Page 1

Owner's Manual

5-1/2 in. PROFESSIONAL

CORDLESS TRIM SAW

Model No.

315.269600

Save this manual for

future reference

_, CAUTION: Read and

follow all Safety Rules and

Operating Instructionsbefore

first use of this product.

Customer Help Line: 1-800-932-3188

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

972000-561

8-98

• Safety

• Features

• Operation

• Maintenance

• Parts List

NRTL

Page 2

• Table of Contents ..,.................. '...................................................................................................................... 2

• Warranty and Introduction_ ............................................................................................................................. 2

• Rules For Safe Operation ..................................................................................... ...................................... 3-5

A. Important Safety Rules For Battery Tools .............................................................................................. 4

B. Important Safety Instructions For Charger ........................................................................................ ;.... 4

C. Important Safety Instructions For Trim Saws ......................................................................................... 5

• Product Specifications and Unpacking .......................................................................................................... 6

• Accessories .................................................................................................................................................... 6

M Features ...................................................................................................................................................... 7-8

• Operation ..................................................................................... :............................................................. 9-17

• Maintenance ................................................................................................................................................. 19

• Battery Pack Removal and Preparation For Recycling ................................................................................ 19

• Exploded View and Repair Paris List ...................................................................................................... 20-21

• Parts Ordering / Service ....................................................................................................... ._....................... 22

_k Look for this symbol to point out important safety precautions, It means attention!!! Your

safety is involved.

FULL ONE YEAR WARRANTY ON CRAFTSMAN PROFESSIONAL CORDLESS TRIM SAW

If this I;RRFIrSMRNProfessional Cordless Trim Saw fails due td.a defect in material or workmanship within one

year from the date of purchase, Sears will repair it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY RETURNING THE TOOL TO THE NEAREST SEARS

STORE IN THE UNITED STATES. ,: I

This warranty gives you specific legal rights, and you may also have other rightswhich vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL_60179

Your trim saw has many features for making cutting

operations more pleasant and enjoyable. Safety,

performance and dependability have been given top

priority in the design of this trim saw making it easy to

maintain and operate.

_1, CAUTIQN: Carefully read through this entire

owner's manual before using your new trim saw.

Pay close attention to the Rules For Safe

Operation, Warnings and Cautions. If you use

your trim saw properly and only for what it is

intended, you will enjoy years of safe, reliable

service.

_I= WARNING:

The operation of any power tool can result in foreign objects being thrown intoyour eyes,

which can result in severe eye damage. Before beginning power tool operation, always wear

safety goggles or safety glasses with side shields and a full face shield when needed. We

recommend Wide Vision Safety Mask for use over eyeglasses or standard safety glasses

with side shields, available at Sears Retail Stores.

2

Page 3

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

the explanations with them, deserve your careful attention and understanding. The safety warnings do

not by themselves eliminate any danger. The instructions or warnings they give are notsubstitutes for

proper accident prevention measures.

SYMBOL MEANING

A

SAFETY ALERT SYMBOL:

Indicatesdanger,warningorcaution.Maybeusedin conjunctionwithothersymbolsorpictographs.

A

A

A

DANGER: Failure to obey a safety warning will result in serious injuryto yourself or to others.

Always follow the safety precautions to reduce the riskof fire, electric shock and personal injury.

WARNING: Failure to obey a safety waming can result in serious injuryto yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

CAUTION: Failure to obey a safety waming may result in property damage or personal injuryto

yourself or to others. Always follow the safety precautions to reduce the riskof fire, electric shock

and personal injury.

NOTE: Advises you of information or instructionsvital to the operation or maintenance of the equipment.

,_ WARNING: Do not attempt to operate this tool

until you have read thoroughly and understand

completely all instructions, safety rules, etc. •

contained in this manual. Failure to comply can

result in accidents involving fire, electric shock, ,

or serious personal injury. Save owner's manual

and review frequently for continuing safe

operation, and instructing others who may use

this tool. •

READ ALL INSTRUCTIONS

M

KNOW YOUR POWER TOOL. Read owner's

manual carefully. Leam its applications and

limitations as well as the specific potential

hazards related to this tool.

GUARD AGAINST ELECTRICAL SHOCK by

preventing body contact with grounded surfaces.

For example: Pipes, radiators, ranges, refrigera-

tor enclosures.

• KEEP WORK AREA CLEAN. Cluttered areas

and benches invite accidents.

AVOID DANGEROUS ENVIRONMENT. Don_

use power tool in damp or wet locations or

expose to rain. Keep work area well lit.

KEEP CHILDREN AND VISITORS AWAY. All

visitors Shouldwear safety glasses and be kept a

safe distance from work area. Do not let visitors

contact tool or extension cord.

• STORE IDLE TOOLS. When not in use tools

should be stored in a dry and high or locked-up

place - out of the reach of children.

3

DON'T FORCE TOOL. It will do the job better

and safer at the rate for which itwas designed.

USE RIGHT TOOL. Don't force small tool _r

attachment to do the job of a heavy duty tool.

Don't use tool for purpose not intended - for

example - A circular saw should never be used

for cutting tree limbs or logs.

WEAR PROPER APPAREL. Do not wear loose

c_lothingor jewelry that can get caught in tool's

moving parts and cause personal injury. Rubber

gloves and nonskid _otwear are recommended

when working out@ors. Wear protective hair

covering to contain long hair and keep it from

being drawn into nearby air vents.

ALWAYS WEAR SAFETY GLASSES. Everyday

eyeglasses have only impact-resistant lenses;

they are NOT safety glasses.

PROTECT YOUR LUNGS. Wear a face mask or

dust mask if operation is dusty.

PROTECT YOUR HEARING. Wear hearing

protection during extended periods of operation.

SECURE WORK. Use clamps or a vise to hold

work. It's safer than using your hand and it frees

both hands to operate tool.

DON'T OVERREACH. Keep proper footing and

balance at all times. Do not use while standing

on a ladder or unstable support,

Page 4

RULES FOR SAFE OPERATION (Continued)

• MAINTAIN TOOLS WITH CARE. Keep tools

sharp at all times, and clean for best and safest

performance. Follow instructionsfor lubricating

and changing accessories.

• REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking to see that

keys and adjusting wrenches are removed from

tool before tuming it on.

• NEVER USE IN AN EXPLOSIVE ATMO-

SPHERE. Normal sparking ofthe motor could

ignite flammable liquids, gases, or fumes.

KEEP HANDLES DRY, CLEAN, AND FREE

FROM OIL AND GREASE. Always use a clean

cloth when cleaning. Never use brake fluids,

gasoline, petroleum-based products or any

strong solvents to clean your tool.

STAY ALERT. Watch what you are doing and

use common sense. Do not operate toolwhen

you are tired. Do not rush.

CHECK DAMAGED PARTS. Before further use

of the tool, a guard or other part that is damaged

should be carefully checked to determine that it

will operate propedy and perform its intended ,V

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting, and any other conditions that may

affect its operation. A guard or other part that is •

damaged should be propedy repaired or

replaced by an authorized service center unless •

indicated elsewhere in this instructionmanual.

• DO NOT USE TOOL IF SWITCH DOES NOT

TURN IT ON AND OFF. Have defective switches

replaced by an authorized service center.

• DRUGS, ALCOHOL, MEDICATION. Do not

operate tool while under the influence of drugs,

alcohol, or any medication.

• CUI-FING INTO ELECTRICAL WIRING IN

WALLS AND FLOORS CAN CAUSE THE

BLADE AND METAL PARTS TO BECOME

ELECTRICALLY LIVE. Do not touch metal parts

when cutting into walls and floors; grasp only the

insulated handle(s) provided on the tool. Make

sure hidden electrical wiring, water pipes, and

mechanical hazards are not in the blade path

when cutting into a wall or floor.

• INSPECT FOR and remove all nails from lumber

before cutting.

IMPORTANT SAFETY RULES FOR BA'I-FERY

TOOLS

Battery tools do not have to be plugged into an

electrical outlet; therefore, they are always in an

operating condition. Be aware of possible

hazards wher_arrying your battery tool, when

making adjustments to it, or when changing

accessories.

USE ONLY THE CHARGER PROVIDED WITH

YOUR BATTERY TOOL. Do not substitute any

other charger. Use of another charger could

cause batteries to explode causing possible

serious injury.

• DO NOT PLACE BATTERY TOOLS OR THEIR

BATTERIES NEAR FIRE OR HEAT. They may

explode.

• DO NOT CHARGE BATTERY TOOL IN A

DAMP OR WET LOCATION.

• Your battery tool should be charged in a location

where the temperature is more than 50°F but

less than 100°F.

Under extreme usage or temperature conditions,

battery leakage may occur. If liquid comes in

contact with your skin, wash immediately with

soap and water, then neutralize with lemon juice

or vinegar. If liquid gets in your eyes, flush them

with clean water for at least 10 minutes, then

seek immediate medical attention.

If carrying your battery tool at your side, make J

sure it is not running and your finger is not on the

switch. Avoid accidental starting.

SECURE WORK before applying power. _EVER

t.

I_oldworkpiece in your hand or across your legs.

WHEN SERVICING USE ONLY IDENTICAL

CRAFTSMAN REPLACEMENT PARTS.

IMPORTANT SAFETY INSTRUCTIONS FOR

CHARGER

• SAVE THESE INS'_'RUCTIONS. This manual

contains important safety and operating

instructions for battery charger part number

977405-000.

r

• BefOre using battery charger, read all instructions

and cautionary markings in this manual, on

battery charger, and product using battery

charger.

_k WARNING: To reduce risk of injury, charge

only nickel-cadmium type rechargeable batteries.

Other types of batteries may burst causing

personal injury and damage.

Do not expose charger to rain or snow.

Use of an attachment not recommended or sold

by the battery charger manufacturer may result

in a risk of fire, electric shock, or injury to

persons.

• To reduce risk of damage to charger body and

cord, pull by charger body rather than cord when

disconnecting charger.

4

Page 5

RULES FOR SAFE OPERATION (Continued)

m Make sure cord is located so that it will not be

stepped on, tripped over, or otherwise subjected

to damage or stress.

An extension cord should not be used unless

absolutely necessary. Use of improper

extension cord could result in a risk of fire and

electric shock. If extension cord must be used,

make sure:

a. That pins on plug of extension cord are the

same number, size and shape as those of

plug on charger.

b. That extension cord is properly wired and in

good electdcal condition; and

c. That wire size is large enough for AC

ampere rating of charger as specified

below:

Cord Length (Feet) 25' 50'

Cord Size (AWG) 16 16

Note: AWG = American Wire Gage

DO NOT OPERATE CHARGER WITH A

M

DAMAGED CORD OR PLUG. If damaged,

have replaced immediately by a qualified

service technician.

m

Do not operate charger if it has received a

sharp blow, been dropped, or otherwise

damaged in any way; take it to a qualified

service technician.

Do not disassemble charger; take it to a

qualified service technician when service or

repair is required. Incorrect reassambly may

result in a dsk of electdc shock or fire.

To reduce dsk of electdc shock, unplug charger

from outlet before attempting any maintenance

or cleaning. Turning off controls will not reduce

this dsk.

n Do not use charger outdoors.

• Disconnect charger from power supply when

not in use.

100' 150'

16 14

IMPORTANT SAFETY INSTRUCTIONS FOR

TRIM SAWS

KEEP GUARDS IN PLACE AND IN WORKING

ORDER. Never wedge or tie lower blade guard

open. Check operation of lower blade guard

before each use. Do not usa if,lower blade guard

does not close bdskly over saw blade.

& WARNING: If saw is dropped, lower blade

guard or bumper may be bent, restrictingfull

return. If lower blade guard or bumper becomes

bent or damaged, replace them before rouse.

• KEEP BLADES CLEAN AND SHARP. Sharp

blades minimize stalling and kickback.

• KEEP HANDS AWAY FROM CUTI'ING AREA.

Keep hands away from blade. Do not reach

undemeath work while blade is rotating. Do not

attempt to remove cut matedal when blade is

moving.

WARNING: Blades coast after tum off.

• USE RIP FENCE. Always use a fence or straight

edge guide when dpping.

SUPPORT LARGE PANELS. To minimize the

dsk of blade pinching and kickback, always

support large panels as shown in Figure 10,

Page 12. When cutting operation requires the

resting of the saw on the workpiece, the saw

should be rested on the larger portion and the

smaller piece cut off.

• LOWER BLADE GUARD.

,_ WARNING: If lower blade guard must be raised

to make a cut, always raise it with the retracting

handle to avoid serious injury. See Figure 22,

Page 17.

GUARD AGAINST KICKBACK. Kickback occurs

when the saw stalls rapidly and is ddven back

towards the operator. Release switch

bpmediataly if blade binds or saw stalls. Don_

remove saw from work dudng a cut while the

blade is moving. See Pages 12 and 13.

m

BEFORE MAKIN_ A CUT, BE SURE THE

DEPTH AND BEVEL ADJUSTMENTS ARE

TIGHT.

USE ONLY CORRECT BLADES. Do not use

blades with incorrec_size holes. Never u_seblade

washers or boltsthat are defective or incorrect.

The maximum blade capacity of your saw is5-1/2

inches.

• NEVER touch the blade or other moving parts

during use.

• NEVER start a saw when its blade is touching

the workpiece.

• NEVER lay a tool down before its moving parts

have come to a complete stop.

SAVE THESE INSTRUCTIONS. Refer to them

frequently and use them to instruct others who

may use this tool. If you loan someone this tool,

loan them these instructionsalso.

/

SAVE THESE INSTRUCTIONS

5

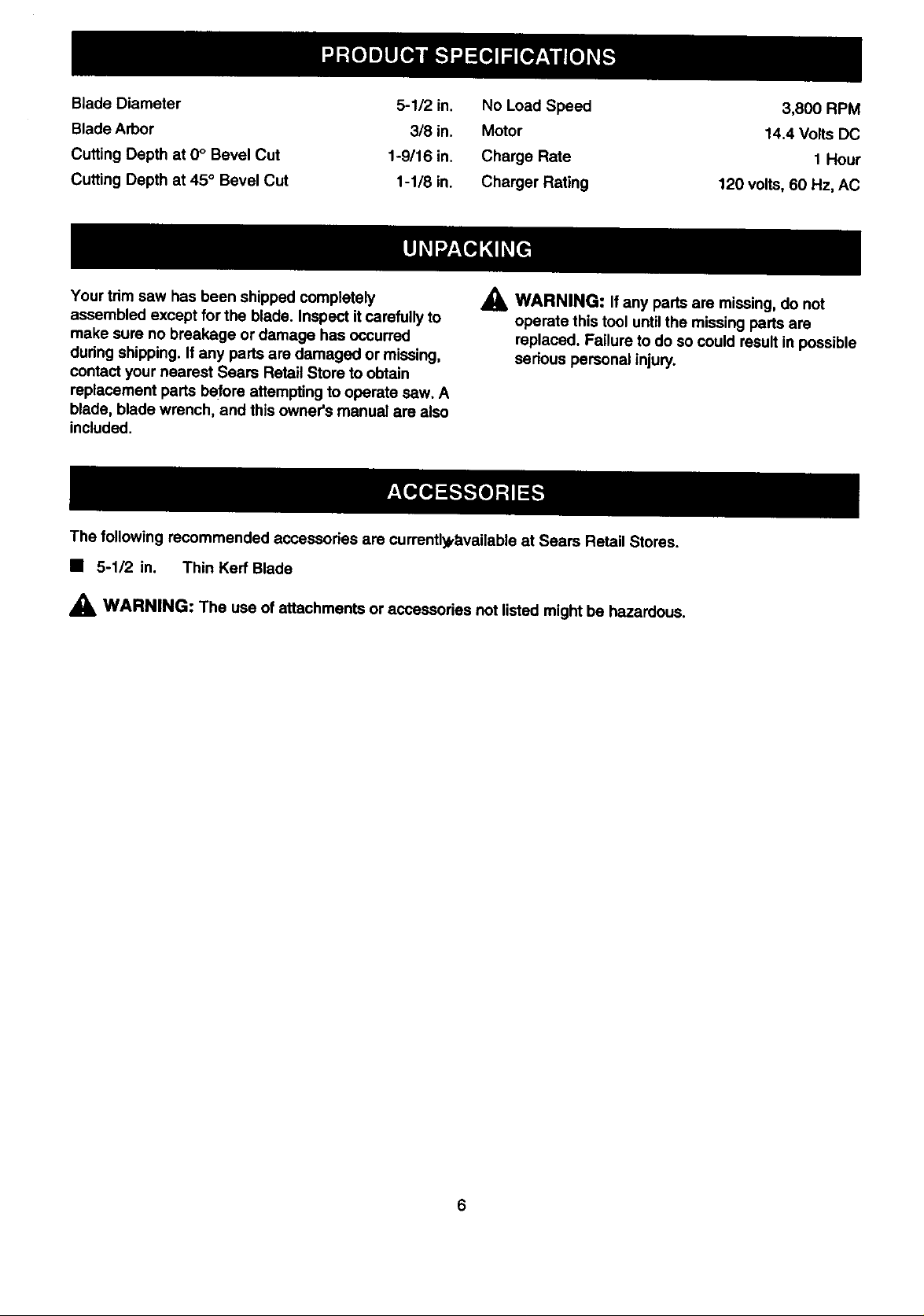

Page 6

Blade Diameter

Blade Arbor

Cutting Depth at 0° Bevel Cut

Cutting Depth at 45 ° Bevel Cut

5-1/2 in.

318in.

1-9/16 in.

1-1/8 in.

No Load Speed

Motor

Charge Rate

Charger Rating

3,800 RPM

14.4 Volts DC

1 Hour

120 volts, 60 Hz, AC

Your trim saw has been shipped completely

assembled except for the blade. Inspect itcarefully to

make sure no breakage or damage has occurred

during shipping. If any parts are damaged or missing,

contact your nearest Sears Retail Store to obtain

replacement parts before attempting to operate saw. A

blade, blade wrench, and this owner's manual are also

included.

The following recommended accessories are currently,l_vailable at Sears Retail Stores.

• 5-1/2 in. Thin Kerr Blade

,_ WARNING: The use of attachments oraccessories not listed might be hazardous.

_I_ WARNING: If any parts are missing, do not

operate this tool until the missing parts are

replaced. Failure to do so could result in possible

serious personal injury.

Page 7

CHARGER

See Figure 2.

Your charger has a =.keyhole" hanging feature for

convenient, space saving storage. Screws should be

installed so that center distances are 1-7/16 inches

apad.

YELLOWANDGREENLIGHT

INDICATESOFTSTARTMODE

GREENLIGHT"ON"

REDUGHT"ON"INDICATES

FASTCHARGINGMODE

BATrERY

CHARGER

BATrERYPACK

1-7/16in.

BACKSIDEOFCHARGER

Fig. 2

IMPORTANT INFORMATION FOR RECHARGING HOT BATTERIES

When using your trim saw continuously, the batteries in your battery pack will become hot. You should let a hot

battery pack cool down for approximately 30 minutes before attempting to recharge. When the battery pack

becomes discharged and is hot, this will cause the yellow and green lights on your battery charger to come on

instead of the red light. The yellow and green lights indicate soft start mode and will switch to green only, indicat-

ing slow charge mode. The red light indicates fast charge mode, I hour charge time. The green light indicates

slow charge m_ode, requiring overnight charging for batteries to reach full charge. If the green light comes on

after letting battery pack cool down, remove itfrom charger for additional cooling. Once the battery pack cools

down, you can recharge battery pack in fast charge mode as normal. Do not leave a hot battery pack in charger

until itcools down. The green light will not go off when battery pack cools. If fast charge mode is desired, you

must physically remove a hot battery pack from the charger, let itcool, then place it back in charger after it has

cooled down.

Note: This situation only occurs when continuous use of your saw causes the batteries to become hot. It does

not occur under normal circumstances. Refer to "CHARGING YOUR TRIM SAW" for normal recharging of

batteries. If the charger does not charge your battery pack under normal circumstances, return both the battery

pack_andcharger to your nearest Sears repair center for electrical check.

7

Page 8

KNOWYOURTRIMSAW

See Figure 2.

Before attempting to use any tool familiarize yourself

with all operating features and safety requirements.

Features include easily operated bevel cut and depth

of cut adjustment mechanisms; positive O° bevel stop;

spindle lock; and blade wrench storage.

_, WARNING: If any parts are missing, do not

operate tool until the missing parts are replaced.

Failure to do so could result in possible serious

personal injury.

GUIDESCREW

(WINGSCREW)

SWITCH

See Figure 2.

Your saw is equipped with a lock-off button which

reduces the possibilityof accidental starting. The lock-

off button is located on the handle above the switch

tdgger. You must depress the lock-off button in order

to pull the switch trigger. The lock resets each time

the trigger is released. Note: You can depress the

lock-off button from either the left or right side.

APPLICATIONS

(Use only for the purpose listed below)

• Cutting all types of wood products (lumber,

plywood, paneling).

RIP

LOCK-OFF

BU'I'rON

SPINDLE

LOCKBUTTON

BLADEWRENCH

STORAGEAREA

(DEPTHADJUSTMENTKNOB)

(BEVELADJUSTMENTKNOB)

DEPTHOF

CUTADJUSTMENT

RIP

GUIDESCREW

(WINGSCREW)

BEVELCUT

ADJUSTMENT

BASE

ASSEMBLY

BLADE

SWITCH

TRIGGER

UPPER

BLADEGUARD

LOWER

BLADEGUARD

RIPGUIDE

8

Page 9

_k WARNING: Always wear safety goggles or

safety glasses with side shields when operating

tools. Failure to do so could result in .objects

being thrown into your eyes, resulting in possible

serious injury.

_k WARNING: Do not allow familiarity with your

trim saw to make you careless. Remember that a

careless fraction of a second is sufficient to inflict

severeinjury.

CHARGING YOUR TRIM SAW

The battery pack for th!stool has been shipped in a

low charge condition to prevent possible problems.

Therefore, you should charge it until light on front of

charger changes from red to green.

Note: Batteries will not reach full charge the first time

they are charged. Allow several cycles (cutting

followed by recharging) for them to become fully

charged.

TO CHARGE

• Charge battery pack only with the charger

provided.

• Make sure power supply Is normal house

voltage, 120 volts, 60 Hz, AC only.

• Connect charger to power supply.

• Place battery pack in charger aligning raised rib in

charger with groove in battery pack.

• Press down on battery pack to be sure contacts on

battery pack engage properly with charger

contacts.

• Normally, the yellow and green lights on charger

will come on. This indicates charger is in soft start

mode and should switch to fast charge mode within

5 minutes. When charger is in fast charge mode

the red lightwill come on. If after a period of 15

minutes the yellow and green lights remain on,

remove battery pack, wait 1 minute and reinsert

battery pack in charger. Ifthe yellow and green

lights continue to remain on after an additional 15

minutes, the battery pack is damaged and willnot

accept a charge. Return battery pack to your

nearest Sears Repair Center for checking or

replacing.

• When your battery pack becomes fully charged, the

red lightwill turn OFF and the green light will turn

ON.

• After normal usage, 1 hour of charging time is

required to be fully charged. A minimum charge

time of 1-1/2 hours is required to recharge a

completely discharged tool•

• The battery pack will become slightly warm to the

touch while charging. This is normal and does not

indicate a problem.

• Do not place charger in an area of extreme heat or

• /

cold. Itwill work best at normal roomtemperature,

,_ C_UTION: Your battery pack contains sp_cial

high temperature batteries to help prevent battery

damage when left on charge for extended periods

oftime. However, once the batteries become fully

charged, we recommend that you unplug your

charger from power supply and remove the

b4?tterypack.

Page 10

_i, WARNING: Always remove battery pack from

your saw when you are assembling parts, making

adjustments, assembling or removing blades,

cleaning, or when not in use. Removing battery

pack will prevent accidental starting that could

cause sedous personal injury.

TO REMOVE BATI'ERY PACK

• Locate latches on end of battery pack and

depress to release battery pack from your saw.

See Figure 3.

DEPRESSLATCHESTO

RELEASEBATTERYPACK

LATCHES

BATrERY

PACK

WARNING: A 5-1/2 in. blade is the maximum

blade capacity of your saw, Never use a blade

that is too thick to allow outer blade washer to

engage withthe flats on the spindle. Larger

blades will come in contact with the blade guard,

while thicker blades will prevent blade screw

from securing blade on spindle. Either of these

situations could result in a sedous accident.

TO ASSEMBLE OR REMOVE BLADE

TO ASSEMBLE BLADE:

• Remove battery pack from saw.

_k WARNING: Failure to remove battery pack from

saw could result in accidental starting causing

possible serious personal injury.

• Locate latcheson end of battery pack and depressto

release battery pack fromyour saw. See Figure 3.

• Remove blade wrench (5 mm hex key) from

storage area. See Figure 2.

• Depress spindle lock button and remove blade

screw and outer blade washer. See Figqre 4.

Fig. 3

• Remove battery pack from your saw.

TO INSTALL BATFERY PACK

See Figure 3.

• Place battery pack in your saw. Align raised rib

inside saw with groove on battery pack.

• Make sure the latches on each side of your

battery pack snap in place and battery pack is

secured in saw before beginning operation.

A CAUTION: When placing battery pack in your

saw, be sure raised rib inside saw aligns with

groove on battery pack and latches snap in place

properly. Improper assembly of battery pack can

cause damage to internal components.

INNER

LOWER OUTER BLADE

BLADE BLADE SCREW

GUARD BLADE WASHER

HANDLE Fig. 4

Note: Turn blade screw clockwiseto remove.

• Wipe a drop of oil onto inner blade washer and

outer blade washer where they contact blade,

A

WARNING: If inner blade washer has been

removed, replace it before placing blade on

spindle. Failure to do so could cause an accident

since blade will not tighten propedy.

10

Page 11

• Fit saw blade inside lower blade guard and onto

spindle. Note: The saw teeth point upward at the

front of saw as shown in figure 4.

• Replace outer blade washer.

• Depress spindle lock button, then mplaoe blade

screw. Tighten blade screw securely.

Note: Turn blade screw countemlockwise to tighten.

• Return blade wrench to storage area.

REMEMBER: Never use a blade that Is too thick to

allow the outer blade washer to engage with the

flats on the spindle.

TO REMOVE BLADE:

• Remove battery pack from saw.

A WARNING: Failure to remove battery pack irom

saw could result in accidental starting causing

possible serious personal injury.

SAW BLADES

The best of saw blades willnot cut efficiently ifthey

are not kept clean, sharp, and properly set. Using a

dull blade will place a heavy load on your saw and

increase the danger of kickback. Keep extra blades on

hand, sothat sharp blades are always available.

Gum and wood pitch hardened on blades will slow

your saw down. Use gum and pitch remover, hot

water, or kerosene to remove these accumulations. Do

not use gasoline.

BLADE GUARD SYSTEM

The lower blade guard attached to your trim saw Is

there for your protection and safety. It should

never be altered for any reason. If It becomes

damaged or begins to return slow or sluggish, do

not operate your saw until the damage has been

repelred or replaced. Always leave guard In

operating position when using saw.

• Remove blade wrench from storage area. See

Figure 2.

• Position your saw as shown in figure 5, depress

spindle lock button, and remove blade screw.

Note: Turn blade screw clockwise to remove.

• Remove outer blade washer. See Figure 4.

Note: Blade can be removed at this polnL

SPINDLE

LOCKBuTroN

BLADE

SCREW

BLADE

WRENCH

Fig. 5

A DANGER: When sawing through workpiece,

lower blade guard does not cover blade on the

underside of workpiece. Since blade is exposed

on underside ofworkpiece, keep hands and

fingers away from cutting area. Any part of your

body coming in contact with moving blade wilt

result in sedous injury. See Figure 6.

LOWERBLADEGUARD

ISIN UP POSITION

WHENMAKINGA CUT

BLADEEXPOSEDON

UNDERSIDEOFWORKPIECE

Fig. 6

Never use saw when guard is not operating

correctly. Guard should be checked for correct

operation before each use. If you drop your saw,

check the lower blade guard and bumper for

damage at all depth settings before reuse.

Note: The guard is operating correctly when It

moves freely and readily returns to the closed

position. If for any reason your lower blade guard

does not close freely, take it to the nearest Sears

Parts and Repair Center for service before using.

/

11

Page 12

KICKBACK

See Figure 7.

TO LESSEN THE CHANCE OF KICKBACK:

• Always keep the correct blade depth setting - the

correct blade depth setting for all cuts should not

exceed 1/4 in. below the material to be cut. See

Figure 9. One blade tooth below the matedal to be

cut works best for most efficient cutting action.

KICKBACK

BLADESETTOO DEEP

The best guard against kickback Is to avoid

dangerous Idractlces.

Kickbackoccurs when the blade stalls rapidly and the

saw is driven back towards you, Blade stalling is

caused by any action which pinches the blade in the

wood.

_k DANGER: Release switch immediately ifblade

binds or saw stalls. Kickback could cause you to

lose control of your saw. Loss of controlcan lead j,,

to serious injury.

KICKBACK IS CAUSED BY:

• Incorrect blade depth setting. See Figure 7.

• Sawing into knots or nails in workpiece.

• Twisting blade while making a cut.

• Making a cut with a dull, gummed up, or impropedy

set blade.

• Incorrectly supporting workpiece. See Figure 8.

Fig. 7

CORRECTBLADEDEPTHSETTING=

BLADEEXPOSEDONE BLADETOOTH

BELOWTHEMATERIALTO BEcur Fig. 9

• Inspect the workpiece for knots or nails before

beginning a cut. Never saw into a knot or nail.

• Make straight cuts. Always use a straight edge

gulch,when ripcutting. This helps prevent twisting

the'btade in the cut.

• Always use clean, sharp and properly set blades.

Never make cuts with,dull blades.

• To avoid pinching the blade, supportthe workpiece

propedy before beginning a cut, The dght and

wrong ways to support large pieces of work are

shown in figures 8 and_lO.

WRONG

• Forcing a cut.

• Cutting warped or wet lumber.

• Tool misuse or incorrect operating procedures.

RIGHT Fig.lO

Fig. 8

12

Page 13

• When making a cut use steady, even pressure.

Never force cuts.

• Do not cut warped or wet lumber.

• Always hold your saw firmly with both hands and

keep your body in a balanced position so as to

resist the forces of kickback should it occur.

When using your saw, always stay alert and

exercise control. Do not remove your saw from

workpiece while the blade Is moving.

DEPTH OF CUT ADJUSTMENT

Always keep correct blade depth setting. The correct

blade depth setting for all cuts should not exceed 1/4

inch below the material to be cut. More blade depth

will increase the chance of kickback and cause the cut

to be rough. One blade tooth below the material to be

cut works best for most efficient cutting action.

TO ADJUST BLADE DEPTH

• Remove battery pack from saw.

,_ WARNING: Failure to remove battery pack from

saw could result in accidental starting causing _"

possible serious personal injury.

STARTING A CUT

Know the right way to use your saw.

See Figure 12.

RIGHT

Never useyour saw as shown infigure 13.

Fig. 12

DEPTH

BASE ADJUSTMENT

ASSEMBLY KNOB

• Loosen depth adjustment knob. See Figure 11.

• Hold base flat against the workpiece and raise or

lower saw*until the required depth is reached.

• Tighten depth adjustment knob securely.

Fig. 11

WRONG

Fig. 13

Never place your hand on the workp|ece behind

your saw while making a cut.

_i_ WARNING: To make sawing easier and safer,

always maintain proper controlof your saw. Loss

of controlof your saw could cause an accident

resulting in possible serious injury.

13

Page 14

TO HELP MAINTAIN CONTROL:

• Always support your workpiece near the cut.

• Support your workpiece so the cut will be on yo=;r

left.

• Clamp your workpiece so itwill not move during the

cut.

Place your workpiece with its good side down.

Note: The good side is the side on which appearance

is important.

Before beginning a cut, draw a guideline along the

desired line of cut. Then place front edge of base on

that part of your workpiece that is solidilysupported.

See Figure 12.

Never place your saw on that part of the

workplece that will fall off when the cut Is made.

See Figure 14.

RIGHT Fig. 15

Depress the lock-off button and squeeze the switch

trigger to start your saw. Always let the blade reach

full speed, then guide your saw into the workpiece.

WRONG

Hold your saw firmly with both hands.

See Figure 15.

Fig. 14

_l, WARNING: The blade coming in contact with

the workpiece before it reaches full speed could

cause your saw to "kickback"towards you*.

re,suiting in serious injury.

When making a cut use steady, even pressure.

Forcing _auses rough.cuts, could shorten the life of

your saw and could cause "kickback."

REMEMBER:

Whel_ sewing through work, the lower blade guard

does not cover the blade, exposing It on the

underside of work. Keep your hands and fingers

away from'cutting area. Any part of your body

coming In contact with the moving blade will

result In;serious Injury.

After you complete your cut release the trigger and

allow the blade to come to a complete stop. Do not

remove your saw from workplece while the blade

is moving.

_k CAUTION: When lifting your saw from the.

workpiece, the blade is exposed on the

underside of your saw until the lower blade guard

closes. Make sure lower blade guard is closed

before setting your saw down on work surface.

TO CROSS CUT OR RIP CUT

When making a cross cut or rip cut, align your line of

cut with the outer blade guide notch on the saw base

as shown in figure 16.

14

Page 15

TOPVIEWOFSAW GUIDELINE

AUGNOUTERBLADEGUIDENOTCHONSAWBASEWITH

UNEOFCUTASSHOWNWHENMAKINGCROSSCUTSOR

RIPCUTS Fig.16

Since blade thicknesses vary, always make a trial cut

in scrap material along a guideline to determine how

much, if any, the guideline must be offset to produce

an accurate cut. Note: The distance from the line of

cut to the guideline is the amount you should offset

the guideline.

WIDTH OF CUT SCALE

See Figure 17.

RIP GUIDE (EDGE GUIDE)

Use the rip guide provided with your saw when

making wide rip cuts. A five inch scale has been

provided on the rip guide. When using the width of cut

scale on the base in combination with the rip guide,

cuts can be made up to 6 in. to the leftof the blade or

8-3/4 in. to the right of the blade.

The rip guide helps prevent the blade from twisting in

a cut. The blade twisting in a cut can cause kickback.

TO ASSEMBLE RIP GUIDE

• Remove battery pack from saw.

& WARNING: Failure to remove battery pack from

saw could result in accidental starting causing

possible serious personal injury.

RIP

GUIDESCREW

BASE

ASSEMBLY

WIDTHOF

CUTSCALE

BLADE

Fig. 17

A width of cut scale has been provided on the base of

your saw. When making straight cross cuts or rip cuts,

the scale can be used to measure up to four inches to

the right side of the blade. It can be used to measure

up to one inch to the left side of the blade.

RIPGUIDE

(EDGEGUIDE)

PLACERIP

GUIDETHRUHOLES i,

Fig. 18

• Place lip guide through holes in saw base as

shown in figure 18.

• Adjust rip guide to the width needed.

• Tighten ripguide screw (wing screw) securely.

When using a ripguide, position the face of the dp

guide firmly against the edge of workpiece. This

makes for a true cut without pinching the blade. The

guiding edge of workpiece must be straight for your

cut to be straight. Use caution to prevent the blade

from binding in the cut.

15

Page 16

TO BEVEL CUT

The angle of cut of your saw may be adjusted to any

desired setting between zero and 50 °. Note: When

making cuts at 50 °, blade should be set at full depth of

cut.

When making 45° bevel cuts, there is a notch in the

saw base to help you line up the blade with the line of

cut. See Figure 19.

BEVEL BEVEL

SCALE ADJUSTMENT

KNOB

When making a bevel cut hold your saw firmlywith

both hands as shown in figure 20.

LOWER

BLADEGUARD

Fig. 20

BLADE

GUIDENOTCH

GUIDEUNE

AUGNINNERBLADEGUIDENOTCHONSAWBASEWITH

UNE OFCUTASSHOWNWHENMAKING45° BEVELCUTS

Fig. 19

Align your line of cut with the inner blade guide notch

on the saw base when making 45° bevel cuts.

Since blade thicknesses vary and different angles

require different settings, always make a trial cut

in scrap material along a guideline to determine

how much you should offset the guideline on the

board to be cut.

Rest the front edge of the base on the workpiece.

Depress the lock-off button and squeeze the switch

tdgger to start your saw. Always let the blade reach

full speed, then guide your saw into the wotkpiece.

_k WARNING: The blade coming in contact with

the workpiece before it reaches full speed _€ould

sC_USesaw to "kickback"toward you resultlhg in

rious injury.

After yoa complete your cut release the tdgger and

allow the blade to come,to a complete stop. After the

blade has stopped, liftyour saw from the workpiece.

TO ADJUST BEVEL SEI"FING

• Remove battery packtfrom saw.

WARNING: FailuPeto remove battery pack from

sawcould result in accidental starting causing

pos_ible sedous personal injury.

• Loosen bevel adjustment knob. See Figure 19.

II Raise motorhousing end of saw untilyou reach

desired angle settingon bevel scale. See Figure 19.

• Tighten bevel adjustment knob securely.

16

WARNING: Attempting bevel cut without knob

securely tightened can result in sedous injury.

Page 17

POSITIVE 0° BEVEL STOP

See Figure 21.

ADJUSTMENT BEVEL

SCREW ADJUSTMENT

KNOB

HEXNUT

BLADE

POSITIVE0° BEVELSTOP

T

COMBINATION

SQUARE

• Turn screw and adjust base untilsquare with saw

blade.

• Tighten hex nut and bevel adjustmentknob securely.

WARNING: Attempting to make cuts without

bevel adjustment knob securely tightened can

result in serious injury.

TO POCKET CUT

See Figure 22.

& WARNING: Always adjust bevel settingtozero

beforemaking a pocketcut. Attempting a pocket

cutat any other settingcan resultin lossof control

ofyoursaw possiblycausing seriousinjury.

Adjust the bevel setting to zero, set blade to correct

blade depth setting, and swing the lower blade guard

up using the lower blade guard handle.

Always raise the lower blade guard with the

handle to avoid serious Injury.

While holding lower blade guard by the handle, firmly

_f4

restthe front of the base fiat against the workpieca

with the rear of the handle raised so the blacJedoes

not touch the workpieca. See Figure 22.

Fig. 21

Your saw has a positive O° bevel stop, that has been

factory adjusted to assure O° angle of your saw blade

when making 90° cuts. However, misalignmant can

occur dudng shipping.

TO CHECK

• Remove battery pack from saw.

,_ WARNING: Failure to remove battery pack from

saw could result in accidental starting causing

possible serious personal injury.

• Place your saw in an upside down position on

workbench. See Figure 21.

• Using a combination square, check squareness of

saw blade to the base of your saw.

TO ADJUST-

• Remove battery pack from saw.

A WARNING: Failure to remove battery pack from

saw could result in accidental starting causing

possible sedous personal injury.

• Loosen bevel adjustment knob.

• Loosen hex nut secudng adjustment screw.

f' LOWERBLADE

GUARDHANDLE

LOWER

BLADEGUARD

POCKETCUT

Depress the lock-off button and squeeze the switch

tdgger to start your saw. Always let the blade reach

full speed then slowly lower blade into the

workplece until base Is flat against workplece.

After you complete your cut release the tdgger and allow

the blade to come to a complete stop.After the blade

has stopped, remove itfrom the workpiece. Comers

may than be cleared out witha hand saw or sabre saw.

_k WARNING: Never tie the lower blade guard in

raised position. Leaving the blade exposed could

lead to sedous injury.

17

Fig. 22

a

Page 18

18

Page 19

,_ WARNING: When servicing, use only identical

Craftsman replacement parts. Use of any other

part may create a hazard or cause product

damage.

Avoid using solvents.when cleaning plastic pads.

Most plastics are susceptible to damage from various

types of commercial solvents and may be damaged

by their use. Use clean cloths to remove dirt, dust, oil,

grease, etc,

_ WARNING: Do not at any time let brake fluids,

gasoline, petroleum-based products, penetrating

oils, etc. come in contact with plastic parts. They

contain chemicals that can damage, weaken or

destroy plastic.

Do not abuse power tools. Abusive practices can

damage tool as well as workpiece.

Only the parts shown on parts list,page twenty one,

are intended to be repaired or replaced by the

customer. All other parts should be replaced by a

qualified service technician at an authorized service

facility.

WARNING: Do not attempt to modify this tool or

create accessodes not recommended for use

with this tool. Any such alteration or modification

is misuse and could result in a hazardous

condition leading to possible serious personal

injury.

BA'R'ERIES

Your saw's battery pack is equipped with 12 nickel-

cadmium rechargeable battedes. Length of service

from each charging will depend on the type of work

you are doing.

The battedes in this tool have been designed to

provide maximum trouble free life. However, like all

batteries, they will eventually wear out. Do not

disassemble battery pack and attempt to replace the

battedes. Handling of these bettedes, especially when

wearing dngs and jewelry, could result in a sedous

bum.

To preserve natural resources, please

recycle or dispose of expired battery

pack propedy.

This product contains nickel-cadmium

battery. Must be disposed of properly.

Local, state, or federal laws may

prohibit disposal of nickel-cadmium

batteries in ordinary trash. Consult

your local waste authority for

information regarding available

recycling end/or disposal options.

To obtain the longest possible battery life, we suggest

the following:

• Store and charge your battedes in a cool area.

Temperatures above normal room temperature

will shorten battery life.

• Never store batteries in a discharged condition.

Recharge them immediately after they are

discharged.

• All battedes gradually lose their charge. The

higher the temperature the quicker they lose their

charge. If you store your toot for long pedods of

time without using it, recharge the battedes every

month or two. This prectlce willprolong battery.

I

BATTERY PACK REMOVAL AND

PREPARATION FOR I_ECYCLING

_i, WARNING: Upon,removal, cover the battery

pack's terminals with heavy duty adhesive tape.

Do r_t attempt to destroy or disassemble battery

pack or remove any of its components. Nickel-

cadmium batteries must be recycled or disposed

of properly. Also, never touch both terminals with

metal objects and/or body parts as short circuit

may result. Keep away from children. Failure to

comply with these wamings could result in fire

and/or sedous injury.

19

Page 20

CRAFTSMAN CORDLESS TRIM SAW - MODEL NUMBER 315.269600

27

6

12

•_26

O

14

18 28

19 20 23

10 21 22

[ 24

5

"2 _ 2_ ' 25

20

Page 21

CRAFTSMAN CORDLESS TRIM SAW- MODEL NUMBER 315.269600

The model number will be found on a plate attached to the motor housing. Always mention the model number in all correspondence regarding your

CORDLESS TRIM SAW or when ordering repair pads.

I

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

PARTS LIST

]

Key

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Part

Number

975546-000

975547-000

975544-000

975548-000

975552-000

975551-000

975549-000

975559-000

975558-000

975550-000

980057-001

975557-000

975545-000

975543-000

975542-000

Description Quan.

Carriage Bolt (M6 x 102 ram) ..........._............. 1

Base Assembly ............................................... 1

Lock Nut ......................................................... 2

Knob ............................................................... 2

Spring ............................................................. 1

Wing Screw .................................................... 1

Base Screw .................................................... 1;

Hex Nut .......................................................... 1

Screw ............................................................. 1

Cardage Bolt (M6 x 13 mm) ........'................... 1' .,.

Data Plate ............ _.,.................................. ",....1

Waming Label. ............... i............................... 1

Upper Blade Guard ........................................ 1

Upper Blade Guard Screw ...................... :...... 3

Bumper .......................... :'"'"r .............. :"........ 1

Key Part

No. Number

16 975541-000

17 975540-000

18 975539-000

19 975538-000

20 975537-000

21 975536-000

22 975534-000

23 975419-001

24 975533-000

25 975532-000

26 980011-000

27 977405-000

28 975554-000

29 975553-000

30 980058-000

972000-561

DescrlpUon Quan.

Bumper Screw ................................................ 1

Spring ............................................................. 1

Lower Blade Guard ........................................ 1

• Ball Bearing (NTN #6200LB) ......................... 1

Bearing Retainer ............................................ 1

Bearing Retainer Screw ................................. 3

Inner Blade Washer ....................................... 1

Saw Blade ...................................................... 1

Outer Blade Washer ....................................... 1

Blade Screw ................................... i............... 1

* Battery Pack (Item No. 9-11062) ................... 1

* Charger (item No. 9-11063) ........................... 1

Rip Guide ....................................................... 1

Blade Wrench (5 mm Hex Key) ..................... 1

Carrying Case - Not Shown ........................... 1

Owner's Manual

* Can Be Purchased Thru RSOS (Retail Special Order System)

21

Page 22

For in,home major brand repair service:

Call 24 hours a day, 7 days a week

1-800-4-MY-Home s. (1-800-469-4663)

Para peoir servicio de reparacibn a domicilio - 1-800-676-5811

In Canada for all your service and parts needs call

Au Canada pour tout le service ou les pi_ces

For the repair or replacement parts you need:

Call 7 am - 7 pro, 7 days a week

1-800-366-PART (1-800-366-7278)

Para ordenar piezas con entre_a a domicilio - 1-800-659-7084,

For the location of a Sears Parts and I_epair Center in your area:

Call 24 hours a day, 7 days a week

- 1-800-665-4455

1-800-488-1222

For information on purchasing a Sears MaintenanCe Agreement

or to inquire about an existing Agreement:

Call 9 am - 5 pm, Monday :- Saturday

1-800-827-6655 "

J

The Service Side of Sears s"

Loading...

Loading...