Page 1

Page 2

Refreshment Center Operator’s Guide Table of Contents

TABLE OF CONTENTS

Introduction................................................................................................................. 1

Power Requ irements ........... .......... .................... .......... ........... .......... .......... .......... .......... ....................... 3

Unpack t h e Mac h i n e ..... .......... .......... .......... .......... .......... ........... .......... .......... .......... .......... ................... 3

Controls and Indicators.......................................................................................................... .......... ..... 4

Turn the Merchandis er ON and OFF.......... .......... .......... ........... .......... .......... .......... .......... .......... ......... 6

Initial Set-Up................................................................................................................ 7

Moving the Merchandiser Through a Narrow Doorway .. ............................. .............. .............. ........... 7

Open the Re ar O u t l e t Diffuser................ .......... .......... ........... .......... .................... .......... .......... ............. 9

Position the Merchandiser .................................................................................................................... 9

Configure Machine for Dual Zone...................................................................................................... 10

Tray Set-Up................ ......... .......... ......... ......... .......... ......... .......... ......... .......... ......... .. 17

Place a Tray in the Loading Position............. ...... ........ ...... ... .... ...... ...... ........ ...... ...... ........ ...... ............ 1 7

Set up Trays to Vend Products ........................................................................................................... 18

Set Up A Tray To Vend Wide Products............................................................................................. 18

Remove a Snack or Candy Tray......................................................................................................... 19

Remove a Bottle Tray......................................................................................................................... 21

Remove an d In stall Column D ivi d ers......... .......... .......... ........... .................... .......... .......... .......... ....... 22

Operate a Tray Outside of the Machine.............................................................................................. 22

Replace a Motor with a Spiral Bearing............................................................................................... 23

Connect a n d D is c o n n ec t a Mo t o r H arness................ .......... ........... .......... .......... .......... .......... .. ........... 24

Remove an d In stall Spirals ........... .......... .......... .......... ........... .......... .......... .................... ..................... 25

Remove a Spiral Coupler............................................................................... .......... ............ ............... 26

Remove an d In stall a Spiral M otor........... .......... .......... ........... .......... .......... .......... .......... .......... ......... 27

Instal l a Ge a r.......... ........ ........ ........ ........ ........ ........ ........ ....... ........ ........ ........ ........ ........ ..................... . 28

Install a Spiral Coupler....................................................................................................................... 29

Move a Tray Up o r Down............. .................... .......... ........... .......... .......... .......... .......... .......... ........... 30

Instal l a Tr ay i n th e Me rchandise r .......... .......... .......... ........... .......... .................. .......... .......... .......... ... 31

Install and Remove a Product Spacer........................................................................ .......... ............... 32

Load the Merchandiser............................................................................................. 33

General Tray Loading:........................................................................................................................ 33

Special Considerations:.......................................................................................................... .......... ... 33

Spiral Wall Retainer Usage................................................................................................................. 34

Product Pusher Usage......................................................................................................................... 35

Config u re t h e Me r c h an d iser to vend “Lun ch Buckets”................... .......... .......... .......... .......... .......... . 35

Configure the Merchandiser for Vending "Top Shelf"....................................................................... 36

Return the Trays to the Vending Position............................. .... .......... ............ .......... ............ .............. 37

Instal l a n d Set P ri c e Labels........ ........ ........ ........ ........ ........ ....... ........ ........ ........ ........ ........ .................. 38

SureVend™................................................................................................................ 41

Health Control........................................................................................................... 42

Final Installation ....................................................................................................... 44

Level th e Merchan d i se r ............. ........ ........ ........ ........ ........ ............... ........ ........ ........ ........ ............. ..... 44

Install the Base Plate........................................................................................................................... 45

Install the Lock Cylinder.................................................................................................................... 46

December 2004 i 4800006

Page 3

Table of Co ntents Refr eshment Cent er Operat or’s

Install the Optional Cash Box Lock............................................................................................... ..... 46

Set Up the Coin Mechanism ............................................................................................................... 47

Load the Coin Mechanism.................................................................................................................. 47

Operat i o n a l Readiness Check.......... ........ .............. ........ ........ ....... ........ ........ ........ .............. ................ 4 8

Spiral In d e x i n g P ro c edure (One Spi ral, One Moto r) .............. ........... .......... .......... .......... .......... ......... 48

Spiral Indexing Procedure (Two Spirals, One Or Two Motors)......................................................... 49

Test the Bill Validator................................................................................... .......... .......... ........... ....... 49

Programmi ng Intro............... ......... .......... ......... ......... .......... ......... .......... ......... ......... 50

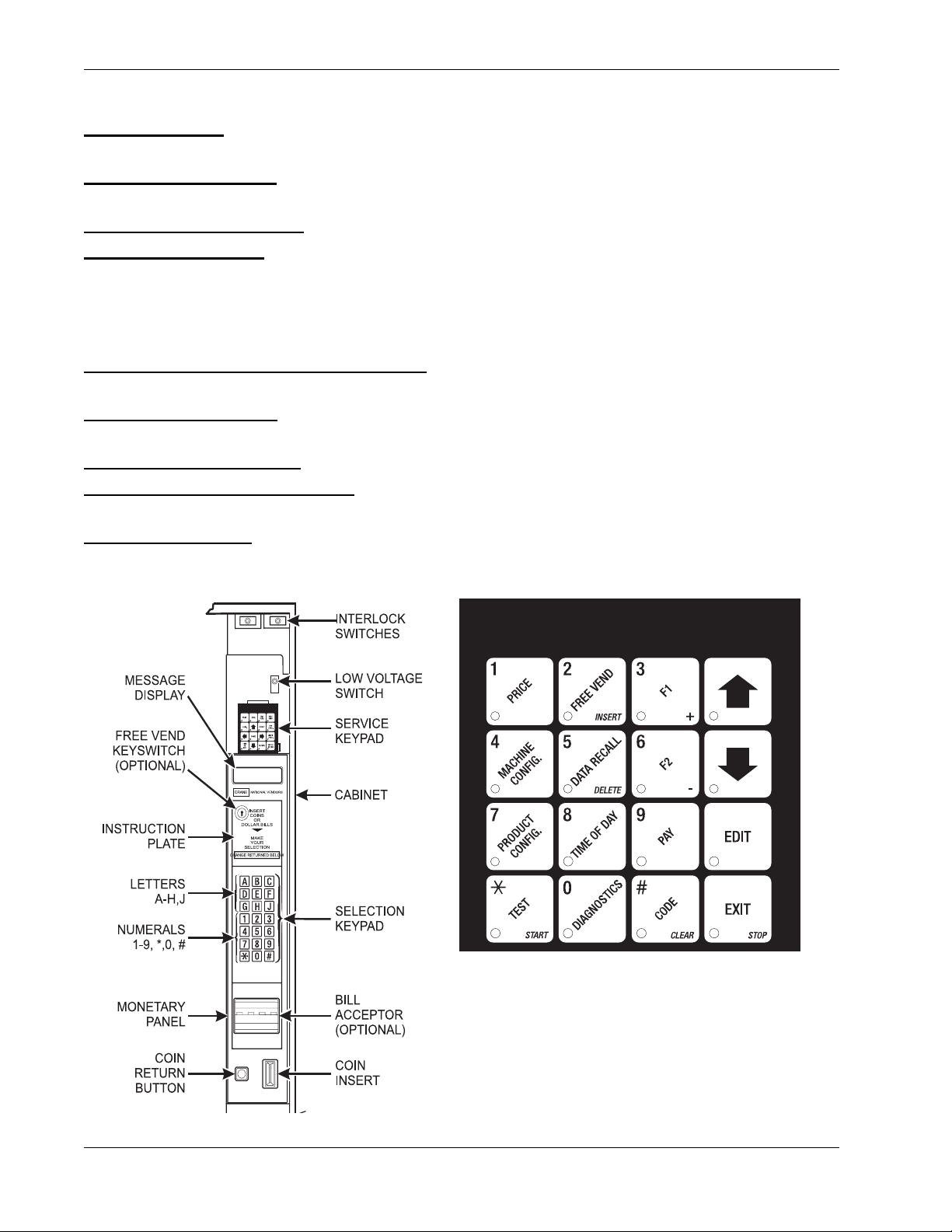

The Displays ........................................................................................................................ ............ ... 50

The Func t i o n Keys........ .......... .......... .......... .......... .......... .......... ........... .......... .......... .......... ................. 51

Other Keys............................................................................................................................. .......... ... 51

Contro l Pa n e l Swi t c h es Explained............ .......... .................... ........... .......... .......... .......... .......... ......... 52

Programming Flow Charts.................................................................................................................. 53

Programmi n g Procedures..... ......... .......... ......... ......... .......... ......... ................... ......... 55

Enter a New Supervisor Code ............................................................................................................ 55

Enter a Freevend Cod e ............ ........ ........ ........ ........ ........ ........ ............... ........ ........ ........ ....................55

Lock Or Unlock Mode Or Payout Keys ........................................................................... ............ ..... 56

Turn Talker Mode On or Off ............................................................................................................. 56

Set DEX O p t i o n s .......... ........ ........ ........ ........ ........ ........ ........ ....... ........ .............. ........ ........ ................57

Select Display Language ................................................................................................................... 58

Selec t Co i n Mechanism .......... ........ .............. ........ ........ ........ ....... ........ ........ ........ ........ ........ .. ............58

Select Card Reader and Options ........................................................................................................ 60

Set Temp e r a t u re ................ ........ ........ ........ ........ ........ ........ ........ ....... ........ ........ ........ ........ ..................64

Enabl e o r D i sa b l e Trays .......... ........ ........ ........ ........ ........ ........ ....... ........ ........ ........ ........ ....................65

Set SureVendUp the SureVend Anti-Jackpot Feature.................................................... .................. 66

Set fir st i n - fi rst out(fifo) mode .............. ........ ........ ........ ........ ....... ................ ........ ........ ....................68

Show the Temperature in Standby Mode .......................................................................................... 69

View Sur ev e n d S o ftware versi o n ................... .......... .......... ........... .......... .......... .......... ....................... 70

View Software Version ...................................................................................................................... 70

Set the Date ........................................................................................................................................ 71

Set Daylight Savings Option .............................................................................................................. 71

Set Time-Of-Day Free Vending .........................................................................................................72

Set Time-Of-Day Discount Vending ................................................................................................. 72

Time Interval Editing .........................................................................................................................72

Select a Standby Message .................................................................................................................. 74

Select a Freevend Message ................................................................................................................ 75

Set Prices ............................................................................................................................................ 78

View Sales Data Three Different Ways ............................................................................................. 79

View Card Reader Paid Sales ............................................................................................................ 79

View Total Paid Vends ...................................................................................................................... 80

Clear All Re settable Da t a .......... .......... .......... .......... .......... ........... .......... .......... .......... ....................... 80

View Amount In Coin Box ...... .......................................................................................................... 81

View Amount In Validator ................................................................................................................ 81

View Discount Sales By Time Interval ............................................................................................. 82

View Free Vends ............ ........ ........ ........ ........ ........ ........ ........ ....... ........ ........ ........ ........ ....................82

View Time Data......................................................................................................................... ........ 83

View To tal Unpaid V ends .................. ........ ........ ........ ........ ....... ........ ........ ........ ........ ........ ................85

4800006 ii December 2004

Page 4

Refreshment Center Operator’s Guide Table of Contents

View Number Of Test Vend s ............ .......... .......... .......... ........... .......... .......... .......... .......... ............... 85

View Mach i n e ID Number .. .......... .......... .................... ........... .......... .......... .......... .......... .......... ......... 85

Test the Motors .................................................................................................................................. 87

Download Data To A PDCD ............................................................................................................. 90

Set Free v end Opti o n s .................. ........ ........ ........ ........ ........ ....... ........ ........ ........ ........ ........ ................ 90

December 2004 iii 4800006

Page 5

Table of Co ntents Refr eshment Cent er Operat or’s

4800006 iv December 2004

Page 6

Refreshment Center Oper ators’ Guide Introduction

Section 1: Introduction

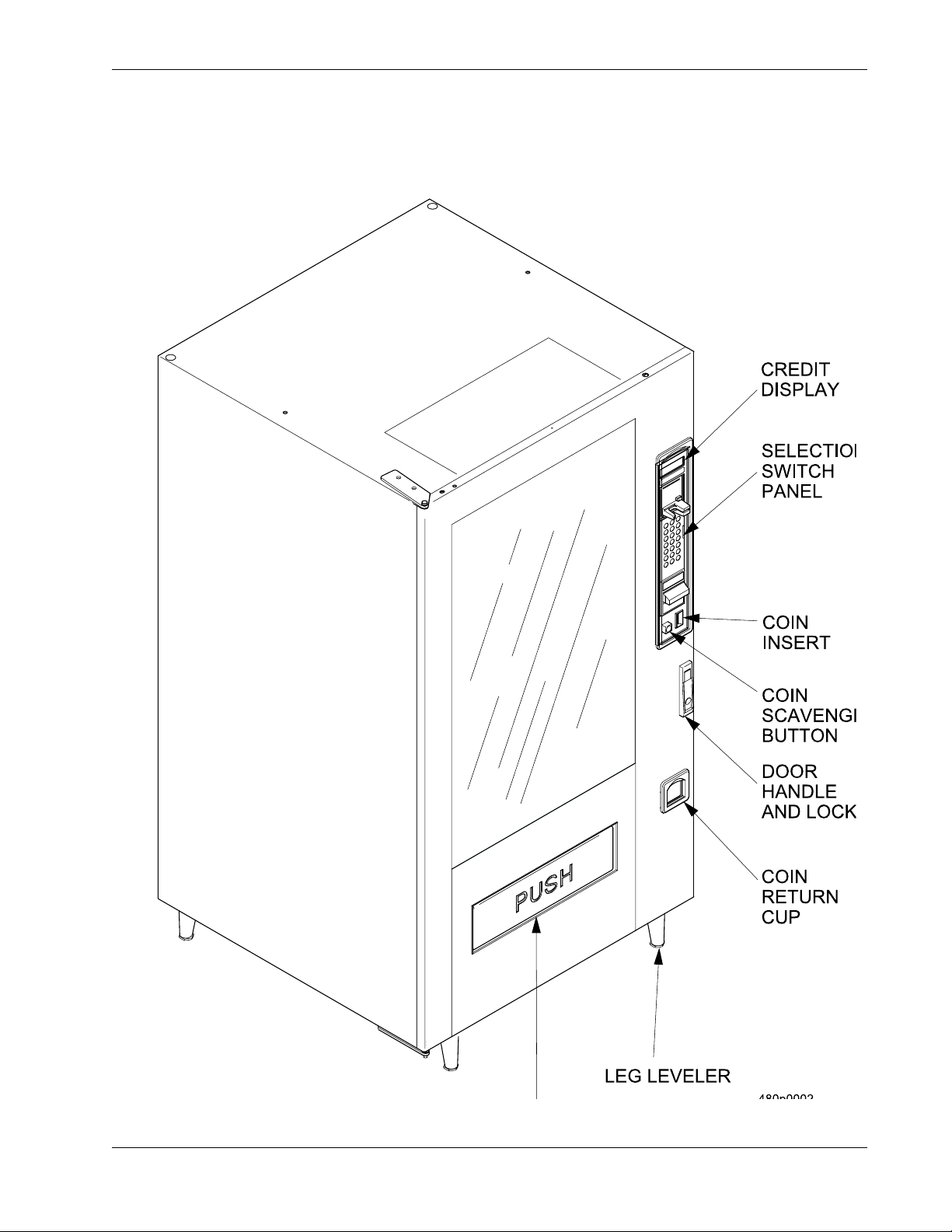

Exterior View

December 2004 1 4800006

Page 7

Introdu cti on Refres hm en t Cen te r Op er ato rs’ Gu ide

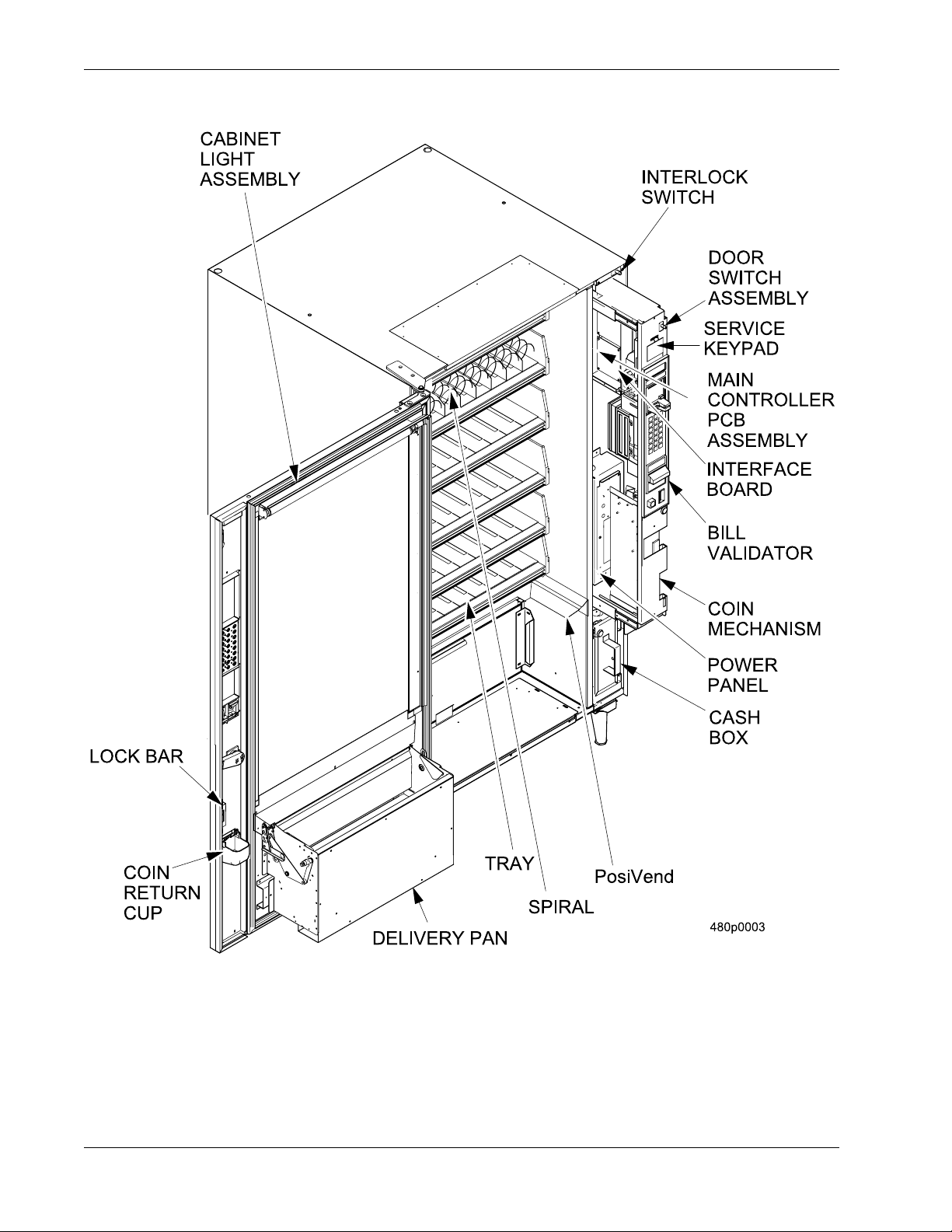

Interior View

4800006 2 December 2004

Page 8

Refreshment Center Oper ators’ Guide Introduction

Power Requirements

The merchandiser is supplied with a service cord for the country of use and is terminated in

a grounding type plug. The wall receptacle used for this merchandiser must be properly

polarized, grounded, and of the correct voltage. Operating the merchandiser from a source

of low voltage will VOID YOUR WARRANTY. Each merchandiser should have its own

electrical circuit and that circuit should be prote cted with a circuit breake r or fuse conforming

to local regulations.

1. Voltage Check - Place the leads of a voltmeter across the LINE (LIVE) and NEUTRAL

terminals of the wall recept acle. The voltm eter should indicate 110-130 volts AC for 120

volt, 60 Hz locations, or 220- 240 volts AC for 230 volt, 50 Hz locations.

2. Polarity Check - Place the leads of a voltmeter across the LINE (LIVE) and GROUND

terminals of the wall recept acle. The voltm eter should indicate 110-130 volts AC for 120

volt, 60 Hz locations, or 220- 240 volts AC for 230 volt, 50 Hz locations.

3. Noise Potential Check - Place the test leads of a voltmeter across the NEUTRAL and

GROUND terminals of the wall receptacle. The meter should indicate 0 volts AC. A

measurement grea ter than 1.5 - 2.0 volts AC could result in problems for the

merchandiser's electronic circuitry caused by electrical noise.

Any deviation from these requirements could result in unreliable performance from your

merchandiser.

Unpack the Machine

Remove all packing materials from the interior of the machine. Keep all documents;

warranty cards, etc. Set aside the base plate kit (if present).

December 2004 3 4800006

Page 9

Introdu cti on Refres hm en t Cen te r Op er ato rs’ Gu ide

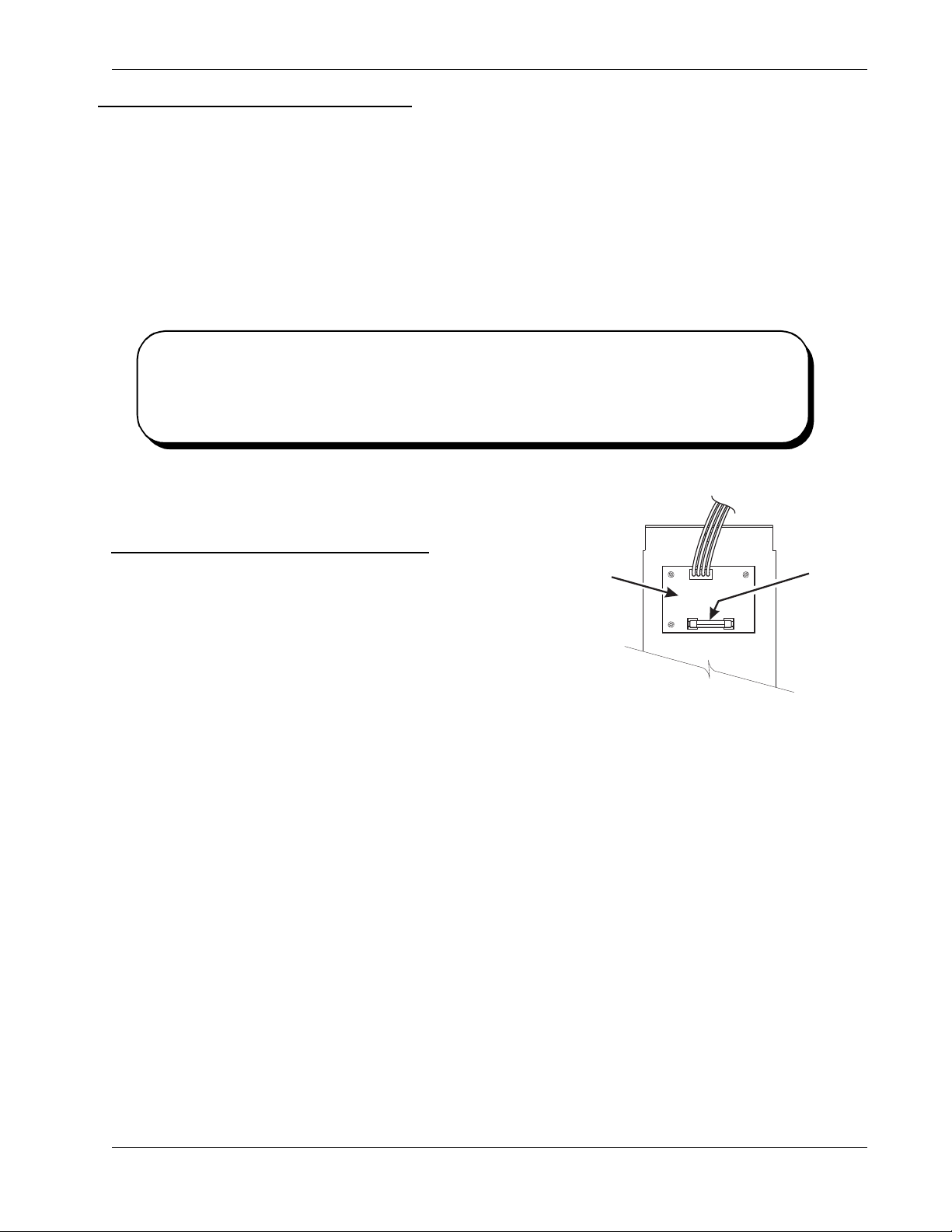

Controls and Indicators

DOOR SWITCH. When the cabinet door is open, this switch turns off the compressor and

evaporator fan.

INTERLOCK SWITCH. (230 volt models only) Turns off the glass heater and display lights

when the cabinet door is open. Pull the switch out to restore high voltage for maintenance.

LOW VOLTAGE SWITCH. Tells the controller software the main door is open or closed.

MESSAGE DISPLAY. This is how the merchandi ser com mun icates wi th the out side wor ld .

Customers can se e messag es about how much money t hey have put into the merchandise r .

The message display also tell s custome rs when a selection is sold out and when vend ing i s

free, inhibited, or discounted. The message display shows you what you are doing when

you program the merchandiser, and can show you what is wrong if there is a failure.

FREE VEND KEYSWITCH (OPTIONAL). This allows someone (other than maintenance

personnel) to set the merchandiser to free vend without opening the door.

SELECTION KEYPAD. The customer uses this keypad to make selections. Maintenance

people may use this keypad during programming.

COIN RETURN BUTTON. Returns any coins paid into the merchandiser prior to a vend.

BILL ACCEPTOR (OPTIONAL). Accepts bills of various denominations, depending upon

the type of bill validator, and how the machine is configured.

SERVICE KEYPAD. The service keypad is located at the top of the monetary panel. It

gives service personnel the means to program, retrieve data from, and view diagnostic

information about, the merchandiser.

4800006 4 December 2004

Page 10

Refreshment Center Oper ators’ Guide Introduction

F

1

E

P

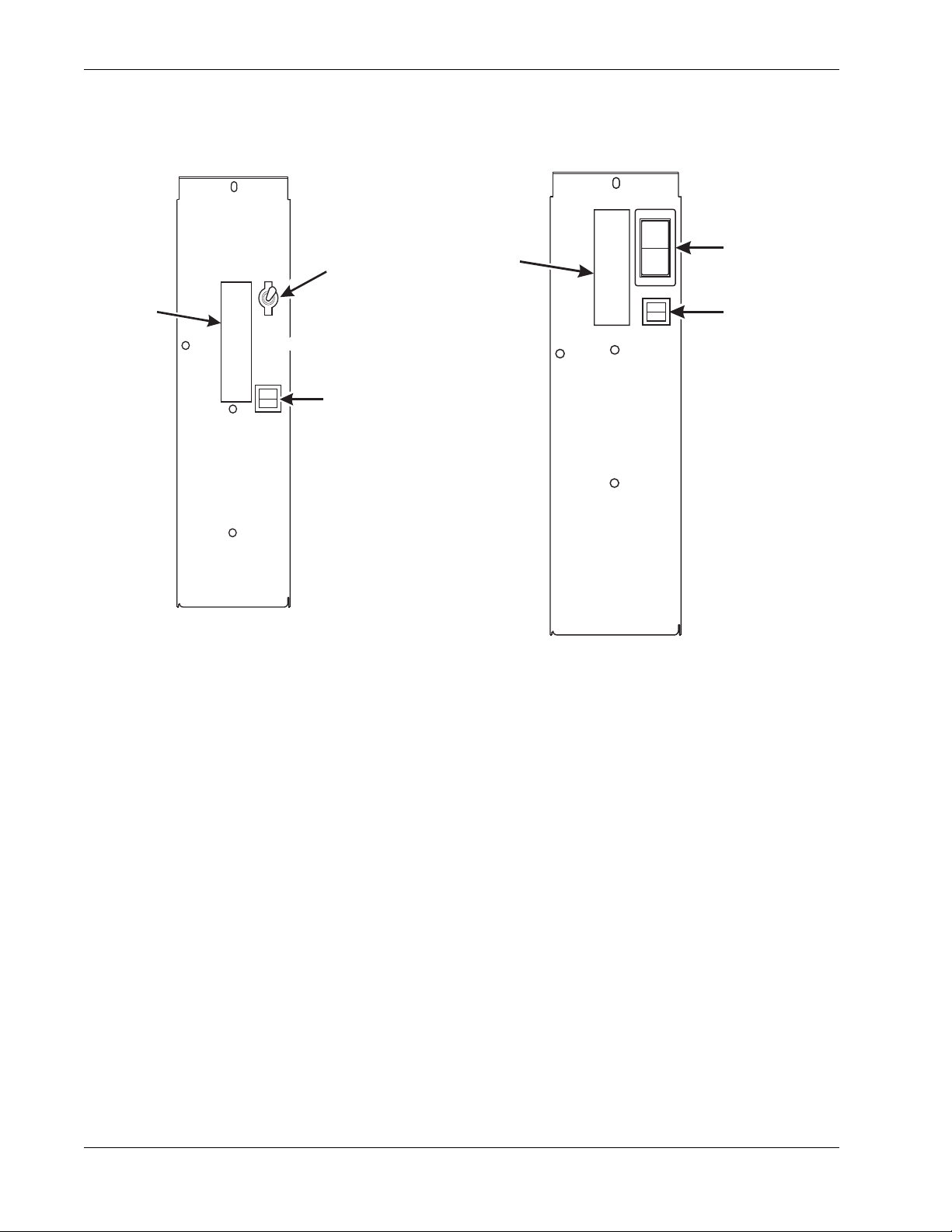

U.S. / CANADA POWER CONTROL PANEL

MAIN CONTROLLER PCB DISPLAY. This display consists of two light emitting diodes

(LED) mounted on the controller PCB.

POWER O N

(LED 1)

HEARTBEAT

(LED 2)

"CAUTION - Risk of explosion if battery is replaced with an incorrect type. Dispose of used batteries according

to the manufacturer's instructions."

When lit, this red LED indicates electrical power is applied to the

controller PCB.

When flashing, this red LED indicates that the controller PCB is

active, and th e s oftw are is operating .

NORMAL CONDITIONS:

When the merchandiser is operating normally, you should see a steady red

POWER ON indicator and a flashing red HEARTBEAT indicator. Contact a

service representative if any other condition exists.

TOP

Back Side of U.S./Canada Power Panel.

circuit board mounted on the rear of the power

panel is a DC power supply for the coin

mechanism. A fuse protects the board circuitry in

the event of a coin mechanism solenoid failure. If

the coin mechanism is not working, check this

fuse. If the fuse is blown, a bad coin mechanism

solenoid c ould be at fault.

The

DC POWER

SUPPLY PCB

OR 110V COIN MECH

˜

BACK SIDE

OF

AGC

FUS

1 AM

December 2004 5 4800006

Page 11

Introdu cti on Refres hm en t Cen te r Op er ato rs’ Gu ide

Turn the Merchandi s e r ON and OFF

I

LABEL

MAIN

ON

OFF

POWER

SWITCH

LOW VOLTAGE

CIRCUIT BREAKER

626p0040

LABEL

O

US / CANADA POWER PANEL INTERNATIONAL POWER PANEL

MAIN

POWER

SWITCH

ELECTRONICS

BREAKER

626P0005

• Power to the merchandiser is con trolled by the mai n power switch, loca ted on the

power panel.

• The power panel is on the right side of the merchandiser, behind the monetary

panel.

WARNING

Lethal voltages are present. Unplug the merchandiser before you perform any of the

following tasks:

• Change a fuse

• Change the fluorescent lamp

• Change the lamp starter

• Connect or disco nnect a ha rness (excep t a moto r harness when the tray has bee n

removed)

Failure to do so may result in personal injury.

4800006 6 December 2004

Page 12

Refr eshment Center Operators’ Guide Initi al Set-Up

Section 2: Initial Set-Up

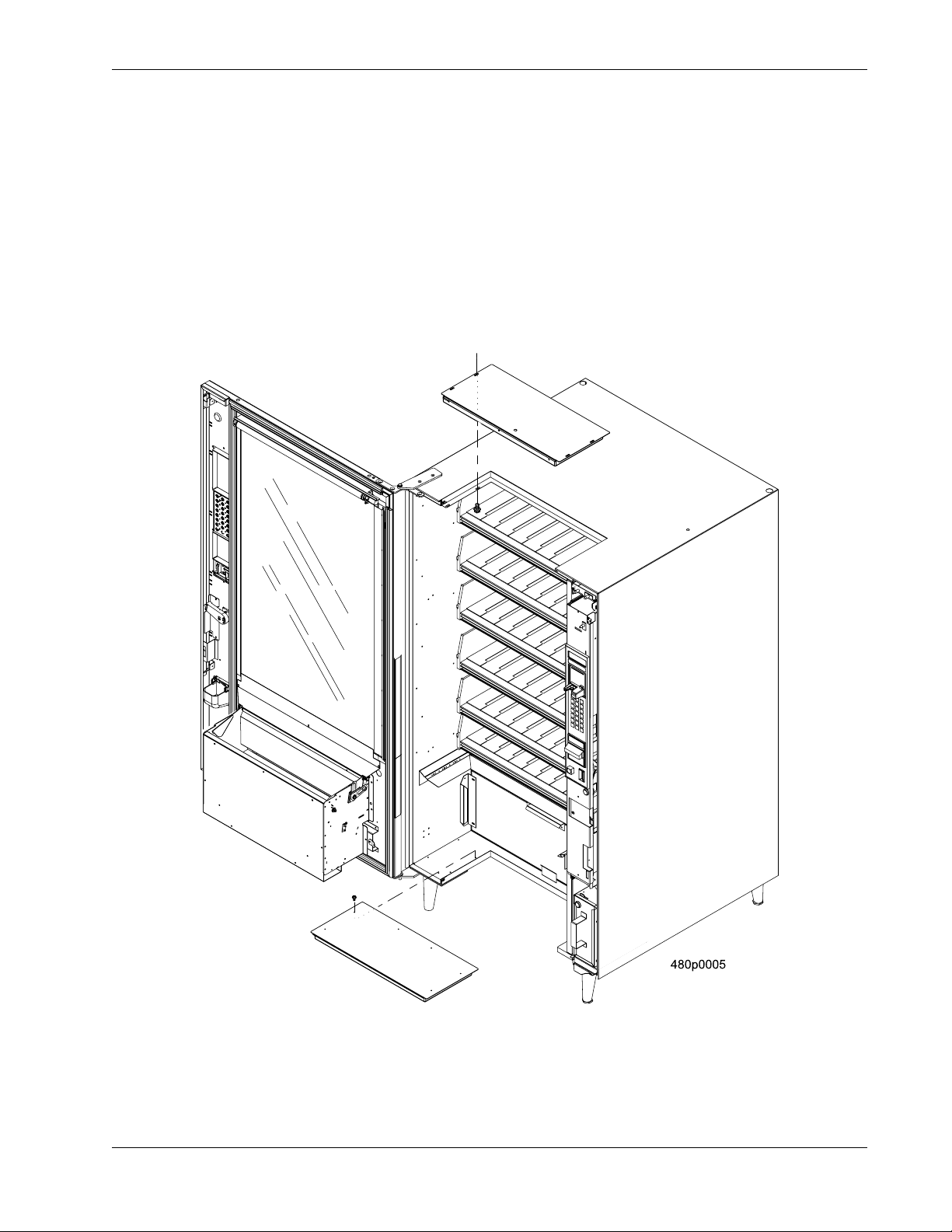

Moving the Merchandiser Through a Narrow Doorway

NOTE

If necessary, this merchandiser can be moved through an opening as narrow as 30

inches by removing panels at the top and bottom of the cabinet.

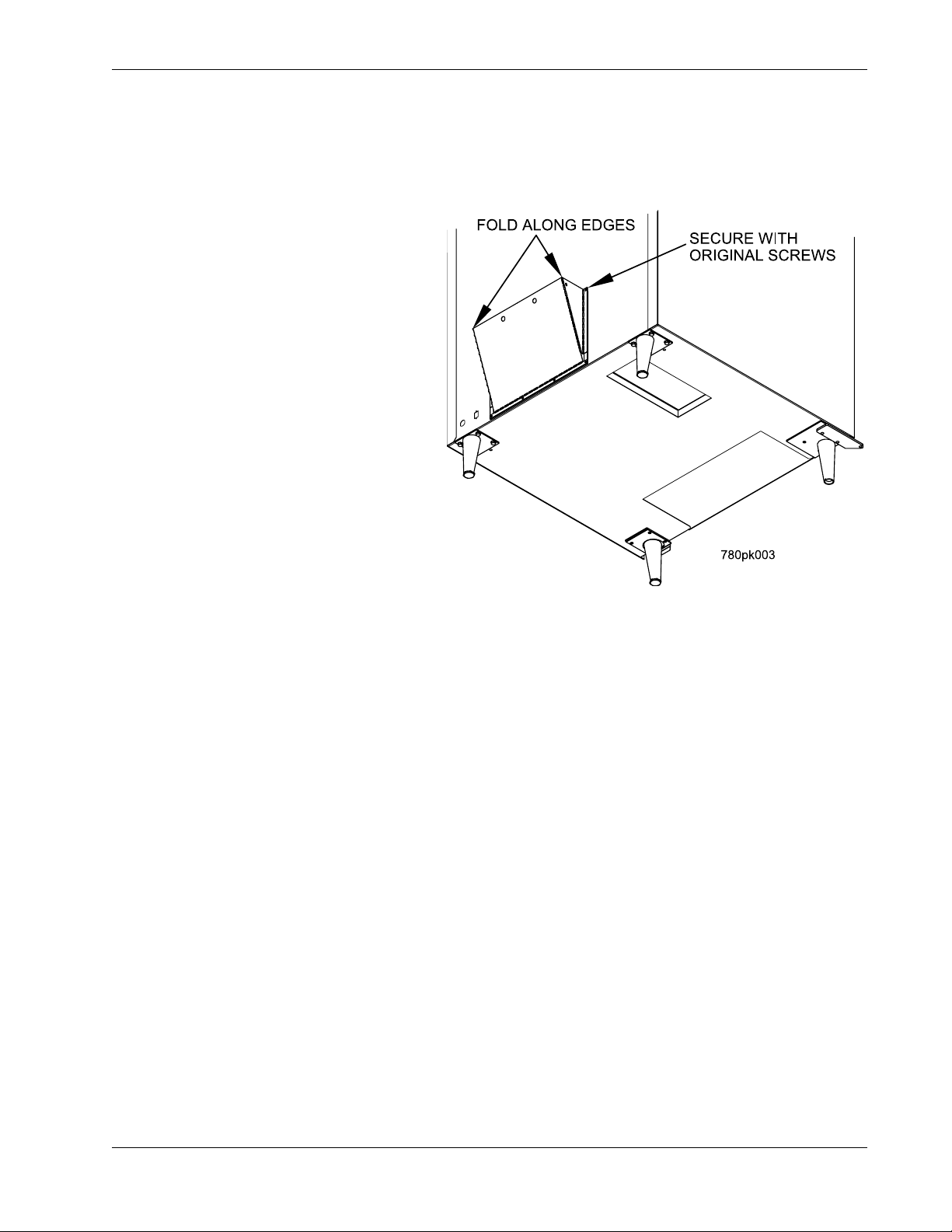

Remove the Bottom and Top Panels:

1. Remove the screws that secure the top and bottom knock-out panels to the cabinet.

2. Lift panels upward to remove them from the cabinet.

December 2004 7 4800006

Page 13

Initial Set-Up Refreshmen t Cen te r Oper ato rs’ Gu ide

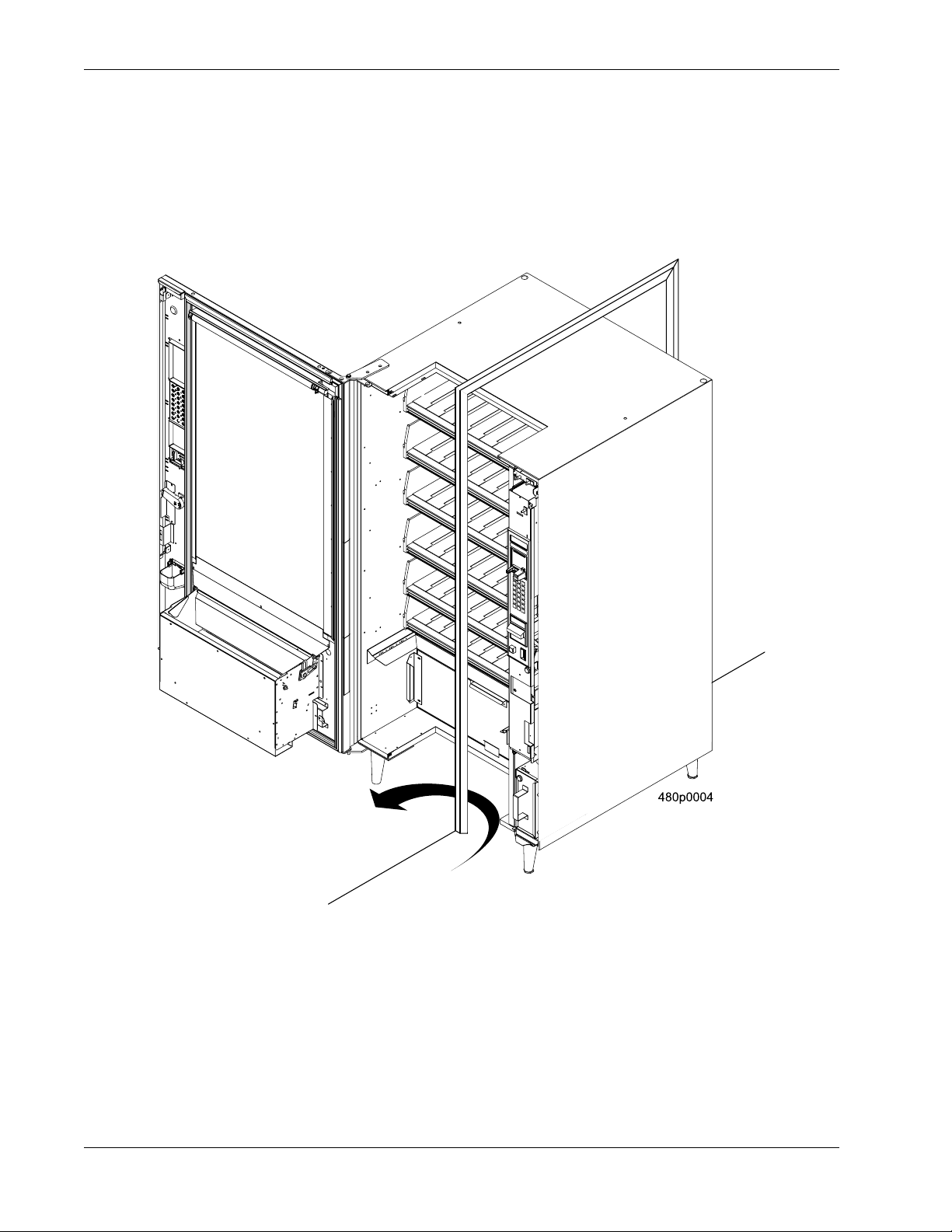

Move the Merchandiser through the Opening:

1. Open the cabinet door and place it square with the left side of the cabinet.

2. Carefully walk the merchandiser through the opening.

Reassemble the Merchandiser:

1. Replace the upper and lower panels.

4800006 8 December 2004

Page 14

Refr eshment Center Operators’ Guide Initi al Set-Up

Open the Rear Outlet Diffuser

The rear outlet diffuser vents warm air up and out of the back of the merchandiser, away

from the air inlet ( on the botto m of the cab i net). It is shi pp ed in th e closed posi tion and must

be opened before the merchandiser is put into service.

1. Remove the two screws holding

the upper corners of the diffuser

against the back of the cabinet.

Notice the two unu sed screw hol es

at the corners.

NOTE:

Wear protective gloves when

bending diffuser to prevent

injury.

2. Pull the top of the diffuser away

from the cabinet, then bend the

diffuser so that the unused screw

holes align with the holes in the

cabinet.

3. Use the two screws removed in

step one to affix the diffuser to the

cabinet in its new “open” position.

CAUTION

The merchandiser will no t fun c tion properly if the Rear Outlet Dif fuser is not open!

Position the Merchandiser

Move the merchandiser to its approximate position. There are certain procedures you

need to perform before it is in its permanent location. Plug in your merchandiser and turn

the power switch to ON.

• You can position this merchandiser anywhere in a bank of machines. It can even

be placed on an end flush against a side wall.

• The merchandiser should be placed at least four inches away from the back wall

(six inches if rear dif fuser is not inst alled). This will provide adequ ate air circula tion

for the refrigeration unit. This will provide adequate air circulation for the

refrigeration unit.

• The merchandiser will operate more efficiently when placed in a shaded location.

• There should be enough room in front of the merchandiser for the door to move

freely.

CAUTION

This machine is only rated for installation at an indoor location.

December 2004 9 4800006

Page 15

Initial Set-Up Refreshmen t Cen te r Oper ato rs’ Gu ide

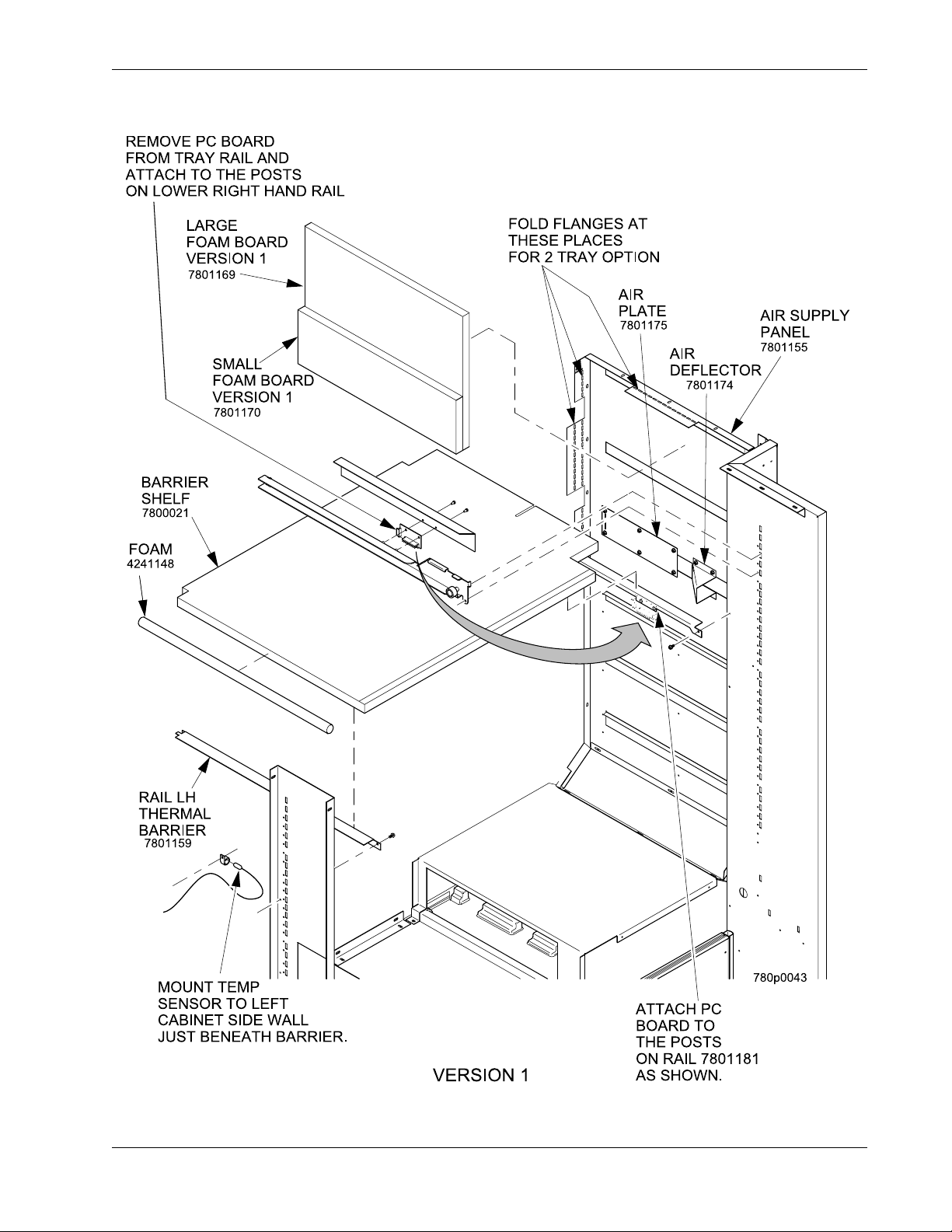

Configure Machine for Dual Zone

To configure your machine for dual zon e you must f irst know what du ct system your mach ine

has. There are two dif ferent duct systems. Th ere is a version 1 duct system which uses a tall

air supply panel (as shown in figure 1 and 2). This air supply panel will extend all the way to

the top of the mach ine. V ersion 2 d uct system which uses a sho rt air supply p anel (as shown

in figure 3) will only extend about half way up the machine.

Both duct systems have two different configurations for the dual zone option. There is a two

tray configuration and a three tray configuration.

If you have a version 1 duct system and you are configuring your machine for a two tray

configuration: (See Figure , “Figure 1,” on page 11)

If you have a version 1 duct system and you are configuring your machine for a three tray

configuration: (See Figure , “Figure 2,” on page 13)

If you have a ver sion 2 duct system and you are config uring your ma chine f or a two tray or a

three tray configuration: (See Figure , “Figure 3,” on page 15)

Note:

If you are not using dual zone in the merchandiser then you must remove the

barrier, foam boards, air deflector, and the air plate.

The temperature sensor will be mounted on the top left hand

side of the cabinet.

4800006 10 December 2004

Page 16

Refr eshment Center Operators’ Guide Initi al Set-Up

Set machine for two tray configuration version 1:

FIGURE 1

December 2004 1 1 4800006

Page 17

Initial Set-Up Refreshmen t Cen te r Oper ato rs’ Gu ide

Version 1 duct system two tray configuration

(See Figure , “Figure 1,” on page 11)

1. You must first remove all trays from your merchandiser.

2. Remove the right tray rail guide for tray A shelf.

3. Remove the tray rail board and the tray shield from the second tray guide rail in the

machine.

4. Re-attached the tray shield to the second tray rail.

5. Mount the tray rail board and the to the right side of the barriers mounting rail standoffs.

6. Remove the temperature sensor bracket mounted to the left hand side of the cabinet.

Do not unplug the sensor, let it hang down the left hand side of the cabinets wall.

7. Position the barrier inside the cabinet just below the second trays rails. Make sure that

the third tray rail connector plug is left underneath the barrier. You will need to remove

the left hand side tray rails underneath the barrier in order to position the barrier.

8. Mount the barriers mounting rails to the sides of the machine using one screw for each

rail.

9. Move the barrier to the back right corner of the cabinet leaving a gap on the left hand

side of the barrier.

10. Place the 1/2” by 1/2” piece of foam tape on the left side of the cabinet in between the

barrier and the cabinet where you have left the gap.

11. Place the large foam board at the upper right side of the air supply panel.

12. Place the small foam board next to the large foam. Make sure that the small boad is at

the bottom of the large board.

13. Bend the flanges on the air supply panel to hold the foam boards in place.

14. Mount the air plate directly under the barrier on the right side of the air supply panel.

15. Mount the air deflector in front of the ai r plate unde r the barr i er. (The opening should be

facing you.)

16. Re-mount all tray rails and re-connect all rail connections.

17. Replace all s nack an d can dy tr ays. You may have to adj ust t he tr ay r ails und erne ath th e

barrier to provide adequate spacing for your trays.

18. Re-mout the temperature probe underneath the barrier in the holes provided on the left

inside wall of the cabinet.

4800006 12 December 2004

Page 18

Refr eshment Center Operators’ Guide Initi al Set-Up

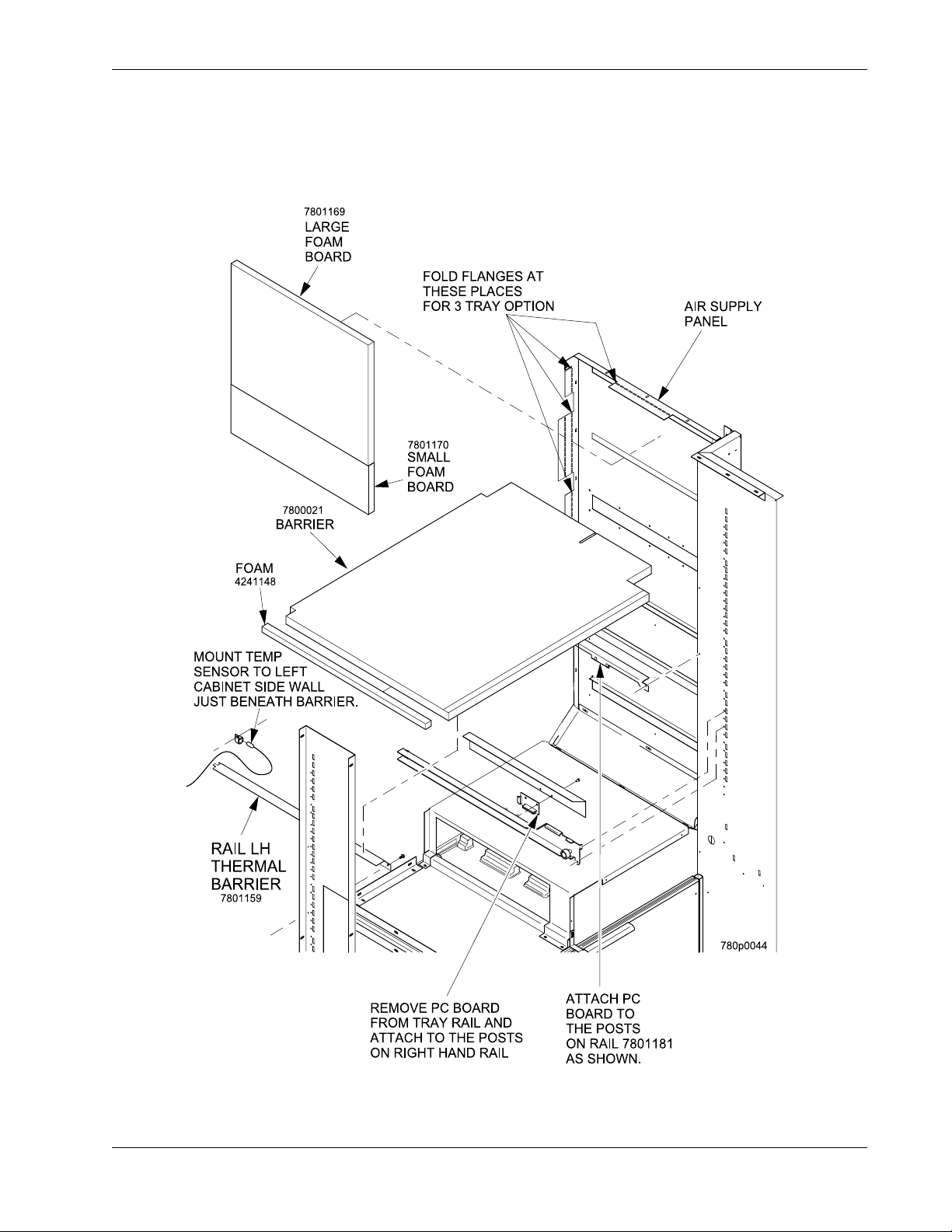

Set the machine for three tray configuration version 1:

Note:

If you are using a three tray conf igurat ion you will not use the a ir deflecto r and

the air plate.

FIGURE 2

December 2004 13 4800006

Page 19

Initial Set-Up Refreshmen t Cen te r Oper ato rs’ Gu ide

Version 1 Duct system three tray configuration

(See Figure , “Figure 2,” on page 13)

1. You must first remove all trays from your merchandiser.

2. Remove the right two tray rail guides for tray A and B shelf.

3. Remove the tray rail board and the tray shield from the third tray guide rail in the

machine.

4. Re-attached the tray shield to the third tray rail.

5. Mount the tray rail board and to the right side of the barriers mounting rail standoffs.

6. Remove the temperature sensor bracket mounted to the left hand side of the cabinet.

Do not unplug the sensor, let it hang down the left hand side of the cabinets wall.

7. Position the barrier inside the cabinet just below the third trays rails. Make sure that the

fourth tray rail connector plug is left underneath the barrier. You will need to remove the

left hand side tray rails underneath the barrier in order to position the barrier.

8. Mount the barriers mounting rails to the sides of the machine using one screw for each

rail.

9. Move the barrier to the back right corner of the cabinet leaving a gap on the left hand

side of the barrier.

10. Place the 1/2” by 1/2” piece of foam tape on the left side of the cabinet in between the

barrier and the cabinet where you have left the gap.

11. Place the large foam board at the upper right side of the air supply panel.

12. Place the small foam board directly underneath the large foam.

13. Bend the flanges on the air supply panel to hold the foam boards in place.

14. Re-mount all tray rails and re-connect all rail connections.

15. Replace all s nack an d can dy tr ays. You may have to adj ust t he tr ay r ails und erne ath th e

barrier to provide adequate spacing for your trays.

16. Re-mout the temperature probe underneath the barrier in the holes provided on the left

inside wall of the cabinet.

4800006 14 December 2004

Page 20

Refr eshment Center Operators’ Guide Initi al Set-Up

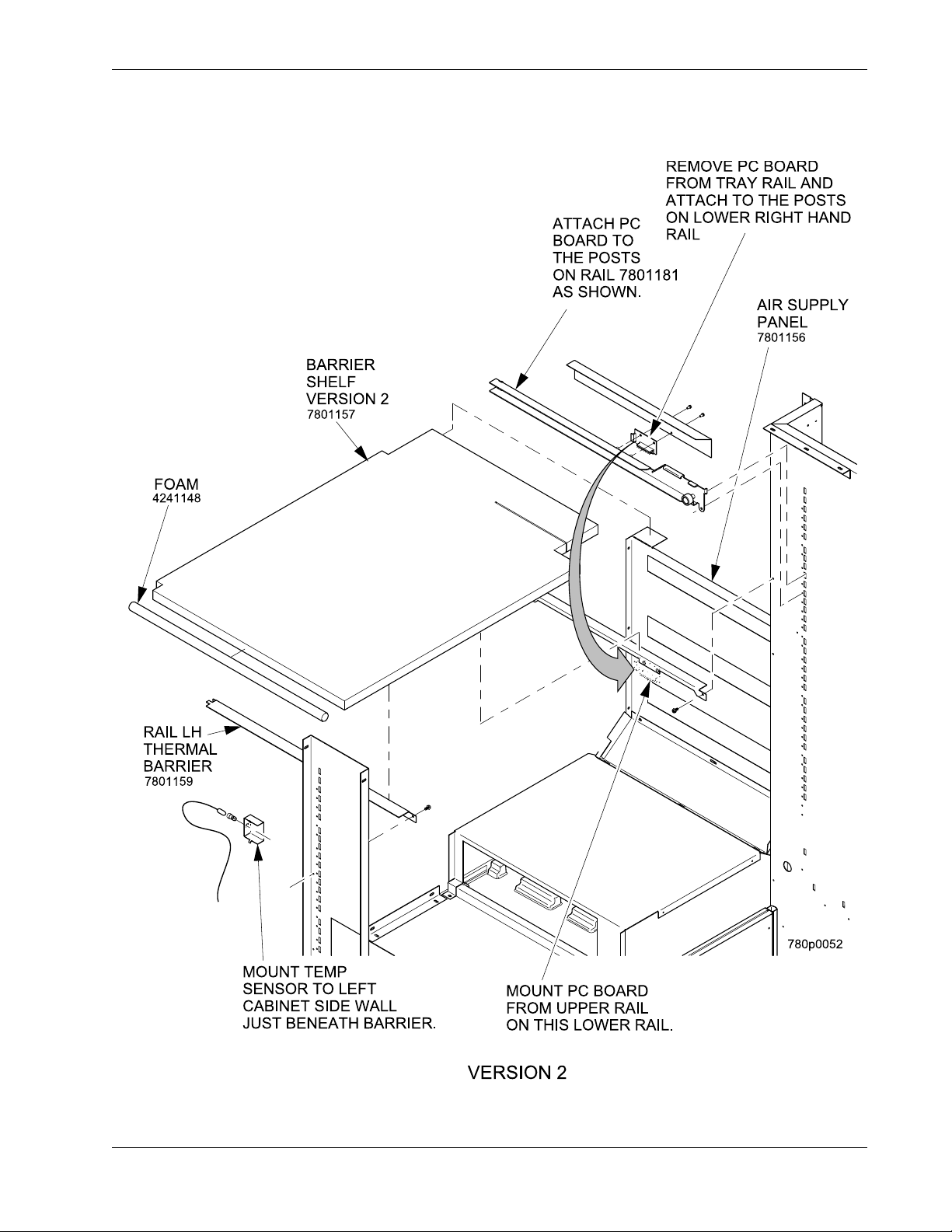

Set the machine for a two or three tray configuration version 2:

FIGURE 3

December 2004 15 4800006

Page 21

Initial Set-Up Refreshmen t Cen te r Oper ato rs’ Gu ide

Version 2 Duct System

(See Figure , “Figure 3,” on page 15)

1. You must first remove all trays from your merchandiser.

2. Remove the right tray rail guide for tray A shelf.

3. For steps 4-8 substitute third tray for second tray if configuring machine for three tray

configuration.

4. Remove the tray rail board and the tray shield from the second tray guide rail in the

machine.

5. Re-attached the tray shield to the second tray rail.

6. Mount the tray rail board to the right side of the barriers mounting rail standoffs.

7. Remove the temperature sensor bracket mounted to the left hand side of the cabinet.

Do not unplug the sensor, let it hang down the left hand side of the cabinets wall.

8. Position the barrier inside the cabinet just below the second trays rails. Make sure that

the third tray rail connector plug is left underneath the barrier. You will need to remove

the left hand side tray rails underneath the barrier in order to position the barrier.

9. Mount the barriers mounting rails to the sides of the machine using one screw for each

rail.

10. Move the barrier to the back right corner of the cabinet leaving a gap on the left hand

side of the barrier.

11. Place the 1/2” by 1/2” piece of foam rope on the left side of the cabinet in between the

barrier and the cabinet where you have left the gap.

12. Re-mount all tray rails and re-connect all rail connections.

13. Replace all s nack an d can dy tr ays. You may have to adj ust t he tr ay r ails und erne ath th e

barrier to provide adequate spacing for your trays.

14. Re-mout the temperature probe underneath the barrier in the holes provided on the left

inside wall of the cabinet.

4800006 16 December 2004

Page 22

Refr eshment Center Operators’ Guide Tray Set-Up

Section 3: Tray Set-Up

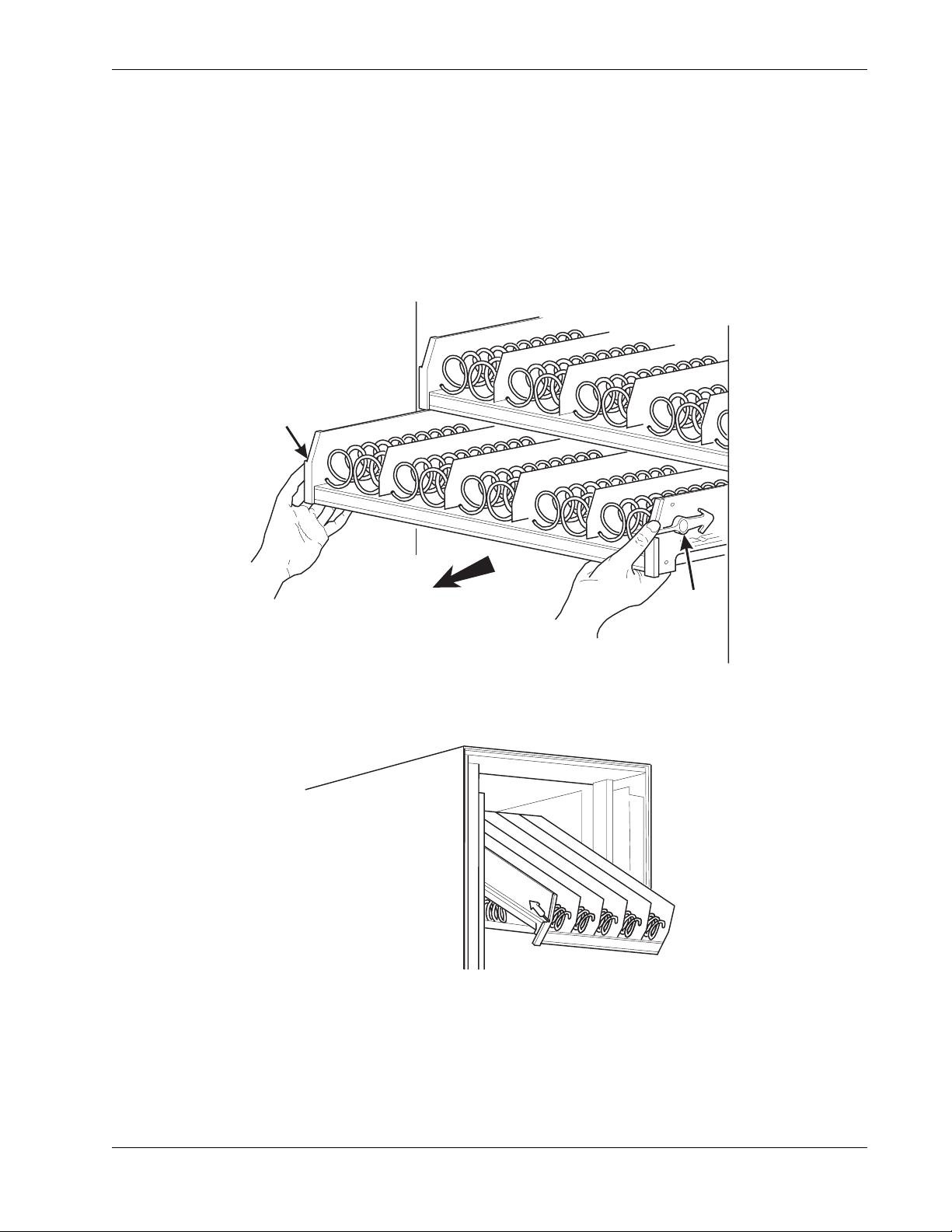

Place a Tray in the Loading Position

1. Place both hands on the tray as shown.

2. Push down on the tray latches with your thumbs.

3a. Bottle Trays: Pull the tray toward you until the slides are fully extended. The bottle tray

can now be loaded--bottle trays do not tilt like snack and candy trays.

3b. Snack and Candy Trays: Pull the tray toward you until you hear and feel the rear tray

rollers drop into a cut-out in the top of the guide rail.

TRAY

LATCH

PULL

TRAY

LATCH

157P0011

4. Continue pulling the tray forward for another inch. You will then be able to tilt the tray

downward into the loading position as shown.The candy or snack tray is now ready for

loading.

SNACK OR CANDY TRAY IN THE LOADING POSITION

NOTE

When the cabinet door is not fully open, the bottom tray will rest on the delivery pan

assembly. Handle the tray with care to avoid scratching the delivery pan assembly.

December 2004 17 4800006

Page 23

Tray Set-U p Refres hm en t Cen te r Op erato r s’ Gu ide

Set up Trays to Vend Products

These instructions will guide you thr ough setting up yo ur trays for vending. You will be asked

to determine if your tray can physically hold the products you intend to vend. If not, you will

be directed to other procedures which will help you get them set u p. F ollow these nine step s

for each tray in your machine:

1. Make sure the tray is in the loading position.

2. Is the column wide enough for the intended product? If so, proceed to the next step.

Otherwise, set up your tray to ven d wid er pr oduct s (se e below, this page). When you're

done, return to step 3 in this procedure.

3. Will the products fit between the spiral turns? If so, proceed to the next step.

Otherwise, change the spiral.

4. Will the product pass u nder the tr ay immediatel y above? If so, pro ceed to the next step.

Otherwise, reposition the tray and guides.

5. Will the product touch products on either side? If not, proceed to the next step.

Otherwise, instal l a product spacer.

6. Load products in the tray.

7. Return the tray to the vending position.

8. Install the price rolls.

9. Install the selection ID numbers.

Set Up A Tray To Vend Wide Products

The following steps will help you configure your tray to vend wide products. When you are

done with the entire wide product steps, return to the set-up procedures above.

NOTE:

Does not apply to bottle trays - they cannot be reconfigure.

1. Remove the tray from the merchandiser and place it on a flat surface.

2. Based on the size of the product you want to vend, decide how many spiral positions it

will occupy. Please remember that the left most spiral in the group must have an even

ID number (0, 2, 4, etc.) For example, if a product is three spirals wide, the le ft spiral will

be ID number 0, and the r ight sp iral will be ID nu mber 2. Be care ful how wide you set u p

for, because some wide products could get hung up in the delivery door.

3. Remove the column dividers inside the group. In the example of three spiral positions,

you would be removing the dividers between spiral ID numbers 0 and 1, and 1 and 2.

4. If your group onl y c onsists of 2 spirals, replace th e r ight m ost m otor with a sp i ral b earin g

and gear, and install a gear on the left most motor. Skip to step 8.

5. Remove all spirals in the group except the left most spiral.

4800006 18 December 2004

Page 24

Refr eshment Center Operators’ Guide Tray Set-Up

6. Do one of the following:

a. If your group has an ODD number of spirals (3, 5, etc.) remove the harnesses from

all motors in the gr oup exce pt the l ef t m ost one . To the right mo st moto r, connect the

harness from the motor immediately to its left.

b. If your group has an EVEN number of spirals (4, 6, etc.) remove the harnesses from

all motors inside the group (leave the har nesses connected to the left most an d right

most motors).

7. Install a spiral at the right most position in your group. Make sure it has the same

product capacity and is opposite to the one in the left most position.

8. Return the tray to the merchandiser.

9. Electronically couple the motors as needed (see "Couple/Uncouple Tray Motors" on

page 67).

10. Return to step 3 in the "Set up Trays to Vend Products" on page 18.

Stu dy thi s proc edur e before you install a tr ay for the first ti me; while yo u ar e ho ld ing th e tr ay

you will not be able to see this area.

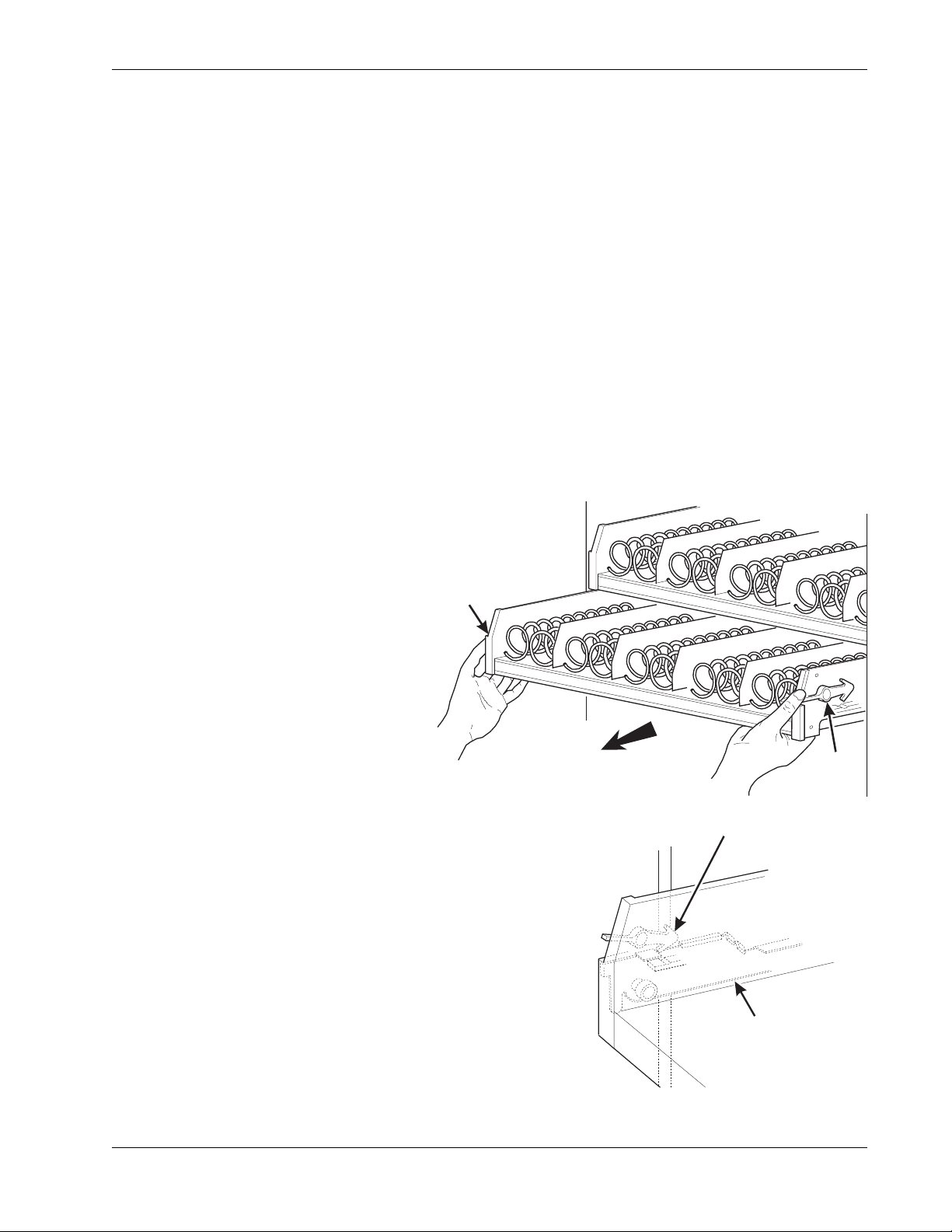

Remove a Snack or Candy Tray

1. Remove all product from the tray.

2. Push down on the tray latches

with your thumbs.

3. Pull the tray toward you until you

hear and feel the rear tray rollers

drop into a cut-out in the top of

the guide rail.

TRAY

LATCH

PULL

TRAY

LATCH

TRAY

LATCH

TRAY

GUIDE

RAIL

December 2004 19 4800006

Page 25

Tray Set-U p Refres hm en t Cen te r Op erato r s’ Gu ide

CUT-OUT

REAR OF

E

RAIL

4. Unplug the tray wiring harness from the

PC board mounted on the tray guide rail

IMMEDIATELY ABOVE the tray you are

removing.

PC BOARD

ATTACHED TO

TRAY GUIDE

TRAY GUIDE RAIL

5. Lift up on the tray and slide it toward the

REAR OF TRAY

back. No more than an inch should be needed

6. The tab near the back of the tray should

align with the cut- out in the top of the g ui de ra il

as shown.

TRAY

ROLLER

TRAY

GUIDE

RAIL

157P0026

7. Lift the tray clear of the guide rail and out of the

merchandiser.

CAUTION

When the cabinet door is not fully open, use extra

care in removing the bottom tray. Failure to do

so may result in damage to the tray or to

the delivery pan assembly.

TAB

(ON TRAY)

TRAY

TRAY GUID

4800006 20 December 2004

Page 26

Refr eshment Center Operators’ Guide Tray Set-Up

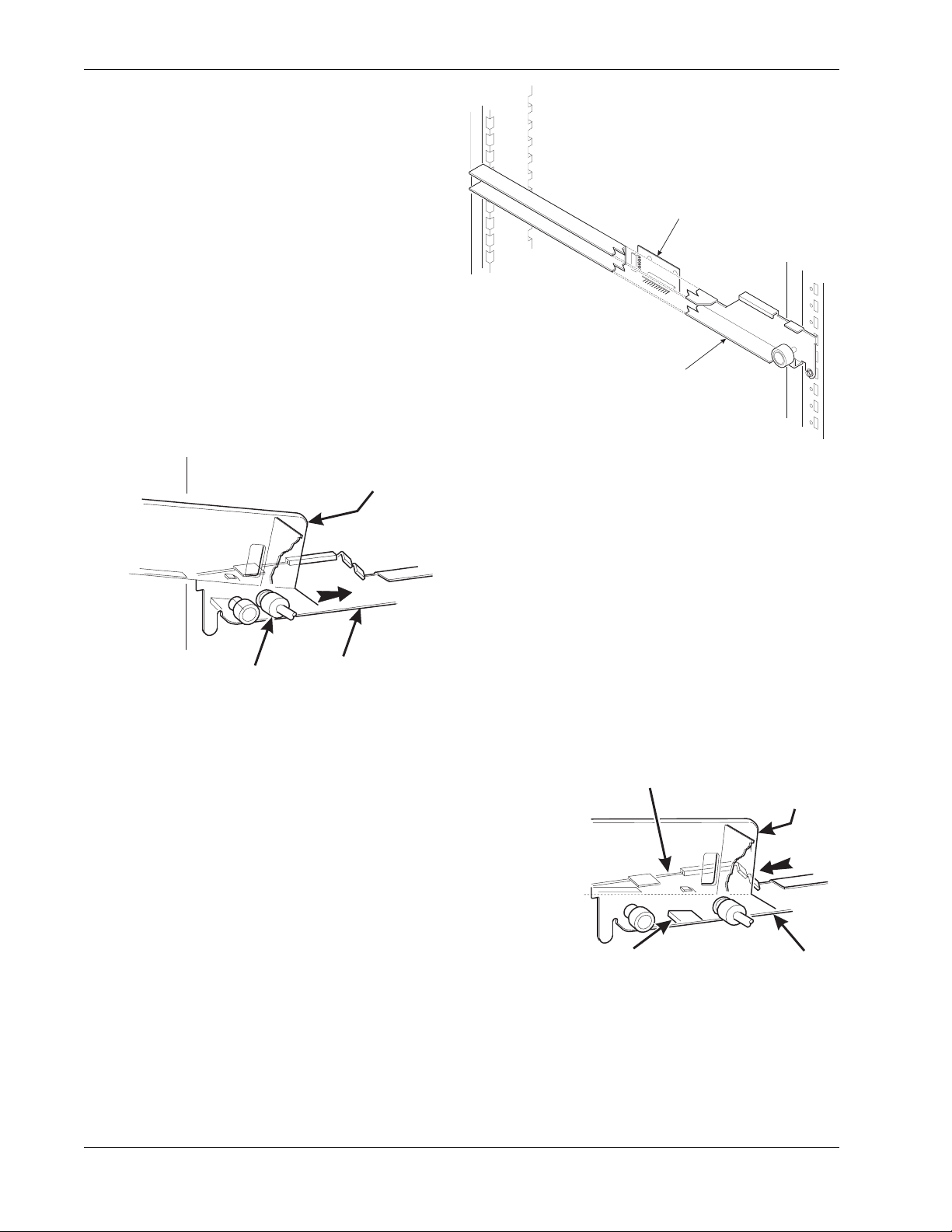

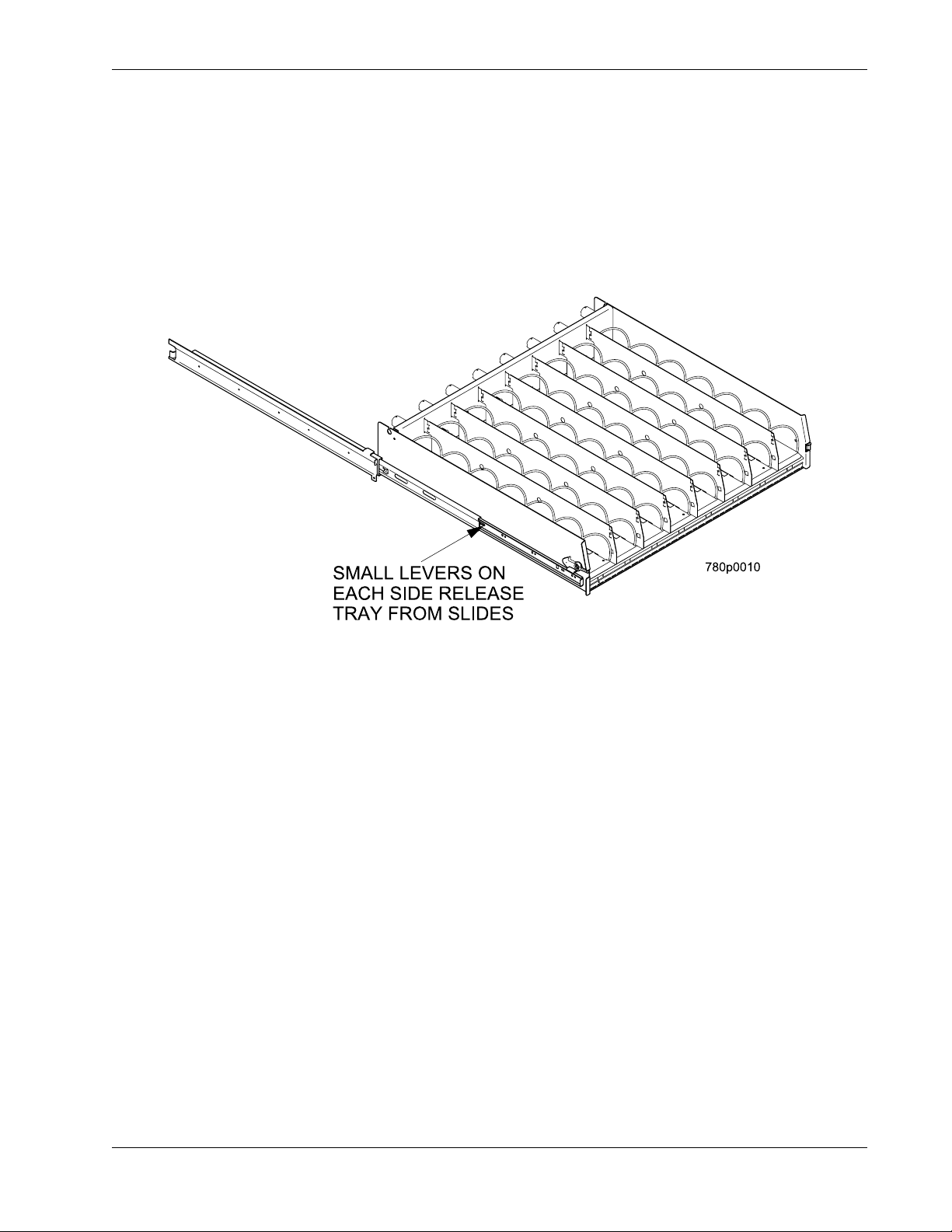

Remove a Bottle Tray

1. Remove all product from the tray.

2. Push down on the tray latches with your thumbs and slide out the tray as far as it will go.

3. Unplug the tray wiring harness from the PC board mounted on the tray guide rail

IMMEDIATELY ABOVE the tray you are removing.

4. Locate a small lever on each s ide of the tray, where it attaches to the slide. The lef t lever

will be up, the right will be down. Press down on the left lever and up on the right lever.

5. Pull the tray towards you, off of the slides.

6. Replace the tray by performing the above steps in reverse order.

NOTE:

It is much easier to replace a bottle tray if you have assistance lining up the

tray rails and slides.

December 2004 21 4800006

Page 27

Tray Set-U p Refres hm en t Cen te r Op erato r s’ Gu ide

DIVIDER

Remove and Install Column Dividers

Note: Not applicable to bottle trays.

1. Push the column divider toward the

back of the tray - .

2. Lift the column divider clear of the tray -

.

2

3. Install the column divider i n the reverse

order of removal.

1

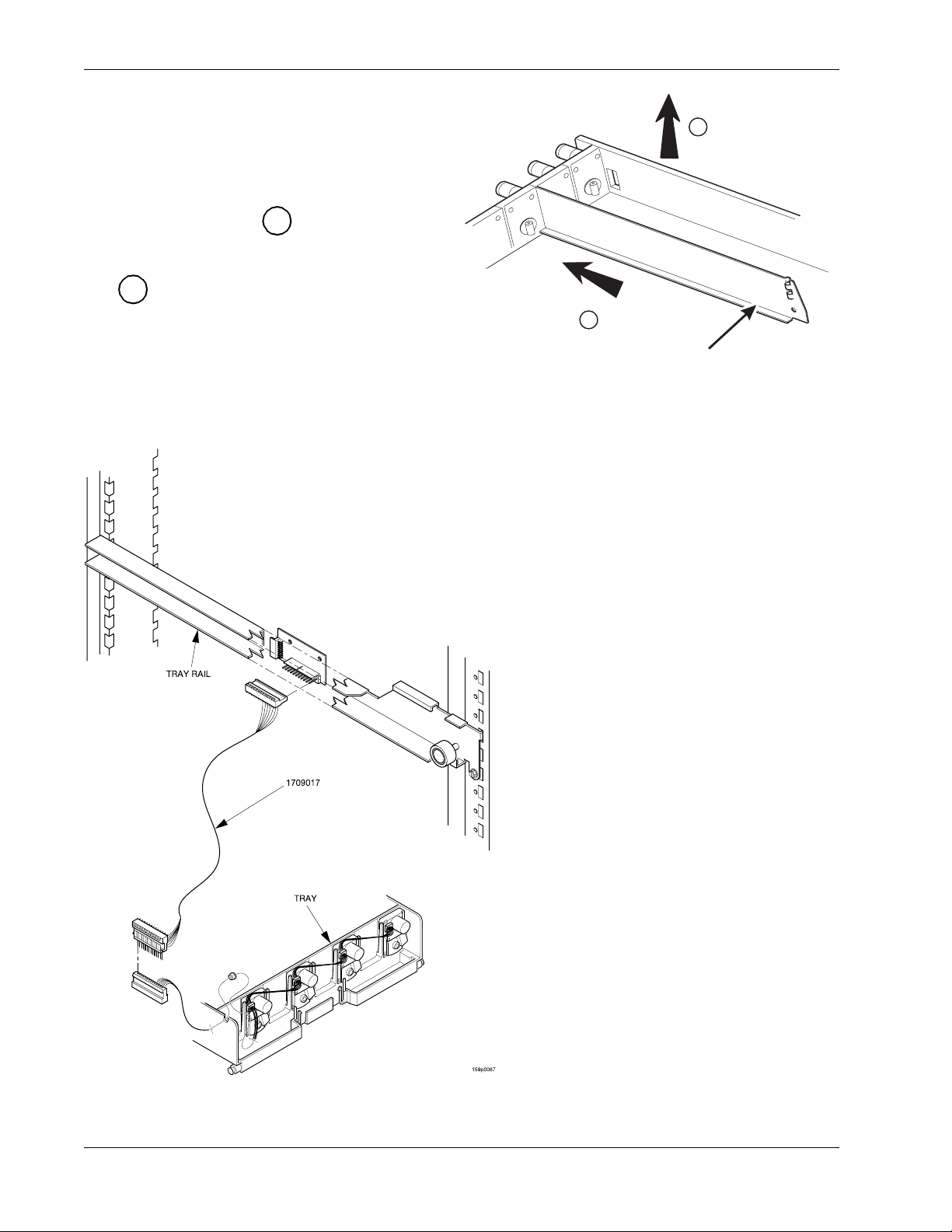

Operate a Tray Outside of the Machine

2

1

COLUMN

Use tray harness extension (P/N

1709018) a vailable from your Nationa l

Vendors Parts department (1-800621-7278). The extension will enable

you to remove the tray from the

machine and still operate the motors

and spirals. Connect it as shown

below:

4800006 22 December 2004

Page 28

Refr eshment Center Operators’ Guide Tray Set-Up

SPIRAL

R

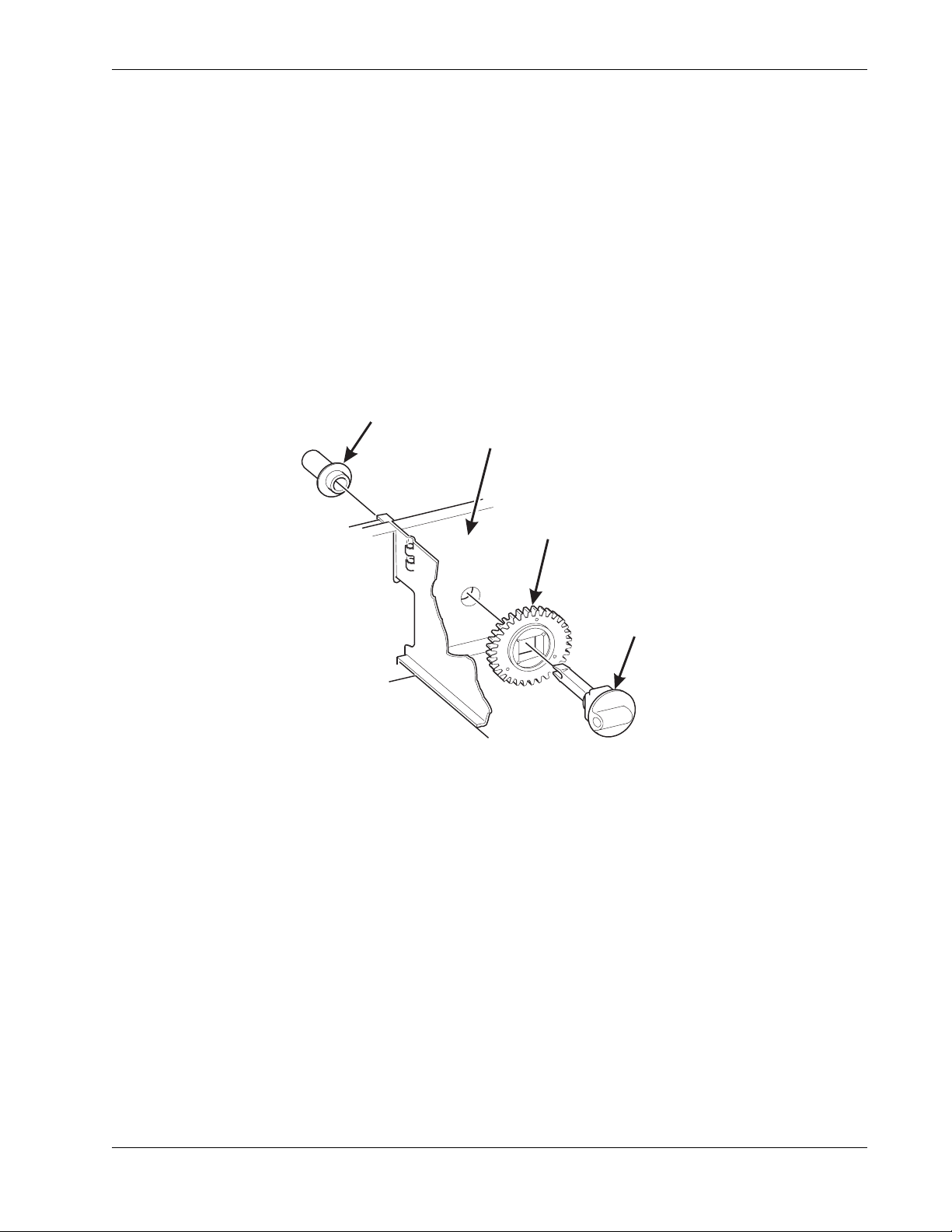

Replace a Motor with a Spiral Bearing

Remove A Motor:

1. Disconnect the harness from the motor.

(See "Connect and Disconnect a Motor Harness" on page 24).

2. Remove the spiral. (See "Remove and Install Spirals" on page 25).

3. Remove the spiral coupler. (See "Remove a Spiral Coupler" on page 26).

4. Remove the motor. (See "Remove and Install a Sp iral Motor" on page 27).

5. Install A Spiral Bearing:

a. Put the gear into position in this set-up as shown.

BEARING

BACKWALL

OF TRAY

GEAR

˜

SPIRAL

COUPLE

b. Install the spiral coupler. (See "Install a Gear" on page 28).

December 2004 23 4800006

Page 29

Tray Set-U p Refres hm en t Cen te r Op erato r s’ Gu ide

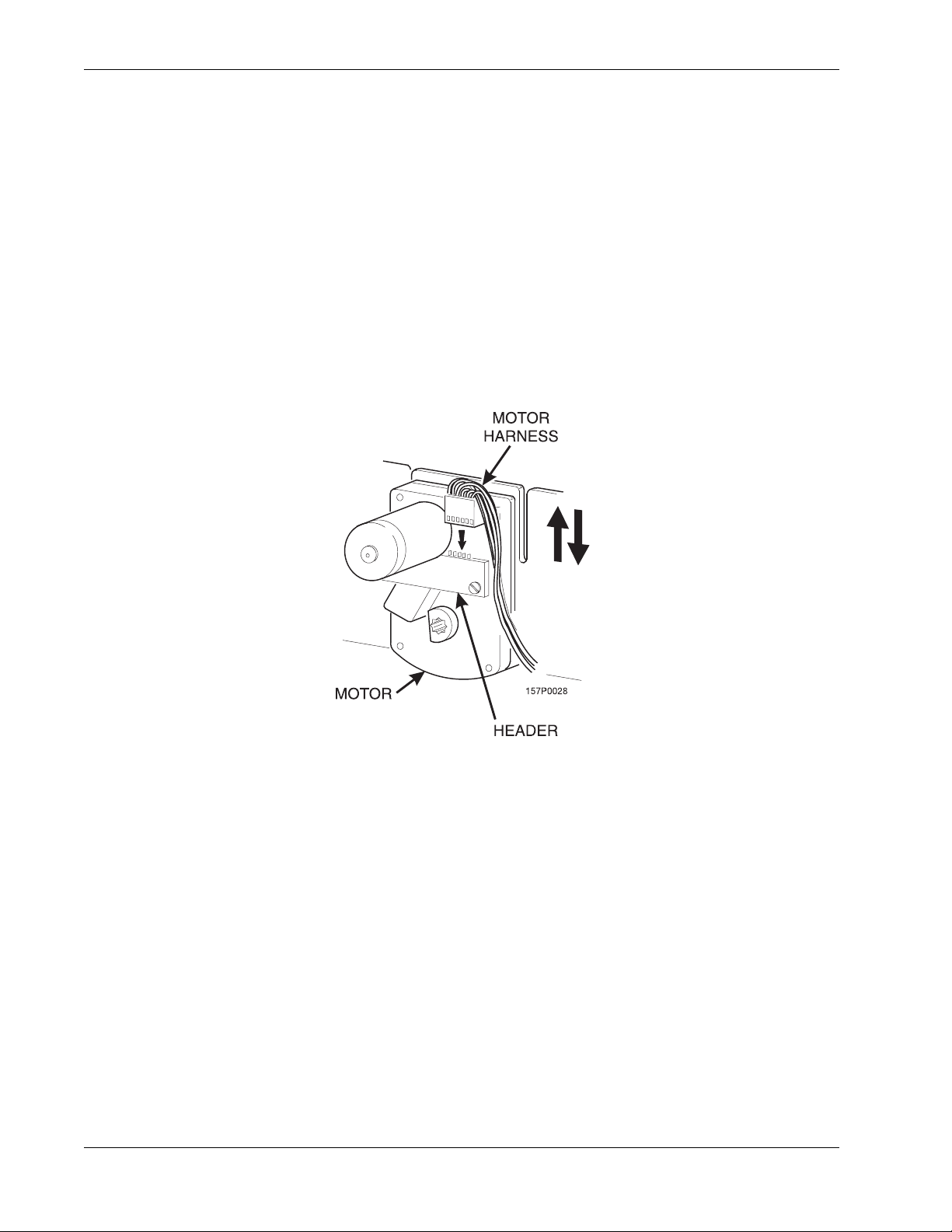

Connect and Disconnect a Motor Harness

CAUTION

To avoid breaking the motor ci rcuit bo ard, hol d the hea der on the circuit bo ard

whenever connecting or disconnecting a motor harness.

Disconnect a Motor Harness:

1. Pull the harness connector away from the circuit board as shown.

2. Tuck the unused part of the harness out of the way in the trough at the back of the tray.

Connect a Motor Harness:

1. Locate the harness connector for the appropriate tray position.

2. Push the harness connector over the header pins on the motor circuit board as shown.

4800006 24 December 2004

Page 30

Refr eshment Center Operators’ Guide Tray Set-Up

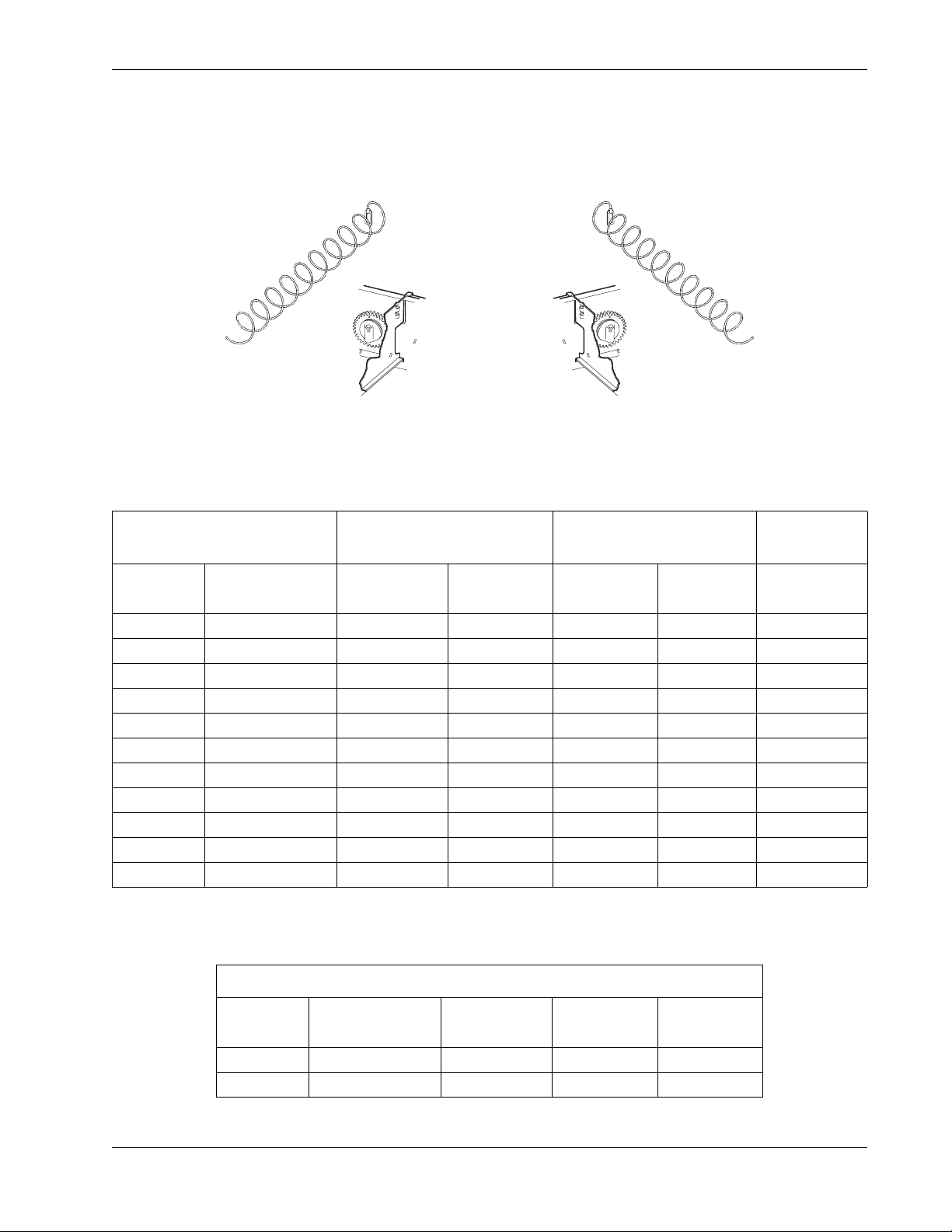

Remove and Install Spirals

• All spirals are the same diameter

• There are two kinds of spirals

Counter Clockwise (left-hand) Clockwise (right-hand)

SNACK AND CANDY TRAY SPIRAL OPTIONS

COUNTER CLOCKWISE

(LEFT HAND)

SPIRAL

COUNT

6 PURPLE 1477103 1477102 1477105 1477104 1477107

8 BLACK 1677247 1677190 1677248 1677189 1477073

9 GRAY 1477152 1477153 1477149 1477150 1477155

11 BLUE 1477023 1477024 1477026 1477027 1457061

13 YELLOW 1477029 1477030 1477032 1477033 1457062

15 RED 1477035 1477036 1477038 1477039 1457063

17 BROWN 1477101 1477100 1477099 1477098 1477106

20 WHITE 1477041 1477042 1477044 1477045 1457064

25 GRE EN 1477047 1477048 1477050 1477051 1457065

30 BLACK 1477053 1477054 1477056 1477057 1477073

38 ORANGE 1477059 1477060 1477062 1477063 1467137

RETAINER

COLOR ASSEMBLY SPIRAL ASSEMBLY SPIRAL RETAINER

CLOCKWISE

(RIGHT HAND)

NOTE

Bottle trays use a 3.25” diameter spiral.

BOTTLE TRAY SPIRAL OPTION

SPIRAL

COUNT

6 DARK GREEN 7807011 7807003 44 07822

7 RED 78070 15 7807016 1457063

December 2004 25 4800006

RETAINER

COLOR ASSEMBLY SPIRAL RETAINER

Page 31

Tray Set-U p Refres hm en t Cen te r Op erato r s’ Gu ide

LIFT

To Remove a Spiral:

1. Pull forward on the retaining clip and remove the end of

the spiral from the spiral coupler as shown.

2. Remove the spiral from the tray.

SPIRAL

To Install a Spiral:

1. Pull the bottom of the retaining clip toward the front of the

spiral.

COUPLER

PULL

2. Lower the spiral into the tray column and insert the end of

the spiral into the spiral coupler as shown.

SPIRAL

RETAINING

CLIP

3. Release the retaining clip.

Choose a Clockwise or Counterclockwise Spiral

1. The type of spiral used is determined by the column position it will occupy in the tray.

2. Refer to the figure below to find the correct spiral type.

A1 A2

A3

A4

A5 A6

A7

A8 A9A0

Note: Bottle spirals are all clockwise.

Remove a Spiral Coupler

1. Pinch together the prongs on the end of the spiral coupler as shown.

2. Pull the coupler forward (in the direction of the arrow as shown)

SPIRAL

PRONGS

4800006 26 December 2004

COUPLER

PULL

Page 32

Refr eshment Center Operators’ Guide Tray Set-Up

R

SPIRAL

Remove and Install a Spiral Motor

Remove a Spiral Motor:

NOTE

Some steps may already be completed

1. Remove the tray. (See "Remove a

Snack or Candy Tray" on page 19).

2. Disconnect the motor harness.

(See "Connect and Disconnect a

Motor Harness" on page 24).

3. Remove the spiral.

(See "Remove and Install Spirals"

on page 25).

4. Remove the spiral coupler.

(See "Remove a Spiral Coupler"

on page 26).

5. Lift the motor clear of the tray.

MOTOR

BACKWALL

OF TRAY

GEAR

˜

SPIRAL

COUPLE

6. Return the tray to the merchandiser.

(See "Install a Tray in the

Merchandiser" on page 31).

Install a Spiral Motor:

1. Remove the tray. (See "Remove a Snack or Candy Tray" on page 19).

2. Place the motor in the correct position at the rear of the tray as shown.

3. Place a gear in position if required by this set-up.

4. Install a spiral coupler in the proper orientation. (See "Install a Gear" on page 28).

5. Connect the motor harness.

(See "Connect and Disconnect a Motor Harness" on page 24).

December 2004 27 4800006

Page 33

Tray Set-U p Refres hm en t Cen te r Op erato r s’ Gu ide

BACK WALL

ORIENTATION 1 ORIENTATION 2

Install a Gear

Use a Gear when:

• Gears are used to mechanically couple the spirals together.

• This happens whenever you have two spirals and only one motor for vending a

selection.

Position the Gear

• Place the gear in between the back of the tray and the spiral coupler.

• There are two possible orientations for the gear:

OF TRAY

GEAR

• There are two rules to follow when orienting gears:

RULE 1 The gears for selections next to each other cannot use the same

orientation.

RULE 2 All gears for a single selection must use the same orientation.

4800006 28 December 2004

Page 34

Refr eshment Center Operators’ Guide Tray Set-Up

SPIRAL

AS VIEWED FROM FRONT OF TRAY

ONE POSITION

C

ONE POSITION

L

SPIRAL

B

Install a Spiral Coupler

1. Place the gear in position if one is required for this set-up.

When Used with a Motor:

2. Hold the motor in place

and push the spiral

coupler throu gh the motor

gear box until it clicks into

position. Be sure the

spiral couplers are

oriented as shown below.

NOTE

The motor output shaft

opening contains eight facets

to allow the spiral coupler to

be installed in any one of

eight positions.

FRONT VIEW OF

MOTOR OUTPUT SHAFT

MOTOR

Spiral Coupler Orientation

COUPLER

OUNTERCLOCKWISE

FROM VERTICAL

LEFT SPIRAL

COUPLER

When Used with a Coupler Bearing:

3. Hold the coupler beari ng in place and push

the spiral coupler through the bearing until

the coupler clicks into position. Be sure the

coupler is in the proper orientation as

shown.

CLOCKWISE

FROM VERTICA

RIGHT SPIRAL

COUPLER

COUPLER

SPIRAL

EARING

December 2004 29 4800006

Page 35

Tray Set-U p Refres hm en t Cen te r Op erato r s’ Gu ide

Move a Tray Up or Down

This merchandiser can be adjusted to vend taller products. Follow the guidelines below:

• Keep in mind that when you increase the product height available to a tray by

lowering it, you will be decreasing the product height available to the tray below.

• If a tray is in the l owest position, the tray below it should no t be in the hi gh est po sition.

• If a tray is in the highest position, the tray above should not be in the lowest position.

• Y o u may nee d to experi ment with various tra y position s to get the best resul ts fo r your

products.

CAUTION

The trays in should not be positioned over an open air discharge vent.

NOTE

Tray movement is limited because the tray harness will limit the amount of

travel available to the tray guide rails.

Proceed as follows:

1. Remove the tray from

the merchan diser . (See

"Remove a Snack or

Candy Tray" on page

19).

REAR GUIDE

MOUNTING CHANNEL

2. Remove the screw th at

secures the right tray

guide rail to the front

guide mounting

PC BOARD

FRONT GUIDE

MOUNTING CHANNEL

channel as shown.

3. Tap up on the guide r ail

CHANNEL

SLOT

and unseat the guide

rail tabs from the

channel slots.

4. Pull the gu ide r ail awa y

from the front and rear

TRAY

GUIDE

RAIL

guide mounting

channels.

SCREW

5. Move the guide rail to

the desired position.

6. Insert the guide rail tabs into the mounting channel slots as shown.

7. Tap down on the guide rail to seat the tabs in the channel slots.

8. Replace the screw that secures the guide rail to the front guide mounting channel.

9. Repeat steps 2 through 8 for the left guide rail.

10. Return the tray to the merchandiser.

(See "Install a Tray in the Merchandiser" on page 31).

1 1. Load products into the trays, and perform test vends. Make sure the trays don't interfere

with the products you are vending, and that all products vend properly.

4800006 30 December 2004

Page 36

Refr eshment Center Operators’ Guide Tray Set-Up

Install a Tray in the Merchandiser

• Study this procedure before you install a tray for the first time; while you are

holding the tray you will not be able to see this area. Proceed as follows:

1. Insert the tray so that the tray rollers

pass over the tray guide rollers.

REAR OF

TRAY

TRAY

GUIDE

5. Hold the tray up while pushing it toward the

rear. Stop when the tab on the tray aligns

with the opening in the tray guide.

CUT-OUT

TRAY

ROLLER

FRONT OF

RAIL

157P0024

2. Bring the tray rol ler to r est on the tr ay

guide.

REAR OF TRAY

TRAY

ROLLER

TRAY

GUIDE

RAIL

157P0026

157P0012

TAB

6. Lower the tray until it rests on the tray guide

roller. Push the tray in all the way.

7. The tray latch will fall into the locking

position.

CUT-OUT

REAR OF

TRAY

3. Tilt the tray upward.

4. Connect the tray wiring harness to

the PC board mounted to the guide

rail JUST ABOVE the tray you are

TAB

(ON TRAY)

157P0025

TRAY GUIDE

RAIL

installing.

NOTE:

Does not apply to bottle trays.

December 2004 31 4800006

Page 37

Tray Set-U p Refres hm en t Cen te r Op erato r s’ Gu ide

PRODUCT

DIVIDER

M

G

Install and Remove a Product Spacer

Install a Product Spacer

The product spacer will keep

a tall, narrow product upright.

Shown at right are spacers

and column dividers on both

deep and shallow trays.

Insert the product spa cer onto

the column divider as shown.

Adjust a Product Spacer

With product loaded in the

tray , ro tate the p roduct space r

up or down to keep the

product upright as shown.

OUNTING

PINS

SPACER

MOUNTIN

PINS

COLUMN

Remove a Product Spacer

Pull the product spacer

mounting pins from the

column divider.

4800006 32 December 2004

Page 38

Refr eshment Center Operators’ Guide Load the Merchandiser

Section 4: Load the Merchandiser

The color of the spiral coupler (the little plastic tab attached to the rear of the spiral will tell

you how many products will fit in the spiral. (See table below).

NOTE

Another way to determine spiral capacity is to count the spaces in the spiral!

SPIRAL CAPACITY COLOR CODES

SPIRAL

CAPACITY

6Purple

8 Black 20 White

9

11 Blue 30 Black

13 Yellow 38 Orange

15 Red

SPIRAL COUPLER

COLOR

Gray 25 Green

SPIRAL

CAPACITY

17

SPIRAL COUPLER

COLOR

Brown

General Tray Loading:

• See "Product Pusher Usage" on page 35 for spirals with capacity of 11, 13, or 15.

• See "S pi ral Wall Retainer Usage" on p age 34 for spira ls with cap aci ty of 20 , 25, 3 0,

or 38.

• Begin loading pr oduct s a t th e fr ont o f the tr ay an d w ork towar d t he b ack. Posit ion th e

product so the package rests on the tray. DO NOT force a product into a spiral.

• If the fit is too tight or too loose, change the spiral size.

(See "Remove and Install Spirals" on page 25).

• Be sure there are no empty positions between products in each spiral.

Special Considerations:

Bagged Products Position package upright, then push the tops slightly toward the rear of

the tray. Also, (see "Product Pusher Usage" on page 35).

Thin Packages Position the package upright.

Also, (see "Spiral Wall Retainer Usage" on page 34).

KitKat The two right-most columns of the cand y tray are design ed to accept the

KitKat candy bar.

December 2004 33 4800006

Page 39

Load the Mer ch an dis er Refres hm en t Cen te r Op erato r s’ Gu ide

SPIRAL

R

ORIENTATION A

DIVIDER

ORIENTATION B

Spiral Wall Retainer Usage

A spiral wall retainer serves to compress the spiral and make it act like a spring to more

forcefully eject a product. D o so me te st vend s and u se a sp iral wal l r et ainer when a prod uct

does not readily leave the spiral.

• Use a spiral wall retainer in the following cases:

• The spiral has a capacity of 20, 25, 30, or 38.

• The product is thin.

• The product is on a candy tray.

• The spiral wall reta iner can also be used with other spirals

and types of products.

• The spiral wall retainer is installed near the front of the

column divider.

• There are two ways to install the spiral wall retainer.

RETAINER

ORIENTATION

AB

WALL

ETAINER

0 and 1 1 and 2

COLUMN

DIVIDER

BETWEEN

THESE

POSITIONS

2 and 3 3 and 4

4 and 5 5 and 6

6 and 7 7 and 8

8 and 9

• To install a spiral wall retainer, insert the retainer in the square slot near the front of

the column divider.

• The spiral wall retainer must be removed in two cases:

• A KitKat bar loaded into either of the two right hand positions of a tray will not

clear the retainer on the column divider between the two positions.

• A product pusher will catch on

a retainer in ORIENTATION A.

4800006 34 December 2004

Page 40

Refr eshment Center Operators’ Guide Load the Merchandiser

T

AS VIEWED FROM FRONT OF TRAY

ONE POSITION

C

ONE POSITION

L

Product Pusher Usage

The product pusher will give the top of a product an

extra tilt to help it fall into the delivery pan.

PRODUC

PUSHER

Use a product pusher in the following cases:

• The spiral has a capacity of 15, 13, or 11.

• The package is non-rigid like bagged

peanuts

The product pusher can also be used with other

spiral and types of products.

A bag of product pushers has been shipped with the

merchandiser. Additional product pushers are

available from the National Vendors' parts department (800-621-7278). To use a product

pusher, snap it on the spiral as shown. You can adjust the product pusher by moving it

around on the spiral to achieve the best vending results.

Confi g ur e t h e

Merchandiser to vend

OUNTERCLOCKWISE

FROM VERTICAL

CLOCKWISE

FROM VERTICA

“Lunch Buckets”

Because of the weight and shape of the

package, National Vendors

recommends that this product be

vended only from the bottom tray.

To vend this product, two adjacent

positions must be coupled together.

The left spiral coupler should be

installed one position counterclockwise

from the vertical position.

FOOD SELECTIONS

LOADED IN SPIRALS

The right spiral couple r should be installed one position

clockwise from the vertical position.

Replace the current spirals with six-count spirals.

These are available from the National Vendors parts

department. (See "Remove and Install Spirals" on

page 25). A pad can be installed in the bottom of the

delivery pan to qui et and cushion product delivery. This

part is available from the National Vendors parts

157P0039

department. Load "Lunch Bucket" products as shown

at left.

LEFT SPIRAL

COUPLER

RIGHT SPIRAL

COUPLER

December 2004 35 4800006

Page 41

Load the Mer ch an dis er Refres hm en t Cen te r Op erato r s’ Gu ide

TOP SHELF

Configure the Merchandiser for Vending "Top Shelf"

National Vendors recommends that this product be vended from a candy tray.

1. Move the tray so the package can be loaded standing on its left or right edge.

( See "Move a Tray Up or Down" on page 30).

2. The following steps must be completed for three adjacent positions on the tray:

NOTE

The left-most position in the group of three must be an even numbered position.

3.

4.

DISCONNECT THIS

MOTOR CONNECTOR

6.

TO THIS MOTOR

LEAVE THIS MOTOR

CONNECTOR ALONE

1. REMOVE COLUMN

DIVIDERS

2. REMOVE

SPIRALS

5.

MOVE CONNECTOR

FROM THIS MOTOR

7. INSTALL AN 11-COUNT LEFT HAND

SPIRAL IN THIS POSITION

INSTALL AN 11-COUNT RIGHT-HAND

8.

SPIRAL IN THIS POSITION

157P0040

NOTE

If the motor harness disconnected in step 5 does not reach, use the motor skip harness, (P/

N 1599024), available from the National Vendors Parts Department (800-621-7278).

PRODUCT

3. Couple the left motor to the right motor. (See "Couple/Uncouple Tray Motors" on

page 67).

4. Load the "Top Shelf" products as shown.

4800006 36 December 2004

Page 42

Refr eshment Center Operators’ Guide Load the Merchandiser

Return the Trays to the Vending Position

1. Lift the tray until it is parallel to the floor as shown.

TRAY

LATCH

PULL

TRAY

LATCH

157P0011

2. Push the tray toward the back of the cabinet. The tray latches on the sides of the tray

will lock into position.

TRAY

LATCH

TRAY

GUIDE

RAIL

157P0027

December 2004 37 4800006

Page 43

Load the Mer ch an dis er Refres hm en t Cen te r Op erato r s’ Gu ide

Install and Set Price Labels

• Price rolls are printed on coiled strips as shown in the illustration below. (The dollar

and cents rolls are factory installed.) If you use another type of currency, you will find

the appropriate price rolls in the plastic bag that contained this manual.

• There are two types of price rolls:

Dollar roll 1 to 12, increments of 1

Cents roll 00 to 95, increments of 05

• Remove the price roll s as re quire d, and i nst all the appro priate ones for your cur rency.

DOLLAR ROLL

CENTS ROLL

157P0043

Install Price Labels:

There are three pairs of slots in the front of the can unit for each position. Install per this

example:

1. Insert the dollar roll in the left-most pair of slots as shown if the price is $1.00 or more.

2. Insert the cents roll in the center pair of slots as shown.

3. The low-number end of the roll

goes in the top slot and the highnumber e nd of th e roll go es in the

PRESS TOP OF ROLL

PAST FLEXIBLE TAB

NEAR TOP EDGE

bottom slot.

INSERT BOTTOM OF ROLL

THROUGH SLOT ALONG

BOTTOM EDGE

4800006 38 December 2004

157P0044

Page 44

Refr eshment Center Operators’ Guide Load the Merchandiser

Adjust the Price Roll:

You can set selection prices within the following range:

Minimum price $.00

Maximum price $99.99

Increment $.05

1. Use your thumb as shown to move each price roll up or down as needed to set the

desired price.

NOTE

You will se e the word STOP near either end of the roll.

157P0045

Selection ID numbers are printed on clear plastic sheets. You will find these in the plastic

bag that contained this manual. You will need to sepa rate them along the scored lines

between the selections. BE CAREFUL when doing this, as it is easy to split the labels.

Install the Selection ID Numbers:

1. Press together the two long edges of the selection ID label.

2. Snap the selection ID label into position on the front of the tray as shown.

DOLLAR

PRICE ROLL

CENTS

PRICE ROLL

SELECTION

IDENTIFICATION

157P0059

December 2004 39 4800006

SELECTION

IDENTIFICATION LABEL

Page 45

Load the Mer ch an dis er Refres hm en t Cen te r Op erato r s’ Gu ide

See the figures below for snack and candy tray positions.

MOTOR POSITION

TOP T RAY TRAY AA0A1A2A3A4A5A6A7A8A9

TRAY BB0B1B2B3B4B5B6B7B8B9

BOTTOM TRAY TRAY CC0C1C2C3C4C5C6C7C8C9

NOTE

This example shows a 3- tray merchandiser.

Some merchandisers can have up to 6 trays.

Examp le of a Basic

Snack Tray ID La bel to Use

A0 A2 A4 A6 A8

Examp le of a Basic

Candy Tray ID Label to Use

A1 A2

A3

A4

A5 A6

A7

A8 A9A0

4800006 40 December 2004

Page 46

Refreshment Center Operators’ Guide SureVend™

Section 5: SureVend™

The SureVend™ product detection system consists of several infrared light emitters and

infrared light detector s that scan the product delive ry area with a p attern of cr isscrossed light

beams. While the machine is idle, the SureVend™ system is constantly calibrating itself for

optimum performance in all temperature, humidity, dust, and alignment conditions. The

SureVend™ detection system is used by the controller to assure that the selected product is

delivered.

• When a customer makes a selection, the controller checks that the SureVend™

detection system is ready and tells it to begin scanning for the product. Different

scanning patterns are used depending upon the size and shape of the product.

• The vending machine controller then starts the delivery motor and constantly

checks the SureVend™ system for detection of the delivered product.

• If no product del ivery is d etected, the controll er continu es to run the deliv ery moto r

for up to three revolutions, pausing momentarily at the home position of each

revolution of the motor.

• If no product is detected after the third revolution, the selection is marked as

empty and the customer's credit is optionally restored to make another selection

or is automatically returned.

• If product delivery is detected before the delivery motor has come to the home

position for the first time, the delivery motor continues running to its home

position.

• If the delivery motor has already p assed the first home position, the motor will stop

immediately upon product detection to avoid the possibility of vending a second

product.

NOTE:

A fatal malfunction in the SureVend™ detection system during the

vend is treated the same as a product delivery. It is assumed

that the malfunction is due to tampering or vandalism.

Anti-Jackpot provides pr otection ag ainst unfo resee able cheating of the S ureV en d™ system.

If a certain number of SureVend™ empty conditions occur, SureVend™ will disable itself for

a few minutes. A SureVend™ empty condition occurs when product delivery is not detected

and the customer's money is restored or returned. Both the number of SureVend™ empty

conditions required to disable SureVend™, and the number of minutes it remains disabled,

are both configur able by the oper ator ( see "S et Sur eVend Up the Sure Vend Anti-Jackpo t

Feature" on page 66).

Once Anti-Jackpot is triggered, the SureVend™ system will be turned off for a certain

number of minutes so that money can no longer be refunded because of vend failure and

thus discourage a thief from remaining. While SureVend™ is disabled, machine will either

revert to home switch operation or go out of service, depending on other selected options

(see "Set Up Basic SureVend™ Options" on page 66).

Once the Anti-jackpot time has elapsed, SureVend™ is re-enabled. The total number of

SureVend™ empty selections, the number of anti-jackpot occurrences, and the date and

time of the most recent occurrence are recorded.

December 2004 41 4800006

Page 47

Health Control Refreshment Center Operators’ Guide

Section 6: Health Control

NOTE:

The following section applies only to the 780 Refreshment Center.

Refreshment Centers configured for Refrigerated Food operation (see "View Or Set

Machine Configuration" on page 64), will have electronic health shutoff control software.

Health Shutoff Control software is required by state and local health authorities and is a

requisite for NAMA approval for perishable food vending.

Health Shutoff Control prevents the merchandiser from vending product that could be

spoiled. It monitors the temperature within the cabinet, and will automatically go into an outof-service mode should any of the following conditions occur:

• The temperature of the refrigerated cabinet does not fall to 41° F (5° C) within 30

minutes after the door of the refrigerated cabinet is closed.

• The temperature of the refrigerated cabinet does not fall to 41° F (5° C) within 30

minutes after a defrost.

• The temperatur e of the cabinet rises above 41° F (5° C) for more than 15 minutes

without the door of the refrigerated cabinet having been open, except within 30

minutes of a defrost.

• For testing purposes, the temperature of the cabinet rises above 41° F (5° C) for

at least one second with the refrigerated door open.

When the health shutoff con trol is triggered, the display will read

“

only top 2 shelves available

configuration. When the monetary door is opened, the message changes to

date, time, and maximum cabinet temperature reached are displayed. If the refrigerated

cabinet door is opened and then closed, the health control timer will reset and the

refrigeration system will have another 30 minutes to cool the cabinet below 41° F (5° C).

The out-of-service condition may occur during initial setup, as it will ta ke time for the

refrigeration system to cool the cabinet the first time. Therefore, National Vendors

recommends leaving the refrigerated compartment empty until the cabinet temperature is

low enough to satisfy the health shutoff control.

Health Control will not be operative for Refreshment Cente rs configu red for Chille d vending

(see "View Or Set Machine Configuration" on page 64). Perishable food must only be

sold from a merchandiser configured for Refrigerated Food operation. Vending perishable

food from a chilled merchandiser will violate state and local health regulations.

” or “

only top 3 shelves available

T E MP ORAR Y OU T OF SE R VIC E

” depending on machine

HC.ER

, and the

,

4800006 42 December 2004

Page 48

Refr eshment Center Operators’ Guide Health Control

Test the Health Control

Use this procedure on model 480 merchandisers configured for refrigerated food to verify

the operation of the Health Control Automatic Shutoff circuitry. The purpose of the Health

Shutoff Control is to disable the vending mechanism whenever the machine does not

o

maintain the air temperature in the food storage compartment at or below 41

temperature shutoff requirement does not apply for 30 minutes after filling, servicing or a

defrost cycle.

NOTES:

a. The Automatic Health Shutoff Control timer resets every time the cabinet door is

closed.

b. The internal cabinet temperature can be viewed on the credit display by pressing

.

1. Check the temperature of the food compartment by pressing to ensure that the

machine is not in the 30-minute recovery period that occurs after the door is closed

following filling, servicing or after a defrost cycle. If the machine is in the 30-minute

recovery period, the time remaining will appear on the display. Before proceeding, wait

until the recovery period ends.

F (5oC). The

2. Open the main door a minimum of 45 degrees to allow the food compartment

temperature sensor to warm. Observe the cabinet temperature on the credit display by

pressing the button. When the temperature on the display rises to 42o F (5.5oC),

the message "

shelves available

Temporary Out o f S ervice

", “

only top 2 shelves avail able

” or “

” depending on machine configuration will display. This verifies that

only top 3

the vending mechanism of the machine has been disabled as required. With the door

open, the sensor temperature will typically reach 42o F (5.5oC) in less than 5 minutes.

3. Press the button and the message "HCER" (Health Control Error) will display.

This is the message a service person would observe after opening the door.

4. Close the main door. You may observe the recovery time and temperature by pressing

again.

December 2004 43 4800006

Page 49

Final Installat io n Refres hm en t Cen te r Op erato r s’ Gu ide

Section 7: Final Installation

Move the merchandiser to its final position:

•Perform “Open the Rear Outlet Diffuser” on page 9 before placing the merchandiser

into its final position.

• You can position this merchandiser anywhere in a bank of machines. It can even be

placed on an end flush against a side wall.

• The merchandiser should be placed at least four inches away from the back wall (six

inches if rear dif fuser is n ot inst alled) . T his will provide a dequa te a ir circu lation f or th e

refrigeration unit.

• The merchandiser will operate more efficiently when placed in a shaded location.

• There should be enough room in front of the merchandiser for the door to move

freely.

WARNING

This machine is only rated for installation in an indoor location.

Level the Merchandiser

1. Use a spirit level to adjust the legs until the

cabinet is level from side to side and front

to back.

NOTE

A slight slope from front to back will

improve the draining of condensate from

merchandisers with refrigerating units.

When the merchan diser is par t of a bank of

machines, level it in refere nce to the other

machines. After leveling is complete,

check that the door operates easily.

4800006 44 December 2004

Page 50

Refreshment Center Operators’ Guide Final Installation

Install the Base Plate

Refer to the figure below while completing the following procedures:

WARNING

Do not move the cabinet while the hex head screws and/or carriage bolts are

loosened. The cabinet would be unstable and could tip and cause injury.

1. Loosen the left leg assembly hex screws to allow mounting a ba se plate bracket.

2. Secure one of the base plate brackets to the leg assembly and tighten the hex screws.

3. Loosen the right leg assembly hex screws to allow mounting the other base plate

bracket.

4. Secure the other base plate bracket to the right leg assembly using the two hex head

screws. Tighten the hex head screws.

5. Insert the short arms of the slides into the hinged tabs of the base plate. Position the

slide so the notch near the short arm is on the bottom side.

6. Insert the long arms of the slides into the base plate brackets.

7. Insert and secure a cotter pin through the hole in the back of each of the slides.

8. Push the base plate toward the merchandiser cabinet. The front tabs of the base plate

brackets should seat in the notches in the long arms of the slides.

December 2004 45 4800006

Page 51

Final Installat io n Refres hm en t Cen te r Op erato r s’ Gu ide

LOCK

LEVER

E

Install the Lock Cylinder

Install an optional lock cylinder in the

merchandiser as follows:

1. Position the lift handle lock lever

as shown.

SPRING

2. Depress the lock spring at the

square hole of the lock cylinder

SQUAR

HOLE

receptacle and pull the lock

springs out through the front.

3. Position the lock cylinder as

shown. Depress the spring

KEY

LOCK

CYLINDER

loaded lock pin.

4. Push the cyli nder into th e cylinder

receptacle in the lever. The pin

shou ld snap into the square hole.

5. If the cylinder pin does not seat in the square hole, press against both ends of the lock

cylinder. Rotate the cylinder until the pin snaps into place.

6. Leave the door open and test the lock mechanism with a key. Do not close the door

until you are certain the key will unlock the lock.

Install the Optional Cash Box Lock

Remove the cash box from the merchandiser.

1. Assemble the lock as shown in the illustration

to the right.

2. Return the cash box to the merchandiser.

LOCK

CYLINDER

LOCK BAR

SCREW

NUT

WASHER

4800006 46 December 2004

Page 52

Refreshment Center Operators’ Guide Final Installation

Set Up the Coin Mechanism

If the changer is not a MARS TRC 6000, proceed to LOADING THE COIN MECHANISM

If the Changer is a MARS TRC 6000, you must set the high quarter switch.

Set the Quarter Switch:

QUARTER SWITCH

POSITION

LOW

HIGH

quarters. The rest are

will store 69 quarters.

ACTION

The coin mechanism

will only sto re 6

sent to th e c oin box.

Fewer qu art ers are

available for change.

The coin mechanism

More quarters are

available for change.

Load the Coin Mechanism

Once you arrive at the steps that tel l you how to setup your coin mechanism, ple ase perform

the following steps:

1. Plug the power cord into the electric outlet and turn ON the main power switch.

2. Press , and press once. Press until either

DUMB MECH

or

MDB MECH

displays (depending upon which coin mech type you have).

3. If you chose

procedure. If you chose

MDB MECH

in the previous step, go to step 4 and perform the rest of this

DUMB MECH

in the previous step, fill the coin tubes with coins.

Make sure the coins are not shingled. You are now finished setting up your coin mech.

Do not perform the rest of this procedure.

4. Press until the standby message is displayed, then press .

5. Insert at least 20 coins of each denomination through the coin chute. Con tinue to fill the

coin tubes either through the coin chute or the tops of the tubes.

6. Visually check the coin tubes to make sure coins are not shingled.

7. Press .

8. If credit is still shown in the display, turn the machine power OFF, then back ON.

December 2004 47 4800006

Page 53

Final Installat io n Refres hm en t Cen te r Op erato r s’ Gu ide

Operational Readiness Check

1. Perform test vends on all selections.

2. Do any of the snack or candy products catch on the tray and fail to vend? If not, skip to

step 3. If so, perform the following procedures on the affected areas until all products

vend properly:

a. Install and/or adjust a product spacer (See "Install a Product Spacer" on page 32).

b. Install a product pusher (See "Product Pusher Usage" on page 35).

c. Install and/or remove spiral wall retainers (See "Spiral Wall Retainer Usage" on

page 34).

d. Perform the appropriate spiral anti-hang-up procedure(s).

3. Test the operation of the coin mechanism.

4. Test the operation of the bill validator.

5. Return all test vended products to the trays.

Spiral Indexing Procedure (One Spiral, One Motor)

The spiral indexing procedures involve rotating spirals one position at a time until the

product vends properly.

1. Home all the motors.

2. Remove the effected spiral.

3. Is the coupler in the proper position?

NO - Move the coupler to the position as shown in "Install a Gear" on page 28. Go to

step 4.

YES - Move the coupler to the next clockwise position (if it's on a right-hand motor), or

the next counterclockwise position (if it's on a left-hand motor). Go to step 4.

4. Replace the spiral.

5. Perform a test vend (see the previous page).

6. Did the product hang up?

NO - You're finished. Continue to test vend the remaining selections until everything

works right.

YES - Go to step 7.

7. Did you previousl y mo ve the coupler to th e next clockw ise or counter clockw ise po siti on?

NO - Move the coupl er to the n ext clockwise p osition (if i t's on a righ t-hand mo tor), or the

next counterclockwise position (if it's on a left-hand motor). Return to step 6.

YES - Return to step 2 in the operational readiness check and try another procedure.

Do not move the coupler again.