Page 1

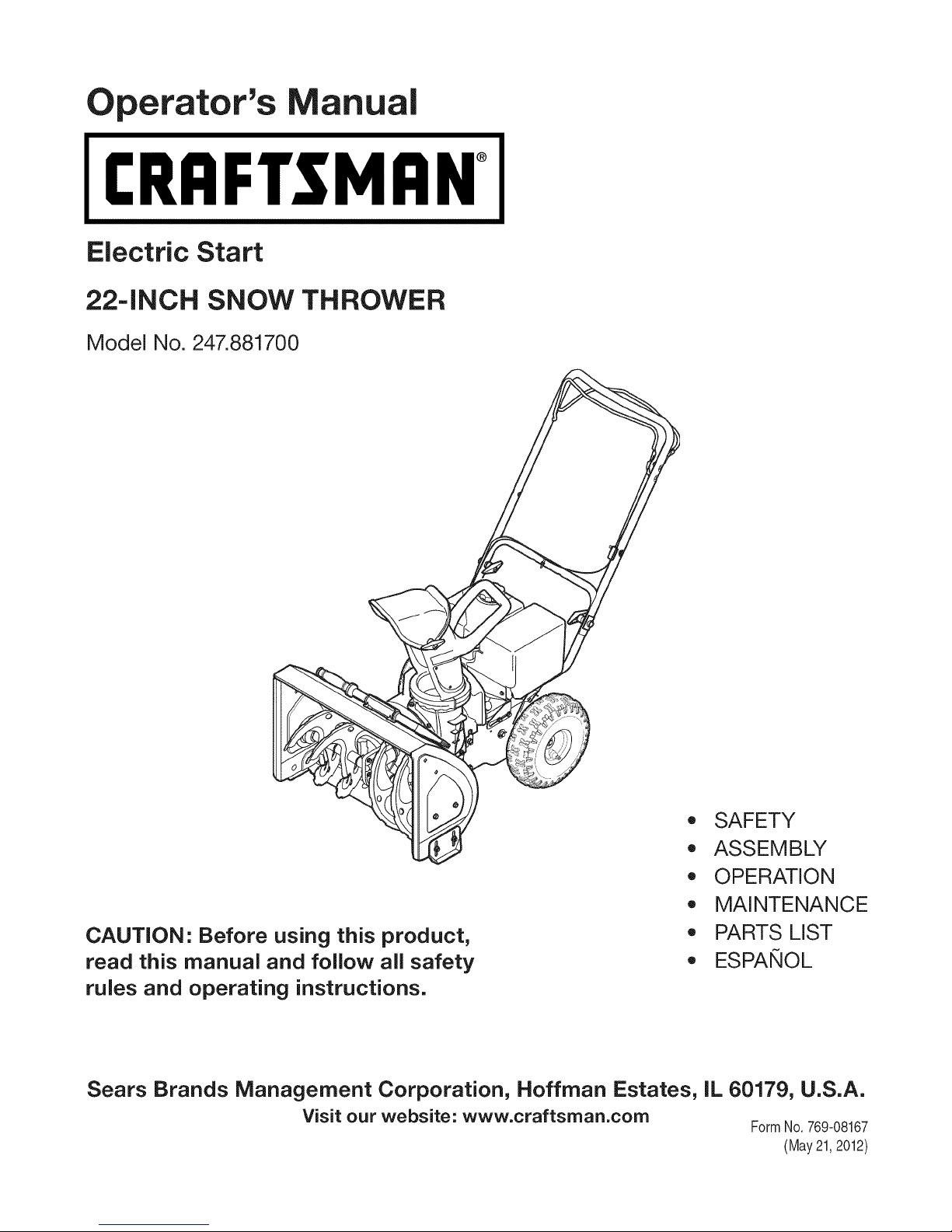

perator_s nual

I:RRFrgMRN°

Electric Start

-INCH SNOW THROWER

Model No. 247.881700

CAUTION: Before using this product,

read this manual and follow all safety

rules and operating instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.corn

,, SAFETY

o ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPANOL

FormNo.769-08167

(May21,2012)

Page 2

WarrantyStatement.................... Page2

SafeOperation Practices ................ Page 3

Assembly ............................ Page 7

Operation ........................... Page 11

Maintenance & Service ................. Page 15

Off-Season Storage ................... Page 20

Troubleshooting ...................... Page 21

Parts List ............................ Page 22

Repair Protection Agreement ............ Page 43

Espa_ol ............................. Page 44

Contact Numbers .................. Back Cover

CRAFTSMANTWOYEAR FULLWARRANTY

FORTWOYEARSfromthe dateof purchase,this productiswarrantedagainstanydefectsin materialor workmanship.A defective

productwillreceivefreerepairor replacementif repairisunavailable.

Forwarranty coverage details to obtain freerepairorreplacement,visittheweb site: www.craftsman.com

Thiswarranty coversONLYdefects in materialandworkmanship. Warrantycoverage does NOTinclude:

• Expendableitemsthatcanwearoutfromnormalusewithinthewarrantyperiod,includingbutnot limitedtoaugers,augerpaddles,

driftcutters,skidshoes,shaveplate,shearpins,sparkplug,aircleaner,belts,andoilfilter.

• Standardmaintenanceservicing,oilchanges,or tune-ups.

Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,or glass.

Tireor wheelreplacementorrepairresultingfromnormalwear,accident,or improperoperationormaintenance.

Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedto damagecausedbyover-speedingtheengine,or from

impactingobjectsthatbendtheframe,augershaft,etc.

• Repairsnecessarybecauseof operatornegligence,includingbutnot limitedto,electricalandmechanicaldamagecausedby

improperstorage,failureto usethepropergradeandamountof engineoil,or failureto maintaintheequipmentaccordingtothe

instructionscontainedintheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedto becontaminatedoroxidized(stale).Ingeneral,fuelshouldbe

usedwithin30 daysof itspurchasedate.

Normaldeteriorationandwearof theexteriorfinishes,orproductlabelreplacement.

Thiswarrantyisvoidif thisproductisever usedwhileprovidingcommercialservicesor if rentedtoanotherperson.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstatetostate.

SearsBrands ManagementCorporation, HoffmanEstates,IL 60179

EngineOilType: 5W-30

EngineOilCapacity: 20ounces

FuelCapacity: 2.3Quarts

SparkPlug: F6RTC(F6TC)

SparkPlugGap: .020"to.030"

© SearsBrands,LLC

ModelNumber.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Page 3

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingto operatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothesafeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron the partoftheoperatorcan resultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionson the machineand

in themanual(s)beforeattemptingtoassembleandoperate.

Failuretodo socan resultinseriousinjurytotheoperatorand/

orbystanders.Keepthismanualin a safeplaceforfutureand

regularreferenceandfororderingreplacementparts.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsof agetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

Neverallowadultsto operatethismachinewithoutproper

instruction.

• Thrownobjectscancauseseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthelike.

Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileitis in operation.Stopmachineifanyoneenters

thearea.

• Exercisecautiontoavoidslippingorfalling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict theuseofthispowermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon themachine.

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbythe auger/

impeller.

• Alwayswearsafetyglassesor eyeshieldsduringoperationand

whileperformingan adjustmentor repairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledin movingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordandreceptaclefor all

machineswithelectricstartengines.

Disengageall controlleversbeforestartingtheengine.

Adjustcollectorhousingheighttocleargravelorcrushedrock

surfaces.

• Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjustto outdoortemperaturebefore

startingtoclearsnow.

3

Page 4

SafeHandling of Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineis spilled

onyourselforyourclotheswhichcan ignite. Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Extinguishallcigarettes,cigars,pipesandother sourcesof

ignition.

• Neverfuel machineindoors.

• Neverremovegascapor addfuel whiletheengineishotor

running.

• Allowenginetocoolat leasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Fill tankto nomorethan1/2inchbelow

bottomoffillerneckto providespaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipe itoff theengineandequipment.Move

machinetoanotherarea.Wait5minutesbeforestartingthe

engine.

• Neverstorethe machineorfuelcontainerinsidewherethereisan

openflame,sparkor pilotlight(e.g.furnace,waterheater,space

heater,clothesdryeretc.).

• Allowmachinetocoolatleast5 minutesbeforestoring.

• Neverfill containersinsidea vehicleor ona truckor trailerbed

witha plasticliner.Alwaysplacecontainersonthe groundaway

fromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthetruckor

trailerandrefuelitonthe ground.Ifthis isnotpossible,thenrefuel

suchequipmenton a trailerwithaportablecontainer,ratherthan

froma gasolinedispensernozzle.

• Keepthe nozzlein contactwiththerimofthefuel tankor

containeropeningatalltimesuntilfuelingiscomplete.Donotuse

a nozzlelock-opendevice.

OPERATION

• Do notputhandsorfeetnear rotatingparts,in theauger/impeller

housingorchuteassembly.Contactwiththerotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleveris a safetydevice.Neverbypass

itsoperation.Doingsomakesthe machineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyin bothdirectionsand

automaticallyreturntothe disengagedpositionwhenreleased.

• Neveroperatewitha missingordamagedchuteassembly.Keep

all safetydevicesinplaceandworking.

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Do notoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcan causea burn.Do not

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingon orcrossinggravel

surfaces.Stayalertforhiddenhazardsortraffic.

Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.Do notoperateon steepslopes.

Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc.Thus,avoidingpossibleproperty

damageorpersonalinjurycausedby a ricochet.

Neverdirectdischargeat children,bystandersand petsor allow

anyoneinfrontof themachine.

Donot overloadmachinecapacityby attemptingto clearsnowat

toofastof a rate.

Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureof yourfootingandkeepa firmholdon thehandles.Walk,

neverrun.

Disengagepowerto theauger/impellerwhentransportingor not

in use.

Neveroperatemachineathightransportspeedson slippery

surfaces.Lookdownand behindandusecarewhenbackingup.

Ifthemachineshouldstartto vibrateabnormally,stopthe engine,

disconnectthesparkplugwireandgrounditagainsttheengine.

Inspectthoroughlyfor damage.Repairanydamagebefore

startingandoperating.

Disengageall controlleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntiltheauger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makingany adjustments,or inspections.

Neverputyourhandinthedischargeor collectoropenings.Do

notunclogchuteassemblywhileengineis running.Shutoff

engineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeunclogging.

Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tirechains,cabsetc.). Forinformation

concerningtheseitems,call1-800-469-4663.

Whenstartingengine,pullcord slowlyuntilresistanceisfelt,then

pull rapidly.Rapidretractionofstartercord(kickback)willpull

handandarmtowardenginefasterthanyoucanlet go.Broken

bones,fractures,bruisesorsprainscouldresult.

Ifsituationsoccurwhichare notcoveredinthismanual,usecare

andgoodjudgment.

Toorderpartsor scheduleserviceforthisproduct,call 1-800-

469-4663.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethedischargechute

is the mostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanout thedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe suretheimpellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,not yourhands.

4

Page 5

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothemaintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstoptheengine.Waituntilthe auger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheengineto preventunintendedstarting.

Checkboltsand screwsforpropertightnessatfrequentintervals

tokeepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonlyaslistedinthe Partspagesof thisoperator's

manual.Useofpartswhichdonot meettheoriginalequipment

specificationsmayleadto improperperformanceandcompro-

misesafety!

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,ifnecessary.Refertotheadjustment

sectioninthisoperator'smanualfor instructions.

Maintainor replacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsand regulationsforgas,oil,etc.to

protecttheenvironment.

Priorto storing,runmachinea few minutestoclear snowfrom

machineand preventfreezeupofauger/impeller.

Neverstorethemachineorfuel containerinsidewherethereisan

openflame,sparkorpilot lightsuchas a waterheater,furnace,

clothesdryeretc.

Alwaysrefertothe operator'smanualforproperinstructionson

off-seasonstorage.

Checkfuelline,tank, cap,andfittingsfrequentlyfor cracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 60 hoursof

operation.AttheendoftheAverageUsefulLifehavethe machine

inspectedannuallybyanauthorizedservicedealerto ensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failuretodo socanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do notmodifyengineinany way.

Tamperingwiththegovernorsettingcanleadtoa runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMiSSiONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOff RoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlessthe engine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any)

Ifa sparkarrestorisused,it shouldbemaintainedineffectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442ofthe CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorfor themufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

Page 6

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

. +

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

"JIp

WARNING--THROWN OBJECTS

This machine may pick up and throw objects which can cause serious personal injury.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas+

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

6

Page 7

iMPORTANT:Thisunitis shippedwiththeenginefullofoil. After

assembly,see page10forfuel andoildetails.

Removing From Carton

1. Cutthe cornersofthecartonandlaythe sidesflaton theground.

Removeall packinginserts.

2. Movethe snowthroweroutof thecarton.

3. Makecertainthe cartonhasbeencompletelyemptiedbefore

discardingit.

DO NOTliftthe snowthrower bythechute handle.

Before Assembly

NOTE:Referenceto right,left, frontor rearoftheunit isfromthe

operatingposition,facingforward,unlessotherwisestated.

Setting Up The Handle

NOTE: Beawareofthe threelooselyfittedcabletiesattachedtothe

lowerhandlethatwill beutilizedlatertosecurethecables.

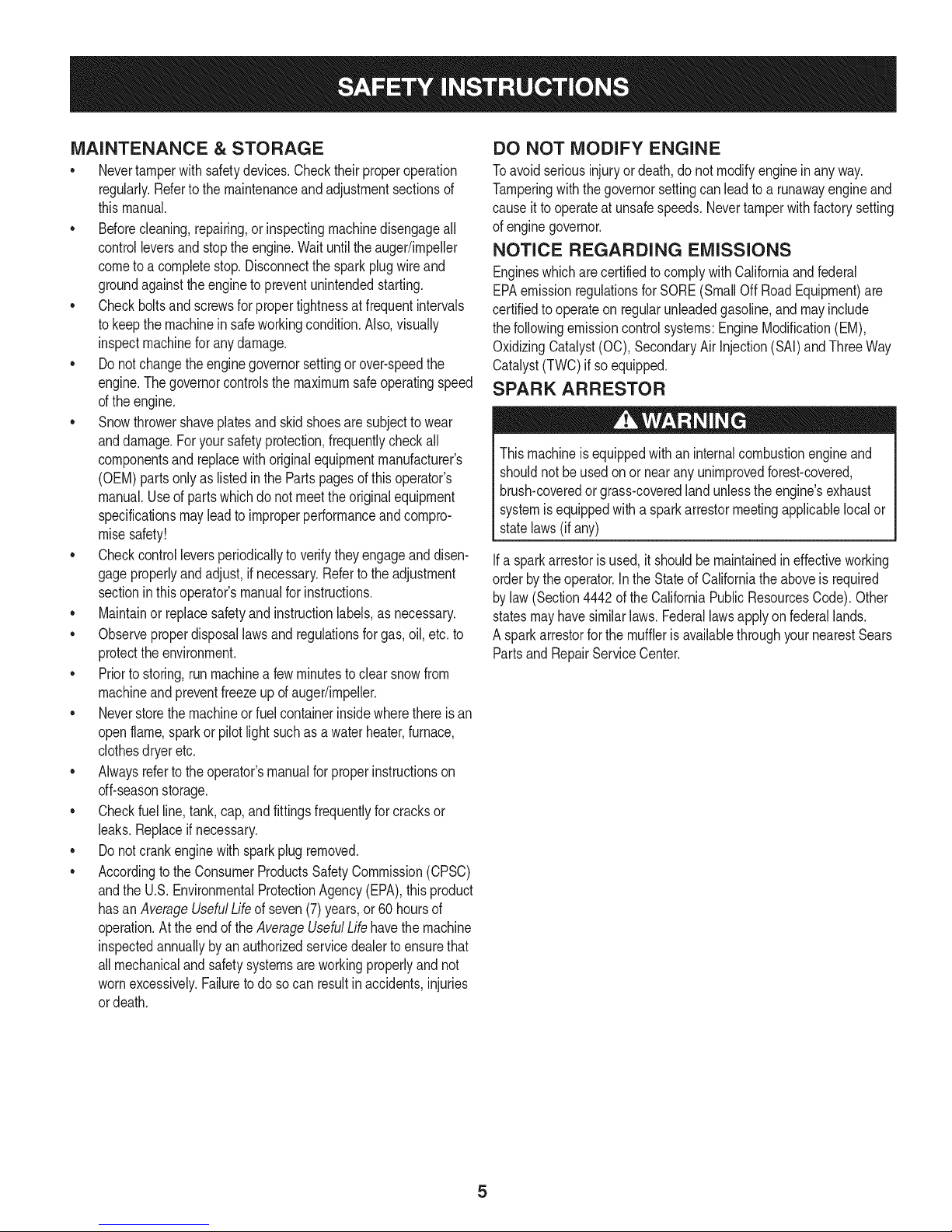

1. Loosenand removethewingknob,saddlewasher,handletaband

carriagescrewoneachsideofthe lowerhandle.SeeFigure1.

2. Slidethe looselyfittedcabletie fromtherightsideofthe lower

handleupto thecrossmemberofthelowerhandle.Leavethe

secondcabletie inplaceonthe rightsideofthe lowerhandle.See

Figure3for reference.

iMPORTANT: itwillbenecessaryto lifttheupperhandlewhile

slidingupthiscabletieto preventdamagetothecable.

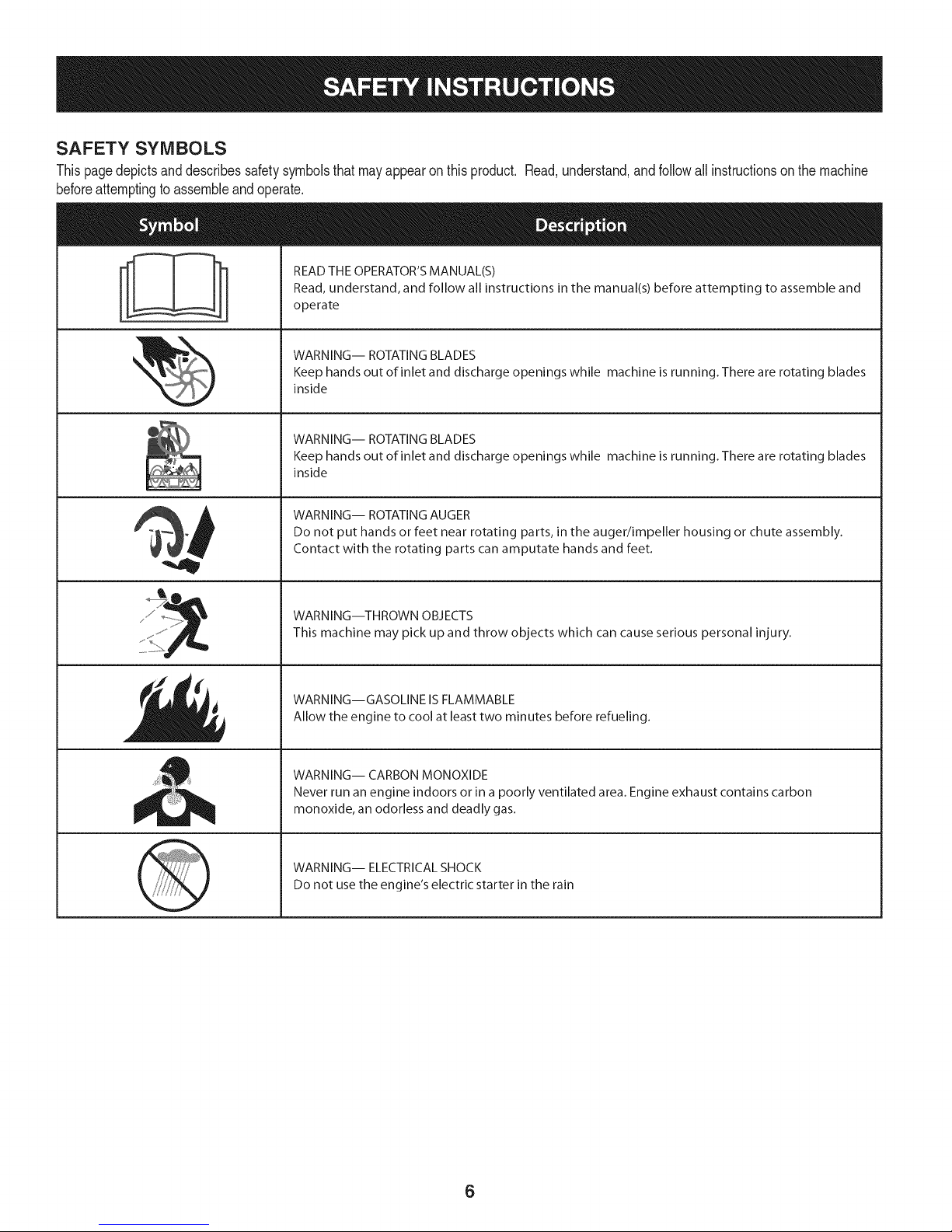

3. Liftthe upperhandleupandpositionit overthelowerhandle,

aligningthe holeswherethewingknobswereremoved(1).See

Figure2.

Figure 1

Becarefulnotto bendor kinkthecables.

4. Inserta carriagescrewfromtheoutsidethrougha handletab,the

upperand lowerhandles,asaddlewasherandintothe wingknob

(2). Repeatonthe otherside.

5. Tightenthewingknobsoneach sideof thehandle.RefertoFigure

2.

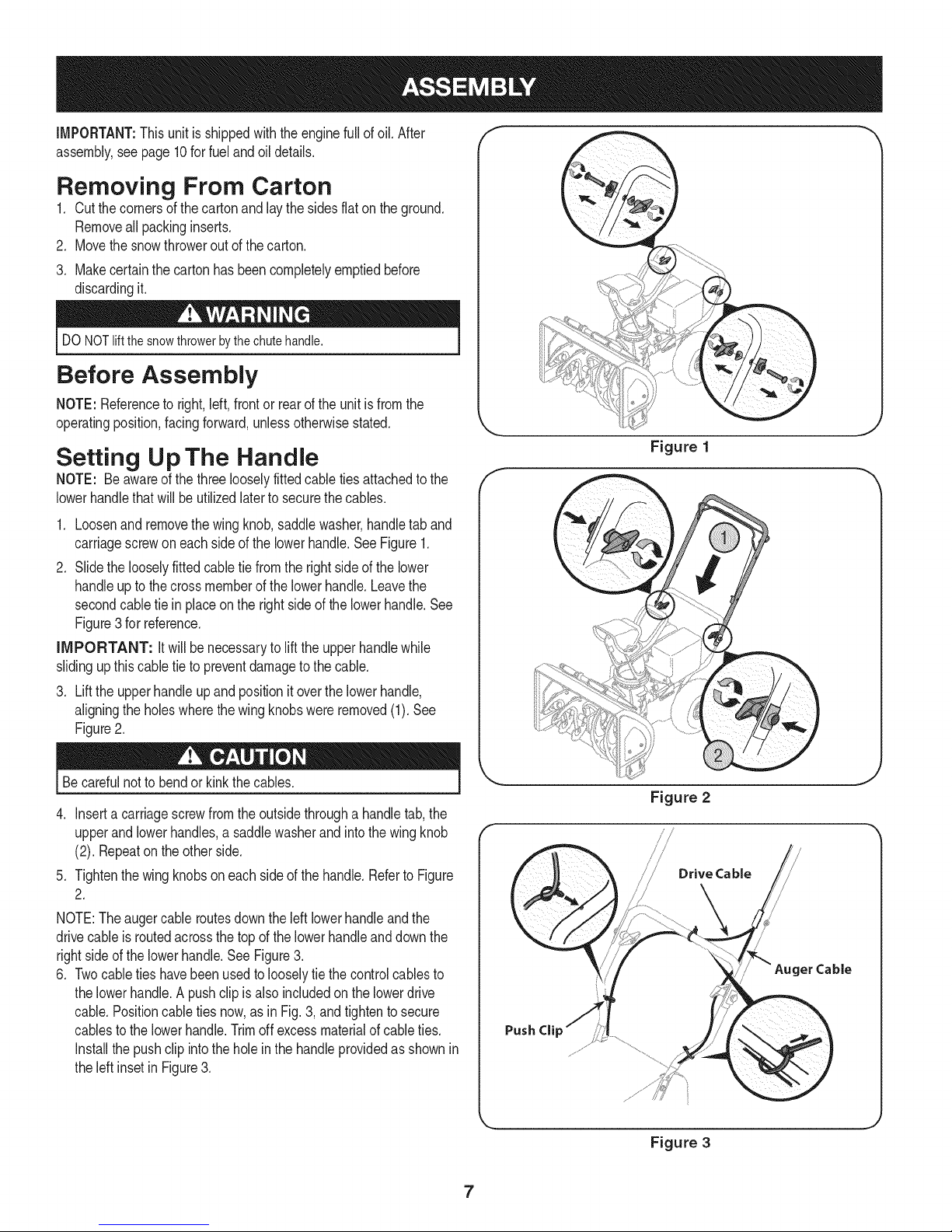

NOTE:Theaugercableroutesdowntheleft lowerhandleandthe

drivecableisroutedacrossthetopof thelowerhandleanddownthe

rightside ofthe lowerhandle.SeeFigure3.

6. Twocabletieshavebeenusedtolooselytie thecontrolcablesto

thelowerhandle.Apushclipis alsoincludedon thelowerdrive

cable.Positioncabletiesnow,as inFig.3,andtightento secure

cablestothe lowerhandle.Trimoff excessmaterialof cableties.

Installthe pushclip intotheholeinthe handleprovidedasshownin

theleftinsetinFigure3.

Figure 2

Drive Cable

/

Auger Cable

Push Cli

Figure 3

7

Page 8

Skid Shoe

Thesnowthrowerskidshoesareadjustedupwardat thefactory

forshippingpurposes.Adjustthemdownward,ifdesired,priorto

operatingthesnowthrower.

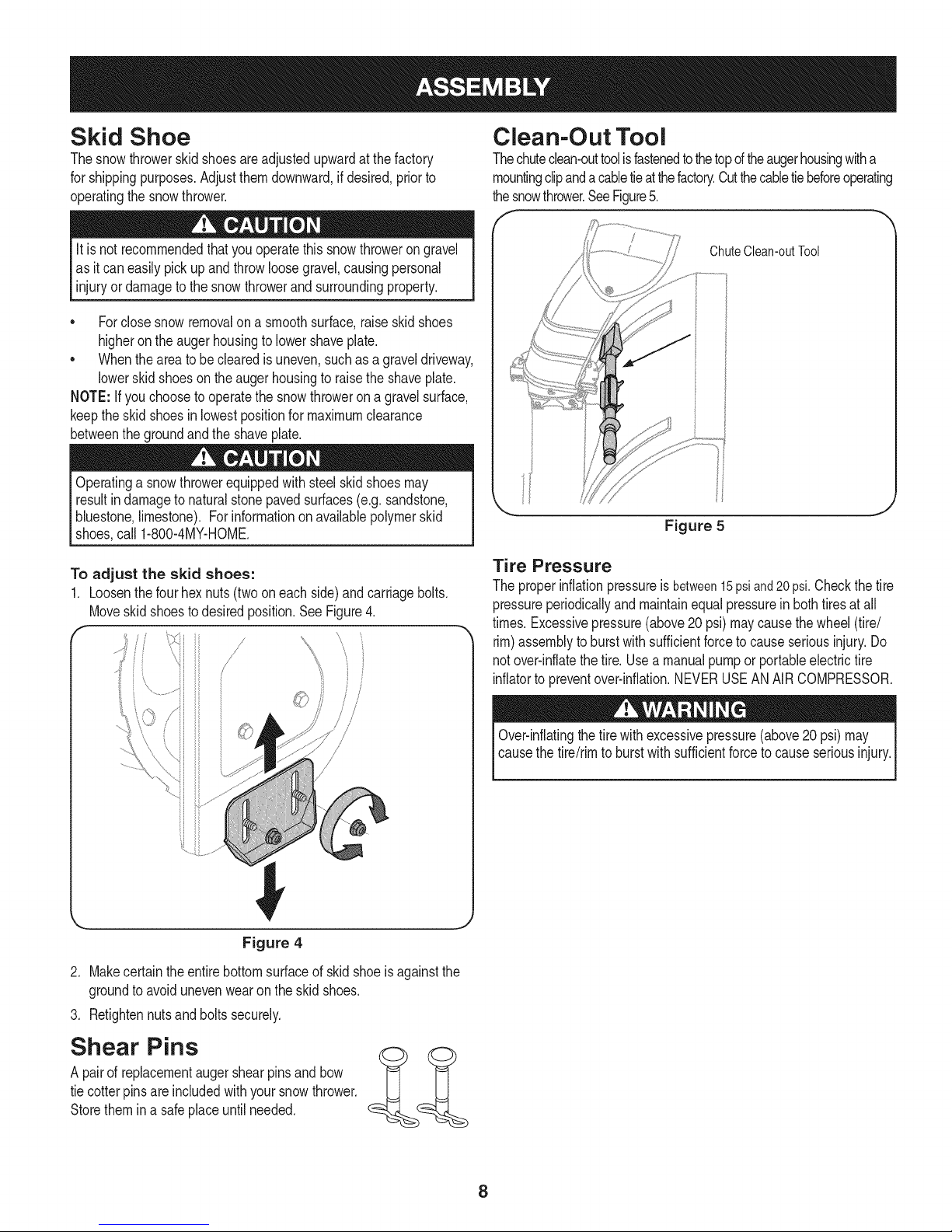

Clean-Out Tool

Thechuteclean-outtoolisfastenedtothetopoftheaugerhousingwitha

mountingclipandacabletieatthefactory.Cutthecabletiebeforeoperating

thesnowthrower.SeeFigure5.

It isnot recommendedthatyouoperatethissnowthrowerongravel

as itcaneasilypickup andthrowloosegravel,causingpersonal

injuryordamagetothe snowthrowerand surroundingproperty.

• Forclosesnowremovalona smoothsurface,raiseskidshoes

higherontheaugerhousingtolowershaveplate.

• Whentheareato beclearedis uneven,suchasagraveldriveway,

lowerskidshoeson theaugerhousingtoraisethe shaveplate.

NOTE:Ifyou choosetooperatethesnowthrowerona gravelsurface,

keepthe skidshoesin lowestpositionformaximumclearance

betweenthegroundandtheshaveplate.

Operatingasnowthrowerequippedwithsteelskidshoesmay

resultindamageto naturalstonepavedsurfaces(e.g.sandstone,

bluestone,limestone).For informationonavailablepolymerskid

shoes,call 1-800-4MY-HOME.

To adjust the skid shoes:

1. Loosenthefourhexnuts(twooneach side)andcarriagebolts.

Moveskidshoestodesiredposition.SeeFigure4.

/

/

//

0! i

ChuteClean-outTool

Figure 5

Tire Pressure

Theproperinflationpressureisbetween15psiand20psi.Checkthe tire

pressureperiodicallyandmaintainequalpressureinbothtiresatall

times.Excessivepressure(above20 psi)maycausethe wheel(tire/

rim)assemblytoburstwithsufficientforceto causeseriousinjury.Do

notover-inflatethetire.Usea manualpumpor portableelectrictire

inflatorto preventover-inflation.NEVERUSEANAIRCOMPRESSOR.

Figure 4

2. Makecertaintheentirebottomsurfaceof skidshoeisagainstthe

groundtoavoidunevenwearontheskidshoes.

3. Retightennutsandboltssecurely.

Shear Pins

A pairof replacementaugershearpinsandbow

tiecotterpinsare includedwithyoursnowthrower.

Storethemina safeplaceuntilneeded.

Over-inflatingthe tirewithexcessivepressure(above20psi)may

causethetire/rimto burstwithsufficientforcetocauseseriousinjury.

8

Page 9

Fuel Recommendations

Useautomotivegasoline(unleadedor low leadedtominimizecombus-

tionchamberdeposits)witha minimumof87octane.Gasolinewith

upto 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neveruseanoil/gasolinemixtureor dirtygasoline.Avoidgetting

dirt,dust,or waterinthefueltank. DONOTuseE85gasoline.

* Refuelin awell-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesorsparksintheareawheretheengineis

refueledorwheregasolineisstored.

* Donotoverfillthefuel tank.Afterrefueling,makesurethe tank

capis closedproperlyandsecurely.

* Becarefulnotto spillfuelwhenrefueling.Spilledfuelor fuelvapor

mayignite.Ifany fuelisspilled,makesurethe areaisdrybefore

startingtheengine.

* Avoidrepeatedor prolongedcontactwithskinor breathingof

vapor.

Adding Fuel

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthe vaporsareexplosive.Neverfuelthe machine

indoorsorwhiletheengineishotor running.Extinguishcigarettes,

cigars,pipesandothersourcesofignition.

Checking Oil Level

Theengineis shippedwithoil intheengine.Youmust,however,

checkthe oil levelpriortooperatingthesnowthrower.Runningthe

enginewithinsufficientoilcancauseseriousenginedamageand

voidtheenginewarranty.

NOTE: Besuretocheckthe engineon a levelsurfacewiththe engine

stopped.

1. Removetheoil fillercap/dipstickand wipethe dipstickclean.See

Figure7.

f-

Alwayskeephandsandfeetclear ofequipmentmovingparts.Donot

usea pressurizedstartingfluid.Vaporsareflammable.

1. Cleanaroundfuel fillbeforeremovingcaptofuel.

2. Afuellevelindicatoris locatedinthefuel tank.Filltankuntil fuel

reachesthefuellevel indictor,Figure6. Becarefulnottooverfill.

FuelLevelIndicator

TopView

)

_,., J

Figure7

2. Insertthe cap/dipstickintotheoilfillerneck,turnthecap 1/4turnuntil

fully seated.

NOTE:On someengines,a threadedcap/dipstickmayexist insteadof

a 1/4turncap asdescribedabove.Inthisinstancedo notfullytighten

the captochecktheoil level.Simplyrestthe capon the threadsto

checkfor properoil level.

3. Removetheoil fillercap/dipstick.Ifthe levelis low,slowlyadd oiluntil

oil levelregistersbetweenhigh(H) andlow(L), Figure7. Referto the

EngineMaintenancesectionfor correctoil viscosityandengineoil

capacity.

NOTE:Do notoverfill.Overfillingwithoil mayresultinenginesmoking,

hardstartingorsparkplugfouling.

4. Replaceandtightencap/dipstickfirmly beforestartingengine.

Figure6

9

Page 10

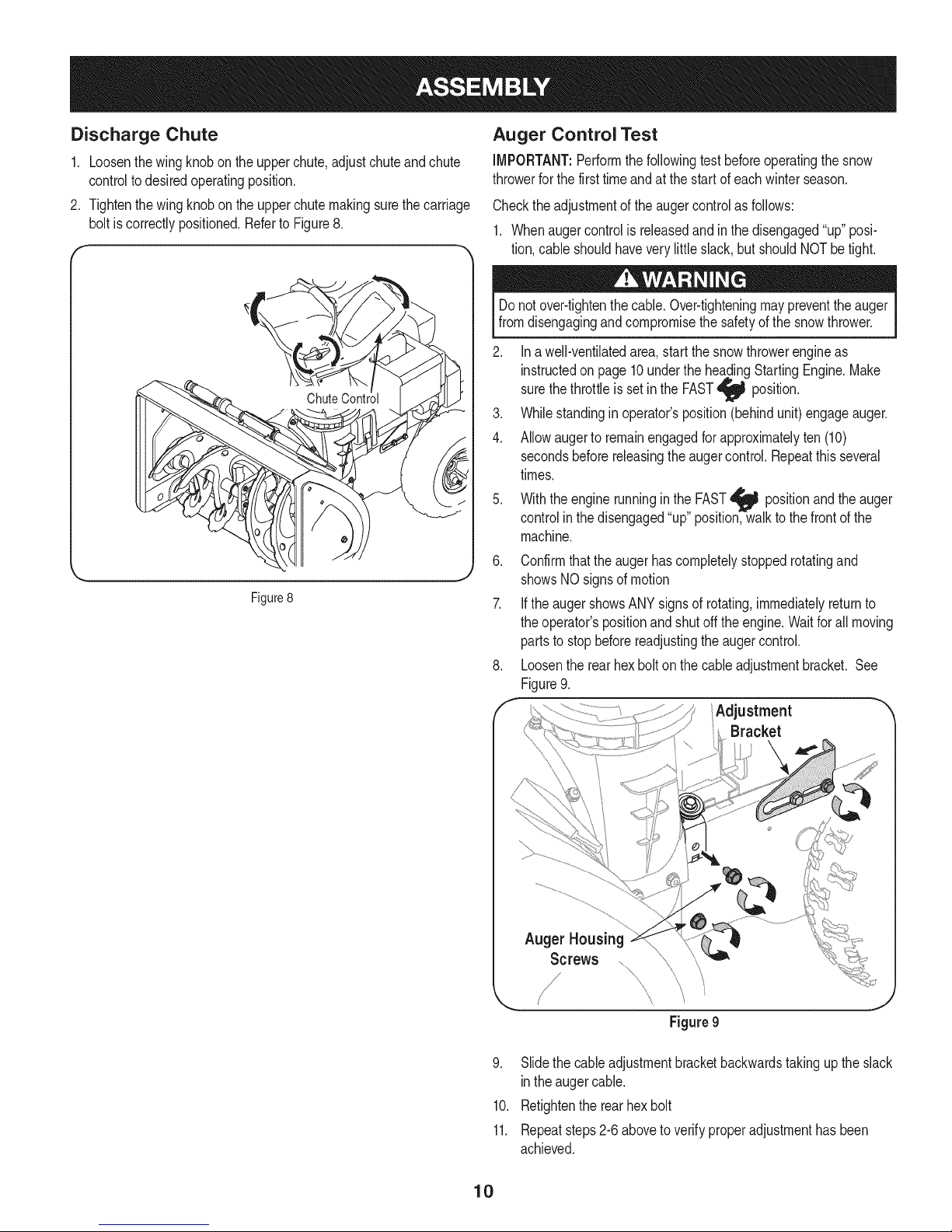

Discharge Chute

1. Loosenthewingknobon the upperchute,adjustchuteand chute

controltodesiredoperatingposition.

2. Tightenthewingknobontheupperchutemakingsurethecarriage

boltiscorrectlypositioned.Referto Figure8.

J

Figure8

Auger Control Test

iMPORTANT:Performthefollowingtestbeforeoperatingthesnow

throwerforthe firsttimeandat thestartof eachwinterseason.

Checktheadjustmentof theaugercontrolasfollows:

1. Whenaugercontrolisreleasedandinthedisengaged"up"posi-

tion,cableshouldhaveverylittleslack,butshouldNOTbetight.

Donot over-tightenthe cable.Over-tighteningmaypreventtheauger

fromdisengagingandcompromisethe safetyofthe snowthrower.

2. Ina well-ventilatedarea,startthesnowthrowerengineas

instructedon page10undertheheadingStartingEngine.Make

sure

thethrottleisset inthe FAST

3. Whilestandinginoperator'sposition(behindunit)engageauger.

4. Allowaugerto remainengagedforapproximatelyten(10)

secondsbeforereleasingthe augercontrol.Repeatthisseveral

times.

5. Withtheenginerunninginthe FAST_ positionand the

controlinthedisengaged"up"position,walktothefrontof the

machine.

6. Confirmthattheaugerhascompletelystoppedrotatingand

showsNOsignsofmotion

7. iftheaugershowsANYsignsof rotating,immediatelyreturnto

theoperator'spositionandshutofftheengine.Waitforallmoving

partsto stopbeforereadjustingtheaugercontrol.

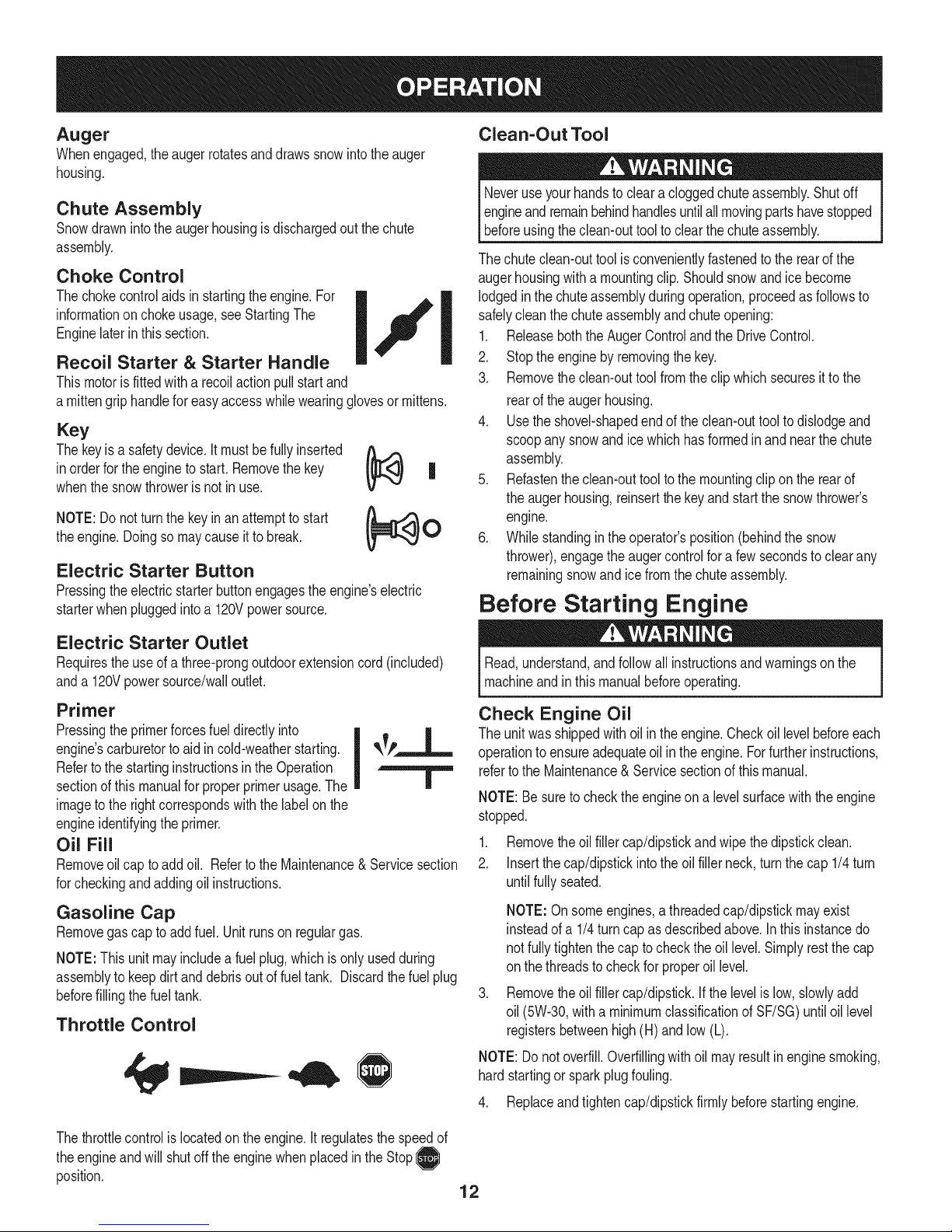

8. Loosentherearhexbolton thecableadjustmentbracket.See

Figure9.

f Adjustment "

position.

auger

Bracket

Auger Housing

Screws

Figure9

9. Slidethecableadjustmentbracketbackwardstakingup the slack

intheaugercable.

10. Retightentherearhexbolt

11. Repeatsteps2-6aboveto verifyproperadjustmenthasbeen

achieved.

10

Page 11

UpperChute

Upper Handle

Drive

AugerControl Control

ChuteAssembl

Clean-out Tool

Auger

ShavePlate

ChuteKnob

_- Skid Shoe

FuelCap

RecoilStarter

Handle

Oil Drain Electric StarterOutlet

Befamiliarwithallthecontrolson thesnowthrowerandtheir properoperation.Knowhowto stopthemachineanddisengagethemquickly.

Snowthrowercontrolsandfeaturesaredescribedbelowandillustrated

in thefigureabove.

Drive Control

Locatedon theundersideof theupperhandle,thedrivecontrolis used

toengage/disengagewheels.Squeezethe drivecontrolagainstthe

upperhandletoengagethe wheels;releasetodisengage.

Auger Control

Theaugercontrolis on thefronttheupperhandle.Squeezethe auger

controlagainsttheupperhandleto engagetheauger;releaseto

disengagethe auger.

Chute Handle

Thedirectionof snowthrowingcorrespondstothedirectionofthe

chuteopening.Usethechutehandletoturn thechuteassemblyinthe

directionyouwishto throwthesnow.

Chute Knob

Thedistancesnowisthrowncanbe adjustedbyeitherraisingor

loweringtheupperchute.Loosenthechuteknobonthe sideof the

upperchutetoadjust.Pivottheupperchutetodesiredposition,and

retightenthechuteknob.Raisingthechutethrowsthe snowfurther.

Shave Plate

Theshaveplatemaintainscontactwithpavementasthesnow

throwerispropelled,allowingsnowcloseto pavement'ssurfacetobe

Nevermakeadjustmentstothechuteassemblyunlessbothaugerand

drivecontrolsaredisengagedandtheoperatorisstandingbesidetheunit.

IMPORTANT:Referto AugerControlTestinthe Assemblysectionof

thismanualpriorto operatingyoursnowthrower.Readandfollowall

instructionscarefullyandperformall adjustmentsto verifyyoursnow

throwerisoperatingsafelyandproperly.

discharged.

Skid Shoe

Thespacebetweenthe shaveplateandthegroundcanbe adjusted.

Forclosesnowremoval,placeskidshoesin the highestposition.Use

middleorlowestpositionwhenareato beclearedis unevenoron

gravelsurfaces.

11

Page 12

Auger

Whenengaged,theaugerrotatesanddrawssnowintotheauger

housing.

Chute Assembly

Snowdrawnintothe augerhousingisdischargedoutthechute

assembly.

Choke Control

Thechokecontrolaidsinstartingtheengine.For

informationonchokeusage,seeStartingThe

Enginelaterinthis section.

I j _ lodgedinthe chuteassemblyduringoperation,proceedasfollowsto

Recoil Starter & Starter Handle

Thismotorisfittedwitha recoilactionpullstart and

a mittengriphandlefor easyaccesswhilewearingglovesor mittens.

Key

Thekeyis a safetydevice.Itmustbefully inserted

inorderforthe enginetostart.Removethe key

whenthe snowthrowerisnot in use.

NOTE:Do notturn thekeyinanattemptto start

theengine.Doingso maycauseitto break.

(_ assembly.

| 5. Refastentheclean-outtooltothe mountingclipon therearof

0 6. Whilestandingintheoperator'sposition(behindthe snow

Electric Starter Button

Pressingtheelectricstarterbuttonengagestheengine'selectric

starterwhenpluggedintoa 120Vpowersource.

Clean=Out Tool

Neveruseyour handstoclearacloggedchuteassembly.Shutoff

engineandremainbehindhandlesuntilall movingpartshavestopped

beforeusingtheclean-outtooltoclear thechuteassembly.

Thechuteclean-outtool isconvenientlyfastenedtothe rearofthe

augerhousingwitha mountingclip.Shouldsnowandice become

safelycleanthechuteassemblyandchuteopening:

1. ReleaseboththeAugerControlandthe DriveControl.

I

2. Stopthe enginebyremovingthekey.

3. Removetheclean-outtoolfromtheclip whichsecuresittothe

rearofthe augerhousing.

4. Usetheshovel-shapedendoftheclean-outtooltodislodgeand

scoopanysnowandice whichhasformedinand nearthechute

theaugerhousing,reinsertthekeyandstartthe snowthrower's

engine.

thrower),engagetheaugercontrolfora fewsecondstoclearany

remainingsnowand icefromthechuteassembly.

Before Starting Engine

Electric Starter Outlet

Requirestheuseofa three-prongoutdoorextensioncord(included)

anda 120Vpowersource/walloutlet.

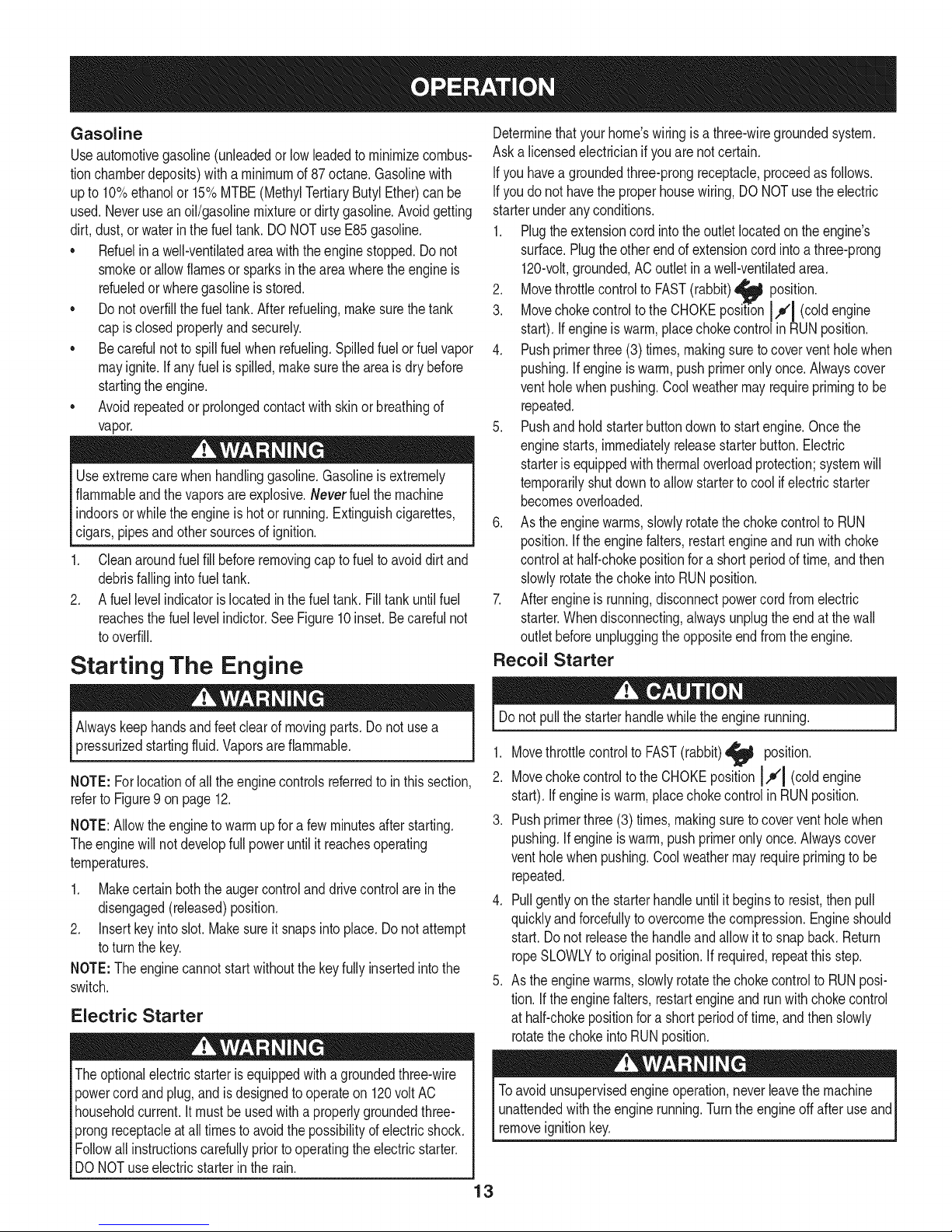

Primer

Pressingtheprimerforcesfueldirectlyinto

engine'scarburetortoaid incold-weatherstarting.

Refertothe startinginstructionsinthe Operation

sectionofthis manualforproperprimerusage.The

imageto therightcorrespondswiththe labelon the

engineidentifyingtheprimer.

Oil Fill

Removeoil cap toaddoil. RefertotheMaintenance& Servicesection

forcheckingandaddingoil instructions.

Gasoline Cap

Removegas capto addfuel.Unitrunsonregulargas.

NOTE:Thisunit mayincludeafuel plug,whichisonlyusedduring

assemblytokeepdirtanddebrisout offuel tank. Discardthefuelplug

beforefillingthefuel tank.

Throttle Control

Read,understand,andfollowall instructionsand warningsonthe

machineandinthis manualbeforeoperating.

Check Engine Oil

Theunitwasshippedwithoilin the engine.Checkoil levelbeforeeach

operationtoensureadequateoil intheengine.Forfurtherinstructions,

refertothe Maintenance& Servicesectionofthis manual.

NOTE:Besuretochecktheengineona levelsurfacewiththeengine

stopped.

1. Removetheoilfiller cap/dipstickandwipethedipstickclean.

2. Insertthecap/dipstickintotheoil fillerneck,turnthecap 1/4turn

untilfullyseated.

NOTE:Onsomeengines,athreadedcap/dipstickmayexist

insteadofa 1/4turncap asdescribedabove.Inthis instancedo

notfullytightenthe captocheckthe oil level.Simplyrestthecap

on thethreadsto checkfor properoil level.

.

Removethe oilfillercap/dipstick.If thelevelis low,slowlyadd

oil (5W-30,witha minimumclassificationofSF/SG)untiloil level

registersbetweenhigh(H) andlow(L).

NOTE:Donotoverfill.Overfillingwithoil mayresultinenginesmoking,

hardstartingor sparkplugfouling.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

Thethrottlecontrolis locatedontheengine.It regulatesthe speedof

theengineandwill shutoff theenginewhenplacedintheStop0

position.

12

Page 13

Gasoline

Useautomotivegasoline(unleadedor low leadedtominimizecombus-

tionchamberdeposits)witha minimumof87octane.Gasolinewith

upto 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neveruseanoil/gasolinemixtureordirtygasoline.Avoidgetting

dirt,dust,or waterinthe fueltank.DONOTuseE85gasoline.

• Refuelina well-ventilatedareawiththe enginestopped.Donot

smokeorallowflamesorsparksintheareawheretheengineis

refueledorwheregasolineisstored.

• Do notoverfillthe fueltank.Afterrefueling,makesurethetank

capis closedproperlyandsecurely.

• Becarefulnot tospill fuelwhenrefueling.Spilledfuelor fuelvapor

mayignite.Ifanyfuel isspilled,makesuretheareaisdrybefore

startingtheengine.

• Avoidrepeatedor prolongedcontactwithskinor breathingof

vapor.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthe vaporsareexplosive.Neverfuelthemachine

indoorsorwhiletheengineishotor running.Extinguishcigarettes,

cigars,pipesand othersourcesofignition.

Cleanaroundfuelfillbeforeremovingcapto fueltoavoiddirtand

debrisfallingintofuel tank.

.

A fuellevelindicatorislocatedinthefueltank. Filltankuntilfuel

reachesthefuellevelindictor.SeeFigure10inset.Becarefulnot

tooverfill.

Starting The Engine

Determinethatyour home'swiringisa three-wiregroundedsystem.

Aska licensedelectricianifyouare notcertain.

Ifyouhavea groundedthree-prongreceptacle,proceedasfollows.

Ifyoudonot havethe properhousewiring,DONOTusetheelectric

starterunderanyconditions.

1. Plugtheextensioncord intothe outletlocatedontheengine's

surface.Plugtheotherendofextensioncordintoa three-prong

120-volt,grounded,ACoutletina well-ventilatedarea.

2. Movethrottlecontrolto FAST(rabbit),_ position.

3. Movechokecontrolto theCHOKEpositionI,,"1(co dengine

start).Ifengineis warm,placechokecontrolinRUNposition.

4. Pushprimerthree(3)times,makingsuretocoverventholewhen

pushing.If engineiswarm,pushprimeronlyonce.Alwayscover

ventholewhenpushing.Coolweathermayrequireprimingto be

repeated.

5. Pushandholdstarterbuttondownto startengine.Oncethe

enginestarts,immediatelyreleasestarterbutton.Electric

starterisequippedwiththermaloverloadprotection;systemwill

temporarilyshutdowntoallow startertocoolifelectricstarter

becomesoverloaded.

6. Astheenginewarms,slowlyrotatethechokecontrolto RUN

position.Iftheenginefalters,restartengineand runwithchoke

controlat half-chokepositionfora shortperiodoftime,andthen

slowlyrotatethechokeintoRUNposition.

7. Afterengineisrunning,disconnectpowercordfromelectric

starter.Whendisconnecting,alwaysunplugtheendatthewall

outletbeforeunpluggingthe oppositeendfromtheengine.

Recoil Starter

Alwayskeephandsandfeetclearofmovingparts.Donot usea

pressurizedstartingfluid.Vaporsareflammable.

NOTE:Forlocationofallthe enginecontrolsreferredto inthissection,

referto Figure9on page12.

NOTE:Allowtheengineto warmupfora fewminutesafterstarting.

Theenginewill notdevelopfullpoweruntilit reachesoperating

temperatures.

1. Makecertainboththe augercontrolanddrivecontrolareinthe

disengaged(released)position.

2. insertkeyintoslot. Makesureit snapsintoplace.Donotattempt

toturnthekey.

NOTE:The enginecannotstartwithoutthekeyfullyinsertedintothe

switch.

Electric Starter

Theoptionalelectricstarterisequippedwitha groundedthree-wire

powercordandplug,andisdesignedtooperateon 120voltAC

householdcurrent.It mustbeusedwitha properlygroundedthree-

prongreceptacleat alltimesto avoidthepossibilityofelectricshock.

Followallinstructionscarefullypriortooperatingtheelectricstarter.

DONOTuseelectricstarterintherain.

Donot pullthestarterhandlewhiletheenginerunning.

1. Movethrottlecontrolto FAST(rabbit)_ position.

2. Movechokecontrolto theCHOKEpositionI.,,¢1(coldengine

start).Ifengineiswarm,placechokecontrolinRUNposition.

3. Pushprimerthree(3) times,makingsureto coverventholewhen

pushing.If engineiswarm,pushprimeronlyonce.Alwayscover

ventholewhenpushing.Coolweathermayrequireprimingto be

repeated.

4. Pullgentlyonthe starterhandleuntilit beginsto resist,thenpull

quicklyandforcefullytoovercomethecompression.Engineshould

start.Donot releasethehandleandallowit tosnapback.Return

ropeSLOWLYto originalposition.Ifrequired,repeatthisstep.

5. As theenginewarms,slowlyrotatethechokecontrolto RUNposi-

tion. Ifthe enginefalters,restartengineandrunwithchokecontrol

at half-chokepositionfora shortperiodoftime,andthenslowly

rotatethechokeintoRUNposition.

Toavoidunsupervisedengineoperation,neverleavethemachine

unattendedwiththeenginerunning.Turntheengineoff afteruseand

removeignitionkey.

13

Page 14

Stopping The Engine

Runenginefor a fewminutesbeforestoppingto helpdryoff any

moistureonthe engine.

1. Movethrottlecontrolto STOP position.

2. Removethe key.Removingthe keywillreducethe possibilityof

unauthorizedstartingoftheenginewhileequipmentisnot inuse.

Keepthekeyina safeplace.The enginecannotstartwithoutthe

key.

3. Wipeanymoistureawayfromthe controlsontheengine..

To Stop The Snow Thrower

1. Tostopthewheels,releasethedrivecontrol.

2. Tostopthrowingsnow,releasethe augercontrol.

3. Tostopengine,movethrottlecontrolleverto OFF 0 andpullout

thekey.Donot turnkey.

Thetemperatureofmufflerandthe surroundingareasmayexceed

1500F.Avoidtheseareas.

Using Snow Thrower to Clear

Snow

CAUTION:Checktheareatobe clearedforforeignobjects.Remove

foreignobjects,if any.

1. Startthe enginefollowingstartinginstructions.

2. Allowtheengineto warmup forafewminutesas theenginewillnot

developfullpoweruntilitreachesoperatingtemperature.

3. Rotatethechuteassemblyto thedesireddirection,awayfrom

bystandersand/orbuildings.

4. Makingcertainno bystandersor obstaclesare infrontof theunit,

squeezetheaugercontrolcompletelyagainsttheupperhandleto

fullyengagetheauger.

5. Whiletheaugercontrolisengaged,squeezethe drivecontrol

completelyagainsttheupperhandletoengagethewheels.Do not

"feather"thedrivecontrol.

6. As thesnowthrowerstartsto move,maintaina firmholdonthe

handle,andguidethe snowthroweralongthepathto becleared.

7. Releasetheaugeranddrivecontrolstostopthe snowthrowing

actionandforwardmotion.

NOTE:Yourunitisequippedwithaclutch inthetransmission.If the

wheelsstopturningwhiletryingtodischargelargevolumesofsnow,

immediatelydisengagethedrivecontrolandallowthe rotatingauger

todischargesnowfromthe housing.Reducetheclearingwidthand

continueoperation.

8. Oneach succeedingpass,readjustthechuteassemblytothe

desiredpositionandslightlyoverlapthepreviouslyclearedpath.

Positioning Discharge Chute

Loosenthechuteknobandpivotupperchutetodesiredposition.Tighten

thechuteknobmakingsurethecarriageboltiscorrectlypositioned.

Raisingthechutethrowssnowfurther.

Rotatechutehandletodesiredoperatingposition.

Donot liftthesnowthroweratanytimeby thechutehandle.

Operating Tips

1. Formostdficientsnowremoval,removesnowimmediatelyafteritfalls.

2. Dischargesnowdownwindwheneverpossible.Slightlyoverlap

eachpreviouspath.

3. Set theskidshoes1/4"belowtheshaveplatefornormalusage.

Theskidshoesmaybeadjustedupwardforhard-packedsnow.

NOTE:It isnotrecommendedthatyouoperatethis snowthroweron

gravelas loosegravelcanbeeasilypickedupandthrownbytheauger

causingpersonalinjuryand/ordamagetothe snowthrower.

4. Ifyou choosetooperatethesnowthrowerongravel,keeptheskid

shoeinthe lowestpositionfor maximumclearancebetweenthe

groundandtheshaveplate.

5. Cleanthesnowthrowerthoroughlyaftereachuse.

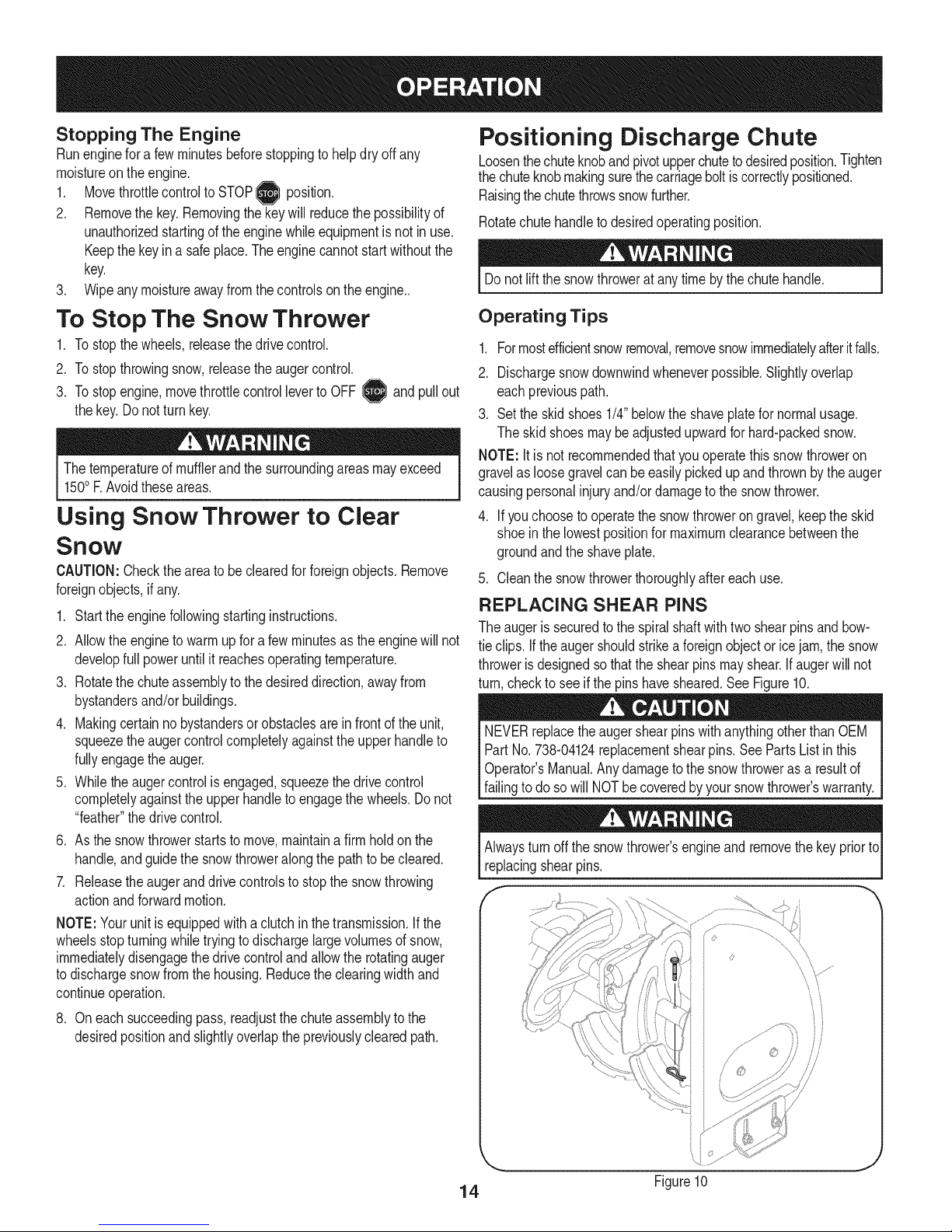

REPLACING SHEAR PINS

Theaugeris securedtothespiralshaftwithtwo shearpinsandbow-

tieclips. Iftheaugershouldstrikea foreignobjector icejam,thesnow

throwerisdesignedsothatthe shearpinsmayshear.Ifaugerwillnot

turn,checkto seeifthepins havesheared.SeeFigure10.

NEVERreplacetheaugershearpinswithanythingotherthanOEM

PartNo.738-04124replacementshearpins.SeePartsListinthis

Operator'sManual.Anydamagetothesnowthroweras a resultof

failingto do sowill NOTbecoveredbyyoursnowthrower'swarranty.

Alwaysturnoffthesnowthrower'sengineand removethekeypriorto

replacingshearpins.

f -,

f9

/

14

J

Figure10

Page 15

Beforeservicing,repairing,lubricatingorinspecting,disengageallcon-

trolsandstopengine.Waituntilallmovingpartshavecometoacomplete

stop.Removethekeytopreventunintendedstarting.Alwayswearsafety

glassesduringoperationorwhileperforminganyadjustmentsorrepairs.

Maintenance Schedule

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumntokeeptrack

ofcompletedmaintenancetasks.Tolocatethe nearestSears

Service Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

EachUseandevery5

hours

1st5 hours

Annuallyor25hours

Annuallyor50hours

Annuallyor100hours

BeforeStorage 1. Fuelsystem 1.

1. Engineoillevel

2. Looseormissinghardware

3. Unitandengine.

1. Engineoil

1. Sparkplug

2. Controllinkagesand pivots

3. Wheels

4. GearshaftandAugershaft

1. Engineoil

1. Sparkplug

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Check

2. Lubewithlightoil

3. Lubewithmultipurposeautogrease

4. Lubewithlightoil

1. Change

1. Clean,adjustgap,or replaceif

ENGINE MAINTENANCE

Checking Engine Oil

Beforelubricating,repairing,or inspecting,disengageall controls

Iandstopengine.Waituntilall movingpartshavecometo acomplete

_stop.

necessary

Runengineuntilit stopsfromlack

offuel

f

NOTE: Checktheoil levelbeforeeachuseandaftereveryfivehours

ofoperationtobesurecorrectoil levelismaintained.

Whenaddingoilto theengine,referto viscositychart below.Engine

oilcapacityis 600ml (approx.20 oz.). Donotover-fill.Usea4-stroke,

oran equivalenthighdetergent,premiumqualitymotoroilcertified

tomeetorexceedU.S.automobilemanufacturer'srequirementsfor

serviceclassificationSG, SRMotoroilsclassifiedSG,SFwillshow

thisdesignationonthecontainer.

1. Removetheoil fillercap/dipstickandwipethe dipstickclean.

2. Insertthe cap/dipstickintotheoilfillerneck,turnthecap1/4turn

untilfullyseated.

NOTE:On someengines,athreadedcap/dipstickmayexist

insteadofa 1/4turncap asdescribedabove.Inthisinstancedo

notfullytightenthe capto checktheoil level.Simplyrestthecap

onthethreadsto checkfor properoil level.

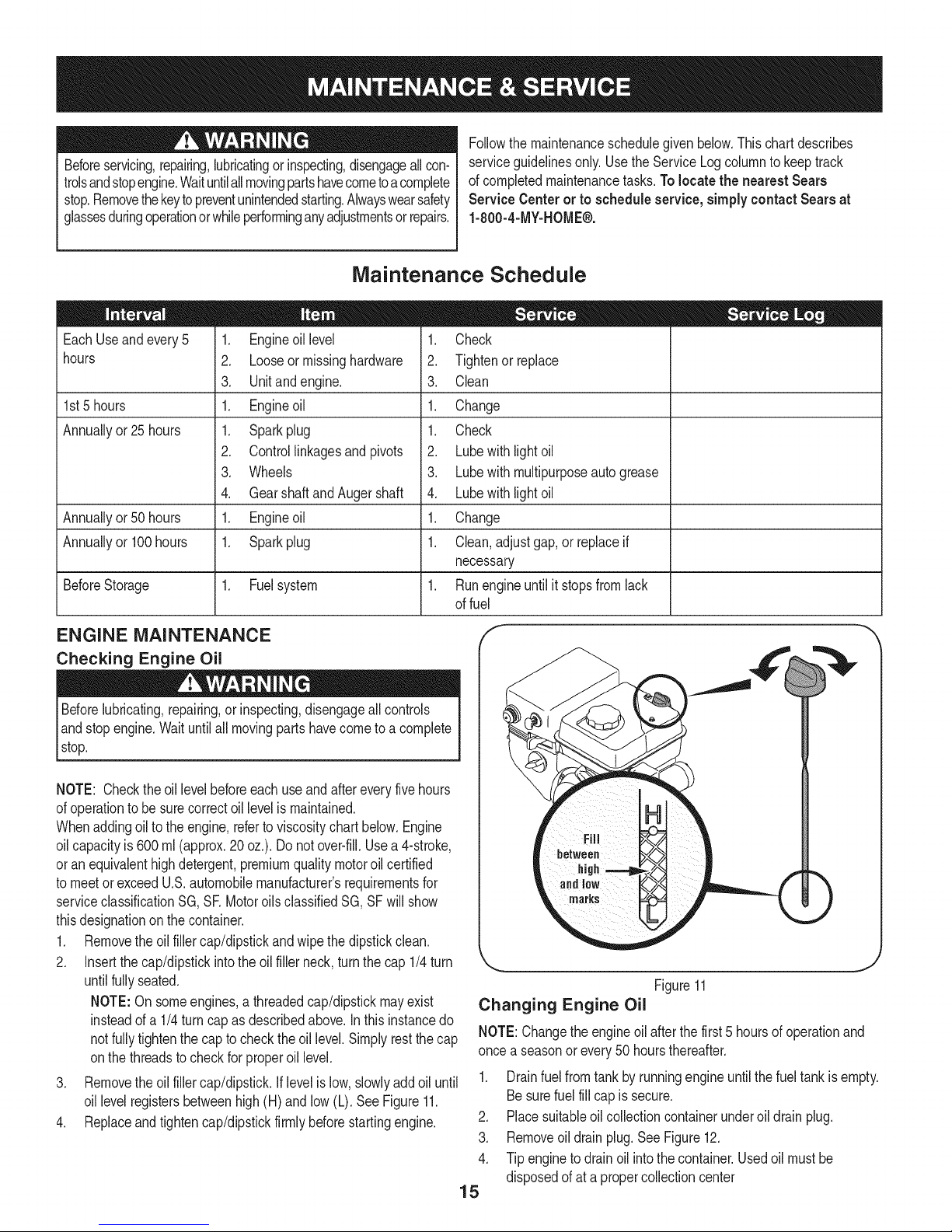

3. Removetheoil fillercap/dipstick.Iflevelislow,slowlyadd oiluntil

oil levelregistersbetweenhigh(H)andlow(L). SeeFigure11.

4. Replaceandtightencap/dipstickfirmlybeforestartingengine.

j

Figure11

Changing Engine Oil

NOTE:Changetheengineoil afterthefirst 5 hoursofoperationand

oncea seasonorevery50 hoursthereafter.

1. Drainfuelfromtankbyrunningengineuntilthefuel tankisempty.

Besurefuel fillcapis secure.

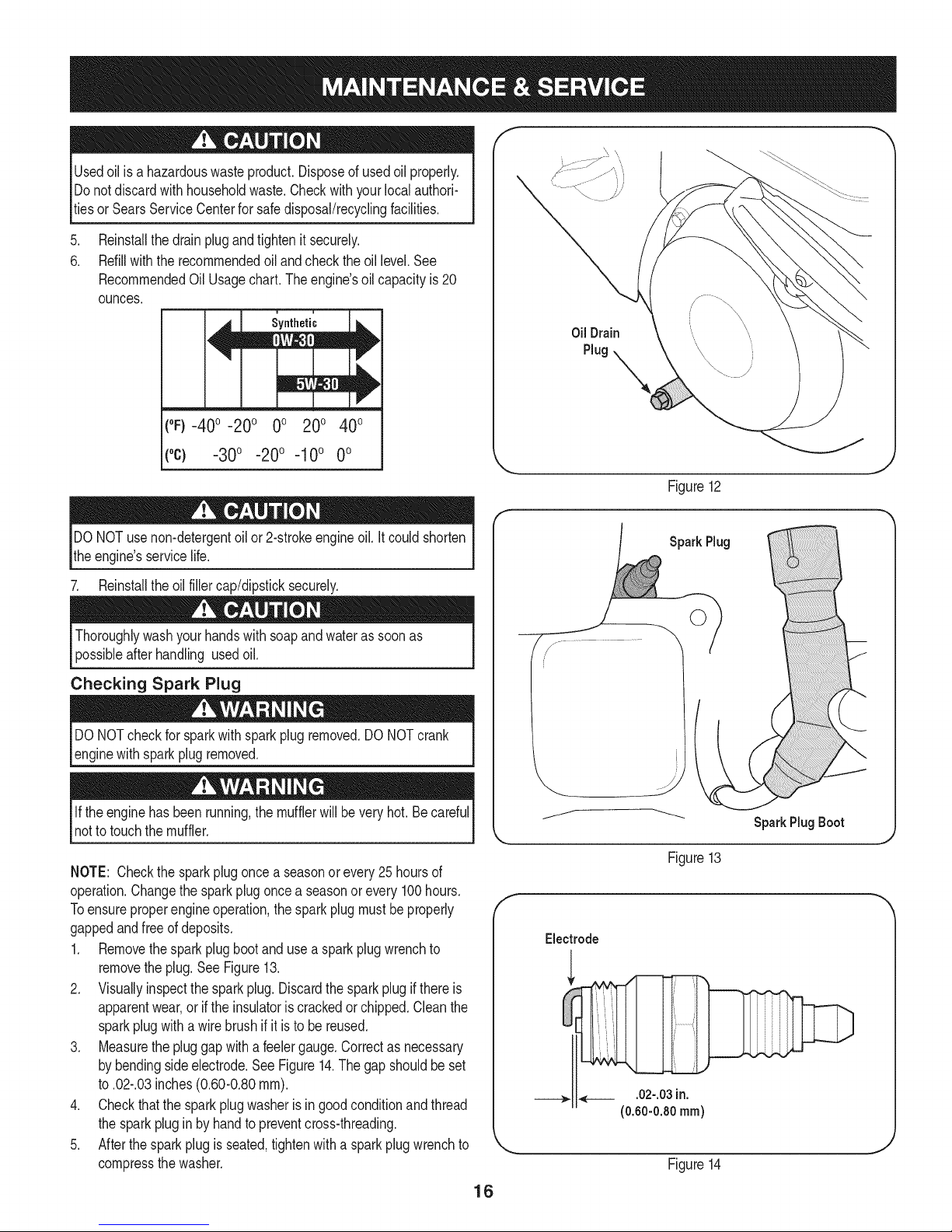

2. Placesuitableoilcollectioncontainerunderoil drainplug.

3. Removeoil drainplug.SeeFigure12.

4. Tipenginetodrainoil intothecontainer.Usedoil mustbe

disposedofat a propercollectioncenter

15

Page 16

Usedoil is a hazardouswasteproduct.Disposeof usedoil properly.

Donotdiscardwith householdwaste.Checkwithyourlocalauthori-

tiesor SearsServiceCenterfor safedisposal/recyclingfacilities.

.

Reinstallthedrainplugandtightenit securely.

6.

Refillwiththerecommendedoil andcheckthe oil level.See

RecommendedOil Usagechart.Theengine'soilcapacityis20

ounces.

i i

(%-400 -200 0o 200 400

f

Oil Drain

Plug

("c) -30° -20° -10° 0°

DONOTuse non-detergentoil or 2-strokeengineoil.Itcouldshorten

theengine'sservicelife.

7. Reinstalltheoilfillercap/dipsticksecurely.

Thoroughlywashyourhandswithsoapandwaterassoonas

possibleafterhandling usedoil.

Checking Spark Plug

DONOTcheckforsparkwithsparkplugremoved.DONOTcrank

enginewithsparkplugremoved.

Iftheenginehasbeenrunning,themufflerwillbevery hot.Becareful

notto touchthemuffler.

NOTE: Checkthesparkplugoncea seasonorevery25hoursof

operation.Changethesparkplugoncea seasonor every100hours.

Toensureproperengineoperation,the sparkplugmustbe properly

gappedandfreeof deposits.

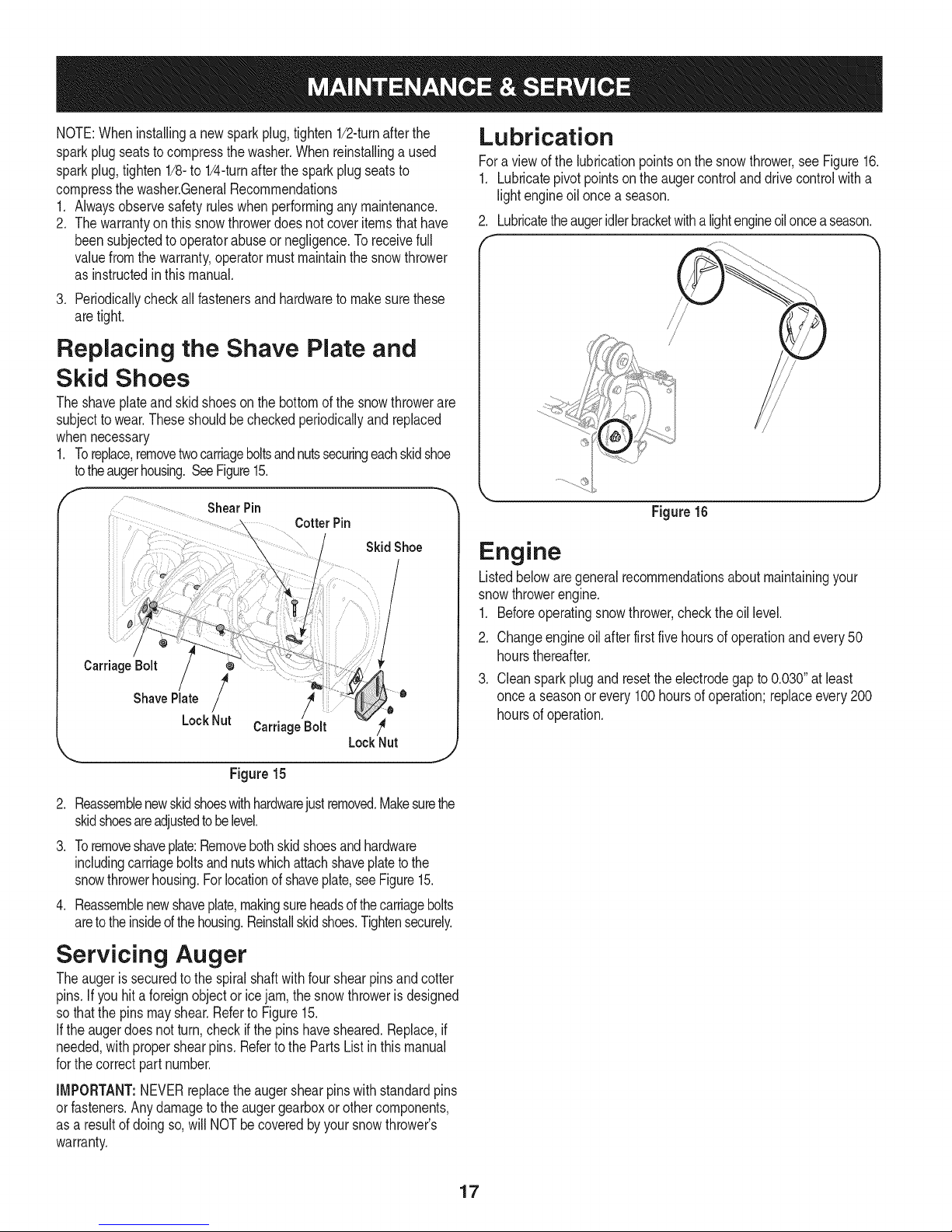

1. Removethesparkplugbootanduse a sparkplugwrenchto

removetheplug.See Figure13.

2. Visuallyinspectthesparkplug.Discardthesparkplugif thereis

apparentwear,orif the insulatoris crackedorchipped.Cleanthe

sparkplugwitha wirebrush ifitisto be reused.

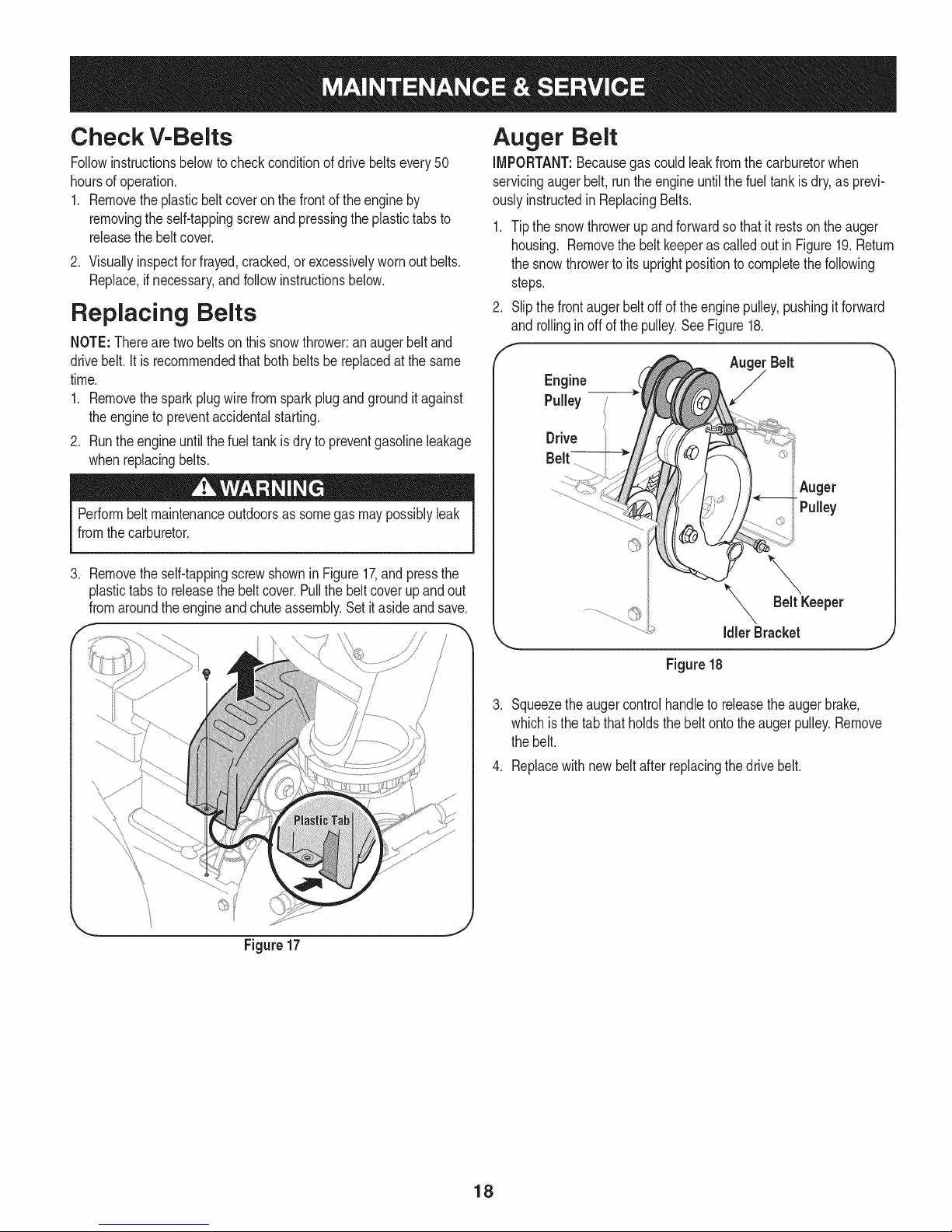

3. Measurethe pluggapwitha feelergauge.Correctas necessary

bybendingsideelectrode.SeeFigure14.Thegapshouldbeset

to.02-.03inches(0.60-0.80ram).

4. Checkthatthe sparkplugwasherisingoodconditionandthread

thesparkplugin by handtopreventcross-threading.

5. Afterthesparkplugis seated,tightenwithasparkplugwrenchto

compressthewasher.

.J

Figure12

SparkPlug

SparkPlug Boot

Figure13

Electrode

___,. ,___ .02-.03in.

(0.60-0.80ram)

Figure14

16

Page 17

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthe

sparkplugseatsto compressthewasher.Whenreinstallinga used

sparkplug,tighten1/81to 1/41turnafterthe sparkplugseatsto

compressthewasher.GeneralRecommendations

1. Alwaysobservesafetyruleswhenperforminganymaintenance.

2. Thewarrantyonthissnowthrowerdoesnotcoveritemsthathave

beensubjectedto operatorabuseor negligence.Toreceivefull

valuefromthe warranty,operatormustmaintainthesnowthrower

asinstructedinthismanual.

3. Periodicallycheckall fastenersand hardwaretomakesurethese

aretight.

Replacing the Shave Plate and

Skid Shoes

Theshaveplateand skidshoesonthebottomofthe snowthrowerare

subjecttowear.Theseshouldbecheckedperiodicallyandreplaced

whennecessary

1. Toreplace,removetwocarriageboltsandnutssecuringeachskidshoe

totheaugerhousing.SeeFigure15.

f

ShearPin

CotterPin

SkidShoe

l

Carriage Bolt

ShavePlate /

LockNut

CarriageBolt /_

Figure15

/

LockNut

J

Lubrication

Fora viewof the lubricationpointsonthesnowthrower,seeFigure16.

1. Lubricatepivotpointsonthe augercontrolanddrivecontrolwitha

lightengineoilonce a season.

2. Lubricatetheaugeridlerbracketwitha lightengineoilonceaseason.

Figure16

Engine

Listedbelowaregeneralrecommendationsaboutmaintainingyour

snowthrowerengine.

1. Beforeoperatingsnowthrower,checkthe oil level.

2. Changeengineoilafterfirstfivehoursofoperationandevery50

hoursthereafter.

3. Cleansparkplugandresettheelectrodegapto 0.030"at least

oncea seasonorevery100hoursofoperation;replaceevery200

hoursof operation.

.

Reassemblenewskidshoeswithhardwarejustremoved.Makesurethe

skidshoesareadjustedtobelevel.

3.

Toremoveshaveplate:Removebothskidshoesandhardware

includingcarriageboltsandnutswhichattachshaveplatetothe

snowthrowerhousing.Forlocationofshaveplate,seeFigure15.

.

Reassemblenewshaveplate,makingsureheadsofthecarriagebolts

aretotheinsideof thehousing.Reinstallskidshoes.Tightensecurely.

Servicing Auger

Theaugeris securedto thespiralshaftwithfourshearpinsandcotter

pins.Ifyouhit a foreignobjectoricejam,thesnowthrowerisdesigned

sothatthe pinsmayshear.Referto Figure15.

Iftheaugerdoesnotturn,check ifthe pinshavesheared.Replace,if

needed,withpropershearpins.Refertothe PartsListinthis manual

forthecorrectpart number.

IMPORTANT:NEVERreplacetheaugershearpinswithstandardpins

orfasteners.Anydamagetotheaugergearboxor othercomponents,

asa resultof doingso,willNOTbecoveredbyyoursnowthrower's

warranty.

17

Page 18

Check V=Belts

Followinstructionsbelowtocheckconditionofdrivebeltsevery50

hoursof operation.

1. Removetheplasticbeltcoveronthe frontofthe engineby

removingtheself-tappingscrewandpressingtheplastictabsto

releasethebeltcover.

2. Visuallyinspectforfrayed,cracked,orexcessivelywornoutbelts.

Replace,ifnecessary,andfollowinstructionsbelow.

Replacing Belts

NOTE:Therearetwobeltson thissnowthrower:anaugerbelt and

drivebelt.it isrecommendedthatbothbeltsbereplacedatthe same

time.

1. Removethesparkplugwirefromsparkplugandgrounditagainst

theengineto preventaccidentalstarting.

2. Runtheengineuntilthefuel tankisdry topreventgasolineleakage

whenreplacingbelts.

Performbeltmaintenanceoutdoorsassomegasmaypossiblyleak

fromthecarburetor.

3. Removetheself-tappingscrewshowninFigure17,andpressthe

plastictabsto releasethebeltcover.Pullthebelt coverupand out

fromaroundtheengineandchuteassembly.Setitasideandsave.

Auger Belt

iMPORTANT:Becausegascouldleakfromthecarburetorwhen

servicingaugerbelt,runthe engineuntilthe fueltankisdry,asprevi-

ouslyinstructedinReplacingBelts.

1. Tip thesnowthrowerupandforwardso that itrestsonthe auger

housing. Removethe beltkeeperascalledoutinFigure19.Return

thesnowthrowertoitsuprightpositiontocompletethefollowing

steps.

2. Slipthe frontaugerbeltoffof theenginepulley,pushingit forward

and rollinginoff ofthepulley.SeeFigure18.

idlerBracket

Figure17

Figure18

Squeezethe augercontrolhandleto releasetheaugerbrake,

whichisthe tabthatholdsthebeltontotheaugerpulley.Remove

thebelt.

4. Replacewithnew beltafterreplacingthedrive belt.

18

Page 19

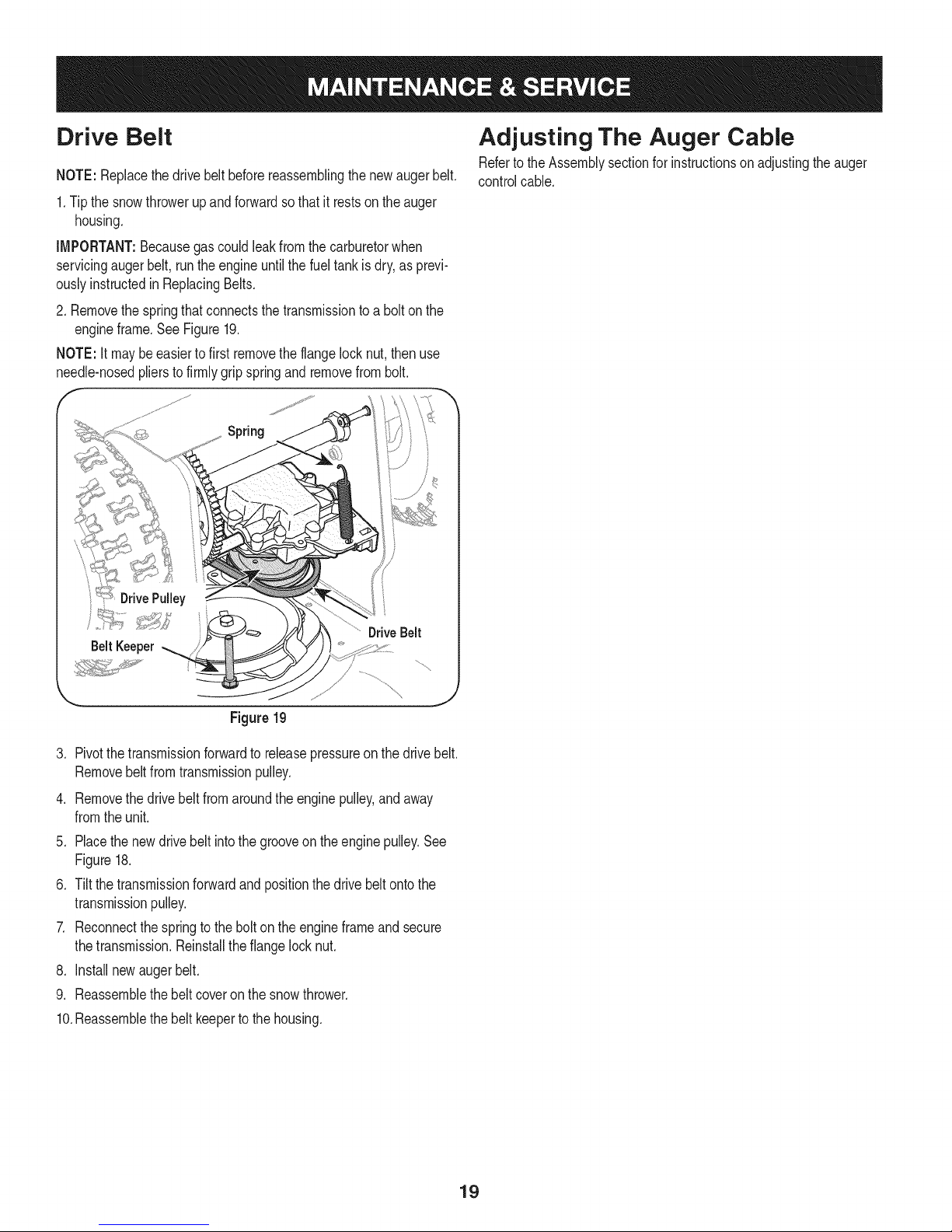

Drive Belt

NOTE:Replacethedrivebelt beforereassemblingthenewaugerbelt.

1.Tip thesnowthrowerupandforwardsothat itrestson theauger

housing.

iMPORTANT:Becausegas couldleakfromthecarburetorwhen

servicingaugerbelt,runthe engineuntilthe fueltankis dry,asprevi-

ouslyinstructedin ReplacingBelts.

2.Removethespringthatconnectsthetransmissionto abolt onthe

engineframe.SeeFigure19.

NOTE:Itmaybeeasiertofirst removetheflangelocknut,then use

needle-nosedplierstofirmlygripspringandremovefrombolt.

F

Spring

Adjusting The Auger Cable

RefertotheAssemblysectionforinstructionson adjustingtheauger

controlcable.

........ _'*'_:" ...............DriveBelt

BeltKeeper

Figure19

3. Pivotthe transmissionforwardto releasepressureon thedrivebelt.

Removebeltfromtransmissionpulley.

4. Removethedrivebeltfromaroundtheenginepulley,andaway

fromtheunit.

5. Placethenewdrivebelt intothe grooveontheenginepulley.See

Figure18.

6. Tiltthe transmissionforwardandpositionthedrivebeltontothe

transmissionpulley.

7. Reconnectthespringto thebolt ontheengineframeandsecure

thetransmission.Reinstalltheflangelocknut.

8. Installnewaugerbelt.

9. Reassemblethe beltcoveronthe snowthrower.

10.Reassemblethe beltkeepertothe housing.

19

Page 20

Ifthe snowthrowerwillnotbe usedfor30 daysorlonger,or ifit isthe endofthesnowseasonwhenthelastpossibilityof snowisgone,the

equipmentneedstobestoredproperly.Followstorageinstructionsbelowtoensuretop performancefromthe snowthrowerformanymoreyears.

PREPARING ENGINE

Enginesstoredover30daysneedtobedrainedoffuelto prevent

deteriorationandgumfromforminginfuel systemoronessential

carburetorparts.Ifthegasolineinyourenginedeterioratesduring

storage,youmayneedto havethecarburetor,andotherfuelsystem

components,servicedor replaced.

1. Removeall fuelfromtank byrunningengineuntilitstops.Donot

attempttopourfuel fromtheengine.

2. Changetheengineoil.

3. Removesparkplugandpourapproximately1oz.(30 rnl)of clean

engineoil intothe cylinder.Pullthe recoilstarterseveraltimesto

distributetheoil,and reinstallthesparkplug.

4. Cleandebrisfromaroundengine,andunder,around,andbehind

muffler.Applya lightfilmofoilonanyareasthatare susceptible

torust.

• Storeina clean,dry andwellventilatedareaawayfromanyap-

pliancethatoperateswithaflameor pilotlight,suchasa furnace,

waterheater,or clothesdryer.Avoidanyareawitha spark

producingelectricmotor,orwherepowertoolsareoperated.

Neverstoresnowthrowerwithfuelintankindoorsorinpoorlyventi-

latedareas,wherefuelfumesmayreachanopenflame,sparkor pilol

lightas ona furnace,waterheater,clothesdryerorgasappliance.

PREPARING SNOW THROWER

Whenstoringthe snowthrowerin anunventilatedormetalstor-

age shed,careshouldbetakentorustprooftheequipment.Using

a lightoilor silicone,coattheequipment,especiallyanychains,

springs,bearingsandcables.

• Removealldirt fromexteriorofengineandequipment.

• Followlubricationrecommendations.

• Storeequipmentin a clean,dry area.

• Inflatethetirestothe maximumPSi.Referto tiresidewall.

• If possible,avoidstorageareaswithhighhumidity.

• Keepthe enginelevelin storage.Tiltingcancausefueloroil

leakage.

2O

Page 21

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometoa

completestop.Removethekeytopreventunintendedstarting.Always

wearsafetyglassesduringoperationorwhileperforminganyadjustments

orrepairs.

Thissectionaddresses minor serviceissues.Tolocate the near-

est SearsService Centerorto scheduleservice,simplycontact

Searsat 1-800-4-MY-HOME®.

Enginefailsto start

1. Chokecontrolnotin Chokeposition.

2. Sparkplugwiredisconnected.

3. Faultysparkplug.

4. Fueltankemptyor stalefuel.

5. Enginenot primed.

6. Safetykeynot inserted.

7. Extensioncordnotconnected(whenusing

electricstart button)

Enginerunningerratically/

inconsistentRPM(huntingor

surging)

1. Enginerunningonchoke.

2. Fuellineblocked,or stalefuel.

3. Wateror dirtinfuelsystem.

4. Carburetoroutofadjustment.

5. Over-governedengine

Engineoverheats

Excessivevibration

1. Carburetornotadjustedproperly.

1. Loosepartsordamagedauger.

Lossof power 1. Sparkplugwireloose.

2. Gascap ventholeplugged.

Unitfailsto propelitself 1. Drivecablein needofadjustment.

2. Drivebeltlooseor damaged.

Unitfailstodischargesnow 1. Chuteassemblyclogged.

2. Foreignobjectlodgedin auger.

3. Augercableinneedof adjustment.

4. Augerbeltlooseor damaged.

5. Shearpin(s)sheared.

1. Movechokecontrolto Chokeposition.

2. Connectwireto sparkplug.

3. Clean,adjustgap,or replace.

4. Filltankwithclean,freshgasoline.

5. Primeengineasinstructedin theOperationSection.

6. Insertkeyfullyintothe switch.

7. Connectoneendof theextensioncordtotheelectric

starteroutletandthe otherendto a three-prong

120-volt,grounded,ACoutlet.

1. Movechokeleverto RUNposition.

2. Cleanfuel lineandfilltankwithfresh,cleangasoline.

3. Runengineuntilit stops.Refillwithfreshfuel.

4. Contacta SearsServiceCenter.

5. Contacta SearsServiceCenter.

1. ContactyourSearsParts& RepairCenter.

1. Stopengineimmediatelyanddisconnectsparkplug

wire.Tightenall boltsandnuts.If vibrationcontinues,

haveunit servicedbya SearsParts&RepairCenter.

1. Connectandtightensparkplugwire.

2. Removeiceandsnowfromgas cap.Becertainvent

holeisclear.

1. Adjustdrivecontrolcable.Referto Serviceand

Maintenancesection.

2. Replacedrivebelt.RefertoService&Maint.section.

1. Stopengineimmediatelyanddisconnectsparkplug

wire.Cleanchuteassemblyandinsideofauger

housingwithclean-outtoolor a stick.

2. Stopengineimmediatelyanddisconnectsparkplug

wire.Removeobjectfromaugerwithclean-outtool

or a stick.

3. Adjustaugercontrolcable.Referto Assembly

section.

4. Replaceaugerbelt.Referto Serviceand Mainte-

nancesection.

5. Replacewith newshearpin(s).

NEED MOR£ H_.LP?

o Find this and a[[ your other product manua|s online.

o Get answers from our team of home experts,

o Get a personalized maintenance p[an for your home.

o Find information and tools to help with home projects.

21

Page 22

Craftsman Snow Thrower IViodel 247.881700

\

/

22

Page 23

Craftsman Snow Thrower IViodel 247.881700

m

M

1

2

3

4

5

6

7

8

9

lO

11

12

13

14

15

16

17

18

19

2o

21

22

23

24

984-04037

71o-o4o71

71o-o451

710-0260A

720-04072A

731-04388A

731-04426A

936-0267

931-04127

931-04353

931-2636A

932-04111

712-04064

931-2643

731-2635

725-0157

710-0134

710-0520

710-04484

712-04063

712-04065

750-04852

715-04020

926-04012

ChuteAssembly

CarriageBolt5/16-18x1.0"

CarriageBolt5/16-18

CarriageBolt5/16-18x.62

WingKnob5/16-18

ChuteHandle

UpperChute

FiatWasher.385x .87x .06

LowerChute

ChuteRing

ChuteAdapter5" Dia.

ChuteAdjustmentSpring

FlangeLockNut 1/4-20

Clean-outTool

Clean-outToolMount

CableTie

CarriageScrew 1/4-20x 0.62"

HexBolt3/8-16x 1.50"

ABScrew5/16-18x .750

FlangeLockNut, 5/16-18

FlangeLockNut, 3/8-16

ShoulderSpacer

SpiralPin

PushOnNut

m

M

731-04218B

25

26

932-0611

27

736-0174

28

938-0281

29

941-0245

30

941-0309

31

950-04191

32

684-04358

33

784-0434-0637

34

790-00075

35

918-04292B

36

684-04113A-0637

37

684-04114A-0637

38

684-04166A-4043

39

714-04040

40

731-04870

41

936-0351

42

738-04124A

43

741-0493A

44

790-00087A-0637

45

790-00117-0637

46

784-5580-4043

47

710-04606A

48

929-0071A

Impeller

ExtensionSpring

WaveWasher

ShoulderScrew3/8-16

Hex FlangeBearing

BallBearing

Spacer

FlatIdler

AugerIdlerBracket

BearingHousing

AugerGearboxAssembly

AugerAssembly- LH

AugerAssembly- RH

AugerHousing,22"

BowTieCotterPin72

Spacer,1.25x.75x 1.00

FlatWasher

ShearPin,.25x 1.50

FlangeBushing

Hex BearingHousing

ShavePlate2.25x21.66LG

SkidShoe

Belt Keeper

ExtensionCord

23

Page 24

Craftsman Snow Thrower Model 247.881700

24

Page 25

Craftsman Snow Thrower IViodel 247.881700

m

1

71o-o572

2

71o-o6o5

3

71o-o4484

4

712-o4o64

5

720-04072A

6

725-0157

7

946-04642

8

946-04640

9

747-04394A-0637

lO

747-04405-0637

11

749-04147

12

749-04495-0637

13

990-00053

14

918-04296B

15

710-0809

16

710-1652

17

711-1364

18

914-0115

19

714-04040

2o

915-0249

717-04066A

21

22

917-04073A

932-0429A

23

24

936-0192

738-04184A

25

738-0924A

26

27

941-0245

28

741-04108

29

756-0625

CarriageScrew5/16-18x 2.25

Mach.Screw 1/4-20x 1.825

Screw5/16-18x .75

FlangeLockNut 1/4-20

WingKnob5/16-18

CableTie

DriveCable

AugerCable

AugerControl

DriveControl

LowerHandle

UpperHandle

HandleTab

TransmissionAssembly

TTScrew1/4-20x 1.25

Screw1/4-20x .625

ClevisPin

CotterPin1/8x 1.0

BowTie CotterPin72

RollPin

Pinion14T

Gear70T

ExtensionSpring

FlatWasher

ShoulderScrew1/4-20

ShoulderScrew1/4-28

Hex FlangeBearing

Hex FlangeBearing

CableRoller

m

M

784-o419C-4O43

30

31

790-00223A-0637

32

790-00224

934-04282B

33

734-04322

34

710-0627

35

736-0242

36

738-04321

37

910-0224

710-0654A

38

39

710-0696

710-1245B

4o

41

931-04162A

42

736-0247

43

736-0505

44

748-04067A

45

950-1355

46

950-1356

47

954-04013

48

954-04014

49

956-04024

5o

756-0569

51

729-04035

52

731-05672A

53

936-0160

54

936-0451

55

731-06749

56

952Z265-SUA

DriveHousingFrame

AugerCable Bracket

AugerCable Adj.Bracket

WheelAssySnowHogGray

Tube,Tire,4.10/3.50-4.0

LockBolt5/16-24x .75

BellWasher.34x .872x .06

Axle

HexScrew#10-16x.500

TT SemsScrew3/8-16x 1.0

HexBolt3/8-24x .875

LockBolt5/16-24x .875

BeltCover

FlatWasher.406IDx 1.25OD

FlatWasher.34IDx 1.50OD

Pulley:Adapter.75Dia.

Spacer.876x 1.25x .19

Spacer.876x 1.25x .86

V-Belt3/8 x 21.108Lg.

V-Belt3/8 x 26.680Lg.

AugerPulley

PulleyHalf

AmpSealedConnector

Spacer

FlatWasher.53x .93x .05

SaddleWasher

CableClip

Engine

25

Page 26

Craftsman Snow Thrower Model 247.881700

777S32636

1OO1£RO=NV313

"]VgNVN S,HOIVH3dOQV]U "_

"S]3VdHgS13AVU9NO9NlVU3dO

N3HMNOilgVOVUIX33Sn"SU3QNVISABIV39UVHOSiQ

133U10U3A3N'S3iUIlrNISI33F80 NMOUHI OIOMOl "t_

"_NJHOVN5NI3JAU3SHO9N199013Nn

3UOd3B03ddOIS3AVHSIUVd9NIAON]IV]JlN[iS_]QNVH

QNJH38NJVNBUONV '3NJON3dOIS'S83A33HOlff]O39VgNBSJQ"£

"31nHO39UVHOSiQ90qONnO1]OO1 InO'NV3qO3Sn "_

"133dQNVSQNVH31V1ffdNVNV3U39ffVUOU3]]3dNJHIIM

lOVlNO3"U39nVQNVU3]]3dNI 9NllVlOUNOUdArMYd33)1"L

777X43688

................OONOT....................

.....USEE85 ORFUEL'

CONTAiNiNG MORE

THAN10% ETHANOL

W

777122164

F •

777S32236

777i23249

m

|22164 AC

777122138

777D16343

777D16340

777D18033

26

Page 27

Craftsman Engine Model 265=SUA For Snow Model 247.881720

24

23

m

I

i

i19

!

i

120

i

i

i

i20

!

!

i

121

i

i

122

i

i

i

i23

!

i

i

124

i

951-11282

710-05001

751-14190

951-11289

712-04214

710-04915

951-10642B

m = I! O

MufflerAssembly

StudM8x36

MufflerStudKit

ExhaustPipeGasket

Nut,M8

BoltM6x12

MufflerShield

27

Page 28

Craftsman EngineModel 265=SUA For Snow Model 247.881720

41 _42

m

34

35

36

37

39

4O

41

42

43

951-10634

712-04213

951-11284

951-10757

951-10637

731-05632

951-10640

951-10635

710-04943

°0

Air CleanerHousing

Nut

ChokeKnob

ThrottleControlKnob

KeySwitch

Key

Choke PushRod

HeaterBox

BoltM6x28

37

35

D = O O

28

Page 29

Craftsman Engine Model 265=SUA For Snow Model 247.881720

63

132- 6asketKit-Complete

133- 6asketKit-External

134-CompleteEngine

62

29

Page 30

Craftsman Engine IViodel 265=SUA For Snow IViodel 247.881720

m

5O

51

52

53

54

55

56

57

58

59

6O

61

62

63

64

65

66

67

68

69

951-11688

951-11632

951-11900

951-11901

710-04915

951-11113

951-11573

951-14053

736-04461

951-11902

714-04078

951-11575

951-11369

951-10307

951-11247A

951-11576

715-04092

715-04096

951-11371

951-12125

951-11246

D = O

PistonRingSet

PistonPinSnapRing

Piston

PistonPin

BoltM6x12

Air Shield

ConnectingRodAssembly

GovernorArm Shaft

Washer5.2xl.9

GovernorSeal

CotterPin

CamshaftAssembly

RadialBallBearing,6205

WoodruffKey

CrankshaftKit

(Incl.62-64,74,79)

GovernorGear/ShaftAssembly

DowelPin7x14

DowelPin9x14

CrankcaseCoverGasket

CrankcaseCover

CrankcaseCoverKit

(Incl.62,68-74)

m

7O

71

73

74

75

76

77

78

79

131

132

133

134

710-04932

951-11283

951-11577

951-11368

951-11248A

951-11062B

951-11350

736-04440

710-04906

951-11370

951-10641

951-11061A

951-10661B

952Z265-SUA

D = O O

BoltM8x32

Oil FillPlugAssembly

O-Ring15.8x2.5

OilSeal,25x41.25x6

CrankcaseKit

(Incl.59,62,74,75,79)

ShortBlockAssembly

(Incl.4,21,27-29,32,44,

46,47,80-53,56-79)

Oil DrainPipeAssy.

Washer10x16x1.5

Oil DrainPlug

OilSeal25x41.25x6

Oil DrainAssembly

GasketKit- Complete

(Incl.4,21,27-29,32,44,

58,59,68,74,77,79)

GasketKit- External

(Incl.4,21,27-29,32,77)

CompleteEngine

3O

Page 31

Craftsman Engine Model 265=SUA For Snow Model 247.881720

15 44 _)

13

48

u_ _ _'45

10

17

132-GasketKit-Complete

133-GasketKit-External

134-CompleteEngine

\6

31

Page 32

Craftsman Engine IViodel 265=SUA For Snow IViodel 247.881720

m

1

2

3a

3b

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

44

45

46

47

48

49

130

132

133

134

710-04968

951-11054A

731-07059

726-04101

951-11565

951-12000

951-11892

751-11124

751-11123

951-11893

710-04902

951-12002

951-12003

951-12004

951-11894

710-04933

951-11895

751-14195

951-10292

951-11898

951-10648

951-11899

715-04108

951-10647A

951-10647A

951-12626

951-11061A

951-10661B

952Z265-SUA

D = W O

BoltM6x16

ValveCover

BreatherHose

BreatherHoseClamp

ValveCoverGasket

ValveSpringRetainer(Intake)

RockerArmAssembly

Nut,PivotLocking

AdjustingNut,Valve

RockerArm

Bolt,Pivot

ExhaustLashCap

ValveSpringRetainer(Exhaust)

ValveSpring

ValveSeal(Intake)

BoltM8x55

PushRodGuide

CylinderHeadAssembly

(Incl.4-14,16,17,21,27,

29,44,48,49)

SparkPlug/F6Rtc

Gasket,CylinderHead

PushRod Kit

Tappet

DowelPin 10x16

ValveKit

ValveKit

ValveCoverKit

GasketKit- Complete

(Incl.4,21,27-29,32,44,

58,59,68,74,77,79)

GasketKit- External

(Incl.4,21,27-29,32,77)

CompleteEngine

32

Page 33

Craftsman Engine IViodel 265=SUA For Snow IViodel 247.881720

135- CarburetorKit

27

28

3O

w

31_

33

Page 34

Craftsman Engine IViodel 265=SUA For Snow IViodel 247.881720

m

25

26

27

28

29

30

30

31

32

33

135

a

b

C

d

e

f

g

h

I

J

k

I

m

n

o

P

q

r

s

t

U

V

W

X

Y

710-04939

710-04910

951-11567

951-11896

951-11569A

951-10639A

951-11824

951-12705

951-11897

951-11112

951-14050

n/a

n/a

n/a

n/a

710-05469

736-04638

n/a

n/a

n/a

n/a

951-11699

951-11906

n/a

n/a

n/a

951-12875

n/a

n/a

n/a

951-11589

n/a

951-11348

710-04945

951-11349

710-04938

D = O O

StudM6x117

StudM6x105

CarburetorInsulatorGasket

CarburetorInsulator

CarburetorGasket

PrimerAssembly

PrimerBulb

CarburetorAssembly

CarburetorGasketPlate

ChokeControl

CarburetorKit

(Incl.h,n,o,p,q,r,s,t,v,x)

ChokeShaft

ChokePlate

ThrottleShaft

ThrottlePlate

ScrewM3x6

LockWasher

Gasket,ThrottlePlate

IdleJet Assembly(0.34)

IdleSpeedAdjustingScrew

PrimerPipe

PrimerHose

HoseClamp

CarburetorBody

FloatPin

EmulsionTube(P18-019)

NeedleValve

MainJet(#73)

NeedleValveSpring

Float

FuelBowlO-Ring

FuelBowl

FuelBowlMountingBoltGasket

FuelBowlMountingBolt

FuelBowlDrainBoltGasket

FuelBowlDrainBolt

34

Page 35

Craftsman Engine Model 265-SUA For Snow Model 247.881720

82

87 94

85

86

92/° _3

93

m

8O

81

82

83

85

86

87

88

89

91

92

93

94

951-10646

951-11110

710-04940

710-04919

951-12416

951-10934

951-10911

712-04209

710-04915

951-10663A

736-04455

710-04974

951-14151

_89 _89 92-_ _/93

D = O O

IgnitionCoilAssembly

Air FlowShield

BoltM6xlO

BoltM6x25

Flywheel

CoolingFan

StarterCup

Nut,Special,M14x1.5

BoltM6x12

BlowerHousing

Gasket6

BoltM6xlO

RecoilStarter

35

Page 36

Craftsman Engine Model 265=SUA For Snow Model 247.881720

96 103 _--117

,115

116

m

95

96

97

98

99

1CO

102

103

104

105

106

107

951-10758

710-05103

951-11108

951-11935

951-10664

951-10665

951-11106

712-04212

710-04908

951-11700

951-10650

710-04915

9s 99

95

D = O

PrimerBracket

BoltM6x12

GovernorSystemShield

GovernorSpring

ThrottleLinkageSpring

ThrottleLinkage

GovernorArm

NutM6

GovernorArmBolt

FuelHoseClamp

FuelLineKit

BoltM6x12

107

m

108

109

110

111

112

113

114

115

116

117

118

951-11914

710-04905

710-04915

951-11913

951-11381

951-10656

951-11904

951-12482

951-12533

951-11933

951-10653B

D = O O

DipstickDecorationCover

Bolt

BoltM6x12

Oil FillTubeAssembly

O-Ring

Oil FillTube

O-Ring

DipstickAssembly

FuelCapAssembly

FuelLevelIndicator

FuelTankAssembly

36

Page 37

Craftsman Engine Model 265=SUA For Snow Model 247.881720

119

120

121

m

i

1119

1

1

1

i 120

!

i

1121

1

1

1

i 122

1

1

1

i 123

!

i

i 124

1

1

1

i 125

!

!

i

i 126

1

1

i 127

1

1

1

i 128

!

i

1

i 129

1

122

710-04914

951-11680

951-11114

712-05015

710-04935

710-04965

710-05182

715-04088

951-10645A

710-04915

951-11109

123

126

126

_i _128

29

D = O !

BoltM6xlO

WireClip

SwitchHousingMountingBracket

Nut,M6

BoltM4x60

BoltM4x55

BoltM6x32

DowelPin8x8

ElectricStarter

BoltM6x12

BlowerHousingShield

37

Page 38

38

Page 39

39

Page 40

MTD CONSUMER GROUP INC (MTD), the California Air Resources Board (CARB)

and the United States Environment Protection Agency (U. S. EPA)

Emission Control System Warranty Statement

(Owner's Defect Warranty Rights and Obligations)

EMISSIONCONTROLSYSTEMCOVERAGEISAPPLICABLETOCERTIFIEDENGINESPURCHASEDINCALIFORNIAIN2005ANDTHERE-

AFTER,WHICHAREUSEDINCALIFORNIA,ANDTOCERTIFIEDMODELYEAR2005ANDLATERENGINESWHICHAREPURCHASEDAND

USEDELSEWHEREINTHEUNITEDSTATES.

Californiaandelsewherein theUnitedStatesEmissionControlDefectsWarrantyCoverage

TheCaliforniaAir ResourcesBoard(CARB),U.S.EPAandMTDarepleasedtoexplaintheemissionscontrolsystemwarrantyonyour modelyear

2006andlatersmalloff-roadengine.InCalifornia,newsmalloff-roadenginesmustbe designed,builtand equippedtomeettheStatesanti-smog

standards.Elsewhereinthe UnitedStates,newnon-road,spark-ignitionenginescertifiedfor model2005andlater,mustmeetsimilarstandardsset

forthbythe U.S.EPA.MTDmustwarrantytheemissioncontrolsystemonyourenginefor theperiodof timelistedbelow,providedtherehasbeen

noabuse,neglector impropermaintenanceofyour smalloff-roadengine.

Youremissioncontrolsystemmayincludepartssuchasthecarburetor,fuel-injectionsystem,the ignitionsystem,andcatalyticconverter,fueltanks,

fuellines,fuel caps,valves,canisters,filters,vaporhoses,clamps,connectors,andotherassociatedemission-relatedcomponents.

Whereawarrantableconditionexists,MTDwill repairyoursmalloff-roadengineat nocosttoyourincludingdiagnosis,partsand labor.

MANUFACTURER'S WARRANTY COVERAGE:

Thisemissionscontrolsystemiswarrantedfor twoyears.Ifanyemission-relatedpartonyourengineisdefective,the partwill berepairedor

replacedbyMTD.

OWNER'S WARRANTY RESPONSIBILITIES:

Asthe smalloff-roadengineowner,youare responsibleforthe performanceofthe requiredmaintenancelistedinyourOwner'sManual.MTD

recommendsthatyouretainall yourreceiptscoveringmaintenanceson yoursmalloff-roadengine,butMTDcannot denywarrantysolelyfor the

lackofreceiptsor foryour failureto ensuretheperformancetoallscheduledmaintenance.

Asthe smalloff-roadengineowner,youshouldhoweverbeawarethatMTDmaydenyyourwarrantycoverageifyoursmalloff-roadengineorpart

hasfaileddue toabuse,neglect,impropermaintenanceor unapprovedmodifications.

Youare responsibleforpresentingyour smalloff-roadenginetoanAuthorizedMTDServiceDealeras soonas a problemexists.Thewarranted

repairsshouldbe completedina reasonableamountoftime,nottoexceed30 days.

Ifyouhaveanyquestionsregardingyourwarrantyrightsand responsibilities,youshouldcontacta MTDServiceRepresentativeat 1-800-800-7310

andaddressisMTDCONSUMERGROUP,RO.Box361131,ClevelandOH,44136-0019.

DEFECTS WARRANTY REQUIREMENTS FOR 1995 AND LATER SMALL OFF-ROAD ENGINES:

Thissectionappliesto 1995andlater smalloff-roadengines.The warrantyperiodbeginsonthedatetheengineor equipmentisdeliveredtoan

ultimatepurchaser.

(a) GeneralEmissionsWarrantyCoverage_

MTDmustwarranttothe ultimatepurchaserandeachsubsequentpurchaserthatthe engineis:

(1)Designed,built,andequippedsoasto conformwithallapplicableregulationsadoptedbytheAirResourcesBoardpursuantto itsauthorityin

Chapters1and2,Part5, Division26of theHealthandSafetyCode;and

(2) Freefromdefectsin materialsandworkmanshipthatcausethefailureofa warrantedparttobeidenticalin all materialrespectsto thepartas

describedin theenginemanufacturer'sapplicationfor certificationfora periodoftwoyears.

.(b)The warrantyonemissions-relatedpartswillbe interpretedas follows:

(1)Anywarrantedpartthatisnot scheduledforreplacementas requiredmaintenanceinthewritteninstructionsrequiredby Subsection(c)

mustbewarrantedforthewarrantyperioddefinedinSubsection(a)(2).Ifanysuchpartfailsduringthe periodof warrantycoverage,it mustbe

repairedor replacedbyMTDaccordingto Subsection(4)below.Anysuchpart repairedor replacedunderthewarrantymustbewarrantedfor

theremainingwarrantyperiod.

(2)Anywarrantedpartthat isscheduledonlyfor regularinspectioninthewritteninstructionsrequiredby Subsection(c) mustbewarrantedfor

thewarrantyperioddefinedinSubsection(a)(2).A statementinsuchwritteninstructionstotheeffectof"repairorreplaceasnecessary"will

notreducetheperiodof warrantycoverage.Anysuchpartrepairedor replacedunderwarrantymustbe warrantedfortheremainingwarranty

period.

(3) Anywarrantedpartthat whichisscheduledfor replacementas requiredmaintenancein thewritteninstructionsrequiredby Subsection(c)

mustbewarrantedfortheperiodof timepriortothe firstscheduledreplacementpointforthat part.Ifthe partfailspriorto thefirst scheduled