranty above. No other express warranties

beyond those mentioned above, given by any person or entity,

including a dealer or retailer, with respect to any product, shall

bind Cub Cadet. The exclusive remedy is repair or replacement

of the product as set forth above. The terms of this warranty

provide the sole and exclusive remedy arising from the sale

and/or lease of the products covered hereby. Cub Cadet shall not

be liable for any incidental or consequential loss or damage

including, without limitation, expenses incurred for substitute or

replacement lawn care services or for rental expenses to

temporarily replace a warranted product.

Some jurisdictions do not allow the exclusion or limitation of incidental

or consequential damages, or limitations on how long an implied

warranty lasts, so the above exclusions or limitations may not apply to

you. This limited warranty gives you specific legal rights, and you may

also have other rights that vary in different jurisdictions.

Cub Cadet LLC - P.O. Box 361131, Cleveland, Ohio 44136-0019; Phone 1-877-282-8684

Form #02004268 Rev. 08-1 04/08/2008

In no event shall recovery of any kind be greater than the amount of

the purchase price of the product sold. Alteration of safety features

of the product shall void this warranty. You assume the risk and

liability for loss, damage, or injury to you and your property and/or to

others and their property arising out of improper use, misuse or

inability to use the product. This limited warranty shall not extend to

anyone other than the original purchaser/Leasee or to the person for

whom it was purchased or leased as a gift.

Loading...

Loading...