Craftsman 24777614 Owner’s Manual

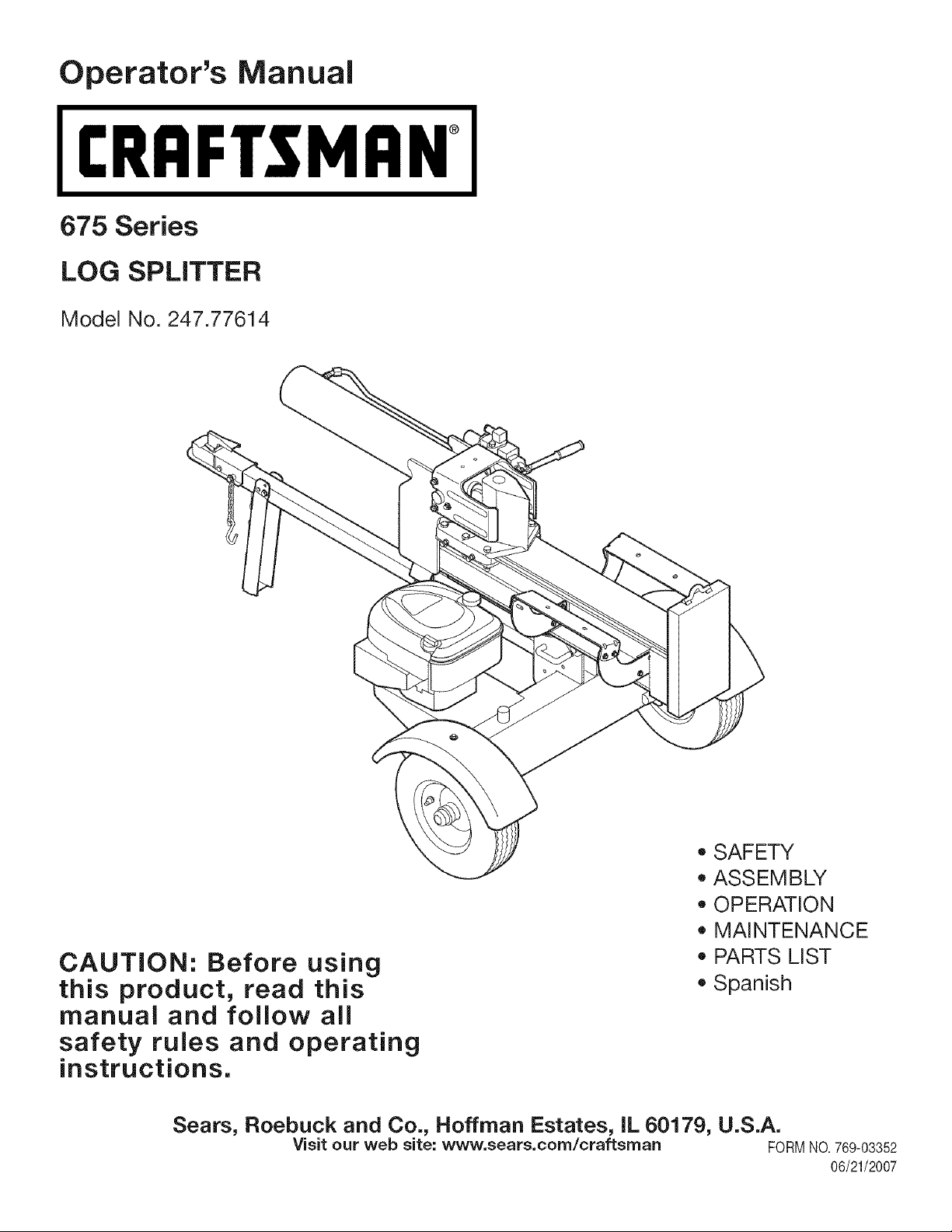

Operator's Manual

I:RRFTSMRN°

675 Series

LOG SPLITTER

Model No. 247.77614

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our web site: www, sears,corn/craftsrnan FORMNO.769-03352

• SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

Spanish

06/21/2007

WarrantyStatement..................................Page2

RepairProtectionAgreement...................Page3

SafeOperationPractices.........................Pages4-5

Assembly..................................................Pages6-7

Operation..................................................Pages8-11

Service&Adjustments.............................Pages12-13

Limited Warranty on Craftsman Log Splitter

Forone (1)yearfromthe dateof purchase,if thisCraftsmanEquipmentismaintained,lubricated,andtunedupaccordingtothe instructionsto

theoperator'smanual,Searswillrepairor replacefreeofchargeanypartsfoundto be defectiveinmaterialorworkmanship.Warrantyserviceis

availablefreeofchargebyreturningCraftsmanequipmentto yournearestSearsServiceCenter.In-homewarrantyserviceisavailablebuta trip

chargewillapply.ThisWarrantyappliesonlywhilethisproductisinthe UnitedStates.

This warranty does not cover:

• Expendableitemswhichbecomewornduringnormaluse,suchas sparkplugs,aircleaners,belts,andoil filters.

Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchas nails,thorns,stumps,or glass.

Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedto,damagecausedbyobjects,suchasstonesor metaldebris,

oversizedstock,impactingobjectsthat bendtheframeor crankshaft,orover-speedingtheengine.

Repairsnecessarybecauseof operatornegligence,includingbutnot limitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethe propergradeand amountofengineoil,orfailuretomaintaintheequipmentaccordingtotheinstructionscontained

in theoperator'smanual.

Engine(fuelsystem)cleaningorrepairscausedbyfuel determinetobe contaminatedor oxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

Equipmentusedforcommercialor rentalpurposes.

WARRANTYSERVICEISAVAILABLEBYRETURNINGTHECRAFTSMANSNOWTHROWERTOTHE NEAREST

SEARSPARTS& REPAIRCENTERINTHEUNITEDSTATES.

This warrantyappliesonlywhilethisproductis in use intheUnitedStates.

TOLOCATETHENEARESTSEARSPARTS& REPAIRCENTERORTOSCHEDULESERVICE,

SIMPLYCONTACTSEARSAT1-800-4-MY-HOME®.

Thiswarrantygivesyouspecificlegalrightsandyoumayalso haveotherrightswhichmayvaryfromstatetostate.

SEARS,ROEBUCKANDCO., D/817WA,HOFFMANESTATES,IL 60179

Maintenance.............................................Pages14-16

OffSeasonStorage..................................Page17

TroubleShooting......................................Page18-19

PartsList...................................................Page20-27

Espa_ol.....................................................Page29

ServiceNumbers......................................BackCover

Engine Series: 126L02-0531

Engine Oil: SAE 30

Engine Oil Capacity: 20 Ounces

Fuel Capacity: 1.5 Quarts

Spark Plug 0030" Gap):Champion® RJ19LM

Hydraulic Fluid/Capacity:Dexron ill/3.0 gal.

Model Number .............................................................

Serial Number ..............................................................

Date of Purchase ..........................................................

Record the model number, serial number

and date of purchase above

Congratulationson makingasmartpurchase.YournewCraftsman®

productisdesignedandmanufacturedforyearsof dependableopera-

tion.Butlikeall products,it mayrequirerepairfromtimetotime.That's

whenhavinga RepairProtectionAgreementcansaveyoumoneyand

aggravation.

Here'swhat'sincludedinthe Agreement:

,, Expertservicebyour 12,000professionalrepairspecialists

,, Unlimitedserviceand nochargefor partsandlaboronall covered

repairs

,, Productreplacementifyourcoveredproductcan'tbe fixed

,, Discountof 10%fromregularpriceofserviceandservice-related

partsnotcoveredby theagreement;also,10%off regularpriceof

preventivemaintenancecheck

,, Fasthelpbyphone- phonesupportfroma Searstechnicianon

productsrequiringin-homerepair,plusconvenientrepair

scheduling

Purchasea RepairProtectionAgreementnowandprotectyourself

fromunexpectedhassleandexpense.

Onceyou purchasetheAgreement,a simplephonecallis all thatit

takesfor youtoscheduleservice.Youcan callanytimedayornight,or

schedulea serviceappointmentonline.

Searshasover12,000professionalrepairspecialists,whohave

accesstoover 4.5millionqualitypartsandaccessories.That'sthe

kindof professionalismyoucancounton tohelpprolongthelifeof

yournewpurchaseforyearsto come.PurchaseyourRepairProtection

Agreementtoday!

Somelimitationsandexclusionsapply. Forpricesandadditional

informationcall 1-800-827-6655.

SearsInstallation Service

ForSearsprofessionalinstallationof homeappliances,garagedoor

openers,waterheaters,andothermajorhomeitems,in theU.S.A.call

1-800-4-MY-HOME®

l_lk ARNING: This symbol pointsout importantsafety instructionswhich, ifnot followed, could endanger the

attemptingto operate this machine. Failureto comply with these instructionsmay result inpersonalinjury.

Whenyou see this symbol- heed itswarning.

personalsafety and/or propertyof yourself and others. Read and followall instructionsinthis manual before

__i ARNING: EngineExhaust,some of its constituents, and certain vehiclecomponentscontain oremit

chemicalsknown to State of Californiato cause cancer and birth defects or other reproductiveharm.

DANGER: This machinewas builtto be operatedaccording to the rulesfor safe operationin this manual.

As withany type of powerequipment, carelessnessor error on thepart of the operatorcan result in

seriousinjury.This machine is capableof amputatinghands and feet and throwingobjects. Failureto

observe the followingsafety instructionscould resultin seriousinjury or death.

General Practices

1. Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingtoassembleandoperate.Keep

thismanualina safeplacefor futureandregularreferenceandfor

orderingreplacementparts.

2. Befamiliarwithall controlsandproperoperation.Knowhowto stop

themachineanddisengagethemquickly.

3. Neverallowchildrenunder16yearstooperatethis machine.

Children,16yearsandover,shouldreadandunderstandinstruc-

tionsandsafetyrulesinthismanualandshouldbetrainedand

supervisedbya parent.

4. Neverallowadultsto operatethismachinewithoutproperinstruc-

tion.

5. Manyaccidentsoccurwhenmorethanonepersonoperatesthe

machine.Ifahelperis assistinginloadinglogs,neveractivatethe

controluntilthe helperisa minimumof 10feetfromthe machine.

6. Keepbystanders,helpers,pets,andchildrenat least20 feetfrom

themachinewhileit isin operation.

7. Neverallowanyonetorideon thismachine.

8. Nevertransportcargoonthis machine.

9. Hydrauliclogsplittersdevelophighfluidpressuresduringopera-

tion.Fluidescapingthroughapin holeopeningcanpenetrateyour

skinandcausebloodpoisoning,gangrene,or death.Giveattention

tothe followinginstructionsatall times:

a. Donotcheckforleakswithyourhand.

b. Donotoperatemachinewithfrayed,kinked,cracked,ordamaged

hoses,fitting,ortubing.

c. Stoptheengineandrelievehydraulicsystempressurebeforechanging

oradjustingfittings,hoses,tubing,orothersystemcomponents.

d. Donotadjustthepressuresettingsofthepumporvalve.

10.Leakscanbedetectedbypassingcardboardor wood,while

wearingprotectiveglovesandsafetyglasses,overthesuspected

area.Lookfordiscolorationofcardboardorwood.

11.Ifinjuredby escapingfluid,seeadoctorimmediately.Serious

infectionorreactioncandevelopif propermedicaltreatmentisnot

administeredimmediately.

12.Keepthe operatorzoneandadjacentareaclearforsafe,secure

footing.

13.If yourmachineisequippedwithaninternalcombustionengine

and itisintendedforuse nearanyunimprovedforest,brush,or

grasscoveredland,theengineexhaustshouldbeequippedwitha

sparkarrester.Makesureyoucomplywithapplicablelocal,state,

andfederalcodes.Takeappropriatefirefightingequipmentwith

you.

14.Thismachineshouldbeusedfor splittingwoodonly,do notuseit

forany otherpurpose.

15.Followthe instructionsinthemanual(s)providedwithany

attachment(s)forthismachine.

Preparation

1. Alwayswearsafetyshoesor heavyboots.

2. Alwayswearsafetyglassesorsafetygogglesduringoperatingthis

machine.

3. Neverwearjewelryor looseclothingthatmightbecomeentangled

in movingor rotatingpartsof themachine.

4. Makesuremachineis onlevelsurfacebeforeoperating.

5. Alwaysblockmachineto preventunintendedmovement,and lock

in eitherhorizontalorverticalposition.

6. Alwaysoperatethismachinefromtheoperatorzone(s)specifiedin

themanual.

7. Logsshouldbe cutwithsquareendspriortosplitting.

8. Uselogsplitterindaylightor undergoodartificiallight.

9. Toavoid personalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vapors

areexplosive.Seriouspersonalinjurycanoccurwhengasolineis

spilledon yourselforyourclotheswhichcan ignite.Washyourskin

andchangeimmediately.

a. Useonlyanapprovedgasolinecontainer.

b. Extinguishallcigarettes,cigars,pipes,andothersourcesofignition.

c. Neverfuelmachineindoors.

d. Neverremovegascaporaddfuelwhiletheengineishotorrunning.

e. Allowenginetocoolatleasttwominutesbeforerefueling.

4

f. Neveroverfillthefueltank.Filltankto nomorethan1/2inchbelow

bottomoffillernecktoprovidespaceforfuelexpansion.

g. Replacegasolinecapandtightensecurely.

h. Ifgasolineisspilled,wipeitofftheengineandequipment,move

machinetoanotherarea.Wait5minutesbeforestartingtheengine.

i. Neverstorethemachineorfuelcontainerinsidewherethereisanopen

flame,sparkorpilotlightasonawaterheater,spaceheater,furnace,

clothesdryerorothergasappliances.

j. Allowmachinetocool5minutesbeforestoring.

Operation

1. Beforestartingthis machine,reviewthe"SafetyInstructions".

Failuretofollowtheserulesmayresultinseriousinjurytothe

operatororbystanders.

2. Neverleavethismachineunattendedwiththe enginerunning.

3. Donotoperatemachinewhileundertheinfluenceofalcohol,drugs,

or medication.

4. Neverallowanyonetooperatethis machinewithoutproperinstruc-

tion.

5. Alwaysoperatethismachinewithallsafetyequipmentinplace

andworking.Makesureall controlsareproperlyadjustedfor safe

operation.

6. Donotchangethe enginegovernorsettingsoroverspeedthe

engine.Thegovernorcontrolsthemaximumsafeoperatingspeed

ofthe engine.

7. Whenloadinga log,alwaysplaceyourhandsonthesidesofthe

log,noton theends,andneveruseyourfootto helpstabilizea log.

Failuretodo so,mayresultin crushedoramputatedfingers,toes,

hand,orfoot.

8. Useonlyyour handtooperatethecontrols.

9. Neverattempttosplitmorethanone logata timeunlesstheram

hasfullyextendedanda secondlogis neededtocompletethe

separationofthefirst log.

10.Forlogswhichare notcut square,theleastsquareendandthe

longestportionof thelogshouldbeplacedtowardthebeamand

wedge,andthesquareendplacedtowardtheend plate.

11.Whensplittinginthe verticalposition,stabilizethelogbefore

movingthecontrol.Splitas follows:

a. Placelogontheendplateandturnuntilitleansagainstthebeamand

isstable.

b. Whensplittingextralargeorunevenlogs,thelogmustbestabilized

withwoodenshimsorsplitwoodbetweenthelogandendplateor

ground.

12.Alwayskeepfingersawayfromany cracksthat openinthe log

whilesplitting.Theycan quicklycloseandpinchoramputateyour

fingers.

13.Keepyourworkareaclean.Immediatelyremovesplitwood around

themachinesoyoudonot stumbleoverit.

14.Nevermovethismachinewhiletheengineis running.

15.Thismachineshouldnotbetowedonanystreet,highwayor public

roadwithoutcheckingtheexistingfederal,state,or localvehicle

requirements.Anylicensingormodificationssuchastaillights,etc.,

neededtocomply,is thesoleresponsibilityof thepurchaser.If a

"StatementofOrigin"isrequiredinyourstate,seeyourlocaldealer.

16.Donottowmachinefasterthan45mph.

17.SeeTransportingtheLogSplittersectioninthis manualfor proper

towinginstructionsonceallfederal,local,or staterequirementsare

met.

Maintenance and Storage

1. Stoptheengine,disconnectthespark plugandgrounditagainst

theenginebeforecleaning,or inspectingthemachine.

2. Stoptheengineandrelievehydraulicsystempressurebefore

repairingoradjustingfittings,hoses,tubing,or othersystem

components.

3. Topreventfires,cleandebrisandchafffromthe engineandmuffler

areas.Iftheengineis equippedwitha sparkarrestermuffler,clean

and inspectit regularlyaccordingtomanufacturersinstructions.

Replaceifdamaged.

4. Periodicallycheckthatall nutsandbolts,hoseclamps,and

hydraulicfittingsaretighttobe sureequipmentisin safeworking

condition.

5. Checkall safetyguardsandshieldsto besuretheyareinthe

properposition.Neveroperatewithsafetyguards,shields,orother

protectivefeaturesremoved.

6. Thepressurereliefvalveispresetat thefactory.Donotadjustthe

valve.

7. Neverattempttomovethis machineoverhilly or uneventerrain

withouta towvehicleoradequatehelp.

8. Foryoursafety,replacealldamagedorworn partsimmediately

withoriginalequipmentmanufacturer's(O.E.M.)partsonly."Useof

partswhichdo notmeettheoriginalequipmentspecificationsmay

leadtoimproperperformanceandcompromisesafety!"

9. Donot alterthismachinein anymanner,alterationssuchasattach-

inga ropeor extensiontothe controlhandle,oraddingto thewidth

or heightofthewedgemayresultinpersonalinjury.

Your Responsibility

Restricttheuseof this powermachinetopersonswhoread,under-

standandfollowthewarningsandinstructionsin thismanualandon

themachine.Alwaysfollowdirectionson safetylabelsfoundonyour

equipment.

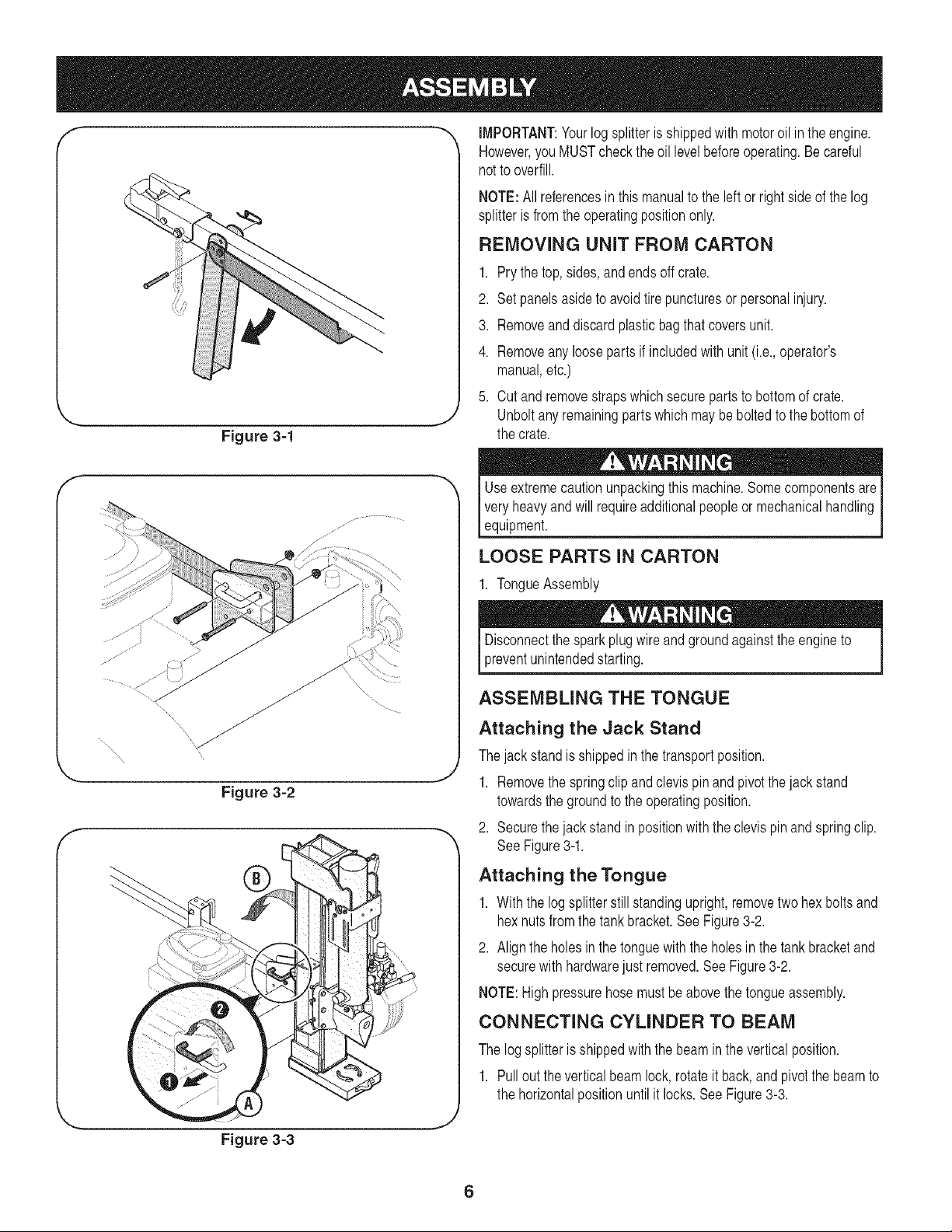

Figure 3-1

IMPORTANT:Yourlogsplitterisshippedwith motoroil in theengine.

However,youMUSTchecktheoil levelbeforeoperating.Becareful

notto overfill.

NOTE:Allreferencesinthismanualto theleftor rightsideofthelog

splitteris fromthe operatingpositiononly.

REMOVING UNIT FROM CARTON

1. Prythe top,sides,andendsoff crate.

2. Setpanelsasideto avoidtirepuncturesorpersonalinjury.

3. Removeanddiscardplasticbagthatcoversunit.

4. Removeanyloosepartsif includedwithunit(i.e.,operator's

manual,etc.)

5. Cutand removestrapswhichsecurepartstobottomofcrate.

Unboltanyremainingpartswhichmaybeboltedto thebottomof

thecrate.

Useextremecautionunpackingthis machine.Somecomponentsare

veryheavyand willrequireadditionalpeopleor mechanicalhandling

equipment.

LOOSE PARTS IN CARTON

1. TongueAssembly

Disconnectthesparkplugwireandgroundagainstthe engineto

preventunintendedstarting. J

\\\

ASSEMBLING THE TONGUE

Attaching the Jack Stand

Thejackstandis shippedinthetransportposition.

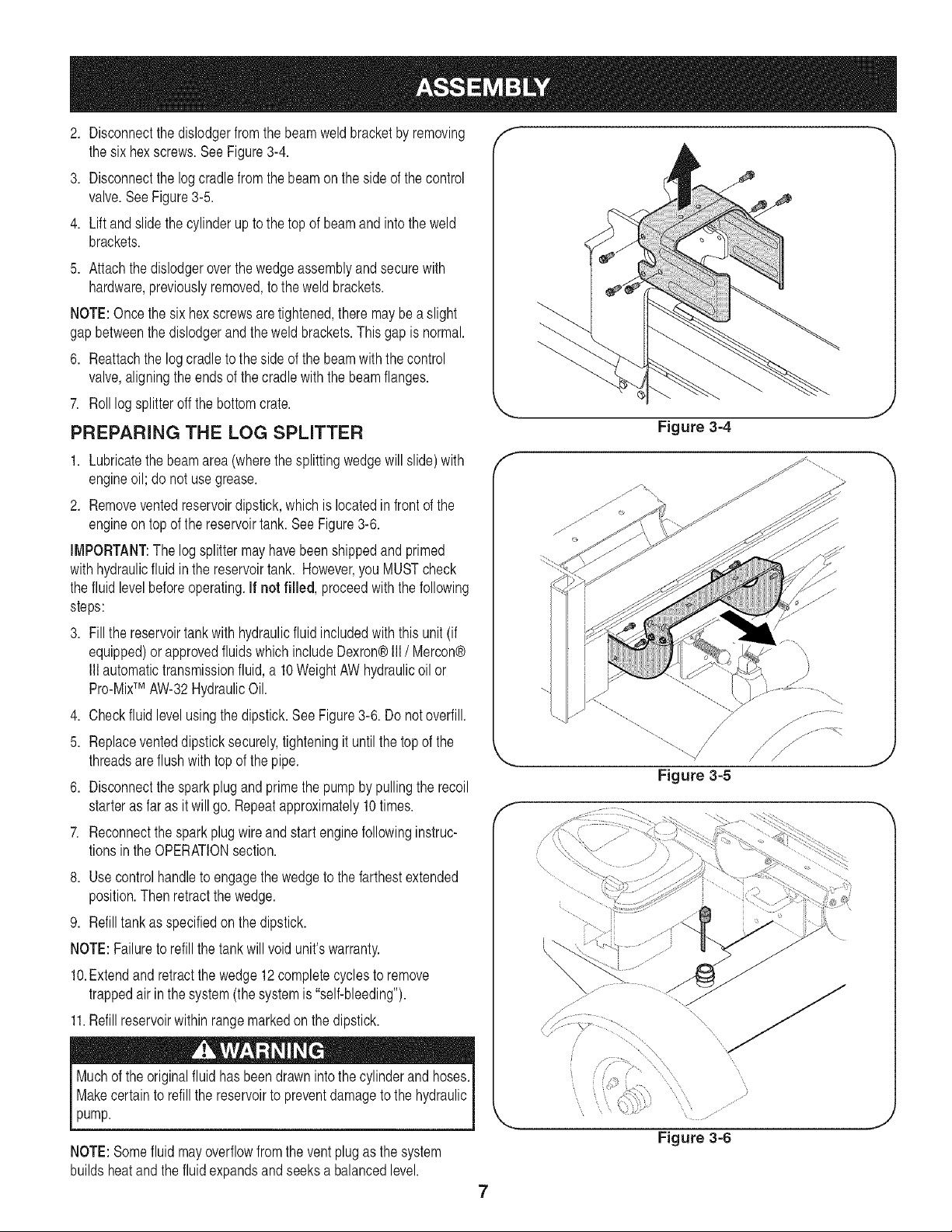

Figure 3=2

f

1. Removethespringclip andclevispinandpivotthejackstand

towardsthegroundtothe operatingposition.

2. Securethejack standinpositionwiththeclevispinandspringclip.

SeeFigure3-1.

Attaching the Tongue

1. Withthelogsplitterstillstandingupright,removetwo hexboltsand

hexnutsfromthe tankbracket.SeeFigure3-2.

2. Aligntheholesin thetonguewiththeholesin thetank bracketand

securewith hardwarejustremoved.SeeFigure3-2.

NOTE:Highpressurehosemustbe abovethetongueassembly.

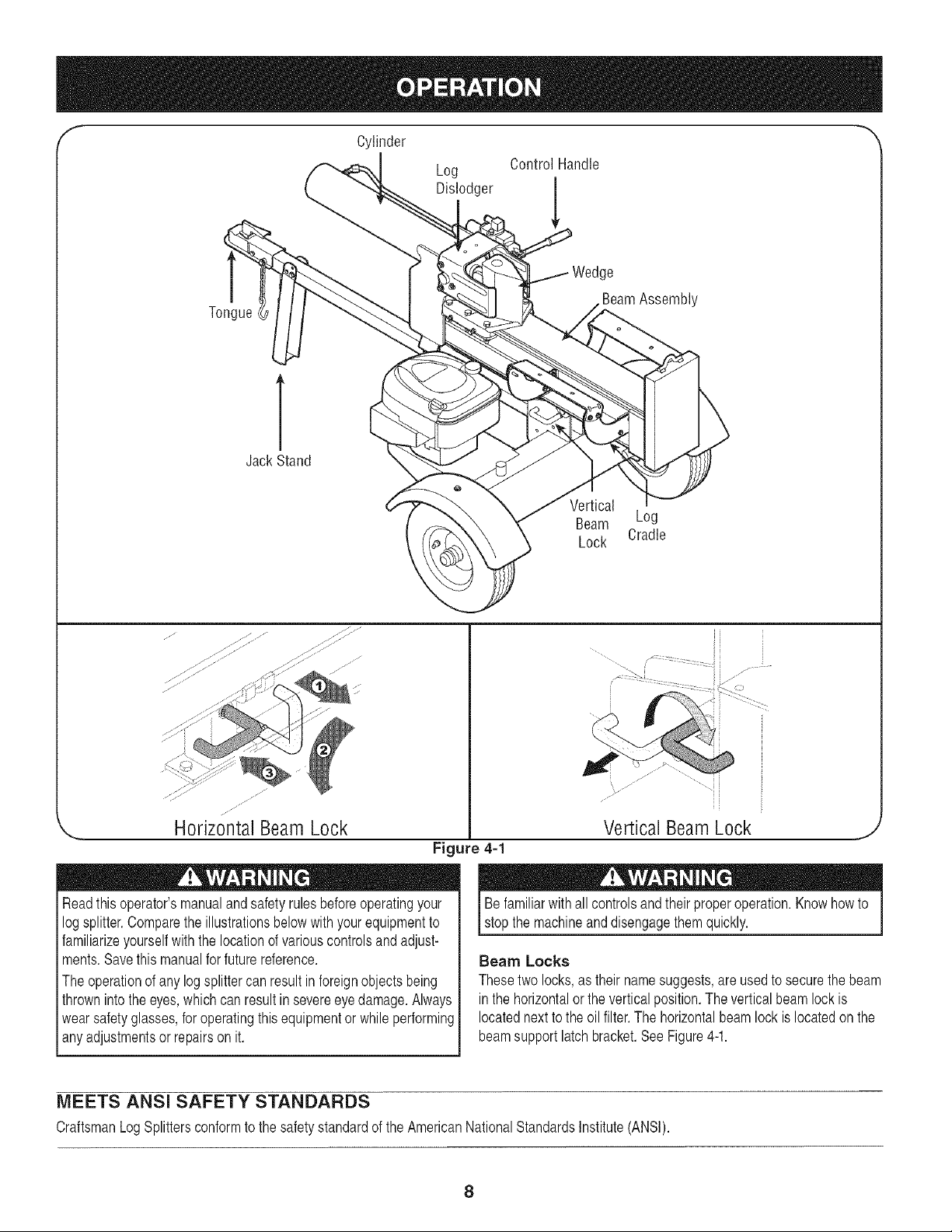

CONNECTING CYLINDER TO BEAM

Thelogsplitterisshippedwiththebeamintheverticalposition.

1. Pulloutthe verticalbeamlock,rotateit back,andpivotthebeamto

thehorizontalpositionuntilitlocks.SeeFigure3-3.

6

2. Disconnectthe dislodgerfromthebeamweldbracketbyremoving

thesixhexscrews.SeeFigure3-4.

3. Disconnectthe logcradlefromthebeamonthesideofthecontrol

valve.SeeFigure3-5.

4. Liftandslidethe cylinderuptothetop ofbeamandintotheweld

brackets.

5. Attachthe dislodgeroverthewedgeassemblyandsecurewith

hardware,previouslyremoved,tothe weldbrackets.

NOTE:Oncethesixhex screwsaretightened,theremaybea slight

gapbetweenthedislodgerandtheweld brackets.Thisgapis normal.

6. Reattachthelogcradletothe sideofthe beamwiththecontrol

valve,aligningtheendsof thecradlewiththe beamflanges.

7. Rolllogsplitteroffthebottomcrate.

PREPARING THE LOG SPLITTER

f --,,

,.. j

Figure 3-4

1. Lubricatethebeamarea(wherethesplittingwedgewillslide)with

engineoil;do notusegrease.

2. Removeventedreservoirdipstick,whichislocatedin frontofthe

engineontopof thereservoirtank.SeeFigure3-6.

IMPORTANT:The logsplittermayhavebeenshippedandprimed

withhydraulicfluidinthe reservoirtank. However,youMUSTcheck

thefluidlevelbeforeoperating.If not filled, proceedwiththefollowing

steps:

3. Fillthe reservoirtankwithhydraulicfluidincludedwiththisunit (if

equipped)or approvedfluidswhichincludeDexron®III/ Mercon®

Ill automatictransmissionfluid,a 10WeightAWhydraulicoil or

Pro-MixTM AW-32HydraulicOil.

4. Checkfluidlevelusingthedipstick.SeeFigure3-6.Donotoverfill.

5. Replaceventeddipsticksecurely,tighteningituntilthetop ofthe

threadsare flushwithtopofthe pipe.

6. Disconnectthe sparkplugand primethepumpbypullingthe recoil

starteras faras it willgo.Repeatapproximately10times.

7. Reconnectthesparkplugwireandstartenginefollowinginstruc-

tionsintheOPERATIONsection.

8. Usecontrolhandletoengagethe wedgeto thefarthestextended

position.Thenretractthe wedge.

9. Refilltankasspecifiedon thedipstick.

NOTE:Failuretorefill thetankwillvoidunit'swarranty.

10.Extendandretractthewedge12completecyclesto remove

trappedairinthe system(thesystemis "self-bleeding").

11.Refillreservoirwithinrangemarkedonthe dipstick.

f

Muchofthe originalfluidhasbeendrawnintothe cylinderandhoses.

Makecertainto refillthe reservoirto preventdamagetothehydraulic

pump.

NOTE:Somefluidmayoverflowfromtheventplugas thesystem

buildsheatandthefluidexpandsandseeksa balancedlevel.

, _ jlJ _

Figure 3=6

7

Cylinder

Log Control Handle

Dislodger

Tongue

BeamAssembly

V

JackStand

Vertical

Beam Log

Lock Cradle

/.jl

if ....

,.. HorizontalBeamLock

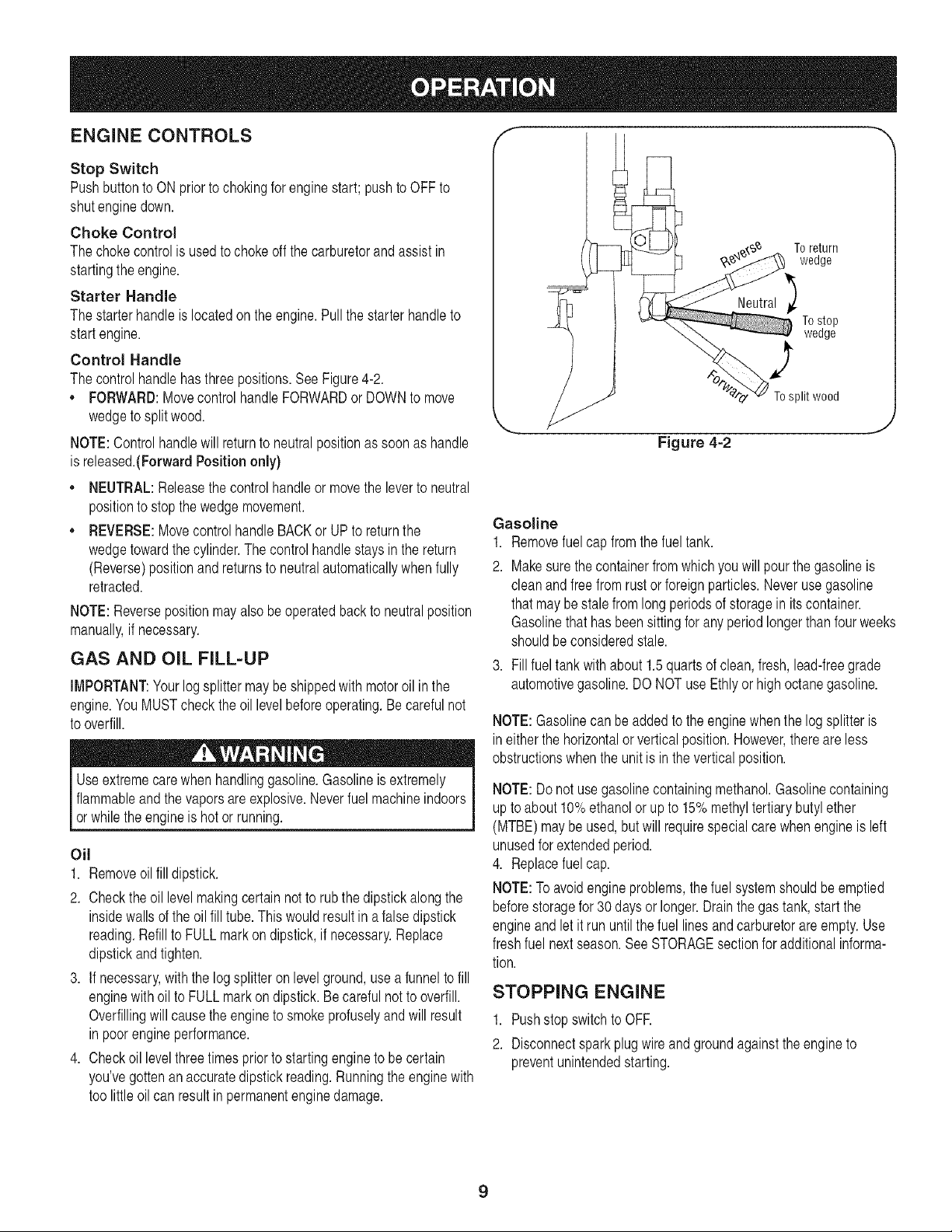

Figure 4-1

Readthisoperator'smanualandsafetyrulesbeforeoperatingyour

logsplitter.Comparetheillustrationsbelowwithyourequipmentto

familiarizeyourselfwiththelocationof variouscontrolsandadjust-

ments.Savethismanualforfuturereference.

Theoperationofany logsplittercanresultin foreignobjectsbeing

thrownintothe eyes,whichcanresultinsevereeyedamage.Always

wearsafetyglasses,for operatingthisequipmentorwhileperforming

anyadjustmentsor repairsonit.

MEETS ANSI SAFETY STANDARDS

CraftsmanLogSplittersconformtothesafetystandardof theAmericanNationalStandardsInstitute(ANSI).

Be familiarwithall controlsandtheirproperoperation.Knowhowto

stopthemachneandd sengagethemqucky.

Beam Locke

Thesetwo locks,astheirnamesuggests,areusedto securethe beam

inthehorizontalorthe verticalposition.Theverticalbeamlockis

locatednexttothe oil filter.Thehorizontalbeamlockislocatedon the

beamsupportlatchbracket.SeeFigure4-1.

8

Vertical BeamLock

,J

ENGINE CONTROLS f --,,

Stop Switch

Pushbuttonto ONpriortochokingfor enginestart; pushtoOFFto

shutenginedown.

Choke Control

Thechokecontrolis usedtochokeoffthecarburetorandassistin

startingtheengine.

Starter Handle

Thestarterhandleislocatedonthe engine.Pullthestarterhandleto

startengine.

Control Handle

Thecontrolhandlehasthreepositions.SeeFigure4-2.

• FORWARD:MovecontrolhandleFORWARDor DOWNto move

wedgeto splitwood.

NOTE:Controlhandlewill returnto neutralpositionassoonas handle

isreleased.(ForwardPosition only)

• NEUTRAL:Releasethecontrolhandleor movetheleverto neutral

positiontostopthe wedgemovement.

• REVERSE:MovecontrolhandleBACKor UPtoreturnthe

wedgetowardthecylinder.The controlhandlestaysin the return

(Reverse)positionandreturnsto neutralautomaticallywhenfully

retracted.

NOTE:Reversepositionmayalsobeoperatedbackto neutralposition

manually,if necessary.

GAS AND OIL FILL-UP

IMPORTANT:Yourlogsplittermaybeshippedwithmotoroil inthe

engine.YouMUSTcheckthe oil levelbeforeoperating.Becarefulnot

tooverfill.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthe vaporsareexplosive.Neverfuelmachineindoors

orwhilethe engineis hotorrunning.

Oil

1. Removeoilfill dipstick.

2. Checktheoil levelmakingcertainnottorubthedipstickalongthe

insidewallsof theoil filltube.This wouldresultin afalsedipstick

reading.Refillto FULLmarkondipstick,ifnecessary.Replace

dipstickandtighten.

3. If necessary,withthelogsplitteronlevelground,usea funneltofill

enginewithoil toFULLmarkondipstick.Becarefulnot tooverfill.

Overfillingwillcausethe enginetosmokeprofuselyandwill result

in poorengineperformance.

4. Checkoillevelthreetimespriortostartingenginetobe certain

you'vegottenanaccuratedipstickreading.Runningtheenginewith

toolittleoilcan resultin permanentenginedamage.

Gasoline

1. Removefuelcapfromthe fueltank.

2. Makesurethe containerfromwhichyouwillpourthe gasolineis

cleanandfree fromrustorforeignparticles.Neverusegasoline

that maybestalefromlongperiodsof storagein itscontainer.

Gasolinethathasbeensittingfor anyperiodlongerthanfourweeks

shouldbeconsideredstale.

3. Fillfuel tankwithabout1.5quartsof clean,fresh,lead-freegrade

automotivegasoline.DONOTuseEthlyor highoctanegasoline.

NOTE:Gasolinecanbeaddedto the enginewhenthe logsplitteris

ineitherthe horizontalorverticalposition.However,thereareless

obstructionswhenthe unitis in the verticalposition.

NOTE:Donotusegasolinecontainingmethanol.Gasolinecontaining

uptoabout10%ethanolorupto 15%methyltertiarybutylether

(MTBE)maybe used,butwillrequirespecialcarewhenengineis left

unusedforextendedperiod.

4. Replacefuelcap.

NOTE:Toavoidengineproblems,thefuelsystemshouldbe emptied

beforestoragefor30 daysorlonger.Drainthegastank,startthe

engineand letitrununtilthefuel linesandcarburetorareempty.Use

freshfuelnextseason.SeeSTORAGEsectionforadditionalinforma-

tion.

STOPPING ENGINE

1. Pushstopswitchto OFR

2. Disconnectsparkplugwireand groundagainsttheengineto

preventunintendedstarting.

_ T_osplit wood

J

Figure 4-2

9

USING THE LOG SPLITTER

1. Placethelogsplitteron level,dryground.

2. Placethebeamineitherthehorizontalor verticalpositionandlock

inplacewiththeappropriatelockingrod.

3. Blockthefrontand backof bothwheels.

4. Placethelogagainsttheendplateandonly splitwoodinthe

directionofthegrain.

5. Tostabilizethelog,placeyourhandonlyon sidesof log.Never

placehandon the endbetweenthe logand the splitting

wedge.

6. Onlyoneadultshouldstabilizethelogandoperatethecontrol

handle,so theoperatorhasfullcontroloverthelogandthesplitting

wedge.

Control Handle

1. MovecontrolhandleFORWARDor DOWNtosplitwood.

2. Releasethecontrolhandleto stopthewedgemovement.

3. MovecontrolhandleBACKorUP toreturnthewedge.

Log Dislodger

Thelogdislodgerisdesignedto removeanypartiallysplitwoodfrom

thewedge.Thismayoccurwhilesplittinglargediameterwoodor

freshlycutwood.

STARTING ENGINE

1. Attachsparkplugwiretosparkplug. Makecertainthemetalcapon

theendof thesparkplugisfastenedsecurelyoverthemetaltip on

thesparkplug.

2. Pushstopswitchto ON.

3. Movechokecontrolto CHOKEposition.

4. Graspstarterhandleandpullropeoutslowlyuntilenginereaches

startof compressioncycle(ropewillpullslightly harderat this

point).

5. Pullropewitha rapid,continuous,fullarmstroke.Keepafirmgrip

onstarterhandle.Letroperewindslowly.

6. Repeat,if necessary,untilenginestarts.Slowlyadjustchoke

towardRUNposition.Waituntilenginerunssmoothlybeforeeach

chokeadjustment.

7. If enginefalters,movecontrollevertoCHOKEposition,thenslowly

backto RUNposition.

8. If weatheris cold,run wedgeup ordownbeam6to 8 timesto

circulatethehydraulicfluid.

Whenstartinga warmengine,themufflerandsurroundingareasare

hotandcan causea burn.Donot touch.

Neverremovepartiallysplitwoodfromthewedgewithyourhands.

Fngersmaybecometrappedbetweensp t wood. J

1. Toremovepartiallysplitwoodfromwedge,movecontrolhandleto

REVERSEpositionuntilwedgeisfullyretractedtoallowsplitwood

portionto contactthe logdislodger.

2. Onceremovedfromwedgewithlogdislodger,splitwoodfrom

oppositeendor inanotherlocation.

Vertical Position

1. Pullthehorizontalbeamlockoutto releasethebeamandpivotthe

beamto theverticalposition.

2. Tolockthe beamintheverticalposition,pulloutonthevertical

beamlockand rotateitto securethebeam.SeeFigure4-1.

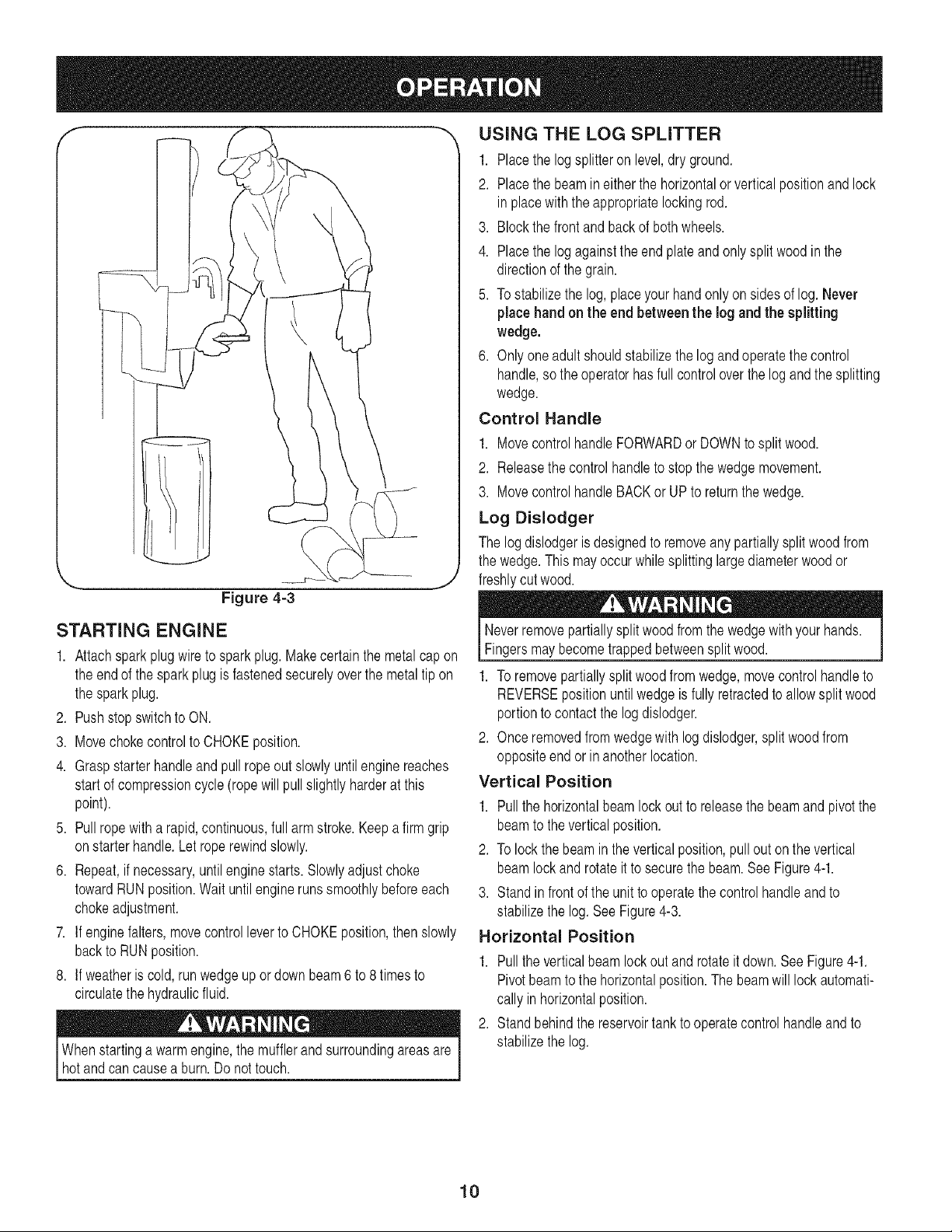

3. Standin frontofthe unittooperatethecontrolhandleandto

stabilizethe log.SeeFigure4-3.

Horizontal Position

1. Pulltheverticalbeamlockoutand rotateitdown.SeeFigure4-1.

Pivotbeamto thehorizontalposition.The beamwilllockautomati-

callyin horizontalposition.

2. Standbehindthe reservoirtankto operatecontrolhandleandto

stabilizethe log.

J

10

Operating Tips

Always:

1. Usecleanfluidandcheckfluid levelregularly.

2. Useanapprovedhydraulicfluid.ApprovedfluidsincludeDexron®

III/Mercon® IIIautomatictransmissionfluid,a 10WeightAW

hydraulicoil orPro-MixTM AW-32HydraulicOil.

3. Useafilter (cleanorreplaceregularly).

4. Useabreathercapon fluidreservoir.

5. Makesurepumpismountedandalignedproperly.

6. Useaflexible"spider"typecouplingbetweenengineandpump

driveshafts.

7. Keephosesclearandunblocked.

8. Bleedair outof hosesbeforeoperating.

9. Flushandcleanhydraulicsystembeforerestartingafterservicing.

10.Use"pipedope"on allhydraulicfittings.

11.Allowtimeforwarm-upbeforesplittingwood.

12.Primethe pumpbeforeinitialstart-upbyturningoverthe engine

withsparkplugdisconnected.

13.Splitwoodalongthe grain(lengthwise)only.

Never:

1. Usewhenfluid isbelow20°F or above150° R

2. Useasolidengine/pumpcoupling.

3. Operatethroughreliefvalvefor long.

4. Attempttoadjustunloadingorreliefvalvesettingswithoutpressure

gauges.

5. Operatewithair inhydraulicsystem.

6. Useteflontapeonhydraulicfittings.

7. Attempttocutwoodacrossthe grain.

8. Attempttoremovepartiallysplitwoodfromthewedgewithyour

hands.Fullyretractwedgetodislodgewoodwith logdislodger.

TRANSPORTING THE LOG SPLITTER

IMPORTANT:AlwaysturnfuelvalvetoOFFpositionbeforetransport-

ingthelogsplitter.

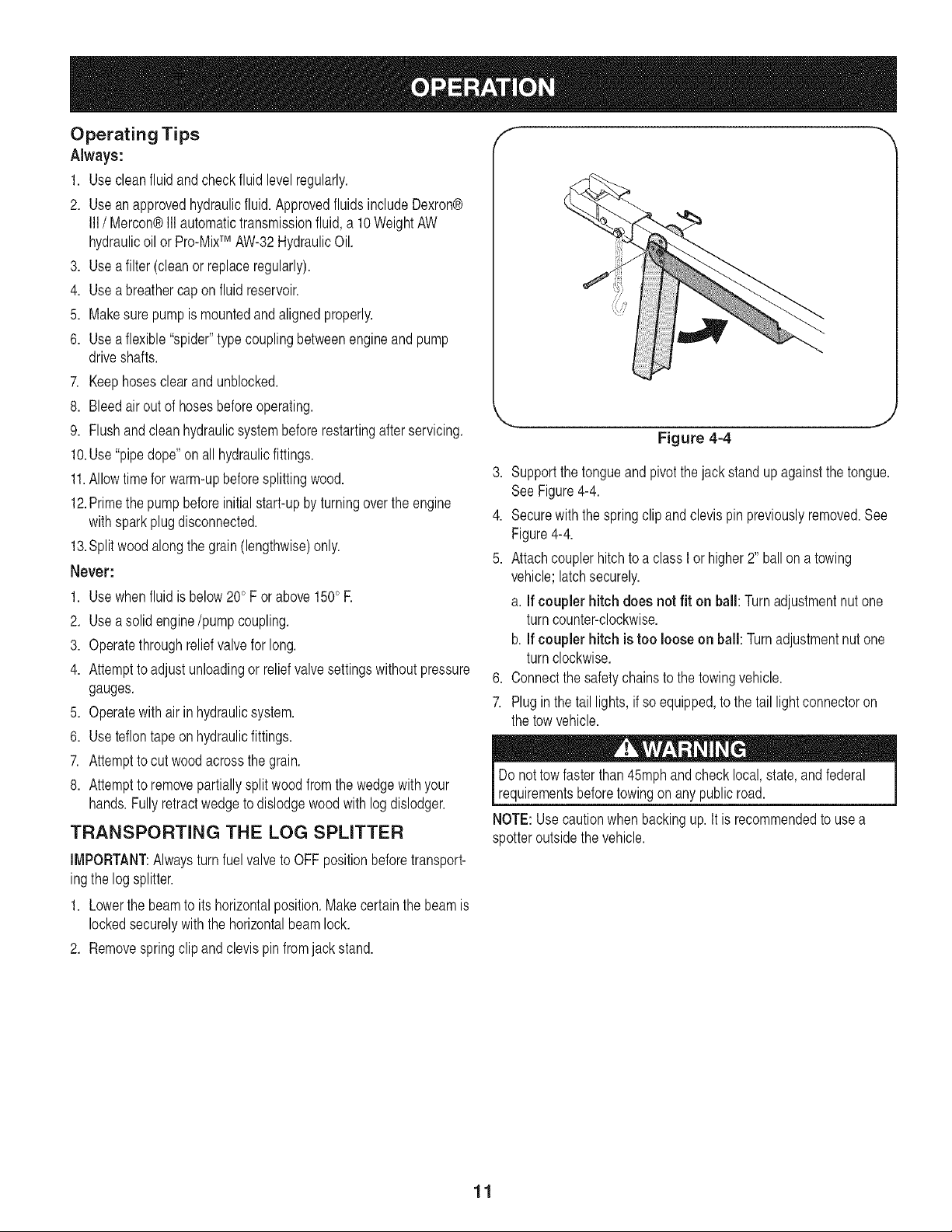

1. Lowerthebeamto its horizontalposition.Makecertainthebeamis

lockedsecurelywiththe horizontalbeamlock.

2. Removespringclipandclevis pinfromjackstand.

f

Figure 4-4

3. Supportthetongueandpivotthejackstandupagainstthetongue.

SeeFigure4-4.

4. Securewiththe springclipandclevispinpreviouslyremoved.See

Figure4-4.

5. Attachcouplerhitchtoa classI or higher2" ballona towing

vehicle;latchsecurely.

a. If couplerhitchdoes not fit on ball: Turnadjustmentnutone

turncounter-clockwise.

b.If coupler hitch is too looseon ball: Turnadjustmentnutone

turnclockwise.

6. Connectthesafetychainstothe towingvehicle.

7. Plugin thetaillights,ifso equipped,to thetail lightconnectoron

thetowvehicle.

nottow

IDo fasterthan andcheck and federal

Irequrementsbeforetowngon anypub croad. J

NOTE:Usecautionwhenbackingup.It isrecommendedtouse a

spotteroutsidethe vehicle.

45mph

local,state,

11

f

Adjustment

Bolt

-Gib

Jam Nut

Lock Nut

Figure 5-1

Donotatany timemakeanyadjustmentswithoutfirststopping

engine,disconnectingsparkplugwire,andgroundingit against

theengine.Alwayswearsafetyglassesduringoperationorwhile

[performng anyadustmentsor repars.

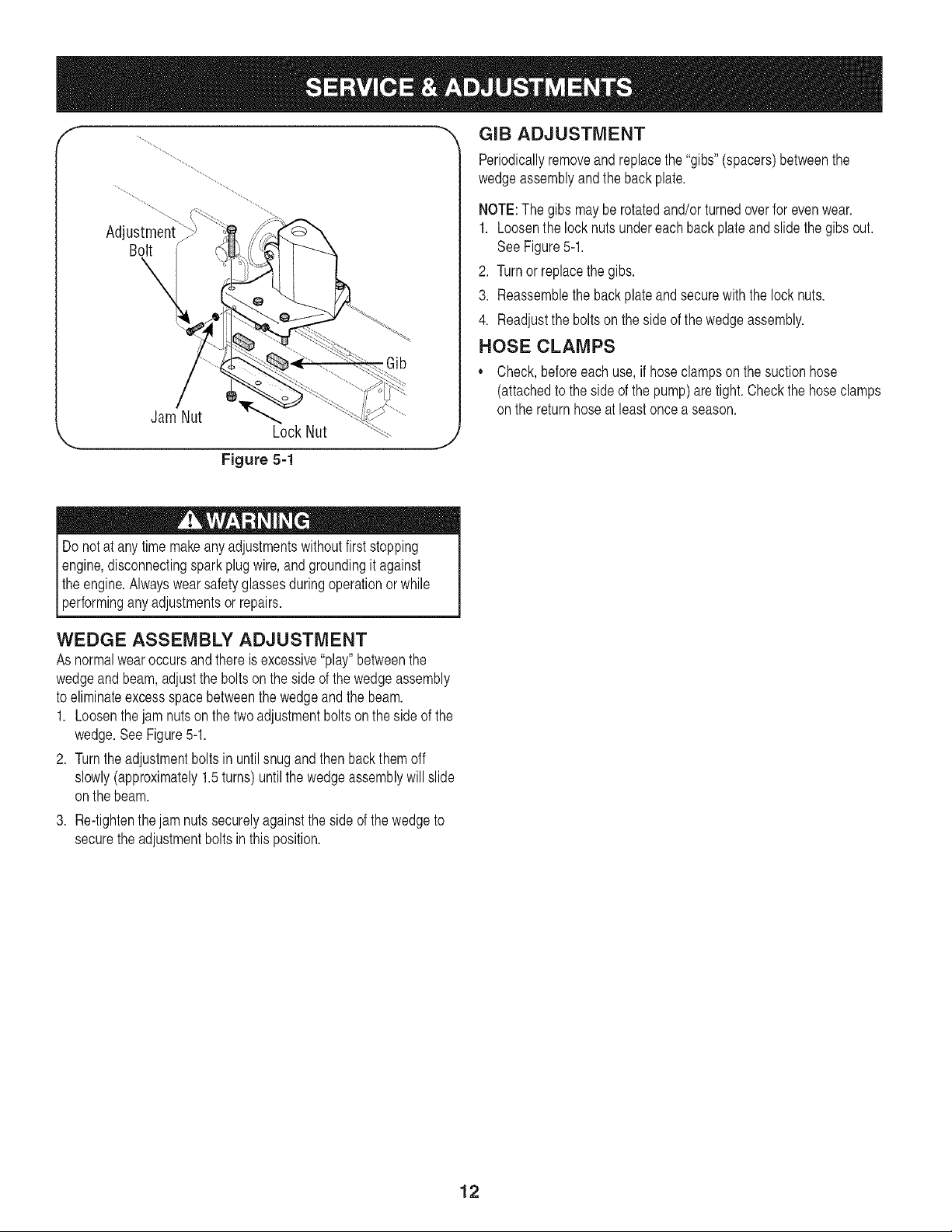

GIB ADJUSTMENT

Periodicallyremoveand replacethe"gibs"(spacers)betweenthe

wedgeassemblyandthe backplate.

NOTE:Thegibsmaybe rotatedand/orturnedoverfor evenwear.

1. Loosenthe locknutsundereachbackplateandslidethegibsout.

SeeFigure5-1.

2. Turnor replacethegibs.

3. Reassemblethebackplateandsecurewiththelock nuts.

4. Readjusttheboltsontheside ofthewedgeassembly.

HOSE CLAMPS

,, Check,beforeeachuse,if hoseclampsonthesuctionhose

(attachedto thesideofthepump)aretight.Checkthehoseclamps

on thereturnhoseatleastonce aseason.

WEDGE ASSEMBLY ADJUSTMENT

Asnormalwearoccursandthereisexcessive"play"betweenthe

wedgeandbeam,adjustthe boltsonthesideofthewedgeassembly

toeliminateexcessspacebetweenthewedgeandthe beam.

1. Loosenthejamnutson thetwoadjustmentboltsonthe sideofthe

wedge.SeeFigure5-1.

2. Turntheadjustmentboltsin untilsnugandthenbackthemoff

slowly(approximately1.5turns)untilthe wedgeassemblywillslide

onthebeam.

3. Re-tightenthe jamnutssecurelyagainstthesideof thewedgeto

securetheadjustmentbolts inthisposition.

12

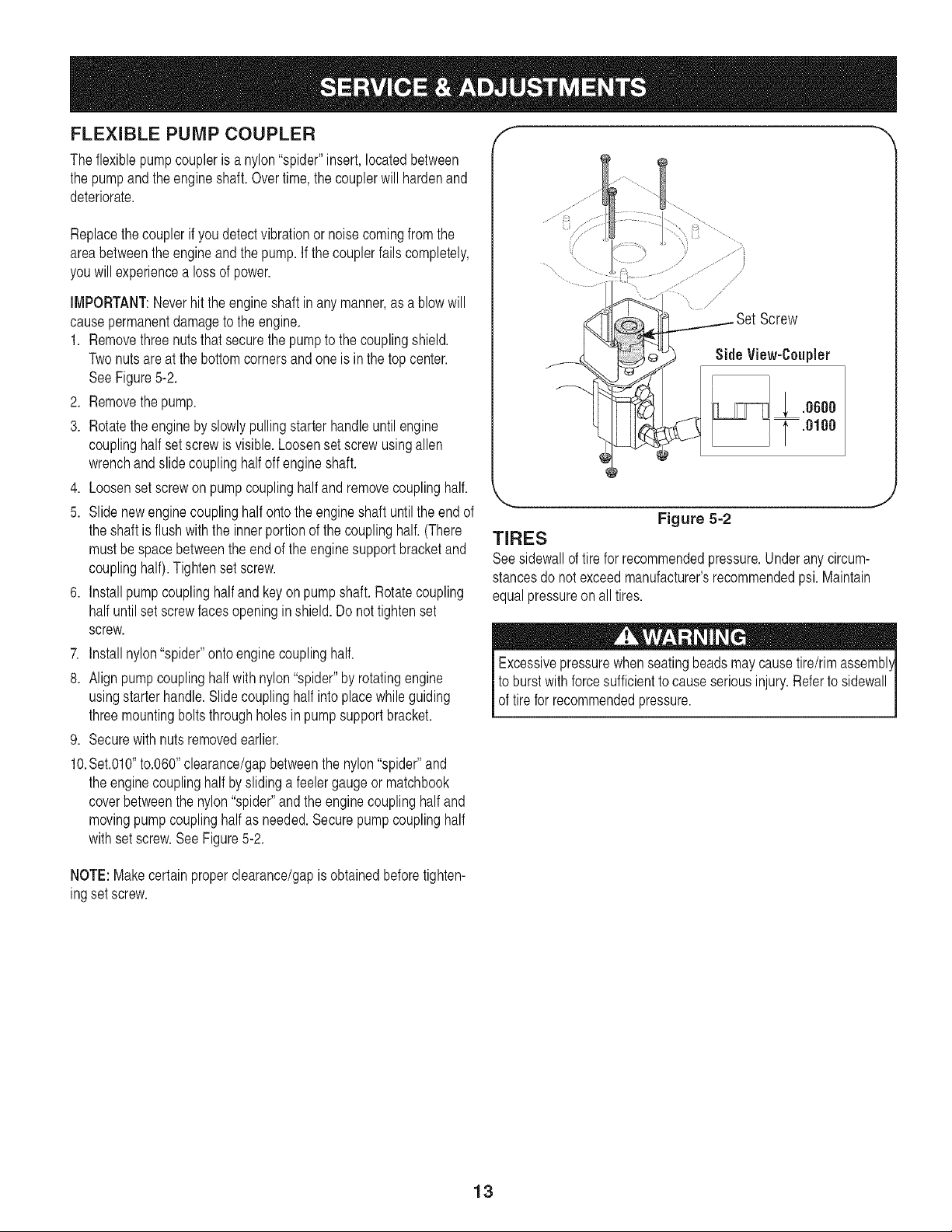

FLEXIBLE PUMP COUPLER

Theflexiblepumpcoupleris a nylon"spider"insert,locatedbetween

thepumpandtheengineshaft.Overtime,the couplerwillhardenand

deteriorate.

Replacethecouplerifyou detectvibrationornoisecomingfromthe

areabetweentheengineandthe pump.If thecouplerfailscompletely,

youwill experiencea lossof power.

IMPORTANT:Neverhit theengineshaftinany manner,asablowwill

causepermanentdamagetotheengine.

1. Removethreenutsthatsecurethepumpto thecouplingshield.

Twonutsareatthe bottomcornersandoneisinthe topcenter.

SeeFigure5-2.

2. Removethepump.

3. Rotatetheenginebyslowlypullingstarterhandleuntil engine

couplinghalfsetscrewis visible.Loosensetscrewusingallen

wrenchandslidecouplinghalfoff engineshaft.

4. Loosensetscrewon pumpcouplinghalfandremovecouplinghalf.

5. Slidenewenginecouplinghalfontotheengineshaft untiltheend of

theshaftisflushwiththe innerportionofthecouplinghalf.(There

mustbespacebetweentheendofthe enginesupportbracketand

couplinghalf).Tightensetscrew.

6. Installpumpcouplinghalfand keyonpumpshaft.Rotatecoupling

halfuntilsetscrewfacesopeninginshield.Donottightenset

screw.

7. Installnylon"spider"ontoenginecouplinghalf.

8. Alignpumpcouplinghalfwith nylon"spider"byrotatingengine

usingstarterhandle.Slidecouplinghalfintoplacewhileguiding

threemountingboltsthroughholesinpumpsupportbracket.

9. Securewithnutsremovedearlier.

10.Set.010"to.060"clearance/gapbetweenthe nylon"spider"and

theenginecouplinghalfbyslidinga feelergaugeor matchbook

coverbetweenthenylon"spider"andtheenginecouplinghalfand

movingpumpcouplinghalfas needed.Securepumpcouplinghalf

withsetscrew.SeeFigure5-2.

//

/

/

Screw

_,, ,J

Figure 5-2

TIRES

Seesidewalloftire forrecommendedpressure.Underanycircum-

stancesdo notexceedmanufacturer'srecommendedpsi. Maintain

equalpressureon alltires.

Excessivepressurewhenseatingbeadsmaycausetire/rimassembl_,

toburstwithforcesufficienttocauseseriousinjury.Referto sidewall

oftire forrecommendedpressure.

NOTE:Makecertainproperclearance/gapisobtainedbeforetighten-

ingsetscrew.

13

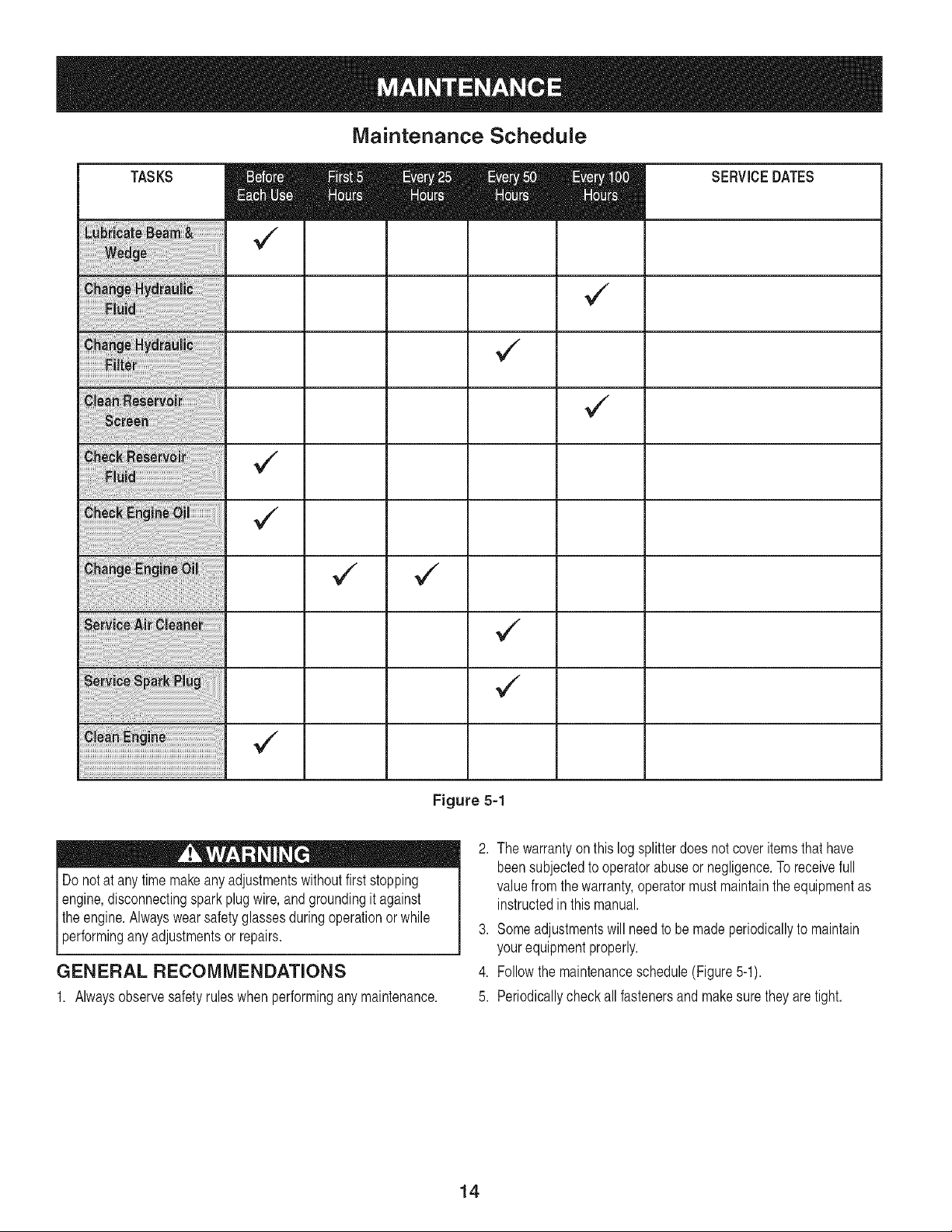

Maintenance Schedule

TASKS

SERVICEDATES

Figure 5-1

Donotatany timemakeanyadjustmentswithoutfirststopping

engine,disconnectingsparkplugwire,andgroundingit against

theengine.Alwayswearsafetyglassesduringoperationorwhile

performinganyadjustmentsor repairs.

GENERAL RECOMMENDATIONS

1. Alwaysobservesafetyruleswhenperformingany maintenance.

2. Thewarrantyonthis logsplitterdoesnotcoveritemsthathave

beensubjectedtooperatorabuseor negligence.Toreceivefull

valuefromthe warranty,operatormustmaintaintheequipmentas

instructedinthis manual.

3. Someadjustmentswillneedto bemadeperiodicallytomaintain

yourequipmentproperly.

4. Followthe maintenanceschedule(Figure5-1).

5. Periodicallycheckall fastenersandmakesuretheyaretight.

14

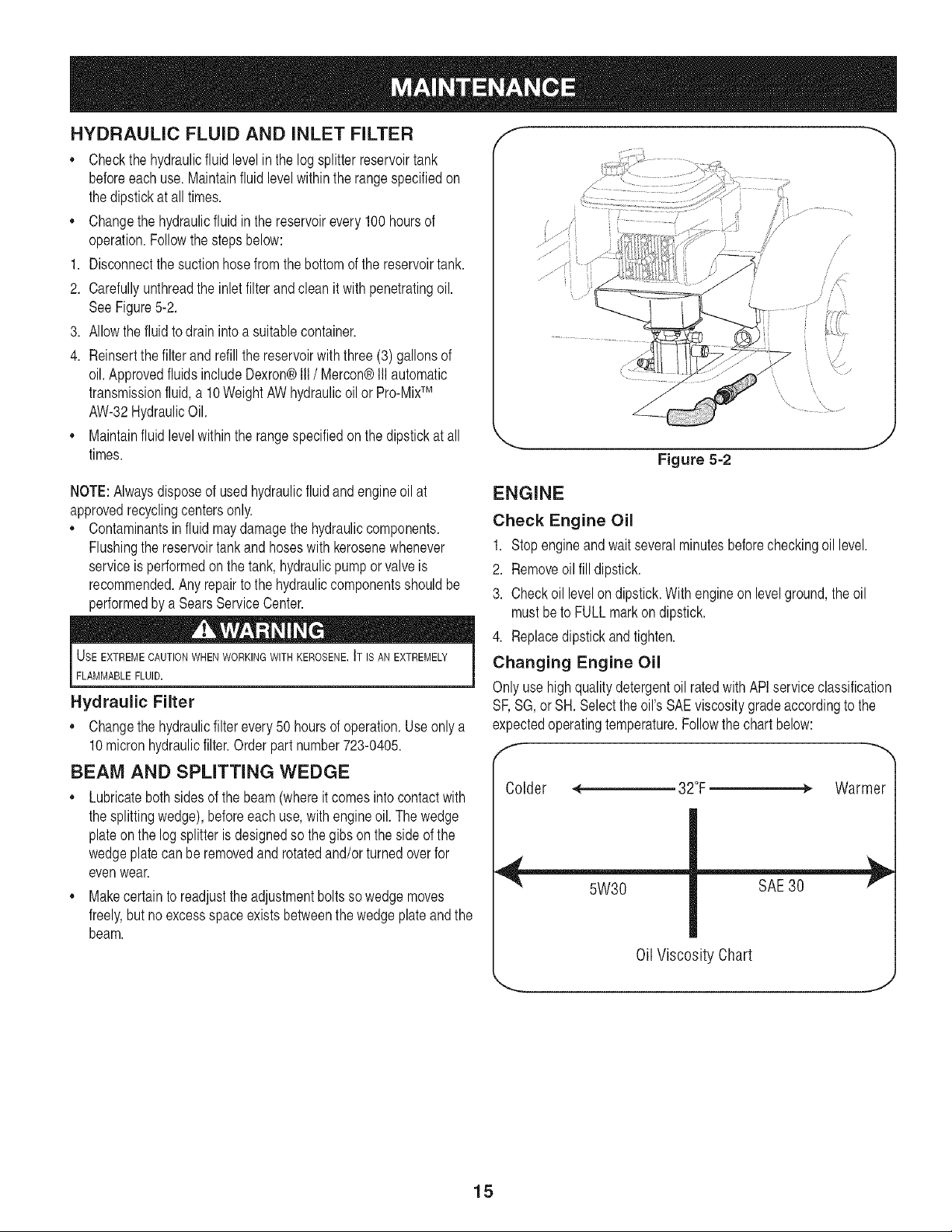

HYDRAULIC FLUID AND iNLET FILTER

,, Checkthehydraulicfluid levelinthelogsplitterreservoirtank

beforeeachuse.Maintainfluidlevelwithintherangespecifiedon

thedipstickat alltimes.

,, Changethehydraulicfluidinthereservoirevery100hoursof

operation.Followthestepsbelow:

1. Disconnectthe suctionhosefromthebottomofthereservoirtank.

2. Carefullyunthreadtheinlet filterandcleanitwithpenetratingoil.

SeeFigure5-2.

3. Allowthe fluidtodrainintoasuitablecontainer.

4. Reinsertthefilterandrefillthe reservoirwiththree(3) gallonsof

oil.ApprovedfluidsincludeDexron®Ill/ Mercon®Illautomatic

transmissionfluid,a 10WeightAWhydraulicoilor Pro-MixTM

AW-32HydraulicOil.

,, Maintainfluidlevelwithinthe rangespecifiedonthedipstickat all

times.

/ ,......... /

Figure 5-2

/

/ /,,

i \ /

NOTE:Alwaysdisposeofusedhydraulicfluidand engineoilat

approvedrecyclingcentersonly.

,, Contaminantsin fluidmaydamagethehydrauliccomponents.

Flushingthereservoirtankand hoseswithkerosenewhenever

serviceis performedon thetank,hydraulicpumporvalveis

recommended.Anyrepairto thehydrauliccomponentsshouldbe

performedbya SearsServiceCenter.

Hydraulic Filter

,, Changethehydraulicfilterevery50 hoursof operation.Useonlya

10micronhydraulicfilter.Orderpartnumber723-0405.

BEAM AND SPLITTING WEDGE

,, Lubricatebothsidesofthe beam(whereitcomesintocontactwith

thesplittingwedge),beforeeachuse,withengineoil.Thewedge

plateonthe log splitterisdesignedso thegibs onthesideof the

wedgeplatecanbe removedandrotatedand/orturnedoverfor

evenwear.

,, Makecertainto readjusttheadjustmentboltssowedgemoves

freely,butnoexcessspaceexistsbetweenthewedgeplateandthe

beam.

ENGINE

Check Engine Oil

1. Stopengineandwaitseveralminutesbeforecheckingoil level.

2. Removeoil filldipstick.

3. Checkoil levelondipstick.Withengineonlevelground,theoil

mustbeto FULLmarkondipstick.

4. Replacedipstickandtighten.

Changing Engine Oil

j

Onlyusehighqualitydetergentoil ratedwithAPIserviceclassification

SF,SG,or SH.Selecttheoil'sSAEviscositygradeaccordingtothe

expectedoperatingtemperature.Followthe chartbelow:

f- --..

Colder -4 32°F _ Warmer

Oil Viscosity Chart

15

Loading...

Loading...