Page 1

Tag 680-4 Printed in USA © 1004

Gooseneck

Gooseneck

Faucet

Faucet

WWall Mount

all Mount

Faucet

Faucet

Lavatory

Lavatory

Faucet

Faucet

650/680 SERIES

650/680 SERIES

INST

INST

ALLA

ALLA

TION INSTRUCTIONS

TION INSTRUCTIONS

THE CHICAGO FAUCET COMPANY

2100 S. Clearwater Drive Des Plaines, IL 60018-5999

Phone: (847) 803-5000 Fax: (847) 803-5454

www.chicagofaucets.com

Trademarks

The Galileo 650/680 Series faucet spout design is licensed

under U.S. patent number D446,843 S and foreign counterparts.

U.S. patents pending on the Galileo 650/680 Series faucet

infrared electronics design. Synapse Commander and Synapse

Infrared are trademarks or registered trademarks of their

respective holders.

Copyrights

© 2003 Chicago Faucets Co. All rights reserved. The information in this manual is subject to change without notice.

Notice to Installers

Please leave this manual with the facility manager after completing the faucet installation. This document contains information

necessary for routine maintenance and servicing.

TABLE OF CONTENTS

Product Overview.....................................................................2

Available Faucet Options.........................................................2

Common Replacement Parts...................................................2

How to Order.............................................................................2

Care and Maintenance .............................................................2

Technical Support ....................................................................2

Safety Information ....................................................................3

Pre-Installation Setup...............................................................3

Model Identification..................................................................3

Component Identification ........................................................4

Las instrucciones en espanol comienzan en la pagina ................................................18

Les instructions en francais commencent a la page ....................................................36

Installation.................................................................................5

Gooseneck Faucet-Single Hole & Cover Plate..................5

Gooseneck Faucet-Wall Mount..........................................6

Lavatory Faucet .................................................................7

Solenoid and Optional Valves............................................8

Electronics Assembly (AC) ................................................9

Electronics Assembly (Battery Operated)........................10

Completed Installations....................................................11

Faucet Operation ....................................................................12

Changing Faucet Operation ..................................................12

Troubleshooting .....................................................................13

Warranty ..................................................................................16

ADA Compliant

Page 2

Printed in USA © 1004

Tag 680-4

2

650 / 680 SERIES

Installation & Maintenance Instructions

AVAILABLE FAUCET OPTIONS

4" and 8" (Centerset) Cover plate

(not available with wall mount versions)

Adjustable mechanical side-mix valve

– Catalog number 123-CP

Multi-unit hardwire transformer option for

Galileo 650/652/653 Series, handles up to eight units

– Catalog number 128-NF

Single unit plug-in transformer option for

Galileo 650/652/653 Series

– Catalog number 126-NF

CARE AND MAINTENANCE

All Chicago Faucets fittings are designed and engineered to

meet or exceed industry performance standards. Care

should be taken while cleaning this product.

• Use of abrasive cleaners, chemicals or solvents can

damage the faucet surface.

• Use mild soap with warm water for cleaning and protecting the life of the Chicago Faucets fittings. Make

sure the sensor eyes are kept clean and free of

obstructions.

• The solenoid assembly includes a strainer to catch particles in the water. Periodically clean the strainer to

keep it from clogging.

PRODUCT OVERVIEW

The Galileo 650/680 Series state-of-the-art motion sensing

faucet systems are designed to make life safer and easier.

The hands-free, touchless convenience produces a more

sanitary environment and promotes water conservation.

This user-friendly patented system adjusts automatically to

the environment. The craftsmanship and electronics design

make these faucets the best value in the market.

Mixing “Y”

– Catalog number 560-045KJKRBF

Thermostatic mixing valve (requires only a single supply

connection to the base fitting), handles up to 5 faucets

– Catalog number 119-NF

Stop Valve (supply-stop valves and check valves must be

used when hot and cold supplies are mixed ahead of the

solenoid valve) (with non-mixing valve models)

– Catalog number 441-LKC

For more information regarding faucet options, visit our website at www.chicagofaucets.com.

COMMON REPLACEMENT PARTS

Spout Assembly, Lavatory 570-001KJKCP

4" Cover Plate Assembly 570-003KJKCP

8" Cover Plate Assembly 570-008KJKCP

Sensor Collar Assembly 570-012KJKCP

Partition Assembly, DC 570-032KJKNF

Partition Assembly, AC 570-033KJKNF

Solenoid Wire Harness Assembly 570-039KJKNF

Electronics Box Assembly, DC 570-059KJKNF

Electronics Box Assembly, AC 570-060KJKNF

Gasket Kit 570-097KJKNF

Screw Kit 570-098KJKNF

Washer Kit 570-099KJKNF

4" Cover Plate Assembly

w/Side Mix Valve 570-071KJKCP

8" Cover Plate Assembly

w/Side Mix Valve 570-135KJKCP

Solenoid Assembly (Deck Mount) 570-144KJKRBF

Solenoid Assembly (Wall Mount) 570-145KJKRBF

Solenoid Rebuild Kit 570-344KJKNF

Wall Collar and Elbow Assembly 570-158KJKCP

HOW TO ORDER

Contact your local Chicago Faucets dealer or visit our website at www.chicagofaucets.com

- Close the supply lines and remove the filter nut.

- Wash or brush the strainer until clean.

- Do not overtighten the strainer when replacing.

• If water conditions are harsh, clean the solenoid and

outlet (spout).

TECHNICAL SUPPORT

For additional technical assistance, visit our website at

www.chicagofaucets.com, or call

1-800-TEC-TRUE (1-800-832-8783)

In addition, the Galileo 650/680 Series faucets support an

optional handheld maintenance tool called Geberit

Commander™. The patented Geberit Commander™ system uses wireless technology to communicate with the

faucet to provide troubleshooting and maintenance information along with faucet history and status, and for making

faucet adjustments.

For more information on the Geberit Commander™ system,

please contact your local Chicago Faucets dealer, or

www.chicagofaucets.com.

Page 3

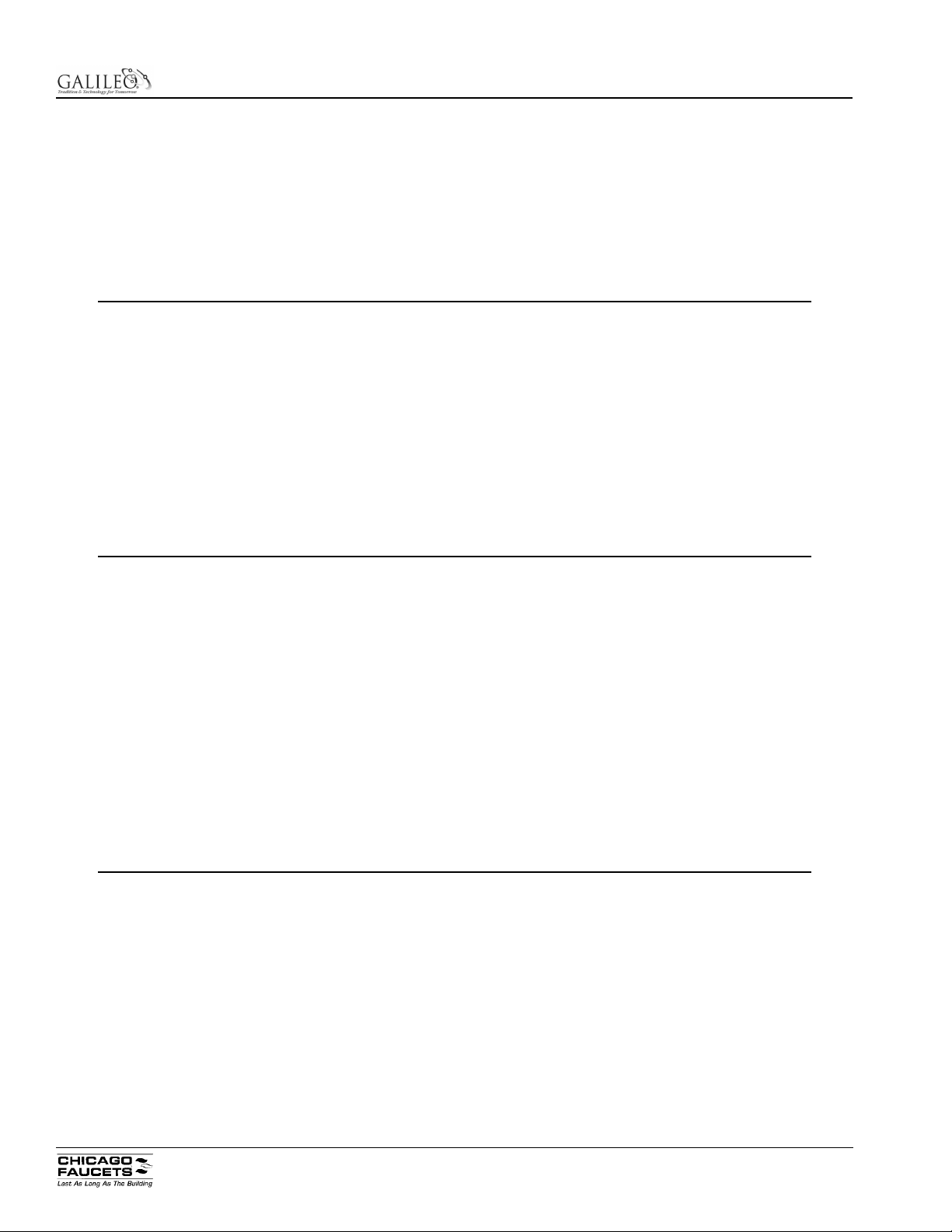

Required Tools and Supplies

Your Galileo faucet comes with all the components needed

for installation, however, tools and some supplies must be

furnished by you.

NOTE: Teflon tape is the recommended sealant.

CAUTION

Do not use pipe dope on faucet and supply

connections. Possible solenoid contamination could

occur and will void any warranty.

Printed in USA © 1004

Tag 680-4

3

650 / 680 SERIES

Installation & Maintenance Instructions

SAFETY INFORMATION

• Read this entire instruction sheet to ensure proper

installation.

• Compliance and conformity to local codes and ordinances is the responsibility of the installer.

• Flush all the water supply lines before making connections.

• File these instructions with the owner or maintenance department.

CAUTION indicates a practice or condition that

MAY result in damage to the equipment if the instruction or notice is ignored.

PRE-INSTALLATION SETUP

CAUTION

Make sure that water supply is completely off before

beginning installation.

Galileo 650 Series (AC) Faucets

The installation site should have access to an electrical box

with 120 volt AC, 60 Hz cycle for input to a transformer.

When installing the 126-NF transformer, the electrical box

should be within 6' of the sink. When installing the 128-NF

transformer, the electrical box should be within 50' of the

sink, if 18-gauge cable is used.

IMPORTANT: DO NOT attempt to operate multiple

faucets using a single-fitting transformer. Always use

128-NF transformer for multiple units.

Two types of transformer are available:

• Single fitting, plug-in

– Catalog number 126-NF

• Single fitting or multiple fittings (one to eight) hardwire

– Catalog number 128-NF

Galileo 680 Series Battery Powered (DC) Faucets

The faucets are powered by four “AA” alkaline batteries

(included).

Lavatory-style faucets are shipped with the spout, collar and

cover plate assembled.

Drill w/7/32" drill bit

Adjustable Locking Pliers

Basin Wrench

1/8" Hex Key (supplied)

Teflon Tape

Flat Blade Screwdriver

MODEL IDENTIFICATION

Gooseneck Faucet – Surface Mount

Model 652 Single Hole AC

Model 652-123 w/Side Valve AC

Model 652-4 w/4" Cover Plate AC

Model 652-4-123 w/4" Cover Plate & Side Valve AC

Model 652-8 w/8" Cover Plate AC

Model 652-8-123 w/8" Cover Plate & Side Valve AC

Model 682 Single Hole DC

Model 682-4 w/4" Cover Plate DC

Model 682-8 w/8" Cover Plate DC

Model 682-8-123 w/8" Cover Plate & Side Valve DC

Gooseneck Faucet – Wall Mount

Model 653 Single Hole AC

Model 683 Single Hole DC

Lavatory Faucet

Model 650 Single Hole AC

Model 650-4 w/4" Cover Plate AC

Model 650-8 w/8" Cover Plate AC

Model 650-8-123 w/8" Cover Plate & Side Valve AC

Model 680 Single Hole DC

Model 680-4 w/4" Cover Plate DC

Model 680-4-123CP w/4" Cover Plate & Side Valve DC

Model 680-8 w/8" Cover Plate DC

Model 680-8-123 w/8" Cover Plate & Side Valve DC

Side Mix Valve

(not available with wall mount)

Model 123-CP

Mixing Y-Valve

Model 560-045KJKRBF

Thermostatic Mixing Valve

Model 119-NF

Transformers

Model 126-NF, Plug-In

Model 128-NF, Hardwire

Replacing An Existing Faucet

Remove existing faucet, handles and supply lines from the

sink and supply stops.

Page 4

Printed in USA © 1004

Tag 680-4

4

650 / 680 SERIES

Installation & Maintenance Instructions

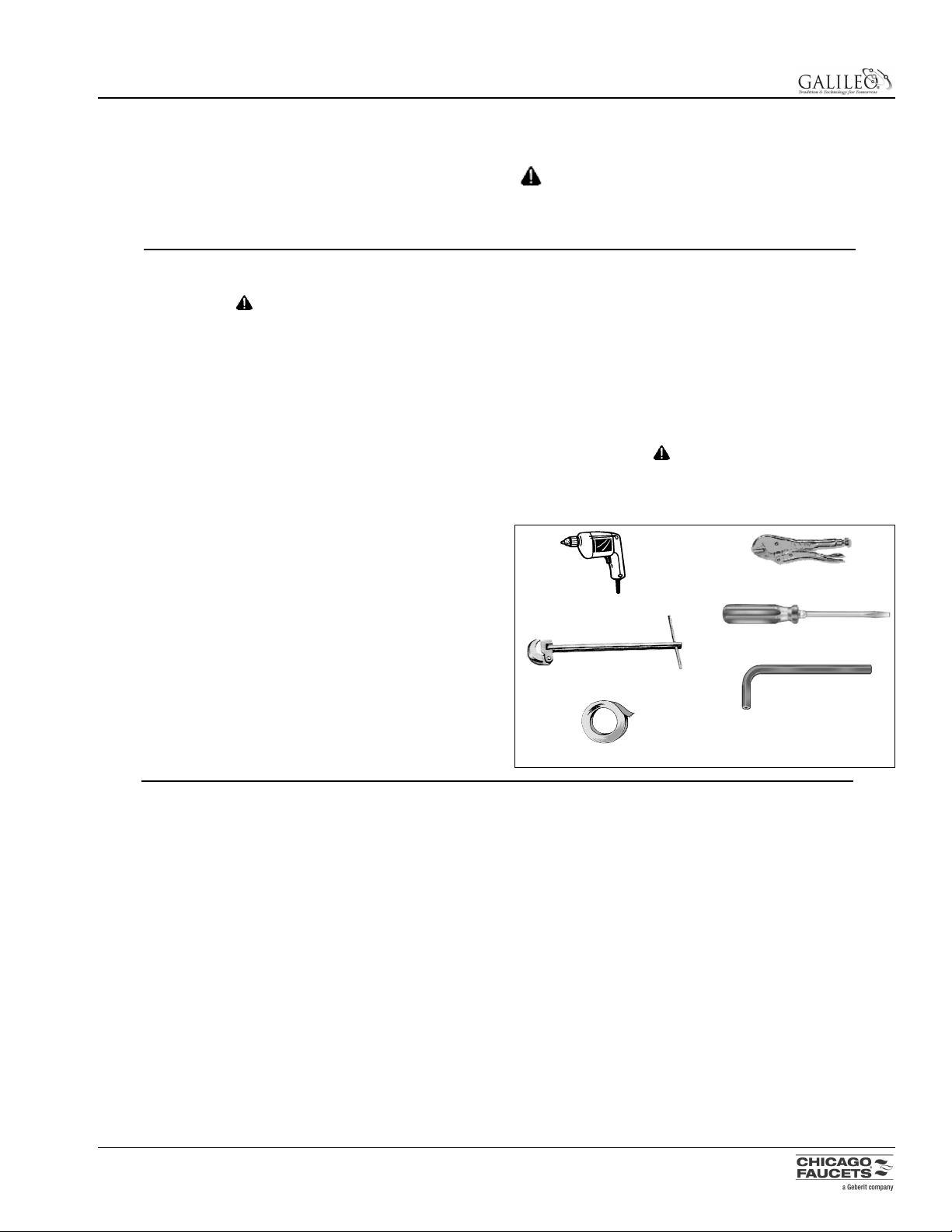

COMPONENT IDENTIFICATION

Care should be taken when unpacking shipping carton to avoid damage to unit and the following components enclosed. If any

parts are missing or damaged, contact your local Chicago Faucets dealer.

Gooseneck Faucet (shown w/cover plate) – Surface Mount

Lavatory Faucet (shown with cover plate) Electronic Box, Solenoid & Side Mix Valve

Gooseneck Faucet – Wall Mount

Spout

Spout

Spout Outlet

(Female)

Spout Outlet

(Female)

Spout Nut

Collar Elbow

Spout Nut

Spout Shank

Cover Plate

(4" or 8")

(if equipped)

Sensor Collar

Collar Gasket

Sensor Collar

Screw

Stilt Washer

Stilt Washer

Shank Washer

Shank Washer

Locking Nut

Locking Nut

Spout Outlet

(Male)

Stilt Washer

Shank Washer

Locking Nut

Sensor Collar

Collar Gasket

Spout

Cover Plate

(4" or 8")

(if equipped)

Screw

Baseplate

Partition Assembly

Electronics

Cover

123 Side Mix Valve

Screw

Screw

Screw

Collar &

Gasket

Outer Strain

Relief Bracket

Solenoid

DIN Connector

Stainless Steel

Flexible Hose

Cable

(Collar Assembly)

Cable

(Solenoid Assembly)

Page 5

Printed in USA © 1004

Tag 680-4

5

650 / 680 SERIES

Installation & Maintenance Instructions

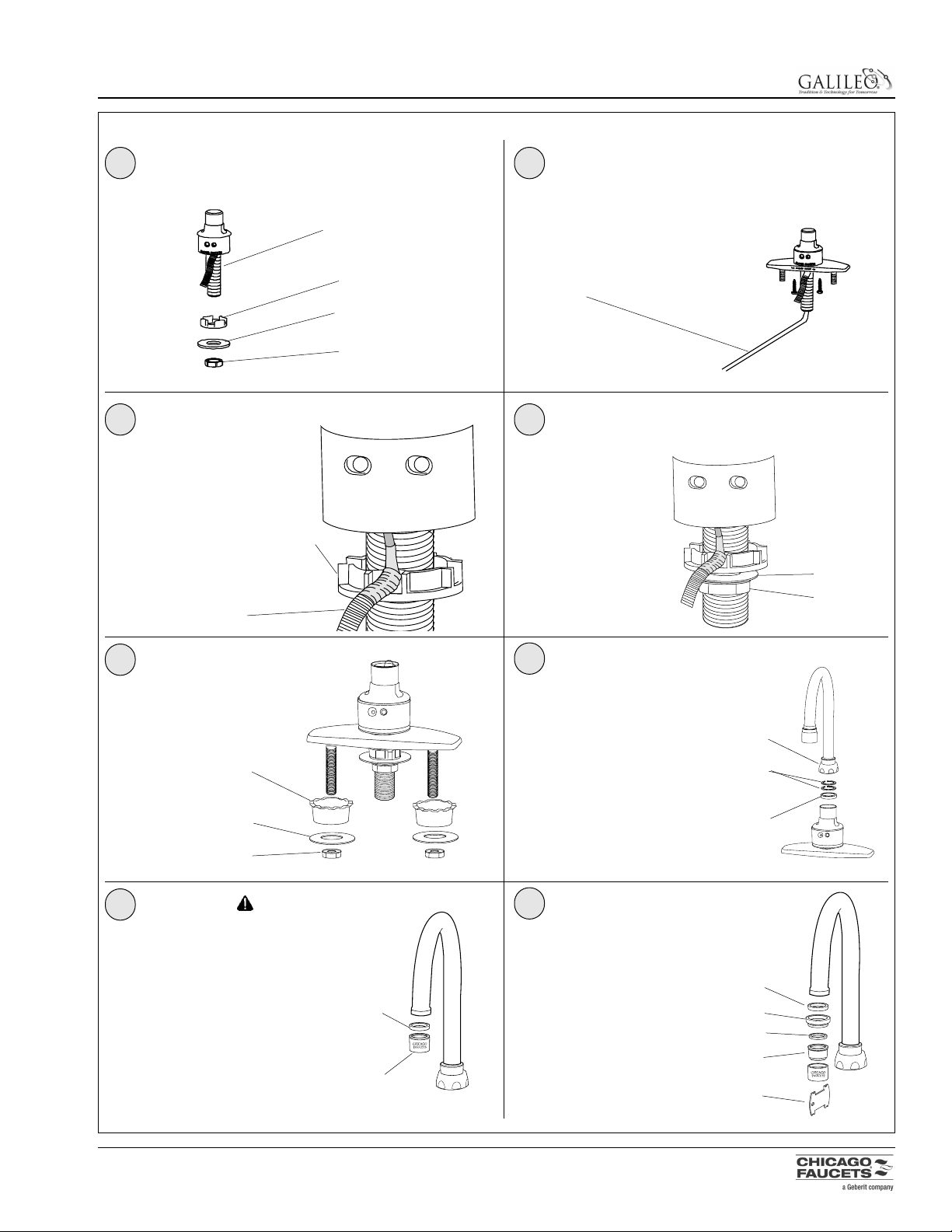

INSTALLATION – GOOSENECK FAUCET – SINGLE HOLE & COVER PLATE

1 2

3

4

7

5

6

8

Remove the locknut (1), washer (2), stilt washer (3) from

the spout shank (4). Remove shank from cover plate (if

supplied).

Install stilt washer (1) all

the way up onto shank,

crown side up. Position

sensor cable (2) through

one of the rounded slots

in the stilt washer (1).

If faucet was installed with

cover plate, secure cover

plate with basin washers (1),

flat washers (2) and locknuts

(3).

Install the shank washer (1) and locknut (2) onto faucet

shank. Tighten locknut securely to prevent collar and spout

from rotating. If necessary, support spout base from above

to prevent twisting.

Install spout nut (1) onto the

spout.

For swivel mount, only install

two plastic split washers (2).

For rigid mount, only install

1/8" thick plastic washer (3).

Mount the spout completely

into the base and securely

tighten the spout nut (1).

Attach the outlet assembly (1) and

aerator gasket (2) to the spout.

The outlet assembly is equipped

from the factory with a 0.5 GPM

cartridge (white screen). To configure the outlet with the 2.2 GPM

cartridge (yellow screen) see step

8.

If 0.5 GPM spout is to be used,

skip step 8 and proceed to

Installation - Solenoid and

Optional Valves, page 8.

To convert outlet assembly to

2.2 GPM:

1. Disassemble outlet assembly using key (1).

2. Remove the 0.5 GPM cartridge (white screen) and

replace it with the 2.2 GPM

cartridge (2).

3. Install the rubber washer

(3), adapter (4) and aerator

gasket (5).

Proceed to Installation Solenoid and Optional

Valves, page 8.

Install faucet assembly into deck hole.

Use plumbers putty to seal faucet to deck.

4

3

2

3

1

1

1

2

3

4

5

2

2

2

2

1

3

1

1

1

2

Be careful not to

nick or cut the sensor cable during

installation.

)

)

CAUTION

Flush water lines before performing this step.

Page 6

Printed in USA © 1004

Tag 680-4

6

650 / 680 SERIES

Installation & Maintenance Instructions

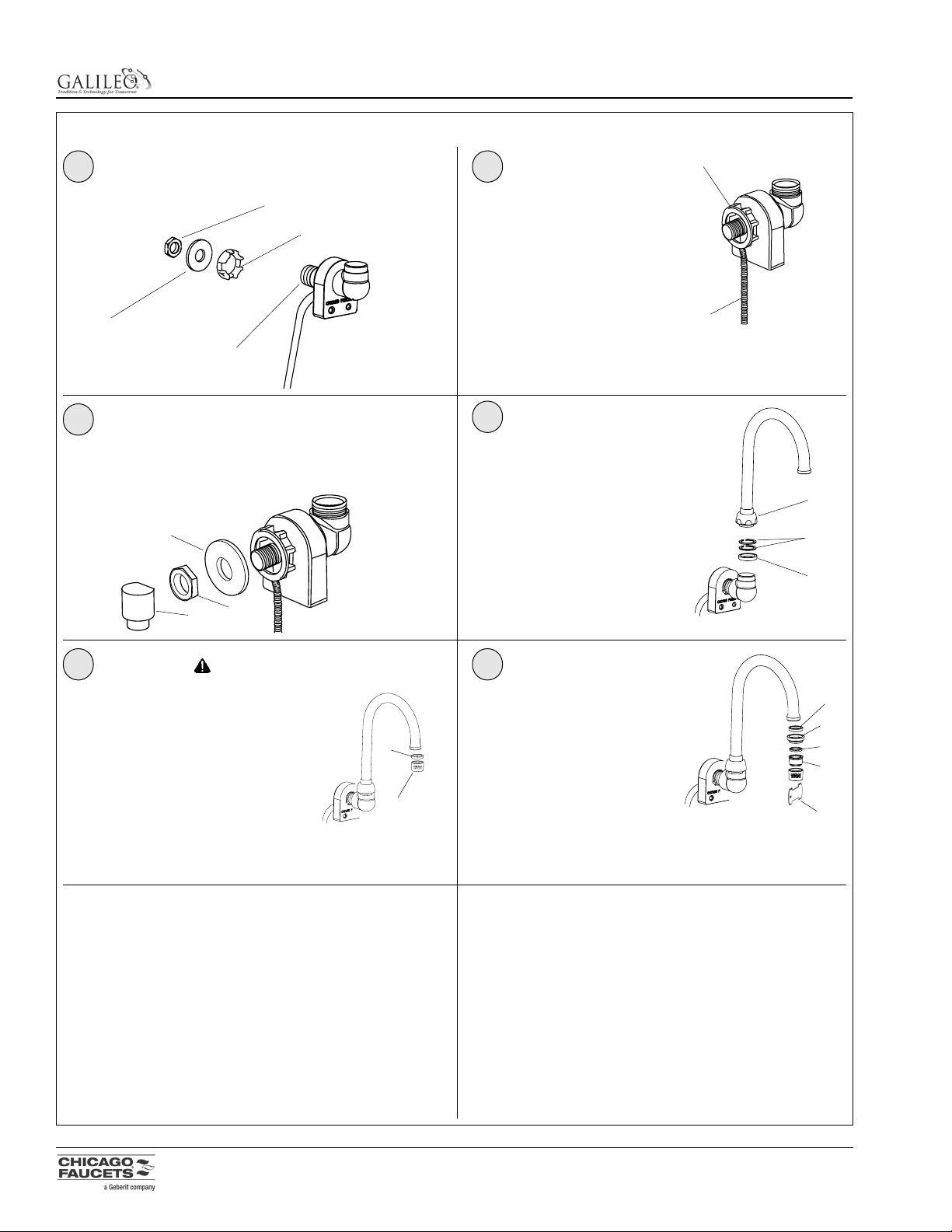

INSTALLATION – GOOSENECK FAUCET – WALL MOUNT

1 2

3

Remove the locknut (1), washer (2), stilt washer (3) from

the shank (4).

Install the shank washer (1) and locknut (2) onto faucet

shank. Tighten locknut securely to prevent spout

from rotating. Install elbow (3) using Teflon tape on threads.

NOTE: Make sure collar is not resting on cable while tightening. Support wall collar assembly while tightening elbow.

Install the sensor collar

assembly into the wall hole.

Install stilt washer (1) all the

way up onto shank, crown

side in. Position sensor

cable (2) through one of the

rounded slots in the stilt

washer

4

3

2

1

1

2

Be careful not to nick or cut the sensor cable during installation.

3

2

1

5

1

2

6

4

Install spout nut (1) onto the

spout.

For swivel mount, only install

two plastic split washers (2).

For rigid mount, only install

1/8" thick plastic washer (3).

Mount the spout completely

into the base and securely

tighten the spout nut (1).

1

1

3

4

5

2

3

2

Attach the outlet assembly (1) and

aerator gasket (2) to the spout. The

outlet assembly is equipped from the

factory with a 0.5 GPM cartridge

(white screen). To configure the outlet

with the 2.2 GPM cartridge (yellow

screen) see step 6.

To convert outlet assembly to 2.2

GPM:

1. Disassemble outlet assembly

using key (1).

2. Remove the 0.5 GPM cartridge

(white screen) and replace it

with the 2.2 GPM cartridge (2).

3. Install the rubber washer (3),

adapter (4) and aerator gasket

(5).

If 0.5 GPM is to be used, proceed to Installation Solenoid and Optional Valves, page 8.

)

Proceed to Installation - Solenoid and Optional

Valves, page 8.

)

CAUTION

Flush water lines before performing this step.

Page 7

Printed in USA © 1004

Tag 680-4

7

650 / 680 SERIES

Installation & Maintenance Instructions

INSTALLATION – LAVATORY FAUCET

1 2

5

7

6

Remove the locknut (1), washer (2), stilt washer (3) from

the spout shank (4).

If faucet was installed with cover plate, secure cover plate

with basin washers (1), flat washers (2) and locknuts (3).

Install the faucet assembly into the deck hole.

Use plumbers putty to seal faucet to deck.

4

3

2

1

Be careful not to nick or cut the

sensor cable during installation.

1

1

2

3

4

5

1

2

2

3

To convert outlet assembly to 2.2 GPM:

1. Disassemble outlet assembly using key (1).

2. Remove the 0.5 GPM cartridge (white screen) and

replace it with the 2.2 GPM cartridge (2).

3. Install the rubber washer (3), adapter (4) and aerator

gasket (5).

4

Install the shank washer (1) and locknut (2) onto faucet

shank. Tighten locknut securely to prevent spout

from rotating. If necessary, support spout base from above

to prevent twisting.

2

1

Attach the outlet assembly (1)

and aerator gasket (2) to the

spout. The outlet assembly is

equipped from the factory with a

0.5 GPM cartridge (white

screen). To configure the outlet

with the 2.2 GPM cartridge (yellow screen) see step 7.

If 0.5 GPM is to be used, proceed to Installation Solenoid and Optional Valves, page 8.

)

)

Proceed to Installation - Solenoid and Optional Valves,

page 8.

3

Install stilt washer (1) all

the way up onto shank,

crown side up. Position

sensor cable (2) through

one of the rounded slots

in the stilt washer (1).

2

1

CAUTION

Flush water lines before performing this step.

Page 8

Printed in USA © 1004

Tag 680-4

8

650 / 680 SERIES

Installation & Maintenance Instructions

INSTALLATION – SOLENOID AND OPTIONAL VALVES

1 2

3

5

7

4

6

8

Attach the supply lines to side valve.

Connect the intermediate supply line (1) to the bottom

outlet of the side valve and to the solenoid assembly inlet.

Use Teflon tape on the threads to ensure a leak-free joint.

If required, install any optional equipment and connect to

the solenoid. The valves listed here require only a single

supply connection to the base fitting on the solenoid.

• Side mix valve (steps 3, 4, 5 & 6)

- Catalog number 123-CP

• Mixing “Y” valve (step 7)

Catalog number 560-045KJKRBF

• Thermostatic mixing valve (not shown)

- Catalog number 119-NF

If used, assemble the “Y” valve (1) to the nipple (2) supplied,

then connect the “Y” valve to the the solenoid assembly inlet.

Use Teflon tape on all threads to ensure a leak-free joint.

Proceed to Installation - Electronic Box

(AC or Battery Operated, depending on model),

page 9 or 10.

If equipped with a side valve, assemble the nut (1) and flat

washer (2) to the valve shank. Install the side valve assembly up into the mounting plate and secure from the top with

the chrome c-clip (3) provided.

Assemble the chrome valve handle (1) to the side valve

using the screw (2) and cap (3) provided.

Thread the union nut (1) of the solenoid assembly to the

faucet shank (2). Use Teflon tape on the threads to

ensure a leak-free joint. Make sure the solenoid is positioned for easy access. Tighten the union nut.

1

1

1

2

2

3

2

3

CAUTION

Do not use pipe dope on

threads. The solenoid

could become contaminated and will void any

warranty.

CAUTION

Do not use pipe

dope on threads.

The solenoid could

become contaminated and will void any

warranty.

CAUTION

Do not use pipe dope

on threads. The solenoid could become

contaminated and will

void any warranty.

1

1

2

NOTE: For single-hole

application substitute

threaded deck flange

for C-clip.

HOT

(red dot)

)

Page 9

Printed in USA © 1004

Tag 680-4

9

650 / 680 SERIES

Installation & Maintenance Instructions

INSTALLATION – ELECTRONIC BOX (AC)

650 / 680 MODEL

ELECTRONICS BOX MOUNTING TEMPLATE

INSTRUCTIONS

1. REMOVE BACKING AND PLACE THIS TEMPLATE WHERE ELECTRONICS

BOX IS TO BE MOUNTED.

2. DRILL 3 PILOT HOLES AT THE LOCATIONS INDICATED ON THIS TEMPLATE.

3. PARTIALLY FASTEN 3#10 WOOD SCREWS (USE ANCHORS IF NECESSARY)

INTO MOUNTING SURFACE.

4. SEPARATE ELECTRONICS COVER FROM BASEPLATE BY LOOSENING

1/8" HEX ALLEN SCREW.

5. ATTACH BASEPLATE TO WALL AND COMPLETE TIGHTENING

SCREWS INTO WALL.

1

3

4

6

7

5

2

8

Install baseplate and mount the electronic box to the wall

location chosen in step 1. Make sure transformer wires (1)

are positioned in the baseplate channel (2) before mounting unit.

CAUTION

DO NOT turn on water supply until all electrical

connections are made.

CAUTION

Faucet will automatically calibrate when sensor cable is connected and power is supplied. DO NOT place objects in front

of collar sensor for first 30 seconds after power-up.

Follow the directions on the electronic box mounting template

supplied. Affix the template to the wall, either level with or

above solenoid valve, and within 12" of the solenoid valve.

When installing the 126-NF transformer, the electrical box

should be within 6' of the sink. When installing the 128-NF

transformer, the electrical box should be within 50' of the sink,

if 18-gauge cable is used.

Install solenoid cable plug (1) into the smaller, telephonestyle jack in the electronic box. Install faucet sensor cable

plug (2) into the larger RJ-45 jack.

Attach strain relief cover (1) with screw (2) using hex key

provided (3).

Feed the wires from the transformer through the baseplate.

Connect the 1/4" spade terminal to the positive (+) terminal

and connect the 3/16" spade terminal to the negative (-)

terminal. Terminals are two different sizes and match

corresponding terminal clips from transformer. Clips are not

provided with the 128-NF transformer.

NOTE: To ensure the

electronic box is level

with or above the solenoid valve, the cables

should create a drip

loop. The electronic box

is designed with the

wire connectors facing

downward to ensure

proper drip loops.

Plug the transformer into the applicable electrical receptacle.

Wait at least 30 seconds, then turn on the water supply.

NOTE: When power is initially supplied, the LED on the electronic

box will blink and an audible indicator chirps twice per second

whenever hand presence is detected. This will continue for 8

minutes and then stop.

Remove the strain relief

cover and screw (1)

using hex key provided

(2).

NOTE: The faucet will automatically calibrate when

sensor cable is connected

and power is supplied. See

step 8.

NOTE: For inwall or multi-unit

installations refer

to instructions

included with the

transformer.

1

2

2

1

1

1

3

2

1

2

2

CAUTION

Do not attempt to operate multiple faucets using a 126-NF

single transformer.

Proceed to FAUCET OPERATION, page 12.

)

Re-attach the electronic box to the baseplate location

using screw(1) and hex key provided (2).

NOTE: When positioning baseplate, make

sure there is enough

room for drip loops in

final installation. See

Note in step 7.

Page 10

Printed in USA © 1004

Tag 680-4

10

650 / 680 SERIES

Installation & Maintenance Instructions

INSTALLATION – ELECTRONIC BOX (BATTERY OPERATED)

650 / 680 MODEL

ELECTRONICS BOX MOUNTING TEMPLATE

INSTRUCTIONS

1. REMOVE BACKING AND PLACE THIS TEMPLATE WHERE ELECTRONICS

BOX IS TO BE MOUNTED.

2. DRILL 3 PILOT HOLES AT THE LOCATIONS INDICATED ON THIS TEMPLATE.

3. PARTIALLY FASTEN 3#10 WOOD SCREWS (USE ANCHORS IF NECESSARY)

INTO MOUNTING SURFACE.

4. SEPARATE ELECTRONICS COVER FROM BASEPLATE BY LOOSENING

1/8" HEX ALLEN SCREW.

5. ATTACH BASEPLATE TO WALL AND COMPLETE TIGHTENING

SCREWS INTO WALL.

1

3

4

7

5

6

8

Mount the electronic box to the wall location using

screw(1) and hex key provided (2).

CAUTION

DO NOT turn on water supply until all electrical

connections are made.

Install solenoid cable plug (1) into the smaller, telephonestyle jack in the transformer. Install faucet sensor cable

plug (2) into the larger RJ-45 jack.

Attach strain relief cover (1) and screw (2) using hex key

provided (3).

Install 4 “AA” alkaline batteries into battery holder. Observe

battery polarity.

Turn on the water supply.

Remove the strain relief cover and screw (1) using hex

key provided (2).

NOTE: When power is initially supplied, the LED on the electronic box will blink and an audible indicator chirps twice per second

whenever hand presence is detected. This will continue for 8

minutes and then stop.

Follow the directions on the electronic box mounting template supplied. Affix the template to the wall, either level with

or above solenoid valve, and within 12" of the solenoid

valve.

NOTE: To ensure the

electronic box is level

with or above the solenoid valve, the cables

should create a drip loop

The electronic box is

designed with the wire

connectors facing downward to ensure proper

drip loops.

1

2

1

2

1

2

3

1

2

3

Proceed to FAUCET OPERATION, page 12.

)

CAUTION

Faucet will automatically calibrate when sensor cable is connected. DO NOT place objects in front of collar sensor for

first 30 seconds after power-up.

NOTE: When positioning

baseplate, make sure

there is enough room for

drip loops in final installation. See Note in step 6.

2

Install baseplate and mount the electronic box to the wall

location chosen in step 1.

With baseplate

NOTE: When positioning baseplate, make

sure there is enough

room for drip loops in

final installation. See

Note in step 6.

1.5V

or UM-3X2

SIZE "AA" or EQUIV.

COMF

1.5V

or UM-3X2

SIZE "AA" or EQUIV.

COMF

Page 11

Printed in USA © 1004

Tag 680-4

11

650 / 680 SERIES

Installation & Maintenance Instructions

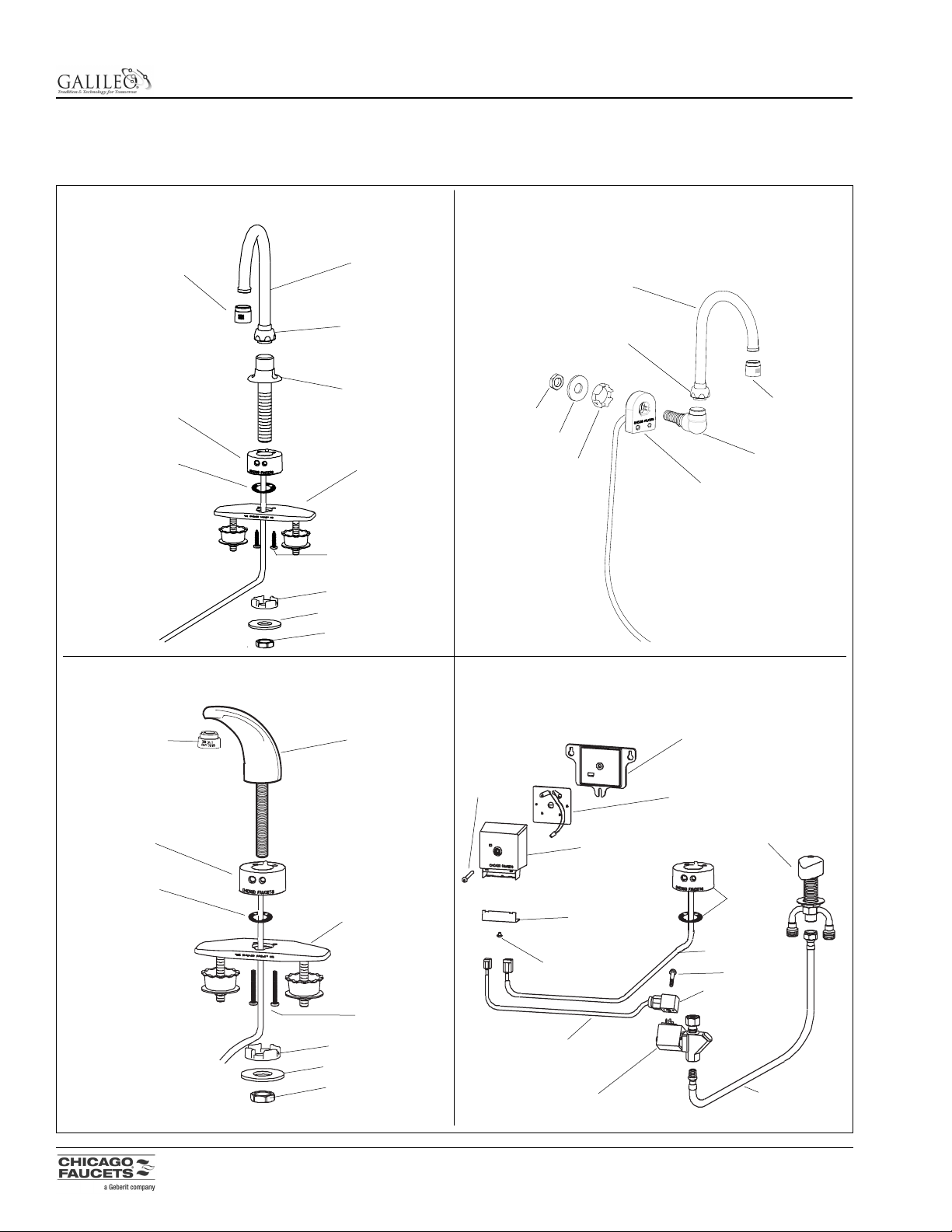

COMPLETED INSTALLATIONS

Gooseneck Faucet – Surface Mount

(shown with cover plate)

Gooseneck Faucet – Surface Mount

(shown with cover plate & side valve)

Gooseneck Faucet – Wall Mount

Lavatory Faucet

(shown with cover plate & side valve)

Lavatory Faucet

(shown with cover plate )

Page 12

CHANGING FAUCET OPERATION

In order to change any faucet option, the DIPswitch must be

used (located inside the electronics cover assembly, see

illustration this page).

Checking/Changing DIPswitch Settings

1. Remove the electronics cover (1) from the baseplate

(2).

2. Lift the partition (3) out to expose the circuit board and

DIPswitch.

3. To change a DIPswitch setting, use a small pointed

object to move the appropriate DIPswitch to ON or

OFF.

Faucet range and mode settings along with their

corresponding DIPswitch settings are outlined in Table 1 and

Table 2

Resetting Faucet Electronics

In order to reset the faucet electronics, a reset button located inside the electronics cover assembly must be pushed in

(see illustration this page).

To reset faucet electronics:

1. Remove hex screw holding the electronics cover to

the baseplate and remove cover.

2. Lift the partition out to expose the circuit board and

reset button.

3. Make sure there are no objects in front of the collar

sensor, then push the button to reset.

4. Wait 30 seconds for faucet to automatically calibrate

to the environment.

5. Activate water flow by placing your hand in front of the

sensor.

6. Place partition into the electronics cover.

7. Place the electronics cover onto the baseplate and

secure with the hex screw.

Printed in USA © 1004

Tag 680-4

12

650 / 680 SERIES

Installation & Maintenance Instructions

ON

ON

OFF

OFF

1 2 3 4 5

1 2 3 4 5

MANUAL

RESET

BUTTON

DIPSWITCHES

Electronics Cover Assembly & DIPswitch

Range Short Normal Far Maximum

Switch 1 off on on off

Switch 2 off off on on

Table 1 - Faucet Range

Normal Scrub Meter Water Saver

Modes Mode Mode Mode Mode

Switch 3 off on off off

Switch 4 off off on off

Switch 5 off off off on

Table 2 - Faucet Mode

FAUCET OPERATION

Range Modes

• Normal - Gooseneck or Lavatory spout, 4-3/4" spout

(factory default)

• Short - Gooseneck, 3-1/2" spout

• Far - Long Gooseneck, 5-3/8" spout

• Maximum - Long Gooseneck, 8" spout

Operating Modes

• Normal Motion Detecting Mode: water flows within 1/4

second after activating sensor (i.e., putting hands in

front of collar) and continues to stay on as long as

motion is detected. Maximum time is 45 seconds

(factory default setting).

• Scrub Mode: water continues to flow for 60 seconds

(default) after deactivating the sensor (removing

hands).

• Metered Mode: water flows for 10 seconds (default)

from first hand detection.

• Water Saver Mode: water flows for a maximum of 5

seconds starting from first hand detection and immediately turns off when hands are removed.

Additional Operating Features

• 12 second, no-motion turn off in normal mode

• Low-battery indication

• Battery life up to one year depending on use

frequency.

3

1

2

Page 13

NOTE: Resetting the faucet electronics causes loss of virtual settings and time in use, and will also start the 8 minute

timer where the LED on the electronics box will blink and an

audible indicator chirps twice per second whenever hand

presence is detected. The optional Geberit Commander™

hand held maintenance tool can also be used to reset all

faucet electronics.

Printed in USA © 1004

Tag 680-4

13

650 / 680 SERIES

Installation & Maintenance Instructions

The optional Geberit Commander™ handheld maintenance

tool makes changing faucet operation settings easy, and

provides access to additional faucet options such as delay

times - all without opening the electronics cover assembly.

For more information, please contact your Chicago Faucets

dealer or visit www.chicagofaucets.com.

TROUBLESHOOTING

Whenever new batteries are installed, AC power is applied,

or a manual reset button is pressed, the LED on the electronics cover will blink and an audible indicator chirps twice

per second whenever hand presence is detected. After 8

minutes, the LED and buzzer function stops.

If an error occurs, the LED will blink and the buzzer will

sound every 30 seconds to assist in diagnosing the problem. When corrective action is taken the LED and buzzer

will stop.

The following chart provides details concerning the number

of beeps and possible errors associated with them .

1 Beep: Indicates low battery.

2 Beeps: Calibration out of range (environment too reflec-

tive).

3 Beeps: Room infrared level out of range; too much sun-

light, heat lamp present, etc.

4 Beeps: Solenoid short circuit.

5 Beeps: Solenoid unplugged or loose/broken solenoid

connection.

See Troubleshooting Chart on pages 14 & 15 for further

troubleshooting information.

Page 14

Printed in USA © 1004

Tag 680-4

14

650 / 680 SERIES

Installation & Maintenance Instructions

Disassemble solenoid and inspect/clean parts.

Reduce pressure to under 80 PSI.

Attach side mix valve outlet to solenoid valve using

flexible hose (page 8).

Change range setting using DIPswitch (page 12)

or Commander™ software.

Turn on water supply.

Check connection.

Replace electronics cover.

Check connection.

Inspect collar wiring for signs of damage or corrosion. Replace if necessary.

Replace cover assembly.

Reduce pressure to under 80 PSI.

Replace batteries (DC only).

Use correctly sized terminal clips (page 9).

Faucets must be wired in parallel from transformer

(transformer to each individual unit), not connected

in a series.

If polarity was reversed, replace partition (part no.

570-033KJKNF).

After 60 seconds, or another Palm

Communication, the faucet will return to operating

mode.

Remove interference; reset electronics using reset

button (page 12) or Commander™ software. Allow

30 seconds for faucet to automatically re-calibrate.

Change range setting using DIPswitch (page 12)

or Commander™ software.

Change range setting using DIPswitch (page 12)

or Commander™ software.

Water runs continuously.

Faucet turns on by itself

(ghosting).

No water flow.

Debris in solenoid (no beeps).

Water pressure too high (no beeps).

Side mix valve installation (no beeps).

Incorrect range setting for spout type and

sink used (2 beeps).

Water not turned on (no beeps).

Solenoid cable not connected to electronics cover (5 beeps).

Solenoid short circuit (4 beeps).

Sensor cable not connected to electronics

cover (no beeps).

Inoperative sensor (no beeps).

Inoperative electronics cover assembly

(no beeps).

Water pressure too high (no beeps).

Low battery voltage (DC only) (1 beep).

6VDC transformer not properly connected

to partition assembly (no beeps).

Wiring of multiple unit 6VDC transformer

(no beeps).

Check wiring polarity.

While communicating with faucet, the

Palm device was pulled away before communications ended (no beeps).

Interference during automatic calibration

(no beeps).

Incorrect range setting for type of spout

and sink used.

Lighting environment affecting sensor

(3 beeps).

Problem Check Possible Solution

Troubleshooting Chart

Range too short or too long.

Page 15

Printed in USA © 1004

Tag 680-4

15

650 / 680 SERIES

Installation & Maintenance Instructions

Replace solenoid.

Change mode or range setting using DIPswitch

(page 12) or Commander™ software.

Clean internal parts or replace solenoid valve.

Clean outlet.

Change mode setting using DIPswitch (page 12)

or Commander™ software.

Electronics cover must be mounted to allow for

drip loops for the sensor and solenoid cables

(pages 9 & 10).

Clean connector.

Reset electronics using reset button (page 12) or

Commander™ software.

Clogged strainer. Clean if necessary.

Clean faucet outlet.

Replace batteries if below 4.2 volts.

Change range setting using DIPswitch (page 12)

or Commander™ software.

Replace sensor.

Faucet works in reverse.

Faucet turns off too soon.

Faucet stays on longer than

normal.

Faucet stopped working.

No Commander™ Palm communications.

Solenoid wiring on DIN connector

(no beeps).

Faucet operating mode (no beeps) or

faucet range setting.

Dirty solenoid valve (no beeps).

Clogged spout outlet.

Faucet in wrong mode (no beeps).

Mounting of electronics cover (no beeps).

Sensor cable connector.

No clicking sound from solenoid during

hand presence (no beeps).

Solenoid valve strainer.

Check if faucet outlet is clogged

(no beeps).

Battery voltage (battery operated only).

Incorrect range setting for spout type and

sink used (no beeps).

Inoperative sensor (no beeps).

Problem Check Possible Solution

Page 16

Printed in USA © 1004

Tag 680-4

16

650 / 680 SERIES

Installation & Maintenance Instructions

WARRANTY

PRICES - Prices quoted herein are subject to change without notice and all orders are accepted subject to prices prevailing at time of order

entry.

TERMS OF PAYMENT - Terms are 2% 45 days 60 net. Cash discounts must be calculated on the total amount of the invoice, before transportation charges and any applicable taxes. A 1-1/2% per month service charge will be added to all past due invoices. Annual rate of 18%.

TAX NOTICE - Any manufacturers' or sales tax applicable thereto will be added to the prices and terms herein contained.

CREDIT APPROVAL - All orders are subject to credit approval by the CHICAGO FAUCET COMPANY'S Credit Department prior to acceptance

of the order. Orders may be refused, delivery may be withheld or shipments stopped in transit on accepted orders without any liability on the

Company's part, if, in its sole opinion, the buyer's ability to pay for the merchandise on the terms and conditions contained herein is in doubt.

All New Accounts must submit a $500.00 net minimum order with credit and bank references.

SHIPPING AND HANDLING - All sales are F.O.B., shipping point. The Company will allow full freight at the prevailing CWT rate on shipments

of Company's products with a net invoice value of $1,500.00 or 24 pieces, * when shipments are within the continental United States and have

as destination the buyer's usual business address or designated job location. Freight allowed on shipments to Alaska shall be calculated

F.A.S., Seattle, Washington. The use of the term "F.A.S., Seattle, Washington" in this paragraph shall not be deemed to impose any risk or

obligation concerning the goods or the shipment thereof upon the Company after the delivery of the goods to the initial carrier. Under no circumstances will a direct C.O.D. shipment be made to the wholesaler's customer.

* Original P.O. must meet FFA terms. Subsequent additions will not be considered towards freight allowance.

Routing of shipments shall be determined at the sole discretion of the Company.

DELIVERY - Delivery to the initial carrier shall constitute delivery to the buyer. CHICAGO FAUCET COMPANY'S responsibility, insofar as

transportation risks are concerned, ceases upon delivery in good order to such carrier, and all goods are shipped at the buyer's risk. The buyer

is requested to check each incoming shipment carefully before acknowledging receipt from the carrier. If goods are visibly damaged the buyer

should insist that written confirmation of the damage be noted on the freight bill by the carrier. If concealed damage is noted after unpacking,

the buyer should immediately notify the carrier involved and obtain verification of the damage from the carrier.

Claims for shortages in orders will not be considered unless presented to the Company within 30 days after receipt of goods by the buyer.

DAMAGE - All claims for damage in transit, shortage, or nondelivery must be filed against the carrier by the buyer.

CHICAGO FAUCET COMPANY will not be responsible for delay in shipment of goods, or for any damages suffered by reasons thereof, when

such delay is occasioned by accident, fire, flood, embargo, strike, war, labor stoppages, inadequate transportation, shortage of materials, delay

or default on the part of vendors, government regulations or any other cause beyond its control.

CHICAGO FAUCETS BRAND PRODUCTS ARE SUBJECT TO THE FOLLOWING WARRANTIES:

LIMITED WARRANTY - The CHICAGO FAUCET COMPANY ("Chicago Faucets") extends to the original consumer the following warranties for

Genuine Chicago Faucets manufactured products and components, or other components under the Chicago Faucets Warranties, (collectively,

the "Products") used in commercial or residential applications.

LIFETIME FAUCET WARRANTY - The "Faucet", defined as any metal cast, forged, stamped or formed portion of the Product, not including

electronic or moving parts or water restricting components, or other components covered under other Chicago Faucet warranties, is warranted

against manufacturing defects for the life of the Product.

FIVE YEAR CARTRIDGE WARRANTY - COMMERCIAL _ The "Cartridge", defined as the metal portion of any Product typically referred to by

the product numbers containing 1-099, 1-100, 1-310, 377X, 217X and 274X, excluding any rubber or plastic components, is warranted against

manufacturing defects for a period of five (5) years from the date of Product purchase. All Cartridges included in Chicago Faucet's Single

Control or Shower Products are also warranted against manufacturing defects for a period of five (5) years from the date of Product purchase.

LIFETIME CARTRIDGE WARRANTY - RESIDENTIAL - For products used in Residential applications, the "Cartridge", as described above, is

warranted for the lifetime of the faucet.

ONE-YEAR FINISH WARRANTY - COMMERCIAL - For Products used in commercial applications, the finish of the Product is warranted

against manufacturing defects for a period of one-year from the date of Product purchase. PVD finishes installed in public or commercial areas

carry a one-year warranty from date of installation.

ONE-YEAR FINISH WARRANTY - RESIDENTIAL - PVD finishes installed in public or commercial areas carry a one-year warranty from date

of installation.

Page 17

Printed in USA © 1004

Tag 680-4

17

650 / 680 SERIES

Installation & Maintenance Instructions

FIVE-YEAR FINISH WARRANTY - RESIDENTIAL - For Products used in residential applications, the finish of the Product is warranted against

manufacturing defects for a period of five (5) years from the date of Product purchase. ForeverShine™ finishes installed in residential-use

applications are warranted not to corrode, tarnish or discolor for the life of the product.

ELECTRONIC FAUCETS MECHANICALS WARRANTY - Are warranted for 5 years from the date of installation.

ELECTRONIC FAUCETS FINISHES WARRANTY - Are warranted for one-year from the date of installation.

ELECTRONIC FAUCETS ELECTRONICS AND SOLENOID WARRANTY - Are warranted for one-year from the date of installation.

OTHER WARRANTIES - All other Products not covered above are warranted against manufacturing defects for a period of one (1) year from

the date of Product purchase.

GEBERIT BRAND PRODUCTS ARE SUBJECT TO THE FOLLOWING WARRANTIES:

KITCHEN ACCESSORIES shall be free from defective material and workmanship for a period of 1-year from date of installation.

BATH WASTE and OVERFLOW products carry a limited lifetime warranty on the material and mechanism

Tessera™ concealed tank & carrier units carry a 10-year limited warranty on the flushing mechanisms and limited lifetime warranty on the tank

and carrier.

PLATED FINISHES carry a one-year limited warranty from date of installation with the exception of those finishes designated as

ForeverShine™.

ForeverShine™ finishes installed in residential-use applications are warranted not to corrode, tarnish or discolor for the life of the product.

ForeverShine™ finishes installed in commercial use applications are warranted for a period of one-year from date of installation.

ELECTRONIC FAUCETS, FLUSHOMETERS AND METERING MECHANICALS WARRANTY - Are warranted for 5 years from the date of

installation.

ELECTRONIC FAUCETS FINISHES WARRANTY - Are warranted for one-year from the date of installation.

ELECTRONIC FAUCETS ELECTRONICS AND SOLENOID WARRANTY - Are warranted for 3 years from the date of installation.

PRESSURE ASSIST TOILET SYSTEMS - Are warranted for 5 years from date of installation (pressure vessel), limited lifetime for the carrier

plus a one-year warranty on toilet bowl and flush actuator plate.

Chicago Faucets will either replace or repair the defective equipment or refund the purchase price, at its option, if an inspection by Chicago

Faucets or its authorized representative discloses any manufacturing defects in material or workmanship during this period. These provisions

do not include the battery shipped with the Electronic Products. Chicago Faucets will not be liable for any labor or other expenses not specifically stated above and disclaim any responsibility for incidental or consequential damages.

Warranties implied by law, including that of merchantability are expressly limited to the period of this warranty. This limitation and exclusion

does not apply in those states that do not allow limitations on the duration of implied warranties. Or the exclusion may not apply to you. This

warranty gives you specific legal rights and you may have other rights, which vary, from state to state.

RETURNED GOODS - Merchandise may not be returned to the Company for credit unless the buyer obtains prior written approval from the

Company. Such approval will be granted only when material to be returned is a Standard or MTO product and is listed in the current price

sheets. Credit will be issued on all material returned by permission, at the prevailing price at time of purchase, less a handling charge of up to

35%. No credit whatever will be allowed on products designated as Custom (Custom products are products not designated as Standard or

MTO) which have been shipped according to customers' specification. Material, which is marred or damaged, will not be accepted. All transportation costs for returned goods must be paid by the buyer.

ORDER MODIFICATION/CANCELLATION - Orders for Standard and MTO products can be modified or cancelled up to the time the order is

being processed for shipment. A Chicago Faucets customer service representative must confirm the status of order to be cancelled or changed

in order to avoid any restocking fees or charges. Changes to the order can potentially extend the acknowledged availability date. Once

entered, Custom products are non-cancelable, and will be shipped and billed to the customer.

The Company reserves the right to make reasonable changes of any kind in its products and their packaging without notice.

MINIMUM CHARGE - No invoice will be made for less than $100.00 (One Hundred Dollars Net) on faucets, valves and fittings or repair parts.

NOTE: Possession of this price sheet by any person is not to be construed as an offer to sell him or anyone else, the goods listed herein at

prices stated.

Loading...

Loading...