Page 1

Operator’s Manual

6.5 Horse Power

LOG SPLITTER

Model No. 247.77466.1

®

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our web site: www.sears.com/craftsman

• SAFETY

• ASSEMBLY

• OPERATION

• MAINTENANCE

• PARTS LIST

FORM NO. 769-00851E

08/15/2006

Page 2

TABLE OF CONTENTS

Warranty Statement ..................................Page 2

Repair Protection Agreement ................... Page 3

Safe Operation Practices ......................... Pages 4-5

Assembly ..................................................Pages 6-7

Operation .................................................. Pages 8-11

Service & Adjustments .............................Pages 12-13

Maintenance .............................................Pages 14-16

Off Season Storage .................................. Page 17

Trouble Shooting ......................................Page 18-19

Parts List ...................................................Page 20-27

Español ..................................................... Page 29

Service Numbers ...................................... Back Cover

WARRANTY STATEMENT

Limited Warranty on Craftsman Log Splitter

For one (1) year from the date of purchase, if this Craftsman Equipment is maintained, lubricated, and tuned up according to the instructions to

the operator’s manual, Sears will repair or replace free of charge any parts found to be defective in material or workmanship. Warranty service is

available free of charge by returning Craftsman equipment to your nearest Sears Service Center. In-home warranty service is available but a trip

charge will apply. This Warranty applies only while this product is in the United States.

This warranty does not cover:

• Expendable items which become worn during normal use, such as spark plugs, air cleaners, belts, and oil filters.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass.

• Repairs necessary because of operator abuse, including but not limited to, damage caused by objects, such as stones or metal debris,

oversized stock, impacting objects that bend the frame or crankshaft, or over-speeding the engine.

• Repairs necessary because of operator negligence, including but not limited to, electrical and mechanical damage caused by improper

storage, failure to use the proper grade and amount of engine oil, or failure to maintain the equipment according to the instructions contained

in the operator’s manual.

• Engine (fuel system) cleaning or repairs caused by fuel determine to be contaminated or oxidized (stale). In general, fuel should be used

within 30 days of its purchase date.

• Equipment used for commercial or rental purposes.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN SNOW THROWER TO THE NEAREST

SEARS PARTS & REPAIR CENTER IN THE UNITED STATES.

This warranty applies only while this product is in use in the United States.

TO LOCATE THE NEAREST SEARS PARTS & REPAIR CENTER OR TO SCHEDULE SERVICE,

SIMPLY CONTACT SEARS AT 1-800-4-MY-HOME®.

This warranty gives you specific legal rights and you may also have other rights which may vary from state to state.

SEARS, ROEBUCK AND CO., D/817WA, HOFFMAN ESTATES, IL 60179

PRODUCT SPECIFICATIONS MODEL NUMBER

Horse Power:

Engine Oil: SAE 30

Engine Oil Capacity: 20 Ounces

Fuel Capacity: 1.5 Quarts

Spark Plug (.030” Gap): Champion® RJ19LM

Hydraulic Fluid/ Capacity:Dexron III/ 3.0 gal.

6.5

Model Number .............................................................

Serial Number ..............................................................

Date of Purchase ..........................................................

Record the model number, serial number

and date of purchase above

2

Page 3

REPAIR PROTECTION AGREEMENT

Congratulations on making a smart purchase. Your new Craftsman®

product is designed and manufactured for years of dependable operation. But like all products, it may require repair from time to time. That’s

when having a Repair Protection Agreement can save you money and

aggravation.

Here’s what’s included in the Agreement:

• Expert service by our 12,000 professional repair specialists

• Unlimited service and no charge for parts and labor on all covered

repairs

• Product replacement if your covered product can’t be fixed

• Discount of 10% from regular price of service and service-related

parts not covered by the agreement; also, 10% off regular price of

preventive maintenance check

• Fast help by phone – phone support from a Sears technician on

products requiring in-home repair, plus convenient repair

scheduling

Purchase a Repair Protection Agreement now and protect yourself

from unexpected hassle and expense.

Once you purchase the Agreement, a simple phone call is all that it

takes for you to schedule service. You can call anytime day or night, or

schedule a service appointment online.

Sears has over 12,000 professional repair specialists, who have

access to over 4.5 million quality parts and accessories. That’s the

kind of professionalism you can count on to help prolong the life of

your new purchase for years to come. Purchase your Repair Protection

Agreement today!

Some limitations and exclusions apply. For prices and additional

information call 1-800-827-6655.

Sears Installation Service

For Sears professional installation of home appliances, garage door

openers, water heaters, and other major home items, in the U.S.A. call

1-800-4-MY-HOME®

3

Page 4

SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could endanger the

personal safety and/or property of yourself and others. Read and follow all instructions in this manual before

attempting to operate this machine. Failure to comply with these instructions may result in personal injury.

When you see this symbol - heed its warning.

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components contain or emit

chemicals known to State of California to cause cancer and birth defects or other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation in this manual.

As with any type of power equipment, carelessness or error on the part of the operator can result in

serious injury. This machine is capable of amputating hands and feet and throwing objects. Failure to

observe the following safety instructions could result in serious injury or death.

General Practices

1. Read, understand, and follow all instructions on the machine and

in the manual(s) before attempting to assemble and operate. Keep

this manual in a safe place for future and regular reference and for

ordering replacement parts.

2. Be familiar with all controls and proper operation. Know how to stop

the machine and disengage them quickly.

3. Never allow children under 16 years to operate this machine.

Children,16 years and over, should read and understand instructions and safety rules in this manual and should be trained and

supervised by a parent.

4. Never allow adults to operate this machine without proper instruc

tion.

5. Many accidents occur when more than one person operates the

machine. If a helper is assisting in loading logs, never activate the

control until the helper is a minimum of 10 feet from the machine.

6. Keep bystanders, helpers, pets, and children at least 20 feet from

the machine while it is in operation.

7. Never allow anyone to ride on this machine.

8. Never transport cargo on this machine.

9. Hydraulic log splitters develop high fluid pressures during operation. Fluid escaping through a pin hole opening can penetrate your

skin and cause blood poisoning, gangrene, or death. Give attention

to the following instructions at all times:

a. Do not check for leaks with your hand.

b. Do not operate machine with frayed, kinked, cracked, or damaged

hoses, fitting, or tubing.

c. Stop the engine and relieve hydraulic system pressure before changing

or adjusting fittings, hoses, tubing, or other system components.

d. Do not adjust the pressure settings of the pump or valve.

10. Leaks can be detected by passing cardboard or wood, while

wearing protective gloves and safety glasses, over the suspected

area. Look for discoloration of cardboard or wood.

11. If injured by escaping fluid, see a doctor immediately. Serious

infection or reaction can develop if proper medical treatment is not

administered immediately.

-

12. Keep the operator zone and adjacent area clear for safe, secure

footing.

13. If your machine is equipped with an internal combustion engine

and it is intended for use near any unimproved forest, brush, or

grass covered land, the engine exhaust should be equipped with a

spark arrester. Make sure you comply with applicable local, state,

and federal codes. Take appropriate firefighting equipment with

you.

14. This machine should be used for splitting wood only, do not use it

for any other purpose.

15. Follow the instructions in the manual(s) provided with any

attachment(s) for this machine.

Preparation

1. Always wear safety shoes or heavy boots.

2. Always wear safety glasses or safety goggles during operating this

machine.

3. Never wear jewelry or loose clothing that might become entangled

in moving or rotating parts of the machine.

4. Make sure machine is on level surface before operating.

5. Always block machine to prevent unintended movement, and lock

in either horizontal or vertical position.

6. Always operate this machine from the operator zone (s) specified in

the manual.

7. Logs should be cut with square ends prior to splitting.

8. Use log splitter in daylight or under good artificial light.

9. To avoid personal injury or property damage use extreme care in

handling gasoline. Gasoline is extremely flammable and the vapors

are explosive. Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite. Wash your skin

and change immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and other sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the engine is hot or running.

e. Allow engine to cool at least two minutes before refueling.

4

Page 5

SAFE OPERATION PRACTICES

f. Never overfill the fuel tank. Fill tank to no more than 1/2 inch below

bottom of filler neck to provide space for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and equipment. move

machine to another area. Wait 5 minutes before starting the engine.

i. Never store the machine or fuel container inside where there is an open

flame, spark or pilot light as on a water heater, space heater, furnace,

clothes dryer or other gas appliances.

j. Allow machine to cool 5 minutes before storing.

Operation

1. Before starting this machine, review the “Safety Instructions”.

Failure to follow these rules may result in serious injury to the

operator or bystanders.

2. Never leave this machine unattended with the engine running.

3. Do not operate machine while under the influence of alcohol, drugs,

or medication.

4. Never allow anyone to operate this machine without proper instruc

tion.

5. Always operate this machine with all safety equipment in place

and working. Make sure all controls are properly adjusted for safe

operation.

6. Do not change the engine governor settings or overspeed the

engine. The governor controls the maximum safe operating speed

of the engine.

7. When loading a log, always place your hands on the sides of the

log, not on the ends, and never use your foot to help stabilize a log.

Failure to do so, may result in crushed or amputated fingers, toes,

hand, or foot.

8. Use only your hand to operate the controls.

9. Never attempt to split more than one log at a time unless the ram

has fully extended and a second log is needed to complete the

separation of the first log.

10. For logs which are not cut square, the least square end and the

longest portion of the log should be placed toward the beam and

wedge, and the square end placed toward the end plate.

11. When splitting in the vertical position, stabilize the log before

moving the control. Split as follows:

a. Place log on the end plate and turn until it leans against the beam and

is stable.

b. When splitting extra large or uneven logs, the log must be stabilized

with wooden shims or split wood between the log and end plate or

ground.

12. Always keep fingers away from any cracks that open in the log

while splitting. They can quickly close and pinch or amputate your

fingers.

13. Keep your work area clean. Immediately remove split wood around

the machine so you do not stumble over it.

14. Never move this machine while the engine is running.

-

15. This machine should not be towed on any street, highway or public

road without checking the existing federal, state, or local vehicle

requirements. Any licensing or modifications such as taillights, etc.,

needed to comply, is the sole responsibility of the purchaser. If a

“Statement of Origin” is required in your state, see your local dealer.

16. Do not tow machine faster than 45mph.

17. See Transporting the Log Splitter section in this manual for proper

towing instructions once all federal, local, or state requirements are

met.

Maintenance and Storage

1. Stop the engine, disconnect the spark plug and ground it against

the engine before cleaning, or inspecting the machine.

2. Stop the engine and relieve hydraulic system pressure before

repairing or adjusting fittings, hoses, tubing, or other system

components.

3. To prevent fires, clean debris and chaff from the engine and muffler

areas. If the engine is equipped with a spark arrester muffler, clean

and inspect it regularly according to manufacturers instructions.

Replace if damaged.

4. Periodically check that all nuts and bolts, hose clamps, and

hydraulic fittings are tight to be sure equipment is in safe working

condition.

5. Check all safety guards and shields to be sure they are in the

proper position. Never operate with safety guards, shields, or other

protective features removed.

6. The pressure relief valve is preset at the factory. Do not adjust the

valve.

7. Never attempt to move this machine over hilly or uneven terrain

without a tow vehicle or adequate help.

8. For your safety, replace all damaged or worn parts immediately

with original equipment manufacturer’s (O.E.M.) parts only. “Use of

parts which do not meet the original equipment specifications may

lead to improper performance and compromise safety! ”

9. Do not alter this machine in any manner, alterations such as attaching a rope or extension to the control handle, or adding to the width

or height of the wedge may result in personal injury.

Your Responsibility

Restrict the use of this power machine to persons who read, understand and follow the warnings and instructions in this manual and on

the machine. Always follow directions on safety labels found on your

equipment.

5

Page 6

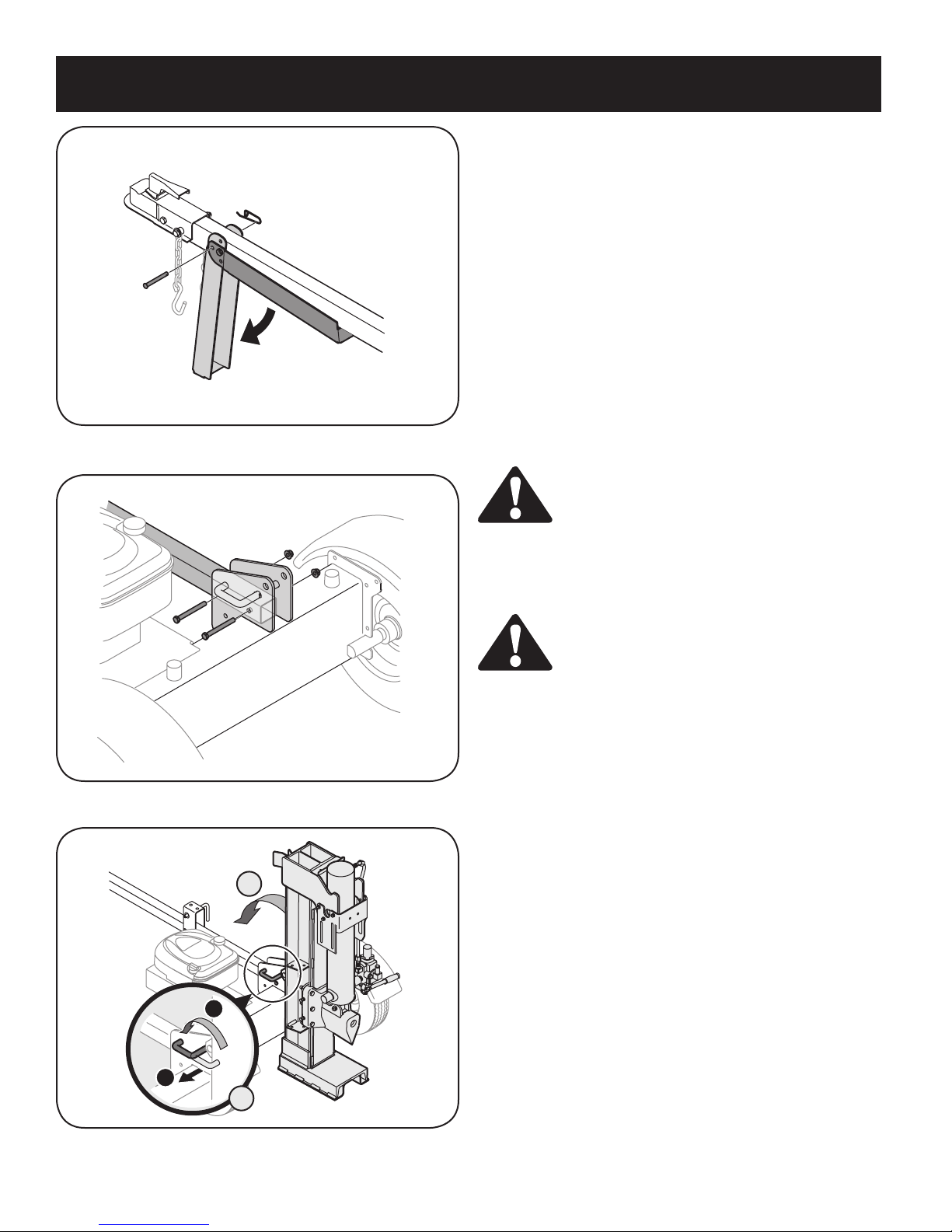

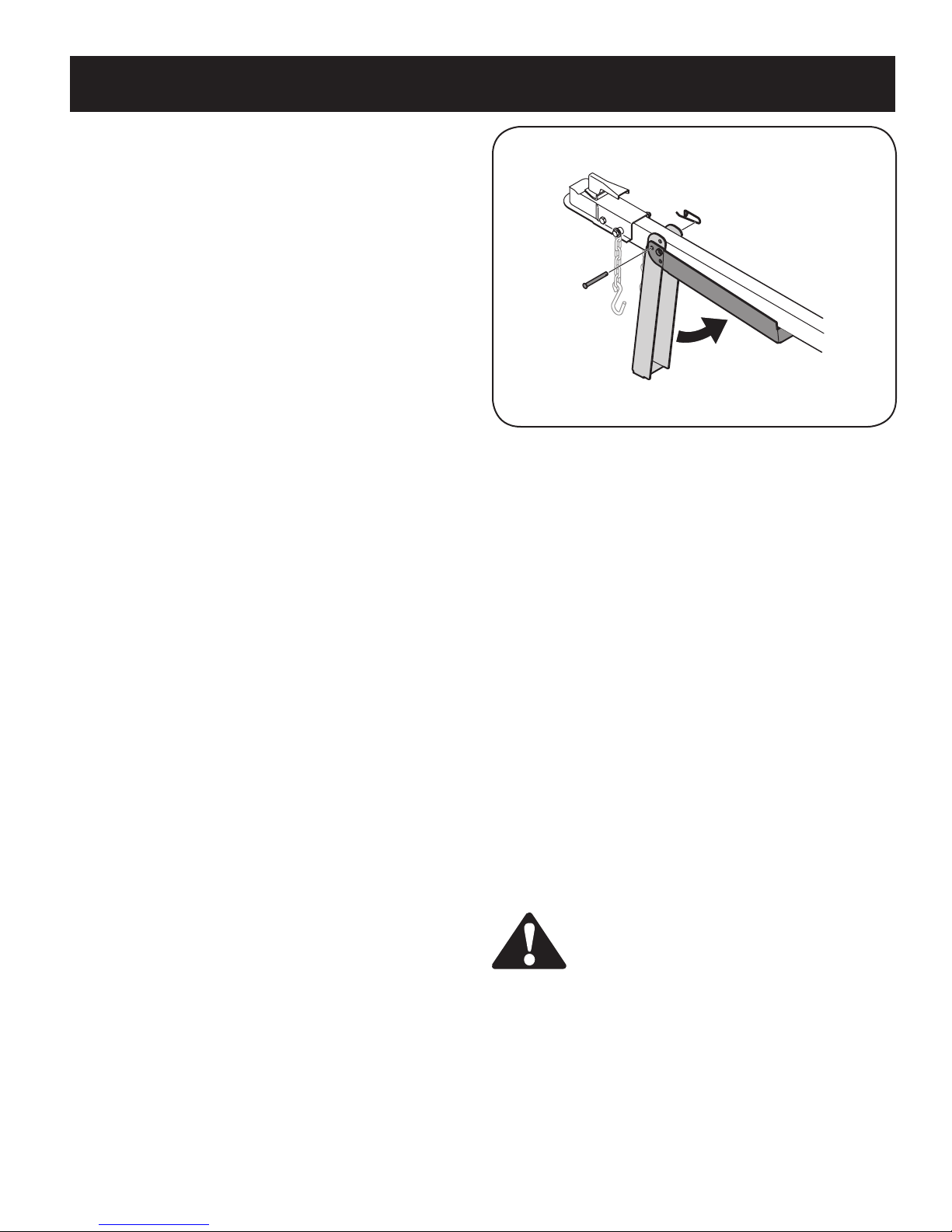

Figure 3-1

ASSEMBLY

IMPORTANT: Your log splitter is shipped with motor oil in the engine.

However, you MUST check the oil level before operating. Be careful

not to overfill.

NOTE: All references in this manual to the left or right side of the log

splitter is from the operating position only.

Removing Unit From Carton

1. Pry the top, sides, and ends off crate.

2. Set panels aside to avoid tire punctures or personal injury.

3. Remove and discard plastic bag that covers unit.

4. Remove any loose parts if included with unit (i.e., operator’s

manual, etc.)

5. Cut and remove straps which secure parts to bottom of crate.

Unbolt any remaining parts which may be bolted to the bottom of

the crate.

WARNING: Use extreme caution unpacking this

machine. Some components are very heavy and will

require additional people or mechanical handling

equipment.

Figure 3-2

B

Loose Parts In Carton

1. Tongue Assembly

WARNING: Disconnect the spark plug wire and

ground against the engine to prevent unintended

starting.

Assembling the Tongue

Attaching the Jack Stand

The jack stand is shipped in the transport position.

1. Remove the spring clip and clevis pin and pivot the jack stand

towards the ground to the operating position.

2. Secure the jack stand in position with the clevis pin and spring clip.

See Figure 3-1.

Attaching the Tongue

1. With the log splitter still standing upright, remove two hex bolts and

hex nuts from the tank bracket. See Figure 3-2.

2. Align the holes in the tongue with the holes in the tank bracket and

secure with hardware just removed. See Figure 3-2.

2

1

A

Figure 3-3

NOTE: High pressure hose must be above the tongue assembly.

Connecting Cylinder to Beam

The log splitter is shipped with the beam in the vertical position.

1. Pull out the vertical beam lock, rotate it back, and pivot the beam to

the horizontal position until it locks. See Figure 3-3.

6

Page 7

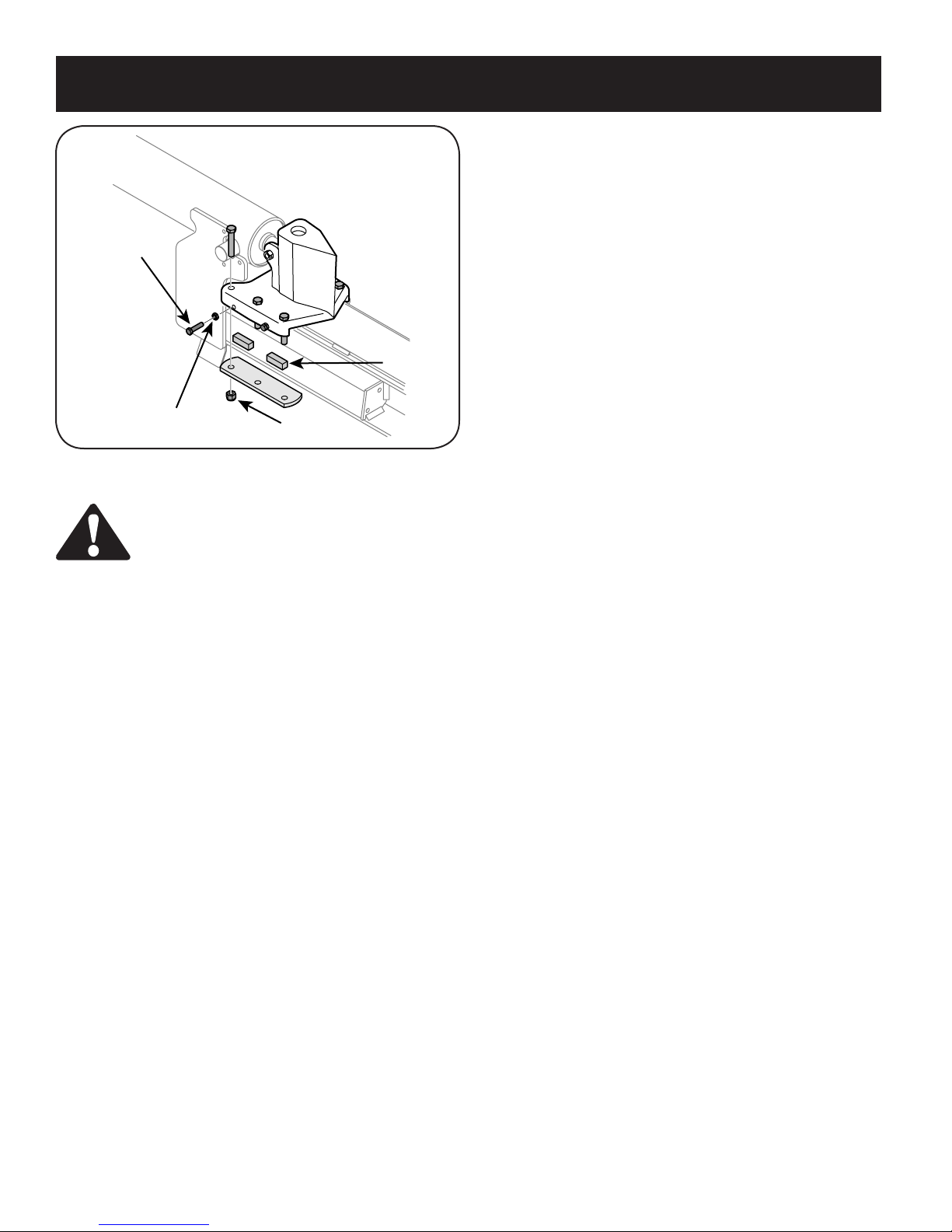

ASSEMBLY

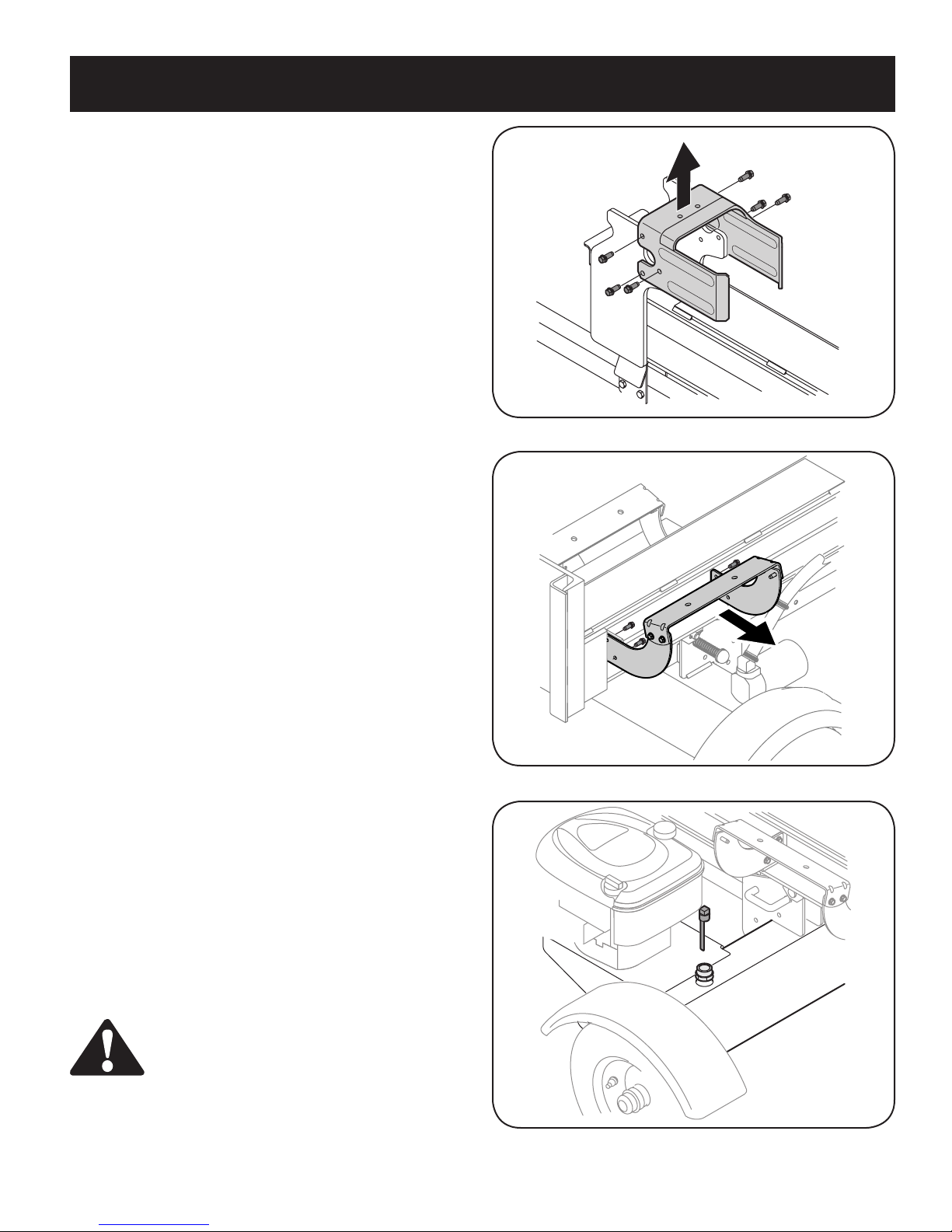

2. Disconnect the dislodger from the beam weld bracket by removing

the six hex screws. See Figure 3-4.

3. Disconnect the log cradle from the beam on the side of the control

valve. See Figure 3-5.

4. Lift and slide the cylinder up to the top of beam and into the weld

brackets.

5. Attach the dislodger over the wedge assembly and secure with

hardware, previously removed, to the weld brackets.

NOTE: Once the six hex screws are tightened, there may be a slight

gap between the dislodger and the weld brackets. This gap is normal.

6. Reattach the log cradle to the side of the beam with the control

valve, aligning the ends of the cradle with the beam flanges.

7. Roll log splitter off the bottom crate.

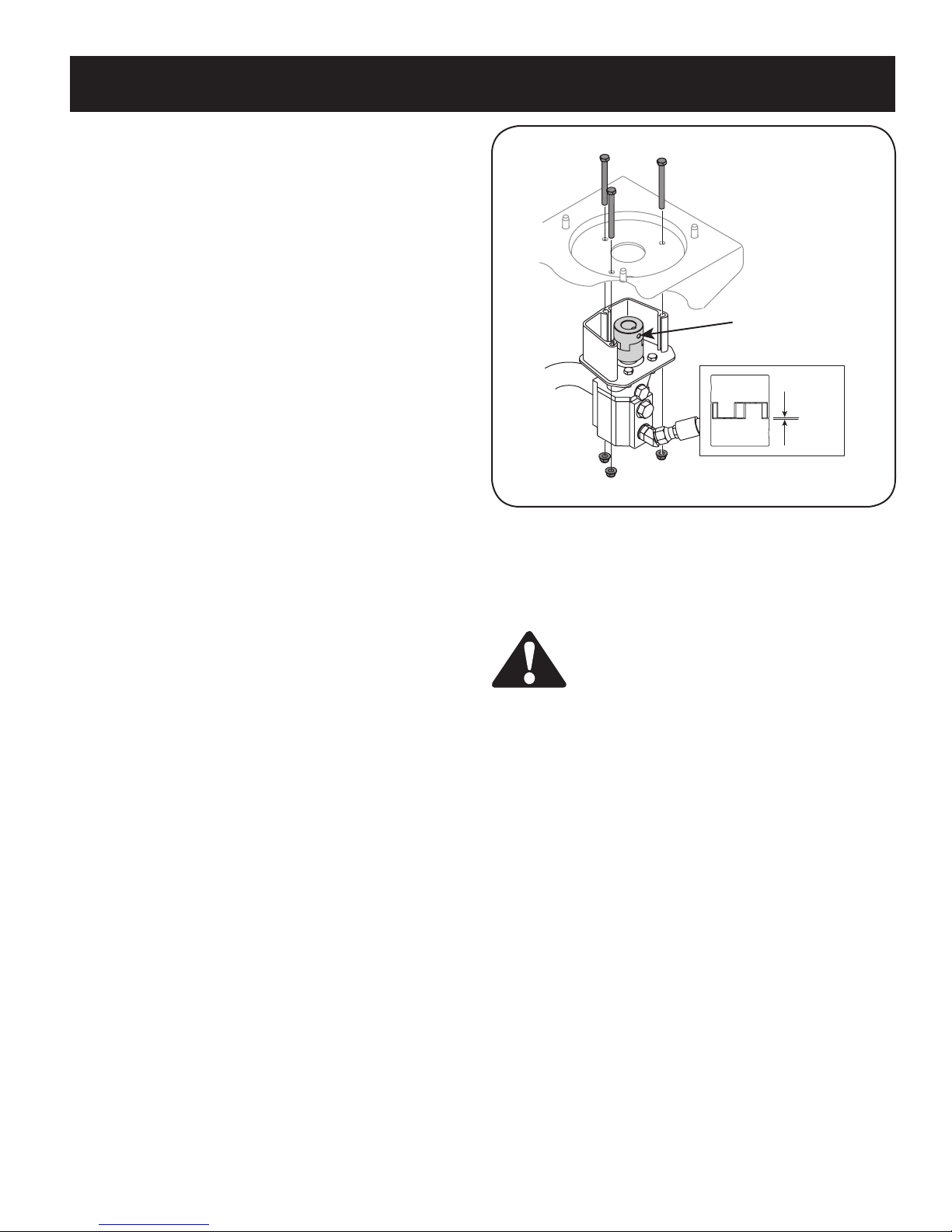

Preparing the Log Splitter

1. Lubricate the beam area (where the splitting wedge will slide) with

engine oil; do not use grease.

2. Remove vented reservoir dipstick, which is located in front of the

engine on top of the reservoir tank. See Figure 3-6.

IMPORTANT: The log splitter may have been shipped and primed

with hydraulic fluid in the reservoir tank. However, you MUST check

the fluid level before operating. If not filled, proceed with the following

steps:

3. Fill the reservoir tank with hydraulic fluid included with this unit (if

equipped) or approved fluids which include Dexron® III / Mercon®

III automatic transmission fluid, a 10 Weight AW hydraulic oil or

Pro-Mix™ AW-32 Hydraulic Oil.

4. Check fluid level using the dipstick. See Figure 3-6. Do not overfill.

5. Replace vented dipstick securely, tightening it until the top of the

threads are flush with top of the pipe.

6. Disconnect the spark plug and prime the pump by pulling the recoil

starter as far as it will go. Repeat approximately 10 times.

7. Reconnect the spark plug wire and start engine following instruc

tions in the OPERATION section.

8. Use control handle to engage the wedge to the farthest extended

position. Then retract the wedge.

9. Refill tank as specified on the dipstick.

-

Figure 3-4

Figure 3-5

NOTE: Failure to refill the tank will void unit’s warranty.

10. Extend and retract the wedge 12 complete cycles to remove

trapped air in the system (the system is “self-bleeding”).

11. Refill reservoir within range marked on the dipstick.

WARNING: Much of the original fluid has been

drawn into the cylinder and hoses. Make certain

to refill the reservoir to prevent damage to the

hydraulic pump.

NOTE: Some fluid may overflow from the vent plug as the system

builds heat and the fluid expands and seeks a balanced level.

Figure 3-6

7

Page 8

OPERATION

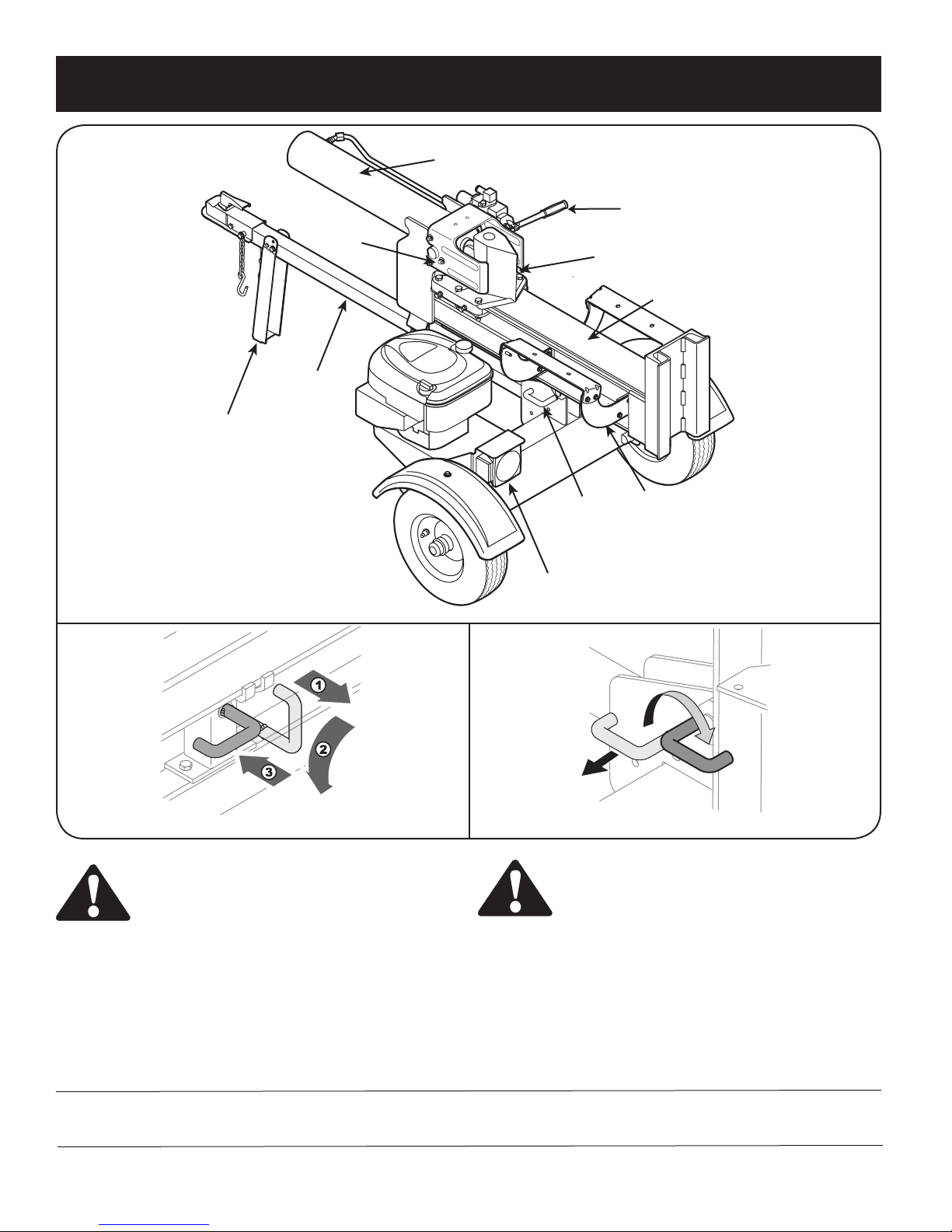

Cylinder

Jack Stand

Log

Dislodger

Tongue

Wedge

Vertical

Beam

Lock

Tail Light

(If Equipped)

Control Handle

Beam Assembly

Log Cradle

Horizontal Beam Lock

WARNING: Read this operator’s manual and safety

rules before operating your log splitter. Compare

the illustrations below with your equipment to

familiarize yourself with the location of various

controls and adjustments. Save this manual for

future reference.

The operation of any log splitter can result in

foreign objects being thrown into the eyes, which

can result in severe eye damage. Always wear safety

glasses, for operating this equipment or while

performing any adjustments or repairs on it.

Meets ANSI Safety Standards

Craftsman Yard Vacuums conform to the safety standard of the American National Standards Institute (ANSI).

Vertical Beam Lock

Figure 4-1

WARNING: Be familiar with all controls and their

proper operation. Know how to stop the machine

and disengage them quickly.

Beam Locks

These two locks, as their name suggests, are used to secure the beam

in the horizontal or the vertical position. The vertical beam lock is

located next to the oil filter. The horizontal beam lock is located on the

beam support latch bracket. See Figure 4-1.

8

Page 9

OPERATION

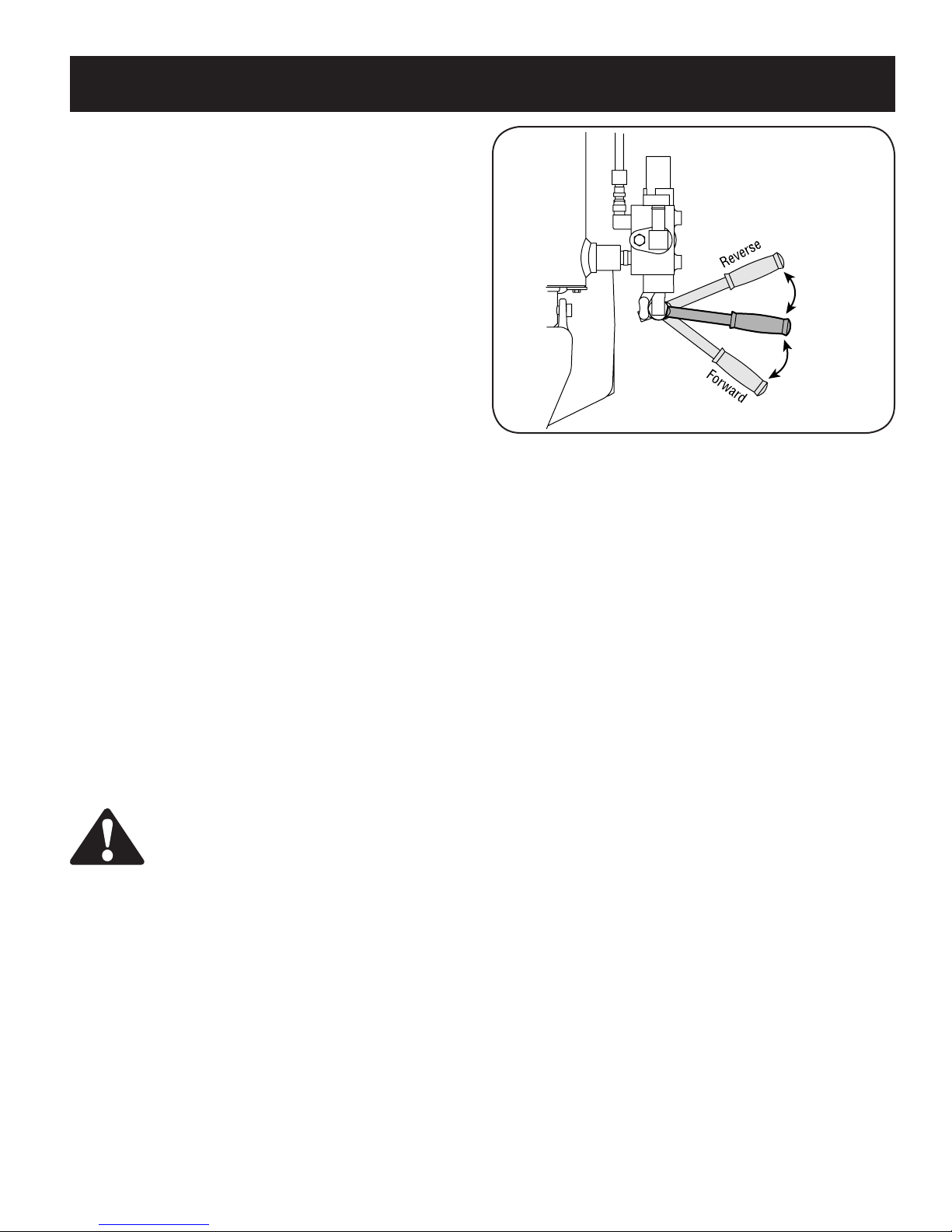

Engine Controls

Stop Switch

Push button to ON prior to choking for engine start; push to OFF to

shut engine down.

Choke Control

The choke control is used to choke off the carburetor and assist in

starting the engine.

To return

wedge

Starter Handle

The starter handle is located on the engine. Pull the starter handle to

start engine.

Control Handle

The control handle has three positions. See Figure 4-2.

• FORWARD: Move control handle FORWARD or DOWN to move

wedge to split wood.

NOTE: Control handle will return to neutral position as soon as handle

is released.(Forward Position only)

NEUTRAL: Release the control handle or move the lever to neutral

•

position to stop the wedge movement.

•

REVERSE: Move control handle BACK or UP to return the

wedge toward the cylinder. The control handle stays in the return

(Reverse) position and returns to neutral automatically when fully

retracted.

NOTE: Reverse position may also be operated back to neutral position

manually, if necessary.

Gas and Oil Fill-Up

IMPORTANT: Your log splitter may be shipped with motor oil in the

engine. You MUST check the oil level before operating. Be careful not

to overfill.

WARNING: Use extreme care when handling

gasoline. Gasoline is extremely flammable and the

vapors are explosive. Never fuel machine indoors or

while the engine is hot or running.

Oil

1. Remove oil fill dipstick.

2. Check the oil level making certain not to rub the dipstick along the

inside walls of the oil fill tube. This would result in a false dipstick

reading. Refill to FULL mark on dipstick, if necessary. Replace

dipstick and tighten.

3. If necessary, with the log splitter on level ground, use a funnel to fill

engine with oil to FULL mark on dipstick. Be careful not to overfill.

Overfilling will cause the engine to smoke profusely and will result

in poor engine performance.

Neutral

To stop

wedge

To split wood

Figure 4-2

4. Check oil level three times prior to starting engine to be certain

you’ve gotten an accurate dipstick reading. Running the engine with

too little oil can result in permanent engine damage.

Gasoline

1. Remove fuel cap from the fuel tank.

2. Make sure the container from which you will pour the gasoline is

clean and free from rust or foreign particles. Never use gasoline

that may be stale from long periods of storage in its container.

Gasoline that has been sitting for any period longer than four weeks

should be considered stale.

3. Fill fuel tank with about 1.5 quarts of clean, fresh, lead-free grade

automotive gasoline. DO NOT use Ethly or high octane gasoline.

NOTE: Gasoline can be added to the engine when the log splitter is

in either the horizontal or vertical position. However, there are less

obstructions when the unit is in the vertical position.

NOTE: Do not use gasoline containing methanol. Gasoline containing

up to about 10% ethanol or up to 15% methyl tertiary butyl ether

(MTBE) may be used, but will require special care when engine is left

unused for extended period.

4. Replace fuel cap.

NOTE: To avoid engine problems, the fuel system should be emptied

before storage for 30 days or longer. Drain the gas tank, start the

engine and let it run until the fuel lines and carburetor are empty. Use

fresh fuel next season. See STORAGE section for additional information.

9

Page 10

OPERATION

Figure 4-3

Stopping Engine

1. Push stop switch to OFF.

2. Disconnect spark plug wire and ground against the engine to

prevent unintended starting.

WARNING: When starting a warm engine, the muffler and surrounding areas are hot and can cause a

burn. Do not touch.

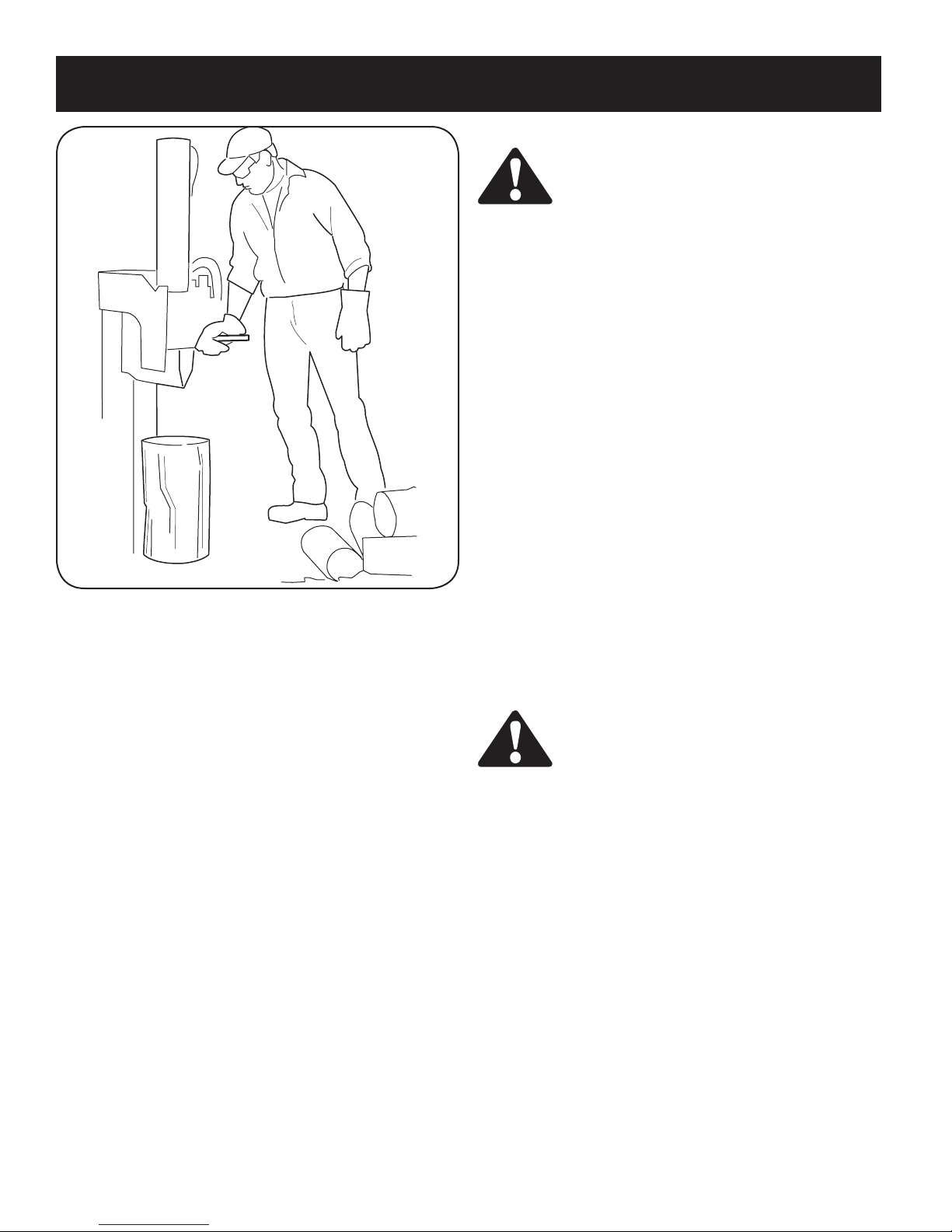

Using the Log Splitter

1. Place the log splitter on level, dry ground.

2. Place the beam in either the horizontal or vertical position and lock

in place with the appropriate locking rod.

3. Block the front and back of both wheels.

4. Place the log against the end plate and only split wood in the

direction of the grain.

5. To stabilize the log, place your hand only on sides of log.

place hand on the end between the log and the splitting

wedge.

6. Only one adult should stabilize the log and operate the control

handle, so the operator has full control over the log and the splitting

wedge.

Control Handle

1. Move control handle FORWARD or DOWN to split wood.

2. Release the control handle to stop the wedge movement.

3. Move control handle BACK or UP to return the wedge.

Log Dislodger

The log dislodger is designed to remove any partially split wood from

the wedge. This may occur while splitting large diameter wood or

freshly cut wood.

Never

Starting Engine

1. Attach spark plug wire to spark plug. Make certain the metal cap on

the end of the spark plug is fastened securely over the metal tip on

the spark plug.

2. Push stop switch to ON.

3. Move choke control to CHOKE position.

4. Grasp starter handle and pull rope out slowly until engine reaches

start of compression cycle (rope will pull slightly harder at this

point).

5. Pull rope with a rapid, continuous, full arm stroke. Keep a firm grip

on starter handle. Let rope rewind slowly.

6. Repeat, if necessary, until engine starts. Slowly adjust choke

toward RUN position. Wait until engine runs smoothly before each

choke adjustment.

7. If engine falters, move control lever to CHOKE position, then slowly

back to RUN position.

8. If weather is cold, run wedge up or down beam 6 to 8 times to

circulate the hydraulic fluid.

WARNING: Never remove partially split wood from

the wedge with your hands. Fingers may become

trapped between split wood.

1. To remove partially split wood from wedge, move control handle to

REVERSE position until wedge is fully retracted to allow split wood

portion to contact the log dislodger.

2. Once removed from wedge with log dislodger, split wood from

opposite end or in another location.

Vertical Position

1. Pull the horizontal beam lock out to release the beam and pivot the

beam to the vertical position.

2. To lock the beam in the vertical position, pull out on the vertical

beam lock and rotate it to secure the beam. See Figure 4-1.

3. Stand in front of the unit to operate the control handle and to

stabilize the log. See Figure 4-3.

10

Page 11

OPERATION

Horizontal Position

1. Pull the vertical beam lock out and rotate it down. See Figure 4-1.

Pivot beam to the horizontal position. The beam will lock automatically in horizontal position.

2. Stand behind the reservoir tank to operate control handle and to

stabilize the log.

Operating Tips

Always:

1. Use clean fluid and check fluid level regularly.

2. Use an approved hydraulic fluid. Approved fluids include Dexron®

III / Mercon® III automatic transmission fluid, a 10 Weight AW

hydraulic oil or Pro-Mix™ AW-32 Hydraulic Oil.

3. Use a filter (clean or replace regularly).

4. Use a breather cap on fluid reservoir.

5. Make sure pump is mounted and aligned properly.

6. Use a flexible “spider” type coupling between engine and pump

drive shafts.

7. Keep hoses clear and unblocked.

8. Bleed air out of hoses before operating.

9. Flush and clean hydraulic system before restarting after servicing.

10. Use “pipe dope” on all hydraulic fittings.

11. Allow time for warm-up before splitting wood.

12. Prime the pump before initial start-up by turning over the engine

with spark plug disconnected.

13. Split wood along the grain (lengthwise) only.

Never:

1. Use when fluid is below 20° F or above 150° F.

2. Use a solid engine /pump coupling.

3. Operate through relief valve for long.

4. Attempt to adjust unloading or relief valve settings without pressure

gauges.

5. Operate with air in hydraulic system.

6. Use teflon tape on hydraulic fittings.

7. Attempt to cut wood across the grain.

8. Attempt to remove partially split wood from the wedge with your

hands. Fully retract wedge to dislodge wood with log dislodger.

Figure 4-4

Transporting the Log Splitter

IMPORTANT: Always turn fuel valve to OFF position before transporting the log splitter.

1. Lower the beam to its horizontal position. Make certain the beam is

locked securely with the horizontal beam lock.

2. Remove spring clip and clevis pin from jack stand.

3. Support the tongue and pivot the jack stand up against the tongue.

See Figure 4-4.

4. Secure with the spring clip and clevis pin previously removed. See

Figure 4-4.

5. Attach coupler hitch to a class I or higher 2” ball on a towing

vehicle; latch securely.

If coupler hitch does not fit on ball: Turn adjustment nut one

a.

turn counter-clockwise.

b.

If coupler hitch is too loose on ball: Turn adjustment nut one

turn clockwise.

6. Connect the safety chains to the towing vehicle.

7. Plug in the tail lights, if so equipped, to the tail light connector on

the tow vehicle.

WARNING: Do not tow faster than 45mph and check

local, state, and federal requirements before towing

on any public road.

NOTE: Use caution when backing up. It is recommended to use a

spotter outside the vehicle.

11

Page 12

SERVICE & ADJUSTMENTS

Gib Adjustment

Periodically remove and replace the “gibs” (spacers) between the

wedge assembly and the back plate.

NOTE: The gibs may be rotated and/or turned over for even wear.

Adjustment

Bolt

Gib

Jam Nut

Lock Nut

Figure 5-1

WARNING: Do not at any time make any adjustments without first stopping engine, disconnecting

spark plug wire, and grounding it against the

engine. Always wear safety glasses during operation or while performing any adjustments or repairs.

Wedge Assembly Adjustment

As normal wear occurs and there is excessive “play” between the

wedge and beam, adjust the bolts on the side of the wedge assembly

to eliminate excess space between the wedge and the beam.

1. Loosen the jam nuts on the two adjustment bolts on the side of the

wedge. See Figure 5-1.

2. Turn the adjustment bolts in until snug and then back them off

slowly (approximately 1.5 turns) until the wedge assembly will slide

on the beam.

3. Re-tighten the jam nuts securely against the side of the wedge to

secure the adjustment bolts in this position.

1. Loosen the lock nuts under each back plate and slide the gibs out.

See Figure 5-1.

2. Turn or replace the gibs.

3. Reassemble the back plate and secure with the lock nuts.

4. Readjust the bolts on the side of the wedge assembly.

Hose Clamps

• Check, before each use, if hose clamps on the suction hose

(attached to the side of the pump) are tight. Check the hose clamps

on the return hose at least once a season.

Flexible Pump Coupler

The flexible pump coupler is a nylon “spider” insert, located between

the pump and the engine shaft. Over time, the coupler will harden and

deteriorate.

Replace the coupler if you detect vibration or noise coming from the

area between the engine and the pump. If the coupler fails completely,

you will experience a loss of power.

IMPORTANT: Never hit the engine shaft in any manner, as a blow will

cause permanent damage to the engine.

12

Page 13

SERVICE & ADJUSTMENTS

1. Remove three nuts that secure the pump to the coupling shield.

Two nuts are at the bottom corners and one is in the top center.

See Figure 5-2.

2. Remove the pump.

3. Rotate the engine by slowly pulling starter handle until engine

coupling half set screw is visible. Loosen set screw using allen

wrench and slide coupling half off engine shaft.

4. Loosen set screw on pump coupling half and remove coupling half.

5. Slide new engine coupling half onto the engine shaft until the end of

the shaft is flush with the inner portion of the coupling half. (There

must be space between the end of the engine support bracket and

coupling half). Tighten set screw.

6. Install pump coupling half and key on pump shaft. Rotate coupling

half until set screw faces opening in shield. Do not tighten set

screw.

7. Install nylon “spider” onto engine coupling half.

8. Align pump coupling half with nylon “spider” by rotating engine

using starter handle. Slide coupling half into place while guiding

three mounting bolts through holes in pump support bracket.

9. Secure with nuts removed earlier.

10. Set.010” to.060” clearance/gap between the nylon “spider” and

the engine coupling half by sliding a feeler gauge or matchbook

cover between the nylon “spider” and the engine coupling half and

moving pump coupling half as needed. Secure pump coupling half

with set screw. See Figure 5-2.

NOTE: Make certain proper clearance/gap is obtained before tightening set screw.

Set Screw

Side View-Coupler

.0600

.0100

Figure 5-2

Tires

See sidewall of tire for recommended pressure. Under any circumstances do not exceed manufacturer’s recommended psi. Maintain

equal pressure on all tires.

WARNING: Excessive pressure when seating beads

may cause tire /rim assembly to burst with force

sufficient to cause serious injury. Refer to sidewall

of tire for recommended pressure.

13

Page 14

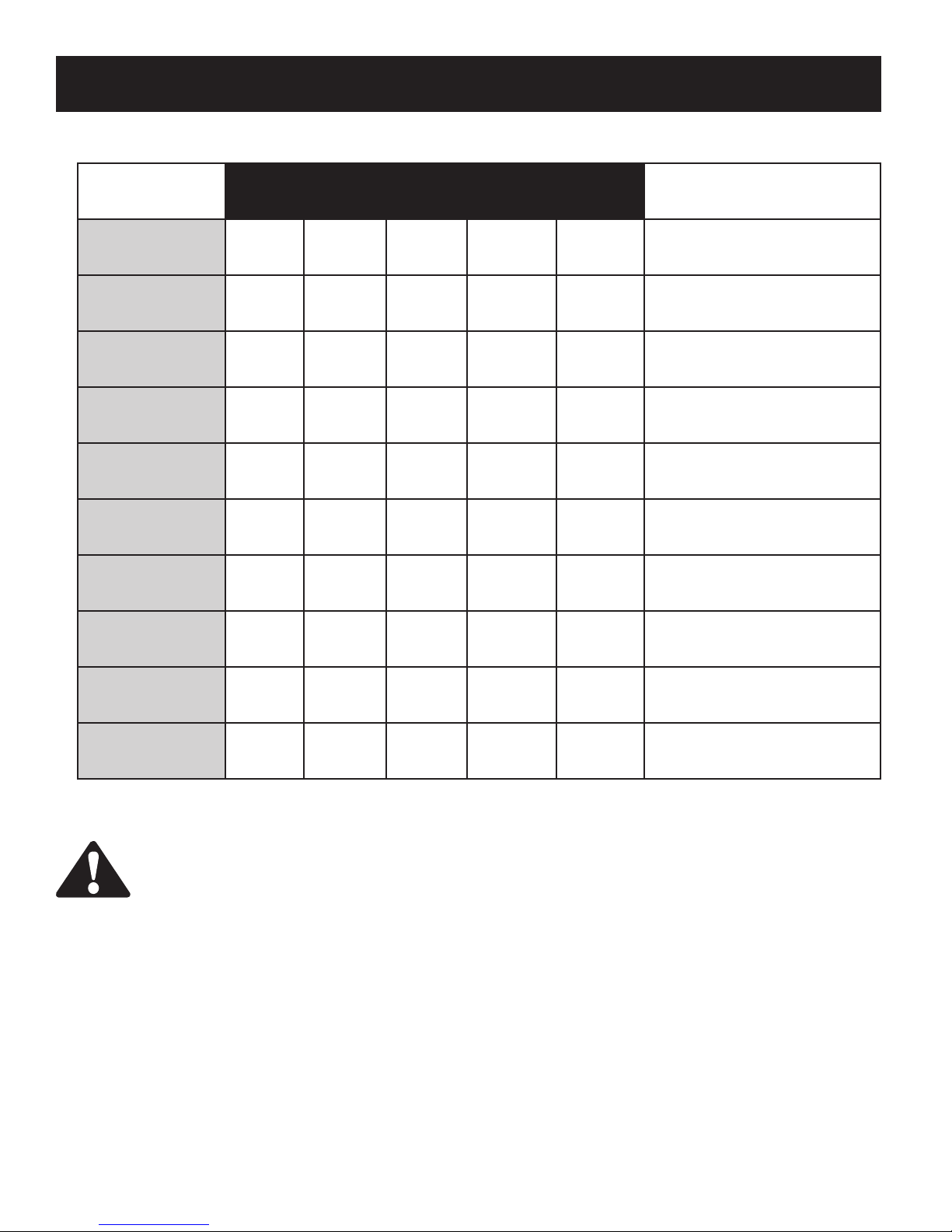

MAINTENANCE

Maintenance Schedule

TASKS

Lubricate Beam &

Wedge

Change Hydraulic

Fluid

Change Hydraulic

Filter

Clean Reservoir

Screen

Check Reservoir

Fluid

Check Engine Oil

Change Engine Oil

Service Air Cleaner

Before

Each Use

First 5

Hours

Every 25

Hours

Every 50

Hours

Every 100

Hours

SERVICE DATES

Service Spark Plug

Clean Engine

WARNING: Do not at any time make any adjustments without first stopping engine, disconnecting

spark plug wire, and grounding it against the

engine. Always wear safety glasses during operation or while performing any adjustments or repairs.

Figure 5-1

General Recommendations

1. Always observe safety rules when performing any maintenance.

2. The warranty on this log splitter does not cover items that have

been subjected to operator abuse or negligence. To receive full

value from the warranty, operator must maintain the equipment as

instructed in this manual.

3. Some adjustments will need to be made periodically to maintain

your equipment properly.

4. Follow the maintenance schedule (Figure 5-1).

5. Periodically check all fasteners and make sure they are tight.

14

Page 15

MAINTENANCE

Hydraulic Fluid and Inlet Filter

• Check the hydraulic fluid level in the log splitter reservoir tank

before each use. Maintain fluid level within the range specified on

the dipstick at all times.

• Change the hydraulic fluid in the reservoir every 100 hours of

operation. Follow the steps below:

1. Disconnect the suction hose from the bottom of the reservoir tank.

2. Carefully unthread the inlet filter and clean it with penetrating oil.

See Figure 5-2.

3. Allow the fluid to drain into a suitable container.

4. Reinsert the filter and refill the reservoir with three gallons of

oil. Approved fluids include Dexron® III / Mercon® III automatic

transmission fluid, a 10 Weight AW hydraulic oil or Pro-Mix™

AW-32 Hydraulic Oil.

• Maintain fluid level within the range specified on the dipstick at all

times.

NOTE: Always dispose of used hydraulic fluid and engine oil at

approved recycling centers only.

• Contaminants in fluid may damage the hydraulic components.

Flushing the reservoir tank and hoses with kerosene whenever

service is performed on the tank, hydraulic pump or valve is

recommended. Any repair to the hydraulic components should be

performed by a Sears Service Center.

Figure 5-2

Engine

Check Engine Oil

1. Stop engine and wait several minutes before checking oil level.

2. Remove oil fill dipstick.

3. Check oil level on dipstick. With engine on level ground, the oil

must be to FULL mark on dipstick.

4. Replace dipstick and tighten.

WARNING: Use extreme caution when working with

kerosene. It is an extremely flammable fluid.

Hydraulic Filter

• Change the hydraulic filter every 50 hours of operation. Use only a

10 micron hydraulic filter. Order part number 723-0405.

Beam and Splitting Wedge

• Lubricate both sides of the beam (where it comes into contact with

the splitting wedge), before each use, with engine oil. The wedge

plate on the log splitter is designed so the gibs on the side of the

wedge plate can be removed and rotated and/or turned over for

even wear.

• Make certain to readjust the adjustment bolts so wedge moves

freely, but no excess space exists between the wedge plate and the

beam.

Changing Engine Oil

Only use high quality detergent oil rated with API service classification

SF, SG, or SH. Select the oil’s SAE viscosity grade according to the

expected operating temperature. Follow the chart below:

Colder

5W30

SAE 30

Warmer

Oil Viscosity Chart

15

Page 16

MAINTENANCE

Service cartridge every 25 operating hours or every season. Service

cartridge more often under dusty conditions.

2

1

3

To Service Air Filter

1. Loosen air cleaner cover screw, but do not remove screw from

cover. Swing cover down to remove from hinge.

2. Inspect filter for discoloration or dirt accumulation. If either is

present, proceed as follows:

a. Clean inside of body and cover thoroughly and remove cartridge.

b. Reassemble new cartridge in the body. Swing cover down and

tighten the screw loosened earlier.

1. .030 (.76 mm) Gap

2. Electrodes

3. Porcelain

Figure 5-3

NOTE: Although multi-viscosity oils (5W30, 10W30, etc.) improve

starting in cold weather, they will result in increased oil consumption

when used above 32°F. Check your engine oil level more frequently to

avoid possible engine damage from running low on oil.

Change engine oil after the first five hours of operation, and every 50

hours thereafter. Change oil every 25 hours of operation if the engine

is operated under heavy load or in high ambient temperatures.

To Drain Oil

Drain oil while engine is warm. Follow the instructions given below.

1. To drain the gas tank, start the engine and let it run until the fuel

line and carburetor are empty.

2. Remove drain plug on the side of the engine and drain oil into a

suitable container.

3. When engine is drained of all oil, replace drain plug and refill with

approximately 20 oz. of fresh oil. Refer to Gas And Oil Fill-up in

OPERATION section.

Service Air Cleaner

The air cleaner prevents damaging dirt, dust, etc., from entering the

carburetor and being forced into the engine and is important to engine

life and performance.

Temperature of muffler and nearby areas may

exceed 150˚ F(65˚C). Avoid these areas.

Service Spark Plug

• Clean the spark plug and reset the gap to.030” at least once a

season or every 50 hours of operation.

• Clean area around spark plug. Remove and inspect spark plug.

• Replace if electrodes are pitted, burned or the porcelain is cracked.

• Check electrode gap with wire feeler gauge and reset gap to.030

inches. See Figure 5-3.

NOTE: Do not sand spark plug. Spark plug should be cleaned with a

wire brush and a commercial solvent.

Clean Engine

• Clean engine periodically, by removing dirt and debris with a cloth

or brush.

NOTE: Cleaning with a forceful spray of water is not recommended as

water could contaminate the fuel system.

• To ensure smooth operation of the engine, keep the governor

linkage, springs, and controls free of debris.

• Every 100 hours of operation, remove combustion deposits from

top of cylinder, head, top of piston, and around valves.

WARNING: Never run the engine without an air

cleaner completely assembled.

16

Page 17

OFF-SEASON STORAGE

Prepare your log splitter for storage at the end of the season or if the

log splitter will not be used for 30 days or more.

WARNING: Never store machine with fuel in the

fuel tank inside of building where fumes may reach

an open flame or spark or where ignition sources

are present such as hot water and space heaters,

furnaces, clothes dyers, stoves, electric motors, etc.

NOTE: Yearly check-up by your local Sears service center is a good

way to ensure your log splitter will provide maximum performance next

season.

Log Splitter

1. Clean the log splitter thoroughly.

2. Wipe unit with an oiled rag to prevent rust, especially on the wedge

and the beam.

Engine

IMPORTANT: It is important to prevent gum deposits from forming in

essential fuel system parts such as carburetor, fuel filter, fuel hose,

or tank during storage. Also, alcohol blended fuels (called gasohol or

using ethanol or methanol) can attract moisture which leads to separation and formation of acids during storage. Acidic gas can damage the

fuel system of an engine while in storage.

1. Drain the fuel tank. Always drain fuel into approved container

outdoors away from open flame. Be sure the engine is cool. Do not

smoke while handling the fuel.

2. Start the engine and let it run until the fuel lines and carburetor are

empty.

IMPORTANT: Never use engine or carburetor cleaner products in the

fuel tank or permanent damage may occur. Use fresh fuel next season.

3. Remove spark plug, pour approximately 1/2 oz. of engine oil into

cylinder and crank slowly to distribute oil.

4. Replace spark plug.

NOTE: Fuel stabilizer is an acceptable alternative in minimizing for

formation of fuel gum deposits during storage.

Please follow the instructions below for storing your log splitter with

fuel and stabilizer in the engine:

1. Add stabilizer to gasoline in fuel tank or storage container. Always

follow the mix ratio found on stabilizer container.

2. Run engine at least 10 minutes after adding stabilizer to allow the

stabilizer to reach the carburetor.

IMPORTANT: Do not drain the gas tank and carburetor if using fuel

stabilizer. Drain all the oil from the crankcase (this should be done

after the engine has been operated and is still warm) and refill the

crankcase with fresh oil.

Other

• Do not store gasoline from one season to another.

• Replace your gasoline can if it starts to rust.

• Store unit in a clean, dry area. Do not store next to corrosive

materials, such as fertilizer.

• Wipe equipment with an oiled rag to prevent rust.

17

Page 18

Engine fails to start

TROUBLESHOOTING

CauseProblem Remedy

1. Spark plug wire disconnected.

2. Fuel tank empty or stale fuel.

3. Choke lever not in CHOKE position.

4. Faulty spark plug.

5. Blocked fuel line.

6. Dirty air cleaner.

1. Connect wire to spark plug.

2. Fill tank with clean, fresh gasoline.

3. Move choke to CHOKE position.

4. Service spark plug following

instructions in the maintenance

section.

5. Clean fuel line.

6. Service air cleaner following

instructions in the maintenance

section.

Engine runs erratic

Engine Overheats

Cylinder rod will not

move

1. Unit running with CHOKE applied, if so

equipped.

2. Spark plug wire loose.

3. Blocked fuel line or stale fuel.

4. Water or dirt in fuel system.

5. Dirty air cleaner.

6. Carburetor not adjusted properly.

1. Engine oil level low.

2. Dirty air cleaner.

3. Carburetor not adjusted properly.

1. Broken drive shaft.

2. Shipping plugs left in hydraulic hoses.

3. Set screws in coupling not adjusted

properly.

4. Loose shaft coupling.

5. Gear sections damaged.

6. Damaged relief valve.

7. Hydraulic lines blocked.

8. Incorrect oil level.

9. Damaged or blocked directional valve.

1. Move choke lever to RUN position.

2. Connect and tighten spark

plug wire.

3. Clean fuel line; fill tank with clean,

fresh (less than 30 days old)

gasoline.

4. Drain fuel tank. Refill with

fresh fuel.

5. Clean or replace air cleaner.

6. Contact Sears service center.

1. Fill crankcase with proper oil.

2. Service air cleaner following

instructions in the maintenance

section.

3. Contact Sears service center.

1. Return unit to Sears service center.

2. Disconnect hydraulic hoses,

remove shipping plugs, reconnect

hoses.

3. See operator’s manual for correct

adjustment.

4. Correct engine/pump alignment as

necessary.

5. Return unit to Sears service center.

6. Return unit to Sears service center.

7. Flush and clean hydraulic system.

8. Check oil level. Refill if necessary.

9. Return unit to Sears service center.

NOTE: This section addresses minor service issues. For further details, contact Sears service information line by calling

1-800-4-MY-HOME.

18

Page 19

Slow cylinder shaft

speed while extending

and retracting.

Leaking Cylinder

TROUBLESHOOTING

CauseProblem Remedy

1. Gear sections damaged.

2. Excessive pump inlet vacuum.

3. Slow engine speed.

4. Damaged relief valve.

5. Incorrect oil level.

6. Contaminated oil.

7. Directional valve leaking internally.

8. Internally damaged cylinder.

1. Broken seals.

2. Scored cylinder.

1. Return unit to Sears service center.

2. Make certain pump inlet hoses are

clear and unblocked. Use short,

large diameter inlet hoses.

3. Return unit to Sears service center.

4. Return unit to Sears service center.

5. Check oil level. Refill if necessary.

6. Drain oil, clean reservoir, and refill.

7. Return unit to Sears service center.

8. Return unit to Sears service center.

1. Return unit to Sears service center.

2. Return unit to Sears service center.

Engine runs but wood

will not split or wood

splits too slowly

Engine stalls during

splitting

Engine will not turn or

stalls under low load

conditions

Leaking pump shaft

seal

Will not split logs

1. Small gear section damaged.

2. Pump check valve leaking.

3. Excessive pump inlet vacuum.

4. Incorrect oil level.

5. Contaminated oil.

6. Directional valve leaking internally.

7. Overloaded cylinder.

8. Internally damaged cylinder.

1. Low horsepower/weak engine.

2. Overloaded cylinder.

1. Engine/pump misalignment.

2. Frozen or seized pump.

3. Low horsepower/weak engine.

4. Hydraulic lines blocked.

5. Blocked directional valve.

1. Broken drive shaft.

2. Engine/pump misalignment.

3. Gear sections damaged.

4. Poorly positioned shaft seal.

5. Plugged oil breather.

1. Reservoir fluid level low.

1. Return unit to Sears service center.

2. Return unit to Sears service center.

3. Make certain pump inlet hoses are

clear and unblocked. Use short,

large diameter inlet hoses.

4. Check oil level. Refill if necessary.

5. Drain oil, clean reservoir, and refill.

6. Return unit to Sears service center.

7. Do not attempt to split wood

against the grain.

8. Return unit to Sears service center.

1. Return unit to Sears service center.

2. Do not attempt to split wood

against the grain. If engine stalls

repeatedly, contact Sears service

center.

1. Correct alignment as necessary.

2. Return unit to Sears service center.

3. Return unit to Sears service center.

4. Flush and clean hydraulic system.

5. Return unit to Sears service center.

1. Return unit to Sears service center.

2. Correct alignment as necessary.

3. Return unit to Sears service center.

4. Return unit to Sears service center.

5. Make certain reservoir is properly

vented.

1. Refill with Dexron III automatic

transmission fluid.

NOTE: This section addresses minor service issues. For further details, contact Sears service information line by calling

1-800-4-MY-HOME.

19

Page 20

PARTS LIST

61

62

64

44

18

65

67

44

19

41

70

69

41

65

55

1

41

71

12

44

15

40

6

75

5

74

68

25

76

22

41

63

23

8

32

23

31

24

42

39

36

16

7

9

34

2

3

4

11

13

20

10

56

58

57

41

17

66

29

30

27

28

26

72

33

59

72

59

50

48

73

45

18

77

A

20

46

47

48

49

51

48

23

61

43

14

35

A

23

54

53

52

21

37

38

Page 21

Craftsman 6.5 H.P. Log Splitter Model 247.77466.1

Ref.

No.

1. 718-0769A Hydraulic Cylinder

2. 727-04166 Hydraulic Tube

3. 710-1018 Hex Cap Screw 1/2-20 x 2.75

4. 737-0192 90 Degree Solid Adapter

5. 718-0481A Control Valve

6. 737-0153 Return Elbow

7. 737-0238 Nipple Pipe 1/2-14

8. 710-1806 Hex Cap Screw 1/2-13 x 3.25

9. 719-0550A Wedge Assembly

10. 712-3058 Hex Lock Nut, 1/2-20

11. 712-0711 Hex Jam Nut 3/8-24

12. 710-0459A Hex Cap Screw 3/ 8-24 x 1.5

13. 781-0351 Adjustable Gib

14. 736-0116 Flat Washer.635 x.93 x.06

15. 712-3022 Hex Lock Nut 1/2-13

16. 681-04071 Beam Assembly

17. 710-3056 Hex Screw, 5/16-18 x 3.25

18. 710-0654A Hex Washer Screw 3/ 8-16 x 1.0

19. 781-1048A Dislodger Bracket

20. 781-0790 Back Plate

21. 737-04093 Inlet Filter

22. 727-0443 Return Hose 3/4” ID x 44” Lg.

23. 726-0132 Hose Clamp 5/8”

24. 737-0316 Filter Housing

25. 723-0405 Oil Filter

26. 734-0873 Hub Cap

27. 714-0162 Cotter Pin

28. 712-0359 Slotted Nut 3/4-16

29. 634-0186 Wheel Assembly

30. 736-0351 Flat Washer.760 ID x.500 OD

31. 737-0312 Adapter 3 /4-14

32. 781-0526A Hose Guard

33. 737-0348A Vented Dipstick

34. 711-1587 Clevis Pin

35. 781-0690 Lock Rod

36. 714-0470 Cotter Pin

37. 726-0214 Push Cap

38. 732-0583 Compression Spring

39. 781-04180 Log Tray Bracket

Part No. Description

Ref.

No.

40. 710-0650 TT Screw, 5/16-18 x.875

41. 712-04065 Flange Lock Nut, 3/8-16

42. 781-04129 Log Tray

43. 681-04040 Frame Assembly

44. 710-0521 Hex Bolt 3/8-16 x 3”

45. 719-0353 Coupling Shield

46. 714-0122 Square Key 3/16” x.75

47. 718-04145 Flexible Coupling

48. 712-04063 Flange Lock Nut, 5/16-18

49. 781-0097 Rear Coupling Support Bracket

50. 781-1024 Fender Mounting Bracket

51. 727-04130 Hose

52. 718-04127 Gear Pump

53. 737-0329 45 Degree Elbow Fitting

54. 727-0502 High Pressure Hydraulic Hose

55. 781-0788 Tongue Assembly

56. 747-1261 Latch Rod

57. 781-1045 Latch

58. 732-3127 Compression Spring

59. 736-0371 Flat Washer

60. 781-0538A† Hose Guard

61. 710-3085 Hex Cap Screw, 3/8-16 x 3.50

62. 736-0185 Flat Washer,.375 x.738 x.063

63. 747-04539 Hydraulic Valve Control

64. 681-04030 Hitch Coupling Assembly

65. 713-0433A Chain

66. 731-2499A Fender

67. 711-0813 Clevis Pin

68. 720-04088 Grip

69. 732-0194 Spring Pin

70. 781-0789 Jack Stand

71. 715-0120 Spiral Pin

72. 710-0650 TT Screw, 5/16-18 x 0.875”

73. 710-0602 TT Screw, 5/16-18 x 1.00

74. 711-04585 Clevis Pin

75. 713-04036 Valve Handle Link

76. 714-0111 Cotter Pin

77. 710-0376 Hex Screw, 5/16-18 x 1.00

Part No. Description

† Not Shown

21

Page 22

PARTS LIST

1019 LABEL KIT

54

50

51

383

337

635

5

584

585

7

684

869

870

287

1

2

3

871

718

8

45

847

523

842

525

524

11

25

26

13

227

562

505

27

34

35

33

868

36

28

29

40

40

27

45

32A

15

32

24

4

12

16

146

741

9

1330 REPAIR MANUAL

1058 OWNER’S MANUAL

306

10

307

46

43

356

22

20

22

Page 23

Sears Craftsman 6.5 H.P. Engine Model No. 123K02

For Log Splitter Model 247.77466.1

832

425

836

222

968

300

445

81

843

613

443

365

966

976

125

163

668

188

159

615

404

970

529

616

692

109

633A

977 CARBURETOR

GASKET SET

163

617

121 CARBURETOR OVERHAUL KIT

134

137

137

617

633

633

276

633A

276

633A

163

104

127

134

133

117

975

333

851

137

276

23

97

163

633

108

104

127

130

95

617

276

334

209

202

Page 24

PARTS LIST

358 ENGINE GASKET SET

3

12

20

842

163

617

524

585

668

7

51

48

1329 REPLACEMENT ENGINE

78

37

304

305

1059

670

190

608

347

497

627

930

332

324

363

23

1005

65

972

957

18

7

601

1036 EMISSIONS LABEL

55

24

1211

1210

592

459

456

689

59

58

7

60

Page 25

Sears Craftsman 6.5 H.P. Engine Model No. 123K02

For Log Splitter Model 247.77466.1

Ref. No. Part No. Description

1. 697322 Cylinder Assembly

2. 399269 Kit-Bushing/Seal

3. 299819† Seal-Oil ( Magneto Side)

4. 493279 Sump-Engine

5. 691160 Head-Cylinder

7. 692249† Gasket-Cylinder Head

8. 695250 Breather Assembly

9. 699472 Gasket-Breather

10. 691125 Screw (Breather Assembly)

11. 691260 Tube-Breather

12. 692232† Gasket-Crankcase

13. 690912 Screw (Cylinder Head)

15. 691680 Plug-Oil Drain

16. 691455 Crankshaft

20. 399781† Seal-Oil (PTO Side)

22. 691092 Screw (Engine Sump)

23. 691992 Flywheel

24. 222698 Key-Flywheel

25. 697339 Piston Assembly (Standard)

697341 Piston Assembly (.020” Oversize)

26. 499425 Ring Set-Piston (Standard)

499427 Ring Set-Piston (.020” Oversize)

27. 691866 Lock-Piston Pin

28. 499423 Pin-Piston

29. 499424 Rod-Connecting

32. 691664 Screw (Connecting Rod)

32A. 695759 Screw (Connecting Rod)

33. 262651 Valve-Exhaust

34. 262652 Valve-Intake

35. 691270 Spring-Valve (Intake)

36. 691270 Spring-Valve (Exhaust)

37. 694086 Guard-Flywheel

40. 692194 Retainer-Valve

43. 691997 Slinger-Governor/Oil

45. 690548 Tappet-Valve

46. 691449 Camshaft

48. 498828 Short Block

50. 497465 Manifold-Intake

51. 272199† Gasket-Intake

54. 691650 Screw (Intake Manifold)

55. 691421 Housing-Rewind Starter

Ref. No. Part No. Description

58. 697316 Rope-Starter (Cut to Required

60. 281434 Grip-Starter Rope

65. 690837 Screw (Rewind Starter)

78. 691108 Screw (Flywheel Guard)

81. 691740 Lock-Muffler Screw

95. 691636 Screw (Throttle Valve)

97. 493267 Shaft-Throttle

104. 691242†† Pin-Float Hinge

108. 691182 Valve-Choke

109. 498593 Shaft-Choke

117. 498978 Jet-Main (Standard)

121. 498260 Kit-Carburetor Overhaul

125. 499059 Carburetor

127. 694468†† Plug-Welch

130. 691203 Valve-Throttle

133. 398187 Float-Carburetor

134. 398188†† Valve-Needle/Seat

137. 693981††* Gasket-Float Bowl

146. 690979 Key-Timing

159. 691753 Bracket-Air Cleaner Primer

163. 272653†*†† Gasket-Air Cleaner

187. 691050 Line-Fuel (Cut to Required Length)

188. 693399 Screw (Control Bracket)

190. 690940 Screw (Fuel Tank)

202. 691829 Link-Mechanical Governor

209. 691864 Spring-Governor

222. 692982 Bracket-Control

227. 690783 Control Lever-Governor

276. 271716††* Sealing Washer

287. 690940 Screw (Dipstick Tube)

300. 692038 Muffler

304. 493294 Housing-Blower

305. 691108 Screw (Blower Housing)

306. 690450 Shield-Cylinder

307. 690345 Screw (Cylinder Shield)

324. 695161 Cup/ Screen Assembly

332. 690662 Nut (Flywheel)

333. 802574 Armature-Magneto

334. 691061 Screw (Armature Magneto)

337. 802592 Plug-Spark

Length)

25

Page 26

PARTS LIST

Ref. No. Part No. Description

347. 691396 Switch-Rocker

356. 693010 Wire-Stop

358. 497316 Engine Gasket Set

363. 19069 Flywheel Puller

365. 692524 Screw (Carburetor)

383. 89838 Wrench-Spark Plug

404. 690272 Washer (Governor Crank)

425. 690670 Screw (Air Cleaner Cover)

443. 692523 Screw (Air Cleaner Primer Base)

445. 491588 Filter-Air Cleaner Cartridge

456. 692299 Plate-Pawl Friction

459. 281505 Pawl-Ratchet

497. 690664 Screw (Stopswitch)

505. 691251 Nut (Governor Control Lever)

523. 495264 Dipstick

524. 692296† Seal-Dipstick Tube

525. 495265 Tube-Dipstick

529. 691923 Grommet

562. 92613 Bolt (Governor Control Lever)

584. 697734 Cover-Breather Passage

585. 691879† Gasket-Breather Passage

592. 690800 Nut (Rewind Starter)

597. 691696 Screw (Pawl Friction Plate)

601. 95162 Clamp-Hose

608. 497680 Starter-Rewind

613. 691340 Screw (Muffler)

615. 690340 Retainer-Governor Shaft

616. 698801 Crank-Governor

617. 270344†*†† Seal-O Ring (Intake Manifold)

627. 692872 Bracket-Stopswitch

633. 691321†† * Seal-Choke /Throttle Shaft

633A. 693867†† * Seal-Choke/ Throttle Shaft

635. 66538 Boot-Spark Plug

668. 493823 Spacer

670. 692294 Spacer-Fuel Tank

Ref. No. Part No. Description

684. 690345 Screw (Breather Passage Cover)

689. 691855 Spring-Friction

692. 690579 Spring-Detent

718. 690959 Pin-Locating

741. 691830 Gear-Timing

832. 499034 Guard-Muffler

836. 690664 Screw (Muffler Guard)

842. 691031† Seal-O Ring ( Dipstick Tube)

843. 691895 Sleeve-Lever

847. 692017 Assembly-Dipstick /Tube

851. 493880 Terminal-Spark Plug

868. 697338 Seal-Valve

869. 691155 Seat-Valve (Intake)

870. 690380 Seat-Valve (Exhaust)

871. 262001 Bushing-Guide (Exhaust)

63709 Bushing-Guide (Intake)

930. 691919 Guard-Rewind

957. 397974 Cap-Fuel Tank

966. 496116 Base-Air Cleaner Primer

968. 692298 Cover-Air Cleaner

970. 691669 Screw (Air Cleaner Primer Bracket)

972. 695887 Tank-Fuel

975. 493640 Bowl-Float

976. 694395 Primer-Carburetor

977. 498261 Set-Carburetor Gasket

1005. 691346 Fan-Flywheel

1019. 494256 Kit-Label

1036. 697457 Label-Emission

1058. MS 5244 Owner’s Manual

1059. 692311 Kit-Screw/Washer

1210. 498144 Assembly-Pulley/Spring (Pulley)

1211. 498144 Assembly-Pulley/Spring (Spring)

1329. 123K02-0018-E1Replacement Engine (Transfer

Governor Spring and Flywheel)

1330. 272147 Repair Manual

†Included in Engine Gasket Set, Key. No. 358

††Included in Carburetor Overhaul Kit, Key. No. 121

*Included in Carburetor Gasket Set, Key. No. 977

26

Page 27

LABELS

(/2):/.4!,

(ORIZONTAL0OSITION,OCK

6%24)#!,

/0%2!4/2g3).3425#4)/.3

0LACELOGSPLITTERONFLATDRYSOLIDGROUND

,OCKINEITHERTHEHORIZONTALORVERTICALPOSITION

3ETTHEENGINETHROTTLEATMAXIMUMSPEED

0LACETHELOGAGAINSTTHEENDPLATE

3TABILIZETHELOGWHENNEEDEDONITSSIDESNEVERONTHE

ENDBETWEENTHELOGANDSPLITTINGWEDGE

/NLYONEADULTSHOULDSTABILIZETHELOGANDOPERATETHE

CONTROL

-OVETHECONTROLHANDLEINTHESPLITTINGDIRECTION

2ELEASETHECONTROLHANDLETOSTOPTHEWEDGEMOVEMENT

$!.'%2

6ERTICAL0OSITION,OCK

2EADOPERATORgSMANUAL

+EEPHANDSAWAYFROMWEDGEENDPLATEPARTLYSPLITWOODANDMOVINGPARTS

(OLDLOGONITSSIDESNOTONENDS

/NLYONEOPERATORPERMITTED!DULTWHOLOADSANDHOLDSLOGMUSTBETHEONE

WHOOPERATESCONTROLHANDLE+EEPBYSTANDERSHELPERSANDCHILDRENATLEAST

FEETAWAY

.EVERCHECKFORLEAKSWITHYOURHANDS(IGHPRESSUREFLUIDCANESCAPETHROUGHA

PINHOLELEAKANDCAUSESERIOUSINJURYBYPUNCTURINGTHESKINANDCAUSINGBLOOD

POISONING

/PERATETHELOGSPLITTERONLEVELSURFACE

,OCKITINVERTICALORHORIZONTALPOSITION

7EARPROTECTIVEWORKGLOVESSAFETYSHOESANDSAFETYGLASSESWATCHYOURFOOTING

.EVEROPERATEUNDERTHEINFLUENCEOFALCOHOLORDRUGS

$ONOTREFUELAHOTORRUNNINGENGINE

3 !#

3

3

)

3

$

+%%0(!.$3AND&%%4!7!9

7! 2. ). '

0%23/.34!"),):).',/'/.30,)44%2

-534"%3!-%0%23/.7(//0%2!4%3

#/.42/,6!,6%

+%%0(!.$3!7!9&2/-7%$'%

!.$-/6).'0!243

#/.42/,

6!,6%

2%6%23%

.%542!,

&/27!2$

,/'

$)3,/$'%2

2ETRACTWEDGE

LODGEDWOODWILLBE

AUTOMATICALLYREMOVED

3 !#

27

Page 28

(This page applicable in the U.S.A. and Canada only.)

Sears, Roebuck and Co., U.S.A. (Sears), the California Air Resources Board (CARB)

and the United States Environmental Protection Agency (U.S. EPA)

Emission Control System Warranty Statement (Owner’s Defect Warranty Rights and Obligations)

EMISSION CONTROL WARRANTY COVERAGE IS APPLICABLE TO CERTIFIED ENGINES PURCHASED IN CALIFORNIA IN 1995 AND THEREAFTER, WHICH ARE USED IN CALIFORNIA, AND TO CERTIFIED MODEL

YEAR 1997 AND LATER ENGINES WHICH ARE PURCHASED AND USED

ELSEWHERE IN THE UNITED STATES (AND AFTER JANUARY 1, 2001 IN

CANADA).

California and United States Emission Control Defects Warranty Statement

The California Air Resources Board (CARB), U.S. EPA and Sears are pleased

to explain the Emission Control System Warranty on your model year 2000 and

later small off-road engine (SORE). In California, new small off-road engines

must be designed, built and equipped to meet the State’s stringent anti-smog

standards. Elsewhere in the United States, new non-road, spark-ignition

engines certified for model year 1997 and later must meet similar standards set

forth by the U.S. EPA. Sears must warrant the emission control system on your

engine for the periods of time listed below, provided there has been no abuse,

neglect or improper maintenance of your small off-road engine. Your emission control system includes parts such as the carburetor, air cleaner, ignition

system, muffler and catalytic converter. Also included may be connectors and

other emission related assemblies. Where a warrantable condition exists, Sears

will repair your small off-road engine at no cost to you including diagnosis, parts

and labor.

Sears Emission Control Defects Warranty Coverage

Small off-road engines are warranted relative to emission control parts defects

for a period of one year, subject to provisions set forth below. If any covered

part on your engine is defective, the part will be repaired or replaced by Sears.

Owner’s Warranty Responsibilities

As the small off-road engine owner, you are responsible for the performance of

the required maintenance listed in your Operating and Maintenance Instructions. Sears recommends that you retain all your receipts covering maintenance

on your small off-road engine, but Sears cannot deny warranty solely for the

lack of receipts or for your failure to ensure the performance of all scheduled

maintenance. As the small off-road engine owner, you should however be

aware that Sears may deny you warranty coverage if your small off-road engine

or a part has failed due to abuse, neglect, improper maintenance or unap-

proved modifications. You are responsible for presenting your small off-road

engine to an Authorized Sears Service Dealer as soon as a problem exists. The

undisputed warranty repairs should be completed in a reasonable amount of

time, not to exceed 30 days.If you have any questions regarding your warranty

rights and responsibilities, you should contact a Sears Service Representative

at 1--800--469--4663. The emission warranty is a defects warranty. Defects are

judged on normal engine performance. The warranty is not related to an in-use

emission test.

Sears Emission Control Defects Warranty Provisions

The following are specific provisions relative to your Emission Control Defects Warranty Coverage. It is in addition to the Sears engine warranty for non-regulated

engines found in the Operating and Maintenance Instructions.

1. Warranted Parts

Coverage under this warranty extends only to the par ts listed below (the

emission control systems parts) to the extent these parts were present on

the engine purchased.

a. Fuel Metering System

• Cold start enrichment system

• Carburetor and internal parts

• Fuel Pump

b. Air Induction System

• Air cleaner

• Intake manifold

c. Ignition System

• Spark plug (s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

• Vacuum, temperature, position, time sensitive valves

and switches

• Connectors and assemblies

2. Length of Coverage

Sears warrants to the initial owner and each subsequent purchaser that

the Warranted Parts shall be free from defects in materials and workman-

ship which caused the failure of the Warranted Parts for a period of one

year from the date the engine is delivered to a retail purchaser.

In the USA and Canada, a 24 hour hot line, 1-800-469-4663, has a menu of pre-recorded messages offering you engine maintenance information.

3. No Charge

Repair or replacement of any Warranted Part will be performed at no

charge to the owner, including diagnostic labor which leads to the

determination that a Warranted Part is defective, if the diagnostic work is

performed at an Authorized Sears Service Dealer. For emissions warranty

service contact your nearest Authorized Sears Service Dealer as listed in

the “Yellow Pages” under “Engines, Gasoline,” “Gasoline Engines,” “Lawn

Mowers,” or similar category.

4. Claims and Coverage Exclusions

Warranty claims shall be filed in accordance with the provisions of the

Sears Engine Warranty Policy. Warranty coverage shall be excluded for

failures of Warranted Parts which are not original Sears parts or because

of abuse, neglect or improper maintenance as set forth in the Sears

Engine Warranty Policy. Sears is not liable to cover failures of Warranted

Parts caused by the use of add-on, non-original, or modified parts.

5. Maintenance

Any Warranted Part which is not scheduled for replacement as required

maintenance or which is scheduled only for regular inspection to the effect

of “repair or replace as necessary” shall be warranted as to defects for the

warranty period. Any Warranted Part which is scheduled for replacement

as required maintenance shall be warranted as to defects only for the

period of time up to the first scheduled replacement for that part. Any

replacement part that is equivalent in performance and durability may

be used in the per formance of any maintenance or repairs. The owner is

responsible for the performance of all required maintenance, as defined in

the Sears Operating and Maintenance Instructions.

6. Consequential Coverage

Coverage hereunder shall extend to the failure of any engine components

caused by the failure of any Warranted Part still under warranty.

28

Page 29

INDICE

Garantía ....................................................Page 29

Protección .................................................

Ensamble .................................................. Page

Funcionamiento ........................................Page 34

Servicio y ajustes ...................................... Page 38

Page 30

32

Mantenimiento .......................................... Page 40

Almacenamiento ....................................... Page 43

Gui De Localización de fallas ...................Page 44

Lista de piezas .......................................... Page 20

GARANTIA

Garantía limitada de la cortadora de troncos Craftsman

Sears reparará o reemplazará gratis toda pieza que se determine defectuosa en material o mano de obra, a partir de un (1) año de la fecha

de compra, si este equipo Craftsman se mantiene, lubrica y afina de acuerdo con las instrucciones en el manual del operador. El servicio de

garantía está disponible gratis devolviendo el equipo Craftsman al centro de servicio Sears más cercano. Esta disponible la garantía en el sitio

pero se aplica un cargo por viaje. Esta Garantía se aplica mientras este producto se encuentre en los Estados Unidos solamente.

Esta Garantía no cubre:

• Artículos consumibles que se desgastan durante el uso normal, tales como bujías, filtros, correas y filtros para aceite.

• Reemplazo o reparaciones de neumáticos causados por perforaciones de objetos externos tales como clavos, espinas, tocones o vidrio.

• Reparaciones necesarias causadas por abuso del operador, incluyendo, pero sin estar limitadas, a daños causados por objetos tales como

piedras o desechos metálicos, materiales de gran tamaño, objetos impactantes que doblan el bastidor o el cigüeñal, o velocidad excesiva del

motor.

• Reparaciones necesarias causadas por negligencia del operador, incluyendo, pero sin estar limitadas, a daños eléctricos o mecánicos causa

dos por almacenamiento inadecuado, falla en usar el grado y cantidad correctos de aceite de motor, o falla en mantener el equipo de acuerdo

con las instrucciones contenidas en el manual del operador.

• Limpieza o reparaciones del sistema de combustible del motor causados por el combustible que se determine estar contaminado u oxidado

(rancio). En general el combustible debe usarse dentro de los 30 días de su fecha de compra.

• Equipo usado para fines comerciales o de alquiler.

-

LLAMAR AL 1-800-4-MY-HOME PARA LOCALIZAR EL CENTRO DE SERVICIO SEARS MAS CERCANO O PARA PROGRAMAR EL SERVICIO.

La garantía le otorga ciertos derechos legales específicos y usted puede tener también otros derechos, que varían de estado a estado.

ESPECIFICATION DEL PRODUCTO

Caballos de fuerza 6.5 HP

Tipo del aceite de motor SAE 30

Cap. de aceite del motor 20 Onzas

Capacidad de combustible 1.5 Cuartos

Bujía (separación de .030”) Champion RJ-19LM

Líquido hidráulico Dexron III / 3.0 gal

Número de modelo....................................................

Número de serie........................................................

Fecha de compra......................................................

Para referencia futura registrar el número de serie y la

fecha de compra y guardar en un lugar seguro.

29

Page 30

PROTECCION

ADVERTENCIA

: Este símbolo indica importantes instrucciones de seguridad la cuales, si no se observan,

pueden poner en peligro la seguridad personal y/o la propiedad suya y de terceros. Lea y siga todas las

instrucciones en este manual antes de intentar operar esta máquina. El no cumplir con estas instrucciones

puede resultar en lesiones personales. Cuando vea este símbolo obedezca a su advertencia.

ADVERTENCIA: El escape del motor, algunos de sus integrantes, y ciertos componentes del vehículo

contienen o emiten substancias químicas conocidas al Estado de California como causantes de cáncer y

defectos de nacimiento u otras lesiones reproductoras.

PELIGRO: Esta máquina fue fabricada para operarse de acuerdo con las reglas para una operación

segura. Al igual que con cualquier tipo de equipo motorizado, el descuido o error por parte del operador

puede resultar en lesiones graves. Esta máquina es capaz de amputar manos y pies y despedir objetos.

La falla en observar las instrucciones siguientes de protección puede resultar en lesiones graves o la

muerte.

CAPACITACION

1. Leer, entender y seguir todas las instrucciones en la máquina y

en el manual(es) antes de operar. Familiarizarse completamente