Craftsman 143.994011 Operator's Manual

SEARS

operator's

manual

MODEL NO. 143.994011

4.0 RESERVE POWER

10 INCH CUBIC (163 cc)

DISPLACEMENT

SOLID STATE IGNITION

CAUTION:

Read RULES for

Safe OPERATION

and INSTRUCTIONS

Carefully

ENGIN

• Operating

• Maintenance

• Repair Parts

[A CalifomiaProposRion65 WARNING: The engine exhaust from this product contains chemicals I

known to the State of California to cause cancer, birth defects or other reproductive harm.

Sold by SEARS, ROEBUCK AND CO., CHICAGO, IL 60684 U.S.A.

and SEARS CANADA, INC., TORONTO, ONTARIO, CANADA

Pdntedin U.S.A. 2-1-99 181-1191-11

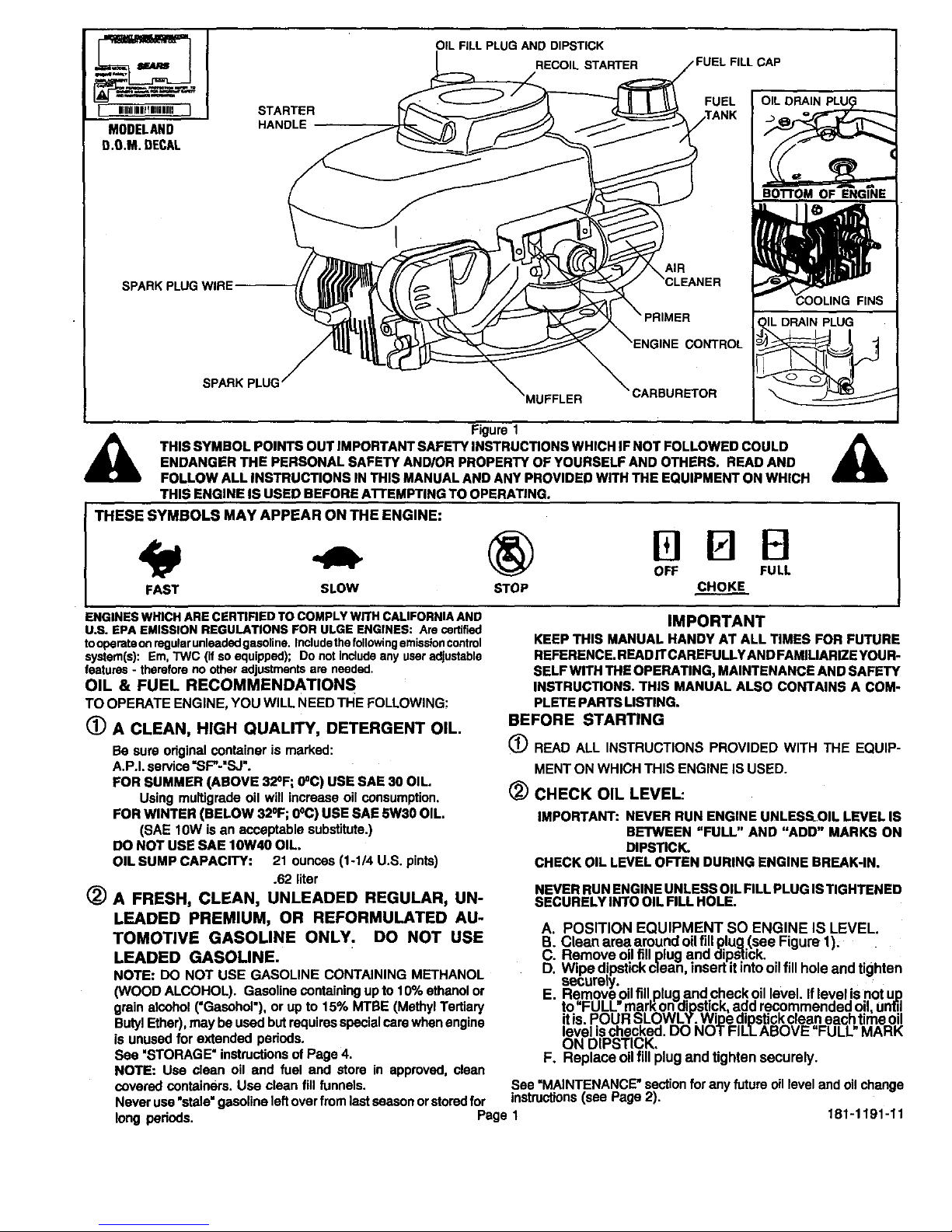

I lllllllll+TllliBfl I

MODELAND

O.o.m. DECAL

STARTER

HANDLE

OIL FILL PLUG AND DIPSTICK

RECOIL STARTER

FUEL

CAP

OIL DRAIN

SPARK PLUG WIRE

SPARK PLUG

MUFFLER

AIR

CARBURETOR

BOTrOM OF ENGINE

DRAIN PLUG

Figure 1

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED COULD ,A_

ENDANGER THE PERSONAL SAFETY ANDIOR PROPERTY OF YOURSELF AND OTHERS. READ AND

FOLLOW ALL INSTRUCTIONS IN THIS MANUAL AND ANY PROVIDED WITH THE EQUIPMENT ON WHICH

THIS ENGINE IS USED BEFORE A'I'rEMPTING TO OPERATING.

THESE SYMBOLS MAY APPEAR ON THE ENGINE:

FAST SLOW

D88

OFF FULL

STOP CHOKE

ENGINES WHICHARE CERTIRED TO COMPLY WITH CALIFORNIAAND

U.S. EPA EMISSION REGULATIONS FOR ULGE ENGINES: Arecertified

tooperateon regularunleadedgasoline.Includethefollowingemissioncontrol

system(s): Em, TWC (if so equipped); Do notIncludeany useradjustable

features- thereforeno otheradjustmentsareneeded.

OIL & FUEL RECOMMENDATIONS

TO OPERATE ENGINE, YOU WILL NEED THE FOLLOWING;

(_ A CLEAN, HIGH QUALITY, DETERGENT OIL.

Be sure originalcontaineris marked:

A,P.I.service"SP'-"SJ'.

FOR SUMMER (ABOVE 32°F; 0°C) USESAE 30 OIL.

Using multigredeoil will increaseoilconsumption.

FOR WINTER (BELOW 32°F; 0°C) USE SAE 5W30 OIL.

(SAE 10W isan acceptablesubstitute.)

DO NOT USE SAE 10W40 OIL.

OIL SUMP CAPACITY: 21 ounces(1-1/4 U.S. pints)

.62 liter

(_) A FRESH, CLEAN, UNLEADED REGULAR, UN"

LEADED PREMIUM, OR REFORMULATED AU-

TOMOTIVE GASOLINE ONLY. DO NOT USE

LEADED GASOLINE.

NOTE: DO NOT USE GASOLINE CONTAININGMETHANOL

(WOOD ALCOHOL). Gasolinecontaining upto 10% ethanolor

grain alcohol('Gasehol'), or up to 15% MTBE (MethylTertiary

ButylEther),may be usedbutrequiresspecialcarewhenengine

is unusedfor extendedperiods,

See "STORAGE"instructionsof Page4.

NOTE: Use clean oil and fuel and store in approved,clean

coveredcontainers. Use clean fill funnels.

Never use"stale"gasolineleftoverfrom lastseasonorstoredfor

long periods.

IMPORTANT

KEEP THIS MANUAL HANDY AT ALL TIMES FOR FUTURE

REFERENCE.READITCAREFULLYANDFAMILIARIZEYOUR-

SELFWITHTHEOPERATING, MAINTENANCE AND SAFETY

INSTRUCTIONS. THIS MANUAL ALSO CONTAINS A COM-

PLETE PARTSLISTING.

BEFORE STARTING

(_ READ ALL INSTRUCTIONS PROVIDED WITH THE EQUIP-

MENT ON WHICH THIS ENGINE IS USED.

(_) CHECK OIL LEVEL:

IMPORTANT: NEVER RUN ENGINE UNLESS_OIL LEVEL IS

BETWEEN "FULL" AND "ADD" MARKS ON

DIPSTICK.

CHECK OIL LEVEL OFTEN DURING ENGINE BREAK-IN.

NEVER RUN ENGINE UNLESS OIL FILL PLUG IS TIGHTENED

SECURELY INTO OIL FILL HOLE.

A. POSITION EQUIPMENT SO ENGINE IS LEVEL.

B. Clean area around oilfi!l_.luq (see Figure 1).

C. Remove oil fill pruganD dipsticK.

D. Wipe dipstickclean, insertitinto oil fill hole and tighten

securely.

E. Remove oilfillplugand check oil level. Ifleve isnot uP

to=FULL" ma_ ondipstick, add recommended oil, until

itis. POUR SLOWLY. WiDe dipstickcleaneach time oil

level is checked. DO NOT FIL'LABOVE "FULL"MARK

ON DIPSTICK.

F. Replace oilfill plug and tighten securely.

See =MAINTENANCE"sectionforanyfutureoil levelandoilchange

instructions(see Page 2).

Page 1 181-1191-11

BEFORE STARTING (Continued)

(_) FILL FUEL TANKwlth 9asotineas speoitiedinthe preceding

"OIL & FUEL RECOMMENDATIONS" item 2.

NEVER MIX OIL WITH GASOLINE

Neveruse "stale"gasolineleftoverfromlastseason orstoredfor

long pednds.

d_lL NEVER FILL FUEL TANK INDOORS. NEVER FILL FUEL TANK

WHEN ENGINE IS RUNNING OR HOT. DO NOT SMOKE WHEN

I FILLING FUEL TANK.

,_ NEVER FILL FUEL TANK COMPLETELY. RLL TANK TO 1/2" 1

BELOW BOI"FOMOF RLLER NECKTO PROVIDE SPACE FOR/

FUEL EXPANSION. WIPE ANY FUEL SPILLAGE FROM EN-/

G NE AND EQUIPMENT BEFORE STARTING ENGINE. /

/

,_ANY UQUERED PETROLEUM (LPG) OR NATURAL GAS FUEL

SYSTEM MUST BE LEAKPROOF AND MEET ALL APPLICA-

I BLE CODES AND REGULATIONS.

(_) CHECK THE FOLLOWING:

_A. BE SURE EQUIPMENT IS IN NEUTRAL GEAR WITH I

CLUTCHES, BELTS, CHAINS AND SAFETY SWITCHES I

DISENGAGED. (FOLLOW EQUIPMENT MANU- I

FACTURER'S INSTRUCTIONS.) THIS SHOULD PLACE

ANY SAFETY SWITCHES IN SAFE STARTING PosmoN.

B. Besure sparkplugwireis attached to spark plug(sea Figure

t).

STARTING

,_ NEVER RUN ENGINE INDOORS ORIN ENCLOSED, POORLY I

VENTILATED AREAS. ENGINE EXHAUST CONTA NS CAR-

BON MONOXIDE, AN ODORLESS AND DEADLY GAS (CAR-

BON MONOXIDE IS ALSO PRESENT IN ENGINE EXHAUST I

FROMUQUID PETROLEUM (LPG) ANDNATURAL GAS FUEL

SYSTEMS).

,_ KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY

FROM ANY MaY NG PARTS ON ENG NE AND EQU PMENT.

STOPPING

(_ Move ENGINE CONTROL (seeFigure 1) to STOP.

(_ AFTER ENGINE IS STOPPED:

,_A. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG

/_ND ATTACH IT TO RETAINING POST (see Rflure 3).

_B. N["VERSTORE ENGINEWITH NJEL INTANKIN_RS OR

IN ENCLOSED, POORLY VENTILATED AREAS, WHERE

FUEL FUMES MAY REACH AN OPEN FLAME, SPARK OR

PILOT LIGHT AS ON A FURNACE, WATER HEATER,

CLOTHES DRYER OR OTHER GAS APPUANCE.

ROPE GUIDE

RETAINING PC)S'[

Rgure3

MAINTENANCE

_LWARNING: TEMPERATURE OF MUFFLER AND NEARBY _k WARNING: TEMPERATURE OF MUFFLER AND NEARBY I

AREAS MAY EXCEED 150°F (65°C). AVOID THESE AREAS. _ AREAS MAY EXCEED 150aF (65oC).AVOID THESE AREAS.I

Move ENGINE CONTROL (see Figure 1) to HI Position.

(_ START ENGINE

A. The carburetoronyourengine hasbeen completelyadjusted

at the factory.When starting a coldengine, push redpdmer

bulbfirmly with your thumb 5 tlmea, allowingpdmerbulbto

retum completely to odginal positionbetween pushes. Re-

peatthe above for each starter operationas necessary.

NOTE: DO NOT USE PRIMER TO RESTART A WARM

ENGINE AFTER A SHORT SHUTDOWN.

B. Grasp starterhandle (see Figure2) andpullropeout,slowly,

untilitpullsslightlyharder.Let roperewindslowly.Then pull

rope witha rapidfullarmstroke. Letrope rewindSLOWLY. Do

not let starter handle snap back against rope guide (see

Figure2).

C. Repeat instructionB it necessary, untilengine starts.

NOTE: Ifengine does notstart, repeat instructionsA, B and

C untilitstarts.

ENGINE SPEED: Engine speed iscontrolledby the ENGINE CON-

TROL see Figure 1).

ENGINE CONTROL shouldbe in HI positionfor high grass condi-

tionsandfor most efficientbaggingin heavy grassconditions,end

in LOW positionfor lightgrass, trimmingand for fuel economy. Page 2

(_) CHECK OIL LEVEL:

Checkoilleveleveryfive(5)operatinghoursoreachtime engine

isused.See"¢DCHECK OIL LEVEL"in"BEFORESTARTING"on

Page 1.

_) CHANGE OIL:

Change oil after first two (2) operatinghours end every 25

operating hourstheraatter, more oftenIf operated in extremely

dusty or dirtyconditions.Change oil while engine Is still warm

from recent running.

_kA. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG

AND ATTACH ITTO RETA N NG POST (see Figure 3).

B. Positionequipmontea engineoil drainpluglsinwost puint on

engine.

C. Remove oildrain plugandoil tillplugto drainoil (sea Figure

1).

D. Replace oil drain plug and tighten securely.

E. Fill oil sumpwith recommendedoil.See"OIL & FUEL REC-

OMMENDATIONS" and "CHECK OIL LEVEL" on Page 1.

F. Replace oil till plug and tightensecurely.

G. Connect spark plug wire to spark plug.

H. Wipe up any spilledoil and/orgasoline.

NOTE: If itisdifficufttoreachthe oildrainptug,drainfuel.Remove

oil fill plug and tip mower on its side. Drainoil into a suitable

container.

181-1191-11

MAINTENANCE (Continued)

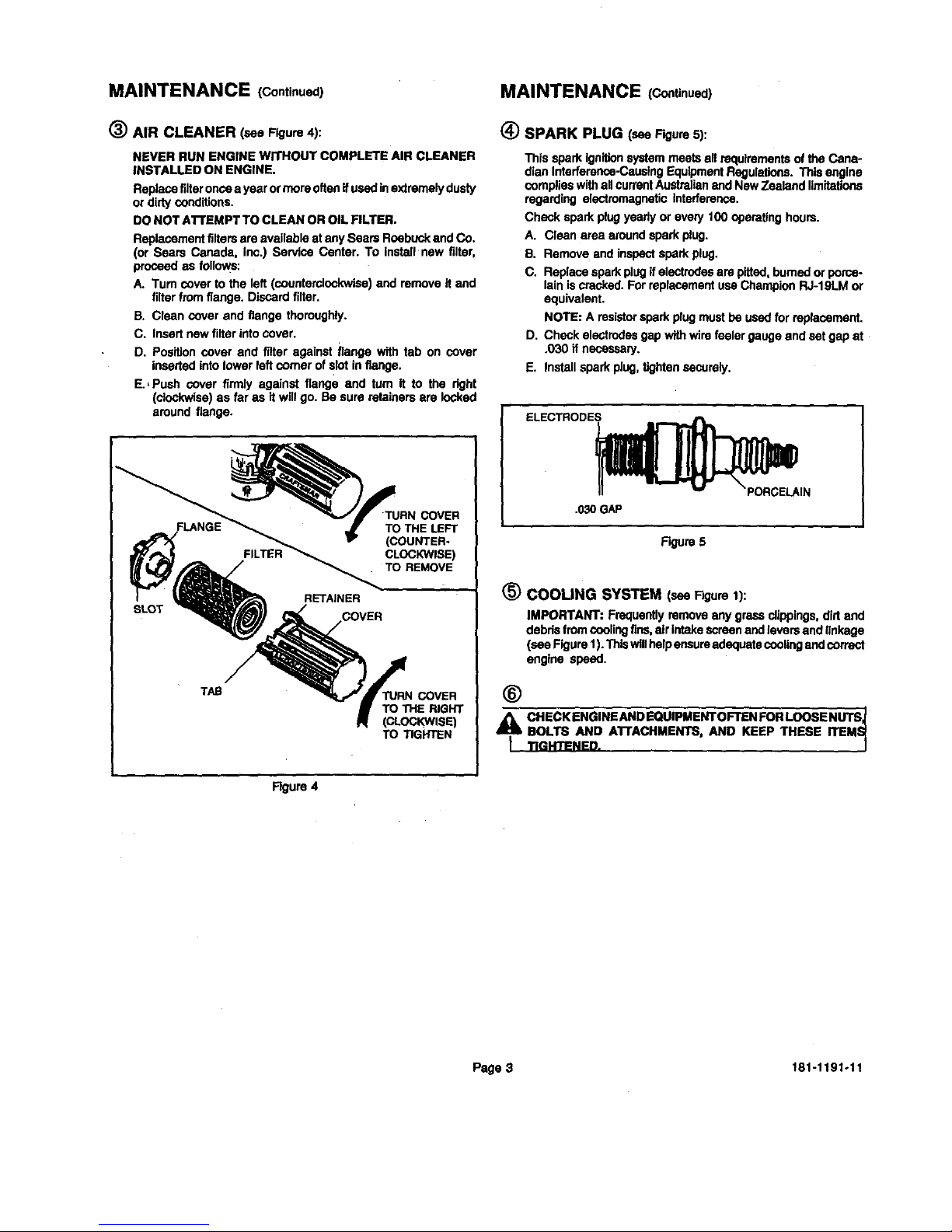

(_ AIR CLEANER (see Figure4):

NEVER RUN ENGINE WITHOUT COMPLETE AIR CLEANER

INSTALLED ON ENGINE.

Replacefilteronce a yearor mereoftenifusedinextremelydusty

or dirty conditions.

DO NOT A'FFEMPT TO CLEAN OR OIL FILTER.

Replacementfiltersere available atany Sears Roebuckend Co.

(or Sears Canada, Inc.) Service Canter. To install new filter,

proceed as follows:

A. Turn cover to the left (counterclockwise)and remove if and

filter fromflange. Discardfiller.

B. Clean cover and flange thoroughly.

C. Insertnew filterinto cover.

D. Positioncover and filter against flange with tab on cover

inserted Into lower left corner ofslot in flange.

E., Push cover firmly against flange and turn it to the right

(clockwise)as far as it willgo. Be sure retainersare locked

around flange.

_fTT_RN COVER

CLOCKWISE)

TO REMOVE

SLOT

RETAINER

COVER

TAB

COVER

TO THE RIGHT

(CLOCIONISE)

TO TIGHTEN

MAINTENANCE (continued)

(_) SPARK PLUG (see Figure 5):

This spark ignitionsystemmeetsall requirementsof the Cana-

dian Interference-CausingEquipmentRegulations. This engine

complies withallcurrentAustralianandNewZealand limitations

regarding electromagnetic interference.

Check spark plugyearly or every 100 operatinghours.

A. Clean area aJ'oundspark plug.

B. Remove and inspectspark plug.

C. Replace sparkplugif electrodesare pitted,burnedor porce-

lain iscradxed.For replacementuseChampionRJ-19LM or

equivalent.

NOTE: A resistorsparkplug mustbe usedforreplacement.

D. Check electrodesgap with wirefeeler gauge and sat gap at

.030 if necessary.

E. Installspark plug,tightensecurely.

ELECTRODE_

.030IIGAP '_ _RCELAIN

F'_urefl

_) COOLING SYSTEM (see Rgure 1):

IMPORTANT: Frequentlyremoveany grass clippings,dirt and

debrisfromcoolingfins,air intakescreenandleversandlinkage

(see Figure 1).This willhelpensureadequatecoolingandcorrect

engine speed.

®

t

_ICHECK ENGINEAND EQUIPMENT NUTSJ

OFTEN FOR LOOSE

BOLTS AND ATrACHMENTS, AND KEEP THESE ITIEMS_

1 "lIGHTENED. |

Figure 4

Page 3 181-1191-11

Loading...

Loading...