Page 1

Page 2

Page 3

Hot Drink Operation and Service Manual

TABLE OF CONTENTS

Warranty ....................................................................................................................... ii

Machine Requirements and Characteristics ......................................................... A-1

Programming............................................................................................................ B-1

Cleaning and Sanitation.......................................................................................... C-1

PAGE iii

Page 4

Hot Drink Operation and Service Manual

Notes

PAGE iv

Page 5

Hot Drink Operation and Service Manual

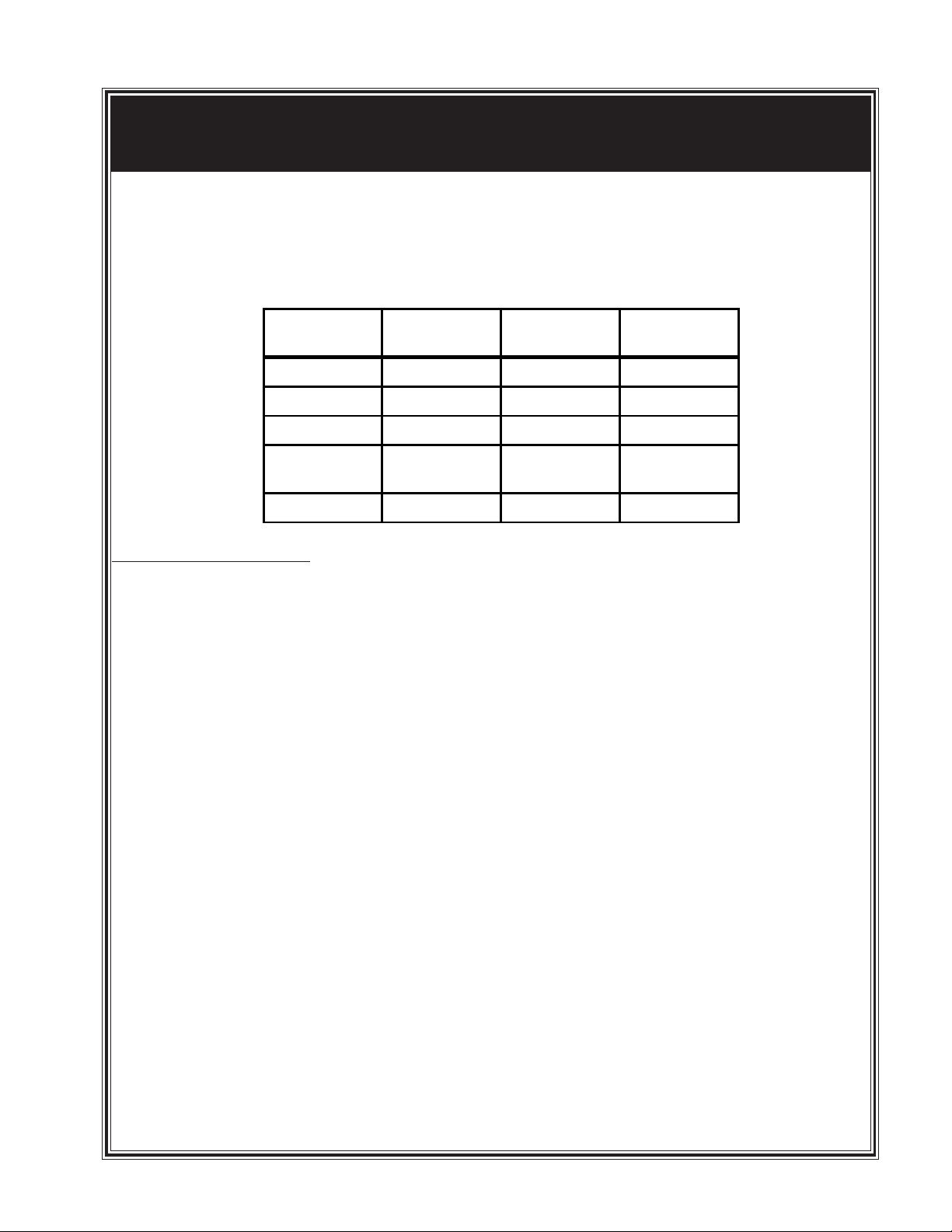

MACHINE REQUIREMENTS AND CHARACTERISTICS

POWER REQUIREMENTS

Power Requirement s

Country Volts

Canada 115 60 15

France 230 50 10

Germany 230 50 10

United

King do m

United States 115 60 15

1. Check the Power Outlet

This merchandiser is supplied with a service cord for the country of use and is terminated in a grounding type

plug. The wall receptacle used for this merchandiser must be properly polarized, grounded, and of the correct

voltage. Operating the merchandiser from a source of low voltage will VOID YOUR WARRANTY. Each

merchandiser should have its own electrical circuit and that circuit should be protected with a circuit breaker

or fuse conforming to local regulations.

Voltage Check - Place the leads of a voltmeter across the LINE (LIVE) and NEUTRAL terminals of the wall

receptacle. The voltmeter should indicate 110-130 volts ac for 120 volt, 60 Hz locations, or 220-240 volts ac

for 230 volt, 50 Hz locations.

Polarity Check - Place the leads of a voltmeter across the LINE (LIVE) and GROUND terminals of the wall

receptacle. The voltmeter should indicate 110-130 volts ac for 120 volt, 60 Hz locations, or 220-240 volts ac

for 230 volt, 50 Hz locations.

230 50 10

Frequency

(Hz)

Current

(Amps)

Noise Potential Check - Place the leads of a voltmeter across the NEUTRAL and GROUND terminals of the

wall receptacle. The voltmeter should indicate 0 volts ac. A measurement greater than 1.5-2.0 volts ac could

result in problems for the merchandiser's electronic circuitry caused by electrical noise.

Any deviation from these requirements could result in unreliable performance from your merchandiser.

PAGE A - 16300021

Page 6

Hot Drink Operation and Service Manual

WATER REQUIREMENTS

The best type of water for coffee brewing is normal hard (tap) water. If your location has chemically softened

water, you should do one of the following things:

•Have a non-softened supply line run to the merchandiser

•Contact your local water filter supplier for information and suggestions

Well water can also be used in the EuroDrink Machine. However, you should have it checked for levels

of carbonates and alkalies. Contact your water filter supplier if these values are relatively high.

What is the Water Pressure at Your Location?

It should be no less than: 10 psi ( 69.0 KPa) at 1/2 gallon/minute

And no more than: 80 psi (522.0 KPa) at 1/2 gallon/minute

If you're not sure about the pressure and flow rate, check with your water company.

What to do With the Water Supply Line:

Locate the supply line at the rear of your merchandiser.

Equip the line with a shut-off valve.

Flush the water supply line before connecting it to the merchandiser. A minimum of five gallons is usually

required before connecting the merchandiser to the supply line. DO NOT flush the merchandiser water

system. If you do, you might introduce water line contaminants into the merchandiser.

PHYSICAL CHARACTERISTICS

Height - 72" (183 cm.)

Depth - 28.5" (72 cm.)

Width - 32" (81 cm.)

Weight - 475 lbs. (215.5 kg.)

PAGE A - 2 6300021

Page 7

Hot Drink Operation and Service Manual

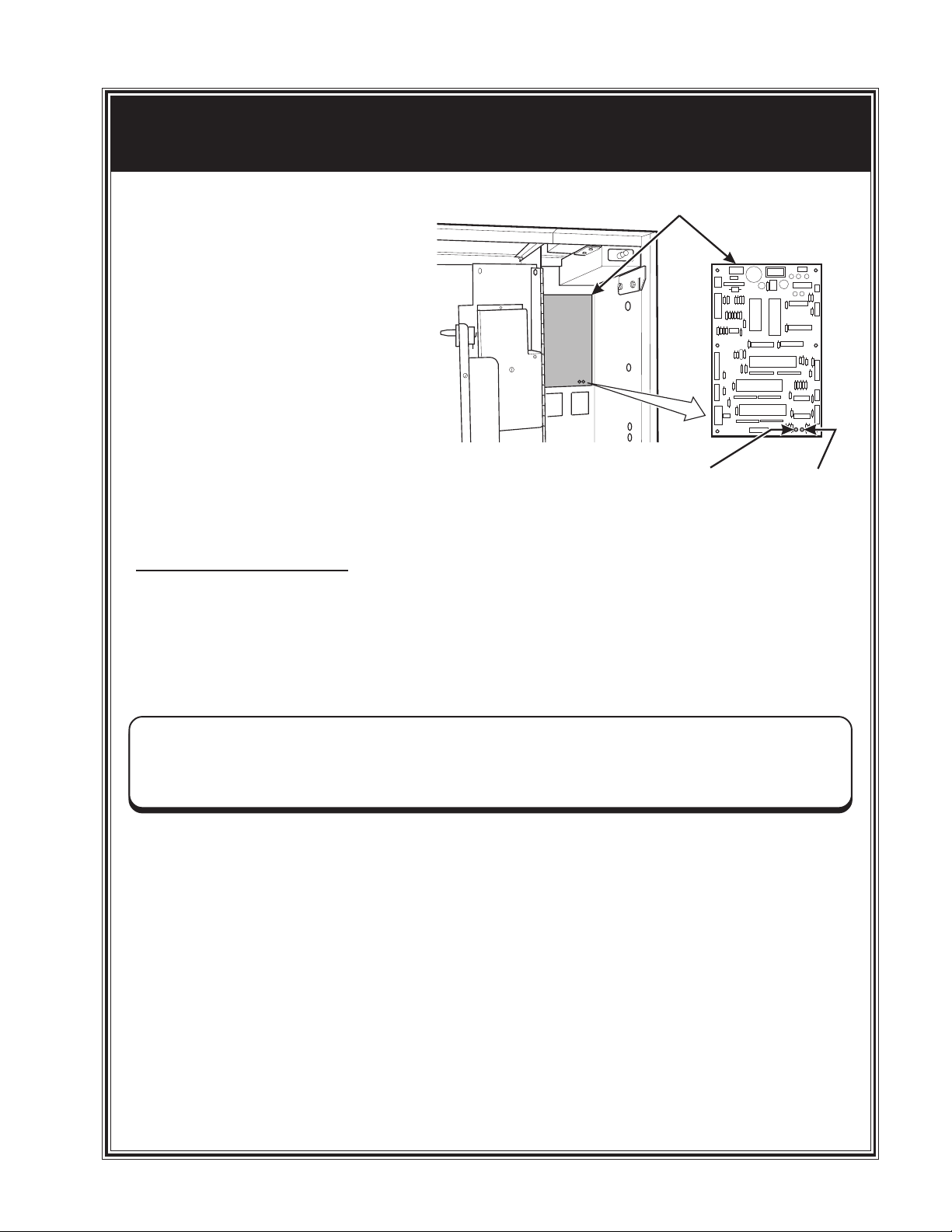

MAIN CONTROLLER

PCB ASSEMBLY

Controller Card

Display

LED1LED2

POWER ON

(LED 1)

Main Controller Card Display. This display consists of two light emitting diodes (LED) mounted on the

controller card.

POWER ON When lit, this red LED indicates electrical power is applied to the controller card.

HEARTBEAT When flashing, this red LED indicates that the controller card is active and the soft-

ware is operating.

NORMAL CONDITIONS:

When the merchandiser is operating normally, you should see a steady red POWER ON indicator

and a flashing red HEARTBEAT indicator. Refer to the maintenance manual if any other condition

exists.

FLASHING

HEARTBEAT

(LED 2)

PAGE A - 36300021

Page 8

Hot Drink Operation and Service Manual

LEVELING THE MERCHANDISER

From a safety standpoint it is very important that the merchandiser be level. A level merchandiser is

less likely to tip over and cause personal injury. Level the merchandiser by moving the leg levelers

in or out for proper adjustment. Pliers or channel locks may be required to loosen the leg levelers.

Level the merchandiser from the right to left and from front to back using a spirit level. When the

merchandiser is part of a bank of machines, it should be leveled in reference to the other machines.

Caution

Have an assistant hold the merchandiser

while you adjust the leg levelers.

SETTING THE QUARTER SWITCH

COIN MECHANISM

Setting the Quarter Switch

If your coin mechanism is not a MARS TRC

6000, skip this procedure and begin loading

the coin mechanism. If your coin mechanism is a MARS TRC 6000, flip down the

top front of the mechanism and set the

quarter switch as shown on the drawing to

the right. Make sure switch #2 is in the

down or "off" position.

HIGH QUARTER

SWITCH

ON

1234

Loading the Coin Mechanism

1. Open the cabinet door and the monetary cabinet

2. Insert coins into their respective tubes.

Make sure each tube is full.

3. Inspect the tubes for shingled coins and

correct if necessary.

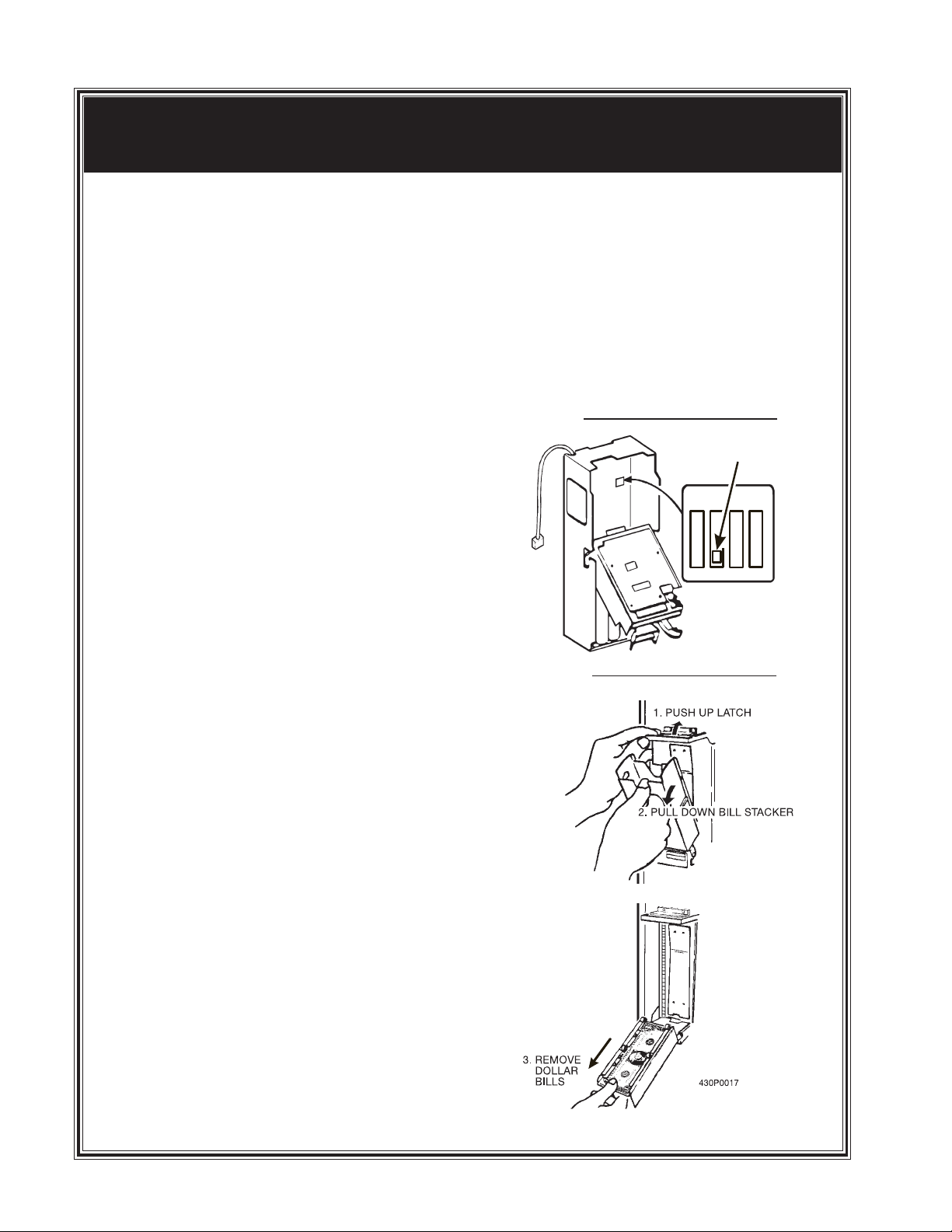

BILL VALIDATOR

Emptying the Stacker

1. Push up on the magazine latch to

release the housing

2. Open the magazine by pulling it down.

3. Remove the bills and close the magazine. Make sure it is secure.

EMPTYING THE BILL STACKER

PAGE A - 4 6300021

Page 9

Hot Drink Operation and Service Manual

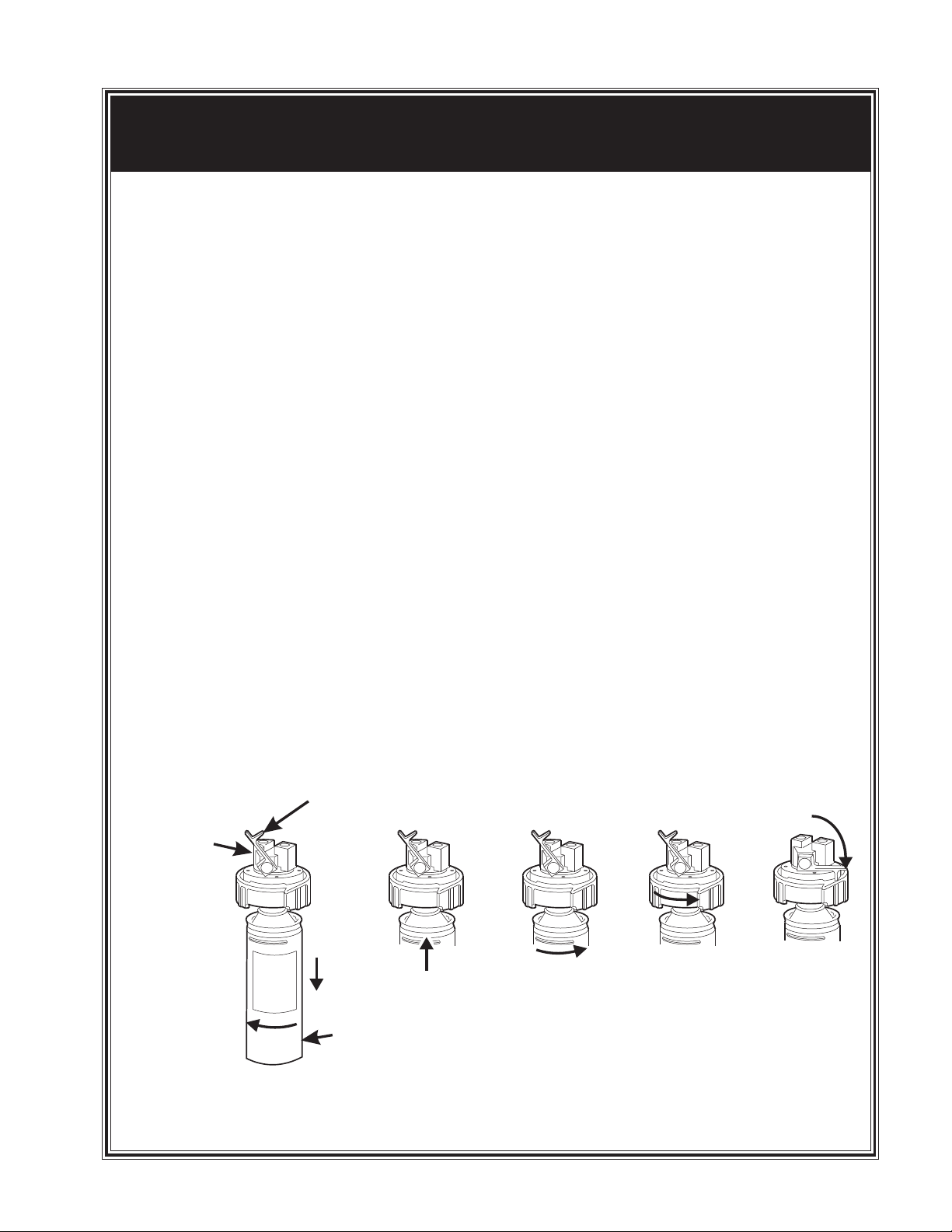

WATER FILTER CARTRIDGE

If your merchandiser has a water filter option, it cannot be operated without a properly installed water filter

cartridge.

Note

Check the water filter installation record. There is a place to write the vend number on the cartridge. The

filter is normally effective for approximately 26,000 7 oz. vends, 22,000 8 oz. vends, 20,000 9 oz. vends,

or 15,000 12 oz. vends. Local conditions may require more frequent replacement.

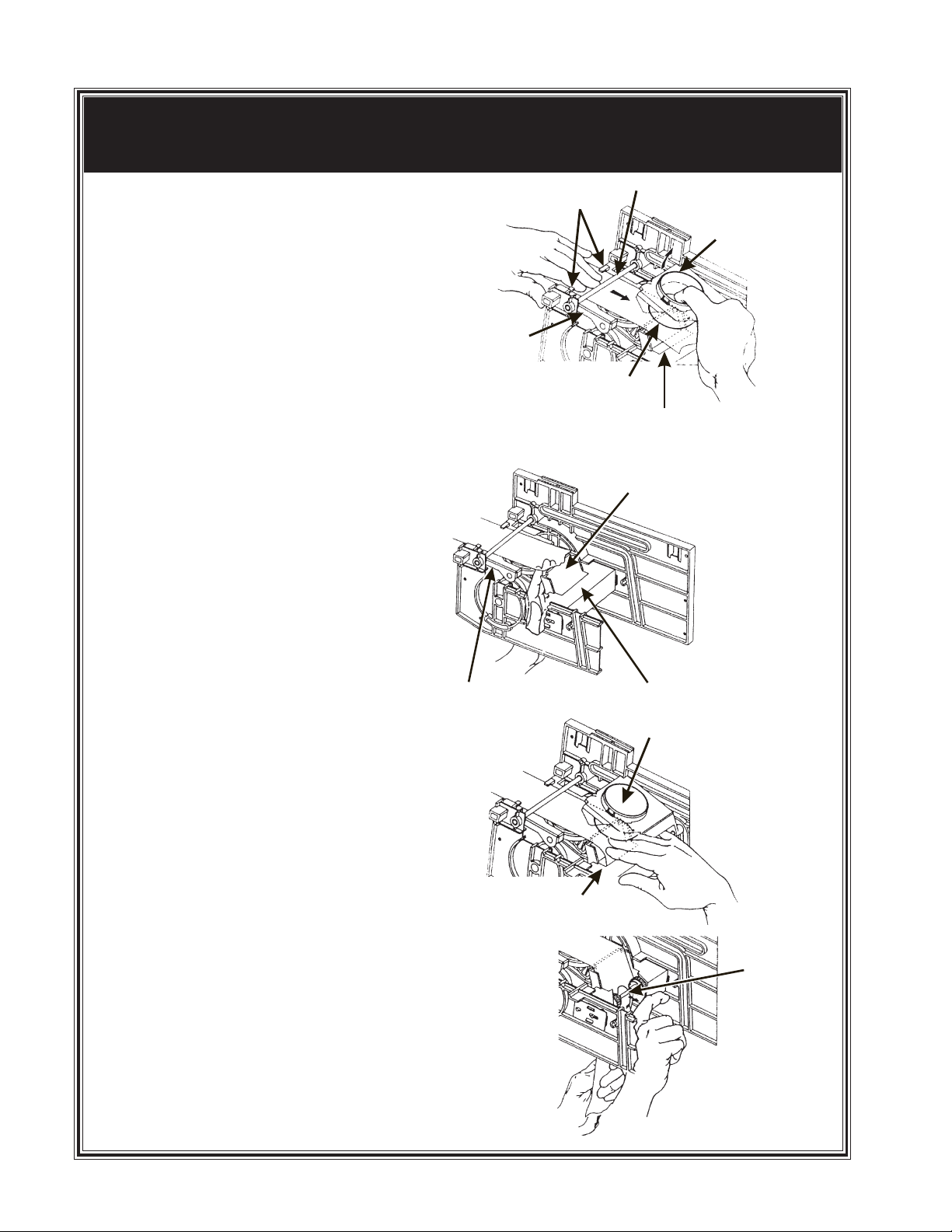

Removal

1. Turn the main power switch to the off position.

2. Flip the lock lever UP (view A). The lock lever on the water filter head is used to open and close the

water inlet to the merchandiser.

3. Rotate the locking collar to the left about 60 degrees until it drops to the filter receiving position.

4. Rotate the filter to the left until it drops free of the locking collar.

Installation

1. Align the raised rib near the top of the cartridge with the ribless portion of the locking collar (view B).

2. Push the cartridge up into the filter head (view B).

3. Rotate the cartridge to the right until the lock lever engages the locking collar (view C).

4. Rotate the locking collar to the right until it moves up into the locking position (view D).

5. Push the lock lever DOWN (view E).

Note

Do not flush the water filter cartridge.

WATER

WATER

INLET

INLET

VALVE

VALVE

LOCK

LEVERLOCK LEVER

WATER

A

VIEW AVIEW

VIEW BVIEW B

FILTERWATER FILTER

VIEW CVIEW

C

626P0010

D VIEW EVIEW E

VIEW DVIEW

PAGE A - 56300021

Page 10

Hot Drink Operation and Service Manual

ADJUSTING WATER VALVES

This should be done in conjunction with setting the

factory default times during Product Configuration

programming.

1. Using a slotted screwdriver, turn the adjustment

screw clockwise to decrease the water flow rate.

2. Turn the adjustment screw counterclockwise to

increase the water flow.

PINS ON MOTOR

PINS ON MOTOR

SHAFT MUST ENGAGE

SHAFT MUST ENGAGE

SLOTS IN CANISTER

SLOTS IN CANISTER

COUPLER

FILL

FILL

CANISTER

CANISTER

COUPLER

WATER

TANK

WATER VALVE

ADJUSTMENT

SCREW

WATER

6

+

123456

-

WATER

VALVE

626P0017

CANISTERS

CANISTER

CANISTER

SHELF

SHELF

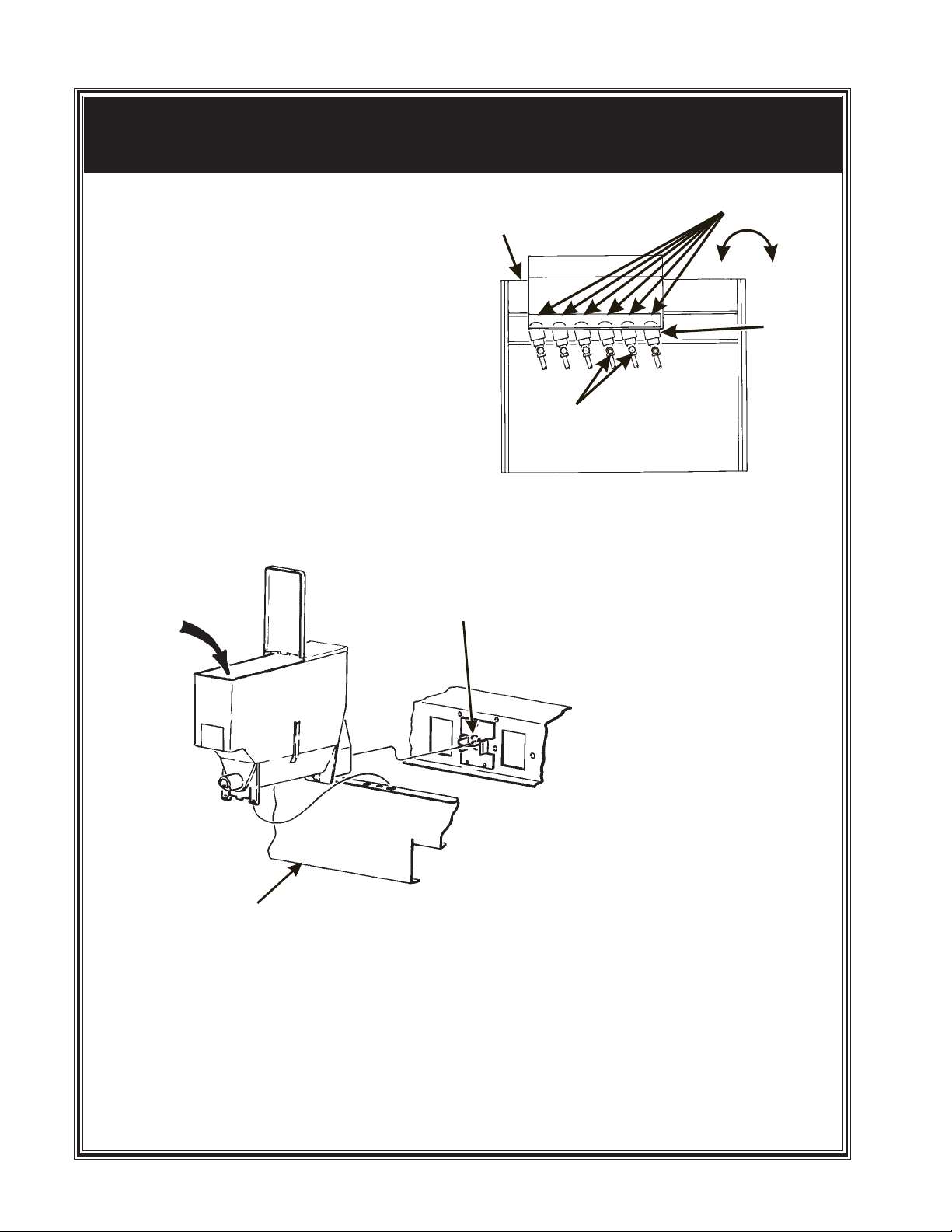

Filling

Open the lid as shown, and carefully pour product

into canister.

Installing

1. Place the canister in the position shown.

2. Engage the pins on the motor shaft with

3. Fit tabs on the canister into the slots on

4. To ensure the canister is correctly engaged

PAGE A - 6 6300021

the slots in the canister coupler.

the canister shelf.

with the rear mounting bracket, gently push

down on the front edge of the canister lid.

Page 11

Hot Drink Operation and Service Manual

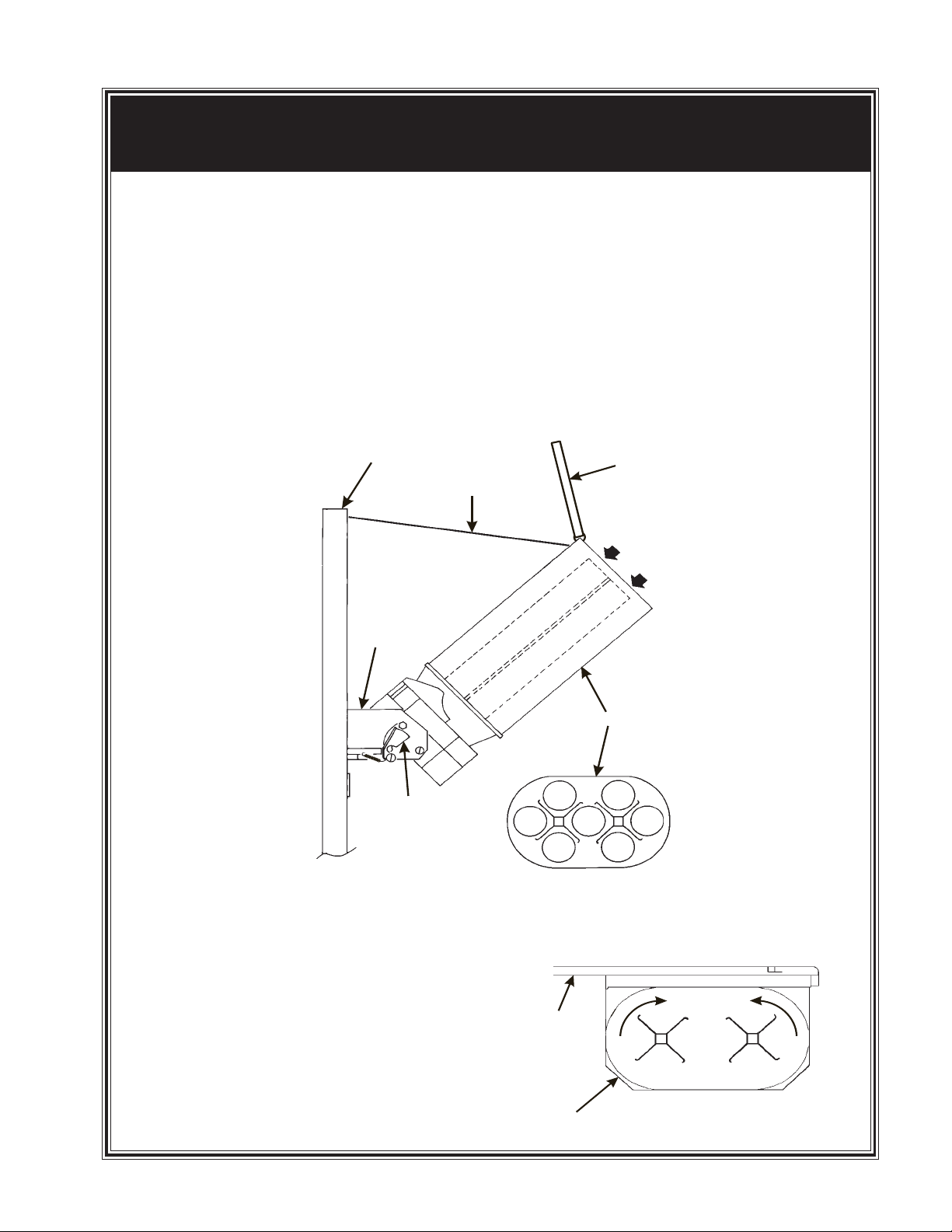

CUP MECHANISM

Loading

1. Support the cup mechanism in the upright position.

2. Push the latch forward to release the cup mechanism. Continue to support the mechanism while you

lower it into the loading position.

3. Remove the turret cover.

4. Open the bottom of the wrapper on a stack of cups.

5. Insert the wrapped cups into the turret and pull the wrapper out.

6. Replace the turret cover after the turret has been loaded

7. Make sure the cup mechanism is locked into the upright position.

CABINET

DOOR

RETAINING

STRAP

LID

LOAD CUPS

HERE

CUP MECH

MOUNTING

BRACKET

CUP TURRET

LATCH

CUPS

TOP VIEW

Cups

1. Use only cups which have been designated for use in a hot beverage vending machine.

2. Check to insure that the cup size you are loading agrees with the cup size selected

during programming

3. Make sure you observe proper hygiene. Touch only

the wrapper and not the cups.

4. Do not fill cups above the level marked on the

outside of the cup turrets or above the "Fill Line"

DOOR

CUP STACK ROTATION

label inside each turret.

5. Check to make sure the cups you are loading are

1B 1A

the same size and brand of those hot drink cups

currently in the turret. Do not intermix.

CUP

MECHANISM

TOP VIEW

PAGE A - 76300021

Page 12

Hot Drink Operation and Service Manual

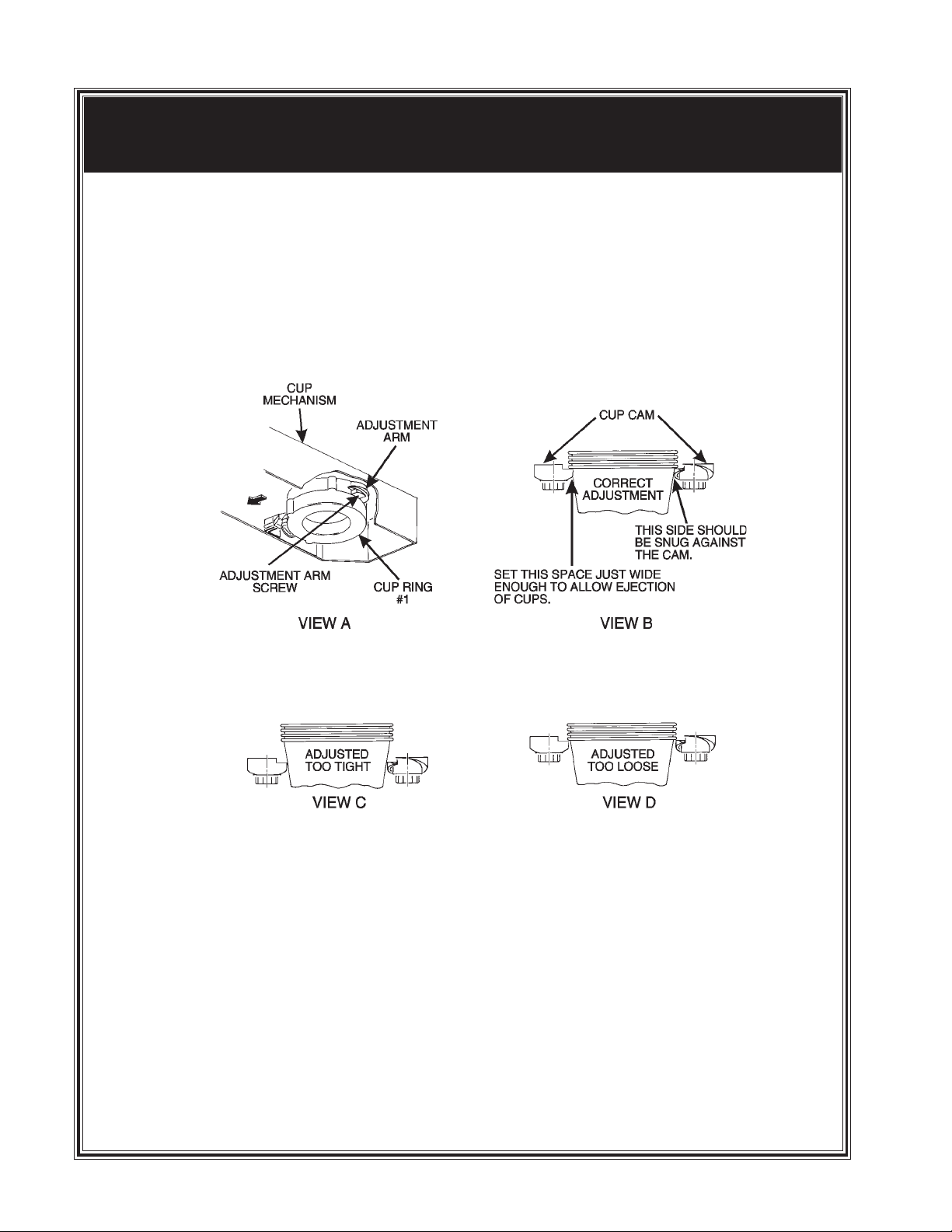

Adjustment

1. Place seven cups in the cup ring

2. Observe the clearance as shown in view B.

3. To adjust, first loosen the adjustment arm screw (view A).

4. Next, move the adjustment arm until the correct clearance is achieved.

5. Finally, hold the adjustment arm in place and tighten the adjustment arm screw.

PAGE A - 8 6300021

Page 13

Hot Drink Operation and Service Manual

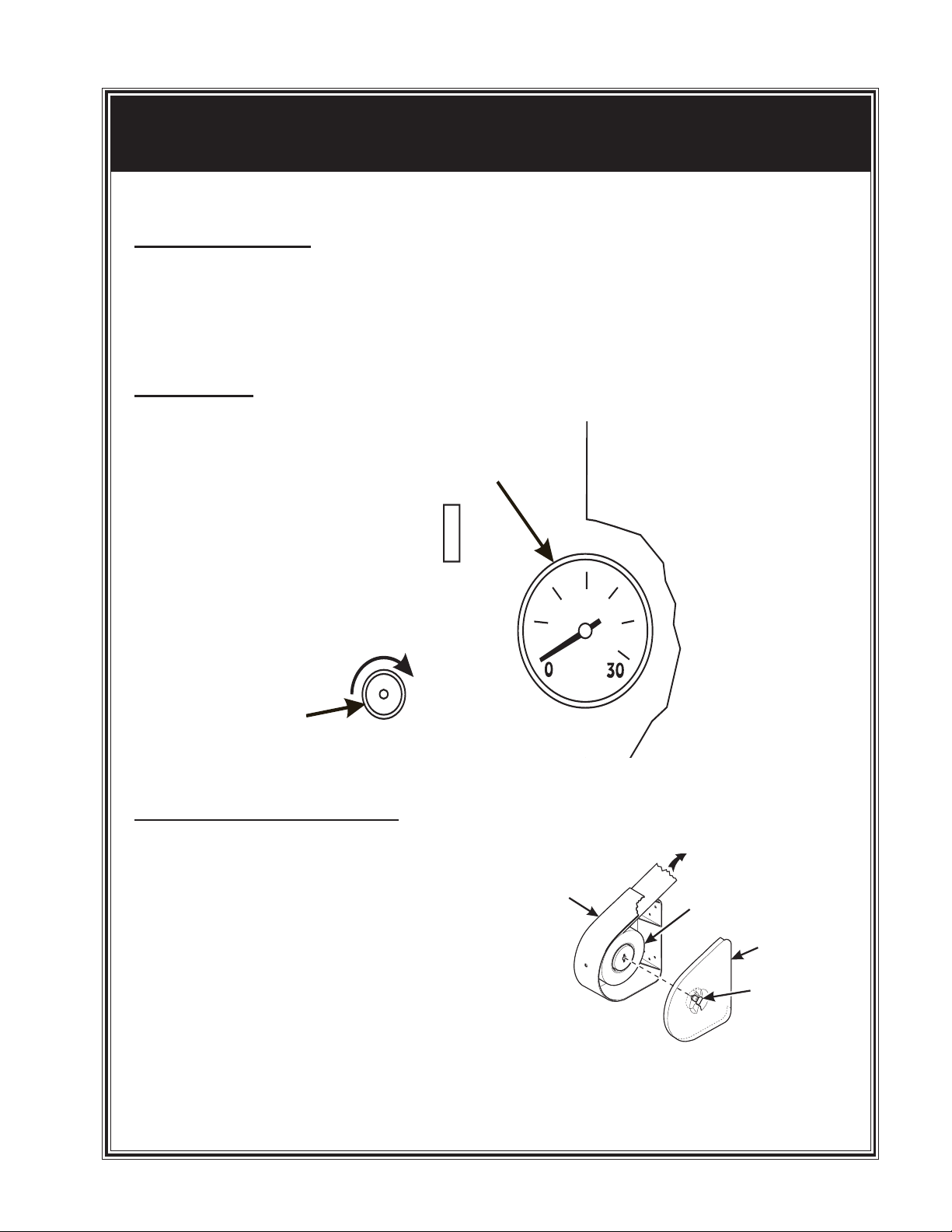

Pressure Adjust Control. This control determines the system pressure provided by the air compressor.

Adjust the pressure as follows:

a. With the compressor running, pinch the brewer inlet air tube.

b. Adjust the pressure to read 10 - 12 psi on the gauge.

This will produce a pressure of 3 - 6 psi using regular coffee and 8¼ oz cups. No further air pressure

adjustments should be necessary.

Pressure Gauge. This indicator shows the amount of air pressure in the system.

PRESSURE

GAUGE

INCREASE

PRESSURE

ADJUST

CONTROL

INGREDIENTS SHELF

LOADING OPTIONAL FILTER PAPER

1. Turn the main power switch to the OFF position.

2. Remove the cup station and grounds bucket.

3. Remove the paper holder cover by turning the

fastener a quarter turn to the left.

4. Insert a roll of paper into the paper holder.

Route the free end of the paper to the brewer

as shown.

5. Replace the cover on the paper holder. Secure it by turning the fastener a quarter turn to

the right.

6. Feed paper over swing arm assembly and

underneath pinion gear shaft.

PAPER

HOLDER

MONETARY

PANEL

TO BREWER

PAPER

ROLL

COVER

FASTENER

PAGE A - 96300021

Page 14

Hot Drink Operation and Service Manual

7. Feed paper through the paper

guides.

8. Raise the basket housing assembly and feed paper over the lip of

the paper mechanism housing.

NOTE

It may be necessary to reach

underneath the brewer between

the paper mechanism housing

and swing arm assembly to push

paper over the lip of the paper

mechanism housing.

9. Reach underneath the brewer

between the paper mechanism

housing and basket housing

assembly and push paper into the

top of the paper mechanism

housing between paper rollers.

PAPER

GUIDES

SWING ARM

ASSEMBLY

LIP OF PAPER MECHANISM HOUSING

PAPER MECHANISM HOUSING

PINION GEAR SHAFT

BASKET HOUSING

ASSEMBLY

LIP OF PAPER MECHANISM HOUSING

SWING ARM ASSEMBLY

10. Reach underneath the brewer and pull

paper roller to the right.

11. Pull paper down between the paper rollers.

12. Release the paper roller.

13. Place the main power switch in the ON position.

14. Enter BREWER TEST mode (see SERVICE)

and cycle the brewer to observe that paper

feeds properly.

15. Replace the cup station and grounds bucket.

PAPER MECHANISM HOUSING

PAPER MECHANISM HOUSING

BASKET HOUSING ASSEMBLY

PAPER

ROLLER

PAGE A - 10 6300021

Page 15

Hot Drink Operation and Service Manual

HOT WATER TANK CLEANING PROCEDURE

Some smell and/or taste problems may occur in new machines. Follow this procedure to clean the hot water

tank if you experience problems:

1. If the machine is in service, remove power from the machine.

2. Dissolve 1 tablespoon of common baking soda in a cup of water.

WARNING

The water tank may be HOT. Be careful when working on the tank.

3. Loosen or remove the hot water tank lid and pour the baking soda solution into the tank.

4. Apply power to the machine.

5. If the tank is not full, fill it.

6. Allow the tank to reach its operating temperature.

7. Leave the solution in the tank for AT LEAST ½ hour. If possible, leave the solution in the tank for 1

hour.

8. Drain the tank.

9. Refill the tank, then drain again.

10. Refill the tank and put the machine back into service.

PAGE A - 116300021

Page 16

Hot Drink Operation and Service Manual

Notes

PAGE A - 12 6300021

Page 17

Hot Drink Operation and Service Manual

PROGRAMMING

Standby

Message

#

DATA

#

PAY OU T

(NDQ = 123)

#

PRICE

#

FAULTS

#

SERVICE

(SEE NEXT

PAGE FOR

DETAILS)

#

SETUP

*

*

#

*

*

Tota l Tes t

Vends

#

Low

**

Change

Message

##

*

Last

Display

Change

Options

#

Mug

Vends

#

Paid

Sales

##

Price

Indiv idual

Select io ns

Firs t

Machine Fault

Display

##

Free

** ** *

Vend

On/Of f

#

Paid

Vends

*

Machine Fau lt

** *

Select

Coin

Mech

#

Unpaid

Sales

*

##

= These ite ms do not appear when an EXEC c oin m ec h is us ed.

Pressi n g an d ho l d i n g # will return to the standby

Second

Display

Validator

*

Options

##

Unpaid

Vends

*

Note:

message fr o m an yw h er e.

Machine Fault

Select

Card

Options

#

View or

Change

Machine I D

*

Declining

Balance

Select

Display

Language

#

#

COF F EE

(SEE NEXT

PAGE FOR

DETAILS)

#

Activate

*

Freevend

Periods

#

Date

DAY

*

#

#

TI ME O F

The diagram on these pages is a map of the programming functions in your merchandiser. These functions will be described in

greater detail, but this will help you get around once you are familiar with how programming works. The symbols * and #

represent special keys that move you around inside the programming modes, and from one mode to another. As you can see on

the diagram, these symbols show up in the pathways in and around the modes.

*

First

Freev end

Period Sta rt

Time

##

*

Firs t

Freev end

Period Sto p

Time

#

Up t o 4 f reev end

Freev end

*

Period

Selections

periods are

support ed.

First

#

Last

Freev end

*

Period Start

Time

Last

Freev end

*

#

Period Sto p

Time

*

*

Last

Freev end

Period

Selections

PAGE B - 16300021

Page 18

Hot Drink Operation and Service Manual

SERVICE

*

Test Vend

*

Softw are

Version Num ber

*

Water Tank

Temp.

*

Cup Tes t

*

Whipper Test

*

Air Com pressor

Test

*

Brew er Test

= These items only appear when a brew er is used.

COFFEE

*

#

#

#

#

#

#

#

Lockout

Select

Regular

Dr in k Si ze

Select

Large

Dr in k Si ze

Water

Throw s

Produc t

Throw s

Sugar

Throw s

Set

Set

Set

#

*

#

*

#

*

#

*

#

*

#

*

Bowl Rinse

*

Br ew er Rinse

*

Fill Water Tank

*

Input Tes t

*

*

#

#

#

#

Set

Lighte n er

Throw s

*

Set

Steep

Time

*

Set Air

Compres or

Run Time

*

Set

Cappuccino

Ratio

*

Set Water

Tank

Temperature

*

Set M achine

Configuration

#

#

#

#

#

#

*

PAGE B - 2 6300021

Page 19

Hot Drink Operation and Service Manual

THE KEYPAD

During vending, customers use the keypad to make

selections. When you pull the door switch to the ON

position, the keypad becomes your programming

input device. For reference, we will show the keypad

on all the pages.

SPECIAL PROGRAMMING KEYS

#

Press this key to move from one function to another.

From within a function, press once to return to the beginning of the function; press

and hold to return to the standby message.

This key moves you around inside of a function.

This key allows you to switch between two or more choices.

This is the "action" key. It will start tests, fill the water tank, etc.

DATA

View several types of sales data:

NOTE

All data is not resettable.

1. Pull out the door switch button to the ON position.

2. Press # until the display shows DATA.

3. If you have the DEX option, press to transfer data into your DEX device.

4. Press . The display shows

$ .XX. This is the dollar and cents amount of paid sales.

**

5. Press . The display shows

XX. This is the count of paid vends.

**

6. Press . The display shows _0$ .XX. This is the dollar and cents amount of unpaid "sales". (Does

not display if the total is zero.)

7. Press . The display shows _0 XX. This is the total count of unpaid vends. (Does not display if the

total is zero.)

8. Press . The display shows MUG XX. This is the count of mug vends. (Does not display if the total

is zero.)

9. Press . The display shows TST XX. This is the total count of test vends. (Does not display if the

total is zero.)

10. Press . The display shows ID XXXXXX. This is the machine ID number. Use - and -

to enter a unique identifier for the machine.

11. Press to return to step 4, or # to exit.

PAGE B - 36300021

Page 20

Hot Drink Operation and Service Manual

PAY OUT (Does not apply to machines with EXEC coin mechanisms.)

Pay out coins:

1. Pull out the door switch button to the ON position.

2. Press # until the display shows

NDQ = 1.2.3 (dumb mech). This is telling you that pressing pays out nickels, pressing pays

out dimes, and pressing pays out quarters.

OR

PAY = 1.2.3 (MDB mech). This is telling you that pressing pays out from tube 1 (nickels), pressing

pays out from tube 2 (dimes), and pressing pays out from tube 3 (quarters).

3. Press the appropriate key once to pay out one coin.

4. Press and hold the appropriate key to pay out coins continuously.

5. Press and hold # to return to the standby message.

PRICE

Set prices for all the selections in your merchandiser:

0A .25

The price display:

Selection letter

Selection size:

blank = regular drink size

1. Pull out the door switch button to the ON position.

2. Press # until the display shows PRICE.

3. Press , and the display shows A .XX. "XX" is the price for the regular size A selection.

4. Press until the selection you want to price is displayed.

OR

Press the letter of the selection you want to price, then press the selection size, and it will be displayed

immediately.

5. Enter a new price with the number keys.

6. Repeat steps 4 and 5 until you have priced all the selections.

OR

7. Press # to return to the PRICE display, or hold # to exit.

1 = large drink size

Selection price

PAGE B - 4 6300021

Page 21

Hot Drink Operation and Service Manual

FAULTS

Display all the active faults on your merchandiser:

1. Pull out the door switch button to the ON position.

2. Press # until the display shows FAULTS.

3. Press to see the list of faults:

NO ERRORS There are no faults on the machine.

KEYPAD XY Key(s) X and Y are stuck.

ROM ERROR Error with ROM.

RAM ERROR RAM is not initialized or is not compatible with the currently loaded soft-

ware. If this message appears, initialize your RAM by performing the

following procedure:

NOTE: Initializing RAM will erase all your data and drink setings. Be

sure you have written this information down before continuing.

Press AND HOLD . You will see CLEARING in the display. Continue

holding until two beeps are heard and the display shows FINISHED.

CONFIG ERR Error with machine configuration.

RING.MTR The cup ring is jammed.

MOT R 12 Cup turret motor 1 or 2 is jammed.

NO CUPS 1 Out of cups.

WASTE PAIL The waste pail is full.

LOW WATER The water level in the tank is low.

COLD TANK Water is too cold to vend.

NO SENSOR Illegal temperature reading.

TANK ERR A fault occurred in the inlet system.

WHIP 123 Whipper motor failure (motor 1, 2, or 3).

BREWER JAM The brewer is jammed.

MECH ERR Problem with the coin mechanism.

CARD. ERR Problem with the card reader.

DBV. ERR Problem with the bill validator.

NONE READY Time of day inhibit is active, or all selections are out of

service.

CHK PRICE Illegal price is detected.

LOCKS SET All selections are locked.

When the first fault item (if any) repeats, you have seen all the faults.

When active faults exist, pulling the door switch will automatically display FAULTS.

4. Press to see more faults or # to exit.

PAGE B - 56300021

Page 22

Hot Drink Operation and Service Manual

SERVICE

View machine status and test certain functions:

1. Pull out the door switch button to the ON position.

2. Press # until the display shows SERVICE.

3. Press . The display shows TEST .00. You can test vend selections. Insert

coins and bills into the merchandiser, and the amount you inserted is displayed.

4. Press . The display shows the software version number.

5. Press . The display shows the water tank temperature. Temperature is

displayed in either degrees Fahrenheit (F) or Celsius (C), depending upon what

was set in the COFFEE mode.

6. Press . The display shows CUP TEST. To drop a cup, press .

7. Press . The display shows WHIP TEST. To test the whipper(s), do one of the following:

a. Press the selection letter that uses the whipper you want to test. For example, pressing will test

whipper #1. (The display shows WHIP 1.)

b. Press the number of the whipper. The display shows the whipper number you pressed. (If you press a

whipper number that does not exist, nothing happens.)

8. Press . The display shows AIR TEST. To test the air compressor, press .

9. Press . The display shows BREW TEST. Press , and each brewer position is displayed:

WARNING

Keep away from the brewer mechanism while it is operating. Coming into contact with moving

parts could injure you.

a. BREW'R BREW - The brewer is in the BREW position.

b. BREW'R FLIP - The brewer is in the FLIP position.

c. BREW'R HOME - The brewer is in the HOME position.

10. Press . The display shows BOWL RINSE. To rinse the bowls, press . Hot water is delivered to

the mixing bowl(s), and the display shows RINSING until the cycle is complete.

11. Press . The display shows BREW RINSE. To rinse the brewer, press . The brewer cycles and the

display shows CLEANING until the cycle is complete.

12. Press . The display shows TANK.FILL.

PAGE B - 6 6300021

Page 23

Hot Drink Operation and Service Manual

a. Press . The display shows: FILLING. This indicates that the tank is filling and/or the error is

cleared. When the tank is full, the display returns to TANK.FILL..

b. If it is taking longer than 12 minutes to fill the tank AND THERE ARE NO LEAKS, you may see

the TANK ERR message again. Just repeat step a after making sure there are no other problems,

such as a restriction in the water inlet line.

NOTE

The heater does not function until the tank is full. The normal heat up time to reach operating

temperature is 90 minutes, depending upon incoming water temperature.

13. Press . The display shows IN KPHL1. This screen lets you test the INput switches.

K = the letter or number of any key (except and

replaces "K"

) being pressed

#

P = waste pail overflow switch

H = water tank upper level

L = water tank lower level (a decimal point appearing after the "L" indicates

that the inlet valve is energized)

1 = cup ring empty sensor

14. Press to return to step 3, or # to exit.

PAGE B - 76300021

Page 24

Hot Drink Operation and Service Manual

SETUP

Configure various machine functions:

1. Pull out the door switch button to the ON position.

2. Press # until the display shows SETUP.

3. Press . The display shows either FREE ALL or FREE OFF. When FREE ALL is displayed, all

selections are free. Press to switch between ALL and OFF.

4. Press . The display shows either DUMB MECH, MDB MECH, EXEC MECH , or NO MECH. Press to

switch between these coin mech choices.

5. Press . The display shows the bill validator choices. Press to switch between the choices:

SER. 1.2.5.10.20 = A serial validator is installed. Press , ,

display the bill (s) which will be accepted.

OR

MDB. 1.2.5.10.20 = An MDB validator is installed. Press , ,

display the bill (s) which will be accepted.

OR

5, 6

, or (respectively) to

5, 6

, or (respectively) to

MDB. <*> = A special MDB validator has been detected after MDB. 1.2.5.10.20 was installed and

interrogated. Press to enter the list of bill(s) or tokens which will be accepted. Press to

scroll through the list and press to turn a particular selection ON or OFF. Press # when you

have completed the list. MDB. <

> will again be displayed.

*

OR

PULSE DBV = A pulse validator is installed.

OR

NO DBV = No bill validator installed.

6. Press . The display shows either:

NO CARD = No card reader is installed,

DUMB CARD = A dumb (12 pin) card reader is installed,

MDB CARD = An MDB card reader is installed.

Press to switch between the choices.

7 Press . The display shows CHANGE X.XX. Change will be given for coins or

bills up to this amount without the customer having to make a selection. For

example, if 1.00 is displayed, the machine will give the customer change for a

dollar without requiring a selection. Entering 0.00 means that no change will be

given without a purchase.

8. Press . The display shows: LOW.MSG X.XX. The customer will see USE

EXACT CHANGE in the display when the amount of available change in the coin

mechanism falls below the level you set for X.XX. Enter a value with the

number keys. For example, if LOW.MSG 1.00 is selected, the customer sees the

USE EXACT CHANGE message when less than a dollar's worth of change is in the

coin mechanism.

PAGE B - 8 6300021

Page 25

Hot Drink Operation and Service Manual

9. Press . The display shows either:

DECLINE.ON = More than one vend is allowed, with a declining balance. This means that the customer

can choose multiple products until the amount of credit is lower than the lowest priced product in the

machine.

OR

DECLINE.OFF = A declining balance is not allowed. Press to switch between these two choices.

10. Press . The display shows either ENGLISH, DEUTSCH, FRANCAIS, ESPANOL, PORTUGUES, SWEDISH or

NEDERLANDS. Press to select the appropriate language for your display.

11. Press to return to step 3, or # to exit.

COFFEE

1. Pull out the door switch button to the ON position.

2. Press # until the display shows COFFEE .

3. Press . The display shows LK. ABCDEFG. When letters A through G are

displayed, it indicates the selections that are locked out. An active selection is

indicated by a dash (-). Pressing the appropriate letter key(s) switches from

active to locked out.

NOTE

If your machine is NOT equipped with the International Coffee option, you MUST lock out

selection C. Failure to do so will allow "vending" a non-existant selection.

4. In the next two steps, you will set up the two drink sizes. Your machine only supports one cup

size. Therefore, the large size drink selection vends a full cup, while the regular size drink selection

vends a partially filled cup. First, be sure that the cups you have loaded in your machine have the

capacity to hold the large size drink volume. Then follow the two steps below to set up the two drink

sizes:

a. Press . The display shows CUP X OZ. Press until the regular size drink volume you

want is displayed.

If you want to load the factory default water and product throw times for your new cup size, press

and hold . The display shows CLEARING, then FINISHED.

b. Press . The display shows CUP.1 X OZ. Press until the large size drink volume you

want is displayed.

If you want to load the factory default water and product throw times for your new cup size, press

and hold . The display shows CLEARING, then FINISHED.

When setting up throw times for water, product, etc., each selection letter shows the

time for a regular size drink and the time for a large drink. The large size drink throw

time is shown with a "1" in front of the selection letter.

PAGE B - 96300021

Page 26

Hot Drink Operation and Service Manual

NOTE

When changing timer setups, you must enter throw times for Caffé Latte (1D) manually. These

times will not be set when loading factory defaults.

CAFFE' LATTE RECIPE

(12 oz. recommended)

1. Make sure the machine is configured to use 12 oz.

cups.

2. Set up the 1D selection as follows:

a. Water: 6.00 seconds = 6 ounces (about 177 ml)

b. Coffee: 4.77 seconds = 17 grams

c. Sugar: 0.24 seconds = 2.5 grams

d. Lightener: 2.8 seconds = 5 grams

e. Steep time: 12.5 seconds

5. Press . The display shows WATER. This is the main screen for setting up water throws. If you don't

want to do this, continue to step 6.

a. Do one of the following:

Press the letter of the selection whose water throw you want to set

OR

Press to go to the A selection, then press until the desired selection is displayed.

b. Example: The display shows WAT. A 5.90. This is the water screen for the A selection. The

numbers on the right are the throw time for the selection (5.90 seconds in this example).

c. Enter a new throw time, using the number keys.

d. Press test throw the water.

e. Repeat steps a through d to set another selection.

f. Press # to return to the WATER display.

6. Press . The display shows PRODUCT. This is the main screen for setting up dry product throws. If

you don't want to do this, continue to step 7.

a. Do one of the following:

Press the letter of the selection whose dry product throw you want to set

OR

Press to go to the A selection, then press until the desired selection

is displayed.

b. Example: The display shows DRY. A 1.90. This is the water screen for the A

selection. The numbers on the right are the throw time for the selection (1.90

seconds in this example).

c. Enter a new throw time, using the number keys.

d. Press test throw the dry product.

e. Repeat steps a through d to set another selection.

f. Press # to return to the PRODUCT display.

PAGE B - 10 6300021

Page 27

Hot Drink Operation and Service Manual

7. Press . The display shows SUGAR. This is the main screen for setting up sugar throws. If you don't

want to do this, continue to step 8.

a. Do one of the following:

Press the letter of the selection whose sugar throw you want to set

OR

Press to go to the A selection, then press until the desired selection is displayed.

NOTE

The A and B selections are represented by a star (*). All other selections using sugar are

represented normally.

b. Example: The display shows SUG. F 1.90. This is the sugar screen for the F selection. The

numbers on the right are the throw time for the selection (1.90 seconds in this example).

c. Enter a new throw time, using the number keys.

d. Press test throw sugar.

e. Repeat steps a through d to set another selection.

f. Press # to return to the SUGAR display.

8. Press . The display shows LIGHTENER. This is the main screen for setting up lightener throws. If

you don't want to do this, continue to step 9.

a. Do one of the following:

Press the letter of the selection whose lightener throw you want to set.

OR

Press to go to the A selection, then press until the desired selection is displayed.

NOTE

The A and B selections are represented by a star (*). All other selections using lightener are

represented normally.

b. Example: The display shows LIT. F .90. This is the lightener screen for the F selection. The

numbers on the right are the throw time for the selection (0.90 seconds in this example).

c. Enter a new throw time, using the number keys.

d. Press test throw lightener.

e. Repeat steps a through d to set another selection.

f. Press # to return to the LIGHTENER display.

9. Press . The display shows STEEP. This is the main screen for setting up

steep times for brewed selections. If you don't want to do this, continue to step

10.

a. Do one of the following:

Press the letter of the selection whose steep time you want to set.

OR

Press to go to the A selection, then press until the desired selection

is displayed.

PAGE B - 116300021

Page 28

Hot Drink Operation and Service Manual

b. Example: The display shows STP. A

screen for the large A selection. The numbers on the right are the steep

time for the selection (2.10 seconds in this example).

c. Enter a new steep time, using the number keys.

d. Repeat steps a through c to set another selection.

e. Press # to return to the STEEP display.

10. Press . The display shows AIR. This is the main screen for setting up air

compressor running times for brewed selections. If you don't want to do this,

continue to step 11.

a. Do one of the following:

Press the letter of the selection whose compressor running time you want

to set.

Press to go to the A selection, then press until the desired selection is displayed.

b. Example: The display shows AIR. A 4.10. This is the air compressor time screen for the A

selection. The numbers on the right are the steep time for the selection (4.10 seconds in this

example).

c. Press J to run the air compressor.

d. Repeat steps a through c to set another selection.

e. Press # to return to the AIR display.

11. Press . The display shows RATIO .25. This is the ratio of chocolate to coffee in a cappuccino

drink. In this example, cappuccino uses 25% chocolate.

a. Enter a new ratio using the number keys. A ratio between 5 and 50% must be present, or you

can't leave this step.

12. Press . The display shows SET XXX°F. This is the setpoint for the hot water tank (in degrees

Fahrenheit). The hot water tank will maintain this temperature within a few degrees. If you don't want

to change the setpoint, continue to step 13.

a. Enter a new setpoint using the number keys. Acceptable range: 149°-205° F (65°-96° C).

b. Press to switch the display between degrees Celsuis and degrees Fahrenheit.

+

2.10. This is the steep time

OR

13. Press . The display shows CONF XXXX. The four "X"s represent the configuration code for your

machine. BE SURE THE CODE MATCHES YOUR MACHINE'S ACTUAL CONFIGURATION! An

invalid configuration will cause an "out of service" condition and a diagnostic message.

a. Enter one of the following configurations using the number keys:

If you have a . . . . . . enter this code:

Single brew machine ................ 2111

Dual brew machine ................... 2121

Freeze dry machine .................. 2131

b. Press to return to step 3 or # to exit.

PAGE B - 12 6300021

Page 29

Hot Drink Operation and Service Manual

sgnitteStluafeDyrotcaFemiTworhTdnathgieWtcudorPyrD.1DelbaT

pucezisrep)smargni(thgieW

___________________________________

AeeffocwerbhserF

AeeffocyrdezeerF

AeeffocyrdezeerfgnortS

BfacedwerbhserF

BfacedyrdezeerF

BfacedyrdezeerfgnortS

D

D

D

E

E

E

FaettnatsnI

FaettnatsnignortS

GetalocohC

HpuoS

HtcudorPelbuloS

noitceleS

zo5zo7zo8zo9zo01zo21

07.5

06.1

09.0

53.0

01.1

56.0

07.5

06.1

09.0

53.0

01.1

56.0

eeffocwerbhserF

OSSERPSE

eeffocyrdezeerF

OSSERPSE

eeffocyrdezeerfgnortS

OSSERPSE

eeffocwerbhserF

ONICCUPPAC

eeffocyrdezeerF

ONICCUPPAC

eeffocyrdezeerfgnortS

ONICCUPPAC

07.5

06.1

09.0

53.0

01.1

56.0

07.5

06.1

09.0

53.0

01.1

56.0

09.0

07.0

01.1

09.0

00.71

08.2

03.4

07.0

0.01

54.2

00.8

02.2

02.1

05.0

05.1

09.0

00.8

02.2

02.1

05.0

05.1

09.0

00.8

02.2

02.1

05.0

05.1

09.0

00.8

02.2

02.1

05.0

05.1

09.0

02.1

00.1

05.1

52.1

00.42

00.4

00.6

00.1

5.31

53.3

00.9

05.2

05.1

06.0

08.1

01.1

00.9

05.2

05.1

06.0

08.1

01.1

00.9

05.2

05.1

06.0

08.1

01.1

00.9

05.2

05.1

06.0

08.1

01.1

05.1

52.1

08.1

06.1

00.82

56.4

00.7

51.1

2.61

00.4

00.01

08.2

06.1

56.0

00.2

02.1

00.01

08.2

06.1

56.0

00.2

02.1

00.01

08.2

06.1

56.0

00.2

02.1

00.01

08.2

06.1

56.0

00.2

02.1

06.1

03.1

00.2

57.1

00.13

51.5

06.7

52.1

8.71

53.4

pucezisrep)sdnocesni(semitworhT

00.11

01.3

08.1

07.0

02.2

53.1

00.11

01.3

08.1

07.0

02.2

53.1

00.11

01.3

08.1

07.0

02.2

53.1

00.11

01.3

08.1

07.0

02.2

53.1

08.1

06.1

02.2

58.1

00.43

56.5

05.8

53.1

7.91

58.4

00.31

56.3

02.2

09.0

06.2

06.1

00.31

56.3

02.2

09.0

06.2

06.1

00.31

56.3

02.2

09.0

06.2

06.1

00.31

56.3

02.2

09.0

06.2

06.1

02.2

58.1

06.2

01.2

00.14

08.6

02.01

56.1

7.32

08.5

PAGE B - 136300021

Page 30

Hot Drink Operation and Service Manual

)deunitnoC(sgnitteStluafeDyrotcaFemiTworhTdnathgieWtcudorPyrD.1DelbaT

*pucezisrep)smargni(thgieW

_________________________________

IoniccuppacnidesuetalocohC

DosserpsenidesuraguS

DosserpsenidesuragusartxE

EoniccuppacnidesuraguS

EoniccuppacnidesuragusartxE

FaetnidesuraguS

FaetnidesuragusartxE

FaetnidesurenethgiL

FaetnidesurenethgilartxE

FaetnidesuetutitsbusraguS

FaetnidesuetutitsbusragusartxE

-*

*

-*

*

-*

*

-*

*

-*

*

-*

*

D

E

noitceleS

zo5zo7zo8zo9zo01zo21

01.3

55.0

01.2

53.0

00.3

05.0

05.3

54.0

06.4

06.0

02.4

55.0

05.5

07.0

02.1

07.0

05.1

58.0

06.0

57.0

08.0

00.1

raguS

ragusartxE

renethgiL

renethgilartxE

etutitsbusraguS

etutitsbusragusartxE

osserpsE=

oniccuppaC=

02.4

55.0

05.5

07.0

02.1

07.0

05.1

58.0

06.0

57.0

08.0

00.1

05.4

57.0

00.3

54.0

53.4

56.0

01.5

56.0

08.6

09.0

00.6

57.0

00.8

00.1

05.1

58.0

00.2

51.1

58.0

50.1

01.1

53.1

00.6

57.0

00.8

00.1

05.1

58.0

00.2

51.1

58.0

50.1

01.1

53.1

00.5

58.0

05.3

55.0

08.4

57.0

00.6

57.0

07.7

00.1

00.7

09.0

00.9

51.1

00.2

51.1

05.2

54.1

00.1

52.1

03.1

06.1

00.7

09.0

00.9

51.1

00.2

51.1

05.2

54.1

00.1

52.1

03.1

06.1

08.5

00.1

00.4

06.0

53.5

08.0

08.6

58.0

05.8

01.1

00.8

00.1

00.01

52.1

05.2

54.1

00.3

07.1

01.1

53.1

04.1

57.1

00.8

00.1

00.01

52.1

05.2

54.1

00.3

07.1

01.1

53.1

04.1

57.1

pucezisrep)sdnocesni(semitworhT

02.6

50.1

05.4

56.0

52.6

09.0

07.7

59.0

04.9

02.1

00.9

51.1

00.11

04.1

00.3

07.1

05.3

00.2

03.1

06.1

06.1

00.2

00.9

51.1

00.11

04.1

00.3

07.1

05.3

00.2

03.1

06.1

06.1

00.2

06.7

03.1

05.5

08.0

02.7

50.1

04.9

02.1

00.11

54.1

00.11

04.1

00.31

56.1

00.4

52.2

05.4

06.2

05.1

09.1

09.1

04.2

00.11

04.1

00.31

56.1

00.4

52.2

05.4

06.2

05.1

09.1

09.1

04.2

oniccuppacrofsemitetalocohC=I

* rotcudorpfoepytehtnopugnidnepedyravlliwworhttnemidnocrotcudorpafothgiewmarglautcaehT

-*

*

PAGE B - 14 6300021

.gnitsetyrotcafnopudesabetamixorppaeranevigsthgiewehT.desutnemidnoc

.Fdna,E,D,C/B/Asnoitcelesrofelbaliavaerasremitetutitsbusragusdna,renethgil,ragusetarapeS

Page 31

)puc.zo5(oniccuppaCrofsgnitteStcudorPyrD.2DelbaT

ETALOCOHC EEFFOCYRDEZEERFEEFFOCWERBHSERF

Hot Drink Operation and Service Manual

PAGE B - 156300021

tnecreP

)tluafed(5101.3

0201.4

5200.5

0308.5

5307.6

0406.7

5404.8

0503.9

tnecreP

)tluafed(5105.4

0208.5

5201.7

0300.8

5303.9

0405.01

5408.11

0501.31

thgieW

)mg(

thgieW

)mg(

gnimiT

)ces(

04.025 05.2)tluafed(5875 05.2)tluafed(5885 52.2

55.045 06.20845 53.20855 51.2

56.065 07.25725 52.25735 50.2

57.095 58.20794 01.20794 09.1

58.016 59.25674 00.25674 08.1

59.036 50.30644 58.10654 07.1

50.166 02.35514 07.15514 55.1

51.186 03.30583 06.10583 54.1

ETALOCOHC EEFFOCYRDEZEERFEEFFOCWERBHSERF

gnimiT

)ces(

55.065 55.2)tluafed(58101 53.4)tluafed(58511 00.4

07.095 07.20879 02.408011 58.4

58.036 09.25729 00.457401 56.3

59.056 00.30709 09.307201 06.3

01.196 02.35668 57.35669 04.3

52.127 53.30618 55.30629 52.3

04.167 55.35577 53.35578 50.3

55.197 07.30527 51.30538 09.2

)lm(emuloV

)lm(emuloV

sgnitteSretaW

tnecreP

)ces(gnimiT)lm(emuloV )ces(gnimiT)lm(emuloV )ces(gnimiT

sgnitteSretaW

tnecreP

)ces(gnimiT)lm(emuloV )ces(gnimiT)lm(emuloV )ces(gnimiT

sgnitteSretaW

tnecreP

)puc.zo7(oniccuppaCrofsgnitteStcudorPyrD.2DelbaT

sgnitteSretaW

tnecreP

sgnitteSretaW

sgnitteSretaW

Page 32

PAGE B - 16 6300021

Hot Drink Operation and Service Manual

)puc.zo8(oniccuppaCrofsgnitteStcudorPyrD.2DelbaT

ETALOCOHC EEFFOCYRDEZEERFEEFFOCWERBHSERF

tnecreP

)tluafed(5104.5

0208.6

5200.8

0303.9

5300.11

0407.21

5400.41

0556.51

tnecreP

)tluafed(518.5

026.7

528.8

035.01

533.21

049.31

543.51

051.71

thgieW

)mg(

thgieW

)mg(

gnimiT

)ces(

56.095 08.2)tluafed(58231 55.5)tluafed(58351 50.5

08.026 59.208821 04.508051 59.4

59.066 02.357221 51.557441 57.4

01.196 04.307711 59.407731 05.4

03.137 07.356211 57.456131 03.4

05.187 59.306801 06.406421 50.4

56.128 02.455501 54.455811 58.3

58.158 04.40519 58.305211 56.3

ETALOCOHC EEFFOCYRDEZEERFEEFFOCWERBHSERF

gnimiT

)ces(

57.006 57.2)tluafed(58041 09.5)tluafed(58271 06.5

00.146 59.208431 56.508551 50.5

51.186 51.357031 05.557251 59.4

53.127 53.307521 03.507441 07.4

06.177 06.356911 50.556831 05.4

08.128 58.306311 08.406331 53.4

00.258 00.455901 56.455621 01.4

52.209 52.405501 05.405421 50.4

)lm(emuloV

)lm(emuloV

sgnitteSretaW

tnecreP

)ces(gnimiT)lm(emuloV )ces(gnimiT)lm(emuloV )ces(gnimiT

sgnitteSretaW

tnecreP

)ces(gnimiT)lm(emuloV )ces(gnimiT)lm(emuloV )ces(gnimiT

sgnitteSretaW

tnecreP

)puc.zo9(oniccuppaCrofsgnitteStcudorPyrD.2DelbaT

sgnitteSretaW

tnecreP

sgnitteSretaW

sgnitteSretaW

Page 33

PAGE B - 176300021

tnecreP

)tluafed(512.6

020.8

528.9

033.11

536.31

043.51

541.71

057.81

tnecreP

)tluafed(516.7

028.9

528.11

039.31

531.61

042.81

544.02

053.22

)puc.zo01(oniccuppaCrofsgnitteStcudorPyrD.2DelbaT

ETALOCOHC EEFFOCYRDEZEERFEEFFOCWERBHSERF

thgieW

)mg(

thgieW

)mg(

gnimiT

)ces(

08.006 08.2)tluafed(58661 00.7)tluafed(58581 04.6

50.156 59.208161 08.608871 51.6

03.107 02.357551 55.657271 59.5

05.147 04.307051 53.607761 08.5

08.108 07.356341 50.656951 05.5

50.258 59.306731 08.506251 52.5

03.209 02.455131 55.555441 59.4

05.249 04.405621 53.505831 57.4

ETALOCOHC EEFFOCYRDEZEERFEEFFOCWERBHSERF

gnimiT

)ces(

00.146 00.3)tluafed(58322 53.9)tluafed(58132 51.8

03.107 03.308512 00.908322 58.7

55.167 06.357802 07.857512 55.7

58.128 09.307102 04.807702 52.7

51.278 51.456391 50.856102 50.7

54.239 54.406581 07.706391 57.6

57.299 57.455871 04.755581 54.6

00.3501 50.505171 01.705871 02.6

)lm(emuloV

)lm(emuloV

sgnitteSretaW

)ces(gnimiT)lm(emuloV )ces(gnimiT)lm(emuloV )ces(gnimiT

sgnitteSretaW

)ces(gnimiT)lm(emuloV )ces(gnimiT)lm(emuloV )ces(gnimiT

tnecreP

tnecreP

sgnitteSretaW

)puc.zo21(oniccuppaCrofsgnitteStcudorPyrD.2DelbaT

sgnitteSretaW

tnecreP

tnecreP

sgnitteSretaW

sgnitteSretaW

Hot Drink Operation and Service Manual

Page 34

Hot Drink Operation and Service Manual

semuloVdnasemiTtluafeDworhTretaW.1WelbaT

pucezisrep)sdnocesni(emiT

_____________________________________________

AeeffocwerbhserF

BfacedwerbhserF

AeeffocyrdezeerF

BfacedyrdezeerF

D)BF(osserpsE

D)DF(osserpsE

FaeT

GetalocohC

noitceleS

zo5zo7zo8zo9zo01zo21

05.4

031

05.4

031

59.4

021

59.4

021

52.2

56

05.2

06

59.4

021

58.4

001

04.6

091

04.6

091

00.7

071

00.7

071

02.3

59

05.3

58

00.7

071

08.6

041

05.7

022

05.7

022

52.8

002

52.8

002

57.3

011

51.4

001

52.8

002

52.8

071

pucezisrep)lmni(emuloV

02.8

042

02.8

042

56.8

012

56.8

012

01.4

021

53.4

501

56.8

012

57.8

081

00.9

562

00.9

562

09.9

042

09.9

042

05.4

331

59.4

021

09.9

042

07.9

002

00.11

513

00.11

513

06.21

503

06.21

503

05.5

851

03.6

351

06.21

503

56.11

042

HpuoS

HtcudorPelbuloS

PAGE B - 18 6300021

08.4

011

58.4

001

59.6

061

08.6

041

52.8

091

52.8

071

07.8

002

57.8

081

00.01

032

07.9

002

51.21

082

56.11

042

Page 35

Hot Drink Operation and Service Manual

TIME OF DAY FEATURES

You can set the clock and calendar features of your machine, as well as set up to four intervals during the day

when the machine will freevend.

1. Pull out the door switch button to the ON position.

2. Press # until the display shows TIME HH.MM . This is the currently set time, expressed in 24-hour

format.

a. If desired, set the time using the number keys. Remember to express the time in 24-hour format:

2:00 pm = 14.00.

3. Press . The display shows the current date: MM/DD YY. For example, 07/25 97 is July 25,

1997.

a. If desired, set the month, day, and year using the number keys.

b. To display the date in the European format (DD-MM), press . Note that the European format

uses a dash (-) instead of a slash (/) between the day and month to avoid confusing the two

formats. The display for our example would then be 25 - 07 97.

4. Press . The display shows FREEV 1 - 3 - . This shows the number of active "time-of-day freevend"

periods. In this example, freevend periods 1 and 3 are active.

a. To turn on or off the freevend periods, press the corresponding number key (1, 2, 3, or 4).

5. Press . The display shows 1.STRT 10.00. This is the start time of the first freevend period, expressed in 24-hour time format. This example shows period #1 beginning at 10:00 am.

a. If desired, enter a new start time using the number keys.

6. Press . The display shows 1.STOP 14.00. This is the stop time of the first freevend period, expressed in 24-hour time format. This example shows period #1 ending at 2:00 pm.

a. If desired, enter a new stop time using the number keys.

The machine will freevend between the hours of 10:00 am and 2:00 pm every day.

7. Press . The display shows *. ABCDEFG. These are the selections to be free vended during this

period. Pressing or will show selections to be free vended by cup size.

8. Press . The display shows 3.STRT 0.00. This is the start time of freevend period #3. Notice that

the display did not show freevend period #2, since it is inactive (see step 4). This time period and any

others are treated exactly the same as freevend period #1.

9. Press once to return to step 2, or press and hold # to exit.

PAGE B - 196300021

Page 36

Hot Drink Operation and Service Manual

Notes

PAGE B - 20 6300021

Page 37

Hot Drink Operation and Service Manual

CLEANING AND SANITATION

Basics

INTRODUCTION

Anyone who services vending machines must use proper sanitary procedures. Health regulations

require that hands be clean when cups, commodities, and food-contact parts are handled or serviced.

In addition, Federal and State Health Departments require regular cleaning and sanitizing procedures

for food contact parts.

The information in this section will explain how to clean and sanitize the merchandiser on a day to

day basis. A clean and well maintained merchandiser will provide a better product and greater safety

for your customers.

CLEANING AND SANITIZING -- WHATS THE DIFFERENCE?

Clean means free of visible soil. In cup vending machine servicing, cleaning is also done to

maintain product quality and to remove food soils, oils, and mineral stains that could affect product

taste, aroma, and appearance.

Sanitizing means the reduction, to safe levels, of the number of disease-causing bacteria that remain

on the surface after cleaning. Therefore, cleaning and sanitizing are done in separate steps, as

prescribed by health regulations and good industry practice.

When you sanitize you create a healthy and hygienic condition. This leads to wholesome food,

which in turn leads to satisfied customers.

HOW DO I SANITIZE?

You can sanitize by using either of these two methods:

Chemicals: The object to be sanitized is treated with a bactericidal compound.

Heat: Raise the temperature of the object high enough to kill bacteria. Water must be at least 170° F.

Hot brew water (if available) is an acceptable sanitizer. When food contact surfaces are washed

and/or rinsed, use the hot water available in the machine.

Turn the machine off before using water on the machine.

In either case, the object must be thoroughly clean and completely rinsed in order for the sanitizing

process to work. Caked-on soils not removed by cleaning, for example, may shield bacteria from a

sanitizing solution.

SANITIZING IS NO SUBSTITUTE FOR A GOOD CLEANING

PAGE C - 16300021

Page 38

Hot Drink Operation and Service Manual

A GOOD PLACE TO START -- YOUR SANITATION KIT

You need to be sure that each machine is clean, safe, and functioning when you leave it. In

order to properly do this, you need to have a complete set of the right tools. In addition to the

screwdrivers, pliers, and test equipment necessary to repair a machine, you need to have the

tools to clean the machine.

Here is a checklist of the items needed for a good sanitation kit:

Sanitation pail

Tube and nozzle brushes for food contact surfaces

Utility brush for dry spillage around canisters, etc.

Disposable towels, wet-strength and lint-free

NOTE

Wiping with towels can re-contaminate sanitized food-contact parts. Therefore, towels

should not be used to dry food-contact surfaces. Instead, these parts should be air dried.

Spray detergent, diluted to desired strength

Urn cleaner packets for coffee stains and oils

Odor control chemicals for pails

Replacement parts (if the exchange method is used)

Cabinet polish or window cleaner for the outside of the machine

Feel free to add some items to this list. For example, you may want to use a portable vacuum

cleaner.

PAGE C - 2 6300021

Page 39

Hot Drink Operation and Service Manual

SANITATION PROCEDURES

Refer to the recommended cleaning and sanitation interval table on the final page of this section.

For each item, complete the procedure as outlined here.

All food-contact parts must be cleaned AND sanitized. Air dry, do not wipe dry.

Ingredient Canisters - Empty and clean the canisters, augers, and spouts by washing with warm

water and detergent. Sanitize with hot water and allow to air dry completely before returning to the

cabinet.

Mixing Bowls - It is important that the mixing bowls be kept clean. The inside of all mixing bowls

should be rinsed whenever the machine is serviced by performing the "Bowl Rinse" operation as

outlined in the Programming section of this manual.

When required by the cleaning and sanitation schedule at the end of this section or more often if

needed, remove the mixing bowls from the dry ingredient shelf. Thoroughly clean the mixing bowls

by washing with warm water and detergent. Sanitize with hot water and allow to air dry before

reassembling.

Food-Contact Parts

NOTE

Whipper Cover and Impellers - Remove lids and impellers from the whipper housings, wash the lids

and impeller housing. Sanitize with hot water and allow to air dry before reassembling.

a. Remove the whipper assembly from its mounting and remove the whipper cover.

b. Using the impeller removal tool (located in the plastic bag assembly), remove the impeller from

the whipper housing as shown.

c. Wash the cover, impeller, and impeller housing. Sanitize with hot water and allow to air dry

before reassembling.

d. To reassemble, see detail A. Note that the whipper motor shaft has a flat section. Make sure

this flat section lines up with the "D" shaped hole in the impeller. Press the impeller all the way

onto the whipper motor shaft. Replace the cover.

PAGE C - 36300021

Page 40

Hot Drink Operation and Service Manual

Beverage Discharge Nozzles - Disconnect the beverage dispensing tube from the nozzles. Remove the nozzles from the mounting bracket. Remove the cap from the nozzle, wash clean and

sanitize the nozzles and cap. Refer to the tubing connection diagram for proper routing.

Brewer, Brewer Basket, and Brewer Funnel - The tubing and brewer may be sanitized by performing the BREW RINSE operation as outlined in the programming section. The machine features an

automatic brewer sanitizing feature also described in the programming section.

At times, it may be necessary to wash and sanitize the individual brewer parts. If so, disconnect

the tubes from the brewer manifold. Remove the brewer barrel and manifold assembly from its

support. Remove the brewer basket and funnel assemblies.

Thoroughly wash all parts using soap and water. Sanitize by rinsing thoroughly with hot water.

Ingredient Chutes - Remove the metal chute(s), wash clean, and sanitize by rinsing with hot water.

Air dry before reinstalling.

Condiment Chute Assembly - Remove the condiment chute and cover from the condiment canisters. Thoroughly wash all parts using soap and water. Sanitize by rinsing thoroughly with hot

water.

Non Food-Contact Parts

Brewer Mechanism Cleaning - Remove the brewer mechanism from its mounting and rinse with

the spray hose.

Cup Delivery Compartment - Remove the compartment from the merchandiser. Wash clean and

rinse with hot water.

Exhaust Fan Filter - Remove the filter from its housing. Wash with soap and water, rinse, wring

dry, and replace into housing.

Grounds Pail - Empty and rinse the grounds pail. Reline the pail with a clean plastic liner.

Waste Pail - Empty, wash, and rinse with hot water. Sprinkle detergent powder in the bottom of

the pail to help control odors.

Ingredient Rinse Tray - Remove product canisters. Wash and rinse with hot water. Allow to air

dry.

PAGE C - 4 6300021

Page 41

Hot Drink Operation and Service Manual

OVERALL CLEANING

Inspect your merchandiser both inside and out. Be sure to check corners and all less visible parts of

the merchandiser.

Clean where needed.

Allow the inside of the cabinet to dry thoroughly before you close the door.

National Vendors recommends using the following supplies:

A commercial glass cleaner on the glass in the cabinet door.

A mild detergent and warm water on the cabinet, brewer, and other NON ELECTRICAL components.

CAUTION!

The plastic parts in your merchandiser should be cleaned with mild detergent and warm

water. The use of other cleaning agents may damage the material, and should be avoided.

Do not get electrical connections or electrical components wet.

Do not use wax or lubricants which contain silicone on or in the merchandidser. Silicone or

silicone vapors can cause electrical failures.

Set the main switch to OFF before cleaning or servicing the merchandiser.

Be sure the area is well ventilated and no open flames are present before using any aerosol

spray.

Use protective glasses or a protective shield if an air hose is used for cleaning or drying.

PAGE C - 56300021

Page 42

Hot Drink Operation and Service Manual

PREVENTIVE MAINTENANCE CLEANING

Periodically, you should visually inspect your merchandiser's hot water tank for excessive lime

and scale buildup. This buildup on the tank walls, water valves, and heater element will vary

dramatically, depending upon water quality. You should develop a cleaning and deliming

schedule based on the apparent local water quality.

NOTE

To aid in removing scale from your merchandiser, National Vendors has a service kit

available: part number 6400080. In addition, if your machine has the Everpure water

inlet filter system option, a second kit (part number 6400086) is also available.

TO

CHOCOLATE

BOWL

TO

SOUP

BOWL

TO

CONDIMENT

BOWL

TO

HOT WATER

VALVE

TUBE ROUTING DIAGRAM

PAGE C - 6 6300021

DISPENSING

NOZZLE

SUPPORT

Page 43

Hot Drink Operation and Service Manual

SLAVRETNINOITATINASDNAGNINAELCDEDNEMMOCERSLAVRETNINOITATINASDNAGNINAELCDEDNEMMOCER

SLAVRETNINOITATINASDNAGNINAELCDEDNEMMOCERSLAVRETNINOITATINASDNAGNINAELCDEDNEMMOCER

SLAVRETNINOITATINASDNAGNINAELCDEDNEMMOCER

METIYLIADYLKEEWYLHTNOMYLRETRAUQYLLAUNNA-IMES

sretsinaCtneidergnIS/C

slwoBgnixiMRS/C

srellepmIdnasdiLreppihWRS/C

selzzoNegrahcsiDegareveBS/C

tnemtrapmoCyrevileDpuCC

retliFnaFtsuahxEC

liaPetsaWC

lennuF,teksaB,rewerBCS

setuhCtneidergnICS

msinahceMrewerBC

liaPsdnuorGC

lavretnisihttaezitinaS=SesniR=RlavretnisihttanaelC=C

PAGE C - 76300021

Page 44

Hot Drink Operation and Service Manual

Notes

PAGE C - 8 6300021

Page 45

Hot Drink Operation and Service Manual

APPENDIX A. THE INFRARED MUG/CUP SENSOR

The infrared mug/cup sensor can sense the presence of a mug or cup without using moving parts.

Indicator light

The sensor is equipped with an indicator light. This light will help you get the best results from the infrared

mug/cup sensor.

Under these conditions:

· Machine door open

· Cup station in place

· No cup in the station

The indicator light should be off. If it is on, it is indicating improper cup station alignment or excessive

sensor sensitivity.

Under these conditions:

· Machine door closed

· Cup station in place

· No cup in the station

Press any letter on the selection switch panel, for example, A. Only the letter A should be showing in the

message display. If “A MUG” is displayed, it indicates one or more of the following:

· Improper cup station alignment

· Excessive sensitivity (the sensor is sensing the delivery door)

· Cup station lens is not clean

Cleaning

As indicated in the Sanitation section, you should remove the cup station to clean it. Pay particular

attention to the dark colored infrared mug/cup sensor lens, which is part of the cup station. If it is not

thoroughly cleaned, the sensor will not work properly.

CAUTION

Do not get liquid inside the sensor unit.

Cleaning the infrared mug/cup sensor unit itself is not usually necessary. If it does require cleaning, just

wipe it with a damp cloth.

Appendix A - 16300021

Page 46

Hot Drink Operation and Service Manual

1. Remove the plastic cap in the rear of the

sensing unit, exposing the potentiometer

adjusting screw, as shown.

2. Turn the screw clockwise to increase

sensitivity of cup detection, or counterclockwise to decrease sensitivity.

VIEWING REAR OF SENSOR ASSEMBLY

3. Calibrate the sensor:

CAUTION

INDICAT OR

LIGHT

Do not adjust sensitivity too far,

or unreliable sensing could result.

ADJUSTING SCREW

a. Using a piece of WHITE poster board or heavy cardboard, make a 5" x 5 5/8" target.

NOTE

IT IS VERY IMPORTANT THAT THIS MATERIAL BE WHITE.

b. Place the target in the cup station just

PLASTIC CAP

beyond the cup deflectors. The target

should be standing vertically; not tilted

forward or backward.

c. With the target in place, turn the adjusting

screw clockwise very slowly until the

indicator just turns ON.

d. Turn the adjusting screw counterclock-

wise very slowly until the indicator just

turns OFF.

4. Replace the plastic cap.

CUP

PLASTIC CAP

SHOWN REMOVED

INDICATOR LIGHT

CUP

DEFLECTORS

5. Insert a mug into the cup station in the vending position and check to see that the red indicator light is

ON.

This calibration will be adequate for most cups or mugs. In some cases, a slightly more sensitive setting

is needed if the cup or mug is a dark color.

Appendix A - 2 6300021

Page 47

Hot Drink Operation and Service Manual

APPENDIX B. THE AUTOMA TIC VEND DOOR

Your merchandiser may be equipped with an automatic vend door. There is no setup or configuration

available for this option. If you should need to test the operation of the door, go to the service mode and

make a test vend. The machine will try to operate the door with every vend.

Appendix B - 16300021

Page 48

Hot Drink Operation and Service Manual

Notes

Appendix B - 2 6300021

Loading...

Loading...