Page 1

ENABLE

An IQ System® to Host Computer Interface

©1999 by Crown International, Inc., P.O. Box 1000, Elkhart, Indiana 46515-1000

U.S.A. Telephone: 219-294-8000. The

Audio Unit of Crown International, Inc. Trademark Notice:

and Crown

national, Inc. Other trademarks are the property of their respective owners.

,®

Amcron® and IQ System

IQ-INT II

®

are registered trademarks of Crown Inter-

is produced by the Professional

PIPTM is a trademark

Printed on

recycled paper.

101937-3

9/99

Page 2

THREE YEAR

FULL WARRANTY

WORLDWIDE

The Crown Audio Division of Crown International, Inc., 1718 West

Mishawaka Road, Elkhart, Indiana 46517-4095 U.S.A. warrants to you,

the ORIGINAL PURCHASER and ANY SUBSEQUENT OWNER of

each NEW Crown1 product, for a period of three (3) years from the date

of purchase by the original purchaser (the “warranty period”) that the

new Crown product is free of defects in materials and workmanship,

and we further warrant the new Crown product regardless of the reason for failure, except as excluded in this Crown Warranty.

1

Note: If your unit bears the name “Amcron,” please substitute it for the

name “Crown” in this warranty.

ITEMS EXCLUDED FROM THIS CROWN WARRANTY

This Crown Warranty is in effect only for failure of a new Crown product

which occurred within the Warranty Period. It does not cover any product which has been damaged because of any intentional misuse, accident, negligence, or loss which is covered under any of your insurance

contracts. This Crown Warranty also does not extend to the new Crown

product if the serial number has been defaced, altered, or removed.

We will remedy any defect, regardless of the reason for failure (except

as excluded), by repair, replacement, or refund. We may not elect refund unless you agree, or unless we are unable to provide replacement, and repair is not practical or cannot be timely made. If a refund is

elected, then you must make the defective or malfunctioning product

available to us free and clear of all liens or other encumbrances. The

refund will be equal to the actual purchase price, not including interest,

insurance, closing costs, and other finance charges less a reasonable

depreciation on the product from the date of original purchase. Warranty work can only be performed at our authorized service centers.

We will remedy the defect and ship the product from the service center

within a reasonable time after receipt of the defective product at our

authorized service center.

You must notify us of your need for warranty service not later than

ninety (90) days after expiration of the warranty period. All components

must be shipped in a factory pack. Corrective action will be taken within

a reasonable time of the date of receipt of the defective product by our

authorized service center. If the repairs made by our authorized service center are not satisfactory, notify our authorized service center

immediately.

DISCLAIMER OF CONSEQUENTIAL AND INCIDENTAL

YOU ARE NOT ENTITLED TO RECOVER FROM US ANY INCIDENTAL DAMAGES RESULTING FROM ANY DEFECT IN THE NEW

CROWN PRODUCT. THIS INCLUDES ANY DAMAGE TO ANOTHER

PRODUCT OR PRODUCTS RESULTING FROM SUCH A DEFECT.

No person has the authority to enlarge, amend, or modify this Crown

Warranty. This Crown Warranty is not extended by the length of time

which you are deprived of the use of the new Crown product. Repairs

and replacement parts provided under the terms of this Crown Warranty shall carry only the unexpired portion of this Crown Warranty.

We reserve the right to change the design of any product from time to

time without notice and with no obligation to make corresponding

changes in products previously manufactured.

No action to enforce this Crown Warranty shall be commenced later

than ninety (90) days after expiration of the warranty period.

THIS STATEMENT OF WARRANTY SUPERSEDES ANY OTHERS

CONTAINED IN THIS MANUAL FOR CROWN PRODUCTS.

Telephone: 219-294-8200. Facsimile: 219-294-8301 Telephone: 219-294-8200. Facsimile: 219-294-8301

SUMMARY OF WARRANTY

WHAT THE WARRANTOR WILL DO

HOW TO OBTAIN WARRANTY SERVICE

DAMAGES

WARRANTY ALTERATIONS

DESIGN CHANGES

LEGAL REMEDIES OF PURCHASER

9/90

The Crown Audio Division of Crown International, Inc., 1718 West Mishawaka Road,

Elkhart, Indiana 46517-4095 U.S.A. warrants to you, the ORIGINAL PURCHASER

and ANY SUBSEQUENT OWNER of each NEW Crown product, for a period of

three (3) years from the date of purchase by the original purchaser (the “warranty

period”) that the new Crown product is free of defects in materials and workmanship. We further warrant the new Crown product regardless of the reason for failure,

except as excluded in this Warranty.

This Crown Warranty is in effect only for failure of a new Crown product which

occurred within the Warranty Period. It does not cover any product which has been

damaged because of any intentional misuse, accident, negligence, or loss which is

covered under any of your insurance contracts. This Crown Warranty also does not

extend to the new Crown product if the serial number has been defaced, altered, or

removed.

We will remedy any defect, regardless of the reason for failure (except as excluded),

by repair, replacement, or refund. We may not elect refund unless you agree, or

unless we are unable to provide replacement, and repair is not practical or cannot

be timely made. If a refund is elected, then you must make the defective or malfunctioning product available to us free and clear of all liens or other encumbrances. The

refund will be equal to the actual purchase price, not including interest, insurance,

closing costs, and other finance charges less a reasonable depreciation on the

product from the date of original purchase. Warranty work can only be performed at

our authorized service centers or at the factory. We will remedy the defect and ship

the product from the service center or our factory within a reasonable time after

receipt of the defective product at our authorized service center or our factory. All

expenses in remedying the defect, including surface shipping costs in the United

States, will be borne by us. (You must bear the expense of shipping the product

between any foreign country and the port of entry in the United States and all taxes,

duties, and other customs fees for such foreign shipments.)

You must notify us of your need for warranty service not later than ninety (90) days

after expiration of the warranty period. All components must be shipped in a factory

pack, which, if needed, may be obtained from us free of charge. Corrective action

will be taken within a reasonable time of the date of receipt of the defective product

by us or our authorized service center. If the repairs made by us or our authorized

service center are not satisfactory, notify us or our authorized service center immediately.

DISCLAIMER OF CONSEQUENTIAL AND INCIDENTAL DAMAGES

YOU ARE NOT ENTITLED TO RECOVER FROM US ANY INCIDENTAL DAMAGES RESULTING FROM ANY DEFECT IN THE NEW CROWN PRODUCT. THIS

INCLUDES ANY DAMAGE TO ANOTHER PRODUCT OR PRODUCTS RESULTING FROM SUCH A DEFECT. SOME STATES DO NOT ALLOW THE EXCLU-

SION OR LIMITATIONS OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

No person has the authority to enlarge, amend, or modify this Crown Warranty. This

Crown Warranty is not extended by the length of time which you are deprived of the

use of the new Crown product. Repairs and replacement parts provided under the

terms of this Crown Warranty shall carry only the unexpired portion of this Crown

Warranty.

We reserve the right to change the design of any product from time to time without

notice and with no obligation to make corresponding changes in products previously manufactured.

THIS CROWN WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, YOU MAY

ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE. No action

to enforce this Crown Warranty shall be commenced later than ninety (90) days

after expiration of the warranty period.

THIS STATEMENT OF WARRANTY SUPERSEDES ANY OTHERS

NORTH AMERICA

SUMMARY OF WARRANTY

ITEMS EXCLUDED FROM THIS CROWN WARRANTY

WHAT THE WARRANTOR WILL DO

HOW TO OBTAIN WARRANTY SERVICE

WARRANTY ALTERATIONS

DESIGN CHANGES

LEGAL REMEDIES OF PURCHASER

CONTAINED IN THIS MANUAL FOR CROWN PRODUCTS.

9/90

Page 3

The information furnished in this manual does not include all of the details of design, production, or variations

of the equipment. Nor does it cover every possible situation which may arise during installation, operation or

maintenance. If you need special assistance beyond the scope of this manual, please contact our Technical

Support Group.

Crown Audio Division Technical Support Group

Plant 2 SW, 1718 W. Mishawaka Rd., Elkhart, Indiana 46517 U.S.A.

Phone: 800-342-6939 (North America, Puerto Rico and Virgin Islands) or 219-294-8200

Fax: 219-294-8301 Fax Back (North America only): 800-294-4094 or 219-293-9200

Fax Back (International): 219-294-8100 Internet: http://www.crownaudio.com

WARNING

TO REDUCE THE RISK OF ELECTRIC

SHOCK, DO NOT EXPOSE THIS

EQUIPMENT TO RAIN OR MOISTURE!

PLEASE NOTE

The following universal symbols may appear on your product and/or in various

sections of this manual. Wherever they appear, they are to be interpreted as follows:

Lightning Bolt Symbol:

This symbol is used to alert the user to the presence of dangerous

voltages and the possible risk of electric shock.

Exclamation Mark Symbol:

This symbol is used to alert the user to refer to the instruction

manual for important operating or maintenance instructions.

FCC Class A Compliance

This equipment has been tested and found to comply with the limits for Class A

Digital Device, pursuant to Part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses and can ra

diate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense.

The user is cautioned that any changes or modifications not expressly approved by

the party responsible for compliance could void the user’s authority to operate the

equipment.

Note: For a system to comply with FCC rules, all components in the system must be

in compliance. Please consult the instruction manuals of all components in an IQ

System for FCC compliance.

Page 4

Important Safety Instructions

IQ-INT II IQ Interface

1) Read these instructions.

2) Keep these instructions.

3) Heed all warnings.

4) Follow all instructions.

5) Do not use this apparatus near water.

6) Clean only with a dry cloth.

7) Do not block any ventilation openings. Install in

accordance with the manufacturer’s instructions.

8) Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus

that produce heat.

9) Do not defeat the safety purpose of the polarized

or grounding-type plug. A polarized plug has two

blades with one wider than the other. A grounding-type plug has two blades and a third grounding prong. The wide blade or the third prong is

provided for your safety. If the provided plug

does not fit into your outlet, consult an electrician

for replacement of the obsolete outlet.

10) Protect the power cord from being walked on or

pinched, particularly at plugs, convenience receptacles, and the point where they exit from the

apparatus.

11) Only use attachments/accessories specified by

the manufacturer.

12) Use only with a cart, stand, bracket, or table

specified by the manufacturer, or sold with the

apparatus. When a cart is used, use caution

when moving the cart/apparatus combination to

avoid injury from tip-over.

13) Unplug this apparatus during lightning storms or

when unused for long periods of time.

14) Refer all servicing to qualified service personnel.

Servicing is required when the apparatus has

been damaged in any way, such as power-supply cord or plug is damaged, liquid has been

spilled or objects have fallen into the apparatus,

the apparatus has been exposed to rain or moisture, does not operate normally, or has been

dropped.

CONTENTS

11

WW

elcomeelcome

1

W

elcome

11

WW

elcomeelcome

1.1 Unpacking _________________________________________ 5

22

FacilitiesFacilities

2

Facilities

22

FacilitiesFacilities

33

InstallationInstallation

3

Installation

33

InstallationInstallation

3.1 Connecting to a Crown Bus Loop ______________________6

3.2 Connecting to a Host Computer _______________________ 9

3.2.1 Connecting to a Modem ________________________ 9

3.2.2 Communication Settings ______________________ 10

44

TT

echnical Inforechnical Infor

4

T

echnical Infor

44

TT

echnical Inforechnical Infor

55

SpecificationsSpecifications

5

Specifications

55

SpecificationsSpecifications

66

ServiceService

6

Service

66

ServiceService

6.1 Worldwide Service ________________________________ 13

6.2 North American Service ____________________________ 13

6.2.1 Service at a North American Service Center _____ 13

6.2.2 Crown Factory Service _______________________ 13

__________________________________________________________________________________________

_____________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

_____________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

_____________________________________________

__________________________________________________________________________________________

mationmation

mation

mationmation

______________________________________________________________________________________

___________________________________________

______________________________________________________________________________________

____________________________________________________________________

__________________________________

____________________________________________________________________

________________________________________________________________________________

________________________________________

________________________________________________________________________________

1111

11

1111

1212

12

1212

1313

13

1313

55

5

55

55

5

55

66

6

66

Page 4

Reference Manual

Page 5

IQ-INT II IQ Interface

A

ENABLE

IN OUT1IN OUT2IN OUT3IN OUT4IN OUT5IN OUT6IN OUT7IN OUT

1

INPUT

2

WIRING

GND

3

CB D E

OUTPUT

WIRING

1

2

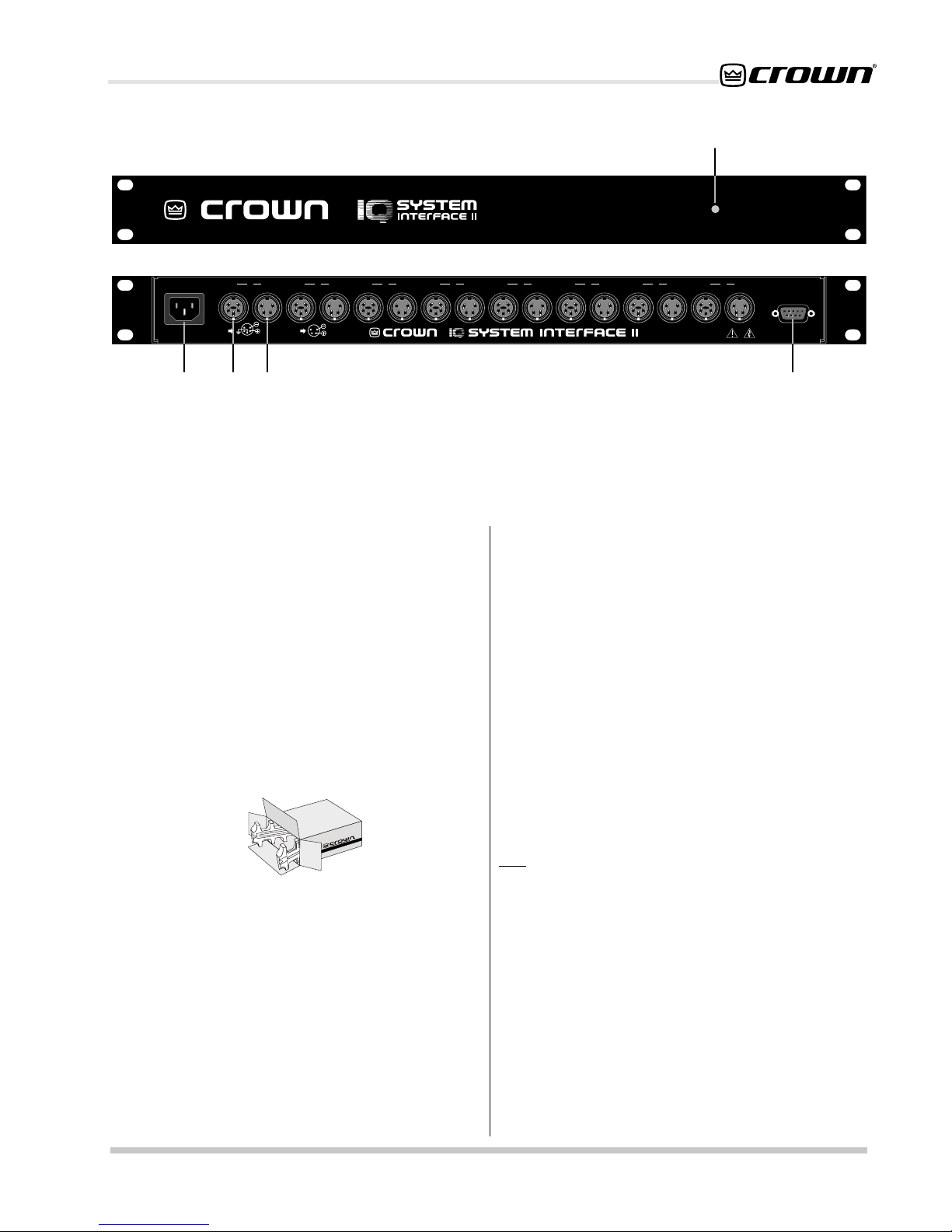

Fig. 1.1 IQ-INT II

1 Welcome

The

IQ-INT II

to eight different Crown Bus loops to a host computer. It

is a self-contained unit with its own Crown Bus drivers,

RS232/RS422 drivers and power supply. It has a

microprocessor that can be directed by the host

computer to execute commands, and it can send and

receive commands and data to and from IQ components

connected to its Crown Bus loops.

This manual will help you successfully install and use

your new interface. Please read all instructions,

warnings, and cautions. Also, for your protection, please

send in the warranty registration card today and save

your bill of sales as it is your official proof of purchase.

is an

IQ System

interface that connects up

8

COMPUTER

RS232 / RS422

USE SIDE ACCESS HOLE TO

SET BAUD RATE AND

OTHER COM SETTINGS.

2 Facilities

A. Enable Indicator

This front panel LED lights when the power cord is

connected to the AC mains and the unit is receiving

power. The

B. Power Inlet

A standard IEC power inlet. 115-VAC units shipped with

Nema® 5-15P power cord. 230-VAC units require a user

supplied IEC power cord.

C. Crown Bus Input Connector

A 5-pin female DIN connector is provided for input

connection to each of eight separate Crown Bus loops.

A mating Switchcraft 502-series connector can be

ordered from Crown (part C 7776-5). Pin 1 is negative

(–), pin 2 is positive (+), and pin 3 is ground. Pins 4 and

5 are not used.

used for the Crown Bus, the shield should be connected

only to pin 3 of the input connector.

IQ-INT II

has no on/off switch.

Note: If shielded twisted-pair wire is

1.1 Unpacking

Please unpack and inspect the new interface for any

damage that may have occurred during transit. If

damage is found, notify the transportation company

immediately. Only you, the consignee, may initiate a

claim for shipping damage. Crown will be happy to

cooperate fully as needed. Save the shipping carton as

evidence of damage for the shipper’s inspection.

Even if the unit has arrived in perfect condition, as most

do, save all packing materials so you will have them if

you ever need to transport the unit. NEVER SHIP THE

UNIT WITHOUT THE FACTORY PACK.

Reference Manual

D. Crown Bus Output Connector

A 4-pin female DIN connector is provided for output

connection to each of eight separate Crown Bus loops.

A mating Switchcraft 502 series connector can be

ordered from Crown (part C 7777-3). Pin 1 is ground

and pin 2 is positive (+). Pins 3 and 4 are not used.

Note: If shielded twisted-pair wire is used for the Crown

Bus, the shield should not be connected to the output

connector.

E. Computer RS232/RS422 Connector

A female, 9-pin D-subminiature connector is provided

for serial connection to a host computer. Both RS232

and RS422 communication standards are supported.

Page 5

Page 6

RS232/RS422

ENABLE

ENABLEDSPI ENABLEDSPI

ODEP

ENABLE

CH1 CH2

IOC

SPI

POWER

OFF

CH1 CH2

IQ-INT II IQ Interface

ODEP

ENABLE

IOC

SPI

POWER

OFF

ODEP

ENABLE

CH1 CH2

CH1 CH2

IOC

SPI

ODEP

IOC

SPI

POWER

OFF

ENABLE

POWER

OFF

Fig. 3.1 An IQ System with an IQ-INT II

3 Installation

The installation of an

major parts: Connecting to one or more Crown Bus loops

and connecting to the host computer.

3.1 Connecting to a Crown Bus Loop

The Crown Bus is a serial communication loop designed

to transmit IQ commands and data. As a communication

standard, it is independent of its wiring. This

characteristic allows you to wire a Crown Bus loop with

either fiber optic cabling or with inexpensive twistedpair wire, whichever is most appropriate. One

can have more than one Crown Bus loop, and each

loop must be unbroken for proper operation.

The

IQ-INT II

This makes it possible to divide the system into zones,

each with its own loop. Using the

multiple Crown Bus loops has several advantages and

disadvantages that are listed next.

Multiloop Advantages

• A break in communication in one loop does not

affect other loops.

• Over 250 IQ components of the same model can

be used in a system.

• The same IQ address can be used more than once

(once for each type of unit on each loop).

• Larger areas can often be covered without using

repeaters or fiber optic cabling.

supports up to eight Crown Bus loops.

IQ-INT II

can be divided into two

IQ System

IQ-INT II

to drive

ODEP

ENABLE

CROWN BUS LOOP 1

CROWN BUS LOOP 2

CH1 CH2

CH1 CH2

IOC

SPI

ODEP

IOC

SPI

POWER

OFF

ENABLE

POWER

OFF

Single Loop Advantages

• The

IQ-INT II

can send and receive data slightly

faster using a single loop.

• “Real-time” levels can be displayed for a greater

number of units.

The

IQ-INT II

is designed to work with inexpensive

twisted-pair wire, so it implements the Crown Bus as a

20-milliamp current loop operating at a baud rate of

38,400. If you want to use fiber optic cabling, contact

Crown’s Technical Support Group for information on the

appropriate transceivers.

Here are some guidelines for twisted-pair wiring:

• A Crown Bus loop must be unbroken

to carry

commands and data to and from connected units.

• Never cross-connect Crown Bus loops. Each

Crown Bus loop is an independent serial

communication circuit. A Crown Bus output is

connected to the input of the first IQ component on

the loop. Each unit’s output connects to the next

unit’s input until the loop returns to the interface

where it is connected to the input for the same loop.

• Use twisted-pair wire

at least 26 AWG in size. Use

twisted-pair wire with a shield when interference is

a concern. The wire should be of good quality and

should have low capacitance (30 picofarads/foot

or less). In most cases, interference is not a problem

and unshielded wire is a better choice because of

Page 6

Reference Manual

Page 7

IQ-INT II IQ Interface

OUT IN

++–

1 Input (–)

2 Input (+)

3 GND

4 Not used

5 Not used

Output (+)

Output (–)

Input (+)

Input (–)

IQ–INT II Input

2

5

3

4

1

Optional Shield

Barrier Block

IQ Component

Output

its lower capacitance. When used with the Crown

Bus, a shield serves two purposes: it helps prevent

data signals from being transmitted to nearby audio

wiring, and helps prevent high external RF levels

from interfering with data transmissions. If you must

install shielded wire, use a low-capacitance shielded

wire like West Penn 452 or equivalent.

• If shielded wire is used, only connect the shield

at the input connection.

Connecting both ends of

the shield may cause a ground loop.

• The total capacitance for each loop should be

40 nanofarads or less.

Add up the loop’s total

capacitance based on the wire’s rating in picofarads

per foot, and allow approximately 60 picofarads for

each connected IQ component. Experience has

shown that loops with 75 or more components

usually require at least one repeater.

• Add an IQ Repeater

for long loops greater than

1,000 feet (305 m) or when required by highcapacitance wire. Although repeaters are

recommended for loops longer than 1,000 feet, it is

often possible to set up reliable loops of 2,000 feet

(610 m) or more without a repeater. Although we

recommend shielded wire, unshielded wire typically

has less capacitance and can support longer loops.

• Never use the ground wire in a mic snake.

At

times, it may be convenient to run Crown Bus data

signals to and from stage monitor amplifiers along

unused wires in a mic snake. If this is done, do not

use the ground wire which is normally connected

to pin 1 on an XLR connector, or data noise will be

added to the audio lines. Use only the signal lines

which normally connect to pins 2 and 3 of the XLR’s.

Note: Because typical mic cables have higher

capacitance, the maximum possible Crown Bus

loop will be shorter than low-capacitance twistedpair wire.

IQ–INT II Output

DIN IQ Component

Input

41

23

Output (–) 1

Output (+) 2

Not used 3

Not used 4

Optional Shield

5

4

3

1 Input (–)

2 Input (+)

3 GND

4 Not used

5 Not used

Fig. 3.2 IQ-INT II Output Connection to a DIN Input.

The following examples show how to connect the

IQ-INT II to other IQ components on the Crown Bus:

IQ–INT II Output

41

23

Output (–) 1

Output (+) 2

Not used 3

Not used 4

O

ptional Shield

Barrier Block IQ

Component

Input

OUT IN

+ – + –

Output (+)

Output (–)

Input (+)

Input (–)

GND

Fig. 3.3 IQ-INT II Output Connection to Barrier Block Input.

1

2

Outside RF interference is seldom a problem for a Crown

Bus loop—especially if shielded twisted-pair wire is used.

However, there are extreme situations when fiber optic

wiring is recommended. For example, locating a Crown

Bus loop next to an AM radio transmission line may

require fiber optic transceivers and cabling. It may also

be more practical to use fiber optics for extremely long

Crown Bus loops when distances exceed several miles.

Three different of connectors are used for Crown Bus

wiring on IQ components. These include DIN connectors,

RJ45 connectors, and removable barrier strip plugs. The

IQ-INT II

uses 5-pin DINs for input and 4-pin DINs for

output. Figure 3.2 shows how to connect IQ components

with DIN connectors.

Reference Manual

Fig. 3.4 Barrier Block IQ Component Connection to an

IQ-INT II

Page 7

Page 8

IQ-INT II IQ Interface

IQ-INT II Output

RJ45 Input

Fig. 3.5 IQ-INT II Output Connection to RJ45 Input.

The IQ components on each Crown Bus loop are

connected in succession. Each loop begins and ends

with the

IQ-INT II

. The output of the interface connects

TO HOST COMPUTER

3

IN

T

U

O

2

IN

T

U

O

1

IN

R

E

W

O

IQ-INT II

P

RJ45 Output

IQ-INT II

Fig. 3.6 RJ45 Output Connection to a IQ-INT-II.

to the input of the first unit, then each unit’s output is

connected to the next unit’s input until the loop returns

to the interface. This is shown in Figure 3.7.

T

U

O

8

IN

T

U

O

7

IN

T

U

O

6

IN

T

U

O

5

IN

T

U

O

4

IN

T

U

O

R

E

T

U

P

M

O

C

IQ

MIXER

PROCESSOR /

IQ–PIP MODULES

AMPLIFIERS WITH

Fig. 3.7 Crown Bus Wiring from Output to Input.

CROWN BUS

Page 8

Reference Manual

Page 9

IQ-INT II IQ Interface

3.2 Connecting to a Host Computer

There are two main communication standards supported

by the

IQ-INT II

computer. They are RS232 and RS422.

RS232 is commonly used with IBM

compatibles. Because it uses unbalanced signal wiring,

it cannot be used for distances over 50 feet (15.2 m).

RS422 uses balanced signal wiring and can be used

for distances up to 2,000 feet (610 m) with data grade

cable.

Although not very common, RS423 communication can

also be used. It is a hybrid of RS232 and RS422 that

uses the unbalanced transmitter (TXD) wiring of RS232

and the balanced receiver (RXD) wiring of RS422. It

provides signal ground isolation between the transmit

and receive lines. With a proper cable, it can be used

over a greater distance than RS232, but over a shorter

distance than RS422. Contact the Crown Technical

Support Group if you want to use RS423 and need more

information.

The following illustrations show how to connect the

INT II

to the most common host serial ports:

for serial communication with a host

®

PCs and

IQ-

PC (RS232)

Cable connectors are numbered as they appear from the front.

Not used

ReceiveData (RXD)

Transmit Data (TXD)

Signal Ground (GND)

Request to Send (RTS)

Clear to Send (CTS)

Fig. 3.8 Standard RS232 Wiring

PC (RS422)

96

The female interface connector is shown as it appears.

Refer to the documentation

provided with your RS422

interface to identify the

correct pin connections.

IQ-INT II

51

96

PIN PIN

1,4,6,9

2

3

5

7

8

51

51

9

2

Transmit Data (TXD)

3

Receive Data (RXD)

5

Signal Ground (GND)

7

Clear to Send (CTS)

8

Request to Send (RTS)

PIN

1

Transmit Data (TXD+)

2

Transmit Data (TXD–)

3

Receive Data (RXD–)

4

Receive Data (RXD+)

5

Signal Ground (GND)

6

Clear to Send (CTS–)

7

Clear to Send (CTS+)

8

Request to Send

9

Request to Send

Fig. 3.9 RS422 Wiring

6

IQ-INT II

15

69

(RTS+)

(RTS–)

3.2.1 Connecting to a Modem

The

IQ-INT II

is also modem compatible. The

IQ-INT II

periodically sends out an “AT” command string {ATS0=1}

that automatically initializes a connected modem to its

max baud rate and auto-answer mode. A standard null

modem cable should be used between the interface

and modem with the exception of pin 4. Pin 4 of the 9-

STANDARD

9-PIN CABLE

MALE MALE

11

22

33

(MUST BE DISABLED)

4

55

66

77

88

99

9-PIN NULL MODEM

FEMALE MALE

11

22

33

4

44

55

66

77

88

99

IQ INTERFACE

pin RS232/242 connector on the back of the interface

should NOT be connected. This pin implements one

side of the RS422 type line receiver and, as such, allows

balanced wiring on a 9-pin connector. This configuration

is not compatible with some 232/null modem

applications. Refer to the diagram below for modem

wiring detail.

9-PIN to 25-PIN

CABLE

FEMALE MALE

18

23

32

420

57

66

74

85

922

MODEM

Reference Manual

Fig. 3.10 Modem Hookup

Page 9

Page 10

IQ-INT II IQ Interface

3.2.2 Communication Settings

Before communication can take place between the unit

and a host computer, the communication standard must

be selected and the communication parameters must

be set with switches accessed through an opening in

the side of the chassis (see Figure 3.11).

IMPORTANT: Be sure to disconnect the AC power

from the unit before changing the communication

standard or parameters.

Setting the communication parameters for RS232 and

RS422 serial communication is accomplished using the

eight segment DIP switch shown in Figure 3.11. The

first five switches set the parity, number of stop bits and

data bits. These five switches should ONLY be set in

the positions shown in Figure 3.11. The last three

switches set the baud rate. Use the fastest baud rate

possible.

IMPORTANT: The communication standard and

parameters of the IQ-INT II and the host computer

must be the same. Any mismatch will prevent

communication from taking place.

The communication parameters of the host computer

are set using the IQ software. Please refer to your IQ

software manual for details.

Here are some important guidelines when configuring

serial communication:

• Use these communication parameters for the

interface and the host computer: The

should be set at one baud rate below

IQ-INT II

the host

computer (refer to your IQ software manual). Stop

bits, data bits and parity checking should be set to

their default values.

• The

IQ-INT II

can be set as high as 38.4 K baud.

Use the highest baud rate possible, but be aware

that the communication circuitry (UART) in some

PC’s cannot function over 9600 baud. We strongly

recommend using a host computer serial interface

with a 16550-compatible UART.

• Do not use twisted-pair wire for RS232 cables

because the unbalanced wiring of RS232 is

susceptible to crosstalk. Instead use an untwisted

cable or ribbon cable. Data grade twisted-pair wire

should be used for RS422.

• If the host computer fails to communicate or reports

communication errors with the

IQ-INT II

and the

communication standard and parameters are

identical, try reducing the baud rate for the interface

and the computer. This may be especially useful

when configuring for communication via modem.

IMPORTANT: The

IQ-INT II

should be set at one baud

rate slower than the modem is set for accurate

communicaton. (Example: 14,400 modem, set

the

IQ INT II

at 9600.)

• If communication problems persist, check the serial

cable for improper wiring or possible shorted or

broken wires.

• For further assistance, refer to the Troubleshooting

section in your

IQ System

software manual, or

contact Crown’s Technical Support Group.

SW1

PARITY

STOP

BITS

DATA

BITS

PARITY

BAUD

RATE

12345678

ON

OFF

1

2

5

6

7

8

ODD

EVEN

38400

19200

9600

4800

2400

1200

600

300

Factory-set switch positions are highlighted.

Fig. 3.11 Communication Settings for the IQ-INT II

Page 10

IN OUT

1

IN OUT

2

IN OUT

3

IN OUT

4

IN OUT

5

IN OUT

6

IN OUT

7

IN OUT

8

C

O

M

P

U

T

E

R

1

1

IN

P

U

T

O

U

T

P

U

T

2

W

I

R

I

N

G

W

G

N

I

R

D

I

N

G

3

2

RS232 / RS422

U

S

E

S

ID

E

A

C

C

E

S

S

H

O

L

E

T

O

S

E

T

B

A

U

D

R

A

T

E

A

N

D

O

T

H

E

R

C

O

M

S

E

T

T

IN

G

S

.

12345678

SW1

Reference Manual

Page 11

IQ-INT II IQ Interface

4 Technical Information

The purpose of the

IQ System

the

IQ-INT II

is to provide a means for

host computer to communicate with the

IQ components. The interface supports RS232, RS422

and RS423 serial data standards. It accepts host

computer communication baud rates from 300 to 38,400

and can drive up to 8 independent Crown Bus loops for

a high level of fault tolerance. In addition, the

supports both the original

IQ System

IQ-INT II

and Ucode

protocols, and it provides Crown’s own robust network

transport layer.

Figure 4.1 shows an

IQ-INT ll

block diagram. The unit

has a standard full-wave bridge power supply. Its primary

transformer can be configured by an internal voltage

select switch for either 115 or 230 VAC; however, this

procedure should only be performed by a qualified

service technician. (The unit will operate reliably over a

wide range of voltages with either AC mains

configuration.) A capacitor-coupled half-wave double

circuit is used to generate –5 volts.

The interface is equipped with an auto-reset feature. The

microprocessor generates an auto-reset signal that can

be used as a reliable power-on reset and an automatic

“warm” reset in case control is lost due to noise or other

anomalies.

The baud rate for communication with the host computer

is determined by the baud rate generator which is

controlled by an 8-segment DIP switch (SW1). Other

serial communication parameters such as data bits, stop

4 OF 8

LINE RECEIVERS

LINE 1

INPUT

LINE 2

INPUT

LINE 3

INPUT

LINE 4

INPUT

LINE 1

OUTPUT

LINE 2

OUTPUT

LINE 3

OUTPUT

LINE 1

RECEIVER

LINE 2

RECEIVER

LINE 3

RECEIVER

LINE 4

RECEIVER

LINE 1

DRIVER

LINE 2

DRIVER

LINE 3

DRIVER

SINGLE POLE

8 POSITION

SWITCH

(ONLY 4 POSITIONS SHOWN)

ADDRESS

SINGLE POLE

8 POSITION

SWITCH

(ONLY 4 POSITIONS SHOWN)

11

12

bits and parity are also set using SW1.

The interface’s microprocessor communicates with other

IQ components using its internal UART to drive each

loop at 38,400 baud. An external UART is used for

communication with the host computer.

Data from the host computer arrives at the serial buffer

which accepts RS232, RS422, and RS423 data

standards. From here the signal goes to the serial input

of the UART which shifts the data from serial to parallel

before proceeding to the microprocessor where it is

loaded into memory. Next, the interface takes care of

any required checksum calculations and other transport

layer processing. Finally, all of the data bytes are

dumped out the microprocessor’s SIO port (the TX pin)

at 38,400 baud.

The microprocessor controls the input and output

selectors that control which loop will receive data. Data

is sent to the selected line driver, which sends the data

onto the current loop to the appropriate IQ component.

The line receiver takes incoming data from IQ

components and sends it through the input selector to

the microprocessor’s SIO input RX pin. The

microprocessor stores the data in memory and handles

the required transport layer processing. The remaining

protocol data is then sent to the UART as parallel signals.

The UART converts the data from parallel to serial and

moves it to the serial output buffer for transmission to the

host computer.

POWER

SUPPLY

RX

INTERNAL UART

TX

MICRO-

PROCESSOR

DATA BUS

BAUD

RATE

GENERATOR

BAUD

RATE

SWITCHES

LINE 4

OUTPUT

LINE 4

DRIVER

4 0F 8

LINE DRIVERS

Reference Manual

OPTION

SWITCHES

PARALLEL TO SERIAL

SERIAL TO PARALLEL

EXT.

UART

Fig. 4.1 IQ-INT II Circuit Block Diagram

SERIAL

BUFFER

TO HOST

COMPUTER

Page 11

Page 12

5 Specifications

General

Internal Controls:

configure the data rate and other parameters for

communication with the host computer. The switch is

accessed through an opening in the side of the

chassis.

Connectors

connectors. Crown Bus Output: Eight 4-pin female

DIN connectors. (The Crown Bus Input and Output

connectors are grouped in pairs to accommodate eight

different loops.) Computer: Female 9-pin “D-shell”

connector.

An 8-segment DIP switch is used to

: :

: Crown Bus Input: Eight 5-pin female DIN

: :

IQ-INT II IQ Interface

Crown Bus Data Communication

Protection: The auto-reset feature is controlled by the

microprocessor. Optically coupled 20-milliamp current

loop receivers provide ground isolation.

Data Rate: 38.4 K baud.

Data Format: Asynchronous binary serial data with 1

start bit, 1 stop bit, 8 data bits and no parity check.

Interface Type

Operation: Half duplex.

::

: 20-milliamp current loop.

::

Indicators: A front panel enable indicator shows that

the unit is plugged in and receiving power.

Power Supply: Standard full-wave bridge power supply

with a unique capacitor-coupled half wave doubler

circuit to generate –5 VDC.

Power Requirements

50-60 Hz. 230-V units: 220- to 240-VAC, 50-60 Hz.

Power Consumption:

100VAC, 50 Hz: 8.1 W 100VAC, 60 Hz: 8.0 W

120VAC, 50 Hz: 10.6 W 120VAC, 60 Hz: 9.9 W

220VAC, 50 Hz: 10.3 W 220VAC, 60 Hz: 10.0 W

240VAC, 50 Hz: 11.6 W 240VAC, 60 Hz: 11.0 W

Finish: Black powder-coated steel chassis and front

panel.

Dimensions: 19-inch (48.3 cm) standard rack mount

width (EIA RS-310-B), 1.75-inch (4.4 cm) height and

6.5-inch (16.5 cm) depth.

Weight: 6 lbs., 4 oz. (2.91 kg)

::

: 115-V units: 100- to 120-VAC,

::

Intelligence: 8-bit microprocessor.

Transmission Distance: Variable from 200 to 3,000 feet

(61 to 914 meters) depending on wire capacitance.

1,000 feet (305 meters) is typical with shielded 26 AWG

twisted pair wire. IQ repeaters or fiber optic

transceivers can be used to cover greater distances.

Host Computer Data Communication

Data Rate: 300, 600, 1200, 2400, 4800, 9600, 19200, or

38400 baud.

Data Format: Asynchronous binary serial data with 1

start bit, 1 stop bit, 8 data bits and no parity check.

Interface Type

Operation: Half duplex.

Data Buffer: 64 bytes.

Intelligence: 8-bit microprocessor.

Transmission Distance: RS232: 50 feet (15.2 m).

RS422: 2,000 feet (610 m).

::

: RS232 or RS422.

::

Page 12

Reference Manual

Page 13

IQ-INT II IQ Interface

6 Service

This unit has very sophisticated circuitry which should

only be serviced by a fully trained technician. This is

one reason why each unit bears the following label:

CAUTION: To prevent electric shock, do not remove

covers. No user serviceable parts inside. Refer servicing to a qualified technician.

6.1 Worldwide Service

Service may be obtained from an authorized service

center. (Contact your local Crown/Amcron representative or our office for a list of authorized service centers.)

To obtain service, simply present the bill of sale as proof

of purchase along with the defective unit to an authorized service center. They will handle the necessary paperwork and repair.

Remember to transport your unit in the original factory

pack.

6.2 North American Service

Service may be obtained in one of two ways: from an

authorized service center or from the factory. You may

choose either. It is important that you have your copy of

the bill of sale as your proof of purchase.

6.2.1 Service at a North American Service Center

This method usually saves the most time and effort.

Simply present your bill of sale along with the defective

unit to an authorized service center to obtain service.

They will handle the necessary paperwork and repair.

Remember to transport the unit in the original factory

pack. A list of authorized service centers in your area

can be obtained from our Technical Support Group.

6.2.2 Factory Service

To obtain factory service, fill out the service information page found in the back of this manual and send it

along with your proof of purchase and the defective

unit to the Crown factory.

For warranty service, we will pay for ground shipping

both ways in the United States. Contact Crown Factory

Service or Technical Support to obtain prepaid shipping labels prior to sending the unit. Or, if you prefer,

you may prepay the cost of shipping, and Crown will

reimburse you. Send copies of the shipping receipts to

Crown to receive reimbursement.

Your repaired unit will be returned via UPS ground.

Please contact us if other arrangements are required.

Always use the

original factory pack

to transport the unit.

Factory Service Shipping Instructions:

1. When sending a Crown product to the factory for

service, be sure to fill out the service information

form that follows and enclose it inside your unit’s

shipping pack. Do not send the service information form separately.

2. To ensure the safe transportation of your unit to

the factory, ship it in an original factory packing

container. If you don’t have one, call or write

Crown’s Parts Department. With the exception of

polyurethane or wooden crates, any other packing material will not be sufficient to withstand the

stress of shipping. Do not use loose, small size

packing materials.

3. Do not ship the unit in any kind of cabinet (wood

or metal). Ignoring this warning may result in extensive damage to the unit and the cabinet. Accessories are not needed—do not send the

product documentation, cables and other hardware.

If you have any questions, please call or write the Crown

Technical Support Group.

Crown Audio Customer Service

Technical Support / Factory Service

Plant 2 SW, 1718 W. Mishawaka Rd., Elkhart,

Indiana 46517 U.S.A.

Telephone:

Facsimile:

Fax Back:

Internet:

Email:

219-294-8200

800-342-6939 (North America,

Puerto Rico, and Virgin Islands only)

219-294-8301 (Technical Support)

219-294-8124 (Factory Service)

219-293-9200 (North America only)

800-294-4094 (North America only)

219-294-8100 (International)

http://www.crownaudio.com

iqsupport@crownintl.com

Reference Manual

Page 13

Page 14

Crown Factory Service Information

Shipping Address: Crown International, Inc., Factory Service, Plant 2 SW, 1718 W. Mishawaka Rd., Elkhart, IN 46517

Phone: 1-800-342-6939 or 1-219-294-8200 Fax: 1-219-294-8124

Owner’s Name: _________________________________________________________________________

Shipping Address: ______________________________________________________________________

Phone Number: _____________________________ Fax Number: _____________________________

Model: ________________________ Serial Number:______________ Purchase Date: ___________

NATURE OF PROBLEM

(Be sure to describe the conditions that existed when the problem occurred and what attempts were made to correct it.)

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

DETACH AND SEND WITH UNIT

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Other equipment in your system: _________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

If warranty has expired, payment will be:

Card Number:___________________________ Exp. Date:_______ Signature:____________________________

ENCLOSE THIS PORTION WITH THE UNIT. DO NOT MAIL SEPARATELY.

❏ ❏

❏ Cash/Check

❏ ❏

❏❏

❏ VISA

❏❏

❏❏

❏ MasterCard

❏❏

❏❏

❏ C.O.D.

❏❏

Loading...

Loading...