CSZ LT 749 User manual

MICRO-TEMP® LT

Operation and Technical Manual

Model 749 Localized Therapy Units

Cincinnati Sub-Zero Products, Inc. ∙ 12011 Mosteller Road ∙ Cincinnati, Ohio 45241, U.S.A. www.cszmedical.com

In Europe: ∙ CEpartner4U ∙ Esdoornlaan 13, 3951 DB Maarn.

The Netherlands

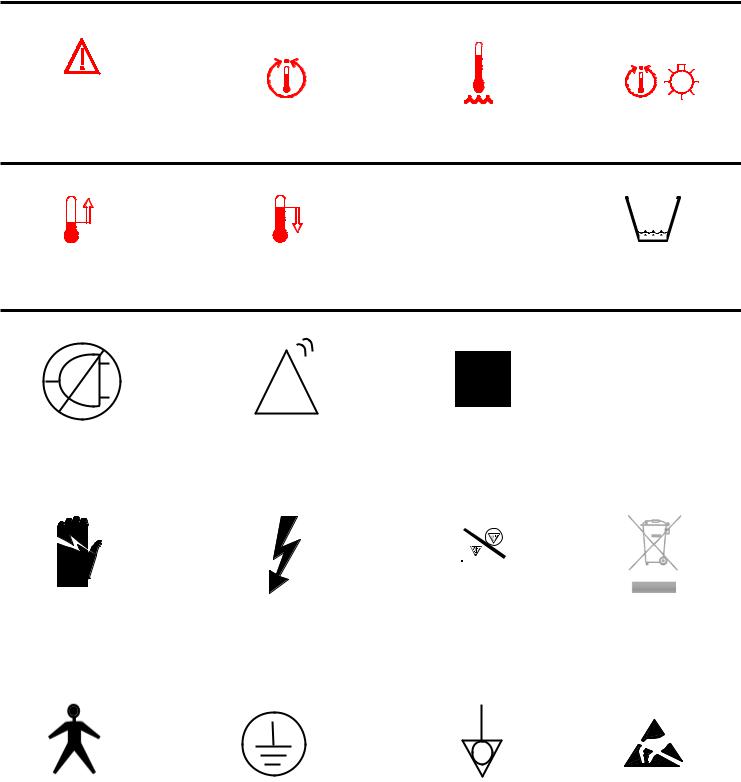

MICRO-TEMP LT Symbols / Definitions

Attention: Read |

|

|

|

Operation Instructions |

Temperature Set |

Water |

Temperature Set |

and Manual Before |

|||

Operating |

|

Temperature |

Point Indicator |

|

|

O / I |

|

Increasing |

Decreasing |

OFF / ON Switch |

Low Water |

Temperature |

Temperature |

|

Level |

|

|

|

~

Power Failure |

CAUTION |

Fuse |

AC Voltage |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Risk of Explosion: |

|

|

|

Disconnect Power |

Danger; Risk of |

Do not use in the |

Separate collection for |

||||

Before Servicing |

Electric Shock |

Presence of Flammable |

electrical and electronic |

||||

|

|

|

|

Anesthetics |

|

equipment |

|

|

|

|

|

|

|

|

|

Type B |

Earth (Ground) |

Equipotentiality |

ESD |

Equipment |

|

|

Susceptibility |

|

|

|

II

MICRO-TEMP LT

OPERATION AND TECHNICAL MANUAL

Cincinnati Sub-Zero Products, Inc., reserves the right to make equipment changes and improvements, which may not be reflected in this manual.

WARNING

∙Read Operation Manual before operating.

∙A physician's order is required for setting pad temperature and use of equipment. As directed by physician, check patient's temperature and skin condition of areas in contact with pad. Check the pad water temperature. Pediatric patients, temperature-sensitive patients with vascular disease, surgical patients, diabetics, and Raynauds disease patients should be checked more frequently. Notify the physician promptly of any change in patient status in order to avoid serious injury or death. Failure to inform the physician of any deviation may result in injury to the patient.

Pediatrics – Infants and children’s body temperature are more responsive to surface heating than adults. Due to their size, the effect of heating a child is more pronounced because of their higher ratio of skin contact area to body mass.

Temperature Sensitive Patients – Patients with impaired peripheral blood circulation and patients who are incapacitated may be more sensitive to temperature changes than patients with normal circulation.

Surgical Patients – Patients with poor circulation due to inadequate heart function, loss of blood, or impaired peripheral blood circulation may be more sensitive to temperature changes.

∙If device is used at home, patient must follow directions prescribed by their physician and be aware of all warnings and cautions mentioned throughout the manual.

∙Observe patient’s skin condition frequently due to individual differences in sensitivity and susceptibility to injury from heat and/or externally applied chemicals or pressure. Patients at greatest risk are those unconscious, on prolonged therapy, diabetics, children, and persons incapacitated, with sensitive skin areas, or poor circulation.

∙Do not use for ECMO (Extracorporeal Membrane Oxygenation) therapy.

∙Heating may affect toxicity of certain prep solutions which has been reported to cause skin injury when remaining on patient’s skin during application of prolonged heat. For moist heat therapy, moisten the pad using distilled water only.

∙The method of temperature control provided by all localized heat therapy units presents the danger of heating body tissues, particularly the skin, to a point where they are injured, i.e., burns. Depending on the extent and severity of a burn, very serious complications may arise.

∙Prevent excessive and/or prolonged tissue pressure and shearing forces, especially over bony prominences, to prevent skin damage that may result.

∙Do not wrap pad so tightly as to constrict blood flow. Do not use pins to secure pad or hoses. Do not allow pad or hoses to come in contact with any sharp object.

∙Do not place additional heat sources between the patient and pad. Skin damage may result.

Manual 57203 Rev. I

DCN: M006-3983

III

WARNING

∙Proper sanitation procedures must be practiced and hygienic safety must be maintained, to prevent contamination. Contamination can affect patient’s health, i.e. skin irritation/rash may result.

∙Any time water is found leaking into or around the unit, connecting hose, and/or pad, turn the unit off, disconnect the power cord from its power source, and correct the problem before proceeding. Water leaks could lead to electric shock.

∙Water leaks present a risk of infection and should be handled accordingly. Proper sanitation procedures should be followed including, but not limited to, the preventative maintenance described in this manual. Leaky pads or hoses, as well as unapproved pads should never be used.

∙Do not use the MICRO-TEMP LT system in the presence of flammable anesthetics. Risk of explosion can result.

∙For continued protection against risk of fire, replace only with same type and rating of fuse.

∙This device is still energized when the inlet switch is in the off position. To completely disconnect the device from the power source, remove the appliance plug from the back of the unit.

∙Always unplug the unit before accessing internal components during service. Failure to unplug the unit could result in electric shock.

∙Do not by-pass ground on power cord plug. Electrical Hazards may result.

∙Do not position unit near any objects that can generate a strong electrical/magnetic field.

Potential electromagnetic interference may result. If interference is observed, re-locate the unit away from such devices.

∙The display may blank momentarily during an electrostatic discharge event, but the essential performance of the unit is not affected and no harm will occur to the patient. If an electrostatic discharge event occurs, check to see if unit is operating properly. If unit does not return to previous operation, turn unit off then back on and reset temperature settings as prescribed.

∙Keep air vents free of debris and obstruction. Blockage of vents could result in the unit overheating which could render the unit unable to provide adequate therapy and excessive surface temperatures could cause injury of patient or operator. Keep unit, specifically the air vents, away from curtains or other obstructions.

∙Remove the MICRO-TEMP LT from service if the outer casing or membrane control panel is cracked or internal components are exposed. Contact with internal components could result in electric shock or thermal injury to the patient or operator and exposure to sharp edges.

∙Before returning the MICRO-TEMP LT to patient use after repairs, the MAINTENANCE CHECKLIST in Section 4 must always be performed. Improper repair and inadequate maintenance can result in system damage and patient injury.

∙The repair, calibration, and servicing of the MICRO-TEMP LT should be performed by qualified Medical Equipment Service Technicians, Certified Biomedical Electronics Technicians, or Certified Clinical Engineers familiar with good repair practices for servicing medical devices, and in accordance with instructions contained in this manual. Improper repair can result in system damage and patient injury.

IV

CAUTION

∙Always drain the MICRO-TEMP LT to a sanitary drain because bio-contaminants may be present in the unit’s water supply.

∙Do NOT fill the reservoir to the bottom of the strainer if there is water in the pad.

This could cause an overflow when the unit is turned on.

∙Working with electronic boards, plugs, and cables requires delicate handling. Proper

Electrostatic Discharge procedure should be followed during replacement of any electronic board.

∙Use only CSZ provided hospital grade power cord assembly and used in conjunction with a properly grounded receptacle or electric shock may result.

∙Do not operate pump without a pad connected or with pad clamps in the “CLOSED” position. Always check clamps to make sure they are fully open.

∙Full or partial covering of pads with materials with high insulative properties (pillows, etc.) could cause excessive retention of heat in the patient leading to injury.

∙The pad surface should be checked for freedom from mechanical damage prior to each application.

∙Complete folding of pad may restrict flow and reduce therapy to patient.

∙Make sure hose and pads are free of kinks that might restrict flow.

∙Check hose couplings to be certain they are properly locked together.

∙Follow pad instructions and Hospital/Physician instructions for applying, storing, and disposal of product.

∙Do not use alcohol. Alcohol may cause pad and unit deterioration.

∙Use distilled water only. Do Not Use De-Ionized water or tap water. Failure to use distilled water may result in poor performance and damage to the Micro-Temp LT.

∙It is recommended that two (2) ounces of Propylene Glycol be added to the reservoir upon fill up.

MICRO-TEMP LT, MAXI-THERM®, MAXI-THERM LITE®, and TEMP-PAD® are registered trademarks of Cincinnati Sub Zero Products, Inc., Cincinnati, Ohio USA.

©Copyright 1982, Cincinnati Sub-Zero Products, Inc. All rights reserved.

V

TABLE OF CONTENTS

TECHNICAL HELP ................................................................................................................................................... |

1 |

||

AUTHORIZED EUROPEAN REPRESENTATIVE: .............................................................................................. |

1 |

||

BEFORE YOU CALL FOR SERVICE.......................................................................................................................... |

1 |

||

IN-WARRANTY REPAIR AND PARTS ..................................................................................................................... |

1 |

||

RECEIVING INSPECTION....................................................................................................................................... |

1 |

||

IMPORTANT SAFETY INFORMATION ............................................................................................................... |

1 |

||

SECTION 1. INTRODUCTION................................................................................................................................ |

2 |

||

1-0. |

GENERAL SAFETY PRECAUTIONS .......................................................................................................... |

2 |

|

1-1. |

GENERAL DESCRIPTION OF THIS MANUAL .......................................................................................... |

2 |

|

1-2. |

GENERAL DESCRIPTION OF THE MICRO-TEMP LT SYSTEM ............................................................. |

2 |

|

1-3. |

CLINICAL APPLICATIONS ......................................................................................................................... |

3 |

|

1-4. |

PHYSICAL DESCRIPTION OF THE MICRO-TEMP LT UNIT................................................................... |

3 |

|

|

1-4.1. EXTERNAL FEATURES - FRONT VIEW ....................................................................................... |

3 |

|

|

1-4.2. EXTERNAL FEATURES - REAR VIEW ......................................................................................... |

5 |

|

|

1-4.3. EXTERNAL FEATURES – MEMBRANE CONTROL PANEL ......... ........................................... |

7 |

|

1-5. REQUIRED ACCESSORIES ................................................................................................................................ |

9 |

||

1-6. |

FUNCTIONAL DESCRIPTION OF THE MICRO-TEMP LT SYSTEM....................................................... |

9 |

|

|

1-6.1. THEORY OF OPERATION............................................................................................................... |

9 |

|

|

1-6.2. HEATING SYSTEM .......................................................................................................................... |

9 |

|

|

1-6.3. CIRCULATING SYSTEM ................................................................................................................. |

9 |

|

|

1-6.4. TEMPERATURE SAFETY CONTROL SYSTEM ......................................................................... |

10 |

|

SECTION 2. GENERAL PREPARATION OF THE MICRO-TEMP LT SYSTEM ........................................ |

11 |

||

2-1. |

INTRODUCTION......................................................................................................................................... |

11 |

|

2-2. |

UNPACKING THE SHIPMENT .................................................................................................................. |

11 |

|

2-3. |

FIRST TIME SET-UP/SYSTEM TEST ROUTINE...................................................................................... |

11 |

|

|

2-3.1. INSPECTING AND ARRANGING THE EQUIPMENT ................................................................ |

11 |

|

|

2-3.2. COMPLETING A SYSTEM TEST ROUTINE ............................................................................... |

12 |

|

2-5. |

PATIENT PREPARATION AND BEDSIDE CARE.................................................................................... |

14 |

|

SECTION 3. OPERATING THE MICRO-TEMP LT UNIT ............................................................................... |

17 |

||

3-1. |

INTRODUCTION......................................................................................................................................... |

17 |

|

3-2. |

ARRANGING THE SYSTEM COMPONENTS .......................................................................................... |

17 |

|

3-3. |

OPERATING THE MICRO-TEMP LT ........................................................................................................ |

19 |

|

3-4. |

CONCLUDING LOCALIZED HEAT THERAPY TREATMENT .............................................................. |

20 |

|

3-5. |

STATUS DISPLAY AND ALARM MESSAGES ........................................................................................ |

20 |

|

SECTION 4. GENERAL MAINTENANCE OF THE MICRO-TEMP LT SYSTEM ....................................... |

23 |

||

4-1. |

INTRODUCTION......................................................................................................................................... |

23 |

|

|

4-1.1. |

TEST EQUIPMENT REQUIRED ............................................................................................. |

23 |

4-2. |

MAINTENANCE OF THE WATER RESERVOIR...................................................................................... |

25 |

|

|

4-2.1. DRAINING THE RESERVOIR ....................................................................................................... |

25 |

|

|

4-2.2. REPLENISHING THE RESERVOIR .............................................................................................. |

25 |

|

|

4-2.3. DISINFECTION/DRY STORAGE PROCEDURE FOR CIRCULATING WATER UNITS........ |

26 |

|

4-3. |

MAINTENANCE OF THE MICRO-TEMP LT EXTERIOR – CLEANING INSTRUCTIONS .................. |

28 |

|

4-4. |

DISPOSAL OF THE LOCALIZED HEAT THERAPY PADS ..................................................................... |

28 |

|

4-5. |

CURRENT LEAKAGE TEST ...................................................................................................................... |

28 |

|

4-6. |

GROUND CONTINUITY TEST .................................................................................................................. |

29 |

|

4-7. |

FLOW RATE TEST ...................................................................................................................................... |

29 |

|

4-8. |

>1°C (2°F) OVER SET POINT CHECK....................................................................................................... |

30 |

|

4-9. |

TEMPERATURE ACCURACY CHECK ..................................................................................................... |

30 |

|

4-10. |

HIGH LIMIT SAFETY CHECK ................................................................................................................... |

31 |

|

4-11. |

LOW WATER ALARM CHECK.................................................................................................................. |

31 |

|

4-12. |

POWER FAILURE ALARM CHECK .......................................................................................................... |

32 |

|

4-13. |

TILT SWITCH ALARM CHECK................................................................................................................. |

33 |

|

VI

SECTION 5. FIELD REPAIR/SERVICE OF THE MICRO-TEMP LT UNIT ................................................. |

34 |

||

5-1. |

|

INTRODUCTION......................................................................................................................................... |

34 |

5-2. ACCESS TO THE INTERIOR OF THE MICRO-TEMP LT UNIT ................................................................... |

36 |

||

|

|

5-2.1. SEPARATING THE FRONT AND REAR ENCLOSURES............................................................ |

36 |

|

|

5-2.2. RECONNECTING THE FRONT AND REAR ENCLOSURES ..................................................... |

36 |

|

|

5-2.3. DISCONNECTING THE CABLES FROM THE CONTROL BOARD .......................................... |

37 |

|

|

5-2.4. DISCONNECTING THE CABLES FROM THE DISPLAY BOARD ............................................ |

37 |

5-3. REPLACEMENT OF THE HEATER................................................................................................................. |

38 |

||

5-4. REPLACEMENT OF THE PUMP ..................................................................................................................... |

39 |

||

5-5. REPLACEMENT OF THE RESERVOIR .......................................................................................................... |

40 |

||

5-6. REPLACEMENT OF THE TWIN BLACK TUBING........................................................................................ |

41 |

||

5-7. |

REPLACEMENT OF THE WATER TEMPERATURE SENSOR (THERMISTOR)........................................ |

41 |

|

5-8. |

REPLACEMENT OF THE I/O POWER SWITCH ............................................................................................ |

43 |

|

5-9. |

|

REPLACEMENT OF FUSES IN THE I/O POWER SWITCH ..................................................................... |

44 |

5-10. REPLACEMENT OF THE WATER LEVEL SENSOR ASSEMBLY ............................................................. |

45 |

||

5-11. |

REPLACEMENT OF THE CONTROL BOARD AND/OR DISPLAY BOARD AND/OR THE |

|

|

MEMBRANE CONTROL PANEL ............................................................................................................................. |

45 |

||

5-12. |

TROUBLESHOOTING GUIDE ................................................................................................................... |

48 |

|

SECTION 6. PARTS INFORMATION.................................................................................................................. |

53 |

|

6-1. INTRODUCTION ............................................................................................................................................... |

53 |

|

6-2. |

ORDERING INFORMATION FOR REPLACEMENT PARTS ........................................................................ |

53 |

6-3. |

RECOMMENDED REPLACEMENT PARTS INVENTORY........................................................................... |

53 |

6-4. |

RETURNING PARTS UNDER WARRANTY .................................................................................................. |

54 |

6-5. |

SHIPPING PARTS ............................................................................................................................................. |

54 |

SECTION 7. SPECIFICATIONS AND CERTIFICATIONS OF THE MICRO-TEMP LT............................. |

61 |

|

TABLE OF FIGURES

Figure 1-1. |

Micro-Temp LT Unit - Front View ....................................................................................................... |

4 |

Figure 1-2. |

Micro-Temp LT - Rear View ................................................................................................................. |

6 |

Figure 1-3. |

Micro-Temp LT – Membrane Control Panel (100/115V) .................................................................. |

8 |

Figure 1-4. |

Micro-Temp LT – Membrane Control Panel (230/240V) .................................................................. |

8 |

Figure 4-1. |

Maintenance Checklist.......................................................................................................................... |

24 |

Figure 5-1. |

Micro-Temp LT Unit - Exposed Rear View ....................................................................................... |

35 |

Figure 6-1. |

Micro-Temp LT Unit - Internal Exploded - Front View .................................................................. |

55 |

Figure 6-2. |

Parts List A............................................................................................................................................. |

55 |

Figure 6-3. |

Micro-Temp LT - Internal Exploded Rear View............................................................................... |

56 |

Figure 6-4. |

Parts List B............................................................................................................................................. |

56 |

Figure 6-5. |

Micro-Temp LT Unit – Reservoir - Side V iew................................................................................... |

57 |

Figure 6-6. |

Parts List C............................................................................................................................................. |

57 |

Figure 6-7.A |

Electrical Wiring Diagrams – 100V & 11 5V ...................................................................................... |

58 |

Figure 6-7.B |

Electrical Wiring Diagram – 230/240V.. ............................................................................................. |

59 |

Figure 6-8. |

Micro-Temp LT Accessories .......................................................................................................... |

60 |

Table 7-1. |

Guidance and Manufacturer’s Declaration – Electromagnetic Emissions for Micro-Temp |

|

|

LT ............................................................................................................................................................ |

63 |

Table 7-2. |

Guidance and Manufacturer’s Declaration – Electromagnetic Immunity for Micro-Temp |

|

|

LT ..................................................................................................................................................... |

63 |

Table 7-3. |

Guidance and Manufacturer’s Declaration – Electromagnetic Immunity for Micro-Temp LT |

|

|

that is Not Used for Life Support ....................................................................................................... |

64 |

Table 7-4. |

Recommended Separation Distances Between Portable and Mobile RF Communications |

|

|

Equipment and the Micro-Temp LT ............................................................................................. |

65 |

VII

TECHNICAL HELP |

|

|

United States and Canada |

Telephone |

1-513-772-8810 |

Cincinnati Sub-Zero Products, Inc. |

Toll Free |

1-800-989-7373 |

12011 Mosteller Road |

Fax |

1-513-772-9119 |

Cincinnati, OH 45241 |

|

|

Authorized European Representative: |

|

|

CEpartner4U |

Telephone |

+31 (0) 6-516.536.26 |

Esdoornlaan 13 |

|

|

3951 DB Maarn |

|

|

The Netherlands |

|

|

BEFORE YOU CALL FOR SERVICE

To help us better serve you, please have the serial number of your MICRO-TEMP LT unit ready when you call for parts or service.

IN-WARRANTY REPAIR AND PARTS

All parts on your MICRO-TEMP LT unit are covered by a one year warranty (parts and labor if returned to CSZ). To return defective parts or units, first obtain a Returned Materials Authorization (RMA) number from our Medical Technical Service department.

RECEIVING INSPECTION

After unpacking the MICRO-TEMP LT System, be sure to inspect the system for concealed damage. Retain all packing material and carefully describe or photograph any damage. Notify the carrier at once and ask for an inspection (in writing). Failure to do this within 15 days may result in loss of claim. Do not return the equipment to Cincinnati Sub-Zero. Call our Medical Technical Service department for further instructions.

IMPORTANT SAFETY INFORMATION

Refer to this manual for instructions and caregiver information. Read and understand all precautionary information before using, prescribing, or servicing the MICRO-TEMP LT unit.

1

INTRODUCTION |

MICRO-TEMP LT, Model 749 |

|

OPERATION AND TECHNICAL MANUAL |

|

|

SECTION 1. INTRODUCTION

1-0. GENERAL SAFETY PRECAUTIONS

To provide the patient maximum safety during the use of the MICRO-TEMP LT localized heat therapy system, a thorough knowledge and understanding of the system and its correct application and operating use are required. Each person who is responsible for use or direction of use of the system, such as physicians, nurses, technicians and operators must read and understand this operating manual and all precautions and warnings prior to use. It is recommended this manual be reviewed at least semi-annually as a refresher to ensure safe operation and application. For proper knowledge and understanding, health care facility inservice is available upon request.

1-1. GENERAL DESCRIPTION OF THIS MANUAL

This manual describes the operation, maintenance, and service of the CSZ MICRO-TEMP LT localized heat therapy system. Section One describes the physical and functional characteristics of the MICRO-TEMP LT System. Section Two explains how to prepare the MICRO-TEMP LT unit for general use. Section Three expresses how to operate the unit. Section Four describes the regular maintenance of the MICRO-TEMP LT unit. Section Five explains Field Repair and Service of the MICRO-TEMP LT unit and contains a troubleshooting guide. Section Six outlines parts information, and Section Seven lists the specifications of the MICRO-TEMP LT.

All individuals who use, operate, or service the unit should be familiar with all parts of this manual. However, Sections One and Two are primarily intended for personnel who unpack and setup the unit. Section three is primarily intended for personnel who operate the unit, and Sections Four through Six are primarily intended for personnel who service and repair the unit. Section (1-4) describes the external features of the MICRO-TEMP LT and Section (3-5) describes the alarm messages.

1-2. GENERAL DESCRIPTION OF THE MICRO-TEMP LT SYSTEM

The CSZ MICRO-TEMP LT (Model 749) Localized Heat Therapy System is used to raise a patient's body part temperature and/or maintain a desired patient body part temperature through conductive heat transfer. The CSZ MICRO-TEMP LT unit is intended for continuous operation and is composed of a heater, a circulating pump, and a microprocessor. This unit requires no field adjustments or calibrations in order to maintain the precise board measurement of temperature and temperature limits.

Distilled water is heated and pumped from the unit to a thermal pad. The pad1 rests under, on top of, or wrapped around the desired area on the patient (i.e. leg, arm, etc.) and is designed so that the water circulates through the pad and returns to the unit.

1 The recommended pad(s) for use are described in Section 1-5.

2

INTRODUCTION |

MICRO-TEMP LT, Model 749 |

|

OPERATION AND TECHNICAL MANUAL |

|

|

The Micro-Temp LT is intended for use in ambient temperatures of 20°C – 35°C (68°F – 95°F). The maximum contact surface temperature at the pad is 42°C (107°F).

1-3. CLINICAL APPLICATIONS

The MICRO-TEMP LT unit is used primarily in hospitals, in home environments (if prescribed by a doctor), and in veterinarian offices.

Medically this system can be used to increase the rate of circulation, and treat skin trauma (i.e. bruises, contusions, abscesses, boils, and burns), inflammation and other medical problems like infection, phlebitis, I.V. infiltration, and neuritis. It can also be used in orthopedic conditions to treat lower back pain, strains, acute injuries, chronic pain, muscle spasm, tendonitis and arthritis.

1-4. PHYSICAL DESCRIPTION OF THE MICRO-TEMP LT UNIT

See Section (7) for specifications and certifications of the MICRO-TEMP LT.

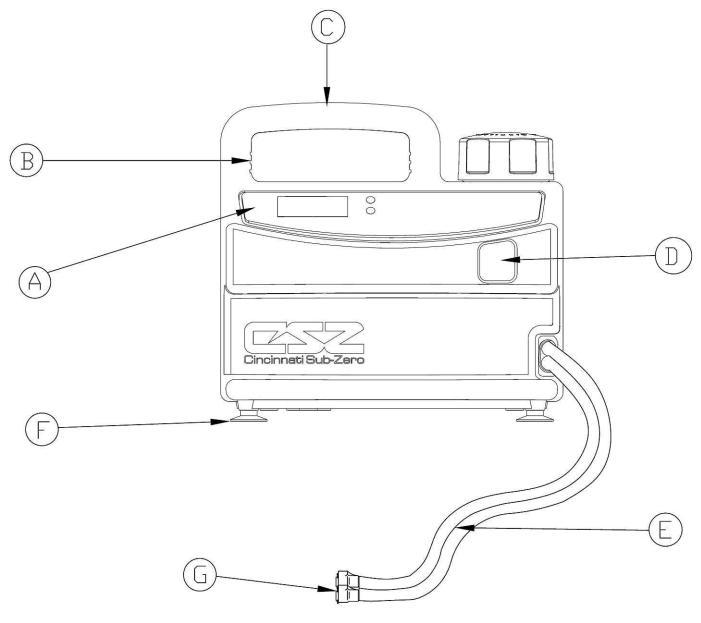

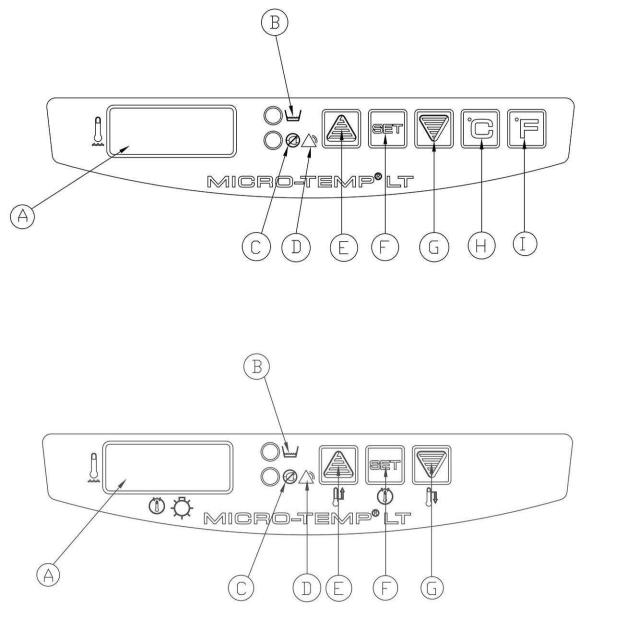

1-4.1. EXTERNAL FEATURES - FRONT VIEW

The external features in Figure (1-1) of the MICRO-TEMP LT unit are described as follows:

A.The membrane on the front of the unit allows the user to change the temperature of the water flowing through the thermal pad. It displays error messages and sounds an alarm if there is a problem with the device. Refer to Section (1-4.3) for a list of controls on the membrane. Refer to Section (3-5) for a list of possible display messages and alarms.

B.The air vents, on both the top and bottom of the unit, provide air circulation for the control board.

C.The built in handle permits the operator to grip and pick up the unit when moving it.

D.The sight window allows the operator to visually see how much water is in the reservoir.

E.The permanently attached hose connects the unit and the thermal pad.

F.The four rubber suction cups on the bottom of the unit prevent the unit from tipping.

G.The coupling attached to the end of the twin black tubing allows a quick disconnect for the heat therapy pad.

3

INTRODUCTION |

MICRO-TEMP LT, Model 749 |

|

OPERATION AND TECHNICAL MANUAL |

|

|

FIGURE 1-1. MICRO-TEMP LT, FRONT VIEW

4

INTRODUCTION |

MICRO-TEMP LT, Model 749 |

|

OPERATION AND TECHNICAL MANUAL |

|

|

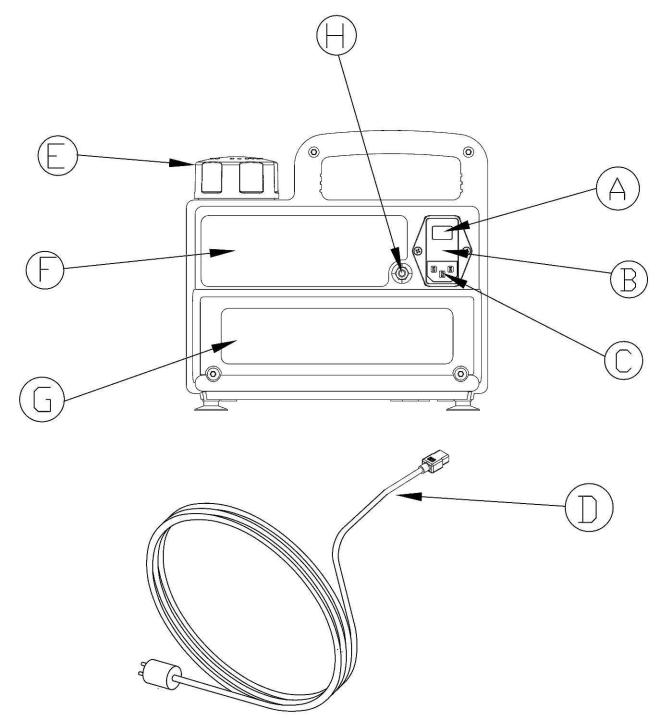

1-4.2. EXTERNAL FEATURES - REAR VIEW

The external features in Figure (1-2) of the MICRO-TEMP LT unit are described as follows:

A.The power switch is a beveled rocker switch labeled “I” for ON and “O” for OFF.

B.The fuse housing holds replaceable fuses that are integrated in the switch assembly to protect against overload conditions.

C.The main power connection is where the detachable power cord connects.

D.The detachable power cord with a hospital grade plug should only be inserted into a properly grounded receptacle. Electrical specifications are described in Section (7).

E.The water fill opening, secured with a reservoir cap, is where the operator pours distilled water into the unit to fill the reservoir.

F.The specification label outlines the MICRO-TEMP LT unit's electrical requirements and the condensed operating instructions allow the operator to see the instructions and appropriately use the unit.

G.The recessed bottom is used to secure and store the permanently attached hose and/or the power cord by wrapping the hose and/or cord around the unit when it is not in use.

H.The equipment grounding terminal is used to perform the ground continuity test.

5

INTRODUCTION |

MICRO-TEMP LT, Model 749 |

|

OPERATION AND TECHNICAL MANUAL |

|

|

FIGURE 1-2. MICRO-TEMP LT, REAR VIEW

6

INTRODUCTION |

MICRO-TEMP LT, Model 749 |

|

OPERATION AND TECHNICAL MANUAL |

|

|

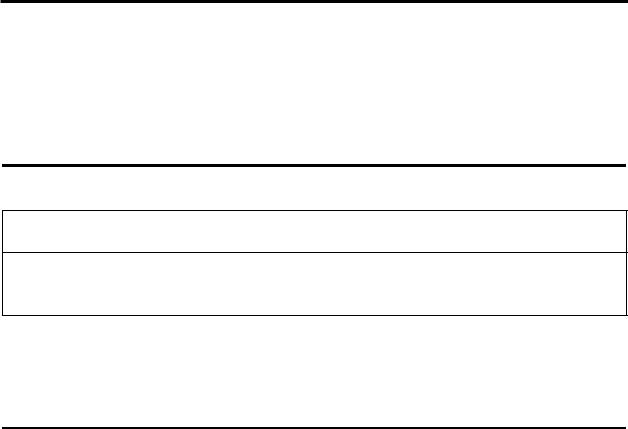

1-4.3. EXTERNAL FEATURES – MEMBRANE CONTROL PANEL

The external features in Figure (1-3) and Figure (1-4) of the MICRO-TEMP LT unit are described as follows:

A.The digital temperature display shows the actual temperature of the circulating water and the set point temperature when the “SET” button is depressed. It also displays alarm messages when a problem occurs, alerting the operator to make a change. Refer to Section (3-5) for a list of possible display messages and alarms.

B.The “Low Water” symbol indicates when the unit is low on water by illuminating the yellow LED to the left of the symbol. Refer to Section (3-5), Step (B) for Low Water Alarm.

C.The “Power Fail” symbol indicates when power has been interrupted by flashing the red LED to the left of the symbol and sounding an audible alarm. Refer to Section (3-5), Step (B) for Power Failure.

D.The “Warning” symbol indicates when the water temperature is >1°C (2°F) over the set point temperature, the water has reached the high limit temperature of 44°C (111° F), the tilt of the unit is beyond approximat ely 20˚ in any direction, or when there is a fault within the unit by flashing/illuminating the red LED to the left of the symbol and sounding an audible alarm. Refer to Section (3-5), Step (B).

E.The Increment button is used to increase the set point temperature when needed.

F.The “SET” temperature button is used to position the set point temperature.

G.The Decrement button is used to decrease the set point temperature when needed.

H.The “°C” button allows the operator to select Ce lsius as the measurement scale by which the unit functions (100V and 115V only).

I.The “°F” button allows the operator to select Fa hrenheit as the measurement scale by which the unit functions (100V and 115V only).

7

INTRODUCTION |

MICRO-TEMP LT, Model 749 |

|

OPERATION AND TECHNICAL MANUAL |

|

|

FIGURE 1-3. MICRO-TEMP LT, MEMBRANE CONTROL PANEL (100V/115V ONLY)

FIGURE 1-4. MICRO-TEMP LT, MEMBRANE CONTROL PANEL (230/240V ONLY)

8

INTRODUCTION |

MICRO-TEMP LT, Model 749 |

|

OPERATION AND TECHNICAL MANUAL |

|

|

1-5. REQUIRED ACCESSORIES

The only essential accessory for the MICRO-TEMP LT unit is a thermal pad. Thermal pads are available with or without a layer of foam bonded to one side and with a non-woven fabric on both sides to allow moist heat therapy when the foam or non-woven fabric is wetted. They are available in a variety of sizes. The maximum thermal pad allowed for the MICRO-TEMP LT is 25” x 19”.

The thermal pad is connected to the unit via the permanently attached eight foot (2.4 meter) hose with “quick-connect” couplings, featuring automatic shut-offs on the end of each hose.

A list of MICRO-TEMP LT System Equipment and accessories are found in Figure (6-8).

1-6. FUNCTIONAL DESCRIPTION OF THE MICRO-TEMP LT SYSTEM

1-6.1. THEORY OF OPERATION

The MICRO-TEMP LT utilizes a linear temperature controller featuring a digital read-out of water and set point temperature (selectable to indicate Celsius or Fahrenheit for 100V and 115V only), and operates between a temperature range of 20°C to 42°C (68°F to 107°F). In addition, this model includes audible alarms and visual indicators for power failure and warning alarms, along with a visual indicator for low water. Safety features include: linear control to ensure accuracy of temperature setting at all times by eliminating the need for calibration; digital display of actual water temperature as well as set point temperature; a low water cut-off switch which shuts off both the heater and circulating pump; an independent high limit sensor to guard against possible over-heating and subsequent patient injury; and a tilt switch alarm which sounds and shuts the unit off when tilted more than approximately 20° in any direction from the horizontal plane.

1-6.2. HEATING SYSTEM

The MICRO-TEMP LT heating system consists of an immersion heater, a water temperature control, and two high temperature safety devices. Temperature ranges of the system are described in Section (1-6.4). The immersion heater is located in the reservoir. The water circulating in the reservoir flows around the immersion heater and is warmed by conductive heat transfer.

The heating system is operational whenever the control system calls for an increase in the temperature of the circulating water. It is important to note that the rate of change in the circulating water temperature is not directly proportional to the rate of change in the temperature of the patient.

1-6.3. CIRCULATING SYSTEM

The MICRO-TEMP LT circulating water system is composed of a magnetically driven circulating pump, a single self contained reservoir, a connecting hose, quick-disconnect fittings, and a localized heat therapy pad.

9

INTRODUCTION |

MICRO-TEMP LT, Model 749 |

|

OPERATION AND TECHNICAL MANUAL |

|

|

The 0.24-gallon (0.9 liters) capacity reservoir is composed of a single circulating unit.

The circulating water flows over and around the heating element and water temperature sensor located in the circulating reservoir. The heated water then flows out of the reservoir, to the circulating pump, through the pump housing and connecting hoses, and then to the localized heat therapy pad. The water circulates through the pad and returns to the unit to be reheated and recycled.

In addition, the reservoir contains a low water level sensor which shuts down the heater and pump, and illuminates the Low Water LED if the water level drops below a preset amount. The unit becomes operational only after the water level is restored to normal.

1-6.4. TEMPERATURE SAFETY CONTROL SYSTEM

The MICRO-TEMP LT unit is designed to carefully measure and control the temperature of the circulating water. It is engineered so that when the temperature of the circulating water reaches the desired set point, the heater cycles in order to maintain the set point temperature. The unit is designed not to exceed or fall below the desired temperature.

As a safety precaution, the MICRO-TEMP LT unit has a >1°C (2°F) over set point alarm and a high temperature alarm.

Each safety device continuously monitors the temperature of the circulating water. As an additional precaution, if the water temperature sensor itself should fail, the unit shuts down and the display indicates EE05. With this safety design, both the patient and the unit are protected from injury or damage caused by extreme temperatures.

NOTE: The operator must regularly monitor the patient whenever localized heat therapy is used.

SAFETY CONTROLS FOR PROTECTION FROM HIGH TEMPERATURE

The circulating water reaches 42.0°C |

± 0.5°C (107°C |

± 1°F), and a microprocessor controls the |

set point. |

|

|

If the circulating water reaches 44°C |

± 0.5°C (111°F |

± 1°F), a safety device shuts off the heater |

and pump, the display alternates between flashing the actual water temperature and flashing “HL,” an alarm continuously sounds, and the red “Warning” LED illuminates. This alarm condition cancels only after the unit is powered down.

If the circulating water reaches >1°C (2°F) over th e set point, the display flashes the actual water temperature, and 2 beeps sound while the red ”Warning” LED flashes. The safety device shuts off the heater. If the water temperature does not return to the set point temperature after 9 minutes, the device will again sound 2 beeps and the “Warning” LED will flash. The actual water temperature will continue to flash until the water temperature reaches the set point.

10

GENERAL PREPARATION |

MICRO-TEMP LT, Model 749 |

|

OPERATION AND TECHNICAL MANUAL |

|

|

SECTION 2. GENERAL PREPARATION OF THE MICRO-TEMP LT SYSTEM

2-1. INTRODUCTION

This section describes the procedures to prepare the MICRO-TEMP LT unit for general use. This entails unpacking the shipment, arranging all the equipment for the first time, and completing a test routine. This section also outlines the bacteriocidal agent preparations, standard safety precautions, and patient preparation/bedside care when using the hyperthermia pad(s). Technical support is available upon request.

2-2. UNPACKING THE SHIPMENT

WARNING

∙Do not use if the outer casing or membrane control panel is cracked or internal components are exposed. Contact with internal components could result in electric shock or thermal injury to the patient or operator.

During the unpacking process, look carefully for signs of shipping damage. If any unacceptable damage is found, notify the transportation company immediately and file a claim. The transportation company is responsible for the shipment after it leaves the factory. If problems other than shipping damage are found, notify your Cincinnati Sub-Zero representative or the Factory.

2-3. FIRST TIME SET-UP/SYSTEM TEST ROUTINE

This section describes the tasks necessary to inspect and arrange the equipment for the first time after unpacking, and describes a System Test Routine to check the membrane control panel.

The System Test Routine can also be used to teach operators who are unfamiliar with the equipment how to use the unit.

2-3.1. INSPECTING AND ARRANGING THE EQUIPMENT

A.Place the MICRO-TEMP LT unit in an uncluttered work space that is accessible to the correct power source with an ambient temperature between 20°C – 35°C (68°F – 95°F) Position the unit so that the membrane control panel faces the operator. See Section

(7) for electrical specifications.

B.Visually inspect the MICRO-TEMP LT unit to determine that there are no missing parts, unusual dents, or punctures.

C.Examine the power cord for cuts or exposed wires and check the power cord for bent or missing prongs.

11

GENERAL PREPARATION |

MICRO-TEMP LT, Model 749 |

|

OPERATION AND TECHNICAL MANUAL |

|

|

D.Review Section (1-4.1), (1-4.2), and (1-4.3) to identify the features of the MICROTEMP LT unit.

E.Collect and arrange a localized heat therapy pad described in Section (1-5).

CAUTION

∙Use distilled water only. Do Not Use De-Ionized water.

∙Do not use alcohol. Alcohol may cause pad deterioration.

∙Do NOT fill the reservoir to the bottom of the strainer if there is water in the pad.

This could cause an overflow when the unit is turned on.

F.Twist off the cap on the water fill opening and gradually pour approximately .9 liters of distilled water and two (2) ounces of Propylene Glycol into the reservoir. Stop pouring when the water reaches the strainer and is visible at the bottom of the water fill opening.

G.Connect the pad to the MICRO-TEMP LT unit by attaching the pad to the couplings at the end of the connecting hose. The pad must be connected to one outlet and one return.

H.Check that the pad is lying flat and that the hose permanently attached to the unit is not twisted or pinched.

I.Check that the power switch of the unit is OFF.

J.Connect the detachable power cord to the unit.

NOTE: If pad is placed above unit, disconnect pad prior to turning off unit. This could cause backflow if pad is not disconnected.

WARNING

∙Do not by-pass ground on power cord plug. Electrical Hazards may result.

K.Insert the plug into a properly grounded receptacle.

2-3.2. COMPLETING A SYSTEM TEST ROUTINE

After arranging the equipment described in Section (2-3.1), complete the System Test Routine describing which switches to press and the changes to observe.

NOTE: If power is supplied to the unit and is removed without actuating the power switch (I/O switch) a power fail alarm is activated. To stop the alarm, restore power to the unit or turn the power switch to the “O” (OFF) position.

A.Make sure that the power switch is in the "I" (ON) position.

1.The digital temperature display indicates that the unit is on.

12

GENERAL PREPARATION |

MICRO-TEMP LT, Model 749 |

|

OPERATION AND TECHNICAL MANUAL |

|

|

a.Upon initial power-up, the unit flashes the 42°C default set point four times, and then flashes the actual water temperature two times before constantly displaying the water temperature.

2.The pump activates and begins circulating water.

B.Press and hold the “SET” button.

1.The display shows 42°C

C.Release “SET” button.

1.The display reverts back to displaying the actual water temperature.

D.Press the “°F” button (100V and 115V only).

1.The water temperature displayed changes from Celsius to Fahrenheit.

E.Press the “˚C” button (100V and 115V only)

1.The water temperature displayed changes from Fahrenheit to Celsius.

NOTE: If at any time the water falls below a preset limit, the low water sensor is activated and the Low Water LED illuminates. The unit shuts down and the operator cannot proceed until this is corrected.

If any of the above are not observed, consult the Troubleshooting Guide in Section (5-12). If they are observed, continue with the test routine.

WARNING

∙Water leaks present a risk of infection to the patient and should be handled accordingly. Proper sanitation procedures should be followed including, but not limited to, the preventative maintenance described in this manual. Leaky pads or hoses should never be used.

F.Check the pad for leaks. If a leak is found, the pad cannot be used. The disposal for reusable pads is described in Section (4-4).

G.Check the couplings at the end of the hose and pad for positive connection.

NOTE: Set point may be displayed in Fahrenheit if the operator is in Fahrenheit mode (100V and 115V only). Otherwise the set point is displayed in Celsius.

H.While depressing the “SET” button, press the Down arrow next to the “SET” button.

1.The set point display temperature changes and the numbers move down the scale. The longer the button is pressed the faster the digits change. When the button is released and repressed, the digits once again change slowly and then increase in speed. The lowest setting is 20°C (68°F).

I.While depressing the “SET” button, press the Up arrow next to the “SET” button.

13

GENERAL PREPARATION |

MICRO-TEMP LT, Model 749 |

|

OPERATION AND TECHNICAL MANUAL |

|

|

1.The set point display changes and the numbers move up the scale. The longer the button is pressed the faster the digits change. When the button is released and repressed, the digits once again change slowly and then increase in speed. The highest setting is 42°C or 1 07°F.

NOTE: If water temperature is >1°C (2 °F) over the set point temperature, the display will flash and the unit will alarm.

J.To complete this test routine, turn the power switch to the “O” (OFF) position.

1.The display goes blank.

K.Disconnect the power cord from the power source and loosely coil it up, securing it with the attached velcro tie.

L.For single-use pads, i.e. TEMP-PAD, MAXI-THERM, and MAXI-THERM LITE pads, follow the instructions packaged with the pad.

The MICRO-TEMP LT unit is now ready for patient use.

2-4. UNIT AND PATIENT RELATED PRECAUTIONS

This unit requires both water and electricity to operate.

Please consult page I, II, and III at the beginning of the manual for a complete list of warnings and cautions related to the MICRO-TEMP LT.

A.Anytime the unit sounds an alarm, the operator should immediately check the status display and act accordingly (e.g., add water, remove from service, etc.). See Section (3-5) for status display and alarm messages.

B.The MICRO-TEMP LT unit is equipped with fuses in the I/O power switch to protect against current overload.

2-5. PATIENT PREPARATION AND BEDSIDE CARE

Effective use of the MICRO-TEMP LT system must include proper patient care prior to and while using the hyperthermia pad(s).

14

GENERAL PREPARATION |

MICRO-TEMP LT, Model 749 |

|

OPERATION AND TECHNICAL MANUAL |

|

|

WARNING

∙A physician's order is required for setting pad temperature and use of equipment. As directed by physician, check the patient's temperature and skin condition of areas in contact with the pad. Check the pad water temperature. Pediatric patients, temperaturesensitive patients with vascular disease, surgical patients, diabetics, and Raynauds disease patients should be checked more frequently. Notify the physician promptly of any change in patient status in order to avoid serious injury or death. Failure to inform the physician of any deviation may result in injury to the patient.

Pediatrics – Infants and children body temperature are more responsive to surface heating than adults. Due to their size, the effect of heating a child is more pronounced because of their higher ratio of skin contact area to body mass.

Temperature Sensitive Patients – Patients with impaired peripheral blood circulation and patients who are incapacitated may be more sensitive to temperature changes than patients with normal circulation.

Surgical Patients – Patients with poor circulation due to inadequate heart function, loss of blood, or impaired peripheral blood circulation may be more sensitive to temperature changes.

∙If device is used at home, patient must follow directions prescribed by their physician and be aware of all warnings and cautions mentioned throughout the manual.

∙Observe patient’s skin condition frequently due to individual differences in sensitivity and susceptibility to injury from heat and/or externally applied chemicals or pressure. Patients at greatest risk are those unconscious, on prolonged therapy, diabetics, children, and persons incapacitated, with sensitive skin areas, or poor circulation.

∙Do not use for ECMO (Extracorporeal Membrane Oxygenation) therapy.

∙The method of temperature control provided by all localized heat therapy units presents the danger of heating body tissues, particularly the skin, to a point where they are injured, i.e., burns. Depending on the extent and severity of a burn, very serious complications may arise.

∙Prevent excessive and/or prolonged tissue pressure and shearing forces, especially over bony prominences, to prevent skin damage that may result.

∙Do not place additional heat sources between the patient and pad. Skin damage may result.

∙Do not use the MICRO-TEMP LT system in the presence of flammable anesthetics. Risk of explosion can result.

∙Do not position unit near any objects that can generate a strong electrical/magnetic field. Potential electromagnetic interference may result.

∙The display may blank momentarily during an electrostatic discharge event, but the essential performance of the unit is not affected and no harm will occur to the patient. If an electrostatic discharge event occurs, check to see if unit is operating properly. If unit does not return to previous operation, turn unit off then back on and reset temperature settings as prescribed.

∙Do not wrap pad so tightly as to constrict blood flow. Do not use pins to secure pad or hoses. Do not allow pad or hoses to come in contact with any sharp object.

15

Loading...

Loading...