Page 1

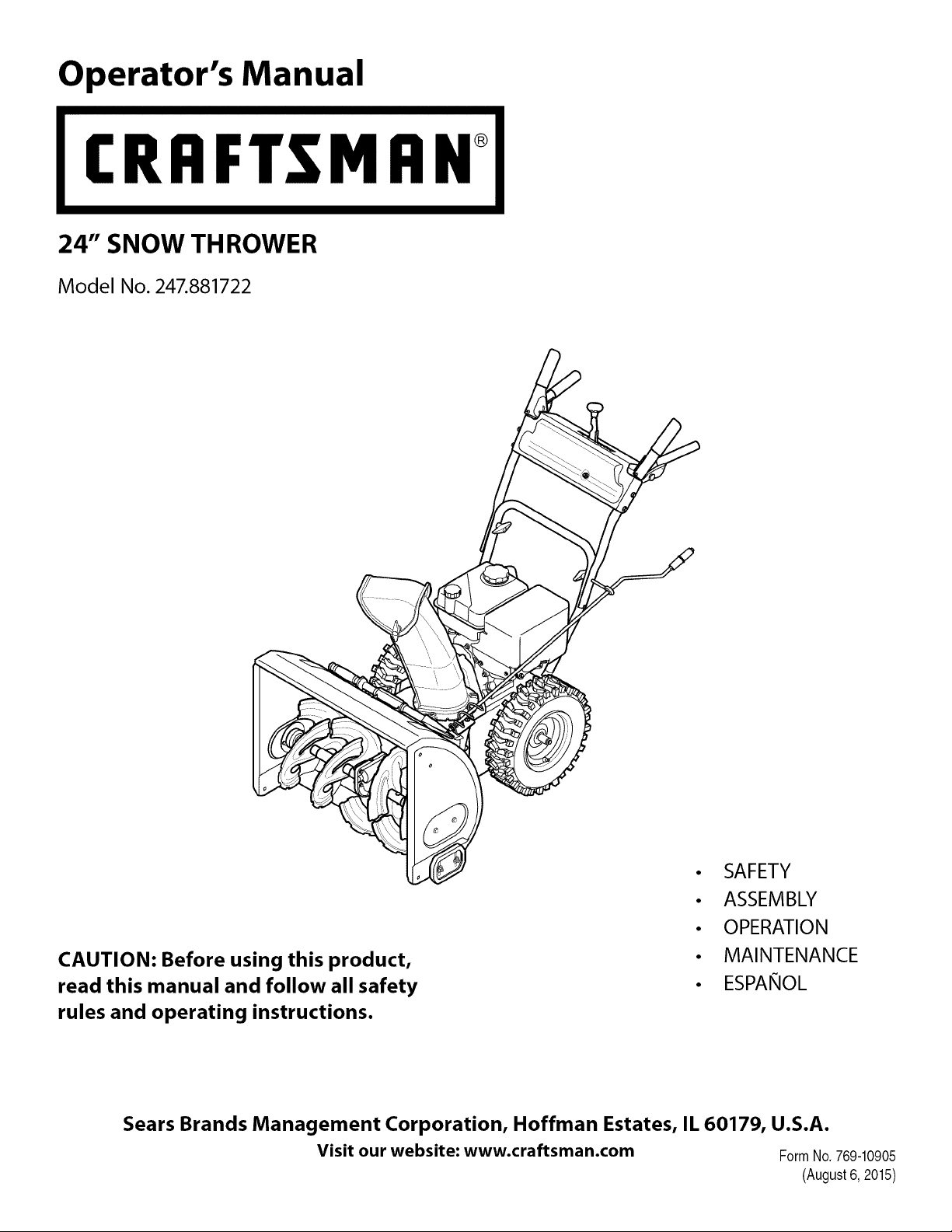

Operator's Manual

CRFIFISMFIN

24" SNOW THROWER

Model No. 247.881722

CAUTION: Before using this product,

read this manual and follow all safety

rules and operating instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FormNo.769-10905

• SAFETY

• ASSEMBLY

• OPERATION

• MAINTENANCE

• ESPANOL

(August6,2015)

Page 2

WarrantyStatement.............................. Page2

SafeOperationPractices......................... Page3

Assembly........................................ Page8

Operation...................................... Page12

Off-SeasonStorage............................. Page23

Troubleshooting............................... Page24

RepairProtectionAgreement................... Page28

Espar_ol........................................ Page29

Service&Maintenance........................... Page16

CRAFTSMANLIMITEDWARRANTY

FORTWOYEARSfromthedateofsale,thisproductiswarrantedagainstanydefectsinmaterialorworkmanship.

WITHPROOFOFSALE,adefectiveproductwill receivefreerepairorreplacementatoptionofseller.

Forwarrantycoveragedetailstoobtainfreerepairorreplacement,visitthewebpage:www.craftsman.com/warranty

ThiswarrantycoversONLYdefectsinmaterialandworkmanship.WarrantycoveragedoesNOTinclude:

• Expendableitemsthat canwearoutfromnormalusewithinthewarrantyperiod,includingbutnotlimitedtoaugers,augerpaddles,driftcutters,skid

shoes,shaveplate,shearpins,sparkplug,aircleaner,belts,andoilfilter.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tirereplacementorrepaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireorwheelreplacementorrepairresultingfromnormalwear,accident,orimproperoperationormaintenance.

• Repairsnecessarybecauseofoperatorabuse,includingbutnotlimitedtodamagecausedbyover-speedingtheengine,orfromimpactingobjectsthat

bendtheframe,augershaft,etc.

• Repairsnecessarybecauseofoperatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproperstorage,failureto

usethepropergradeandamountofengineoil,orfailuretomaintaintheequipmentaccordingtotheinstructionscontainedintheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedtobecontaminatedoroxidized(stale).Ingeneral,fuelshouldbeusedwithin30days

ofitspurchasedate.

• Normaldeteriorationandwearoftheexteriorfinishes,orproductlabelreplacement.

Thiswarrantyisvoidifthisproductiseverusedwhileprovidingcommercialservicesorifrentedtoanotherperson.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstateto state.

SearsBrandsManagementCorporation,HoffmanEstates,IL60179

Engine Oil:

Oil Capacity:

Fuel:

5W-30

20 ounces

Unleaded Gasoline

Model Number

Serial Number

Date of Purchase

Fuel Capacity:

Spark Plug:

Spark Plug Gap:

© Sears Brands, LLC 2

2.3 quarts

F6RTC (Sears Part #951-10292)

.020" to 0.030"

Record the model number, serial number,

and date of purchase above.

Page 3

Thissymbolpointsout importantsafety instructionswhich,ifnot

followed,couldendangerthe personalsafetyand/orproperty of

yourselfandothers.Readandfollow all instructionsinthismanual

beforeattempting to operatethis machine.Failureto complywith these

instructionsmayresultinpersonalinjury.Whenyou seethissymbol,HEED

ITSWARNING!

Thismachinewasbuilt to beoperatedaccordingtothesafeoperation

practicesinthismanual.Aswith anytype of powerequipment,

carelessnessorerroronthe part of theoperatorcanresultinseriousinjury.

Thismachineiscapableof amputating fingers, hands,toesand feet and

throwingdebris.Failuretoobservethefollowing safety instructionscould

resultinseriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someofitsconstituents,and certainvehiclecomponents

containor emit chemicalsknowntoStateof Californiatocausecancerand

birth defectsorother reproductiveharm.

TRAINING

Read,understand,andfollowall instructionsonthemachineandinthe

manual(s)beforeattemptingtoassembleandoperate.Failuretodosocan

resultinseriousinjurytotheoperatorand/orbystanders.Keepthismanual

inasafeplaceforfutureandregularreferenceandfororderingreplacement

parts.

Befamiliarwith allcontrolsandtheirproperoperation.Knowhowto stop

themachineanddisengagethemquickly.

Neverallowchildrenunder14yearsof agetooperatethismachine.Children

14andovershouldreadandunderstandtheinstructionsandsafeoperation

practicesinthis manualandonthemachineandbetrainedandsupervised

byanadult.

Neverallowadultsto operatethismachinewithout properinstruction.

Thrownobjectscancauseseriouspersonalinjury.Planyoursnow-throwing

patterntoavoiddischargeof materialtowardroads,bystandersandthelike.

Keepbystanders,petsandchildrenatleast75feetfromthemachinewhileit

isin operation.Stopmachineif anyoneentersthearea.

Exercisecautiontoavoidslippingorfalling,especiallywhenoperatingin

reverse.

PREPARATION

Thoroughlyinspecttheareawheretheequipmentistobeused.Removeall

doormats,newspapers,sleds,boards,wiresandotherforeignobjects,which

couldbetrippedoverorthrownbytheauger/impeller.

Alwayswearsafetyglassesoreyeshieldsduringoperationandwhile

performinganadjustmentor repairto protectyoureyes.Thrownobjects

whichricochetcancauseseriousinjuryto theeyes.

Donotoperatewithout wearingadequatewinteroutergarments.Donot

wearjewelry,longscarvesorotherlooseclothing,whichcouldbecome

entangledinmovingparts.Wearfootwearwhichwill improvefootingon

slipperysurfaces.

Usea groundedthree-wireextensioncordandreceptacleforall machines

with electricstartengines.

Your Responsibility--Restrict theuseofthis power machineto

personswhoread,understandandfollow thewarningsandinstructionsin

thismanualandonthe machine.

SAVETHESEINSTRUCTIONS!

Disengageallcontrolleversbeforestartingtheengine.

Adjustcollectorhousingheightto cleargravelorcrushedrocksurfaces.

Neverattempttomakeanyadjustmentswhileengineisrunning,except

wherespecificallyrecommendedin theoperator'smanual.

Letengineandmachineadjusttooutdoortemperaturebeforestartingto

clearsnow.

Safe Handling of Gasoline:

Toavoidpersonalinjuryor property damageuseextremecareinhandling

gasoline.Gasolineisextremely flammableandthe vaporsareexplosive.

Seriouspersonalinjurycanoccurwhen gasolineisspilledonyourselforyour

clotheswhich canignite. Washyour skinandchangeclothesimmediately.

Useonlyanapprovedgasolinecontainer.

Neverfill containersinsidea vehicleorona truckortrailerbedwithaplastic

liner.Alwaysplacecontainersonthegroundawayfromyourvehiclebefore

filling.

Whenpractical,removegas-poweredequipmentfromthetruckor

trailerandrefuelitontheground.Ifthisis notpossible,thenrefuelsuch

equipmentonatrailerwith aportablecontainer,ratherthanfromagasoline

dispensernozzle.

Keepthenozzleincontactwiththerimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.Donotuseanozzlelock-opendevice.

Extinguishallcigarettes,cigars,pipesandothersourcesofignition.

Neverfuelmachineindoors.

Neverremovegascaporaddfuelwhiletheengineishotorrunning.Allow

enginetocoolatleasttwominutesbeforerefueling.

Neveroverfill fueltank.Filltanktonomorethan1/2inchbelowbottomof

fillernecktoallowspaceforfuelexpansion.

Replacegasolinecapandtightensecurely.

Ifgasolineisspilled,wipeit offtheengineandequipment.Moveunitto

anotherarea.Wait5 minutesbeforestartingtheengine.

Page 4

Toreducefirehazards,keepmachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillageandremoveanyfuelsoakeddebris.

Neverstorethemachineorfuelcontainerinsidewherethereisanopen

flame,sparkorpilotlightasonawaterheater,spaceheater,furnace,clothes

dryerorothergasappliances.

OPERATION

Donotputhandsorfeetnearrotatingparts,intheauger/impellerhousing

orchuteassembly.Contactwith therotatingpartscanamputatehandsand

feet.

Theauger/impellercontrolleverisasafetydevice.Neverbypassits

operation.Doingsomakesthemachineunsafeandmaycausepersonal

injury.

Thecontrolleversmustoperateeasilyin bothdirectionsandautomatically

returntothedisengagedpositionwhenreleased.

Neveroperatewith amissingordamagedchuteassembly.Keepallsafety

devicesinplaceandworking.

Neverrunanengineindoorsor inapoorlyventilatedarea.Engineexhaust

containscarbonmonoxide,anodorlessanddeadlygas.

Donotoperatemachinewhileundertheinfluenceofalcoholordrugs.

Mufflerandenginebecomehotandcancauseaburn.Donottouch.Keep

childrenaway.

Exerciseextremecautionwhenoperatingonorcrossinggravelsurfaces.Stay

alertforhiddenhazardsortraffic.

Exercisecautionwhenchangingdirectionandwhileoperatingonslopes.Do

notoperateonsteepslopes.

Planyoursnow-throwingpatternto avoiddischargetowardswindows,

walls,carsetc.Thus,avoidingpossiblepropertydamageorpersonalinjury

causedbyaricochet.

Neverdirectdischargeatchildren,bystandersandpetsorallowanyonein

frontofthemachine.

Donotoverloadmachinecapacitybyattemptingtoclearsnowattoofastof

arate.

Neveroperatethismachinewithoutgoodvisibilityorlight.Alwaysbesureof

yourfootingandkeepafirmholdonthehandles.Walk,neverrun.

Disengagepowertotheauger/impellerwhentransportingornotin use.

Neveroperatemachineathightransportspeedsonslipperysurfaces.Look

downandbehindandusecarewhenbackingup.

Ifthemachineshouldstartto vibrateabnormally,stoptheengine,

disconnectthesparkplugwireandgrounditagainsttheengine.Inspect

thoroughlyfordamage.Repairanydamagebeforestartingandoperating.

Disengageallcontrolleversandstopenginebeforeyouleavetheoperating

position(behindthehandles).Waituntiltheauger/impellercomesto

acompletestopbeforeuncloggingthechuteassembly,makingany

adjustments,orinspections.

Neverputyourhandin thedischargeorcollectoropenings.Donotunclog

chuteassemblywhileengineisrunning.Shutoff engineandremainbehind

handlesuntilallmovingpartshavestoppedbeforeunclogging.

Useonlyattachmentsandaccessoriesapprovedbythemanufacturer(e.g.

wheelweights,tirechains,cabsetc.).

Whenstartingengine,pull cordslowlyuntil resistanceisfelt,thenpull

rapidly.Rapidretractionofstartercord(kickback)will pullhandandarm

towardenginefasterthanyoucanletgo.Brokenbones,fractures,bruisesor

sprainscouldresult.

Ifsituationsoccurwhicharenotcoveredinthismanual,usecareandgood

judgment.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththerotatingimpellerinsidethedischargechuteisthemost

commoncauseofinjuryassociatedwith snowthrowers.Neveruseyourhandto

cleanoutthedischargechute.

Toclearthechute:

a. SHUTTHEENGINEOFF!

b. Wait10secondsto besuretheimpellerbladeshavestopped

rotating.

c. Alwaysuseaclean-outtool,notyourhands.

MAINTENANCE & STORAGE

Nevertamperwithsafetydevices.Checktheir properoperationregularly.

Refertothemaintenanceandadjustmentsectionsofthismanual.

Beforecleaning,repairing,orinspectingmachinedisengageallcontrol

leversandstoptheengine.Waituntiltheauger/impellercometo acomplete

stop.Disconnectthesparkplugwireandgroundagainsttheengineto

preventunintendedstarting.

Checkboltsandscrewsforpropertightnessatfrequentintervalsto keepthe

machineinsafeworkingcondition.Also,visuallyinspectmachineforany

damage.

Donotchangetheenginegovernorsettingorover-speedtheengine.The

governorcontrolsthemaximumsafeoperatingspeedoftheengine.

Snowthrowershaveplatesandskidshoesaresubjecttowearanddamage.

Foryoursafetyprotection,frequentlycheckallcomponentsandreplace

with originalequipmentmanufacturer's(OEM)partsonlyaslistedinthe

Partspagesofthisoperator'smanual.Useofpartswhichdonot meetthe

originalequipmentspecificationsmayleadtoimproperperformanceand

compromisesafety!

Checkcontrolleversperiodicallytoverifytheyengageanddisengage

properlyandadjust,if necessary.Refertotheadjustmentsectioninthis

operator'smanualfor instructions.

Maintainorreplacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsandregulationsforgas,oil,etc.toprotectthe

environment.

Priortostoring,runmachineafewminutestoclearsnowfrommachineand

preventfreezeupof auger/impeller.

Neverstorethemachineorfuelcontainerinsidewherethereisanopen

flame,sparkorpilotlight suchasawaterheater,furnace,clothesdryeretc.

Alwaysrefertotheoperator'smanualforproperinstructionsonoff-season

storage.

4

Page 5

Checkfuelline,tank,cap,andfittingsfrequentlyforcracksor leaks.Replace

if necessary.

Donotcrankenginewith sparkplugremoved.

Accordingto theConsumerProductsSafetyCommission(CPSC)andthe

U.S.EnvironmentalProtectionAgency(EPA),thisproducthasanAverage

Useful Lifeofseven(7)years,or60hoursofoperation.Attheendof

theAverage Useful Lifehavethemachineinspectedannuallybyan

authorizedservicedealertoensurethatallmechanicalandsafetysystems

areworkingproperlyandnotwornexcessively.Failureto dosocanresultin

accidents,injuriesordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modifyengineinanyway. Tampering

with the governorsetting canleadto arunawayengineandcauseitto

operateat unsafespeeds.Nevertamperwith factorysetting of engine

governor.

NOTICE REGARDING EMISSIONS

Engineswhichare certifiedto complywith CaliforniaandfederalEPA

emissionregulationsfor SORE(Sinai[OffRoadEquipment)arecertified

tooperateonregularunleadedgasoline,andmayincludethe following

emissioncontrolsystems:EngineModification (EM),OxidizingCatalyst(0C),

SecondaryAirinjection(SAI)andThreeWayCatalyst(TWC)if soequipped.

Page 6

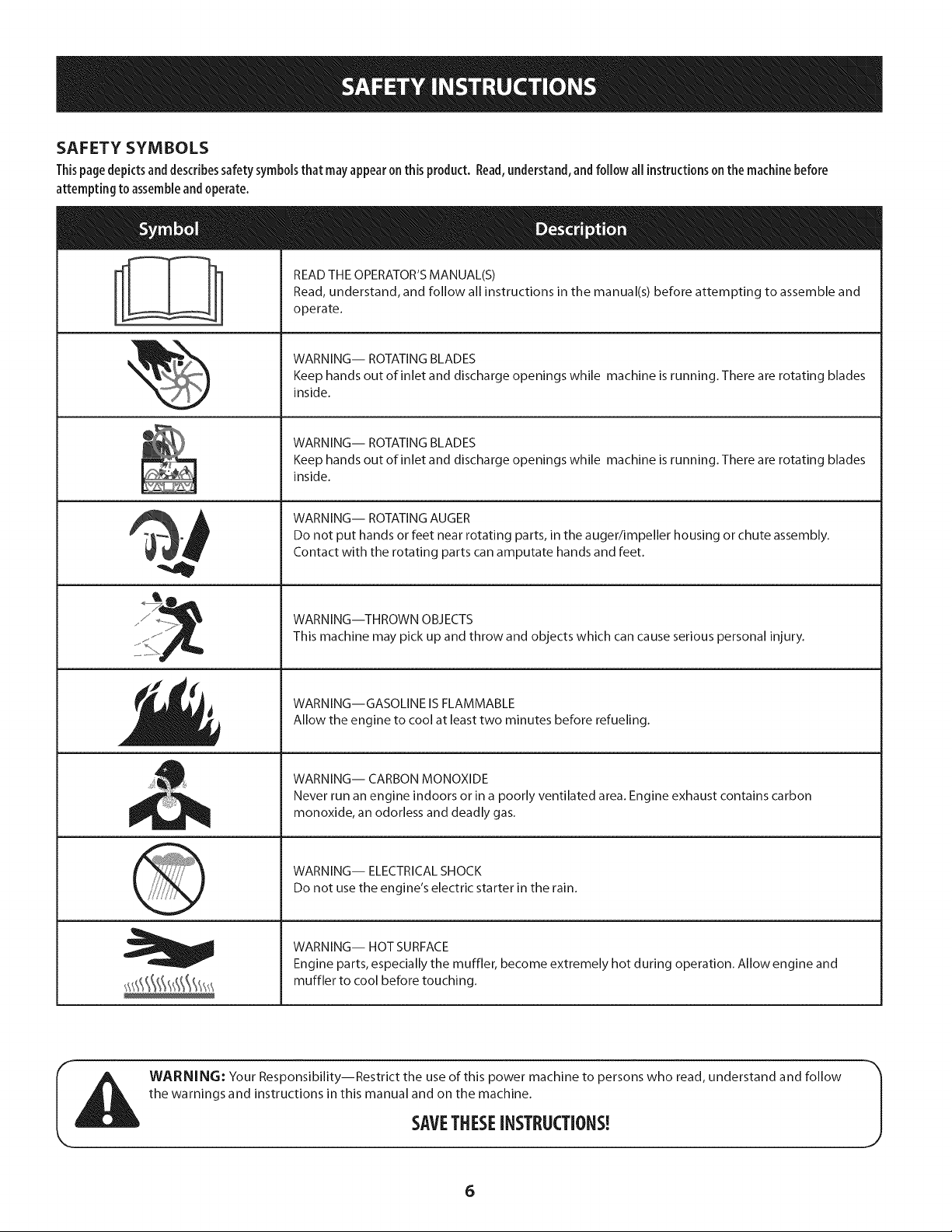

SAFETY SYMBOLS

Thispage depicts and describes safety symbols that may appear on this product. Read,understand, and follow all instructionson the machine before

attempting to assemble and operate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate.

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside.

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside.

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which cancause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

WARNING: Your Responsibility--Restrict the use of this power machine to persons who read, understand and follow

the warnings and instructions in this manual and on the machine.

SAVETHESEiNSTRUCTIONS!

6

Page 7

This page left intentionallyblank.

7

Page 8

NOTE:Referencestorightor leftsideofthesnowthroweraredeterminedfrom

behindtheunitin theoperatingposition(standingdirectlybehindthesnow

thrower,facingthehandlepanel).

Removing FromCarton

1. Cutthecornersofthecartonandlaythesidesflat ontheground.Remove

anddiscardallpackinginserts.

2. Movethesnowthroweroutof thecarton.

3. Makecertainthecartonhasbeencompletelyemptiedbeforediscardingit.

Assembly

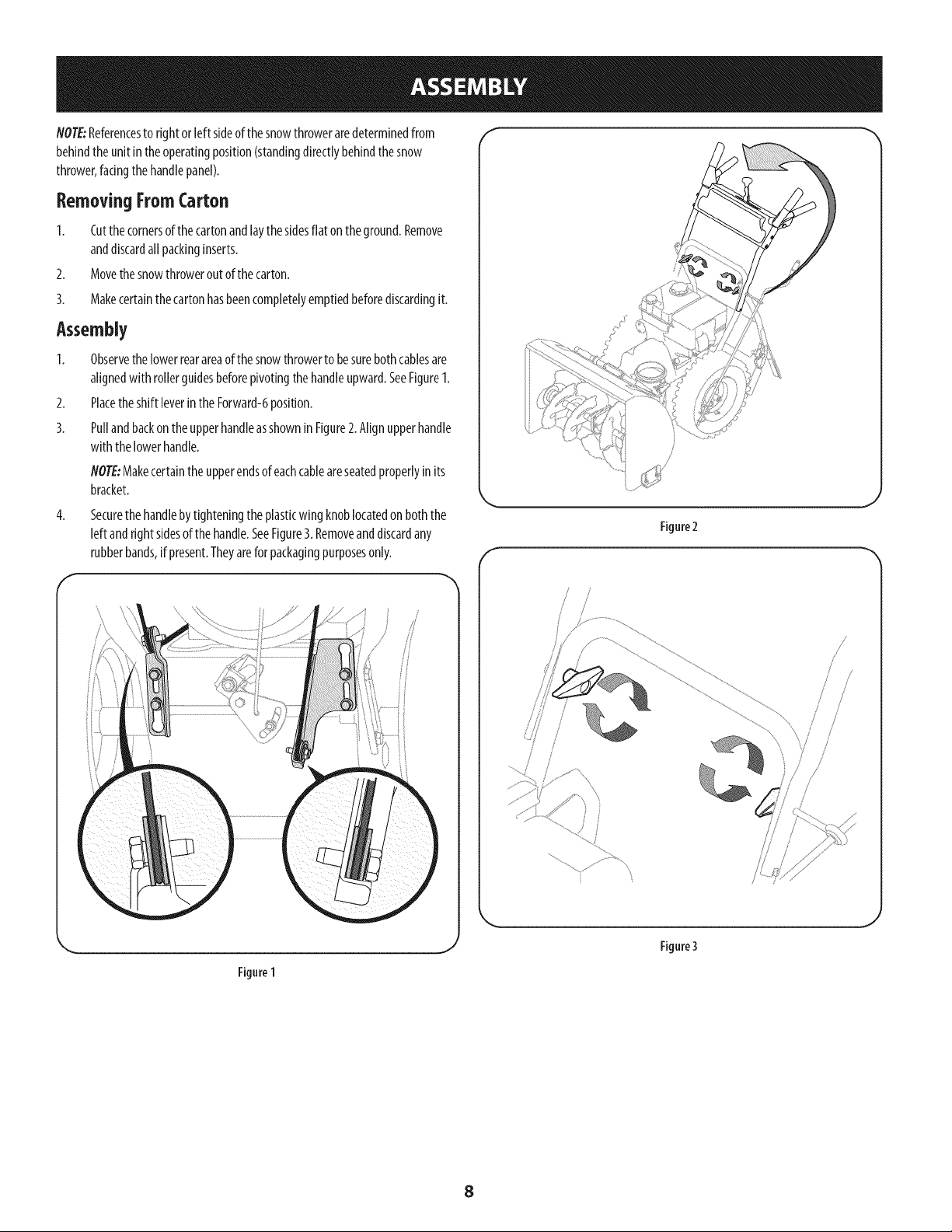

1. Observethelowerrearareaofthesnowthrowertobesurebothcablesare

alignedwith rollerguidesbeforepivotingthehandleupward.SeeFigure1.

2. Placetheshift leverinthe Forward-6position.

3. Pullandbackontheupperhandleasshownin Figure2.Alignupperhandle

with thelowerhandle.

NOTE:Makecertaintheupperendsofeachcableareseatedproperlyin its

bracket.

4. Securethehandlebytighteningtheplasticwingknoblocatedonboththe

leftandrightsidesof thehandle.SeeFigure3.Removeanddiscardany

rubberbands,ifpresent.Theyareforpackagingpurposesonly.

f

k.

Figure2

Figure1

/

/

j

J

Figure3

8

Page 9

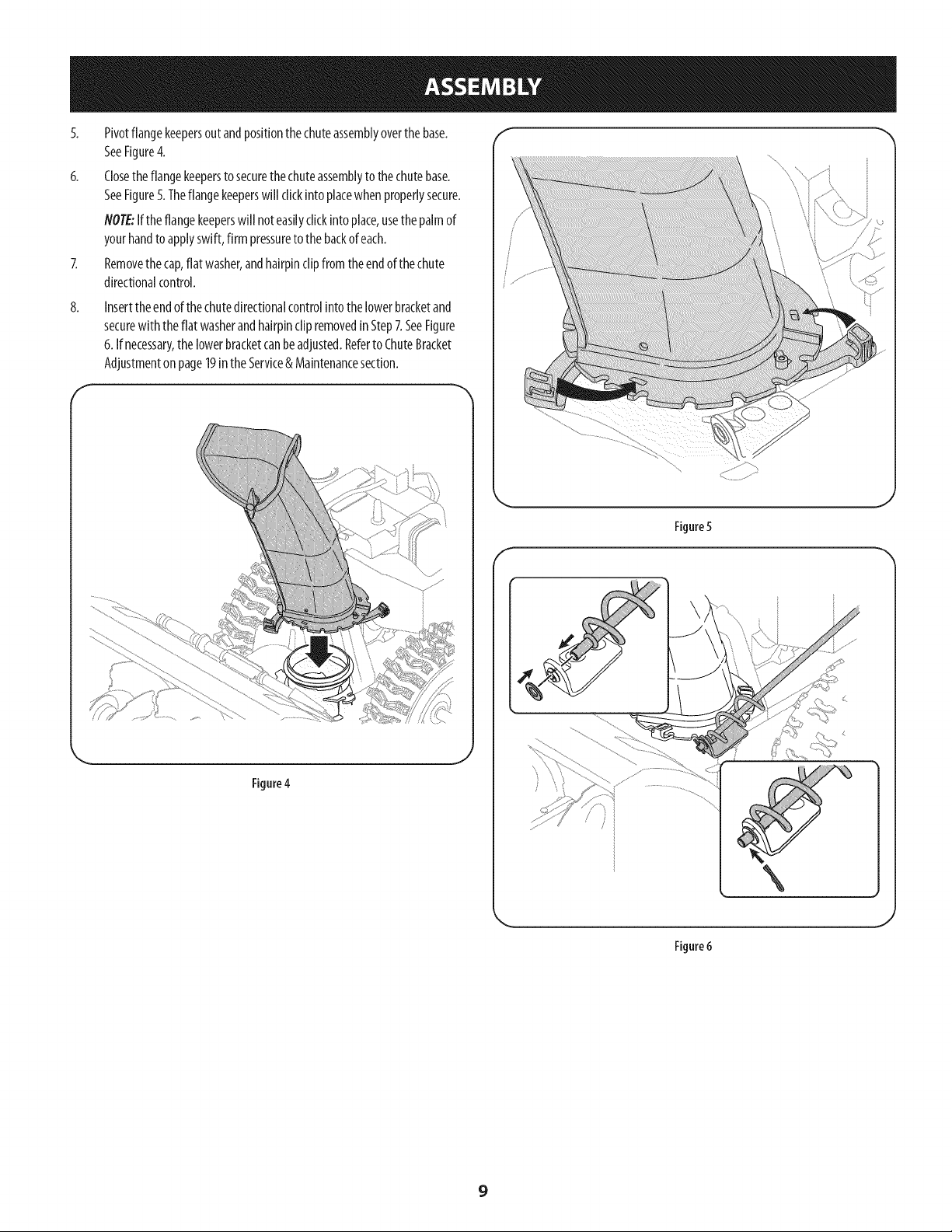

Pivotflangekeepersoutandpositionthechuteassemblyoverthe base.

SeeFigure4.

6.

Closetheflangekeeperstosecurethechuteassemblyto thechutebase.

SeeFigure5.Theflangekeeperswill clickintoplacewhenproperlysecure.

NOTE:Iftheflangekeeperswill noteasilyclickintoplace,usethepalmof

yourhandtoapplyswift,firm pressureto thebackofeach.

Removethecap,flat washer,andhairpinclipfromtheendofthechute

directionalcontrol.

8.

Inserttheendofthechutedirectionalcontrolintothelowerbracketand

securewith theflatwasherandhairpinclipremovedinStep7.SeeFigure

6.Ifnecessary,thelowerbracketcanbeadjusted.RefertoChuteBracket

Adjustmentonpage19in theService& Maintenancesection.

Figure5

f

Figure4

J

J

Figure6

9

Page 10

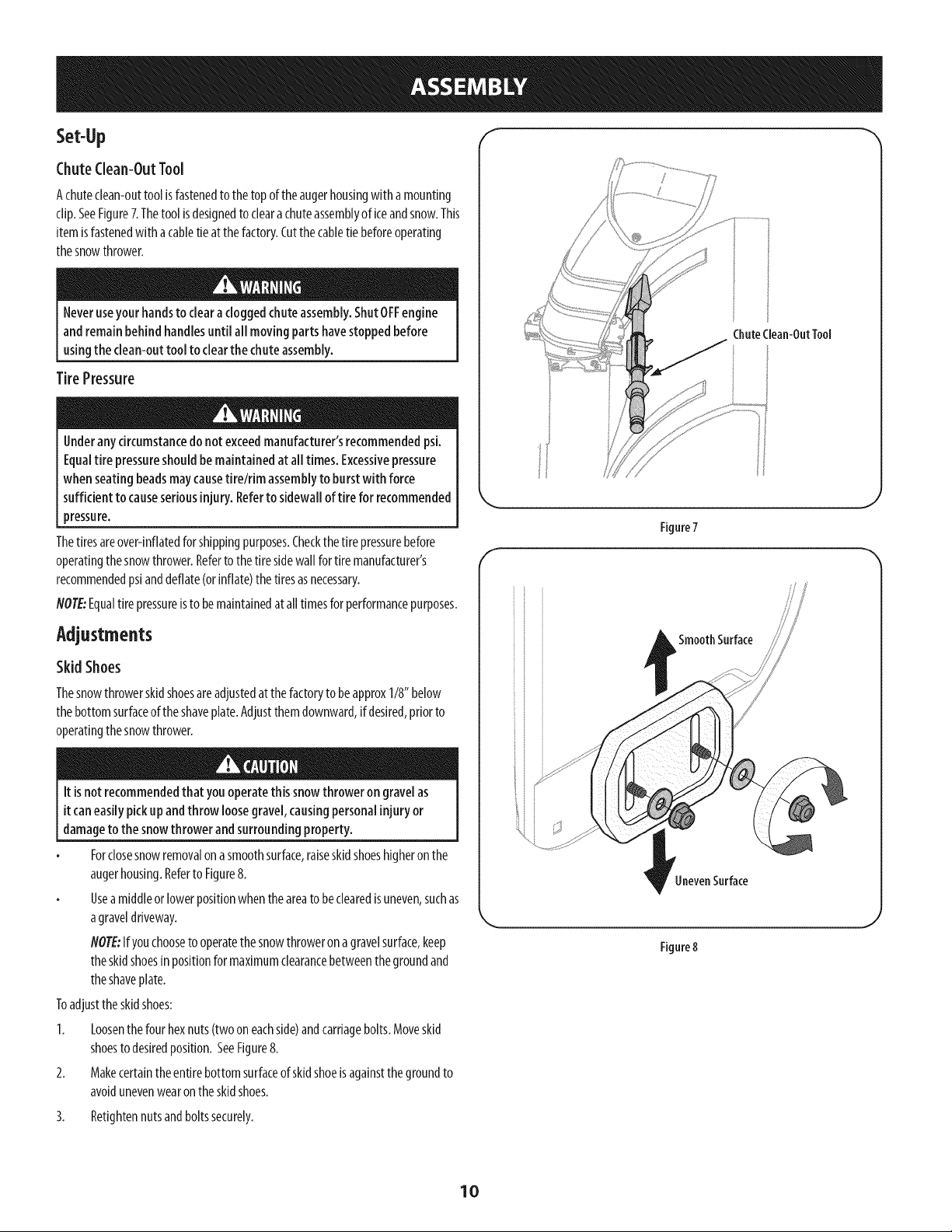

Set-Up f

ChuteClean-OutTool

Achuteclean-outtoolisfastenedtothetopoftheaugerhousingwithamounting

clip.SeeFigure7.Thetoolisdesignedtoclearachuteassemblyof iceandsnow.This

itemisfastenedwitha cabletieatthefactory.Cutthecabletie beforeoperating

thesnowthrower.

Neveruseyour handstoclearacloggedchuteassembly.ShutOFFengine

andremainbehindhandlesuntil all movingparts havestoppedbefore

usingthe clean-outtool to clearthe chuteassembly.

TirePressure

Underanycircumstancedo notexceedmanufacturer'srecommendedpsi.

Equaltire pressureshouldbemaintainedat alltimes. Excessivepressure

when seatingbeadsmaycausetirelfim assemblyto burstwith force

sufficient tocauseseriousinjury. Refertosidewall oftire for recommended

pressure.

Thetiresareover-inflatedforshippingpurposes.Checkthetire pressurebefore

operatingthesnowthrower.Refertothetiresidewallfor tiremanufacturer's

recommendedpsianddeflate(orinflate)thetiresasnecessary.

NOTE:Equaltire pressureisto bemaintainedat alltimesforperformancepurposes.

ChuteClean-OutTool

J

Figure7

f

//

//

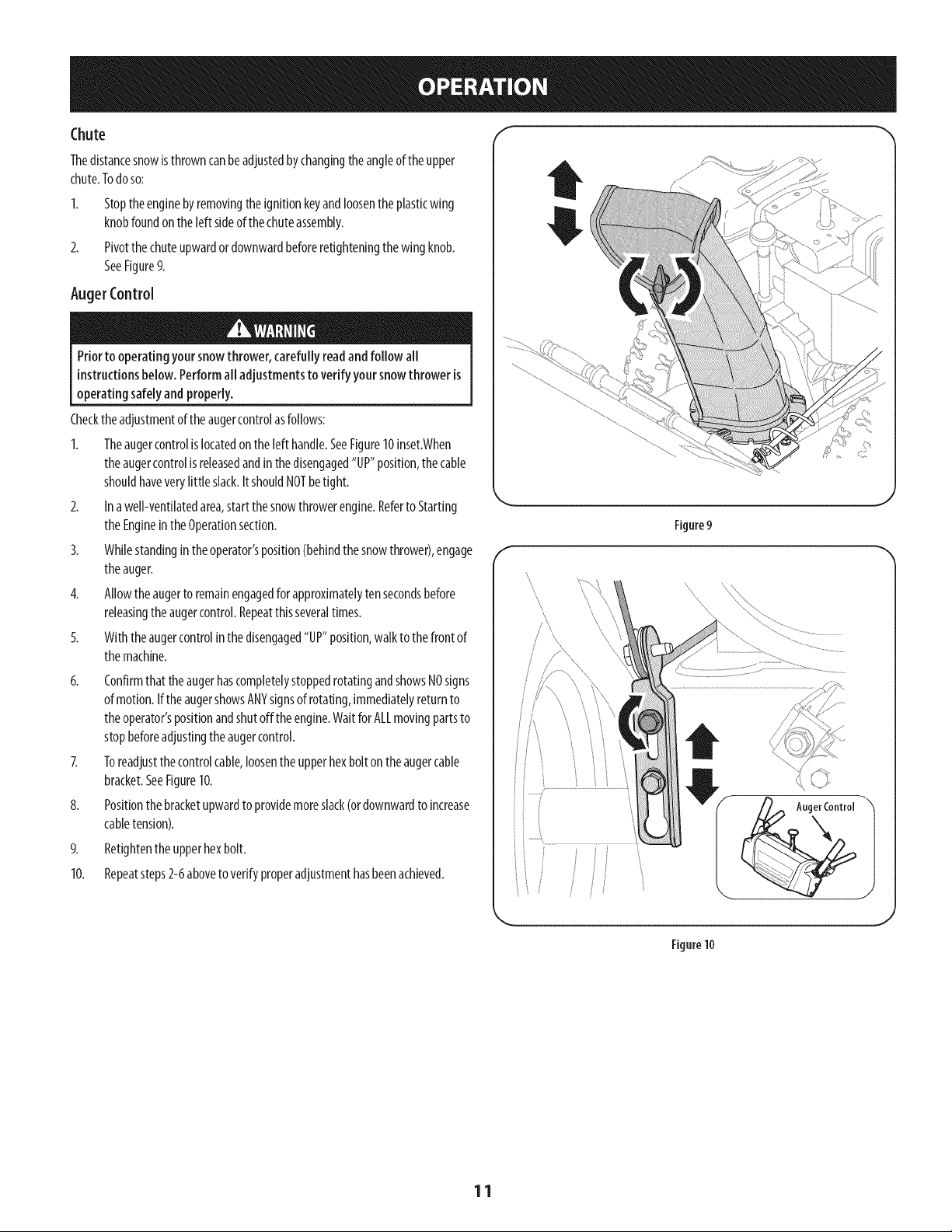

Adjustments

SkidShoes

Thesnowthrowerskidshoesareadjustedat thefactorytobeapprox1/8"below

thebottomsurfaceof theshaveplate.Adjustthemdownward,if desired,priorto

operatingthesnowthrower.

Itisnotrecommendedthat youoperatethis snowthroweron gravelas

itcaneasilypickupandthrow loosegravel,causingpersonalinjuryor

damageto thesnowthrower andsurroundingproperty.

Forclosesnowremovalon asmoothsurface,raiseskidshoeshigheronthe

augerhousing.Referto Figure8.

Useamiddleorlowerpositionwhentheareatobeclearedisuneven,suchas

agraveldriveway.

NOTE:Ifyouchoosetooperatethesnowthroweronagravelsurface,keep

theskidshoesinpositionformaximumclearancebetweenthegroundand

theshaveplate.

Toadjusttheskidshoes:

1. Loosenthefour hexnuts(twooneachside)andcarriagebolts.Moveskid

shoestodesiredposition.SeeFigure8.

2. Makecertaintheentirebottomsurfaceof skidshoeisagainstthegroundto

avoidunevenwearontheskidshoes.

SmoothSurface

UnevenSurface

\

Figure8

3. Retightennutsandboltssecurely.

10

Page 11

Chute f %

Thedistancesnowisthrowncanbeadjustedbychangingtheangleoftheupper

chute.Todoso:

Stoptheenginebyremovingtheignitionkeyandloosenthe plasticwing

knobfoundontheleft sideofthechuteassembly.

2_

Pivotthechuteupwardordownwardbeforeretighteningthewingknob.

SeeFigure9.

AugerControl

Priorto operatingyoursnowthrower, carefullyreadandfollow all

instructionsbelow.Performalladjustmentsto verifyyoursnowthrower is

operatingsafelyandproperly.

Checktheadjustmentoftheaugercontrolasfollows:

1. Theaugercontrolislocatedontheleft handle.SeeFigure10inset.When

theaugercontrolisreleasedandinthedisengaged"UP"position,thecable

shouldhaveverylittle slack.ItshouldNOTbetight.

2. Ina well-ventilatedarea,startthesnowthrowerengine.Referto Starting

theEngineintheOperationsection.

3. Whilestandingintheoperator'sposition(behindthesnowthrower),engage

theauger.

4. Allowtheaugerto remainengagedfor approximatelytensecondsbefore

releasingtheaugercontrol.Repeatthisseveraltimes.

5. Withtheaugercontrolin thedisengaged"UP"position,walktothefront of

themachine.

6. Confirmthat theaugerhascompletelystoppedrotatingandshowsNOsigns

ofmotion.IftheaugershowsANYsignsofrotating,immediatelyreturnto

theoperator'spositionandshutofftheengine.WaitforALLmovingpartsto

stopbeforeadjustingtheaugercontrol.

7. Toreadjustthecontrolcable,loosentheupperhexboltontheaugercable

bracket.SeeFigure10.

8. Positionthebracketupwardtoprovidemoreslack(ordownwardtoincrease

cabletension).

9. Retightentheupperhexbolt.

10. Repeatsteps2-6aboveto verifyproperadjustmenthasbeenachieved.

Figure9

f

\\

,J

11

J

Figure10

Page 12

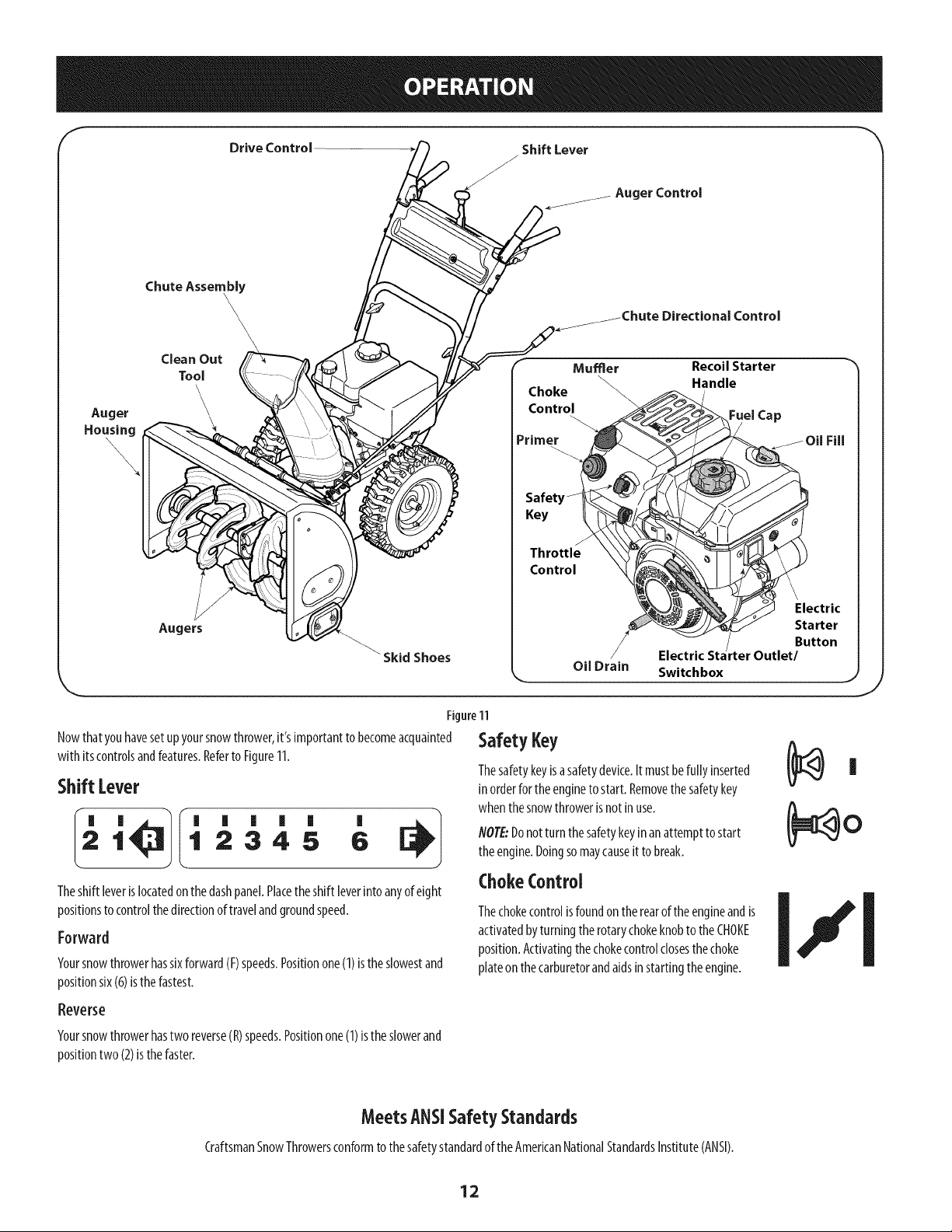

Drive Control

Shift Lever

J

J

Auger Control

Chute Assembly

Clean Out

Auger

Housing

Tool

\

\

\

\,

\

Augers Starter

_'_" Skid Shoes Electric :/

Figure11

Nowthatyouhavesetupyoursnowthrower,it'simportanttobecomeacquainted

with itscontrolsandfeatures.Referto Figure11.

ShiftLever

JChute Directional Control

Mumer Recoil Starter

Choke

Control

)rimer

SafetyJ

Key

Throttle

Control

Oi[ Drain

Handle

e[ Cap

Switchbox

SafetyKey

Thesafetykeyisasafetydevice.Itmustbefullyinserted

inorderfortheengineto start.Removethesafetykey

whenthesnowthrowerisnotinuse.

Electric

Button

J

1 2345 6

I_ '_1 ' ' ' ' ' '

Theshiftleverislocatedonthedashpanel.Placetheshiftleverintoanyofeight

positionstocontrolthedirectionoftravelandgroundspeed.

Forward

Yoursnowthrowerhassixforward(F)speeds.Positionone(1)isthe slowestand

positionsix(6)isthe fastest.

Reverse

Yoursnowthrowerhastworeverse(R)speeds.Positionone(1)istheslowerand

positiontwo(2)isthefaster.

MeetsANSiSafetyStandards

CraftsmanSnowThrowersconformtothesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

flOTE:Donotturnthesafetykeyinanattempttostart

theengine.Doingsomaycauseittobreak.

ChokeControl

Thechokecontrolisfoundontherearoftheengineandis

activatedbyturningtherotarychokeknobtotheCHOKE

position.Activatingthechokecontrolclosesthechoke

plateonthecarburetorandaidsinstartingtheengine.

12

Page 13

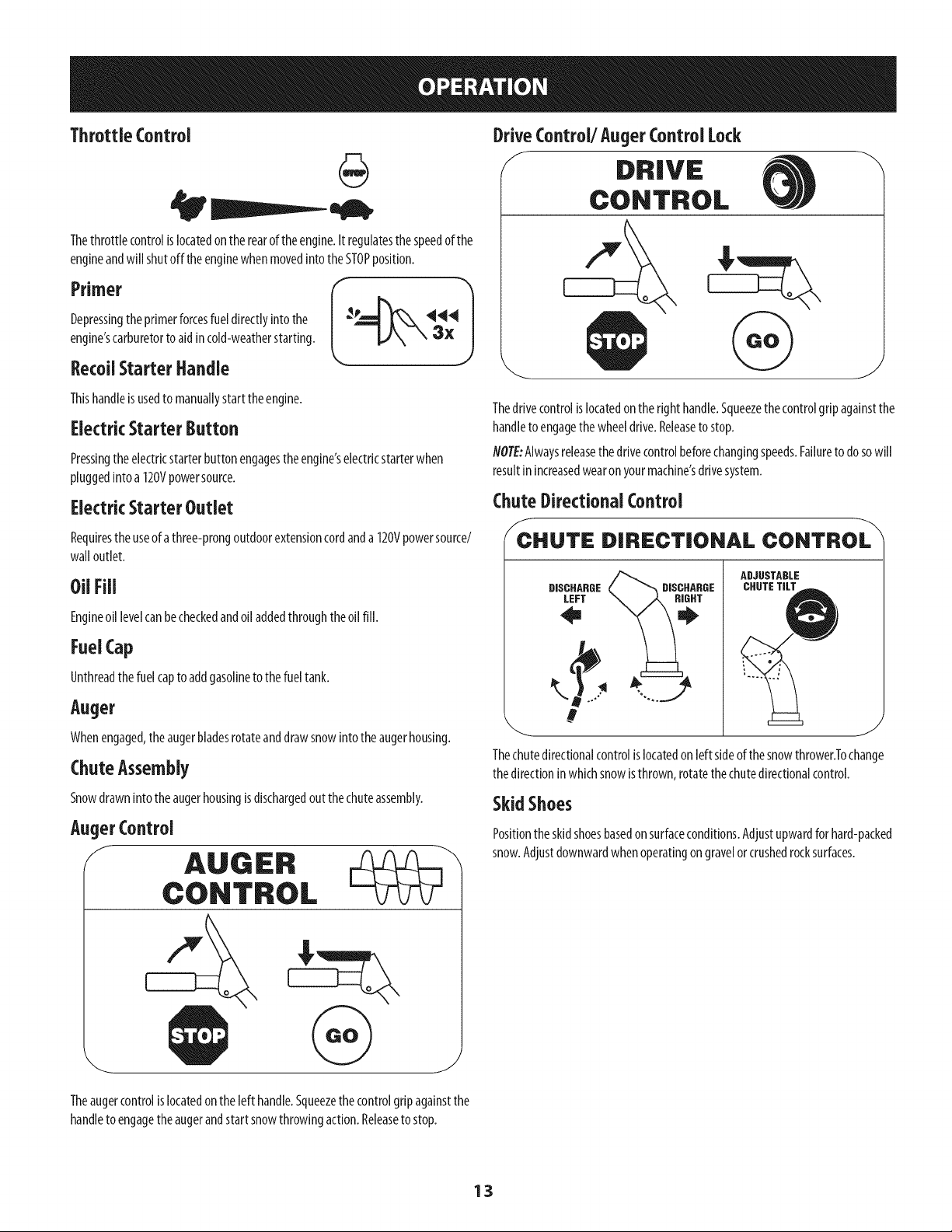

ThrottleControl

Thethrottlecontrolislocatedontherearoftheengine.It regulatesthespeedofthe

engineandwillshutoff theenginewhenmovedintotheSTOPposition.

Depressingtheprimerforcesfueldirectlyintothe _e 444

engine'scarburetorto aidincold-weatherstarting. 3 X

RecoilStarter Handle

DriveControl/Auger Control Lock

f DRIVE

CONTROL

Thishandleisusedto manuallystarttheengine.

ElectricStarter Button

Pressingtheelectricstarterbuttonengagestheengine'selectricstarterwhen

pluggedintoa 120Vpowersource.

ElectricStarter Outlet

Requirestheuseofathree-prongoutdoorextensioncordanda120Vpowersource/

walloutlet.

OilFill

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill.

FuelCap

Unthreadthefuelcaptoaddgasolineto thefueltank.

Auger

Whenengaged,theaugerbladesrotateanddrawsnowintotheaugerhousing.

ChuteAssembly

Snowdrawnintotheaugerhousingisdischargedoutthechuteassembly.

AugerControl

f

AUGER

Thedrivecontrolislocatedontheright handle.Squeezethecontrolgripagainstthe

handletoengagethewheeldrive.Releasetostop.

NOTE:Alwaysreleasethedrivecontrolbeforechangingspeeds.Failuretodosowill

resultinincreasedwearonyourmachine'sdrivesystem.

ChuteDirectional Control

f

CHUTE DIRECTIONAL CONTROL

ADJUSTABLE

DISCHARGE

LEFT

Thechutedirectionalcontrolislocatedonleftsideofthesnowthrower.Tochange

thedirectioninwhichsnowisthrown,rotatethechutedirectionalcontrol.

SkidShoes

Positiontheskidshoesbasedonsurfaceconditions.Adjustupwardforhard-packed

snow.Adjustdownwardwhenoperatingongravelorcrushedrocksurfaces.

CHUTETILT

CONTROL

Theaugercontrolislocatedonthelefthandle.Squeezethecontrolgripagainstthe

handletoengagetheaugerandstartsnowthrowingaction.Releaseto stop.

13

Page 14

Clean-OutTool

Neveruseyour handstodear acloggedchuteassembly.ShutOFFengine

andremainbehindhandlesuntil all movingparts havestoppedbefore

usingthe clean-outtool to clearthe chuteassembly.

Thechuteclean-outtoolisconvenientlyfastenedto therearoftheaugerhousing

with amountingclip.Shouldsnowandicebecomelodgedinthechuteassembly

duringoperation,proceedasfollowstosafelycleanthechuteassemblyandchute

opening:

1. Releaseboththeaugercontrolandthedrivecontrol.

2. Stoptheenginebyremovingthesafetykeyorpositionthethrottletothe

STOPposition.

3. Removetheclean-outtoolfromtheclipwhichsecuresitto therearofthe

augerhousing.

4. Usetheshovel-shapedendoftheclean-outtool todislodgeandscoopany

snowandicewhichhasformedinandnearthechuteassembly.

5. Refastentheclean-outtooltothemountingclipontherearoftheauger

housing,reinserttheignitionkeyandstartthesnowthrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnowthrower),engage

theaugercontrolforafewsecondstoclearanyremainingsnowandicefrom

thechuteassembly.

BeforeStarting Engine

Read,understand,andfollow all instructionsandwarningsonthe

machineandin this manualbeforeoperating.

Oil

Theunitwasshippedwithoilintheengine.Checkoillevelbeforeeachoperationto

ensureadequateoilin theengine.

NOTE:Besuretochecktheengineonalevelsurfacewith theenginestopped.

1. Removetheoilfillercap/dipstickandwipethedipstickclean.

2. Insertthecap/dipstickintotheoilfillerneck,butdoNOTscrewitin.

3. Removetheoilfillercap/dipstick.Ifthelevelislow,slowlyaddoil(5W-30,

with aminimumclassificationof SF/SG)until oillevelregistersbetweenhigh

(N)andlow(L).

NOTE:Donotoverfill.Overfillingwith oil mayresultinenginesmoking,hard

startingorsparkplugfouling.

4.

Replaceandtightencap/dipstickfirmlybeforestartingengine.

Gasoline

Useautomotivegasoline(unleadedorlowleadedto minimizecombustionchamber

deposits)with aminimumof87octane.Gasolinewith upto10%ethanolor15%

MTBE(MethylTertiaryButylEther)canbeused.Neveruseanoil/gasolinemixture

ordirtygasoline.Avoidgettingdirt, dust,orwaterinthefueltank.DONOTuseE85

gasoline.

Refuelin awell-ventilatedareawith theenginestopped.Donotsmokeor

allowflamesorsparksin theareawheretheengineisrefueledorwhere

gasolineisstored.

Donotoverfillthefueltank.Afterrefueling,makesurethetankcapisclosed

properlyandsecurely.

Becarefulnottospillfuelwhenrefueling.Spilledfuelorfuelvapormay

ignite.Ifanyfuelisspilled,makesuretheareaisdry beforestartingthe

engine.

Avoidrepeatedorprolongedcontactwith skinorbreathingofvapor.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsare explosive.Neverfuel the machineindoorsor

while the engineishotor running.Extinguishcigarettes,cigars,pipesand

othersourcesof ignition.

1. Cleanaroundfuelfill beforeremovingcaptofuel.

2. Filltankuntilfuelreaches1/2inchbelowthebottomofthefillerneckto

allowspacefor fuelexpansion.Becarefulnottooverfill.

Starting Engine

Alwayskeephandsandfeet clearof movingparts.Donotuseapressurized

starting fluid. Vaporsareflammable.

NOTE:Allowtheenginetowarmupfor afewminutesafterstarting.Theenginewill

notdevelopfull poweruntilit reachesoperatingtemperatures.

1. Makecertainboththeaugercontrolanddrivecontrolarein thedisengaged

(released)position.

2. Insertsafetykeyintoslot.Makesureitsnapsintoplace.Donotattemptto

turnthesafetykey.

NOTE:Theenginecannotstartwithoutthesafetykeyfullyinsertedintothe

ignitionswitch.

ElectricStarter

Theelectric starteris equippedwith a groundedthree-wire plug,and

isdesignedto operateon120VAChouseholdcurrent. It must beused

with a properlygroundedthree-prongreceptacleat alltimes toavoid

the possibilityof electrk shock.Followall instructionscarefullypriorto

operatingthe electricstarter. DONOTuseelectric starterinthe rain.

Determinethatyourhome'swiringisathree-wiregroundedsystem.Aska licensed

electricianifyouarenotcertain.

Ifyouhavea groundedthree-prongreceptacle,proceedasfollows.Ifyoudonot

havetheproperhousewiring,DONOTusetheelectricstarterunderanyconditions.

1. Pluganextensioncordintotheoutletlocatedontheengine'ssurface.Plug

theotherendofextensioncordintoathree-prong120V,grounded,ACoutlet

inawell-ventilatedarea.

Theextensioncordcanbeany length, but must beratedfor 15Aat125V,

groundedandratedfor outdoor use.

14

Page 15

2. Movethrottlecontrolto FAST(rabbit)_Jl[r position.

3 MovechoketotheCHOKEI"I pos t on co,deng nestart ,feng ne s

warm,placechokein RUNposition.

4. Pushprimerthreetimes,makingsuretocoverventholeinprimerbulbwhen

pushing.Ifengineiswarm,pushprimeronlyonce.AIwayscoverventhole

whenpushing.Coolweathermayrequireprimingto berepeated.

5. Pushstarterbuttontostartengine.Oncetheenginestarts,immediately

releasestarterbutton.Electricstarterisequippedwiththermaloverload

protection;systemwill temporarilyshutdowntoallowstartertocoolif

electricstarterbecomesoverloaded.

6.

Astheenginewarms,slowlyrotatethechokecontrolto RUNposition.Ifthe

enginefalters,restartengineandrunwith chokeat half-chokepositionfor a

shortperiodoftime,andthenslowlyrotatethechokeinto RUNposition.

Afterengineisrunning,disconnectpowercordfromelectricstarter.When

disconnecting,alwaysunplugtheendatthewalloutletbeforeunplugging

theoppositeendfromtheengine.

ToEngageDrive

I. Withthethrottlecontrolinthe Fast(rabbit)_l_II position,moveshiftlever

NOTE:Whenselectingadrivespeed,usetheslowerspeedsuntilyouare

comfortableandfamiliarwiththeoperationofthesnowthrower.

2. Squeezethedrivecontrolagainstthe handleandthesnowthrowerwill

NOTE:NEVERrepositiontheshiftlever(changespeedsordirectionoftravel)

withoutfirst releasingthe drivecontrolandbringingthesnowthrowerto a

completestop.Doingsowillresultinprematureweartothesnowthrower'sdrive

system.

ToEngageAuger

RecoilStarter

Replacing Shear Pins

Eachaugerbladeissecuredtothespiralshaftwith ashearpinandbow-tieclip.If

Donotpullthe starterhandlewhilethe engineisrunning.

L

I. Movethrottle controlto FAST(rabbit)_J_II position.

2. MovechoketotheCHOKEI,.'Iposition(coldenginestart).Ifengineis

warm,placechokein RUNposition.

3. Pushprimerthreetimes,makingsuretocoverventholewhenpushing.

Ifengineiswarm,pushprimeronlyonce.AIwayscoverventholewhen

pushing.Coolweathermayrequireprimingtoberepeated.

4. Pullgentlyonthestarterhandleuntilit beginsto resist,then pullquickly

andforcefullytoovercomethecompression.Donotreleasethehandleand

allowit tosnapback.ReturnropeSLOWLYto originalposition.If required,

repeatthisstep.

5. Astheenginewarms,slowlyrotatethechokecontroltoRUNposition.Ifthe

enginefalters,restartengineandrunwith chokeat half-chokepositionfor a

shortperiodoftime,andthenslowlyrotatethechokeinto RUNposition.

anaugerbladestrikesa foreignobjectoricejam,thepinwill shearoff toprevent

damagetotheblade.Ifanaugerbladedoesnotturn,checkto seeif itspinhas

shearedoff. SeeFigure12.

intooneofthesixforward(F)positionsortwo reverse(R)positions.Selecta

speedappropriatefor thesnowconditionsandapaceyou'recomfortable

with.

move.Releaseit anddrivemotionwillstop.

Toengagetheaugerandstartthrowingsnow,squeezetheaugercontrol

againstthe lefthandle.Releaseto stoptheauger.

NEVERreplacetheaugershearpinswithanything otherthan SearsModel#

88389orOEMPartNo.738-04124Areplacementshearpins.Anydamageto

the augergearboxorothercomponentsasaresultof failing to dosowill

NOTbecoveredby yoursnowthrower'swarranty.

Alwaysturnoff the snowthrower'sengineandremovethesafetykeyprior

to replacingshearpins.

f

Toavoidunsupervisedengineoperation,neverleavethemachine

unattendedwith theenginerunning.Turntheengineoffafteruseand

removesafetykey.

StoppingEngine

Afteryouhavefinishedsnowthrowing,runengineforafew minutesbefore

stoppingto helpdryOFFanymoistureontheengine.

I. Movethrottle controlto OFFposition.

2. Removethesafetykey.Removingthesafetykeywillreducethepossibilityof

unauthorizedstartingoftheenginewhileequipmentisnotinuse.Keepthe

safetykeyinasafeplace.Theenginecannotstartwithoutthesafetykey.

3. Wipeanymoistureawayfromthecontrolsontheengine.

15

Figure12

Page 16

MAINTENANCESCHEDULE

Beforeperforminganytype of maintenance/service,disengageall controls

andstopthe engine.Wait until all movingparts havecometoa complete

stop.Disconnectsparkplug wire andground it againstthe engineto

preventunintendedstarting.

Followthemaintenanceschedulegivenbelow.Thischartdescribesservice

guidelinesonly.UsetheServiceLogcolumntokeeptrackofcompleted

maintenancetasks.TolocatethenearestSearsServiceCenterortoscheduleservice,

callthefollowingtollfreenumber:l-888-331-4569.

EachUseandevery5hours

First5hours

Annuallyor25hours

Annuallyor50hours

Annuallyor100hours

BeforeStorage

1. Engineoil level

2. Looseormissinghardware

3. Unitandengine.

I. Engineoil

I. Sparkplug

2. Controllinkagesandpivots

3. Wheels

4. GearshaftandAugershaft

I. Engineoil

I. Sparkplug

I. Fuelsystem

GENERALRECOMMENDATIONS

CheckingEngineOil

Beforelubricating, repairing,orinspecting,disengageall controlsandstop

engine.Waituntil all movingparts havecometo acompletestop.

NOTE:Checktheoillevelbeforeeachusetobesurecorrectoillevelismaintained.

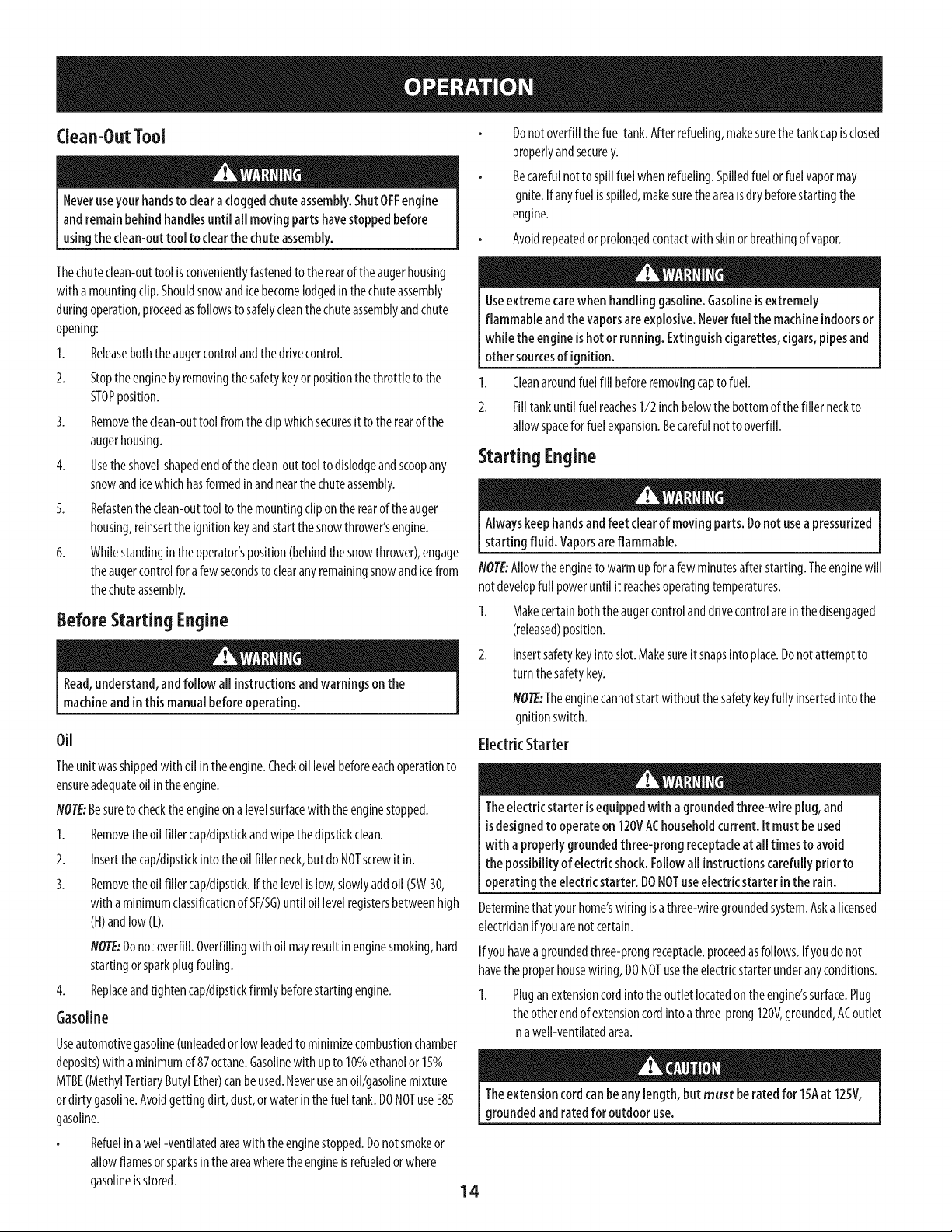

Whenaddingoiltotheengine,refertoviscositychartonthenextpage.Engineoil

capacityis600ml (approx.20oz.).Donotover-fill.Usea4-stroke,oranequivalent

highdetergent,premiumqualitymotoroilcertifiedtomeetorexceedU.S.

automobilemanufacturer'srequirementsfor serviceclassification%, SEMotoroils

classifiedSG,SFwill showthisdesignationonthecontainer.

1. Removetheoilfillercap/dipstkkandwipethedipstickclean.

2. Insertthecap/dipstkkintotheoilfillerneck,butdoNOTscrewitin.

3. Removetheoilfillercap/dipstick.Iflevelislow,slowlyaddoiluntiloillevel

registersbetweenhigh(H)andlow(L).SeeFigure13.

4. Replaceandtightencap/dipstkkfirmlybeforestartingengine.

ChangingEngineOil

NOTE"Changetheengineoilafterthefirstfivehoursofoperationandoncea

seasonorevery50hoursthereafter.

I. Drainfuelfromtankbyrunningengineuntil thefueltankisempty.Besure

fuelfill capissecure.

2. Placesuitableoilcollectioncontainerunderoil drainplug.

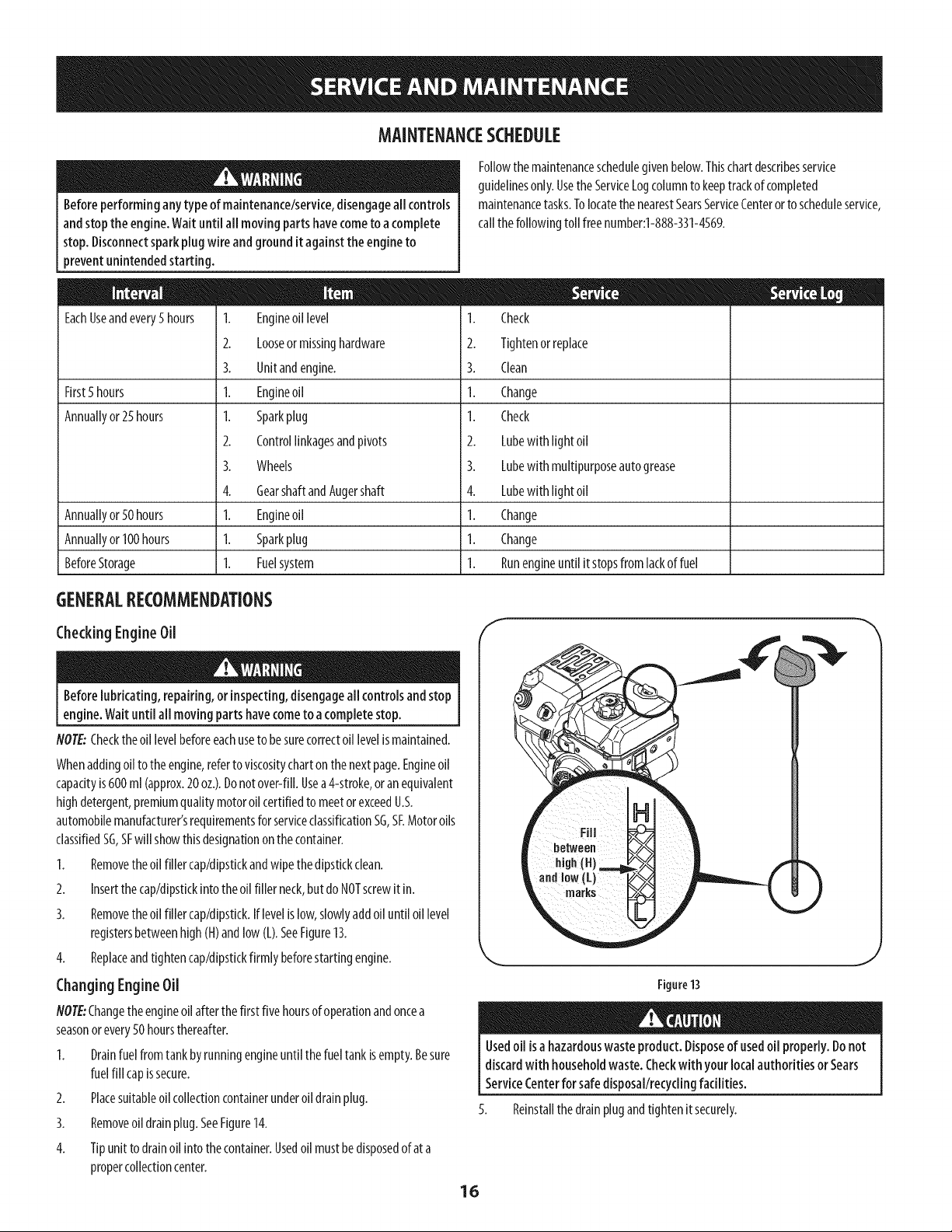

3. Removeoildrainplug.SeeFigure14.

4. Tipunittodrainoiiintothecontainer.Usedoiimustbedisposedofat a

propercollectioncenter.

1. Check

2. Tightenorreplace

3. Clean

1. Change

1. Check

2. Lubewithlight oil

3. Lubewithmultipurposeautogrease

4. Lubewithlight oil

1. Change

1. Change

1. Runengineuntilitstopsfromlackoffuel

f

)

J

Figure13

Usedoii isa hazardouswasteproduct.Disposeof usedoilproperly.Donot

discardwith householdwaste.Checkwith your localauthorities or Sears

ServiceCenterforsafedisposal/recyclingfacilities.

5. Reinstallthedrainplugandtightenitsecurely.

16

Page 17

6. Refillwith therecommendedoilandchecktheoil level.SeeRecommended f _'_

OilUsagechart.Theengine'soilcapacityis20oz.

(°F)-40o-20 o 0o 200 400

("c) -30° -20° -10 ° 0°

DONOTusenondetergentoil or 2-strokeengineoil. It couldshortenthe

engine'sservicelife.

7. Reinstalltheoilfiller cap/dipsticksecurely.

E

Thoroughlywashyour handswith soapandwater assoonaspossibleafter

handling usedoil.

CheckingSparkPlug

OilDrain

Plug \

Figure14

SparkPlug

DONOTcheckfor sparkwith sparkplug removed.DONOTcrankenginewith

sparkplug removed.

Ifthe enginehasbeenrunning,the muffler will beveryhot. Becarefulnot

to touchthe muffler.

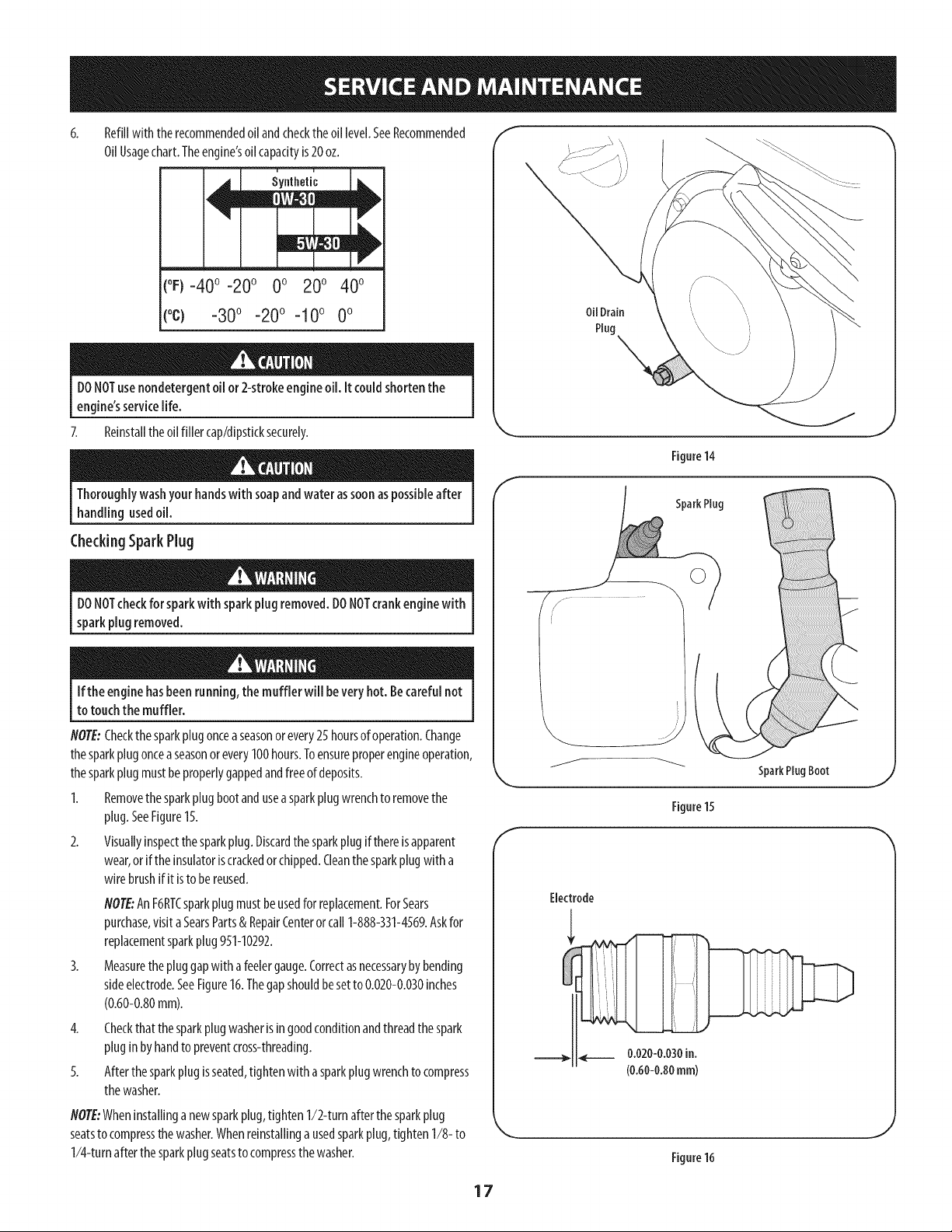

NOTE:Checkthe sparkplugonceaseasonorevery25hoursofoperation.Change

thesparkplugonceaseasonorevery100hours.Toensureproperengineoperation,

thesparkplugmustbeproperlygappedandfreeofdeposits.

1. Removethesparkplugbootandusea sparkplugwrenchtoremovethe

plug.SeeFigure15.

2. Visuallyinspectthesparkplug.Discardthesparkplugif thereisapparent

wear,orif theinsulatoriscrackedorchipped.Cleanthesparkplugwitha

wirebrushifit isto bereused.

NOTE:AnF6RTCsparkplugmustbeusedforreplacement.ForSears

purchase,visitaSearsParts& RepairCenterorcall1-888-331-4569.Askfor

replacementsparkplug951-10292.

3.

Measurethepluggapwithafeelergauge.Correctasnecessarybybending

sideelectrode.SeeFigure16.Thegapshouldbesetto0.020-0.030inches

(0.60-0.80mm).

4. Checkthatthesparkplugwasherisin goodconditionandthreadthespark

pluginbyhandtopreventcross-threading.

5. Afterthesparkplugisseated,tightenwith asparkplugwrenchtocompress

thewasher.

NOTE:Wheninstallinganewsparkplug,tighten1/2-turnafterthesparkplug

seatsto compressthewasher.Whenreinstallinga usedsparkplug,tighten1/8-to

1/4-turnafterthesparkplugseatsto compressthewasher.

SparkPLugBoot

Figure15

Electrode

Figure16

17

Page 18

Thesparkplugmustbetightenedsecurely.Aloosesparkplugcanbecome

veryhotandcandamagetheengine.

Lubrication

GearShaft

Thegear(hex)shaftshouldbelubricatedatleastonceaseasonorafterevery25

hoursofoperation.

I. Topreventspillage,removeallfuelfromtankbyrunningengineuntilit

stops.

2. Carefullypivotthesnowthrowerupandforwardsothatit restsontheauger

housing.

3. Removethelowerframecoverfromtheundersideof thesnowthrowerby

removingtheself-tappingscrewswhichsecureit.

4. Applya lightcoatingofBostikRegulargradeNever-Seez®tothehexshaft.

SeeFigure17.

NOTE:Whenlubricatingthehexshaft,becarefulnottogetanylubricantonthe

aluminumdriveplateorrubberfrictionwheel.Doingsowill hinderthesnow

thrower'sdrivesystem.WipeOFFanyexcessorspilledlubricant.

Wheels

Atleastonceaseason,removebothwheels.Cleanandcoatthe axleswith a

multipurposeautomotivegreasebeforereinstallingwheels.

ChuteDirectionalControl

Onceaseason,lubricatetheeyeboltbushingandthespiralwith 3-in-1oil.

J

Figure17

f

AugerShaft

Atleastonceaseason,removetheshearpinsonaugershaft.Sprayanygeneral

purposelubricantinsideshaft,andaroundthespacersandflangebearingsfoundat

eitherendoftheshaft.SeeFigure18.

ShavePlateand SkidShoes

Theshaveplateandskidshoesonthebottomofthesnowthroweraresubjectto

wear.Theyshouldbecheckedperiodicallyandreplacedwhennecessary.

NOTE:Theskidshoeson thismachinehavetwo wearedges.Whenonesidewears

out,theycanberotated180°tousetheotheredge.

Toremoveskidshoes:

Removethetwocarriagebolts,washers,andhexflangenutsthatsecure

eachskidshoeto thesnowthrower.

2. Reassemblenewskidshoeswith thefourcarriagebolts(twooneachside),

washers,andhexflangenuts.Referto Figure19.

Toremoveshaveplate:

I. Allowtheenginetorununtilit isoutoffuel.Donotattemptto pourfuel

fromtheengine.

2. Carefullypivotunit upandforwardsothatit restsontheaugerhousing.

3. Removethecarriageboltsandhexnutswhichattachit to thesnowthrower

housing.

4. Reassemblenewshaveplate,makingsureheadsofcarriageboltsaretothe

insideofhousing.Tightensecurely.SeeFigure19.

F

Figure18

NOTE:Augers not shown for clarity.

Figure19

/'

/

/

18

Page 19

Adjustments

Shift Cable

Ifthefull rangeofspeeds(forwardandreverse)cannotbeachieved,refertothe

figuretothefight andadjusttheshiftcableasfollows:

I. Placetheshiftlever[nthefastestforwardspeedposition(F6).

2. Loosenthehex nutontheshiftcableindexbracket.SeeFigure20.

3. Pivotthebracketdownwardtotakeupslackinthecable.

4. Retightenthehexnut.

DriveControl

Whenthedrivecontrol[sreleasedand[nthedisengaged"UP"position,thecable

shouldhaveverylittle slack.ItshouldNOTbetight. Also,[fthere[sexcessiveslack

[nthedrivecableor iftheunitexperiencesintermittentdrivewhileusing,thecable

mayneedtobeadjusted.Checktheadjustmentofthedrivecontrolasfollows:

I. Withthedrivecontrolreleased,pushthesnowthrowergentlyforward.The

unitshouldrollfreely.

2. Engagethedrivecontrolandgentlyattemptto pushthesnowthrower

forward.Thewheelsshouldnotturn.Theunitshouldnotroll freely.

3. Withthedrivecontrolreleased,movetheshift leverbackandforthbetween

theR2positionandtheF6positionseveraltimes.Thereshouldbeno

resistanceintheshiftlever.

f

/

t

/

Figure20

4. Ifanyoftheabovetestsfailed,thedrivecableisinneedofadjustment.

Proceedasfollows:

a. ShutOFFtheengineasinstructed[ntheOperationsection.

b. Loosenthelowerhexboltonthedrivecablebracket.SeeFigure21.

c. Positionthebracketupwardto providemoreslack(ordownwardto

increasecabletension).

d. Retightenthelowerhexbolt.

e. Performsteps1-3to confirmadjustment.

Chute Bracket

Ifthespiralatthebottomofthechutedirectionalcontrolisnotfullyengagingwith

thechuteassembly,thechutebracketcanbeadjusted.Todoso:

1. Loosenthetwo nutswhichsecurethechutebracketandrepositionit

slightly.SeeFigure22.

2. Retightenthenuts.

k..........................

Figure21

19

Figure22

Page 20

AugerControl

Refertopage11intheAssemblysectionfor instructionsonadjustingtheauger

controlcable.

SkidShoes

Refertopage10intheAssemblysectionfor instructionsonadjustingtheskid

shoes.

Belt Replacement

Auger Belt

Toremoveandreplaceyoursnowthrower'saugerbelt,proceedasfollows:

I. Topreventspillage,removeallfuelfromtankbyrunningengineuntilit

stops.

2. Removetheplasticbeltcoveronthefrontof theenginebyremovingthetwo

self-tappingscrews.SeeFigure23.

3. Loosenandremovethetwo boltsandflat washerssecuringthebeltguide.

SeeFigure24.Removebelt guide.

4. Rolltheaugerbeltofftheenginepulley.SeeFigure25.

5. Carefullypivotthesnowthrowerupandforwardsothatit restsontheauger

housing.

6. Removetheframecoverfromtheundersideofthesnowthrowerby

removingtheself-tappingscrewswhichsecureit. SeeFigure26.

f

J

Figure24

f

i i

Figure23

// /

Figure25

f

2O

Figure26

Page 21

Loosenandremovetheshoulderscrewwhichactsasabeltkeeper.

RefertoFigure27.

8.

Removethebeltfromaroundtheaugerpulley,andslipthebeltbetweenthe

supportbracketandtheaugerpulley.SeeFigure28.

NOTE:Engagingtheaugercontrolwill easeremovalandreinstallationof the

belt.

Reassembleaugerbeltbyfollowinginstructionsin reverseorder.

flO?E:DoNOTforgettoreinstalltheshoulderscrewandreconnectthespring

totheframeafterinstallingareplacementaugerbelt.SeeFigure27and

Figure28.

10.

PerformtheAugerControltestoutlinedintheAssemblysectionof this

manual.

Drive Belt

flOTE:Severalcomponentsmustberemovedandspecialtoolsarerequiredinorder

toreplacethesnowthrower'sdrivebelt.ContactthenearestSearsParts& Repair

Centerto havethedrivebeltreplaced.

//

Bracket

Friction Wheel Removal

Ifthesnowthrowerfailstodrivewiththedrivecontrolengaged,andperforming

thedrivecontrolcableadjustmentfailstocorrecttheproblem,thefrictionwheel

mayneedtobereplaced.Followtheinstructionsbelow.Examinethefrictionwheel

rubberfor signsofwearorcrackingandreplacewheelif necessary.

1. Topreventspillage,removeallfuelfromtankbyrunningengineuntil it

stops.

2. Placetheshiftleverinfirst Forward(F1)position.

3. Carefullypivotthesnowthrowerupandforwardsothatit restsontheauger

housing.

4. Removetheframecoverfromtheundersideofthesnowthrowerby

removingtheself-tappingscrewswhichsecureit.

5. Removetheright-handwheelbyremovingthescrewandbellwasherwhich

secureittotheaxle.SeeFigure29.

ioi

Figure28

Rgure29

Figure27

J

21

Page 22

6. Carefullyremovethehexnutandwasherwhichsecuresthehexshaftto

thesnowthrowerframeandlightlytaptheshaft'sendtodislodgetheball

bearingfromtherightsideoftheframe.SeeFigure30.

NOTE:Becarefulnottodamagethethreadsontheshaft.

7. Carefullypositionthehexshaftdownwardandtotheleftbeforecarefully

slidingthefrictionwheelassemblyoff theshaft.SeeFigure31.

NOTE:Ifyou'rereplacingthefrictionwheelassemblyasawhole,discardthe

wornpartandslidethe newpartontothehexshaft.

8. Followthestepsaboveinreverseorderto reassemblecomponents.

9. Performthetestpreviouslydescribedinthe DriveControlsection.

Ifyou'redisassemblingthefrictionwheelandreplacingonlytherubberring,

proceedasfollows:

NOTE:Notallfrictionwheelsareserviceable.Ifthisisthecase,simplyreplacethe

frictionwheelassembly.

1. Removethefourscrewswhichsecurethefrictionwheel'ssideplates

together.SeeFigure32.

2. Removetherubberringfrombetweenthe plates.

3. Reassemblethesideplateswith a newrubberring.

NOTE:Whenreassemblingthefrictionwheelassembly,makesurethatthe

rubberring iscenteredandseatedproperlybetweenthesideplates.Tighten

eachscrewonlyonerotationbeforeturningthewheelclockwiseand

proceedingwith thenextscrew.Repeatthisprocessseveraltimestoensure

theplatesaresecuredwith equalforce(between6ft-lbsand9ft-lbs).

4. Slidethefrictionwheelassemblybackontothehexshaftandfollowthe

stepsaboveinreverseorderto reassemblecomponents.

5,

Performthetestpreviouslydescribedinthe DriveControlsection.

f

f

J

Figure31

f

Figure30

J

Figure32

22

Page 23

Ifthesnowthrowerwill notbeusedfor 30daysorlonger,oriftheendofthesnowseason,theequipmentneedstobestoredproperly.Followstorageinstructionsbelowto

ensuretopperformancefromthesnowthrowerforfutureuse.

PreparingEngine

Enginesstoredover30daysneedto bedrainedoffuelto preventdeteriorationand

gumfromforminginfuelsystemoronessentialcarburetorparts.If thegasolinein

yourenginedeterioratesduringstorage,youmayneedtohavethecarburetor,and

otherfuelsystemcomponents,servicedorreplaced.

1. Removeallfuelfromtankbyrunningengineuntil it stops.Donotattemptto

pourfuelfromtheengine.

2. Changetheengineoil.

3. Removesparkplugandpourapproximately1oz.(30ml)ofcleanengineoil

intothecylinder.Pulltherecoilstarterseveraltimestodistributetheoil,and

reinstallthesparkplug.

4. Cleandebrisfromaroundengine,andunder,around,andbehindmuffler.

Applyalightfilm ofoilonanyareasthat aresusceptibleto rust.

Storeinaclean,dryandwellventilatedareaawayfromanyappliancethat

operateswith aflameorpilotlight,suchasa furnace,waterheater,or

clothesdryer.Avoidanyareawitha sparkproducingelectricmotor,orwhere

powertoolsareoperated.

Neverstoresnowthrowerwith fuel in tank indoorsor in poorlyventilated

areas,wherefuelfumesmayreachanopenflame,sparkor pilotlight ason

afurnace,water heater,clothesdryeror gasappliance.

PreparingSnowThrower

Whenstoringthe snowthrowerin anunventilatedormetalstorageshed,

careshouldbetakentorustprooftheequipment.Usingalightoilorsilicone,

coattheequipment,especiallyanychains,springs,bearingsandcables.

Removealldirt fromexteriorofengineandequipment.

Followlubricationrecommendations.

Storeequipmentinaclean,dryarea.

Inflatethetirestothetire manufacturersrecommendedpressure.Referto

tire sidewall.

Storesnowthrowerin operatingpositionwith bothwheelsandshaveplate

onlevelgroundsurface.

Ifpossible,avoidstorageareaswith highhumidity.

Keeptheenginelevelduringstorage.Tiltingcancausefueloroilleakage.

23

Page 24

Disconnectthe sparkplugwireandgrounditagainsttheenginetoprevent

unintendedstarting.Beforeperforminganytypeof maintenance/service,

disengageallcontrolsandstoptheengine.Waituntilall movingparts

havecometo acompletestop.Alwayswearsafetyglassesduringoperation

orwhileperforminganyadjustmentsorrepairs.

Thissectionaddressesminorserviceissues.TolocatethenearestSearsServiceCenterortoscheduleservice,callthe followingtoll free number:

1-888-331-4569.

Enginefailstostart

Enginerunningerratically/

inconsistentRPM(huntingor

surging)

Excessivevibration

Lossofpower

Unitfailstopropelitself

I. ChokecontrolnotinCHOKEposition.

2. Sparkplugwiredisconnected.

3. Faultysparkplug.

4. Fueltankemptyorstalefuel.

5. Enginenotprimed.

6. Safetykeynotinserted.

Extensioncordnotconnected(whenusingelectricstart

button,onmodelssoequipped).

I. EnginerunningonCHOKE.

2. Stalefuel.

3. Waterordirtinfuelsystem.

4. Carburetoroutofadjustment.

5. Over-governedengine.

I. Loosepartsordamagedaugerorimpeller.

I. Sparkplugwireloose.

2. Gascapventholeplugged.

I. Drivecableinneedofadjustment.

2. Drivebeltlooseordamaged.

3. Wornfrictionwheel.

I. MovechokecontroltoCHOKEposition.

2. Connectwiretosparkplug.

3. Clean,adjustgap,orreplace.

4. Filltankwithclean,freshgasoline.

5. PrimeengineasinstructedintheOperationsection.

6. Insertsafetykeyfullyintotheswitch.

7. Connectoneendoftheextensioncordtotheelectricstarter

outletandtheotherendtoathree-prong120V,grounded,AC

outlet.

I. Movechokecontrolto RUNposition.

2. Filltankwithclean,freshgasoline.

3. Drainfueltankbyrunningengineuntilitstops.Refillwith fresh

fuel.

4. ContactyourSearsParts& RepairCenter.

5. ContactyourSearsParts& RepairCenter.

I. Stopengineimmediatelyanddisconnectsparkplugwire.

Tightenallboltsandnuts.Ifvibrationcontinues,haveunit

servicedbyaSearsParts& RepairCenter.

I. Connectandtightensparkplugwire.

2. Removeiceandsnowfromgascap.Becertainventholeisclear.

I. Adjustdrivecontrolcable.Referto ServiceandMaintenance

section.

2. Havedrivebeltreplaced.ContactyourSearsParts& Repair

Center.

3. Replacefrictionwheel.RefertoServiceandMaintenance

section.

24

Page 25

Unitfailstodischargesnow 1. Chuteassemblyclogged. 1. Stopengineimmediatelyanddisconnectsparkplugwire.Clean

2. Foreignobjectlodgedinauger.

3. Augercableinneedofadjustment.

4. Augerbeltlooseordamaged.

5. Shearpin(s)sheared.

Chutefailstoeasilyrotate180-200

degrees

Unitplowssnowinsteadof 1. Low/slowgroundspeedinwet!slushysnow1-3"deep. 1. Increasegroundspeed.AlwaysoperateengineatFULLthrottle.

blowingit 2. Shearpin(s)sheared. 2. Replacewithnewshearpin(s).RefertoOperationsection.

1. Chuteassembledincorrectly.

chuteassemblyandinsideofaugerhousingwithclean-outtool.

2. Stopengineimmediatelyanddisconnectsparkplugwire.

Removeobjectfromaugerwithclean-outtool.

3. Adjustaugercontrolcable.RefertoAssemblysection.

4. Replaceaugerbelt.RefertoServiceandMaintenancesection.

5. Replacewithnewshearpin(s).RefertoOperationsection.

1. Disassemblechutecontrolandreassembleasdirectedinthe

Assemblysection.

25

Page 26

FEDERALand/or CALIFORNIAEMISSIONCONTROLWARRANTYSTATEMENT

YOURWARRANTYRIGHTSANDOBLIGATIONS

MTD Consumer Group Inc, the United States Environmental Protection Agency (EPA), and for those products certified for sale in the state

of California, the California Air Resources Board (CARB) are pleased to explain the emission control system (ECS) warranty on your 2014-

2015 small off-road spark-ignited engine and equipment (outdoor equipment). In California, new outdoor equipment must be designed,

built and equipped to meet the State's stringent anti-smog standards (in other states, outdoor equipment must be designed, built, and

equipped to meet the U.S. EPA small off-road spark ignition engine regulations). MTD Consumer Group Inc must warrant the ECSon your

outdoor equipment for the period of time listed below, provided there has been no abuse, neglect, or improper maintenance of the outdoor

equipment.

Your ECS may include parts such asthe carburetor, fuel-injection system, ignition system, catalytic converter, fuel tanks, fuel lines, fuel caps,

valves, canisters, filters, vapor hoses, clamps, connectors, and other associated emission-related components.

Where a warrantable condition exists, MTD Consumer Group Inc will repair your outdoor equipment at no cost to you including diagnosis,

parts, and labor.

MANUFACTURER'SWARRANTYCOVERAGE:

This emission control system is warranted for two years. If any emission-related part on your outdoor equipment is defective, the part will be

repaired or replaced by MTD Consumer Group Inc.

OWNER'SWARRANTYRESPONSIBILITIES:

As the outdoor equipment owner, you are responsible for performance of the required maintenance listed in your owner's manual. MTD

Consumer Group Inc recommends that you retain all receipts covering maintenance on your outdoor equipment, but MTD Consumer Group Inc

cannot deny warranty solely for the lack of receipts.

As the outdoor equipment owner, you should however be aware that MTD Consumer Group Inc may deny you warranty coverage if your

outdoor equipment or a part has failed due to abuse, neglect, improper maintenance, or unapproved modifications.

You are responsible for presenting your outdoor equipment to MTD Consumer Group Inc's distribution center or service center as soon as

the problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If you have a question

regarding your warranty coverage, you should contact the MTD Consumer Group Inc Service Department at 1-800-800-7310 or at

http://su pport.mtd prod ucts.com.

GENERALEMISSIONSWARRANTYCOVERAGE:

MTD Consumer Group Inc warrants to the ultimate purchaser and each subsequent purchaser that the outdoor equipment is: (1) designed,

built, and equipped so as to conform with all applicable regulations; and (2) free from defects in materials and workmanship that cause the

failure of a wa rranted part for a period of two years.

The warranty period begins on the date the outdoor equipment is delivered to an ultimate purchaser or first placed into service.

Subject to certain conditions and exclusions as stated below, the warranty on emission-related parts is as follows:

1. Any warranted part that is not scheduled for replacement as required maintenance in the written instructions supplied is warranted for

the warranty period stated above. If the part fails during the period of warranty coverage, the part will be repaired or replaced by MTD

Consumer Group Inc according to subsection (4) below. Any such part repaired or replaced under warranty will be warranted for the

remainder of the period.

2. Any warranted part that is scheduled only for regular inspection in the written instructions supplied is warranted for the warranty period

stated above. Any such part repaired or replaced under warranty will be warranted for the remaining warranty period.

3. Any warranted part that is scheduled for replacement as required maintenance in the written instructions supplied is warranted for the

period of time before the first scheduled replacement date for that part. If the part fails before the first scheduled replacement, the part

will be repaired or replaced by MTD Consumer Group Inc according to subsection (4) below. Any such part repaired or replaced under

warranty will be warranted for the remainder of the period prior to the first scheduled replacement point for the part.

4.

Repair or replacement of any warranted part under the warranty provisions herein must be performed at a warranty station at no charge

to the owner.

5. Notwithstanding the provisions herein, warranty services or repairs will be provided at all of our distribution centers that are franchised to

service the subject engines or equipment.

6. The outdoor equipment owner will not be charged for diagnostic labor that is directly associated with diagnosis of a defective, emission-

related warranted part, provided that such diagnostic work is performed at a warranty station.

7. MTD Consumer Group Inc is liable for damages to other engine or equipment components proximately caused by a failure under

warranty of any warranted part.

8. Throughout the off-road engine and equipment warranty period stated above, MTD Consumer Group Inc will maintain a supply of

warranted parts sufficient to meet the expected demand for such parts.

9. Any replacement part may be used in the performance of any warranty maintenance or repairs and must be provided without charge to

the owner. Such use will not reduce the warranty obligations of MTD Consumer Group Inc.

Page 27

10. Add-onormodifiedpartsthatarenotexemptedbytheAirResourcesBoardmaynotbeused.Theuseofanynon-exemptedadd-onor

modifiedpartsbytheultimatepurchaserwillbegroundsfordisallowingawarrantyclaim.MTDConsumerGroupIncwillnotbeliableto

warrantfailuresofwarrantedpartscausedbytheuseofanon-exemptedadd-onormodifiedpart.

WARRANTEDPARTS:

The repair or replacement of any warranted part otherwise eligible for warranty coverage may be excluded from such warranty coverage if MTD

Consumer Group Inc demonstrates that the outdoor equipment has been abused, neglected, or improperly maintained, and that such abuse,

neglect, or improper maintenance was the direct cause of the need for repair or replacement of the part. That notwithstanding, any adjustment

of a component that has a factory installed, and properly operating, adjustment limiting device is still eligible for warranty coverage. Further,

the coverage under this warranty extends only to parts that were present on the off-road equipment purchased.

The following emission warranty parts are covered (if applicable):

1. Fuel Metering System

Cold start enrichment system (soft choke)

Carburetor and internal parts (or fuel injection system)

Fuel pump

Fuel tank

2. Air Induction System

Air cleaner

Intake manifold

3. Ignition System

Spark plug(s)

Magneto ignition system

4. Exhaust System

Catalytic converter

SAI (Reed valve)

5. Miscellaneous Items Used in Above System

Vacuum, temperature, position, time sensitive valves and switches

Connectors and assemblies

6. Evaporative Control

Fuel hose

Fuel hose clamps

Tethered fuel cap

Carbon canister

Vapor lines

050790Rev.C

Page 28

Congratulationsonmakingasmartpurchase.YournewCraftsman®productisdesignedandmanufacturedforyearsof

dependableoperation.Butlikeallproducts,it mayrequirerepairfromtimetotime.That'swhenhavingaRepairProtection

Agreementcansaveyoumoneyandaggravation.

Here'swhat the RepairProtectionAgreement*includes:

[] Expertservicebyour10,000professionalrepairspecialists

[] Unlimited serviceand nocharge forpartsandlaboronallcoveredrepairs

[] Productreplacementupto $1500ifyourcoveredproductcan'tbefixed

[] Discountof 25%fromregularpriceof serviceandrelatedinstalledpartsnotcoveredbytheagreement;also,25%off

regularpriceofpreventivemaintenancecheck

[] Fasthelpby phone - wecallitRapidResolution- phonesupportfromaSearsrepresentative.Thinkof usasa"talking

owner'smanual."

OnceyoupurchasetheRepairProtectionAgreement,asimplephonecallisallthatit takesforyoutoscheduleservice.You

cancallanytimedayornight,orscheduleaserviceappointmentonline.

TheRepairProtectionAgreementisa risk-freepurchase.Ifyoucancelforanyreasonduringtheproductwarrantyperiod,

wewill provideafull refund.Or,aproratedrefundanytimeaftertheproductwarrantyperiodexpires.PurchaseyourRepair

ProtectionAgreementtoday!

Somelimitations and exclusionsapply. Forpricesand additional informationinthe U.S.A.call 1-800-827-6655.

*Coveragein Canadavariesonsomeitems.Forfull detailscall SearsCanadaat 1-800-361-6665.

SearsInstallation Service

ForSearsprofessionalinstallationof homeappliances,garagedooropeners,waterheaters,andothermajorhomeitems,in

theU.S.A.call1-888-331-4569,andinCanadacall1-800-469-4663.

28

Page 29

Declarad6n de garantia ....................... P_gina 29

Pr_cticas operaci6n seguras ................... P_gina 30

Montaje ...................................... P_gina 34

Operad6n .................................... P_gina 38

Almacenamiento fuera de temporada ......... P_gina 50

Solucidn de problemas ........................ P_gina 51

Acuerdo de proteccidn para reparaciones ...... P_gina 55

Numero de servicio .................. Cubierta posterior

Servido y Mantenimiento ..................... P_gina 42

CRAFTSMANDEGARANTIALIMITADA

PORDOSANOSapartirdelafechadelacompra,esteproductoest_garantizadopordefectosenlosmaterialesylamanodeobra.

CONELCOMPROBANTEDEVENTA,unproductodefectuosorecibir_lareparaci6nosustituci6ngratuita,aopci6ndelvendedor.

GARANTIADEPORVIDALIMITADAADICIONALenla tolva de UPPERy LOWER

PARASIEMPREYCUANDOSEUTILIZAporelpropietariooriginaldespu_sdelsegundoahodesdelafechadecompra,elconductosuperioreinferiordeeste

quitanievesest_ngarantizadoscontracualquierdefectodematerialesomanodeobradebeserverificadoporunproveedordeservicioautorizadoSears.

CONELCOMPROBANTEDEVENTA,ustedrecibir_unarampanuevadeformagratuita.Ustedesresponsableporelcostodelamanodeobradeinstalaci6ny

otrosgastosocasionadosparaverificareldefect&

Paraobtenerinformaci6nsobreelalcancedelagarantiaysolicitarlareparaci6noelreemplazogratuita,visiteelsitioWeb:www.craftsman.com/warranty

EstagarantiacubreI]NICAMENTElosdefectosenlosmaterialesyen lamanodeobra.EstagarantiaNOcubre:

• Elementosnorenovablesquepuedendesgastarseporelusonormal,duranteelplazodelagarantia,incluyendoentreotros,lasbarrenas,laspaletasde

lasbarrenas,loscortadoresdedesplazamiento,laszapatasantideslizantes,laplacaderaspado,lospasadoresdecuchilla,labujia,elfiltrodeaire,las

correasyelfiltro deaceite.

Serviciosdemantenimientoest_ndar,cambiosdeaceiteoafinaci6n.

Cambiodeneum_ticosoreparacionesporpinchadurasconobjetosexternoscomoclavos,espinas,toconesovidrios.

Reemplazooreparaci6ndeneum_ticosoruedascomoresultadodeldesgastenormal,unaccidente,ofuncionamiento

omantenimientoincorrectos.

• Reparacionesrequeridascomoresultadodelusoinadecuadoporpartedeloperador,incluyendoentreotroseldahoocasionadoporobjetosque

impactanlam_quinayquetuercenelbastidor,elejedelabarrena,etc.,odebidoaqueelmotorrueaceleradoenexceso.

Reparacionesnecesariasdebidoanegligenciadeloperador,incluyendoentreotros,dahosmec_nicoyel_ctricoocasionadopor

unalmacenamientonoapropiado,fallaporelusodeaceitedegradoy/ocantidadnoapropiadosofallapornodarmantenimiento

alequipodeacuerdoconlasinstruccionescontenidasenelmanualdeloperador.

Limpiezaoreparacionesdelmotor(sistemadecombustible)debidasacombustiblequesedeterminaest_contaminadouoxidado(viejo).Engeneral,el

combustibledebeutilizarseenunperiodonomayorde30diasapartirdesuadquisici6n.

Eldeterioroydesgastenormaldelosacabadosexteriores,oreemplazodelaetiquetadelproducto.

LapresentegarantiaseanulasiseutilizaesteproductoalgunavezparaprestarservicioscomercialesosiseIoalquilaaotrapersona.

Estagarantialeotorgaderechoslegalesespecificos,peroustedpodriagozardeotrosderechosenraz6ndesulugarderesidencia.

SearsBrandsManagementCorporation,HoffmanEstates,IL60179

Aceite del motor: 5W-30

Combustible: Gasolina sin plomo

Motor: Craftsman

Numero de modelo

Numero de serie

Fecha de compra

© Sears Brands, LLC

Registre el numero de modelo, numero de serie y fecha

29

de compra m_s arriba.

Page 30

Lapresenciadeestesimboloindicacluesetrata deinstrucciones

importantesdeseguridadcluesedebenrespetarparaevitar poneren

peligrosuseguridadpersonaly/o materialy la deotraspersonas.Leaysiga

todaslasinstruccionesdeestemanualantesdeponer enfuncionamiento

estam_guina.Sinorespetaestasinstruccionespodriaprovocarlesiones

personales.Cuandoyeaestesimbolo,ipresteatenci6na laadvertencia!

Estam_quinafue construidaparaseroperadadeacuerdoconlasreglas

deseguridadcontenidasenestemanual.AIigualqueconcualquiertipo

deequipomotorizado,undescuidooerrorporparte del operadorpuede

produdr lesionesgraves.Estam_quinaescapazdeamputarmanosypies

ydearrojarobjetoscongranfuerza.Deno respetarlasinstrucdonesde

seguridadsiguientessepuedenprodudrlesionesgraveso la muerte.

PROPOSICION 65 DE CALiFORNiA

Elescapedel motor deesteproducto,algunosdesuscomponentesy

algunoscomponentesdel vehiculocontieneno liberansustanciasquimicas

queelestadodeCalifornia consideraquepuedenprodudrc_ncer,defectos

denadmiento uotros problemasreproductivos.

CAPACITACION

Lea,entiendaycumplatodaslasinstruccionesincluidasenlam_quinayen

losmanualesantesdemontarlayutilizarla.Guardeestemanualenunlugar

seguroparaconsultasfuturasy peri6dicas,asicomoparasolicitarrepuestos.

Leael Manualdel0peradorysigatodaslasadvertenciase instruccionesde

seguridad.Elfracasodehacerasipuedecausarlaheridaseriaaloperadory/o

personaspresentes.

Familiaricesecontodosloscontrolesyconelusoadecuadodelosmismos.

Sepac6modetenerlam_quinaydesactivarloscontrolesr_pidamente.

Nopermitanuncaquelosnifosmenoresde14afrosutilicenestam_quina.

Losniffosde14afrosenadelantedebenleeryentenderlasinstrucciones

deoperaci6nynormasdeseguridadcontenidasenestemanual,yenla

m_quinaydebenserentrenadosysupervisadosporunadulto.

Nuncapermitaquelosadultosoperenestam_quinasinrecibirantesla

instrucci6napropiada.

Losobjetosarrojadospotlam_quinapuedenproducirlesionesgraves.

Planifiqueel patr6nenelquevaairarrojandonieveparaevitarquela

descargadematerialserealicehacialoscaminos,losobservadores,etc.

Mantengaalosobservadores,ayudantes,mascotasynifospotIomenosa

75piesdelam_quinamientraslamismaest_enfuncionamiento.Detengala

m_quinasialguienseacerca.

Seaprecavidoparaevitarpatinarseo caerseespecialmentecuandooperala

m_quinaenreversa.

Su responsabilidad--Restrinja elusodeesta m_quinamotorizada

alaspersonasquelean,comprendanyrespetenlasadvertendase

instruccionesqueaparecenenestemanualyen lam_quina.

iGUARBEESTASINSTRUCCIONES!

PREPARATlVOS

Inspecdoneminudosamenteel_readondeutiiizar_el equipo.Saquetodoslos

felpudos,peri6dicos,trineos,tablas,cablesyotrosobjetosextraffosconlosque

podriatropezaroquepodrianserarrojadosporlabarrena/impulsor.

Paraprotegerselosojosutilicesiempreanteojosoantiparrasde seguridad

mientrasoperalam_quinaomientraslaajustaorepara.Losobjetos

arrojadosquerebotanpuedenproducirlesionesocularesgraves.

Nooperelam_quinasinlavestimentaadecuadaparaestaral airelibreen

inviemo.Noutilicealhajas,bufandaslargasuotrasprendassueltasque

podrianenredarseenlaspartesm6viles.Utiiiceuncalzadoespecialpara

superficiesresbaladizas.

Useunprolongadoryuntomacorrientedetrescablesconconexi6natierra

paratodaslasm_quinasconmotoresdeencendidoel_ctrico.

Ajustelaalturadelacajadeltomacorrienteparalimpiarlagravao las

superficiesconpiedrastrituradas.

Desengranetodaslaspalancasdecontrolantesdearrancarel motor.

Nuncaintenterealizarajustesmientraselmotorest_en marchaexceptoen

loscasosespecificamenterecomendadosenel manualdel operador.

Dejequeelmotorylam_quinaseadaptenalatemperaturaexteriorantes

decomenzarasacarlanieve.

30

Page 31

Manejo seguro de la gasolina

Paraevitariesionespersonalesodaffosmaterialestengamuchocuidadocuando

trabajecongasolina.Lagasolinaessumamenteinflamabley susvaporespueden

causarexplosiones.Sisederramagasolinaencimaosobrelaropasepuedelesionar

gravementeyaquesepuedeincendiar.L_veselapielyc_mbiesederopade

inmediato.

Utilices61olosrecipientesparagasolinaautorizados.

Apaguetodosloscigarrillos,cigarros,pipasyotrasfuentesdecombusti6n.

Nuncacarguecombustibleenlam_quinaenunespadocerrado.

Nuncasaquelatapadelcombustibleniagreguecombustiblemientrasel

motorest_calienteoenmarcha.

DejequeelmotorseenfrieporIomenosdosminutosantesdevolvera

cargarcombustible.

NuncaIleneenexcesoeldep6sitodecombustible.Lleneeltanqueanom_s

de1/2pulgadapordebajodelabasedelcuellodeIlenadodejandoespacio

paraladilataci6ndel combustible.

Vuelvaacolocarlatapadelagasolinayajt_stelabien.

Limpieelcombustiblequesehayaderramadosobreel motoryelequipo.

Trasladelam_quinaaotrazona.Espere5minutosantesdeencenderel

motor.

Nuncaalmacenelam_quinao elredpientedecombustibleenunespacio

cerradodondehayafuego,chispasoluzpiloto(porejemplo,hornos,

calentadoresdeagua,calefactores,secadoresderopa,etc.).

Dejequelam_quinaseenfrieporIomenos5minutosantesdeguardarla.

Nuncallenelosredpientesenelinteriordeunvehkuloocami6nocajade

remolqueconrecubrimientospl_sticos.Coloquesiemprelosrecipientesenel

pisoylejosdelvehkuloantesdellenarlos.

Siesposible,retireelequipoagasolinadelcami6noremolqueyll_neloen

elsuelo.Siestonoesposible,lleneelequipoenunremolqueconcontenedor

port_til,envezdedesdeunaboquilladispensadoradegasolina.

Mantengalaboquilladispensadoraencontactoconelbordedeldep6sito

decombustibleoconlaaberturadel redpienteentodo momento,hasta

terminarlacarga.Noutiliceundispositivodeapertura/cierredeboquilla.

FUNCIONAMIENTO

Nopongalasmanosolospiescercade[aspiezasrotatorias,enlacajadela

barrena/impulsoroenel montajedelcanaldedescarga.Hacercontactocon

piezasgiratoriaspuederesultarenlaamputad6ndemanoso pies.

Lapalancadecontroldelabarrena/impulsoresundispositivodeseguridad.

Nuncaevitesufundonamiento.Dehacerlolaoperad6ndelam_quinaes

riesgosaypuedeocasionarlesiones.

Laspalancasdecontroldebenfundonarbienenambasdirecdonesy

regresarautom_ticamentealaposid6ndedesengranecuandoselassuelta.

Nuncaoperelam_quinasifaltaunmontajedelcanalo sielmismoest_

daffado.Mantengatodoslosdispositivosdeseguridadensulugaryen

funcionamiento.

Nuncaendendaelmotorenespacioscerradoso enunazonaconpoca

ventilad6n.Elescapedelmotorcontienemon6xidodecarbono,ungas

inodoroyfetal.

Noutilicelam_quinabajolainfluenciadelalcoholo lasdrogas.

Elsilendadoryel motorsecalientany puedencausarquemaduras.Nolos

toque.Mantengaalosniffosalejados.

Seasumamenteprecavidocuandooperelam_quinasobreunasuperfide

congravaocuandolacruce.Mant_ngasealertaporsisepresentanpeligros

ocultosotr_nsito.

Tengacuidadocuandocambiededireccibnocuandooperelam_quinaen

pendientes.Nouselam_quinaenpendientespronundadas.

Planifiqueelpatr6nenelquevaair arrojandonieveparaevitarquela

descargadematerialseproduzcahadalasventanas,lasparedes,los

autom6viles,etc.yevitarasiposiblesdaffosmaterialeso lesionesproducidas

porlosrebotes.

Nuncadirijaladescargahacialosniffos,losobservadoreso lasmascotasni

dejequenadieseparedelantedelam_quina.

Nosobrecarguelacapacidaddelam_quinatratandodesacarlanievemuy

r_pidamente.

Nuncaopereestam_quinasinbuenavisibilidadoiluminad6n.Siempredebe

estarsegurodequeest_bienafirmadoysujetandofirmementelasmanijas.

Camine,nuncacorra.

Cortelacorrientealabarrena/impulsorcuandotransportelam_quinao

cuandolamismanoest_enuso.

Nuncaoperelam_quinaaaltaveloddaddedesplazamientosobre

superficiesresbaladizas.Mirehaciaabajoyhaciaarrasytengacuidado

cuandovayamarchaatr_s.

Silam_quinacomenzaraavibrardemaneraanormal,detengaelmotor,

desconecteelcabledelabujiayp6ngalademaneraquehagamasacontra

el motor.Inspeccionelam_quinaminudosamenteparaversiest_daffada.

Reparetodoslosdaffosantesdeencendery operarlam_quina.

Desengranetodaslaspalancasdecontrolydetengaelmotorantesdedejar

la posici6ndeoperaci6n(detr_sdelasmanijas).Espereaquelabarrena/

impulsorsedetengaporcompletoantesdedestaparelmontajedelcanalo

realizarajusteseinspecdones.

Nuncapongalasmanosenlasaberturasdedescargao derecolecci6n.Utilice

siemprelaherramientadelimpiezaqueseadjuntaparadestaparlaabertura

dedescarga.Nodestapeelmontajedelcanalmientrasel motorest_en

fundonamiento.Antesdedestaparlo,apagueel motorypermanezcadetr_s

delasmanijashastaquetodaslaspartesm6vilessehayandetenido.

Uses61ounionesyaccesoriosaprobadosporelfabricante(porejemplo,

pesasparalasruedas,cadenasparalosneum_ticos,cannas,etc.).Para

obtenerm_sinformaci6nacercadeestostemas,Ilameal1-800-469-4663.

31

Page 32

Paraencenderel motor,jaiedelacuerdalentamentehastaquesienta

resistenda,luegojaler_pidamente.Elreplieguer_pidodelacuerdade

arranque(tensi6nderetroceso)lejalar_lamanoyelbrazohadaelmotor

m_sr_pidodeIoqueustedpuedesoltar.Elresultadopuedenserhuesos

rotos,fracturas,hematomaso esguinces.

Sisepresentansituadonesquenoest_nprevistasenestemanual,sea

cuidadosoyuseelsentidocomfin.

Parapedirrepuestososerviciohorarioparaesteproducto,Ilamea1-800-

469-4663.

MANTENIMIENTO Y ALMACENAMIENTO

Nuncaalterelosdispositivosdeseguridad.Controleperi6dicamenteque

fundonencorrectamente.Rem[tasealasseccionesdemantenimientoy

ajustedeestemanual.

Antesderealizarlalimpieza,repararorevisarlam_quina,desengrane

todaslaspalancasdecontrolydetengaelmotor.Espereaquelabarrena/

impulsorsedetengaporcompleto.Desconecteelcabledelabujiayp6ngalo

haciendomasacontraelmotorparaevitarqueseenciendaaccidentalmente.

Controlefrecuentementequetodoslospernosytornillosest_nbien

ajustadosparacomprobarquelam_quinaseencuentraencondidones

segurasdefuncionamiento.Adem_s,hagaunainspecci6nvisualdela

m_quinaparaverificarsiest_dafrada.

Nocambielaconfigurad6ndelreguladordelmotorniaceleredemasiado

elmismo.Elreguladordel motorcontrolalaveloddadm_ximasegurade

funcionamientodel motor.

Lasplacasderaspadoylaszapatasantideslizantesqueseusanconla

m_quinaquitanievesedesgastanysedafran.Paraprotegersuseguridad,

verifiquefrecuentementetodosloscomponentesyreempl_celoss61ocon

partesdelosfabricantesdeequiposoriginales(OEM).iEIusodepiezasque

nocumplenconlasespecificadonesdelequipooriginalpuederesultaren

rendimientoinadecuadoadem_sdeponerenfresgolaseguridad!

Reviselaspalancasdecontrolperi6dicamenteparaverificarqueengraneny

desengranenadecuadamenteyajtistelossiesnecesario.Consulte[asecd6n

deajustesdeestemanualdeloperadorparaobtenerinstrucciones.

Mantengaoreemplacelasetiquetasdeseguridadeinstruccionessegtinsea

necesario.

SegunlaComisi6ndeSegufrdaddeProductosparaelConsumidordelos

EstadosUnidos(CPSC)ylaAgenciadeProtecci6nAmbientaldelosEstados

Unidos(EPA),esteproductotJeneunavidafitil mediadesiete(7)afros,6

60horasdefundonambnto.AI finalizarlavidafitil media,adquierauna

m_quinanuevaohagainspecdonaranualmente6staporundistribuidorde

servidoautofrzadoparacerciorarsedequetodoslossistemasmec_nkosyde

seguridadfundonancorrectamentey notienenexcesivodesgaste.SinoIo

hate,puedenproducirseaccidentes,lesionesomuerte

Nuncaalmacenelam_quinaoel recipientedecombustibleenunespacio

cerradodondehayafuego,chispasoluzpilotocomoporejemplo,

calentadoresdeagua,hornos,secadoresderopa,etc.

Consultesiempreelmanualdeloperadorparaobtenerinstrucdones

adecuadasparaelalmacenambntofueradetemporadaVerifique

frecuentementelaI[neadecombustible,eltanque,eltap6n,ylosaccesorios

buscandorajaduraso p6rdidas.Reemplacedesernecesario.

Nod6arranqueal motorsinoest_labujiadeencendido.

NO MODIFIQUE EL MOTOR

Paraevitarlesionesgraveso lamuerte,no modifiqueel motorbajoninguna

circunstancia.Sicambialaconfigurad6ndelreguladorelmotorpuede