Page 1

owners

manual

MODEL NO.

247.88110

CAUTION:

Read SAFETY

RULES and

INSTRUCTIONS

carefully

Sold by SEJARS, ROEBUCK AND CO« dilcagojll. 60607 USA.

PART NO. 770-4447

CRAFTSMAN

HI WHEEL

SELF PROPELLED

ROTARY MOWER

• Assembly

• Operating

• Maintenance

• Repair Parts

Etnd

SIMPSONS-SBARS LIMITBD. Toronto

PRINTED IN U. S.A.

Page 2

IMPORTANT

SAFE OPERATION PRACTICES FOR WALK-BEHIND MOWERS

TRAINING

1. Read the Operating and Service Instruction Manual

carefully. Be thoroughly familiar with the controls

and the proper use of the equipment.

2. Never allow children to operate a power mower.

3. Keep the area of operation clear of all persons,

particularly small children, and pets.

PREPARATION

1. Thoroughly inspect the area where the equipment is

to be used and remove all stones, sticks, wire, bones

and other foreign objects.

2. Do not operate equipment when barefoot or wearing

open sandals. Always wear substantial footwear.

3.

Check the fuel before starting the engine. Do not fill

the gasoline tank indoors, when the engine is running,

or while the engine is still hot. Wipe off any spilled

gasoline before starting the engine.

4.

Disengage the self-propelled mechanism or drive

clutch on units so equipped before starting the engine

(motor).

Never attempt to make a wheel adjustment while the

engine (motor) is running.

Mow only in daylight or in good artificial light.

Never operate the equipment in wet grass. Always be

sure of your footing; keep a firm hold on the handle

and walk, never run.

OPERATION

1. Do not change the engine governor settings or

overspeed the engine.

2. Do not put hands or feet near or under rotating parts.

Keep clear of the discharge opening at all times.

3. Stop the blade(s) when crossing gravel drive, walks or

roads.

4. After striking a foreign object, stop the engine

(motor), remove the wire from spark plug,

thoroughly inspect the mower for any damage, and

repair the damage before restarting and operating the

mower.

5.

If the equipment should start to vibrate abnormally,

stop the engine (motor) and check immediately for

the cause. Vibration is generally a warning of trouble.

6.

Stop the engine (motor) whenever you leave the

equipment, before cleaning the mower housing, and

when making any repairs or inspections.

When cleaning, repairing or inspecting, make certain

the blade and all moving parts have stopped.

Disconnect the spark plug wire, and keep the wire

away from the plug to prevent acciderttal starting.

Do not run the engine indoors.

8.

9.

Shut the engine (motor) off and wait until the blade

comes to a complete stop before removing the grass

catcher or unclogging chute.

10.

Mow across the face of slopes, never up-and-down.

Exercise extreme caution when changing direction on

slopes. Do not mow excessively steep slopes.

11.

Always disconnect electric mowers (line operated)

before cleaning, repairing or adjusting.

12.

Never operate mower without proper guards, plates

or other safety protective devices in place.

Keep washout ports and other mower-housing service

13.

openings closed when mowing.

MAINTENANCE AND STORAGE

1. Check the blade and the engine mounting bolts at

frequent intervals for proper tightness.

2. Keep all nuts, bolts, and screws tight to be sure the

equipment is in safe working condition.

3. Never store the equipment with gasoline in the tank

inside of a building where fumes may reach an open

flame or spark. Allow the engine to cool before

storing in any enclosure.

4. To reduce fire hazard, keep the engine free of grass,

leaves, or excessive grease.

5. Check the grass catcher bags frequently for wear or

deterioration. Replace with new bags for safety

protection.

Page 3

iMHWMMW iiwwmwmt

CRAFTSMAN 1-YEAR GUARANTEE

If during the first year this Craftsman product fails to give proper performance due to

defects in material or workmanship, we will make all necessary repairs, free of charge.

This guarantee service is available through any of our stores or service centers through

out the United States or Canada.

MMöMMMMiMMMMMM

MAINTENANCE AGREEMENT

A MODERN, LOW-COST MAINTENANCE AGREEMENT IS AVAILABLE ON THIS PRODUCT TO EXTEND

THE GUARANTEE. CONTACT YOUR NEAREST SEARS STORE.

CUSTOMERS RESPONSIBILITIES

ALWAYS USE CARE WHEN OPERATING THE HI WHEEL ROTARY MOWER. KEEP CLEAR OF MOVING

PARTS. DO NOT WORK ON HI WHEEL ROTARY MOWER WITH ENGINE RUNNING. AVOID STRIKING

OR RUNNING INTO SOLID OBJECTS OR DEBRIS IN THE AREA TO BE WORKED. READ AND OBSERVE

THE RULES FOR SAFE OPERATION. KEEP THE HI WHEEL ROTARY MOWER CLEAN. FOLLOW A

REGULAR MAINTENANCE AND CHECK SCHEDULE TO PROVIDE EFFICIENT AND SAFE OPERATION.

A WELL-CARED FOR HI WHEEL ROTARY MOWE R WILL LAST LONGER AND OPERATE MORE EFFI

CIENTLY. ALWAYS BE CAREFUL FOR YOURSELF AND FOR OTHERS

SET UP INSTRUCTIONS

IT IS SUGGESTED THAT THIS MANUAL BE READ IN ITS ENTIRETY BEFORE ATTEMPTING TO ASSEMBLE

OR OPERATE THE HI WHEEL ROTARY MOWER.

THE SEARS HI WHEEL ROTARY MOWER HAS BEEN COMPLETELY ASSEMBLED AT THE FACTORY,

EXCEPT FOR THE HANDLE AND OPERATING CONTROLS WHICH HAVE BEEN LEFT UNASSEMBLED

FOR SHIPPING PURPOSES. ALL PARTS SUCH AS NUTS, WASHERS, BOLTS, ETC., NECESSARY TO COM

PLETE ASSEMBLY OF THE HANDLE AND CONTROLS HAVE BEEN PRE-INSERTED IN THE PLACES THEY

ARE TO BE USED OR PLACED IN A PLASTIC BAG.

ASSEMBLE THE UNIT AS OUTLINED. REFER TO ILLUSTRATIONS FOR ASSEA^BLY ASSISTANCE.

Page 4

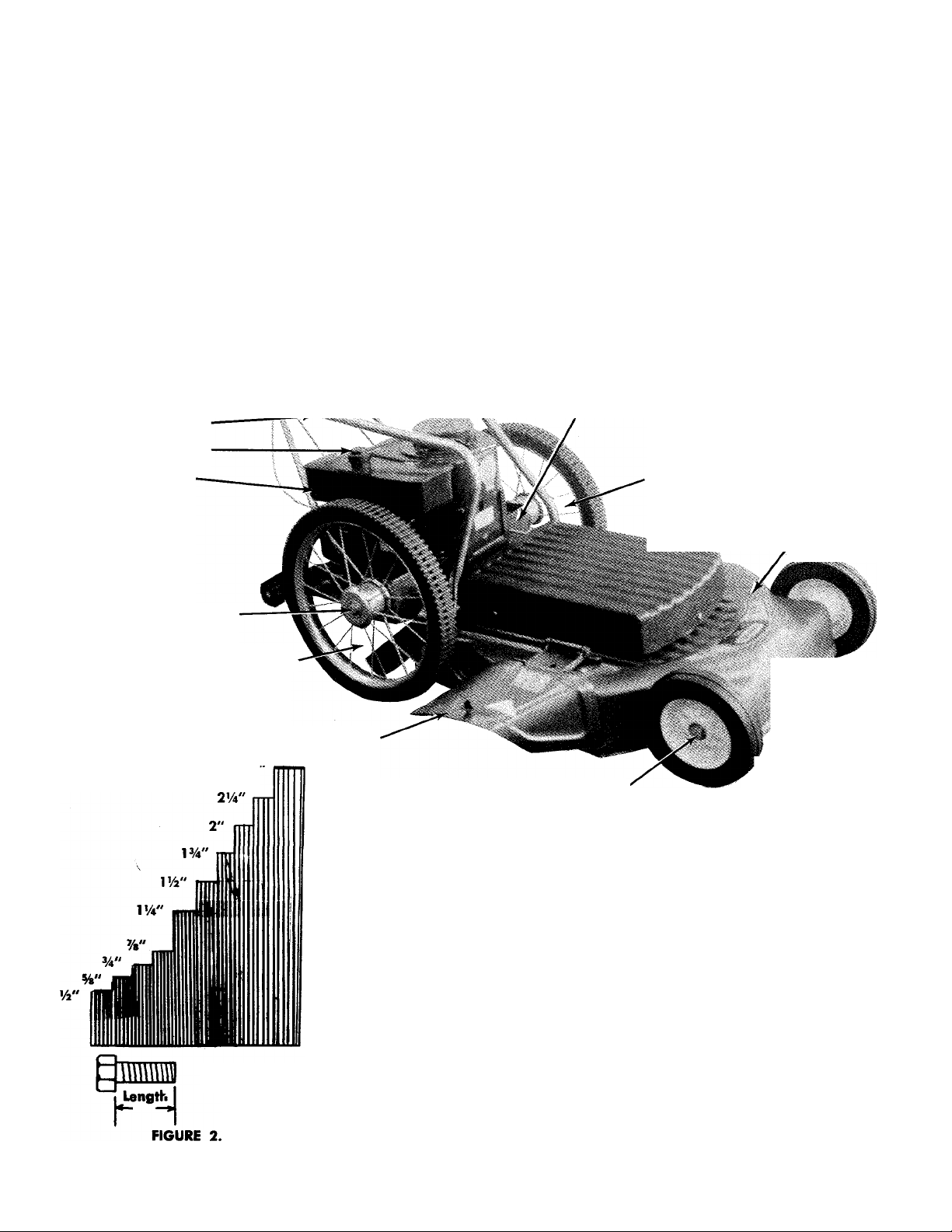

REFERENCE PHOTO FOR ASSEMBLY AND INSTRUCTIONS

Upper Handle (2)

Throttle Control

L

K;-

/

Blade Engaging

Lever (Under Handle ',

Panel)

Throttle Control Cable.

R.H. Brace

Gasoline Filler Cap

Gasoline Tank

Rear Wheel Axle Bolt

Grips (2)

Handle Panel

Lower Handle (One Piece)

L. H Brace

/ X-

Starter Handle

Oil Fill and Drain Left Side of Engine

Rear Wheel Assembly

Shroud

Deck Assembly

Rear Protective Shield Assembly

Chute Deflector Assembly

2'/2

Measure Screws Here

Length

Front Wheel Axle Bolt'

LIST OF CONTENTS IN HARDWARE PACK

(11) He.-: Center Locknuts 14-20 Thread.

(3) He>, Head Bolts 14-20 Thread x 114" Long.

(3) Hex Head Bolts 14-20 Thread xl Vi" Long.

(2) Hex Head Bolts V4-20 Thread x 2Vi" Long.

(2) Slotted Hex Head Screws 8-32 Thread x Vi" Long,

n) Speed Nut.

(1) Truss Head Machine Screw 10-24 Thread x %"

Lonn

(1) Hex I'-ad Bolt %-16 Thread x 1" Long.

(1) Hex head Bolt %-16 Thread x %" Long.

(2) Flat Washers %" I.D.xl54" O.D. x 5/32 Thick.

(1) Flat Washer V4" I.D. x’/2" O.D. x 1/16" Thick

(1) Flat Washer Vi" l.D. x O.D. x 1/32" Thick.

Refer to figure 4.

Front Wheel Assembly

Page 5

INDEX

Safe Operation Practices

Guarantee

Maintenance Agreement

Customer's Responsibilities

Set-Up Instructions------------------------------------------------------ 3

Reference Photo

Bolt Measurement Chart

List of Contents in Hardware Pack

Index

Assembly Instructions______________________________5

Controls ________________________________________ 10

Operation

To Start the Engine

Efficient Operation

Adjustment

Mower Lubrication

Engine Lubrication ---------------------------------------------------- 16

Engine Maintenance---------------------------------------------------- 17

Carburetor Adjustment

Storage Instructions

Engine Service----------------------------------------------------------

Trouble Shooting Chart------------------------------------------------19

______________________________________

______________________________________

___________________________

---------------------------------

-----------------------------------------------------

------------------------------------------------------

2

11

12

13

15

Exploded Parts Illustration

Parts List of Parts for AAower

Exploded Parts Illustration

Parts List of Parts for Mower

Exploded Parts Illustration

Parts List of Parts for Mower

4

Blade Spindle Detail

Blade Idler Bracket Detail

Belt Idler Reference Photos

Notes __________________________________________ 28

Notes

_______-__________________________________

Exploded Parts lllustretion for Engine

Parts List for Engine

Parts List for Engine

Exploded Parts Illustration for Engine Magneto

Exploded Parts lllustrstion for Carburetor

Exploded Parts lllustrcition for Rewind Starter

How to Order Repair Parts

_________________________

______________________

________________________

_______________________

_________________________

_______________________

__________________________

________________________

____________

______________________________

______________________________

________

__________

________

_________________________

20

21

22

23

24

25

26

27

29

30

31

32

33

34

35

36

Grease Gun

FIGURE 3. TOOLS REQUIRED

ASSEMBLY INSTRUCTIONS

Lockojr Hriclul

iLoekoul Lever '■*

MmSE

lAuumbly

I Nat Washer_j

. , M- Mr 10-24XH" Hex Hd. Bolt W-20ji;!

|Hpx Hd

IPX nd ^ Hex Hd Biilt_

!•» ^ dl * « •

FIGURE 4. LOOSE HARDWARE

NOTE: Reference to right hand and left hand of your

unit is from the operator's position.

Sletipd Hex tid

cr 8-32 X'4'

S t r- ,,

I D X '-s" O.D. ■ Truss!

• Truss Hd Mach^Scr Throtffe Clamp

SSL ^ 1 I Hex Hd bell .-20 x

nhei^*^ 16 X . af * •

'A" O.D.

- ^Hex Cenfet'LiiekV

^ Nut Lij-aa ii

IW".

Page 6

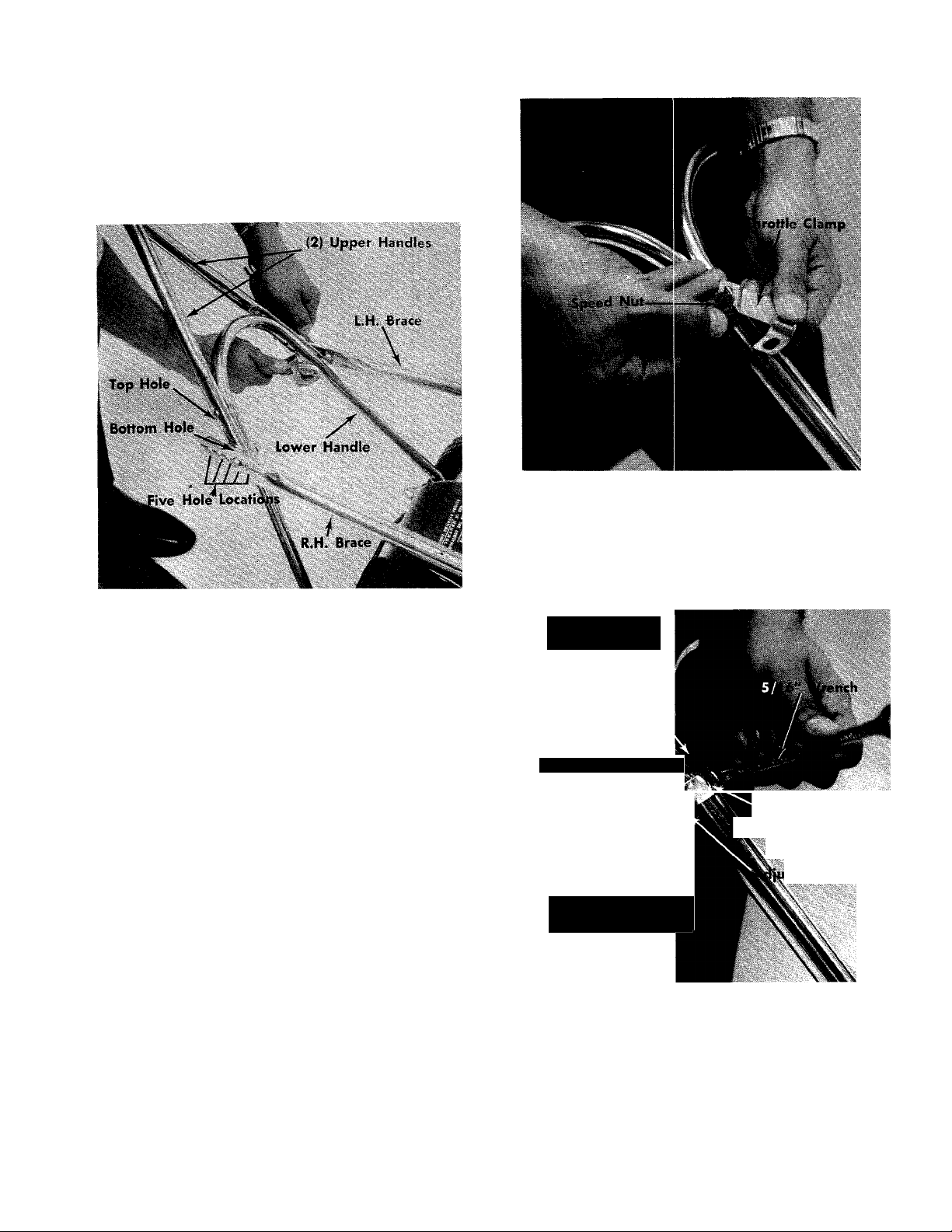

Lower Handle

(2) Flatwashers

%" I.D. X 1 'A" O.D.

Hex Hd. Bolt—

--16x 1'

FIGURE 5 LOWER HANDLE ASSEMBLY

Step 1.

Step 2.

a. Place the right hand brace in position on frame

and secure with one (1) Hex Hd. Bolt 14-20 x 2Vi".

Refer to figures 6 and 7.

NOTE: Do not tighten.

Adjustable

Wrench

Fram

a. Place the lower handle in position on the frame.

b. Place two (2) flat washers %" I.D. x 114" O.D.

between the handle and frame only on the right

hand side. See figure 5.

c. Secure the right hand side of lower handle with

one (1) Hex Hd. Bolt %-16x 1" Long.

NOTE: Just run bolt in two or three threads. Do

not tighten.

d. Secure the left hand side of lower handle with

one (1) Hex Hd. Bolt %-16x %" Long.

NOTE: No washers are required for the left hand

side. Again just run the bolt in two or three

threads. Do not tighten.

^ ■ left Hand Brace

X.

Right Hand Brace

FIGURE 7. BRACE ASSEMBLY

b. Place the left hand brace in position on frame

and secure with one (1) Hex Hd. Bolt 14-20 x 2V2”.

Refer to figures 6 and 7.

NOTE: Do not tighten.

2) Upper Handles

Hex Center Lock Nut

U-20 Thd.

-5/16" Wrench

'Second Hole

FIGURE 6. RIGHT AND LEFT HAND BRACE

Hex Hd Bolt 14-20 x l’/4"

4'.

FIGURE 8. UPPER HANDLE ASSEMBLY

c. Place the two (2) upper handles together using

the second hole. See figure 8.

Page 7

d. Secure the two (2) upper handles together with

one (1) Hex Hd. Bolt %-20xl%" and one (1)

Hex Center Lock Nut '/4-20 Thd.

NOTE: Do not tighten. See figure 8.

e. Place the two (2) upper handles assembled in

position with the lower handle. See figure 9.

FIGURE 10. THROTTLE CLAMP ASSEMBLY

Step 3.

FIGURE 9. HANDLE AND BRACE ASSEMBLY

f. Place a bolt, regardless of length, in the top hole

of the lower handle to help hold handle in po

sition when working.

g. The right and left hand braces have five (5) hole

locations for mounting the braces to the lower

handle. The reason for having five (5) hole lo

cations is so that you may adjust the handle

height to suit you.

h. Upon selecting the desired height of handle,

secure with one (1) Hex Hd Bolt ’^-20xl'/i"

and one Hex Center Lock Not '^-20 Thd.

NOTE: Use the bottom hole of lower handle

only. See figure 9. Do not tighten.

a. Place the speednut on the throttle clamp. See fig

ure 10.

Throttle Clamp

with Speed Nut

Upper Handles %

«Hex Hd. Bolt

'4-20x1'/2"

stable Wrench

Hex Center Lock Nut

'/4-20 Thd.

FIGURE 11. THROTTLii CLAMP ASSEMBLY

b. Place the throttle clamp with speed nut in po

sition on upper handle.

NOTE: Be sure the speed nut is towards the top

of handle. See figure 11.

c. Secure the throttle clamp with one (1) Hex Hd.

Bolt 14-20x1 VS" Long end one (1) Hex Center

Lock Nut 14-20 Thd.

Page 8

FIGURE 12. LOCKOUT BRACKET ASSEMBLY

d. Place the lockout bracket assembly under the

"T" portion of the upper handle with the bolt

ends facing up. See figure 12.

e. Place the clamp bracket over the bolt ends in the

lockout bracket assembly and secure with three

(3) Hex Center Lock Nuts Vi-20 Thd. See figure

12. Tighten nuts tight.

b. Secure two (2) Self Tapping Screws 8-32 x ’/2"

holding throttle control to handle with a screw

driver tightly. See figure 13.

Step 5.

a. Place the handle panel with throttle control at

tached in position on handle assembly. See fig

ure 14.

Handle Panel

Si

Hex Center Lock Nut

'4-20 Thd.

Hex Hd. Bolt

V4-2OX Vy Lg.

Handle Assembly

FIGURE 14. HANDLE PANEL ASSEMBLY TO HANDLE

Step 4.

a. Start the two (2) self tapping screws 8-32 x ’/2"

in by hand which hold the throttle control to the

handle panel. See figure 13.

Throttle Control

(2) Self Tapping

Screws 8-32 x

Handle Panel

FIGURE 13. THROTTLE ASSEMBLY TO PANEL

Page 9

b. Secure bottom of handle panel to handle as

sembly with two (2) Hex Hd. Bolts Va-2Q x 1 '/2"

and two (2) Hex Center Lock Nuts '/4-20 Thd.

See figure 14.

c. Secure top of handle panel to speed nut with

one (1) Truss Hd Machine Screw 10-24 x %" Long.

See figure 15.

'russ Hd. Mach. Screw

10-24 X 3s" Lg.

■^7*

-----

Handle

i.

FIGURE 16 DRIVE PINION CLEARANCE

|W/S$HtR BOLTS

li LOCKOUT

lever

FIGURE 15. HANDLE PANEL ASSEMBLY TO HANDLE

Step 6.

a. Tighten all nuts and bolts on handle assembly,

braces and handle to frame, securely with

wrenches.

Step 7.

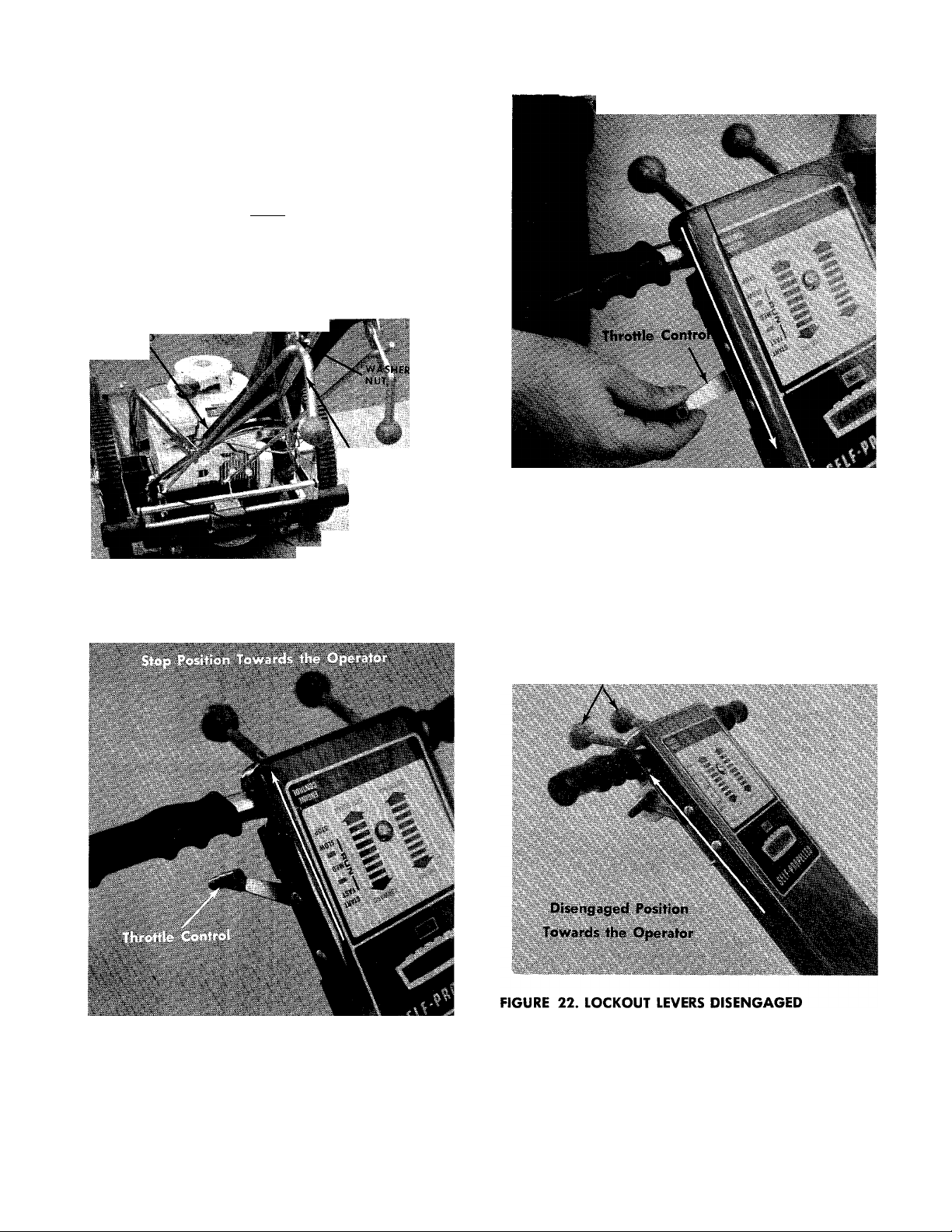

Assemble one of the control rods and lockout

levers to the self-propelling mechanism with

the ferrule (G) and washer (H) at the bottom

and washer (F) and nut (E) on the lockout lever

as shown in figures 17 and 18.

NOTE

Both lockout levers and rods are the

same. Be sure the control rod is on the

Left Hand side of the lockout lever as

shown in figure 17.

CAUTION

Check the distance between the drive

pinions and the r^ar tires. When the

lockout lever is disengaged, the pinion

should be no more than 1/8" from the

rear tire. Adjust the rod in the ferrule

if necessary to obtain the 1/8" distance.

See figure 16.

FIGURE 17.SELF-PROPEL CONTROL ASSEMBLY

Blade Control

Rod

Self-Propel Control Rod

SELF-PROPEL

CONTROL ROD

FIGURE I B. FERRULE ADJUSTMENT

Page 10

Step 7. Assemble the other control rod and lockout

lever to the pivot lever on the lower Left Hand

side of the mower with ferrule and washer.

Assemble the lockout lever to the upper han

dle with washer and nut as shown in figures

18 and 19.

NOTE

With the blade lockout lever in the dis

engaged position, adjust the rod in the

ferrule so that there is just enough

resistance to hold the blade lockout lev

er in place.

BLADE rCNTKI 1

LOCKOUT I EVER

art Position Away from Operator^

FIGURE 21. THROTTLE CONTROL START POSITION

ULE

WASHit

FIGURE 19. BLADE CONTROL ASSEMBLY

CONTROLS

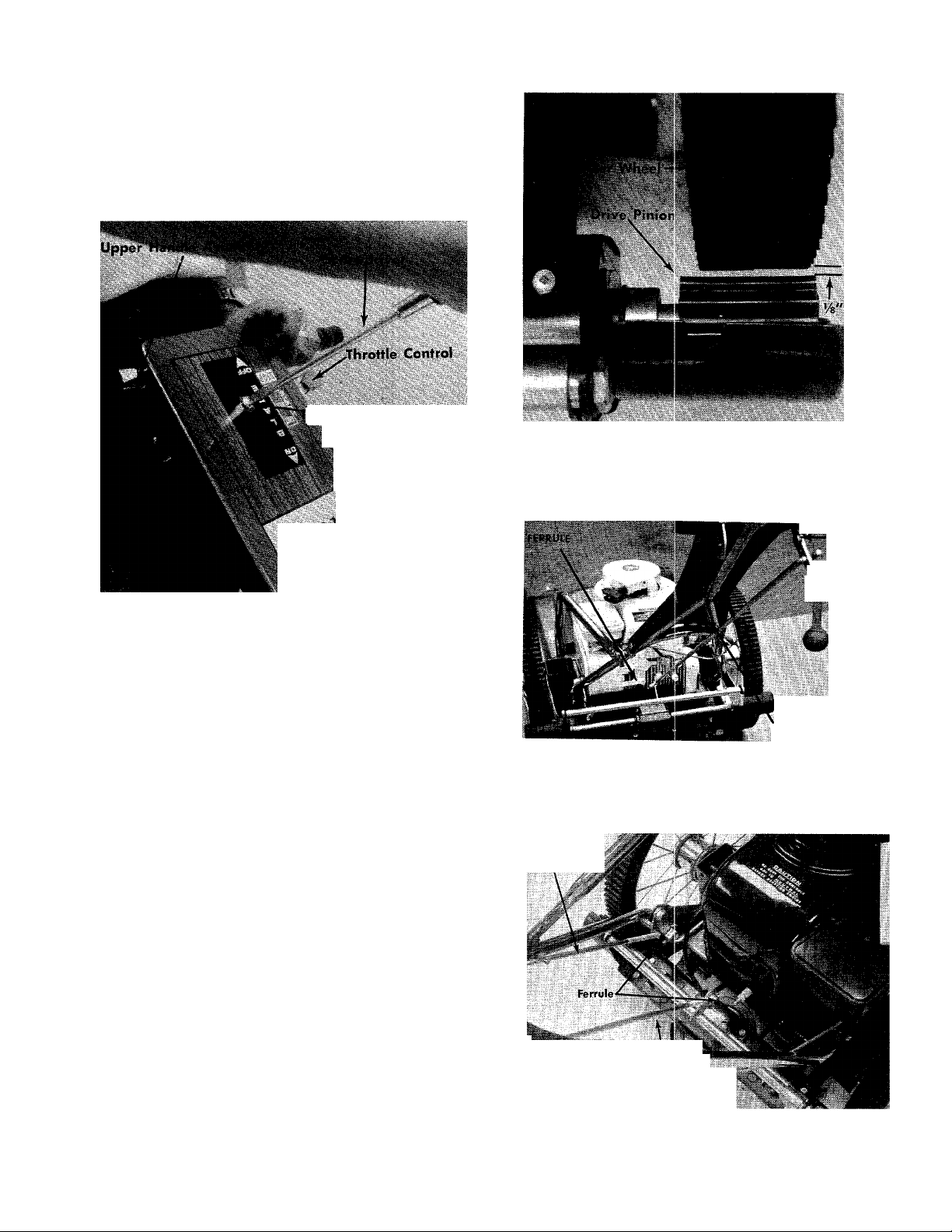

2. Figure 21 shows throttle control in the START posi

tion.

Lockout Levers in Disengaged Position

FIGURE 20. THROTTLE CONTROL STOP POSITION

1. Figure 20 shows throttle control in the STOP posi

tion. Throttle should remain in this position any

time the unit is not in use or when any mainte

nance is being performed.

Figure 22 shows lockout lever in the OFF position

(Disengaged) lever all the way up. Lockout levers

must remain in this position when starting.

10

Page 11

OPERATION

CAUTION

Lockout Lever

Engaged Position

FIGURE 23. DRIVE MECHANISM ENGAGED

Stop the engine and disconnect the

spark plug wire from the spark plug

before making any adjustments. See

figure 25.

FIGURE 25. SPARK PLUG WIRE BEING REMOVED

1. Blade Spindle Assembly—The blade spindle as

sembly is equipped with a grease fitting. Use grass

discharge chute for access to the fitting located un

der the deck. Use multi-purpose grease. Lubricate

PRIOR to initial use and every 25 hours thereafter.

See figure 26.

CAUTION: Be sure spark plug wire is disconnected

and grounded. See figure 25.

FIGURE 24 BLADE ENGAGED

4. Figures 23 and 24 show lockout levers engaged and

locked over center.

FIGURE 26. INITIAL LUBRICATION OF BLADE SPINDLE

ASSEMBLY

11

Page 12

2. Service engine with clean fresh regular gasoline.

3. Service engine with SAE 30 weight motor oil. Fill

oil fill opening to overflow. See figure 27.

TO START THE ENGINE

1. Be sore the engine has been serviced with the pro

per oil and fuel.

2. Move the lockout lever to the DISENGAGED posi

tion.

3. Move the throttle control lever to the START posi

tion.

4. Place one foot on the left side of the deck. See fig

ure 28.

5. Grasp the starter handle and pull out sharply and

hold it in the out position. (Do not let cord snap

back.) The cord should not be pulled out more

man about two feet. If the engine fails to start, al

low the cord to wind back into the housing, then

' pull out sharply again. Refer to figure 28.

K

Starter Handle

FIGURE 27. OIL FILL LOCATION

4. Move the lockout lever to the DISENGAGED posi

tion. (All the way towards the operator.)

5. Move the throttle cotnrol lever to the START posi

tion. (All the way forward.)

6. Put blade into motion by moving blade control

handle to ON position.

To engage the blade with the engine running:

a. Move the throttle control lever to FAST position.

b. Engage the blade engagement handle SLOWLY.

c. Adjust engine speed.

7. Appropriate clothing should be worn when cutting

brush or heavy weeds. Safety shoes and safety

glasses are highly recommended.

8. The operation of any powered outdoor equipment

can result in foreign objects being thrown into the

eyes, which can result in severe eye damage. Al

ways wear safety glasses or eye shields before com

mencing power tool operation. We recommend

Wide Vision Safety Mask for over spectacles, or

standard safety glasses... available at Sears re

tail or catalog stores.

^I^One Foot On Left Side of Deck

FIGURE 28. STARTING

EFFICIENT OPERATION

CAUTION

Stop the engine and disconnect the

spark plug wire from the spark plug

before making any adjustments.

Deck—The underside of rpower deck should be

cleaned after each period of use as grass clippings,

leaves, dirt and other matter accumulates. This

accumulation of grass clippings, etc., is undesirable

as it will invite rust and corrosion and may cause

an uneven discharge of grass clippings at next

cutting.

12

Page 13

2. The deck may be cleaned by tilting the mower

backward or on its side and scraping clean with a

suitable tool or by washing with a stream of wa

ter from a garden hose.

CAUTION

Do not direct the stream of water at a

hot engine as damage to the engine

may result.

3. For best results do not cut wet grass because it tends

to stick to the underside of the mower, thus pre

venting proper discharge of grass clippings. If wet

grass must be cut, reduce walking speed to help

distribute the clippings more effectively.

New grass should be treated as wet grass, other

wise a normal walking speed is about the right

pace for efficient mowing.

The best mowing pattern is one that allows the

clippings to discharge towards the uncut part of

the lawn. This permits recutting of the clippings

to further pulverize them. When cutting high

weeds, discharge towards cut portion then recut

at right angle to first direction.

Lawns should be cut in fall as long as there is

growth.

WARNING

1

1. The mower should not be operated without the

entire grass catcher or chute deflector in place.

2. The mower should not be operated without the

protective shield on the rear of the deck in place.

Lower Support

ive Hole .Locations

Lowe^^aiidle

/

FIGURE 29. HANDLE ADJUSTMENT

2. Remove hex lock nut holding the lockout lever in

position.

3. Remove the hex head bolts and nuts holding the

lower supports to lower handle.

4. Position handle for desired height and reassemble

lower supports to the lower handle. See figure 29.

CAUTION

Stop the engine and disconnect the

spark plug wire from the spark plug

before making any adjustments.

IMPORTANT

After striking a foreign object, stop the

engine (motor), remove wire from spark

plug. Thoroughly inspect the mower for

any damage and repair the damage be

fore restarting and operating the

mower.

ADJUSTMENT

CAUTION

Stop the engine and disconnect the

spark plug wire from the spark plug

tefore making any adjustments.

1. Handles may be adjusted by changing the posi

tion of the lower support mounting holes. When

this change is made, it may also be necessary to

check the adjustment of the control rod. See figures

29 and 30.

1. Lockout rod adjustment is made as shown in figure

30.

Lockout Rod

FIGURE 30. LOCKOUT ROD ADJUSTMENT

13

Page 14

2. Remove the hex lock nut holding the lockout lever

in position.

3. Turn the lockout rod and lever in or out of the fer

rule until the lockout lever lines up with the lock

out bracket.

4. Secure lockout lever in position with hex lock nut.

CAUTION

Stop the engine and disconnect the

spark plug wire from the spark plug

before making any adjustments.

1. Cutting height adjustment is made by removing

and moving axle bolts to the desired positions. All

axle bolts must be mounted in the same relative

position to the deck. When wheels are mounted to

the deck, the crown shape washers must be assem

bled with the crown away from the deck. This is

necessary to prevent the axle bolts from loosening.

Refer to figures 31, 32 and 33.

FIGURE 32. REAR WHEEL HEIGHT ADJUSTMENT

Front Wheel

FIGURE 31. FRONT WHEEL HEIGHT ADJUSTMENT

2. Upon reassembling the rear wheel, be sure the

crown washer is positioned in the inner frame

bracket. See figure 32.

Rear Wheel

FIGURE 33. CROWN WASHER LOCATION FOR REAR

WHEEL

CAUTION

Axle Bolt

Stop the engine and disconnect the

spark plug wire from the spark plug

before making any adjustments.

14

Page 15

1. Throttle Control—If throttle adjustment becomes

necessary, the throttle control wire may be reset

as follows:

a. Loosen, but do not remove, screw securing throt

tle control wire assembly at engine.

b. Move throttle control lever on handle to START

position.

c. Move lever to which control wire is fastened to

engine to full START position. Retighten screw

to secure throttle control wire assembly. See fig

ure 34.

FIGURE 35. REAR WHEEL LUBRICATION

CAUTION

Stop the engine and disconnect the

spark plug wire from the spark plug

before making any adjustments.

Throttle Conduit

FIGURE 34. THROTTLE ADJUSTMENT

MOWER LUBRICATION

CAUTION

Stop the engine and disconnect the

spark plug wire from the spark plug

before making any adjustments.

1. Wheel bearings are ball bearings front and rear.

Lubricate at least once a season with SAE 30 weight

motor oil.

a. Front wheels to be oiled at the axle bolt.

b. Rear wheels to be oiled at oil caps in rear wheel.

See figure 35.

2. Throttle—Periodically lubricate throttle control lever

and entire length of throttle wire assembly with

a few drops of SAI: 30 engine oil for ease of oper

ation.

CAUTION

Stop the engine and disconnect the

spark plug wire from the spark plug

before making any adjustments.

3. Friction point between idler bracket assembly and

deck should be greased once each season with a

multi-purpose grease. See figure

CAUTION

Stop the engine and disconnect the

spark plug wire from the spark plug

before making any adjustments.

4. Protective Shield—The pivot points on the protective

shield should be lubricated periodically with oil

to prevent any rust or binding up.

CAUTION

Stop the engiine and disconnect the

spark plug wire from the spark plug

before making any adjustments.

15

Page 16

5. Blade Spindle Assembly

The blade spindle assembly, located on the underside

of the mowing deck, is equipped with a grease fitting

Use grass discharge chute for access to the fitting lo

cated under the deck. Use multi-purpose grease. Lubri

cate prior to initial use and every 25 hours thereafter.

See figure 36.

CAUTION

ENGINE LUBRICATION

CAUTION

Stop the engine and disconnect the

spark plug wire from the spark plug

before making any adjustments.

Be sure spark plug wire is disconnected

and grounded.

6. Gear Box

Check lubricant in the self-propelled drive gear box.

This must be maintained half full at all times and

should be checked after each 25 hours of operation.

The gear box is packed at the factory with Alduralube

Heavy or Temprite No. 2. It is suggested that this or an

equivalent type and quality fibrous high heat wheel

bearing grease be used in maintaining this mechanism.

Grease can be ordered by part number 727-111. Hori

zontal bronze bearings under the self-propelled drive

mechanism should be lubricated with SAE 30 engine

oil. Refer to figure 37.

1. Position equipment so that engine is setting level.

Remove oil filler plug. See figure 38.

FIGURE 38. OIL FILL LOCATION

FIGURE 37. GEAR BOX LUBRICATION

7. Chute Deflector—The torsion spring and pivot point

should be lubricated periodically with oil to prevent

any rust or binding up. Deflector must work freely.

2. Pour oil into opening which you removed the oil

filler plug from.

3. During initial "Break-in" period oil level should

be watched closely.

Oil . . . Use the following:

Summer—Above 32° F—SAE 30 (SAE 10W30 is

an acceptable substitute).

Winter-Below 32°F-SAE 5W20 (SAE 10 or

5W30 are acceptable subsitutes).

Winter-Below 0°F Only—SAE 1OW with 10%

kerosene.

4. Change oil first two (2) hours of operation and

check oil level every five (5) operating hours or

each time equipment is used.

5. Change oil every twenty-five (25) operating hours

or sooner if equipment is operated in extremely

dusty or dirty conditions.

6. Oil can be changed by removing the oil drain plug

located on the right hand side of the engine. See

figure 39.

16

Page 17

7. Tip mower on its right hand side and remove the

oil drain plug.

FIGURE 39. OIL DRAIN LOCATION

ENGINE MAINTENANCE

NOTE

Always tip engine toward oil drain hole.

Be sure oil drains completely.

Replace oil drain plug and refill with oil as di

rected on page 1, or engine nameplate.

3. CHECK OIL every nve (5) operating hours or each

time equipment is used.

a. If engine has dip stick, keep oil level at mark

indicated by adding if necessary.

4. CLEANING ENGINE—This is an air-cooled engine

which operates most efficiently when the cooling

fins are clean.

Clean cylinder fins .tnd underside of tank or housing

thoroughly of all accumulated grass and debris.

5. AIR CLEANERS-

a. Polyurethane T>pe—Serviceable. Clean element

every ten (10) hours or oftener if engine runs

rich and emits black smoke from the exhaust.

Service by removing air cleaner cover. Remove

polyurethane element and wash in detergnt and

water solution by squeezing similar to a sponge.

Squeeze out cleaning solution. Re-oil element

by applying generous quantity of oil to sides

and open ends. Squeeze to distribute oil and to

remove excess oil. Reinstall element and air

cleaner cover as illustrated in figure 40.

CAUTION

Stop the engine and disconnect the

spark plug wire from the spark plug

before making any adjustments.

To obtain long life and trouble-free service from your

engine, certain normal maintenance must be per

formed as outlined below:

1. Check unit on which engine is mounted. Hard start

ing can result if blades are loose, belts or chains

too tight, etc. Periodically check bowden wire con

trols. If the wire has loosened it may not put the

carburetor on full choke when starting or open the

throttle wide enough for the RUN or FAST position.

2. Change oil in crankcase after first two (2) hours of

operation. Then, follow instructions outlined un

der OIL, page 16.

CAUTION

Disconnect high tension wire at spark

plug to prevent accidental starting of

engine. Unscrew oil drain plug located

on side of engine (figure 1).

Element

Housing

Sci'een

^'] Bracket

.Attaching

Screw

Element

FIGURE 40.

17

Page 18

CARBURETOR ADJUSTMENTS STORAGE INSTRUaiONS

Do not make unnecessary adjustments. Factory set

tings are correct for most applications. If adjustments

are needed, proceed as follows:

1. Close power adjusting needle (figure 41 or figure

42) by turning to right (clockwise). Close finger

tight only. Forcing will cause damage.

2. Open one turn (counterclockwise).

3. Close idle adjusting needle (figure 41 or figure

42), by turning to right (clockwise). Close finger

tight only. Forcing will cause damage.

Power Drain

Adjusting

Float Feed Carburetor

FIGURE 41.

4. Open one and one-half turns (I'/a) counterclock

wise (figure 41 or figure 42).

5. Start engine. Follow starting instructions.

6. With throttle open (carburetor control at RUN or

FAST position), adjust power adjusting needle one-

eighth ('/s) turn at a time forward or backward un

til engine runs smoothly. If engine tends to stall

under load, enrich slightly (counterclockwise).

Diaphraghm Carburetor

Power

Adjusting

FIGURE 42.

In event engine is to be stored for any length of time

(30 days or more) or at the end of mowing season, pre

pare as follows:

1. Drain gas tank completely by removing fuel line

at the carburetor or fuel tank, whichever is easier.

CAUTION

Drain into container outdoors away

from fire or flame.

2. DRAIN CARBURETOR.

Drain by pressing upward on bowl drain (figure 7).

3. Inside protection of engine for storage is performed

by removing spark plug and pouring one ounce

of SAE 30 oil through spark plug hole into cylinder.

Crank engine without starting several times to

spread oil over cylinder walls.

IMPORTANT: A yearly checkup or tuneup by the SEARS

Service Department is a good way of ensuring that

your rotary mower will provide maximum perform

ance for the next season.

Store the rotary mower in a protected area and cover

the unit for additional protection.

ENGINE SERVICE

Unless the operator is fully qualified to make engine

adjustments and repairs, it is recommended that such

work be done by technicians trained to work on

rotary mower type gasoline engines.

The Repair Parts section of this manual contains a list

of engine replacement parts and illustrations to assist

the trained technician in making repairs and ordering

proper replacement parts.

The following chart. Trouble Shooting, is provided as

a guide for correcting minor problems when the trou

ble is known.

7. Hold throttle lever closed or move carburetor con

trol to IDLE or SLOW position and adjust idle ad

justing needle until engine runs smoothly, pro

ceeding as in step 6 above.

8. Allow several seconds between each adjustment

when performing either step six (6) or seven (7)

to allow engine to react to new setting.

9. Maximum engine speeds are preset at factory and

should not be changed except by a qualified serv

ice station repairman who has the necessary equip

ment.

18

Page 19

TROUBLE SHOOTING CHART

CAUTION: ALWAYS DISCONNECT SPARK PLUG BEFORE ATTEMPTING ANY REMEDY.

TROUBLE

Engine fails to start.

Hard starting or loss of

power.

LOOK FOR

Blocked fuel line or

empty gas tank.

Defective spark

plug.

Throttle setting.

Loose connections Spark plug wire loose.

Dirty air cleaner.

Carburetor improp

erly adjusted.

Clean fuel line; check fuel supply.

Spark plug lead wire disconnected.

Faulty spark plug—spark should jump gap between control

electrode and side electrode. If spark does not jump, re

place spark plug.

NOTE: Use insulated pliers 1o hold the spark plug wire.

Throttle control lever not in the starting position.

Remove air cleaner and clean as outlined in paragraph

Engine Maintenance.

Review paragraph Carburetor Adjustment.

REMEDY

Excessive vibration.

Unit fails to propel

itself.

Unit fails to discharge

grass.

Engine overheats.

Bent or damaged

blade spindle.

Loose parts.

Drive belt loose or

defective.

Lockout rod adjust

ment.

Discharge chute

clogged.

Foreign object

lodged in deck.

Obstructions in air

passages.

Grass and dirt in

engine shroud.

Stop engine immediately; tighten all bolts and make all nec

essary repairs. If vibration continues, have the unit serviced

by a competent repairman.

Stop engine immediately; tighten all bolts and make all

necessary repairs.

Adjust drive belt; replace if defective.

Review paragraph on Adjustments, page 13.

Clean discharge chute and inside of deck.

Remove object from deck. See CAUTION following step 1 in

paragraph Operation.

Remove any obstruction from air passages in shroud.

Clean cooling fins.

Oil level.

Fill crankcase to proper oil level.

19

Page 20

CRAFTSMAN HI WHEEL SELF-PROPELLED ROTARY MOWER MODEL 247.88110

K>

o

(D

TJ

Q

■ o

Q

</)

Page 21

CRAFTSMAN HI WHEEL SELF-PROPELLED ROTARY MOWER MODEL 247.88110

REF.

NO.

1 712-107

2

3 9354

4

5 7889

6 8373

7

M

8 8376

9

10 712-107

11

12

13

14

15 9362

16

17

18 738-234

19

PART

NO.

Hex Center Locknut 14-20 Thd.

8378 Clamp Bracket

Upper Handle (2-Req'd.)

720-157 Grip

Plastic Ball

Lockout Lever Ass'y- with Plastic

711-180 Control Rod

Lockout Bracket Ass'y-

736-108 Flat Washer .510" I.D. x .75"

Hex Center Locknut 14-20 Thd.

712-107

710-106

710-606 Hex Scr. 1/4-20 X 1.50" Lg.*

712-107 Hex Center Locknut 14-20 Thd.

8327

712-130 Hex Inserted Lockout %-l 6 Thd.

9372

Hex Center Locknut 14-20 Thd.

Hex Scr. 1/4-20 X 1.25" Lg.*

Lower Handle

Lower Handle Support—L.H.

Shoulder Scr. .500" Dia. x .295

Pivot Bracket

DESCRIPTION

Ball

O.D. X .033

REF.

NO.

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38 711-180

PART

NO.

711-180

711-179 Adjustment Ferrule

710-253

710-102

712-107

11991

736-119.

712-123

11990-347

710-473

746-171

712-526

710-473

752-404

746-128

710-606

712-526 Speed Nut #10-24

Control Rod

Hex Scr. %-16 X .62" Lg.*

Hex Scr. 1/4-20 x 2.50" Lg.*

Hex Center Locknut ’/4-20 Thd.

Lower Handle Support—R.H.

Spring Lockwasher 5/16" Scr.*

Hex Nut 5/ 16-24 Thd.*

Handle Panel

Truss Mach. Scr. 10-24 x .50"

Throttle Control Ass'y.—Comp.

Speed Nut 10-24

Truss Mach. Scr. 10-24 x .50"

Engine Model No. V60-70259H

Cable Clip for %" Tubing

Hex Scr. 1/4-20 X 1.50" Lg.*

7861

Clamp Bracket

Control Rod

DESCRIPTION

Lg.*

Lg.*

* Standard Hardware Items—May Be Purchased Locally.

Page 22

CRAFTSMAN HI WHEEL SELF-PROPELLED ROTARY MOWER MODEL 247.88110

(D

TD

Q

T3

Q

</)

Page 23

CRAFTSMAN HI WHEEL SELF-PROPELLED ROTARY MOWER MODEL 247.88110

REF.

NO.

1 710-121

2 736-114

3

4

5

6

7

8

9

10

11

12

13

14

15

M

u

16

17

18

19

20

21

22

23

24

25

26

'¿/

28

29

30

31

32

33

34

35

36

PART

NO.

Hex Scr. ’/2-20 X .75" Lg. Special

Internal Lockwasher ’/2" Scr.*

748-108 Flange Bearing .503" I.D.

748-136

7146

748-110 Flange Bearing .630" I.D.

8187-347 Gear Box Cover

710-148 Hex Washer Hd. F-Tapp. Scr.

748-135

711-180 Control Rod

711-179

8331

8189 Gear Box

710-289

736-329

710-252

8348

748-110 Flange Bearing .630" I.D.

710-421

715-247

711-415 Clevis Pin .375" Dia.

736-300

714-121

736-329

712-287

1100/-J4/

711-169 Collar %" I.D.

736-108

8772-347

712-287

736-329

748-226

8774-347

714-229

Pinion Gear .50" I.D. 14 Teeth

Pinion Shaft

Bevel Gear .62" I.D.—28 Teeth

Adjustable Ferrule

Pull Bar Assembly

Hex Scr. ’/4-20 X .50" Lg.*

Spring Lockwasher ’A" Scr.*

Hex Scr. '/4-20 X .75" Lg.*

Drive Shaft

Set Scr. 5/16-18 X .25" Lg.*

Spring Pin Spirol 3/16" Dia. x

7120

Nylon Pinion

Cotter Pin 5/32" Dia. x 1.00" Lg.*

Spring Lockwasher ’A" Scr.*

Stop—Drive Plate

Spring Lockwasher ’A" Scr.*

9927

Sheave Ass'y-—5.50 x .50

DESCRIPTION

#8-32 X .38" Lg.*

1.00" Lg.

Flat Washer .385" I.D. x .87" O.D.

X.06

Hex Nut ’A-20 Thd.*

Flat Washer .510" I.D. x .75" O.D. x

.033

Belt Guard

Hex Nut ’/4-20 Thd.*

Hex Flange Bearing .503" I.D.

Bottom Frame Ass'y-

#2 Woodruff-—Key 3/32 x ’/2" Dia.

Hardened

REF.

NO.

37 11996-347 Spacer Plate Ass'y.

38 710-409

39 754-121 "V"-Belt ’/2" X 31.8" Lg. (Drive

40 756-205

41

42

43 710-152 Hex Scr. %-24 x 1.00" Lg. Heat

44 710-528 Hex Scr. 5/16-18 x I’A" Lg.*

45 736-119 Spring Lockwasher 5/16" Scr.*

46

47 8324-347

48 736-119 Spring Lockwasher 5/16" Scr.*

49 712-267

50 8298 Idler Bracket Ass'y. with Brake Shoe

51

52

53

54

55 9373 Control Rod

56 732-137 Extension Spring

57

58

59

60

61

62

63

64

65

66

67

68 736-105

PART

NO. DESCRIPTION

Hex Scr. 5/16-24 x 1.75" Lg.*

Belt)

Two Step Engine Pulley

736-235

736-217 Spring Lockwasher %" Scr. Heavy

712-130 Hex Inserted Locknut %-16 Thd.

756-370

736-300 Flat Washer .385" I.D. x .87" O.D.

712-158 Hex Center Locknut 5/16-18 Thd.

732-158 Blade Tension Spring

754-109 "V"-Belt ’/2 X 43" Lg. (For Blade)

738-234

736-108 Flat Washer .510" I.D. x .750" O.D.

712-922

736-921 Spring Lockwasher ’/2" Scr.*

8279-347 Frame Ass'y.—Comp.

736-147

10523-347

Flat Washer .406" I.D. x 1.25" O.D.

X.164

Duty

Treated

Belt Guard

Hex Nut 5/16-18 Thd.*

Idler Bearing Ass'y.

X .06

7353

9371

Belt Clip

Shoulder Scr. .500" Dia. x .295

X .033

Brake Lever

Hex Jam Nut ’/2-20 Thd.

9925 Sheave Ass'y.—4" Dia. (Blade

Spindle)

Extern Lockwasher #10

Top Drive Frame Ass'y.

Belleville Washer %" I.D.

^Standard Hardware Items—May Be Purchased Locally.

Page 24

'//■

Page 25

CRAFTSMAN HI WHEEL SELF-PROPELLED ROTARY MOWER MODEL 247.88110

REF.

NO.

1

2

3 8279-347

4

5 710-567

6 736-329

7 11446-347 Deck Assembly

8

9 713-132

M

(II

10 741-113 Ball Bearing .504" I.D. x 1.38" Dia.

11

12 11141-347

13 732-253 Torsion Spring

14

15

16 711-555

17

18

19

20

21

PART

NO.

710-117

710-158

710-209

11197-347

738-114 Shoulder Scr. .498" Dia. x 4.755"

726-106 Push Nut ’/4" Rod

11130-347

10769

734-438 16" Rear Wheel Ass'y. Comp.

734-180 16" Rear Wheel—Less Tire

734-391 Semi Pneumatic Tire 16 x 1.75

741-114 Ball Bearing .504" I.D. x 1.12" Dia.

738-213 Shoulder Scr. .498" Dia. x 1.450"

Hex Scr. 5/16-24 x 1.00" Lg. 22

Heat Treated

Hex Scr. 5/16-24 X 1.25" Lg.*

Frame Ass'y-—Complete

Hex Sems Scr. %-16 x .62" Lg.*

Hex Sems Scr. 14-28 x %" Lg. 27 710-117 Hex Scr. 5/16-24 x 1.00" Lg.

Spring Lockwasher L4" Scr.*

Protective Shield Ass'y.—Comp.

Oil Cap 29

Chute Deflector Ass'y.

Adapter Plate

Pivot Pin

Blade Adapter Kit

DESCRIPTION

Lg.

Gear Tread

Lg.

REF.

NO.

23 736-105

24 712-123 Hex Nut 5/16-24 Thd.*

25

26

28 710-459 Hex Scr. %-24 x 1.50" Lg. Heat

30

31

32

33

34

35 736-119 Spring Lockwasher 5/16" Scr.*

36

37 7805

38 710-473

39 731-230

40

41

42

43

PART

NO. DESCRIPTION

9383-501

736-129 Spring Lockwasher 5/16" Scr.*

742-125 22" Blade

736-217 Spring Lockwasher %" Scr. Heavy

748-189

712-123

736-119

712-123 Hex Nut 5/16-24 Thd.*

11679-347

712-526

770-4447

775-1121

Front Wheel Ass'y. Comp.

Belleville Washer

Heat Treated

Treated

Duty

7919

Scalp Plate

Blade Adapter

Hex Nut 5/16-24 Thd.*

Spring Lockwasher 5/16" Scr.*

8809 Reinforcement Plate

Blade Spindle Ass'y.—Comp.

Truss Mach. Scr. #10-24 x .50"

Lg.*

Blade Spindle Cover

Chute Deflector Ass'y.—Comp.

Speed Nut #10-24

Owners Manual (Not Illustrated)

Model Plate (Not Illustrated)

*Standard Hardware Items—May Be Purchased Locally.

Page 26

BLADE SPINDLE ASSEMBLY 901-7805

2. Zerk Fitting should face Discharge Chute of Deck.

3. Lubricate every 8 to 10 hours with Shell General

Purpose Grease or Equivalent.

BLADE IDLER BRACKET ASSEMBLY DETAIL

Brake Shoe 754-647

Rivet 728-649

BELT WEAR

Belt clips improperly positioned will cause premature

belt wear. The belt clip must completely clear the belt

when the belt is tightened. It should also assist in free

ing the belt from the blade spindle pulley when the

belt is loose. This may be checked by removing the

blade spindle cover.

Bracket Assembly 8298

Idler Bearing 756-370

Hex Lock Nut

>12-372

Belt Clip

7353

26

Page 27

p Must Not Toiiti]^

Where Blade Is

27

Page 28

NOTES:

28

Page 29

NOTES

29

Page 30

TECUMSE H 4 -aCLE ENG INE

MODEL NUMBER: V60-70259H

f-

-----

137

30

Page 31

TECUMSE H 4 -CY CLE E NGIN E

Ref.

No.

Part

No. Part Name

Ref.

No.

MODEL NUMBER: V60-70259H

Part

No.

Part Name

1

33361

2

27652

4 27876B Seal, Oil equivalent)

5 27877A Valve, Intake (Stemdard) (Incl.

27880A Valve, Intake (1/32” oversize)

5

6 27878A

6 27880A

7 27882

8 27881

9 32581

11 33799

12 29783 Pin, Crankshaft gear

13 27884

14

14

14 33314

15

15 33316

15

16 27888

17

18 30682

19

20 28264

21

22 33157

23

24

25

27

28

29

34 27897

35

36

39

43

44

47

48

49

33312

33313

33315

33317

31380B

26073

27893

*30684

31471B

31355

29117

31356

27642

650548

31335

650488

27625

*29673

*28938B

30938A

30939A

Cylinder Assy. (Incl. Nos. 2 &

4)

Pin, Dowel

No. 9)

(Incl. No. 9)

Valve, Exhaust (Standard)

(Incl. No. 9)

Valve, Exhaust (1/32” over- 10-24x1/2

size) (Incl. No. 9)

Cap, Upper valve spring

Spring, Valve

Cap, Lower valve spring

Crankshaft Assy. (Incl. Nos. 12

& 13)

Gear, Crankshaft

Piston & Pin Assembly (Incl. 2

of No. 16) (Standard)

Piston & Pin Assembly (Incl. 2

of No. 16) (.010 oversize)

Piston & Pin Assembly (Inch 2

of No. 16) (.020 oversize)

Ring Set, Piston (StandEird)

Ring Set, Piston (.010 oversize)

Ring Set, Piston (.020 oversize)

Ring, Piston pin retaining

Rod Assembly, Connecting

(Incl. Nos. 18,19 & 20)

Bolt, Connecting rod

Washer, Connecting rod bolt

Nut, Hex, 5/16-24

Lifter, Valve

Camshaft (Compression Release)

Gasket, Mounting flange

Flange Assembly, Mounting

(Incl. Nos. 25, 27, 29, 34, 43,

44 & 110)

Screen, Oil filter

Screw, Slotted hex hd. self

tap., 8-32 X 5/16 washer, 1/4-20 x 11/16

Pump Assembly, Oil

Plug, Pipe

Seal, Oil

Screw, Hex slotted washer hd..

8-32 X 3/8

Clamp, Governor lever

Screw, Hex hd. Sems, 1/4-20 x

1-1/4

Plug, Oil filler (Incl. No. 44)

Gasket, Oil filler plug

Gasket, Cylinder head

Head, Cylinder

Cover, Cylinder head

51 650697

52 33636

53 *27896

54 28423

55

56

57

59

60

61

63 650152

64 650378

65

69

71

82 32181

83 30200

84

87

88

89

90

91

92

93

94 29536

95

96

98

99

101 650489

102

103 31361

104

105

106

109

110

111

112

28424 Element, Breather

28425

27627

650128

*27915

31358

*26756

6201 Screw, Hex hd. cap, 1/4-28 x

29752 Nut, Hex, 1/4-28

*27272

31691

28820

30727

31692

*27930

28269

650696

31588

650561

30884

28277

31823

30669

32582

31357

31707

30668

30591 Gear Assembly, Governor

29193 Ring, Retaining

Screw, Hex hd. cap, 5/16-18 x

2-1/2

Plug, Spark (Champion J-8 or

Gasket, Valve chamber cover

Body Assembly, Breather

Cover, Valve chamber

Tube, Breather

Screw, Fil. slotted hd. Sems,

Gasket, Intake pipe

Pipe, Intake

Screw, Fil. slotted hd. Sems,

8-32 X 3/8

Screw, Fil. hd. Sems, 5/16-18 x

1-1/8

Gasket, Carburetor

7/8

Control Assy., Speed (Incl.

Nos. 161 & 162)

Screw, Slotted hex washer hd..

10-24 X 1/2

Gasket, Air cleaner bracket-tocarbm’etor

Bracket, Air cleaner

Screw, Phil. fil. hd. mach.

Sems, 10-32 x 1/2

Element, Air cleaner

Body, Air cleaner

Gasket, Muffler flange

Muffl(3r Assembly

Screw, Hex hd. cap, 5/16-18 x

2-3/4

Baffle, Blower housing

Plate, Locking muffler

Screw, Phil, hex hd. Sems,

1/4-20 X 5/8

Key, ]?lywheel

Washes, Flat

Screw, Hex hd. Sems with flat-

Link, Governor

Spring, Governor

Rod, Governor (Incl. No. 99)

Link, Governor spring

Lever, Governor

Spacer

Shaft,, Mechanical governor

*Indicates Parts Included in

Gasket Set, Ref. No. 166.

31

Page 32

TECUMSE H 4 -CY CLE E NGIN E

Ref.

No.

Part

No. Part Name

MODEL NUMBER: V60-70259H

Ref.

No.

Part

No.

Part Name

113

114

115

117

118

119

121

122

123

124

126

127

128

129

131

30588A

27793

28942

30622

31752

650128

30688

27275

650490

8116

32584

32387A

32125

590417

29747A

Spool, Governor

Clip, Conduit

Screw & Lockwasher, Slotted

hex.hd., 10-32 x 3/8

Extension, Blower housing

Decal, Air cleaner

Screw, Fil. slotted hd. Sems,

10-24x1/2

Screw, Hex hd. cap Sems,

1/4-20x1/2

Clip, Hi tension wire retaining

Washer, Belleville

Nut, Hex, 1/2-20

Tank Assy., Fuel (Inch No.

127)

Cap, Fuel

Cup, Starter

Screen, Starter cup

Screw, Hex hd. Sems, cap,

5/16-24 X 3/4

134

137

139

141

142

143

149

159

161

162

163

164

165

166

29774

29716

31398

28670

31345

32629A

31324

28468

31342

650549

610689A

631444

590420

33234

Line, Fuel

Screw, Pan hd. P.C.R. with

lockwasher, 1/4-28 x 7/16

Decal, Instruction

Stud, Drive

Plate, Identification

Housing, Blower

Decal, Name & H.P.

Wire, Ground

Spring, Compression

Screw, Speed adjustment, 5-40

X 7/16 fil. slotted hd. mach.

Magneto

Carburetor

Starter, Rewind

Gasket Set (Incl. items

marked*)

*Indicates Parts Included in

Gasket Set, Ref. No. 166.

32

Page 33

MAGNETO NO. 610689A

Ref.

No.

Part

No.

610689A Magneto

1 30555

2 30551

3 30550

4

5

6 30547A Breaker Assembly

7

8 610408 Nut, Terminal

9 29181

33695

30992 Cam, Breaker

610385 Washer, Terminal

Flywheel

Spring, Breaker box dust cover

Cover, Breaker box dust 14)

Gasket, Dust cover

Screw and Washer Assembly,

Breaker

Part Name

33

Ref.

No.

10

11

13

14

15

16

17

18

19

20

Part

No.

610593

30843

30560A

30554

30548A

30545

30561A

30549

29629

31311

Part Name

Screw, Condenser fastening

Tab, Ground terminal

Coil Assembly (Inch Ref. No.

Wire, Ignition lead

Condenser

Core and Plate Group

Stator Assembly

Felt, Cam wiper

Spring, Coil wedge

Clip, Coil locking

Page 34

Ref.

No.

Part

No.

Part Name

Ref.

No.

631444 Carbxiretor 16

Part

No.

631025

Part Name

Bowl & Drain Assy., Float

1 31834 Shaft & Lever Assy., Throttle (Inch No. 17)

2

631279

3 631036

4 650506 Screw, 4-40 x 3/16 18

5 630766

6 650417

7

630973

8 630739

9 631037

10 *630748

Spring, Throttle return 17 27136A

Shutter, Throttle

Plunger Assy., Drain (Inch No.

18)

*27554 Gasket, Drain plunger

Spring, Idle regulating screw 21 27110

Gasket, Bowl-to-body

Screw, Idle regulating 22 *631026 Adjustment Screw Assy., Main

Shaft & Lever Assy., Choke (Inch Nos. 8, 21, 23 & 30)

Washer, Flat 23 *630740

“O” Ring, Adjustment screw

Shutter, Choke 24 *631078 Screw, Idle adjustment

Plug, Welch 25

*631028 Gasket, Bowl-to-body

11 *631027 Plug, Welch 26 631445 Fitting, Fuel inlet

12 *631021

Inlet Needle, Seat & Clip Assy. 30 630738 Spring, Main adjustment screw

(Inch No. 13)

31 630821 Spring, Choke return

13 631022 Clip, Inlet needle 32 631029 Repair Kit (Incl. items

14

15

631023

*631024 Shaft, Float

Float, Carburetor

marked*)

34

Page 35

REWIND STARTER NO. 590420

Ref.

No.

1 590409

2 590410 Retainer, R.H.

3 590411

4 590148

5 590412

6

Part

No.

590420

590413A

Starter, Rewind

Screw, Retainer

Spring, Brake

Dog, Starter

Spring, R.H. dog

Pulley

Part Name

Ref.

No.

7

8

9

10

11 590459 Pin, Centering

Part

No.

590414 Spring & Keeper Assy.

590415 Housing Assy., Starter

590386 Rope, Starter

590387

Handle Assy., Starter

Part Name

Page 36

owners

How to ORDER Repair Parts

The Model Number will be found on a plate attached to your

mower at the right-hand side of the frame. Always mention the

Model Number when requesting service or repair parts for your

22 INCH HI WHEEL SELF PROPELLED ROTARY MOWER.

manual

MODEL NO.

247.88110

Sears

SERVICE

All parts listed herein may be ordered through SEARS, ROEBUCK

AND CO. or SIMPSONS-SEARS LIMITED. When ordering parts by

mail, selling prices will be furnished on request or parts will be

shipped at prevailing prices and you will be billed accordingly.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING

INFORMATION AS SHOWN IN THIS LIST.

1. The PART NUMBER

2. The PART DESCRIPTION

3. The MODEL NUMBER 247.88110

4. The NAME OF ITEM22 INCH HI WHEEL SELF PROPELLED

ROTARY MOWER

5. ENGINE MODEL NO. V60-70259H

is at

Yoar

SERVICE

wherever Yea

Your Sears merchandise takes on added value when you discover

live or move

that Sears has over 2,000 Service Units throughout the country.

Each is staffed by Sears-trained, professional technicians using

Sears approved parts and methods.

in the U.S.A.

Sold by SEARS, ROEBUCK AJND CO.,

and

SIMPSONS-SEARS LIMITED.

PART NO. 770-4447 PRINTED IN U.S.A. (12-72)

CbicagoJU. 60607

Toronto

UJaA.

Loading...

Loading...