Page 1

Operator’s Manual

7.5 Horse Power

CHIPPER SHREDDER

Model No. 247.776360

®

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our web site: www.sears.com/craftsman

• SAFETY

• ASSEMBLY

• OPERATION

• MAINTENANCE

• PARTS LIST

FORM NO. 769-02543

05/24/2006

Page 2

TABLE OF CONTENTS

Warranty Statement ..................................Page 2

Safe Operation Practices .........................Pages 3-4

Assembly ..................................................Page 6

Operation .................................................. Pages 7-9

Maintenance .............................................Pages 10-11

Off-Season Storage .................................. Page 12

Trouble Shooting ......................................Page 13

Parts List ...................................................Page 14-16

Español ..................................................... Page 17

Service Numbers ...................................... Back Cover

WARRANTY STATEMENT

One -Year Warranty on Craftsman Chipper Shredder

For one year from the date of purchase, when this Craftsman Chipper Shredder is maintained, lubricated and tuned up according to the instructions in the owner’s manual, Sears will repair, free of charge, any defect in material and workmanship. If this Craftsman chipper shredder is used

for commercial or rental purposes, this warranty applies for only 30 days from the date of purchase.

This warranty does not cover:

• Expendable items which become worn during normal use, such as spark plug, blades and air cleaner.

• Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure to maintain the equipment according

to the instructions contained in the owner’s manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN CHIPPER SHREDDER TO THE NEAREST

SEARS PARTS & REPAIR CENTER IN THE UNITED STATES.

This warranty applies only while this product is in use in the United States.

TO LOCATE THE NEAREST SEARS PARTS & REPAIR CENTER OR TO SCHEDULE SERVICE,

SIMPLY CONTACT SEARS AT 1-800-4-MY-HOME®.

This warranty gives you specific legal rights and you may also have other rights which may vary from state to state.

SEARS, ROEBUCK AND CO., D/817WA, HOFFMAN ESTATES, IL 60179

Repair Protection Agreements

Congratulations on making a smart purchase. Your new Craftsman®

product is designed and manufactured for years of dependable operation. But like all products, it may require repair from time to time. That’s

when having a Repair Protection Agreement can save you money and

aggravation.

Here’s what’s included in the Agreement:

• Expert service by our 12,000 professional repair specialists

• Unlimited service and no charge for parts and labor on all covered

repairs

• Product replacement if your covered product can’t be fixed

• Discount of 10% from regular price of service and service-related

parts not covered by the agreement; also, 10% off regular price of

preventive maintenance check

• Fast help by phone – phone support from a Sears technician on

products requiring in-home repair, plus convenient repair

scheduling

Purchase a Repair Protection Agreement now and protect yourself

from unexpected hassle and expense.

Once you purchase the Agreement, a simple phone call is all that it

takes for you to schedule service. You can call anytime day or night, or

schedule a service appointment online.

Sears has over 12,000 professional repair specialists, who have

access to over 4.5 million quality parts and accessories. That’s the

kind of

professionalism you can count on to help prolong the life of your new

purchase for years to come. Purchase your Repair Protection Agreement today!

Some limitations and exclusions apply. For prices and additional

information call 1-800-827-6655.

Sears Installation Service

For Sears professional installation of home appliances, garage door

openers, water heaters, and other major home items, in the U.S.A. call

1-800-4-MY-HOME®

PRODUCT SPECIFICATIONS MODEL NUMBER

Horse Power: 7.5 Horse Power

Engine Oil: SAE 30

Oil Capacity: 20 Ounces

Fuel:

Spark Plug: Champion® RC-12YC

Engine: Briggs and Stratton 150112-0408

Unleaded Gasoline

Model Number .............................................................

Serial Number ..............................................................

Date of Purchase ..........................................................

Record the model number, serial number

and date of purchase above

2

Page 3

SAFE OPERATION PRACTICES

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components contain or emit

chemicals known to State of California to cause cancer and birth defects or other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation in this manual. As with any type

of power equipment, carelessness or error on the part of the operator can result in serious injury. This machine is capable

of amputating hands and feet and throwing objects. Failure to observe the following safety instructions could result in

serious injury or death.

WARNING: This symbol points out important safety instructions which, if not followed, could endanger the

personal safety and/or property of yourself and others. Read and follow all instructions in this manual before

attempting to operate this machine. Failure to comply with these instructions may result in personal injury.

When you see this symbol. HEED ITS WARNING!

Training

1. Read, understand, and follow all instructions on the machine and in the

manual(s) before attempting to assemble and operate. Keep this manual

in a safe place for future and regular reference and for ordering replacement parts.

2. Be familiar with all controls and their proper operation. Know how to stop

the machine and disengage them quickly.

3. Never allow children under 16 years old to operate this machine. Children

16 years old and over should read and understand the operation instructions and safety rules in this manual and should be trained and supervised

by a parent.

4. Never allow adults to operate this machine without proper instruction.

5. Keep bystanders, helpers, pets, and children at least 75 feet from the

machine while it is in operation. Stop machine if anyone enters the area.

6. Never run an engine indoors or in a poorly ventilated area. Engine exhaust

contains carbon monoxide, an odorless and deadly gas.

7. Do not put hands and feet near rotating parts or in the feeding chambers

and discharge opening. Contact with the rotating impeller can amputate

fingers, hands, and feet.

8. Never attempt to unclog either the feed intake or discharge opening,

remove or empty vacuum bag, or inspect and repair the machine while the

engine is running. Shut the engine off and wait until all moving parts have

come to a complete stop. Disconnect the spark plug wire and ground it

against the engine.

Preparation

1. Thoroughly inspect the area where the equipment is to be used. Remove

all rocks, bottles, cans, or other foreign objects which could be picked up

or thrown and cause personal injury or damage to the machine.

2. Always wear safety glasses or safety goggles during operation or while

performing an adjustment or repair, to protect eyes. Thrown objects which

ricochet can cause serious injury to the eyes.

3. Wear sturdy, rough-soled work shoes and close-fitting slacks and shirts.

Loose fitting clothes or jewelry can be caught in movable parts. Never

operate this machine in bare feet or sandals. Wear leather work gloves

when feeding material in the chipper chute.

4. Before starting, check all bolts and screws for proper tightness to be sure

the machine is in safe working condition. Also, visually inspect machine for

any damage at frequent intervals.

5. Maintain or replace safety and instructions labels, as necessary.

6. To avoid personal injury or property damage use extreme care in handling

gasoline. Gasoline is extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is spilled on yourself

or your clothes which can ignite. Wash your skin and change clothes

immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and other sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the engine is hot or running.

e. Allow engine to cool at least two minutes before refueling.

f. Never over fill fuel tank. Fill tank to no more than 1/2 inch below bottom

of filler neck to provide space for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and equipment. Move

machine to another area. Wait 5 minutes before starting the engine.

i. Never store the machine or fuel container inside where there is an open

flame, spark, or pilot light (e.g. furnace, water heater, space heater,

clothes dryer, etc.).

j. To reduce a fire hazard, keep machine free of grass, leaves, or other

debris build-up. Clean up oil or fuel spillage and remove any fuel

soaked debris.

k. Allow machine to cool at least 5 minutes before storing.

3

Page 4

SAFE OPERATION PRACTICES

Operation

1. Do not put hands and feet near rotating parts or in the feeding chambers

and discharge opening. Contact with the rotating impeller can amputate

fingers, hands, and feet.

2. Before starting the machine, make sure the chipper chute, feed intake, and

cutting chamber are empty and free of all debris.

3. Thoroughly inspect all material to be shredded and remove any metal,

rocks, bottles, cans, or other foreign objects which could cause personal

injury or damage to the machine.

4. If the impeller strikes a foreign object or if your machine should start

making an unusual noise or vibration, immediately shut the engine off.

Allow the impeller to come to a complete stop. Disconnect the spark plug

wire, ground it against the engine and perform the following steps:

a. Inspect for damage.

b. Repair or replace any damaged parts.

c. Check for any loose parts and tighten to assure continued safe opera

tion.

5. Do not allow an accumulation of processed material to build up in the

discharge area. This can prevent proper discharge and result in kickback

of material through the feed opening.

6. Do not attempt to shred or chip material larger than specified on the

machine or in this manual. Personal injury or machine damage could

result.

7. Never attempt to unclog either the feed intake or discharge opening while

the engine is running. Shut the engine off, wait until all moving parts have

stopped, disconnect the spark plug wire and ground it against the engine

before clearing debris.

8. Never operate without vacuum bag and discharge chute properly attached

to the machine. Never empty or change vacuum bag while the engine is

running. Zippered end of vacuum bag must be kept closed at all times

during operation.

9. Never operate without either the inlet nozzle or optional hose attachment

properly attached to the machine. Never attempt to attach or change either

attachment while the engine is running.

10. Keep all guards, deflectors and safety devices in place and operating

properly.

11. Keep your face and body back and to the side of the chipper chute while

feeding material into the machine to avoid accidental kickback injuries.

12. Never operate this machine without good visibility or light. Always be sure

of your footing and keep a firm hold on the handles.

13. Do not operate this machine on a gravel surface.

14. Do not operate this machine while under the influence of alcohol or drugs.

15. Muffler and engine become hot and can cause a burn. Do not touch.

16. Never pick up or carry machine while the engine is running.

-

Maintenance & Storage

1. Never tamper with safety devices. Check their proper operation regularly.

2. Check bolts and screws for proper tightness at frequent intervals to keep

the machine in safe working condition. Also, visually inspect machine for

any damage and repair, if needed.

3. Before cleaning, repairing, or inspecting, stop the engine and make certain

the impeller and all moving parts have stopped. Disconnect the spark plug

wire and ground it against the engine to prevent unintended starting.

4. Do not change the engine governor settings or overspeed the engine. The

governor controls the maximum safe operating speed of the engine.

5. Maintain or replace safety and instruction labels, as necessary.

6. Follow this manual for safe loading, unloading, transporting, and storage

of this machine.

7. Never store the machine or fuel container inside where there is an open

flame, spark or pilot light such as a water heater, furnace, clothes dryer,

etc.

8. Always refer to the operator’s manual for proper instructions on off-season

storage.

9. If the fuel tank has to be drained, do this outdoors.

10. Observe proper disposal laws and regulations for gas, oil, etc. to protect

the environment.

Do not modify engine

To avoid serious injury or death, do not modify engine in any way. Tampering

with the governor setting can lead to a runaway engine and cause it to operate

at unsafe speeds. Never tamper with factory setting of engine governor.

Notice regarding Emissions

Engines which are certified to comply with California and federal EPA emission

regulations for SORE (Small Off Road Equipment) are certified to operate on

regular unleaded gasoline, and may include the following emission control systems: Engine Modification (EM) and Three Way Catalyst (TWC) if so equipped.

Your Responsibility

Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

4

Page 5

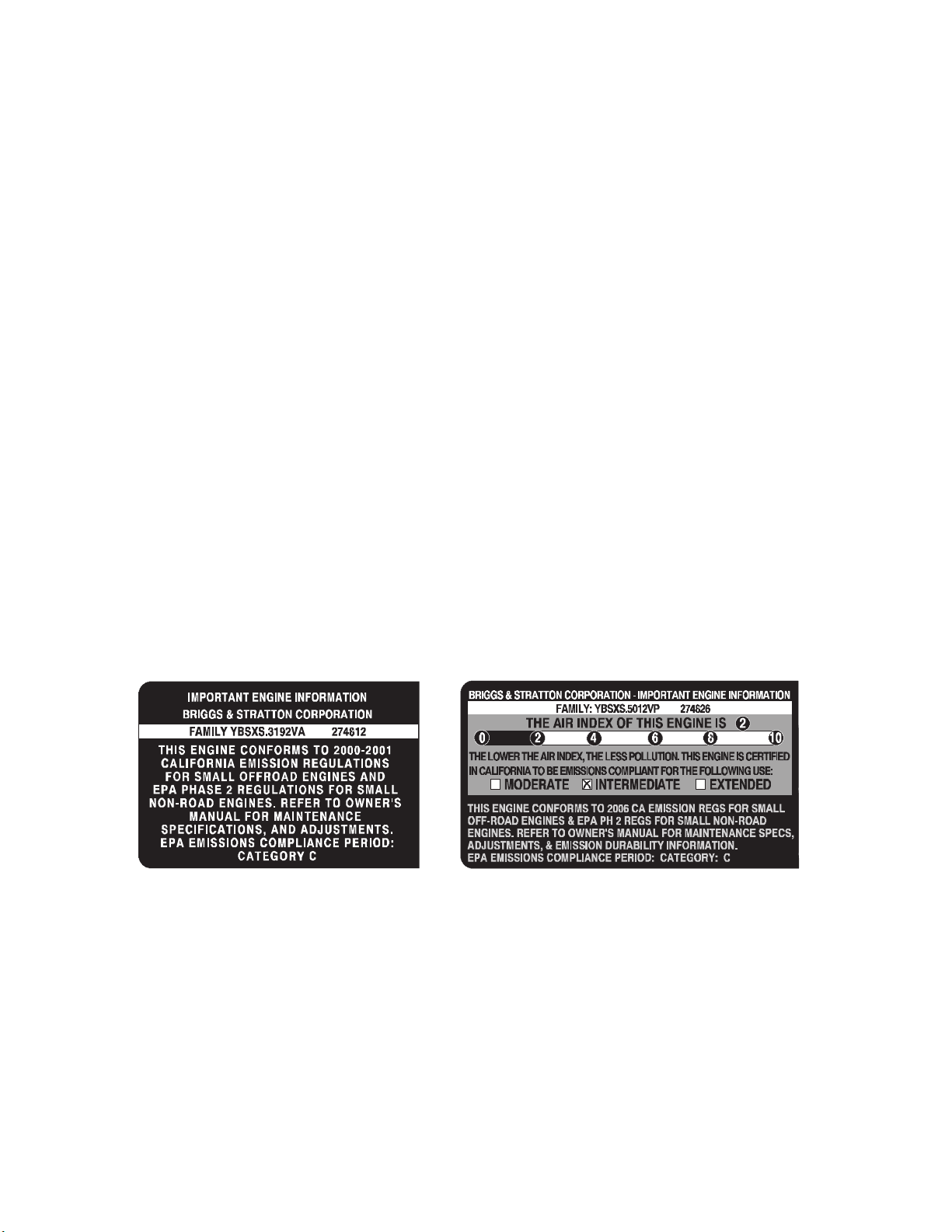

Look For Relevant Emissions Durability Period and

Air Index Information On Your Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB) Tier 2 Emission Standards must

display information regarding the Emissions Durability Period and the Air Index. Sears, Roebuck and Co., U.S.A.

makes this information available to the consumer on our emission labels.

The Emissions Durability Period describes the number of hours of actual running time for which the engine is

certified to be emissions compliant, assuming proper maintenance in accordance with the Operating & Maintenance Instructions. The following categories are used:

Moderate: Engine is certified to be emission compliant for 125 hours of actual engine running time.

Intermediate: Engine is certified to be emission compliant for 250 hours of actual engine running time.

Extended: Engine is certified to be emission compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore, the Emissions

Durability Period of an engine with an intermediate rating would equate to 10 to 12 years.

The Air Index is a calculated number describing the relative level of emissions for a specific engine family. The

lower the Air Index, the cleaner the engine. This information is displayed in graphical form on the emissions label.

After July 1, 2000, Look For Emissions Compliance Period

On Engine Emissions Compliance Label

After July 1, 2000 certain Sears, Roebuck and Co., U.S.A. engines will be certified to meet the United States

Environmental Protection Agency (USEPA) Phase 2 emission standards. For Phase 2 certified engines, the Emissions Compliance Period referred to on the Emissions Compliance label indicates the number of operating hours

for which the engine has been shown to meet Federal emission requirements.

For engines less than 225 cc displacement, Category C = 125 hours, B = 250 hours and A = 500 hours.

For engines of 225 cc or more, Category C = 250 hours, B = 500 hours and A = 1000 hours.

The displacement engines of Model Series 150112 is 249 cc.

This is a generic representation of the emission label typically found on a certified engine.

5

Page 6

ASSEMBLY

IMPORTANT: This unit is shipped without gasoline or

oil in the engine. After assembly, see OPERATION sec-

tion of this manual for proper fuel and engine oil fill-up.

This Chipper Shredder has been completely assembled

at the factory, except for the debris collection bag,

which is stowed in the chipper chute for shipping.

Removing Unit From Carton

1. Remove staples, break glue on top flaps or cut tape

at carton end and peel along top flap to open carton.

2. Remove any loose parts.

3. Cut down along carton edges and lay carton down

flat.

4. Remove packing material, if present. Lift unit from

the rear and discard bottom pad, if present. Roll unit

out of carton. Check carton thoroughly for loose

parts.

Loose Parts In Carton

a. One Debris Collection Bag

b. One Pair of Safety Glasses

c. One 20 oz. Bottle of Engine Oil

d. One Operator’s Manual

Attaching The Debris

Collection Bag

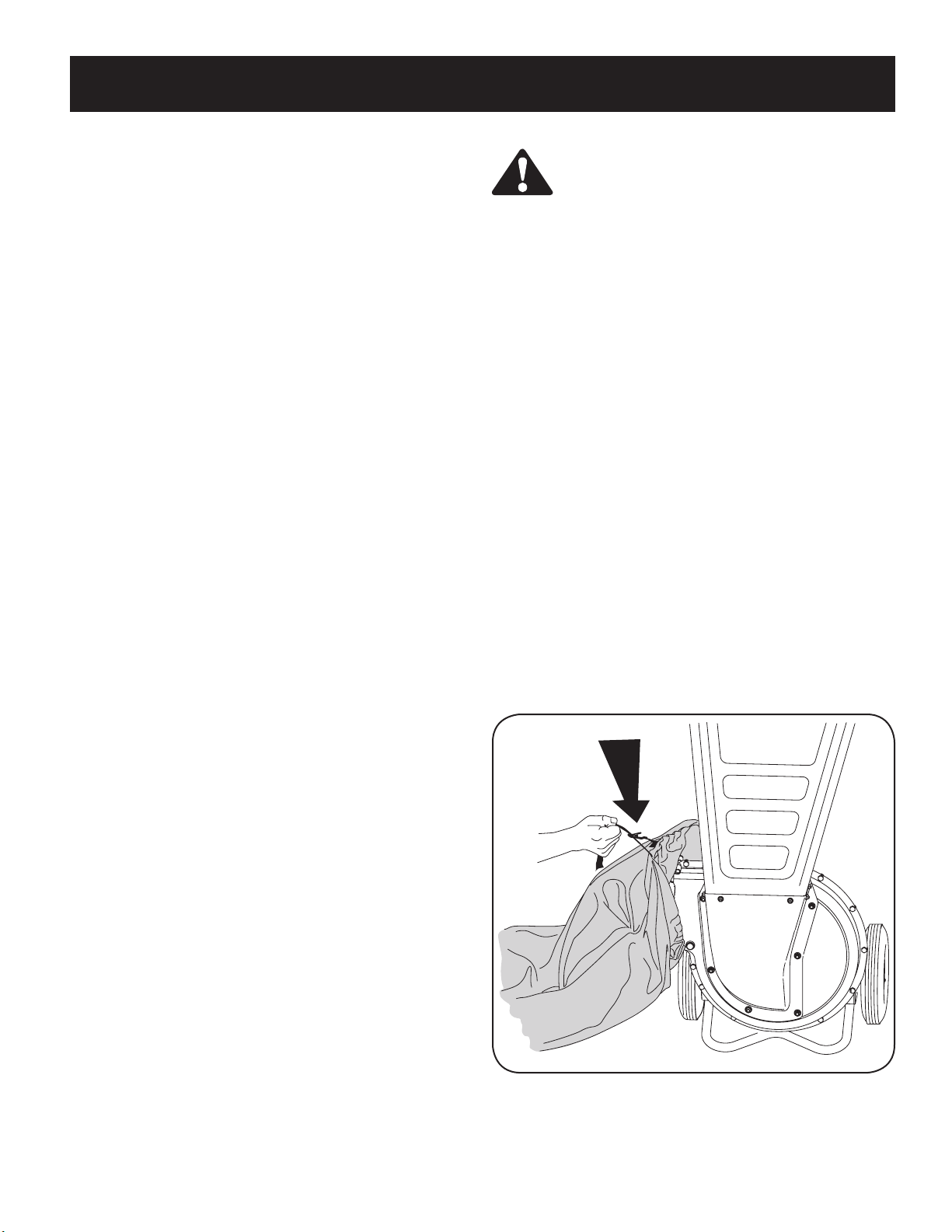

2. To attach the bag:

a. Place the opening of the bag completely over the

chute deflector.

b. Position the bag so that the wing knobs which

secure the chute deflector to the impeller housing

are completely covered.

c. Pull on the drawstrap until the bag is tight around

chute deflector opening. See Figure 1.

Figure 1

6

Page 7

Page 8

STOP

STOP

OPERATION

WARNING: The operation of any chipper shredder

can result in foreign objects being thrown into the

eyes, which can damage your eyes severely. Always

wear the safety glasses provided with this unit or

eye shields before chipping or shredding and while

performing any adjustments or repairs.

Gas and Oil Fill-Up

Service the engine with gasoline and oil as instructed in the separate

Briggs & Stratton engine manual packed with your chipper shredder.

Read instructions carefully.

WARNING: Never fill fuel tank indoors with engine

running or until the engine has been allowed to cool

for at least two minutes after running.

Starting Engine

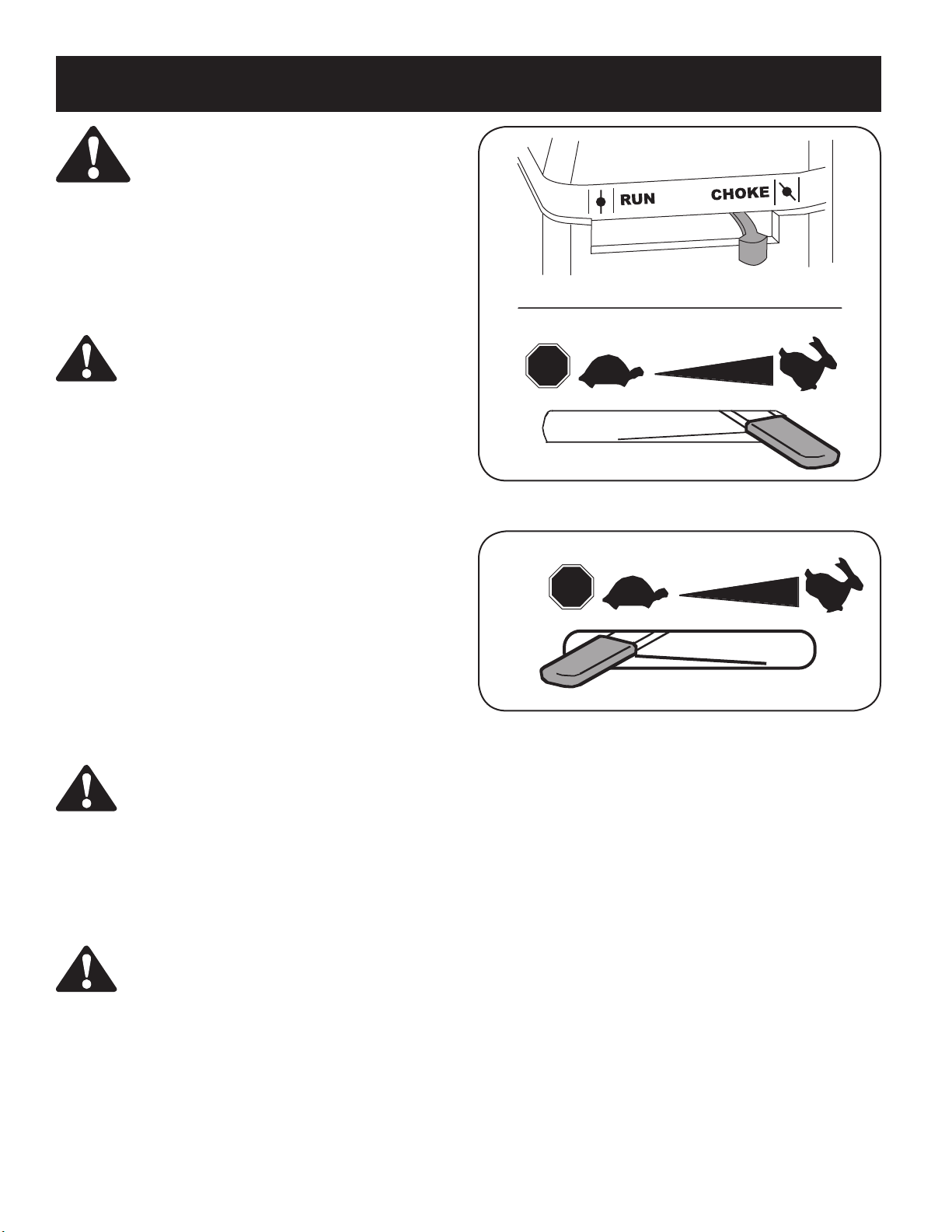

1. Move choke control lever to CHOKE position. See Figure 5.

NOTE: A warm engine may not require choking.

2. Move throttle control lever to FAST (rabbit) position. See Figure 5.

3. Grasp starter handle and pull rope out slowly until engine reaches

start of compression cycle (rope will pull slightly harder at this

point).

Figure 5

NOTE: A “clanking” noise may be heard when pulling the starter rope.

It is completely normal and does NOT indicate a malfunction of any

kind.

4. Pull rope with a rapid, continuous, full arm stroke. Keep a firm grip

on starter handle. Let rope rewind slowly.

5. Repeat the previous steps until engine starts. When engine starts,

move choke control gradually to RUN position until the engine is

running smoothly.

WARNING: Never run the engine indoors or in a

poorly ventilated area. Engine exhaust contains

carbon monoxide, an odorless and deadly gas.

Stopping Engine

1. Move throttle control lever to STOP position. See Figure 6.

NOTE: See your engine manual packed with your unit for more

detailed instructions.

CAUTION: Never stop the engine by moving the choke lever into the

CHOKE position. Backfire, fire or engine damage could

result.

Figure 6

8

Page 9

OPERATION

Shredding

Yard waste such as leaves and pine needles can be placed in the

hopper for shredding. After material has been processed by the shredder blade and flails, it will be forced out of the chute deflector, and, if

attached, into a debris collection bag.

Observe the following guidelines when shredding yard debris:

1. Never attempt to shred material other than normal yard debris

(leaves, twigs, pine cones, etc.).

2. Avoid shredding fibrous plants such as tomato vines until they are

thoroughly dried out. Fresh vines do not shred well and tend to

wrap themselves around the impeller and flails.

3. Place reasonable amounts of debris into the hopper at a time. Do

not overload the hopper.

4. Allow the material in the hopper to be drawn into the blades and

shredded before adding additional debris to the hopper. Failure to

due so may result in a clogged hopper, clogged chute deflector or a

stalled engine.

5. Avoid placing twigs longer than 24 inches into the hopper. Twigs

longer than 24 inches may result in a clogged hopper.

6. Never place branches with a diameter greater than 1/2-inch in

the hopper. Doing so can result in serious damage to the unit’s

shredder blade, flails or impeller.

Clearing the Hopper

Should the hopper become clogged with debris during operation,

proceed as follows:

1. Grasp the handle with both hands and gently agitate the chipper

shredder to help loosen debris, drawing it into the impeller.

If the clog does not clear, proceed as follows:

1. Stop engine.

2. Use your hands to remove any debris found near the top of the

hopper.

3. Use a branch (or other available device, i.e. broomstick) to dislodge

debris located toward the base of the hopper.

4. Restart engine.

Chipping

WARNING: Never operate the chipper shredder

without chipper chute lowered into the operating

position.

Branches up to 2” in diameter can be fed into the chipper chute.

Observe the following guidelines when chipping branches:

1. Keep both hands firmly on the branch as you feed it into the chipper

chute.

2. Never feed more than one branch into the chipper chute at a time.

3. Never feed anything other than branches (or wood) into the chipper

chute.

4. Apply intermittent pressure (force, in short pulses) while feeding

larger (2-inch diameter) branches into the chipper chute, to avoid

bogging or stalling the engine.

IMPORTANT: Never feed branches with a diameter greater than

two (2) inches into the chipper chute. Doing so can result in serious

damage to your unit’s chipper blades, flails or impeller.

NOTE: For best performance, always operate the unit with sharp

chipper blades. If a noticeable loss in performance is encountered

while chipping branches, the chipper blades should be replaced.

Emptying the Debris Collection Bag

1. Stop engine.

2. Squeeze the locking buckle release the bag’s drawstrap before

loosening it from the chute deflector. See Figure 7.

3. Empty the bag and reattach to the chute deflector opening. Refer to

Figure 2.

NOTE: If you’re unable to pull the starter rope as a result of accumulated debris near the impeller, follow instructions under the heading

Cleaning the Reduction Chamber in the “Maintaining Your Chipper

Shredder” section of this manual.

Figure 7

9

Page 10

A

C

B

MAINTENENCE

WARNING: Always stop engine, disconnect spark

plug, and ground against engine before cleaning,

lubricating or doing any kind of maintenance on your

machine.

Lubrication

1. Lubricate the chipper chute hinge a with light oil once a season.

2. Lubricate the pivot points on the chute deflector with light oil once a

season.

3. Refer to the Briggs & Stratton Owner/Operator manual packed with

your unit for engine lubrication instructions.

Engine Care

Refer to the Maintenance section of the Briggs & Stratton Owner/Operator manual packed with your unit. Read and follow instructions

carefully.

1. Check engine oil level before each use as instructed in the

separate engine manual.

2. Clean air cleaner’s precleaner every 25 hours under normal

conditions. Clean every few hours under extremely dusty conditions. Replace the air cleaner cartridge once a season. To service

the air cleaner, refer to the separate engine manual.

3. The spark plug should be cleaned and the gap reset once a

season. Refer to the separate engine manual for correct plug type

and gap specifications.

Figure 8

4. When the area is cleaned, pivot the shredder screen downward and

re-secure with the clevis pin and hairpin clip removed earlier.

5. Reattach the debris collection bag to the chute deflector, if desired.

Chipper Shredder Care

Before each use, visually inspect your chipper shredder for loose (or

missing) nuts and bolts. Securely tighten (or replace) all hardware

before operating the chipper shredder.

Cleaning The Reduction Chamber

WARNING: The impeller’s shredder blade and chipper

blades are sharp. Wear leather work gloves to protect

your hands when cleaning out the reduction chamber.

If the reduction chamber becomes clogged with debris, the shredder

screen can be pivoted upward so that you can clean the surrounding

area. To do so, proceed as follows:

1. Stop engine, disconnect spark plug, and make certain the chipper

shredder has come to a complete stop.

WARNING: The muffler and surrounding area will be

hot if the engine has been running. Use caution and

protect your hands if working near the muffler.

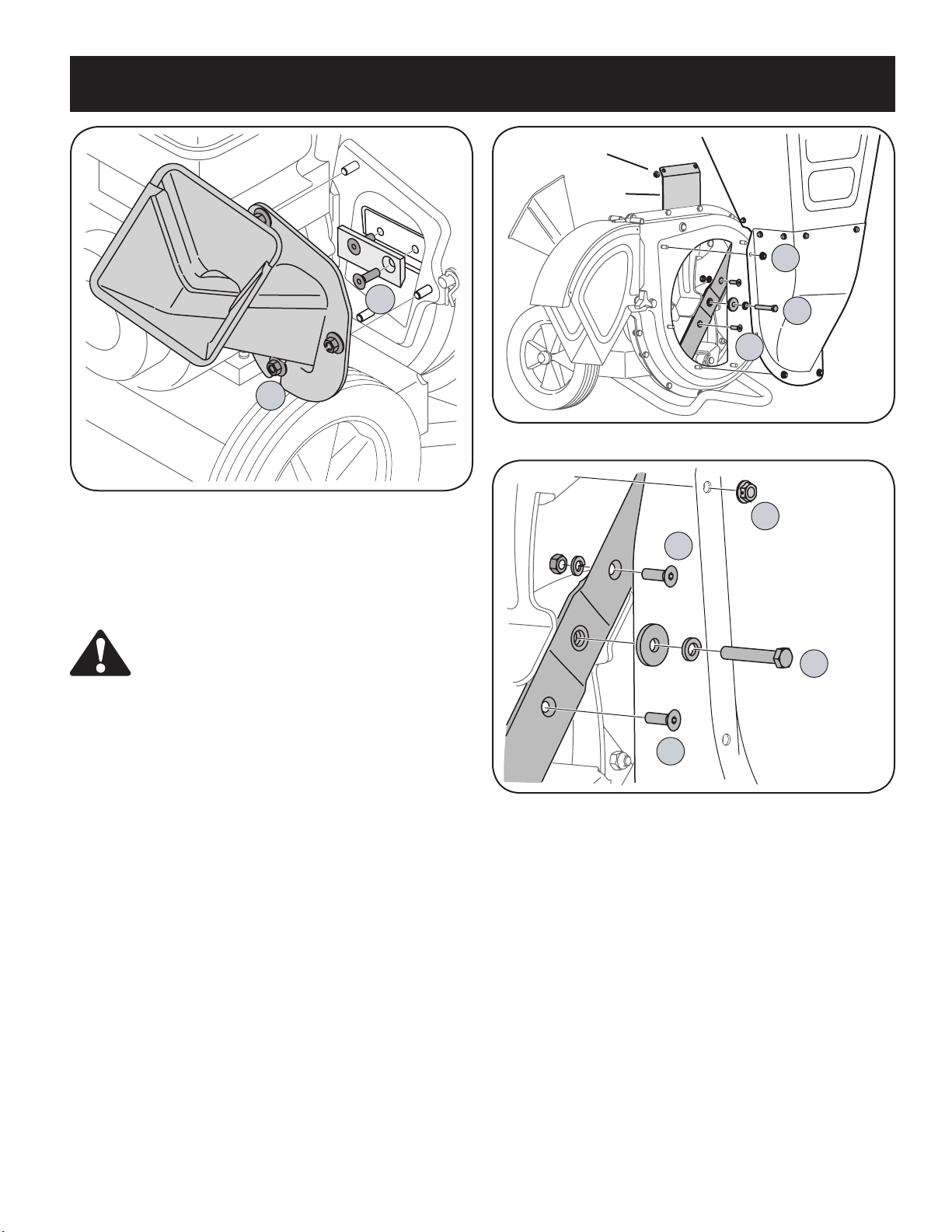

2. a. If attached, remove debris bag. Remove the two wing knobs on

either side of the chute deflector and pivot the chute deflector

upward. See Figure 8.

b. Remove the hairpin clip from the clevis pin which extends

through the housing and shredder screen. See Figure 8.

Remove clevis pin.

c. Pivot the shredder screen upward and clean the surrounding

area by scraping away debris.

3. Confirm that the spark plug wire is disconnected and away from

spark plug. Pull on the starter rope two-to-three times to purge any

remaining debris from the reduction chamber

Sharpening Or Replacing Chipper Blades

WARNING: The impeller’s chipper blades are sharp.

Wear leather work gloves to protect your hands.

1. Stop engine, disconnect spark plug, and make certain the chipper

shredder has come to a complete stop.

2. Pivot the shredder screen upward as instructed under the heading

Cleaning the Reduction Chamber.

3. a. Remove the chipper chute by removing three hex nuts and

washers which secure it to the impeller housing. See Figure 9.

• Rotate the impeller by hand until one of the two chipper blades is

visible through the impeller housing opening.

b. Remove the blade by removing the internal hex screws, lock

washers and hex nuts which secure it to the impeller.

NOTE: Use a 3/16” hex key (Allen) wrench on the outside of the blade

and a 1/2” box (or socket) wrench on the inside of the impeller. Hold

the Allen wrench stationary and rotate the box (or socket) wrench to

loosen the nut.

4. Install a replacement (or sharpened) blade (Part No. 742-0544A)

with the hardware removed earlier.

IMPORTANT: If sharpening the blade, protect hands by using gloves.

Follow the original angle of grind and make sure to remove an equal

amount from each blade.

5. To replace the other blade, rotate the impeller to expose the second

blade and repeat the steps above.

10

Page 11

Figure 9

A

B

Support

Bracket

Flange Nut

C

B

A

C

B

B

A

MAINTENENCE

Figure 10

NOTE: Make certain blades are reassembled with the sharp edge

outward (toward the chipper chute). Torque hardware to between 20

ft.-lbs and 25 ft.-lbs.

Sharpening Or Replacing the Shredder Blade

WARNING: The shredder blade is sharp. Wear leather

work gloves to protect your hands.

1. Stop engine,disconnect spark plug, and make certain that all

moving parts have come to a complete stop.

2. Remove the two flange nuts (and hex bolts) which secure the hop

per support bracket to the impeller housing. Retain the hardware.

See Figure 10.

3. Pivot the shredder screen upward as instructed under the heading

Cleaning the Reduction Chamber.

4. a. Remove six flange nuts which secure hopper inlet guide to

impeller housing. See Figure 11.

• Carefully separate the hopper assembly from the impeller

housing and set it aside.

• Insert a piece of wood into the chute deflector opening to

stabilize the impeller and prevent it from rotating when removing

the shredder blade.

b. Remove the two internal hex screws, hex lock nuts, and lock

washers which secure the shredder blade to the impeller. See

Figure 11.

NOTE: Use a 3/16” hex key (Allen) wrench on the outside of the

shredder blade and a 1/2” box (or socket) wrench on the inside of the

shredder blade. Hold the Allen wrench stationary and rotate the box

(or socket) wrench to loosen the nut.

c. Remove the hex bolt, lock washer, and flat washer to completely

free shredder blade. See Figure 11.

-

Figure 11

IMPORTANT: If sharpening the blade for reuse, follow the original

angle of grind as a guide. Make certain each cutting edge receives an

equal amount of grinding to prevent an unbalanced blade. Remove

metal from the heavy side until it is balanced evenly.

IMPORTANT: When reassembling the blade, tighten center bolt to

between 45 ft.-lbs and 60 ft.-lbs and the two out bolts to between 20

ft.-lbs and 25 ft.-lbs.

Storing Your Chipper Shredder

1. Clean the equipment thoroughly.

2. Wipe equipment with an oiled rag to prevent rust.

3. Refer to engine manual for correct engine storage instructions

4. Store unit in a clean, dry area. Do not store next to corrosive

materials such as fertilizer.

11

Page 12

OFF-SEASON STORAGE

Prepare your Craftsman Chipper Shredder for storage at the end of

the season or if the unit will not be used for 30 days or longer. A yearly

check-up by your local Sears Parts & Repair Center is a good way to

ensure that the unit runs properly next season.

Chipper Shredder

• Clean the equipment thoroughly.

• Wipe equipment with an oiled rag to prevent rust. Use a light oil or

silicone to wipe.

• Store unit in a clean, dry area. Do not store next to corrosive

materials such as fertilizer.

Engine

• Service the engine as instructed in the separate Briggs & Stratton

engine manual packed with your chipper shredder.

Other

• Do not store gasoline from one season to another.

• Replace the gasoline can if it starts to rust. Rust and/or dirt in the

gasoline will cause problems.

• Store unit in a clean, dry area. Do not store next to corrosive

materials, such as fertilizer.

NOTE: If storing in an unventilated or metal storage shed, be certain to

rustproof the equipment by coating with a light oil or silicone.

12

Page 13

TROUBLESHOOTING

CauseProblem Remedy

Engine fails to start

Engine runs erratic

1. Throttle lever not in correct starting

position (if equipped).

2. Spark plug wire disconnected.

3. Choke not in CHOKE position (if

equipped).

4. Fuel tank empty or stale fuel.

5. Engine not primed (if equipped).

6. Faulty spark plug.

7. Blocked fuel line.

8. Engine flooded.

1. Spark plug wire loose.

2. Unit running on CHOKE (if equipped).

3. Blocked fuel line or stale fuel.

4. Vent in gas cap plugged.

5. Water or dirt in fuel system.

6. Dirty air cleaner.

7. Carburetor out of adjustment.

1. Move throttle lever to FAST or

START position.

2. Connect wire to spark plug.

3. Move choke lever to CHOKE

position.

4. Fill tank with clean, fresh gasoline.

5. Prime engine as instructed in

Engine Manual.

6. Clean, adjust gap, or replace.

7. Clean fuel line.

8. Wait a few minutes to restart, but

do not prime.

1. Connect and tighten spark

plug wire.

2. Move choke lever to OFF position.

3. Clean fuel line; fill tank with clean,

fresh gasoline.

4. Clear vent.

5. Drain fuel tank. Refill with

fresh fuel.

6. Refer to engine manual.

7. See authorized service dealer.

Engine overheats

Occasional skips

(hesitates) at

high speed

Excessive

Vibration

Unit does not

discharge

Rate of discharge

slows considerably

or composition of

discharged material

changes

1. Engine oil level low.

2. Dirty air cleaner.

3. Carburetor not adjusted properly.

1. Spark plug gap too close.

2. Carburetor idle mixture adjustment

improperly set.

1. Loose parts or damaged impeller.

1. Chute deflector clogged.

2. Foreign object lodged in impeller.

3. Low engine RPM.

1. Low engine RPM.

2. Chipper blade dull.

1. Fill crankcase with proper oil.

2. Refer to engine manual.

3. See authorized service dealer.

1. Adjust gap to .030”.

2. See authorized service dealer.

1. See authorized service dealer.

1. Stop engine immediately and

disconnect spark plug wire. Clean

flail screen and inside of discharge

opening.

2. Stop engine and disconnect spark

plug wire. Remove lodged object.

3. Always run engine at full throttle.

1. Always run engine at full throttle.

2. Replace chipper blade or see your

authorized service dealer.

13

Page 14

PARTS LIST

Sears Craftsman 7.5 HP Chipper Shredder Model 247.776360

1 681-04009 Impeller Assembly Complete

2 710-1054 Machine Screw, 5/16-24 x 1.0

3 711-0833B Clevis Pin,.496

4 712-0411 Hex Lock Nut, 5/16-24

5 715-0166 Spiral Pin,.156 x 1.0

6 719-0329 Flail

7 736-0119 Lock Washer, 5/16

8 742-04050 Shredder Blade

9 742-0544A Chipper Blade

10 781-0735 Retainer Clip

14

Page 15

PARTS LIST

17

15

14

20

13

22

28

10

38

34

25

39

37

9

8

42

7

21

32

22

31

29

6

6

4

4

3

27

4

19

18

6

6

30

42

6

26

2

1

11

22

12

2

23

24

22

35

38

40

41

22

12

20

36

16

33

5

12

Sears Craftsman 7.5 HP Chipper Shredder Model 247.776360

15

Page 16

PARTS LIST

Sears Craftsman 7.5 HP Chipper Shredder Model 247.776360

1 681-0095 Chipper Chute Assembly

2 726-0201 Speed Nut, .3125ID

3 736-0173 Flat Washer, .28 x.74 x.063

4 710-3013 Hex Cap Screw, 1/4-20 x.5

5 712-3010 Hex Nut, 5/16-18

6 712-3027 Hex Lock Nut 1/4-20

7 681-04009 Impeller Assembly

(See page 13 for Impeller Parts)

8 736-0247 Flat Washer,.406 x 1.25

9 736-0217 Lock Washer, 3/8

10 710-1254 Hex Cap Screw, 3/8-24 x 2.2

11 737-0195 Elbow Fitting

12 736-0242 Bell Washer.340 ID x.872 OD

13 736-0451 Washer,.320 ID x.93 OD

14 726-0214 Push Cap, 5/8

15 734-1600 Wheel, 10 x 2.5

16 750-0786 Spacer, .64 x .88 x .38

17 738-0813 Axle, 22.47”

18 681-04011 Shredder Hopper Assembly

19 710-0809 Hex Cap Screw, 1/4-20 x 1.25

20 710-0805 Hex Cap Screw, 5/16-18 x 1.50

21 719-04070 Shredder Screen

22 712-3004A Flange Lock Nut, 5/16-18

23 681-0048 Knob Assembly (Incl. ref.# 12 & 61)

24 681-0094 Chute Deflector Assembly

25 711-0835 Clevis Pin, .50 x 4.62

26 714-0149B Internal Cotter Pin

27 749-04103 Hopper Handle

28 749-04104 Tube Support

29 781-04007 Shredder Plate

30 781-04027 Hopper Support Bracket

31 781-04033 Inlet Guide

32 681-0117 Inner Flail Housing Assembly

33 681-0184 Frame Assembly

34 681-04002 Outer Flail Housing Assembly

35 710-0157 Hex Cap Screw, 5/16-24 x.75

36 710-0502A Hex Sems Screw, 3/8-16 x 1.25

37 710-0825 Hex Cap Screw, 1/4-20 x 3.75

38 710-3025 Hex Cap Screw, 5/16-18 x.625

39 726-0211 U-Nut, 5/16-18

40 736-0119 Lock Washer, 5/16

41 736-0170 Special Lock Washer, 5/16

42 750-0793 Hinge Spacer,.265 x.380 x 1.66

— 664-04023 Debris Collection Bag (Not Shown)

— 723-0400 Safety Glasses

16

Page 17

PARTS LIST

Sears Craftsman 7.5 HP Chipper Shredder Model 247.776360

17

Page 18

(This page applicable in the U.S.A. and Canada only.)

Sears, Roebuck and Co., U.S.A. (Sears), the California Air Resources Board (CARB)

and the United States Environmental Protection Agency (U.S. EPA)

Emission Control System Warranty Statement (Owner’s Defect Warranty Rights and Obligations)

EMISSION CONTROL WARRANTY COVERAGE IS APPLICABLE TO CERTIFIED ENGINES PURCHASED IN CALIFORNIA IN 1995 AND THEREAFTER, WHICH ARE USED IN CALIFORNIA, AND TO CERTIFIED MODEL

YEAR 1997 AND LATER ENGINES WHICH ARE PURCHASED AND USED

ELSEWHERE IN THE UNITED STATES (AND AFTER JANUARY 1, 2001 IN

CANADA).

California and United States Emission Control Defects Warranty Statement

The California Air Resources Board (CARB), U.S. EPA and Sears are pleased

to explain the Emission Control System Warranty on your model year 2000 and

later small off-road engine (SORE). In California, new small off-road engines

must be designed, built and equipped to meet the State’s stringent anti-smog

standards. Elsewhere in the United States, new non-road, spark-ignition

engines certified for model year 1997 and later must meet similar standards set

forth by the U.S. EPA. Sears must warrant the emission control system on your

engine for the periods of time listed below, provided there has been no abuse,

neglect or improper maintenance of your small off-road engine. Your emission control system includes parts such as the carburetor, air cleaner, ignition

system, muffler and catalytic converter. Also included may be connectors and

other emission related assemblies. Where a warrantable condition exists, Sears

will repair your small off-road engine at no cost to you including diagnosis, parts

and labor.

Sears Emission Control Defects Warranty Coverage

Small off-road engines are warranted relative to emission control parts defects

for a period of one year, subject to provisions set forth below. If any covered

part on your engine is defective, the part will be repaired or replaced by Sears.

Owner’s Warranty Responsibilities

As the small off-road engine owner, you are responsible for the performance of

the required maintenance listed in your Operating and Maintenance Instructions. Sears recommends that you retain all your receipts covering maintenance

on your small off-road engine, but Sears cannot deny warranty solely for the

lack of receipts or for your failure to ensure the performance of all scheduled

maintenance. As the small off-road engine owner, you should however be

aware that Sears may deny you warranty coverage if your small off-road engine

or a part has failed due to abuse, neglect, improper maintenance or unap-

proved modifications. You are responsible for presenting your small off-road

engine to an Authorized Sears Service Dealer as soon as a problem exists. The

undisputed warranty repairs should be completed in a reasonable amount of

time, not to exceed 30 days.If you have any questions regarding your warranty

rights and responsibilities, you should contact a Sears Service Representative

at 1--800--469--4663. The emission warranty is a defects warranty. Defects are

judged on normal engine performance. The warranty is not related to an in-use

emission test.

Sears Emission Control Defects Warranty Provisions

The following are specific provisions relative to your Emission Control Defects Warranty Coverage. It is in addition to the Sears engine warranty for non-regulated

engines found in the Operating and Maintenance Instructions.

1. Warranted Parts

Coverage under this warranty extends only to the parts listed below (the

emission control systems parts) to the extent these parts were present on

the engine purchased.

a. Fuel Metering System

• Cold start enrichment system

• Carburetor and internal parts

• Fuel Pump

b. Air Induction System

• Air cleaner

• Intake manifold

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

• Vacuum, temperature, position, time sensitive valves

and switches

• Connectors and assemblies

2. Length of Coverage

Sears warrants to the initial owner and each subsequent purchaser that

the Warranted Parts shall be free from defects in materials and workmanship which caused the failure of the Warranted Parts for a period of one

year from the date the engine is delivered to a retail purchaser.

In the USA and Canada, a 24 hour hot line, 1-800-469-4663, has a menu of pre-recorded messages offering you engine maintenance information.

3. No Charge

Repair or replacement of any Warranted Part will be performed at no

charge to the owner, including diagnostic labor which leads to the

determination that a Warranted Part is defective, if the diagnostic work is

performed at an Authorized Sears Service Dealer. For emissions warranty

service contact your nearest Authorized Sears Service Dealer as listed in

the “Yellow Pages” under “Engines, Gasoline,” “Gasoline Engines,” “Lawn

Mowers,” or similar category.

4. Claims and Coverage Exclusions

Warranty claims shall be filed in accordance with the provisions of the

Sears Engine Warranty Policy. Warranty coverage shall be excluded for

failures of Warranted Parts which are not original Sears parts or because

of abuse, neglect or improper maintenance as set forth in the Sears

Engine Warranty Policy. Sears is not liable to cover failures of Warranted

Parts caused by the use of add-on, non-original, or modified parts.

5. Maintenance

Any Warranted Part which is not scheduled for replacement as required

maintenance or which is scheduled only for regular inspection to the effect

of “repair or replace as necessary” shall be warranted as to defects for the

warranty period. Any Warranted Part which is scheduled for replacement

as required maintenance shall be warranted as to defects only for the

period of time up to the first scheduled replacement for that part. Any

replacement part that is equivalent in performance and durability may

be used in the performance of any maintenance or repairs. The owner is

responsible for the performance of all required maintenance, as defined in

the Sears Operating and Maintenance Instructions.

6. Consequential Coverage

Coverage hereunder shall extend to the failure of any engine components

caused by the failure of any Warranted Part still under warranty.

18

Page 19

REPAIR PROTECTION AGREEMENT

Congratulations on making a smart purchase. Your new Craftsman®

product is designed and manufactured for years of dependable operation. But like all products, it may require repair from time to time. That’s

when having a Repair Protection Agreement can save you money and

aggravation.

Here’s what’s included in the Agreement:

• Expert service by our 12,000 professional repair specialists

• Unlimited service and no charge for parts and labor on all covered

repairs

• Product replacement if your covered product can’t be fixed

• Discount of 10% from regular price of service and service-related

parts not covered by the agreement; also, 10% off regular price of

preventive maintenance check

• Fast help by phone – phone support from a Sears technician on

products requiring in-home repair, plus convenient repair

scheduling

Look For Relevant Emissions Durability Period and

Air Index Information On Your Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB)Tier 2 Emission Standards must display information regarding the

Emissions Durability Period and the Air Index. Sears, Roebuck and Co., U.S.A. makes this information available to the consumer on our emission

labels.

The Emissions Durability Period describes the number of hours of actual running time for which the engine is certified to be emissions compliant, assuming proper maintenance in accordance with the Operating & Maintenance Instructions. The following categories are used:

Purchase a Repair Protection Agreement now and protect yourself

from unexpected hassle and expense.

Once you purchase the Agreement, a simple phone call is all that it

takes for you to schedule service. You can call anytime day or night, or

schedule a service appointment online.

Sears has over 12,000 professional repair specialists, who have

access to over 4.5 million quality parts and accessories. That’s the

kind of professionalism you can count on to help prolong the life of

your new purchase for years to come. Purchase your Repair Protection

Agreement today!

Some limitations and exclusions apply. For prices and additional

information call 1-800-827-6655.

Sears Installation Service

For Sears professional installation of home appliances, garage door

openers, water heaters, and other major home items, in the U.S.A. call

1-800-4-MY-HOME®

Moderate: Engine is certified to be emission compliant for 125 hours of actual engine running time.

Intermediate: Engine is certified to be emission compliant for 250 hours of actual engine running time.

Extended: Engine is certified to be emission compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore, the Emissions Durability Period of an engine with

an intermediate rating would equate to 10 to 12 years.

The Air Index is a calculated number describing the relative level of emissions for a specific engine family. The lower the Air Index, the cleaner

the engine. This information is displayed in graphical form on the emissions label.

After July 1, 2000, Look For Emissions Compliance Period On

Engine Emissions Compliance Label

After July 1, 2000 certain Sears, Roebuck and Co., U.S.A. engines will be certified to meet the United States Environmental Protection Agency

(USEPA) Phase 2 emission standards. For Phase 2 certified engines, the Emissions Compliance Period referred to on the Emissions Compliance

label indicates the number of operating hours for which the engine has been shown to meet Federal emission requirements. For engines less

than 225 cc displacement, Category C = 125 hours, B = 250 hours and A = 500 hours. For engines of 225 cc or more, Category C = 250 hours, B

= 500 hours and A = 1000 hours.

The displacement engines of Model Series 210000 is 344 cc, 280000 is 465 cc, 310000 engines is 501 cc.

19

Page 20

NOTES

20

Page 21

Manual del operador

7.5 caballos de fuerza

CORTADORA TRITURADORA

Número de modelo 247.776360

PRECAUCIÓN: antes de

utilizar este producto, lea

este manual y siga todas

las reglas de seguridad

y las instrucciones de

operación.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visite nuestro sitio web: www.sears.com/craftsman

• SEGURIDAD

• ENSAMBLADO

• OPERACIÓN

• MANTENIMIENTO

• LISTADO DE PIEZAS

N° DE FORMULARIO 769-02543

05/24/2006

Page 22

ÍNDICE

Declaración de garantía ...........................Página 22

Prácticas de operación seguras ...............Páginas 23-24

Ensamblado ..............................................Página 26-27

Funcionamiento ........................................Páginas 28-29

Mantenimiento .............................................................Páginas 30-31

Almacenamiento fuera de temporada ...... Página 32

Solución de problemas.............................Página 33

Lista de piezas .................................................Página 34-37

Números de servicio ...................... Cubierta posterior

DECLARACIÓN DE GARANTÍA

Garantía de dos años para la cortadora trituradora Craftsman

Durante dos años a partir de la fecha de compra, siempre que a esta cortadora trituradora se le realice el servicio de mantenimiento,

lubricación y puesta a punto de acuerdo a las instrucciones del manual del propietario, Sears reparará sin cargo cualquier defecto

de materiales o mano de obra. Si esta cortadora trituradora Craftsman se utiliza para propósitos comerciales o de alquiler, esta

garantía se aplica sólo durante 30 días a partir de la fecha de compra.

Esta garantía no cubre:

• Elementos desechables que se desgastan por el uso normal, incluyendo entre otros, bujías, cuchillas y filtros de aire.

• Reparaciones necesarias debido a abuso o negligencia del operador, incluyendo abolladura del cigüeñal y falla por no realizar

mantenimiento del equipo de acuerdo con las instrucciones contenidas en el manual del propietario.

EL SERVICIO DE GARANTÍA ESTÁ DISPONIBLE PARA LOS USUARIOS QUE LLEVEN LA CORTADORA TRITURADORA AL CENTRO

DE PIEZAS Y REPARACIONES DE SEARS MÁS CERCANO DENTRO DE LOS ESTADOS UNIDOS.

Esta garantía es válida únicamente mientras el producto se utilice dentro de los Estados Unidos.

PARA UBICAR AL CENTRO DE SERVICIO TÉCNICO SEARS MÁS CERCANO O PARA PROGRAMAR EL SERVICIO TÉCNICO,

SIMPLEMENTE CONTACTE A SEARS AL 1-800-4-MY-HOME®.

Esta garantía le otorga derechos legales específicos; usted también puede tener otros derechos, los cuales varían de un estado a otro.

SEARS, ROEBUCK AND CO., D/817WA, HOFFMAN ESTATES, IL 60179

Acuerdos de protección sobre reparaciones

Felicitaciones por haber realizado una adquisición inteligente. El

producto Craftsman® que ha adquirido está diseñado y fabricado

para brindar muchos años de funcionamiento confiable. Pero como

todos los productos a veces puede requerir de reparaciones. Es en

ese momento cuando el disponer de un Acuerdo de protección para

reparaciones le puede ahorrar dinero

y problemas.

A continuación se detallan los puntos incluidos en el Acuerdo:

• Servicio experto prestado por nuestros 12.000 especialistas en

reparaciones profesionales

• Servicio ilimitado sin cargo para las piezas y la mano de obra en

todas las reparaciones cubiertas

• Reemplazo del producto si no es posible reparar el producto cubierto

• Descuento de 10% del precio normal del servicio y de las piezas

relacionadas con el mismo que no estén cubiertas por el

acuerdo; además, 10% de descuento del precio normal de la

verificación de mantenimiento preventivo

• Ayuda rápida por teléfono – asistencia telefónica a cargo de un

técnico de Sears para los productos que requieren reparación

a domicilio, además de una programación conveniente para la

reparación

ESPECIFICACIONES

DEL PRODUCTO

Caballos de fuerza 7.5 caballos de fuerza

Aceite del motor: SAE 30

Capacidad de aceite: 20 Onzas

Combustible:

Bujía de encendido: Champion® RC-12YC

Motor: Briggs and Stratton 150112-0408

Gasolina sin plomo

Adquiera ahora un acuerdo de protección para reparaciones y

protéjase de problemas y gastos inesperados.

Una vez adquirido el acuerdo, puede programar el servicio con

tan sólo realizar una llamada telefónica. Puede llamar en cualquier

momento del día o de la noche, o programar un servicio en línea.

Sears dispone de más de 12.000 especialistas en reparaciones

profesionales que tienen acceso a más de 4.5 millones de piezas y

accesorios de gran calidad. Este es el tipo de

profesionalismo en el que puede confiar para que le ayude a

prolongar la vida útil del producto recientemente adquirido en

los años por venir. ¡Adquiera hoy su acuerdo de protección para

reparaciones!

Se aplican determinadas limitaciones y exclusiones. Para obtener

precios e información adicional llame al 1-800-827-6655.

Servicio de instalación de Sears

Para la instalación profesional de Sears de artefactos domésticos,

dispositivos de apertura de portones de garage, calentadores de

agua y otros artículos del hogar en los Estados Unidos, llame al

1-800-4-MY-HOME®

NÚMERO DE MODELO

Número de modelo ......................................................

Número de serie ...........................................................

Fecha de compra .........................................................

Registre el número de modelo, número de serie

y fecha de compra más arriba

22

Page 23

PRÁCTICAS DE OPERACIÓN SEGURAS

ADVERTENCIA: El escape del motor de este producto, algunos de sus componentes y algunos componentes del vehículo contienen o emiten productos químicos que el estado de California considera que

pueden producir cáncer, defectos de nacimiento u otros problemas reproductivos.

PELIGRO: Esta máquina está diseñada para ser utilizada respetando las reglas de seguridad contenidas en este manual.

Al igual que con cualquier tipo de equipo motorizado, un descuido o error por parte del operador puede producir lesiones

graves. Esta máquina es capaz de amputar manos y pies y de arrojar objetos con gran fuerza. De no respetar las instrucciones de seguridad siguientes se pueden producir lesiones graves o la muerte.

ADVERTENCIA: La presencia de este símbolo indica que se trata de instrucciones importantes de

seguridad que debe respetar para evitar poner en riesgo su seguridad personal y/o material y la de

otras personas. Lea y siga todas las instrucciones en este manual antes de iniciar la operación de esta

máquina. En caso de no seguir estas instrucciones podría provocar lesiones personales. Cuando vea

este símbolo SIGA LA ADVERTENCIA.

Capacitación

1. Lea, comprenda y respete todas las instrucciones que figuran en la

máquina o en este (os) manual(es) antes de proceder al ensamblado

y operación del equipo. Guarde este manual en un lugar seguro para

consultas futuras y regulares, así como para solicitar repuestos.

2. Familiarícese con todos los controles y con el uso adecuado de los mis

mos. Sepa cómo detener la máquina y cómo desengranar los controles

rápidamente.

3. Nunca permita que niños menores de 16 años operen esta máquina. Los

niños de 16 años y mayores deben leer y comprender las instrucciones de

operación y las reglas de seguridad contenidas en este manual, y también

deben ser capacitados y estar supervisados por uno de los padres.

4. Nunca permita que adultos sin los conocimientos adecuados acerca de la

máquina la operen.

5. Mantenga a los observadores, ayudantes, mascotas y a los niños por

lo menos a 22,9 m. (75 pies) de la máquina mientras la misma está en

funcionamiento. Detenga la máquina si alguien entra en la zona.

6. Nunca encienda un motor en espacios cerrados o en una zona con poca

ventilación. El escape del motor contiene monóxido de carbono, un gas

inodoro y letal.

7. No ponga las manos o los pies cerca de las piezas rotatorias o en las

cámaras de alimentación ni en la abertura de descarga. El contacto con el

motor rotatorio puede producir la amputación de dedos, manos o pies.

8. Nunca trate de destapar la toma de alimentación o la abertura de

descarga, ni trate de sacar o vaciar la bolsa de la aspiradora, ni de revisar

y reparar la máquina mientras el motor está en marcha. Apague el motor

y espere hasta que todas las piezas móviles se hayan detenido por

completo. Desconecte el cable de la bujía y póngalo de manera que haga

masa contra el motor.

-

Preparativos

1. Revise minuciosamente la zona donde se utilizará el equipo. Retire todas

las piedras, botellas, latas u otros objetos extraños que puedan ser levantados o arrojados causando lesiones personales o daños a la máquina.

2. Para protegerse los ojos utilice siempre anteojos o antiparras de

seguridad mientras opera la máquina o mientras la ajusta o repara. Los

objetos arrojados que rebotan pueden lesionar gravemente la vista.

3. Utilice zapatos de trabajo resistentes, de suela fuerte, y pantalones y

camisas ajustados. Las prendas sueltas o las alhajas pueden quedar

atrapadas en las piezas móviles. Nunca utilice la máquina descalzo o con

sandalias. Utilice guantes de trabajo de cuero cuando alimente material

por el canal de la cortadora.

4. Antes de encender la máquina controle que todos los pernos y tornillos estén

bien ajustados para comprobar que la máquina se encuentra en condiciones

seguras de operación. Además, realice una inspección visual de la máquina a

intervalos frecuentes para controlar si la misma está dañada.

5. Mantenga o reemplace las etiquetas de seguridad e instrucciones según

sea necesario.

6. Sea sumamente cuidadoso al manipular la gasolina para evitar lesiones

o daños. La gasolina es altamente inflamable y sus vapores pueden

causar explosiones. Se puede lesionar gravemente si derrama gasolina

sobre usted o sobre la ropa ya que se puede encender. Lávese la piel y

cámbiese de ropa de inmediato.

a. Utilice sólo recipientes para gasolina autorizados.

b. Apague todos los cigarrillos, cigarros, pipas y otras fuentes de combustión.

c. Nunca cargue combustible en la máquina en un espacio cerrado.

d. Nunca saque la tapa de la gasolina ni agregue combustible mientras el

motor está caliente o en marcha.

e. Deje que el motor se enfríe por lo menos dos minutos antes de volver a

cargar combustible.

f. Nunca recargue el tanque de combustible en exceso. Llene el tanque no

más de 1/2 pulgada por debajo de la base del cuello del filtro para dejar

espacio para la dilatación del combustible.

g. Vuelva a colocar la tapa de la gasolina y ajústela bien.

h. Limpie la gasolina derramada sobre el motor y el equipo. Traslade la

máquina a otra zona. Espere 5 minutos antes de encender el motor.

i. Nunca almacene la máquina o el recipiente de combustible en un espacio

cerrado donde haya fuego, chispas o luz piloto (por ejemplo, hornos,

calentadores de agua, calefactores, secadores de ropa, etc.)

j. Para reducir el riesgo de incendio mantenga la máquina limpia de pasto,

hojas y de acumulación de otros desechos. Limpie los derrames de aceite

o combustible y saque todos los desechos embebidos con combustible.

K. Deje que la máquina se enfríe por lo menos 5 minutos antes de guardarla.

23

Page 24

PRÁCTICAS DE OPERACIÓN SEGURAS

Funcionamiento

1. No ponga las manos o los pies cerca de las piezas rotatorias o en las

cámaras de alimentación ni en la abertura de descarga. El contacto con el

motor rotatorio puede producir la amputación de dedos, manos o pies.

2. Antes de encender la máquina compruebe que el canal de la cortadora, la

toma de alimentación y la cámara de corte están vacías y sin desechos.

3. Inspeccione minuciosamente todo el material que desea triturar y saque

los objetos metálicos, piedras, botellas, latas u otros objetos extraños que

pueden ocasionar lesiones o dañar la máquina.

4. Si el motor golpea un objeto extraño o si la máquina empieza a producir

un sonido poco común o una vibración, apague el motor de inmediato.

Deje que el motor se detenga por completo. Desconecte el cable de la

bujía, póngalo de manera que haga masa contra el motor y siga estos

pasos:

a. Inspeccione la máquina para ver si está dañada.

b. Repare o reemplace las piezas dañadas.

c. Controle si hay piezas flojas y ajústelas para asegurar que la máquina

funcione de manera segura y continua.

5. No permita que se acumule material procesado en la zona de descarga.

El mismo puede obstaculizar la descarga adecuada y provocar el retorno

del material a través de la abertura de alimentación.

6. No intente triturar ni picar material de mayor tamaño al especificado en la

máquina o en este manual. Se podrían producir lesiones o daños.

7. Nunca trate de destapar la toma de alimentación o la abertura de

descarga mientras el motor está en marcha. Apague el motor y espere

hasta que todas las piezas que se mueven se hayan detenido por

completo, desconecte el cable de la bujía y póngalo de manera que haga

masa contra el motor antes de sacar los escombros.

8. Nunca opere la máquina sin que la bolsa de la aspiradora y el canal de

descarga estén conectados a la máquina como corresponde. Nunca vacíe

ni cambie la bolsa de la aspiradora mientras el motor está en marcha. El

extremo con cierre de la bolsa de la aspiradora debe quedar cerrado todo

el tiempo mientras la opera.

9. Nunca opere la máquina si el pico de ingreso o la unión opcional para la

manguera no están conectados a la máquina adecuadamente. Nunca

intente conectar o cambiar ninguna de estas uniones mientras el motor

está en marcha.

10. Mantenga todos los protectores, desviadores y dispositivos de seguridad

en su lugar y en buenas condiciones.

11. Mientras alimenta material dentro de la máquina mantenga su rostro y

su cuerpo detrás y hacia un costado del canal de la cortadora para evitar

lesiones por retrocesos accidentales.

12. Nunca opere esta máquina si no tiene buena visibilidad o iluminación.

Siempre debe estar seguro de que está bien afirmado y sostenga bien las

manijas.

13. No opere esta máquina en superficies con grava.

14. No opere esta máquina estando bajo los efectos del alcohol o de drogas.

15. El silenciador y el motor se calientan y pueden producir quemaduras. No

los toque.

16. Nunca levante o transporte la máquina cuando está en movimiento.

Mantenimiento y almacenamiento

1. Nunca altere los dispositivos de seguridad. Controle periódicamente que

funcionen de forma adecuada.

2. Verifique frecuentemente que los pernos y tornillos estén ajustados

correctamente para asegurarse de que la máquina esté trabajando de

manera segura. Además, realice una inspección visual de la máquina

para controlar si la misma está dañada y repárela de ser necesario.

3. Antes de limpiar, reparar o inspeccionar la máquina, detenga el motor

y compruebe que el mismo y que todas las piezas móviles se hallan

detenido. Desconecte el cable de la bujía y póngalo de manera que haga

masa contra el motor para evitar que se encienda de manera accidental.

4. No cambie la configuración del regulador del motor ni acelere demasiado

el mismo. El regulador controla la velocidad máxima segura de operación

del motor.

5. Mantenga o reemplace las etiquetas de seguridad e instrucciones según

sea necesario.

6. Siga las instrucciones de este manual para que la carga, descarga,

transporte y almacenamiento de esta máquina sean seguros.

7. Nunca almacene la máquina o el recipiente de combustible en un espacio

cerrado donde haya fuego, chispas o luz piloto como por ejemplo,

calentadores de agua, hornos, secadores de ropa, etc.

8. Consulte siempre el manual de operación para las instrucciones

adecuadas para el almacenamiento fuera de temporada.

9. Si es necesario evacuar el tanque de combustible, hágalo en exteriores.

10. Respete las leyes y reglamentaciones referentes a la disposición correcta

de combustible, aceite, etc. para proteger el medio ambiente.

No modifique el motor

Para evitar lesiones graves o la muerte, no modifique el motor bajo ninguna

circunstancia. Si cambia la configuración del regulador el motor puede

descontrolarse y operar a velocidades inseguras. Nunca cambie la configuración de fábrica del regulador del motor.

Aviso referido a emisiones

Los motores que están certificados y cumplen con las regulaciones de

emisiones federales EPA y de California para SORE (Equipos Small Off Road

Equipment) están certificados para operar con gasolina común sin plomo y

pueden incluir los siguientes sistemas de control de emisiones: Modificación

de motor (EM) y catalizador de tres vías (TWC) si está equipado de esa

manera.

Su responsabilidad

Restrinja el uso de esta máquina eléctrica a personas que lean, comprendan

y respeten las advertencias e instrucciones que aparecen en ese manual y

en la máquina.

24

Page 25

Busque el período de duración de emisiones importantes yla información de clasificación de aire en

la etiqueta de emisiones de su motor

Los motores cuyo cumplimiento con los estándares de emisión Tier 2 de la Comisión de Recursos Ambientales de California (CARB)

esté certificado deben exhibir la información relacionada con el período de duración de las emisiones y la clasificación de aire. Sears,

Roebuck and Co., de los Estados Unidos ponen esta información a disposición del consumidor en nuestras etiquetas de emisiones.

El Período de Duración de las Emisiones describe el número de horas de tiempo real de funcionamiento para el cual se certifica que

el motor cumple con las reglas de emisión, descontando el mantenimiento adecuado del mismo según las instrucciones de operación y mantenimiento. Se utilizan las siguientes categorías:

Moderado:Se certifica que el motor cumple con las reglas de emisión durante 125 horas de tiempo real de funcionamiento del motor .

Inmediato:Se certifica que el motor cumple con las reglas de emisión durante 250 horas de tiempo real de funcionamiento del motor .

Extendido:Se certifica que el motor cumple con las reglas de emisión durante 500 horas de tiempo real de funcionamiento del motor .

Por ejemplo, una cortadora de césped típica que se empuja desde atrás se usa entre 20 y 25 horas por año. Por lo tanto, el Período

de Duración de Emisiones de un motor con una clasificación intermedia sería equivalente a entre 10 y 12 años.

Laclasificación de aire es un número calculado para describir el nivel relativo de emisiones para un grupo de motores en particular.

Cuanto menor sea la clasificación de aire, mayor es la limpieza del motor. La información se presenta de forma gráfica en la etiqueta

de emisiones.

Después del 1 de julio de 2000, busque el período de cumplimiento de las reglas de

emisiones en la etiqueta de cumplimiento de las reglas de emisiones del motor

Después del 1 de julio de 2000 se certificará que determinados motores Sears, Roebuck and Co., de los Estados Unidos

cumplen con los estándares de emisiones de la fase 2 de la Agencia de Protección Ambiental de los Estados Unidos (USEPA). Para los motores certificados para la etapa 2, el período de cumplimiento con las reglas de emisiones al cual se hace

referencia en la etiqueta de cumplimiento con las reglas de emisiones indica el número de horas de funcionamiento para el

cual se ha demostrado que el motor cumple con los requerimientos federales de emisión.

Para los motores con desplazamiento inferior a 225 cc, Categoría C = 125 horas, B = 250 horas y A = 500 horas.

Para los motores con desplazamiento de 225 cc o más, Categoría C = 250 horas, B = 500 horas y A = 1000 horas.

El desplazamiento de los motores de la serie modelo 150112 es 249 cc.

La presente es una representación genérica de la etiqueta de emisión que se encuentra generalmente en un

motor certificado.

25

Page 26

ENSAMBLADO

IMPORTANTE: Esta unidad es enviada sin gasolina

ni aceite en el motor. Después del montaje, consulte

la sección de FUNCIONAMIENTO para el correcto

llenado de combustible y aceite del motor.

Esta cortadora trituradora ha sido montada totalmente

en la fábrica, excepto por la bolsa de recolección de

desechos, la cual se guarda dentro del canal de la

cortadora para su envío.

Extracción de la unidad de la caja

1. Saque las grapas, rompa el pegamento de las aletas

superiores o corte la cinta del extremo de la caja y

tire a lo largo de la aleta superior para abrir la caja.

2. Saque todas las piezas sueltas.

3. Corte a lo largo de los bordes de la caja y aplánela.

4. Quite el material de empaque, en caso de existir.

Levante la unidad de la parte posterior y deseche la

almohadilla de la base, si está presente. Deslice la

unidad hasta sacarla de la caja de cartón. Inspeccione minuciosamente la caja para detectar si hay

piezas sueltas.

Piezas sueltas dentro de la caja

a. Una bolsa de recolección de desechos

b. Un par de gafas de seguridad

c. Una botella de 20 oz. de aceite para motor

d. Un Manual del operador

Colocación de la bolsa

de recolección de desechos

2. Para adosar la bolsa:

a. Coloque la abertura de la bolsa completamente

sobre el deflector del canal.

b. Coloque la bolsa de manera que se cubran

completamente las perillas mariposa que aseguran el deflector del canal a la caja del motor.

c. Tire de la tira de extracción hasta que la bolsa

quede ajustada alrededor de la abertura del

deflector del canal. Vea la Figura 1.

26

Figura 1

Page 27

Page 28

OPERACIÓN

ADVERTENCIA: Al operar una cortadora trituradora

puede ser que objetos extraños sean arrojados a

los ojos lo cual puede dañarlos gravemente. Utilice

siempre los anteojos de seguridad provistos con esta

unidad o protectores para ojos antes de picar o triturar

el material o mientras realiza ajustes o reparaciones.

Llenado de gasolina y aceite

Cargue el motor con gasolina y aceite como se indica en el manual de

Briggs & Stratton, suministrado por separado que viene embalado con

la cortadora trituradora. Lea cuidadosamente las instrucciones.

ADVERTENCIA: Nunca cargue el tanque de combustible

en espacios cerrados con el motor en marcha o hasta

que haya dejado que el mismo se enfríe por lo menos

dos minutos después de haber estado en marcha.

Encendido del motor

1. Mueva la palanca de control de obturación a la posición CHOKE

(obturación). Vea la Figura 5.

NOTA: Si el motor está tibio la obturación puede no ser necesaria.

2. Mueva la palanca de control del regulador a la posición FAST

(rápido, representado por una liebre). Vea la Figura 5.

3. Tome la manija del arrancador y tire de la cuerda hacia afuera

lentamente hasta que el motor alcance el comience del ciclo de

compresión (la cuerda tirará un poco más fuerte en este punto).

Figura 5

NOTA: Es posible que se escuche un ruido “metálico” cuando tire de

la cuerda de arranque. Es totalmente normal y NO significa que exista

algún tipo de problema de funcionamiento.

4. Tire de la cuerda con un golpe de brazo rápido, total y continuo.

Apriete bien la manija del arrancador. Deje que la cuerda se enrolle

lentamente.

5. Repita los pasos anteriores hasta que el motor se encienda. Una

vez encendido el motor mueva el control de obturación gradualmente hasta la posición RUN (en marcha) hasta que el motor

funcione sin problemas.

ADVERTENCIA: Nunca encienda el motor en espacios

cerrados o en una zona poco ventilada. El escape del

motor contiene monóxido de carbono, un gas inodoro

y letal.

Detención del motor

1. Mueva la palanca de control del regulador a la posición STOP

(detención). Vea la Figura 6.

NOTA: Si desea instrucciones más detalladas consulte el manual del

motor embalado junto con la unidad.

PRECAUCIÓN: Nunca detenga el motor moviendo la

palanca de obturación hasta la posición CHOKE (obturación). Se pueden producir explosiones al carburador,

incendios o daños al motor.

Figura 6

28

Page 29

Figura 7

Page 30

MANTENIMIENTO

ADVERTENCIA: Detenga siempre el motor, desconecte la bujía y haga masa contra el motor antes de

limpiar, lubricar o hacer llevar a cabo cualquier clase

de mantenimiento en su máquina.

Lubricación

1. Lubrique la bisagra del canal de la cortadora con un aceite

ligero una vez por temporada.

2. Lubrique los puntos de pivote del deflector del canal con un

aceite ligero una vez por temporada.

3. Consulte el manual del propietario/operador de Briggs &

Stratton que viene embalado con su unidad para ver las

instrucciones de lubricación del motor.

Cuidados para el motor

Consulte la sección de Mantenimiento del manual del propietario/operador de Briggs & Stratton que viene embalado con su unidad. Lea y

siga las instrucciones cuidadosamente.

1. Verifique el nivel de aceite del motor antes de cada uso como se

indica en el manual del motor que se suministra por separado.

2. Limpie el prefiltro del filtro de aire cada 25 horas en condiciones

normales de uso. Limpie a intervalos de pocas horas cuando haya

mucho polvo. Reemplace el cartucho del filtro de aire una vez

por temporada. Para realizar el mantenimiento del filtro de aire,

consulte el manual del motor que se suministra por separado.

3. La bujía debe limpiarse y se debe reponer la distancia disruptiva una vez por temporada. Consulte el manual del motor que

se suministra por separado para obtener especificaciones

sobre el tipo de bujía y la distancia disruptiva adecuada.

Cuidado de la cortadora trituradora

Antes de cada uso, inspeccione visualmente la cortadora trituradora

para detectar si hay tuercas o pernos sueltos (o que falten). Ajuste con

firmeza (o reemplace) todos los elementos de ferretería antes de operar

la cortadora trituradora.

Limpieza del canal de reducción

ADVERTENCIA: Las cuchillas de trituración y de corte

del motor están afiladas. Use guantes de trabajo de

cuero para protegerse las manos cuando limpie la

cámara de reducción.

Si la cámara de reducción se tapa con desechos, la criba de desgranado se puede girar hacia arriba para que pueda limpiar la

zona circundante. Para hacerlo proceda de la siguiente manera:

1. Detenga el motor, desconecte la bujía y compruebe que la cortadora trituradora se haya detenido por completo.

ADVERTENCIA: El silenciador y la zona circundante

están calientes si el motor ha estado en funcionamiento. Sea precavido y protéjase las manos si trabaja

cerca del silenciador.

2. a. Si está instalada, retire la bolsa de desechos. Saque las

dos perillas a mariposa de ambos lados del deflector del

canal y gire el mismo hacia arriba. Vea la Figura 8.

b. Saque el broche de horquilla de la chaveta que se extiende a

través de la caja del motor y de la criba de la trituradora.

Vea la Figura 8. Saque la chaveta de horquilla.

c. Gire la criba de desgranado hacia arriba y limpie la zona cir-

cundante sacando todos los desechos mediante raspado.

3. Confirme que el cable de la bujía esté desconectado y lejos de la

misma. Tire de la cuerda del arrancador entre dos y tres veces para

purgar todos los desechos restantes de la cámara de reducción

Figura 8

4. Cuando la zona está limpia, gire la criba de desgranado hacia

abajo y vuelva a ajustarla con la chaveta de horquilla y el

broche de horquilla que sacó anteriormente.

5. Vuelva a colocar la bolsa de recolección de desechos en el

deflector del canal, si lo desea.