Page 1

Page 2

This machine has been engineered to our own rigid safety and performance standards. It has been designed to comply with sanitation and health guideli nes recommended b y the Automatic Me rchandising Health-Industry Council (AMHIC) and i t

conform s w it h all o th e r NA MA sa f ety recommenda tions.

This machine has been manufactured in accordance with the safety standards o f both

Underwriter’s Laboratories and the Canadian Standards Association. To maintain this

degree of safety and to continue to achieve the level of performance built into this

machine, it is important that installatio n and maintenance be performed so as to not

alter the original co nstruction or wiring and that replacement par ts are as specified in

the P arts and Service Manual. Your investment in this equipment will be protected by

using this Operator’s Guide and the Parts and Service Manual in your operation, ser-

vice and maintenance work. By following pres cribed procedures, machine performance and safety will be preserved.

Page 3

EUROTWIN OPERATOR’S GUIDE

Table of Contents

Initial Set- up............ .... ... .... ................ ... .... .... .... ............... .... .... .... ............... .... ... .... .......1

Power Requirements................................................................................................. 1

Water Require m en ts .............. .... .... ... ................ ... .... .... ............... .... .... .... .... .............. 1

Water Pressure ..................................................................................................... 1

Supply Line Req ui re men ts. .... .... ............... .... ... .... ................ ... .... .... ............... .... ... 1

Flushing The Water Supply Line ........................................................................... 1

Positioning The Merchandiser .................................................................................. 2

Final Installation ........................................................................................................ 2

Connect The Merchandiser To The Water Supply............................................ 2

Connect The Merchandiser To The Power Source........................................... 2

Level The Merchandiser.................................................................................... 3

Set Up The Menu Assembly ......... ............... .... .... .... .... ............... .... .... ... ........... 4

Install Optio ns . ............... .... .... .... ............... .... .... ... .... ................ ... .... .... ............... .... ... 5

Install The Coi n Bo x Lock......... .... .... .... .... ............... .... .... ... ................ ... .... .... ... 5

Mount The Base Plate Brackets ....................................................................... 5

Mount The Base Plate And Slides .................................................................... 6

Install The Water Filter Cartridge ...................................................................... 7

Get The Machine Ready To Vend Drinks.................................................................. 8

Set Up The Co2 Tank ........ .... ... .... ............... .... .... .... ............... .... .... .... ... ........... 8

Fill The Hot Water Tank ................................................................................... 8

Load The Cup Mechanism................................................................................ 9

Load And Set Up Hot Drink Products............................................................. 10

Adjustments And Minor Maintenance......................................................................... 11

Emptying The Bi ll Stacke r...... .... ... .... .... ............... .... .... .... ............... .... .... ... .... ..... 11

Adjusting The Air Press ure C ont rol (Mo de l 63 9 Onl y). ....... ... .... .... .... ............... . 11

Cup Mechanism Adjustment .............................................................................. 12

Hot Water Valve Adju s tmen t...... ............... .... ... .... ................ ... .... .... ............... .... . 13

Cold Water Valve Adjustment............................................................................. 13

View A ................................................................................................................. 13

View B................................................................................................................. 13

Syrup Pump Adjus t ment............... .... .... .... .... ............... .... .... ... ................ ... .... .... . 14

Canister Installation ............................................................................................ 15

Programming .............................................................................................................. 16

How To Program Your Eurotwin......................................................................... 16

The Display s............... .... .... .... ............... .... .... ... ................ .... ... .... ............... .... .... . 17

The Function Ke ys . .... .... .... .... ............... .... .... ... ................ .... ... .... ............... .... .... . 17

Other Keys .......................................................................................................... 17

Control Panel Switch Functions Explained......................................................... 18

Programming Flowcharts.................................................................................... 19

Programming Procedures........................................................................................... 23

Gain Access To The Supervisor Mode ............................................................... 24

Enter A New Supervisor Code............................................................................ 24

Enter A New Freevend Code .............................................................................. 24

Lock Or Unlock Mode Or Payout Keys............................................................... 25

Set Printer Or Dex Options ................................................................................. 25

Lock Or Unlock Data Clearing Access ............................................................... 26

Assign A Code To View Data Without Opening The Door.................................. 26

Select Printer Baud Rate (Printer Mode Only) .................................................... 27

6390031 Page i July, 20 01

Page 4

EUROTWIN OPERATOR’S GUIDE

Select Bill Validator And Options........................................................................ 28

Select Card Reader And Options ....................................................................... 29

Select Coin Mechanism And Options................................................................. 30

Select Monetary Options.................................................................................... 31

Select Display Language .................................................................................... 32

Set Up Winner Mode .......................................................................................... 33

Set Up Mug Discount.......................................................................................... 34

Set Up Machine Configuration Options (Supervisor Mode Only) ....................... 34

Identify The Active Selections In The Merchandiser

(Supervisor Only)................................................................................................. 36

Set Up Cup Sizes................................................................................................ 36

Set Up A Hot Drink ............................................................................................. 38

Collecting Dry Product Gram Throws................................................................. 40

Collecting Hot Water Throws.............................................................................. 43

Set Up A Cold Drink............................................................................................ 45

Collecting Cold Water And Syrup Throws......................................................... 46

View Software Version ........................................................................................ 46

Set Hot And Cold Temperature .......................................................................... 47

Set The Automatic Brewer Rinse Time

(Brewer Equipped Machines Only) ..................................................................... 48

Set The Automatic Mixing Bowl Rinse Time....................................................... 49

Set The Time Of Day........................................................................................... 50

Set The Day Of The Week................................................................................... 50

Set Month, Day, And Year .................................................................................. 50

Set Time-of-day Inhibited Vending ..................................................................... 51

Set Time-of-day Free Vending............................................................................ 51

Set Time-of-day Discount Vending..................................................................... 51

Time Interval Editing ........................................................................................... 52

Select A Standby Message................................................................................. 54

Select An Out-of -ser vic e M ess ag e.......................... .... .... .... ............... .... ... .... ..... 54

Select A Freevend Message............................................................................... 55

Edit Custom Messages....................................................................................... 56

The End Of Message Character.......................................................................... 56

Entering Your Message....................................................................................... 57

View Water Tank And Cold Plate Temperature .................................................. 58

View Machine Configuration Setting................................................................... 58

Payout Coins....................................................................................................... 59

Set Prices............................................................................................................ 60

Set Entire Machine To One Price . . ................................................................... 60

Set The Price Of An Individual Selection . . . ...................................................... 60

Set All Cup Sizes To One Pri c e . . . .............. ... .... .... ............... .... .... .... .... ............ 60

Set All Sizes Of A Selection To One Price . . ..................................................... 61

View Nonresettable Sales And Vend Data.......................................................... 61

View Data Three Different Ways ......................................................................... 62

View Total Paid Sales ......................................................................................... 62

View Total Paid Vends........................................................................................ 62

Clear All Resettable Data.................................................................................... 63

Clear Paid Sales Data Only................................................................................. 63

View Amount In Coin Box (Not Shown If Zero)................................................... 63

View Amount In Validator (Not Shown If Zero).................................................... 64

View Freevend Sales By Time Interval (Not Shown If Zero)................................ 64

View Discount Sales By Time Interval................................................................. 64

6390031 Page ii July, 2001

Page 5

EUROTWIN OPERATOR’S GUIDE

View Free Vends (Not Shown If Zero)................................................................. 65

View Winners (Not Shown If Zero) ...................................................................... 65

View Time Data................................................................................................... 66

View Total Unpaid Sales..................................................................................... 67

View Total Unpaid Vends.................................................................................... 67

View Number Of Test Vends (Not Shown If Zero)............................................... 67

View Number Of Mug Vends (Not Shown If Zero) .............................................. 67

View Machine Id Number.................................................................................... 68

Test Vend Selections And Verify Credit Added.................................................. 68

Test The Display ................................................................................................. 68

Test Drop A Cup ................................................................................................. 69

Test The Whipper(s)............................................................................................ 69

Test The Air Compressor .................................................................................... 69

Test The Brewer.................................................................................................. 70

Rinse The Mixing Bowls...................................................................................... 70

Rinse The Brewer................................................................................................ 70

Purge The Carbonator ........................................................................................ 71

Clear Tank Errors And Fill The Tank ................................................................... 71

Test Switches Or Sensors .................................................................................. 71

View Diagnostic Messages................................................................................. 72

Download Da ta To A PDCD.............. .... .... .... ............... .... .... ... ................ ... .... .... . 74

Set Freevend Options ......................................................................................... 74

Cleaning And Sanitation ............................................................................................. 75

Basics ................................................................................................................. 75

Overall Clea ning.. ... .... .... ............... .... .... .... ............... .... .... .... ............... .... ... .... ..... 77

Preventive Maintenance Cleaning ...................................................................... 77

Cleaning Procedures .......................................................................................... 77

Sanitation Procedures ........................................................................................ 78

Appendix A. The Infrared Mug/cup Sensor ..............................................................A-1

Appendix B. Modify Canister To Vend 12 Oz. Cups.................................................B-1

Appendix C. Clean The Hot Water Tank.................................................................. C-1

Appendix D. The Free Vend Keyswitch Option.........................................................D-1

6390031 Page ii i July, 2001

Page 6

EUROTWIN OPERATOR’S GUIDE

NK

A

L

B

T

F

E

L

Y

L

L

NA

TIO

N

E

NT

I

IS

GE

A

P

S

HI

T

6390031 Page iv July, 20 01

Page 7

EUROTWIN OPERATOR’S GUIDE

INITIAL SET-UP

I. POWER REQUIREMENTS

This merchandiser requires power as shown in the following table. NOTE: Each merchandiser should have its own electrical circuit

Power Requirements

Country Volts Frequency (Hz) Current (Amps)

Canada 115 60 15

France 230 50 10

Germany 230 50 10

Unite d Kin g d om 230 50 10

United States 115 60 15

II. WATER REQUIREMENTS

The best type of water for coffee brewing is normal hard water. If your location has

chemically softened water, one of the following steps is advi sed:

• Have a non-softened su pply line run to the merchandiser

• Contact your loc al water filter supplier for informatio n and suggestions

Well wate r can also be used in the EuroTwin Machine. However, you should have it

checked for levels of carbonates and alkalies. Contact your water filter supplier if

these values are relatively high.

WA TER PRESSURE

• Minimum water pressure: 20 psi (138.0 KPa) at 1/2 gallon/minute

• Maximum water pressure: 80 psi (522.0 KPa) at 1/2 gallon/minute

SUPPLY LINE REQUIREMENTS

• Locate the supply line at the rear of the merchandiser.

• Equip the line with a shut-off valve.

FLUSHING THE WATER SUPPLY LINE

Flush the water supply line bef ore connecting it to t he merchandiser. A minimum of

five gallons is usually required before connecting the merchandiser to the supply line.

DO NOT flush the merchandiser water system to avoid introducing possible water line

contaminants into the merchandiser.

6390031 Page 1 July, 2001

Page 8

EUROTWIN OPERATOR ’S GUID E

III. POSITIONING THE MERCHANDISER

You can position this merchandiser anywhere in a bank of machines. It can even be

placed on the end flush against a side wall.

Leave enough room in front of the merchandiser for the door to move freely.

BE SURE THE REAR OF THE MERCHANDISER IS AT LEAST 6" AWAY FROM THE

WALL. THIS WILL ENSURE WARM MOIST AIR IS VENTED OUT OF THE

MACHINE’S INTERIOR AND THE REFRIGERATOR CONDENSER FAN IS NOT

OBSTRUCTED.

WARNING

THIS MACHINE IS ONLY RATED FOR INSTALLATI ON IN AN

INDOOR LOC ATION.

IV. FINAL I N S TALLATI O N

1. CONNECT THE MERCHANDISER TO THE WATER SUPPLY

a. You wil l need the following:

• A coil of copper tubin g with out side di ameter of 3/8 i nch (9.5 mm) o r greate r. The

appropriate plastic tubing may be substituted.

• A 3/8 inch (9.5 mm) flare fitting

b. Connect the merchandiser to your water supply.

2. CONNECT THE MERCHANDISER TO THE POWER SOURCE

Power to the merchandiser is controlled by the main power switch, located on the

power panel.

a. Make sure the main power switch is OFF.

b. Connect the merchandiserís power cord to your wall outlet.

July, 2001 Page 2 6390031

Page 9

EUROTWIN OPERATOR’S GUIDE

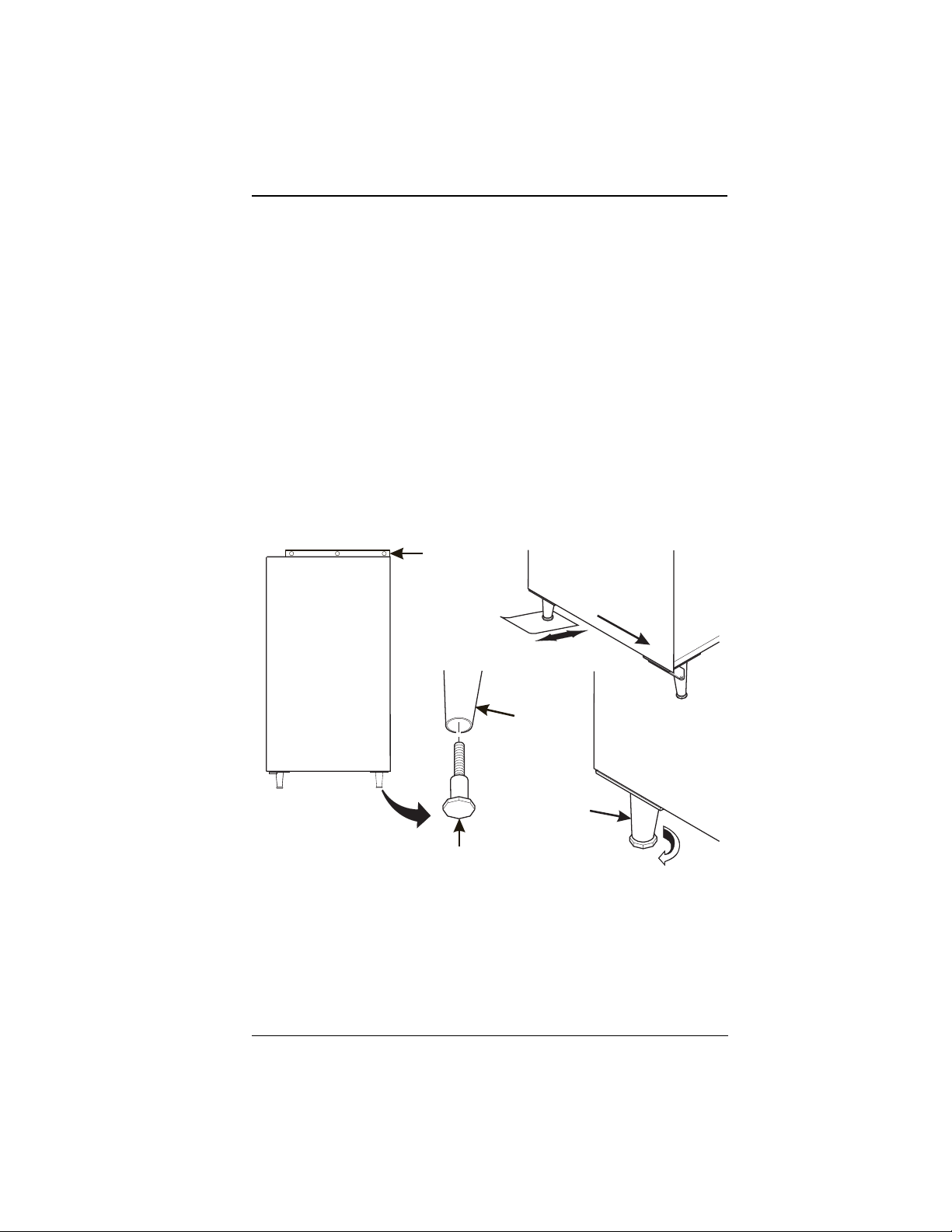

3. LEVEL THE MERCHANDISER

a. Place a spirit level on the top front edge of the cabinet with the door fully

closed. Adjust the fro nt legs only until the cabi net is reasonably lev el.

b. Hold the door open about 4 inches.

WARNING

HAVE AN ASSISTANT HOLD THE MERCHANDISER WHILE YOU

ADJUST THE LEG LEVELERS.

c. Adjust the back legs so that the back leg leveler on the hing e side is off the

floor just enough so a piece of paper can slide under it with only a bit of resi stance.

d. For proper weight distribution on all four legs, raise the back leg on the hinge

side by unscrewing the leveler 1¾ turns.

NOTE

You may need to use pliers or channel locks to loosen the leg levelers.

SPIRIT LEVEL

FRONT

LEG

LEFT REAR

LEG

LEG

LEVELER

1-1/2 TURNS

6390031 Page 3 July, 2001

Page 10

EUROTWIN OPERATOR ’S GUID E

4. SET UP THE MENU ASSEMBLY

a. From the inside of the door, remove the two screws as indicat ed, and remove

the end cap as shown.

b. Loosen the rema ining 10 screws as indicat ed 1/2 turn. Do not loosen the

screws any more than necessary to avoid stripping out the menu frame.

c. Remove the menu board. If it is still held too tightly, repeat step 6.

d. Set up the menu board as desired and reinstall it in the reve rse order of disas-

sembly.

REMOVE THE MENU BOARD

END CAP AND SLIDE OUT THE

MENU BOARD.

LOOSEN

THESE

REMOVE

THESE

SCREWS

SCREWS

LOOSEN

THESE

SCREWS

July, 2001 Page 4 6390031

Page 11

EUROTWIN OPERATOR’S GUIDE

V. INSTALL OPTIONS

1. INSTALL THE COIN BOX LOCK

a. Install the lock cylinder, washer , and nut in the order shown.

b. Tighten the nut.

c. Install the lock bar as shown, and secu re with the screw.

LOCK BAR

NUT

LOCK

CYLINDER

2. MOUNT THE BASE PLATE BR ACKETS

WASHER

SCREW

a. Secure a base plate bracket at each of the remai ning pair s of holes wit h two of

the hex head screws.

6390031 Page 5 July, 2001

Page 12

EUROTWIN OPERATOR ’S GUID E

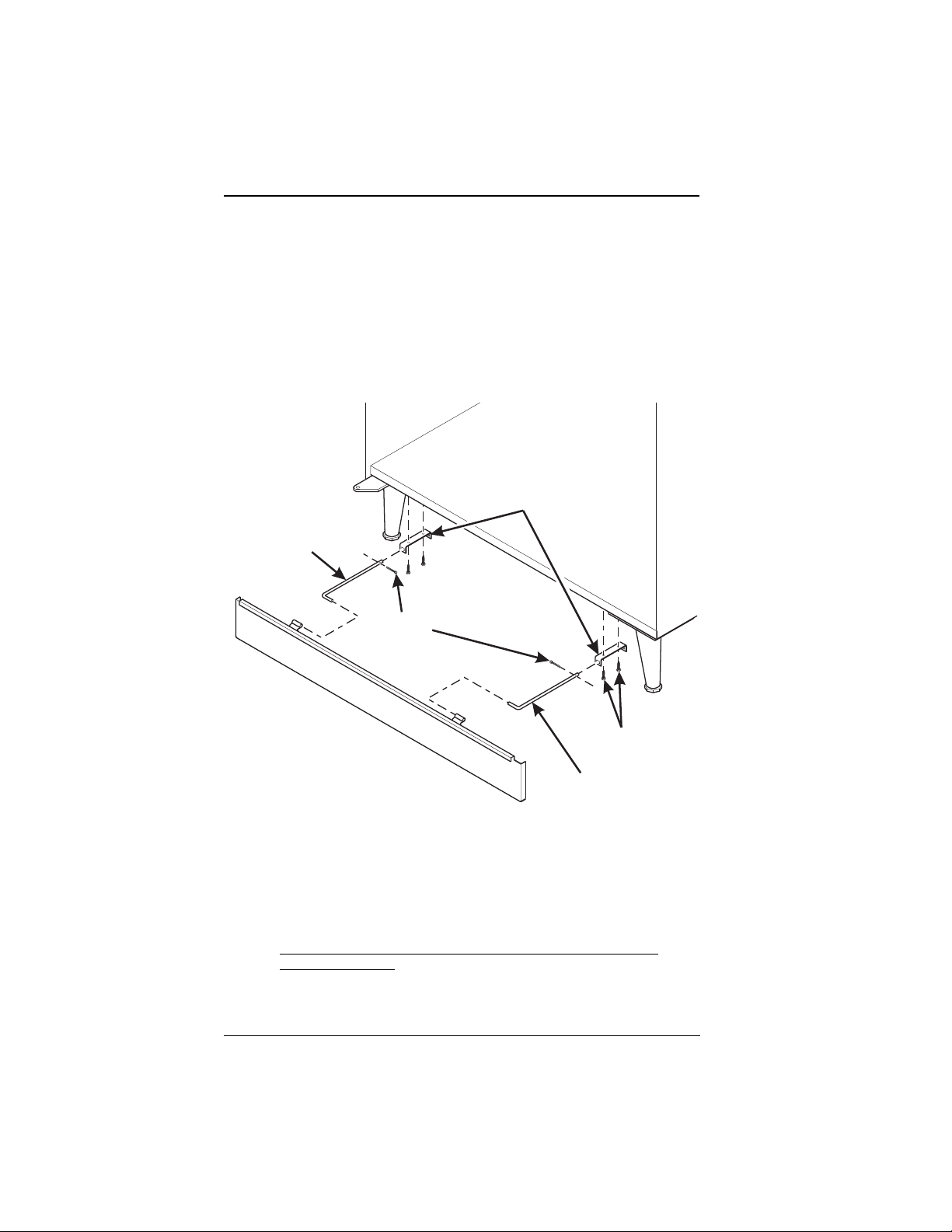

3. MOUNT THE BASE PLATE AND SLIDES

a. Insert the short arm of the slides into th e hinged tabs of the base plate. Posi-

tion the slide so the notch near the short arm is on the bottom side.

b. Insert the long arms of the slides into the base plate brackets.

c. Insert a cotter pin through th e hole in the back end of each slide. Secure the

pins in place.

d. Push the base plate towa rd the merchan diser cabinet. The front tab of the

base plate bracket should seat in the notch in the long arm of the slide.

BASE PLATE

MOUNTING

LEFT HAND

BASE PLATE

SLIDE

COTTER

PIN

BRACKET

HEX HEAD

SCREW

RIGHT HAND

BASE PLATE

SLIDE

CAUTION

The mounting brackets are subject to damage when moving the

machine with a fork lift.

Remove the brackets prior to moving the machine with a fork lift

to prevent damage.

July, 2001 Page 6 6390031

Page 13

EUROTWIN OPERATOR’S GUIDE

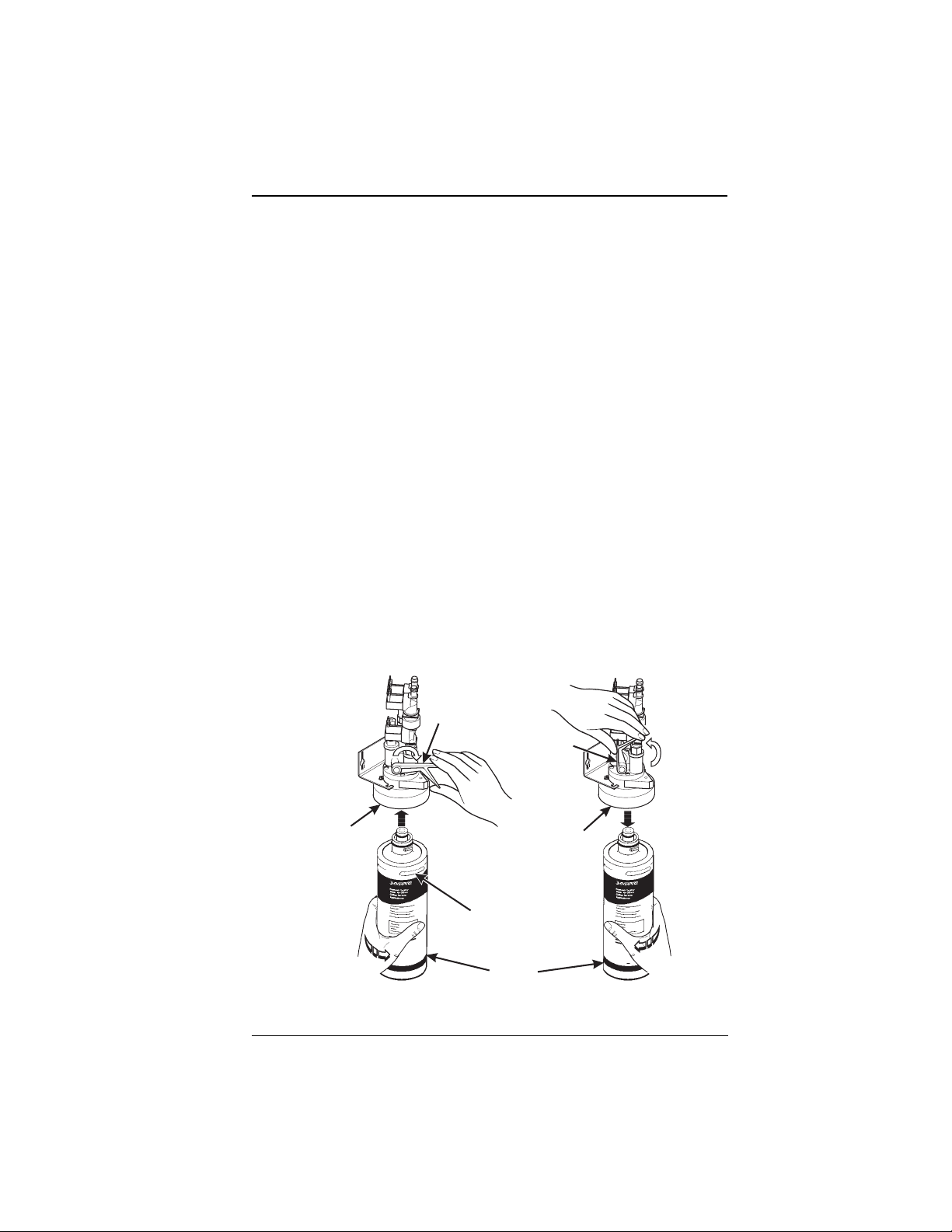

4. INSTALL THE WAT ER FILTER CARTRIDGE

IF YOUR M ERCHANDISER HAS THE WATER FILTER OPTION, IT

CANNOT BE OPERATED WITHOUT A PROPERLY INSTALLED

WATER FILTER CARTRIDGE.

NOTE

Check the water filter installation record. There is a place to write

the vend number on the cartridg e. The cartridge is effectiv e for a

maximum of 26,000 7 oz. vends, 22,000 8 oz. vends, 20,000 9 oz.

vends, or 15,000 12 oz. vends. Local conditions may require more

frequent replacement.

a. Yo ur filter cartridge is shi pped inside the waste pail. Locate it and remove the

wrapping.

b. Remove the liquid waste pail (if pr esent) to gain access to the wat er filter head

assembly, located at the right rear of the machine.

c. Install the filter as shown.

TO INSTALL FILTER:

1. ALIGN RAISED RIB ON

FILTER CARTRIDGE WITH

MATING SLOT IN HEAD

ASSEMBLY.

2. FIRMLY INSERT FILTER

CARTRIDGE INTO HEAD

ASSEMBLY AND ROTATE

COUNTER-CLOCKWISE

1/4 TURN TO THE STOP.

3. OPEN THE WATER SHUT-OFF

VALVE BY PUSHING THE

HANDLE TO THE HORIZONTICAL

POSITION AS SHOWN BELOW.

TO REMOVE FILTER:

1. CLOSE THE WA TER SHUT-OFF

VALVE BY LIFTING THE HANDLE

TO THE VERTICAL POSITION AS

SHOWN BELOW.

2. ROTATE THE FILTER

CLOCKWISE AND PULL

DOWN AS SHOWN.

WATER SHUT-OFF

VALVE HANDLE

WATER SHUT-OFF

VALVE HANDLE

RIB

EVERPURE

FILTER

CARTRIDGE

EVERPURE

FILTER HEAD

ASSEMBLY

4

H

EVERPURE

FILTER HEAD

ASSEMBLY

RAISED

4

H

6390031 Page 7 July, 2001

Page 14

EUROTWIN OPERATOR ’S GUID E

VI. GET THE MACHINE READY TO VEND DRINKS

1. SET UP TH E CO2 TANK

a. Place the power switch in the OFF position.

b. Inst all a full CO

c. Remove the CO

d. Locate the CO

plastic washer (in plastic bag).

e. Insert the tapered washer into the fl ar e nut of the CO

unit.

f. Using two wrenches, tighten the line to the regulator.

g. Insert the flat washer into the regulator nut.

h. Using two wrenches, connect the regulator to the tank outlet and tig hten in

place.

Not using a wrench on the tank side may damage the CO2 tank,

resulting in personal injury.

tank on the floor area in front of the cooling unit.

2

tank lid.

2

regulator and flat plastic washer (in a box), and the tapered

2

line connected to the

2

WARNING:

i. Open CO

j. Adjust the CO

k. Lock the adjustment screw in place.

l. Remove the cooling machine cover and actuate the pressure relief valve

located on top of the carbonator tank for 3 to 5 seconds.

m. Check for gas leaks along the CO

2. FILL THE HOT WATER TANK

If you hav e th e wa ter fil ter op ti on an d HAVE NOT yet instal led th e wa ter f il ter, retu rn to

step 7 and install the filter as instructed.

a. Turn on the water at its source.

b. Check for any water leaks.

c. Turn the machine po wer switch ON. The carbonator pump will start automati-

cally and will fill the car bonator with water.

d. Press .

e. Press until the display shows

f. Press again and let water flow into the tank.

g. The display will show

show

tank valve.

2

regulator so that the secondary gauge reads 5.50 bar (80 PSI).

2

TANK.FILL.

line.

2

TANK. FILL.

FILLING TANK. After the tank is filled the display will

July, 2001 Page 8 6390031

Page 15

EUROTWIN OPERATOR’S GUIDE

NOTE

The tank will take some time to fill and reach its operating temperature.

h. If this is the first time that the tank is being filled, perform the tank cleaning pro-

cedure given in Appendix C.

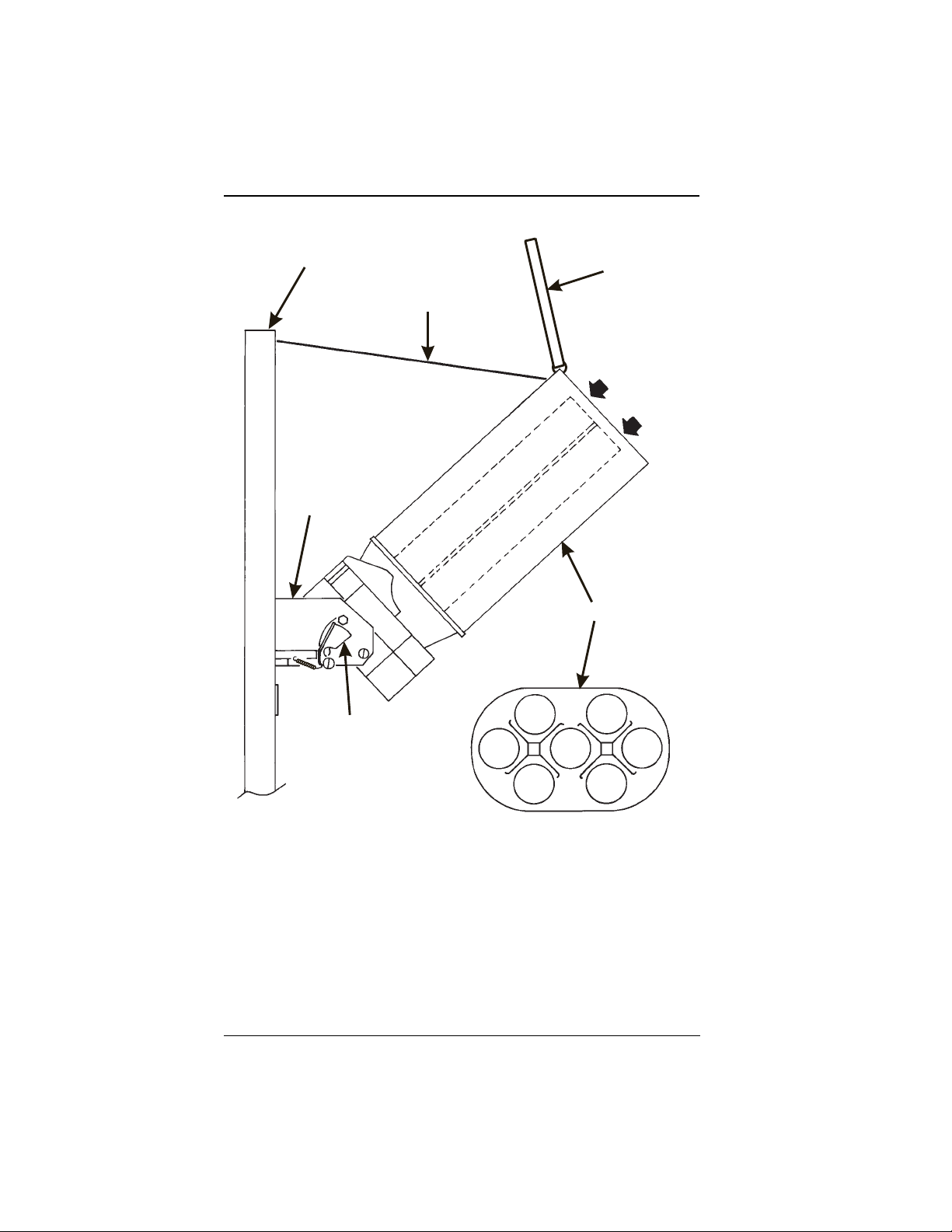

3. LOAD THE CUP MECHANISM

CAUTION

Use only cups which have be en designed for use in a hot beverage

vending machine.

The size of cup you load must agree with the cup size that you will select during programming.

a. Support the cup mechanism in the upright position.

b. Push the la tch forw ard to r elease the cu p mechan ism. Contin ue to su pport the

cup mechanism while you lower it into the loading positi on.

c. Remove the turret cover.

OBSERVE PROPER HYGIENE - DO NOT TOUCH THE CUPS!

d. Open the bottom of the wrapper on a stack of cups.

e. Insert the wrapped cups into the turret and pull the wrapper out.

DO NOT FILL CUPS ABOVE THE LEVEL MARKED ON THE OUT-

SIDE OF TH E CU P TURRETS OR AB O V E TH E “F I LL LINE”

LABEL INSIDE EACH TURR ET, OR MOTOR JAMS WILL OCCUR.

USE ONLY THE SAME SIZE AND BRAND OF HOT DRINK CUPS

IN EACH TURRET; DO NOT INTERMIX!

f. Replace the turret cover after the turrets have been loaded.

g. Be sure the cup mechanism is locked into the upright position.

TURRET DESIGNATIONS

CUP STACK ROTATION

DOOR

1B 1A

CUP

MECHANISM

TOP VIEW

6390031 Page 9 July, 2001

Page 16

EUROTWIN OPERATOR ’S GUID E

CABINET

DOOR

RETAINING

STRAP

CUP MECH

MOUNTING

BRACKET

LID

LOAD CUPS

HERE

CUP TURRET

LATCH

CUPS

TOP VIEW

4. LOAD AND SET UP HOT DRINK PRODUCTS

a. Fill each canister with its res pective product .

b. Once the hot water tank has reached its operating temperature, perform test

vends (see COLL ECTING DRY PRODUCT GRAM THROWS and CO LLECT-

ING HOT WA TER THROWS). Adjustments may be necessary to water, prod-

uct, or condiment throw times, or to the hot water valves. Refer to the

appropriate sections in this manual for instructions on how to do this.

July, 2001 Page 10 6390031

Page 17

EUROTWIN OPERATOR’S GUIDE

ADJUSTMENTS AND MINOR MAINTENANCE

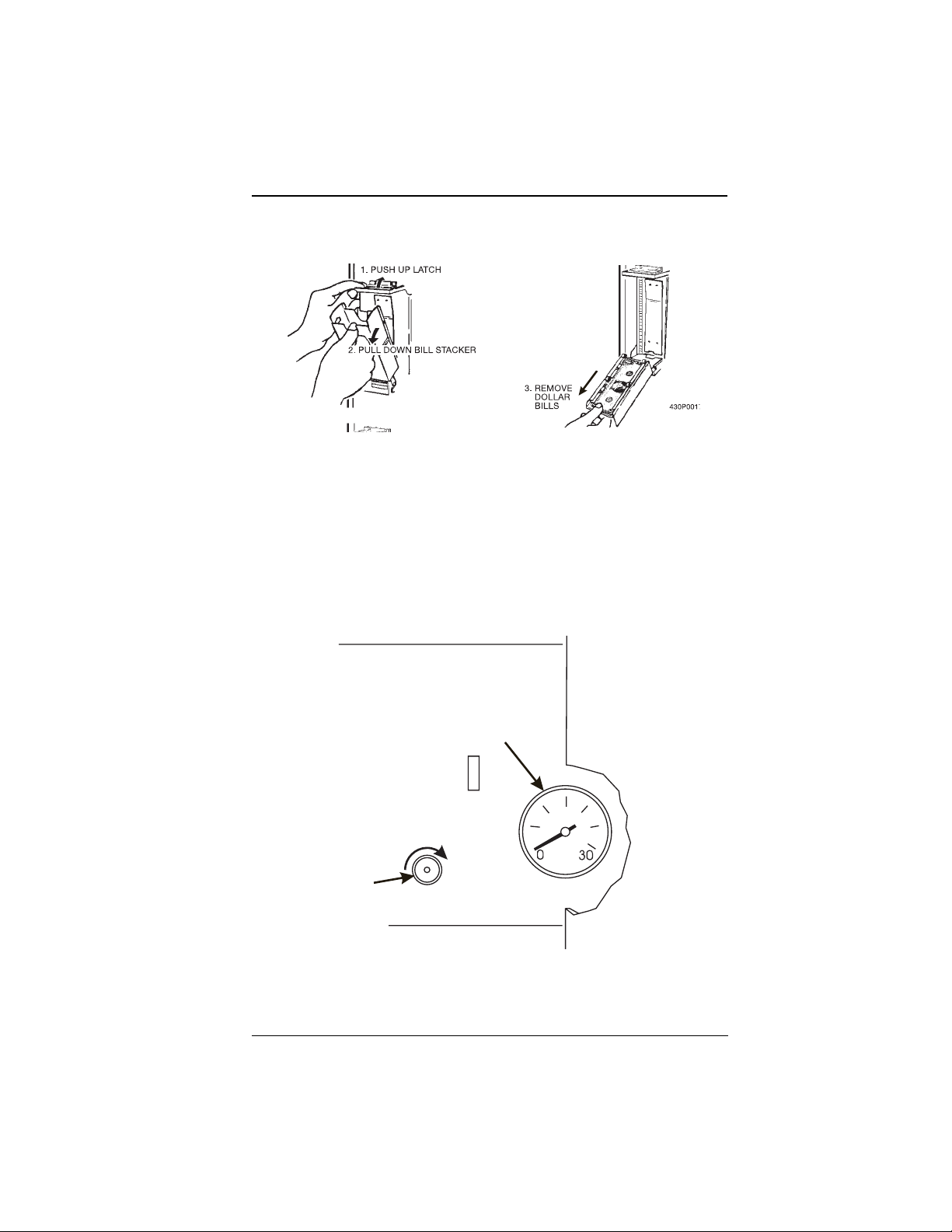

EMPTYING THE BILL STACKER

ADJUSTING THE AIR PRESSURE CONTROL (MODEL 639 ONLY).

This control determines the system pressure prov ided by the air compressor. Adjust

the pressure as follows:

a. With the compressor running, pinch the brewer inlet air tube.

b. Adjust the pressure to read 1 0 - 12 psi on the gauge.

This will produce a pressu re of 3 - 6 psi using regul ar coffee and 8º oz cups . No further air pressure adjustments should be necessar y.

PRESSURE

ADJUST

CONTROL

PRESSURE

GAUGE (AIR)

INCREASE

INGREDIENTS SHELF

MONETARY

PANEL

AIR PRESSURE CONTROLS

6390031 Page 11 July, 2001

Page 18

EUROTWIN OPERATOR ’S GUID E

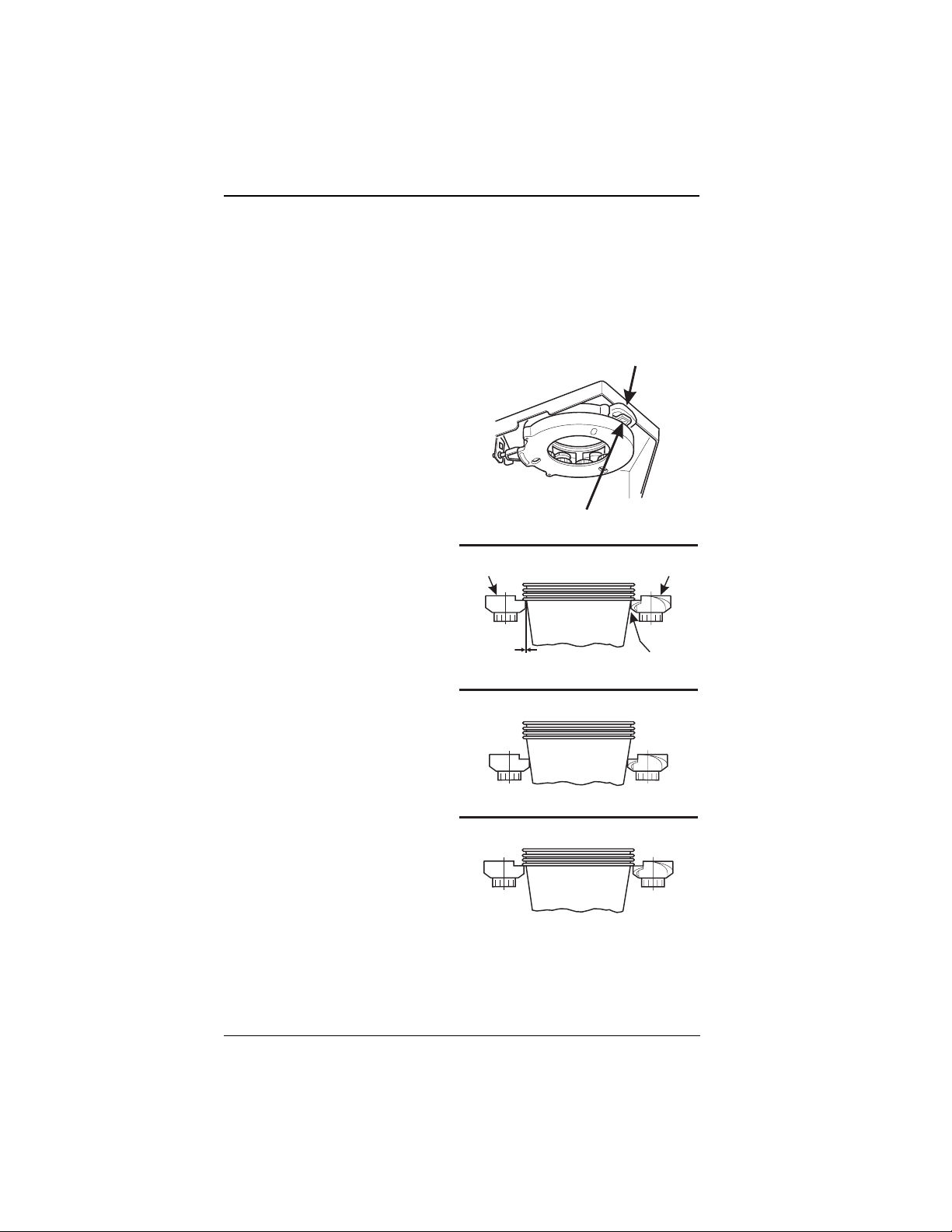

CUP MECHANISM ADJUSTMENT

1. Pl ac e se v en cu p s in the cup ring.

2. Observe the clearance as shown in view B.

3. If necessary adjust by f irst loosening the adjust men t ar m screw (view A).

4. Move adjustment arm until correct clearance is achieved.

5. Hold adjustment arm in place and tighten adjustment arm screw.

ADJUSTMENT

ARM

VIEW A

LOOSEN SCREW

MOVE ARM

CUP

CAM

CORRECT

VIEW B

This clearance is just

large enough to allow

ADJUSTMENT

cup ejection

This side is snug

against cam

CUP

CAM

ADJUSTED

TOO TIGHT

ADJUSTED

TOO LOOSE

316P0118

July, 2001 Page 12 6390031

Page 19

EUROTWIN OPERATOR’S GUIDE

HOT WATER VALVE ADJUSTMENT

The hot water valves do not u sually require adjustment, but in some cas es adequate

water volume cannot be achieved by the throw time setting alone (see the programming section). IF ABSOLUTELY NECESSAR Y, adjust the valves in conjunction with

setting the fac tory default timers.

1. Using a slotted scr ewdriver, turn the adjustment screw cl ockwise t o decre ase the

water flow rate.

2. Turn the adjustment screw counterclockwise to increase the water flow rate.

WATER

TANK

WATER VALVE

ADJUSTMENT

SCREW

123456

WATER

+

6

-

WATER

VALVE

COLD WATER VALVE ADJUSTME NT

Cold water valves do not us ually require adjustment, but in cert ain cases adequate

water volume cannot be achieved by adjusting the throw time setting alone (see the

programming section). IF ABSOLUTELY NECESSARY, ADJUST THE VALVES IN

CONJUNCTION WITH SETTING THE TIMERS.

1. Turn the carbonated water adjustment screw counterclockwise (CCW) until it

stops in the fully open position. Do not force it to stop the flow because it is not

a positive closure system.

2. Turn it clockwise (CW) 3 full turns.

3. Turn the non-carbonated water adjustment screw CCW until it stops. Do not

force it to stop the flow because it is not a positive closur e system.

4. Turn it back clockwise (CW) 1 full turn.

6390031 Page 13 July, 2001

Page 20

EUROTWIN OPERATOR ’S GUID E

CARBONATED

WATER VALVE

NON-CARBONATED

WATER VALVE

ADJUSTMENT

SCREW

SYRUP PUMP ADJUSTMENT

The syrup pumps do not usually require a d justment, but in some cases adeq ua te volume cannot be achieved by the thro w time setting alone (see the prog ramming section). IF ABSOLUTELY NECESSARY, ADJUST THE VALVES IN CONJUNCTION WITH

SETTING THE FACTORY DEFAULT TIMERS.

1. Loosen the locknut on the syrup pump adjustment screw.

2. T urn the screw clockwise (CW) until it is flush with the upper face of the locknut.

3. T urn the screw counterclockwise (CCW) 3 full turns.

4. Tighten the locknut to secure the screw.

5. Repeat steps 1 through 4 for the other syrup valve.

July, 2001 Page 14 6390031

Page 21

EUROTWIN OPERATOR’S GUIDE

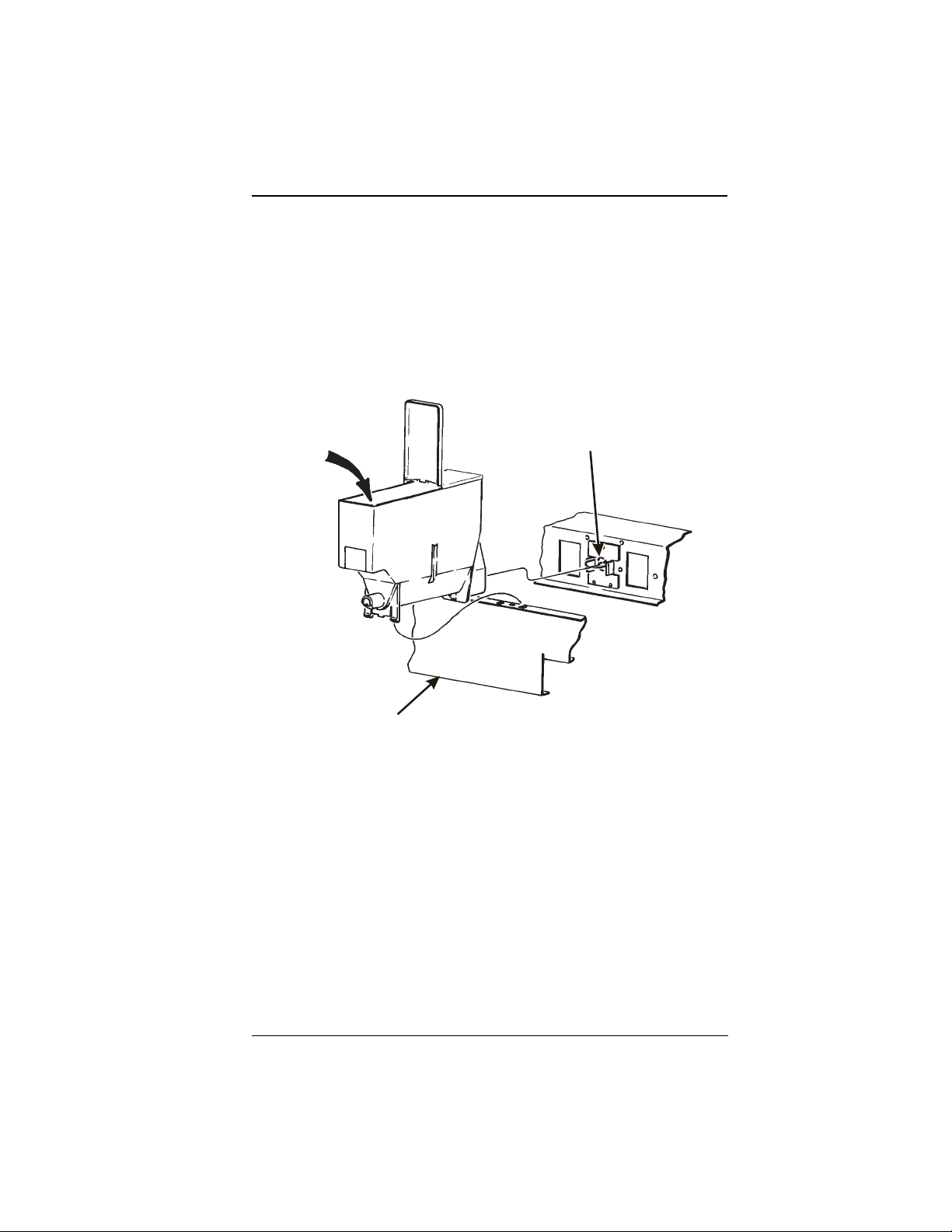

CANISTER INSTALLATION

1. Place the canister in position as shown.

2. Engage the pins on the motor shaft with the slo ts in the canister coupler.

3. Fit tabs on caniste r into t he slots on the canister shelf.

4. To ensure canister is correctly engaged with the rear moun ting bracket, gently

push down on the front edge of the canister lid.

PINS ON MOTOR

PINS ON MOTOR

SHAFT MUST ENGAGE

SHAFT MUST ENGAGE

SLOTS IN CANISTER

SLOTS

IN CANISTER

COUPLER

FILL

FILL

CANISTER

CANISTER

COUPLER

626P0017

CANISTER

CANISTER

SHELF

SHELF

6390031 Page 15 July, 2001

Page 22

EUROTWIN OPERATOR ’S GUID E

PROGRAMMING

HOW TO PROGRAM YOUR EUROTWIN

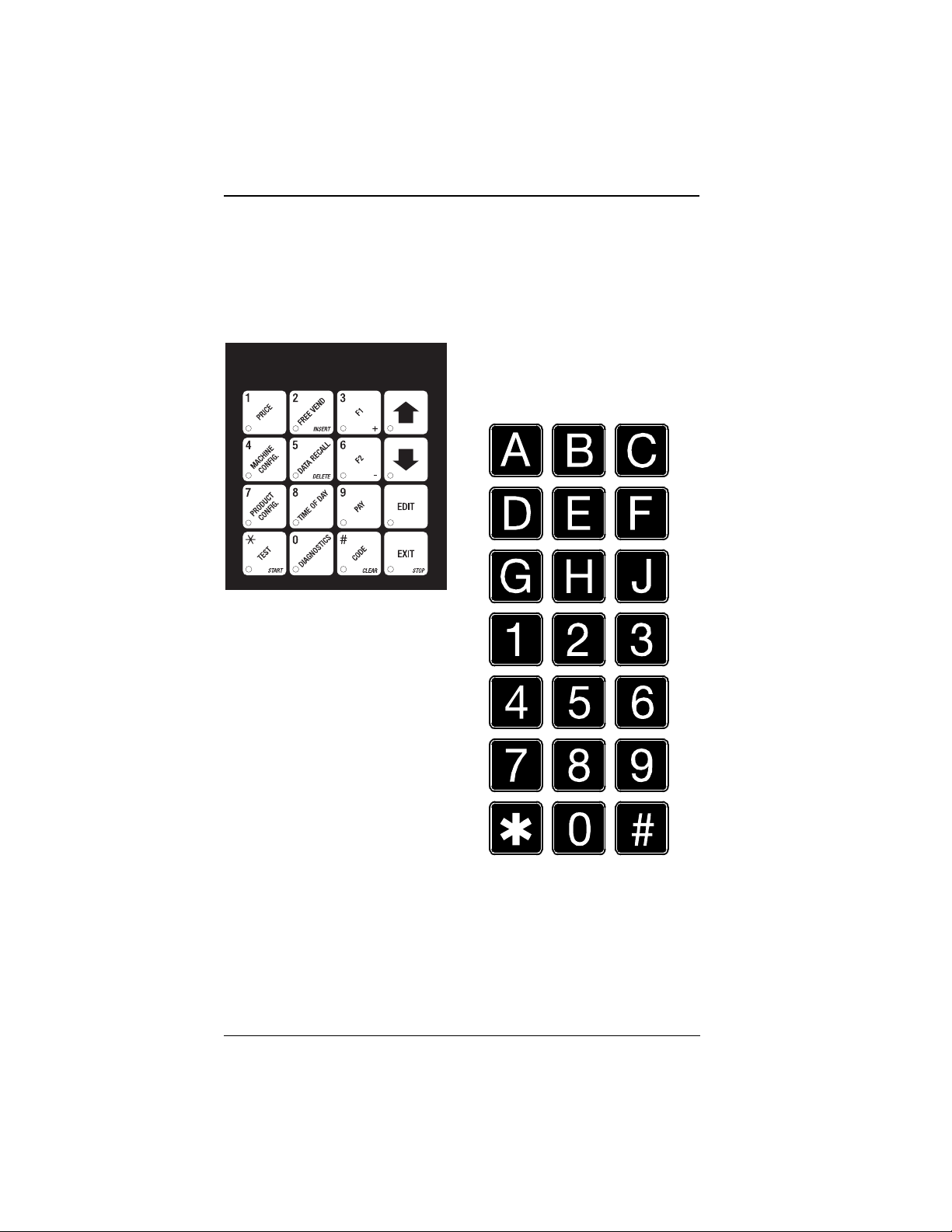

Some setup, test, and maintenance operations are computer controlled. The control

panel switches (see fi gure 1) and the selection panel switches (see figure 2) regulate

these oper a tio ns .

Figure 1. Contro l Pane l

157p0 248

Figure 2. Selec ti on Pa ne l

July, 2001 Page 16 6390031

Page 23

EUROTWIN OPERATOR’S GUIDE

THE DISPLAYS

The 10-character display performs two functions, and is referred to in this book as

"the display":

1. It shows the customer’s selection and how much credit is in the machine, as well

as the ready, service, and time of day messages.

2. It provides infor mation and feedback to the servi ce person during mainten ance.

X

I

8

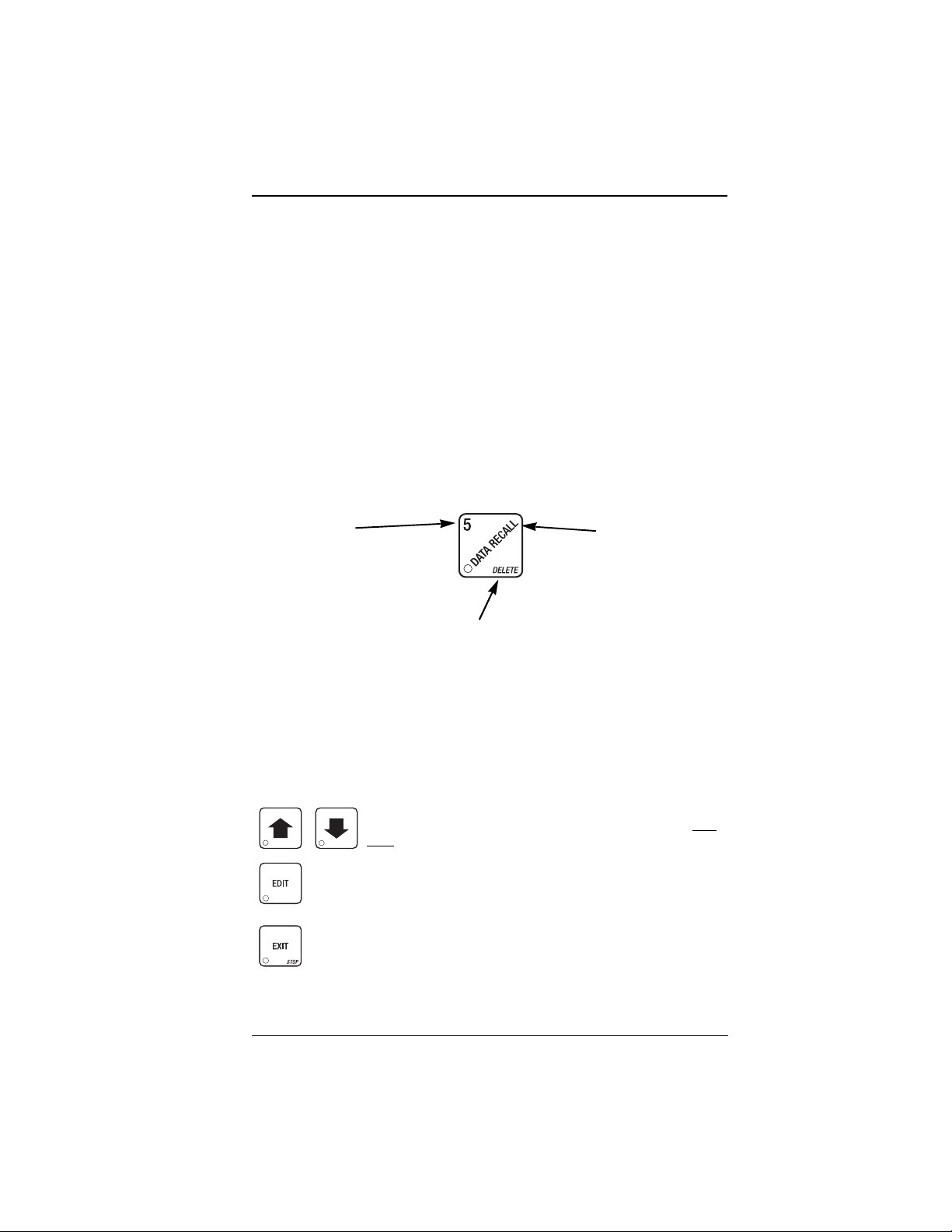

THE FUNCTION KEYS

The keys on the control panel can be used for up to three things:

THE NUMBER

YOU MIGHT BE ASKED TO ENTER A

NUMERICAL

THIS

OTHER KEYS

The MOVEMENT keys on the co ntrol pane l let you mov e inside a m ode, and b ack and

forth between modes. To see how these keys let you move aro und, stud y the flow

diagram on the next page.

VALUE

.

KEY WILL ENTER A

This is your "activate" or "choose" key. It "opens a door" to additional information and let s you begin a programming task once you are inside of a

mode. Sometimes, it is used as a toggle swi tch to show you your ch oices

during a programming task.

This is your "end" key. Pressing it one or more times will move you back to

the start of the mode, or all the way back to the standby message.

PRESSING

"5".

THE SECONDARY PURPOSE

THIS IS THE KEY’S "SECOND JOB

FOR EXAMPLE, THIS KEY CAN BE USED

DELETE A CHARACTER WHEN YOU

TO

ARE

EDITING CUSTOM MESSAGES

The up and down arrow ke ys are your "leg s" , which let you move

up and down the list of tasks. These keys are what let you continue from one step to the next in prog ramming procedures.

THIS IS THE MAIN JOB OF THE KEY

THE

YOU

IN THIS EXAMPLE, YOU CAN VIEW STORED

SALES

".

.

THE PRIMARY PURPOSE

.

STANDBY MESSAGE, IT WILL ALLOW

TO

ENTER A PROGRAMMING MODE

DATA

.

FROM

.

6390031 Page 17 July, 2001

Page 24

EUROTWIN OPERATOR ’S GUID E

CONTROL PANEL SWITCH FUNCTIONS EXPLAINED

Each of the control panel switches has one or more jobs to do. This lis t will give you a

short overview of those jobs..

Press this button to put your machine into the Price Setting mode. You

can see maximum and minimum machin e pr ices, and change prices for

entire machine or in dividual selection.

Press this button to set up how the Free Vend mode will operat e.

Press this button to view the water tank and cold plate temperatures, software version number, machine configuratio n, and active selection stat us.

Press this button to:

• Select display language

• Select coin mechanism and

options

Press this button to view total sales and vends by whole machine, selection, or drink size. Clear resettable data.

Press this button to:

• Download data into your portable data collection device (PDCD), OR

• Set printer baud rate, depending upon which device you are using

Press this butto n to:

• Set machine configuration

• Set up drinks

• Set which selections are act ive

Press this button to:

• Set time of day

• Set day, month, year

• Set up tim e of day intervals for

inhibit, freevend, and discount

vending

Press this button to pay one or more coins from the coin mechanism.

• Select bill validator and o ptions

• Set winner feature

• Set cup size

• Select sanitation and rinse times

• Set ta nk temper ature

• Select display messag e s

• Edit messages

Allow s yo u to se e an y fau lt or condition that has place d the mac h ine out of

service

Press this butto n to:

• Perform TEST VENDS

• Test machine functions

Press this butto n to:

• Enter the SUPERVISOR mode

• Change the SUPERVISOR access code

• Lock and unlock access to functions

July, 2001 Page 18 6390031

• Tes t display s

• Fill the water tank

Page 25

EUROTWIN OPERATOR’S GUIDE

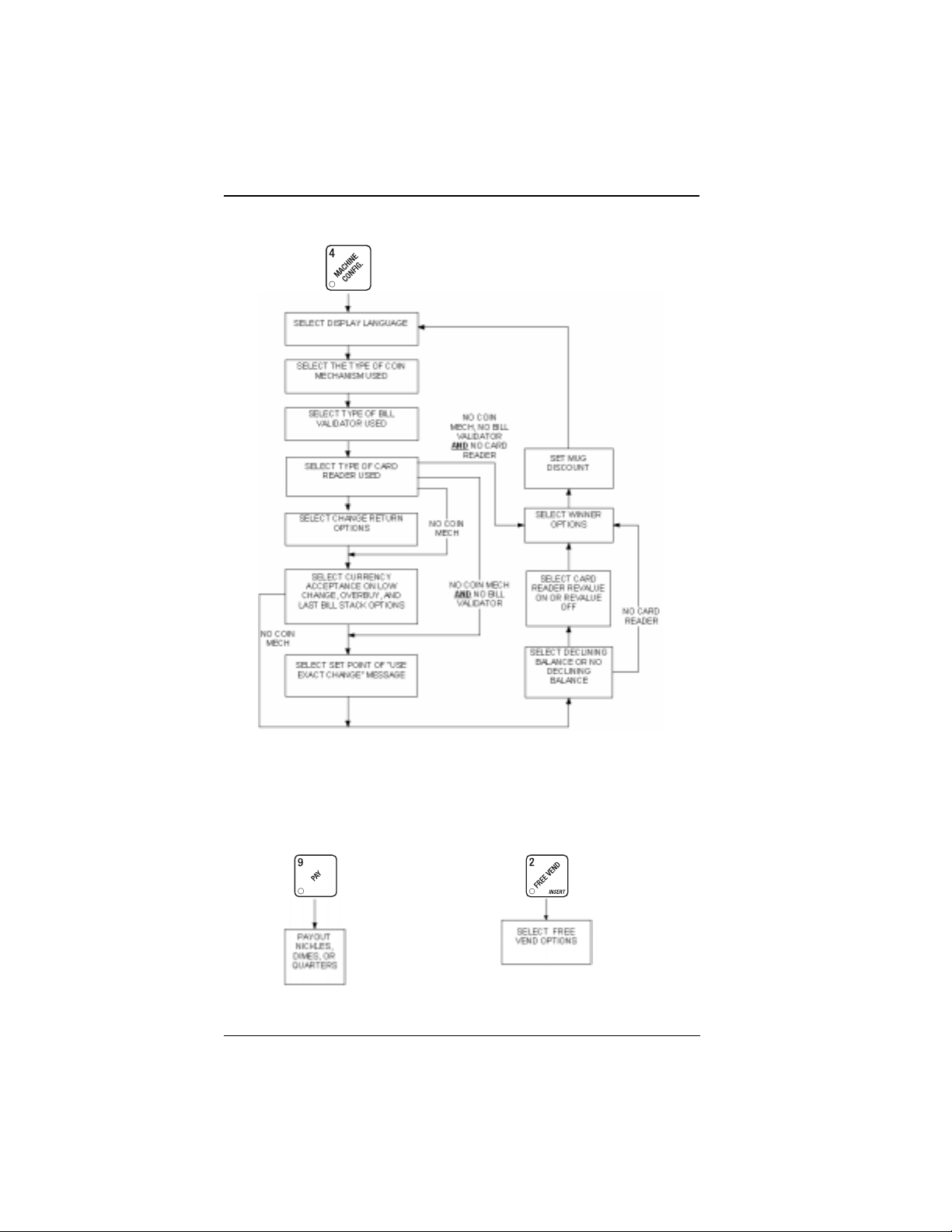

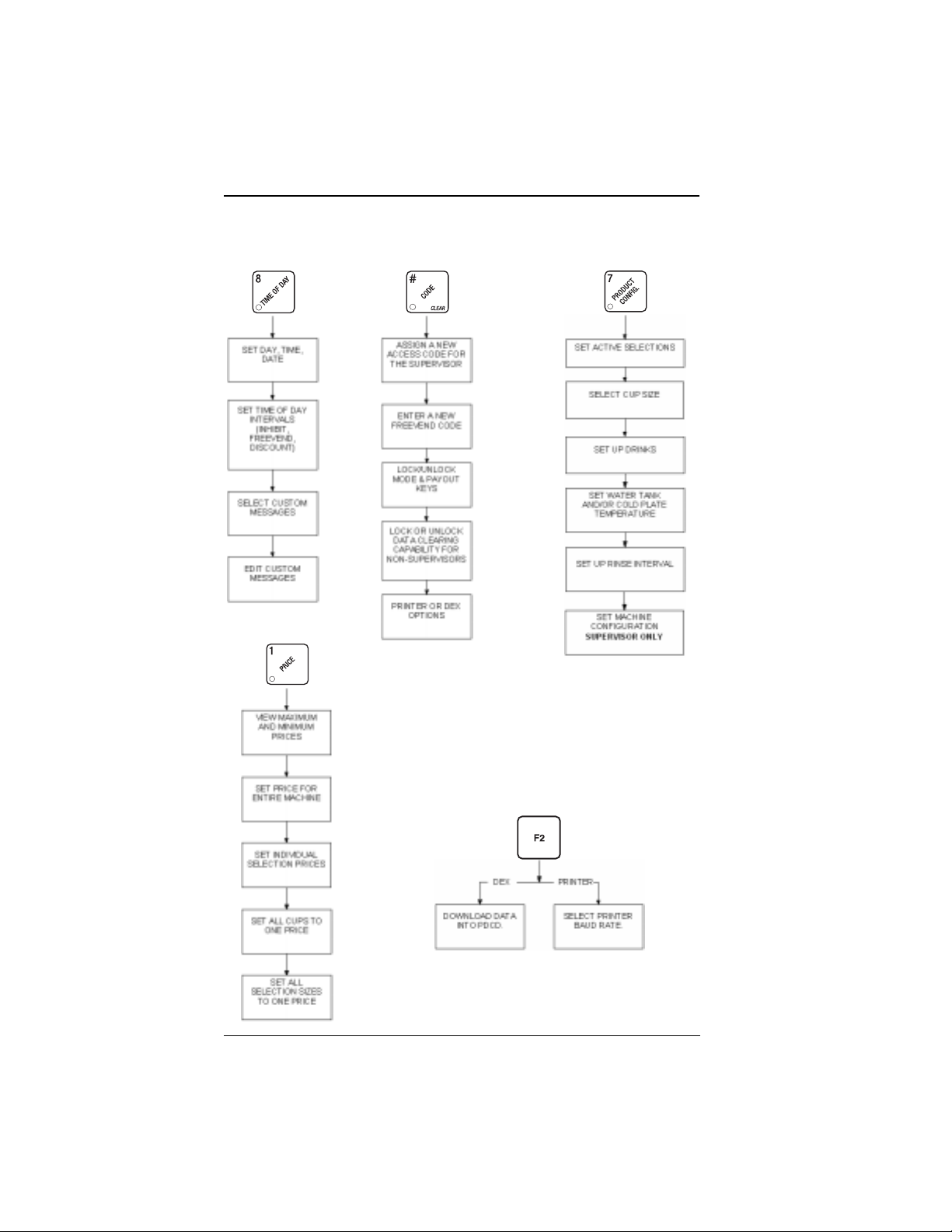

PROGRAMMING FLOWCHARTS

The flowcharts on the following pages will provide you with a "map" to the different

programming features of your machi ne. Once yo u are familiar with the detailed programming steps given later in this section, you can use the flowcharts as a shortcut.

Each chart begins with the key you will use to access those st eps. Follow the lines

and arrows fr o m one step to another. A rectangular box contains the functions or

tasks you will perf orm at that point. Sometimes, you have to make a deci sion. For

example, look at the MACHINE CONFIGURATION chart. At one point, you are asked

to select your monetary options (coin mech, bill validator, etc.). Depending upon your

choice, you wi ll take a different pat h. Note that if you have no mech, no validator, and

no card reader, you bypass a whole lot of other options and are tak e n right to the winner selection screen. Just follow the lines and arrows, and you will get through it.

6390031 Page 19 July, 2001

Page 26

EUROTWIN OPERATOR ’S GUID E

Payout Coins

PAGE 59

Machine Configuration

PAGE 32

PAGE 30

PAG E 28

PAGE 29

PAGE 30

PAGE 31

PAGE 30

PAGE 30

PAGE 30

PAGE 29

PAGE 31

Free Vend

PAGE 74

July, 2001 Page 20 6390031

Page 27

EUROTWIN OPERATOR’S GUIDE

Tests Misc.

PAGE 68

PAGE 68

PAGE 69

PAGE 69

PAGE 69

PAGE 70

View

Diagnostics

PAGE 70

PAGE 70

PAGE 71

PAGE 71

PAGE 71

PAGE 58

PAG E 46

PAGE 58

View and/or

Clear Data

PAGE 61 THRU PAGE 67

PAGE 63

PAGE 63

PAGE 68

PAGE 72

6390031 Page 21 July, 2001

Page 28

EUROTWIN OPERATOR ’S GUID E

Time of Day Supervisor Functions Product Configuration

PAGE 50

PAGE 51

PAGE 55

PAG E 56

Pricing

PAGE 60

PAGE 60

PAGE 24

PAGE 24

PAGE 25

PAGE 26

PAGE 25

PAGE 36

PAGE 36

PAGE 38

PAGE 47

PAGE 48

PAG E 34

DEX/Printer

PAG E 60

PAGE 60

PAGE 60

PAGE 74

PAGE 27

July, 2001 Page 22 6390031

Page 29

EUROTWIN OPERATOR’S GUIDE

PROGRAMMING PROCEDURES

The pages that follow contain all the programming steps you will need for the EuroTwin merchandiser. Each procedure is presented so that it "stands alone". This means

that you can look up a procedure , go dir ectly to it, perform the pr ocedur e, quit the pr ocedure then go on about your business.

However, after looking at the pro g ramming flowcharts, you should notice that several

procedures are grouped under each mode key (such as ), and you can move

between them by u sing t he up and do wn a rrow keys. Th erefore, you don’t have to exit

a procedure befo re performing another one.

Most procedures respond to you t he same way, li ke how to enter, leave, and move

around inside them. Her e is a short guide to help you thro ugh t hese common steps:

• To move directly from one procedure to another (pro vided they are both grouped

under the same mode key), use and .

• When you are finished with a function, you will want to CONTINUE. To do that,

you can press (you may have to press it more than once, depending on

how far into a p rocedu re you ar e). You can then perf orm anoth er prog ramming o r

maintenance f unction. If you are completely done with maintenance, just shut

the merchandiser door.

• Text that looks like this:

the monetary panel.

• Definitions and helpful information will appear in shadow boxes:

6390031 Page 23 July, 2001

DISPLAY represents what you will see in the display on

Page 30

EUROTWIN OPERATOR ’S GUID E

GAIN ACCESS TO THE SUPERVISOR MODE

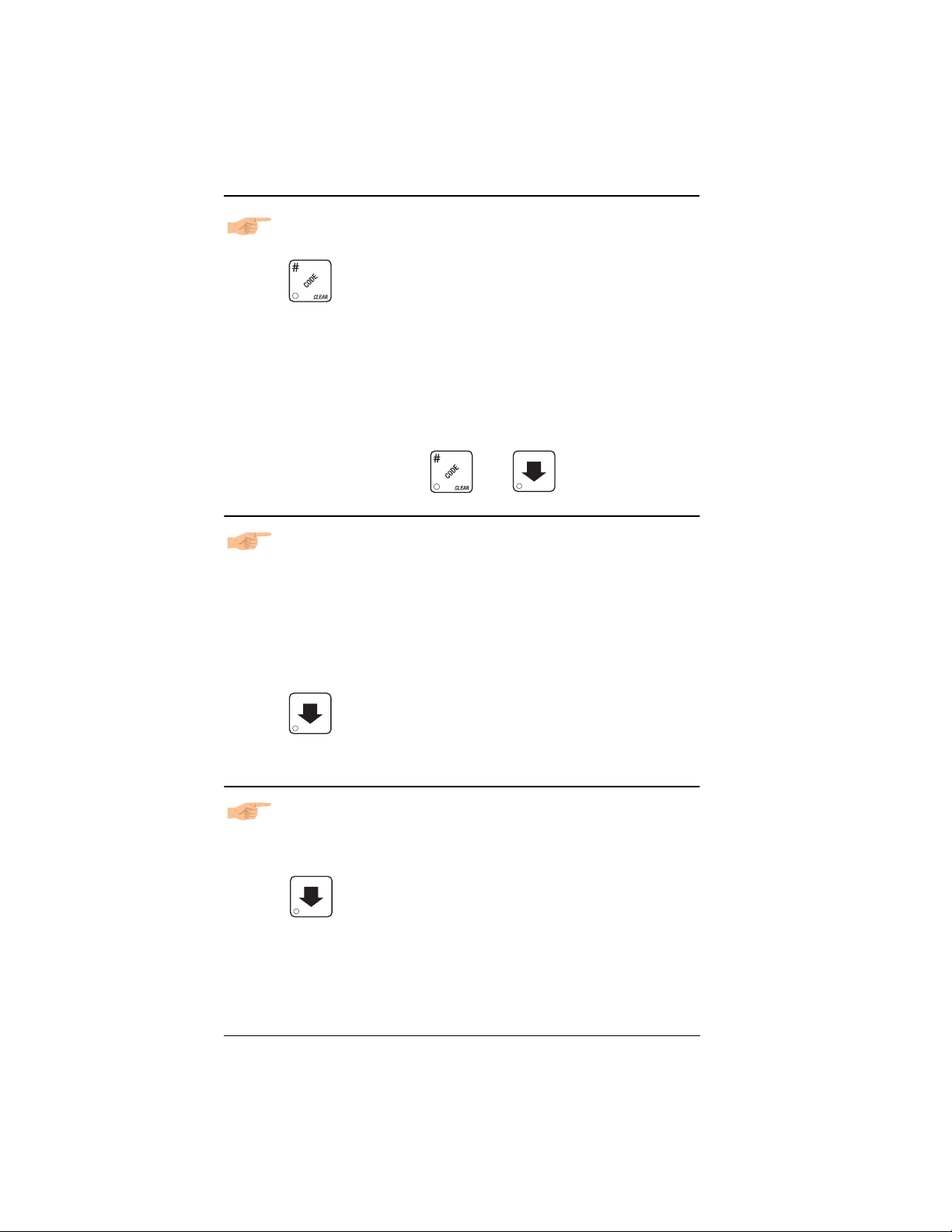

1. Press . The displ ay sh ow s: ENTER CODE. You must enter the four-digit

supervisor code within 6 seconds to gain access.

NOTE

A new machine has a factory-set super visor code of 0000.

When you have entered the right code, you will hear two beeps and see

UNLOCKED in th e di s pl a y. After a few m om e n ts , th e

standby message returns.

2. At the standby message , press , then . You are now ready to

perform various supervisor functions.

ENTER A NEW SUPERVISOR CODE

1. If you a lr ead y ent er e d you r sup er viso r co de, skip to st ep 3. If n ot, foll ow th e ste ps

in GAIN ACCESS TO SUPERVISOR MODE, then return here.

IMPORTANT

If you enter a new code, be sure t o keep a written record of it. Ther e

is no other way to access the SUPERVISOR mode.

3. Press until the di splay sho ws

rent superviso r code. Use the number keys to enter a new code.

2. CONTINUE.

SUPER XXXX. The X’s r epresent the cur-

ENTER A NEW FREEVEND CODE

1. If you a lr ead y ent er e d you r sup er viso r co de, skip to st ep 4. If n ot, foll ow th e ste ps

in GAIN ACCESS TO SUPERVISOR MODE, then return here.

4. Press until the display shows

rent freevend code. U s e the nu mber keys to enter a new code.

See Appendix D for more inform ation on the freevend keyswi tch.

2. CONTINUE.

July, 2001 Page 24 6390031

FREE XXXX. The X’s represent the cur-

NOTE

Page 31

EUROTWIN OPERATOR’S GUIDE

LOCK OR UNLOCK MODE OR PAYOUT KEYS

1. If you a lr ead y ent er e d you r sup er viso r co de, skip to st ep 1. If n ot, foll ow th e ste ps

in GAIN ACCESS TO SUPERVISOR MODE, then return here.

1. Pre ss until the d isp la y show s eit her

refers to the number or character shown on the mode or payou t key in question

(1 through 9, # and *). To see if a key is locked or unlocked, press that key.

2. Press to change between locked and unlocked. When anyone other

than the supervisor t ries to enter a locked mode, the display shows

NOTE

The following mode keys cannot be locked out:

2. CONTINUE.

X. LOCKED or X. UNLOCKED. "X"

LOCKED.

SET PRI N TE R OR DEX OPTIONS

1. If you a lr ead y ent er e d you r sup er viso r co de, skip to st ep 3. If n ot, foll ow th e ste ps

in GAIN ACCESS TO SUPERVISOR MODE, then return here.

3. Press until the dis p la y shows one of the foll o wing:

PRINTER means that data will be se nt di rectly to a printer,

OR

DEX ONLY means that data remains i n me mory after it is downloaded into a por-

table data collection devi ce,

OR

DEX +C LR means that reset table data is cleared after it is downloaded into a por-

table data collection devi ce.

4. Press to switch between the three choices.

2. CONTINUE.

6390031 Page 25 July, 2001

Page 32

EUROTWIN OPERATOR ’S GUID E

LOCK OR UNLOCK DATA CLEARING ACCESS

1. If you a lr ead y ent er e d you r sup er viso r co de, skip to st ep 2. If n ot, foll ow th e ste ps

in GAIN ACCESS TO SUPERVISOR MODE, then return here.

1. Press until the displ ay shows either

LOCKED means that non-supervisors cannot clea r reset table machi ne sale s and

vend d ata from the key.

2. Press to switch between

#. LOCKED and #. UNLOCKED.

#. LOCKED or #. UNLOCKED.

NOTE

The supervisor can cl ear da ta r egard less of th is set ting, pr o vided t he

supervisor code was cor rectly entered first.

2. CONTINUE.

ASSIGN A CODE TO VIEW DATA WITHOUT OPENING

THE DOOR

If the prop er code is entered, s a les and vend data can be viewed without opening the

machine’s door.

1. Follow the steps in GAIN ACCESS TO THE SUPERVISOR MODE.

2. Press until the displ ay shows

rently entered code. Use the number keys to enter a new code, if desired.

NR XXXX. The X's repr esent the cur-

3. CONTINUE.

July, 2001 Page 26 6390031

Page 33

EUROTWIN OPERATOR’S GUIDE

SELECT PRINTER BAUD RATE (PRINTER MODE

ONLY)

BAUD

RATE

1. Press . One of the following is displayed:

The speed of data transfer, expressed in bytes per

second. Your printer can r ecei ve data at a cert ain rat e,

and you must tell the machine what that rate is.

BAUD 1200 BA UD 2400 BAUD 48 00 BAUD 9600

1. Press until the correct baud rate for your printer is displayed.

2. CONTINUE.

6390031 Page 27 July, 2001

Page 34

EUROTWIN OPERATOR ’S GUID E

SELECT BILL VALIDATOR AND OPTIONS

1. Press , then press until one of th e fo ll o win g is di sp la y ed :

NO DBV

SER.1.2.5.10.20

MDB.1.2.5.10.20

MDB. <*>

No bills will be accepted or there is no bill validator

installed (you can exit the function).

The serial bill validator is selected and will accept $1, $2,

$5, $10, and $20 bills. Use BILL SELECTION METHOD

below to change the bills which will be accepted.

A standard MDB bill validator is selected. It will accept $1,

$2, $5, $10 and $20 bills. Use BILL SELECTION

METHOD below to change the bills which will be

accepted.

An MDB bill validator which accepts non- standar d bill s or

tokens is connected and o perating. Press to

enter list of bills. (See INITIAL SETUP OF NON-STAN-

DARD BILL VALIDATOR on the following page.)

BILL LIST OPERATION:

Use and to scroll through the list of

bills.

Use to turn the bill acceptance ON or OFF.

Use to move up to the top level screen.

1. 1.00 ON - 1. = Bill validator channel 1, each bill

has its o wn ch a nnel

1.00 = Bill value

ON = $1.00 bill will be accepted

1. 1.00 OFF - OFF = $1.00 bill will not be accept ed

TKN - Token bills (same as coupon bills)

July, 2001 Page 28 6390031

Page 35

EUROTWIN OPERATOR’S GUIDE

INITIAL SETUP OF NON-STANDARD BILL VALIDATOR:

Connect the bill validator, select MDB in the bill validator

selecti on scr eens . The stan dar d

will appear first. Exit the bill validator setup by pressing

. Bill information is now collected from the valida-

tor. Re-enter the bill validator selection screen an d the

non-standard sc r e en "

MDB. <*>" will appear.

MDB.1.2.5.10.20 sc reen

PULSE DBV

Press to choose the desired option.

2. CONTINUE.

The pulse bill validator will accept $1 bills.

SELECT CARD READER AND OPTIONS

1. Press , then press until the current card reader is shown in the

display. Press to choose the desired card reader.

2. CONTINUE.YOUR CHOICES ARE:

If you selected NO CARD you can exit the function.

1. Press until one of the following is displayed:

NO CARD, DUMB CARD, OR MDB CARD.

NOTE

REVALUE.ON - Allows credit to be transferred onto the car d

REVALUE.OFF - Credit cannot be transferred to the card

Press to display t he desired choice.

3. CONTINUE.

6390031 Page 29 July, 2001

Page 36

EUROTWIN OPERATOR ’S GUID E

SELECT COIN MECHANISM AND OPTIONS

1. Press , then press until the current COIN MECHANISM is

shown in the display. Press to choose the desired coin mechanism.

Your choices are:

2. Press until the display shows CHANGE X.X X.

Coins and bills which are less than or equal to this value will be returned without

Examples:

DUMB MECH, MDB MECH, EXEC MECH, or NO MECH.

a purchase being made.

CHANGE 0 .00 - Forced vend; NO change returned without a purchase.

CHANGE .25 - Nickels, dimes, and quarters returned without purchase.

CHANGE 1 .00 - $1 bills and SBAs wi ll be returned as change without pur-

chase. Nickels, dimes, and quarters are also returned.

3. Press until the display shows:

LOW.MSG X.XX. The display will show

USE EXACT CHANGE when the amount of available change in the coin mecha-

nism falls below the value of "X.XX". Enter a value with the number keys. For

example, if

displayed when less than a dollar’s worth of change is in the coin mechanism.

4. CONTINUE.

LOW.MSG 1.00 is displayed, the USE EXACT CHANGE message is

July, 2001 Page 30 6390031

Page 37

EUROTWIN OPERATOR’S GUIDE

SELECT MONETARY OPTIONS

This function lets you:

• Set declining balance,

• Set currency acceptance on low change,

• Set overbuy options,

• Set last bill stacking options

DECLINING

BALANCE

1. Press , then press until one of th e fo ll o win g is di sp la y ed :

Once credit is established, multiple ven d s may

occur until the coin return is pressed.

DECLINE.ON - More than one vend is allowed, with a declining balance.

OR

DECLINE.OFF - A declining balance is not allowed.

Press to display the desired choice.

1. Press until one of the following is displayed:

ACC <$$ X.XX - The last bill which meets or exceeds maximum price will

be held in escrow.

OR

ACC.ST K X.XX - The last bill whic h meets or exceeds maximum price and

MDB coupon bills (token bills) will be immediately

stacked.

Example: If setting is

This setting will immediately stack the second $1.0 0 bill

inserted.

Press to display the desired choice.

ACC.STK 1.00 and maximum price is $1.50.

The value of "X.XX" has two purposes:

a. The value of "X.XX" tells the machine how big a bill or coin to accept even

though there is not enough change in the coin mech to cover all possible

paybacks.

• For example, enter 1.00. Therefore, the ma chine will take a dollar bill or coin

even though there is less than $1.00's worth of change. Entering 5.00 tells the

machine to take a five even though ther e is less than $5.00's worth of change,

and so forth.

NOTE: This could cause a customer to be short-changed.

6390031 Page 31 July, 2001

Page 38

EUROTWIN OPERATOR ’S GUID E

• Entering 0.00 means that bills or coin s w ill only be accepted if there is enough

change to cover them.

b. The value of "X.XX" tells the machine how much the customer is allowed to

overbuy a product. The customer will be sh ort-ch anged when an overbuy

occurs.

Example:

For a value of $0.25: if ther e is no change in the machine and the customer

insers a $1.00 bil l. The cust o mer can purchase a product for $0.75 even though

the change cannot be paid back. The customer will be short-chan ged. Normally

a purchase will not be approved unless all change can be paid.

Entering 0.00 means that the vend will only be approved when the correct change

can be returned (overbuy disabled).

2. CONTINUE.

SELECT DISPLAY LANGUAGE

1. Press . The current LANGUAGE is shown in the display. Press

to choose the desired language. Your choices are:

ENGLISH, DEUTSCH,

FRANCAIS, ESPANOL, PORT UGUES, NEDERLANDS, or SWEDISH.

2. CONTINUE.

July, 2001 Page 32 6390031

Page 39

EUROTWIN OPERATOR’S GUIDE

SET UP WINNER MODE

WINNER

1. Press , then press until one of th e fo ll o win g is di sp la y ed :

At preselected intervals, a customer may receive

a refund for a selection. You can select the intervals and qualifying selectio ns.

WINNER OFF Winner function is disabled.

OR

WIN XXX Winners are allowed at certain intervals, represented by "XXX" .

Press to display the desired choice.

If you selected

1. The display shows

occur per each winner vend . For example, an inte rval number of 50 means that a

winne r can happ en any one time during the next 50 vends. Using the number

keys, enter an interval number between 10 and 9999.

2. Press . The display shows

represent which selections are allowed winn ers. Press the appr o priate letter key

to enable a sel ection, press the key again to disable it. For example, pressing A,

C, and E will cause the display to look like this: A - C - E - - - -_, meaning that all

A, C, and E selections can have a winner.

WINNER OFF, you can exit the function.

WIN XXX. XXX repres ents the number of vends which must

b

- - - - - - - - - . The dashes in the display

ADVANCED OPTIONS:

• Press to enable all selections.

• Press to deactivate all selections.

• Press 0 or 1 to enable winners by cup size.

AN EXAMPLE . . .

You want to enable winners on all selections except E and F. Do the following:

a. Press . The letters A through J appear in the display instead of the dashes.

b. Press "E" and "F". The letters E and F in the display are replaced by dashes.

2. CONTINUE.

6390031 Page 33 July, 2001

Page 40

EUROTWIN OPERATOR ’S GUID E

SET UP MUG DISCOUNT

You can establish a discount for customers who use thei r own mug.

1. Press , then press until the display shows

example shows the exis ting discount amount is zero .

1. Enter a discount amount. This will be in cents, fo r exam ple pres s or 5 to

enter a discount amount of 5 cents.

2. CONTINUE.

MUG DSC .00. This

SET UP MACHINE CONFIGURATION OPTIONS

(SUPERVISOR MODE ONLY)

1. Press then until the display shows D- J- WXYZ.

• "D" is the current status of the automatic deliver y door. A dash (-) means the

automatic door is turned off; a plus sign (+) means the door is turned on. Press

to turn the door ON OR OFF.

• "J" is the curr ent st atus of th e whipper s. A pl us sign (+) means drinks w ill not be

whipp ed unles s the J key is pressed during the vend. A dash (-) means drin ks

always be w hippe d unl ess th e J key is pr essed duri ng the v end. P res s J to

WILL

switch back and forth between these two choices.

• "WXYZ" is the machine conf iguration code, explained as follows:

Machine Type Configuration

Enter for (W) Definition

1 Reserved for alternate use

2 EuroT win

Soup and Sugar Substitute Configuration

Enter for (X) Definition

1 Canister 5 is no t used

2 Canister 5 contains sugar substitute

3 Canister 5 contains soup

4 Canister 5 contains topping mi x

July, 2001 Page 34 6390031

Page 41

EUROTWIN OPERATOR’S GUIDE

::

SINGLE

BREW

DUAL

A machine with only one brewed selection (the

second selection is fre eze-dried).

A machine with two brewed selections.

BREW

Brewer Configuration

Enter for (Y) Definition

1 Single brew - coffee or leaf tea (Model 639)

2 Dual brew - Coffee and decaf coffee (Model 639)

3 Freeze dry only - no brewer (Mo del 631)

Canister Mapping (See figure below)

Menu Selection Letters for Canister Numbers

Enter for (Z)

3 (single condi-

ment only)

21

1FBA

2FAB

3BFA

4BAF

5AFB

6ABF

INDEX: A = Coffee B = Decaf F = Tea

CUP FOR TAKING

CUP FOR TAKING

WATER THROWS

WATER THROWS

CUP DELIVERY

CUP DELIVERY

STATION

STATION

639P0080

6390031 Page 35 July, 2001

Page 42

EUROTWIN OPERATOR ’S GUID E

IDENTIFY THE ACTIVE SELECTIONS IN THE MERCHA NDISE R (S UPERV I S O R O N LY)

1. Press , then press until the display shows something like this:

0. AB CDEFGH. This display means that all regular size selections (0A - 0H) are

available for vend ing. An unavailable selection has its letter rep laced by a blank

space.

1. Press the appropriate letter to toggle the display on or off.

2. Press to display cold selections for this size (

3. Press to view the active selections for the large size cup.

0. - - -5689).

NOTE

Unconfigured selections will not appear in the product setups o r

diagnostics.

2. CONTINUE.

SET UP CUP SIZES

This machine is capable of vending two dif fer en t drink sizes, even though ther e is only

one size cup loaded. For example, if you have 10 ounce cups in your machine, you

can vend any two available drink sizes UP TO AND INCLUDING 10 ounces. Make

sure that the cups yo u have loaded are physical ly larger than the selected sizes.

1. Press then until the display shows

rently selected drink size for the r eg ular drink, and "Y" is the currently selected

drink size for the large drink.

4. Press until t he desired regular drink size is displayed; press

until the desired large drink size is displayed.

X. Y. OZ. "X" is the cur-

July, 2001 Page 36 6390031

Page 43

EUROTWIN OPERATOR’S GUIDE

5. Any changes made to the cup sizes must be "locked in". There are two ways to

do this :

a. If you are keeping some cup sizes the same, or putting the same cups in dif-

ferent cup rings, press and hold . The display momentarily shows

CLEAR-

ING, two beeps sound, then shows FINISHED. This will reassign the old

throw times to the new cup size, if poss ible.

b. If you are loading all different size cups, or want to load all new default times,

press and hold . The displ ay momentarily sho ws

sound, then shows

all cup sizes, clearing any custom th row times you have established. (See

the ta bles on the following pages for the factory default times.)

2. CONTINUE.

FINISHED. This will reload the factory default times for

CLEARING, two beeps

6390031 Page 37 July, 2001

Page 44

EUROTWIN OPERATOR ’S GUID E

SET UP A HOT DRINK

Be sure th at t he cu p size s yo u se t in SE T UP CU P SI Z ES agree with the cup sizes

actually in your machi ne. All procedures for setting up the hot drinks are similar, so

this example will demonst rate how to set up the A selection, regul ar size fresh brew

coffee.

1. Press then until the display shows

represents the selection (A, B, etc.). The dash (

selection.

1. Press A. (If you were setting up the A selection for the large size drink, you would

press 1 first, then A.) The display shows

rently set water throw time for the A selection is 8.25 seconds. Enter a new time

if desir e d.

2. Press . The display shows

set dry product throw time for the A selection is .60 seconds. Enter a new time if

desired.

3. Pressing after each displa y will cause the following screen s to appear:

WAT. A 8.25 . This means that the cur-

DRY. A .60. This means that the currently

SETUP -

-) represents the size of the

B

. The star (B)

DRY. A+ View and change the settings for an extra strong drink

SUG. A View and change the settings for the sugar throw time

SUG. A + View and chan ge the settings for extra sugar throw time

LIT. A View and change the settings for the lightener throw time

LIT. A+ View and change the settings for extra lightener throw time

SUB. A View and change the settings for the sugar substitut e throw

time

SUB. A + View and change the settings for extra sugar substitute throw

time

STP. A View and change the stee p time

STP. A+ View and change the stee p time for an extra strong drink

AIR. A View and change the air compressor running time

July, 2001 Page 38 6390031

Page 45

EUROTWIN OPERATOR’S GUIDE

WHP. A XXX Press to view and ch ange the whipper settings as fol-

lows:

ON- The last 3 seconds of the drink is always whipped

ON+ The whole drink is always whipped

OFF The drink is never whipped

• If J + is selected (see VIEW MACHINE OPTIONS):

OPT- The last 3 seconds of the drink is whipped only when the J key

is pressed

OPT+ The whole drink is whipped only when the J key is pressed

• If J - is selected (see VIEW MACHINE OPTIONS):

OPT- The last 3 seconds of the drink is whipped unless the J key is

OPT+ The whole drink is whipped unless the J key is pressed

Some selections will not sh ow all of t hese it ems. Fo r example, the C

selection has only the water throw time displayed. The E selection

will have some addit ional selections:

pressed

DIFFERENCES:

WA.2 E View and set the water throw time for the cappuccino second

product (chocolate)

DR.2 E View and set the chocola te throw time for cappuccino

OPTIONS:

a. At any of the preceding displays, you can press to test throw that

item.

b. At any of the preceding displays, you can press

switch pa ne l) to ste p thr ou gh a list of that item’s throw tim es for other selection s where th at item is active. For example, pr essing # at the

play will show the throw time for

one selection to another without going to the

WAT. B. This is a handy way to move from

NOTE

If you try to set up a selection that is not configured, the SETUP

screen will remain in the display.

2. CONTINUE.

b

or # (on the selection

SETUP screen first.

Collecting Dry Pr oduct Gram Throws

WAT. A dis-

6390031 Page 39 July, 2001

Page 46

EUROTWIN OPERATOR ’S GUID E

COLLECTING DRY PRODUCT GRAM THROWS

Measuring the gram throw allows you to get the right amount of dry product or condiment into your hot drink. To do this, you need a container to catch the product throw

and an accurate gram scale to measure its weight.

1. Make a measuring container by cutting down a pape r cup until it fits under the

canister spout as shown.

1. Weigh the measuring cup and zero th e gram scale accordingly.

2. Make 5 test throws as instructed in the programming steps.

3. Weigh each test thro w, then add all 5 weights together and div ide by 5 to get an

average weight.

4. If necessary, a dju st the throw t im e and repeat steps 3 and 4 unti l you get the correct produ ct or condiment weight.

Tables D1 and D2 show the factory default settings for the various dry products sold

by the merchandiser. They are good starting points for you to use in setting up your

machine. In the end, the amount of dry product or condi men ts you use in your drinks

depends upon taste and man ufacturersí recommendations. Recommended weights

and times are for gui dance only , and you do not have to adhere to them.

SUGAR

SUBSTITUTE

COVER

LIGHTENER

CHUTE

MIXING

BOWL

COLLECTING

INGREDIENT

THROWS

SUGAR

COLLECTING

CONDIMENT

THROWS

CUP POSITION

FOR TEST

THROW

FRESH BREW

COFFEE

CANISTER

CHUTE

CUP POSITION

FOR TEST THROW

July, 2001 Page 40 6390031

Page 47

EUROTWIN OPERATOR’S GUIDE

Table D1. Dry Product Weight and Throw Time Factory Default Settings

Weight (in gr am s ) per si ze c up

Selection

A Fresh brew coffee

A Freeze dry coffee

A Strong freeze dry coffee

B Fresh brew decaf

B F reeze dry decaf

B Strong freeze dry decaf

Fresh brew coffee

D

ESPRESSO

Freeze dry coffee

D

ESPRESSO

Strong freeze dry coffee

D

ESPRESSO

Fresh brew coffee

E

CAPPUCCINO

Freeze dry coffee

E

CAPPUCCINO

Strong freeze dry coffee

E

CAPPUCCINO

FInstant tea

F Strong i nstant tea

GChocolate

HSoup

H Soluble Product

Throw times (in seconds) per size cup

5oz. 7oz. 8oz. 9oz. 10oz. 12oz.

5.70

8.00

9.00

10.00

1.60

2.20

2.50

2.80

0.90

1.20

1.50

1.60

0.35

0.50

0.60

0.65

1.10

1.50

1.80

0.65

5.70

1.60

0.90

0.35

1.10

0.65

5.70

1.60

0.90

0.35

1.05

0.65

5.70

1.60

0.90

0.35

1.05

0.65

0.90

0.70

1.10

0.90

17.00

2.80

4.30

0.70

10.0

2.45

0.90

8.00

2.20

1.20

0.50

1.50

0.90

8.00

2.20

1.20

0.50

1.50

0.90

8.00

2.20

1.20

0.50

1.50

0.90

1.20

1.00

1.50

1.25

24.00

4.00

6.00

1.00

13.5

3.35

28.00

1.10

9.00

2.50

1.50

0.60

1.80

1.10

9.00

2.50

1/50

0.60

1.80

1.10

9.00

2.50

1/50

0.60

1.80

1.10

1.50

1.25

1.80

1.60

4.65

7.00

1.15

16.2

4.00

2.00

1.20

10.00

2.80

1.60

0.65

2.00

1.20

10.00

2.80

1.60

0.65

2.00

1.20

10.00

2.80

1.60

0.65

2.00

1.20

1.60

1.30

2.00

1.75

31.00

5.15

7.60

1.25

17.8

4.35

11.00

3.10

1.80

0.70

2.20

1.35

11.00

3.10

1.80

0.70

2.20

1.35

11.00

3.10

1.80

0.70

2.20

1.35

11.00

3.10

1.80

0.70

2.20

1.35

1.80

1.60

2.20

1,85

34.00

5.65

8.50

1.35

19.7

4.85

13.00

3.65

2.20

0.90

2.60

1.60

13.00

3.65

2.20

0.90

2.60

1.60

13.00

3.65

2.20

0.90

2.60

1.60

13.00

3.65

2.20

0.90

2.60

1.60

2.20

1.85

2.60

2.10

41.00

6.80

10.20

1.65

23.7

5.80

6390031 Page 41 July, 2001

Page 48

EUROTWIN OPERATOR ’S GUID E

Table D1. Dry Product Weight and Throw Time Factory Default Settings (Cont.)

Weight (in gr am s ) per si ze c up

Selection

Chocolate used in cappuccino

Sugar used in espresso

Extra sugar used in espresso

Sugar used in cappuccino

Extra sugar used in cappuccino

Sugar used in tea

Extra sugar used in tea

Lightener used in tea

Extra lightener used in tea

Sugar substitute used in tea

Extra sugar substiture used in tea

Sugar

Extra sugar

Lightener

Extra lightener

Sugar substitute

Extra sugar substitute

The actual gram weight of a product or condimentthrow will vary dependin g

upon the type of product or condiment used. The weights given are appro ximate based upon factory testing

Separate sugar, lightener, and su g ar substitute timers ar e available for selections A/B/C, D, E, and F.

Throw times (in seconds) per size cup

5oz. 7oz. 8oz. 9oz. 10oz. 12oz.

3.10

4.50

5.00

5,80

6.20

7.60

0.55

0.75

0.85

1.00

1.05

1.30

2.10

3.00

3.50

4.00

4.50

5.50

0.35

0.45

0.55

0.60

0.65

0.80

3.00

4.35

4.80

5.35

6.25

0.50

3.50

0.45

4.60

0.60

4.20

0.55

1.50

0.70

1.20

0.70

1.50

0.85

0.60

0.75

0.80

1.00

4.20

0.55

5.50

0.70

1.20

0.70

1.50

0.85

0.60

0.75

0.80

1.00

0.65

5.10

0.65

6.80

0.90

6.00

0.75

2.00

1.00

1.50

0.85

2.00

1.15

0.85

1.05

1.10

1.35

6.00

0.75

8.00

1.00

1.50

0.85

2.00

1.15

0.85

1.05

1.10

1.35

0.75

6.00

0.75

7.70

1.00

7.00

0.90

2.50

1.15

2.00

1.15

2.50

1.45

1.00

1.25

1.30

1.60

7.00

0.90

9.00

1.15

2.00

1.15

2.50

1.45

1.00

1.25

1.30

1.60

0.80

6.80

0.85

8.50

1.10

8.00

1.00

3.00

1.25

2.50

1.45

3.00

1.70

1.10

1.35

1.40

1.75

8.00

1.00

10.00

1.25

2.50

1.45

3.00

1.70

1.10

1.35

1.40

1.75

11.00

0.90

7.70

0.95

9.40

1.20

9.00

1.15

3.50

1.40

3.00

1.70

3.50

2.00

1.30

1.60

1.60

2.00

9.00

1.15

1.40

3.00

1.70

3.50

2.00

1.30

1.60

1.60

2.00

7.20

1.05

9.40

1.20

11.00

1.45

11.00

1.40

4.50

1.65

4.00

2.25

4.50

2.60

1.50

1.90

1.90

2.40

11.00

1.40

13.00

1.65

4.00

2.25

4.50

2.60

1.50

1.90

1.90

2.40

July, 2001 Page 42 6390031

Page 49

EUROTWIN OPERATOR’S GUIDE

COLLECTING HOT WATER THROW S

National Vendors recommends the factory default times be used for hot water throws

to ensure pr o per mixing. Table W1 gives the factory default wate r throw times for the

various size cups and product selections.

WARNING

This water is HOT! Be careful.

For a non-brewed selection, collect the water thro w s as follows:

1. Place a cup in the cup delivery station.

1. Ensure the merchandiser is using the facto ry defaults for the cup sizes (see SET

UP CUP SIZES).

2. Initiate the water throw for a selection.

3. Remove the cup and pour the water into a graduated cylinder.

4. Refer to table W1 for the correct volume of water.

5. Adjust the THROW TIME for that selec tio n and r ep ea t ste ps 2 th ro u gh 4 unt i l the

correct volume of water is thrown.

6. If you are unable to get the desired amount of water, reset the throw time to the

factory default, then adjust the water valves. You may then readjust the throw

times to fine-tune your water throws.

For a brewed selection, collect the water throws as follows:

1. Remove water supply hose from the brewer as shown on the next page.

7. Place the end of the hose in a graduated cylinder.

8. Follow steps 2 through 6 given for the non-brewed selection.

9. Replace the water supply hose on the brewer.

CUP FOR TAKING

CUP FOR TAKING

WATER THROWS

WATER THROWS

CUP DELIVERY

CUP DELIVERY

STATION

STATION

6390031 Page 43 July, 2001

Page 50

EUROTWIN OPERATOR ’S GUID E

Table W1. Water Throw Default Times and Volumes

Selection

5oz. 7oz. 8oz. 9oz. 10oz. 12oz.

A Fresh brew coffee

A Freeze dry coffee

B Fresh brew decaf

B Freeze dry decaf

D Espresso (F B)

D Espresso (FD)

FTea

GChocolate

H Soup or plain water

H Soluble Product 4.85

2.15

130

4.95

120

2.15

130

4.95

120

2.25653.20953.75

2.50603.50854.15

4.95

120

4.85

100

4.80

110

100

Time (in seconds) per size cup

Volume (in ml) per size cup

3.00

3.45

3.80

4.10

190

220

240

265

7.00

8.25

8.65

9.90

170

200

210

240

3.00

3.45

3.80

190

7.00

170

7.00

170

6.80

140

6.95

160

6.80

140

220

8.25

200

110

100

8.25

200

8.25

170

8.25

190

8.25

170

240

8.65

210

4.10

120

4.35

105

8.65

210

8.75

180

8.70

200

8.75

180

4.10

265

9.90

240

4.50

133

4.95

120

9.90

240

9.70

200

10.00

230

9.70

200

4.90

315

12.60

305

4.90

315

12.60

305

5.50

158

6.30

153

12.60

305

11.65

240

12.15

280

11.65

240

REMOVE THIS

TUBE

GRADUATED

CYLINDER

July, 2001 Page 44 6390031

Page 51

EUROTWIN OPERATOR’S GUIDE

SET UP A COLD DRINK

Be sure th at t he cu p size s yo u se t in SE T UP CU P SI Z ES agree with the cup s izes

actually in your machi ne. All procedures for setting up the cold drink s are similar, so

this example will demonst rate how to set up the 5 selection.

1. Press then until the display shows

1. Press 1 and 5. (For the "6" sel ection you would press 1 and 6, and so on.) The

display shows

cold water throw time for this selection is 6.80 seconds. Enter a new time if

desired.

2. Press . The display shows

set carbonated cold water throw time for this selection is 6.80 seconds. Enter a

new time if desired.

3. Pressing after each displa y will cause the following screen s to appear:

CLD. 15 6.80. This means that the curr ently set non-carbonated

CRB. 15 6.80. This means that the currently

SETUP -

b

.

SRP. 15 View and change the syrup throw time

PCT. 15 View and change the s etting s fo r the p ercen tage o f c arbonation

(0- 100)

4. At any of the preceding displays, you can press to test throw that item.

2. CONTINUE.

NOTE

The typical cold drink setup allows both a carbonated and still (noncarb) version. There may be cases when y ou w ish to serve o nly one

or the other.

To set up a still (non-carb) only, set the carbonat ion percentage

PCT. 15 . XX) to zero (PCT. 15. 00) . This setup will cause bot h ver-

(

sions to ve nd with no carbona tion.

To set up a carb only drink, set the desired c a rbonatio n level on the

percent screen, then press . The display shows an asterisk

to indicate this selection is carb only (

again to remove the aster isk and allow still drinks.

6390031 Page 45 July, 2001

PCT. 15 b XX). Press

Page 52

EUROTWIN OPERATOR ’S GUID E

COLLECTING COLD WATER AND SYRUP THROWS

1. Place a cup in the cup delivery station.

1. Ensure the merchandiser is using the facto ry defaults for the cup sizes (refer to

SET UP CUP SIZES, page 36).

2. Initiate the water (or syrup) throw for a selection.

3. Remove the cup and pour the liquid into a gradu ated cylinder.

4. Compare the measured throw to th e vo lume as shown in table W2.

5. Adjust throw times to get the desired volume.

6. If you are unable to get the right volume by adjusting the throw times, reset throw

times to the factory default, then adjust the w ater (o r syrup) valve for that selection (see ADJUSTMENTS AND MINOR MAINTENANCE, page 11). Repeat

steps 2 through 6 until the correct volume is thrown.

Table W2. Cold Water and Syrup Throw Default Times and Volumes

CUP SIZE

ML.OZ.ML.OZ. ML.OZ. ML.OZ.

177 6 25 0.85 2.5 125 4.2 4.25 125 4.2 4.25

207 7 30 1 3 150 5 5.25 150 5 5.25

244 8.25 36 1.2 3.5 181 6.1 6 181 6.1 6

266 9 40 1.4 4 200 6.7 7 200 6.7 7

296 10 45 1.5 4.25 222 7.5 8 222 7.5 8

355 12 50 1.7 4.5 250 8.5 9 250 8.5 9

SYRUP PLAIN WATER CARB. WATER

VOLUME

TIME

(SEC)