Page 1

I

MODELNOS.

247.797852

247.797853

Caution:

ReadandFollow

AllSafetyRules

andinstructions

BeforeOperating

ThisEquipment

5 HORSEPOWER

3 CUTTUNG STAGE

MULCHUNG AND BAGGING

CHBPPER-SHREDDER

Assembly

Operation

Maintenance

Serviceand Adjustment

RepairParts

SEARS,ROEBUCKANDCO.,Chicago,IL 60684 U.S.A.

Page 2

SAFETY RULES

WARNING: TO REDUCE THE POTENTIAL FOR ANY INJURY, COMPLY WITH THE FOLLOWING

SAFETY INSTRUCTIONS. FAILURE TO COMPLY WITH THE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY.

TRAINING

e Read this owner's manual carefully in its entirety before

attempting to assemble or operate this machine Be com-

pletely familiar with the corrtrols and the proper use of this

machine before operating it Keep this manual in a safe

place for future and regular reference and for ordering

replacement parts

e Children must never be allowed to operate this equipment

e No one should operate this unit while intoxicated or while

taking medication that impairs the senses or reactions

e This equipment should never be operated in the vicinity

of children, pets or other persons

e Never run your machine in an enclosed area as the

exhaust from the engine contains carbon monoxide, which

is an odorless, tasteless and deadly poisonous gas

e Never place your hands or any part of your body or cloth-

ing inside the feeding chamber, discharge chute, or near

any moving part while the machine or engine is running.

e If it is necessary for any reason to inspect or repair the

feeding chamber or any part of the machine where a mov-

ing part can come in contact with your body or clothing,

stop the machine, allow it to cool, disconnect the spark

plug wire from the spark plug and move it away from the

spark plug before attempting such inspection or repair,

PREPARATION

e Wear safety glasses provided with your unit while operat-

ing the chipper-shredder to prevent injury from any mate-

rial which may be ejected out of the openings

e Wear proper apparel Avoid wearing loose fitting clothing

Wear gloves when handling material

e HANDLE GASOLINE WITH CARE as it is an extremely

flammable fuel

e Cbeck the fuel before starting the engine Do not fill the

fuel tank irrdoors,while the engine is running, or while the

engine is still hot Turn the unit off and let the engine coo!

before refueling

e Fuel your chipper-shredder in a clean area Do not

smoke while refueling

e Fuel tank cap must be secure at all times except during

refueling

e Avoid spilling gasoline or oil Wipe the unit clean of any

spilled fuel or oil.

e Store fuel and oil in approved containers, away from heat

or open flame, and out of reach of children

® This machine should be operated only upon a levelsurface

e Assure that all screws, nuts and bolts and other fasteners

are properly secured

OPERATION

e When feeding shreddable material into this equipment,

be extremely careful that pieces of metal, rocks, bottles,

cans or other foreign objects are not included Personal

irrjury or damage to the machine could result

e If the cutting mechanism strikes any foreign object or if

your machine should start making an unusual noise or

vibration, immediately stop the engine, disconnect the

spark plug wire from the spark plug arrd move it away

from the spark plug Allow the machine to stop and take

the following steps:

Inspect for damage

Replace or repair any damaged parts

Check for any loose parts and tighten to assure contin-

ued safe operation

e The engine must be kept clean of debris and other accu-

mulations.

e Do not allow an accumulation of processed material to

build up in the discharge area as this will prevent proper

discharge and can result in kick-back from feed opening

e Never place your hands or any other part of your body or

clothing inside the feeding chamber, discharge chute or

near any moving part while the engine is running

e Keep all guards and deflectors in place arrd in good work-

ing condition to assure continued safe operation

e Always stand clear of the discharge area when operating

this machine

e Keep your face and body back from the feed opening to

avoid accidental bounce back of any material.

e Do not over-reach Keep proper balance arrd footing at all

times

• The engine governor settings on your machine must not

be altered, changed, or tampered with The governor

controls the maximum safe operating speeds and pro-

tects the engine and all moving parts from damage

caused by ovetspeed.

e Do not transport machine while engine is running

e Do not operate engine if air cleaner or cover directly over

carburetor air intake is removed, except for adjustment

Removal of such parts could create a fire hazard

MAINTENANCE AND STORAGE

e When this equipment is stopped for servicing, inspection,

storage or to change an accessory, make sure the spark

plug wire is disconnected from the spark plug and moved

away from the spark plug The machine should be

allowed to cool down before making such irrspection,

adjustments, service, etc Maintain your machine with

care and keep it clean for the best and continued safe

operation

e Do not use flammable solutions to clean the air filter

e When not in use, your machine should be stored out of

the reach of children Keep where gasoline fumes will not

reach an open flame or spark For long periods of stor-

age, refer to the "Storage" section of this manual

LOOK FOR THIS SYMBOLTO POINT OUTJ

IMPORTANT SAFETY PRECAUTIONS. ITI

MEANS--ATTENTION!!! BECOMEALERT!!!

YOURSAFETYIS INVOLVED.

]

Page 3

CONGRATULATIONS on your purchase of a Sears

Craftsman Chipper-Shredder It has been designed, engi-

neered and manufactured to give you the best possible

dependability and performance

Should you experience any problem you cannot easily rem-

edy, please contact your nearest Sears Service Center/

Department. We have competent, well4rained technicians

and the proper tools to service or repair this unit

Please read and retain this manual The instructions will

enable you to assemble and maintain your chipper-shredder

properly Always observe the "SAFETY RULES "

MODEL

NUMBER

3ERIAL

NUMBER

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE FOUND

ON A LABEL ATTACHED TO THE FRAME OF THE

CHIPPER-SHREDDER

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE

i

PRODUCT SPECRRCATRONS

Horsepower: 5 0

Displacement: 12,57 cu. in.

Fuel Capacity: 3 Quarts

Spark Plug (Gap 030 in): Champion

J19LM or

Equivalent

Magnetron ® Ignition Air Gap: 0125 in

MADNTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product, Contact your nearest Sears store for details

CUSTOMER RESPONSUB LBTaES

e Read and observe the safety rules

e Follow a regular schedule in maintaining, caring for and using your chipper-shredder

e Follow the instructions under "Maintenance" and "Storage" sections of this Owner's Manual

WARRANTY

ONEYEARLIMITEDWARRANTYONCRAFTSMANGASCHIPPER-SHREDDER

For one year from the date of purchase, when this Craftsman Chipper-Shredder is maintained, lubricated and

tuned up according to the instructions in the owner's manual, Sears will repair, free of charge, any defect in

material and workmanship

If this Craftsman Chipper-Shredder is used for commercial or rental purposes, this warranty applies for only 30

days from the date of purchase

This warranty does not cover:

e Expendable items which become worn during normal use, such as blades, chipper blades, flails, air cleaners,

spark plugs and catcher bags

e Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure to

maintain the equipment according to the instructions contained in the owner's manual

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN CHIPPER-SHREDDER TO THE

NEAREST SEARS SERVICE CENTER/DEPARTMENT IN THE UNITED STATES THIS WARRANTY

APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED STATES

This warranty gives you specific legal rights, and you may also have other rights which may vary from state to

state

SEARS, ROEBUCK AND CO,, Department 731CR-W, Sears Tower, Chicago, IL 60684

3

Page 4

TABLE OF CONTENTS

SAFETY RULES .............................................................. 2

PRODUCT SPECIFICATIONS ............................................3

CUSTOMER RESPONSIBILITIES ..................................3

WARRANTY ..........................................................................3

INDEX .......................................................................................................4

ASSEMBLY ........................................................................5, 6

OPERATION .......................................................... 7-10

MAINTENANCE ................................................................10, 11

INDEX

A

Adjustments:

Carburetor, ...............................................................................14

Engine Speed ........................................................ 15

Assembly Instructions:

Catcher Bag .......................................................................6

Chute Crank Deflector ............................................ 6

Hopper' Assembly ....................................................................6

Catcher Bag ................................................................. 6

C

Catcher Bag .......................................................................6

Controls ........................................................................... 7

Customer Responsibilities ....................................................3

E

Engine:

Maintenance ....................................................................10, 11

Starting ..........................................................................8

Stopping ................................................................. 9

Storage .....................................................................................12

F

Fuel .................................................................................. 8

L

Lubrication ..................................................................... 10

M

Maintenance:

Agreement ........................................................... 3

Engine .......................................................................................10, 11

Chipper-Shredder ...........................................................10

STORAGE .........................................................................12

SERVICE AND ADJUSTMENT ............................ 13-15

SERVICE RECOMMENDATIONS ........................................15

TROUBLE SHOOTING ...................................................16

REPAIR PARTS--CHIPPER-SHREDDER .........17, 18

REPAIR PARTS--ENGINE .........................................19-23

PARTS ORDERING/SERVICE ................... Back Cover

O

Oil ..........................................................................................8

Operating Tips .................................................................9, 10

R

Release Bar .........................................................................7

Repairs'Replacement Parts ........................................17-23

Responsibilities, Customer, ................................................3

S

Safety Rules ..................................................................... 2

Sharpening .................................................................13, 14

Service Recommendations .......................................... 15

Spark Plug ..................................................................... 11

Specifications ................................................................. 3

Storage ...............................................................................12

T

Table of Contents ...............................................................4

Trouble Shooting ..................................................................16

U

Unclogging .......................................................................13

Unpacking ......................................................................................5

W

Warranty ...........................................................................3

WARNING: This unit is equipped with an internal combustion engine and should not be used on or near any

unimproved forest-covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped

with a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be main-

tained in effective working order' by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code)_

Other states may have similar law& Federal laws apply on federal land& A spark arrester for the muffler (see

page 23) is available through your Sears Authorized Service Center.

Page 5

ASSEMBLY INSTRUCTnONS

m

r._i7

Flat ---_/t_

Washer [ _ ) ]

5/16" I.D.

HeX Lock

ut 5/16-18

Thread

Hex Bolt

•,,----5/16-18 x 8-3/8" Long

IMPORTANT: This unit is shipped WITHOUT GASO-

LINE or OIL After assembly, see operation section of

this manual for proper fuel and engine oil recommen-

dations.

NOTE: To determine right and left hand sides of your

chipper-shredder, stand behind and face the hopper

(engine is at the front of the unit).

Your chipper-shredder has been completely assem-

bled at the factory, except for the hopper assembly

(hopper hood and upper leaf ramp section have been

sub-assembled), upper guide assembly, chute deflec-

tor and the catcher bag. The hardware pack and safe-

ty glasses are also included in the carton.

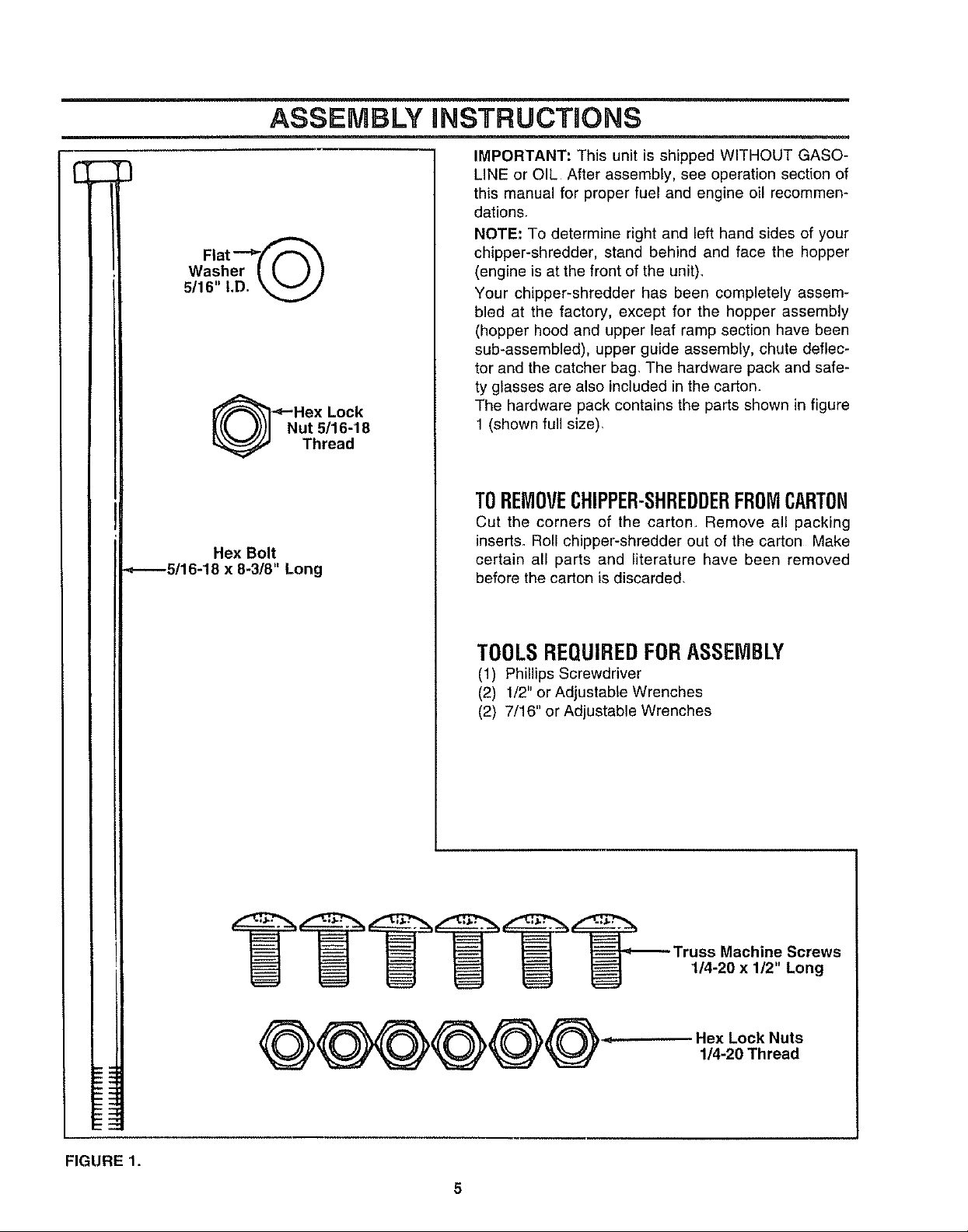

The hardware pack contains the parts shown in figure

1 (shown full size).

TOREMOVECHIPPER-SHREDDERFROMCARTON

Cut the corners of the carton Remove all packing

inserts. Roll chipper-shredder out of the carton Make

certain all parts and literature have been removed

before the carton is discarded,

_=:

TOOLSREQUIREDFORASSEMBLY

(1) Phillips Screwdriver

(2) 1/2" or Adjustable Wrenches

(2) 7/16" or Adjustable Wrenches

.oxLock.ats

_=VJ V_ _' _ ' 1/4-20 Thread

FIGURE 1.

Page 6

HOWTOSET-UPYOURCHIPPER-SHREDDER

Hex

Nut ,.

Knob

J

FIGURE 2,

/

FIGURE 3.

Hopper Pivot

Door

ASSEMBLE THIS \

TRUSS SCREW

AND NUT FIRST

Release"

Bar

FIGURE 4.

FIGURE 5.

Stop

Washer

Release

8-3/8" Long

Flat Washer

Hex Lock Nut

Guide

Assembly

Bar

Remove Truss

Screw and Nut

Drawstring

Bolt

Chute

Deflector

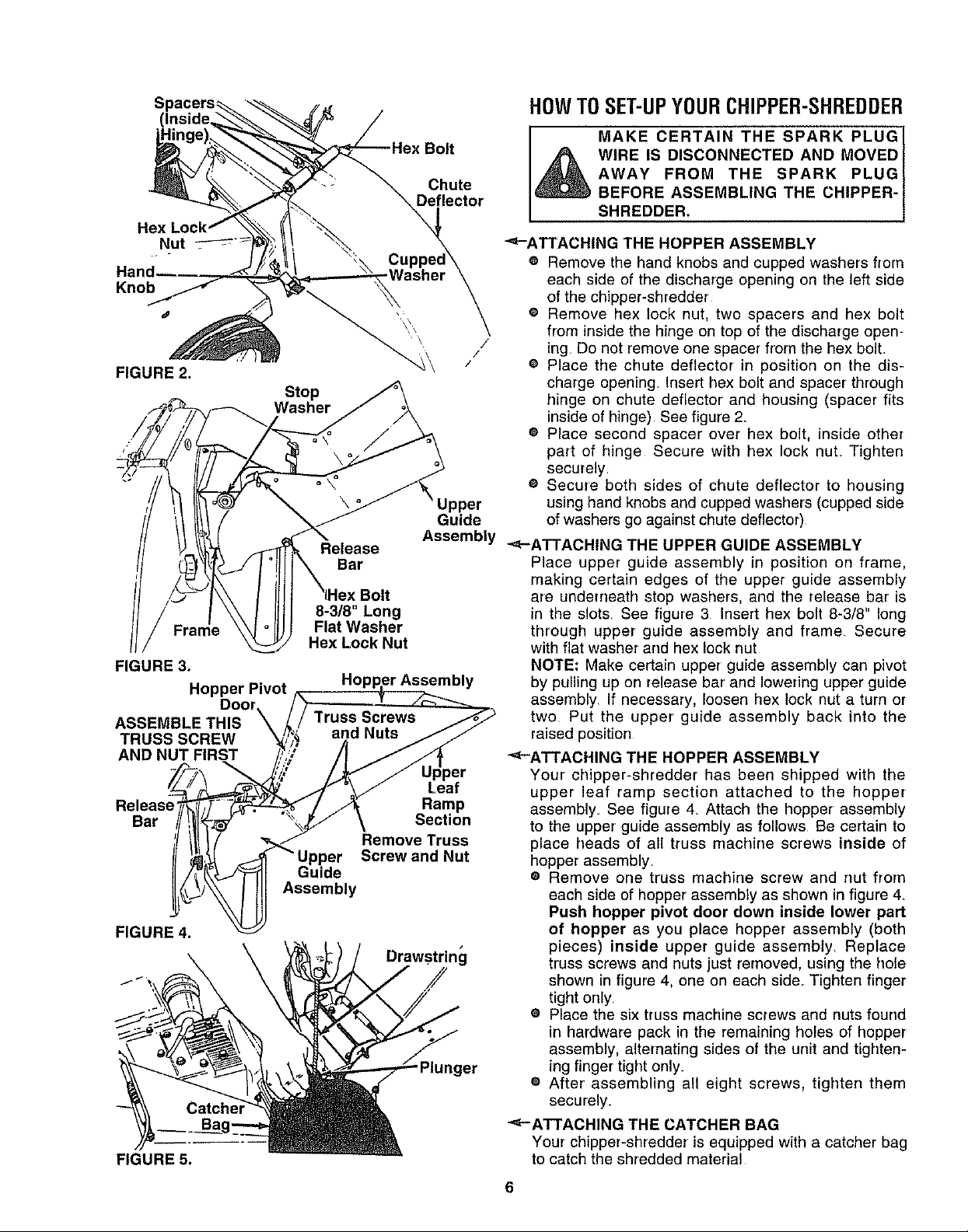

_"-ATTACHING THE HOPPER ASSEMBLY

e Remove the hand knobs and cupped washers from

each side of the discharge opening on the left side

of the chipper-shredder

e Remove hex lock nut, two spacers and hex bolt

\ /

/

Upper using hand knobs and cupped washers (cupped side

Guide of washers go against chute deflector)

Assembly "<,-ATTACHING THE UPPER GUIDE ASSEMBLY

ly by pulling up on release bar and lowering upper guide

Leaf

Ramp

Section

/

from inside the hinge on top of the discharge open-

ing Do not remove one spacer from the hex bolt.

e Place the chute deflector in position on the dis-

charge opening Insert hex bolt and spacer' through

hinge on chute deflector and housing (spacer fits

inside of hinge) See figure 2.

e Place second spacer over hex bolt, inside other

part of hinge Secure with hex lock nuL Tighten

securely.

® Secure both sides of chute deflector to housing

Place upper guide assembly in position on frame,

making certain edges of the upper guide assembly

are underrreath stop washers, and the release bar is

in the slots. See figure 3 Insert hex bolt 8-3/8" long

through upper guide assembly and frame_ Secure

with flat washer and hex lock nut

NOTE: Make certain upper guide assembly can pivot

assembly If necessary, loosen hex lock nut a turn or

two Put the upper guide assembly back into the

raised position

"<_-ATTACHING THE HOPPER ASSEMBLY

Your chipper-shredder has been shipped with the

upper leaf ramp section attached to the hopper

assembly. See figure 4. Attach the hopper assembly

to the upper guide assembly as follows Be certain to

place heads of all truss machine screws inside of

hopper assembly.

® Remove one truss machine screw and nut from

each side of hopper assembly as shown in figure 4.

Push hopper pivot door down inside lower part

of hopper as you place hopper assembly (both

pieces) inside upper guide assembly Replace

truss screws and nuts just removed, using the hote

shown in figure 4, one on each side. Tighten finger

tight only.

e Place the six truss machine screws and nuts found

in hardware pack in the remaining holes of hopper

assembly, alternating sides of the unit and tighten-

ing finger tight only.

® After' assembling all eight screws, tighten them

securely.

"<-ATTACHING THE CATCHER BAG

Your chipper-shredder is equipped with a catcher bag

to catch the shredded material

MAKE CERTAIN THE SPARK PLUG]

WIRE IS DISCONNECTED AND MOVED /

AWAY FROM THE SPARK PLUG /

BEFORE ASSEMBLING THE CHIPPER- /

SHREDDER. j

6

Page 7

e To attach the bag, place the opening of the bag

over the chute deflector so it completely covers the

chute opening. Depress the plunger on the draw-

string, and pull on the drawstring until the bag is tight

around the chute opening Release plunger to lock it

into position, See figure 5,

OPERATION

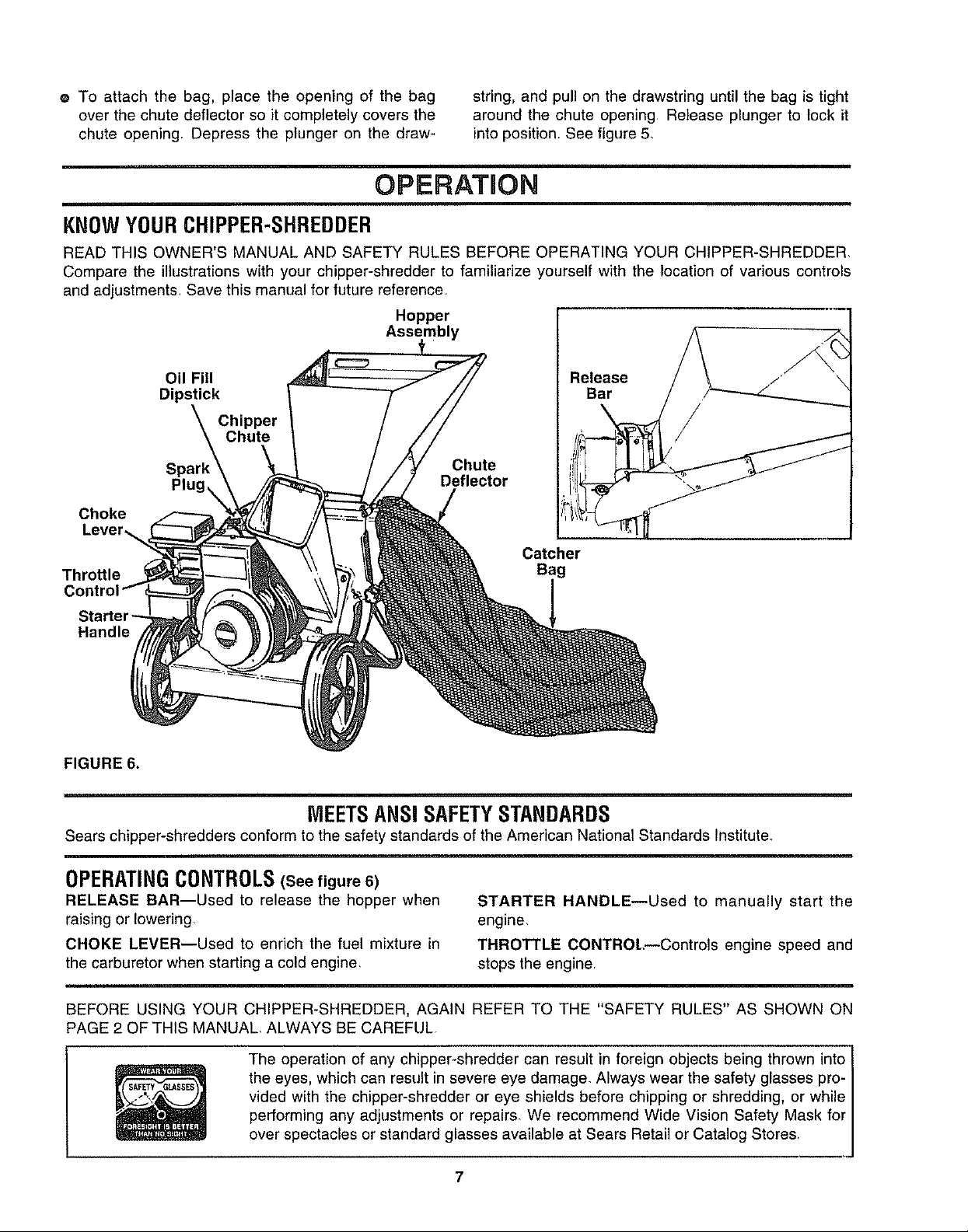

KNOWYOURCHIPPER-SHREDDER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR CHIPPER-SHREDDER

Compare the illustrations with your chipper-shredder to familiarize yourself with the location of various controls

and adjustments, Save this manual for future reference,

Hopper

Assembly

Oil Fill

Dipstick

Chipper

Chute

Spark Chute

Plug \ Deflector

Choke

Catcher

Throttle Bag

Handle

FIGURE 6.

Release

Bar

MEETSANSiSAFETYSTANDARDS

Sears chipper-shredders conform to the safety standards of the American National Standards Institute_

OPERATINGCONTROLS(See figure 6)

RELEASE BAR--Used to release the hopper when

raising or lowering

CHOKE LEVER--Used to enrich the fuel mixture in

the carburetor when starting a cold engine.

BEFORE USING YOUR CHIPPER-SHREDDER, AGAIN REFER TO THE "SAFETY RULES" AS SHOWN ON

PAGE 2 OF THIS MANUAL, ALWAYS BE CAREFUL.

The operation of any chipper-shredder can result in foreign objects being thrown into

the eyes, which can result in severe eye damage. Always wear the safety glasses pro-

vided with the chipper-shredder or eye shields before chipping or shredding, or while

performing any adjustments or repairs_ We recommend Wide Vision Safety Mask for

over spectacles or standard glasses available at Sears Retail or Catalog Stores,

STARTER HANDLE--Used to manually start the

engine,

THROTTLE CONTROL--Controls engine speed and

stops the engine.

7

Page 8

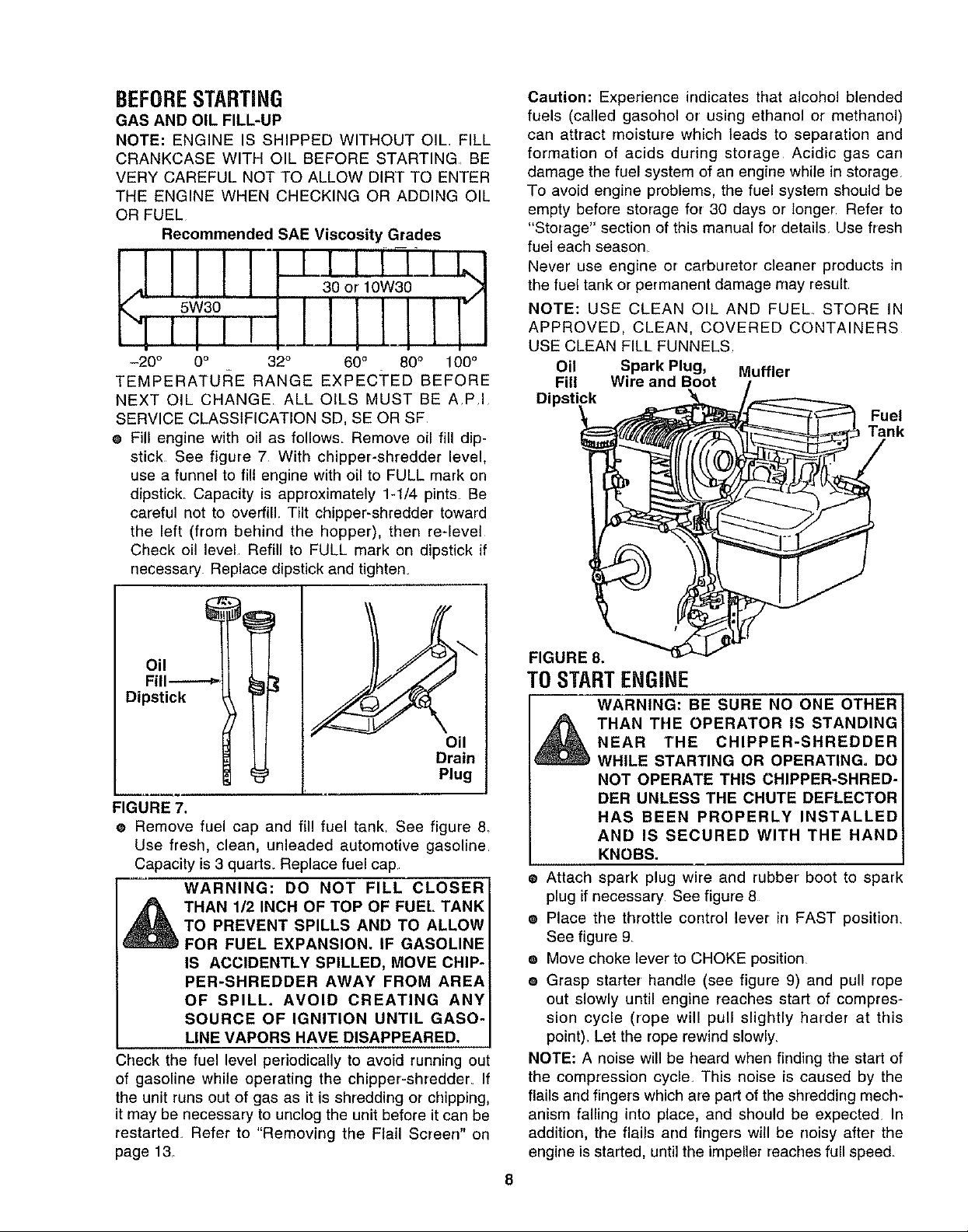

BEFORESTARTING

GAS AND OIL FILL-UP

NOTE: ENGINE IS SHIPPED WITHOUT OIL FILL

CRANKCASE WITH OIL BEFORE STARTING. BE

VERY CAREFUL NOT TO ALLOW DIRT TO ENTER

THE ENGINE WHEN CHECKING OR ADDING OIL

OR FUEL

Recommended SAE Viscosity Grades

<llllll' 00!1o'w -%l

!,'T,,t_I_L_I.!1[I

-20 ° 0° 32° 60° 80° 100 °

TEMPERATURE RANGE EXPECTED BEFORE

NEXT OIL CHANGE ALL OILS MUST BE API

SERVICE CLASSIFICATION SD, SE OR SF

® Fill engine with oil as follows. Remove oil fill dip-

stick See figure 7 With chipper-shredder level,

use a funnel to fill engine with oil to FULL mark on

dipstick Capacity is approximately 1-1/4 pints Be

careful not to overfill, Tilt chipper-shredder toward

the left (from behind the hopper'), then re-level

Check oil level Refill to FULL mark on dipstick if

necessary Replace dipstick and tighten.

Caution: Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol)

can attract moisture which leads to separation and

formation of acids during storage Acidic gas can

damage the fuel system of an engine while in storage

To avoid engine problems, the fuel system should be

empty before storage for 30 days or longer Refer to

"Storage" section of this manual for details Use fresh

fuel each season.

Never use engine or carburetor cleaner products in

the fuel tank or permanent damage may result

NOTE: USE CLEAN OIL AND FUEL. STORE IN

APPROVED, CLEAN, COVERED CONTAINERS

USE CLEAN FILL FUNNELS.

Oil Spark Plug, Muffler

Fill Wire and Boot

Dipstick

Fuel

Tank

Oil

Fill.-----_

Dipstick

Oil

Drain

Plug

FIGURE 7.

® Remove fuel cap and fill fuel tank. See figure 8

Use fresh, clean, unleaded automotive gasoline.

Capacity is 3 quarts. Replace fuel cap

WARNING: DO NOT FILL CLOSER

THAN 1/2 INCH OF TOP OF FUEL TANK

TO PREVENT SPILLS AND TO ALLOW

FOR FUEL EXPANSION. IF GASOLINE

IS ACCIDENTLY SPILLED, MOVE CHIP-

PER-SHREDDER AWAY FROM AREA

OF SPILL. AVOID CREATING ANY

SOURCE OF IGNITION UNTIL GASO-

LINE VAPORS HAVE DISAPPEARED.

Check the fuel level periodically to avoid running out

of gasoline wMle operating the chipper-shredder. If

the unit runs out of gas as it is shredding or chipping,

it may be necessary to unclog the unit before itcan be

restarted, Refer to "Removing the Flail Screen" on

page 13

FIGURE 8.

TOSTARTENGINE

WARNING: BE SURE NO ONE OTHER

THAN THE OPERATOR IS STANDING

NEAR THE CHIPPER-SHREDDER

WHILE STARTING OR OPERATING, DO

NOT OPERATE THIS CHIPPER-SHRED-

DER UNLESS THE CHUTE DEFLECTOR

HAS BEEN PROPERLY INSTALLED

AND IS SECURED WITH THE HAND

KNOBS.

• Attach spark plug wire and rubber boot to spark

plug if necessary See figure 8

• Place the throttle control lever in FAST position.

See figure 9.

e Move choke lever to CHOKE position

e Grasp starter handle (see figure 9) and pull rope

out slowly until engine reaches start of compres-

sion cycle (rope will pull slightly harder at this

point)_ Let the rope rewind slowly,

NOTE: A noise will be heard when finding the start of

the compression cycle. This noise is caused by the

flails and fingers which are part of the shredding mech-

anism falling into place, and should be expected In

addition, the flails and fingers will be noisy after the

engine is started, until the impeller reaches full speed.

8

Page 9

e Pull rope with a rapid, continuous, full arm stroke,

Keep a firm grip on start handle Let rope rewind

slowly Do not let starter handle snap back against

starter

e Repeat preceding two instructions until engine

fires When engine starts, move choke lever on

engine halfway between CHOKE and RUN

NOTE: If engine does not fire after three attempts,

move choke lever halfway between CHOKE and RUN

position and try again See figure 9

,__

CI40_E

I

Throttle Control

The chipper-shredder is designed for three different

methods of operation

e Leaves and small branches up to 1/2" diameter can

be fed into the hopper assembly when it is in the

raised position See figure 10 If it becomes neces-

sary to push material into the chipper-shredder,

use a small diameter stick--NOT YOUR HANDS

The stick should be small enough that it will be

ground up if gets into the impeller assembly

WARNING: DO NOT PUT MATERIAL

LARGER THAN 1/2" IN DIAMETER INTO

THE HOPPER ASSEMBLY. MATERIAL

UP TO A MAXIMUM OF 3" IN DIAMETER

MATERIAL MAY BE FED INTO THE

CHIPPER CHUTE. DO NOT ATTEMPT

TO SHRED OR CHIP ANY MATERIAL

LARGER THAN 3" IN DIAMETER. PER-

SONAL INJURY OR DAMAGE TO THE

MACHINE COULD RESULT.

FIGURE 9o

e Move throttle control to IDLE position for a few min-

utes warm-up Move choke lever to RUN position

as engine warms up

NOTE: In order to idle smoothly, a new engine may

require 3 to 5 minutes running above slow idle speed

Idle speed has been adjusted to be correct after this

break-in period_

TOSTOPENGINE

o Move throttle control lever to STOP position See

figure 9

e Disconnect spark plug wire and move away from

spark plug to prevent accidental starting while

equipment is unattended

HOWTOUSEYOURCHIPPER-SHREDDER

Do not attempt to shred or chip any material other

than vegetation found in a normal yard (ie, branches,

leaves, twigs, etc,)

WARNING: THE CHIPPER-SHREDDER

DISCHARGES MATERIALS WITH CON-

SIDERABLE VELOCITY. KEEP AWAY

FROM THE AREA AROUND THE CHUTE

DEFLECTOR. ALWAYS STOP THE

ENGINE AND DISCONNECT THE

SPARK PLUG WIRE WHEN REMOVING

OR ATTACHING THE BAG WHEN

CHANGING CONTAINERS OR WHEN

REMOVING THE SHREDDED MATERI-

AL. WEAR SAFETY GLASSES AND

GLOVES WHENEVER USING YOUR

CHIPPER-SHREDDER.

\ No Larger

Than 1/2"

Hopper

Assembly

FIGURE 10.

e Leaves and small twigs can be raked into the hop-

per assembly when the hopper assembly is low-

ered to the ground See figure 11 Small branches

up to 1/2" diameter can also be fed into the hop-

per assembly in this position See figure 12

FIGURE 11r

9

Page 10

No

1/2" Diameter

FIGURE 12.

e To lower the hopper assembly, use one hand to

grasp the handle at the top of the hopper assembly

and lift slightly, Pull up on the release bar, and

lower the hopper assembly to the ground Release

the bar'. See figure 13.

Hopper

Assembly

e Bulky material, such as stalks or heavy branches,

up to 3" in diameter, should be fed into the chipper

chute See figure 14

WARNING: MAKE CERTAIN THE CHIP-

PER CHUTE DOOR IS CLOSED WHEN

NOTINUSE.

3"Maximum

Diame_r

Chipper

Chute

FIGURE 14.

Release

Bar

FIGURE 13.

MAINTENANCE

GENERALRECOMMENDATIONS

• Periodically check all fastener's and be sure they

are tight.

® Follow the Service Recommendation Schedule on

page 15.

CHIPPER-SHREDDER

LUBRICATION

Lubricate the pivot points on the release bar, hopper

assembly, chute deflector and chipper chute once a

season using a light off

IMPORTANT: There is a flail screen located inside

the housing in the discharge area If the flail screen

becomes clogged, remove and clean as instructed in

the Service and Adjustments section on page 13 For

best performance, it is important to keep the shred-

ding blade and the chipper blades sharp If the com-

position of the material being discharged changes

(becomes stringy, etc) or if the rate at which the

material is discharged slows down considerably, it is

likely that the shredding blade and/or chipper blades

are dull and need to be sharpened or replaced, Refer

to Service and Adjustments section, page 13.

ENGINE

LUBRICATION

Check engine oil level regularly--approximately every

five hours of operation and before each usage. Stop

engine and wait several minutes before checking oil

level With engine level, the oil must be to FULL mark

on dipstick (refer to figure 7). Change engine oil after

the first five hours of operation, and every twenty-five

hours thereafter

• Drain oil while engine is warm.

Remove oil drain plug. Refer to figure 7_ Tip the

chipper-shredder, and catch oil ir} a suitable con-

tainer

10

Page 11

When engine is drained of all oil, replace drain plug

securely_

e Refill with fresh oil Above 32°, use oil labeled SAE

30 or 10W30 Below 32 °, use oil labeled 5W20

Capacity is approximately 1-1/4 pints Refer to

"Gas and Oil Fill-Up" on page 8

e Replace dipstick.

AIR CLEANER

The air cleaner prevents damaging dirt, dust, etc,

from entering the carburetor and being forced into the

engine and is important to engine life and per-

formance

Never run your engine without air cleaner com-

pletely assembled,

To Service Air Cleaner:

Clean cartridge at three month intervals or every 25

hours, whichever occurs first, See figure 15 Service

more often under dusty conditions.

e Loosen screws and tilt cover as illustrated

e Carefully remove pre-cleaner and cartridge

e Clean cartridge by tapping gently on a flat surface

If very dirty, replace cartridge and pre-cleaner or

clean as follows:

Wash in a low or non-sudsing detergent and warm

water solution CAUTION: Do not use petroleum

solvents such as kerosene to clean cartridge

Rinse thoroughly with flowing water from inside out

until water is clear

Allow cartridge to stand and air dry thoroughly

before using DO NOT OIL CARTRIDGE OR PRE-

CLEANER DO NOT USE PRESSURIZED AIR TO

CLEAN OR DRY CARTRIDGE,

water is not recommended as water could contami-

nate the fuel system,

Yearly or every 25 hours, whichever occurs first.

remove the blower housing and clean the areas

shown in figure 16 to avoid overspeeding, overheating

and engine damage Clean more often if necessary

WARNING: PERIODICALLY CLEAN

MUFFLER AREA TO REMOVE ALL

GRASS, DIRT AND COMBUSTIBLE

DEBR S.

Clean Out

Chaff and Dirt

FIGURE 16.

SPARK PLUG

The spark plug should be cleaned and the gap reset

to 030" at least once a season or every 50 hours of

operation See figure 17 Spark plug replacement is

recommended at the start of each season, Refer to

engine parts list for correct spark plug type

NOTE: Do not sandblast spark plug Spark plug

should be cleaned by scraping or wire brushing and

washing with a commercial solvent

.030" Feeler Gauge

\

e Install cartridge and pre-cleaner Then close cover

and fasten screws securely

;crew

ge

Base

FIGURE 15.

CLEAN ENGINE

Clean engine periodically Remove dirt and debris

with a cloth or brush Cleaning with a forceful spray of

Spark Plug

FIGURE '17.

MUFFLER

Do not operate the chipper-shredder without a muffler

or tamper with the exhaust system. Damaged mufflers

or spark arresters could create a fire hazard Inspect

periodically, and replace if necessary If your engine

is equipped with a spark arrester screen assembly,

remove every 50 hours for cleaning and inspection

Replace if damaged

CLEANING

® The chipper-shredder may be cleaned by running

water from a hose through the hopper assembly

and chipper chute with the engine running Allow

the chipper-shredder to dry thoroughly

® Wash the bag periodically with water Allow to dry

thoroughly in the shade Do not use heat

11

Page 12

STORAGE

NEVER STORE YOUR CHIPPER-

AN EN-

_SHREDDER INDOORS OR IN

To prevent engine damage if chipper-shredder is not

used for more than 30 days, follow the steps below

NOTE: GASOLINE MUST BE REMOVED OR

TREATED TO PREVENT GUM DEPOSITS FROM

FORMING IN THE TANK, FILTER, HOSE AND CAR-

BURETOR DURING STORAGE ALSO DURING

STORAGE, ALCOHOL-BLENDED GASOLINE THAT

USES ETHANOL OR METHANOL (SOMETIMES

CALLED GASOHOL) ATTRACTS WATER IT ACTS

ON THE GASOLINE TO FORM ACIDS WHICH DAM-

AGE THE ENGINE

To remove gasoline, run engine until tank is empty

and engine stops Then disconnect fuel line at carbu-

retor or fuel tank Be careful not to damage fuel line,

fittings or fuel tank Drain any remaining fuel from the

system If you do not want to remove gasoline, Sears

Craftsman Fuel Stabilizer No 33500 may be added to

CLOSED, POORLY VENTILATED AREA

IF GASOLINE REMAINS IN THE TANK.

FUMES MAY REACH AN OPEN FLAME,

SPARK OR PILOT' LIGHT FROM A FUR-

NACE, WATER HEATER, CLOTHES

DRYER, CIGARETTE, ETC.

any gasoline left in the tank to minimize gum deposits

and acids If the tank is almost empty, mix stabilizer

with fresh gasoline in a separate container and add

some to the tank Always follow instructions on

stabilizer container. Then run engine at least 10

minutes after stabilizer is added to allow mixture

to reach carburetor. Store chipper-shredder in

safe place° See warning in previous column.

You can help keep your engine in good operating

condition during storage by:

e Changing oil

O

Lubricating the piston/cylinder area by first remov-

ing the spark plug and squirting clean engine oil

into the spark plug hole Then cover' the spark plug

hole with a rag to absorb oil spray_ Next, rotate the

engine by pulling the starter two or three times

Finally, reinstall spark plug arrd attach spark plug

wire

Protect the chipper-shredder during storage by:

e Thoroughly cleaning the chipper-shredder

e If storing in an unventilated or metal storage shed,

coat metal parts with a light oil or silicone to pre-

vent rust

e Store in a clean, dry area Do not store next to cor-

rosive materials, such as fertilizer_

12

Page 13

SERVKCE & ADJUSTMENT

WARNING: ALWAYS STOP ENGINE

AND DISCONNECT SPARK PLUG WIRE

AND MOVE IT AWAY FROM SPARK I

PLUG BEFORE PERFORMING ANY

ADJUSTMENTS OR REPA RS.

REMOVINGTHEFLAILSCREEN

If the discharge area becomes clogged, remove the

flail screen and clean area as follows

e Stop the engine, make certain the chipper-shredder

has come to a complete stop and disconnect spark

plug wire from the spark plug before unclogging the

chute

e Loosen the two hand knobs on each side of the

chute deflector Lift the chute deflector up, and tie it

out of the way

e Remove two hairpin clips from the clevis pins which

extend through the housing Remove the clevis

pins Lift the flail screen from inside the housing

See figure 18

e Clean the screen by scraping or washing with

water Reinstall the screen

NOTE: Be certain to reassemble the flail screen with

the curved side down as shown in figure 18.

Chute

_Hex

Nuts .Flail

Washers Screen

Hairpin

Clips,

Clevis

Pins

NOTE: When reassembling, the cupped washer goes

on the bottom of the chipper chute with the cupped

side against the chute

e Rotate the impeller assembly by hand until you

locate one of the chipper blades in the chipper

chute opening Remove the blade, using a 3/16"

allen wrench on the outside of the blade and 1/2"

wrench on the impeller assembly (inside the hous-

ing) See figure 19

e Remove the other blade in the same manner

@

FIGURE 19.

Replace or sharpen blades If sharpening, make cer-

tain to remove an equal amount from each blade,

Reassemble in reverse order

Make certain blades are reassembled with the sharp

edge facing the direction shown in figure 19 (sharp

edge is assembled toward the slotted opening in the

impeller assembly)

Chipper

Chute

Hand Knobs

FIGURE 18.

SHARPENINGOR REPLACINGTHE BLADES

CHIPPER BLADES

® Disconnect spark plug wire and move it away from

spark plug.

® Remove the flail screen as instructed in previous

section.

® Remove the chipper chute by removing three hex

nuts and washers A 1/2" wrench is required, See

figure 18

SHREDDING BLADE

The shredding blade may be removed for sharpening

or replacement as follows,

® Disconnect spark plug wire and move it away from

spark plug

® Lower the hopper assembly, Block up the housing

See figure 20

e Remove the six hex lock nuts and lock washers

from the housing weld bolts using a 1/2" wrench.

Separate the chipper-shredder into two halves.

® Remove the back-up plate

NOTE: When reassembling, make certain the open-

ing on the back-up plate is toward the bottom of the

unit The back-up plate may be reversed to provide a

new cutting edge

13

Page 14

Pi

Sharp

of

Torque

Wrenctl

Allen

Screws

e When reassembling the blade, tighten to between

550 and 650 inch pounds, or lacking torque

wrench, tighten securely

FLAILS

The flails, located inside the housing, may be

reversed when they become dull It is suggested that

this procedure be performed by your nearest Sears

Service Department

CARBURETORADJUSTMENT

WARNING: IF ANY ADJUSTMENTS ARE

ENGINE IS RUNNING (E.G. CARBURE-

MAUE TO THE ENGINE WHILE THE

TOR), KEEP CLEAR OF ALL MOVING

PARTS. BE CAREFUL OF HEATED SUR-

FACES AND MUFFLER.

FIGURE 2O,-Model 247.797853 Shown

e Loosen the two hand knobs and cupped washers

which secure the chute deflector, arrd raise the

chute deflector

e Insert a 1/2" or 3/4" diameter pipe through the flail

screen into the impeller to keep it from turning, or

remove the flail screen and insert a piece of wood

(2 x 4) intothe chute opening

e Model 247.797853 only: Remove the two outside

screws on the blade, using a 3/16" allen wrench

and a 1/2" wrench

e Remove the blade by removing the center bolt, lock

washer and flat washer

NOTE: Use caution when removing the blade to avoid

contacting the weld bolts on the housing

e When sharpening the blade, follow the original

angle of grind as a guide It is extremely important

that each cutting edge receives an equal amount of

grinding to prevent an unbalanced blade. An unbal-

anced blade will cause excessive vibration when

rotating at high speeds and may cause damage to

the unit.

e The blade can be tested for balance by balancing it

on a round shaft screwdriver or nail Remove metal

from the heavy side until it is balanced evenly See

figure 21

Na. \ /

f ,,

/

Bl!de '__1" --_j_

FIGURE 21,

Minor carburetor adjustment may be required to com-

pensate for differences in fuel, temperature, altitude

or load

NOTE: A DIRTY AIR CLEANER WILL CAUSE

ENGINE TO RUN ROUGH BE CERTAIN AIR

CLEANER IS CLEAN AND ATTACHED TO THE

CARBURETOR BEFORE ADJUSTING CARBURE-

TOR DO NOT MAKE UNNECESSARY ADJUST-

MENTS FACTORY SETTINGS ARE SATISFACTO-

RY FOR MOST APPLICATIONS AND CONDITIONS.

/

Never attempt to change maximum engine speed It is

pre-set at the factory and should be changed only by

a qualified service technician who has the necessary

equipment

The carburetor may need re-adjusting if engine lacks

power or does not idle properly If adjustments are

needed, proceed as follows

e Close needle valve (see figure 22) clockwise

( f-* ) finger tight only. Forcing may cause damage

Then open 1-1/2 turns counterclockwise ( _ )

e Start engine and allow to warm for five minutes

e With throttle in FAST position, close needle valve

clockwise ( ,_ ) until engine starts to lose speed

(lean mixture) Then slowly open needle valve

counterclockwise (f',) until engine JUST BEGINS

to run unevenly This mixture should be rich

enough for best performance under load.

e Place throttle control in IDLE position

If engine idles, no further adjustment is necessary

If engine idles too fast, turn idle speed adjusting

screw counterclockwise ( _ ) until slower speed is

obtained

If engine dies, turn idle speed adjusting screw 1/4

turn clockwise ( ,_ ). Place throttle control in FAS]_'

position and restart engine

Move throttle control to IDLE position_ If engine

does not idle, repeat step c

14

Page 15

• Test the engine by using the chipper-shredder If

engine tends to stall or die out, it usually indicates

that the mixture is slightly lean and it may be nec-

essary to open (_ ) the needle valve slightly to

provide a richer mixture This richer mixture may

cause a slight unevenness in idling

Throttle

Idle Speed Stop

Adjusting Screw

Throttle

Needle Valve

FIGURE 22.

SERVaCE RECOMMENDATIONS

ENGINESPEED

Your engine speed has been factory set Do not

attempt to increase engine speed or it may result in

personal injury, If you believe the engine is running

too fast or too slow, take your chipper-shredder to the

nearest SEARS Service Center for repair and adjust-

ment,

SERVICERECORD

Fill in dates as you

complete regular service

Check Fuel

Drain Fuel

Check Engine Oil Level

Change Engine Oil

Oil Pivot Points

Service Air Cleaner

Clean Engine Cylinder Fins

Replace or Clean Spark Plug

Spark Arrester Muffler

SCHEDULE

First Before Every Every Begin- Before

5 Each 25 50 ning Each Storage

Hours Use Hours Hours Season

,]

,1

.j

V

,l

,/

V

,/

SERVICEDATES

,]

The Service Recommendations Chart is supplied to

assist the operator in proper maintenance of the chip-

per-shredder, This is only a check list; instructions will

be found in the Maintenance and Service Adjustment

sections of this manual

15

Page 16

TROUBLE SHOO'rING

PROBLEM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Engine fails to start e Fuel tank empty, or stale fuel e

• Spark plug wire disconnected e

e Faulty spark plug e

Loss of power;

operation erratic

Engine overheats

Too much vibration

e Spark plug wire loose

e Unit running on CHOKE

e Blocked fuel line or stale fuel

e Water or dirt in fuel system

e Carburetor out of adjustment

e Didy air cleaner

e Carburetor not adjusted

properly

e Engine oil level low

e Loose parts or damaged

impeller

Unit does not

e Discharge chute clogged

discharge

• Foreign object lodged in impeller

Fill tank with clean, fresh fuel

Connect wire to spark plug

Clean, adjust gap or replace

e Connect and tighten spark plug wire

e Move choke lever to OFF position

e Clean fuel line; fill tank with clean

fresh gasoline

e Disconnect fuel line at calburetor to d

tank Refill with fresh fuel

e Adjust carburetor or contact your SE.Z

Service Center

e Service air cleaner See Maintenance

of this manual

e Corrtact your SEARS Service Center

e Fill crankcase with proper oil

e

Stop engine immediately and disconn

spark plug wire Tighten all bolts errd i

Make all necessary repairs If vibration continues,

have unit serviced by a SEARS Service Center

e Stop engine immediately and disconn

spark plug wire Clean flail screen and inside

of blower housing See Service/Adjustments

section of this manual

e Stop engine immediately and discenn

spark plug wire. Remove lodged objec

]in fuel

Rate of discharge

slows considerably or

composition of

discharged material

changes

e Shredding blade and/or chipper

blades dull

e Sharpen or replace shredding and chi

blades

NOTE: For repairs beyond the minor adjustments listed above, please contact your nearest SEARS Service Center

16

Page 17

SEARS CRAFTSMAN 5 H.P. CHIPPER-SHREDDER MODEL NOS. 247.797852

Repair Parts 247.797853

22

11

7

57

Model

59

35

36

17

Page 18

SEARS CRAFTSMAN 5 H.R CHIPPER-SHREDDER MODEL NOS. 247.797852

Repair Parts 247.797853

KEY

NO,

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

22

23

24

25

26

27

28

29

3O

31

32

33

34

35

36

PART

NO,

13431

742-0571

710-0818

714-0114

736-0217

736-0247

11459B

711-0564

711-0833A

711-0834

715-0249

736-0192

781-0484

681-0002

781-0490

710-1054

712-0411

736-0119

710-0825

736-0142

750-0793

711-0835

712-0291

714-3010

781-0457

714-0149B

781-0480

712-3010

736-0242

720-0170

747-0744A

732-0542

781-0489

781-0475

736-0170

712-3010

781-0510

DESCRIPTION KEY PART

Blade (247 797852)

Blade (247.797853)

Hex Patch Bolt 3/8-24 x 2" Lg

(Gr 8)

Sq. Key 1/4 x 2.0" Lg,

L-Wash 3/8" I.D HD.

FI-Wash 406"1D x 125"

OD Hdn

Flail

Flail Spacer

Clevis Pin .496" Dia

Flail Spacer w/160" Dia, Hole

Spring Roll Pin 1.12" Lg,

FI-Wash ,531" I.D. x .94" O,D

Impeller Ass'y (247.797852)

Impeller Ass'y (247,797853)

Chipper Blade

Flat Hd. Scr 5/16-24 x ,75" Lg

Hex Top L-Nut 5/16-24 (Gr, 5)

L-Wash. 5/16" ID*

Hex Bolt 1/4-20 x 375" Lg.*

FI-Wash 281" ID x.50" OD

Chute Hinge Spacer 1.66" Lg

Clevis Pin 5" Dia. x 462" Lg

Hex Ctr. L-Nut 1/4_20 Thd,

Cotter Pin

Shredder Screen

Internal Cotter Pin 3/8" Di&

Chute Deflector Ass'y,

Hex Nut 5/16-18 Thd (Gr. 5)

Bell-Wash ,345" I,D x 88"

Hand Knob

Chipper Door Rod

Torsion Spring 1.14" Lg

Chipper Door

Chipper Chute Ass'y

Spec, L-Wash, 5/16" ID,

Hex Nut 5/16-18 Thd (Gr 5)

Shredder Frame

NO, NO,

37 710-0157

38 736-0119

39 7t0-3008

40 710-0380

41 681-0004

42 781-0474A

43 735-0639

44 130212-3250-01

45 747-0531A

46 742-0546

47 712_0429

48 710-0601

49 11480

50 736-0264

51 710-0542

52 781-0487B

53 16522B

54 781-0494

55 16524B

56 710-0286

57 712_0107

58 11461B

59 726-0214

6O 736-0187

61 75O-O786

62 738-0814

63 734-1600

64 732-0629

65 747-0747

66 781-0492

67 781-0493

68 726-0106

-- 764-0199A

-- 723-0400

-- 770-7110G

DESCRIPTION

Hex Bolt 5/16-24 x _75" Lg,

L-Wash, 5/16" I.D,*

Hex Bolt 5/16-18 x 75" Lg

(Gr 5)

Hex Bolt 5/16-18 x 1.75" Lg*

Flail Housing Ass'y,--LH

Flail Housing Ass'y,--R H

Spark Plug Boot

Engine--B&S 130212-3250-01

Release Bar

Torsion Spring 106" Lg.

Elastic Lock Nut 5/16-18 Thd

Hex Wash Hd. Self-Tap Scr

5/16-t8 x .75" Lg

Stop Washer

Fl_Wash, 5/16" I.D

Hex Bolt 5/16-18 x 838" Lg

Back-Up Plate

Inlet Guide Ass'y

Pivot Hopper Hood

Upper Guide Ass'y

Truss Mach Scr 1/4-20 x _5"

Lg

Hex L-Nut 1/4-20 Thd

Upper Leaf Ramp Section

Push Cap 5/8" Di& Rod

FI-Wash. 64" I D x 1.24"

Spacer 64" I,D, x _38"Lg,

Shredder Axle

Wheel Ass'y Comp,

Torsion Spring

Hopper Door Rod

Hopper--Pivot Door

Hopper Lockout Brkt.

Cap Speed Nut 1/4" Rod

Bag (Not Shown)

Safety Glasses (Not Shown)

Owner's Manual

*Common Hardware--May Be Purchased Locally

NOTE: Specifications subject to change without

notice or obligation

18

Page 19

BRIGGS AND STRATTON 5 H.P. ENGINE MODEL NO. 130212-3250-01

Repair Parts

26

7

337

35

36

615

230

16

741

46

220

219

SEEREPAIRINS'TRt_TION

MANUAL

(_22

19

Page 20

BRIGGS AND STRATTON 5 H.P. ENGINE MODEL NO. 130212-3250-01

Repair Parts

3o5__

24

655

71

73

305

37

*REQUIRES

SPECIAL TOOLS

TO INSTALL.

SEE REPAIR

INSTRUCTION

MANUAL=

2O

Page 21

BRIGGS AND STRATTON 5 H.P. ENGINE MODEL NO. 130212-3250-01

Repair Parts

127A

124

392

435

96G{

969

9 414 153

208

1012

190

191

725

_ 209

527

153

529

526

11

21

Page 22

BRIGGS AND STRATTON 5 H.P. ENGINE MODEL NO. 130212-3250-01

Repair Parts

KEY

NO,

10

11

12

13

14

15

16

18

19

20

21

22

23

24

25

26

27

28

29

30

31

PART

NO_

395990

297565

Cylinder Assembly 32 92296

Bushing--Cylinder 33 211119

Note: Requires special tools 34 261044

for installation 35 260552

3

5

7

8

9

299819

211542

*272157

294178

*27549

93394i

665781

*270080

Seal--Oil 36 26478

Head--Cylinder 37 222443

Gasket--Cylinder Head 40 93312

Breather--Valve Chamber 45 260642

Gasket--Valve Cover 46 212733

Screw--Breather Mtg. Sere 52 "271936

Grornmet--Breather Tube 55 299431

Gasket--Crankcase--.015" 56 295871

Thick (Standard) 57 490179

*270125

Gasket--Crankcase--005" 58 66884

Thick

*270126

Gasket--Crankcase-- 009" 59 490653

Thick 60 490652

94221

Screw--Cylinder Head 65 94128

(2_3/32" Long)

93369

Screw--Cylinder Head 66 399671

(2-15/32" Long) 67 394897

91249

Plug--Pipe, 1/4" Std Square 68 63770

Head 70 298799

492926

Crankshaft 71 394506

To Replace Crankshaft Gear 73 221923

Pin, Order Part No. 230978 74 93490

493916

297603

Cover Ass'y 75 224061

Bushing--Crankcase Cover 90 492611

Note: Requires special tools 95 93499

for instatlation_

298504

66768

94607

Seal--Oil 96 223793

Plug--Oil Filler 97 490048

Screw--Crankcase Cover 108 491177

Mounting Sere 118 23t 533

297229

222698

298904

298905

298906

298907

Flywheel--Magneto 124 93357

Key--Flywheel 127 220352

Piston Ass'y --Standard 127A 223789

Piston Ass'y,-- 010" O,S, 149 26336

Piston Ass'y.--.020" O S 152 260575

Piston Ass'y.--.030" OS, 153 490589

PISTON RING SETS: 154 93527

Note: For Chrome Piston Ring

Set--Standard Size--Order 163 271935

Part No 299742_ 180 492927

298982

298983

298984

298985

26026

298909

298908

299430

Ring Set--Standard Piston 181 490075

Ring Set-- 010" O S. Piston 190 94094

Ring Set--_020" O_S. Piston

Ring Set--.030" OS Piston 191 *271928

Lock--Piston Pin 200 223886

Pin Ass'y,--Piston--Standard 201 262280

Pin Ass'y --Piston--.005" OS 202 262270

Rod Ass'y --Connecting 203 280720

Note: For Connecting Rod 204 222962

with .020" undersize Crankpin

Bore--Order No, 390459. 205 231520

221890

221876

Dipper--Connecting Rod 208 262279

Lock--Conn, Rod Screw 209 262288

DESCRIPTION KEY PART

NO. NO,

DESCRIPTION

Screw--Connecting Rod

Valve--Exhaust

Valve--Intake

Spring--Intake Valve

Spring--Exhaust Valve

Guard--Flywheel

Retainer--Valve Spring

Tappet--Valve

Gear--Cam

Gasket--Carburetor Mounting

Housing--Rewind Starter

Pulley--Rewind Starter

Spring-Rewind Starter

Rope--Rewind Starter--63"

Long

Insert--Starter Handle

Handle--Rewind Starter

Screw--Stamped Steel

Housing Mtg. Sere

Clutch Ass'y--Rewind Starter

Housing--Starter Clutch

Ball--Clutch

Ratchet--Rewind Starter

Washer--Clutch Retainer

Screen--Starter Pulley

Screw--Sem

Washer--Spring

Carburetor Assembly

Screw--Throttle Valve to Shaft

Sere

Throttle--Carburetor

Shaft and Lever--Throttle

Valve Group--Choke

ValvelNeedle

Screw--Hex Head

Plug--Welch

Plug--Welch (Mixing Chamber)

Spring--Needle Valve

Spring--Throttle Adjustment

Screw Ass'y_ 4,

Screw--Machine, Rd. Hd.--

5-40 x 5/8"

Gasket--Air Cleaner Mounting

Tank Assembly--Fuel

Cap--Fuel Tank

Screw--Fuel Tank Mounting

Sem

Gasket--Fuel Tank Mounting

Guide--Air

Link--Governor

Link--Throttle

Crank--Bell

Bushing--Governor Lever

(Flat)

Screw--Shoulder

Rod--Control

Spring--Governor

22

Page 23

BRIGGS AND STRATTON 5 H.P. ENGINE MODEL NO. 130212-3250-01

Repair Parts

KEY

NO

216

2t9

220

222

223

224

227

230

256

284

298

299

304

305

306

307

308

333

335

337

346

356

358

363

373

383

392

394

414

432

433

434

435

441

467

523

524

525

526

527

528

529

PART

NO.

262359

391737

221551

490649

223455

93491

490374

222450

223813

94419

261409

393368

490169

94608'

221511

93758

221512

397358

93414

492167

93705

398808

397145

19069

92987

89838

262328

270026

220982

221377

93265

210959

93141

224240

280715

492249

271485

280508

94409

223786

231550

67838

DESCRIPTION NO. NO.,

KEY PART

Link--Choke 535

Gear--Governor 542

Washer--Thrust 552

Bracket--Control

Lever--Governor Control 562

Rivet--Governor Control Lever 592

Mounting 608

Lever Ass'y--Governor 611

Washer--Governor Lever 614

Bell Crank 615

Screw--Self-Tapping 616

Lock Nut--Muffler 621

Muffler--Exhaust 634

Housing--Blower 635

Screw--Blower Housing 643

Mounting 643A

Shield--Cylinder 655

Screw--Cylinder Shield 676

Mounting Sere

Cover--Cylinder Head 679

Armature Assembly 680

Screw--Armature Mtg Sem 725

Plug--Spark 7/8" High-- 741

48 MM 779

Screw--Sem 842

Wire--Ground 847

Gasket Set 851

Flywheel Puller (Optional 869

Accessory) 870

Nut--Hex

Wrench--Spark Plug

Spring--Fuel Pump Diaphragm

Diaphragm 871

Washer

Cap--Spring

Pin--Diaphragm Cover

Cover--Diaphragm 916

Screw--Diaphragm Cover 966

Bracket--Oil Fill 967

Knob--Control 968

Cap--Oil Fill 969

Gasket--Oil Fill Cap 971

Nipple--Oil Fill 987

Screw--Tank Bracket 995

Mounting Sem 1012

Clamp--Breather Tube 1016

Tube--Breather 1019

Grommet--Breather Tube

491435

93572

231079

92613

231O82

390463

391813

93306

93307

231077

396847

271853

66538

280737

280726

222598!

395700

270382

221839

223867

261696

262276

270920

493367

221798

211787

211172

262001

280321

492797

491588

223765

490073

94018

398970

223887

490507

490817

491100

DESCRIPTION

Element--Air Cleaner

Screw

Bushing--Governor Crank

(1/4" I D)

Bolt--Governor Lever

Nut--Hex --10-24

Starter Ass'y--Rewind

Fuel Pipe and Clip Assembly

Cotter--Hairpin

Retainer--E_Ring

Crank--Governor (1/4" Dia )

Switch--Stop

Washer--Throttle Shaft (Foam)

Elbow--Spark Plug

Retainer--Foam Element

Retainer--Air Filter

Anchor Spring

Deflector--Exhaust

(Direct Outlet)

Washer Choke Shaft (Foam)

Washer Choke Shaft (Brass)

Shield--Heat

Gear--Timing

Link--Bell Crank

Seal--Tube

Oil Fill Ass'y

Cable Terminal--Ignition

Seat--Intake Valve (Standard)

Seat--Exhaust Valve

(Standard)

Note: For Options see Repair

Manual

Guide--Exhaust Valve

Note: 63709 Guide--Intake

Valve See Repair Instruction

Manual.

Gear Rack--Governor

Base--Air Cleaner

Filter--Air

Cover--Air Cleaner

Screw--Cover Mtg

Screw--Air Cleaner

Seal--Throttle Shaft

Bracket--Link

Link--Retainer

Spacer

Decal (Label) Kit

*Included in Gasket Set--

Part No, 397145

SPARK ARRESTING MUFFLER ASSEMBLY 392390

(Optional Equipment)

Consists of the following:

392154 Screen (1 required)

223372 Deflector (1 required)

93705 Screw (4 required)

23

Page 24

OWNER'S

MANUAL

5 HORSEPOWER

3 CUTTING STAGE

MULCHING AND BAGGaNG

CHBPPER-SHREDDER

Each chipper-shredder has its own model number. Each

engine has its own model number.

The model number for your chipper-shredder will be found

on a label attached to the frame_

The model number for the engine will be found on the

blower housing of the engine.

All parts listed herein may be ordered through Sears,

Roebuck and Co_ Service Centers and most Retail Stores.

HOWTOORDER

REPAIRPARTS

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION:

* PRODUCT- "5 H.P. Chipper-Shredder"

* MODEL NUMBER - 247.797852

247.797853

* ENGINE MODEL NO. - 130212-3250-01

* PART NUMBER

* PART DESCRIPTION

Your Sears merchandise has added value when you con-

sider that Sears has service units nationwide staffed with

Sears trained technicians...professional technicians specifi-

cally trained on Sears products, having the parts, tools and

the equipment to insure that we meet our pledge to you__we

service what we sell/'

j

SEARS, ROEBUCK AND CO.

770-7110G 7/91

, Chicago, IL 60684

U.S.A.

Printed in U.S,A.

Loading...

Loading...