Page 1

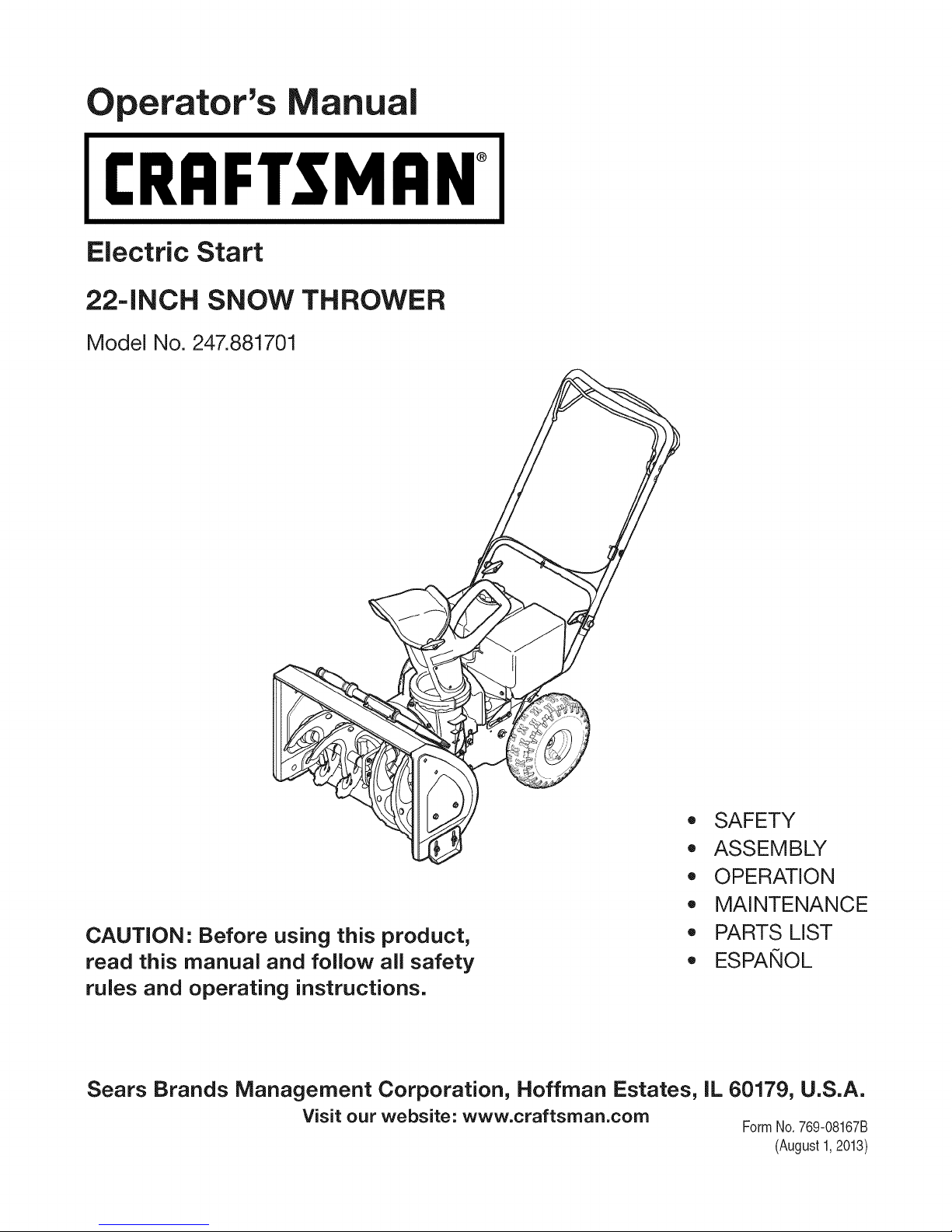

perator_s nual

I:RRFrgMRN°

Electric Start

-INCH SNOW THROWER

Model No. 247.881701

CAUTION: Before using this product,

read this manual and follow all safety

rules and operating instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.corn

,, SAFETY

o ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPANOL

FormNo.769-08167B

(August1,2013)

Page 2

WarrantyStatement.................... Page2

SafeOperation Practices ................ Page 3

Assembly ............................ Page 7

Operation ........................... Page 11

Maintenance & Service ................. Page 15

Off-Season Storage ................... Page 20

Troubleshooting ...................... Page 21

Parts List ............................ Page 22

Repair Protection Agreement ............ Page 41

Espa_ol ............................. Page 42

Contact Numbers .................. Back Cover

CRAFTSMANTWOYEAR FULLWARRANTY

FORTWOYEARSfromthe dateof purchase,this productiswarrantedagainstanydefectsin materialor workmanship.A defective

productwillreceivefreerepairor replacementif repairisunavailable.

Forwarranty coverage details to obtain freerepairorreplacement,visittheweb site: www.craftsman.com

Thiswarranty coversONLYdefects in materialandworkmanship. Warrantycoverage does NOTinclude:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,includingbutnot limitedtoaugers,augerpaddles,

driftcutters,skidshoes,shaveplate,shearpins,sparkplug,aircleaner,belts,andoilfilter.

• Standardmaintenanceservicing,oilchanges,or tune-ups.

Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,or glass.

Tireor wheelreplacementorrepairresultingfromnormalwear,accident,or improperoperationormaintenance.

Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedto damagecausedbyover-speedingtheengine,or from

impactingobjectsthatbendtheframe,augershaft,etc.

• Repairsnecessarybecauseof operatornegligence,includingbutnot limitedto,electricalandmechanicaldamagecausedby

improperstorage,failureto usethepropergradeandamountof engineoil,or failureto maintaintheequipmentaccordingto the

instructionscontainedintheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedto becontaminatedoroxidized(stale).Ingeneral,fuelshouldbe

usedwithin30 daysof itspurchasedate.

Normaldeteriorationandwearof theexteriorfinishes,orproductlabelreplacement.

Thiswarrantyisvoidif thisproductisever usedwhileprovidingcommercialservicesor if rentedtoanotherperson.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstatetostate.

SearsBrands ManagementCorporation, HoffmanEstates,IL 60179

EngineOilType: 5W-30

EngineOilCapacity: 20ounces

FuelCapacity: 2.3Quarts

SparkPlug: F6RTC(F6TC)

SparkPlugGap: .020"to.030"

© SearsBrands,LLC

ModelNumber.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Page 3

Thissymbolpointsout importantsafety instructionswhich,ifnot

followed,couldendangerthe personalsafetyand/orproperty of

yourselfandothers.Readandfollow allinstructions inthismanual

beforeattempting to operatethis machine.Failureto complywith these

instructionsmayresultinpersonalinjury.Whenyouseethis symbol,HEED

ITSWARNING!

Thismachinewasbuilt tobeoperatedaccordingto thesafeoperation

practicesinthis manual.Aswith anytype of powerequipment,

carelessnessorerroronthe part of the operatorcanresultinseriousinjury.

Thismachineiscapableof amputatingfingers, hands,toesandfeet and

throwingdebris.Failuretoobservethefollowing safetyinstructionscould

resultinseriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof its constituents,and certainvehiclecomponents

containor emit chemicalsknownto Stateof Californiatocausecancerand

birth defectsorother reproductiveharm.

TRAINING

Read,understand,andfollowall instructionsonthemachineandinthe

manual(s)beforeattemptingto assembleandoperate.Failuretodosocan

resultinseriousinjurytotheoperatorand/orbystanders.Keepthis manual

inasafeplaceforfutureandregularreferenceandfororderingreplacement

parts.

Befamiliarwithallcontrolsandtheirproperoperation.Knowhowto stop

themachineanddisengagethemquickly.

Neverallowchildrenunder14yearsofagetooperatethismachine.Children

14andovershouldreadandunderstandtheinstructionsandsafeoperation

practicesinthismanualandonthemachineandbetrainedandsupervised

byanadult.

Neverallowadultsto operatethismachinewithout properinstruction.

Thrownobjectscancauseseriouspersonalinjury.Planyoursnow-throwing

patterntoavoiddischargeof materialtowardroads,bystandersandthelike.

Keepbystanders,petsandchildrenatleast75feetfromthemachinewhileit

isin operation.Stopmachineif anyoneentersthearea.

Exercisecautiontoavoidslippingorfalling,especiallywhenoperatingin

reverse.

PREPARATION

Thoroughlyinspecttheareawheretheequipmentisto beused.Removeall

doormats,newspapers,sleds,boards,wiresandotherforeignobjects,which

couldbetrippedoverorthrownbytheauger/impeller.

Alwayswearsafetyglassesoreyeshieldsduringoperationandwhile

performinganadjustmentor repairto protectyoureyes.Thrownobjects

whichricochetcancauseseriousinjuryto theeyes.

Donotoperatewithout wearingadequatewinteroutergarments.Donot

wearjewelry,longscarvesorotherlooseclothing,whichcouldbecome

entangledinmovingparts.Wearfootwearwhichwill improvefootingon

slipperysurfaces.

Useagroundedthree-wkeextensioncordandreceptacleforallmachines

with electricstartengines.

Your Responsibility--Restrict theuseofthis powermachineto

personswhoread,understandandfollow the warningsand instructionsin

thismanualandonthe machine.

SAVETHESEINSTRUCTIONS!

Disengageallcontrolleversbeforestartingtheengine.

Adjustcollectorhousingheighttocleargravelorcrushedrocksurfaces.

Neverattempttomakeanyadjustmentswhileengineisrunning,except

wherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjusttooutdoortemperaturebeforestartingto

clearsnow.

Safe Handling of Gasoline:

Toavoidpersonalinjuryorpropertydamageuseextremecareinhandling

gasoline.Gasolineisextremelyflammable andthe vaporsareexplosive.

Seriouspersonalinjurycanoccurwhengasolineisspilledonyourselforyour

clotheswhichcanignite.Washyour skinandchangeclothesimmediately.

Useonlyanapprovedgasolinecontainer.

Neverfill containersinsideavehicleoronatruckortrailerbedwitha plastic

liner.AIwaysplacecontainersonthegroundawayfromyourvehiclebefore

filling.

Whenpractical,removegas-poweredequipmentfromthetruckor

trailerandrefuelitontheground.Ifthisis notpossible,thenrefuelsuch

equipmentonatrailerwith aportablecontainer,ratherthanfromagasoline

dispensernozzle.

Keepthenozzleincontactwiththerimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.Donotuseanozzlelock-opendevice.

Extinguishallcigarettes,cigars,pipesandothersourcesofignition.

Neverfuelmachineindoors.

Neverremovegascaporaddfuelwhiletheengineishotorrunning.Allow

enginetocoolatleasttwo minutesbeforerefueling.

Neveroverfill fueltank.Filltankto nomorethan1/2inchbelowbottomof

fillernecktoallowspacefor fuelexpansion.

Replacegasolinecapandtightensecurely.

Ifgasolineisspilled,wipeit offthe engineandequipment.Moveunitto

anotherarea.Wait5 minutesbeforestartingtheengine.

Page 4

Toreducefirehazards,keepmachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupofforfuelspillageandremoveanyfuelsoakeddebris.

NeverstorethemachineorfuelcontainerJnddewherethereisanopen

flame,sparkorpilotlightasonawaterheater,spaceheater,furnace,clothes

dryerorothergasappliances.

OPERATION

Donotputhandsorfeetnearrotatingparts,intheauger/impellerhousing

orchuteassembly.Contactwiththerotatingpartscanamputatehandsand

feet.

Theauger/impellercontrolleverisasafetydevice.Neverbypassits

operation.Doingsomakesthemachineunsafeandmaycausepersonal

injury.

Thecontrolleversmustoperateeasilyin bothdirectionsandautomatically

returntothedisengagedpositionwhenreleased.

Neveroperatewith amissingordamagedchuteassembly.Keepallsafety

devicesin placeandworking.

Neverrunanengineindoorsor inapoorlyventilatedarea.Engineexhaust

containscarbonmonoxide,anodorlessanddeadlygas.

Donotoperatemachinewhileundertheinfluenceof alcoholordrugs.

Mufflerandenginebecomehotandcancauseaburn.Donottouch.Keep

childrenaway.

Exerciseextremecautionwhenoperatingonorcrossinggravelsurfaces.Stay

alertforhiddenhazardsortraffic.

Exercisecautionwhenchangingdirectionandwhileoperatingonslopes.Do

notoperateonsteepslopes.

Planyoursnow-throwingpatterntoavoiddischargetowardswindows,

walls,carsetc.Thus,avoidingpossiblepropertydamageorpersonalinjury

causedbyaricochet.

Neverdirectdischargeatchildren,bystandersandpetsorallowanyonein

frontofthemachine.

Donotoverloadmachinecapacitybyattemptingtoclearsnowattoofastof

arate.

Neveroperatethismachinewithoutgoodvisibilityorlight.Alwaysbesureof

yourfootingandkeepafirm holdonthehandles.Walk,neverrun.

Disengagepowertotheauger/impellerwhentransportingornotinuse.

Neveroperatemachineathightransportspeedsonslipperysurfaces.Look

downandbehindandusecarewhenbackingup.

Ifthemachineshouldstarttovibrateabnormally,stoptheengine,

disconnectthesparkplugwireandgrounditagainsttheengine.Inspect

thoroughlyfordamage.Repairanydamagebeforestartingandoperating.

Disengageallcontrolleversandstopenginebeforeyouleavetheoperating

position(behindthehandles).Waituntiltheauger/impellercomesto

acompletestopbeforeuncloggingthechuteassembly,makingany

adjustments,orinspections.

Neverputyourhandinthedischargeorcollectoropenings.Donotunclog

chuteassemblywhileengineisrunning.Shutoff engineandremainbehind

handlesuntilallmovingpartshavestoppedbeforeunclogging.

Useonlyattachmentsandaccessoriesapprovedbythemanufacturer(e.g.

wheelweights,tirechains,cabsetc.).

Whenstartingengine,pull cordslowlyuntil resistanceisfelt,thenpull

rapidly.Rapidretractionofstartercord(kickback)will pullhandandarm

towardenginefasterthanyoucanletgo.Brokenbones,fractures,bruisesor

sprainscouldresult.

Ifdtuationsoccurwhicharenotcoveredinthismanual,usecareandgood

judgment.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwith therotatingimpellerinsidethedischargechuteisthemost

commoncauseofinjuryassociatedwithsnowthrowers.Neveruseyourhandto

cleanoutthedischargechute.

Toclearthechute:

a. SHUTTHEENGINEOFF!

b. Wait10secondsto besuretheimpellerbladeshavestopped

rotating.

c. Alwaysuseaclean-outtool,notyourhands.

MAINTENANCE & STORAGE

Nevertamperwith safetydevices.Checktheirproperoperationregularly.

Referto themaintenanceandadjustmentsectionsof thismanual.

Beforecleaning,repairing,orinspectingmachinedisengageallcontrol

leversandstoptheengine.Waituntil theauger/impellercometo acomplete

stop.Disconnectthesparkplugwireandgroundagainsttheengineto

preventunintendedstarting.

Checkboltsandscrewsforpropertightnessat frequentintervalsto keepthe

machineinsafeworkingcondition.Also,visuallyinspectmachineforany

damage.

Donotchangetheenginegovernorsettingorover-speedtheengine.The

governorcontrolsthemaximumsafeoperatingspeedoftheengine.

Snowthrowershaveplatesandskidshoesaresubjecttowearanddamage.

Foryoursafetyprotection,frequentlycheckallcomponentsandreplace

with originalequipmentmanufacturer's(OEM)partsonlyaslistedinthe

Partspagesofthisoperator'smanual.Useof partswhichdonot meetthe

originalequipmentspecificationsmayleadto improperperformanceand

compromisesafety!

Checkcontrolleversperiodicallyto verifytheyengageanddisengage

properlyandadjust,if necessary.Refertotheadjustmentsectioninthis

operator'smanualfor instructions.

Maintainorreplacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsandregulationsforgas,oil,etc.to protectthe

environment.

Priorto storing,runmachineafewminutesto clearsnowfrommachineand

preventfreezeupof auger/impeller.

Neverstorethemachineorfuelcontainerinsidewherethereisanopen

flame,sparkorpilotlightsuchasa waterheater,furnace,clothesdryeretc.

Alwaysrefertotheoperator'smanualforproperinstructionsonoff-season

storage.

4

Page 5

Checkfuelline,tank,cap,andfittingsfrequentlyfor cracksor leaks.Replace

if necessary.

Donotcrankenginewithsparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)andthe

U.S.EnvironmentalProtectionAgency(EPA),thisproducthasan Average

Useful Lifeof seven(7)years,or60hoursofoperation.Attheendof

theAverage Useful Lifehavethemachineinspectedannuallybyan

authorizedservicedealerto ensurethat allmechanicalandsafetysystems

areworkingproperlyandnotwornexcessively.Failureto dosocanresultin

accidents,injuriesordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donotmodifyengineinanyway.Tampering

with thegovernorsetting canleadto arunawayengineandcauseit to

operateat unsafespeeds.Nevertamperwith factorysetting ofengine

governor.

NOTICE REGARDING EMiSSiONS

Engineswhichare certifiedto complywith CaliforniaandfederalEPA

emissionregulationsfor SORE(SmallOff RoadEquipment)arecertified

tooperateonregularunleadedgasoline,and mayincludethe following

emissioncontrolsystems:EngineModification (EM),OxidizingCatalyst(0C),

SecondaryAirinjection(SAI)andThreeWayCatalyst(TWC)ifsoequipped.

SPARK ARRESTOR

e

Thismachineisequippedwith aninternalcombustionengineandshould

not beusedonornearanyunimprovedforest-covered,brushcoveredor

grass-coveredland unlessthe engine'sexhaustsystemisequippedwith a

sparkarrestormeetingapplicablelocalorstatelaws(if any).

Ira sparkarrestoris used,it shouldbemaintainedin effectiveworking order

bythe operator.In theStateofCaliforniatheaboveisrequiredbylaw (Section

4442ofthe CaliforniaPublicResourcesCode).Otherstates mayhavesimilar

laws.Federallawsapplyonfederallands.

Asparkarrestorfor the muffler isavailablethroughyour nearestSearsParts

andRepairServiceCenter.

Page 6

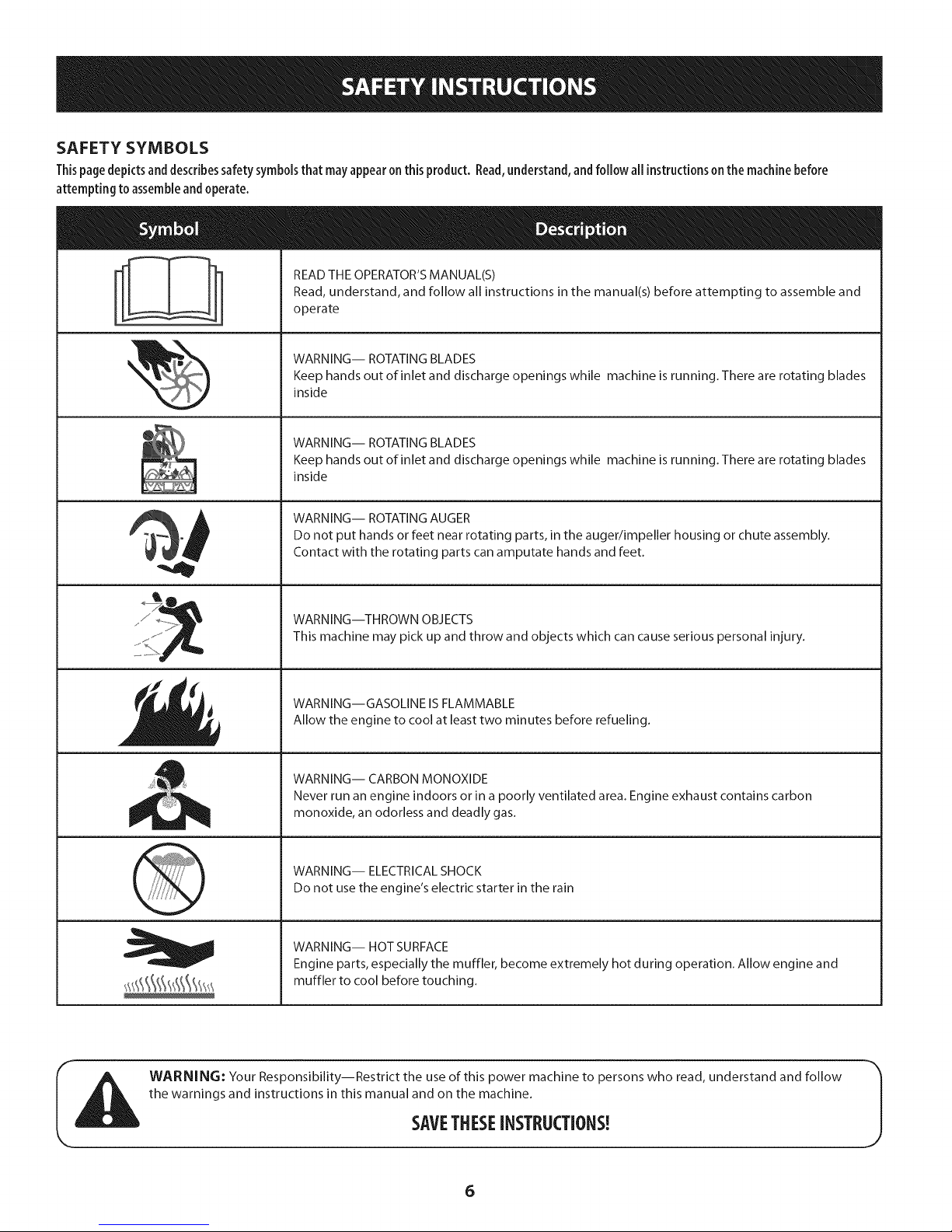

SAFETY SYMBOLS

Thispage depicts and describes safety symbols that may appear on this product. Read,understand, and follow all instructions on the machine before

attempting to assemble and operate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can causeserious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

WARNING: Your Responsibility--Restrict the use of this power machine to persons who read, understand and follow

the warnings and instructions in this manual and on the machine.

SAVETHESEiNSTRUCTIONS!

6

Page 7

IMPORTANT: This unit isshipped with the engine full of oil. After

assembly, see page 10for fuel and oil details.

Removing FromCarton

1. Cutthecornersof thecartonandlaythesidesflat ontheground.Removeall

packinginserts.

2. Movethesnowthroweroutof thecarton.

3. Makecertainthecartonhasbeencompletelyemptiedbeforediscardingit.

DoNOTlift the snowthrower bythe chutehandle.

Before Assembly

NOTE:Referencetoright,left,frontorrearoftheunit isfromtheoperating

position,facingforward,unlessotherwisestated.

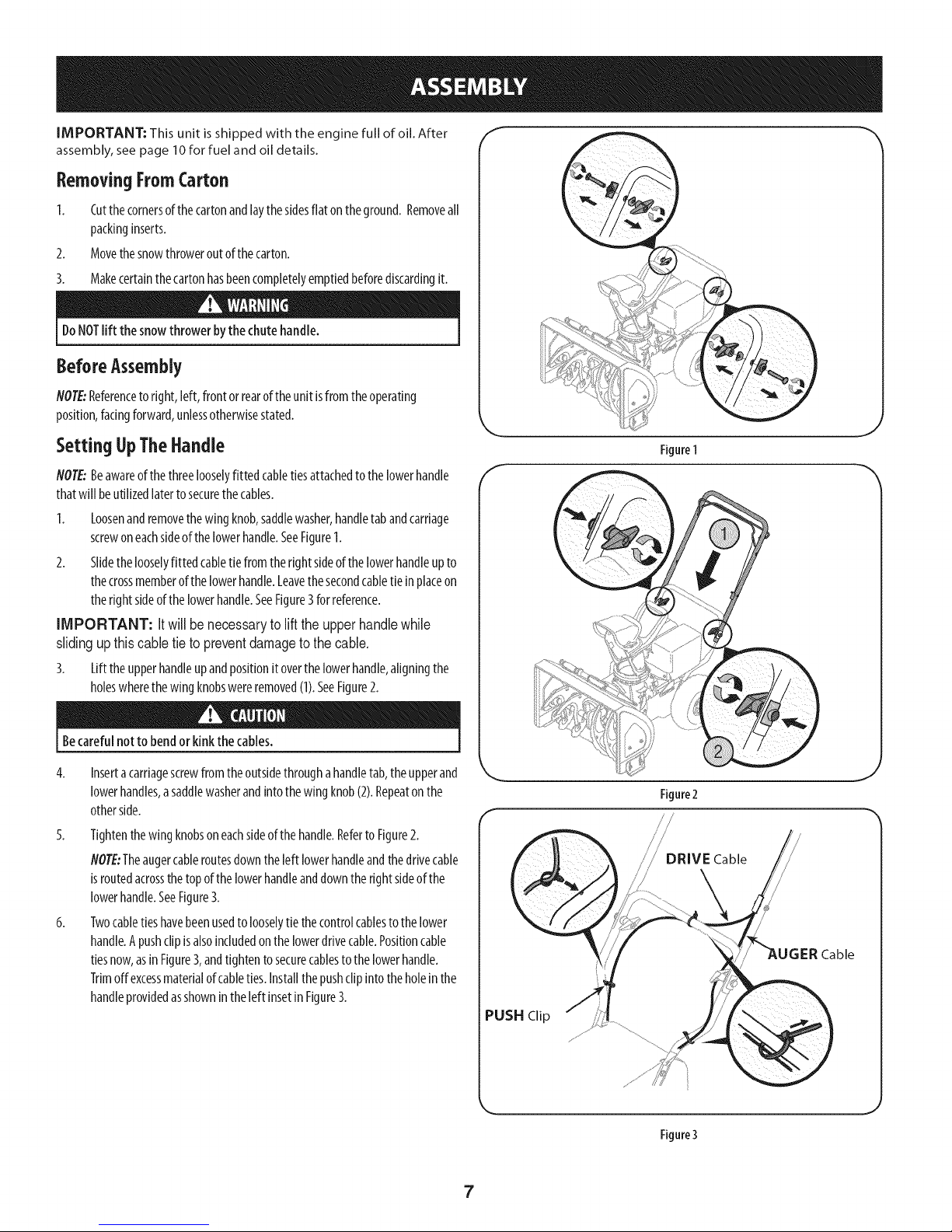

Setting UpTheHandle

NOTE:Beawareofthethreelooselyfitted cabletiesattachedtothelowerhandle

thatwill beutilizedlatertosecurethecables.

1. Loosenandremovethewingknob,saddlewasher,handletabandcarriage

screwoneachsideofthelowerhandle.SeeFigure1.

2. Slidethelooselyfitted cabletiefromtherightsideofthelowerhandleupto

thecrossmemberof thelowerhandle.Leavethesecondcabletiein placeon

therightsideofthelowerhandle.SeeFigure3forreference.

IMPORTANT: Itwill be necessary to lift the upper handle while

sliding up this cable tie to prevent damage to the cable.

3. Lifttheupperhandleupandpositionit overthelowerhandle,aligningthe

holeswherethewingknobswereremoved(1).SeeFigure2.

Becarefulnotto bend orkinkthe cables.

4. Inserta carriagescrewfromtheoutsidethroughahandletab,theupperand k,,,

lowerhandles,asaddlewasherandintothewingknob(2).Repeatonthe

otherside. _-

5. Tightenthewingknobsoneachsideof thehandle.Referto Figure2.

NOTE:Theaugercableroutesdowntheleft lowerhandleandthedrivecable

isroutedacrossthetopofthe lowerhandleanddowntherightsideof the

lowerhandle.SeeFigure3.

6. Twocabletieshavebeenusedto looselytiethecontrolcablesto the lower

handle.Apushclipisalsoincludedonthe lowerdrivecable.Positioncable

tiesnow,asinFigure3,andtightentosecurecablesto thelowerhandle.

Trimoff excessmaterialofcableties.Installthepushclipintotheholein the

handleprovidedasshownin theleftinsetin Figure3.

7

Figure2

/

DRIVE Cable

Cable

PUSH Clip

Figure3

Page 8

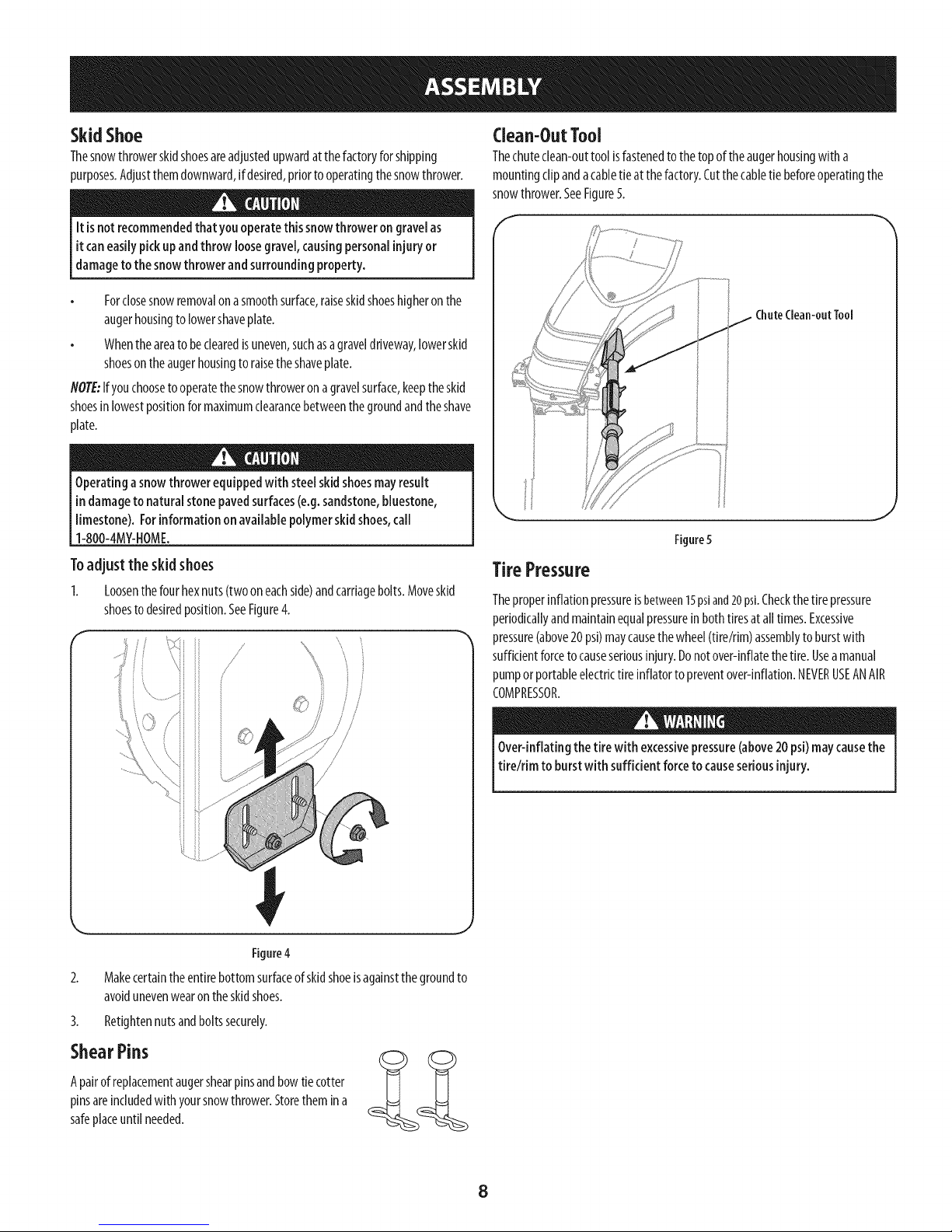

SkidShoe

Thesnowthrowerskidshoesareadjustedupwardatthefactoryforshipping

purposes.Adjustthemdownward,if desired,priorto operatingthesnowthrower.

Itisnot recommendedthat youoperatethis snowthrower ongravelas

itcaneasilypickupandthrow loosegravel,causingpersonalinjuryor

damageto the snowthrowerand surroundingproperty.

Clean-OutTool

Thechuteclean-outtool isfastenedtothetopoftheaugerhousingwitha

mountingclipandacabletie atthefactory.Cutthecabletiebeforeoperatingthe

snowthrower.SeeFigure5.

Forclosesnowremovalonasmoothsurface,raiseskidshoeshigheronthe

augerhousingtolowershaveplate.

Whentheareato beclearedisuneven,suchasagraveldriveway,lowerskid

shoesontheaugerhousingtoraisetheshaveplate.

flOT£:Ifyouchooseto operatethesnowthroweronagravelsurface,keeptheskid

shoesinlowestpositionfor maximumclearancebetweenthegroundandtheshave

plate.

Operatingasnowthrower equippedwith steelskidshoesmayresult

in damageto natural stonepavedsurfaces(e.g.sandstone,bluestone,

limestone).Forinformationonavailable polymerskidshoes,call

1-800-4MY-HOME.

Toadjust the skid shoes

I. Loosenthefourhexnuts(twooneachside)andcarriagebolts.Moveskid

shoestodesiredposition.SeeFigure4.

//

iii

/

/

//

ChuteClean-out Tool

Figure5

TirePressure

Theproperinflationpressureisbetween15psiand20psi.Checkthetire pressure

periodicallyandmaintainequalpressureinbothtiresatalltimes.Excessive

pressure(above20psi)maycausethewheel(tire/rim)assemblytoburstwith

sufficientforcetocauseseriousinjury.Donotover-inflatethetire. Useamanual

pumporportableelectrictire inflatorto preventover-inflation.NEVERUSEANAIR

COMPRESSOR.

Over-inflatingthe tire with excessivepressure(above20psi)maycausethe

tire/rim to burstwith sufficient forceto causeseriousinjury.

Figure4

2. Makecertaintheentirebottomsurfaceof skidshoeisagainstthegroundto

avoidunevenwearontheskidshoes.

3. Retightennutsandboltssecurely.

ShearPins

Apairofreplacementaugershearpinsandbowtiecotter

pinsareincludedwith yoursnowthrower.Storethemina

safeplaceuntilneeded.

8

Page 9

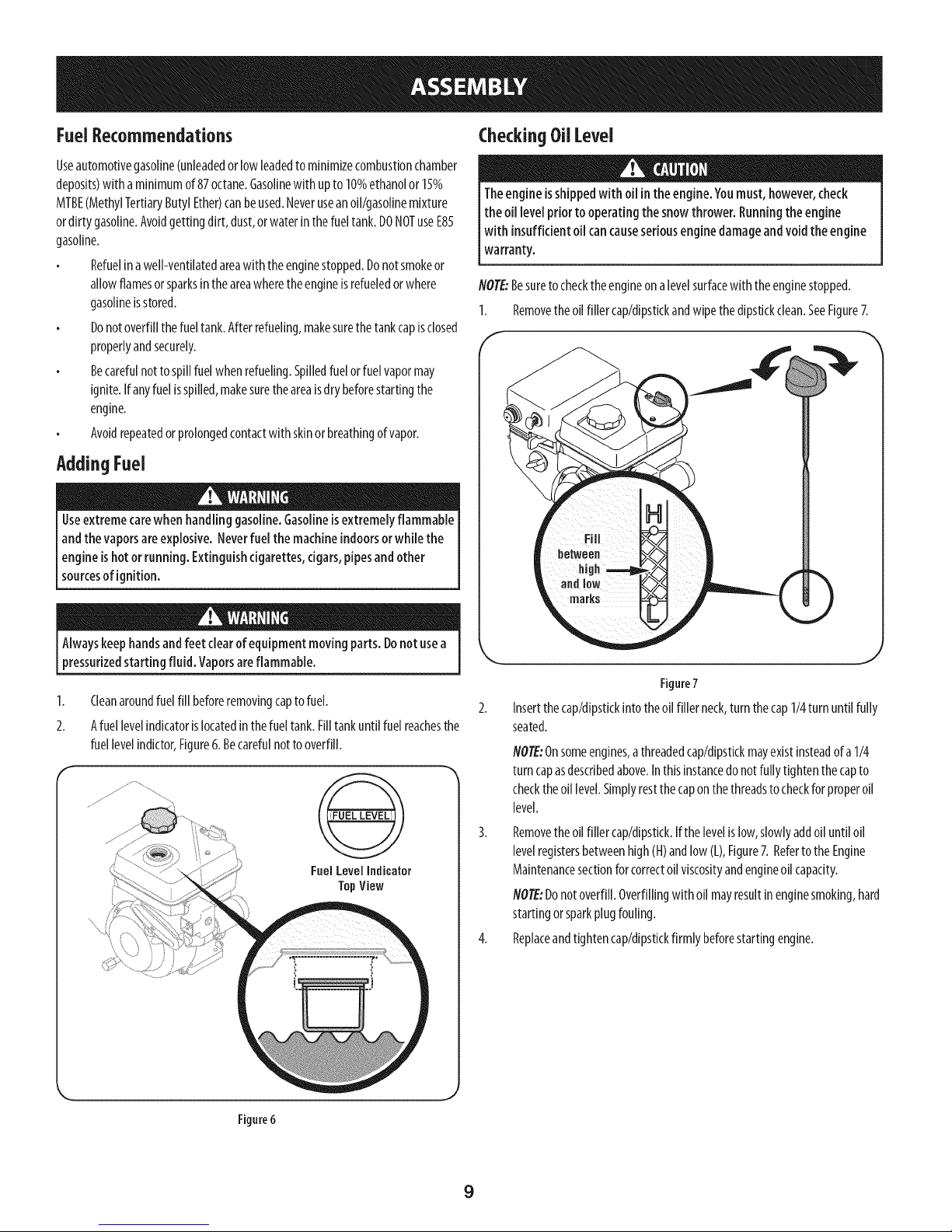

FuelRecommendations

Useautomotivegasoline(unleadedorlowleadedto minimizecombustionchamber

deposits)witha minimumof87octane.Gasolinewith upto10%ethanolor15%

MTBE(MethylTertiaryButylEther)canbeused.NeveruseanoWgasolinemixture

ordirtygasoline.Avoidgettingdirt,dust,orwaterinthefueltank.DONOTuseE85

gasoline.

Refuelinawell-ventilatedareawith theenginestopped.Donotsmokeor

allowflamesorsparksintheareawheretheengineisrefueledorwhere

gasolineisstored.

Donotoverfillthefueltank.Afterrefueling,makesurethetankcapisclosed

properlyandsecurely.

Becarefulnotto spillfuelwhenrefueling.Spilledfuelorfuelvapormay

ignite.Ifanyfuelisspilled,makesuretheareaisdrybeforestartingthe

engine.

Avoidrepeatedorprolongedcontactwith skinorbreathingofvapor.

AddingFuel

Useextremecarewhen handlinggasoline.Gasolineisextremelyflammable

andthevaporsare explosive.Neverfuel themachineindoorsorwhile the

engine ishotor running.Extinguishcigarettes,cigars,pipesandother

[sourcesof gnt on.

CheckingOilLevel

Theengineisshippedwith oil intheengine.Youmust,however,check

the oil levelpriorto operatingthe snowthrower. Runningtheengine

with insufficientoil cancauseseriousenginedamageandvoidthe engine

warranty.

NOTE:Besuretochecktheengineonalevelsurfacewith theenginestopped.

1. Removetheoilfiller cap/dipstickandwipethedipstickclean.SeeFigure7.

Alwayskeephandsandfeet clearof equipmentmoving parts. Donotusea

pressurizedstarting fluid. Vaporsareflammable.

I.

Cleanaroundfuelfill beforeremovingcapto fuel.

2.

Afuel levelindicatorislocatedinthefueltank.Filltankuntilfuelreachesthe

fuellevelindictor,Figure6.Becarefulnottooverfill.

Fuel Level Indicator

TopView

j

Figure7

Insertthecap/dipstickintotheoil filler neck,turnthecap1/4turnuntil fully

seated.

NOTE:Onsomeengines,athreadedcap/dipstickmayexistinsteadofa 1/4

turncapasdescribedabove.Inthisinstancedonotfullytightenthecapto

checktheoil level.Simplyrestthecaponthethreadstocheckfor properoil

level.

3. Removetheoilfillercap/dipstick.Ifthe levelislow,slowlyaddoil untiloil

levelregistersbetweenhigh(H)andlow(L),Figure7.RefertotheEngine

Maintenancesectionforcorrectoil viscosityandengineoilcapacity.

NOTE:Donotoverfill.Overfillingwithoil mayresultinenginesmoking,hard

startingorsparkplugfouling.

4. Replaceandtightencap/dipstickfirmly beforestartingengine.

Figure6

9

Page 10

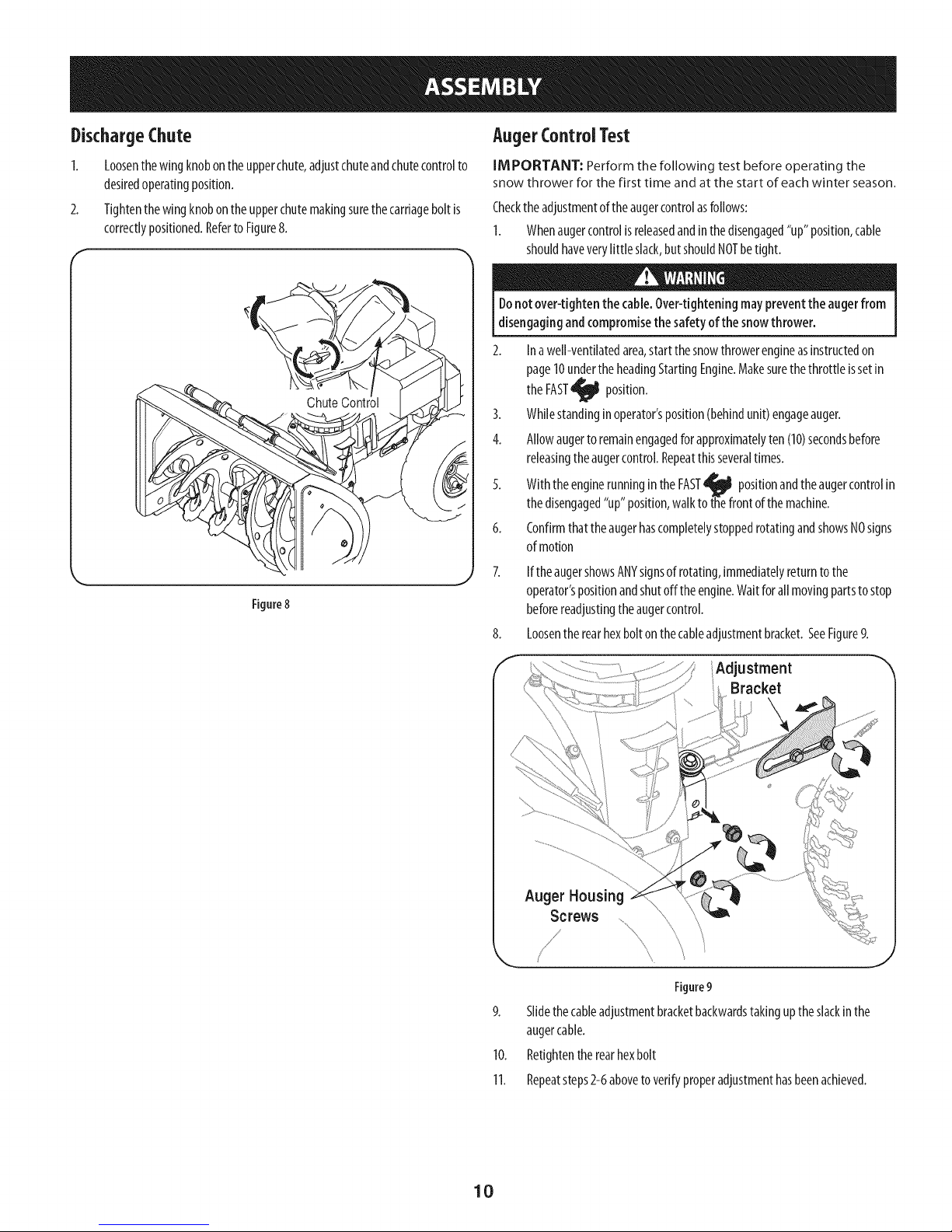

DischargeChute

Loosenthewing knobontheupperchute,adjustchuteandchutecontrolto

desiredoperatingposition.

2.

Tightenthewingknobontheupperchutemakingsurethecarriageboltis

correctlypositioned.RefertoFigure8.

F

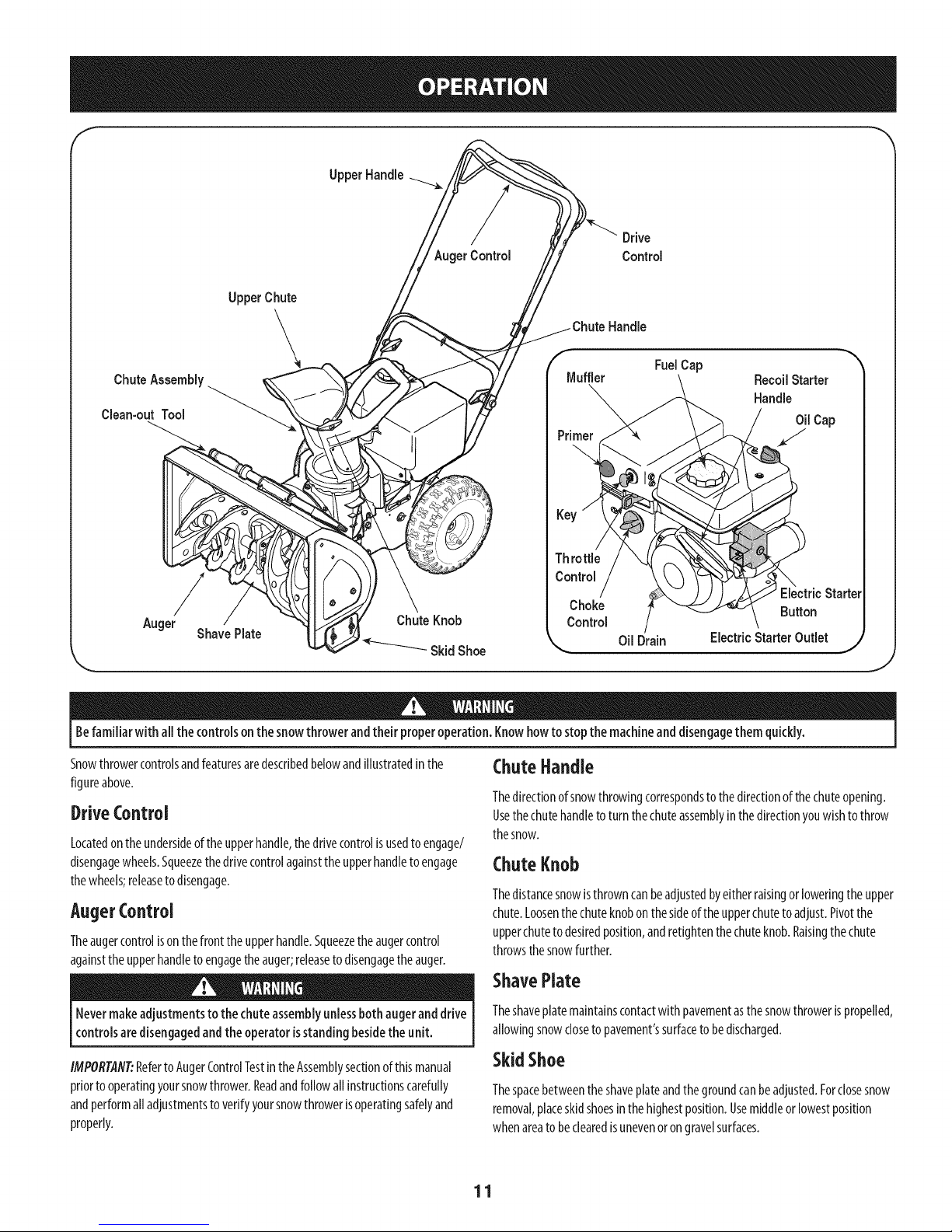

AugerControlTest

IMPORTANT: Perform the following test before operating the

snow thrower for the first time and at the start of each winter season.

Checktheadjustmentoftheaugercontrolasfollows:

1. Whenaugercontrolisreleasedandinthedisengaged"up"position,cable

shouldhaveverylittle slack,butshouldNOTbetight.

Donotover-tighten the cable.Over-tighteningmaypreventthe augerfrom

disengagingandcompromisethe safetyof the snowthrower.

2. Inawell-ventilatedarea,startthesnowthrowerengineasinstructedon

page10undertheheadingStartingEngine.Makesurethethrottle issetin

the FAST_j_!t position.

3. Whilestandinginoperator'sposition(behindunit)engageauger.

4. Allowaugertoremainengagedforapproximatelyten(10)secondsbefore

releasingtheaugercontrol.Repeatthisseveraltimes.

5. Withtheenginerunningin theFAST4_1 positionandtheaugercontrolin

thedisengaged"up"position,walktothefrontofthemachine.

6. ConfirmthattheaugerhascompletelystoppedrotatingandshowsNOsigns

ofmotion

\

Figure8

7. IftheaugershowsANYsignsofrotating,immediatelyreturntothe

operator'spositionandshutoff theengine.Waitforallmovingpartstostop

beforereadjustingtheaugercontrol.

8. Loosentherearhexboltonthecableadjustmentbracket.SeeFigure9.

F i Adjustment

Bracket

Auger Housing

Screws

Figure9

9. Slidethecableadjustmentbracketbackwardstakinguptheslackinthe

augercable.

10. Retightentherearhexbolt

11. Repeatsteps2-6abovetoverifyproperadjustmenthasbeenachieved.

10

Page 11

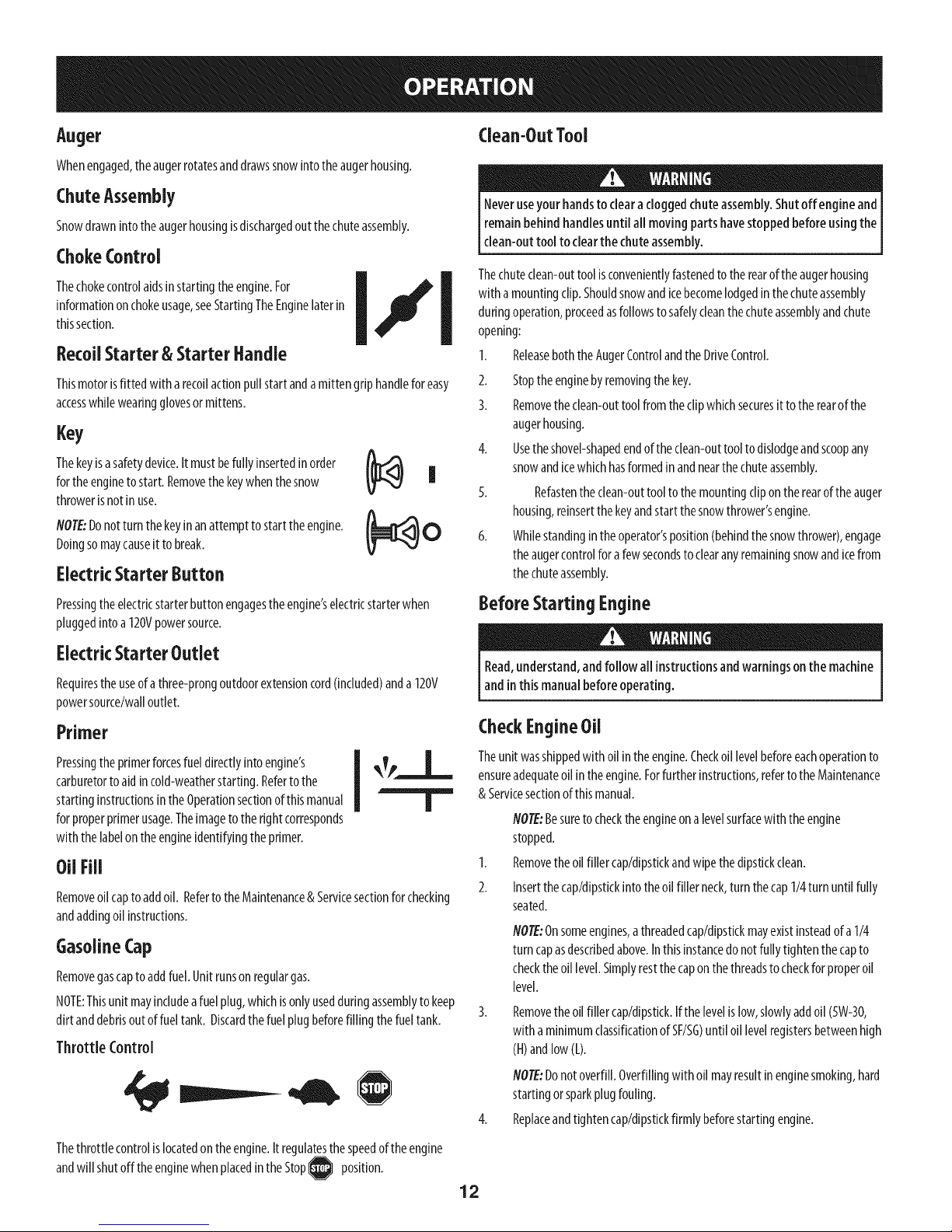

UpperChute

Upper HandJe

Drive

AugerControl Control

ChuteAssembJ

Clean-out Tool

Auger

Befamiliarwith all thecontrolsonthesnow throwerandtheirproperoperation.Knowhowto stopthemachineanddisengagethemquickly.

Snowthrowercontrolsandfeaturesaredescribedbelowandillustratedinthe

figureabove.

DriveControl

Locatedontheundersideoftheupperhandle,thedrivecontrolisusedtoengage/

disengagewheels.Squeezethedrivecontrolagainsttheupperhandleto engage

thewheels;releaseto disengage.

AugerControl

Theaugercontrolisonthefronttheupperhandle.Squeezetheaugercontrol

againsttheupperhandleto engagetheauger;releasetodisengagetheauger.

ShavePlate

ChuteHandle

Thedirectionofsnowthrowingcorrespondsto thedirectionof thechuteopening.

Usethechutehandletoturnthechuteassemblyinthedirectionyouwishtothrow

thesnow.

ChuteEnob

Thedistancesnowisthrowncanbeadjustedbyeitherraisingorloweringtheupper

chute.Loosenthechuteknobonthesideoftheupperchutetoadjust.Pivotthe

upperchutetodesiredposition,andretightenthechuteknob.Raisingthechute

throwsthesnowfurther.

FuelCap

RecoilStarter

Handle

Oil Drain Electric StarterOutlet

ShavePlate

Nevermakeadjustmentstothechute assemblyunlessbothaugeranddrive

controlsaredisengagedandtheoperatorisstandingbesidetheunit.

IMPORTANT:Referto AugerControlTestin theAssemblysectionofthismanual

priortooperatingyoursnowthrower.Readandfollowallinstructionscarefully

andperformalladjustmentsto verifyyoursnowthrowerisoperatingsafelyand

properly.

Theshaveplatemaintainscontactwithpavementasthesnowthrowerispropelled,

allowingsnowclosetopavement'ssurfacetobedischarged.

SkidShoe

Thespacebetweentheshaveplateandthegroundcanbeadjusted.Forclosesnow

removal,placeskidshoesinthehighestposition.Usemiddleorlowestposition

whenareato beclearedisunevenorongravelsurfaces.

11

Page 12

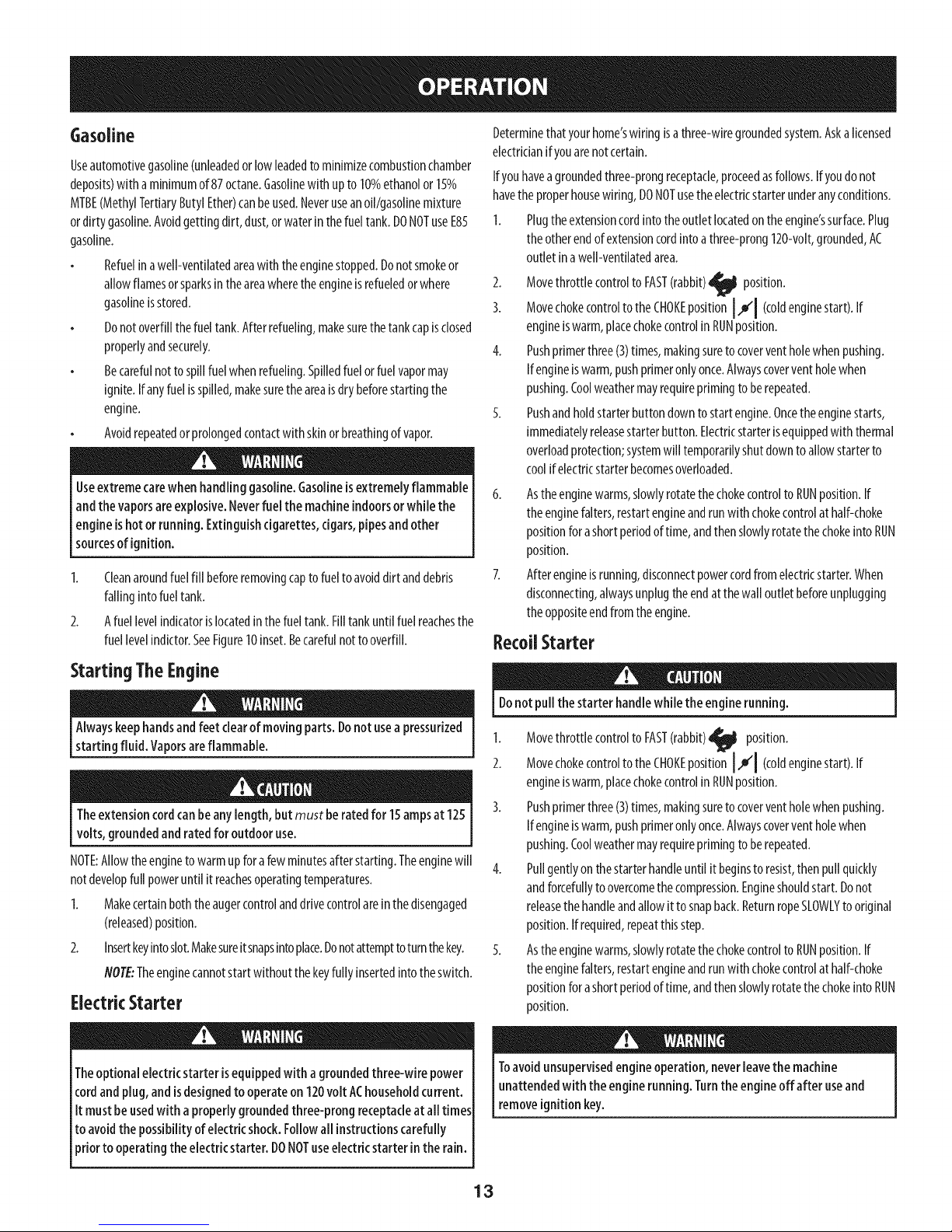

Auger

Whenengaged,theaugerrotatesanddrawssnowintotheaugerhousing.

Clean-OutTool

ChuteAssembly

Snowdrawnintotheaugerhousingisdischargedoutthechuteassembly.

ChokeControl

Thechokecontrolaidsinstartingtheengine.For

informationonchokeusage,seeStartingTheEnginelaterin

thissection.

I/ _ Thechutedean-outtoolisconvenientlyfastenedtothe rearof theaugerhousing

RecoilStarter & StarterHandle

Thismotorisfittedwith arecoilactionpullstartandamittengriphandleforeasy

accesswhilewearingglovesormittens.

Key

Thekeyisasafetydevice.Itmustbefullyinsertedinorder

fortheenginetostart.Removethe keywhenthesnow U ,v Ii

throweris notinuse.

flOTE:Donotturnthekeyinanattempttostarttheengine, i_ 0

Doingsomaycauseit to break.

ElectricStarter Button

Pressingtheelectricstarterbuttonengagestheengine'selectricstarterwhen

pluggedintoa 120Vpowersource.

Neveruseyourhandsto cleara cloggedchuteassembly.Shutoffengineand

remainbehind handlesuntil all movingpartshavestoppedbeforeusngthe|

clean-outtool to clearthe chute assembly.

with amountingclip.Shouldsnowandicebecomelodgedinthechuteassembly

duringoperation,proceedasfollowstosafelycleanthechuteassemblyandchute

[

opening:

1. ReleaseboththeAugerControlandtheDriveControl.

2. Stoptheenginebyremovingthekey.

3. Removetheclean-outtoolfromtheclipwhichsecuresit totherearof the

augerhousing.

4. UsetheshoveFshapedendoftheclean-outtooltodislodgeandscoopany

snowandicewhichhasformedinandnearthechuteassembly.

5. Refastentheclean-outtool tothemountingclipontherearoftheauger

housing,reinsertthekeyandstart thesnowthrower'sengine.

6. Whilestandingintheoperator'sposition(behindthesnowthrower),engage

theaugercontrolforafewsecondstoclearanyremainingsnowandicefrom

thechuteassembly.

Before Starting Engine

]

Electric Starter Outlet

Requirestheuseofathree-prongoutdoorextensioncord(included)anda120V

powersource/walloutlet.

Primer

carburetorto aidincold-weatherstarting.Refertothe

startingPressingthe primerforcesfueldirectlyintoengine'Soperation I _'TP/_

instructionsinthe sectionofthismanual

forproperprimerusage.Theimageto the rightcorresponds

with thelabelontheengineidentifyingtheprimer.

OilFill

Removeoilcaptoaddoil. RefertotheMaintenance& Servicesectionfor checking

andaddingoil instructions.

GasolineCap

Removegascapto addfuel.Unitrunsonregulargas.

NOTE:Thisunitmayincludeafuelplug,whichisonlyusedduringassemblytokeep

dirtanddebrisoutoffueltank. Discardthefuelplugbeforefillingthefueltank.

ThrottleControl

Read,understand,andfollow all instructionsand warningsonthe machine

andinthis manualbeforeoperating.

CheckEngineOil

Theunitwasshippedwith oil intheengine.Checkoil levelbeforeeachoperationto

ensureadequateoil intheengine.Forfurtherinstructions,refertothe Maintenance

&Servicesectionofthismanual.

flOTE:Besuretochecktheengineona levelsurfacewith theengine

stopped.

1.

Removetheoilfillercap/dipstkkandwipethedipstickclean.

2.

Insertthecap/dipstickintotheoil filler neck,turnthecap1/4turnuntil fully

seated.

flOTE:Onsomeengines,athreadedcap/dipstickmayexistinsteadofa 1/4

turncapasdescribedabove.Inthisinstancedonotfullytightenthecapto

checktheoil level.Simplyrestthecaponthethreadstocheckfor properoil

level.

Removetheoilfillercap/dipstick.Ifthelevelislow,slowlyaddoil(5W-30,

with aminimumclassificationof SF/SG)until oil levelregistersbetweenhigh

(H)andlow(L).

flOTE:Donotoverfill.Overfillingwithoil mayresultinenginesmoking,hard

startingorsparkplugfouling.

Replaceandtightencap/dipstickfirmly beforestartingengine.

Thethrottlecontrolislocatedontheengine.It regulatesthespeedof theengine

andwillshutoff theenginewhenplacedintheStop

position.

12

Page 13

Gasoline

Useautomotivegasoline(unleadedorlowleadedto minimizecombustionchamber

deposits)witha minimumof87octane.Gasolinewithupto10%ethanolor15%

MTBE(MethylTertiaryButylEther)canbeused.Neveruseanoil/gasolinemixture

ordirtygasoline.Avoidgettingdirt, dust,orwaterinthefueltank.DONOTuseE85

gasoline.

Refuelinawell-ventilatedareawith theenginestopped.Donotsmokeor

allowflamesorsparksintheareawheretheengineisrefueledorwhere

gasolineisstored.

Donotoverfillthefueltank.Afterrefueling,makesurethetankcapisclosed

properlyandsecurely.

Becarefulnotto spillfuelwhenrefueling.Spilledfuelorfuelvapormay

ignite.Ifanyfuelisspilled,makesuretheareaisdrybeforestartingthe

engine.

Avoidrepeatedorprolongedcontactwith skinorbreathingofvapor.

Useextremecarewhenhandling gasoline.Gasolineisextremelyflammable

andthevaporsareexplosive.Neverfuelthe machineindoorsor whilethe

engine ishotor running.Extinguishcigarettes,cigars,pipesandother

sourcesof ignition.

Cleanaroundfuelfill beforeremovingcaptofueltoavoiddirtanddebris

fallingintofueltank.

2.

Afuel levelindicatorislocatedin thefueltank.Filltankuntilfuelreachesthe

fuellevelindictor.SeeFigure10inset.Becarefulnotto overfill.

Determinethatyourhome'swiringisa three-wiregroundedsystem.Askalicensed

electricianifyouarenotcertain.

Ifyouhaveagroundedthree-prongreceptacle,proceedasfollows.If youdonot

havetheproperhousewiring,DONOTusetheelectricstarterunderanyconditions.

1. Plugtheextensioncordintotheoutlet locatedontheengine'ssurface.Plug

theotherendofextensioncordintoathree-prong120-volt,grounded,AC

outletinawell-ventilatedarea.

2. MovethrottlecontroltoFAST(rabbit)_ position.

3. Movechokecontro,totheCHOKEpos t onI,"1/co,denginestart).If

engineiswarm,placechokecontrolinRUNposition.

4. Pushprimerthree(3)times,makingsureto coverventholewhenpushing.

Ifengineiswarm,pushprimeronlyonce.Alwayscoverventholewhen

pushing.Coolweathermayrequireprimingto berepeated.

5. Pushandholdstarterbuttondowntostartengine.Oncetheenginestarts,

immediatelyreleasestarterbutton.Electricstarterisequippedwith thermal

overloadprotection;systemwill temporarilyshutdowntoallowstarterto

coolifelectricstarterbecomesoverloaded.

6. Astheenginewarms,slowlyrotatethechokecontrolto RUNposition.If

theenginefalters,restartengineandrunwith chokecontrolathalf-choke

positionforashortperiodoftime,andthenslowlyrotatethechokeintoRUN

position.

7. Afterengineisrunning,disconnectpowercordfromelectricstarter.When

disconnecting,alwaysunplugtheendatthewalloutletbeforeunplugging

theoppositeendfromtheengine.

RecoUStarter

Starting TheEngine

Alwayskeephandsandfeet clearof moving parts.Donotuseapressurized

starting fluid. Vaporsareflammable.

Theextensioncordcanbeanylength, but must be ratedfor 15ampsat 125

volts,groundedand ratedforoutdoor use.

NOTE:Allowtheenginetowarmupforafew minutesafterstarting.Theenginewill

notdevelopfullpoweruntilitreachesoperatingtemperatures.

1. Makecertainboththeaugercontrolanddrivecontrolareinthedisengaged

(released)position.

2. Insertkeyintoslot.Makesureitsnapsintoplace.Donotattempttoturnthekey.

flOTE:Theenginecannotstartwithoutthekeyfullyinsertedintotheswitch.

ElectricStarter

Theoptional electricstarter isequippedwith agroundedthree-wirepower

cordandplug, andisdesignedto operateon 120voltAChouseholdcurrent.

It mustbeusedwith aproperlygroundedthree-prong receptacleatall times

toavoidthe possibilityof electricshock.Followall instructionscarefully

prior tooperating theelectric starter.DONOTuseelectricstarter inthe rain.

Donotpull the starter handlewhiletheenginerunning.

1. MovethrottlecontroltoFAST(rabbit)_ position.

2. Movechokecontrolto theCHOKEposition1,,_'1(coldenginestart).If

engineiswarm,placechokecontrolinRUNposition.

3. Pushprimerthree(3)times,makingsureto coverventholewhenpushing.

Ifengineiswarm,pushprimeronlyonce.Alwayscoverventholewhen

pushing.Coolweathermayrequireprimingto berepeated.

4. Pullgentlyonthestarterhandleuntil itbeginsto resist,thenpullquickly

andforcefullytoovercomethecompression.Engineshouldstart.Donot

releasethehandleandallowitto snapback.ReturnropeSLOWLYto original

position.If required,repeatthisstep.

5. Astheenginewarms,slowlyrotatethechokecontrolto RUNposition.If

theenginefalters,restartengineandrunwith chokecontrolathalf-choke

positionforashortperiodoftime,andthenslowlyrotatethechokeintoRUN

position.

Toavoidunsupervisedengineoperation,neverleavethe machine

unattendedwith theenginerunning.Turnthe engineoffafter useand

removeignition key.

13

Page 14

Stopping TheEngine

Runenginefor afewminutesbeforestoppingto helpdryoffanymoistureonthe

engine.

1. MovethrottlecontroltoSTOP_-_

2. Removethekey.Removingthekeywill reducethepossibilityof

unauthorizedstartingoftheenginewhileequipmentisnotinuse.Keepthe

keyinasafeplace.Theenginecannotstartwithoutthekey.

3. Wipeanymoistureawayfromthecontrolsontheengine..

position.

ToStopTheSnowThrower

1. Tostopthewheels,releasethedrivecontrol.

2. Tostopthrowingsnow,releasetheaugercontrol.

3. Tostopengine,movethrottlecontrollevertoOFF_ andpulloutthekey.

Donotturn key.

Thetemperatureof muffler andthe surroundingareasmayexceed150 F.

Avoidthese areas.

o

UsingSnowThrowerto ClearSnow

CAUTION:Checktheareatobeclearedforforeignobjects.Removeforeignobjects,

if any.

1. Starttheenginefollowingstartinginstructions.

2. Allowtheengineto warmupfora fewminutesastheenginewill not

developfull poweruntil it reachesoperatingtemperature.

3. Rotatethechuteassemblyto thedesireddirection,awayfrombystanders

and/orbuildings.

4. Makingcertainnobystandersorobstaclesareinfrontof theunit,squeeze

theaugercontrolcompletelyagainsttheupperhandletofully engagethe

auger.

5. Whiletheaugercontrolisengaged,squeezethedrivecontrolcompletely

againsttheupperhandleto engagethewheels.Donot"feather"thedrive

control.

6. Asthesnowthrowerstartstomove,maintainafirm holdonthe handle,and

guidethesnowthroweralongthepathtobecleared.

7. Releasetheaugeranddrivecontrolstostopthesnowthrowingactionand

forwardmotion.

Donotliftthe snowthrower atanytime bythe chutehandle.

Operating Tips

1. Formostefficientsnowremoval,removesnowimmediatelyafteritfalls.

2. Dischargesnowdownwindwheneverpossible.Slightlyoverlapeachprevious

path.

3. Settheskidshoes1/4"belowtheshaveplatefor normalusage.Theskid

shoesmaybeadjustedupwardfor hard-packedsnow.

NOTE:It isnotrecommendedthatyouoperatethissnowthrowerongravel

asloosegravelcanbeeasilypickedupandthrownbytheaugercausing

personalinjuryand/ordamageto thesnowthrower.

4. Ifyouchoosetooperatethesnowthrowerongravel,keeptheskidshoein

the lowestpositionformaximumclearancebetweenthegroundandthe

shaveplate.

5. Cleanthesnowthrowerthoroughlyaftereachuse.

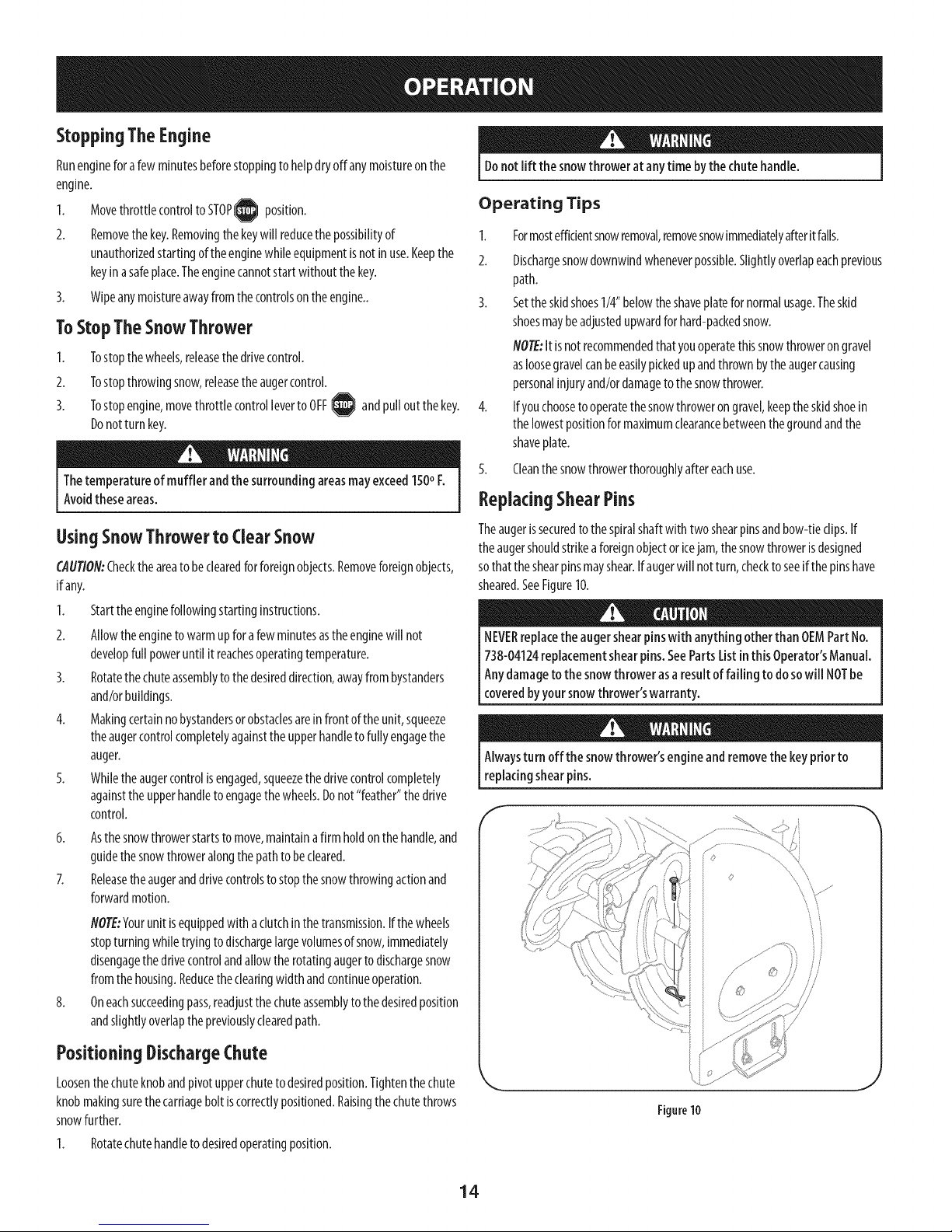

ReplacingShearPins

Theaugerissecuredtothespiralshaftwithtwo shearpinsandbow-tieclips.If

theaugershouldstrikeaforeignobjectoricejam,thesnowthrowerisdesigned

sothattheshearpinsmayshear.Ifaugerwill notturn,checkto seeifthepinshave

sheared.SeeFigure10.

NEVERreplacethe augershearpinswithanything otherthanOEMPartNo.

738-04124replacementshearpins.SeePartsListinthis Operator'sManual.

Anydamagetothe snowthrower asaresultoffailing todo sowill NOTbe

coveredbyyoursnowthrower'swarranty.

Alwaysturn off the snowthrower's engineand removethekey priorto

replacingshearpins.

f

..............

NOTE:Yourunit isequippedwith aclutchinthetransmission.Ifthewheels

stopturningwhiletryingto dischargelargevolumesofsnow,immediately

disengagethedrivecontrolandallowtherotatingaugertodischargesnow

fromthe housing.Reducetheclearingwidthandcontinueoperation.

8.

Oneachsucceedingpass,readjustthechuteassemblyto thedesiredposition

andslightlyoverlapthepreviouslyclearedpath.

PositioningDischargeChute

Loosenthechuteknobandpivotupperchuteto desiredposition.Tightenthechute

knobmakingsurethecarriageboltiscorrectlypositioned.Raisingthechutethrows

snowfurther.

1. Rotatechutehandletodesiredoperatingposition.

14

Figure10

/ /

/ /

J

Page 15

Beforeservicing,repairing,lubricatingorinspecting,disengageallcontrols

andstopengine.Waitunti}allmovingpartshavecometoacomp}etestop.

Removethekeytopreventunintendedstarting.Alwayswearsafetyglasses

duringoperationorwhile performinganyadjustmentsorrepairs.

Maintenance Schedule

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrack

ofcompletedmaintenancetasks.Tolocate the nearest Sears

Service Centeror to schedule service,simplycontactSearsat

1-800-4-MY-HOME®.

Each Useand every 5

hours

1st5 hours

Annuallyor25hours

Annually or 50 hours

Annually or 100 hours

1. Engineoillevel

2. Looseormissinghardware

3. Unitandengine.

1. Engineoil

1. Sparkplug

2. Controllinkagesand pivots

3. Wheels

4. GearshaftandAugershaft

1. Engineoil

1. Sparkplug

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Check

2. Lubewithlightoil

3. Lubewithmultipurposeautogrease

4. Lubewithlightoil

1. Change

1. Clean,adjustgap,or replaceif

necessary

Before Storage 1. Fuel system 1.

Runengineuntilit stopsfromlack

offuel

ENGINEMAINTENANCE f

CheckingEngineOil

Beforelubricating,repairing,orinspecting,disengageallcontrolsandstop

enghe.Wat unt a mov ngpartshavecometoa compete stop.

NOTE:Checktheoillevelbeforeeachuseandaftereveryfive hoursofoperationto

besurecorrectoillevelismaintained.

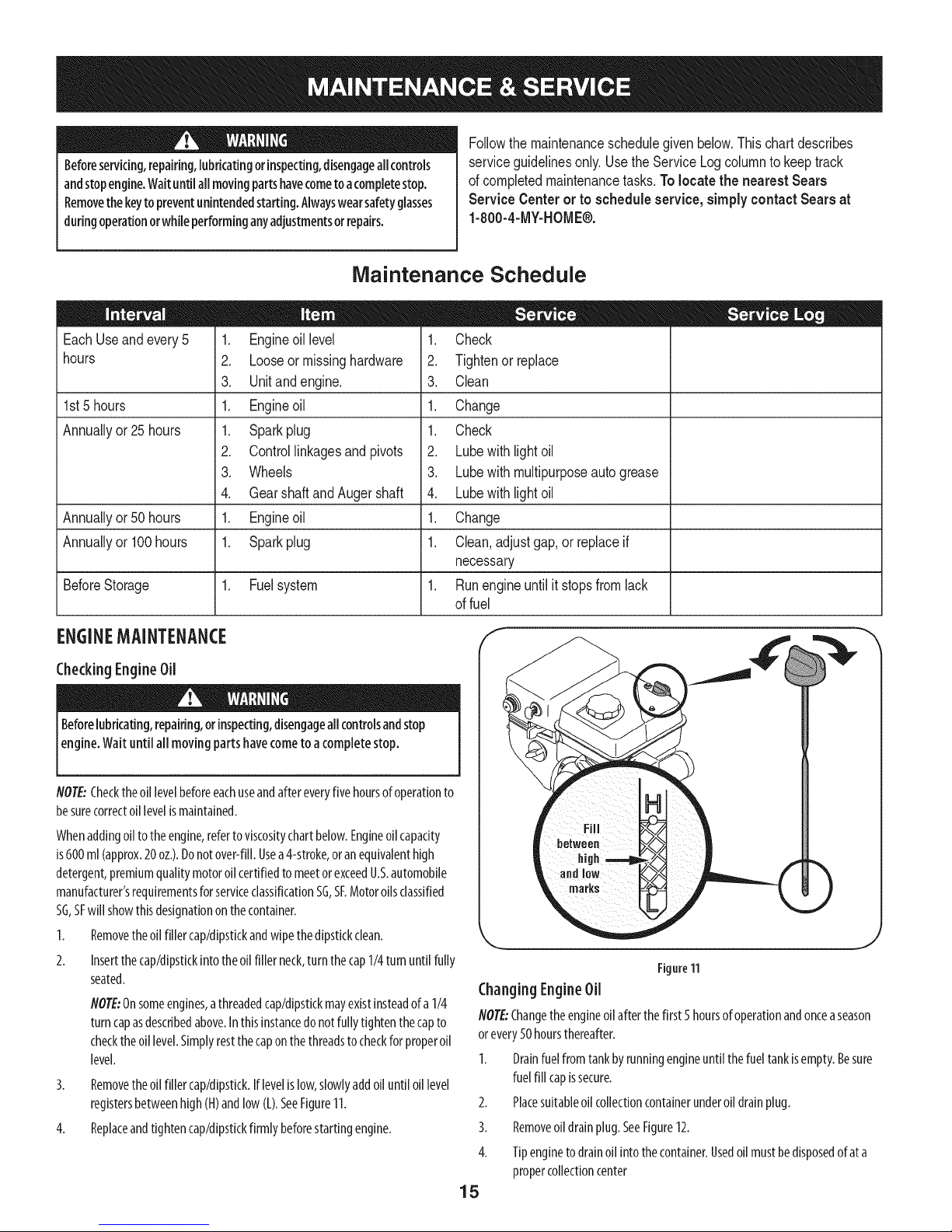

Whenaddingoilto theengine,refertoviscositychartbelow.Engineoilcapacity

is600ml(approx.20oz.).Donotover-fill.Usea4-stroke,oranequivalenthigh

detergent,premiumqualitymotoroilcertifiedto meetorexceedU.S.automobile

manufacturer'srequirementsforserviceclassificationSG,SEMotoroilsclassified

SG,SFwill showthisdesignationonthecontainer.

1. Removetheoilfiller cap/dipstkkandwipethedipstickclean.

2. Insertthecap/dipstkkintotheoilfillerneck,turnthecap1/4turnuntil fully

seated.

NOTE:Onsomeengines,athreadedcap/dipstkkmayexistinsteadofa1/4

turncapasdescribedabove.Inthisinstancedonotfully tightenthecapto

checktheoillevel.Simplyrestthecaponthethreadsto checkforproperoil

level.

3. Removetheoilfiller cap/dipstick.Iflevelislow,slowlyaddoiluntiloillevel

registersbetweenhigh(H)andlow(L).SeeFigure11.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

,, j

Figure11

ChangingEngineOil

NOTE:Changetheengineoilafterthefirst5 hoursofoperationandonceaseason

orevery50hoursthereafter.

1. Drainfuelfromtankbyrunningengineuntilthefueltankisempty.Besure

fuelfill capissecure.

2. Placesuitableoil collectioncontainerunderoildrainplug.

3. Removeoildrainplug.SeeFigure12.

4. Tipengineto drainoilintothecontainer.Usedoil mustbedisposedofata

propercollectioncenter

15

Page 16

Usedoil isahazardouswasteproduct.Disposeof usedoil properly.Donot

discardwith householdwaste.Checkwith yourlocalauthoritiesor Sears

ServiceCenterfor safedisposal/recyclingfacilities.

5. Reinstallthedrainplugandtightenit securely.

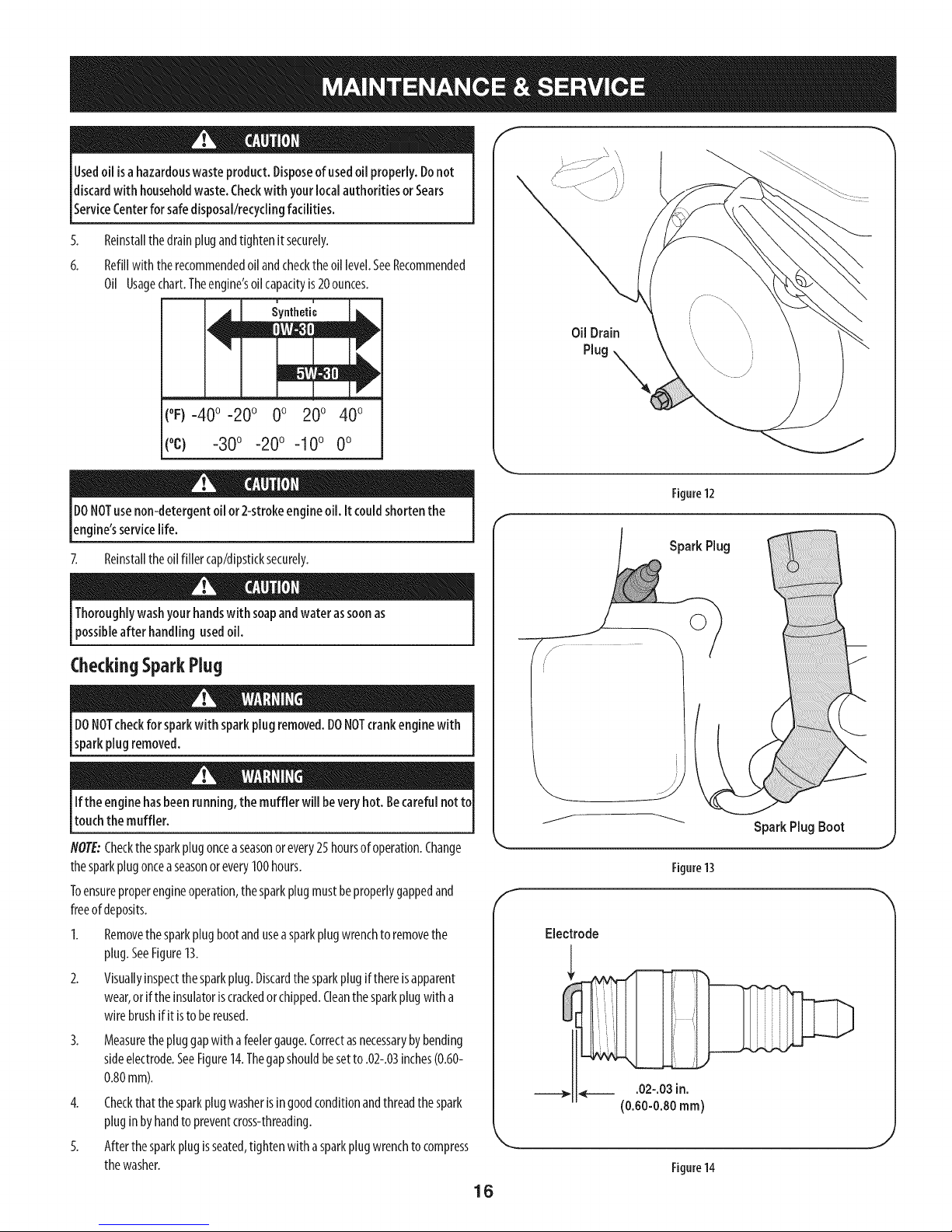

6. Refillwith therecommendedoilandchecktheoil level.SeeRecommended

Oil Usagechart.Theengine'soilcapacityis20ounces.

i i

Synthetic

(oF)-40o-20 o 0o 200 400

(oc) -30° -20° -10° 0°

DONOTusenon-detergent oil or2-strokeengineoil. It couldshortenthe

engine'sservicelife.

7. Reinstalltheoilfiller cap/dipsticksecurely.

Thoroughlywashyourhandswith soapandwaterassoonas

possibleafterhandling usedoil.

Oil Drain

Plug

Figure12

SparkPlug

CheckingSparkPlug

DONOTcheckfor sparkwith sparkplugremoved.DONOTcrankenginewith

sparkplugremoved.

Ifthe enginehasbeenrunning,the muffler willbeveryhot.Becarefulnot to

touchthe muffler.

NOTE:Checkthesparkplugonceaseasonorevery25hoursofoperation.Change

thesparkplugonceaseasonorevery100hours.

Toensureproperengineoperation,thesparkplugmustbeproperlygappedand

freeofdeposits.

1. Removethesparkplugbootandusea sparkplugwrenchtoremovethe

plug.SeeFigure13.

2. Visuallyinspectthesparkplug.Discardthesparkplugif thereisapparent

wear,orif theinsulatoriscrackedorchipped.Cleanthesparkplugwith a

wirebrushifit istobereused.

3.

Measurethepluggapwith afeelergauge.Correctasnecessarybybending

sideelectrode.SeeFigure14.Thegapshouldbesetto .02-.03inches(0.60-

0.80mm).

4. Checkthatthesparkplugwasherisingoodconditionandthreadthespark

pluginbyhandtopreventcross-threading.

5. Afterthesparkplugisseated,tightenwith asparkplugwrenchtocompress

thewasher.

SparkPlug Boot

Figure13

Electrode

___,. ___ .02-.03in.

(0.60-0.80ram)

Figure14

16

Page 17

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthesparkplugseats

tocompressthewasher.Whenreinstallingausedsparkplug,tighten1/8-to1/4-

turnafterthesparkplugseatstocompressthewasher.GeneralRecommendations.

1. Alwaysobservesafetyruleswhenperforminganymaintenance.

2. Thewarrantyonthissnowthrowerdoesnotcoveritemsthathavebeen

subjectedtooperatorabuseor negligence.Toreceivefullvaluefromthe

warranty,operatormustmaintainthesnowthrowerasinstructedinthis

manual.

3. Periodicallycheckai[fastenersandhardwareto makesurethesearetight.

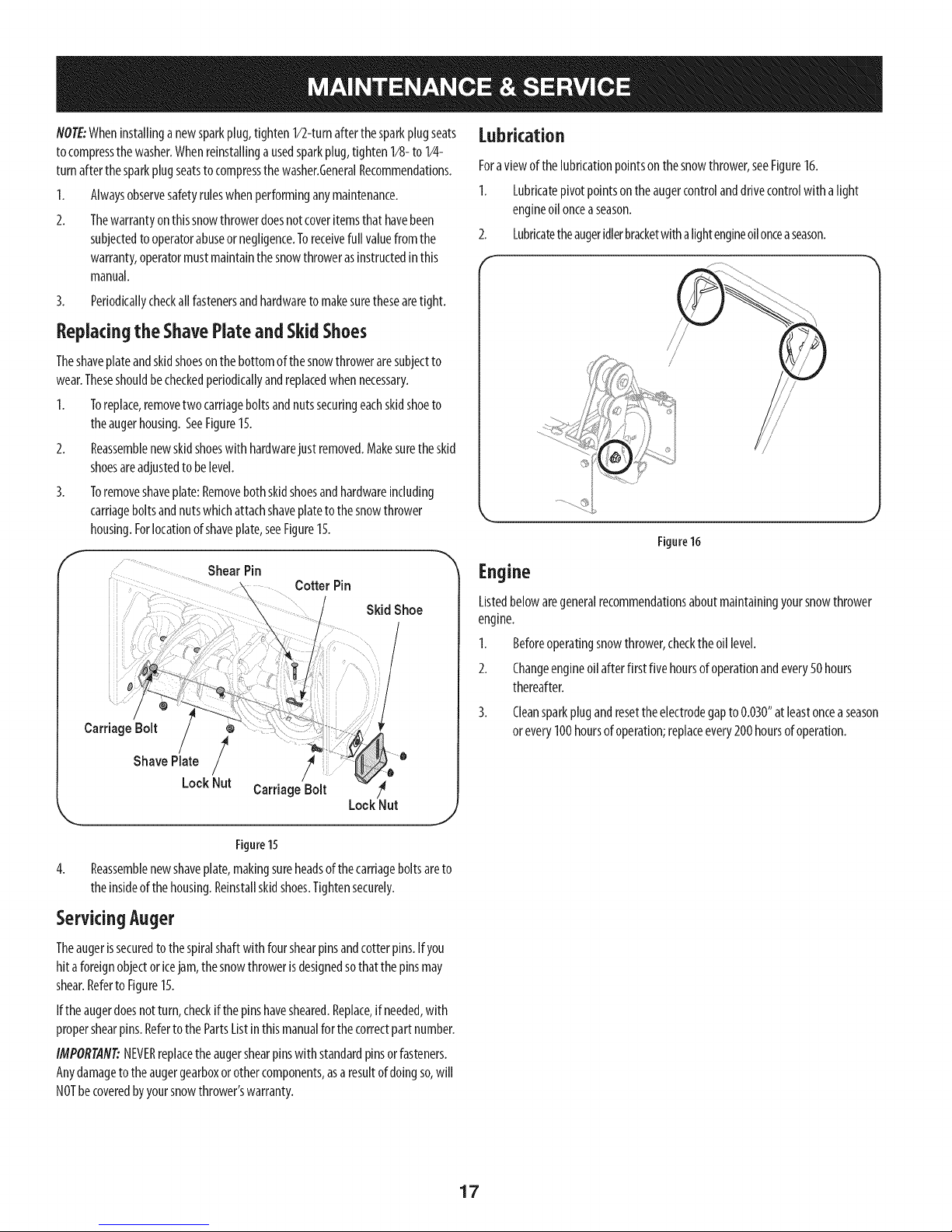

Replacingthe ShavePlateand SkidShoes

Theshaveplateandskidshoesonthebottomofthesnowthroweraresubjectto

wear.Theseshouldbecheckedperiodicallyandreplacedwhennecessary.

1. Toreplace,removetwocarriageboltsandnutssecuringeachskidshoeto

theaugerhousing.SeeFigure15.

2. Reassemblenewskidshoeswith hardwarejustremoved.Makesuretheskid

shoesareadjustedto belevel.

3. Toremoveshaveplate:Removebothskidshoesandhardwareincluding

carriageboltsandnutswhichattachshaveplatetothesnowthrower

housing.Forlocationofshaveplate,seeFigure15.

Lubrication

Foraviewofthelubricationpointsonthesnowthrower,seeFigure16.

1. Lubricatepivotpointsontheaugercontrolanddrivecontrolwith alight

engineoilonceaseason.

2. Lubricatetheaugeridlerbracketwithalightengineoilonceaseason.

Figure16

ShearPin

i iii

Carriage Bolt

ShavePJate / /

Lock Nut

Figure15

4.

Reassemblenewshaveplate,makingsureheadsofthecarriageboltsareto

theinsideofthehousing.Reinstallskidshoes.Tightensecurely.

Cotter Pin

SkidShoe

Carriage Bolt /_

Lock Nut

ServicingAuger

Theaugerissecuredtothespiralshaftwith fourshearpinsandcotterpins.Ifyou

hitaforeignobjectoricejam,thesnowthrowerisdesignedsothatthe pinsmay

shear.RefertoFigure15.

Iftheaugerdoesnotturn,checkif thepinshavesheared.Replace,if needed,with

propershearpins.RefertothePartsListinthismanualforthecorrectpartnumber.

IMPORTAN_NEVERreplacetheaugershearpinswithstandardpinsorfasteners.

Anydamageto theaugergearboxorothercomponents,asaresultofdoingso,will

NOTbecoveredbyyoursnowthrower'swarranty.

Engine

Listedbelowaregeneralrecommendationsaboutmaintainingyoursnowthrower

engine.

1. Beforeoperatingsnowthrower,checktheoillevel.

2. Changeengineoilafterfirstfivehoursof operationandevery50hours

thereafter.

3. Cleansparkplugandresettheelectrodegapto0.030"atleastonceaseason

orevery100hoursof operation;replaceevery200hoursofoperation.

17

Page 18

CheckV-Belts

AugerBelt

Followinstructionsbelowto checkconditionofdrivebeltsevery50hoursof

operation.

1. Removetheplasticbeltcoveronthefrontoftheenginebyremovingthe

self-tappingscrewandpressingtheplastictabstoreleasethe beltcover.

2. Visuallyinspectfor frayed,cracked,orexcessivelywornoutbelts.Replace,if

necessary,andfollowinstructionsbelow.

ReplacingBelts

NOTE:Therearetwobeltsonthissnowthrower:anaugerbeltanddrivebelt.Itis

recommendedthatbothbeltsbereplacedatthesametime.

1. Removethesparkplugwirefromsparkplugandgroundit againstthe

enginetopreventaccidentalstarting.

2. Runtheengineuntilthefueltankisdrytopreventgasolineleakagewhen

replacingbelts.

Performbelt maintenanceoutdoorsassomegasmaypossiblyleakfrom the

carburetor.

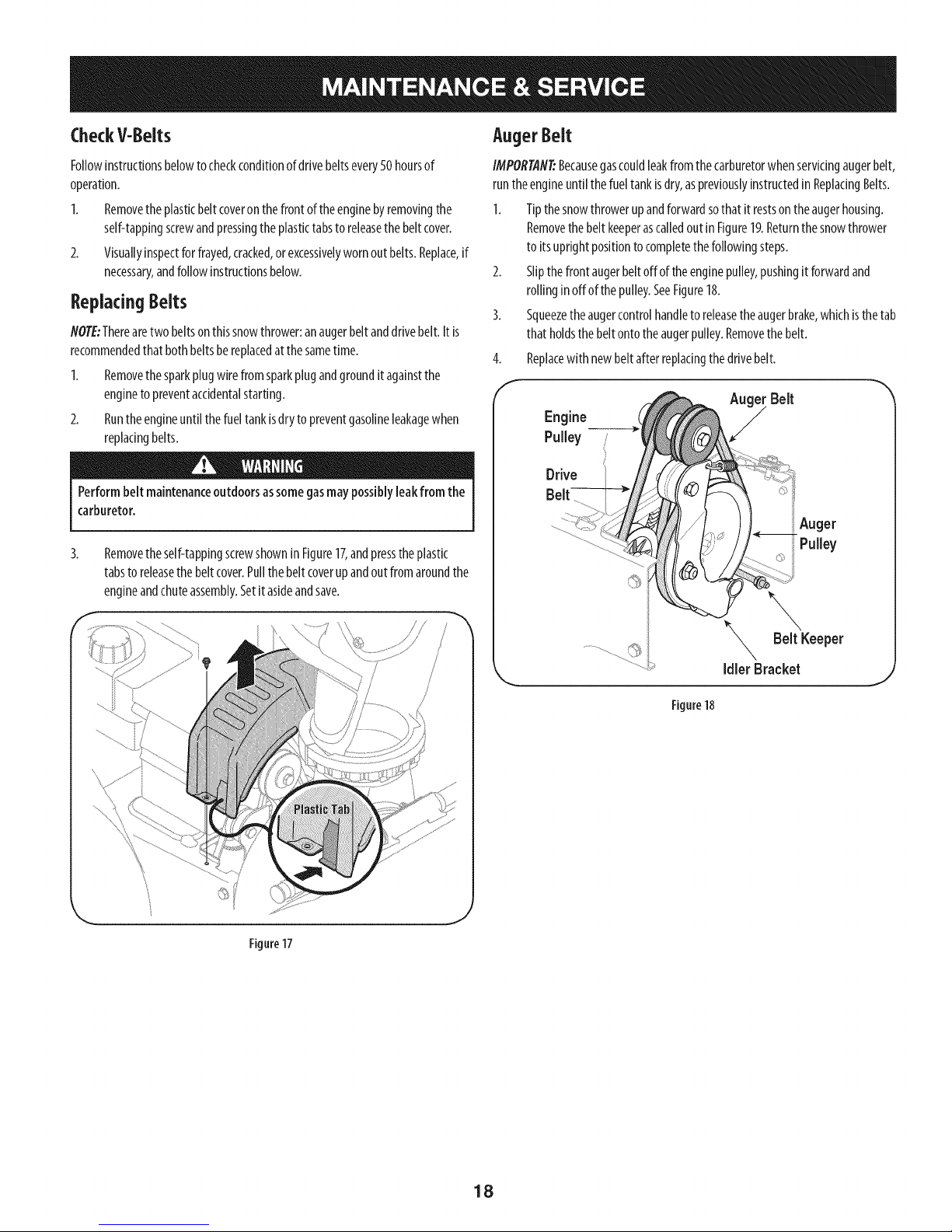

3.

Removetheself-tappingscrewshownin Figure17,andpresstheplastic

tabstoreleasethebeltcover.Pullthebeltcoverupandoutfromaroundthe

engineandchuteassembly.Setit asideandsave.

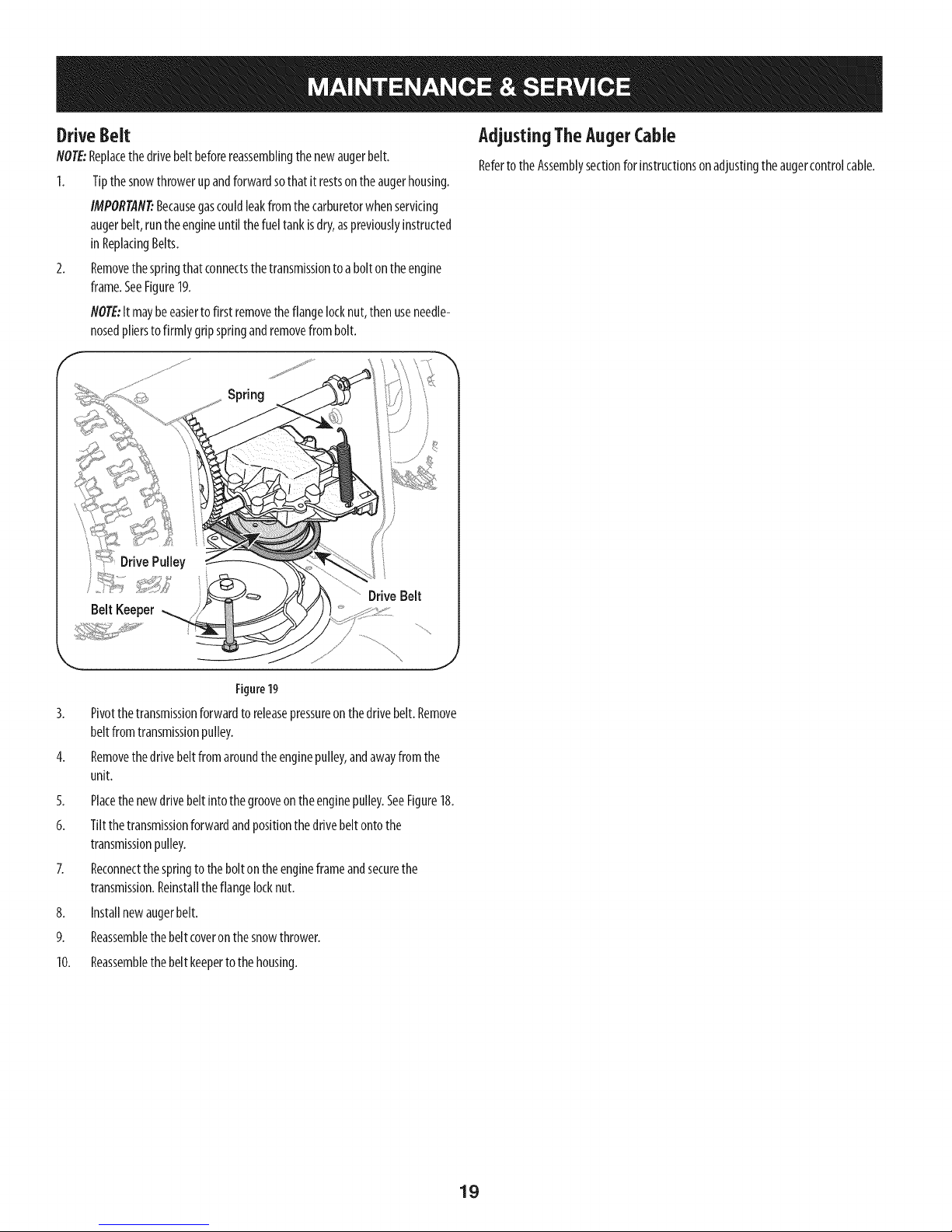

IMPORTANT:Becausegascouldleakfromthecarburetorwhenservicingaugerbelt,

runtheengineuntilthefueltankis dry,aspreviouslyinstructedin ReplacingBelts.

1. Tipthesnowthrowerupandforwardsothatit restsontheaugerhousing.

Removethebeltkeeperascalledoutin Figure19.Returnthesnowthrower

to itsuprightpositiontocompletethefollowingsteps.

2. Slipthefrontaugerbeltoffof theenginepulley,pushingit forwardand

rollinginoffofthe pulley.SeeFigure18.

3. Squeezetheaugercontrolhandleto releasetheaugerbrake,whichisthetab

thatholdsthebeltontotheaugerpulley.Removethe belt.

4. Replacewithnewbeltafterreplacingthedrivebelt.

Belt

Engine

Pulley

Drive

Belt-

Auger

Pulley

\

Figure17

_ Belt Keeper

Idler Bracket

/

/

J

Figure18

18

Page 19

Drive Belt

NOTE:Replacethedrivebeltbeforereassemblingthenewaugerbelt.

1. Tipthesnowthrowerupandforwardsothatitrestsontheaugerhousing.

IMPOR@NT:Becausegascouldleakfromthecarburetorwhenservicing

augerbelt,runtheengineuntilthefueltankisdry,aspreviouslyinstructed

inReplacingBelts.

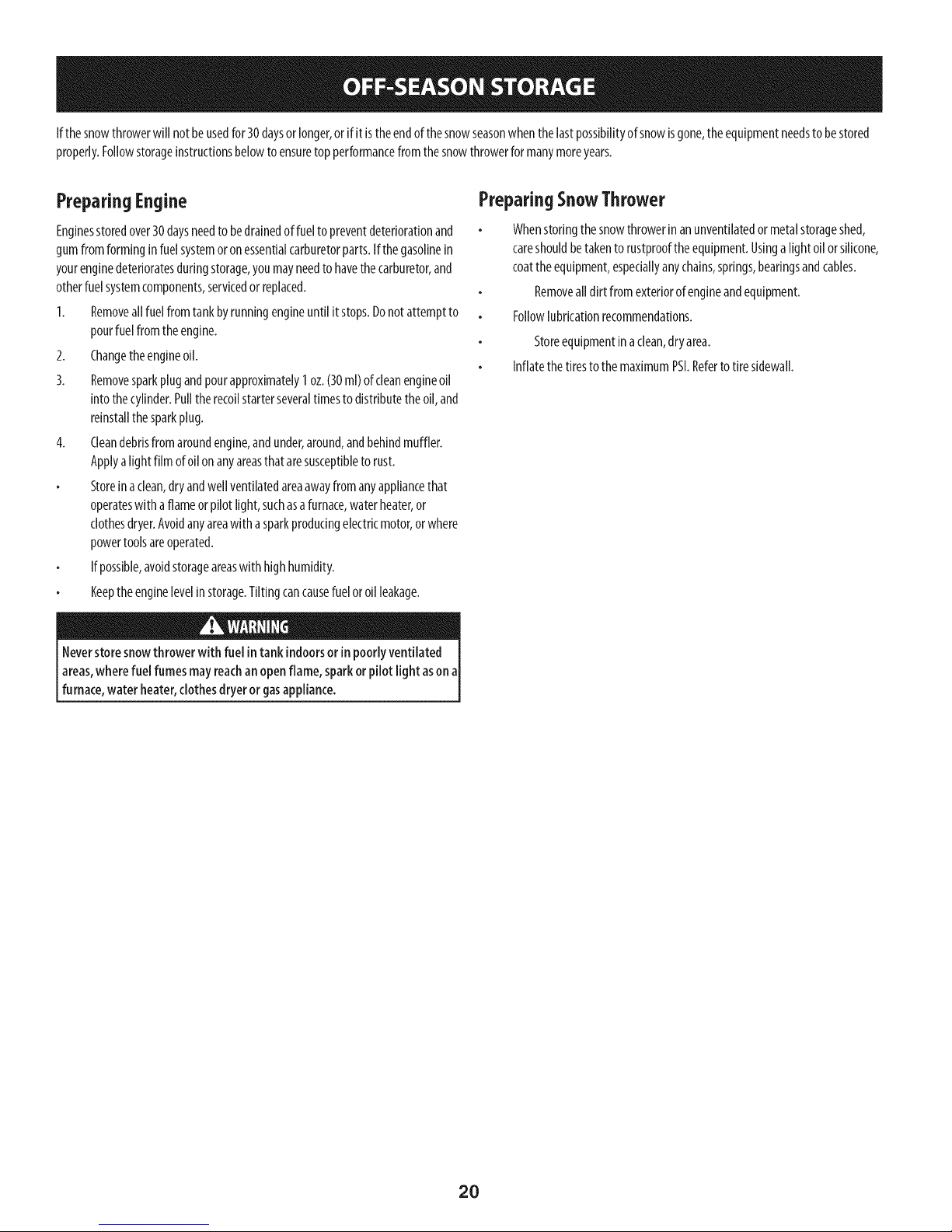

2. Removethespringthatconnectsthetransmissiontoaboltontheengine

frame.SeeFigure19.

NOTE:Itmaybeeasierto firstremovetheflangelocknut,thenuseneedle-

nosedpliersto firmly gripspringandremovefrombolt.

Spring

AdjustingTheAugerCable

Referto theAssemblysectionfor instructionsonadjustingtheaugercontrolcable.

Figure19

3. Pivotthetransmissionforwardtoreleasepressureonthedrivebelt.Remove

beltfromtransmissionpulley.

4. Removethedrivebeltfromaroundtheenginepulley,andawayfromthe

unit.

5. Placethenewdrivebeltintothegrooveontheenginepulley.SeeFigure18.

6. Tiltthetransmissionforwardandpositionthedrivebeltontothe

transmissionpulley.

7. Reconnectthespringto theboltontheengineframeandsecurethe

transmission.Reinstalltheflangelocknut.

8.

Installnewaugerbelt.

9.

Reassemblethebeltcoveronthesnowthrower.

10.

Reassemblethebeltkeepertothe housing.

19

Page 20

Ifthesnowthrowerwill notbeusedfor30daysorlonger,orifit istheendofthesnowseasonwhenthelastpossibilityofsnowisgone,theequipmentneedstobestored

properly.Followstorageinstructionsbelowtoensuretopperformancefromthesnowthrowerformanymoreyears.

PreparingEngine

Enginesstoredover30daysneedtobedrainedoffuelto preventdeteriorationand

gumfromforminginfuelsystemoronessentialcarburetorparts.If thegasolinein

yourenginedeterioratesduringstorage,youmayneedto havethecarburetor,and

otherfuelsystemcomponents,servicedorreplaced.

1. Removeallfuelfromtankbyrunningengineuntilit stops.Donotattemptto

pourfuelfromtheengine.

2. Changetheengineoil.

3. Removesparkplugandpourapproximately1oz.(30ml)ofcleanengineoil

intothecylinder.Pulltherecoilstarterseveraltimestodistributetheoil,and

reinstallthesparkplug.

4. Cleandebrisfromaroundengine,andunder,around,andbehindmuffler.

Applya lightfilm ofollonanyareasthat aresusceptibletorust.

Storeinaclean,dryandwellventilatedareaawayfromanyappliancethat

operateswith aflameorpilotlight,suchasafurnace,waterheater,or

clothesdryer.Avoidanyareawitha sparkproducingelectricmotor,orwhere

powertoolsareoperated.

Ifpossible,avoidstorageareaswith highhumidity.

Keeptheenginelevelinstorage.Tiltingcancausefueloroil leakage.

!

Neverstoresnowthrower with fuel intank indoorsor inpoorlyventilated [

areas,wherefuel fumesmayreachanopenflame, sparkorpilotlight asonaJ

fumace,water heater,cothesdryeror gasapp ante. j

PreparingSnowThrower

Whenstoringthesnowthrowerin anunventilatedormetalstorageshed,

careshouldbetakento rustprooftheequipment.Usinga lightoil orsilicone,

coattheequipment,especiallyanychains,springs,bearingsandcables.

Removealldirtfromexteriorof engineandequipment.

Followlubricationrecommendations.

Storeequipmentinaclean,dryarea.

InflatethetirestothemaximumPSI.Refertotire sidewall.

I

2O

Page 21

Beforeperforminganytypeofmaintenance/service,disengageallcontrolsandstop

theengine.Waituntilallmovingpartshavecometoacompletestop.Removethekey

topreventunintendedstarting.Alwayswearsafetyglassesduringoperationorwhile

performinganyadjustmentsorrepairs.

Thissectionaddressesminorserviceissues.TolocatethenearestSearsService

Centerortoscheduleservice,simplycontactSearsat 1-800-4-MY-HOME®.

Enginefailsto start

1. Chokecontrolnotin Chokeposition.

2. Sparkplugwiredisconnected.

3. Faultysparkplug.

4. Fueltankemptyorstalefuel.

S. Enginenotprimed.

6. Safetykeynotinserted.

Extensioncordnotconnected(whenusingelectric

startbutton)

Enginerunningerratically/

inconsistentRPM(huntingor

1. Enginerunningonchoke.

2. Fuellineblocked,orstalefuel.

surging)

3. Waterordirt infuelsystem.

4. Carburetoroutofadjustment.

S. Over-governedengine

Engineoverheats

Excessivevibration

1. Carburetornotadjustedproperly.

1. Loosepartsordamagedauger.

Lossofpower 1. Sparkplugwireloose. 1.

2. Gascapventholeplugged. 2.

Unitfailsto propelitself 1. Drivecableinneedof adjustment. 1.

1. Movechokecontrolto Chokeposition.

2. Connectwiretosparkplug.

3. Clean,adjustgap,orreplace.

4. Filltankwith clean,freshgasoline.

S. PrimeengineasinstructedintheOperationSection.

6. Insertkeyfullyintotheswitch.

7. Connectoneendoftheextensioncordto theelectric

starteroutlet andtheotherendto athree-prong120-volt,

grounded,ACoutlet.

1. MovechokelevertoRUNposition.

2. Cleanfuel lineandfill tankwith fresh,cleangasoline.

3. Runengineuntil it stops.Refillwithfreshfuel.

4. Contacta SearsServiceCenter.

S. Contacta SearsServiceCenter.

1. ContactyourSearsParts& RepairCenter.

1. Stopengineimmediatelyanddisconnectsparkplugwire.

Tightenall boltsandnuts.Ifvibrationcontinues,haveunit

servicedbyaSearsParts& RepairCenter.

Connectandtightensparkplugwire.

Removeiceandsnowfromgascap.Becertainventholeis

clear.

Adjustdrivecontrolcable.RefertoServiceandMaintenance

section.

2. Drivebeltlooseordamaged. 2.

Unitfailstodischargesnow 1. Chuteassemblyclogged. 1.

2. Foreignobjectlodgedin auger.

3. Augercablein needofadjustment.

4. Augerbeltlooseordamaged.

S. Shearpin(s)sheared.

Replacedrivebelt.Referto Service& Maint.section.

Stopengineimmediatelyanddisconnectsparkplugwire.

Cleanchuteassemblyandinsideofaugerhousingwith clean-

outtoolorastick.

2. Stopengineimmediatelyanddisconnectsparkplugwire.

Removeobjectfromaugerwith clean-outtool orastick.

3. Adjustaugercontrolcable.Referto Assemblysection.

4. Replaceaugerbelt.Referto ServiceandMaintenancesection.

S. Replacewith newshearpin(s).

NEED MORE HELP?

o Find this and all your other p_oduct manuals online.

oGet answers from our team of home experts.

Get a personalized maintenance plan for your home,

o Find information and tools to help with home projects.

21

Page 22

Craftsman Snow Thrower IViodel 247.881701

\

/

22

Page 23

Craftsman Snow Thrower IViodel 247.881701

m

M

1

2

3

4

5

6

7

8

9

lO

11

12

13

14

15

16

17

18

19

2o

21

22

23

24

984-04037

71o-o4o71

71o-o451

710-0260A

720-04072A

731-04388A

731-04426A

936-0267

931-04127

931-04353

931-2636A

932-04111

712-04064

931-2643

731-2635

725-0157

710-0134

710-0520

710-04484

712-04063

712-04065

750-04852

715-04020

926-04012

ChuteAssembly

CarriageBolt5/16-18x1.0"

CarriageBolt5/16-18

CarriageBolt5/16-18x.62

WingKnob5/16-18

ChuteHandle

UpperChute

FiatWasher.385x .87x .06

LowerChute

ChuteRing

ChuteAdapter5" Dia.

ChuteAdjustmentSpring

FlangeLockNut 1/4-20

Clean-outTool

Clean-outToolMount

CableTie

CarriageScrew 1/4-20x 0.62"

HexBolt3/8-16x 1.50"

ABScrew5/16-18x .750

FlangeLockNut, 5/16-18

FlangeLockNut, 3/8-16

ShoulderSpacer

SpiralPin

PushOnNut

m

M

731-04218B

25

26

932-0611

27

736-0174

28

938-0281

29

941-0245

30

941-0309

31

950-04191

32

684-04358

33

784-0434-0637

34

790-00075

35

918-04292B

36

684-04113A-0637

37

684-04114A-0637

38

684-04166A-4043

39

714-04040

40

731-04870

41

936-0351

42

738-04124A

43

741-0493A

44

790-00087A-0637

45

790-00117-0637

46

784-5580-4043

47

710-04606A

48

929-0071A

Impeller

ExtensionSpring

WaveWasher

ShoulderScrew3/8-16

Hex FlangeBearing

BallBearing

Spacer

FlatIdler

AugerIdlerBracket

BearingHousing

AugerGearboxAssembly

AugerAssembly- LH

AugerAssembly- RH

AugerHousing,22"

BowTieCotterPin72

Spacer,1.25x.75x 1.00

FlatWasher

ShearPin,.25x 1.50

FlangeBushing

Hex BearingHousing

ShavePlate2.25x21.66LG

SkidShoe

Belt Keeper

ExtensionCord

23

Page 24

Craftsman Snow Thrower Model 247.881701

24

Page 25

Craftsman Snow Thrower IViodel 247.881701

m

1

71o-o572

2

71o-o6o5

3

71o-o4484

4

712-o4o64

5

720-04072A

6

725-0157

7

946-04642

8

946-04640

9

747-04394A-0637

lO

747-04405-0637

11

749-04147

12

749-04495-0637

13

990-00053

14

918-04296B

15

710-0809

16

710-1652

17

711-1364

18

914-0115

19

714-04040

2o

915-0249

717-04066A

21

22

917-04073A

932-0429A

23

24

936-0192

738-04184A

25

738-0924A

26

27

941-0245

28

741-04108

29

756-0625

CarriageScrew5/16-18x 2.25

Mach.Screw 1/4-20x 1.825

Screw5/16-18x .75

FlangeLockNut 1/4-20

WingKnob5/16-18

CableTie

DriveCable

AugerCable

AugerControl

DriveControl

LowerHandle

UpperHandle

HandleTab

TransmissionAssembly

TTScrew1/4-20x 1.25

Screw1/4-20x .625

ClevisPin

CotterPin1/8x 1.0

BowTie CotterPin72

RollPin

Pinion14T

Gear70T

ExtensionSpring

FlatWasher

ShoulderScrew1/4-20

ShoulderScrew1/4-28

Hex FlangeBearing

Hex FlangeBearing

CableRoller

m

M

784-o419C-4O43

30

31

790-00223A-0637

32

790-00224

934-04282B

33

734-04322

34

710-0627

35

736-0242

36

738-04321

37

910-0224

710-0654A

38

39

710-0696

710-1245B

4o

41

931-04162A

42

736-0247

43

736-0505

44

748-04067A

45

950-1355

46

950-1356

47

954-04013

48

954-04014

49

956-04024

5o

756-0569

51

729-04035

52

731-05672A

53

936-0160

54

936-0451

55

731-06749

56

952Z265-SUA

DriveHousingFrame

AugerCable Bracket

AugerCable Adj.Bracket

WheelAssySnowHogGray

Tube,Tire,4.10/3.50-4.0

LockBolt5/16-24x .75

BellWasher.34x .872x .06

Axle

HexScrew#10-16x.500

TT SemsScrew3/8-16x 1.0

HexBolt3/8-24x .875

LockBolt5/16-24x .875

BeltCover

FlatWasher.406IDx 1.25OD

FlatWasher.34IDx 1.50OD

Pulley:Adapter.75Dia.

Spacer.876x 1.25x .19

Spacer.876x 1.25x .86

V-Belt3/8 x 21.108Lg.

V-Belt3/8 x 26.680Lg.

AugerPulley

PulleyHalf

AmpSealedConnector

Spacer

FlatWasher.53x .93x .05

SaddleWasher

CableClip

Engine

25

Page 26

Craftsman Snow Thrower IViodel 247.881701

777S32636

f

IOOJLJLg0=NV313

"WRNVt_S,U01VU3d0OV3U"_;

"S33VJHRS13AVU9NO9NllVid3d0

N3HMNOllflV3VU1X33Sn"SU30NVISABlV 39UVHOSIQ

IO3UIOH3A3N'S3IUNFNJS1331'80NMOUHIQIOAVOl "_

"3NIH3V_I9NIOIAU::ISH0 9NI99013Nll

3HO_3B03ddOlS3MH SlUVd9NIAO_llVlilNnS310NVH

ONIH:t8NIV_BUQNV':INIDN]dOlS'SUBA3IH31nl3:IDVgNBSIO"_

"31nH339UVH3SIO501ONROlI001 IRO-NV3103SR "Z

"133dONV SONVH31Vlrld_V NV3U39nVUOU_113d_iHIiM

1OVlN0O"U39fiV0NVH3"l'13d_l9NilVl0_l _0U:I IVMVd33H"L

777X43688

..................eONOT

USEE85 ORFUEL...........

COHTAiHiHGMOBE

THAH 10% ETHAHOL

777122164

777S32236

777i23249

i/

122164 AC

777i22138

S

777D19075

777D16340

777D18033

26

Page 27

CraftsmanEngineModel 265-SUAFor SnowModel 247.881721

23

24

m

D _ o w

19

951-11282

20

710-05001

20

751-14190

21

951-11289

22

712-04214

23

710-04915

24

951-I0642B

Muffler Assembly

Stud M8x36

Muffler Stud Kit

Exhaust Pipe Gasket

Nut, M8

Bolt M6x12

Muffler Shield

27

Page 28

CraftsmanEngineModel265-SUAForSnowModel 247.881721

41 _42

34

35

36

37

39

4O

41

42

43

951-10634

712-04213

951-11284

951-10757

951-10637

731-05632

951-10640

951-10635

710-04943

°0

Air Cleaner Housing

Nut

Choke Knob

Throttle Control Knob

Key Switch

Key

Choke Push Rod

Heater Box

Bolt M6x28

37

35

D _ o 0

28

Page 29

CraftsmanEngineModel265-SUAForSnowModel 247.881721

132- GasketKit-Complete

133- GasketKit-External

134-CompleteEngine

63

62

29

Page 30

CraftsmanEngineModel 265-SUAForSnowModel 247.881721

52

951-11900

53

951-11901

54

710-04915

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

73

74

75

76

77

78

79

131

132

133

134

951-11113

951-11573

951-14053

736-04461

951-11902

714-04078

951-11575

951-11369

951-10307

951-11247A

951-11576

715-04092

715-04096

951-11371

951-12125

951-11246

710-04932

951-11283

951-11577

951-11368

951-11248A

951-11062B

951-11350

736-04440

710-04906

951-11370

951-10641

951-11061A

951-10661B

952Z265-SUA

Air Shield

Connecting Rod Assembly

Governor Arm Shaft

Washer 5.2xl.9

Governor Seal

Cotter Pin

Camshaft Assembly

Woodruff Key

Crankshaft Kit (Incl.62-64,74,79)

Governor Gear/Shaft Assembly

Crankcase Cover Gasket

Crankcase Cover

Crankcase Cover Kit (Incl. 62,68-74)

Oil Fill Plug Assembly

O-Ring 15.8x2.5

Oil Seal, 25x41.25x6

Crankcase Kit (Incl.59,62,74,75,79)

Short Block Assembly

(Incl. 4,21,27-29,32,44, 46,47,80-53,56-79)

Oil Drain Pipe Assy.

Washer 10x16xl.5

Oil Drain Plug

Oil Seal 25x41.25x6

Oil Drain Assembly

Gasket Kit - Complete

(Incl.4,21,27-29,32,44, 58,59,68,74,77,79)

Gasket Kit - External (Incl. 4,21,27-

29,32,77)

Complete Engine

D - o 0

Piston

Piston Pin

Bolt M6x12

Radial Ball Bearing, 6205

Dowel Pin 7x14

Dowel Pin 9x14

Bolt M8x32

3O

Page 31

CraftsmanEngineModeJ265-SUAFor SnowModeJ247.881721

13

48

15 44

10

17

132- GasketKit-CompJete

133-GasketKit-External

134- CompleteEngine

\6

31

Page 32

CraftsmanEngineModel 265-SUAForSnowModel 247.881721

1

710-04968

2

951-11054A

3a

731-07059

3b

726-04101

4

951-11565

5

951-12000

6

951-11892

7

751-11124

8

751-11123

9

951-11893

10

710-04902

11

951-12002

12

951-12003

13

951-12004

14

951-11894

15

710-04933

16

951-11895

17

751-14195

18

951-10292

44

951-11898

45

951-10648

46

951-11899

47

715-04108

48

951-10647A

49

951-10647A

130

951-12626

132

951-11061A

133

951-10661B

134

952Z265-SUA

D _ ® 0

Bolt M6x16

Valve Cover

Breather Hose

Breather Hose Clamp

Valve Cover Gasket

Valve Spring Retainer (Intake)

Rocker Arm Assembly

Nut, Pivot Locking

Adjusting Nut ,Valve

Rocker Arm

Bolt, Pivot

Exhaust Lash Cap

Valve Spring Retainer (Exhaust)

Valve Spring

Valve Seal (Intake)

Bolt M8x55

Push Rod Guide

Cylinder Head Assembly

(Incl.4-14,16,17,21,27, 29,44,48,49)

Spark Plug/F6Rtc

Gasket, Cylinder Head

Push Rod Kit

Tappet

Dowel Pin 10x16

Valve Kit

Valve Kit

Valve Cover Kit

Gasket Kit - Complete

(Incl.4,21,27-29,32,44, 58,59,68,74,77,79)

Gasket Kit - External (Incl. 4,21,27-

29,32,77)

Complete Engine

32

Page 33

CraftsmanEngineModel265-SUAForSnowModel 247.881721

27

28

135- CarburetorKit

3O

w

31_

33

Page 34

CraftsmanEngineModel 265-SUAForSnowModel 247.881721

25

710-04939

26

710-04910

27

951-11567

28

951-11896

29

951-11569A

30

951-10639A

30

951-11824

31

951-12705

32

951-11897

33

951-11112

135

951-14050

a

n/a

b

n/a

n/a

C

d

n/a

e

710-05469

f

736-04638

n/a

g

h

n/a

I

n/a

n/a

J

k

951-11699

I

951-11906

m

n/a

n

n/a

n/a

0

951-12875

P

n/a

q

r

n/a

n/a

s

t

951-11589

U

n/a

951-11348

V

710-04945

W

X

951-11349

710-04938

Y

D _ o 0

Stud M6x117

Stud M6x105

Carburetor Insulator Gasket

Carburetor Insulator

Carburetor Gasket

Primer Assembly

Primer Bulb

Carburetor Assembly

Carburetor Gasket Plate

Choke Control

Carburetor Kit

(Incl.h,n,o,p,q,r,s,t,v,x)

Choke Shaft

Choke Plate

Throttle Shaft

Throttle Plate

Screw M3x6

LockWasher

Gasket, Throttle Plate

Idle Jet Assembly (0.34)

Idle Speed Adjusting Screw

Primer Pipe

Primer Hose

Hose Clamp

Carburetor Body

Float Pin

Emulsion Tube (P18-019)

Needle Valve

Main Jet (#73)

Needle Valve Spring

Float

Fuel Bowl O-Ring

Fuel Bowl

Fuel Bowl Mounting Bolt Gasket

Fuel Bowl Mounting Bolt

Fuel Bowl Drain Bolt Gasket

Fuel Bowl Drain Bolt

34

Page 35

CraftsmanEngineModel 265-SUAFor SnowModel 247.881721

82

8O

81

82

83

85

86

87

88

89

91

92

93

94

951-10646

951-11110

710-04940

710-04919

951-12416

951-10934

951-10911

712-04209

710-04915

951-10663A

736-04455

710-04974

951-14151

D - o o

Ignition Coil Assembly

Air Flow Shield

Bolt M6xlO

Bolt M6x25

Flywheel

Cooling Fan

Starter Cup

Nut, Special, M14xl.5

Bolt M6x12

Blower Housing

Gasket 6

Bolt M6xlO

Recoil Starter

35

Page 36

CraftsmanEngineModel 265-SUAForSnowModel 247.881721

96 103 _117

_115

116

m

95

96

97

98

99

100

102

103

104

105

106

107

951-10758

710-05103

951-11108

951-11935

951-10664

951-10665

951-11106

712-04212

710-04908

951-11700

951-10650

710-04915

96- 9s 99

95

D _ o o

Primer Bracket

Bolt M6x12

Governor System Shield

Governor Spring

Throttle Linkage Spring

Throttle Linkage

Governor Arm

NutM6

Governor Arm Bolt

Fuel Hose Clamp

Fuel Line Kit

Bolt M6x12

105

107

108

109

110

111

112

113

114

115

116

117

118

951-11914

710-04905

710-04915

951-11913

951-11381

951-10656

951-11904

951-12482

951-12533

951-11933

951-10653B

D _ o o

Dipstick Decoration Cover

Bolt

Bolt M6x12

Oil Fill Tube Assembly

O-Ring

Oil Fill Tube

O-Ring

Dipstick Assembly

Fuel Cap Assembly

Fuel Level Indicator

Fuel Tank Assembly

36

Page 37

CraftsmanEngineModel 265-SUAFor SnowModel 247.881721

119

120

121

122_

m

119

120

121

122

123

124

125

126

127

128

129

122

710-04914

951-11680

951-11114

712-05015

710-04935

710-04965

710-05182

715-04088

951-I0645A

710-04915

951-11109

123

_i _128

29

D - o o

Bolt M6xlO

Wire Clip

Switch Housing Mounting Bracket

Nut, M6

Bolt M4x60

Bolt M4x55

Bolt M6x32

Dowel Pin 8x8

Electric Starter

Bolt M6x12

Blower Housing Shield

37

Page 38

38

Page 39

FEDERALand/or CALIFORNIAEMISSIONCONTROLWARRANTYSTATEMENT

YOURWARRANTYRIGHTSANDOBLIGATIONS

MTD Consumer Group Inc, the United States Environmental Protection Agency (EPA), and for those products certified for sale in the state of

California, the California Air Resources Board (CARB) are pleased to explain the emission (evaporative and/or exhaust) control system (ECS)

warranty on your 2013 and later small off-road spark-ignited engine and equipment (outdoor equipment engine). In California, new outdoor

equipment engines must be designed, built and equipped to meet the State's stringent anti-smog standards (in other states, outdoor

equipment engines must be designed, built, and equipped to meet the U.S. EPA small off-road spark ignition engine regulations). MTD

Consumer Group Inc must warrant the ECSon your outdoor equipment engine for the period of time listed below, provided there has been no

abuse, neglect, or improper maintenance of the outdoor equipment engine.

Your ECS may include parts such as the carburetor, fuel-injection system, ignition system, catalytic converter, fuel tanks, fuel lines, fuel caps,

valves, canisters, filters, vapor hoses, clamps, connectors, and other associated emission-related components.

Where a warrantable condition exists, MTD Consumer Group Inc will repair your outdoor equipment engine at no cost to you including

diagnosis, parts, and labor.

MANUFACTURER'SWARRANTYCOVERAGE:

This emission control system is warranted for two years. If any emission-related part on your outdoor equipment engine is defective, the

part will be repaired or replaced by MTD Consumer Group Inc. In the event that a component is covered for longer than two years by the

Manufacturer's equipment warranty, the longer coverage period will apply.

/

OWNERSWARRANTYRESPONSIBILITIES:

As the outdoor equipment engine owner, you are responsible for performance of the required maintenance listed in your owner's manual. MTD

Consumer Group Inc recommends that you retain all receipts covering maintenance on your outdoor equipment engine, but MTD Consumer

Group Inc cannot deny warranty solely for the lack of receipts.

As the outdoor equipment engine owner, you should however be aware that MTD Consumer Group Inc may deny you warranty coverage if

your outdoor equipment engine or a part has failed due to abuse, neglect, improper maintenance, or unapproved modifications.

You are responsible for presenting your outdoor equipment engine to MTD Consumer Group Inc's distribution center or service center as soon

as the problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If you have a question

regarding your warranty coverage, you should contact the MTD Consumer Group Inc Service Department at 1-800-800-7310 or at

http://su pport.mtd prod ucts.com.

GENERALEMISSIONSWARRANTYCOVERAGE:

MTD Consumer Group Inc warrants to the ultimate purchaser and each subsequent purchaser that the outdoor equipment engine is: (1)

designed, built, and equipped so as to conform with all applicable regulations; and (2) free from defects in materials and workmanship that

cause the failure of a warranted part for a period of two years.

The warranty period begins on the date the outdoor equipment engine is delivered to an ultimate purchaser or first placed into service.

Subject to certain conditions and exclusions as stated below, the warranty on emission-related parts is as follows:

1. Any warranted part that is not scheduled for replacement as required maintenance in the written instructions supplied is warranted for

the warranty period stated above. If the part fails during the period of warranty coverage, the part will be repaired or replaced by MTD

Consumer Group Inc according to subsection (4) below. Any such part repaired or replaced under warranty will be warranted for the

remainder of the period.

2. Any warranted part that is scheduled only for regular inspection in the written instructions supplied is warranted for the warranty period

stated above. Any such part repaired or replaced under warranty will be warranted for the remaining warranty period.

3. Any warranted part that is scheduled for replacement as required maintenance in the written instructions supplied is warranted for the

period of time before the first scheduled replacement date for that part. If the part fails before the first scheduled replacement, the part

will be repaired or replaced by MTD Consumer Group Inc according to subsection (4) below. Any such part repaired or replaced under

warranty will be warranted for the remainder of the period prior to the first scheduled replacement point for the part.

4.

Repair or replacement of any warranted part under the warranty provisions herein must be performed at a warranty station at no charge

to the owner.

5. Notwithstanding the provisions herein, warranty services or repairs will be provided at all of our distribution centers that are franchised to

service the subject engines or equipment.

6. The outdoor equipment engine owner will not be charged for diagnostic labor that is directly associated with diagnosis of a defective,

emission-related warranted part, provided that such diagnostic work is performed at a warranty station.

7. MTD Consumer Group Inc is liable for damages to other engine or equipment components proximately caused by a failure under

warranty of any warranted part.

8. Throughout the off-road engine and equipment warranty period stated above, MTD Consumer Group Inc will maintain a supply of

warranted parts sufficient to meet the expected demand for such parts.

9. Any replacement part may be used in the performance of any warranty maintenance or repairs and must be provided without charge to