Page 1

OWNER’S

MANUAL

MODEL NO.

247.797900

CRRFTSMRN

Caution:

Read and Follow

All Safety Rules

and Instructions

Before Operating

This Equipment

SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A.

5 HORSEPOWER

AIR SWEEPER

Assembly

Operation

Customer Responsibilities

Service and Adjustment

Repair Parts

rited in U.S.A.

770-8839L 8/95

Page 2

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSON

AL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL

A

A

BEFORE ATTEMPTING TO OPERATE YOUR AIR SWEEPER. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL: ^ HEED ITS WARNING.

Your air sweeper was built to be operated according to the rules tor safe operation in this manual. As with

DANGER: any type of power equipment, carelessness or error on the part of the operator can result in serious injury.

This unit is capable of amputating fingers and hands and throwing objects.

SAFE OPERATION PRACTICES

I. GENERAL OPERATION

i 1. Read this owner’s guide carefully in its entirety before

attempting to assemble this machine. Read, understand, and

follow all instructions on the machine and in the manual(s)

before operation. Be completely familiar with the controls and

the proper use of the machine before operating it. Keep this

manual in a safe place for future and regular reference and for

ordering replacement parts.

2. Your air sweeper is a powerful tool, not a plaything. Therefore,

exercise extreme caution at all times. Your unit has been

designed to perform one job; to blow leaves. Do not use it for

any other purpose.

3. Never allow children under 14 to operate the unit. Children 14

years and older should only operate under close parental

supervision. Only responsible individuals who are familiar with

these rules of safe operation should be allowed to use your

unit.

4. Keep the area of operation clear of all persons, particularly

small children and pets. Stop the engine when they are in the

vicinity of the unit.

5. Aiways wear safety glasses or safety goggles during operation

and while performing an adjustment or repair, to protect eyes

from debris or foreign objects that may be thrown from

machine.

6. Wear close fitting slacks and shirt. Shirt and slacks that cover

the arms and legs are recommended. Do not wear loose fitting

clothes or jewelry and secure hair so it is above shoulder

length. They can be caught in moving parts.

7. Do not operate the unit while under the influence of alcohol or

drugs.

8. Never place your hands or any part of your body or clothing

near rotating parts. Keep clear of the discharge opening at all

times. Never insert your hands, fingers, feet, or any other part

of your body or clothing into the discharge or air-intake open

ings as the rotating impeller inside the housing can cause seri

ous injury.

9. Never operate unit without directional discharge chute and

plastic impeller guard properly affixed to unit. These devices

shield the operator from accidental contact with the rotating

impeller.

10. Keep all guards and safety devices in place and operating prop

erly.

II. Exercise caution when operating blower. Do not allow the dis

charge to point in the direction of by-standers or pets.

12. if your machine should start making an unusual noise or vibra

tion, immediately stop the engine, disconnect the spark plug

wire and move the wire away from the spark plug. Allow the

machine to stop and take the following steps:

• Inspect for damage.

• Repair or replace any damaged parts.

• Check for any loose parts and tighten to assure continued

safe operation.

13. Muffler and engine become hot and can cause a burn. Do not

touch.

14. Do not allow leaves or other debris to build-up on engine’s

muffler. The debris could ignite and cause a fire.

15. Do not operate engine if air cleaner or cover over carburetor

air-intake is removed, except for adjustment. Removal of such

parts could create a fire hazard.

16. Only use accessories approved for this machine by the manu

facturer. Read, understand, and follow all instructions provid

ed with the approved accessory.

17. Only operate unit in good daylight. Do not operate unit at night

or in dark areas where your vision may be impaired.

18. If situations occur which are not covered by this manual, use

care and good judgment. Contact your dealer for assistance.

Jl. CHILDREN

Tragic accidents can occur if the operator is not alert to the presence

of small children. Children are often attracted to the blowing activity.

Never assume that children will remain where you last saw them.

1. Keep children out of the work area and under the watchful eye

of a responsible adult other than the operator.

2. Be alert and turn the unit off if a child enters the area.

3. Never allow children under the age of 14 to operate the air

sweeper.

,111. SERVICE

1. Use extreme care in handling gasoline and other fuels. They

are extremely flammable and the vapors are explosive.

a. Store fuel and oil in approved containers, away from heat

and open flame, and out of the reach of children.

b. Check and add fuel before starting the engine. Never

remove gas cap or add fuel while the engine is running.

Allow engine to cool at least two minutes before refueling.

c. Replace gasoline cap securely and wipe off any spilled

gasoline before starting the engine as it may cause a fire or

explosion.

d. Extinguish all cigarettes, cigars, pipes and other sources of

ignition.

e. Never refuel unit indoors because flammable vapors will

accumulate in the area.

f. Never store the machine or fuel container inside where

there is an open flame or spark such as a gas hot water

heater, clothes dryer or furnace.

2. Never run your machine in an enclosed area as the exhaust

from the engine contains carbon monoxide, which is an odor

less, tasteless and deadly poisonous gas.

3. To reduce fire hazard, keep engine and muffler free of leaves,

grass, and other debris build-up. Clean up fuel and oil spillage.

Allow unit to cool at least 5 minutes before storing.

4. Before cleaning, repairing, or inspecting, make certain the

impeller and all moving parts have stopped. Disconnect the

spark plug wire and keep wire away from spark plug to prevent

accidental starting. Do not use flammable solutions to clean

air filter.

5. Keep all nuts, bolts, and screws tight to be sure the equipment

is in safe working condition.

6. Never tamper with safety devices. Check their proper opera

tion regularly.

7. Do not alter or tamper with the engine’s governor setting. The

governor controls the maximum safe operating speed of the

engine. Over-speeding the engine is dangerous and will cause

damage to the engine and to other moving parts of the

machine.

Page 3

OWNER’S MANUAL

A

WARNING — YOUR RESPONSIBILITY

Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

CONGRATULATIONS on your purchase of a Sears

Craftsman Air Sweeper. It has been designed, engineered

and manufactured to give you the best possible dependabil

ity and performance.

Should you experience any problem you cannot easily rem

edy, please contact your nearest Sears Service Center/

Department in the United States. We have competent, welltrained technicians and the proper tools to service or repair

this unit.

Please read and retain this manual. The instructions will

enable you to assemble and maintain your air sweeper

properly. Always observe the “SAFETY RULES.”

MODEL

NUMBER,

SERIAL

NUMBER,

DATE OF

PURCHASE.

THE MODEL AND SERIAL NUMBERS WILL BE FOUND

ON A LABEL ATTACHED TO THE FRAME OF THE AIR

SWEEPER.

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

247.797900

CUSTOMER RESPONSIBILITIES

Read and observe the safety rules.

Follow a regular schedule in maintaining, caring for

and using your air sweeper.

Follow the instructions under “Customer Respons

ibilities” and “Storage” sections of this Owner’s

Manual.

PRODUCT SPECIFICATIONS

Horsepower:

Displacement: 12.57 cu. in.

Fuel Capacity:

(Unleaded)

Engine Oil

API Classification SF, SG or SH

Spark Plug (Gap .030 in.):

Magnetron® Ignition Air Gap:

(20 ounces)

Champion

Equivalent)

5.0

1 Gallon

SAE 30

J19LM (or

.0125 in.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product. Contact your nearest Sears store for details.

WARNING: This unit is equipped with an internal combus

tion engine and should not be used on or near any unim

proved forest-covered, brush-covered or grass-covered land

unless the engine’s exhaust system is equipped with a

spark arrester meeting applicable local or state laws (if any).

If a spark arrester is used, it should be maintained in effec

tive working order by the operator.

In the State of California the above is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands. A spark arrester for the muffler is available

through your nearest Sears Authorized Service Center (See

the REPAIR PARTS section of this manual.)

WARRANTY

FULL ONE YEAR WARRANTY ON CRAFTSMAN POWER BLOWER

For one year from the date of purchase, when this Craftsman power blower is maintained, lubricated, and tuned

up according to the operating and maintenance instructions in the operator’s manual. Sears will repair, free of

charge, any defect in material or workmanship.

This warranty excludes the spark plug and air cleaner, which are expendable parts and become worn during

normal use.

if this power blower is used for commercial or rental purposes, this warranty applies for only 30 days from the

date of purchase.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER IN THE

UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED

STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

SEARS ROEBUCK AND CO., DEPT. 817WA, HOFFMAN ESTATES, IL 60179

Page 4

TABLE OF CONTENTS

SAFETY RULES

PRODUCT SPECIFICATIONS.............

WARRANTY

INDEX

....................................

ASSEMBLY

OPERATION

CUSTOMER RESPONSIBILITIES ........................10, 11

Accessories..........................

Adjustments: Agreement

Carburetor........................

Engine Speed

Throttle

Assembly Instructions

Controls

Customer Responsibilities.................

Engine:

Fuel

Lubrication

................................

Maintenance

Starting

Stopping...........................

Storage

........................................

...................

..........................

...........................

.........................

A

..................

.............................

.......

C

E

....................

.............................

.............................

F

L

...........................

.................................

.................................

.................................

.................................

.............................5, 6

..............................7-9

.................................

...............................

...............................

...............................

.............................5, 6

.................................

...................

........................10, 11

.................................

.................................

...............................

.................................

...............................

3, 10, 11

2

3

3

4

4

13

13

13

7

9

8

12

8

10

STORAGE

SERVICE AND ADJUSTMENT

TROUBLE SHOOTING..

PARTS ORDERING/SERVICE

REPAIR PARTS—AIR SWEEPER

REPAIR PARTS—ENGINE

INDEX

Maintenance:

Air Sweeper

Schedule

Engine

Oil.........................................

Repair/Replacement Parts

Responsibilities, Customer

Safety Rules

Service Recommendations...........................

Spark Plug..........................

Specifications

Storage

Table of Contents..............

Trouble Shooting

Unpacking

Warranty

...........................

........................

............................

...............................

..........................

............................

....................

...................

.......................

....................

..............

.......................

.......................

................

.............................

M

0

R

............................

..........................

S

T

u

w

....................

....................

....................

....................

.............

..............

......................

....................

....................

.............

...............

..............

...........

.......................2

....................

....................

......................

....................

.......................4

....................

.......................5

.......................3

12

13

14

14

15, 16

17-21

10

10

10, 11

8, 10

15-21

3, 9, 10

10

11

12

14

3

3

AIR SWEEPER ACCESSORIES

These accessories were available when the air sweeper was

purchased. They are also available at most Sears retail outlets, catalog

and service centers. Most Sears stores can order repair parts for you,

when you provide the model number of your air sweeper.

ENGINE

AIR SWEEPER

Page 5

ASSEMBLY INSTRUCTIONS

IMPORTANT: This unit is shipped WITHOUT GASO

LINE or OIL. After assembly, see operation section of

this manual for proper fuel and engine oil recommen

dations.

NOTE: To determine right and left hand side of your

air sweeper, stand behind the handle in the operating

position.

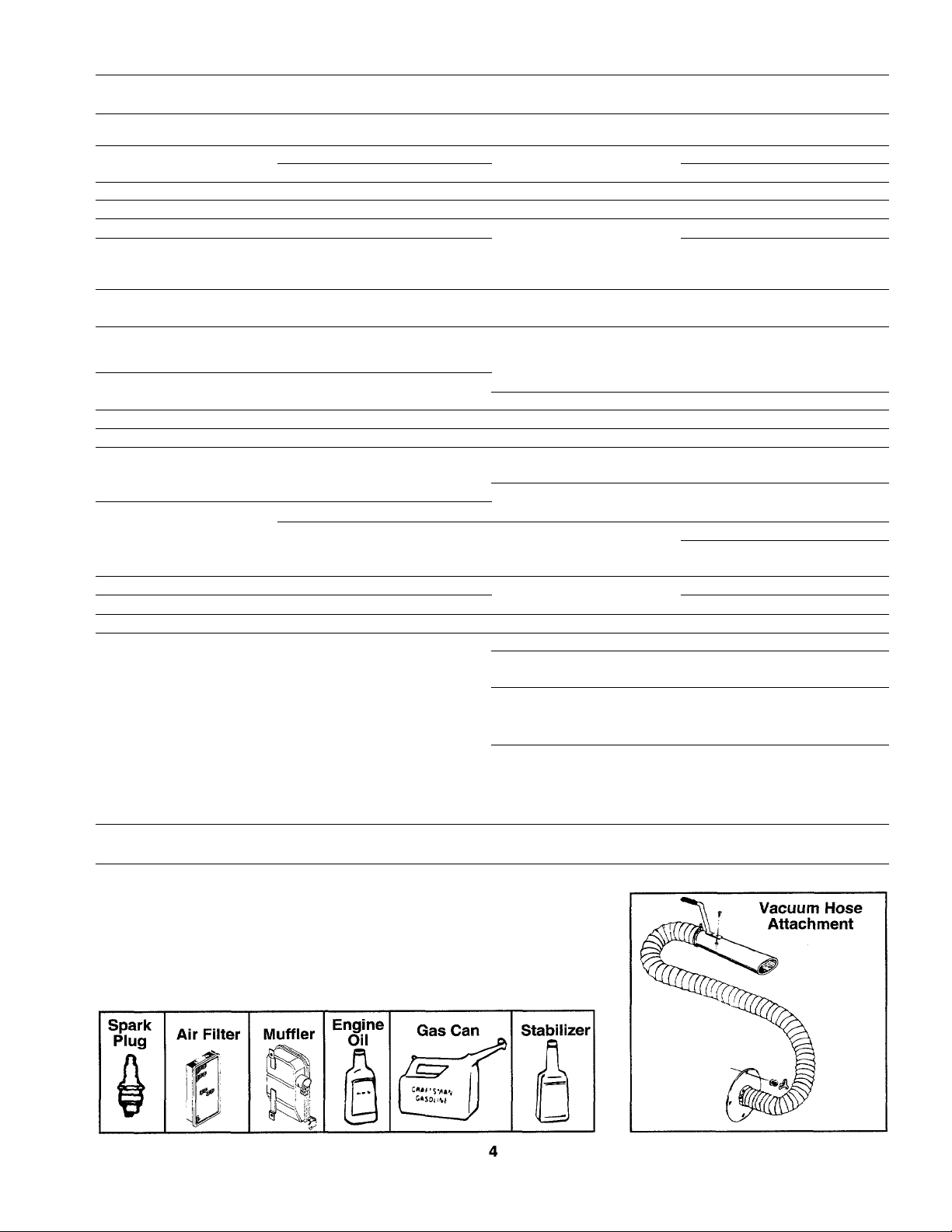

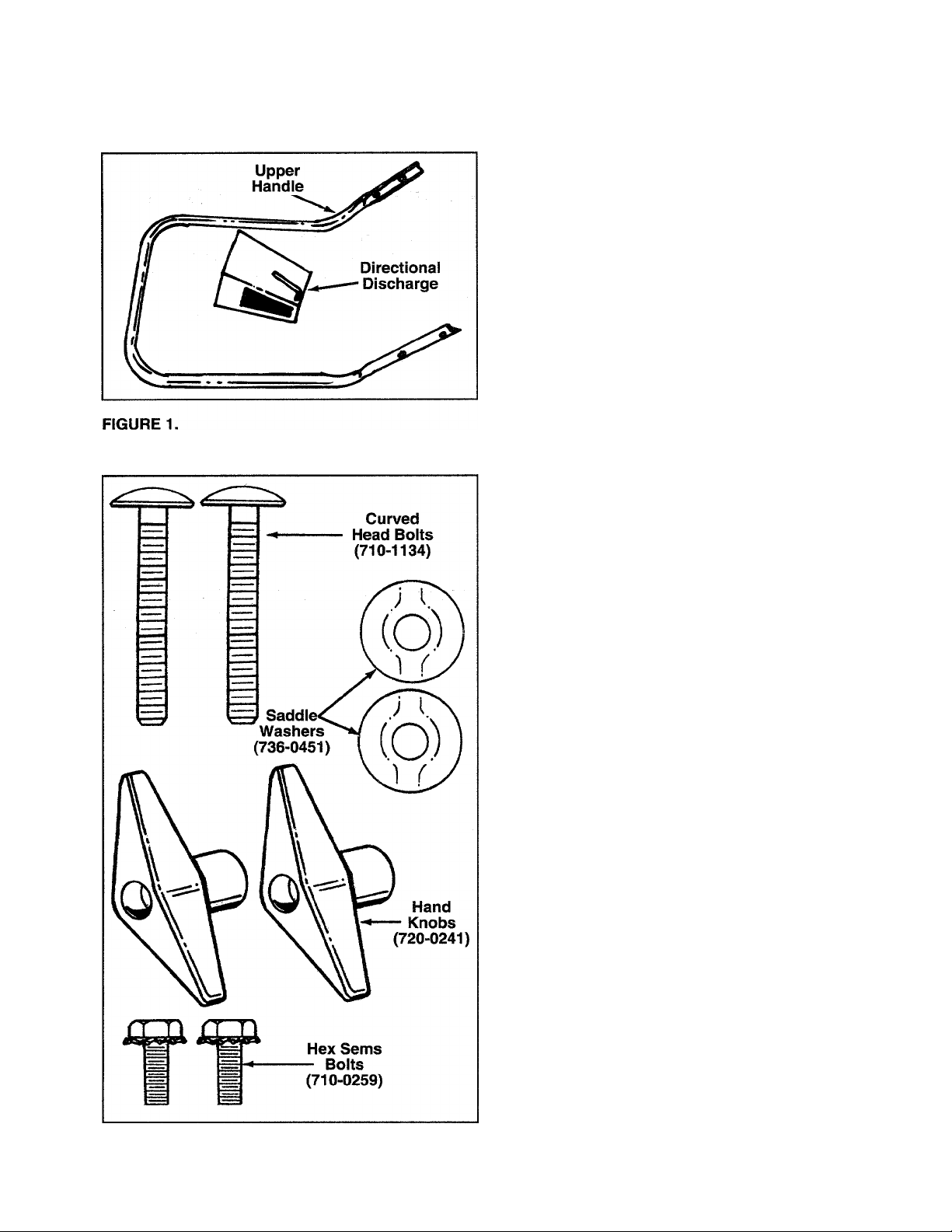

UNPACKING

Your air sweeper, has been completely assembled at

the factory except for the upper handle and directional

discharge. See figure 1. The hardware pack is also

-included in the carton. The hardware pack contains

parts shown in figure 2.

• Remove staples or break glue on the top flaps of

the carton.

• Cut carton down along each corner and lay carton

down flat. Roll air sweeper out of the carton.

• Make certain all parts and literature have been

removed before the carton is discarded.

TOOLS REQUIRED FOR ASSEMBLY

(1 ) 1/2" or Adjustable Wrench

FIGURE 2.

Page 6

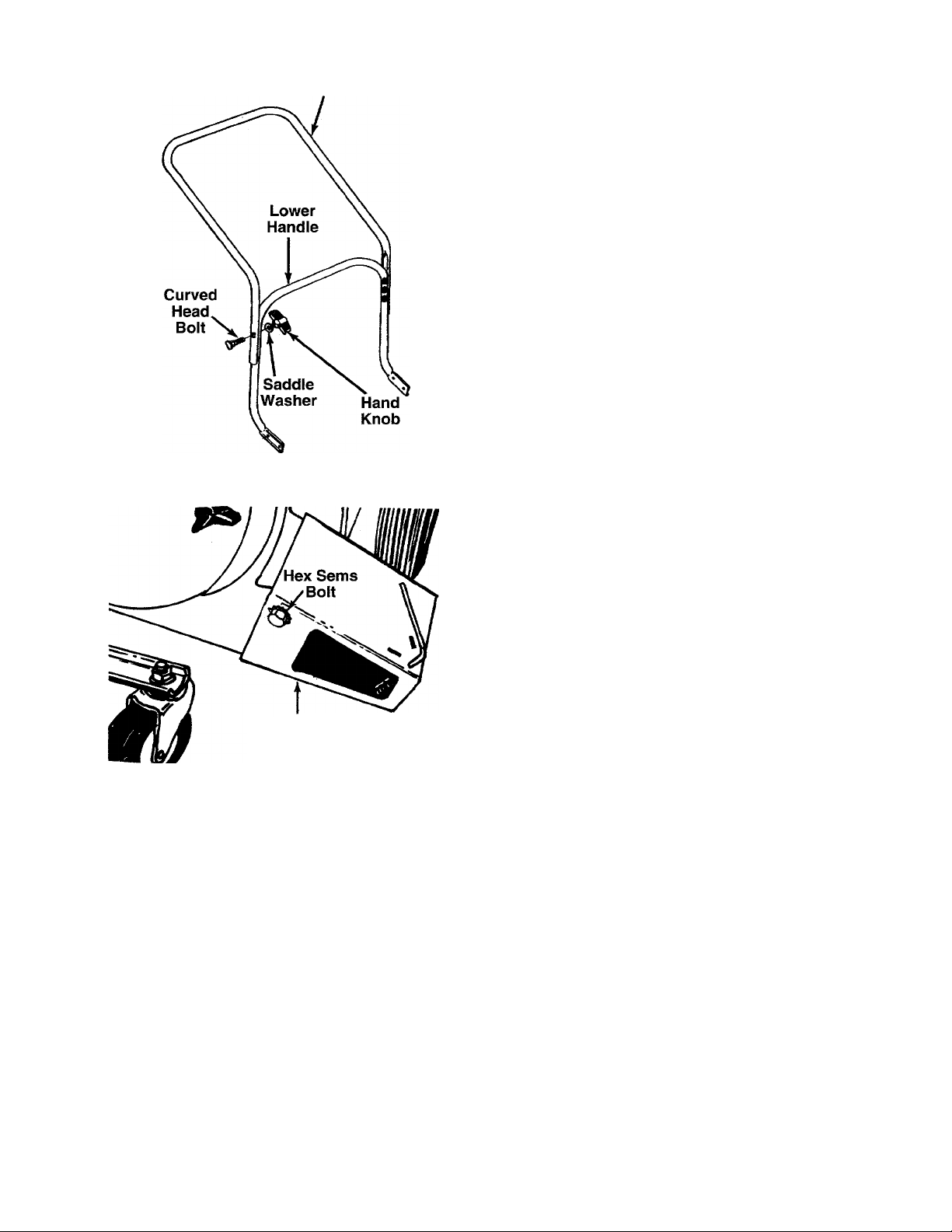

FIGURE 3.

Upper Handle

HOW TO SET-UP YOUR AIR SWEEPER

ATTACHING THE UPPER HANDLE

Place the upper handle over the lower handle, lining

up the holes in the upper handle with the middle

holes In lower handle. Secure with curved head bolts,

■saddle washers and hand knobs. See figure 3.

FIGURE 4.

ATTACHING THE DIRECTIONAL DISCHARGE

Slip end of directional discharge over chute opening.

- Secure in position with hex sems bolts. See figure 4.

Directional

Discharge

Page 7

OPERATION

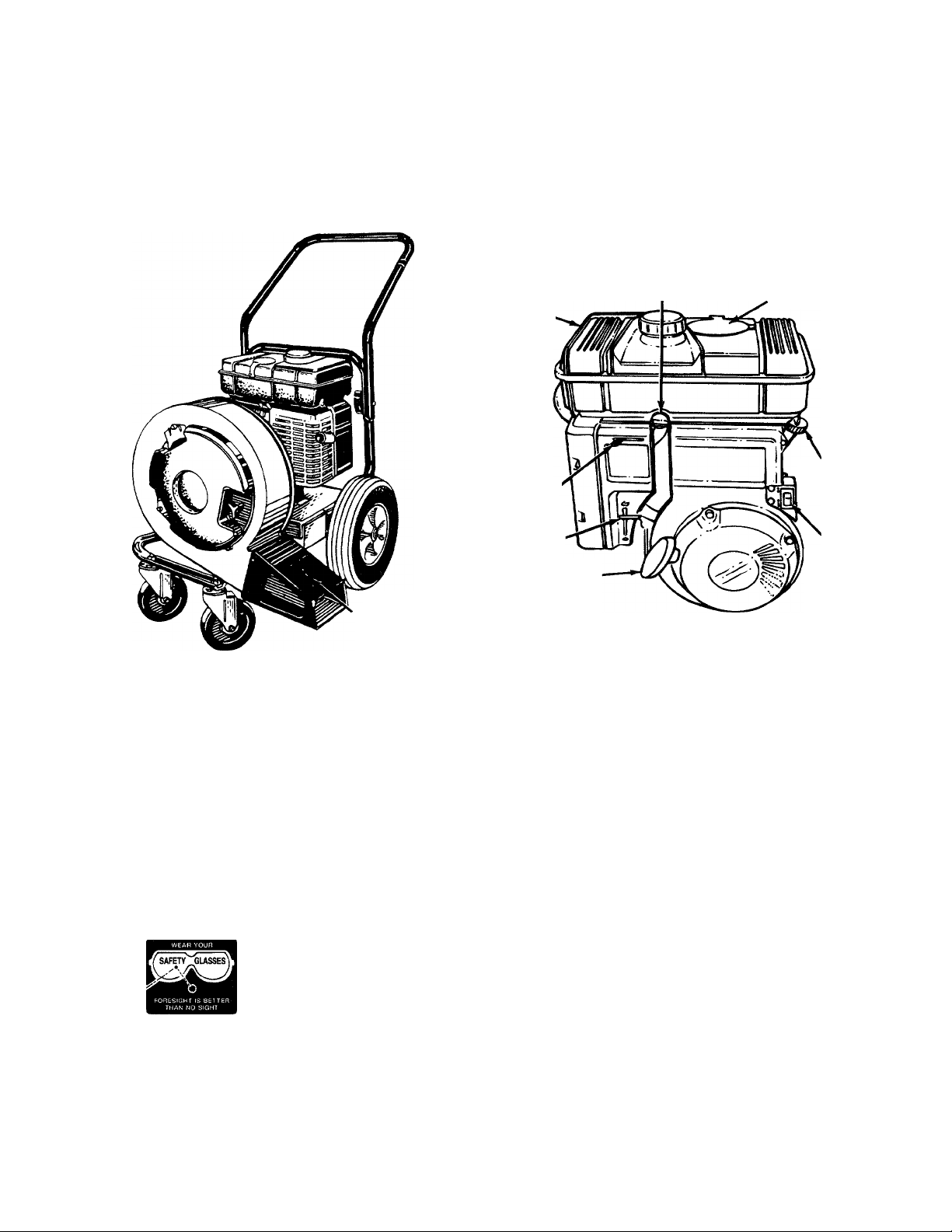

KNOW YOUR AIR SWEEPER

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR AIR SWEEPER.

Compare the illustrations with your air sweeper to familiarize yourself with the location of various controls and

adjustments. Save this manual for future reference.

Directional

Discharge

FIGURE 5.

Handle

OPERATING CONTROLS (See figure 5)

DIRECTIONAL DISCHARGE HANDLE—Used to

change the direction in which air is discharged to the

front or to the side.

CHOKE LEVER—Used to enrich the fuel mixture in

the carburetor when starting a cold engine.

STARTER HANDLE—Used to manually start the

engine.

Fuel

Shut-Off

Fuel

Tank*

Choke/

Lever

Throttle

Control

Starter

Handle

ENGINE SHUT-OFF SWITCH—Used to stop the

engine.

FUEL SHUT-OFF VALVE—Used to stop the flow of

fuel into the carburetor.

THROTTLE CONTROL—Permits selection of fast or

slow engine speed.

Valve

Spark Plug,

Wire and Boot

(Under Cover)

Oil Fill

Dipstick

Engine

Shut-Off

Switch

BEFORE USING YOUR AIR SWEEPER AGAIN REFER TO THE

OF THIS MANUAL. ALWAYS BE CAREFUL.

The operation of any air sweeper can result in foreign objects being thrown into the

eyes, which can result in severe eye damage. Always wear safety glasses before

starting power tool operation or while performing any adjustments or repairs. We rec

ommend Wide Vision Safety Mask for over spectacles or standard glasses available

at Sears Retail or Catalog Stores.

TO STOP ENGINE

• Move throttle control lever to SLOW position.

• Move engine shut-off switch to OFF position. See

figure 5.

Disconnect spark plug wire and move away from

spark plug to prevent accidental starting while

equipment is unattended.

Close fuel shut-off valve when equipment is not in

use to prevent fuel leakage.

‘SAFETY RULES” AS SHOWN ON PAGE 2

Page 8

HOW TO USE YOUR AIR SWEEPER

WARNING: DO NOT AT ANY TIME MAKE

ANY ADJUSTMENT TO THE UNIT WITH

A

TWO-WAY DISCHARGE

The air sweeper can be adjusted to discharge toward

the front of the unit or to the side. Simply push down

on the handle and swing door toward the front to dis

charge out the side, or to the side to discharge out the

front. See figure 6.

FIGURE 6.

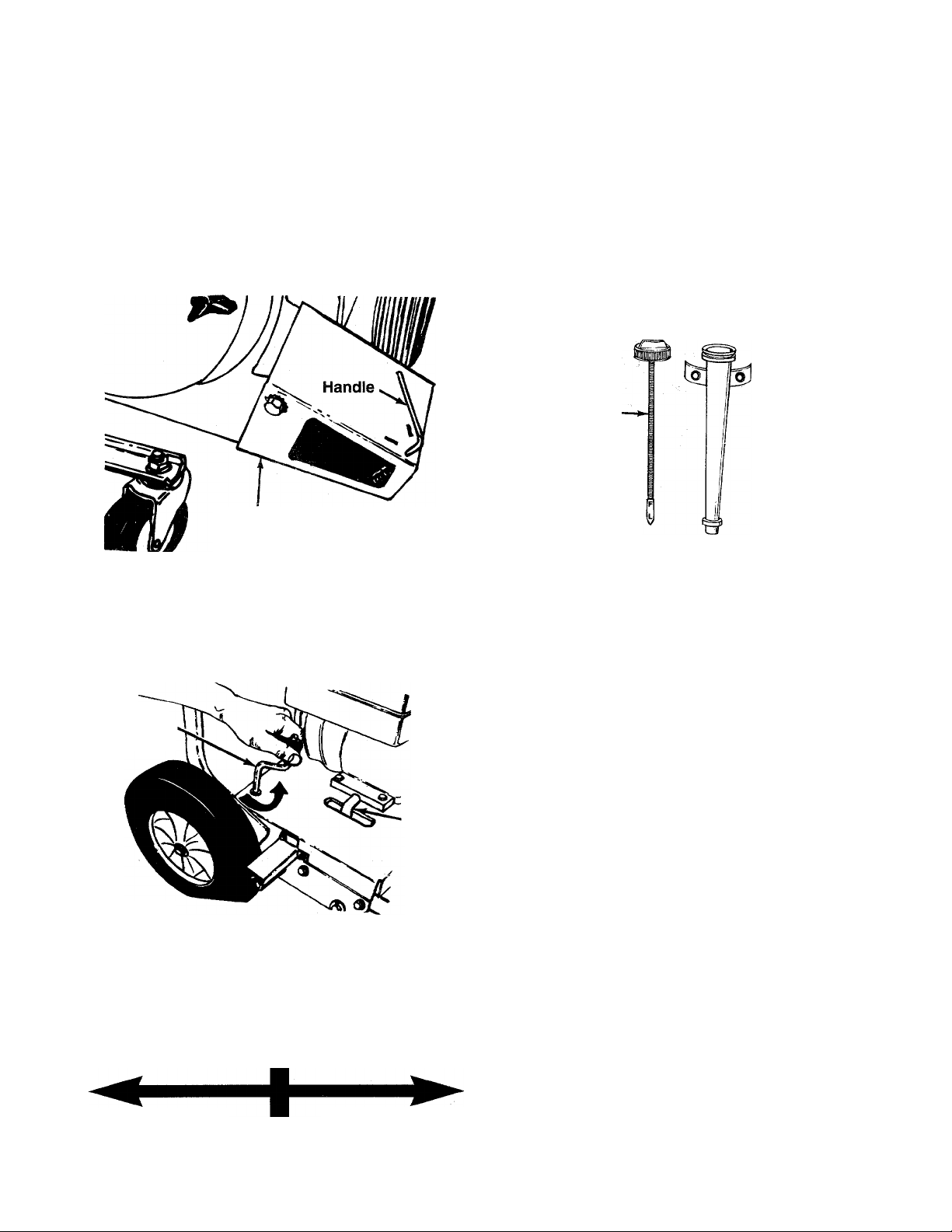

HEIGHT ADJUSTMENT

The height adjustment crank is located on the right

hand side of the air sweeper. See figure 7. Turn the

crank clockwise to raise the discharge chute. Turn the

crank counterclockwise to lower.

Adjustment

FIGURE 7.

OUT FIRST STOPPING ENGINE AND DIS

CONNECTING SPARK PLUG WIRE.

Directional

Discharge

Height

Crank

Oil

Drain

GAS AND OIL FILL-UP

OIL

Only use high quality detergent oil rated with API ser

vice classification SF, SG or SH. Select the oil’s vis

cosity grade according to your expected operating

temperature.

Colder

------------------------

5W30

32°F

-----------------

SAE 30

► Warmer

NOTE: Although multi-viscosity oils (5W30, 10W30,

etc.) improve starting in cold weather, these multi

viscosity oils will result in increased oil consumption

when used above 32°F. Check your oil level more fre

quently to avoid possible engine damage from run

ning low on oil.

• Fill engine with oil as follows. Remove oil fill dip

stick. See figure 8. With air sweeper level, use a

funnel to fill engine with oil to FULL mark on dip

stick. Capacity is approximately 1-1/4 pints. Be

careful not to overfill. Tilt air sweeper toward the

left, then re-level. Check oil level. Refill to FULL

mark on dipstick if necessary. Replace dipstick and

tighten.

Oil

Fill

Dipstick

FIGURE 8.

GAS

• Remove fuel cap and fill fuel tank with about 1 gal

lon of clean, fresh, lead-free grade automotive

gasoline. DO NOT use Ethyl or high octane gaso

line. Be certain container is clean and free from

rust or foreign particles. Never use gasoline that

may be stale from long periods of storage in the

container. Replace fuel cap.

WARNING: DO NOT FILL CLOSER THAN

1/2 INCH OF TOP OF FUEL TANK TO

A

WARNING: EXPERIENCE INDICATES THAT ALCO

HOL BLENDED FUELS (CALLED GASOHOL OR

USING ETHANOL OR METHANOL) CAN ATTRACT

MOISTURE WHICH LEADS TO SEPARATION AND

FORMATION OF ACIDS DURING STORAGE.

ACIDIC GAS CAN DAMAGE THE FUEL SYSTEM

OF AN ENGINE WHILE IN STORAGE. TO AVOID

ENGINE PROBLEMS, THE FUEL SYSTEM

SHOULD BE EMPTIED OR TREATED WITH FUEL

STABILIZER BEFORE STORAGE FOR 30 DAYS

OR LONGER. USE FRESH FUEL NEXT SEASON.

SEE “STORAGE ’ SECTION FOR ADDITIONAL

INFORMATION.

PREVENT SPILLS AND TO ALLOW FOR

FUEL EXPANSION. IF GASOLINE IS

ACCIDENTLY SPILLED, MOVE AIR

SWEEPER AWAY FROM AREA OF

SPILL. AVOID CREATING ANY SOURCE

OF IGNITION UNTIL GASOLINE VAPORS

HAVE DISAPPEARED.

Page 9

NEVER USE ENGINE OR CARBURETOR CLEAN

ER PRODUCTS IN THE FUEL TANK OR PERMA

NENT DAMAGE MAY OCCUR.

Spark Plug,

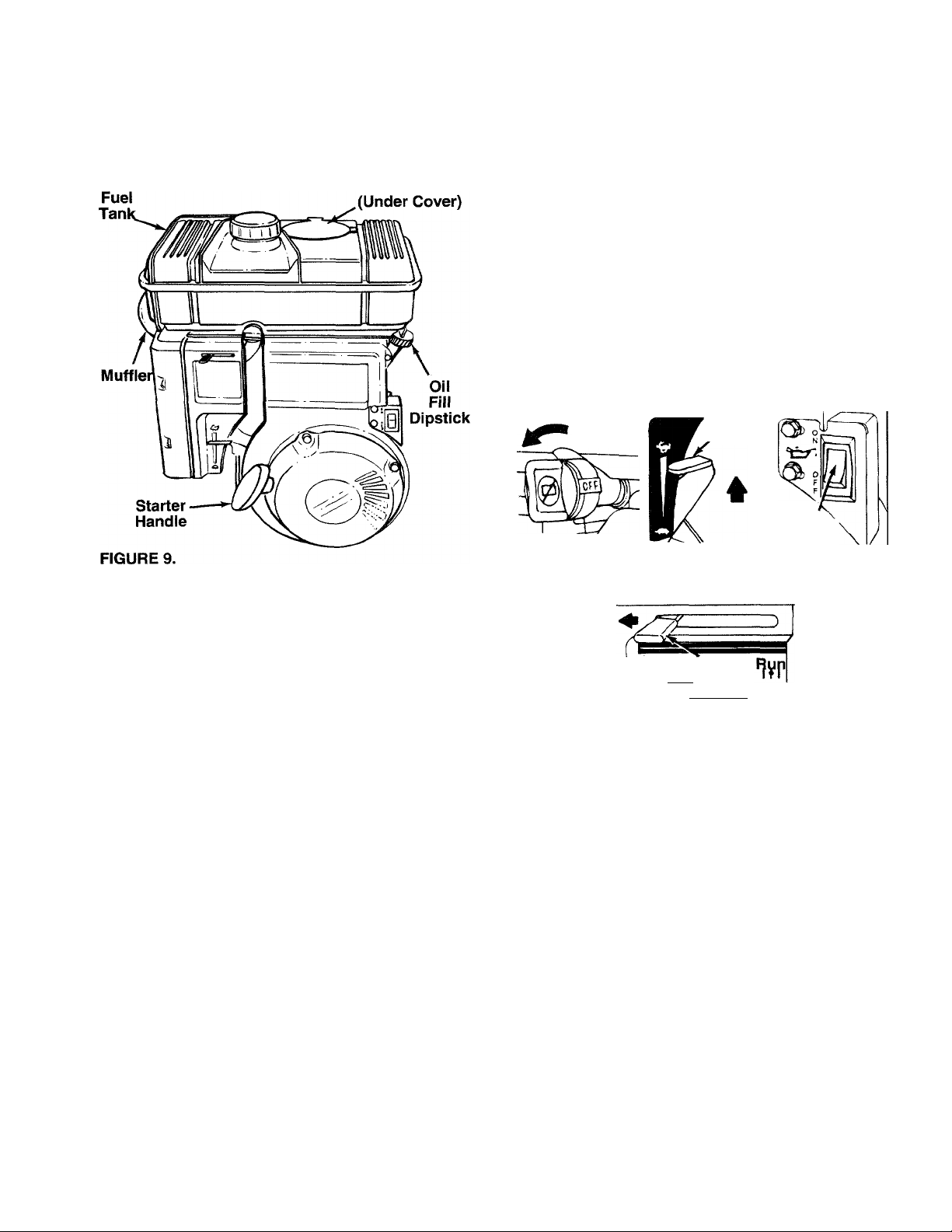

• Grasp starter handle (see figure 9) and pull rope

out slowly until engine reaches start of compres

sion cycle (rope will pull slightly harder at this

point). Let the rope rewind slowly.

• Pull rope with a rapid, continuous, full arm stroke.

Keep a firm grip on starter handle. Let rope rewind

slowly. Do not let starter handle snap back against

starter.

• Repeat preceding two instructions until engine

fires. When engine starts, move choke lever on

engine halfway between CHOKE and RUN.

NOTE: If engine does not fire after three attempts,

move choke lever halfway between CHOKE and RUN

position and try again. See figure 10.

TO START ENGINE

WARNING: DO NOT OPERATE THIS AIR

SWEEPER UNLESS THE DIRECTIONAL

A

• Open cover (on top of fuel tank) and attach spark

plug wire and rubber boot to spark plug if neces

sary. See figure 9.

• Open fuel shut-off valve by turning in direction of

arrow. See figure 10.

• Place the throttle control lever in FAST position.

NOTE: If the throttle control lever fails to stay in the

desired position or if it is hard to move, refer to the

service and adjustment section.

• Move choke lever down to CHOKE position.

• Place the engine shut-off switch in ON position.

DISCHARGE HAS BEEN PROPERLY

INSTALLED AND IS SECURED. REVOLV

ING BLADES—KEEP HANDS AWAY

FROM ALL OPENINGS.

See figure 10.

See figure 10.

On

Position

Fuei Shut-Off

Vaive

?№ Choke

FÌGURE10.

Fast

Position

Throttie

Position

CHOKE

On

Position'

Engine Shut-Off

Switch

TO STOP ENGINE

• Move throttle control lever to SLOW position.

• Move engine shut-off switch to OFF position. See

figure 10.

• Disconnect spark plug wire and move away from

spark plug to prevent accidental starting while

equipment is unattended.

• Close fuel shut-off valve when equipment is not in

use to prevent fuel leakage.

Page 10

CUSTOMER RESPONSIBILITIES

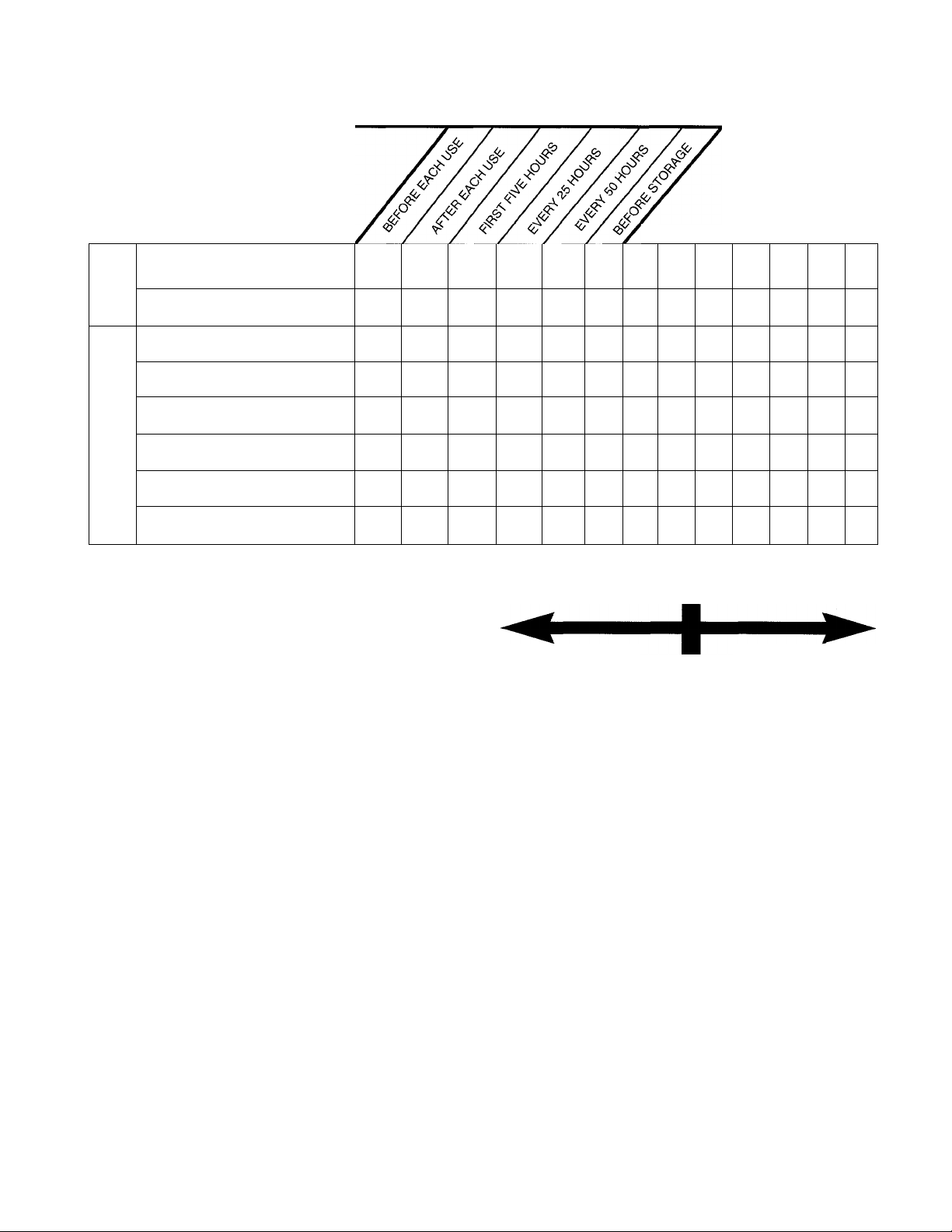

MAINTENANCE SCHEDULE

FILL IN DATES

AS YOU COMPLETE

REGULAR SERVICE

ho

Oil Pivot Points

=)

o

o

cc

Clean Air Sweeper

CL

SERVICE DATES

a/

V

a/

UJ

z

(5

z

lU

V CHECK

Check Engine Oil

Change Engine Oil

Service Air Cleaner

Clean Engine Cylinder

Spark Plug

Muffler

V

GENERAL RECOMMENDATIONS

WARNING: ALWAYS STOP THE ENGINE

AND DISCONNECT THE SPARK PLUG

A

• Periodically check all fasteners and be sure they

are tight.

• Follow the Maintenance Schedule above.

WIRE BEFORE PERFORMING ANY

MAINTENANCE OR ADJUSTMENTS.

AIR SWEEPER

LUBRICATION

• Lubricate the pivot points and the spring on the

directional discharge at least once a season using

a light oil.

CLEANING

• The air sweeper may be cleaned by running water

from a hose through the hopper assembly and

chipper chute with the engine running. Allow the air

sweeper to dry thoroughly.

ENGINE

ENGINE OIL

Only use high quality detergent oil rated with API ser

vice classification SF, SG or SH. Select the oil's vis

cosity grade according to your expected operating

temperature.

V

V

V

V

a/

Colder

NOTE: Although multi-viscosity oils (SAE30, 10W30,

etc.) improve starting in cold weather, these multi- vis

cosity oils will result in increased oil consumption

when used above 32°F. Check your oil level more fre

quently to avoid possible engine damage from run

ning low on oil.

Your four-cycle engine will normally consume some

oil—therefore, check engine oil level regularly approx

imately every five hours of operation and before each

usage. Stop engine and wait several minutes before

checking oil level. With engine level, the oil must be to

FULL mark on dipstick (refer to figure 8). Change

engine oil after the first five hours of operation, and

every twenty-five hours thereafter.

To Drain Oil:

• Drain oil while engine is warm.

a. Remove oil drain plug. Refer to figure 7. Catch

oil in a suitable container.

b. When engine is drained of all oil, replace drain

plug securely.

• Refill with fresh oil. Refer to GAS AND OIL FILL

UP section.

• Replace dipstick.

a/

V

a/

32°F Warmer

5W30

SAE 30

10

Page 11

AIR CLEANER

The air cleaner prevents damaging dirt, dust, etc.,

from entering the carburetor and being forced into the

engine and is important to engine life and per

formance.

Never run your engine without air cleaner com

pletely assembled.

To Service Air Cleaner:

Service pre-cleaner after every 25 hours of use, or at

least once a season. Service cartridge every 100 hours

of use, or at least once a season. Service pre-cleaner

and cartridge more often under dusty conditions.

• Loosen air cleaner cover screws. Remove cover

and air cleaner assembly from base. See figure 11.

• Remove air cleaner assembly from inside cover

and disassemble.

• To service foam pre-cleaner: Remove pre-cleaner.

Wash in liquid detergent and water. Squeeze dry in

a clean cloth. Saturate in engine oil. Squeeze in a

clean, absorbent cloth to remove all excess oil. If

pre-cleaner is very dirty, replace it.

• To service cartridge: Clean by tapping gently on a

flat surface. If very dirty, replace. Do not oil cartridge.

NOTE: Do not use petroleum solvents (e.g. kerosene)

or pressurized air to clean cartridge. They will cause

cartridge to deteriorate.

• Reassemble retainer on pre-cleaner and cartridge

(screen side of pre-cleaner toward cartridge

pleats). Place assembly into cover.

• Insert tabs on cover into slots in base and tighten

cover screws securely.

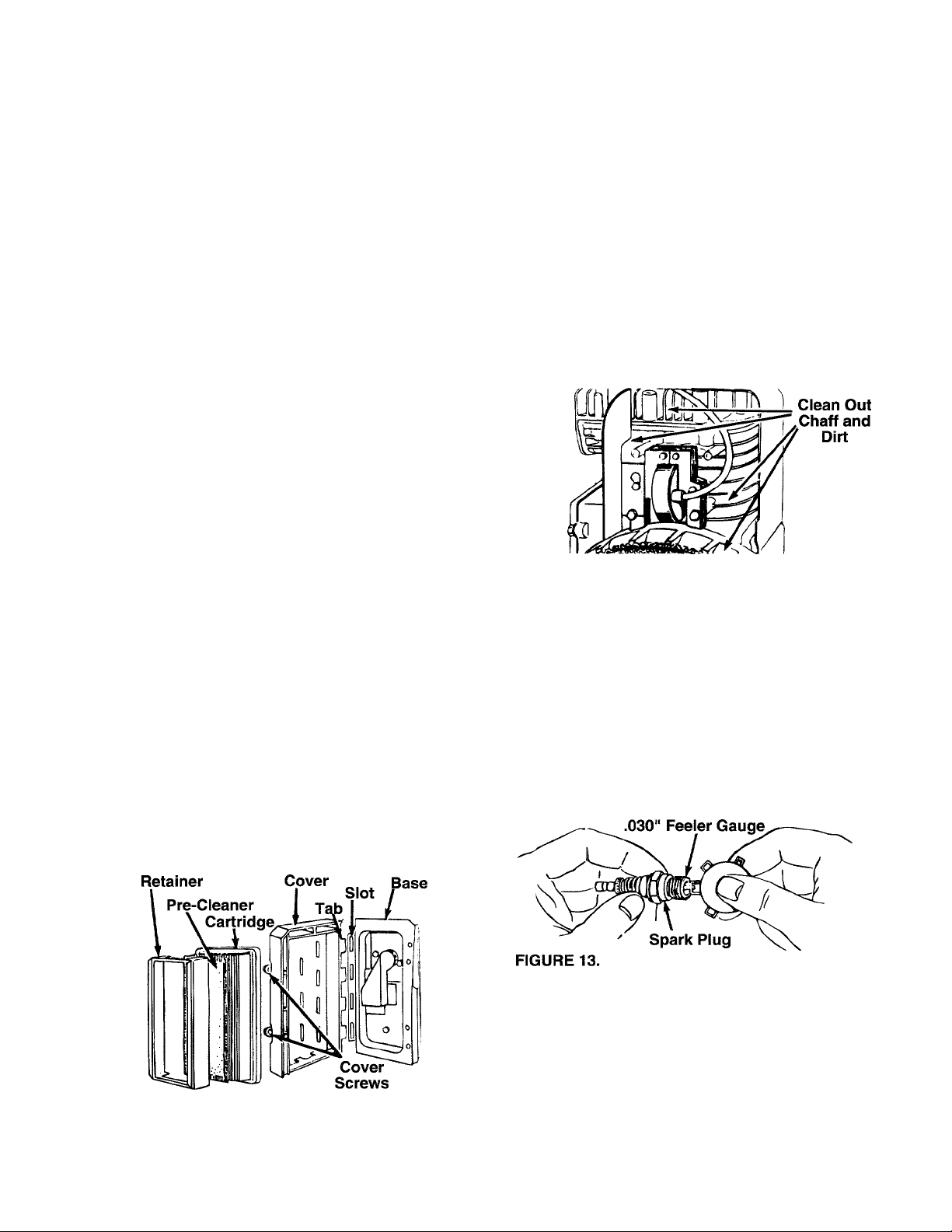

CLEAN ENGINE

Clean engine periodically. Remove dirt and debris

with a cloth or brush. Cleaning with a forceful spray of

water is not recommended as water could contami

nate the fuel system.

Yearly or every 25 hours, whichever occurs first,

remove the blower housing and clean the areas

shown in figure 12 to avoid overspeeding, overheating

and engine damage. Clean more often if necessary.

WARNING: PERIODICALLY CLEAN MUF

FLER AREA TO REMOVE ALL GRASS,

A.

FIGURE 12.

SPARK PLUG

The spark plug should be cleaned and the gap reset

to .030" at least once a season or every 50 hours of

operation. See figure 13. Spark plug replacement is

recommended at the start of each season. Refer to

engine parts list for correct spark plug type.

NOTE: Do not sandblast spark plug. Spark plug

should be cleaned by scraping or wire brushing and

washing with a commercial solvent.

DIRT AND COMBUSTIBLE DEBRIS.

FIGURE 11.

MUFFLER

Do not operate the air sweeper without a muffler or

tamper with the exhaust system. Damaged mufflers or

spark arresters could create a fire hazard. Inspect

periodically, and replace if necessary. If your engine

is equipped with a spark arrester screen assembly,

remove every 50 hours for cleaning and inspection.

Replace if damaged.

11

Page 12

STORAGE

Prepare your air sweeper for storage at the end of the

season or if the unit will not be used for 30 days or

more.

WARNING: NEVER STORE MACHINE

WITH FUEL IN THE FUEL TANK INSIDE

A

NOTE: A yearly check-up by your local Sears Service

Center is a good way to make certain your air

sweeper will provide maximum performance for the

next season.

OF BUILDING WHERE FUMES MAY

REACH AN OPEN FLAME OR SPARK, OR

WHERE IGNITION SOURCES ARE

PRESENT SUCH AS HOT WATER AND

SPACE HEATERS, FURNACES, CLOTHES

DRYERS, STOVES, ELECTRIC MOTORS,

ETC.

AIR SWEEPER

• Clean the air sweeper thoroughly.

• Wipe unit with an oiled rag to prevent rust (use a

light oil or silicone).

ENGINE

IMPORTANT: IT IS IMPORTANT TO PREVENT

GUM DEPOSITS FROM FORMING IN ESSENTIAL

FUEL SYSTEM PARTS SUCH AS CARBURETOR,

FUEL FILTER, FUEL HOSE, OR TANK DURING

STORAGE. ALSO, EXPERIENCE INDICATES THAT

ALCOHOL BLENDED FUELS (CALLED GASOHOL

OR USING ETHANOL OR METHANOL) CAN

ATTRACT MOISTURE WHICH LEADS TO SEPARA

TION AND FORMATION OF ACIDS DURING STOR

AGE. ACIDIC GAS CAN DAMAGE THE FUEL SYS

TEM OF AN ENGINE WHILE IN STORAGE.

• Drain the fuel tank.

• Start the engine and let it run until the fuel lines and

carburetor are empty.

• Never use engine or carburetor cleaner products in

the fuel tank or permanent damage may occur.

• Use fresh fuel next season.

NOTE: Fuel stabilizer is an acceptable alternative in

minimizing the formation of fuel gum deposits during

storage. Add stabilizer to gasoline in fuel tank or stor

age container. Always follow the mix ratio found on

stabilizer container. Run engine at least 10 minutes

after adding stabilizer to allow the stabilizer to reach

the carburetor. Do not drain the gas tank and carbure

tor if using fuel stabilizer.

• Drain all the oil from the crankcase (this should be

done after the engine has been operated and is still

warm) and refill the crankcase with fresh oil.

• If you have drained the fuel tank, protect the inside

of the engine as follows. Remove spark plug, pour

approximately 1/2 ounce (approximately one table

spoon) of engine oil into cylinder and crank slowly

to distribute oil. Replace spark plug.

OTHER

• Do not store gasoline from one season to another.

• Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your gasoline will cause problems.

• Store unit in a clean, dry area. Do not store next to

corrosive materials, such as fertilizer.

NOTE: If storing in an unventilated or metal storage

shed, be certain to rustproof the equipment by coating

with a light oil or silicone.

12

Page 13

SERVICE & ADJUSTMENT

WARNING: ALWAYS STOP ENGINE AND

DISCONNECT SPARK PLUG WIRE AND

A

MOVE IT AWAY FROM SPARK PLUG

BEFORE PERFORMING ANY ADJUST

MENTS OR REPAIRS.

THROTTLE ADJUSTMENT

To adjust throttle control lever, loosen or tighten wing

nut until throttle control lever moves with some resis

tance and still remains in desired position when

engine is running. See figure 14.

Throttle

Control

Lever

The carburetor may need re-adjusting if engine lacks

power or does not idle properly. If adjustments are

needed, proceed as follows.

• Close idle mixture valve (see figure 15) clockwise

() finger tight only. Forcing may cause damage.

Then open 1-1/2 turns counterclockwise ().

• Start engine and allow to warm for five minutes.

• Move throttle control lever to IDLE position.

• Rotate throttle counterclockwise (i^ ) and hold

against idle speed adjusting screw. Turn idle speed

adjusting screw until engine is running at 1750

RPM.

• Turn idle mixture valve clockwise () (lean mix

ture) until engine JUST starts to slow. Then turn it

counterclockwise ((rich mixture) until engine

starts to run unevenly. Set at midpoint between rich

and lean mixture.

• Recheck idle RPM and readjust if necessary.

• Move throttle control lever to FAST position.

Engine should accelerate without hesitation or

sputtering. If it does not, carburetor should be read

justed, usually to a slightly richer mixture.

FIGURE 14.

CARBURETOR ADJUSTMENT

WARNING: IF ANY ADJUSTMENTS ARE

MADE TO THE ENGINE WHILE THE

A

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude

or load.

NOTE: A dirty air cleaner will cause engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor. Do not

make unnecessary adjustments. Factory settings are

satisfactory for most applications and conditions.

Never attempt to change maximum engine speed. It is

pre-set at the factory and should be changed only by

a qualified service technician who has the necessary

equipment.

ENGINE IS RUNNING (E.G. CARBURE

TOR), KEEP CLEAR OF ALL MOVING

PARTS. BE CAREFUL OF HEATED SUR

FACES AND MUFFLER.

ENGINE SPEED

Your engine speed has been factory set. Do not

attempt to increase engine speed or it may result in

personal injury. If you believe the engine is running

too fast or too slow, take your air sweeper to the

nearest SEARS Service Center for repair and adjust

ment.

13

Page 14

TROUBLE SHOOTING

PROBLEM POSSIBLE CAUSE(S)

Engine fails to start • Engine shut-off switch OFF.

Loss of power; • Spark plug wire loose.

operation erratic • Unit running on CHOKE.

Engine overheats • Carburetor not adjusted properly.

Too much vibration • Loose parts or damaged

Unit does not

discharge

• Fuel shut-off valve closed.

• Fuel tank empty, or stale fuel.

• Spark plug wire disconnected. • Connect wire to spark plug.

• Faulty spark plug.

• Biocked fuel line or stale fuel.

• Water or dirt in fuel system.

• Carburetor out of adjustment.

• Dirty air cleaner.

• Engine oil level low.

• Air flow restricted.

crankshaft.

• Directional discharge clogged.

• Foreign object lodged in air vane

plate assembly.

CORRECTIVE ACTION

• Move switch to ON position.

• Open fuel shut-off valve.

• Fill tank with clean, fresh fuel.

• Clean, adjust gap or replace.

• Connect and tighten spark plug wire.

• Move choke lever to OFF position.

• Clean fuel line; fill tank with clean fresh gasoline.

• Disconnect fuel line at carburetor to drain fuel

tank. Refill with fresh fuel.

• Adjust carburetor or contact your SEARS Service Center.

• Service air cleaner. See Customer Responsibilities

section of this manual.

• Contact your SEARS Service Center.

• Fill crankcase with proper oil.

• Remove blower housing and clean.

• Stop engine immediately and disconnect

spark plug wire. Tighten all bolts and nuts.

Make all necessary repairs. If vibration continues,

have unit serviced by a SEARS Service Center.

• Stop engine immediately and disconnect

spark plug wire. Clean discharge area and inside

of blower housing.

• Stop engine immediately and disconnect

spark plug wire. Remove lodged object.

NOTE: For repairs beyond the minor adjustments listed above, please contact your nearest SEARS Service Center.

HOW TO ORDER REPLACEMENT PARTS

Each air sweeper has its own model number. Each

engine has its own model number.

The model number for your air sweeper will be found

on a label attached to the frame.

The model number for the engine will be found on the

blower housing of the engine.

All parts listed herein may be ordered through Sears,

Roebuck and Co. Service Centers and most Retail

Stores.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE

THE FOLLOWING INFORMATION:

‘PRODUCT - “5 H.P. Air Sweeper”

‘MODEL NUMBER - 247.797900

‘ENGINE MODEL NO. -133412-0059-01

‘PART NUMBER

‘PART DESCRIPTION

Your Sears merchandise has added value when you

consider that Sears has service units nationwide

staffed with Sears trained technicians...professional

technicians specifically trained on Sears products,

having the parts, tools and the equipment to ensure

that we meet our pledge to you...“we service what we

sell.”

14

Page 15

SEARS CRAFTSMAN 5 H.P. AIR SWEEPER MODEL NO. 247.797900

Repair Parts

REF.

NO.

PART

NO.

1 749-0784

2 726-0100

720-0171

3

736-0117

4

133412-0059-01

5

710-0442

6

7 16453

736-0119

8

712-0267

9

736-0187

10

11 714-0115

12 712-0206

736-0921

13

14 734-1036

15 16273

710-0726

16

17 14529

747-0542

18

DESCRIPTION

Upper Handle

Push Nut 3/8" Rod

REF.

NO.

20

21 710-0170

Crank Knob

FI-Wash. .385" I.D. x .62"

22 736-0162

Engine—B&S 133412-0059-01 23

Hex Bolt 5/16-18 X 1.50" Lg.‘

24 750-0528

Engine Mounting Frame Ass’y.

L-Wash. 5/16" I.D.*

Hex Nut 5/16-18 Thd.*

FI-Wash. .63" I.D. X 1.25"

Cotter Pin 1/8" Dia. x 1.0"

Hex Nut 1/2-13 Thd.*

25

26

27 710-0118

28

29 09966

L-Wash. 1/2" I.D.* 30

Swivel Caster Wheel 5" Dia. 31

X 1.25"

Caster Arm Ass’y.

Hex Wash. Hd. “AB” Tap Scr.

5/16" X .75" Lg.

Caster Arm Bracket

32 734-1035

33 751-0596

34 710-0227 Hex Wash. Hd. AB-Tap Scr.

—

Height Adjustment Crank

PART

NO.

736-0159

FI-Wash. .34" I.D. x .87" O.D.

DESCRIPTION

Hex Locking Bolt 5/16-24 x

.64" Lg.

Fi-Wash.

736-0300

FI-Wash. .38" I.D. x .57"

Spacer .382" I.D. x .50"

X.180" Lg.

736-0169

L-Wash. 3/8" I.D.*

712-0354 Hex Nut 3/8-8 Thd.

Hex Bolt 5/16-18 X.75" Lg.*

711-0797 Ferrule

Hand Knob

710-0487 Carriage Bolt 5/16-18 x 2.0"

749-0785 Lower Handle

Wheel Ass’y. Comp. 12" x 3"

Outlet Pipe

#8 X .5" Lg.

770-8839L Owner’s Manual

‘Common Hardware—May Be Purchased Locally. NOTE: Specifications subject to change without

notice or obligation.

15

Page 16

SEARS CRAFTSMAN 5 H.R AIR SWEEPER MODEL NO. 247.797900

Repair Parts

KEY

NO.

PART

NO.

1

14539

2

710-0600 Hex Self-Tap Scr. 5/16" x .5"

3

710-0118

4

736-0119 L-Wash. 5/16" I.D.* 17 736-0217

14541

5

6 710-0627

7

710-0260 Carriage Bolt 5/16-18 x .62" 22

Engine Housing Brace Ass’y.

Hex Bolt 5/16-18 X.75" Lg.* 16 710-0191 Hex Bolt 3/8-24 x 1.25"*

Right Angle Bracket

Hex Locking Bolt 5/16-24 x .75"

DESCRIPTION

KEY

NO.

14

15 14563 Nozzle Plate Ass’y.

18 681-0075 Air Vane Plate Ass’y.

19

8 14479 Directional Discharge Ass’y.

11

736-0119 L-Wash. 5/16" I.D.*

12 712-0267

Hex Nut 5/16-18 Thd.* 24 720-0170

23

13 731-0608 Blower Guard

*Common Hardware—May Be Purchased Locally.

16

PART

NO.

DESCRIPTION

711-0758 Hex Shoulder Nut .50" I.D.

L-Wash. 3/8" I.D.-H.D.

14496A

Blower Housing Ass’y.-Comp.

710-0259 Hex Sems Bolt 5/16-18 x .62"

736-0242

Lg*

Bell-Wash. .34" I.D. x .87" O.D.

3-Arm Thumb Scr. 5/16-18 x .75“

Lg.

Page 17

BRIGGS AND STRATTON 5 H.P. ENGINE MODEL NO. 133412-0059-01

Repair Parts

11

REF.

NO.

1

2 399268

3

5

7

8

9

10

11 66578

13

13A

14 94679

15

200

227 494906

230

305A 94619

306

307 94680

308

337

383

528

552

562

592

614 93306

615

616

635

869

870

871 262001

978

979

982

1019

PART

NO.

495133

*299819

214040

*272157

495774

*27549

94621

94221

94167

94387

223886 Guide—Air

94742

224820

224740

802592 Plug—Spark

89838

231818

231079

92613

231082 Nut—Hex

93307

231077

66538

211787

211436

*271736

494807 Cover—Oil Gard®

94658

495861

Cylinder Assembly

Bushing—Cylinder

Seal—Oil

Head—Cylinder

Gasket—Cylinder Head

Breather—Valve Chamber

Gasket—Valve Cover

Screw—Breather Mtg.

Grommet—Breather Tube

Screw—Cylinder Head (2-5/16"

Stud—Cylinder Head

Screw—Cylinder Head (2-15/32"

Plug—Pipe, 1/4" Std., Square Head

Lever Ass’y—Governor

Washer—Governor Lever

Screw—Hex Hd.

Shield—Cylinder

Screw—Cylinder Shield

Cover—Cylinder Head

Wrench—Spark Plug

Tube—Breather

Bushing—Governor Crank

Bolt—Governor Lever

Cotter-Pin

Retainer—E-Ring

Crank—Governor

Elbow—Spark Plug

Seat—Intake Valve

Seat—Exhaust Valve (Cobalite®)

Guide—Exhaust Valve

Note: 63709 Guide—Intake

Valve.

Gasket—Cover

Screw—Oil Gard® Cover

Label Kit

DESCRIPTION

Long)

Long)

528^

If 614

230 615

305A

REQUIRES SPECIAL TOOLS

TO INSTALL. SEE REPAIR

INSTRUCTION MANUAL.

984

REF.

NO.

75

98A

165

201

209

222 494899

232 260585

284 94620

346

347 493521

663

984 224746

Included in Gasket Set—Part No. 495661.

PART

NO.

495659

493280 Screw Ass’y.—Speed Adj.

94692 Nut—Wing

262865

262283

93705

93343

Washer Kit

Link—Governor

Spring—Governor

Plate—Gov. Control

Spring—Link

Screw—Hex Hd.

Screw—Sem

Switch—Rocker

Screw—Sem

Bracket—Indicator Light

DESCRIPTION

Assemblies include all parts shown in frames.

17

Page 18

BRIGGS AND STRATTON 5 H.P. ENGINE MODEL NO. 133412-0059-01

Repair Parts

REF.

NO.

12 *270080 Gasket—Crankcase (.015" Thick,

16

18

19 495660 Bushing—Crankcase Cover

20 495307 Seal—Oil

21 66768 Plug—Oil Filler

22 94682 Screw—Crankcase Cover

24

25 393819

26

27 26026

28 298909 Pin Ass’y.—Piston (Std.)

29 299430 Rod Ass’y.—Connecting

30 221890

32 94745

33 211119

34

35

36

40

45

46 212733

219

220 221551

284 94620

441 224240 Bracket—Oil Fill

523

524 *271485

525 280578 Tube—Oil Fill

741 261696

842 *270920 Seal—Oil Fill Cap

847

Included in Gasket Set—Part No. 495661.

PART

NO.

*270125

*270126 Gasket—Crkcse. (.009" Thick)

495845

493916

222698

393820 Piston Ass’y. (.010" O.S.)

393821

393822

399067

399014 Ring Set—Piston (.010" O.S.)

399015 Ring Set—Piston (.020" O.S.)

399016 Ring Set—Piston (.030" O.S.)

298908 Pin Ass’y.—Piston (.005" O.S.)

390459 Rod Ass’y.—Connecting

261044

260552 Spring—Intake Valve

26478 Spring—Exhaust Valve

93312 Retainer—Spring

260642 Tappet—Valve

494845

494416 Dipstick and Cap Ass’y.

494417

Gasket—Crkcse. (.005" Thick)

Crankshaft

Note: To Replace Crankshaft

Gear Pin—Order Part No. 230978.

Cover Ass’y-—Crankcase

Key—Flywheel

Piston Ass’y. (Std.)

Piston Ass’y. (.020" O.S.)

Piston Ass’y. (.030" O.S.)

Ring Set—Piston (Std.)

Lock—Piston Pin

Dipper—Conn. Rod

Screw—Conn. Rod

Valve—Exhaust

Valve—Intake

Gear—Cam

Gear—Governor

Washer—Thrust

Screw—Hex Hd.

Seal—Oil Fill

Gear—Timing

Tube Ass’y.—High Oil Fill

DESCRIPTION

Std.)

Mounting Sem

(.020" Undersize Crankpin Bore)

‘REQUIRES SPECIAL TOOLS

TO INSTALL. SEE REPAIR

INSTRUCTION MANUAL.

Assemblies include all parts shown in frames.

18

Page 19

BRIGGS AND STRATTON 5 H.P. ENGINE MODEL NO. 133412-0059-01

Repair Parts

REF.

NO.

PART

NO.

51 *272295

52

*272585

53 94706

•

94098

398185

224783

95

98

104

108

111 262820

116

118

•A

•493765

124 94681

125

127

130

495652 Carburetor Assembly

•

223470

131 493556

133

134 •398188

137

398187

•

141 495651

164

611

281247

494451

634 •A

634A •A

955 495650

975 493640

DESCRIPTION

Gasket—Carburetor Mtg.

Gasket—Intake Port

Screw—Adapter Mtg.

Screw—Round Head

Screw—Idle Adjusting

Pin—Hinge (Sold in Kit Only)

Valve—Choke

Spring—Lever

Gasket—Sealing

(Sold in Kit Only)

Valve and Spring—Needle

Screw—Hex Washer Head

Plug—Welch

Valve—Throttle

Shaft and Lever—^Throttle

Float Assembly—Carburetor

Valve—Inlet (Includes Seat)

Gasket—Bowl (Sold in Kit Only)

Shaft—Choke

Manifold—Intake

Elbow—Fuel Pipe

Seal—Shaft (Sold in Kit Only)

Seal—Choke Shaft

(Sold in Kit Only)

Screw—Fuel Bowl

Bowl Assembly—Carburetor

REF.

NO.

159

445

535

642 281188

843

966

969 94120

971 94727

PART

NO.

280871

494511

495246

280149

494902

DESCRIPTION

Support—Filter

Filter—Air Cleaner

Element—Air Cleaner

Cover—Air Cleaner

Sleeve—Lever

Base—Air Cleaner

Screw—Hex Head

Screw—Hex Head

Included in Gasket Set—Part No. 495661.

Included in Carburetor Overhaul Kit—Part No. 493762.

i Included in Carburetor Gasket Set—Part No. 490937.

REF.

NO.

54 94705

284 94620

300

613 94729

832 494903

864

883 *272309

PART

NO.

DESCRIPTION

Screw—Hex Head

Screw—Hex Hd.

494562

Muffler—Exhaust

Screw—Sem

Guard—Muffler

494904 Flange—Muffler

Gasket—Exhaust

Muffler Spark Arrester Kit

Part No. 494905 (Optional Equipment)

Assemblies include all parts shown in frames.

19

Page 20

BRIGGS AND STRATTON 5 H.P. ENGINE MODEL NO. 133412-0059-01

Repair Parts

REF.

NO.

182

184

185

187

PART

NO.

DESCRIPTION

224709 Bracket—Fuel Tank

93559

94010

393815

Screw—Hex Hd.

Nut—Hex

Line-Fuel

(11" Long, Cut to Suit)

187A

188 94357 Screw—Hex Head

429

601

495218 Pipe—Fuel (Molded)

281190

Cover—Spark Plug

93053 Clamp—Fuel Pipe (Green)

Note: 93807 Clamp—Fuel Pipe

(Black)

957 493988 Cap-Fuel Tank

958 494539

972

495345

Valve Ass’y-—Fuel Shut-Off

Tank Ass’y-—Fuel

Inciuded in Gasket Set—Part No. 495661.

958

^188

REF.

NO.

55 494846

56

57 262594

58

PART

NO.

DESCRIPTION

Housing—Rewind Starter

493824 Pulley—Rewind Starter

Spring—Rewind Starter

280406

Rope—Rewind Starter

(Cut to Required Length)

59

60 393152

65 94686

69 280973

69A 224322 Washer—Rewind Starter

456

459 492833

461 262626

515 262625

608

1016

396892 Insert—Starter Handle

Handle—Rewind Starter

Screw—Starter Mtg.

Washer—Rewind Starter

224321 Retainer—Rewind Starter

Pawl—Starter

Pin—Starter

Spring—Torsion

494782 Starter Ass’y.—Rewind

224278

Cover—Rewind Starter

Assemblies include all parts shown in frames.

20

Page 21

BRIGGS AND STRATTON 5 H.P. ENGINE MODEL NO. 133412-0059-01

Repair Parts

REF.

NO.

23 297229

37 222443

73

304 494790

305 94619

332

333 397358

335

356

356A

363

455 494770

851

REF.

NO.

3

7 *272157

9

12 *270080

20

51 *272295

52 *272585

104

116

118 •493765

121

127

134

137

358

524

634 •A

634A

842 *270920 Seal—Oil Fill Cap

883

977 490937

978 *271736

PART

NO.

Flywheel—Magneto

Guard—Flywheel

224633

92284 Nut—Flywheel

93414 Screw—Armature Mounting Sem

495135

495118 Wire Assembly

19069

221798

PART

NO.

*299819

*27549

*270125

*270126

*495307 Seal—Oil

•

•A

493762 Carburetor Overhaul Kit

•

•398188

•

495661

*271485

•A Seal—Choke Shaft (Sold in Kit

*272309

Screen—Rotating

Housing—Blower (Red)

Screw—Blower Housing Mounting

Armature Group

Wire Assembly

Puller—Flywheel

Hub—Starter

Cable Terminal—Ignition

Seal—Oil

Gasket—Cylinder Head

Gasket—Valve Cover

Gasket—Crankcase

Gasket—Crankcase

Gasket—Crankcase

Gasket—Carburetor Mtg.

Gasket—Intake Port

Pin—Hinge (Sold in Kit Only)

Gasket—Sealing (Sold in Kit

Valve and Spring—Needle

Plug—Welch

Valve—Inlet (Includes Seat)

Gasket—Bowl (Sold in Kit Only)

Gasket Set

Seal—Oil Fill

Seal—Shaft (Sold in Kit Only).

Gasket—Exhaust

Gasket Set—Carburetor

Gasket—Cover

DESCRIPTION

(Armature to Switch)

(Stop Switch to Ground)

DESCRIPTION

(.015" Thick, Standard)

(.005" Thick)

(.009" Thick)

Only)

Only)

§ 0 ©

104

127 116

© @

137 i

634A 634

121 CARBURETOR OVERHAUL KIT

Included in Gasket Set—Part No. 495661.

Included in Carburetor Overhaul Kit—Part No. 493762.

Included in Carburetor Gasket Set—Part No. 490937.

Assemblies include all parts shown In frames.

977 CARBURETOR

GASKET SET

21

Page 22

Page 23

MANUAL DEL

PROPIETARIO

NUMERO DEL

MODELO

247.797900

CRflFTSMRN

Precaución:

Lea y observe

todas las reglas

e instrucciones

de seguridad antes

de operar este

equipo

SEARS, ROEBUCK AND C0„ Chicago, IL 60684 U.S.A.

5.0 CABALLOS DE FUERZA

BARREDOR DE AIRE

Armado

Operación

Responsabilidades dei Cliente

Servicio y Ajuste

Piezas de Reparación

___________

770-8839L 8/95

Page 24

IMPORTANTE ■ NORMAS DE SEGURIDAD

ESTE SIMBOLO INDICA INSTRUCCIONES IMPORTANTES PARA SU SEGURIDAD. DEBEN SEGUIRSE RIGUROSAMENTE PARA

EVITAR PELIGROS PARA EL OPERADOR Y OTROS. LEA LAS SIGUIENTES INSTRUCCIONES DE ESTE MANUAL ANTES DE INSTA

LAR EL EQUIPO DE ILUMINACION. FALTA DE OBEDECER ESTAS INSTRUCCIONES PUEDE RESULTAR EN DAÑO PERSONAL.

A

CUANDO VEA ESTE SIMBOLO^PRESTE ATENCION A SU ADVERTENCIA.

A

PELIGRO' igual que con cualquier máquina , falta de cuidado o error por parte del

Su barredor de aire fue diseñado para operar según ias reglas de seguridad de este

A

I. OPERACION

1. Lea este manual del propietario antes de tratar de ensamblar

A

esta máquina. Lea, comprenda y siga todas las instrucciones

de la máquina y del manual antes de la operación. Es nece

sario familiarizarse con los controles y el uso correcto de la

máquina antes de ponerla en funcionamiento. Mantenga este

manual en un lugar seguro para poder consultarlo como sea

necesario y para hacer el pedido de repuestos.

2. Su barredor de aire es una herramienta muy potente, no un

juguete. Por lo tanto, es sumamente importante manejarlo

siempre con mucha precaución. Su unidad ha sido diseñada^

para cumplir con solo la función de soplar hojas. No la utilice

para ninguna otra función.

3. No permita que los niños menores de 14 años utilicen la

máquina. Niños mayores de 14 años deben operarla sola

mente bajo la supervisión de un adulto. Solamente personas

responsables que saben estas reglas de seguridad deben usar

su unidad.

4. Mantenga el área de operaciones libre de personas, sobretodo

niños pequeños y animales domésticos. Apague el motor

cuando se encuentren cerca de la unidad.

5. Utilice siempre anteojos de seguridad durante la operación y

siempre que efectúe un ajuste o reparación, para proteger los

ojos de objetos y escombros que pueden ser arrojados por la

máquina.

6. Vista con ropa ajustada. Se recomiendan pantalones y

camisas que cubran los brazos y las piernas. No use ropa

suelta ni alhajas y lleve el cabello bien atado más arriba de los

hombros, porque de lo contrario pueden ser cogidos por

piezas en movimiento.

7. No opere esta unidad bajo la influencia del alcohol o drogas.

8. Nunca coloque sus manos o cualquier parte del cuerpo o ropa

cerca de piezas en movimiento. Manténgase siempre lejos de

la abertura de expulsión. Nunca meta sus manos, dedos, pies

o cualquier otra parte del cuerpo o ropa en las aberturas de

expulsión o de toma de aire ya que la impulsor giratorio dentro

de la caja puede causar serias lesiones.

9. Nunca opere la unidad sin una pieza de descarga direccional y

un protector de impulsor plástico adecuadamente fijado a la

unidad. Estos aparatos protegen el operador del contacto acci

dental con el impulsor giratorio.

10. Mantenga todos los resguardos y aparatos de seguridad en su

lugar y funcionando de manera adecuada.

II. Tenga mucho cuidado al operar el soplador. No permita que el

descargador este apuntando en dirección a personas o ani

males domésticos.

12. Si su máquina empieza a hacer ruidos o una vibración extraña,

inmediatamente apague el motor, desconecte el cable de bujía

y muévalo lejos de la bujía. Permita que la máquina pare com

pletamente y siga los siguientes pasos:

• Inspeccione para ver si hay daños.

• Repare o reemplace cualquier pieza dañada.

• Revise que no hayan piezas sueltas y si las hay apriételas

para asegurar una operación segura.

13. El silenciador y el motor se calientan mucho y pueden causar

una quemadura. No toque.

14. No permita que se acumulen hojas u otros objetos en el silen

ciador del motor. Los escombros pueden prenderse y causar

un incendio.

15. No opere el motor si el depurador de aire o la cobertura sobre

el toma de aire del carburador esta quitada, excepto para hacer

ajustes. La remoción de tales piezas puede crear un peligro de

incendio.

operador puede resultar en lesiones serias, manos y arrojar objetos.

Esta unidad puede cortar los dedos y las

16. Use solamente accesorios aprobados por el fabricante para

esta máquina. Lea, comprenda y siga todas las instrucciones

suministradas con el accesorio aprobado.

17. Opere la unidad solamente en buena luz del día. No la use

durante la noche o en áreas oscuras donde su visión no es

adecuada.

18. Si ocurren situaciones que no están mencionadas en este man

ual, tenga mucho cuidado y use su sentido común. Llame a su

distribuidor para recibir asistencia.

II. NIÑOS

^Accidentes trágicos pueden suceder si el operador no está alerto a

la presencia de niños pequeños. Los niños a menudo son atraídos

por el soplado. Nunca suponga que los niños permanecerán en el

mismo sitio donde Ud. los vio hace poco.

1. Mantenga a ios niños lejos del área de trabajo y bajo la super

visión de un adulto además del operador de la máquina.

2. Este alerta y apague la unidad si algún niño se acerca al área.

3. Nunca permita que niños menores de 14 años utilicen el

barredor.

III. MANTENIMIENTO

1. Tenga mucho cuidado con la gasolina y otros tipos de com

bustibles. Son extremadamente inflamables y los gases son

explosivos.

a. Almacene el combustible y el aceite en contenedores ade

cuados, lejos de fuentes de calor, llamas y lejos del alcance

de los niños.

b. Revise y añada el combustible necesario antes de encender

el motor. Nunca quite el tapón del tanque o añada com

bustible mientras de que la máquina se encuentre en fun

cionamiento. Permita que enfríe el motor por lo menos por

dos minutos antes de llenar el tanque.

c. Vuelva a colocar el tapón del tanque de gasolina y limpie los

residuos de gasolina antes de encender de nuevo el motor

ya que puede causar fuego o una explosión.

d. Apague todos los cigarrillos, puros, pipas y otras fuentes de

ignición.

e. Nunca llene el tanque bajo techo porque los gases inflam

ables se acumularán en el área.

f. Nunca almacene la máquina o el contenedor de combustible

bajo techo donde haya fuego o chispas tales como un calen

tador de agua caliente (de gas), una secadora u horno.

2. Nunca use su máquina en un lugar cerrado ya que el escape

del motor contiene monóxido de carbono, el cual es un gas

venenoso mortal sin olor ni sabor.

3. Para reducir el peligro de incendio, mantenga el motor y el

silenciador limpio, sin hojas, zacate u otros tipos de residuos.

Limpie los derrames de combustible y de aceite. Permita que

la unidad enfríe por lo menos por cinco minutos antes de

almacenarla.

4. Antes de limpiar, reparar o inspeccionar la máquina, asegúrese

de que el impulsor y todas las piezas movibles se hayan

detenido. Desconecte el cable de bujía y muévalo lejos de la

bujía para evitar el arranque accidental. No utilice soluciones

inflamables para limpiar el filtro de aire.

5. Mantenga bien apretados todas las tuercas, tornillos y pernos

para asegurar que el equipo se encuentre en buena condición

de operación.

6. Nunca cambie o altere los aparatos de seguridad. Revise el

funcionamiento adecuado regularmente.

7. No cambie ni altere la programación del regulador del motor.

El regulador controla la velocidad máxima de operación segura

del motor. Un aumento de velocidad es peligroso y causará

daños al motor y a otras piezas en movimiento de la máquina.

Page 25

Manual del Propietario

Etiqueta de

Seguridad

A

ADVERTENCIA — su RESPONSABILIDAD

Limite el uso de esta unidad a personas que ieen, comprenden y siguen ias

advertencias e instrucciones de este manual y de la máquina.

FELICIDADES por la compra de su barredor de aire

Craftsman de Sears. Ha sido diseñado, mecanizado y

fabricado para darle la mejor seguridad y rendimiento.

Si usted tiene algún problema que no puede resolver fácil

mente, por favor envíe el barredor de aire a

Centro/Departamento de Reparaciones de Sears en los

Estados Unidos. Contamos con personal competente y las

herramientas adecuadas para dar mantenimiento y reparar

la unidad.

Por favor lea y mantenga este manual. Estas instrucciones

le permitirán ensamblar y mantener su barredor de aire

adecuadamente. Siempre preste atención a las “NORMAS

DE SEGURIDAD.”

NUMERO

DEL MODELO 247.797900

NUMERO

DE SERIE.

FECHA DE

COMPRA_

EL MODELO Y EL NUMERO DE SERIE SE ENCUEN

TRAN EN UN ROTULO PEGADO A LA ARMAZON.

USTED DEBE TOMAR EL NUMERO DE SERIE Y LA

FECHA DE COMPRA Y MANTENER LA INFORMACION

EN LUGAR SEGURO PARA FUTURA REFERENCIA.

RESPONSABILIDADES

DEL PROPIETARIO

• Lea y observe las notas de seguridad.

• Siga un horario regular de mantenimiento, cuidado y uso

de su barredor de aire.

• Siga las instrucciones que se encuentran en ias sec

ciones “Responsabilidades del Cliente” y “Almacenaje”

en el Manual del Propietario.

ESPECIFICACIONES DEL PRODUCTO

Caballos de Fuerza

Desplazamiento

Capacidad de Combustible

Aceite de Motor

API Classificación SF, SG o SH

Bujía (Espacio .030")

Tapa de Aire de Encendido Magnetron .0125"

ADVERTENCIA: Esta unidad está equipada con un motor

interno de combustión y no se debe usar en ningún o cerca

a un terreno forestal, con arbustos o con césped al menos

que el sistema de escape dei motor tenga un amortiguador

de chispas que cumpla con las normas locales o del estado

(si existen). Si se usa un amortiguador de chispas, el oper

ador lo debe mantener en buena condición de operación.

En ei Estado de California lo antes mencionado es requeri

do por la ley (Sección 4442 del Código de Recursos

Públicos de California). Otros estados puede que tengan

leyes similares. Las normas federales aplican a los ter

renos federales. Un amortiguador de chispas para la silen

ciador es disponible en el Centro de Servicio Autorizado de

Sears. (Véase sección REPUESTOS de este manual.)

1 Galón (sin plomo)

J19LM (o Equivalente)

5.0

12.57" cúbico

SAE 30

20 onzas

Champion

CONTRATO DE MANTENIMIENTO

Un Contrato de Mantenimiento de Sears es disponible en

este producto. Llame a su tienda Sears más cercana para

más información.

GARANTIA POR UN AÑO COMPLETO EN EL BARREDOR DE AIRE CRAFTSMAN

Garantía por un año a partir de la fecha de compra, siempre que este barredor de aire se mantenga en buen estado, se

lubrique y se afine de acuerdo con las instrucciones de mantenimiento del manual del operador. Sears reparará sin costo

alguno cualquier defecto del material o de elaboración.

Esta garantía excluye la bujía y el depurador, las cuales son piezas de duración limitada y se desgastan con el uso normal.

Si este barredor de aire se usa para razones comerciales o para el alquiler, esta garantía aplica sólo por 30 días a partir de

la fecha de compra.

LA GARANTIA ESTA DISPONIBLE A TRAVES DE SU CENTRO DE SERVICIO SEARS MAS CERCANO EN LOS ESTA

DOS UNIDOS. ESTA GARANTIA APLICA SOLAMENTE MIENTRAS ESTE PRODUCTO ESTE EN USO DENTRO DE

LOS ESTADOS UNIDOS.

Esta garantía le proporciona derechos legales específicos y es posible que usted tenga otros derechos que varían de esta

do a estado.

SEARS ROEBUCK AND CO., SEPT. 817WA, HOFFMAN ESTATES, IL 60179

Page 26

TABLA DE MATERIAS

REGLAS DE SEGURIDAD

ESPECIFICACIONES DEL PRODUCTO

ACUERDO DE MANTENIMIENTO

RESPONSABILIDADES DEL

PROPIETARIO

GARANTIA

ACCESORIOS................................................................4

_______

Éstos accesorios eran disponibles cuando se adquirió el barredor de aire. También se pueden adquirir en la may

oría de los almacenes de venta y centros de servicio. La mayoría de las tiendas Sears pueden pedir los

repuestos para usted, una vez que usted proporcione el número del modelo de su barredor de aire.

...............................................

.....................................................................

ACCESORIOS DEL BARREDOR DE AIRE

.........................................

......................

................................

4, 10, 11

2, 3

4

4

4

ARMADO

OPERACION...............................................................7-9

RESPONSABILIDADES DEL PROPIETARIO ...10, 11

ALMACENAJE..............................................................12

MANTENIMIENTO Y AJUSTES

GUIA PARA RESOLUCION DE PROBLEMAS

PIEZAS DE REPUESTO..............................................19

.....................................................................

.............................

12, 13

.............

_______

5, 6

18

MOTOR

BARREDOR DE AIRE

Page 27

INSTRUCCIONES DE ARMADO

IMPORTANTE: Esta unidad es enviada SIN GASOLINA O

ACEITE. Después de ensamblarla, vea la sección de

operación de este manual para seguir las recomendaciones

adecuadas de aceite y combustible.

NOTA: Para determinar cuál es el lado derecho y el

izquierdo de su barredor, colóquese detrás de la palanca en

la posición de operación.

DESEMPAQUE

Su barredor, ha sido completamente ensamblado en la

fábrica excepto por la palanca superior y la pieza de

descarga '{tireccional. Véase figura 1. La bolsa con los

herrajes también está incluida en el cartón. El paquete de

el herraje contiene las piezas que se demuestran en la

figura 2.

• Quite la grapas o rompa la goma en las tapas del cartón.

• Corte el cartón a lo largo de cada esquina y déjelo caer

al suelo. Saque el barredor del cartón.

• Asegúrese de que todas las piezas y la información

adjunta haya sido removida antes de botar el cartón.

HERRAMIENTAS REQUERIDAS PARA EL ENSAMBLAJE

(1) Una llave de tuerca ajustable de 1/2”

Page 28

FIGURA 3.

Palanca

Superior

COMO MONTAR SU BARREOOR DE AIRE

FIJACION DE LA PALANCA SUPERIOR

Coloque la palanca superior sobre la palanca inferior, aline

ando los agujeros de la palanca superior con los de la infe

rior. Fije con pernos de cabeza encorvada, con arandelas

' de soporte y botones de mano. Véase figura 3.

FIGURA 4.

FIJACION DE LA PIEZA DE DESCARGA DIRECCIONAL

Deslice el extremo de la pieza de descarga sobre la

abertura del canal. Fije en posición con los pernos

hexágonos con arandelas de seguridad. Véase figura 4.

Pieza de

Descarga

Direccional

Page 29

OPERACION

CONOZCA BIEN SU BARREDOR DE AIRE

LEA ESTE MANUAL DEL PROPIETARIO Y LAS NORMAS DE SEGURIDAD ANTES DE OPERAR SU BARREDOR DE

AIRE.

Compare las ilustraciones con su barredor de aire para familiarizarse con los puntos de varios controles y ajustes. Guarde

este manual para futura referencia.

Válvula de Bujía, Cable y

Cierre de Cubierta (Debajo

Combustible

Tanque de

Combustible-

Silenciador,)

X

de la Tapa)

Palanca de la Pieza de

Descarga Direccional

FIGURA 5.

CONTROLES DE OPERACION (Véase figura 5)

PALANCA DE LA PIEZA DE DESCARGA DIRECCIONAL—Usela para cambiar ia dirección de descarga de

aire hacia el frente o al lado.

PALANCA DE CHOQUE—Usada para enriquecer la

mezcla de comestible en el carburador al encender un

motor frío.

Palanca i

Choque <

Control de

Regulador '

Palanca de

Arranque

NOTA: Ver también la figura 12.

INTERRUPTOR PARA APAGAR EL MOTOR—Usado para

apagar el motor.

VALVULA DE CIERRE DE COMBUSTIBLE—Usada para

cerrar el paso de combustible al carburador.

CONTROL DE REGULADOR—Permite la selección de

velocidad rápida o despacio del motor.

Varilla para

, Comprobar el

Nivel del

Aceite

Interruptor

para

Apagar el

Motor

PALANCA DE ARRANQUE-

manualmente.

ANTES DE USAR SU BARREDOR DE AIRE, HAGA OTRA VEZ REFERENCIA A LAS “NORMAS DE SEGURIDAD”

DEMOSTRADAS EN LA PAGINA 2 DE ESTE MANUAL. SIEMPRE TENGA CUIDADO.

-Usada para arrancar el motor

La operación de cualquier barredor de aire puede resultar en todo tipo de objetos volando y

siendo tirados a los ojos, lo cual puede dañar severamente los ojos. Use siempre anteojos de

seguridad o protección antes de encender la unidad o mientras la este ajustando o reparando.

Recomendamos una Careta Ancha de Seguridad para usarla sobre gafas o anteojos de

seguridad estándar. Disponibles en las Tiendas Sears.

Page 30

PARA APAGAR EL MOTOR

• Mueva la palanca del control de regulador a la posición

SLOW.

• Mueva el interruptor a la posición OFF. Véanse figuras 8

a 12.

• Desconecte el cable de bujía y aléjelo de la bujía para

prevenir el arranque accidental mientras el equipo está

solo.

• Cierre la válvuia de corte de comestible siempre que ei

equipo no este en uso para prevenir ei escape de com

bustible.

COMO USAR SU BARREDOR DE AIRE

ABASTECIMIENTO DE GASOLINA Y ACEITE

ACEITE

Use solamente aceite con detergente de alta calidad clasifi

cado con API: SF, SG o SH. Selecciones el grado de vis

cosidad del aceite de acuerdo con la temperatura de

operación atmosférica.

Más Frio-*- 32°F

5W30

'Más Caliente

SAE 30

ADVERTENCIA: NO AJUSTE BAJO NINGUNA

CIRCUNSTANCIA LA UNIDAD, SIN PRIMERO

A

DESCARGA DE DOS DIRECCIONES

El barredor de aire puede ajustarse para descargar hacia el

frente de la unidad o hacia el lado. Simplemente empuje

hacia a bajo la palanca y gire la puerta hacia el frente para

descargar hacia el lado o al lado para descargar hacia ade

lante. Véase figura 6.

APAGAR EL MOTOR Y DESCONECTAR EL

CABLE DE BUJÍA.

Pieza de

Descarga

Direccional

NOTA: A pesar de que el aceite de múltiple viscosidad

(5W30, 10W30, etc.) ayuda a arrancar la máquina en tiem

po frío, el aceite de múltiple viscosidad resultarán en un

aumento de consumo cuando se usan sobre los 32°F.

Revise el nivel del aceite más a menudo para evitar posi

bles daños al motor por tener poco aceite.

• Llene el motor con aceite del siguiente modo. Quite la

varilla para comprobar el nivel del aceite. Véase figura 8.

Con el barredor de aire plaño, use un embudo para

llenar el motor con aceite hasta la marca FULL de la

varilla de medición. La capacidad aproximada es de

1-1/4 pintas. Tenga cuidado de no llenarlo demasiado.

Revise el nivel del aceite. Llene hasta la marca FULL de

la varilla de medición si es necesario. Vuelva a instalar la

varilla y apriétela.

Varilla para Comprobar -

el Nivel del Aceite

FIGURA 6.

AJUSTE DE ALTURA

La manivela para ajustar la altura se encuentra al lado

derecho del barredor. Véase figura 7. Gire la manivela

hacia la derecha para levantar el canal de descarga. Gírelo

en posición contraria para bajarlo.

Manivela para

Ajustar la

Altura

Drenaje de

Aceite

FIGURA 7.

FIGURA 8.

GASOLINA

Quite el tapón y llene el tanque de combustible con

aproximadamente up galón de gasolina para automóvil

limpia, fresca y sin ptqmo. NO USE Etilo o gasolina con

alto octano. Asegúres^ de que el contenedor este limpio

y que no este herrumbrado ni tenga residuos. Nunca use

gasolina que tiene mucho tiempo de estar en almacenaje

en el contenedor. Vuelva a colocar el tapón del tanque.

ADVERTENCIA: Úp LLENE DEMASIADO EL

TANQUE. DEJE UN ESPACIO DE 1/2 PULGA

A

DA DEL BORDE PARA PREVENIR EL

CHORREO Y PARA PERMITIR LA EXPAN

SION DEL COMBUSTIBLE. SI SE RIEGA LA

GASOLINA ACCIDENTALMENTE, MUEVA EL

CORTADOR DE LEÑO A OTRA AREA LIMPIA.

EVITE CREAR CUALQUIER FUENTE DE IGNI

CION HASTA QUE LOS VAPORES DE LA

GASOLINA HAYAN DESAPARECIDO.

Page 31

ADVERTENCIA: LA EXPERIENCIA INDICA QUE LOS

COMBUSTIBLES DE ALCOHOL MEZCLADOS (CONOCI

DOS COMO GASOL O USO DE ETANOL O METANOL)

PUEDEN ATRAER HUMEDAD LO CUAL LLEVA A LA

SEPARACION Y FORMACION DE ACIDOS DURANTE EL

ALMACENAJE. EL GAS ACIDO PUEDE DAÑAR EL

SISTEMA DE COMBUSTION DE UN MOTOR DURANTE

EL ALMACENAJE. PARA EVITAR PROBLEMAS CON EL

MOTOR, EL SISTEMA DE COMBUSTIBLE SE DEBE

VACIAR O TRATAR CON UN ESTABILIZADOR DE COM

BUSTIBLE ANTES DE ALMACENAR LA MAQUINA POR

30 DIAS O MAS TIEMPO. USE COMBUSTIBLE FRESCO

LA PROXIMA ESTACION. VEA LA SECCION “ALMACE

NAJE” PARA MAS INFORMACION.

NUNCA USE PRODUCTOS PARA LIMPIAR EL CARBU

RADOR O EL MOTOR EN EL TANQUE DE COM

BUSTIBLE O DE LO CONTRARIO PUEDE CAUSAR

DAÑO PERMANENTE.

Bujía, Cable y

Cubierta (Debajo

de la Tapa)

Tanque de

:)ombustible

Silenciador

Variiia para

Comprobar

el Nivel dei

Palanca de

Arranque

FIGURA 9.

PARA ARRANCAR EL MOTOR

• Abra la tapa (encima del tanque de combustible) y

conecte el cable de bujía y la cubierta de hule a la bujía

como sea necesario. Véase la figura 9.

• Abra la válvula de cierre de combustible dándole vuelta

en dirección de la flecha. Véase figura 10.

• Coloque la palanca de control del regulador en la posi

ción FAST. Véase figura 10.

NOTA: Si la palanca de control del regulador no se

mantiene en la posición deseada o si es difícil de mover,

vea la sección de mantenimiento y ajustes.

• Mueva la palanca de choque hacia abajo a la posición

de CHOKE.

• Coloque el interruptor del motor en la posición ON.

Véase figura 10.

Aceite

En posición

Váivuia para Cierre

de Comestibie

Posición

rápida

Reguiador

Posición

de

Arranque

interruptor para

Apagar ei Motor

Э

^WPosìcìónàeT^

—

---

-----

Choque —

Marcha

CHOQUE

FIGURA 10.

• Tome el mango del arrancador (Véase figura 9) y jale la

cuerda despacio hasta que el motor alcance el comienzo

del ciclo de compresión (la cuerda tirará un poco más

fuerte en este punto). Permita que la cuerda se enrolle

despacio.

• Jale la cuerda de manera rápida y continua. Mantenga

firme la palanca de arranque. Permita que la cuerda se

enrolle despacio. No permita que la palanca de arranque

se devuelva bruscamente contra el arrancador.

• Repita las dos instrucciones anteriores hasta que se

encienda el motor. Cuando encienda, mueva la palanca

de choque en el motor a mitad entre CHOKE y RUN.

NOTA: Si el motor no se enciende después de tres inten

tos, mueva la palanca de choque a mitad en la posición

entre CHOKE y RUN y vuelva a intentar. Véase figura 10.

PARA APAGAR EL MOTOR

• Mueva la palanca de control del regulador a la posición

SLOW.

• Mueva el interruptor para apagar el motor a la posición

OFF. Véase figura 10.

• Desconecte el cable de bujía y aléjelo de la bujía para