Page 1

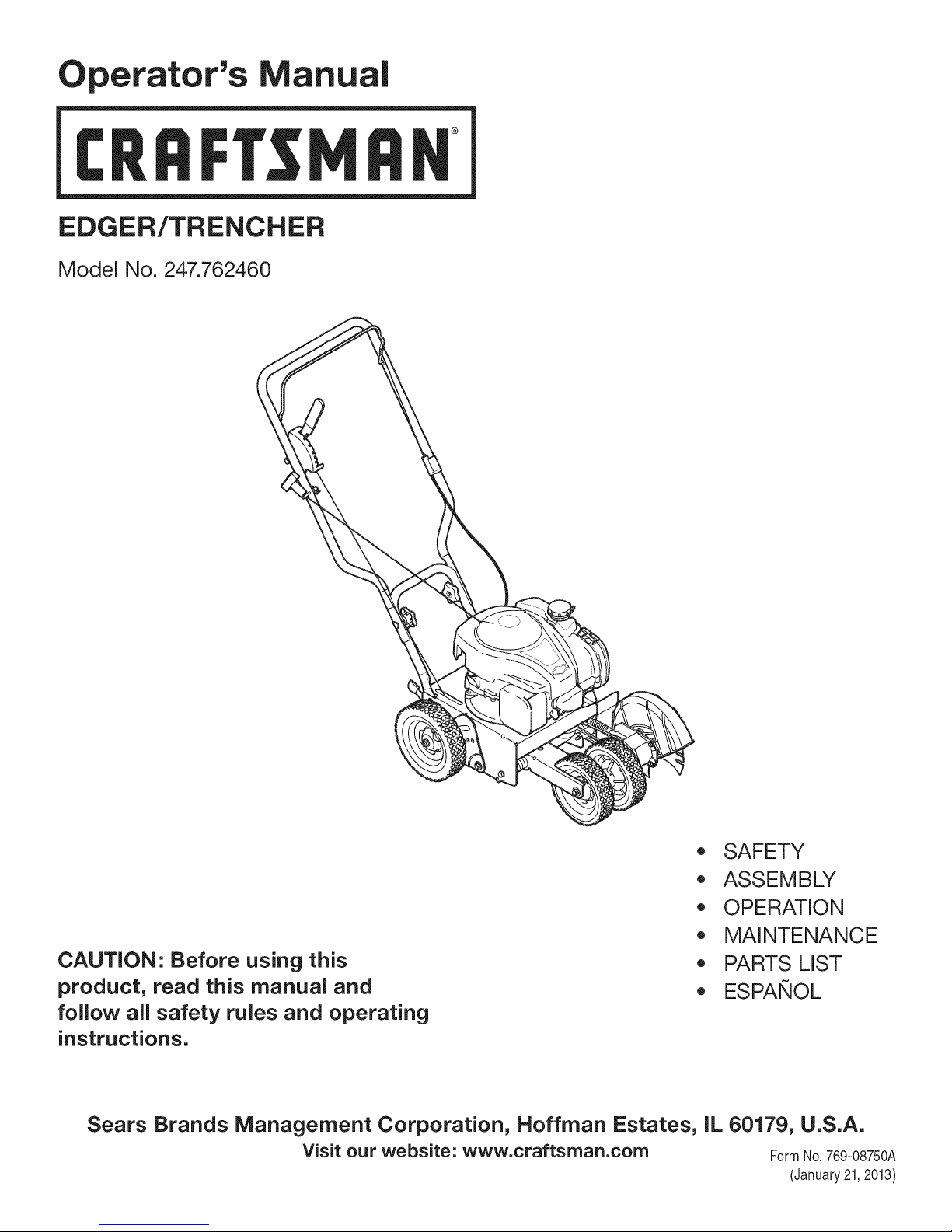

Operator's Manual

CRRFr MRN

EDGER/TRENCHER

Model No. 247.762460

CAUTION" Before using this

product, read this manual and

follow all safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FormNo.769-08750A

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPAKIOL

(January21,2013)

Page 2

WarrantyStatement.............................. Page2

SafetyInstructions............................ Pages3-5

Assembly..................................... Pages6-8

Operation................................... Pages9-11

ServiceandMaintenance.................... Pages12-16

CraftsmanTwoYearFullWarranty

FORTWOYEARSfromthedateofpurchase,thisproductiswarrantedagainstanydefectsinmaterialorworkmanship.Defectiveproductwillreceivefree

repairorfreereplacementifrepairisunavailable.

Forwarrantycoveragedetailstoobtainrepairorreplacement,visitthewebsite:www.craftsman.com.

ThiswarrantycoversONLYdefectsinmaterialandworkmanship.WarrantycoveragedoesNOTinclude:

• Expendableitemswhichcanwearoutfromnormalusewithinthewarrantyperiod,suchasbelts,filters,sparkplugsoredgingblades.

• Productdamageresultingfromuserattemptsat productmodificationorrepairorcausedbyproductaccessories.

Off-Season Storage .............................. Page 17

Troubleshooting ................................ Page 18

Parts List .................................... Page 20-28

Espa_ol ......................................... Page 31

Service Numbers ............................ Back Cover

• Repairsnecessarybecauseofaccidentorfailuretooperateormaintaintheproductaccordingto allsuppliedinstructions.

• Preventativemaintenanceorrepairsnecessaryduetoimproperfuelmixture,contaminatedorstalefuel.

Thiswarrantyisvoidifthisproductiseverusedwhileprovidingcommercialservicesorifrentedto anotherperson.

Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstateto state.

SearsBrandsManagementCorporation,NoffmanEstates,IL60179

Engine Oil: SAE 30

Fuel: Unleaded Gasoline

Engine: Briggs & Stratton

Model Number

Serial Number

Date of Purchase

Record the model number, serial number,

and date of purchase above.

© Sears Brands, LLC 2

Page 3

Thissymbolpointsout importantsafetyinstructionswhich, ifnot

followed,couldendangerthe personalsafetyand/orproperty of

yourselfandothers.Readandfollow all instructions inthis manual

beforeattempting to operatethis machine.Failureto complywith these

instructionsmayresultinpersonalinjury.Whenyouseethis symbol,HEED

ITSWARNING!

Thismachinewasbuilt tobeoperatedaccordingtothesafeoperation

practicesinthismanual.Aswith anytype of powerequipment,

carelessnessorerroronthe part ofthe operatorcanresultinseriousinjury.

Thismachineiscapableof amputatingfingers, hands,toesandfeet and

throwingdebris.Failuretoobservethefollowing safety instructionscould

resultinseriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someofits constituents,andcertainvehiclecomponents

containor emit chemicalsknowntoStateof Californiato causecancerand

birth defectsorother reproductiveharm.

GENERAL OPERATION

Readthisoperator'smanualcarefullyinitsentiretybeforeattemptingto

assemblethis machine.Read,understand,andfollowallinstructionson the

machineandinthemanual(s)beforeoperation.Keepthismanualinasafe

placeforfutureandregularreferenceandfororderingreplacementparts.

Becompletelyfamiliarwiththecontrolsandtheproperuseofthismachine

beforeoperatingit.

Thismachineisaprecisionpieceof powerequipment,nota plaything.

Therefore,exerciseextremecautionatalltimes.Yourmachinehasbeen

designedto performonejob:toedgelawn.Donotuseitforanyother

purpose.

Neverallowchildrenunder14yearsof agetooperatethismachine.Children

14andovershouldreadandunderstandtheinstructionsandsafeoperation

practicesinthismanualandonthemachineandbetrainedandsupervised

byanadult.

Onlyresponsibleindividualswhoarefamiliarwiththeserulesofsafe

operationshouldbeallowedtousethis machine.

Tohelpavoidbladecontactora thrownobjectinjury,stayinoperatorzone

behindhandlesandkeepchildren,bystanders,helpersandpetsatleast75

feetfromlawnedgerwhileit isinoperation.Stopmachineifanyoneenters

area.

Thoroughlyinspecttheareawheretheequipmentistobeused.Removeall

stones,sticks,wire,bones,toysandotherforeignobjectswhichcouldbe

trippedoverorpickedupandthrownbytheblade.Thrownobjectscancause

seriouspersonalinjury.

Alwayswearsafetyglassesorsafetygogglesduringoperationandwhile

performinganadjustmentor repairto protectyoureyes.Thrownobjects

whichricochetcancauseseriousinjurytotheeyes.

Wearsturdy,rough-soledworkshoesandclose-fittingslacksandshirts.

Shirtsandpantsthatcoverthearmsandlegsandsteel-toedshoesare

recommended.Neveroperatethis machineinbarefeet,sandals,slipperyor

lightweight(e.g.canvas)shoes.

Your Responsibility--Restrict theuseofthis powermachineto

personswhoread,understandandfollow thewarningsand instructionsin

thismanualandonthe machine.

SAVETHESEINSTRUCTIONS!

Neverattempttomakeanyadjustmentswhiletheengineisrunning,except

wherespecificallyrecommendedintheoperator'smanual.

Donotput handsorfeetnearrotatingparts.Contactwith therotatingblade

canamputatehandsandfeet.

Thebladecontrolhandleisasafetydevice.Neverbypassitsoperation.Doing

so,makesthemachineunsafeandmaycausepersonalinjury.

Neveroperatewithoutbladeguard,debrisshieldandbladecontrolhandlein

placeandworking.

Neveroperatewith damagedsafetydevices.Failuretodoso,canresultin

personalinjury.

Neverrunanengineindoorsorinapoorlyventilatedarea.Engineexhaust

containscarbonmonoxide,anodorlessanddeadlygas.

Donotoperatemachinewhileunderthe influenceofalcoholordrugs.

Mufflerandenginebecomehotandcancauseaburn.Donottouch.

Neveroperatethismachinewithoutgoodvisibilityorlight.Alwaysbesureof

yourfootingandkeepafirm holdonthehandles.Walk,neverrun.

Donotoperatethismachineif ithasbeendroppedordamaged.Return

machinetoyournearestauthorizedservicingdealerforexaminationand

repair.

Donotoperatethismachinewith adamagedorexcessivelyworncutting

blade.

Neverattempttoclearmaterialfromthebladeguardwhiletheengineis

running.Shuttheengineoff,disconnectthesparkplugwireandground

againsttheengineto preventunintendedstarting.

Donotoverloadmachinecapacitybyattemptingtoedgeattoofastof arate.

Stayalertfor unevensidewalks,terrainetc.Alwayspushslowlyoverrough

surfaces.Donotusethismachineongravelsurfaces.

Donotoperatemachineinrainorwetsoilconditions.

Alwaysoperatemachinefrombehindthehandlesandpositionyourself

wherethedirectlineofsightto cuttingbladeisblockedbyguards.

Page 4

Alwaysstopenginewhenedgingortrimmingisdelayedorwhen

transportingmachinefromonelocationtoanother.

Neverleavearunningmachineunattended.Stoptheengine,disconnect

sparkplugwireandgroundagainsttheenginetopreventunintended

starting.

Onlyusepartsandaccessoriesmadeforthismachinebythemanufacturer.

Failuretodoso,canresultinpersonalinjury.

Ifsituationsoccurwhicharenotcoveredinthismanual,usecareandgood

judgment.

CHILDREN

Tragicaccidentscanoccuriftheoperatorisnotalerttothepresenceofchildren.

Childrenareoftenattractedto powerequipmentsuchaslawnedgers.Theydonot

understandthedangers.Neverassumethatchildrenwill remainwhereyoulastsaw

them.

Keepchildrenoutoftheedgingareaandunderwatchfulcareofa

responsibleadultotherthantheoperator.

Bealertandturnlawnedgeroffif achildentersthearea.

Beforeandwhilemovingbackwards,lookbehindanddownfor small

children.

Useextremecarewhenapproachingblindcorners,doorways,shrubs,trees,

orotherobjectsthatmayobscureyourvisionofachildwhomayrunintothe

lawnedger.

Keepchildrenawayfromhotorrunningengines.Theycansufferburnsfrom

ahotmuffler.

Neverallowchildrenunder14yearsof agetooperatethismachine.Children

14andovershouldreadandunderstandthe instructionsandsafeoperation

practicesinthismanualandonthemachineandbetrainedandsupervised

byanadult.

SERVICE

Safe Handling of Gasoline:

Toavoidpersonalinjuryorpropertydamageuseextremecareinhandling

gasoline.Gasolineisextremelyflammable andthevaporsareexplosive.

Seriouspersonalinjury canoccurwhengasolineisspilledonyourselforyour

clotheswhichcanignite. Washyourskin andchangeclothesimmediately.

Useonlyanapprovedgasolinecontainer.

Neverfill containersinsideavehicleoronatruckortrailerbedwith aplastic

liner.Alwaysplacecontainersonthegroundawayfromyourvehiclebefore

filling.

Removegas-poweredequipmentfromthetruckortrailerandrefuelit on

theground.If thisisnotpossible,thenrefuelsuchequipmentonatrailer

with aportablecontainer,ratherthanfromagasolinedispensernozzle.

Keepthenozzleincontactwiththerimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.Donotuseanozzlelock-opendevice.

Extinguishallcigarettes,cigars,pipesandothersources

ofignition.

Neverfuelmachineindoorsbecauseflammablevaporswillaccumulatein

thearea.

Neverremovegascaporaddfuelwhileengineishotorrunning.Allow

enginetocoolatleasttwominutesbeforerefueling.

Neverover-fillfueltank.Toallowforexpansionofthefuel,donotfill above

thebottomof thefueltankneck.

Replacegasolinecapandtightensecurely.

Ifgasolineisspilled,wipeit offthe engineandequipment.Movemachineto

anotherarea.Wait5 minutesbeforestartingengine.

Neverstorethemachineorfuelcontainernearanopenflame,sparkorpilot

lightasonawaterheater,spaceheater,furnace,clothesdryerorothergas

appliances.

Toreducefire hazard,keepmachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillageandremoveanyfuel-soakeddebris.

Allowmachinetocoolatleast5minutesbeforestoring.

General Service:

Neverrunanengineindoorsorinapoorlyventilatedarea.Engineexhaust

containscarbonmonoxide,anodorlessanddeadlygas.

Beforecleaning,repairing,orinspecting,makecertainthebladeandall

movingpartshavestopped.Disconnectthesparkplugwireandground

againsttheenginetopreventunintendedstarting.

Checkthebladeandenginemountingboltsatfrequentintervalsforproper

tightness.Also,visuallyinspectbladefordamage(e.g.,bent,cracked,

worn)Replacebladewiththeoriginalequipmentmanufacture's(O.E.M.)

bladeonly,listedinthismanual."Useofpartswhichdonotmeetthe

originalequipmentspecificationsmayleadtoimproperperformanceand

compromisesafety!"

Lawnedgerbladesaresharpandcancut.Wrapthebladeorweargloves,

anduseextracautionwhenservicingthem.

Keepallnuts,bolts,andscrewstight to besuretheequipmentisinsafe

workingcondition.

Nevertamperwith safetydevices.Checktheirproperoperationregularly.

Afterstrikingaforeignobject,stoptheengine,disconnectthesparkplug

wireandgroundagainsttheengine.Thoroughlyinspectthelawnedgerfor

anydamage.Repairthedamagebeforestartingandoperatingthelawn

edger.

Neverattempttomakeawheeladjustmentwhiletheengineis running.

Manycomponentsonyournewedgercanwearwithcontinueduse.For

safetyprotection,frequentlycheckalledgercomponentsandreplace

immediatelywith originalequipmentmanufacturer's(O.E.M.)parts

only,listedinthismanual."Useof partswhichdonotmeettheoriginal

equipmentspecificationsmayleadto improperperformanceand

compromisesafety!"

Donotchangetheenginegovernorsettingoroverspeedtheengine.The

governorcontrolsthemaximumsafeoperatingspeedof theengine.

Maintainorreplacesafetyandinstructionlabels,asnecessary.

Observeproperdisposallawsandregulationsforusedgas,oil,etc..Improper

disposaloffluidsandmaterialscanharmtheenvironment.

4

Page 5

Accordingto theConsumerProductsSafetyCommission(CPSC)andtheU.S.

EnvironmentalProtectionAgency(EPA),thisproducthasanAverageUseful

Lifeofseven(7)years,or70hoursofoperation.AttheendoftheAverage

UsefulLifehavethemachineinspectedannuallybyanauthorizedservice

dealerto ensurethatall mechanicalandsafetysystemsareworkingproperly

andnotwornexcessively.Failuretodo socanresultinaccidents,injuriesor

death.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modify engineinanyway.Tampering

with thegovernorsetting canleadto arunawayengineandcauseit to

operateat unsafespeeds.Nevertamperwith factorysetting ofengine

governor.

NOTICE REGARDING EMiSSiONS

Engineswhich are certifiedto complywith Californiaandfederal EPA

emissionregulationsfor SORE(Sinai[Off RoadEquipment)arecertified

tooperateonregularunleadedgasoline,and mayincludethefollowing

emissioncontrolsystems:EngineModification (EM),OxidizingCatalyst(0C),

SecondaryAirinjection(SAI)andThreeWayCatalyst(TWC)ifsoequipped.

SPARK ARRESTOR

Thismachineisequippedwith aninternalcombustionengineandshould

not beusedonor nearanyunimprovedforest-covered,brushcoveredor

grass-coveredlandunlesstheengine'sexhaustsystemisequippedwith a

sparkarrestormeetingapplicablelocalor statelaws(if any).

Ifasparkarrestor isused,itshouldbemaintained ineffective workingorder

bytheoperator.In theStateofCaliforniathe aboveisrequiredby law(Section

4442ofthe CaliforniaPublicResourcesCode).Otherstatesmayhavesimilar

laws.Federallawsapply onfederallands.

Asparkarrestorfor the muffler isavailablethrough your nearestSearsParts

andRepairServiceCenter.Call1-800-469-4663for ServiceCenterlocations.

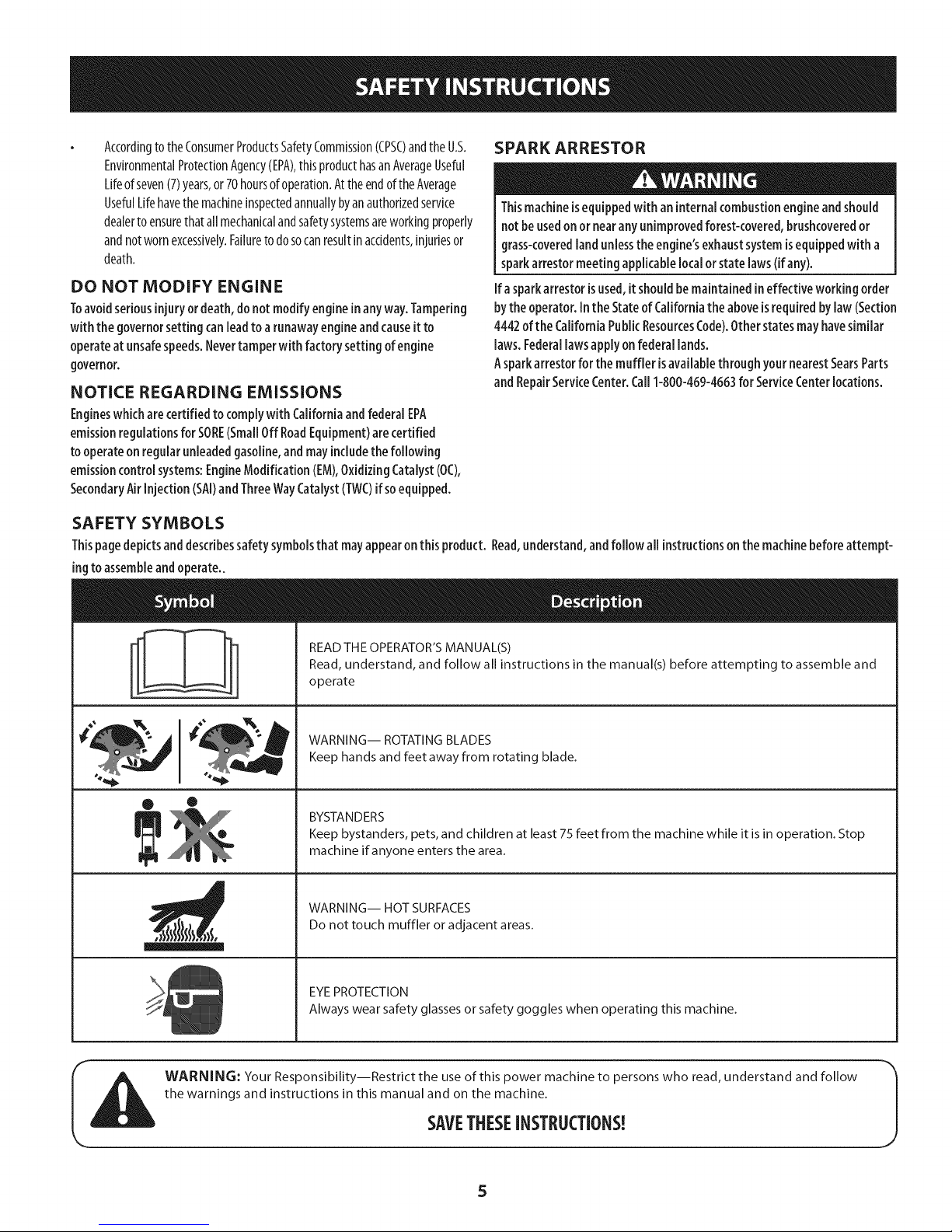

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthat mayappearon this product. Read,understand,andfollow all instructionsonthe machinebeforeattempt-

ingto assembleandoperate..

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATINGBLADES

Keephands and feet awayfrom rotating blade.

® O

I!I

WARNING: Your Responsibility--Restrict the use of this power machine to persons who read, understand and follow

the warnings and instructions in this manual and on the machine.

BYSTANDERS

Keep bystanders, pets, and children at least 75 feet from the machine while it is in operation. Stop

machine if anyone enters the area.

WARNING-- HOT SURFACES

Do not touch muffler or adjacent areas.

EYEPROTECTION

Always wear safety glassesor safety goggles when operating this machine.

SAVETHESEINSTRUCTIONS!

Page 6

IMPORTANT:Thisunitisshippedwithout gasolineoroil intheengine.Becertainto

serviceenginewithgasolineandoilasinstructedintheOperationsectionbefore

startingorrunningyourmachine.

NOTE:Referencetorightandlefthandsideoftheedgerisobservedfromthe

operatingposition.

BladeControl

Upper

Handle \

\

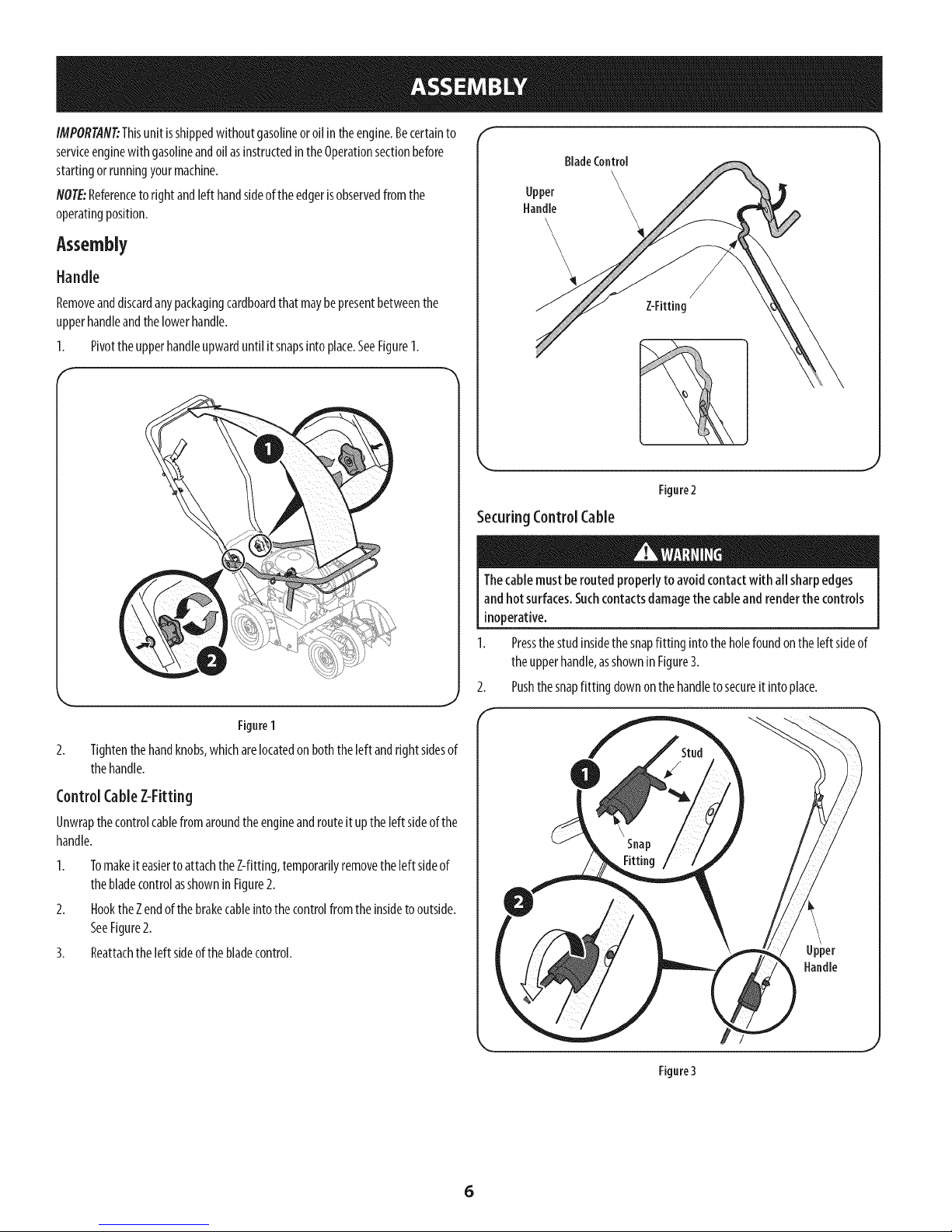

Assembly

Handle

Removeanddiscardanypackagingcardboardthatmaybepresentbetweenthe

upperhandleandthelowerhandle.

1. Pivottheupperhandleupwarduntil itsnapsintoplace.SeeFigure1.

f

\

\

\

Z-Fitting

Figure2

SecuringControlCable

Thecablemust beroutedproperlyto avoidcontactwith allsharpedges

andhot surfaces.Suchcontactsdamagethe cableand renderthe controls

inoperative.

1. Pressthestudinsidethesnapfitting intotheholefoundontheleftsideof

theupperhandle,asshownin Figure3.

2. Pushthesnapfitting downonthehandletosecureit intoplace.

Figure1

2. Tightenthehandknobs,whicharelocatedonboththeleftandrightsidesof

thehandle.

ControlCableZ-Fitting

Unwrapthecontrolcablefromaroundtheengineandrouteitupthe leftsideofthe

handle.

1. Tomakeit easiertoattachtheZ-fitting,temporarilyremovetheleft sideof

thebladecontrolasshowninFigure2.

2. HooktheZendofthe brakecableintothecontrolfromtheinsidetooutside.

SeeFigure2.

3. Reattachtheleftsideofthebladecontrol.

Upper

Handle

\

Figure3

6

Page 7

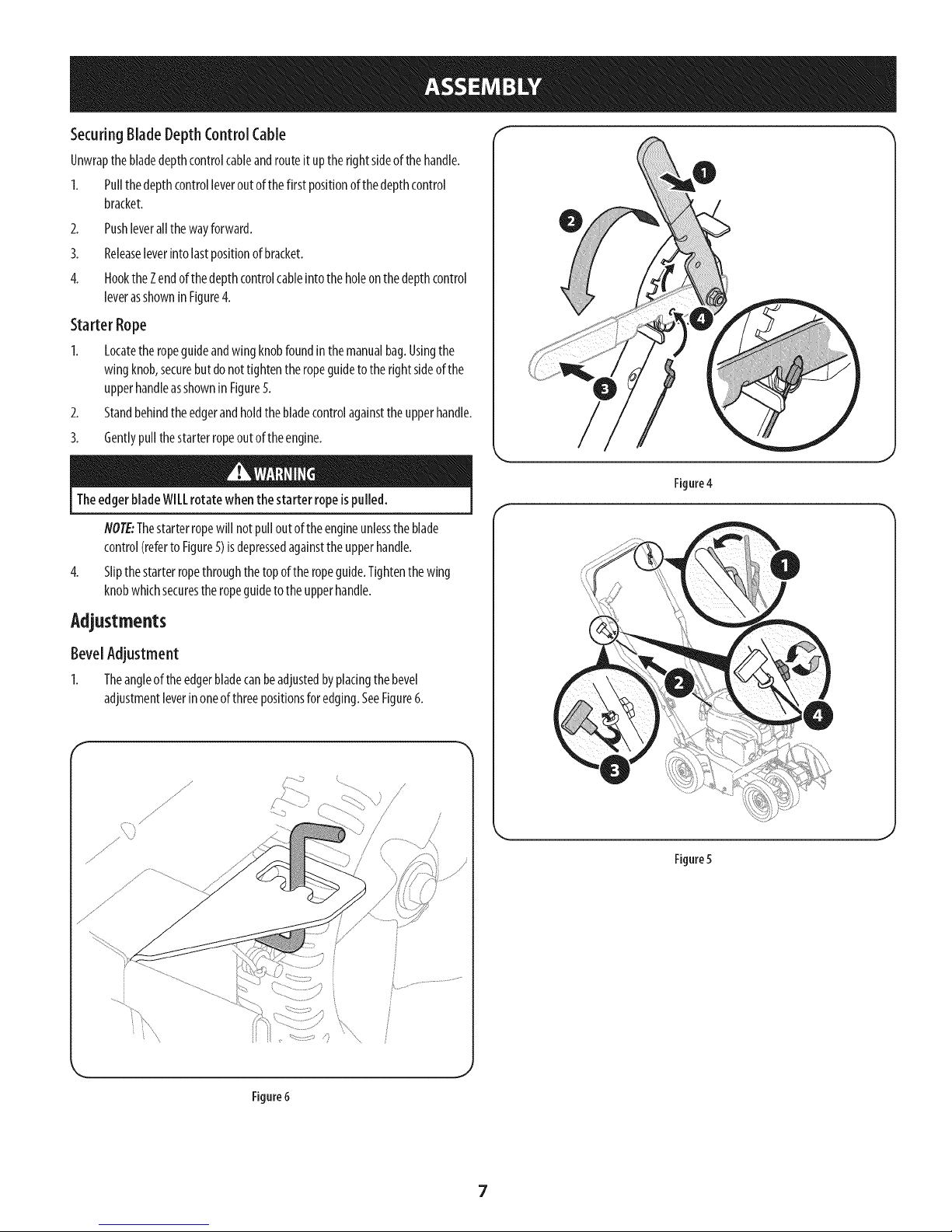

SecuringBladeDepthControlCable

Unwrapthebladedepthcontrolcableandrouteit uptherightsideofthehandle.

1. Pullthedepthcontrolleveroutofthefirstpositionofthedepthcontrol

bracket.

2. Pushleverallthewayforward.

3. Releaseleverintolastpositionofbracket.

4. HooktheZendofthedepthcontrolcableintotheholeonthedepthcontrol

leverasshownin Figure4.

Starter Rope

1. Locatetheropeguideandwingknobfoundinthemanualbag.Usingthe

wingknob,securebutdonottightentheropeguideto therightsideofthe

upperhandleasshownin Figure5.

2. Standbehindtheedgerandholdthebladecontrolagainsttheupperhandle.

3. Gentlypullthestarterropeoutoftheengine.

TheedgerbladeWiLLrotatewhen thestarter ropeispulled.

flOTE:Thestarterropewill notpulloutof theengineunlessthe blade

control(refertoFigure5)isdepressedagainsttheupperhandle.

4. Slipthestarterropethroughthetopoftheropeguide.Tightenthewing

knobwhichsecurestheropeguidetothe upperhandle.

Figure4

Adjustments

BevelAdjustment

1. Theangleof theedgerbladecanbeadjustedbyplacingthebevel

adjustmentleverinoneofthreepositionsforedging.SeeFigure6.

\

Figure6

Figure5

J

7

Page 8

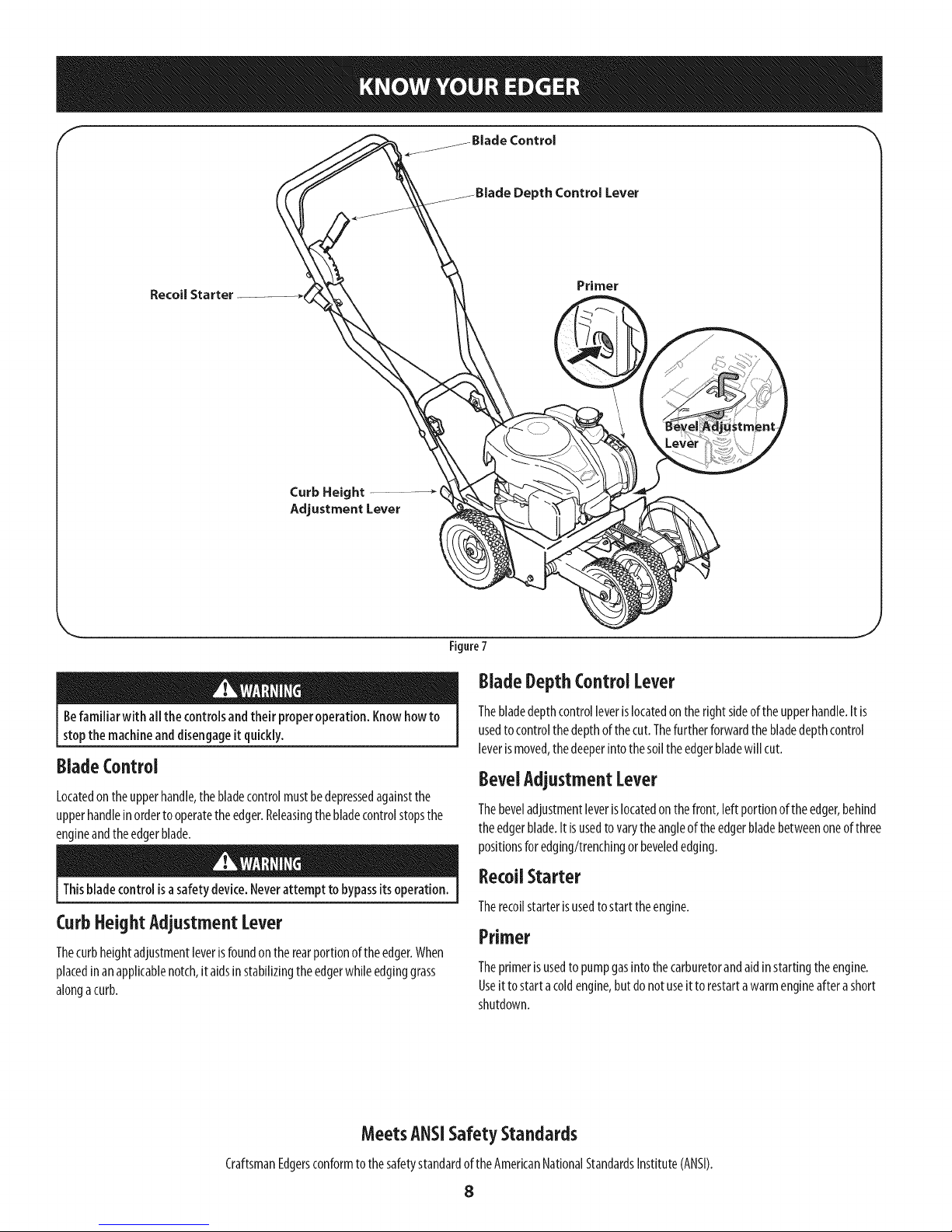

Depth Control Lever

Recoil Starter

Curb Height

Adjustment Lever

Befamiliarwithallthecontrolsandtheirproperoperation.Knowhowto

stopthemachineanddisengageitquickly.

BladeControl

Locatedontheupperhandle,thebladecontrolmustbedepressedagainstthe

upperhandleinordertooperatetheedger.Releasingthebladecontrolstopsthe

engineandtheedgerblade.

Primer

J

Figure7

BladeDepthControl Lever

Thebladedepthcontrolleverislocatedontherightsideoftheupperhandle.It is

usedtocontrolthedepthofthecut.Thefurtherforwardthebladedepthcontrol

leverismoved,thedeeperintothesoiltheedgerbladewillcut.

BevelAdjustmentLever

Thebeveladjustmentleverislocatedonthefront,left portionoftheedger,behind

theedgerblade.It isusedto varytheangleoftheedgerbladebetweenoneofthree

positionsforedging/trenchingor bevelededging.

Thisbladecontrolisasafety device.Neverattempt to bypassitsoperation.

CurbHeightAdjustmentLever

Thecurbheightadjustmentleverisfoundonthe rearportionoftheedger.When

placedinanapplicablenotch,it aidsinstabilizingtheedgerwhileedginggrass

alongacurb.

CraftsmanEdgersconformtothesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

RecoilStarter

Therecoilstarterisusedtostart theengine.

Primer

Theprimerisusedtopumpgasintothecarburetorandaidinstartingtheengine.

Useitto startacoldengine,butdonotuseitto restartawarmengineafterashort

shutdown.

MeetsANSISafety Standards

8

Page 9

GASANDOILFILUUP f

IMPORTAN#Thisunitisshippedwithoutgasolineoroilintheengine.Becertainto

serviceenginewith gasolineandoil asinstructedinthis sectionbeforestartingor

runningyourmachine.

OU(one15ouncebottleshippedwithunit)

FirstTimeUse

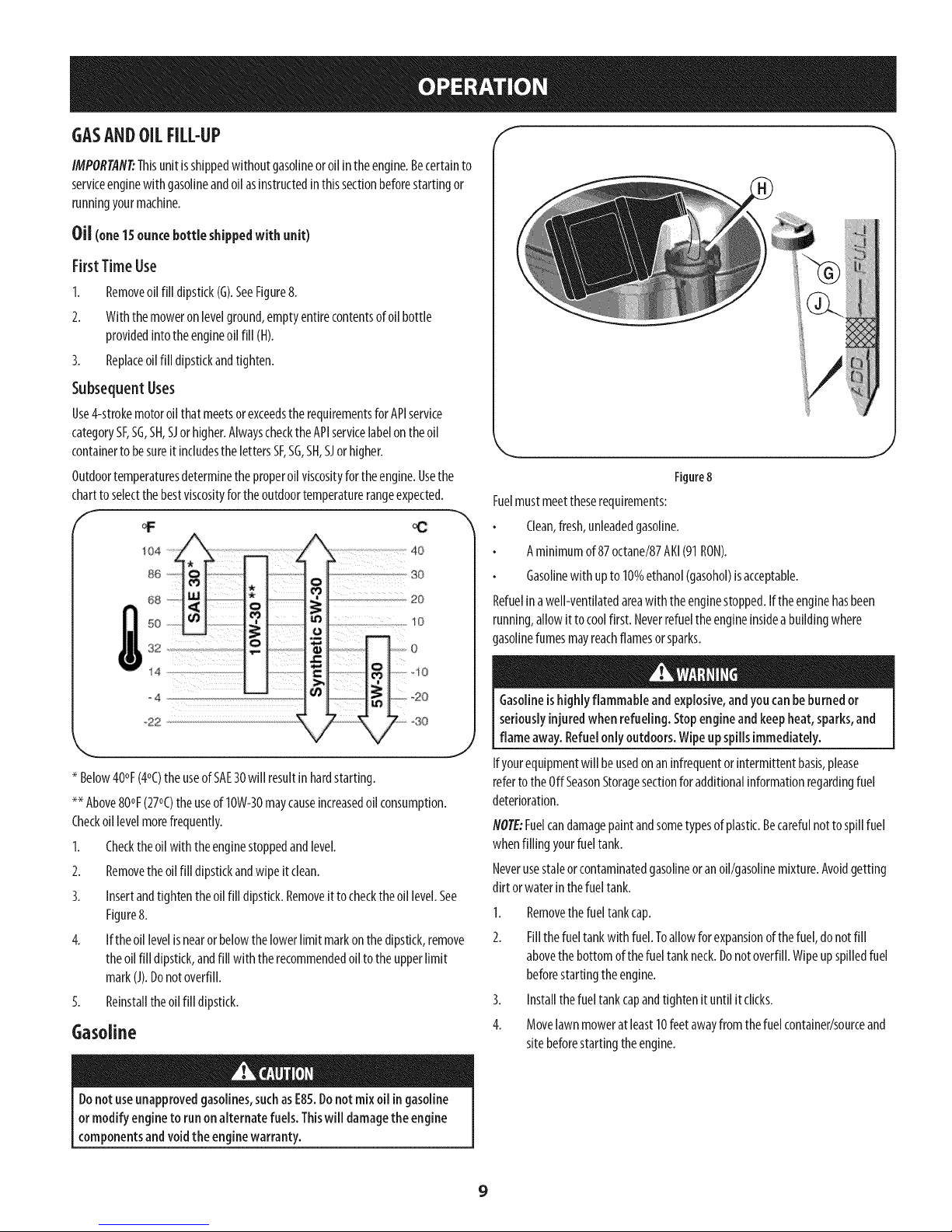

1. Removeoilfill dipstick(G).SeeFigure8.

2. Withthemoweronlevelground,emptyentirecontentsofoilbottle

providedintotheengineoil fill (H).

3. Replaceoilfill dipstickandtighten.

SubsequentUses

Use4-strokemotoroilthatmeetsorexceedstherequirementsforAPIservice

categorySF,SG,SH,SJorhigher.AlwayschecktheAPIservicelabelontheoil

containertobesureitincludesthelettersSF,SG,SH,SJorhigher.

Outdoortemperaturesdeterminetheproperoil viscosityfortheengine.Usethe

chartto selectthebestviscosityfortheoutdoortemperaturerangeexpected.

f

i

40

30

20

1:0

............................o

Fuelmustmeettheserequirements:

Refuelinawell-ventilatedareawith theenginestopped.Iftheenginehasbeen

running,allowit tocoolfirst.Neverrefueltheengineinsideabuildingwhere

gasolinefumesmayreachflamesorsparks.

J

Figure8

Clean,fresh,unleadedgasoline.

Aminimumof87octane/87AKI(91RON).

Gasolinewith upto 10%ethanol(gasohol)isacceptable.

* Below40°F(4°C)theuseofSAE30will resultinhardstarting.

** Above80°F(27°C)theuseof 10W-30maycauseincreasedoilconsumption.

Checkoillevelmorefrequently.

1. Checktheoil with theenginestoppedandlevel.

2. Removetheoilfill dipstickandwipeit clean.

3. Insertandtightentheoilfill dipstick.Removeit to checktheoillevel.See

Figure8.

4. Iftheoil levelisnearorbelowthelowerlimit markonthedipstick,remove

theoilfill dipstick,andfill withtherecommendedoiltotheupperlimit

mark(J).Donotoverfill.

.5. Reinstalltheoilfill dipstick.

Gasoline

Donotuseunapprovedgasolines,suchasE85.Donot mix oil ingasoline

or modifyengineto runonalternatefuels.Thiswill damagethe engine

componentsandvoidtheenginewarranty.

Gasolineishighlyflammable andexplosive,andyoucanbeburned or

seriouslyinjuredwhenrefueling. Stopengineandkeepheat,sparks,and

flameaway.Refuelonlyoutdoors.Wipeupspillsimmediately.

Ifyourequipmentwill beusedonaninfrequentorintermittentbasis,please

refertotheOffSeasonStoragesectionfor additionalinformationregardingfuel

deterioration.

NOTE:Fuelcandamagepaintandsometypesofplastic.Becarefulnottospillfuel

whenfillingyourfueltank.

Neverusestaleorcontaminatedgasolineoranoil/gasolinemixture.Avoidgetting

dirt orwaterinthefueltank.

1. Removethefueltankcap.

2. Fillthefueltankwithfuel.Toallowforexpansionofthefuel,donotfill

abovethe bottomofthefueltankneck.Donotoverfill.Wipeupspilledfuel

beforestartingtheengine.

3. Installthefueltankcapandtightenituntilitclicks.

4. Movelawnmoweratleast10feetawayfromthefuelcontainer/sourceand

sitebeforestartingtheengine.

9

Page 10

Besurenooneother than the operatorisstandingnearthe lawnmower

while starting engineoroperating mower.Neverrunengine indoorsor

inenclosed,poorlyventilatedareas.Engineexhaustcontainscarbon

monoxide,anodorlessanddeadlygas.Keephands,feet, hairandloose

dotNng awayfromanymoving partsonengineandlawnmower.

ToStart Engine

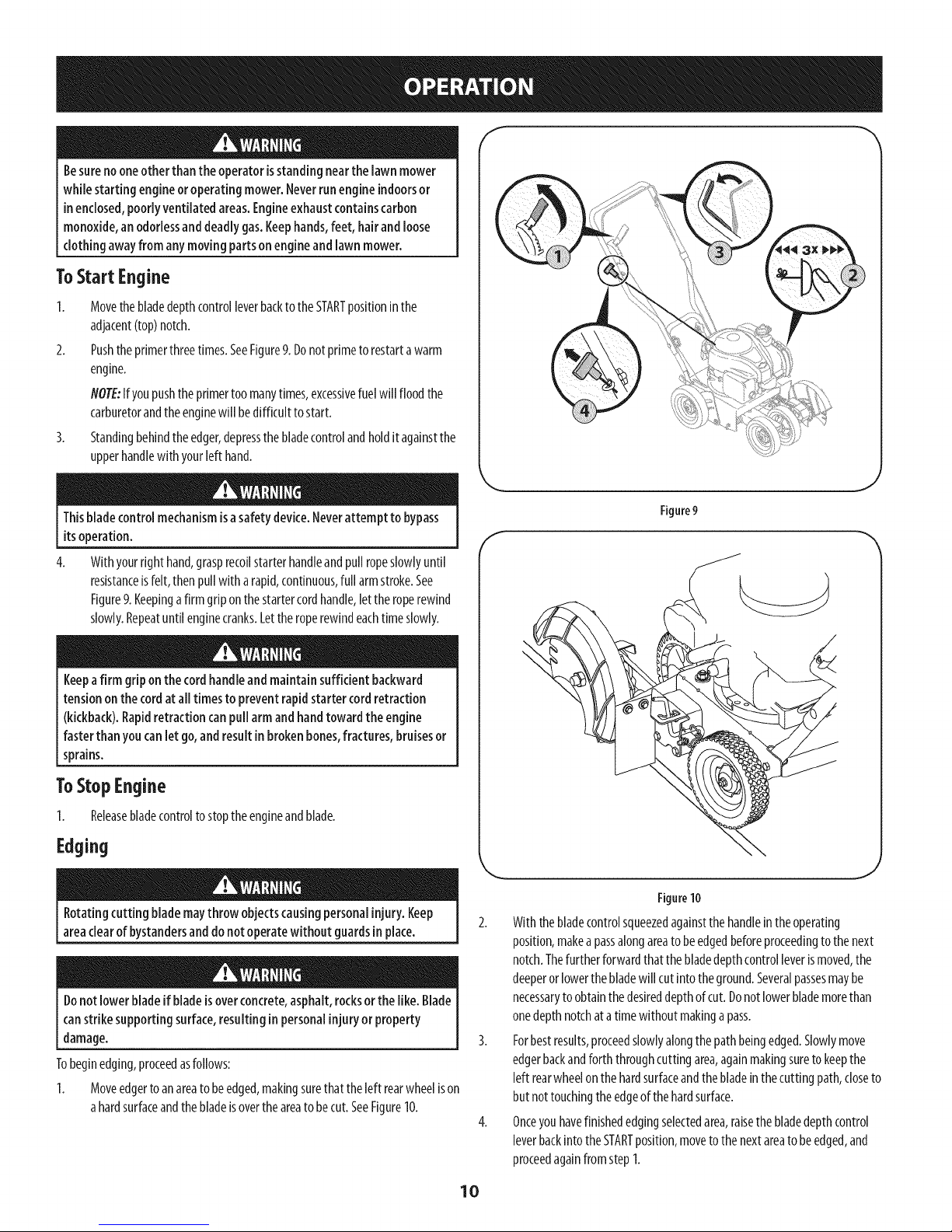

1. Movethebladedepthcontrolleverbackto theSTARTpositioninthe

adjacent(top)notch.

2. Pushtheprimerthreetimes.SeeFigure9.Donotprimetorestartawarm

engine.

NOTE:Ifyoupushtheprimertoomanytimes,excessivefuelwillfloodthe

carburetorandtheenginewill bedifficulttostart.

3. Standingbehindtheedger,depressthebladecontrolandholdit againstthe

upperhandlewithyourleft hand.

f

Thisbladecontrolmechanismisasafetydevice.Neverattempt to bypass

itsoperation.

4. Withyourfight hand,grasprecoilstarterhandleandpullropeslowlyuntil

resistanceisfelt,thenpullwith arapid,continuous,full armstroke.See

Figure9.Keepingafirm griponthestartercordhandle,lettheroperewind

slowly.Repeatuntilenginecranks.Lettheroperewindeachtimeslowly.

Keepafirm grip onthe cordhandleandmaintain sufficient backward

tensiononthe cordatall timesto preventrapidstartercordretraction

(kickback).Rapidretraction canpullarmand handtowardthe engine

fasterthanyoucanlet go,and resultin brokenbones,fractures,bruisesor

sprains.

ToStop Engine

1. Releasebladecontrolto stoptheengineandblade.

Edging

Rotatingcutting blademaythrow objectscausingpersonalinjury.Keep

areaclearof bystandersanddonotoperatewithout guardsinplace.

Donotlowerbladeif bladeisoverconcrete,asphalt,rocksorthe like. Blade

canstrikesupportingsurface,resultinginpersonalinjuryor property

damage.

Tobeginedging,proceedasfollows:

1. Moveedgertoanareatobeedged,makingsurethattheleft rearwheelison

ahardsurfaceandthebladeisovertheareatobecut.SeeFigure10.

Figure9

Figure10

2. Withthebladecontrolsqueezedagainstthe handleintheoperating

position,makeapassalongareato beedgedbeforeproceedingtothenext

notch.Thefurtherforwardthatthebladedepthcontrolleverismoved,the

deeperorlowerthebladewill cutintotheground.Severalpassesmaybe

necessaryto obtainthedesireddepthofcut.Donotlowerblademorethan

onedepthnotchata timewithoutmakingapass.

3. Forbestresults,proceedslowlyalongthe pathbeingedged.Slowlymove

edgerbackandforththroughcuttingarea,againmakingsuretokeepthe

leftrearwheelonthehardsurfaceandthebladeinthecuttingpath,closeto

butnottouchingthe edgeof thehardsurface.

4. Onceyouhavefinishededgingselectedarea,raisethebladedepthcontrol

leverbackintotheSTARTposition,movetothenextareatobeedged,and

proceedagainfromstep1.

10

Page 11

EdgingAlongACurb

Trenching

Therightrearwheelof theedgercanbeloweredintooneoffive positionstoease

thetaskofedgingalongacurb.Toadjusttheheightofcurbwheel,proceedas

follows:

Lowertherightrearwheelbymovingthecurbheightadjustmentlever

slightlytotheleft. SeeFigure11.

f CurbHeight _'_

Adjustment ,

Lever

Youcanutilizetheedger'soptionaltrenchingfeatureinordertocreatea wider

cuttingpathforsuchthingsaslayingwireforlandscapelighting.

Disconnectthesparkplugwire andgroundagainstthe enginebefore

performing the following steps.

Theedgerbladeissharp.Wearleatherwork glovestoprotectyourhands

whenworkingaroundthe edgerblade.

Usetwowrenches(onewrenchtopreventhexboltheadfromspinningand

theotherto unthreadtheflangenut)to removeflangenutthatsecures

edgerblade,leavingtheedgerbladeinplace.SeeFigure13.

Additional

EdgerBlade

Figure11

2. Pivottherightrearwheelintoanapplicablepositioninrelationtothe height

ofthecurbto beedgedalong.

3. Releasethecurbheightadjustmentlevertolockthewheelinposition.

Beveling

Inordertoachievea bevellededge,setthebeveladjustmentlever(referto

AssemblySection)inthefirst (left hand)or third(righthand)notchtoplacethe

edgerbladeinpositionfor beveling.SeeFigure12.

f

FlangeNut

EdgerBlade

FlatWasher

Figure13

2. Installtheflatwasherandadditionaledgerbladesuppliedwith your

machine.SeeFigure13.

3. Securewith theflangenutremovedearlier.Useatorquewrenchtotighten

theflangenuttobetween37foot-lbs,and50foot-lbs.

NOTE:Makecertainthatdrivebeltisseatedcorrectlyonbladespindleandthat it

isridingsmoothlyonspindlesheaves(seeFigure21)andisnotpinchedbetween

them.Repeatfirstthreestepsif beltispinched.

Right-HandPosition

Figure12

Left-HandPosition

.J

11

Page 12

MAINTENANCESCHEDULE

Beforeperforminganytypeof maintenance/service,disengageall controls

andstopthe engine.Wait until allmoving partshavecometoacomplete

stop.Disconnectsparkplug wireand grounditagainstthe engineto

preventunintendedstarting.

Followthemaintenanceschedulegivenbelow.Thischartdescribesservice

guidelinesonly.UsetheServiceLogcolumntokeeptrackofcompleted

maintenancetasks.TolocatethenearestSearsServiceCenterortoscheduleservice,

simplycontactSearsat1-800-4-MY-HOME®.

EachUse

IstMonthor5hours

Annuallyor25hours

Annuallyor50hours

Annually

BeforeStorage

1. Engineoil level

2. Looseormissinghardware

3. Aircleaner

4. Unitandengine

1. Engineoil

1. Aircleanerf

2. Controllinkages/pivotsandwheels

1. Engineoil ff

1. Sparkplug

2. AirCleaner

1. Fuelsystem

1. Check

2. Tightenorreplace

3. Check

4. Clean

1. Change

1. Clean

2. Lubewith lightoil

1. Change

1. Replace

2. Replace

1. Runengineuntilitstopsfromlackoffuel,or

addstabilizertoafulltankoffreshfuelprior

tostorage.

Cleanmoreoftenunderdustyconditionsorwhenairbornedebrisispresent.Replaceaircleanerifverydirty.

ff Changeoilevery25hourswhenoperatingtheengineunderheavyloadorinhightemperatures.

12

Page 13

Alwaysstopengine,disconnectsparkplugwire, andgroundagainstengine

beforeperforming anytype of maintenanceon yourmachine.

General Recommendations

Alwaysobservesafetyruleswhenperforminganymaintenance.

Thewarrantyonthisedger/trencherdoesnotcoveritemsthat havebeen

subjectedtooperatorabuseornegligence.Toreceivefull valuefrom

warranty,operatormustmaintaintheequipmentas

instructedhere.

Changingofengine-governedspeedwillvoidenginewarranty.

Alladjustmentsshouldbecheckedat leastonceeachseason.

Periodicallycheckallfastenersandmakesurethesearetight.

Engine Maintenance

SparkPlug

Forgoodperformance,thesparkplugmustbeproperlygappedandfreeof

deposits.Replacethesparkplugannually.

1. Disconnectthecapfromthesparkplug,andremoveanydirt fromthespark

plugarea.

2. Usethepropersizesparkplugwrenchtoremovethesparkplug.

NOTE:Replacewith aChampionRC12YCsparkplug.

3. Checkthegap(A)with a wiregauge(B).SeeFigure14.Sparkpluggap

shouldbe0.020in (0.51mm).If necessary,resetthegap.

4. Installandtightenthesparkplugtotherecommendedtorque(180Ib-in[20

Nm]).

5. Attachthesparkplugcaptothesparkplug.

Air Cleaner

J

Figure14

f

Adirtyaircleanerwill restrictairflow tothecarburetorandcausepoorengine

performance.Inspectthefilter eachtimetheengineisoperated.Youwill needto

cleanthefiltermorefrequentlyif youoperatetheengineinverydustyareas.

Cleantheaircleanerevery25hoursofoperationoroncea season.Replacetheair

cleanerannually.

Neverstart orrunthe enginewith the aircleanerassemblyortheair filter

removed.

NOTE:Donotusepressurizedairorsolventstocleanthefilter. Pressurizedaircan

damagethefilterandsolventswilldissolvethefilter.

Theaircleanersystemusesafoamelementthatcanbewashedandreused.

1. Openthecover(B)andremovethefoamelement((). SeeFigure15.

2. Washthefoamelementinliquiddetergentandwater.Squeezedrythefoam

elementin acleancloth.

3. Saturatethefoamelementwith cleanengineoil.Toremovetheexcess

engineoil,squeezethefoamelementinacleancloth.

4. Installthefoamelementandclosethecover.

J

Figure15

13

Page 14

CheckEngineOil f

Checkoil levelbeforeeachoperation.Besureoil levelismaintained.

1. Checkthe oilwiththeenginestoppedandlevel.

2. Removetheoilfill dipstick(G)andwipeit clean.SeeFigure16.

3. Insertandtightendipstick.Removeit tochecktheoillevel.

4. Iftheoillevelisnearorbelowthelowerlimit markonthedipstick,remove

theoilfillercap/dipstick,andfill with therecommendedoil (H)totheupper

limit mark(J).Donotoverfill.

5. Reinstalltheoilfill dipstick.

ChangeEngineOil

Gasolineand itsvaporsareextremely flammableandexplosive.Fireor

explosioncancausesevereburnsor death.

Changeengineoilafterthefirstfivehoursofoperation,andeveryfiftyhoursor

onceaseasonthereafter.

Whenyoudrainthe oil from thetop oilfill tube,the fuel tank must be

empty orfuel canleak out andresultin afire orexplosion.Toempty the

fuel tank, runthe engineuntil it stopsfromlackoffuel.

1. Withengineoff butstillwarm,disconnectthesparkplugwire(F)andkeepit

awayfromthesparkplug.

2. Placeasuitablecontainernexttotheenginetocatchtheusedoil.

3. Removetheoilfill dipstick(E)anddraintheo11intothecontainerbytipping

theenginetowardtheoil filler neck.SeeFigure1Z

Figure16

f

Air Filter

Usedoil isa hazardouswasteproduct. Disposeofusedoil properly. Donot

discardwith householdwaste.Checkwithyourlocalauthoritiesor Sears

ServiceCenterforsafedisposal/recyclingfacilities.

4.

Withtheenginein alevelposition,fill tothe upperlimit markonthedipstick

with therecommendedoil.

Runningthe enginewith alowoil levelcancauseenginedamage.

5. Reinstalltheoiifill dipsticksecurely.

CleanEngine

Dailyorbeforeeveryuse,cleangrass,chaffor accumulateddebrisfrom

engine.Keeplinkage,spring,andcontrolsclean.Keepareaaroundand

behindmufflerfreeofanycombustibledebris.

Keepingenginecleanallowsairmovementaroundengine.

Enginepartsshouldbekeptcleantoreducetheriskofoverheatingand

ignitionofaccumulateddebris.

Donotusewatertocleanengineparts.Watercouldcontaminatefuel

system.Usea brushor drycloth.

14

Page 15

Lubrication

Wheels

EdgerBladeCare

Lubricatethewheelsandbearingsatleastonceaseasonwithalightoil.Alsoif the

wheelsareremovedfor anyreason,lubricatethesurfaceoftheaxleboltandthe

innersurfaceofthewheelwith lightoil.

PivotPoints

Lubricatethepivotpointsonthebladecontrol,bladedepthcontrollever,the blade

adjustmentlever,andcurbheightadjustmentleverwith lightoilat leastoncea

season.

Beating Block

Lubricatethebearingblockevery25hoursoratleastonceaseason.Simplyapply

oilateachendofthecoverplate.SeeFigure18.

Theedgerbladeissharp.Wearleatherwork glovestoprotect yourhands

whenworkingaroundthe edgerblade.

Periodicallyinspectthebladefor cracks,especiallyifyoustrikea foreignobject.

Replacewhennecessary.Followthestepsbelowforbladeservice.

1. Disconnectsparkplugbootfromsparkplug.

2. Usetwowrenches(onewrenchtopreventthehexboltheadfromspinning

andtheothertoremovetheflangenut)to removetheedgerblade.Referto

Figure19.

FlangeNut

Figure18

Lubricate

Figure19

Removeanddiscardtheedgerbladebutretaintheflangenutandflat

washer.

Installtheflatwasher,replacementedgerblade,andflangenut removed

earlier.Useatorquewrenchtotightentheflangenuttobetween37foot-

Ibs.and50foot-lbs.

NOTE:Makecertainthatthedrivebeltisseatedcorrectlyontheblade

spindleandthatit isridingsmoothlyonthespindlesheaves(seeFigure21)

andisnotpinchedbetweenthem.Repeatthefirstthreestepsifthebeltis

pinched.

15

Page 16

Belt Replacement

NOTE:Toaidinreassembly,notetheorientationofthedrivebeltonthetwo idler

pulleysandtheengineflywheelpulleypriortoperformingthefollowingsteps.

RefertoFigure20.

Theedgerdrivebeltissubjecttowearandshouldbereplacedifanysignsof

cracking,shreddingorrottingarepresent.Toreplacethebelt,proceedasfollows:

1. Workinginfrontoftheedger,loosentheflangelocknutontopofframe,

allowingtheidlerpulleyassemblytopivotslightlyoutfromtheframe.See

Figure20.

FlangeLock

Nut

gme IdlerPulley

_,_,:_Flywheel ......................Assembly

....",!_i, Pulley

Figure20

2. Withyourotherhand,carefullyreachundertherearoftheedgerandremove

thebeltfromaroundtheengineflywheelpulley.SeeFigure20.

3. Removethespindlesheavesbeltguardbyremovingthe twoself-tapping

screwswhichsecureit tothebladeplateassembly.SeeFigure21.

Carefullyremovethebeltfromoffof thepulleys,againmakingsuretonote

theorientationofthebelt.Discardthebelt.SeeFigure21.

f

BeltGuard

TopPt Bottom Pulley

EngineFlywheel Pulley

SpindleSheave

Figure21

5. Workingfromthefrontoftheedger,placethebeltontothespindlesheaves,

routeit backontothetopandbottomidlerpulleys,andthenplaceit onto

theengineflywheelpulley.

NOTE:Makecertainthatthe"V" sideof thebeltisseatedintothetoppulley

andtheflat sideofthe beltisseatedintothebottompulley.SeeFigure21.

6. Reinstallthespindlesheavesbeltguardwith theselftappingscrews

removedearlier.

Makecertainthatthedrivebeltison theengineflywheelpulleyandidler

pulleys,andretightentheflangelocknutonthetopoftheframe.

NOTE:Makecertainthatthedrivebeltisseatedcorrectlyandthatit isriding

smoothlyonthespindlesheavesandisnotpinchedbetweenthem.Repeat

thefirstthreestepsif thebeltispinched.

Neveroperatetheedgerwithout thespindlesheavesbelt guard in place.

16

Page 17

Neverstoreedgerwith fuel intank indoorsor in poorlyventilated areas

wherefuelfumesmayreachanopenflame,spark,or pilot light asona

furnace,waterheater,clothesdryer,or gasappliance.

PreparingTheEngine

Forenginesstoredover30days:

Topreventgumfromforminginfuelsystemoroncarburetorparts,run

engineuntilit stopsfromlackoffueloraddagasolineadditivetothegas

inthetank.If youuseagasadditive,runtheengineforseveralminutesto

circulatetheadditivethroughthecarburetor--afterwhichtheengineand

fuelcanbestoredupto24months.

Whileengineisstillwarm,changetheoil.

Cleanengineofsurfacedebris.

PreparingThelawn mower

Cleanandlubricateedgerthoroughlyasdescribedinthelubrication

instructions.

Donotuseapressurewasherorgardenhosetocleanyourunit.

Coatedgerbladewithchassisgreasetopreventrusting.

Referto PreparingtheEngineforcorrectenginestorageinstructions.

Storemowerinadry,cleanarea.Donotstorenexttocorrosivematerials,

suchasfertilizer.

Whenstoringanytypeofpowerequipmentinapoorlyventilatedormetalstorage

shed,careshouldbetakento rust-prooftheequipment.Usinga lightoil orsilicone,

coattheequipment,especiallycablesandallmovingpartsofyouredgerbefore

storage.

17

Page 18

Disconnectthe sparkplugwireandgrounditagainsttheenginetoprevent

unintendedstarting.Beforeperforminganytypeofmaintenance/service,

disengageallcontrolsandstoptheengine.Waituntilall movingparts

havecometoacompletestop.Alwayswearsafetyglassesduringoperation

orwhileperforminganyadjustmentsorrepairs.

Thissectionaddressesminorserviceissues.Tolocatethe nearestSearsServiceCenterorto scheduleservice,simply contact Searsat 1-800-4-MY-HOME_.

EngineFailstostart

Enginerunserratic

Engineoverheats 1.

Occasionalskips(hesitates) 1.

Idlespoorly 1.

Excessivevibration 1.

Drive-beltSlips 1.

1. Bladecontroldisengaged.

2. Sparkplugbootdisconnected.

3. Fueltankemptyorstalefuel.

4. Enginenotprimed(Ifequippedwith primer).

5. Faultysparkplug.

6.

Engineflooded. 6.

7.

Blockedfuelline. 7.

1.

Sparkplugbootloose. 1.

2.

Stalefuel. 2.

3.

Ventingascapplugged. 3.

4.

Waterordirtinfuelsystem. 4.

5.

Dirtyaircleaner. 5.

6.

Blockedfuelline. 6.

Engineoillevellow. 1.

2.

Airflowrestricted. 2.

Sparkpluggaptooclose. 1.

Sparkplugfouled,faulty,orgaptoowide. 2.

2.

Dirtyaircleaner. 3.

Edgerbladebentordamaged. 1.

2.

Bladespindlebentordamaged. 2.

Beltwornorstretched. 1.

1. Engagebladecontrol.

2. Connectwiretosparkboot.

3. Filltankwithclean,freshgasoline.

4. PrimeengineasinstructedintheOperationsection.

5. Clean,adjustgap,orreplace.

Waitafew minutestorestart.

ContactyourSearsParts&RepairCenterto havefuelline

cleaned.

Connectandtightensparkplugboot.

Filltankwithclean,freshgasoline.

Clearvent.

Runengineuntilit stopsfromlackoffuel.Refillwithfreshfuel.

Referto AirCleanerinEngineMaintenancesection.

ContactyourSearsParts&RepairCenterto havefuelline

cleaned.

Fillcrankcasewithproperoil.

Cleanareaaroundandontopofengine.

Adjustgap.RefertoSparkPluginEngineMaintenancesection.

Resetgaporreplacesparkplug.

Referto AirCleanerinEngineMaintenancesection.

Replaceblade.

ContactyourSearsParts&RepairCenterto haveunitinspected.

Replacedrivebelt.SeeBeltReplacementinServiceand

Maintenancesection.

NEED MORE HELP?

Y?_:£1.1f:_ndLbe answe:_and _o:_eer__a_age_y_i£eo_o_ -. for free!

Find this and aLLyour other product manuals online.

Get answers from our team of home experts.

Get a personalized maintenance plan for your home.

:: Find informat:ion and tools to help with home projects.

managemylife

18

Page 19

19

Page 20

CraftsmanEdger/Trencher--ModelNo.247.762460

49

TrencherKit

58

I

4oI®

62

39

Page 21

CraftsmanEdgedTrencher-- ModelNo.247.762460

1

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

3O

31

32

33

34

35

2

3

4

5

6

7

8

9

687-02022

687-02585

687- 02126

710-0191

710- 0411

710-04389

710-0599

710-0654A

710-0726

710-0870

710-1143A

710-1174

710-1205

710-3180

711-05696

711-04440

712-04063

712-04065

712-0417A

714-3010

718-04012

720-0142

720-0279

720-04072A

726-0299

931-04207

731-05063

731-05064

732-0188A

932-0369

732-04045

932- 04169

734-1264

734-1268

736-04019

Curb Height Adjustment Lever

Curb Height Adjuster Plate

Blade Plate Assembly

Screw 3/8-24

Screw 3/8-16

Hex Screw, 5/16-18

Self-tapping Screw, 1/4-20

Screw, 3/8-16

Hex Screw, 5/16-12

Hex Screw 5/16-18

Hex Screw, 5/8-18

Carriage Bolt, 5/16-18

Rope Guide (Eye Bolt)

Hex Screw, 5/16-18

Axle Shaft .50x6.65

Frame Spacer .50x9.25

Lock Flange Nut, 5/16-18

Flange Nut 3/8-16

Flange Nut, 5/8-18

Clevis Pin 3/32 x .625

Bearing Cup

Grip

Wing Nut

Star Knob

Push Cap 1/2" rod

Bearing Block

Debris Guard

Blade Guard

Double Torsion Spring

Compression Spring

Torsion Spring

Compression Spring

Wheel 7 x 1.75 T-Tread

Wheel 8 x 1.75 T-Tread

Flat Washer, .531 x 1.25 x .181

m

m

36

37

38

39

4O

41

42

43

44

45

46

47

48

49

5O

51

52

53

54

55

56

57

58

59

6O

61

62

63

64

65

66

67

68

N/A

936-0232

736-0234

736-0258

936-04088

936-0452

738-04149

738-0706C

738-0929

941-0524A

746-04035

946-04036

747-04110A

747-0976A-0637

749-04183A-0637

749-04234-0637

950-04105

750-04129

950-04142

750-0547

954-04032B

756-04148

956-0449

756-1150A

781-0427-0637

781-0741A

781-0742-0637

781-0748-0637

787-01081A-4044

787-01240-4044

787-01304-4044

712-04217

750-05548

750-0664

Wave Washer .531 x .781 x .013

Flat Washer, .385 x 1.5 x .075

Flat Washer .385 x 1.0 x .135 ±

Flat Washer .635x1.24x.181

Bell Washer,.396 x 1.140

Shoulder Screw, 3/8-16

Shoulder Screw

Shoulder Screw, 3/8-16

Bearing, .625 ID x 1.57 OD

Control Cable (Briggs & Stratton)

Wheel Adjustment Cable

Blade Adjustment Rod

Bail Handle

Upper Handle

Lower Handle

Spacer, .63 x 1.12 x 1.06

Spacer

Pulley Mount Spacer

Spacer, .64 x.88 x .50

Belt

Flat Idler Pulley, 2.50D

Sheave

Combination Flywheel Pulley

Belt Guard

Depth Index Bracket

Depth Index Lever

Tri-Star Blade

Bracket Plate

Wheel Bracket

Frame

Flange Lock Nut, 3/8-16

Spcr., .525 x .775 x .93

Spcr., .5051D x .88OD x .440

Engine (see breakdown)

B& S Model No. 09P702-0004-F1

21

Page 22

CraftsmanEngineModel No.09P702-OOO4-F1ForCraftsmanEdger/TrencherModel No.247.762460

3O

615 _

404 ®

I

24

741 I

27

46

1 718 0 12

22

Page 23

CraftsmanEngineModel No.09P702-OOO4-F1ForCraftsmanEdger/TrencherModel No.247.762460

850

I022

1026J

914

121CARBURETOROVERHAULKIT

I04

o

0

d 623 0

163

217

617 0

635

358 ENGINE GASKET SET

623 0

163 d

842

524 _

868@

23

Page 24

CraftsmanEngineModel No.09P702-OOO4-FIForCraftsmanEdger/TrencherModel No.247.762460

3os

60

58

2o2

209 S

745A 9

356

188 _il

745

I 1036 EMISSIONS L ABEL [

957

930

3328

7s

621

922

850

300 b__

455

334_

37

24

Page 25

CraftsmanEngineModel No.09P702-OOO4-FIForCraftsmanEdger/TrencherModel No.247.762460

318 _i_

1238

623

118

117

@1°4%

@

1127 4

163

@

0

d

25

1395_:_

875

535

Page 26

CraftsmanEngineModel No.09P702-OOO4-FIForCraftsmanEdger/TrencherModel No.247.762460

590519 Cylinder Assembly

3 299819s Kit-Bushing/Seal (Magneto Side)

4 590569 Sump-Engine

5 590525 Head-Cylinder

7 799586 Gasket-Cylinder Head

11 590522 Tube-Breather

12 799587 Gasket-Crankcase

13 590512 Screw (Cylinder Head)

16 590538 Crankshaft

20 391483s Seal-Oil (PTO Side)

22 692551 Screw (Crankcase Cover/Sump) (1/4-

20x1.19)

22A 590763 Screw (Crankcase Cover/Sump) (1/4-

20x.78)

23 590544 Flywheel

24 222698s Key-Flywheel (Aluminum)

25 590521 Piston Assembly (Standard)

26 590523 Ring Set (Standard)

27 691588 Lock-Piston Pin

28 699659 Pin-Piston

29 590518 Rod-Connecting

32 691664 Screw (Connecting Rod)

33 590531 Valve-Exhaust

34 590530 Valve-Intake

35 590532 Spring-Valve (Intake)

36 590532 Spring-Valve (Exhaust)

37 590582 Guard-Flywheel

40 590528 Retainer-Valve

43 697799 Slinger-Governor/Oil

45 590514 Tappet-Valve

46 590524 Camshaft

48 N/A Short Block (Not Available At

This Printing)

591108 Rope-Sta rter

60 691915 Grip-Starter Rope

75 590546 Washer (Flywheel)

78 793480 Screw (Flywheel Guard)

104 590558 Pin-Float Hinge

117 591997 Jet-Main (Standard)

118 591994 Jet-Main (High Altitude)

121 590589 Kit-Carburetor Overhaul

122 590549 Spacer-Carburetor

125 590556 Carburetor

130 691190 Valve-Throttle (Original Carburetor)

133 591120 Float-Ca rburetor

155 590529 Plate-Cylinder Head

163 799580 Gasket-Air Cleaner

187 791766 Line-Fuel (Cut to Required Length)

188 793480 Screw (Control Bracket)

192 590535 Adjuster-Rocker Arm

202 590517 Link-Mechanical Governor

209 590541 Spring-Governor (Purple)

222 590560 Bracket-Control

227 590520 Lever-Governor Control

238 590533 Cap-Valve

300 590565 Muffler

305 590586 Screw (Blower Housing)

318 793480 Screw (Mounting Bracket)

332 690662 Nut (Flywheel)

333 799582 Armature-Magneto

334 691061 Screw (Magneto Armature)

337 692051 Plug-Spark

356 692390 Wire-Stop

358 590590 Gasket Set-Engine

404 690272 Washer (Governor Crank)

455 590545 Cup-Flywheel

26

Page 27

CraftsmanEngineModel No.09P702-OOO4-FIForCraftsmanEdger/TrencherModel No.247.762460

590551 Bracket-Mounting (Carburetor)

505 793515 Nut (Governor Control Lever)

523 796503 Dipstick

524 691876 Seal-Dipstick Tube

535 799579 Filter-Air Cleaner Foam

562 793514 Bolt (Governor Control Lever)

601 791850 Clamp-Hose (Green)

613 590562 Screw (Muffler)

615 690340 Retainer-Governor Shaft

616 590516 Crank-Governor

617 270344s Seal-O Ring (Intake Manifold)

621 692310 Switch-Stop

623 799581 Seal-O Ring (Carburetor Spacer)

635 692076 Boot-Spark Plug

718 690959 Pin-Locating (Cylinder)

724 697478 Retainer-Seal

741 796210 Gear-Timing

745 691146 Screw (Brake) (#10-32x.86)

745A 690859 Screw (Brake) (#10-32x.5)

770 591139 Kit-Rewind/Blower Housing

830 590536 Stud-Rocker Arm

842 691031 Seal-O Ring (Dipstick)

847 590572 Dipstick/Tube Assembly

850 100106 Sealant-Silicone

868 590534 Seal-Valve

875 590584 Base-Air Cleaner

914 591103 Screw (Rocker Cover)

922 692135 Spring-Brake

923 691487 Brake

930 590585 Guard-Rewind

957 799585 Cap-Fuel

968 590581 Cover-Air Cleaner

972 590568 Fuel-Tank

591116 Bowl-Float

1022 591255 Gasket-Rocker Cover

1023 590513 Cover-Rocker

1026 590515 Rod-Push

1029 590526 Arm-Rocker (Exhaust)

1029A 590527 Arm-Rocker (Intake)

1036 Label-Emissions (Available from a Briggs

& Stratton Authorized Dealer)

1058 381266TRI Operator's Manual

1127 590554 Screw (Float Bowl to Carburetor Body)

1238 590550 Screw (Carburetor Spacer)

1263 697124 Reed-Breather

1264 793453 Screw (Breather Reed)

1329 N/A Replacement Engine (Not Available At

This Printing)

1330 N/A Repair Manual (Not Available At This

Printing)

1395 590552 Screw (Air Cleaner Base to Carburetor)

Carburetor Overhaul Kit Key No. 121

Engine Gasket Set Key No. 358

27

Page 28

CraftsmanEdgedTrencher--ModelNo.247.762460

777S32140

777S30282

Operation Of This Equipment May Create SparksThat Can Start Fires Around Dry Vegetation. A

Regulations RelatingToFirs Prevention Requirements.

777S33503 777120102

777D18783

h_heel Adjustment Bracket (Right Wheel). ml

777122074

777122073

28

Page 29

(ThispageapplicableintheU.S.A.andCanadaonly.)

Sears Brands Management Corporation (Sears),the California Air Resources Board (CARB)

and the United States Environmental Protection Agency (U,S, EPA)

EmissionControl System Warranty Statement (Owner's Defect Warranty Rights and Obligations)

EMISSIONCONTROLWARRANTYCOVERAGEISAPPLICABLETOCERTIFIEDENGINES ANDTOCERTIFIEDMODELYEAR1997ANDLATERENGINESWHICHAREPURCHASEDAND

PURCHASEDINCALIFORNIAIN1995ANDTHEREAFTER,WHICHAREUSEDINCALIFORNIA,USEDELSEWHEREINTHEUNITEDSTATES(ANDAFTERJANUARY1,2001INCANADA).

California and United States Emission Control Defects Warranty Statement

TheCaliforniaAirResourcesBoard(CARB),U.S.EPAandSearsarepleasedto explainthe

EmissionControlSystemWarrantyonyourmodelyear2000andlatersmalloff-road

engine(SORE).InCalifornia,newsmalloff-roadenginesmustbedesigned,builtand

equippedto meettheState'sstringentanti-smogstandards.Elsewhereinthe United

States,newnon-road,spark-ignitionenginescertifiedformodelyear1997andlater

mustmeetsimilarstandardssetforthbytheU.S.EPA.Searsmustwarranttheemission

Sears Emission Control Defects Warranty Coverage

Smalloff-roadenginesarewarrantedrelativetoemissioncontrolpartsdefectsfora

periodofoneyear,subjecttoprovisionssetforthbelow.Ifanycoveredpartonyour

Owner's Wa rra nty

Asthesmalloff-roadengineowner,youareresponsiblefortheperformanceofthe

requiredmaintenancelistedinyourOperatingandMaintenanceInstructions.Sears

recommendsthat youretainallyourreceiptscoveringmaintenanceonyoursmall

off-roadengine,butSearscannotdenywarrantysolelyforthelackofreceiptsorfor

yourfailuretoensurethe performanceofallscheduledmaintenance.Asthesmall

off-roadengineowner,youshouldhoweverbeawarethatSearsmaydenyyouwarranty

coverageifyoursmalloff-roadengineorapart hasfailedduetoabuse,neglect,

Soars Emission Control Defects Warranty Provisions

ThefollowingarespecificprovisionsrelativetoyourEmissionControlDefectsWarranty

Coverage.Itisinadditionto theSearsenginewarrantyfornon-regulatedenginesfound

in theOperatingandMaintenanceInstructions.

1. WarrantedParts

Coverageunderthiswarrantyextendsonlytothepartslistedbelow(the

emissioncontrolsystemsparts)totheextentthesepartswerepresentonthe

enginepurchased.

a. FueIMeteringSystem

• Coldstartenrichmentsystem

• Carburetorandinternalparts

• FuelPump

b. AirlnductionSystem

• Aircleaner

• Intakemanifold

c. IgnitionSystem

• Sparkplug(s)

• Magnetoignitionsystem

d. CatalystSystem

• Catalyticconverter

• Exhaustmanifold

• Airinjectionsystemorpulsevalve

e. MiscellaneousItemsUsedinAboveSystems

• Vacuum,temperature,position,timesensitivevalvesandswitches

• Connectorsandassemblies

2. Lengthof Coverage

Searswarrantstotheinitialownerandeachsubsequentpurchaserthatthe

WarrantedPartsshallbefreefromdefectsinmaterialsandworkmanshipwhich

causedthefailureoftheWarrantedPartsforaperiodofoneyearfromthedate

theengineisdeliveredtoaretailpurchaser.

Inthe USAandCanada,a24hourhotline,1-800-469-4663,hasamenuofpre-recordedmessagesofferingyouenginemaintenanceinformation.

controlsystemonyourenginefortheperiodsof timelistedbelow,providedtherehas

beennoabuse,neglectorimpropermaintenanceofyoursmalloff-roadengine.Your

emissioncontrolsystemincludespartssuchasthecarburetor,aircleaner,ignition

system,mufflerandcatalyticconverter.Alsoincludedmaybeconnectorsandother

emissionrelatedassemblies.Whereawarrantableconditionexists,Searswill repair

yoursmalloff-roadengineatnocosttoyouincludingdiagnosis,partsandlabor.

engineisdefective,thepartwill berepairedorreplacedbySears.

Responsibilities

impropermaintenanceorunapprovedmodifications.Youareresponsibleforpresenting

yoursmalloff-roadenginetoanAuthorizedSearsServiceDealerassoonasaproblem

exists.Theundisputedwarrantyrepairsshouldbecompletedinareasonableamount

oftime,nottoexceed30days.Ifyouhaveanyquestionsregardingyourwarrantyrights

andresponsibilities,youshouldcontactaSearsServiceRepresentativeat 1-800-469-

4663.Theemissionwarrantyisadefectswarranty.Defectsarejudgedonnormalengine

performance.Thewarrantyisnotrelatedtoanin-useemissiontest.

3. NoCharge

RepairorreplacementofanyWarrantedPartwillbeperformedatnochargeto

theowner,includingdiagnosticlaborwhichleadsto thedeterminationthata

WarrantedPartisdefective,ifthediagnosticworkisperformedatanAuthorized

SearsServiceDealer.Foremissionswarrantyservicecontactyournearest

AuthorizedSearsServiceDealeraslistedinthe"YellowPages"under"Engines,

Gasoline,""GasolineEngines,""LawnMowers,"orsimilarcategory.

4. ClaimsandCoverageExclusions

Warrantyclaimsshallbefiledinaccordancewiththe provisionsoftheSears

EngineWarrantyPolicy.Warrantycoverageshallbeexcludedforfailuresof

WarrantedPartswhicharenotoriginalSearspartsorbecauseofabuse,neglect

orimpropermaintenanceassetforth intheSearsEngineWarrantyPolicy.Sears

isnotliabletocoverfailuresofWarrantedPartscausedbytheuseofadd-on,

non-original,ormodifiedparts.

5. Maintenance

AnyWarrantedPartwhichisnotscheduledforreplacementasrequired

maintenanceorwhichisscheduledonlyforregularinspectionto theeffectof

"repairorreplaceasnecessary"shallbewarrantedastodefectsforthewarranty

period.AnyWarrantedPartwhichisscheduledfor replacementasrequired

maintenanceshallbewarrantedasto defectsonlyfortheperiodoftimeup

tothefirstscheduledreplacementforthatpart.Anyreplacementpartthatis

equivalentin performanceanddurabilitymaybeusedin theperformanceof

anymaintenanceorrepairs.Theownerisresponsiblefor theperformanceof

all requiredmaintenance,asdefinedintheSearsOperatingandMaintenance

Instructions.

ConsequentialCoverage

Coveragehereundershallextendtothefailureofanyenginecomponentscaused

bythefailureof anyWarrantedPartstill underwarranty.

GDOC-100188Rev.B

29

Page 30

Congratulationsonmakingasmartpurchase.YournewCraftsman®productisdesignedandmanufacturedforyearsof

dependableoperation.Butlikeallproducts,it mayrequirerepairfromtimetotime.That'swhenhavingaRepairProtection

Agreementcansaveyoumoneyandaggravation.

Here'swhat the RepairProtectionAgreement_includes:

[] Expertservice byour10,000professionalrepairspecialists

[] Unlimitedserviceand nochargeforpartsandlaboronallcoveredrepairs

[] Productreplacementupto $1500ifyourcoveredproductcan'tbefixed

[] Discountof 25%fromregularpriceof serviceandrelatedinstalledpartsnotcoveredbytheagreement;also,25%off

regularpriceofpreventivemaintenancecheck

[] Fasthelpby phone- wecallitRapidResolution- phonesupportfromaSearsrepresentative.Thinkofusasa"talking

owner'smanual."

OnceyoupurchasetheRepairProtectionAgreement,asimplephonecallisallthatit takesforyoutoscheduleservice.You

cancallanytimedayornight,orscheduleaserviceappointmentonline.

TheRepairProtectionAgreementisarisk-freepurchase.Ifyoucancelfor anyreasonduringtheproductwarrantyperiod,

wewill provideafull refund.Or,a proratedrefundanytimeaftertheproductwarrantyperiodexpires.PurchaseyourRepair

ProtectionAgreementtoday!

Somelimitations and exclusionsapply. Forpricesand additional informationinthe U.S.A.call 1-800-827-6655.

_CoverageinCanadavarieson someitems.Forfull detailscall SearsCanadaat 1-800-361-6665.

SearsInstallationService

ForSearsprofessionalinstallationof homeappliances,garagedooropeners,waterheaters,andothermajorhomeitems,in

theU.S.A.orCanadacall1-800-4-MY-HOME®.

3O

Page 31

Your Home

For troubleshooting, product manuals and expert advice:

managernylife

www.managemylife.com

For repair - in your home - of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner's manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME ® (1-800-469-4663)

Call anytime, day or night (U.S.A. and Canada)

www.sears.com www.sears.ca

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call anytime for the location of your nearest

Sears Parts & Repair Service Center

1-800-488-1222 (U.S.A.) 1-800-469-4663 (Canada)

www.sears.com www.sears.ca

To purchase a protection agreement on a product serviced by Sears:

1-800-827-6655 (U.S.A.) 1-800-361-6665 (Canada)

Para pedir servicio de reparaci6n

a domicilio, y para ordenar piezas:

1-888-SU-HOGAR ®

(1-888-784-6427)

www.sears.com

® Registered Trademark / TMTrademark of KCD IP, LLC in the United States, or Sears Brands, LLC in other countries

® Marca Registrada ! TMMarca de Fabrica de KCD IP, LLC en Estados Unidos, o Sears Brands, LLC in otros paises

MCMarque de commerce ! MDMarque deposee de Sears Brands, LLC

Au Canada pour service en frangais:

1-800-LE-FOYER Mc

(1-800-533-6937)

www.sears.ca

Loading...

Loading...