Page 1

Operator’s Manual

YARD VACUUM

Model No. 247.77003

CAUTION: Before using this product,

read this manual and follow all safety

rules and operating instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

© Sears Brands, LLC

• SAFETY

• UNPACKING

• ASSEMBLY

• OPERATION

• MAINTENANCE

• ESPAÑOL

Visit our website: www.craftsman.comUsed Under License

Form No. 769-15410

(May 22, 2018)

Page 2

TABLE OF CONTENTS

Warranty Statement ..............................Page 2

Safe Operation Practices ......................Pages 3-5

Unpacking .......................................Page 6

Assembly .....................................Pages 7-9

Operation ..................................Pages 10-14

Service & Maintenance ......................Pages 15-19

Off-Season Storage ............................. Page 20

Troubleshooting .............................Page 21-22

Español ........................................ Page 24

WARRANTY STATEMENT

CRAFTSMAN LIMITED WARRANTY

FOR TWO YEARS from the date of sale, this product is warranted against defects in material or workmanship.

WITH PROOF OF SALE, a defective product will receive free repair. If the product cannot be repaired it will be replaced free of charge.

For warranty coverage details to obtain free repair, visit the web page: www.craftsman.com/warranty

This warranty covers ONLY defects in material and workmanship. Warranty coverage does NOT include:

• Expendable items that can wear out from normal use within the warranty period, such as the blades, spark plug, air cleaner, flail screen and catcher

bag.

• Product damage resulting from user attempts at product modification or repair or caused by product accessories.

• Repairs necessary because of accident or failure to operate or maintain the product according to all supplied instructions.

• Preventive maintenance, or repairs necessary due to improper fuel mixture, contaminated or stale fuel.

This warranty is void if this product is ever used while providing commercial services or if rented to another person.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

MODEL NUMBERPRODUCT SPECIFICATIONS

Engine Oil: SAE 10w-30

Model Number ________________________________

Fuel: Unleaded Gasoline

Engine: Craftsman

© Sears Brands, LLC

Serial Number _________________________________

Date of Purchase _______________________________

Record the model number, serial number,

and date of purchase above.

2

Page 3

SAFETY INSTRUCTIONS

WARNING

This symbol points out important safety instructions which, if not

followed, could endanger the personal safety and/or property of

yourself and others. Read and follow all instructions in this manual

before attempting to operate this machine. Failure to comply with these

instructions may result in personal injury. When you see this symbol, HEED

ITS WARNING!

WARNING

CALIFORNIA PROPOSITION 65

Engine Exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to State of California to cause cancer and

birth defects or other reproductive harm.

TRAINING

• Read, understand, and follow all instructions on the machine and in the

manual before attempting to assemble and operate. Keep this manual in

a safe place for future and regular reference and for ordering replacement

parts.

• Read the Operator’s Manual and follow all warnings and safety instructions.

Failure to do so can result in serious injury to the operator and/or bystanders.

• Be familiar with all controls and their proper operation. Know how to stop

the machine and disengage them quickly.

• Never allow children under 16 years of age to operate this machine. Children

16 and over should read and understand the instructions and safe operation

practices in this manual and on the machine and be trained and supervised

by an adult.

• Never allow adults to operate this machine without proper instruction.

• Keep bystanders, pets, and children at least 75 feet from the machine while

it is in operation. Stop machine if anyone enters the area.

• Never run an engine indoors or in a poorly ventilated area. Engine exhaust

contains carbon monoxide, an odorless and deadly gas.

• Do not put hands and feet near rotating parts or in the feeding chambers

and discharge opening. Contact with the rotating impeller can amputate

fingers, hands, and feet.

• Never attempt to unclog either the feed intake or discharge opening, remove

or empty bag, or inspect and repair the machine while the engine is running.

Shut the engine off and wait until all moving parts have come to a complete

stop. Disconnect the spark plug wire and ground it against the engine.

PREPARATION

• Thoroughly inspect the area where the equipment is to be used. Remove

all rocks, bottles, cans, or other foreign objects which could be picked up or

thrown and cause personal injury or damage to the machine.

• Always wear safety glasses or safety goggles during operation and while

performing an adjustment or repair, to protect your eyes. Thrown objects

which ricochet can cause serious injury to the eyes.

DANGER

This machine was built to be operated according to the safe operation

practices in this manual. As with any type of power equipment,

carelessness or error on the part of the operator can result in serious injury.

This machine is capable of amputating fingers, hands, toes and feet and

throwing debris. Failure to observe the following safety instructions could

result in serious injury or death.

WARNING

Your Responsibility—Restrict the use of this power machine to

persons who read, understand and follow the warnings and instructions in

this manual and on the machine.

SAVE THESE INSTRUCTIONS!

• Wear sturdy, rough-soled work shoes and close-fitting slacks and shirts.

Loose fitting clothes or jewelr y can be caught in movable parts. Never

operate this machine in bare feet or sandals. Wear leather work gloves when

feeding material in the chipper chute.

• Before star ting, check all bolts and screws for proper tightness to be sure the

machine is in safe working condition. Also, visually inspect machine for any

damage at frequent intervals.

• Maintain or replace safety and instruc tions labels, as necessary.

Safe Handling of Gasoline:

To avoid personal injury or property damage use extreme care in handling

gasoline. Gasoline is extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is spilled on yourself or your

clothes which can ignite. Wash your skin and change clothes immediately.

• Use only an approved gasoline container.

• Never fill containers inside a vehicle or on a truck or trailer bed with a plastic

liner. Always place containers on the ground away from your vehicle before

filling.

• When practical, remove gas-powered equipment from the truck or

trailer and refuel it on the ground. If this is not possible, then refuel such

equipment on a trailer with a portable container, rather than from a gasoline

dispenser nozzle.

• Keep the nozzle in contact with the rim of the fuel tank or container opening

at all times until fueling is complete. Do not use a nozzle lock-open device.

• Extinguish all cigarettes, cigars, pipes and other sources of ignition.

• Never fuel machine indoors.

• Never remove gas cap or add fuel while the engine is hot or running. Allow

engine to cool at least two minutes before refueling.

• Never over fill fuel tank. Fill tank to no more than ½ inch below bottom of

filler neck to allow space for fuel expansion.

• Replace gasoline cap and tighten securely.

• If gasoline is spilled, wipe it off the engine and equipment. Move unit to

another area. Wait 5 minutes before starting the engine.

3

Page 4

SAFETY INSTRUCTIONS

• To reduce fire hazards, keep machine free of grass, leaves, or other debris

build-up. Clean up oil or fuel spillage and remove any fuel soaked debris.

Never store the machine or fuel container inside where there is an open flame, spark

or pilot light as on a water heater, space heater, furnace, clothes dryer or other gas

appliances.

OPERATION

• Do not put hands and feet near rotating parts or in the feeding chambers

and discharge opening. Contact with the rotating impeller can amputate

fingers, hands, and feet.

• Before star ting the machine, make sure the chipper chute, feed intake, and

cutting chamber are empty and free of all debris.

• Thoroughly inspect all material to be shredded and remove any metal, rocks,

bottles, cans, or other foreign objects which could cause personal injury or

damage to the machine.

• If the impeller strikes a foreign object or if your machine should start making

an unusual noise or vibration, immediately shut the engine of f. Allow the

impeller to come to a complete stop. Disconnect the spark plug wire, ground

it against the engine and perform the following steps:

a. Inspect for damage.

b. Repair or replace any damaged parts.

c. Check for any loose parts and tighten to assure continued safe

operation.

• Do not allow an accumulation of processed material to build up in the

discharge area. This can prevent proper discharge and result in kickback of

material through the feed opening.

• Do not attempt to shred or chip material larger than specified on the

machine or in this manual. Personal injur y or machine damage could result.

• Never attempt to unclog either the feed intake or discharge opening while

the engine is running. Shut the engine off, wait until all moving parts have

stopped, disconnec t the spark plug wire and ground it against the engine

before clearing debris.

• Never operate without vacuum bag and discharge chute properly attached

to the machine. Never empty or change vacuum bag while the engine is

running. Vacuum bag must be kept closed at all times during operation.

• Never operate without either the inlet nozzle or optional hose attachment

(if applicable) properly attached to the machine. Never attempt to attach or

change either attachment while the engine is running.

• Keep all guards, deflectors and safety devices in place and operating

properly.

• Keep your face and body back and to the side of the chipper chute while

feeding material into the machine to avoid accidental kickback injuries.

• Never operate this machine without good visibility or light. Always be sure of

your footing and keep a firm hold on the handles.

• Do not operate this machine on a paved, gravel or non-level surface.

• Do not operate this machine while under the influence of alcohol or drugs.

• Muffler and engine become hot and can cause a burn. Do not touch.

• Never pick up or carry machine while the engine is running.

• If situations occur which are not covered in this manual, use care and good

judgement.

MAINTENANCE & STORAGE

• Never tamper with safety devices. Check their proper operation regularly.

• Check bolts and screws for proper tightness at frequent intervals to keep the

machine in safe working condition. Also, visually inspect machine for any

damage and repair, if needed.

• Before cleaning, repairing, or inspecting, stop the engine and make certain

the impeller and all moving parts have stopped. Disconnect the spark plug

wire and ground it against the engine to prevent unintended starting.

• Do not change the engine governor settings or overspeed the engine. The

governor controls the maximum safe operating speed of the engine.

• Maintain or replace safety and instruc tion labels, as necessary.

• Follow this manual for safe loading, unloading, transporting, and storage of

this machine.

• Never store the machine or fuel container inside where there is an open

flame, spark or pilot light such as a water heater, furnace, clothes dryer, etc.

• Allow machine to cool at least 5 minutes before storing.

• Always refer to the operator’s manual for proper instructions on off-season

storage.

• If the fuel tank has to be drained, do this outdoors.

• Observe proper disposal laws and regulations for gas, oil, etc. to protect the

environment.

• According to the Consumer Products Safety Commission (CPSC) and the U.S.

Environmental Protection Agency (EPA), this product has an Average Useful

Life of seven (7) years, or 60 hours of operation. At the end of the Average

Useful Life have the machine inspected annually by an authorized service

dealer to ensure that all mechanical and safety systems are working properly

and not worn excessively. Failure to do so can result in accidents, injuries or

death.

DO NOT MODIFY ENGINE

To avoid serious injury or death, do not modify engine in any way. Tampering

with the governor setting can lead to a runaway engine and cause it to

operate at unsafe speeds. Never tamper with factory setting of engine

governor.

NOTICE REGARDING EMISSIONS

Engines which are certif ied to comply with California and federal EPA

emission regulations for SORE (Small Off Road Equipment) are certified

to operate on regular unleaded gasoline, and may include the following

emission control systems: Engine Modification (EM), Oxidizing Catalyst (OC),

Secondary Air Injection (SAI) and Three Way Catalyst (TWC) if so equipped.

4

Page 5

SAFETY INSTRUCTIONS

SPARK ARRESTOR

WARNING

This machine is equipped with an internal combustion engine and should

not be used on or near any unimproved forest-covered, brushcovered or

grass-covered land unless the engine’s exhaust system is equipped with a

spark arrestor meeting applicable local or state laws (if any).

If a spark arrestor is used, it should be maintained in effective working order

by the operator. In the State of California the above is required by law (Section

4442 of the California Public Resources Code). Other states may have similar

laws. Federal laws apply on federal lands.

To obtain a spark arrestor for the muffler, call Craf tsman at 1-888-331-4569.

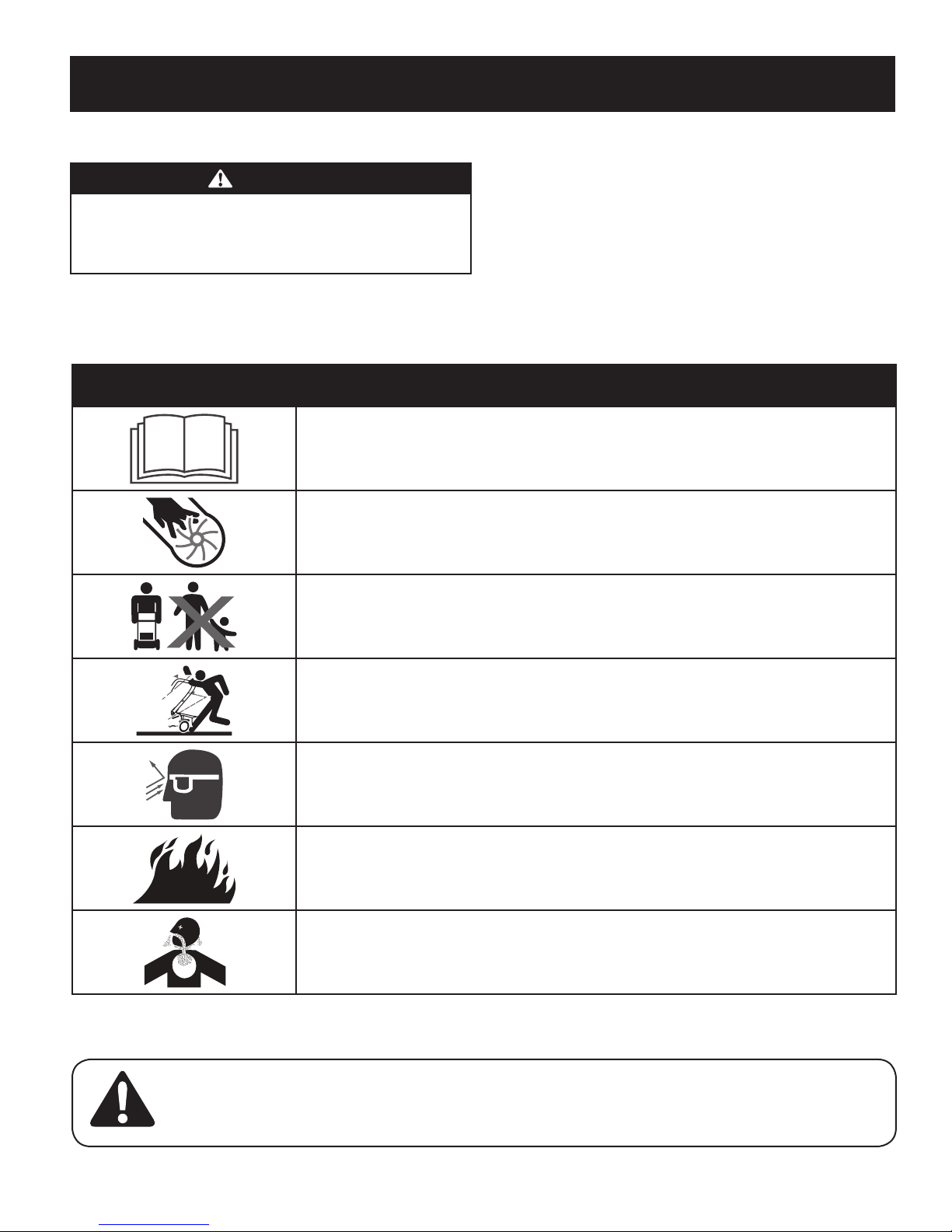

SAFETY SYMBOLS

This page depic ts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the machine before

attempting to assemble and operate.

Symbol Description

READ THE OPERATOR’S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING— ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

BYSTAN DERS

Keep bystanders, pets, and children at least 75 feet from the machine while it is in operation. Stop

machine if anyone enters the area.

WARNING— THROWN OBJECTS

This machine may pick up and throw and objects which can ricochet.

EYE PROTECTION

Always wear safety glasses or safety goggles when operating this machine.

WARNING—GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING— CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING: Your Responsibility—Restrict the use of this power machine to persons who read, understand and follow

the warnings and instructions in this manual and on the machine.

SAVE THESE INSTRUCTIONS!

5

Page 6

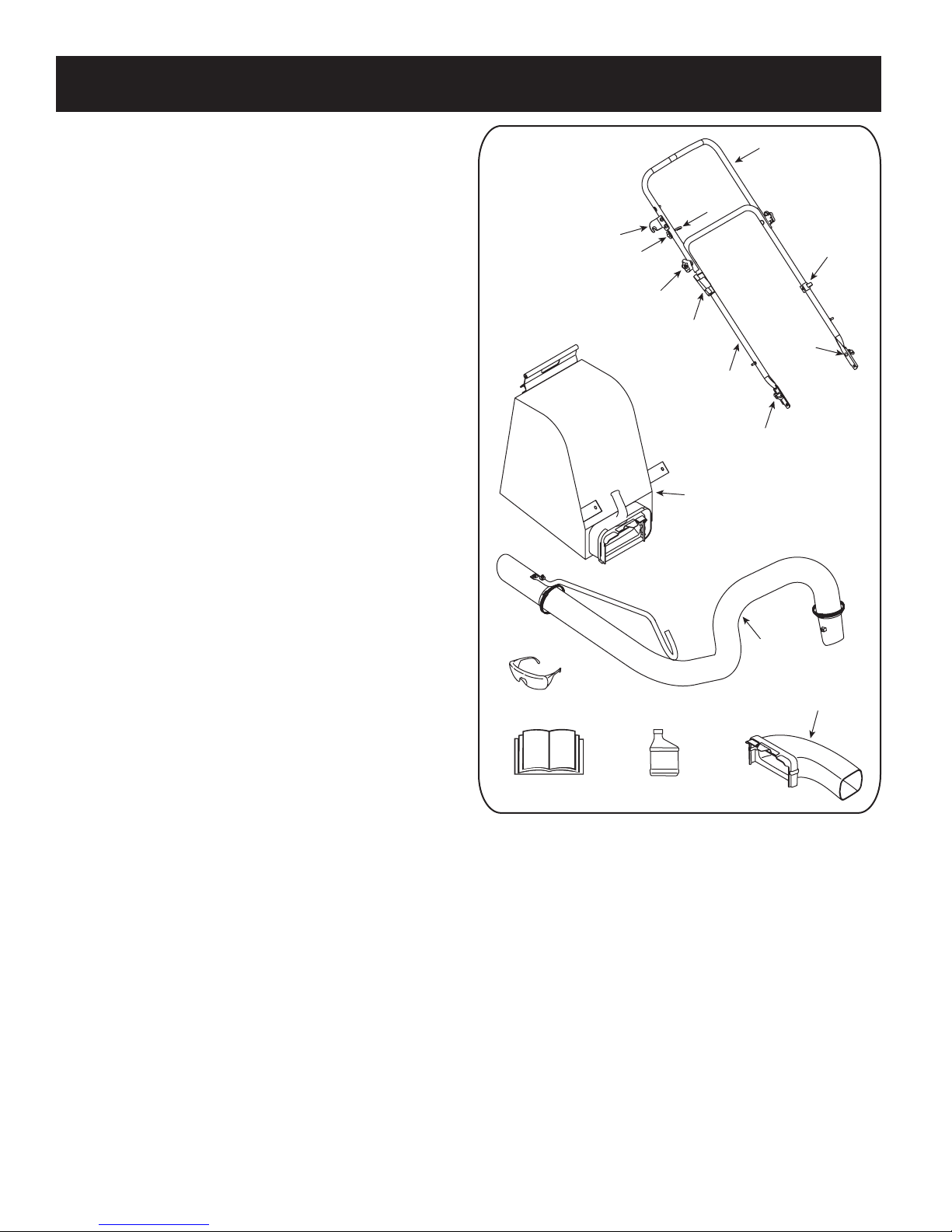

UNPACKING

Bag

Hose

Assembly

Blower Chute

Carriage

Screw

Upper Hose

Handle Bracket

Rope Guide

Star Knob

Wing Nut

Cable Guide

Bottle of Engine Oil

Operator’s Manual

Safety Glasses

Lower Hose

Handle Bracket

Lower Handle

Wing Nut

Upper Handle

IM PORTANT: This unit is shipped without gasoline or oil in the engine. Be certain

to service engine with gasoline and oil as instructed in the Operation section of this

manual before operating your machine.

NOTE: Reference to right and left hand side of the Yard Vacuum is observed from the

operating position looking forward to the front of the machine.

Removing Unit From Carton

1. Cut each corner of the carton vertically from top to bottom.

2. Remove all loose parts and loose packing material.

3. Lift unit from the rear to detach it from underlying carton material and roll

unit out of carton.

4. Check carton thoroughly for any other loose parts.

NOTE: Make sure not to crimp cables while removing loose parts or the

entire unit from the carton.

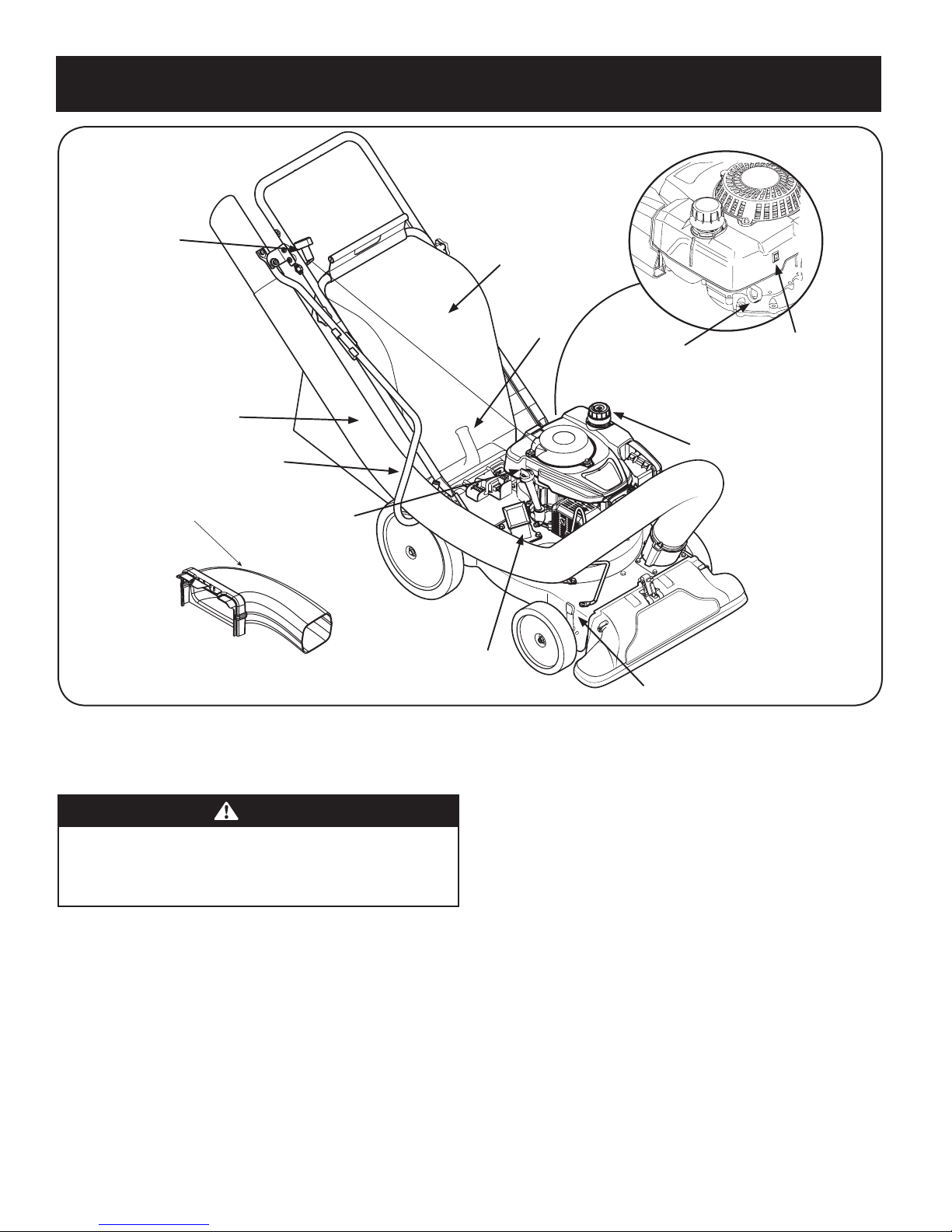

Loose Parts In Carton (See Figure 1)

• Upper and Lower Handle

• Hose Assembly

• Safety Glasses

• Engine Oil (May be located in bag)

• Bag

• Blower Chute

• Operator’s Manual

Figure 1

6

Page 7

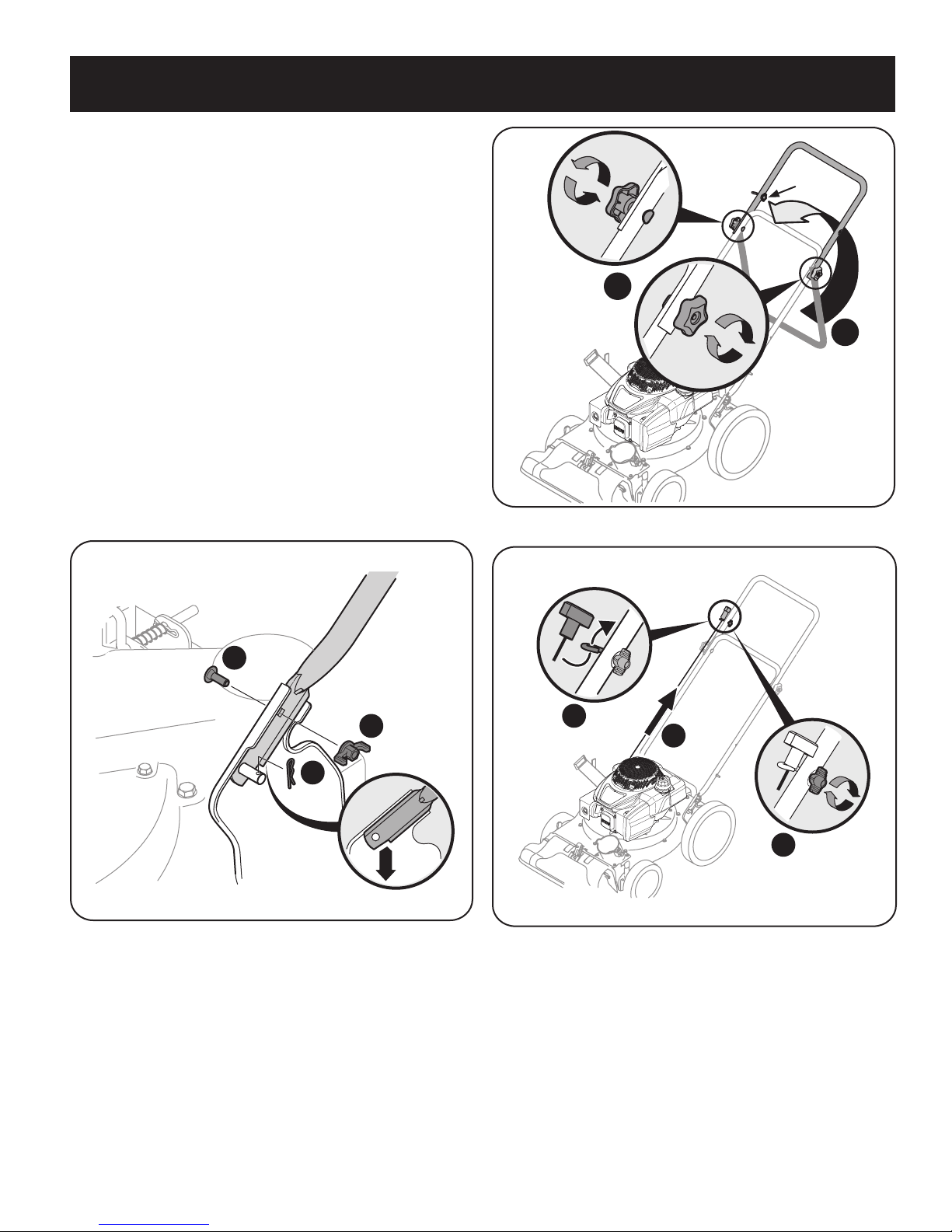

ASSEMBLY

a

b

b

Rope Guide

c

d

a

b

c

Attaching The Handle

1. Remove the hairpin clips from the handle brackets and remove the carriage

screws and wing nuts from the lower handle.

a. Place the bottom holes in lower handle over the pins on the handle

brackets and secure with hairpin clips. See Figure 2.

b. Insert carriage screws through upper hole in lower handle from the

inside and secure with wing nuts. See Figure 2.

c. Unfold the upper handle until it aligns with lower handle. Make sure

the rope guide is on the right side of upper handle. See Figure 3.

IM PORTANT: Make sure the cables are routed outside the lower handle. Also,

do not crimp the cables while lifting up the handles.

d. Secure the two handles by tightening the handle knobs (carriage

bolts must be seated properly into the handle). See Figure 3.

2. Loosen the wing nut that secures the rope guide to the right side of upper

handle.

a. Pull the starter rope out of the engine slowly. See Figure 4.

b. Slip the starter rope into the rope guide.

c. Tighten the wing nut. See Figure 4.

Figure 3

Figure 2

Figure 4

7

Page 8

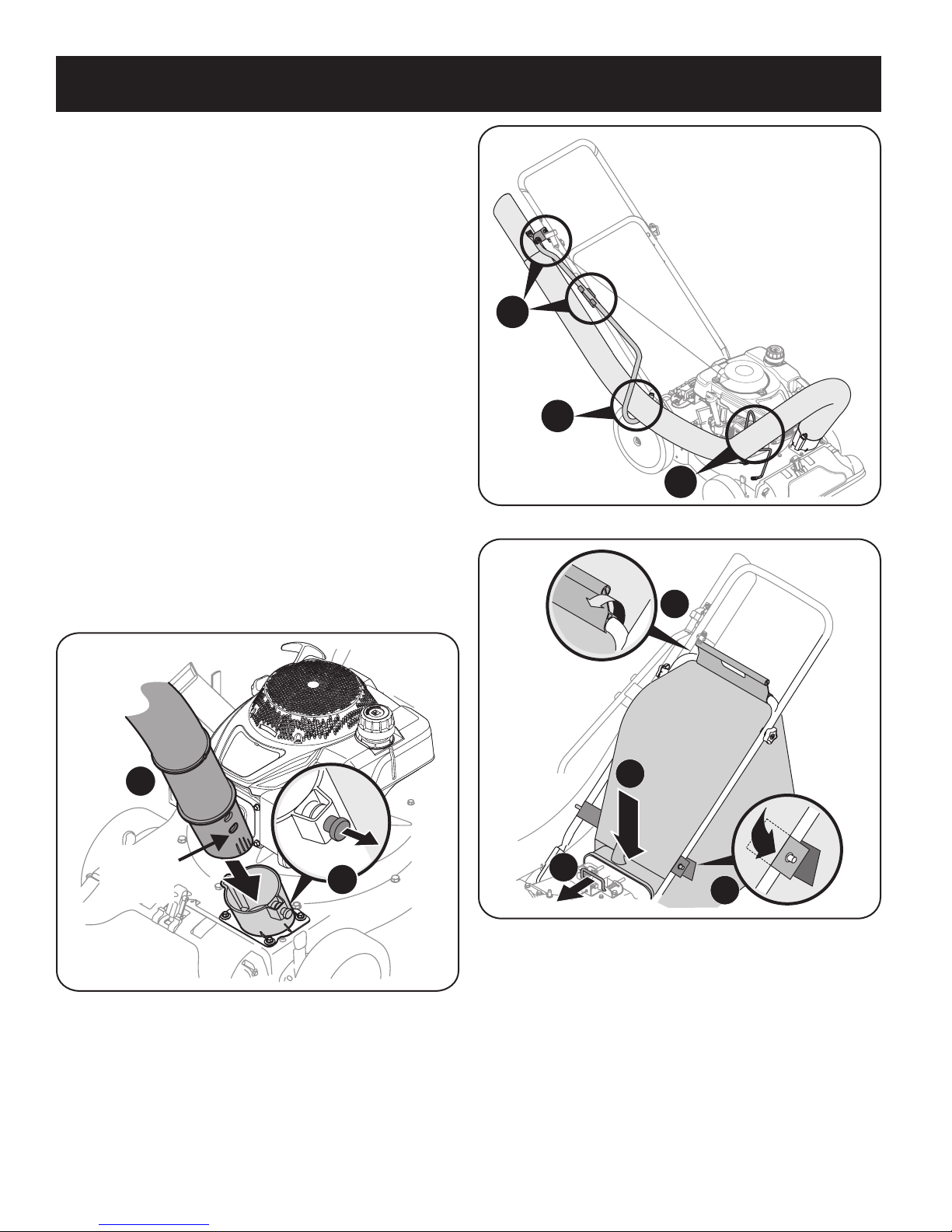

ASSEMBLY

1

Align pin

with this

hole.

2

5

5

4

4

3

1

2

Attaching The Hose Assembly

1. Slide hose adapter of hose assembly into the base adapter located on the left

front of the Yard Vacuum. See Figure 5.

2. Pull spring loaded pin out on the base and align pin with the first hole

(closest to the end of the tube) in the hose adapter.

3. Release the pin to lock the hose in place.

4. Snap the hose handle first into the upper hose handle bracket and then into

the lower hose handle bracket. See Figure 6.

5. Lay hose tubing in curved end of handle next to chipper chute and into hose

cradle.

Attaching The Bag

1. Grasp bag handle with one hand and slide locking rod on mounting bracket

with other hand toward engine. Use the end of mounting bracket as leverage

when sliding the locking rod. See Figure 7.

2. Slip bag over the rim of the discharge opening and release locking rod to

secure bag in place.

3. Snap bag clip to the top of the lower handle.

4. Place the lower straps on the bag over the top of lower handle, hooking them

on the studs. See Figure 7.

NOTE: The bag/chute switch button attached to the mounting bracket must

be fully depressed by the tip of front tab on bag handle when securing the

bag or engine will not start.

Figure 6

Figure 5

Figure 7

8

Page 9

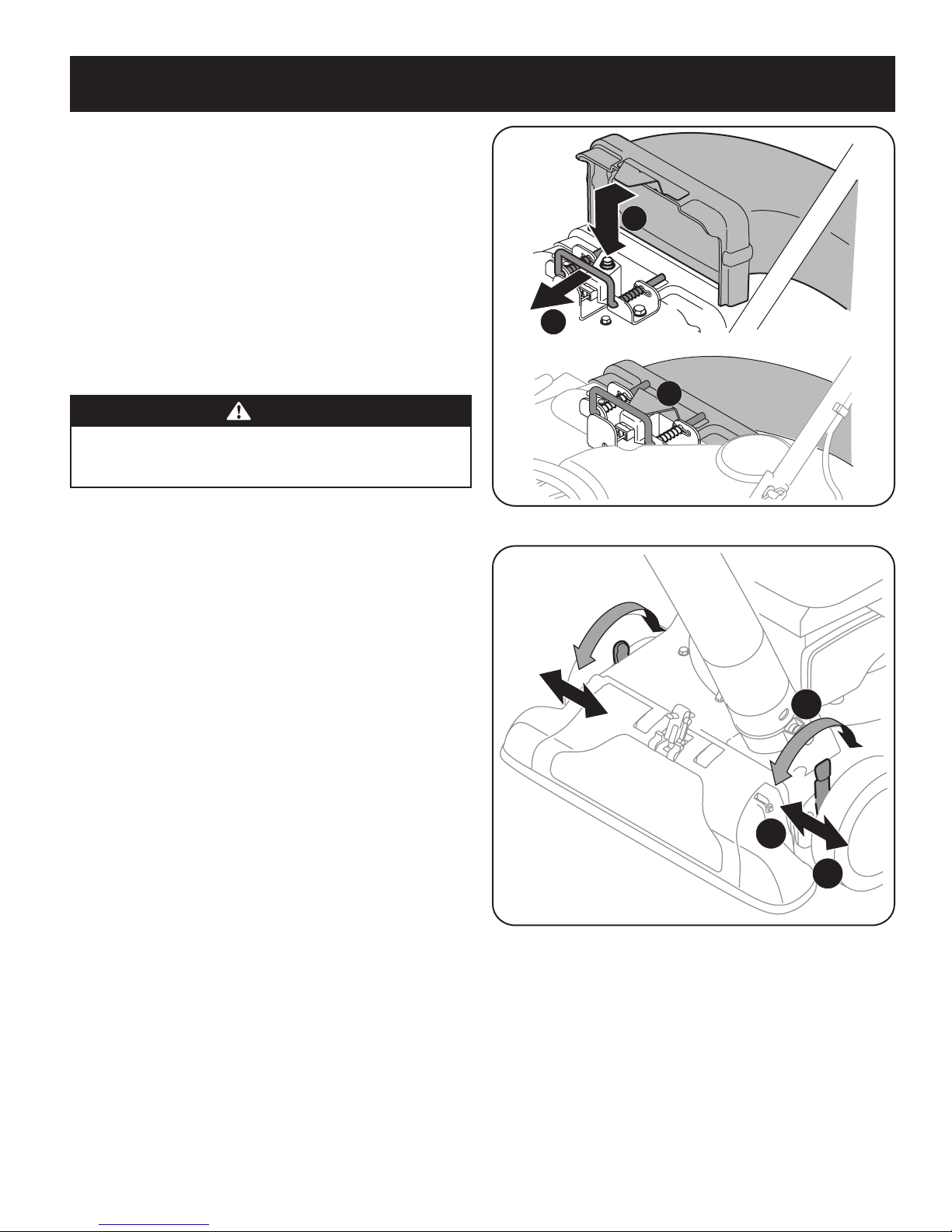

ASSEMBLY

1

2

2

3

2

1

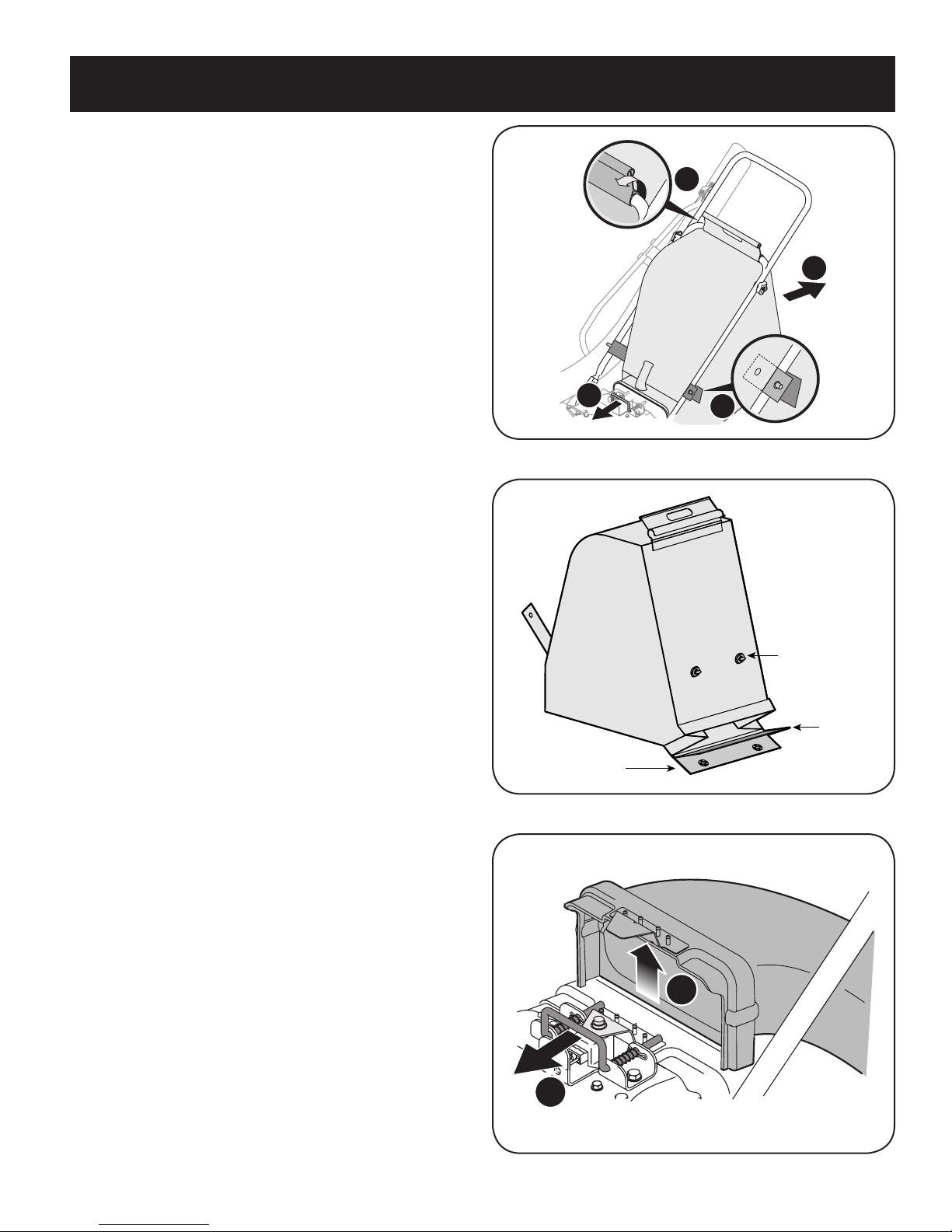

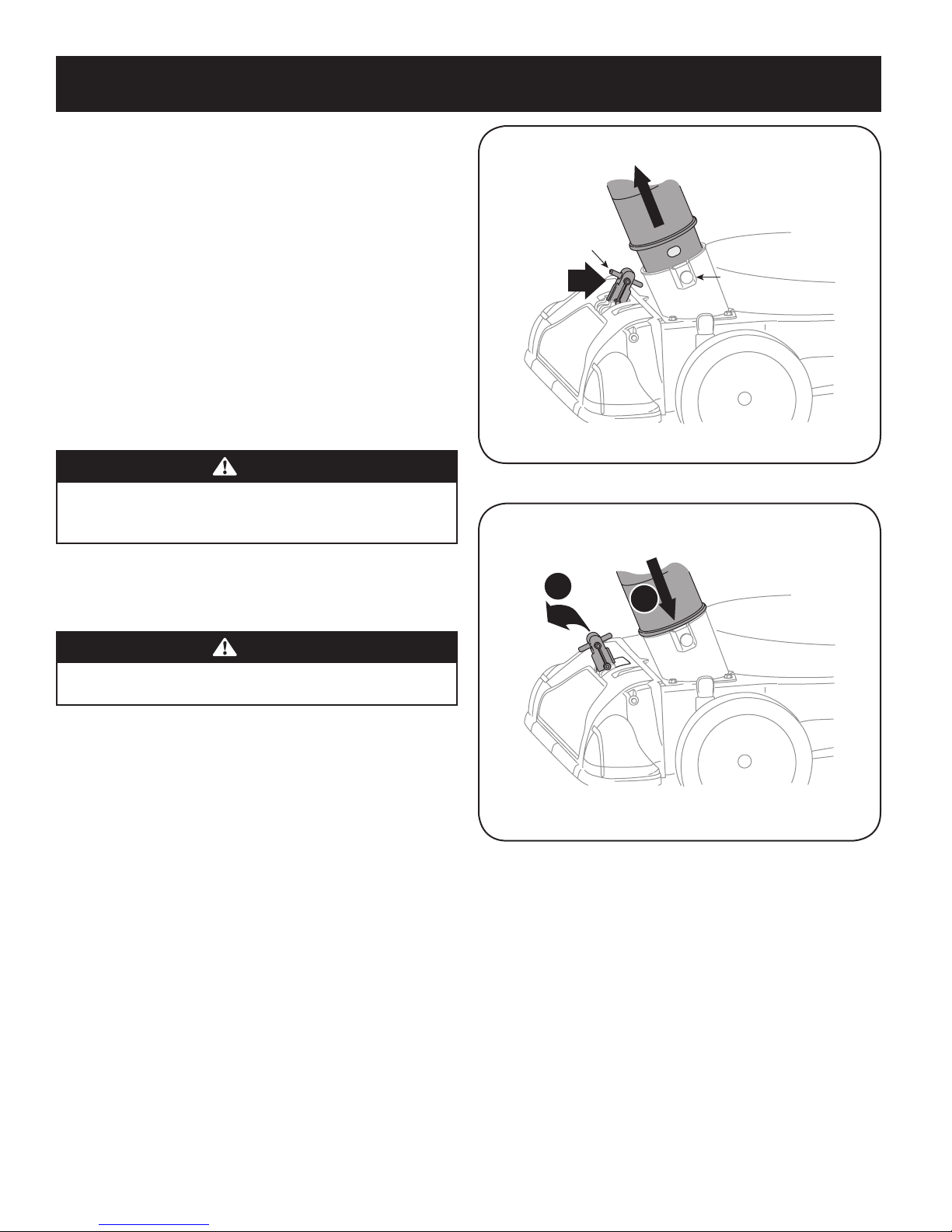

Attaching The Blower Chute

NOTE: The bag must be removed before installing the blower chute.

1. Grasp blower chute with one hand and slide locking rod on mounting bracket

with other hand toward engine. Use the end of mounting bracket as leverage

when sliding the locking rod. See Figure 8.

2. Slip blower chute over rim of discharge opening and release locking rod to

secure chute in place, as in Figure 8.

NOTE: The bag/chute switch button attached to the mounting bracket must

be fully depressed by the tip of front tab on the blower chute or engine will

not start.

IM PORTANT: Raise the nozzle height to the highest setting when using the

blower chute. Refer to nozzle height adjustment below.

WARNING

Always stop engine and disconnec t spark plug wire before performing any

maintenance or adjustments. Always wear safety glasses during operation

or while performing any adjustments or repairs.

Nozzle Height Adjustment

The nozzle can be adjusted to any five positions, ranging from 5/8” to 4-1/8” ground

clearance. The nozzle height has to be adjusted according to yard conditions.

1. Depress nozzle height adjustment lever towards wheel. See Figure 9.

2. Move the height adjustment lever forward or backward to adjust the nozzle

upwards or downwards. Make sure both levers are in the same position.

3. Release lever towards deck.

NOTE: In general, raise the nozzle height to vacuum a thick layer of leaves

or to operate with the blower chute. Lower the nozzle height for smoother

surfaces.

Figure 8

Figure 9

9

Page 10

OPERATION

Nozzle Height

Adjustment Lever

Chipper Chute

Gasoline Fill

Oil Fill

Hose Handle

Hose Assembly

Recoil Starter

Bag

Bag Handle

Choke Control

ON/OFF Switch

Blower Chute

Now that you have set up your yard vacuum for operation, get acquainted with its

controls and features. These are described below and illustrated on this page. This

knowledge will allow you to use your new equipment to its fullest potential.

WARNING

The operation of any yard vacuum can result in foreign objects being

thrown into the eyes, which can damage your eyes severely. Always wear

the safety glasses provided with this unit or eye shields while operating or

performing any adjustments or repairs on it.

Chipper Chute

Allows twigs and small branches up to 1-1/2” in diameter to be fed into the impeller

for chipping. See Figure 10.

Nozzle Height Adjustment Lever

Used to adjust the nozzle ground clearance ranging approximately from 5/8” to

4-1/ 8”.

Craftsman Yard Vacuums conform to the safety standard of the American National Standards Institute (ANSI).

Figure 10

Nozzle

Yard waste such as leaves or pine needles can be vacuumed up through the nozzle

for shredding.

Hose Assembly

Used as an alternative to the nozzle to vacuum yard waste such as leaves or pine

needles in hard to reach places. See Figure 10.

Nozzle/ Hose Vac Lever

The nozzle/hose vac handle is located on top of the nozzle. Use it to switch vacuum

suction between the nozzle and the hose assembly.

Hose Handle

Used to guide hose assembly when vacuuming.

Bag Handle

Used to grasp bag in order to assist in attaching, removing, and emptying bag. See

Figure 10.

Meets ANSI Safety Standards

10

Page 11

OPERATION

G

J

H

Blower Chute

When attached to unit, the blower chute is used to discharge yard waste such as

leaves, pine needle, or small twigs across yard.

Choke Control

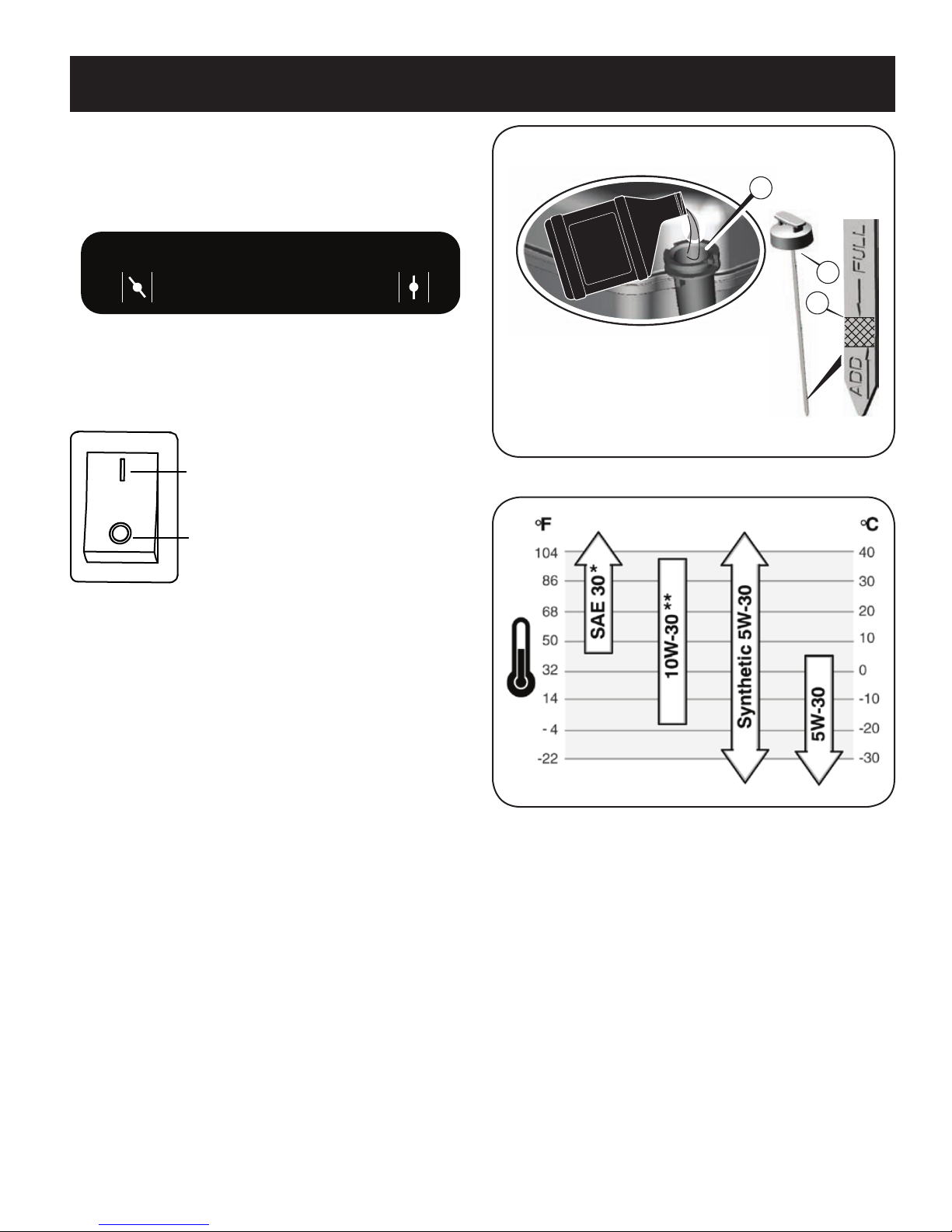

CHOKE RUN

The choke control is used to choke the carburetor and assist in starting the engine.

ON/OFF Switch

The ON/OFF switch controls the engine stop function. Turn the switch ON when

starting the engine and turn it to OFF when you want to shut it down.

ON (Ignition)

OFF

Gas And Oil Fill-Up

IM PORTANT: This unit is shipped without gasoline or oil in the engine. Be certain to

service engine with gasoline and oil as instructed in this section before starting or

running your machine.

Oil (one bottle shipped with unit)

First Time Use

1. Remove oil fill dipstick (G). See Figure 11.

2. With the yard vaccum on level ground, empty entire contents of oil bottle

provided into the engine oil fill (H).

3. Replace oil fill dipstick and tighten.

Subsequent Uses

Use 4-stroke motor oil that meets or exceeds the requirements for API service

category SF, SG, SH, SJ or higher. Always check the API service label on the oil

container to be sure it includes the letters SF, SG, SH, SJ or higher.

Outdoor temperatures determine the proper oil viscosity for the engine. Use the

chart shown in Figure 12 to select the best viscosity for the outdoor temperature

range expected.

Figure 11

Figure 12

* Below 40ºF (4ºC) the use of SAE 30 will result in hard starting.

** Above 80ºF (27ºC) the use of 10W-30 may cause increased oil consumption.

Check oil level more frequently.

1. Check the oil with the engine stopped and level.

2. Remove the oil fill dipstick and wipe it clean.

3. Insert and tighten the oil fill dipstick. Remove it to check the oil level. See

Figure 11.

4. If the oil level is near or below the lower limit mark on the dipstick, remove

the oil fill dipstick, and fill with the recommended oil to the upper limit

mark. Do not overf ill.

5. Reinstall the oil fill dipstick.

11

Page 12

OPERATION

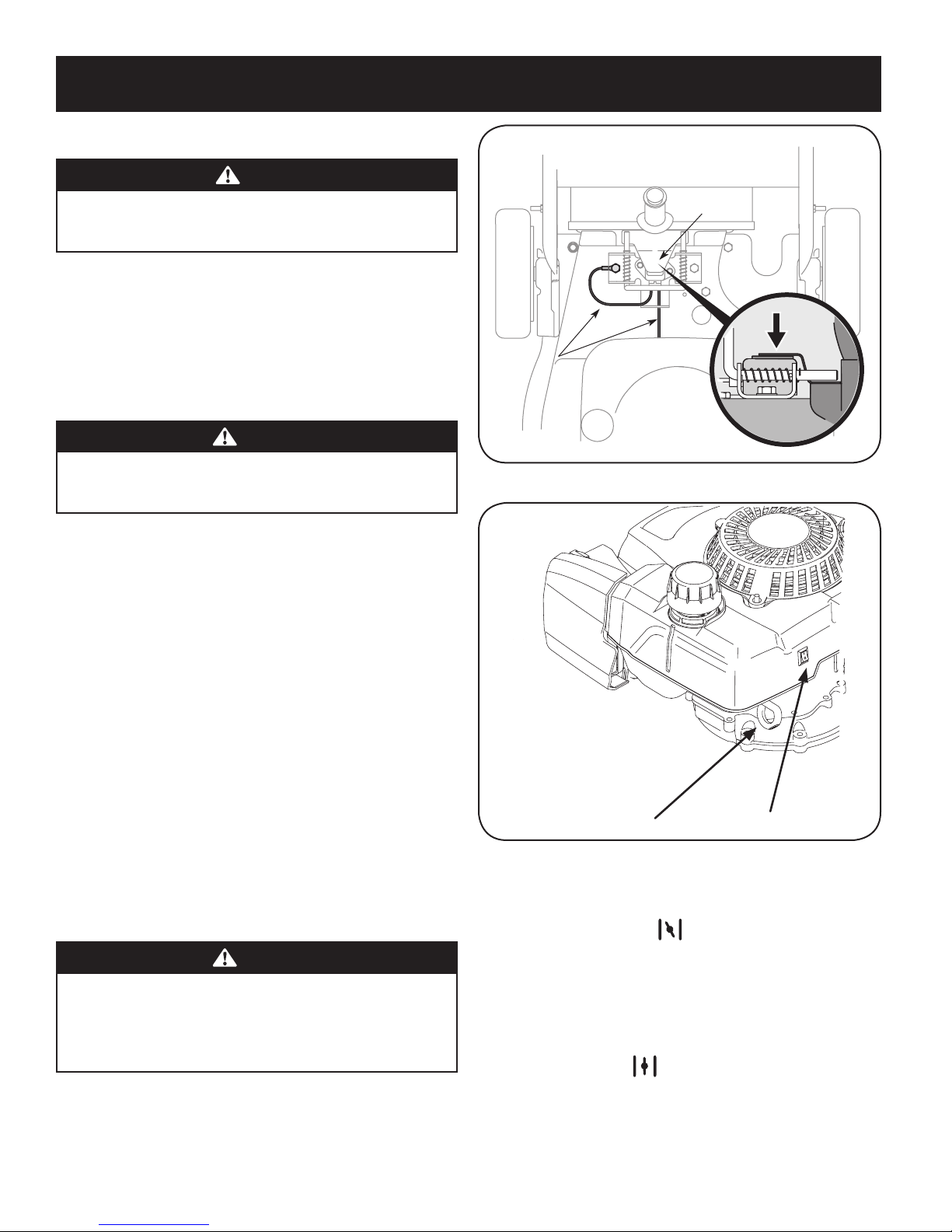

Side View

Top View

Front Tab

Bag/Chute

Switch Wire

Choke Control

ON/OFF Switch

Gasoline

CAUTION

Do not use unapproved gasolines, such as E85. Do not mix oil in gasoline

or modify engine to run on alternate fuels. This will damage the engine

components and void the engine warranty.

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 87 octane/87 AKI (91 RON).

• Gasoline with up to 10% ethanol (gasohol) is acceptable.

Refuel in a well-ventilated area with the engine stopped. If the engine has been

running, allow it to cool first. Never refuel the engine inside a building where

gasoline fumes may reach f lames or sparks.

WARNING

Gasoline is highly flammable and explosive, and you can be burned or

seriously injured when refueling. Stop engine and keep heat, sparks, and

flame away. Refuel only outdoors. Wipe up spills immediately.

If your equipment will be used on an infrequent or intermittent basis, please

refer to the Off Season Storage sec tion for additional information regarding fuel

deterioration.

NOTE: Fuel can damage paint and some types of plastic. Be careful not to spill fuel

when filling your fuel tank.

Never use stale or contaminated gasoline or an oil/gasoline mixture. Avoid getting

dirt or water in the fuel tank.

1. Remove the fuel tank cap.

2. Fill the fuel tank with fuel. To allow for expansion of the fuel, do not fill

above the bottom of the fuel tank neck. Do not overfill. Wipe up spilled fuel

before starting the engine.

3. Install the fuel tank cap and tighten it until it clicks.

4. Move yard vaccum at least 10 feet away from the fuel container/source and

site before starting the engine.

NOTE: Check the fuel level periodically to avoid running out of gasoline while

operating the yard vacuum. If the unit runs out of gas as it is chipping, it may be

necessary to unclog the discharge area before it can be restarted. Refer to SERVICE

AND MAINTENANCE sec tion.

Starting The Engine

Be sure no one other than the operator is standing near the yard vaccum

while starting engine or operating vacuum. Never run engine indoors

or in enclosed, poorly ventilated areas. Engine exhaust contains carbon

monoxide, an odorless and deadly gas. Keep hands, feet, hair and loose

clothing away from any moving parts on engine and yard vacuum.

IM PORTANT: The bag/chute switch button must be fully depressed by the tip of

front tab on bag handle or blower chute for engine to start. See Figure 13.

NOTE: Make sure bag/chute switch wire is connected to engine and grounded to

mounting bracket.

WARNING

Figure 13

Figure 14

1. Move ignition ON/OFF switch to ON. See Figure 14.

2. Pull out the choke control located on the engine. Pulling out the choke

control puts it into the CHOKE position.

NOTE: Use of the choke may not be necessary if the engine is warm or the air

temperature is high.

3. Pull the rope with a rapid, continuous, full arm stroke. Keep a firm grip on

the starter handle. Let the rope rewind slowly.

4. Repeat, if necessary, until engine star ts. As the engine warms up, move the

choke control to the RUN position.

12

Page 13

OPERATION

1

2

3

4

Buttons

Inner

Flap

Outer Flap

1

2

Stopping The Engine

1. Move engine switch to OFF position. See Figure 14.

To Empty Bag

1. Unhook bag straps from the lower handle.

2. Unsnap bag clip from the top of lower handle. See Figure 15.

3. Grasp bag handle with one hand and pull lock rod on mounting bracket with

other hand toward engine to release.

4. Lift bag off back of unit.

5. Twist the two buttons on the back of the bag to unlock and empty contents.

See Figure 16. Hold bag handle and bag clip while emptying the contents.

6. Compress bag opening and fold inner flap over opening.

7. Fold outer flap over inner flap and inser t buttons on the bag through metal

outlets. See Figure 16.

8. Twist the buttons to lock bag. Place bag back onto unit as instructed in the

ASSEMBLY section.

To Remove Blower Chute

1. Grasp blower chute with one hand and pull lock rod on mounting bracket

with other hand toward engine to release. Refer to Figure 17.

2. Remove blower chute from over the rim of the discharge opening.

Figure 15

Figure 16

Figure 17

13

Page 14

OPERATION

Vac Lever

Pin

1

2

Using The Nozzle Vacuum

1. Place nozzle/hose vac lever in the top position on the nozzle to vacuum

through nozzle. See Figure 18.

2. The spring loaded pin must be in the first hole (closest to the end of the

tube) of the hose adapter to operate the nozzle vac.

3. Place both hands on top of the upper handle and push unit over yard waste.

• Yard waste such as leaves and pine needles can be vacuumed up through the

nozzle for shredding. After material has been shredded by the flail blades

on the impeller assembly, it will be discharged into catcher bag or through

blower chute.

• Do not attempt to shred or chip any material other than vegetation found in

a normal yard (i.e. branches, leaves, twigs, etc.) Avoid fibrous plants such as

tomato vines or palm fronds until they are thoroughly dried out. Materials

such as stalks or heavy branches up to 1-1/2” in diameter may be fed into the

chipper chute.

WARNING

Do not attempt to shred, chip, or vacuum any material larger than

specified on the machine or in this manual. Personal injury or damage to

the machine could result.

IM PORTANT: The flail screen is located inside the housing in the discharge area. If

the flail screen becomes clogged, remove and clean as instructed in the Service &

Maintenance section. For best performance, it is also important to keep the chipper

blade sharp. See blade sharpening instructions in Service and Maintenance section.

WARNING

Do not at any time make any adjustments without first stopping engine

and disconnecting spark plug wire.

Using The Hose Assembly

1. Place nozzle/hose vac lever in the bottom position on the nozzle to redirect

vacuum to the hose assembly. See Figure 19.

2. The spring loaded pin must be in the second hole of the hose adapter to

operate the hose assembly.

3. Unhook the hose from upper handle bracket and grasp the hose handle to

guide while vacuuming yard waste such as leaves or pine needles in hard to

reach places.

Figure 18

Figure 19

14

Page 15

SERVICE AND MAINTENANCE

Electrode

0.020 in. (.51mm)

MAINTENANCE SCHEDULE

WARNING

Before performing any type of maintenance/service, disengage all controls

and stop the engine. Wait until all moving parts have come to a complete

stop. Disconnec t spark plug wire and ground it against the engine to

prevent unintended starting. Always wear safety glasses during operation

or while performing any adjustments or repairs.

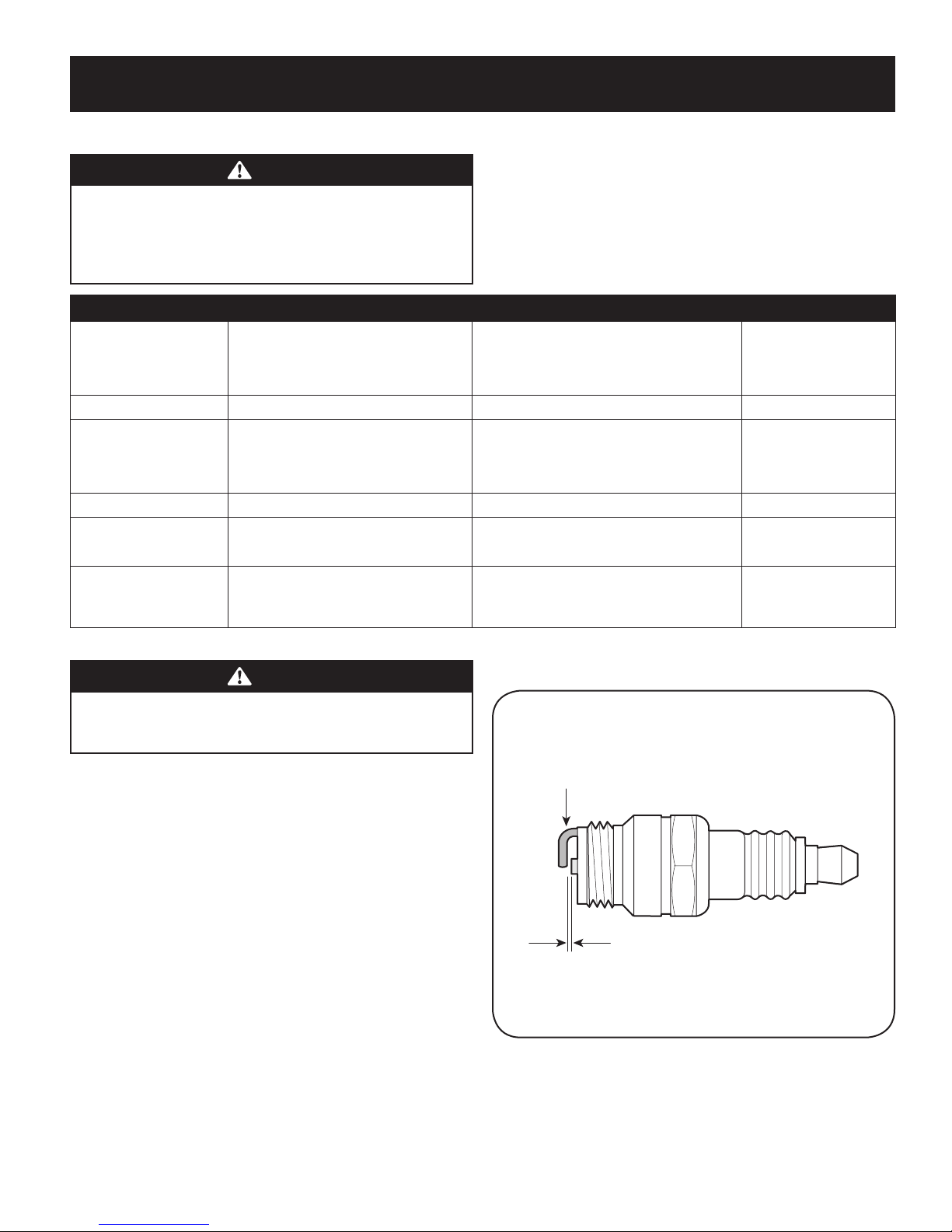

Interval Item Service Service Log

Each Use and every 5 hours 1. Engine oil level

2. Loose or missing hardware

3. Unit and engine.

1st 5 hours 1. Engine oil 1. Change

Annually or 25 hours 1. Air filter

2. Control linkages, pivots, & wheels

3. Underside of deck

Annually or 50 hours 1. Engine oil 1. Change

Annually 1. Spark plug

2. Air Filter

Before Storage 1. Fuel system 1. Run engine until it stops from lack of fuel, or

† Clean more often under dusty conditions or when airborne debris is present.

Follow the maintenance schedule given below. This chart describes service

guidelines only. Use the Service Log column to keep track of completed

maintenance tasks. To schedule service by an authorized dealer, call Craftsman at

1-88 8-331-4569.

1. Check

2. Tighten or replace

3. Clean

1. Clean

2. Lube with light oil

3. Clean

1. Replace

2. Replace

add stabilizer to a full tank of fresh fuel prior

to storage.

WARNING

Always stop engine and disconnec t spark plug wire before performing any

maintenance or adjustments. Always wear safety glasses during operation

or while performing any adjustments or repairs.

General Recommendations

• Always observe safety rules when performing any maintenance.

• The warranty on this yard vacuum does not cover items that have been

subjected to operator abuse or negligence. To receive full value from

warranty, operator must maintain the equipment as instructed here.

• Some adjustments will have to be made periodically to maintain your unit

properly.

• Periodically check all fasteners and make sure these are tight.

Engine Maintenance

Spark Plug

Clean spark plug and reset the electrode gap to 0.020” at least once a season;

replace annually.

1. Disconnect the cap from the spark plug, and remove any dirt from the spark

plug area.

2. Use the proper size spark plug wrench to remove the spark plug.

3. Check the gap with a wire gauge. See Figure 20. Spark plug gap should be

0.020 in (0.51 mm). If necessary, reset the gap.

Figure 20

4. Install and tighten the spark plug to the recommended torque (180 lb-in [20

Nm]).

5. Attach the spark plug cap to the spark plug.

15

Page 16

SERVICE AND MAINTENANCE

Oil Fill/ Dipstick

Muffler

Air filter

Air Filter

A dirty air f ilter will restrict air flow to the carburetor and cause poor engine

performance. Inspect the filter each time the engine is operated. You will need to

clean the filter more frequently if you operate the engine in very dusty areas.

Clean the air filter every 25 hours of operation or once a season. Replace the air filter

annually.

WARNING

Never start or run the engine with the air filter assembly or the air filter

removed.

NOTE: Do not use pressurized air or solvents to clean the filter. Pressurized air can

damage the filter and solvents will dissolve the f ilter.

1. Press the two tabs that hold the cover and tilt plastic housing cover on side of

engine down. See Figure 21.

2. Remove air filter from plastic housing cover.

3. To loosen debris, gently tap the filter on a hard surface. If the filter is

excessively dirty, replace with a new filter.

4. Insert cover’s tabs into slots in bottom of base.

5. Tilt cover up into place and secure with fastener.

Figure 21

Check Engine Oil

Check oil level before each operation. Be sure oil level is maintained.

1. Check the oil with the engine stopped and level.

2. Remove the oil fill dipstick and wipe it clean.

3. Insert and tighten dipstick. Remove it to check the oil level.

4. If the oil level is near or below the lower limit mark on the dipstick, remove

the oil filler cap/dipstick, and fill with the recommended oil to the upper

limit mark. Do not overfill.

5. Reinstall the oil fill dipstick.

Change Engine Oil

WARNING

Gasoline and its vapors are extremely flammable and explosive. Fire or

explosion can cause severe burns or death.

Change engine oil after the first five hours of operation, and every f ifty hours or

once a season thereafter.

WARNING

When you drain the oil from the top oil f ill tube, the fuel tank must be

empty or fuel can leak out and result in a fire or explosion. To empty the

fuel tank, run the engine until it stops from lack of fuel.

1. With engine off but still warm, disconnect the spark plug wire and keep it

away from the spark plug.

2. Place a suitable container next to the engine to catch the used oil.

3. Remove the oil fill dipstick and drain the oil into the container by tipping the

engine toward the oil filler neck. See Figure 22.

Figure 22

CAUTION

Used oil is a hazardous waste product. Dispose of used oil properly. Do not

discard with household waste. Check with your local authorities or Sears

Service Center for safe disposal/recycling facilities.

4. With the engine in a level position, fill to the upper limit mark on the dipstick

with the recommended oil.

CAUTION

Running the engine with a low oil level can cause engine damage.

5. Reinstall the oil fill dipstick securely.

16

Page 17

SERVICE AND MAINTENANCE

Clean Engine

• Daily or before every use, clean grass, chaff or accumulated debris from

engine. Keep linkage, spring, and controls clean. Keep area around and

behind muffler free of any combustible debris.

• Keeping engine clean allows air movement around engine.

• Engine parts should be kept clean to reduce the risk of overheating and

ignition of accumulated debris.

CAUTION

Do not use water to clean engine parts. Water could contaminate fuel

system. Use a brush or dry cloth.

Lubrication

Wheels

Place a few drops of SAE 30 oil on each shoulder screw once a season.

Nozzle Height Adjustment Levers

Lubricate nozzle height adjustment levers with light oil.

Locking Rod

Lubricate the lock rod and compression springs which attach to the mounting

bracket.

Figure 23

Nozzle/Hose Vac Lever

Lubricate the nozzle/hose vac lever on top of the nozzle once a season with light oil.

Cleaning Equipment

Clean underside of the yard vacuum once a season to prevent build-up of debris.

Follow steps below for this job:

1. Disconnect and ground spark plug wire. Empty the fuel tank by running

engine until tank is dry.

2. Tip the yard vacuum so that it rests on its side, keeping the muf fler side

down. Hold yard vacuum firmly.

3. Scrape and clean the underside of the deck and nozzle with a suitable tool.

Do not spray with water.

IM PORTANT: Do not use a pressure washer or garden hose to clean your unit.

These may cause damage to bearings, or the engine. The use of water will result in

shortened life and reduce serviceability.

4. Put the yard vacuum back on its wheels on the ground.

Cleaning The Flail Screen

If the discharge area becomes clogged, remove the flail screen and clean area as

follows:

1. Stop the engine. Make certain the chipper/shredder vacuum has come to a

complete stop.

2. Before unclogging the discharge chute, disconnect and ground the spark

plug wire.

3. Remove the vacuum bag or blower chute from the unit as instructed in the

OPERATION section to obtain access to flail screen.

Figure 24

4. Remove the three self tapping screws securing the belt cover, and remove

belt cover. See Figure 23.

5. Remove self tapping screw on right side of unit that attaches to the flail

screen. See Figure 24.

17

Page 18

SERVICE AND MAINTENANCE

Hub Cap

Thrust Washer

Bell Washer

Pivot Arm Assembly

Front Support Brace and Lock Nut

Shoulder Screw

Lock Nut

Wheel

Wave

Washer

6. Remove hex screw on top of rear housing near mounting bracket and the

flange lock nut that secures flail screen. See Figure 24.

7. Remove and clean the screen by scraping or washing with water. See Figure

25 below.

8. Reinstall the screen.

WARNING

Before performing any type of maintenance on the machine, wait for

all parts to stop moving and disconnect and ground the spark plug wire.

Failure to follow this instruction could result in personal injury or property

damage.

Sharpening Or Replacing Chipper Blade

NOTE: Before tipping the unit, empty the fuel tank by running engine until tank is

dry, and empty the oil reservoir as described in To Drain Oil.

1. Disconnect and ground the spark plug wire.

2. Remove bag assembly or blower chute.

3. Remove the three hex cap screws holding the chipper chute to the upper

housing. See Figure 26.

4. Remove the front hubcaps, flange lock nuts, front wheels, and wave washers

that attach to the pivot arm assemblies. See Figure 27.

5. Remove the shoulder screws, thrust washers, and bell washers that go

through the pivot arms to the front support brace. The front suppor t brace

and lock nut can be removed at this time as well.

6. Remove the four screws on the upper housing that secure the nozzle cover.

See Figure 28.

Figure 25

Figure 26

18

Figure 27

Figure 28

Page 19

SERVICE AND MAINTENANCE

Black

Plastic

Nozzle

Shoulder Screws

Flat Head Cap Screws

Chipper Blade

Nuts

Impeller

7. Carefully tilt and support the unit up to provide access underneath to the

nozzle mounting hardware and impeller. Remove the three shoulder bolts

securing the black plastic lower flail housing to the lower housing. Refer to

Figure 29.

8. Tilt top of black plastic lower flail housing toward the engine to remove.

9. Using a 3/16” allen wrench, remove the flat head cap screws that hold the

chipper blade to the impeller. These screws are accessible through the

opening created when the chipper chute was removed earlier. See Figure 30.

10. The nuts on the flat head cap screws can be reached from underneath using

a 1/2-inch socket, universal, and extension. See Figure 31.

11. Replace or sharpen chipper blade. The blade can be sharpened with a f ile or

on a grinding wheel.

WARNING

The chipper blade is sharp. When sharpening blade, wear leather work

gloves to protect your hands and follow the original angle of grind.

12. Reassemble by performing the previous steps in the opposite order and

manner of removal.

NOTE: Tighten blade screws to 210 - 250 in-lbs. Make certain chipper blade is

reassembled with the sharp edge facing upward.

Figure 30

Figure 29

Figure 31

19

Page 20

OFF-SEASON STORAGE

WARNING

Never store yard vacuum with fuel in tank indoors or in poorly ventilated

areas where fuel fumes may reach an open flame, spark, or pilot light as on

a furnace, water heater, clothes dryer, or gas appliance.

Preparing The Engine

For engines stored over 30 days:

• To prevent gum from forming in fuel system or on carburetor parts, run

engine until it stops from lack of fuel or add a gasoline additive to the gas

in the tank. If you use a gas additive, run the engine for several minutes to

circulate the additive through the carburetor—after which the engine and

fuel can be stored up to 24 months.

• While engine is still warm, change the oil.

• Clean engine of surface debris.

Preparing The Yard Vacuum

• Clean and lubricate yard vacuum thoroughly as described in the lubrication

instructions.

• Do not use a pressure washer or garden hose to clean your unit.

• Refer to Preparing the Engine for correct engine storage instructions.

• Store unit in a dry, clean area. Do not store next to corrosive materials, such

as fertilizer.

When storing any type of power equipment in a poorly ventilated or metal storage

shed, care should be taken to rust-proof the equipment. Using a light oil or silicone,

coat the equipment, especially cables and all moving parts of your yard vaccum

before storage.

20

Page 21

TROUBLESHOOTING

WARNING

Disconnect the spark plug wire and ground it against the engine to prevent

unintended starting. Before performing any type of maintenance/service,

disengage all controls and stop the engine. Wait until all moving parts

have come to a complete stop. Always wear safety glasses during operation

or while performing any adjustments or repairs.

This section addresses minor service issues. To schedule repair by an authorized service dealer call Craftsman at 1-888-331-4569.

Problem Cause Remedy

Engine Fails to start 1. Ignition ON/OFF switch in OFF position.

2. Choke control not in CHOKE position.

3. Spark plug boot disconnec ted.

4. Faulty spark plug.

5. Fuel tank empty or stale fuel.

6. Blocked fuel line.

7. Cannot pull recoil starter cord.

8. Safety switch not depressed.

9. Safety switch wire is not connec ted to engine or not

properly grounded.

Engine runs erratic 1. Unit running on CHOKE.

2. Spark plug boot loose.

3. Stale fuel.

4. Water or dirt in fuel system.

5. Dirty air cleaner.

6. Low engine RPM.

7. Blocked fuel line.

1. Move Ignition ON/OFF switch to ON position.

2. Move choke control to CHOKE position.

3. Connect wire to spark boot.

4. Clean, adjust gap, or replace.

5. Fill tank with clean, fresh gasoline.

6. Call Craftsman at 1-888-331-4569 to have fuel line cleaned.

7. Obstruction lodged in impeller. Disconnect spark plug wire and

remove lodged object.

8. Safety switch must be depressed by the front tab on the bag

handle when securing the bag.

9. Connect safety switch wire to engine connector and ground to

mounting bracket.

1. Move choke control to RUN position.

2. Connect and tighten spark plug boot.

3. Fill tank with clean, fresh gasoline.

4. Run engine until it stops from lack of fuel. Refill with f resh fuel.

5. Refer to Air Cleaner in Engine Maintenance sec tion.

6. Always run engine at full throttle.

7. Call Craftsman at 1-888-331-4569 to have fuel line cleaned.

Engine overheats 1. Engine oil level low.

2. Air flow restricted.

Occasional skips (hesitates) 1. Spark plug gap too close. 1. Adjust gap. Refer to Spark Plug in Engine Maintenance section.

1. Fill crankcase with proper oil.

2. Clean area around and on top of engine.

21

Page 22

TROUBLESHOOTING

Problem Cause Remedy

Idles poorly 1. Spark plug fouled, faulty, or gap too wide.

2. Dirty air cleaner.

Excessive vibration 1. Loose par ts or damaged impeller. 1. Stop engine immediately and disconnect spark plug wire. Call

Unit does not discharge 1. Discharge area clogged.

2. Foreign object lodged in impeller.

3. Low engine RPM.

4. Vacuum bag is full.

Rate of discharge slows

considerably or composition of

discharged material changes.

1. Low engine RPM.

2. Chipper blade dull.

1. Reset gap or replace spark plug.

2. Refer to Air Cleaner in Engine Maintenance section.

Craftsman at 1-888-331-4569 for inspection and repair

1. Stop engine immediately and disconnect spark plug wire. Clean

flail screen and inside of discharge opening.

2. Stop engine and disconnect spark plug wire. Remove lodged

object.

3. Always run engine at full throttle.

4. Empty bag.

1. Always run engine at full throttle.

2. Refer to Sharpening or Replacing Chipper Blade section, or call

Craftsman at 1-888-331-4569 for chipper blade ser vice.

22

Page 23

(This page applicable in the U.S.A. and Canada only.)

Sears Brands Management Corporation (Sears), the California Air Resources Board (CARB)

and the United States Environmental Protection Agency (U.S. EPA)

Emission Control System Warranty Statement (Owner’s Defect Warranty Rights and Obligations)

EMISSION CONTROL WARRANTY COVERAGE IS APPLICABLE TO CERTIFIED ENGINES

PURCHASED IN CALIFORNIA IN 1995 AND THEREAFTER, WHICH ARE USED IN CALIFORNIA,

California and United States Emission Control Defects Warranty Statement

The California Air Resources Board (CARB), U.S. EPA and Sears are pleased to explain the

Emission Control System Warranty on your model year 2000 and later small of f-road

engine (SORE). In California, new small off-road engines must be designed, built and

equipped to meet the State’s stringent anti-smog standards. Elsewhere in the United

States, new non-road, spark-ignition engines certified for model year 1997 and later

must meet similar standards set forth by the U.S. EPA. Sears must warrant the emission

Sears Emission Control Defects Warranty Coverage

Small off-road engines are warranted relative to emission control parts defects for a

period of one year, subject to provisions set forth below. If any covered part on your

Owner’s Warranty Responsibilities

As the small off-road engine owner, you are responsible for the performance of the

required maintenance listed in your Operating and Maintenance Instructions. Sears

recommends that you retain all your receipts covering maintenance on your small

off-road engine, but Sears cannot deny warranty solely for the lack of receipts or for

your failure to ensure the per formance of all scheduled maintenance. As the small

off-road engine owner, you should however be aware that Sears may deny you warranty

coverage if your small off-road engine or a part has failed due to abuse, neglec t,

Sears Emission Control Defects Warranty Provisions

The following are specific provisions relative to your Emission Control Defects Warranty

Coverage. It is in addition to the Sears engine warranty for non-regulated engines found

in the Operating and Maintenance Instructions.

1. Warranted Parts

Coverage under this warranty extends only to the parts listed below (the

emission control systems parts) to the extent these parts were present on the

engine purchased.

a. Fuel Metering System

• Cold start enrichment system

• Carburetor and internal parts

• Fuel Pump

b. Air Induction System

• Air cleaner

• Intake manifold

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

• Vacuum, temperature, position, time sensitive valves and switches

• Connectors and assemblies

2. Length of Coverage

Sears warrants to the initial owner and each subsequent purchaser that the

Warranted Parts shall be free from defects in materials and workmanship which

caused the failure of the Warranted Parts for a period of one year from the date

the engine is delivered to a retail purchaser.

AND TO CERTIFIED MODEL YEAR 1997 AND LATER ENGINES WHICH ARE PURCHASED AND

USED ELSEWHERE IN THE UNITED STATES (AND AFTER JANUARY 1, 2001 IN CANADA).

control system on your engine for the periods of time listed below, provided there has

been no abuse, neglect or improper maintenance of your small off-road engine. Your

emission control system includes parts such as the carburetor, air cleaner, ignition

system, muffler and catalytic converter. Also included may be connectors and other

emission related assemblies. Where a warrantable condition exists, Sears will repair

your small off-road engine at no cost to you including diagnosis, parts and labor.

engine is defective, the part will be repaired or replaced by Sears.

improper maintenance or unapproved modifications. You are responsible for presenting

your small off-road engine to an Authorized Sears Service Dealer as soon as a problem

exists. The undisputed warranty repairs should be completed in a reasonable amount

of time, not to exceed 30 days. If you have any questions regarding your warranty rights

and responsibilities, you should contact a Sears Service Representative at 1-800-469-

4663. The emission warranty is a defects warranty. Defects are judged on normal engine

performance. The warranty is not related to an in-use emission test.

3. No Charge

Repair or replacement of any Warranted Part will be performed at no charge to

the owner, including diagnostic labor which leads to the determination that a

Warranted Part is defective, if the diagnostic work is performed at an Authorized

Sears Service Dealer. For emissions warranty service contact your nearest

Authorized Sears Service Dealer as listed in the “Yellow Pages” under “Engines,

Gasoline,” “Gasoline Engines,” “Lawn Mowers,” or similar category.

4. Claims and Coverage Exclusions

Warranty claims shall be filed in accordance with the provisions of the Sears

Engine Warranty Policy. Warranty coverage shall be excluded for failures of

Warranted Parts which are not original Sears parts or because of abuse, neglect

or improper maintenance as set forth in the Sears Engine Warranty Policy. Sears

is not liable to cover failures of Warranted Parts caused by the use of add-on,

non-original, or modified parts.

5. Maintenance

Any Warranted Part which is not scheduled for replacement as required

maintenance or which is scheduled only for regular inspec tion to the effect of

“repair or replace as necessary” shall be warranted as to defects for the warranty

period. Any Warranted Part which is scheduled for replacement as required

maintenance shall be warranted as to defects only for the period of time up

to the first scheduled replacement for that part. Any replacement part that is

equivalent in performance and durability may be used in the per formance of

any maintenance or repairs. The owner is responsible for the performance of

all required maintenance, as defined in the Sears Operating and Maintenance

Instructions.

6. Consequential Coverage

Coverage hereunder shall extend to the failure of any engine components caused

by the failure of any Warranted Part still under warranty.

073808 Rev. A

Page 24

ÍNDICE

Declaración de garantía .......................Página 24

Prácticas operación seguras ...................Página 25

Desembalaje ..................................Página 29

Montaje ......................................Página 30

Operación ....................................Página 33

Servicio y Mantenimiento .....................Página 38

Almacenamiento fuera de temporada .........Página 44

Solución de problemas ........................Página 45

Número de servicio .................. Cubierta posterior

DECLARACIÓN DE GARANTÍA

CRAFTSMAN DE GARANTÍA LIMITADA

POR DOS AÑOS a partir de la fecha de compra, este producto está garantizado contra cualquier defecto de material o mano de obra.

CON EL COMPROBANTE DE VENTA, un producto defectuoso recibirá la reparación. Si el producto no puede ser reparado recibirá sustitución gratuita.

Para obtener información detallada cobertura de la garantía para obtener la reparación, visite el sitio web: www.craftsman.com/warranty

Esta garantía cubre los defectos SOLO de materiales y fabricación. La garantía no incluye:

• Elementos reutilizables que pueden gastarse por el uso normal dentro del periodo de garantía, tales como las cuchillas, bujías, filtro de aire, pantalla de

desgranado y una bolsa.

• Producto daños resultantes de los intentos del usuario de modificación del producto, reparación o causados por accesorios de productos.

• Reparaciones necesarias debido al accidente o por no operar o mantener el producto según las instrucciones provistas.

• El mantenimiento preventivo o reparaciones necesarias debido a una mezcla incorrecta de combustible, combustible contaminado o pasado.

Esta garantía es inválida si este producto se utiliza al mismo tiempo la prestación de servicios comerciales o si se alquila a otra persona.

Esta garantía le otorga derechos legales específicos, y usted también puede tener otros derechos que varían de estado a estado.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

NÚMERO DE MODELOESPECIFICACIONES DEL PRODUCTO

Aceite del motor: SAE 10w-30

Combustible: Gasolina sin plomo

Motor: Craftsman

Número de modelo _____________________________

Número de serie ________________________________

Fecha de compra _______________________________

Registre el número de modelo, número de serie y fecha

de compra más arriba.

© Sears Brands, LLC

24

Page 25

INSTRUCCIONES DE SEGURIDAD

ADVERTENCIA

La presencia de este símbolo indica que se trata de instrucciones

importantes de seguridad que se deben respetar para evitar poner en

peligro su seguridad personal y/o material y la de otras personas. Lea y siga

todas las instrucciones de este manual antes de poner en funcionamiento

esta máquina. Si no respeta estas instrucciones podría provocar lesiones

personales. Cuando vea este símbolo, ¡preste atención a la advertencia!

ADVERTENCIA

PROPOSICIÓN 65 DE CALIFORNIA

El escape del motor de este producto, algunos de sus componentes y

algunos componentes del vehículo contienen o liberan sustancias químicas

que el estado de California considera que pueden producir cáncer, defectos

de nacimiento u otros problemas reproductivos.

CAPACITACIÓN

• Lea, entienda y cumpla todas las instrucciones incluidas en la máquina y en

los manuales antes de montarla y utilizarla. Guarde este manual en un lugar

seguro para consultas futuras y regulares, así como para solicitar repuestos.

• Lea el Manual del Operador y siga todas las advertencias e instrucciones de

seguridad. El fracaso de hacer así puede causar la herida seria al operador y/o

personas presentes.

• Familiarícese con todos los controles y su operación adecuada. Sepa cómo

detener la máquina y cómo desengranar los controles rápidamente.

• No permita nunca que los niños menores de 16 años utilicen esta

máquina. Los niños de 16 años y más mayores deben leer y comprender

las instrucciones de operación y las reglas de seguridad contenidas en este

manual, y también deben ser capacitados y estar supervisados por uno de

los padres.

• Nunca permita que los adultos operen esta máquina sin recibir antes la

instrucción apropiada.

• Mantenga a los transeúntes, ayudantes, mascotas y niños al menos a 75 pies

de la máquina mientras está operando. Detenga la máquina si alguien entra

en la zona.

• Nunca encienda un motor en espacios cerrados o en una zona con poca

ventilación. El escape del motor contiene monóxido de carbono, un gas

inodoro y letal.

• No ponga las manos o los pies cerca de las piezas rotatorias o en las cámaras

de alimentación ni en la abertura de descarga. El contacto con el motor

rotatorio puede producir la amputación de dedos, manos o pies.

• Nunca trate de destapar la toma de alimentación o la aber tura de descarga,

ni trate de sacar o vaciar la bolsa de la aspiradora, ni de revisar y reparar la

máquina mientras el motor está en marcha. Apague el motor y espere hasta

que todas las piezas móviles se hayan detenido por completo. Desconecte el

cable de la bujía y póngalo de manera que haga masa contra el motor.

PELIGRO

Esta máquina fue construida para ser operada de acuerdo con las reglas

de seguridad contenidas en este manual. Al igual que con cualquier tipo

de equipo motorizado, un descuido o error por parte del operador puede

producir lesiones graves. Esta máquina es capaz de amputar manos y pies

y de arrojar objetos con gran fuerza. De no respetar las instrucciones de

seguridad siguientes se pueden producir lesiones graves o la muerte.

ADVERTENCIA

Su responsabilidad—Restrinja el uso de esta máquina motorizada

a las personas que lean, comprendan y respeten las advertencias e

instrucciones que aparecen en este manual y en la máquina.

¡GUARDE ESTAS INSTRUCCIONES!

PREPARATIVOS

• Inspeccione minuciosamente el área donde utilizará el equipo. Retire

todas las piedras, botellas, latas u otros objetos extraños que puedan ser

levantados o arrojados causando lesiones personales o daños a la máquina.

• Para protegerse los ojos utilice siempre anteojos o antiparras de seguridad

mientras opera la máquina o mientras la ajusta o repara. Los objetos

arrojados que rebotan pueden lesionar gravemente la vista.

• Utilice zapatos de trabajo resistentes, de suela fuer te, así como pantalones

y camisas ajustados. Las prendas sueltas o las alhajas pueden quedar

atrapadas en las piezas móviles. Nunca utilice la máquina descalzo o con

sandalias. Utilice guantes de trabajo de cuero cuando alimente material por

el canal de la cortadora.

• Antes de encender la máquina controle que todos los pernos y tornillos estén

bien ajustados para comprobar que la máquina se encuentra en condiciones

seguras de operación. Además, realice una inspección visual de la máquina a

intervalos frecuentes para controlar si la misma está dañada.

• Mantenga o reemplace las etiquetas de seguridad e instrucciones según sea

necesario.

25

Page 26

INSTRUCCIONES DE SEGURIDAD

Manejo seguro de la gasolina

Para evitar lesiones personales o daños materiales sea sumamente cuidadoso al

manipular la gasolina. La gasolina es altamente inflamable y sus vapores pueden

causar explosiones. Se puede lesionar gravemente si derrama gasolina sobre usted

o sobre la ropa ya que se puede encender. Lávese la piel y cámbiese de ropa de

inmediato.

• Utilice sólo recipientes para gasolina autorizados.

• Nunca llene los contenedores en el interior de un vehículo o camión o caja de

camioneta con recubrimientos plásticos. Coloque siempre los recipientes en

el piso y lejos del vehículo antes de llenarlos.

• Retire el equipo a gasolina del camión o remolque y llénelo en el piso. Si esto

no es posible, entonces llene dicho equipo en un remolque con un recipiente

portátil, en vez de desde un dispensador de gasolina.

• Mantenga la boquilla de llenado en contacto con el borde de la entrada del

tanque de gasolina o contenedor en todo momento hasta que esté lleno. No

utilice un dispositivo para abrir/cerrar la boquilla.

• Apague todos los cigarrillos, cigarros, pipas y otras fuentes de combustión.

• Nunca cargue combustible en la máquina en un espacio cerrado.

• Nunca saque la tapa del gas ni agregue combustible mientras el motor está

caliente o en marcha. Deje que el motor se enfríe por lo menos dos minutos

antes de volver a cargar combustible.

• Nunca recargue el tanque de combustible. Llene el tanque no más de 1/2

pulgada por debajo de la base del cuello del filtro para dejar espacio para la

dilatación del combustible.

• Vuelva a colocar la tapa de la gasolina y ajústela bien.

• Limpie la gasolina derramada sobre el motor y el equipo. Traslade la

máquina a otra zona. Espere 5 minutos antes de encender el motor.

• Nunca almacene la máquina o el recipiente de combustible en un espacio

cerrado donde haya fuego, chispas o luz piloto (por ejemplo, hornos,

calentadores de agua, calefactores, secadores de ropa, etc.)

• Para reducir el riesgo de incendio mantenga la máquina limpia de pasto,

hojas y de acumulación de otros desechos. Limpie los derrames de aceite o

combustible y saque todos los desechos embebidos con combustible.

FUNCIONAMIENTO

• No ponga las manos o los pies cerca de las piezas rotatorias o en las cámaras

de alimentación ni en la abertura de descarga. El contacto con el motor

rotatorio puede producir la amputación de dedos, manos o pies.

• Antes de encender la máquina compruebe que el canal de la cortadora, la

toma de alimentación y la cámara de corte están vacías y sin desechos.

• Inspeccione minuciosamente todo el material que desea triturar y saque

los objetos metálicos, piedras, botellas, latas u otros objetos extraños que

pueden ocasionar lesiones o dañar la máquina.

• Si el motor golpea un objeto extraño o si la máquina empieza a producir un

sonido poco común o una vibración, apague el motor de inmediato. Deje que

el motor se detenga por completo. Desconecte el cable de la bujía, póngalo

de manera que haga masa contra el motor y siga estos pasos:

a. Inspeccione la máquina para ver si está dañada.

b. Repare o reemplace las piezas dañadas.

c. Controle si hay piezas flojas y ajústelas para asegurar que la máquina

funcione de manera segura y continua.

• No permita que se acumule material procesado en la zona de descarga. El

mismo puede obstaculizar la descarga adecuada y provocar el retorno del

material a través de la abertura de alimentación.

• No intente triturar ni picar material de mayor tamaño al especificado en la

máquina o en este manual. Se podrían producir lesiones o daños.

• Nunca trate de destapar la toma de alimentación o la aber tura de descarga

mientras el motor está en marcha. Apague el motor y espere hasta que todas

las piezas que se mueven se hayan detenido por completo, desconecte el

cable de la bujía y póngalo de manera que haga masa contra el motor antes

de sacar los escombros.

• Nunca opere la máquina sin que la bolsa de la aspiradora y el canal de

descarga estén conectados a la máquina como corresponde. Nunca vacíe

ni cambie la bolsa de la aspiradora mientras el motor está en marcha. El

extremo con cierre de la bolsa de la aspiradora debe quedar cerrado todo el

tiempo mientras la opera.

• Nunca opere la máquina si el pico de ingreso o la unión opcional para la

manguera no están conectados a la máquina adecuadamente. Nunca intente

conectar o cambiar ninguna de estas uniones mientras el motor está en

marcha.

• Mantenga todos los protectores, desviadores y dispositivos de seguridad en

su lugar y en buenas condiciones.

• Mientras alimenta material dentro de la máquina mantenga su rostro y

su cuerpo detrás y hacia un costado del canal de la cortadora para evitar

lesiones por retrocesos accidentales.

• Nunca opere esta máquina sin buena visibilidad o iluminación. Siempre debe

estar seguro de que está bien afirmado y sostenga bien las manijas.

• No opere esta máquina en superficies con grava.

• No opere esta máquina estando bajo los efectos del alcohol o de drogas.

• El silenciador y el motor se calientan y pueden producir quemaduras. No los

toque.

• Nunca levante o transporte la máquina cuando el motor está encendido.

• Si se presentan situaciones que no están previstas en este manual sea

cuidadoso y use el sentido común. Marque para contac tar el departamento

de atención al cliente y obtener el nombre de su distribuidor más cercano.

26

Page 27

INSTRUCCIONES DE SEGURIDAD

MANTENIMIENTO Y ALMACENAMIENTO

• Nunca manipule los dispositivos de seguridad de manera imprudente.

Controle periódicamente que funcionen de forma adecuada.

• Controle frecuentemente que todos los pernos y tornillos estén bien

ajustados para comprobar que la máquina se encuentra en condiciones

seguras de funcionamiento. Además, realice una inspección visual de la

máquina para controlar si la misma está dañada y repárela de ser necesario.

• Antes de limpiar, reparar o inspeccionar la máquina, detenga el motor y

compruebe que el mismo y que todas las piezas móviles se hallan detenido.

Desconecte el cable de la bujía y póngalo de manera que haga masa contra el

motor para evitar que se encienda de manera accidental.

• No cambie la configuración del regulador del motor ni acelere demasiado el

mismo. El regulador controla la velocidad máxima segura de operación del

motor.

• Mantenga o reemplace las etiquetas de seguridad e instrucciones según sea

necesario.

• Siga las instrucciones de este manual para cargar, descargar, transportar y

almacenar de manera segura esta máquina.

• Nunca almacene la máquina o el recipiente de combustible en un espacio

cerrado donde haya fuego, chispas o luz piloto como por ejemplo,

calentadores de agua, hornos, secadores de ropa, etc.

• Deje que la máquina se enfríe por lo menos 5 minutos antes de guardarla.

• Consulte siempre el manual del operador para conocer las instrucciones

adecuadas para el almacenamiento fuera de temporada.

• Si debe vaciar el tanque de combustible, hágalo al aire libre.

• Respete las normas referentes a la disposición correcta y las

reglamentaciones sobre gas, combustible, etc. para proteger el medio

ambiente.

• Según la Comisión de Seguridad de Productos para el Consumidor de los

Estados Unidos (CPSC) y la Agencia de Protección Ambiental de los Estados

Unidos (EPA), este producto tiene una vida útil media de siete (7) años, ó

60 horas de funcionamiento. Al finalizar la vida útil media, adquiera una

máquina nueva o haga inspeccionar anualmente ésta por un distribuidor de

servicio autorizado para cerciorarse de que todos los sistemas mecánicos y de

seguridad funcionan correctamente y no tienen excesivo desgaste. Si no lo

hace, pueden producirse accidentes, lesiones o muer te.

NO MODIFIQUE EL MOTOR

Para evitar lesiones graves o la muerte, no modifique el motor bajo ninguna

circunstancia. Si cambia la configuración del regulador el motor puede

descontrolarse y operar a velocidades inseguras. Nunca cambie la configuración de

fábrica del regulador del motor.

AVISO REFERIDO A EMISIONES

Los motores que están certificados y cumplen con las regulaciones de emisiones

federales EPA y de California para SORE (Equipos pequeños todo terreno) están

certificados para operar con gasolina común sin plomo y pueden incluir los

siguientes sistemas de control de emisiones: Modificación de motor (EM) y

catalizador de tres vías (TWC) si están equipados de esa manera.

GUARDACHISPAS

ADVERTENCIA

Esta máquina está equipada con un motor de combustión interna y no

debe ser utilizada en o cerca de un terreno agreste cubierto por bosque,

malezas o hierba excepto si el sistema de escape del motor está equipado

con un amortiguador de chispas que cumpla con las leyes locales o

estatales correspondientes, en caso de haberlas.

Si se utiliza un amortiguador de chispas el operador lo debe mantener en

condiciones de uso adecuadas. En el Estado de California las medidas anteriormente

mencionadas son exigidas por ley (Artículo 4442 del Código de Recursos Públicos

de California). Es posible que existan leyes similares en otros estados. Las leyes

federales se aplican en territorios federales.

Puede conseguir el guardachispas por Craftsman a 1-888-331-4569.

27

Page 28

INSTRUCCIONES DE SEGURIDAD

SÍMBOLOS DE SEGURIDAD

Esta página describe los símbolos y figuras de seguridad internacionales que pueden aparecer en este producto. Lea el manual del operador para obtener la

información terminada sobre seguridad, reunirse, operación y mantenimiento y reparación.

Símbolo Descripción

LEA EL MANUAL(S) DEL OPERADOR

Lea, comprenda, y siga todas instrucciones en el manual (manuales) antes procurar para reunir y

operar.

ADVERTENCIA— GIRANDO HOJAS

Mantenga manos fuera de aperturas de cala y descarga mientras máquina corre. Allí giran hojas

adentro.

ESPECTADORES

Mantenga a espectadores, los animales favoritos, y los niños por lo menos 75 pies de la máquina

mientras está en la operación. Pare máquina si cualquiera entra el área

ADVERTENCIA— OBJETOS TIRADOS

Esta máquina puede recoger y poder tirar y los objetos que pueden rebotar.

PROTECCION DE OJO

Siempre lleve gafas de seguridad o gafas de seguridad al operar esta máquina.

ADVERTENCIA— GASOLINA ES INFLAMABLE

Permita que el motor se enfríe al menos dos minutos antes del reabastecimiento de combustible.

ADVERTENCIA— MONOXIDO DE CARBONO

Nunca corra un motor dentro ni en un área mal ventilada. El escape del motor contiene monóxido de

carbono, un gas inodoro y mortal.

ADVERTENCIA: Su responsabilidad-Restringir el uso de esta máquina motorizada a las personas que lean, comprendan y

respeten las advertencias e instrucciones de este manual y en la máquina.

GUARDE ESTAS INSTRUCCIONES!

28

Page 29

IMP ORTANTE: Esta unidad se envía sin gasolina ni aceite en el motor. Antes de

Manija Superior

Guía de la

Cuerda

Guía del

Cable

Tornillo

del Carro

Bolsa

Montaje de la

Manguera

Canal de

Soplado

Botella de Aceite

para Motor

Manual del Operador

Anteojos de

Seguridad

Tuerca de

Mariposa

Manija

Inferior

Soporte para

la Manija de la

Manguera Inferior

Perilla Manual

Tuerca de

Mariposa

Soporte para la Manija

de la Manguera Superior

operar la máquina cargue el motor con gasolina y aceite como se indica en la sección

de Operación en este manual.

NOTA : Las referencias a los lados derecho e izquierdo de la aspiradora para patios se

hacen observando la máquina desde la posición de operación.

Apertura De La Caja De Cartón

1. Corte cada una de las esquinas de la caja verticalmente, de la parte superior

a la base.

2. Saque todas las piezas sueltas y el material de empaque suelto.

3. Eleve la unidad desde la parte posterior para separarla del material de la caja

que quede debajo, y haga rodar la unidad fuera de la caja.

4. Verifique cuidadosamente si en la caja queda alguna parte suelta.

NOTA : Asegúrese de no doblar los cables mientras extrae de la caja las partes

sueltas o toda la unidad.

Piezas Sueltas Dentro De La Caja (Vea la Figura 1)

• Manija superior e inferior

• Montaje de la manguera

• Bolsa

• Canal de soplado

• Anteojos de seguridad

• Aceite para motor (puede estar en el interior de la bolsa)

• Manual del operador

DESEMBALAJE

Figura 1

29

Page 30

MONTAJE

a

b

b

guía

c

d

a

b

c

Montaje De La Manija

1. Saque los broches de horquilla de los soportes de la manija, y saque los

tornillos del carro y las tuercas de mariposa de la manija inferior.

a. Sitúe los agujeros inferiores de la manija inferior sobre los pernos de

los soportes de la manija, y asegúrelos con broches de horquilla. Vea

la Figura 2.

b. Inserte los tornillos del carro desde el lado de afuera a través del

agujero superior de la manija inferior y asegúrelos con tuercas de

mariposa. Vea la Figura 2.

c. Despliegue la manija superior hasta que quede alineada con la