CSZ EZT-430i Configuration Manual

EZT-430i

Single/Dual Loop Controller

Configuration Manual

EZT-430i

Safety Information in this Manual

Notes, cautions and warnin gs appear throughout this book to draw your attention to important operational and

safety information.

A “NOTE” marks a short message to alert you to an important detail.

A “CAUTION” safety alert appears with information that is important for protecting your equipment and

performance.

A “WARNING” safety alert appears with information that is important for protecting you, others and equ ipment

from damage. Pay very close attention to all warni ngs that apply to your application.

This symbol (an exclamation point in a triangle) precedes a general CAUTION or WARNING

statement.

This symbol (a lightning bolt in a lightning bolt in a triangle) precedes an electric shock hazard

CAUTION or WARNING safety statement.

Technical Assistance

If you encounter a pr oblem with your EZT-430i controller, revie w all of your configurati on information to ver ify

that your selections are c onsistent with your applicat ion: inputs; outputs; alarms; limits ; etc. If the problem

persists after check ing the above, you can get technical as sistance by dialing 1 (513) 772-8810 or by faxing

your request to 1 ( 513) 772-9119, Monda y thru Friday, 7:30 a.m. to 5:30 p.m. Eastern Standard T ime. You

can also email your request to cszinc@cszinc.com

An applications engineer wi ll discus s your appl icati on with you.

Please have the following informa tion available:

• Complete Model #’s and/or Serial #’s for Component(s) in Question

• Complete Software Versio n #’s

• All Configuration Information

• All User Manuals

Warranty and return information is on the back cover o f th is manual.

.

Your Comments

Your comments or suggestions on this manual are welcome. Please send them to:

Cincinnati Sub Zero, 12011 Mosteller Road, Cincinnati, OH 45241

Telephone: +1 (513) 772-8810 751-5444; fax: +1 (513) 772-9119

cszinc@cszinc.com

The EZT-430i is copyrighted by Cincinnati Sub Zero, © 2012, all rights reserved (www.cszindustrial.com

CSZ EZT-430i Preface

)

EZT-430i

1 What is EZT-430i? ..................................................................................................... 1.1

1.1 Features ............................................................................................................................................... 1.1

2 Configurator Overview ............................................................................................. 2.1

2.1 Configurator Menu ............................................................................................................................... 2.2

3 Configuring EZT-430i ................................................................................................... 1

3.1 Loop Setup .............................................................................................................................................. 1

3.2 Loop Address Utility ................................................................................................................................ 2

3.3 User Communications ............................................................................................................................. 3

3.4 Loop Configuration .................................................................................................................................. 4

3.4.1 Input Sensor Selection ..................................................................................................................... 4

3.4.2 Input Unit Selection .......................................................................................................................... 5

3.4.3 Decimal Point .................................................................................................................................... 5

3.4.4 Input Low/High Scale ........................................................................................................................ 5

3.4.5 Input Filter ......................................................................................................................................... 6

3.4.6 Event Input Function ......................................................................................................................... 6

3.4.7 Low/High Setpoint Limits .................................................................................................................. 7

3.4.8 Output 1 Function ............................................................................................................................. 7

3.4.9 Output 1 Failure Transfer ................................................................................................................. 8

3.4.10 Output 1 ON-OFF Control Hysteresis .............................................................................................. 9

3.4.11 Output 1 Cycle Time ......................................................................................................................... 9

3.4.12 Output 1 Low/High Limit Values ....................................................................................................... 9

3.4.13 Output 2 Function ............................................................................................................................. 9

3.4.14 Output 2 Failure Transfer ............................................................................................................... 10

3.4.15 Output 2 Low/High Limit Values ..................................................................................................... 10

3.4.16 Output 3 Function ........................................................................................................................... 11

3.4.17 Output 3 Failure Transfer ............................................................................................................... 11

3.4.18 Output 4 Function ........................................................................................................................... 11

3.4.19 Output 4 Failure Transfer ............................................................................................................... 12

3.4.20 Output 4 Low/High Limit Values ..................................................................................................... 12

3.4.21 Output 4 Retransmit Low/High Scale ............................................................................................. 12

3.4.22 Alarm (1-3) Function ....................................................................................................................... 13

3.4.23 Alarm (1-3) Mode ............................................................................................................................ 14

3.4.24 Alarm (1-3) Indication ..................................................................................................................... 15

3.4.25 Alarm (1-3) Setpoint ....................................................................................................................... 15

3.4.26 Alarm (1-3) Hysteresis .................................................................................................................... 15

3.4.27 Setpoint at Start of Automatic Program .......................................................................................... 16

3.4.28 Setpoint at End of Automatic Program ........................................................................................... 16

3.4.29 Power Fail Recovery ...................................................................................................................... 17

3.4.29.1 Enabling Holdback ................................................................................................................... 18

3.5 Calibration ............................................................................................................................................. 20

3.6 Functions ............................................................................................................................................... 21

3.7 Startup View .......................................................................................................................................... 24

3.8 Alarm/Event Tagnames......................................................................................................................... 25

3.8.1 Alarm Names .................................................................................................................................. 25

3.8.2 Event Names .................................................................................................................................. 25

3.9 Custom Name\Address ......................................................................................................................... 26

Table of Contents CSZ EZT-430i i

EZT-430i

1 What is EZT-430i?

The EZT-430i system combines all of the features of a loop controll er, video/chart rec order and data logging

system into a single/intuit ive device. Email, SMS (text mes saging), FTP (file transfer prot ocol for automated

data backup) and remote view/control (Web server/VNC server) are standard with EZT-430i and can be

accessed via LAN/WAN using a PC, tablet or smart phone device.

Future Designs “EZT-430i” provides a 4.3”color touch screen interface with standard “Smart Device” user

interface features for single and dual loo p OEM control appl ications. All loo p configuration a nd runtime user

access is configurable at the device with no PC software required. OEM’s have the ability to configure

runtime features (screen availability, menus, language, etc...) to easily customize the system for their

requirements. These conf igurations can be imported/e xported to any other EZT-430i single/dual loop device

for setup (from scratch) within minutes.

Individual high performance board level PID loop control boards ( one for each loop) of fer up to four control

outputs each, powerful pro filing capabilities with up to three ev ents and full auto tune functionalit y with high

resolution process inputs.

1.1 Features

Each of the EZT-430i loop control boards provide a single digital input that can be programmed as a

automatic program control input for run, hold or ab ort, a manual mode or failure transfer control input or a

program advance to next segment control input.

Each of the loop control boards also provide up to four control outputs which can be used as PID control

outputs for heat/cool, direct outputs for controlling external equipment related to the application through

software switches called events, or be programmed to act as system alarm outputs.

EZT-430i can be operated in single set point or auto matic program control mode. Program entr y is made

easy through the use of c opy, paste and delete m enu selections. Programs can be copie d to the external

USB memory stick and then imported to another EZT-430i controller which eliminates the need to enter

duplicate programs into multiple systems.

Data file analysis tools m ake looking at historical data a s imple task. Any control variable s aved to the data

file can be plotted on the historical data chart for any time frame within the data file’s total time range.

The built in Ethernet func tio nal ity includes a ‘Web Server’ to pr ov ide acc ess to all EZT-430i data (view onl y), a

VNC interface for remote control and monitoring and an NTS clock, all available via a local Intranet

connection (wired or wireless), or the World Wide Web using standard software like Microsoft’s Internet

Explorer.

EZT-430i pr ovides a ric h set of tools f or control intera ction and proc ess monitoring. Views include single and

dual loop views, charts, ala rm, automated progr am status as well as hist orical data, alarm log and a udit trail

views. The menu driven interface eliminates screen “clutter” by providing an easy to use “Smart Device”

interface for interaction between the user and EZT-430i.

EZT-430i can store more than one year of data on its SD memory card. Data logging can be enabled

manually or automaticall y during program operation. Data back up is provided with a USB memory stick for

plug and play transf er of files to any PC runn ing Microsoft Windows XP operating system s and via the FTP

back-up utility.

EZT-430i protects s ystem access with 4 level secur ity (user rights based), audit trai ls that docum ent all user

activity and ensures data integrity by digitally signing all data files and audit trails to meet regulatory

requirements.

What is EZT-430i? CSZ EZT-430i 1.1

EZT-430i

The EZT-430i controller includes the following features:

• Single/Dual loop controller models (automatic program operation included).

• Touch screen, “Smart Device” user interface (UI).

• Video recorder mode for view only applications.

• Email, SMS, FTP, VNC and Web functionality standard.

• Remote View/Control using PC, Tablet or Smartphone.

• Detailed maintenance, alarm monitoring and alarm history.

• User configurable data logging and historical data viewer.

• 4 level security with digitally signed audit trails and data files.

• National time server connectivity with daylight savings.

• Multi-lingual user interface supports over 25 languages.

• 30,000 hour LED display

1.2 CSZ EZT-430i What is EZT-430i?

EZT-430i

2 Configurator Overvi ew

The EZT-430i conf igurator is a powerful too l that allows full custom ization of EZT-430i. It is a program that

allows the OEM or user to set up control system options for the EZT-430i runtime application. The

configurator program will not run at the same time as the main runtime software.

The configurator can be r un when the runtime soft ware is exited and the “Exit and run configurator on next

power-up” option is selected. The next time the unit is re-powered the configurator will run.

Control functions of each loop control board can be changed while the OEM or operator is editing the

configuration of EZT-430i through the conf igurator program, so any equipment being control led b y the o utp ut s

should be placed in an “off” state so that any changes will not cause an unsafe condition or damage to

equipment.

NOTE: Each time the EZT-430i configurator s oftware is exite d; the con troller ru ntime sof tware w ill run a fter

the unit is re-powered.

The EZT-430i configurator provides the following functionality:

• Set the number of control loops that EZT-430i will use (single/dual).

• Provide control loop configuration settings for input type, output function, set point range, etc.

• Select the type of user communications for Modbus Slave interface.

• ‘Splash Screen’ name editing for custom OEM or user requirements.

• Enable/disable options for runtime menu and screen availability.

• Text editing for all system event and alarm output names.

Configurator Overview CSZ EZT-430i 2.1

EZT-430i

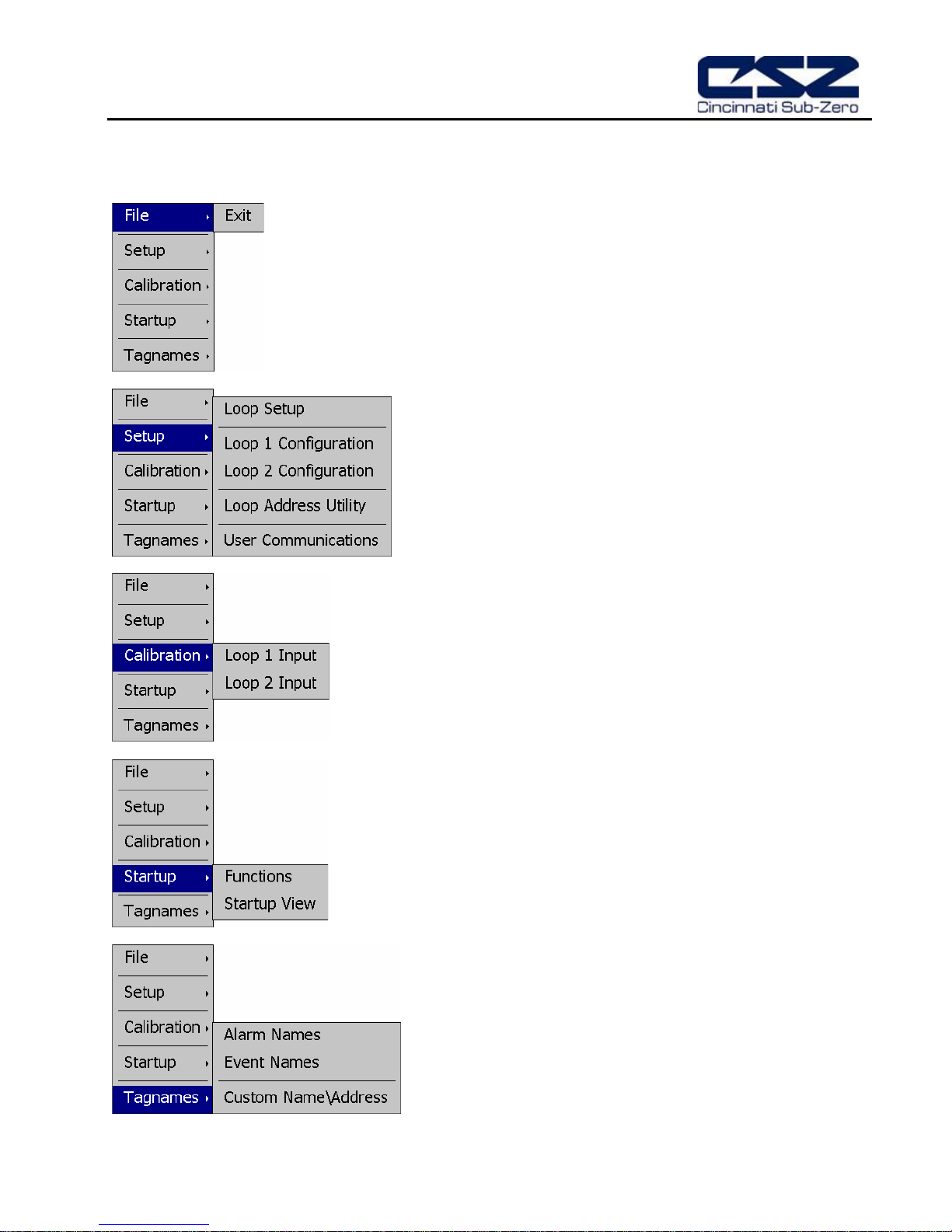

The File menu provides the exit function for the configurator.

the controller type

(single/dual loop), the loop control board settings, user

menu also provides access to edit the splash screen

2.1 Configurator Menu

The configurator menu is accessed by pressing the “Monitor” icon at the top left of the screen.

After selecting this m enu item and exiting the c onfigurator, the

controller runtime software will run after the unit is re-powered.

The Setup menu provides access to the primary controller

setup options. These options include

communications sel ection and the loop addr ess utility that can

be used to automatically assign the proper communications

address to an attached loop control board.

The Calibration menu provides access to the input offset

calibration settings for the loop control boards .

The Startup m enu prov ides acces s to enab le an d dis abl e EZT430i runtime screens/menus and the desired startup view

selection.

The Tagnames menu provides access to the text editing

functions of the configurator which allow the event and alarm

names to be changed to m atch their use in the system. The

information that is shown when the runtime application starts.

2.2 CSZ EZT-430i Configurator Overview

EZT-430i

3 Configuring EZT-430i

IMPORTANT: Once all configuration settings ar e m ade, y o u m us t select “Exit” from the File men u to ex it t he

configurator prior to cy cling power to EZT-430i. All configuration f iles are wr itte n upon ex iting

the configurator. Do not c ycle power prior to exiting the config urator or settings will be lost

and EZT-430i will not operate properly when entering the runtime application.

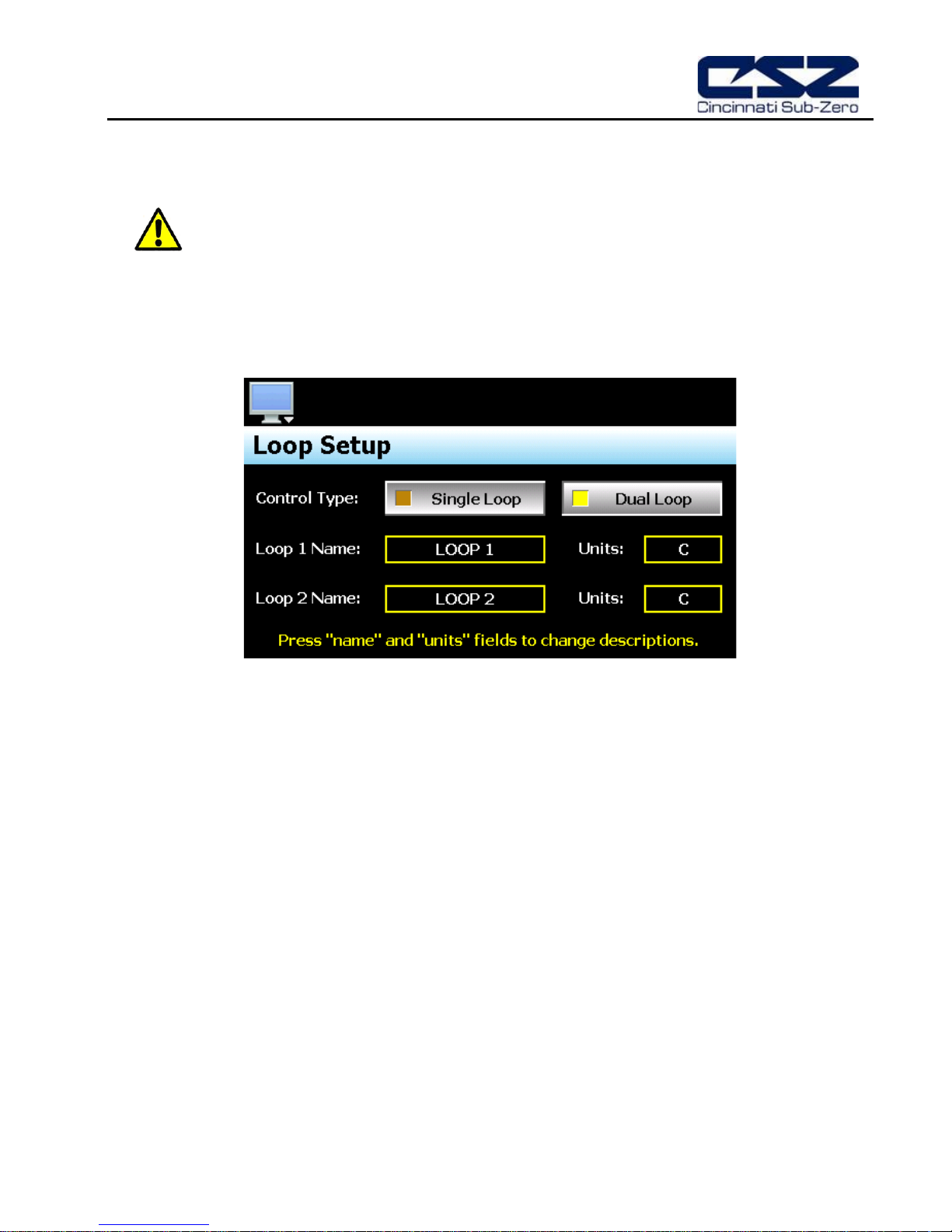

3.1 Loop Setup

The “Loop Setup” screen is acc essed f rom the Setup m enu. It prov ides the control type selec tion and entries

for setting the loop names and display units.

The Control Type selection sets the number of loop control boards that will be attac hed to EZT-430i, one

(single loop) or two (dual loop). When the EZT-430i runtime application is s tart e d, EZT-430i will autom at ically

configure all loop view displays, charts and available data log point selections based on the control type

selection and individual loop setup.

The Loop Name fields are used to enter a s pecific na me for eac h control loop , up to 11 c haracters i n length.

This name will be used throughout the EZT-430i runtime application and can be used to provide a more

detailed description as to the function of the loop in the application. Default tag names are LOOP 1 and

LOOP 2.

The Units fields are used to enter the engineering units for the loop with up to four characters maximum .

This value is shown on the singl e and dua l view loop s creens in the EZT-430i runtim e application. W hen the

loop input t ype selection is set for temperature, the field w ill be fixed at either “C” or “F” based on the units

selection for the loop unde r loop setup. If the loop input t ype is set for a linear input type (0-1 0V or 4-20mA

for example), the engineer i ng un its c an be e dit ed an d c hange d to th e r equ ired u ni ts f or the m eas ured pr ocess

value.

Configuring CSZ EZT-430i A.1

EZT-430i

3.2 Loop Address Utility

In order for EZT-430i to properl y communicate with eac h of the loop contr ol boards, they m ust be configured

for the proper communications address. The factory default communication settings of the loop control

boards are set for a c ommunicat ions addres s of on e, which cor respond t o the pr oper settings for loop 1. For

a single loop EZT-430i contr ol system, no further s ettings are required . Simply connect the com munications

wiring between the control board and the EZT-430i interface, and the system is ready to go.

For a dual loop EZT-430i control system, one of the control boards must be set for address two which

corresponds with loop 2 of EZT-430i. If a display m odule is not avai lable to c onn ect to the lo op co ntrol board

in order to set its address, the Loop Address Utility can be used. It is accessed from the Setup menu.

In order to use the ut ility, only one loop control boar d can be connected to EZT-430i at a time. S ince the

default address of all control boar ds are 1, if more than one was connec ted, they would both respond to th e

same command which would c ause them both to be set to a dif f erent addr es s. I f both loo p cont ro l bo ar ds are

connected, disconnect the communications wiring from the loop control board that you DO NO T want to set

the address on. An a lternative is to rem ove power from the loop contr ol board rather than discon necting the

communications wiring.

With only one loop control board powered on or connected to EZT-430i via the communications link, press the

“Assign to Loop” button for the loop that you want to assign the control board to. The utility will begin

scanning for the loop c ontrol b oard and set its addres s to the proper addres s on ce found. If the utilit y fails to

set the address, check the wiring to insure it is properly connected. If the loop control board has been

previously used for anot her app lication, it m ay be poss ible th at the addres s or other comm unications setti ngs

have been changed, w hich pr event th e ut ility from working. In th is c as e, a d isp lay module must be connec ted

to the loop control board to set the proper communications settings:

Address: 1 or 2 (for loop 1 or loop 2)

Baud rate: 9600

Parity: Even

IMPORTANT: The loop input number cor responds to the communicat ions address that must b e set in the

loop control board for EZT-430i to access it pr operly. If the communications address is not

set properly in the loop control, EZT-430i will not be able to communicate with it, or may

communicate with the wrong loop control and assign the incorrect set points and control

parameters to it.

A.2 CSZ EZT-430i Configuring

EZT-430i

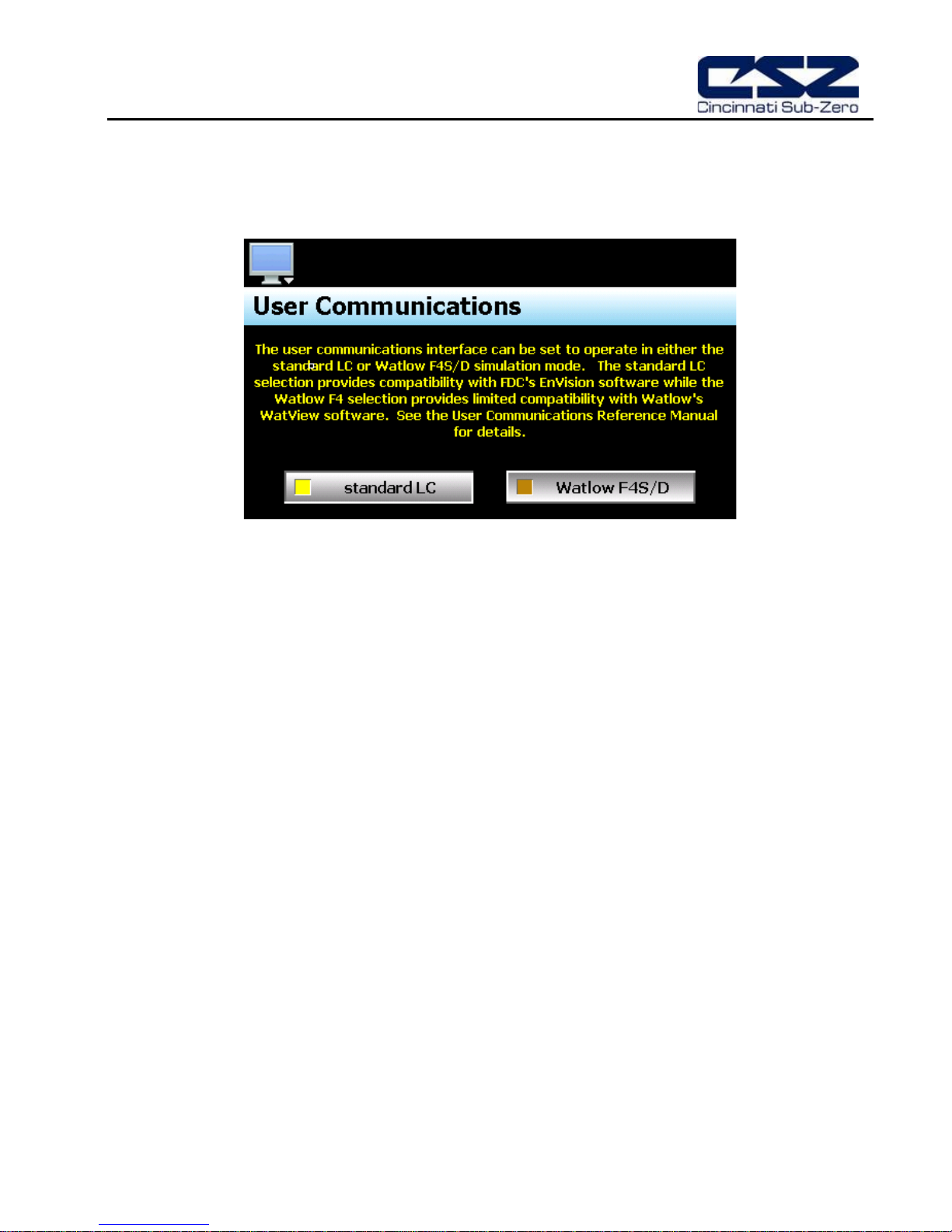

3.3 Use r Com m uni cati ons

The Modbus s lave inter face of EZT-430i can be set to operate in on e of t wo modes. T he default se tting is to

provide the standard us er interf ac e f or use with CSZ’s Envision sof tware. This selection assigns values to the

Modbus slave register table in the proper positions to allow communications between EnVision and EZT-430i.

The second selection c onfigures the Modbus sla ve interface to simulate the co mmunications interface f or a

“Watlow F4S/D” controller. This selection assigns EZT-430i control values to the corresponding register

addresses of a Watlow F4S/D control ler allowing limited com patibilit y with W atlow’s W atView s oftware. This

provides current users of the F4 controller and WatView software a control option for the replacement for

aging F4 controllers while k eeping the comm on software i nterface witho ut the need f or training on t he use of

different software.

IMPORTANT: The Watlow F4S/D interface is limited to basic set point adjustment, event output control;

profile operation and single profile download using WatView’s profile editor. Attempting

unsupported functions may cause errors in the operati on of WatView software an d require it

to be restarted.

See the EZT-430i Cincinnati User Communications Reference Manual for details on the use

of the Modbus slave interface including communications settings, register addresses and

their associated values as well as the functionality of the selected interface type.

Configuring CSZ EZT-430i A.3

Loading...

Loading...