Page 1

Operator’s Manual

7.5 Horse Power

CHIPPER SHREDDER

Model No. 247.776350

CAUTION: Before

using this product,

read this manual and

follow all safety rules

and operating

instructions.

For answers to your questions about this product, call:

1-800-659-5917

Sears Craftsman Help Line

(5 am. - 5 pm., Mon. - Sat.)

• Safety

• Operation

• Maintenance

• Storage

• Español, p. 29

Sears, Roebuck And Co., Hoffman Estates, IL 60179 U.S.A.

Visit our website: www.sears.com/craftsman

Printed in U.S.A.

FORM NO.

769-00831A.fm

(4/2004)

Page 2

TABLE OF CONTENTS

Content Page

Warranty 2

Safety 3

Assembly 6

Operation 8

Maintenance 13

Content Page

Service and Adjustments 15

Storage 17

Troubleshooting 18

Parts List 20

Español 29

WARRANTY

Limited Warranty on Craftsman Chipper Shredder

For one (1) year from the date of purchase, if this Craftsman Equipment is maintained, lubricated, and tuned up

according to the instructions to the operator’s manual, Sears will repair or replace free of charge any parts found to

be defective in material or workmanship. Warranty service is available free of charge by returning Craftsman

equipment to your nearest Sears Service Center. In-home warranty service is available but a trip charge will apply.

This Warranty applies only while this product is in the United States.

This Warranty does not cover:

• Expendable items which become worn during normal use, such as sp ark plugs, air cleaners, belts, and oil

filters.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass.

• Repairs necessary because of operator abuse, including b ut not limited to, damage caused by objects, such as

stones or metal debris, oversized stock, impacting objects that b end the frame or crankshaft, or over-speeding

the engine.

• Repairs necessary because of operator negligence, including but not limited to, electrical and me chanical

damage caused by improper storage, failure to use the proper grade and amount of engine oil, or failure to

maintain the equipment according to the instructions contained in the operator’s manual.

• Engine (fuel system) cleaning or repairs caused by fuel determine to be contaminated or oxidized (stale). In

general, fuel should be used within 30 days of its purchase date.

• Equipment used for commercial or rental purposes.

TO LOCATE THE NEAREST SEARS SERVICE CENTER OR TO SCHEDULE SERVICE, CONT ACT SEARS AT

1-800-4-MY-HOME®.

This warranty gives you specific legal rights and you may also have other rights, which vary from state to state.

PRODUCT SPECIFICATION

Horsepower: 7.5 Horse Power

Engine Oil Type SAE 30

Engine Oil Capacity 20 Ounces

Fuel Capacity: 3 Quarts

Spark Plug Champion QC-12YC

Spark Plug Gap .030"

Model Number.........................................................

Serial Number...........................................................

Date of Purchase......................................................

Record both serial number and date of purchase and

keep in a safe place for future reference.

2

247.776350

Page 3

SAFETY

WARNING: This symbol points out important safety instructions which, if n ot followed, could

endanger the personal safety and/or property of yourself and others . Read and follow all instructions in

this manual before attempting to operate this machine. Failure to comply with these instruction s may

result in personal injury. When you see this symbol - heed its warning.

WARNING: Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to State of Calif ornia to cause cancer

and birth defects or other reproductive harm.

DANGER

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious in jury or death.

: This machine was built to be operated according to the rules for safe operation in this

TRAINING

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe

place for future and regular reference and for

ordering replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 16 years old to operate

this machine. Children 16 years old and over

should read and understand the operation

instructions and safety rules in this manual and

should be trained and supervised by a parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Keep bystanders, helpers, pets, and children at

least 75 feet from the machine while it is in

operation. Stop machine if anyone enters the area.

6. Never run an engine indoors or in a poorly

ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

7. Do not put hands and feet near rotating parts or in

the feeding chambers and discharge opening.

Contact with the rotating impeller can amputate

fingers, hands, and feet.

8. Never attempt to unclog the chipper chute or

discharge opening, remove or empty bag, or

inspect and repair the machine while the engine is

running. Shut the engine off and wait until all

moving parts have come to a complete stop.

Disconnect spark plug wire and keep away from

spark plug.

PREPARATION

1. Thoroughly inspect the area where the equipment

is to be used. Remove all rocks, bottles, cans, or

other foreign objects which could be picked up or

thrown and cause personal injury or damage to the

machine.

2. Always wear safety glasses or safety goggles

during operation or while performing an adjustment

or repair, to protect eyes. Thrown objects which

ricochet can cause serious injury to the eyes.

3. Wear sturdy, rough-soled work shoes and closefitting slacks and shirts. Loose fitting clothes or

jewelry can be caught in movable parts. Never

operate this machine in bare feet or sandals. Wear

leather work gloves when feeding material in the

chipper chute.

4. Before starting, check all bolts and screws for

proper tightness to be sure the machine is in safe

working condition. Also, visually inspect machine

for any damage at frequent intervals.

5. To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and

other sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes

before refueling.

f. Never over fill fuel tank. Fill tank to no more

than 1/2 inch below bottom of filler neck to

provide space for fuel expansion.

3

Page 4

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine

and equipment. Move machine to another

area. Wait 5 minutes before starting the

engine.

i. Never store the machine or fuel container

inside where there is an open flame, spark,

or pilot light (e.g. furnace, water heater,

space heater, clothes dryer, etc.)

j. To reduce a fire hazard, keep machine free

of grass, leaves, or other debris build-up.

Clean up oil or fuel spillage and remove any

fuel soaked debris.

k. Allow machine to cool at least 5 minutes

before storing.

OPERATION

1. Do not put hands and feet near rotating parts or in

the feeding chambers and discharge opening.

Contact with the rotating impeller can amputate

fingers, hands, and feet.

2. Before starting the machine, make sure the chipper

chute, feed intake, and cutting chamber are empty

and free of all debris.

3. Thoroughly inspect all material to be shredded and

remove any metal, rocks, bottles, cans, or other

foreign objects which could cause persona l injury

or damage to the machine.

4. If it becomes necessary to push material through

the shredder hopper, use a small diameter stick. Do

not use your hands or feet.

5. If the impeller strikes a foreign object or if your

machine should start making an unusual noise or

vibration, immediately shut the engine off. Allow the

impeller to come to a complete stop. Disconnec t

spark plug wire and keep away from spark plug.

Perform the following steps:

a. Inspect for damage.

b. Repair or replace any damaged parts.

c. Check for any loose parts and tighten to

assure continued safe operation.

6. Do not allow an accumulation of processed

material to build up in the reduction chamber. This

can prevent proper discharge and result in kickback

of material through the feed opening.

7. Do not attempt to shred or chip ma terial larger than

specified on the machine or in this manual.

Personal injury or machine damage could result.

8. Never attempt to unclog the chipper chute or

discharge opening while the engine is running.

Shut the engine off, wait until all moving parts have

stopped, disconnect spark plug wire and keep

away from spark plug before clearing debris.

9. Never operate without the shredder hopper,

chipper chute, or chute deflector properly attached

to the machine. Never install or remove debris

collection bag while the engine is running.

10. Keep all guards, deflectors and safety devices in

place and operating properly.

11. Keep your face and body back and to the s ide of

the chipper chute while feeding material into the

machine to avoid accidental kickback injuries.

12. Never operate this machine without good visibility

or light.

13. Do not operate this machine on a paved, gravel or

non-level surface.

14. Do not operate this machine while under the

influence of alcohol or drugs.

15. Muffler and engine become hot and can cause a

burn. Do not touch.

16. Never pick up or carry machine while the engine is

running.

MAINTENANCE AND STORAGE

1. Never tamper with safety devices. Check their

proper operation regularly.

2. Check bolts and screws for proper tightness at

frequent intervals to keep the machine in safe

working condition. Also, visually inspect machine

for any damage and repair, if needed.

3. Before cleaning, repairing, or inspecting, stop the

engine and make certain the impeller and all

moving parts have stopped. Disconnect spark plug

wire and keep away from spark plug to prevent

unintended starting.

4. Do not change the engine governor settings or

overspeed the engine. The governor controls the

maximum safe operating speed of the engine.

5. Maintain or replace safety and instruction labels, as

necessary.

6. Follow this manual for safe loading, unloading,

transporting, and storage of this machine.

7. Never store the machine or fuel container inside

where there is an open flame, spark or pilot ligh t

such as a water heater, furnace, clothes dryer, etc.

8. Always refer to the operator’s manual for proper

instructions on off-season storage.

9. If the fuel tank has to be drained, do this outdoors.

10. Observe proper disposal laws and regulations for

gas, oil, etc. to protect the environment.

WARNING: - YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who read,

understand and follow the warnings and instructions in this ma nual and on the machine.

4

Page 5

Look For Relevant Emissions Durability Period and

Air Index Information On Your Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB) Tier 2 Emission Sta ndards must

display information regarding the Emission s Durability Period and the Air Index. Sears, Roebuck and Co., U.S.A.

makes this information available to the consumer on our emission labels.

The Emissions Durability Period describes the number of hours of actual running time for which the engine is certified to

be emissions compliant, assuming proper maintenance in accordance with the Operating & Maintenance Instructions.

The following categories are used:

Moderate:Engine is certified to be emission compliant for 125 hours of actual engine running time.

Intermediate:Engine is certified to be emission compliant for 250 hours of actual engine running time.

Extended:Engine is certified to be emission compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore, the Emissions Durability

Period of an engine with an intermediate rating would equate to 10 to 12 years.

The Air Index is a calculated number describing the relative level of emissions for a specific engine family. The lower the

Air Index, the cleaner the engine. This information is displayed in graphical form on the emissions label.

After July 1, 2000, Look For Emissions Compliance Period On

Engine Emissions Compliance Label

After July 1, 2000 certain Sears, Roebuck and Co., U.S.A. engines will be certified to meet the United States

Environmental Protection Agency (USEPA) Phase 2 emission standards. For Phase 2 certified engines, the Emissions

Compliance Period referred to on the Emissions Compliance label indicates the number of operating hours for which the

engine has been shown to meet Federal emission requirements. For engines less than 225 cc displacement, Category C

= 125 hours, B = 250 hours and A = 500 hours. For engines of 225 cc or more, Category C = 250 hours, B = 500 hours and

A = 1000 hours.

The displacement engines of Model Series 120000 is 206 cc.

This is a generic representation of the emission label typically found on a certified engine.

5

Page 6

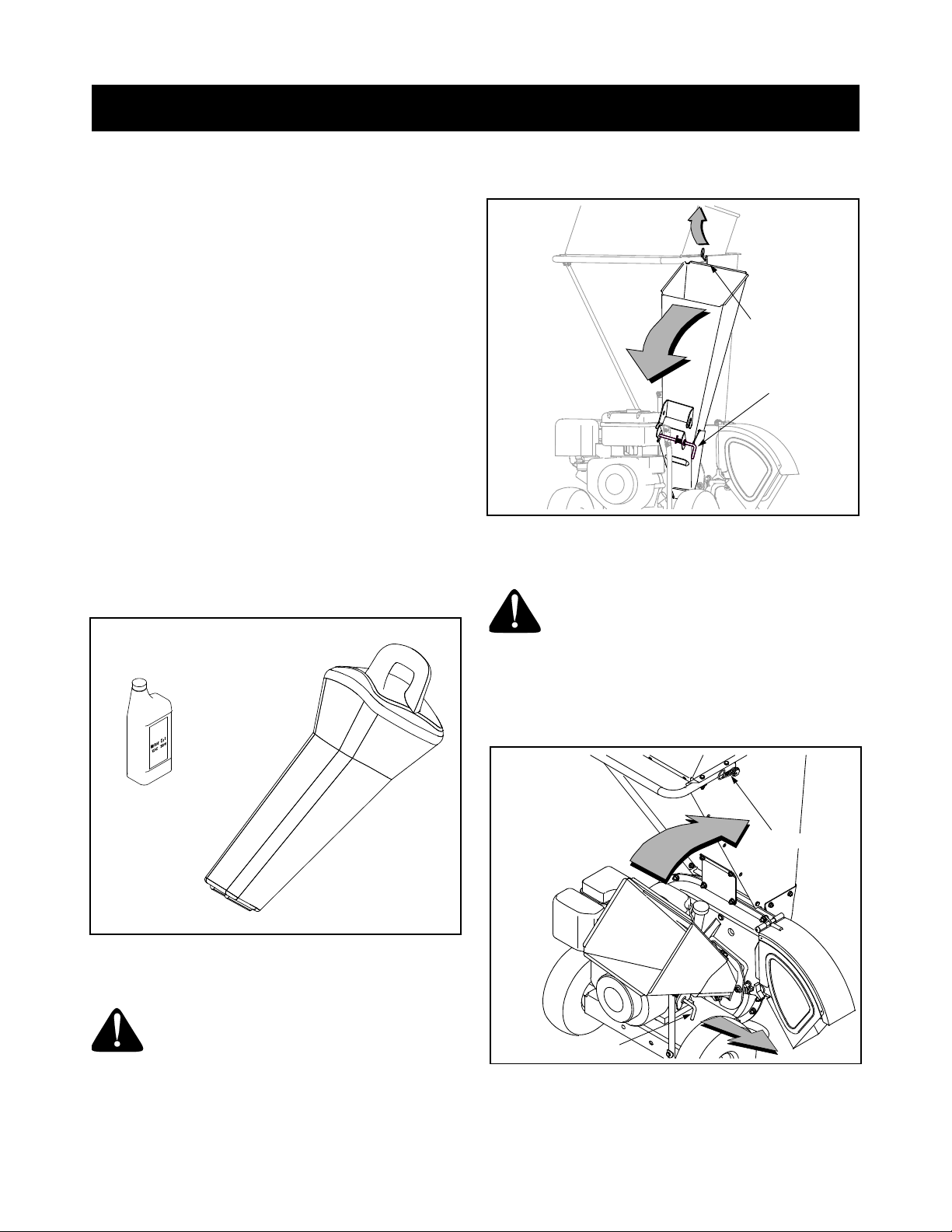

ASSEMBLY

IMPORTANT:

oil in the engine. After assembly, see OPERATION

section of this manual for proper fuel and engine o il fillup.

This Chipper Shredder has been completely assembled

at the factory, except for the debris collection bag,

which is stowed in the chipper chute for shipping.

This unit is shipped without gasoline or

Removing Unit From Carton

• Remove staples, break glue on top flaps or cut tape

at carton end and peel along top flap to open

carton.

• Remove any loose parts.

• Cut down along carton edges and lay carton down

flat.

• Remove packing material. Lift unit from the rear

and discard bottom pad. Roll unit out of carton.

Check carton thoroughly for loose parts.

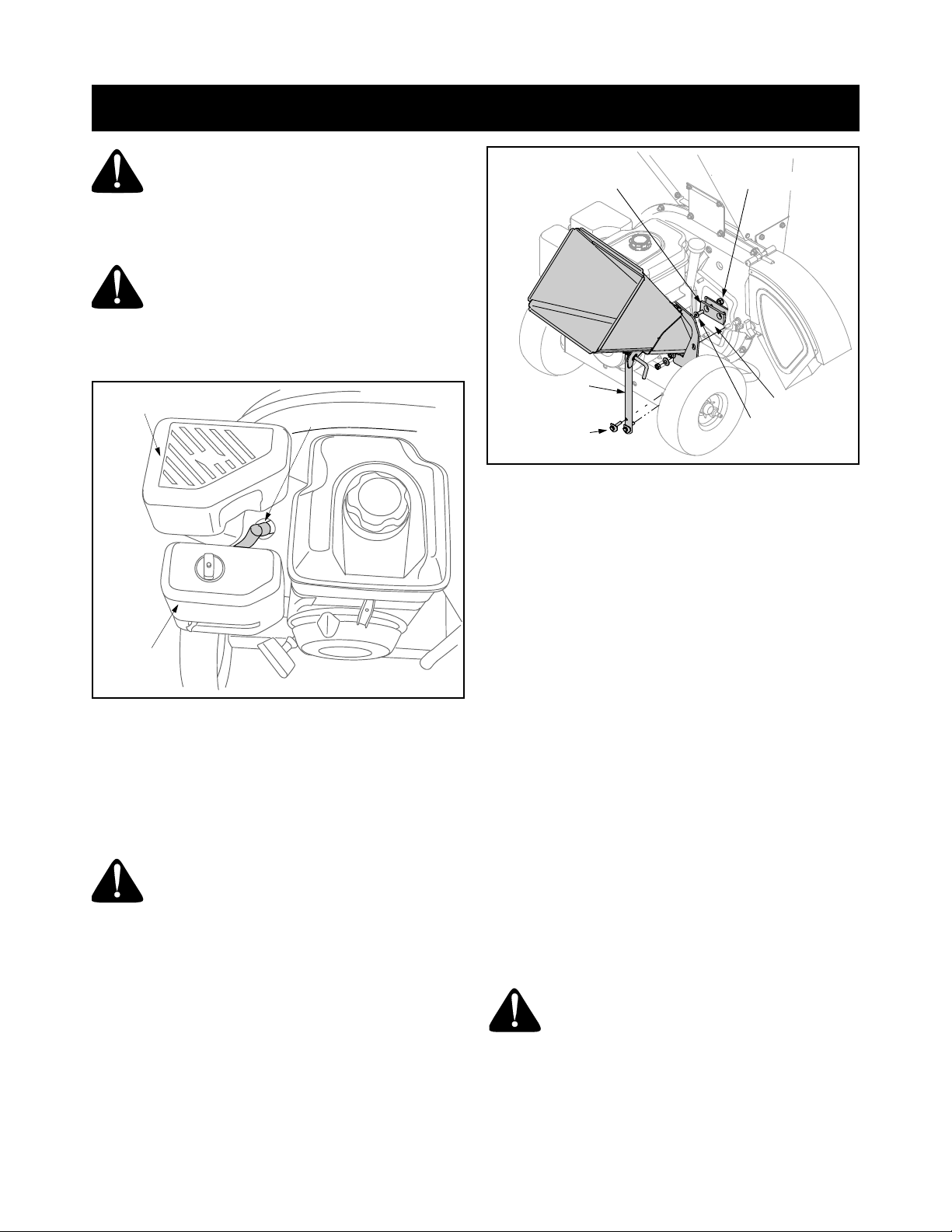

Loose Parts In Carton (See Figure 1)

• One Tamper

• One Debris Collection Bag (Not Shown)

• One Pair of Safety Glasses (Not Shown)

• One 20-oz. Bottle of Engine Oil

• One Operator’s Manual

• Pull the spring latch upward and gently pivot the

chipper chute down until it clicks into the lock rod.

See Figure 2.

1.

Spring Latch

2.

Lock Rod

Figure 2

Raising the Chipper Chute

WARNING: Ne ver o perate the chipper

shredder without chipper chute lowere d into

the operating position.

20-oz. Bottle

of Engine Oil

Tamper

Figure 1

Lowering the Chipper Chute

WARNING: Never operate the chipp er

shredder without chipper chute lowered into

the operating position.

For shipping reasons, the unit is cartoned with its

chipper chute in a raised position. To pivot it downward,

into the operating position, proceed as follows:

For convenience when storing, the chipper chute can

be pivoted upward. To do so, proceed as follows:

• Pull the lock rod outward and pivot the chipper

chute upward until it clicks into the spring latch. See

Figure 3.

2.

Spring Latch

1.

Lock Rod

Figure 3

6

Page 7

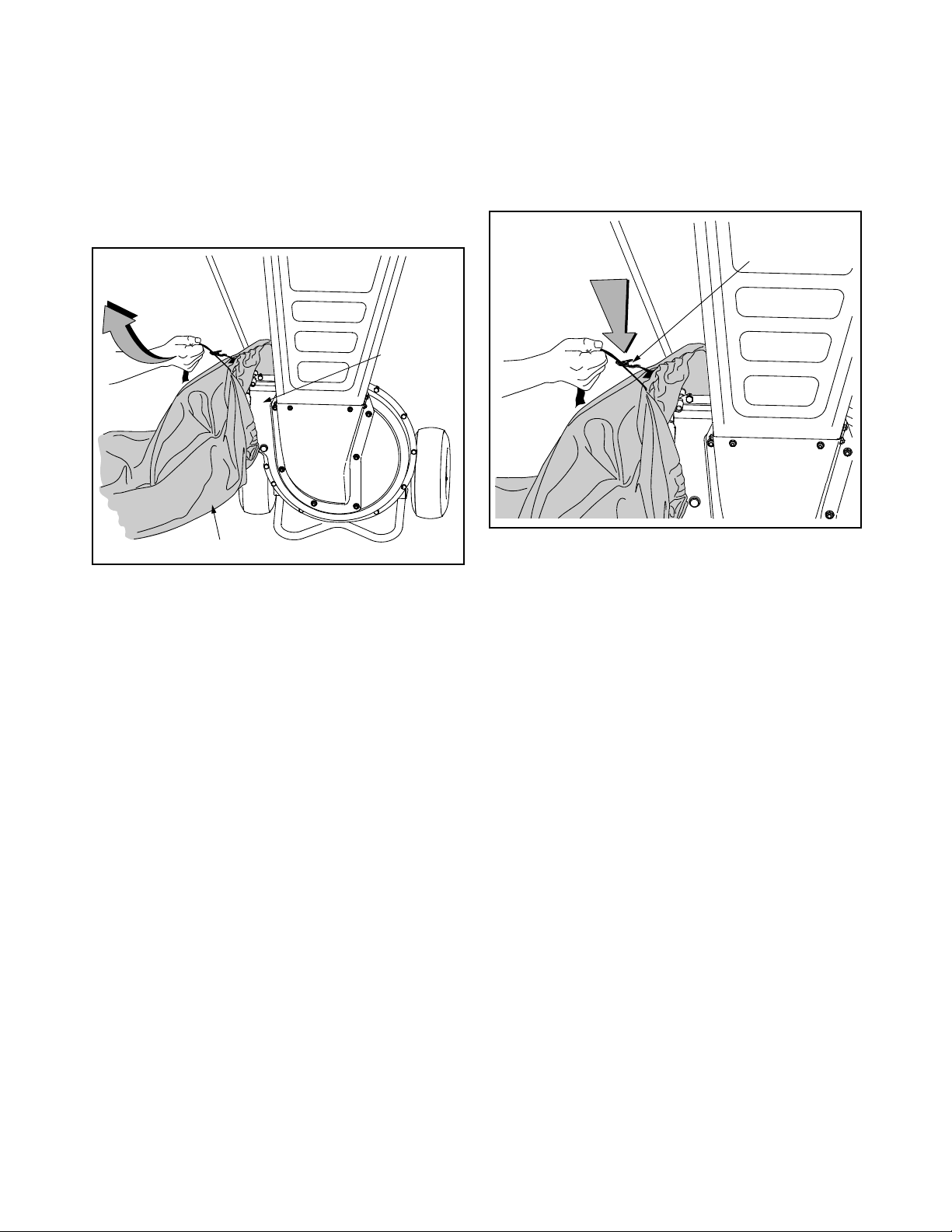

Attaching The Debris Collection Bag

• To attach the bag, place the opening of the bag

completely over the chute deflector.

• Position the bag so that the wing knobs which

secure the chute deflector to the housing are

completely covered.

• Pull on the drawstrap until the bag is tight around

chute deflector. See Figure 4.

Housing

Emptying the Debris Collection Bag

• Squeeze the locking buckle to release the bag’s

drawstrap before loosening it from the chute

deflector. See Figure 5

• Empty the bag and reattach to the chute deflector

opening. Refer to Figure 4.

Locking Buckle

Debris Collection Bag

Figure 4

Figure 5

7

Page 8

OPERATION

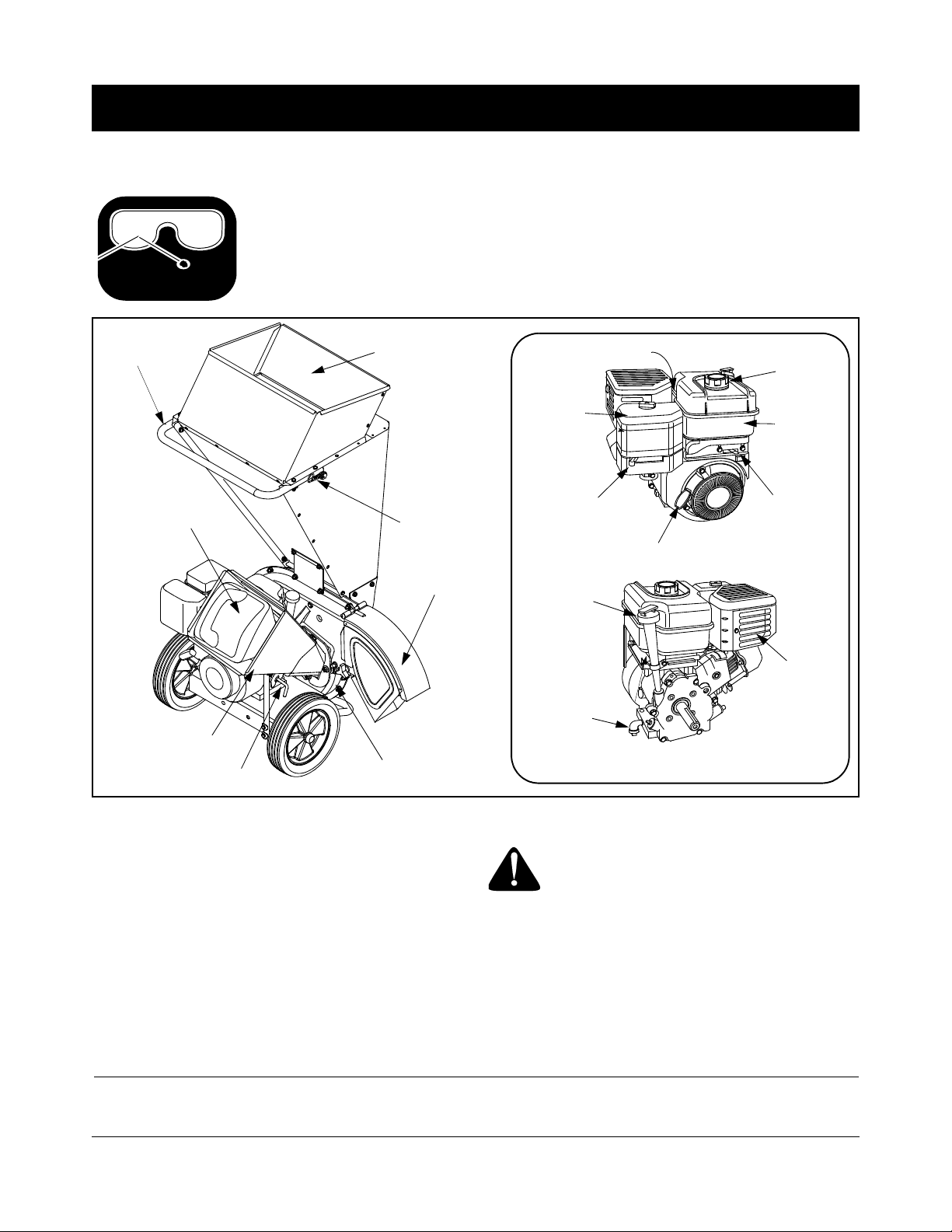

Know Your Chipper Shredder

WEAR Y OU R

SAFETY GLASSES

FORESIGHT IS BETTER

THAN NO SIGHT

Handle

Tamper

Read this operator’s manual and safety rules before operating your Chipper Shredder.

Compare the illustrations below with your equipment to familiarize yourself with the location

of various controls and adjustments. Save this manual for future reference.

The operation of any Chipper Shredder can result in foreign o bjects being thrown into the

eyes, which can result in severe eye damage. Always wear s afety glasses, provided with

the Chipper Shredder, while operating this equipment or while performing any adjustments

or repairs on it.

Hopper

Spring Latch

Chute Deflector

Spark Plug Wire

Air

Cleaner

Choke

Control

Starter Handle

Oil Fill /

Dipstick

Fuel Fill

Fuel Tank

Throttle

Lever

Oil Drain

Chipper Chute

Lock Rod

Reduction Chamber

Engine

Figure 6

Operating Controls (See Figure 6)

Spring Latch

The spring latch is located on the top of the hopper. It is

used to secure the chipper chute in a raised position for

storage or for transporting.

Handle

Use the handle when transporting the chipper

shredder.

Lock Rod

The lock rod is located on the chipper chute sup port. It

is used to release or lock the chipper chute in a lowered

position for operation.

WARNING: Never operate the chipper

shredder with the chipper chute in the raised

position. Release the spring latch to lower the

chipper chute into the operating position

before starting the engine.

Chipper Chute

Branches up to 3” in diameter may be fed into th e

chipper chute for chipping.

Meets ANSI safety standards

Craftsman Chipper Shredders conform to the safety standard of the American National Sta ndards Institute (ANSI).

Muffler

8

Page 9

Tamper

Use the tamper to assist in feeding branches into the

chipper chute.

Hopper

Leaves, twigs and branches up to 1/2-inch in

diameter may be placed into the hopper for shredding.

IMPORTANT: Never place branches with a diameter

greater than 1/2-inch in the hopper. Doing so can result

in serious damage to your unit’s shredder blade, flails

or impeller.

Engine

NOTE: In the s tate of California, the 11 0000 series

engines covered in this manual are certified by th e

California Air Resources Board to meet emissions

standards for 250 hours. Such certification does not

grant the purchaser, owner or operator of this engine

any additional warranties with respect to the

performance or operational life of this engine. This

engine is warranted solely according to the product and

emissions warranties stated elsewhere in this manual.

Bore 2-11/16 in. (68 mm)

Stroke 2-13/64 in. (56 mm)

Displacement 12.48 cu. in.(206 cc)

IMPORTANT: For practical operation, the horsepower

loading should not exceed 85% of rated horsepower.

Engine power will decrease 3-1/2% for each 1,000 feet

(300 meters) above sea level and 1% for each 10° F

(5.6° C) above 77° F (25° C). Engine will operate

satisfactorily at an angle up to 15 degrees.

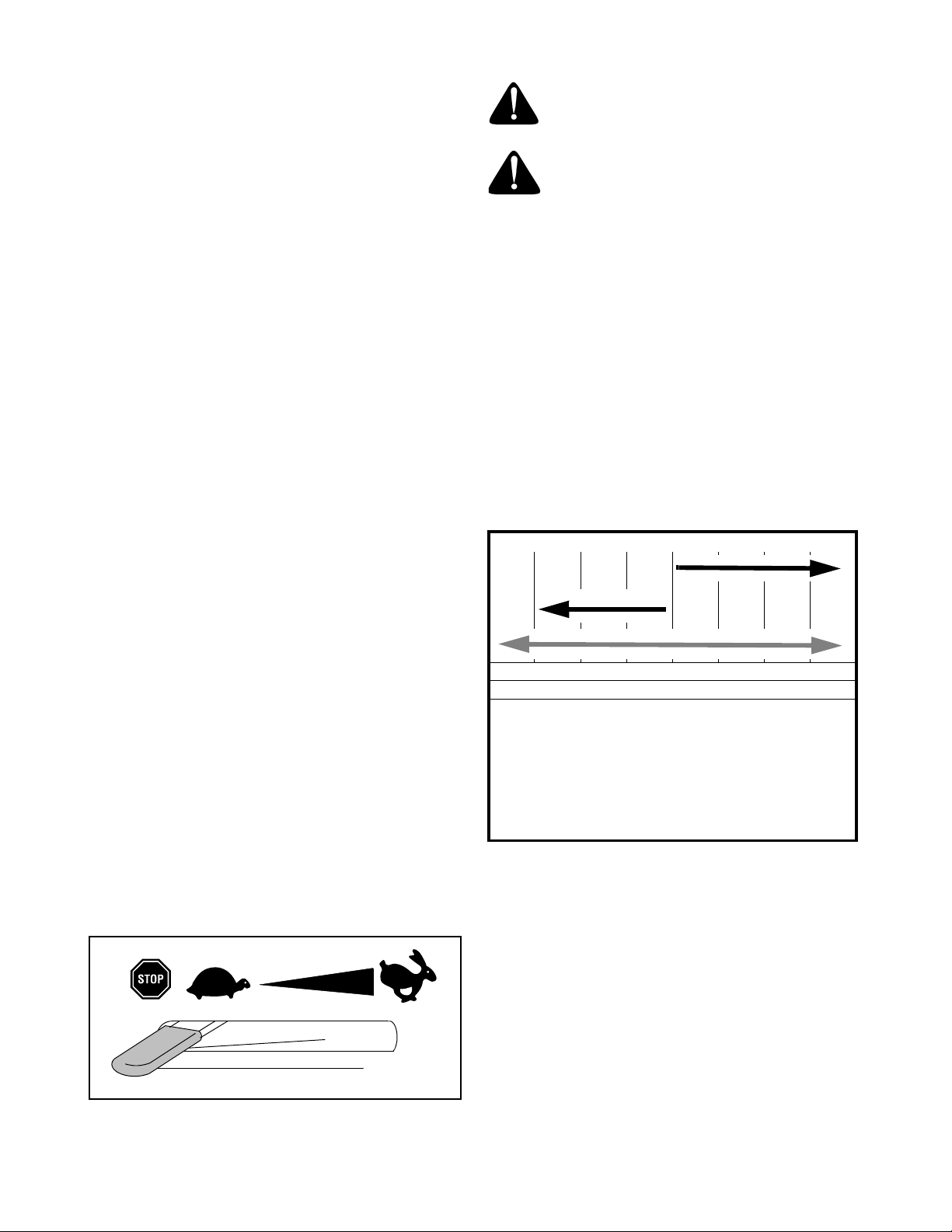

Throttle Lever

The throttle lever controls the engine speed and stop

function.

Choke Control

The choke control closes the choke plate on the

carburetor and aids in starting a cold engine.

Starter Handle

The starter handle is located on the engine. Pull the

starter handle to start engine.

Stopping Engine

• Move throttle control lever to STOP position. See

Figure 7.

WARNING: When moving throttle control

lever, be careful of heated surfaces on muffler

guard.

CAUTION: Never stop the engine by

moving the choke lever into the CHOKE

position. Backfire, fire or engine damage

could result.

Gas And Oil Fill-up

Oil (one 20-oz. bottle included)

IMPORTANT: The chipper shredder is shipped without

oil in the engine.

Type of Oil

1. Refer to the chart below for proper grade of oil.

2. Use a high quality detergent oil classified “For

service SF, SG,SH, SJ” or higher.

3. Do not use special additives.

Synthetic oil meeting ILSAC GF-2, API certification and

API service symbol with “SJ/CF Energy Conserving” or

higher is an acceptable oil at all temperatures. Use of

synthetic oil does not alter required oil change interv als.

SAE Viscosity Grades

30

5W-30, 10W-30

Synthetic 5W-30, 10W-30

°F -20° 0° 20° 40° 60° 80° 100°

Starting temperature range anti cipated befo re next oil ch ange

* CAUTION: Air cooled engines run hotter than automotive

engines. The use of non-synthetic multi-visc osity oils (5W30, 10W-30 etc.) in temperatures abov e 40°F will result in

higher than normal oil consumption. When using a multiviscosity oil, check oil leve l more frequently .

** CAUTION: SAE 30 oil, if used below 40°F, will result in

hard starting and possible engin e bore damage due to

inadequate lubrication.

• Remove oil fill dipstick.

• With the Chipper Shredder on level ground, use a

funnel to fill engine with oil to FULL mark on

dipstick. Capacity is 20 oz. (0.6 liter). Be care ful

not to overfill. Overfilling will cause the engine to

smoke profusely and will result in poor engine

performance. T he oil bottle packaged with your

Chipper Shredder contains 20 oz. of oil.

• Before operating the chipper shredder, check the

oil level as follows:

• Wipe the dipstick with a clean cloth and reinsert it in

the oil fill tube.

Figure 7

9

Page 10

• Tighten the dipstick before removing it and check

the oil fill level. See Figure 8.

Full

Figure 8

• To avoid engine problems, the fuel system should

be emptied before storage for 30 days or longer.

Drain the gas tank, start the engine and let it run

until the fuel lines and carburetor are empty. Use

fresh fuel next season. See STORAGE section for

additional information.

WARNING: Use extreme c are when

handling gasoline. Gasoline is extremely

flammable and the vapors are explosive.

Never fuel machine indoors or while the

engine is hot or running. Extinguish

cigarettes, cigars, pipes, and other sources of

ignition.

NOTE: Do not allow the dips tick to rub along the inside

walls of the oil fill tube when removing it. Doing so may

result in a false dipstick reading.

• Check oil level three times prior to starting engine to

be certain you’ve gotten an accurate dipstick

reading.

IMPORTANT: Running the engine with too little oil can

result in permanent engine damage.

Gasoline

Type of Fuel

• Use clean, fresh, regular unleaded gasoline with a

minimum of 85 octane. Fresh fuel prevents gum

from forming in the fuel system or on essential

carburetor parts. Purchase fuel in quantity that can

be used within 30 days.

• Do not use gasoline which contains Methanol.

• Do not mix oil with gasoline.

• Your chipper shredder’s engine is certified to

operate on gasoline. Exhaust Emission Control

System: EM (Engine Modifications).

NOTE: Some fuels, called oxy genated or reformulated

gasoline, are gasoline blended with alcohols or ethers.

Excessive amounts of these blends can damage th e

fuel system or cause performance problems. If any

undesirable operating symptoms occur, use gasoline

with a lower percentage of alcohol or ether.

Check the fuel level periodically to avoid running out of

gasoline while operating the chipper shredder. If the

unit runs out of gas while operating, it may be

necessary to unclog the unit before it can be restarted.

Refer to SERVICE AND ADJUSTMENT section.

Starting Engine

WARNING: The muffler and surrou nding

area will be hot if the engine has been

running. Use caution and protect your hands if

working near the muffler.

• If not already attached, attach spark plug wire to

spark plug. Make certain the rubber boot on the end

of the spark plug is snapped securely over the

metal tip on the spark plug. Refer to Figure 9 for

spark plug wire location.

Spark Plug Wire

Fuel Fill-up

• Remove fuel cap from the fuel tank.

• Make sure the container from which you will pour

the gasoline is clean and free from rust or foreign

particles. Never use gasoline that may be stale

from long periods of storage in its container.

Gasoline that has been sitting for any period longer

than four weeks is considered stale.

• The fuel tank has a capacity of three (3) quarts. Fill

fuel tank with clean, fresh, unleaded regular,

unleaded premium or reformulated automotive

gasoline only.

• Replace fuel cap.

Figure 9

10

Page 11

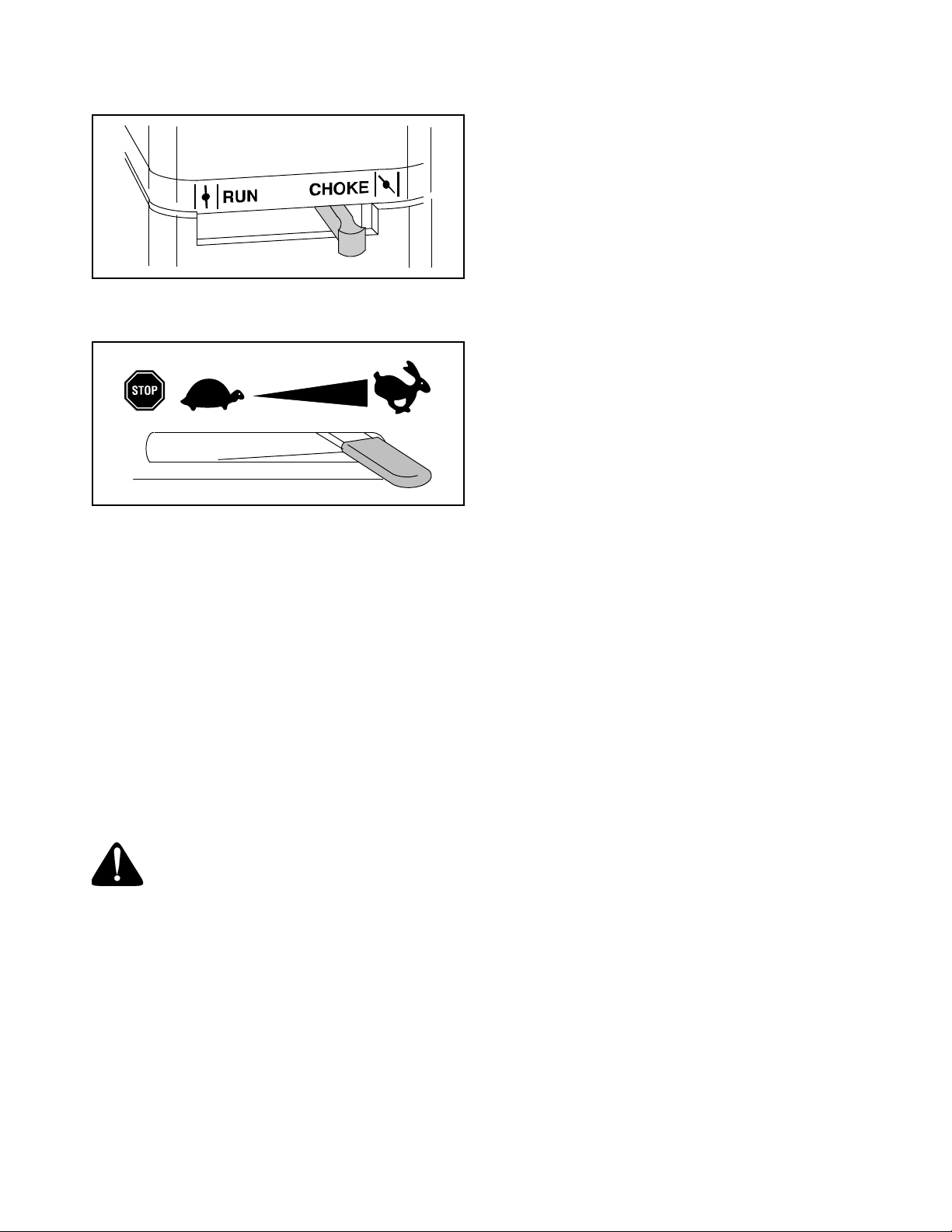

• Move choke lever to CHOKE position. (A warm

engine may not require choking). See Figure 10.

Figure 10

• Move throttle control lever to FAST (rabbit) position.

See Figure 11.

Figure 11

• Grasp the starter handle and pull the rope out

slowly until resistance is felt. When it becomes

slightly harder to pull the rope, slowly allow the rope

to recoil. Then pull rope with a rapid, continuous,

full arm stroke. Keep a firm grip on starter handle.

• Repeat the previous steps until engine starts. When

engine starts, move choke control gradually toward

the RUN position until the engine is running

smoothly.

NOTE: A “clanky” noise may be heard when pulling

the starter rope. It is completely normal and does NOT

indicate a malfunction of any kind. The noise is caused

by the flails (part of the shredding mechanism) pivoting

on the chipper shredder’s impeller as it rotates.

• Avoid shredding fibrous plants such as tomato

vines until they are thoroughly dried out. Fresh

vines do not shred well and tend to wrap

themselves around the impeller and flails.

• Place reasonable amounts of debris into the hopper

at a time. Do not overload the hopper.

• Allow the material in the hopper to be drawn into the

blades and shredded before adding additional

debris to the hopper. Failure to due so may result in

a clogged hopper, clogged chute deflector or a

stalled engine.

• Avoid placing twigs longer than 24 inches into the

hopper. Twigs longer than 24 inches may result in a

clogged hopper.

IMPORTANT: Never place branches with a diameter

greater than 1/2-inch in the hopper. Doing so can result

in serious damage to your unit’s shredder blade, flails or

impeller.

Clearing the Hopper

Should the hopper become clogged with debris during

operation, proceed as follows:

• Grasp the handle with both hands and gently

agitate the chipper shredder to help loosen debris,

drawing it into the impeller.

If the clog does not clear, proceed as follows:

• Stop engine.

• Use your hands to remove any debris found near

the top of the hopper.

• Use a branch (or other available device, i.e.

broomstick) to dislodge debris located toward the

base of the hopper.

• Restart engine.

NOTE: If you’re unable to pull the starter rope as a

result of accumulated debris near the impeller, fo llow

instructions under the heading Cleaning the

Reduction Chamber.

• Allow the rope to recoil slowly.

WARNING: Never run the engine indoors

or in a poorly ventilated area. Engine exhaust

contains carbon monoxide, an odorless and

deadly gas.

Shredding

Yard waste such as leaves and pine needles can be

placed in the hopper for shredding. After material has

been processed by the shredder blade and flails, it will

be forced out of the chute deflector, and, if attached,

into a debris collection bag. Observe the following

guidelines when shredding yard debris:

• Never attempt to shred material other than normal

yard debris (leaves, twigs, pine cones, etc.).

11

Page 12

Chipping

WARNING: Never operate the chipp er

shredder without chipper chute lowered into

the operating position.

Branches up to 3” in diameter can be fed into the

chipper chute. See Figure 6.Observe the following

guidelines when chipping branches:

• Keep both hands firmly on the branch as you feed it

into the chipper chute.

• Never feed more than one branch into the chipper

chute at a time.

• Never feed anything other than branches (or wood)

into the chipper chute.

• Use the tamper to assist in feeding branches into

the chipper chute.

• Apply intermittent pressure (force, in short pulses)

while feeding larger (2- 3-inch diameter) branches

into the chipper chute, to avoid bogging or stalling

the engine.

IMPORTANT: Never feed branches with a diameter

greater than three (3) inches into the chipper chute.

Doing so can result in serious damage to your unit’s

chipper blades, flails or impeller.

• Disconnect spark plug wire and keep away from

spark plug. Refer to Page 15.

WARNING: The muffler and surrou nding

area will be hot if the engine has been

running. Use caution and protect your hands if

working near the muffler.

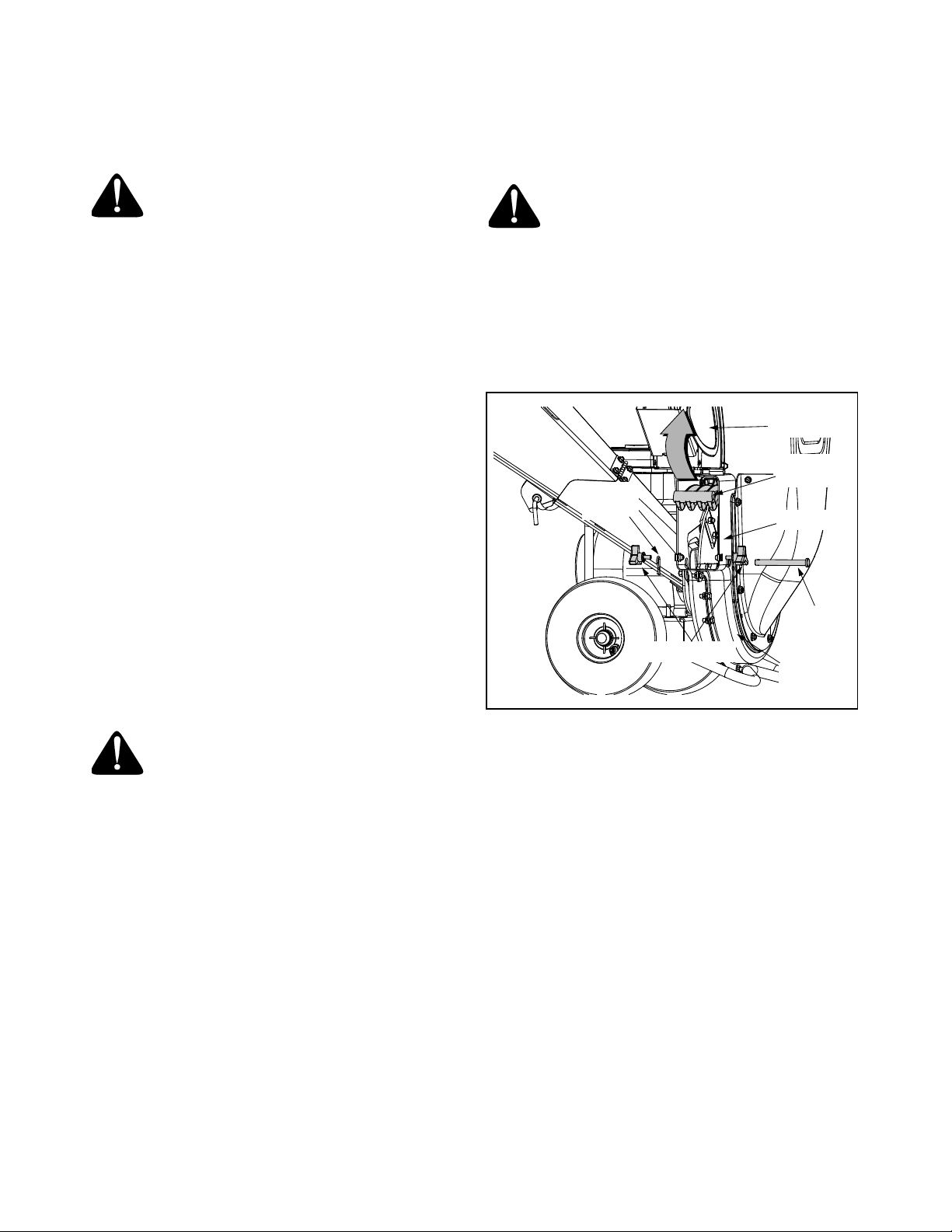

• Remove the two wing knobs on either side of the

chute deflector and pivot the chute deflector

upward. See Figure 12.

• Remove the hairpin clip from the clevis pin which

extends through the housing and shredder screen.

See Figure 12. Retain the clevis pin and hairpin

clip.

Chute

Deflector

Shredder

Hairpin

Clip

Screen

Housing

NOTE: For best performance, always operate the unit

with sharp chipper blades. If a noticeable loss in

performance is encountered while chipping branches,

the chipper blades should be replaced.

Cleaning the Reduction Chamber

WARNING: The impeller’s shredder blade

and chipper blades are sharp. Wear leather

work gloves to protect your hands when

cleaning out the reduction chamber.

If the reduction chamber becomes clogged with debris,

the shredder screen can be pivoted upward so that you

can clean the surrounding area. To do so, proceed as

follows:

• Stop the engine and wait until all moving parts have

come to a complete stop.

Clevis

Pin

Wing Knobs

Reduction

Chamber

Figure 12

• Pivot the shredder screen upward and clean the

surrounding area by scraping away debris.

• Confirm that the spark plug wire is disconnected

and away from spark plug.

• Pull on the starter rope two-to-three times to purge

any remaining debris from the reduction chamber

• When the area is cleaned, pivot the shre dder

screen downward and re-secure with the clevis pin

and hairpin clip removed earlier.

• Reattach the debris collection bag to the chute

deflector, if desired.

12

Page 13

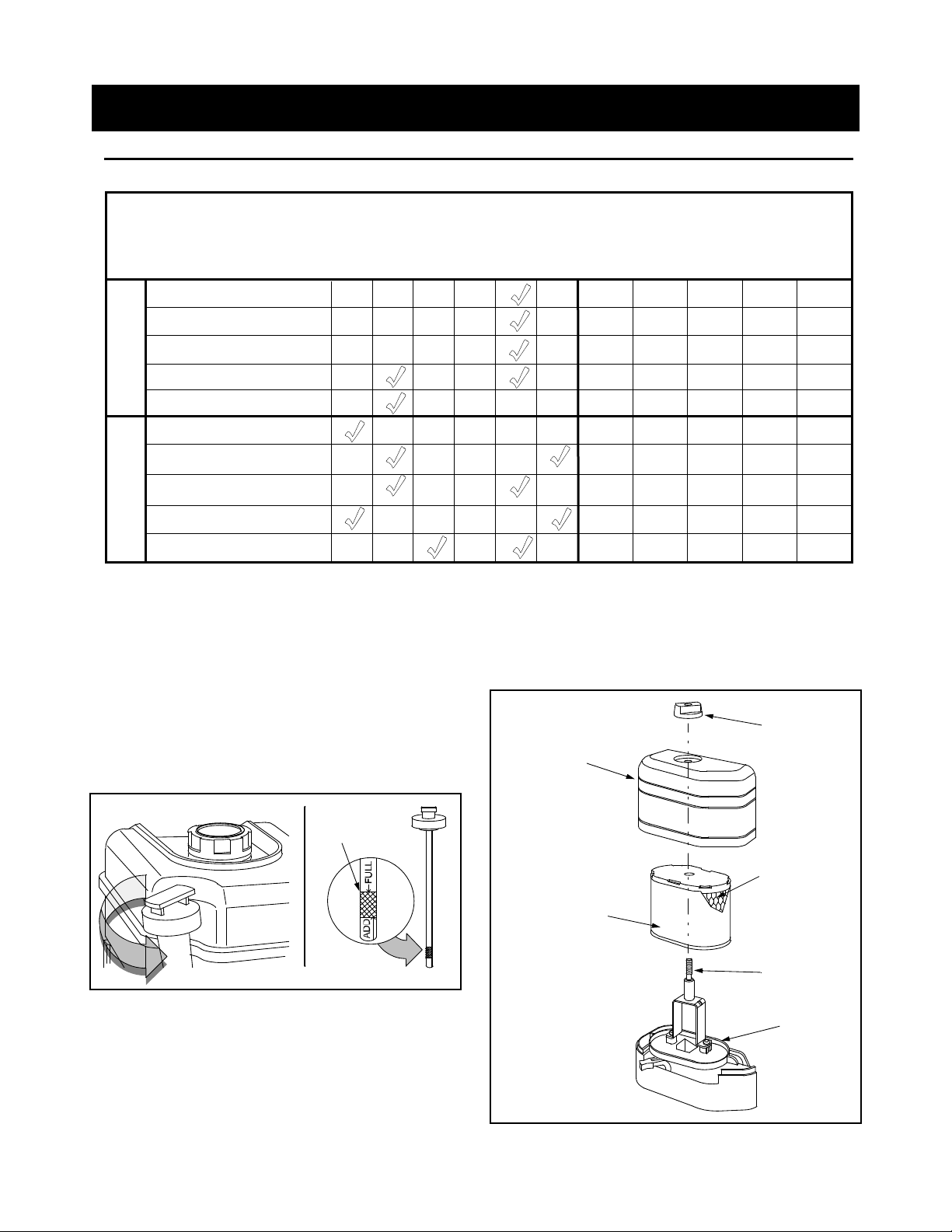

Customer Responsibilities

MAINTENANCE

SCHEDULE

Lube Spring Latch

T

Lube Chipper Chute Hinge

C

U

Lube Chute Deflector

D

O

R

Inspect Chipper Blades

P

Inspect Shredder Blade

Check Oil Level

E

Change Oil

N

I

G

N

Clean Air Filter Precleaner

E

Clean Engine

Check Spark Plug

MAINTENANCE

e

s

s

r

r

u

h

c

a

5

e

2

e

r

y

r

o

f

e

v

e

B

E

u

u

o

o

h

h

0

5

y

r

e

v

E

E

s

r

s

u

o

h

0

0

1

y

r

e

v

n

O

n

e

o

g

s

a

r

a

o

e

t

s

s

a

e

r

e

o

f

c

e

B

SERVICE

DATES

Lubrication

Spring Latch: Lubricate the latch with light oil once a

season

Chipper Chute Hinge: Lubricate the hinge with light oil

once a season.

Chute Deflector: Lubricate the pivot points on the

chute deflector with light oil once a season.

Engine: Check engine oil level before each use as

follows:

• Remove the dipstick and wipe with a clean cloth.

Full

Figure 13

• Replace and tighten dipstick.

• Remove and check the oil fill level. Add oil if

necessary (Refer to Page 9 for proper oil type).

Air Cleaner

Clean air cleaner’s precleaner every 25 hours under

normal conditions. To remove air cleaner, proceed as

follows:

• Remove knob and cover. See Figure 14.

Knob

Cover

Air Cleaner

Cartridge

Pre-cleaner

Stud

Base

13

Figure 14

Page 14

• Lift air cleaner assembly (air cleaner cartridge and

precleaner) off stud.

• Push clean (or new) air cleaner assembly onto

stud. Air cleaner must fit securely on base.

• Push cover squarely onto base and tighten knob.

NOTE: Clean pre-c leaner every few hours under

extremely dusty conditions. To clean pre-cleaner,

separate it from cartridge and wash in liquid detergent

and water. Air dry thoroughly. Do not oil pre-cleaner.

Re-assemble dry pre-cleaner onto clean

cartridge.Replace the air cleaner cartridge once a

season.

IMPORTANT: Do not use pressurized air or solvents to

clean cartridge. Pressurized air can damage cartridge.

Solvents will dissolve cartridge.

Cleaning Engine

• Promptly wipe off any fuel or oil spilled on the

machine with clean cloth.

• Using a brush or cloth, remove debris from the

finger guard on the engine daily to prevent

overheating of the engine. Do not use water to

clean engine parts. Water could contaminate the

fuel system.

• Keep the throttle linkage, springs and controls free

of debris.

• Clean muffler area and remove any debris before

operating the unit.

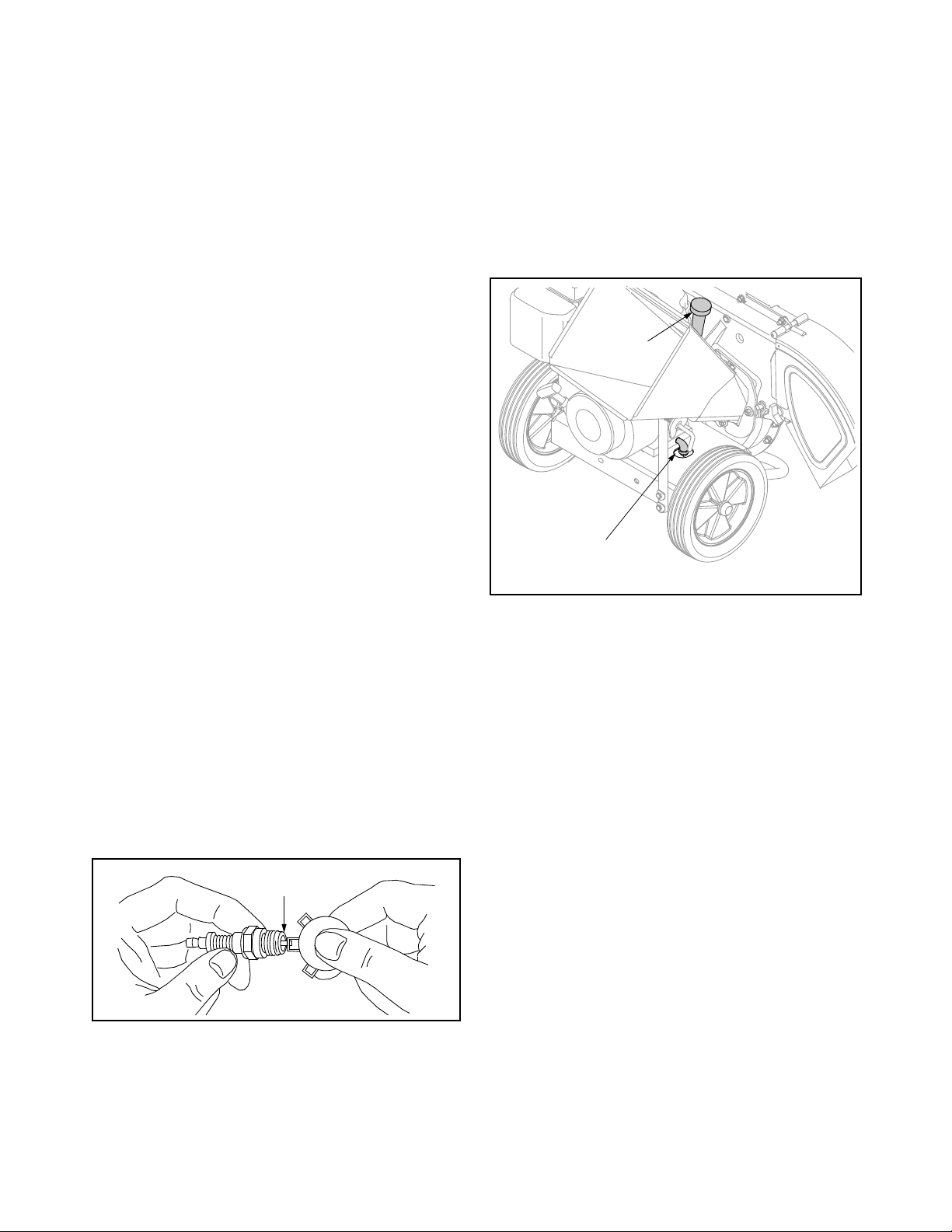

Spark Plug

• Clean area around the spark plug base.

• Remove and inspect the spark plug.

• Replace the spark plug if electrodes are pitted,

burned, or the porcelain is cracked. See Figure 15.

• Clean the spark plug and reset the gap to.030" at

least once a season or every 100 hours of

operation. See Figure 15. Replace if necessary.

Refer to parts list section for part number.

NOTE: Do not sandblas t spark plug. Spark plug should

be cleaned by scraping or wire brushing and washing

with a commercial solvent.

Changing Oil

To drain oil from the engine’s crankcase, proceed as

follows:

• Run the engine for a few minutes to allow the oil to

warm up. Warm oil flows more easily and will carry

away more impurities when draining oil.

• Position the chipper shredder on level surface and

place an appropriate receptacle with a capacity of

at least one quart beneath the oil drain tube. See

Figure 16.

Oil Dipstick

Oil Drain Tube

Figure 16

• Remove the oil dipstick.

• Use a 3/8” wrench to unthread the oil plug from the

drain tube, allowing the used oil to flow out.

• Replace the oil plug and add 20 oz. of new oil

(Refer to Page 9 for proper oil type). Do NOT

overfill.

• Replace dipstick and check oil level (Refer to Page

9).

.030” (0.76 mm)

Figure 15

14

Page 15

SERVICE AND ADJUSTMENTS

WARNING: Always stop engine,

disconnect spark plug wire and keep away

from spark plug, before performing any

service or adjustments on your machine.

Disconnecting Spark Plug

Chipper Blade

Lock Washer & Nut

WARNING:

area will be hot if the engine has been

running. Use caution and protect your hands if

working near the muffler.

Locate the spark plug wire between the muffler and air

cleaner. See Figure 17.

Muffler

Air Cleaner

Disconnect the spark plug wire by gently pulling the

rubber boot from the spark plug. Keep the wire away

from spark plug while servicing your chipper shred der

to prevent accidental starting of the engine.

The muffler and surrounding

Spark Plug Wire

Figure 17

Replacing the Chipper Blades

WARNING: The impeller’s chipper blades

are sharp. Wear leather work gloves to

protect your hands.

• Stop the engine and make certain the chipper

shredder has come to a complete stop.

• Disconnect spark plug wire and keep away from

spark plug.

• Pivot the shredder screen upward as instructed

under the heading Cleaning the Reduction

Chamber.

• Remove the chipper chute support brace from the

frame by removing the two hex bolts and saddle

washers which secure it. See Figure 18.

Support Brace

Impeller

Hex Bolts &

Saddle Washers

Figure 18

• Remove the chipper chute by removing three hex

nuts and washers which secure it to the impeller

housing. See Figure 18.

• Rotate the impeller by hand until one of the two

chipper blades is visible through the impeller

housing opening.

• Remove the blade by removing the internal hex

screws, lock washers and hex nuts which secure it

to the impeller. Retain the hardware.

NOTE: Use a 3/16” hex key (Allen) wrench on the

outside of the blade and a 1/2” box (or socket) wrench

on the inside of the impeller. See Figure 18. Hold the

Allen wrench stationary and rotate the box (or socket)

wrench to loosen the nut.

• Install a replacement blade (Part No. 742-0544)

with the hardware removed earlier.

IMPORTANT: Make certain blades are reassembled with

the sharp edge outward (toward the chipper chute).

Torque hardware to between 20 ft.-lbs and 25 ft.-lbs.

• To replace the other blade, rotate the impeller to

expose the second blade and repeat the steps

above.

Internal

Hex Screw

Replacing the Shredder Blade

WARNING: The impeller’s chipper blade s

are sharp. Wear leather work gloves to

protect your hands.

• Stop the engine and make certain that all moving

parts have come to a complete stop.

15

Page 16

• Remove the two flange nuts (and hex bolts) which

secure the hopper support bracket to the impeller

housing. Retain the hardware. See Figure 19.

Support

Bracket

Flange Nuts

Figure 19

• Pivot the shredder screen upward as instructed

under the heading Cleaning the Reduction

Chamber.

• Remove the six flange nuts which secure the

hopper inlet guide to the impeller housing. See

Figure 20.

chute deflector

Shredder

Blade

Internal

Hex Screws

Impeller

Flange

Nuts

Inlet

Guide

• Insert a piece of wood into the chute deflector

opening to stabilize the impeller and prevent it from

rotating when removing the shredder blade.

• Remove the two internal hex screws which secure

the shredder blade to the impeller. See Figure 20.

NOTE: Use a 3/16” hex key (Allen) wrench on the

outside of the shredder blade and a 1/2” box (or socket)

wrench on the inside of the shredder blade. See Figure

20. Hold the Allen wrench stationary and rotate the box

(or socket) wrench to loosen the nut.

• Remove the hex bolt, lock washer, and flat washer

to completely free the shredder blade.

IMPORTANT: If sharpening the blade for reuse , follow

the original angle of grind as a guide. It is extremely

important that each cutting edge receives an equal

amount of grinding to prevent an unbalanced blade.

An unbalanced blade will cause excessive vibration

when rotating at high speeds and may cause damage

to the unit. The blade can be tested for balance by

inserting a screwdriver through its center hole. Remove

metal from the heavy side until it is balanced evenly.

IMPORTANT: When reassembling the blade, tighten

center bolt to between 45 ft.-lbs and 60 ft.-lbs and the

two out bolts to between 20 ft.-lbs and 25 ft.-lbs.

Carburetor Adjustment

The carburetor on this engine is low emission. It is

equipped with a non-adjustable idle mixture valve and

governed idle. Governed idle and top speed have been

set at the factory. If adjustment is required, see a Sears

Service Center.

NOTE: Engines operated at about 3000 to 5000 feet

(900 to 1500 meters) above sea level may require a

high altitude carburetor nozzle. If erratic performance is

observed, contact a Sears Service Center for cost to

install/purchase a high altitude carburetor nozzle, if

available.

Weld Studs

Hex Bolt, Lock Washer

& Flat Washer

Figure 20

• Carefully separate the hopper assembly from the

impeller housing and set it aside.

16

Page 17

STORAGE

Chipper Shredder

• Clean the equipment thoroughly.

• Wipe equipment with an oiled rag to prevent rust.

• Store unit in a clean, dry area. Do not store n ext to

corrosive materials such as fertilizer.

Engine

Engines stored over 30 days need special attention.

1. To prevent gum from forming in fuel system or on

essential carburetor parts:

a. if fuel tank contains oxygenated or reformulated

gasoline (gasoline blended with an alcohol or an

ether), run engine until it stops from lack of fuel,

or

b. if fuel tank contains gasoline, either run engine

until it stops from lack of fuel, or add a gasoline

additive to the gas in the tank. If you use a gas

additive, run the engine for several minutes to

circulate the additive through the carburetor.

Then, engine and fuel can be stored up to 24

months.

2. While engine is still warm, change oil.

3. Remove spark plug and pour about one (1) oz. (30

ml.) of engine oil into spark plug hole. Replace

spark plug and slowly pull the starter rope to

distribute oil.

4. Clean engine of surface debris, chaff or grass.

5. Store in a clean, dry area.

WARNING: Do not s tore in same area as a

stove, furnace, water heater, or other

appliance that uses a pilot light or has a

device that can create a spark.

17

Page 18

TROUBLESHOOTING

Problem Cause Remedy

Engine fails to start 1. Spark plug wire disconnected.

2. Fuel tank empty or stale fuel.

3. Throttle control lever not in

correct starting position.

4. Choke not in CHOKE position.

5. Engine not primed.

6. Blocked fuel system.

7. Faulty spark plug.

Engine runs erratic 1. Spark plug wire loose.

2. Unit running on CHOKE.

3. Dirt in fuel system

4. Stale fuel.

5. Dirty air cleaner.

6. Carburetor out of adjustment.

Too much vibration 1. Loose parts or damaged

impeller.

2. Blade(s) damaged or not

properly sharpened.

Engine overheats 1. Engine oil level low.

2. Dirty air cleaner.

3. Carburetor not adjusted

properly.

Occasional skip

(hesitates) at high

speed

Unit does not

discharge

Rate of discharge

slows considerably or

composition of

discharged material

changes.

1. Spark plug gap too narrow. 1. Adjust gap to.030” (0.76 mm)

1. Chute deflector clogged.

2. Foreign object lodged in

reduction chamber.

3. Low engine RPM.

1. Low engine RPM.

2. Chipper blades or shredder

blade dull.

1. Connect wire to spark plug.

2. Fill tank with clean, fresh gasoline.

3. Move throttle lever to FAST position.

4. Move choke to CHOKE position.

5. Prime engine.

6. See Sears Service Center to have fuel

system cleaned.

7. Clean, adjust gap, or replace.

1. Connect and tighten spark plug wire.

2. Move choke lever to OFF position.

3. See Sears Service Center to have fuel

system cleaned.

4. See Sears Service Center to have fuel

system cleaned. Fill tank with clean, fresh

gasoline.

5. Clean or replace air cleaner.

6. See authorized service dealer.

1. See Sears Service Center.

2. Replace or sharpen blade(s).

1. Fill crankcase with proper oil.

2. Clean or replace air cleaner.

3. See Sears Service Center.

1. Stop engine immediately and disconnect

spark plug wire. Clean shredder screen and

inside of discharge opening.

2. Stop engine and disconnect spark plug wire.

Remove lodged object.

3. Always run engine at full throttle.

1. Always run engine with the throttle in the

FAST position.

2. Replace blades or see your Sears Service

Center.

NOTE: For repairs beyond the minor adjustments listed above, please con tact your local Sears Service Center.

18

Page 19

(This page applicable in the U.S.A. and Canada only.)

Sears, Roebuck and Co., U.S.A. (Sears), the California Air Resources Board (CARB)

and the United States Environmental Protection Agency (U.S. EPA)

Emission Control System Warranty Statement (Owner’s Defect Warranty Rights and Obligations)

EMISSION CONTROL WARRANTY COVERAGE IS APPLICABLE TO

CERTIFIED ENGINES PURCHASED IN CALIFORNIA IN 1995 AND

THEREAFTER, WHICH ARE USED IN CALIFORNIA, AND TO

CERTIFIED MODEL YEAR 1997 AND LATER ENGINES WHICH ARE

PURCHASED AND USED ELSEWHERE IN THE UNITED STATES (AND

AFTER JANUARY 1, 2001 IN CANADA).

California and United States Emission Control Defects Warranty Statement

The California Air Resources Board (CARB), U.S. EPA and Sears are

pleased to explain the Emission Control System Warranty on your model

year 2000 and later small off-road engine (SORE). In Califo rnia, new small

off-road engines must be designed, built and eq uipp ed t o meet th e Stat e’s

stringent anti-smog standards. Elsewhere in the United States, new nonroad, spark-ignition engines certified for model year 1997 and later must

meet similar standards set forth by the U.S. EPA. Sears must warrant the

emission control system on your engine for the period s of time listed below,

provided there has been no abuse, neglect or improper maintenance of

your small off-road engine. Your emission control system includes parts

such as the carburetor, air cleaner, ignition system, muffler and catalytic

converter. Also included may be connectors and other emission related

assemblies. Where a warrantable condition exists, Sears will repair your

small off-road engine at no co st to you in cluding diagnos is, parts a nd labor.

Sears Emission Control Defects Warranty Coverage

Small off-road engines are warranted r elative to emission control

parts defects for a period of two years, subject to provisions set forth

below. If any covered part on your engine is defective, the part will be

repaired or replaced by Sears.

Owner’s Warranty Responsibilities

As the small off-road engine owner, you are responsible for the

performance of the required maintenance listed in your Operating and

Maintenance Instructions. Sears recommends that you retain all your

receipts covering maintenance on your small off-road engine, but Sears

cannot deny warranty solely for the lack of receipts or for your failure to

ensure the performance of all scheduled maintenance. As the small offroad engine owner, you should however be aware that Sears may deny

you warranty coverage if your small off-road engine or a part has failed due

to abuse, neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your small off-road engine to an

Authorized Sears Service Dealer as soon as a problem exists. The

undisputed warranty repairs should be completed in a reasonable amount

of time, not to exceed 30 days.If you have any questions regarding your

warranty rights and responsibilities, you should contact a Sears Service

Representative at 1--800--469--4663. The emission warranty is a defects

warranty. Defects are judged on normal engine perf ormance. The warra nty

is not related to an in-use emission test.

Sears Emission Control Defects Warranty Provisions

The following are specific provisions relative to your Emission Control Defects Warranty Coverage. It is in addition to the Sears engine warranty for nonregulated engines found in the Op erating and Maint enance Instru ctions.

1. Warranted Parts

Coverage under this warranty extends only t o the parts lis ted below

(the emission control systems part s) to the e xtent these part s were

present on the engine purchase d.

a. Fuel Metering System

• Cold start enrichment system

• Carburetor and internal parts

• Fuel Pump

b. Air Induction System

• Air cleaner

• Intake manifold

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

e. Miscellaneous Items Used in Above Sys tems

• Vacuum, temperature, position, t ime sensitive v alves

and switches

• Connectors and assemblies

2. Length of Cove rage

Sears warrants to the initial owner an d each subsequent purchaser

that the Warranted Parts shall be free from defe cts in materi als and

workmanship which caused the fa ilure of the Wa rranted Part s for a

period of two years from the date the engine is delivere d to a retail

purchaser.

In the USA and Canada, a 24 hour hot line, 1-800-469--4663, has a menu of pre-recorded message s offering you engine maintena nce information.

3. No Charge

Repair or replacement of any Warranted Part will be performed at no

charge to the owner, including diagnostic labor which leads to the

determination that a Warranted Part is de fective, if t he diagnostic

work is performed at an Authorize d Sears Service Deal er. For

emissions warranty service contact your nearest Au thorized Sears

Service Dealer as listed in the “Yellow Pages” under “Engines,

Gasoline,” “Gasoline Engines,” “Lawn Mowers,” or similar categor y.

4. Claims and Coverage Exc lusions

Warranty claims shall be filed in accordance with the provisions of the

Sears Engine Warranty Policy. Warr anty coverage shall be excluded

for failures of Warranted Parts which are not original Sears parts or

because of abuse, neglect or impr oper maintenance as set forth in the

Sears Engine Warranty Policy. Sears is n ot liable to co ver failures of

Warranted Parts caused by the use o f add-on, non- original, or

modified parts.

5. Maintenance

Any Warranted Part which is not scheduled for replacement as

required maintenance or which is schedu led only for regular

inspection to the effect of “rep air or replace as necessary” shall be

warranted as to defects for the warrant y period. Any Warr anted Part

which is scheduled for replacement as required maintenance shall be

warranted as to defects only for th e period of time up to the first

scheduled replacement for that par t. Any replac ement part tha t is

equivalent in performance and durability may be used in the

performance of any maintenance or repairs. The owner is re sponsible

for the performance of all required m aintenance, as defin ed in the

Sears Operating and Maintenance Inst ructions.

6. Consequential Coverage

Coverage hereunder shall extend to t he failure of any engine

components caused by the failure of any Warranted Part still under

warranty.

19

Page 20

PARTS LIST

Sears Craftsman 7.5 H.P. Chipper Shredder Model 247.776350

26

37

42

25

A

57

29

18

6

19

4

27

6

6

B

6

7

16

22

22

30

14

9

11

58

2

3

46

59

12

5

B

22

35

41

40

22

4

6

13

15

3

13

51

17

8

10

1

49

22

12

33

50

23

24

21

4

4

6

4

31

22

6

6

42

44

32

47

43

56

34

55

54

39

45

22

38

53

28

5

13

20

36

52

48

20

A

38

20

Page 21

Sears Craftsman 7.5 H.P. Chipper Shredder Model 247.776350

Ref.

No.

1. 681-04006 Upper Chipper Chute Assembly

2. 681-04007 Lower Chipper Chute Assembly

3. 710-0106 Hex Cap Screw, 1/4-20 x 1.25

4. 710-3013 Hex Cap Screw, 1/4-20 x.5

5. 712-3010 Hex Nut, 5/16-18

6. 712-3027 Hex Lock Nut 1/4-20

7. 714-0104 Cotter Pin

8. 728-0175 Pop Rivet

9. 732-0306A Compression Spring,.531 x 1.75

10. 735-0249A Chute Flap

11. 736-0140 Flat Washer

12. 736-0242 Bell Washer.340 ID x.872 OD

13. 736-0451 Washer,.320 ID x.93 OD

14. 747-04163 Lock Rod

15. 749-1004 Chipper Chute Support

16. 781-04032 Chipper Chute Hinge

17. 781-0633 Chute Flap Strip

18. 681-04011 Shredder Hopper Assembly

19. 710-0809 Hex Cap Screw, 1/4-20 x 1.250

20. 710-0805 Hex Cap Screw, 5/16-18 x 1.50

21. 712-0431 Flange Lock Nut, 3/8-16

22. 712-3004A Flange Lock Nut, 5/16-18

23. 732-04167 Torsion Spring

24. 736-0182 Spring Washer,.50 x 1.0 x.022

25. 736-0326 Flat Washer,.50 x 1.0 x.0125

26. 738-0430 Shoulder Screw, 3/8-16,.50 x.685

27. 749-04103 Hopper Handle

28. 749-04104 Tube Support

29. 781-04007 Shredder Plate

30. 781-04027 Hopper Support Bracket

31. 781-04033 Inlet Guide

Part No. Part Description

Ref.

No.

32. 681-0117 Inner Flail Housing Assembly

33. 681-0184A Frame Assembly

34. 681-04002 Outer Flail Housing Assembly

35. 710-0157 Hex Cap Screw, 5/16-24 x.75

36. 710-0502A Hex Sems Screw, 3/8-16 x 1.25

37. 710-0825 Hex Cap Screw, 1/4-20 x 3.75

38. 710-3008 Hex Cap Screw, 5/16-18 x.75

39. 726-0211 U-Nut, 5/16-18

40. 736-0119 Lock Washer, 5/16

41. 736-0170 Special Lock Washer, 5/16

42. 750-0793 Hinge Spacer,.265 x.380 x 1.66

43. 681-0048 Knob, 5/16-18

44. 681-0094 Chute Deflector Assembly

45. 711-0835 Clevis Pin,.50 x 4.62

46. 714-0149B Internal Cotter Pin

47. 719-04070 Shredder Screen

48. 726-0214 Push Cap, 5/8

49. 737-0195 Oil Drain Tube

50. 750-0786 Spacer,.64 x.88 x.38

51. 738-0814 Axle, 21.21”

52. 734-1600 Wheel, 10 x 2.5

53. 710-1254 Hex Cap Screw, 3/8-24 x 2.25

54. 736-0217 Lock Washer, 3/8

55. 736-0247 Flat Washer,.406 x 1.25

56. 681-04009 Impeller Assembly

57. 736-0173 Flat Washer,.28 x.74 x.063

58. 726-0233 Push Nut,.25ID x.50OD

59. 726-0201 Speed Nut,.3125ID

— 664-04024 Debris Collection Bag (Not Shown)

— 723-0400 Safety Glasses (Not Shown)

Part No. Part Description

(See below for Impeller Parts)

Ref.

No.

1. 681-04009 Impeller Assembly Complete

2. 710-1054 Machine Screw, 5/16-24 x 1.0

3. 711-0833B Clevis Pin,.496

4. 712-0411 Hex Lock Nut, 5/16-24

5. 715-0166 Spiral Pin,.156 x 1.0

6. 719-0329 Flail

7. 736-0119 Lock Washer, 5/16

8. 742-04050 Shredder Blade

9. 742-0544 Chipper Blade

10. 781-0735 Retainer Clip

NOTE: When ordering replacement painted parts,

add the applicable color code to the part number.

Part No. Part Description

Sears Red: 0721

Oyster Grey: 0662

Powder Black: 0637

21

1

9

8

10

2

6

4

3

5

7

2

Page 22

Sears Craftsman 7.5 H.P. Chipper Shredder Model 247.776350

5

33

35

36

34

868

40

238

40

13

51

1022

192

619

830

7

155

1029

1026

1034

45

993

1023

11

914

635

914A

383

337

17

1022

914B

306

307

219

220

746

742

46

24

22

16

332

18

20

12

146

741

27

28

21

2

1

552

3

89

29

718

25

15

27

30

32A

26

32

22

Page 23

Sears Craftsman 7.5 H.P. Chipper Shredder Model 247.776350

122

51

118

365

125

109

633

163

108

127

276

98

977 CARBURETOR GASKET SET

51

137

692

163

130

97

633A

186

95

467

134

133

975

117

968

104

137

276

276

137

104

3

51

633A

633

121 CARBURETOR OVERHAUL KIT

134

633

122

967

633A

127

276

51

445

163

20

358 ENGINE GASKET SET

993

12

883

122

717

961

971A

875

7

163

868

163

1022

51

23

971

Page 24

Sears Craftsman 7.5 H.P. Chipper Shredder Model 247.776350

222

616

615

227

427

773

271

668

562

505

621

504

188

334

281

209

632

333

663

209A

847

523

842

287

524

356

851

187

601

190

972

957

836A

832

836

300

613

883

24

Page 25

Sears Craftsman 7.5 H.P. Chipper Shredder Model 247.776350

608

58

60

55

459

689

456

1211

65

597

1210

363

23

1022

304

305

1095 VALVE GASKET GASKET

7

993

1005

455

332

1070

1329 REPLACEMENT ENGINE

1330 REPAIR MANUAL

48 SHORT BLOCK

868

51

25

Page 26

Sears Craftsman 7.5 H.P. Chipper Shredder Model 247.776350

Ref.

No.

1 699505 Cylinder Assembly

2 399269 Bushing/Seal Kit (Magneto Side)

3 299819 Seal-Oil

5 699486 Head-Cylinder

7 698210 Gasket-Cylinder Head

11 693647 Breather Tube

12 699485 Gasket-Crankcase

13 699482 Screw (Cylinder Head)

15 691686 Plug-Oil Drain

16 699452 Crankshaft

18 699596 Cover-Crankcase

20 692550 Seal-Oil

21 281658 Cap-Oil Fill

22 699478 Screw (Crankcase Cover)

23 699488 Flywheel

24 222698 Key-Flywheel

25 499627 Piston Assembly (Standard)

26 499631 Ring Set (Standard)

27 691866 Lock-Piston Pin

28 499423 Pin-Piston

29 690124 Rod-Connecting

30 692562 Connecting Rod Dipper

32 691664 Screw (Connecting Rod)

32A 695759 Screw (Connecting Rod)

33 499642 Valve-Exhaust

34 499641 Valve-Intake

35 691304 Spring-Valve

36 691304 Spring-Valve

40 692194 Retainer-Valve

45 690977 Tappet-Valve

46 696813 Camshaft

48 699581 Short Block

51 692555 Gasket-Intake (2 Required)

55 691422 Housing-Rewind Starter

58 693389 Rope-Starter

60 691951 Grip-Starter Rope

65 699228 Screw (Rewind Starter)

89 691682 Plug-Oil

95 691636 Screw (Throttle Valve)

97 690024 Shaft-Throttle

98 398185 Kit-Idle Speed

104 691242 Pin-Float Hinge

108 692567 Valve-Choke

109 693628 Shaft-Choke

117 698344 Jet-Main (Standard)

118 694176 Jet-Main (High Altitude)

Part No. Part Description

692789 Piston Assembly (.020" O/S)

692786 Ring Set (.020" O/S)

Ref.

No.

121 696998 Carburetor Overhaul Kit

122 693749 Spacer-Carburetor

125 698475 Carburetor

127 691739 Plug-Welch

130 691181 Valve-Throttle

133 398187 Float-Carburetor

134 398188 Valve-Needle

137 693981 Gasket-Float Bowl

146 690979 Key-Timing

155 698214 Plate-Cylinder Head

163 696979 Gasket-Air Cleaner

186 692317 Connector-Hose

187 693401 Line-Fuel (Molded)

188 699479 Screw (Control Bracket)

190 699220 Screw (Fuel Tank)

192 694543 Adjustor-Rocker Arm

209 692571 Spring-Governor

209A 691278 Spring-Governor

219 693578 Gear-Governor

220 691724 Washer (Governor Gear)

222 699589 Bracket-Control

227 692573 Lever-Governor

238 691300 Cap-Valve

271 694256 Lever-Control

276 271716 Washer-Sealing

281 699639 Plate-Trim

287 699629 Screw (Dipstick Tube)

300 693593 Muffler

304 699598 Housing-Blower

305 699480 Screw (Blower Housing)

306 693610 Shield-Cylinder

307 699483 Screw (Cylinder Shield)

332 699359 Nut (Flywheel)

333 695711 Armature-Magneto

334 699477 Screw (Magneto Armature)

337 691043 Plug-Spark

356 695814 Wire-Stop

358 699638 Gasket Set

363 19069 Flywheel Puller

365 692568 Screw (Carburetor)

383 19374 Wrench-Spark Plug

427 694255 Nut (Control Bracket)

445 697029 Filter A/C Cartridge

455 692591 Cup-Flywheel

456 692299 Pawl Friction Plate

459 281505 Ratchet Pawl

467 691668 Knob-Air Cleaner

504 694254 Washer Set

Part No. Part Description

26

Page 27

Sears Craftsman 7.5 H.P. Chipper Shredder Model 247.776350

Ref.

No.

505 691251 Nut (Governor Control Lever)

523 693618 Dipstick

524 281370 Seal-Dipstick Tube

552 692346 Bushing-Governor Crank

562 691112 Bolt (Governor Control Lever)

597 691696 Screw (Pawl Friction Plate)

601 95162 Clamp-Hose

608 693394 Rewind Starter

613 699209 Screw (Muffler)

615 692576 Governor Shaft Retainer

616 692547 Crank-Governor

619 699230 Screw (Cylinder Head)

621 692310 Switch-Stop

632 693408 Spring/Link Mechanical Governor

633 693867 Choke/Throttle Shaft Seal (Throttle)

633A 691321 Choke/Thrott le Shaft Seal (Choke)

635 805529 Boot-Spark Plug

663 699206 Screw (Control Panel)

668 694257 Spacer

689 691855 Spring-Friction

692 690572 Spring-Detente (Choke)

717 693462 Air Cleaner Bracket

718 690959 Pin-Locating

741 695087 Gear-Timing

742 692564 Ring-Retaining

746 692566 Gear-Idler

773 694258 Retainer

830 694544 Stud-Rocker Arm

832 693583 Guard-Muffler

836 699203 Screw (Muffler Guard)

836A 699632 Screw (Muffler Guard)

851 493880 Spark Plug Terminal

Part No. Part Description

Ref.

No.

847 693617 Dipstick/Tube Assembly

868 692044 Seal-Valve

875 697030 Base-Air Cleaner

883 691893 Gasket-Exhaust

914 699481 Screw (Rocker Cover) (Bottom)

914A 692557 Screw (Rocker Cover) (Top)

914B 697551 Screw (Rocker Cover)

957 694261 Cap-Fuel Tank

961 698304 Screw (Air Cleaner Bracket)

967 273356 Filter-Pre Cleaner

968 693460 Cover-Air Cleaner

971 690349 Screw (Air Cleaner Base)

971A 94929 Screw (Air Cleaner Base)

972 694260 Tank-Fuel

975 493640 Bowl-Float

977 697001 Gasket Set-Carburetor

993 694088 Gasket-Cylinder Head Plate

1005 692592 Fan-Flywheel

1019 690035 Label Kit

1022 691890 Gasket-Rocker Cover

1023 499924 Cover-Rocker

1026 693517 Rod-Push

1029 691230 Rocker Arm

1095 698215 Gasket Set-Valve

1034 691343 Push Rod Guide

1036 697004 Emission Label

1070 699201 Screw (Flywheel Fan)

1210 498144 Pulley/Spring Assembly (Pulley)

1211 498144 Pulley/Spring Assembly (Spring)

1329 121312-0145 Replacement Engine

1330 272147 Repair Manual

Part No. Part Description

27

Page 28

Sears Craftsman 7.5 H.P. Chipper Shredder Model 247.776350

777S32258

777D07574

¨¨

¨

777S32272

HINGED UPPER CHIPPER CHUTE:

DANGER

ROTATING CUTTING BLADES.

KEEP HANDS AND FEET OUT

OF OPENINGS WHILE MACHINE

IS RUNNING.

STORAGE - To save space, Chute may be unlocked and latched in the raised position.

OPERATION - Chute must be in the lowered and

locked position. Refer to

operator's manual for proper

use of the Chipper.

Storage only

777S30189

Operating position

777S30181

Engine Labels

Air Cleaner 751B275754

Fuel Tank 751B274030

Recoil 751B274350

777S30180

28

Page 29

ÍNDICE

Contenido Página

Garantía 29

Seguridad 30

Montaje 33

Funcionamiento 35

Mantenimiento 40

Contenido Página

Servicio y ajustes 42

Almacenamiento 44

Guía Para La Solución De Prob lemas 45

Acuerdo De Protección Para Reparaciones 47

GARANTÍA

Garantía limitada de la cortadora trituradora Craftsman

Por el período de un (1) año a partir de la fecha de compra, siemp re que a este equipo Craftsman se le realice el

servicio de mantenimiento, lubricación y sintonización de acuerdo a las instrucciones del manua l del operador,

Sears reparará o reemplazará sin cargo todas las piezas que present en defectos de material es o mano de obra. El

servicio de garantía está disponible sin cargo si lleva su equipo Craftsman al Centro de Servicio Técnico de Sears

más cercano. El servicio de garantía a domicilio está disponible pero se aplicará un cargo de traslado. Esta

garantía es válida únicamente mientras el producto se encuentre dentro de los Estados Unidos.

Esta garantía no cubre:

• Artículos de duración limitada que sufren desgaste bajo condiciones normales de uso, tales como bujías, filtros de aire,

correas y filtros de aceite.

• Reemplazo o reparaciones de llantas causadas por pinchaduras con objetos exteriores como, por ejemplo, clavos, espinas,

palos o vidrios, etc.

• Reparaciones necesarias debido a abuso del operador, incluyendo pero sin limitarse a los daños causados por objetos,

tales como piedras o desechos de metal, troncos de un tamaño demasiado grande, objetos que hacen impacto que pueden

doblar la estructura o el cárter o pueden sobreacelerar el motor.

• Reparaciones necesarias debido a negligencia del operador, incluyendo entre otros, daños mecánico y eléctrico

ocasionados por un almacenamiento no apropiado, falla por el uso de aceite de grado y/o cantidad no apropiada o falla por

no dar mantenimiento al equipo de acuerdo con las instrucciones contenidas en el manual del operador.

• Limpieza o reparaciones al motor (sistema de combustible) provocadas por un combustible contaminado u oxidado (viejo).

En general, el combustible debe utilizarse

• Equipos utilizados para fines comerciales o de alquiler.

en un período no mayor de 30 d ías

a partir de la fecha de su adquisición..

PARA UBICAR EL CENTRO DE SERVICIO TÉCNICO SEARS MÁS CERCANO O PARA PROGRAMAR EL

SERVICIO TÉCNICO, SIMPLEMENTE COMUNÍQUESE CON SEARS AL TELÉFONO 1-800-4-MY-HOME

Esta garantía le otorga derechos legales específicos y usted podría gozar de otros derechos que varían de un

estado a otro..

ESPECIFICIFICACIONES DEL PRODUCTO

Caballaje: 7.5 Caballaje

Tipo de aceite para motor SAE 30

Capacidad de aceite para motor 20 onzas

Capacidad de combustible: 3 cuartos

Bujía Champion QC-12YC

Separación de la bujía .030"

Número de Modelo..................................................

Número de Serie......................................................

Fecha de compra......................................................

Registre el número de serie y la fecha de compra y

conserve en un sitio seguro pa ra referencia f utura.

29

247.776350

Page 30

SEGURIDAD

ADVERTENCIA: La presencia de este símbolo indica que se trata de instrucciones impo rtantes de

seguridad que debe respetar para evit ar poner en riesgo su seguridad personal y / o material y de otra s

personas. Lea y siga todas las instrucciones en este manual antes de iniciar la operación de esta

máquina. En caso de no seguir estas instrucciones podría provocar lesi ones personales. Cuando

encuentre este símbolo - respete la adve rtencia que apar ece a continuac ión del mismo.

ADVERTENCIA El escape del motor de este producto, algunos de sus componentes

y algunos componentes del vehículo contienen o emiten productos químicos que el

estado de California considera que pueden producir cáncer , defectos de nacimiento u

otros problemas reproductivos .

PELIGRO: Esta máquina está diseñada para ser utilizada respetando las reglas de seguridad

contenidas en este manual. Al igual que con cualquier tipo de equip o eléctrico, un descuido o error de

parte del operador puede producir lesiones graves. Esta máquina es capaz de amputar manos y pies y

de arrojar objetos con gran fuerza. De no respetar las instruccion es de seguridad siguientes se pueden producir

lesiones graves o la muerte.

CAPACITACIÓN

1. Lea, entienda y siga todas las instrucciones

incluidas en la máquina y en el / los manual/es

antes de armarla y operarla. Guarde este manual

en un lugar seguro para referencias futuras y

regulares y para solicitar repuestos.

2. Familiarícese con todos los controles y su

operación apropiada. Sepa cómo detener la

máquina y cómo desengranar los controles

rápidamente.

3. No permita nunca que los niños menores de 16

años operen esta máquina. Los niños de 16 años y

más deben leer y comprender las instrucciones de

operación y las reglas de seguridad contenidas en

este manual y deben ser capacitados y

supervisados por uno de los padres.

4. Nunca permita que los adultos operen esta

máquina sin recibir antes instrucción apropiada.

5. Mantenga a los observadores, ayudantes,

mascotas y a los niños por lo menos a 75 pies de la

máquina mientras la misma está en

funcionamiento. Detenga la máquina si alguien

entra en la zona.

6. Nunca encienda un motor en espacios cerrados o

en una zona con poca ventilación. El escape del

motor contiene monóxido de carbono, un gas

inodoro y letal.

7. No ponga las manos o los pies cerca de las piezas

rotatorias o en las cámaras de alimentación ni en la

abertura de descarga. El contacto con el motor

rotatorio puede producir la amputación de dedos,

manos o pies.

8. No intente nunca destapar el canal de la cortadora

o la abertura de descarga, ni trate de sacar o vaciar

la bolsa vacía ni de revisar y reparar la m áquina

mientras el motor está en marcha. Apa gue el motor

y espere hasta que todas las piezas móviles se

hayan detenido por completo. Desconecte el cable

de la bujía y manténgalo alejado de la misma.

PREPARAC IÓN

1. Inspeccione minuciosamente el área en donde

utilizará el equipo. Retire todas las piedras,

botellas, latas u otros objetos extraños que p uedan

ser levantados o arrojados causando lesiones

personales o daños a la máquina.

2. Para protegerse los ojos utilice siempre anteojos o

antiparras de seguridad mientras opera la máquina

o mientras la ajusta o repara. Los objetos ar rojados

que rebotan pueden lesionar gravemente la vista.

3. Utilice zapatos de trabajo resistentes, de suela

fuerte y pantalones y camisas ajustados. Las

prendas sueltas o las alhajas pueden quedar

atrapadas en las piezas movibles. Nunca opere

esta máquina estando descalzo o con sandalias.

Utilice guantes de trabajo de cuero cuando

alimente material por el canal de la cortadora.

4. Antes de encender la máquina controle que todos

los pernos y tornillos estén bien ajustados para

comprobar que la máquina se encuentra en

condiciones seguras de operación Además realice

una inspección visual de la máquina a intervalos

frecuentes para controlar si la misma está dañada.

5. Para evitar lesiones o daños sea sumamente

cuidadoso al manipular la gasolina. La gasolina es

altamente inflamable y los vapores son explosivos.

Se puede lesionar gravemente si derrama gasolina

sobre usted o sobre la ropa ya que se puede

encender. Lávese la piel y cámbiese de ropa de

inmediato.

a. Utilice sólo recipientes para gasolina

autorizados.

b. Apague todos los cigarrillos, cigarros, pipas y

otras fuentes de combustión.

c. Nunca cargue combustible en la máquina en

un espacio cerrado.

d. Nunca saque la tapa del gas ni agregue

combustible mientras el motor está caliente o

en marcha.

30

Page 31

e. Deje que el motor se enfríe por lo menos dos

minutos antes de volver a cargar

combustible.

f. Nunca recargue el tanque de combustible.

Llene el tanque no más de 1/2 pulgada por

debajo de la base del cuello del filtro para

dejar espacio para la dilatación del

combustible.

g. Vuelva a colocar la tapa de la gasolina y

ajústela bien.

h. Limpie la gasolina derramada sobre el motor

y el equipo. Traslade la máquina a otra zona.

Espere 5 minutos antes de encender el

motor.

i. Nunca almacene la máquina o el recipiente

de combustible en un espacio cerrado donde

haya fuego, chispas o luz piloto (por ejemplo,

hornos, calentadores de agua, calefactore s,

secadores de ropa, etc.)

j. Para reducir el riesgo de incendio ma ntenga

la máquina limpia de pasto, hojas y de

acumulación de otros desechos. Limpie los

derrames de aceite o combustible y saque

todos los desechos embebidos con

combustible.

k. Deje que la máquina se enfríe por lo menos

5 minutos antes de guardarla.

FUNCIONAMIENTO

1. No ponga las manos o los pies cerca de las piezas

rotatorias o en las cámaras de alimentación n i en la

abertura de descarga. El contacto con el motor

rotatorio puede producir la amputación de dedos,

manos o pies.