Page 1

Page 2

Your new merchandiser has been engineered to our own rigid safety and

performance standards. It has been designed to comply with sanitation and

health guidelines recommended by the Automatic Merchandising Health-Industry

Council (AMHIC) and it conforms to all NAMA safety recommendations.

This machine has been manufactured in accordance with the safety standards of

both Underwriter’s Laboratories and the Canadian Standards Association. To

maintain this degree of safety and to continue to achieve the level of

performance built into this machine, it is important that installation and

maintenance be performed so as to not alter the original construction or wiring

and that replacement parts are as specified in the Parts Manual

in this equipment will be protected by using this Operators’ Guide

. Your investment

and the Parts

Manual in your operation, service and maintenance work. By following prescribed

procedures, machine performance and safety will be preserved.

Models 180, 181, 448 & 449

Parts and Support

Call

Models 980 & 981

Parts and Support

Call

For faster service, please have your

account number ready before calling

National Vendors

Parts: 1-800-621-7278

Service: 1-800-628-8363

www.cranems.com

www.automaticproducts.com

Automatic Products

Parts: 1-800-784-6438

Service: 1-800-523-5932

12955 ENTERPRISE WAY · BRIDGETON, MISSOURI 63044-1200 USA

Page 3

Merchant™ Operators’ Guide Table of Contents

Table of Contents

Preliminary................................................................................................................ 5

Power Requirements...................................................................................................................... 5

Unpacking the Merchandiser......................................................................................................... 5

Controls and Indicators.................................................................................................................. 6

Turning the Merchandiser ON and OFF........................................................................................ 8

Initial Set-Up.............................................................................................................. 9

Moving the Merchandiser Through a Narrow Doorway............................................................... 9

Positioning the Merchandiser...................................................................................................... 11

Snack Section Set-Up.............................................................................................. 11

Placing Trays in the Loading Position......................................................................................... 11

Setting Up Trays to Vend Products............................................................................................. 12

Setting Up Trays to Vend Wide Products.................................................................................... 12

Removing Standard Trays ........................................................................................................... 13

Installing Standard Trays............................................................................................................. 14

Removing a Bottle Tray............................................................................................................... 15

Installing a Bottle Tray................................................................................................................ 15

Removing and Installing Column Dividers................................................................................. 16

Operating Trays Outside the Merchandiser................................................................................. 16

Replacing a Motor With a Spiral Bearing ................................................................................... 16

Connecting and Disconnecting a Motor Harness ........................................................................ 17

Removing and Installing Spirals.................................................................................................. 18

Removing a Spiral Coupler ......................................................................................................... 20

Removing and Installing a Spiral Motor ..................................................................................... 20

Installing a Gear........................................................................................................................... 21

Installing a Spiral Coupler........................................................................................................... 22

Moving Trays Up or Down.......................................................................................................... 23

Installing and Removing Product Spacers................................................................................... 25

Loading Trays with Product ........................................................................................................ 26

Spiral Capacity Color Codes ....................................................................................................... 26

Returning the Trays to the Vending Position .............................................................................. 31

Installing and Setting Price Labels.............................................................................................. 32

Installing Selection ID Labels ..................................................................................................... 34

Motor Position............................................................................................................................. 35

Final Installation ..................................................................................................... 36

Leveling the Merchandiser.......................................................................................................... 36

Installing the Base Plate............................................................................................................... 37

Setting Up and Loading the Coin Mechanism............................................................................. 38

TriTeq Lock Information............................................................................................................. 38

Final Checkout......................................................................................................... 39

Operational Readiness Check...................................................................................................... 39

Spiral Indexing Procedure (Two Spirals, One Or Two Motors) ................................................. 40

Spiral Indexing Procedure (One Spiral, One Motor)................................................................... 40

1810025 i August 2009

Page 4

Table of Contents Merchant™ Operators’ Guide

Testing the Bill Validator ........................................................................................................... 41

Service Keypad Shortcut Keys ................................................................................................... 43

Programming: Data Recall..................................................................................... 45

View Non Resettable Sales and Vend Data................................................................................ 45

View Non Resettable Sales and Vend Data By Product............................................................. 47

View Non Resettable Sales and Vend Data - Cash .................................................................... 49

View Non Resettable Sales and Vend Data - Cashless .............................................................. 51

View Non Resettable Sales and Vend Data - Token.................................................................. 53

View Resettable Sales and Vend Data ....................................................................................... 55

View Resettable Sales and Vend Data - Cash ............................................................................ 59

View Resettable Sales and Vend Data - Cashless ...................................................................... 61

Clear Resettable Sales and Vend Data........................................................................................ 65

View Timed Events - Main Door Openings............................................................................... 66

View Timed Events - Power Losses........................................................................................... 67

View Timed Events - Last Data Clear........................................................................................ 68

View Timed Events - Last Price Setting..................................................................................... 69

View Timed Events - Last Vend................................................................................................. 70

View Timed Events - Last Clock Set.......................................................................................... 71

View Timed Events - Last Timed Backup.................................................................................. 72

View Identification Numbers - Main PCB................................................................................. 73

View Identification Numbers - Coin Mechanism....................................................................... 74

View Identification Numbers - Bill Validator............................................................................ 75

View Identification Numbers - Card Reader.............................................................................. 76

Print Data.................................................................................................................................... 77

Programming: Diagnostic....................................................................................... 78

Check for Errors.......................................................................................................................... 78

Diagnostic Error Messages......................................................................................................... 79

Programming: Test ................................................................................................. 82

Test Vend a Selection................................................................................................................. 82

Test Vend Without SureVend™................................................................................................. 83

Test SureVend™ Calibration ..................................................................................................... 84

Testing the Motors - Motor Test Summary................................................................................ 85

Homing the Motors - Motor Status Detail.................................................................................. 86

Table: Motor Status Detail Menu Screen ................................................................................... 88

Test the Coin Return Motor........................................................................................................ 89

Test the Display.......................................................................................................................... 92

Test the Keypads - Keypad Entry............................................................................................... 93

Programming: Prices .............................................................................................. 94

Set Prices for Individual Selections............................................................................................ 94

Set One Price for the Entire Machine......................................................................................... 95

Set Prices by Trays ..................................................................................................................... 96

Programming: Product Configuration.................................................................. 97

View Configuration Version....................................................................................................... 97

Turn SureVend™ On and Off..................................................................................................... 98

Set SureVend™ Options............................................................................................................. 99

Set SureVend™ Anti-Jackpot Timer........................................................................................ 101

August 2009 ii 1810025

Page 5

Merchant™ Operators’ Guide Table of Contents

Set SureVend™ Anti-Jackpot Trigger....................................................................................... 102

Selection Configuration............................................................................................................. 103

FIFO (First In, First Out)........................................................................................................... 104

FIFO Setup - Adding Groups .................................................................................................... 104

FIFO Setup - Deleting Groups................................................................................................... 105

FIFO Setup - Editing Groups..................................................................................................... 106

FIFO Setup - View FIFO Mappings.......................................................................................... 107

Couple Motors........................................................................................................................... 108

Special Vend Modes.............................................................................................. 109

Timed Events-Time of Day Events ........................................................................................... 109

Timed Events - Backup Events.................................................................................................. 119

Winner Mode............................................................................................................................. 122

Combo Vends ............................................................................................................................ 125

Token Enable............................................................................................................................. 128

Enable OK Button...................................................................................................................... 129

Programming: Free Vend..................................................................................... 130

Turn Free Vend On/Off............................................................................................................. 130

Programming: System Settings............................................................................ 131

Machine Information - ID Number............................................................................................ 131

Machine Information - Location................................................................................................ 133

Set the Date................................................................................................................................ 135

Set the Time............................................................................................................................... 136

Set Daylight Saving Time.......................................................................................................... 137

Select a Language...................................................................................................................... 138

Select the Coin Mechanism....................................................................................................... 139

View Coins In/Out..................................................................................................................... 140

Set Change Without Purchase ................................................................................................... 141

Set Low Change Message.......................................................................................................... 142

Select the Bill Validator............................................................................................................. 143

Set Accept on Low Change ....................................................................................................... 144

Set Bill Acceptance.................................................................................................................... 146

Set Token/Coupon Acceptance.................................................................................................. 147

Select the Card Reader............................................................................................................... 148

Set Card Revalue ....................................................................................................................... 149

Set Multiple Vend Mode ........................................................................................................... 151

Set Credit for Failed Vend......................................................................................................... 153

Set Communication Mode......................................................................................................... 155

Set Data List .............................................................................................................................. 156

Set CA304 Data Type................................................................................................................ 157

Set Data Reset Mode ................................................................................................................. 158

Set Event Reset Mode................................................................................................................ 159

Set Printer Baud Rate................................................................................................................. 160

Connect and Disconnect the Data Key...................................................................................... 161

Firmware Selection (Serial Flash Menu)................................................................................... 162

Save Configuration Data to Data Key....................................................................................... 163

Save Configuration and Sales Data to Data Key....................................................................... 165

1810025 iii August 2009

Page 6

Table of Contents Merchant™ Operators’ Guide

View Image Info (Data Description) on Data Key................................................................... 167

Load Configuration Data from Data Key to Machine.............................................................. 169

Delete Configuration Data or Configuration and Sales Data from Data Key .......................... 171

View Last Backup..................................................................................................................... 173

Backup Data.............................................................................................................................. 174

Restore Data.............................................................................................................................. 175

Set Screen Contrast................................................................................................................... 176

View Software Version............................................................................................................. 177

View SureVend™ Version....................................................................................................... 178

View IO Board Software .......................................................................................................... 179

Set Temperature........................................................................................................................ 180

Select Tray and Selections to be Controlled by Health Control............................................... 181

Set Temperature Units.............................................................................................................. 183

Set Idle Screen Time/Temp Options......................................................................................... 184

Set Idle Screen Message........................................................................................................... 186

Set Custom Messages ............................................................................................................... 188

Reset Custom Messages............................................................................................................ 190

NUMERIC/CHARACTER TABLE......................................................................................... 191

Talker Setup.............................................................................................................................. 192

Programming: Security Codes............................................................................. 193

Enter Security Code.................................................................................................................. 193

Edit the Supervisor PIN............................................................................................................ 194

Lock/Unlock Menu Items......................................................................................................... 195

Programming: Security Codes............................................................................. 198

448/449 Merchant Refrigeration Removal............................................................................... 198

448/449 Merchant Refrigeration Installation............................................................................ 198

Schematic.................................................................................................................................. 199

August 2009 iv 1810025

Page 7

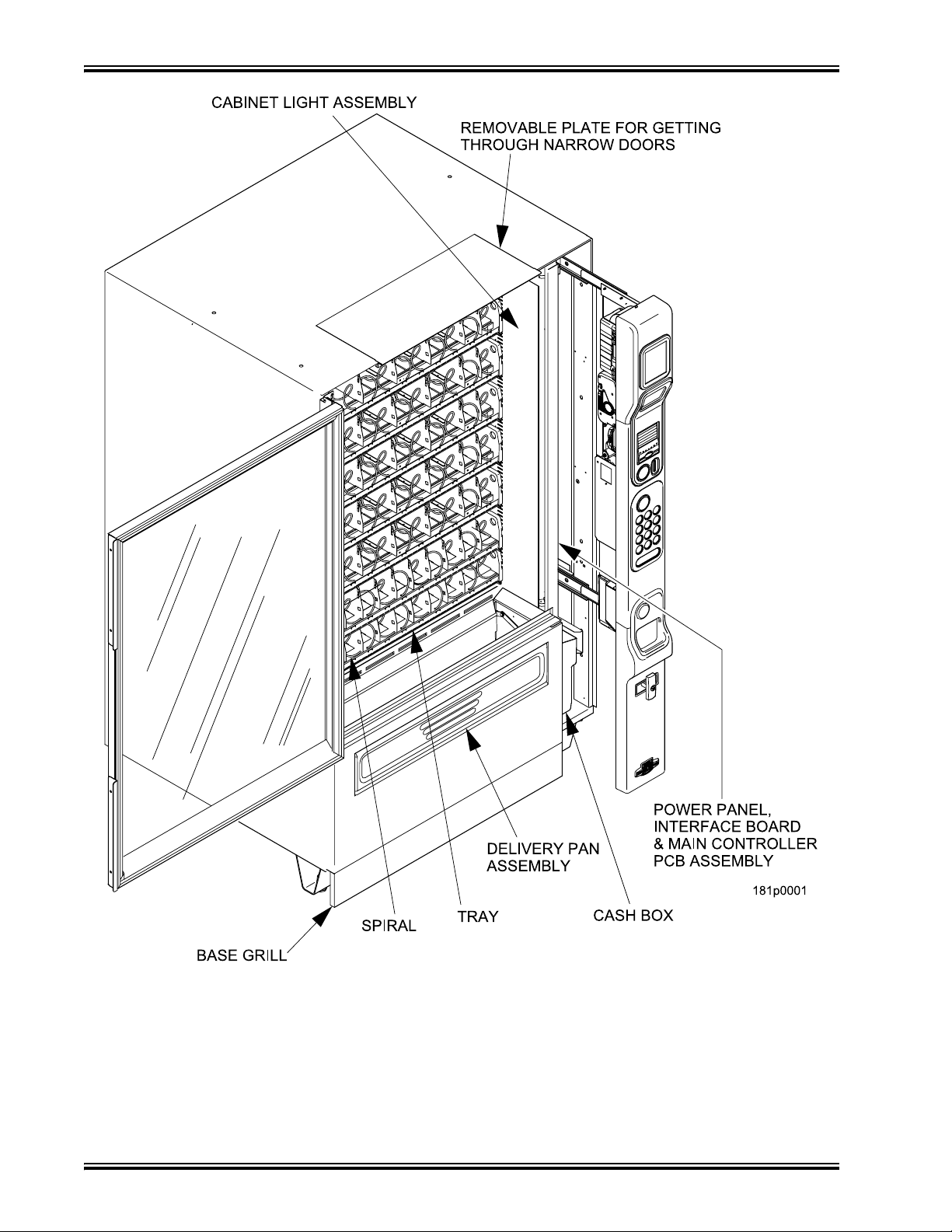

Merchant™ Operators’ Guide Initial Setup

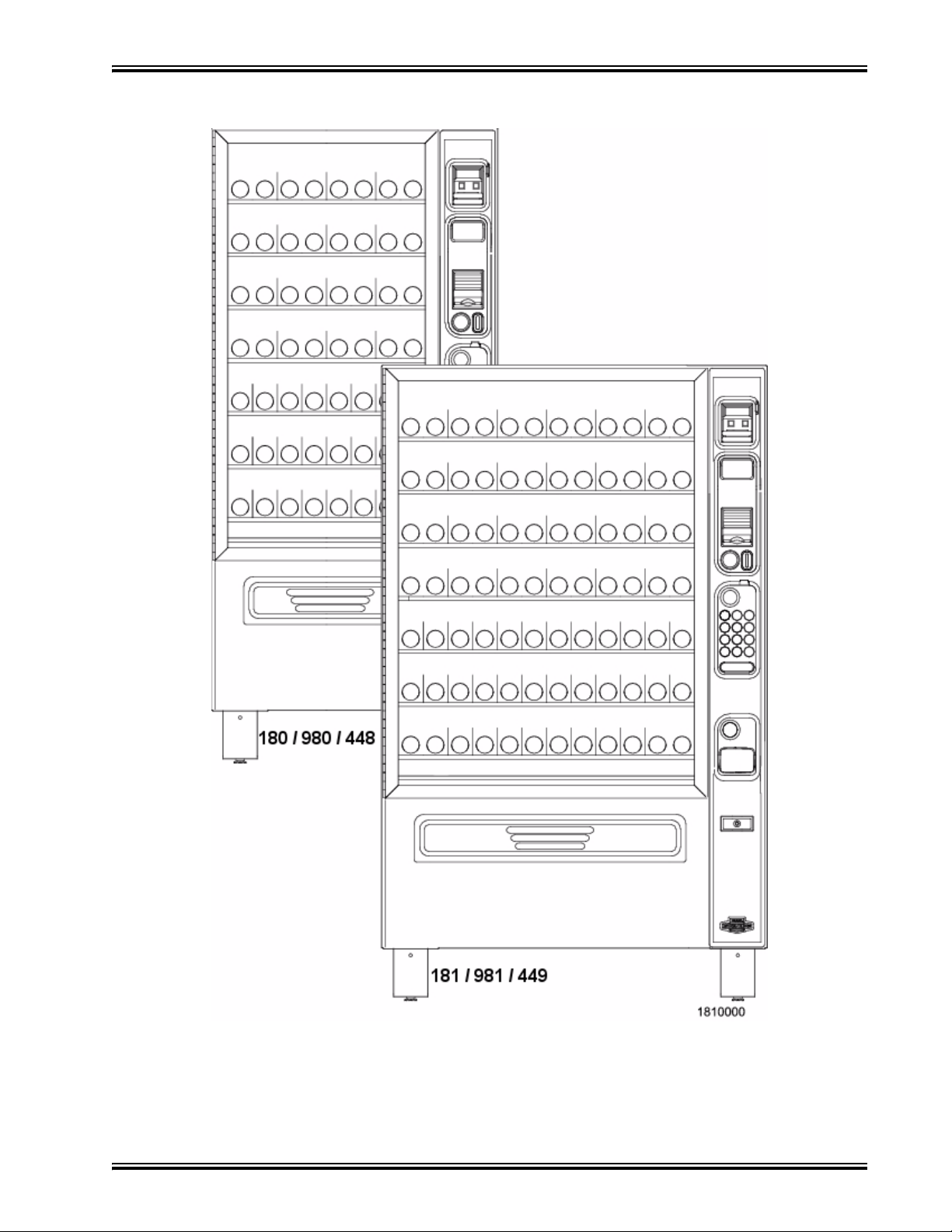

FRONT EXTERIOR VIEWS

1810025 1 August 2009

Page 8

Initial Setup Merchant™ Operators’ Guide

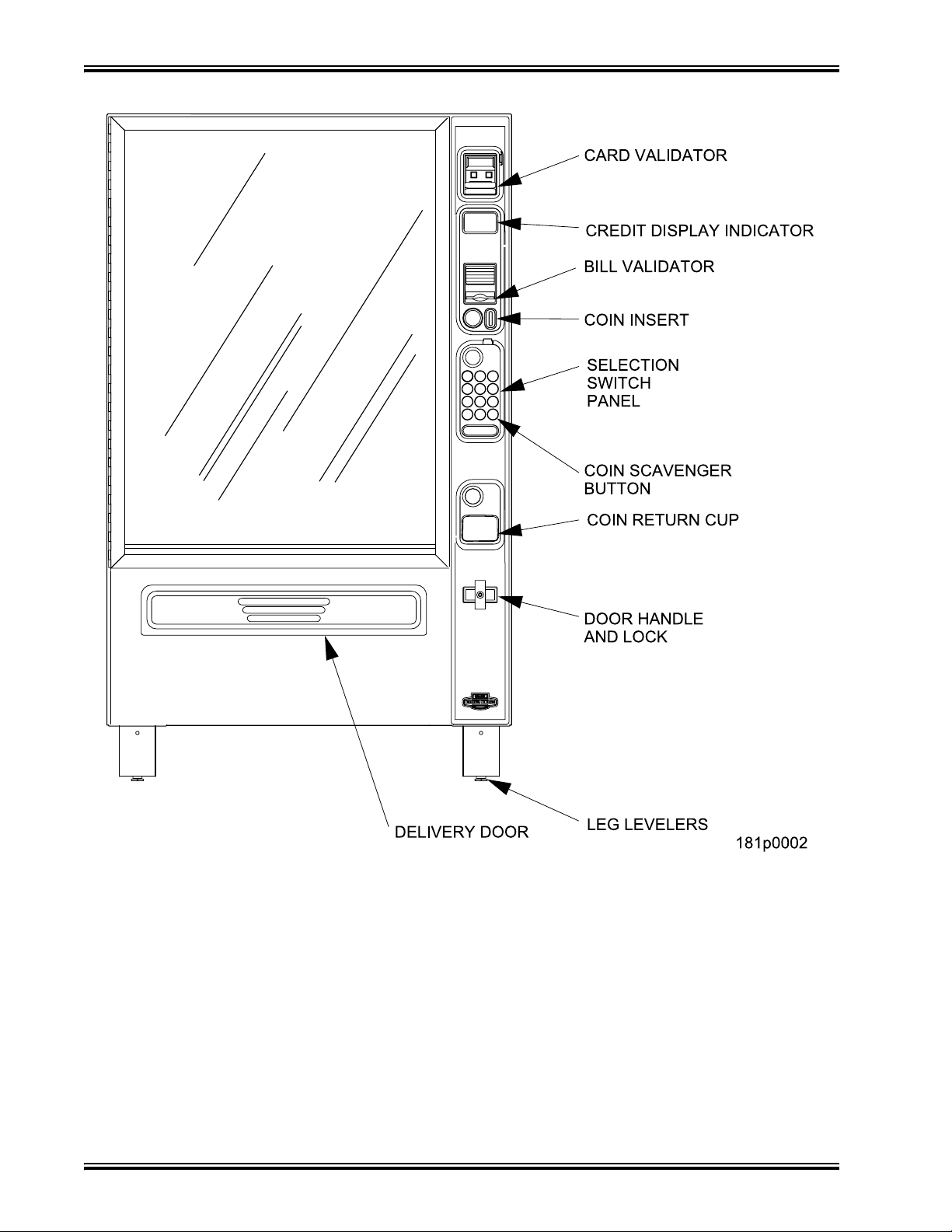

STANDARD

MODEL 181 - EXTERIOR VIEW

(Models 180, 980, 981, 448 and 449 have similar appearance)

August 2009 2 1810025

Page 9

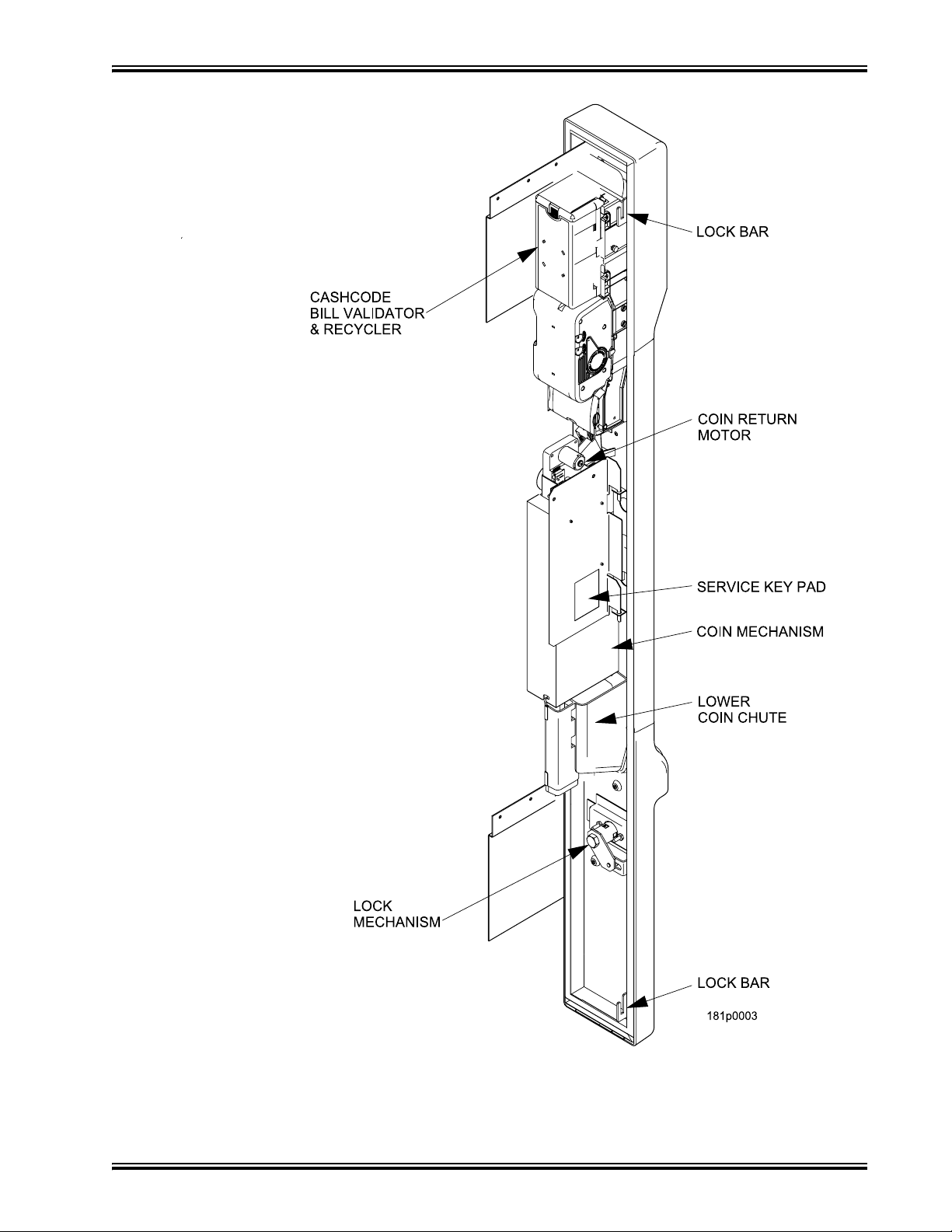

Merchant™ Operators’ Guide Initial Setup

STANDARD

ALL MODELS - MONETARY

1810025 3 August 2009

Page 10

Initial Setup Merchant™ Operators’ Guide

INTERIOR VIEW

August 2009 4 1810025

Page 11

Merchant™ Operators’ Guide Initial Setup

Preliminary

Power Requirements

The merchandiser is supplied with a service cord for the country of use and is terminated in a

grounding type plug. The wall receptacle used for this merchandiser must be properly polarized,

grounded, and of the correct voltage. Operating the merchandiser from a source of low voltage will

VOID YOUR WARRANTY. Each merchandiser should have its own 15 Amp electrical circuit and that

circuit should be protected with a circuit breaker or fuse conforming to local regulations.

1. Voltage Check - Place the leads of a voltmeter across the LINE (LIVE) and NEUTRAL termi-

nals of the wall receptacle. The voltmeter should indicate 110-130 volts ac for 120 volt, 60 Hz

locations, or 220- 240 volts ac for 230 volt, 50 Hz locations.

2. Polarity Check - Place the leads of a voltmeter across the LINE (LIVE) and GROUND terminals of the wall receptacle. The voltmeter should indicate 110-130 volts ac for 120 volt, 60 Hz

locations, or 220- 240 volts ac for 230 volt, 50 Hz locations.

3. Noise Potential Check - Place the test leads of a voltmeter across the NEUTRAL and

GROUND terminals of the wall receptacle. The meter should indicate 0 volts ac. A measurement greater than 1.5 - 2.0 volts ac could result in problems for the merchandiser's electronic

circuitry caused by electrical noise.

NOTE

Any deviation from these requirements could result

in unreliable performance from your merchandiser.

Unpacking the Merchandiser

Remove all packing materials from the interior of the merchandiser. Keep all documents; warranty

cards, etc. Set aside the base plate kit (if present).

1810025 5 August 2009

Page 12

Initial Setup Merchant™ Operators’ Guide

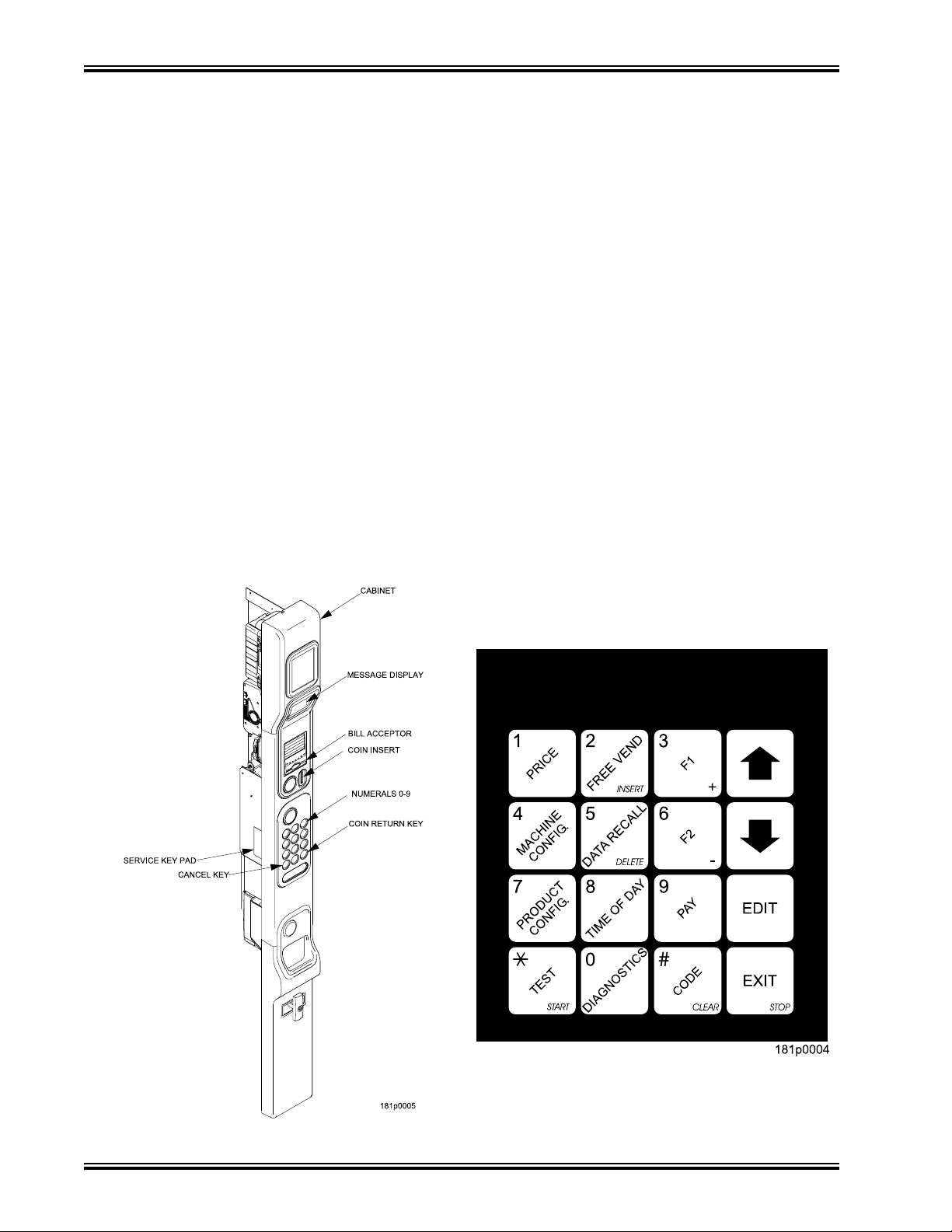

A

Controls and Indicators

INTERLOCK SWITCH

When the monetary slide is open, this switch turns off the optional fan (if so equipped.)

MESSAGE DISPLAY

This is how the merchandiser communicates with the outside world. Customers can see messages

about how much money they have put into the merchandiser. The message display also tells

customers when a selection is sold out and when vending is free, inhibited, or discounted. The

message display shows you what you are doing when you program the merchandiser, and can show

you what is wrong if there is a failure.

SELECTION KEYPAD

The customer uses these switches to make selections.

COIN RETURN KEY

Pressing this button returns any coins that have been paid into the merchandiser prior to a vend.

CANCEL KEY

Pressing this button clears any selection keys.

BILL ACCEPTOR (OPTIONAL)

ccepts bills in various denominations, depending upon the type of bill validator, and how the

merchandiser is configured.

SERVICE KEYPAD

The service keypad is located on the inside of the monetary section. It gives service personnel the

means to program, retrieve data from, and view diagnostic information about, the merchandiser.

August 2009 6 1810025

Page 13

Merchant™ Operators’ Guide Initial Setup

Controls and Indicators (continued)

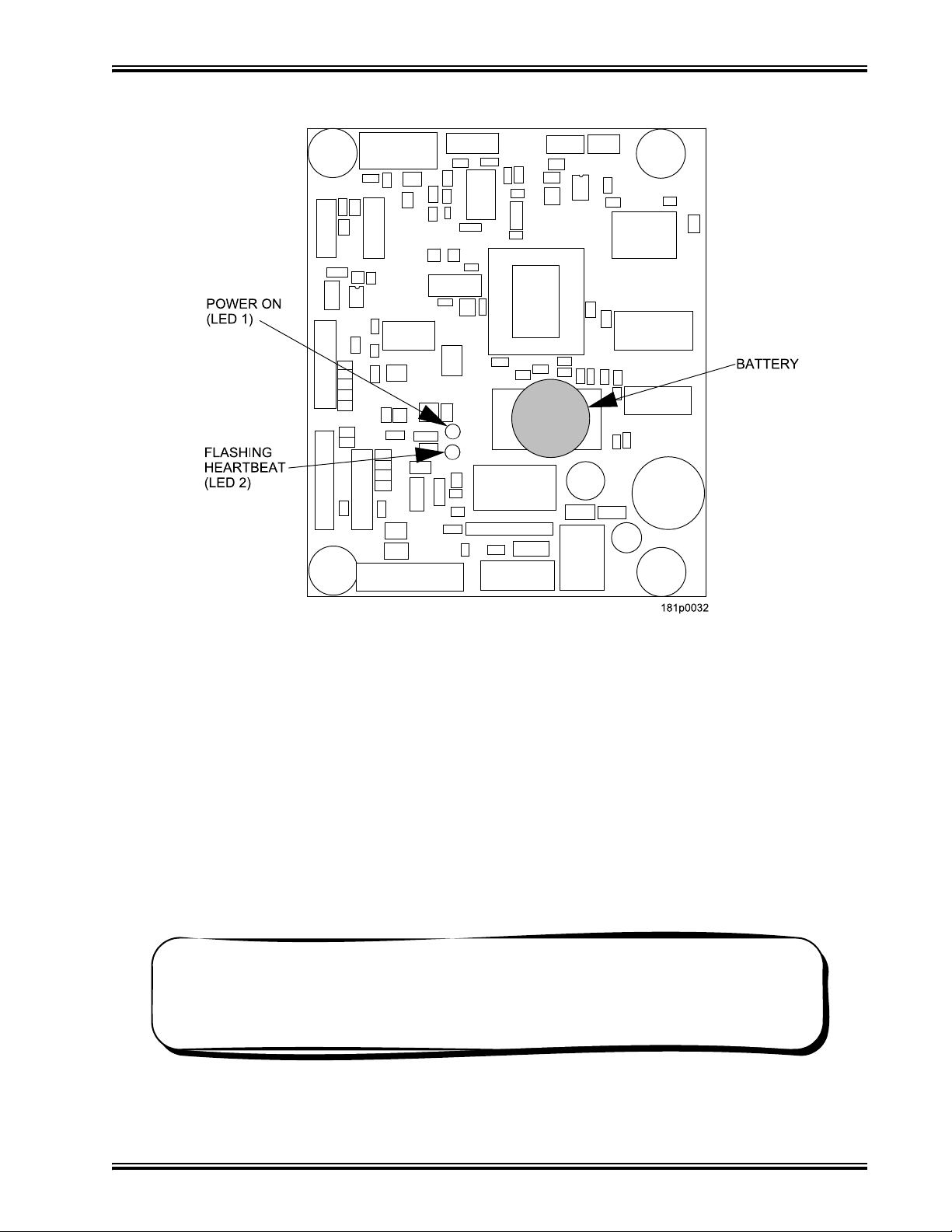

MAIN CONTROLLER PCB DISPLAY

This display consists of two light emitting diodes (LED) mounted on the controller PCB.

POWER ON

(L.E.D. 1)

HEARTBEAT

(L.E.D. 2)

When lit, this red LED indicates electrical power is applied to the

controller PCB.

When flashing, this red LED indicates that the controller PCB is

active, and the software is operating.

WARNING

Risk of explosion if battery is replaced with an incorrect type. Battery type is CR2032 / 3V

Dispose of used batteries according to the manufacturer's instructions.

NORMAL CONDITIONS:

When the merchandiser is operating normally, you should see a steady

red POWER ON indicator and a flashing red HEARTBEAT indicator.

Contact a service representative if any other condition exists.

1810025 7 August 2009

Page 14

Initial Setup Merchant™ Operators’ Guide

Turning the Merchandiser ON and OFF

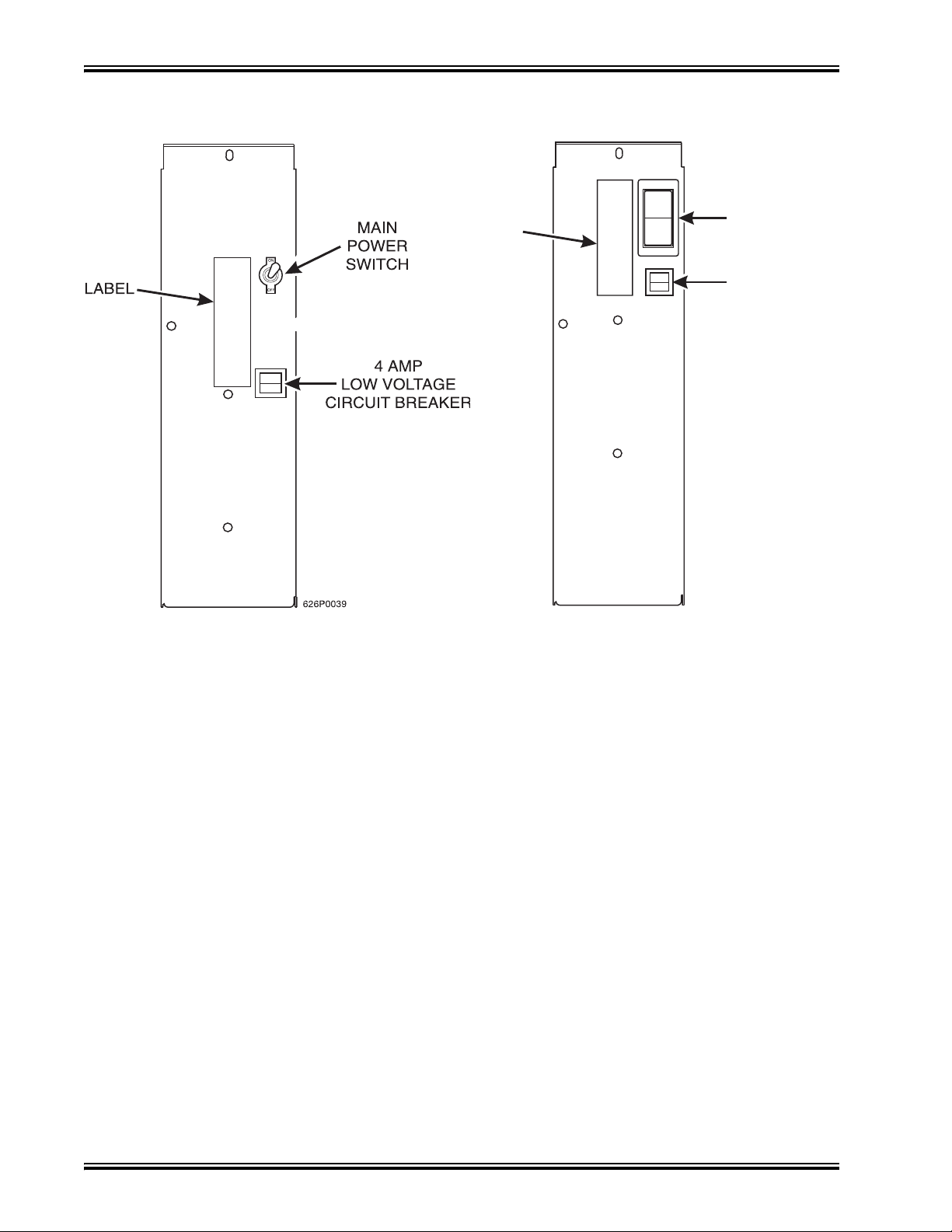

U.S./CANADA POWER PANEL

I

LABEL

O

INTERNATIONAL POWER PANEL

MAIN

POWER

SWITCH

ELECTRONICS

BREAKER

626P0005

• Power to the merchandiser is controlled by the main power switch, located on the power

panel.

• The power panel is on the right side of the merchandiser, behind the monetary door.

WARNING

Lethal voltages are present. Unplug the merchandiser whenever

you do one of the following tasks:

• Change the fluorescent lamp.

• Change the ballast.

• Connect or disconnect a harness

(except a motor harness when the tray has been removed.)

Failure to do so may result in personal injury.

August 2009 8 1810025

Page 15

Merchant™ Operators’ Guide Initial Setup

Initial Set-Up

Moving the Merchandiser Through a Narrow Doorway

NOTE

If necessary, this merchandiser can be moved through an opening as

narrow as 30 inches by removing panels at the top and bottom of the cabinet.

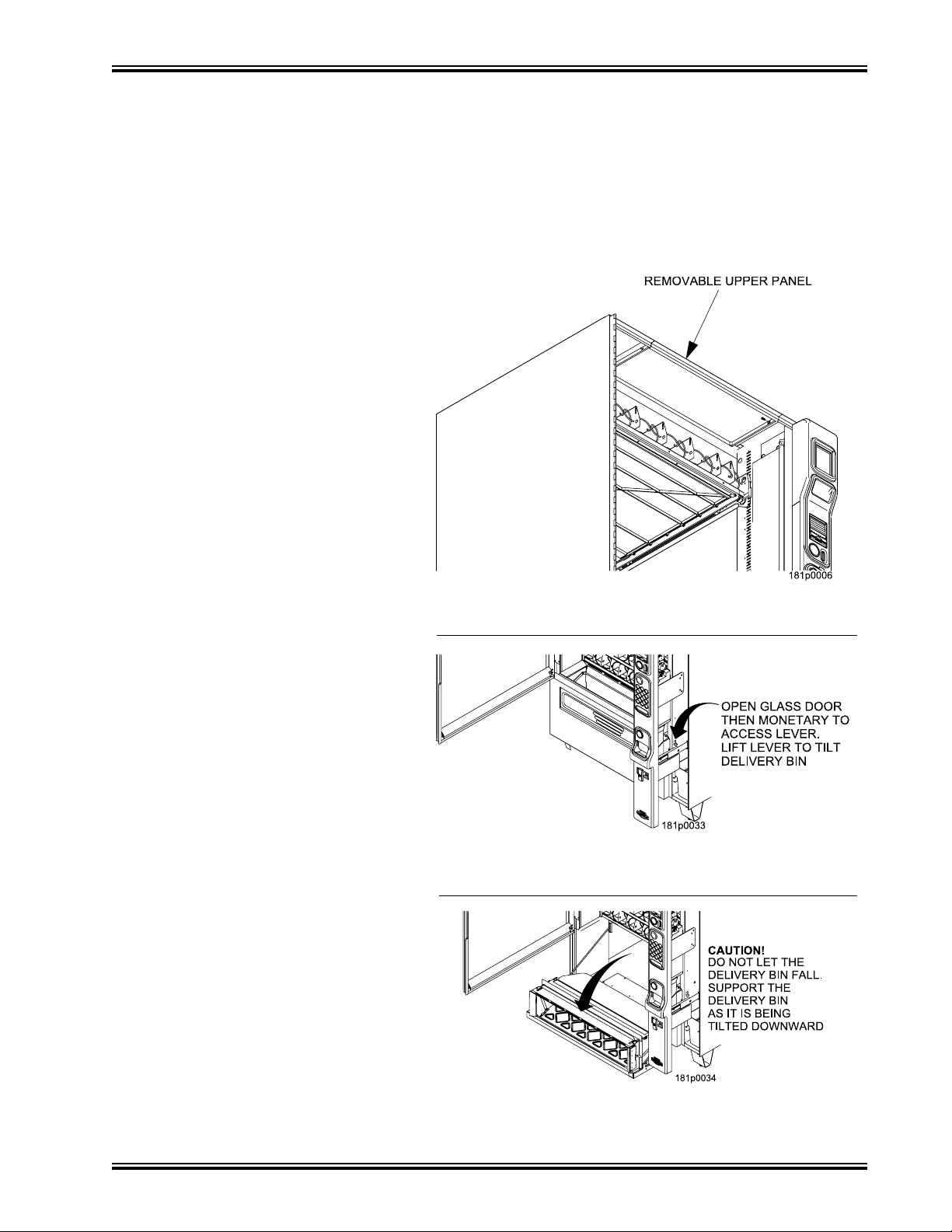

REMOVING THE TOP PANEL

(Refer to Figure 1 at right.)

1. Remove the two screws that

secure each end of the panel to

the cabinet.

2. Pull the panel forward to remove it

from the merchandiser.

REMOVING THE LOWER PANEL

AND DELIVERY BIN

(Refer to Figures 2 and 3 at right.)

1. Open the slide-out monetary and

the glass door. Locate the silver

tab of the delivery bin latch on the

lower delivery bin side of the

monetary wall.

2. Lift the latch up to allow the

delivery bin assembly to hinge

down.

3. Lift up the delivery bin slightly and

lift up on the drop rods to allow the

rods to clear the stop brackets.

4. Slide the delivery bin assembly to

the right to clear the hinges. The

delivery bin assembly will not be

attached to the machine.

5. Unhook the SureVend™ harness

at the SureVend™ board, noting

the wire routing.

6. Remove the screws that secure

the bottom panel to the cabinet.

7. Pull the panel forward to remove it

from the cabinet.

Figure 1

Figure 2

NOTE

To fit the merchandiser through

some of the most narrow doorways,

you may have to remove the trays.

If you do, follow the procedure as

outlined on the following page.

1810025 9 August 2009

Figure 3

Page 16

Initial Setup Merchant™ Operators’ Guide

Moving the Merchandiser Through a Narrow Doorway (continued)

CAUTION

Be careful to not damage the tray harnesses

when removing trays from the merchandiser.

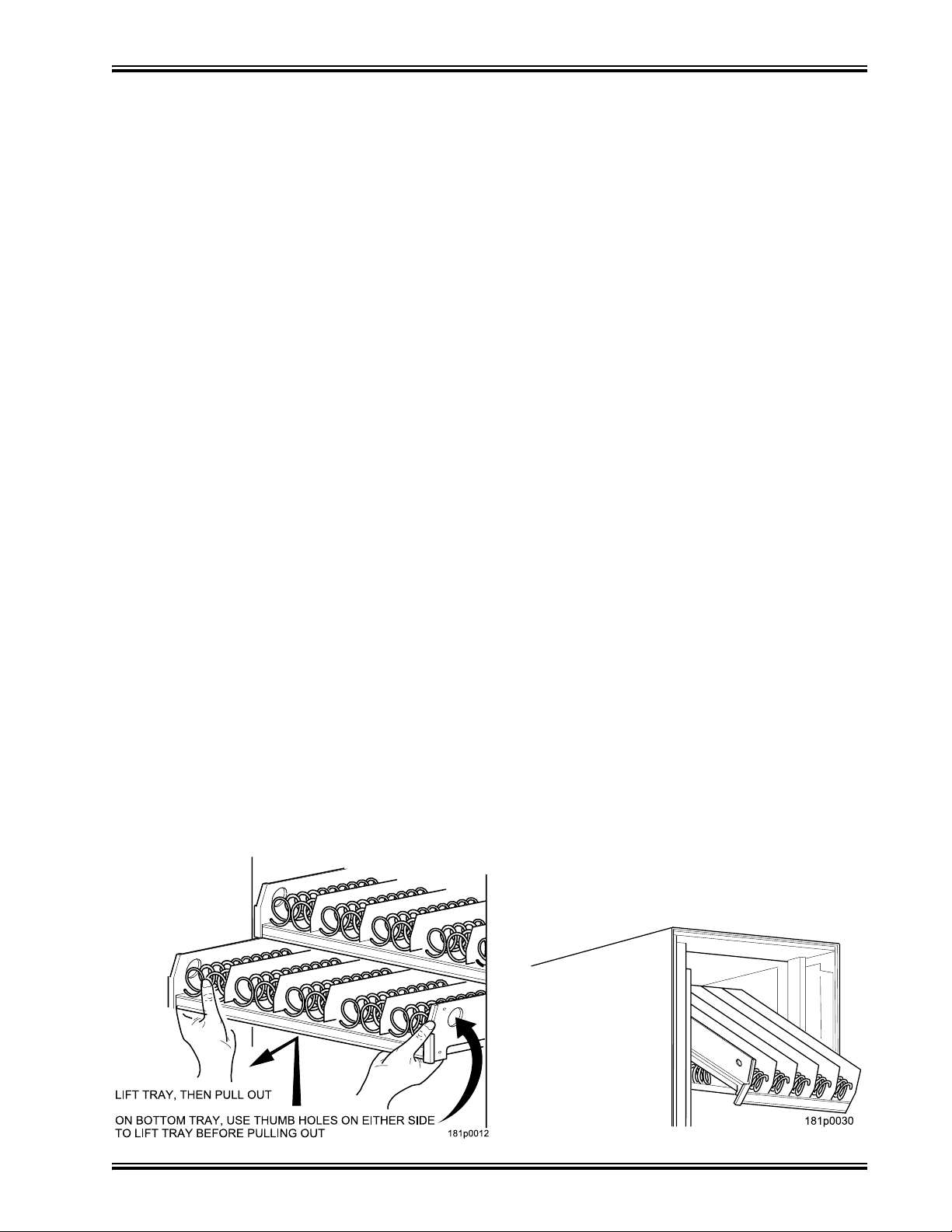

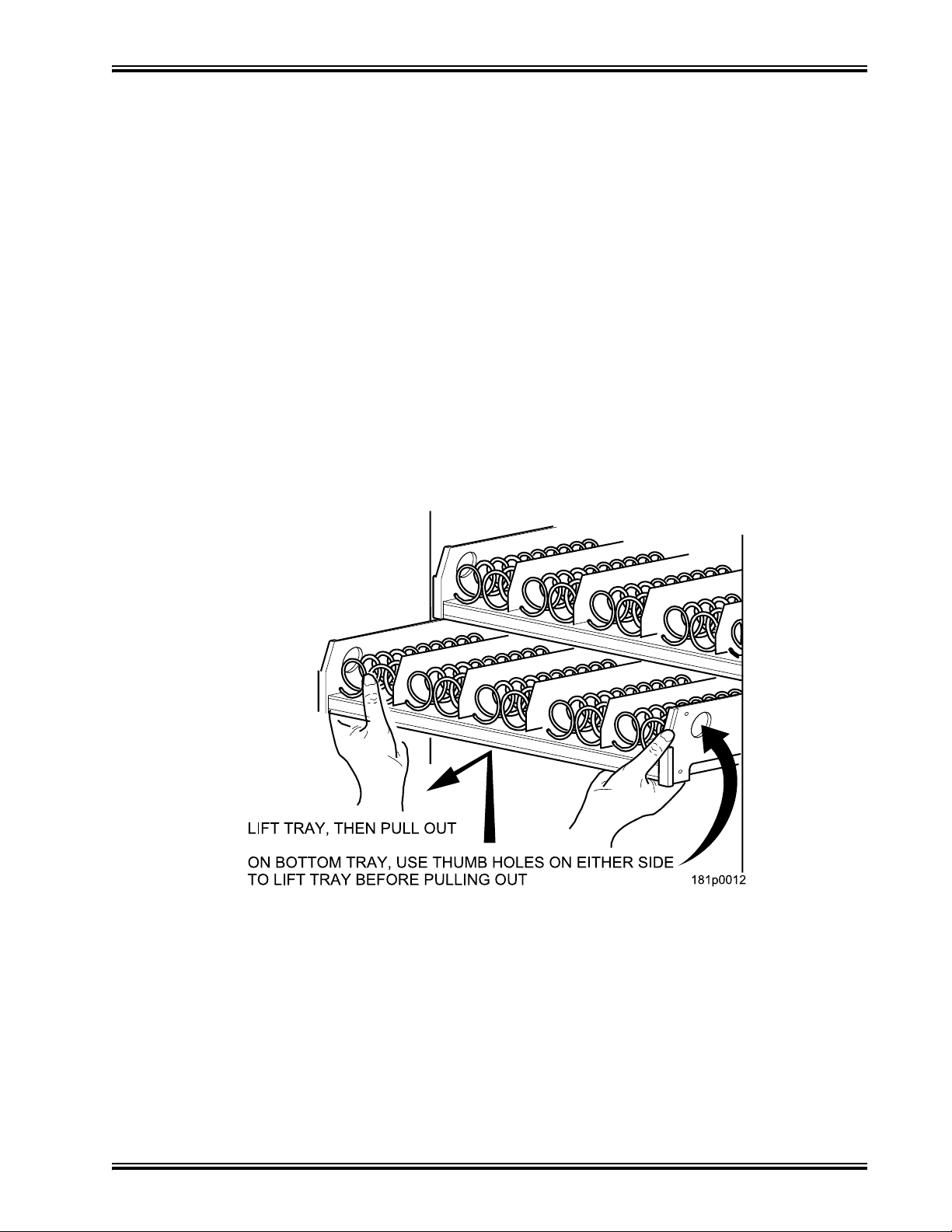

REMOVING THE TRAYS

1. Unplug the tray harnesses from the PCB mounted inside the slide-out monetary.

2. Pull the harnesses through the cabinet.

3. Lift up the front of the tray, so that the stop built into the tray clears the roller, then pull

the tray forward and let it return to horizontal position.

Pull the tray forward in the horizontal position until the back stop on the tray hits the roller,

then lift the tray straight up to clear the roller and remove the tray from the merchandiser.

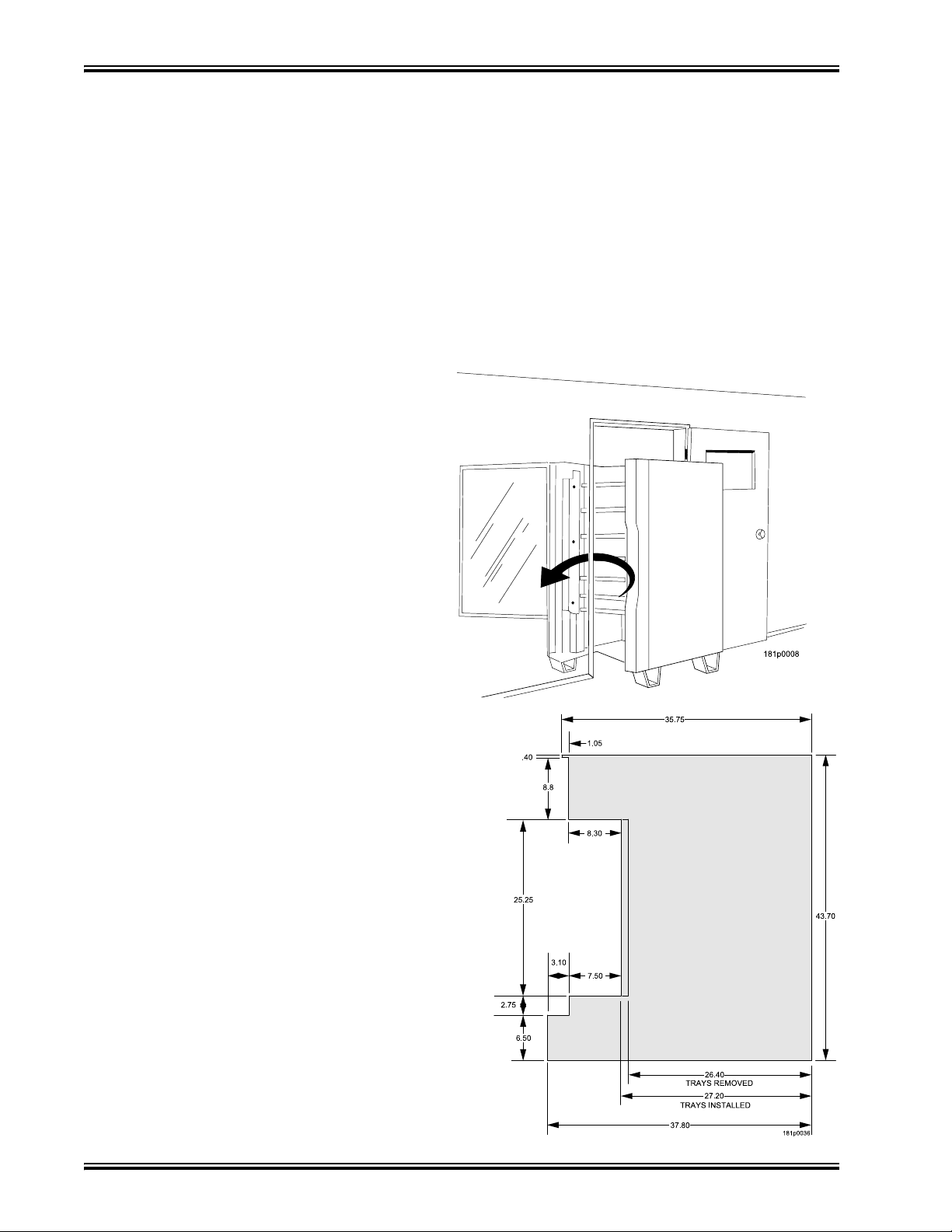

MOVING THE MERCHANDISER

THROUGH THE OPENING

1. Open the cabinet door and

place it square with the left side

of the cabinet.

2. Carefully walk the merchandiser

through the opening.

REASSEMBLING THE

MERCHANDISER

Replace the upper and lower panels and delivery

bin.

If you are not sure that you can fit your

merchandiser through the doorway, use the

dimensioned drawing to make a cut out in

cardboard. The drawing shown has the following

removed:

•Delivery bin assembly

•Upper knockout and the anti-theft bar

•Lower knockout

•Main Glass Door

•Trays removed if needed

August 2009 10 1810025

Page 17

Merchant™ Operators’ Guide Initial Setup

Positioning the Merchandiser

WARNING

This merchandiser is only rated for

installation in an INDOOR location.

Move the merchandiser to its approximate position. (There are some procedures you need to do

before it is in its permanent location.) Plug in your merchandiser and turn the power switch to ON.

• You can position this merchandiser anywhere in a bank of machines. It can even be placed

on an end flush against a side wall.

• The merchandiser should be located at least one inch away from the back wall.

• There should be enough room in front of the merchandiser for the door to move freely.

Now that you have placed your merchandiser near its permanent location, you need to set up

some of the special options you may have............... Go on to the next page and continue with

the snack section set up.

Snack Section Set-Up

Placing Trays in the Loading Position

WARNING

The bottom tray will rest on the delivery pan assembly. Take care

to avoid striking your fingers against the delivery pan assembly.

1. Lift up the front of the tray, so that the stop built into the tray clears the roller, then pull

the tray forward and let it return to horizontal position.

2. Continue pulling the tray forward, then when you are able, tilt the tray downward into the

loading position as shown below.

1810025 11 August 2009

Page 18

Initial Setup Merchant™ Operators’ Guide

Setting Up Trays to Vend Products

These instructions will guide you through setting up your trays for vending. You will be asked to

determine if your tray can physically hold the products you intend to vend. If not, you will be directed

to other procedures which will help you get them set up. Follow these nine steps for each tra y in your

merchandiser:

1. Make sure the tray is in the loading position.

2. Is the column wide enough for the intended product? If so, proceed to the next step. Otherwise,

set up your tray to vend wider products (see below, this page). When you're done, return to

step 3 in this procedure.

3. Will the products fit between the spiral turns? If so, proceed to the next step. Otherwise,

change the spiral.

4. Will the product pass under the tray immediately above? If so, proceed to the next step.

Otherwise, reposition the tray and guides.

5. Will the product touch products on either side? If not, proceed to the next step. Otherwise,

install a product spacer.

6. Load products in the tray.

7. Return the tray to the vending position.

8. Install the price rolls.

9. Install the selection ID numbers.

Setting Up Trays to Vend Wide Products

The following steps will help you configure your trays to vend wide products. When you have

completed the procedures called out in each step, return to the next step in the procedure. When you

are done with the entire wide product steps, return to the set-up procedures above.

1. Remove the tray from the merchandiser, unplug harness and place on a flat surface.

2. Based on the size of the product you want to vend, decide how many spiral positions it will

occupy. Please remember that the leftmost spiral in the group must have an ODD ID number

(1, 3, 5, etc.) For example, if a product is three spirals wide, the left spiral will be ID number 1,

and the right spiral will be ID number 3. Be careful how wide you set up for , because really wide

products could get hung up in the delivery door.

3. Remove the column dividers inside the group. In the example of three spiral positions, you

would be removing the dividers between spiral ID numbers 1 and 2, and 2 and 3.

4. If your group only consists of 2 spirals, replace the rightmost motor with a spiral bearing and

gear, and install a gear on the leftmost motor. Skip to step 8.

5. Remove all spirals in the group except the leftmost spiral.

6. Do one of the following:

a. If your group has an ODD number of spirals (3, 5, etc.) remove the harnesses from all

motors in the group except the leftmost one. To the rightmost motor, connect the harness

from the motor immediately to its left.

b. If your group has an EVEN number of spirals (4, 6, etc.) remove the harnesses from all

motors inside the group (leave the harnesses connected to the leftmost and rightmost

motors).

7. Install a spiral at the rightmost position in your group. Make sure it has the same product

capacity and is opposite to the one in the leftmost position.

8. Return the tray to the merchandiser. See “Installing Standard Trays in the Merchandiser” on

page 14

9. Electronically couple the motors as needed Return to step 3 in the sect ion “Setting Up Trays to

Vend Products” on page 12, above.

August 2009 12 1810025

Page 19

Merchant™ Operators’ Guide Initial Setup

Removing Standard Trays

CAUTION

Be careful to not damage the tray harnesses

when removing trays from the merchandiser.

NOTE

Study this procedure before you remove a tray for the first time;

while you are holding the tray you will not be able to see this area.

1. Unplug the tray harnesses from the PCB mounted inside the slide-out monetary.

2. Pull the harnesses through the cabinet.

3. Lift up the front of the tray, so that the stop built into the tray clears the roller, then pull the tray

forward and let it return to horizontal position.

4. Pull the tray forward in the horizontal position until the back stop on the tray hit s the rolle r, then

lift the tray straight up to clear the roller and remove the tray from the merchandiser.

1810025 13 August 2009

Page 20

Initial Setup Merchant™ Operators’ Guide

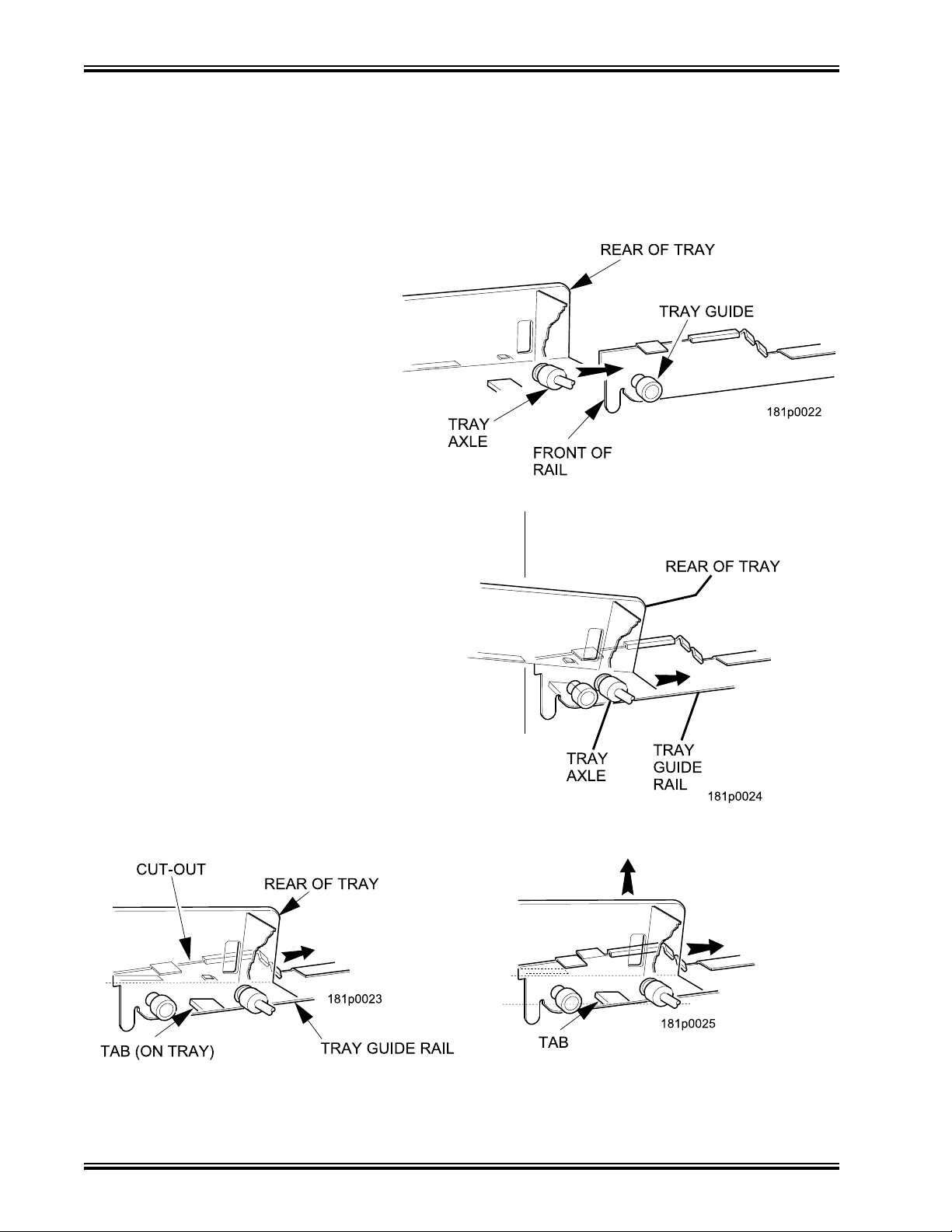

Installing Standard Trays

Study this procedure before you install a tray for the first time; while you are holding the tray you will

not be able to see this area.

Proceed as follows:

1. Place the back of the tray in

the machine so the back tabs

on the tray are behind the tray

rail rollers.

2. Slide the tray straight back into

the machine, insuring that the tray

axle stop is engaged in the tray

rail. Keep pushing the tray back

until it hits the front stop.

3. Lift the front of the tray, so the

stop built into the tray clears the

roller. Push the tray forward and let

it return to horizontal. It will “lock

in” to place.

4. Load the tray harnesses into the

cabinet, over the tray rail and into

the cabinet behind the slide out

monetary. Reach through the hole

provided in the monetary section

and grab the tray harness. Plug

the Tray harness into the correct

PCB tray harness header.

5. Slide the harnesses up into the

round hole provided and secure

them with the plastic grommet. Pull

the slack of the harnesses back

into the cabinet.

August 2009 14 1810025

Page 21

Merchant™ Operators’ Guide Initial Setup

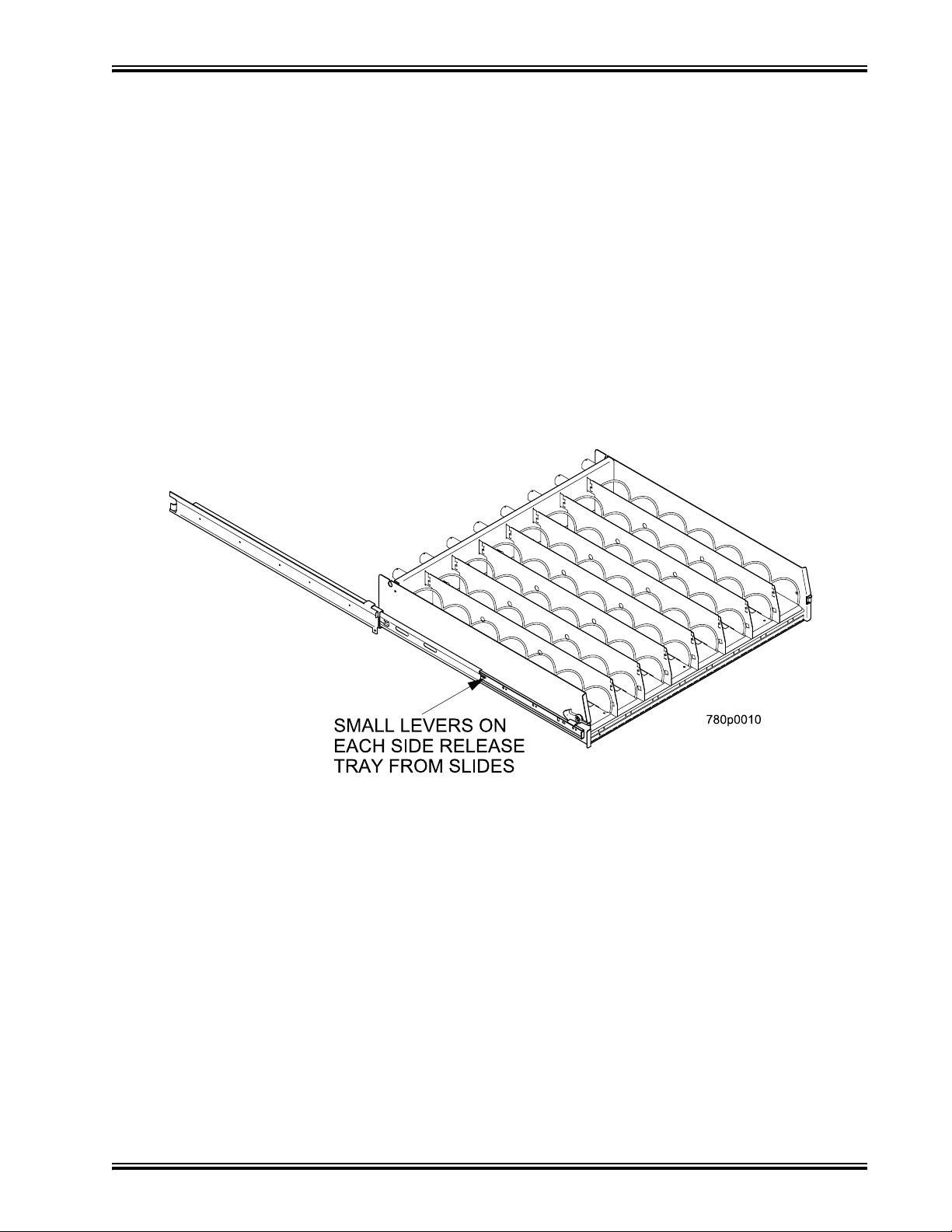

Removing a Bottle Tray

CAUTION

Be careful to not damage the tray harnesses

when removing trays from the merchandiser.

1. Remove all product from the tray.

2. Push down on the left and right front tray latches with your thumbs and slide out the tray as far

as it will go.

3. Unplug the tray harnesses from the PCB mounted inside the slide-out monetary.

4. Pull the harnesses through the cabinet.

5. Locate a small lever on each side of the tray , wh ere it attaches to the slide. The lef t lever will be

up, the right will be down. Press down on the left lever and up on the right lever.

6. Pull the tray towards you, off of the slides.

Installing a Bottle Tray

1. Push the slides back into the cabinet until they stop.

2. With the tray held at a 45ºangle (with the back higher than the front), align the lower edg e of the

rail on the tray with the lower edge of the rail in the cabinet on both sides.

3. Slowly raise the shelf to a horizontal position, and push the shelf all the way back into the cabinet.

4. Push down on the left and right hand front tray latches with your thumbs and slide the tray forward against the intermediate stop to test that the tray is correctly engaged.

5. Re-route the harnesses through the cabinet.

6. Plug the tray harnesses into the PCB mounted inside the slide-out monetary.

NOTE

It is much easier to replace a bottle tray if you have assistance lining up the

tray rails and slides.

1810025 15 August 2009

Page 22

Initial Setup Merchant™ Operators’ Guide

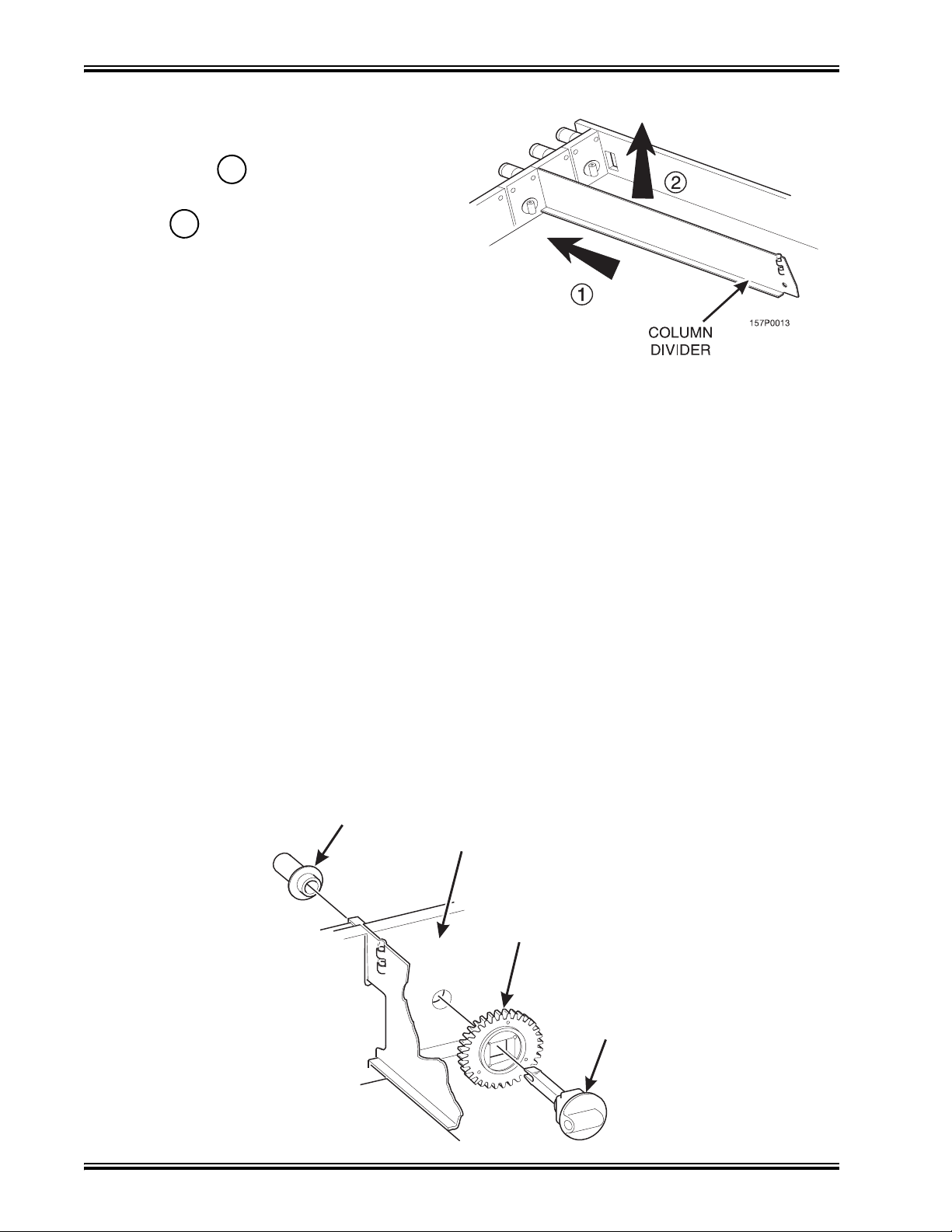

R

lli

SPIRAL

R

emoving and Insta

1. Push the column divider toward the back

of the tray - .

2. Lift the column divider clear of the

tray - .

3. Install the column divider in the reverse

order of removal.

2

1

ng Column Dividers

Operating Trays Outside the Merchandiser

The tray harnesses are long enough to remove the trays and set the middle and bottom trays

on the floor in front of the merchandiser and the top trays on the top of the merchandiser without

unplugging the tray harnesses.

Replacing a Motor With a Spiral Bearing

REMOVING A MOTOR

1. Disconnect the harness from the motor.

(See “Connecting and Disconnecting a Motor Harness” on page 17).

2. Remove the spiral. (See “Removing and Installing Spirals” on page 18).

3. Remove the spiral coupler. (See “Removing a Spiral Coupler” on page 20).

4. Remove the motor. (See “Removing and Installing a Spiral Motor” on page 20).

INSTALLING A SPIRAL BEARING

1. Put the gear into position if required in this set-up as shown.

(See “Installing a Gear” on page 21).

2. Install the spiral coupler. (See “Installing a Spiral Coupler” on page 22).

A coupled spiral does not use a motor.

BEARING

BACKWALL

OF TRAY

GEAR

˜

SPIRAL

COUPLE

August 2009 16 1810025

Page 23

Merchant™ Operators’ Guide Initial Setup

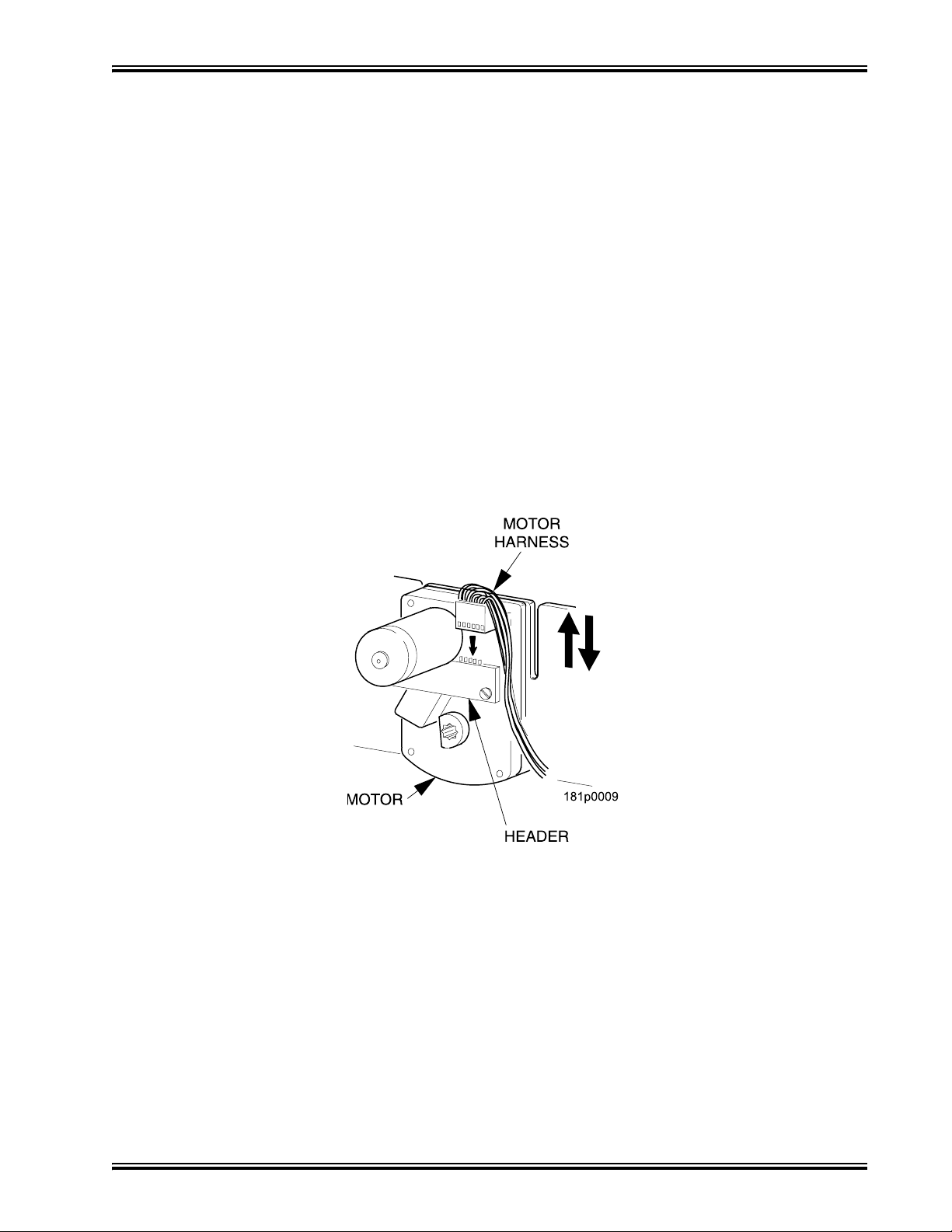

Connecting and Disconnecting a Motor Harness

CAUTION

To avoid breaking the motor circuit board, hold the header on the

circuit board whenever connecting or disconnecting a motor harness.

DISCONNECTING A MOTOR HARNESS

1. Pull the harness connector away from the circuit board as shown.

2. Tuck the unused part of the harness out of the way in the trough at the back of the tray.

CONNECTING A MOTOR HARNESS

3. Locate the harness connector for the appropriate tray position.

4. Push the harness connector over the header pins on the motor circuit board as shown.

1810025 17 August 2009

Page 24

Initial Setup Merchant™ Operators’ Guide

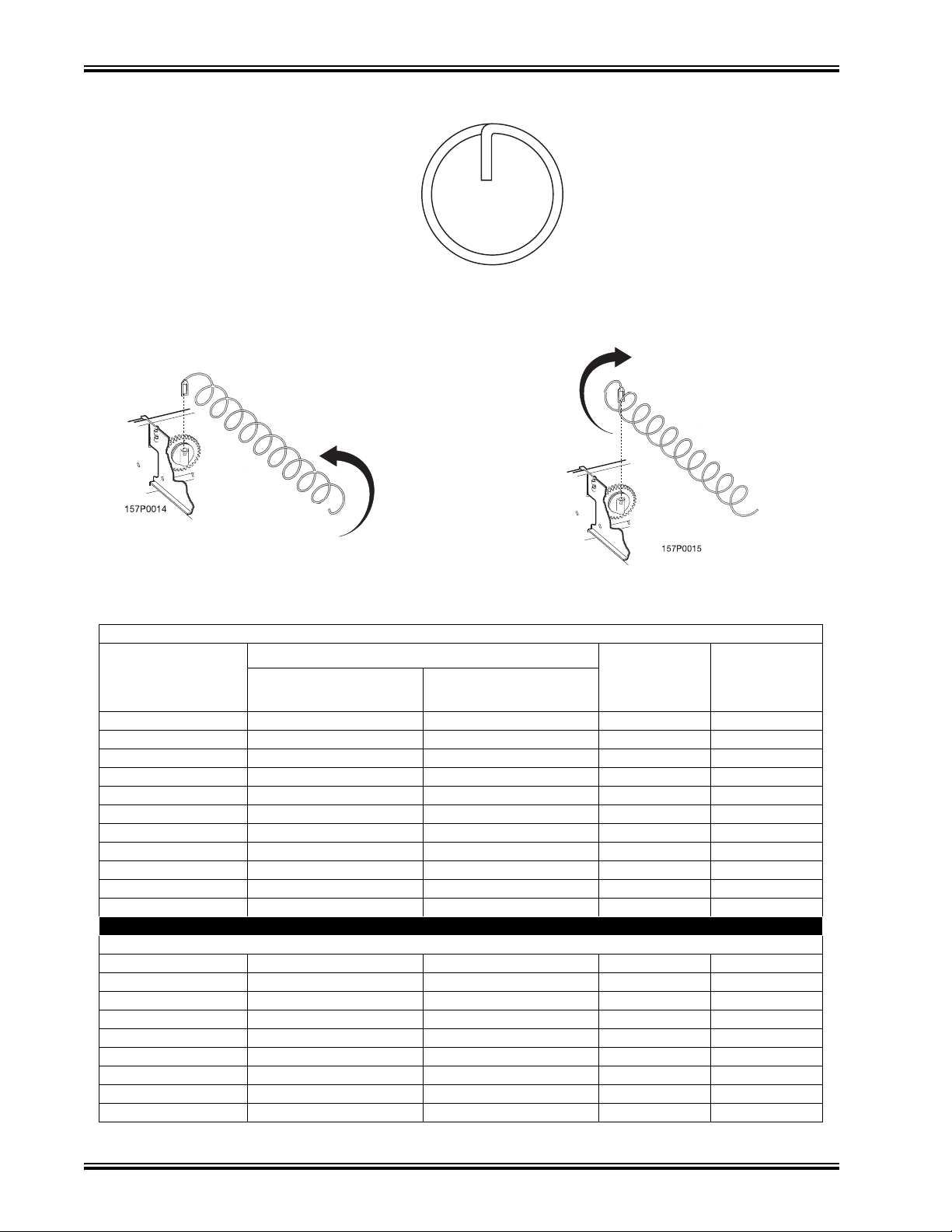

Removing and Installing Spirals

• All spirals are the same diameter:

• There are two types of spirals:

COUNTER-CLOCKWISE (left hand) CLOCKWISE (right hand)

• Spirals are available in the capacities shown below.

MODELS 180, 181, 980, 981

ITEM CAPACITY

OF SPIRAL

5 (Optional) 1477178 1477179 Orange 4.57”

6 (Optional) 1477102 1477104 Purple 3.78”

9 (Optional) 1477153 1477150 Gray 2.46”

11 (Standard) 1477024 1477027 Blue 1.98”

13 (Standard) 1477030 1477033 Yellow 1.65”

15 (Standard) 1477036 1477039 Red 1.41”

17 (Standard) 1477100 1477098 Brown 1.23”

20 (Standard) 1477042 1477045 White 1.02”

25 (Optional) 1477048 1477051 Green .75”

30 (Optional) 1477054 1477057 Black .60”

38 (Optional) 1477060 1477063 Orange .44”

4 1707048 1707050 Green 3.66”

5 1707044 1707046 Tan 2.90”

6 1707040 1707042 Purple 2.46”

7 1707057 1707059 Brown 2.23”

8 1707017 1707019 Gray 1.81”

10 1707005 1707007 Blue 1.44”

12 1707009 1707011 Yellow 1.18”

14 1707013 1707015 Red 1.00”

18 1707021 1707023 White .75”

COUNTER

CLOCKWISE (LH)

PART NUMBER

CLOCKWISE (RH)

MODELS 448, 449

CLIP

COLOR

Dimension

Between

Coils

August 2009 18 1810025

Page 25

Merchant™ Operators’ Guide Initial Setup

LIFT

Removing and Installing Spirals (continued)

REMOVING A SPIRAL

1. Pull forward on the retaining clip and

remove the end of the spiral from the

spiral coupler as shown.

2. Remove the spiral from the tray.

INSTALLING A SPIRAL

1. Pull the bottom of the retaining clip

toward the front of the spiral.

2. Lower the spiral into the tray column

and insert the end of the spiral into

the spiral coupler as shown.

3. Release the retaining clip.

PULL

SPIRAL

COUPLER

SPIRAL

RETAINING

CLIP

SHOULD I USE A CLOCKWISE OR A COUNTERCLOCKWISE SPIRAL?

1. The type of spiral used is determined by the column position it will occupy in the tray.

2. Refer to the figure below to find the correct spiral type.

1810025 19 August 2009

Page 26

Initial Setup Merchant™ Operators’ Guide

R

˜

SPIRAL

Removing a Spiral Coupler

1. Pinch together the prongs on the end of the

spiral coupler as shown.

2. Pull the coupler forward in the direction of

PRONGS

SPIRAL

COUPLER

the arrow as shown.

PULL

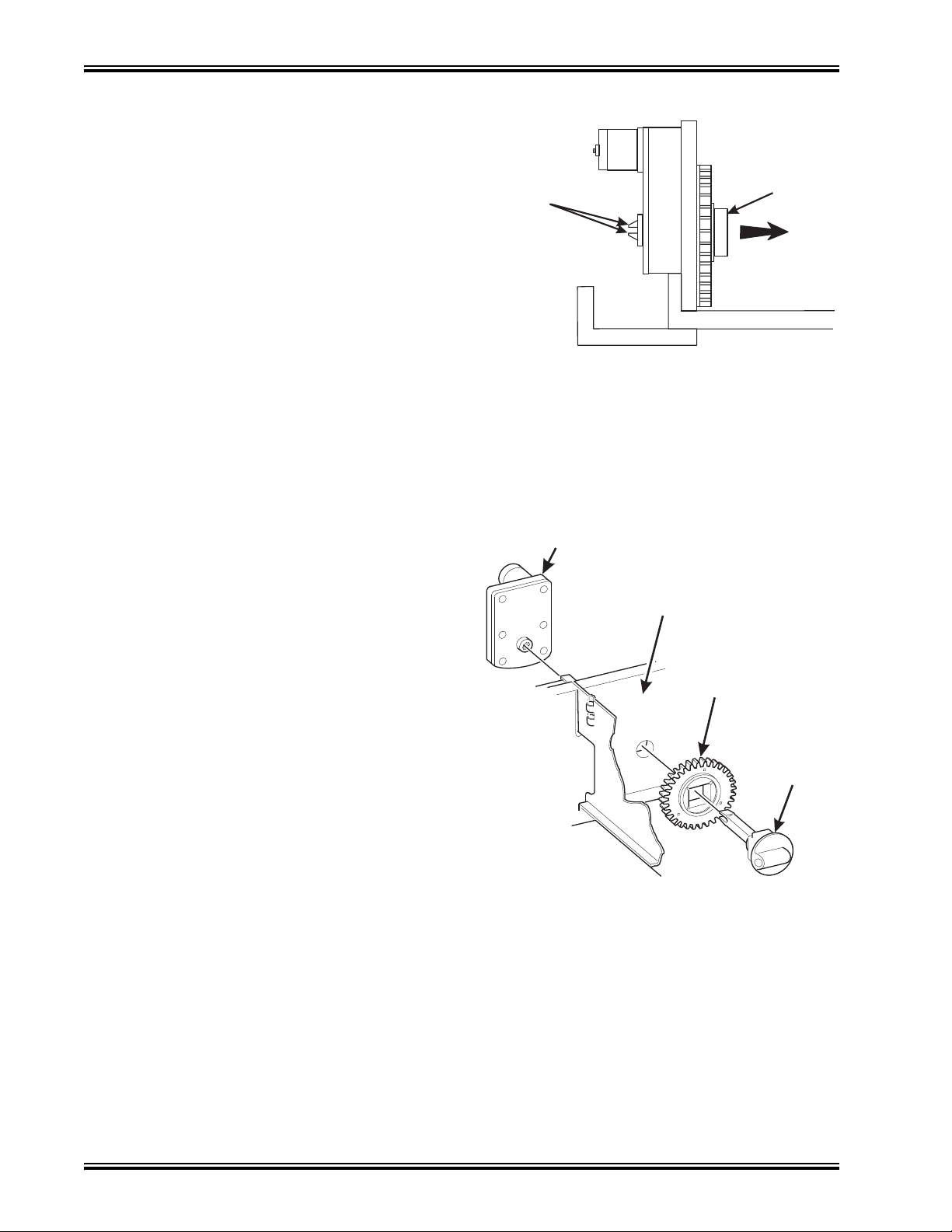

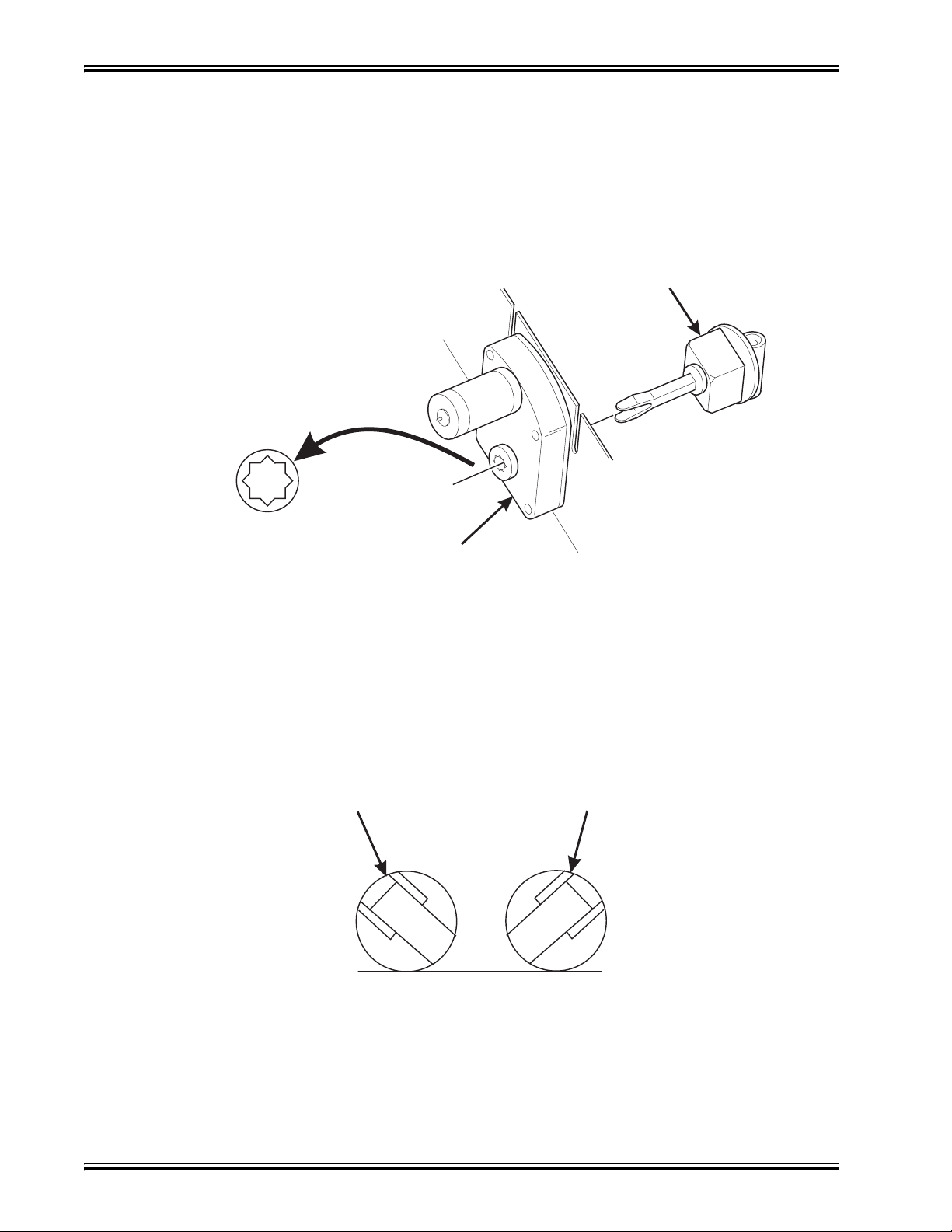

Removing and Installing a Spiral Motor

REMOVING A SPIRAL MOTOR

NOTE

Some steps may already be completed.

1. Remove the tray.

(See “Removing Standard Trays” on page 13).

2. Disconnect the motor harness.

(See “Connecting and Disconnecting a Motor

Harness” on page 17).

3. Remove the spiral.

(See“Removing and Installing Spirals” on

page 18).

4. Remove the spiral coupler.

(See “Removing a Spiral Coupler” on page 20).

5. Lift the motor clear of the tray.

6. Return the tray to the merchandiser.

INSTALLING A SPIRAL MOTOR

1. Remove the tray.

(See “Removing Standard Trays” on page 13).

2. Place the motor in the correct position at the rear of

the tray as shown.

3. Place a gear in position if required by this set-up.

(See “Installing a Gear” on page 21).

4. Install a spiral coupler in the proper orientation.

(See “Installing a Spiral Coupler” on page 22).

5. Connect the motor harness.

(See “Connecting and Disconnecting a Motor Harness” on page 17).

6. Return the tray to the merchandiser.

See “Installing Standard Trays in the Merchandiser” on page 14

MOTOR

BACKWALL

OF TRAY

GEAR

SPIRAL

COUPLE

August 2009 20 1810025

Page 27

Merchant™ Operators’ Guide Initial Setup

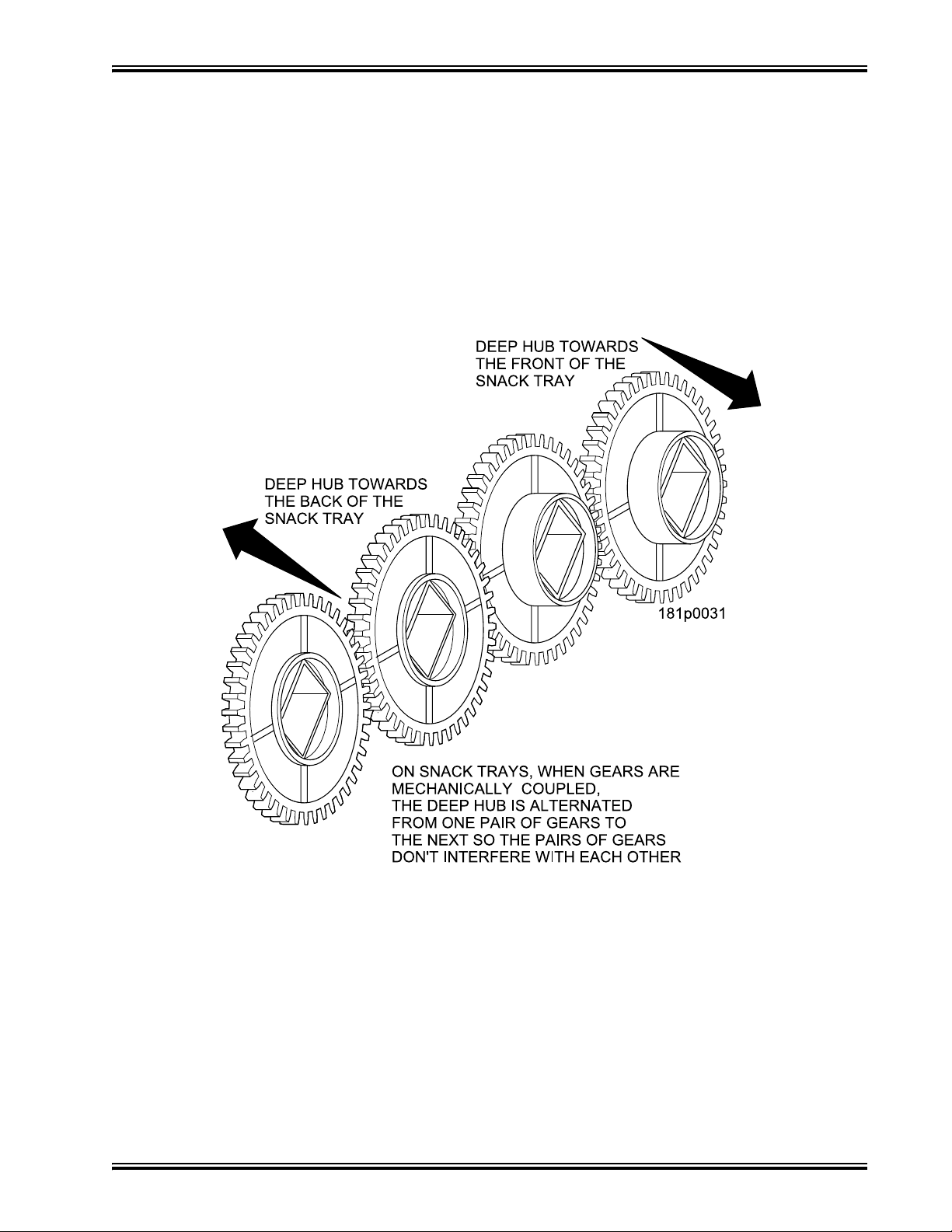

Installing a Gear

WHEN ARE GEARS USED?

• Gears are used to mechanically couple the spirals together.

• This happens whenever you have two spirals and only one motor for vending a selection.

WHERE ARE THE GEARS PLACED?

• The gear is placed between the back of the tray and the spiral coupler.

HOW IS THE GEAR ORIENTED?

• There are two possible orientations for the gear:

• There are two rules to follow when orienting gears:

RULE 1 – The gears for single spiral selections next to each other cannot use the

same gear orientation.

RULE 2 – All gears for a single coupled or double spiral selection must use the

same orientation.

1810025 21 August 2009

Page 28

Initial Setup Merchant™ Operators’ Guide

SPIRAL

AS VIEWED FROM FRONT OF TRAY

ONE POSITION

C

ONE POSITION

L

Installing a Spiral Coupler

Place the gear in position if one is required for this set-up. (See “Installing a Gear” on page 21.)

WHEN USED WITH A MOTOR

Hold the motor in place and push the spiral coupler through the motor gear box until it clicks into

position. Be sure the spiral couplers are oriented as shown below:

COUPLER

FRONT VIEW OF

MOTOR OUTPUT SHAFT

The motor output shaft opening contains eight facets to allow

the spiral coupler to be installed in any one of eight positions.

SPIRAL COUPLER ORIENTATION

OUNTERCLOCKWISE

FROM VERTICAL

MOTOR

NOTE

CLOCKWISE

FROM VERTICA

LEFT SPIRAL

COUPLER

August 2009 22 1810025

RIGHT SPIRAL

COUPLER

Page 29

Merchant™ Operators’ Guide Initial Setup

SPIRAL

Installing a Spiral Coupler (continued)

WHEN USED WITH A COUPLER BEARING

Hold the coupler bearing in place and push the spiral coupler through the bearing until the coupler

clicks into position. Be sure the coupler is in the proper orientation as shown.

COUPLER

SPIRAL

BEARING

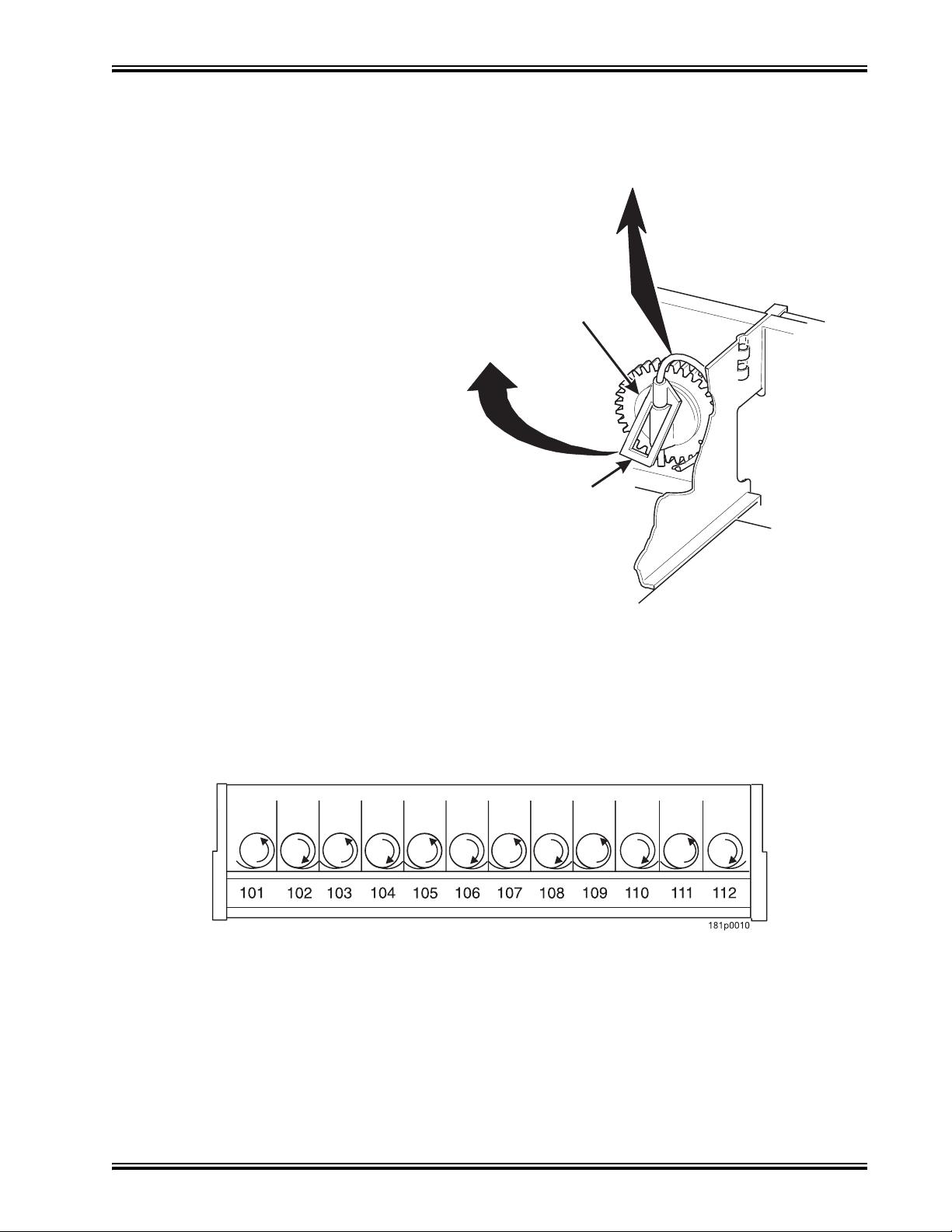

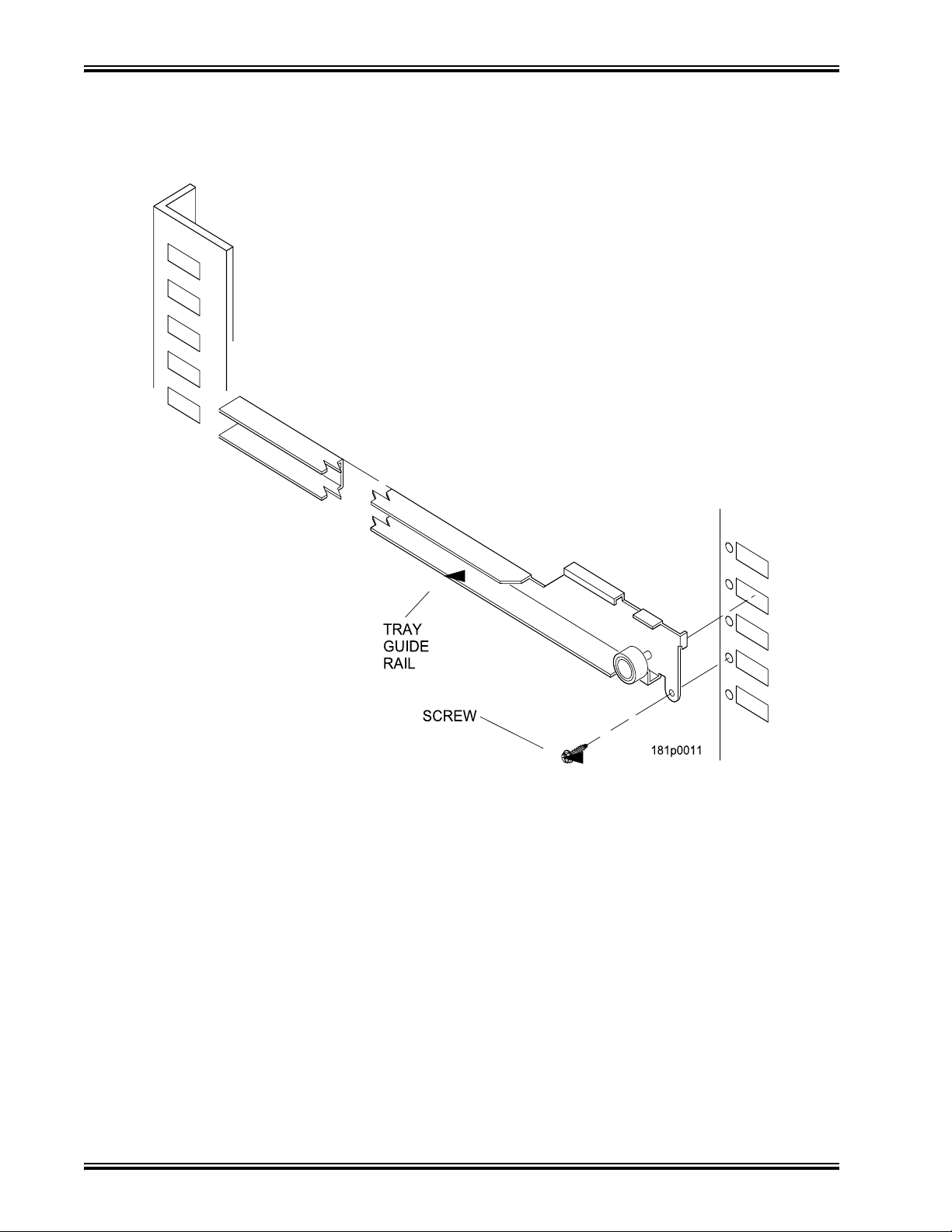

Moving Trays Up or Down

This merchandiser can be adjusted to vend taller products. Some guidelines must be followed:

• Keep in mind that when you increase the product height available to a tray by lowering it, you

will be decreasing the product height available to the tray below.

• If a tray is in the lowest position, the tray below it should not be in the highest position.

• If a tray is in the highest position, the tray above it should not be in the lowest position.

• You will need to experiment with various tray positions to get the best results for your

products.

Proceed as follows:

1. Remove the tray from the merchandiser. (See“Removing Standard Trays” on page 13).

2. Remove the screw that secures the right tray guide rail to the front guide mounting channel as

shown.

3. Tap up on the guide rail and unseat the guide rail tabs from the channel slots.

4. Pull the guide rail away from the front and rear guide mounting channels.

5. Move the guide rail to the desired position.

6. Insert the guide rail tabs into the mounting channel slots as shown.

7. Tap down on the guide rail to seat the tabs in the channel slots.

8. Replace the screw that secures the guide rail to the front guide mounting channel.

9. Repeat steps 2 through 8 for the left guide rail.

10. Return the tray to the merchandiser. See “Installing Standard Trays in the Merchandiser” on

page 14

1810025 23 August 2009

Page 30

Initial Setup Merchant™ Operators’ Guide

Moving Trays Up or Down (continued)

11. Load products into the trays, and perform test vends. Make sure the trays don't interfere with

the products you are vending, and that all products vend properly.

August 2009 24 1810025

Page 31

Merchant™ Operators’ Guide Initial Setup

PRODUCT

DIVIDER

M

G

Installing and Removing Product Spacers

INSTALLING A PRODUCT SPACER

• The product spacer will keep a tall, narrow product upright.

• Shown below are spacers and column dividers on both deep and shallow trays.

• Insert the product spacer onto the column divider as shown.

SPACER

OUNTING

PINS

MOUNTIN

PINS

COLUMN

REMOVING A PRODUCT SPACER

• Pull the product spacer mounting pins from the column divider.

1810025 25 August 2009

Page 32

Initial Setup Merchant™ Operators’ Guide

Loading Trays with Product

Table 1: SPIRAL CAPACITY COLOR CODES

The color of the spiral coupler

(the little plastic tab attached

to the rear of the spiral) will

tell you how many products

will fit in the spiral (see the

tables at right).

NOTE

Another way to determine

spiral capacity is to count

the spaces in the spiral.

SPIRAL

CAPACITY

6 Purple 20 White

11 Blue 25 Green

13 Yellow 30 Black

15 Red 38 Orange

MODELS 180, 181, 980, 981

SPIRAL

COUPLER

COLOR

MODELS 448, 449

SPIRAL

CAPACITY

8Grey

10 Blue

12 Yellow

14 Red

18 White

SPIRAL

CAPACITY

SPIRAL COUPLER

COLOR

SPIRAL COUPLER

COLOR

LOADING TRAYS WITH PRODUCTS IN GENERAL

• See “PRODUCT PUSHER USAGE” on page 28 for spirals with capacity of 11, 13, or 15.

• See “SPIRAL WALL RETAINER USAGE” on page 27 for spirals with capacity of 20, 25, 30,

or 38.

• Begin loading products at the front of the tray and work toward the back. Position the product

so the package rests on the tray. DO NOT force a product into a spiral.

• If the fit is too tight or too loose, change the spiral size.

(See “Removing and Installing Spirals” on page 18).

• Be sure there are no empty positions between products in each spiral.

SPECIAL CONSIDERATIONS

Bagged Products Position package upright, then push the tops slightly toward the rear of

the tray. Also, (see “PRODUCT PUSHER USAGE” on page 28).

Thin Packages Position the package upright.

Also, (see “SPIRAL WALL RETAINER USAGE” on page 27).

Kit Kat The two right-most columns of the candy tray are designed to accept the

Kit Kat candy bar.

WARNING

When set to “Ambient” or “Chilled Snack” this merchandiser

does not have a health control circuit. It is not approved for the

vending of perishable food items in these modes.

August 2009 26 1810025

Page 33

Merchant™ Operators’ Guide Initial Setup

SPIRAL

A

ORIENTATION A

DIVIDER

ORIENTATION B

Loading Trays with Product (continued)

SPIRAL WALL RETAINER USAGE

spiral wall retainer serves to compress the spiral and make it act like a

spring to more forcefully eject a product. Do some test vends and use a

spiral wall retainer when a product does not readily leave the spiral.

• Use a spiral wall retainer in the following cases:

- The spiral has a capacity of 20, 25, 30, or 38.

- The product is thin.

- The product is on a candy tray.

• The spiral wall retainer can also be used with other spirals and types of

products.

• The spiral wall retainer is installed near the front of the column divider.

WALL

RETAINER

There are two ways to install the spiral wall retainer.

RETAINER

ORIENTATION

AB

COLUMN

DIVIDER

BETWEEN

THESE

0 and 1 1 and 2

2 and 3 3 and 4

4 and 5 5 and 6

POSITIONS

6 and 7 7 and 8

8 and 9

• To install a spiral wall retainer, insert the retainer in the square slot near the front of the

column divider.

• The spiral wall retainer must be removed in two cases:

- A Kit Kat bar loaded into either of the two right hand positions of a tray will not clear the

retainer on the column divider between the two positions.

- A product pusher will catch on a retainer in ORIENTATION A.

1810025 27 August 2009

Page 34

Initial Setup Merchant™ Operators’ Guide

AS VIEWED FROM FRONT OF TRAY

ONE POSITION

C

ONE POSITION

L

A

A

T

Loading Trays with Product (continued)

PRODUCT PUSHER USAGE

The product pusher will give the top of a product an extra tilt to

PRODUC

PUSHER

help it fall into the delivery pan.

Use a product pusher in the following cases:

• The spiral has a capacity of 15, 13, or 11.

• The package is non-rigid like bagged peanuts.

The product pusher can also be used with other spiral and types

of products.

bag of product pushers has been shipped with the merchandiser. Additional product pushers are

available from the National Vendors part department. To use a product pusher, snap it on the spiral

as shown. You can adjust the product pusher by moving it around on the spiral to achieve the best

vending results.

PREPARING THE MERCHANDISER FOR VENDING "LUNCH BUCKET"

OUNTERCLOCKWISE

FROM VERTICAL

CLOCKWISE

FROM VERTICA

Because of the weight and shape of the package,

National Vendors recommends that this product be

vended only from the bottom tray.

To vend this product, two adjacent positions must be

coupled together.

(See “Installing a Gear” on page 21 for mechanical

coupling directions and see “Couple Motors” on

page 108 for electrical coupling directions).

The left spiral coupler should be installed one

LEFT SPIRAL

COUPLER

RIGHT SPIRAL

COUPLER

position counterclockwise from the vertical position.

The right spiral coupler should be installed one

position clockwise from the vertical position.

Replace the current spirals with six-count spirals. These are available from the National Vendors

parts department. (See “Removing and Installing Spirals” on page 18).

pad can be installed in the bottom of the delivery pan to quiet and cushion product delivery.

This part is available from the National Vendors parts department.

Load "Lunch Bucket" products as shown below:

FOOD SELECTIONS

LOADED IN SPIRALS

157P0039

Proper Loading of "Lunch Bucket"

August 2009 28 1810025

Page 35

Merchant™ Operators’ Guide Initial Setup

Loading Trays With Product (continued)

PREPARING THE MERCHANDISER FOR VENDING "TOP SHELF"

National Vendors recommends that this product be vended from a candy tray.

Move the tray so the package can be loaded standing on its left or right edge.

(See “Hold the coupler bearing in place and push the spiral coupler through the bearing until the cou-

pler clicks into position. Be sure the coupler is in the proper orientation as shown.” on page 23).

The following steps must be completed for three adjacent positions on the tray:

NOTE

The left-most position in the group of three

must be an even numbered position.

LEAVE THIS MOTOR

CONNECTOR ALONE

1. REMOVE COLUMN

DIVIDERS

3.

2. REMOVE

SPIRALS

4.

DISCONNECT THIS

MOTOR CONNECTOR

MOVE CONNECTOR

FROM THIS MOTOR

6.

TO THIS MOTOR

5.

7. INSTALL AN 11-COUNT LEFT HAND

SPIRAL IN THIS POSITION

INSTALL AN 11-COUNT RIGHT-HAND

8.

SPIRAL IN THIS POSITION

157P0040

NOTE

If the motor harness you disconnected in step 5 does not reach, use the

motor skip harness, P/N 1599024, available from the National Vendors Parts Department.

Couple the left motor to the right motor. (See “Couple Motors” on page 108.)

1810025 29 August 2009

Page 36

Initial Setup Merchant™ Operators’ Guide

TOP SHELF

Loading Trays With Product (continued)

Load the "Top Shelf" products as shown below:

PRODUCT

Motor Skip Harness

August 2009 30 1810025

Page 37

Merchant™ Operators’ Guide Initial Setup

Returning the Trays to the Vending Position

1. Lift the tray until it is parallel to the floor as shown.

2. Push the tray toward the back of the cabinet.

1810025 31 August 2009

Page 38

Initial Setup Merchant™ Operators’ Guide

Installing and Setting Price Labels

• Price rolls are printed on coiled-up strip s as shown in this example. If you use another type of

currency, you will find the appropriate price rolls in the plastic bag that contained this manual.

• The price roll installed indicates.30 to 2.35 in.05 increments.

• Remove the price rolls as required, and install the appropriate one(s) for your currency.

• If the product to be vended is to cost more than $2.35, install per this example:

1. Insert the dollar roll in the left-most pair of slots as shown if the price is $1.00 or more.

2. Insert the cents roll in the center pair of slots as shown.

3. The low-number end of the roll goes in the top slot and the high-number end of the roll goes in

the bottom slot.

August 2009 32 1810025

Page 39

Merchant™ Operators’ Guide Initial Setup

Installing and Setting Price Labels (continued)

ADJUSTING THE PRICE ROLL

You can set selection prices within the following range:

Minimum price $.00

Maximum price $12.95

Increment $.05

Use your thumb as shown to move each price roll up or down as needed to set the desired price.

NOTE

You will see the word STOP near either end of the roll.

157P0045

1810025 33 August 2009

Page 40

Initial Setup Merchant™ Operators’ Guide

Installing Selection ID Labels

Selection ID numbers are printed on clear plastic sheets. You will find these in the plastic bag that

contained this manual. You will need to sep arate them along the scored lines between the selections.

CAUTION

BE CAREFUL when doing this, because it is easy to split the labels.

TO INSTALL SELECTION ID NUMBERS

1. Press together the two long edges of the selection ID label.

2. Snap the selection ID label into position on the front of the tray as shown.

August 2009 34 1810025

Page 41

Merchant™ Operators’ Guide Initial Setup

Installing Selection ID Labels (continued)

WHICH ID LABEL GOES WITH WHICH SELECTION?

See the figures below for snack and candy tray positions.

Table 1: Motor Position

TOP TRAY

BOTTOM

TRAY

SQUAT

TRAY

EXAMPLE OF A BASIC

SNACK TRAY

ID LABEL TO USE

TRAY

100

TRAY

200

TRAY

300

TRAY

700

101 102 103 104 105 106 107 108 109 110 111 112

201 202 203 204 205 206 207 208 209 210 211 212

301 302 303 304 305 306 307 308 309 310 311 312

702 703 704 705 706 707 708 709 710 711

NOTE

The example above shows a 4-tray merchandiser.

Some merchandisers can have up to 7 trays.

EXAMPLE OF A BASIC

CANDY TRAY

ID LABEL TO USE

EXAMPLE OF A BASIC

SQUAT TRAY

ID LABEL TO USE

1810025 35 August 2009

Page 42

Final Installation Merchant™ Operators’ Guide

Final Installation

Move the merchandiser to its final position

• You can position this merchandiser anywhere in a bank of machines.

It can even be placed on an end flush against a side wall.

• There should be enough room in front of the merchandiser for the door to move freely.

WARNING

This merchandiser is only rated for installation in an indoor location.

Leveling the Merchandiser

Using a spirit level, adjust the legs until the cabinet is level from side to side and front to back.

NOTE

A slight slope from front to back will improve the draining of condensate from merchandisers with

refrigerating units. When the merchandiser is part of a bank of machines, level it in reference to the

other machines. After leveling is complete, check that the door operates easily.

August 2009 36 1810025

Page 43

Merchant™ Operators’ Guide Final Installation

Installing the Base Plate

Refer to the figure below while completing the following procedures:

1. Insert the long arms of the slides into the holes in the legs.

2. Insert and secure a cotter pin through the hole in the back of each of the slides.

3. Push the base plate toward the merchandiser cabinet. The front tabs of the base plate

brackets should seat in the notches in the long arms of the slides.

WARNING!

Do not use this base plate on Models 448 or 449!

Doing so could result in damage to the refrigeration unit.

1810025 37 August 2009

Page 44

Final Installation Merchant™ Operators’ Guide

Setting Up and Loading the Coin Mechanism

Once you arrive at the steps that tell you how to setup your coin mechanism, please perform the

following steps:

CAUTION

The main power switch must be turned OFF before you go any further!

1. If not already plugged in, plug the power cord into the electric outlet and turn ON the main power switch.

2. Perform the steps outlined in the procedure to “Select the Coin Mechanism” on page 139

TriTeq Lock Information

If your machine has a TriTeq lock installed in it, please call 1-410-223-2140 for all service issues.

August 2009 38 1810025

Page 45

Merchant™ Operators’ Guide Final Checkout

Final Checkout

Now, you have connected your merchandiser to the utilities, placed it in its final location, loaded it

with products, and set the prices. Before you lock the door and move on, you should check to see if

your merchandiser will vend products. In case of problems, perform the operational readiness

checks beginning on this page.

Operational Readiness Check

1. Perform test vends on all selections.(See “Test Vend a Selection” on page 82.)

2. Do any of the snack or candy products catch on the tray and fail to vend? If not, skip to step 3.

If so, perform the following procedures on the affected areas until all products vend properly:

a. Install and/or adjust a product spacer. (See “Installing and Removing Product Spacers” on

page 25.)

b. Install a product pusher. (See “PRODUCT PUSHER USAGE” on page 28.)

c. Install and/or remove spiral wall retainers.(See “SPIRAL WALL RETAINER USAGE” on

page 27.)

d. Perform the appropriate spiral anti-hang-up procedure(s) (See the “Spiral Indexing Proce-

dures” on the next page.)

3. Test the operation of the coin mechanism (See “Setting Up and Loading the Coin Mechanism”

on page 38 for the proper procedure.)

4. Test the operation of the bill validator.(See “Testing the Bill Validator” on page 41.)

5. Return all test vended products to the trays.

1810025 39 August 2009

Page 46

Final Checkout Merchant™ Operators’ Guide

Spiral Indexing Procedure (One Spiral, One Motor)

The spiral indexing procedures involve rotating spirals one position at a time until the product

vends properly.

1. Home all the motors (see “Homing the Motors - Motor Status Detail” on page 86.)

2. Remove the affected spiral.

3. Is the coupler in the proper position?

NO - Move the coupler to the position as shown in “Installing a Spiral Coupler” on page 22.

Go to step 4.

YES - Move the coupler to the next clockwise position (if it's on a right-hand motor), or the next

counterclockwise position (if it's on a left-hand motor). Go to step 4.

4. Replace the spiral.

5. Perform a test vend (see the previous page).

6. Did the product hang up?

NO - You're finished. Continue to test vend the remaining selections until everything

works properly.

YES - Go to step 7.

7. Did you previously move the coupler to the next clockwise or counterclockwise position?

NO - Move the coupler to the next clockwise position (if it's on a right-hand motor), or the next

counterclockwise position (if it's on a left-hand motor). Return to step 6.

YES - Return to step 2 in the operational readiness check and try another procedure. Do not

move the coupler again.

Spiral Indexing Procedure (Two Spirals, One Or Two Motors)

The spiral indexing procedures involve rotating spirals one position at a time until the product

vends properly.

1. Home all the motors (see“Homing the Motors - Motor Status Detail” on page 86.)

2. Remove the left hand spiral of the affected pair.

3. Is the coupler in the proper position?

NO - Move the coupler to the position as shown in “Installing a Spiral Coupler” on page 22.

Go to step 4.

YES - Move the left coupler to the next counterclockwise position. Go to step 4.

4. Replace the left hand spiral.

5. Remove the right hand spiral, spiral coupler, and gear (if used) of the affected pair as a unit.

6. Rotate this unit until the right hand spiral mirrors the position of the left hand spiral.

7. Replace the right hand spiral, spiral coupler, and gear (if used).

8. Perform a test vend (see “Test Vend a Selection” on page 82.)

9. Did the product hang up?

NO - You're finished. Continue to test vend the remaining selections until everything

works properly.

YES - Go to step 10.

10. Did you previously move the left hand coupler to the next counterclockwise position?

NO - Remove the left hand spiral of the affected pair. Turn the left spiral coupler to the next

counterclockwise position. Return to step 4.

YES - Return to step 2 in the operational readiness check and try another procedure. Do not

move the coupler again.

August 2009 40 1810025

Page 47

Merchant™ Operators’ Guide Final Checkout

Testing the Bill Validator

1. Insert a $1 bill into the validator.

2. Push the coin return button.

• If Change without Purchase (See “Set Change Without Purchase” on page 141.) is set less

than $1.00 and the bill is stacked - no money is returned - you must make a selection in

order to receive any change. Proceed to step 3.

• If Change without Purchase (See “Set Change Without Purchase” on page 141.) is set less

than $1.00 and the bill is NOT stacked - the $1.00 bill will be returned.

• If Change without Purchase (See “Set Change Without Purchase” on page 141.) is set to

$1.00 or more - you will receive four quarters in change.

3. Make a selection. The correct selection should be vended and correct change should be

returned.

NOW WHAT?

There are many things you can do with your

merchandiser to make it more flexible. Refer to

the following Programming Section beginning

with “Programming: Introduction” on page 42

for this and other procedures.

1810025 41 August 2009

Page 48

Programming: Introduction Merchant™ Operators’ Guide

Programming: Introduction

The Display

The Merchant™ features our new interactive menu display. The LCD display makes navigating the

programming menu structure easy and intuitive.

•The top line of the screen is the menu title.

•Selected items are highlighted in white.

System Settings

Data Transfer

•Press or to highlight an item.

•Press to select it. In the example at

right, pressing will display the

Screen Contrast menu.

•Pay attention to the bottom line of the display as it often shows important information. In certain

configuration menus, it will display the current value for the selected item. In the example

above, we can see that the setting for Screen Contrast is reading “= 9”. This is a valuable

way to quickly check the settings of the merchandiser, and to confirm that a value you

changed is correct.

•To return to the Idle mode from any screen, simply press until the display shows an

idle message.

Serial Flash

Backup/Restore Data

Screen Contrast

Software Version

= 9

The Keypads

This merchandiser has two keypads:

a. Service Keypad This 16 button keypad is located on the upper left hand side of the

monetary assembly and is only available with the merchandiser’s door open. This is the

principal keypad operators use to program the merchandiser.

b. Customer Keypad This is the 13 button keypad on the front of the merchandiser.

Customers use it to make selections, and operators can use it to enter numbers when

programming the merchandiser

.

5

6

SERVICE KEYPAD

August 2009 42 1810025

CUSTOMER KEYPAD

Page 49

Merchant™ Operators’ Guide Programming: Introduction

Service Keypad Shortcut Keys

From the idle mode, these service keys will take you directly to specific programs without having to

go through the Main Menu.

.

Press this button to put your machine into the Price Setting menu. You can see maximum

and minimum machine prices, and change prices for entire machine, entire tray, or individual

selections.

Press this button to select the Free Vend modes.

Press this button to view the temperature of a cold unit, or software ver sio n nu m bers .

Press this button to enter the System Settings menu to:

• Select display language.

• Select coin mechanism bill validator,

card reader, and options.

Press this button to view total sales and vends by whole machine or selection.

Clear resettable data.

• Set Display Options.

• Set Data Transfer Options.

• Set Temperature and more.

Press this button to enter the Data Transfer menu (found in System Settings menu):

Press this button to enter the Product Configuration menu to:

• Set machine configuration

• Set which selections are active

• Set FIFO

Press this button to set time of day and date.

Press this button to fill the coin mech to pay one or more coins from the coin mechanism and to

see the tube status.

• Allows you to see any fault in the machine.

Press this button to:

• Perform test vends

• Test various machine functions

Press this button to enter the Supervisor mode.

• Couple/uncouple tray motors

• Set up SureVend™ options

• Test displays

1810025 43 August 2009

Page 50

Programming: Introduction Merchant™ Operators’ Guide

Other Keys

The MOVEMENT keys on the service keypad move you around a menu , and back and forth between

menus. Along with the number keys on the Customer Keypad, every function for the Mercha nt™ can

be programmed with these keys.

Use the up and down arrow keys to scroll through any menu list and highlight the

desired option. An option is not selected until it is highlighted and is

pressed.

This key performs these functions: First, from the idle mode, it enters the Main

Menu. Second, in a menu screen, it selects the highlighted option and moves to

that screen. Third, in a screen that requires a value to be entered, it “locks in” the

entered value and moves up to the parent menu.

This is your "end" key. Pressing it one or more times will move you up the menu

hierarchy, ending back at the idle mode.

Important

Note:

When in a screen that requires a selection, use rather than to lock in

the entered value and move up to the previous menu. will move to the

previous menu without locking in the entered value, except on tho se menu screens

using the “X” boxes.

August 2009 44 1810025

Page 51

Merchant™ Operators’ Guide Programming: Data Recall

Programming: Dat a Recall

View Non Resettable Sales and Vend Data

1. Press until you reach the Main

+

Menu, then use or to select

Data Recall and press .

2. In the Data Recall menu, use

+

or to select Non Resetta-

ble Sales Data and press .

3. To view Overall Totals for the merchan-

diser, select Overall Totals and press

_

_

Main Menu

Data Recall

Diagnostic

Test

Price

Product Configuration

Press EDIT to Select

Data Recall

Non Resettable Sales Data

Resettable Sales Data

Timed Events

Identification Numbers

Print Data

Press EDIT to Select

5

6

5

6

.

Non Resettable Sales Data

Overall Totals

By Product

Cash

Cashless

Token

Press EDIT to Select

5

6

1810025 45 August 2009

Page 52

Programming: Data Recall Merchant™ Operators’ Guide

View Non Resettable Sales and Vend Data (continued)

4. The Overall Totals menu displays both the

total dollar amount and total vend amounts

for the following data:

•Sales

• Discount

•Test Vend

• Surcharge

• Free Vend

5. For example,

Sales-$ Displays the total merchandiser sales in dollars.

Sales-# Displays the total number of merchandiser vends (Sales totals includes Discount

and Surcharge totals.)

Discount-$ Displays the total dollar value of all discounts in dollars (ex. 5 discount vends of

10% on $1.00 selection will total $.50.)

Discount-# Displays the total number of discounted vends.

Test Vend-$ Displays the total dollar value of all test vends.

Test Vend-# Displays the total number of test vends.

*Surcharge-$ Displays the total dollar value of all surcharges.

Sales-$ 688.75

Sales-# 551

Discounts-$ 0.50

Discounts-# 5

Test Vend-$ 8.75

Test Vend-# 7

Overall Totals

5

6

*Surcharge-# Displays the total number of surcharge vends.

Free Vend-$ Displays the total dollar value of free vends.

Free Vend-# Displays the total number of free vends.

* - Surcharge refers to the amount of money charged above the cost to accommodate a coin mech

and bill validator function when separate prices are set for card reader.

6. Press and to scroll through the entire list.

7. Press once to return to the Non Resettable Sales Data menu or continue to press

to return to the Main Menu.

August 2009 46 1810025

Page 53

Merchant™ Operators’ Guide Programming: Data Recall

View Non Resettable Sales and Vend Data By Product

1. Press until you reach the Main

+

_

Menu, then use or to

select Data Recall and press .

2. In the Data Recall menu,

+

_

use or to select Non

Resettable Sales Dat a and press

.

3. In the Non Resettable Sales Data

+

_

menu, use or to select By

Main Menu

Data Recall

Diagnostic

Test

Price

Product Configuration

Press EDIT to Select

Data Recall

Non Resettable Sales Data

Resettable Sales Data

Timed Events

Identification Numbers

Print Data

Press EDIT to Select

5

6

5

6