Page 1

1670097

Models 167, 177, 168, 457, 458, 764, 765, 784, 787

Snack/Refreshment Center 2

Snack Center 4

NATIONAL VENDORS

CRANE

ABC

DEF

GHJ

123

456

789

0#

Q

NATIONAL VENDORS

CRANE

ABC

DEF

GHJ

123

456

789

0#

Q

NATIONAL VENDORS

157P0004

CRANE

ABC

DEF

GHJ

123

456

789

0#

Q

NATIONAL VENDORS

CRANE

ABC

DEF

GHJ

123

456

789

0#

Q

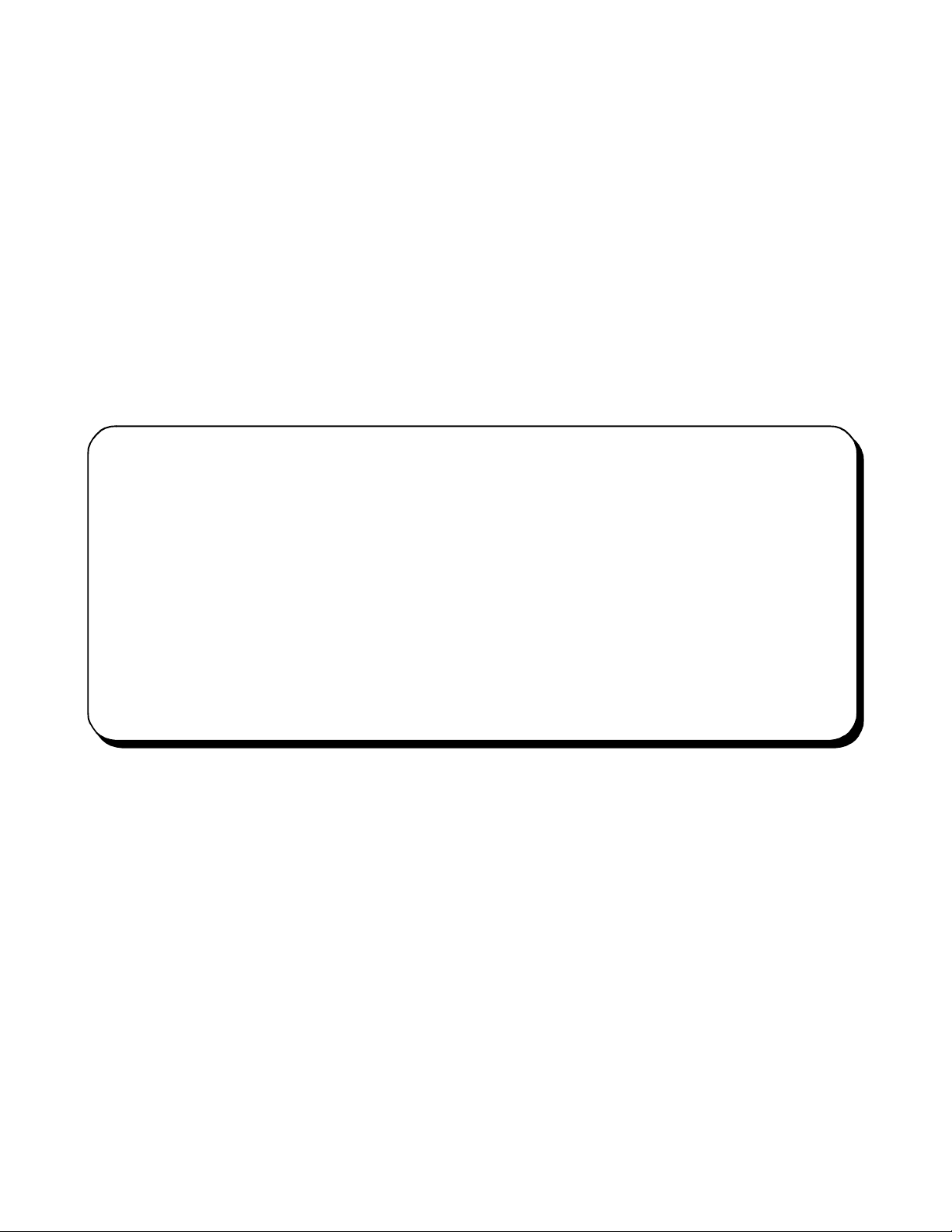

797

798

167

177

457

764

784

787

168

458

765

Set-Up & Operators’ Guide

12955 Enterprise Way

Bridgeton, Missouri 63044-1200

(314) 298-3500 / Service: (800) 628-8363

www.CraneMS.com

Copyright© 12-06

1670097

Page 2

How to use this guide

Since your merchandiser came equipped with a can module, the Snack Center Setup and Operator's

Guide has instructed you to get this booklet to continue your setup. Follow the steps for setting up your

can module, then return to the spot in the Setup and Operator's Guide that sent you here. You may

notice some other books in your plastic bag, also. The Programming Guide is a reference for you to use

later, after your machine is up and running. Use the Programming Guide to access the many advanced

features included with your machine.

DO NOT DISPOSE OF THIS BOOKLET! Even though you may have finished with it today, you

might find the need to set your merchandiser up again. We recommend returning it to the plastic bag, and

storing it inside the cabinet. That way, it is readily available at a future time.

This machine has been engineered to our own rigid safety and performance standards. It has been

designed to comply with sanitation and health guidelines recommended by the Automatic Merchandising Health-Industry Council (AMHIC) and it conforms with all other NAMA safety recommendations.

This machine has been manufactured in accordance with the safety standards of both Underwriter’s

Laboratories and the Canadian Standards Association. To maintain this degree of safety and to continue to achieve the level of perf orma nce built into this machine, it is important that installation a nd

maintenance be performed so as to not alter the original construction or wiring, and that replacement parts are as specified in the Parts Manual. Your investment in this equipment will be protected by using this Setup and Operator's Guide and the Par ts Manual in your operation, service

and maintenance work. By following the prescribed procedures, machine performance and safety

will be preserved.

Page 3

Snack / Refreshment Center Setup and Operator's Guide

Table of Contents

Preliminary.......................................................................................................................................... 5

Initial Set-Up.......................................................................................................................... .......... ... 9

1. MOVE THE MERCHANDISER THROUGH A NARROW DOORWAY............ .................... .............. . 9

remove the top panel: 9

remove the bottom panel: 9

take the merchandiser through the opening: 10

reassemble the merchandiser: 10

2. POSITION THE MERCHANDISER......... .............. ............... .................... .............. .............. ........... 10

Snack Se ction Set- U p.................. .................... .............. ..................... .................... ........................... 12

1. PLACE A TRAY IN THE LOADING POSITION...... ............... .............. .............. .................... ......... 12

1. SET UP TRAYS TO VEND PRODUCTS................ ............... .................... .............. .............. ........... 13

2. SET UP A TRAY TO VEND WIDE PRODUCTS.. ........ ..................... .............. .............. ................. 1 3

3. REMOVING A TRAY ...... .............. .............. .............. ..................... .............. .............. .............. ..... 14

4. REMOVING AND INSTALLING COLUMN DIVIDERS ........ .............. .............. .................... ........... 1 6

5. OPERATE A TRAY OUTSIDE THE MACHINE.............. ............... .................... .............. .............. . 16

1. REPLACING A MOTOR WITH A SPIRAL BEARING.... ......... .................... .............. .............. ....... 17

removing a motor: 17

installing a spiral bearing: 17

disconnecting a motor harness: 18

connecting a motor harness: 18

2. CONNECTING AND DISCONNECTING A MOTOR HARNESS .. ........ .............. .................... ........... 1 8

3. REMOVING AND INSTALLING SPIRALS.... ........ ..................... .............. .............. .................... ..... 19

to remove a spiral: 20

to install a spiral: 20

should i use a clockwise or a counterclockwise spiral? 20

1. REMOVING A SPIRAL COUPLER .................... ............... .............. .................... .............. ............. 21

22

1. REMOVING AND INSTALLING A SPIRAL MOTOR ............. .............. .............. .................... ......... 22

removing a spiral motor: 22

installing a spiral motor: 22

when are gears used? 23

where are the gears placed? 23

how is the gear oriented? 23

2. INSTALLING A GEAR..... .................... .............. ............... .................... .............. .............. ............. 23

3. INSTALLING A SPIRAL COUPLER. .................... ............... .............. .................... .............. ........... 2 4

4. MOVING A TRAY UP OR DOWN... .............. ..................... .............. .............. .................... ........... 2 6

5. INSTALLING A TRAY IN THE MERCHANDISER..................... .............. .................... .............. ..... 27

10. INSTALLING AND REMOVING A PRODUCT SPACER..... ........ .............. .................... .............. ... 2 8

loading a tray with products in general: 29

special considerations: 29

1. LOAD TRAYS WITH PRODUCT....................... ............... .............. .................... .............. ............. 29

spiral wall retainer usage: 30

B.. LOAD TRAYS WITH PRODUCT (CONTINUED)................ .............. .................... .............. ......... 31

preparing the merchandiser for vending "lunch bucket": 31

preparing the merchandiser for vending "top shelf": 32

1. RETURN THE TRAYS TO THE VENDING POSITION....... ........ .................... .............. .............. ..... 33

1670097 Page i December 2005

Page 4

Snack / Refreshment Center Setup and Operator's Guide

Table of Contents

installing price labels: 34

2. INSTALL AND SET PRICE LABELS.............. .............. ..................... .............. .............. ................. 3 4

adjusting the price roll: 35

installing selection id numbers: 36

3. INSTALL SELECTION ID LABELS....... .............. .............. ..................... .............. .............. ........... 36

which id label goes with which selection? 37

Set Up The Gum and Min t Unit .................. .............. ..................... .................... .............. .............. . 38

1. INSTALL PRICE LABELS ............... .............. .................... ............... .............. .................... ........... 38

2. PUT THE GUM AND MINT DISPENSER IN THE LOADING POSITION........ .................... ............. 38

3. LOAD THE GUM AND MINT DISPENSER WITH PRODUCT........................................................ 39

5. REMOVING AND INSTALLING COLUMN REDUCERS........ ............... .............. .............. ............... 40

to remove a column reducer: 40

to install a column reducer: 40

4. RETURN THE GUM AND MINT DISPENSER TO THE VENDING POSITION...... ........ .............. ..... 40

Final In stall a ti o n........ .................. ............ .................. ............ ................. .................. ........................ 41

1. LEVEL THE MERCHANDISER.......... .............. .................... ............... .............. .................... ......... 41

method 1: 42

method 2: 42

1. INSTALL THE BASE PLATE......................... .............. ............... .................... .............. .............. ... 44

3. INSTALL THE OPTIONAL CASH BOX LOCK .......... ............... .................... .............. .............. ..... 45

2. INSTALL THE LOCK CYLINDER ..................... .............. ............... .................... .............. ............. 45

1. SET UP THE COIN MECHANISM................. .............. ............... .................... .............. .............. ... 4 6

1. LOAD THE COIN MECHANISM..... .............. .................... ............... .............. .................... ........... 4 7

Programming .................................................................................................................................... 48

the service keypad 48

1. SET PRICES ................................................................................................................................. 48

2. VIEW THE CHILLER OR CAN UNIT TEMPERATURE..... ......... .............. .................... .............. ... 4 8

Final Checkout....................................................................................................................... ........ ... 4 9

1. TEST VEND SELECTIONS................ .............. .................... ............... .............. .................... ......... 49

2. OPERATIONAL READINESS CHECK ..... .............. .............. ............... .................... .............. ......... 49

4. SPIRAL INDEXING PROCEDURE

(TWO SPIRALS, ONE OR TWO MOTORS)... ........ .............. ............... .................... .............. .............. . 50

3. SPIRAL INDEXING PROCEDURE (ONE SPIRAL, ONE MOTOR)................................................. 50

5. TESTING THE BILL VALIDATOR ................ .............. ............... .................... .............. .............. ... 5 1

December 2005 Page ii 1670097

Page 5

Snack / Refreshment Center Setup and Operator's Guide

NATIONAL VENDORS

CRANE

ABC

DEF

GHJ

123

456

789

0#

Q

NATIONAL VENDORS

CRANE

ABC

DEF

GHJ

123

456

789

0#

Q

797, 798

784, 787

NATIONAL VENDORS

CRANE

NATIONAL VENDORS

ABC

DEF

GHJ

123

456

789

Q

0#

CRANE

ABC

DEF

GHJ

123

456

789

0#

Q

167, 177

457, 764

168, 458

765

157p0296

1670097 Page 1 December 2005

Page 6

Snack / Refreshment Center Setup and Operator's Guide

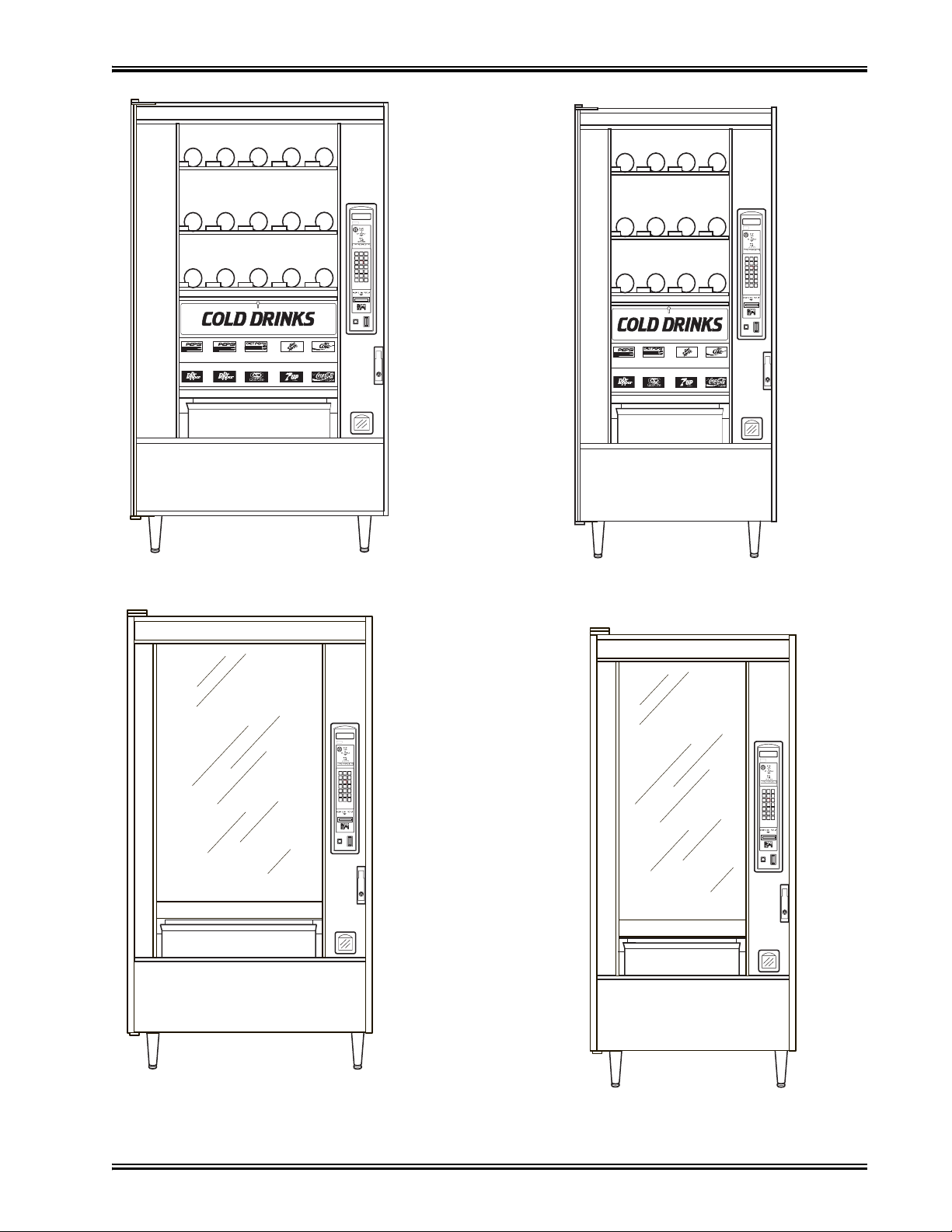

Model 168 - Exterior View

(Models 167, 457, 458, 764, 765 have similar appearance)

December 2005 Page 2 1670097

Page 7

Snack / Refreshment Center Setup and Operator's Guide

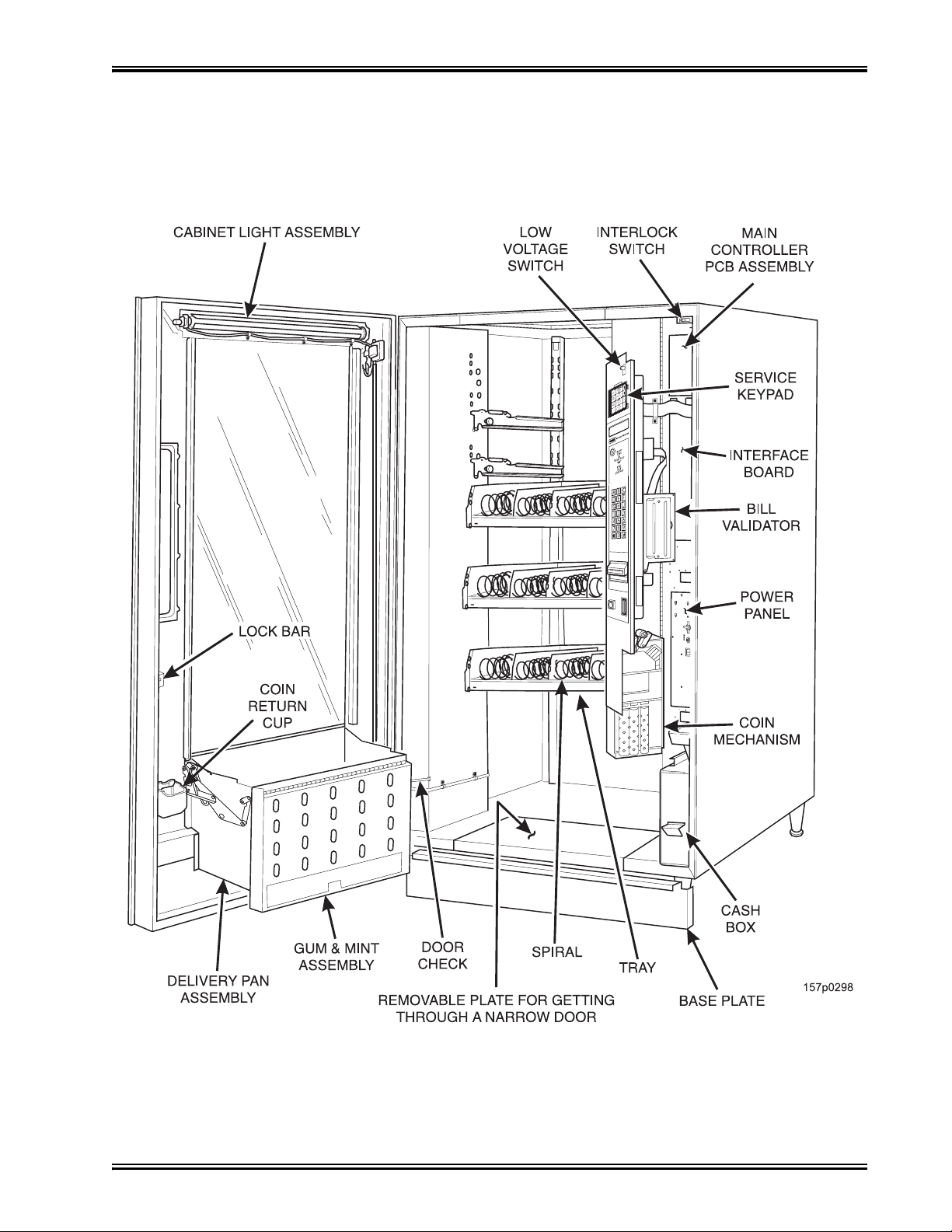

Model 168 - Interior View

(Model 167 has similar appearance)

1670097 Page 3 December 2005

Page 8

Snack / Refreshment Center Setup and Operator's Guide

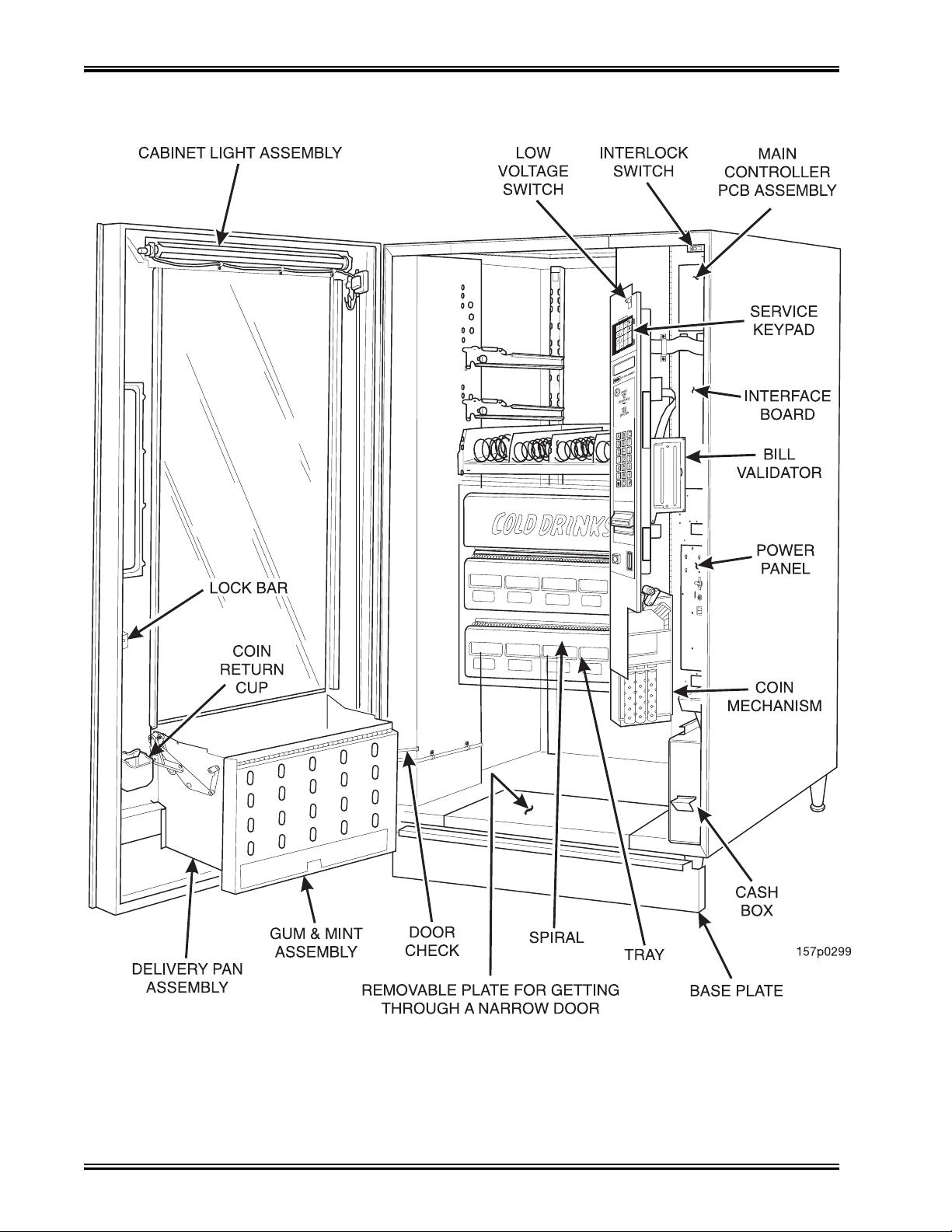

Model 797 - Interior View

December 2005 Page 4 1670097

Page 9

Snack / Refreshment Center Setup and Operator's Guide

Preliminary

Power Requirements

The merchandiser is supplied with a service cord for the country of use and is terminated in a grounding type plug. The wall receptacle used for this merchandiser must be properly polarized, grounded,

and of the correct voltage. Operating the merchandiser from a source of low voltage will VOID

YOUR WARRANTY. Each merchandiser should have its own electrical circuit and that circuit

should be protected with a circuit breaker or fuse conforming to local regulations.

1. Voltage Check - Place the leads of a voltmeter across the LINE (LIVE) and NEUTRAL termi-

nals of the wall receptacle. The voltmeter should indicate 110-130 volts ac for 120 volt, 60 Hz

locations, or 220- 240 volts ac for 230 volt, 50 Hz locations.

2. Polarity Check - Place the leads of a voltmeter across the LINE (LIVE) and GROUND termi-

nals of the wall receptacle. The voltmeter should indicate 110-130 volts ac for 120 volt, 60 Hz

locations, or 220- 240 volts ac for 230 volt, 50 Hz locations.

3. Noise Potential Check - Place the test leads of a voltmeter across the NEUTRAL and

GROUND terminals of the wall receptacle. The meter should indicate 0 volts ac. A measurement greater than 1.5 - 2.0 volts ac could result in problems for the merchandiser's electronic

circuitry caused by electrical noise.

Any deviation from these requirements could result in unreliable performance from your merchandiser.

Unpack the Machine

Remove all packing materials from the interior of the machine. Keep all documents; warr ant y cards,

etc. Set aside the base plate kit (if present).

1670097 Page 5 December 2005

Page 10

Snack / Refreshment Center Setup and Operator's Guide

INTERLOCK SWITCH. When the cabinet door is open, this switch turns off the glass heater,

o

L

s.

M

t

e

d

c

,

a

F

p

S

m

C

r-

c

B

t

S

v

e

m

Controls and Indicators

ptional fan (if so equipped) and turns on the service light (not present on all models).

OW VOLTAGE SWITCH. Informs the controller software of the main door open or closed statu

ESSAGE DISPLAY. This is how the merchandiser communicates with the outside world. Cus-

omers can see messages about how much money they have put into the merchandiser. The messag

isplay also tells customers when a sel ecti on is sold out and when vending is free, inhibited, or disounted. The message display shows you what you are doing when you program the merchandiser

nd can show you what is wrong if there is a failure.

REE VEND KEYSWITCH (OPTIONAL). This allows someone (other than maintenance

ersonnel) to set the merchandiser to free vend without opening the door.

ELECTION SWITCH PANEL. The customer uses these switches to make selections. Also,

aintenance people may use this switch panel during programming and other support modes.

OIN RETURN BUTTON. Pressing this button returns any coins that have been paid into the me

handiser prior to a vend.

ILL ACCEPTOR (OPTIONAL). Accepts bills in various denominations, depending upon the

ype of bill validator, and how the machine is configured.

ERVICE KEYPAD. The service keypad is located at the top of the monetary panel. It gives ser-

ice personnel the means to program, retrieve data from, and view diagnostic information about, th

erchandiser.

MESSAGE

DISPLAY

FREE

FREE

TEST

DATAPRICE

VEND

VEND

DRY

PAYOUT

CONF.

PROD.

LIQUID

HOME

PROD.

TIME

ENTER/

SERVICE

OF

ACTION

DAY

INTERLOCK

SWITCH

LOW VOLTAGE

SWITCH

SERVICE

KEYPAD

NATIONALVENDORS

ACT

CREDIT

CARD READER

LETTERS

A-H,J

NUMERALS

1-9, *,0, #

MONETARY

PANEL

COIN

RETURN

BUTTON

CRANE

INSERT

COINS

OR

DOLLARBILLS

MAKE

YOUR

SELECTION

CHANGERETURNED BELOW

AB

DEF

G

H

12

56

4

789

0#

Q

C

J

3

157P0086

CABINET

SELECTION

SWITCH

BILL

ACCEPTOR

COIN

INSERT

December 2005 Page 6 1670097

Page 11

Snack / Refreshment Center Setup and Operator's Guide

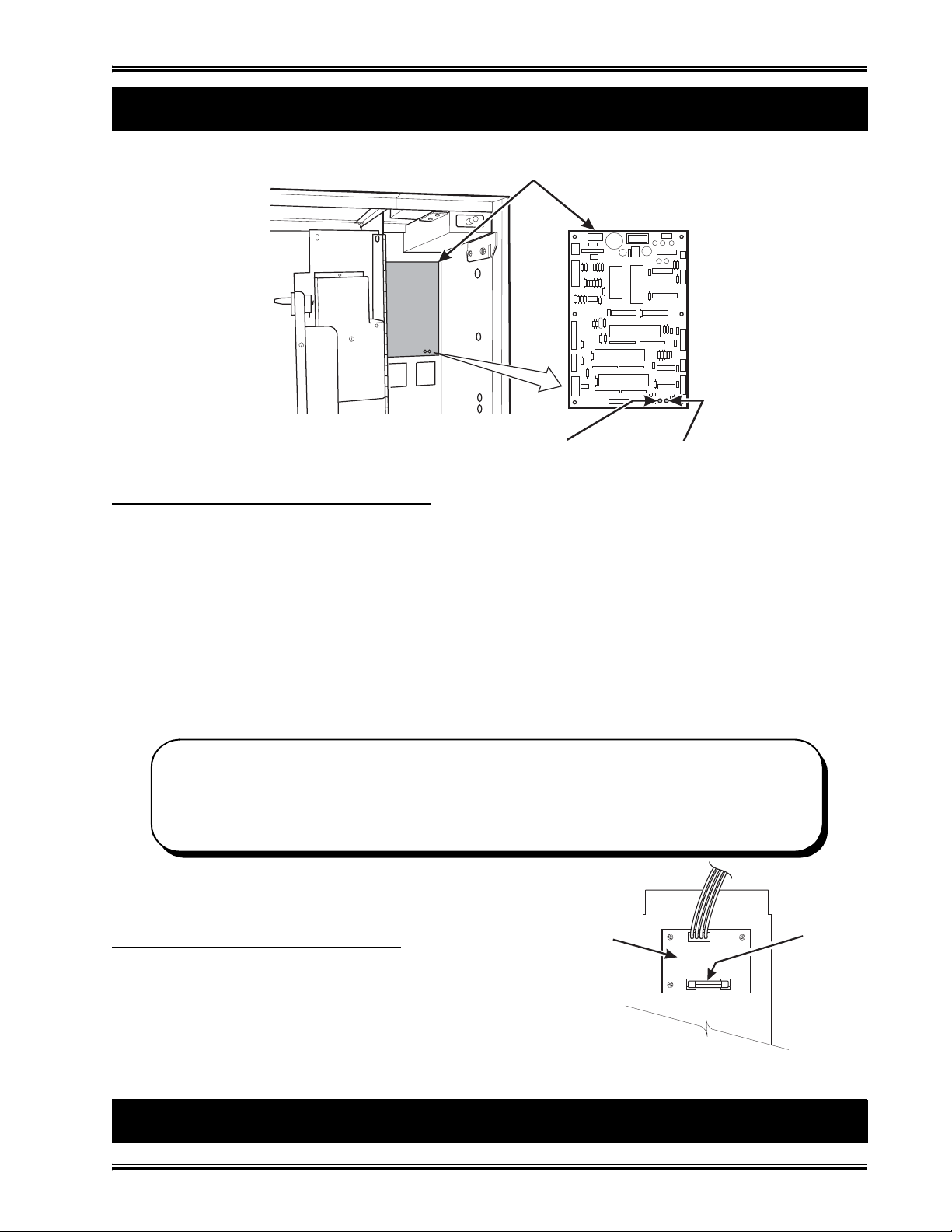

MAIN CONTROLLER

T

1

E

P

U.S. / CANADA POWER CONTROL PANEL

B

b

p

t

s

c

a

t

Controls and Indicators (continued)

PCB ASSEMBLY

LED1LED2

POWER ON

(LED 1)

FLASHING

HEARTBEA

(LED 2)

MAIN CONTROLLER PCB DISPLAY. This display consists of two light emitting diodes (LED)

mounted on the controller PCB.

POWER ON

(L.E.D. 1)

HEARTBEAT

(L.E.D. 2)

"CAUTION - Risk of explosion if battery is replaced with an incorrect type. Dispose of used batteries according to the manufacturer's instructions."

When lit, this red LED indicates electrical power is applied to

the controller PCB.

When flashing, this red LED indicates that the controller PCB

is active, and the software is operating.

NORMAL CONDITIONS:

When the merchandiser is operating normally, you should see a steady red POWER

ON indicator and a flashing red HEARTBEAT indicator. Contact a service represen-

tative if any other condition exists.

TOP

DC POWER

ack Side of U.S./Canada Power Panel. The circuit

oard mounted on the rear of the power panel is a dc

ower supply for the coin mechanism. A fuse protects

he board circuitry in the event of a coin mechanism

olenoid failure. If the coin mechanism is not working,

heck this fuse. If the fuse is blown, a bad coin mechnism solenoid could be at fault. (Board may not be

here if machine is setup for MDB.)

How to Turn the Merchandi ser ON and OFF

1670097 Page 7 December 2005

SUPPLY PCB

FOR 110V COIN MECH

˜

BACK SIDE

OF

AGC

FUS

1 AM

Page 12

Snack / Refreshment Center Setup and Operator's Guide

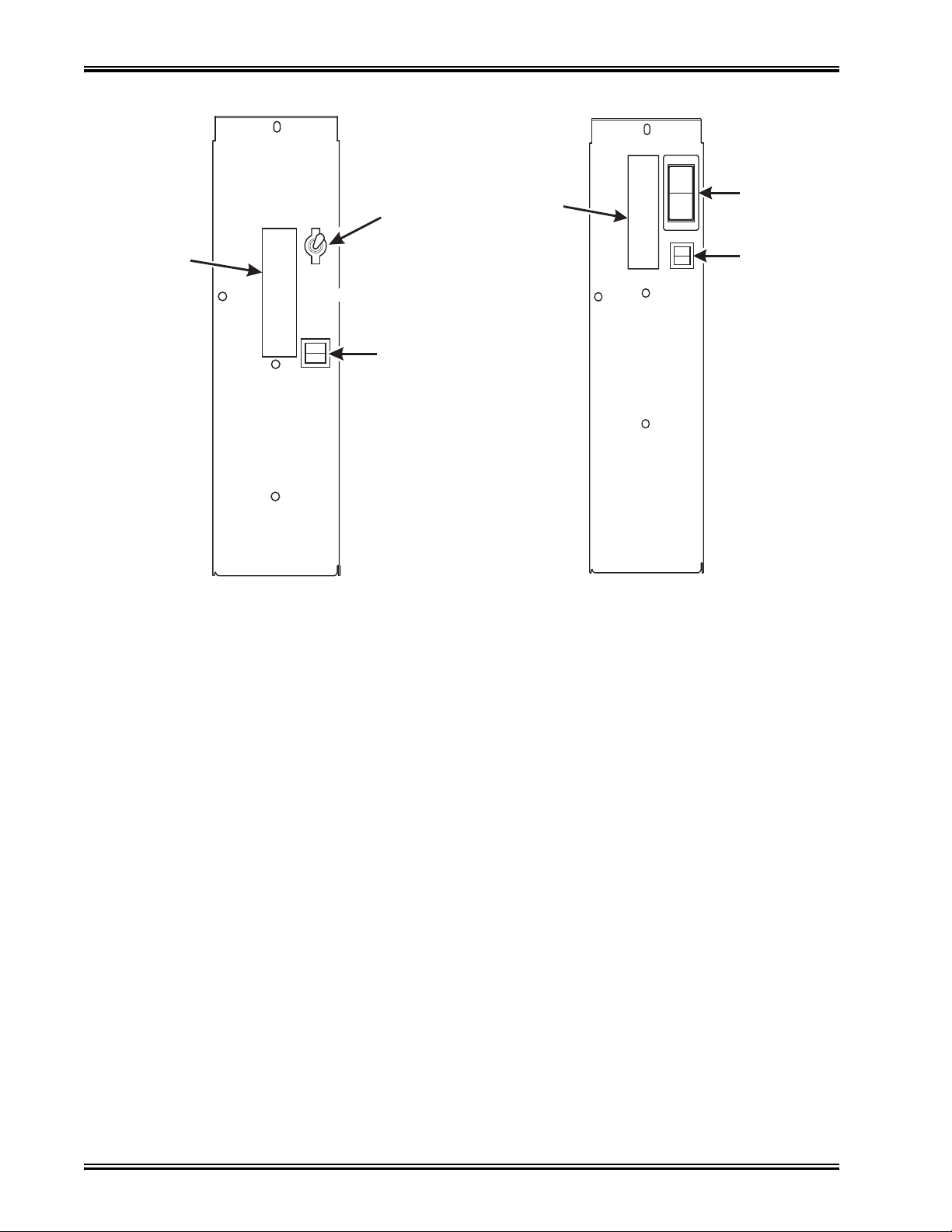

I

LABEL

MAIN

ON

OFF

POWER

SWITCH

LABEL

O

LOW VOLTAGE

CIRCUIT BREAKER

626P0039

U.S./CANADA POWER PANEL INTERNA TI ONAL POWER P ANEL

MAIN

POWER

SWITCH

ELECTRONICS

BREAKER

626P0005

• Power to the merchandiser is controlled by the main power switch, located on the power panel.

• The power panel is on the right side of the merchandiser, behind the monetary door.

WARNING

Lethal voltages are present. Unplug the merchandiser whenever

you do one of the following tasks:

• Change a fuse

• Change the fluorescent lam p

• Change the lamp st a r ter

• Connect or dis connect a harness (except a motor harn ess when

the tray has been removed)

Failure to do so may result in personal injury .

December 2005 Page 8 1670097

Page 13

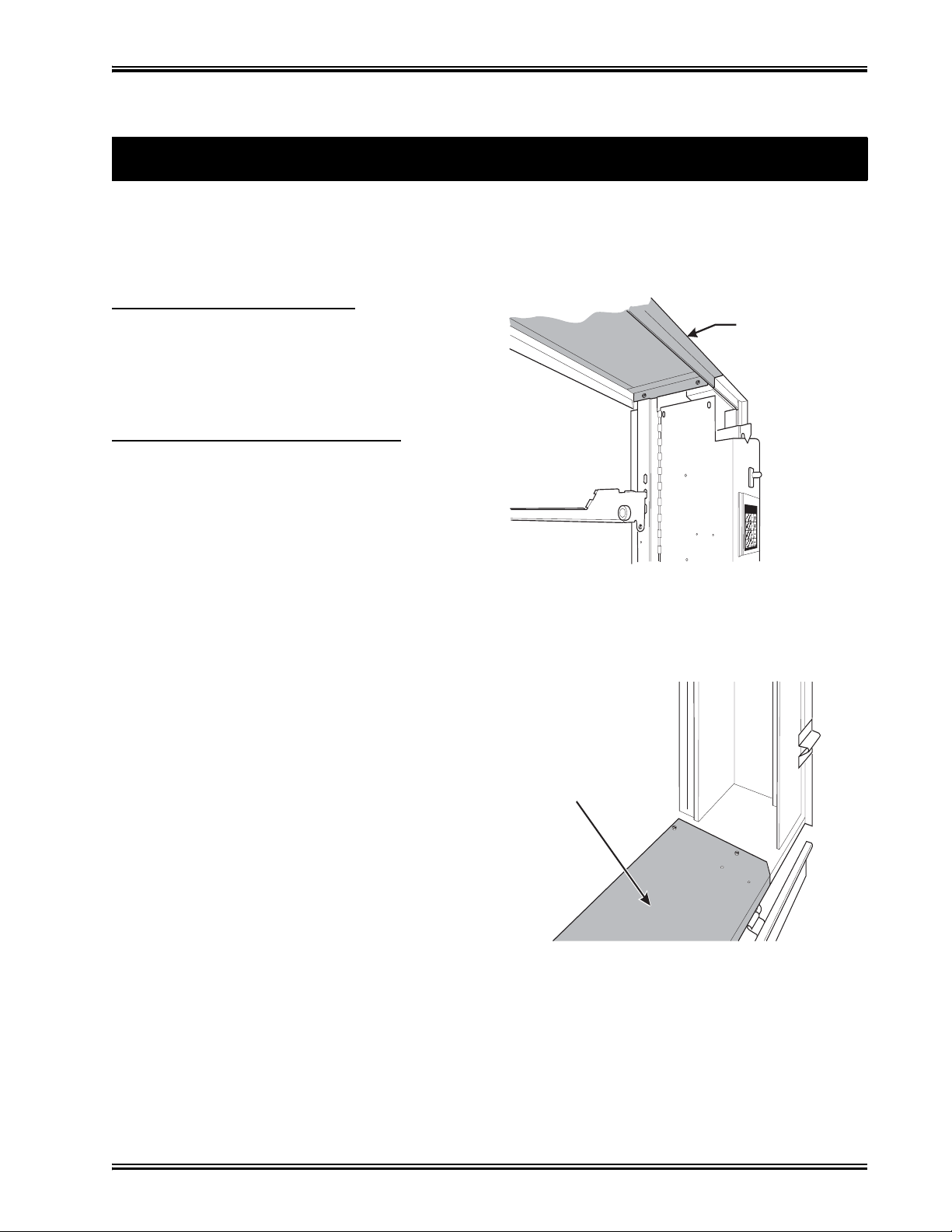

1. Move the Merchandiser Th rough a Narrow Doorway

H

VIEW LOOKING INTO THE BOTTOM OF THE CABINET

REMOVE THE TOP PANEL:

1

2

R

1

2

NOTE: If necessary, this merchandiser can be moved through an opening as narrow as 30

inches by removing panels at the top and bottom of the cabinet.

only 28” deep, and do not require panels to be removed.

. Remove the two screws that secure each end of

the panel to the cabinet.

. Pull the panel forward to remove it from the

merchandiser.

EMOV E THE BO TTOM PANEL:

. Remove the screws that secure the panel to the

cabinet.

. Pull the panel forward to remove it from the

cabinet.

Snack / Refreshment Center Setup and Operator's Guide

Initial Set-Up

Merchandisers 457 and 458 are

REMOVABLE PANEL

FOR GETTING THROUG

A NARROW DOORWAY

VIEW LOOKING INTO THE TOP OF THE CABINET

REMOVABLE PANEL

FOR GETTING THROUGH

A NARROW DOORWAY

˜

1670097 Page 9 December 2005

Page 14

Snack / Refreshment Center Setup and Operator's Guide

T

T

1

2

R

C

1

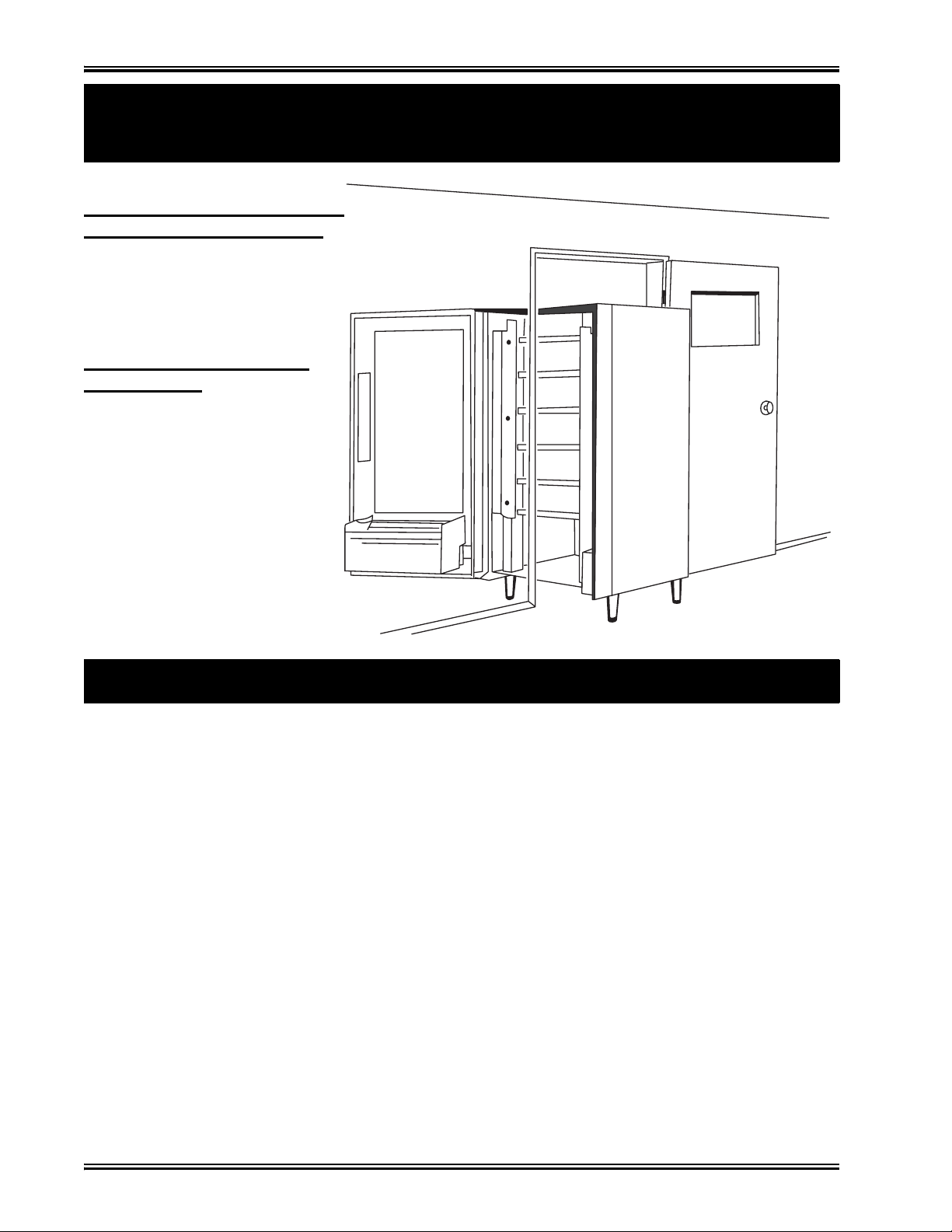

1. Move the Merchandiser Th rough a Narrow Doorway

(continued)

AKE THE MERCHANDISER

HROUGH THE OPENING:

. Open the cabinet door and place it square with the

left side of the cabinet.

. Carefully walk the merchan-

diser through the opening.

EASSEMBLE THE MERHANDISER:

. Replace the upper and lower

panels.

2. Position the Merchandiser

Move the merchandiser to its approximate position. (There are some procedures you need to do

before it is in its permanent location.) Plug in your merchandiser and turn the power switch to ON.

• You can position this merchandiser anywhere in a bank of machines. It can even be placed on an

end flush against a side wall.

• The 167 and 168 merchandisers should be located at least one inch away from the back wall.

• The 764, 765, 784, 787, 797, and 798 merchandisers should be placed at least six inches away

from the back wall. This will provide adequate air circulation for the refrigeration unit.

• The 764, 765, 787, 797, and 798 merchandisers will operate more efficiently when placed in a

shaded location.

• There should be enough room in front of the merchandiser for the door to move freely.

WARNING

This machine is only rated for installation in an indoor location.

December 2005 Page 10 1670097

Page 15

Snack / Refreshment Center Setup and Operator's Guide

Time Out!

Now that you have placed your machine near its permanent location, you need to set up some of the

special options you may have.

NOW, IF YOUR MACHINE IS EQUIPPED WITH A CAN-

MODULE . . .

Grab the booklet entitled "CAN MODULE SETUP AND OPERATOR'S GUIDE" and follow the

setup procedures contained in it. After you have done that, come right back here and proceed with the

next step.

N

E

X

T

Go on to the next page and continue with the snack set up.

1670097 Page 11 December 2005

Page 16

Snack / Refreshment Center Setup and Operator's Guide

Snack Section Set-Up

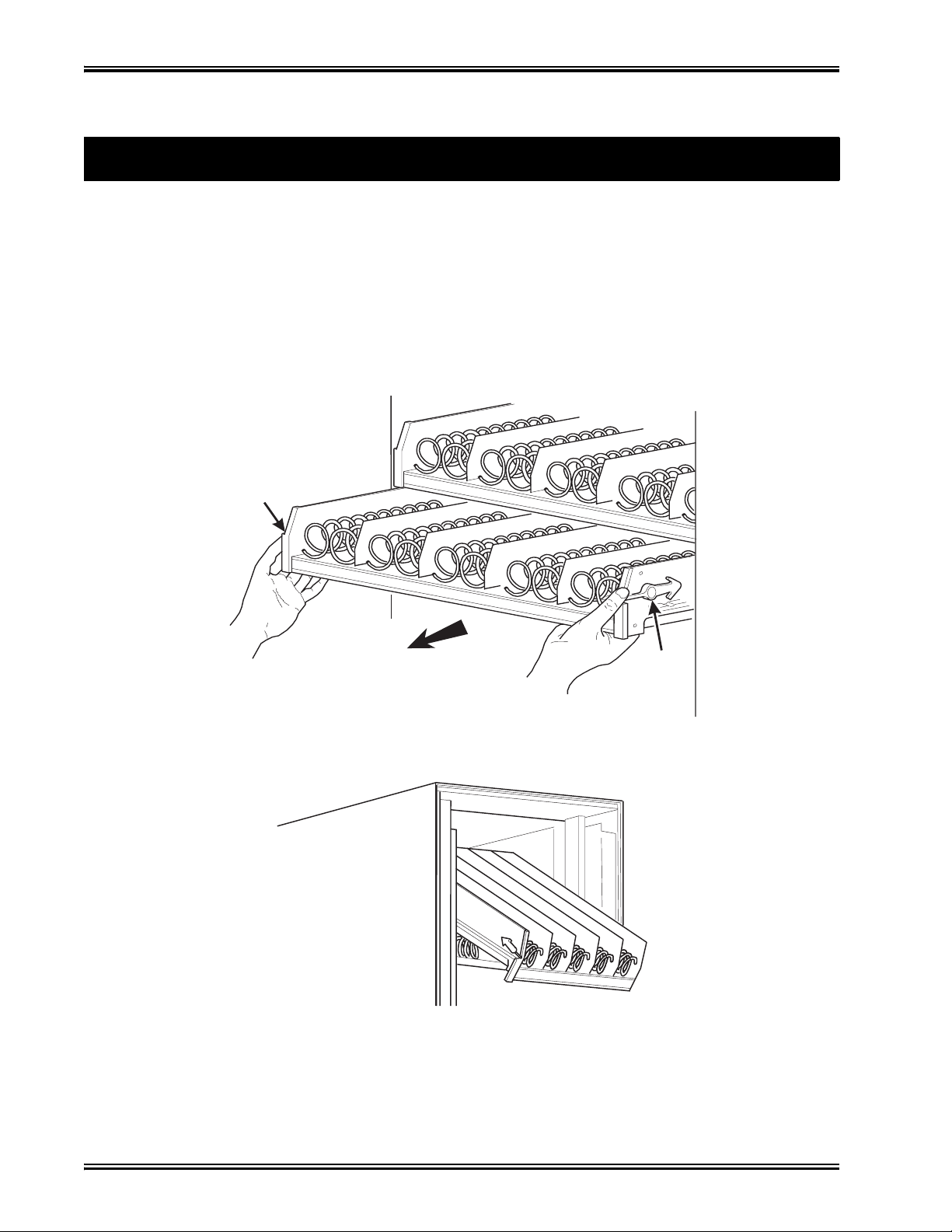

1. Place a Tray in the Loading Position

2. Place both hands on the tray as shown.

3. If your machine has tray latches, lightly push back on the tray with your palms. This will

release the tray latches on the sides of the tray. Otherwise, skip to step 5.

4. Push down on the tray latches with your thumbs.

5. Pull the tray toward you until you hear and feel the rear tray rollers drop into a cut-out in the top

of the guide rail. Skip to step 6

6. Lightly lift the front of the tray and pull the tray toward you until you hear and feel the tray roll-

ers drop into the cut-out in the top of the guide rail.

.

TRAY

LATCH

PULL

TRAY

LATCH

157P0011

7. Continue pulling the tray forward for another inch. You will then be able to tilt the tray down-

ward into the loading position as shown.

NOTE

When the cabinet door is not fully open, the bottom tray will rest

on the delivery pan assembly. Handle the tray with care to avoid

scratching the delivery pan assembly.

December 2005 Page 12 1670097

Page 17

Snack / Refreshment Center Setup and Operator's Guide

1. Set up Trays to Vend Products

These instructions will guide you through setting up your trays for vending. You will be asked to

determine if your tray can physically hold the products you intend to vend. If not, you will be

directed to other procedures which will help you get them set up. Follow these nine steps for each

tray in your machine:

1. Make sure the tray is in the loading position.

2. Is the column wide enough for the intended product? If so, proceed to the next step. Otherwise,

set up your tray to vend wider products ( see below, this page). When you're done, return to step

3 in this procedure.

3. Will the products fit between the spiral turns? If so, proceed to the next step. Otherwise,

change the spiral.

4. Will the product pass under the tray immediately above? If so, proceed to the next step. Other-

wise, reposition the tray and guides.

5. Will the product touch products on either side? I f not, proceed to the next step. Otherwise,

install a product spacer.

6. Load products in the tray.

7. Return the tray to the vending position.

8. Install the price rolls.

9. Install the selection ID numbers.

2. Set Up A Tray To Vend Wide Products

The following steps will help you configure your tray to vend wide products. When you have completed the procedures called out in each step, return to the next step in the procedure. When you are

done with the entire wide product steps, return to the set-up procedures above.

1. Remove the tray from the merchandiser and place on a flat surface.

2. Based on the size of the product you want to vend, decide how many spiral positions it will

occupy . Please remember that the leftmost spiral in the group must have an even ID number (0,

2, 4, etc.) For example, if a product is three spirals wide, the left spiral will be ID number 0, and

the right spiral will be ID number 2. Be careful how wide you set up for, because really wide

products could get hung up in the delivery door.

3. Remove the column dividers inside the group. In the example of three spiral positions, you

would be removing the dividers between spiral ID numbers 0 and 1, and 1 and 2.

4. If your group only consists of 2 spirals, replace the rightmost motor with a spiral bearing and

gear, and install a gear on the leftmost motor. Skip to step 8.

5. Remove all spirals in the group except the leftmost spiral.

6. Do one of the following:

a. If your group has an ODD number of spirals (3, 5, etc.) remove the harnesses from all

motors in the group except the leftmost one. To the rightmost motor, connect the harness

from the motor immediately to its left.

b. If your group has an EVEN number of spirals (4, 6, etc.) remove the harnesses from all

motors inside the group (leave the harnesses connected to the leftmost and rightmost

motors).

1670097 Page 13 December 2005

Page 18

Snack / Refreshment Center Setup and Operator's Guide

Study this procedure before you install a

t

t

P

1

2

3

4

y

TRAY

7. Install a spiral at the rightmost position in your group. Make sure it has the same product capac-

ity and is opposite to the one in the leftmost position.

8. Return the tray to the merchandiser.

9. Electronically couple the motors as needed (see your Programming Guide for information).

10. Return to step 3 in the Set Up Trays to Vend Products procedure, above.

ray for the first time; while you are holding

he tray you will not be able to see this area.

roceed as follows:

. If your machine has tray latches, push

with your palms. This releases the

tray latches. Otherwise, skip to step 4.

. Push down on the tray latches with

your thumbs.

. Pull the tray forward until you hear

and feel the rear tray rollers drop into

a cut-out in the top of the guide rail.

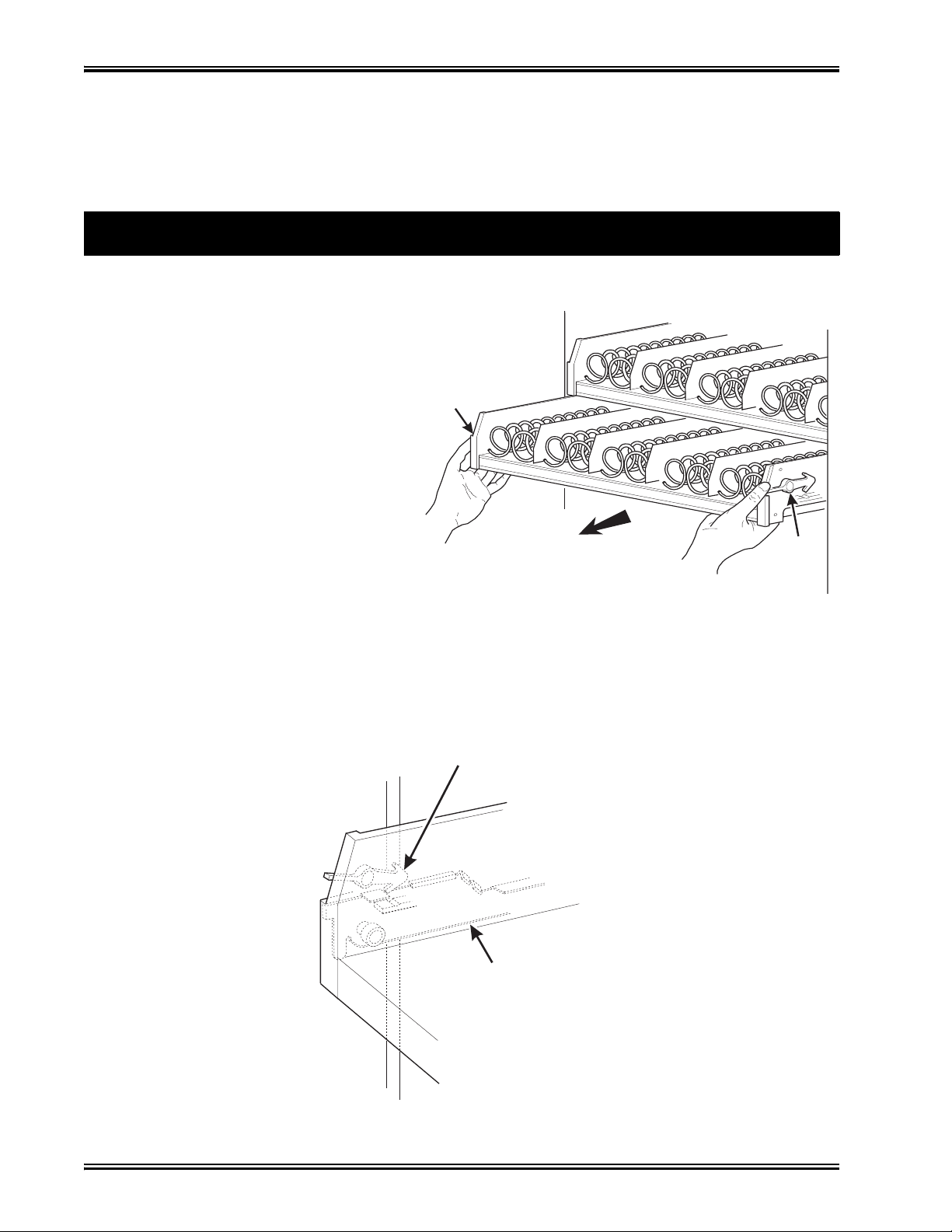

3. Removing a Tray

TRAY

LATCH

PULL

TRAY

LATCH

157P0011

. Lightly lift the front of the tray and pull the tray toward you until you hear and feel the rear tra

rollers drop into a cut-out in the top of the guide rail.

LATCH

TRAY

GUIDE

RAIL

157P0027

December 2005 Page 14 1670097

Page 19

Snack / Refreshment Center Setup and Operator's Guide

CUT-OUT

REAR OF

E

RAIL

5. Unplug the tray wiring harness from

6

3. Removing a Tr ay (conti nued)

the PC board mounted on the tray

guide rail JUST ABOVE the tray you

are removing.

PC BOARD

ATTACHED TO

TRAY GUIDE

TRAY GUIDE RAIL

. Lift up on the tray and slide it toward the back.

No more than an inch should be needed

TRAY

7. The tab near the back of the tray should align with the cutout in the top of the guide rail as shown.

8. Lift the tray clear of the guide rail and out of the merchandiser.

TAB

(ON TRAY)

TRAY GUID

CAUTION

When the cabinet door is not fully open, use extra care in removing

the bottom tray. Failure to do so may result in damage to the tray

or to the delivery pan assembly.

TRAY

ROLLER

REAR OF TRAY

TRAY

GUIDE

RAIL

157P0026

1670097 Page 15 December 2005

Page 20

Snack / Refreshment Center Setup and Operator's Guide

DIVIDER

1. Push the column divider toward the back of

2

3

4. Removing and Ins talling Column Dividers

the tray - .

. Lift the column divider clear of the tray -

.

2

. Install the column divider in the reverse

order of removal.

1

1

2

COLUMN

5. Operate a Tray Outside the Mach i ne

Tray harness extension (P/N 1709017) is available from your National Vendors Parts department.

The extension will enable you to remove the tray from the machine and still operate the motors and

spirals. Connect it as shown:

December 2005 Page 16 1670097

Page 21

Snack / Refreshment Center Setup and Operator's Guide

SPIRAL

R

1. Replacing a Motor With a Spiral B e aring

REMOVING A MOTOR:

1. Disconnect the harness from the motor.

(See CONNECTING AND DISCONNECTING A MOTOR HARNESS), below.

2. Remove the spiral. (See REMOVING AND INSTALLING SPIRALS).

3. Remove the spiral coupler. (See REMOVING A SPIRAL COUPL ER) .

4. Remove the motor. (See REMOVING AND INSTALLING A SPIRAL MOTOR).

INSTALLING A SPIRAL BEARING:

1. Put the gear into position if required in this set-up as shown. (See INSTALLING A GEAR).

2. Install the spiral coupler. (See INSTALLING A SPIRAL COUPLER).

BEARING

BACKWALL

OF TRAY

GEAR

˜

SPIRAL

COUPLE

1670097 Page 17 December 2005

Page 22

Snack / Refreshment Center Setup and Operator's Guide

CAUTION

D

1

2

C

1

2

2. Connecting and Disconnecting a Motor Harness

To avoid breaking the motor circuit board, hold the header on the

circuit board whenever connec ting or disconnecting a motor harness.

ISCONNECTING A MOTOR HARNESS:

. Pull the harness connector away from the circuit board as shown.

. Tuck the unused part of the harness out of the way in the trough at the back of the tray.

ONNECTING A MOTOR HARNESS:

. Locate the harness connector for the appropriate tray position.

. Push the harness connector over the header pins on the motor circuit board as shown.

December 2005 Page 18 1670097

Page 23

Snack / Refreshment Center Setup and Operator's Guide

• All spirals are the same diameter:

•

3. Removing and Installing Spirals

There are two types of spirals:

COUNTER-CLOCKWISE (left hand) CLOCKWISE (right hand)

• Spirals are available in eight dif ferent capacities. Four of the s e are standa rd, and f our a re options .

ITEM CAPACITY

OF SPIRAL

6 (Optional) 1477104 1477102 Purple

11 (Standard) 1477027 1477024 Blue

13 (Standard) 1477033 1477030 Yellow

15 (Standard) 1477039 1477036 Red

20 (Standard) 1477045 1477042 White

25 (Optional) 1477051 1477048 Green

30 (Optional) 1477057 1477054 Black

38 (Optional) 1477063 1477060 Orange

PART NUMBER

CLOCKWISE

(RH)

COUNTER

CLOCKWISE (LH)

CLIP

COLOR

1670097 Page 19 December 2005

Page 24

Snack / Refreshment Center Setup and Operator's Guide

LIFT

3. Removi ng and Installing Spirals (cont inued)

SPIRALS FOR MODELS 172, 173, 452, AND 453

PART NUMBER

ITEM CAPACITY

OF SPIRAL

CLOCKWISE

(RH)

COUNTER

CLOCKWISE (LH)

8 1707017 1707019 Grey

10 1707005 1707007 Blue

12 1707009 1707011 Yellow

14 1707013 1707015 Red

18 1707021 1707023 White

TO REMOVE A SPIRAL:

1. Pull forward on the retaining clip and remove the end of the spiral from the spiral coupler as

shown.

2. Remove the spiral from the tray.

PULL

SPIRAL

COUPLER

CLIP

COLOR

SPIRAL

RETAINING

TO INSTALL A SPIRAL:

CLIP

1. Pull the bottom of the retaining clip toward the front of the spiral.

2. Lower the spiral into the tray column and insert the end of the spiral into the spiral coupler as

shown.

3. Release the retaining clip.

SHOULD I USE A CLOCKWISE OR A COUNTERCLOCKWISE SPIRAL?

1. The type of spiral used is determined by the column position it will occupy in the tray.

2. Refer to the figure below to find the correct spiral type.

A1 A2

December 2005 Page 20 1670097

A3

A4

A5 A6

A7

A8 A9A0

Page 25

Snack / Refreshment Center Setup and Operator's Guide

1. Removing a Spiral Coupler

1. Pinch together the prongs on the end of the spiral coupler as shown.

2. Pull the coupler forward (in the direction of the arrow as shown)

SPIRAL

COUPLER

PRONGS

PULL

1670097 Page 21 December 2005

Page 26

Snack / Refreshment Center Setup and Operator's Guide

R

SPIRAL

1

2

3

4

5

6

I

1

2

3

4

.

5

6

1. Removing and Installing a Spiral Motor

REMOVING A SPIRAL MOTOR:

NOTE:

Some steps may already be complete d.

. Remove the tray. (See REMOVING A TRAY).

. Disconnect the motor harness.

(See CONNECTING AND DISCONNECTING A

MOTOR HARNESS).

. Remove the spiral.

(See REMOVING AND INSTALLING SPIRALS).

. Remove the spiral coupler.

( See REMOVING A SPIR AL COUPLER).

. Lift the motor clear of the tray.

. Return the tray to the merchandiser.

(See IN STALLING A TRAY IN THE MERCHANDISER).

NSTALLING A SPIRAL MOTOR:

MOTOR

BACKWALL

OF TRAY

GEAR

˜

SPIRAL

COUPLE

. Remove the tray. (See REMOVING A TRAY).

. Place the motor in the correct position at the rear of the tray as

shown.

. Place a gear in position if required by this set-up.

(See INSTALLING A GEAR).

. Install a spiral coupler in the proper orientation. (See INSTALLING A SPIRAL COUPLER)

. Connect the motor harness.

(See CONNECTING AND DISCONNECTING A MOTOR HARNESS).

. Return the tray to the merchandiser.

( See INSTALLING A TRAY IN THE MERCHANDISER).

December 2005 Page 22 1670097

Page 27

Snack / Refreshment Center Setup and Operator's Guide

BACK WALL

ORIENTATION 1 ORIENTATION 2

2. Installing a Gear

WHEN ARE GEARS USED?

• Gears are used to mechanically couple the spirals together.

• This happens whenever you have two spirals and only one motor for vending a selection.

WHERE ARE THE GEARS PLAC ED?

• The gear is placed between the back of the tray and the spiral coupler.

HOW IS THE GEAR ORIENTED?

• There are two possible orientations for the gear:

OF TRAY

GEAR

• There are two rules to follow when orienting gears:

RULE 1-The gears for selections next to each other cannot use the same orientation .

RULE 2-All gears for a single selection mu st use the same orient atio n.

1670097 Page 23 December 2005

Page 28

Snack / Refreshment Center Setup and Operator's Guide

SPIRAL

AS VIEWED FROM FRONT OF TRAY

ONE POSITION

C

ONE POSITION

L

3. Installing a Spiral Coupler

1. Place the gear in position if one is required for this set-up. (See INSTALLING A GEAR).

WHEN USED WITH A MOTOR:

2. Hold the motor in place and push the spiral coupler through the motor gear box until it clicks

into position. Be sure the spiral couplers are oriented as shown below.

NOTE

The motor output shaft opening contains eight

facets to allow the spiral coupler to be installed in any one of

eight p osition s.

COUPLER

FRONT VIEW OF

MOTOR OUTPUT SHAFT

SPIRAL COUPLER ORIENTATION

OUNTERCLOCKWISE

FROM VERTICAL

LEFT SPIRAL

COUPLER

MOTOR

CLOCKWISE

FROM VERTICA

RIGHT SPIRAL

COUPLER

December 2005 Page 24 1670097

Page 29

Snack / Refreshment Center Setup and Operator's Guide

SPIRAL

3. Installing a Spiral Coupler (continued)

WHEN USED WITH A COUPLER BEARING:

3. Hold the coupler bearing in place and push the spiral coupler through the bearing until the coupler clicks into position. Be sure the coupler is in the proper orientation as shown.

COUPLER

SPIRAL

BEARING

1670097 Page 25 December 2005

Page 30

Snack / Refreshment Center Setup and Operator's Guide

Proceed as follows:

1

2

3

4

5

6

7

8

9

1

1

4. Moving a Tray Up or Down

This merchandiser can be adjusted to vend taller products. Some guidelines must be followed:

• Keep in mind that when you increase the product height available to a tray by l owering it, you will

be decreasing the product height available to the tray below.

• If a tray is in the lowest position, the tray below it should not be in the highest position.

• If a tray is in the highest position, the tray above it should not be in the lowest position.

• You will need to experiment with various tray positions to get the best results for your products.

CAUTION:

The trays in a model 764 and 765 merchandiser should not be posi-

tioned over an open air discharge vent.

NOTE:

Tray movement is limited bec ause the tr ay harness will limit the

amount of travel available to the tray guide rails.

. Remove the tray from the merchan-

diser. (See REMOVING A

TRAY).

. Remove the screw that secures

the right tray guide rail to the

front guide mounting channel as

shown.

. Tap up on the guide rail and unseat

the guide rail tabs from the channel slots.

. Pull the guide rail away from the front and rear guide

mounting channels.

. Move the guide rail to the desired position.

. Insert the guide rail tabs into the mounting CVchannel

slots as shown.

. Tap down on the guide rail to seat the tabs in the channel slots.

. Replace the screw that secures the guide rail to the front guide

mounting channel.

. Repeat steps 2 through 8 for the left guide rail.

0. Return the tray to the merchandiser.

( See INSTALLING A TRAY IN THE MERCHANDISER).

1. Load products into the trays, and perform test vends. Make sure the trays don't interfere with

the products you are vending, and that all products vend properly.

REAR GUIDE

MOUNTING CHANNEL

PC BOARD

TRAY

GUIDE

RAIL

SCREW

FRONT GUIDE

MOUNTING CHANNEL

CHANNEL

SLOT

December 2005 Page 26 1670097

Page 31

Snack / Refreshment Center Setup and Operator's Guide

1

2

3

4

5. Installing a Tray in the Merchandiser

• Study this procedure before you install a tray for the first time; while you are holding the tray you

will not be able to see this area. Proceed as follows:

. Insert the tray so that the tray rollers pass

over the tray guide rollers.

5. Hold the tray up while pushing it toward

the rear. Stop when the tab on the tray

aligns with the opening in the tray guide.

REAR OF

TRAY

TRAY

GUIDE

TRAY

ROLLER

157P0024

FRONT OF

RAIL

CUT-OUT

157P0012

TAB

. Bring the tray roller to rest on the tray

guide.

6. Lower the tray until it rests on the tray

guide roller. Push the tray in all the way.

7. The tray latch will fall into the locking

position.

REAR OF TRAY

CUT-OUT

TRAY

ROLLER

TRAY

GUIDE

RAIL

157P0026

REAR OF

TRAY

. Tilt the tray upward.

. Connect the tray wiring harness to the PC

board mounted to the guide rail JUST

ABOVE the tray you are installing.

TAB

(ON TRAY)

157P0025

TRAY GUIDE

RAIL

1670097 Page 27 December 2005

Page 32

Snack / Refreshment Center Setup and Operator's Guide

PRODUCT

DIVIDER

M

G

10. Installing and Removing a Product Spacer

INST ALLING A PRODUCT

SPAC ER:

The product spacer will keep a

tall, narrow product upright.

Shown at right are spacers and

column dividers on both deep and

shallow trays.

Insert the product spacer onto the

column divider as shown.

OUNTING

PINS

SPACER

MOUNTIN

PINS

COLUMN

ADJUSTING A PRODUCT

SPAC ER:

With product loaded in the tray,

rotate the product spacer up or

down to keep the product upright

as shown.

REMOVING A PRODUCT

SPAC ER:

Pull the product spacer mounting

pins from the column divider.

December 2005 Page 28 1670097

Page 33

Snack / Refreshment Center Setup and Operator's Guide

r

to

it

).

e

1. Load Trays With Product

SPIRAL CAP ACITY COLOR CODES

SPIRAL

CAPACITY

6 Purple 20 White

11 Blue 25 Green

13 Yellow 30 Black

15 Red 38 Orange

SPIRAL COUPLER

COLOR

SPIRAL

CAPACITY

SPIRAL COUPLER

Spiral Capacity Color Codes

Models 172, 177, 173, 452, 457, and 458

SPIRAL

CAPACITY

8Grey

10 Blue

12 Yellow

14 Red

18 White

SPIRAL COUPLER

COLOR

COLOR

The color of the spiral couple

(the little plastic tab attac hed

the rear of the spiral will tell

)

you how many products will f

in the spiral. (See table at left

NOTE:

Another way to determine

spiral capacity is to count th

spaces in the sp i ral!

LOADING A TRAY WITH PRODUCTS IN GENERAL:

•(See PRODUCT PUSHER USAGE) for spirals with capacity of 11, 13, or 15.

•(See SPIRAL WA LL RETAINER USAGE) for spirals with capacity of 20, 25, 30, or 38.

• Begin loading products at the front of the tray and work toward the back. Position the product so

the package rests on the tray . DO NOT force a product into a spiral.

• If the fit is too tight or too loose, change the spiral size.

(See REMOVING AND INSTALLING A SPIRAL).

• Be sure there are no empty positions between products in each spiral.

SPECIAL CONSIDERATIONS:

Bagged Products - Position package upright, then push the tops slightly toward the rear of the tray .

Also, (see PRODUCT PUSHER USAGE).

Thin Packages - Posi ti on the package upright.

Also, (see SPIRAL WALL RETAINER USAGE).

KitKat - The two right-most columns of the candy tray are designed to accept the

KitKat candy bar.

Chilled Candy - Use the lowest trays for candy that is to be chilled.

WARNING

This me rchandi ser doe s not hav e a healt h control circuit . It is not

approved for the vending of perishable food items.

1670097 Page 29 December 2005

Page 34

Snack / Refreshment Center Setup and Operator's Guide

SPIRAL

R

SPIRAL WALL RETAINER USAGE:

A

s

r

•

•

•

T

ORIENTATION A

DIVIDER

ORIENTATION B

A. Load Trays With Product (continued)

spiral wall retainer serves to compress the spiral and make it act like a

pring to more forcefully eject a product. Do some test vends and use a spi-

al wall retainer when a product does not readily leave the spiral.

ETAINER

WALL

Use a spiral wall retainer in the following cases:

- The spiral has a capacity of 20, 25, 30, or 38.

- The product is thin.

- The product is on a candy tray.

The spiral wall retainer can also be used with other spirals and types of

products.

The spiral wall retainer is installed near the front of the column divider.

here are two ways to install the spiral wall retainer.

RETAINER

ORIENTATION

AB

0 and 1 1 and 2

COLUMN

DIVIDER

BETWEEN

THESE

POSITIONS

• To install a spiral wall retainer, insert the retainer in the square slot near the front of the column

divider.

2 and 3 3 and 4

4 and 5 5 and 6

6 and 7 7 and 8

8 and 9

• The spiral wall retainer must be removed in two cases:

- A KitKat bar loaded into either of the two right hand positions of a tray will not clear the

retainer on the column divider between the two positions.

- A product pusher will catch on a retainer in ORIENTATION A.

December 2005 Page 30 1670097

Page 35

Snack / Refreshment Center Setup and Operator's Guide

T

AS VIEWED FROM FRONT OF TRAY

ONE POSITION

C

ONE POSITION

L

P

o

U

•

•

T

A

a

l

a

v

P

V

B

N

v

T

c

T

c

T

t

R

p

e

b

N

B. Load Trays With Product (continued)

RODUCT PUSHER USAGE: The product pusher will give the top

f a product an extra tilt to help it fall into the delivery pan.

PRODUC

PUSHER

se a product pusher in the following cases:

The spiral has a capacity of 15, 13, or 11.

The package is non-rigid like bagged peanuts

he product pusher can also be used with other spiral and types of products.

bag of product pushers has been shipped with the merchandiser. Additional product pushers are

vailable from the National Vendors' parts department. To use a product pusher, snap it on the spira

s shown. You can adjust the product pusher by moving it around on the spiral to achieve the best

ending results.

REPARING THE MERCHANDISER FOR

ENDING "LUNCH BUCKET":

OUNTERCLOCKWISE

FROM VERTICAL

CLOCKWISE

FROM VERTICA

ecause of the weight and shape of the package,

ational Vendors recommends that this product be

ended only from the bottom tray.

o vend this product, two adjacent positions must be

oupled together .

(See INSTALLING A GEAR, for

mechanical coupling directions, or see

the Programming Guide for electrical

coupling directions).

LEFT SPIRAL

COUPLER

RIGHT SPIRAL

COUPLER

he left spiral coupler should be installed one position

ounterclockwise from the vertical position.

he right spiral coupler should be installed one posi-

ion clockwise from the vertical position.

eplace the current spirals with six-count spirals. These are available from the National Vendors

arts department. (See REMOVING AND INSTALLING SPIRALS). A pad can be installed in th

ottom of the delivery pan to quiet and cushion product delivery. This part is available from the

ational Vendors parts department. Load "Lunch Bucket" products as shown.

1670097 Page 31 December 2005

FOOD SELECTIONS

LOADED IN SPIRALS

157P0039

Proper Loading of "Lunch Bucket"

Page 36

Snack / Refreshment Center Setup and Operator's Guide

TOP SHELF

NOTE

C. Loading a Tray With Product (continued)

PREPARING THE MERCHANDISER FOR VENDING "TOP SHELF":

National Vendors recommends that this product be vended from a candy tray.

Move the tray so the package can be loaded standing on its left or right edge.

( See MOVING A TRAY UP OR DOWN).

The following steps must be completed for three adjacent positions on the tray:

NOTE

The left-most position in the group of three

must be an even numbered position.

1. REMOVE COLUMN

DIVIDERS

2. REMOVE

SPIRALS

MOVE CONNECTOR

6.

TO THIS MOTOR

FROM THIS MOTOR

If the motor harness you disconnected in

step 5 does not

reach, use the motor skip

harness, P/N 1599024, available

from the National Vendors Parts

Department.

LEAVE THIS MOTOR

CONNECTOR ALONE

5.

7. INSTALL AN 11-COUNT LEFT HAND

SPIRAL IN THIS POSITION

3.

4.

DISCONNECT THIS

MOTOR CONNECTOR

INSTALL AN 11-COUNT RIGHT-HAND

8.

SPIRAL IN THIS POSITION

157P0040

PRODUCT

Couple the left motor to the right motor . (See the Programming Guide).

Load the "Top Shelf" products as shown.

December 2005 Page 32 1670097

Page 37

Snack / Refreshment Center Setup and Operator's Guide

1. Return the Trays to the Vending Position

1. Lift the tray until it is parallel to the floor as shown.

TRAY

LATCH

PULL

TRAY

LATCH

157P0011

2. Push the tray toward the back of the cabinet. The tray latches on the sides of the tray will lock

into position.

TRAY

LATCH

TRAY

GUIDE

RAIL

157P0027

1670097 Page 33 December 2005

Page 38

Snack / Refreshment Center Setup and Operator's Guide

• Price rolls are printed on coiled-up strips as shown in this example. (The dollar and cents rolls are

n

•

•

2. Install and Set Price Labels

factory installed.) If you use another type of currency, you will find the appropriate price rolls i

the plastic bag that contained this manual.

There are two types of price rolls installed:

Dollar roll - 1 to 12, increments of 1

Cents roll - 00 to 95, increments of 05

Remove the price rolls as required, and install the appropriate one(s) for your currency.

DOLLAR ROLL

CENTS ROLL

157P0043

INSTALLING PRICE LABELS:

• There are three pairs of slots in the front of the can unit for each position. Install per this example:

1. Insert the dollar roll in the left-most pair of slots as shown if the price is $1.00 or more.

2. Insert the cents roll in the center pair of slots as shown.

3. The low-number end of the roll goes in the top slot and the high-number end of the roll goes in

the bottom slot.

PRESSTOPOFROLL

PAST FLEXIBLE TAB

NEAR TOP EDGE

INSERT BOTTOM OF ROLL

THROUGH SLOT ALONG

BOTTOM EDGE

December 2005 Page 34 1670097

157P0044

Page 39

Snack / Refreshment Center Setup and Operator's Guide

2. Install and Set Price Labels (continued)

ADJUSTING THE PRICE ROLL:

You can set selection prices within the following range:

Minimum price $.00

Maximum price $12.95

Increment $.05

1. Use your thumb as shown to move each price roll up or down as needed to set the desired price.

NOTE

You will see the word STOP near either end of the roll.

157P0045

1670097 Page 35 December 2005

Page 40

Snack / Refreshment Center Setup and Operator's Guide

3. Install Selection ID Labels

Selection ID numbers are printed on clear plastic sheets. You will find these in the plastic bag that

contained this manual. You will need to separate them along the scored lines between the selections.

BE CAREFUL when doing this, because it is easy to split the labels. INST ALLING SELECTION ID NUMBERS:

1. Press together the two long edges of the selection ID label.

2. Snap the selection ID label into position on the front of the tray as shown.

DOLLAR

PRICE ROLL

CENTS

PRICE ROLL

SELECTION

IDENTIFICATION

157P0059

SELECTION

IDENTIFICATION LABEL

December 2005 Page 36 1670097

Page 41

Snack / Refreshment Center Setup and Operator's Guide

3. Install Selection ID Labels (continued)

WHICH ID LABEL GOE S WIT H WHICH SE LECTION?

See the figures below for snack and candy tray positions.

Motor Position

TOP TRA Y TRAY A A0 A1 A2 A3 A4 A5 A6 A7 A8 A9

TRAY B B0 B1 B2 B3 B4 B5 B6 B7 B8 B9

BOTTOM TRAY TRAY C C0 C1 C2 C3 C4 C5 C6 C7 C8 C9

NOTE

This example shows a 3-tray merchandiser. Some merchandisers

can have up to 6 trays.

EXAMPLE OF A BAS IC SNAC K

TRAY ID LABEL TO USE

EXAMPLE OF A BA SIC CANDY

TRAY ID LABEL TO USE

A0 A2 A4 A6 A8

A1 A2

A3

A4

A5 A6

A7

A8 A9A0

1670097 Page 37 December 2005

Page 42

Snack / Refreshment Center Setup and Operator's Guide

The column ID labels have already been attached to the delive

p

1

LOOP

The gum and mint assembly is hinged to the delivery pan

a

T

h

o

g

1

Set Up The Gum and Mint Unit

1. Install Price Labels

ry door, and a set of self-adhesive price labels are in the

lastic bag that contained this manual.

. Stick the desired price label next to the column ID

number as shown.

COLUMN

ID LABEL

2. Put the Gum and Mint Dispenser in the Loading Position

ssembly and is held in the vending position by two magnets.

he gum and mint assembly is held in the loading position by a

ook and a loop. One end of the hook is attached to the right side

f the door. The loop is mounted on the right side of the

um and mint assembly.

. Use the loop as a handle and raise the gum and mint

magazine with your left hand. With your right

hand, move the free end of the hook so it catches

the loop. This will hold the magazine while you

are loading it with product, as shown.

HOOK

December 2005 Page 38 1670097

Page 43

Snack / Refreshment Center Setup and Operator's Guide

DISPENSING POSITION

R

1. The gum and mint assembly lid is held closed by two

2

3

4

3. Load the Gum and Mint Dispenser With Product

magnets. Open the lid toward the inside of the

merchandiser door.

WARNING

Keep your hand on the

product pusher until it is

locked in place. Failure to

do so may result in personal

injury or in damage to the

dispenser.

. Move the product pusher into the loading position:

a. Pull back on the pusher.

b. Pull down on the pusher and lock the front glide

. Load the product:

into position.

a. Push the product forward.

b. Be sure the last item is completely under the

product retaining clip.

PRODUCT

PUSHER

FRONT

GLIDE

PRODUCT

ETAINING LIP

LOADING POSITION

˜

. Move the product pusher into the dispensing posi-

tion:

a. Pull the product pusher down to unlock the front

guide.

b. Slide the product pusher toward the product.

WARNING

Keep your hand on the

product pusher until it

comes to rest behind the last

item in the column. Failure

to do so may result in

personal injury or in damage to the dispenser.

1670097 Page 39 December 2005

Page 44

Snack / Refreshment Center Setup and Operator's Guide

LOOP

1. Make sure all product pushers are in the vending position.

2

3

4

5

LOCKING

R

The two left-most vending columns (as seen from the loading side) can be adjusted for two different

w

W

W

w

T

1

2

T

1

2

4. Return the Gum and M int Di spenser to the Vendi ng

Position

. Close the gum and mint assembly lid.

. Hold the loop on the right side of the magazine with your left

hand. Release the hook with your right hand and lower the

magazine.

. Continue to hold the loop until the magazine has

been fully lowered.

. Pivot the gum and mint assembly back to the vend-

ing position.

HOOK

5. Removing and Installing Column Reducers

idths.

hen a column reducer is in place, the width of the column will be 31/16 inches.

hen a column reducer is removed, the width of the column

ill be 37/8 inches.

O REMOVE A COLUMN REDUCER:

. Pull the reducer away from the cabinet door to disengage the

locking tabs.

. Lift up to remove the reducer from the gum and mint assembly.

O INSTALL A COLUMN REDUCER:

. Place the reducer on the gum and mint dispenser so the locking

tabs are in the slots.

. Push the reducer toward the cabinet door to lock the

reducer in place.

COLUMN

EDUCER

TAB

SLOT

December 2005 Page 40 1670097

Page 45

Snack / Refreshment Center Setup and Operator's Guide

Final Installation

Move the merchandiser to its final position:

• You can position this merchandiser anywhere in a bank of machines. It can even be placed on an

end flush against a side wall.

• The 167 and 168 merchandisers should be located at least one inch away from the back wall.

• The 764, 765, 784, 787, 797, and 798 merchandisers should be placed at least six inches away

from the back wall. This will provide adequate air circulation for the refrigeration unit.

• The 764, 765, 797, and 798 merchandisers will operate more efficiently when placed in a shaded

location.

• There should be enough room in front of the merchandiser for the door to move freely.

WARNING

This machine is only rated for installation in an indoor location.

1. Level the Merchandiser

1. Using a spirit level, adjust the legs until the cabinet is level from side to side and front to back.

NOTE

A slight slope from front to back will improve the draining of condensate from merchandisers with refrigerating units. When the

merchandiser is part of a bank of mach ines, level it in reference to

the other machines. After leveli n g is comp let e, check that the door

operates easily.

SPIRIT LEVEL

CRANE

NATIONAL VENDORS

LEG

LEG

LEVELER

FRONT

LEFT REAR

LEG

1-1/2 TURNS

1670097 Page 41 December 2005

Page 46

Snack / Refreshment Center Setup and Operator's Guide

REFRIGERATION

M

E

L

METHOD 2

Refrigeration Modules

Complete the setup of chilled snack features (models 764, and 789):

1. Connect a Refrigeration Module to an External Drain

(Optional)

METHOD 1:

1. Remove the condensate drain tube from the refrigeration module.

2. Connect a new drain tube to the refrigeration module housing.

3. Route the new tube to an external drain or to an overflow bucket.

ODULE HOUSING

CONDENSATE

DRAIN TUBE

TO

CONDENSATE

PAN

REFRIGERATION

MODULE HOUSING

METHOD 1

METHOD 2:

1. Connect a drain tube to the condensate pan.

2. Route the drain tube to an external drain or to an overflow bucket.

CONDENSATE

PAN

NEW DRAIN TUB

(½ ID)

TO EXTERNA

DRAIN OR

OVERFLOW

BUCKET

December 2005 Page 42 1670097

TO

EXTERNAL

DRAIN

DRAIN TUBE

(½ ID)

Page 47

Snack / Refreshment Center Setup and Operator's Guide

AIR DUCT

VENT

The air discharge and return vents are located in the right front and rear side wall. The vents are

a

s

.

I

m

u

2. Adjust the Air Discharge and Return Vents (Chiller Only)

djusted by loosening the screw and sliding the air duct shutter up or down as required. With the

hutter all the way up, the vent is fully open. The vent is closed when the shutter is all the way down

deally , the temperature at the top tray should be the same as that at the bottom tray. Using a ther-

ometer to monitor temperature, adjust the air discharge and return vents

ntil the temperatures are as close together as possible.

CAUTION

Do not close off all discharge vents.

Doing so can damage the refrigeration

unit.

SHUTTER

SCREW

AIR

DISCHARGE

1670097 Page 43 December 2005

Page 48

Snack / Refreshment Center Setup and Operator's Guide

1. Install the Base Plate

Refer to the figure below while completing the following procedures:

WARNING

Do not move the cabinet while the hex head screws and/or carriage

bolts are loosened. The cabinet would become unstable and likely

to tip and cause injury.

1. Remove the waste pail and the grounds pail from the merchandiser (refreshment center only).

2. Remove the floor liner from the merchandiser (refreshment center only).

3. Remove the two caps as shown.

4. Loosen the left leg assembly carriage bolts and nuts to allow mounting a base plate bracket.

5. Secure one of the base plate brackets to the leg assembly using the two carriage bolts. Tighten

the carriage bolts and nuts.

6. Loosen the right leg assembly hex screws to allow mounting the other base plate bracket.

7. Secure the other base plate bracket to the right leg assembly using the two hex head screws.

Tighten the hex head screws.

8. Insert the short arms of the slides into the hinged tabs of the base plate. Position the slide so the

notch near the short arm is on the bottom side.

9. Insert the long arms of the slides into the base plate brackets.

10. Insert and secure a cotter pin through the hole in the back of each of the slides.

11. Push the base plate toward the merchandiser cabinet. The front tabs of the base plate brackets

should seat in the notches in the long arms of the slides.

12. Replace the caps, liner, and pail(s) removed previously.

CAPS

SLIDE - LH

BASE PLATE BRACKET

SLIDE - RH

BASE PLATE

December 2005 Page 44 1670097

COTTER PIN

Page 49

Snack / Refreshment Center Setup and Operator's Guide

LOCK

LEVER

E

Install an optional lock cylinder in the merc

1

2

3

4

5

6

1. Remove the cash box from the merchandiser.

2

3

2. Install the Lock Cylinder

handiser as follows:

SPRING

. Position the lift handle lock lever as shown.

. Depress the lock spring at the square hole

of the lock cylinder receptacle and pull the

lock springs out through the front.

. Position the lock cylinder as shown.

Depress the spring loaded lock pin.

. Push the cylinder into the cylinder

receptacle in the lever. The pin

should snap into the square hole.

KEY

LOCK

CYLINDER

. If the cylinder pin does not seat in the square

hole, press against both ends of the lock cylinder. Rotate the

cylinder until the pin snaps into place.

. Leaving the door open, test the lock mechanism with a

key.

3. Install the Optional Cash Box Lock

. Assemble the lock as shown in the illustration to the right.

.Return the cash box to the merchandiser.

LOCK BAR

SQUAR

HOLE

LOCK

CYLINDER

SCREW

NUT

WASHER

1670097 Page 45 December 2005

Page 50

Snack / Refreshment Center Setup and Operator's Guide

1. Set Up the Coin Mechanism

If the changer is not a MARS TRC 6000, proceed to LOADING THE COIN MECHANISM

If the Changer is a MARS TRC 6000, you must set the high quarter switch.

SETTING THE QUARTER SWITCH:

QUARTER SWITCH

POSITION

LOW

HIGH

ACTION

The coin mechanism

will only store 6 quar-

ters. The rest are sent to

the coin box. Fewer

quarters are available

for change.

The coin mechanism

will store 69 quarters.

More quarters are

available for change.

December 2005 Page 46 1670097

Page 51

Snack / Refreshment Center Setup and Operator's Guide

1. Load the Coin Mechanism

Once you arrive at the steps that tell you how to setup your coin mechanism, please perform the following steps:

CAUTION:

THE MAIN POWER SWITCH MUST BE TURNED OFF BEFORE YOU GO ANY FURTHER!

1. If your coin mechanism is a MARS 6000 or TRC 6010 XV, set the high quarter switch as

shown, then continue. If your coin mech is another model, disregard this step. Continue.

2. If not already plugged in, plug the power cord into the electric outlet and turn ON the main

power switch.

3. Press , and press once. Press until either

DUMB MECH

or

MDB M ECH

is displayed

(depending upon which coin mech type you have).

4. If you chose

dure. If you chose

MDB MECH

arj_=jb`e

in the previous step, skip to step 5 and perform the rest of this proce-

in the previous step, fill the coin tubes with coins. Make sure the

coins are not shingled. You are now finished setting up your coin mech. Do not perform the

rest of this procedure.

5. Press until the standby message is displayed, then press .

6. Insert at least 20 coins of each denomination through the coin chute. Continue to fill the coin

tubes either through the coin chute or the tops of the tubes.

7. V isually check the coin tubes to make sure coins are not shingled.

8. Press .

8. If credit is still shown in the display, turn the machine power OFF, then back ON.

1670097 Page 47 December 2005

Page 52

Snack / Refreshment Center Setup and Operator's Guide

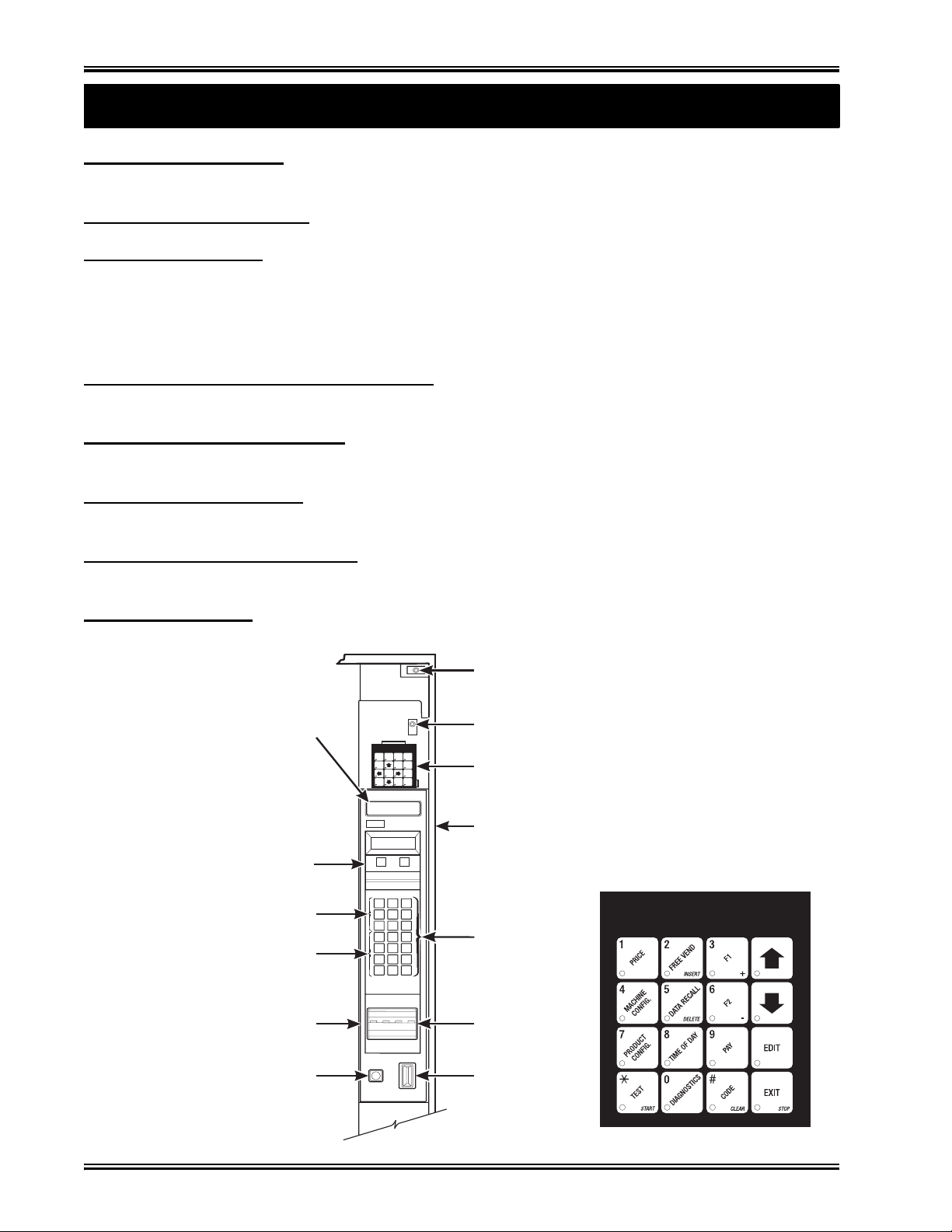

The service keypad (shown on the left) is your major tool to

n

le

Programming

THE SERVICE KEYPAD

program your merchandiser. If you just need to get your

merchandiser up and running, you only have to set prices.

That procedure is given below. For a thorough explanatio

of how to do all the custom programming f eatures availab

to you, consult your Programming Guide. It will tell you

how to:

• Set up custom time-of-day vending periods;

• Look at sales and vending data;

• Test various machine func tions;

• Customize trays for vending uniq ue products;

• Enter custom display messages;

• And much more!

1. Set Prices

1. Press . The display shows **

prices set in the machine.

2. Press the number of the selection to be priced. (Example: B1.) The display shows

Enter a price using the number keys. The selection is now priced.

3. Press another letter key, or to price another selection.

Refer to your Programming Guide for other pricing options.

OKRM=KOR

NOTE

. This display shows the maximum and minimum

_N==uKuu

.

2. View the Chiller or Can Unit Temperature

After your merchandiser has been running for a while, you may want to see if the chiller or can unit

(optional) is getting cold. The following procedure can be performed whether the main door is open

or closed:

1. Press on the selection switch panel. The temperature is displayed.

2. If desired, you can change the temperature by following the procedure given in your Programming Guide.

December 2005 Page 48 1670097

Page 53

Snack / Refreshment Center Setup and Operator's Guide

Final Checkout

Now , you have connected your merchandiser to the utilities, placed it in its final location, loaded it

with products, and set the prices. Before you lock the door and move on, you should check to see if

your merchandiser will vend products. In case of problems, perform the operational readiness checks

beginning on the next page.

1. Test Vend Selections

1. Press . The display shows

2. Deposit coins and/or currency to establish credit higher than the price of the selection. The display shows

3. Use the selection switch panel to enter the selection number you want to vend. The display

shows

The selection is vended, then correct change and the credit are returned.

4. Test vend other selections, if desired.

qbpqKuu

mof`bKuu

. XX is the amount of credit you established.

. XX is the price of the selection.

qbpqKMM

.

2. Operational Readiness Check

1. Perform test vends on all selections.

2. Do any of the snack or candy products catch on the tray and fail to vend? If not, skip to step 3.

If so, perform the following procedures on the affected areas until all products vend properly:

a. Install and/or adjust a product spacer.

b. Install a product pusher.

c. Install and/or remove spiral wall retainers.

d. Perform the appropriate spiral anti-hang-up procedure(s) (see below).

3. Test the operation of the coin mechanism (see the Programming Guide for the

proper procedure.).

4. Test the operation of the bill validator.

5. Return all test vended products to the trays.

1670097 Page 49 December 2005

Page 54

Snack / Refreshment Center Setup and Operator's Guide

3. Spiral Indexing Procedu re (One Spiral, One Moto r)

The spiral indexing procedures involve rotating spirals one position at a time until the product vends

properly.

1. Home all the motors (see the Programming Guide).

2. Remove the affected spiral.

3. Is the coupler in the proper position?

NO - Move the coupler to the position as shown in INST ALLING A SPIRAL COUPLER. Go to

step 4.

YES - Move the coupler to the next clockwise position (if it's on a right-hand motor), or the next

counterclockwise position (if it's on a left-hand motor). Go to step 4.

4. Replace the spiral.

5. Perform a test vend (see the previous page).

6. Did the product hang up?

NO - You're finished. Continue to test vend the remaini ng sel ections until everyth ing works right.

YES - Go to step 7.

7. Did you previously move the coupler to the next clockwise or counterclockwise position?

NO - Move the coupler to the next clockwise position (if it's on a right-hand motor), or the next

counterclockwise position (if it's on a left-hand motor). Return to step 6.

YES - Return to step 2 in the operational readine ss check and try another procedure. Do not move

the coupler again.

4. Spiral Indexing Procedure

(Two Spirals, One Or Two Motors)

The spiral indexing procedures involve rotating spirals one position at a time until the product vends

properly.

1. Home all the motors (see the Programming Guide).

2. Remove the left hand spiral of the affected pair.

3. Is the coupler in the proper position?

NO - Move the coupler to the position as shown in INST ALLING A SPIRAL COUPLER. Go to

step 4.

YES - Move the left coupler to the next counterclockwise position. Go to step 4.

4. Replace the left hand spiral.

5. Remove the right hand spiral, spiral coupler, and gear (if used) of the affected pair as a unit.

6. Rotate this unit until the right hand spiral mirrors the position of the left hand spiral.

7. Replace the right hand spiral, spiral coupler, and gear (if used).

8. Perform a test vend (see the previous page).

9. Did the product hang up?

NO - You're finished. Continue to test vend the remaini ng sel ections until everyth ing works right.

YES - Go to step 10.

10. Did you previously move the left hand coupler to the next counterclockwise position?

NO - Remove the left hand spiral of the affected pair. Turn the left spiral coupler to the next

counterclockwise position. Return to step 4.

YES - Return to step 2 in the operational readine ss check and try another procedure. Do not move

the coupler again.

December 2005 Page 50 1670097

Page 55

Snack / Refreshment Center Setup and Operator's Guide

5. Testing the Bill Validator

1. Insert a $1 bill into the validator.

2. Push the coin return button.

THE BILL VALIDATOR IS IN THE ESCROW MODE - No money is returned - you must

make a selection in order to receive any change. Go to step 3.

THE BILL VALI DATOR IS NOT IN THE ESCROW MODE - You should receive four

quarters in change. Go to step 3.

3. Make a selection. the correct selection should be vended and correct change should be returned.

NOW WHAT?

There are many things you can do with your merchandiser to make it more flexible. Refer to the Program-

ming Guide for this and other procedures.

1670097 Page 51 December 2005

Page 56

Snack / Refreshment Center Setup and Operator's Guide

December 2005 Page 52 1670097

Page 57

Errata Page

Replace the coin mechanism setup procedure in your

"Complete the installation" section, with the following corrected procedure !

Once you arrive at the steps that tell you how to set up your coin mechanism, please perform the

following steps instead:

WARNING!

The main power switch must be turned OFF before you go any further!

1. If your coin mechanism is a MARS 6000 or TRC 6010 XV , set the high quarter switch as shown,

then continue. If your coin mech is another model, disregard this step. Continue.

2. If not already plugged in, plug the power cord into the electric outlet and turn ON the main pow-

er switch.

3. Press , and press once. Press until either

displayed (depending upon which coin mech type you have).

4. If you chose

dure. If you chose

the coins are not shingled. You are now finished setting up your coin mech. Do not perform

the the rest of this procedure.

5. Press until the standby message is displayed, then press .

6. Insert at least 20 coins of each denomination through the coin chute. Continue to fill the coin

tubes either through the coin chute or the tops of the tubes.

7. Visually check the coin tubes to make sure coins are not shingled.

8.Press .

MDB MECH

DUMB MECH

in the previous step, skip to step 5 and perform the rest of this proce-

in the previous step, fill the coin tubes with coins. M ake sure

DUMB MECH

or

MDB MECH

is

December 2005 Page 53 1670097

Page 58

WARRANTY STATEMENT

LIMITED WARRANTY. Subject to the limitations specified herein, this merchandiser is warranted for one (1)

year against defective parts and workmanship. Any part or parts which are proven to be defective within one

(1) year of the date of shipment will be repaired or replaced free of charge when the defective part is returned,

with transportation charges prepaid, to the destination designated by CRANE MECHANDISING SYSTEMS

Warranty Department.

Refrigeration system’s are warranted for (2) yea r s agai nst defective parts and workmanship. Any part or part s of the

refrigeration system which are proven to be defect ive within (2) years of the date of shipment of the merchandiser

will be repa ired or replaced free of charge whe n the defective part(s) is returned, with trans portation charges prepaid,

to the destination designated by the Crane Merchandising Systems Warranty Department. Any part or parts that are

proven to be free from de fect wil l be asses se d a diagn ostic ch ar ge. T his di agnostic char ge wi ll be a dded to t he pr ice of

any replacement unit which might have been se nt as an advanced replacement, as well as any shipping and handling

fees that may have accrued as a result of shipping th e original refriger ation unit. The charges will be the sole respon

sibility of the original purchaser.

This warranty does not include any cost of service rendered or repairs made by custom er or it’ s agents on Merchandiser, or parts, u nless authorization to incur such expense has b ee n given in writing by CRANE MERCHANDISING

SYSTEMS prior to incurring such expense. This warranty does not cover labor and service charges performed by

CRANE MERCHANDISING SYSTEMS service technicians. Customer shall pay all labor costs with respect to war

ranty repairs.

-

-

This warranty does not appl y to A) electric al componen ts, wiri ng, or circuit s and/or for all mecha nica l parts or assemblies damaged as a result of operating the Merchandiser at other than the design voltage and frequency specified on

the Electrica l Rating Tag, or B) in event of vanda lism, fire or neglig ence, or C) incandescent lamps, neon lamps, flu

orescent lamps, ballasts, starters or other expendable items or D) when other manufactured components are installed

in Crane Merchandising Systems Merchandisers.

Replacement parts sold by CRANE MERCHANDISING SYSTEMS as After Market shall be covered for three

months from the date shown on the parts invoice. Purchas er must obtain prior RETURN AUTHORIZATION for

return of all parts, following guidelines given by Crane Merchandising Systems