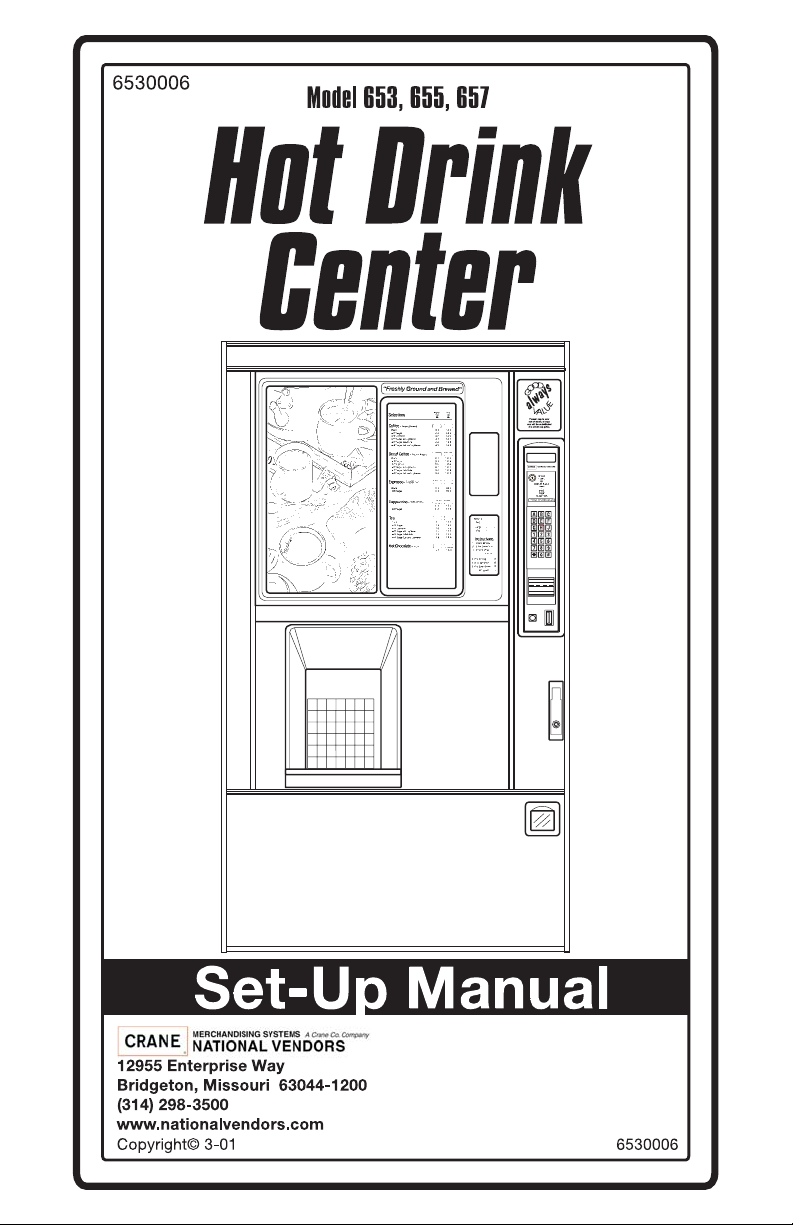

Page 1

Page 2

This machine has been engineered to our own rigid safety and performance standards. It

has been designed to comply with sanitation and health guidelines recommended by the

Automatic Merchandising Health-Industry Council (AMHIC) and it conforms with all other

NAMA safety recommendations.

This machine has been manufactured in accordance with the safety standards of both

Underwriter’s Laboratories and the Canadian Standards Association. To maintain this

degree of safety and to continue to achieve the level of performance built into this machine,

it is important that installation and maintenance be performed so as to not alter the original

construction or wiring and that replacement parts are as specified in the Parts Manual.

Your investment in this equipment will be pr otected by using the Programming Guide, this

Set-Up Guide, and the Parts Manual in your operation, service and maintenance work. By

following prescribed procedures, machine performance and safety will be pr eser ved.

Page 3

Hot Drink Center Set- Up Manual

Table of Contents

SPECIFICATIONS .............................................................................................. 1

MAJOR PARTS................................................................................................... 4

CONTROLS AND INDICATORS...................................................................... 8

INITIAL SET-UP............................................................................................... 15

I. Location Preparation................................................................................ 15

Water Requirements .............................................................................16

II. Positioning the Merchandiser.................................................................. 17

III. Connecting Everything............................................................................ 17

Connect the Merchandiser to the Water Supply: ..............................17

Connect the Merchandiser to the Electrical Power Supply: .............17

IV. Final Mechanical Preparation.................................................................. 17

Level the Merchandiser: ...................................................................17

Mount the Base Plate: .......................................................................18

Set Up the Menu Assembly ..............................................................19

Install the Water Filter Cartridge: .....................................................21

Load the Optional Filter Paper: ........................................................24

Install the Optional Coin Box Lock ..................................................26

Load the Coin Mechanism ................................................................26

Fill the Tank: ............................................................................ ..... ...27

Fill the Canisters: ..................................................... ..... ...... ..............27

Load Cups: ........................................................................................28

Tell the Machine About the Cup Size(s): .........................................29

Test the Machine: .............................................................................30

ADJUSTMENTS AND MINOR MAINTENANCE ......................................... 31

I. Water Valve Adjustment......................................................................... 31

II. Cup Mechanism Adjustment................................................................... 32

III. Grinder Adjustment................................................................................. 33

IV. Disengaging the Grinder.......................................................................... 34

V. Canister Installation................................................................................. 34

SANITATION.................................................................................................... 35

I. Basics....................................................................................................... 35

II. Clean the Hot Water Tank....................................................................... 37

III. Sanitation Procedures .......................... ................................. ...... ............. 37

Food-Contact Parts ...............................................................................37

Non Food-Contact Parts .......................................................................38

IV. Overall Cleaning.................................................. .................................. .. 39

V. Preventive Maintenance Cleaning........................................................... 39

APPENDIX A. THE FREE VEND KEYSWITCH OPTION........................ A-1

APPENDIX B. THE INFRARED MUG/CUP SENSOR ............................... B-1

APPENDIX C. DEX/UCS INTERFACE OPERATION................................ C-1

6530006 i

March, 2001

Page 4

Hot Drink Center Set-Up Manual

APPENDIX D. MODIFY CANISTER TO VEND 12 OZ. CUPS................ D-1

ii 6530006

March, 2001

Page 5

Hot Drink Center Set- Up Manual

SPECIFICATIONS

SPECIFICATIONS COMMON TO ALL MACHINES

DIMENSIONS 72" (183 cm) high

38.12" (97 cm) wide

28.5" (72 cm) deep

WEIGHT 570 lbs (258.5 kg)

WATER REQUIREMENTS Minimum: 20 psi (137.8 kPa)

Maximum: 80 psi (551.2 kPa)

AMBIENT TEMPERATURE Minimum: 41× F (5× C)

Maximum: 90× F (32× C)

OPERATING ENVIRONMENT For indoor use only

CUP CAPACITIES

(APPROXIMATE)

CANISTER CAPACITIES

(APPROXIMATE)

MODEL 633 FRESH BREW Up to nine selections of fresh brew regular and

MODEL 635 FREEZE DRIED Up to nine selections of freeze dried regular cof -

MODEL 637 FRESH BREW

WITH

BEAN GRINDER

7 oz cups (squat) - 1150

8.25 oz cups - 1050

9 oz cups (squat) - 1100

10 oz cups - 1000

12 oz cups - 940

Regular coffee be ans - 14 lbs

Ground coffee - 13 lbs

Freeze dry coffee - 2 lbs

Decaf coffee beans - 9.5 lbs

Ground decaf coffee - 9 lbs

Freeze dry decaf - 2 lbs

Chocolate - 10 lbs

Soup - 6.7 lbs

Sugar - 11 lbs

Lightener - 4.5 lbs

Sugar substitute - 4 lbs

Tea (freeze dry) - 1.5 lbs

6th and 7th products (freeze dry) - 6 lbs each

PRODUCT OPTIONS

decaf coffee, freeze dried regular and decaf cof

fee, fresh brew and freeze dried tea, soup, chocolate, cappuccino, espresso, and caffè latte.

fee, decaf coffee, tea, soup, chocolate, cappuccino, espresso, and caffè latte.

Up to nine s elect ions o f fres h gr ound a nd bre wed

regular and decaf coffee, freeze dried regular and

decaf coffee, fresh brew and freeze dried tea,

soup, chocolate, cappuccino, espresso, and caffè

latte.

-

6530006 1

March, 2001

Page 6

Hot Drink Center Set-Up Manual

SPECIFICATIONS COMMON TO ALL MACHINES (Continued)

OPTIONS AND ACCESSORIES

OPTIONS Coffee brewer filter paper (5000 vends per roll)

Coin box lock

Base grille kit

Automatic delivery door

Flex Ace door lock and key

Van Door lock and key

Sugar substitute kit

6th product kit

Cup/mug electronic sensor (cup hold switch kit)

Snap-on ingredient canister

extension sleeves (4 tall)

Everpure water filter system

CUNO water filter system

Debit card validator

Free vend keyswitch

Data printer kit

Ingredient rinse tray

2 6530006

March, 2001

Page 7

Hot Drink Center Set-Up Manual

SPECIFICATIONS UNIQUE TO 115 VOLT MACHINES

ELECTRICAL 115 Volts AC

60 Hertz

12 Amps

Single phase

OPTIONS AND ACCESSORIES

COIN MECHANISM MARS TRC-6000

COINTRON 3000

MARS TRC-6010XV (24 V)

Maka/Conlux Model USPX-004 (24 V)

Coin Acceptors Model 9302-LF (24 V)

BILL VALIDATORS MARS VFM1 pulse

MARS VFM3 serial

MAKA pulse

COINCO

SPECIFICATIONS UNIQUE TO 220 - 240 VOLT MACHINES

ELECTRICAL 220-240 Volts AC

50 Hertz

10 Amps

2 kW

Single phase

OPTIONS AND ACCESSORIES

COIN MECHANISM Executive coin mechanism interface

6530006 3

March, 2001

Page 8

Hot Drink Center Set-Up Manual

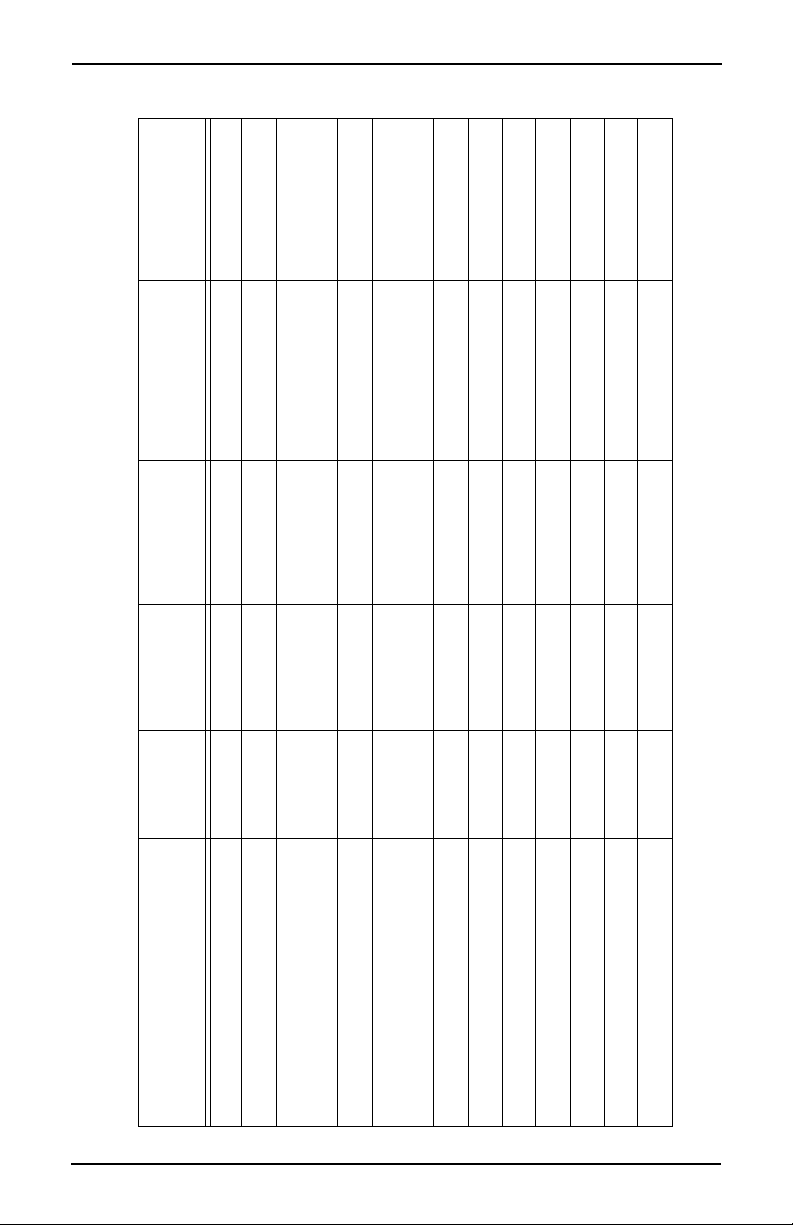

MAJOR PARTS

The diagrams on the following pages will acquaint you with the major parts of the Hot Drink Center. For more detailed information, please consult your PARTS MANUAL. If you do not have a PARTS MANUAL, contact National Vendors Parts Department.

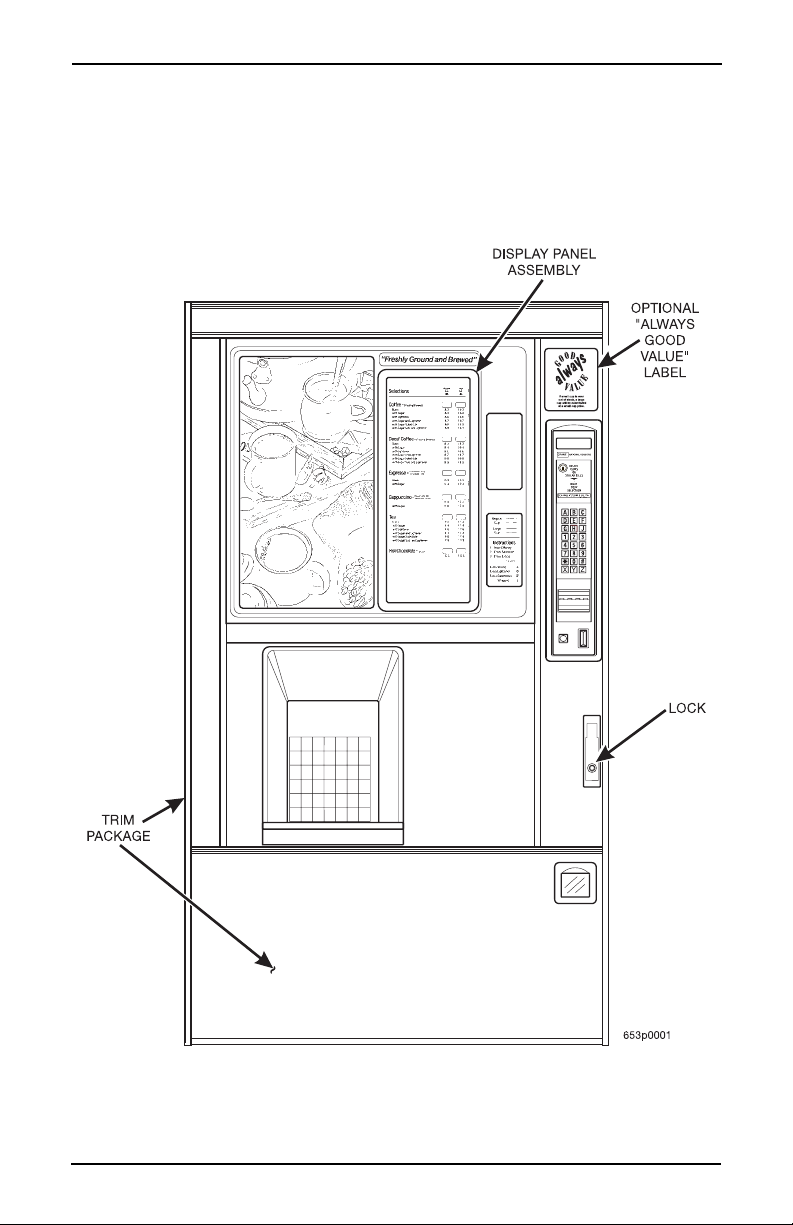

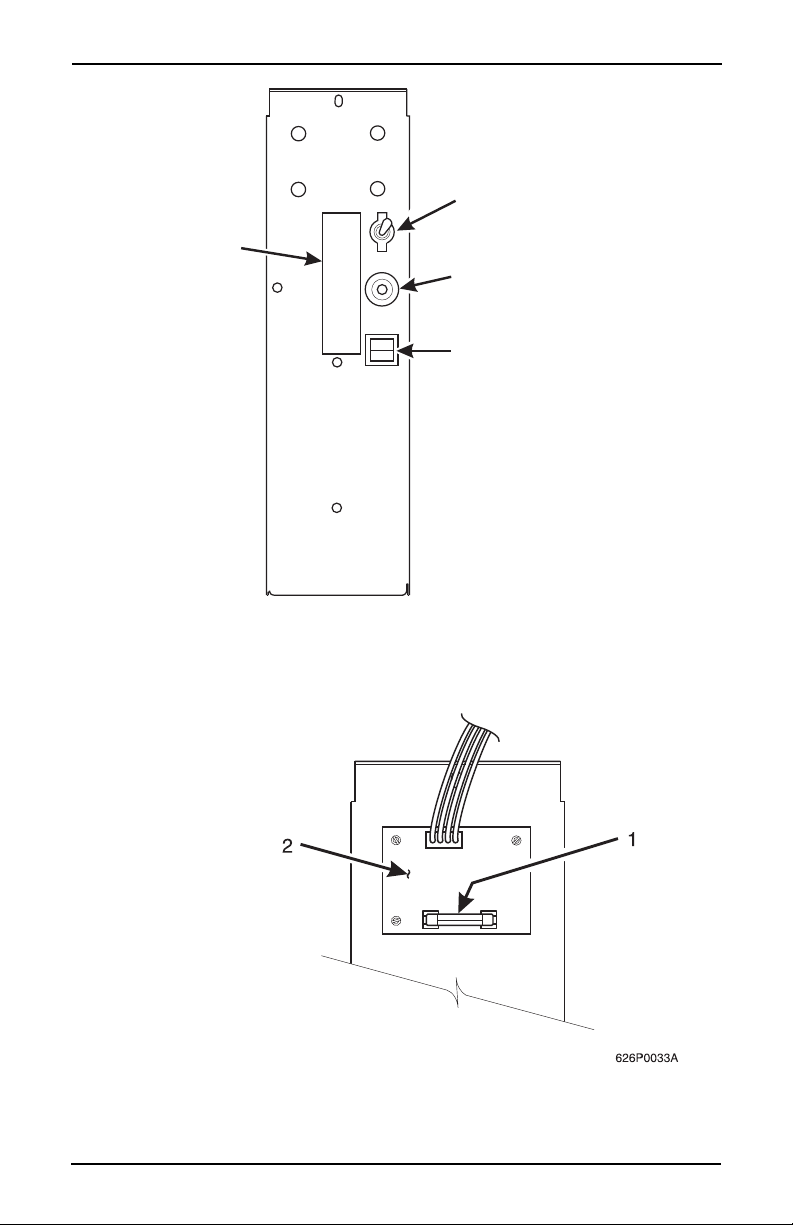

Door Assembly - Exterior

4 6530006

March, 2001

Page 9

Hot Drink Center Set-Up Manual

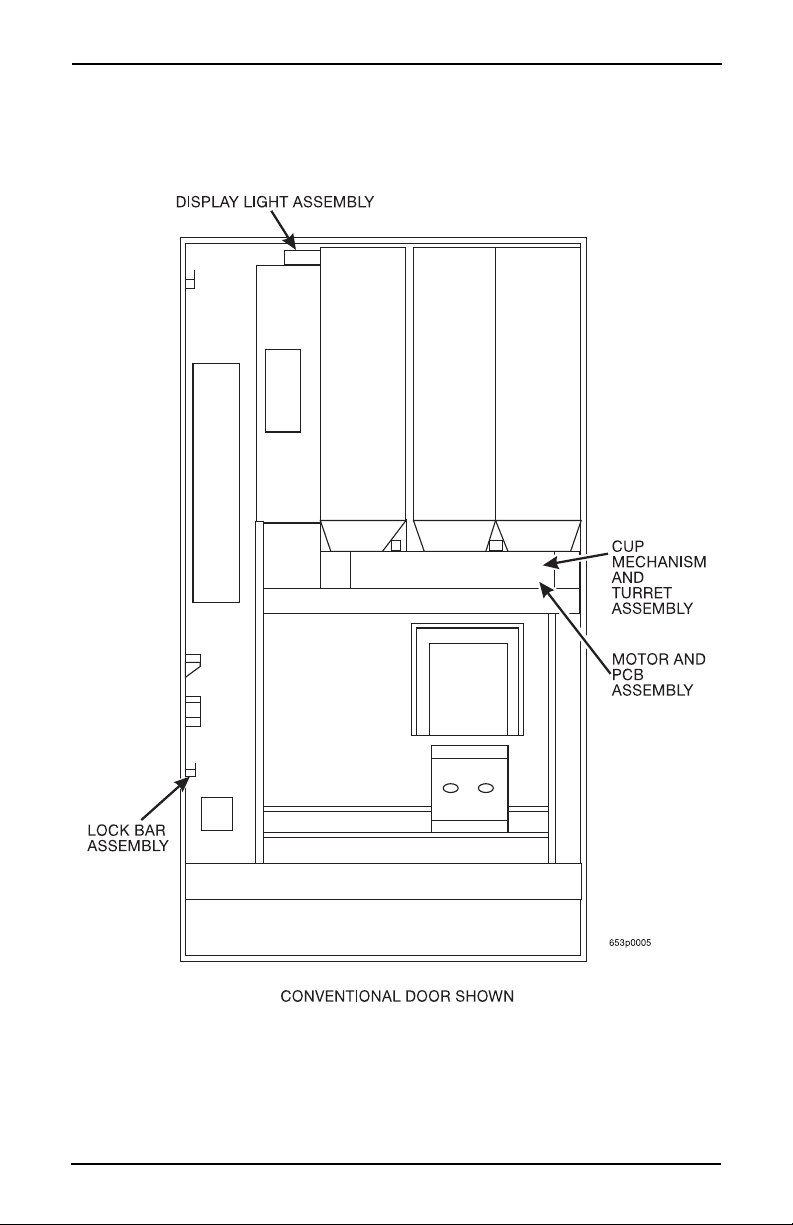

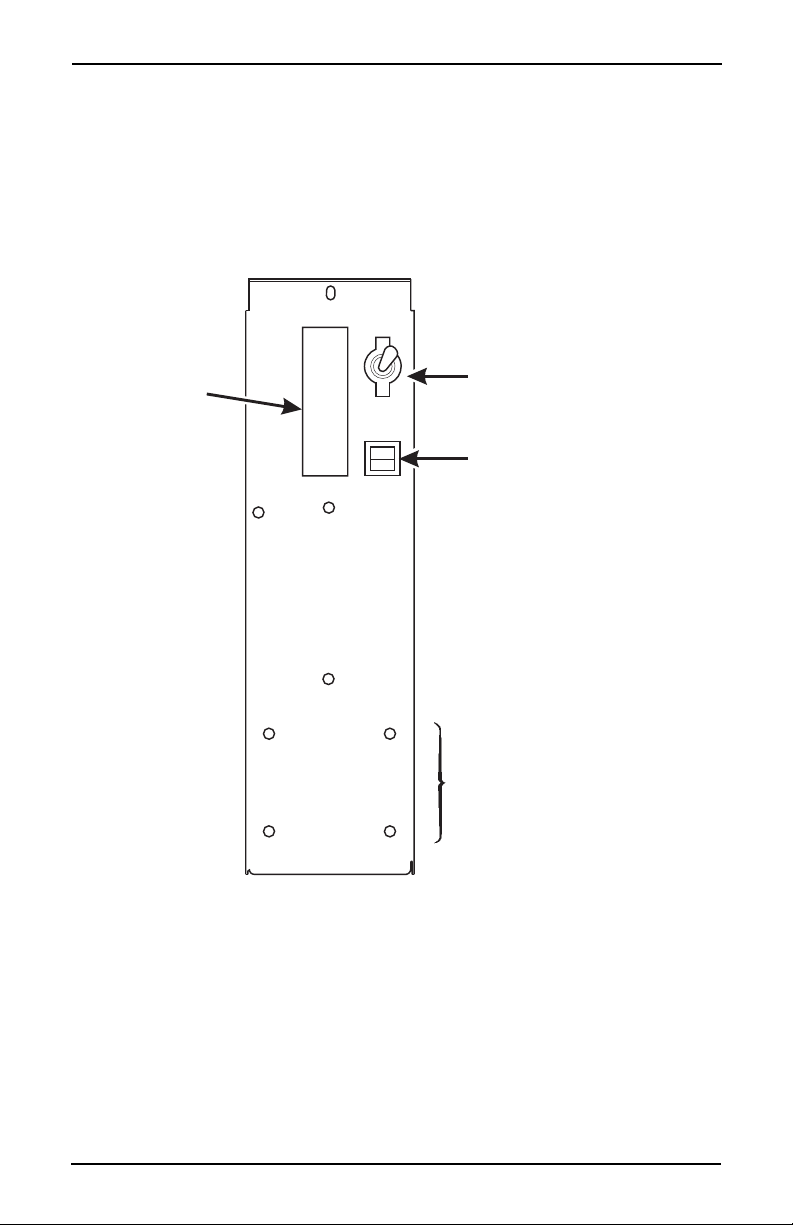

Door Assembly - Interior

6530006 5

March, 2001

Page 10

Hot Drink Center Set-Up Manual

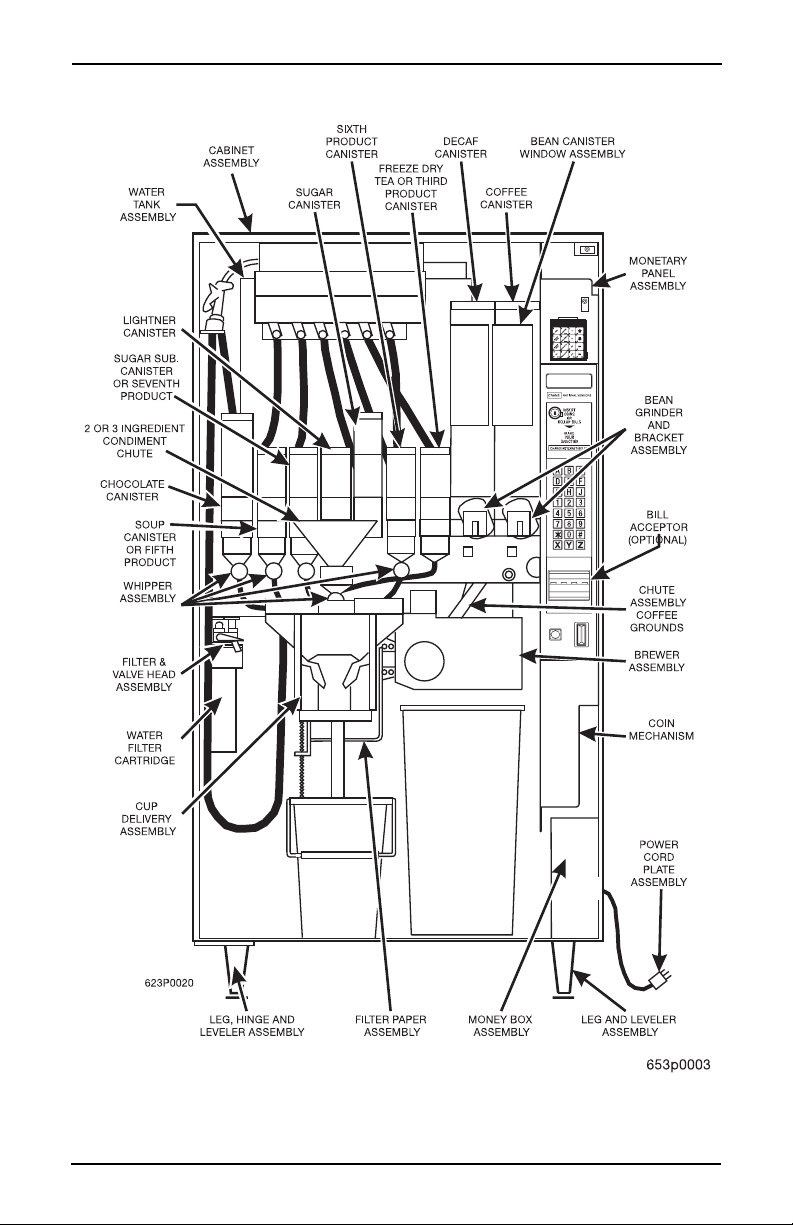

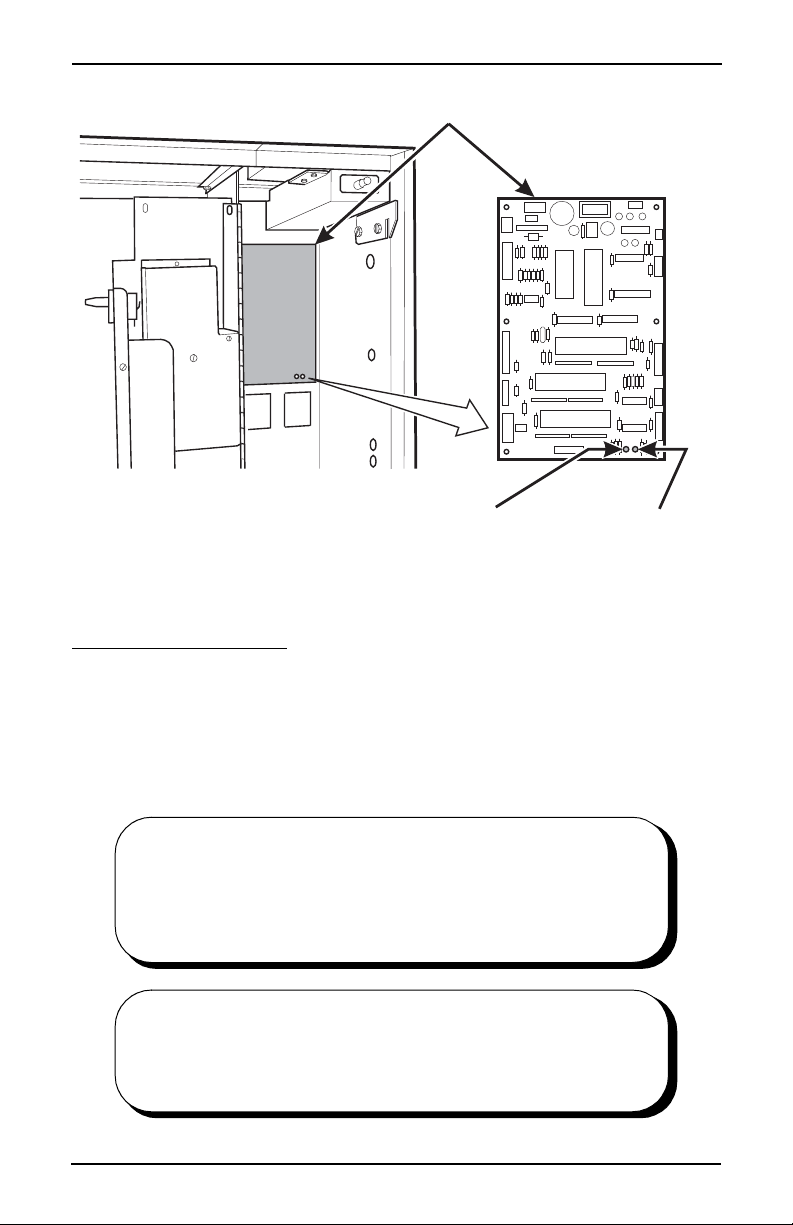

Cabinet Assembly Interior - Part 1

6 6530006

March, 2001

Page 11

Hot Drink Center Set-Up Manual

MAIN CONTROLLER

R

BRACKET ASSEMBLY

O

PCB ASSEMBLY

INTERFACE

BOARD

˜

AIR

COMPRESSO

ASSEMBLY

POWER

VERFLOW

SWITCH

ASSEMBLY

˜

PANEL

ASSEMBLY

OPTIONAL INFRARED

CUP/MUG SENSOR

EXHAUST FAN

BREWER DRIVE

ASSEMBLY

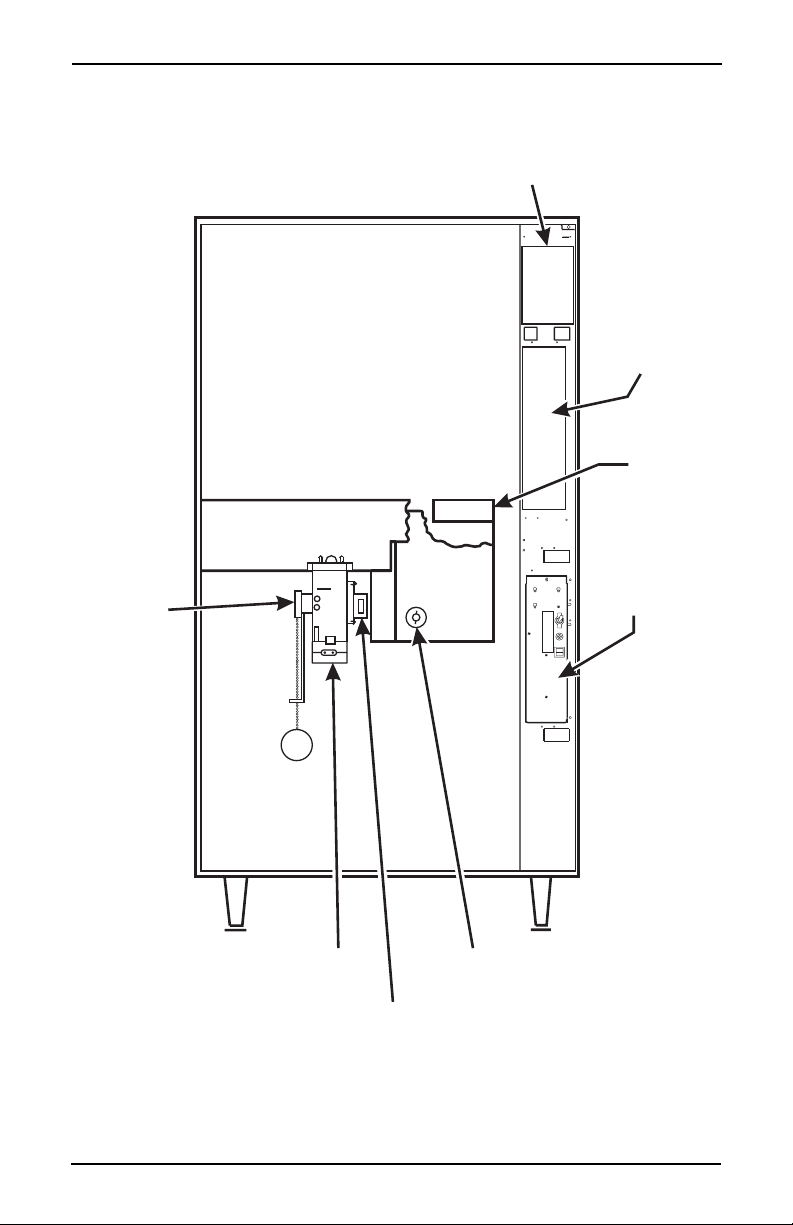

Cabinet Assembly Interior - Part 2

6530006 7

March, 2001

Page 12

Hot Drink Center Set-Up Manual

S

CONTROLS AND INDICATORS

POWER PANE L. You may have one of three power panels, depending upon

where you live. The controls are fundamentally the same, however.

Circuit Breakers and Fuses. Circuit breakers and fuses protect the merchan-

diser against failures in the power supply or any of the electrical components. If

a circuit breaker trips and canno t be res et, or if a fuse repeatedly blows, contact a

field service representative.

Back Side of U.S./ Canada Power Control Panel. The circuit board mounted

on the rear of the U.S. and Canadian power co ntrol panel is a dc power suppl y for

the coin mechanism. A fuse protects the board circuitry in the event of a coin

mechanism solenoid failure. If the coin mechanism is not working, check this

fuse. If the fuse is blown, a bad coin mechanism solenoid could be at fault.

Main Power Switch. This is the main ON/OFF switch for the merchandiser.

WARNING

T o protect against electrical shocks and possible damage to the

machine, turn this switch OFF when performing any mainte

nance on the merchandiser.

-

I

LABEL

Power Control Panel (France/Germany/ Spain)

8 6530006

O

MAIN

POWER

SWITCH

ELECTRONIC

BREAKER

626P0005

March, 2001

Page 13

LABEL

Hot Drink Center Set-Up Manual

MAIN

ON

OFF

Power Control Panel (U.S./Canada)

POWER

SWITCH

MAIN

CIRCUIT

BREAKER

LOW VOLTAGE

CIRCUIT BREAKER

626P0006

Back Side of U.S./Canada Power Panel

6530006 9

March, 2001

Page 14

Hot Drink Center Set-Up Manual

ON

MAIN POWER

ELECTRONICS

CIRCUIT BREAKER

LABEL

OFF

SWITCH

MOUNTING STUDS

FOR MEXICO ONLY

626P0035a

Power Control Panel (U.K./Mexico)

10 6530006

March, 2001

Page 15

Hot Drink Center Set-Up Manual

MAIN CONTROLLER

T

PCB ASSEMBLY

LED1 LED2

POWER ON

(LED 1)

FLASHING

HEARTBEA

(LED 2)

Main Controller PCB Display

Main Controller PCB Display. This display consists of two light emitting diodes (LED)

mounted on the controller PCB.

POWER ON

(LED 1)

HEARTBEAT

(LED 2)

When lit, this red LED indicates electrical powe r is applied to the controller

PCB.

When flashing, this red LED indicates that the controller PCB is active, and

the software is operating.

NORMAL CONDITIONS:

When the merchandiser is operating normally, you should see a

steady red POWER ON indicator. The red HEARTBEAT indi cator should be flashing with a balanced on/off pattern (on for

the same length of time that it is off).

ERROR CONDITIONS:

If an error is present, the red HEARTBEAT indicator will flash

with an unbalanced on/off pattern (on longer than it is off). The

error(s) can be viewed under the DIAGNOSTICS mode.

6530006 11

March, 2001

Page 16

Hot Drink Center Set-Up Manual

Monetary Panel

12 6530006

March, 2001

Page 17

Hot Drink Center Set-Up Manual

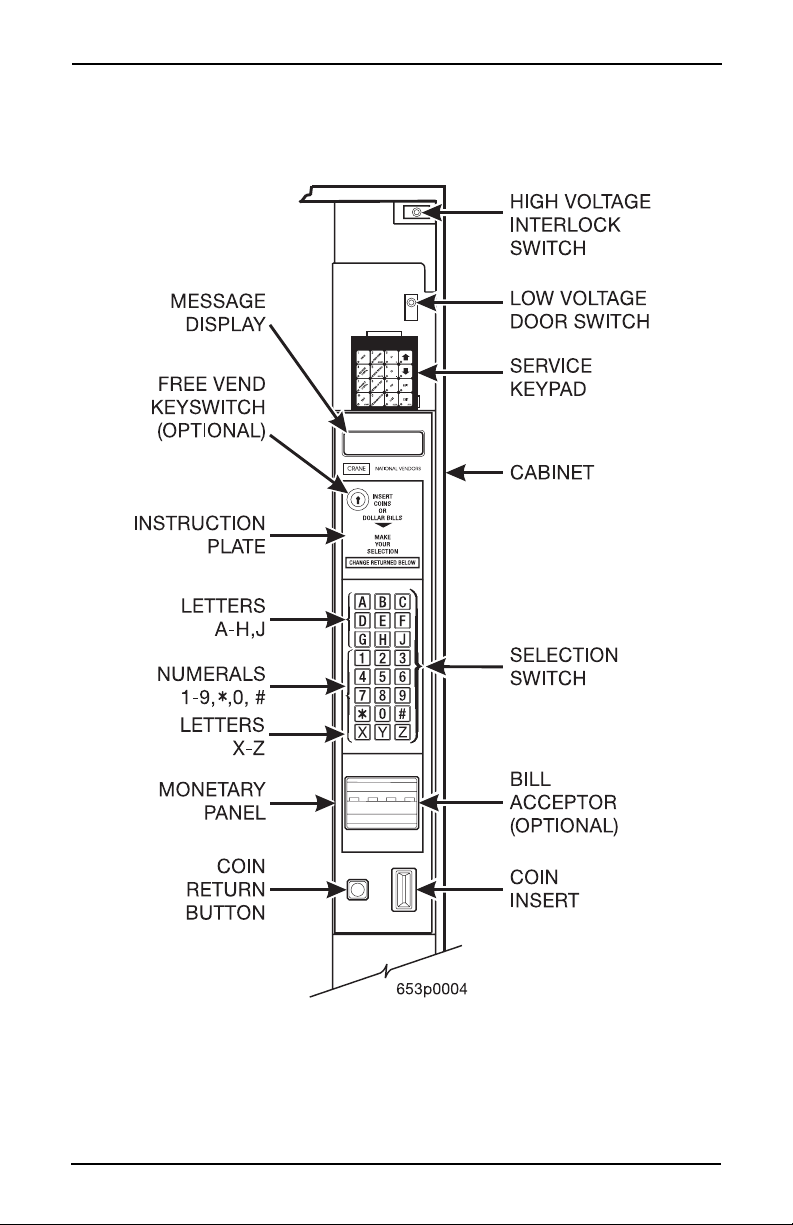

High V oltage In terlock Switch (U.S./ Canada). When the cabinet door is open ,

this switch turns off the optional fan and bean light (if so equipped) and turns on

the service light.

High V o ltage Interlock Switch (International). When the cabinet d oor is o pen,

this switch turns off all high voltage to the cabinet. Pulling the switch out

restores high voltage for maintenance purposes.

Low Voltage Door Switch. Informs the controller software of the main door

open or closed status.

Message Display. This is how the merchandiser communicates with the outside

world. Customers can see messages about ho w much money they have put into

the merchandiser. The message display also tells customers when a selection is

sold out and when vendi ng is free, in hibit ed, or discoun ted. The mes sage displ ay

shows you what you are doing when you program the merchandiser, and can

show you what is wrong if there is a failure.

Free Vend Keyswitch. This allows someone (other than maintenance people) to

set the merchandiser to free vend without opening the door.

Selection Switch Panel. The customer uses these switches to make selections.

Also, maintenance people may use this switch panel during programming and

other support modes.

Coin Return Button. Pressing this button returns any coins that have been paid

into the merchandiser prior to a vend.

Bill Acceptor (Optional). Accepts bills in various denominations, depending

upon the type of bill validator, and how the machine is configured.

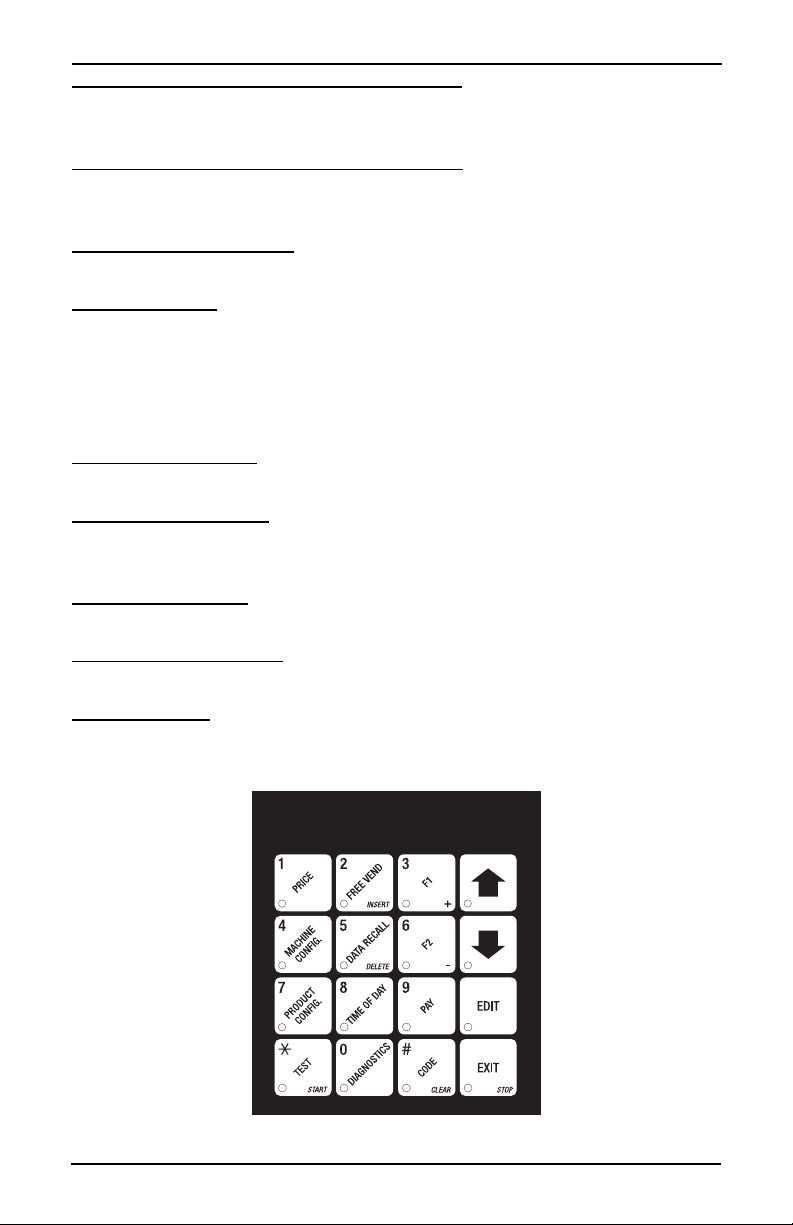

Service Keypad. The service keypad is located at the top of the monetary pan el.

It gives service personnel the means to program, retrieve data from, and view

diagnostic information about, the merchandiser.

Service Keypad

6530006 13

March, 2001

Page 18

Hot Drink Center Set-Up Manual

Y

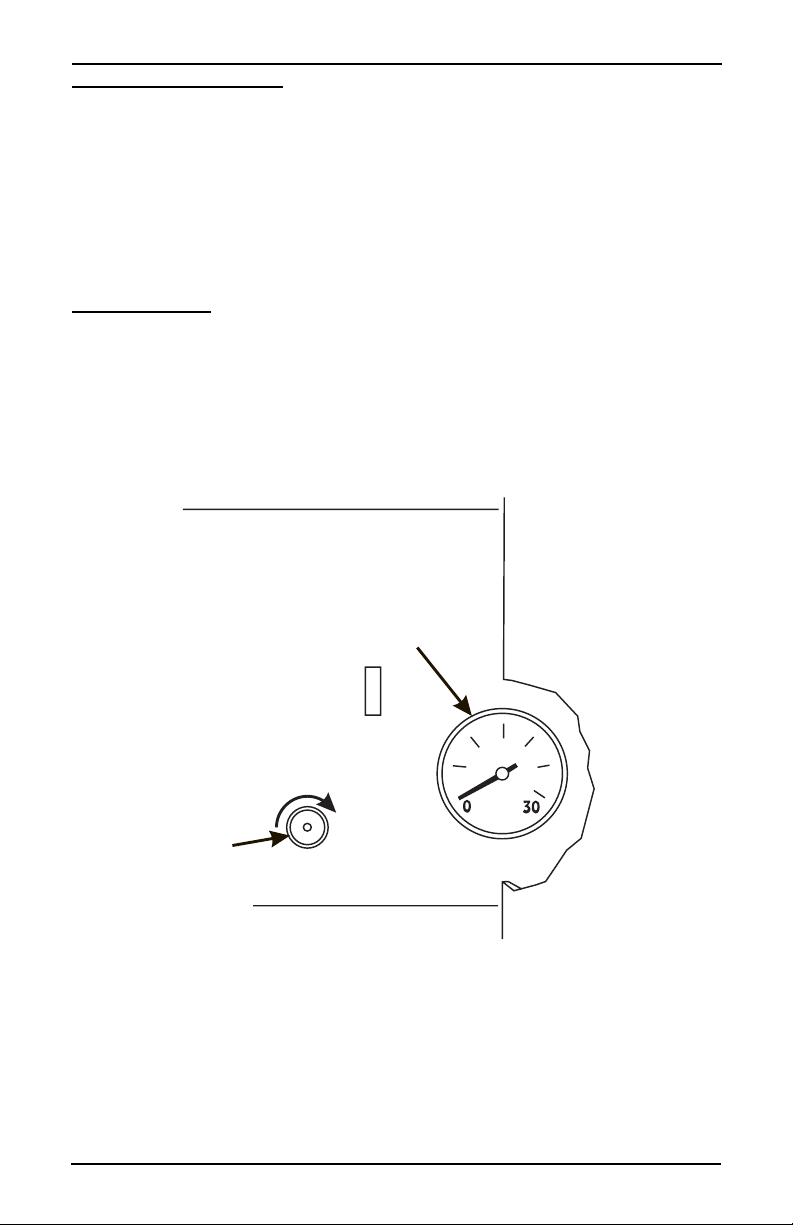

Pressure Adjust Control. This control determines the system pressure provided

by the air compressor. Adjust the pressure as follows:

a. With the compressor running, pinch the brewer inlet air tube.

b. Adjust the pressure to read 10 - 12 psi on the gauge.

This will produce a pressure of 3 - 6 psi using regular coffee and 8¼ oz cups. No

further air pressure adjustments should be necessary.

Pressure Gauge. This indicator shows the amount of air pressure in the system.

PRESSURE

ADJUST

CONTROL

PRESSURE

GAUGE

INCREASE

INGREDIENTS SHELF

MONETAR

PANEL

Press ure Control and Indicator

14 6530006

March, 2001

Page 19

Hot Drink Center Set-Up Manual

INITIAL SET-UP

I. Location Preparation

After your machine is unpacked and placed near its permanent location , you need

to make sure you have the proper electrical and water service.

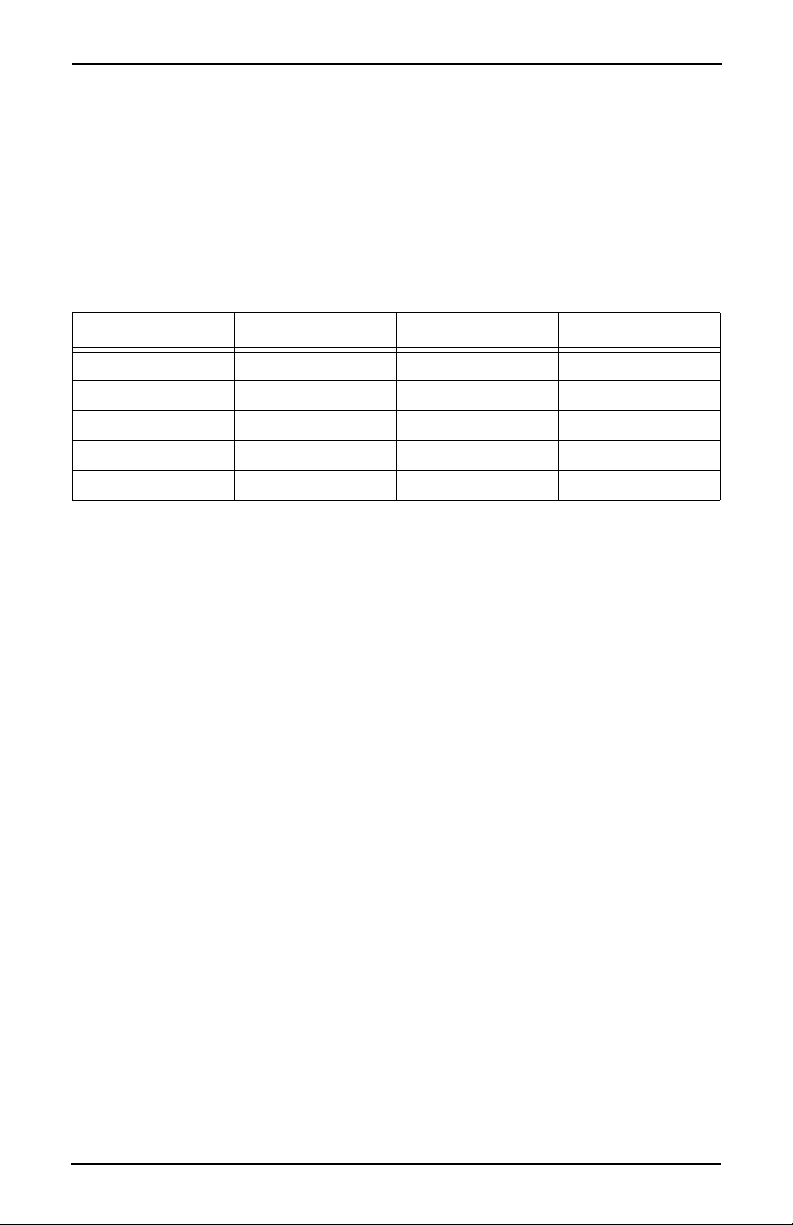

This merchandiser needs electrical power as shown in the following table.

NOTE: Each merchandiser should have its own electrical circuit.

Power Requirements

Country Volts Frequency (Hz) Current (Amps)

Canada 115 60 15

France 230 50 10

Germany 230 50 10

United Kingdom 230 50 10

United States 115 60 15

This merchandiser is supplied with a service cord for the country of use and is

terminated in a grounding type plug. The wall receptacle used for this merchan

diser must be prop erly polarized , grounded , and of the correct voltage. Operating

the merchandiser from a source of low voltage will VOID YOUR WARRANTY .

Each merchandiser should have its own electrical circuit and that circuit should

be protected with a circuit breaker or fuse conforming to local regulations.

-

Voltage Check - Place the leads of a voltmeter across the LINE (LIVE) and

NEUTRAL terminals of the wall receptacle. The voltmeter should indicate

110-130 volts ac for 120 volt, 60 Hz locations, or 220-240 volts ac for 230

volt, 50 Hz locations.

Polarity Check - Place the leads of a voltmeter across the LINE ( LIVE) and

GROUND terminals of the wall receptacle. The voltmeter should indicate

110-130 volts ac for 120 volt, 60 Hz locations, or 220-240 volts ac for 230

volt, 50 Hz locations.

Noise Potential Check - Place the leads of a voltmeter across the NEUTRAL and GROUND terminals of the wall receptacle. The voltmeter

should indicate 0 volts ac. A measurement greater than 1.5-2.0 volts ac

could result in problems for the mercha ndiser's electronic ci rcuitry caused by

electrical noise.

Any deviation from these requirements could result in unreliable performance

from your merchandiser.

6530006 15

March, 2001

Page 20

Hot Drink Center Set-Up Manual

Water Requirements

The best type of water for coffee brewing is normal hard (tap) water. If your

location has chemically softened water, you should do one of the following

things:

• Have a non-softened supply line run to the merchandiser

• Contact your local water filter supplier for information and suggestions

Well water can also be used in the Hot Drink Center. However,

you should have it checked for levels of carbonates and alka

lies. Contact your water filter supplier if these values are rela-

tively high.

What is the Water Pressure at Your Location?

It should be no less than: 10 psi ( 69.0 K Pa) at 1/2 gall on/minute

And no more than: 80 psi (522.0 KPa) at 1/2 gallon/minute

If you're not sure about the pressure and flow rate, check with your water company.

What to do With the Water Supply Line:

• Locate the supply line at the rear of your merchandiser.

• Equip the line with a shut-off valve.

-

Flush the water supply line before connecting it to the merchandiser. A minimum of five gallons is usually required before connecting the merchandiser to

the supply line. DO NOT flush the merchandiser water system. If you do, you

might introduce water line contaminants into the merchandiser.

16 6530006

March, 2001

Page 21

Hot Drink Center Set-Up Manual

II. Positioning the Mercha ndiser

You can position this merchandiser anywhere in a bank of machines. It can even

be placed on the end flush against a side wall. Be sure yo u leave enough roo m in

front of the merchandiser for the door to move freely.

BE SURE THE REAR OF THE MERCHANDISER IS AT LEAST 6

INCHES (15 cm) AWAY FROM THE WALL. THIS WILL ALLOW

WARM MOIST AIR TO BE VENTED OUT OF THE MACHINE'S INTE

RIOR.

WARNING

THIS MACHINE IS ONLY RATED FOR INSTALLATION IN AN

INDOOR LOCATION.

III. Connecting Everything

1. Connect the Merchandiser to the Water Supply:

a. You will need the following:

• A coil of copper tubing with outside diameter of 3/8 inch (9.5 mm) or

greater. The appropriate plastic tubing may be substituted. The tubing

must be long enough to reach from the water sour ce to you r machin e with

enough left over to form a loop about 2 feet (60 cm) in diameter. This

will allow you to move the machine without straining the water line.

• A 3/8 inch (9.5 mm) flare fitting.

-

b. Connect the merchandiser to your water supply.

2. Connect the Merchandiser to the Electrical Power Supply:

Power inside the merchandiser is controlled by the main power switch, located

on the power panel.

a. Make sure the main power switch is OFF.

b. Connect the merchandiser’s power cord to your wall outlet.

IV. Final Mechanical Preparation

1. Level the Merchandiser:

a. Using a spirit level, adjust the front and rear leg levelers until the

machine is level from side to side and back to front.

6530006 17

March, 2001

Page 22

Hot Drink Center Set-Up Manual

a

o

.

.

e

B

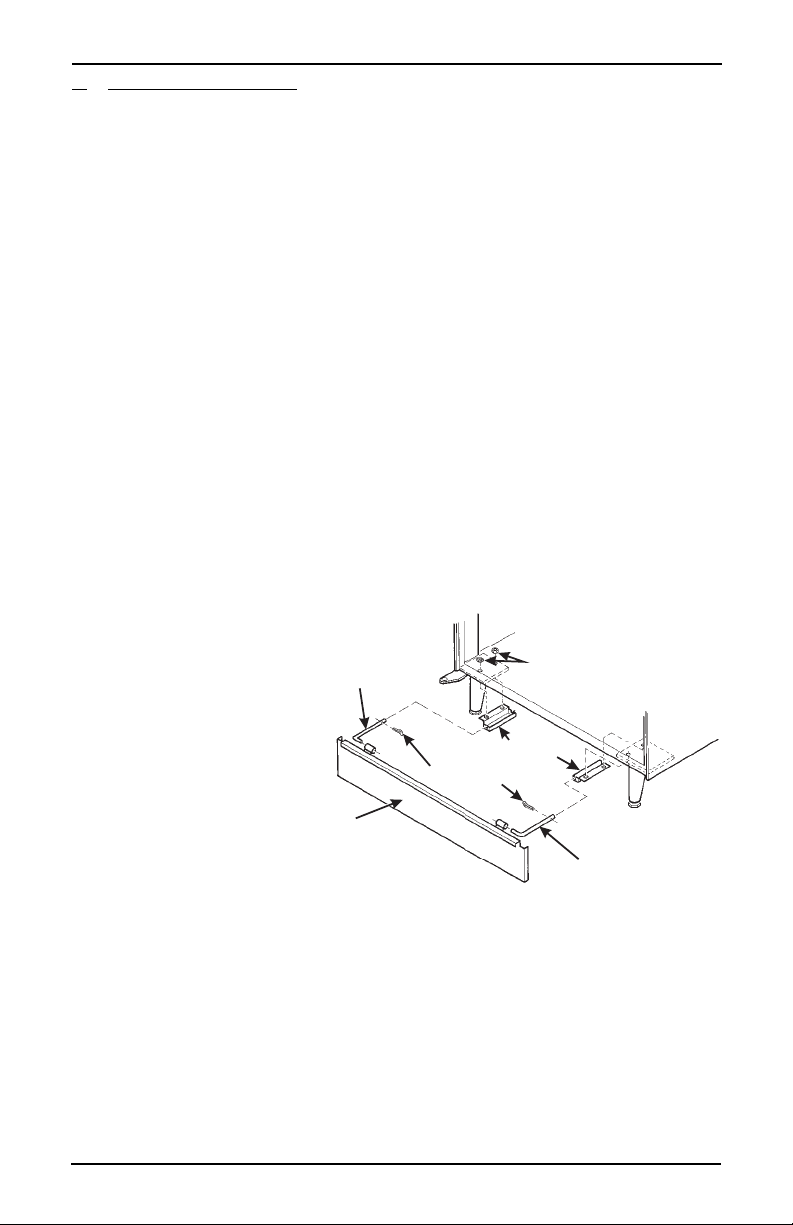

2. Mount the Base Plate: WARNING

DO NOT MOVE THE CABINET WHILE HEX HEAD

SCREWS AND/OR CARRIAGE BOLT S ARE LOOS

ENED. THE CABINET WOULD BECOME UNSTABLE

AND LIKELY TO TIP AND CAUSE INJURY.

a. Remove the pail(s) from the inside of the merchandiser.

b. Remove the floor liner from the inside of the merchandi ser.

c. Remove the two caps as shown.

d. Lo osen the left leg assembly carri age bolts and nuts to allow mounting

base plate bracket.

e. Secure one of the base plate brackets to the leg assembly using the tw

carriage bolt. Tighten the carriage bolts and nuts.

f. Loosen the right leg assembly hex head screws to allow mounting the

other base plate bracket.

g. Secure the other base plate bracket to the right leg assembly using the

two hex head screws. Tighten the hex head screws.

h. Insert the short arms of the slides into the hinged tabs of the base plate

Position the slide so the notch near the short arm is on the bottom side

i. Insert the long

arms of the

slides into the

base plate

SLIDE - L.H.

CAPS

brackets.

j. Insert and

secure a cotter

pin throug h

BASE PLATE BRACKET

COTTER PIN

the hole in the

back of each

of the slides.

ASE PLATE

ASSEMBLY

k. Push the base

plate toward

the merchandiser cabinet.

The front tabs of the base plate brackets should seat in the notches in th

long arms of the slides.

l. Replace the caps, liner, and pail(s) removed previously.

-

SLIDE - R.H.

18 6530006

March, 2001

Page 23

Hot Drink Center Set-Up Manual

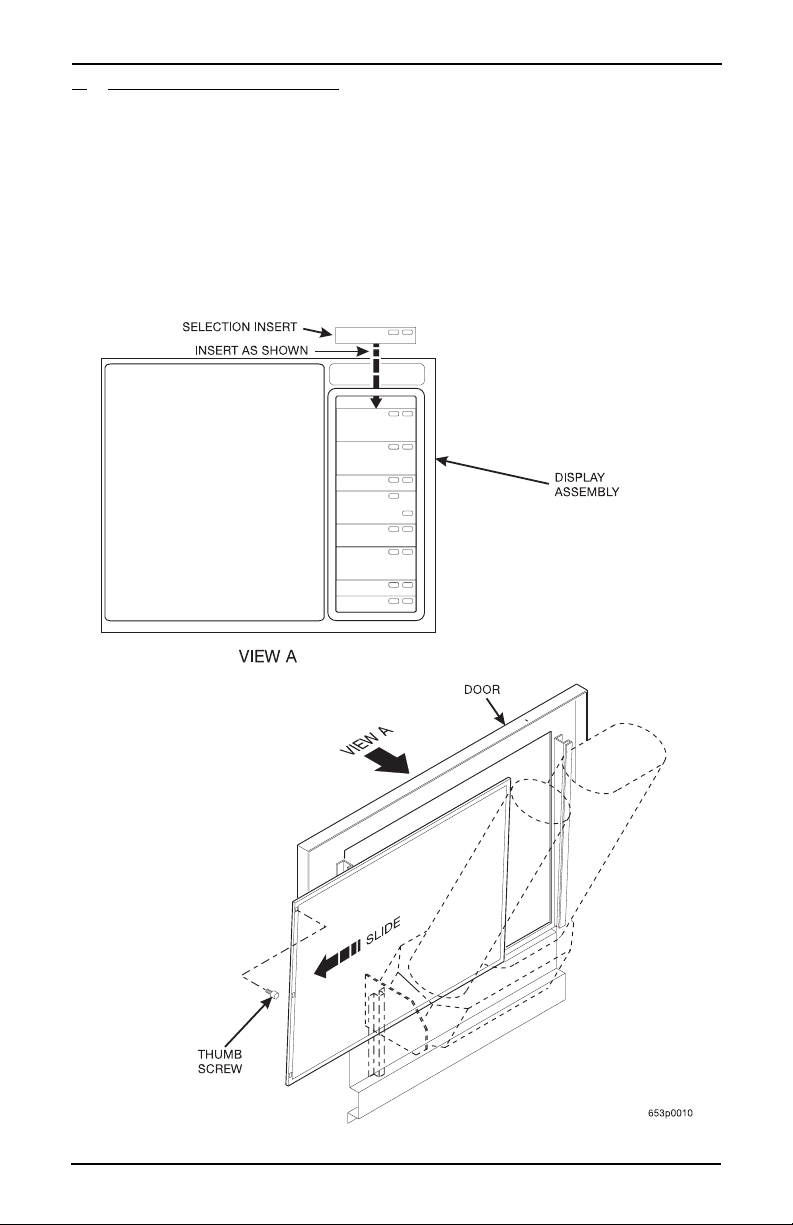

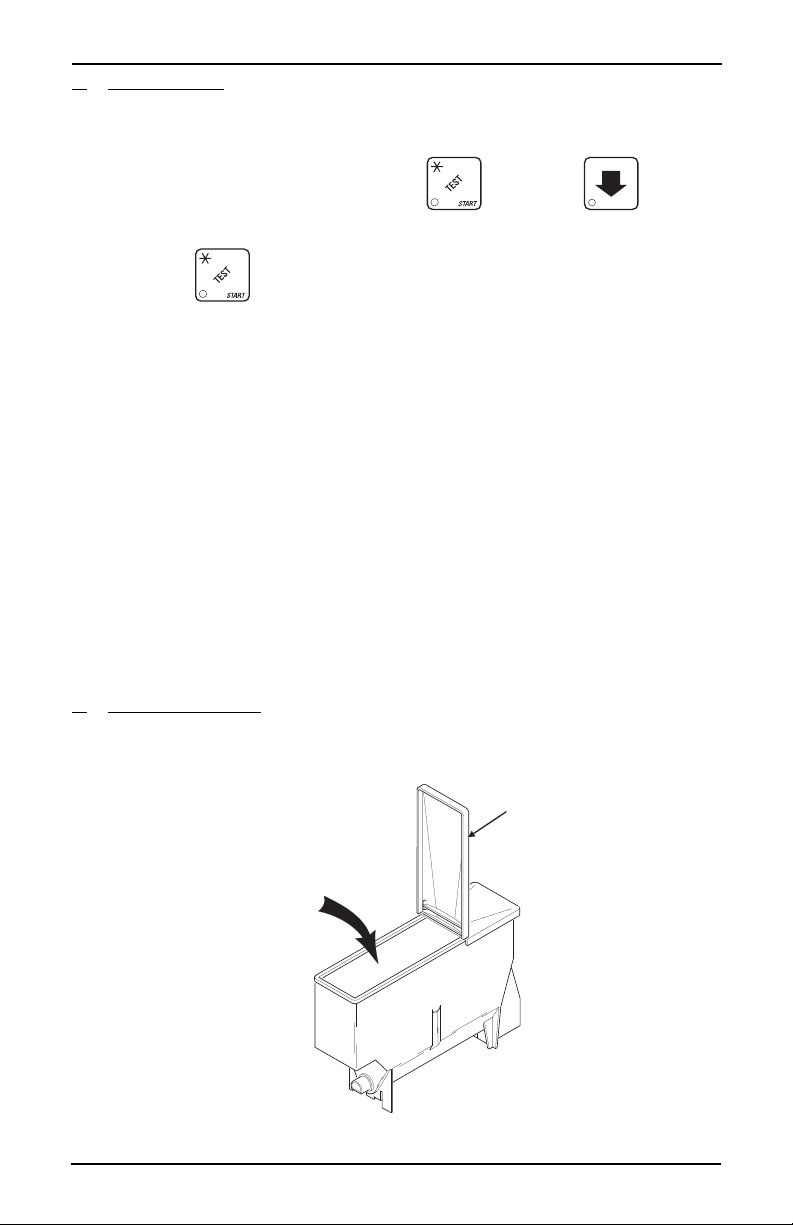

3. Set Up the Menu Assembly

Glass door:

a. Swivel the cup turrets away from the door.

b. Remove the thumb screws as shown, and slide out the menu assembly.

c. Install selection inserts as shown.

d. Reinstall the menu assembly in the reverse order of assembly.

6530006 19

March, 2001

Page 24

Hot Drink Center Set-Up Manual

Solid door:

a. From the inside of the door, remove 2 menu retaining knurl screws.

b. From the ou tside of the door, slide the clear menu window up to acess

the menu strips and price and cup size labels.

c. Set up the menu as appropriate for your machine.

d. Reinstall the menu assembly in the reverse order of assembly.

20 6530006

March, 2001

Page 25

Hot Drink Center Set-Up Manual

1

C

4. Install the Water Filter Cartridge: IF YOUR MERCHANDISER HAS THE WATER FILTER

OPTION, IT CANNOT BE OPERATED WITHOUT A

PROPERLY INSTALLED WATER FILTER CAR

TRIDGE. If you do not have the water filter option, continue

with "Fill the Tank"

.

UNO BRAND ...

NOTE

Check the water filter installation record. There is a place to write

the vend number on the cartridge. The cartridge is effective for a

maximum of 64,000 7 oz. vends, 56,000 8 oz. vends, 50,000 9 oz.

vends, or 37,000 12 oz. vends. Local conditions may require more

frequent replacement.

CUNO FILTER

FILTER

LOCKING

TAB

TO INSTALL

THE FILTER:

1. INSERT NEW FILTER,

ROTATE COUNTERCLOCKWISE UNTIL

FILTER LOCKING TAB

SNAPS INTO GROOVE

AS SHOWN.

HEAD ASSEMBLY

GROOVE

-

. CLOSE THE WATER SHUT

-OFF VALVE BY TURNING

THE KNOB TO THE

HORIZONTAL POSITION

AS SHOWN.

SHUT-OFF

TO REMOVE FILTER:

WATER

KNOB

2. LIFT THE FILTER

LOCKING TAB,

ROTATE FILTER

CLOCKWISE AND

PULL DOWN AS

SHOWN.

CUNO

FILTER

FILTER

LOCKING

TAB

6530006 21

March, 2001

Page 26

Hot Drink Center Set-Up Manual

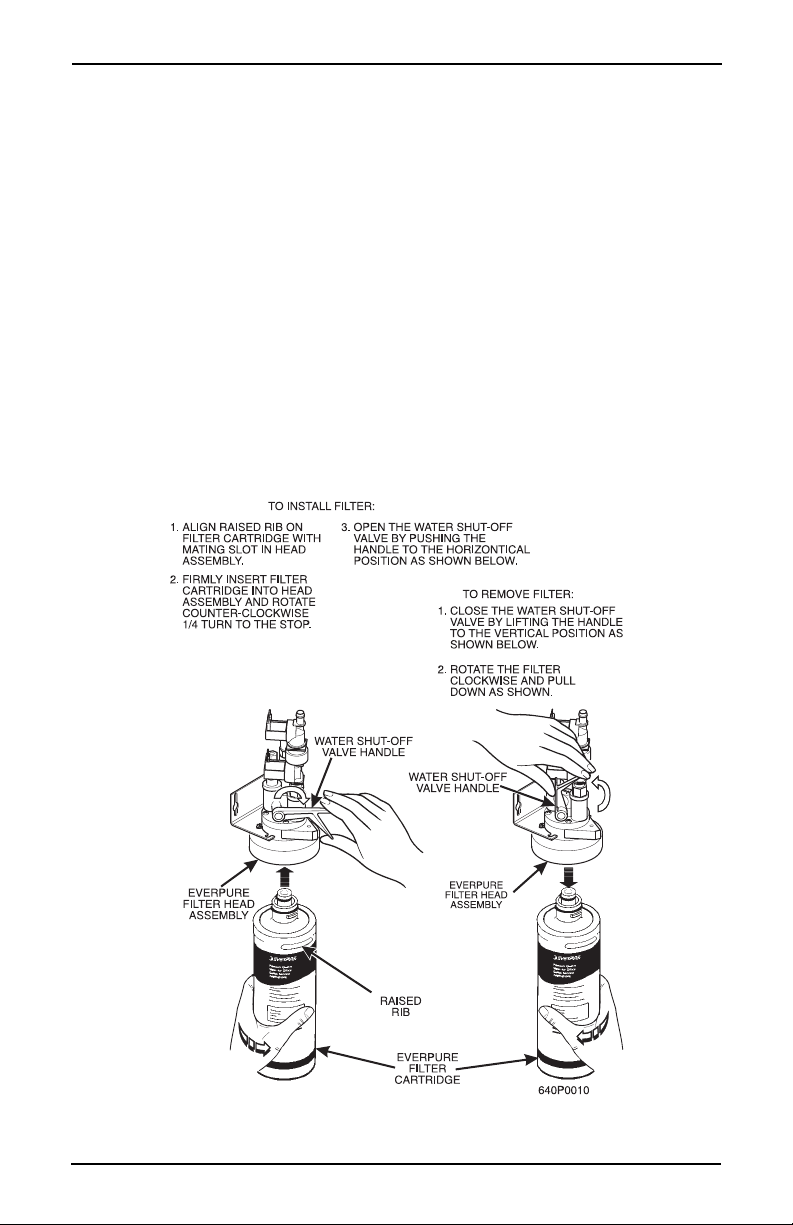

EVERPURE BRAND ...

NOTE

Check the water filter installation record. There is a place to

write the vend number on the cartridge. The cartridge is effec

tive for a maximum of 26,000 7 oz. ven ds , 22,0 00 8 o z. vend s,

20,000 9 oz. vends, or 15,000 12 oz. vends. Local conditions

may require more frequent replacement.

National Vendors recommends that you d o the fol lowing procedu re the first time

you fill the tank in your merchandiser:

a. Remove the small inner "O" ring from the filter cartridge.

b. Install the filter cartridge.

c. Turn on the water at its source, and perform the tank filling procedure.

d. Turn off the water at its source, remove the filter cartridge, and replace

the "O" ring.

e. Install the filter cartridge.

-

22 6530006

March, 2001

Page 27

Hot Drink Center Set-Up Manual

E

HYDROLIFE BRAND...

INSTALLATION:

1. Place the filter inside the canister. Be sure the o-ring is seated in the canister just below the threads.

2. Screw the canister and filter assembly onto the filter head until it comes to a stop.

3. Open the water valve on the inlet line by rotating the handle to the vertical position as s hown.

REMOVAL

4. Close the valve on the inlet line by rotating the handle into the horizontal position as s hown.

5. Relieve water pressure by performing two or three water throws (see the Programming Guide).

6. Unscrew the filter and canister assembly from the filter head. Remove the filter from the canister.

OPEN

POSITION

INSTALL

HYDROLIFE

FILTER HEAD

O-RING

REMOV

OPEN

POSITION

VALVE

CLOSED

POSITION

FILTER

CANISTER

6530006 23

March, 2001

Page 28

Hot Drink Center Set-Up Manual

H

R

TO BREWER

PAPER

PINION GEAR SHAFT

G

L

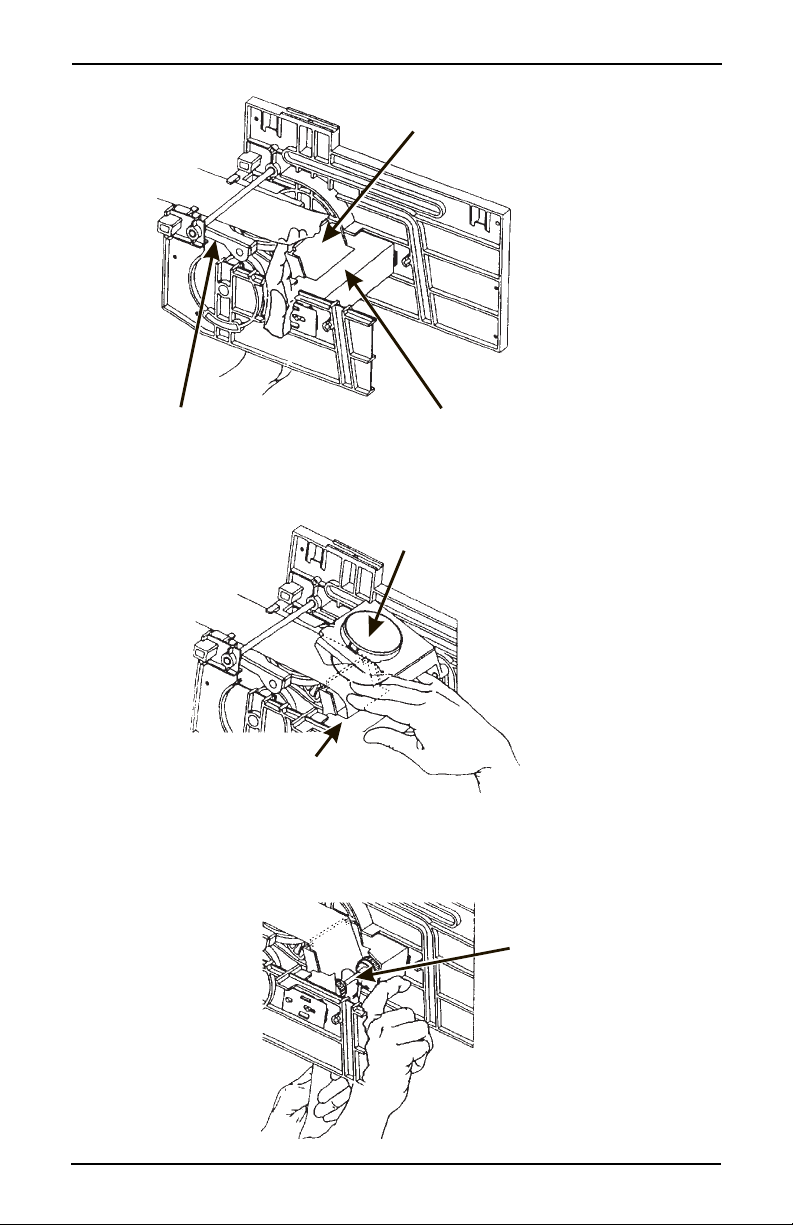

1. Load the Optional Filter Paper:

a. Be sure the main power switch is in the OFF position.

b. Remove the cup station and grounds bucket.

c. Remove the paper holder cover by turning the fastener a quarter turn to

the left.

d. Insert a roll of paper into the paper holder. Route the free end of the

paper to the brewer as shown.

e. Replace the cover on the paper holder. Secure it by turning the fastener

a quarter turn to the right.

f. Feed paper over swing arm assembly and underneath pinion gear shaft.

PAPER

OLDER

PAPER

ROLL

COVER

FASTENE

g. Feed paper through the paper guides.

h. Raise the basket housing assembly and feed paper over th e lip of the

paper mechanism housing.

GUIDES

BASKET HOUSIN

ASSEMBLY

SWING ARM

ASSEMBLY

IP OF PAPER MECHANISM HOUSING

It may be necessary to reach underneath the brewer between

PAPER MECHANISM HOUSING

NOTE

the paper mechanism housing and swing a rm as sembly to p ush

paper over the lip of the paper mechanism housing.

24 6530006

March, 2001

Page 29

Hot Drink Center Set-Up Manual

G

SWING ARM ASSEMBLY

Y

R

LIP OF PAPER MECHANISM HOUSIN

PAPER MECHANISM HOUSING

i. Reach underneath the brewer between the paper mechanism housing

and basket housing assembly and push paper into the top of the paper

mechanism housing between paper rollers.

BASKET HOUSING ASSEMBL

PAPER MECHANISM HOUSING

j. Reach underneath the brewer and pull paper roller to the right.

k. Pull paper down between the paper rollers.

l. Release the paper roller.

6530006 25

March, 2001

PAPER

ROLLE

Page 30

Hot Drink Center Set-Up Manual

2

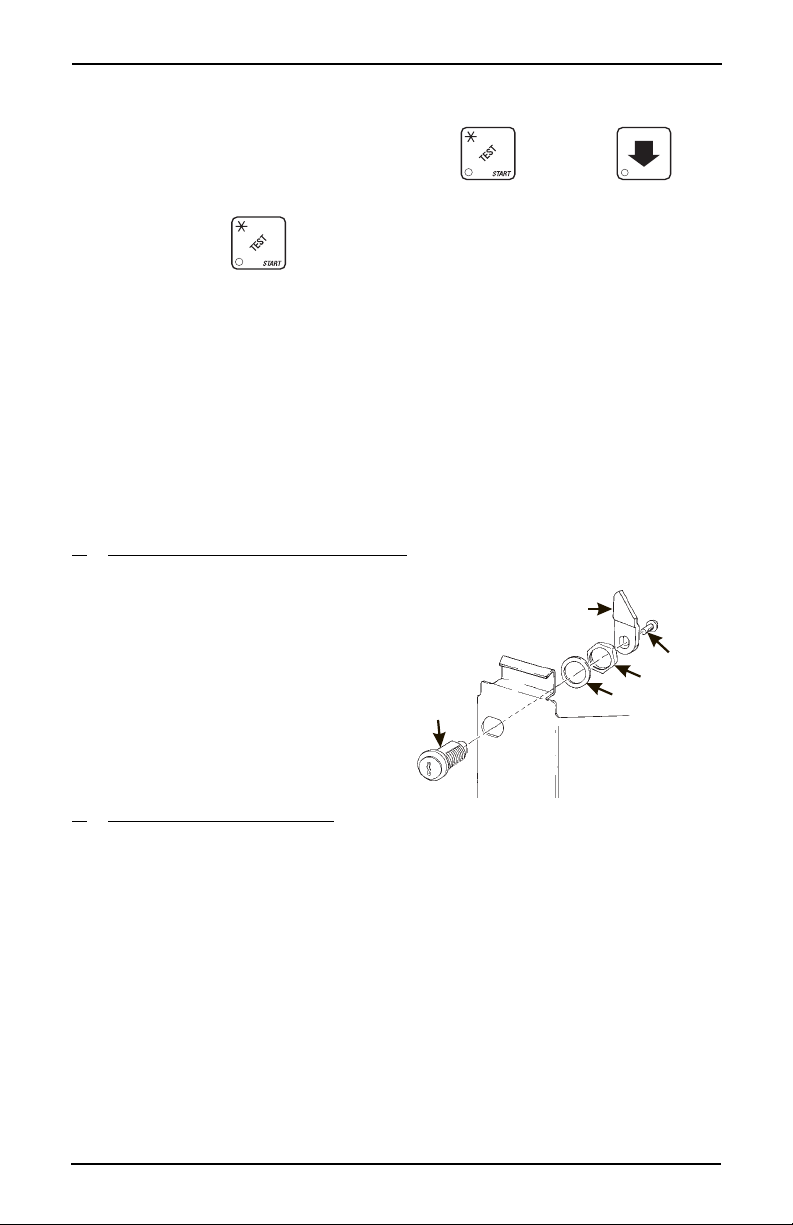

m. Place the main power switch in the ON position.

n. Test the brewer to be sure the paper feeds properly:

1. On th e maintenance k eypad, pres s , then press until

the display shows BREW TEST.

2. Press to test each brewer position:

WARNING

Keep away from the brewer mechanism while it is operating.

Coming into contact with moving parts could injure you.

BREW 'R BREW The brewer is in the BREW POSITION.

BREW 'R FLIP The brewer is in the FLIP position.

BREW 'R HOME The brewer is in the HOME position.

3. Make sure the filter paper feeds properly without jamming.

o. Replace the cup station and grounds bucket.

. Install the Optional Coin Box Lock

a. Install the lock cylinder,

washer, and nut in the order

shown.

b. Tighten the nut.

c. Install the lock bar as shown,

and secure with the screw.

LOCK

CYLINDER

LOCK BAR

SCREW

NUT

WASHER

3. Load the Coin Mechanism

a. Open the cabinet door and the monetary door.

b. Insert coins into their respective tubes until each tube has been filled.

c. Inspect the tubes for shingled coins and correct if necessary.

26 6530006

March, 2001

Page 31

Hot Drink Center Set-Up Manual

D

4. Fill the Tank:

a. Make sure the main power switch is ON.

b. Turn on the water at its source.

c. On the maintenance keypad, press , then press u ntil the

display shows TANK.FILL.

d. Press . Y ou should hear water running into the tank, and the dis-

play will show FILLING. The water will run until either the tank is full or

12 minutes go by, whichever happens first.

NOTE

The inlet water valve only stays open for 12 minutes at a tim e.

This is a safety feature to prevent water from running into a

leaky system and making a mess. It is possible for your tank to

take longer than 12 minutes to fill if your location has low

water pressure. To be on the safe side, check for leaks if the

water runs a long time. If you find none, every thing is normal;

you just have low water pressure.

e. When you hear the water stop running, repeat steps 3 and 4. Un der no r-

mal circumstances, nothing will happen. If water starts running and the

display shows FILLING again, your pressure is low and it is just taking a

long time to fill the tank. Repeat this step if necessary to be sure your

water tank is full.

5. Fill the Canisters:

a. Open the lid as shown, and carefully pour the appropriate product into

the canister. Repeat for all canisters in the machine.

LI

FILL

CANISTER

6530006 27

March, 2001

Page 32

Hot Drink Center Set-Up Manual

D

VIEW LOOKING DOWN

TURRET DESIGNATIONS

6. Load Cups: CAUTION

Use only cups which have been designed for use in a h ot beverage vending machine.

a. Support the cup mechanism in the upright position.

b. Push the latch forward to release the cup mechanism. Continue to s u p-

port the cup mechanism while you lower it into the loading position.

c. Remove the turret cover.

OBSERVE PROPER HYGIENE - DO NOT TOUCH THE CUPS!

d. Open the bottom of the wrapper on a stack of cups.

e. Insert the wrapped cups into the turret and pull the wrapper out.

DO NOT FILL CUPS ABOVE THE LEVEL MARKED

ON THE OUTSIDE OF THE CUP TURRETS OR

ABOVE THE “FIL L LINE” LABE L IN SID E EAC H TUR

RET, OR MO TOR JAMS WILL OCCUR.

USE ONLY THE SAME SIZ E AND BRAND OF HOT

DRINK CUPS IN EACH TURRET; DO NOT INTERMIX!

f. Replace the turret cover after the turrets have been loaded.

g. Be sure the cup mechanism is locked into the upright position.

-

CUP STACK ROTATION

OOR

1B 1A2

CUP

MECHANISM

28 6530006

March, 2001

Page 33

CABINET

DOOR

CUP MECH

MOUNTING

BRACKET

Hot Drink Center Set-Up Manual

LID

RETAINING

STRAP

LOAD CUPS

HERE

CUP TURRET

LATCH

CUPS

TOP VIEW

7. Tell the Machine About the Cup Size(s):

Your Hot Drink Center can vend two different cup sizes, so you will need to

"tell" the merchandiser the sizes of cups you have loaded into it.

a. Press , then press until the display shows CUP X OZ .

b. Press until the capacity of the regular size cups you loaded is

displayed.

6530006 29

March, 2001

Page 34

Hot Drink Center Set-Up Manual

c. Press , an d t he display shows CUP.1 X OZ.

d. Press until the capacity of the large size cups you loaded is dis-

played.

8. Test the Machine:

Your Hot Drink Center is now ready to vend coffee, just as soon as the water in

the tank reaches its operating temperature. Press

, and a reading of the

tank temperature is displayed. When the display shows 94° C (202° F), it is

ready for vending.

a. Close the door, make a selection, and enjoy your cup of coffee!

b. You will now need to do the following before your machine is ready to

start earni ng money:

• Set prices

• Set up the menu

• Establish time of day vending periods (if desired)

• Customize the drink recipes (if desired)

• Set up custom messages (if desired)

Refer to the Programming Guide for details on these and other pro cedur es.

30 6530006

March, 2001

Page 35

Hot Drink Center Set-Up Manual

ADJUSTMENTS AND MINOR MAINTENANCE

This section contains procedures not normally used during setup, but may come

in handy later on.

I. Water Valve Adjustment

W ater v alves do not us ually require ad justment, bu t in some cas es adequate wate r

volume cannot be achieved by the throw time setting alone (see the Program

ming Guide). IF ABSOLUTELY NECESSARY, adjust the valves in conjunc-

tion with setting the factory default timers during the product configuration

programming mode.

a. Using a slotted screwdriver, turn the adjustment screw clockwi se to

decrease the water flow rate.

b. Turn the adjustment screw counterclockwise to increase the water flow

rate.

-

6530006 31

March, 2001

Page 36

Hot Drink Center Set-Up Manual

II. Cup Mechanism Adjustme nt

a. Place seven cups in the cup ring.

b. Observe the clearance as shown in view B.

c. If necessary adjust by first loosening the adjustment arm screw (view

A).

d. Move adjustment arm until correct clearance is achieved.

e. Hold adjustment arm in place and tighten adjustment arm s crew.

ADJUSTMENT

ARM

VIEW A

LOOSEN SCREW

MOVE ARM

CUP

CAM

CUP

CAM

CORRECT

VIEW B

This clearance is just

large enough to allow

32 6530006

ADJUSTMENT

cup ejection

ADJUSTED

TOO TIGHT

ADJUSTED

TOO LOOSE

This side is snug

against cam

316P0118

March, 2001

Page 37

Hot Drink Center Set-Up Manual

A

si

g

b

c

f

T

t

a

g

G

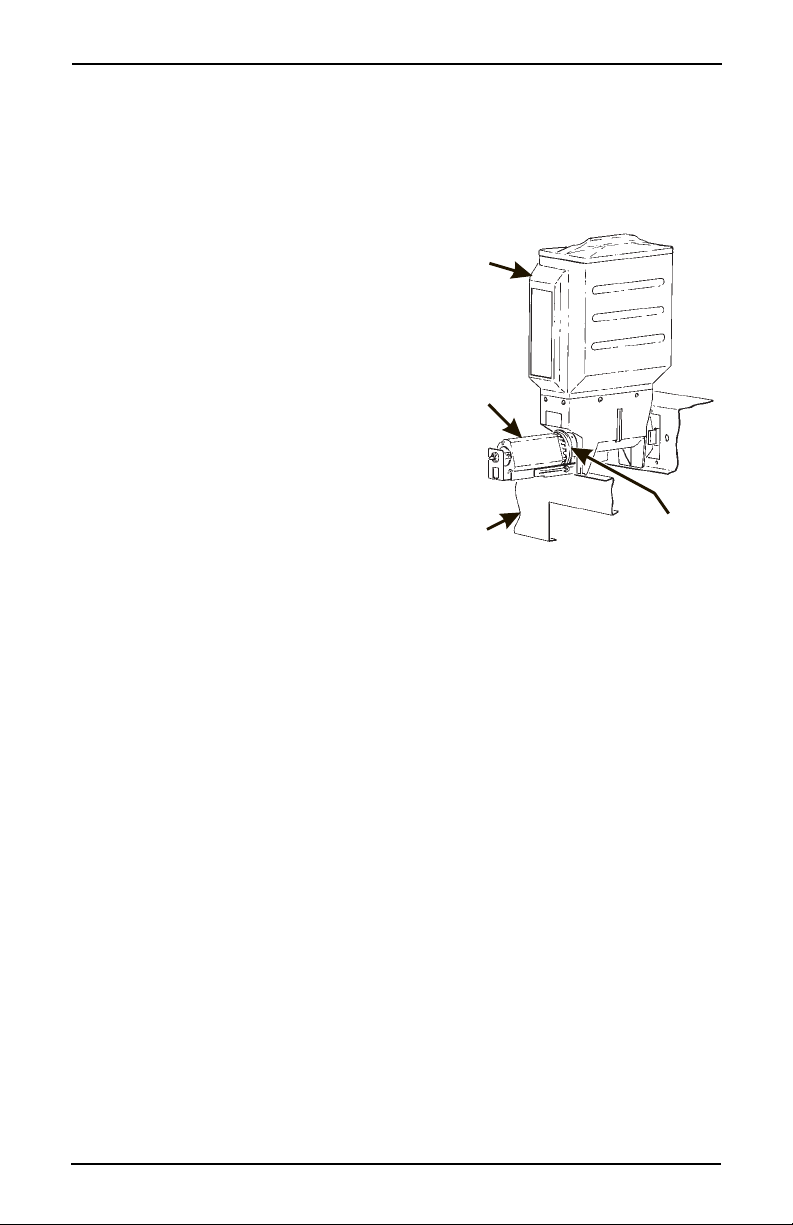

III. Grinder Adju stment

grind that is within the acceptable range will result in more controlled dispen

ng of grounds into the brew basket, and better extraction of coffee flavors. A

rind that is too coarse resu lts in poor extraction and spraying grounds in the

rewer area. A grind that is too fine can overload the grinder motor as well as

log the screens in the brew basket and

unnel.

he degree-of-grind scale attached to

he grinder motor represents an accept-

ble range of grinds. Do not set the

rinder beyond the limits of thi s scale.

a. Push the locking collar

toward the canister and turn

the grinder motor.

b. Turn clockwise for a finer

grind and counterclockwis e

for a coarser grind. A notch

on the locking collar indicates

the grind on the scale.

Do not turn the grinder motor too far in the clockwise direction. The grinder blades will come into contact and may be

damaged.

c. Adjusting the grind may make it necessary to readjust the throw time.

Use the factory default times as a starting point and proceed according

to the directions in the "COLLECTING DRY PRODUCT GRAM

THROWS" section of the Programming Guide.

BEAN

CANISTER

GRINDER

MOTOR

CANISTER

SHELF

CAUTION

LOCKIN

COLLAR

6530006 33

March, 2001

Page 38

Hot Drink Center Set-Up Manual

t

BRACKET ASSEMBLY

GRINDER

T

Y

FILL

CANISTER

CANISTER

SHELF

PINS ON MOTOR

SHAFT MUST ENGAGE

SLOTS IN CANISTER

COUPLER

IV. Disengaging the Grinder

At certain times, the bean grinder(s) need to be disengaged from the bean canister(s).

WARNING

Keep your fingers clear of all moving par ts.

a. Using a screwdriver han-

dle or other suitable tool,

push up on the catch

GRINDER

BRACKE

ASSEMBL

spring far enough to free

the catch spring pin from

the grinder shelf bracket

assembly.

b. Pull the grinder and

CATCH

SPRING

grinder bracket assembly

towards you.

c. Pivot the grinder and

grinder bracket assembly

CATCH SPRING PIN

GRINDER SHELF

down.

d. Re-engage the grinder by pivoting it back up into position.

V. Canister Installation

a. Place the canister

in position as

shown.

b. En gage the pins

FILL

CANISTER

PINS ON MOTOR

SHAFT MUST ENGAGE

SLOTS IN CANISTER

COUPLER

on the motor shaft

with the slots in

the canister coupler.

c. Fit tabs on canis-

ter into the slots

on the canister

shelf.

d. To ensu re canis-

ter is correctly

engaged with the rear mounting bracket, gently push down on the fron

edge of the canister lid.

CANISTER

SHELF

626P0017

e. Canister Caps. The parts bag contains a number of red vinyl caps.

Place these caps over the canister nozzle as shown to avoid spilling

product when removing and replacing the canisters.

34 6530006

March, 2001

Page 39

Hot Drink Center Set-Up Manual

SANIT ATION

I. Basics

INTRODUCTION

Anybody who services vending machines must use proper sanitizing procedures.

Health regulations require that hands be clean when cups, commodities, and

food-contact parts are handled or serviced.

In addition, Federal and State Health Departments require regular cleaning and

sanitizing procedures for food contact parts.

The information in this section will explain how to clean and sanitize the merchandiser on a day to day basis. A clean and well maintained merchandiser will

provide a better product and greater safety for your customers.

CLEANING AND SANITIZING -- WHAT’S THE DIFFERENCE?

Clean means “free of visible soil”. In cup vending machine servicing, cleaning is

also done to maintain product quality and to remove food soils, oils, and mineral

stains that could affect product taste, aroma, and appearance.

Sanitizing means the reduction, to safe levels, of the number of disease-causing

bacteria that remain on the surface after cleaning. Therefore, cleaning and sani

tizing are done in separate steps, as prescribed by health regulations and good

industry practice.

-

When you sanitize you create a healthy and hygienic condition. This leads to

wholesome food, which in turn leads to satisfied customers.

SANITIZING IS NO SUBSTITUTE FOR A GOOD CLEANING

HOW DO I SANITIZE?

You can sanitize by using either of these two methods:

Chemicals: The object to be sanitized is treated with a bactericidal compound.

Heat: Raise the temperature of the object high enough to kill bacteria.

Water must be at least 170° F.

Hot brew water (if available) is an acceptable sanitizer. When food contact

surfaces are washed and/or rinsed, use the hot water available in the

machine.

Turn the machine off before using water on the machine.

6530006 35

March, 2001

Page 40

Hot Drink Center Set-Up Manual

In either case, the object must be thoroughly clean and completely rinsed i n order

for the sanitizing process to work. Caked-on soils not removed by cleaning, for

example, may shield bacteria from a sanitizing solution.

A GOOD PLACE TO START -- YOUR SANITATION KIT

You need to be sure that each machine is clean, safe, and functioning when you

leave it. In order to properly do this, you need to have a complete set of the right

tools. In addition to the screwdrivers, pliers, and test equipment necessary to

repair a machine, you need to have the tools to clean the machine.

Here is a checklist of the items needed for a good sanitation kit:

Sanitation pail

Tube and nozzle brus hes for food contact surfaces

Utility brush for dry spillage around canisters, etc.

Disposable towels, wet-strength and lint-free

NOTE

Wiping wit h towels can recontaminate sanitized food-contact

parts. Therefore, towels should not be used to dry food-contact

surfaces. Instead, these parts should be air dried.

Spray detergent, diluted to desired strength

Urn cleaner packets for coffee stains and oils

Odor control chemicals for pails

Replacement parts (if the exchange method is used)

Cabinet polish or window cleaner for the outside of the machine

Feel free to add some items to this list. For example, you may want to use a portable vacuum cleaner.

36 6530006

March, 2001

Page 41

Hot Drink Center Set-Up Manual

II. Clean the Hot Water Tank

Some smell and/or taste problems may occur in new machines. Follow this procedure to clean the hot water tank if you experience problems:

7. If the machine is in service, remove power from the machine.

8. Dissolve 1 tablespoon of common baking soda in a cup of water.

WARNING

The water tank may be HOT. Be careful when working on the

tank.

9. Loosen or remove the hot water tank lid and pour th e baking soda solution into the tank.

10. Apply power to the machine.

11. If the tank is not full, fill it.

12. Allow the tank to reach its operating temperature.

13. Leave the solution in the tank for AT LEAST ½ hour. If possible, leave the

solution in the tank for 1 hour.

14. Drain the tank.

15. Refill the tank, then drain again.

16. Refill the tank and put the machine back into service.

III. Sanitation Procedures

Refer to the recommended cleaning and sanitat ion interval table on the fi nal page

of this section. For each item, complete the procedure as outlined here.

Food-Contact Parts

NOTE

All food-contact parts must be cleaned and sanitized. Air dry,

do not wipe dry.

Ingredient Canisters - Empty and wash the canisters, augers, and spouts.

Sanitize with hot water and allow to air dry completely before returning to

cabinet.

Mixing Bowls - The inside of all mixing bowls can be rinsed by performing

the “Bowl Rinse” operation as outlined in the Programming sectio n of this

manual.

If needed, remove mixing bowls from the dry ingredient shelf. Wash the

mixing bowl lids and sanitize with hot water. Allow to completely air dry

before reassembling.

Whipper Lids and Impellers - Remove lids and imp ellers from the whipper housings, wash the lids and impeller housing. Sanitize with hot water

and allow to air dry before reassembling.

6530006 37

March, 2001

Page 42

Hot Drink Center Set-Up Manual

Beverage Discharge Nozzles - Disconnect the beverage dispensing tube

from the nozzles. Remove the n ozzles from the mou nting bracket. Remov e

the cap from the nozzle, wash clean and sanitize the nozzles and cap. Refer

to the tubing connection diagram for proper routing.

Brewer, Brewer Basket, and Brewer Funnel - The tubing and brewer may

be sanitized by performing the BREW RINSE operation as outlined in the

programming section. The machine features an automatic brewer sanitizing

feature also described in the programming section.

At times, it may be necessary to wash and sanitize the individual brewer

parts. If so, disconnect the tubes from the brewer manifold. Remove the

brewer barrel and manifold assembly from its support. R emov e the brewer

basket and funnel assemblies.

Thoroughly wash all parts using soap and water. Sanitize by rinsing thoroughly with hot water.

Coffee Chutes - Remove the metal chute(s), wash clean, and sanitize by

rinsing with hot water. Air dry before reinstalling.

Condiment Chute Assembly - Remove the condiment chute and cover

from the condiment canisters. Thoroughly wash all parts using soap and

water. Sanitize by rinsing thoroughly with hot water.Non Food-Contact

Parts

Non Food-Contact Parts

Cup Delivery Compartment - Remove the compartment from the mer-

chandiser. Wash clean and rinse with hot water.

Exhaust Fan Filter - Remove the filter from its housing. Wash with soap

and water, rinse, wring dry, and replace into housing.

Waste Pail - Empty, wash, and rinse with hot water. Sprinkle detergent

powder in the bottom of the pail to help control odors.

Ingredient Rinse Tray - Remove product canisters. Wash and rinse with

hot water. Allow to air dry.

38 6530006

March, 2001

Page 43

Hot Drink Center Set-Up Manual

IV. Overall Cleaning

Inspect your merchandiser both inside and out. Be sure to check corners and all

less visible parts of the merchandiser.

Clean where needed.

Allow the inside of the cabinet to dry thoroughly before you close the door.

National Vendors recommends using the following s upplies:

• A commercial glass cleaner on the glass in the cabinet door.

• A mild detergent and warm water on the cabinet, brewer, and other NON

ELECTRICAL components.

WARNING

The plastic parts in your merchandiser shou ld be cleaned with

mild detergent and warm water. The use of other cleaning

agents may damage the material, and should be avoided.

V. Preventive Maintenance Cleaning

Periodically, you should visually inspect your merchandiser's hot water tank for

excessive lime and scale buildup. This buildup on the tank walls, water valves,

and heater element will vary dramatically, depending upon water quality. You

should develop a cleaning and deliming schedule based on the apparent local

water quality.

NOTE

To aid in removing scale from your merchandiser, National

Vendors has a service kit available: part number 6400080. In

addition, if your machine has the Everpure water inlet filter

system option, a second kit (part number 6400086) is also

available.

6530006 39

March, 2001

Page 44

Hot Drink Center Set-Up Manual

TUBE ROUTING DIAGRAM

40 6530006

March, 2001

Page 45

Hot Drink Center Set-Up Manual

SEMI-

ANNUALLY

CS

CS

Recommended Cleaning And Sanitation Intervals

ITEM DAILY WEEKLY MONTHLY QUARTERLY

Ingredient Canisters CS

Mixing Bowls CS

Whipper Funnels and

Impellers

Beverage Discharge Nozzles CS

Brewer, Brewer Basket and

Brewer Funnel

Bean Grinder Coffee Chutes CS

Bean Grinder Housing S

Brewer Mechanism C

Cup Delivery Compartment C

Exhaust Fan Filter C

Grounds Pail C

Waste Pail C

S = Sanitize at this interval C = Clean only at this interval

6530006 41

March, 2001

Page 46

Hot Drink Center Set-Up Manual

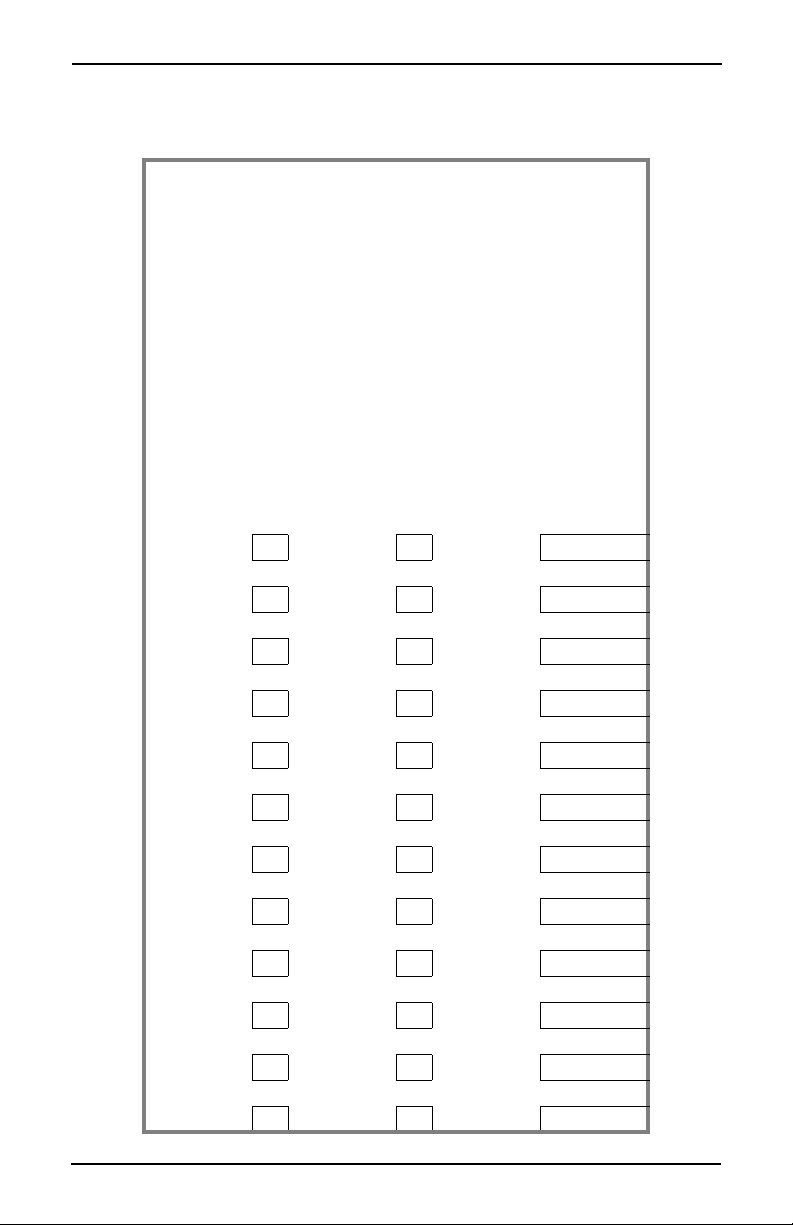

Make copies of this cleaning record, cut it out, and keep it in the plastic bag

mounted on the inside of the door. It will be your record of cleaning your Hot

Drink Center.

Record of Cleaning

20_____

S

RT

A

JAN

FEB

P

T

C

A

T

N

O

C

D

O

O

F

N

O

N

N

O

C

D

O

O

F

S

RT

A

P

T

C

A

T

Y

B

MAR

APR

MAY

JUN

JUL

AUG

SEP

OCT

NOV

DEC

42 6530006

March, 2001

Page 47

Hot Drink Center Set-Up Manual

APPENDIX A. THE FREE VEND KEYSWITCH OPTION

The free vend keyswitch allows someone to set up free vending without needing

to open the door.

It is a good idea to establish a free vend code. This will prevent an unauthorized

person from setting the machine to free vend, even if they have a key.

1. Press . Enter your 4-digit supervisor code. Press .

2. Press again, then press until the disp lay shows FREE XXXX. Enter a 4-digit free vend code.

NOTE

To keep the user from having to enter a code, you can enter

0000 as your code. See the steps below for details.

3. CONTINUE.

USING THE FREE VEND KEY SWITCH:

If you have set your freevend option to FREE W/KEY:

4. Place your key in the free vend keyswitch and turn it to the right. (If the keyswitch is already turned to the right, turn it to the left, then back to the right.) The di splay shows: ENTER CODE.

NOTE

If your freevend code is set to 0000, you will not see this display. Skip to step 6.

5. Enter your 4-digit freevend code. If you do this successfully within 6 seconds, you will hear two beeps, and the display shows: UNLOCKED.

6. The display shows NO MONEY REQUIRED (or whatever custom message you set up for the freevend period). Remove your key. All vends are free until the keyswitch is turned to the left again.

7. To take the machine off free vend, insert your key, turn the keyswitch to the left, and remove the key.

If you have set your freevend option to FREE OFF or FREE ALL:

1. If the freevend key is turned to the right, the machine will go out of service.

6530007 A-1

March, 2001

Page 48

Hot Drink Center Set-Up Manual

Notes . . .

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

A-2 6530007

March, 2001

Page 49

Hot Drink Center Set-Up Manual

APPENDIX B. THE INFRARED MUG/CUP SENSOR

The infrared mug/cup sensor can sense the presence of a mug or cup without

using movin g parts.

Indicator Light

The sensor is equipped with an indicator light. This light will help you get the

best results from the infrared mug/cup sensor.

Under these conditions, the indicator light should be off:

• Machine door open

• Cup station in place

• No cup in the station

If it is on, it is indicating improper cup station alignment or excessive sensor sensitivity.

Testing the light...Under these conditions:

• Machine door closed

• Cup station in place

• No cup in the station

Press any letter on the selection switch panel, for example, A. Only the letter A

should be showing in the message display. If “A MUG” is displayed, the sensor

thinks there is a mug in the station. The fault could be one or more of the follow

ing:

-

• Improper cup station alignment

• Excessive sensitivity (the sensor is sensing the delivery door)

• Cup station lens is not clean

Cleaning

As indicated in the Sanitation section, you should remove the cup s tation to clean

it. Pay particular attention to the dark colored infrared mug/cup sensor lens,

which is part of the cup station. If it is not thoroughly cleaned, the sensor will not

work properly.

CAUTION

Do not get liquid inside the sensor unit.

Cleaning the infrared mug/cup sensor unit itself is not usually necessary. If it

does require cleaning, just wipe it with a damp cloth.

6530007 B-1

March, 2001

Page 50

Hot Drink Center Set-Up Manual

Calibration

1. Remove the plastic cap in the rear of the sensing un it, exposing the potentiometer adjusting screw, as shown in figure B1.

2. Turn the screw clockwise to in crease sensitiv ity of cup detection, or counterclockwise to decrease sensitivity.

3. Calibrate the sensor:

CAUTION

Do not adjust sensitivity too far, or unreliable sensing could

result.

a. Using a piece of WHITE poster bo ard or h eavy cardb oard , make a 5" x

5 5/8" target.

NOTE

IT IS VERY IMPORTANT THAT THIS MATERIAL BE

WHITE.

b. Place the target in the cup station just beyond the cup deflectors (see fig-

ure B-2). The target should be standing vertically; not tilted forward or

backward.

c. With the target in place, turn the adjusting screw clockwise very slowly

until the indicator just turns ON.

d. Turn the adjusting screw counterclockwise very slowly until the indica-

tor just turns OFF.

4. Replace the plas tic cap.

5. Insert a mug into the cup station in the vending position and check to see that the red indicator light is ON.

This calibration will be adequate for most cups or mugs. In some cases, a

slightly more sensitive setting is needed if the cup or mug is a dark color.

B-2 6530007

March, 2001

Page 51

I

NDICATOR

D

VIEWING REAR OF SENSOR ASSEMBLY

PLASTIC CAP

T

LIGHT

Hot Drink Center Set-Up Manual

ADJUSTING SCREW

Figure B1.

PLASTIC CAP

SHOWN REMOVE

INDICATOR LIGH

CUP

DEFLECTORS

CUP

Figure B2.

6530007 B-3

March, 2001

Page 52

Hot Drink Center Set-Up Manual

Notes . . .

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

B-4 6530007

March, 2001

Page 53

Hot Drink Center Set-Up Manual

APPENDIX C. DEX/UCS INTERFACE OPERATION

Connect your portable data collection device (PDCD) to the harness hanging

inside the monetary door, and operate it per its instructions.

SELECT DATA TRA N SFER METHOD:

6. Press . The display shows: ENTER CODE. You must enter the fourdigit supervisor code within 6 seconds to gain access.

NOTE

A new machine has a factory-set supervisor code of 0000.

When you have entered the right code, you will hear two beeps and see

SUPERVISOR in the display.

7. Press until the display sh ows DEX+CLR or DEX ONLY.

DEX+CLR = Data will be cleared after collection is complete.

DEX ONLY = Data will remain in merchandiser memory after collection is

complete.

NOTE

A third selection - PRINTER - is available, but selecting it will

disable the dex/ucs interface.

8. Press to switch between the two options.

9. Press to exit.

This procedure does not need to be repeated u nless you des ir e to change the d a ta

transfer option. However, it might be prudent to check the setting prior to down

load to ensure unintentional clearing of data.

DOWNLOAD DATA:

1. Press . The display shows DEX.MODE while data is being transferred.

6530007 C-1

March, 2001

-

Page 54

Hot Drink Center Set-Up Manual

Notes . . .

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

C-2 6530007

March, 2001

Page 55

Hot Drink Center Set-Up Manual

APPENDIX D. MODIFY CANISTER TO VEND 12 OZ.

CUPS

Proceed as follows:

2. Remove all cups, then remove the turret center and turret base assembly from the canister.

3. Break off all 8 tabs on the bottom of the turret base as shown.

NOTE

You will no longer be able to vend smaller cups from this

canister! To return to vending smaller cups you must

replace the modified turret base with an original turret

base (part number 6233048) from National Vendors Parts

Department.

4. Replace the turret center and turret base in the canister and load cups.

5. Dro p a cup. If it drops pro perly, you are finished with the procedure, if not,

continue with step

6. Remove all cups, then remove the canister from the cup mechanism assembly.

7. Remove the funnel, replace the canister, and reload cups.

8. Dro p a cup. If it drops pro perly, you are finished with the procedure, if not,

continue with step

9. Order a universal cup ring (part number 6333008) from National Vendors Parts Department.

6.

9.

6530007 D-1

March, 2001

Page 56

Hot Drink Center Set-Up Manual

P

TURRET

CENTER

TURRET

BASE

BREAK OFF

ALL TABS

OPTIONAL

TWIN DRINK

CENTER CU

CANISTER

TURRET

CENTER

TURRET

BASE

BREAK OFF

ALL TABS

CANISTER

FUNNEL

D-2 6530007

March, 2001

Page 57

WARRANTY STATEMENT

LIMITED WARRANTY. Subject to the limitations specified herein, this mer chandiser is warranted for one (1)

year against defective parts and workmanship. Any part or parts which are proven to be defective within one

(1) year of the date of shipment will be repaired or replaced free of charge when the defective part is returned,

with transportation charges prepaid, to the destination designated by CRANE MECHANDISING SYSTEMS

Warranty Department.

Refrigeration system’s are warranted for (2) years against defective parts and workmanship. Any part or parts of the

refrigeration system which are proven to be defective within (2) years of the date of shipment of the merchandiser

will be repaired or replaced free of charge when the defective part(s) is r eturned, with transportation charg es prepaid,

to the destination designated by the Crane Merchandising Systems Warranty Department. Any part or parts that are

proven to be free from defect will be assessed a diagnostic charge. This diagnostic charge will be added to the price of

any replacement unit which might have been sent as an advanced replacement, as well as any shipping and handling

fees that may have accrued as a result of shipping the original refrigeration unit. The charges will be the sole respon

sibility of the original purchaser.

This warranty does not include any cost of service rendered or repairs made by cu stomer or it’s agents on Merchandiser, or parts, unless authorization to incur such expense has been given in writing by CRANE MERCHANDISING

SYSTEMS prior to incurring such expense. This warranty does not cover labor and service charges performed by

CRANE MERCHANDISING SYSTEMS service technicians. Customer shall pay all labor costs with respect to war

ranty repairs.

This warranty does not apply to A) electrical components, wiring, or circuits and/or for all mechanical parts or assemblies damaged as a result of operating the Merchandiser at other than the design voltage and frequency specified on

the Electrical Rating Tag, or B) in event of vandalism, fire or negligence, or C) incandescent lamps, neon lamps, flu

orescent lamps, ballasts, starters or other expendable items or D) when other manufactured components are installed

in Crane Merchandising Systems Merchandisers.

-

-

-

Replacement parts sold by CRANE MERCHANDISING SYSTEMS as After Market shall be covered for three

months from the date shown on the parts invoice. Purchaser must obtain prior RETURN AUTHORIZATION for

return of all parts, following guidelines given by Crane Merchandising Systems

New, unused parts purchased as AFTER MARK ET, can be returned within 30 days from date of parts invoice, with

prior authorization from CRANE MERCHANDISING SYSTEMS.

CRANE'S LIABILITY FOR ANY AND ALL LOSSES AND DAMAGES TO CUSTOMERS RESULTING

FROM ANY CAUSE WHAT SOEVER INCLUDING CRANE'S NEGLIGENCE, ALLEGED DAMAGE OR

DEFECTIVE GOODS, IRRESPECTIVE OF WHETHER SUCH DEFECTS ARE DISCOVERABLE OR

LATEN T, SHALL IN NO EVENT EXCEED THE REPAIR OR RE PLACEMENT OF DEFECTIVE OR

DAMAGED GOODS OR, AT THE ELECTION OF CRANE, THE PURCHASE PRICE OF THE PARTICU

LAR GOODS WITH RESPECT TO WHICH LOSSES OR DAMAGES ARE CLAIMED. CRANE

RESERVES THE RIGHT TO REPLACE OR REPAIR DEFECTIVE OR DAMAGED GOODS WITH

REMANUFACTURED PARTS OR MACHINES.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED, INCLUDING

WITHOUT LIMIT ATION, W ARRANTIES O F MERCHANT AB ILITY OR FITNESS FOR A PARTICULAR

PUPOSE. CRANE MERCHANDISING SYSTEMS SHALL NOT BE RESPONSIBLE FOR CONSEQUEN

TIAL OR PUNITIVE DAMAGES. CRANE MERCHANDISING SYSTEMS NEITHER ASSUMES NOR

AUTHORIZES ANY PERSON TO ASSUME FOR IT ANY OBLIGATION OR LIABILITY IN CONNEC

TION WITH THE SALE OF SAID EQUIPMENT OR ANY PART THEREOF.

Crane Merchandising Systems

A CRANE CO. Company

12955 Enterprise Way

-

-

Bridgeton, MO 63044

-

Page 58

Loading...

Loading...