Page 1

OWNER’S

MANUAL

MODEL NO.

247.799620

CRRFTSMflN

9 HORSEPOWER

SELF-PROPELLED

Caution;

Read and Follow

All Safety Rules

and Instructions

Before Operating

This Equipment

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 U.S.A.

CHIPPER-SHREDDER-VACUUM

Assembly

Operation

Customer Responsibilities

Service and Adjustment

Repair Parts

*rinted in U.S.A.

770-0352L 5/96

Page 2

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSONAL

SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE

▲

ATTEMPTING TO OPERATE YOUR POWER CHIPPER-MCUUM. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL- - ^ HEED ITS WARNING.

Your chipper-vacuum vas built to be operated according to the rules for safe operation in

this manual. As with a ny type of power equipment, carelessness or error on the part of the

DANGER: operator can result in serious injury. This unit is capable of amputating fingers and hands

A

and throwing objects. Failure to observe the following safety instructions could result in

serious injury or death.

SAFE OPERATION PRACTICES

A

I. GENERAL OPERATION

Read this owner’s guide carefully in its entirety befo e attempt

ing to assemble this machine. Read, understand, an j follow all

instructions on the machine and in the manuai(s) be’ore opera

tion. Be completely familiar with the controls and the proper use

of the machine before operating it. Keep this manu il in a safe

place for future and regular reference and for order! ig replace

ment parts.

• Your chipper-vacuum is a powerful tool, not a plaything.

Therefore, exercise extreme caution at all times. Ycjr unit has

been designed to perform two jobs; to chip and vacu jm vegeta

tion found in a normal yard. Do not use it for any oth ir purpose.

• Never allow children under 16 to operate the unit, '¡hildren 16

years and older should only operate under close part ntal super

vision. Only responsible individuals who are familial with these

rules of safe operation should be allowed to use your jnit.

• Keep the area of operation clear of all persons, partic ilarly small

children and pets. Stop the engine when they are in the vicinity

of the unit.

• When feeding material into this equipment, be extremely careful

that pieces of metal, rocks, bottles, cans or other fort ign objects

are not included. Personal injury or damage to tl e machine

could result.

• Always wear safety glasses or safety goggles, durin ] operation

and while performing an adjustment or repair, to protect eyes

from foreign objects that may be thrown from the ma :hine.

• Wear sturdy, rough-soled work shoes and close fi ting slacks

and shirt. Shirt and slacks that cover the arms ard legs and

steel-toed shoes are recommended. Do not wear I )ose fitting

clothes or jewelry, and secure hair above shoulder length. They

can be caught in moving parts. Never operate a unit n bare feet,

sandals or sneakers. Wear gloves when feeding ma:erial in the

chipper chute.

• Do not operate the unit while under the influence o alcohol or

drugs.

• Do not over-reach. Keep proper footing and balance it all times.

• Never place your hands or any part of your body or c othing near

or under rotating parts. Keep clear of the discharge opening at

all times Never insert your hands or any part of ynur body or

clothing into the nozzle, chipper chute or discharge opening as

the rotating impeller can cause serious injury.

If it is necessary for any reason to unclog the feed ir

charge openings or to inspect or repair any part of 1

where a moving part can come in contact with yc

clothing, stop the machine, allow it to cool, disconne

plug wire from the spark plug and move it away fro

plug before attempting to unclog, inspect or repair.

Never operate unit without vacuum bag and disci

properly affixed to unit. Large zippered end of b

closed to prevent objects from being blown out.

take or disne machine

ur body or

:t the spark

n the spark

arge chute

ig must be

• Never operate unit without either the inlet nozzle or optional

hose attachment properly affixed to unit. These devices shield

the operator from accidental contact with the rotating impeller.

Never attempt to convert the unit from nozzle to hose mode or

vice versa with the engine running.

• Never attempt to remove or empty vacuum bag when engine is

running. Shut the engine off and wait for the impeller to come to

a complete stop before removing the bag. The impeller contin

ues to rotate for a few seconds after the engine is shut off.

Never place any part of the body in the impeller area until you

are sure the impeller has stopped rotating.

• Keep all guards and safety devices in place and operating prop

erly.

• Do not allow an accumulation of processed material to build up

in the discharge area as this will prevent proper discharge and

can result in kick-back from the chipper chute.

• Keep your face and body back from chipper chute to avoid acci

dental bounce back of any material.

• If the cutting mechanism strikes a foreign object or if your

machine should start making an unusual noise or vibration,

immediately stop the engine, disconnect the spark plug wire and

move the wire away from the spark plug. Allow the machine to

stop and take the following steps.

• Inspect for damage

• Repair or replace any damaged parts.

• Check for any loose parts and tighten to assure continued

safe operation.

• Muffler and engine become hot and can cause a burn. Do not

touch.

• Do not allow leaves or other debris to build up on engine’s muf

fler. The debris could ignite and cause a fire.

• Do not operate engine if air cleaner or cover over carburetor airintake is removed, except for adjustment. Removal of such

parts could create a fire hazard.

Jl. CHILDREN

Tragic accidents can occur if the operator is not alert to the pres

ence of small children. Children are often attracted to the chipping

and vacuuming activity. Never assume that children will remain

where you last saw them.

• Keep children out of the work area and under the watchful eye of

a responsible adult other than the operator.

• Be alert and turn the unit off if a child enters the area.

• Never allow children under the age of 16 to operate the chippervacuum.

III. SERVICE

Use extreme care in handling gasoline and other fuels. They are

extremely flammable and the vapors are explosive.

• Store fuel and oil in approved containers, away from heat

and open flame, and out of the reach of children.

Page 3

• Check and add fuel before starting the engine. Never

remove gas cap or add fuel while the engine is running.

Allow engine to cool at least two minutes before refueling.

• Replace gasoline cap securely and wipe off any spilled

gasoline before starting the engine as it may cause a fire or

explosion.

• Extinguish all cigarettes, cigars, pipes and other sources of

ignition.

• Never refuel unit indoors because flammable vapors will

accumulate in the area.

• Never store the machine or fuel container inside where

there is an open flame or spark such as a gas hot water

heater, clothes dryer or furnace.

• Never run your machine in an enclosed area as the exhaust from

the engine contains carbon monoxide, which is a odorless,

tasteless and deadly poisonous gas.

• To reduce fire hazard, keep engine and muffler free of leaves,

grass, and other debris build-up. Clean up fuel and oil spillage.

Allow unit to cool at least 5 minutes before storing.

• Before cleaning, repairing, or inspecting, make certain the

impeller and all moving parts have stopped. Disconnect the

spark plug wire and keep wire away from spark plug to prevent

accidental starting. Do not use flammable solutions to clean air

filter.

Keep all nuts, bolts, and screws tight to be sure the equipment is

in safe working condition.

Never tamper with safety devices. Check their proper operation

regularly.

After striking a foreign object, immediately stop the engine, dis

connect the spark plug wire from the spark plug, and thoroughly

inspect the unit for any damage. Repair damage before starting

and operating unit.

Do not alter or tamper with the engine’s governor setting. The

governor controls the maximum safe operating speed of the

engine. Over-speeding the engine is dangerous and will cause

damage to the engine and to other moving parts of the machine.

Check the vacuum bag frequently for wear. Replace if worn or

damaged.

Keep vacuum bag free of debris when not in use.

OWNER’S

MANUAL

SAFETY LABEL

A

Restrict the use of this power machine to persons who read,

understand and follow the warnings and instructions in this

manual and on the machine.

WARNING — YOUR RESPONSIBILITY

Page 4

CONGRATULATIONS on your purchase of a Sears

Craftsman Chipper-Vacuum. It has been designed,

engineered and manufactured to give you the best possible

dependability and performance.

Should you experience any problem you cant ot easily

remedy, please contact your nearest Sears Servit e Center/

Department in the United States, We have competent, welltrained technicians and the proper tools to service or repair

this unit.

Please read and retain this manual. The instru étions will

enable you to assemble and maintain your chippor-vacuum

properly. Always observe the “SAFETY RULES.”

MODEL

NUMBER.

SERIAL

NUMBER.

DATE OF

PURCHASE.

247.799620

PRODUCT SPECIFICATIONS

Horsepower: 9.0

Engine Oii Capacity:

API Classification SF, SG or SH

Fuel Capacity:

Approximately 1 Gallon

SAE 30

(20 Ounces)

(Unleaded)

Spark Piug (Gap .030 in.):

Champion

J-8C (or

Equivalent)

Tire Pressure:

24 p.s.i.

MAINTENANCE AGREEMENT

THE MODEL AND SERIAL NUMBERS WILL BE FOUND

ON A LABEL ATTACHED TO THE FRAME DF THE

CHIPPER-VACUUM.

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, taring for

and using your chipper-vacuum.

• Follow the instructions under “Customer Respon

sibilities” and “Storage” sections of this Owner’s

Manual.

A Sears Maintenance Agreement is available on this

product. Contact your nearest Sears store for details.

WARNING: This unit is equipped with an internai combus

tion engine and should not be used on or near any unim

proved forest-covered, brush-covered or grass-covered land

unless the engine’s exhaust system is equipped with a

spark arrester meeting applicable local or state laws (if any).

If a spark arrester Is used. It should be maintained in effec

tive working order by the operator.

In the State of California the above is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands. A spark arrester for the muffler is available

through your nearest Sears Authorized Service Center (See

the REPAIR PARTS section of this manual.)

WARRANTY

FULL ONE YEAR WARRAMTY ON CRAFTSMAN GAS CHIPPER-VACUUM

For one year from the date of purchase, when this Craftsman chipper-vacuum is maintained, lubricated, and

tuned up according to the operating and nr aintenance instructions in the operator’s manual. Sears will repair,

free of charge, any defect in material or workmanship.

This warranty excludes the chipper blades flails, air cleaners, spark plugs, catcher bags and tires, which are

expendable parts and become worn during normal use.

If this chipper-shredder is used for comme cial or rental purposes, this warranty applies for only 30 days from

the date of purchase.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER IN THE

UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED

STATES.

This warranty gives you specific legai rights, and you may also have other rights which vary from state to state.

SEARS ROEBUCK AND CO., DEPT. 817WA, HOFFMAN ESTATES, IL 60179

Page 5

TABLE OF CONTENTS

SAFETY RULES

PRODUCT SPECIFICATIONS

MAINTENANCE AGREEMENT............................4

CUSTOMER RESPONSIBILITIES..............4, 12, 13

WARRANTY

INDEX

ACCESSORIES

ASSEMBLY

...................................................................

.................................................

.............................

.........................................................

....................................................

.......................................................

2, 3

4

4

5

5

6-8

INDEX

Accessories

Adjustments:

Carburetor............

Clutch Cable

Engine Speed

Shift Rod

Assembly Instructions.

Catcher Bag

Controls

Customer Responsibilities.

Engine:

Lubrication

Maintenance

Starting

Stopping

Storage

Fuel.

Lubrication.

.............

........

......

..............

...................

..........................

.................

...............

.......................

.....................

.......................

..18

....

...18

...17

.6-8

...........

8, 12

...........

.4, 13, 14

I

......

13

.13, 14

.......

12

...9, 12

......

18

.11

.13

OPERATION

CUSTOMER RESPONSIBILITIES

STORAGE...........................................................14

SERVICE AND ADJUSTMENT

TROUBLE SHOOTING.......................................18

PARTS ORDERING/SERVICE...........................18

REPAIR PARTS—CHIPPER-VACUUM

REPAIR PARTS—ENGINE...........................26-29

Maintenance:

Agreement .......

Schedule

8

9

Engine

Chipper-Vacuum

Oil

.........................

Operating Tips

Repair/Replacement Parts .

Responsibilities, Customer.

Safety Rules ..

Sharpening ....

Spark Plug

Specifications.

Storage

Table of Contents

Trouble Shooting.

Unclogging.

Unpacking..

Warranty ................................................................4

...................................................

.....................

M

..........

..............

.....

R

...

........

U

W

.................

.......

.....

.4, 13, 14

........

....

..........

..........

..........

8-11

12, 13

14-17

19-25

........

......

13

.13, 14

.13, 18

.13

.10

20-35

2, 3

15, 16

14

4

18

...5

.19

.15

...6

4

ACCESSORIES

These accessories were available when the chipper-vacuum was purchased. They are also available at most

Sears retail outlets, catalog and service centers. Most Sears stores can order repair parts for you, when you

provide the model number of your chipper-vacuum.

Spark

Plug

Air

Filter

ENGINE

Muffler Engine

Oil

Gas Can

Stabilizer

CHIPPER-VACUUM

Page 6

ASSEMEILY INSTRUCTIONS

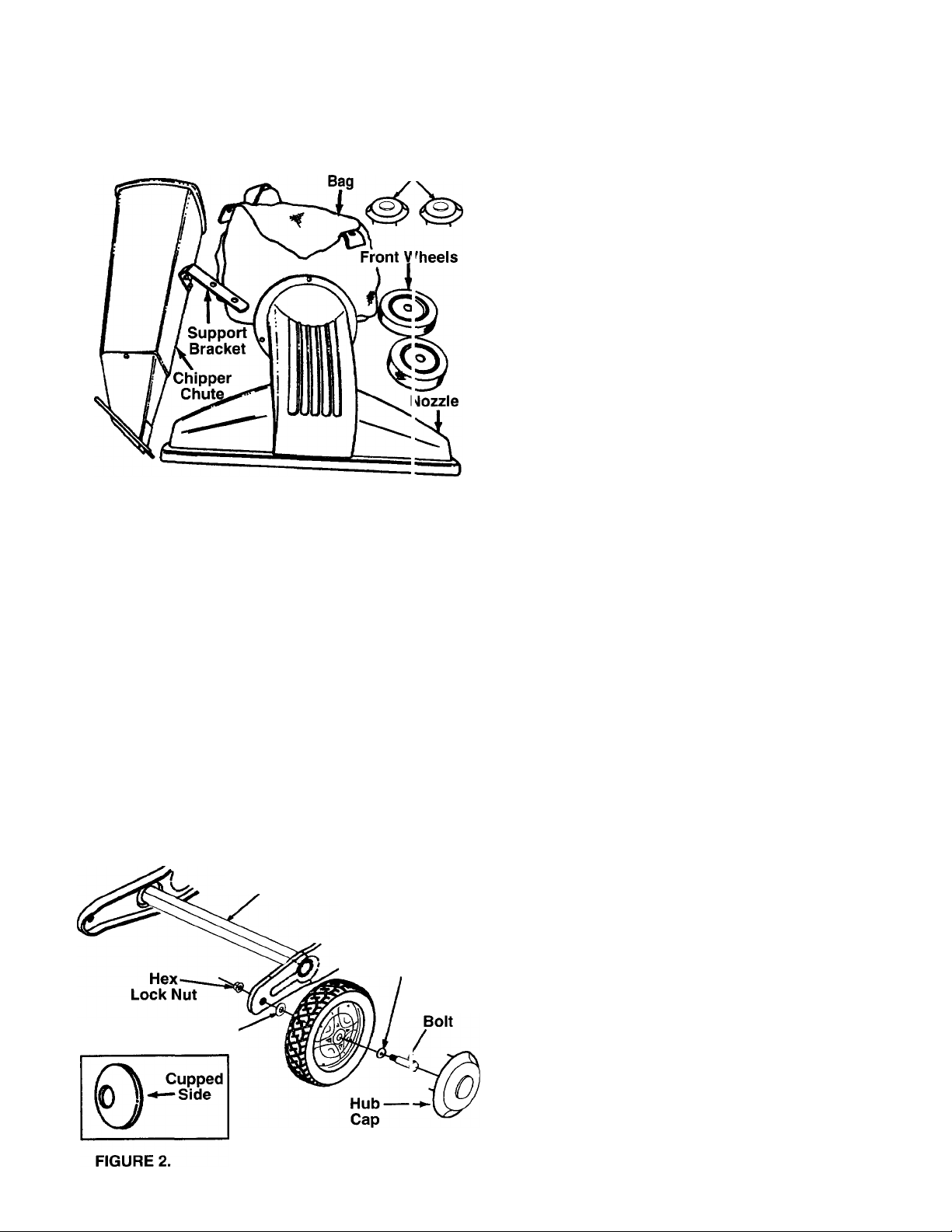

FIGURE 1.

Hub Caps

LOOSE PARTS IN CARTON

(2) Front Wheels

(2) Hub Caps

(1) Nozzle Assembly

(1) Chipper Chute

(1) Support Bracket

tNot Shown

IMPORTANT: This unit is shipped WITHOUT GASO

LINE or OIL in the engine. After assembly, see opera

tion section of this manual for proper fuel and engine

oil recommendations.

NOTE: To determine right and left hand sides of your

chipper-vacuum, stand behind and face the unit

(Refer to figure 7).

Your chipper-vacuum has been completely assem

bled at the factory except for the front wheels, hub

caps, nozzle, chipper chute, support bracket and bag.

A pair of safety glasses and bottle of oil are also

included in the carton.

(See Figure 1)

(1) Bag

(1) Shift Knob

(1) Tamper Plugt

(1) Safety Glassest

(1) Bottle of Oi If

REMOVING CHIPPER-VACUUM FROM CARTON

Cut the corners of the carton. Remove all packing

inserts and loose parts. Push down on handle to lift

front of chipper-vacuum, and roll chipper-vacuum out

of the carton. Make certain all parts and literature

have been removed before the carton is discarded.

Wheel Bracket

Cupped Washer.

Wave

Washer

Shoulder

TOOLS REQUIRED FOR ASSEMBLY

(1) 3/4" Open End Wrench

(2) 1/2" or Adjustable Wrenches

Ò) 9/16" Wrench

(1) Funnel

Ò) Set of Pliers

(1) 7/16" Wrench

SETTING-UP YOUR CHIPPER-VACUUM

ATTACHING THE FRONT WHEELS

• Tilt unit backward so that it rests on the handle

(place a piece of the carton under handle to avoid

scratches). Remove the cardboard packing

material around the wheel brackets.

• Remove the hex lock nuts and shoulder bolts from

the front of the wheel brackets. See figure 2.

• Place wave washer on shoulder bolt. Insert

shoulder bolt through wheel, with the head of the

shoulder bolt through the flat side of the wheel.

• Assemble wheel to outside of wheel bracket.

Secure with cupped washer and hex lock nut.

Tighten the nut. The cupped side of washer goes

on end of shoulder bolt between the wheel and the

bracket.

Page 7

• Align the four tabs on the hub caps with the four

holes in the wheel. Press in each tab until it locks in

place. The hub cap edges must be flush with the

wheel rim when installed properly.

• Push the hub cap onto the wheel so that the edges

of the hub cap flush with the rim of the wheel.

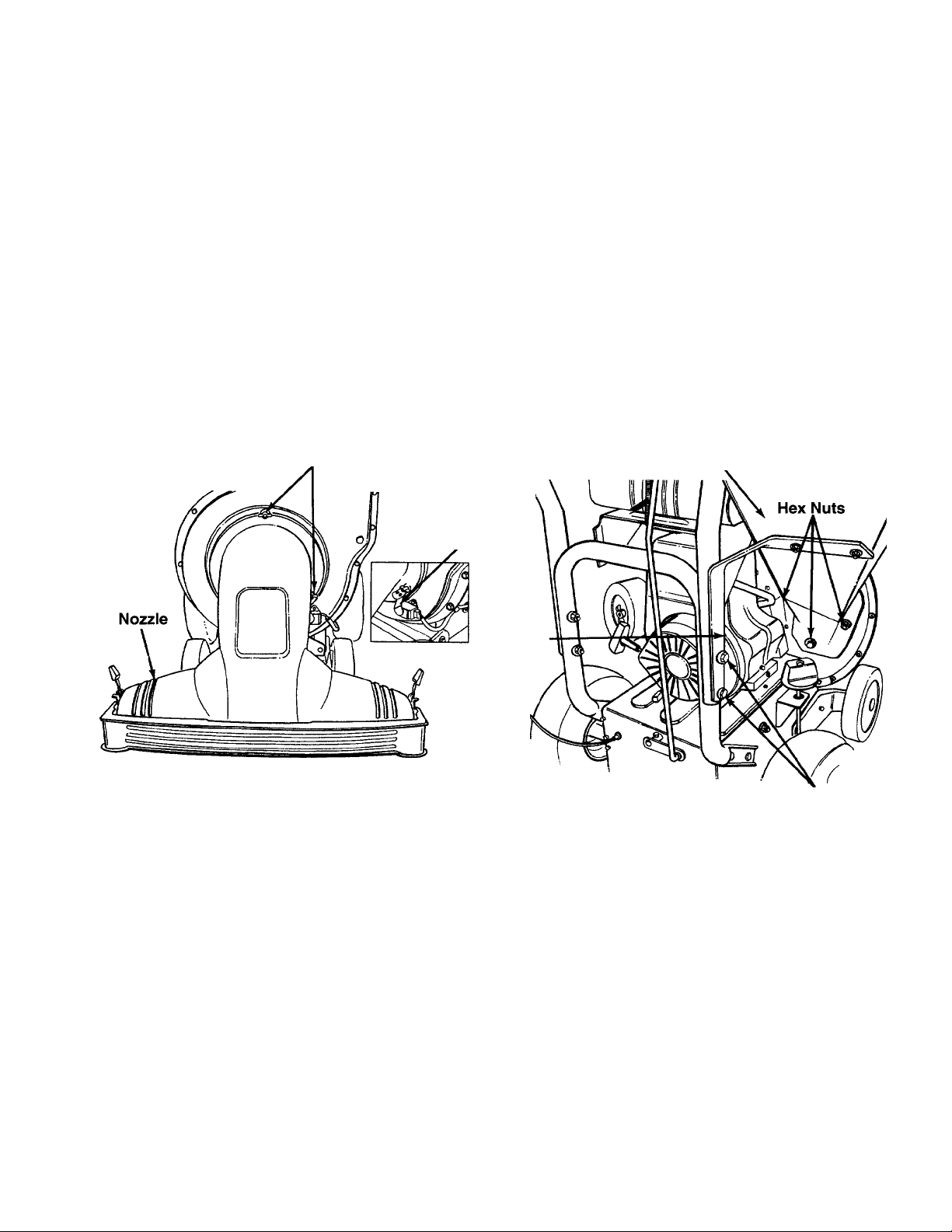

ATTACHING THE NOZZLE (See figure 3)

• Remove the three wing nuts from the front of the

chipper-vacuum. Place the nozzle in position over

the three weld studs. Secure with the wing nuts just

removed.

NOTE: The metal tab in the nozzle must depress the

safety switch on the front of the chipper-vacuum or

the engine will not start.

• Set unit in upright position.

• Remove the two hex bolts, flat washers, and nuts

which are attached to the support bracket. See

figure 4.

• Use this hardware to attach the support bracket to

the bottom of the chipper chute loosely. Be sure to

fix the hardware so that the heads of the hex bolts

and washers are inside the chipper chute.

• Place the support bracket over the two bolts in the

handle. Push up the chipper chute in order to better

align the holes in the support bracket with the bolts

in the handle. Put the nuts back on.

• Tighten all hardware securely first on the chipper

chute, then on the support bracket, and finally on

the handle.

Wing Nuts

Metal Tab

Support

Bracket

FIGURE 3.

ATTACHING THE CHIPPER CHUTE AND

SUPPORT BRACKET

• Remove the two hex lock nuts from the hex bolts

which secure the right side of the upper handle to

the lower handle. Leave the bolts in place. See

figure 4.

• Remove the three cupped washers and hex nuts

from the weld studs. You will find these weld studs

beside the opening on the right side of the chipper

vacuum. See figure 4.

• Place the chipper chute over the weld studs.

Secure with cupped washers and hex nuts that you

earlier removed. See figure 4. Do not tighten it all

the way.

NOTE: Cupped side of the washer goes against the

chipper chute. See figure 2 inset to find out the

cupped side of a washer.

Chipper

Chute

Hex Lock Nuts

FIGURE 4.—View from the operator’s position

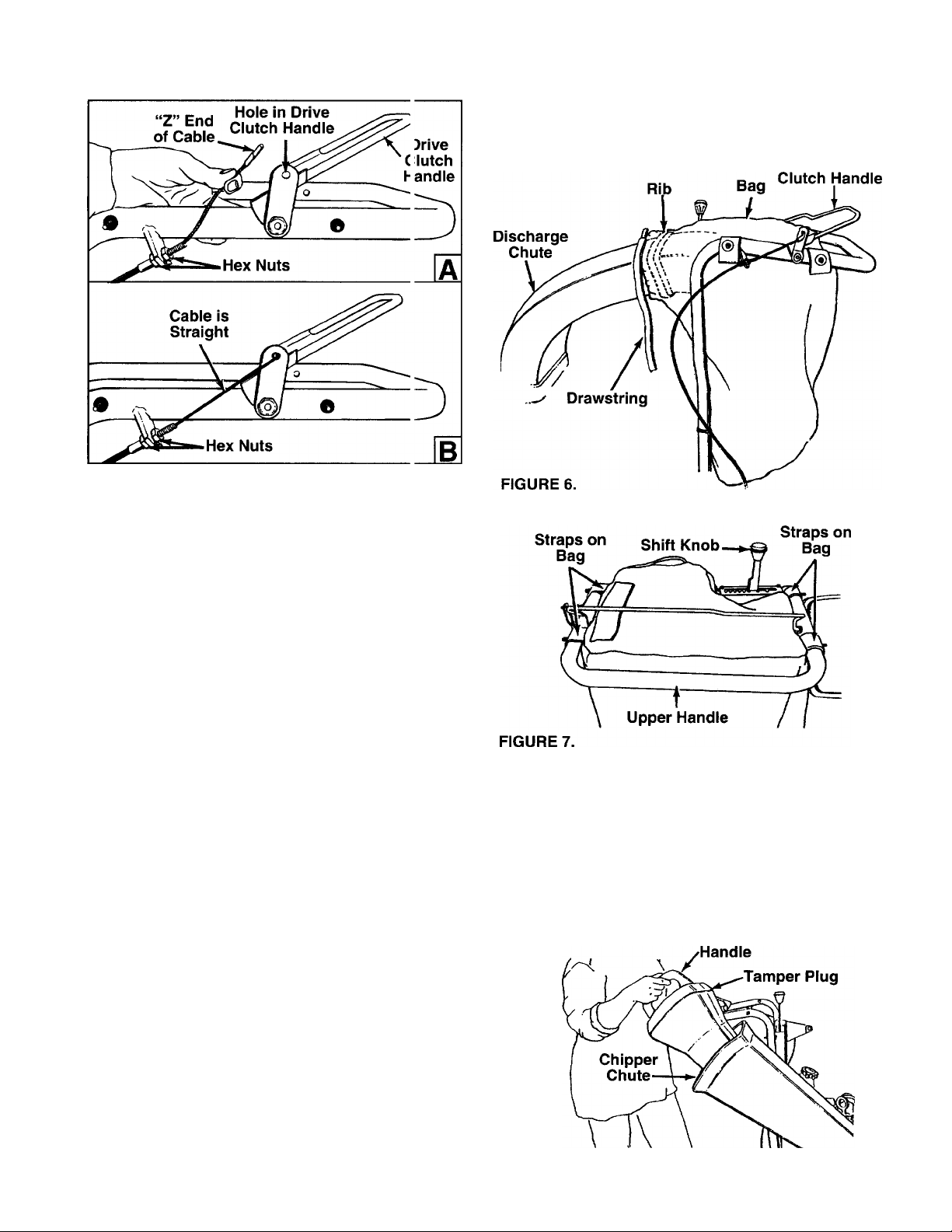

ATTACHING THE CLUTCH CABLE (See figure 5)

The clutch cable has been assembled at the factory.

You will have to attach the clutch cable to the drive

clutch handle.

• Loosen the hex nuts at the cable bracket and

remove.

• Holding the drive clutch handle up, hook the “Z”

end of the cable into the drive clutch handle from

the outside to the inside. See figure 5A. You will

need a pair of pliers for this.

• Next keeping the clutch handle up, tighten the back

hex nut approximately halfway with no slack in the

cable when it is attached and the “Z” end is in

place.

Page 8

• Squeeze the clamp on the drawstring and pull the

FIGURE 5.

ADJUSTING THE CLUTCH CABLE

• While adjusting the hex nuts at the cable t racket,

make sure that there is no slack in the cable, but

the cable is not tight. See figure 5B. Do not over

tighten the cable.

To check the clutch adjustment, proceed as fol ows.

• Push the chipper-vacuum backward and lorward

with the drive clutch handle released. It should

move freely. If it does not, loosen both hex nuts at

the cable bracket. See figure 5B. Turn botlom nut

counterclockwise to loosen the cable.

• Holding against the upper handle, engage tf e drive

clutch handle and try to push the unit backward

and forward. The wheels should lock up.

• If the wheels do not lock up, loosen both h jx nuts

INSERTING THE TAMPER PLUG

The handle of the tamper plug must be vertical.

• Match the angle of the tamper plug with the angle

at the cable bracket. Turn front nut clock vise to

tighten the cable.

• Recheck the adjustment. Tighten both the h 3X nuts

when you have adjusted it correctly.

• Insert the tamper plug into the chipper chute.

NOTE: Tamper plug should remain in the chipper

chute whenever the chute is not in use.

INSTALLING THE SHIFT KNOB

• Thread the shift knob onto the end of tte shift

lever.

ATTACHING THE BAG

• Place bag inside the handle assembly. £ lip the

opening on the bag over the discharge chute. Make

sure that it is over the rib on the discharge chute.

See figure 6.

• Place the four straps on top of the bag o rer the

upper handle, hooking them on the studs. See fig

ure 7. Make sure that the bag goes under tfe drive

clutch handle.

FIGURE 8.

drawstring tight. Release the clamp.

Drive

of the chipper chute. See figure 8.

Page 9

OPERATION

OPERATING CONTROLS

SHIFT LEVER—The shift lever determines ground

speed of your unit. It may be placed in one of eight

positions. Of these eight, six positions are to go for

ward, and two positions are to go in reverse.

Forward: Six speeds according to the six positions of

the shift lever are available; position one is the slow

est, and position six is the fastest.

Reverse: Two speeds according to the two positions

of the shift lever are available; position R (extreme

right) is the faster of the two.

DRIVE CLUTCH HANDLE (BAIL)—If you squeeze

the drive clutch handle against the upper handle, you

will engage the wheel drive. If you release the drive

clutch handle, you will stop the wheel drive.

CHOKE LEVER—This chipper-shredder unit is

equipped with a choke lever which is used to start a

cold engine.

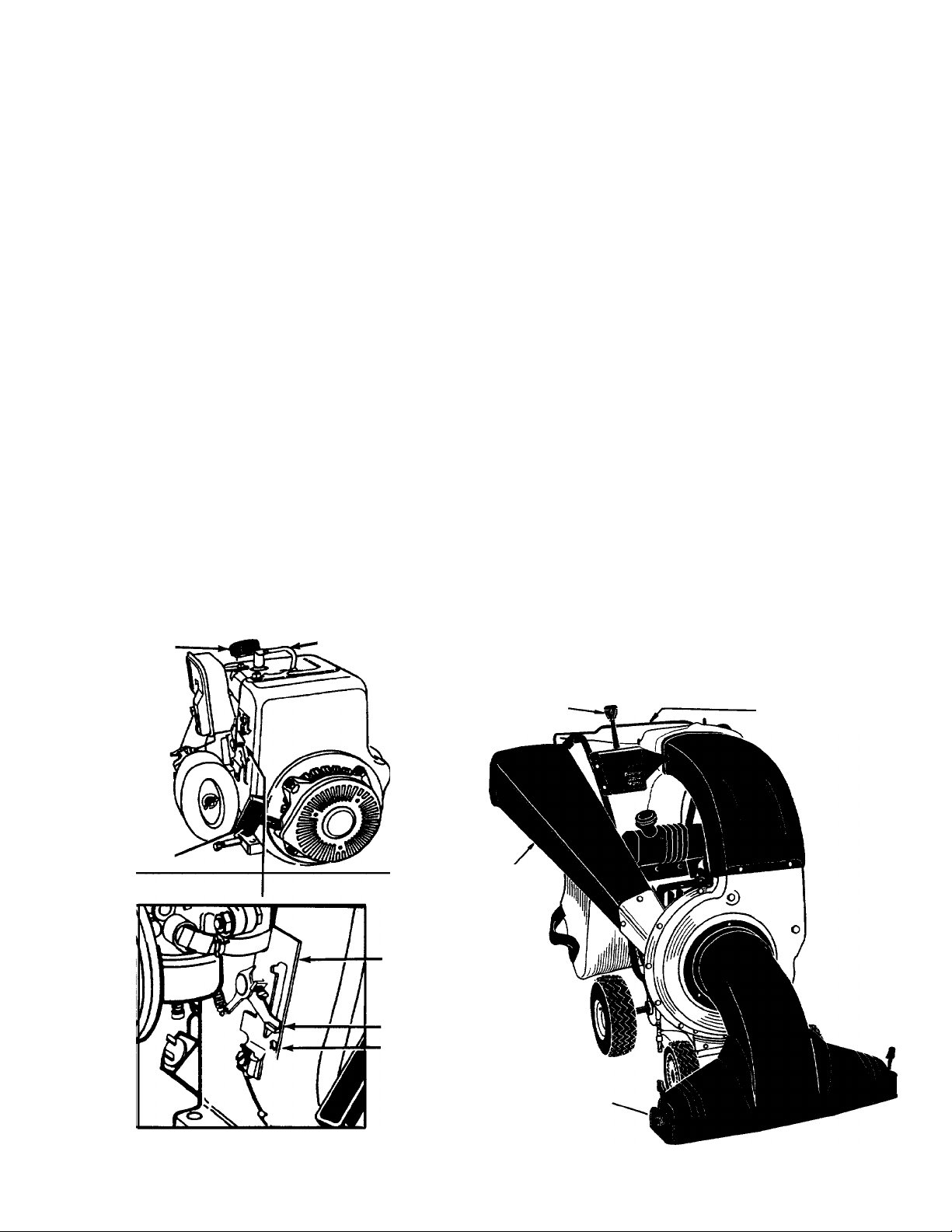

(See Figure 9)

STARTER HANDLE—This is used to start the engine

manually.

THROTTLE CONTROL—This controls the engine

speed and stops the engine. It is located right above

the starter handle.

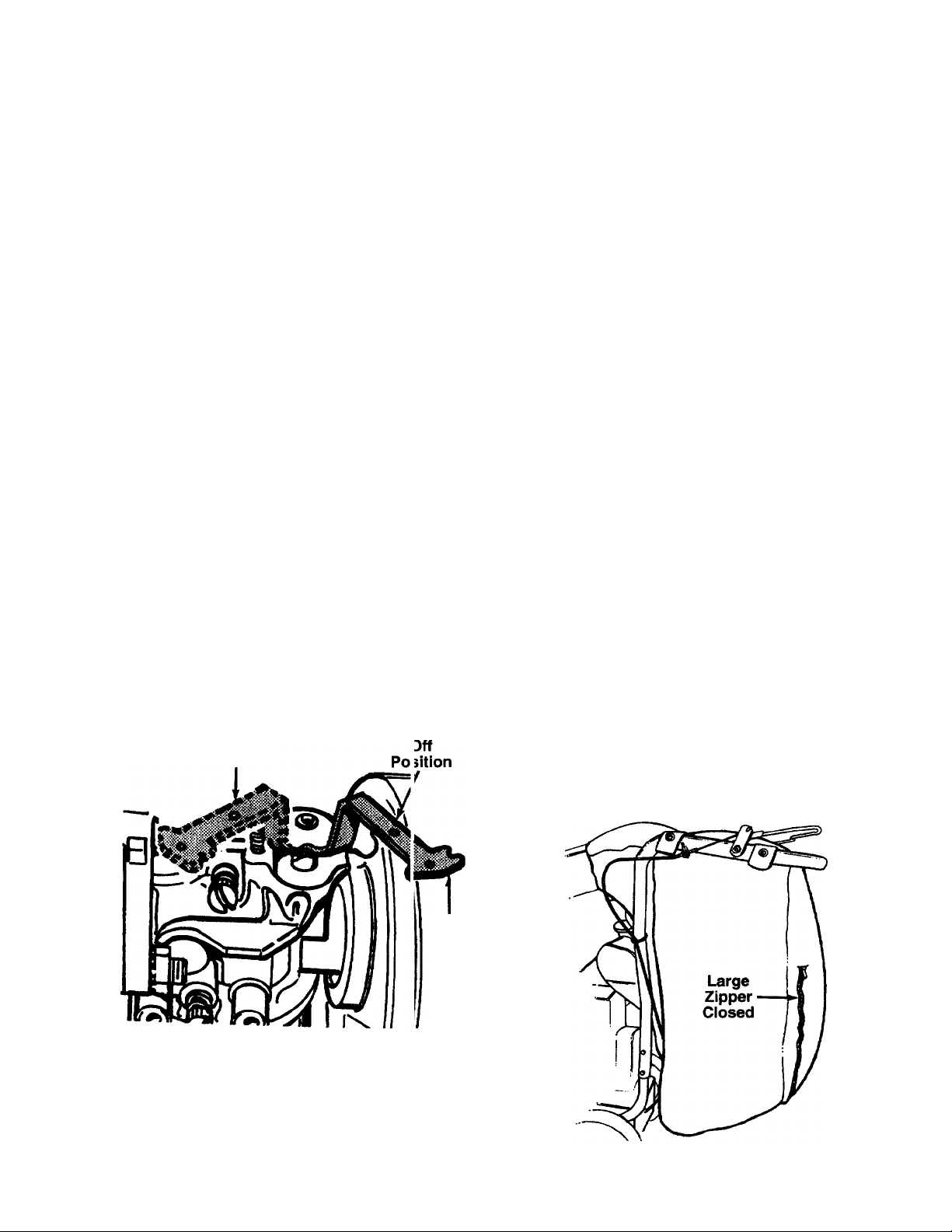

TO STOP THE ENGINE

• Move throttle control lever to STOP position. See

figure 9.

• Disconnect spark plug wire and move away from

the spark plug to prevent accidental starting while

the equipment is unattended.

Oil Fill-

Dipstick

Choke

Lever ■

Starter

Handle

Spark Plug

Wire and Boot

Fast

■Throttle

Stop

Shift

Lever

Chipper

Chute

Drive Clutch

Handle

FIGURE 9.

Nozzle

Page 10

BEFORE USING YOUR CHIPPER-VACUUM

THIS MANUAL ALWAYS BE CAREFUL

The operation of any chipp ir-vacuum can result in foreign objects being thrown into the eyes, which

can damage your eyes se^ erely.

shieids before chipping, nr while performing any adjustments or repairs.

Vision Safety Mask for over spectacles or standard glasses available at Sears Retail Stores.

REFER TO THE “SAFETY RULES” AS SHOWN ON PAGE 2 OF

Always wear the safety glasses provided with this unit or eye

USING THE CHIPPER-VACUUM

NOTE: Your chipper-vacuum unit has a safely switch

at the front of the housing. The nozzle or hose attach

ment must be in place on the chipper-vacuun before

the engine can be started.

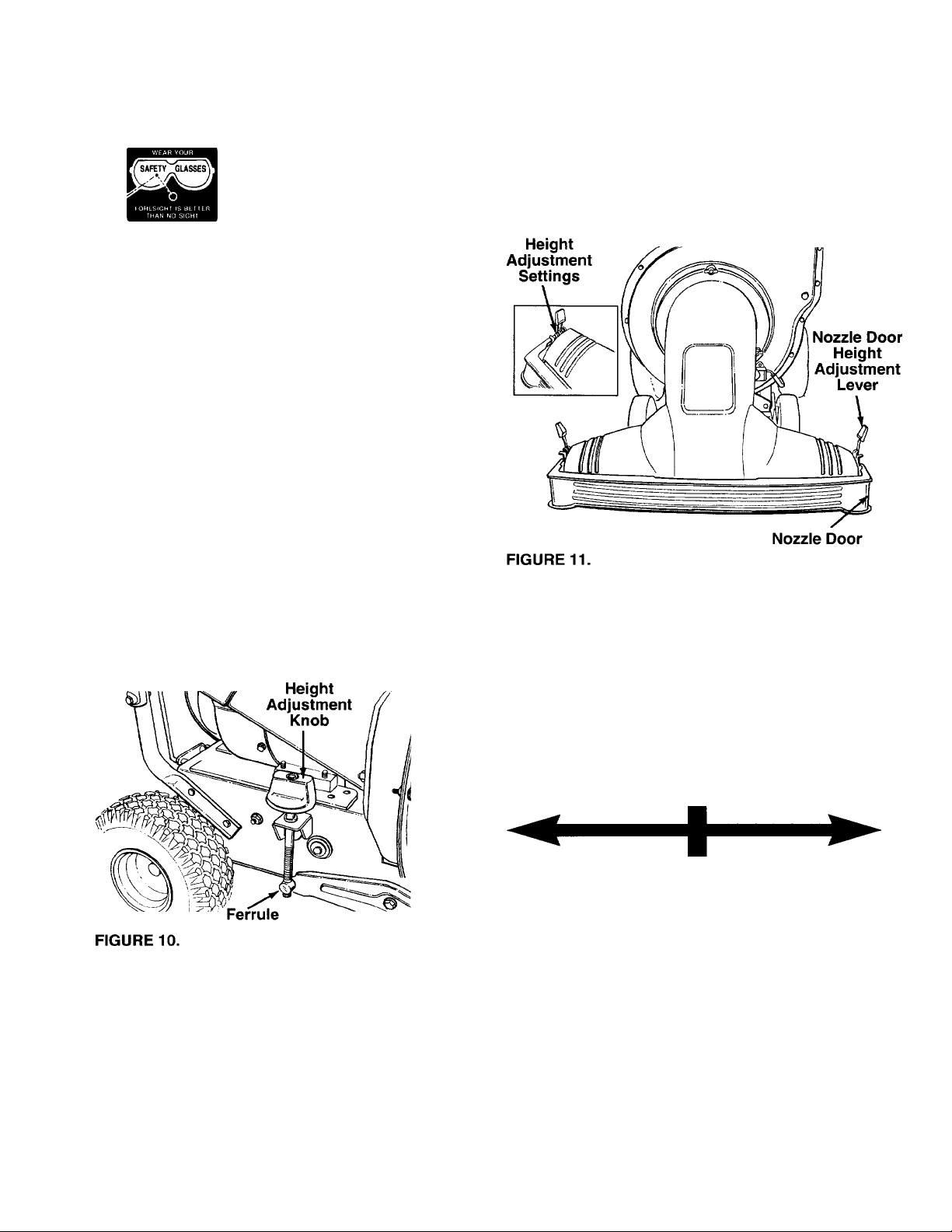

TO ADJUST THE NOZZLE HEIGHT

A. The height adjustment knob is located on the right

hand side of the chipper-vacuum. See figu e 10 for

its actual location. Adjusting the height here will

also raise or lower the height of the no2zle. For

further adjustment of the nozzle height t( i control

the flow, see the next section.

• Turn the knob clockwise to raise the wheels and

adjust the height of the unit.

• Turn the knob counterclockwise to lower th-j unit.

NOTE: Do not turn the knob too far to preven: the rod

from coming out of the ferrule.

We recommend Wide

NOTE: In general, raise the nozzle height to vacuum

a thick layer of leaves; lower the nozzle height for

smoother surfaces.

B. Your chipper-vacuum unit has a noz2le door

height adjustment lever with three set ings on

each side of the nozzle door. See figure ' 1 for its

actual location. The nozzle door height h is to be

adjusted according to the conditions.

• Slide the height adjustment lever forward Dr back

ward for adjusting the nozzle door upv ards or

downwards.

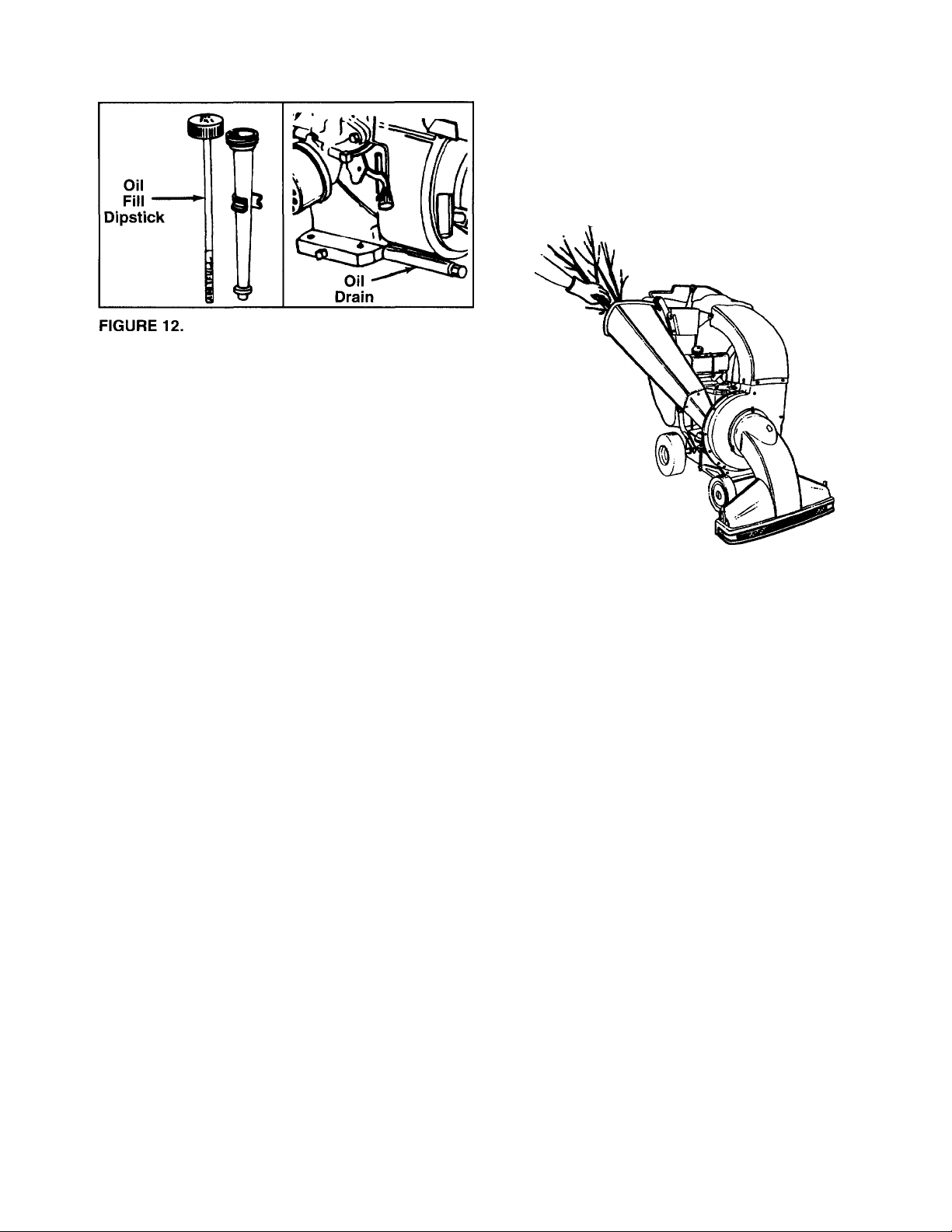

GAS AND OIL FILL-UP

OIL

Only use high quality detergent oil rated with API

service classification SF, SG or SH. Select the oil’s

viscosity grade according to your expected operating

temperature.

Colder

5W30

NOTE: Although multi-viscosity oils (5W30, 10W30,

etc.) improve starting in cold weather, these multi

viscosity oils will result in increased oil consumption

when used above 32°F. Check your oil level more

frequently to avoid possible engine damage from

running low on oil.

• Use engine oil provided. Remove oil fill dipstick.

See figure 12. With chipper-vacuum level, use a

funnel to fill engine with oil to FULL mark on dip

stick. Capacity is approximately 20 ounces. Be

careful not to overfill. Oil bottle provided contains

20 oz. of oil. Tilt chipper-vacuum toward the left

(from behind the hopper), then re-level. Check oil

level. Refill to FULL mark on dipstick if necessary.

Replace dipstick and tighten.

32“F Warmer

SAE 30

10

Page 11

GAS

Remove fuel cap and till fuel tank with approxi

mately 1 gallon of clean, fresh, lead-free grade

automotive gasoline. DO NOT use Ethyl or high

octane gasoline. Be certain container is clean and

free from rust or foreign particles. Never use gaso

line that may be stale from long periods of storage

in the container. Replace fuel cap.

WARNING: DO NOT FILL CLOSER THAN

1/2 INCH OF TOP OF FUEL TANK TO

A

Check the fuel level periodically to avoid running out

of gasoline while operating the chipper-vacuum. If the

unit runs out of gas as it is chipping, it may be neces

sary to unclog the unit before it can be restarted.

Refer to “Removing the Flail Screen” in SERVICE

AND ADJUSTMENT section.

PREVENT SPILLS AND TO ALLOW FOR

FUEL EXPANSION. IF GASOLINE IS

ACCIDENTLY SPILLED, MOVE CHIPPERVACUUM AWAY FROM AREA OF SPILL.

AVOID CREATING ANY SOURCE OF

IGNITION UNTIL GASOLINE VAPORS

HAVE DISAPPEARED.

USING THE CHIPPER CHUTE

NOTE: Do not try to chip any material other than veg

etation like branches, leaves, twigs, etc., in a normal

yard. Such materials of up to 3" diameter may be fed

into the chipper chute. See figure 13.

FIGURE 13.

WARNING: DO NOT FEED ANY MATERI

AL MORE THAN 3" DIAMETER

▲

VEGETATION INTO THE CHUTE. PER

SONAL INJURY AND/OR DAMAGE TO

THE UNIT COULD RESULT IF YOU TRY

TO FEED ANY MATERIAL OTHER THAN

SPECIFIED HERE.

If necessary, use the tamper plug to push the

material into the chipper chute. See figure 8 for the

location of the tamper plug.

Place tamper plug inside the chute when not in use

to deaden the noise.

WARNING: EXPERIENCE INDICATES THAT ALCO

HOL BLENDED FUELS (CALLED GASOHOL OR

USING ETHANOL OR METHANOL) CAN ATTRACT

MOISTURE WHICH LEADS TO SEPARATION AND

FORMATION OF ACIDS DURING STORAGE.

ACIDIC GAS CAN DAMAGE THE FUEL SYSTEM

OF AN ENGINE WHILE IN STORAGE. TO AVOID

ENGINE PROBLEMS, THE FUEL SYSTEM

SHOULD BE EMPTIED OR TREATED WITH FUEL

STABILIZER BEFORE STORAGE FOR 30 DAYS

OR LONGER. USE FRESH FUEL NEXT SEASON.

SEE “STORAGE” SECTION FOR ADDITIONAL

INFORMATION.

NEVER USE ENGINE OR CARBURETOR CLEAN

ER PRODUCTS IN THE FUEL TANK OR PERMA

NENT DAMAGE MAY OCCUR.

WARNING: NEVER PLACE

A

For best performance, keep the chipper blades

sharp.

If the discharged material starts to become stringy,

or if the rate of discharge slows down considerably,

the chipper blades may have become dull. To

sharpen or replace the blade, refer to Service and

Adjustment section.

If the flail screen, located inside the housing in the

discharge area, becomes clogged, remove the

screen and clean. For instructions on cleaning the

screen, refer to the Service and Adjustment sec

tion.

INSIDE THE CHIPPER CHUTE.

HANDS

11

Page 12

TO START THE ENGINE

IMPORTANT: IF YOUR UNIT SHOWS ANY 5IGN OF

MOTION WITH THE CLUTCH HANDLE DISEN

GAGED, SHUT THE ENGINE OFF IMMECIATELY.

READJUST FOLLOWING INSTRUCTIONS FOR

"FINAL ADJUSTMENT” IN THE ASSEMBLY

SECTION OF THIS OWNER’S GUIDE.

WARNING: MAKE SURE THAT NO ONE

OTHER THAN THE OPERATOR IS

A

• Attach spark plug wire and rubber boot to spark

plug if necessary. See figure 9 for location,

• Place the throttle control lever in FAST poi ition.

• Move choke lever to full choke position as in figure

• Place one foot on the left rear wheel to pr event the

• Grasp starter handle and pull rope out slowly until

engine reaches start of compression c^cle. The

STANDING NEAR THE CHIPPERVACUUM UNIT WHILE STARTING OR

OPERATING.

DO NOT OPERATE THIS UNIT UNLESS

THE NOZZLE, DISCHARGE CHUTE, AND

THE BAG HAVE BEEN PROPERLY

INSTALLED.

14.

unit from skidding while starting.

rope will pull slightly harder at this point, Let the

rope rewind slowly.

• Pull the rope with a rapid, continuous, full arm

stroke.

• Keep a firm grip on the starter handle. Let the rope

rewind slowly. Do not let the starter handle snap

back against the starter.

• Repeat until engine cranks up. When the engine

starts, move the choke lever halfway between

CHOKE and OFF.

• Move throttle control to IDLE position for a few min

utes to warm up the engine. Move it back when

running.

• Move the choke lever to OFF position as the

engine warms up.

NOTE: To idle smoothly, a new engine may require 3

to 5 minutes of running at above the slow idle speed.

The idle speed has been adjusted for proper running

after this break-in period.

TO STOP ENGINE

• Move throttle control lever to STOP position.

• Disconnect spark plug wire and move away from

spark plug to prevent accidental starting while

equipment is unattended.

TO EMPTY BAG

Open the large zipper on the bag to empty the bag.

See figure 15. Be certain the zipper is ciosed when

operating the unit.

Fuli Choke

Position

Choke

Lever

FiGURE 14.

NOTE: While the engine is reaching the con ipression

cycle, you may hear a noise. This noise is caused by

the flails and fingers falling into place and i s normal.

This noise will continue till impeller reaches full speed.

FIGURE 15.

12

Page 13

CUSTOMER RESPONSIBILITIES

GENERAL RECOMMENDATIONS

WARNING: ALWAYS STOP THE ENGINE

AND DISCONNECT THE SPARK PLUG

A

• Periodically check all fasteners and be sure they

are tight.

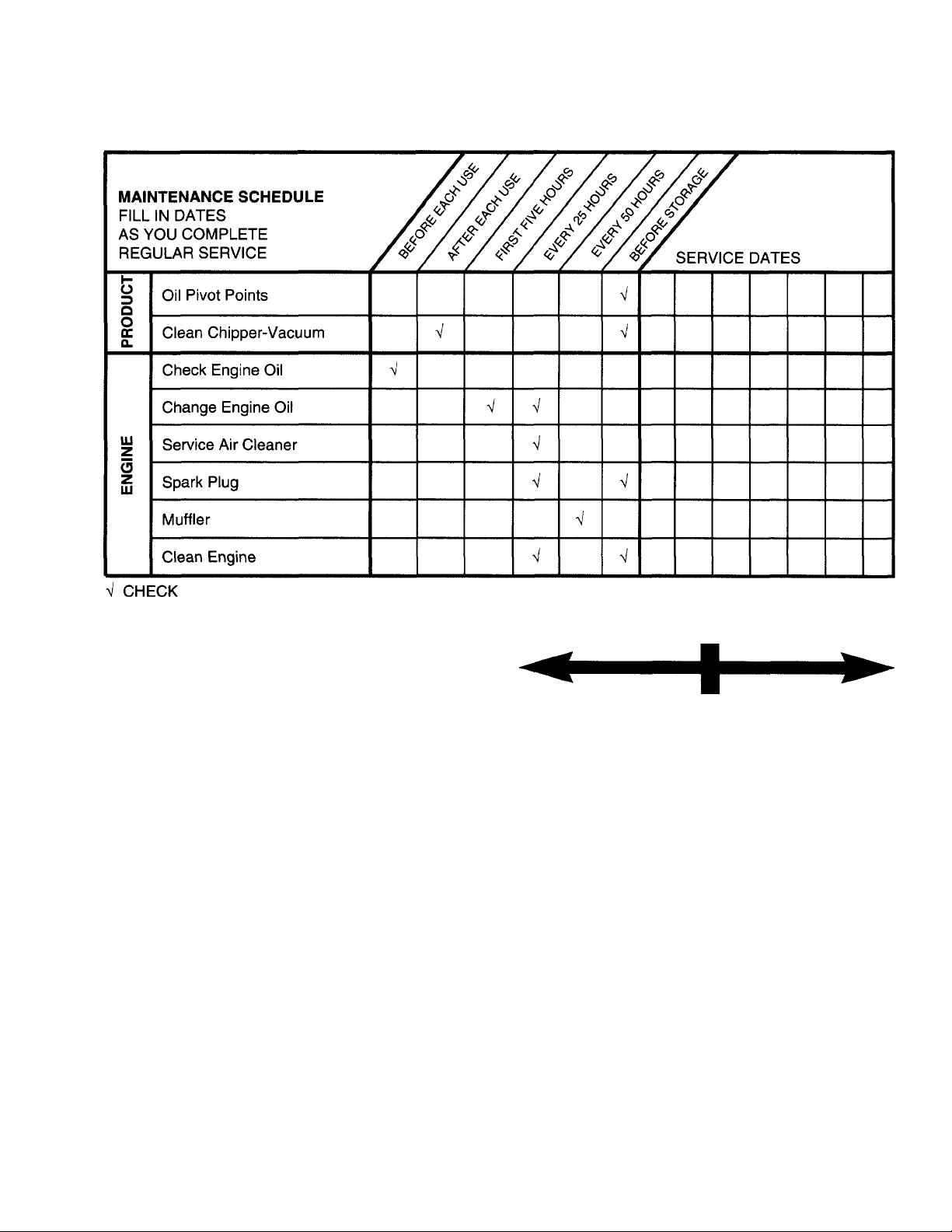

• Follow the Maintenance Schedule above.

WIRE BEFORE PERFORMING ANY

MAINTENANCE OR ADJUSTMENTS.

CHIPPER-VACUUM

LUBRICATION

Lubricate the pivot points on the height adjustment

mechanism once a season using a light oil.

CLEANING

• Clean the chipper-vacuum thoroughly after each

use.

• Wash the bag periodically with water. Allow to dry

thoroughly in the shade. Do not use heat.

ENGINE

ENGINE OIL

Only use high quality detergent oil rated with API

service classification SF, SG or SH. Select the oil’s

viscosity grade according to your expected operating

temperature.

Colder

5W30

NOTE: Although multi-viscosity oils (SE30, 10W30,

etc.) improve starting in cold weather, these multi

viscosity oils will result in increased oil consumption

when used above 32°F. Check your oil level more

frequently to avoid possible engine damage from

running low on oil.

Your four-cycle engine will normally consume some

oil—therefore, check engine oil level regularly approx

imately every five hours of operation and before each

usage. Stop engine and wait several minutes before

checking oil level. With engine cooled down, the oil

level must reach FULL mark on dipstick (refer to

figure 12). Change engine oil after the first five hours

of operation, and every twenty-five hours thereafter.

To Drain Oil:

• Drain oil while engine is warm.

a. Remove oil drain cap. Refer to figure 12. Catch

oil in a suitable container.

b. When engine is drained of all oil, replace drain

cap securely.

• Refill with fresh oil. Refer to GAS AND OIL FILL

UP section.

• Replace dipstick.

32°F

Warmer

SAE 30

13

Page 14

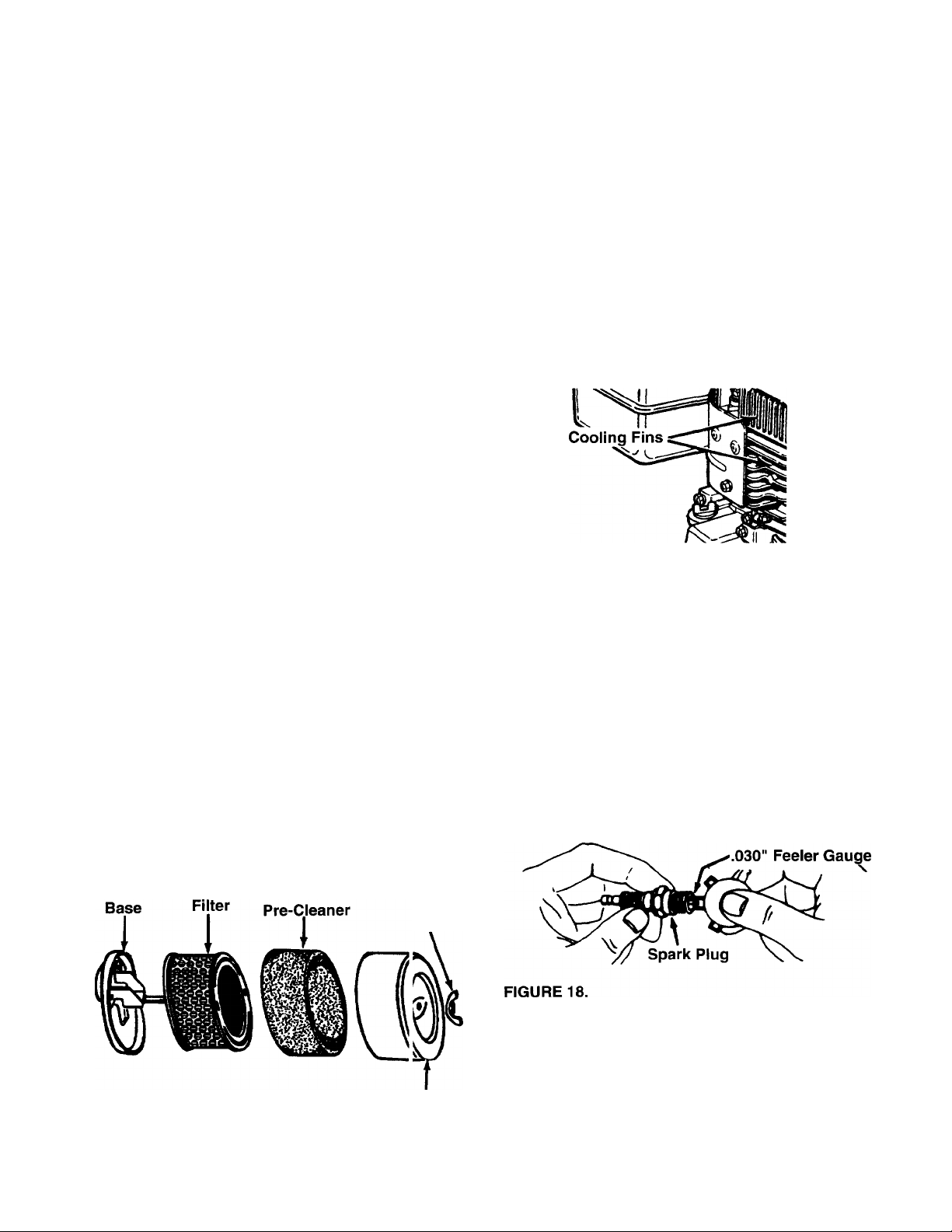

AIR CLEANER

The air cleaner prevents damaging dirt, du st, etc.,

from entering the carburetor, and being forced into the

engine. It is important to keep the engine clear to pro

long engine life and improve performance.

Never run your engine without air cleaner com

pletely assembled.

To Service Air Cleaner:

Service pre-cleaner after every 25 hours of us e, or at

least once a season. Replace filter every 100 hours of

use, or at least once a season. Service pre-clesner and

filter more often under dusty conditions.

• Remove wing nut and cover. See figure 16.

• Slide pre-cleaner off filter. Clean the inside of base

and cover thoroughly.

• Clean pre-cleaner as follows.

Wash in water and detergent solution, and £ queeze

(do not twist) until all dirt is removed.

Rinse thoroughly in clear water.

Wrap in a clean cloth and squeeze (do not twist)

until completely dry, or allow to air dry.

• If necessary, replace filter (do not attempt tc clean).

• Install new filter on base. Slide pre-dearer over

filter.

• Install cover and wing nut. Tighten w ng nut

securely.

CLEAN ENGINE

Clean engine periodically. Remove dirt and debris

with a cloth or brush. Cleaning with a forceful spray of

water is not recommended as water could contami

nate the fuel system.

Yearly or every 25 hours of using, whichever occurs

first, remove the air intake screen and blower

housing, and clean the areas shown in figure 17 to

avoid overspeeding, overheating and engine damage.

Clean more often if necessary.

A

FIGURE 17.

SPARK PLUG

The spark plug should be cleaned and the gap reset

to .030" at least once a season or after every 50

hours of operation. See figure 18. Spark plug replace

ment is recommended at the start of each season.

Replace spark plug if electrodes are pitted, burned,

fouled with deposits, or porcelain is cracked. Refer to

engine parts list for correct spark plug type.

NOTE: Do not sandblast spark plug. Spark plug

should be cleaned by scraping or wire brushing and

washing with a commercial solvent.

WARNING: PERIODICALLY CLEAN MUF

FLER AREA TO REMOVE ALL GRASS,

DIRT AND COMBUSTIBLE DEBRIS.

FIGURE 16.

Л/ing

Nut

( ¡over

MUFFLER

Do not operate the chipper-vacuum without a muffler

or tamper with the exhaust system. Damaged mufflers

or spark arresters could create a fire hazard. Inspect

periodically, and replace if necessary. If your engine

is equipped with a spark arrester screen assembly,

remove after every 50 hours of using for cleaning and

inspection. Replace if damaged.

14

Page 15

SERVICE & ADJUSTMENT

WARNING: ALWAYS STOP ENGINE AND

DISCONNECT SPARK PLUG WIRE AND

A

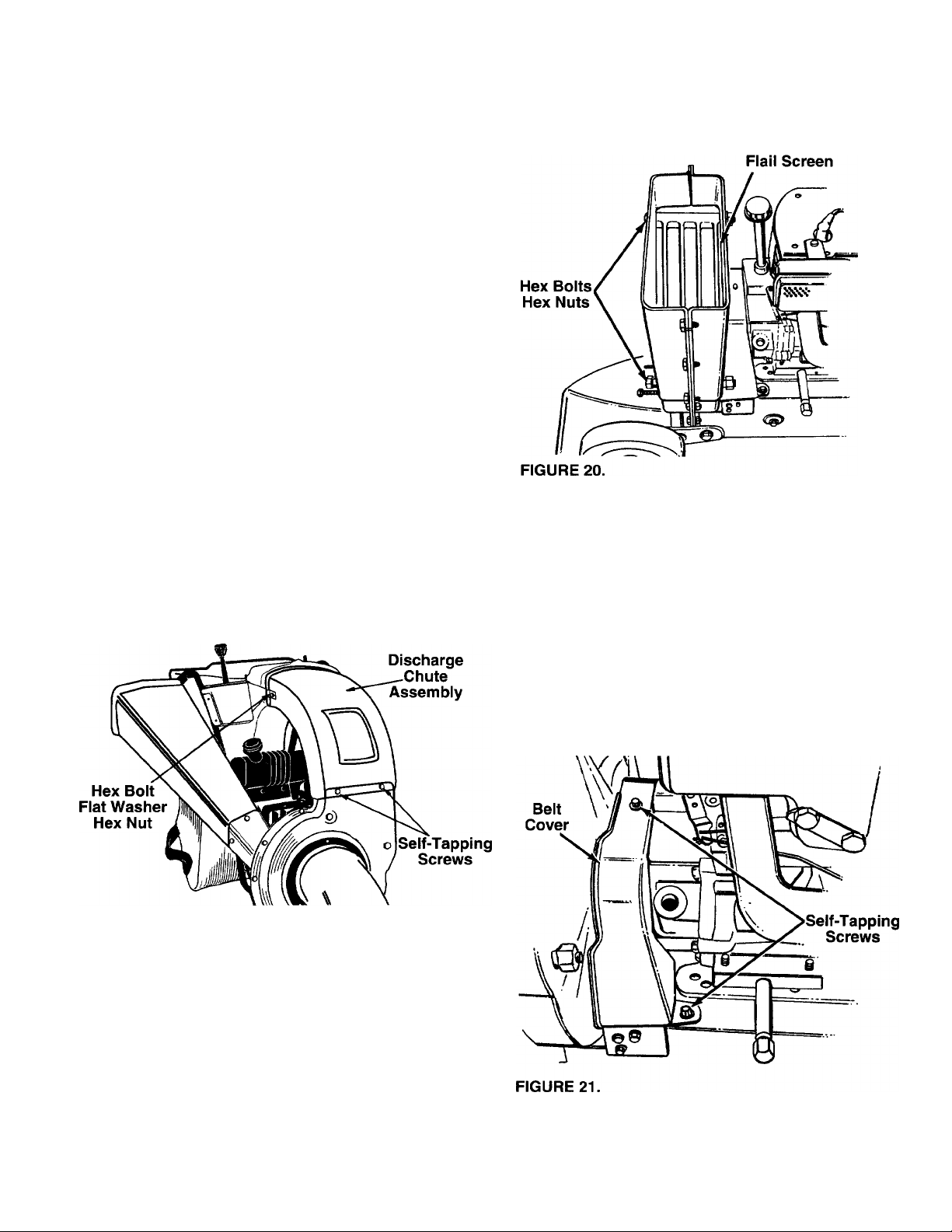

REMOVING THE FLAIL SCREEN

If the discharge area becomes clogged, remove the

flail screen and clean area as follows.

• Stop the engine. Make certain the chipper-vacuum

has come to a complete stop. Disconnect the spark

plug wire before unclogging the discharge chute.

• Remove the vacuum bag from the unit.

• Remove the four self-tapping screws from the

bottom of the discharge chute. (Be careful not to

drop the hardware into the chute.) Remove the dis

charge chute assembly. See figure 19.

MOVE IT AWAY FROM SPARK PLUG

BEFORE PERFORMING ANY ADJUST

MENTS OR REPAIRS.

• Clean the screen by scraping or washing with

water. Reinstall the screen.

NOTE: Be certain to reassemble the flail screen with

the curved side down as shown in figure 20.

SHARPENING OR REPLACING CHIPPER BLADES

• Disconnect the spark plug wire and move away

from the spark plug.

• Remove the flail screen as instructed in the previ

ous section.

• Remove the belt cover on the front of the engine by

removing the two self-tapping screws. See figure 21.

FIGURE 19.

• Remove the two hex bolts and hex nuts which

extend through the housing. Lift the flail screen

from inside the housing. See figure 20.

Remove the access plate by removing two hex lock

nuts. See figure 22.

15

Page 16

Frame Cover

FIGURE 22.

WARNING: MAKE SURE TO V/EAR

HEAVY DUTY GLOVES FOR THIS JOB.

A

• Locate one of the chipper blades in the c ccess

plate opening by rotating the impeller asserr bly by

hand. Remove the blade using a 3/16" aiien

wrench on the outside of the blade and 1/2" \/rench

on the impeller assembly, inside the hojsing.

Torque hardware to 250-350 inch pounds.

• Remove the other blade in the same m;inner.

Replace or sharpen blades. If sharpening, make

certain to remove an equal amount frorr each

blade. Reassemble in reverse order.

NOTE: Make sure that the blades are reasse mbied

with the sharp edge facing upward, as viewe i from

the access plate opening.

WHILE ACCESSING THE CHIPPER

BLADE, YOU MAY HAVE TO CLEA vl THE

SCREW HEAD OF DUST AND

SHREDDED PARTICLES TO ENABLE

THE ALLEN WRENCH TO OPERATE.

HANDLE THE WRENCH CAREFULLY SO

THAT YOU DO NOT CUT YOUR HAND

ON THE CHIPPER BLADE.

FIGURE 23.

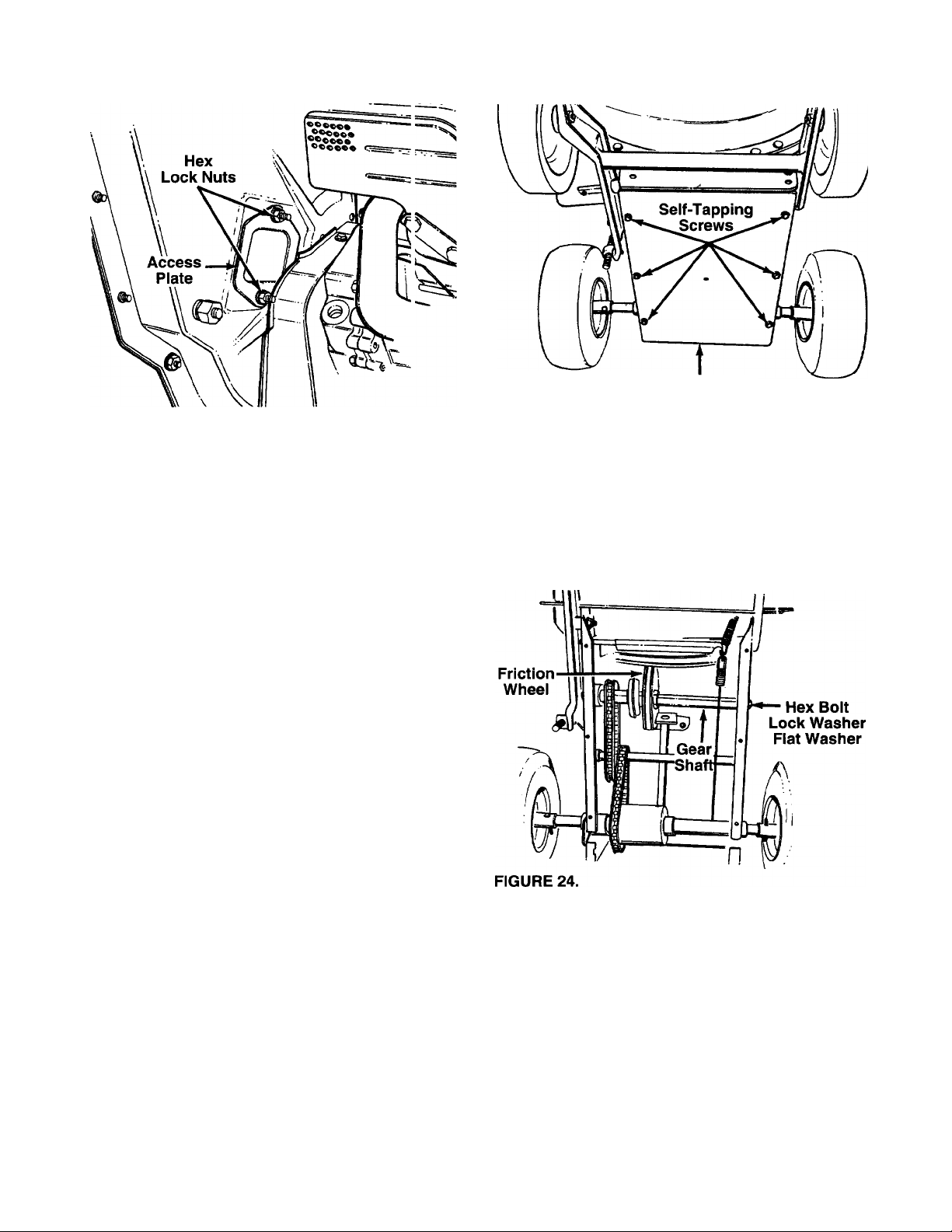

Remove the gear shaft from the unit by removing

the hex bolts, lock washers and flat washers from

each side of the frame. See figure 24. Hold the fric

tion wheel assembly, and slide the gear shaft out of

the unit toward the right side.

CHANGING THE FRICTION WHEEL RUBBER

The rubber on the friction wheel is subject to wear

and should be checked after 50 hours of operation,

and periodically thereafter. Replace friction wheel

rubber if any signs of wear or cracking are found.

• Drain the gasoline and oil from the ch ppervacuum.

• Tip the unit backward so it rests on the handl 3S.

• Remove the frame cover by removing eight self

tapping screws from underneath the chippervacuum. See figure 23. (Only six of the eight

screws are shown in the figure.)

16

• Remove the six screws from the friction wheel

assembly (three from each side). Remove the fric

tion wheel rubber from between the friction wheel

plate.

• Reassemble new friction wheel rubber to the fric

tion wheel assembly, tightening the six screws in

rotation and with equal force.

• Slide the friction wheel assembly up onto the shift

mechanism, then slide the gear shaft back into the

unit. Reassemble in reverse order.

• Readjust the clutch cable. Refer to adjustment sec

tion.

Page 17

ADJUSTING THE CLUTCH CABLE

To adjust the clutch cable, refer to the “Clutch Cable

Adjustment” section of Assembly Instructions.

ADJUSTING THE SHIFT ROD

If the shift rod is at 1 or R1 position, but the unit does

not show any forward or reverse movement as the

case may be, the shift rod wiil need to be adjusted.

See figure 25.

• Remove the bag from the unit.

• Remove the hairpin ciip and the fiat washer from

the upper end of the shift rod.

• Pull the ferrule out of the hole in the shift lever.

Make sure that you do not displace the wave wash

er from the ferrule.

• Place the shift iever in the 6th position which is aii

the way to the left.

REPLACING THE BELT

WARNING: Disconnect the spark plug

A

• Remove the plastic beit cover on the front of the

engine by removing two self-tapping screws. Refer

to figure 21.

• Drain the gasoiine and oii from the chipper-

vacuum.

• Tip the unit backward so that it rests on the

• Remove the frame cover by removing eight self

tapping screws from underneath the chippervacuum.

• Remove the idier puiley bracket as foiiows. See

figure 26.

• Take the tension off the belt by pivoting the idler

• Remove three self-tapping screws, and lift off the

wire and move away from the spark plug.

handies.

pulley toward you, and line up the holes in the idler

bracket assembly. Insert a nail or similar object

through the holes to hold the idler pulley in this

position.

idler bracket assembly.

• Push down on the shift rod.

• Thread the ferrule up or down the shift rod two

turns so that the ferrule lines up with the upper hoie

in the shift lever.

• Secure the ferrule to the shift lever using the fiat

washer and the hairpin clip.

Engine Pulley

Idler

Idler

Bracket

'Assembl

Self-Tapping

FIGURE 26.

• Remove the hex bolt and lock washer from the

• Loosen the nut on the stop bolt until there is clear

• Slip the belt between the friction wheel and friction

NOTE: The support bracket must rest on the stop bolt

after the new belt has been assembled.

m \

Screws

engine pulley. See figure 26. Slip the engine pulley

off the engine shaft, and remove the belt from the

pulley.

ance between the support bracket and the friction

wheel disc. See figure 27.

wheel disc. Remove and replace belt. Reassemble

following instruction in reverse order.

Pulley

a

17

Page 18

Support

ADJUSTING THE CARBURETOR

A

The carburetor has been pre-set at the factory and

should not require adjustment. However, if your

engine does not operate properly due to suspected

carburetor problems, take your chipper-vacuum to

your nearest SEARS Service Center.

SETTING ENGINE SPEED

Your engine speed has been factory set. Do not

attempt to increase engine speed or it may result in

personal injury. If you believe the engine is running

too fast or too slow, take your chipper-vacuum to the

nearest SEARS Service Center for repair and adjust

ment.

STORAGE

WARNING: IF ANY ADJUSTMENTS ARE

MADE TO THE ENGINE WHILE THE

ENGINE IS RUNNING (E.G. CARBURE

TOR), KEEP CLEAR OF ALL MOVING

PARTS. BE CAREFUL OF HEATED SUR

FACES AND MUFFLER.

Prepare your chipper-vacuum for storage at he end

of the season or if the unit will not be used for 30 days

or more.

WARNING: NEVER STORE MACHINE

WITH FUEL IN THE FUEL TANK INSIDE

A

NOTE: A yearly check-up by your local Sears Service

Center is a good way to make certain your ohippervacuum will provide maximum performance for the

next season.

OF BUILDING WHERE FUMEii MAY

REACH AN OPEN FLAME OR SPA RK, OR

WHERE IGNITION SOURCES ARE

PRESENT SUCH AS HOT WATER AND

SPACE HEATERS, FURNACES, CLOTHES

DRYERS, STOVES, ELECTRIC MOTORS,

ETC.

• Run the engine till the fuel tank is empty.

• Start the engine and let it run until the fuel lines and

• Never use engine or carburetor cleaner products in

• Use fresh fuel next season.

NOTE: Fuel stabilizer is an acceptable alternative in

minimizing the formation of fuel gum deposits during

storage. Add stabilizer to gasoline in fuel tank or stor

age container. Always follow the mix ratio found on

stabilizer container. Run engine at least 10 minutes

after adding stabilizer to allow the stabilizer to reach

the carburetor. Do not drain the gas tank and carbure

tor if using fuel stabilizer.

• Drain all the oil from the crankcase (this should be

CHIPPER-VACUUM

• Clean the chipper-vacuum thoroughly.

• Wipe unit with an oiled rag to prevent rus (use a

light oil or silicone).

• If you have drained the fuel tank, protect the inside

ENGINE

IMPORTANT: IT IS IMPORTANT TO PREVENT

GUM DEPOSITS FROM FORMING IN ESSENTIAL

FUEL SYSTEM PARTS SUCH AS CARBUFIETOR,

FUEL FILTER, FUEL HOSE, OR TANK DURING

STORAGE. ALSO, EXPERIENCE INDICATES THAT

ALCOHOL BLENDED FUELS (CALLED GA30H0L

OR USING ETHANOL OR METHANOL) CAN

ATTRACT MOISTURE WHICH LEADS TO SEPARA

TION AND FORMATION OF ACIDS DJRING

STORAGE. ACIDIC GAS CAN DAMAGE TH E FUEL

SYSTEM OF AN ENGINE WHILE IN STORACiE.

OTHER

• Do not store gasoline from one season to another.

• Replace your gasoline can if your can starts to rust.

• Store unit in a clean, dry area. Do not store next to

NOTE: If storing in an unventilated or metal storage

shed, be certain to rustproof the equipment by coating

with a light oil or silicone.

carburetor are empty.

the fuel tank or permanent damage may occur.

done after the engine has been operated and is still

warm) and refill the crankcase with fresh oil.

of the engine as follows. Remove spark plug, pour

approximately 1/2 ounce (approximately one table

spoon) of engine oil into cylinder and crank slowly

to distribute oil. Replace spark plug.

Rust and^r dirt in your gasoline will cause problems.

corrosive materials, such as fertilizer.

18

Page 19

TROUBLE SHOOTING

PROBLEM POSSIBLE CAUSE(S)

Engine fails to start

Loss of power;

operation erratic • Unit running on CHOKE.

Engine overheats • Carburetor not adjusted

Too much vibration

Unit does not

discharge

Rate of discharge

slows considerably or

composition of

discharged material

changes

• Fuel tank empty, or stale fuel. • Fill tank with clean, fresh fuel.

• Spark plug wire disconnected. • Connect wire to spark plug.

• Faulty spark plug.

• Nozzle safety switch not depressed.

• Spark plug wire loose.

• Blocked fuel line or stale fuel.

• Water or dirt in fuel system.

• Carburetor out of adjustment.

• Dirty air cleaner.

properly.

• Engine oil level low.

• Loose parts or damaged

impeller.

• Discharge chute clogged.

• Foreign object lodged in impeller.

• Vacuum bag is full.

• Chipper blades dull.

CORRECTIVE ACTION

• Clean, adjust gap or replace.

• Adjust metal tab so it depresses the safety switch.

• Connect and tighten spark plug wire.

• Move choke lever to OFF position.

• Clean fuel line; fill tank with clean

fresh gasoline.

• Disconnect fuel line at carburetor to drain fuel

tank. Refill with fresh fuel.

• Adjust carburetor or contact your SEARS

Service Center.

• Service air cleaner. See Customer Responsibilities

section of this manual.

• Contact your SEARS Service Center.

• Fill crankcase with proper oil.

• Stop engine immediately and disconnect

spark plug wire. Tighten all bolts and nuts.

Make all necessary repairs. If vibration continues,

have unit serviced by a SEARS Service Center.

• Stop engine immediately and disconnect

spark plug wire. Clean flail screen and inside

of blower housing. See Service/Adjustments

section of this manual.

• Stop engine immediately and disconnect

spark plug wire. Remove lodged object.

• Empty bag.

• Sharpen or replace chipper blades.

NOTE: For repairs beyond the minor adjustments listed above, please contact your nearest SEARS Service Center.

19

Page 20

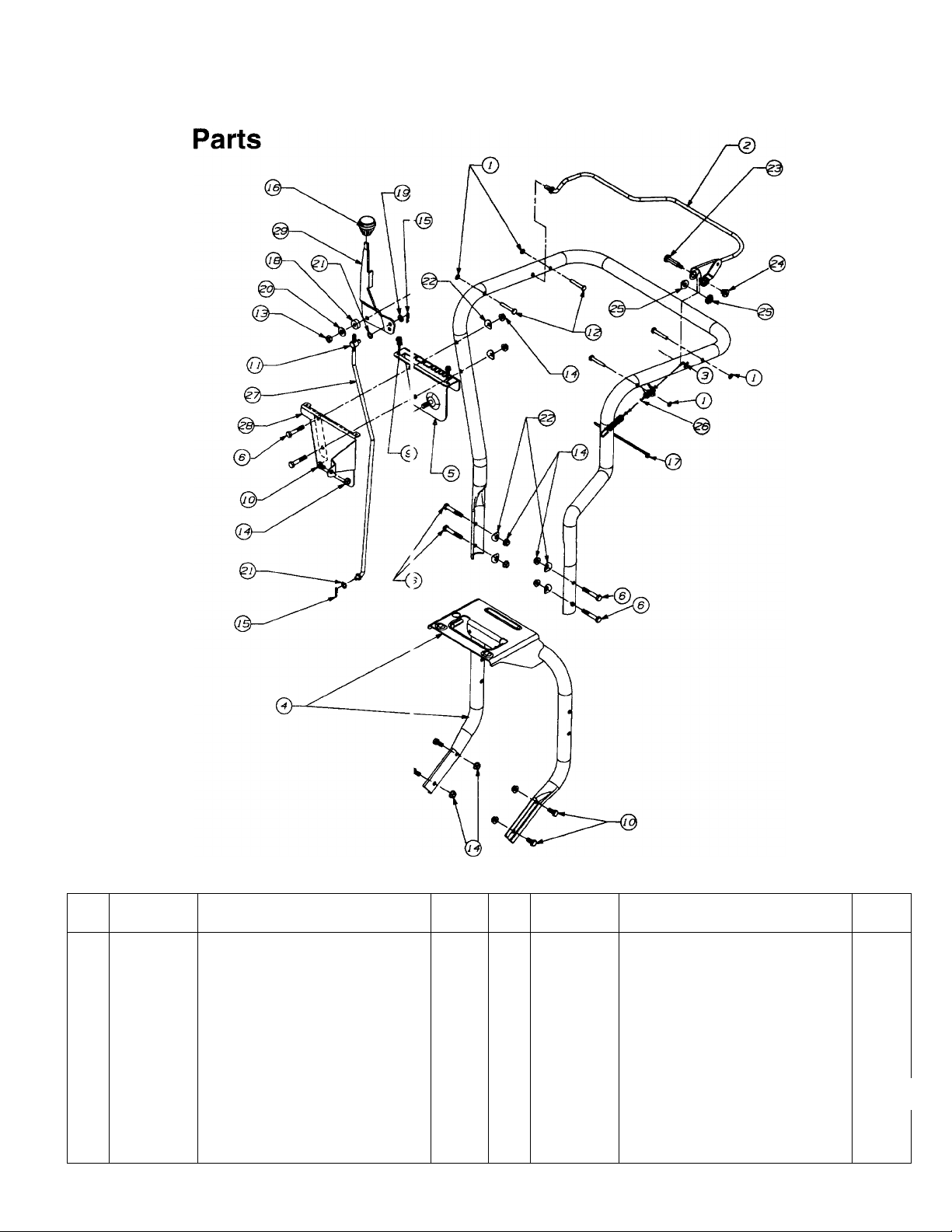

SEARS CRAFTSMAN CHIPPER-VACUUM MODEL 247.799620

REF.

NO.

10 710-3008

PART

NO.

1 1539-019

2 647-0019

3 649-0008

4 649-0012

5 681-0076

6 710-0116

710-0896

9

DESCRIPTION

PUSHNUT

CONTROL ASSY

HANDLE ASSY-UPPER

HANDLE-LOWER

BRACKET ASSY-SHIFT

SCREW-HEX

SCREW-HEX

SCREW-HEX 5

11 711-0677 FERRULE

711-0737 PIN-STUD

12

13

712-0116

NUT-HEX LOCK

14 712-3004A NUT-HEX LOCK

714-0104 PIN-COTTER

15

16 720-0232

KNOB-SHIFT

QTY.

4

REF.

NO.

17 725-0157 CABLE TIE

PART

NO.

1 18 735-0126

1

1

19

20

736-0264

736-0300

1 21 736-0413

6

22 736-0451

2 23 738-0560

24

1

4 26

1

25

27

738-0561

741-0402

746-0921

747-0626

11 28 781-0626

2 29

784-0297A

1

20

DESCRIPTION QTY.

1

WASHER-RUBBER

WASHER-FLAT

WASHER-FLAT

WASHER-SPRING

WASHER-SADDLE

SCREW-SHOULDER

NUT-SHOULDER

BEARING-FLANGE PLASTIC

CABLE-CLUTCH

ROD-SHIFT

COVER-SHIFT

HANDLE-SHIFT

1

1

1

2

6

1

1

2

1

1

1

1

Page 21

SEARS CRAFTSMAN CHIPPER-VACUUM MODEL 247.799620

Repair Parts

REF.

NO.

PART

NO.

DESCRIPTION

QTY.

REF.

NO.

PART

NO.

DESCRIPTION

1 629-0241 HARNESS—CHIPPER-VAC 1 13 712-3010 NUT-HEX (GR 5)

2 681-0059

3 681-0060

4 710-0382

710-0604 SCREW-HEX SELF TAP

5

710-0607

6

7 710-0772

8 710-1268

9 710-3008

712-0384

10

11 712-0421

HOUSING ASSY—INNER 1 14

HOUSING ASSY—OUTER 1 15

SCREW-HEX 2

SCREW-HEX SELF TAP

SCREW-HEX

SCREW-HEX SELF TAP 2 20

SCREW-HEX 2 21 736-0242 WASHER-BELL

NUT-HEX LOCK 2

KNOB

12 712-3004A NUT-HEX LOCK

719-0326

723-0438

16 725-1700 COVER-SWITCH 1

10

8 18

17

725-3166

726-0272 CLAMP

3 19 731-1613 COVER-SWITCH 1

736-0119

22 781-0598 BLADE-FLAIL HOUSING

3 23 781-0599 BLADE-FLAIL HOUSING

4 24

781-0627

SCREEN

SEAL-RUBBER

SNAP MOUNT SWITCH

WASHER-LOCK

COVER-CHIPPER 1

21

QTY.

3

1

2

1

1

3

3

1

1

Page 22

SEARS CRAFTSMAN CHIPPER-VAI^UUM MODEL 247.799620

Repair Parts

REF.

NO.

1

PART

NO.

DESCRIPTION

681-0051 IMPELLER ASSY COMP

(INCL. REF. NOS. 2 THRU 12)

2

3

710-1273

736-0217

SCREW-HEX 1

WASHER-LOCK

4 736-0247 WASHER-FLAT 1

681-0052 IMPELLER ASSY 1

5

711-0833B PIN-CLEVIS

6

7

710-1054

712-0411 NUT-HEX LOCK 4

8

715-0162 PIN-ROLL SPRING 3

9

SCREW-FLAT HEAD 4

10 719-0329 BLADE-FLAIL 3

11 736-0119 WASHER-LOCK

12

781-0490

BLADE-CHIPPER 4

QTY.

1

1

3

4

REF.

NO.

PART

NO.

1 710-0642

2 631-0043

3 731-1608

DESCRIPTION QTY.

HEX WASHER SCREW

NOZZLE ASSEMBLY

CHUTE 1

4 735-0247 NOZZLE FLAP

764-0484 VACUUM BAG 1

5

6 781-0666

7 631-0033

8 712-0431

720-0190 HEIGHT ADJ. KNOB

9

732-0754 SPRING LEVER 2

10

11 736-3084

781-0637 NOZZLE DOOR BRKT. 2

12

738-0913

13

NOZZLE STABILIZER BRKT. 1

NOZZLE DOOR ASSY 1

FLANG. LOCK NUT 2

FL-WASHER 2

SHOULDER SCREW 2

14 736-0173 FLAT WASHER 5

5

1

1

2

REF.

NO.

1

PART

NO.

681-0068

2

710-0258

712-3027 NUT-LOCK

3

DESCRIPTION

CHUTE ASSEMBLY 1

SCREW-HEX

4 731-1574 CHUTE-UPPER

5 781-0625

—

731-1617 TAMPER PLUG (Not Shown)

6 736-0173

BRACKET SUPPORT

WASHER

QTY.

5

5

1

1

1

5

22

Page 23

SEARS CRAFTSMAN CHIPPER-VACUUM MODEL 247.799620

Repair Parts

REF.

NO.

10 736-0329

11

12 754-0256 V-BELT

13 756-0313

14

15

16 781-0611 BRACKET-IDLER PIVOT

17

PART

NO.

1 710-0230 SCREW-HEX 1

2 710-0723

3 710-0896 SCREW-HEX

4 710-0646 SCREW-HEX

5 712-0266 NUT-HEX LOCK 1

712-3004A NUT-HEX LOCK FL

6

719-0330A

7

731-1584 COVER-BELT

8

9 732-0745 SPRING-TORSION 1

748-0234

756-0985 PULLEY

756-0984 PULLEY

781-0614

DESCRIPTION QTY.

SCREW-HEX 1

5

1

2

ADAPTER-MOUNTING 1

1

WASHER-LOCK

SHOULDER SPACER

1

1

1

IDLER-FLAT

1

1

1

1

BRACKET-IDLER 1

REF.

NO.

1

2

PART

NO.

681-0096

738-0955

DESCRIPTION QTY.

BRKT. ASSY.-WHEEL PIVOT

SCREW-SHOULDER

3 710-0924 SCREW-MACHINE PAN HD.

4

710-3008

SCREW-HEX 2

5 711-1041 FERRULE-ADJUSTABLE

712-3004A NUT-HEX FLANGE 2

6

7

712-0431

NUT-HEX FLANGE LOCK

8 714-0115 PIN-COTTER

9 716-0104 E-RING

10 720-0236 PLASTIC KNOB

11

736-0270

12

736-0300 FLAT WASHER

13

736-0369 FLAT WASHER

14

732-0645 COMPRESSION SPRING

BELL WASHER

15 747-0631 ADJUSTABLE ROD

16

711-0242

17

781-0605

736-0247 FLAT WASHER 2

18

SPACER

BRKT.-HEIGHT ADJ.

1

2

1

1

2

1

1

1

1

2

2

1

1

1

1

23

Page 24

SEARS CRAFTSMAN CHIPPER-VACUUM MODEL 247.799620

Repair Parts

24

Page 25

SEARS CRAFTSMAN CHIPPER-VACUUM MODEL 247.799620

Repair Parts

REF.

NO.

10

11

12

13

PART

NO.

684-0042A

1

2 618-0168

656-0012A

3

4 681-0055

681-0058

5

681-0082

6

681-0072 ARM ASSY-SHIFT 1 29 736-0160 WASHER-FLAT

7

681-0081

8

9 781-0638A

DESCRIPTION QTY.

FRICTION WHEEL ASSY 1 23 714-0474 COTTER PIN 1

DIFFERENTIAL ASSY COMP. 1

FR. WHEEL DISC ASSY 1 25 713-0284 CHAIN

SUPPORT BRKT. ASSY 1 26 732-0209 EXTENSION SPRING

AXLE BRKT. ASSY 2

SHAFT ASSY-SHIFT 1 28

FRAME ASSY 1 30 736-0267 WASHER-FLAT

FRAME PLATE

710-0502A SCREW-HEX SELF-TAP.

710-0653 SCREW-HEX WASHER 2 33 738-0908 IDLER BOLT

710-0788 SCREW-HEX WASHER

710-0896

SCREW-HEX 8 35 748-0382 SPACER

14 710-3008 SCREW-HEX 6

711-1073

15

711-1028 SHAFT-JACK

16

712-0241 NUT-HEX 2 39 750-0980 SPACER

17

712-0711 NUT-HEX JAM 1 40 750-0981 SPACER

18

712-3004A

19

713-0330

20

713-0374 CHAIN 1 43 750-0998 SPACER

21

22 713-0413

SHAFT-HEX

NUT-HEX FLANGE LOCK

SPROCKET & HUB 1 42

SPROCKET10T 1

REF.

NO.

24 716-0102

27

1

31

4 32

1 34

36

1

1

5

37

38 750-0979 SPACER

41 781-0612A

PART

NO.

DESCRIPTION QTY.

SNAP RING 1

736-0105 WASHER-BELL

736-0119

WASHER-LOCK

736-0287 WASHER-FLAT

736-3089

WASHER-FLAT

741-0563 BALL BEARING

750-0351 SLEEVE

750-0978 SPACER

FRAME COVER

784-5590

SHIFT BRACKET

1

2

3

2

1

2

4

2

1

2

1

1

1

1

1

1

1

1

1

REF.

NO.

PART

NO.

DESCRIPTION QTY.

1 634-0118 WHEEL ASSY COMPLETE

4" X 10" 2

634-0101 RIM ASSY COMPLETE 2

734-0210 TIRE PNEUMATIC 4" X 10" 2

711-1017 PIN-CLEVIS

2

712-0431 NUT-HEX FLANGE 2

3

714-0104

4

5 731-0355A

734-1268 WHEEL 2" X 8" 2

6

PIN-COTTER 2

HUB CAP 2

7 736-0105 WASHER-BELL 2

8

736-0232

WASHER-WAVE 2

9 738-0213 SCREW-SHOULDER 2

734-0255 VALVE STEM 2

10

2

25

Page 26

SEARS CRAFTSMAN CHIPPER-VAC JUM MODEL 247.799620

Repair Parts

REF.

NO.

PART

NO.

1

618-0168 DIFFERENTIAL ASSY

DESCRIPTION

COMPLETE 1

2

710-1206 SCREW-HEX 4

3 711-1035

4

711-1037 AXLE-SHAFT 10.95" LONG 1

5

711-1038

SHAFT-CROSS

AXLE-SHAFT 9.82" LONG

6 713-0445 SPROCKET 22 T 1

7 716-0232

RING-RETAINING

(2 PER AXLE)

8 717-1358

GEAR-DIFFERENTIAL 14T

9 717-1437 GEAR-DIFFERENTIAL 10T

10

719-0333

11

719-0334 HOUSING-DIFFERENTIAL LF 1

12

748-0383 BEARING-FLANGE 2

13

737-0300

14

— SEALANT-LOCTITE 5699

HOUSING-DIFFERENTIAL RM

GREASE

QTY.

1

1

4

2

2

1

1 OZ

REF.

NO.

1

PART

NO.

710-0258

DESCRIPTION QTY.

SCREW-HEX 2

2 712-3027 NUT-HEX LOCK FLANGE 2

3

4

5

6

7

726-0205

751-0535

751-0603

751-0610

726-0209

CLAMP-HOSE 2

HOSE-FUEL LINE 9" 1

CAP-FUEL 1

TANK-FUEL 1 GALLON 1

CABLE TIE 1

8 736-0173 FLAT WASHER 1

26

Page 27

SEARS CRAFTSMAN 9 H.P. ENGINE MODEL NO. 143.959003

FOR CHIPPER-VACUUM MODEL NO. 247.799620

Repair Parts

400

Page 28

SEARS CRAFTSMAN 9 H.P. ENGINE MODEL NO. 143.959003

FOR CHIPPER-VACUUM MODEL NO. >47.799620

Repair Parts

KEY

NO.

1

2

4 32678

5

15 30699C

15A 30700

15B 650494

16

17

18

19 34663

20

25 36460

26

28

30 36283

35

36

37

38

40

40

40

41 34329A Piston & Pin Ass’y. (Std.) (1 icl. 43)

41 34330A

41 34331A

42 34332

42 34333

42

43

45

46

47

48

49

50

60

65

69

70

71 35377

72

75

80 31845

81 30590A

82

83

84 29193

86

87

89

90

92

93

100

101

PART

NO.

35385

27652

30969

33454

29916

650548

35319 Oil Seal

650561

30322

29826

29918

29216

29642

34552

34553

34554

34334

27888

35373A

650908

650882

34034

35374

36569

33273A

650128

35262A

35445A

27642

35319

35378

30588A

650833

650832

32589

611090

650880

650881

35135

610118

Cylinder (Incl. 2 & 20)

Dowel Pin 103

Oil Drain Extension

Extension Cap

Governor Rod 120

Governor Yoke

Screw, 6-40 X 5/16"

Governor Lever

Governor Lever Clamp 126

Screw, 8-32x5/16"

Speed Control Spring 128

Blower Housing Baffle

Screw, 1/4-20 x 5/8" 135

Lock Nut, 8-32

Crankshaft

Screw, 10-32 X 3/4" 149

Lock Washer 149 A

Lock Nut, 10-32

Retaining Ring

Piston, Pin & Ring Set (Std.)

Piston, Pin & Ring Set 170

Piston, Pin & Ring Set (.02(" OS)

Piston & Pin Ass’y- (.010" C S)

Piston & Pin Ass’y- (.020" C S)

Ring Set (Std.)

Ring Set (.010" OS)

Ring Set (.020" OS)

Piston Pin Retaining Ring 203

Connecting Rod Ass’y. (Inc . 46,

Connecting Rod Bolt

Connecting Rod Bolt

Valve Lifter

Oil Dipper

Camshaft (MCR)

Blower Housing Extension

Screw, 10-24 x 1/2" 239

Cylinder Cover Gasket

Cylinder Cover (Incl. 71, 7£ & 80)

Crankshaft Bushing

Oil Drain Plug

Oil Seal

Governor Shaft

Washer

Governor Gear Ass’y. (Incl 81)

Governor Spool

Retaining Ring

Screw, 1/4-20 X 1-3/16"

Screw, 1/4-20 X 1-11/16"

Flywheel Key

Flywheel

Lock Washer

Flywheel Nut

Solid State Ignition

Spark Plug Cover

DESCRIPTION

(Incl. 15A& 15B) 125

(.010" OS)

(Incl. 43)

(Incl. 43)

47 & 49) 206

KEY

NO.

102 650872

110 35187 Ground Wire

119 36448

125

126 34035

127 650691

129

130

139 33369

140 650836

150 27881 Valve Spring

151 32581

169

171

172 28425 Valve Cover

173

174 650128

178

182 30088A

184 33263

185

186

200

204 650549

207 33878

209

215

223

224

238

240

242

245 33268

245A 35881

250

251

260 333750

261 650788

262

264A 650802 Screw, 1/4-20 x 5/8"

265

275

276 31588

277 650729

281

282 650760

285 35985B

PART

NO.

650814

36449

27878A

27880A Exhaust Valve (1/32" OS)

34036

650690

650738 Screw, 1/4-20 x 5/8"

650694A Screw, 5/16-18x2"

33636

27882

35862 Valve Spring Cap

27896A Valve Cover Gasket

28423

28424

35350

29752 Nut & Lock Washer, 1/4-28

34707 Intake Pipe

34661

34677 Control Bracket (Incl. 203 & 204)

31342

610973

650821

32410 Control Knob

650378 Screw, Torx T-30, 5/16-18 x 1-1/8"

27915A Intake Pipe Gasket

28820

27272A

33266

33267 Air Cleaner Bracket

33269A

650513

29747B Screw, Torx T-40, 5/16-24 x

33272B

34185B Muffler

33013

DESCRIPTION

Solid State Mounting Stud

Screw, Torx T-15, 10-24 x 1"

Cylinder Head Gasket

Cylinder Head

Exhaust Valve (Std.) (Incl. 151)

(Incl. 151)

Intake Valve (Std.) (Incl. 151)

Intake Valve (1/32" OS) (Incl. 151)

Washer

Belleville Washer

Resistor Spark Plug (RJ17LM)

Governor Gear Bracket

Screw, 10-24 x 1/2

Valve Spring Cap

Valve Spring Keeper

Breather Body

Breather Element

Breather Tube

Screw, 10-24 x 1/2"

Screw, 1/4-28 x 1"

Carburetor To Intake Pipe Gasket

Governor Link

Compression Spring

Screw, 5-40x7/16"

Terminal

Throttle Link

Screw, 10-32 X 1/2"

Screw, 10-32x1/2"

Air Cleaner Gasket

Air Cleaner Body

Air Cleaner Filter

Air Cleaner Filter

Air Cleaner Cover

Wing Nut, 1/4-20

Blower Housing

Screw, 5/16-18x3/4"

21/32"

Cylinder Head Cover

Locking Plate

Screw, 5/16-18x3-3/16"

Starter Bubble Cover

Screw, 8-32 X 3/8"

Starter Cup

28

Page 29

SEARS CRAFTSMAN 9 H.P. ENGINE MODEL NO. 143.959003

FOR CHIPPER-VACUUM MODEL NO. 247.799620

Repair Parts

KEY

NO.

286 35446

287

290 30705

292 26460

296

305 35554

307

308 35540

310 36205

325 29443

327

342

RPM Setting:

High Speed: 3450 to 3750

-ow Speed: 1700

PART

NO.

29752

34279B

35499

35392

30063

Starter Screen 370 36261 Instruction Decal

Nut & Lock Washer, 1/4-28 370A

Fuel Line

Fuel Line Clamp 370C

Starter Screen 380

Oil Fill Tube 390

“0”-Ring

Fill Tube Clip with 590704 starter. Refer to the design of the

Dipstick air intake louvers for part identification.

Wire Clip Individual starter parts do not interchange.

Starter Plug

Screw, Torx T-30, 1/4-20 x 1/2"

DESCRIPTION

OPTIONAL SPARK ARRESTER

Part No. 34479A

KEY

NO.

370B 35532

400 36454 Gasket Set

PART

NO.

35703 Throttle Decal

35274

632689 Carburetor (Incl. 184)

590671

Note: This engine could have been built

*(lncl. Part Nos. 27272A, 27896A, 27915A,

29673, 33263, 33629, 34698A, 35262 & 36448)

Logo Decal

Instruction Decal

Rewind Starter

DESCRIPTION

KEY

NO.

—

2 632244 Throttle Return Spring

4

5 631183

10

11

12 631184 Dust Seal Washer

13 631183

14 632248

15 630735

16

17 650417 Throttle Crack Screw/ldle Speed

18 630766

20 632281

21

22 630739

23

25

27 631024 Float Shaft

28 632019

29 631028

30

31

40 632239 Main Adj. Screw Ass’y- (Incl. 41

41

42 630739 High Speed Mixture Screw

43 630738

44

47

48

60

PART

NO.

632689

1 632243 Throttle Shaft & Lever Assembly

631184

632517

6

7

650506

632249 Choke Shaft & Lever Assembly

632043

632164 Fuel Fitting

630766

630740

631867 Float Bowl

631021 Inlet Needle, Seat & Clip

631022 Spring Clip

630740

27110

630748

631027 Welch Plug, Atmospheric Vent

632347 Repair Kit* (Incl. Items Marked

Carburetor (Incl. 184 of Engine

Dust Seal Washer

Dust Seal (Throttle)

Throttle Shutter

Shutter Screw

Choke Return Spring

Dust Seal (Choke)

Choke Shutter

Choke Positioning Spring

Tension Spring

Idle Mixture Screw

Tension Spring

Idle Mixture Screw Washer

Idle Mixture Screw “0”-Ring

Float

Float Bowl “0”-Ring

High Speed Mixture Screw

High Speed Mixture Screw

Bowl Nut Washer

Welch Plug, Idle Mixture Well

DESCRIPTION

Parts List)

Screw

(Incl. 31)

thru 44)

“0”-Ring

Washer

Tension Spring

PK in Notes)

29

Page 30

SEARS CRAFTSMAN 9 H.P. ENGINE II10DEL NO. 143.959003

FOR CHIPPER-VACUUM MODEL NO. 247.799620

Repair Parts

PARTS LIST FOR RECOIL STARTER

KEY

NO.

_

11 590683

12

13

PART

NO.

590671

590599A Spring Pin (Incl. 4)

1

2 590600

590679

3

4 590601

590678 Brake Spring

5

590680

6

590412

7

590681

8

Recoil Starter

Washer

Retainer

Washer

Starter Dog

Dog Spring

Pulley & Rewind Spring Ass’y-

DESCRIPTION

Starter Housing Ass’y.

590456

Starter Rope (114" x 11/64" Dia.)

590387 Starter Handle

7/^ ^'^7

6^

6

4

^5

2

3

PARTS LIST FOR RECOIL STARTER (OPTION/ L)

KEY

NO.

_

11

12

13

PART

NO.

590704

1 590599A

590600

2

590696

3

4 590601

590697

5

590698

6

590699 Dog Spring

7

590700 Pulley & Rewind Spring Ass’y

8

Recoil Starter

Spring Pin (Incl. 4)

Washer

Retainer

Washer

Brake Spring

Starter Dog

DESCRIPTION

590705 Starter Housing Ass’y.

590535

590701

Starter Rope (98" x 9/64" Dia.

Starter Handle

I

-11

30

t-

O

-----

2

----1

Page 31

Page 32

Page 33

Page 34

TABLA DE LOCALIZACION DE FALLAS

PROBLEMA

El motor no arranca

CAUSA

• Tanque de combustible vacío,

0 combustible rancio.

• Está desconectado el conductor

de la bujía.

• Bujía defectuosa.

• El interruptor de seguridad de

la boquilla no está accionado.

Pérdida de potencia,

funcionamiento errático

El motor se

sobrecalienta

Demasiada vibración • Piezas flojas o hélice dañada.

• El conductor de la bujía está flojo.

• La unidad está funcionando en

CHOKE

• La tubería de combustible está

bloqueada o combustible rancio.

• Agua 0 combustible en el sistema

de combustible.

• El carburador está desajustado.

• Filtro de aire sucio.

• El carburador no está ajustado

apropiadamente.

• El nivel de aceite del motor es bajo.

CORRECTIVE ACTION

• L ene el tanque con combustible limpio y fresco.

• C onecte el conductor a la bujía.

• L impie, ajuste la separación o reemplace.

• / juste la aleta de metal de manera de

c ccionar el interruptor de seguridad.

• C onecte y ajuste el conductor de la bujía.

• r lueva la palanca del regulador a la posición OFF.

• l impie la tubería de combustible; llene el tanque

t on gasolina limpia y fresca.

• [ lesconecte la tubería de combustible en el

(arburador para drenar el tanque de combustible.

1 lene con combustible fresco.

• > juste el carburador o consulte con su

(dentro de Servicio SEARS.

• 1 impie el filtro de aire. Vea la sección

(le Responsabilidades del Cliente de este manual.

• (Consulte con su Centro de Servicio SEARS.

• 1 .lene el cárter con aceite apropiado.

• ; apague inmediatamente el motor y desconecte el

(onductor de la bujía. Ajuste todos los pernos y

1 uercas. Efectúe todas las reparaciones nece: larias. Si continúa la vibración haga reparar la

inidad en un Centro de Servicio SEARS.

La unidad no descarga

La velocidad de descarga

disminuye

considerablemente o

cambia la composición

del material descargado.

NOTA; Por favor consulte con su Centro de Servicio SEARS más cercano )ara reparaciones diferentes a los ajustes menores

listados arriba.

• Está taponada la canaleta de

descarga.

• Hay un objeto extraño en la hélice.

• La bolsa de la aspiradora está llena.

• Las cuchillas de la astilladora

están desafiladas.

• \pague inmediatamente el motor y desconecte

5l conductor de la bujía. Limpie el tamiz de la

Jesgranadora y el interior de la armadura del

ventilador. Vea la sección de Servicio/Ajustes

de este manual.

• Apague inmediatamente el motor y desconecte

3l conductor de la bujía. Retire el objeto atrapado.

• /acíe la bolsa.

• Vile 0 reemplace las cuchillas de la astilladora.

19

Page 35

Ménsula de

AJUSTE DEL CARBURADOR

ADVERTENCIA: MANTENGASE ALEJADO DE

TODAS LAS PIEZAS MOVILES, EJERZA

A

El carburador ha sido ajustado de fábrica y no debe requerir

ajustes. Sin embargo, si su motor no funciona apropiada

mente debido a probiemas sospechosos dei carburador,

lleve su astilladora-aspiradora a su Centro de Servicio

Sears más cercano.

CUIDADO CON LAS SUPERFICIES

CALIENTES Y CON EL SILENCIADOR, SI SE

EFECTUAN AJUSTES AL MOTOR MIENTRAS

EL MOTOR ESTA FUNCIONANDO (POR EJ.

EL CARBURADOR).

GRADUACION DE LA VELOCIDAD DEL MOTOR

La velocidad de su motor ha sido graduada de fábrica. No

intente incrementar la velocidad dei motor o puede resuitar

en lesiones personales. Si usted piensa que el motor está

funcionando demasiado rápido o demasiado lento, lleve su

astilladora-aspiradora a su Centro de Servicio Sears más

cercano para reparar y ajustar.

ALMACENAMIENTO

Prepare inmediatamente su astiiladora-aspiradora para

almacenamiento al final de la temporada o si no se usará

durante 30 días o más.

ADVERTENCIA: NUNCA ALMACENE LA

MAQUINA CON COMBUSTIBLE EN EL

A

NOTA: Una revisación anual por su Centro de Servicio

Sears es una buena manera de asegurarse que su astil

ladora-aspiradora proveerá el máximo rendimiento para la

próxima temporada.

TANQUE DE COMBUSTIBLE, DENTRO DE UN

EDIFICIO DONDE LOS HUMOS PUEDEN

ALCANZAR UNA LLAMA ABIERTA O CHISPA,

O DONDE ESTEN PRESENTES FUENTES DE

IGNICION TALES COMO CALENTADORES DE

AGUA CALIENTE Y DE ESPACIO, HORNOS,

SECADORAS DE ROPA, COCINAS, MOTORES

ELECTRICOS, ETC.

ASTILLADORA-ASPIRADORA

• Limpie compietamente ia astiliadora-aspiradora

• Frote la unidad con un trapo aceitado para prevenir la

oxidación (use un aceite iiviano o siiiconas)

MOTOR

IMPORTANTE: ES IMPORTANTE EVITAR QUE SE FOR

MEN DEPOSITOS DE GOMA EN PIEZAS ESENCIALES

DEL SISTEMA DE COMBUSTIBLE TALES COMO EL

CARBURADOR, EL FILTRO DE COMBUSTIBLE, LA

MANGUERA DE COMBUSTIBLE O EL TANQUE

DURANTE EL ALMACENAMIENTO. TAMBIEN LA EXPE

RIENCIA INDICA QUE LOS COMBUSTIBLES MEZCLA

DOS CON ALCOHOL (LLAMADOS GASOHOL O QUE

USAN ETANOL Q METANOL) PUEDEN ATRAER LA

HUMEDAD, LQ QUE RESULTA EN LA SEPARACIQN Y

FQRMACIQN DE ACIDOS DURANTE EL ALMACE

NAMIENTO. EL GAS ACIDICO PUEDE DAÑAR EL SIS

TEMA DE COMBUSTIBLE DEL MOTOR MIENTRAS ESTA

EN ALMACENAMIENTO.

• Arranque el motor y permita que funcione hasta que ias

tuberías de combustible y el carburador estén vacíos.

• Nunca use productos limpiadores dei motor o del carbu

rador en el tanque de combustible ya que puede ocurrir

un daño permanente.

• Use combustible fresco la próxima temporada.

NOTA: El estabilizador de combustible es una alternativa