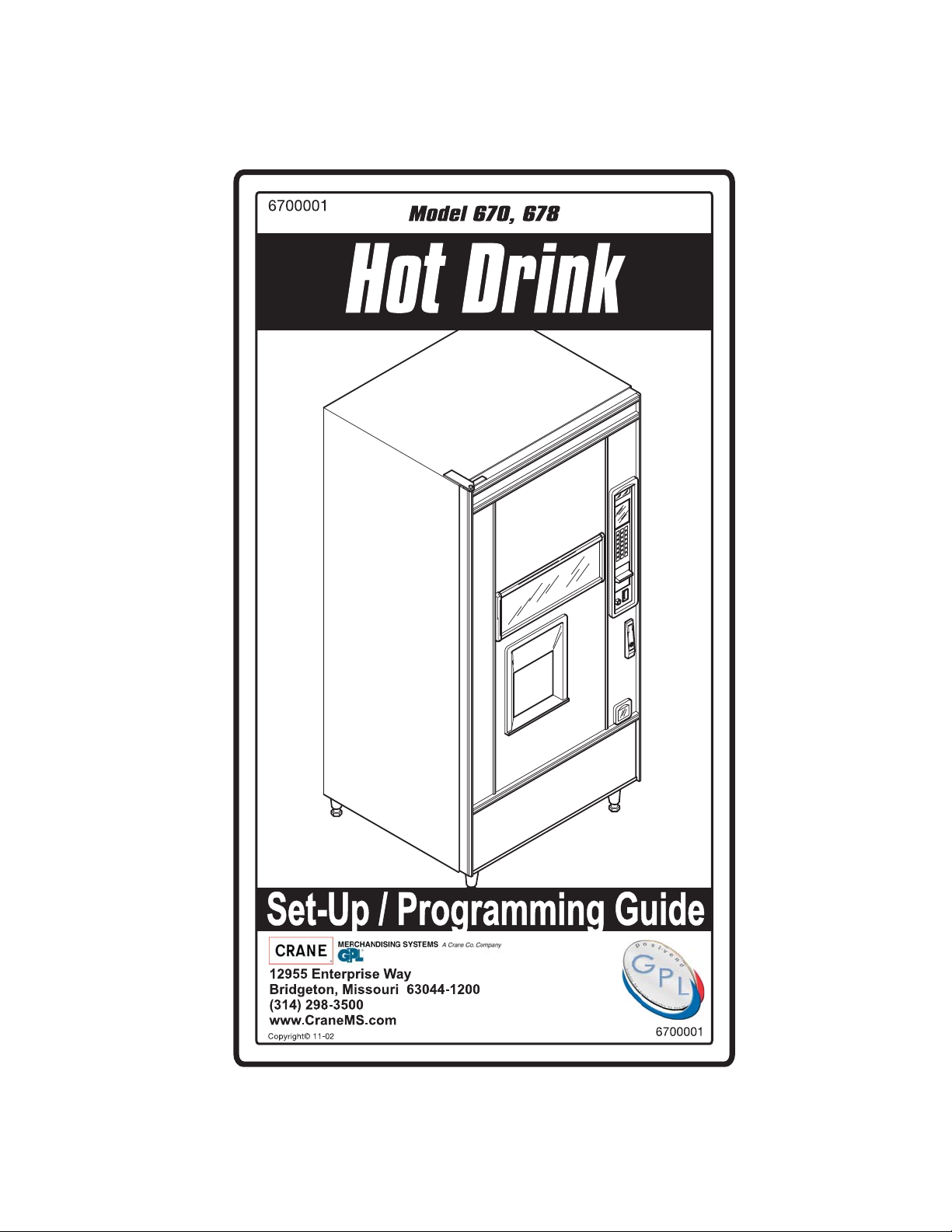

Page 1

Page 2

This machine has been engineered to our own rigid safety and performance

standards. It has been designed to comply with sanitation and health guidelines

recommended by the Automatic Merchandising Health-Industry Council (AMHIC)

and it conforms with all other NAMA safety recommendations.

This machine has been manufactured in accordance with the safety

standards of both Underwriter’s Laboratories and the Canadian Standards

Association. To maintain this degree of safety and to continue to achieve the level

of performance built into this machine, it is important that installation and

maintenance be performed so as to not alter the original construction or wiring and

that replacement parts are as specified in the Parts and Service Manual. Your

investment in this equipment will be protected by using this Operator’s Guide and

Parts and Service Manual in your operation, service and maintenance work. By

the

following prescribed procedures, machine performance and safety will be

preserved.

This Merchandiser is warranted for one (1) year against defective parts and

workmanship. Any part or parts which are proven to be defective within one (1)

year of the date of shipment will be repaired or replaced free of charge when the

defective part is returned, with transportation charges prepaid, to the destination

designated by the National Vendors Warranty Department.

This warranty applies only to the original purchaser of the Merchandiser

and is null and void if the Merchandiser is sold during the period of warranty.

This warranty does not apply to a) electrical components, wiring, or circuits

and/or for all mechanical parts or assemblies damaged as a result of operating the

Merchandiser at other than the design voltage and frequency specified on the

Electrical Rating Tag, or b) in event of vandalism, fire or negligence, or c)

incandescent lamps, neon lamps, fluorescent lamps, ballasts, starters or other

expendable items or d) when other manufactured components are installed in

National Vendors Merchandisers.

National Vendors is not responsible for any cost of service rendered or

repairs made by customer or its agents on Merchandiser or parts unless authorization to incur such expense has been given in writing by National Vendors prior to

incurring such expense.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES

EXPRESSED OR IMPLIED, INCLUDING WITHOUT LIMIT ATION, WARRANTIES OF MERCHANT ABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

NA TIONAL VENDORS SHALL NOT BE RESPONSIBLE FOR CONSEQUENTIAL OR PUNITIVE DAMAGES. National Vendors neither assumes nor

authorizes any person to assume for it any obligation or liability in connection with

the sale of said equipment or any part thereof.

Page 3

HOT DRINK SETUP/PROGRAMMING GUIDE

TABLE OF CONTENTS

SPECIFICATIONS ................................................................................................ V

MAJOR PARTS ................................................................................................... VII

CONTROLS AND INDICATORS.......................................................................XI

I. LOCATION PREPARATION ........................................................................... 1

Electrical Power Requirements ........................................................................ 1

II. POSITIONING THE MERCHANDISER......................................................3

III. CONNECTING EVERYTHING ..................................................................... 3

1. Connect the Merchandiser to the Water Supply ......................................... 3

IV. FINAL MECHANICAL PREPARATION ..................................................... 4

1. Level the Merchandiser ............................................................................... 4

2. Mount the Base Plate .................................................................................. 5

3. Install the Water Filter Cartridge ................................................................. 6

Hydrolife Brand................................................................................................ 8

Installation ................................................................................................... 8

Removal ....................................................................................................... 8

Load the Optional Filter Paper ......................................................................... 9

(CONTINUED) ................................................................................................ 9

Replace The Cup Station And Grounds Bucket ............................................. 11

Install The Optional Coin Box Lock .............................................................. 11

Set Up And Load The Coin Mechanism........................................................ 1 2

Standard Coin Mechanism............................................................................. 1 2

MDB Coin Mechanism .................................................................................. 12

Fill The Tank .................................................................................................. 14

Fill The Canisters ........................................................................................... 14

Load Cups ...................................................................................................... 15

Cup Size(s) ..................................................................................................... 16

Set Prices ........................................................................................................ 17

Set Up The Menu ........................................................................................... 17

Establish Time Of Day Vending Periods........................................................ 17

Customize The Drink Recipes .......................................................................17

Set Up Custom Messages ...............................................................................1 7

Posivend™ .....................................................................................................17

V . ADJUSTMENTS AND MINOR MAINTENANCE ...................................... 19

1. Empty the Bill Stacker .............................................................................. 19

2. Adjust the Water Valves ............................................................................ 19

3. Adjust the Air Pressure .............................................................................. 20

4. Install Canisters ........................................................................................20

5. Adjust the Cup Mechanism ....................................................................... 2 1

VIEW A...................................................................................................... 21

VIEW B...................................................................................................... 21

6. Set Up the Menu Assembly....................................................................... 22

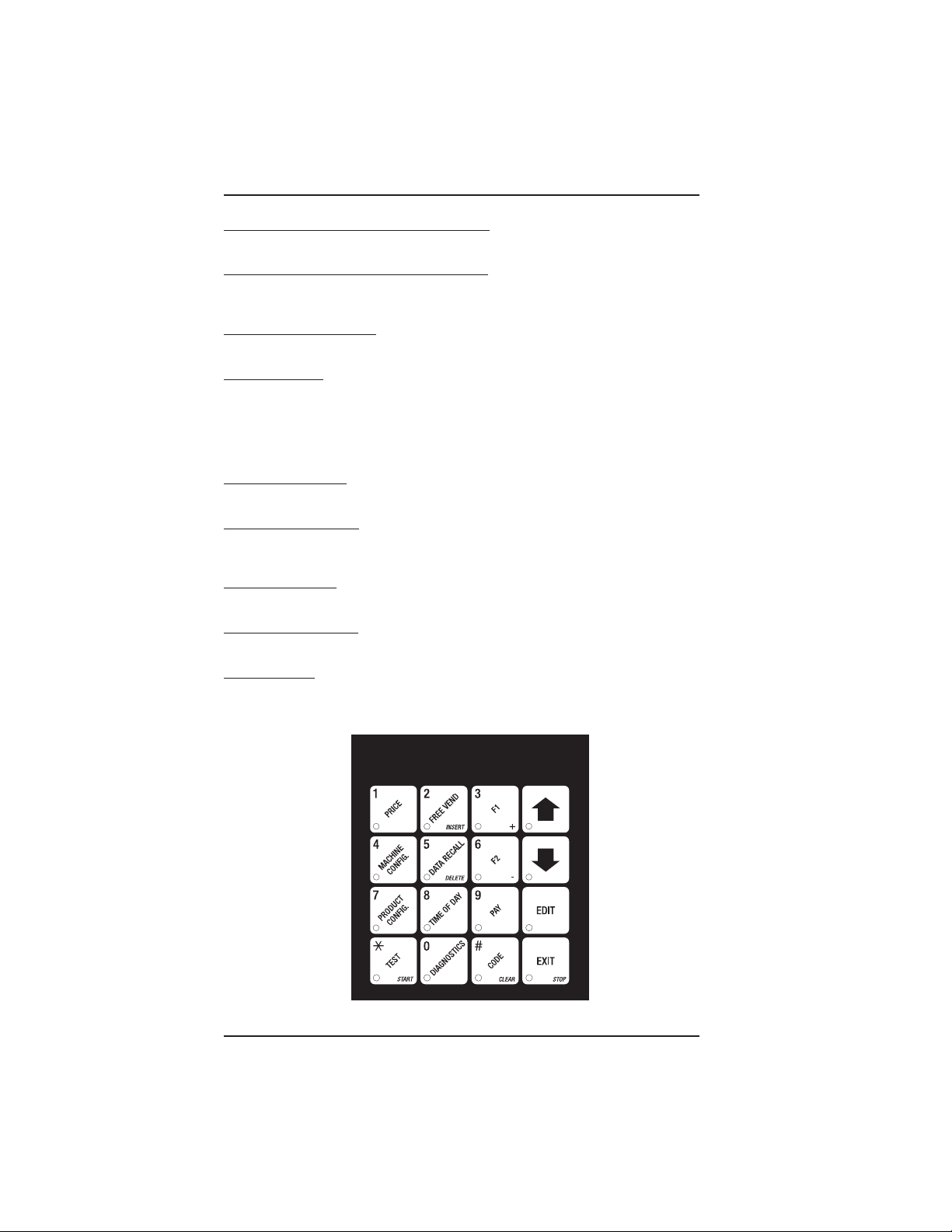

GETTING AROUND ............................................................................................. 23

THE SERVICE KEYPAD ....................................................................................... 23

THE SELECTION SWITCH P ANEL ..................................................................... 23

PROGRAMMING THE HOT DRINK ................................................................... 23

THE DISPLA YS ......................................................................................................24

THE FUNCTION KEYS ......................................................................................... 25

OTHER KEYS ........................................................................................................ 25

TABLE OF CONTENTS

November, 2002 i 6700001

Page 4

HOT DRINK SETUP/PROGRAMMING GUIDE

III. CONTROL PANEL SWITCHES EXPLAINED ........................................ 26

PROGRAMMING PROCEDURES........................................................................ 28

THE SUPERVISOR MODE ................................................................................... 28

GAIN ACCESS TO THE SUPERVISOR MODE................................................... 29

ENTER A NEW SUPERVISOR CODE.................................................................. 29

ENTER A FREEVEND CODE ............................................................................... 29

THE SUPERVISOR MODE ................................................................................... 29

LOCK OR UNLOCK MODE OR PAYOUT KEYS ............................................... 30

SET PRINTER OR DEX OPTIONS ....................................................................... 30

LOCK OR UNLOCK DA TA CLEARING ACCESS ............................................. 31

SELECT DISPLA Y LANGUAGE........................................................................... 31

SELECT COIN MECHANISM AND OPTIONS ................................................... 32

SELECT BILL VALIDA T OR AND OPTIONS ....................................................... 33

BILL LIST OPERATION ........................................................................................33

SELECT MONET AR Y OPTIONS.......................................................................... 35

SELECT CARD READER AND OPTIONS .......................................................... 37

SET UP WINNER MODE ...................................................................................... 38

ADV ANCED OPTIONS.......................................................................................... 38

SET UP THE MUG DISCOUNT ............................................................................ 39

SET THE PRINTER BAUD RATE ........................................................................ 39

LOCK OR UNLOCK SELECTIONS .....................................................................40

DISABLE SELECTIONS IN THE MERCHANDISER ......................................... 40

ASSIGN CUP SIZES T O SELECTIONS................................................................ 41

(SUPERVISOR MODE ONLY) .............................................................................. 41

SET UP A HOT DRINK .......................................................................................... 42

WHIPPER OPTIONS .............................................................................................. 43

DIFFERENCES(OPTIONS) ................................................................................... 44

VIEW OR SET THE HOT WATER TANK TEMPERA TURE .............................. 44

SET UP LOW TEMPERATURE DISPENSING..................................................... 45

TSET UP LOW POWER SETTINGS ..................................................................... 45

SET THE RA TIO OF CHOCOLATE IN CAPPUCCINO....................................... 47

SET THE BREWER RINSE TIME INTERVAL ..................................................... 47

THE BOWL RINSE TIME...................................................................................... 48

TURN POSIVEND™ ON OR OFF ........................................................................ 48

OPTIONAL OR MANDATORY POSIVEND™ .................................................... 49

SET UP THE POSIVEND™ ANTI-JACKPOT TIMER ......................................... 49

VIEW NUMBER OF MUG VENDS ...................................................................... 50

VIEW MACHINE ID NUMBER ............................................................................ 50

VIEW CUP RING CYCLES RELATED TO POSIVEND™.................................. 50

VIEW TIMES NO CUP WAS DETECTED AFTER A CUP RING CYCLED....... 51

VIEW HOME SWITCH USAGE RELATED TO POSIVEND™ ..........................51

VIEW POSIVEND™ LAST RECORDED CALIBRATION.................................. 52

VALUE ....................................................................................................................52

VIEW POSIVEND™ AVERAGE CALIBRATION VALUE ................................. 52

CONTINUE ............................................................................................................. 52

CLEAR T ANK ERRORS AND FILL THE T ANK ................................................. 52

SET THE MACHINE TYPE CONFIGURATION CODE ...................................... 53

SET UP THE CUP ONLY OPTION (SUPERVISOR MODE ONLY).................... 55

SET UP DELIVERY DOOR OPTIONS (SUPERVISOR MODE ONLY) .............55

6700001 ii November, 2002

Page 5

HOT DRINK SETUP/PROGRAMMING GUIDE

COLLECTING DRY PRODUCT GRAM THROWS............................................. 56

DRY PRODUCT WEIGHT AND THROW TIME FACTOR Y DEFAUL T

SETTINGS .............................................................................................................. 57

CAPPUCCINO RECIPE ......................................................................................... 59

CAPPUCCINO ........................................................................................................ 59

MOTOR SPEED BY LOCATION .......................................................................... 60

HINTS ................................................................................................................... 60

CAFFÉ LA TTE RECIPE......................................................................................... 64

CAFFÉ LA TTE........................................................................................................ 64

ENTER THE SUPERVISOR CODE ...................................................................... 64

SET THE MACHINE TO VEND A LARGE "D" SELECTION ............................64

SET UP YOUR SELECTION ................................................................................. 65

EUROPEAN CAPPUCCINO ................................................................................. 65

RECONFIGURE THE MACHINE ......................................................................... 65

COLLECTING W A TER THROWS ........................................................................ 67

EUROPEAN CAPPUCCINO RECIPE ...................................................................67

WA TER THROW DEF AULT TIMES AND VOLUMES ....................................... 68

SET PRICES FOR INDIVIDUAL SELECTIONS .................................................. 69

SET THE PRICE FOR A CUP ONLY ..................................................................... 70

SET ONE PRICE FOR THE ENTIRE MACHINE ................................................ 70

SET ONE PRICE FOR ALL REGULAR SIZE DRINKS ....................................... 70

SET ONE PRICE FOR ALL LARGE SIZE DRINKS ............................................ 71

SET THE TIME....................................................................................................... 71

SET THE DA Y OF THE WEEK ............................................................................. 71

SET THE DATE AND YEAR ................................................................................. 72

SET TIME-OF-DA Y INHIBITED VENDING ........................................................ 72

SET TIME-OF-DA Y DISCOUNT VENDING........................................................ 73

SET TIME-OF-DA Y FREE VENDING .................................................................. 73

TIME INTER V AL EDITING................................................................................... 74

ST AND BY.............................................................................................................. 75

SELECT A ST ANDBY MESSAGE ........................................................................ 76

SELECT AN OUT-OF-SER VICE MESSAGE........................................................ 77

SELECT A FREEVEND MESSAGE ...................................................................... 77

EDIT CUSTOM MESSAGES................................................................................. 78

THE END OF MESSAGE CHARACTER ............................................................. 78

ENTERING YOUR MESSAGE ............................................................................. 79

THE CHARACTER SET ........................................................................................ 79

TEST VEND SELECTIONS AND VERIFY CREDIT ADDED ............................ 80

TEST THE DISPLA Y.............................................................................................. 80

TEST THE CUP MECHANISM ............................................................................. 81

TEST THE AUT OMA TIC DOOR (OPTIONAL) ................................................... 81

TEST THE WHIPPERS .......................................................................................... 81

TEST THE AIR COMPRESSOR............................................................................ 82

TEST THE BREWER ............................................................................................. 82

RINSE ALL MIXING BOWLS............................................................................... 83

VIEW FREEVEND SALES BY TIME INTER VAL ............................................... 83

VIEW DISCOUNT SALES BY TIME INTER VAL ................................................ 84

VIEW FREE VENDS.............................................................................................. 84

VIEW WINNERS.................................................................................................... 85

VIEW TIME DA TA ................................................................................................. 85

November, 2002 iii 6700001

Page 6

HOT DRINK SETUP/PROGRAMMING GUIDE

VIEW TOT AL UNP AID SALES ............................................................................. 87

VIEW TOT AL UNP AID VENDS............................................................................ 87

VIEW NUMBER OF TEST VENDS...................................................................... 87

VIEW SALES DATA BY PRICE ............................................................................87

SET FREEVEND OPTIONS ..................................................................................88

NO MONEY REQUIRED....................................................................................... 88

VIEW MACHINE ID NUMBER ............................................................................ 89

VIEW NON-RESETT ABLE SALES AND VEND DAT A...................................... 89

VIEW DATA THREE DIFFERENT WA YS ............................................................ 89

RINSE THE BREWER ........................................................................................... 90

FILL THE T ANK ..................................................................................................... 90

TEST VARIOUS SENSORS AND SWITCHES..................................................... 91

P A YOUT COINS ..................................................................................................... 91

VIEW TOT AL PAID SALES .................................................................................. 92

VIEW CARD READER PAID SALES ..................................................................92

VIEW TOT AL PAID VENDS ................................................................................. 92

CLEAR ALL RESETTABLE DATA ....................................................................... 93

CLEAR PAID SALES DA TA ONL Y ...................................................................... 93

VIEW AMOUNT IN COIN BOX ........................................................................... 93

VIEW AMOUNT IN VALIDATOR ........................................................................ 94

VIEW DIAGNOSTIC MESSAGES ........................................................................ 94

DOWNLOAD DATA T O A PDCD.......................................................................... 98

CHANGE MACHINE ID NUMBER...................................................................... 99

VIEW THE WA TER T ANK TEMPERATURE....................................................... 99

VIEW THE CURRENT SOFTWARE VERSION NUMBER ................................ 99

VIEW THE SELECTION MACHINE TYPE ....................................................... 100

VIEW THE SELECTION CONFIGURATION ..................................................... 100

SANITATION ......................................................................................................101

Basics ...........................................................................................................101

How Do I Sanitize? ......................................................................................101

Chemicals ..................................................................................................... 101

Heat

Food-Contact Parts .......................................................................................1 03

Non Food-Contact Parts ............................................................................... 104

OVERALL CLEANING .....................................................................................104

Preventive Maintenance Cleaning ............................................................... 1 04

APPENDIX A. THE OPTIONAL PRINTER .................................................... A1

APPENDIX B. THE INFRARED MUG/CUP SENSOR ................................. B3

Indicator Light ............................................................................................... B3

Cleaning ........................................................................................................ B3

Calibration ..................................................................................................... B4

APPENDIX C. DEX/UCS INTERFACE OPERATION................................... C7

Select Data Transfer Method......................................................................... C7

Download Data.............................................................................................. C 7

APPENDIX C. DEX/UCS INTERFACE OPERATION.................................. C7

APPENDIX D. MODIFY CANISTER TO VEND 12 OZ. CUPSD9

APPENDIX E. CLEAN THE HOT WATER TANK...................................... E11

APPENDIX F. THE FREE VEND KEYSWITCH OPTION ........................ F13

Using The Free Vend Key Switch ................................................................ F13

6700001 iv November, 2002

Page 7

HOT DRINK SETUP/PROGRAMMING GUIDE

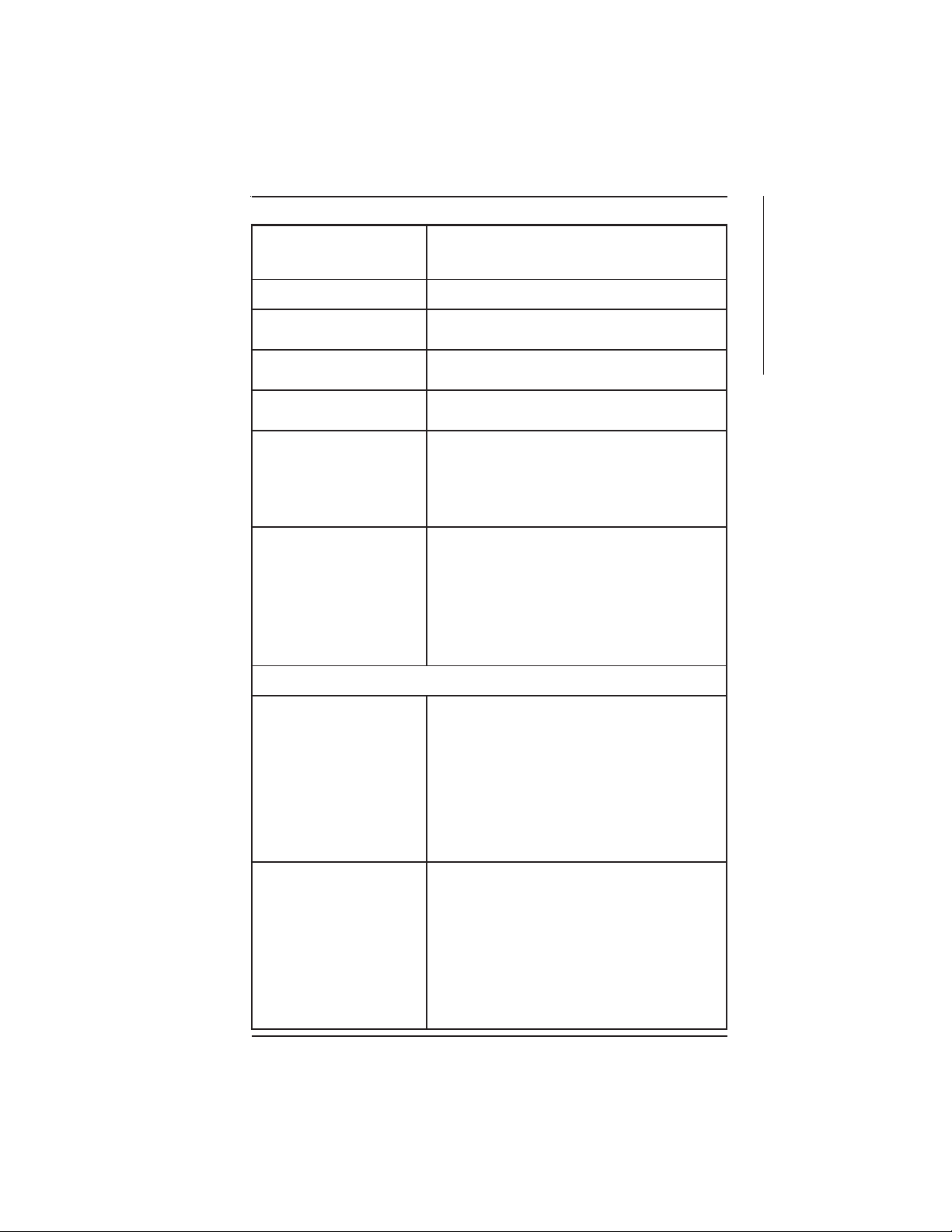

SENIHCAMLLAOTNOMMOCSNOITACIFICEPS

SNOISNEMID hgih)mc381("27

THGIEW )gk5.512(sbl574

STNEMERIUQERRETAW )aPk8.731(isp02:muminiM

ERUTAREPMETTNEIBMA )C°5(F°14:muminiM

GNITAREPO

TNEMNORIVNE

SEITICAPACPUC

)ETAMIXORPPA(

SEITICAPACRETSINAC

)ETAMIXORPPA(

ediw)mc18("23

peed)mc27("5.82

)aPk2.155(isp08:mumixaM

)C°23(F°09:mumixaM

ylnoesuroodniroF

569-spuczo5

508-)tauqs(spuczo7

537-spuczo52.8

077-)tauqs(spuczo9

096-spuczo01

066-spuczo21

)ylno436ledoM(sbl31-eeffocwerbhserF

sbl2-eeffocyrdezeerF

)ylno436ledoM(sbl9-facedwerbhserF

sbl2-facedyrdezeerF

sbl5.1)yrdezeerf(aeT

sbl01-etalocohC

)sbl4(sbl7.6-)etutitsbusragusro(puoS

sbl11-raguS

sbl5.4-renethgiL

SNOITPOTCUDORP

SPECIFICATIONS

werBhserF076ledoM :noitarugifnoCdradnatS

aetyrdezeerF

snoitceles

:snoitarugifnoClanoitpO

noitcelesretawtoH

noitcelespuoS

RO

deirDezeerF876ledoM :noitarugifnoCdradnatS

eeffocyrdezeerF

facedyrdezeerF

aetyrdezeerF

snoitceles

:snoitarugifnoClanoitpO

noitcelesretawtoH

noitcelespuoS

RO

)dnuorg-erp(eeffocwerbhserF

facedyrdezeerfROwerbhserF

"ylnopuc"dna,etalocohctoh,oniccuppac,osserpsE

tnemidnocetutitsbusraguS

"ylnopuc"dna,etalocohctoh,oniccuppac,osserpsE

tnemidnocetutitsbusraguS

November, 2002 Page - v 6700001

Page 8

HOT DRINK SETUP/PROGRAMMING GUIDE

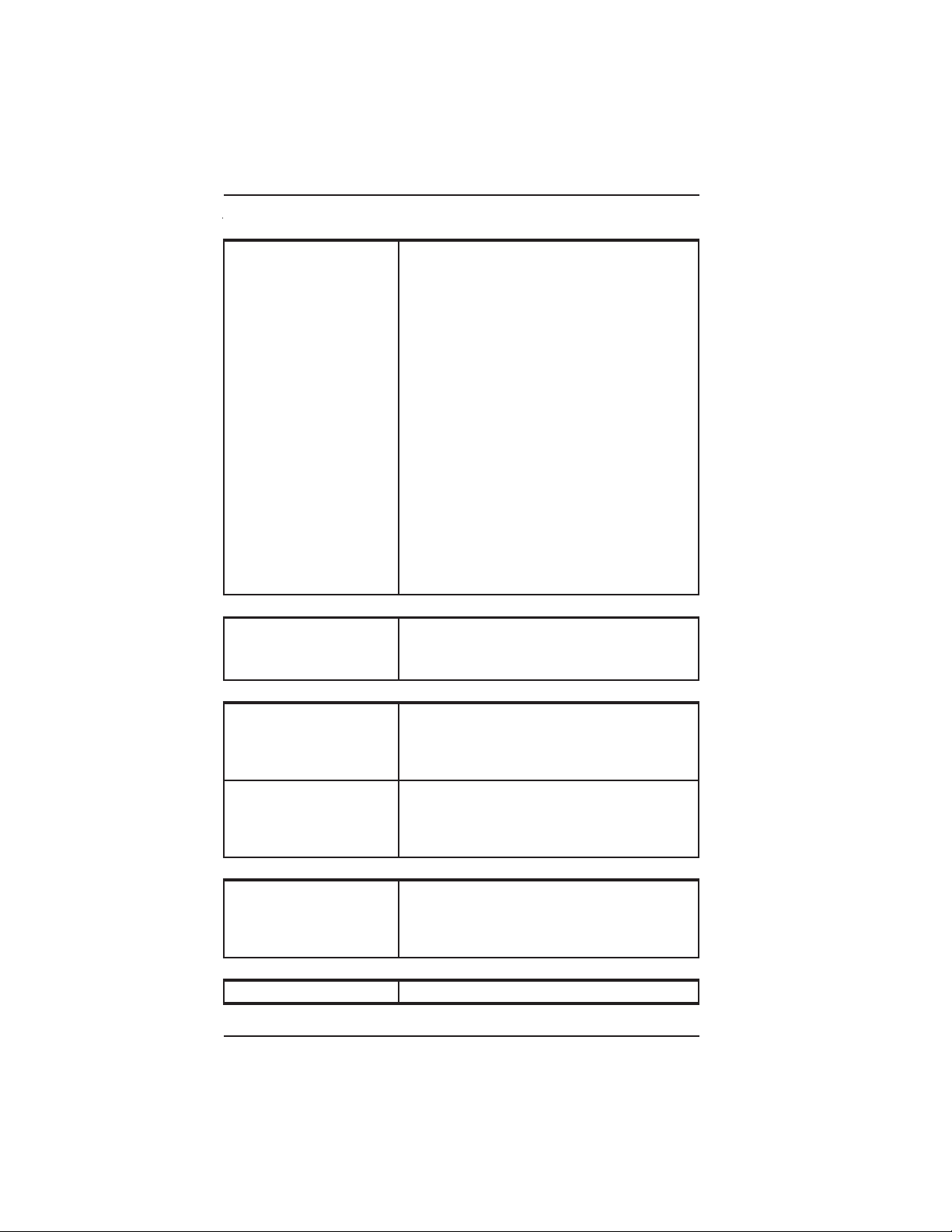

SNOITPO roodyreviledcitamotuA

)dedis1(tikellirgesaB

)dedis3(tikellirgesaB

kcolxobnioC

tikretnirpataD

redaerdractibeD

tikgnipirtsrooD

tikretlifretaweruprevE

tikretlifretawonuC

tikretlifretawefiL-ordyH

tikreppihwpuoS

yekdnakcolroodecAxelF

yekdnakcolroodnaV

hctiwsyekdneveerF

tiketutitsbusragusropuoS

yartesnirtneidergnI

dneVisoP

tiknoitcelesretawtoH

)ylno436ledoM(

roodtenibacrof

LACIRTCELE CAstloV511

ztreH06

spmA21

esahpelgniS

0006-CRTSRAM

0003NORTNIOC

MSINAHCEMNIOC

SROTADILAVLLIB eslup1MFVSRAM

laires3MFVSRAM

eslupAKAM

OCNIOC

BDM

LACIRTCELE CAstloV042-022

ztreH05

spmA01

Wk2

esahpelgniS

MSINAHCEMNIOC ecafretnimsinahcemniocevitucexE

)deunitnoc(SENIHCAMLLAOTNOMMOCSNOITACIFICEPS

)llat"4(seveelsnoisnetxeretsinactneidergnino-panS

)tikhctiwsdlohpuc(rosnescinortcelegum/puC

rewerbrof)llorrepsdnev0005(tikrepapretliF

tniap"yargderutxeT"ro"etihwderutxeT"foeciohC

SENIHCAMTLOV511OTEUQINUSNOITACIFICEPS

SEIROSSECCADNASNOITPO

)V42(VX0106-CRTSRAM

)V42(400-XPSUledoMxulnoC/akaM

)V42(FL-2039ledoMsrotpeccAnioC

SENIHCAMTLOV042-022OTEUQINUSNOITACIFICEPS

SEIROSSECCADNASNOITPO

6700001 Page - vi November, 2002

Page 9

HOT DRINK SETUP/PROGRAMMING GUIDE

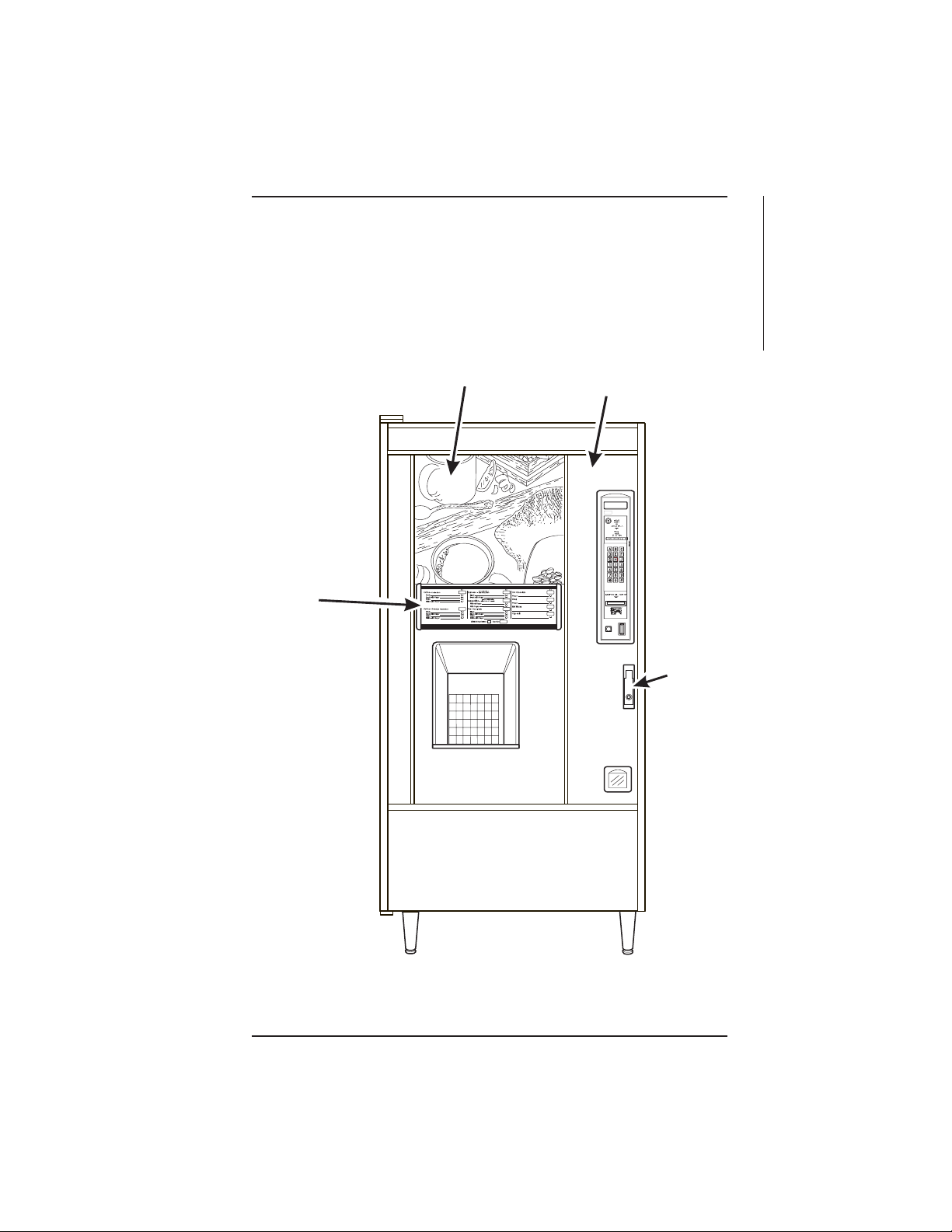

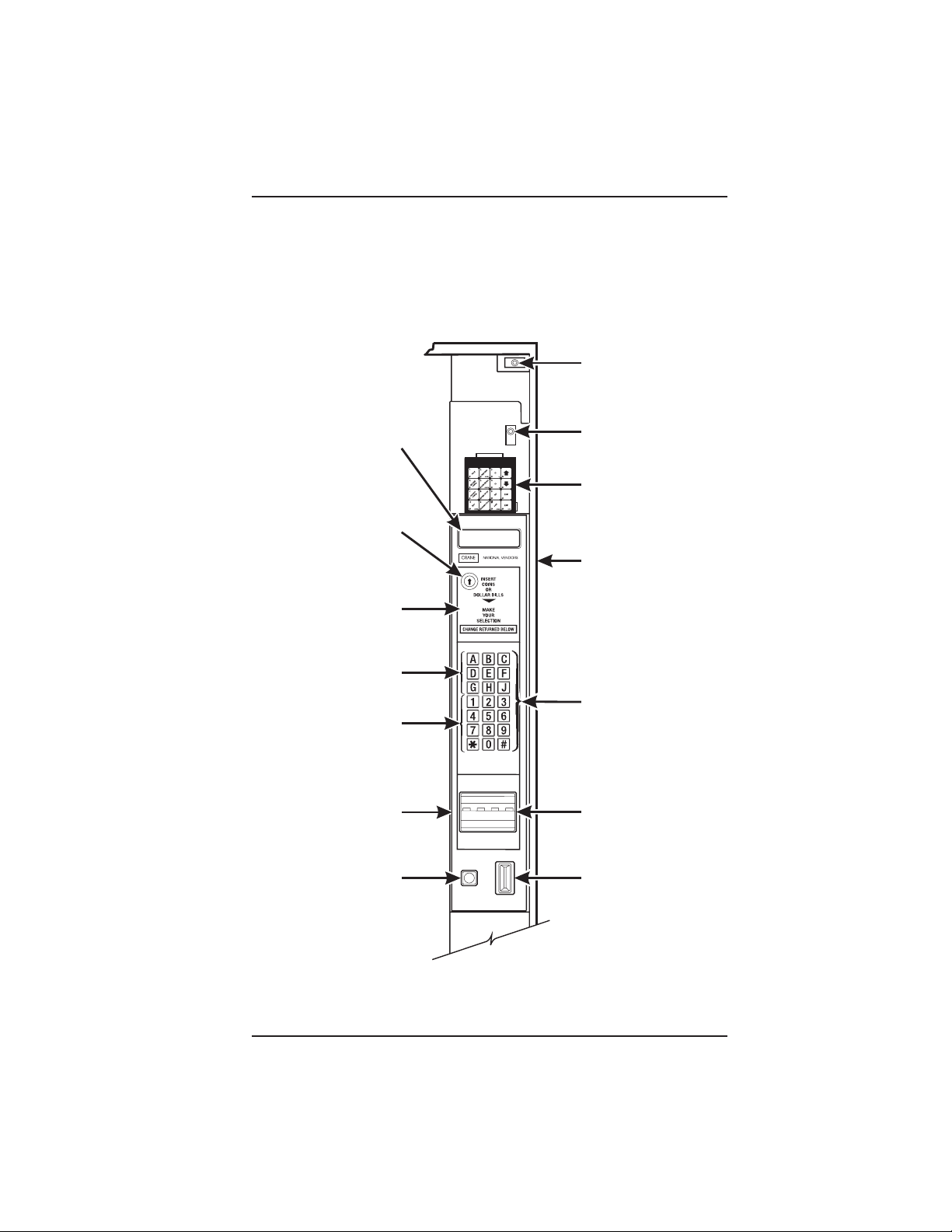

POINT OF

K

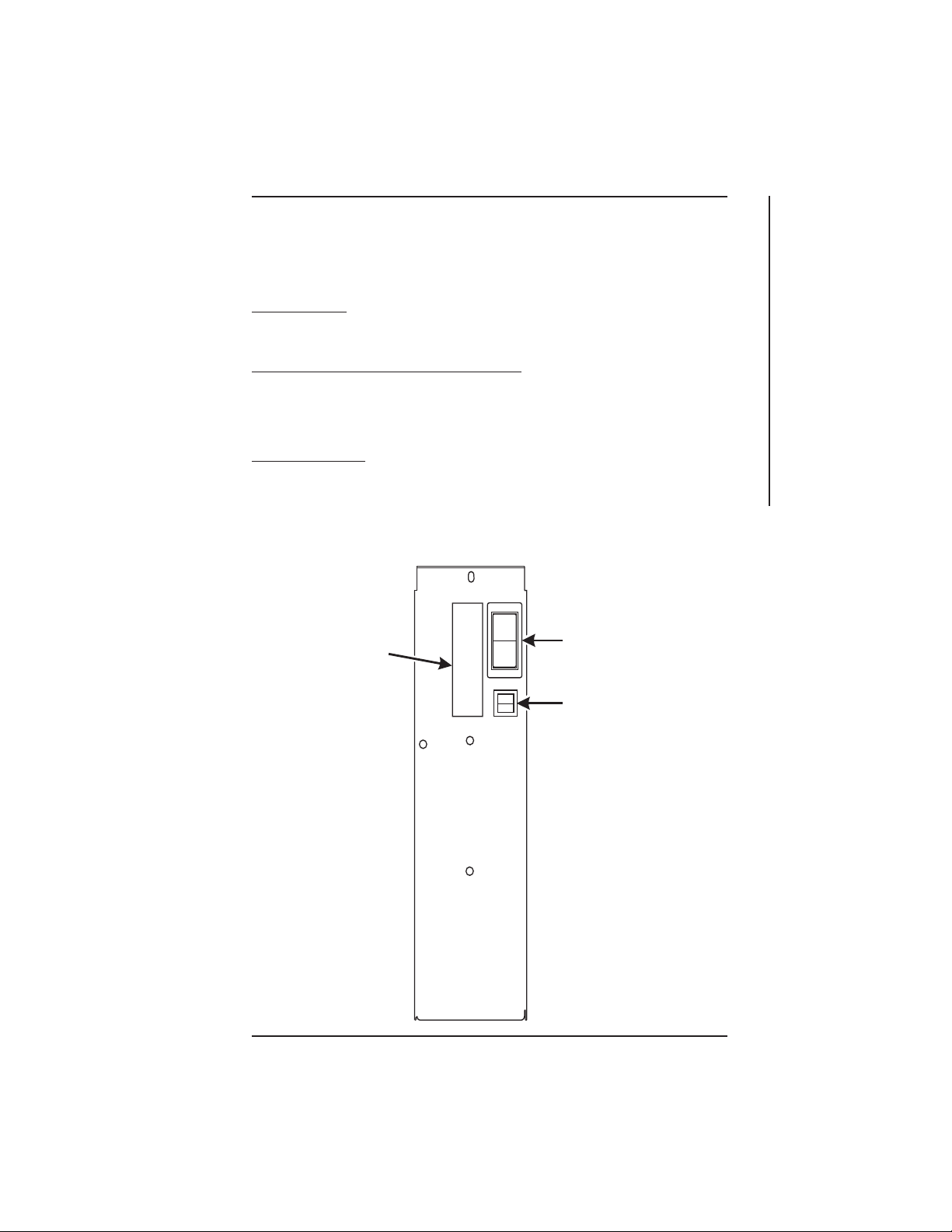

MAJOR PARTS

The diagrams on the following pages will acquaint you with the major parts of the Hot Drink

merchandiser. For more detailed information, please consult your PARTS MANUAL. If you

do not have a PARTS MANUAL, contact National Vendors Parts Department.

MENU

ASSEMBLY

PURCHASE

PHOTO

˜

EXTERIOR

DOOR

ASSEMBLY

˜

CRANE

NATIONAL VENDORS

MAJOR PARTS

LOC

FRONT OF MERCHANDISER

November, 2002 Page - vii 6700001

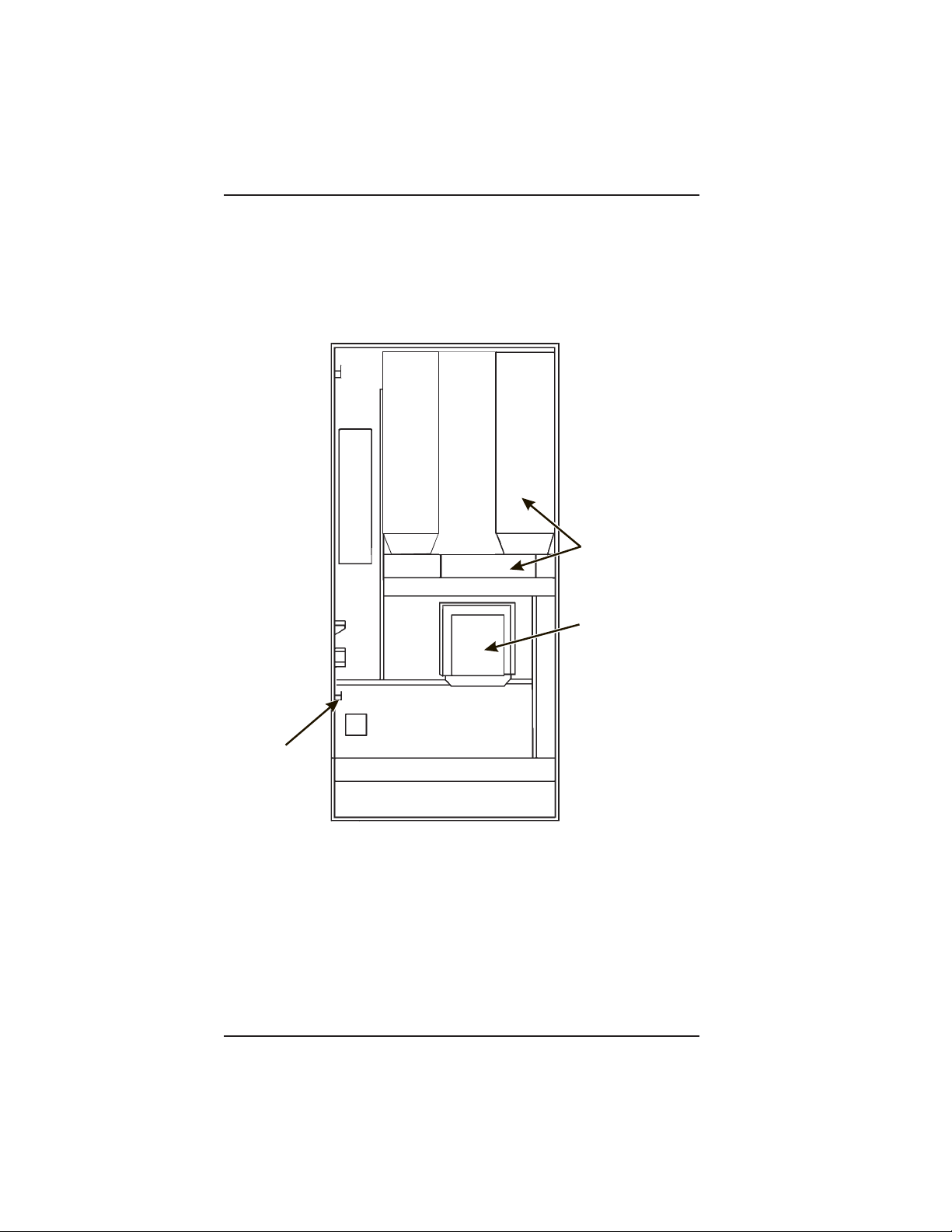

Page 10

HOT DRINK SETUP/PROGRAMMING GUIDE

CUP MECHANISM

TURRET ASSEMBLY

AND MOTOR AND PCB

ASSEMBLY

DELIVERY DOOR

LOCK BAR

ASSEMBLY

636p0048

FRONT VIEW OF MERCHANDISER

BACK SIDE OF MERCHANDISER DOOR

6700001 Page - viii November, 2002

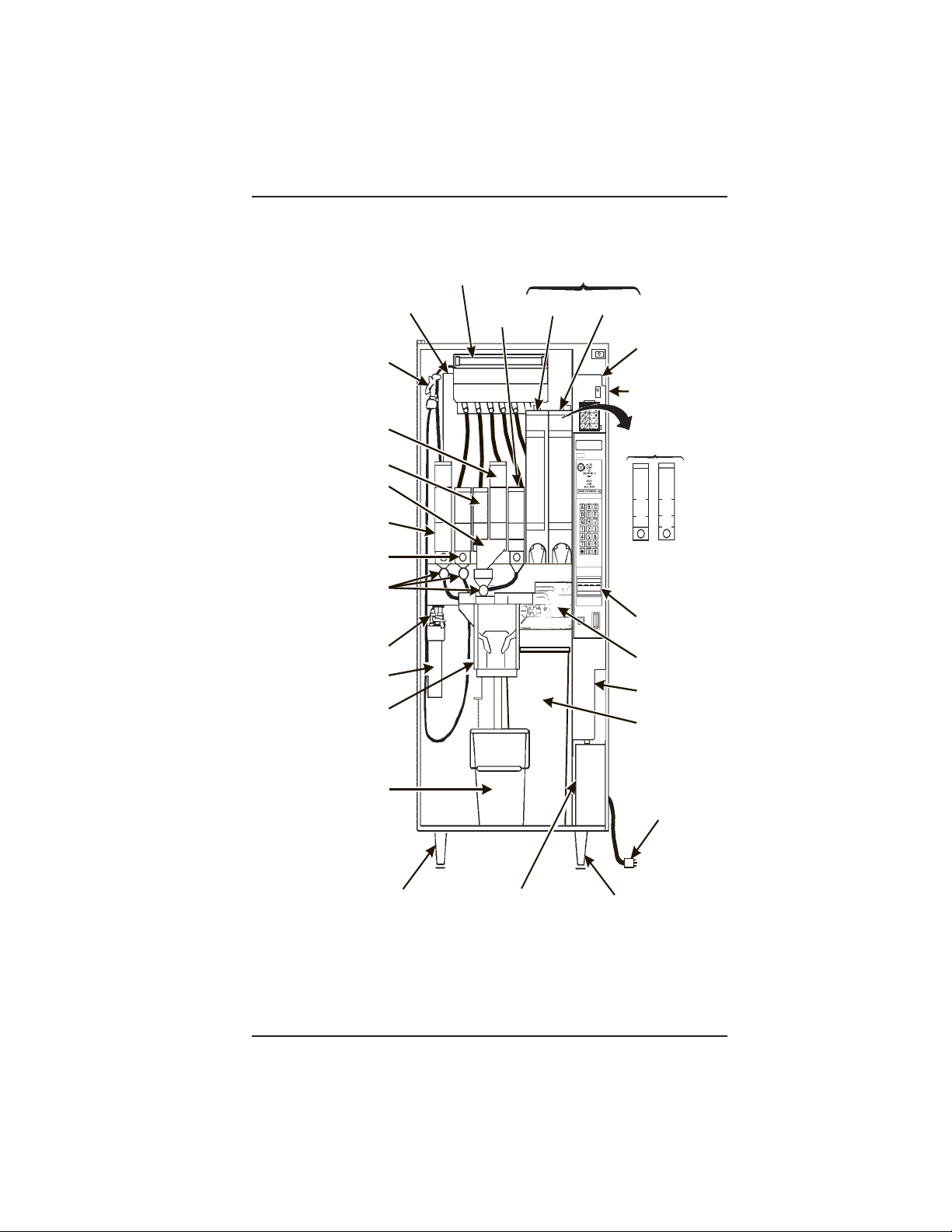

Page 11

HOT DRINK SETUP/PROGRAMMING GUIDE

ASSEMBLY

T

SERVICE LIGHT

D

E

C

A

F

C

O

F

F

E

E

WATER TANK

RINSE

HOSE

ASSEMBLY

SUGAR

CANISTER

LIGHTENER

CANISTER

WO INGREDIENT

CHUTE

CHOCOLATE

CANISTER

SOUP OR SUGAR

SUBSTITUTE

CANISTER

DRINK WHIPPER

ASSEMBLY

FILTER & VALVE

HEAD ASSEMBLY

WATER FILTER

CARTRIDGE

CUP DELIVERY

ASSEMBLY

ASSEMBLY

ASSEMBLY

F.D. TEA

CANISTER

( OPTIONAL )

F.B. DECAF

CANISTER

F.B. COFFEE

CANISTER

NATIONAL VENDORS

CRANE

MONETARY

PANEL

ASSEMBLY

CABINET

( OPTIONAL )

F.D. CANISTERS

C

D

O

E

F

C

F

A

E

F

E

BILL

ACCEPTOR

(OPTIONAL)

BREWER

(OPTIONAL)

COIN

MECHANISM

GROUNDS

PAIL

LIQUID

WASTE

PAIL

LEVELER ASSEMBLY

LEG, HINGE, &

COIN BOX

ASSEMBLY

POWER CORD

&

PLATE ASSEMBLY

LEG & LEVELER

MERCHANDISER CABINET INTERIOR

November, 2002 Page - ix 6700001

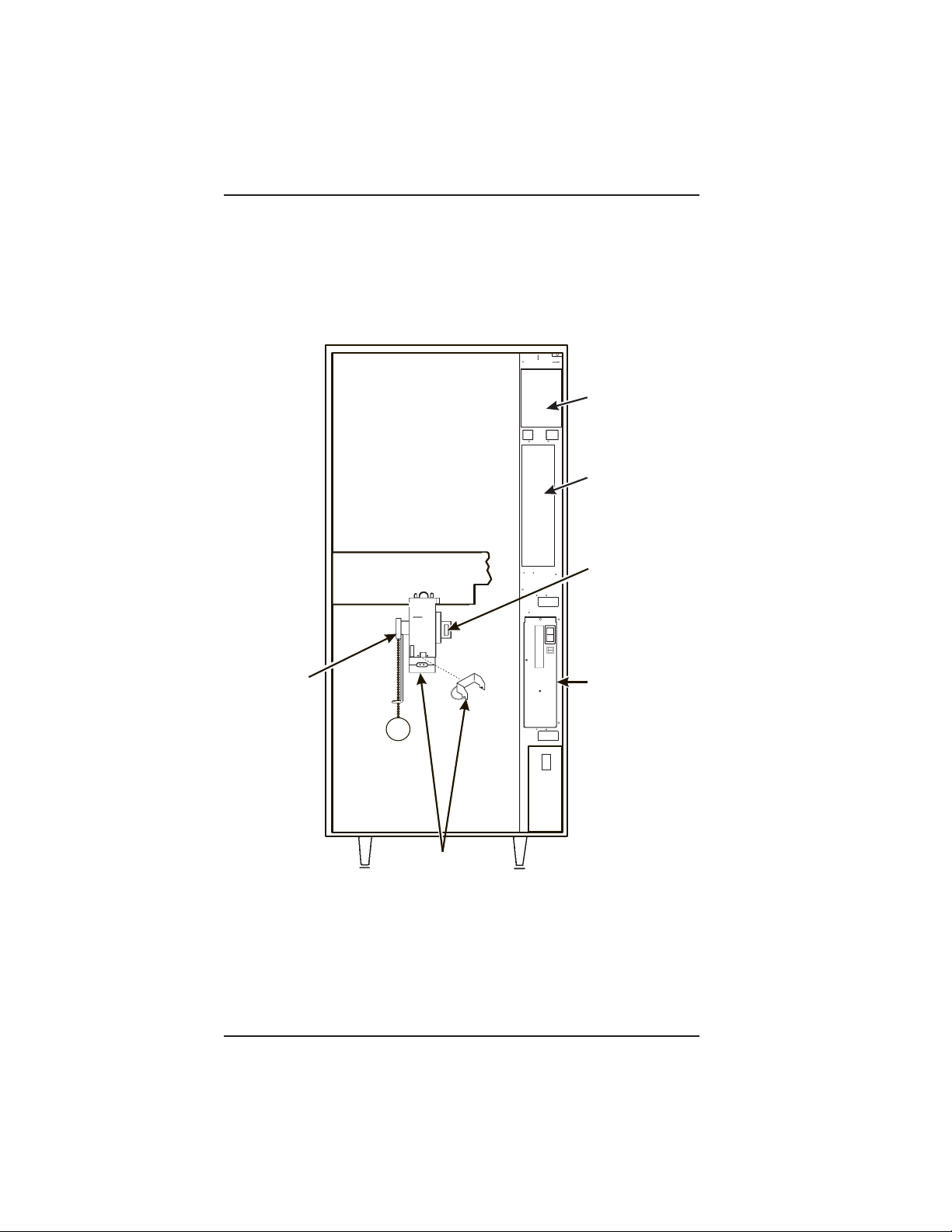

Page 12

HOT DRINK SETUP/PROGRAMMING GUIDE

˜

˜

I

O

MAIN

CONTROLLER

PCB ASSEMBLY

INTERFACE

BOARD

EXHAUST

FAN

BRACKET

ASSEMBLY

OVERFLOW

SWITCH

ASSEMBLY

OPTIONAL INFRARED

CUP/MUG SENSOR

OR

Posi-Vend

636P0047

POWER

PANEL

ASSEMBLY

MERCHANDISER CABINET INTERIOR

6700001 Page - x November, 2002

Page 13

HOT DRINK SETUP/PROGRAMMING GUIDE

CONTROLS AND INDICATORS

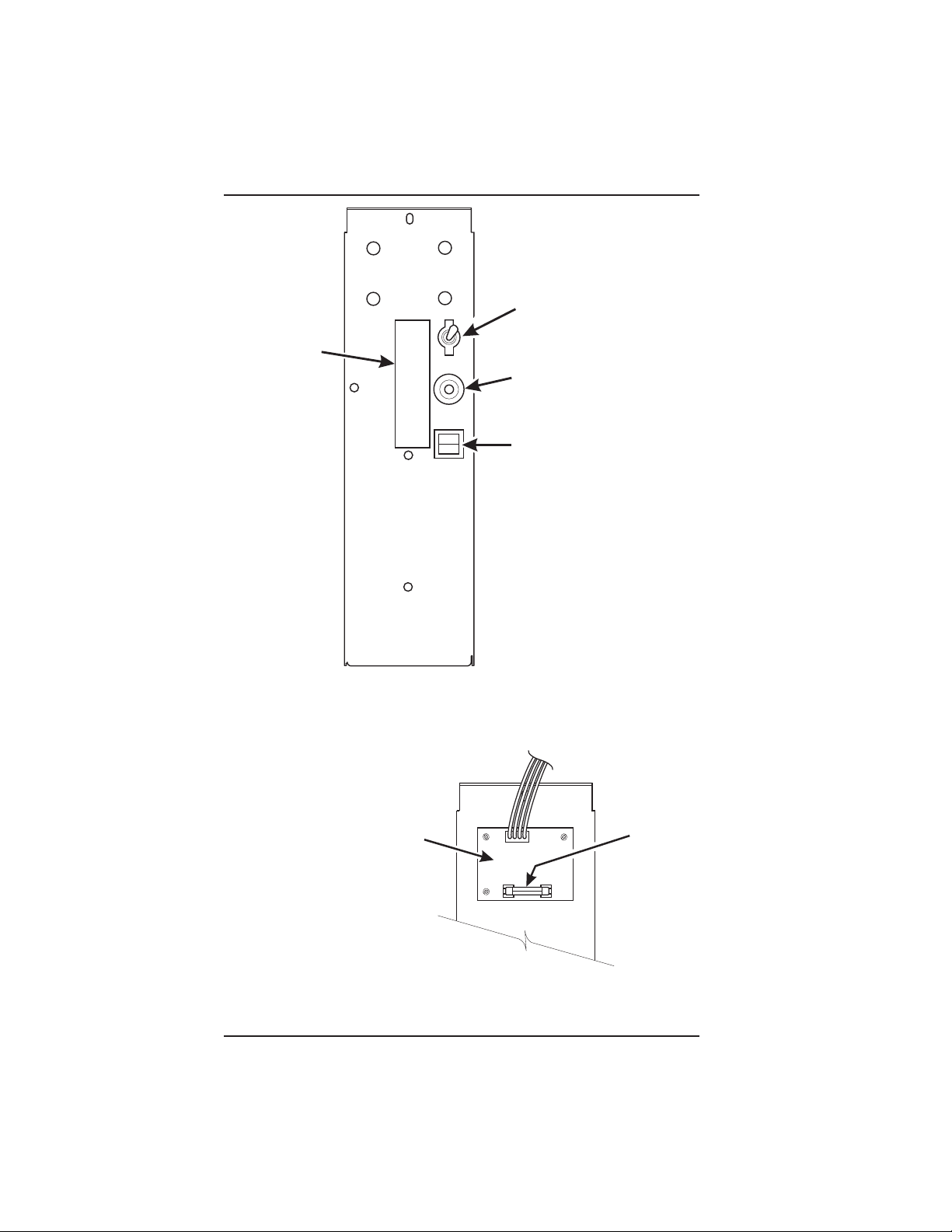

POWER PANEL. You may have one of three power panels, depending upon where you

live. The controls are fundamentally the same, however.

Circuit Breakers. Circuit breakers protect the merchandiser against failures in the power

supply or any of the electrical components. If a circuit breaker trips and cannot be reset,

consult your troubleshooting manual.

Back Side of U.S./ Canada Power Control Panel. The circuit board mounted on the rear

of the U.S. and Canadian power control panel is a dc power supply for the coin

mechanism. A fuse protects the board circuitry in the event of a coin mechanism solenoid

failure. If the coin mechanism is not working, check this fuse. If the fuse is blown, a bad

coin mechanism solenoid could be at fault.

Main Power Switch. This is the main ON/OFF switch for the merchandiser.

To protect against electrical shocks and possible damage to the

machine, turn this switch OFF when performing any maintenance on the merchandiser.

WARNING

I

MAIN

POWER

LABEL

O

SWITCH

ELECTRONICS

BREAKER

CONTROLS AND INDICATORS

626P0005

November, 2002 Page - xi 6700001

Page 14

HOT DRINK SETUP/PROGRAMMING GUIDE

1

E

P

MAIN

POWER

SWITCH

MAIN

LABEL

ON

OFF

CIRCUIT

BREAKER

LOW VOLTAGE

CIRCUIT BREAKER

626P0006

POWER CONTROL PANEL

(U.S./CANADA)

TOP

DC POWER

SUPPLY PCB

FOR 110V COIN MECH

BACK SIDE OF U.S./CANADA POWER CONTROL PANEL

6700001 Page - xii November, 2002

˜

AGC

FUS

1 AM

Page 15

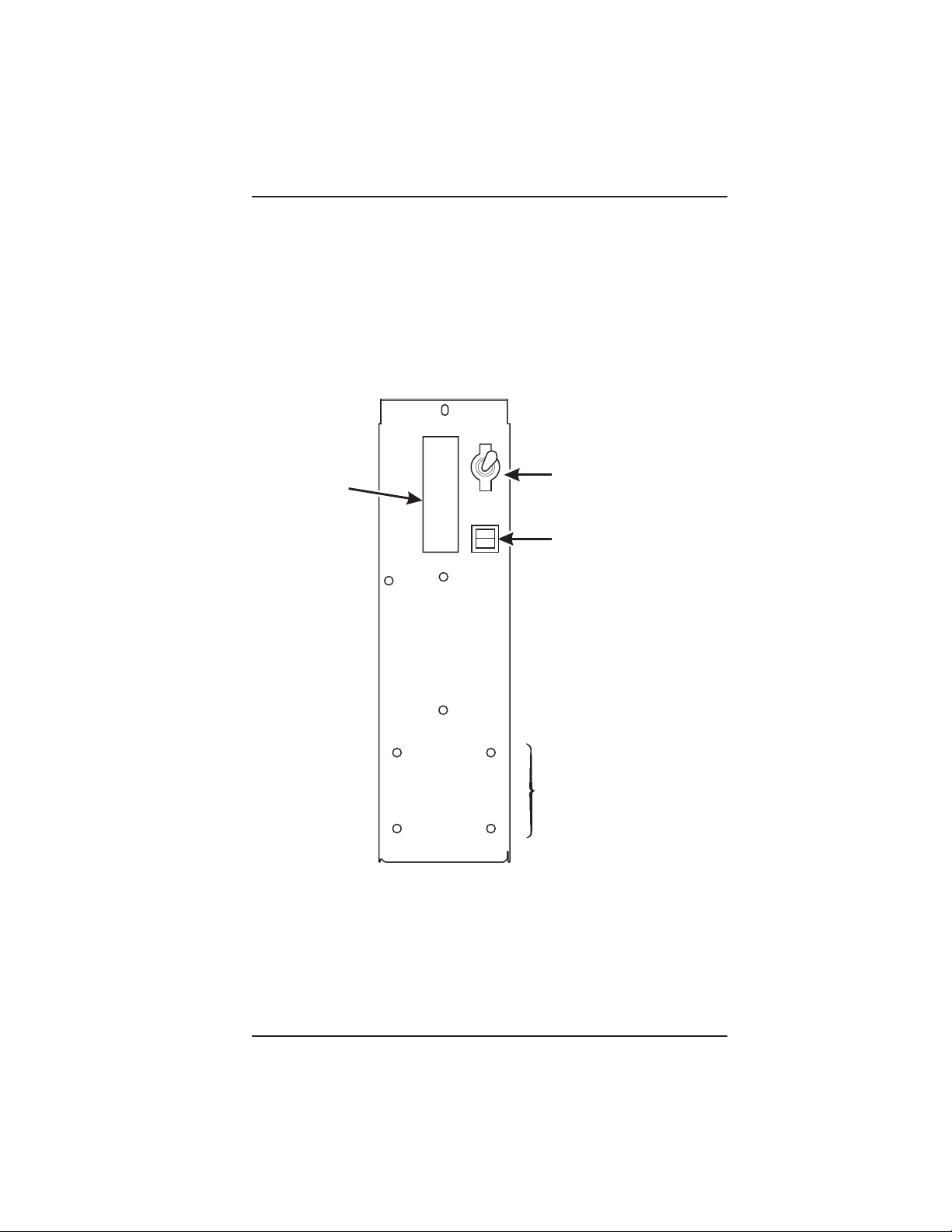

L

ABEL

R

HOT DRINK SETUP/PROGRAMMING GUIDE

ON

MAIN POWER

OFF

SWITCH

ELECTRONICS

CIRCUIT BREAKE

MOUNTING STUDS

FOR MEXICO ONLY

POWER CONTROL PANEL

(U.K. / MEXICO)

November, 2002 Page - xiii 6700001

Page 16

HOT DRINK SETUP/PROGRAMMING GUIDE

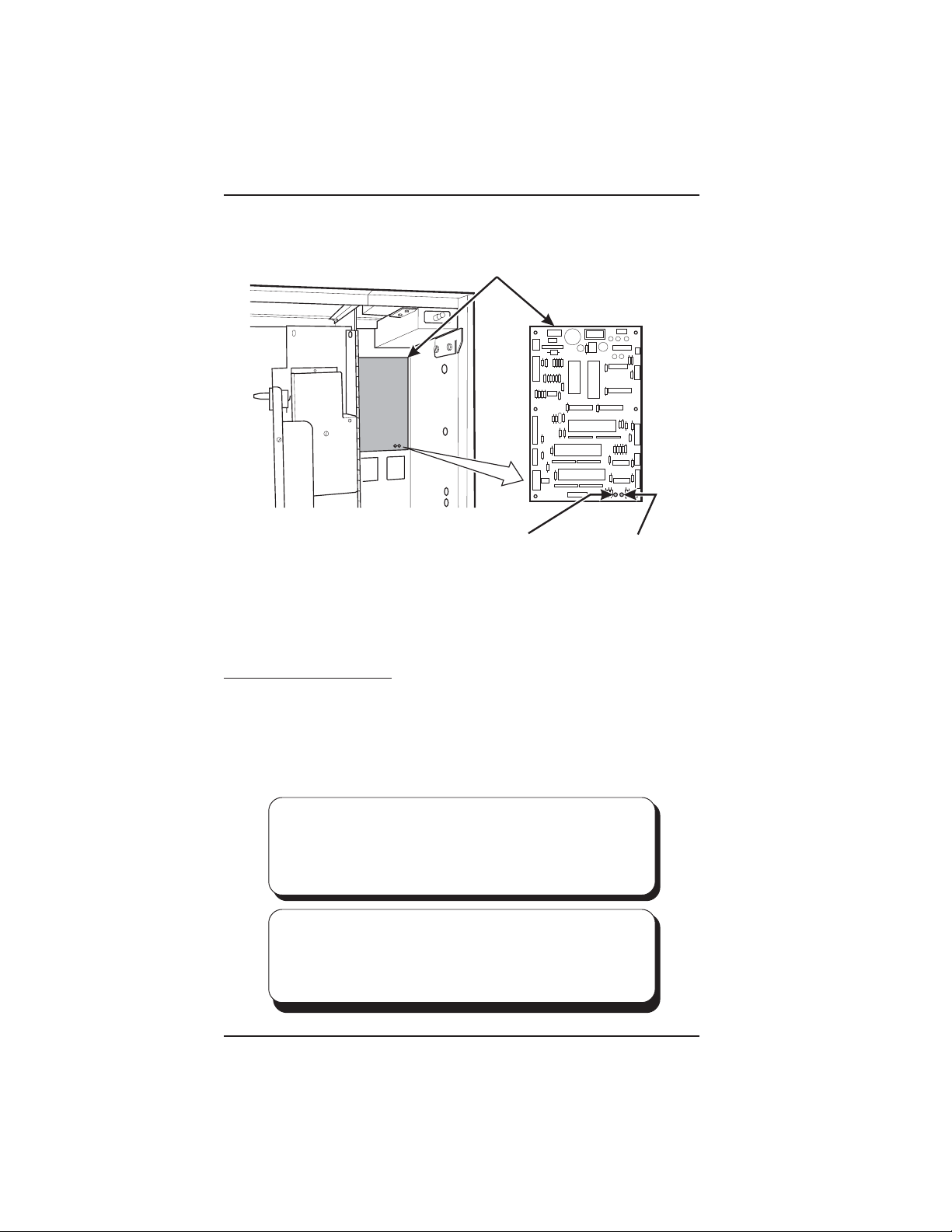

MAIN CONTROLLER

T

PCB ASSEMBLY

LED1LED2

POWER ON

(LED 1)

FLASHING

HEARTBEA

(LED 2)

MAIN CONTROLLER PCB DISPLAY

Main Controller PCB Display. This display consists of two light emitting diodes (LED)

mounted on the controller PCB.

POWER ON When lit, this red LED indicates electrical power is applied to

(LED 1) the controller PCB.

HEARTBEAT When flashing, this red LED indicates that the controller PCB is

(LED 2) active, and the software is operating.

NORMAL CONDITIONS:

When the merchandiser is operating normally, you should see a

steady red POWER ON indicator. The red HEARTBEAT indicator

should be flashing with a balanced on/off pattern (on for the same

length of time that it is off).

ERROR CONDITIONS:

If an error is present, the red HEARTBEAT indicator will flash with an

unbalanced on/off pattern (on longer than it is off). The error(s) can be

viewed under the DIAGNOSTICS mode.

6700001 Page - xiv November, 2002

Page 17

HOT DRINK SETUP/PROGRAMMING GUIDE

E

E

H

I

HIGH VOLTAG

INTERLOCK

SWITCH

MESSAGE

DISPLAY

LOW VOLTAG

DOOR SWITC

SERVICE

FREE VEND

KEYPAD

KEYSWITCH

(OPTIONAL)

CABINET

NSTRUCTION

PLATE

LETTERS

A-H,J

NUMERALS

SELECTION

SWITCH

1-9, *,0, #

MONETARY

PANEL

COIN

RETURN

BUTTON

BILL

ACCEPTOR

(OPTIONAL)

COIN

INSERT

MONETARY PANEL

November, 2002 Page - xv 6700001

Page 18

HOT DRINK SETUP/PROGRAMMING GUIDE

High Voltage Interlock Switch (U.S./ Canada). When the cabinet door is open, this

switch turns off the optional fan and bean light (if equipped), and turns on the service light.

High Voltage Interlock Switch (International). When the cabinet door is open, this

switch turns off all high voltage to the cabinet. Pulling the switch out restores high voltage

for maintenance purposes.

Low Voltage Door Switch. Informs the controller software of the main door open or

closed status.

Message Display. This is how the merchandiser communicates with the outside world.

Customers can see messages about how much money they have put into the merchandiser. The message display also tells customers when a selection is sold out and when

vending is free, inhibited, or discounted. The message display shows you what you are

doing when you program the merchandiser, and can show you what is wrong if there is

a failure.

Free Vend Keyswitch. This allows someone (other than maintenance people) to set the

merchandiser to free vend without opening the door.

Selection Switch Panel. The customer uses these switches to make selections. Also,

maintenance people may use this switch panel during programming and other support

modes.

Coin Return Button. Pressing this button returns any coins that have been paid into the

merchandiser prior to a vend.

Bill Acceptor (Optional). Accepts bills in various denominations, depending upon the

type of bill validator, and how the machine is configured.

Service Keypad. The service keypad is located at the top of the monetary panel. It gives

service personnel the means to program, retrieve data from, and view diagnostic

information about, the merchandiser.

SERVICE KEYPAD

6700001 Page - xvi November, 2002

Page 19

HOT DRINK SETUP/PROGRAMMING GUIDE

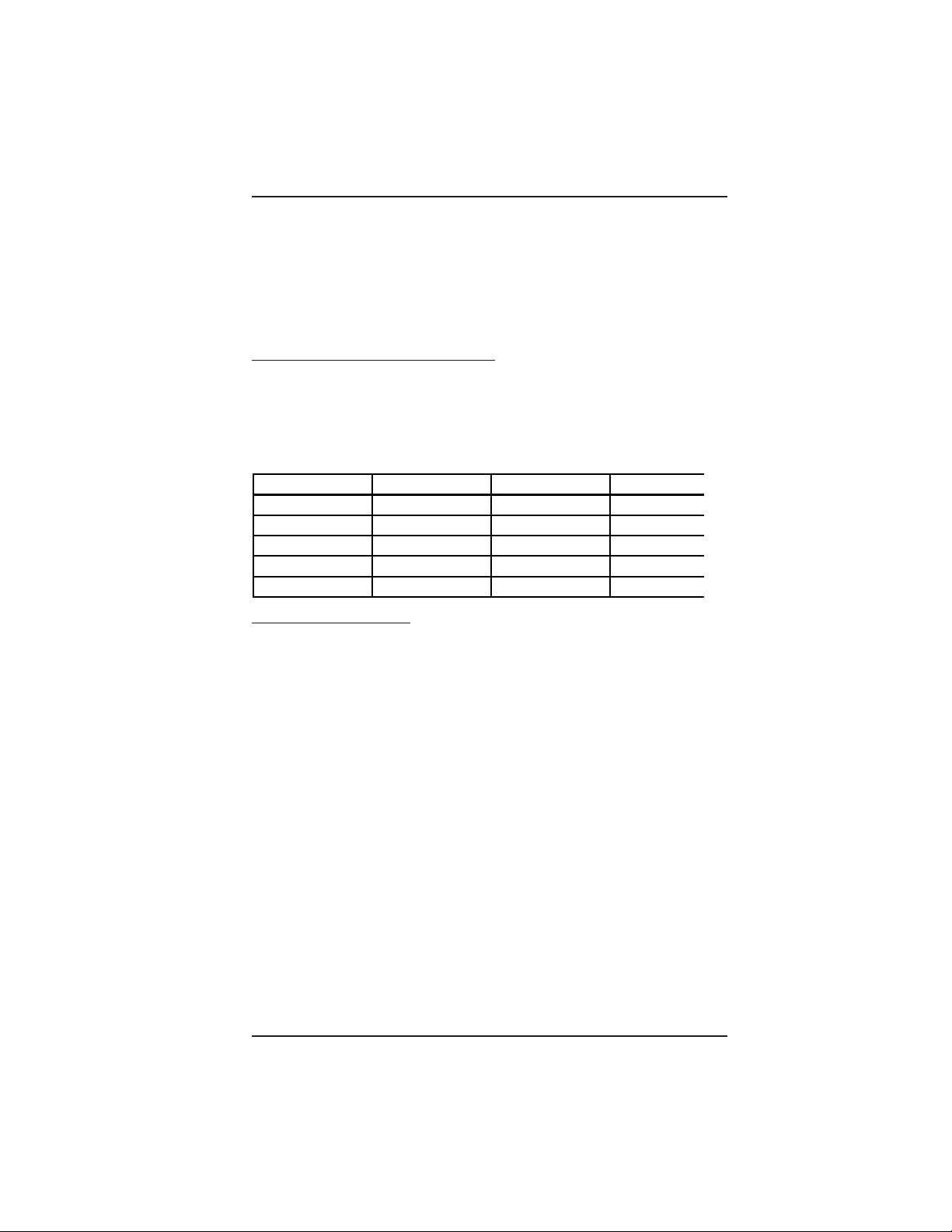

Current (Amps

INITIAL SETUP

I. LOCATION PREPARATION

After your machine is unpacked and placed near its permanent location, you need

to make sure you have the proper electrical and water service.

ELECTRICAL POWER REQUIREMENTS

This merchandiser needs electrical power as shown in the following table.

Each merchandiser should have its own electrical circuit.

Country Volts Frequency (Hz)

Canada 115 60 15

France 230 50 10

Germany 230 50 10

United Kingdom 230 50 10

United States 115 60 15

1. Check the Power Outlet

This merchandiser is supplied with a service cord for the country of use and is terminated in a grounding type plug. The wall receptacle used for this merchandiser must be

properly polarized, grounded, and of the correct voltage. Operating the merchandiser

from a source of low voltage will VOID YOUR WARRANTY. Each merchandiser should

have its own electrical circuit and that circuit should be protected with a circuit breaker or

fuse conforming to local regulations.

Voltage Check - Place the leads of a voltmeter across the LINE (LIVE) and

NEUTRAL terminals of the wall receptacle. The voltmeter should indicate 110-130

volts ac for 120 volt, 60 Hz locations, or 220-240 volts ac for 230 volt, 50 Hz

locations.

Polarity Check - Place the leads of a voltmeter across the LINE (LIVE) and

GROUND terminals of the wall receptacle. The voltmeter should indicate 110-130

volts ac for 120 volt, 60 Hz locations, or 220-240 volts ac for 230 volt, 50 Hz

locations.

NOTE

Power Requirements

Noise Potential Check - Place the leads of a voltmeter across the NEUTRAL and

GROUND terminals of the wall receptacle. The voltmeter should indicate 0 volts

ac. A measurement greater than 1.5-2.0 volts ac could result in problems for the

merchandiser's electronic circuitry caused by electrical noise.

Any deviation from these requirements could result in unreliable performance from your

merchandiser.

6700001 Page - 1 November, 2002

Page 20

HOT DRINK SETUP/PROGRAMMING GUIDE

WATER REQUIREMENTS

The best type of water for coffee brewing is normal hard (tap) water. If your location

has chemically softened water, you should do one of the following things:

• Have a non-softened supply line run to the merchandiser

• Contact your local water filter supplier for information and suggestions

Well water can also be used in the Hot Drink Machine. However, you should

have it checked for levels of carbonates and alkalies. Contact your water filter

supplier if these values are relatively high.

What is the Water Pressure at Your Location?

It should be no less than: 10 psi ( 69.0 KPa) at 1/2 gallon/minute

And no more than: 80 psi (522.0 KPa) at 1/2 gallon/minute

If you're not sure about the pressure and flow rate, check with your water company.

What to do With the Water Supply Line:

Locate the supply line at the rear of your merchandiser.

Equip the line with a shut-off valve.

Flush the water supply line before connecting it to the merchandiser. A minimum of

five gallons is usually required before connecting the merchandiser to the supply line.

DO NOT flush the merchandiser water system. If you do, you might introduce water

line contaminants into the merchandiser.

November, 2002 Page - 2 6700001

Page 21

HOT DRINK SETUP/PROGRAMMING GUIDE

II. POSITIONING THE

MERCHANDISER

You can position this merchandiser anywhere in a bank of machines. It can even be

placed on the end flush against a side wall. Be sure you leave enough room in front

of the merchandiser for the door to move freely.

BE SURE THE REAR OF THE MERCHANDISER IS AT LEAST 6" AWAY

FROM THE WALL. THIS WILL ALLOW WARM MOIST AIR TO BE VENTED

OUT OF THE MACHINE'S INTERIOR.

THIS MACHINE IS ONLY RATED FOR INSTALLATION IN AN

INDOOR LOCATION.

WARNING:

III. CONNECTING EVERYTHING

1. Connect the Merchandiser to the Water Supply:

a. You will need the following:

• A coil of copper tubing with outside diameter of 3/8 inch (9.5 mm) or greater.

The appropriate plastic tubing may be substituted. The tubing must be long

enough to reach from the water source to your machine with enough left over

to form a loop about 2 feet (60 cm) in diameter. This will allow you to move the

machine without straining the water line.

• A 3/8 inch (9.5 mm) flare fitting.

b. Connect the merchandiser to your water supply.

2. Connect the Merchandiser to the Electrical Power Supply:

Power inside the merchandiser is controlled by the main power switch, located on the

power panel.

a. Make sure the main power switch is OFF.

b. Connect the merchandiser’s power cord to your wall outlet.

6700001 Page - 3 November, 2002

Page 22

HOT DRINK SETUP/PROGRAMMING GUIDE

SPIRIT LEVEL

LEVELER

IV. FINAL MECHANICAL

PREPARATION

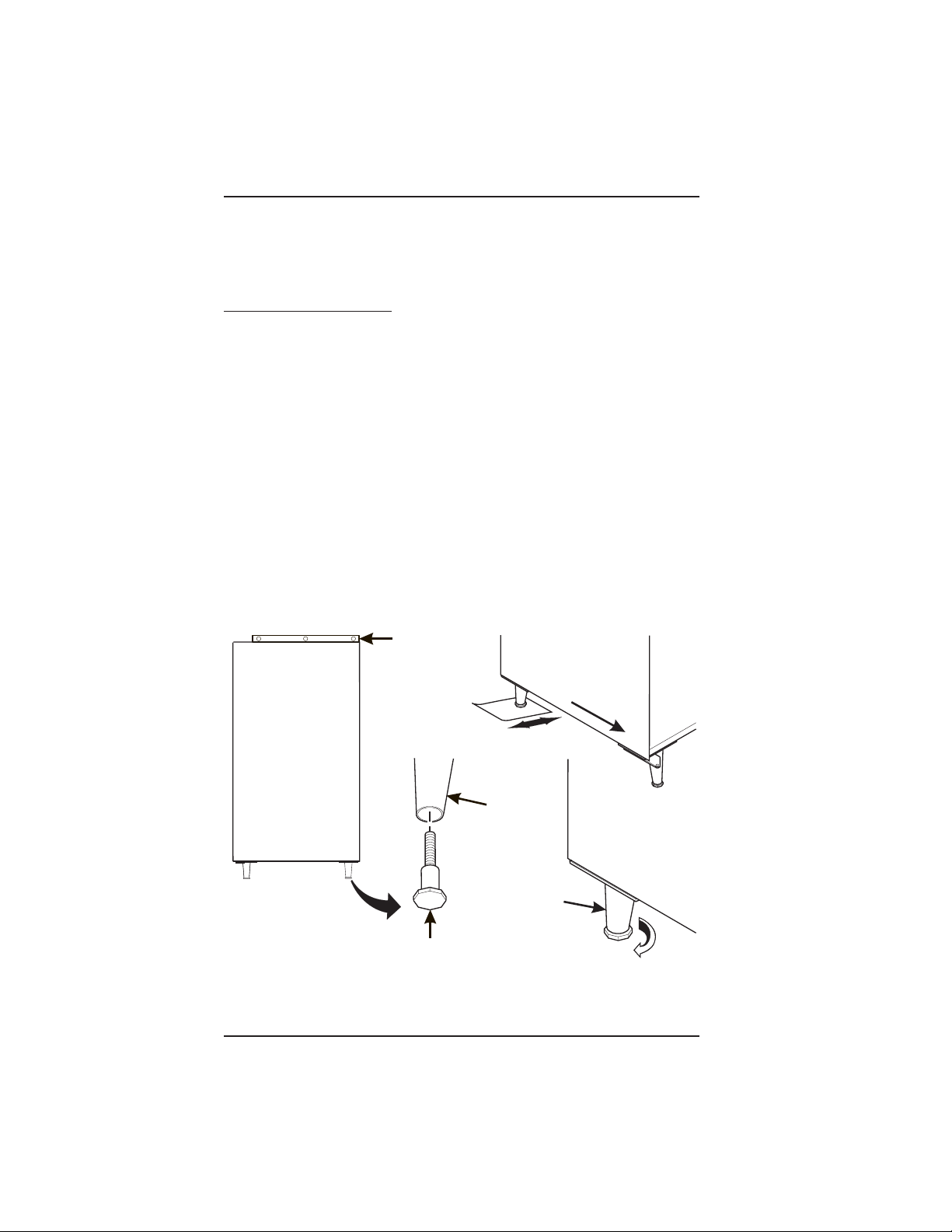

1. Level the Merchandiser:

a. Place a spirit level on the top front edge of the cabinet with the door fully

closed. Adjust the front legs only until the cabinet is reasonably level.

b. Hold the door open about 4 inches.

HAVE AN ASSISTANT HOLD THE MERCHANDISER WHILE

YOU ADJUST THE LEG LEVELERS.

c.Adjust the back legs so that the back leg leveler on the hinge side is off the

floor just enough so a piece of paper can slide under it with only a bit of

resistance.

d. For proper weight distribution on all four legs, raise the back leg on the hinge

side by unscrewing the leveler 1½ turns.

You may need to use pliers or channel locks to loosen the leg

levelers.

WARNING

NOTE

FRONT

LEG

November, 2002 Page - 4 6700001

LEG

LEFT REAR

LEG

1-1/2 TURNS

Page 23

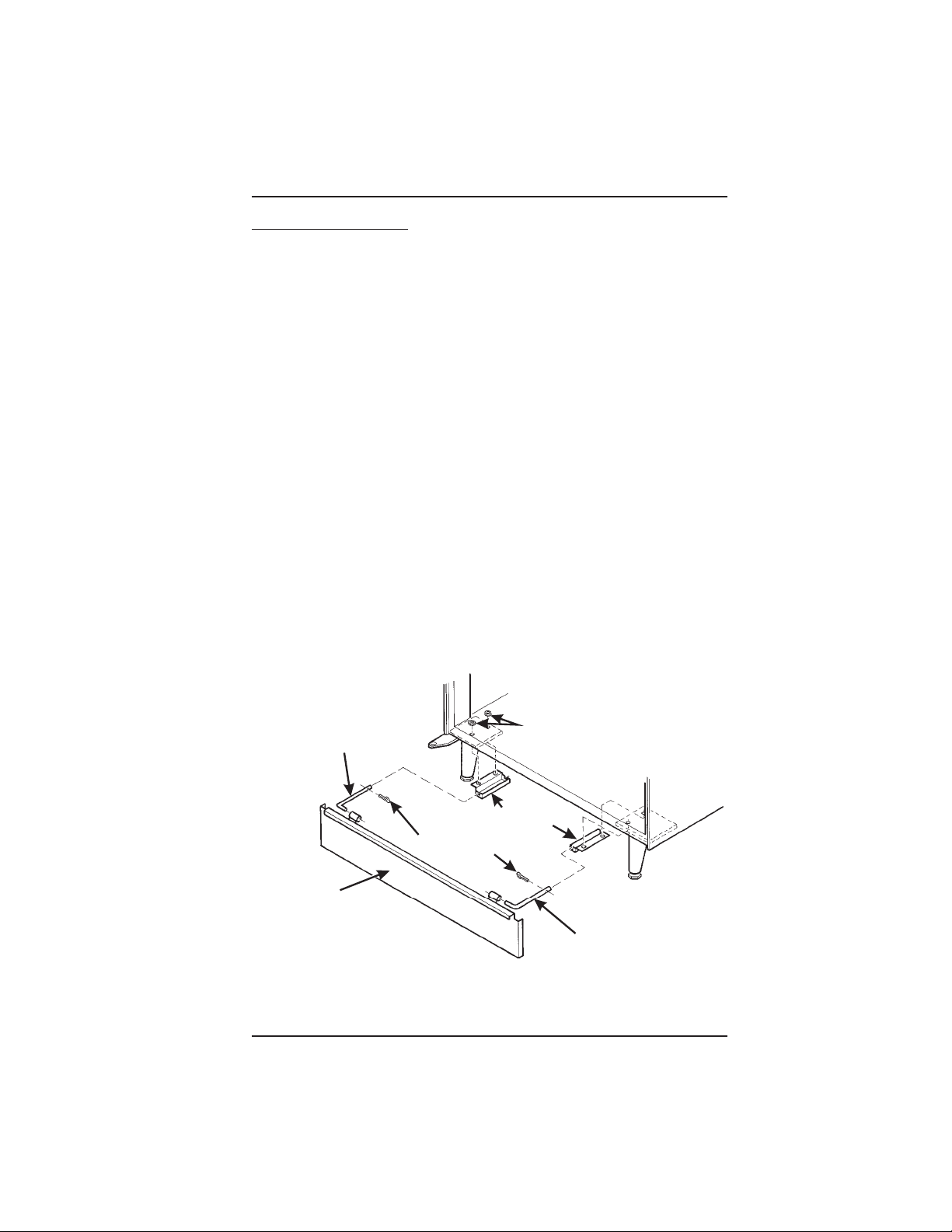

2. Mount the Base Plate:

B

HOT DRINK SETUP/PROGRAMMING GUIDE

DO NOT MOVE THE CABINET WHILE HEX

HEAD SCREWS AND/OR CARRIAGE

BOLTS ARE LOOSENED. THE CABINET

WOULD BECOME UNSTABLE AND LIKELY TO TIP AND CAUSE INJURY.

a. Remove the pail(s) from the inside of the merchandiser.

b. Remove the floor liner from the inside of the merchandiser.

c. Remove the two caps as shown.

d. Loosen the left leg assembly carriage bolts and nuts to allow mounting a base plate

bracket.

e. Secure one of the base plate brackets to the leg assembly using the two carriage

bolt. Tighten the carriage bolts and nuts.

f. Loosen the right leg assembly hex head screws to allow mounting the other base

plate bracket.

g. Secure the other base plate bracket to the right leg assembly using the two hex

head screws. Tighten the hex head screws.

h. Insert the short arms of the slides into the hinged tabs of the base plate. Position

the slide so the notch near the short arm is on the bottom side.

i. Insert the long arms of the slides into the base plate brackets.

j. Insert and secure a cotter pin through the hole in the back of each of the slides.

k. Push the base plate toward the merchandiser cabinet. The front tabs of the base

plate brackets should seat in the notches in the long arms of the slides.

l. Replace the caps, liner, and pail(s) removed previously.

WARNING

CAPS

SLIDE - L.H.

BASE PLATE BRACKET

COTTER PIN

ASE PLATE

ASSEMBLY

SLIDE - R.H.

6700001 Page - 5 November, 2002

Page 24

HOT DRINK SETUP/PROGRAMMING GUIDE

1

3. Install the Water Filter Cartridge:

IF YOUR MERCHANDISER HAS THE WATER FILTER OPTION, IT CANNOT BE OPERATED WITHOUT A PROPERLY

INSTALLED WATER FILTER CARTRIDGE. If you do not have

the water filter option, continue with "Fill the Tank".

CUNO BRAND ...

Check the water filter installation record.

There is a place to write the vend number

on the cartridge. The cartridge is effective

for a maximum of 64,000 7 oz. vends,

56,000 8 oz. vends, 50,000 9 oz.

vends, or 37,000 12 oz. vends. Local

conditions may require more fre-

quent replacement.

CUNO FILTER

FILTER

LOCKING

TAB

TO INSTALL

THE FILTER:

1. INSERT NEW FILTER,

ROTATE COUNTERCLOCKWISE UNTIL

FILTER LOCKING TAB

SNAPS INTO GROOVE

AS SHOWN.

HEAD ASSEMBLY

GROOVE

NOTE

. CLOSE THE WATER SHUT

-OFF VALVE BY TURNING

THE KNOB TO THE

HORIZONTAL POSITION

AS SHOWN.

WATER

SHUT-OFF

KNOB

TO REMOVE FILTER:

2. LIFT THE FILTER

LOCKING TAB,

ROTATE FILTER

CLOCKWISE AND

PULL DOWN AS

SHOWN.

CUNO

FILTER

FILTER

LOCKING

TAB

November, 2002 Page - 6 6700001

Page 25

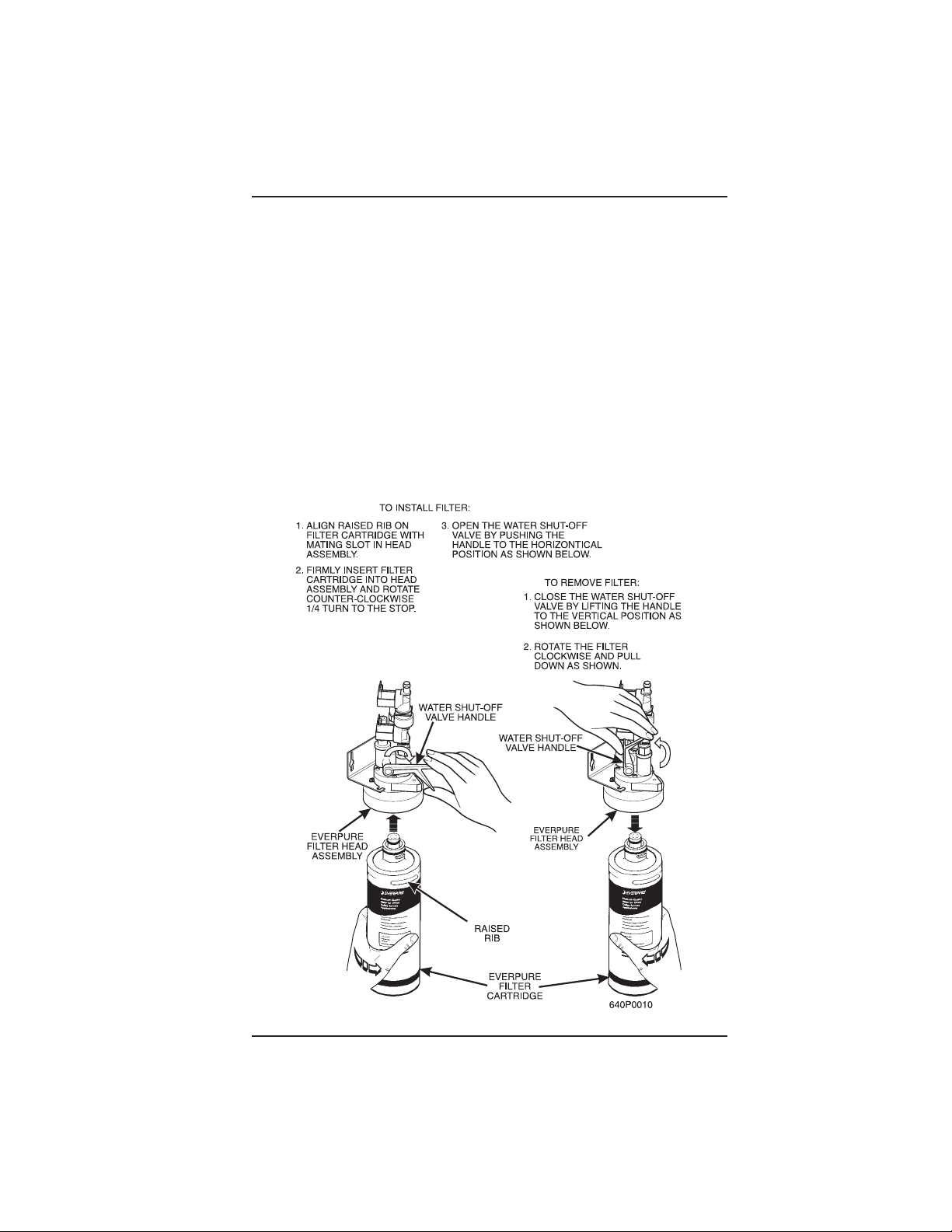

EVERPURE BRAND ...

HOT DRINK SETUP/PROGRAMMING GUIDE

Check the water filter installation record. There is a place to

write the vend number on the cartridge. The cartridge is

effective for a maximum of 26,000 7 oz. vends, 22,000 8 oz.

vends, 20,000 9 oz. vends, or 15,000 12 oz. vends. Local

conditions may require more frequent replacement.

National Vendors recommends that you do the following procedure the first time you

fill the tank in your EuroDrink merchandiser:

a. Remove the small inner "O" ring from the filter cartridge.

b. Install the filter cartridge.

c. Turn on the water at its source, and perform the tank filling procedure.

d. Turn off the water at its source, remove the filter cartridge, and replace the

"O" ring.

e. Install the filter cartridge.

NOTE

6700001 Page - 7 November, 2002

Page 26

HOT DRINK SETUP/PROGRAMMING GUIDE

E

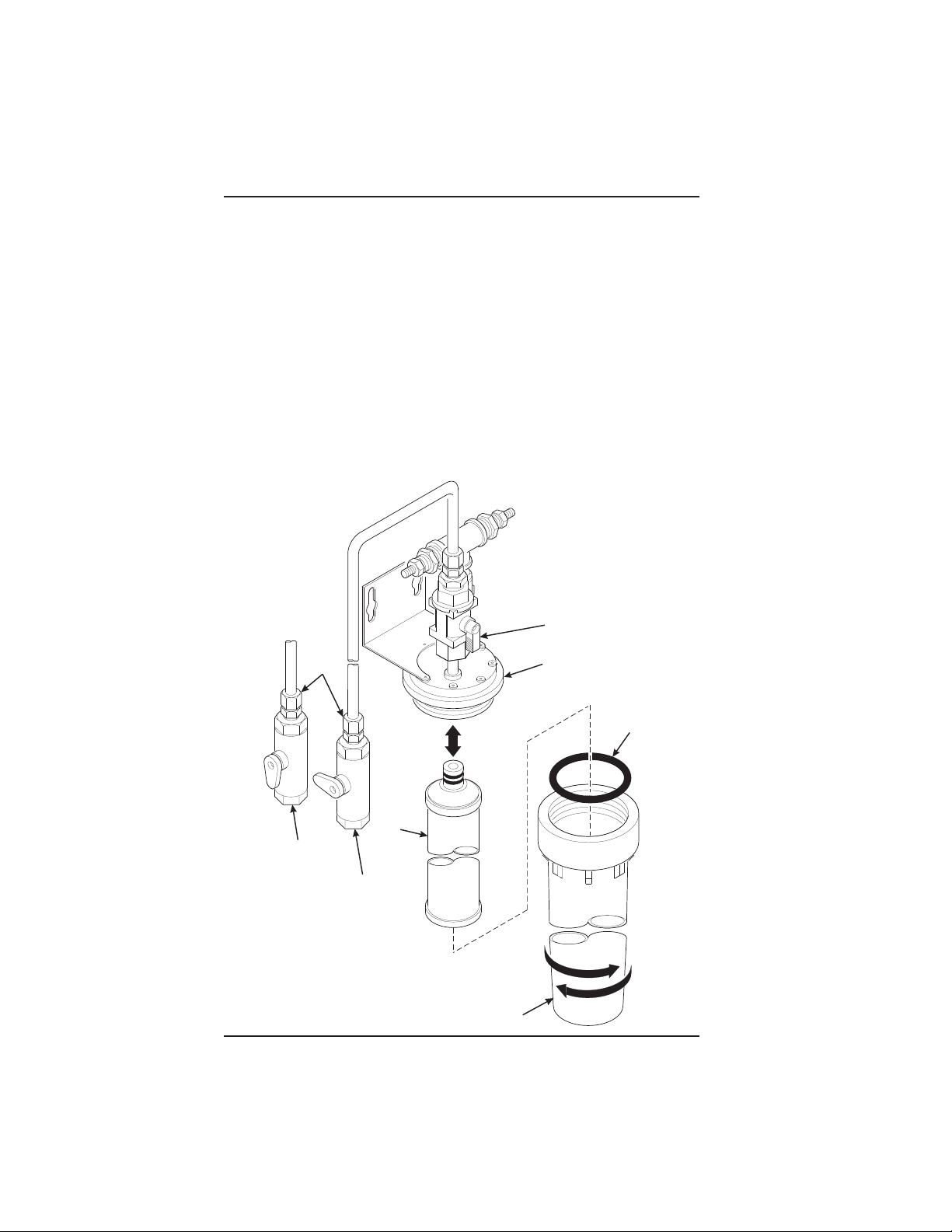

HYDROLIFE BRAND

INSTALLATION:

1. Place the filter inside the canister. Be sure the o-ring is seated in the canister just

below the threads.

2. Screw the canister and filter assembly onto the filter head until it comes to a stop.

3. Open the water valve on the inlet line by rotating the handle to the vertical position

as shown.

REMOVAL

1. Close the valve on the inlet line by rotating the handle into the horizontal position

as shown.

2. Relieve water pressure by performing two or three water throws (see the

programming section).

3. Unscrew the filter and canister assembly from the filter head. Remove the filter

from the canister.

OPEN

POSITION

INSTALL

HYDROLIFE

FILTER HEAD

O-RING

REMOV

OPEN

POSITION

VALVE

CLOSED

POSITION

FILTER

CANISTER

November, 2002 Page - 8 6700001

Page 27

HOT DRINK SETUP/PROGRAMMING GUIDE

H

R

TO BREWER

PAPER

PINION GEAR SHAFT

G

L

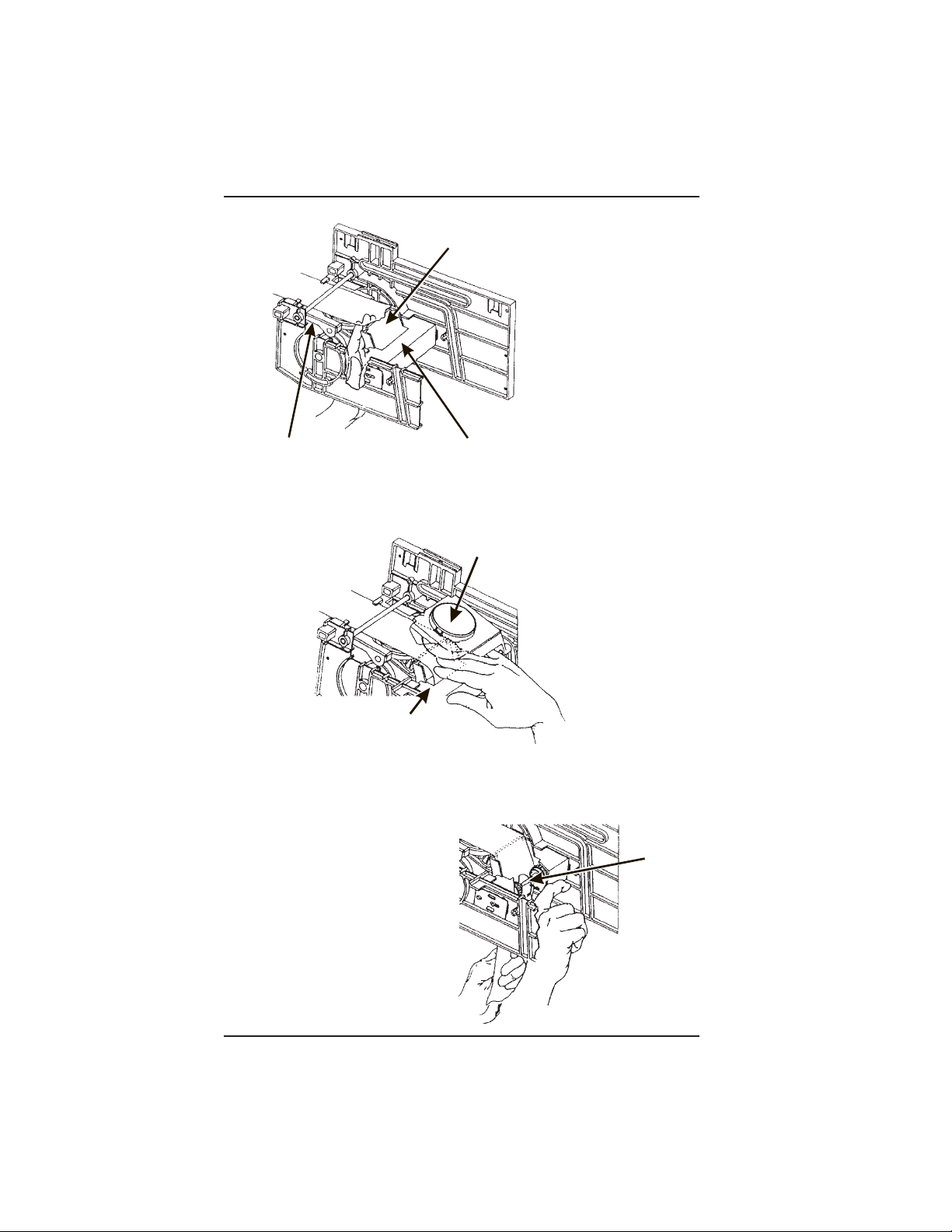

4. Load the Optional Filter Paper:

a. Be sure the main power switch is in the OFF position.

b. Remove the cup station and grounds bucket.

c. Remove the paper holder cover by turning the fastener a quarter turn to the left.

d. Insert a roll of paper into the paper holder. Route the free end of the paper to the

brewer as shown.

e. Replace the cover on the paper holder. Secure it by turning the fastener a quarter

turn to the right.

f. Feed paper over swing arm assembly and underneath pinion gear shaft.

PAPER

OLDER

g. Feed paper through the paper guides.

h. Raise the basket housing assembly and feed paper over the lip of the paper

mechanism housing.

GUIDES

SWING ARM

ASSEMBLY

IP OF PAPER MECHANISM HOUSING

PAPER

ROLL

COVER

FASTENE

BASKET HOUSIN

ASSEMBLY

PAPER MECHANISM HOUSING

It may be necessary to reach underneath the brewer between

the paper mechanism housing and swing arm assembly to

6700001 Page - 9 November, 2002

push paper over the lip of the paper mechanism housing.

NOTE

(CONTINUED)

Page 28

HOT DRINK SETUP/PROGRAMMING GUIDE

R

Y

G

SWING ARM ASSEMBLY

LIP OF PAPER MECHANISM HOUSIN

PAPER MECHANISM HOUSING

i. Reach underneath the brewer between the paper mechanism housing and basket

housing assembly and push paper into the top of the paper mechanism housing

between paper rollers.

BASKET HOUSING ASSEMBL

PAPER MECHANISM HOUSING

j. Reach underneath the brewer and pull paper roller to the right.

k. Pull paper down between the paper rollers.

l. Release the paper roller.

m. Place the main power switch in the

ON position.

n. Test the brewer to be sure the

paper feeds properly:

PAPER

ROLLE

November, 2002 Page - 10 6700001

Page 29

HOT DRINK SETUP/PROGRAMMING GUIDE

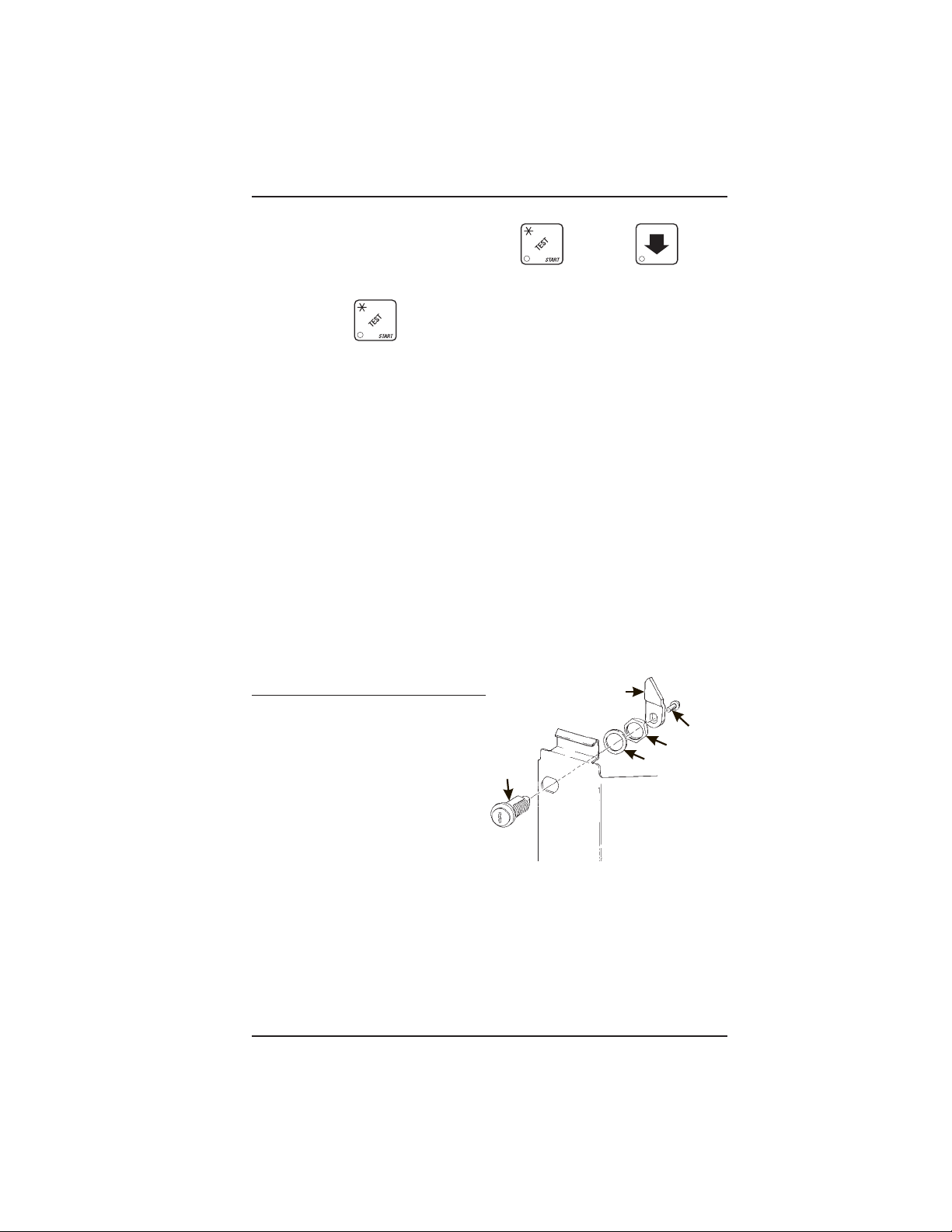

1. On the maintenance keypad, press , then press until the

display shows

2. Press to test each brewer position:

Keep away from the brewer mechanism while it is operating.

Coming into contact with moving parts could injure you.

BREW TEST.

WARNING

BREW 'R BREW The brewer is in the BREW position.

BREW 'R FLIP The brewer is in the FLIP position.

BREW 'R HOME The brewer is in the HOME position.

3. Make sure the filter paper feeds properly without jamming.

4. Replace the cup station and grounds bucket.

5. Install the Optional Coin Box Lock

a. Install the lock cylinder, washer, and nut in

the order shown.

b. Tighten the nut.

c. Install the lock bar as shown,

and secure with the screw.

LOCK

CYLINDER

LOCK BAR

SCREW

NUT

WASHER

6700001 Page - 11 November, 2002

Page 30

HOT DRINK SETUP/PROGRAMMING GUIDE

6. Set Up and Load the Coin Mechanism

Standard Coin Mechanism

Setting the Quarter Switch. If your coin mechanism is not a MARS TRC 6000, skip

this procedure and begin LOADING THE COIN MECHANISM.

a. Flip down the front of the coin

mechanism as shown, and set the quarter switch.

Load the Coin Mechanism.

a. Open the cabinet door and the monetary door.

b. Insert coins into their respective tubes until each tube has been filled.

c. Inspect the tubes for shingled coins and correct if necessary.

MDB Coin Mechanism

Install the coin mechanism as follows:

Make sure the main power switch is turned OFF before you

work on the merchandiser. Failure to do so could result in

death or injury.

a. Turn OFF the main power switch. Refer to the instructions provided with the coin

mechanism and remove the coin validator assembly.

b. Loosen the coin mechanism mounting screws on the merchandiser so they stand

off about 1/8" (0.3 cm).

c. Position the coin mechanism so the three keyed holes fit over the mounting screws.

Pull down on the coin mechanism to seat the screws in the keyways.

d. Tighten the mounting screws and reinstall the coin validator assembly.

WARNING

November, 2002 Page - 12 6700001

Page 31

HOT DRINK SETUP/PROGRAMMING GUIDE

e. The following figure shows a coin mechanism, bill validator, and card reader

connected to one another via an MDB. Some monetary configurations may not

include all of these devices. Connect your coin mechanism as shown:

f. Turn ON the main power switch. Select MDB MECH in the SELECT COIN

MECHANISM AND OPTIONS procedure on page 2-11. Press until the

standby message is displayed, then press . Insert enough coins through

the coin slot into the coin tubes to more than cover the empty sensor. Insert coins

one at a time and ensure they lay flat in the tubes. The amount of coins you insert

is internally recorded.

g. Payout about 6 coins to ensure proper loading.

h. Finish inserting coins through the coin slot to fill all the tubes with coins.

i. Visually check the coin tubes to make sure coins are not shingled.

6700001 Page - 13 November, 2002

Page 32

HOT DRINK SETUP/PROGRAMMING GUIDE

C

C

7. Fill the Tank:

a. Make sure the main power switch is ON.

b. Turn on the water at its source.

c. On the maintenance keypad, press

shows TANK.FILL.

d. Press . You should hear water running into the tank, and the display will

FILLING. The water will run until either the tank is full or 12 minutes go by,

show

whichever happens first.

The inlet water valve only stays open for 12 minutes at a time.

This is a safety feature to prevent water from running into a

leaky system and making a mess. It is possible for your tank

to take longer than 12 minutes to fill if your location has low

water pressure. To be on the safe side, check for leaks if the

water runs a long time. If you find none, everything is normal;

you just have low water pressure.

e. When you hear the water stop running, repeat steps 3 and 4. Under normal

circumstances, nothing will happen. If water starts running and the display shows

NOTE

, then press until the display

FILLING again, your pressure is low and it is just taking a long time to fill the tank.

Repeat this step if necessary to be sure your water tank is full.

8. Fill the Canisters:

Open the lid as shown, and carefully pour the appropriate product into the canister.

Repeat for all canisters in the machine.

FILL

CANISTER

ANISTER

AP

November, 2002 Page - 14 6700001

Page 33

9. Load Cups:

HOT DRINK SETUP/PROGRAMMING GUIDE

Use only cups which have been designed for use in a hot

beverage vending machine.

a. Support the cup mechanism in the upright position.

b. Push the latch forward to release the cup mechanism. Continue to support the

cup mechanism while you lower it into the loading position.

c. Remove the turret cover.

OBSERVE PROPER HYGIENE - DO NOT TOUCH THE CUPS!

d. Open the bottom of the wrapper on a stack of cups.

e. Insert the wrapped cups into the turret and pull the wrapper out.

DO NOT FILL CUPS ABOVE THE LEVEL MARKED ON THE

OUTSIDE OF THE CUP TURRETS OR ABOVE THE “FILL LINE”

LABEL INSIDE EACH TURRET, OR MOTOR JAMS WILL OCCUR. USE ONLY THE SAME SIZE AND BRAND OF HOT DRINK

CUPS IN EACH TURRET; DO NOT INTERMIX!

f. Replace the turret cover afrter theturrets have benn loaded.

g. Be sure the cup mechanism is locked into the upright position.

CAUTION

6700001 Page - 15 November, 2002

Page 34

HOT DRINK SETUP/PROGRAMMING GUIDE

10. Cup Size(s):

a. Make sure the cup sizes you select agree with the cups you have actually

loaded during setup.

b. Press , the display shows X. Y. OZ. “X” is the currently selected drink

size for the cups in turret 2 (normally large cups), “Y” is the currently selected drink

size for the cups in turret 1. (Normally regular cups).

c. Press

cup ring size.

d. Any changes made to the cup sizes must be “locked in”. There are two ways to

do this:

1) If you are keeping some cup sizes the same, or putting the cups in different cup

rings, press and hold

sound, then shows FINISHED. This will reassign the old throw times to the new cup ring,

if possible.

2) If you are loading all different size cups, or want to load all new default times, press

and hold . The display momentarily shows CLEARING, two beeps sound, then

shows FINISHED. This will reload the factory default times you have established. (See

the tables on the following pages for the factory default times).

e. CONTINUE

to change the #1 cup ring size; press to change the #2

. The display momentarily shows CLEARING, two beeps

November, 2002 Page - 16 6700001

Page 35

HOT DRINK SETUP/PROGRAMMING GUIDE

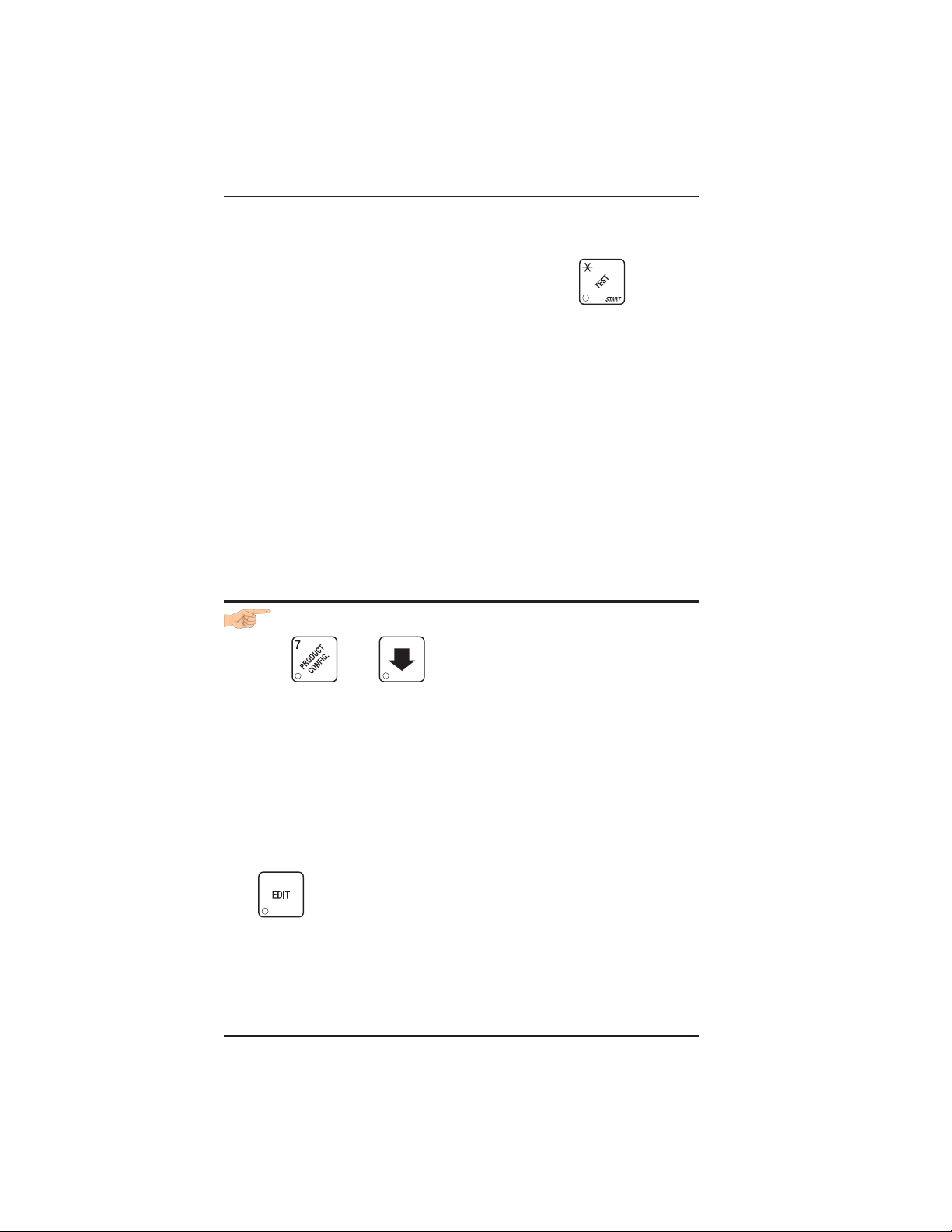

11. Test the Machine:

Your Hot Drink merchandiser is now ready to vend coffee, just as soon as the water

in the tank reaches its operating temperature. Press , and a reading of the

tank temperature is displayed. When the display shows 94° C (202° F), it is ready

for vending.

a. Close the door, make a selection, and enjoy your cup of coffee!

b. You will now need to do the following before your machine is ready to start earning

money:

• Set prices

• Set up the menu

• Establish time of day vending periods (if desired)

• Customize the drink recipes (if desired)

• Set up custom messages (if desired)

Refer to the Programming section for details on these and other procedures.

12. PosiVend:™

PosiVend™ensures that a cup is always available in the cup station before any money

is collected or product delivered. The sensing system is a beam of infra-red light

across the cup station which is broken by the cup when it falls into posi-tion.

The PosiVend™ software monitors the cup station sensor during the time

the cup ring is cycled and for three seconds afterward. If a cup is not

detected, the soft-ware will first determine if a second cup ring with the

same size cups exists and will then try to drop a cup from the second ring.

If the second ring also fails to drop a cup or is not usable, the software will

repeat the attempt from the first cup ring to attempt to clear any jams in the

cup delivery area. Each ring will be tried up to two times. If a cup is still not

detected by the infrared sensor then several things happen:

• Any ring that failed twice in a row is placed temporarily out-of-service for a length

of time that is determined by the user,

• The customer’s credit is either restored for another vend attempt or is returned

automatically,

• Three beeps are sounded and the message SELECT ANOTHER SIZE is flashed if

another size cup ring is available, or the message INSERT MUG is flashed in the event

that no other cups are available. The customer may always get his money back by

pressing the coin return button.

INSERT MUG is the default message.

You may customize this message if desired.

6700001 Page - 17 November, 2002

Page 36

HOT DRINK SETUP/PROGRAMMING GUIDE

Special rules exist to protect both the customer and the operator from loss.

First and foremost, the customer is protected because no drink is spoiled

nor money lost because a cup fails to fall to the cup station. The customer

is given every chance to get his original choice of cup size by trying at least

twice per ring to eject a cup. If two rings are available with the same cup

size, the system will alternately try to vend a cup from each ring until the

cup is delivered or both rings are placed out-of-service.

The operator is protected by the anti-jackpot program of the system. It is

con-ceivable that a customer could prevent cups from reaching the sensing

area of the cup station in order to steal the cups and then get his or her

money back for the vend. Under the PosiVend™ Anti-Jackpot system, the

operator can lose no more than two cups in a row per ring. Then that ring is

temporarily placed out-of-ser-vice both to protect the customer and to

discourage theft. The amount of time that the cup ring is out-of-service is

programmable from 0 to 99 minutes. After the time has elapsed, the cup ring

will return to service but the count of the two failures is kept. If the

previous problem was theft, then the next vend attempt from that ring will

be successful and the count of the two previous failures will be erased. If

the problem is an actual system failure, then the third failure will

permanently place that cup ring out of service until a service technician

visits the machine.

Alternate cup vends and mug vends still work as before. If a cup ring is out

of service due to PosiVend™ the alternate vend will only be from a selected

large cup to a small cup at the small cup price. An induced PosiVend™

failure cannot cause an alternate vend from a selected small cup to a large

cup at the small cup price. This protects the operator from customers trying

to get large cup drinks at a small cup price. (PosiVend™ will not

automatically switch to a different cup size in mid-vend because it cannot

be ensured that correct change will be returned for the new price.)

PosiVend™ can be turned off if desired, (See TURN POSIVEND™ ON OR

OFF page 49).

November, 2002 Page - 18 6700001

Page 37

HOT DRINK SETUP/PROGRAMMING GUIDE

R

WATER

V. ADJUSTMENTS AND MINOR

MAINTENANCE

1. Empty the Bill Stacker

2. Adjust the Water Valves

Water valves do not usually require adjustment, but in some cases adequate water

volume cannot be achieved by the throw time setting alone (see the programming

section). IF ABSOLUTELY NECESSARY, adjust the valves in conjunction with setting

the factory default timers during the Product Configuration programming mode.

1. Using a slotted screwdriver, turn the adjustment screw clockwise to decrease

the water flow rate.

2. Turn the adjustment screw counterclockwise to increase the water flow rate.

WATER

TANK

123456

WATER VALVE

ADJUSTMENT

6700001 Page - 19 November, 2002

SCREW

6

+

-

WATE

VALVE

Page 38

HOT DRINK SETUP/PROGRAMMING GUIDE

FILL

CANISTER

CANISTER

SHELF

PINS ON MOTOR

SHAFT MUST ENGAGE

SLOTS

IN CANISTER

COUPLER

Y

3. Adjust the Air Pressure.

This control determines the system pressure provided

by the air compressor. Adjust as follows:

a. With the compressor running, pinch the brewer inlet

air tube.

b. Adjust the pressure to read 10 - 12 psi on the

gauge.

This will produce a pressure of 3 - 6 psi using regular

coffee and 8¼ oz cups. No further air

pressure adjustments should be

necessary.

PRESSURE

ADJUST

CONTROL

4. Install Canisters.

1. Place the canister in position as shown.

2. Engage the pins on the motor shaft with the slots in the canister coupler.

3. Fit tabs on canister into the slots on the canister shelf.

4. To ensure canister is correctly engaged with the rear mounting bracket, gently

push down on the front edge of the canister lid.

PRESSURE

GAUGE

INCREASE

INGREDIENTS SHELF

MONETAR

PANEL

PINS ON MOTOR

SHAFT MUST ENGAGE

SLOTS IN CANISTER

FILL

CANISTER

CANISTER

SHELF

November, 2002 Page - 20 6700001

COUPLER

626P0017

Page 39

HOT DRINK SETUP/PROGRAMMING GUIDE

5. Adjust the Cup Mechanism.

1. Place seven cups in the cup ring.

2. Observe the clearance as shown in view B.

3. If necessary adjust by first loosening the adjustment arm screw (view A).

4. Move adjustment arm until correct clearance is achieved.

5. Hold adjustment arm in place and tighten adjustment arm screw.

ADJUSTMENT

ARM

VIEW A

LOOSEN SCREW

MOVE ARM

CUP

CAM

CUP

CAM

VIEW B

This clearance is just

large enough to allow

cup ejection

6700001 Page - 21 November, 2002

CORRECT

ADJUSTMENT

ADJUSTED

TOO TIGHT

ADJUSTED

TOO LOOSE

This side is snug

against cam

316P0118

Page 40

HOT DRINK SETUP/PROGRAMMING GUIDE

N

S

6. Set Up the Menu Assembly.

1. From the inside of the door, remove the two screws as indicated, and remove the

end cap as shown.

2. Loosen the remaining 10 screws as indicated 1/2 turn. Do not loosen the screws

any more than necessary to avoid stripping out the menu frame.

3. Remove the menu board. If it is still held too tightly, repeat step 2.

4. Set up the menu board as desired and reinstall it in the reverse order of

disassembly.

REMOVE THE MENU BOARD

END CAP AND SLIDE OUT THE

MENU BOARD.

LOOSEN

THESE

SCREWS

REMOVE

THESE

SCREWS

LOOSE

THESE

SCREW

November, 2002 Page - 22 6700001

Page 41

HOT DRINK SETUP/PROGRAMMING GUIDE

PROGRAMMING THE HOT DRINK

Getting Around

Getting around the Hot Drink software is pretty easy once you know the

features that are available to you, and how to use them. The three main

parts you will use are the SERVICE KEYPAD, the SELECTION SWITCH

PANEL, and the DISPLAY.

The Service Keypad

For most of your programming

jobs, you will be using the

service keypad conveniently

located on the monetary

panel. The service keypad

has 16 keys. The three

columns on the left are the

mode keys. The right hand

column contains the

movement keys.

PROGRAMMING THE HOT DRINK

The Selection Switch Panel

AB

DEF

G

H

C

J

The selection switch panel is also

located on the monetary panel. Unlike the service keypad, it is accessible when the cabinet door is closed.

These are the keys the customer will

use to make selections. You can also

use these keys during programming

procedures.

XYZ

636P0044

6700001 Page - 23 November, 2002

Page 42

HOT DRINK SETUP/PROGRAMMING GUIDE

The Displays

The 10-character display performs two functions, and is referred to in

this book as "the display":

1. It shows the customer's selection and how much credit is in the

machine, as well as the ready, service, and time of day messages.

2. It provides information and feedback to the service person during

maintenance.

DISPLAY

November, 2002 Page - 24 6700001

Page 43

HOT DRINK SETUP/PROGRAMMING GUIDE

The Function Keys

The FUNCTION keys on the service keypad can be used for up to three

things:

THE PRIMARY PUR-

POSE

THIS IS THE MAIN JOB OF

THE

KEY. FROM THE

THE NUMBER

YOU MIGHT BE ASKED TO

ENTER

A NUMERICAL VAL-

UE. YOU CAN DO THIS

IN

TWO WAYS: PRESSING

THIS

KEY IS THE SAME AS

PRESSING

THE "5" ON

STANDBY

PROGRAMMING

THE SECONDARY

PURPOSE THIS IS THE

KEY

'S "SECOND JOB". THIS

KEY

CAN BE USED TO DELETE

A

CHARACTER WHEN YOU

ARE

MESSAGE, IT WILL

ALLOW

YOU TO ENTER A

MODE. IN

EDITING CUSTOM MES-

Other Keys

The MOVEMENT keys on the control panel let you move inside a mode,

and back and forth between modes. To see how these keys let you

move around, study the flow diagram on the next page.

The up and down arrow keys are your "legs", which let

you move up and down the list of tasks. These keys are

what let you continue from one step to the next in

programming procedures.

This is your "activate" or "choose" key. It "opens a door" to

additional information and lets you begin a programming task

once you are inside of a mode. Sometimes, it is used as a

toggle switch to show you your choices during a programming

task.

This is your "end" key. Pressing it one or more times will move

you back to the start of the mode, or all the way back to the

standby message.

This key lets you start an action, such as a test.

6700001 Page - 25 November, 2002

Page 44

HOT DRINK SETUP/PROGRAMMING GUIDE

III. CONTROL PANEL SWITCHES EXPLAINED

Press this button to put your machine into the Price Setting

mode. You can see maximum and minimum machine

prices, and change prices for entire machine or individual

selection.

Press this button to set up how the Free Vend mode will

operate.

Press this button to view the water tank temperature,

software version number, machine and accessory configuration, and active selection status.

Press this button to:

• Select display language

• Select coin mechanism and

options

• Select bill validator and options

• Select card reader and

• Select monetary options

• Set winner feature

options

Press this button to:

• View total sales and vends

by whole machine, selection, or drink size

Press this button to:

• Download data into your portable data collection device

(PDCD), OR

• Set printer baud rate, depending upon which device you

are using

Press this button to:

• Set machine type configuration

• Set which selections are

active

November, 2002 Page - 26 6700001

• Clear resettable data

• View or set machine

• Set up blended selections

• Set up cup sizes

Page 45

HOT DRINK SETUP/PROGRAMMING GUIDE

Press this button to:

• Set time of day

• Set day, month, year

• Set up time of day intervals for

inhibit, freevend, and discount

vending

Press this button to pay one or more coins from the coin

mechanism.

• Allows you to see any fault or condition that has placed

the machine out of service

• Select display messages

• Edit messages

• Set message scrolling speed

Press this button to:

• Perform TEST VENDS

• Test machine functions

Press this button to:

• Enter the SUPERVISOR mode

• Change the SUPERVISOR access

code

• Test displays

• Fill the water tank

• Lock and unlock

access to functions

6700001 Page - 27 November, 2002

Page 46

HOT DRINK SETUP/PROGRAMMING GUIDE

Programming Procedures

SOME CONVENTIONS:

The pages that follow contain all the programming procedures for the Hot

Drink. If you need to do a specific task, you can find it immediately by

using the Programming Index. Most of the procedures have things in

common, and here is a short guide to help you through these conventional

presentations:

All programming procedures assume that you are starting with the

standby message showing in the display. If not, just press until

you get there.

Each programming procedure is highlighted by a pointing hand:

so it will stand out.

PROGRAMMING PROCEDURES

To exit a mode (CONTINUE) at any time, press . Sometimes

you may have to press the key more than once in order to exit all the

way to the standby message.

Text that looks like this: DISPLAY represents what you will see

in the display on the monetary panel.

Definitions and helpful information will appear in shadow boxes:

HELPFUL HINT

THE SUPERVISOR MODE

The supervisor is allowed to do things that a normal user cannot, like

controlling access to certain modes. The supervisor can lock out any

of the programming modes to anyone who does not have the right "key".

Once a supervisor enters the proper code, he or she will be able to:

• Change the supervisor access code

• Lock out any or all of the service keypad modes

• Select whether price lines are used

• Set whether data is cleared after being downloaded into a portable

data collection device

• Grant or deny access to data items during DATA RECALL

• Modify the machine configuration

November, 2002 Page - 28 6700001

Page 47

HOT DRINK SETUP/PROGRAMMING GUIDE

GAIN ACCESS TO THE SUPERVISOR MODE

1. Press . The display shows: ENTER CODE. You must

enter the four-digit supervisor code within 6 seconds to gain

access.

NOTE

A new machine has a factory-set supervisor code of

0000.

When you have entered the right code, you will hear two beeps

and see UNLOCKED in the display.

ENTER A NEW SUPERVISOR CODE

1. Follow the steps in GAIN ACCESS TO THE SUPERVISOR

MODE.

2. Press , then until the display shows SUPER XXXX.

The X's represent the current supervisor code. Use the number keys

to enter a new code.

IMPORTANT!

If you enter a new code, be sure to keep a written

record of it. There is no other way to access the

SUPERVISOR mode.

3. CONTINUE.

ENTER A FREEVEND CODE

1. Follow the steps in GAIN ACCESS TO THE SUPERVISOR

MODE.

2. Press until the display shows FREE XXXX.

THE SUPERVISOR MODE

The X'sreresent the current freevend code. Use the number keys to

enter a new code. If the code is anything other than "0000", it must

be entered after the key lock is turned in order to enable free vends.

3. CONTINUE

6700001 Page - 29 November, 2002

Page 48

HOT DRINK SETUP/PROGRAMMING GUIDE

LOCK OR UNLOCK MODE OR PAYOUT KEYS

1. Follow the steps in GAIN ACCESS TO THE SUPERVISOR

MODE.

2. Press until the display shows either X. LOCKED or

X. UNLOCKED. "X" refers to the number or character shown on the

mode or payout key in question (1 through 9, # and *). To see if a

key is locked or unlocked, press that key.

3. Press to change between locked and unlocked. When

anyone other than the supervisor tries to enter a locked mode, the

display shows LOCKED.

NOTE

The following mode keys cannot be locked out:

4. CONTINUE.

SET PRINTER OR DEX OPTIONS

1. Follow the steps in GAIN ACCESS TO THE SUPERVISOR

MODE.

2. Press until the display shows:

PRINTER means that data will be sent directly to a printer,

OR

DEX ONLY means that data remains in memory after it is down-

loaded into a portable data collection device (PDCD),

OR

DEX +CLR means that resettable data is cleared after it is down

loaded into a PDCD.

3. Press to change between the three choices.

4. CONTINUE.

November, 2002 Page - 30 6700001

Page 49

HOT DRINK SETUP/PROGRAMMING GUIDE

LOCK OR UNLOCK DATA CLEARING ACCESS

1. Follow the steps in GAIN ACCESS TO THE SUPERVISOR

MODE.

2. Press until the display shows either #. LOCKED or

#. UNLOCKED. LOCKED means that non-supervisors cannot clear

resettable machine sales and vend data from the key.

3. Press to switch between #. LOCKED and #. UNLOCKED.

NOTE

The supervisor can clear data regardless of this

setting, provided the supervisor code was correctly

entered first.

4. CONTINUE

SELECT DISPLAY LANGUAGE

1. Press . The current LANGUAGE is shown in the display.

Press to choose the desired language. Your choices are:

ENGLISH, DEUTSCH, FRANCAIS, ESPANOL, PORTUGUESE,

SWEDISH, or

NEDERLANDS.

2. CONTINUE

6700001 Page - 31 November, 2002

Page 50

HOT DRINK SETUP/PROGRAMMING GUIDE

SELECT COIN MECHANISM AND OPTIONS

1. Press , then press until the current COIN

MECHANISM is shown in the display. Press to choose the

desired coin mechanism. Your choices are: DUMB MECH,

MDB MECH, EXEC MECH, or NO MECH

NOTE

If you selected EXEC MECH you can exit the function.

2. Press until the display shows CHANGE X.XX.

Coins and bills which are less than or equal to this value will be

returned without a purchase being made.

Examples:

CHANGE 0.00 - Forced vend; NO change returned without a

purchase.

CHANGE .25 - Nickels, dimes, and quarters returned with-

out purchase.

CHANGE 1.00 - $1 bills and SBAs will be returned as

change without purchase. Nickels, dimes, and

quarters are also returned.

3. Press until the display shows: LOW.MSG X.XX. The

display will show USE EXACT CHANGE when the amount of available change in the coin mechanism falls below the value of "X.XX".

Enter a value with the number keys. For example, if LOW.MSG

1.00 is displayed, the USE EXACT CHANGE message is dis-

played when less than a dollar's worth of change is in the coin

mechanism.

4. CONTINUE.

November, 2002 Page - 32 6700001

Page 51

HOT DRINK SETUP/PROGRAMMING GUIDE

SELECT BILL VALIDATOR AND OPTIONS

1. PRESS

IS DISPLAYED:

, THEN PRESS UNTIL ONE OF THE FOLLOWING

NO DBV - No bills will be accepted or there is no bill

validator installed (you can exit the function).

SER.1.2.5.10.20 -The serial bill validator is selected and will

accept $1, $2, $5, $10, and $20 bills. Use

BILL SELECTION METHOD below to change

the bills which will be accepted.

MDB.1.2.5.10.20 -A standard MDB bill validator is selected.

It will accept $1, $2, $5, $10 and $20 bills.

Use BILL SELECTION METHOD below to

change the bills which will be accepted.

BILL SELECTION METHOD:

The standard $1, $2, $5, $10 and $20 bills

are enabled by pressing the 1, 2, 5, 6, or 7

key(s), respectively, to display which bill(s)

will be accepted.

MDB. <*> - An MDB bill validator which accepts non-

standard bills or tokens is connected and

operating. Press to enter list of bills.

(See INITIAL SETUP OF NONSTANDARD

BILL VALIDATOR on the following page.)

BILL LIST OPERATION:

Use and to scroll through the

list of bills.

Use to turn the bill acceptance ON or

OFF.

Use to move up to the top level

screen.

6700001 Page - 33 November, 2002

Page 52

HOT DRINK SETUP/PROGRAMMING GUIDE

1. 1.00 ON -1. = Bill validator channel

1, each bill has its own channel

1.00 = Bill value

ON = $1.00 bill will be accepted

1. 1.00 OFF -OFF = $1.00 bill will not be

accepted

TKN - Token bills (same as coupon

bills)

INITIAL SETUP OF NONSTANDARD BILL VALIDATOR:

Connect the bill validator, select MDB in the

bill validator selection screens. The stan-

dard "MDB.1.2.5.10.20" screen will appear first. Exit the bill validator setup by

pressing . Bill information is now col-

lected from the validator. Re-enter the bill

validator selection screen and the nonstand-

ard screen "MDB. <

>" will appear.

*

PULSE DBV - The pulse bill validator will accept $1 bills.

Press to choose the desired option.

2. CONTINUE.

November, 2002 Page - 34 6700001

Page 53

HOT DRINK SETUP/PROGRAMMING GUIDE

SELECT MONETARY OPTIONS

This function lets you:

• Set declining balance,