Page 1

Operator’s Manual

4.5 Horse Power

YARD VACUUM

Model No. 247.770100

CAUTION: Before using

this product, read this

manual and follow all

Safety Rules and

Operating Instructions.

• Safety

ES

• Assembly

•Operation

• Maintenance

•Parts

•Español

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our Sears website: www.sears.com/craftsman

Printed in U.S.A.

ECO No. 002480

FORM NO.

770-10233E.fm

(8/00)

Page 2

TABLE OF CONTENTS

Content Page

Warranty 2

Safety 3

Assembly 5

Operation 7

Maintenance 10

Content Page

Service and Adjustments 12

Storage 14

Troubleshooting 15

Parts List 16

WARRANTY

Limited Warranty on Craftsman Yard Vac uum

For one (1) year from the date of purchase, if this Craftsman Equipment is maintained, lubricated, and tuned up

according to the instructions to the operator’s manual, Sears will repair or replace free of charge any parts found

to be defective in material or workmanship. Warranty service is available free of charge by returning Craftsman

equipment to your nearest Sears Service Center. In-home warranty service is available but a trip charge will

apply. This Warranty applies only while this product is in the United States.

This Warranty does not cover:

• Expendable items which become worn during normal use, such as spark plugs, air cleaners, belts, and oil

filters.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass.

• Repairs necessary because of operator abuse, including but not limited to, damage caused by objects, such

as stones or metal debris, oversized stock, impacting objects that bend the frame or crankshaft, or overspeeding the engine.

• Repairs necessary because of operator negligence, including but not limited to, electrical and mechanical

damage caused by improper storage, failure to use the proper grade and amount of engine oil, or failure to

maintain the equipment according to the instructions contained in the operator’s manual.

• Engine (fuel system) cleaning or r epairs caused by fuel determin e to be contaminated or oxidiz ed (stale). In

general, f uel sho uld be us ed within 30 days of its purchase date.

• Equipment used for commercial or rental purposes.

TO LOCATE THE NEAREST SEARS SERVICE CENTER OR TO SCHEDULE SERVICE, SIMPLY CONTACT

SEARS AT 1-80 0-4-M Y-HOME.

This warranty gives you specific legal rights and you may also have other rights, which vary from state to state.

PRODUCT SPECIFICATION

Horsepower: 4.5 Horse Power

Engine Oil Type SAE 30

Engine Oil Capacity 20 Ounces

Fuel Capacity: 1 1/2 Quarts

Spark Plug Champion RJ-19LM

Spark Plug Gap .030"

Model Number............. .......... ............. .......... ...........

Serial Number........... ............. .......... ............. .......... ..

Date of Purchase.......... ............. .......... ............. ........

Record both serial number and date of purchase and

keep in a safe place for future reference.

2

247.770100

Page 3

SAFETY

WARNING: This symbol points out important safety instructions which, if not followed, could

endanger the personal safety and/or property of yourself and others. Read and follow all

instructions in this manual before attempting to operate this machine. Failure to comply with these

instructions may result in personal injury. When you see this symbol - heed its warning.

WARNING: Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to State of California to cause cancer

and birth defects or other reproductive harm.

DANGER

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and throwing objects.

Failure to obser ve the f ollow ing saf ety ins truct ions could r esult i n seri ous inj ury or death.

: This machine was built to be operated according to the rules for safe operation in this

TRAINING

1. Read, understand, and follow all instructions on

the machine and in the manual(s) before

attempting to assemble and operate. Keep this

manual in a safe place for future and regular

reference and for ordering replacement parts.

2. Be familiar with all controls and their proper

operation . Know how to st op the ma chine a nd

disengage them quickly.

3. Never allow children under 16 years old to

operate this machine. Children 16 years old and

over should read and understand the operation

instructions and safety rules in th is manual and

should be trained and supervised by a parent.

4. Never allow adults to operate this machine

without proper instruction.

5. Keep bystanders, helpers, pets, and children at

least 75 feet from the machine while it is in

operation. Stop machine if anyone enters the

area.

6. Never run an engine indoors or in a poorly

ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

7. Do not put hands an d feet ne ar rotati ng parts or in

the feeding chambers and discharge opening.

Contact with the rotating impeller can amputate

fingers, hands, and feet.

8. Never attempt to unclog either the feed intake or

discharge opening, remove or empty vacuum

bag, or inspect and repair the machine while the

engine is running. Shut the engine off and wait

until all moving parts have come to a complete

stop. Disconnect the spark plug wire and ground

it against the engine.

PREP ARATION

1. Thorou ghly i nspec t the ar ea wher e the

equipment is to be used. Re move all rocks,

bottles, cans, or ot her forei gn objects which could

be picked up or thrown and cause personal injury

or damage to the machine.

2. Always wear safety glasses or safety goggles

during operation or while performing an

adjustment or repair, to protect eyes. Thrown

objects which ricochet can cause serious injury to

the eyes.

3. Wear sturdy, rough-soled work shoes and closefitting slacks and shirts. Loose fi tting c lothes or

jewelry can be caught in movable parts. Nev er

operate this machine in bare feet or sandals.

Wear leather work gloves when feeding material

in the chipper chute.

4. Before starting, check all bolts and screws for

proper tightness to be sure the machine is in safe

working condition. Also, visually inspect machine

for any dama ge at f requent inte rvals .

5. Maintain or replace safety and instructions labels,

as necessary.

6. To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are

explosive. Serious personal injury can occur

when gasoline is spilled on yourself or your

clothes which can ignite. Wash your skin and

change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and

other sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add while the

engine is hot or running.

e. Allow engine to cool at least two minutes

before refueling.

f. Never over fill fuel tank. Fill tank to no more

than 1/2 inch below bottom of filler neck to

provide space for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine

and equipment. Move machine to another

area. Wait 5 minutes before starting the

engine.

3

Page 4

i. Never store t he machi ne or fu el cont aine r

inside where there is an open flame, spark,

or pilot light (e.g. furnace, water heater,

space heater, clothes dryer, etc.)

j. To reduce a fire hazard, keep machine free

of grass, leaves, or other debris build-up.

Clean up oil fuel spillage and remove any fuel

soaked debris.

k. Allow machin e to cool at leas t 5 minu tes

before stor ing.

OPERATION

1. Do not put hands and feet near rotating parts or in

the feedin g chambe rs and d ischar ge ope ning.

Contact wit h the r otati ng impe ller c an ampu tate

fingers, hands, and feet.

2. Before starting the machine, make sure the chipper

chute, feed intake, and cutting chamber are empty

and free of all debris.

3. Thoroughly inspect all material to be shredded and

remove any metal, rocks, bottles, cans, or other

foreign objects which could cause personal injury

or damage to the machine.

4. If the impeller strikes a foreign object or if your

machine should start making an unusual noise or

vibration, immediately shut the engine off. Allow the

impeller to come to a complete stop. Disconne ct

the spark plug wire, ground it against the engine

and perform the following steps:

a. Inspect for damage.

b. Repair or replace any damaged parts.

c. Check for any l oose pa rts and tighte n to

assure continued safe operation.

5. Do not allow an accumulation of processed

material to build up in the discharge area. This can

prevent proper discharge and result in kickback of

material through the feed opening.

6. Do not attempt to shr ed or chi p mate rial l arger t han

specified on the m achin e or in t his manu al.

Personal injury or machine damage could result.

7. Never attempt to unclog either the feed intake or

discharge opening while the engine is running.

Shut the engine off, wait until all moving parts have

stopped, disconnect the spark plug wire and

ground it against the engine before clearing debris.

8. Never operate without vacuum bag and discharge

chute properly attached to the machine. Never

empty or change vacuum bag while the engine is

running. Zippered end of vacuum bag must be kept

closed at all times during operation.

9. Never operate without either the inlet nozzle or

optional hose attachment properly attached to the

machine. Never attempt to attach or change either

attachment while the engine is running.

10. Keep all guards, deflectors and safety devices in

place and operating properly.

11. Keep your face and body back and to the side of

the chipper chute while feeding material into the

machine to avoid accidental kickback i njuries.

12. Never operate this machine without good visibility

or light. Always be sure of your footing and keep a

firm hold on the handles.

13. Do not operate this machine on a gravel surface.

14. Do not operate this machine while under the

influence of alcohol or drugs.

15. Muffler and engine become hot and can cause a

burn. Do not touch.

16. Never pick up or carry machine while the engine is

running.

MAINTENANCE AND STORAGE

1. Never tamper with safety devices. Check their

proper operation regularly.

2. Check bolts and screws for pr oper t ightn ess at

frequent intervals to keep the machine in safe

working condition. Also, visually inspect machine

for any dama ge and r epair , if ne eded.

3. Before cleaning, repairing, or inspecting, stop the

engine and make certain the impeller and all

moving parts have stopped. Disconnect the spark

plug wire and ground it against the engine to

prevent unintended starting.

4. Do not change the engi ne gove rnor set ting s or

overspeed the engine. The governor controls the

maximum safe operating speed of the engine.

5. Maintain or replace safety and instruction labels, as

necessary.

6. Follow this manual for safe loading, unloading,

transporting, and storage of this machine.

7. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

such as a water heater, furnace, clothes dryer, etc.

8. Always refer to the o perator ’s ma nual fo r prope r

instruct ions o n off-se ason s torag e.

9. If the fuel tank has to be drained, do this outdoors.

10. Observe proper disposal laws and regulations for

gas, oil, etc. to protect the environment.

4

Page 5

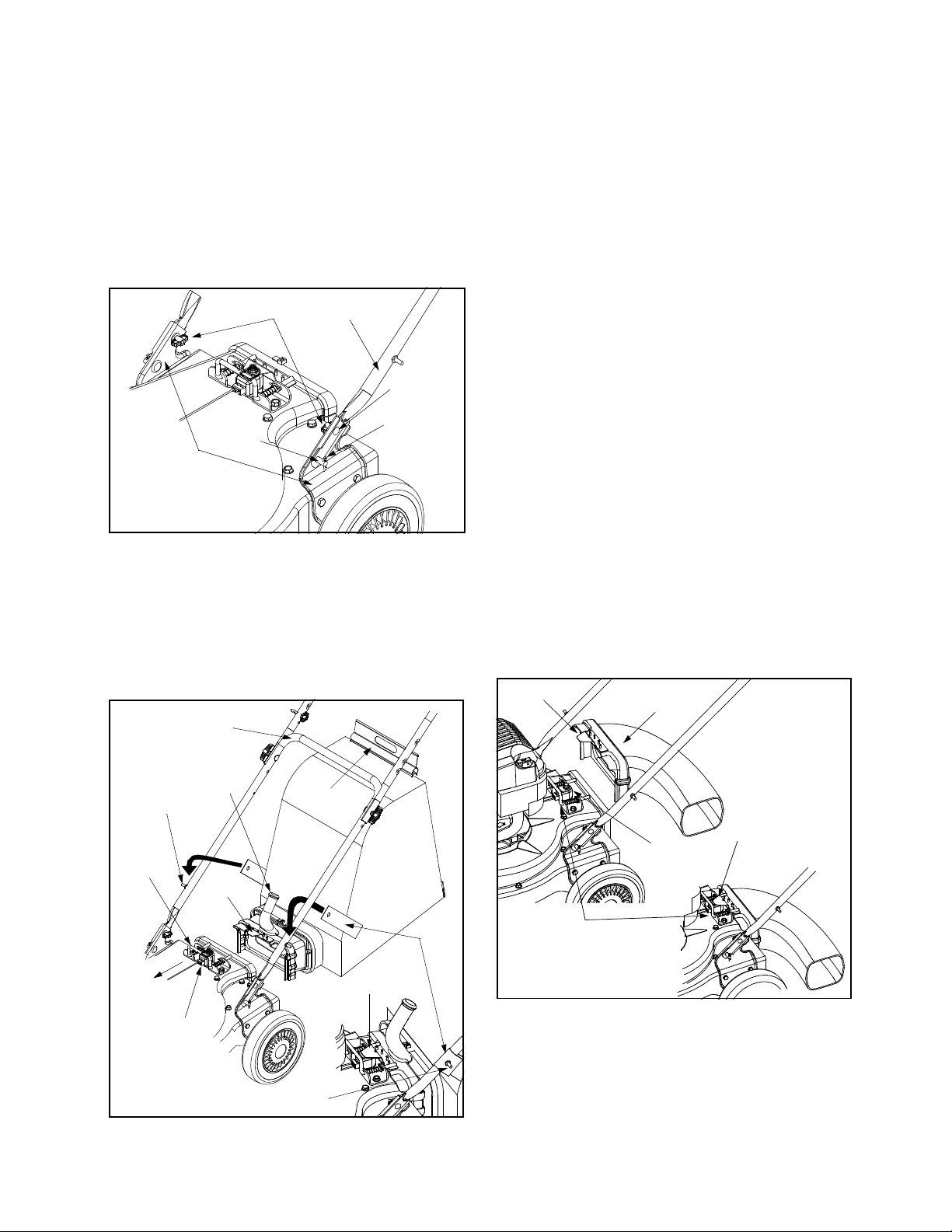

Rope

Guide

20-oz. Bottle

of Engine Oil

Wing

Nuts

Blower

Chute

Wing

Nut

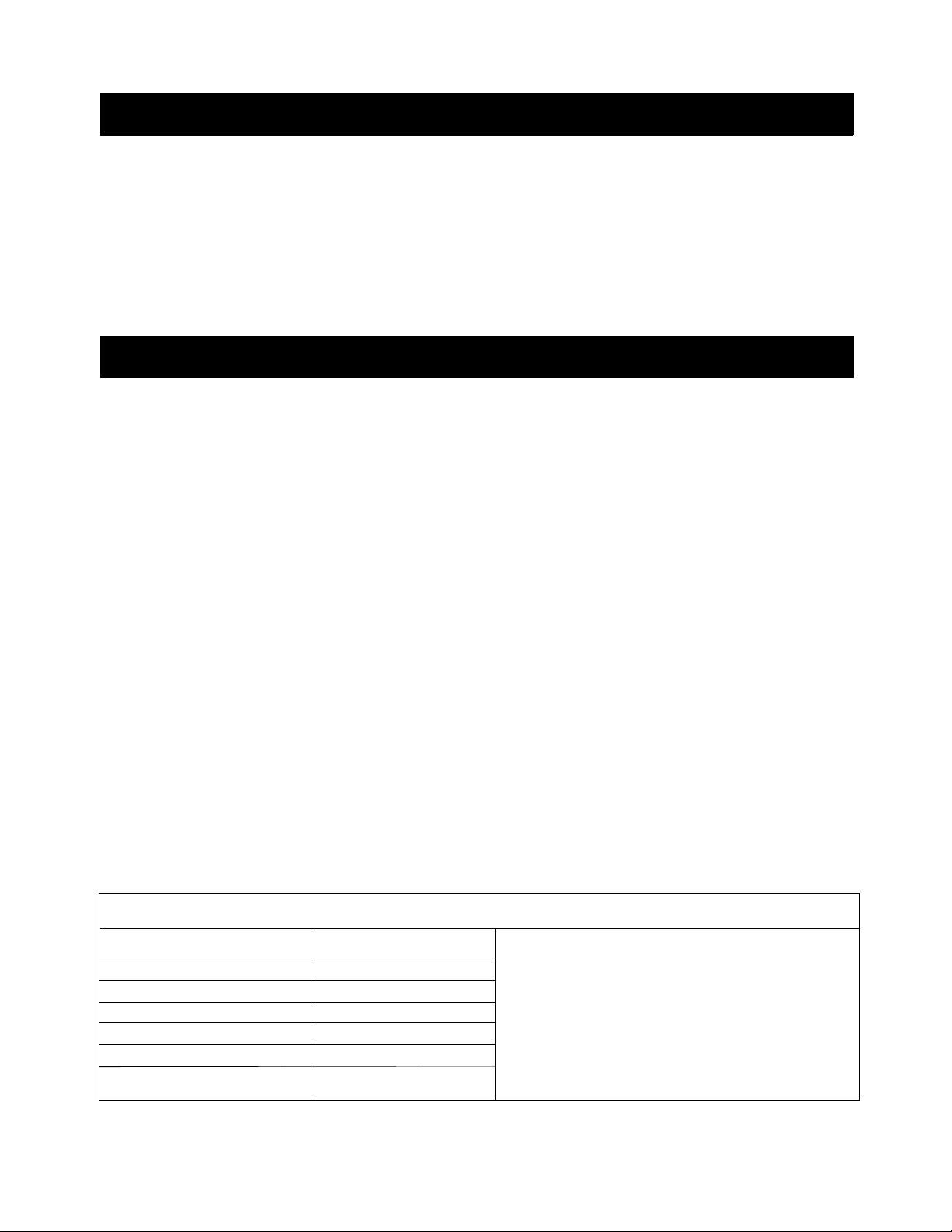

ASSEMBLY

NOTE: Reference to right an d left hand side of the

Yard Vacuum is observed from the operating

position. See Figure 1.

This Yard Vacuum has been completely assembled

at the factory, except for the handle, bag, and blower

chute. These parts are ship ped loose in the carton.

A pair of safe ty gla ss es and a 20- oz. bot t le of eng i ne

oil are also included in the carton. See Figure 1.

REMOVING UNIT FROM CAR TON

• Cut the corners of the carton.

• Remove all loose parts.

• Remove packing material.

• Lift unit from the rear to discard packing material

• Check carton thoroughly for any other loose

LOOSE PAR TS IN CART ON (See Figur e 1)

Upper

Handle

• Handle Assembly

•Bag

• Blower Chute

• Safety Glass es (Not Sh own)

• A 20-oz. Bottle of Engine Oil (may be located in

• Operator’s Manual

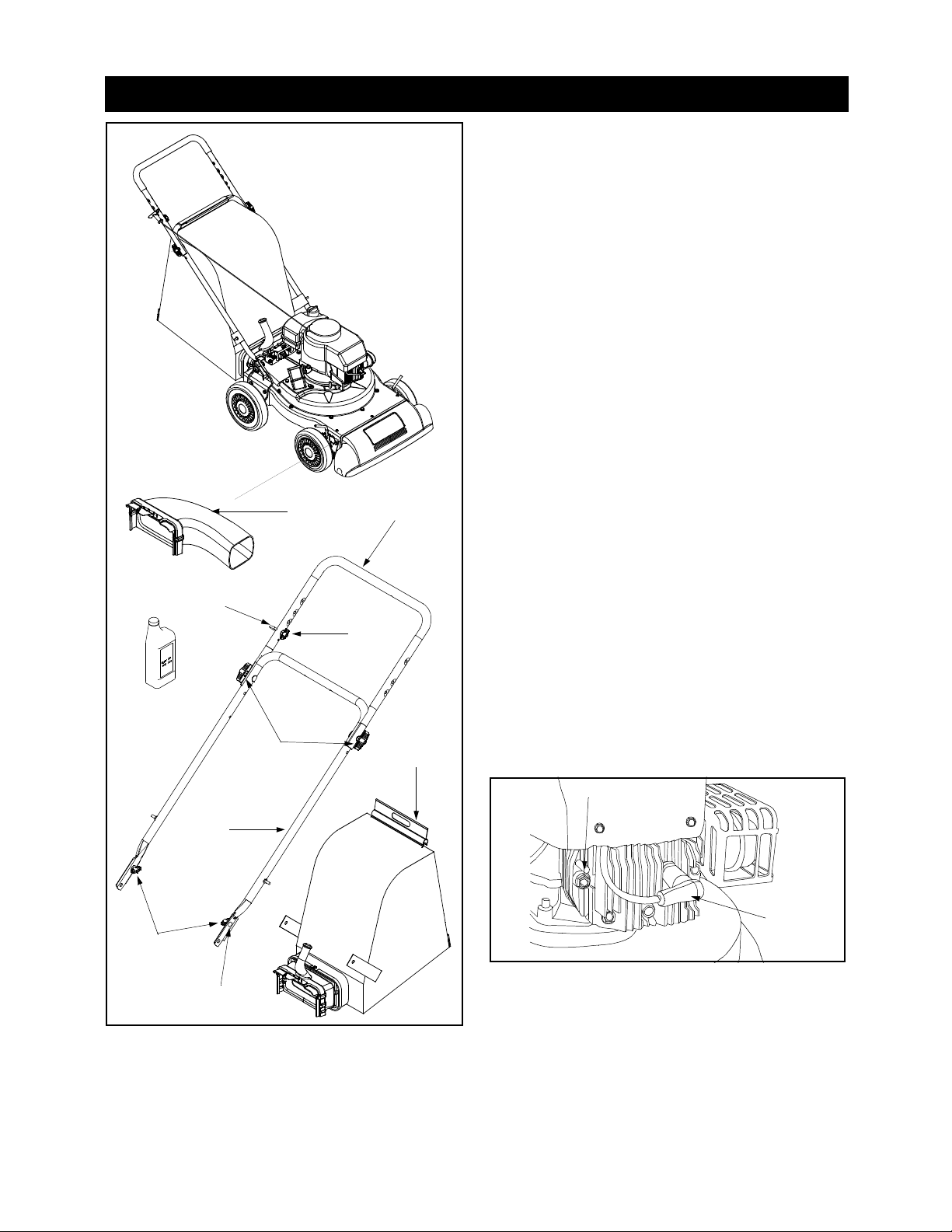

DISCONNECTING SP ARK PLUG

Before proceeding with assembly of your new Yard

Vacuum, disconnect the sp ark plug wire from the

spark plug and ground onto the retaining post on the

engine. This will preven t acc idental starting of the

Bag

engine. See Figure 2.

from under unit and roll unit out of carton.

parts.

bag)

Lower

Handle

Wing

Nuts

Carriage

Screw

Figure 1

IMPORT ANT :

oil in the engine. After assembly, see OPERATION

section of this manual for proper fuel and engine oil

fill-up.

This unit is shipped without gasoline or

Retaining Post

Spark

Plug Wire

Figure 2

A TT ACHING THE HANDLE

• Unfold the upper handle until it aligns with lower

handle. Make sure the rope guide is on the right

side of upper handle. See Figure 1.

5

Page 6

• Secure the two handles by tightening the upper

wing nuts (carriage bolts must be seated properly

into the handle).

• Remove the hairpin clips from the handle

brackets and the carriage bolts and wing nuts

from the lower handle. See Figure 3.

• Place each bottom hole in lower handle over the

pins on handl e brack ets an d secu re with hairpi n

clips.

• Insert carriage bolts thru upper hole in lower

handle from the outside and secure with wing

nuts.

Lower

Handle

Carriage

Bolt

Hairpin

Clip

Handle

Brackets

Wing Nuts

Pin

Figure 3

• Loosen the wing nut that secures the rope guide

to the right side of upper handle.

• Pull the s tarte r rope ou t of th e engi ne slowl y and

slip the st arter rope int o the ro pe gui de. Tig hten

the wing nut.

• Grasp bag handle with one hand and pull locking

rod on mounting bracket with other hand toward

engine. See Figure 4.

• Slip bag over the rim of the discharge opening

and release locking rod to secure bag in place.

• Snap bag clip to the top of the lower handle.

• Place t he lower st raps on th e bag over the top of

lower handle, hooking them on the studs.

NOTE: The bag/chute switch bu tton attached to the

mounting bracket mus t be fully depress ed by the tip

of front tab on bag handle when securing the bag or

engine will not start.

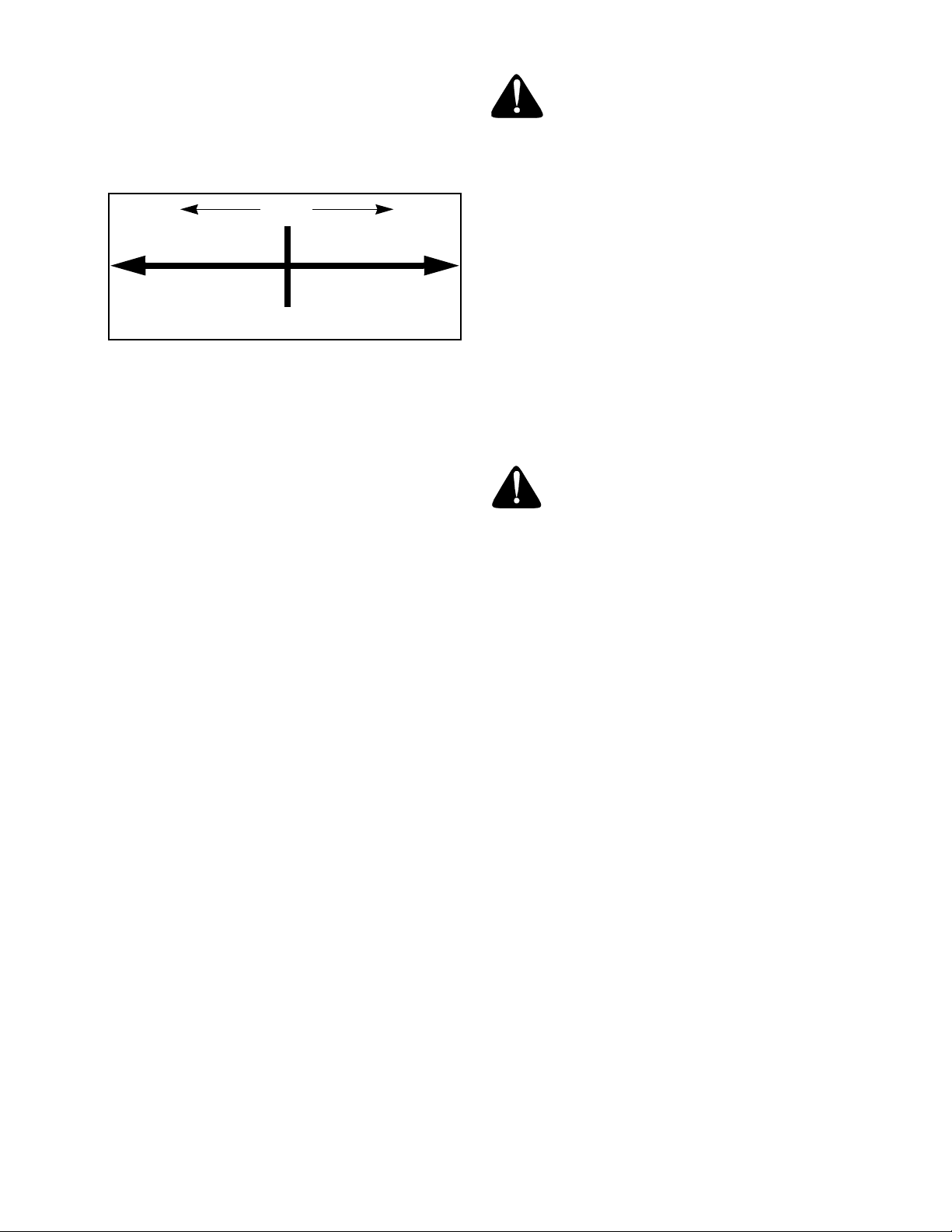

A TTACHING THE BLOWER CHUTE

NOTE: The bag must be removed before installing

the blower chute.

• Grasp blower chute with one hand and pull lock-

ing rod on mounting bracket with other hand

toward engine. See Figure 5.

• Slip blower chute over rim of discharge open-

ing and release locking rod to secure chute in

place.

• Raise the nozzle height to the highest setting

when using the blo wer chut e. Refer to noz zle

height adjustment in the ADJUSTMENT section.

NOTE: The bag/chute switch bu tton attached to the

mounting bracket mus t be fully depress ed by the tip

of front tab on the blower chute or engine will not

start.

A TT ACHING THE BAG

Lower

Handle

Bag

Handle

Stud

Locking

Rod

To Engine

Bag/Chute

Switch

Front

Tab

Figure 4

Bag

Clip

Stud

Front

Tab

Strap

Front

Tab

Blower

Chute

Front

Tab

Safety

Switch

Locking

Rod

Figure 5

6

Page 7

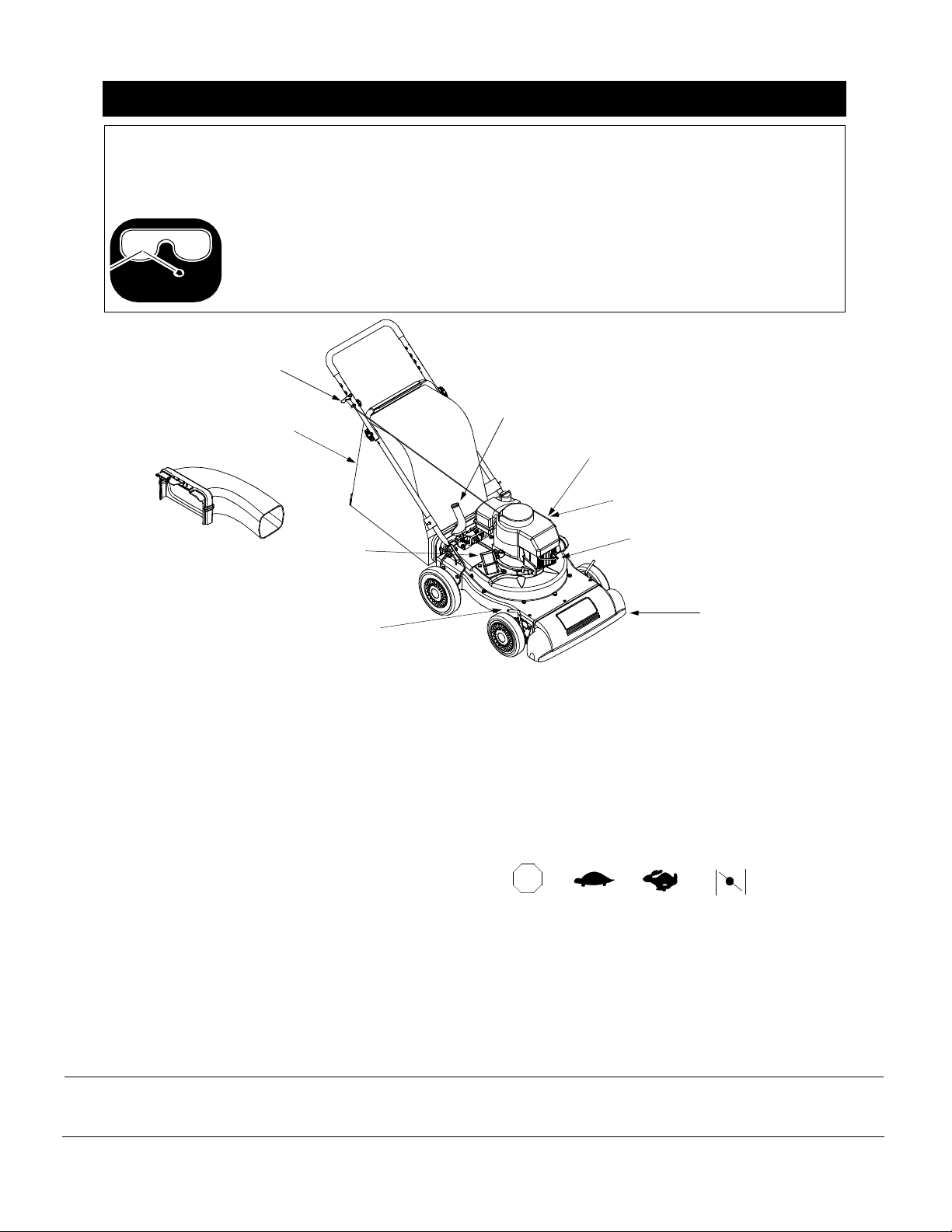

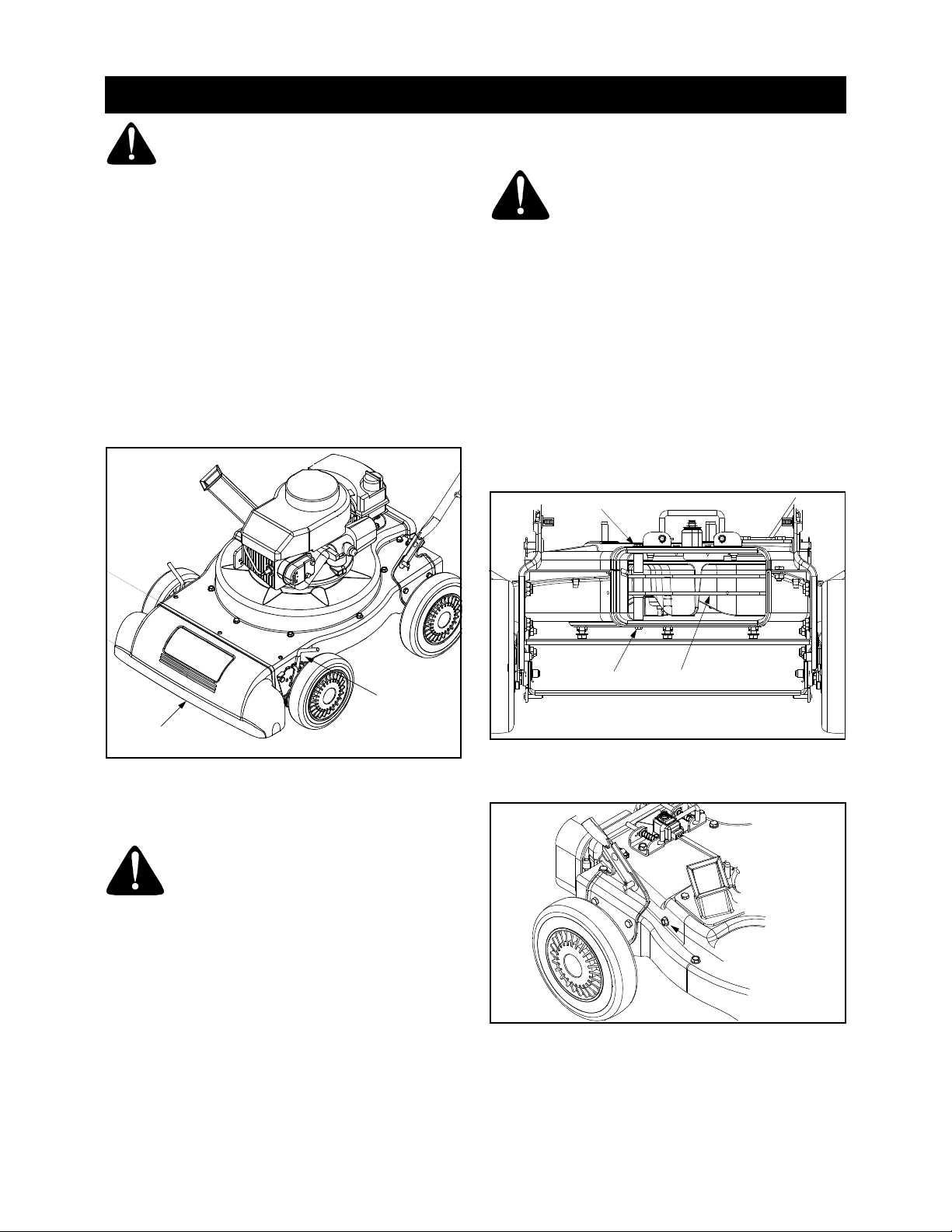

OPERATION

Know Your Yard Vacuum

Read this operator’s manual and safety rules before operating your Yard Vacuum. Compare the illustrations

below with your equipment to familiarize yourself with the location of various controls and adjustments. Save

this manual for future reference.

WEAR YOUR

SAFETY GLASSES

FORESIGHT IS BETTER

THAN NO SIGHT

The operation of any Yard Vacuum can result in foreign objects being thrown into the eyes,

which can result in severe eye damage. Always wear safety glasses, provided with the

Yard Vacuum, for operating this equipment or while performing any adjustments or repairs on

it.

Starter

Handle

Bag

Blower Chute

Nozzle Height

Adjustment Lever

Chipper

Chute

Figure 6

OPERA TING CONTROLS (See Figure 6)

Chipper Chute

Allows twigs and small branches up to 1 1/2" in

diameter to be fed into the impeller for chipping.

Nozzle

Yard waste s uch as l eaves an d pine needle s can be

vacuumed up through the nozzle for shredding.

Catcher Bag

Collects shredded material fed in through the chipper

chute or vacuumed in through the nozzle.

Blower Chute

When attac hed to u nit, t he blow er chut e is used to

blow or scat ter ya rd wast e such as leav es, pine

needle, or small twigs across yard.

Bag Handle

Used to grasp bag in order to assist in attaching,

removing , and empt ying ba g.

Bag Handle

Throttle Control/

Choke Lever

Primer

Spark Plug Wire

Nozzle

Nozzle Height Adjustment Lever

Used to adjust the nozzle ground clearance ranging

from 5/8" to 3 3/4".

Throttle Control / C hoke Lever

This singl e lever cont rols th e engine speed, stop

function, and the choke of the carburetor. Through

four separate positions on the lever fro m left to right,

the operation is as follows:

Stop

Engine

Off

Slow/

Idle

Start/

Run

Choke

Primer

The primer is used to assist in cold starting an engine.

Starter Handle

Used to start the engine.

Meets ANSI safety standards

Craftsman Yard Vacuums conform to the safety standard of the American National Standards Institute (ANSI).

7

Page 8

GAS AND OIL FILL-UP

Oil (one 20-oz. bottle shipped with unit)

Only use high quality detergent oil rated with API

service classification SF, SG, or SH. Select the oil’s

SAE viscos ity gr ade acco rdin g to the ex pecte d

operating temperature. Follow the chart below.

32

°

Colder

5W30 SAE 30

Oil Viscosity Chart

NOTE: Alt hough multi-viscosity oils (5W30, 10W30,

etc.) improve starting in cold weathe r, the y will result

in increa se d oi l con sum pt io n w hen us ed abo ve 32°F .

Check your engine oil level m ore frequently to avoid

possible engine damage from running low on oil.

• Remove oil fill dipstick.

• With the Yard Vacuum on level ground, use a

funnel to fill engine with oil to FULL mark on

dipstick. Capacity is approximately 20 oz. Be

careful not to overfill. Overfilling will cause the

engine to smoke profusely and will result in poor

engine performance. The oil bottle packaged

with your Yard Vacuum contains 20 oz. of oil.

• Check the oil level making certain not to rub the

dipstick along the inside walls of the oil fill tube.

This would result in a false dipstick reading. Refill

to FULL mark on dipstick, if necessary. Replace

dipstick and tighten.

• Check oil level three times prior to starting engine

to be certain you’ve gotten an accurate dipstick

reading. R unnin g the eng ine wi th too littl e oil ca n

result in permanent engine damage.

Gasoline

• Remove f uel ca p from the fuel t ank.

• Make sure the container from which you will pour

the gasoline is clean and free from rust or foreign

particles. Never use gasoline that may be stale

from long periods of storage in its container.

Gasoline t hat ha s been si tting for any period

longer than four weeks should be considered

stale.

• Fill fuel tank with clean, fresh, unleaded regular,

unleaded premium or reformulated automotive

gasoline only. DO NOT use Ethyl or high octane

gasoline. Do not u se gas oline co ntain ing

METHANOL. R eplac e fuel ca p.

• To avoid engine problems, the fuel system

should be emptied before storage for 30 days or

longer. Drain the gas tank, start the engine and

let it run until the fuel lines and carburetor are

empty. Use fresh fuel next season. See

STORAGE section for additional information.

F

Warmer

WARNING: Use extreme care when

handling gasoline. Gasoline is e x tr emel y

flammable and the vapo rs ar e exp losiv e.

Never fuel machin e indoors o r while the

engine is hot or running. Extinguish

cigarettes, cigars, pipes, and other

sources of ignition.

• Check the fuel level periodically to avoid running

out of gasoline while operating the Yard Vacuum.

If the unit runs ou t of gas as it is c hippi ng, it may

be necessary to unclog the unit before it can be

restarted. Refer to SERVICE AND

ADJUSTMENT section.

TO STOP ENGINE

• Move throttle control lever to STOP or OFF

position.

• Disconnect spark plug wire and ground it to the

post to prev ent ac cident al sta rtin g while the

equipment is unat tended .

WARNING: When moving throttle control

lever, be careful of heated surfaces and

sharp edges on muf fler guard .

TO ST AR T ENGINE

1. Attach spark plug wire and rubber boot to spark

plug.

2. The bag/chute switch button must be fully

depressed by the tip o f front tab on bag handle

or blower chute for engine to start.

3. Make sure bag/chute s witch wire is conne cted to

engine and grounded to mounting bracket.

4. Gas tank should be fille d 3/4 to full before start ing.

5. When temperature is ab o ve 32 degrees F:

• Move throttle control / choke level to START/

RUN position.

• Depress t he prim er bulb firml y with y our

thumb three times. Wait about two seconds

between each push. Do not use the primer to

restart a warm engine after a short shutdown.

See Figure 7.

When temperature is b el o w 32 degrees F:

• Move throttle control / choke lever on engine

to CHOKE position. (A warm engine may not

require choking.) See Figure 7.

• If not using choke to start engine, move throttle control / choke lever to START/RUN position.

• Depress the primer bulb firmly with your

thumb three times. Wait about two seconds

between each push.

NOTE: See air cleaner on side of engine for further

starting instructio ns.

8

Page 9

Throttle Control/

Choke Lever

Primer

Figure 7

6. Standing behind the unit, grasp starter handle

and pull rope out until you f eel a drag.

7. Pull the rope with a rapid, continuous, full arm

stroke. Keep a firm grip on the starter handle.

Let the rope rewind slowly.

8. Repeat, if necessar y, until engine starts. When

engine starts, move thr ot tl e /choke lever gradually to START/RUN position .

9. If engine falters, mov e control lever to CHOKE

position, then back to START/RUN position.

10. ALWAYS keep the throttle control in the START/

RUN position when operating the Yard Vacuum.

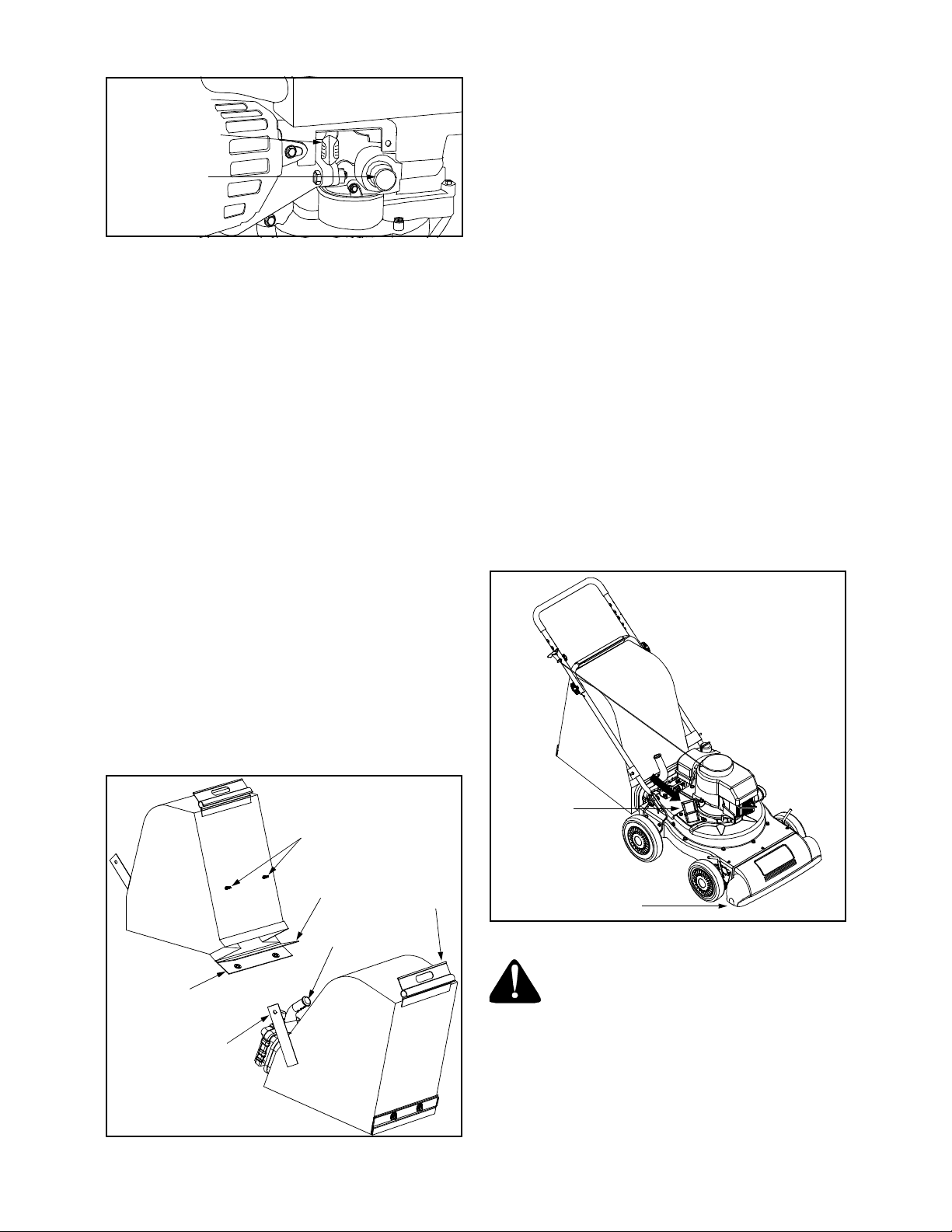

TO EMPTY BAG

• Unhook bag straps from the lower handle and

unsnap bag cl ip fro m top of the lowe r handl e.

See Figure 8.

• Grasp bag handle with one hand and pull lock rod

on mounting bracket with other hand toward

engine to rel eas e.

• Remove bag from over the rim of the discharge

opening. Re fer to F igure 4 .

• Twist the two buttons on the back of the bag to

unlock and empty contents. See Figure 8.

• Hold bag handle and bag clip while emptying the

contents.

• Compress bag open ing an d fold in ner fl ap over

opening.

• Fold outer flap over inner flap and insert buttons

on the bag th rough m etal o utlet s.

• Twist the buttons to lock bag.

TO REMOVE BLOWER CHUTE

• Grasp blower chute with one hand and pull lock

rod on mounting bracket with other hand toward

engine to release. Refer to Figure 5.

• Remove blower chute from over the rim of the

discharge opening.

OPERATION

Place both hands on top of upper handle to push unit

over yard waste. Yard waste such as leaves and pine

needles are vacuumed up through the nozzle and

shredded by the flail blades on the impeller assembly

and discharged into catcher bag or through blower

chute. Do not attempt to shred or chip any material

other than vegetation found in a normal yard (i.e.

branches, leaves, twigs, etc.). Avoid fibrous plants

such as toma to vi nes unti l they a re thor ough ly dried

out. Material such as stalks or heavy branches up to

1 1/2" in diameter may be fed into the chipper chute.

See Figure 9.

Outer Flap

Strap

Figure 8

Buttons

Inner Flap

Bag Handle

Bag

Clip

Chipper

Chute

Nozzle

Figure 9

WARNING: Do not attempt to shred,

chip, or vacuum any materia l larger than

specified on the machine or in this

manual. Personal injury or damage to

the machine could result.

IMPORT ANT:

housing in the discharge area. If the flail screen

becomes clogged, stop engine and remove and clean

as instructed in the SERVICE AND ADJUSTMENT

section.

9

The flail screen located inside the

Page 10

MAINTENANCE

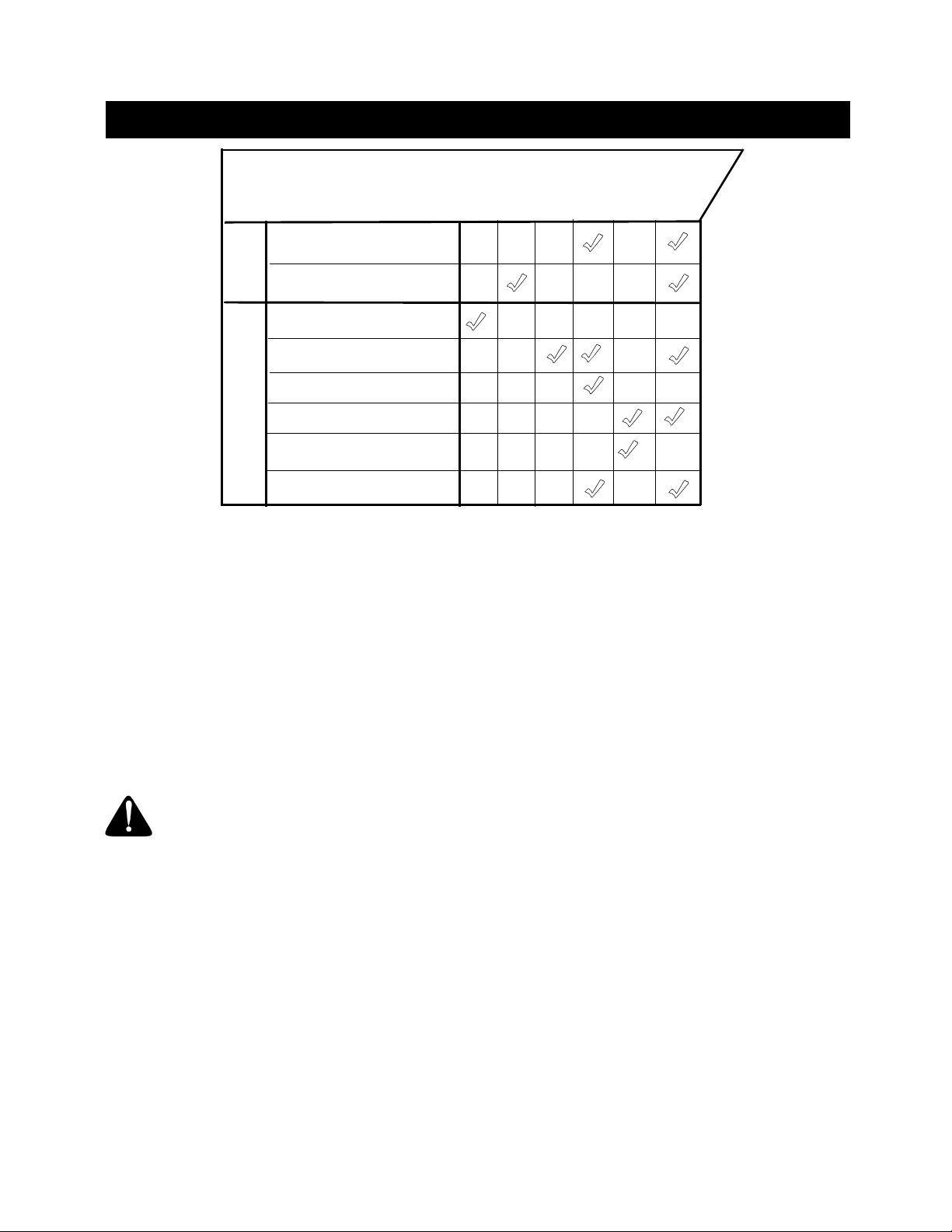

MAINTENANCE

SCHEDULE

T

C

Lubrication

U

D

O

R

Clean equipment

P

Check engine oil

Change engine oil

E

N

I

Service air cleaner

G

N

E

Service spark plug

Service muffler

Clean engine

GENERAL RECOMMENDA TIONS

• Always observe safety rules when performing any

maintenance.

• The warranty on this Yard Vacuum does not

cover items that have been subjected to operator

abuse or negligence. To receive full value from

the warran ty, ope rator m ust mai ntai n the

equipment as instructed in this manual.

• Some adjustments will need to be made

periodically to maintain your equipment properly.

• Follow the maint enanc e schedu le.

• Periodically check all fasteners and make sure

they are tig ht.

WARNING: Always stop the engine and

disconnect and ground the spark plug

wire before performing any maintenance

or adjustments.

e

e

s

s

u

u

r

h

c

a

e

e

e

r

r

e

fo

t

f

e

A

B

u

h

o

c

h

a

5

t

s

r

i

F

s

r

u

s

o

h

5

2

y

r

e

v

E

u

o

h

0

5

y

r

e

v

E

e

s

r

g

a

r

o

t

s

e

r

o

f

e

B

CLEAN EQUIPMENT

• Clean the Yard Vacuum thoroughly after each

use.

• Wash the bag periodically with water. Allow to

dry thoroughly in the shade.

• If the flail screen becomes clogged, remove and

clean as instructed in the SERVICE AND

ADJUSTMENT s ectio n.

NOTE: Cleaning with a forceful spray of water is not

recommended as it could contaminate the fuel

system.

CHECK ENGINE OIL

• Remove oil fill dipstick.

• Check oil level on dipstick. Level should be at

FULL mark.

• Replace dipstick and tighten.

LUBRICATION

• Wheels- Place a few drops of SAE 30 oil on each

shoulder screw once a season.

Refer to •.

• Nozzle height adjustment levers- Lubricate

nozzle height adjustment levers with light oil.

Refer to Figure 6.

• Locking Rod- Lubricate the lock rod and

compression springs which attach to the

mounting bracket. Refer to Figure 4.

CHANGE ENGINE OIL

• Only use high quality detergent oil rated with API

service classification SF, SG, or SH. Sel ect the

oil’s SAE viscosity grade according to the

expected operating temperature. Refer to

operation section for viscosity chart .

• Stop engine and wait several minutes before

checking oil level. With engine on level ground,

the oil must be to FULL mark on dipstick.

• Change engine oil after the first five hours of

operation, and ev ery tw enty-fi ve hou rs

thereafter.

10

Page 11

TO DRAIN OIL

Drain oil while engine is warm. Follow the instructions

given below.

• Drain the gas tank, start the engine and let it run

until the fuel line and carburetor are empty.

• Remove oil fill dipstick.

• Tip unit on its side to drain through the oil fill tube.

• When engine is drained of all oil, refill with

approximately 20 oz. of fresh oil. Refer to Gas

And Oil Fill-up in OPERATION section.

• Replace dipstick.

SERVICE AIR CLEANER

The air cleaner prevents damaging dirt, dust, etc.,

from entering the carburetor and being forced into the

engine and is important to engine life and

performance. The air cleaner consists of a foam filter.

Never run the engine without an air cleaner

completely assembled.

To Service Air Cleaner:

• Remove foam filter from plastic housing on top of

engine.

• Wash in water and detergent solution, and

squeeze (do not twist) until all dirt is removed.

• Rinse thoroughly in clear water.

• Wrap in a clean cloth and squeeze (do not twist)

until completely dry, or allow to air dry.

• Saturate with engine oil and squeeze to distribute

oil and remove excess oil.

• Replace foam filter in plastic housing

NOTE: If the foam filter is torn or damaged in any

way, replace it.

WARNING:

muffler and nearby areas may exceed

o

F(65

150

WARNING: Temperature of

o

C). Avoid these areas.

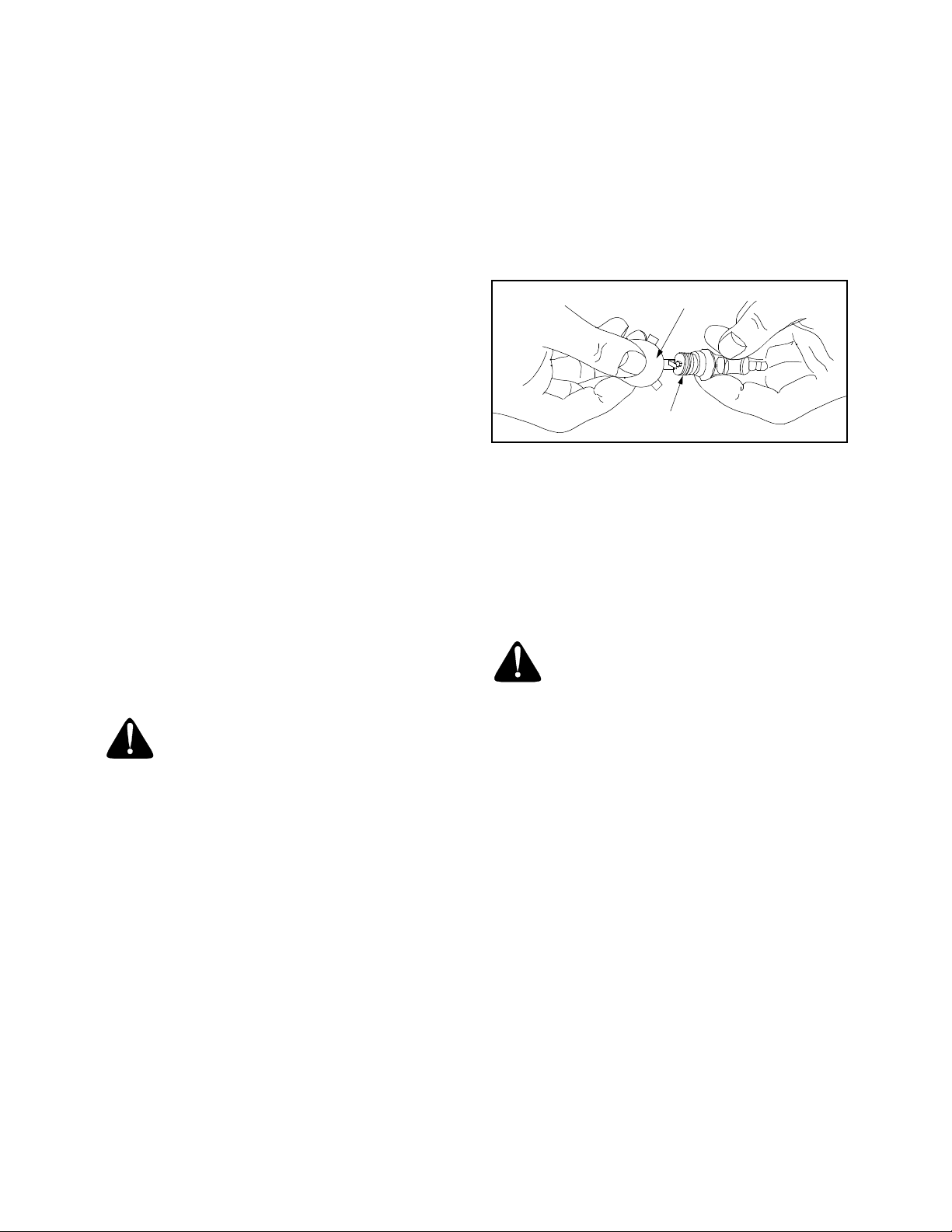

SERVICE SPARK PLUG

• Clean the spark plug and reset the gap to .030" at

least once a season or every 50 hours of

operation. See Figure 10. Spark plug

replacement is recommended at the start of each

season. Refer to engine parts list for correct

spark plug type.

NOTE: Do not sandblast spark plug. Spark plug

should be cleaned by scrapin g or wire brushing and

washing with a commercial solvent.

.030" Feeler Gauge

Spark Plug

Figure 10

SERVICE MUFFLER

• Inspect muffle r peri odical ly, an d repl ace if

necessary.

• If your engine is equipped with a spark arrester

screen assembly, remove after every 50 hours of

use for cleaning and inspection. Replace if

damaged.

WARNING: Do not operate the Yard

Vacuum without a muffler or tamper with

the exhaust system. Damaged mufflers

or spark arresters could create a fire

hazard.

CLEAN ENGINE

• Clean engine by removing dirt and debris with a

cloth or brush.

• Frequently remove grass clippings, dirt, and

debris from cooling fins, air intake screen, levers,

and linkage. This will help ensure adequate

cooling and engine speed.

11

Page 12

SERVICE AND ADJUSTMENTS

WARNING: Do not at any time make any

adjustment to the unit without first

stopping engine and disconnecting

spark plug wire.

NOZZLE HEIGHT ADJUSTMENT

The nozzle can be adjusted to any of five positions,

ranging from 5/8" to 3 3/4" ground clearance. The

nozzle height has to be adjusted according to the

conditions. Move the height adjustment levers

forward or backward to adjust the nozzle upward or

downward. I t may be n ecessar y to ap ply sli ght

pressure to lower handle assembly, when shifting

adjustment levers. See Figure 11.

NOTE: In general, raise the nozzle height to vacuum

a thick layer of le aves or to operate with th e blower

chute. Low er th e noz zle he ight f or s moother surf aces.

nearest S ears Se rvice C enter for re pair and adju stment.

WARNING: Do not attem pt to alter the

engine speed by tampering with the

engine’s governor linkage. Doing so

could result in serious persona l injury

and damage to the engine. The engine

RPM has been s et at th e facto ry.

REMOVING THE FLAI L SCREEN

If the discharge area becomes clogged, remove the

flail screen and clean area as follows.

• Stop the e ngine. Make ce rtain t he chi pper

shredder vacuum has come to a complete stop.

• Disconnect and ground the spark plug wire

before unclogging the discharge chute.

• Remove th e vacuum bag or bl ower ch ute fr om

the unit as instructed in the OPERATION section

to obtain access to flail screen. See Figure 12.

Hex Screw & Flat Washer

Height

Nozzle

Figure 11

Adjustment

Lever

CARBURETOR ADJUSTMENT

WARNING: If any adjustments (e.g.

carburetor) are made to the engine

while the engine is running, keep clear

of all moving parts. Be careful of heated

surfaces and muffler.

The carburetor has been pre-set at the factory and

should not r equire adju stment . If your engin e does

not operate properly due to suspected carburetor

problems, take your Yard Vacuum to a Sears Service

Center for repair and adjustment.

ENGINE SPEED

The engine speed on your Yard Vacuum has been

set at the factory. Do not attempt to increase the

engine RPM. If you think that the engine is running

too fast or too slow, take your Yard Vacuum to the

Lock Nut

• Remove hex screw on right side of unit that

attaches to the flail screen. See Figure 13.

• Remove hex screw and flat washer on top o f rear

housing near mounting bracket and the lock nut

that secures flail screen. See Figure 12.

• Remove and clean the screen by scraping or

washing with water. Reinstall the scr een.

Flail Screen

REAR VIEW

Figure 12

Figure 13

Remove

Hex Screw

12

Page 13

SHARPENING OR REPLACING CHIPPER

BLADE

Because the engine on this unit has a tapered

crankshaft, a special impeller removal tool (part

number 753-0638) is required to remove the impeller

assembly. For further assistance, contact your Sears

Service Cent er.

NOTE: When tipping the unit, empty the fuel tank and

keep engine s park p lug si de up.

• Disconnect and ground t he spark pl ug wire.

• Remove the f ront hu bcaps , shoul der scr ews,

wave washers, and bell washers that attach to

the front wheels. See Figure 14.

• Remove the shoulder screws that go through the

pivot arms and height bracket adjusters to the

front suppo rt brac e.

• Remove lock nut that secures flail screen to the

lower housing. The flail screen does not have to

be removed. Refer to Figure 12.

• Remove the hex bolt, lock washer, and flat

washer that secure the impeller assembly to the

crankshaft. See Figure 16.

Upper

Chipper

Blade

BOTTOM VIEW

Housing

Impeller

Assembly

Hex Bolt

Lock Washer

Flat Washer

Flail

Blade

Height

Bracket

Adjuster

Pivot

Arm

Shoulder

Screw

Bell

Washer

Wave Washer

Shoulder

Screw

Hubcap

Figure 14

• Remove the t hree sc rews on the upp er hous ing

that secure the nozzle cover and the nine screws

that secure the lower housing to the upper

housing. Se e Fig ure 15.

Figure 16

• Apply lubricant to the threads of impeller removal

tool and then thread the tool into the crankshaft.

Stop when the impeller assembly can move on

the crankshaft.

• Remove the impeller assembly from the

crankshaft. Unthread the impeller removal tool

from the impeller assembly.

• Remove the chipper blade using a 3/16" allen

wrench on the outside of the blade and 1/2"

wrench on the underside of impeller assembly.

• Replace or sharpen chipper blade.

• When sharpening blade, protect hands by using

gloves and follow the original angle of grind.

• Reassemble by performing the previous steps in

reverse order.

• Tighten blade screws to 210 - 250 in-lbs.

• Tighten impeller bolt to 375 - 425 in-lbs.

NOTE: Make certain chipper blade is reassembled

with the sharp edge facing upward. See Figure 17.

Flail

Blade

Chipper

Blade

Nozzle

Screws

Figure 15

Lower

Housing

Screws

Impeller

Assembly

Figure 17

13

Page 14

STORAGE

Prepare your Craf tsman Y ard Vacuu m for st orage at

the end of the season or if the unit will not be used for

30 days or longer. A yearly check-up by your local

Sears Service Center is a good way to ensure that the

unit runs pr operl y next se ason.

Yard Vacuum

• Clean the equipment thoroughly.

• Wipe equipment with an oiled rag to prevent rust.

Use a light oil or silicone to wipe.

• Service the engine following instructions below.

• Store unit in a clean, dry area. Do not store next to

corrosive materials such as fertilize r.

Engine

IMPORT ANT :

from forming in essential fuel system parts su ch as

the carburetor, fuel filter, fuel hose, or tank during

storage. Also, alcohol blended fuels (called gasohol or

using ethanol or methanol) can attract moisture which

leads to separation and formation of acids during

storage. Acidic gas can damage the fuel system of an

engine while in storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. Follow

these instruction:

• Drain the fuel tank.

• Start the engine and let it run until the fuel lines

and carburet or are empty.

• Drain carburetor.

• Never use engine or carburetor cleaner products

in the fuel tank or permanent damage may occur.

It is important to prevent gum deposits

NOTE: Fuel stabilizer is an acceptable alternative in

minimizing the formation of fuel gum deposits during

storage.

• Add stabilizer to gasoline in fuel tank or storage

container.

• Always follow the mix ratio found on stabilizer

container.

• Run engine at least 10 minutes after adding

stabilizer to allow the stabilizer to reach the

carburetor.

• Do not drain the gas tank and carburetor if using

fuel stabilizer. Drain all the oil from the

crankcas e (thi s should be done after t he engi ne

has been operated and is still warm) and refill the

crankcas e with f resh oil .

If you hav e drai ned the fuel t ank, pr otect t he insi de of

the engine as follows:

• Remove spark plug, pour approximately 1/2

ounce (approximately one tablespoon) of engine

oil into cylinder and crank slowly to distribute oil.

• Replace spark plug.

Other

• Do not store gasoline from one season to

another.

• Replace the gasoline can if it starts to rust. Rust

and/or dirt in the gasoline will cause problems.

• Store unit in a clean, dry area. Do not store next

to corrosive materials, such as fertilizer.

NOTE: If storing in an unventilated or metal storage

shed, be certain to rustpr oof the equip ment by co ating with a light oil or silicone.

14

Page 15

TROUBLESHOOTING

Problem Possible Cause(s) Corrective Action

Engine fails to start 1. Fuel tank empty or stale fuel.

2. Spark plug wire disconnected.

3. Cannot pull recoi l cord.

4. Choke not in ON pos itio n.

5. Faulty spark plug.

6. Safety switch not depressed.

7. Safety switch wire is not

connected to engine or not

properly grounded.

Loss of power;

operation erratic

Too much vibration 1. Loose parts or damaged

Engine overheats 1. Carburetor not adjusted

Unit does not

discharge

Rate of dis charg e

slows considerably or

composition of

discharged material

changes

1. Spark plug wire lo ose.

2. Unit running on CHOKE.

3. Blocked fuel line or stale fuel.

4. Water or dirt in fuel system.

5. Carburetor out of adjust ment.

6. Low engine RPM.

impeller.

2. Engine oil level low

1. Discharge chute clogged.

2. Foreign object lo dged in

impeller.

3. Low engine RPM.

4. Vacuum bag is full.

1. Low engine RPM.

2. Chipper blade dull.

1. Fill tank with clean, fresh gasoline. Fuel will not

last over thirty days unless a fuel stabilizer is

added.

2. Connect wire to spark plug.

3. Obstruction lodged in impeller. Disconnect

spark plug wire and remove lodged object.

4. Move CHOKE to ON position.

5. Clean, adjust gap or replace.

6. Safety switch must be depressed by the front

tab on the bag handle when securing the bag.

7. Connect safety switch wire to engine connector

and ground to mounting bracket.

1. Connect and tighten spark plug wire.

2. Move choke lever to OFF position.

3. Clean fuel line; fill tank with clean fresh

gasoline. Fuel will not last over thirty days

unless a fuel stabilizer is used.

4. Disconnect fuel line at carburetor to drain fuel

tank. Refill with fresh fuel.

5. Contact your Sears Service Center.

6. Always run engine at full throttle.

1. Stop engine immediately and disconnect spark

plug wire. Have unit serviced by a Sears

Service Center.

1. Contact your Sears Service Center.

2. Fill crankcase with proper selection of oil.

1. Stop engine immediately and disconnect spark

plug wire. Clean flail screen and ins ide of

discharge opening. See Maintenance section of

this manual .

2. Stop engine immediately and disconnect spark

plug wire. Remove lodged object.

3. Always run engine at full throttle.

4. Empty bag.

1. Always run engine at full throttle.

2. Replace chipper blade or see your Sears

Service Center.

NOTE: For repairs beyond the minor adjustments listed above, please contact your local Sears Service Center.

15

Page 16

PARTS LIST

Sears Craftsman 4.5 H.P. Yard Vacuum Model 247.770100

2

Ground To

Mounting Bracket

To Engine

12

13

19

4

10

11

13

1

39

3

5

6

8

17

7

9

14

18

16

35

26

34

23

33

7

21

24

27

28

15

29

22

7

20

5

16

25

30

31

32

37

36

36

38

36

16

Page 17

Sears Craftsman 4.5 H.P. Yard Vacuum Model 247.770100

Ref.

No.

1. 725-1700 Switch Cover

2. 725-3166 Safety Switch

3. 710-0224 Hex Washer Screw #10-16 x .50

4. 629-0920 Wire Harness

5. 710-0604A Hex Washer Screw 5/16-18 x .625

6. 714-0104 Cotter Pin

7. 736-0264 Flat Washer.330 ID x.630 OD

8. 732-0962 Compression Spring

9. 781-0778 Mounting Bracket

10. 747-1153 Lock Rod

11. 710-3008 Hex Cap Screw 5/16-18 x .75

12. 681-0122 Chipper Chute Assembly

13. 726-0454 U-Clip Lock Nut 5/16-18

14. 736-0607 External Lock Washer 5/16

15. 710-0502A Hex Washer Screw 3/8-16 x 1.25

16. 710-0969 Screw #12-16 x 1.0

17. 710-3195 Hex Cap Screw 5/16-18 x 4.5

18. 710-3025 Hex Cap Screw 5/16-18 x .625

19. 710-0604A Hex Washer Screw 5/16-18 x .625

20. 781-0720 Upper Housing

Part No. Part Description

Ref.

No.

21. 710-1054 Hex Screw 5/16-24 x 1.0

22. 781-0490 Chipper Blade

23. 736-0119 Lock Washer 5/16

24. 712-0411 Hex Lock Nut 5/16-24

25. 681-0152 Impeller Assembly

26. 719-0329 Flail Blade

27. 781-0735 Pin Clip

28. 711-1401 Clevis Pin

29. 715-0166 Spiral Pin

30. 736-0247 Flat Washer.375 ID x 1.25 OD

31. 736-0217 Lock Washer 3/8

32. 710-0818 Hex Cap Screw 3/8-24 x 2.0

33. 681-0154 Screen Assembly

34. 710-3038 Hex Cap Screw 5/16-18 x .875

35. 781-0721 Lower Housing

36. 712-3004A Lock Nut 5/16-18

37. 731-1905 Nozzle Cover

38. 712-0158 Lock Nut 5/16-18

39. 731-1613 Safety Switch Cover

Part No. Part Description

NOTE: For painted parts, please refer to the list of color codes below. Please add the applicable color code, wherever needed,

to the part number to order a replacement part. For i nstance, if a part, numbered 700-xxxx, is painted polo green, the part number to order would be 700-xxxx-0689.

Polo Green: 0689

Oyster Grey: 0662

Powder Black: 0637

17

Page 18

Sears Craftsman 4.5 H.P. Yard Vacuum Model 247.770100

35

11

2

4

3

5

7

9

10

6

8

9

11

1

5

12

22

12

12

14

14

17

23

12

13

17

27

25

28

31

14

26

32

29

15

30

18

16

17

19

33

21

18

20

34

33

21

18

Page 19

Sears Craftsman 4.5 H.P. Yard Vacuum Model 247.770100

Ref.

No.

1. 720-0295 Foam Grip

2. 749-0438C Upper Handle

3. 720-0279 Knob

4. 710-1205 Eye Bolt

5. 720-0276 Handle Knob 5/16-18

6. 710-1174 Carriage Bolt

7. 749-0907A Lower Handle

8. 664-0094 Bag Assembly

9. 711-1293 Studs

10. 712-0397 Wing Nut 1/4-20

11. 710-0703 Carriage Screw 1/4-20 x .75

12. 726-0453 Lock U-Clip Nut 3/8-16

13. 781-0777 Rear Wheel Support Brace

14. 712-3004A Flange Lock Nut 5/16-18

15. 714-0104 Cotter Pin

16. 681-0155 Handle Bracket Ass”y LH

17. 710-3025 Hex Cap Screw 5/16-18 x .625

Part No. Part Description

681-0156 Hndle Brkt Ass”y RH (Not Shown)

Ref.

No.

18. 736-0105 Bell Washer.401 ID x.870 OD

19. 734-1992 Wheel 9 x 2

20. 738-1015 Shoulder Screw 3/8-16

21. 731-0981A Hubcap

22. 781-0725 Front Wheel Support Brace

23. 781-0765 Hgt Bracket Adjuster LH

25. 748-0417 Pivot Arm

26. 747-1100 Handle Height Adjuster

27. 738-1017 Shoulder Screw 3/8-16

28. 732-0864 Height Adjuster Plate Spring

29. 710-0653 Hex Washer Screw 1/4-20 x .375

30. 782-0578 Spring Lever Support Brack et

31. 710-0642 Hex Washer Screw 1/4-20 x .75

32. 734-1978 Wheel 8 x 2

33. 736-0232 Wav e Washer .531 ID x .781 OD

34. 738-0213 Shoulder Screw

35. 631-0090 Blower Chute Assembly

Part No. Part Description

781-0766 Hgt Bracket Adj RH (Not Shown)

NOTE: For painted parts, please refer to the list of color codes below. Please add the applicable color code, wherever needed,

to the part number to order a replacement part. For i nstance, if a part, numbered 700-xxxx, is painted polo green, the part number to order would be 700-xxxx-0689.

Polo Green: 0689

Oyster Grey: 0662

Powder Black: 0637

19

Page 20

Sears Craftsman 4.5 H.P. Engine Model No. 143.004500

For Yard Vacuum Model 247.770100

370K

390

215

204

223

417

182

416

130

209

203

185

186

184

178

279

135

275

200

277

206

239

245A

400

224

380

125

179

207

120

280

900

150

110

279A

42

174

260

119

172

126

83

82

80

370R

110A

151A

41

48

169

261

324

150

245

101

151

81

43

90

2

50

30

52

45

103

75

45

100

93

92

12A

313

20

16

89

72

262

285

6

73

287

370A

260

1

14

19

17

18

46

72A

69

70

86

301

300

292

290

292

7

15

310

307

309

305

306

238

240

20

Page 21

Sears Craftsman 4.5 H.P. Engine Model No. 143.004500

For Yard Vacuum Model 247.770100

Ref.

No.

1. 37266 Cylinder

2. 26727 Dowel Pin

6. 33734 Breather Element

7. 37247 Breather Ass’y

12A. 36558 Breather Cover & Tube

14. 28277 Washer

15. 30589 Governor Rod

16. 34839A Governor Lever

17. 31335 Governor Lever Clamp

18. 651018 Torx Screw 8-32 x 19/64”

19. 36281 Extension Spring

20. 32600 Oil Seal

30. 37527 Crankshaft

40. 40027 Piston, Pin & Ring Set (Std)

41. 40025 Piston & Pin Ass’y (Std)

42. 40006 Ring Set (Std)

43. 20381 Piston Pin Retaining Ring

45. 36777 Connecting Rod Ass’y

46. 32610A Connecting Rod Bolt

48. 27241 Valve Lifter

50. 37460 Camshaft

52. 29914 Oil Pump Ass’y

69. 35261 Mounting Flange Gasket

70. 36249B Mounting Flange

72. 30572 Oil Drain Plug

72A. 28534 Oil Drain Plug

73. 28833 Drain Plug Gasket

75. 27897 Oil Seal

80. 30574A Governor Shaft

81. 30590A Washer

82. 30591 Governor Gear Ass’y

83. 30588A Governor Spool

86. 650488 Screw 1/4-20 x 1-1/4

89. 611004 Flywheel Key

90. 611112 Flywheel

92. 650815 Bell Washer

93. 650816 Flywheel Nut

100. 34443B Solid State Ignition

101. 610118 Spark Plug Cover

103. 651007 Torx Screw 10- 24 x 15/16”

104. 37480 Cam Bushing

110. 37574 Ground Wire

110A. 37331 Ground Wire

119. 36787 Cylinder Head Gasket

120. 36825 Cylinder Head

125. 37288 Exhaust Valve

126. 37289 Intake Valve

130. 6021A Screw 5/16-18 x 1-1/2”

135. 35395 Resistor Spark Plug

150. 31672 Valve Spring

151. 31673 Valve Spring Cap

151A. 40017 Intake Valve Seal

Part No. Part Description

40028 Piston, Pin & Ring Set (.010” OS)

40026 Piston & Pin Ass’y (.010” OS)

40007 Ring Set (.010” OS)

Ref.

No.

169. 36783 Valve Cover Gasket

172. 36784 Valve Cover

174. 30200 Screw 10-24 x 9/16”

178. 29752 Nut & Lock Washer 1/4-28

179. 30593 Retainer Clip

182. 6201 Screw 1/4-28 x 7/8”

184. 26756 Carburetor To Intake Pipe Gasket

185. 36785 Intake Pipe

186. 34337 Governor Link

200. 32264A Control Bracket

203. 31342 Compression Spring

204. 651029 Torx Screw 5-40 x 7/1 6”

206. 610973 Terminal

207. 34336 Throttle Link

209. 30200 Screw 10-24 x 9/16”

215. 32410 Control Knob

223. 650451 Screw 1/4-20 x 1”

224. 36786 Intake Pipe Gasket

238. 650806 Screw 10-32 x 1/2”

239. 34338 Air Cleaner Gasket

240. 37115 Air Cleaner Body

245. 37116 Air Cleaner Filter

245A. 37117 Pre-Air Cleaner Filter

250. 37118 Air Cleaner Cover

260. 37151 Blower Housing

261. 30200 Screw 10-24 x 9/16”

262. 650831 Screw 1/4-20 x 1/2”

275. 36790A Muffler

277. 650988 Screw 1/4-20 x 2-5/16”

279. 650737 Screw 1/4-20 x 1/2”

279A. 650902 Screw 10-32 x 7/16”

280. 37171A Heat Shield

285. 35000A Starter Cup

287. 650926 Screw 8-32 x 21-64”

290. 34357 Fuel Line

292. 26460 Fuel Line Clamp

300. 35586 Fuel Tank

301. 36246 Fuel Cap

305. 35577 Oil Fill Tube

306. 36996 O-Ring

307. 35499 O-Ring

309. 650562 Screw 10-32 x 1/2”

310. 35578 Dipstick

313. 34080 Spacer

324. 33177 Terminal

370A. 36261 Lubrication Label

370K. 36695 Starter Label

370R. 37317 Warning Label

370S. 37590 Instruction / Primer Label

380. 640278 Carburetor

390. 590737 Rewind Starter

400. 36792B Gasket Set

416. 36085 Spark Arrestor

417. 650821 Screw 10-32 x 1/2”

900. 750856A Short Block

Part No. Part D escription

21

Page 22

Sears Craftsman 4.5 H.P. Engine Model No. 143.004500

For Yard Vacuum Model 247.770100

1

10

2

11

7

6

18

4

4

5

16

17

20A

35

20

25

28

48

47

3

14

7

29

30

31

27

37

36

37

60

44

40

22

Page 23

Sears Craftsman 4.5 H.P. Engine Model No. 143.004500

For Yard Vacuum Model 247.770100

Ref.

No.

1. 631615 Throttle Shaft & Lever Assembly

2. 631767 Throttle Return Spring

3. 640278 Carburetor

4. 631184 Dust Seal Washer

5. 631183 Dust Seal

6. 640070 Throttle Shutter

7. 650506 Shutter Screw

10. 630973 Choke Shaft & Lever Assembly

11. 632045 Choke Return Spring

14. 640150 Choke Shutter

16. 631807 Fuel Fitting

17. 651025 Idle Speed Screw

18. 630766 Tension Spring

20. 640027 Idle Restrictor Screw

20A. 640053 Idle Jet Cap

Part No. Part Description

Ref.

No.

25. 631867 Float Bowl

27. 631024 Float Shaft

28. 632019 Float

29. 631028 Float Bowl O-Ring

30. 631021 Inlet Needle, Seat, & Clip

31. 631022 Spring Clip

35. 640259 Primer Bulb

36. 632735 Main Nozzle Tube

37. 632547 Main Nozzle Tube O-Ring

40. 640050 High Speed Bowl Nut

44. 27110A Bowl Nut Washer

47. 630748 Idle Mixture Well Plug

48. 631027 Atmospheric Vent Plug

60. 632760 Repair Kit

Part No. Part Description

23

Page 24

Sears Craftsman 4.5 H.P. Engine Model No. 143.004500

For Yard Vacuum Model 247.770100

13

12

11

9

7

6

4

5

2

1

8

7

6

3

Ref.

No.

1. 590599A Spring Pin

2. 590600 Washer

3. 590696 Retainer

4. 590601 Washer

5. 590697 Brake Spring

6. 590698 Starter Dog

7. 590699 Dog Spring

8. 590700 Pulley & Rewind Spring Ass’y

9. 590694 Recoil Starter

11. 590695 Starter Housing Ass’y

12. 590535 Starter Rope

13. 590701 Starter Handle

Part No. Part Description

Ref.

No.

1. 590737 Rewind Starter

3. 590740 Retainer

6. 590616 Starter Dog

7. 590617 Dog Spring

8. 590618A Pulley & Rewind Spring Ass’y

11. 590687A Starter Housing Ass’y

12. 590535 Starter Rope

13. 590701 Starter Handle

14. 590760 Spring Clip

Part No. Part Description

13

12

14

1

7

6

11

8

3

24

Page 25

CONTENIDO

Contenido Página

Garantía 25

Seguridad 26

Montaje 28

Operación 30

Mantenimiento 33

Contenido Página

Servicio y ajustes 35

Almacenamiento 38

Localización de averías 39

Lista de repuestos 16

GARANTIA

Garantía de un año sobre la aspiradora para jardines Craftsm an

Por un período de un año a partir de la fecha de compra, Sears reparará gratis cualquier defecto en el material o

fabricación de esta aspiradora para jardines Craftsman, siempre y cuando haya sido mantenida, lubricada y

afinada de acuerdo a las instrucciones de manejo y mantenimiento dadas en el manual del operador.

Esta garantía excluye las cuchillas, cuchillas astilladoras, flagelos, filtros de aire, bujías, recolectores y

neumáticos, consideradas piezas consumibles que se gastan durante el uso normal.

LA GARANTIA DE SERVICIO ESTA DISPONIBLE PONIENDOSE EN CONTACTO CON EL CENTRO DE

SERVICIO SEARS MAS CERCANO EN EE.UU. ESTA GARANTIA TIENE VALIDEZ SOLAMENTE MIENTRAS

EL PRODUCTO SE ENCUENTRA EN USO EN LOS ESTADOS UNIDOS.

Esta garantía le da derechos legales específicos, y usted puede tener otros derechos los cuales varían de un

estado a otro.

Sears, Roebuck and Co., D/817WA, Hoffman Estate s, Il 60179

ASPIRADORA PARA JARDINES

ATENCION: An tes de usar este producto, lea este manual y res pete todas

las reglas de seguridad e instrucciones de manejo.

ESPECIFICACIONES DEL PRODUCTO

Potencia: 4.5 caballos de fuerza

Tipo de aceite de motor SAE 30

Capacidad de acei te de mot or 20 onzas

Capacidad de combustible: 1 1/2 cuartos de galón

Bujía Champion RJ-19LM

Distancia entre electrodos

Número de modelo ............ ............. .......... ..........

Número de serie............ ............. .......... ............. ..

Fecha de compra..... .......... ...... .......... ....... ......... ..

Anote el núm ero de s erie y l a fech a de compr a y

guárdelos en un lugar seguro para usar de

referencia en el futuro.

247.770100

25

Page 26

SEGURIDAD

ADVERTENCIA: Este sím bolo indica instrucciones de seguridad muy importantes las que, si no

se siguen, podrían poner en peligro la seguridad personal y/o causar daños físicos. Antes de

intentar manejar esta aspiradora para jardines, se debe leer y seguir todas las instrucciones que

aparecen en este manual. Si no se cumplen estas instrucciones se corre el riesgo de sufrir lesiones.

Cuando en el manual aparece este símbolo, respetar su a dvertencia.

ADVERTENCIA: El gas de escape emitido por el motor de esta máquina contiene componentes

químicos que en el Estado de California son considerados como causantes de cáncer, defectos de

nacimiento u otros daños a los órganos de la reproducción.

ADVERTENCIA: La aspiradora para jardines fue fabricada para ser manejada de acuerdo a las reglas

de seguridad descritas en este m anual. Como sucede con cualquier tipo de equipo motorizado, el descuido

o error de parte del operador puede tener como resultado graves lesiones. Esta máquina es capaz de

amputar dedos y manos y lanzar objetos con fuerza. Si no se siguen las instrucciones de seguridad

siguientes se está expuesto a sufrir graves lesiones o la muerte.

OPERACION EN GENERAL

• Leer todo este manual del operador

cuidadosamente antes de intentar armar la

máquina. Leer, comprender y seguir todas las

instrucciones que se encuentran en la máquina y

en el manual (manuales) antes de manejarla.

Aprender completamente el manejo de los

controles y el uso correcto de la máquina antes de

manejarla. Guardar este manual en un lugar

seguro para usarlo como un libro de consulta en el

futuro y cuando sea necesario pedir piezas de

repuesto.

• La aspiradora para jardines es una herramienta

muy potente, no es un juguete. Por lo tanto, actuar

con sumo cuidado en todo momento. La máquina

fue diseñada para astillar, triturar, aspirar y soplar

(cuando está equipada con el accesorio) la

vegetación encontrada en un jardín o patio normal.

No se debe usar para ningún otro propósito.

• No dejar nunca que niños menores de 16 años de

edad manejen esta máquina. Los niños mayores

de 16 años siempre deben manejarla bajo la

supervisión de un adulto. Solamente debe

permitírseles manejar esta máquina a las personas

responsables que conozcan bien estas reglas de

seguridad de manejo.

• Mantener el lugar de trabajo despejado de

personas, especialmente niños pequeños. Apagar

el motor cuando se encuentren cerca de la

máquina.

• Cuando se esté introduciendo material a este

equipo, tener mucho cuidado de no incluir pedazos

de metal, rocas, botellas, latas u otros objetos

extraños. Se podría causar lesiones personales o

dañar la máquina.

• Siempre usar anteojos o gafas de seguridad,

durante el manejo y mientras se hacen ajustes o

reparaciones, para protegerse los ojos contra

objetos extraños que puedan ser lanzados por la

máquina.

• Usar zapatos de trabajo gruesos y con suela

áspera, y pantalones y camisa bien ceñidos. Se

recomienda usar camisas y pantalones que cubran

los brazos y las piernas, y zapatos con puntas de

acero. No usar ropa suelta o joyas, y atarse el

cabello más arriba de los hombros. Pueden quedar

atrapados en las piezas en movimiento. Nunca

manejar la máquina descalzo, con sandalias o

zapatillas. Ponerse guantes para introducir el

material en el tubo de triturado.

• No manejar la máquina si se ha ingerido alcohol o

drogas.

• No tratar de alcanzar más lejos de lo normal.

Mantener bien apoyado los pies y buen equilibrio

en todo momento.

• No poner nunca las manos ni ninguna parte del

cuerpo o indumentaria cerca de las piezas que

están girando. Siempre mantenerse alejado de las

bocas de descarga. Nunca meter las manos ni

ninguna parte del cuero o indumentaria en la

boquilla, tubo de triturar o boca de descarga, pues

el rotor giratorio puede causar graves lesiones.

• Si por cualquier razón es necesario desatascar la

toma de alimentación o la boca de descarga o

inspeccionar o reparar alguna pieza de la máquina

en una parte donde una pieza en movimiento

podría quedar en contacto con el cuerpo o

indumentaria, apagar el motor, esperar hasta que

se enfríe, desconectar el cable de la bujía y

apartarlo de la bujía antes de intentar desatascar,

inspeccionar o reparar.

• Nunca manejar la máquina sin que tenga instalado

el recolector de la aspiradora o, si está equipada

con tubo soplador, bien conectado a la máquina. El

extremo abierto grande del recolector (bolsa) debe

estar cerrado para impedir que salgan objetos

soplados por la parte trasera del recolector.

• Cuando se trabaje con la función de soplador (esta

máquina puede tener incluido el accesorio de tubo

de soplado opcional):

• No situarse ni caminar delante de la boca de

descarga del soplador ni apuntársela a las

personas, animales, vehículos, etc. que se

encuentren cerca. Los objetos que salen

lanzados por la boca de descarga puede

causar lesiones personales o daños a la

propiedad.

• No dirigir la descarga del soplador contra una

pared u otra obstrucción vertical. El material

descargado puede rebotar hacia el operador.

• Ajustar la altura de la boquilla de aspiración a

la posición más alta para reducir la posibilidad

de que aspiren objetos más pesados (por ej.,

26

Page 27

piedras, pedazos de vidrio o de metal) y sean

lanzados por la boca de descarga. Al elevar la

boquilla a la posición más alta también

incrementa la admisión de aire para lograr

mejor funcionamiento del soplado r.

• No intentar nunca retirar o vaciar el recolector

mientras el motor está funcionando. Apagar el

motor y esperar hasta que el rotor esté detenido

antes de retirar el recolector (bolsa). El rotor

continúa girando por algunos segundos después

de apagar el motor. Nunca acercar ninguna parte

del cuerpo al área del rotor sin antes asegurarse

de que ha parado de girar.

• Mantener todos los protectores y dispositivos de

seguridad en su lugar y en buen estado de

funcionamiento.

• No dejar que se acumule material tratado en el

área de descarga, pues impedirá la descarga

adecuada.

• Cuando se introduzca material en la astilladora, no

situarse con la cara o el cuerpo directamente

delante del tubo de la astilladora. Situarse a un

lado. El material que se está introduciendo puede

rebotar fuera del tubo.

• Si el mecanismo de corte choque con un objeto

extraño o si la máquina empieza a hacer un ruido o

vibración inusual, apagar inmediatamente el motor,

desconectar el cable de la bujía y apartarlo de la

bujía. Dejar que la máquina se pare y proceder de

la manera siguiente:

• Buscar si hay daño

• Reparar o cambiar las pi ezas dañadas.

• Buscar piezas flojas y apretarlas para asegurar

un buen funcionamiento.

• El silenciador y el motor se calientan y puede

causar quemaduras. No tocarlos.

• No dejar que las hojas u otros desechos se

acumulen en el silenciador del motor. Los desechos

pueden encender se y causar un incendio.

• No hacer funcionar el motor si el filtro de aire o la

tapa encima de la toma de aire del carburador no

está colocada. El retiro de dichas piezas puede

crear un peligro de incendio.

NIÑOS

Pueden ocurrir accidentes de trágicas consecuencias si el

operador no está alerta a la presencia de niños pequeños.

Los niños son frecuentemente atraídos a los lugares

donde se está astillando y aspirando hojas, ramas, etc.

Nunca suponer que los niños van a permanecer en el

lugar donde se les vio la última vez.

• No dejar que los niños se acerquen al lugar de

trabajo y mantenerlos vigilados por un adulto

aparte del operador.

• Estar alerta y apagar el motor si un niño se

aproxima al lugar.

• Nunca permitir que niños menores de 16 años de

edad manejen la aspiradora para jardines.

SERVICIO

• Tener sumo cuidado cuando se maneje gasolina y

otros combustibles. Son muy inflamab les y sus

vapores son explosivos.

• Guardar el combustible y el aceite en

contenedores aprobados, lejos del calor y

llamas expuestas, y lejos del alcance de los

niños.

• Revisar el nivel y cargar combustible antes de

arrancar el motor. Nunca quitar la tapa del

tanque de combustible ni añadir combustible

mientras el motor está funcionando. Siempre

dejar que el motor se enfríe por lo menos

durante dos minutos antes de cargar

combustible.

• Antes de arrancar el motor, colocar la tapa del

tanque de gasolina bien apretada y li mpiar con

un trapo la gasolina que pueda haberse

derramado ya que podría causar un incendio o

explosión.

• Apagar los cigarrillos, cigarros, pipas y otras

fuentes de ignición.

• Nunca cargar combustible en el interior de

edificios porque pueden acumularse vapores

inflamables en el área.

• Nunca guardar la máquina o el contenedor de

combustible en interiores donde haya una

llama expuesta o chispas, como por ejemplo,

un calentador de agua caliente, secadora de

ropa o un calefactor de gas.

• No hacer funcionar nunca la máquina en un lugar

cerrado pues el gas de escape del motor contiene

monóxido de carbono, el cual es un gas inodoro,

insípido y mortalmente venenoso.

• Para reducir el peligro de incendio, mantener el

motor y el silenciador libres de hojas, pasto y otra

acumulación de desechos. Limpiar el combustible y

aceite derramado. Dejar que la máquina se enfríe

durante por lo menos 5 minutos antes de guardarla.

• Antes de limpiar reparar o inspeccionar, cerciorarse

de que el rotor y todas las piezas móviles se hayan

detenido. Desconectar el cable de la bujía y

apartarlo de la bujía para impedir el arranque

accidental del motor. No usar soluciones

inflamables para limpiar el filtro de aire.

• Mantener todas las tuercas, pernos y tornillos

apretados para asegurar que el equipo esté en

buenas condiciones de funcionamiento.

• Nunca estorbar los dispositivos de seguridad.

Probar su funcionamiento periódicamente.

• Después de chocar con un objeto extraño, apagar

inmediatamente el motor, desconectar el cable de

la bujía y hacer una inspección minuciosa de la

máquina en busca de algún daño. Reparar el daño

antes de arrancar el motor y manejar la máquina.

• No alterar ni estorbar el ajuste del gobernador del

motor. El gobernador controla la velocidad máxima

segura del motor. El hacer funcionar el motor a

sobrevelocidad es peligroso y se dañará el motor y

las otras piezas móviles de la máquina.

• Revisar el recolector (bolsa) de la aspiradora

frecuentemente. Cambiarlo si está desgastado o

dañado.

• Mantener el recolector sin desechos cuando no

esté en uso.

27

Page 28

Tubo de

soplado

MONTAJE

NOTE: Para determinar los lados derecho e

izquierdo de la aspiradora para jardines, situarse

detrás de la máquina, en po sición de man ejarla. Ver

la figura 1.

La aspiradora para jardines fue armada en la fábrica,

con la excepción del manillar, recolector y tubo de

soplado. Estos componentes se envían suelt os en la

caja de cartón. En la caja también se incluyen

anteojos de seguridad y una botella de 20 onzas de

aceite para motor. Ver la figura 1.

DESEMBALAJE

• Cortar las esquinas de la caja.

• Quite todas las piezas flojas.

• Quite el material de embalaje.

• Levante la unidad de la parte posterior para

desechar el material de embalaje de la unidad

inferior y de la unidad del rodillo de cartón.

• Controle el cartón a conciencia para saber si hay

cualquier otra pieza floja.

Guía de

la cuerda

Botella de 20 oz.

aceite para

motor

Manillar

inferior

Tuercas de

mariposa

Tornillo de

carruaje

Tuercas de

mariposa

Tuerca de

mariposa

Manillar

superior

Bolsa

PIEZAS SUELT AS

Ver la figura 1

• Montaje del manillar

• Recolector (bolsa)

• Montaje del tubo de soplado

• Anteojos de seguridad (no se muestran)

• Botella de 20 onzas de aceite para motor

• Manual del operador

DESCONEXION DE LA BUJIA

Antes de co menzar a armar l a nueva a spirado ra para

jardines, desconectar el cable de la bujía y conectarlo

a tierra en el pil ar rete nedor en el mot or. Es to

impedirá el arranque accidental del motor. Ver la

figura 2.

Pilar retene d or

Cable

de bujía

Figura 2

Figura 1

IMPORT ANT :

gasolina y sin acei te en el motor. Despué s de

armarla, ver la sección OPERACION en este manual

para informarse sobre el llenado de aceite del motor y

el tipo de combustible.

Esta máquina salió de fábrica sin

INST ALACION DEL MANILLAR

• Plegar el manillar superior hasta que quede

alineado con el manillar inferior. Ver la figura 1.

• Fijarl o bie n apreta ndo la s tuerc as de mar iposa

superiores, las cuales conectan juntos los dos

manillares.

28

Page 29

• Retirar las chavetas de las escuadras del

manillar y los tornillos de carruaje (cabeza de

hongo y cuello cuadrado) y tuercas de mariposa

del manillar inferior. Ver la figura 3.

• Colocar el manillar inferior sobre los pasadores

en las escuadras y fijarlos con las chavetas,

tornillos de carruaje y tuercas de mariposa.

Tuercas de

mariposa

Pasador

Escuadras

del manillar

Manillar

inferior

Tornillo de

carruaje

Chaveta

• Deslizar el recolector por encima del borde de la

boca de descarga y soltar la varilla de fijación

para sujetar el recolector en su lugar.

• Colocar las correas inferiores del recolector

sobre el manillar inferior, enganchándolas en los

espárragos.

• Encajar el clip del recolector en la parte superior

del manillar inferior.

NOTE: Cuando se coloque el recolector en la

máquina, el botón interruptor de seguridad adosado

a la escuadra de montaje debe quedar totalmente

oprimido por la lengüeta delantera ubicada en el

mango del recolector, de lo contrario el motor no

arrancará.

INST ALACION DEL TUBO DE SOPLADO

NOTE: Antes de instalar el tub o de so plado s e debe

retirar el recolector.

Figura 3

• En el lado derecho del manillar superior se

encuentra una guía para la cuerda. Aflojar la

tuerca de mariposa que sujeta la guía.

• Tirar la cuerda de arranque fuera del motor

lentamente y deslizarla a través de la guía.

Apretar la tuerca de mariposa.

INST ALACION DEL RECOLECTOR

Manillar

inferior

Bag

Stud

Locking

Rod

To Engine

Handle

Front

Tab

Bag

Clip

Front

Tab

Strap

• Asir el t ubo de s oplado con una mano y, co n la

otra mano, tirar de la varilla de fijación en la

escuadra de montaje hacia el motor.

5.

Ver la figura

• Desliza r el tu bo de sop lado por encima del

borde de la boca de descarga y soltar la varilla

de fijaci ón para s ujet ar el tubo en su lu gar.

• Cuando se va a usar el tubo de soplado, elevar la

boquilla a la posición más alta. Ver el ajuste de la

boquilla en la sección AJUSTES.

NOTE: El botón inter ruptor de segurid ad adosado a

la escuadra de montaje debe quedar totalmente

oprimido por la lengüeta de lantera ubicada en tubo

de soplado, de lo contrario el motor no arrancará.

Front

Tab

Blower

Chute

Front

Tab

Safety

Switch

Bag/Chute

Switch

Stud

Figura 4

• Asir el mango del recolector con una mano y, con

la otra mano, tirar de la varilla de fijación en la

escuadra de montaje hacia el motor.

Ver la figura 4.

Locking

Rod

Figura 5

29

Page 30

OPERACION

Conozca su aspiradora para jardines

Lea este manual del operador y las reglas de seguridad antes de manejar su aspiradora para jardines.

Compare las ilustraciones presentadas más abajo con su equipo para que conozca bien la ubicación de los

distintos contro les y ajustes . Guard e este manual para co nsulta rlo e n el futu ro.

USE SUS

ANTEOJOS DE

SEGURIDAD

SEGURIDAD

MAS VALE PREVENIR

QUE CURAR

El manejo de cualquier aspiradora para jardines sopladora puede causar el lanzamiento de

objetos extraños contra los ojos y lesionarlos gravemente. Use siempre los anteojos de

seguridad, suministrados con la aspiradora para jardines Craftsman, para manejar este

equipo o mientras le hace trabajos de ajuste o reparación.

Mango de arranque

Recolector

(bolsa)

Palanca de estrangulador/

control del acelerador

Mango del

recolector

Cebador

Tubo de soplado

Tubo de

astillado

Palanca de ajuste

de altura de la boquilla

CONTROLES DE OPERACION

Tubo de astillado

Permite introducir ramillas y ramas pequeñas de

hasta 1-1/2" de diámetro en el rotor para astillarlas.

Boquilla